Patents

Literature

629results about How to "Reduce clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

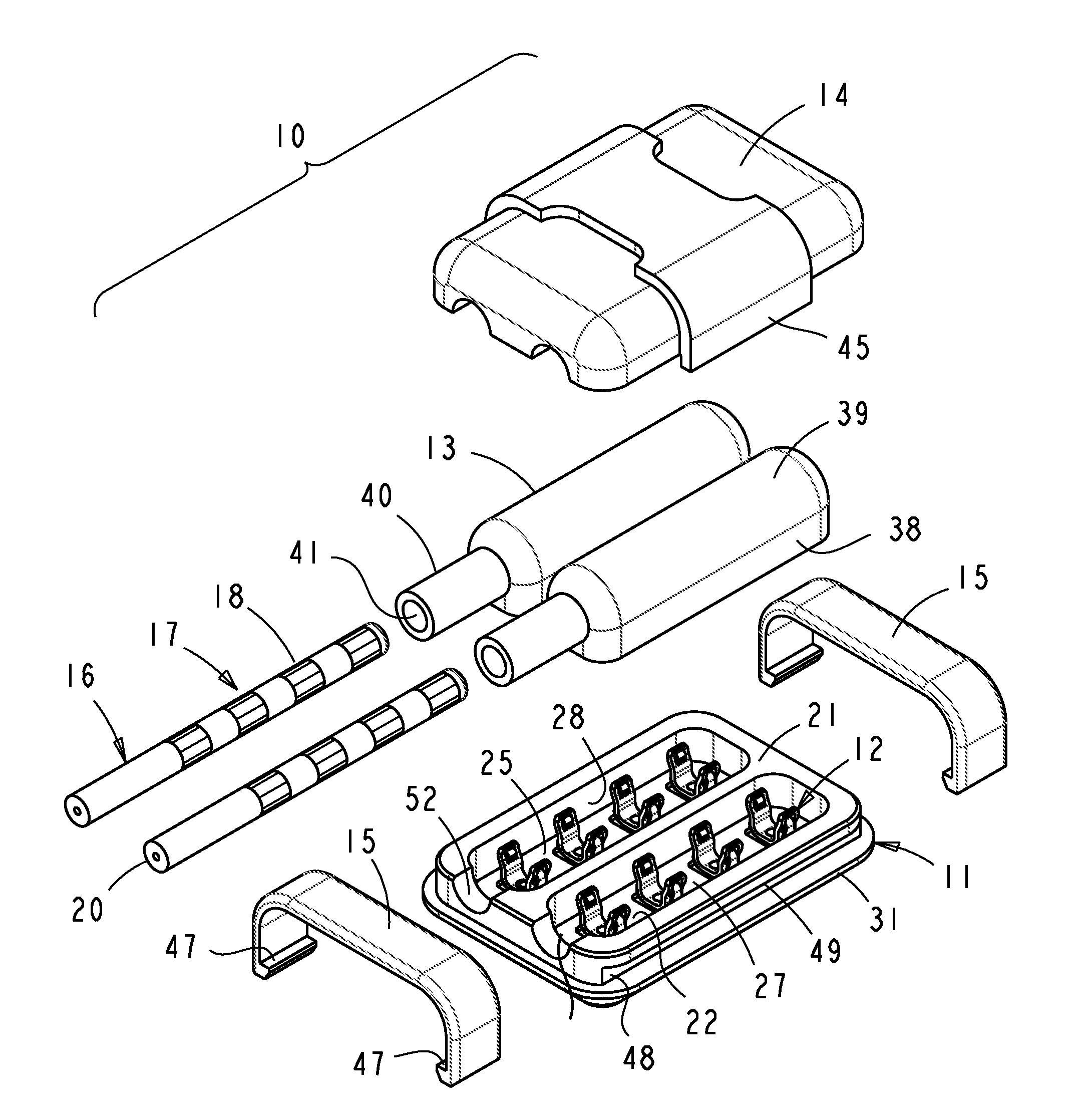

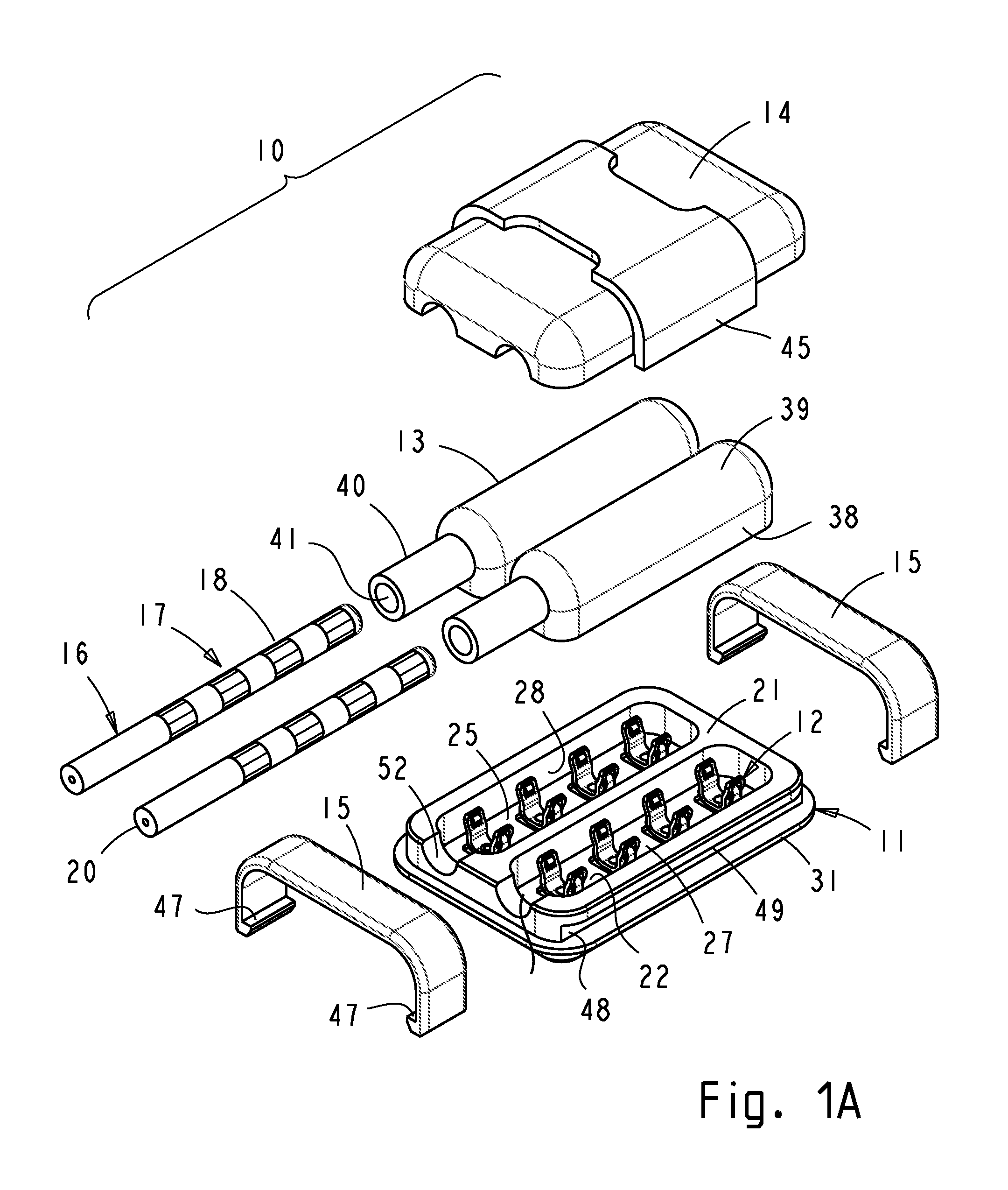

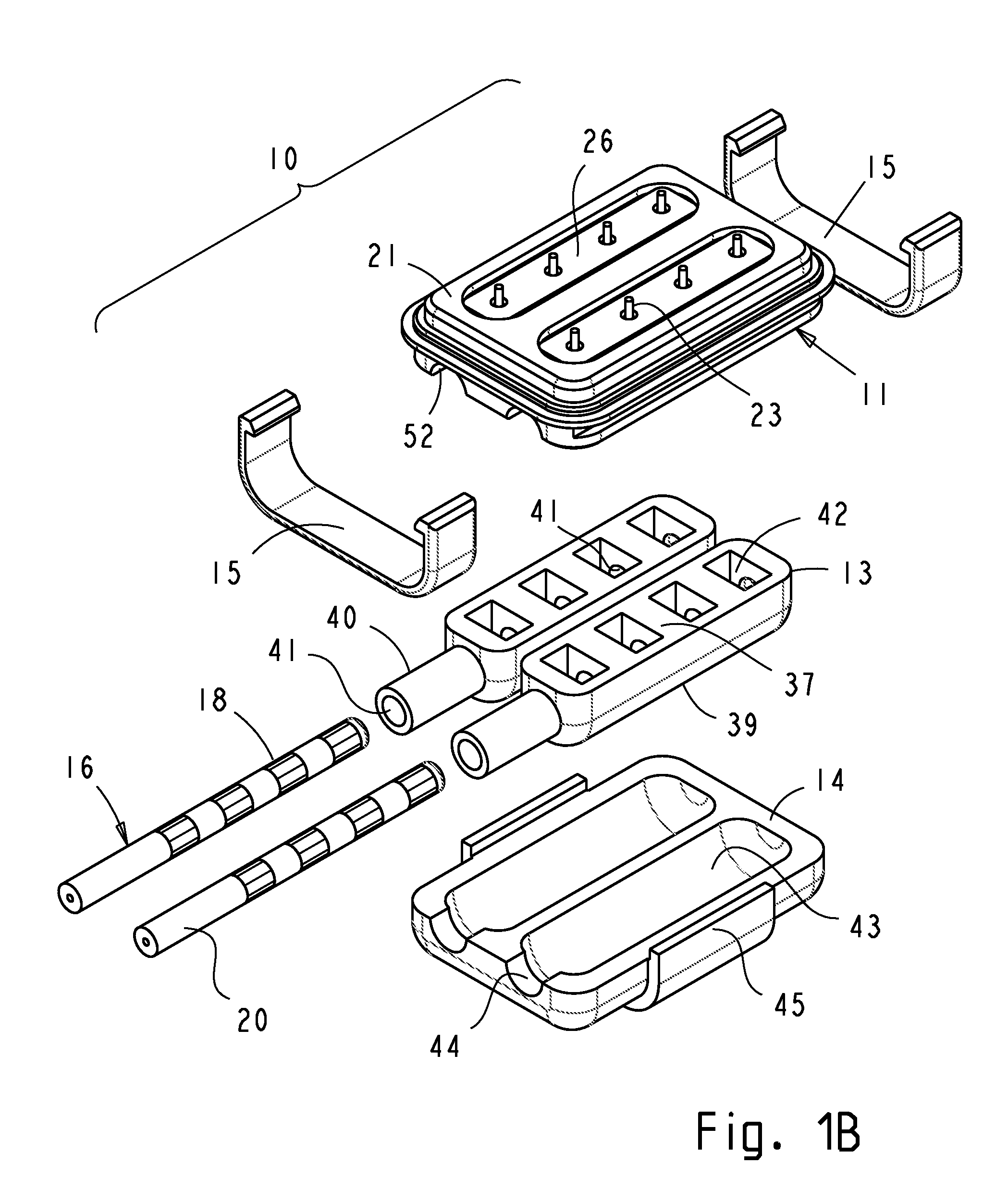

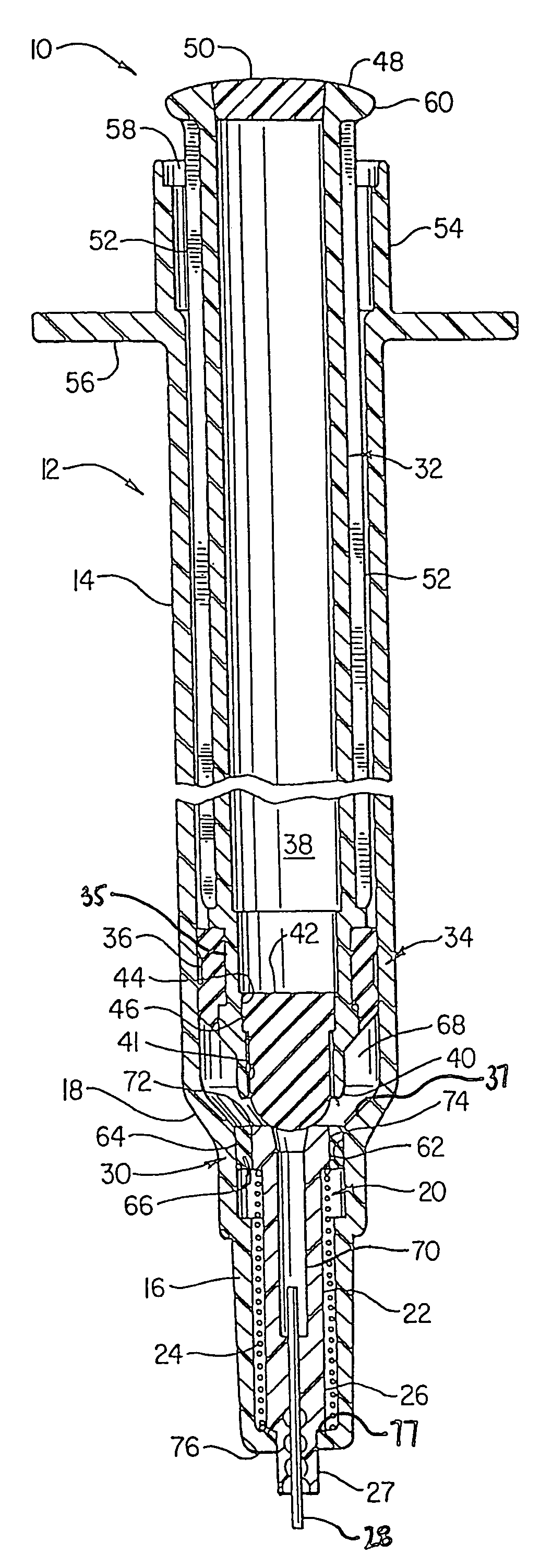

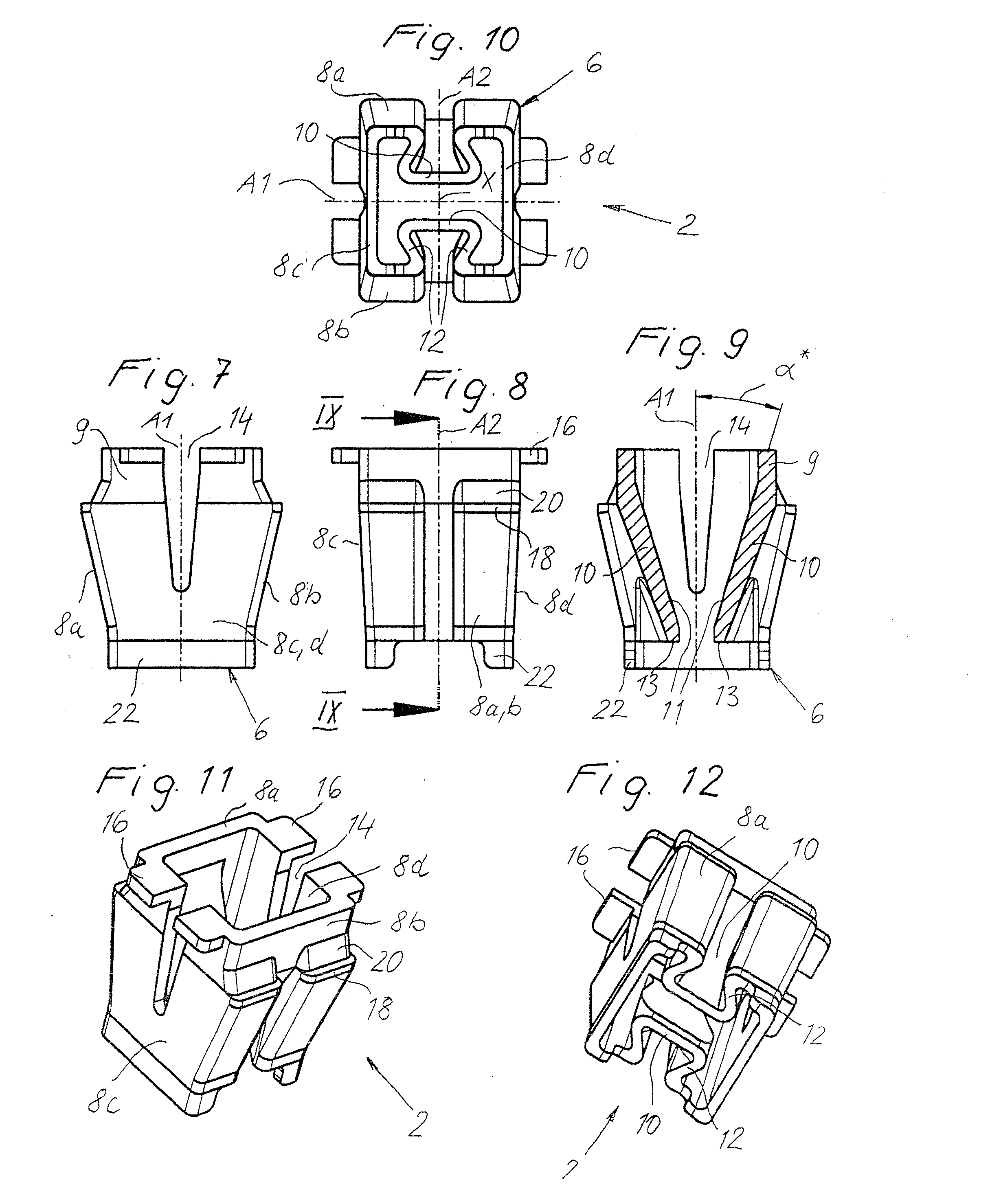

Implantable connector with protected contacts

InactiveUS7736191B1Avoid deformationAvoid accidental damageElectrotherapyCoupling device detailsElectrical conductorMedical device

An implantable connector electrically connects multi-conductor leads to an implantable medical device such as a neurostimulator. The connector is assembled directly into a hermetic feedthrough of the implantable device and utilizes the feedthrough housing as a sustaining structure for connector clamping. The receptacle contacts detachably connect proximal lead contacts to corresponding feedthrough pins, which provide pass-through connections to electronic circuitry contained in a hermetically sealed case. The receptacle contact has resilient contact tines designed to engage a corresponding lead contact in a sliding manner. The receptacle contact is integrated with a contact guard which protects the receptacle contact from inadvertent handling damage. The contact guard is substantially more rigid than the resilient contact to resist deformation. The contact guard protectively shields the receptacle contact tines and prevents unintended contact tine excursion. In one embodiment, the contact guard is pre-attached to the receptacle contact prior to joining to the feedthrough pin. In another embodiment, the contact guard is an integral part of the feedthrough pin. Numerous embodiments with contact preload are provided.

Owner:SOCHOR JERZY ROMAN

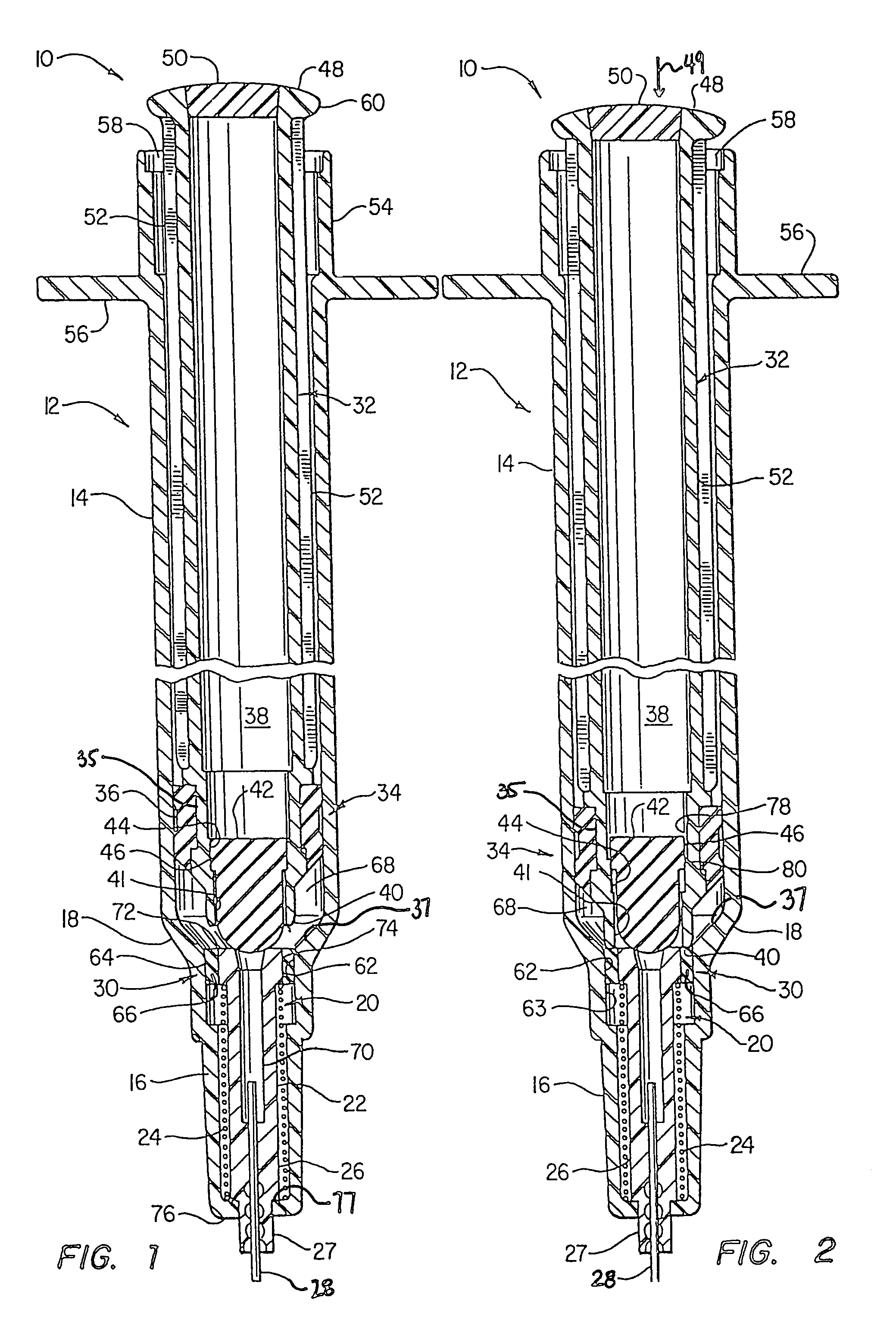

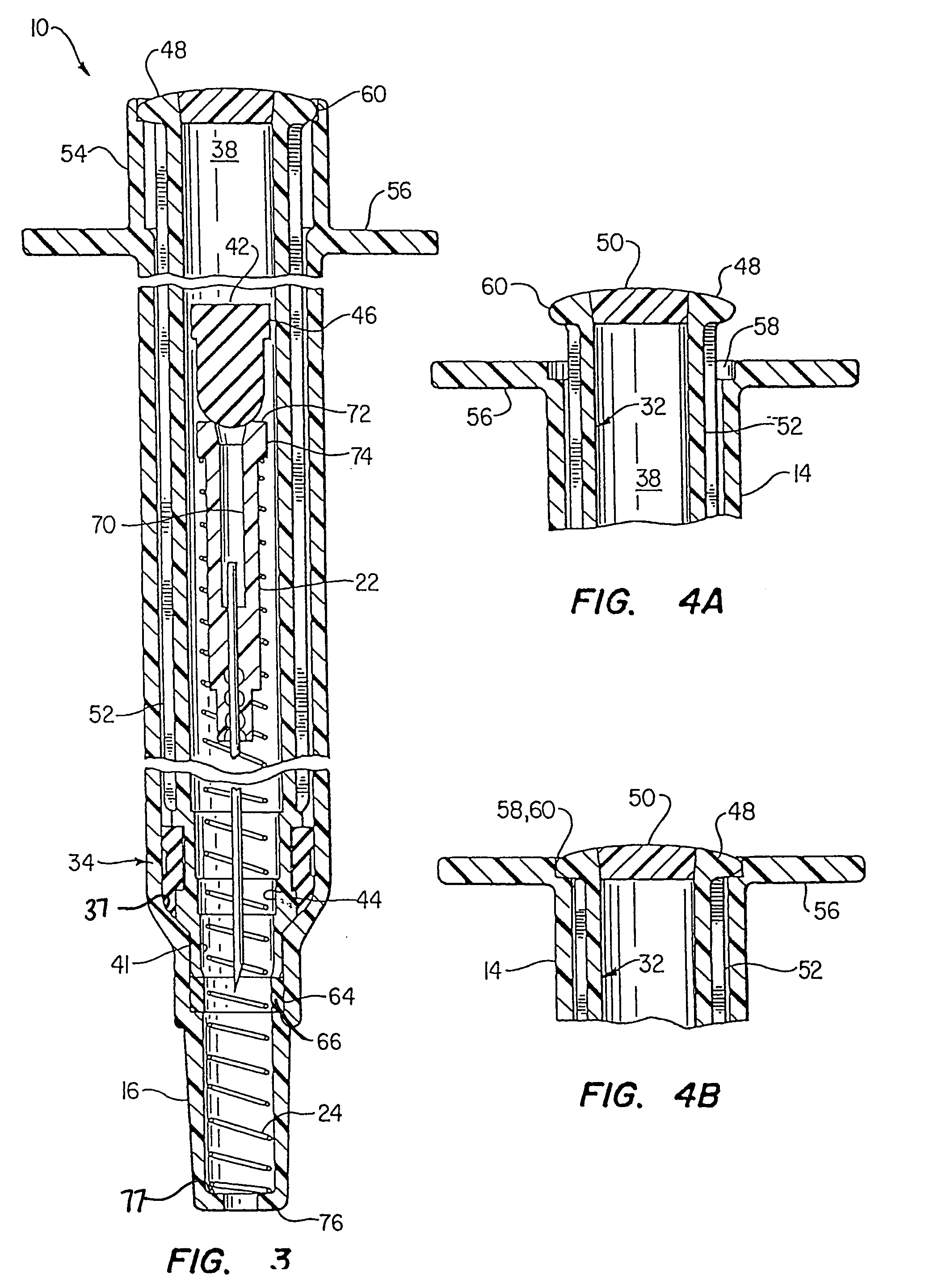

Retractable syringe assembly designed for one use

InactiveUS7351224B1Prevent retractionReduce clamping forceInfusion syringesInfusion needlesSingle injectionSyringe needle

A syringe assembly having a retractable needle, the syringe assembly being rendered unusable after a single injection and having a hollow syringe body, a retraction mechanism with a spring disposed in the front portion of the syringe and an inner head, a continuous retainer member surrounding the inner head, and a bridging portion disposed between the continuous retainer member and the inner head, wherein the bridging portion couples the continuous retainer member and the inner head to form a fluid seal between a fluid passageway and the barrel prior to retraction, and a plunger reciprocally disposed inside the barrel and forming a variable chamber between the plunger and the needle holder prior to and during retraction, wherein the continuous retainer member is releasable from the inner head of the needle holder when the plunger is further depressed inside the barrel following injection.

Owner:SHAW CO

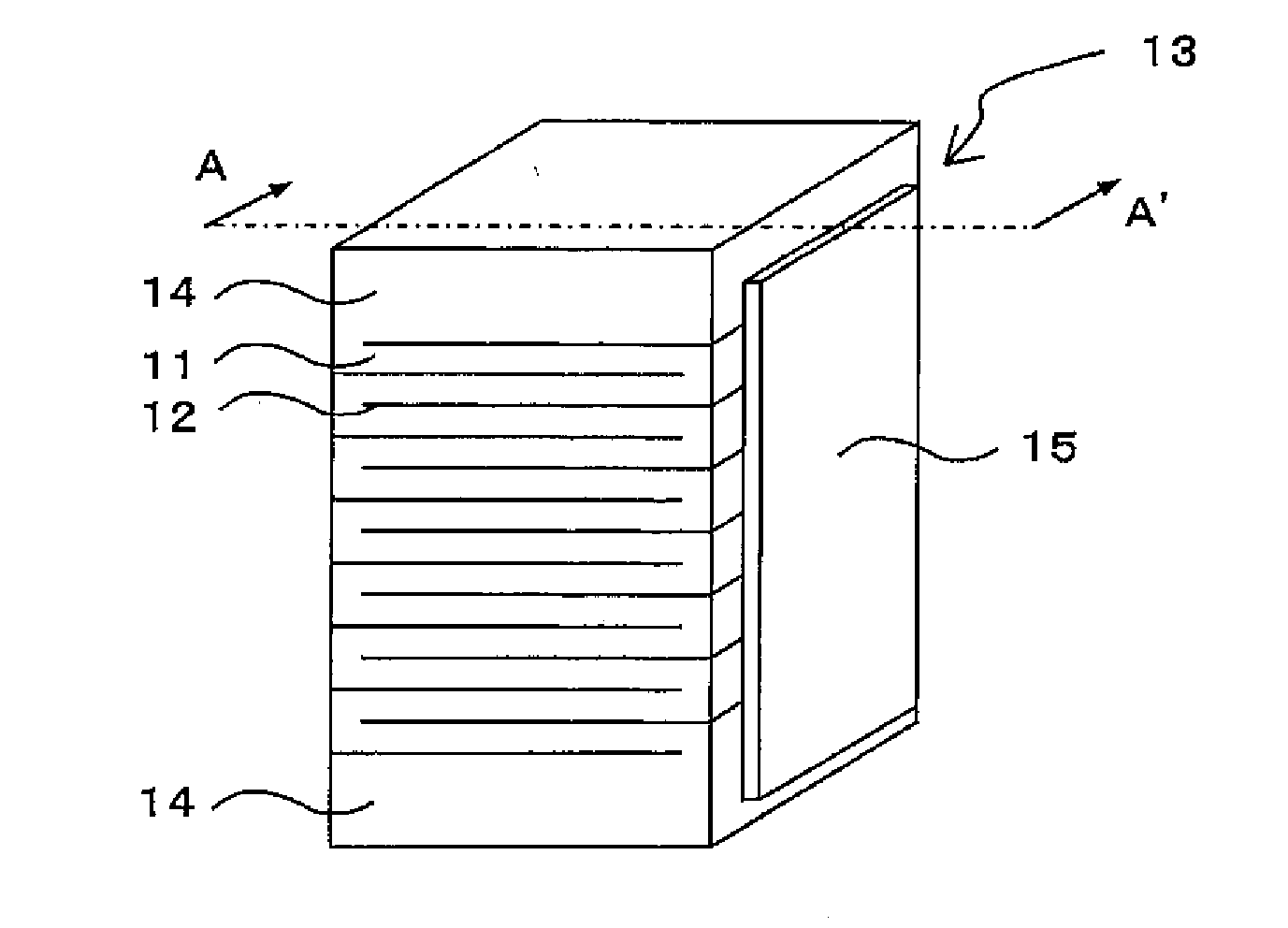

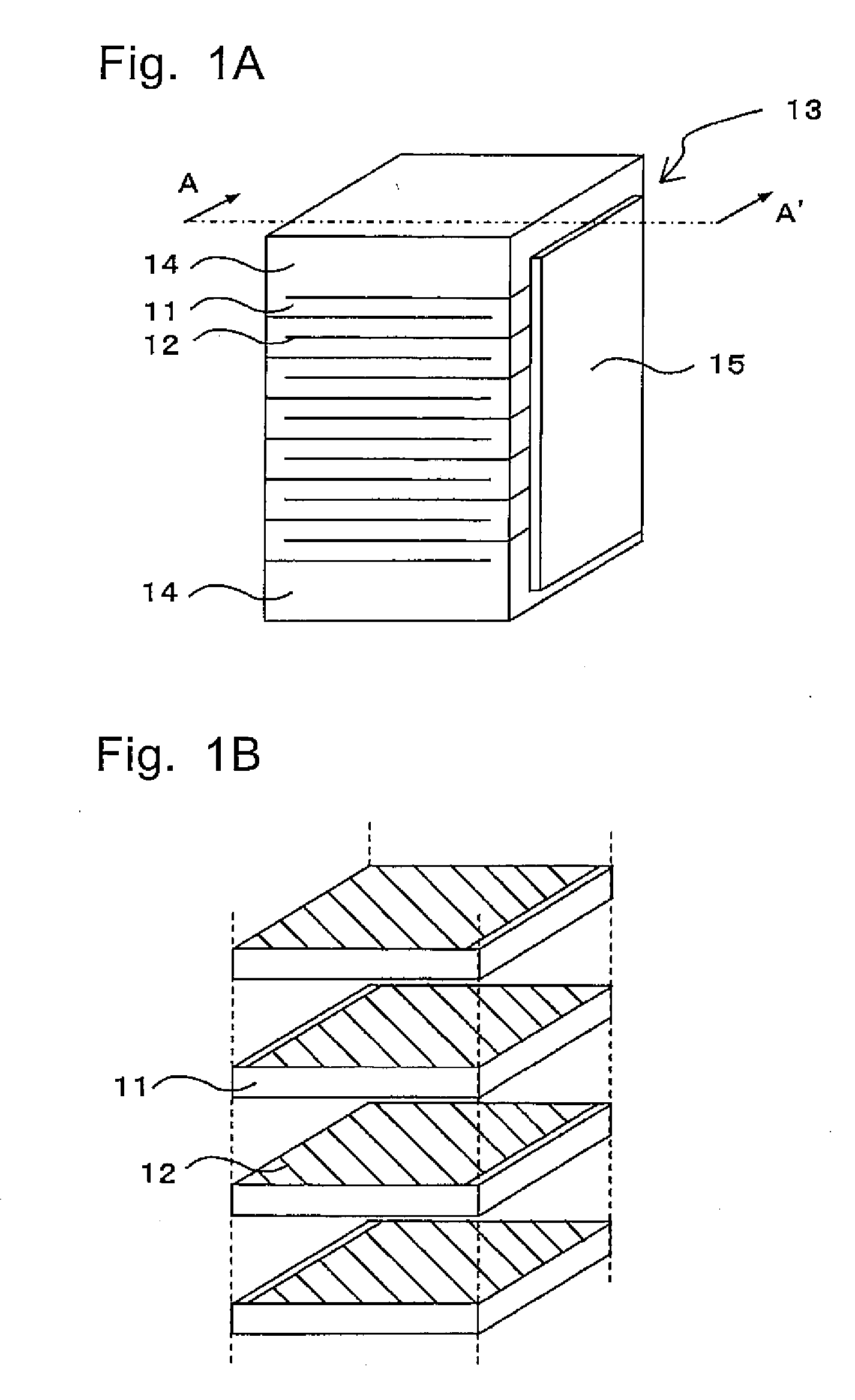

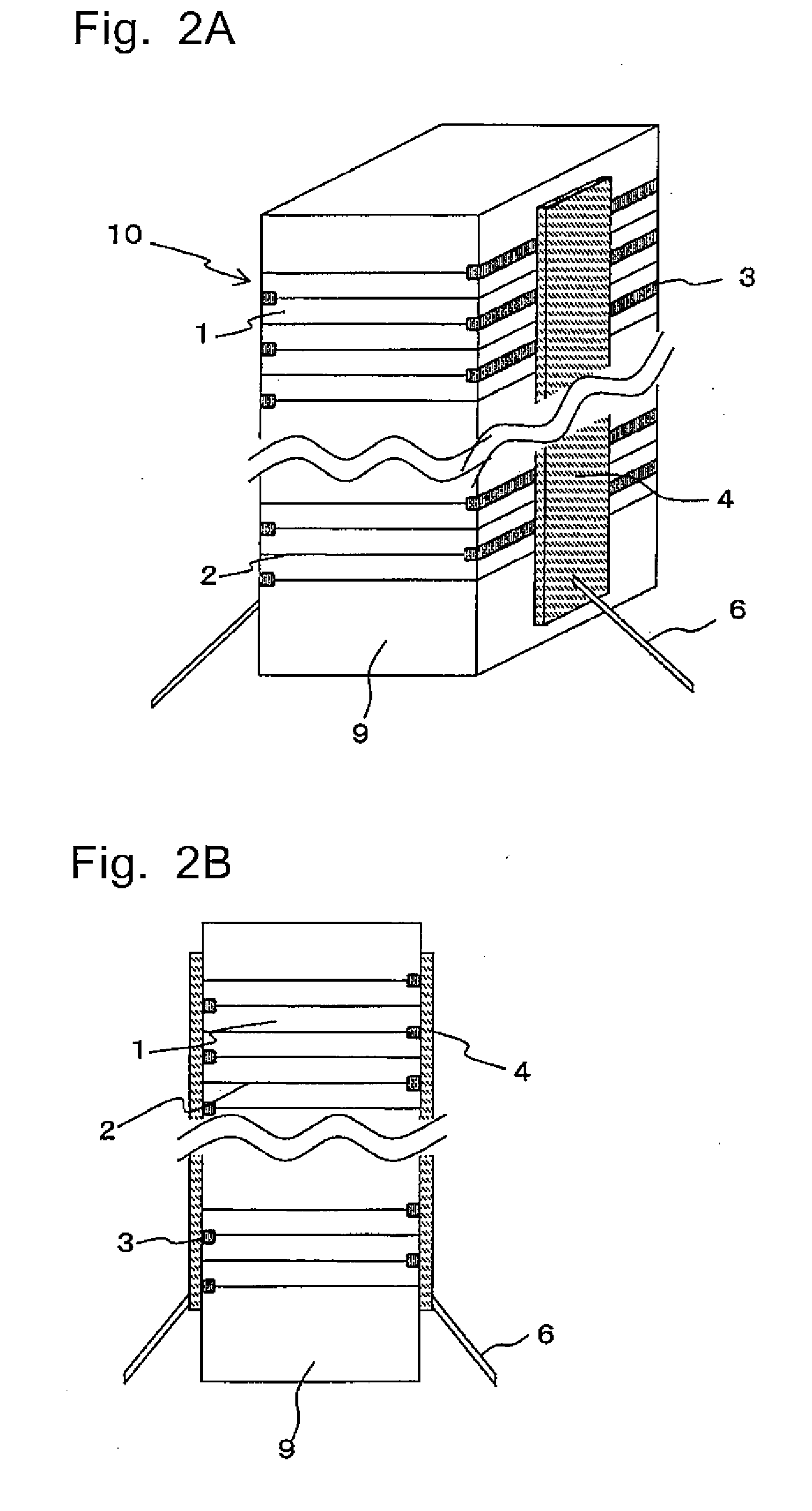

Multi-Layer Piezoelectric Element and Method for Manufacturing the Same

ActiveUS20070278907A1Increase displacementIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsFlexural strength

A multi-layer piezoelectric element having high durability which allows it to increase the amount of displacement of a piezoelectric actuator under high voltage and high pressure and does not undergo a change in the amount of displacement during continuous operation in a high electric field and under a high pressure over a long time period is provided. The multi-layer piezoelectric element comprises a stack of at least one piezoelectric layer and a plurality of internal electrodes consisting of first and second internal electrodes placed one on another, a first external electrode formed on a first side face of the stack and connected to the first internal electrode and a second external electrode formed on a second side face of the stack and connected to the second internal electrode, wherein the bonding strength between the piezoelectric layer and the internal electrode is weaker than the bending strength of the piezoelectric layer.

