Patents

Literature

345 results about "Fluff pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluff pulp (also called comminution pulp or fluffy pulp) is a type of chemical pulp made from long fibre softwoods. Important parameters for fluff pulp are bulk and water absorbency.

Whitened fluff pulp

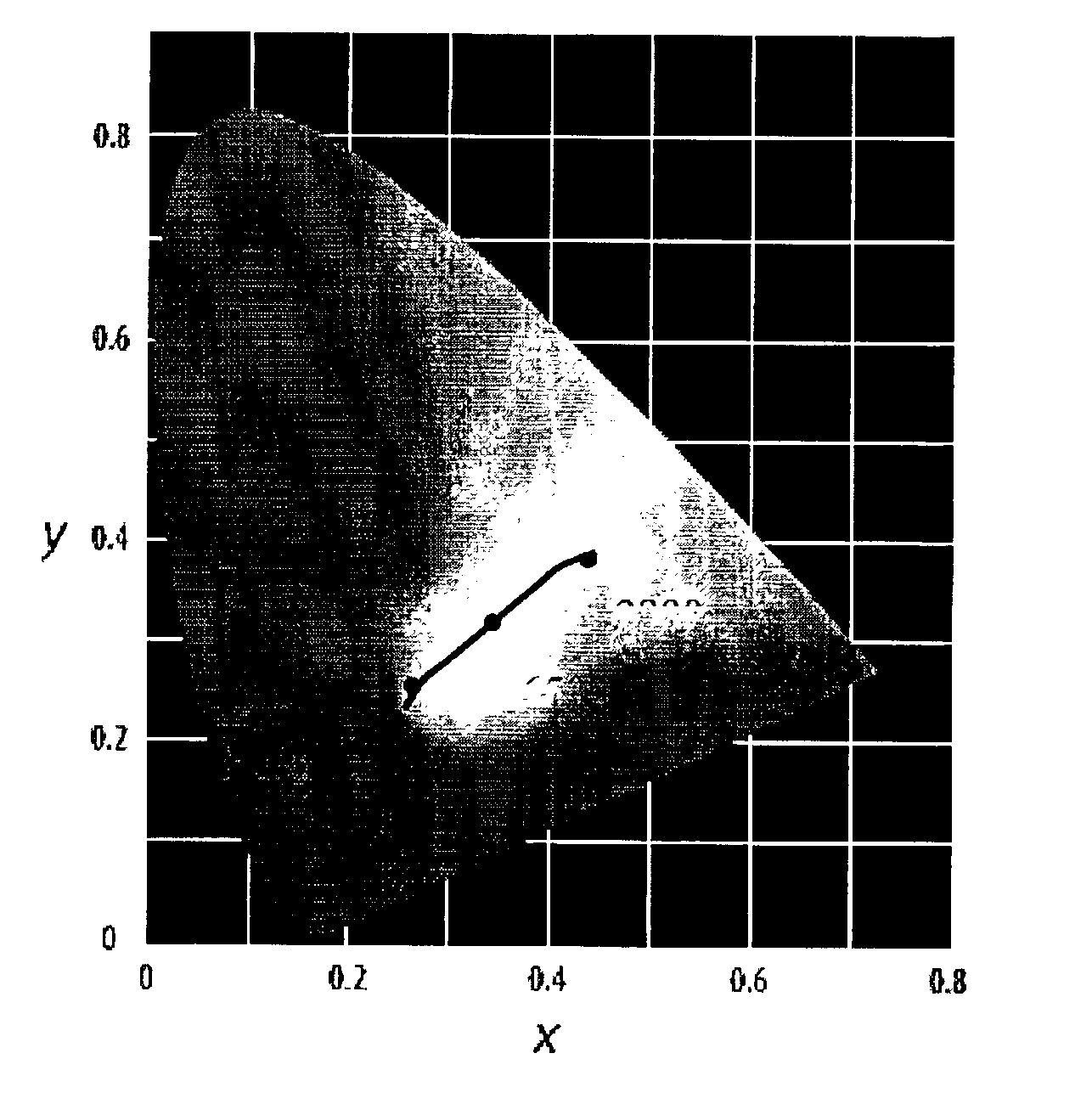

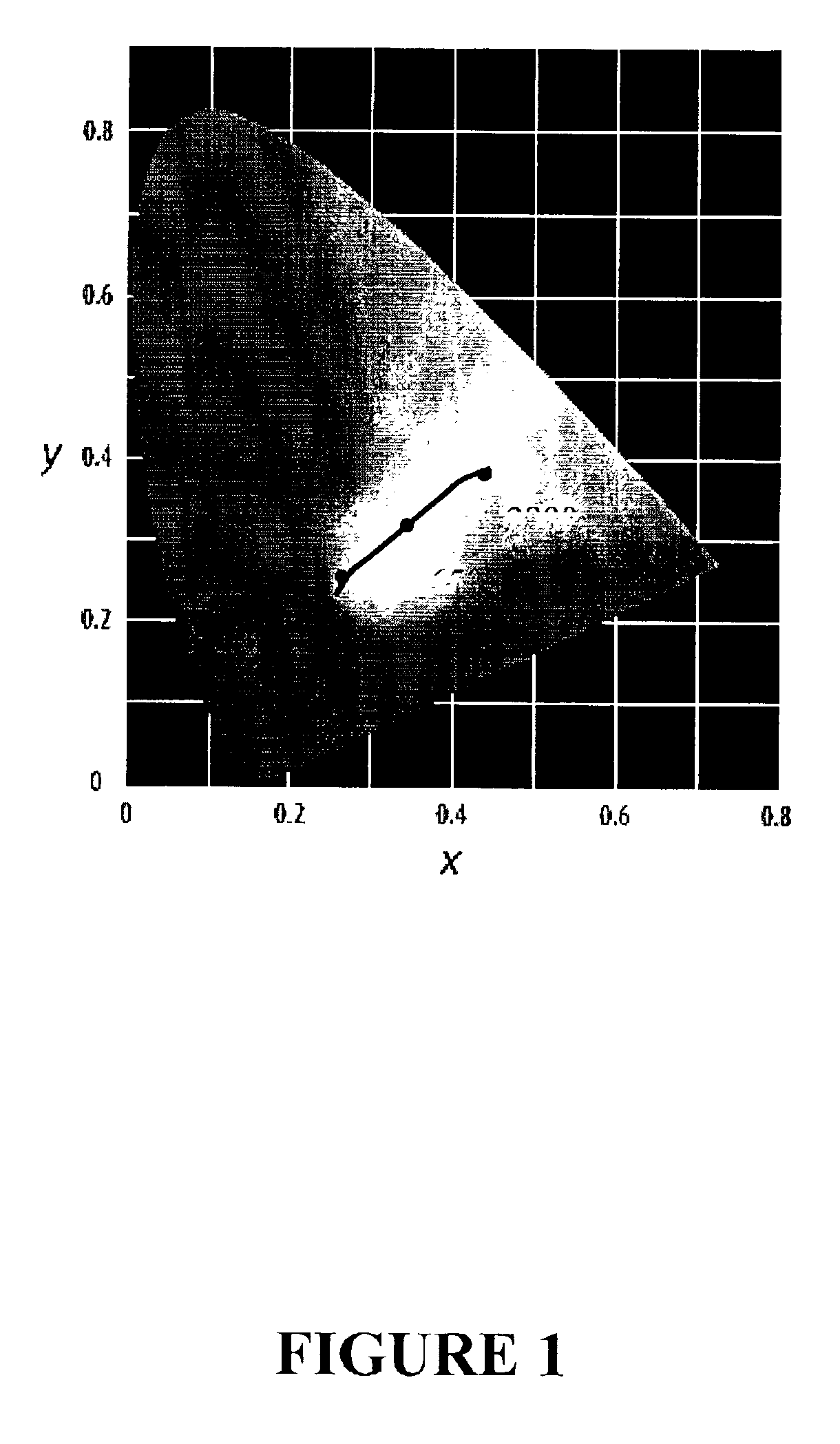

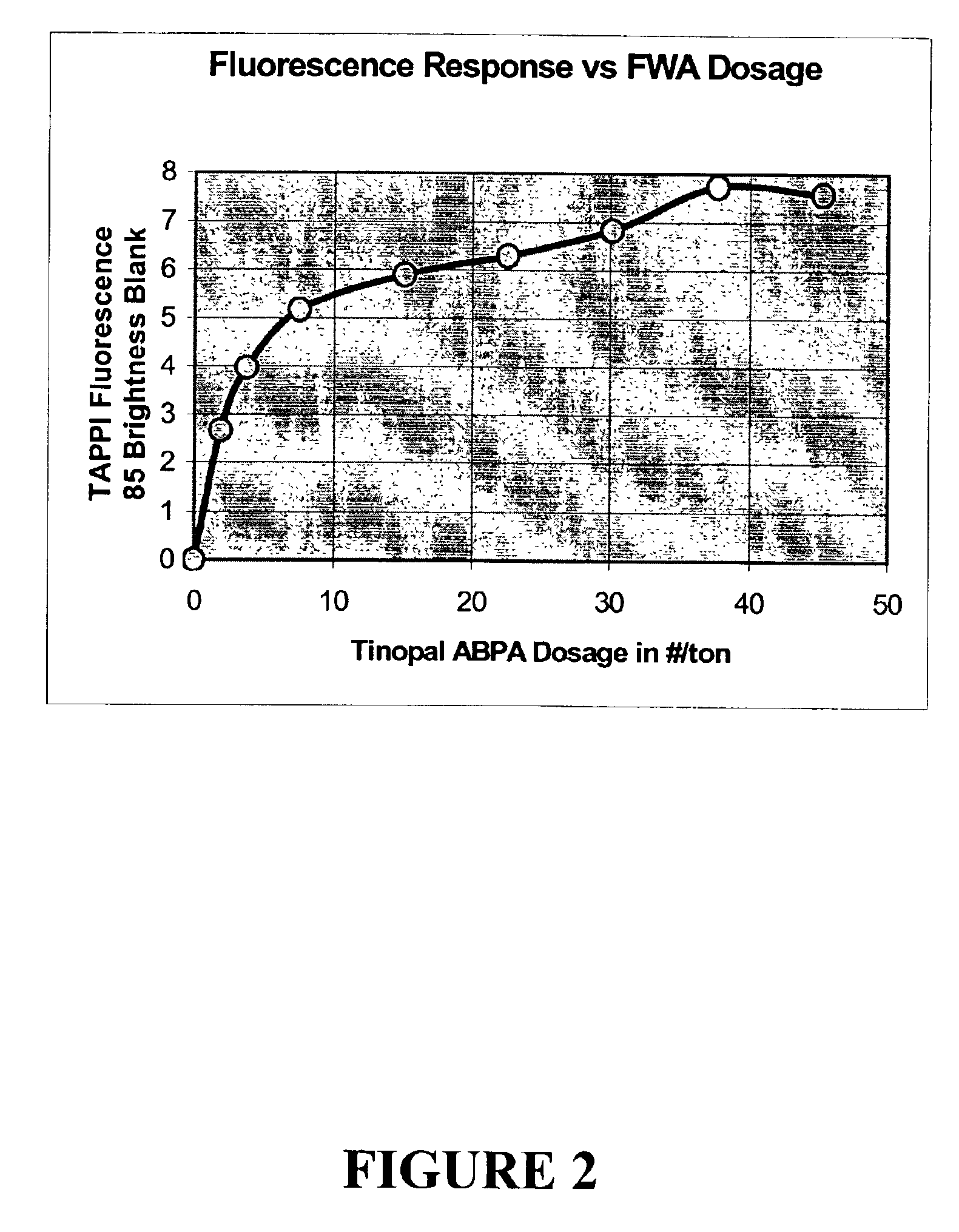

InactiveUS6893473B2Luminescent/fluorescent substance additionPaper/cardboardWhitening AgentsFluff pulp

Whitened fluff pulp and methods for making whitened fluff pulp. The whitened pulp is a fluff pulp that has been treated with one or more of a white pigment, a colorant, or a fluorescent whitening agent.

