Patents

Literature

5404 results about "Moulding device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

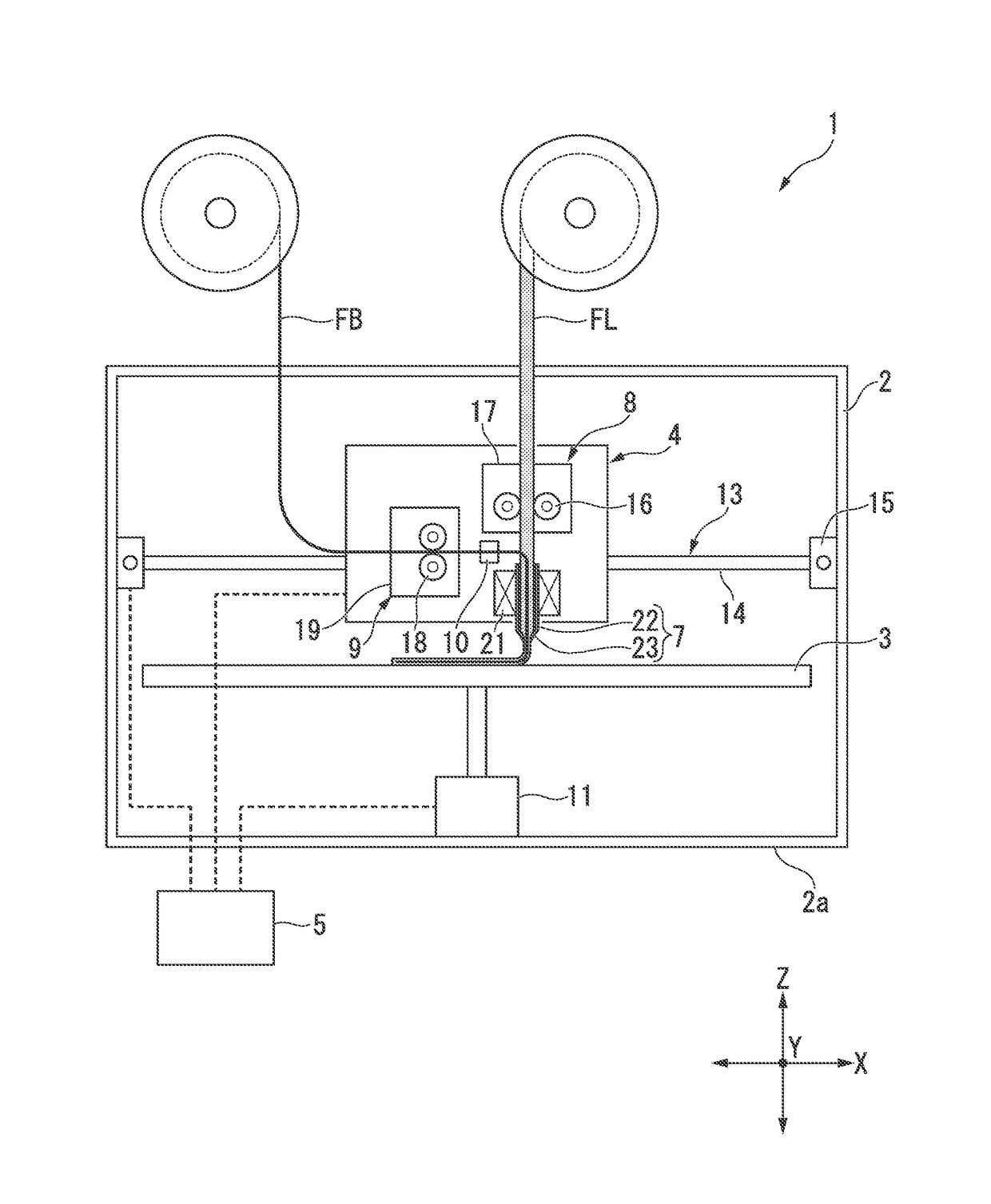

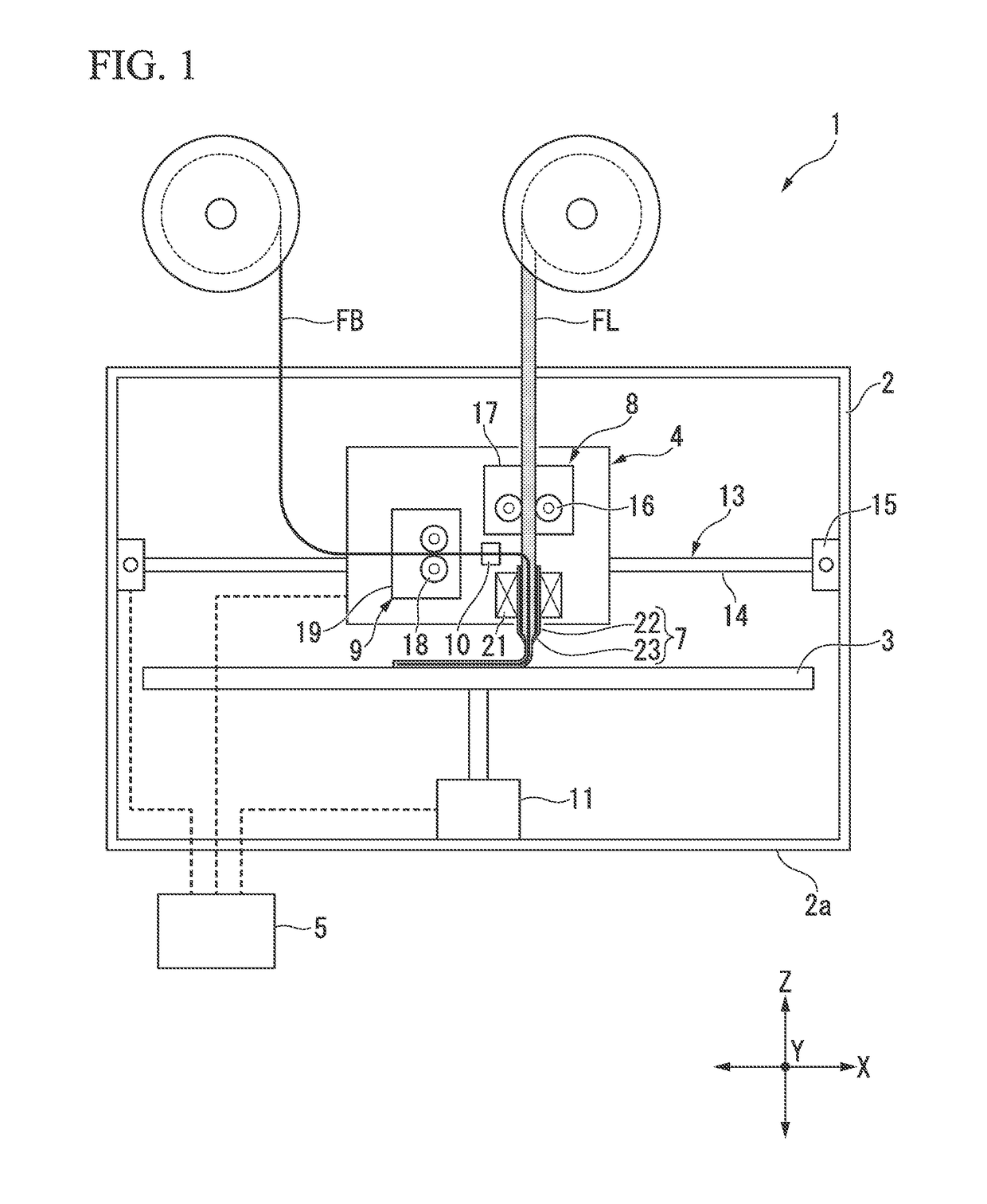

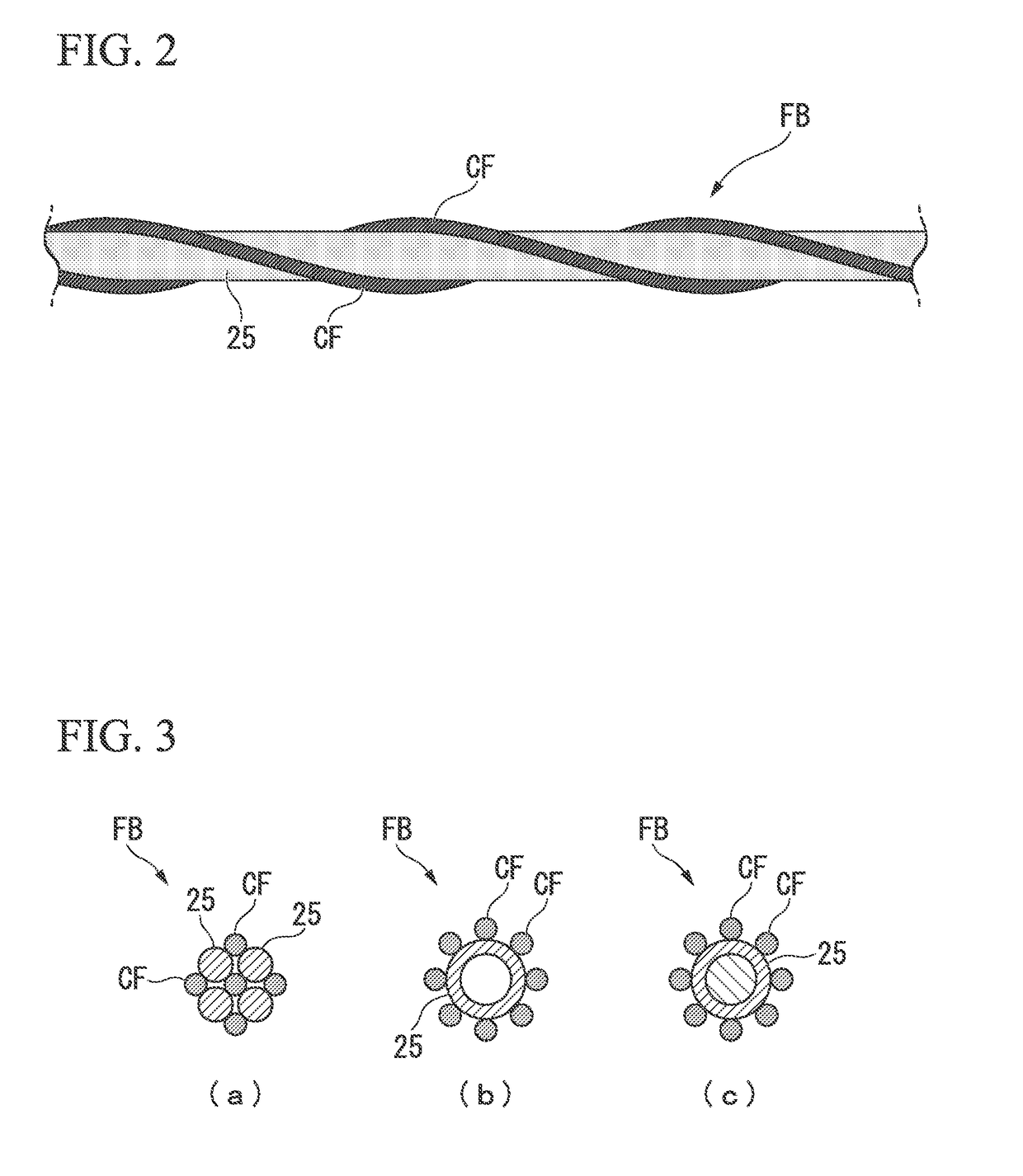

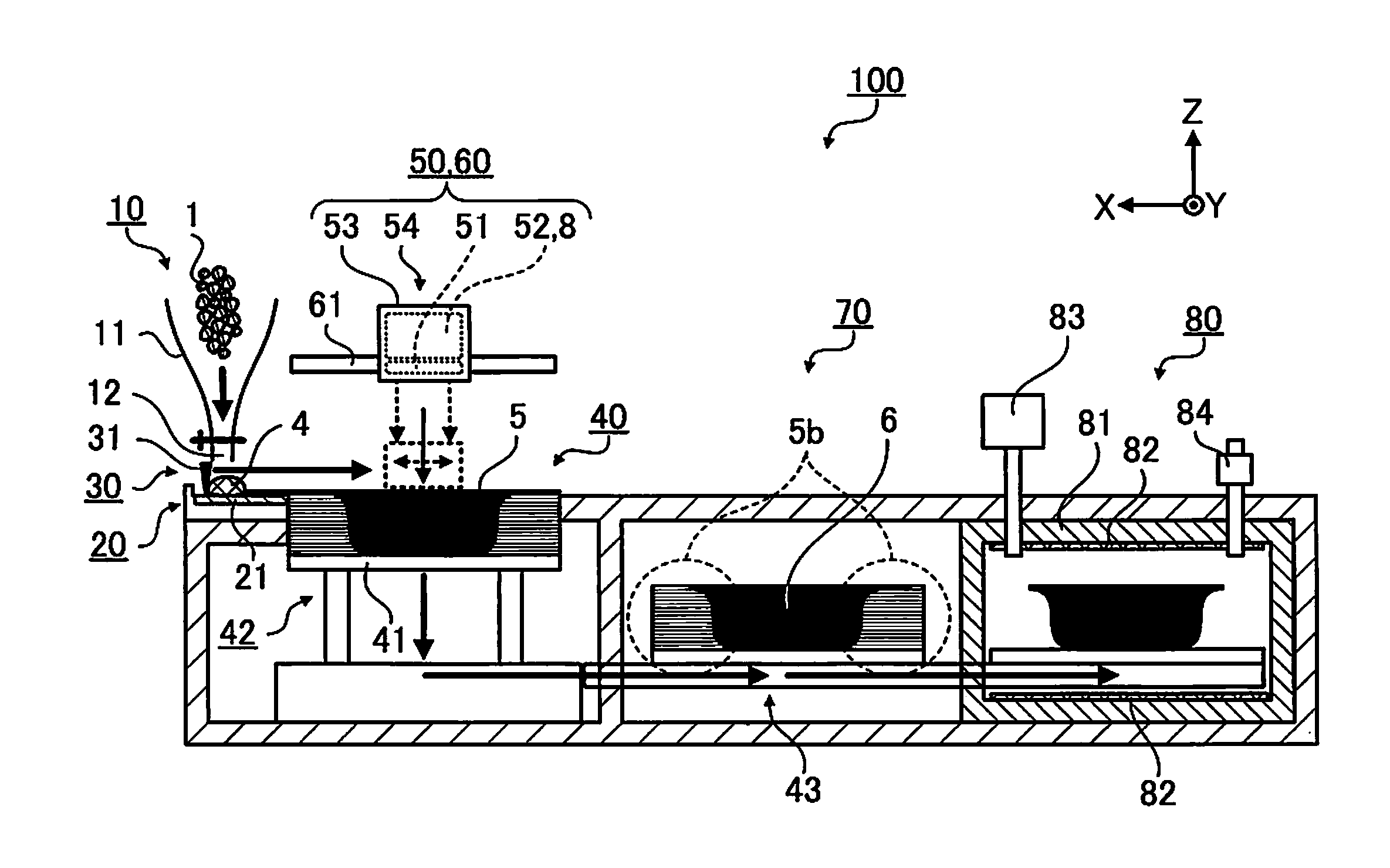

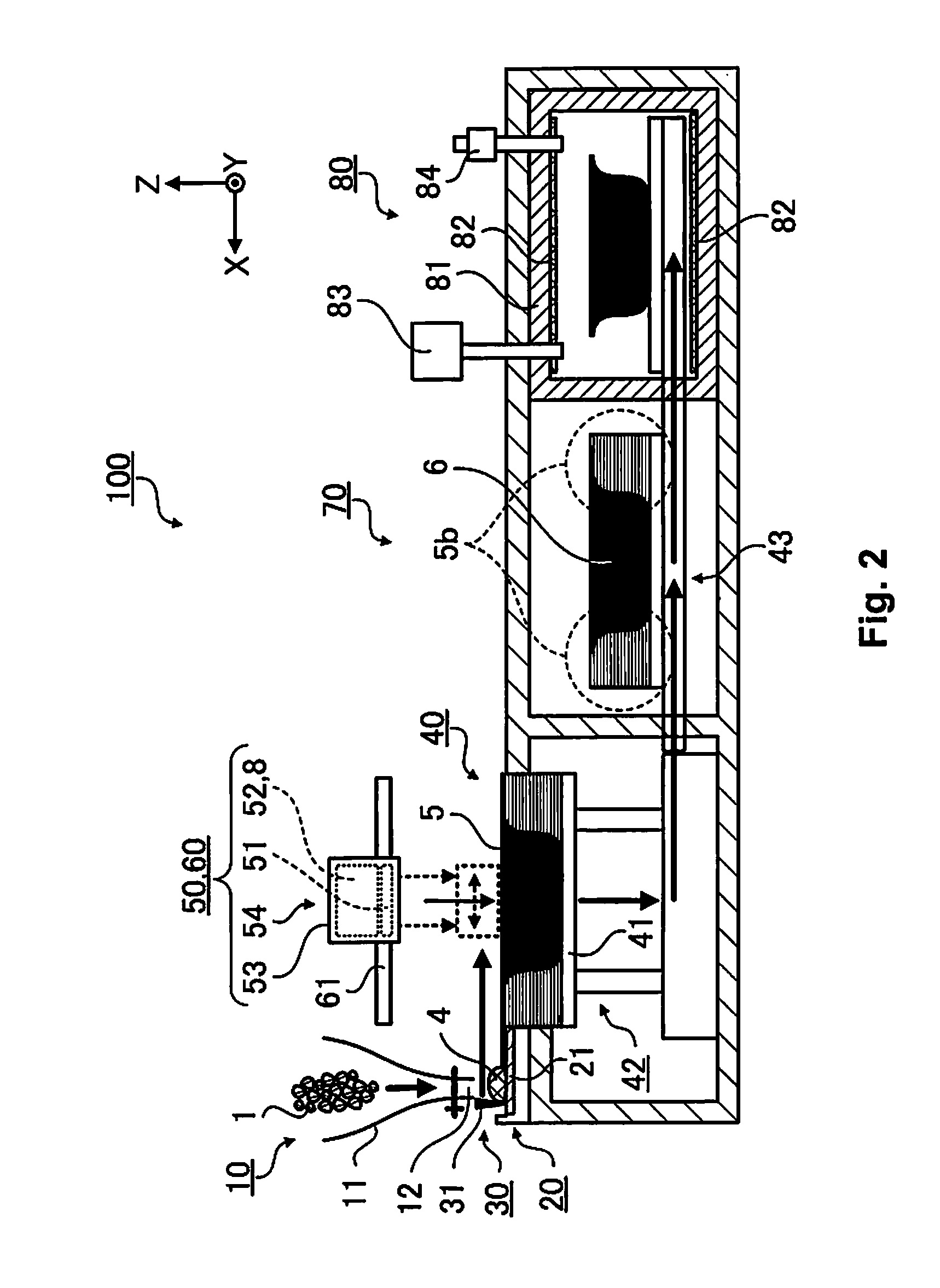

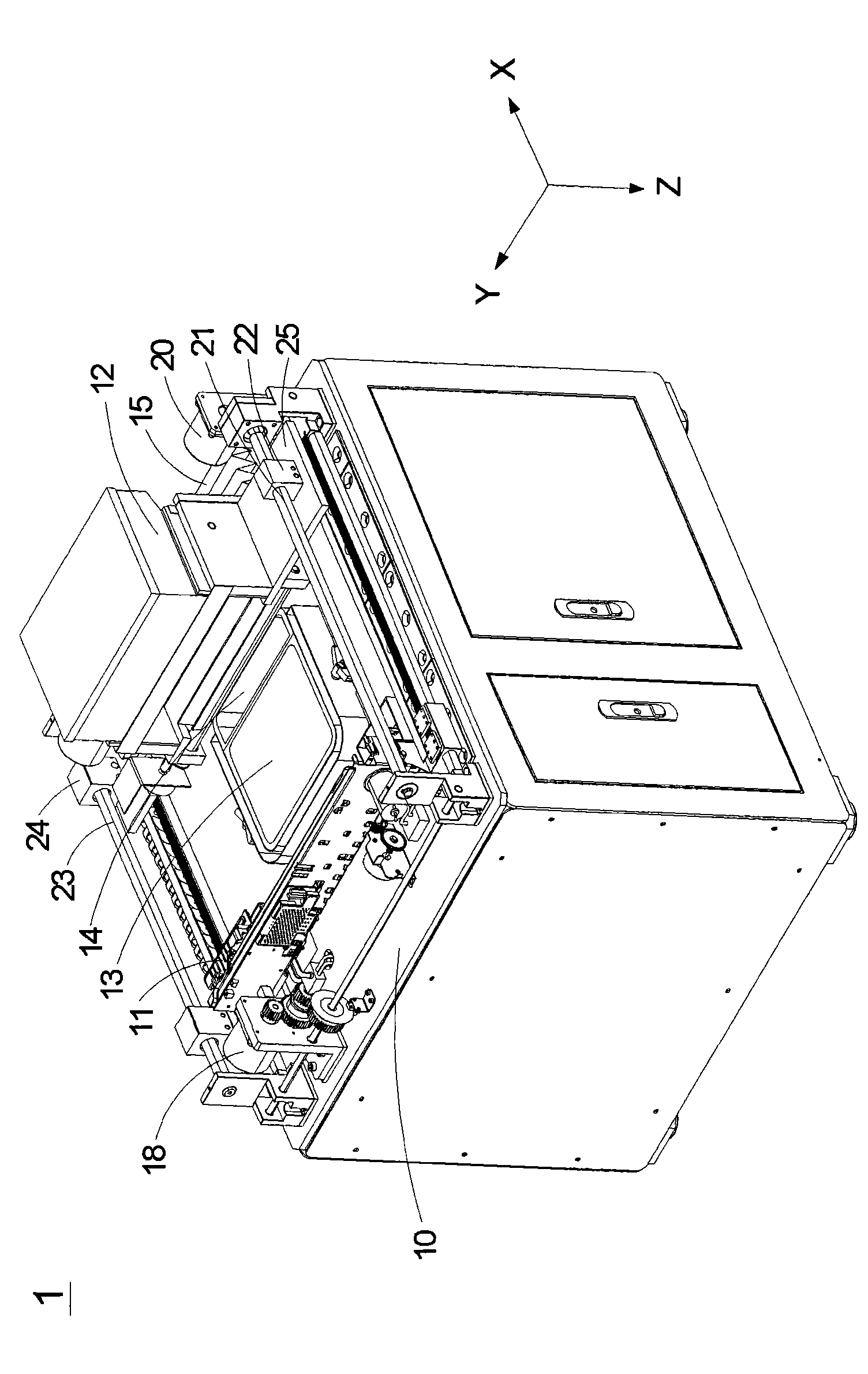

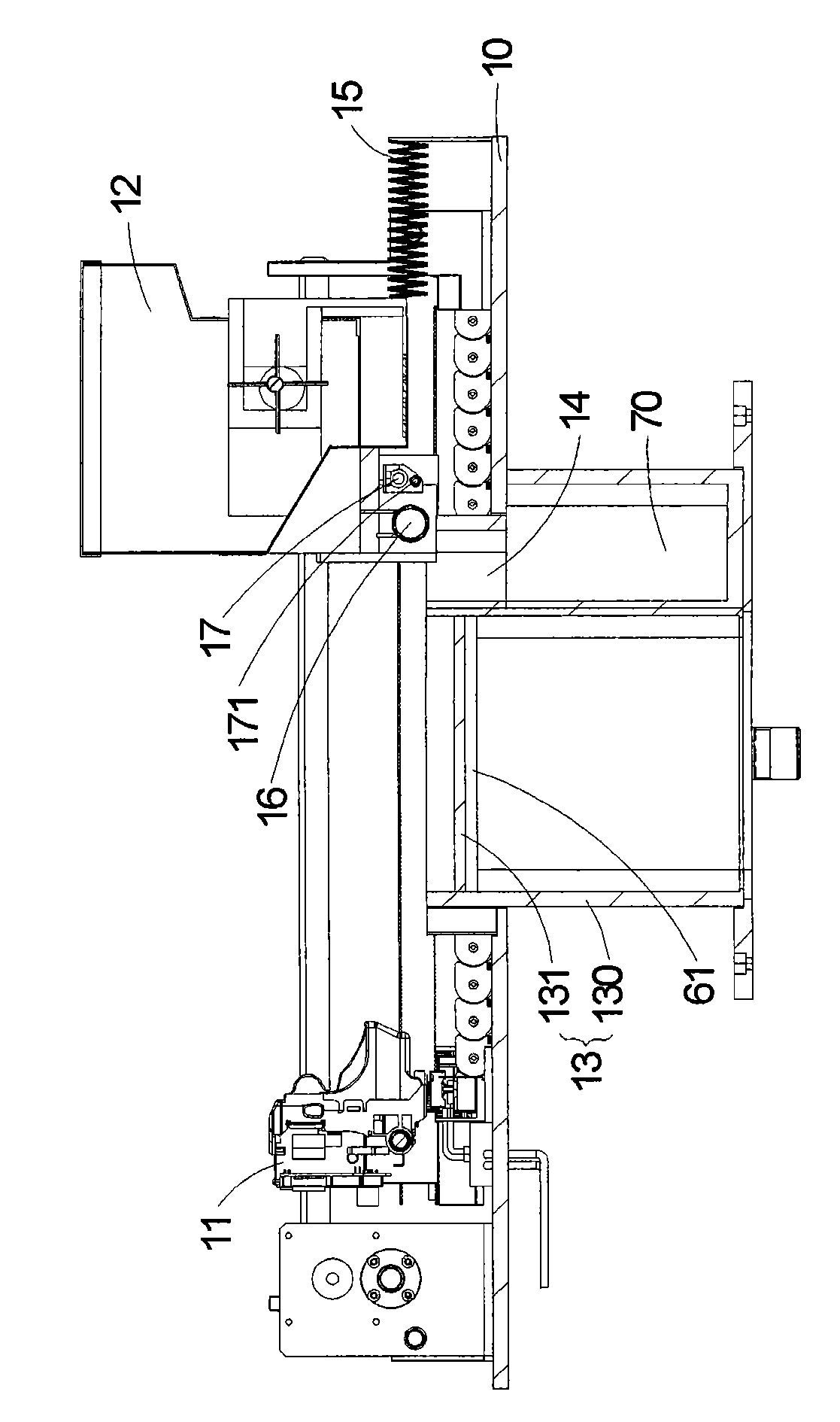

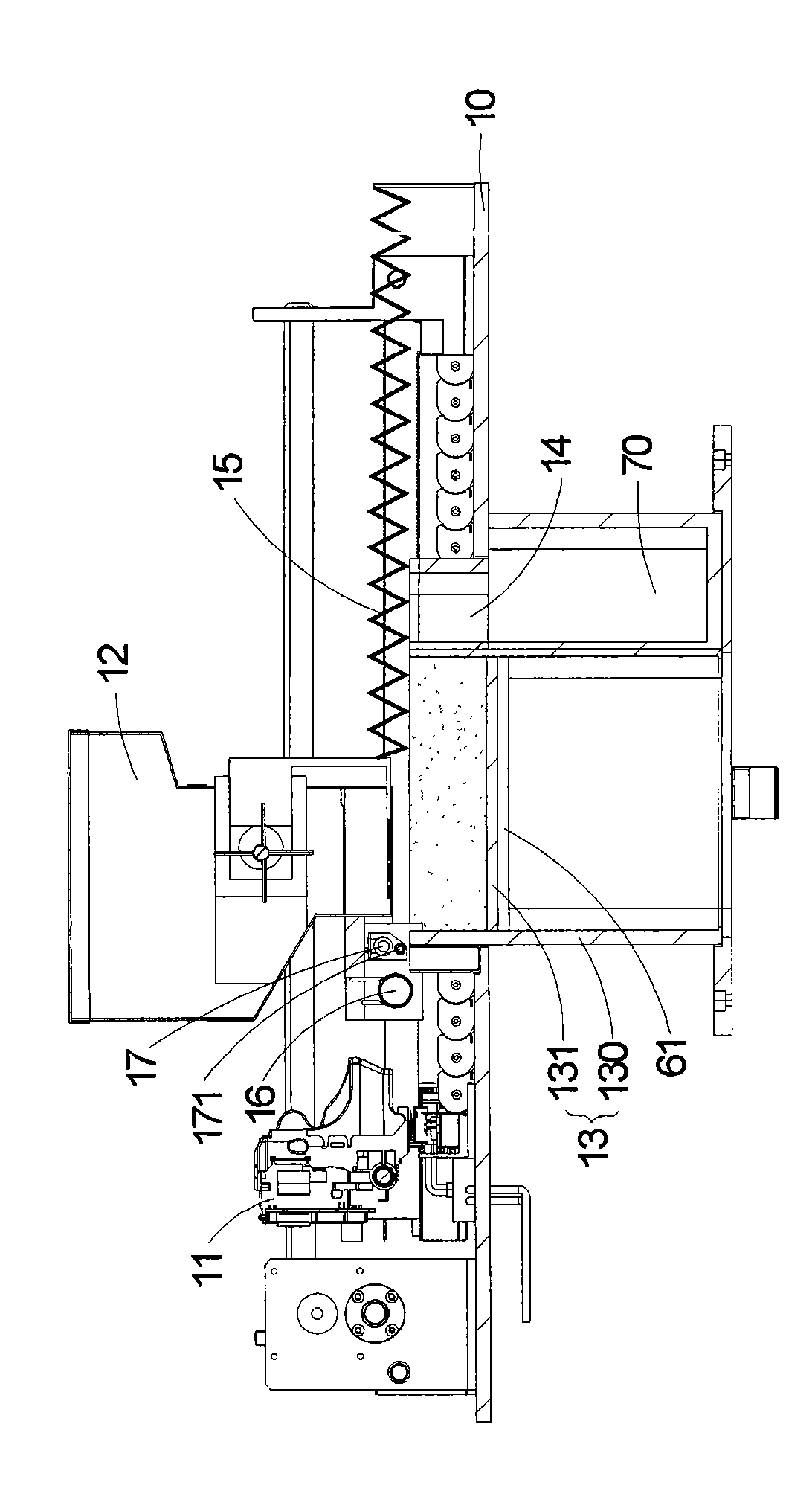

Three-dimensional printing system, three-dimensional printing method, molding device, fiber-containing object, and production method thereof

ActiveUS20170210074A1Improve structural strengthHigh strengthManufacturing heating elements3D object support structuresFiber3 dimensional printing

A three-dimensional printing system (1) includes: a head (2) to which a first continuous material (FL) including a resin and a second continuous material (FB) including fibers are fed; a platform (3) on which a printing material based on the first and second continuous materials from the head is stacked; a cutting device (10) which is capable of cutting at least fibers; and a controller (5) which controls an operation device including at least one of the head, the platform, and the cutting device.

