Patents

Literature

269results about How to "Reduce downtime for maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

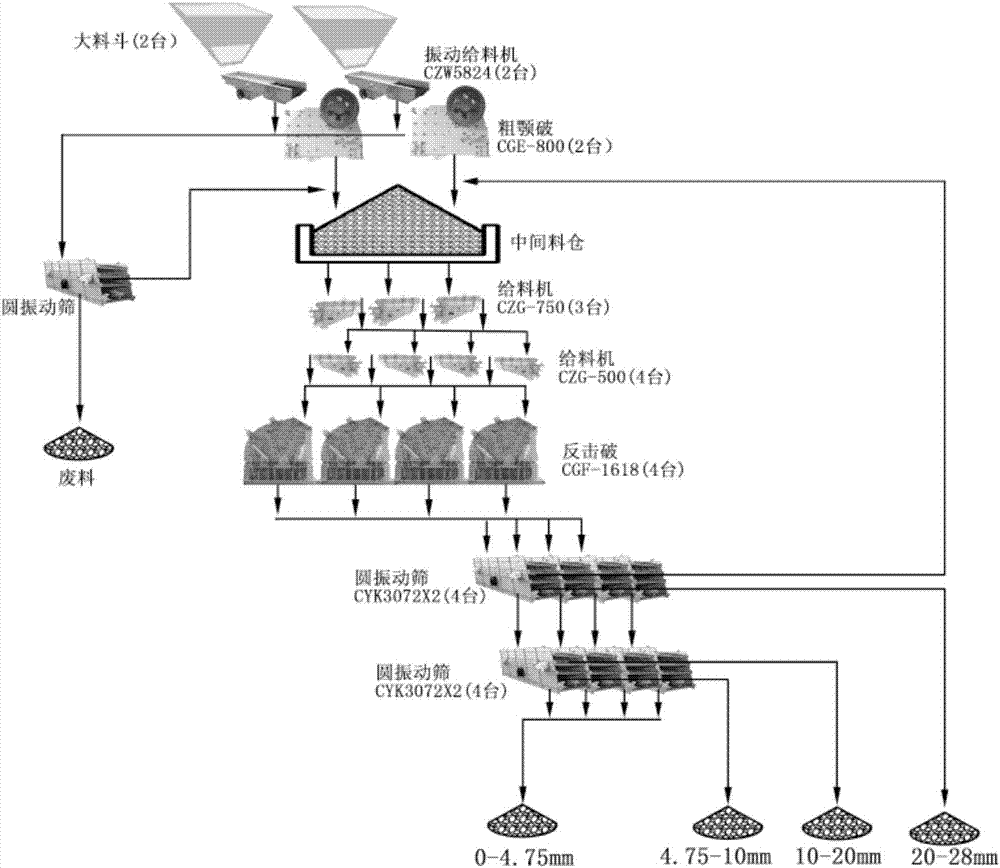

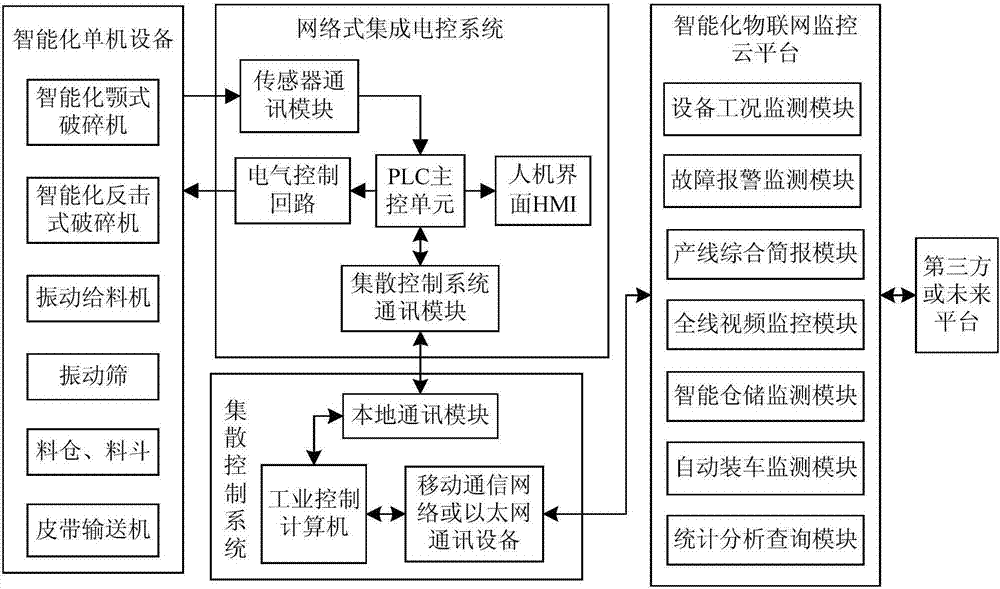

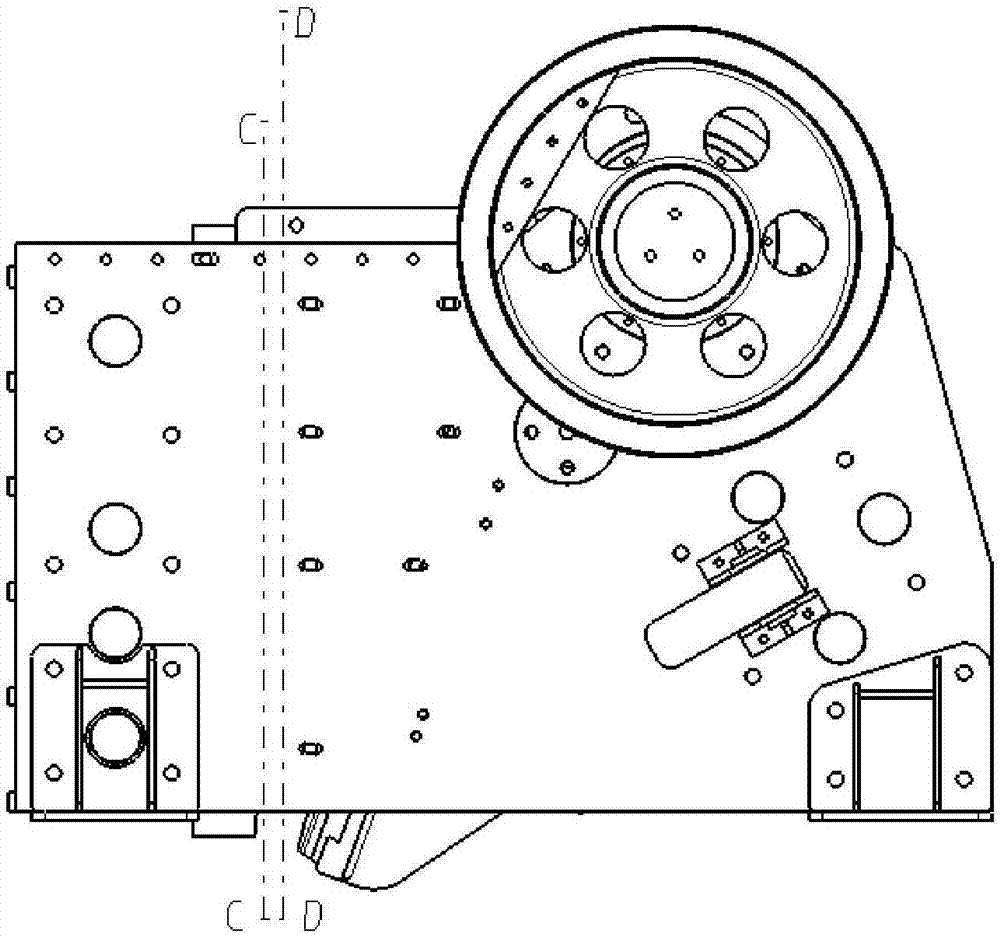

Intelligent gravel aggregate production line

ActiveCN107153410AIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlProduction lineDowntime