Owner:WEYERHAEUSER CO

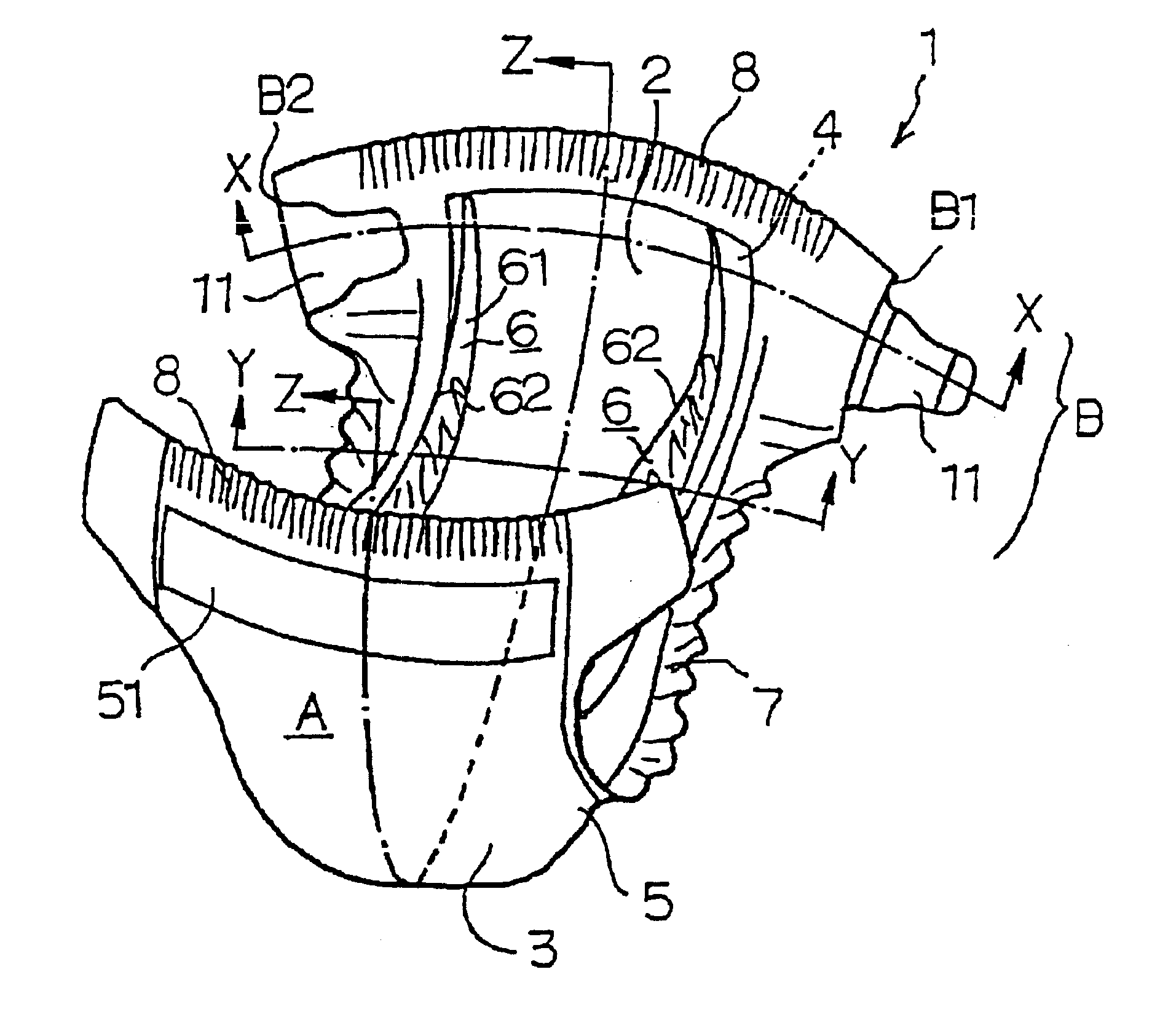

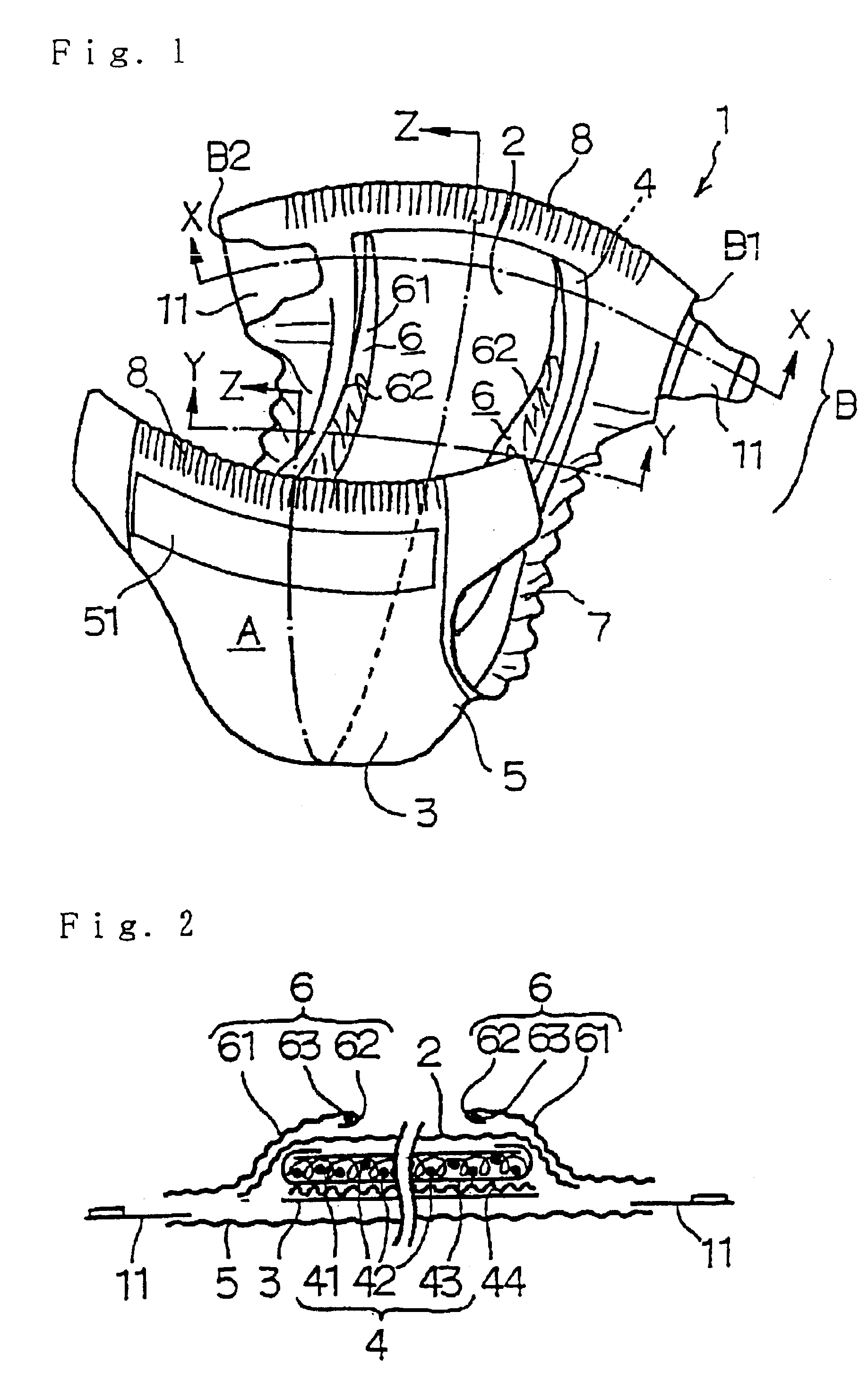

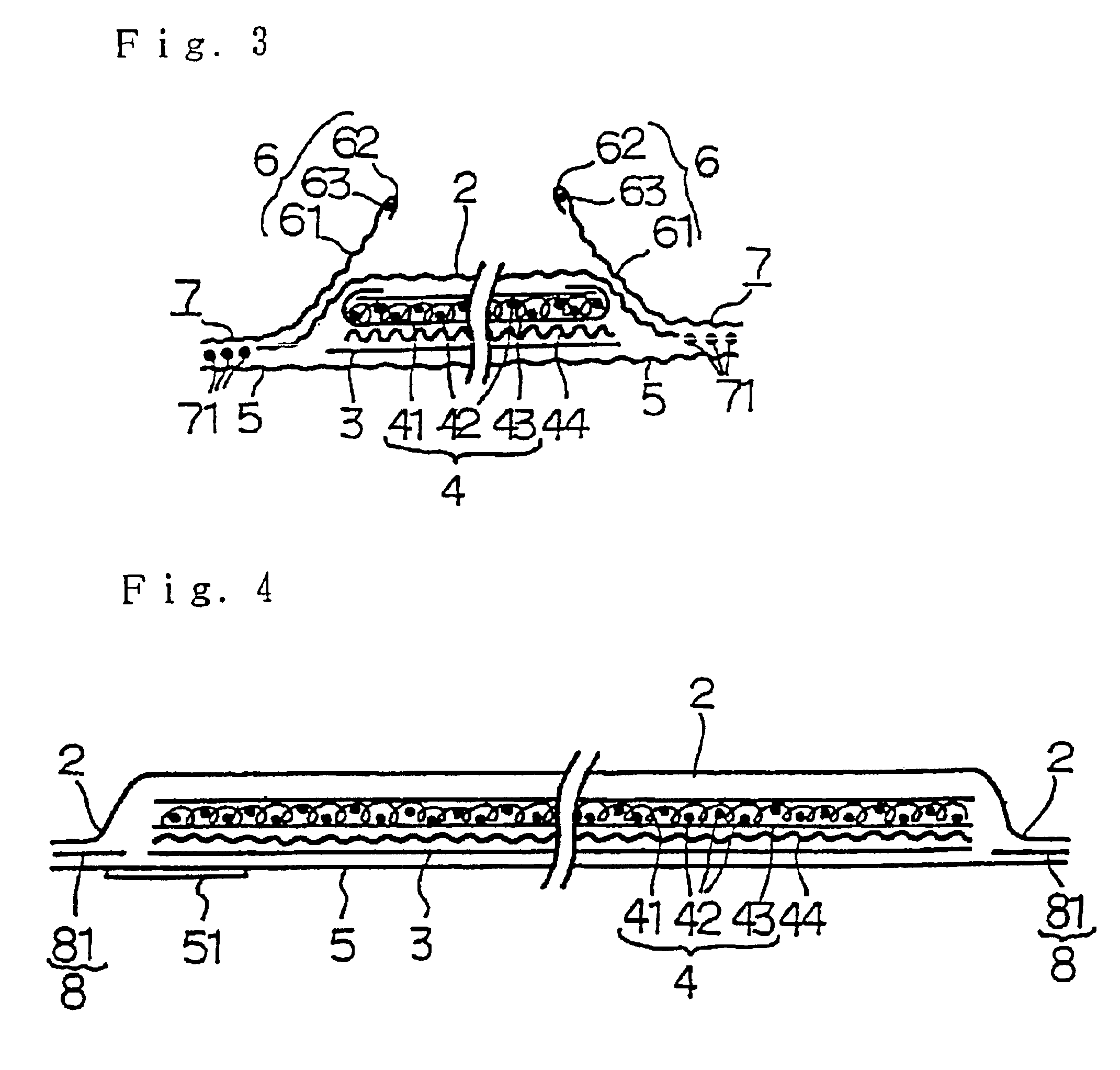

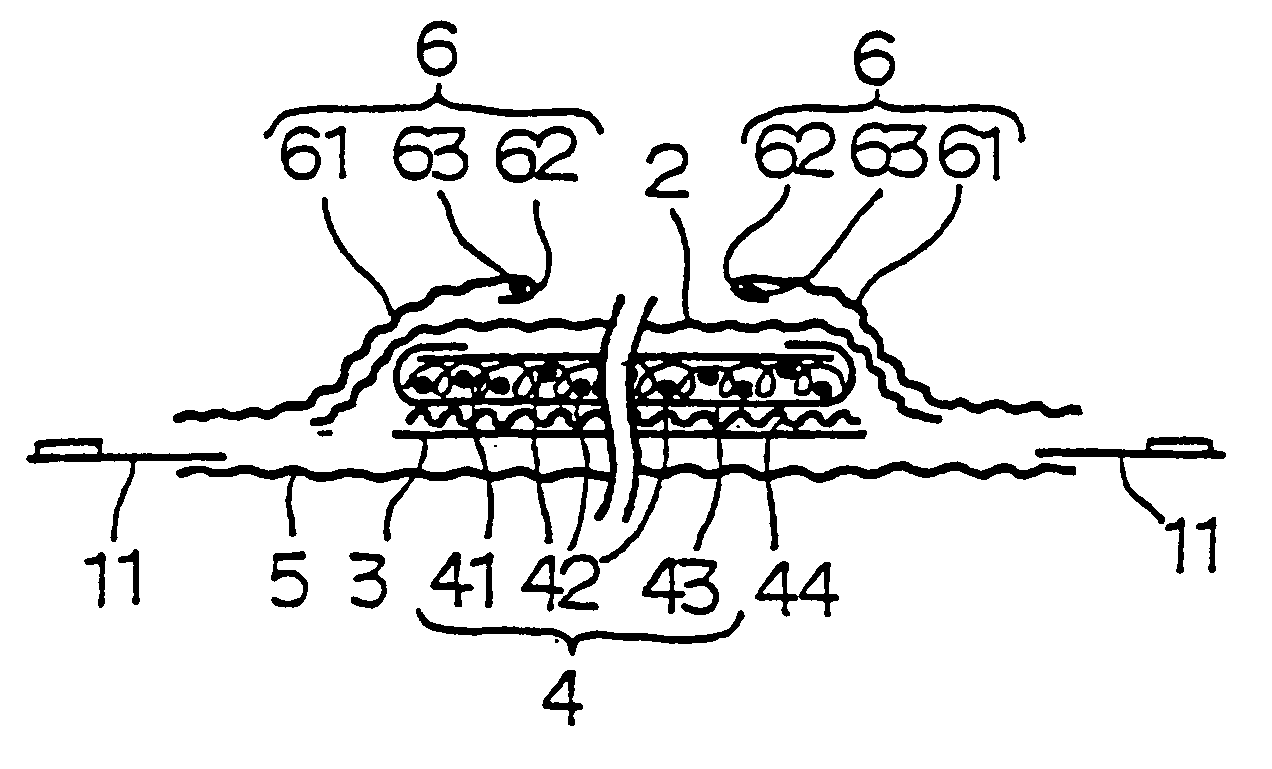

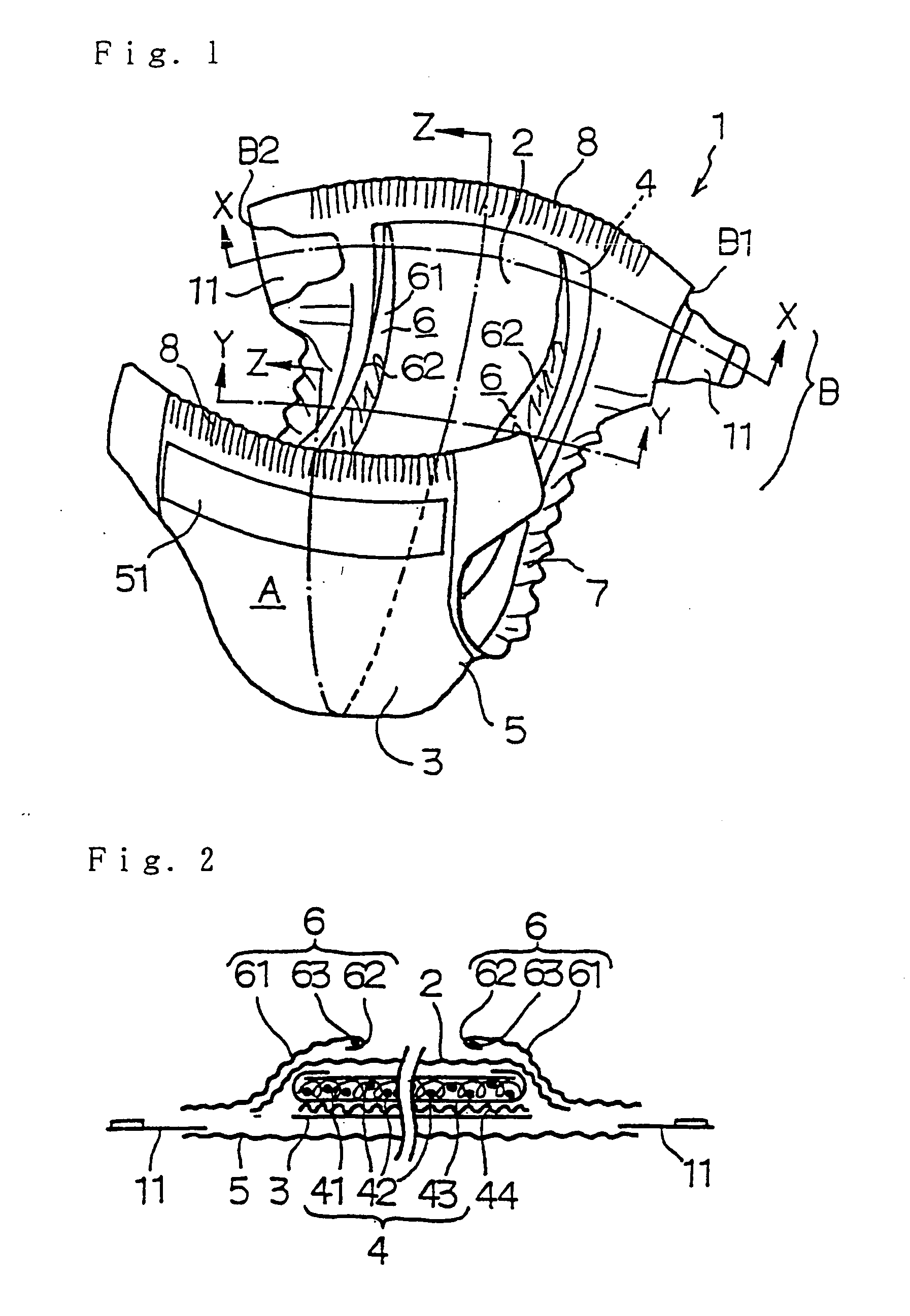

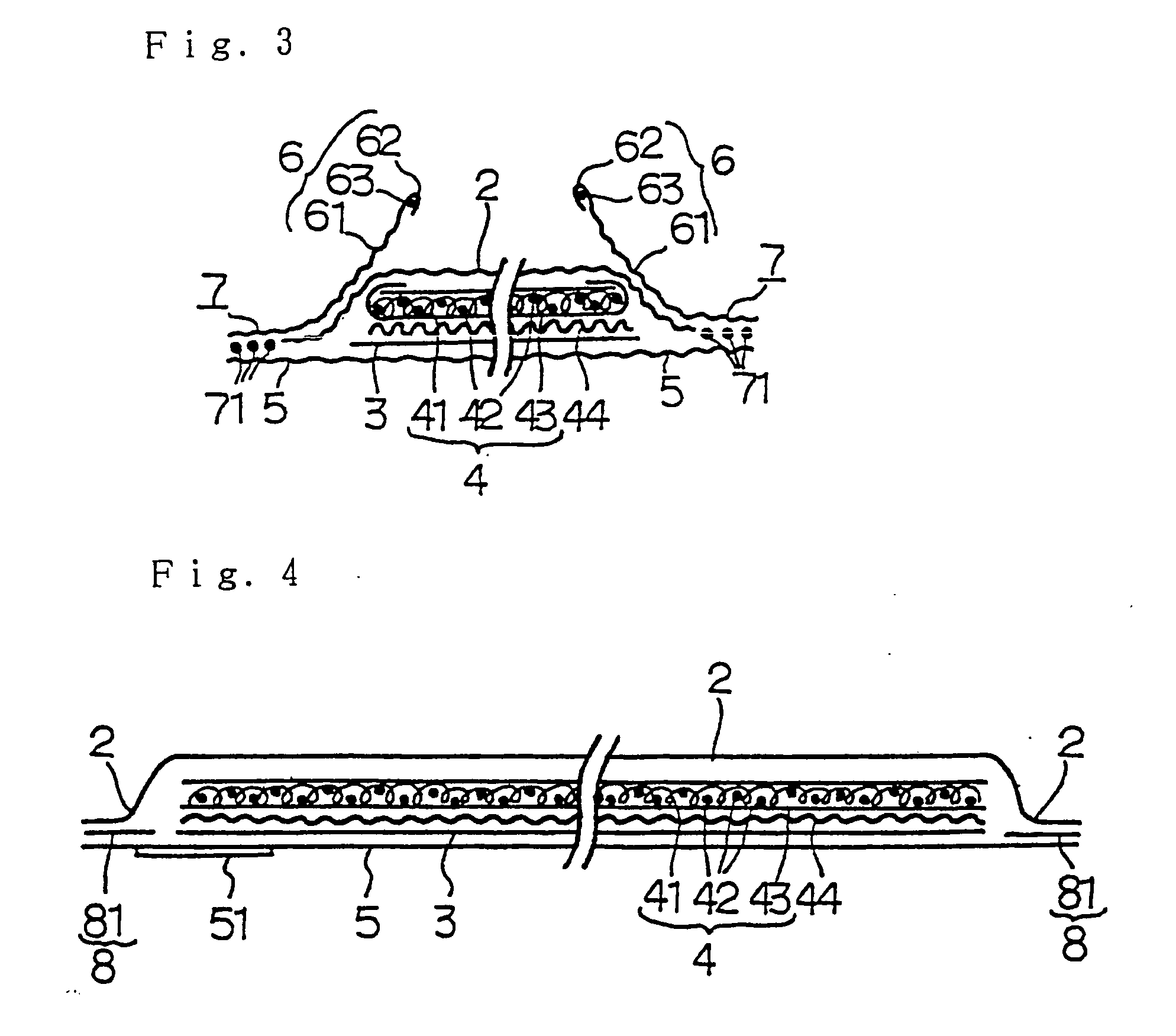

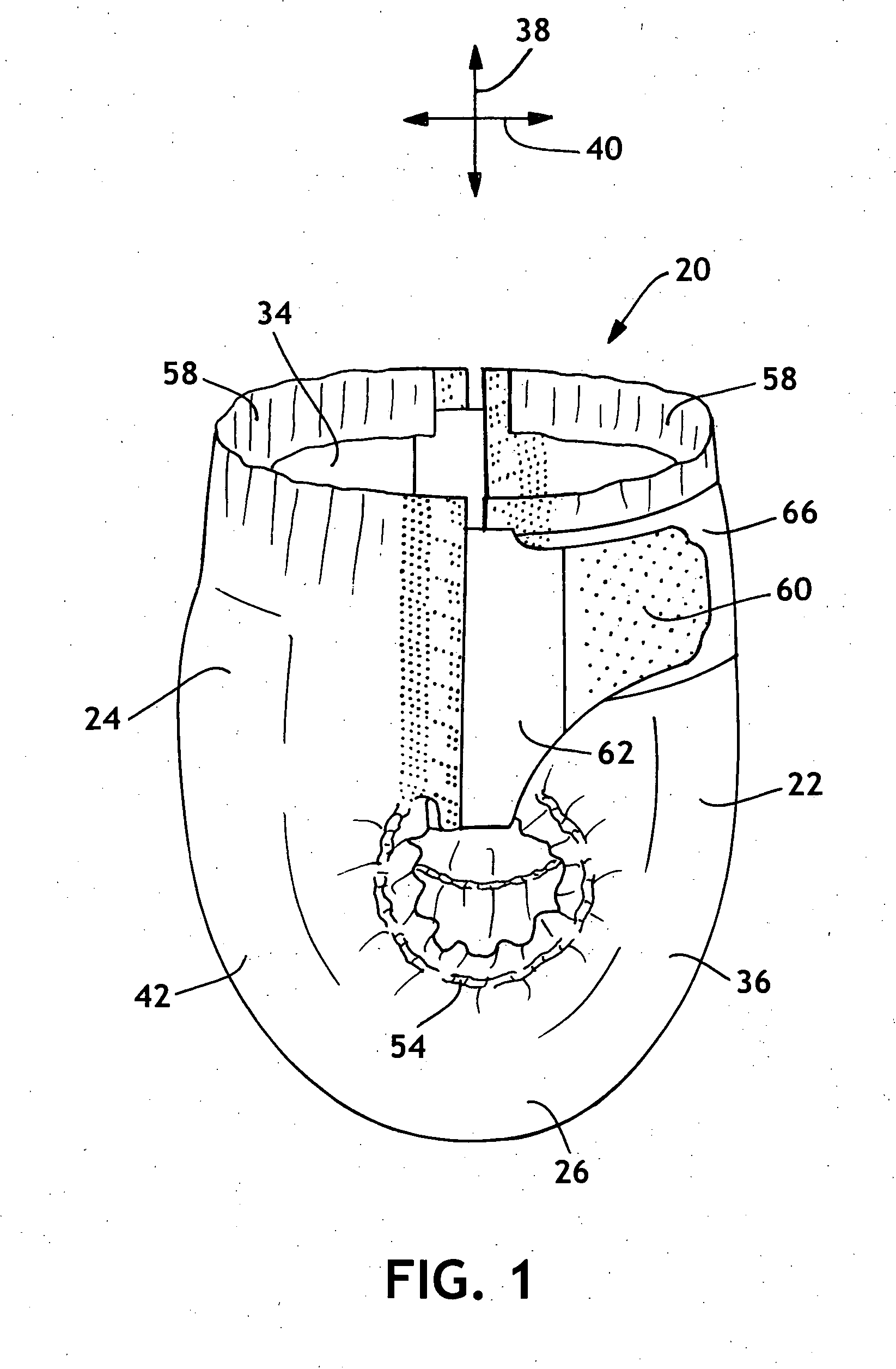

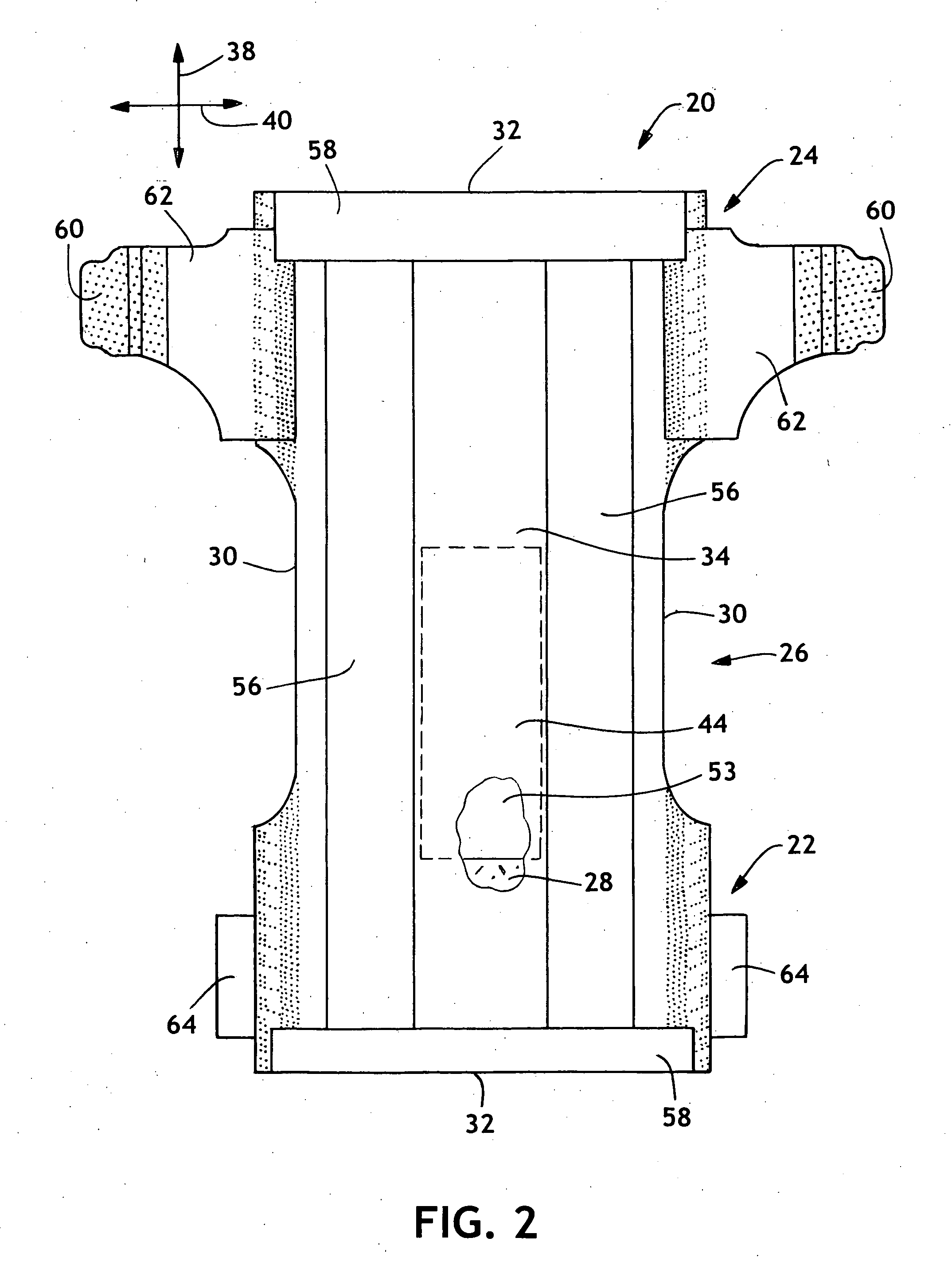

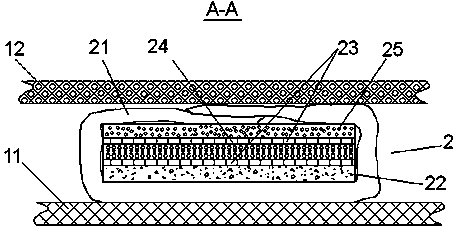

Disposable diaper and absorbent member used therein

InactiveUS6891080B2Light and compact and convenientImprove sealingBaby linensTamponsPolymer scienceFluff pulp

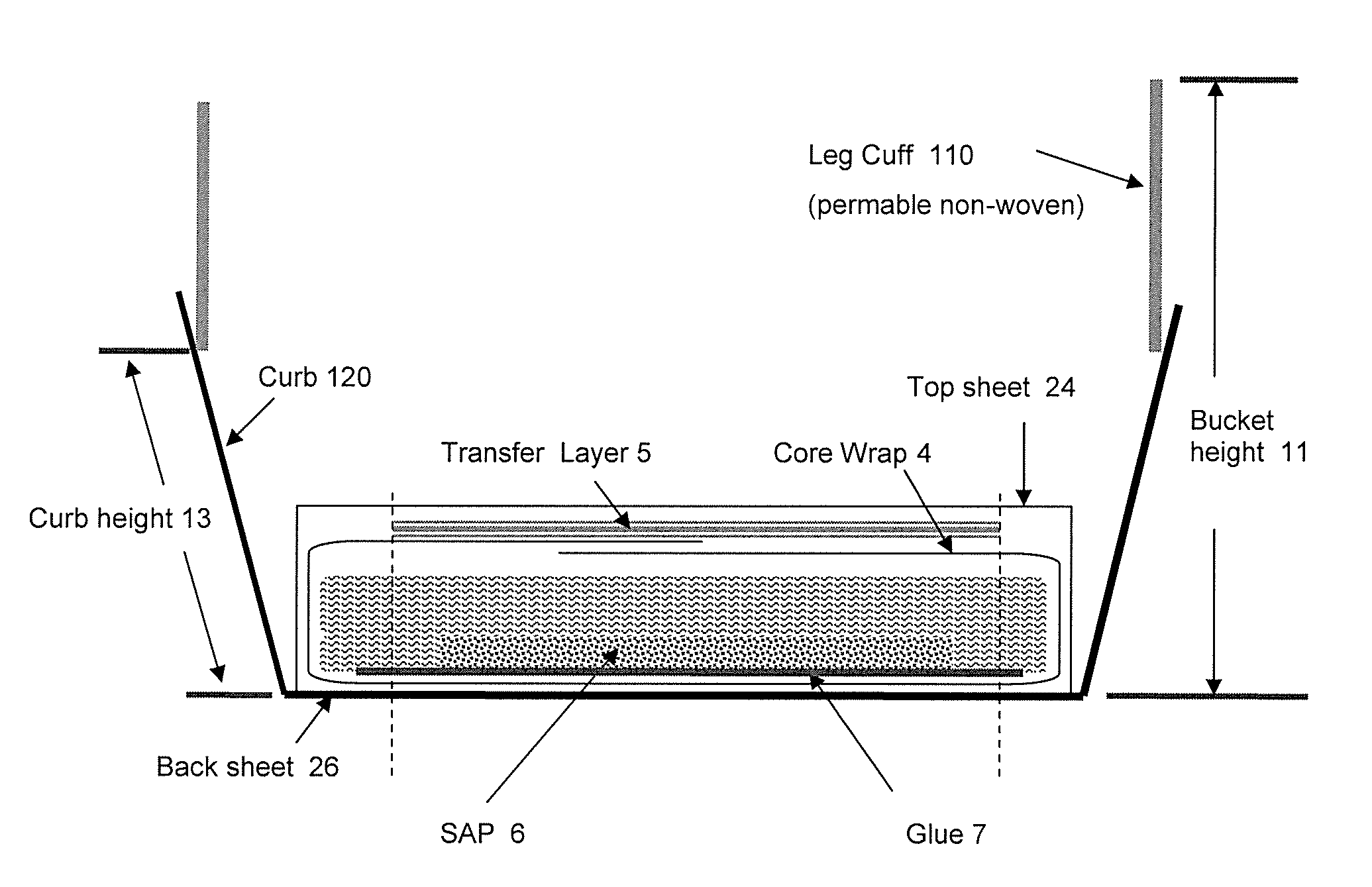

A disposable diaper is provided comprising a liquid permeable topsheet, a liquid impermeable backsheet, and a liquid retentive absorbent member interposed between the topsheet and the backsheet. The absorbent member comprises, in admixture, a superabsorbent polymer A having a rate of absorption of 8 g / 30 sec / 0.3 g or more measured by DW method and a superabsorbent polymer B having a rate of absorption of 5 g / 30 sec / 0.3 g or less measured by DW method at a polymer A / polymer B weight ratio of 90 / 10 to 10 / 90. The admixture optionally further comprises fluff pulp in an amount of from 0 to 30% by weight.

Owner:KAO CORP

Disposable diaper

InactiveUS20050154363A1Light and compact and convenientImprove sealingBaby linensTamponsPolymer scienceFluff pulp

A disposable diaper is provided comprising a liquid permeable topsheet, a liquid impermeable backsheet, and a liquid retentive absorbent member interposed between the topsheet and the backsheet. The absorbent member comprises, in admixture, a superabsorbent polymer A having a rate of absorption of 8 g / 30 sec / 0.3 g or more measured by DW method and a superabsorbent polymer B having a rate of absorption of 5 g / 30 sec / 0.3 g or less measured by DW method at a polymer A / polymer B weight ratio of 90 / 10 to 10 / 90. The admixture optionally further comprises fluff pulp in an amount of from 0 to 30% by weight.