Owner:KYOCERA CORP

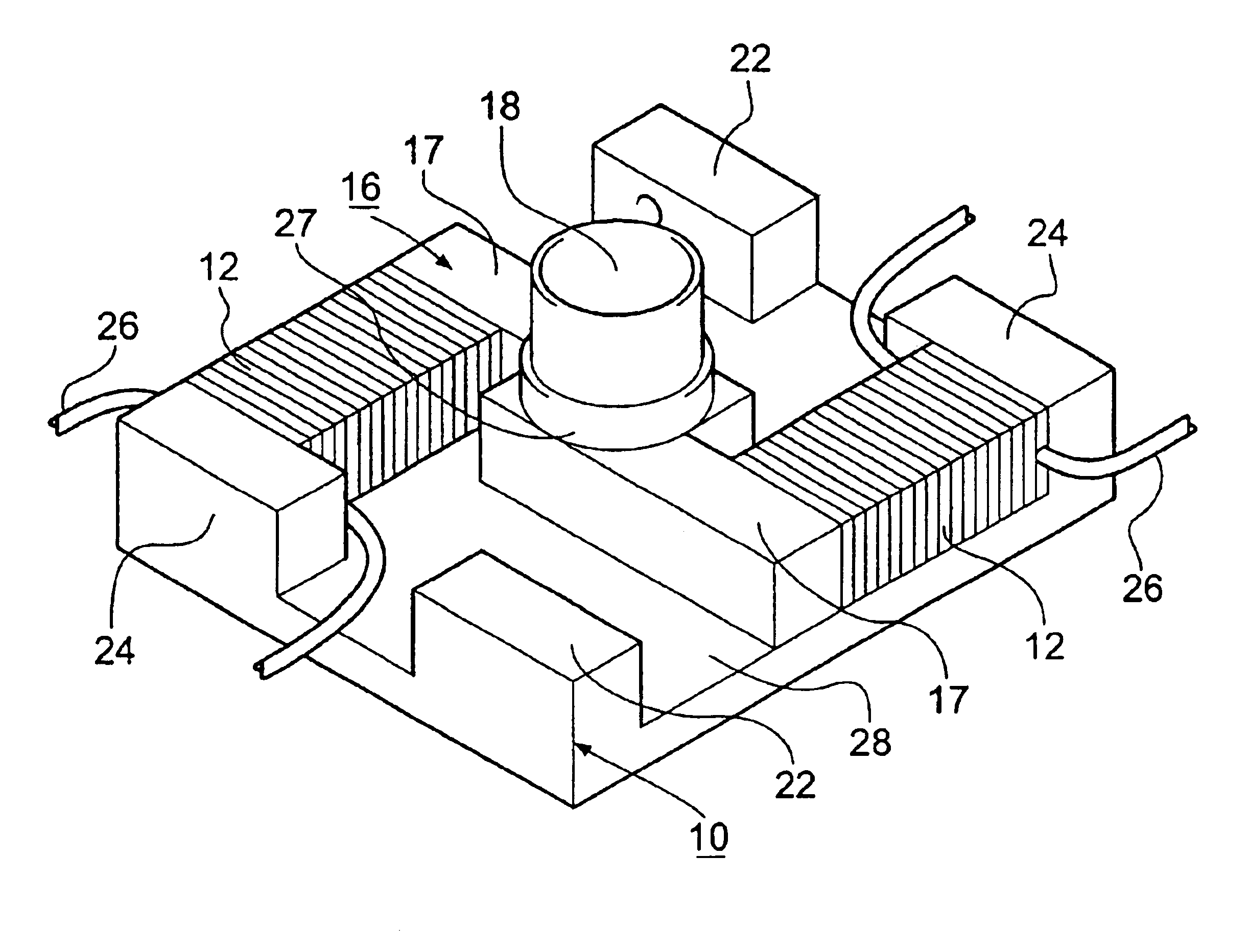

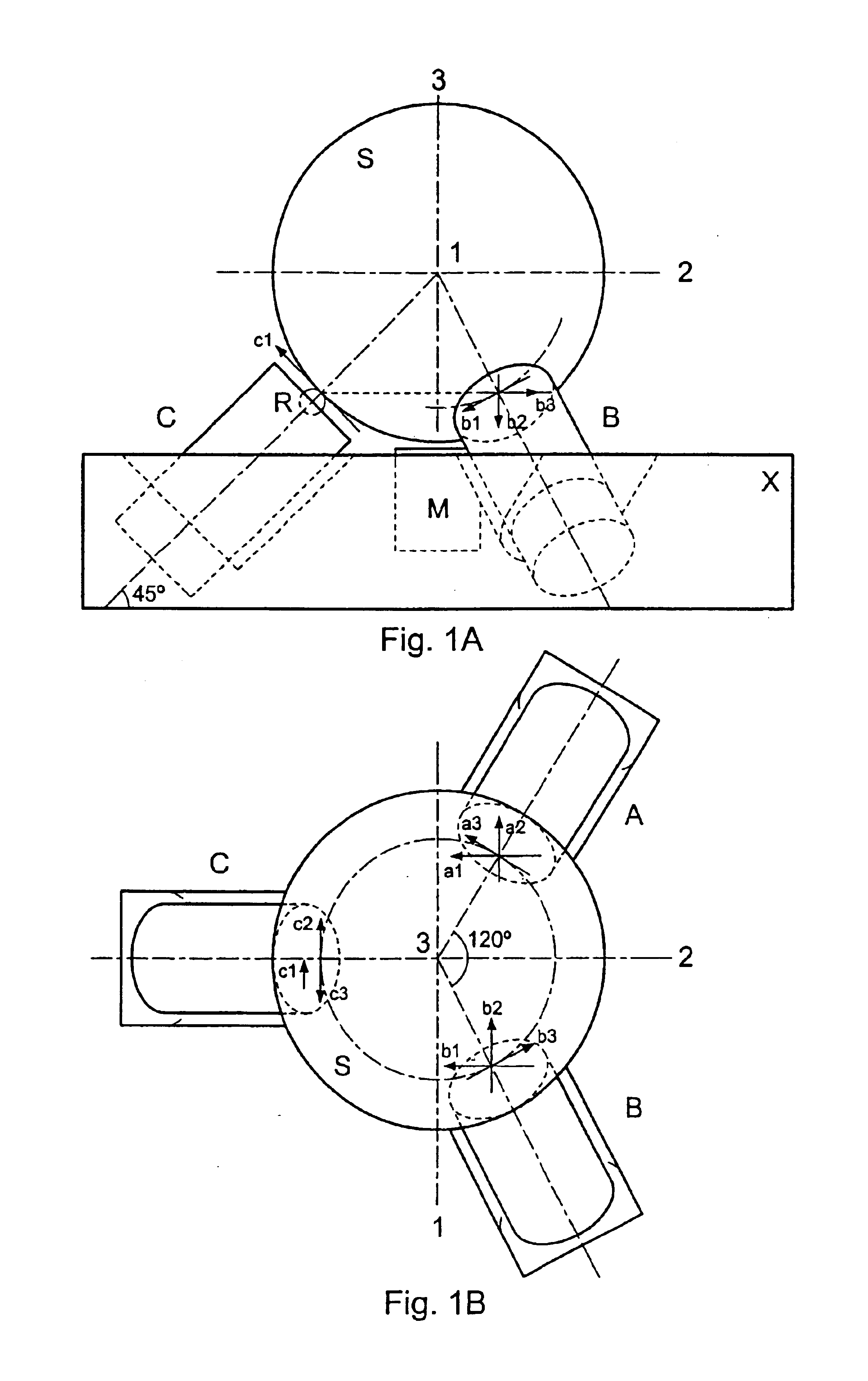

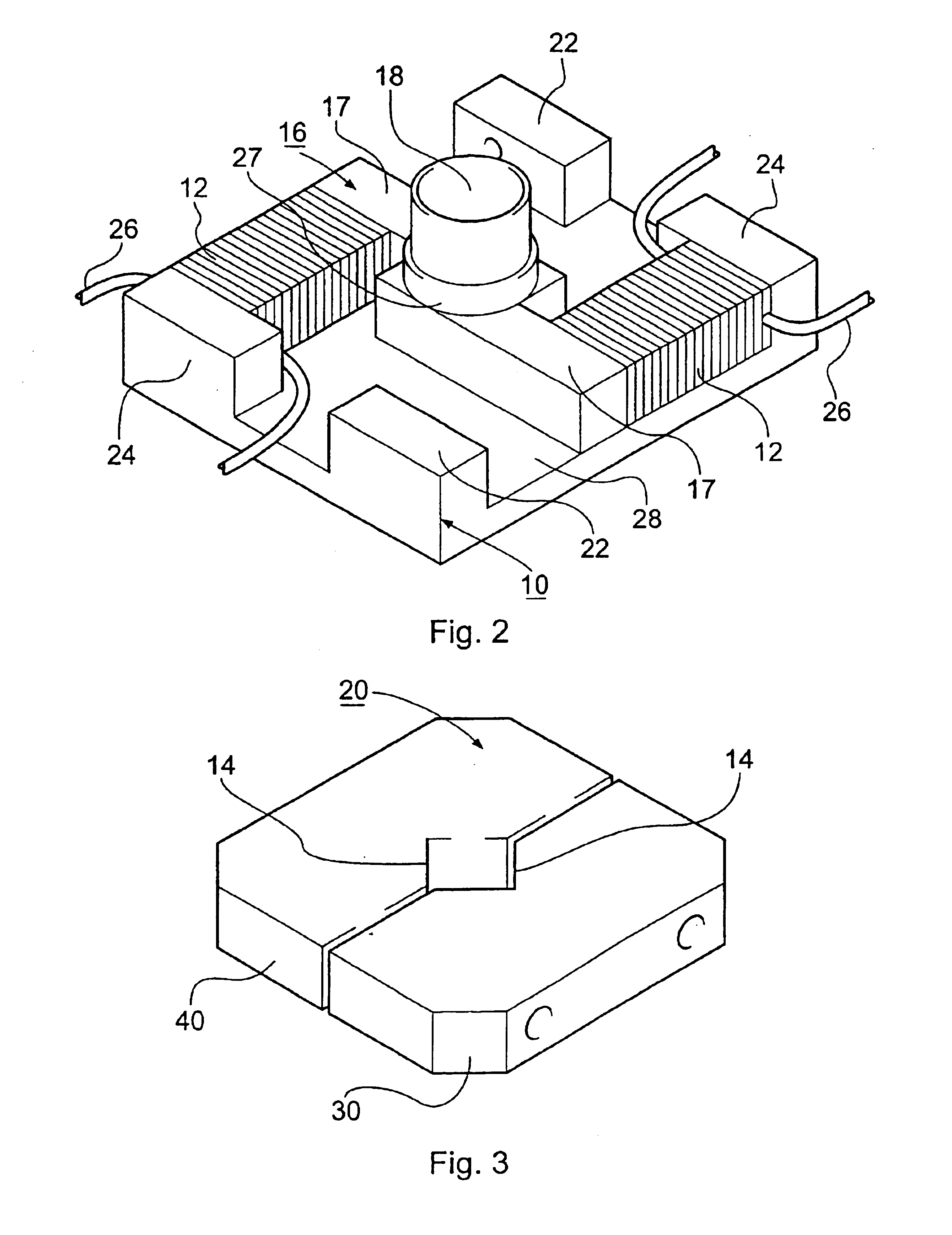

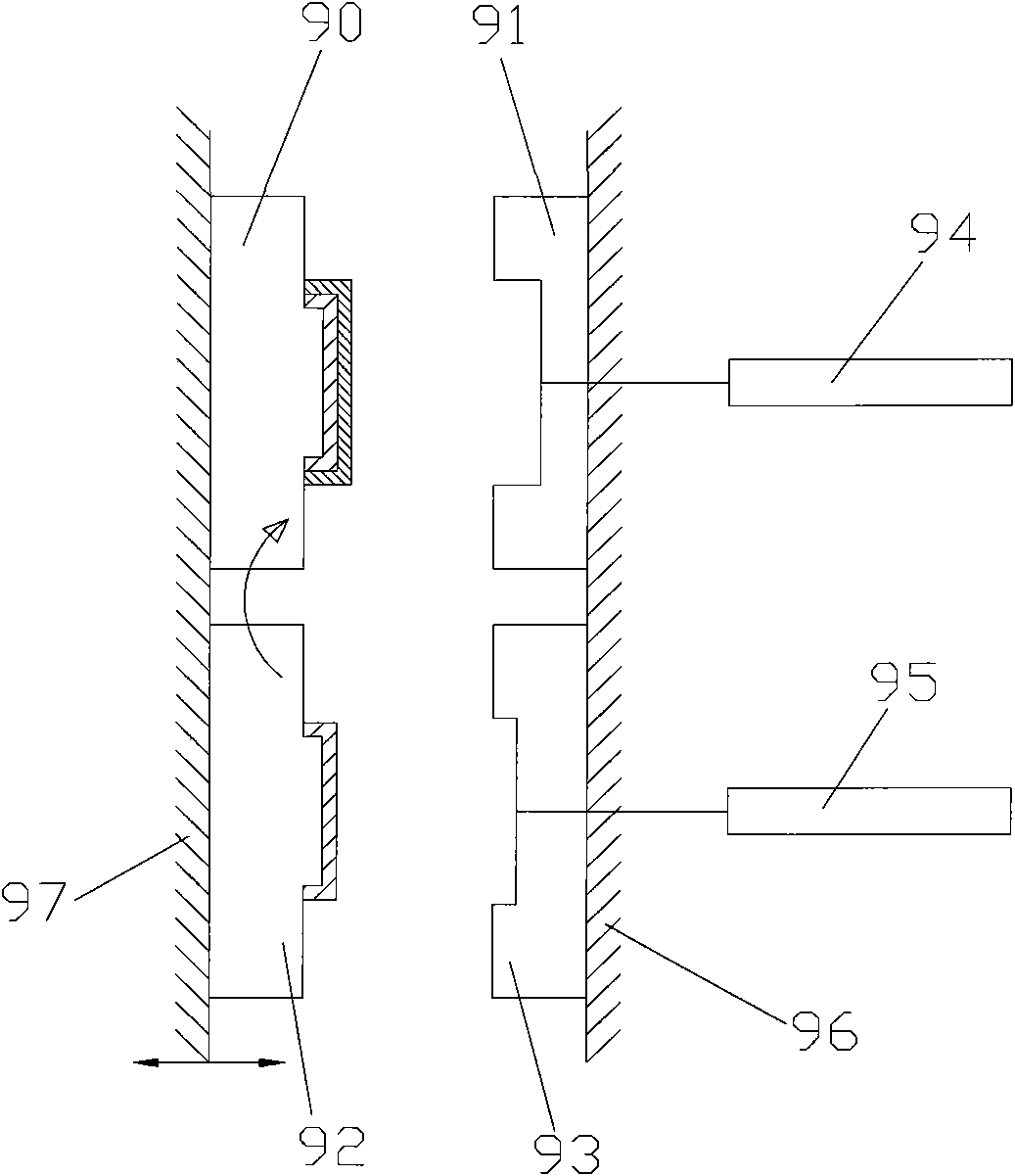

Inertial rotation device

InactiveUS6940210B2Reduce clamping forceEasy to operatePiezoelectric/electrostriction/magnetostriction machinesNanotechnologyElectricityPiezoelectric actuators

An inertial positioning device comprising: a base plate (10); a top plate (20) for mounting an element to be rotated; a rotation member (16) having a column (18) on which the top plate is mounted in frictional engagement for slip-stick rotational motion; and a pair of piezoelectric actuators (12) each secured to the base plate at one end and to lateral extensions (17) of the rotation member at their other ends. Simultaneous actuation of the piezoelectric actuators rotates the column of the rotation member about its axis. When a suitable asymmetric drive signal is supplied to the piezoelectric actuators, the top plate is rotated by slip-stick motion. The device is compact, has a good load capacity for an inertial motor and is operable in extreme environments such as liquid helium temperatures, high vacuum and high magnetic fields.

Owner:ATTOCUBE SYST AG

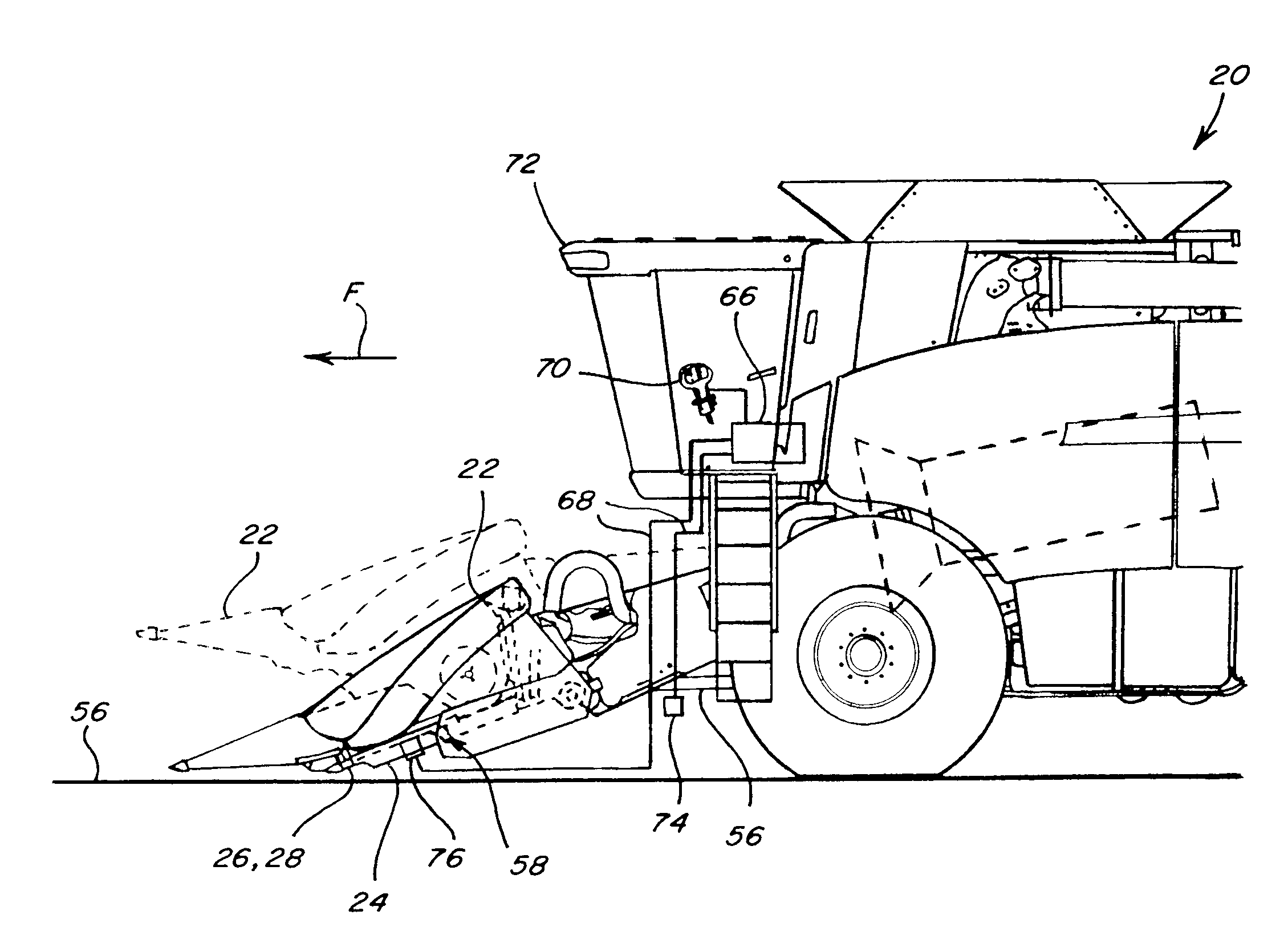

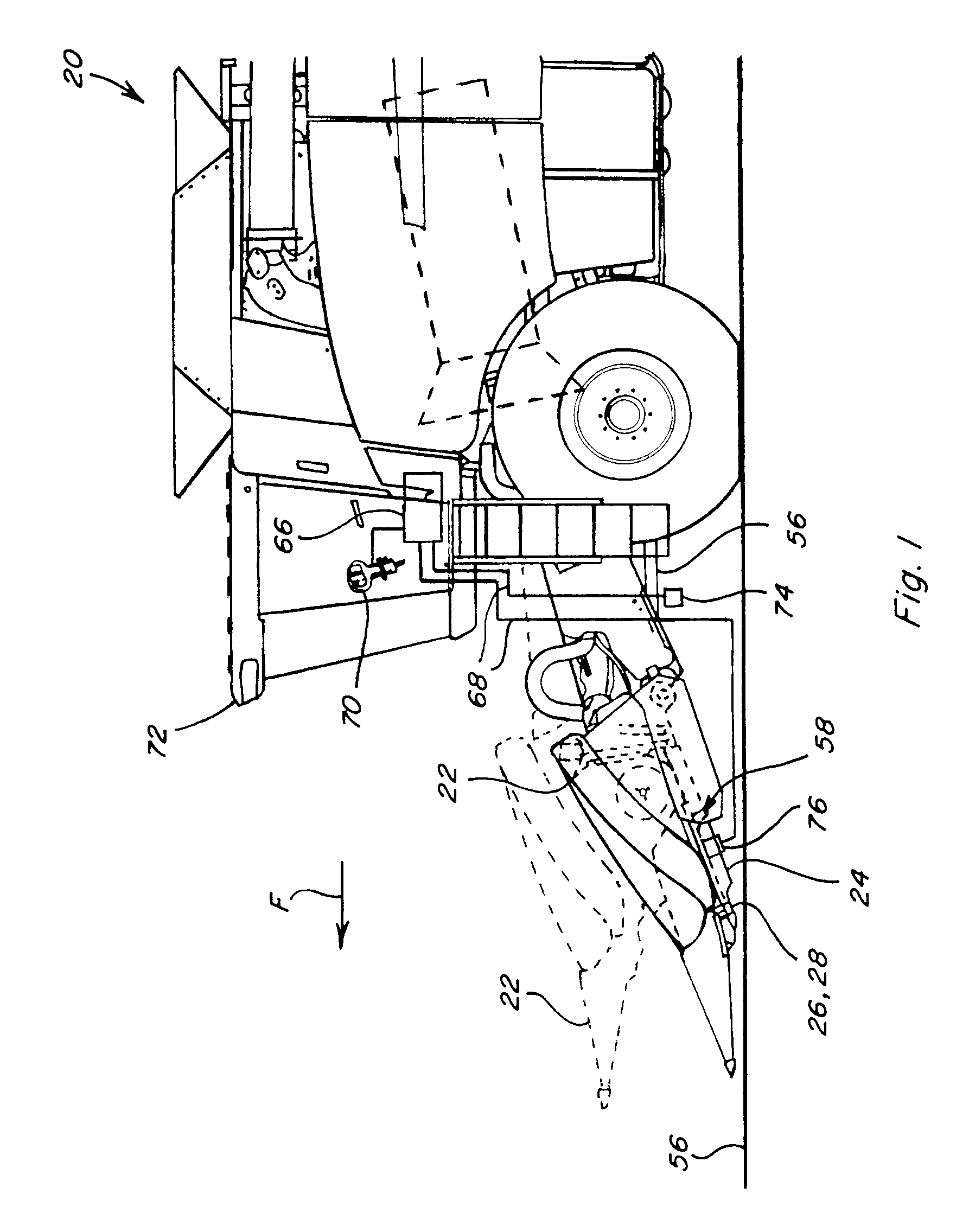

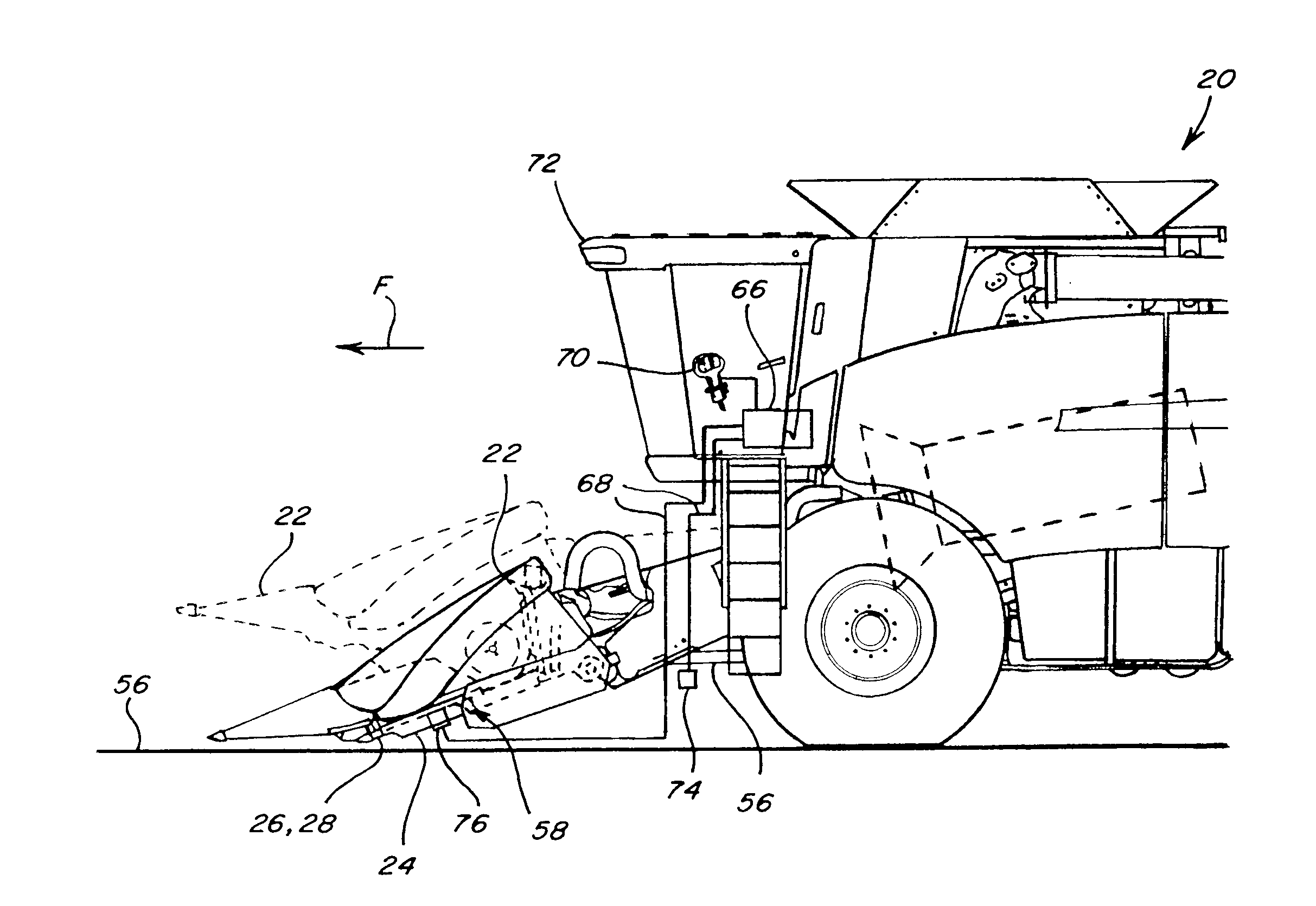

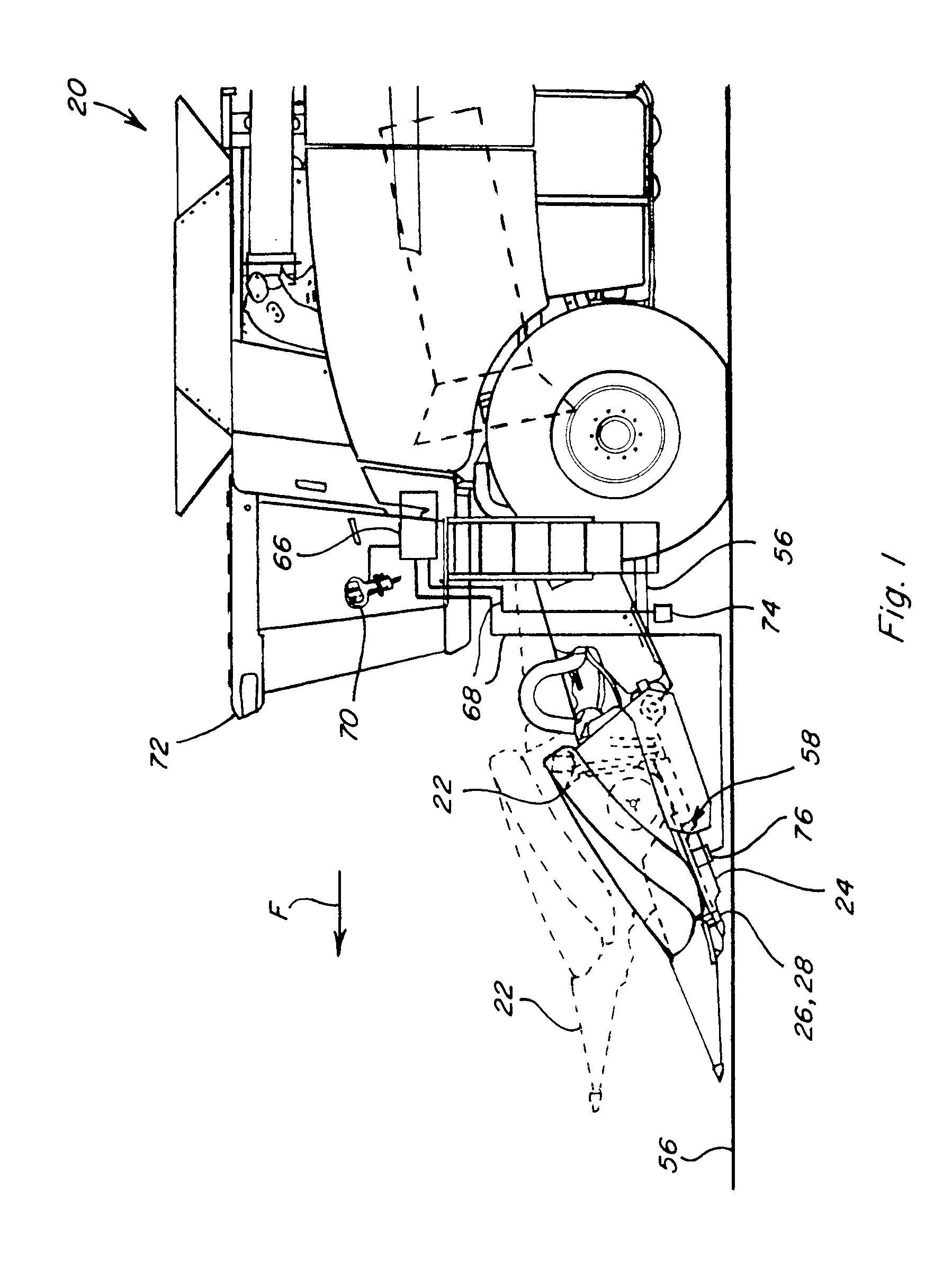

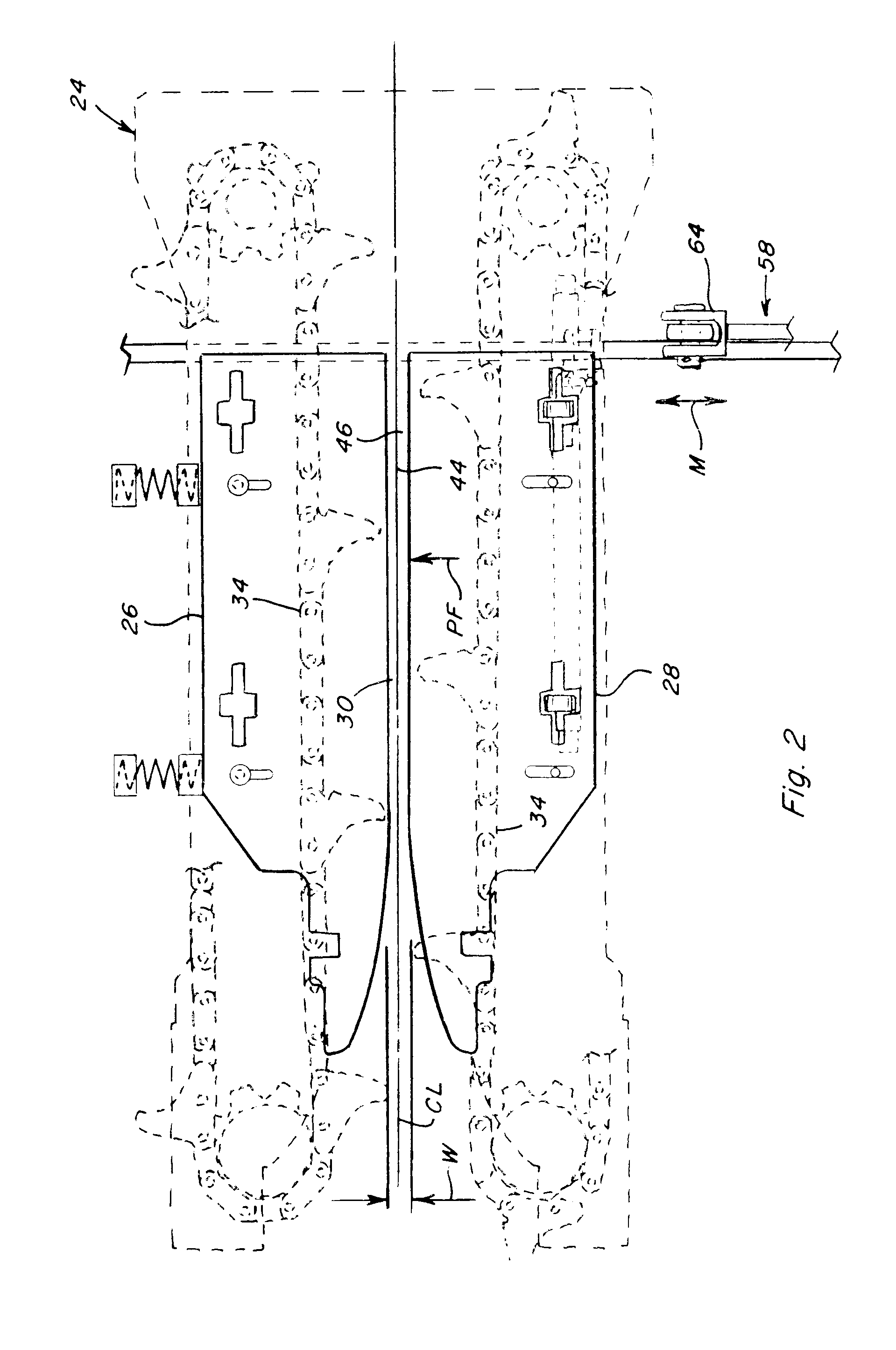

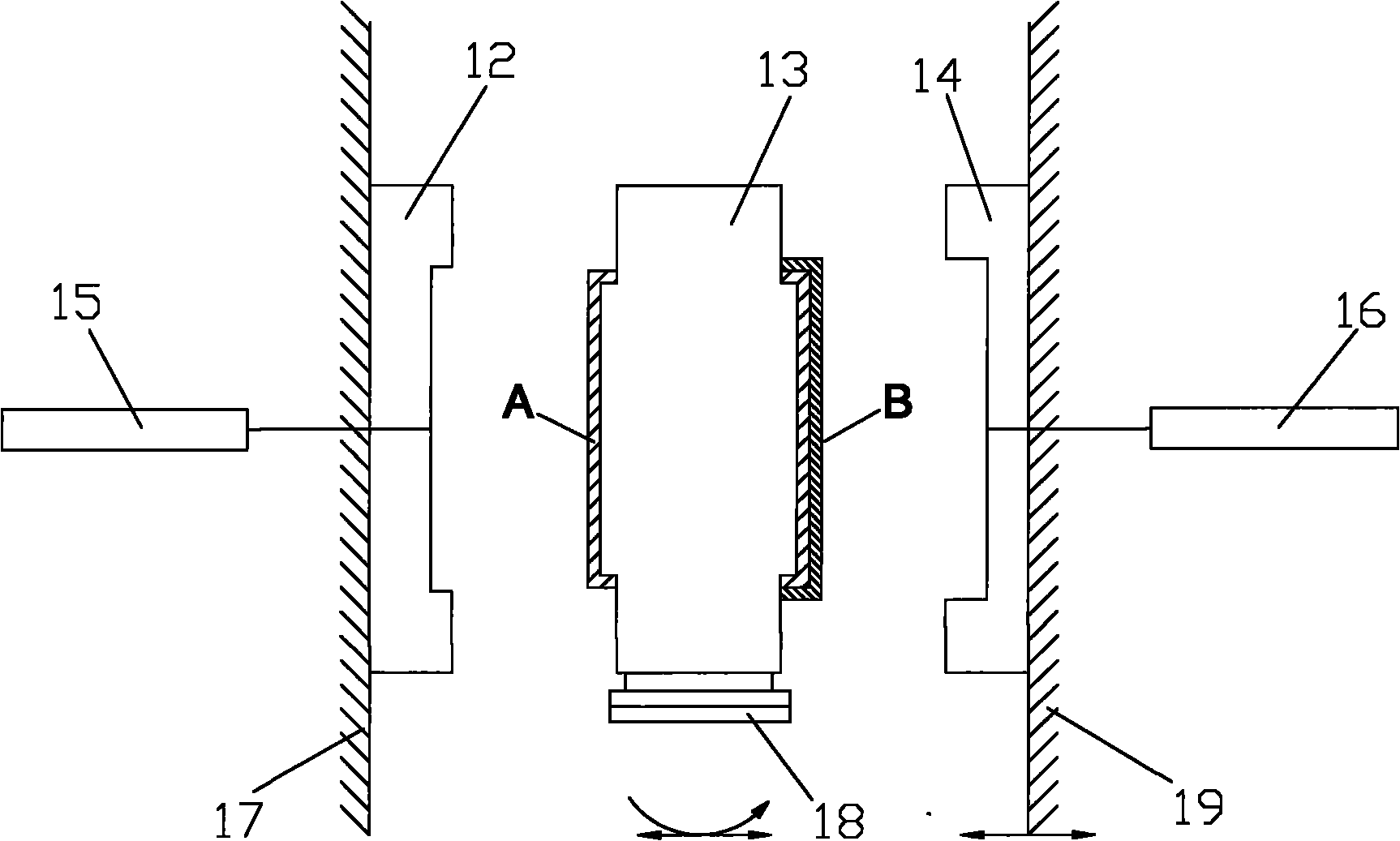

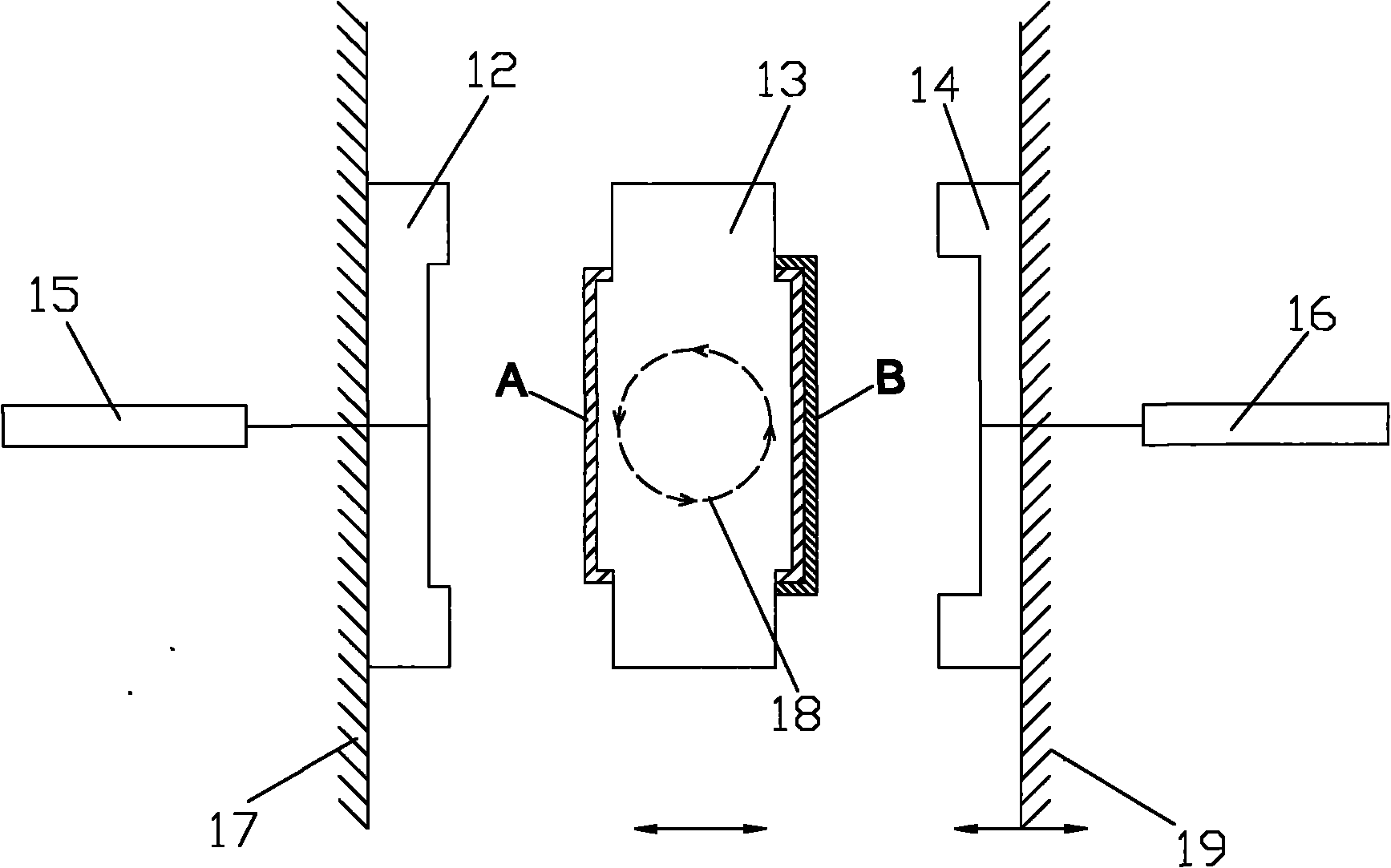

System and method for automatically controlling deck plate position on a corn header

ActiveUS8224534B2Overcomes shortcomingIncrease widthVehicle testingGrain huskingAutomatic controlEngineering

The system and method automatically controls the position of at least one deck plate of a harvesting unit of a corn header so as to increase the width of a stalk receiving channel or reduce pinching forces between the plates when entering a stand of corn to facilitate alignment with the corn rows, and to change the position after a suitable time period or other condition or event, to narrow the channel width and / or increase pinching force, to reduce kernel loss while also monitoring forces exerted against the plates by the stalks and responsively adjusting the plate position for maintaining a desired force on the stalks or width.