Owner:NIHON UNIVERSITY +1

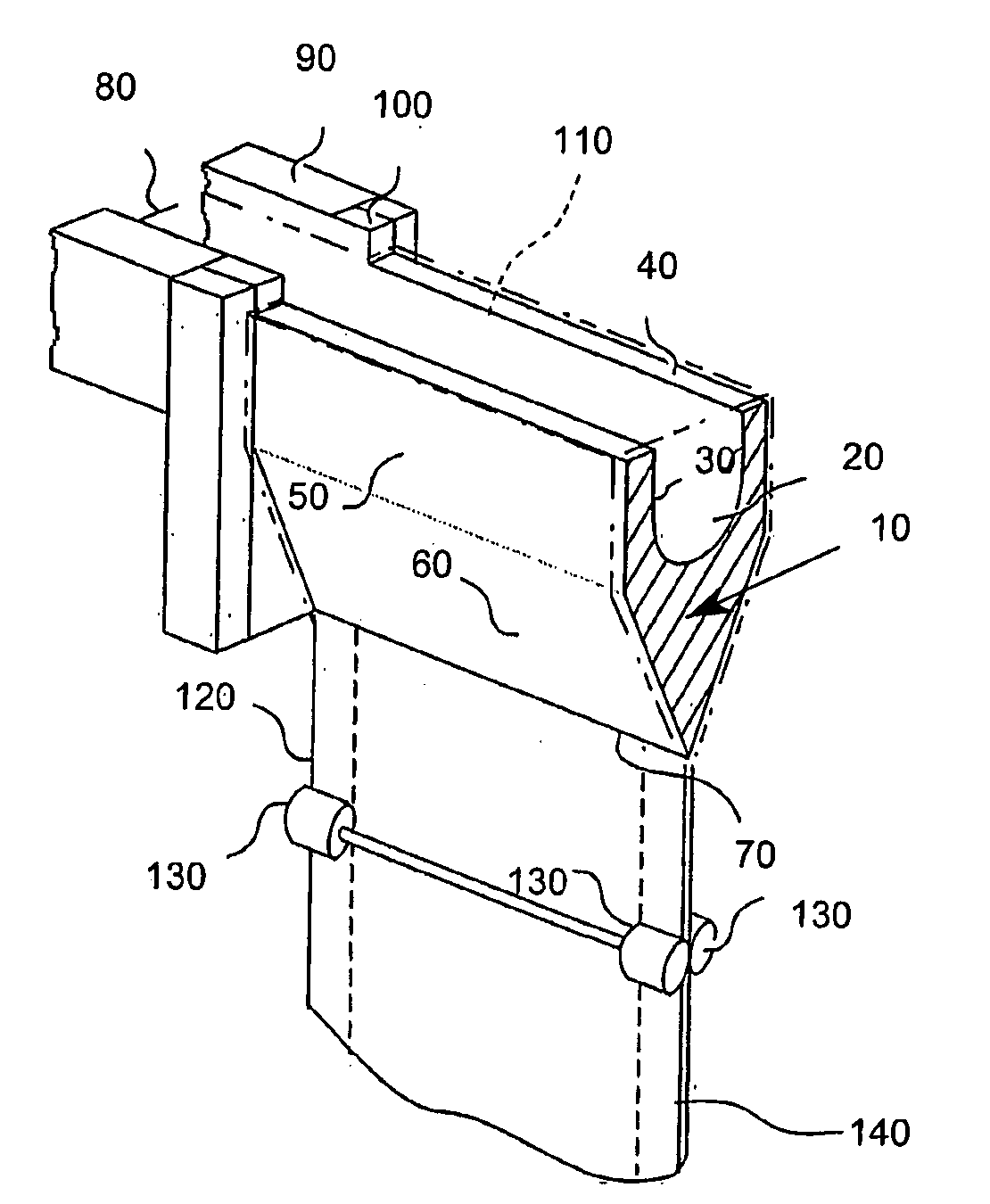

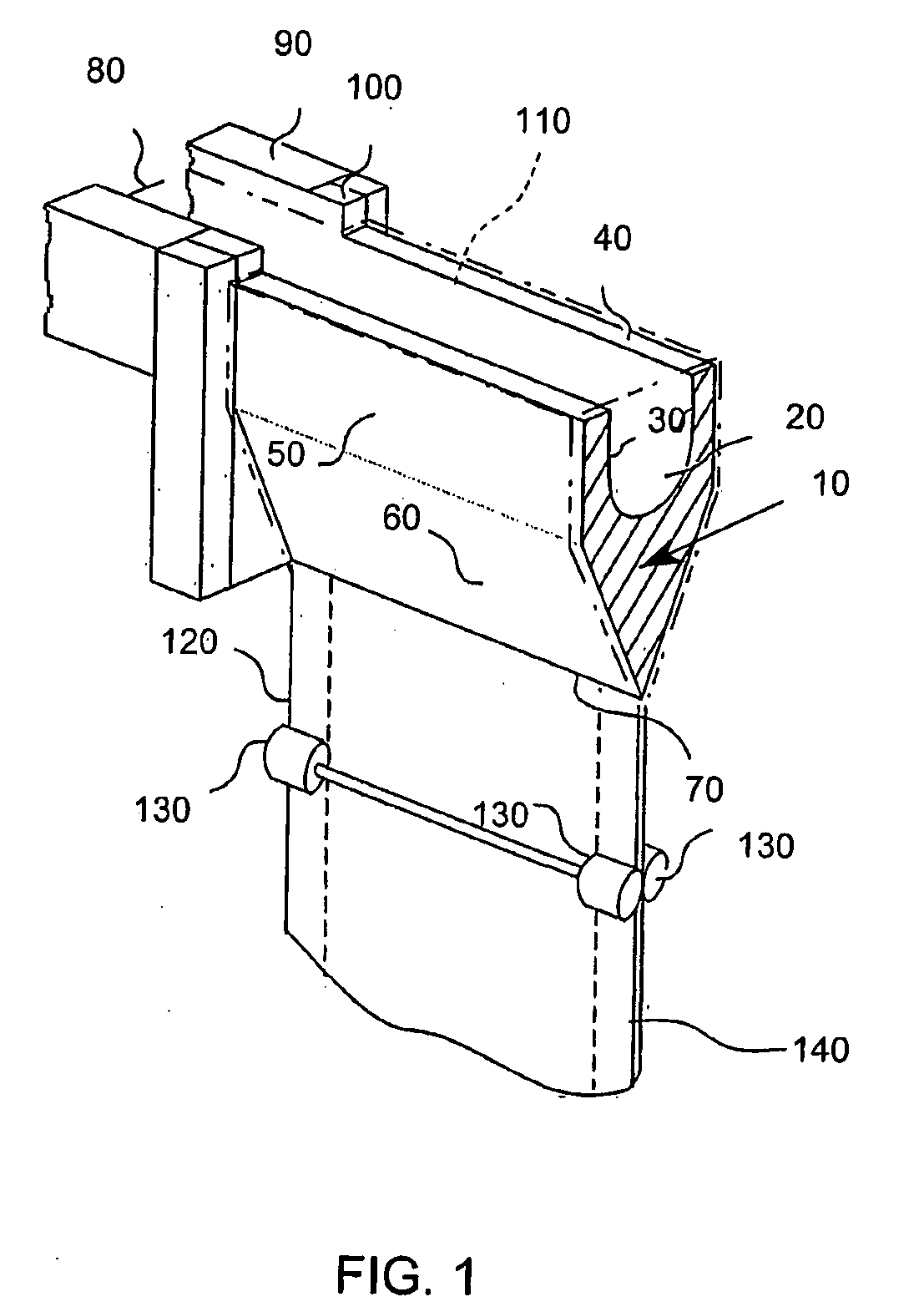

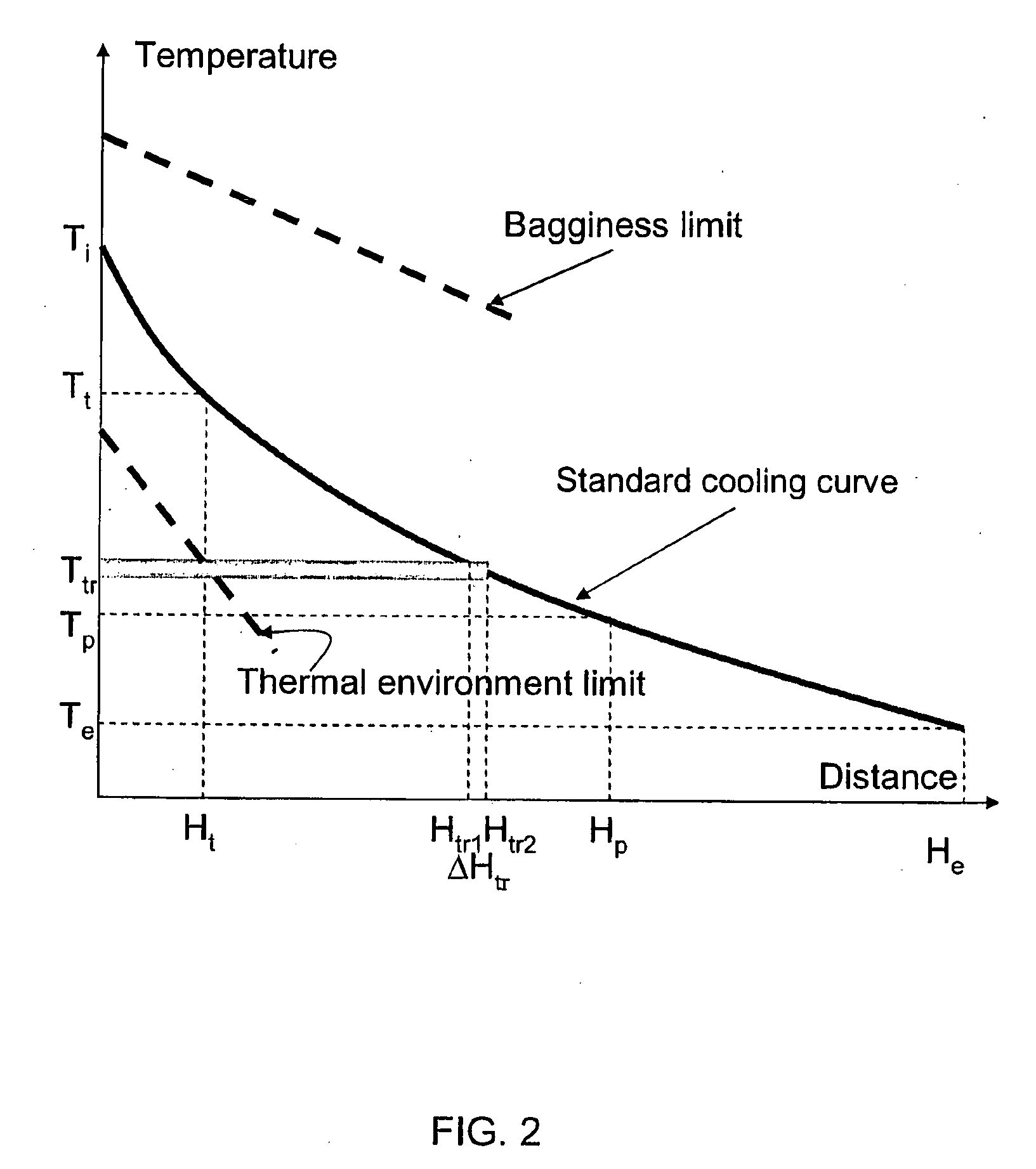

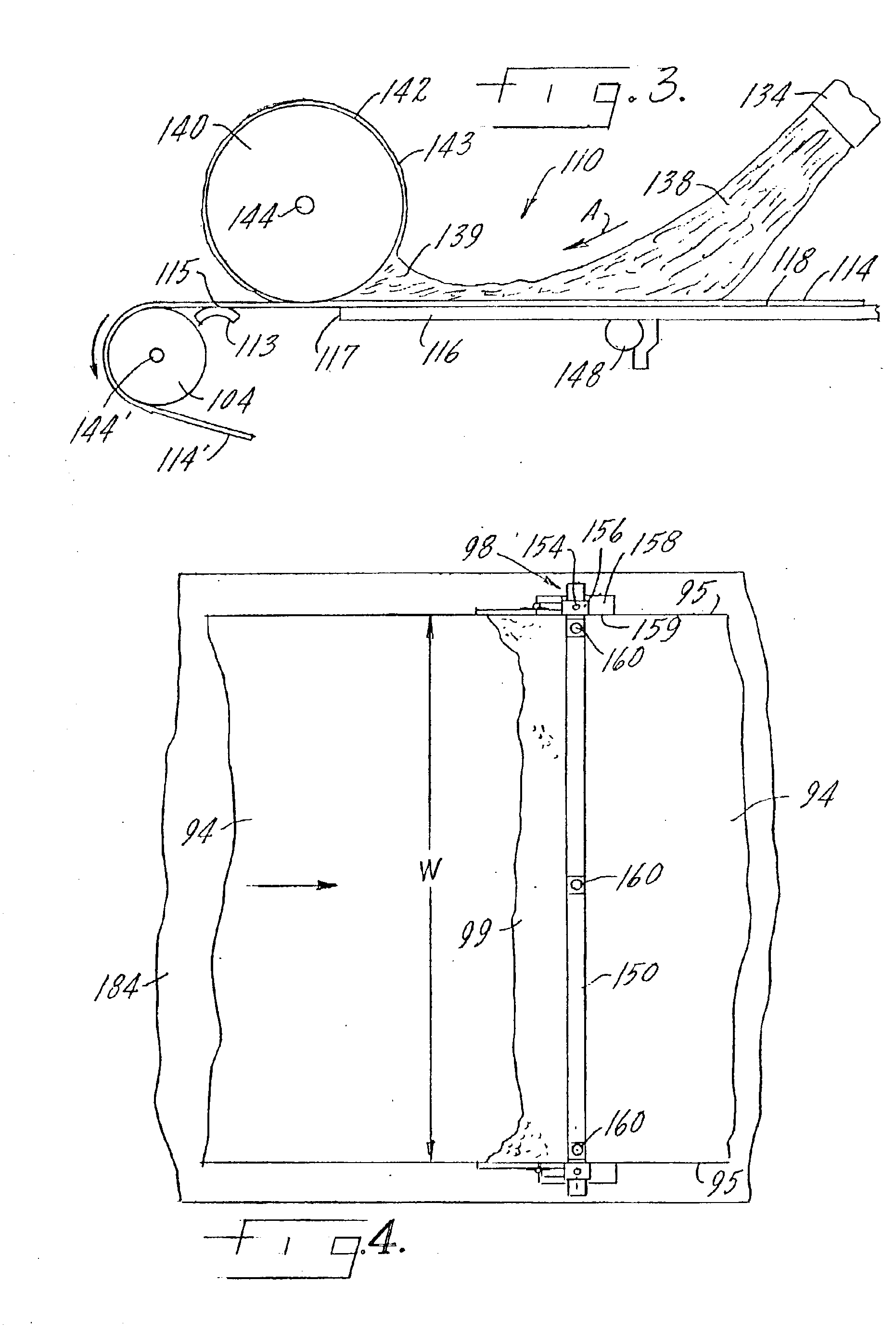

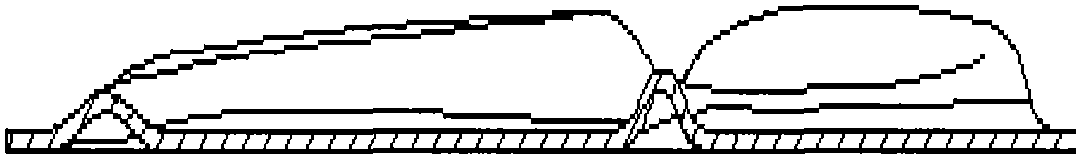

Method of making a glass sheet using controlled cooling

InactiveUS20090100873A1Increase rate increaseHigh trafficGlass drawing apparatusGlass forming apparatusFluid phaseEngineering

Methods of drawing glass sheet via a downdraw process are provided. In certain aspects, the methods utilize rapid cooling below the root (70) of the forming apparatus (10). Such rapid cooling can, for example, facilitate the use of glass having a liquidus viscosity less than about 100,000 poise. In other aspects, the methods utilize slow cooling between the viscosities of 1011 poises and 1014 poises. Such slow cooling can facilitate the production of glass substrates which exhibit low levels of compaction. In further aspects, substrates are removed from the glass sheet at elevated temperatures which can facilitate increases in the production rates of downdraw machines. In still further aspects, rapid cooling below the root, slow cooling between the viscosities of 1011 poises and 1014 poises, and / or substrate removal at elevated temperatures are combined. Such combinations can facilitate economically effective utilization of downdraw equipment.

Owner:CORNING INC

Gypsum board forming device

A gypsum board forming device having a gypsum forming station including two laterally disposed edger shoes, and at least one laterally disposed edger bar clamping element on the edger bar. In one embodiment a laterally extending forming plate extends over the top surface of the formed gypsum board, the forming plate including a plurality of micropore conduits through which pressurized water is supplied to provide a film of smoothing water over the top surface of the gypsum board. In another embodiment the edger shoes have a flapper mechanism for retaining unset slurry skimmed off the surface of the gypsum board by the edger bar.

Owner:BPB LTD

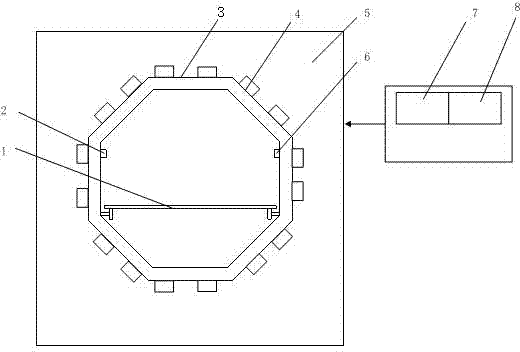

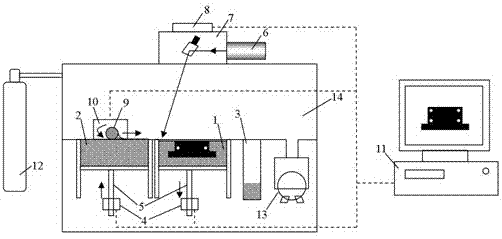

Method and device for curing fiber-reinforced resin-based composite material component by utilizing microwaves

ActiveCN103587130ASolve for uniformitySolve power problemsResin-Based CompositeFiber-reinforced composite

The invention relates to a method and a device for curing a fiber-reinforced resin-based composite material component by utilizing microwaves. The microwaves which are generated by a microwave source with linearly-adjustable power are guided into a resonant cavity, and the microwaves penetrate through and heat the composite material, so that the composite material can be quickly cured and formed. By adopting the advanced octagonal microwave-mode resonant cavity, the uniformity of an electromagnetic field inside the device can be realized; the interference of the reflection wave on the microwave source can be reduced by adopting an automatic impedance matching system, so that the optimal transmission of the microwave power can be realized. A vacuum pipe connector and a temperature sensor are arranged on the inner side wall of the octagonal multi-mode resonant cavity, a glass worktable is arranged inside the resonant cavity, and the rotation of a ball screw is controlled through a stepper motor to control the back-forth movement of the worktable. A choking groove is adopted to prevent the leakage of the microwave. By adopting the method and the device, the problems of the traditional autoclave forming method that the time for manufacturing the fiber-reinforced composite material is long, the energy consumption is high and the heat is non-uniform can be solved, the curing time can be saved, and the quality and performance of the composite material component can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

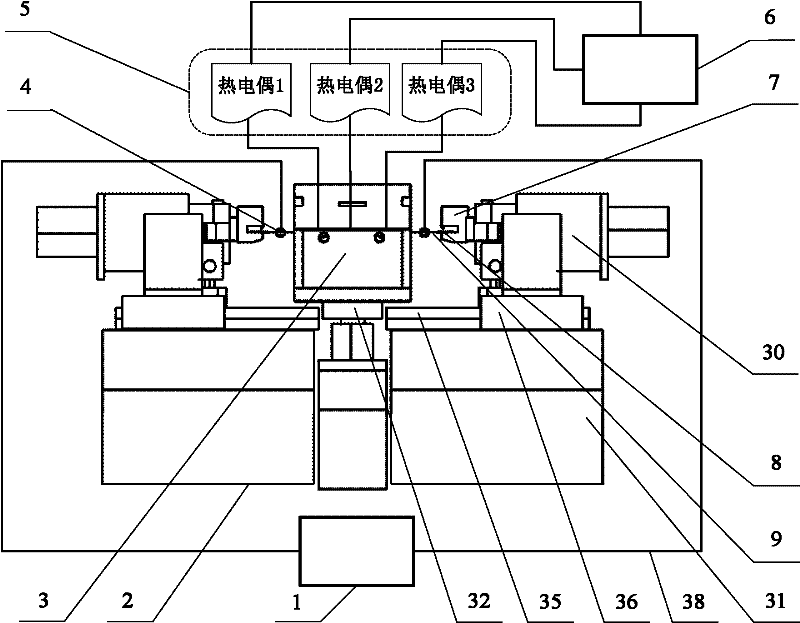

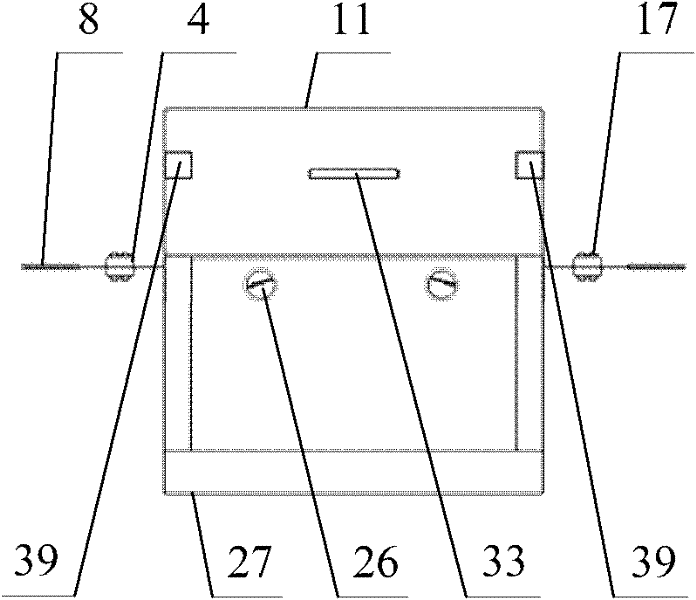

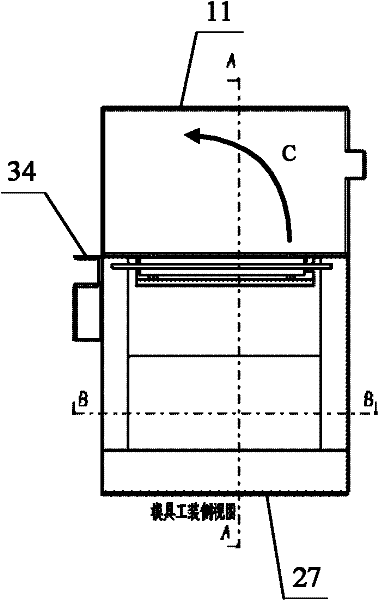

Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

ActiveCN102500675AViscoplastic deformation facilitatesAvoid lostShaping toolsTemperature controlProcess integration

The invention provides a hot forming tool of a titanium alloy thin-wall part, comprising five parts, namely stretching equipment, a mould device, a blank, a power supply system and a temperature control system, wherein the mould device is arranged on a central worktable of the stretching equipment; the blank passes through a side wall crack of the mould device; an insulating and heat-insulation cushion layer is used for insulating the blank, a clamp of the stretching equipment, the surface of a mould and a tool of the mould; the power supply system is switched on to electrify an electrode clamping plate and generate a current in the blank; the blank is heated and the temperature of the blank is measured and controlled by the temperature control system; and after the temperature of the blank reaches a target temperature, the part is formed on the surface on the mould by the blank in an adhered manner through carrying out hot forming processes successively including stretching, covering, stretching, heat preservation and creep deformation and the like on the stretching equipment. A machining method of the hot forming tool of the titanium alloy thin-wall part comprises eight steps. According to the invention, the heating efficiency, the process integration, the material formation and the formation precision of the titanium alloy thin-wall part in manufacture are greatly improved, so that the hot forming tool of the titanium alloy thin-wall part and the machining method of the hot forming tool have a practical value and a popularization value.

Owner:BEIHANG UNIV

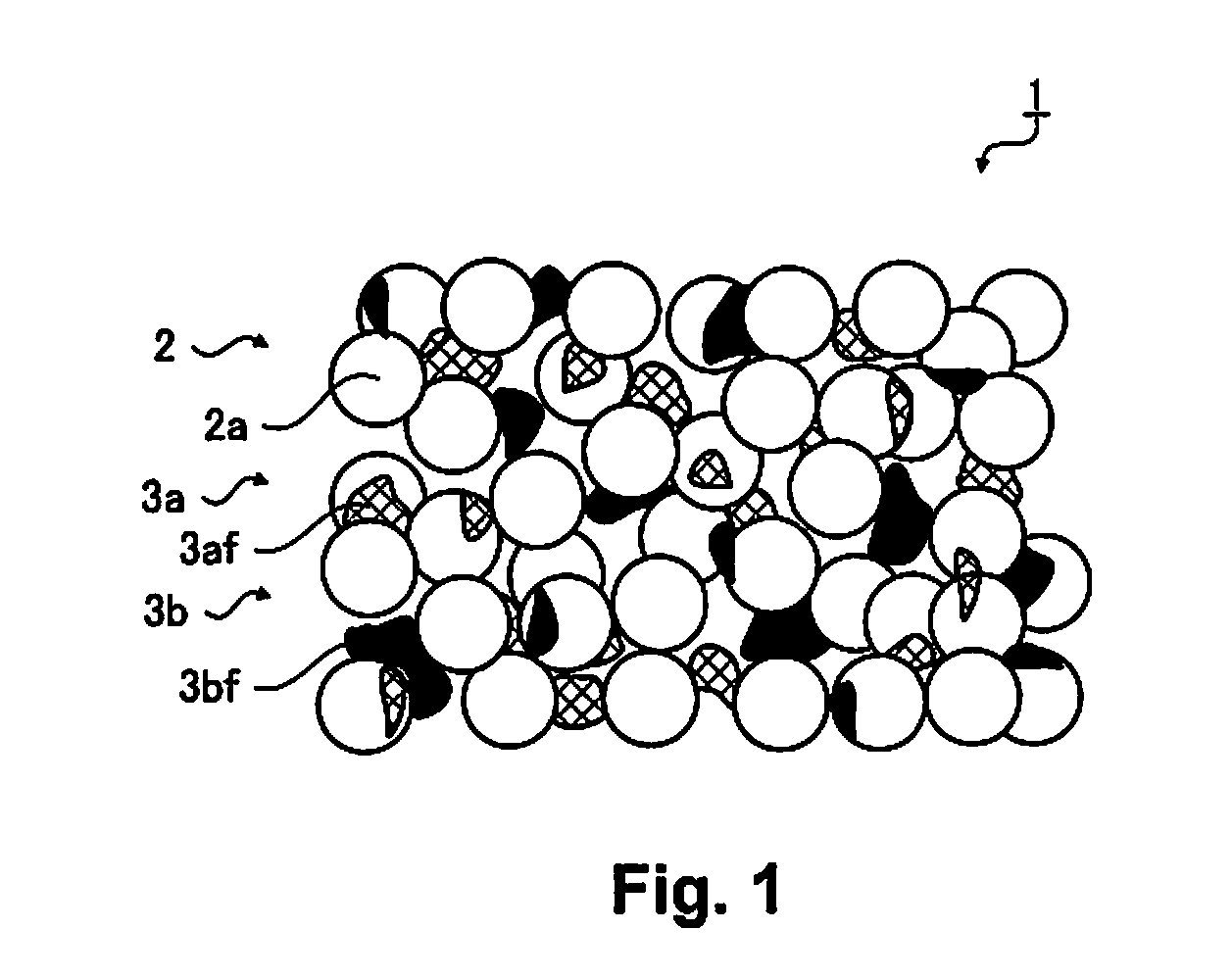

Sinter mold material, sintering and molding method, sinter mold object, and sintering and molding apparatus

InactiveUS20150224575A1Improve fill rateNon-fibrous pulp additionTransportation and packagingInorganic particleInorganic particles

A sintering and molding method includes forming a fluid mold material by heating a sinter mold material, which includes inorganic particles, a binder material and a binder material which bond together the inorganic particles, to a temperature equal to or more than the melting points of the binder materials, forming a mold layer by spreading the fluid mold material, layering a mold layer, applying UV ink to a desired region on the mold layer, forming a mold cross sectional pattern by curing the UV ink which is applied to a desired region on the mold layer, finishing a mold object by removing a region, where the UV ink is not applied, in the mold layer, carrying out heat treatment on the mold object at a temperature which is less than the initial temperature of thermal decomposition of the binder material, and carrying out sintering treatment on the mold object.

Owner:SEIKO EPSON CORP

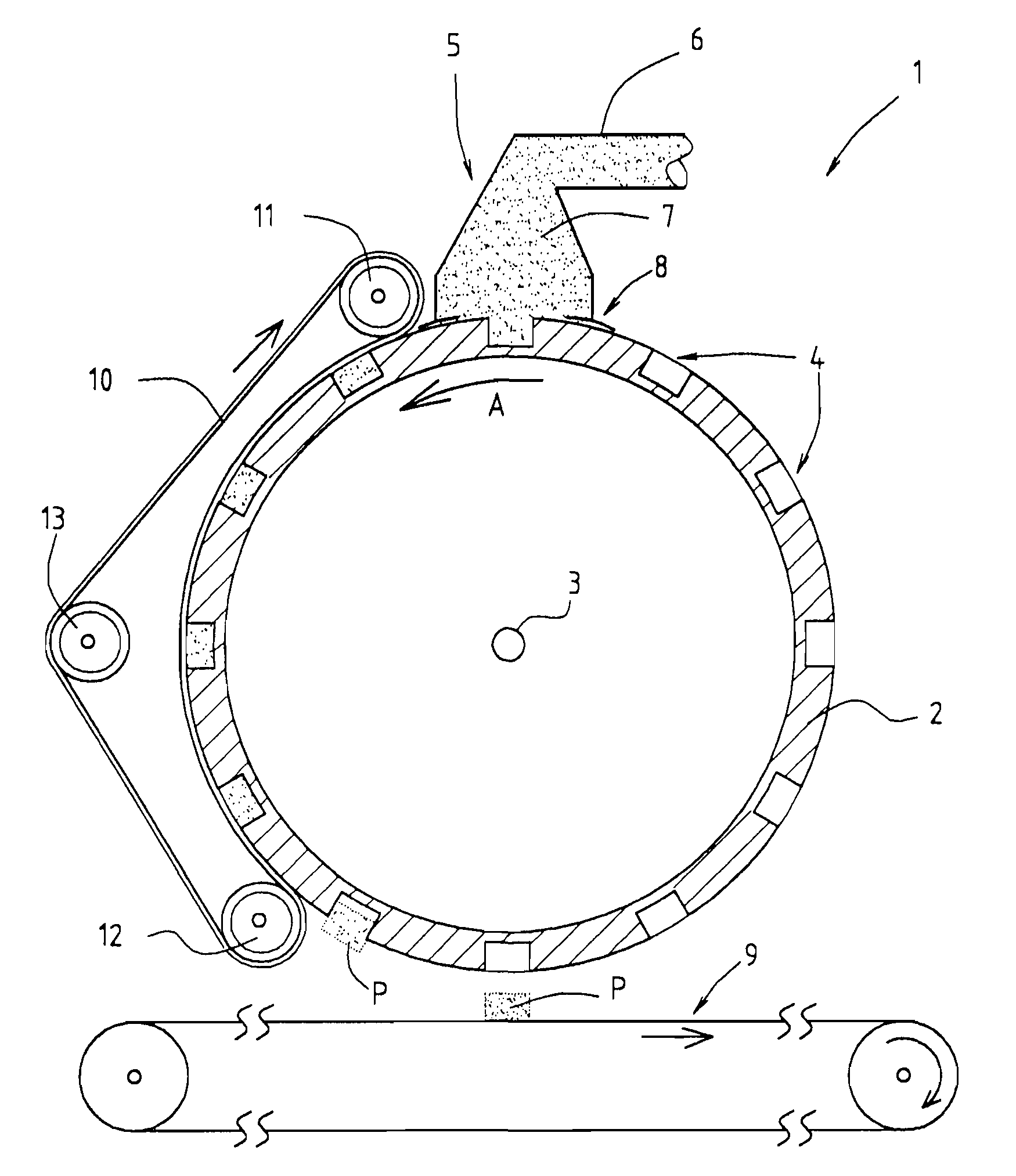

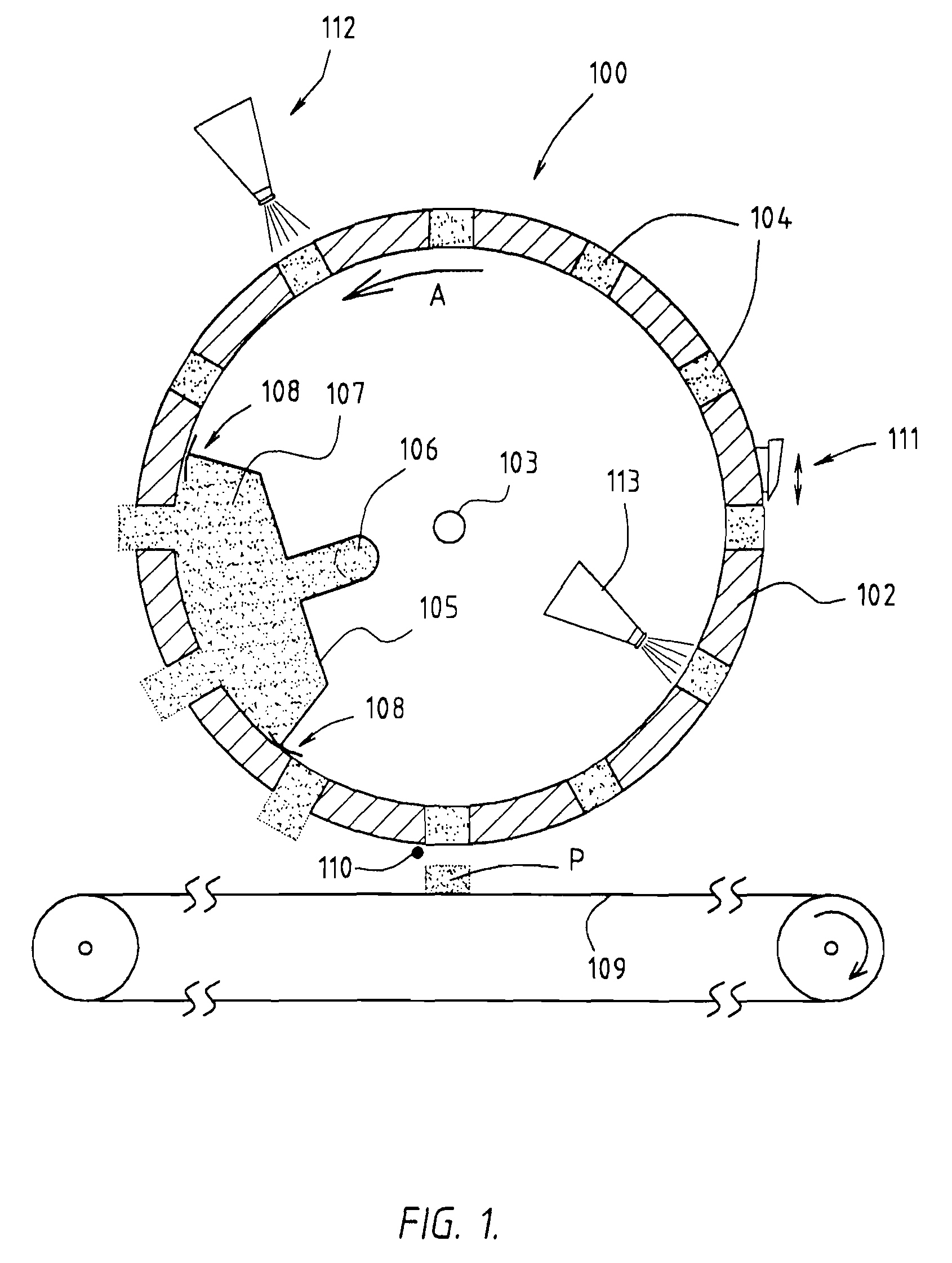

Moulding

InactiveUS20070224306A1High priceLarge capacityConfectioneryCeramic shaping apparatusPartial fillingMaterials science

