Absorptive core, absorptive core molding equipment and absorptive core manufacture method

A technology for absorbent cores and molding equipment, which is applied in the field of absorbent cores, absorbent core manufacturing, and absorbent core molding equipment. Reduce the possibility of body fluid leakage, reduce the possibility of leakage, and facilitate the effect of liquid seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

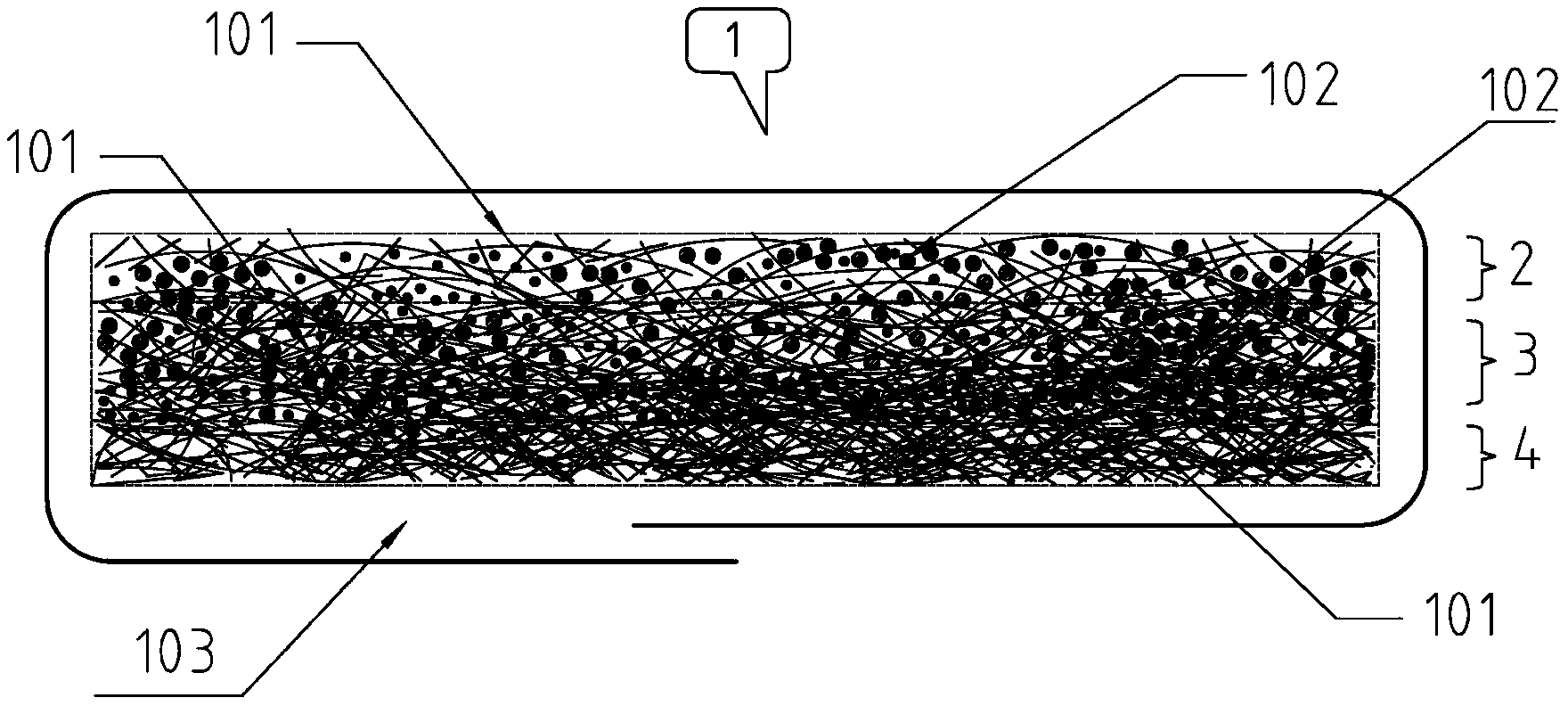

[0053] See attached figure 1 , the structure of the absorbent core 1 is mainly divided into three layers, the absorbent core surface layer 2 is a thin surface layer composed of a certain amount of fluff pulp fibers 101 and a small amount of polymer absorbent resin particles 102 uniformly mixed, the absorbent core middle layer 3 is composed of A large number of fluff pulp fibers 101 and a large number of polymer absorbent resin particles 102 are uniformly mixed to form a middle thick layer, and the bottom layer 4 of the absorbent core is a thin bottom layer composed of a certain amount of fluff pulp fibers 101 .