Owner:BLUE LEAF I P INC

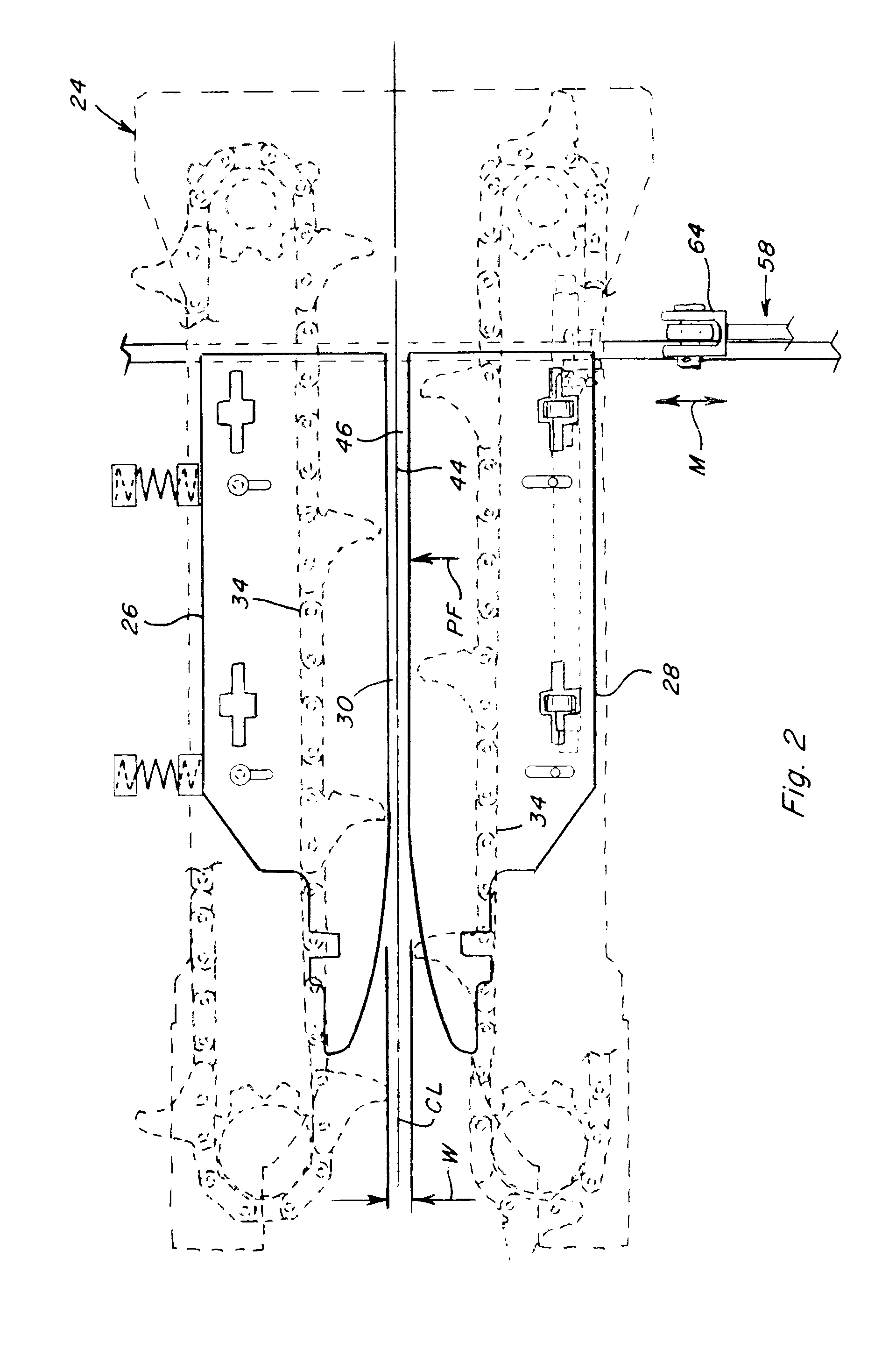

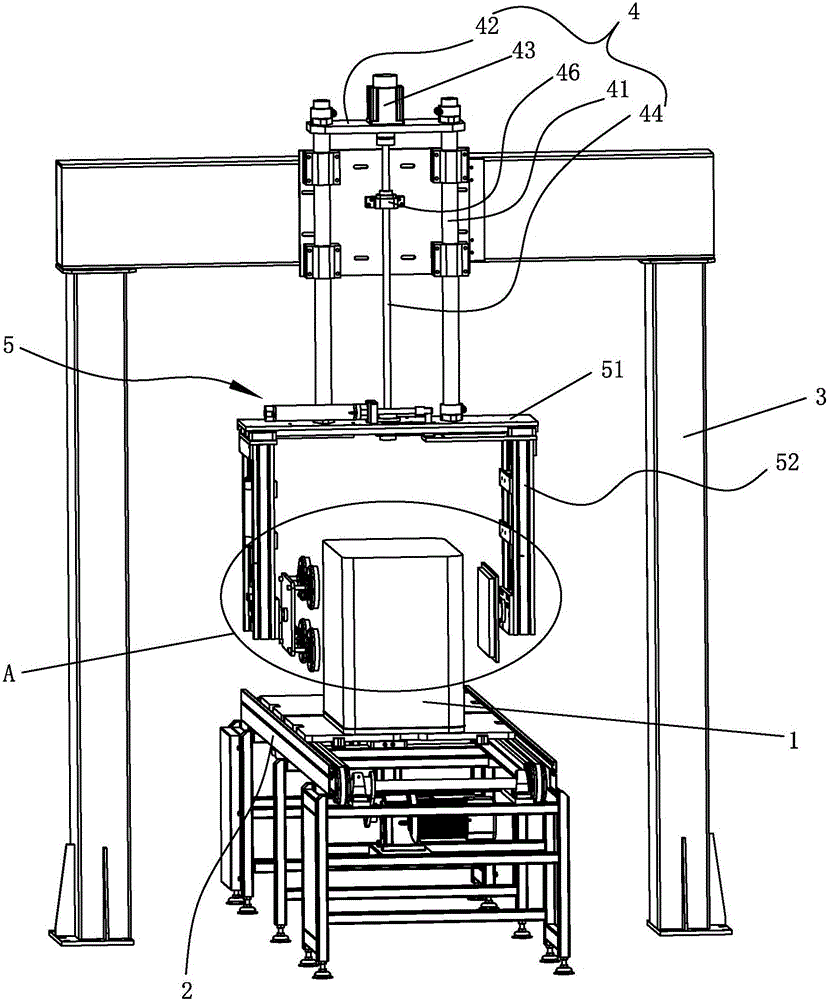

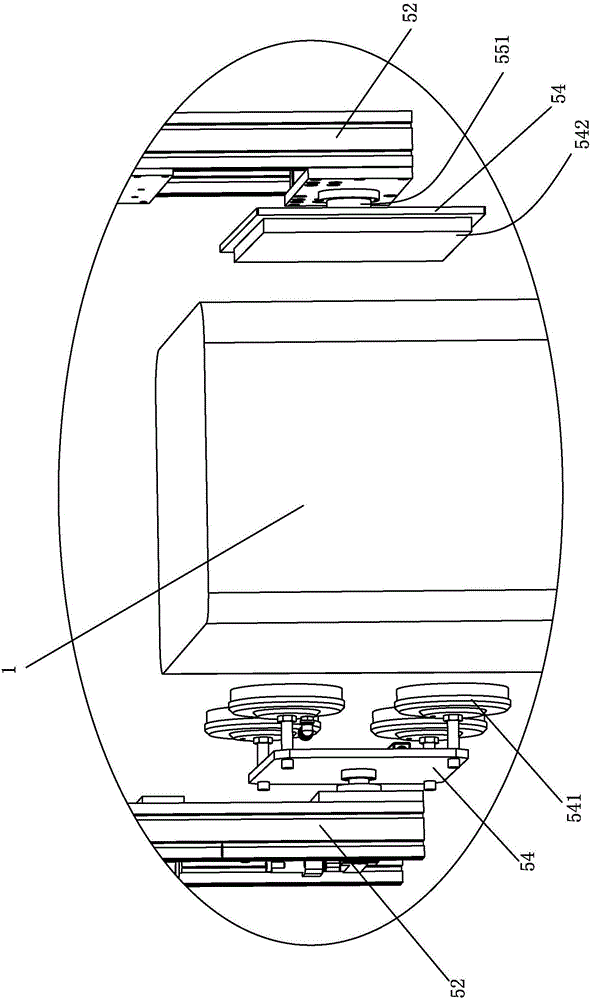

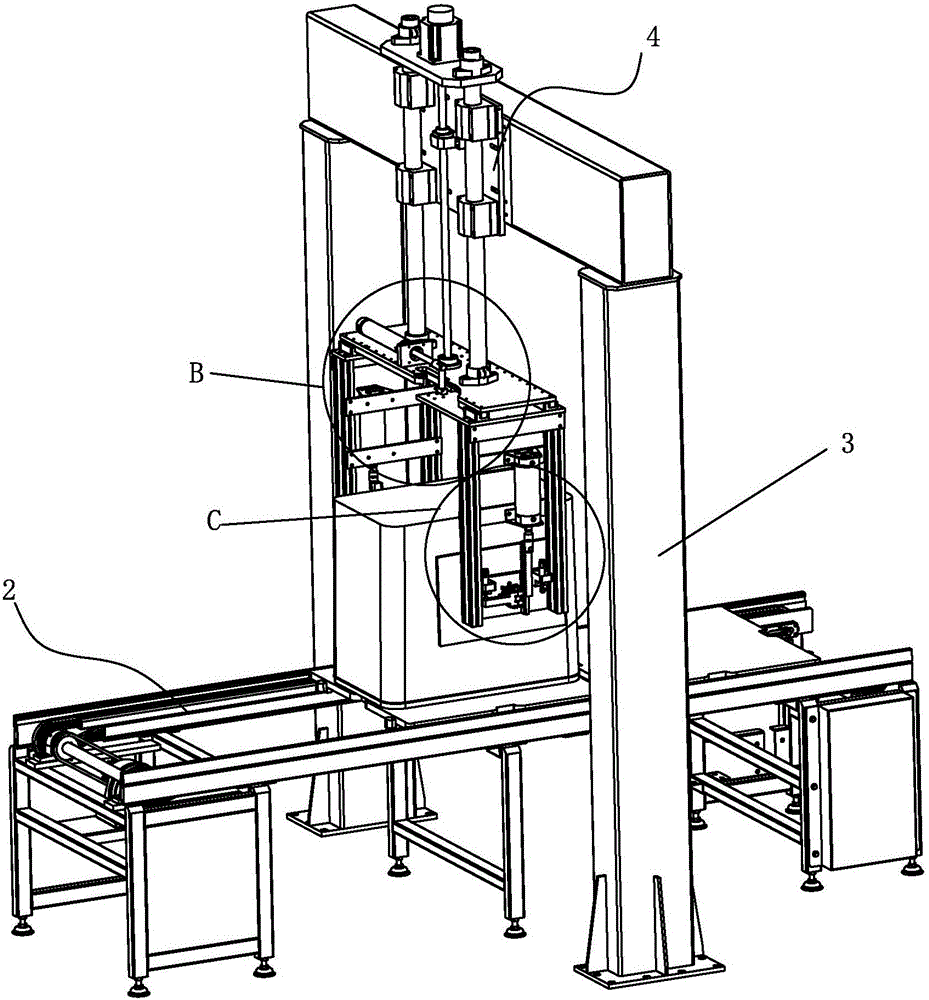

On-line automatic overturning equipment

InactiveCN106044140AReduce labor intensityImprove work efficiencyConveyorsConveyor partsEngineeringPortal frame

The invention discloses on-line automatic overturning equipment. The on-line automatic overturning equipment comprises a conveying line for conveying boxes and a portal frame arranged on the conveying line in a straddling manner; a lifting mechanism is arranged on the portal frame; the lower end of the lifting mechanism is connected with a clamping overturning mechanism; the clamping overturning mechanism comprises a clamping seat and two clamping arms; the clamping seat is connected to the lower end of the lifting mechanism; the two clamping arms are slidably connected onto the clamping seat; the clamping seat is provided with a clamping driving assembly which drives the two clamping arms to carry out clamping or releasing action; the lower ends of the two clamping arms are rotatably connected with clamping blocks for clamping the boxes respectively; an overturning driving assembly which is used for driving the corresponding clamping block to overturn so as to overturn the boxes is arranged between each clamping arm and the corresponding clamping block. Under collaborative operation of the lifting mechanism and the clamping overturning mechanism, the boxes from the conveying line are automatically overturned at an angle, by the clamping overturning mechanism, the boxes can be quickly and efficiently overturned at an angle, work efficiency is improved, labor intensity of workers is reduced, and production cost is reduced.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

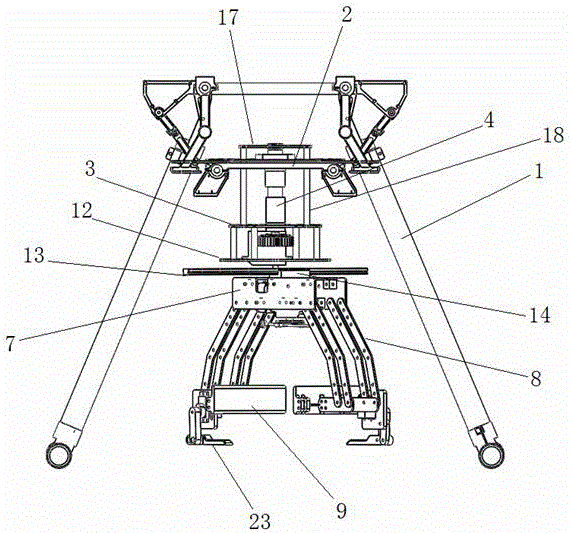

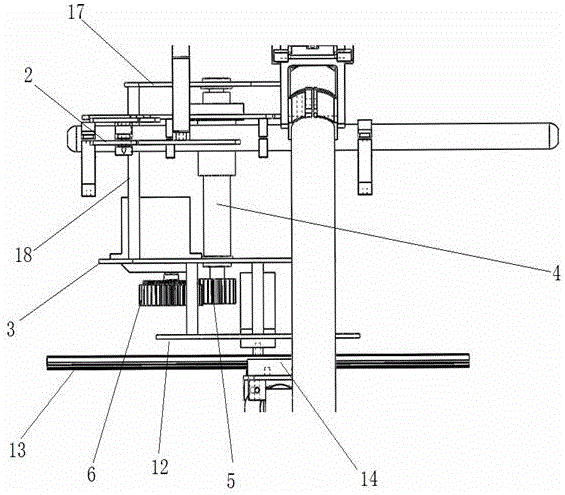

Flight carrier system of unmanned aerial vehicle

InactiveCN105799935APrecise positioningAvoid labor intensityProgramme-controlled manipulatorRemote controlled aircraftRemote controlFlight vehicle

The invention discloses a flight carrier system of an unmanned aerial vehicle.The flight carrier system comprises a lifting mechanism and a grabbing mechanism.The lifting mechanism comprises a fixing carrier plate, a lifting carrier plate and a lifting lead screw.A driven tooth is arranged at one end of the lifting lead screw.A driving tooth is arranged on the lifting carrier plate.The driving tooth drives the driven tooth to rotate to control the lifting lead screw to be lifted.The lifting lead screw is lifted to drive the lifting carrier plate to move.The grabbing mechanism comprises a base, a movable arm and a traction device controlling the movable arm.The base is provided with a pair of movable arms, a rotating handle and a traction rod.The rotating handle rotates forward and reversely to pull the traction rod to extend and contract to drive the two movable arms.The grabbing mechanism is provided with a bottom carrying mechanism.Compared with the prior art, the flight carrier system of the unmanned aerial vehicle has the advantages that by means of longitudinal moving of the lifting mechanism and clamping of goods through the grabbing mechanism, the unmanned aerial vehicle can transport the goods by means of remote control, labor force is saved, and the working efficiency is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

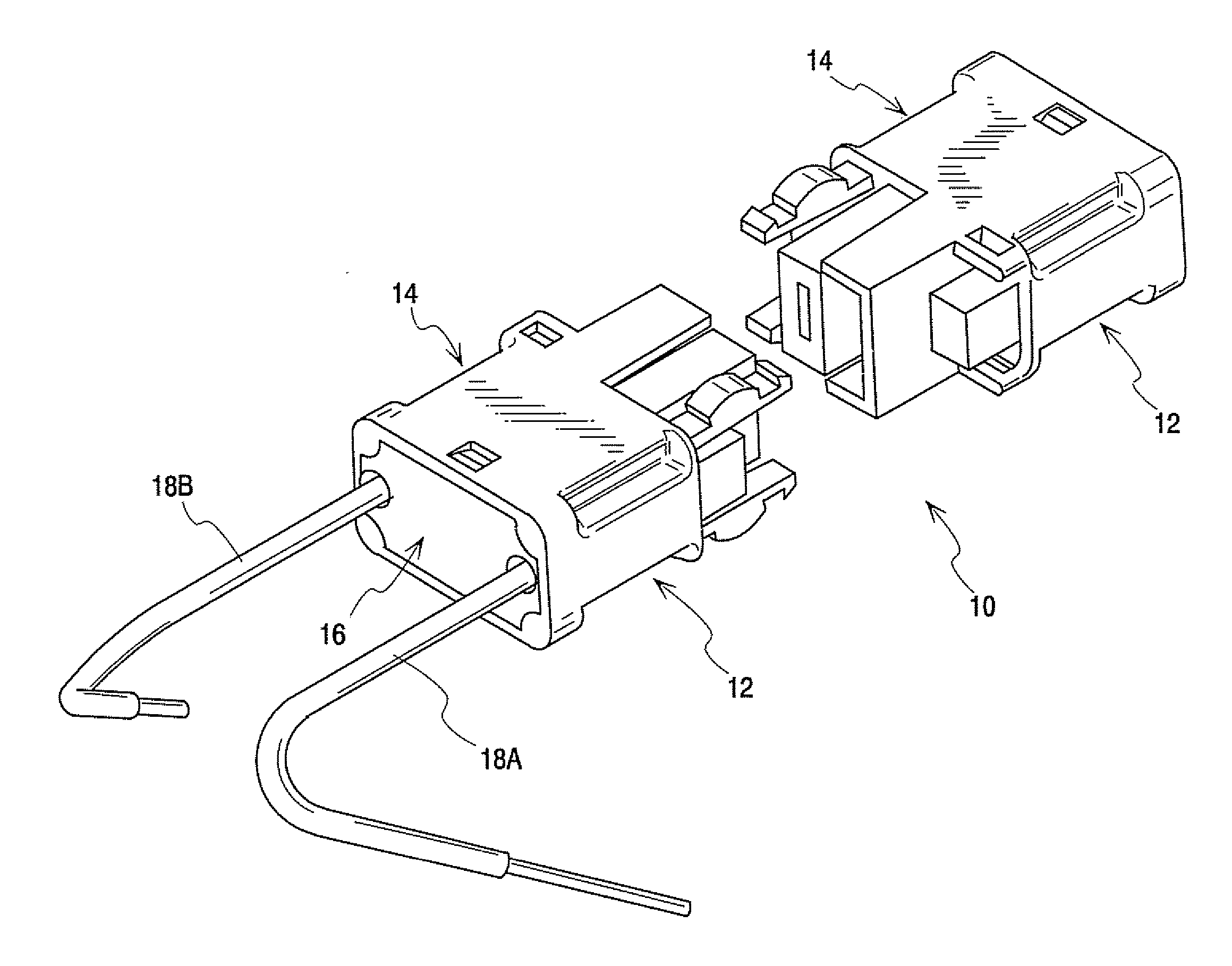

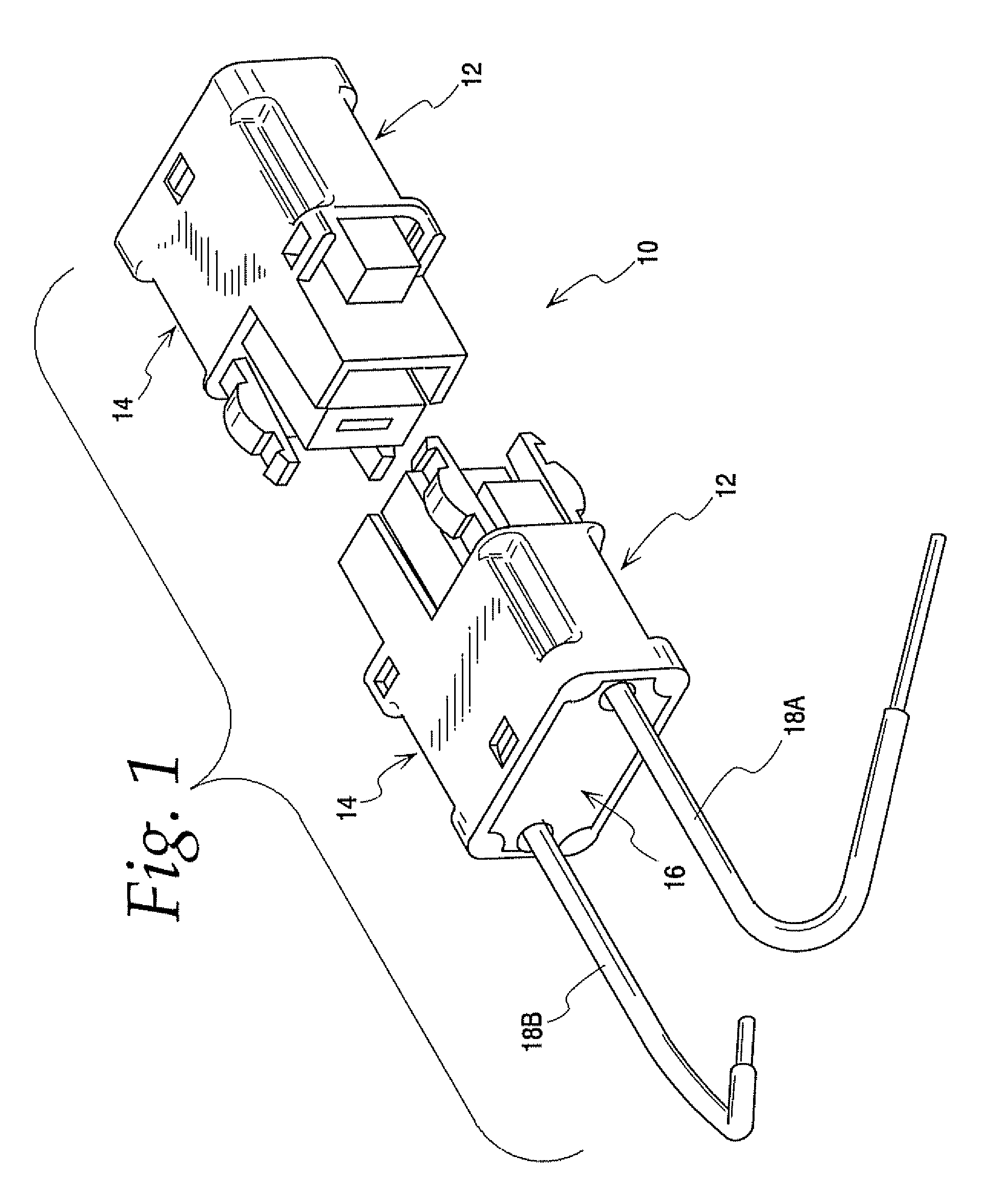

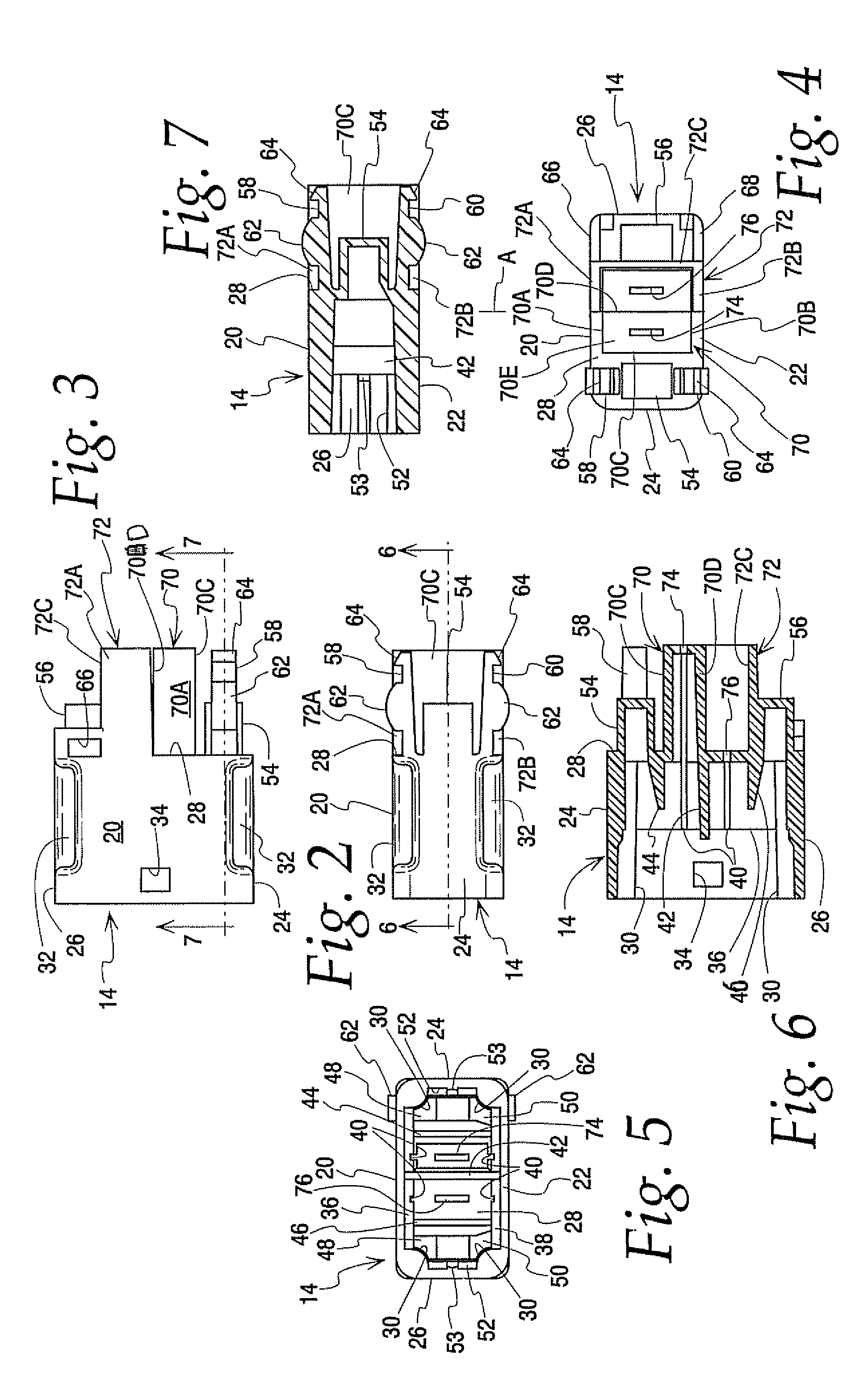

Electrical Disconnect With Push-In Connectors

ActiveUS20060286864A1Improve securityAvoid shortingTwo pole connectionsSecuring/insulating coupling contact membersEngineeringElectric wire

A wire connector has an enclosure including a housing and a cap and one or more contacts supported in the enclosure. The contacts each have outer ends opposite wire ports in the cap to receive a stripped end of a wire in a push-in engagement. One set of contacts has a male blade and the other set of contacts has a female socket at the inner or forward ends thereof. The housings are arranged so that two housings are releasably engagable with one another. When two housings are engaged the male contacts electrically engages the female contacts of the other housing. The female contacts include a sacrificial tine that is always first to make and last to break engagement with the male contact so that any degradation due to arcing always occurs at the sacrificial tine.

Owner:IDEAL IND INC

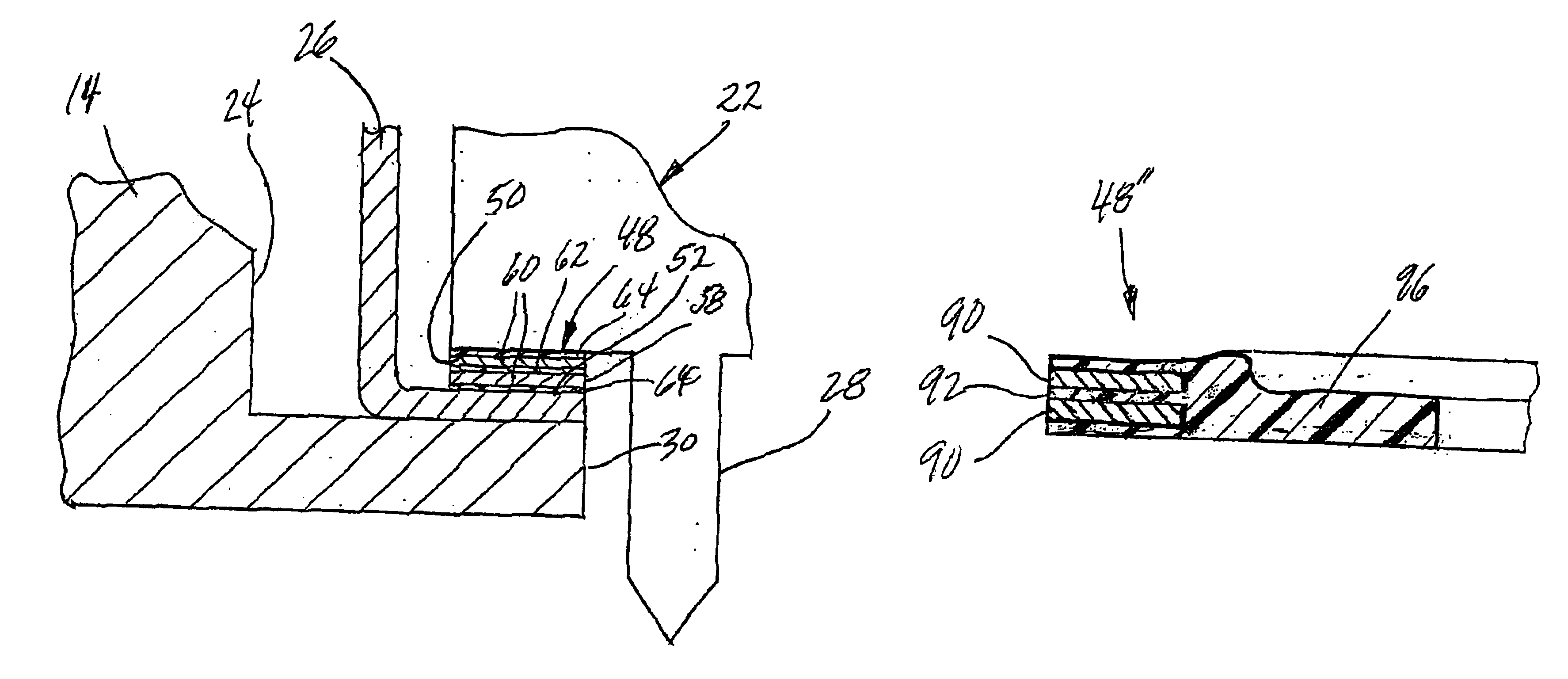

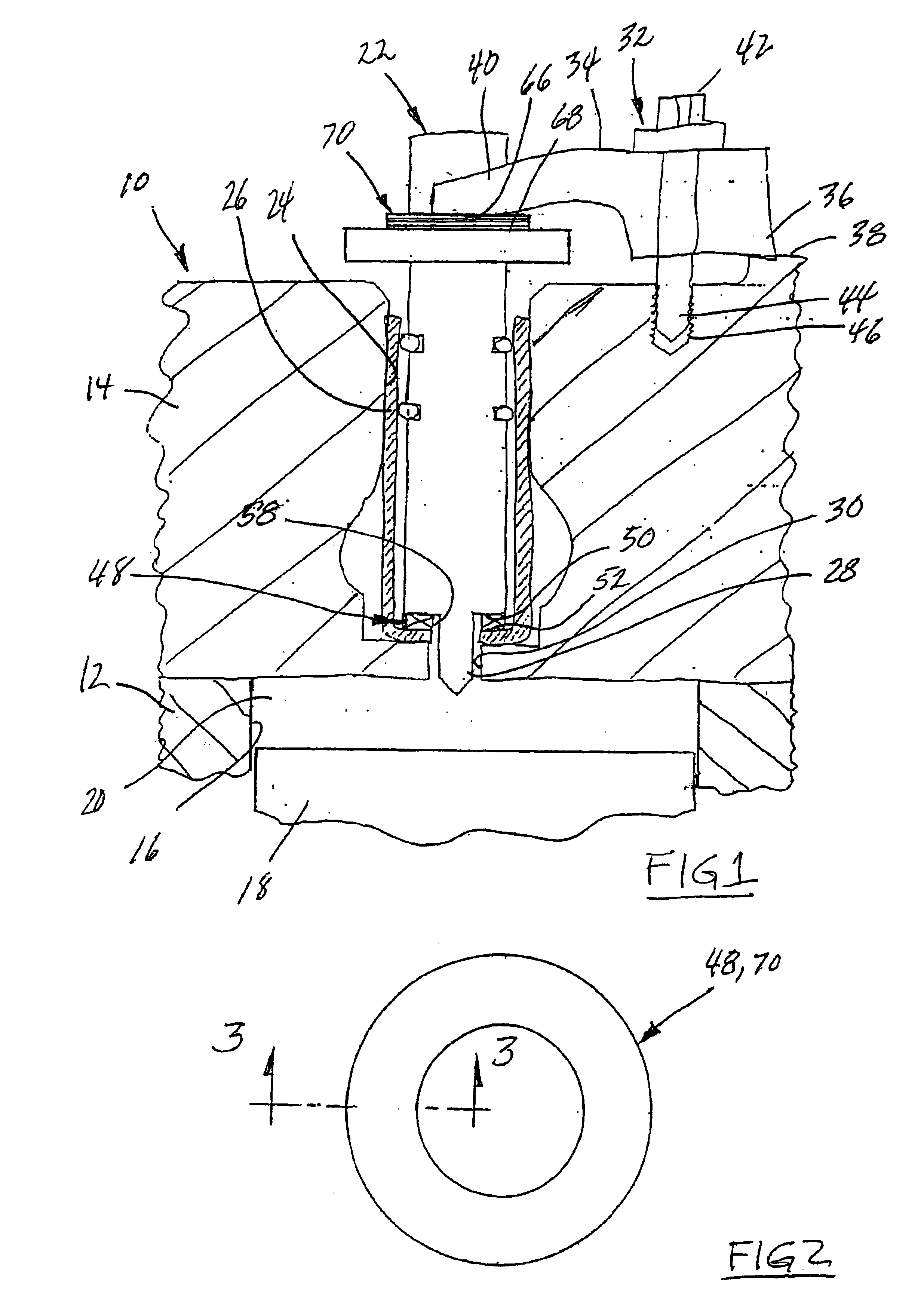

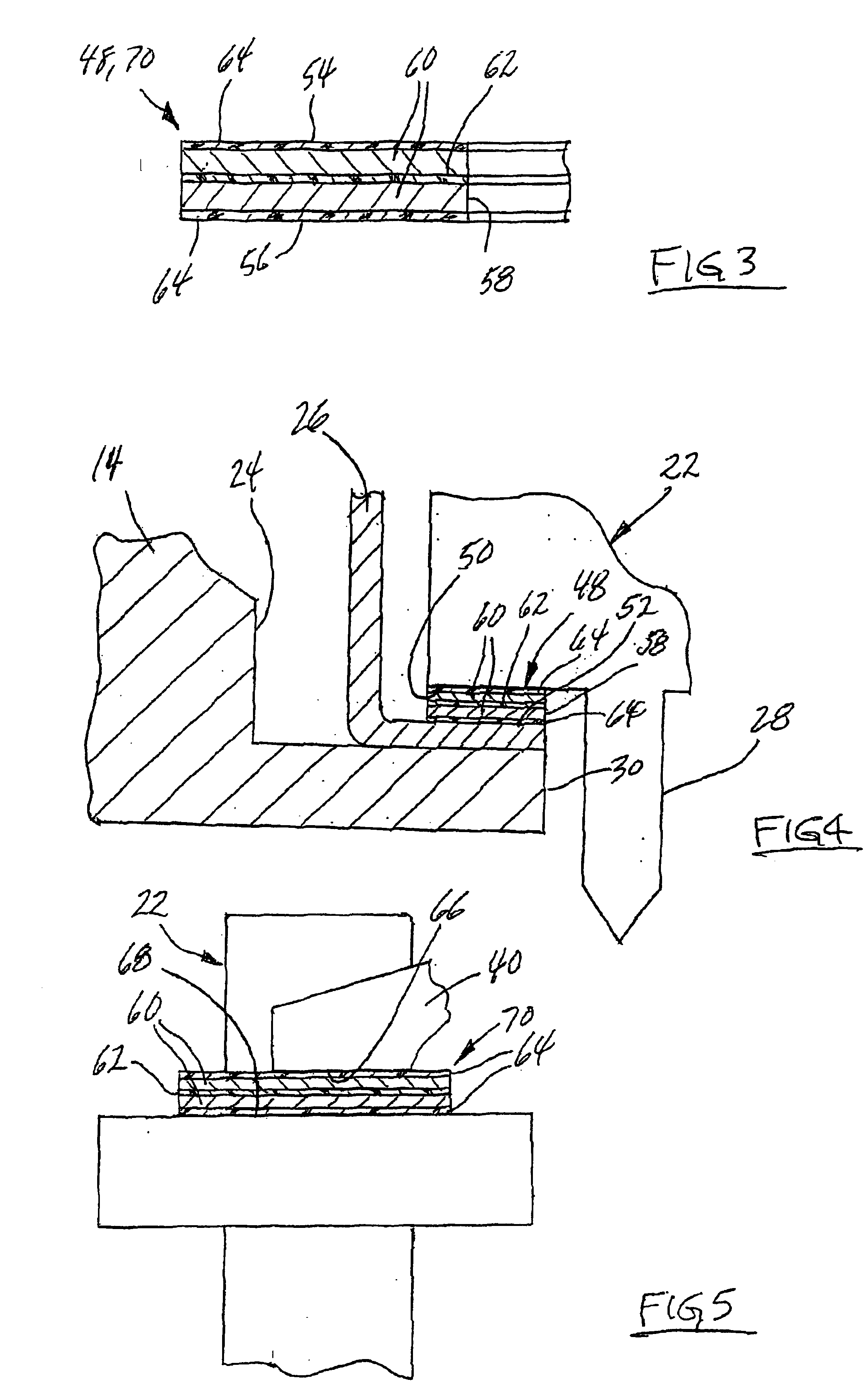

Gasket for fuel injector

InactiveUS6866026B2Effective seal against leakageTransmission limitEngine sealsNoise reducing fuel injectionCylinder headEngineering

A gasket (48, 48′, 48″) and (70) for disposition between a fuel injector (22) and a cylinder head (14) comprises compressible polymer layers (62, 64, 74, 92) and incompressible and flat metal layers (60, 72, 90) sandwiched between the polymer layers. In the embodiments of FIGS. 6-8, a polymer body (80, 96) is disposed radially inwardly of the incompressible layer (72) or layers (90) and includes a bead portion (86) thicker than the total thickness of the incompressible and polymer layers (72), and (74, 90) and (92). The body (80, 96) also includes a recess portion (82-84) having a thickness less than the total thickness to define a recess (88) adjacent the bead portion (86). The bead portion (86) is disposed radially between the recess portion (82-84) and the incompressible layer (72 or 90).