Owner:STORK PMT

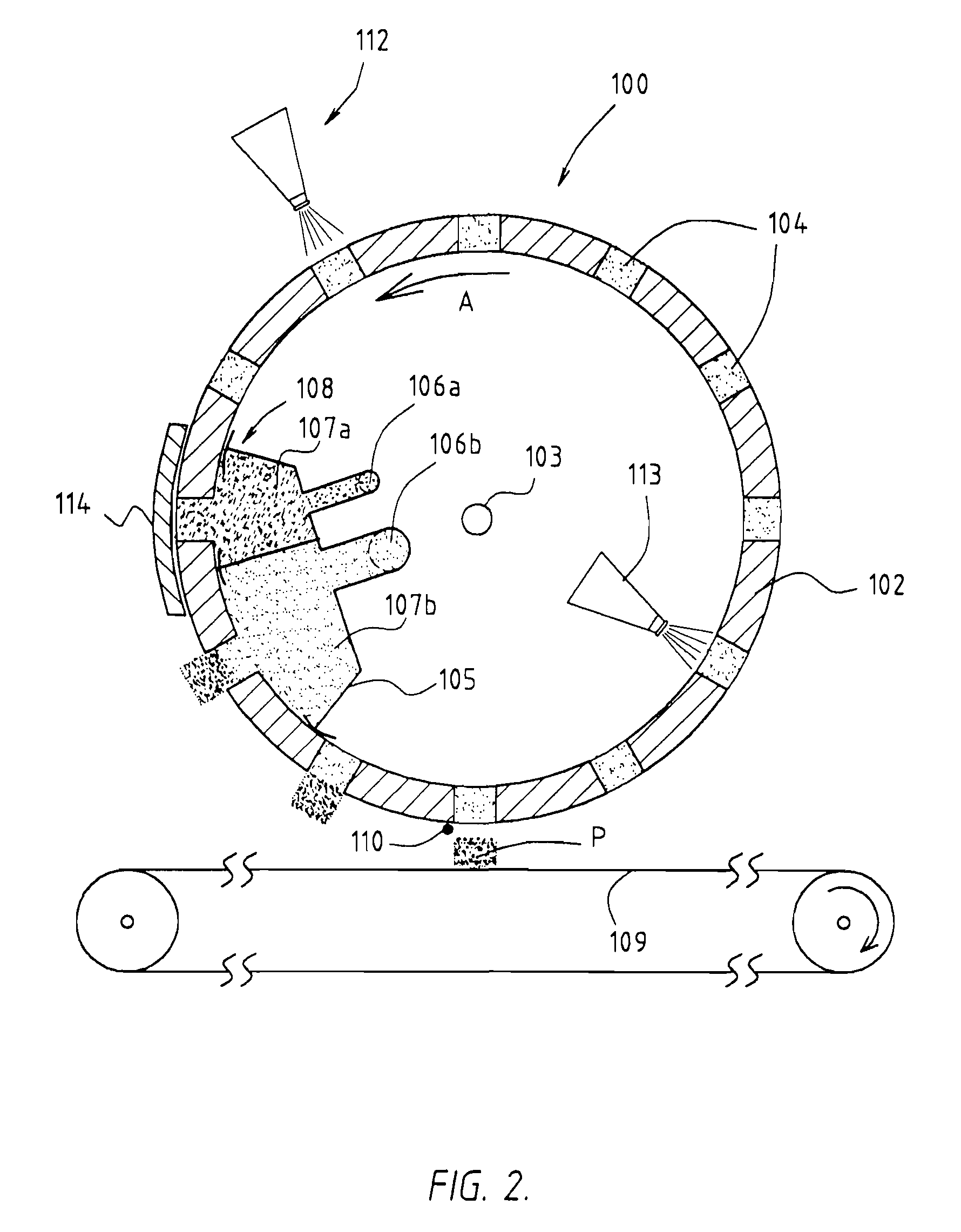

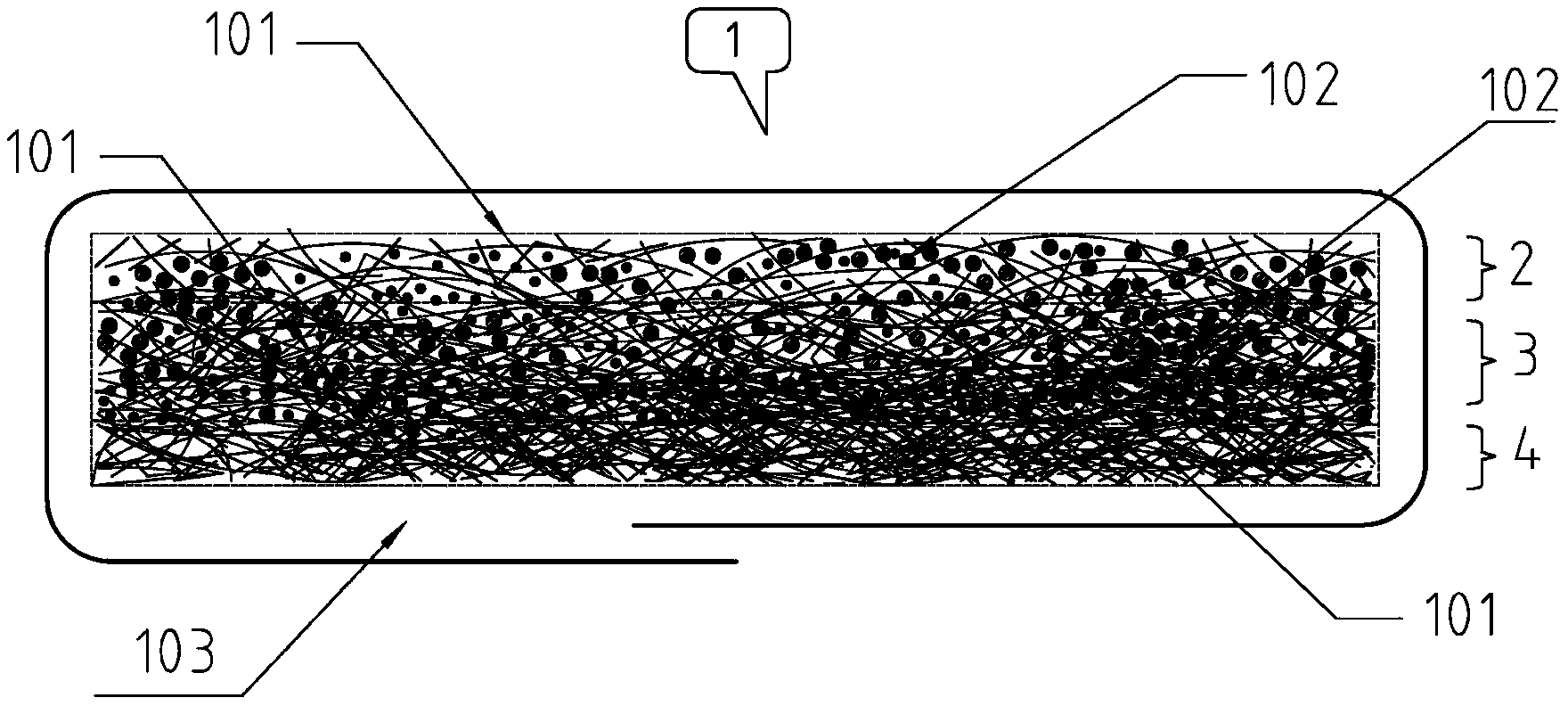

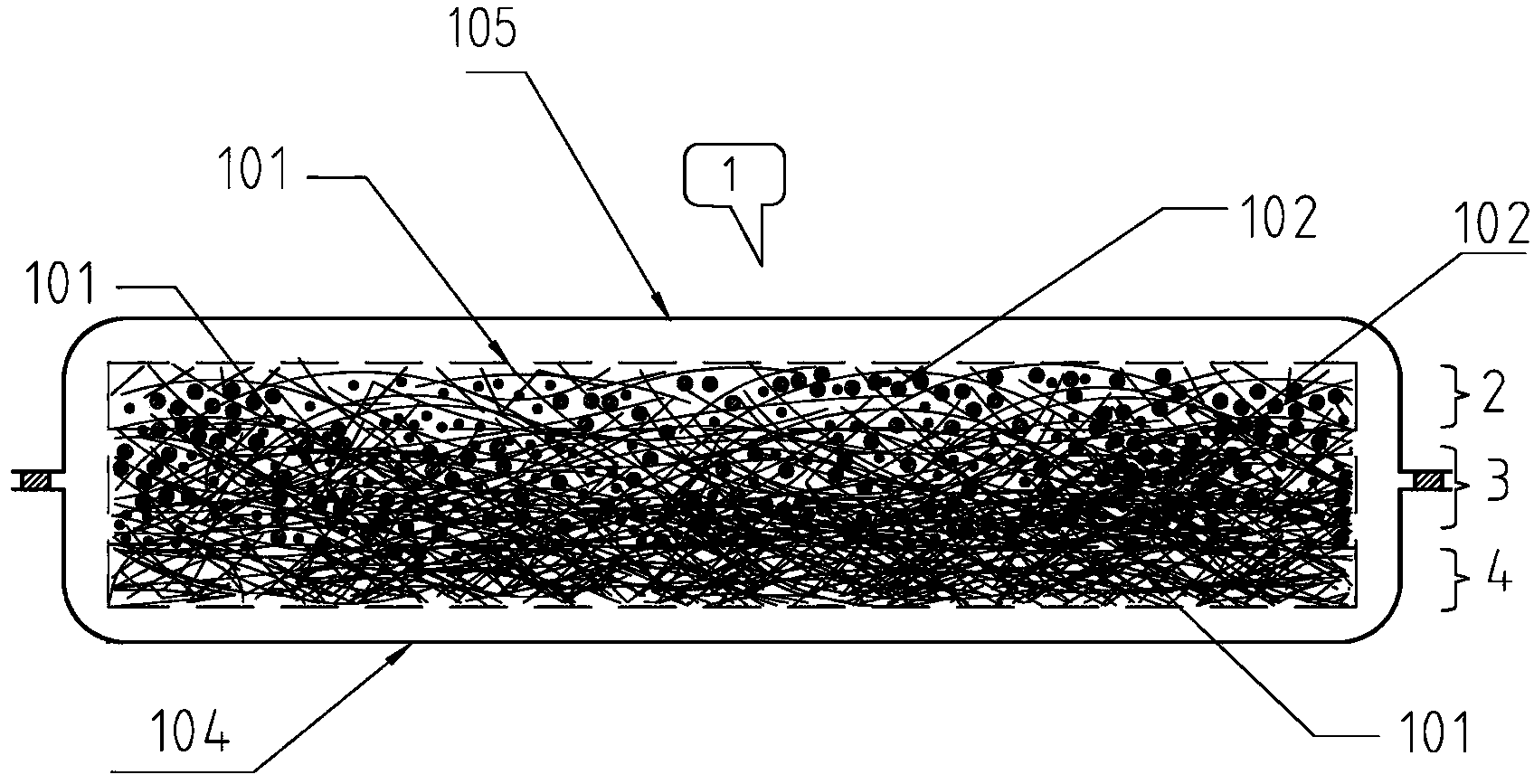

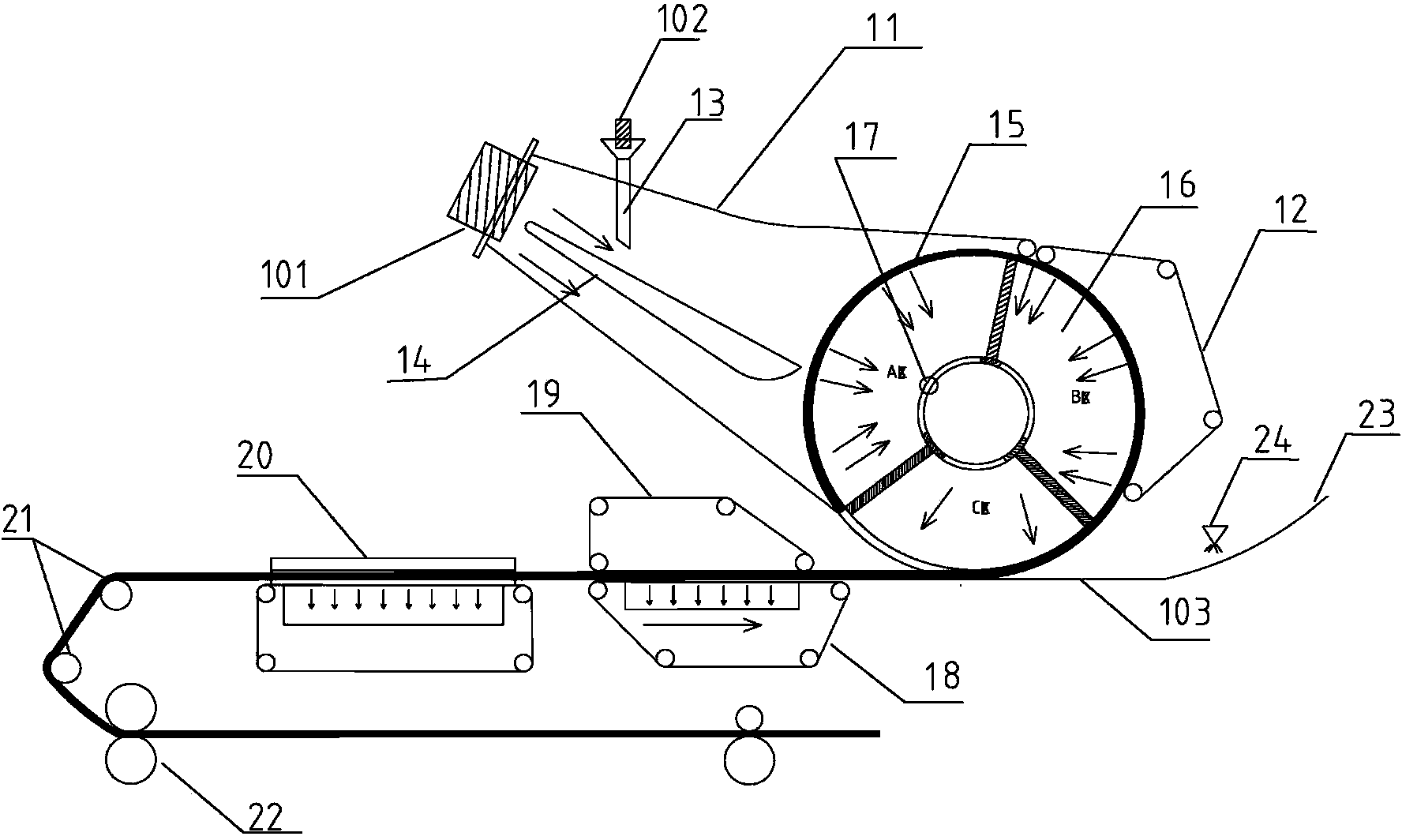

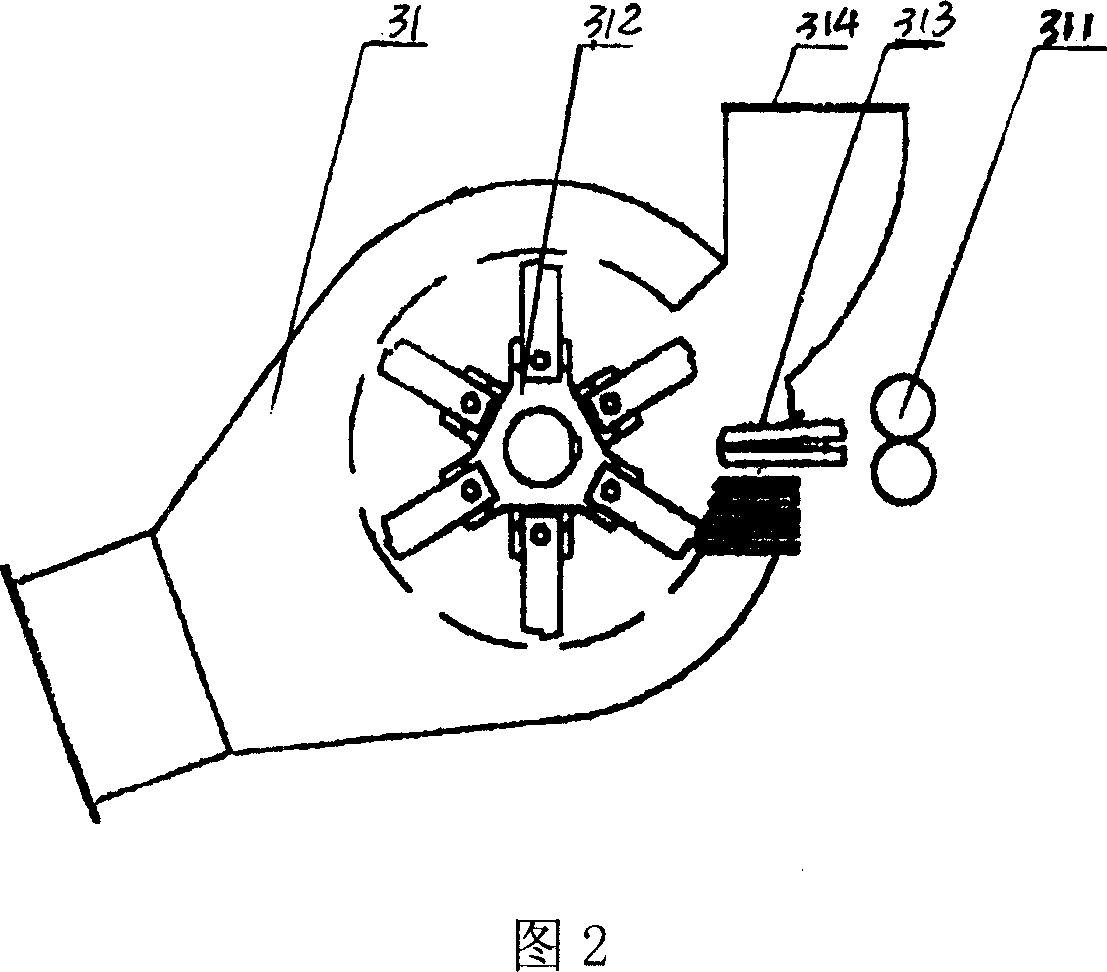

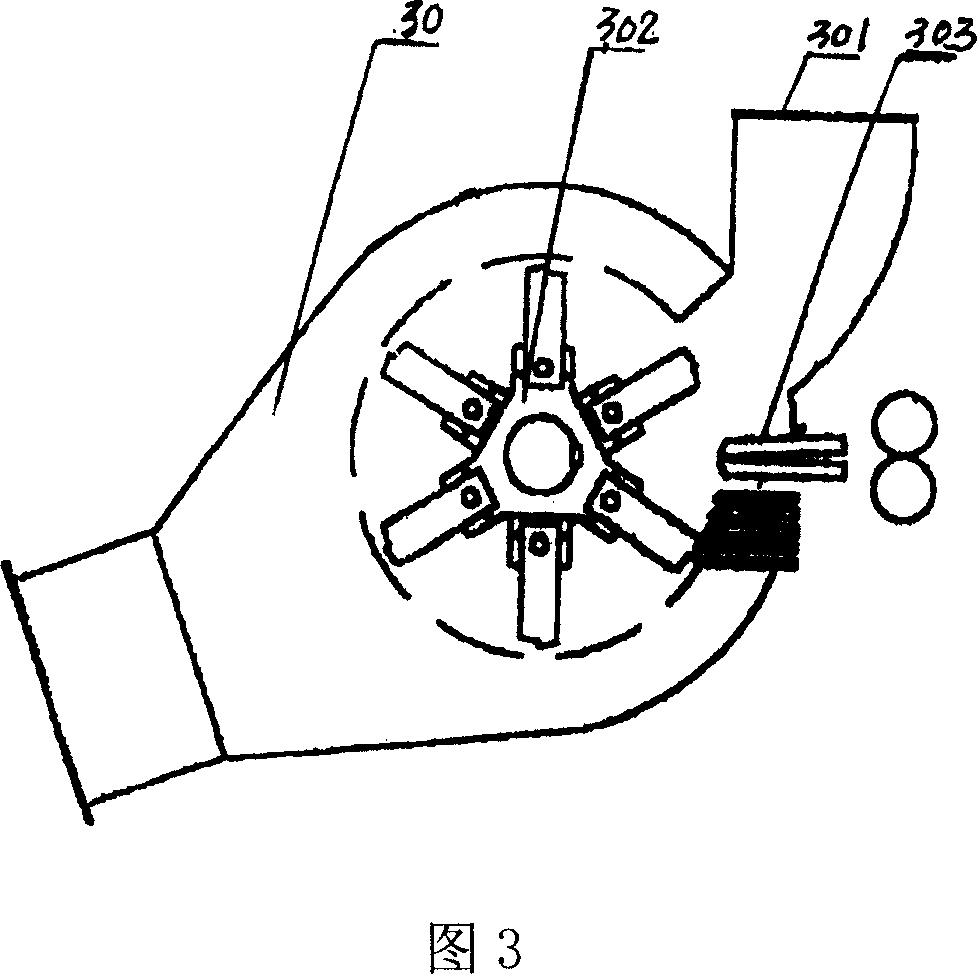

Absorptive core, absorptive core molding equipment and absorptive core manufacture method

The invention relates to the manufacture field of absorptive sanitary articles and automatic production equipment and discloses an absorptive core. The absorptive core comprises an absorptive core surface layer, an absorptive core middle layer and an absorptive core bottom layer, wherein the tightness degrees of the absorptive core middle layer and the absorptive core bottom layer are larger than the tightness degree of the absorptive core surface layer. The invention further discloses absorptive core molding equipment and an absorptive core manufacture method. The gathering degrees of fluff pulp fibers in the surface layer, the middle layer and the bottom layer of the absorptive core are from relative looseness to compactness, and the gradient density design can rapidly absorb body fluid, is favorable to fluid permeation and effectively reduces the possibility that the body fluid leaks from the absorptive sanitary articles. When the absorptive core of the structure is manufactured, a molding screen is effectively prevented from being blocked by high molecular absorption resin granules, time and cost which are spent on cleaning and maintaining the molding screen are saved, and the production efficiency of the absorptive core molding device is further improved.

Owner:ZUIKO (SHANGHAI) CORP

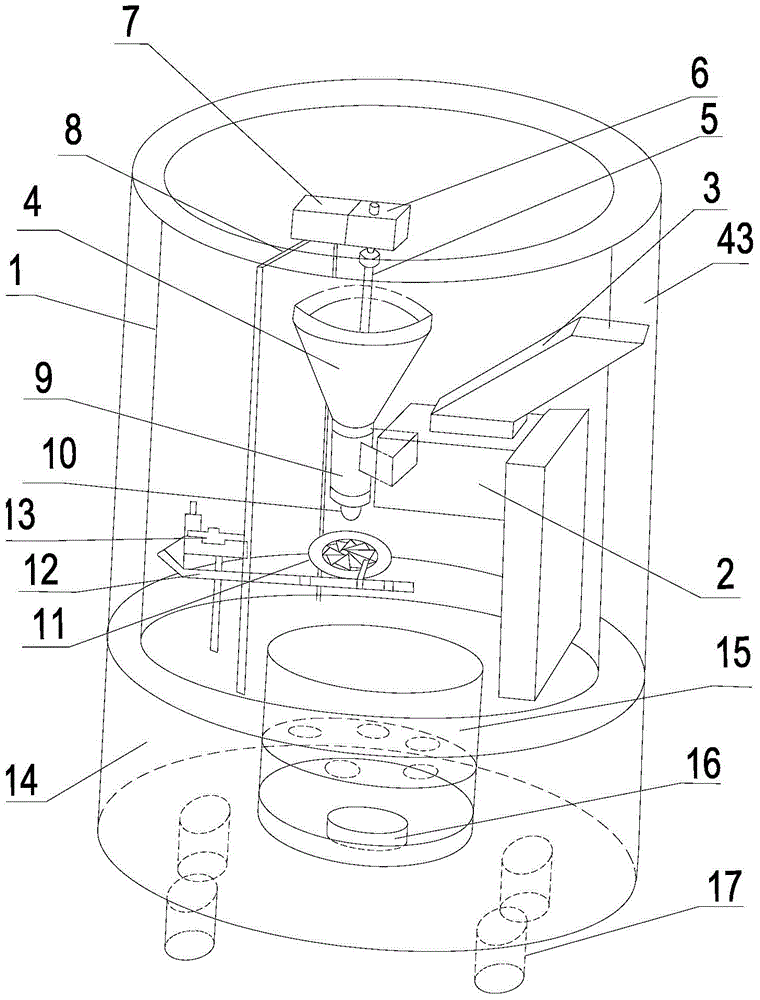

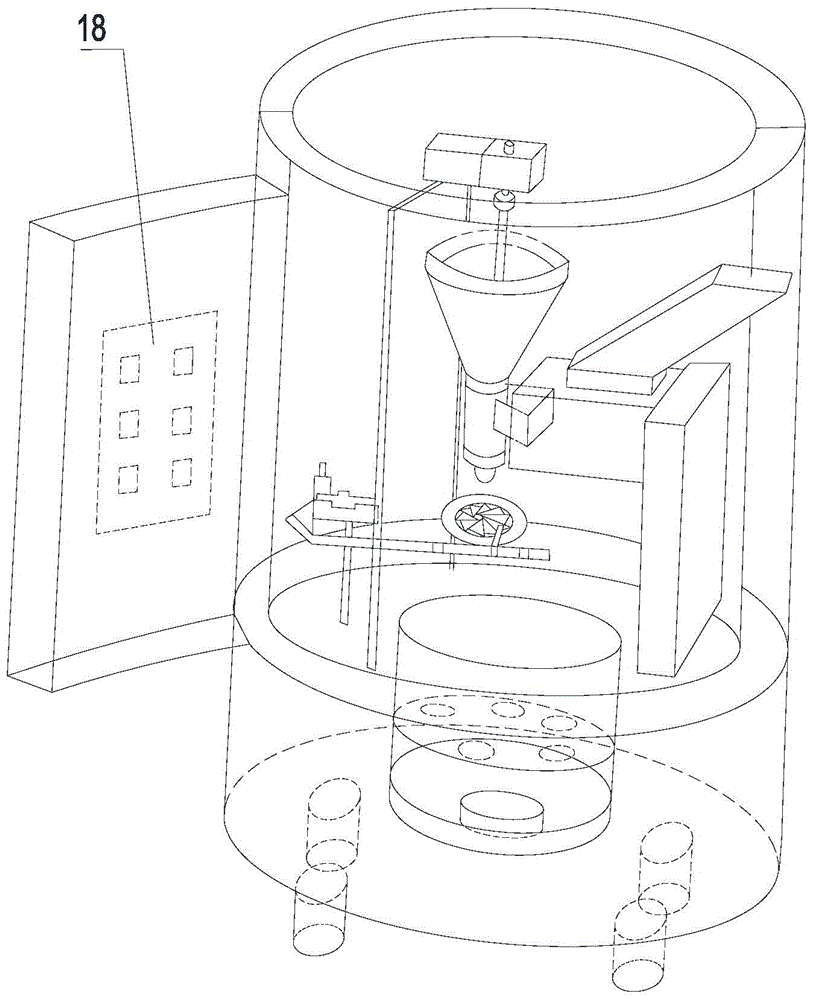

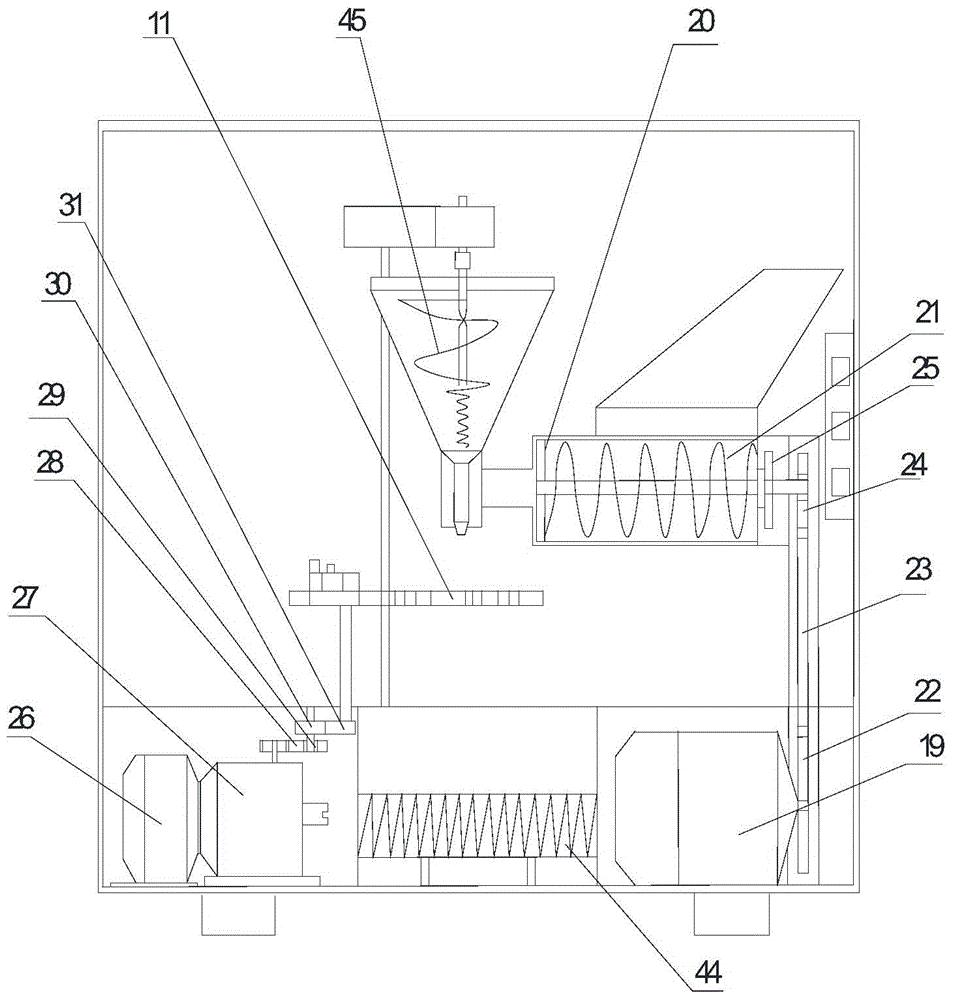

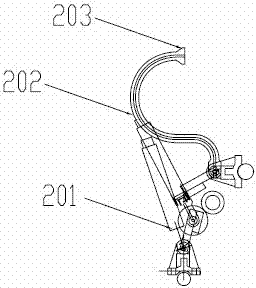

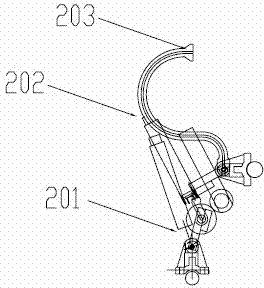

Stereoscopic moulding device

InactiveCN101850615AReduced service lifeLiquid surface applicatorsSpraying apparatusSpray nozzleEngineering

The invention relates to a stereoscopic moulding device, used for moulding a stereoscopic article. The stereoscopic moulding device at least comprises a dismountable construction tank, a movable powder supply tank, a printing assembly, a heating assembly, a lifting device, a spray nozzle cleaning device, a spray nozzle sealing device and a jet-printing moulding and powder spreading isolated operation device; wherein the movable powder supply tank can move above the dismountable construction tank to supply construction powder, so as to feed powder; the printing assembly is arranged below the dismountable construction tank; the spray nozzle sealing device comprises a bearing seat, at least one sealing part and a moisturizing device; the jet-printing moulding powder spreading isolated operation device comprises a telescopic dust boot which is connected with one side of the powder supply tank, so as to cover and be linked with the construction powder in the construction tank when the powder supply tank moves.