Owner:KAO CORP

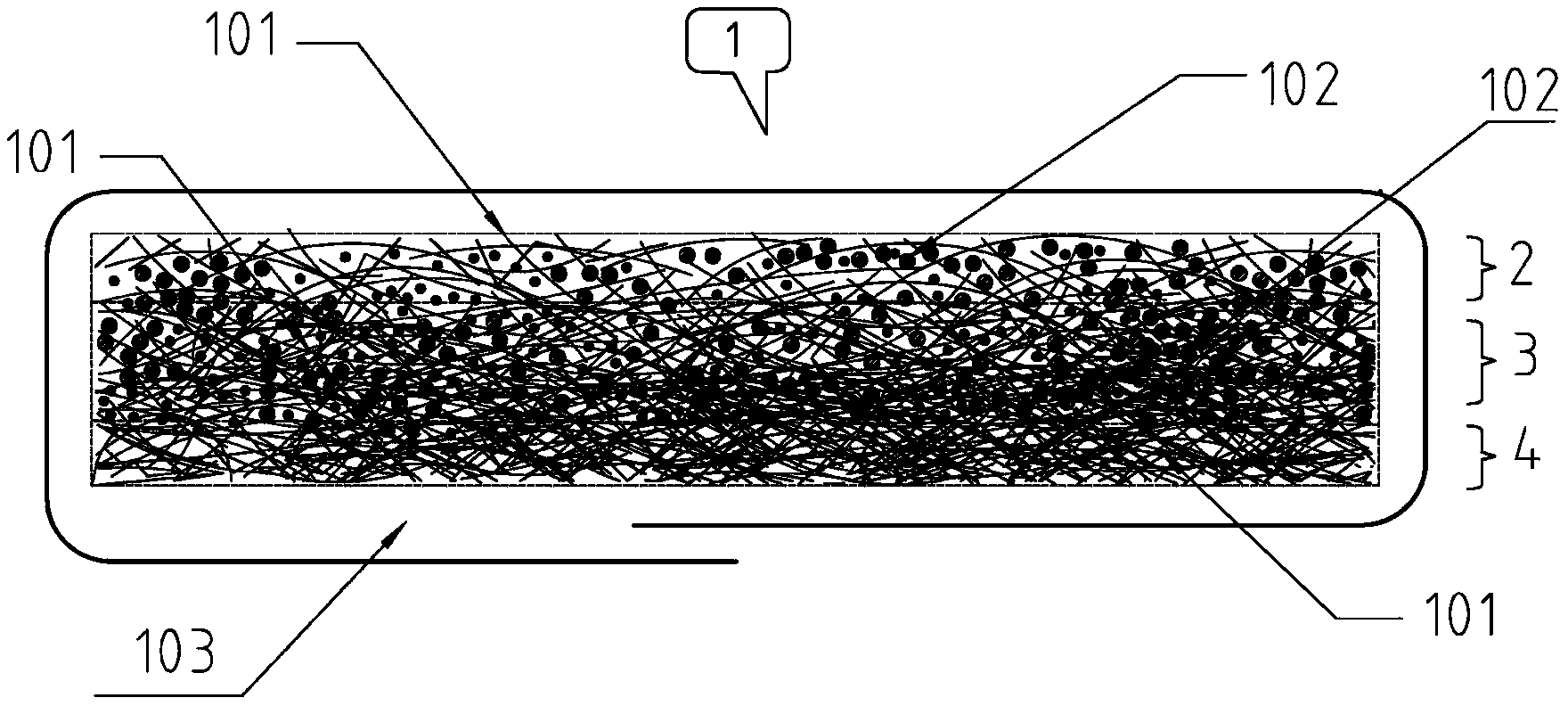

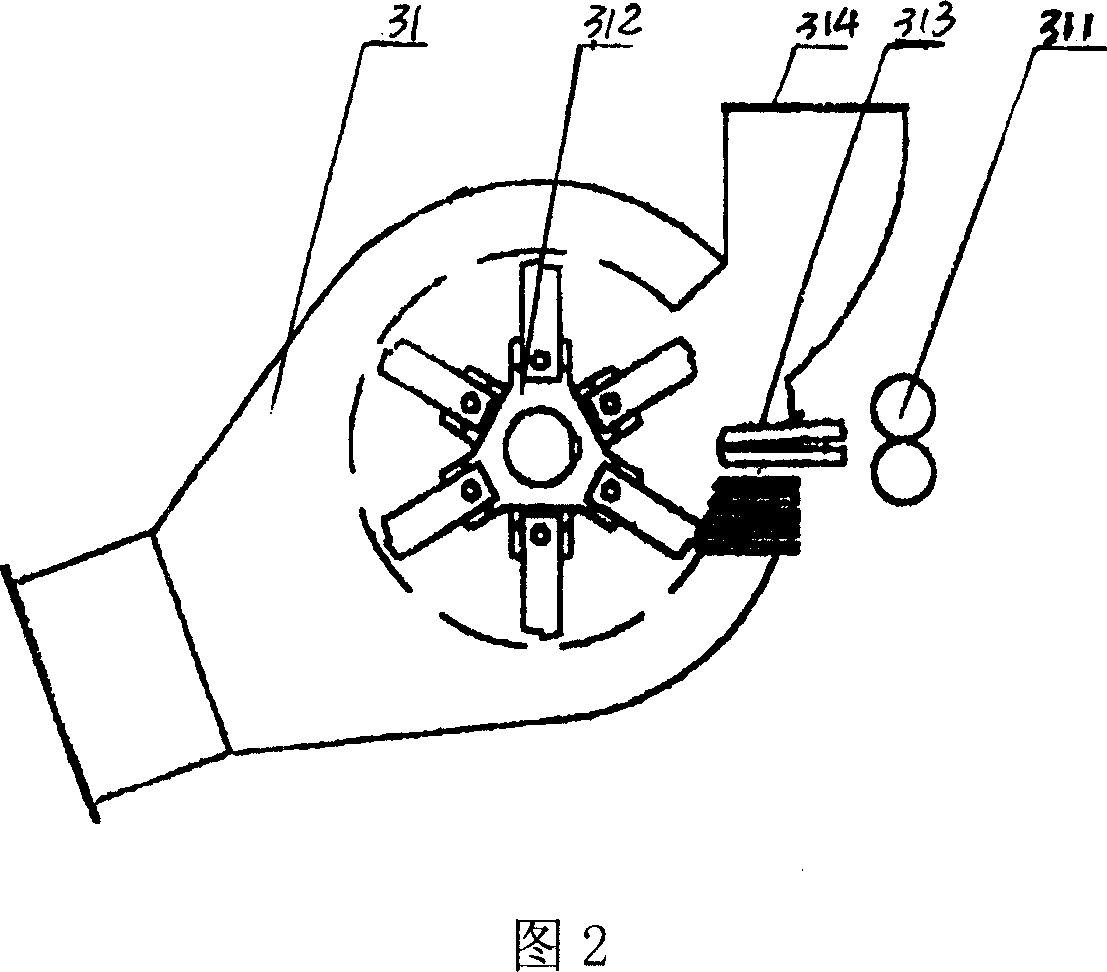

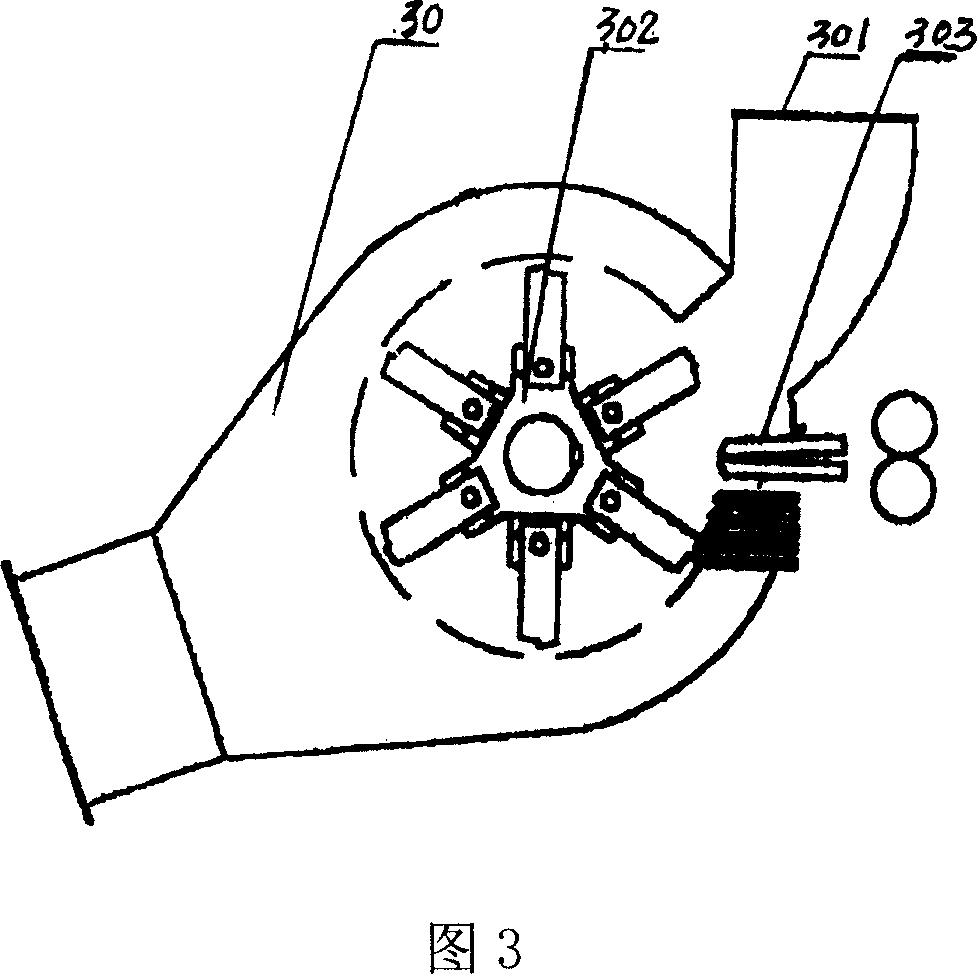

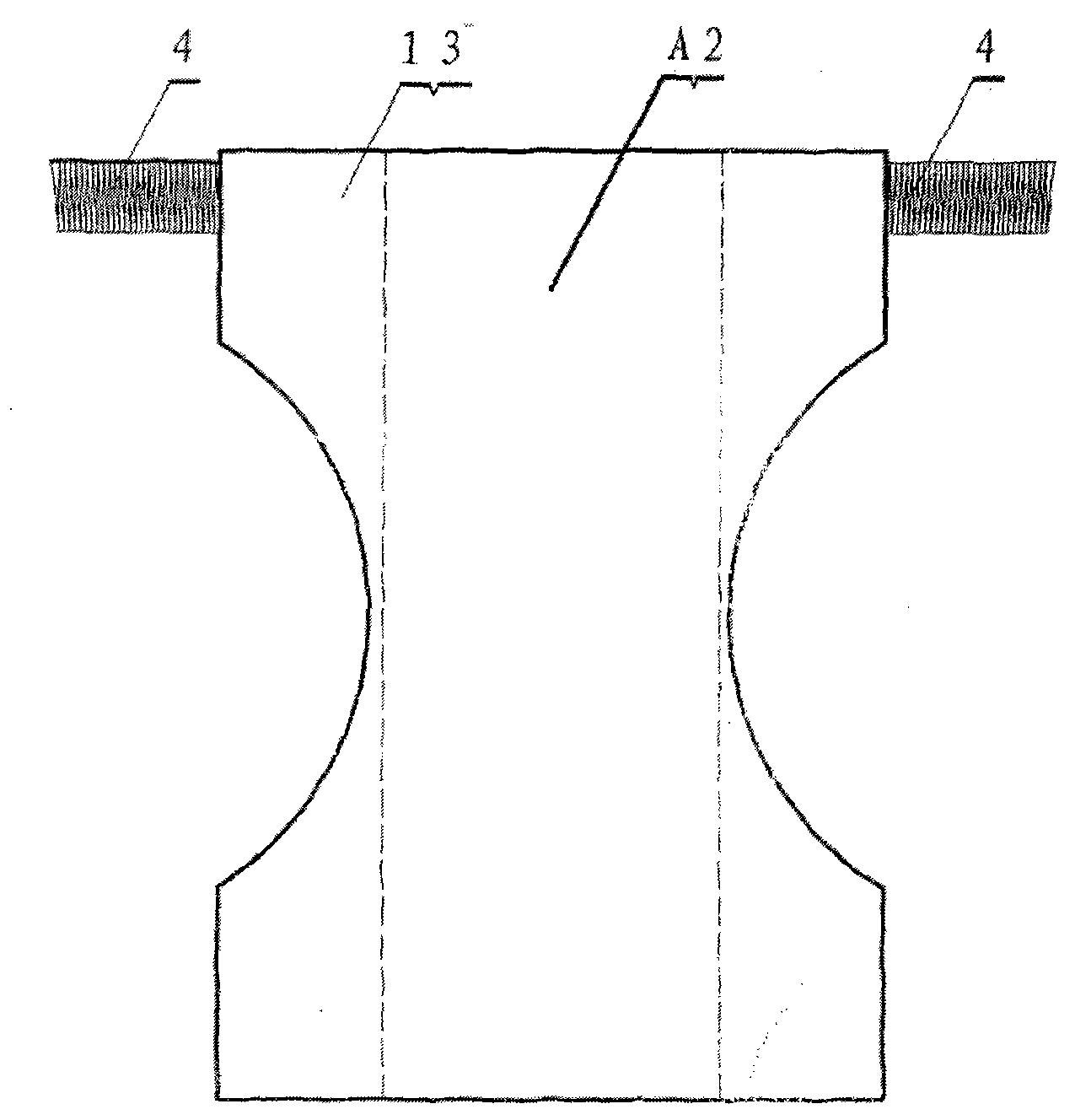

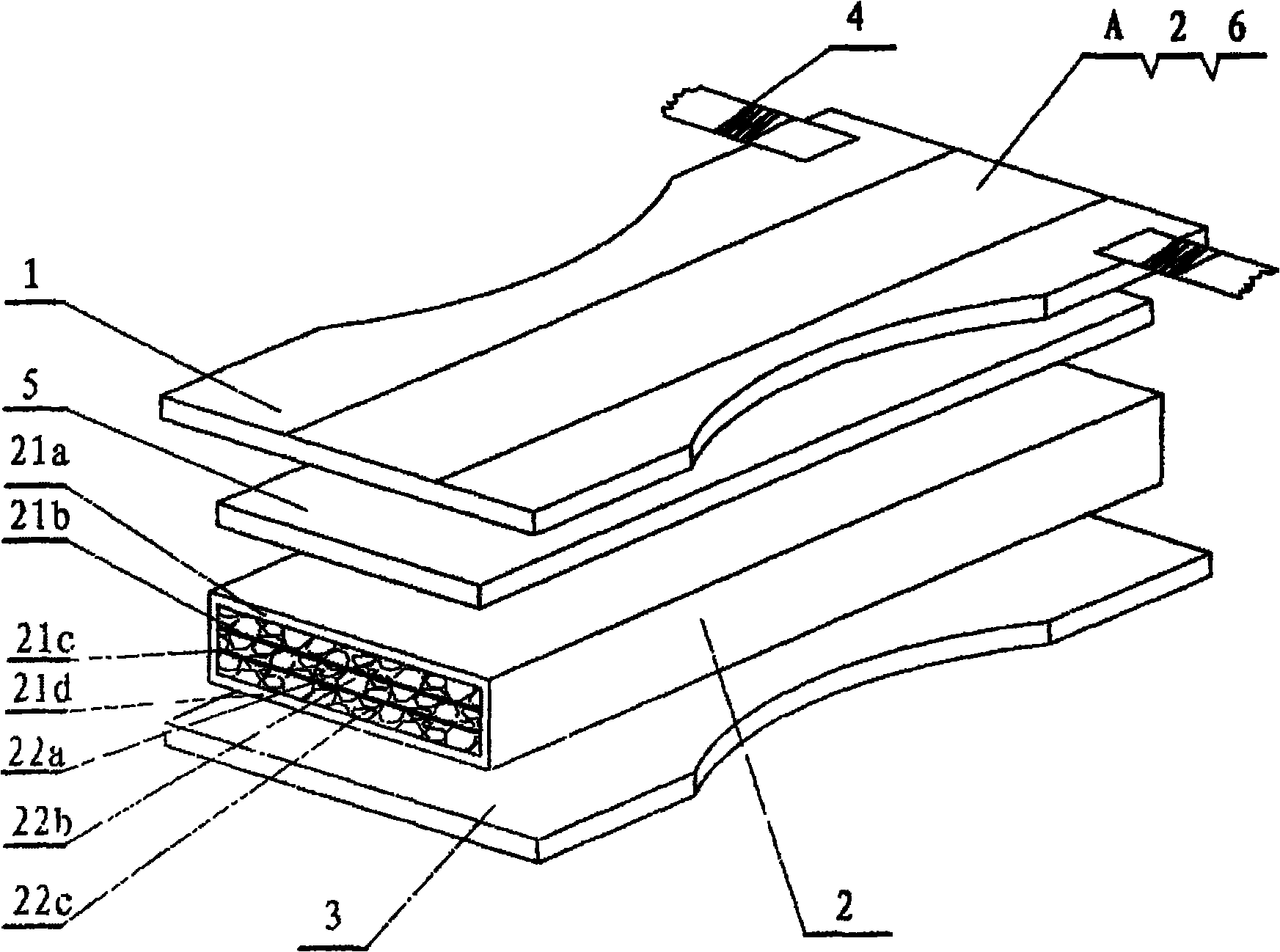

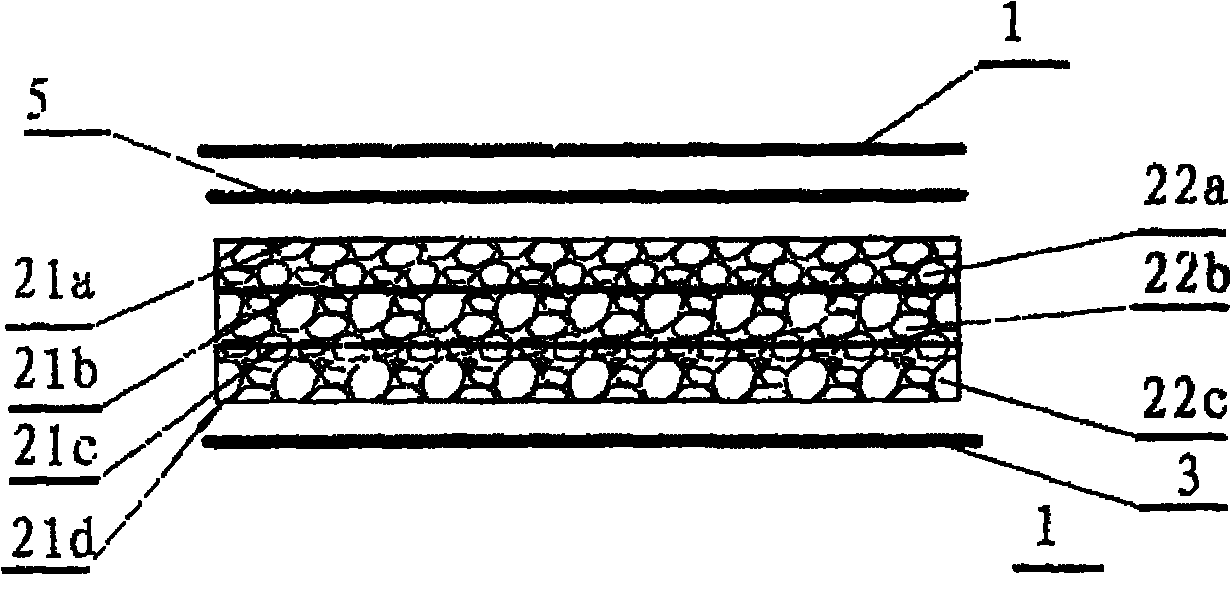

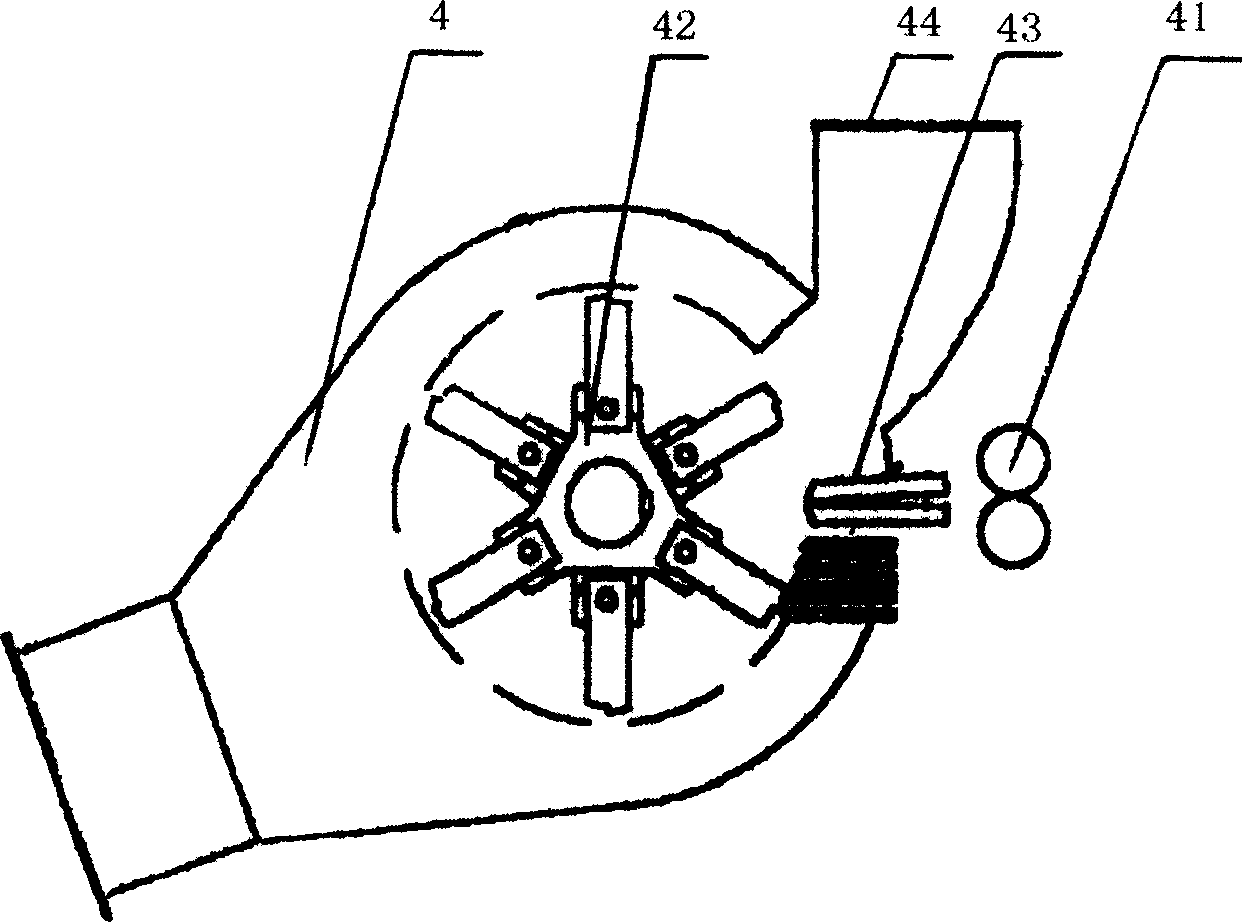

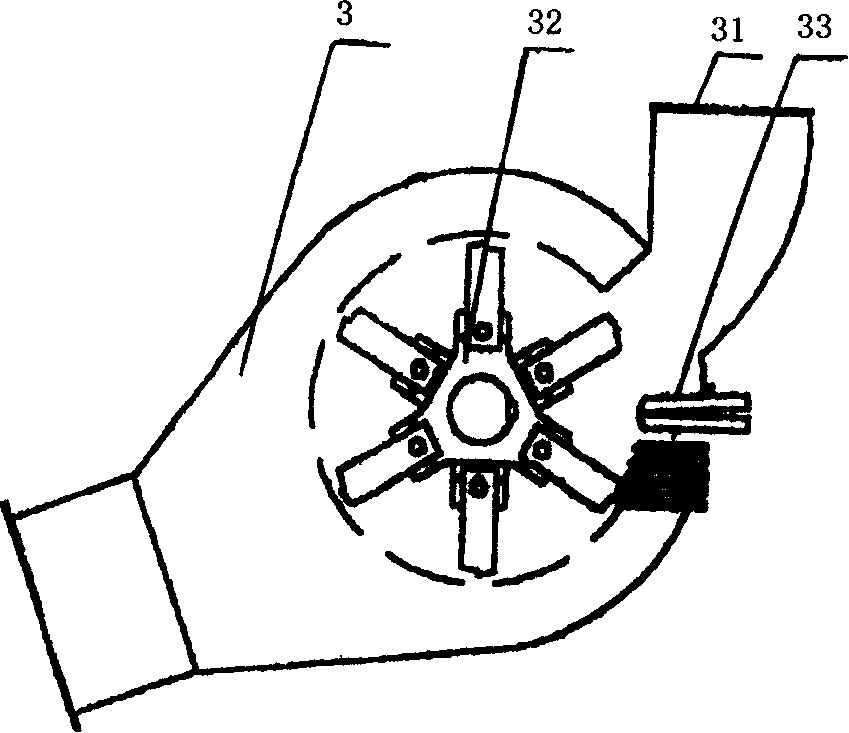

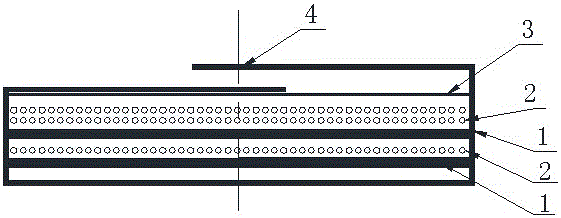

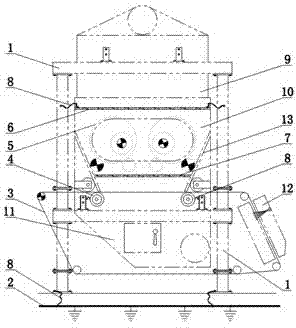

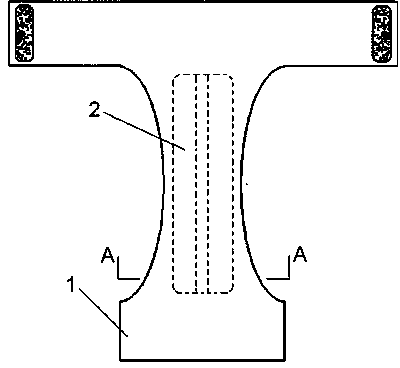

Absorptive core, absorptive core molding equipment and absorptive core manufacture method

The invention relates to the manufacture field of absorptive sanitary articles and automatic production equipment and discloses an absorptive core. The absorptive core comprises an absorptive core surface layer, an absorptive core middle layer and an absorptive core bottom layer, wherein the tightness degrees of the absorptive core middle layer and the absorptive core bottom layer are larger than the tightness degree of the absorptive core surface layer. The invention further discloses absorptive core molding equipment and an absorptive core manufacture method. The gathering degrees of fluff pulp fibers in the surface layer, the middle layer and the bottom layer of the absorptive core are from relative looseness to compactness, and the gradient density design can rapidly absorb body fluid, is favorable to fluid permeation and effectively reduces the possibility that the body fluid leaks from the absorptive sanitary articles. When the absorptive core of the structure is manufactured, a molding screen is effectively prevented from being blocked by high molecular absorption resin granules, time and cost which are spent on cleaning and maintaining the molding screen are saved, and the production efficiency of the absorptive core molding device is further improved.

Owner:ZUIKO (SHANGHAI) CORP

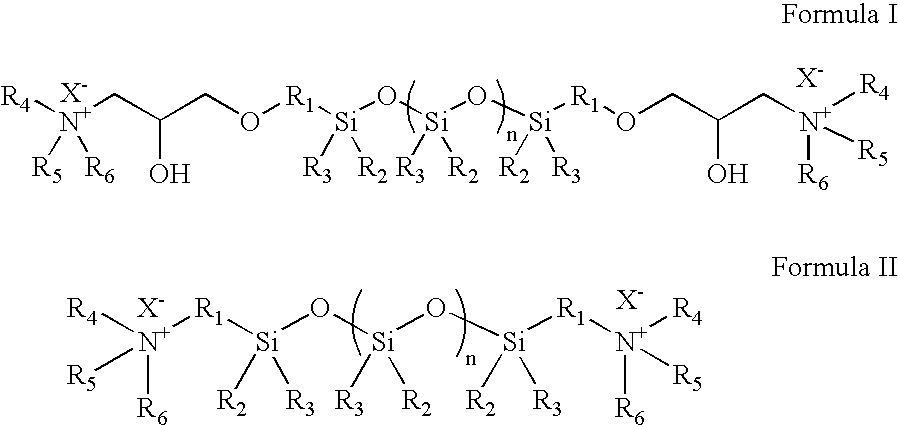

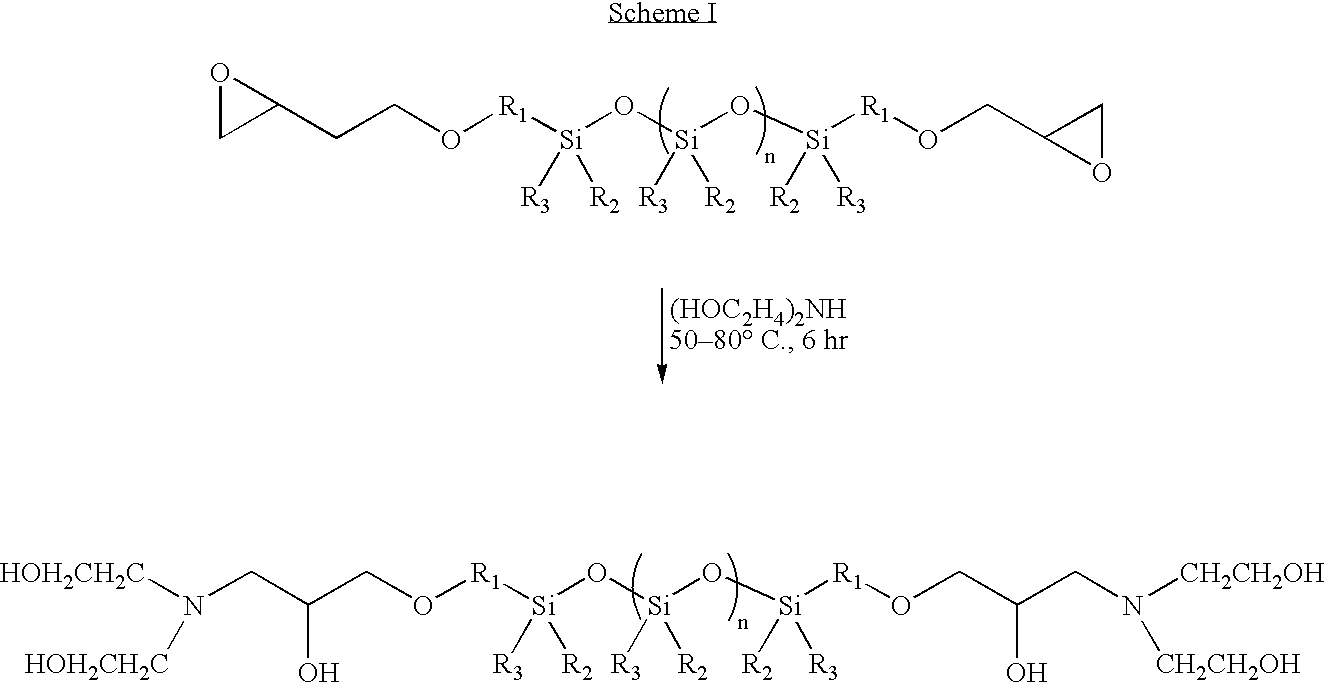

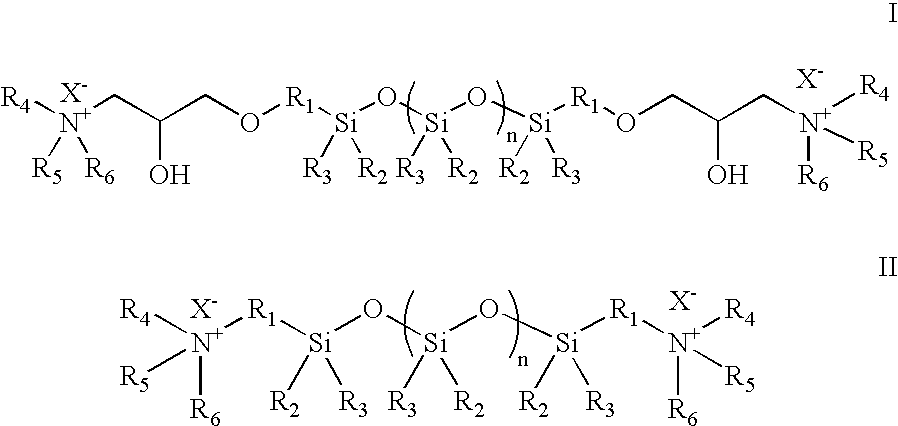

Treatment composition for making acquisition fluff pulp in sheet form

InactiveUS20060184147A1Low knot contentReduce discolorationPulp properties modificationOther chemical processesCross-linkCellulose

A treatment composition for making acquisition fluff pulp in sheet form, having a cross-linking agent and an anti-hydrogen-bonding agent. The cross-linking agent may be a polycarboxylic acid, aldehyde, urea-based derivatives or a mixture thereof. The anti-hydrogen-bonding agent may be a silicon polymer terminated with at least one quaternary amine functional group. A method of making acquisition fluff pulp using the treatment composition involves treating a cellulosic base fiber with a treatment composition solution to impregnate the fiber with the treatment composition, and then drying and curing the impregnated fiber. The resultant acquisition fluff pulp may be utilized in an acquisition layer and / or an absorbent core of an absorbent article intended for body waste management.

Owner:RAYONIER PERFORMANCE FIBERS

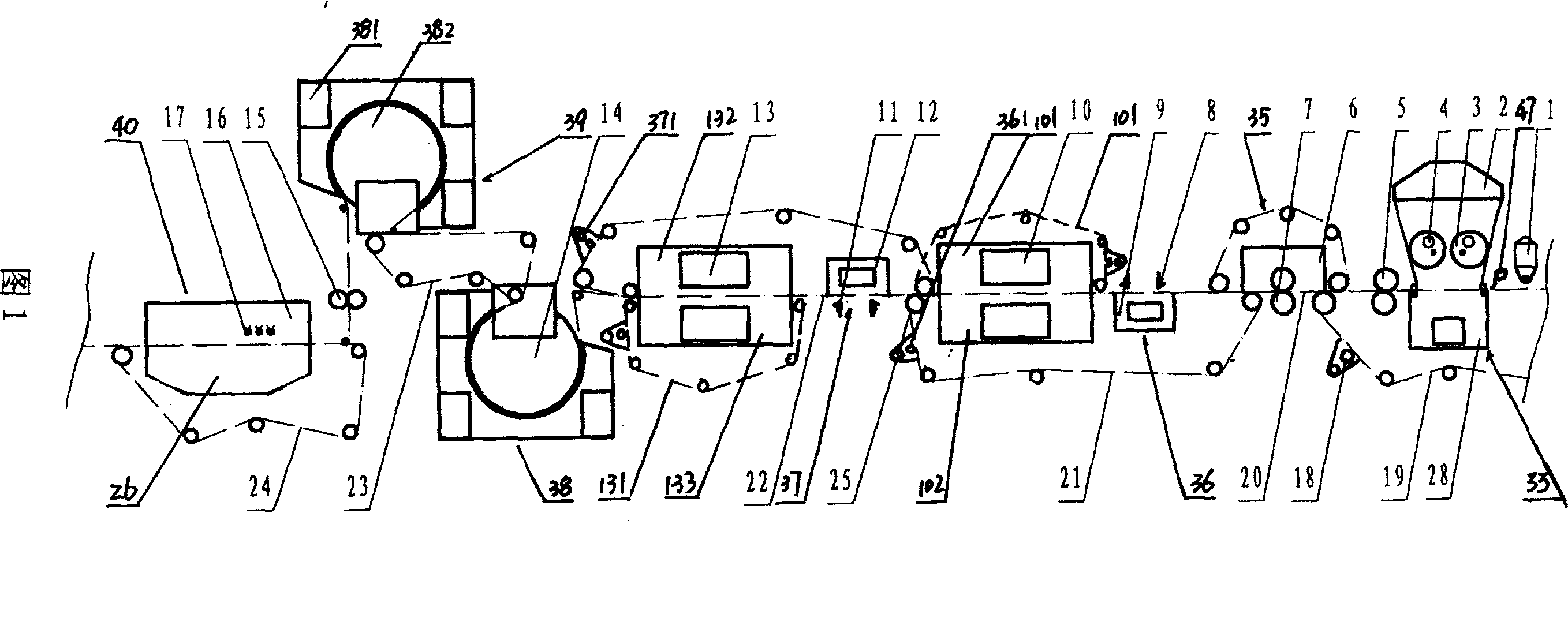

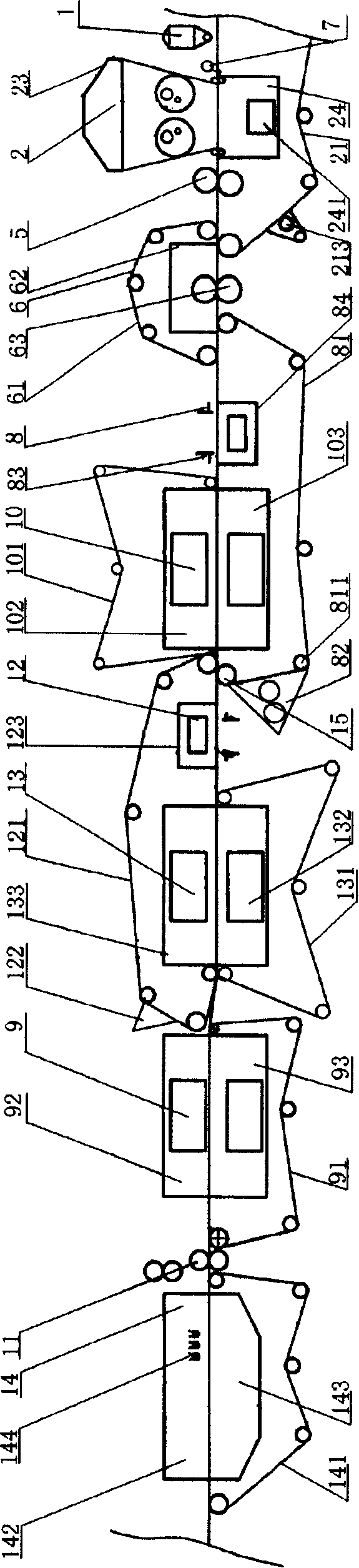

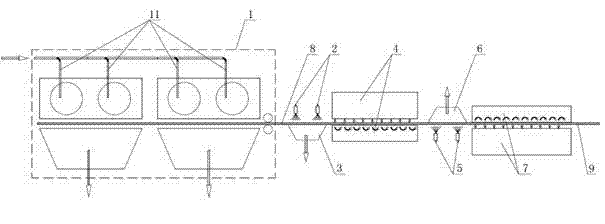

Dry-process papermaking machine through meshwork formed by airflow method

The present invention relates to an air-laying dry paper machine. It includes at least more then one forming device, sizing device, drying device and cooling device which are successively mounted on the machine frame from front to rear. Said sizing device includes at least more than two sizing devices and box type drying box. Between the forming device and sizing device an embossing device and pre-presing hot roller unit can be added, and between drying device and cooling device a calendaring device is added. Besides, it also includes fluff pulp fluffer, fibrids opening, conveying and metering device and powder additive device.