Owner:FEDERAL MOGUL WORLD WIDE LLC

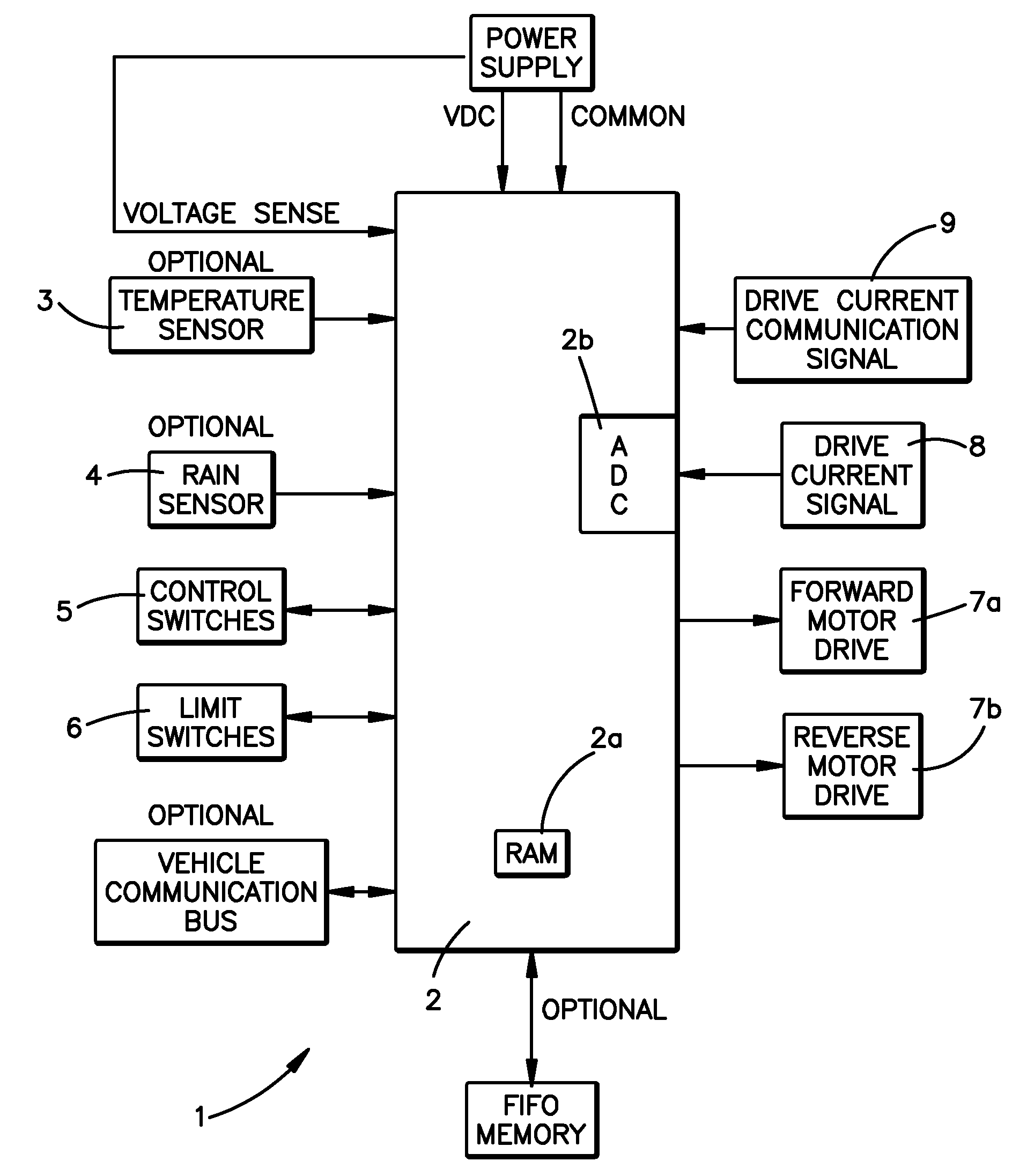

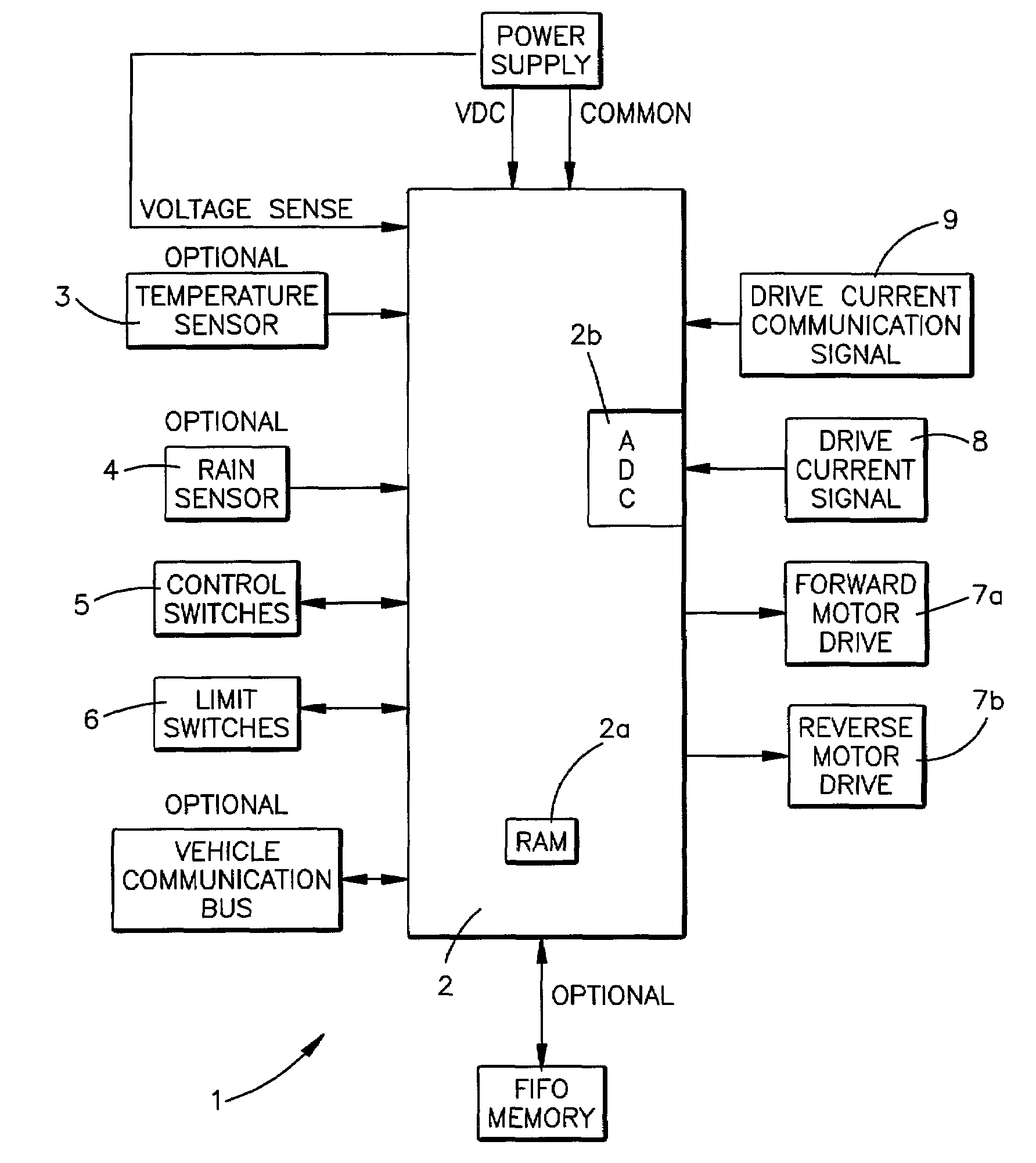

Collision monitoring system

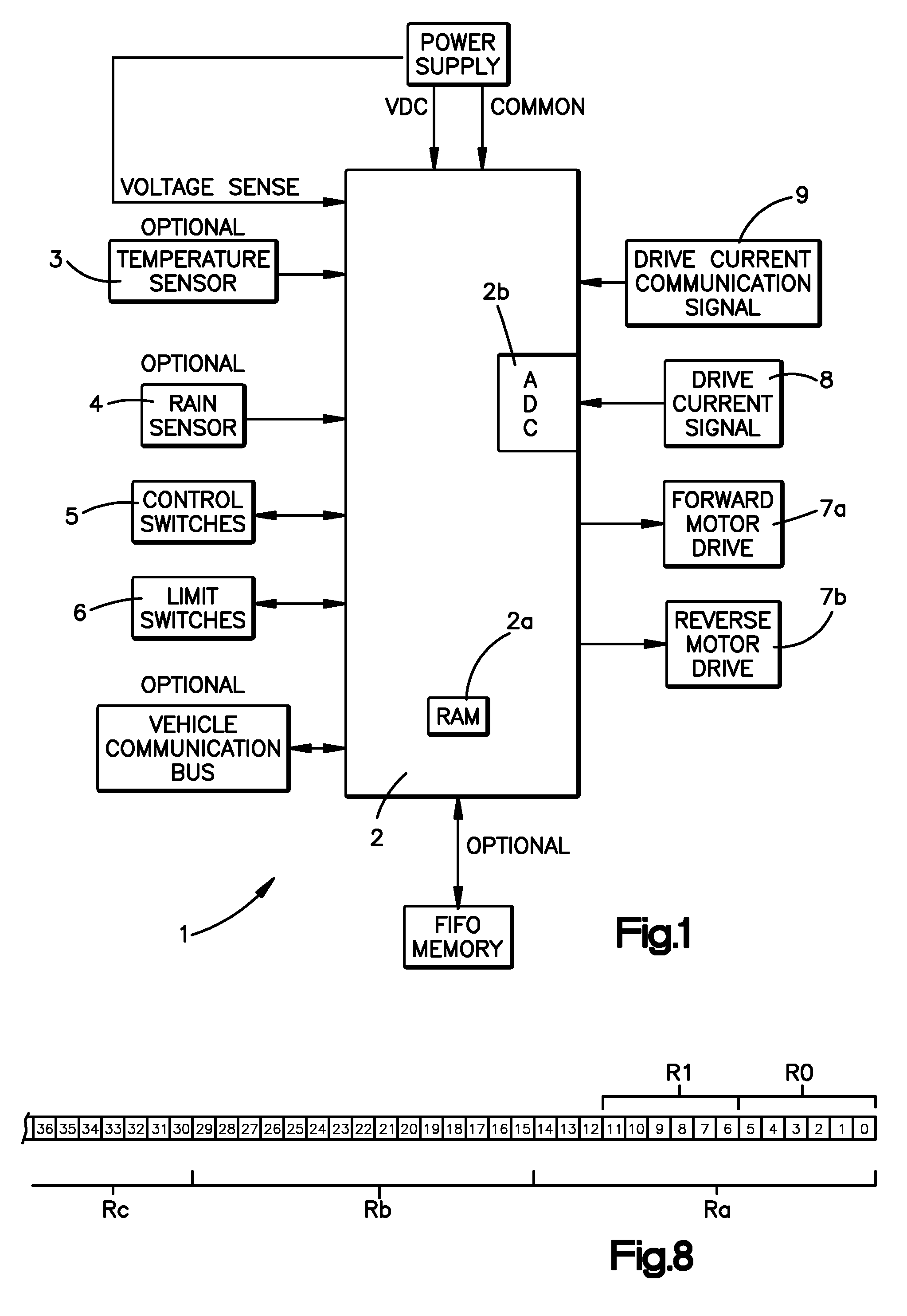

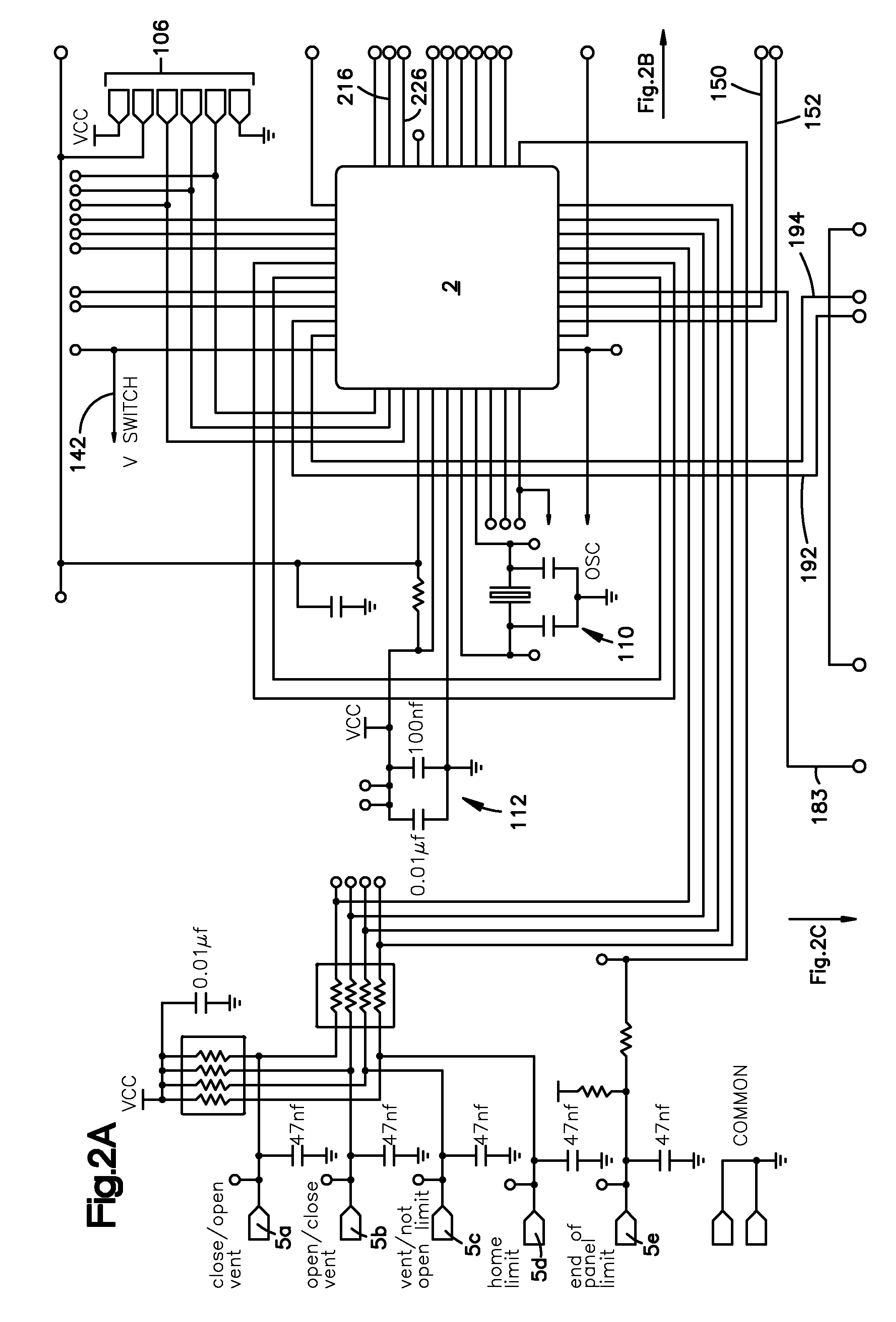

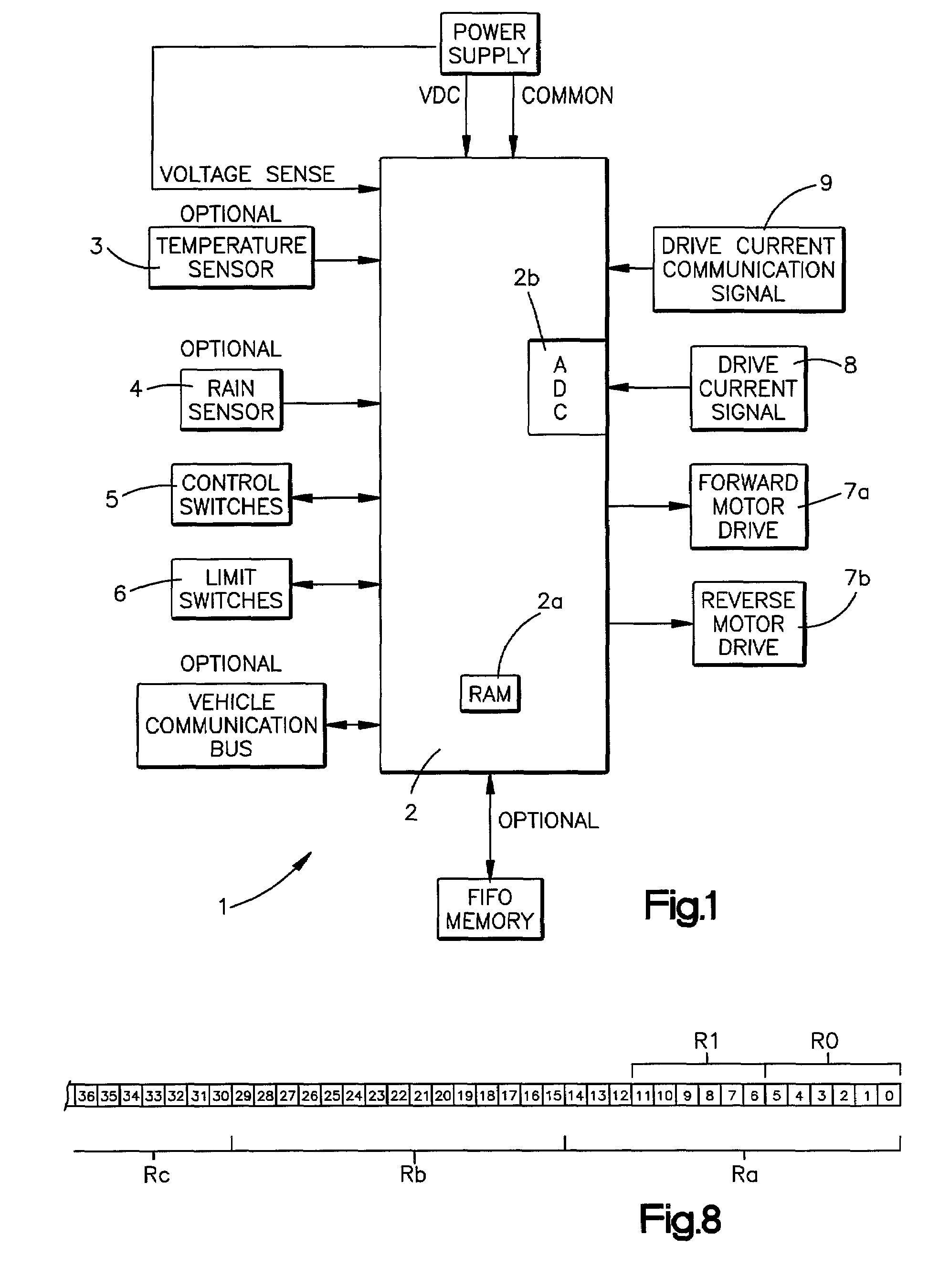

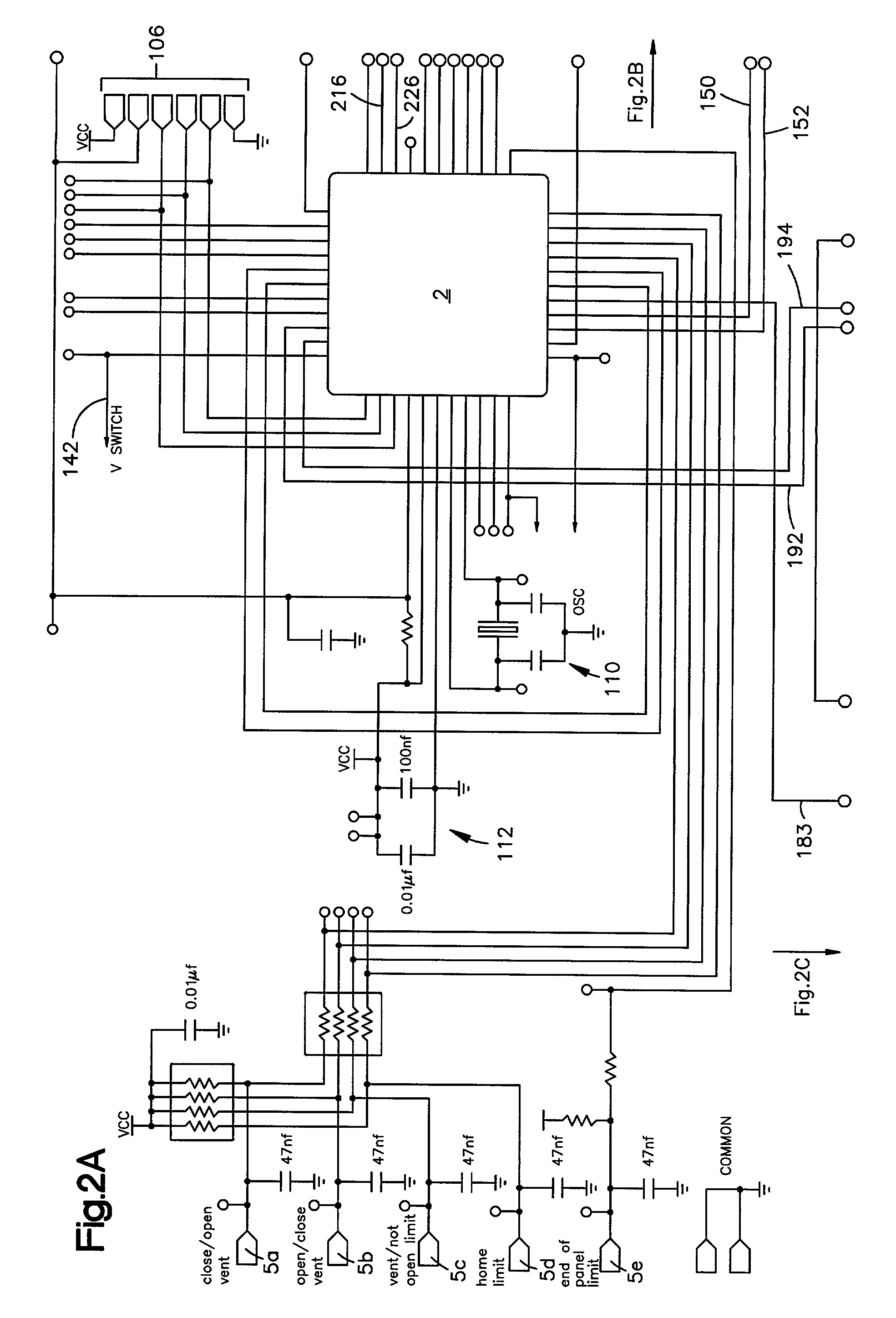

InactiveUS20090272035A1Easy to operateSensitive detectionParameter calibration/settingDC motor speed/torque controlMonitoring systemEngineering

Disclosed is an improved system and method for sensing both hard and soft obstructions for a movable panel such as a sunroof. A dual detection scheme is employing that includes an optical sensing as the primary means and electronic sensing of motor current as a secondary means. The secondary means utilizes system empirical precharacterization, fast processing algorithms, motor parameter monitoring including both current sensing and sensorless electronic motor current commutation pulse sensing, and controller memory, to adaptively modify electronic obstacle detection thresholds in real time without the use of templates and cycle averaging techniques.

Owner:UUSI

System and method for automatically controlling deck plate position on a corn header

ActiveUS20120029757A1Overcomes shortcomingIncrease widthVehicle testingGrain huskingAutomatic controlEngineering

The system and method automatically controls the position of at least one deck plate of a harvesting unit of a corn header so as to increase the width of a stalk receiving channel or reduce pinching forces between the plates when entering a stand of corn to facilitate alignment with the corn rows, and to change the position after a suitable time period or other condition or event, to narrow the channel width and / or increase pinching force, to reduce kernel loss while also monitoring forces exerted against the plates by the stalks and responsively adjusting the plate position for maintaining a desired force on the stalks or width.

Owner:BLUE LEAF I P INC

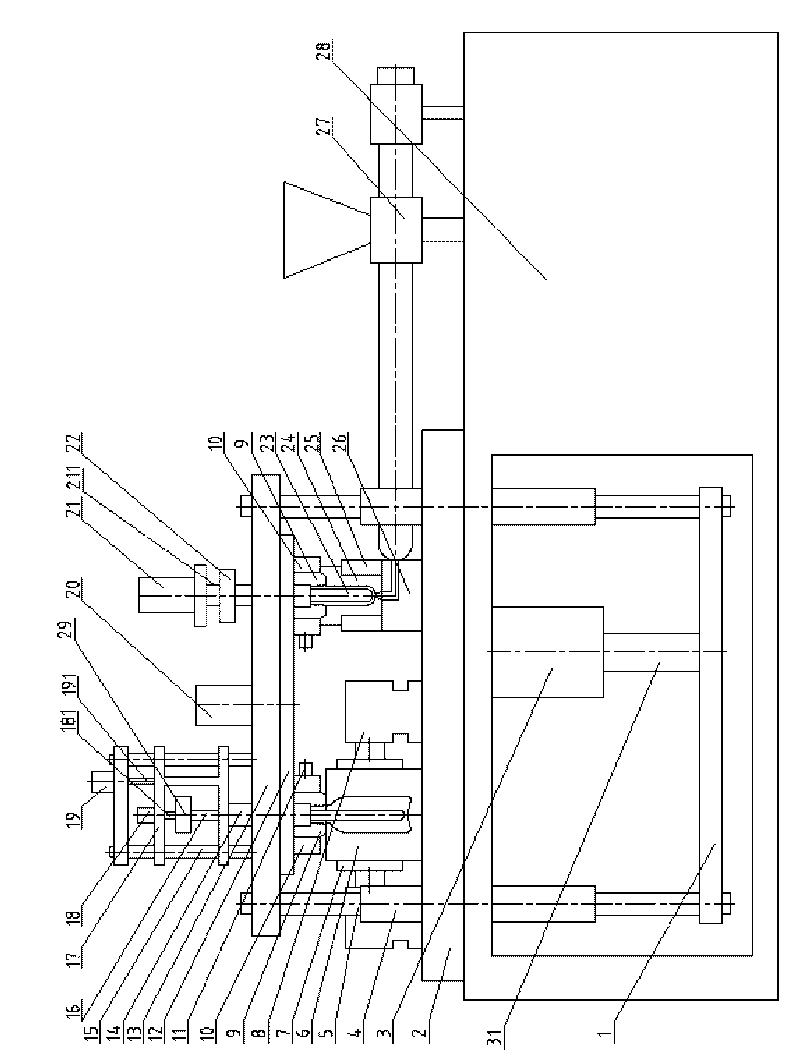

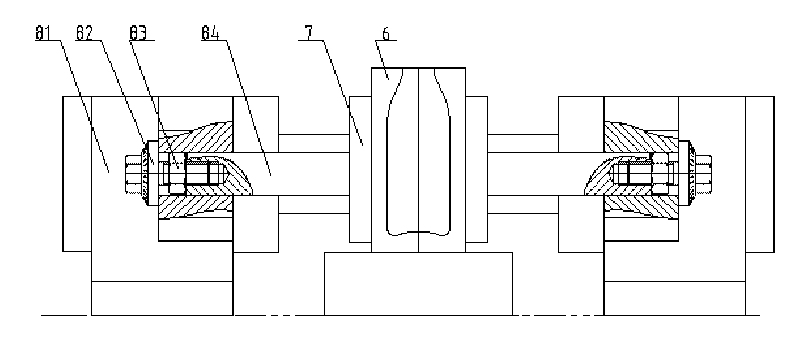

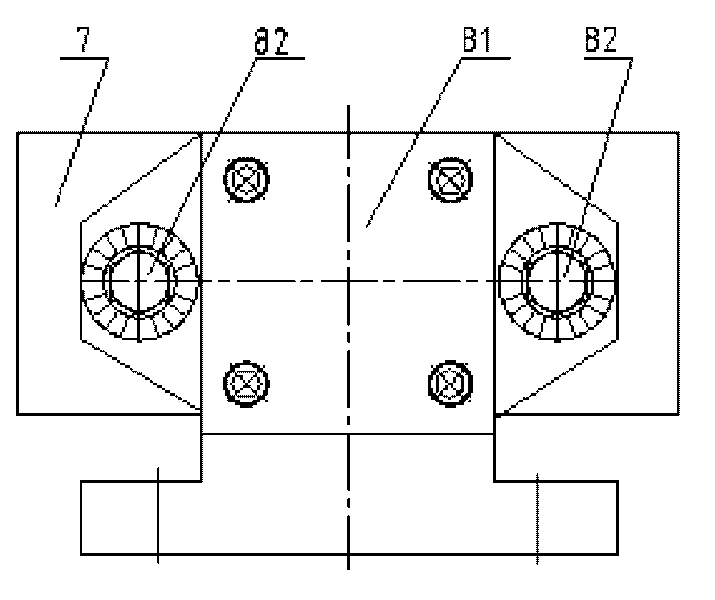

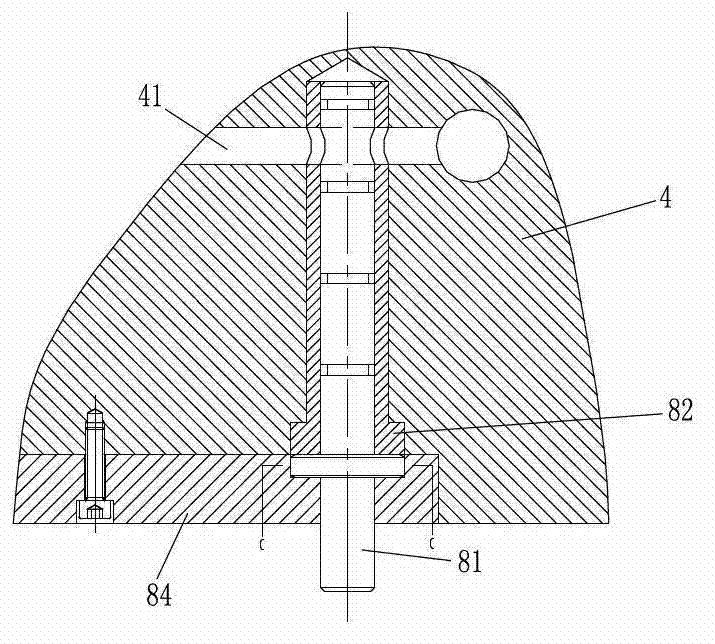

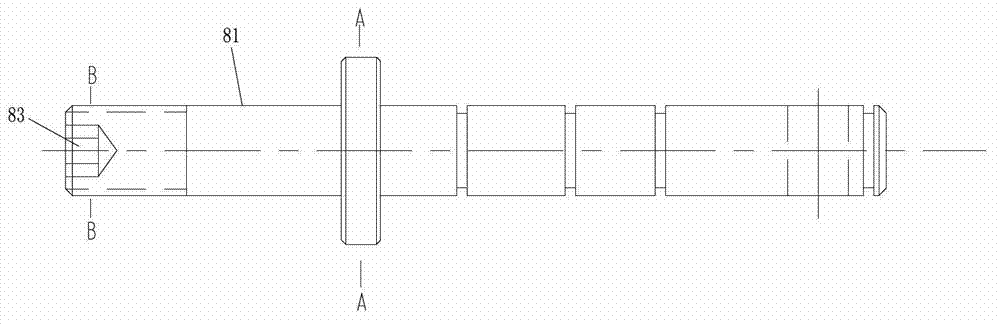

Double-station reciprocating rotary type injection stretch blow hollow forming machine

The invention discloses a double-station reciprocating rotary type injection stretch blow hollow forming machine which comprises a host machine and a mould. The host machine comprises a machine frame, a worktable panel, an injecting system, an injection molding and mould locking system, a blow molding and mould closing system, and a stretching device; wherein, the worktable panel is horizontally fixed on the machine frame, the injecting system is horizontally arranged on the machine frame, the injection molding and mould locking system is vertical to the worktable panel, the blow molding and mould closing system is horizontally arranged on the worktable panel, and the stretching device is vertically arranged. The injection molding and mould locking system comprises an upper mould plate, a lower mould plate, a mould locking oil cylinder, a guide post, a rotary driving mechanism, a rotary disc and a core-pumping oil cylinder. The lower mould plate is connected with the upper mould plate by the guide post which vertically penetrates through the worktable panel, the mould locking oil cylinder is fixed below the worktable panel, the piston rod end of the mould locking oil cylinder is connected with the lower mould plate, the rotary disc is arranged at the lower end face of the upper mould plate, and the rotary driving mechanism which is arranged at the upper part of the upper mould plate is connected with the rotary disc in a rotating manner. The rotary disc is driven by the rotary driving mechanism to drive a mouth module I and a mouth module II to carry out reciprocating rotation at 180 degrees in an interval manner, so as to finish station exchanging between blank injection and stretching blow molding, thereby realizing that the two functions of blank injection and stretching blow molding can be finished at the same time.

Owner:柳州市精业机器有限公司

Clamp for holding of flat objects

InactiveUS7207529B2Reduce clamping forceIncrease clamping forcePipe supportsElectrical apparatusEngineeringMechanical engineering

Owner:NEWFREY

Lathe work method for thin-walled parts of middle-small diameter

ActiveCN101015863AImprove stabilityReduce distortionAutomatic control devicesTurning toolsEngineeringMechanical engineering

The invention discloses a method for turning middle and small thin-wall element, wherein the invention uses auxiliary clamper on general turning machine, first based on the outer diameter of element, produces a slim sheath with same diameter and middle slim as auxiliary clamper, machines the blank of object element, then puts the draw-in gear into the inner hole of slim sheath, puts them together into three-claw positioning clamping disc of turning machine, clamping and machining roughly and finely, and since the invention uses slim sheath as auxiliary clamper, the long-disc claw can obtain uniform dispersed clamping force on the surface of object element, to reduce unit clamping force, reduce vibration and deformation or the like. And the invention improves efficiency via transferring thin-wall element on three-claw automatic positioning clamping disc.