Owner:MICROJET TECH

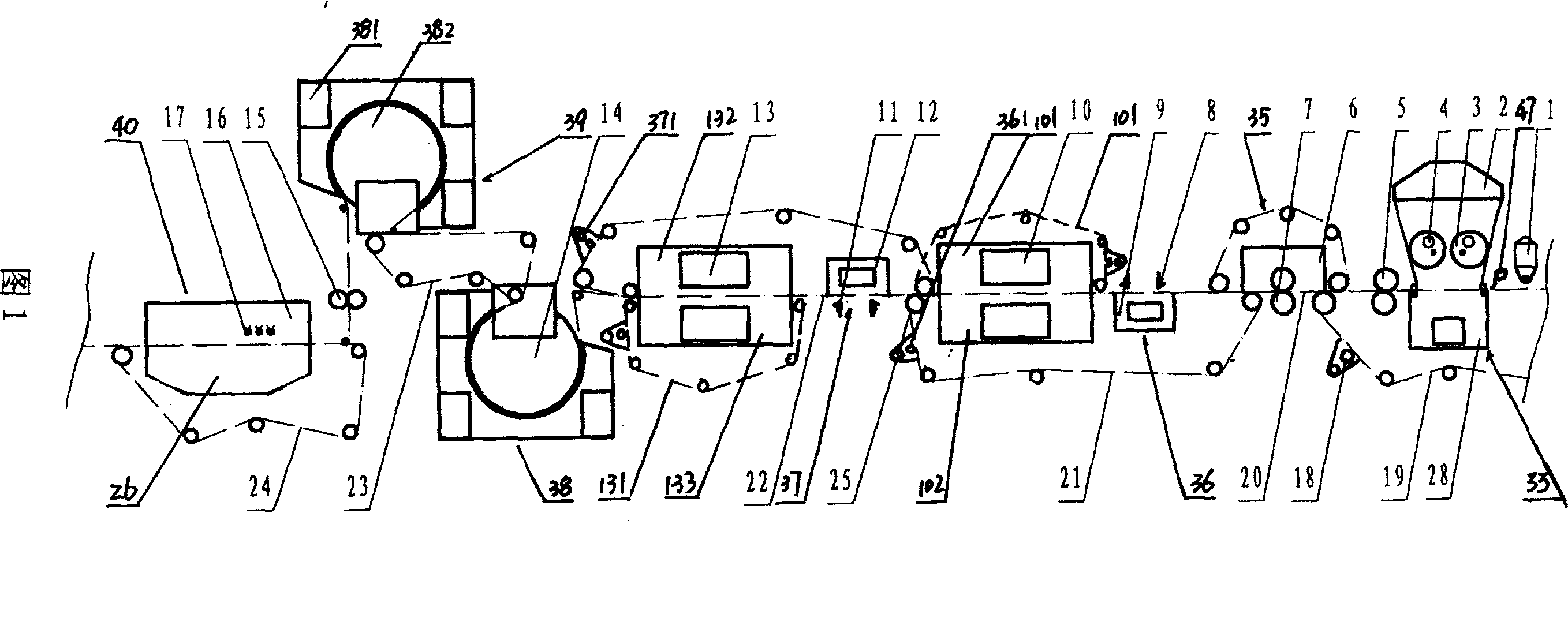

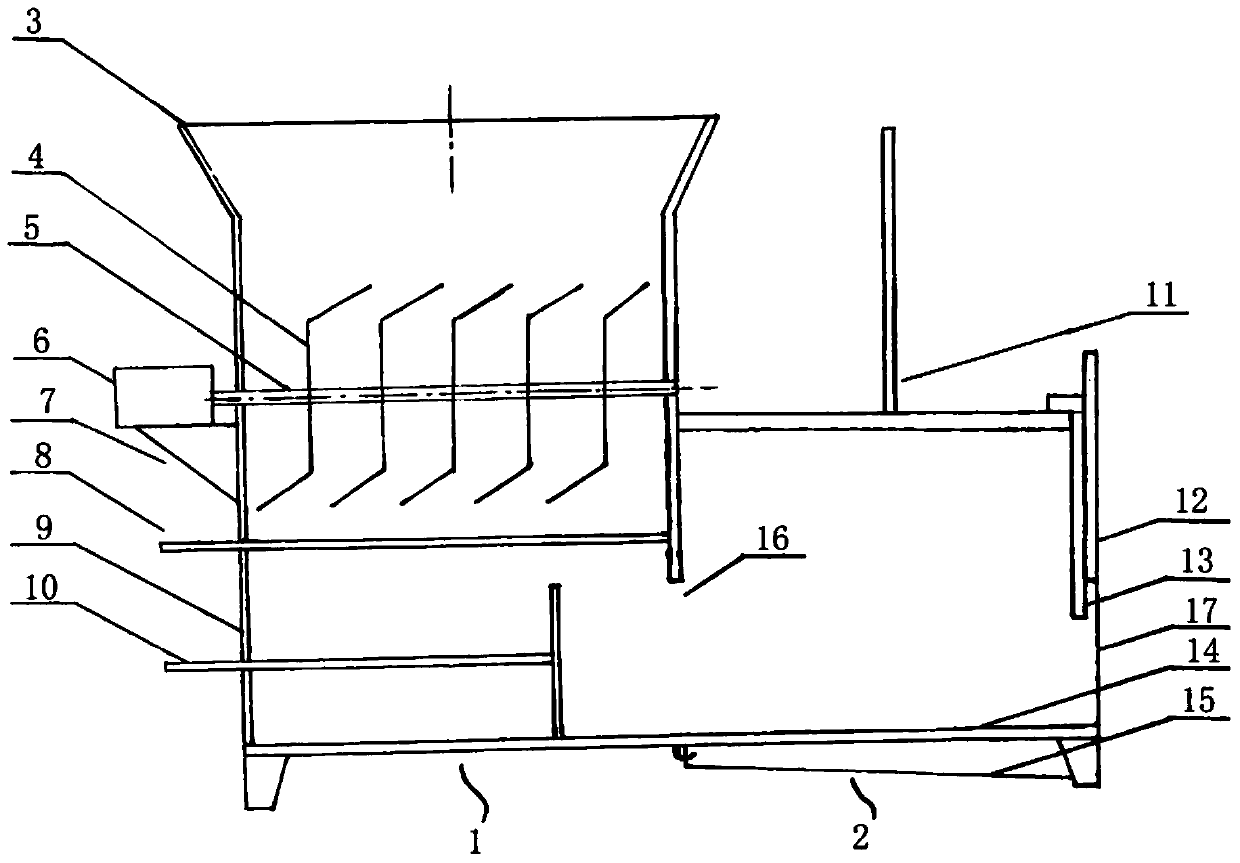

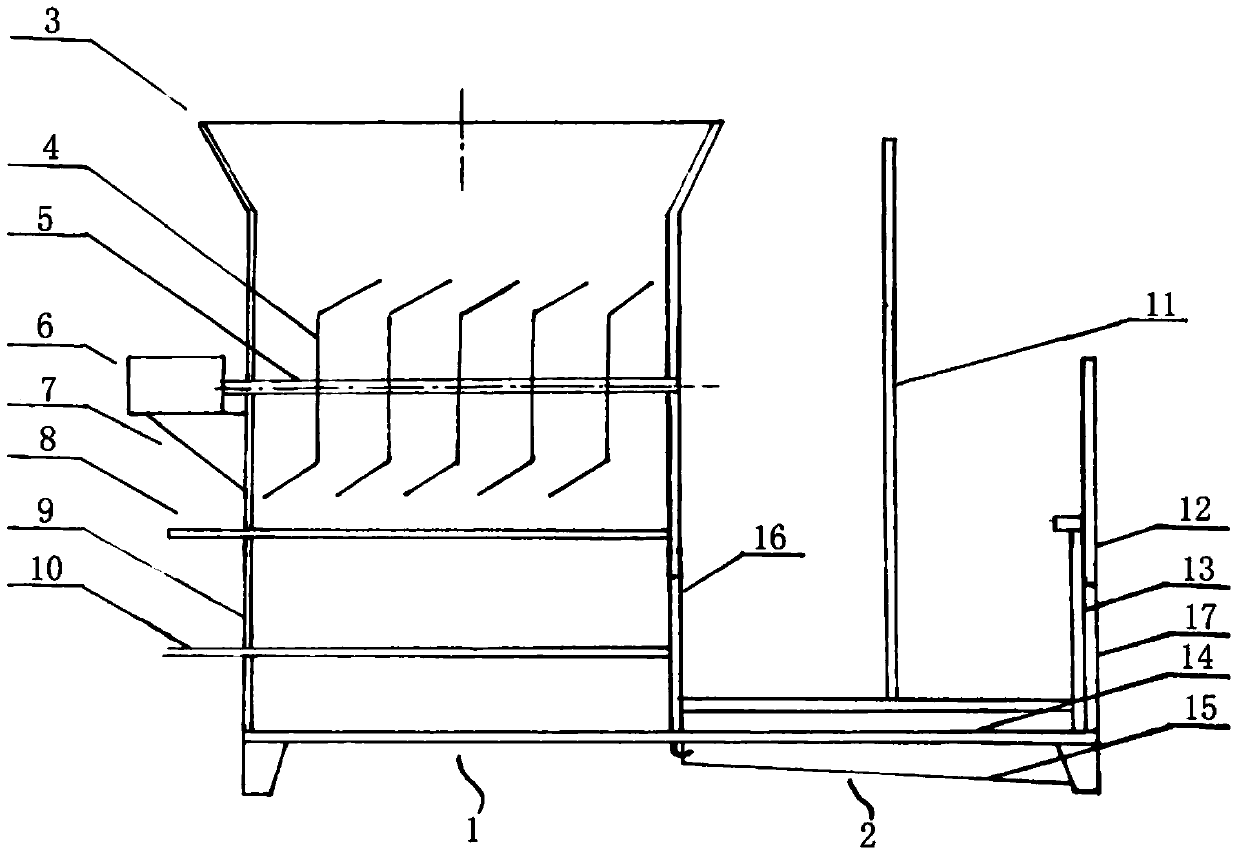

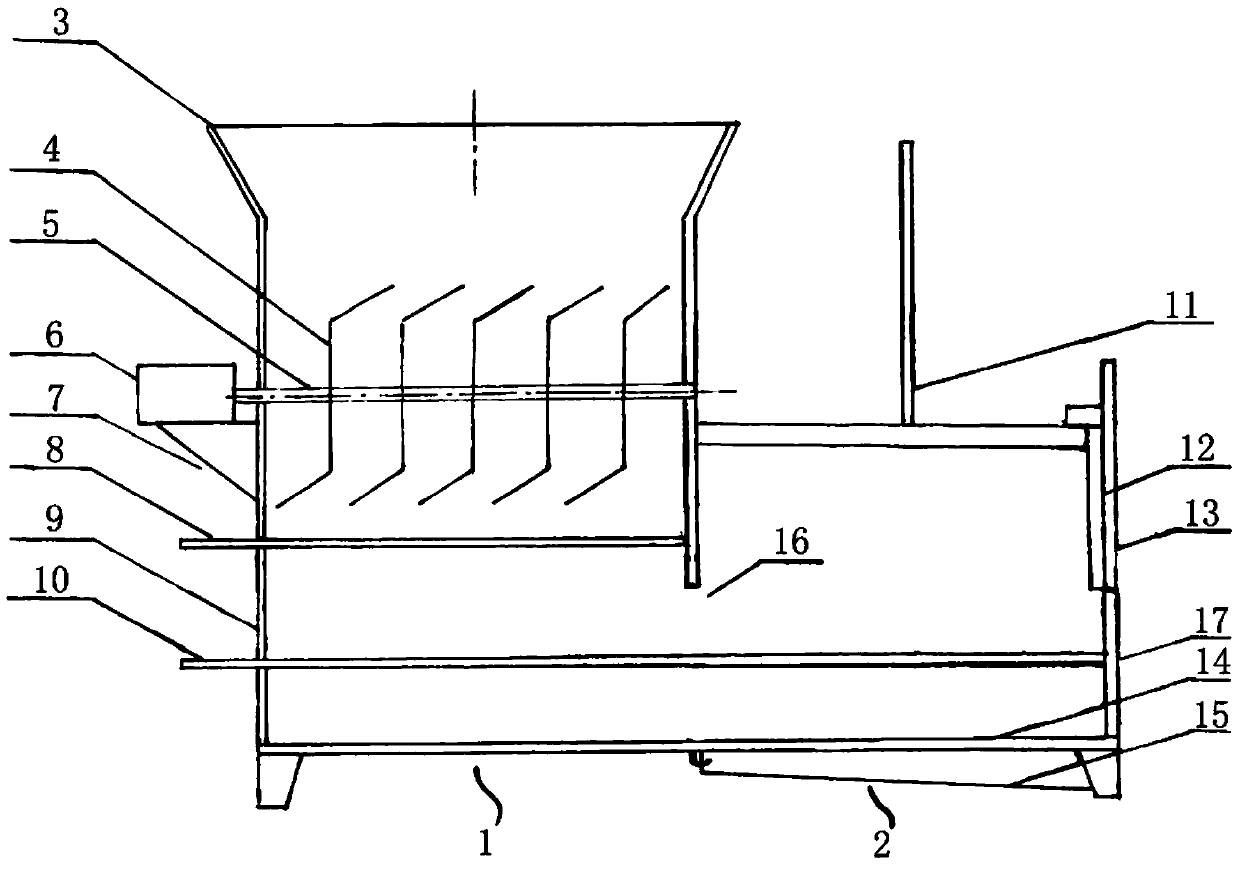

Dry-process papermaking machine through meshwork formed by airflow method

The present invention relates to an air-laying dry paper machine. It includes at least more then one forming device, sizing device, drying device and cooling device which are successively mounted on the machine frame from front to rear. Said sizing device includes at least more than two sizing devices and box type drying box. Between the forming device and sizing device an embossing device and pre-presing hot roller unit can be added, and between drying device and cooling device a calendaring device is added. Besides, it also includes fluff pulp fluffer, fibrids opening, conveying and metering device and powder additive device.

Owner:中丝(上海)新材料科技有限公司

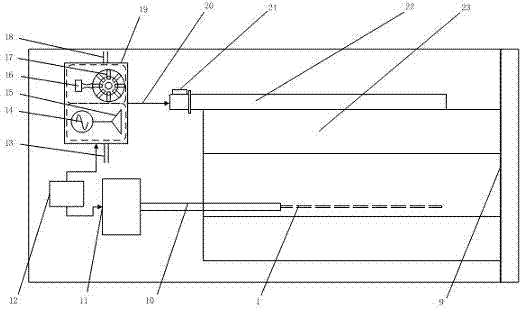

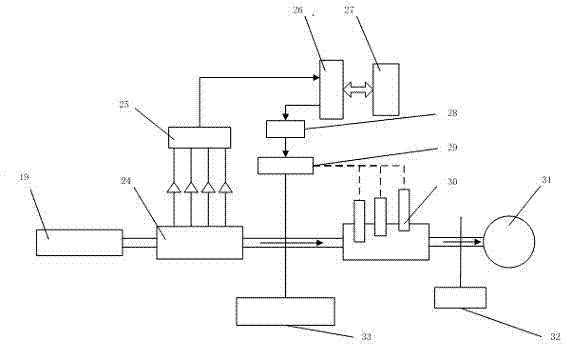

Forming device and method of aluminum-based silicon carbide particle reinforced composite material and member thereof

ActiveCN103695681ASimple molding processDense and uniform internal tissueCarbide siliconControl system

The invention provides a forming device and method of an aluminum-based silicon carbide particle reinforced composite material and a member thereof. The forming device comprises a laser system, a powder spreading system, an inert atmosphere system and a control system. By using the forming device, quick formation of the aluminum-based silicon carbide particle reinforced composite material and the member thereof can be realized. The forming method provided by the invention is simple, and adopts digitized manufacturing. The formed product is compact and uniform in texture, and any complicated members can be directly manufactured without being secondarily processed.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

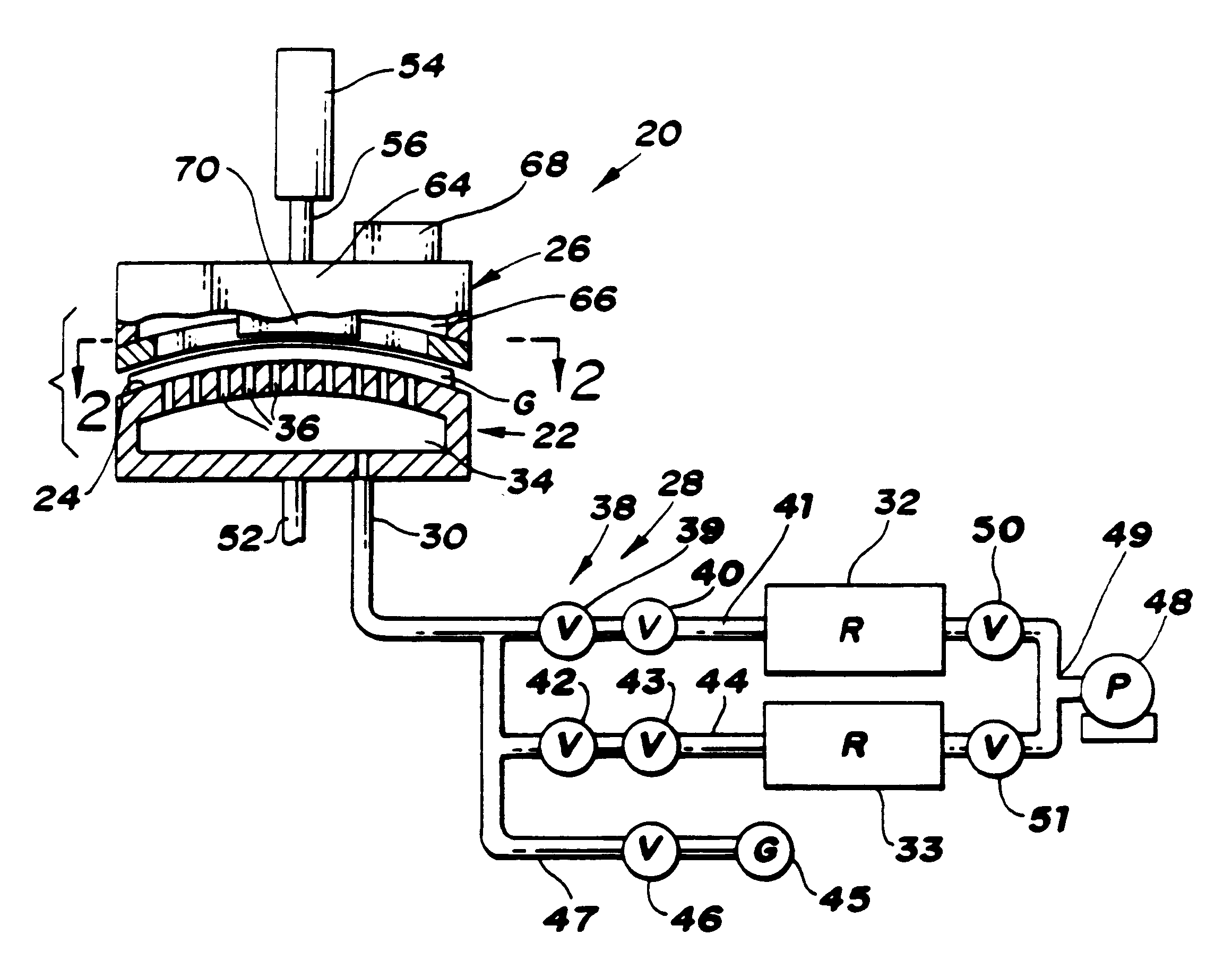

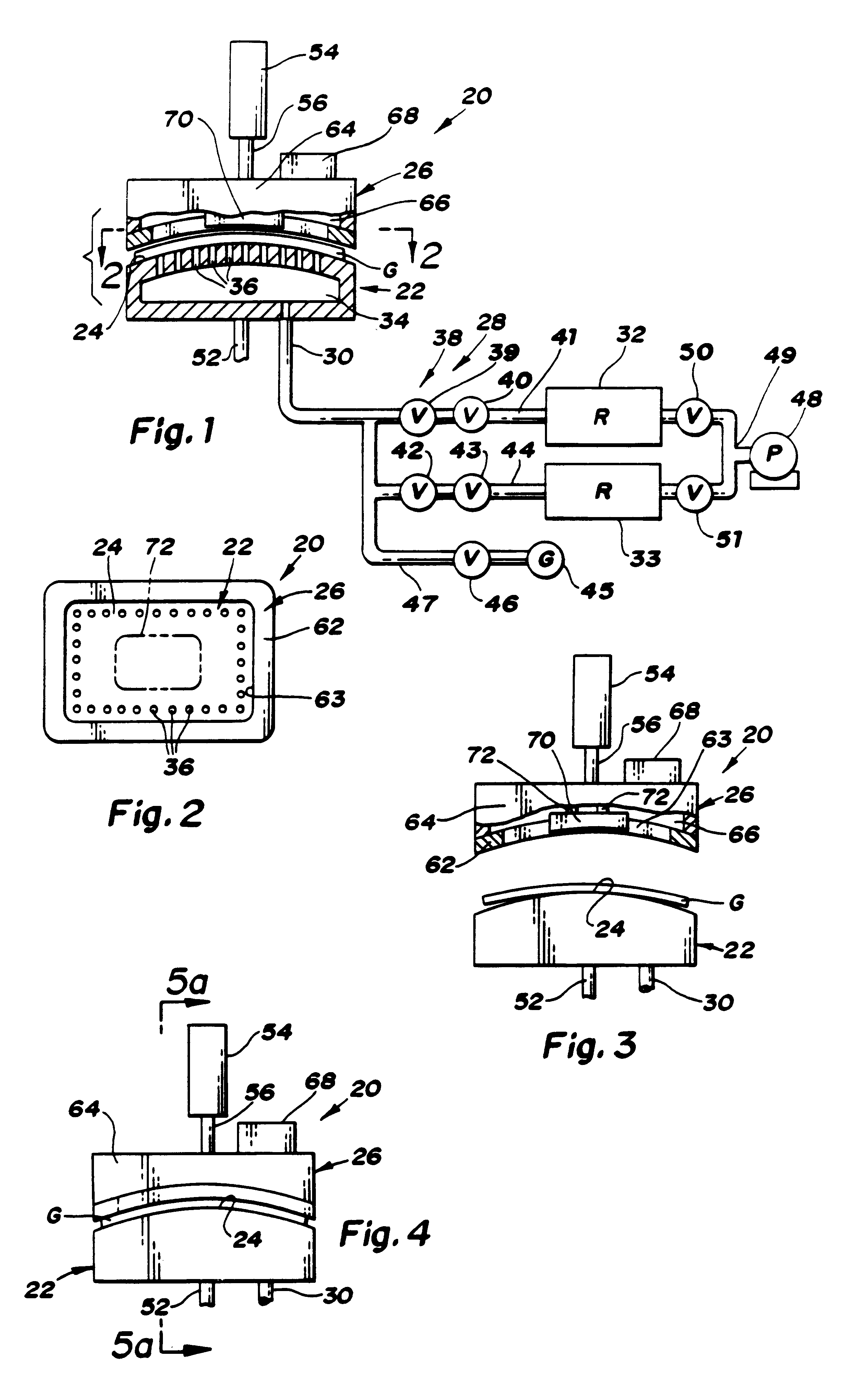

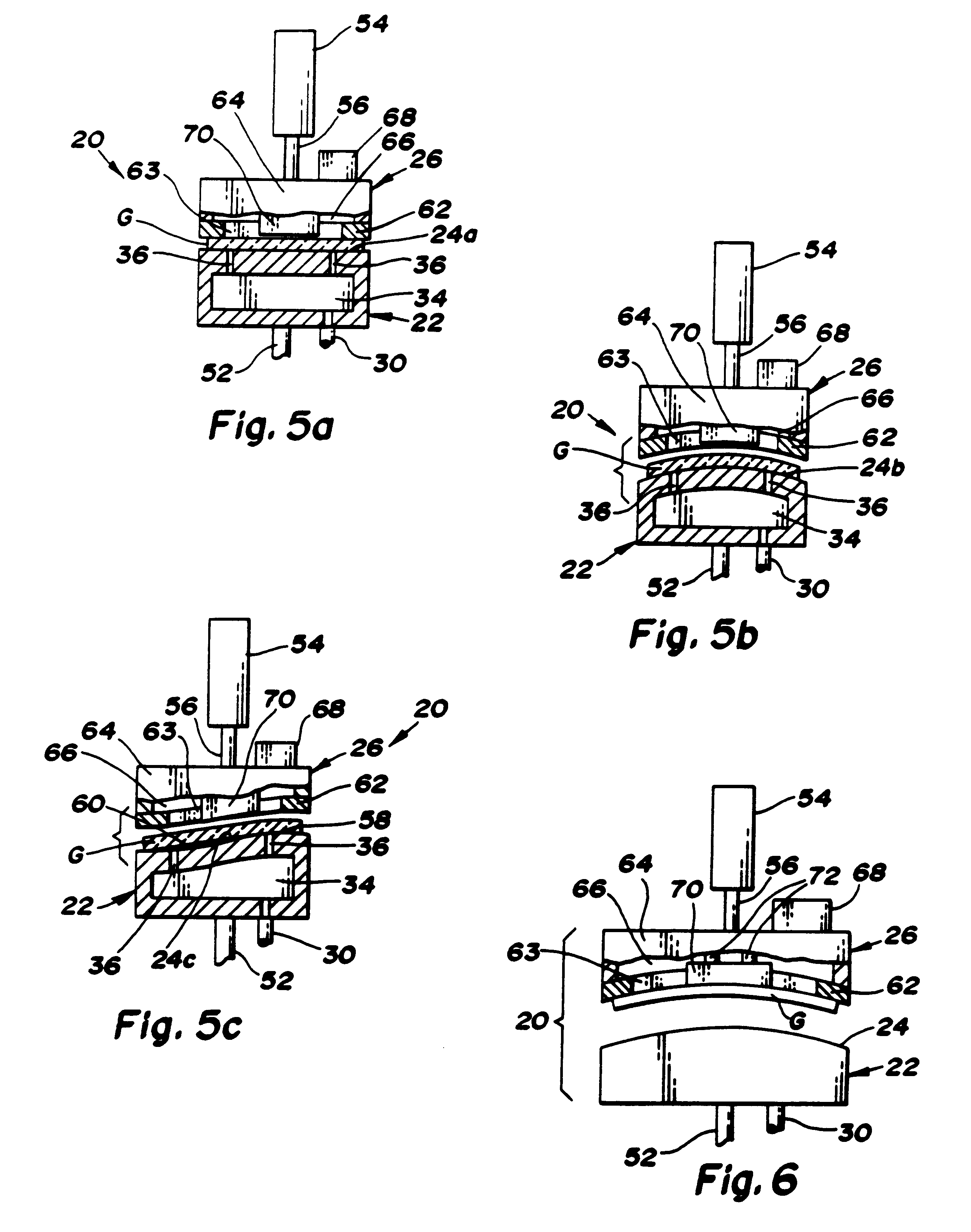

Apparatus for vacuum impulse forming of heated glass sheets

InactiveUS6227008B1Reduced optical distortionIncrease vacuumGripping headsGlass reforming apparatusGlass sheetMaterials science

Apparatus (20,120) for forming a heated glass sheet G is disclosed as including a vacuum mold (22,22a,122,122a) having a full surface (24,24a,124,124a) against which a peripheral mold (26,26a,126,126a) presses the glass sheet periphery and with which at least one vacuum reservoir (32,33) is communicated within the interior of the sealed glass sheet periphery to form the glass sheet to the shape of the vacuum mold surface. Valving (38) of a vacuum system (28) is preferably operable to provide the vacuum impulse in two stages with an initial limited extent of vacuum and a subsequent greater extent of vacuum by communication first with one vacuum reservoir (32) and subsequently with another vacuum reservoir (33). Different embodiments of the vacuum mold have the vacuum mold surface facing upwardly and downwardly with convex and concave shapes. Glass sheet shapes including straight line elements such as cylindrical and conical bends as well as shapes including curvatures in transverse directions and inverse curvatures can be effectively provided by this vacuum impulse forming.

Owner:GLASSTECH

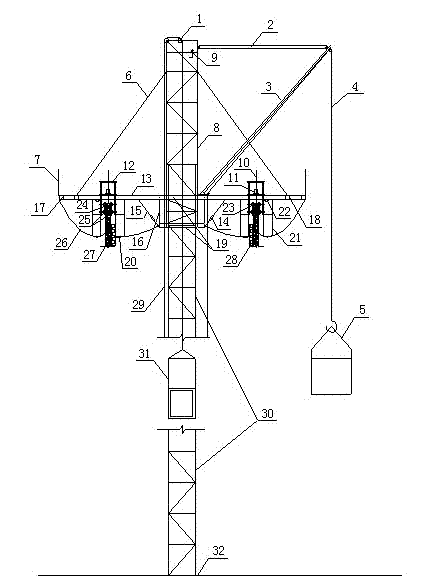

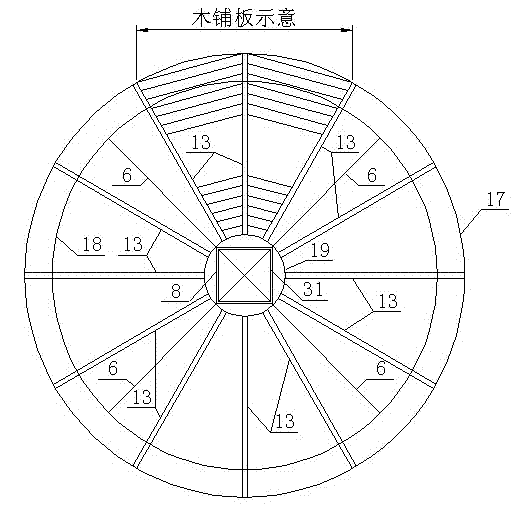

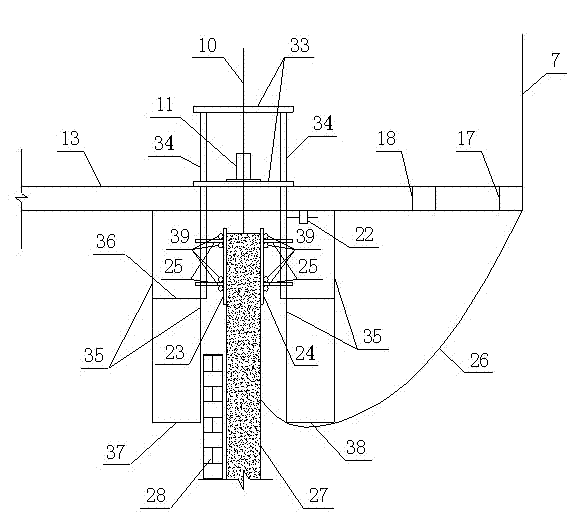

Construction method of circular reinforced concrete chimney cylinder wall and hydraulic sliding mould device

ActiveCN102535843ALess one-time investmentReduce construction costsForms/shuttering/falseworksBuilding material handlingReinforced concreteAssembly disassembly

The invention discloses a construction method of a circular reinforced concrete chimney cylinder wall, and a hydraulic sliding mould device, wherein a hydraulic sliding mould construction method is a rapid construction method of dynamically and continuously molding concrete; loads such as an operation platform and a template are completely supported on a support rod which is stabilized by low-age concrete and has small rigidity; the operation platform and the template are driven to climb along the cylinder wall by a hydraulic jack; and the hydraulic jack climbs on the support rod by an oil path system. The hydraulic sliding mould construction employing the sliding mould as an external cylinder wall and building a lining adopts an ''outside sliding and inside building'' construction process featured by synchronously constructing the external cylinder wall and the lining. The hydraulic sliding mould construction is featured by dynamic continuous construction, having fast construction speed in comparison with mould reverse, symmetrically distributing the hydraulic jack on the circumference of the chimney cylinder wall, forming the template by combining a fixed template with a moveable plate and a contracting and separating template, convenient to assemble and dismount as well as regulate the diameter and the circumference of the combined template structure, capable of gradually decreasing the diameter and the circumference of the combined template structure along with the diameter change of the chimney diameter. The hydraulic sliding mould construction is advantaged in few invested construction operators and convenient management.