Owner:中丝(上海)新材料科技有限公司

Paper diaper

InactiveCN102462586AEvenly distributedReasonable distributionBandagesFluff pulpPulp and paper industry

The invention relates to a paper diaper, comprising a permeable non-woven fabric inner covering layer, a watertight leak-proof outer covering layer, an absorbing core layer and a connecting piece surrounding in a trousers shape, wherein the absorbing core layer is formed by multi-layer compound materials, dust-free papers or small white papers or a macromolecule absorbing material layer clipped among non-woven fabrics formed by laminating the macromolecule absorbing material layer and the dust-free papers or small white papers or the non-woven fabric layer and covering the dust-free papers or small white papers or the non-woven fabrics; or the absorbing core layer is formed by blending the macromolecule absorbing material layer and pulp fibers and macromolecule materials and covering the dust-free papers or small white papers or the non-woven fabrics. The absorbing core layer abandons wood pulp, fluff pulp and paper pulp; when ensuring the absorbing capacity, the product thickness is greatly reduced and the using comfort is improved. The macromolecule absorbing material layer is clipped among paper spacing layers; the local collected uniform thickness caused by the free flowing of thicker macromolecule absorbing material layer, even local loss is avoided; urine is easily discharged and permeated; the urine delivery and diffusion blocked by the quickly expanded upper-layer macromolecule absorbing material layer, which contacts with the urine for a long time, is reduced; the absorbing effect of the macromolecule absorbing material is used furthest; and the function of locking urine is realized.

Owner:ZHEJIANG CONBA HEALTH PROD

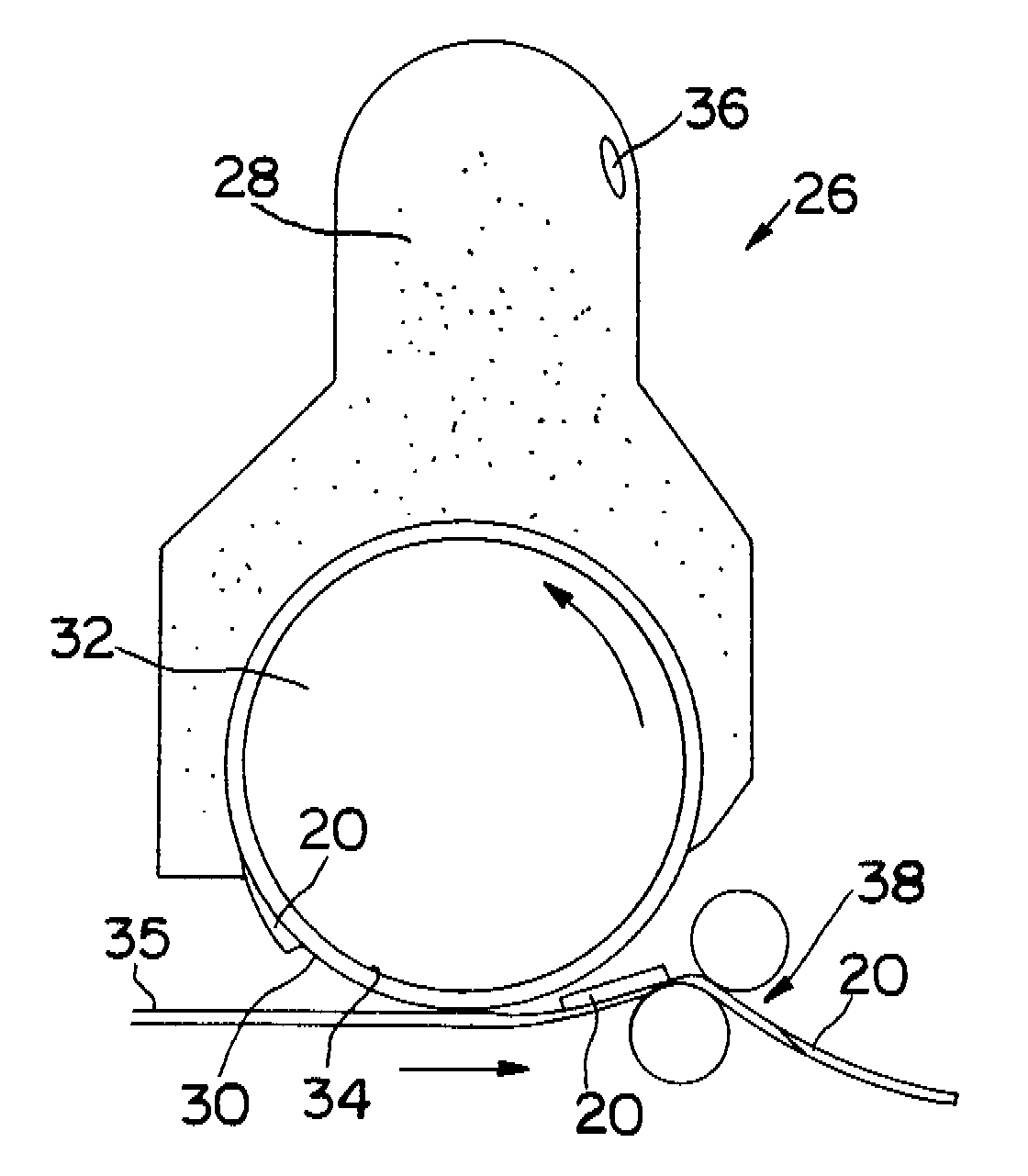

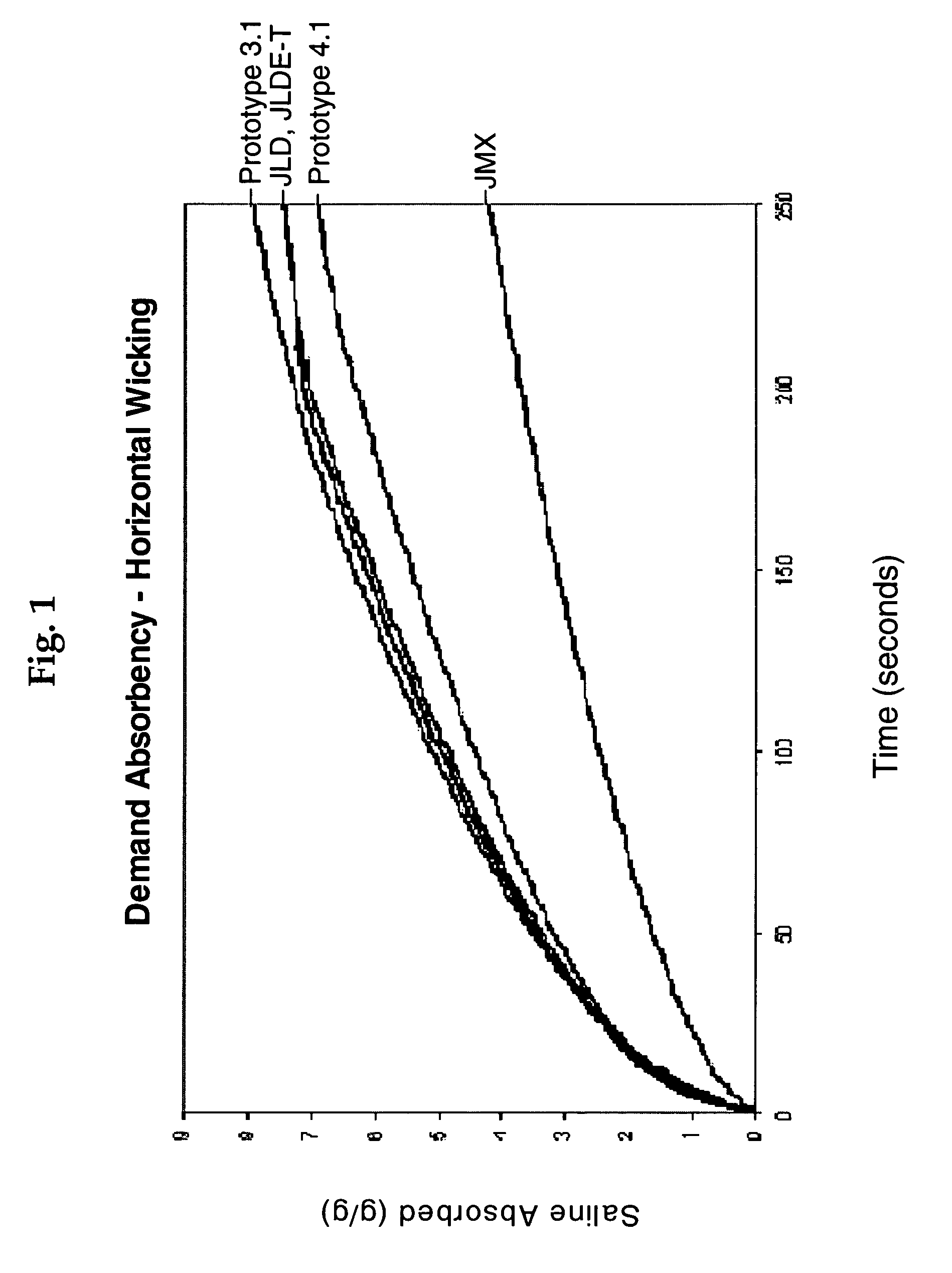

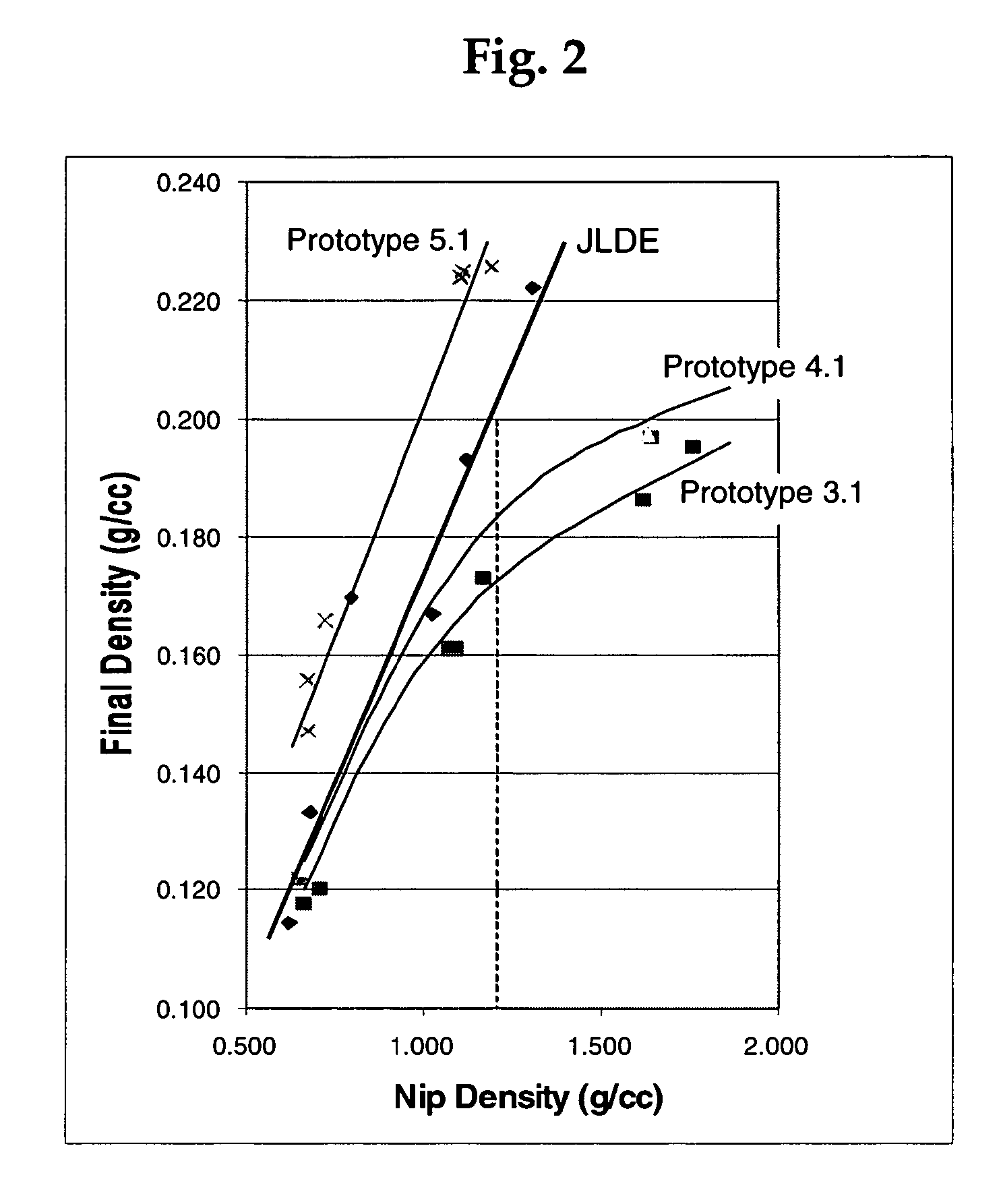

Method for producing thin, high capacity absorbent structure

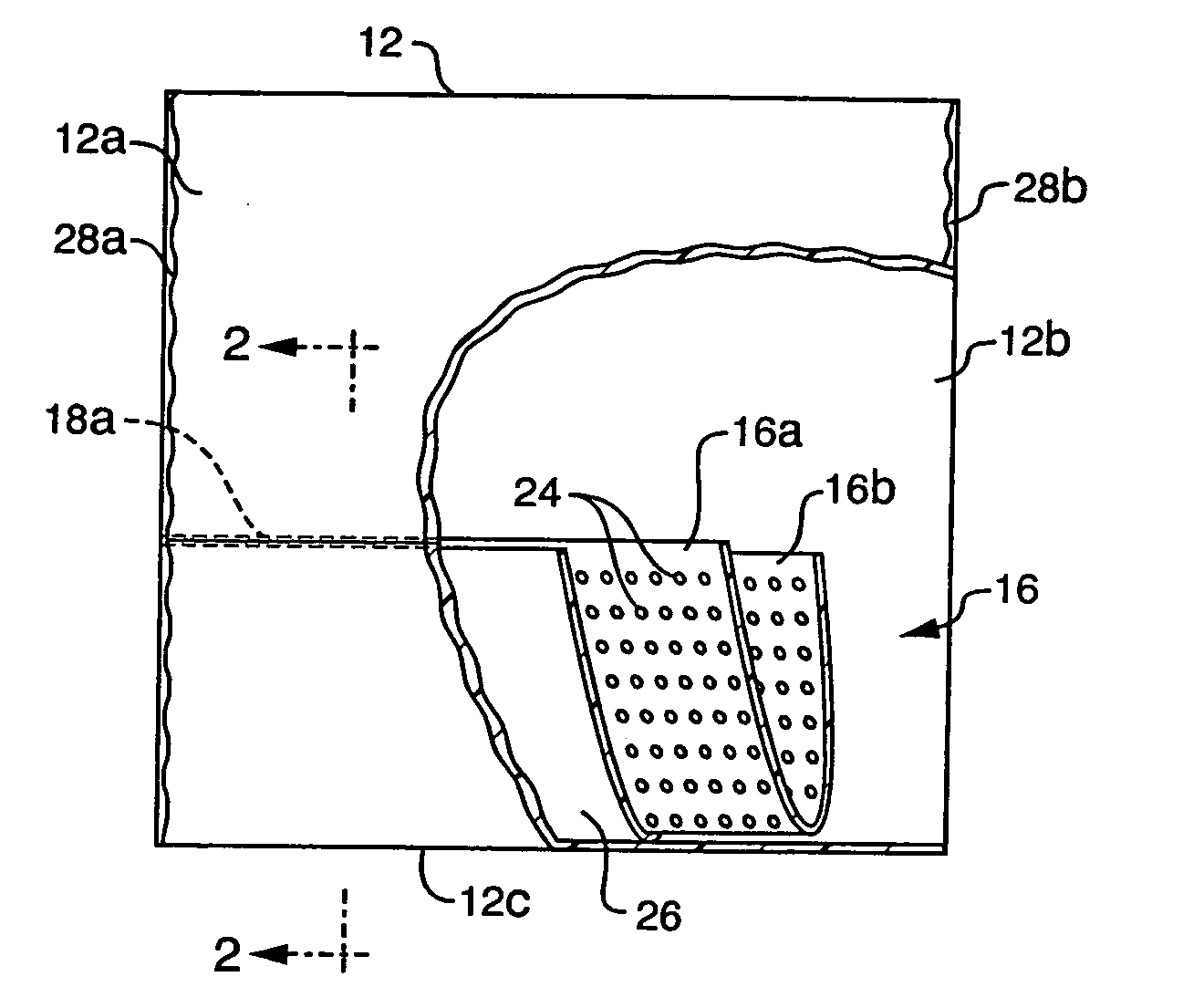

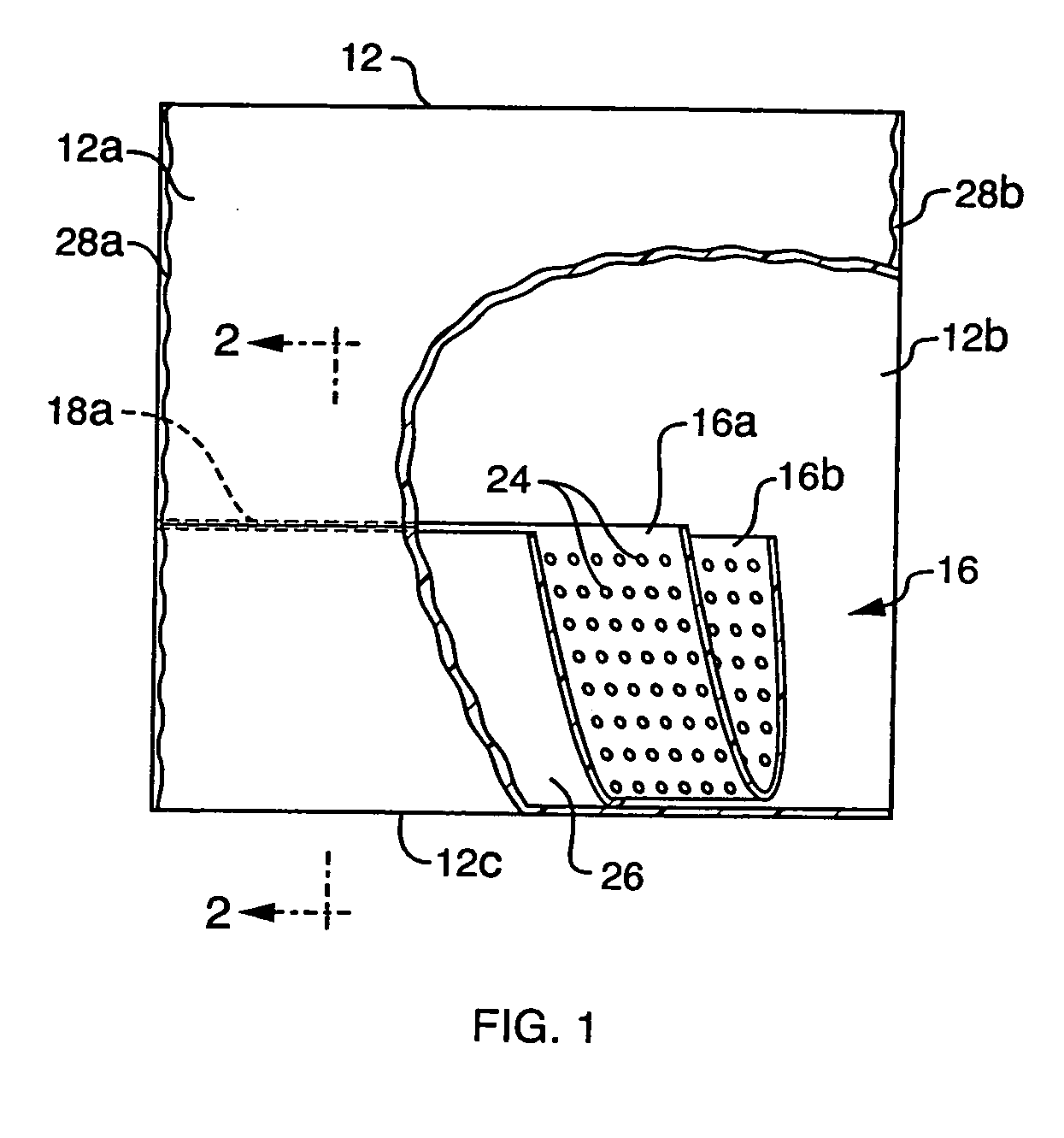

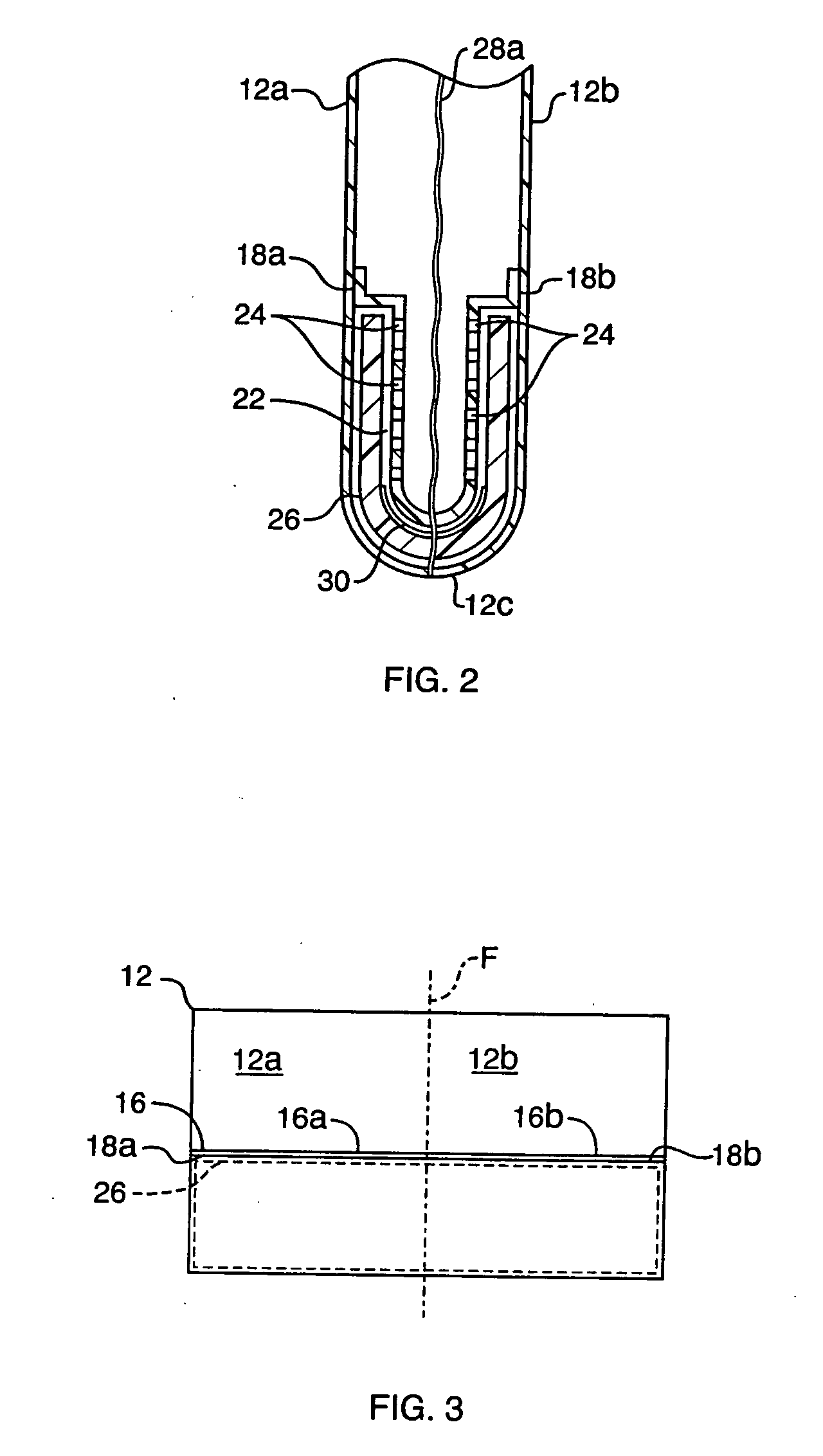

A method of making absorbent pads is disclosed. The method includes homogeneously mixing superabsorbent material and fluff in a forming chamber of an online drum former and wrapping a porous fabric over a forming screen on a forming drum of the drum former. The method further includes forming an absorbent pad from the homogeneously mixed superabsorbent material and fluff pulp as the homogeneously mixed superabsorbent material and fluff pulp exits the forming chamber onto the forming screen and compacting the absorbent pad to a density of at least 0.28 grams per cubic centimeter after the absorbent pad leaves the forming screen.

Owner:KIMBERLY-CLARK WORLDWIDE INC

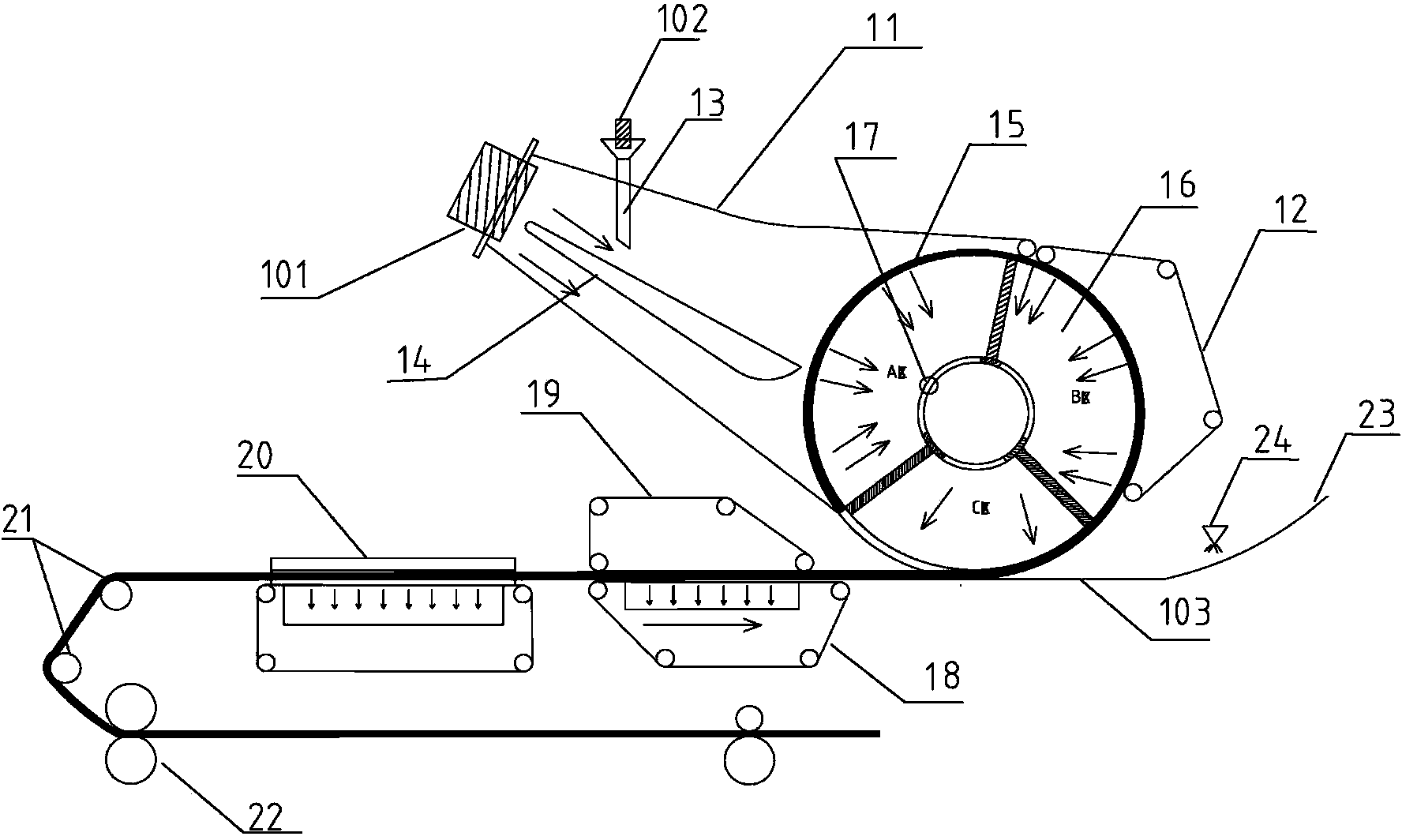

Air current method forming net dry method paper machine

InactiveCN101204825AMechanical working/deformationDrying solid materials with heatFluff pulpConductor Coil

An air-laid web-forming dry paper machine comprises at least one forming device, a sizing device and a cooling device which are arranged on a frame from front to back in turn, and the sizing device comprise at least two sizing devices and box type drying ovens. An embossing device and a preloading thermal roll group are additionally arranged between the forming devices and the sizing device and a curing device and a calendaring device are additionally arranged between the sizing device and the cooling device. The unwindering devices are arranged at the front and / or rear sides of the forming device or / and between two forming devices and different types of roll-shaped coiled materials are rolled on the winding-up rollers of the undwindering device. The air-laid web-forming dry paper machine also comprises a fluff pulp hydropress providing the forming device with the materials, a heat binding fiber opening and conveying measurement device and powder adding devices. As more than two sizing devices are adopted and a plurality of unwindering devices and powder adding devices are arranged, the dry paper with a plurality of structures and fibers is produced by sizing and laying the forming fiber nets having different properties on the paper webs many times and adding different uses of powders.