Owner:XIAN SHAANGU POWER

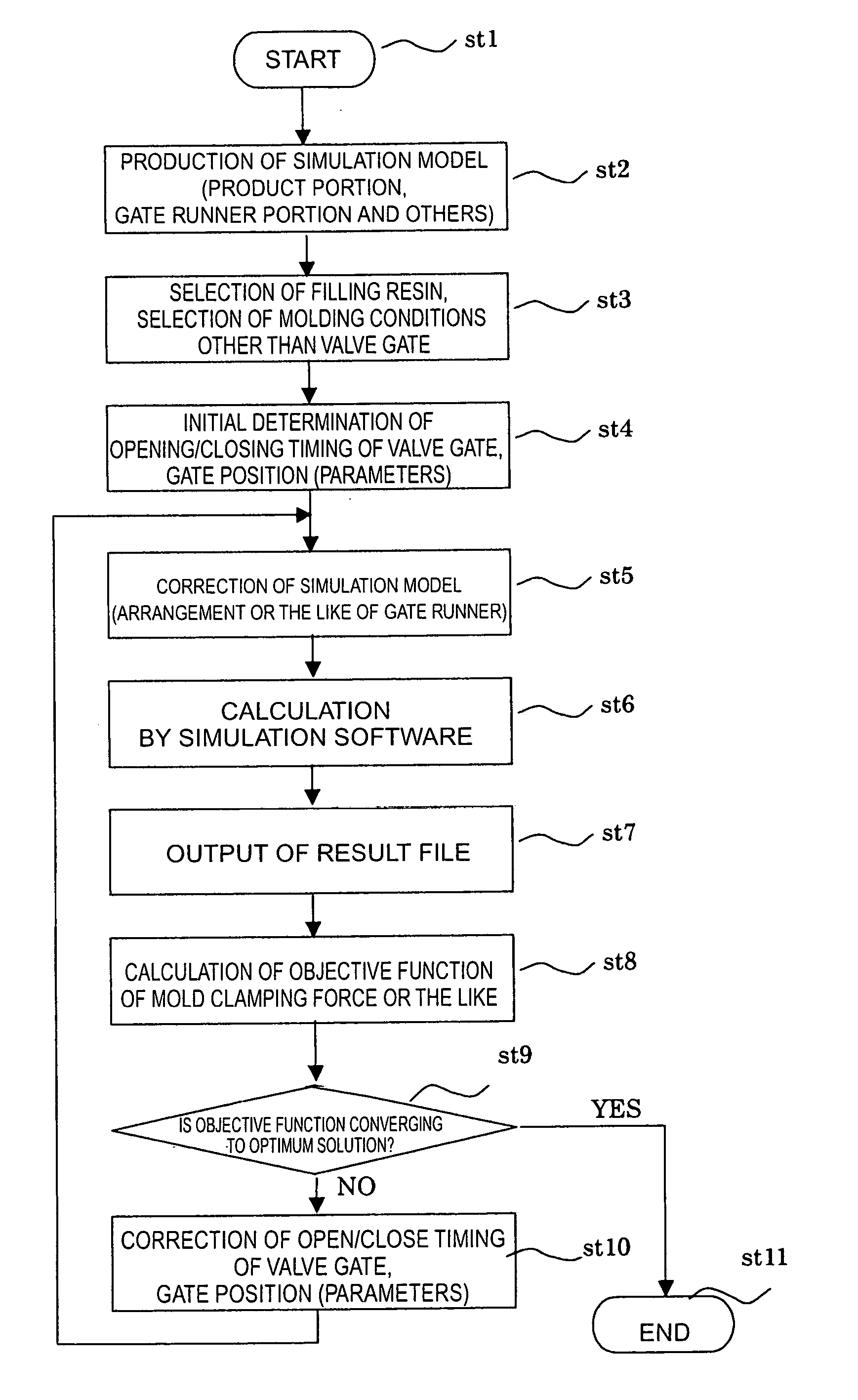

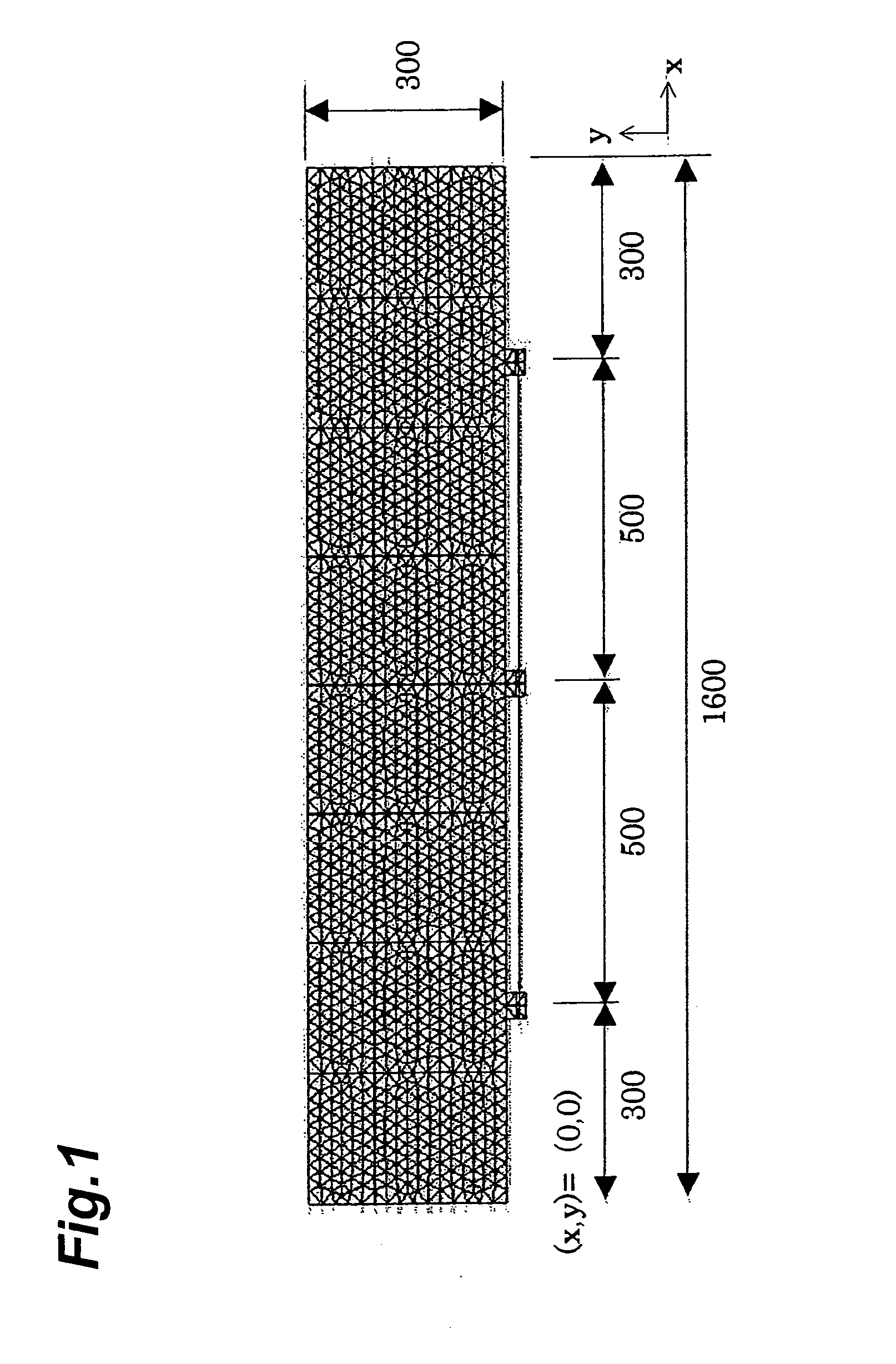

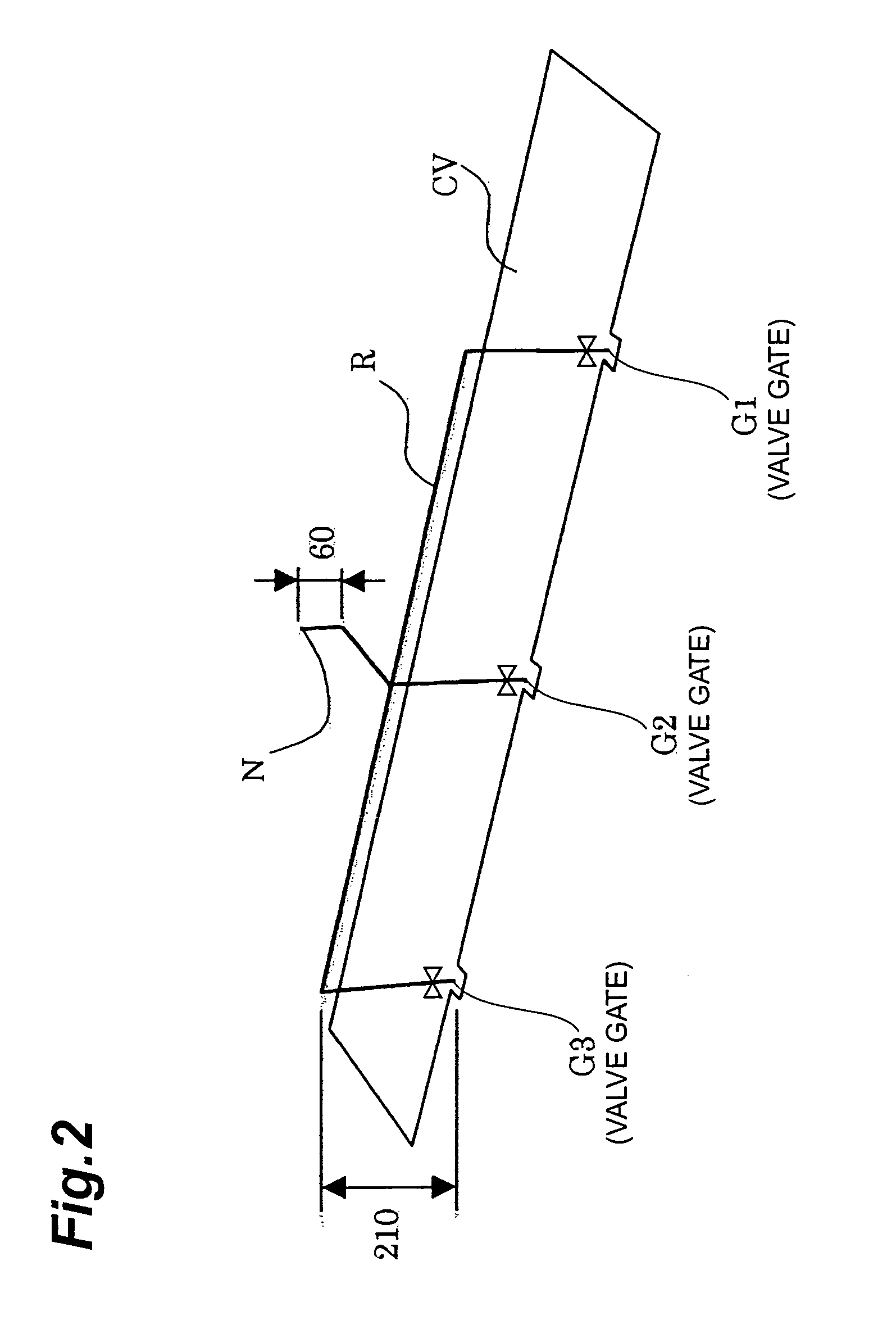

Method for designing a mold, method for producing an injection molding, program and injection molding device

InactiveUS20050082706A1Improve impact resistanceReduce clamping forceAuxillary shaping apparatusDesign optimisation/simulationComputer aidComputer-aided

An object of the present invention is to provide a method for designing a mold and a method for producing an injection molding in which a mold clamping force or weld line occurrence can be more accurately controlled in the case of injection molding of a resin product. In the case where an injection molding is carried out using a mold having a plurality of resin inflow conduits G1, G2, G3 to a cavity CV, a mold design parameter in relation to at least one of the arrangement, the shapes and the sizes of the resin inflow conduits is determined by the combination of a numerical analysis method for calculating an injection molding process and a computer-aided optimization method, for the purpose of obtaining a preferable injection molding condition. Thereby the mold design parameter can be promptly and accurately calculated without repetition of trial and error manually.

Owner:SUMITOMO CHEM CO LTD

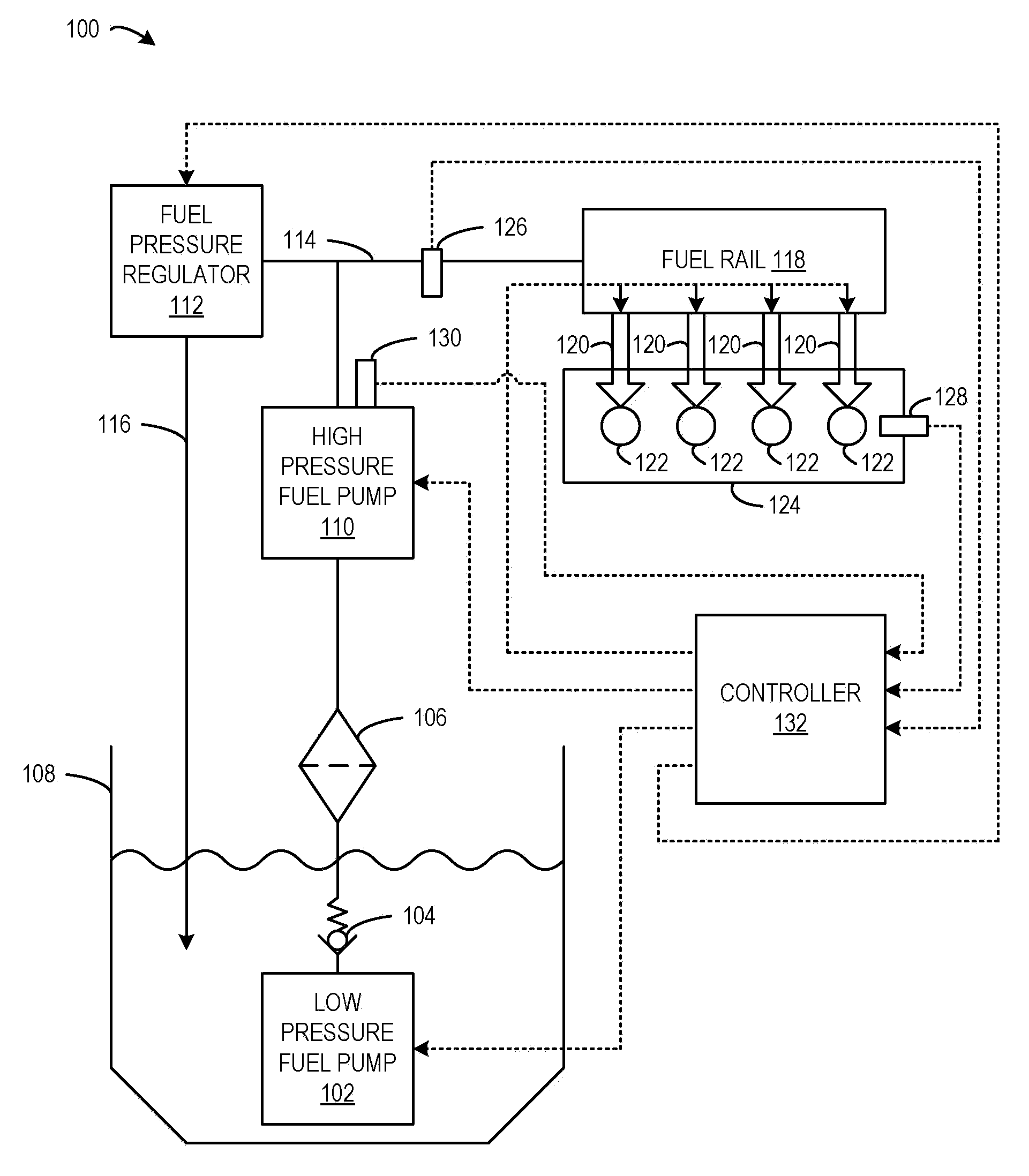

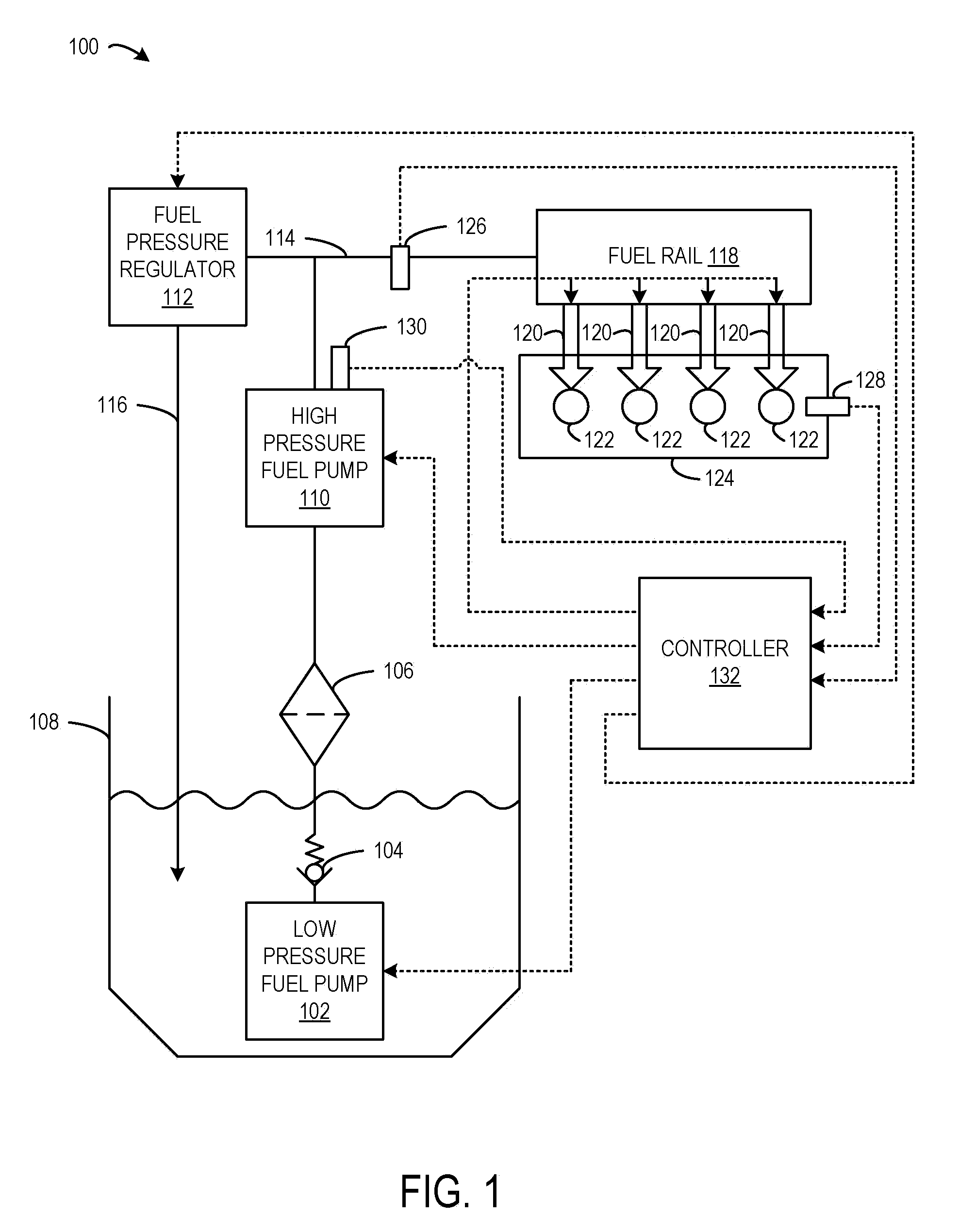

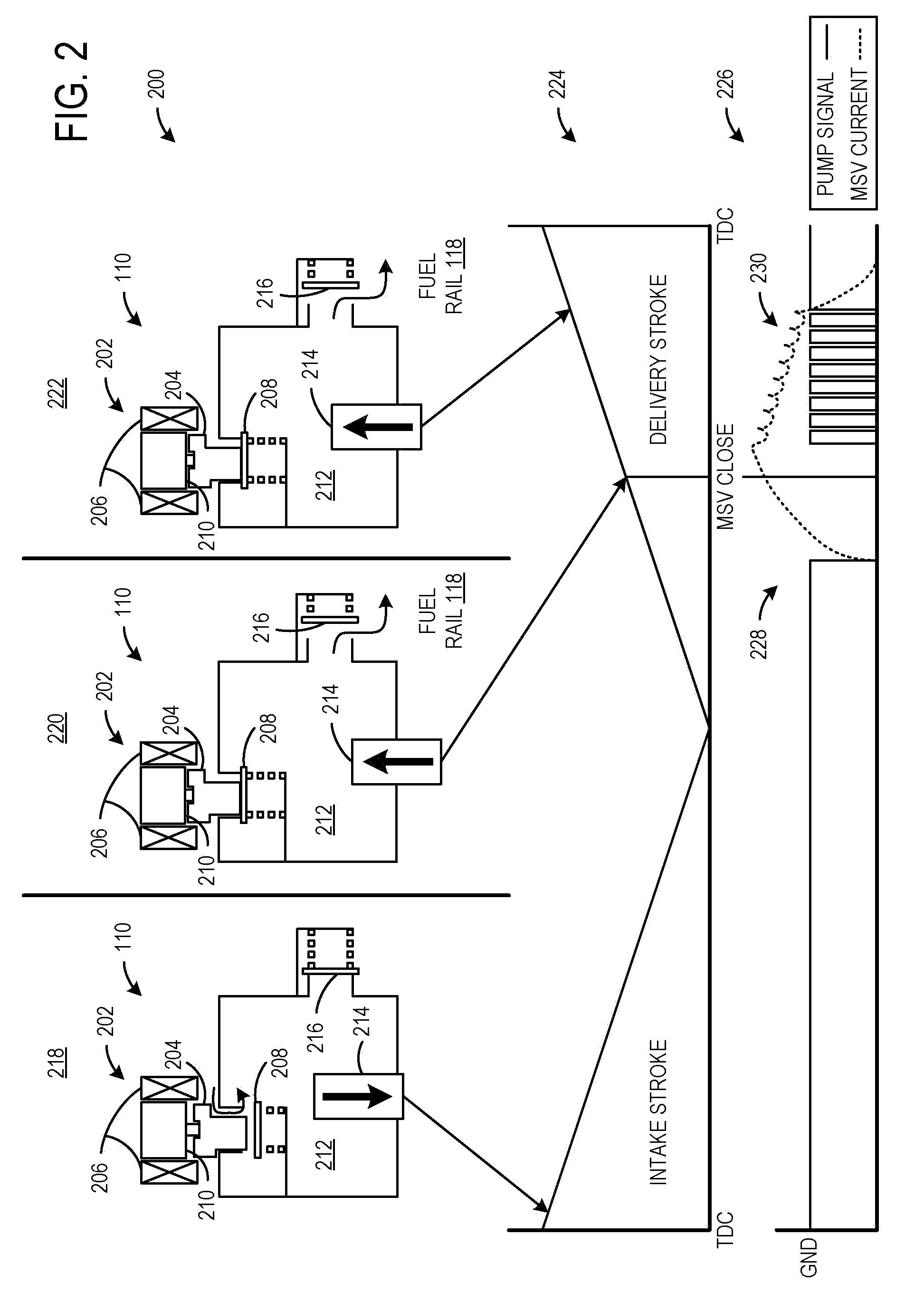

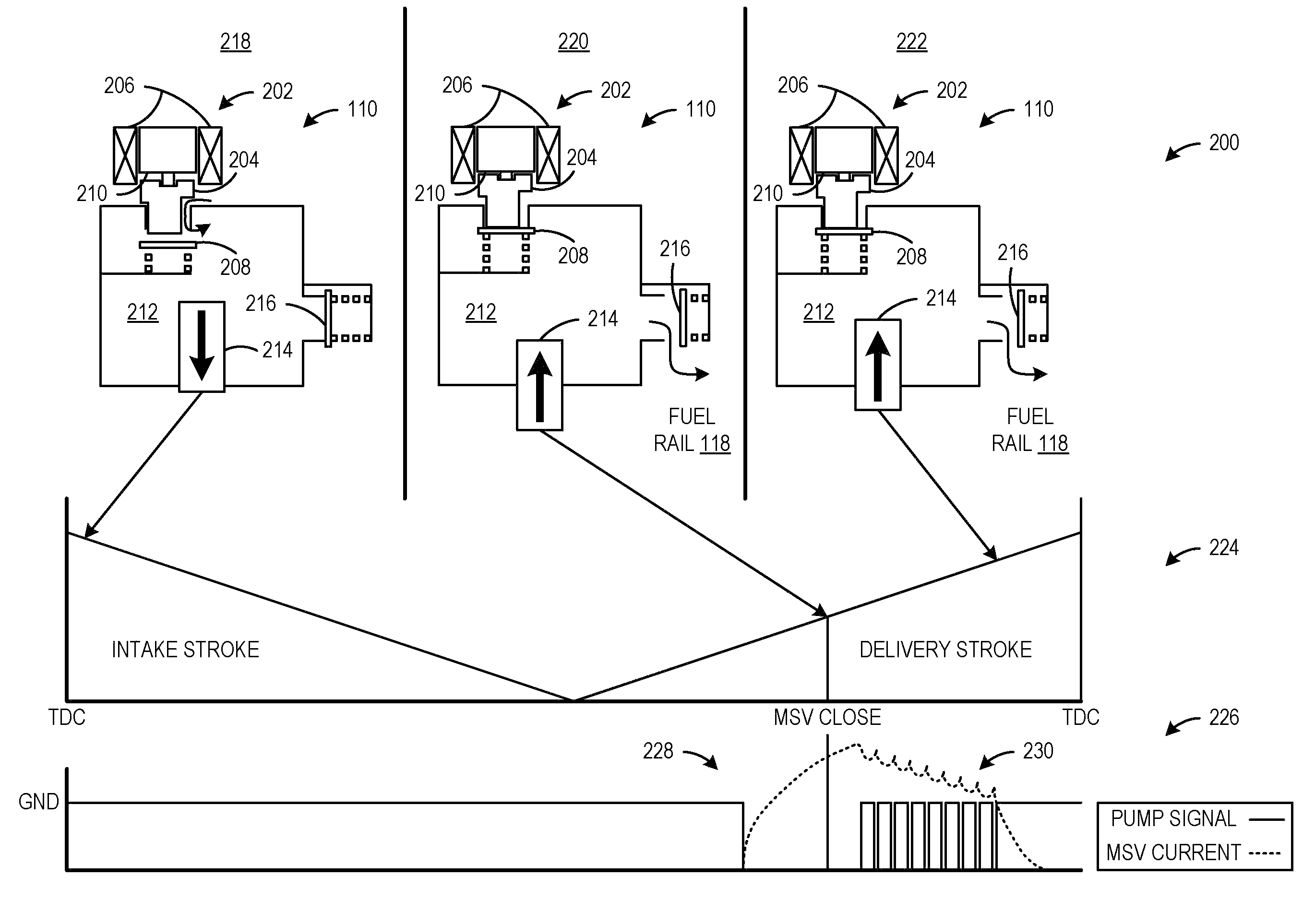

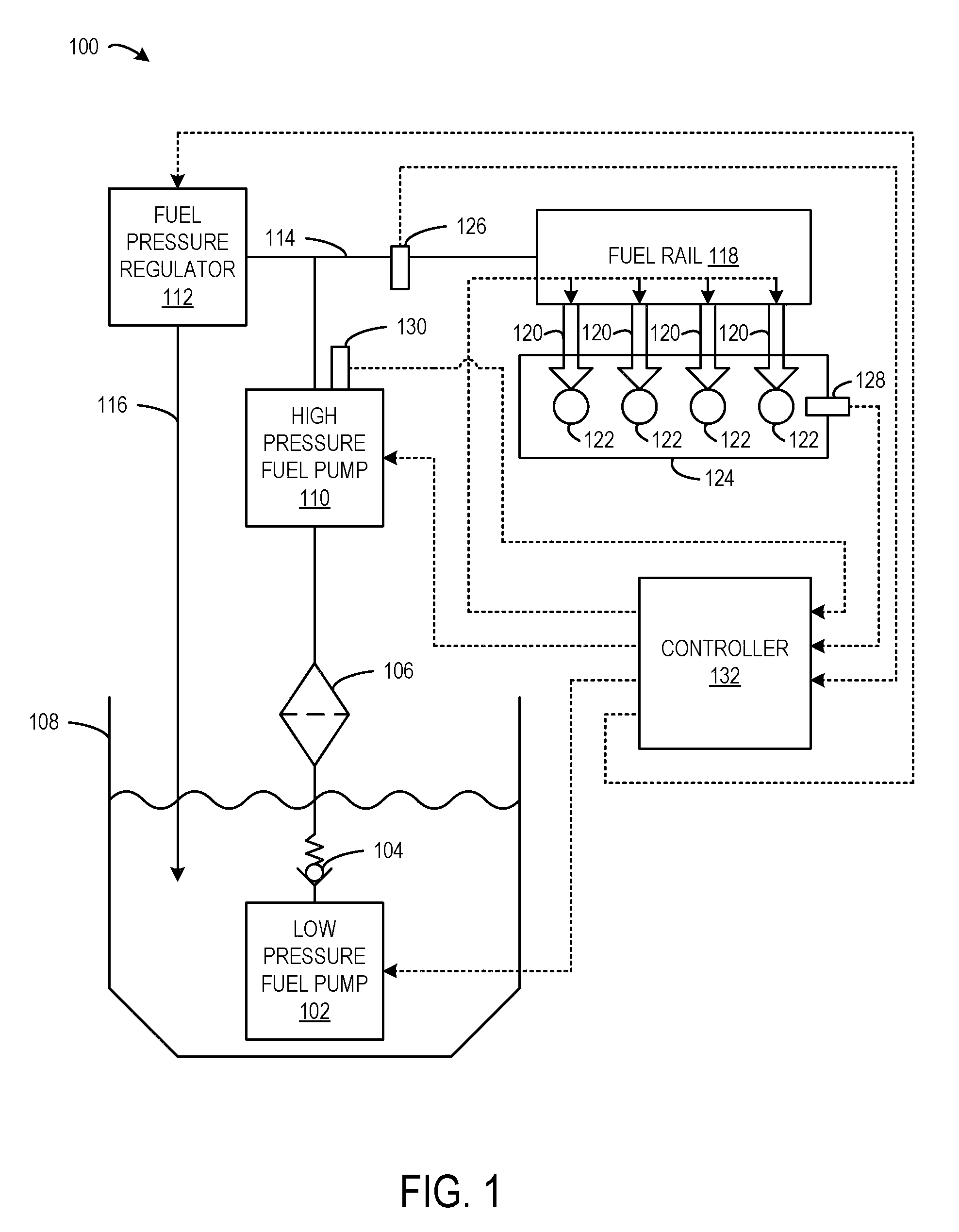

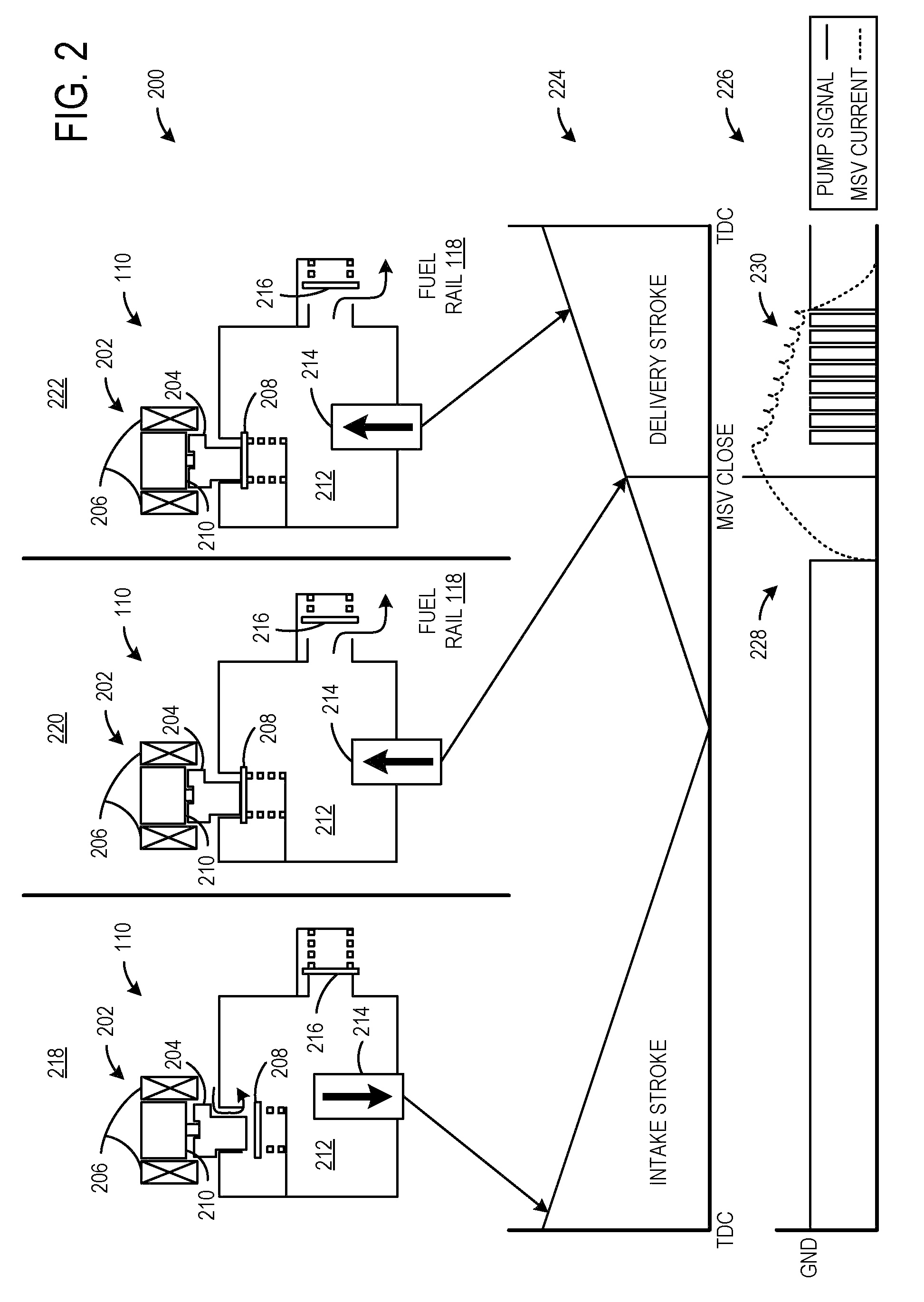

High pressure fuel pump control for idle tick reduction

ActiveUS20100139624A1Improve drivabilityReduce clamping forceElectrical controlMachines/enginesIdle reductionSolenoid valve

A method for controlling a mechanical solenoid valve of a high-pressure fuel pump to supply fuel to an engine is provided. The method includes: during an idle condition, adjusting a pull-in current of the mechanical solenoid valve utilized to control closing of the mechanical solenoid valve based on a fuel pressure downstream of the high-pressure fuel pump, wherein the pull-in current is reduced when possible while enabling the mechanical solenoid valve to close as indicated by an increase in the downstream fuel pressure.