Owner:马鞍山钢铁建设集团有限公司

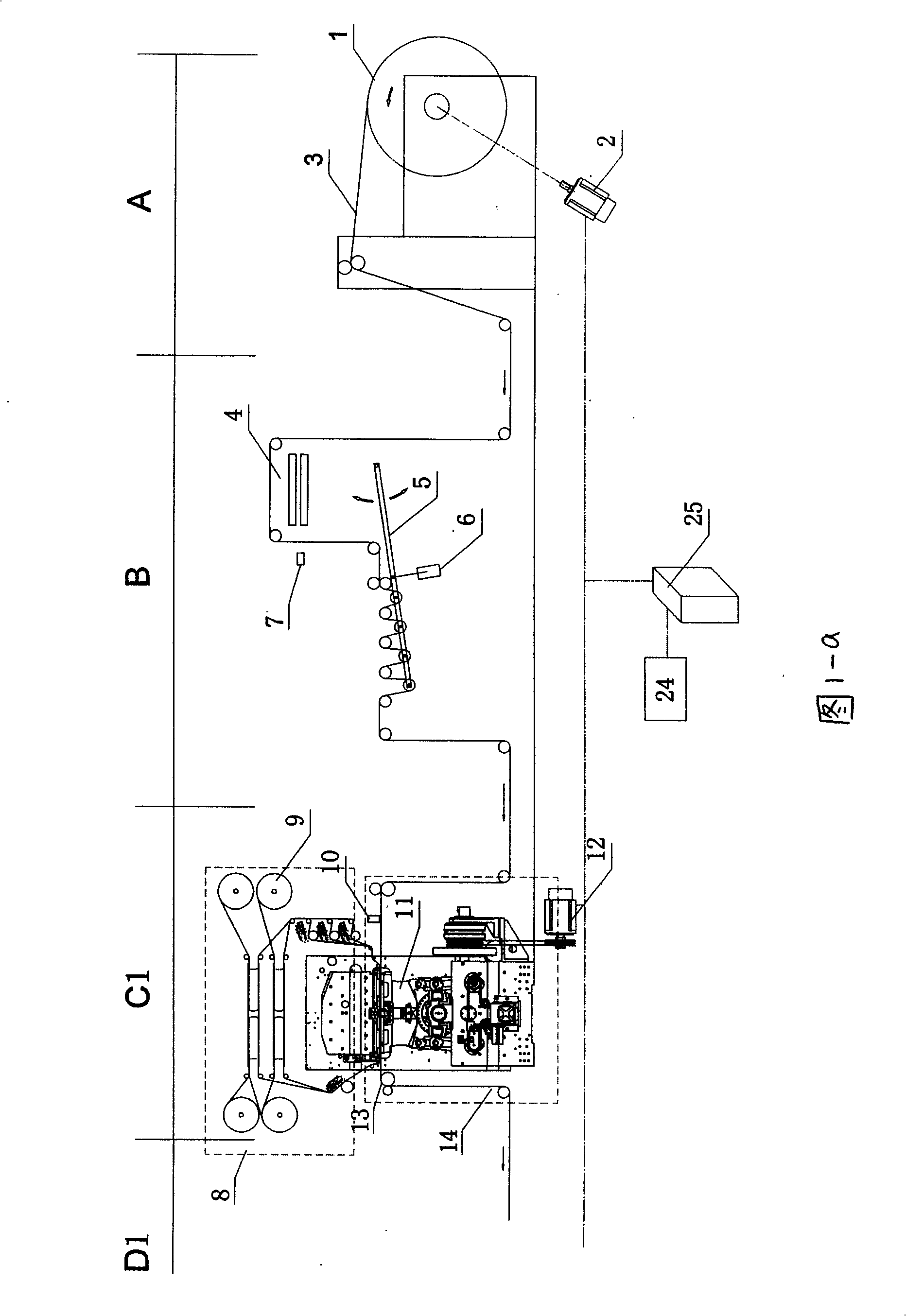

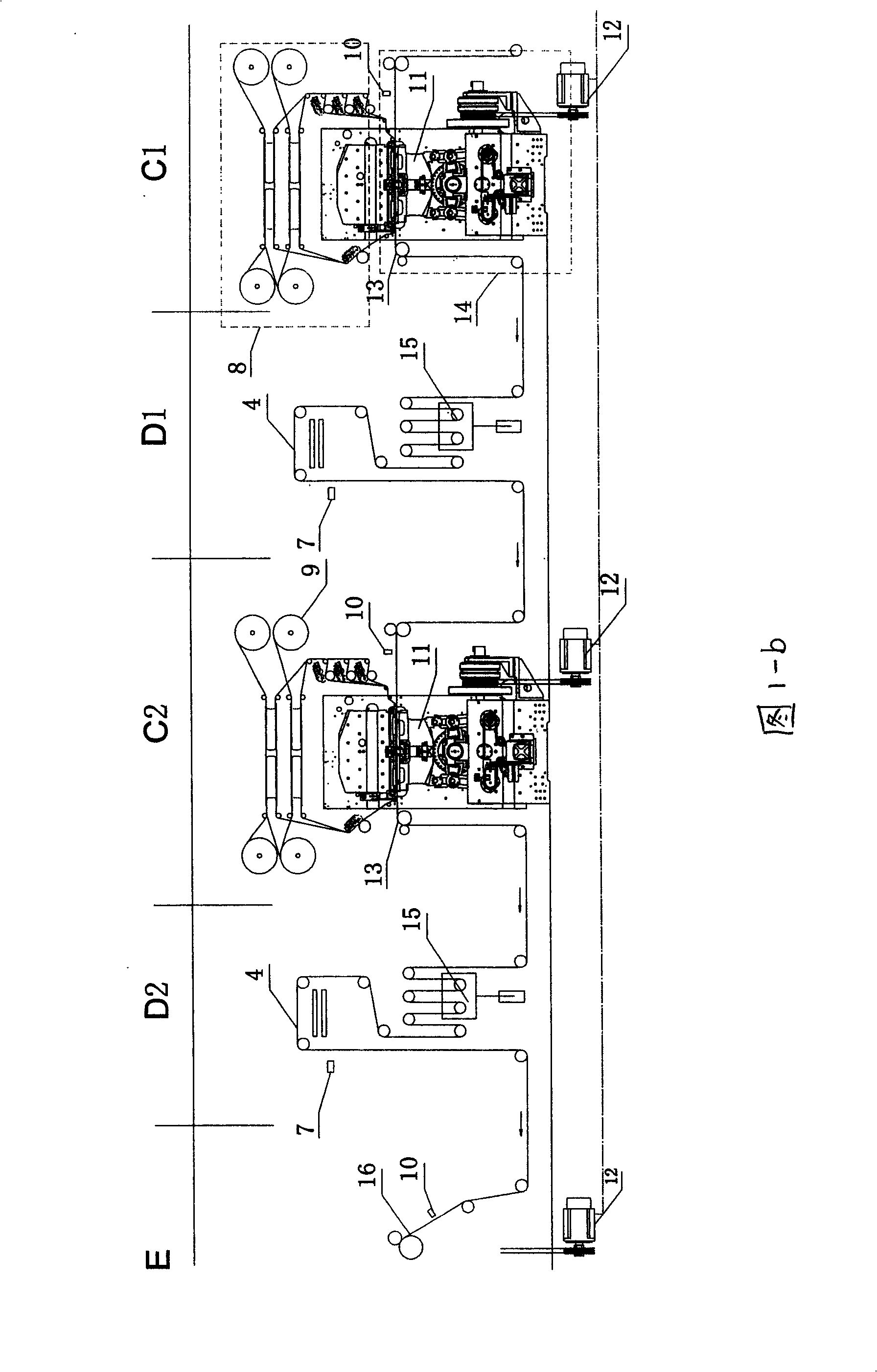

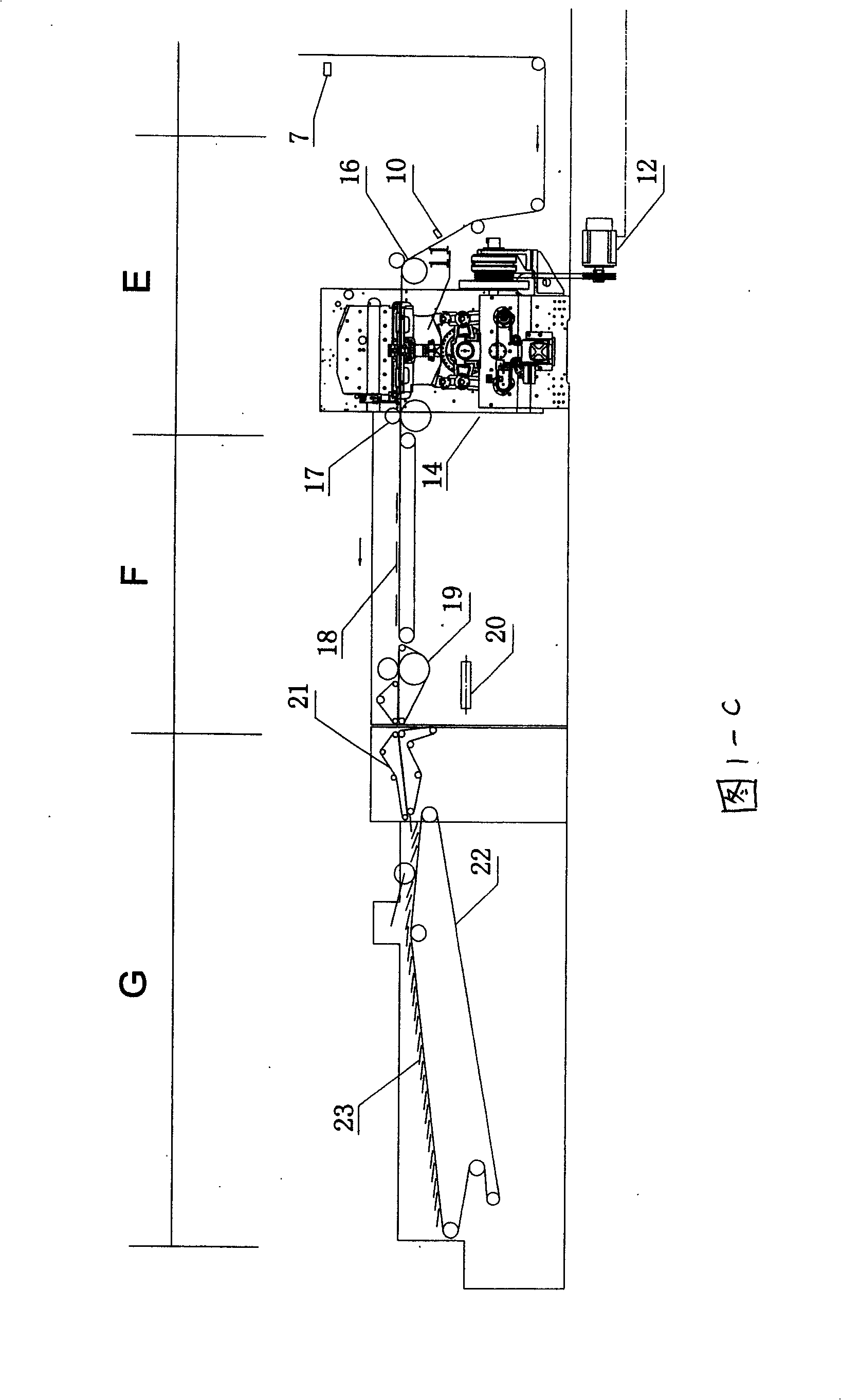

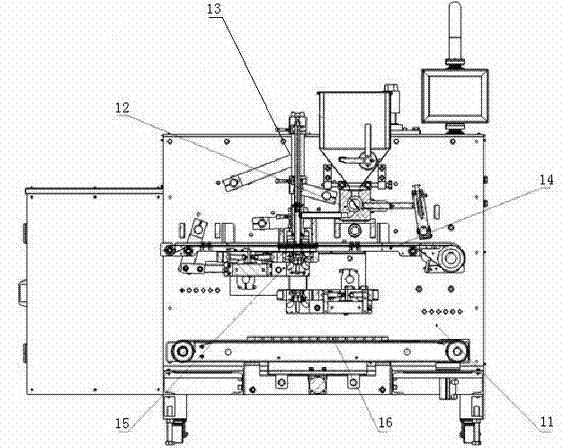

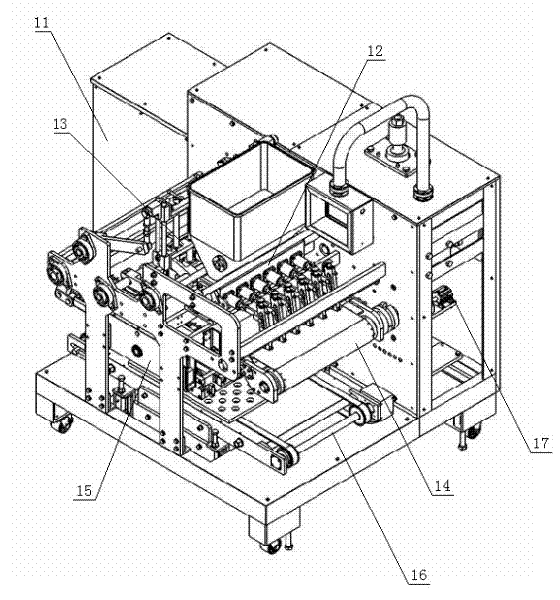

Unit type mold cutter for reeled paper

ActiveCN101407127AProduction effectively adapts toProduction adaptationTransfer printingPlaten pressesHot stampingRolling paper

The invention relates to a roll paper unit-type die cutting machine. The machine consists of a roll paper releasing and winding device, a paper storage device, a hot stamping unit, a tensile force control device, a die cutting unit and a waste cleaning device, wherein the roll paper releasing and winding device consists of roll paper, a motor and paper, the paper storage device consists of a deviation rectifying device, a swinging rod, a constant-force device and a detection sensor of the deviation rectifying device, the hot stamping unit consists of an aluminum foil conveying device, aluminum foil, a sensor, a moving platform, a motor, a paper drawing device and a press mould device, the tensile force control device consists of a deviation rectifying device, a detection sensor of the deviation rectifying device and a constant-force device, the die cutting device consists of a sensor, a motor, a press mould device, a paper drawing device and a paper receiving device, the waste cleaning device consists of paper, waste cleaning device and a slitter edge conveying device, and a sheet material collecting device consists of a paper separating and conveying device, a conveyor belt and paper.

Owner:MASTERWORK GROUP CO LTD

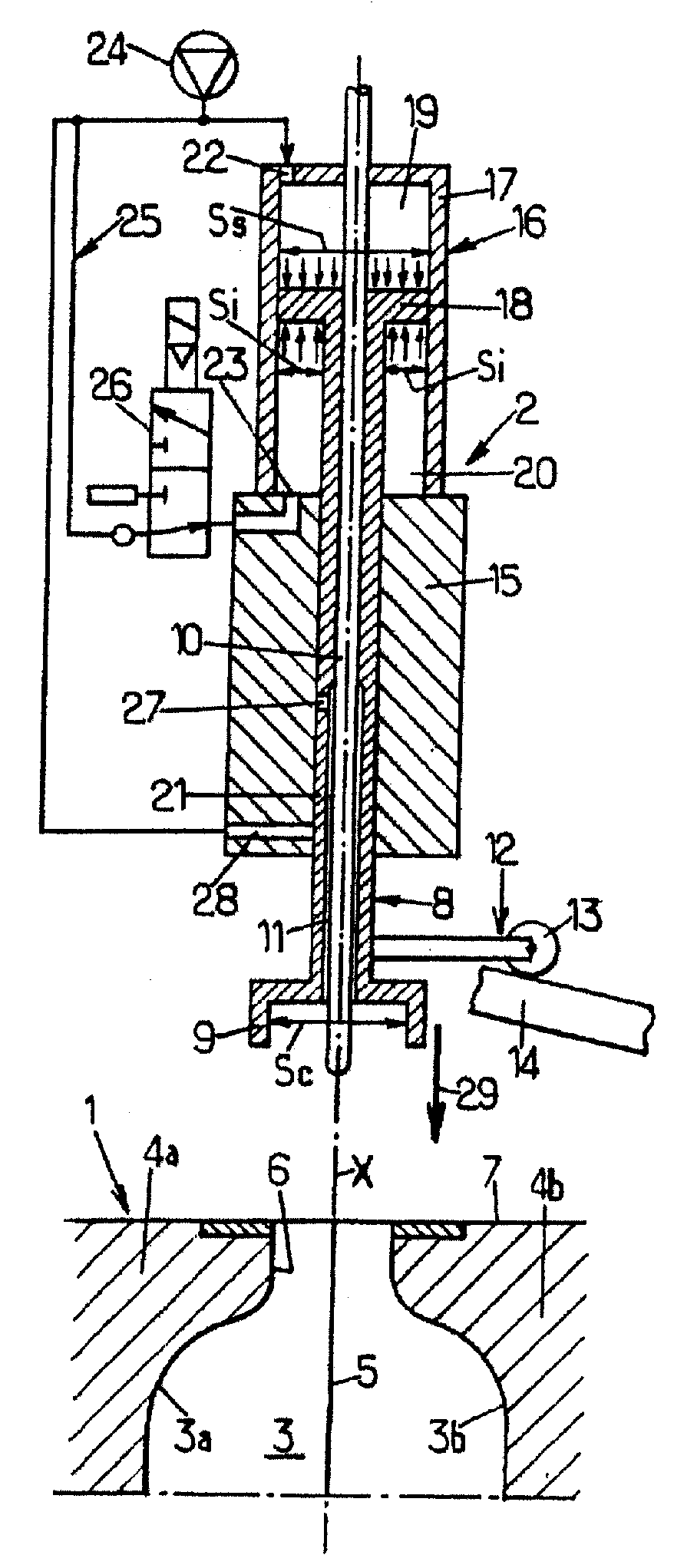

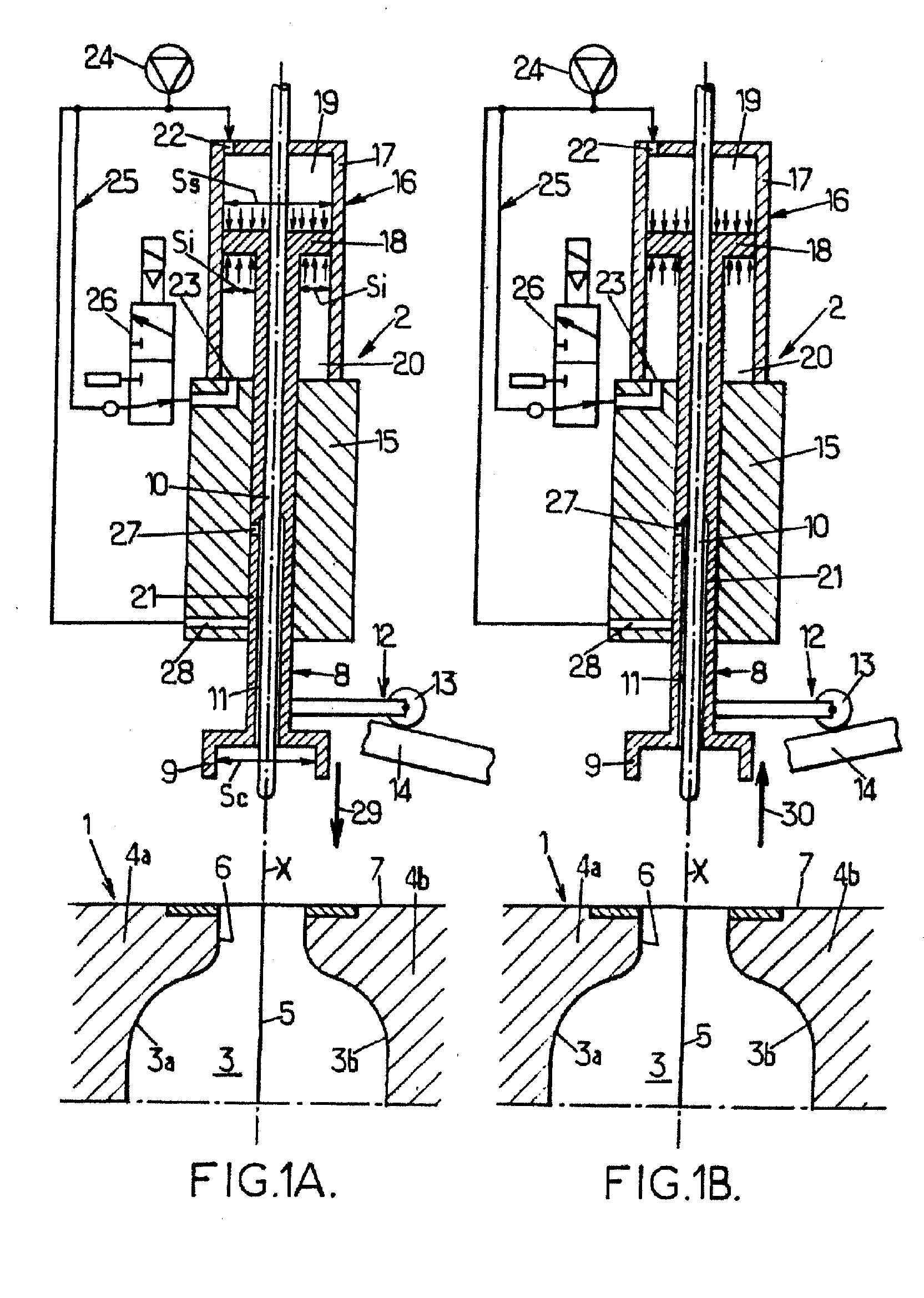

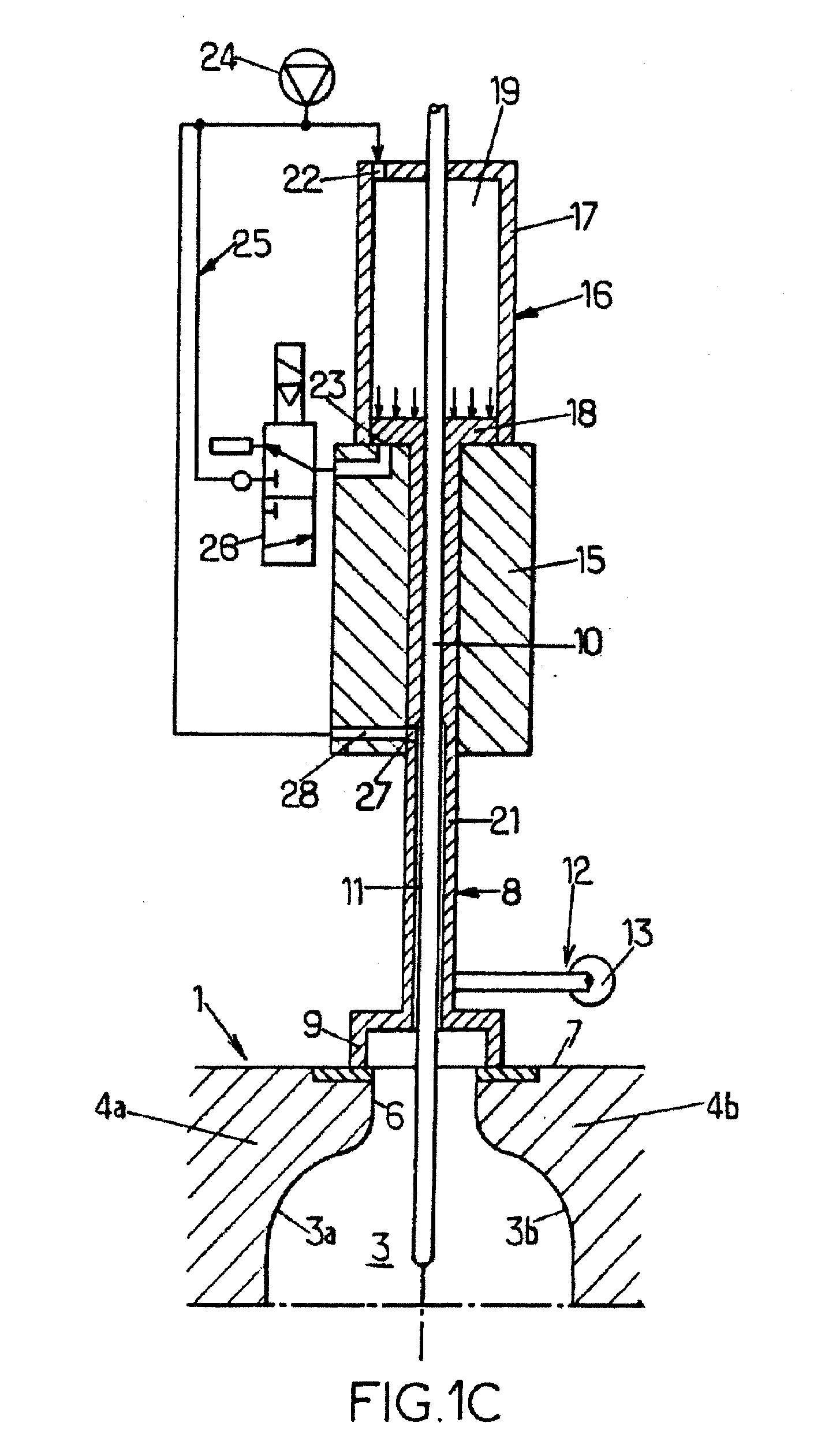

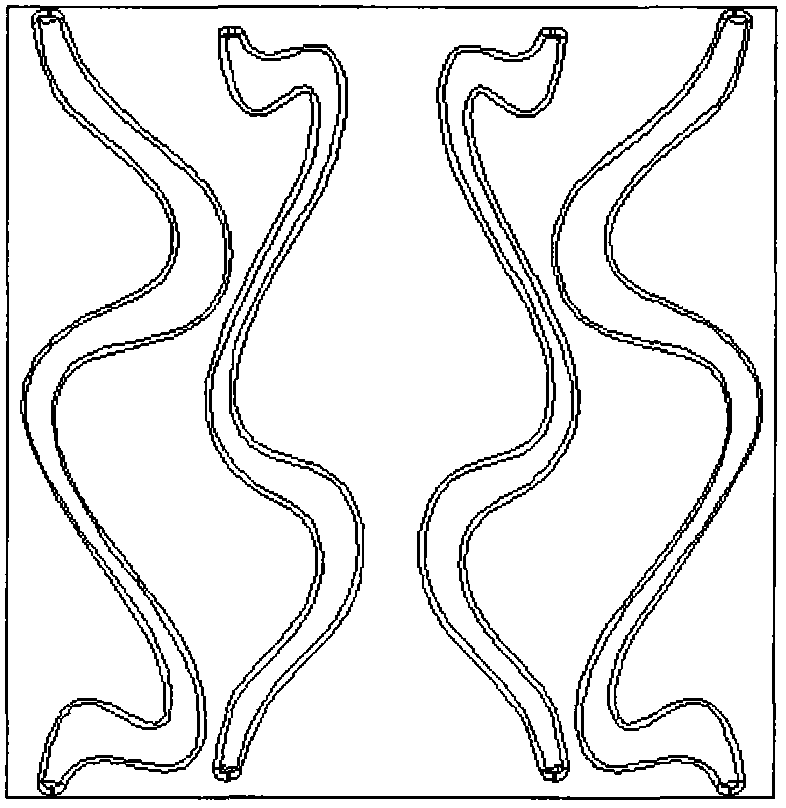

Device for moulding thermoplastic containers by blow-moulding or stretch blow-moulding

Device for moulding thermoplastic containers by blow-moulding hot preforms, comprising a mould (1) and blow-moulding means (2) comprising a bell nozzle (8) which is axially displaceable between a raised position and a blow-moulding position in abutment against the mould; the driving means comprising mechanical means (12) with a cam follower roller (13) / cam (14) and pneumatic means (16) with a piston (18) integral with the upper end of the nozzle and sliding in a fixed enclosure (17), defining therein an upper chamber (19) connected to a source (24) of control fluid and a lower chamber (20) connected to this source and to the upper chamber via a solenoid valve (26); the upper face of the piston has a surface area which is greater than that of its lower face and that of the bell (9) of the nozzle.

Owner:SIDEL PARTICIPATIONS SAS

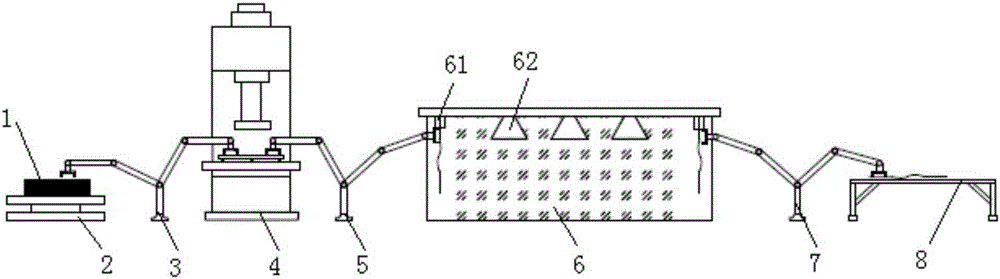

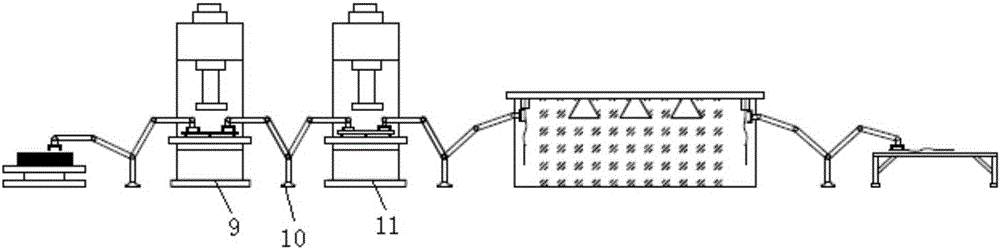

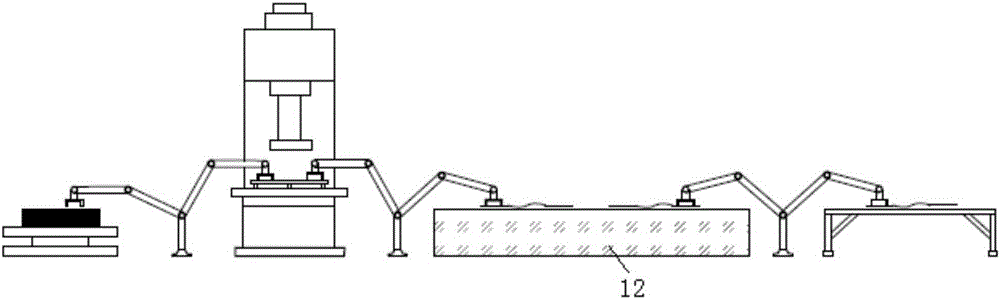

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

Smashing, compressing and moulding equipment for fruit and vegetable garbage and moulding method thereof

ActiveCN104259172ASave storage spaceSolve the problem of accumulation and deteriorationSolid waste disposalGrain treatmentsEngineeringSanitation

The invention relates to the technical field of environmental sanitation equipment and particularly relates to smashing and compressing equipment, more particularly smashing, compressing and moulding equipment for fruit and vegetable garbage. The equipment comprises a compressing and moulding device and a cutting and smashing device. The cutting and smashing device comprises a smashing material inlet and a smashing bin. Main shafts pass through the smashing bin and then are connected to a power mechanism outside of the smashing bin. The main shafts are provided with fly-cutter groups. A material collecting plate is disposed below the fly-cutter groups. A material pushing plate moving left and right is disposed at the left side below the material collecting plate. A smashed material outlet is disposed at the right side below the material collecting plate. A compression material inlet of the compressing and moulding device is disposed at the right side of the smashed material outlet. By adopting the technical scheme, the equipment is advantaged by integrating smashing and compression, and being simple in operation, high in efficiency and small in occupied space.