[0054] The tightness of the uniform mixing and bonding of the fluff pulp fibers 101 on the surface layer of the absorbent core and the polymer absorbent resin particles 102 is smaller than the uniform mixing and bonding of the fluff pulp fibers 101 and the polymer absorbent resin particles 102 in the middle layer 3 and the bottom layer of the absorbent core 4 degree. ...

Embodiment 2

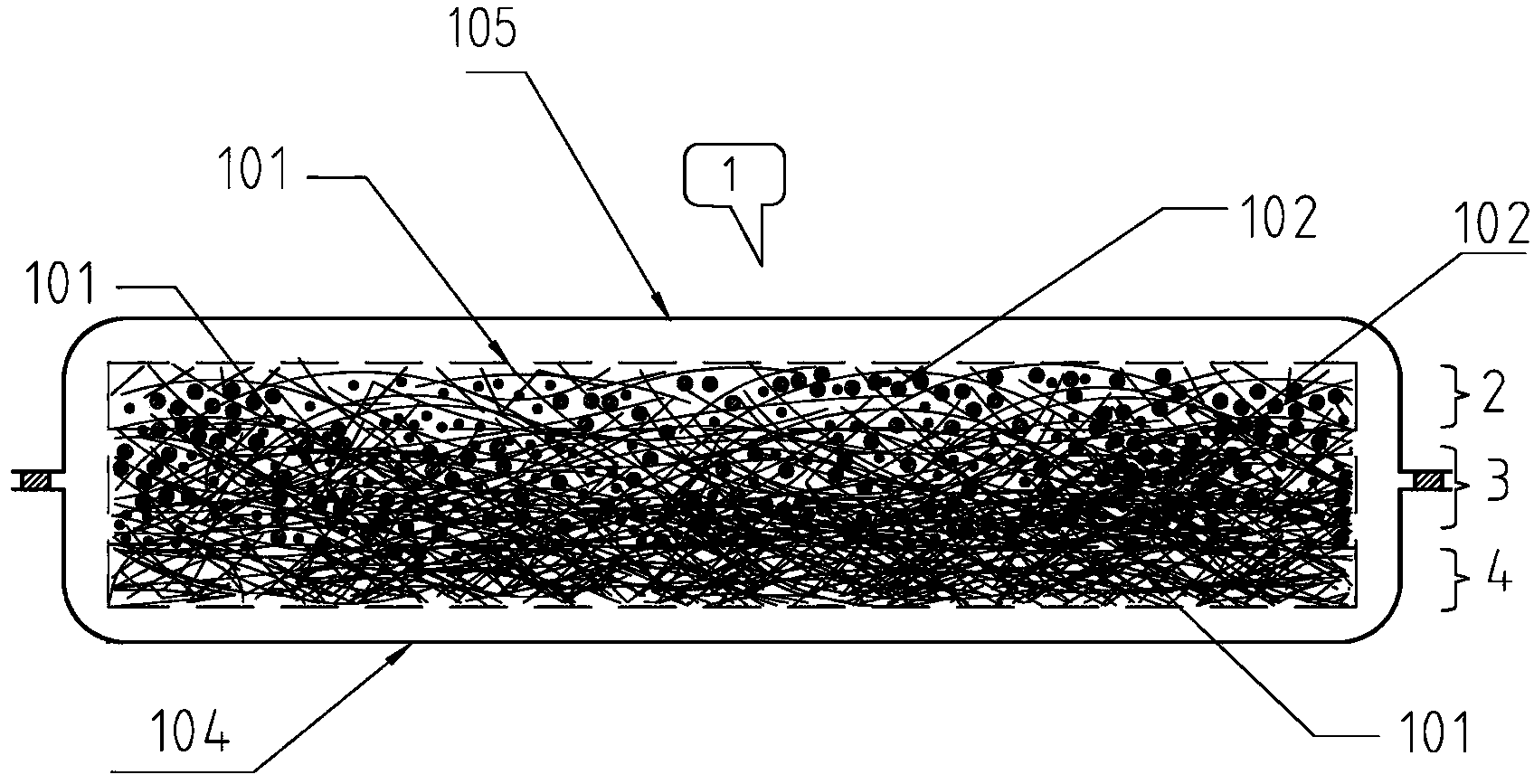

[0058] This embodiment is basically the same as Embodiment 1 of the absorbent core 1, except that the coating layer 103 is different. The upper layer 105 of the coating layer is covered on the surface layer 2 of the absorbent core, and the bottom layer 4 of the absorbent core is covered. The lower layer of the covering layer 104, the upper layer of the covering layer 105 and the lower layer of the covering layer 104 are bonded and fixed with the surface layer 2 of the absorbent core and the bottom layer of the absorbent core 4 by hot melt adhesive (not shown in the figure), and the upper layer of the covering layer 105 The overlapping area with the side edge of the lower layer of the cladding layer 104 is bonded with hot melt adhesive.