Owner:FORD GLOBAL TECH LLC

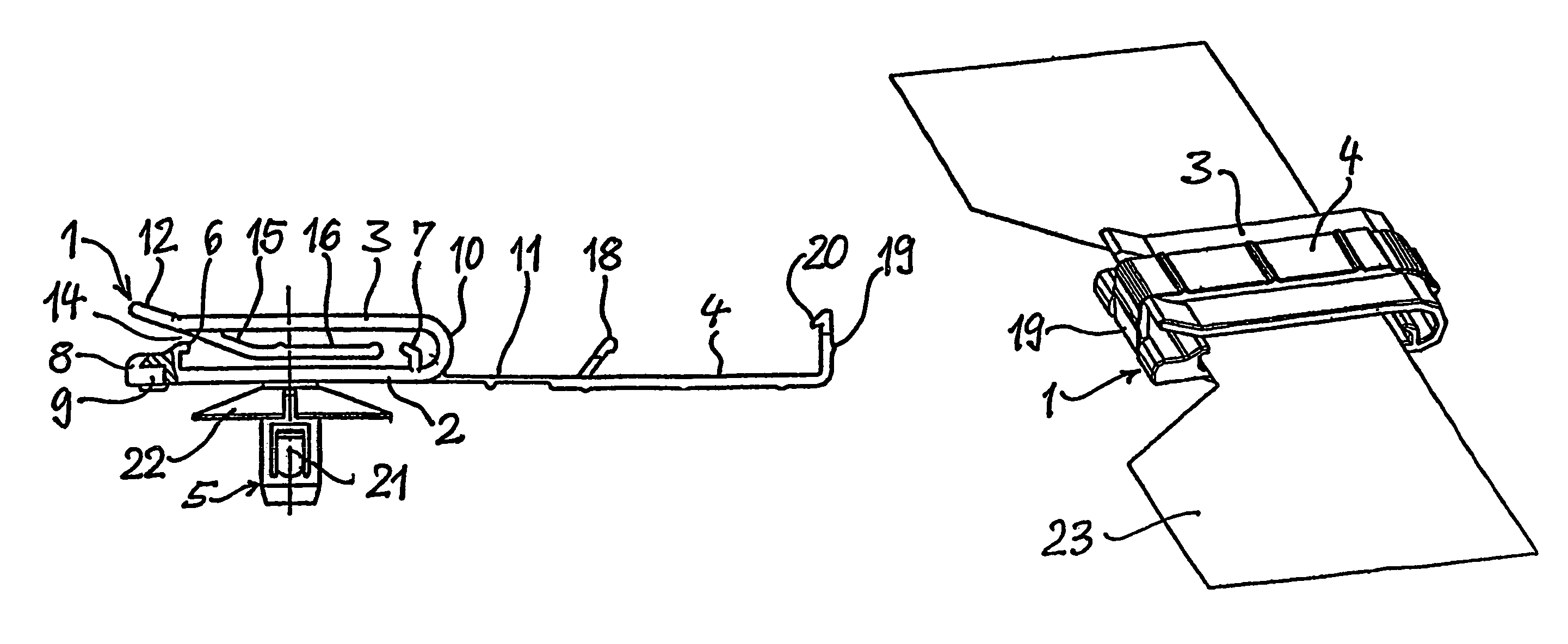

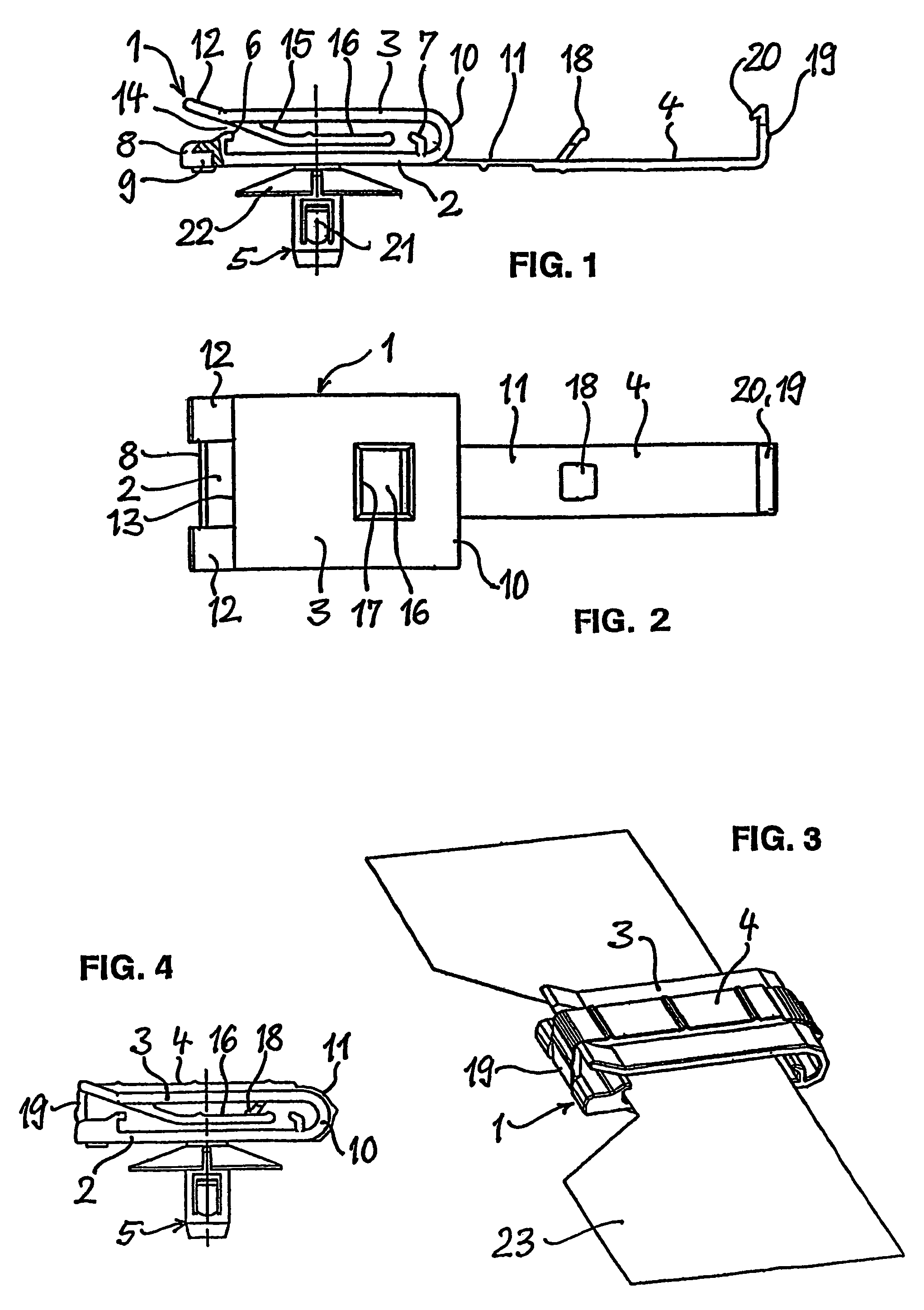

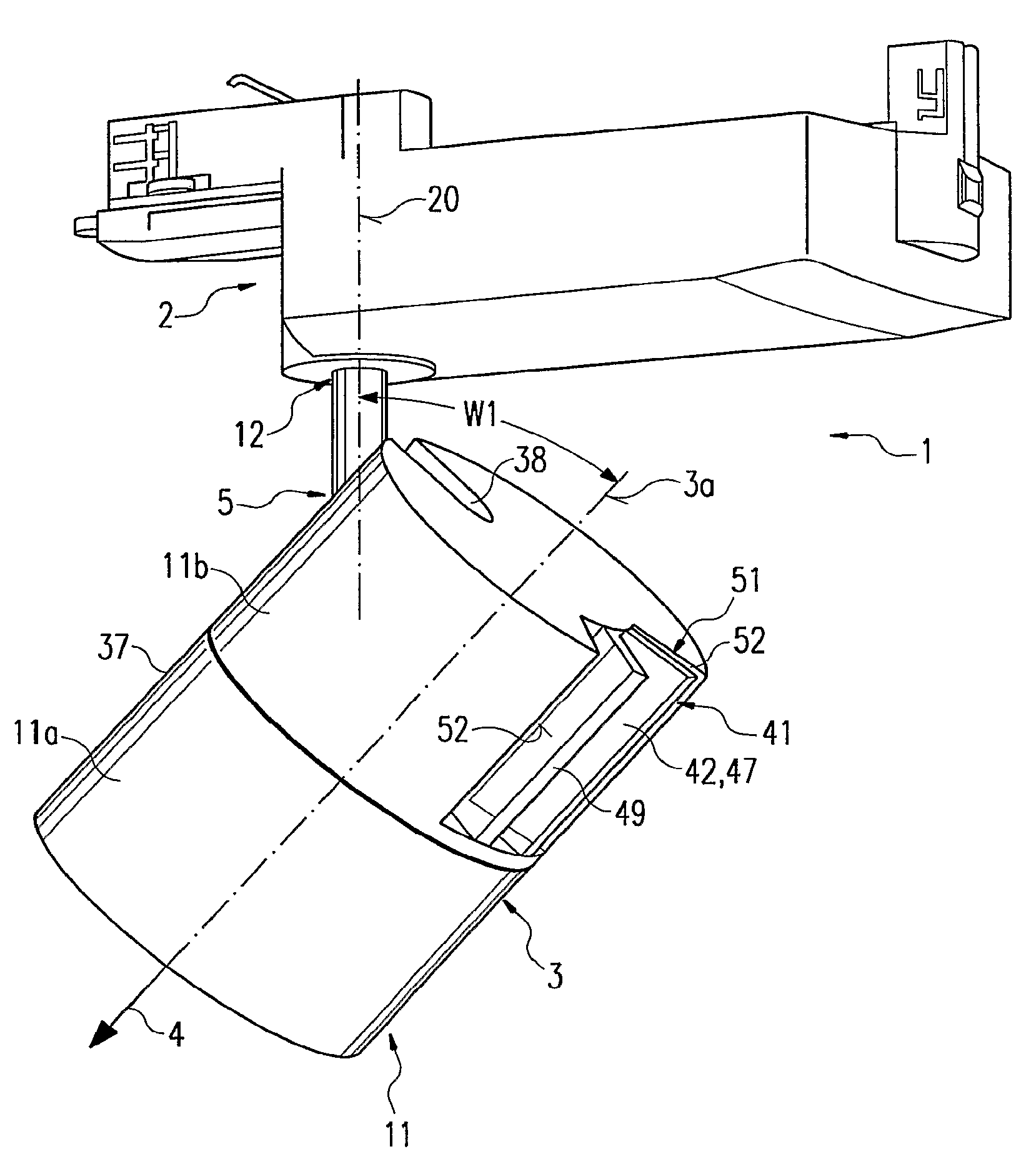

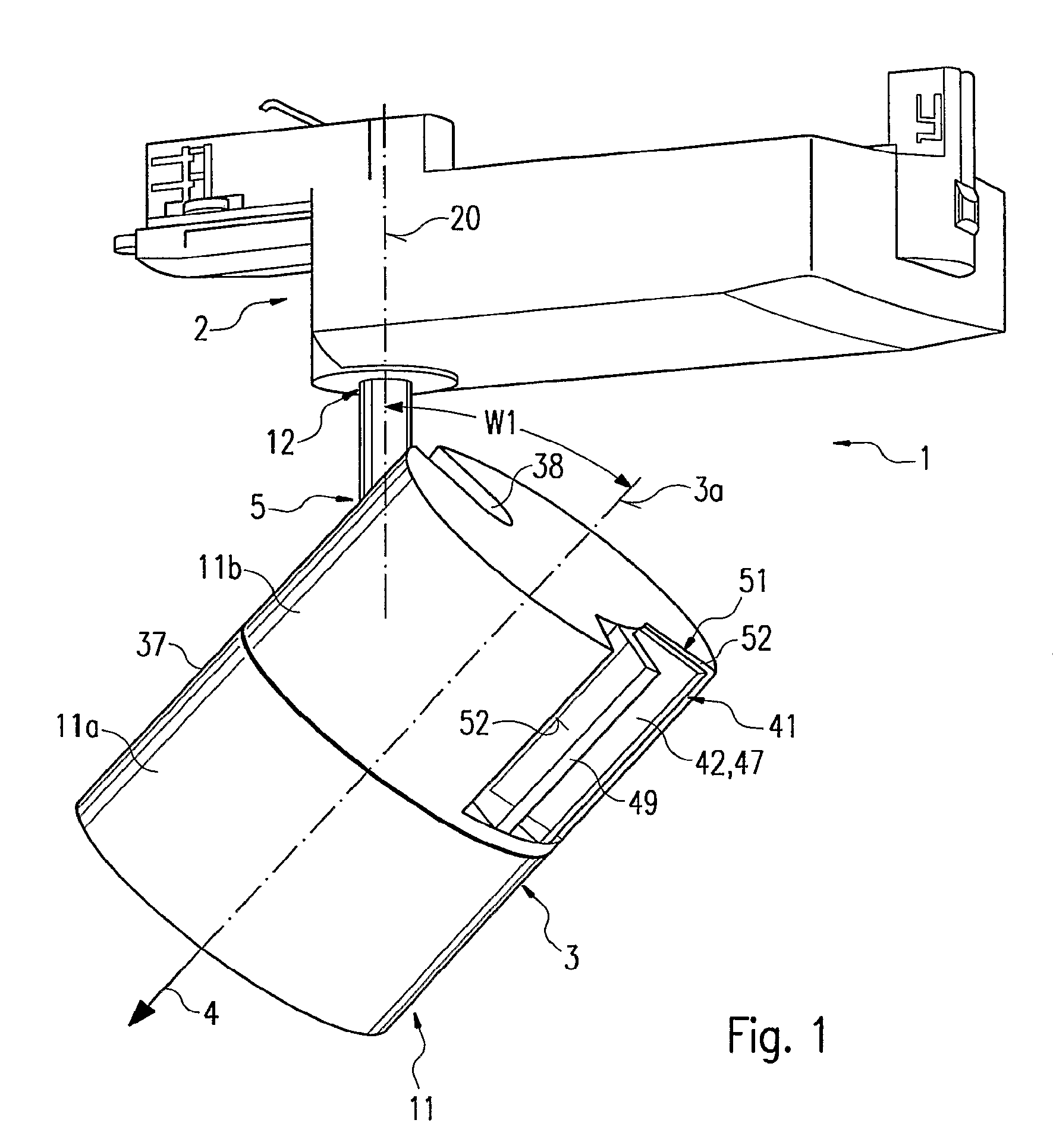

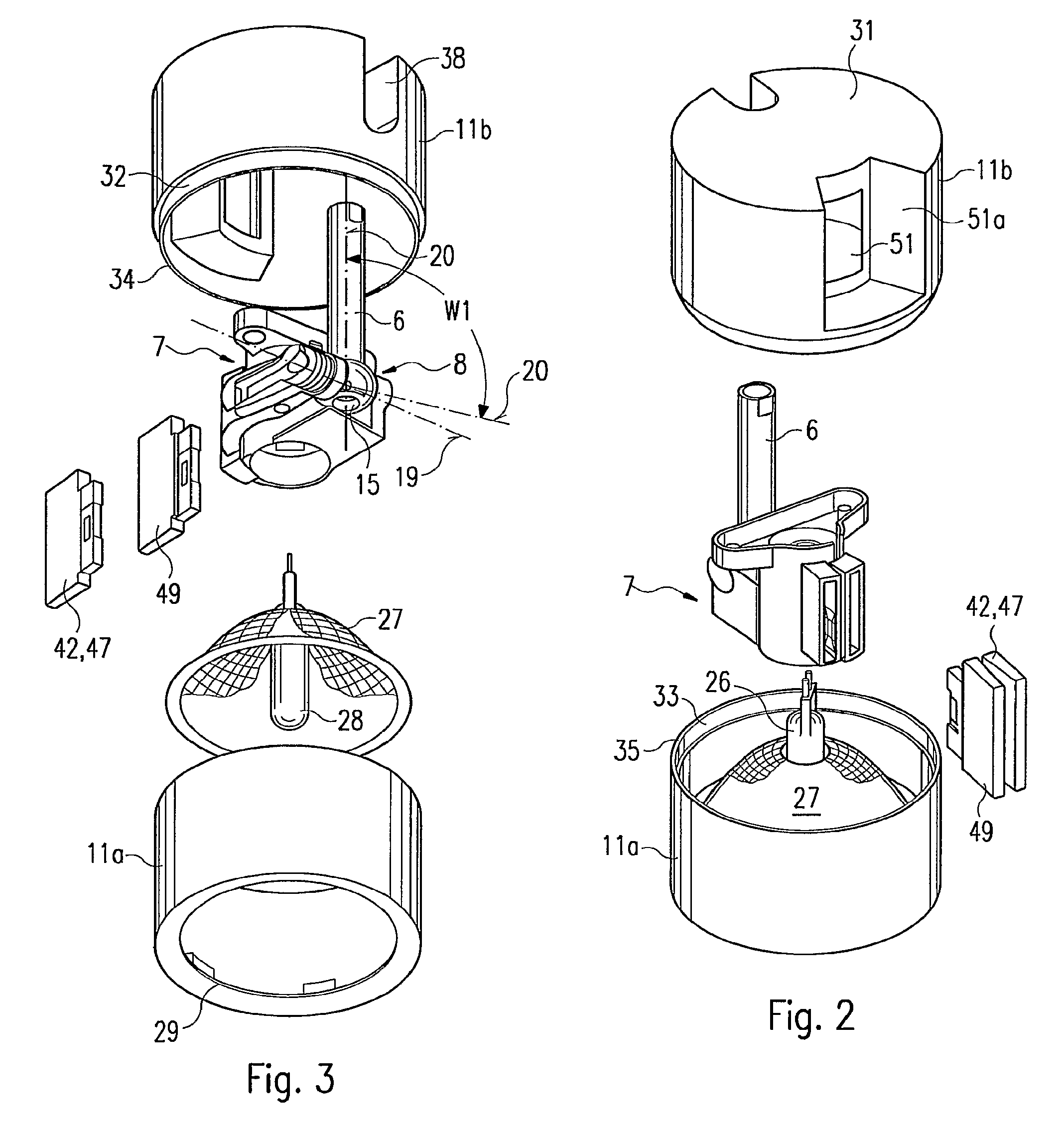

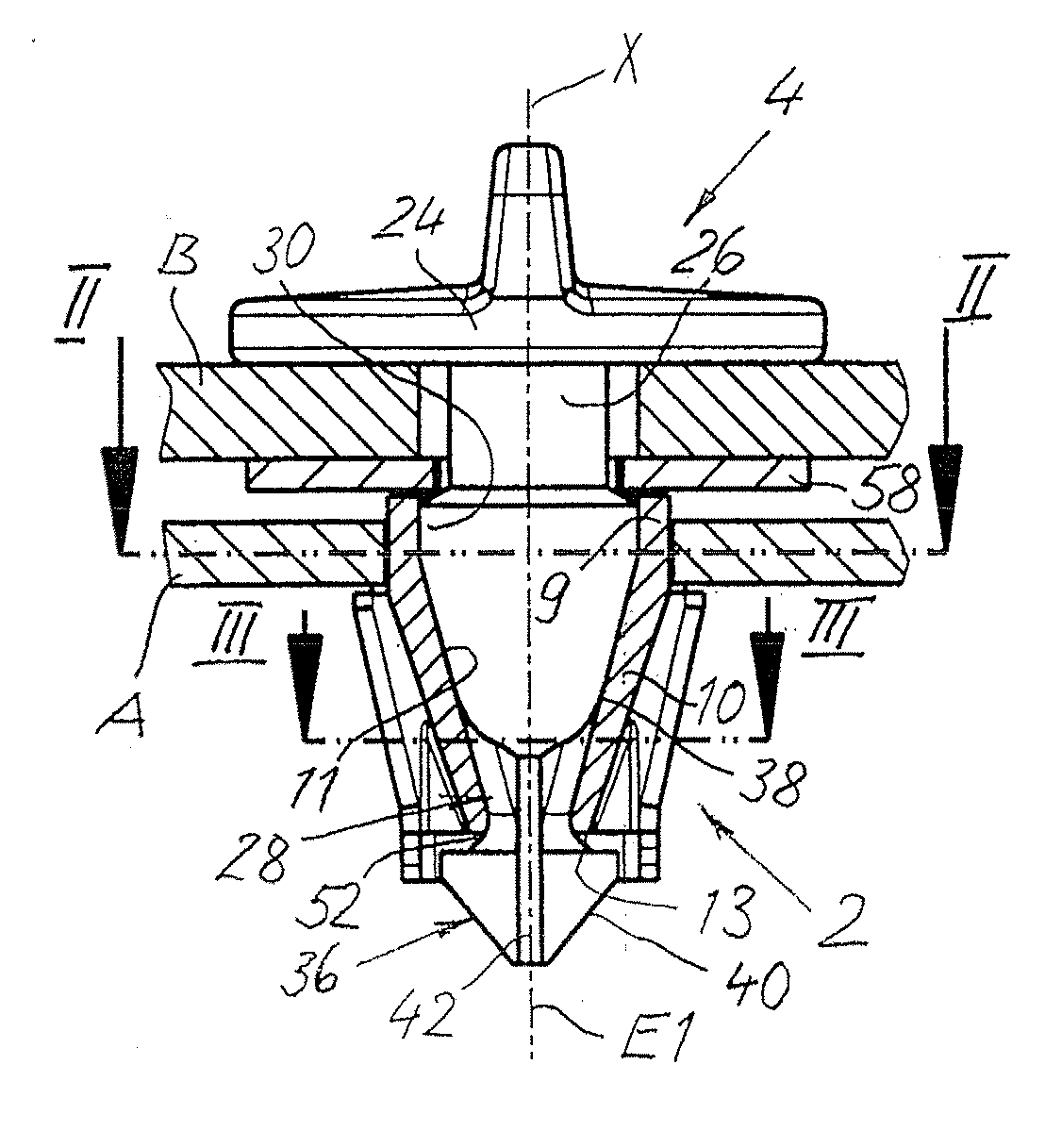

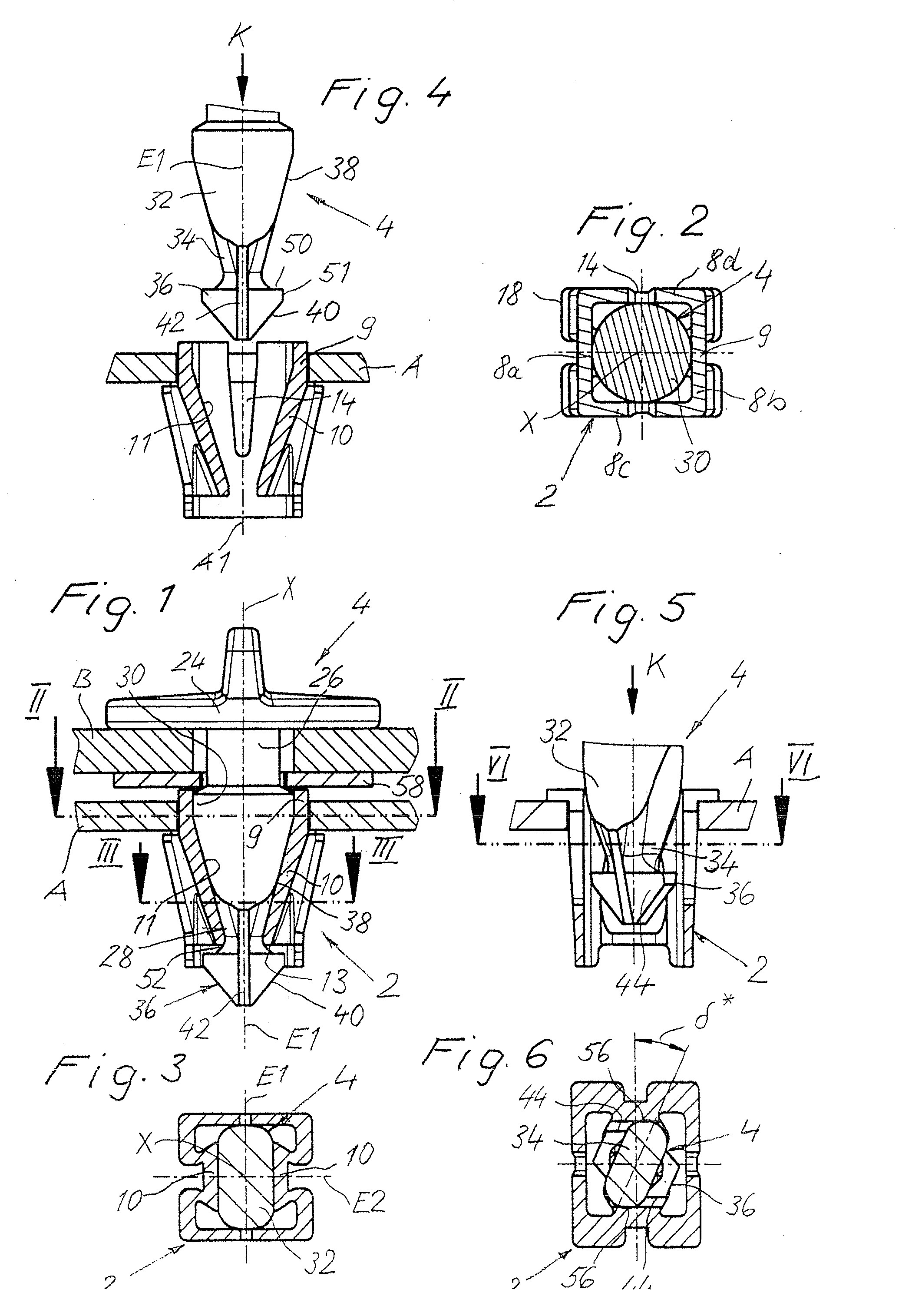

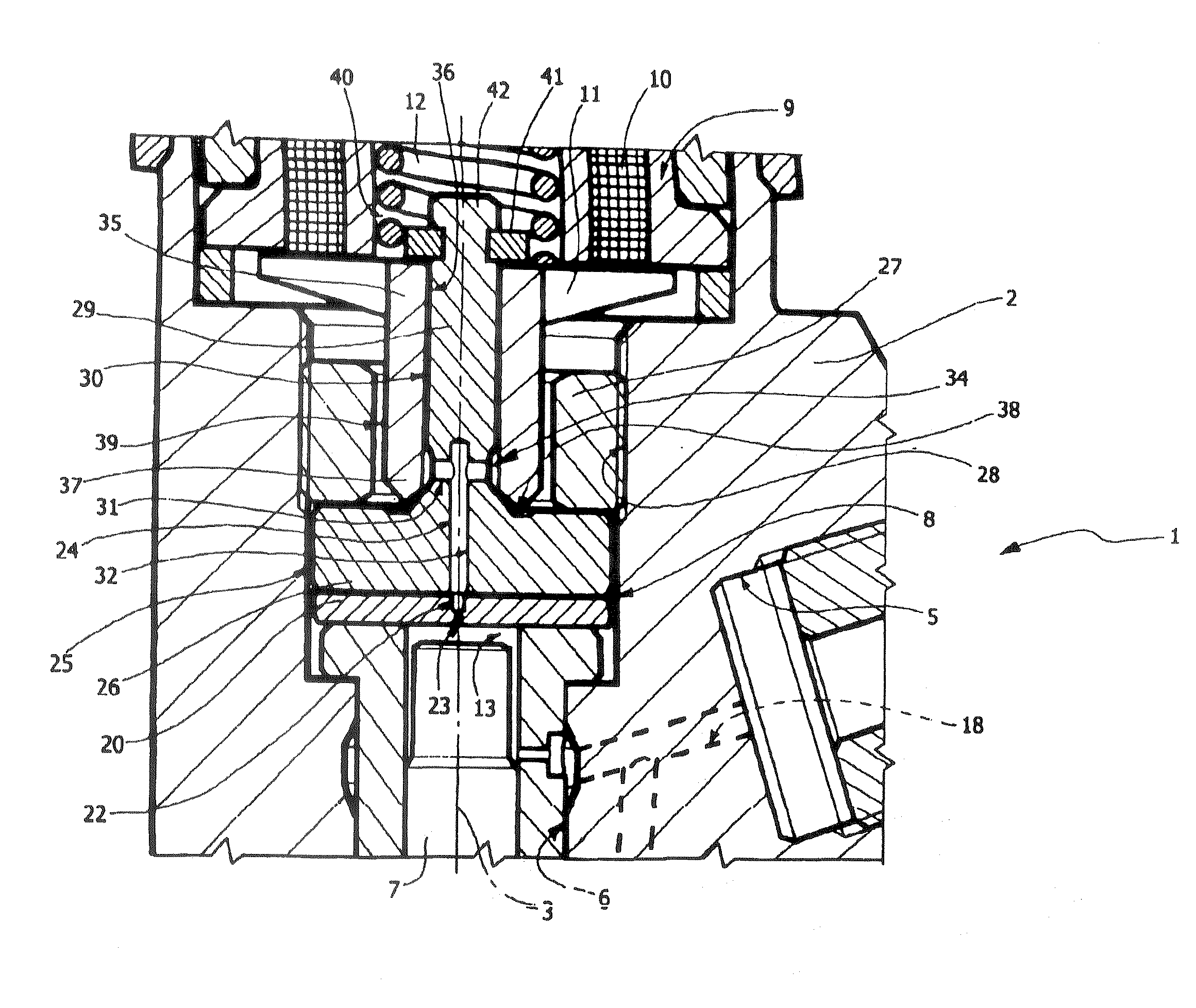

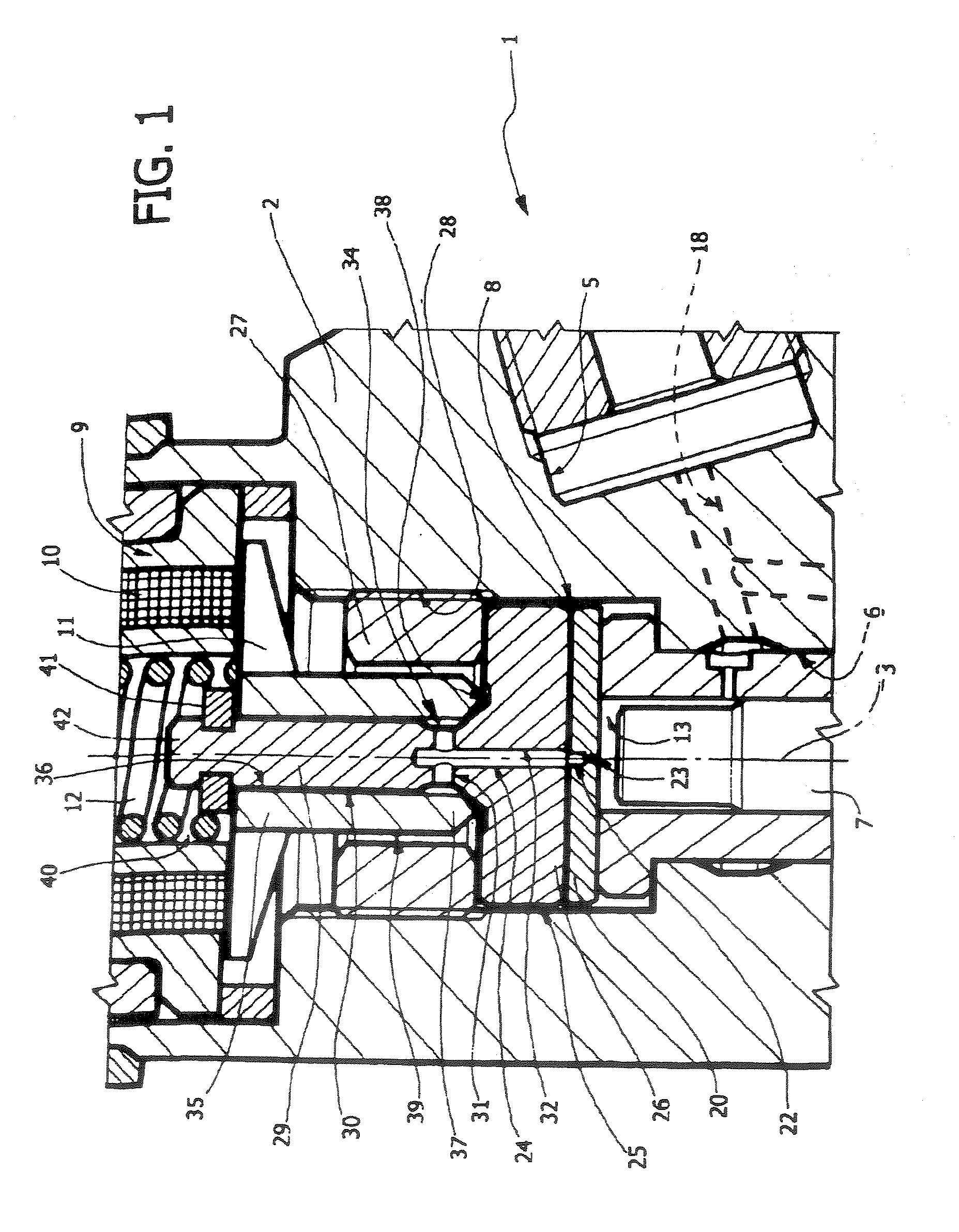

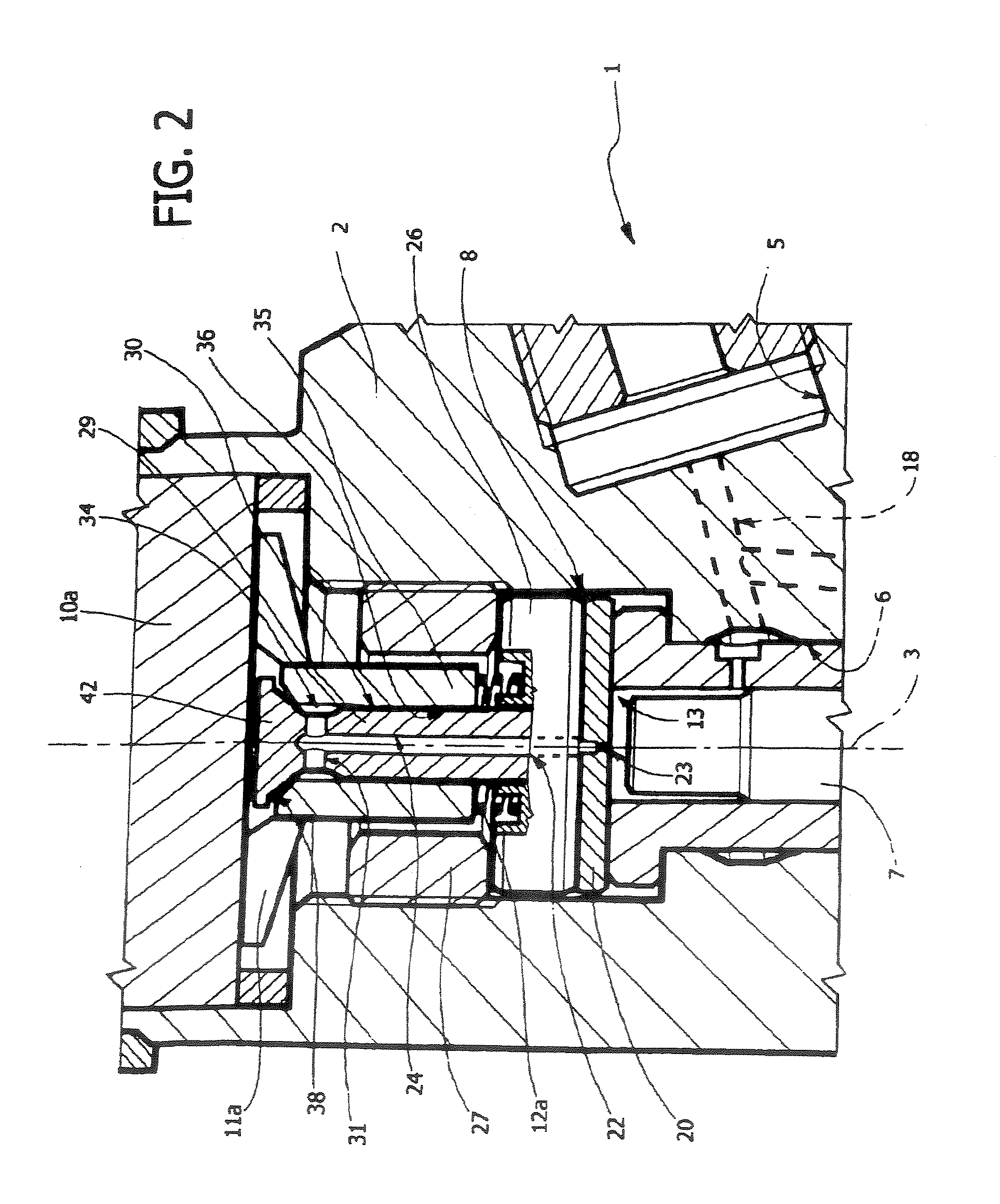

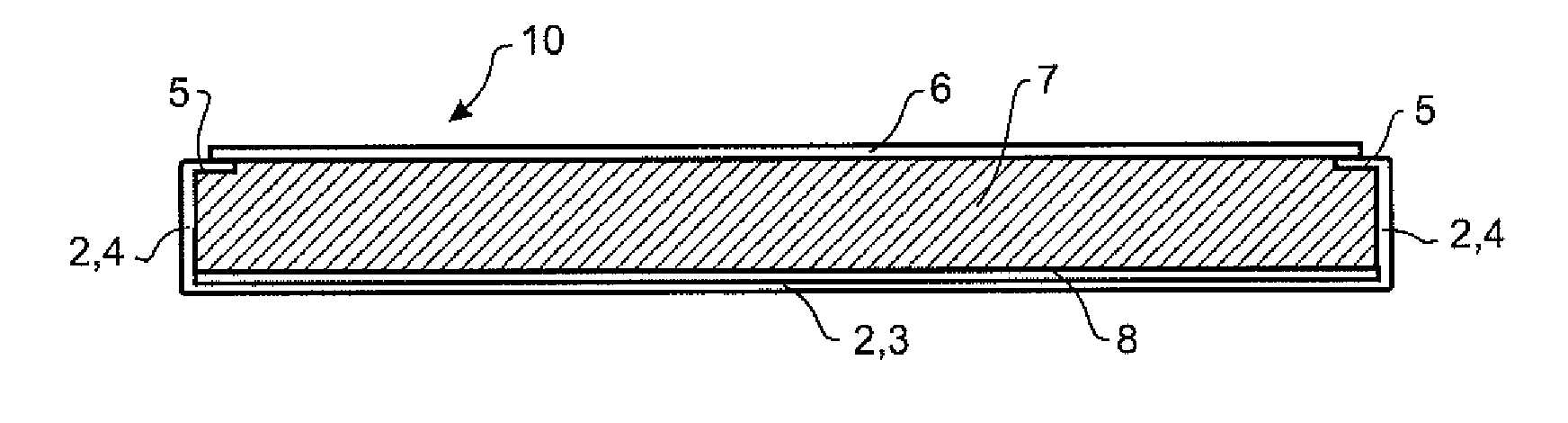

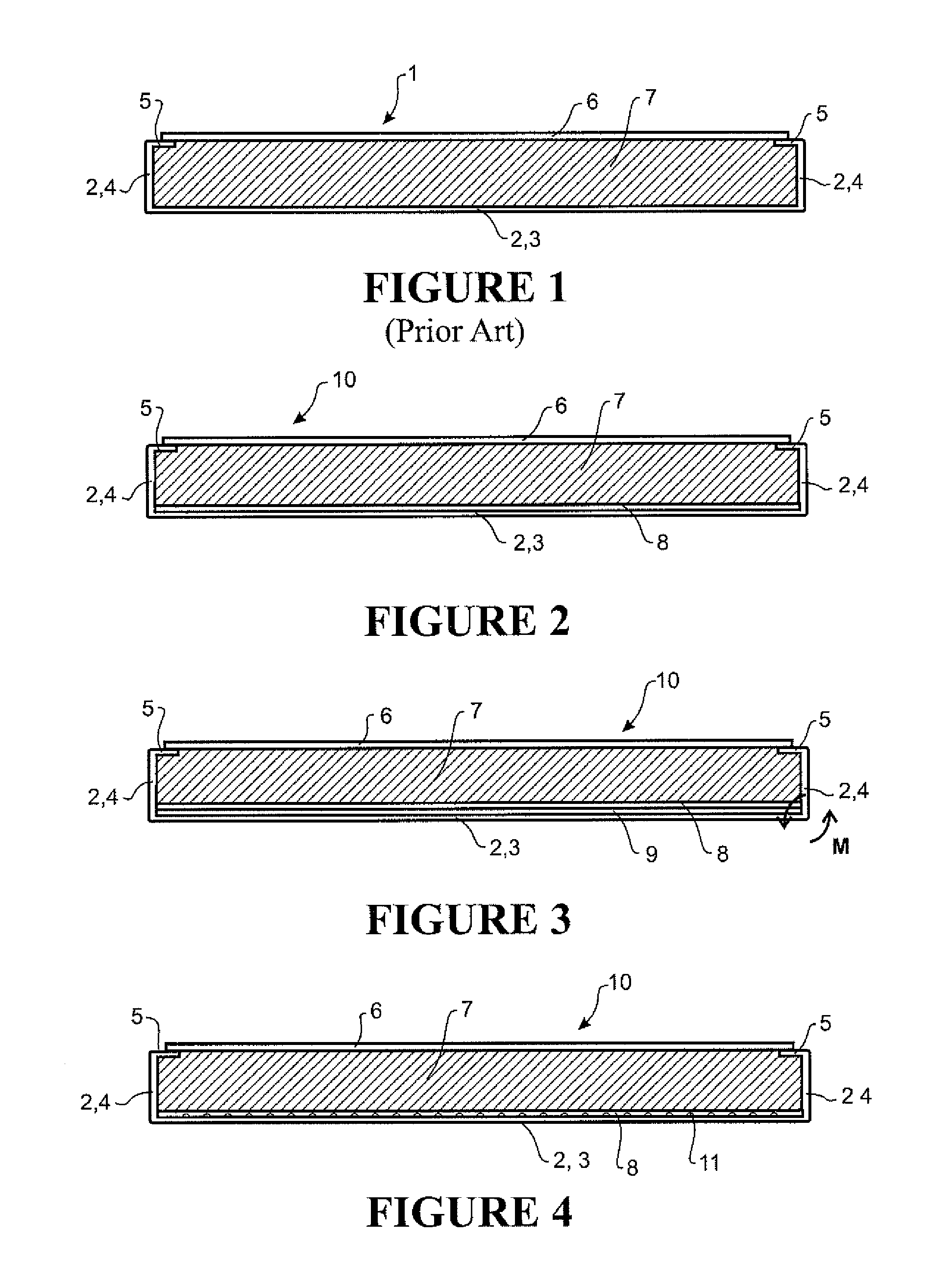

Luminaire comprising a spotlight and adjustable holding device for a spotlight

InactiveUS7762688B2Remove clamp forceLong service lifeLighting support devicesStands/trestlesEngineeringMechanical engineering

The invention relates to a lamp (1) comprising a projector (3) and an adjustable holding device (5), by means of which the projector (3) is joined to a base part (2) of the lamp (1). The holding device (5) is provided with an elongate support element (6), a holding element (7) at least for part of the projector (3), a joint (8) between the support element (6) and the holding element (7), and a clamping device (9) for locking the joint (8). The joint (8) and the clamping device (9) are disposed in a projector housing (11). In order to ensure that the projector (3) is easy to handle for adjustment purposes, a removing mechanism (41), with the aid of which the clamping force of the clamping device (9) can be reduced or canceled, is arranged in the projector housing (11). Said removing mechanism (41) is accessible from outside the projector housing (11) in order to be manually manipulated while being provided with a manually actuated actuating element (42) which is located at a distance next to a supporting element (49) that is fixed to the housing. The actuating element (42) can be moved towards the supporting element (49) by having two fingers of an operator's hand engage over both elements (42, 49).