Owner:上海新金桥建设发展有限公司

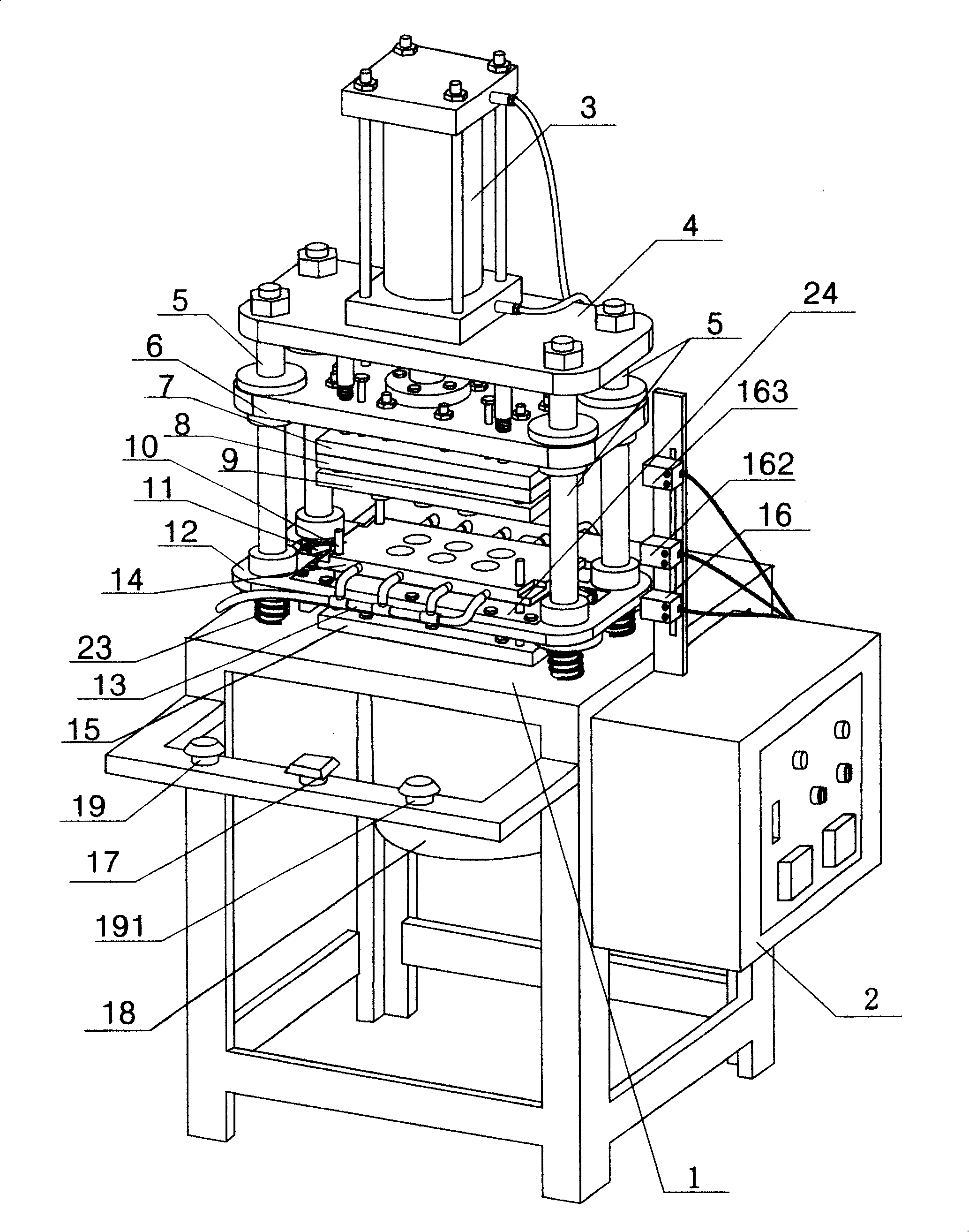

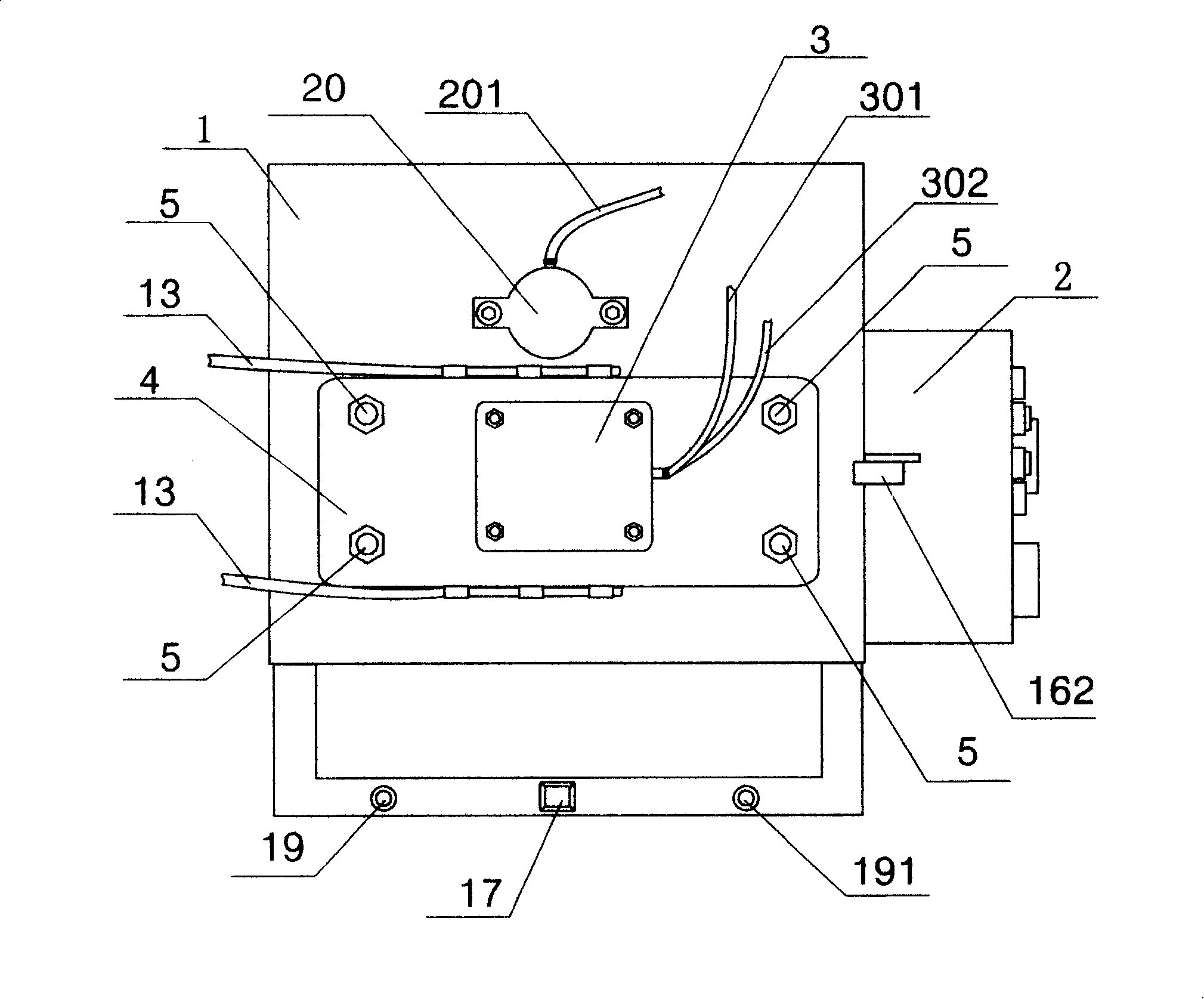

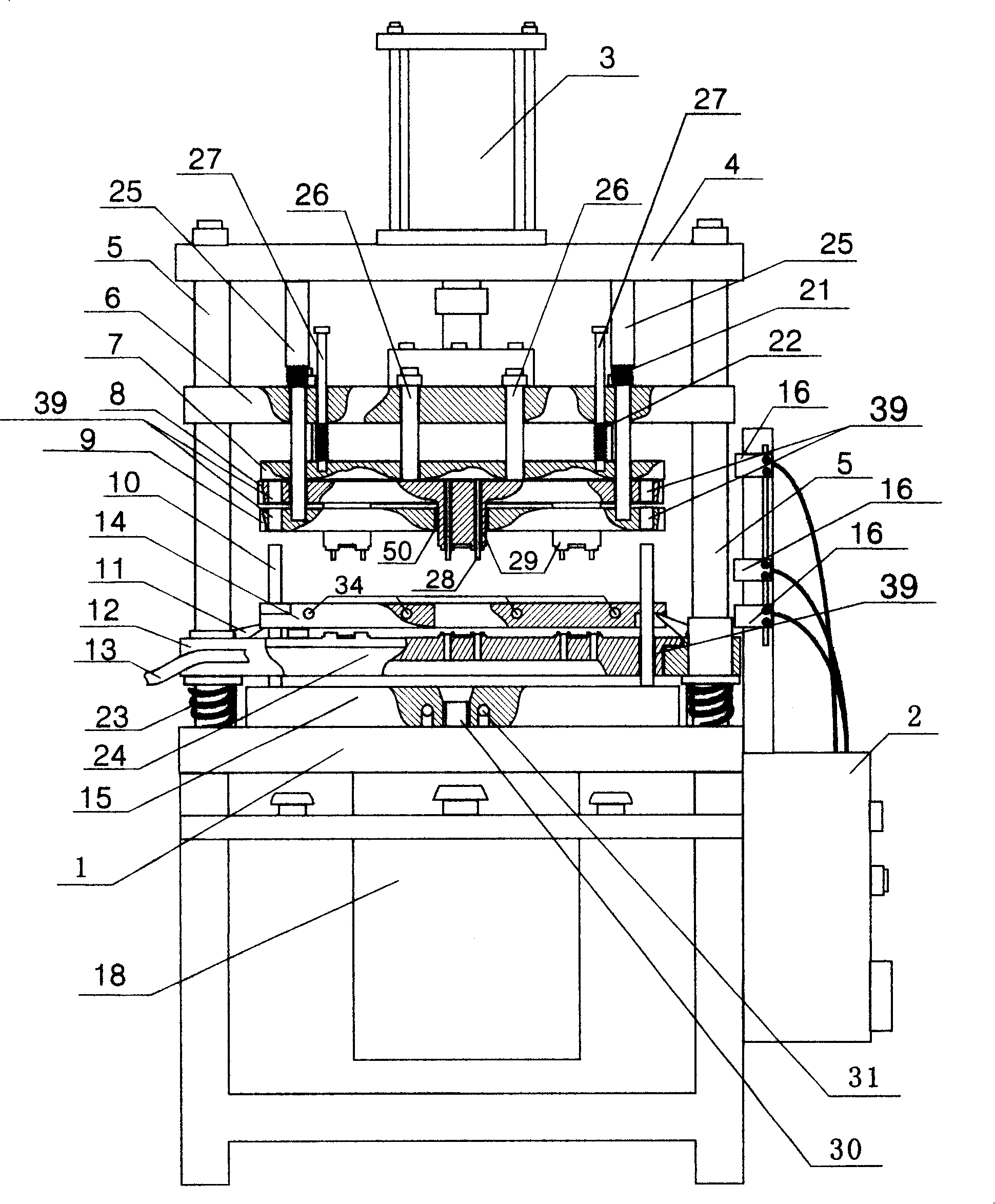

Ceramics injection moulding automatic molding equipment

InactiveCN101229656AImprove balanceGuaranteed accuracyCeramic shaping apparatusPressure castingControl system

The invention discloses an automatic forming machine with a ceramic hot pressure casting, which includes a machine frame, a control system, a material storing bucket, a material conveying pipe, a constant temperature heating part, a guide pillar, an upper guide plate, a lower guide plate, a die and an air cylinder. The invention is characterized in that the feeding plate is firmly arranged on the bottom plate of a machine station and is sleeved with one end of the material conveying pie with the two ends open; the another end of the material conveying pipe is extended into the material storing bucket arranged below the bottom plate; the die consists of a panel, a frame board, a stripper, a fixed plate and a faller; a cavity arranged above the lower guide plate is used for embedding and wrapping the panel in the die neatly; the lower surface of the panel is provided with a feeding groove; the die prying devices are respectively arranged on the left side and the right side of the bottom plate; a plurality of copper pipes with cooling effect are passed through the frame board; in the device, type needles on the faller are inserted into type holes on the panel to resect waste material.

Owner:魏金富

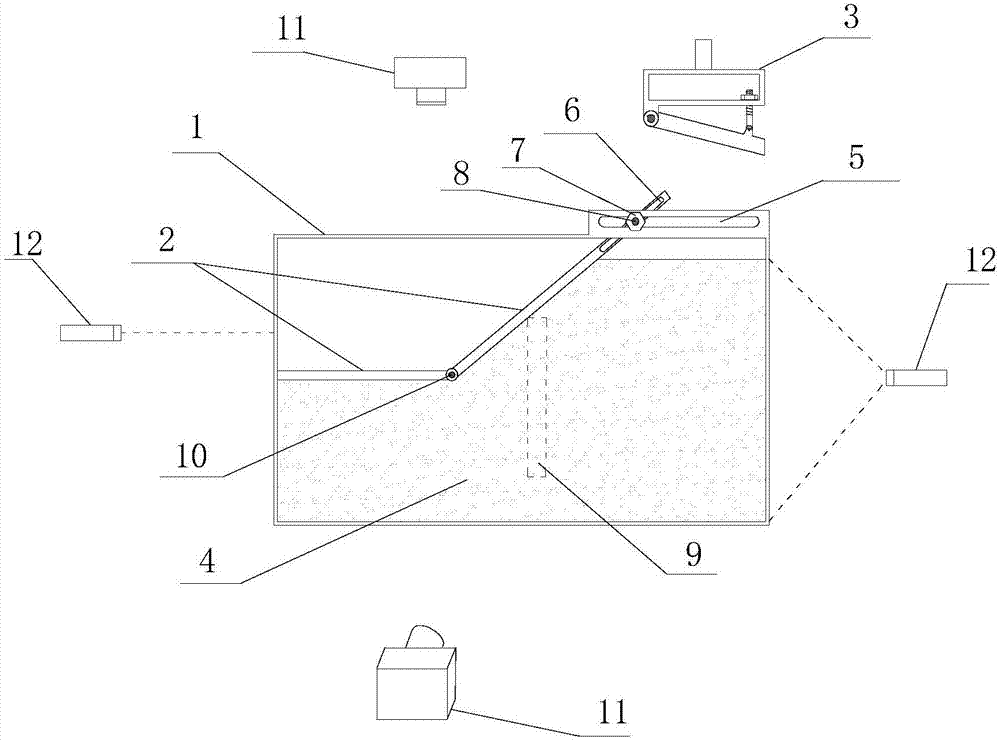

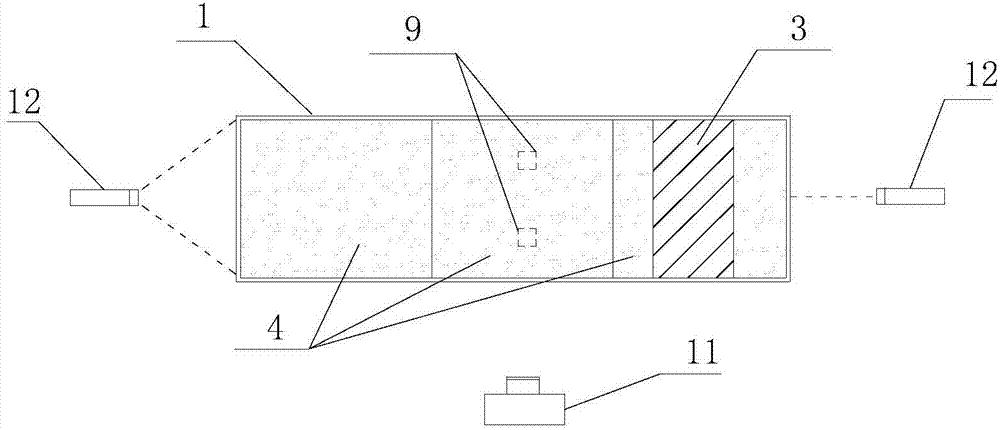

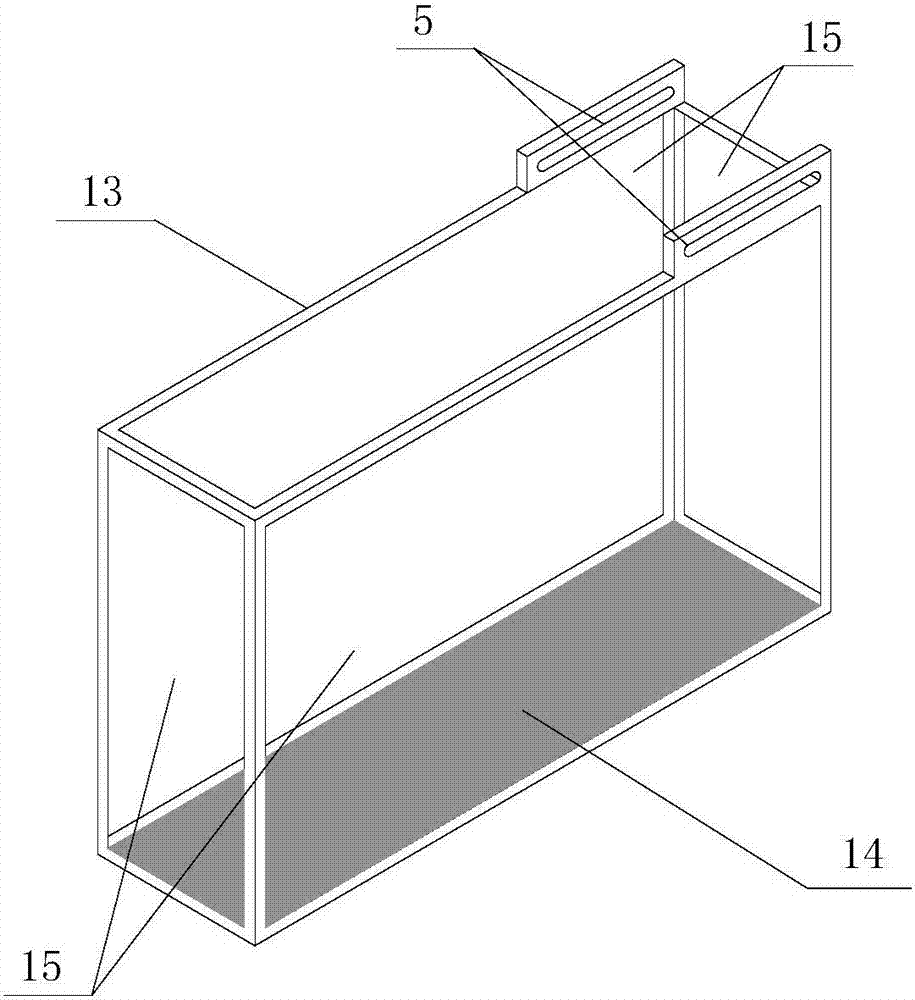

Anti-sliding pile-reinforced slope visualization model test device and method

InactiveCN107228791ASimple and fast operationEase of research impactStrength propertiesLaser transmitterVisual observation

The invention relates to an anti-sliding pile-reinforced slope visualization model test device and method and belongs to the technical field of geotechnical engineering and geological engineering. The device mainly comprises a molding box, a slope molding device, a loading device, transparent soil, anti-sliding piles, laser launchers and digital cameras. The molding box is a transparent box having four organic glass sides. The transparent soil slope and the anti-sliding piles are arranged in the box. The loading device is fixed to a loading machine and applies load to the top of the slope. The laser launchers are respectively arranged in left and right sides of the molding box. The digital cameras are respectively arranged on the top view surface and the front view surface of the molding box and are used for taking clear images of the top and side of the box. Compared with the existing test device and method, the test device and method provided by the invention realize visual observation of anti-sliding pile deformation, replacement of soil beside the pile and formation and damage of the soil arch between piles, have high measurement accuracy and strong repeatability, and can be widely used for research of the mechanism of slope anti-sliding pile deformation-caused internal damage.