Owner:中丝(上海)新材料科技有限公司

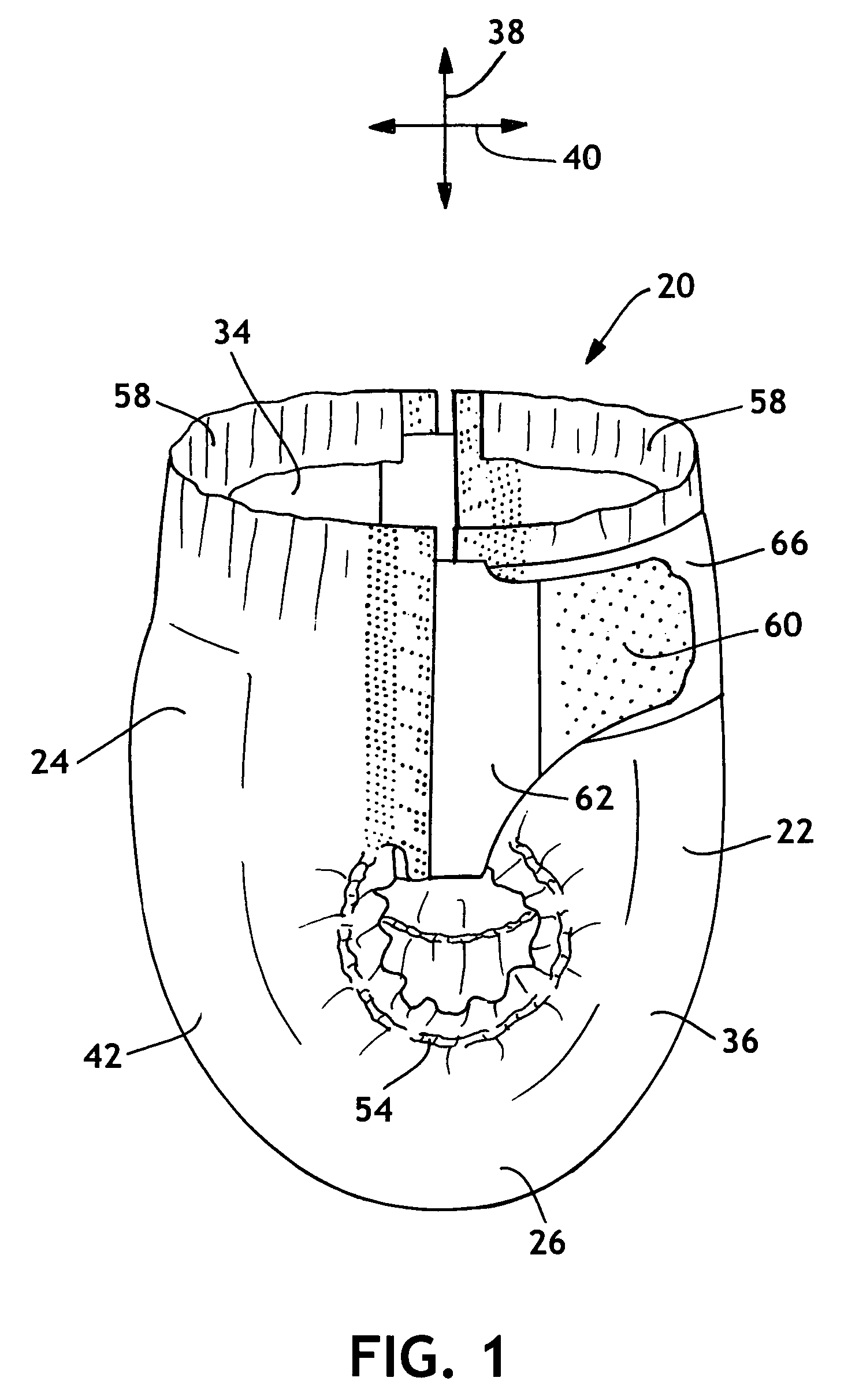

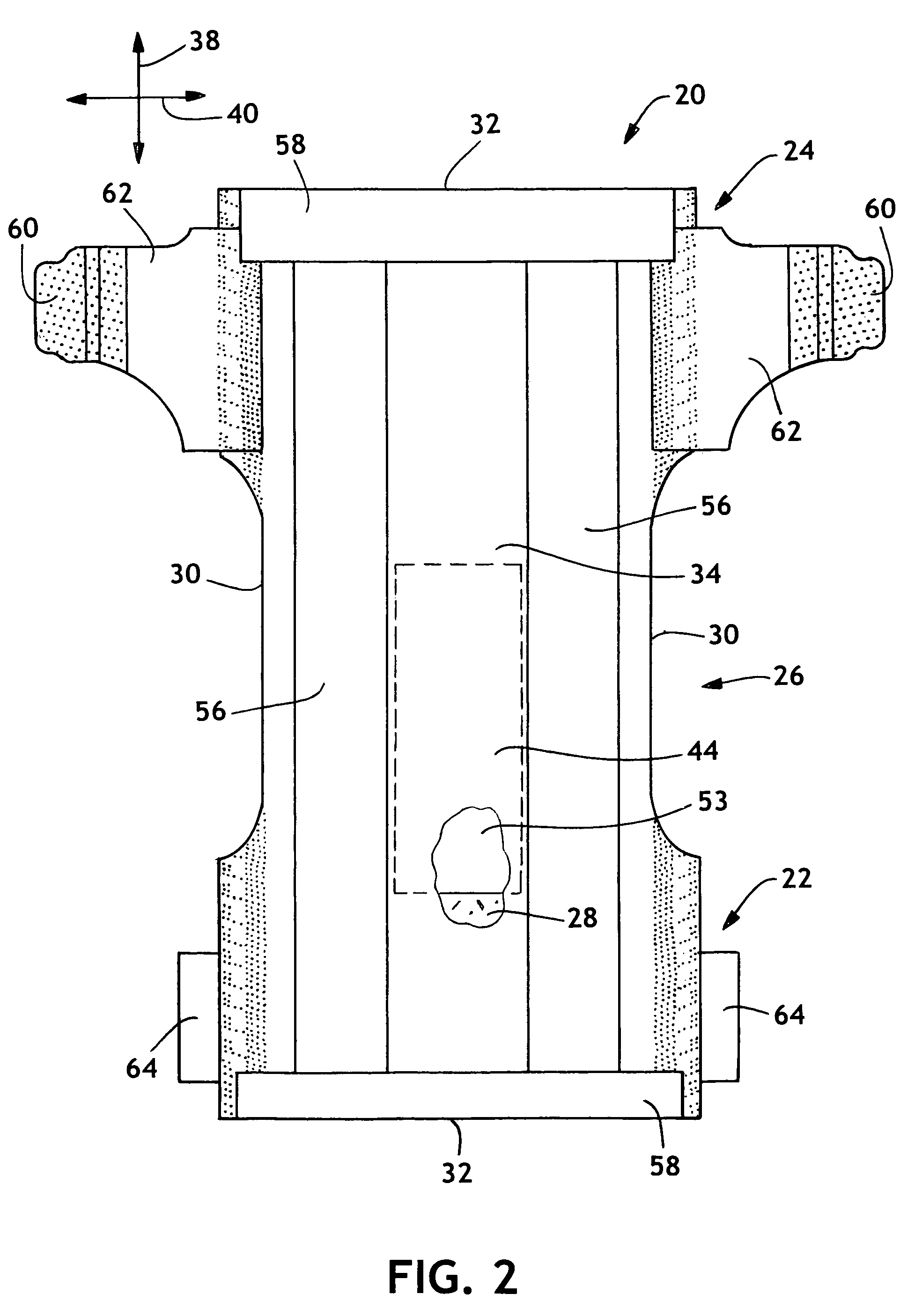

Absorbent Articles Having A Pulpless Absorbent Core With Improved Performance

The embodiments provide an absorbent garment that has an absorbent core that provides for both good leakage and dryness performance. Absorbent garments having a pulpless synthetic core have comparable functionality when compared to more costly absorbent garments having an absorbent core comprising conventional amounts of fluff pulp. The absorbent garments of the embodiments incorporate features that provide good leakage performance and rewet values, while costing considerably less.

Owner:LITVAY JOHN D

Highly wettable - highly flexible fluff fibers and disposable absorbent products made of those

An absorbent core comprising fluff pulp fiber treated with polysiloxane, wherein the absorbent core has a density of about 0.15 g / cm3 or greater and a Young's modulus of about 75 psi or less. The polsiloxane may comprise an amino-functional moiety. The absorbent core may comprise superabsorbent, and may be employed in a disposable absorbent product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Dry-type paper-making method reengineering tobacco production process

ActiveCN103082392AExcellent spreading rateExcellent filling valueTobacco preparationFluff pulpWater content

The invention discloses a dry-type paper-making method reengineering tobacco production process which is characterized in that tobacco fibrous raw materials, or fluff pulp fibrous raw materials, or tobacco and fluff pulp fibrous raw materials are manufactured into base pieces with a high filling value through a dry-method paper-making machine by utilizing an airflow sedimentation method, tobacco powder and rubber mixture are sprayed on the front side and the reverse side of each core base piece, the base pieces are made into tobacco sheet finished products through drying and follow-up procedures, a negative pressure vacuum drawing way is adopted for spraying, the sprayed tobacco powder and the rubber mixture are absorbed in the core base pieces in an attaching mode, and the process is a way of spraying-drying and secondary spraying-drying. A coating rate of the manufactured tobacco sheet finished products is larger than or equal to 46%, the filling value is larger than or equal to 6.0 cm<3> / g, and water content is smaller than or equal to 12%.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

Plasticizing formulation for fluff pulp and plasticized fluff pulp products made therefrom

InactiveUS7854822B2Natural cellulose pulp/paperMechanical working/deformationCyclohexanedimethanolFluff pulp

Owner:RAYONIER PERFORMANCE FIBERS +1

A method for producing moisture paper tissue material

The invention provides a method for producing moisture paper tissue material, which is characterized in that, the specific steps are as follows: opening viscose fiber and fluff pulp wood pulp fiber respectively, placing them into the fine pulverizer, and mixing them according to the weight ratio 25-45:55-75, producing mixed fiber into paper web with dry method of papermaking, carrying spunlace reinforcement, and then drying for obtaining moisture paper tissue material.

Owner:DONGHUA UNIV

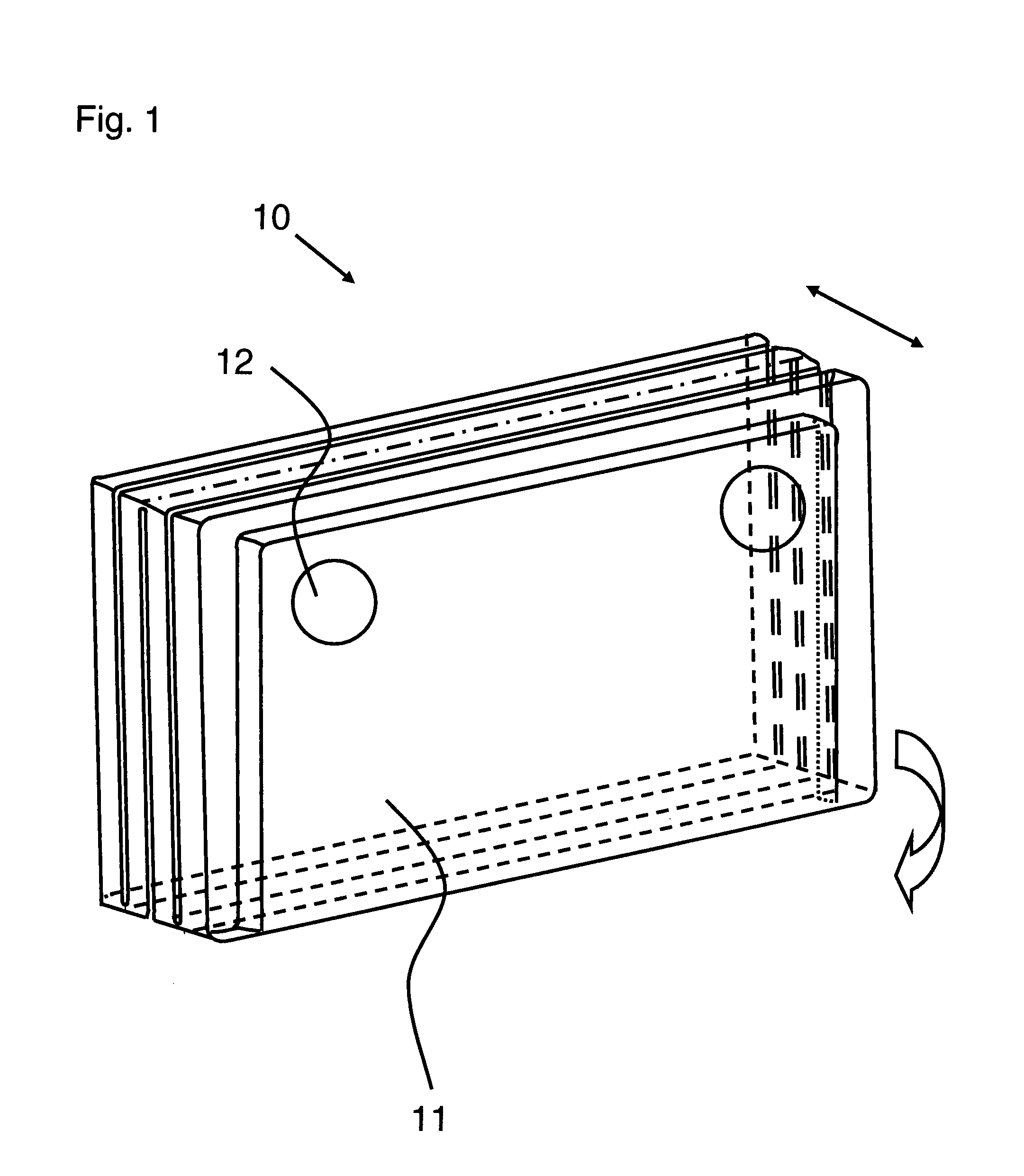

Trash bag for wet trash

A trash bag for containing wet trash has an outer ply of fluid imperious material defining an outer front wall and an outer rear wall of the bag, and an inner ply of fluid pervious material defining an inner front wall and an inner rear wall of the bag. The inner and outer plies form a compartment between them which contains a highly fluid absorbent material. The material is capable of capturing any fluids that enter the compartment from the interior of the bag thereby minimizing fluid leakage from the bag in the event that the outer ply of the bag is breeched. The material in the compartment may be combined with or include any of a variety of additional substances designed to act on, react to or counter the effects of fluids absorbed by the material. A low-cost, consumer version of the trash bag eliminates the inner ply, and simply comprises an outer ply of fluid impervious material with an inner liner of fluid absorbent material such as cellulose fluff pulp in sheet form.

Owner:JACOBY JAY +1

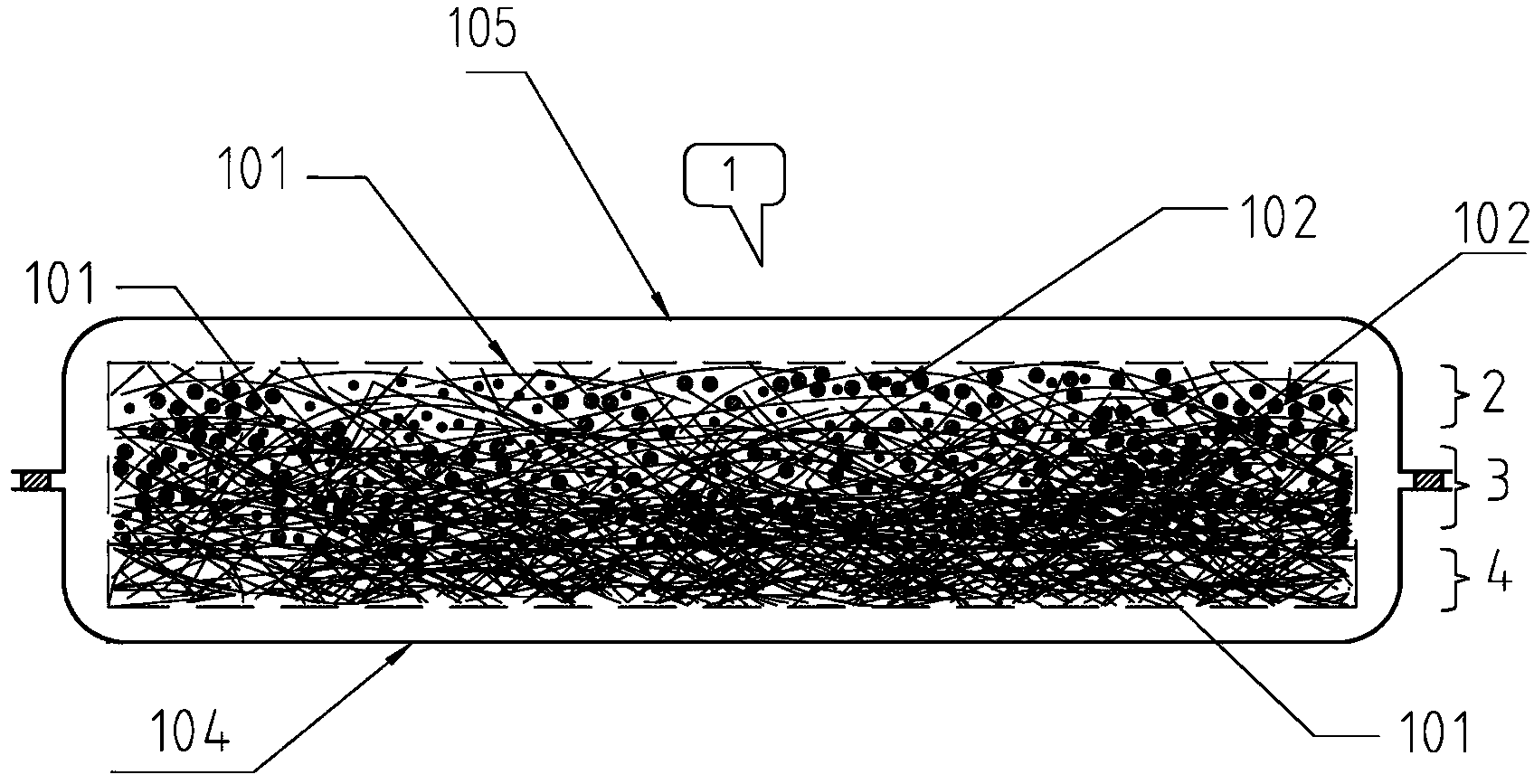

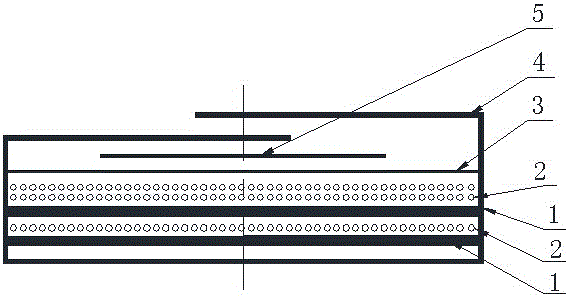

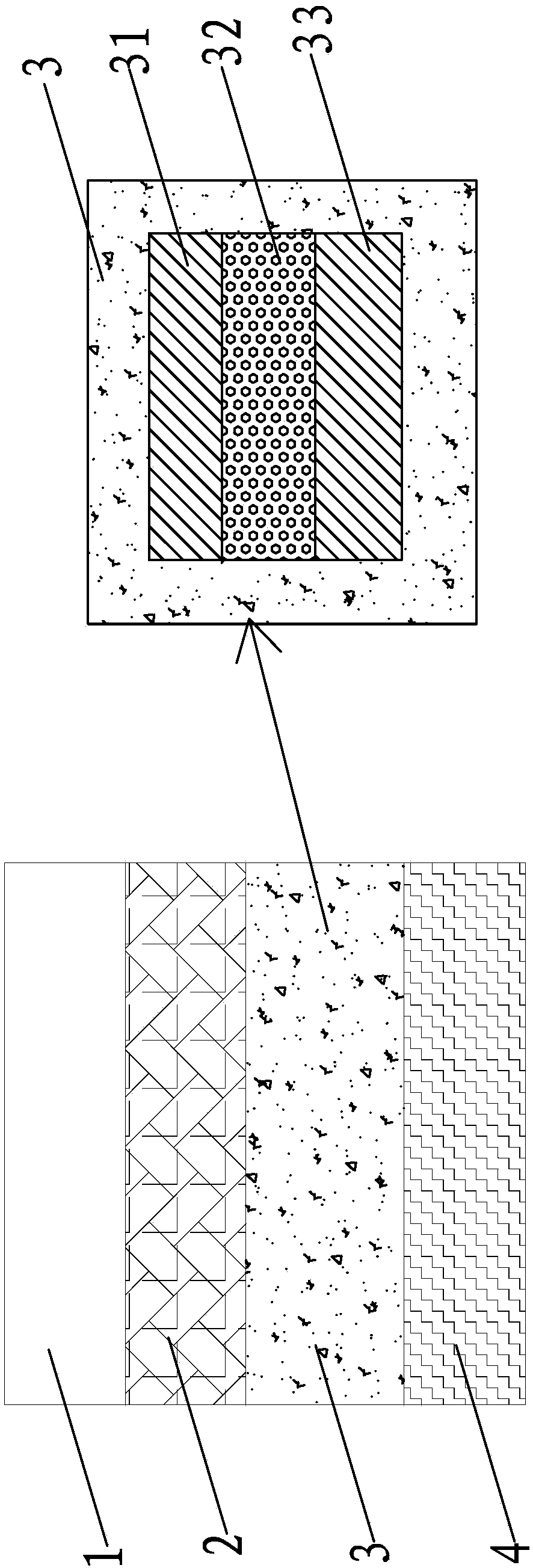

Fully coating ultrathin liquid absorption core and production method

InactiveCN106137555ASolve the problem of uneven distributionReduce thicknessAbsorbent padsBaby linensAbsorption capacityPolymer resin

The invention relates to a fully coating ultrathin liquid absorption core and a production method. The fully coating ultrathin liquid absorption core enables polymer resin to be uniformly distributed between swelling non-woven fabric lines, can guarantee complete exertion of the liquid absorption performance of the polymer resin and can reduce the thickness of an absorption body effectively on the premise that the polymer resin is not required to be located by a fluff pulp carrier or an adhesive. The fully coating ultrathin liquid absorption core comprises a coating layer, wherein a liquid absorption layer is located on the coating layer, a covering layer is located on the liquid absorption layer, a flow guiding layer is located on the covering layer, and closing sides of the coating layer are located at the edge of the flow guiding layer. The fully coating ultrathin liquid absorption core has the following advantages: 1, fluff pulp is not required to be taken as a fixing substrate of the polymer resin, so that the thickness of the absorption body is reduced greatly, and the problem of non-uniform distribution of the polymer resin on the fluff pulp is solved; 2, the adhesive is not required to fix the polymer resin, and accordingly, the absorption capacity of the polymer resin is exerted sufficiently; 3, the production cost is reduced greatly, and the production efficiency is improved remarkably.

Owner:ZHEJIANG YONGCHUANG MACHINERY

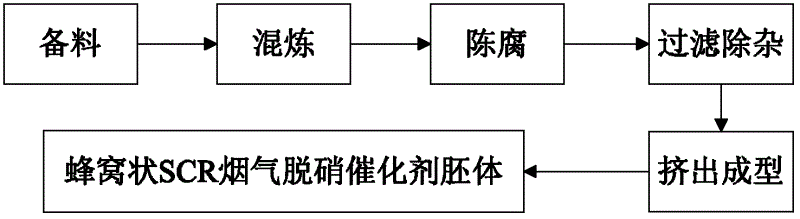

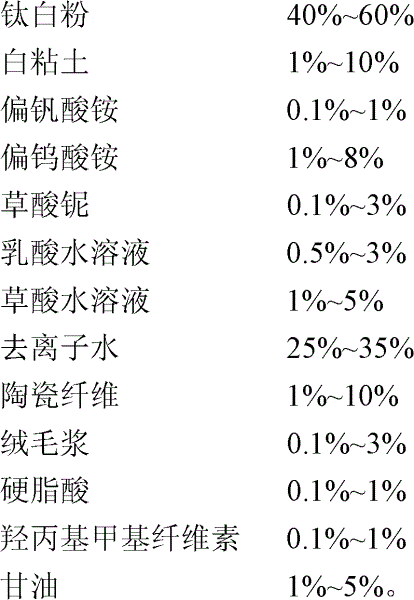

Honeycomb SCR smoke denitration catalyst embryoid body and preparation method thereof

ActiveCN102614866AImprove plasticityImprove adhesionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTungstateNiobium

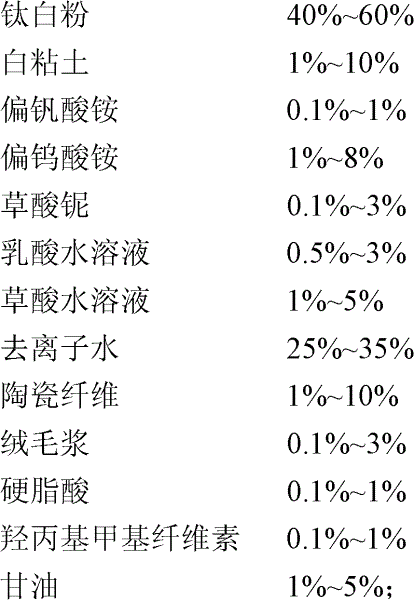

The invention discloses a honeycomb SCR (Selective Catalytive Redution) smoke denitration catalyst embryoid body and a preparation method thereof. The honeycomb SCR smoke denitration catalyst body consists of the following raw materials as per percentage by weight: 40 to 60 percent of titanium dioxide, 1 to 10 percent of white clay, 0.1 to 1 percent of ammonium metavanadate, 1 to 8 percent of ammonium meta-tungstate, 0.1 to 3 percent of niobium oxalate, 0.5 to 3 percent of lactic acid aqueous solution, 1 to 5 percent of oxalic acid aqueous solution, 25 to 35 percent of deionized water, 1 to 10 percent of ceramic fiber, 0.1 to 3 percent of fluff pulp, 0.1 to 1 percent of stearic acid, 0.1 to 1 percent of hydroxypropyl methyl cellulose and 1 to 5 percent of glycerol. The honeycomb SCR smokedenitration catalyst embryoid body has high plasticity, caking property and mechanical strength. The method is simple and convenient in operation and low in cost. Each component of the prepared catalyst body is dispersed uniformly; the catalyst body is easy in forming and demolding in the extrusion process and has high finished product rate; and the catalyst prepared by the embryoid body has highdenitration efficiency.