Owner:ZUMTOBEL LIGHTING GMBH & CO KG

High pressure fuel pump control for idle tick reduction

ActiveUS8091530B2Improve drivabilityReduce clamping forceElectrical controlMachines/enginesIdle reductionSolenoid valve

A method for controlling a mechanical solenoid valve of a high-pressure fuel pump to supply fuel to an engine is provided. In one example, current supplied to the mechanical solenoid valve is adjusted according to a pressure downstream of the fuel pump. The method can reduce current used to operate the mechanical solenoid valve as well as pump noise, at least during some conditions includes.

Owner:FORD GLOBAL TECH LLC

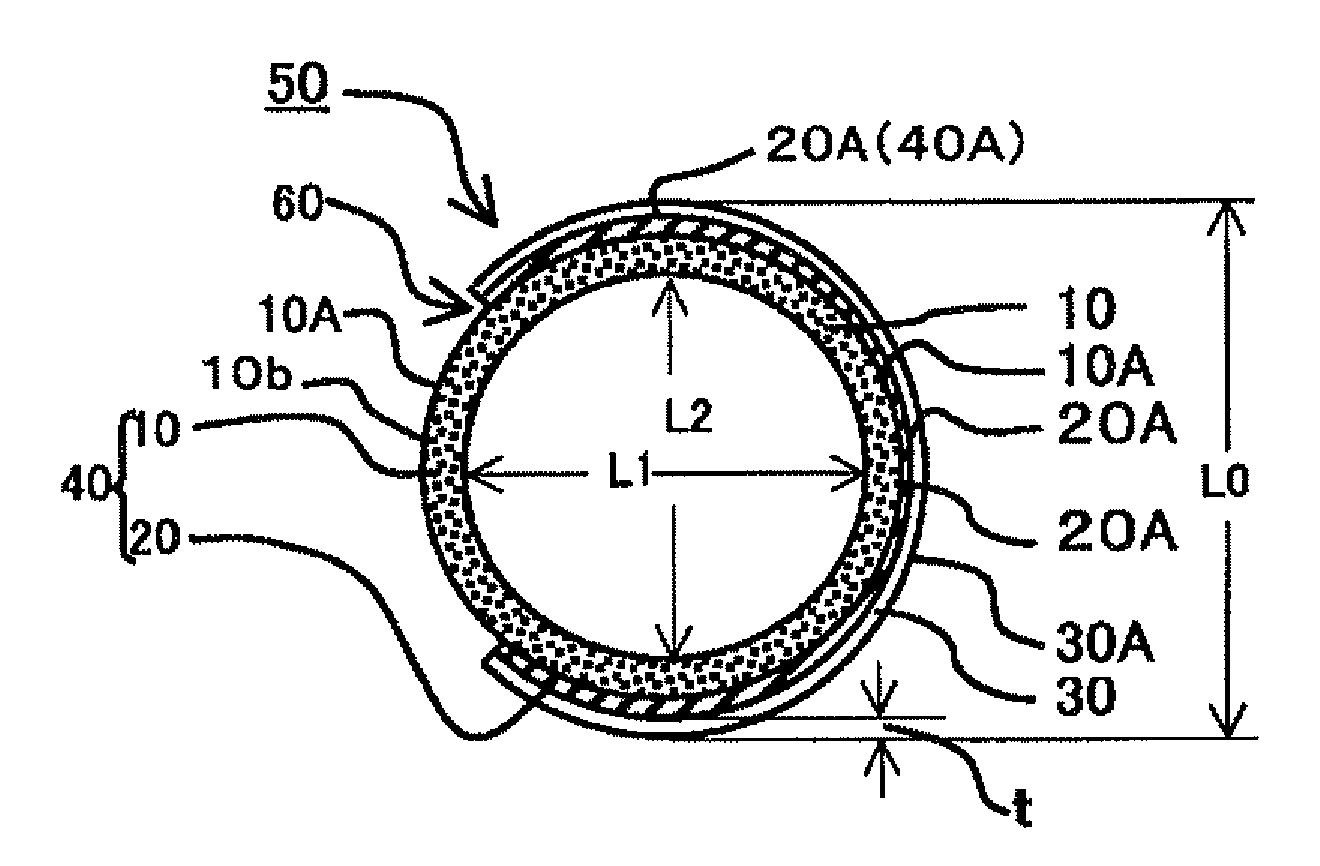

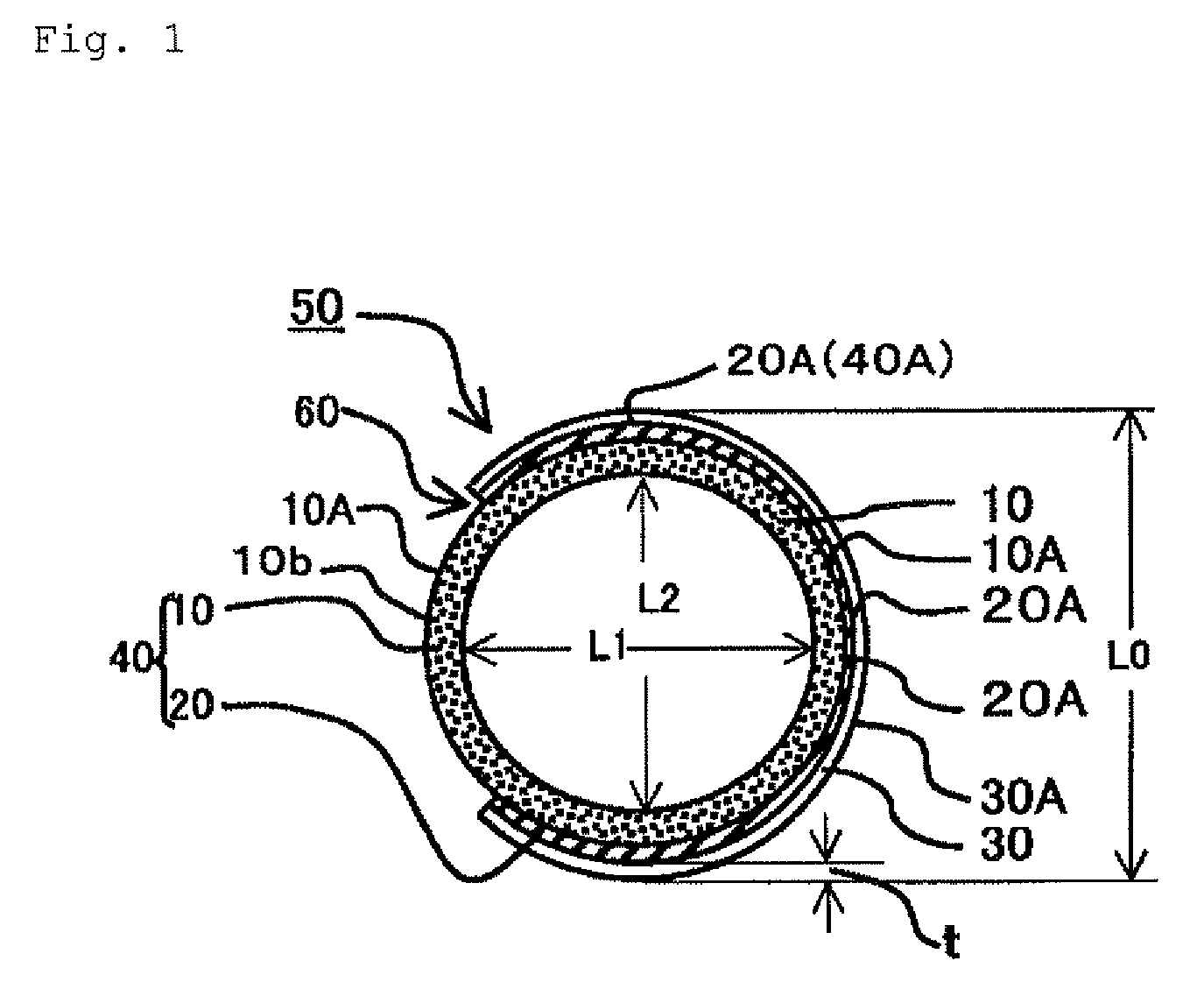

Low-compression force metal gaskets

A low-compression force metal gasket includes a coating layer containing a polymer material on at least a sealing surface of the gasket, and the coating layer satisfies the following conditions (1) to (3): (1) the layer comprises a resin, a rubber or a mixture thereof having an oxygen gas permeability coefficient at 25° C. of 10×10−12 to 0.1×10−12 (m2 / s); (2) when the layer is compression deformed, the storage elastic modulus (E′) at 200° C. is in the range of 1.0×107 to 1.0×102 Pa; and (3) the coating layer has a thickness of 1 to 40 μm. The gasket provides a high seal at a low clamping force.

Owner:VALQUA LTD +1

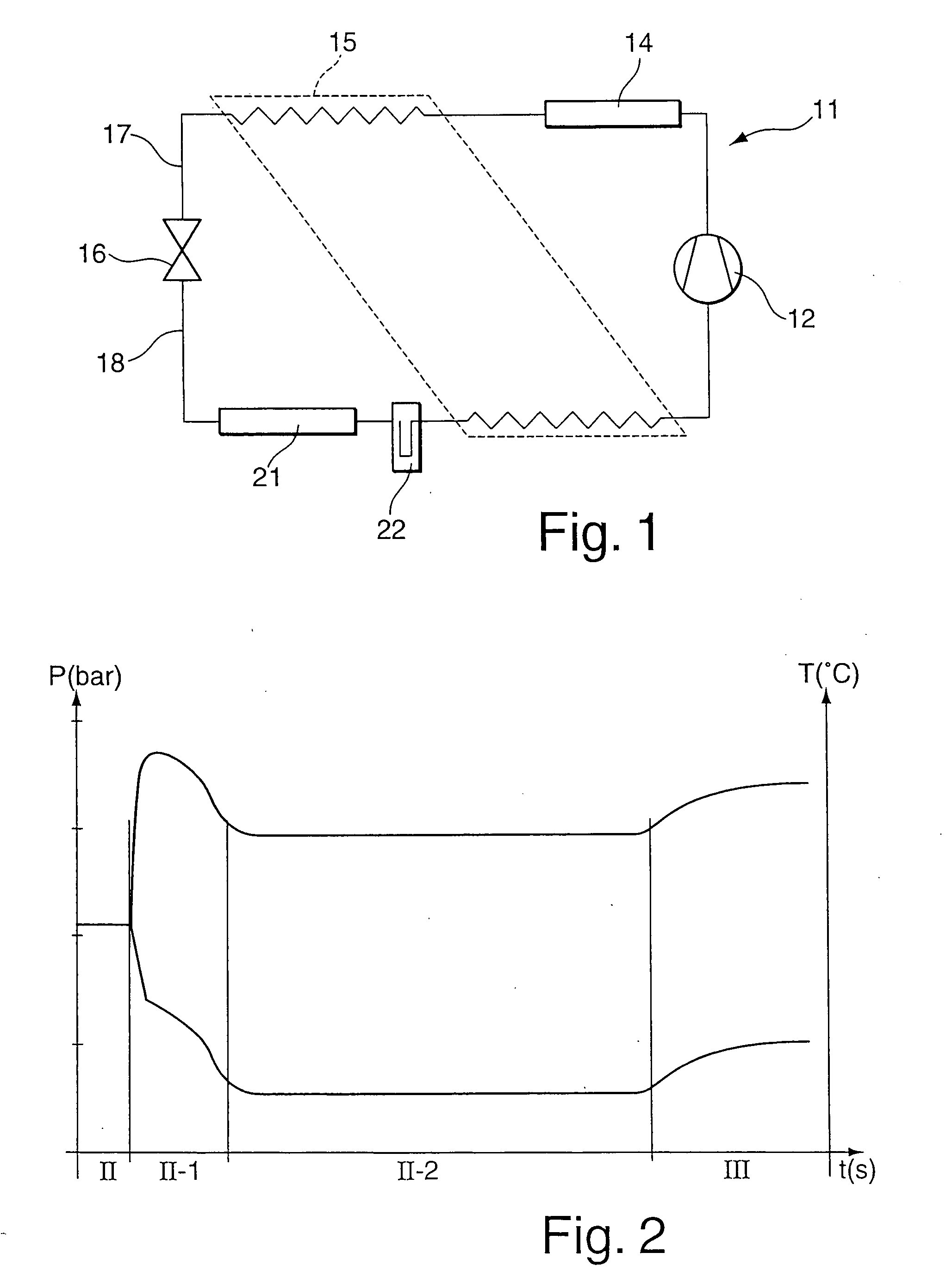

Method for controlling an expansion valve and expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant

InactiveUS20070295016A1Rapid responseRapid of spaceMechanical apparatusCompression machinesPressure riseEngineering

The invention relates to a method for controlling an expansion valve, in particular for vehicle air-conditioning systems operated with CO2 as the refrigerant, with a valve housing which has a feed opening and a removal opening, with a valve-closing member which closes a valve seat of a passage opening arranged between the feed and removal openings, and with a resetting device which acts in the closing direction of the valve-closing member, an adjusting element, which is assigned to the valve-closing member, on the low-pressure side being activated via a predetermined threshold value as the low pressure rises or as the temperature on the low-pressure side rises and actuates at least one actuating element by means of which a closing force of the resetting device acting on the valve-closing member is reduced such that a passage opening is enlarged or a passage of a bypass valve arranged on the low-pressure side, which passage is arranged parallel to the passage opening, is opened.

Owner:OTTO EGELHOF

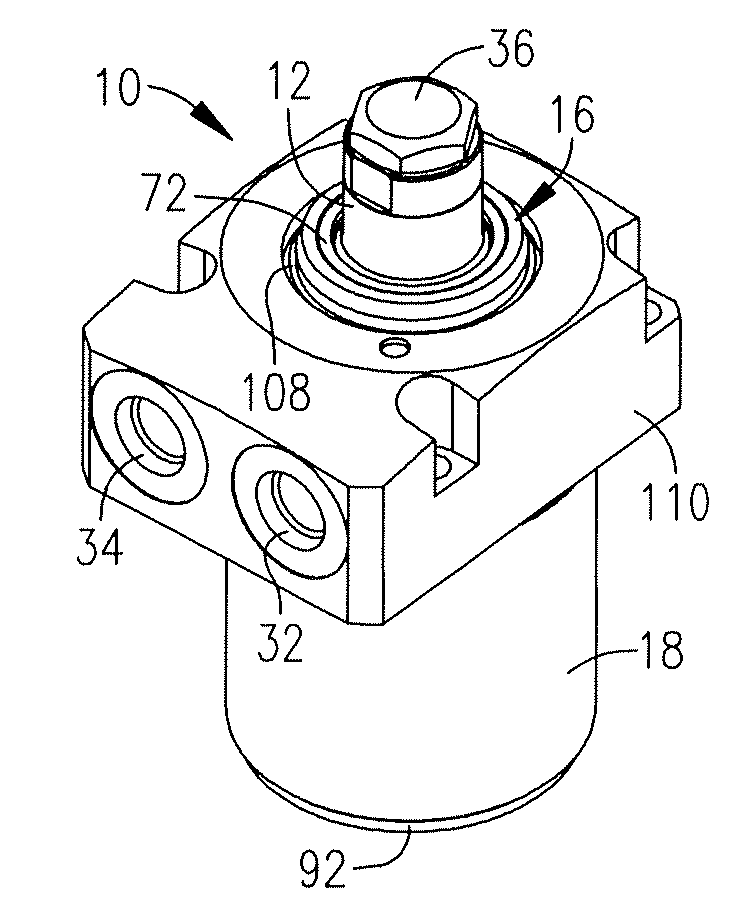

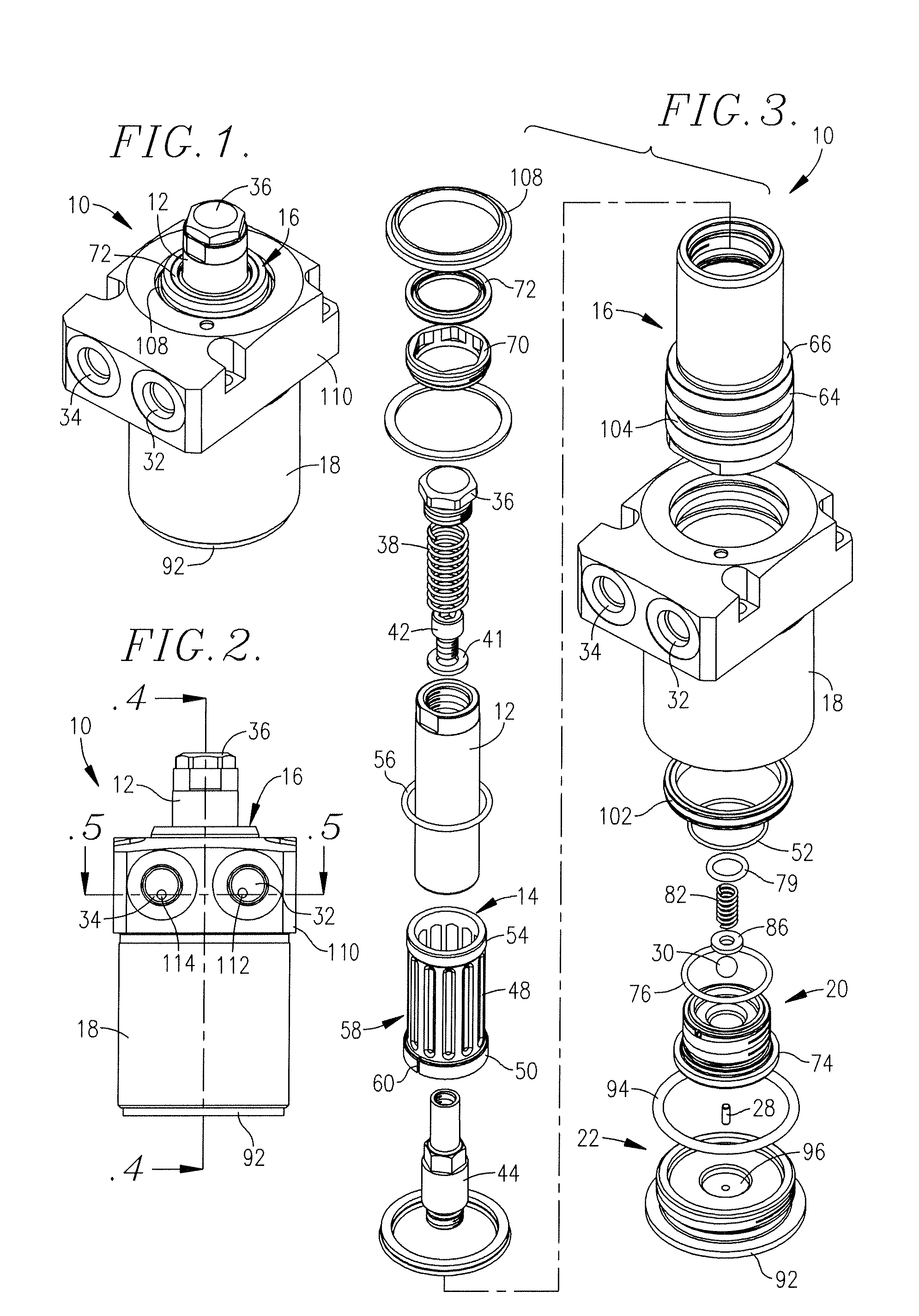

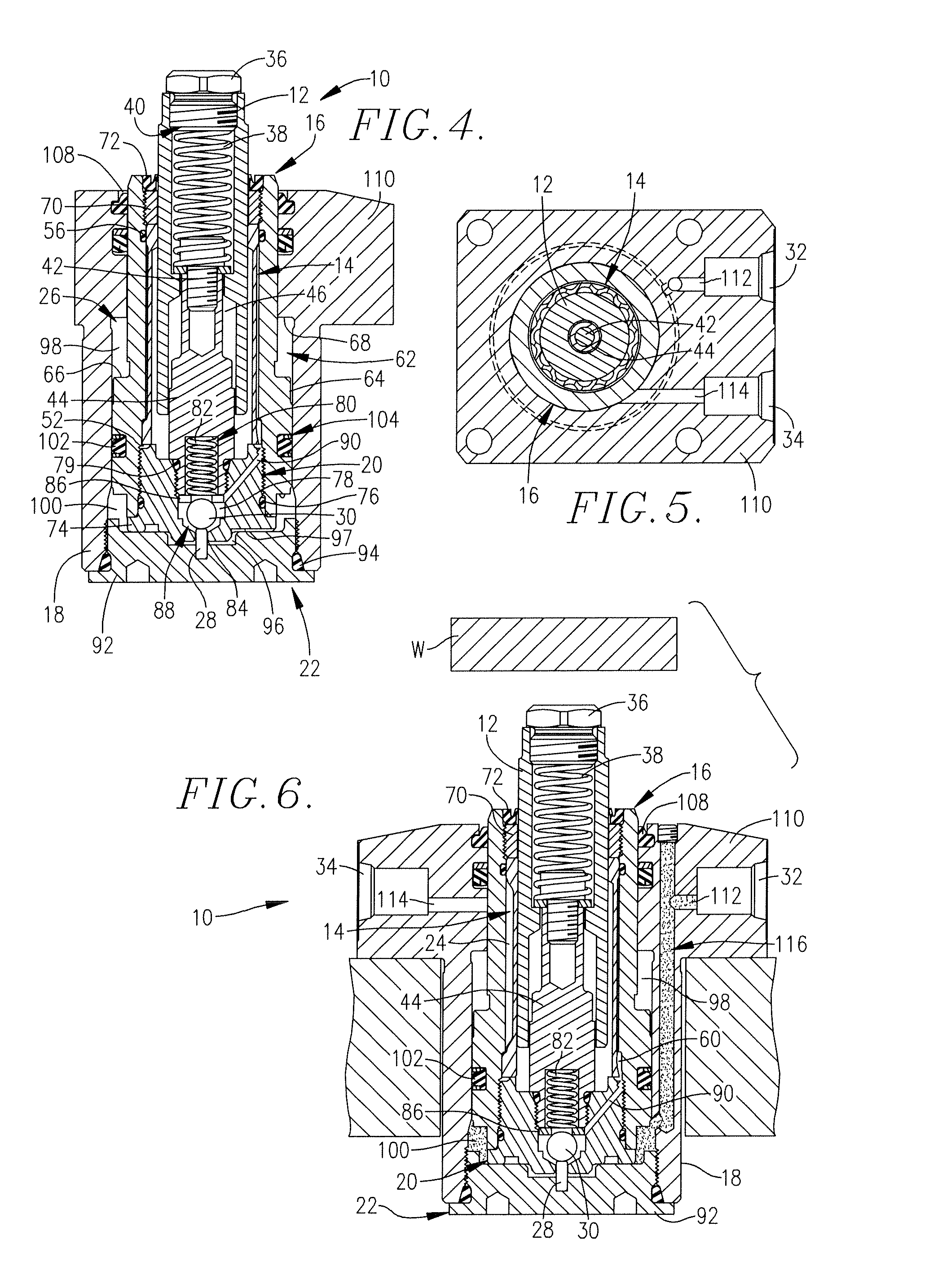

Double acting work support with internal sequence control

InactiveUS20100052233A1Easy to processIncrease pressureMetal working apparatusPositioning apparatusEngineeringPlunger

A work support comprises a plunger, a transmission member, a first chamber, a second chamber, a third chamber, a clamping mechanism, a plug, and a body. The plunger may be slidably retained within the clamping mechanism, which in turn is firmly held within the transmission member. The transmission member may extend and retract from the body corresponding to a pressure in the first chamber and the second chamber. Extension of the transmission member also extends the plunger such that the plunger may contact and receive a load from a work piece. The third chamber may be located between the outer surface of the clamping mechanism and the inner surface of the transmission member. Increasing pressure in the first chamber while decreasing pressure in the second chamber extends the transmission member and opens the plug which blocks the entry to the third chamber. Pressure in the third chamber closes the gap between the clamping mechanism and the plunger and applies a clamping force to the plunger.

Owner:VEKTEK LLC

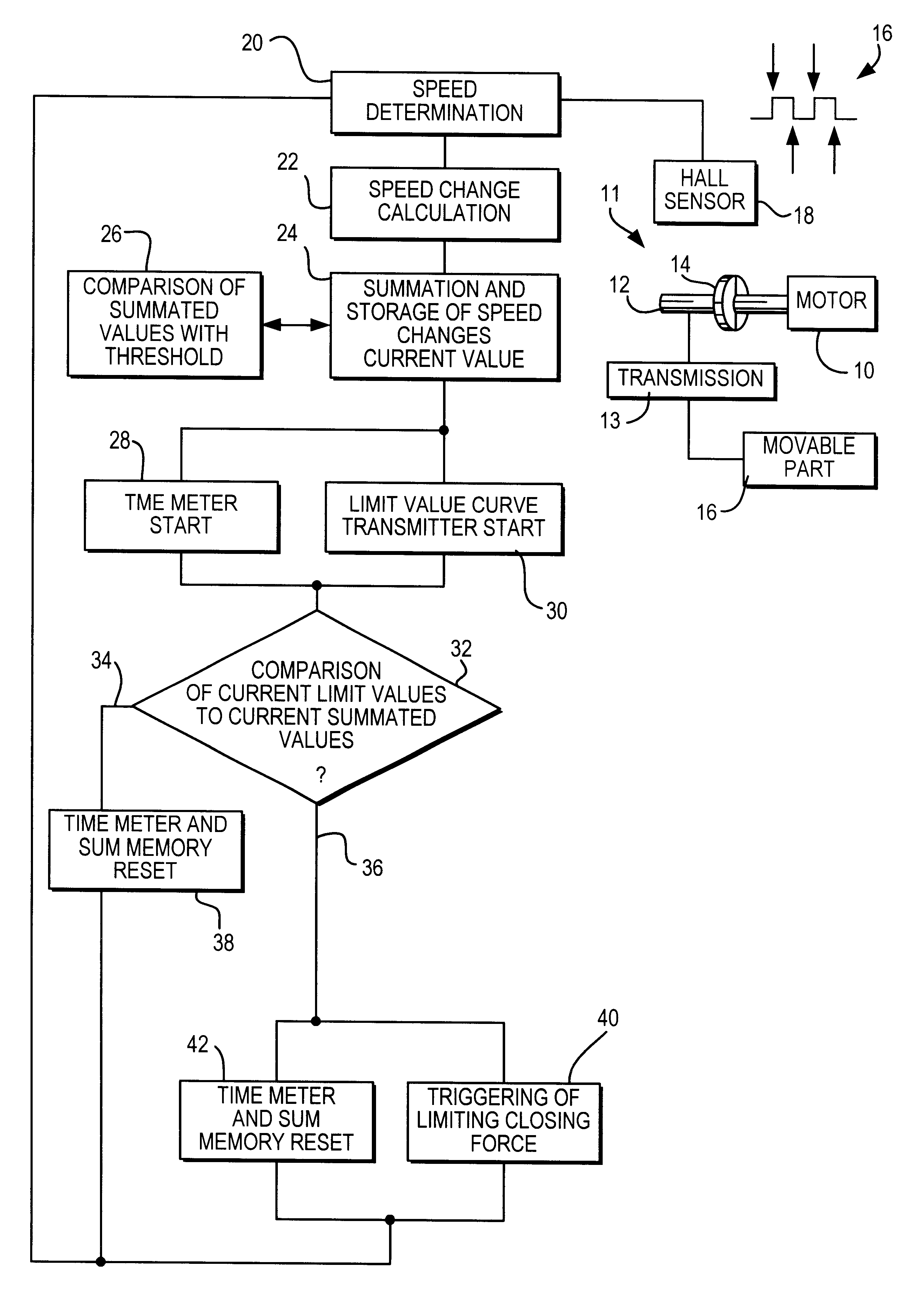

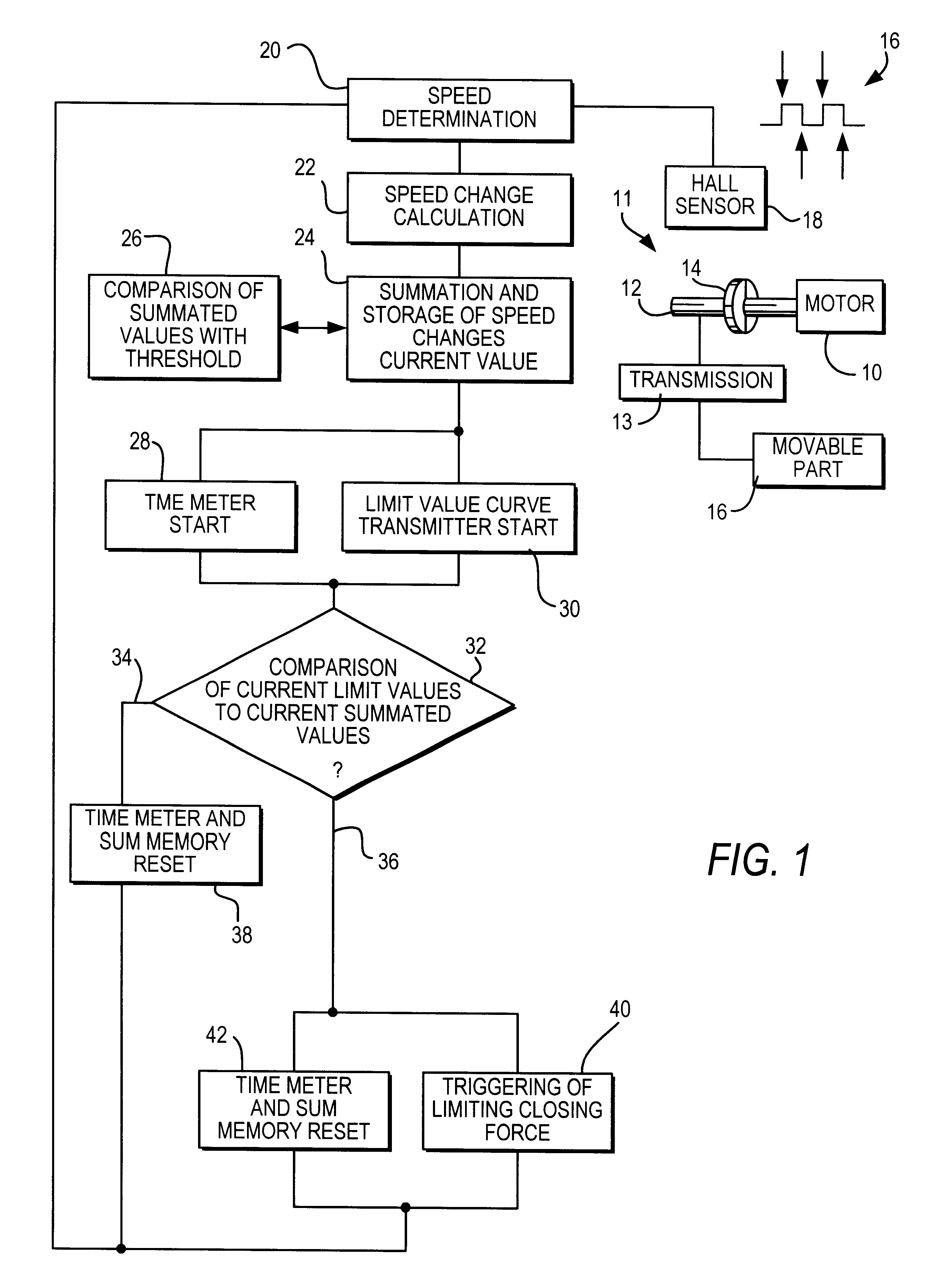

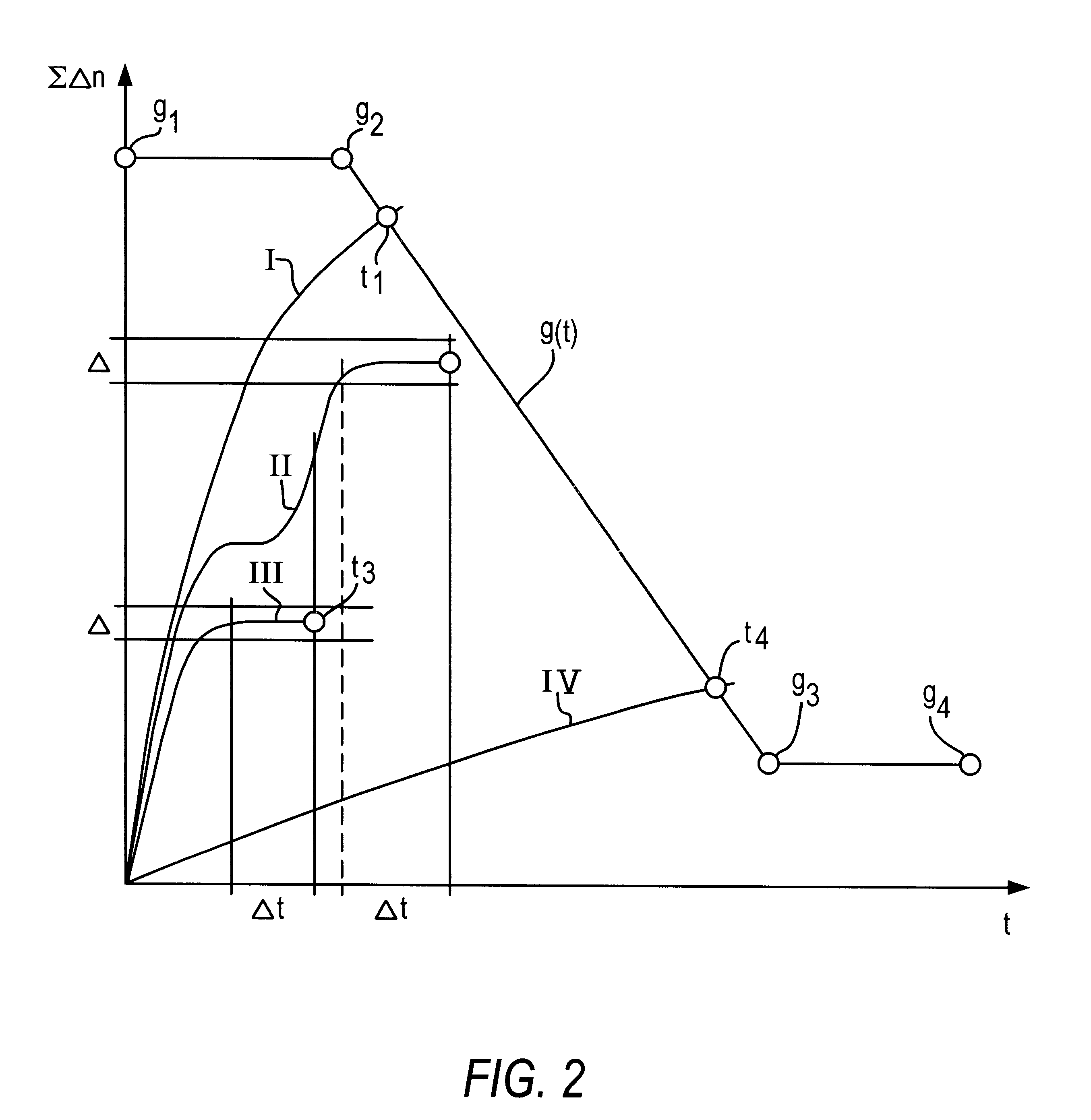

Method for limiting the closing force of movable components

InactiveUS6504332B1Easy to adaptReduce clamping forceParameter calibration/settingDC motor speed/torque controlIn vehicleCurrent threshold

A method for limiting the closing force of movable components (16), in particular windows and sliding roofs in vehicles is provided. The windows and roofs are powered by an electric motor driven servo drive. The inventive method comprises at least the following steps: determination of the actual motor rotation speed n by evaluating periodic signals from a sensor connected to a servo drive; calculation of a typical parameter on which reflects a change in motor rotation speed; summation and saving of an actual typical parameter in a sum storage device; starting of a timing device and a threshold sensor, in the event that the summed parameter value totals exceed a parameter threshold value; comparison of an actual threshold value g(t) with an actual, summed parameter value; triggering of a mechanism to limit the closing force and resetting of the timing device and the summed value storage device, if the respective current value of the summed parameters are the same as or equal to or larger than the respective current threshold value g(t); termination of the comparing procedure and resetting of the timing device in addition to the summed value memory, if the respective value of the summed parameter is smaller than the respective current threshold value and is within a predefined tolerance and additionally, a predefined time unit remains constant.

Owner:ROBERT BOSCH GMBH

Multicolor injection mould device

The embodiment of the invention discloses a multicolor injection mould device which comprises a middle rotating mould and a plurality of lateral moulds, wherein the middle rotating mould is a cylinder with a plurality of side faces; one of the lateral moulds is a fixed mould, and the others are moving moulds which can translate relative to the fixed mould; the middle rotating mould is a moving mould which can translate and rotate relative to the lateral mould as the fixed mould; and the lateral moulds are arranged around the middle rotating mould and respectively form mould cavities together with the corresponding side faces of the middle rotating mould. The multicolor injection mould device of the embodiment of the invention can be used for finishing the moulding formation of dual-color moulding parts and even multicolor moulding parts by adopting one set of mould, which greatly improves the stress state of an injection moulding machine and lowers the requirement of the injection mould on the mould clamping force of the injection moulding machine.

Owner:KONKA GROUP +2

Collision monitoring system

InactiveUS7548037B2Different resistanceImproved detection of obstacleParameter calibration/settingMotor/generator/converter stoppersMonitoring systemEngineering

Disclosed is an improved system and method for sensing both hard and soft obstructions for a movable panel such as a sunroof. A dual detection scheme is employing that includes an optical sensing as the primary means and electronic sensing of motor current as a secondary means. The secondary means utilizes system empirical precharacterization, fast processing algorithms, motor parameter monitoring including both current sensing and sensorless electronic motor current commutation pulse sensing, and controller memory, to adaptively modify electronic obstacle detection thresholds in real time without the use of templates and cycle averaging techniques.