Owner:TONGJI UNIV

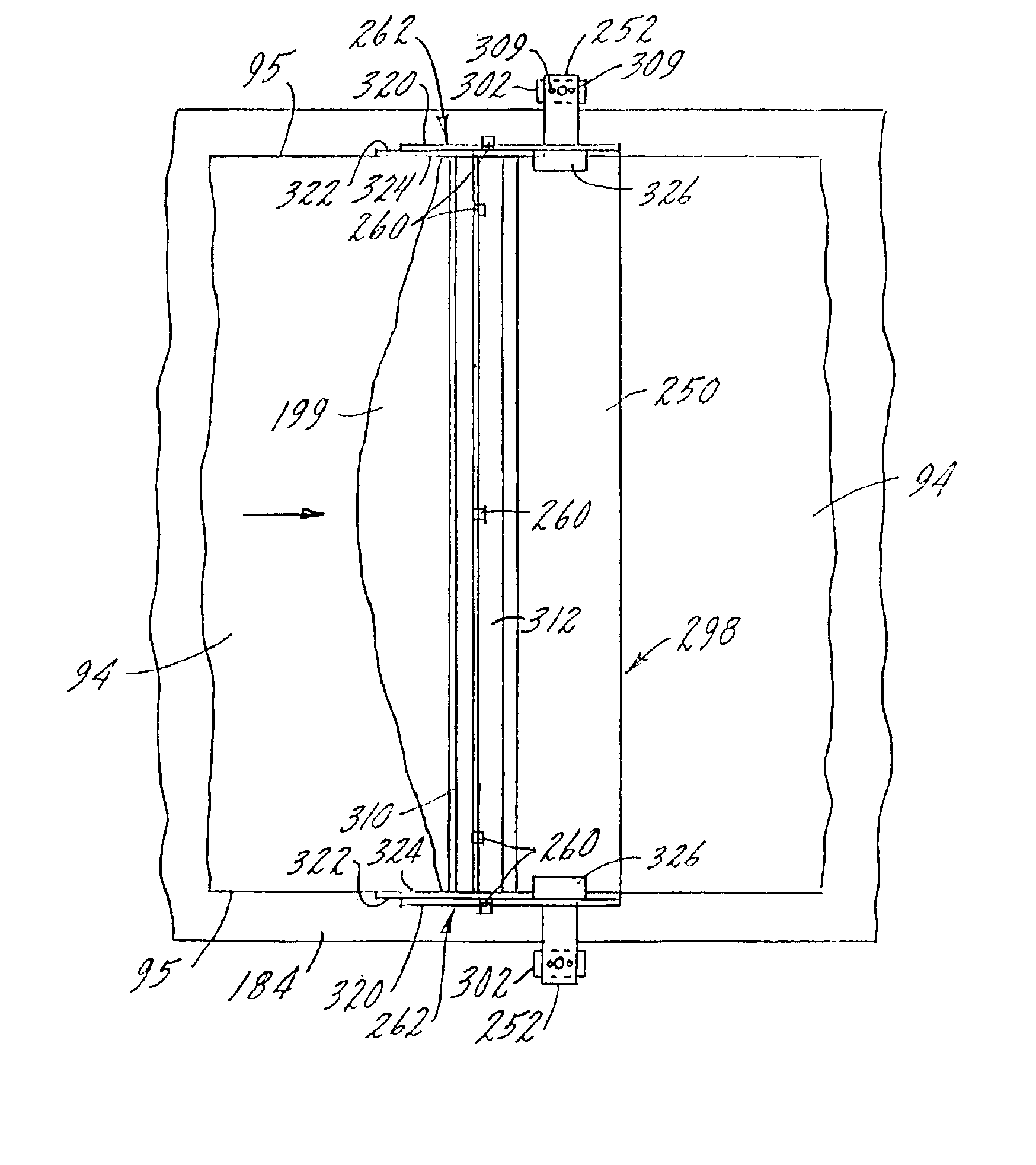

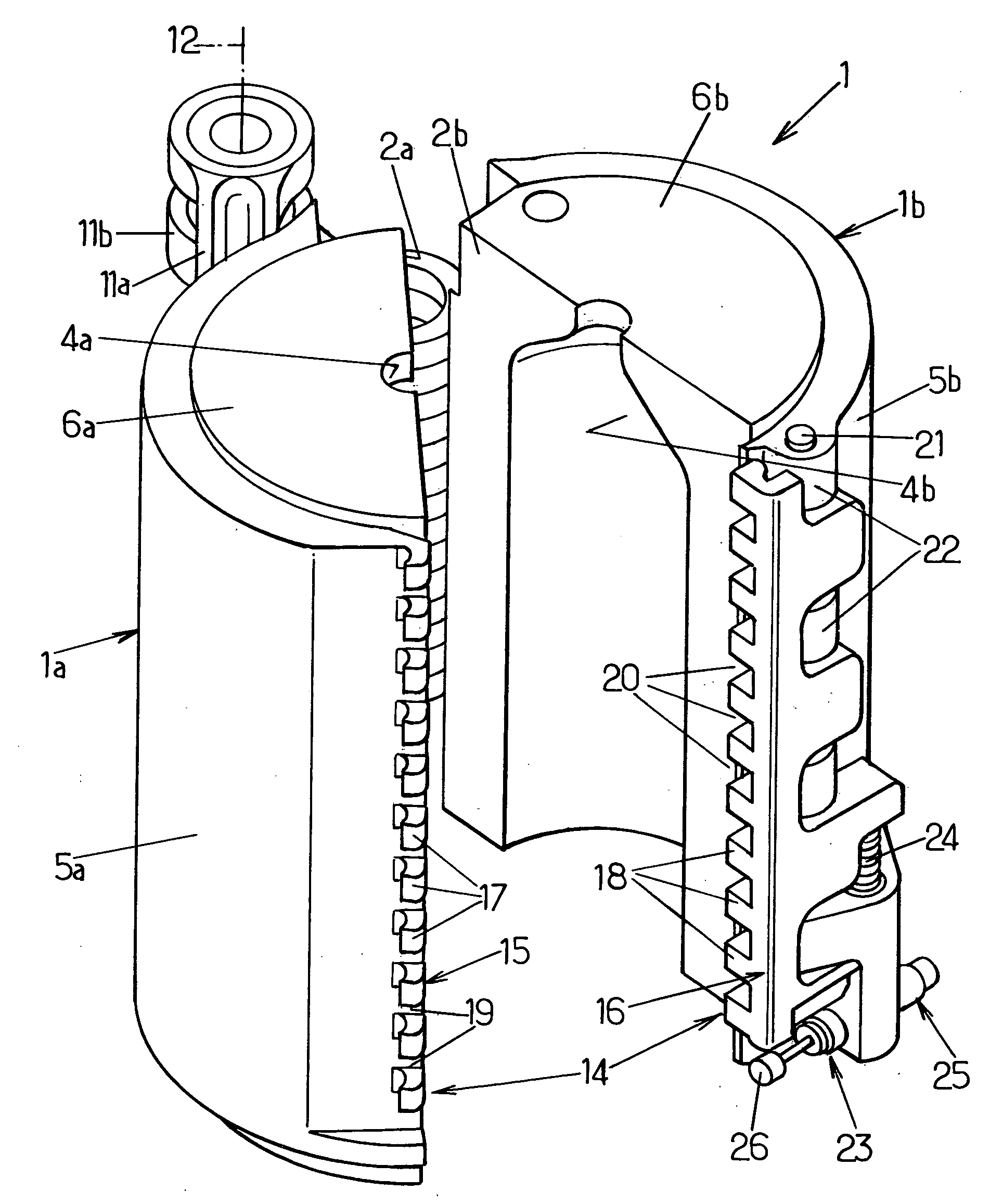

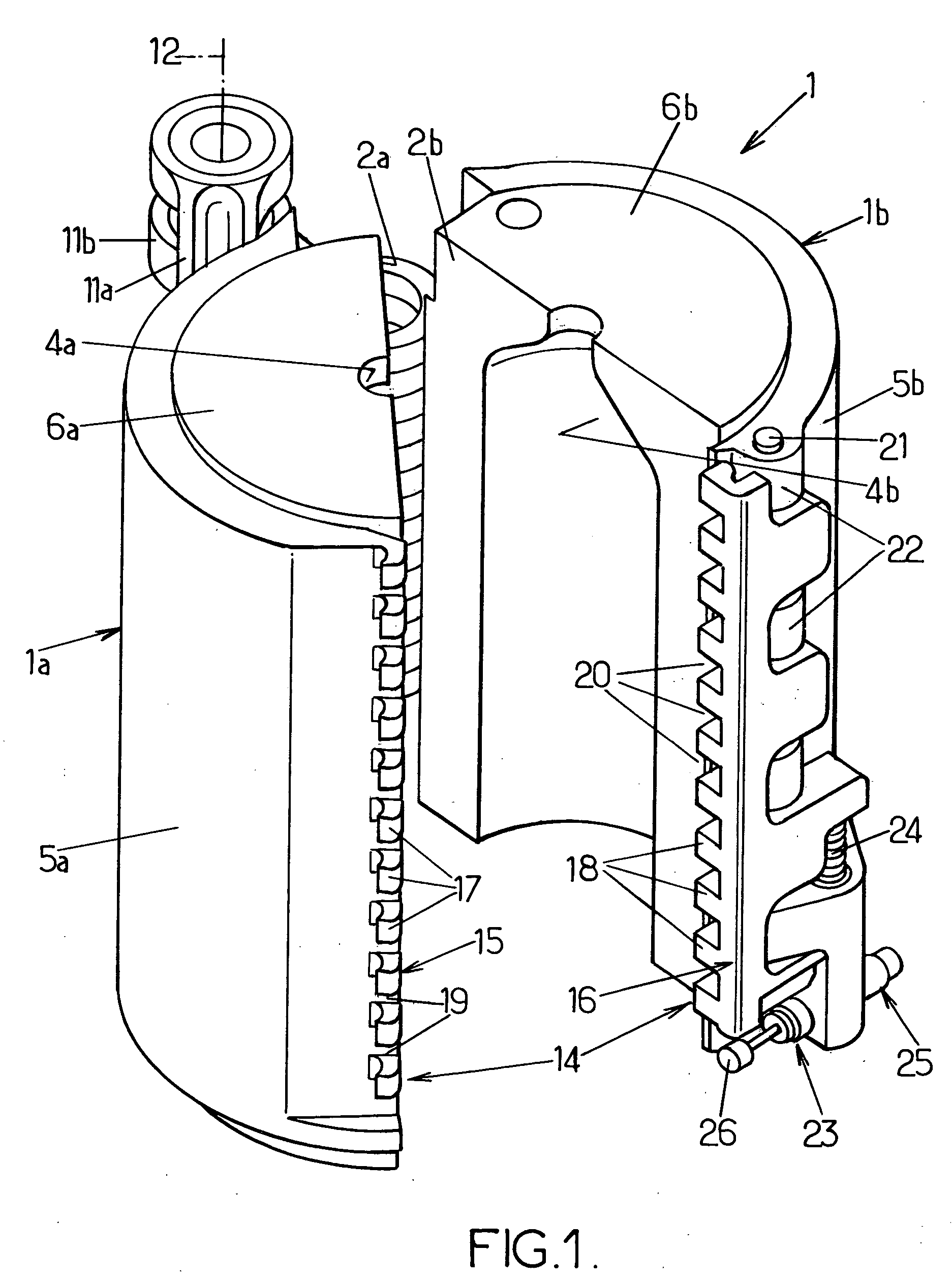

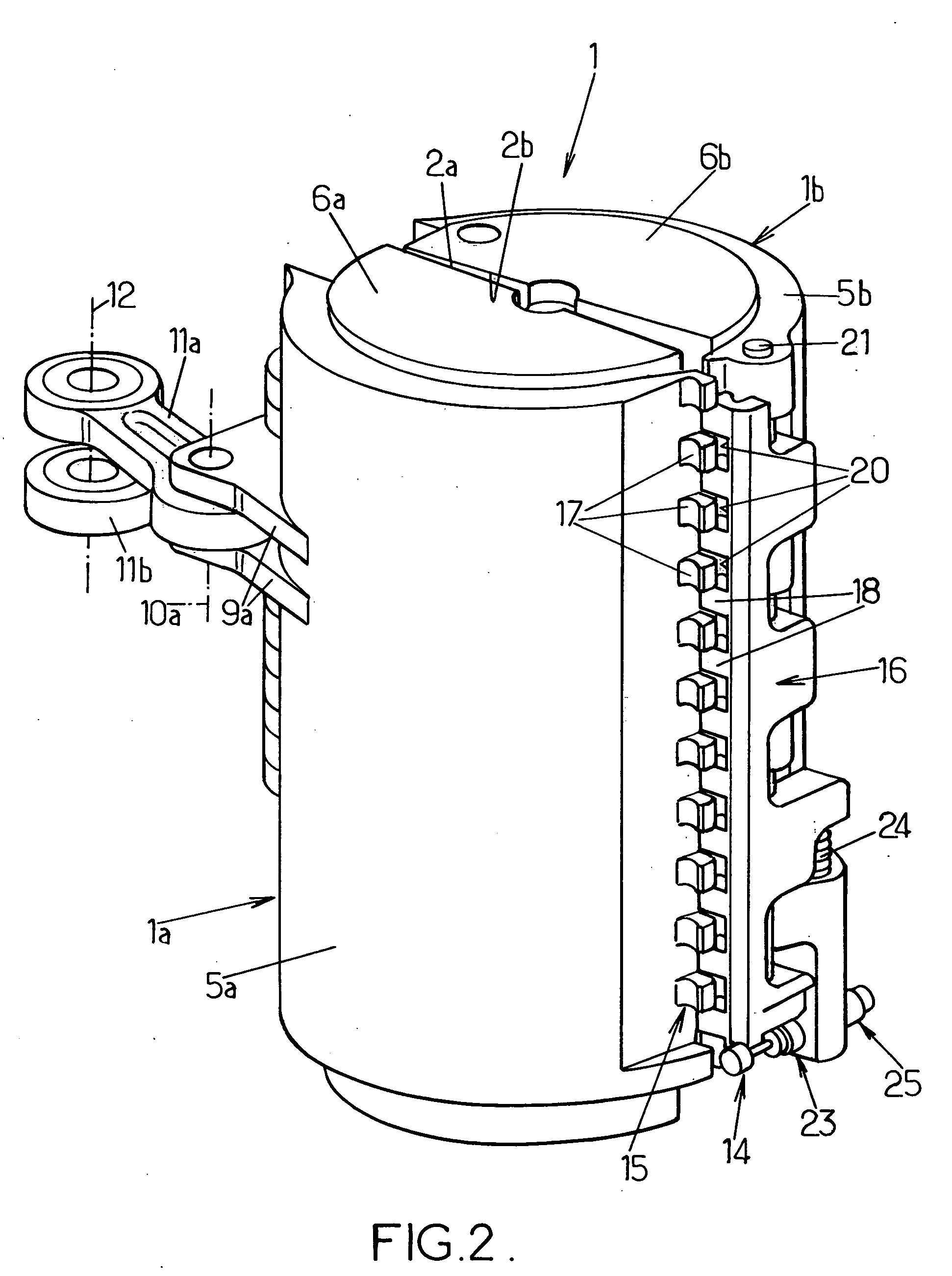

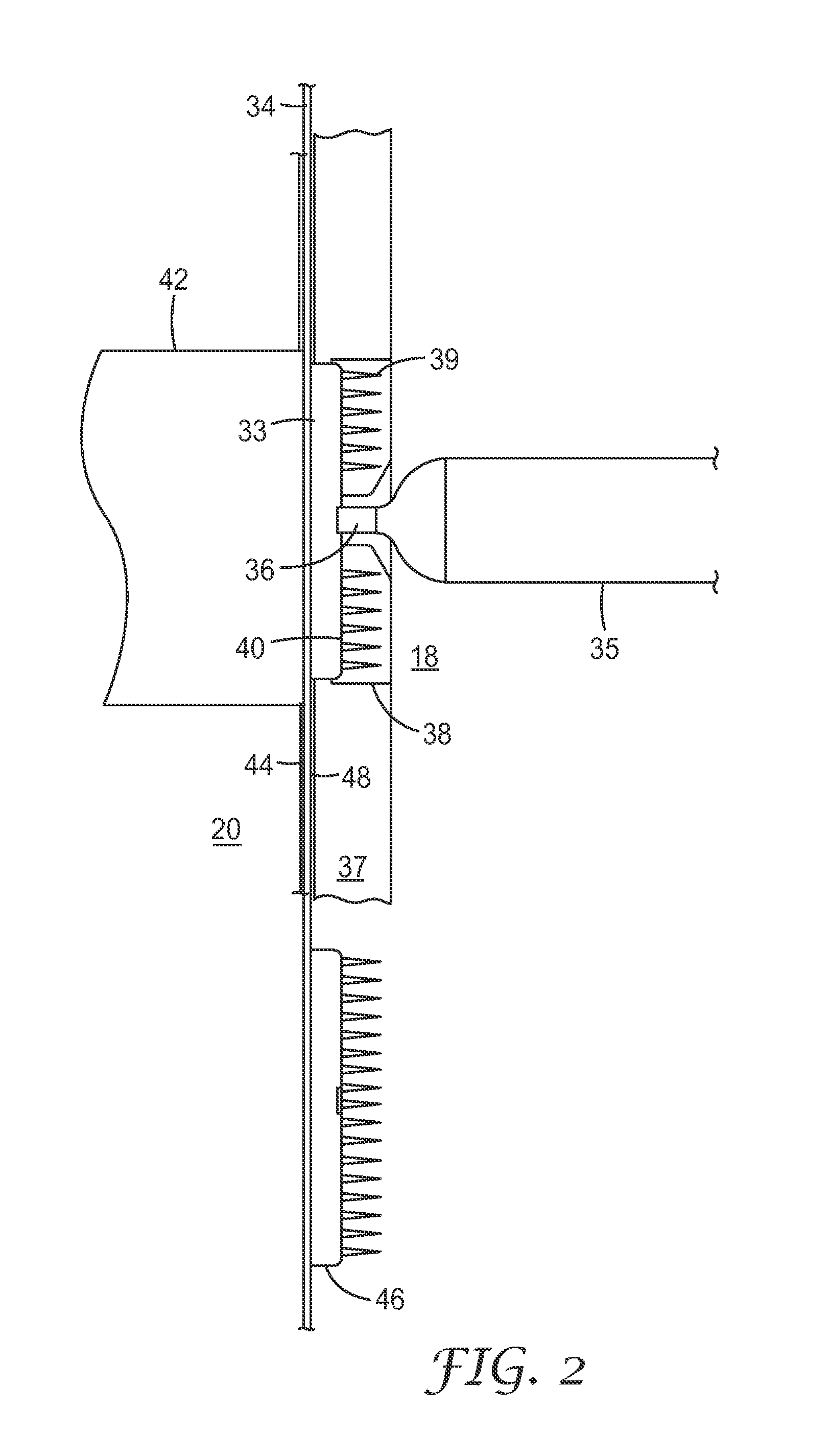

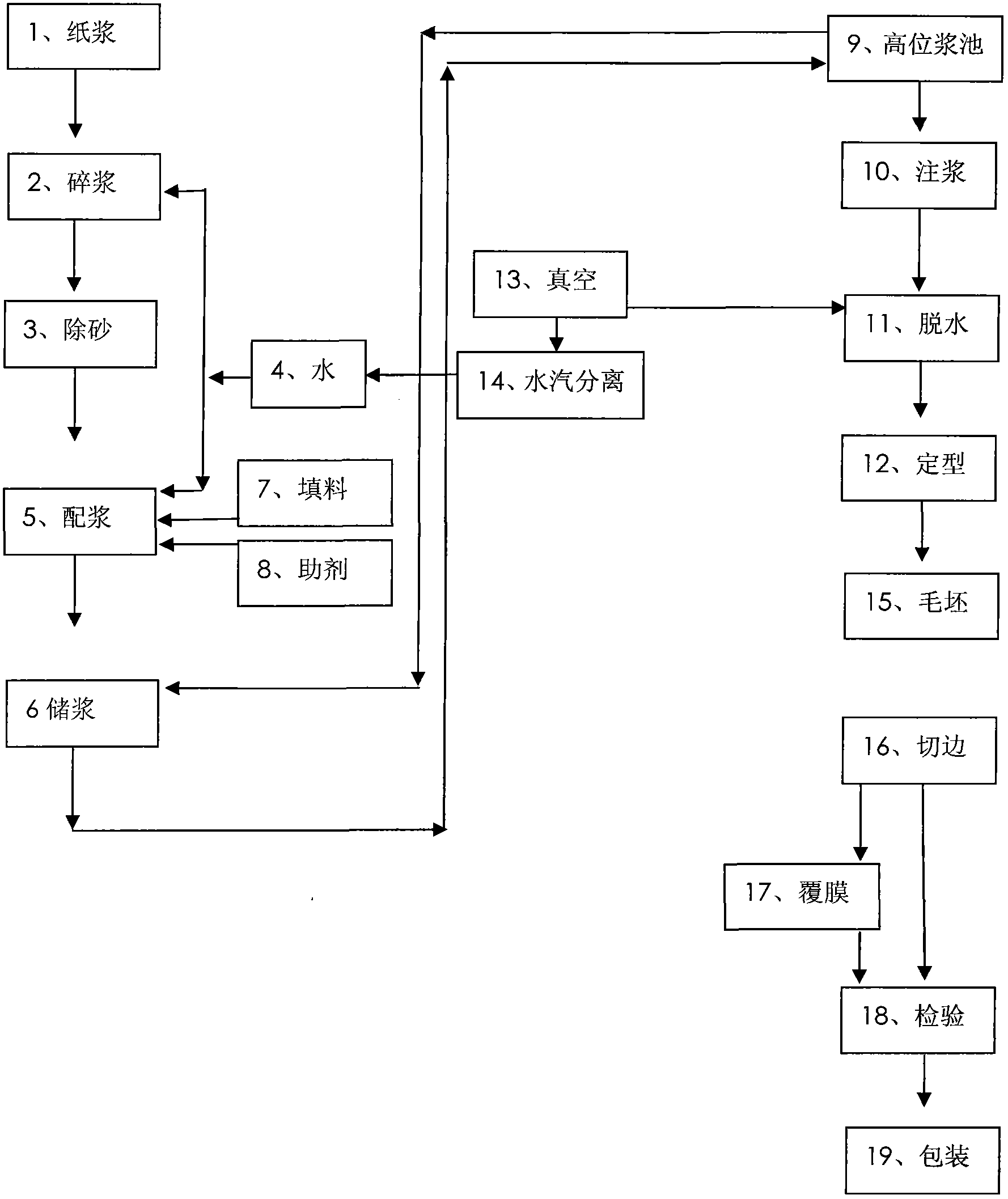

Moulding device for the production of containers in thermoplastic material

A moulding device for the production of containers in thermoplastic material, by blowing or blow-drawing, including a mould with two mould halves mutually mobile and provided with a locking device with two lock elements extending over the total height of the respective mould halves and provided with a number of projecting fingers in catches spaced at intervals, one lock element being fixed on one mould half and the other lock element sliding on the other mould half under the action of an actuator device.

Owner:SIDEL PARTICIPATIONS SAS

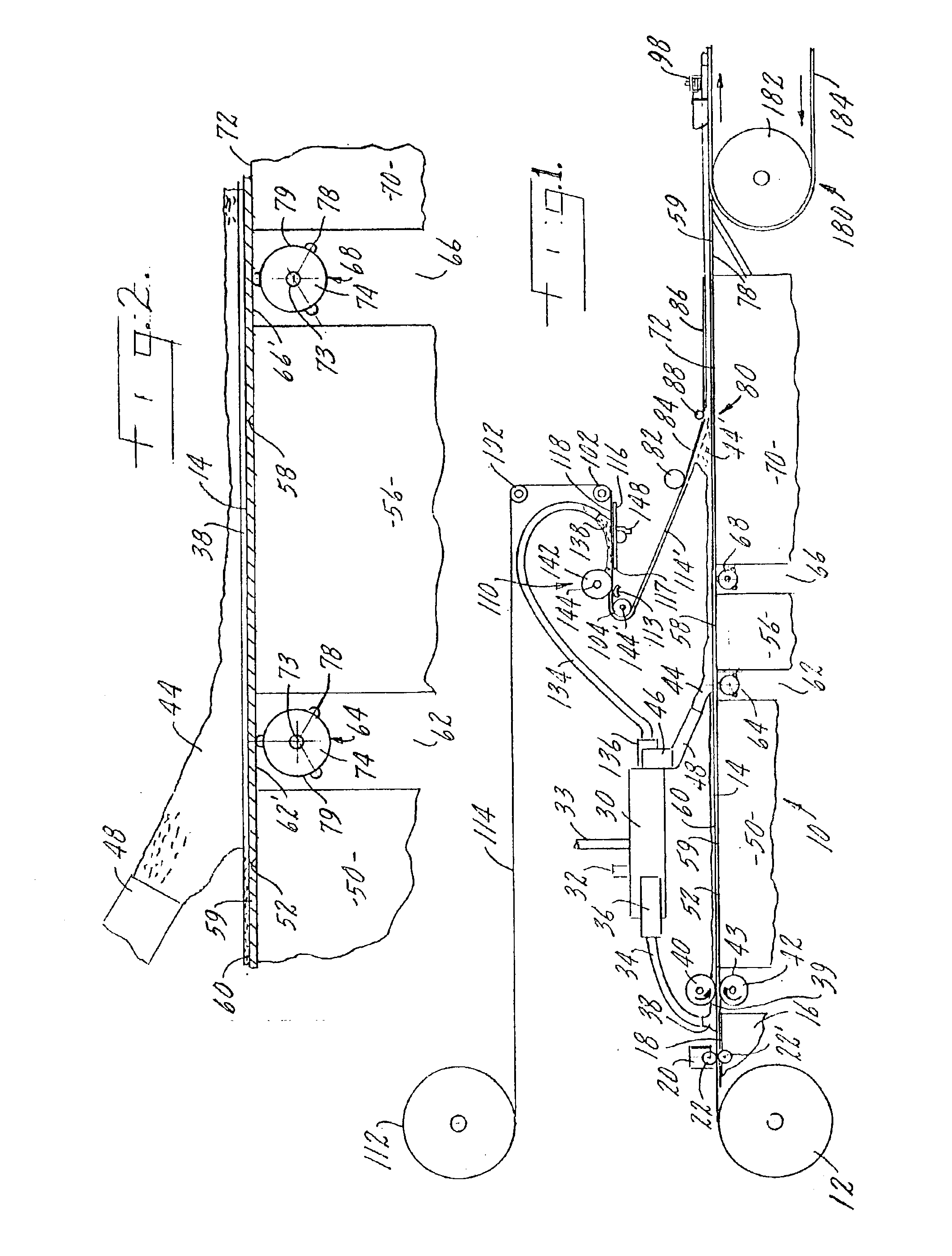

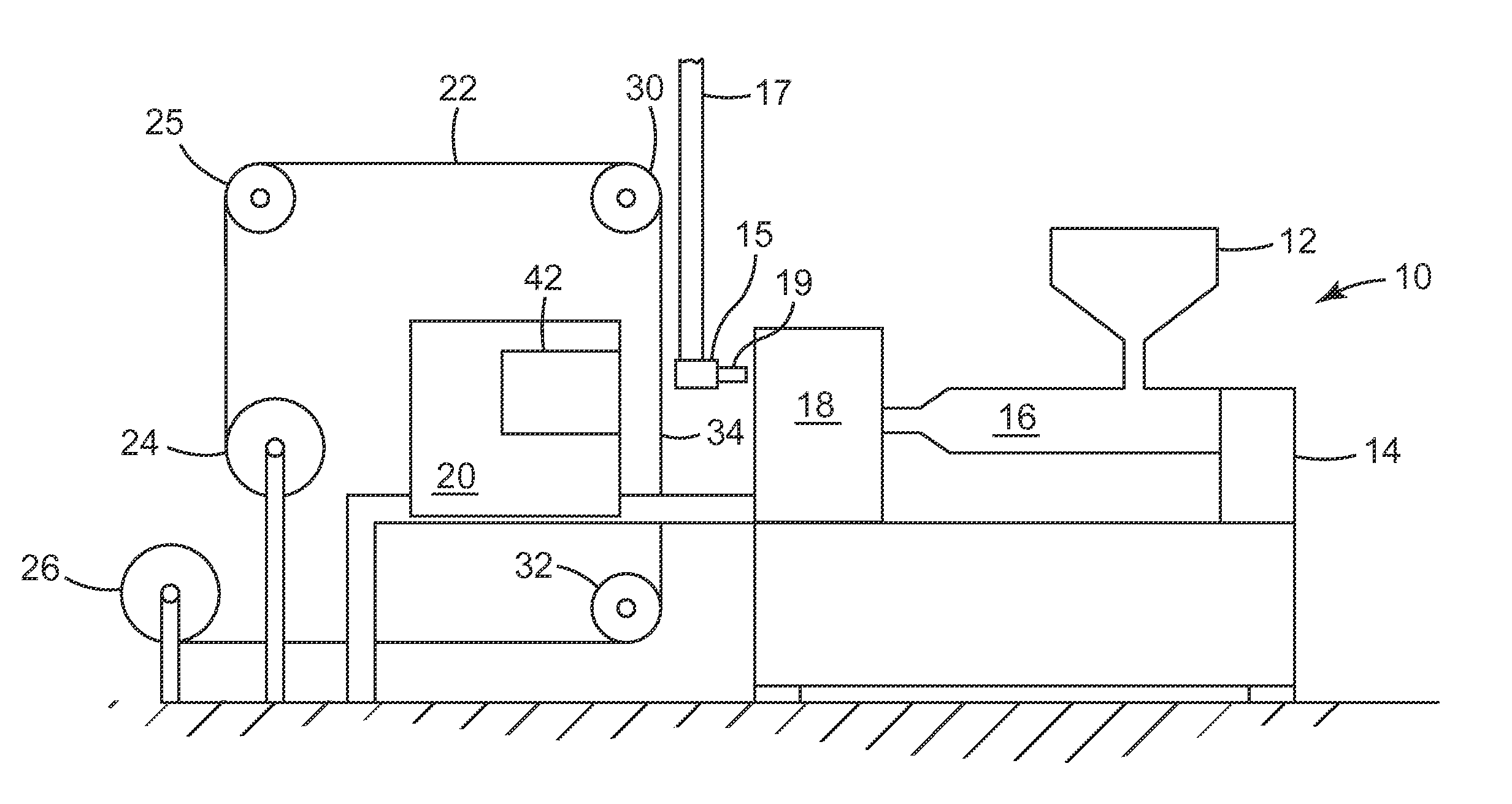

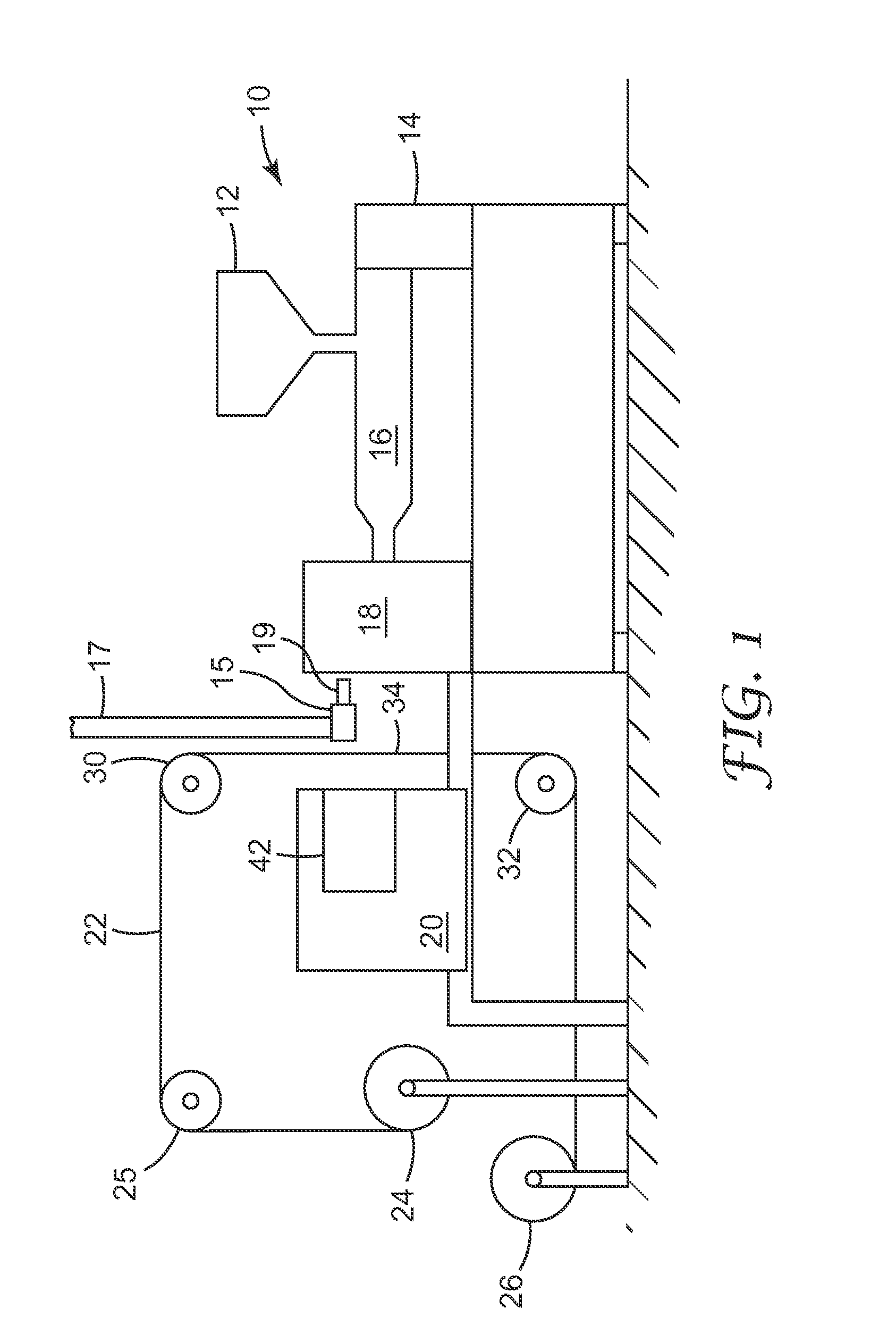

Ultrasonic injection molding on a web

ActiveUS20100159197A1Short mold cycle timeImprove fidelityTurning machine accessoriesOptical articlesInjection mouldingPolymer melt

Injection molding, parts onto a carrier web (34) located between mold halves (18,20). Flow of polymer melt into the mold is assisted by application of ultrasonic energy to the mold cavity. After the molding operation, mold halves are separated, and the carrier web is advanced, or indexed, to a next position for another molding sequence. Molding apparatus comprises a moving mold face (20), that can move toward and away from a first mold member (18) (which can be stationary) in which the mold cavity is located, a means (24,25,26,30,32) for moving and / or indexing carrier web between the first mold member and the moving mold face, means (16) to inject polymer melt into the mold cavity, and an ultrasonic system (42) providing ultrasonic energy to the mold cavity. The carrier web can transport molded parts to subsequent process steps, such as coating, drying, inspection, curing, assembly or packaging.