Owner:ZHEJIANG UNIV +1

Processes for producing fluff pulp and ethanol from sugarcane

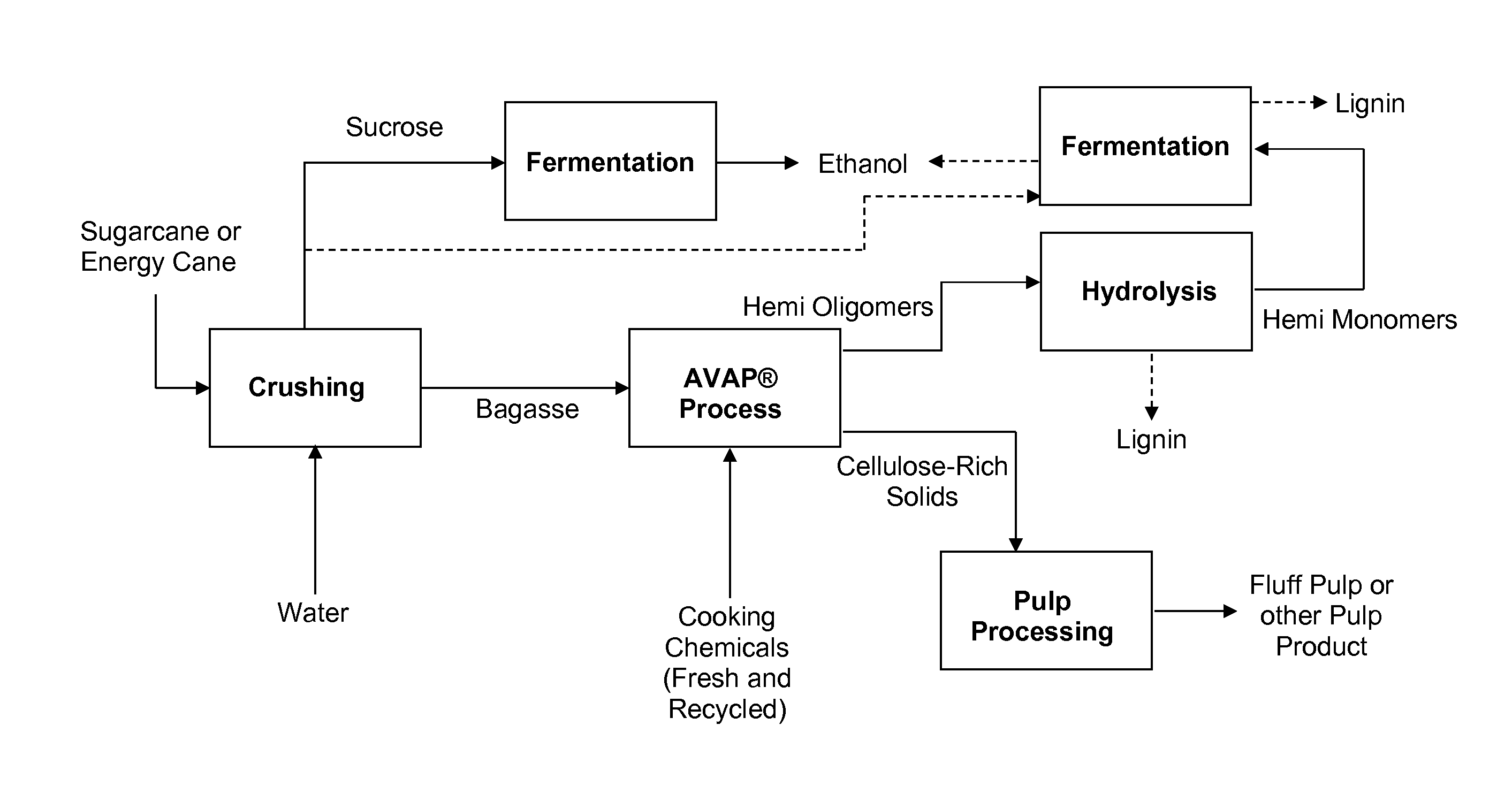

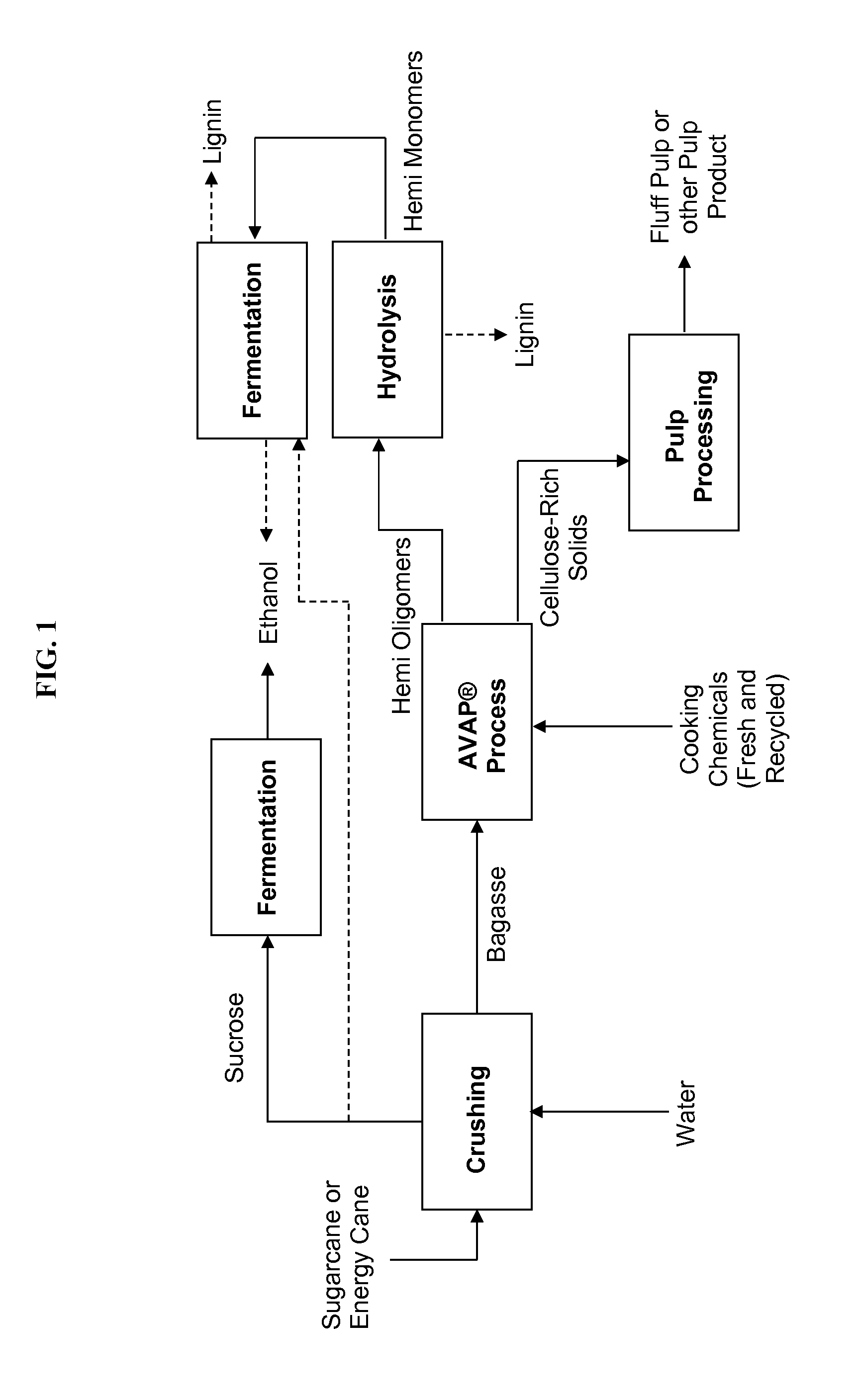

The disclosure provides a process for producing fluff pulp and ethanol from sugarcane bagasse or straw, comprising: fractionating the feedstock in the presence of an acid catalyst, a solvent for lignin, and water, to generate a solid / liquid slurry comprising cellulose-rich solids, hemicelluloses, and lignin; separating the solid / liquid slurry into a solid stream and a liquid stream; further treating the cellulose-rich solids to produce fluff pulp; hydrolyzing the hemicelluloses to generate hemicellulose monomers; and fermenting at least a portion of the hemicellulose monomers to cellulosic ethanol. Lignin is removed from the process during one or more steps and combusted to provide energy for process requirements. The process is integrated with, and provides energy to, a first-generation process that ferments sugarcane-derived sucrose to first-generation ethanol. Similar processes are possible with energy cane, corn, and other crops.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

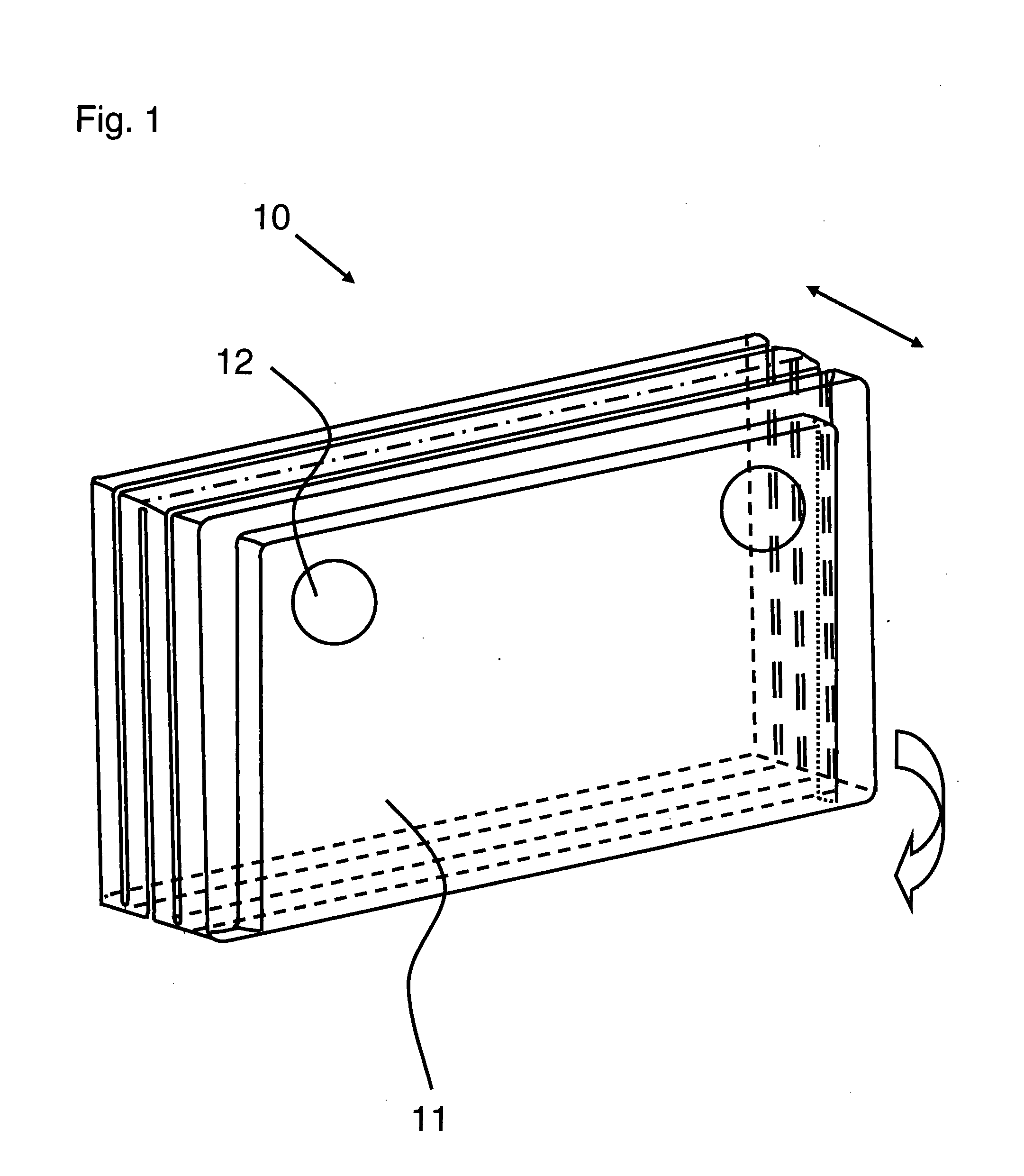

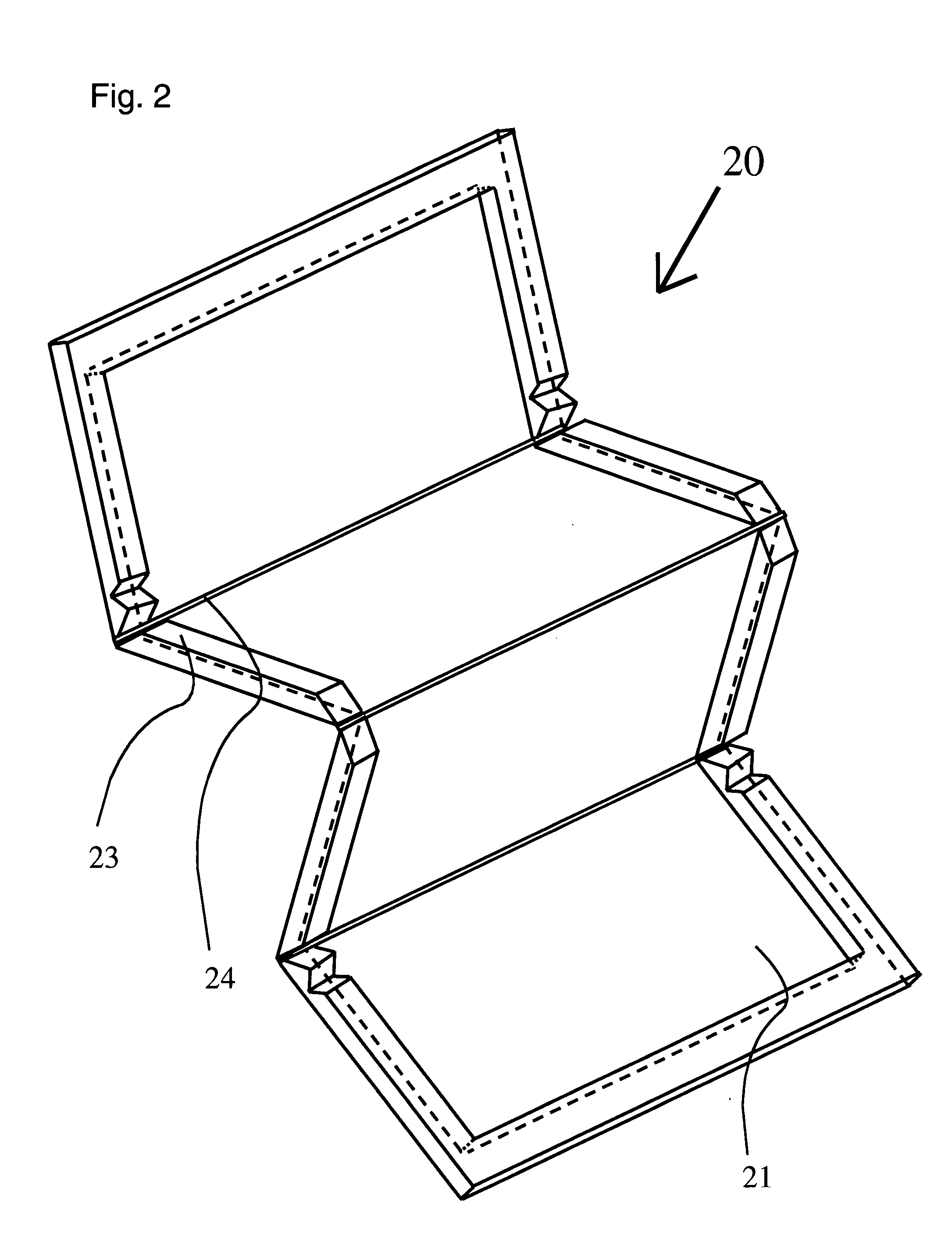

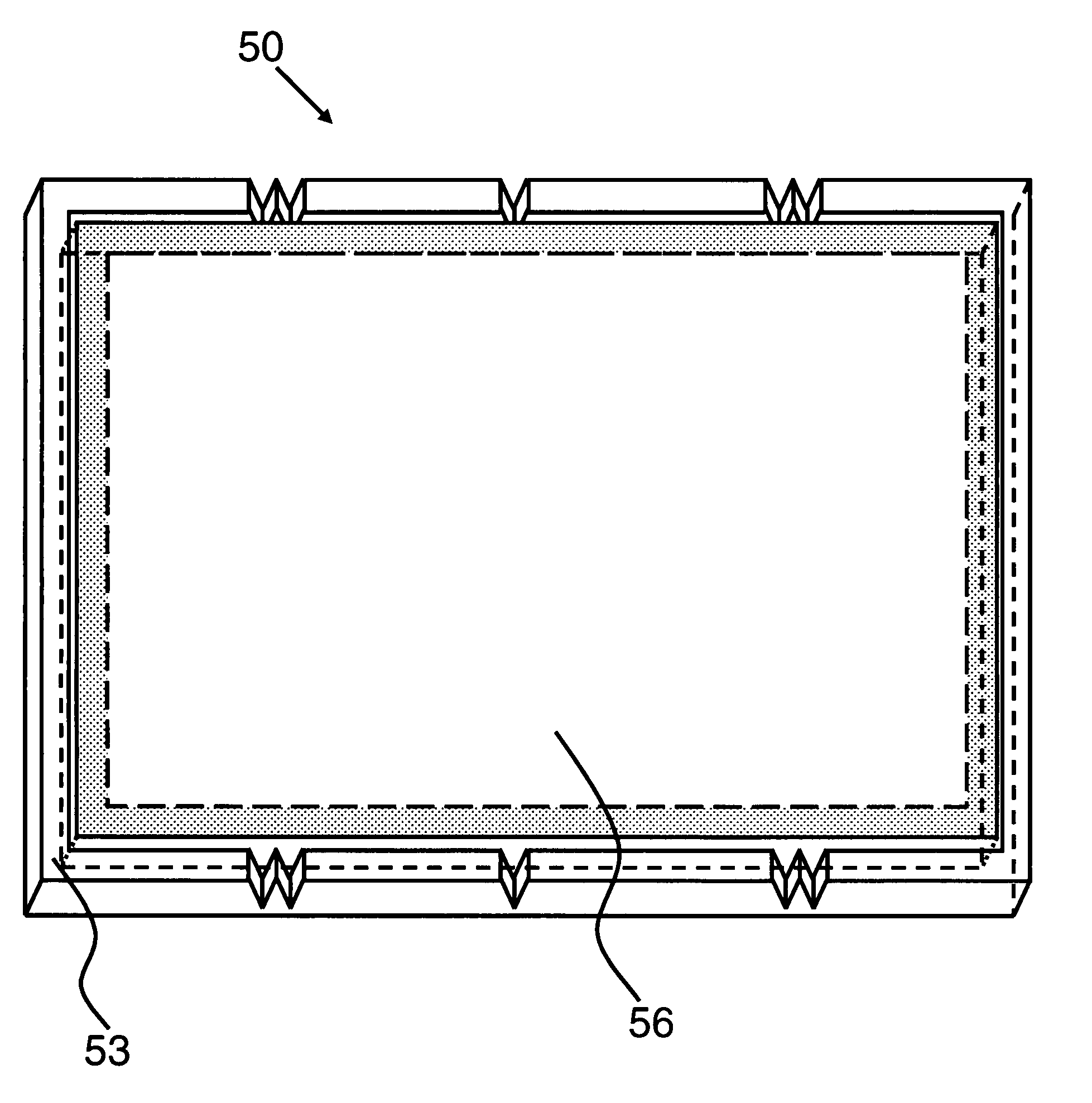

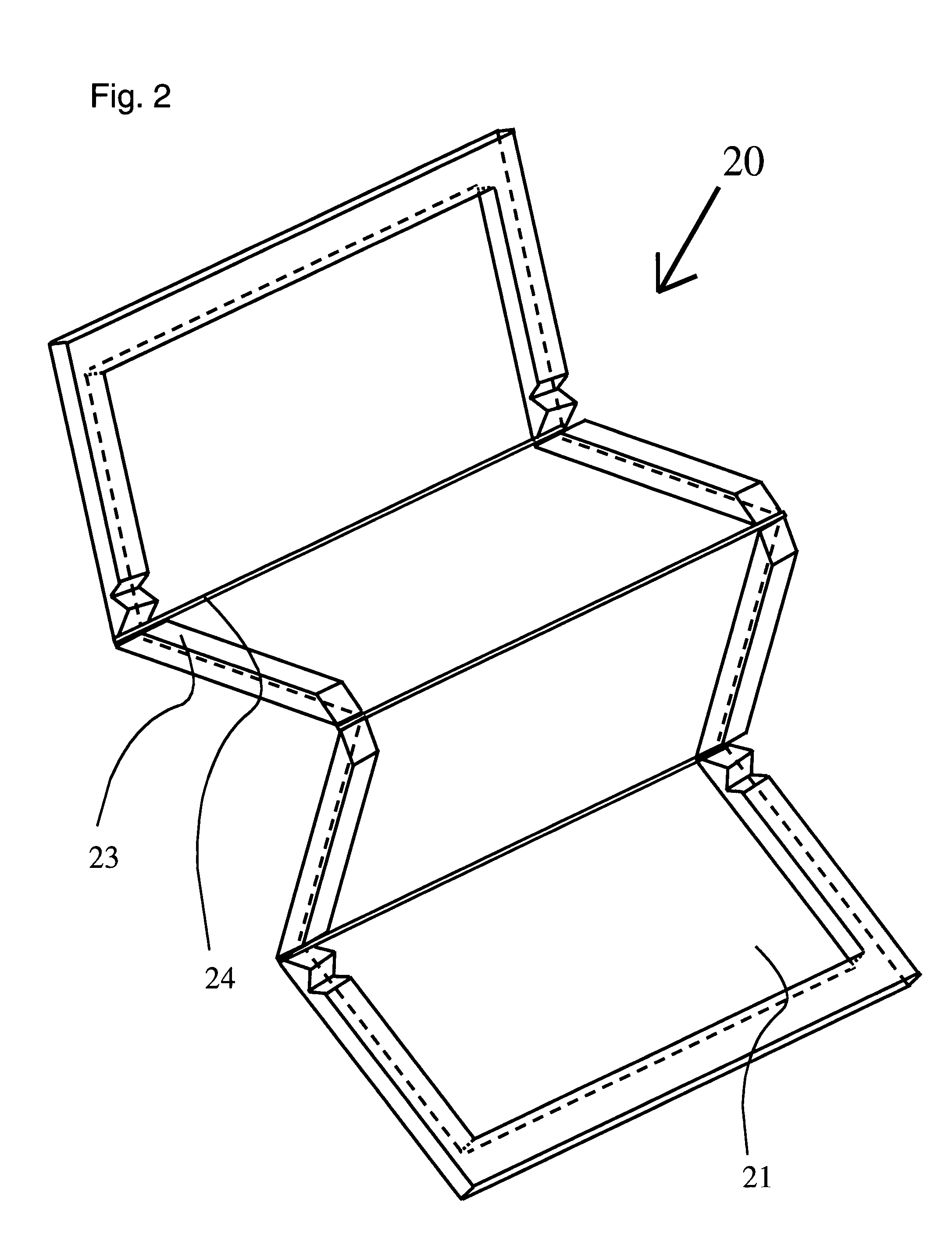

Compact foldable animal litter pan with disposable adhesive waste collection sheets

InactiveUS20080083376A1Large cell sizePrevent slippingAnimal housingOther apparatusPolymeric surfaceFluff pulp

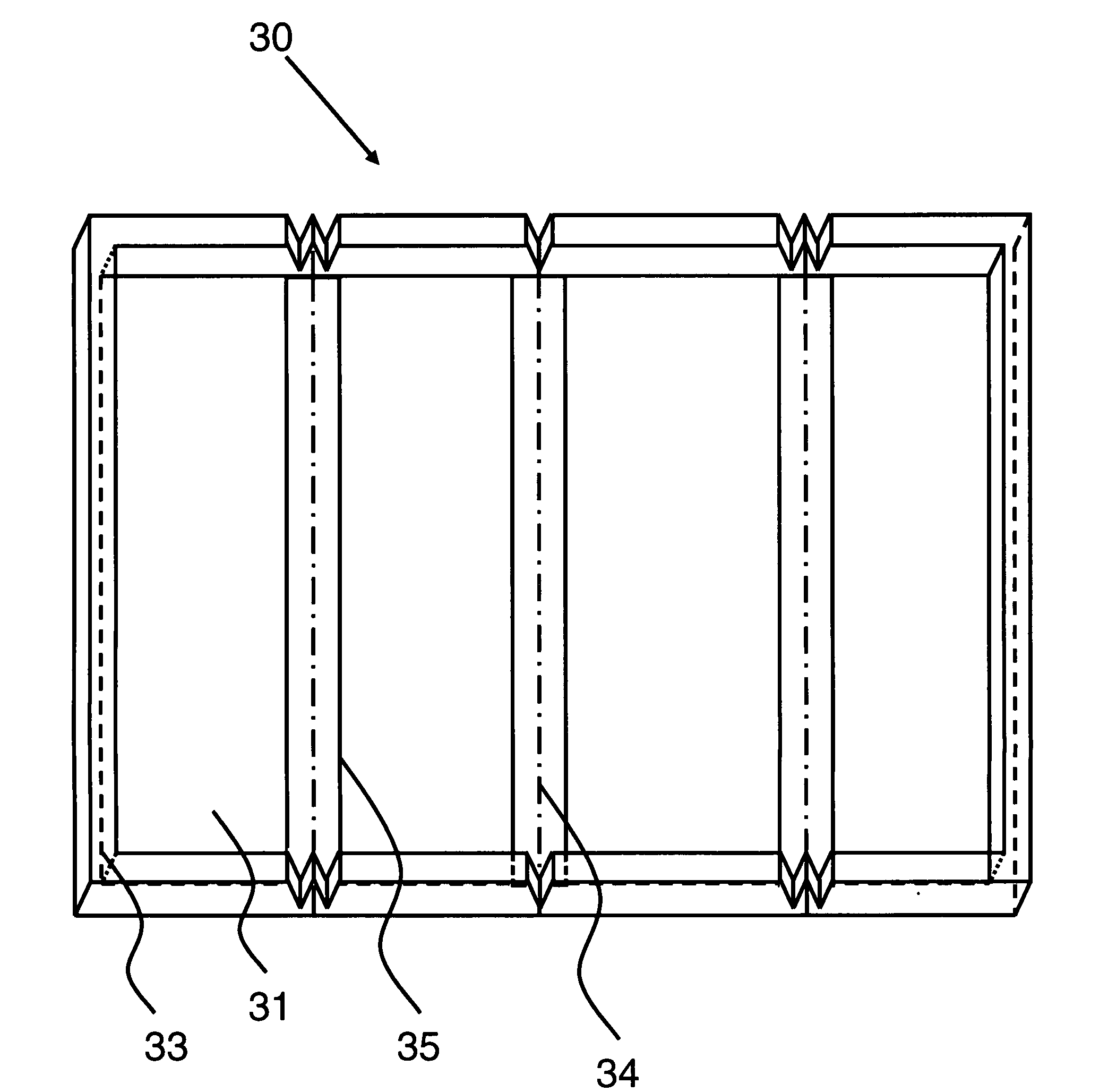

A collapsible animal litter pan has polymeric surfaces that are immune to urine soaking. A plurality of hinges collapse and expand the litter pan. The litter pan has sidewalls that locate, receive and stabilize a urine absorption sheet. The urine absorption sheet has a liquid impervious bottom layer, a urine absorption layer composed of cotton, cellulose fluff pulp, commuted pulp, soft wood fine chips, or hydrophilic paper and combinations thereof, together with superabsorbent polymers and a top, liquid permeable, layer. The top and bottom layers are bonded to constrain the urine absorbent layer. An adhesive coating is applied to the bottom layer of the urine absorption sheet for temporarily adhering the sheet to the foldable litter pan for enhanced stability of the urine absorption sheet. Animal urine is substantially completely absorbed by the urine absorbent sheet, and the soiled sheet replaced with a fresh sheet without soiling the litter pan.

Owner:I DID IT

Natural color fluff pulp and preparation method thereof

InactiveCN103850145AAvoid harmAvoid pollutionNatural cellulose pulp/paperCellulose material pulpingFluff pulpPulp and paper industry

The invention aims to provide a natural color fluff pulp which is really healthy and environmentally friendly. The natural color fluff pulp is characterized by being prepared from one raw material or a plurality of raw materials through mixing, and has performance parameters meeting the fluff pulp national standard GB / T21331-2008. The materials adopted by the natural color fluff pulp are not blanched, not added with a brightener or a color developing agent during the production process; a natural color fluff pulp product does not contain cancerogenic substance such as dioxin or adsorptive organic halide, harm to the human body and pollution to the environment caused by chemicals used in the blanching or brightening process are eliminated, 100% natural color of plant fiber is kept; the natural color fluff pulp is applicable to the field of hygienic products; a manufactured hygienic product has excellent performances and improved practicability; the natural color fluff pulp is sanitary, safe and environmentally friendly, and has good protection property for physiological hygiene and physical and psychological health of the human body.

Owner:BEIJING ZHENGLI HENGFENG PULP & PAPER

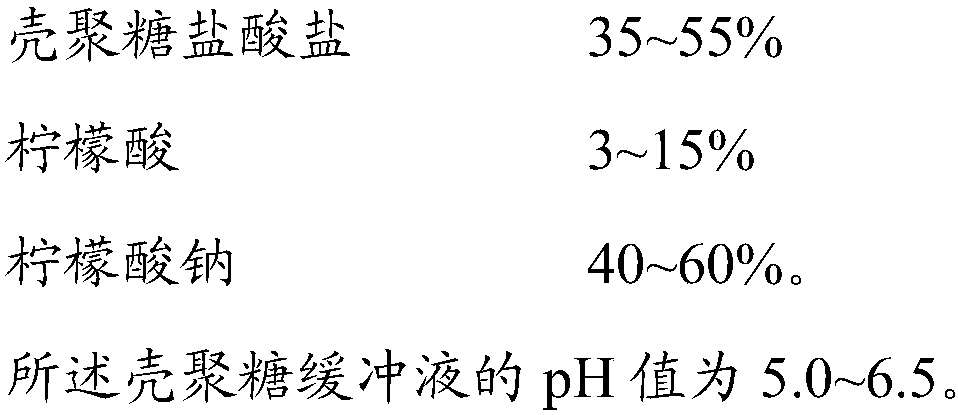

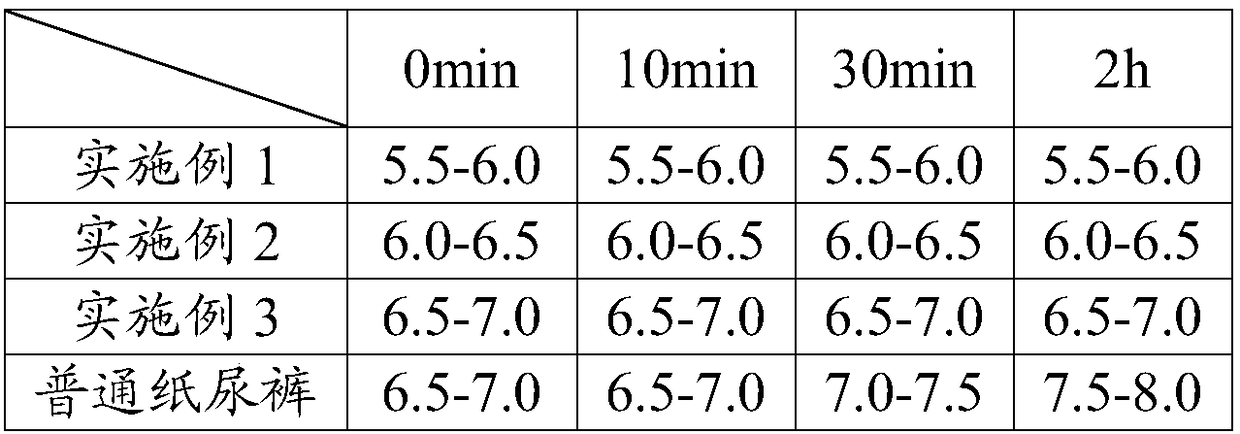

Infant paper diaper with excellent antibacterial performance

PendingCN108553219AStable weak acid environmentInhibitory activityAbsorbent padsBandagesFluff pulpBuffer solution

The invention discloses to an infant paper diaper with excellent antibacterial performance. The infant paper diaper with excellent antibacterial performance comprises a paper diaper body, wherein thepaper diaper body comprises a liquid permeable layer, a guide layer, a coating layer and a liquid impermeable bottom film layer which are sequentially compounded from top to bottom, the coating layeris coated with an absorbent core body, the absorbent core body is sequentially provided with an upper absorbent layer, an absorbent core material and a lower absorption layer from top to bottom, wherein the absorbent core material comprises a high-molecular water-absorbing resin, a chitosan buffer solution and a fluff pulp, the weight ratio of the high-molecular water-absorbing resin, the chitosanbuffer solution and the fluff pulp is 6-15:0.5-2:15-25. The paper diaper with excellent antibacterial performance solves the problem that the paper diaper has no antibacterial effect or safety uncertainty of the silver-containing antibacterial agent in the prior art, can maintain the pH environment of the paper diaper, and reduces the stimulation of the diaper on the skin.