The invention provides an intelligent gravel aggregate production line, and relates to the technical field of gravel aggregate production. The intelligent gravel aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system and an intelligent internet of things monitoring cloud platform, wherein various sensors are additionally arranged on the basis of an original crushing screening production line; sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is realized, and therefore, the sensor information is transmitted to the intelligent internet of things monitoring cloud platform; and production data storage and safety are managed in a unified mode on the basis of classifying and combing through cloud computation. The intelligent gravel aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases response speed; internet of things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

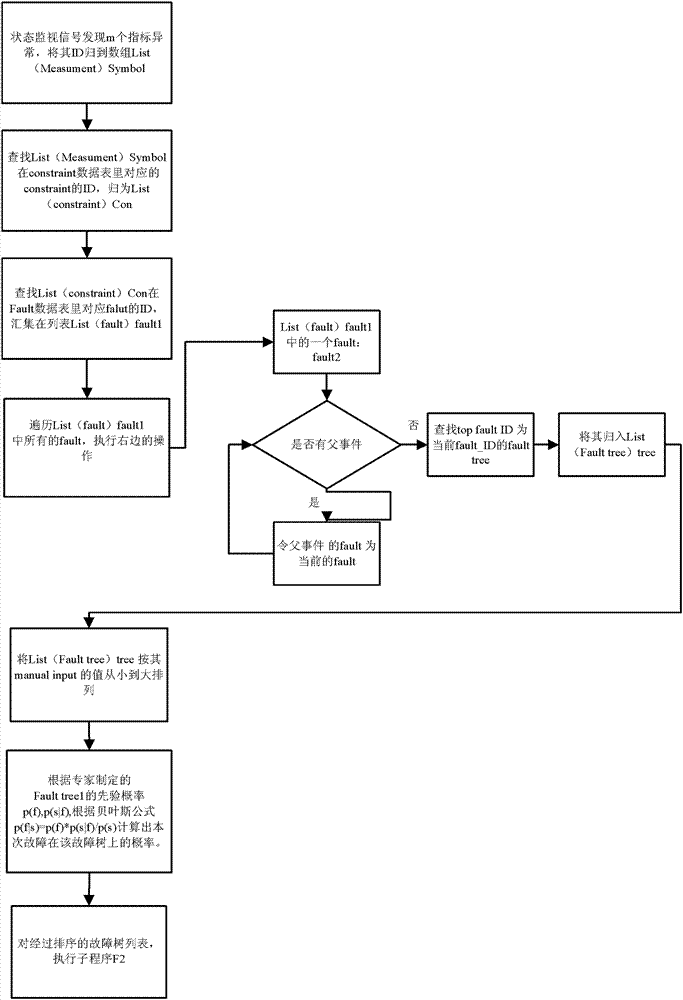

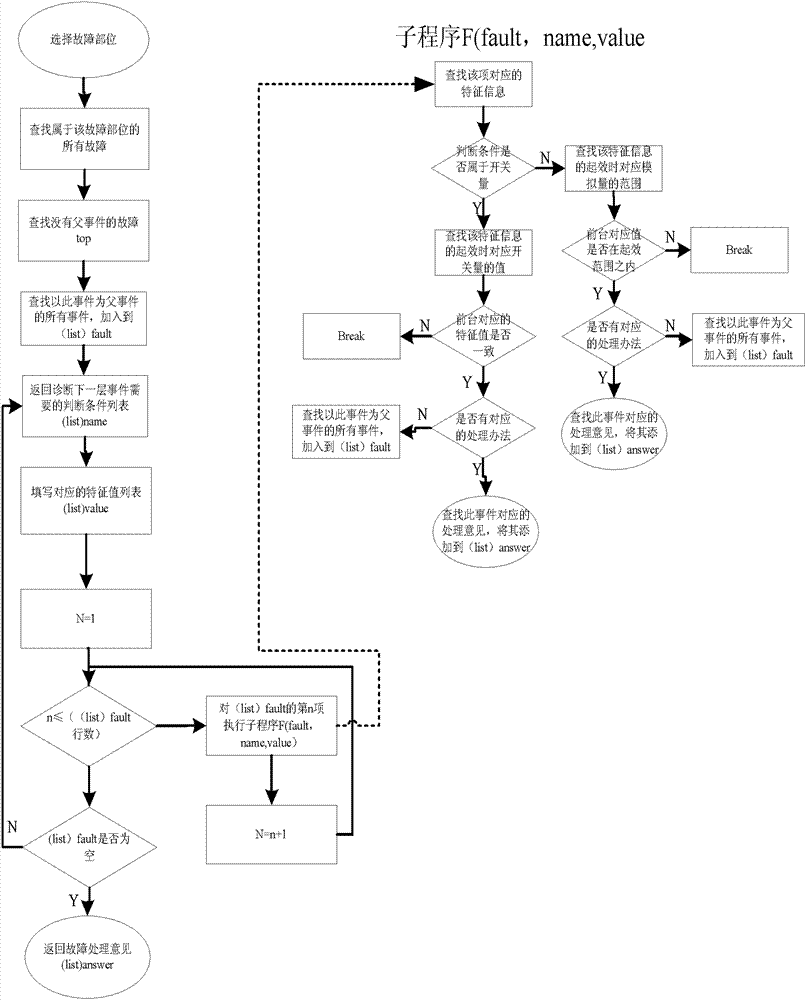

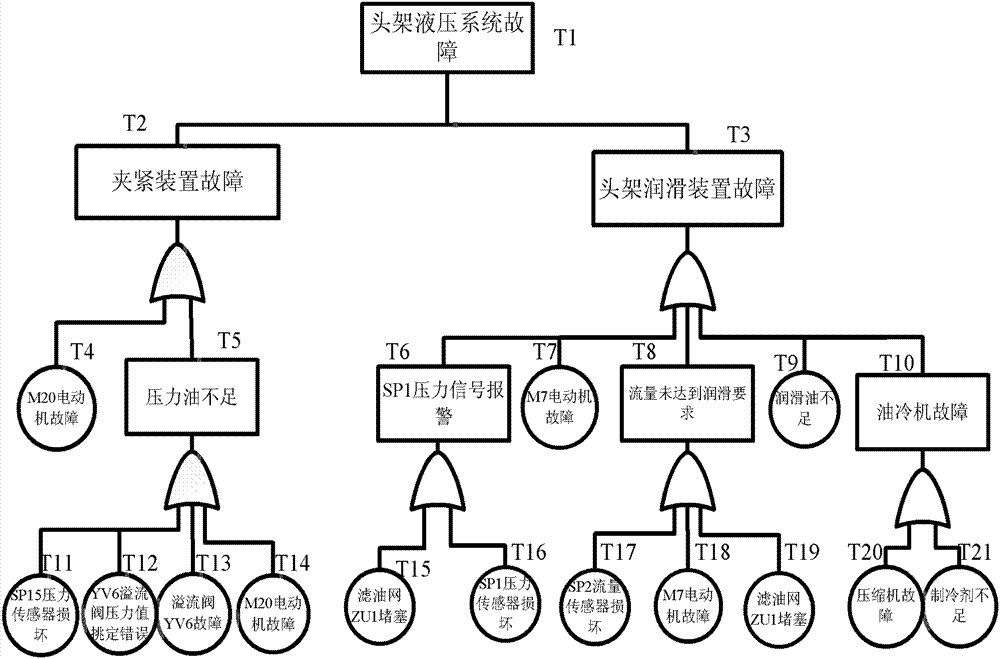

Intelligent fault diagnosis method of numerical control machine tool

InactiveCN102819239AExact searchQuick searchProgramme controlComputer controlNumerical controlDiagnosis methods