Owner:3M INNOVATIVE PROPERTIES CO

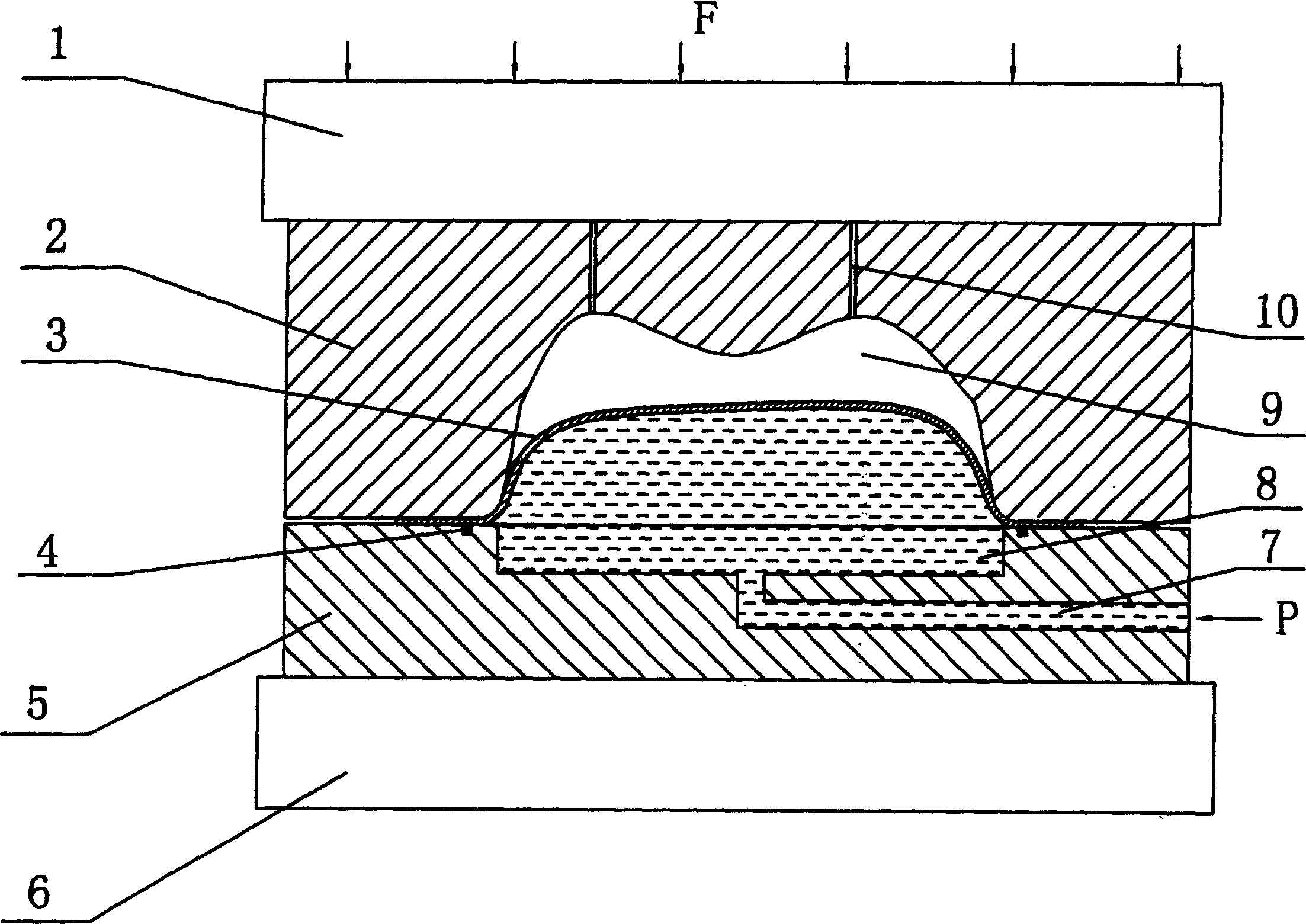

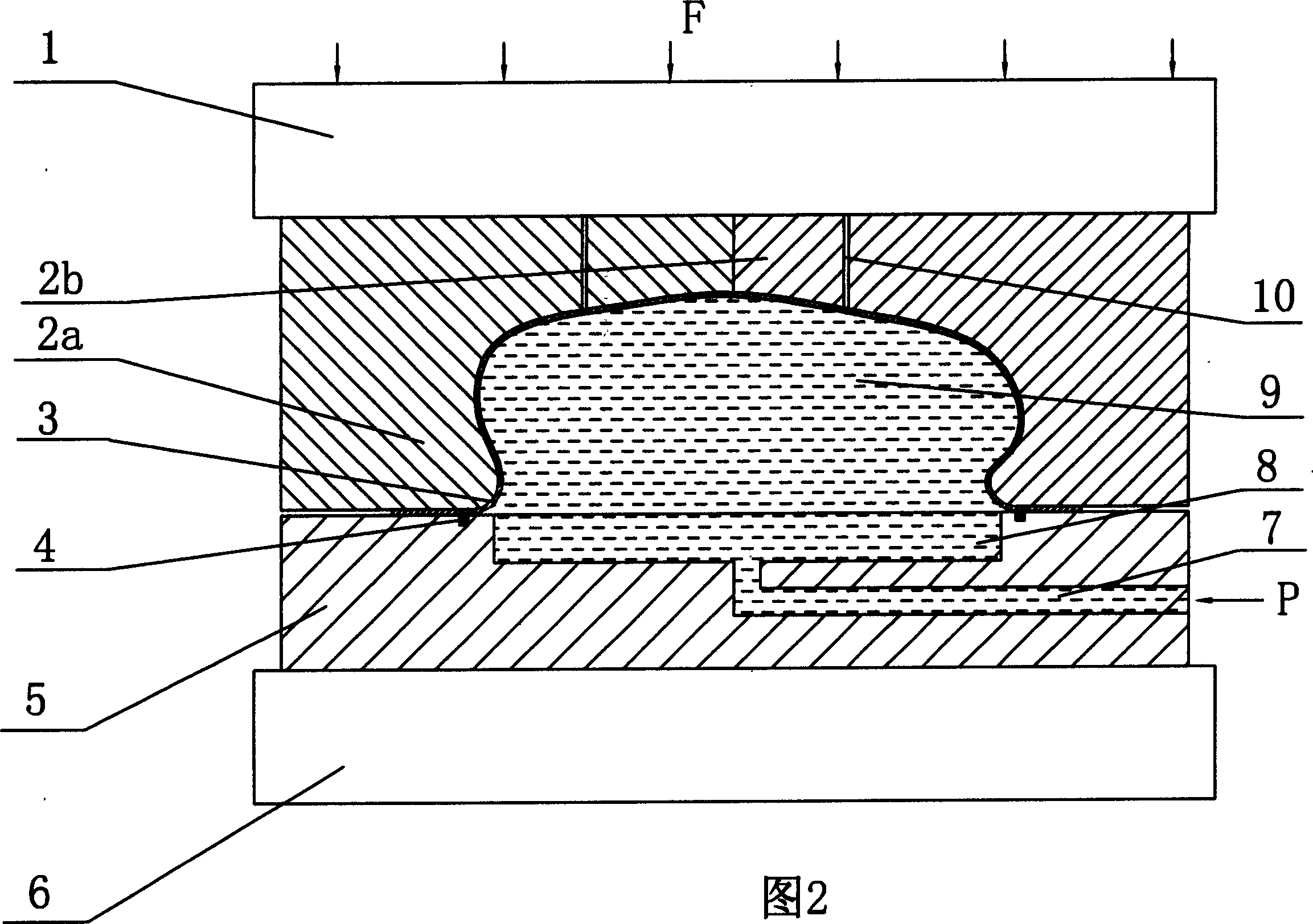

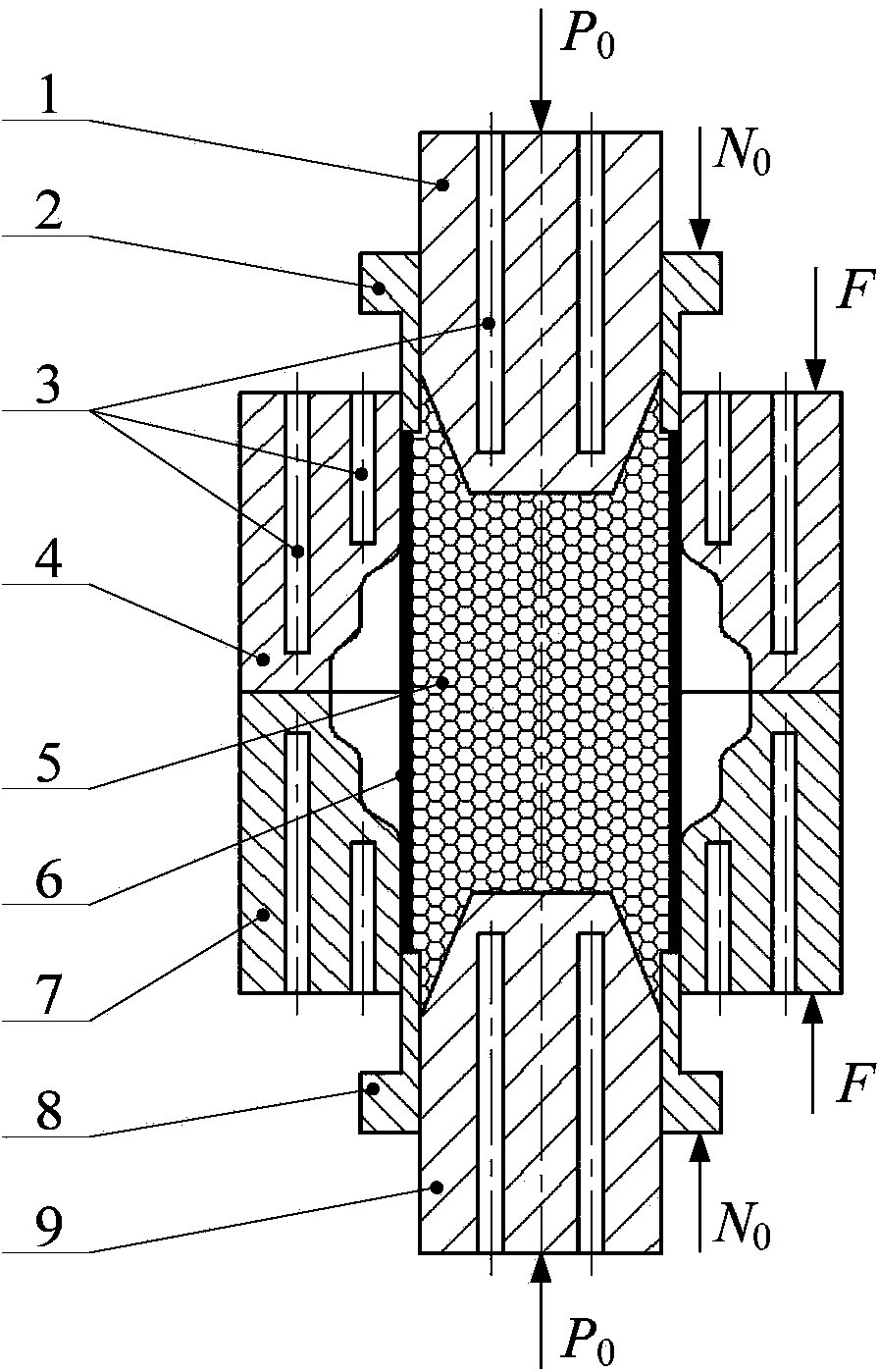

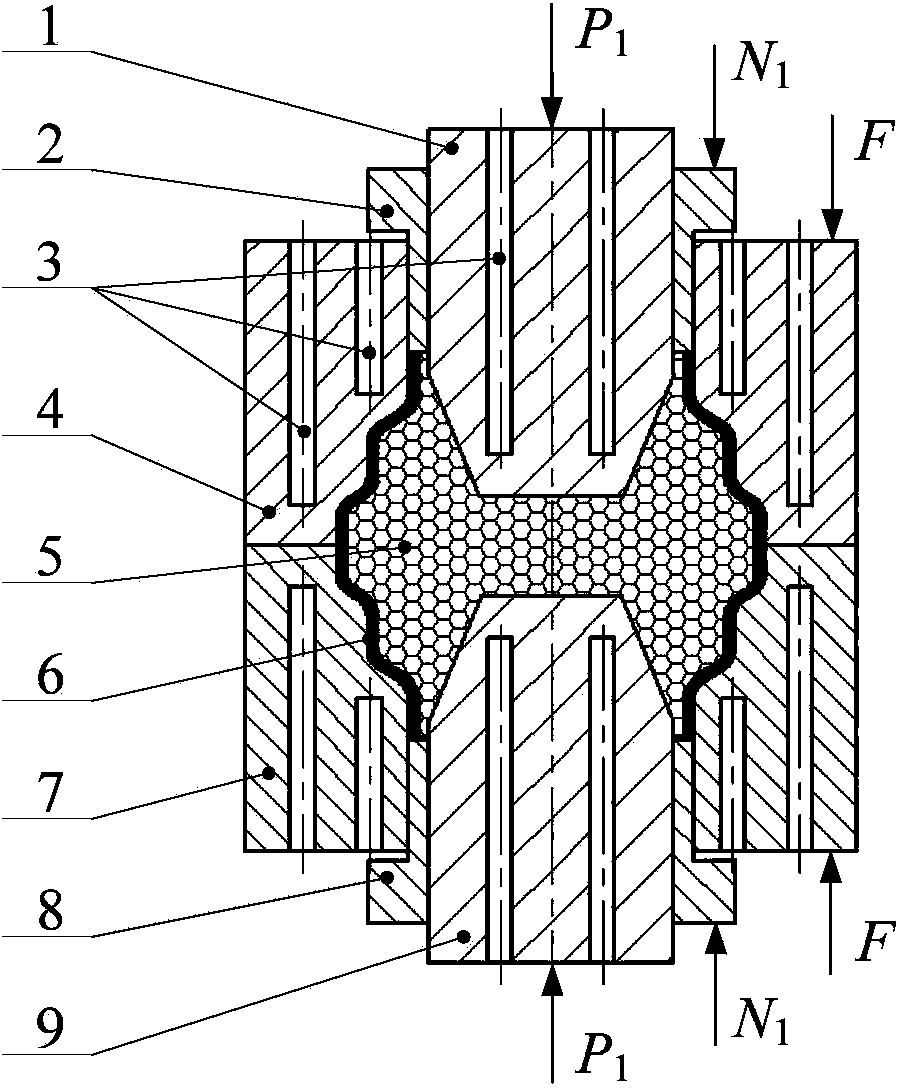

Metal plate material hydraulic shaping method and its mould device

InactiveCN1559719AImprove the development effectIngenious designShaping toolsEngineeringMechanical engineering

A hydraulic shaping method for metal plate includes such steps as filling hydraulic oil in hydraulic chamber, arranging the metal plate material to be shaped between hydraulic chamber and female die, moving female die down, applying force to plate and female for pressing edge and locking die, and filling high-pressure liquid to deform the metal plate. Its hydraulic die set is composed of upper die plate, female die and hydraulic plate.

Owner:GUANGDONG UNIV OF TECH

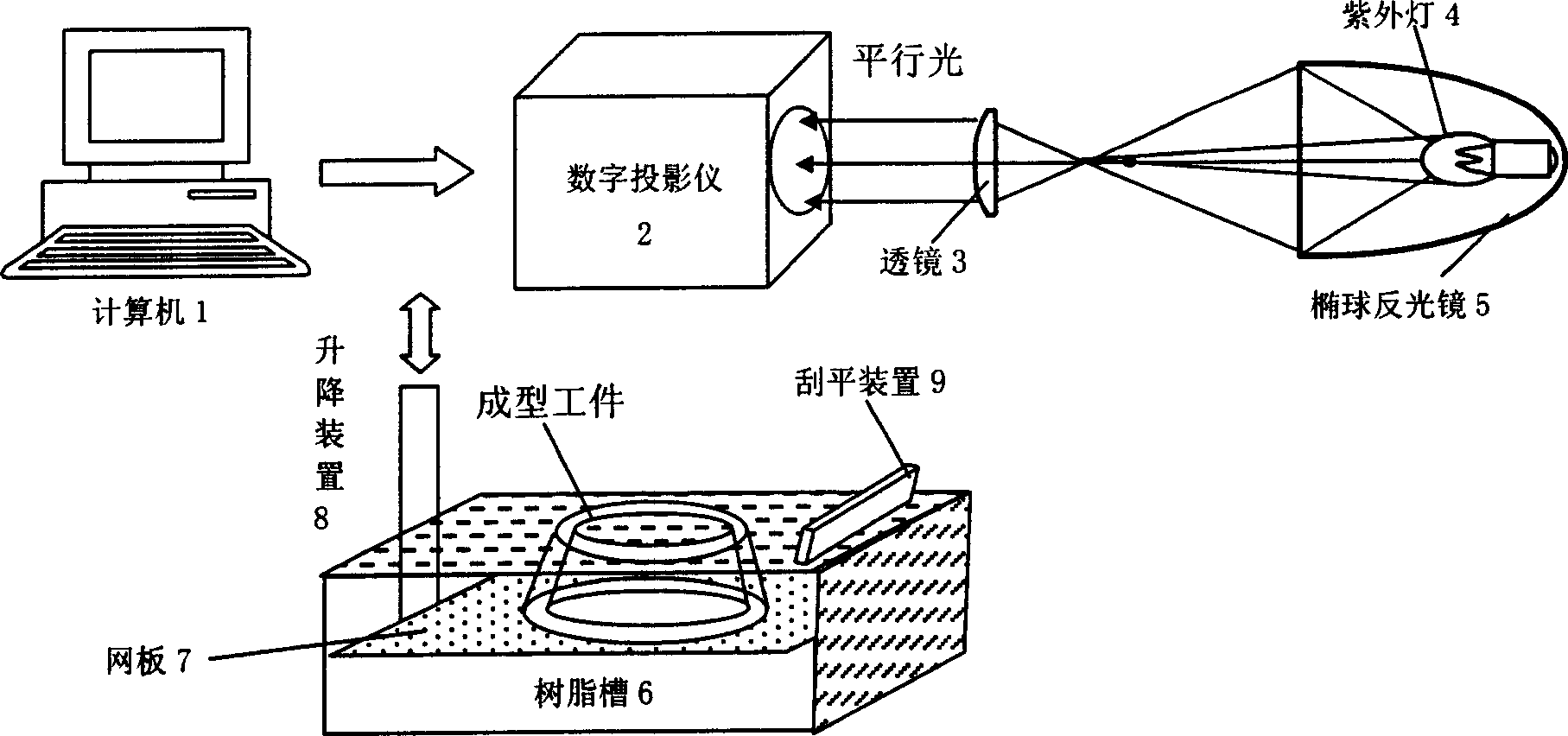

Digital projection photocurable rapid shaping apparatus and method

The invention discloses a digital projection photofixation quick molding device which includes the computer, the digital projecting apparatus, the lens, the ultraviolet light, the ellipsoidal reflector, the resin canal, the screen, the lifting motion and the striking device. It projects the figure of the CAD section on the surface of the liquid photosensitive resin by the digital projecting apparatus. When the forming layer reaches a solidified degree, the forming platform falls down to the height of a layer thickness, and the surface of the forming layer is covered with the liquid photosensitive resin, then to solidify the next layer. The invention has the high precision and simple process, so it can be used for the quick forming field.

Owner:XI AN JIAOTONG UNIV

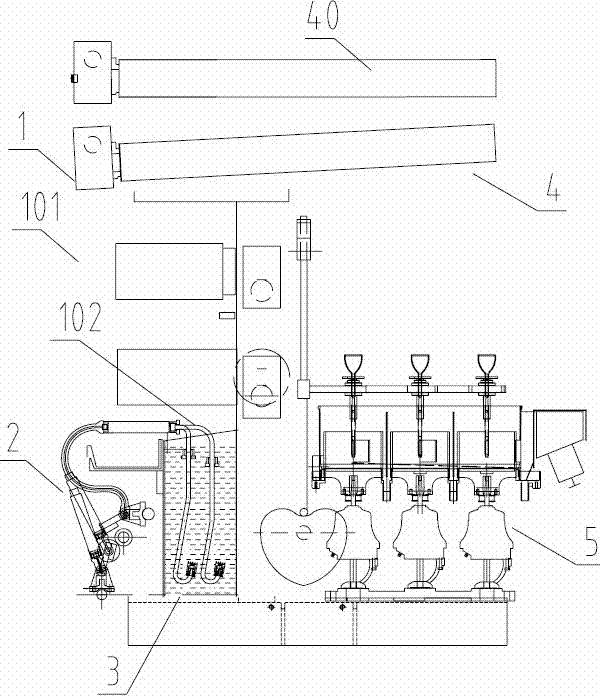

Household fully automatic steamed stuffed bun making machine

ActiveCN104798845ABeautiful shapeReduce demandDough shapingDough processingControl systemEngineering

The invention discloses a household fully automatic steamed stuffed bun making machine. The machine comprises a body, a flour delivery system, a stuffing delivery system, a forming device, a steaming system, a control system and an annular base, wherein the body is of a hollow structure; the annular base is of a hollow structure; the lower part of the body is connected with the annular base; the flour delivery system comprises a flour mixing box, a flour feed hopper, a flour mixing screw, a head and a second motor; a side face of the flour mixing box is fixedly provided with the head; a hole is formed in the middle of the head; one side of the hole is communicated with the flour mixing box; the lower end of the hole is communicated with a stuffing nozzle; a supporting pattern plate is fixedly arranged in the flour mixing box; the flour mixing screw is arranged on the supporting pattern plate and is connected with the second motor through a first transmission device; the control system mainly comprises a control panel; the control panel is controlled by using a single-chip microprocessor; the single-chip microprocessor is connected with the first motor, the second motor, a third motor and a variable frequency motor respectively. According to the machine, fully automatic flour mixing, skin making, material mixing, forming and steaming are realized; the machine has the advantages of cook and serve, small-scale making, attractive steamed stuffed bun shape and the like.

Owner:GUANGDONG HENGLIAN FOOD MACHINERY

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

Solid particle medium thermal expansion forming method for light alloy tubular component

InactiveCN103894469ASimple process controlLow input costShaping toolsEnvironmental resistanceThermal expansion

Owner:YANSHAN UNIV

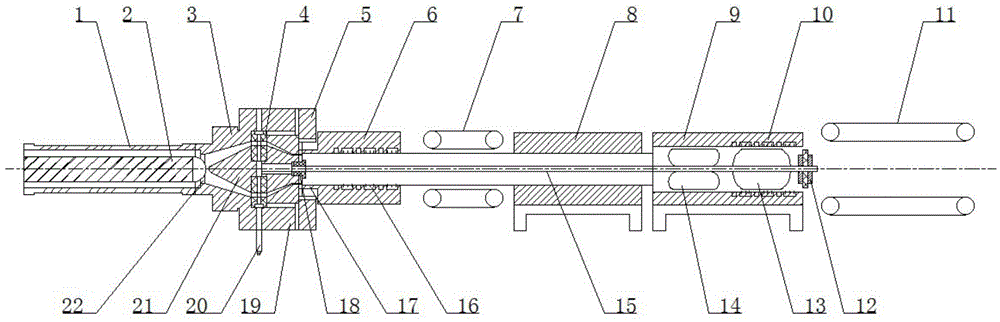

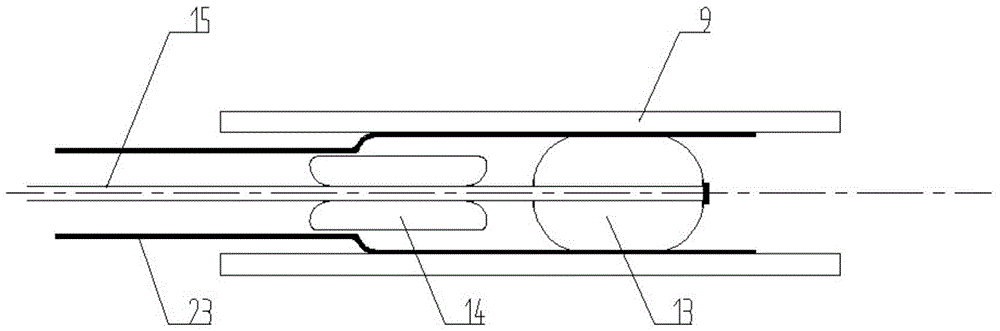

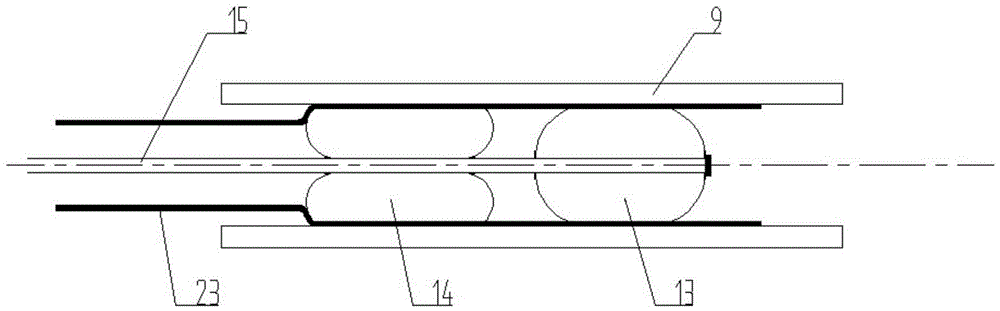

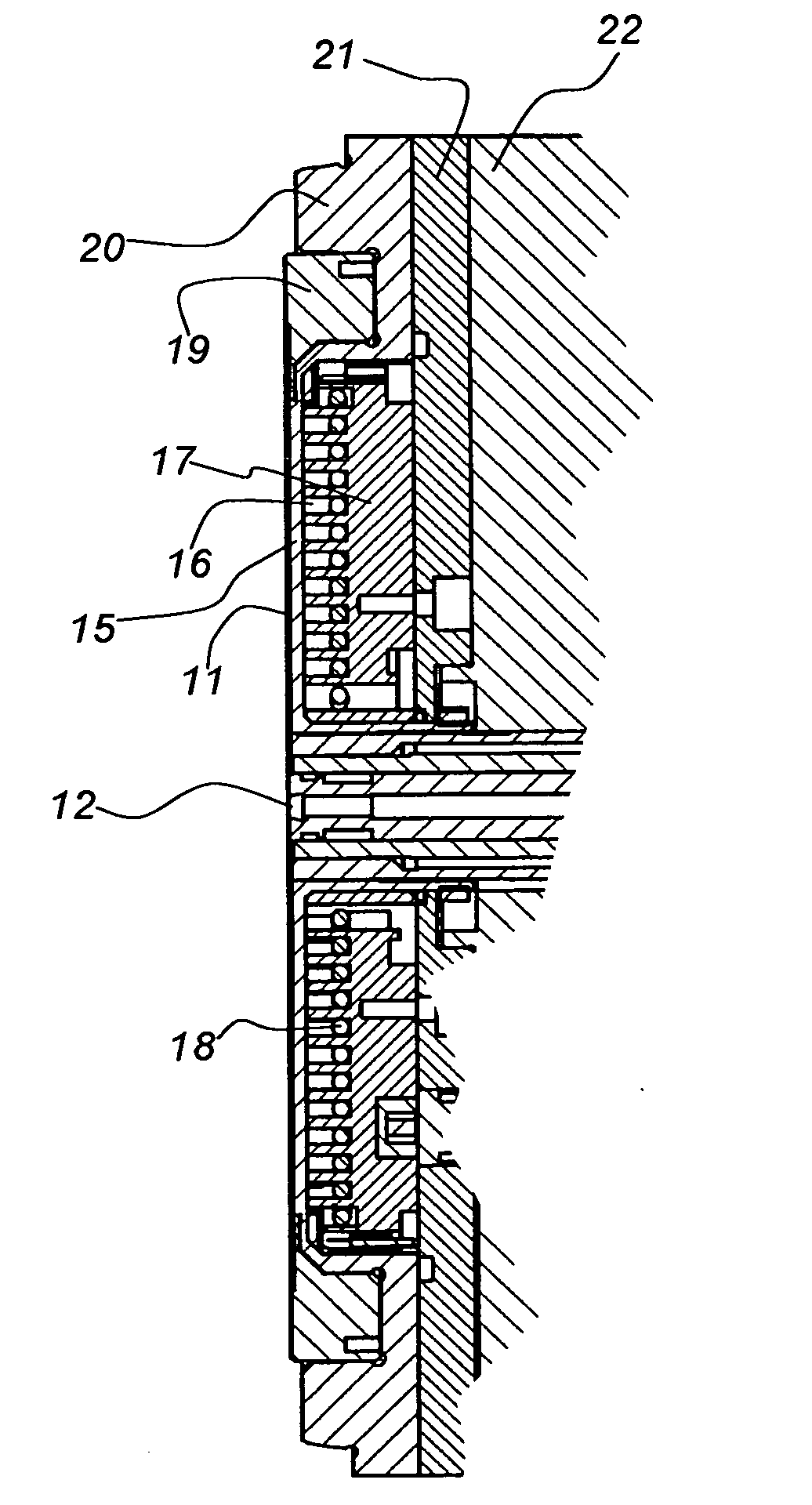

Production equipment and process for large-diameter biaxial-stretching PVC pipe fitting

ActiveCN104149354ARealize continuous productionEnhanced axial mechanical propertiesTubular articlesProduction linePipe fitting

The invention discloses production equipment and process for a large-diameter biaxial-stretching PVC pipe fitting. The equipment mainly comprises a tapered double-screw extruder, an extruder head, a vacuum sizing device A, a first traction device, a reheating device, a stretching and diameter expanding molding device, a vacuum sizing device B and a second traction device which are sequentially and linearly arrayed to form a production line; the stretching and diameter expanding molding device is composed of an inflation rod, an expansion bag, an expansion sizing mould and a shaping bag; each of the expansion bag and the shaping bag is of an annular bag-shaped structure; the expansion bag is continuously expanded and retracted under the action of the inflation rod; a pipe fitting to be expanded moves by a certain distance through the action of an outer ring circular-arc surface of the expansion bag when the expansion bag is expanded once, so that each point of the pipe fitting can be subjected to annular expansion; the stretching is generated in the axial direction of the pipe fitting through a stretching ratio between the first traction device and the second traction device. By adopting the production equipment and process, the continuous production of the diameter-expanded pipe fitting is successfully realized, the thermal contraction of the pipe fitting is small and the axial mechanical property can be enhanced.

Owner:BEIJING UNIV OF CHEM TECH

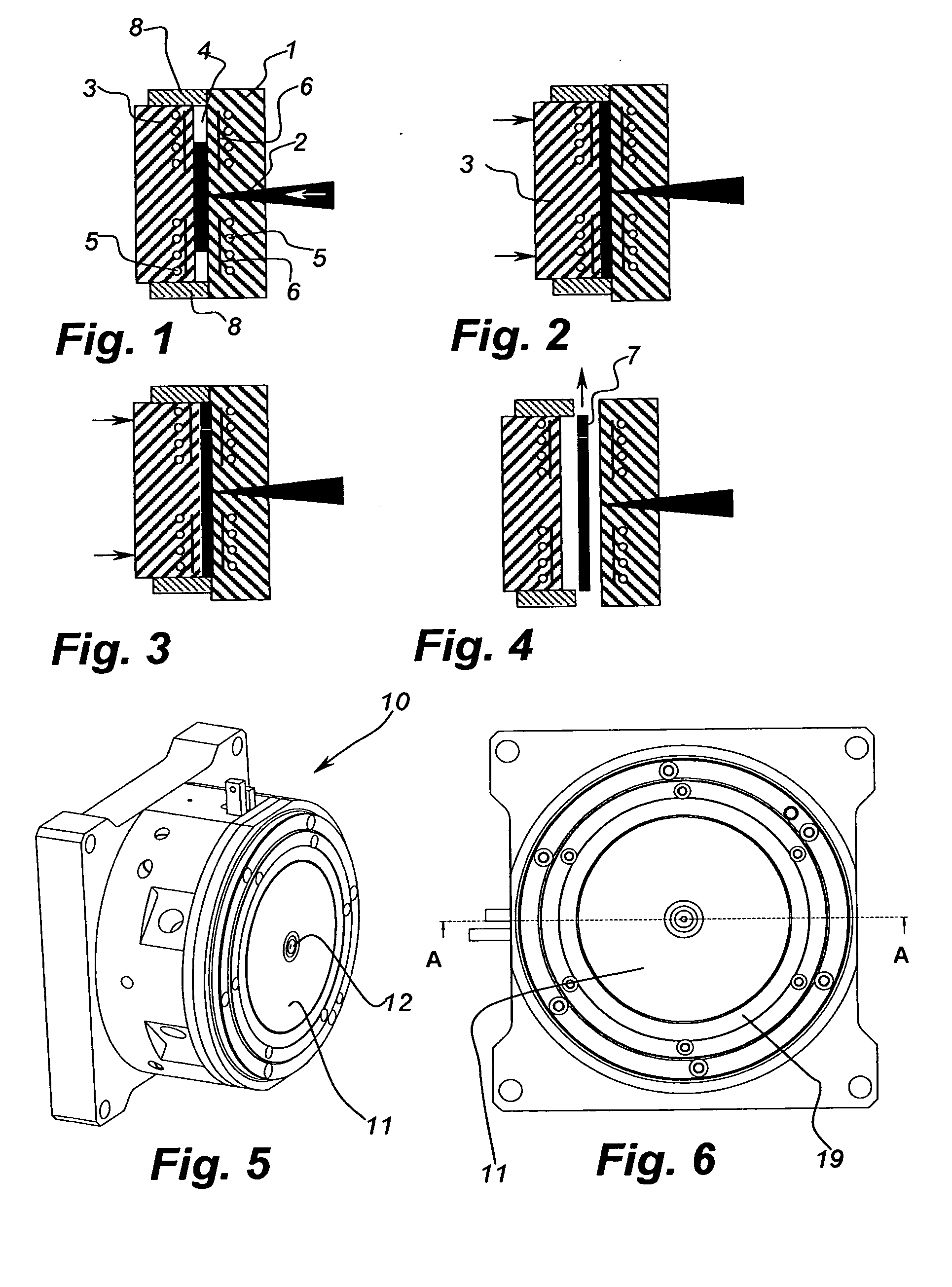

Moulding Device and Method

InactiveUS20090068306A1Efficient heatingReduce complexityRecord carriersOptical articlesInjection mouldingConductor Coil

An injection-moulding device is disclosed, comprising at least first and second mould parts, defining a mould cavity, wherein at least one of the mould parts comprises heating means, for heating the mould part in the vicinity of a mould cavity surface, said heating means comprising an inductive coil having a plurality of windings and being powered by an oscillator. The mould part comprises a top member, at the mould cavity surface, and, beneath the top member, a carrier member comprising grooves for taking up said coil windings, wherein the top member resistivity is lower than 1.5*10−6 Ωm, the top member relative magnetic permeability is lower than 10, the carrier member resistivity is higher than 20*10−6 Ωm, and the carrier member relative magnetic permeability is higher than 50.

Owner:TCTECH SWEDEN

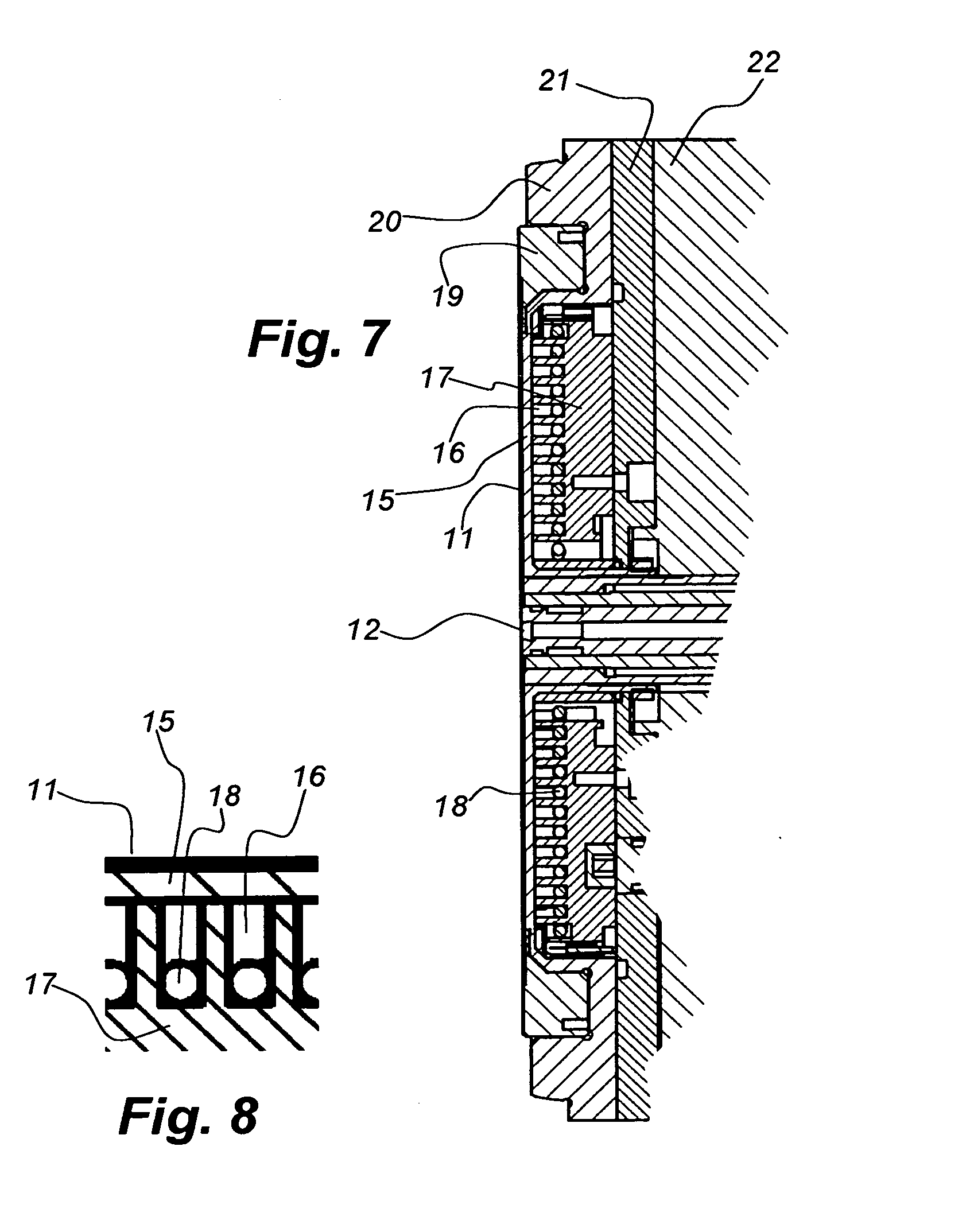

Three-dimensional pulp moulding decorating plate as well as manufacturing method and application thereof

ActiveCN102691388APromote environmental protectionFlame retardantCovering/liningsThree-dimensional effectsPulp and paper industryMolded pulp

The invention relates to a three-dimensional pulp moulding decorating plate as well as a manufacturing method thereof by using a common pulp moulding device and a practical application thereof in the field of decoration. The height of the three-dimensional protruding part of the three-dimensional pulp moulding decorating plate ranges from 5mm to 150mm and the ordinary wallpaper is not as high as the protruding part. The three-dimensional pulp moulding decorating plate can be spliced and cut, and the wallpaper with the same specification and different patterns can be spliced into more patterns.

Owner:BEIJING TONGLANHAI TECH CO LTD

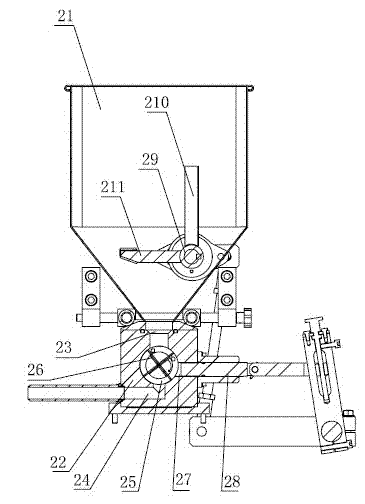

Food encrusting device

ActiveCN102177928AIncrease the number ofDoes not affect normal operationDough shaping and cutting apparatusDough dividingBiomedical engineeringFood products

The invention relates to the technical field of food machines, in particular to a food encrusting device, which comprises a food encrusting device machine frame, a food encrusting device stuffing injection component, food encrusting, stuffing pushing and wrapper cutting devices, a wrapper delivering component, a food encrusting device wrapper forming device, a food encrusting device conveying mechanism and a food encrusting device driving mechanism, wherein the food encrusting device stuffing injection component has a plurality of independent discharging channels and a plurality of food encrusting, stuffing pushing and wrapper cutting devices which are arranged in a way of corresponding to the discharging channels and complete stuffing pushing and wrapper cutting at the same station. The food encrusting device has the advantages that: the stuffing injection and wrapper cutting device are arranged in a linear mode, so a plurality of the stuffing injection and wrapper cutting devices can operate without interference, and even if one stuffing injection and wrapper cutting device has a fault, other stuffing injection and wrapper cutting devices can still work normally; and due to the linear arrangement mode, in a range matched with a driving mechanism, the stuffing injection and wrapper cutting devices can be increased randomly, so large-scale production can be realized, and the working efficiency is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com