Owner:QUANZHOU YALIN NEW MATERIAL TECH

Highly wettable-highly flexible fluff fibers and disposable absorbent products made of those

An absorbent core comprising fluff pulp fiber treated with polysiloxane, wherein the absorbent core has a density of about 0.15 g / cm3 or greater and a Young's modulus of about 75 psi or less. The polysiloxane may comprise an amino-functional moiety, The absorbent core may comprise superabsorbent, and may be employed in a disposable absorbent product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

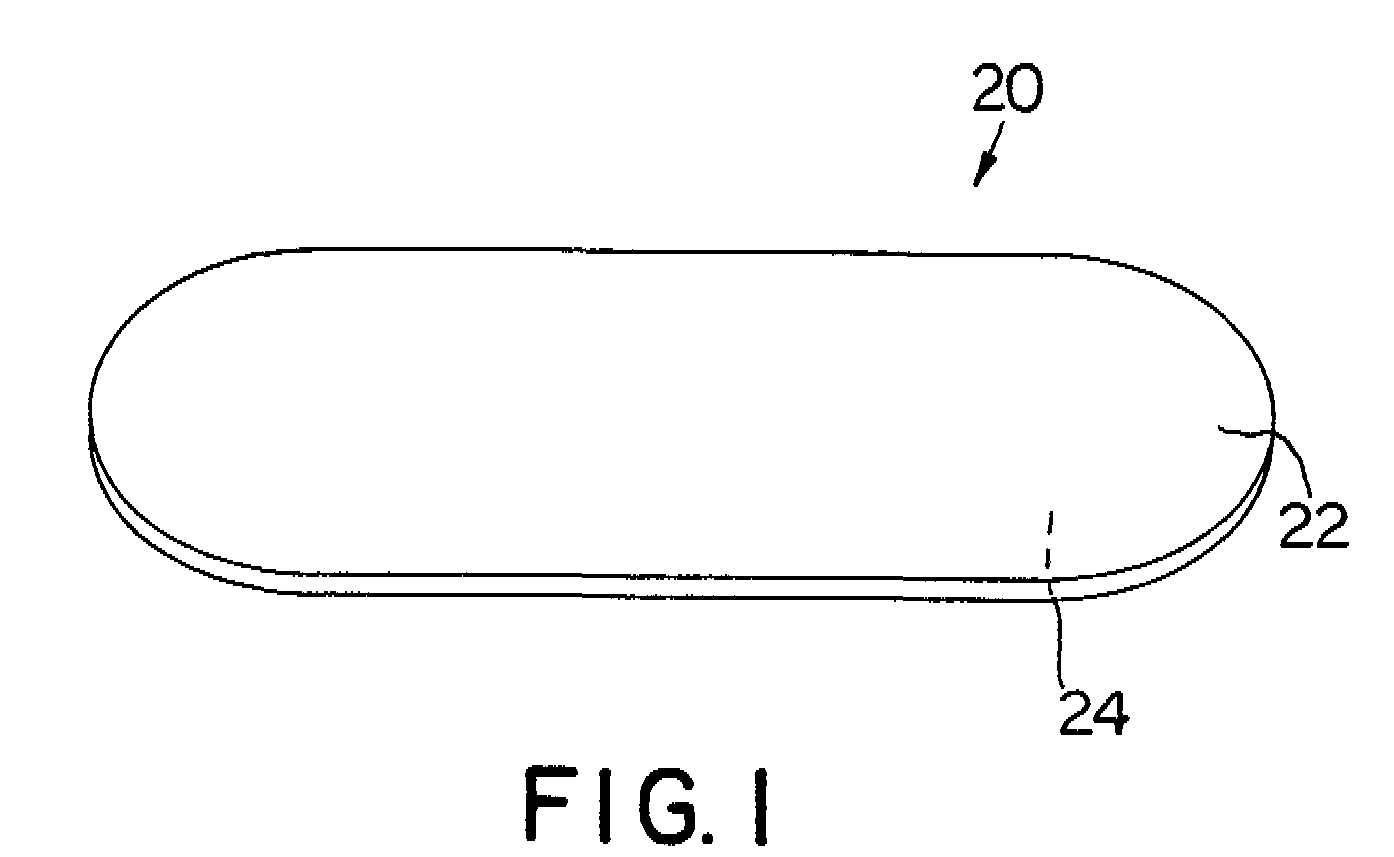

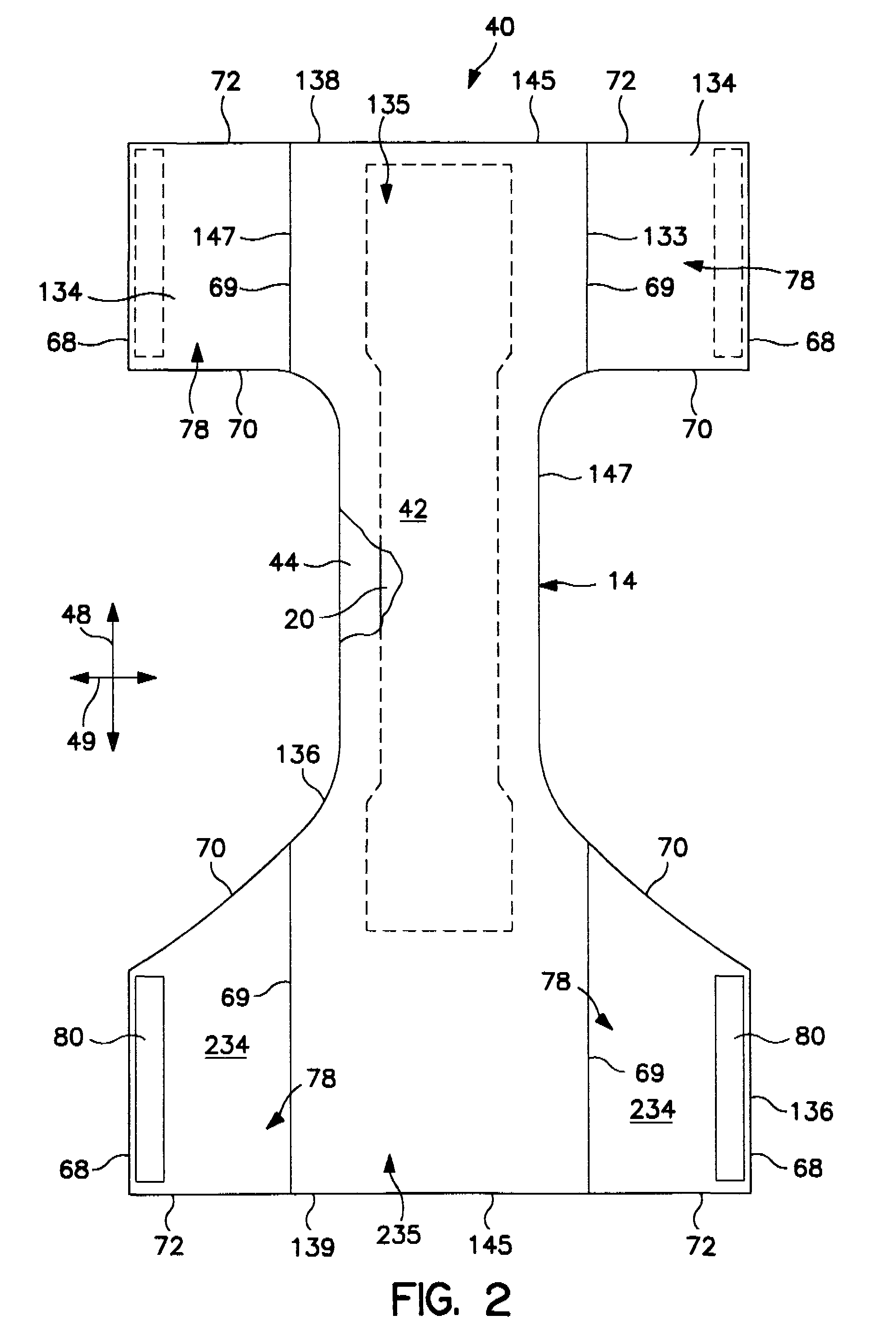

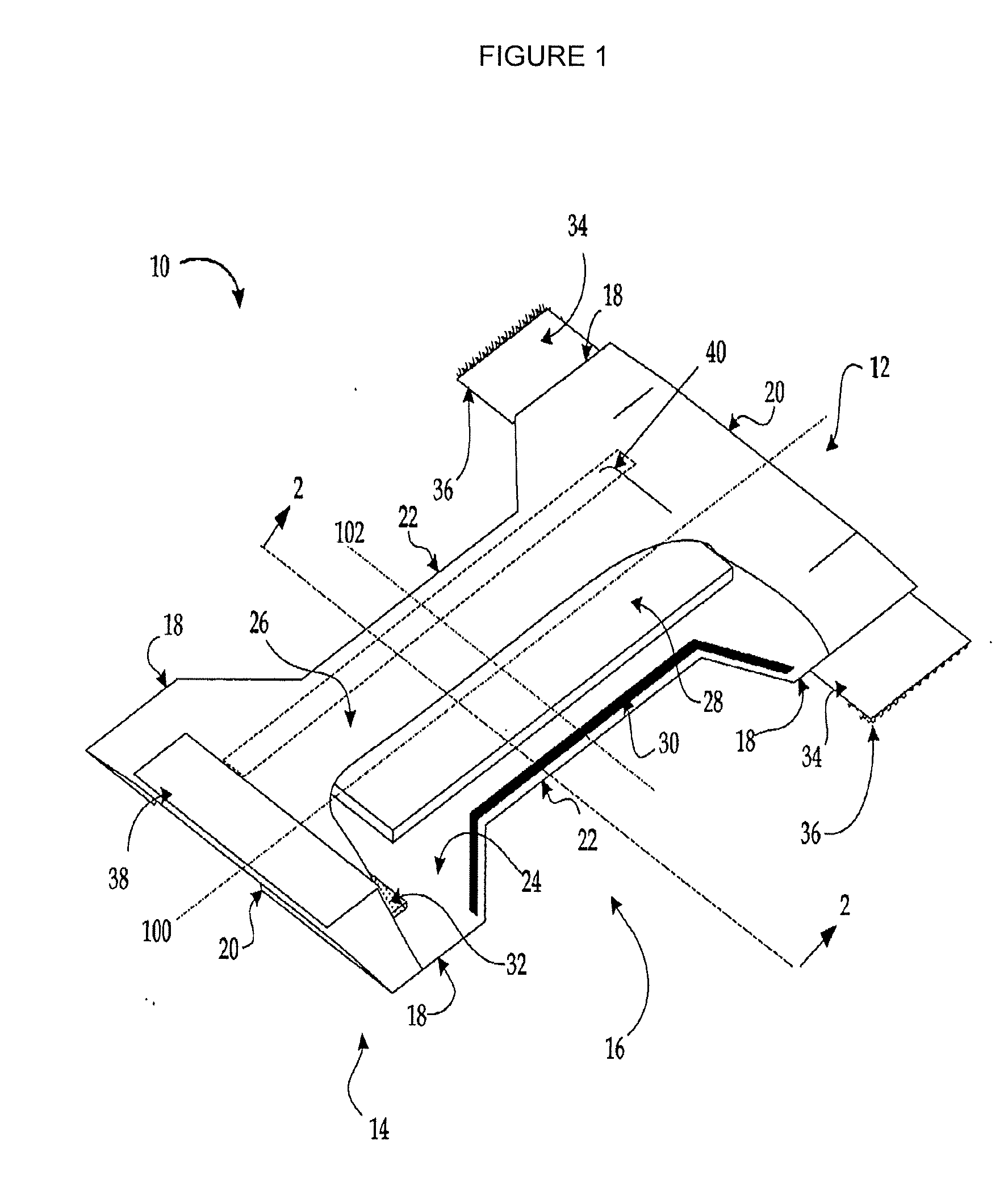

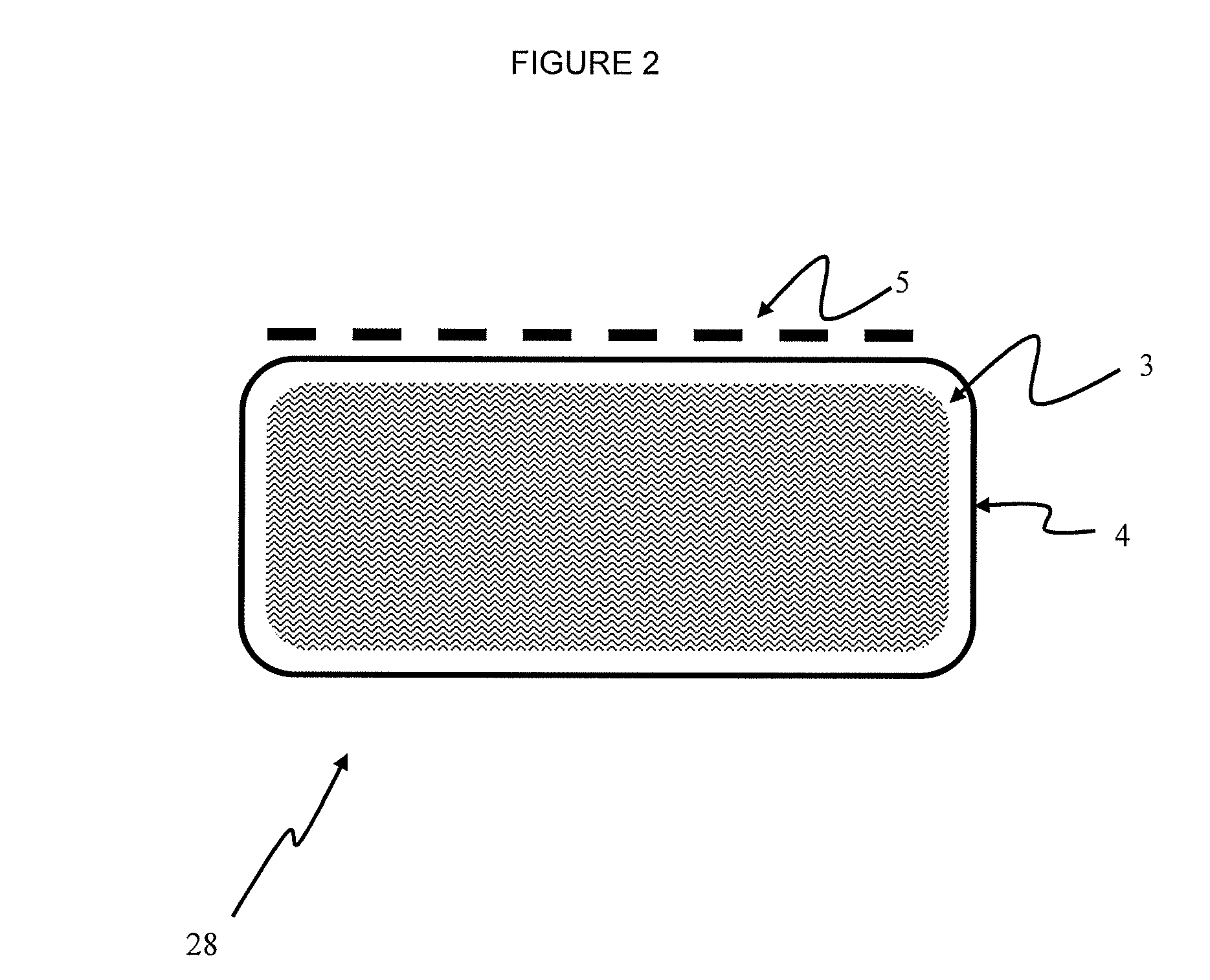

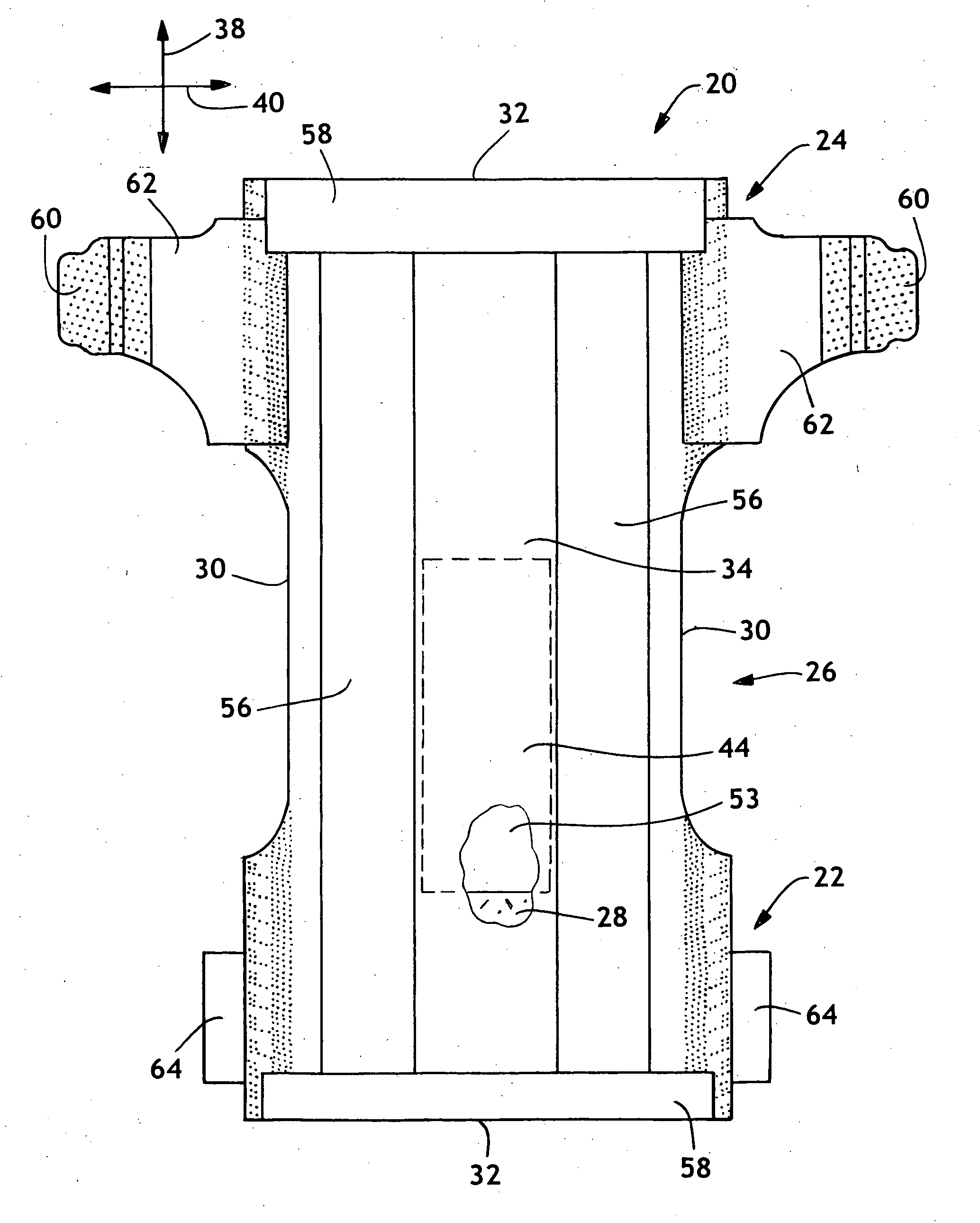

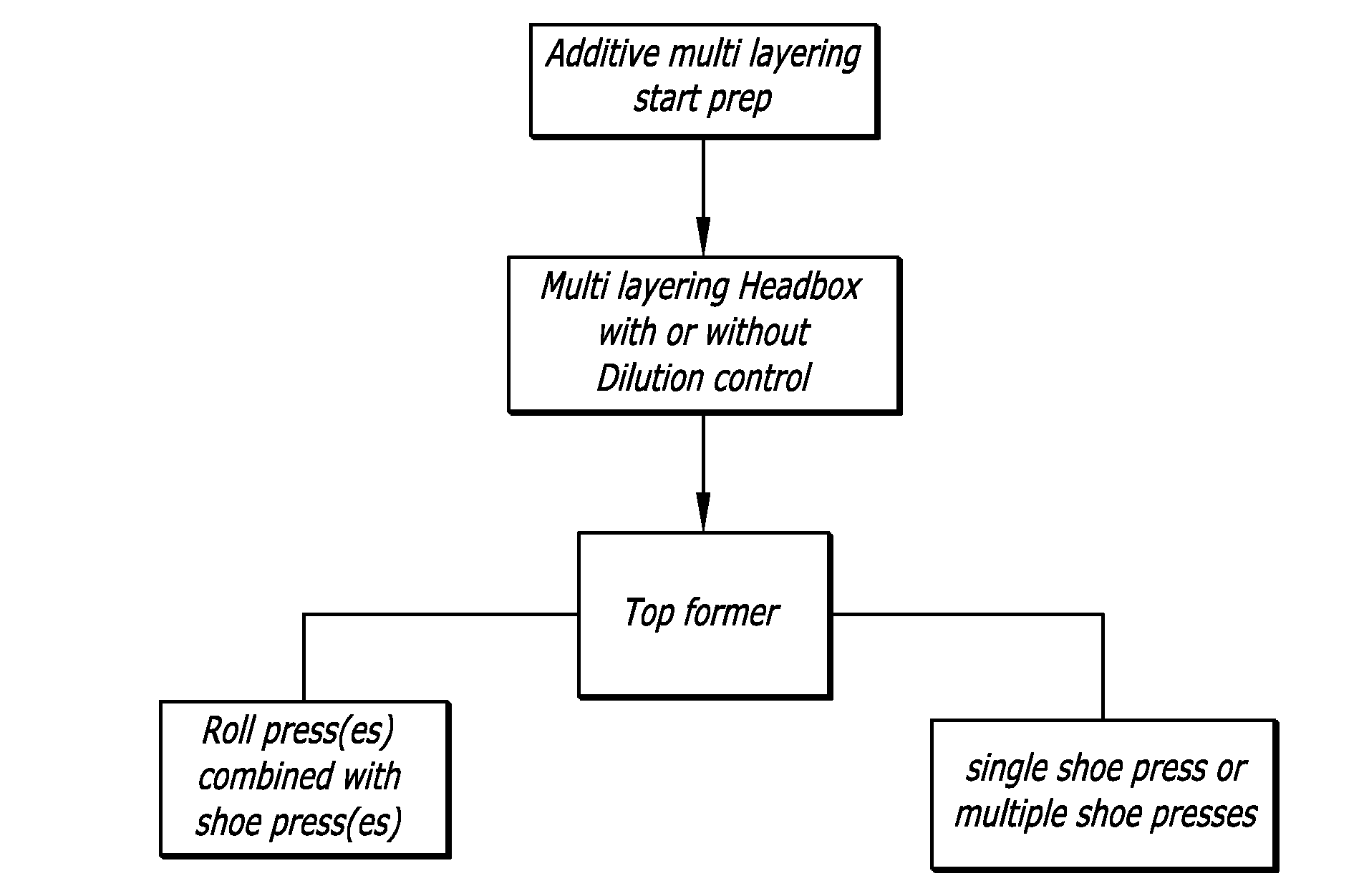

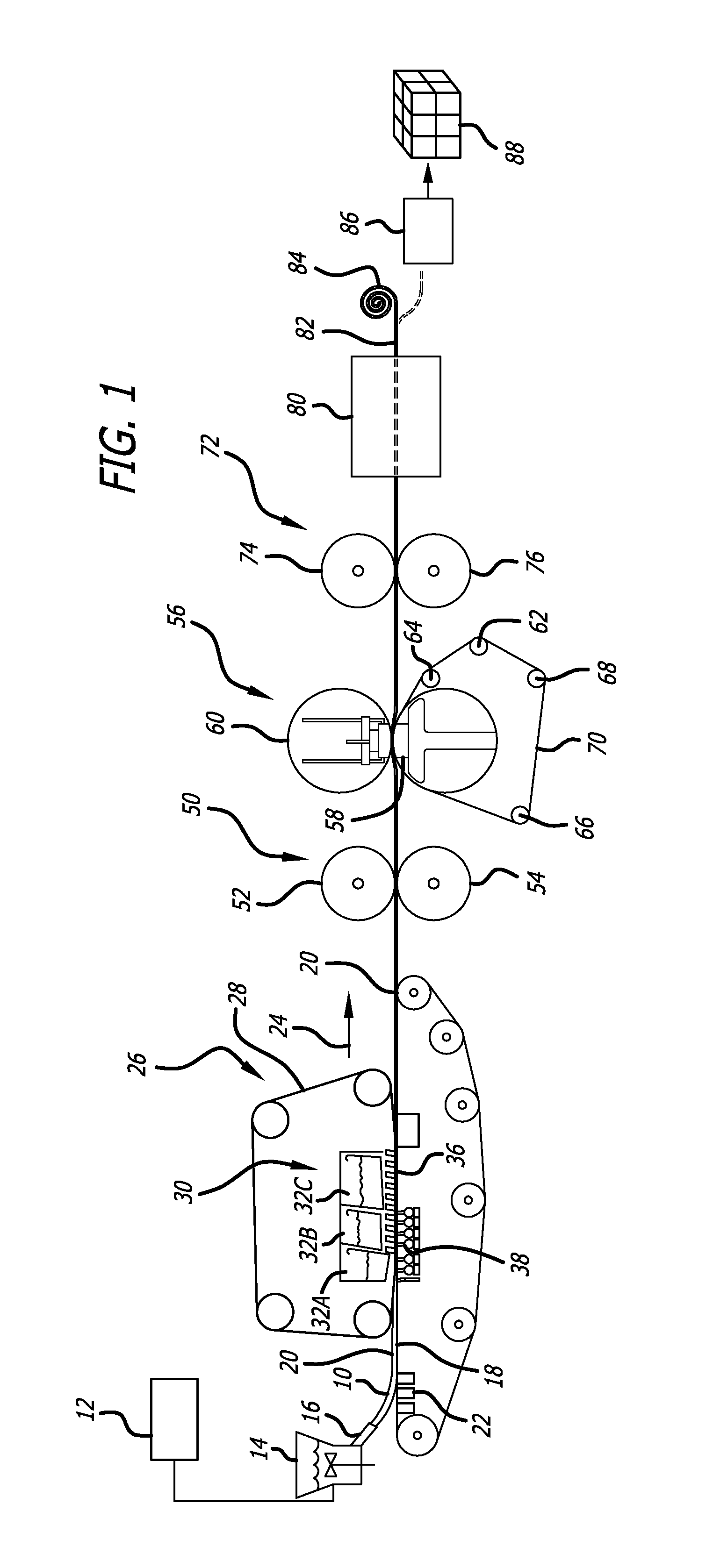

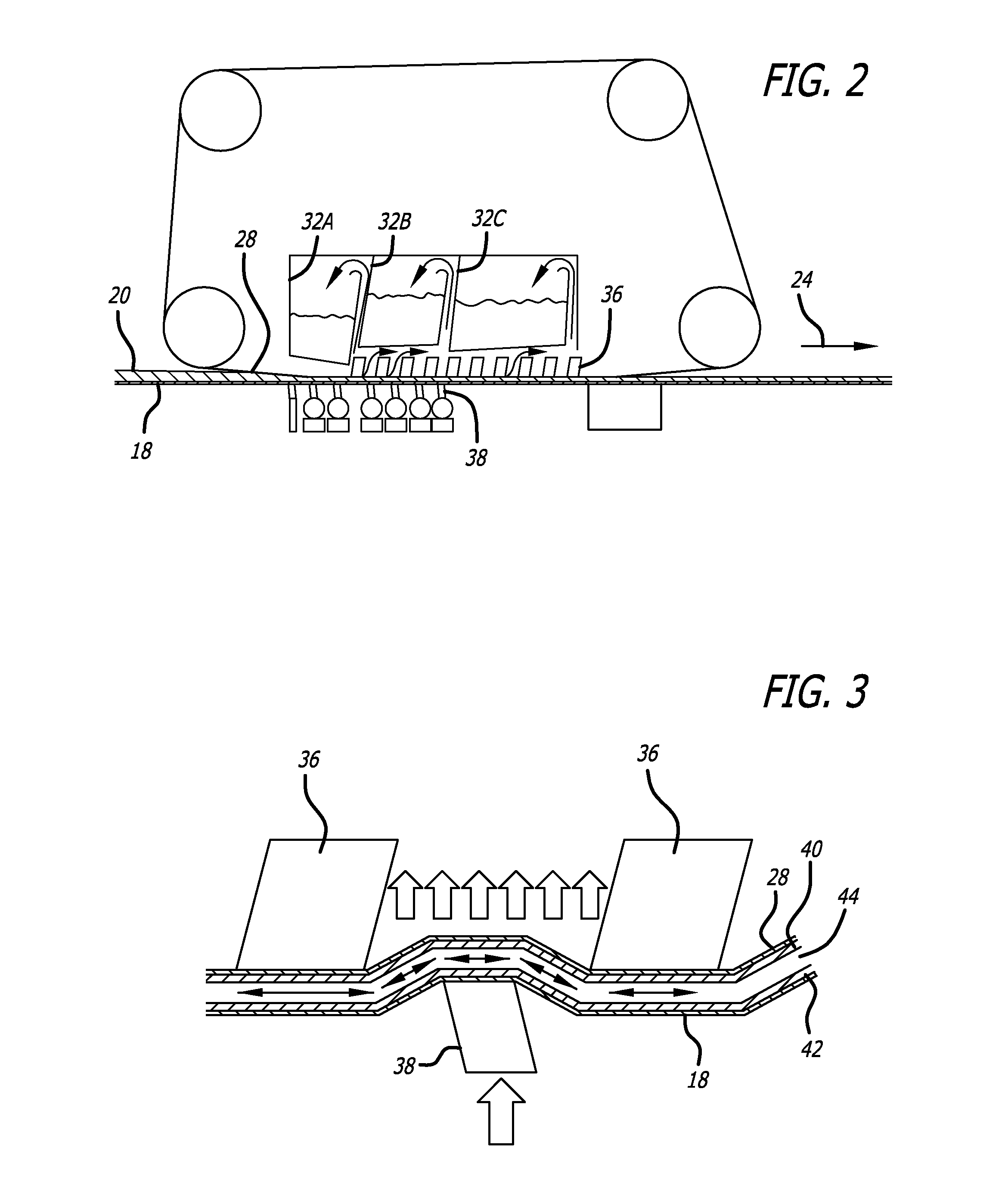

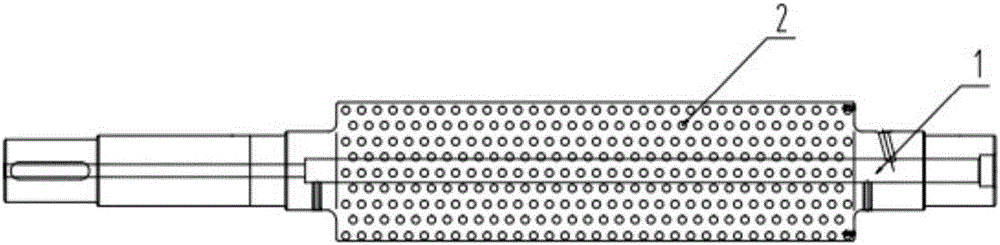

Methods and apparatus for forming fluff pulp sheets

ActiveUS20130213594A1Reduce in quantityLow variabilityNon-fibrous pulp additionNatural cellulose pulp/paperPaper sheetFluff pulp