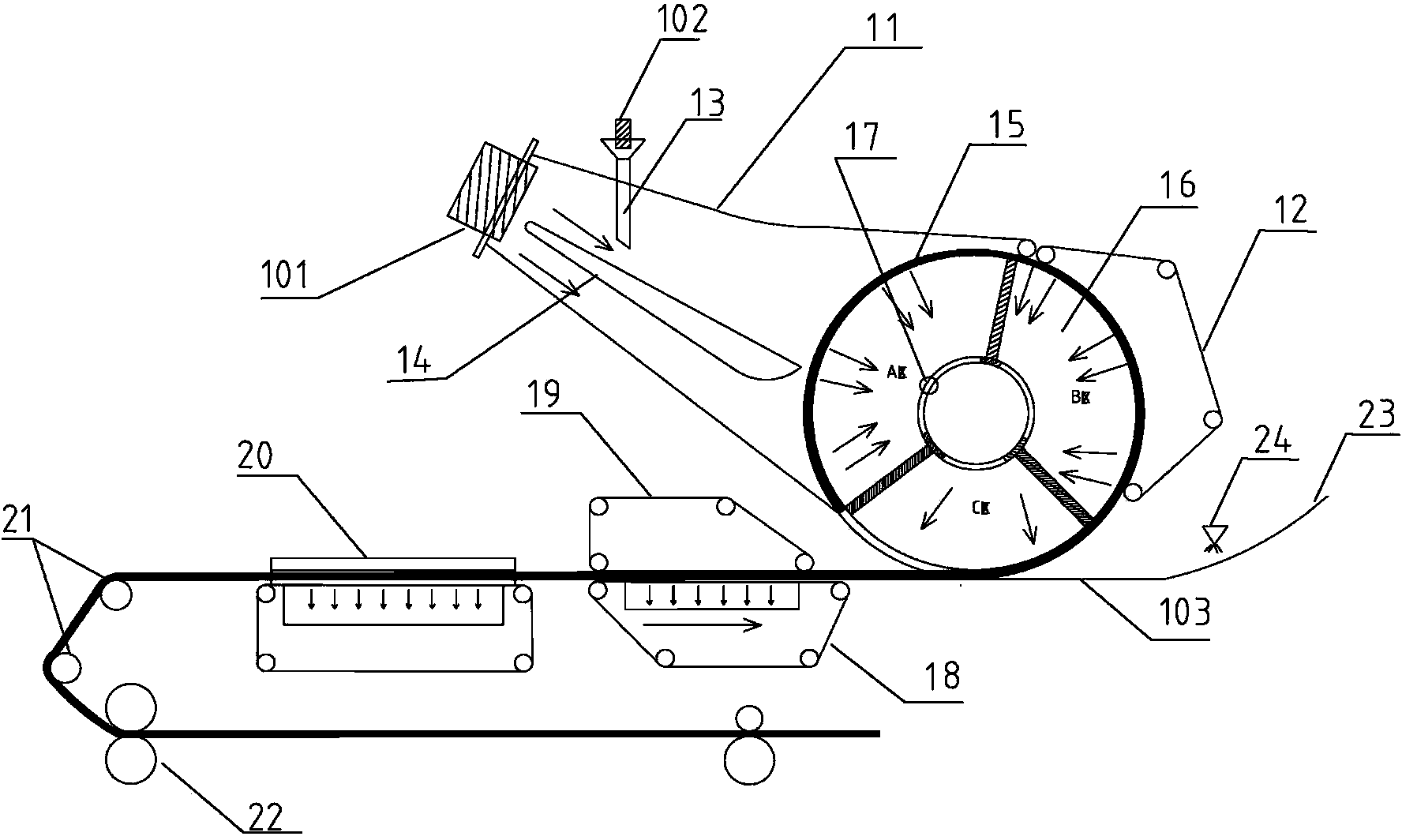

[0059] Absorbent core forming equipment embodiment one

[0060] The absorbent core forming equipment includes a fiber deposit chamber 11, a fiber deposit drum 16, a transmission unit, a covering material delivery unit 23, a transfer unit and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com