Multicolor injection mould device

A multi-color injection molding and mold technology, which is applied in the field of mold devices, can solve problems such as unbalanced force, complex process, and numerous processes, and achieve the effects of reducing occupied space, improving force conditions, and saving clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings.

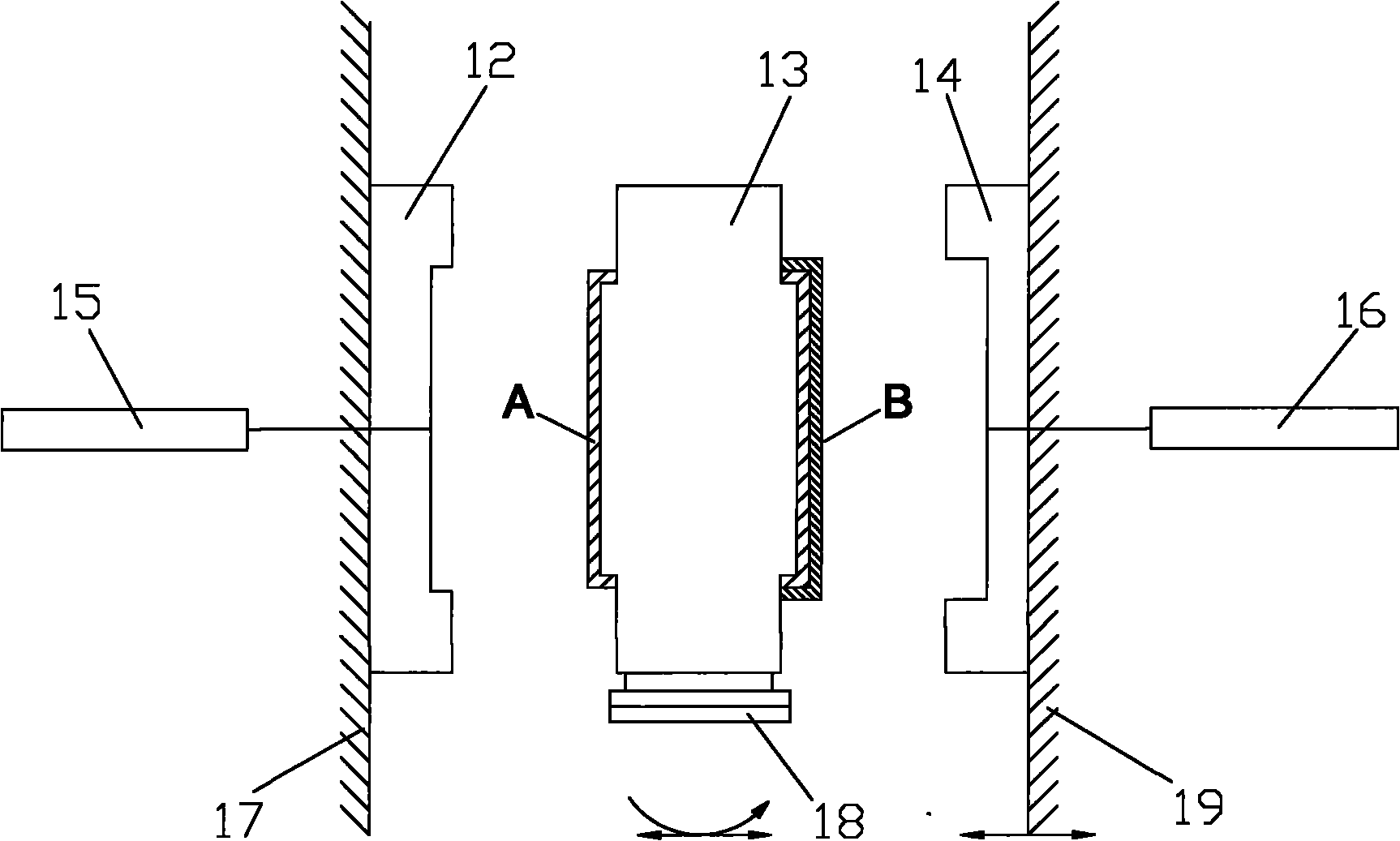

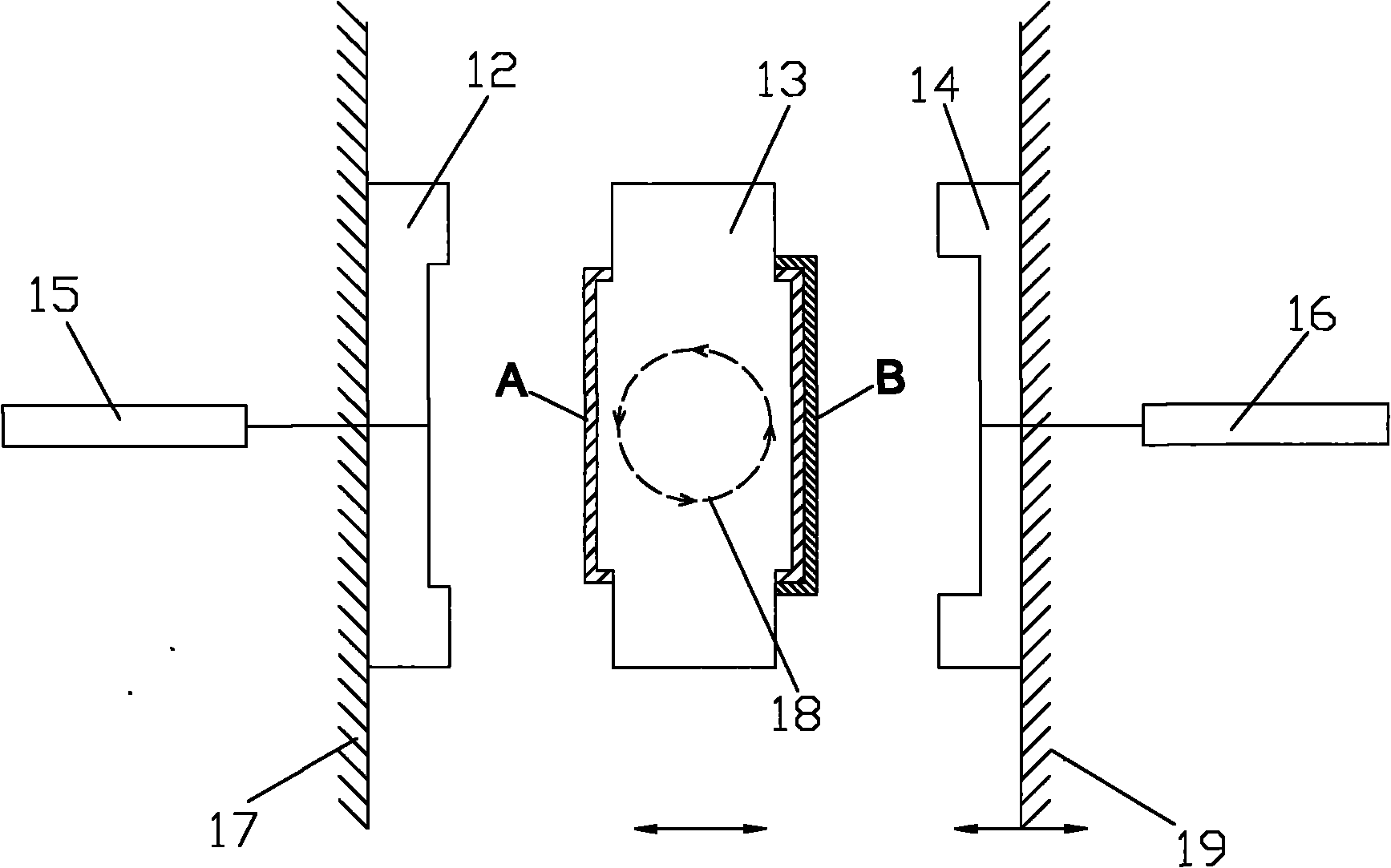

[0022] Please refer to figure 2 with image 3 As shown, the multi-color injection mold device of the embodiment of the present invention includes a first side mold 12, an intermediate rotating mold 13, a second side mold 14, a first barrel 15 and a second barrel 16.

[0023] In the molding machine using the multi-color injection mold device, a fixed disk 17, a rotating tray 18, and a moving disk 19 are also provided.

[0024] The first side mold 12 is a fixed mold, which is fixed on the fixed plate 17 in the molding machine, and the first barrel 15 is arranged on the side of the first side mold 12, which is connected to the mold of the first side mold 12 through a feed pipe. Cavity.

[0025] The second side mold 14 is a movable mold, which is fixed on a movable plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com