The invention provides an intelligent fault diagnosis method of a numerical control machine tool. The intelligent fault diagnosis method uses fault tree diagnosis as a base, faults are diagnosed by combining a Bayes probability and rule reasoning method, fault cause is found, and maintenance advices are proposed. The intelligent fault diagnosis method includes: firstly extracting fault information from historical maintenance records and machine tool operation instructions, and establishing a numerical control machine tool fault information knowledge base; searching fault trees belonging to a fault position in the fault information knowledge base according to fault characteristic information, calculating probability of occurrence of each fault tree under the current condition if a plurality of fault trees fit conditions, and determining sequence for diagnosing the fault trees according to size of the probability; and finally judging whether all sub-events of top events of the fault trees occur, returning to a fault treatment method corresponding to the events and serving as a solution if the sub-evens are bottom events of the fault trees, otherwise searching sub-events of the events continuously until finding all bottom events fit the fault characteristic information. The intelligent fault diagnosis method of the numerical control machine tool is rapid in diagnosis speed and accurate and reasonable in diagnosis result.

Owner:TONGJI UNIV

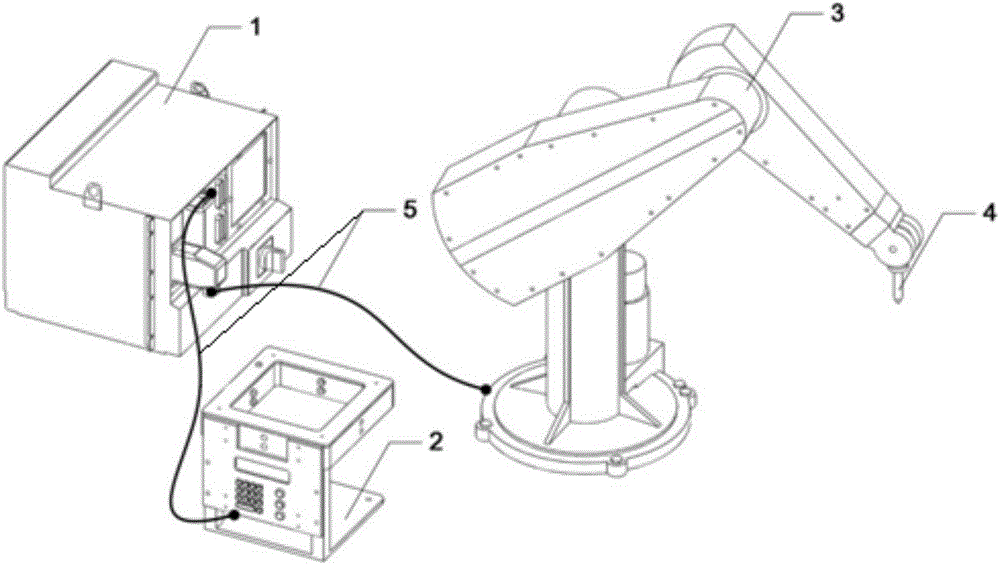

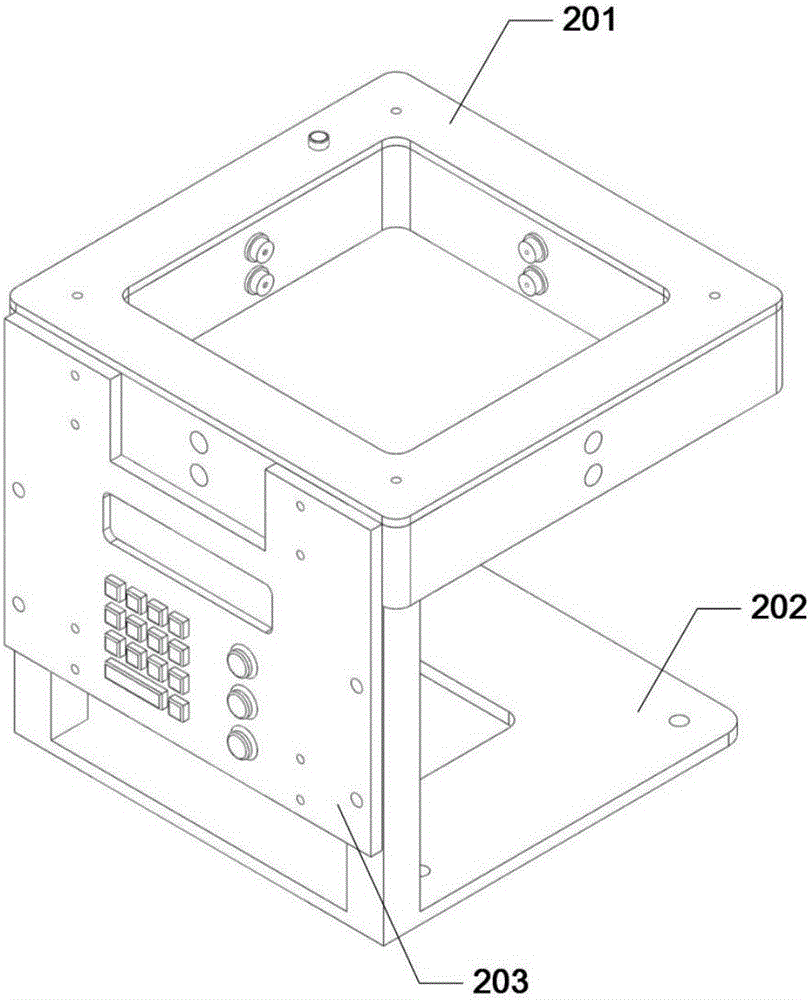

