Process for producing high-molecular water-absorbent resin dust-free paper

A technology for polymer water absorption and production process, applied in the field of papermaking, can solve the problems of increasing downtime for cleaning and maintenance, affecting the normal operation of machinery and equipment, affecting the absorption performance of sanitary products, etc. The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

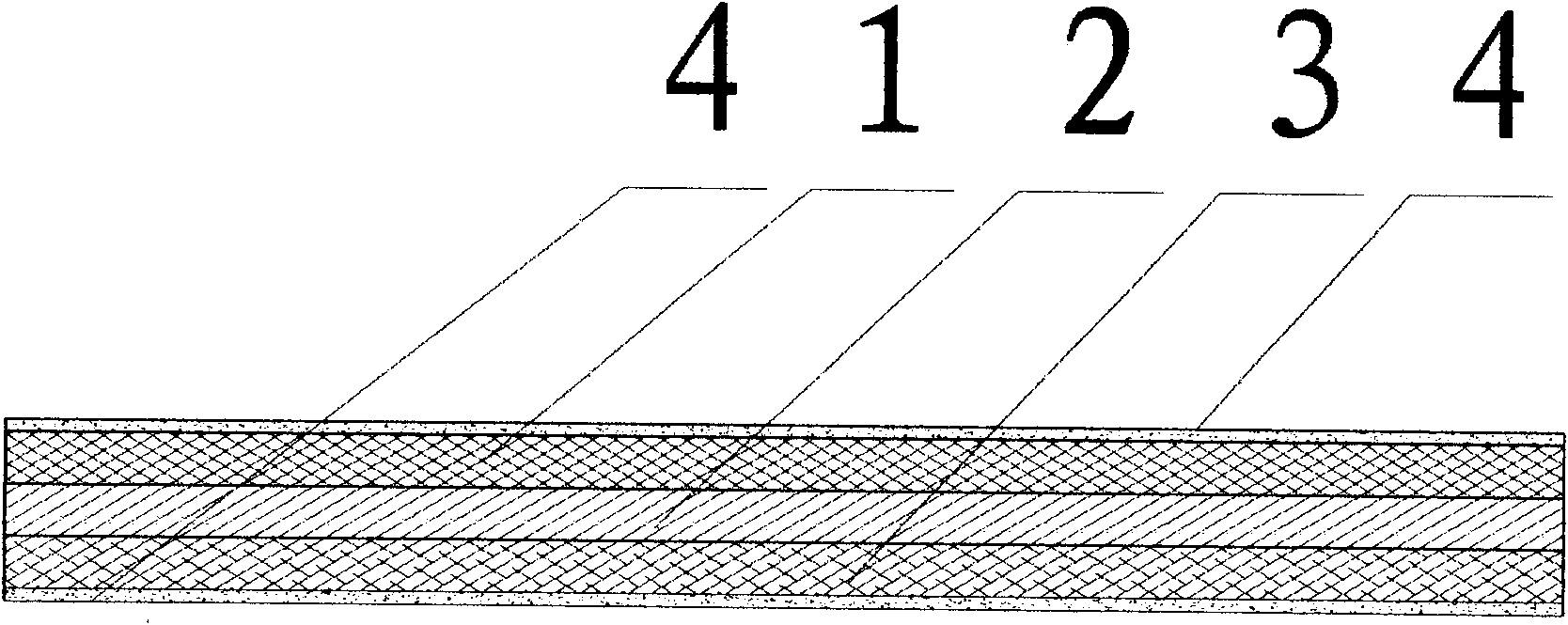

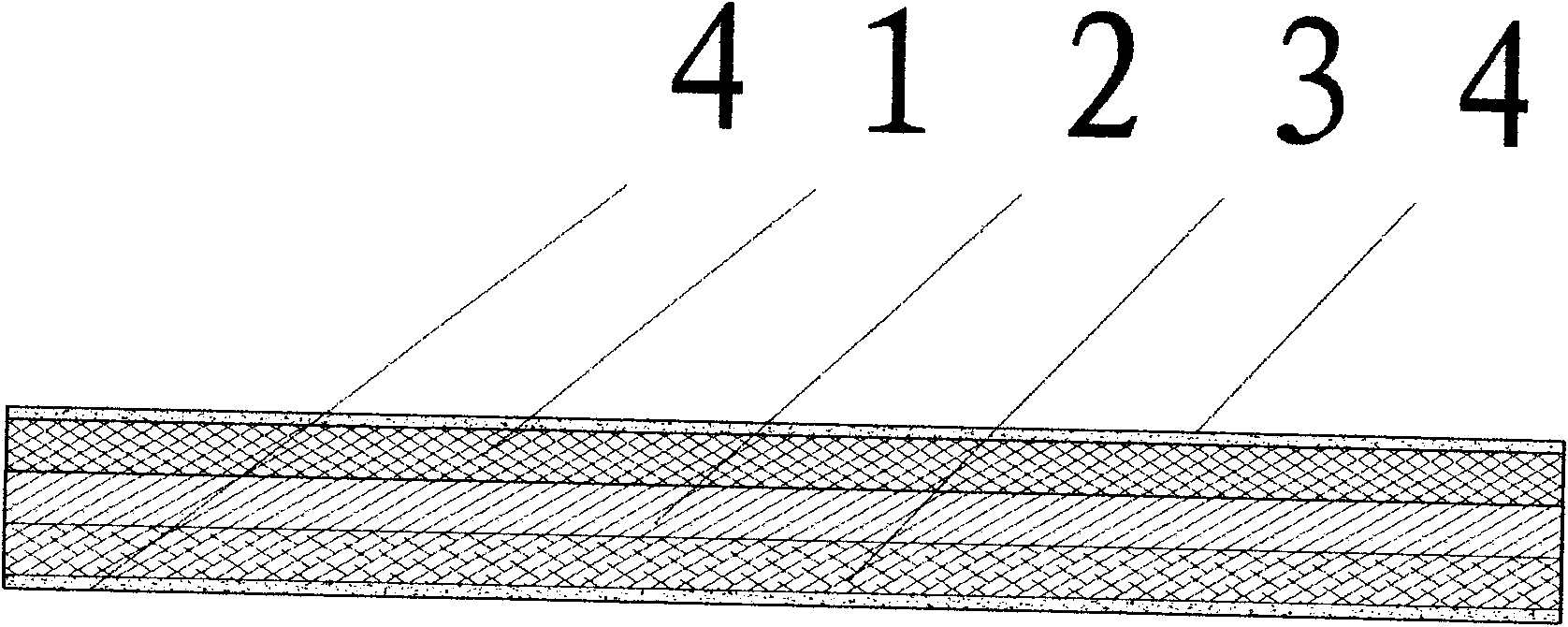

[0008] As shown in the figure, this polymer water-absorbent resin dust-free paper production process uses fluff pulp wood pulp fiber, hot-melt composite fiber and polymer water-absorbent resin (SAP) as raw materials, and consists of three mixed layers: the top layer 1 is fluff Pulp, composite fiber and water-retaining polymer water-absorbent resin (SAP) mixed layer, the middle layer 2 is a mixed layer of fluff pulp, composite fiber and fast water-absorbing polymer water-absorbent resin (SAP), the bottom layer 3 is a fluff pulp + composite fiber structure, And apply glue on top and bottom surface4.

[0009] The production process is to first mix the fluff pulp wood pulp fiber, hot-melt composite fiber and polymer water-absorbent resin (SAP) through the forming box: firstly, the crushed wood pulp and the opened hot-melt composite fiber are sent to the corresponding in the forming box. There are two counter-rotating drums in the forming box, and there is a loose needle roller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com