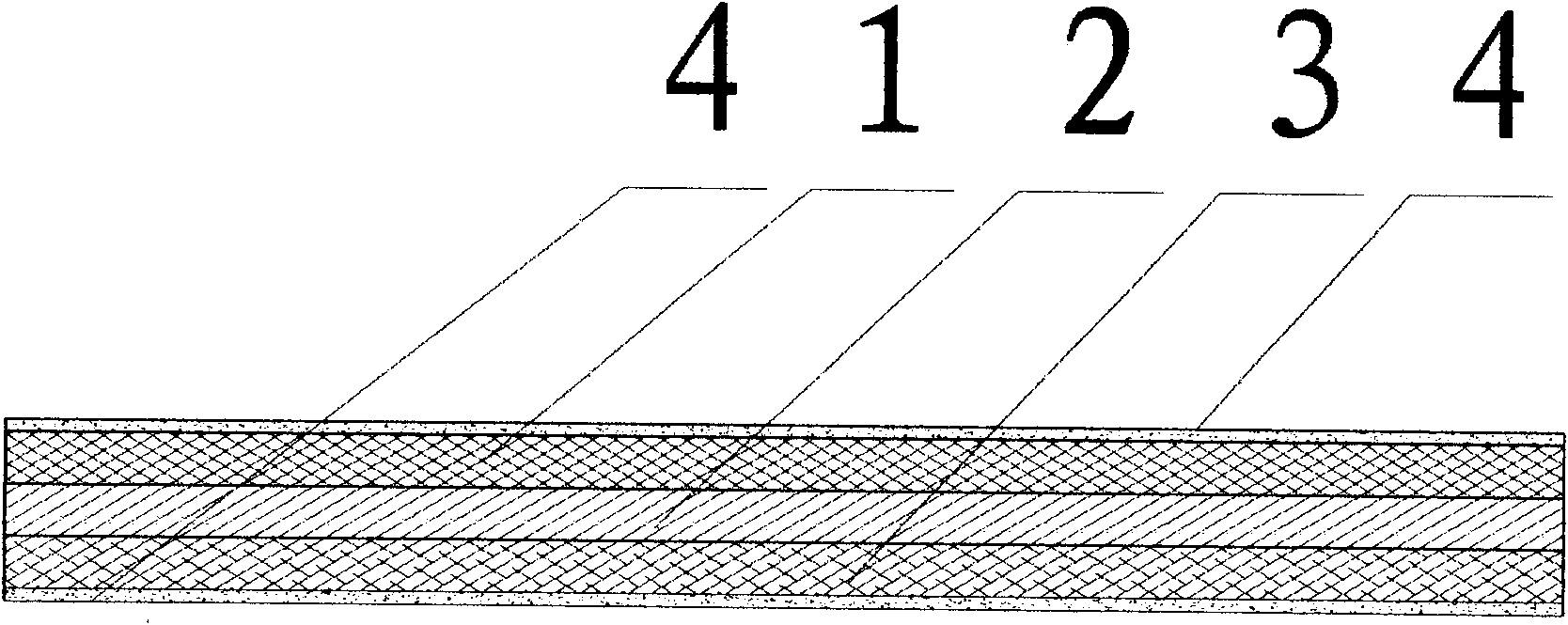

Processes for making fluff pulp sheets mechanically eliminate many unwanted fiber-to-fiber bonding (fiber bundles) in the sheet. Pulp slurry is deposited on a moving bottom forming wire to form a stock web. Pulp slurry is brought into contact with a moving top forming wire. The stock web is subjected to up and down dewatering creating separately formed layers to reduce fiber-to-fiber bonding. The stock web can be subjected to strong pulsating shear forces as it is being advanced along the bottom forming wire to break fiber bundles. The pulp slurry can be deposited on the bottom forming wire utilizing a headbox with dilution control to selectively adjust the concentration of the pulp slurry. Shoe presses can be used to dewater the web after it is subjected to the pulsating shear forces.

Owner:INT PAPER CO

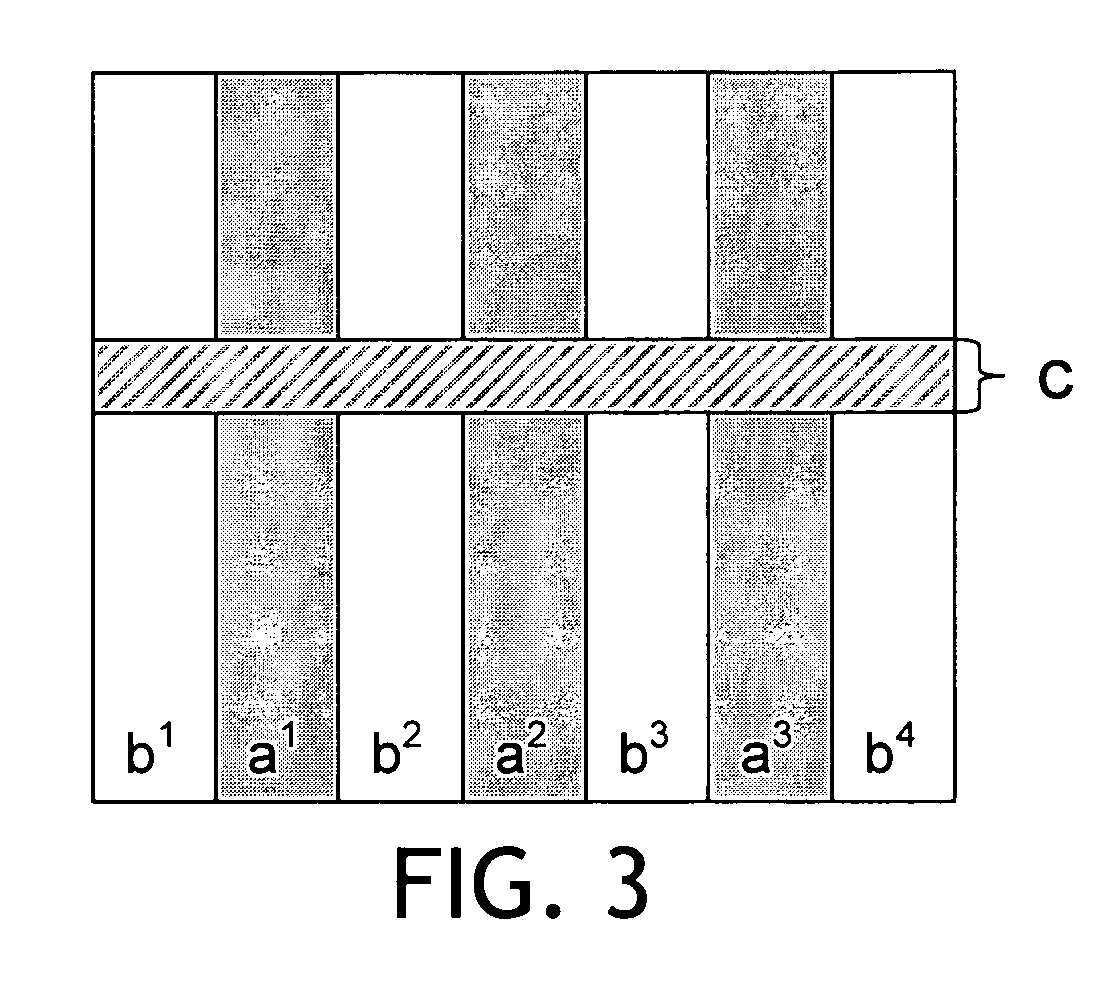

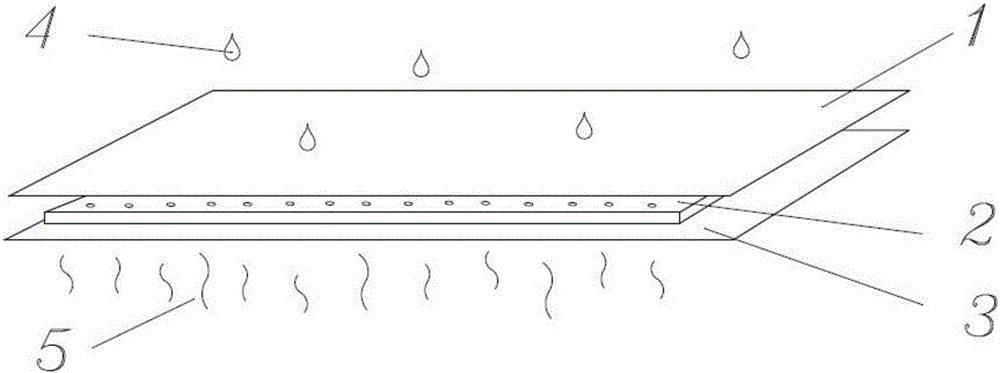

Process for producing high-molecular water-absorbent resin dust-free paper

InactiveCN102337701AEffective lockingReduce reverse osmosisNon-fibrous pulp additionSpecial paperReverse osmosisFluff pulp

The invention belongs to the papermaking technical field, more specifically relates to a process for producing the high-molecular water-absorbent resin dust-free paper. The process for producing the high-molecular water-absorbent resin dust-free paper takes fluff pulp wood pulp fiber, hot melt composite fiber and high-molecular water-absorbent resin (SAP) as the raw materials and the dust-free paper is composed of three-layer mixing layers. The process for producing high-molecular water-absorbent resin dust-free paper comprises the following steps: mixing the raw materials through a molding case, penetrating through hot air, wherein a heat bonding point between the hot melt fiber and wood pulp fiber formed by surface melting and flowing which are generated by the hot melt fiber during the heating process has the heat bonding effect, spraying latex on the double faces of the paper web and then drying by hot-air in a drying cylinder, rewinding to obtain the finished product. The present invention has the beneficial effects that the dust-free paper has good penetration performance and imbibition capability, is capable of effectively holding liquid, minimizing the reverse osmosis of liquid and maintaining the dry surface of the product, and has less dust and high tensile strength.

Owner:NANNING QIAOHONG NEW MATERIALS

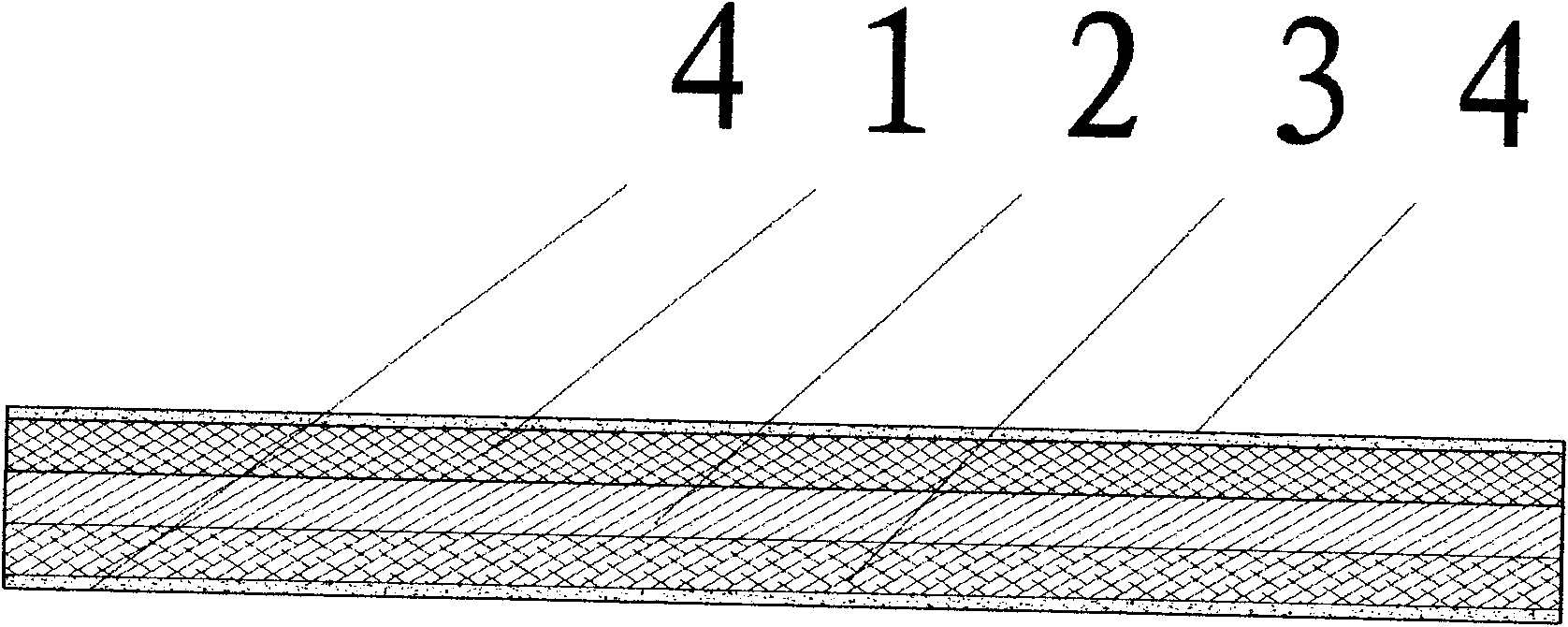

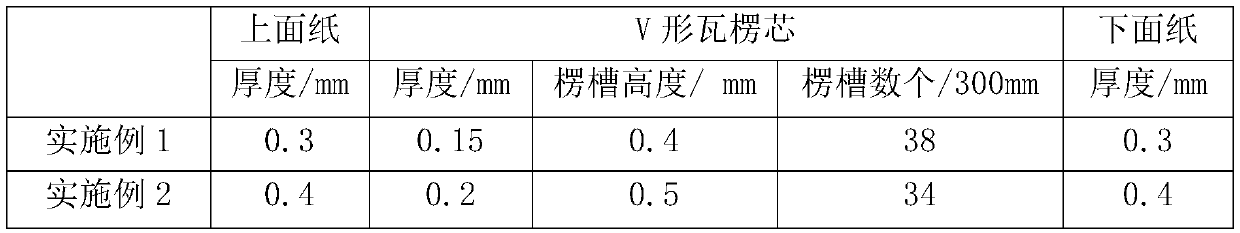

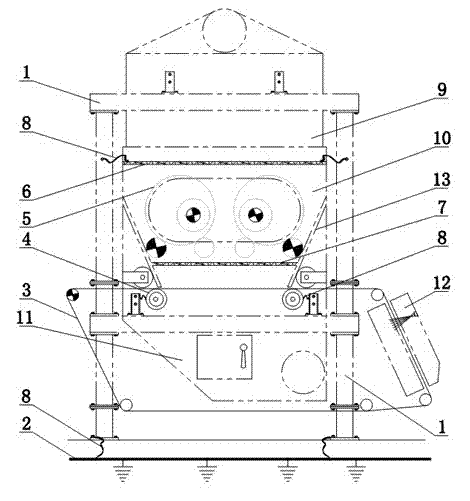

Wear resistant high-strength corrugated board and preparation method thereof

ActiveCN110344279ASimple preparation processEasy to operateSpecial paperPaper/cardboardSodium sorbatePolyvinyl alcohol

The invention discloses a wear resistant high-strength corrugated board and a preparation method thereof. The corrugated board is formed by compounding upper-faced paper, a V-shaped corrugated core and lower-faced paper, the V-shaped corrugated core is composed of a corrugated core base layer and protective layers sizing on both sides of the base layer, the corrugated core base layer is prepared from the following raw materials in parts: 100 parts of red pine wood pulp, 30-50 parts of bamboo pulp, 20-30 parts of fluff pulp, 40-60 parts of waste paper pulp, 1-5 parts of cyclodextrin, 10-15 parts of oxidated cassava starch, 4-8 parts of composite reinforced fibers, 1-3 parts of cationic polyacrylamide, 0.01-0.1 part of sodium sorbate, 0.1-0.3 part of antimonous oxide, 0.1-0.5 part of poval,5-7 parts of polydimethylsiloxane, and each protective layer is prepared from the following components in percentage by weight: 40-60% of a hydroxylation graphene modified ylate emulsion, 5-10% of sodium caseinate, 20-30% of cationic rosin size and 15-20% of montmorillonite. The corrugated board has the high mechanical strength, excellent wear resistance, excellent shock resistance, excellent water resistance and excellent moisture resistance, has certain antibacterial and mildew-proof effects, the preparation technology is simple, operation is convenient and fast, and repeat sizing is not needed.

Owner:纸享家(上海)环保科技有限责任公司

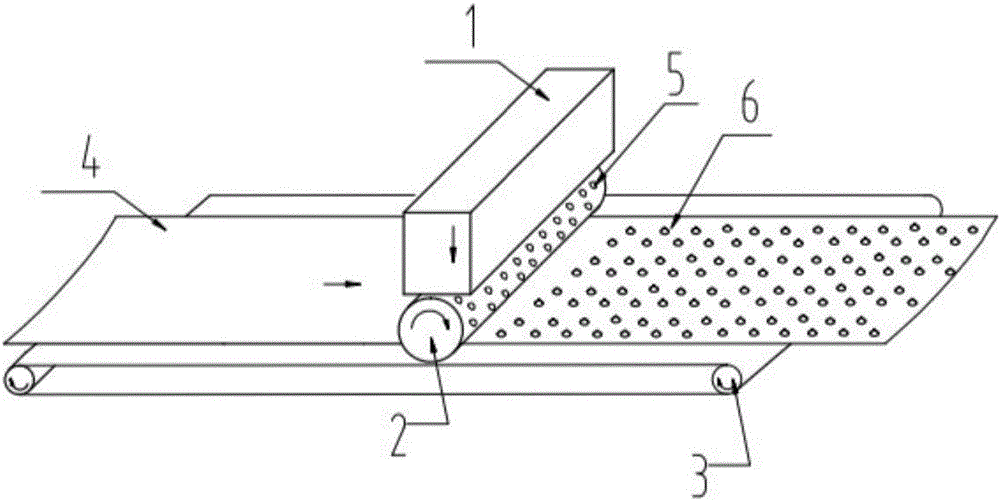

Technique and device for dry formation of low basis weight fluff pulp and capable of eliminating electrostatic flocculation

ActiveCN102551186AFacilitate transfer and strippingImprove uniformityTobacco preparationFlocculationFluff pulp

The invention provides a technique and a device for dry formation of low basis weight fluff pulp and capable of eliminating electrostatic flocculation. The technique for dry formation of low basis weight fluff pulp and elimination of electrostatic flocculation within a quantitative range of from 15g / m2 to 30g / m2, a high-mesh-number woven copper net serving as a formation net is used with an electrostatic elimination device to produce a fluff pulp fiber underlayer of reconstructed tobacco, uniform formation is facilitated, electrostatic elimination is facilitated, and transfer and removal of the formed underlayer fibers from the formation net are facilitated. The technique and the device are characterized in that the formation net is a woven endless net of metal wires, zero potential nets are square-hole static-eliminated nets respectively and horizontally disposed at the top and the bottom of a cylindrical screen, and a frame grounding system is an independent equipotential system using a frame as zero potential.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

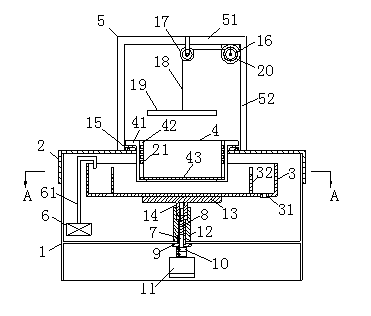

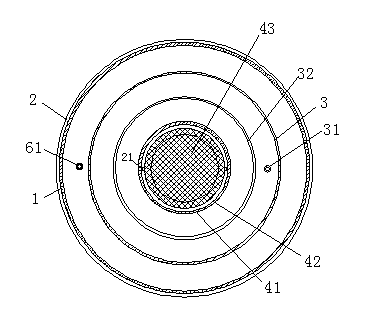

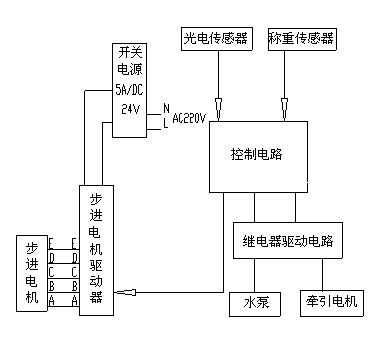

Automatic determinator for fluffy performance and water absorbency of fluff pulp

InactiveCN103018157AControl water levelSimple structureUsing mechanical meansWeighing by absorbing componentMicrocontrollerCoupling

The invention relates to an automatic determinator for fluffy performance and water absorbency of fluff pulp. The automatic determinator comprises a determinator main body and a control circuit, wherein the determinator main body comprises a water storage tank which is in a circular groove structure, a water absorbent tank which is disposed in the water storage tank and is a circular groove with the diameter thereof smaller than that of the water storage tank, an overflow separated plate disposed in the water absorbent tank, a lifting component of the water absorbent tank comprises a adjusting shaft, a spring, a spring seat, a shaft coupling and a stepping motor; a sample plate is supportably disposed in a circular hole at the center of the upper cover of the water tank; edge of a ring-shaped outer sleeve is supportably located on three weighing sensors; a plurality of groups of photoelectric sensors are vertically embedded in an inner sleeve; and the photoelectric sensors are connected to an AD port of a single-chip computer of the control circuit. The automatic determinator can effectively control immersed water level of the sample plate due to the adoption of the lifting mechanism of the water absorbent tank, allowing the measured data to be more accurate. The automatic determinator has the advantages of small size, simple structure, convenient use and the like, can be usedin experiments, has wide application and popularization value, and can be widely applied in detection of characteristic quality indexes of the fluff pulp.

Owner:TECHN CENT FOR SAFETY OF INDAL PRODS TIANJIN ENTRY EXIT INSPECTION QUARANTINE BUREAU

Flexile deformation proof urinal pad premix paper urinal pad and production method of paper urinal pad

ActiveCN104068968AFast absorptionPrevent lump breakageSanitary towelsBandagesFluff pulpNonwoven fabric

The invention discloses a paper urinal pad of flexile deformation proof urinal pad premix and a production method of the paper urinal pad. The paper urinal pad comprises a surrounding piece which is formed by composite of a ventilated composite membrane and punched non-woven fabric; a core body is arranged between the ventilated composite membrane and the punched non-woven fabric in a clamping manner; a premix layer, a fluffy cloth layer and a wet strength paper layer are laid in the core body sequentially; SAP is coated between the premix layer and the fluffy cloth layer, as well as the fluffy cloth layer and the wet strength paper layer; the circumference is wrapped by air-laid paper wrapping layer through thermosol; the air-laid paper wrapping layer is superposed on the outer layer of the wet strength paper layer. The paper urinal pad is combined by adopting advantages of the two production technologies of integrally formed compound core body technology and fluff slurry mixing high absorption resin; absorption speed of the diaper is improved effectively; lump and fracture of the diaper after absorption are prevented effectively; the paper urinal pad is very high in tenacity, and high in comfort degree.

Owner:江西艾叶草药业有限责任公司

Compact foldable animal litter pan with disposable adhesive waste collection sheets

A collapsible animal litter pan has polymeric surfaces that are immune to urine soaking. A plurality of hinges collapse and expand the litter pan. The litter pan has sidewalls that locate, receive and stabilize a urine absorption sheet. The urine absorption sheet has a liquid impervious bottom layer, a urine absorption layer composed of cotton, cellulose fluff pulp, commuted pulp, soft wood fine chips, or hydrophilic paper and combinations thereof, together with superabsorbent polymers and a top, liquid permeable, layer. The top and bottom layers are bonded to constrain the urine absorbent layer. An adhesive coating is applied to the bottom layer of the urine absorption sheet for temporarily adhering the sheet to the foldable litter pan for enhanced stability of the urine absorption sheet. Animal urine is substantially completely absorbed by the urine absorbent sheet, and the soiled sheet replaced with a fresh sheet without soiling the litter pan.

Owner:I DID IT

Medical nursing pad for preventing bedsore

ActiveCN106038073AImprove drynessImprove comfortUpholstery manufactureNursing bedsSpecific functionReverse osmosis

The invention provides a medical nursing pad for preventing bedsore. The medical nursing pad comprises a surface layer, a core layer and a bottom layer, wherein the core layer comprises fluff pulp and a super absorbent polymer (SAP) material, and is wrapped with toilet paper; pointy SAPs are distributed on the core layer; an infiltrating liquid is absorbed and locked by the SAPs in an inverted funnel-shaped SAP region of the core layer, so that the reverse osmosis quantity of the nursing pad after liquid absorption is minimized; and meanwhile, water moisture separated from the liquid reaches the bottom layer through a longitudinal moisture channel formed by gaps among fluff pulp fibers in the core layer and determined by a density range, and diffuses out of the medical nursing pad through nanoscale breathable micropores in the bottom layer. The medical nursing pad can quickly absorb and firmly lock the moisture and the reverse osmosis quantity of the nursing pad is minimized, so that the nursing pad is kept dry and comfortable; and meanwhile, the moisture channel can be provided, so that the medical nursing pad can keep a specific function of moisture osmosis, and the purpose of preventing the bedsore is achieved after the medical nursing pad is combined with the specific function.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com