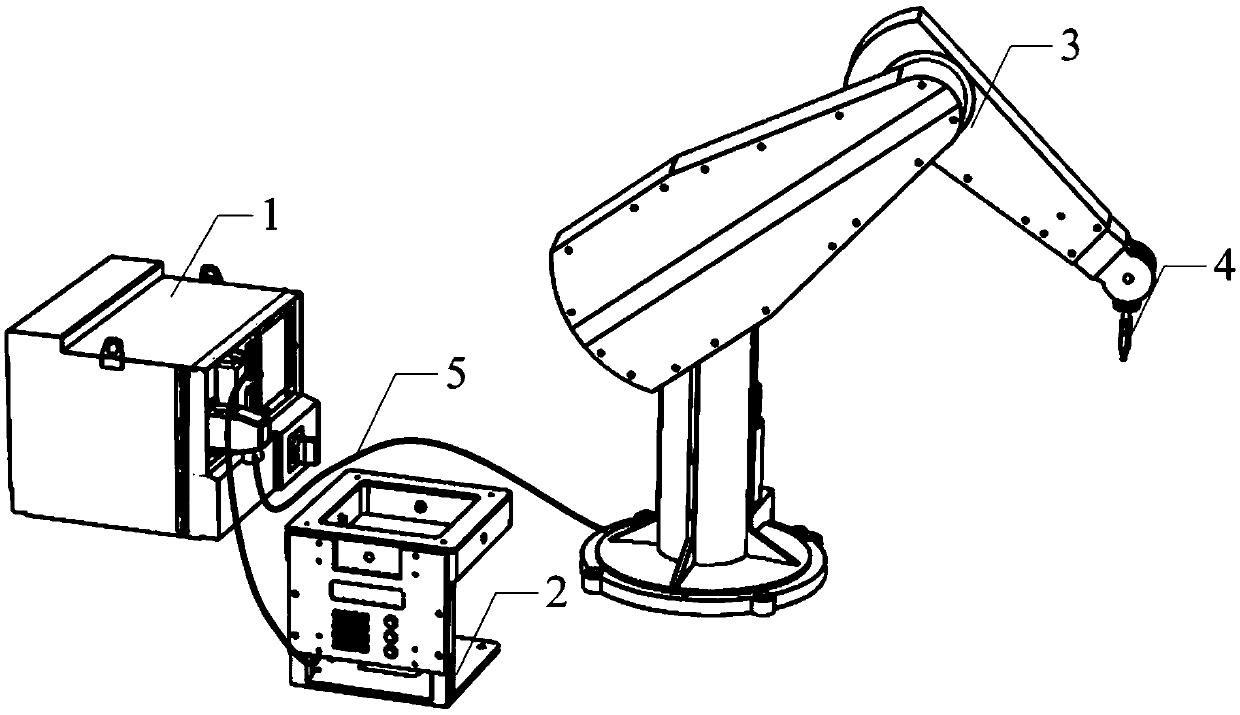

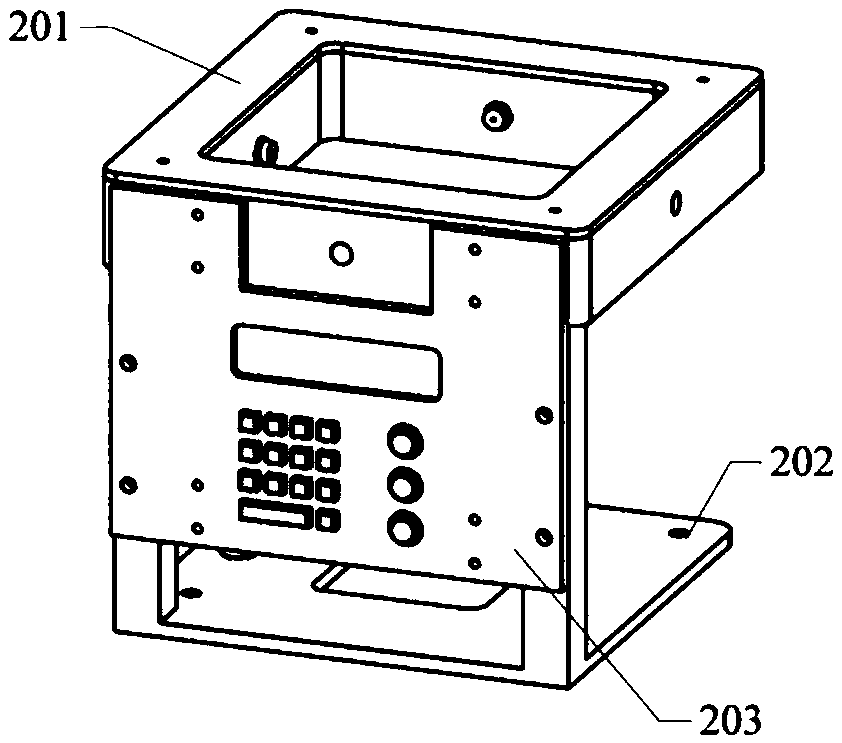

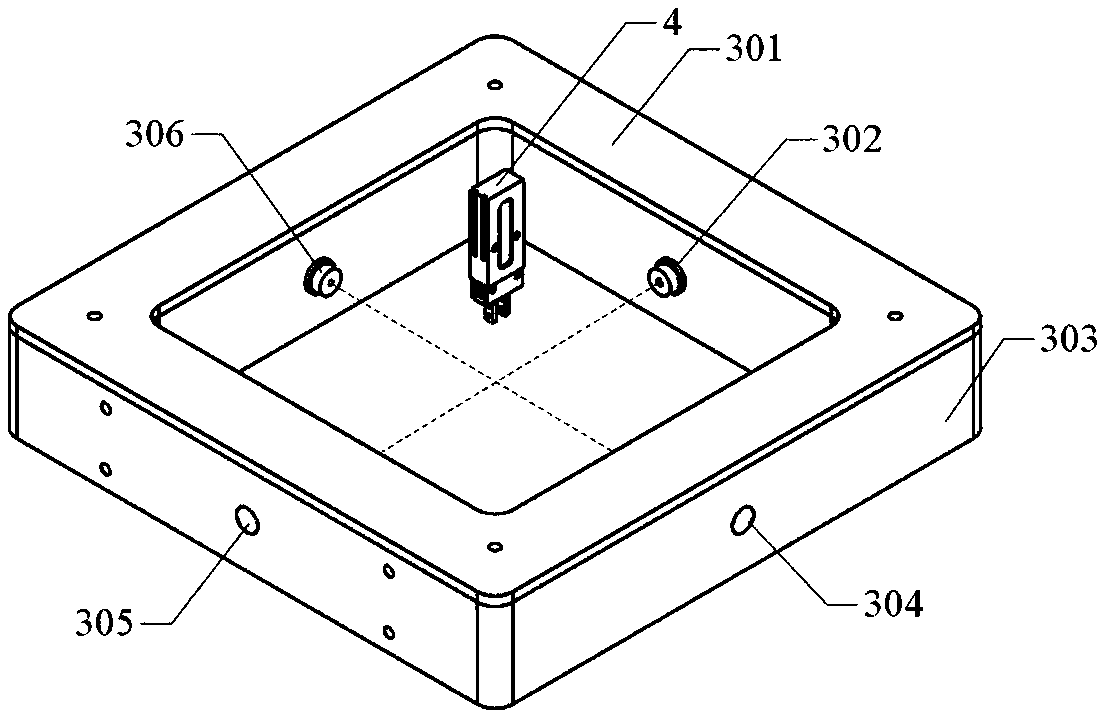

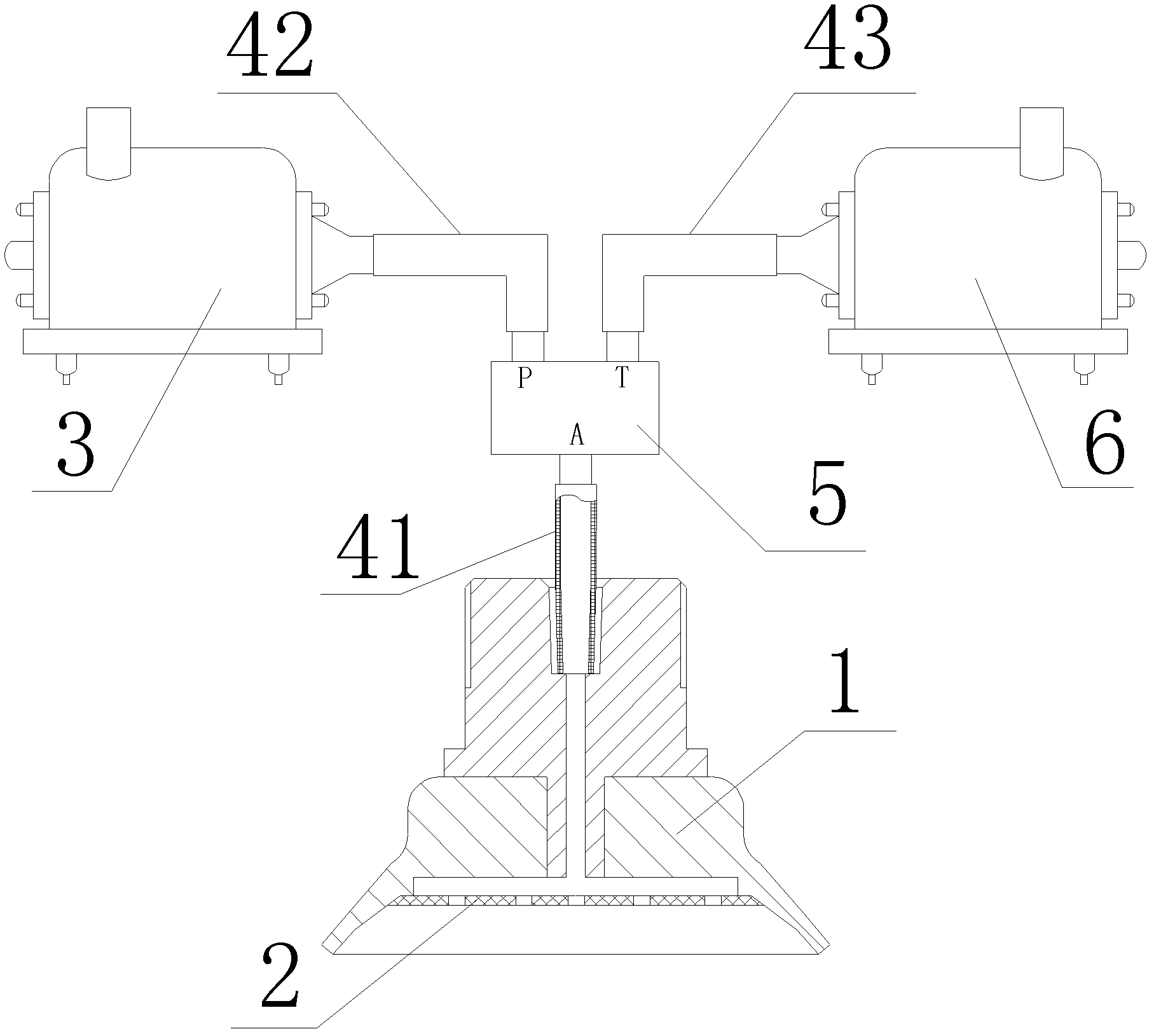

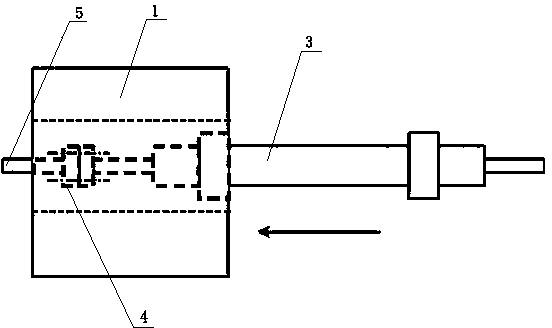

TCP online quick calibration method and device applied to industrial robot

ActiveCN105945948AImprove working accuracyReduce downtime for maintenanceProgramme controlProgramme-controlled manipulatorProduction lineComputer science

The invention discloses a TCP online quick calibration method and device applied to an industrial robot. The device comprises a control cabinet, a TCP calibration device, the industrial robot, a terminal tool and control buses; the control cabinet is separately connected with the TCP calibration device and the industrial robot through the control buses; the terminal tool is mounted on the industrial robot; the TCP calibration device includes a TCP detecting device, a calibration controller and a mounting base; the TCP detecting device is fixedly mounted on one side of the industrial robot through the mounting base; and a measuring plane is parallel to a XOY plane of an industrial robot base coordinate system. According to on-off signals of a correlation photoelectric sensor, the pose data of a flange is recorded, and the pose deviations of the terminal tool in X / Y axis and Z axis directions are calculated and compensated; and through multiple times of repeated operations, the TCP calibration errors are reduced, the operation precision of the industrial robot is effectively improved, the stop maintenance time of the industrial robot is reduced, and the automation degree of an industrial production line is improved.

Owner:南京速之海自动化设备有限公司

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

High-performance fire-resistant abrasion-proof composite material

The present invention discloses a high-performance flame-proof abrasion-resisting composite material which is prepared mainly by the components of particle material alumina or / and corundum or / and mullite 50-70 parts; hard particle 5-25 parts; binding agent 8-25 parts; aluminum oxide micro powder or / and silicon micronized quartz powder 8-15 parts and surfactant 0.1 parts. The composite material is developed according to the scientific knowledge obtained in the long-term researching and producing for the flame-proof abrasion-resisting composite material in our company and absorbing the latest accomplishment of the present material science, the material has the advantages of increasing the high-temperature bonding strength and toughness of the composite material, increasing the binding ability of the interface between the composite material and the equipment, facilitating the two sides forming a compact and high-strength whole body, optimizing the capability of the composite material in the high-temperature state, prolonging the service lifetime of the equipment, reducing the number of the breakdown maintenance, reducing the material consumption and the labor intensity of the worker thereby obtaining the purpose of increasing the economic benefit of the enterprise.