Owner:UUSI

Quick connect closure for connecting two structural members

InactiveUS20080056816A1Operating reliability can be highEasy to manufactureCouplings for rigid shaftsSheet joiningPlastic materialsEngineering

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

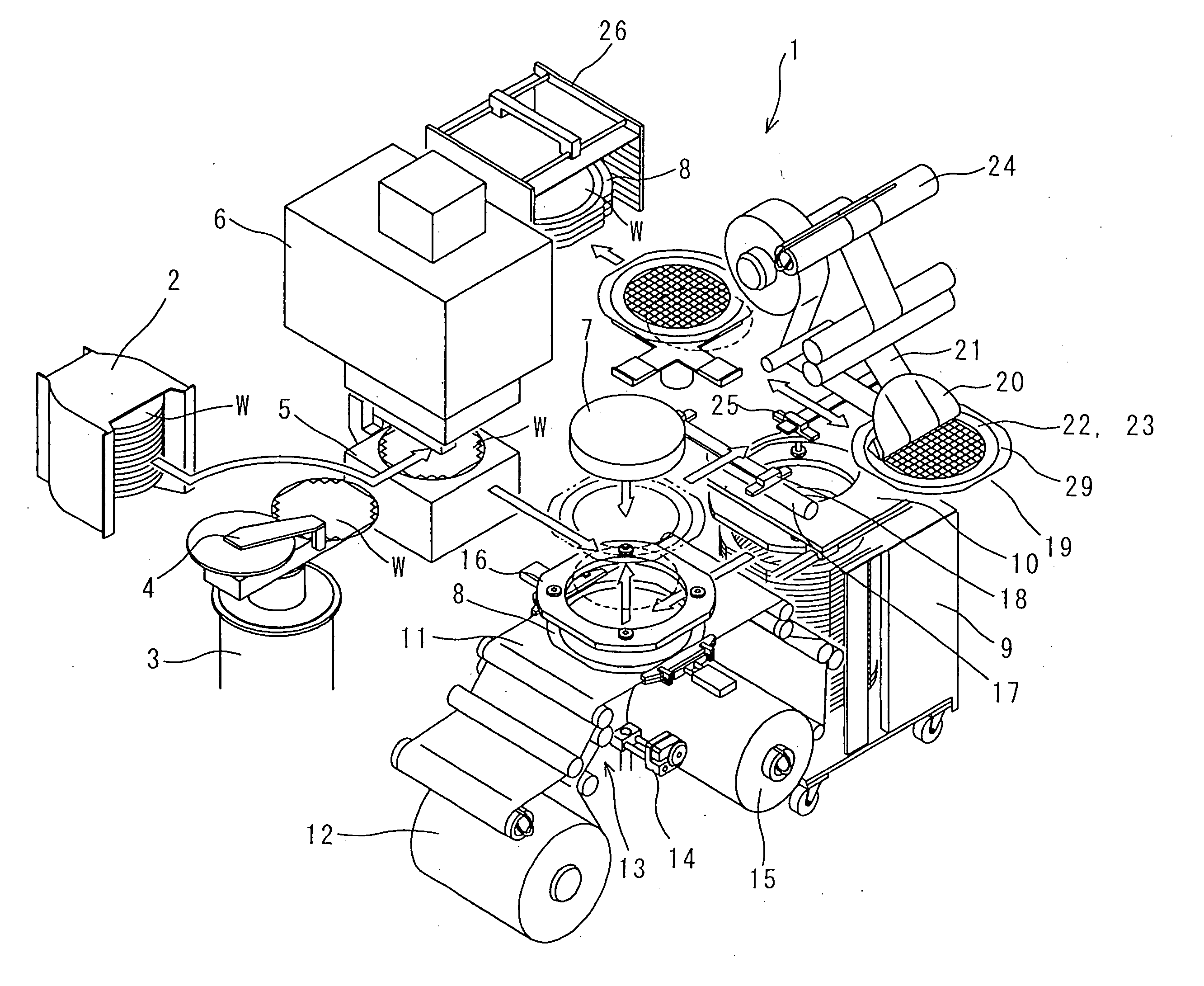

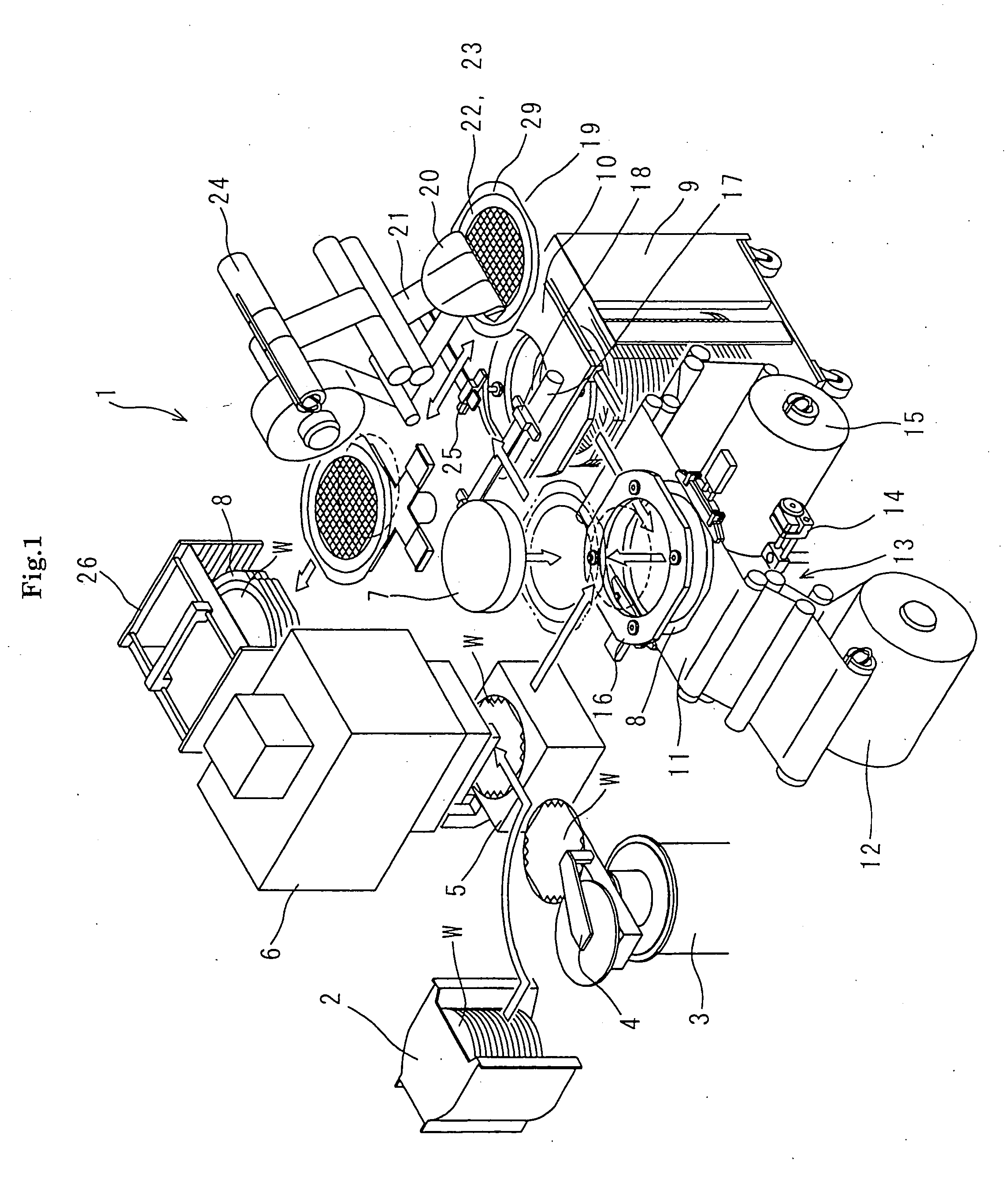

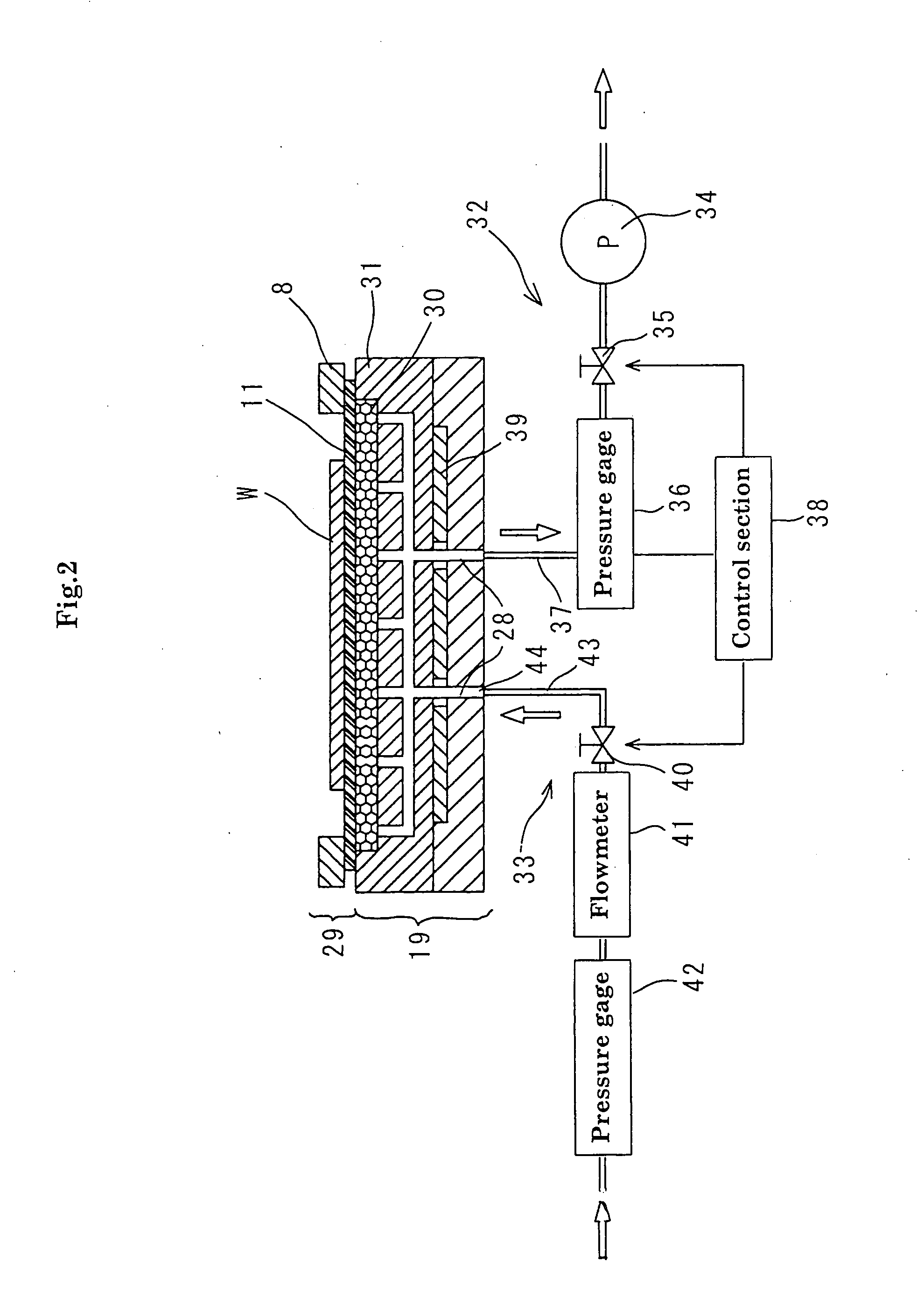

Releasing method and releasing apparatus of work having adhesive tape

InactiveUS20050067097A1Avoid damageReduce clamping forceSleeve/socket jointsLayered productsEngineeringMechanical engineering

In a method for releasing a work having an adhesive tape from a holding member which sucks and holds the work having the adhesive tape, the work having the adhesive tape is released from the holding member while supplying a gas which reduces a holding force of the holding member between the holding member and the work having the adhesive tape.

Owner:NITTO DENKO CORP

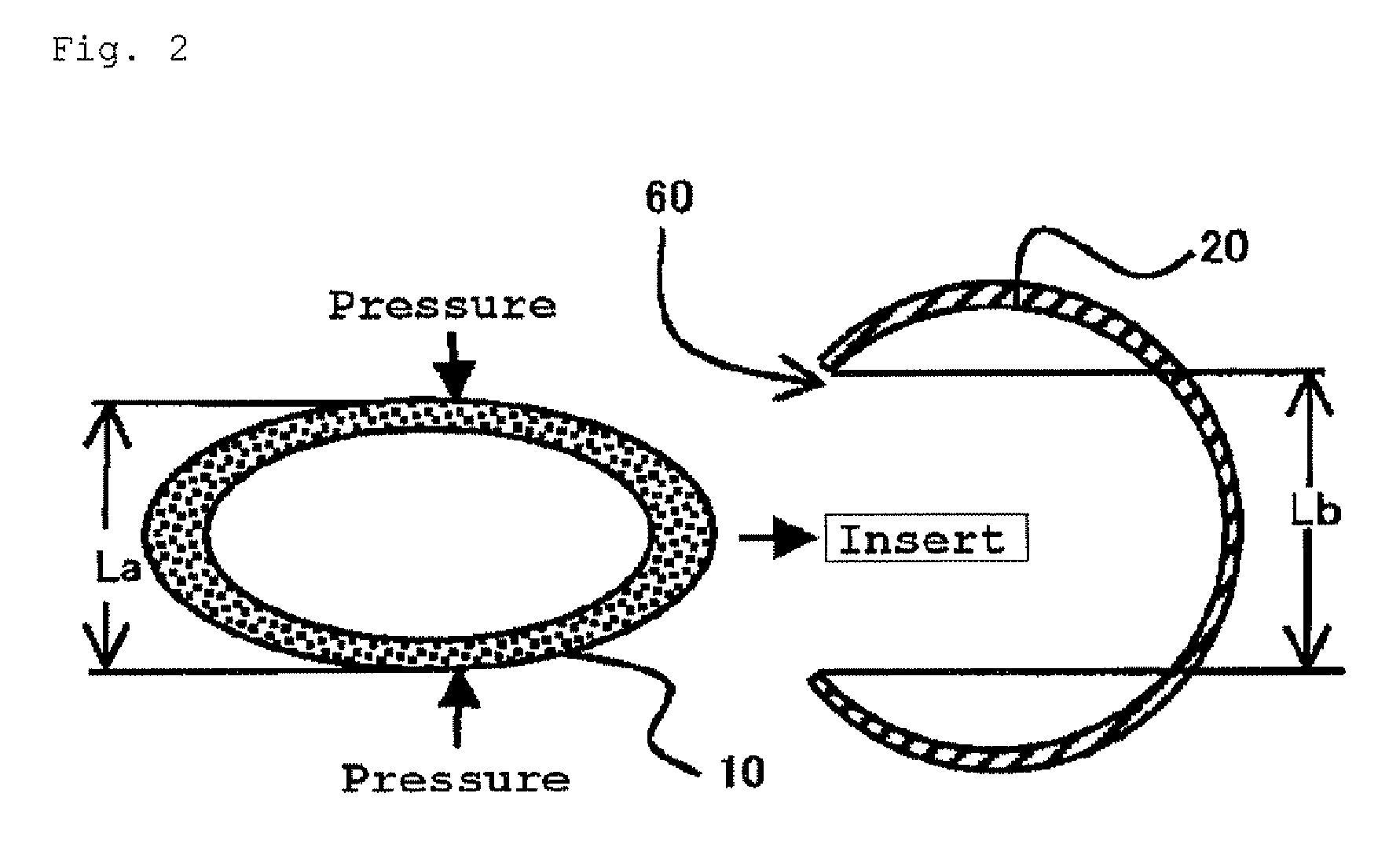

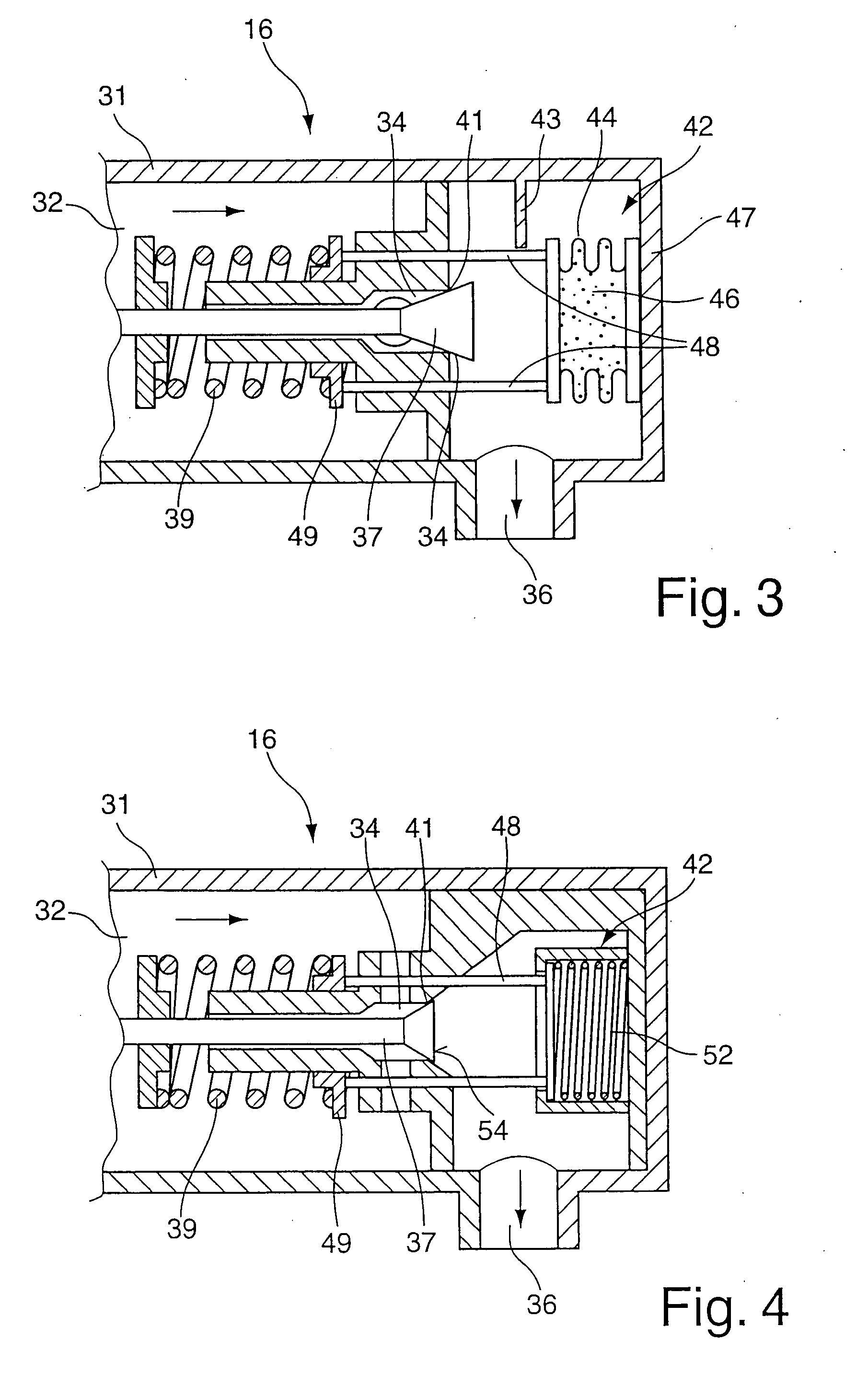

Servo valve for controlling an internal combustion engine injection

ActiveUS20070205302A1Reduce clamping forceEasy to produceSpray nozzlesFluid pressure injection controlComing outEngineering

A control servo valve is housed inside the casing of an internal combustion engine fuel injector, and has an actuator, a control chamber communicating with a fuel inlet and with a fuel outlet passage, and a shutter movable along an axis by the actuator between a closed position and an open position to close and open the outlet passage respectively; the servo valve also has a fixed axial rod interposed between the actuator and the control chamber; the outlet passage comes out through an outer lateral surface of the axial rod; and the shutter is defined by a sleeve which slides axially on the outer lateral surface, and, in the closed position, closes the outlet passage so as to be subjected to a zero axial resultant force by the pressure of the fuel.

Owner:CENT RICERCHE FIAT SCPA

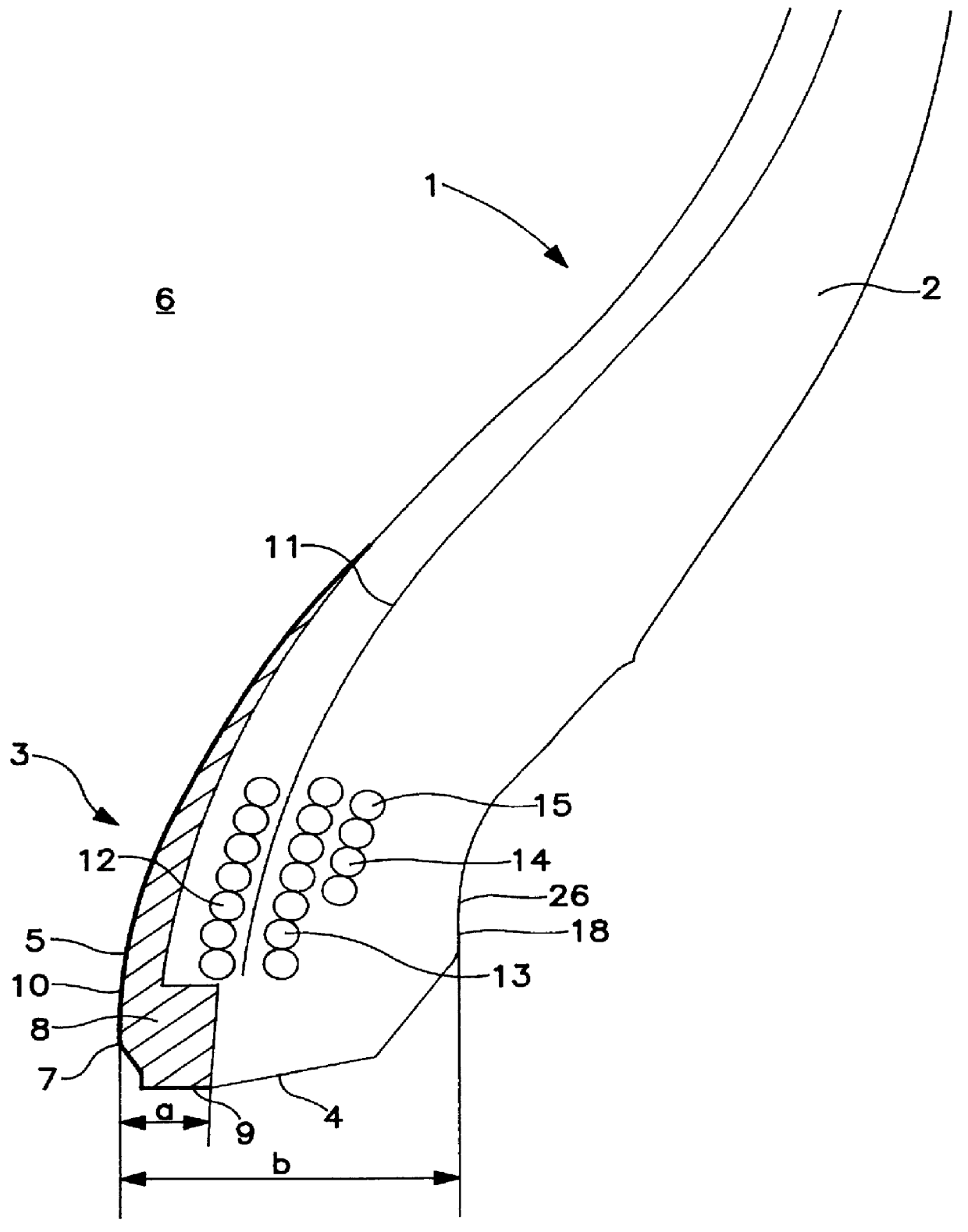

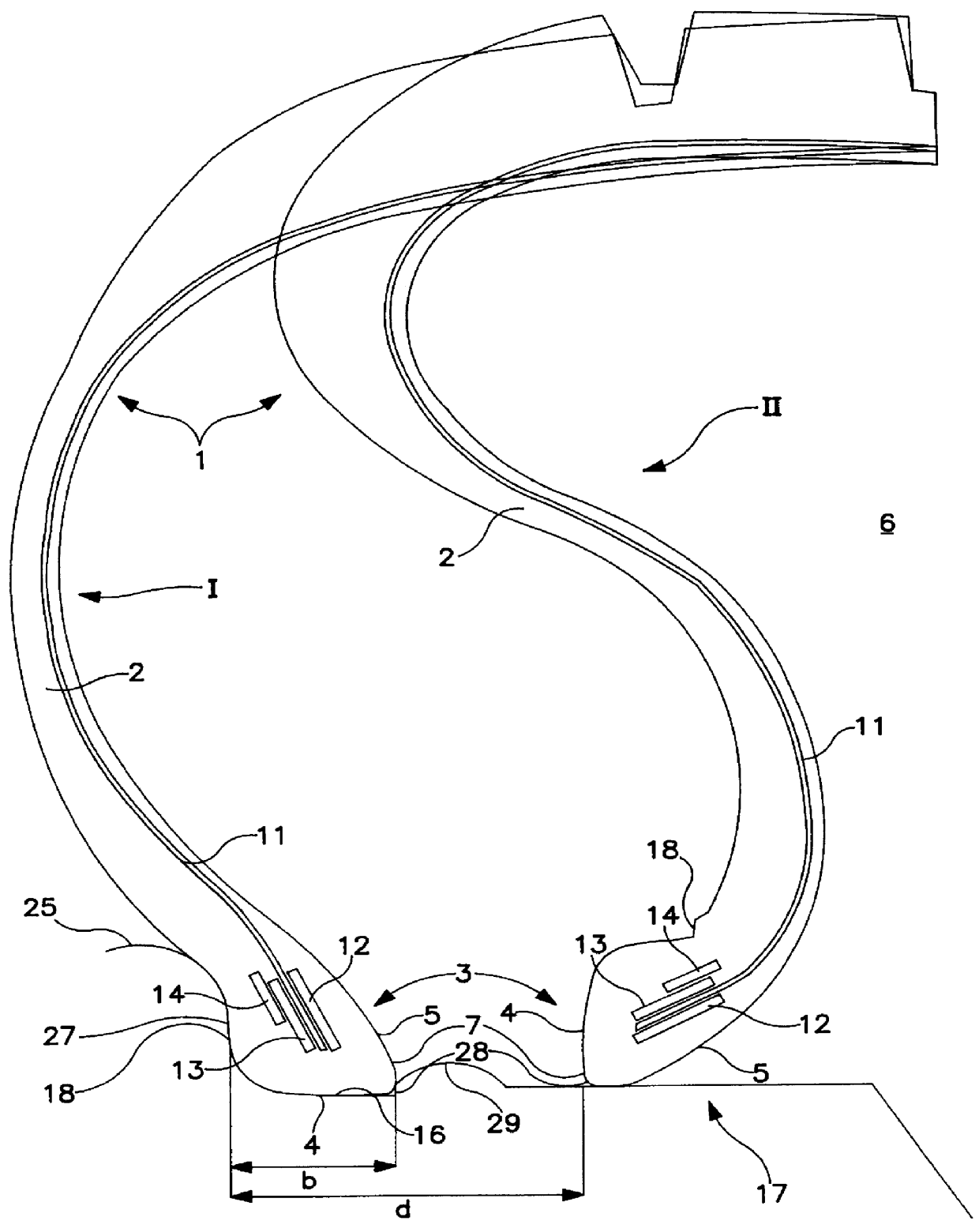

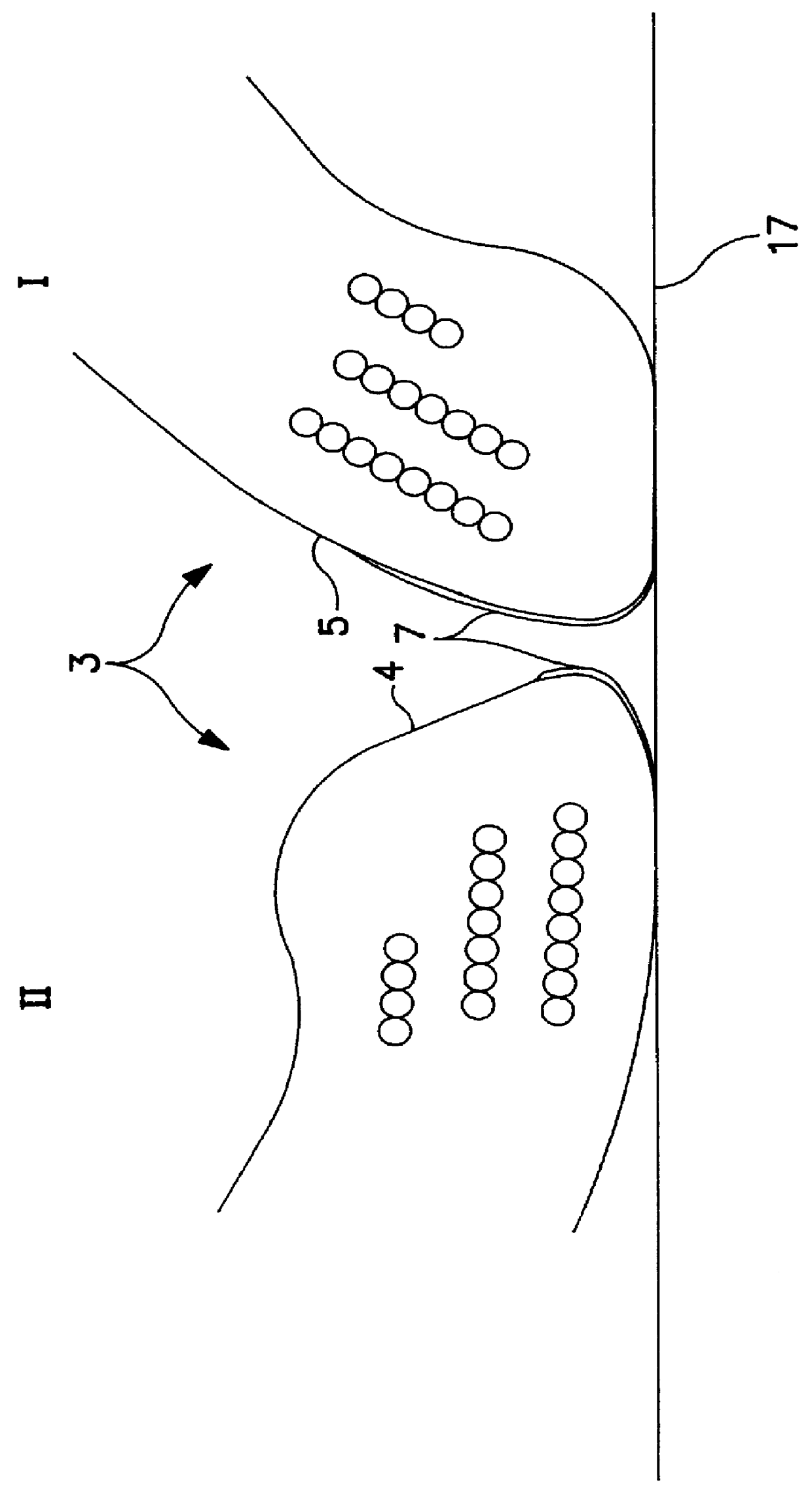

Tire with beads designed to ease removal from rim

InactiveUS6116313AImprove performancePrevent rotationWithout separate inflatable insertsSpecial tyresEngineeringMechanical engineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

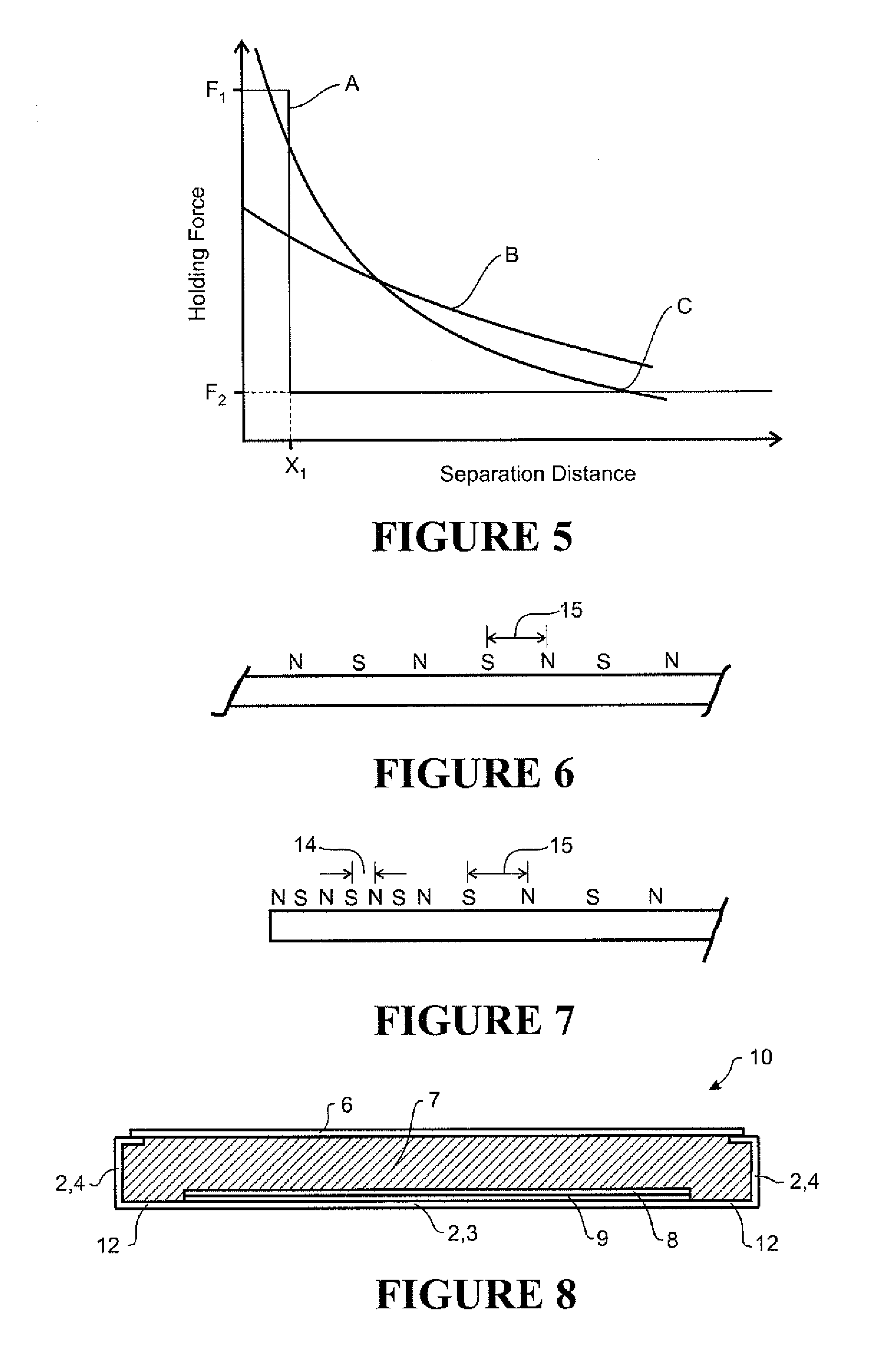

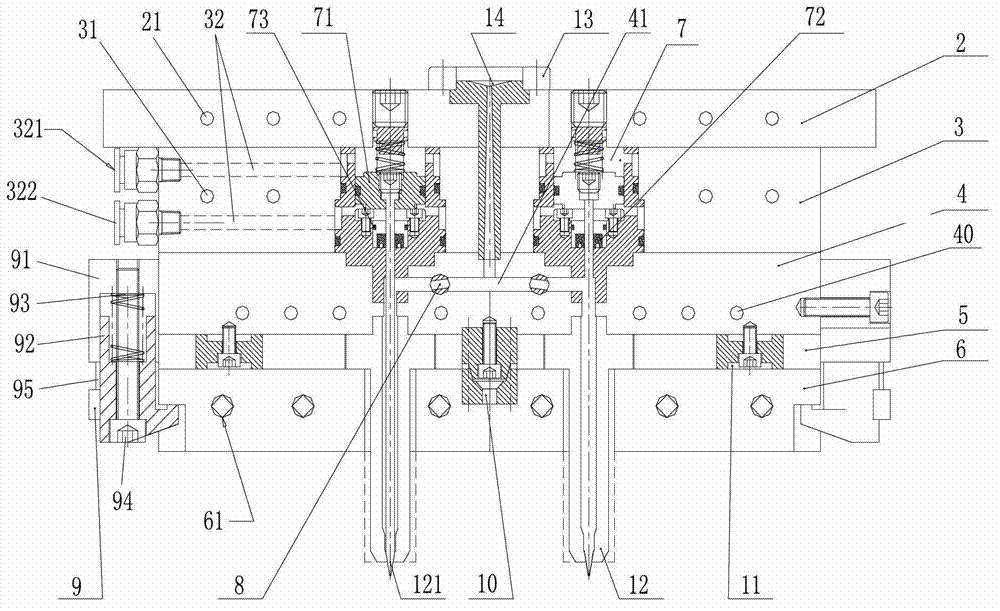

Appliance door

ActiveUS20110115355A1Reduce clamping forceIncrease the separation distanceDomestic cooling apparatusLighting and heating apparatusFilling materialsEngineering

The present invention relates to a door for an appliance. The door has a front panel and a rear panel and edges extending between the front panel and rear panel to create an internal cavity between the front panel and the rear panel. A filler material is contained in the internal cavity, and an intermediate material is interposed between a rear surface of the front panel and the filler material. The intermediate material or front panel is adapted to retain the front panel relative to the filler material by a magnetic field and release a portion of the front panel relative to the filler material upon excessive localized deformation of the filler material.

Owner:FISHER & PAYKEL APPLIANCES LTD

Modularized cold runner system

ActiveCN102825730AShorten the production cycleShorter injection molding cycle timesEngineeringHeat balance

A modularized cold runner system relates to an injection molding die of a colder runner. The system can effectively isolate heat exchange between a high-temperature mold cavity and a low-temperature cold runner system, maintain heat balance of the whole modularized cold runner system, always keep low-temperature flow, prevent materials from being heated and vulcanized in the flow channel, and achieve molding for products without the runner. The system is good in controllability and versatility. The system is provided with, from top to bottom, a stationary mold base plate, a sprue bush, a cylinder installing plate, a cylinder, a cold runner plate, a heat isolation plate, a heating plate, a fluid modulation apparatus, a conicity locating piece, pressure blocks, a water-cooled needle-valve nozzle and a quickly-changed clamp, wherein the stationary mold base plate, the cylinder installing plate, the cold runner plate, the heat isolation plate and the heating plate are sequentially arranged from top to down and fixedly connected through fasteners.

Owner:XIAMEN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com