Owner:郑州市鑫磊冶金材料有限公司

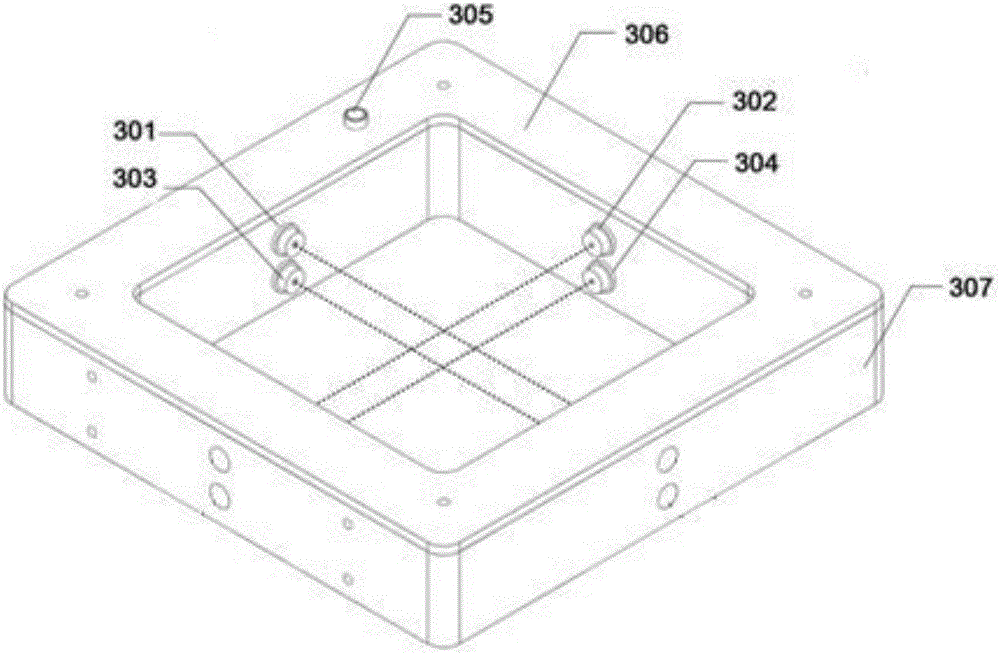

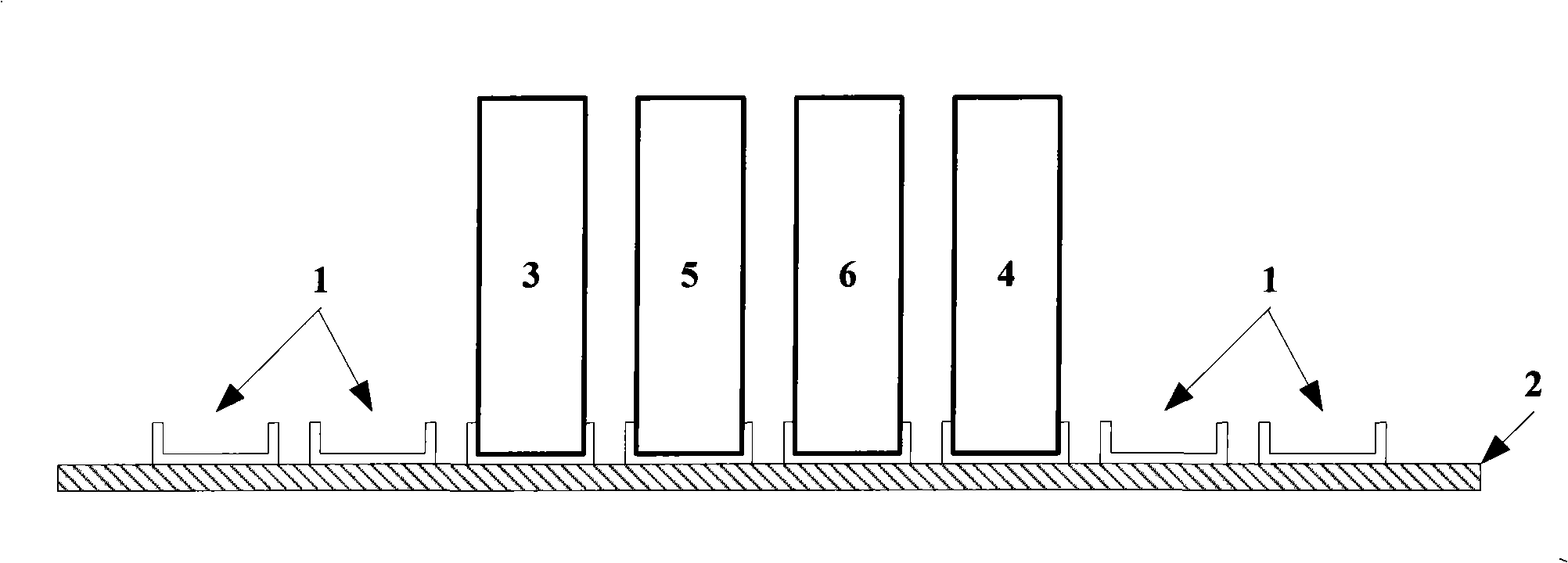

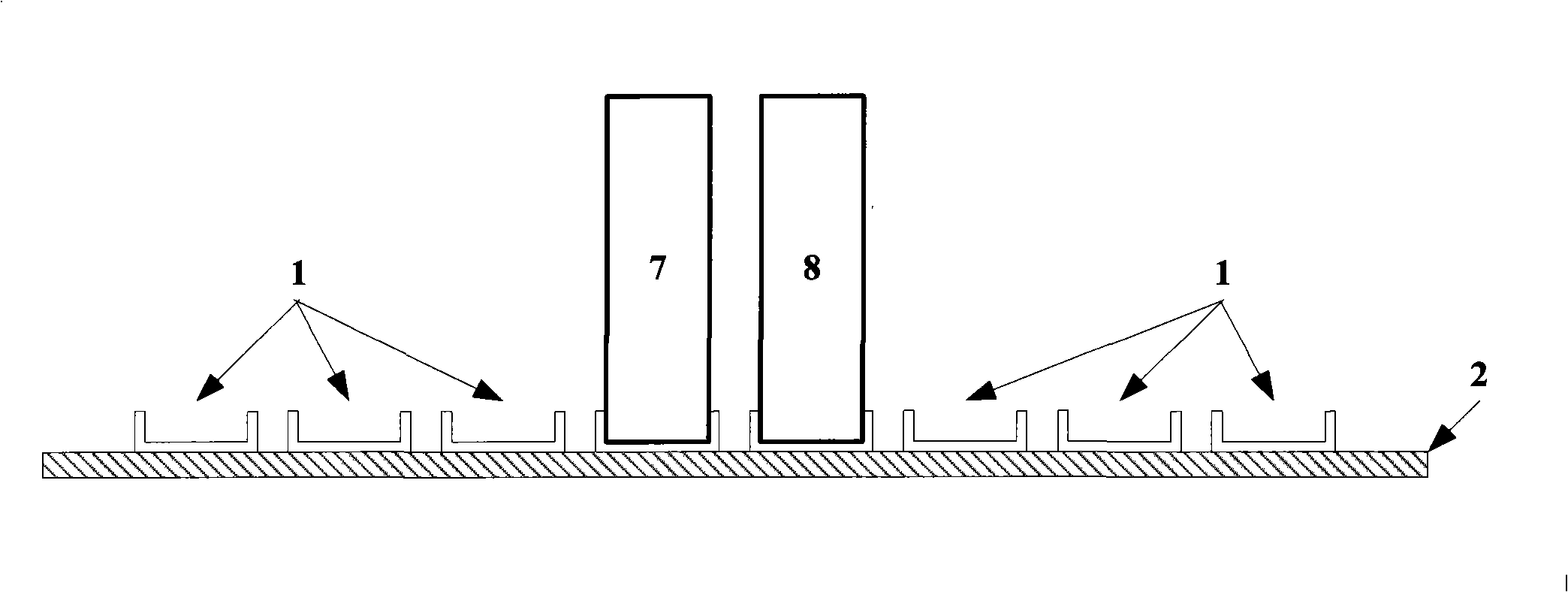

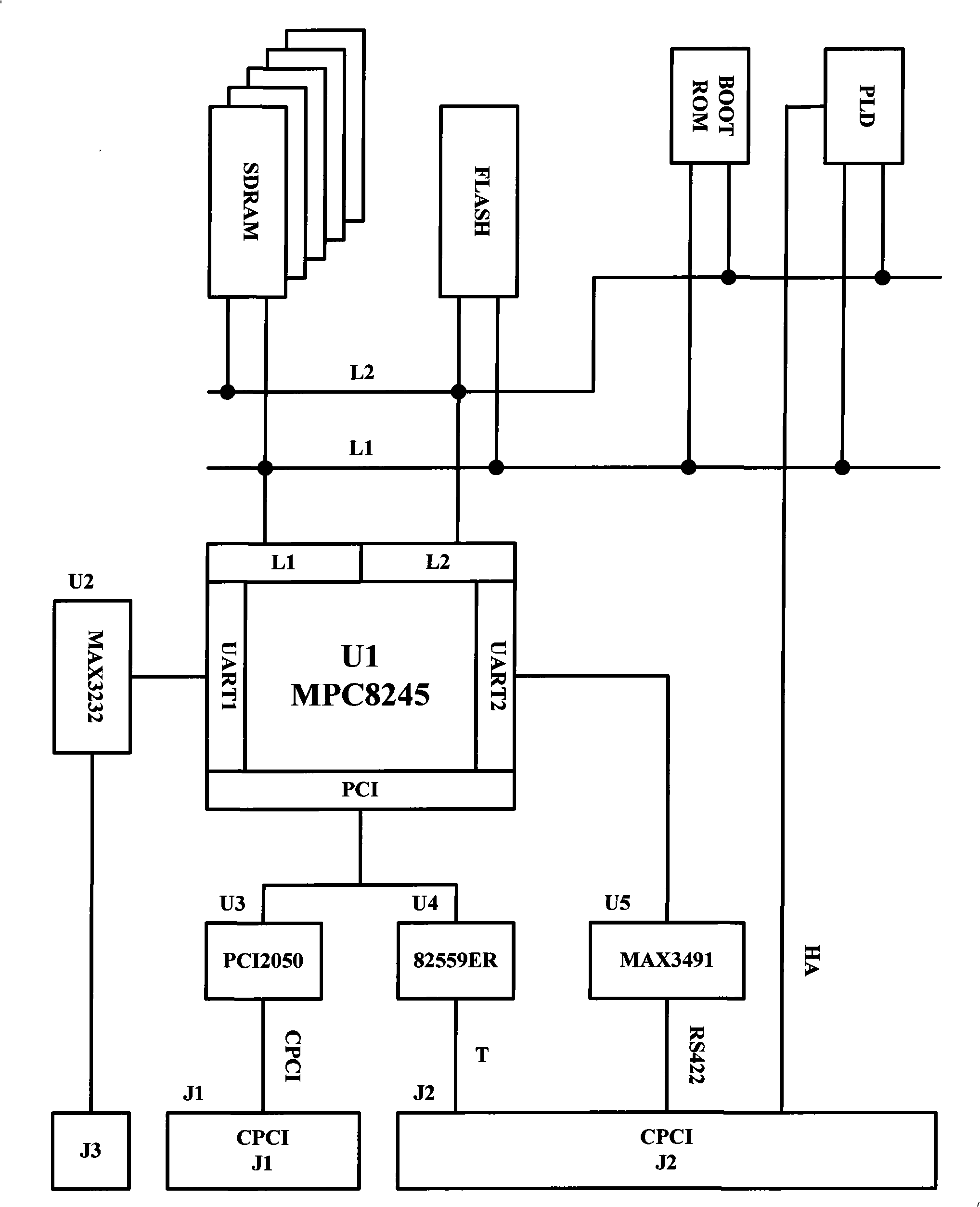

Compact integrated redundancy controller and control method thereof

ActiveCN101271332ASolve the hidden dangers that are prone to single point failureSolve the hidden danger of single point of failureSafety arrangmentsTotal factory controlCheck pointTransceiver

The invention provides a compact integrated redundancy controller and a controlling method thereof. The controller is provided with two controllers which have identical structure and can be used alternatively by displacing. Each controller is provided with a storage chip, a flash memory chip, a firmware chip and a programmable apparatus which are respectively connected with a main control chip; the controller is also provided with a first serial port transceiver, a second serial port transceiver, a PCI bridge piece and a network card controller. The serial port transceivers are connected with a CPCI connector by a RS422 serial port; the network card controller is connected with the CPCI connector by an Ethernet port; the PCI bridge piece is connected with the CPCI connector by a CPCI bus; the serial port transceivers are also connected with a maintenance serial port; a programmable apparatus PLD is also connected with the CPCI connector by a HA control signal. The methods comprise the starting method of main / standby controllers, the method that a standby controller is upgraded into a main controller automatically and a check point protocol control method when the main controller and the standby controller are switched in a system. The controller and the method can upgrade the system controller of a traditional CPCI system into a double-redundancy standby system, which solves the hidden trouble that single-point failure can easily occur in a CPCI system controller.

Owner:BEIJING FOUNTAIN MICROSYST

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

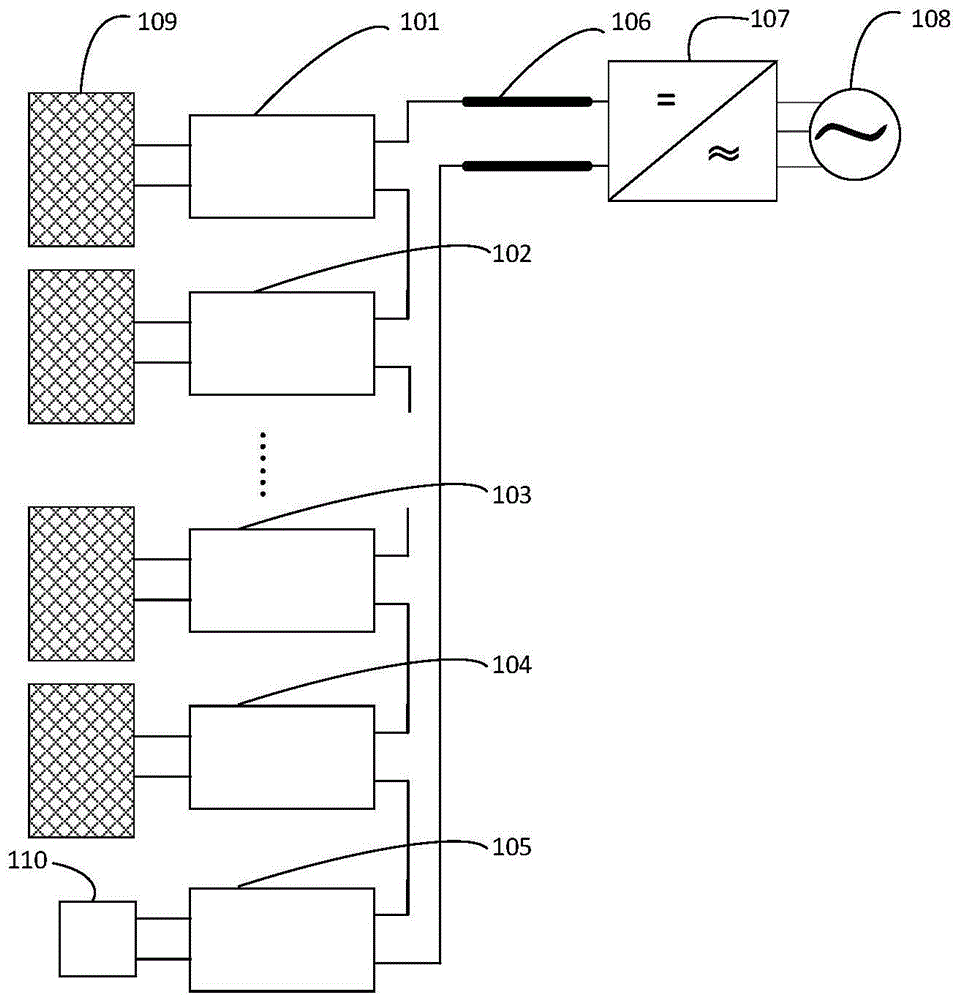

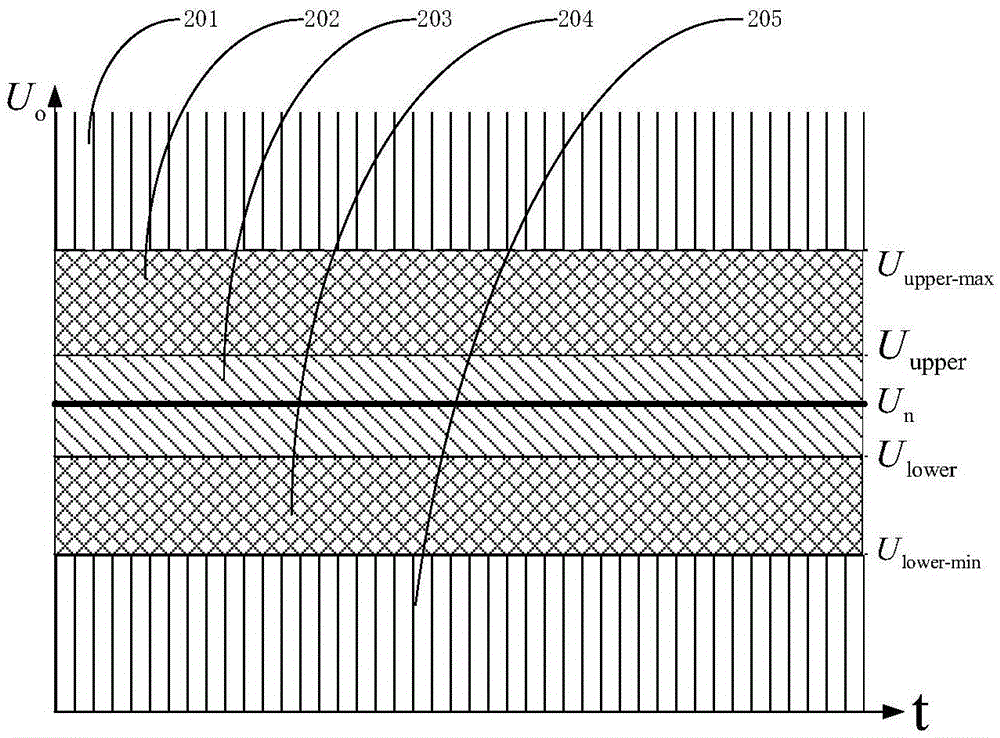

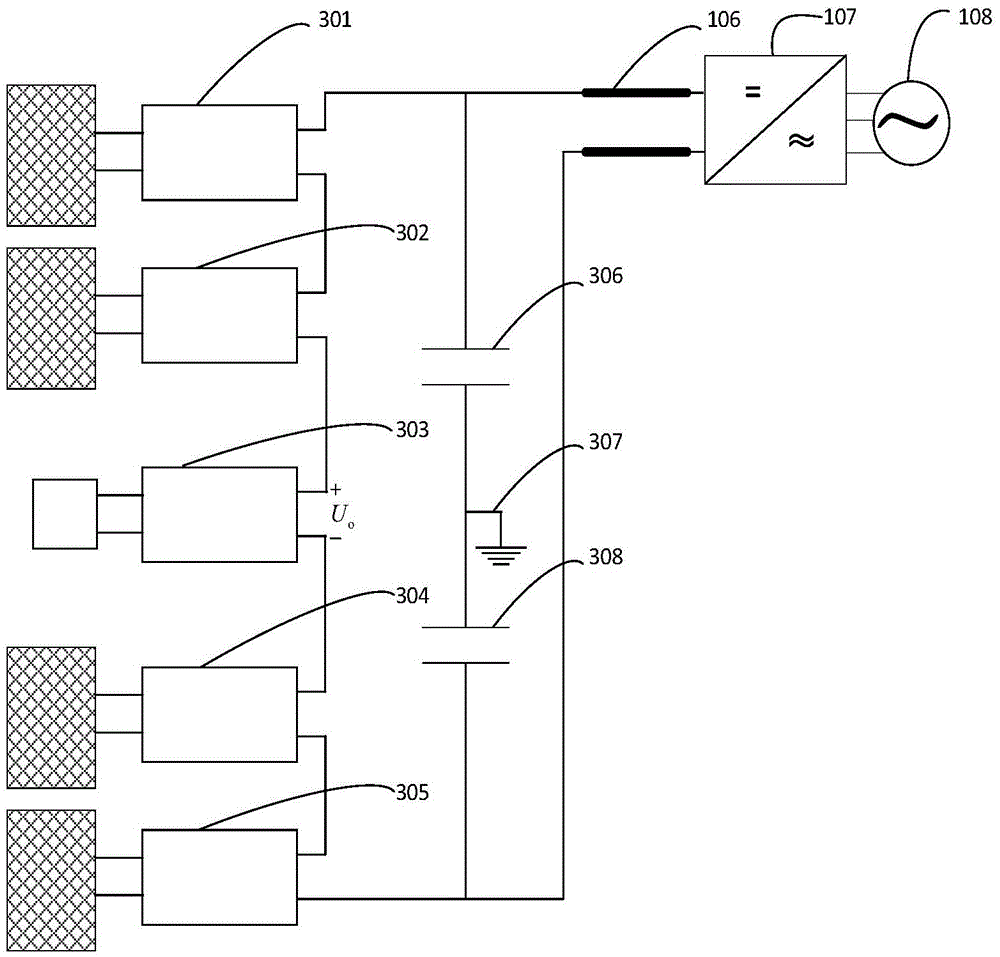

Photovoltaic high-voltage and direct-current series grid-connected system comprising dynamic voltage compensator

ActiveCN105490298AAvoid frequent switchingAvoid instabilitySingle network parallel feeding arrangementsAc network voltage adjustmentGrid connected inverterPower limits

The invention provides a photovoltaic high-voltage and direct-current series grid-connected system comprising a dynamic voltage compensator. The photovoltaic high-voltage and direct-current series grid-connected system comprises a plurality of photovoltaic direct-current grid-connected inverters and at least one dynamic voltage compensator, wherein input ends of the plurality of photovoltaic direct-current grid-connected inverters are independent and output ends are connected in series; the input ends of the plurality of photovoltaic direct-current grid-connected inverters are connected with a photovoltaic module respectively; and the output ends of the plurality of photovoltaic direct-current grid-connected inverters are connected in series and are connected with the input end of the dynamic voltage compensator in series. Through coordination and cooperation of the dynamic voltage compensator and the photovoltaic direct-current grid-connected inverters, the probability that the photovoltaic direct-current grid-connected inverters enter a power limiting mode; the generating capacity of the photovoltaic system is improved; and output voltage exceeding of the photovoltaic direct-current grid-connected inverters caused by power fluctuation of the photovoltaic module is overcome.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

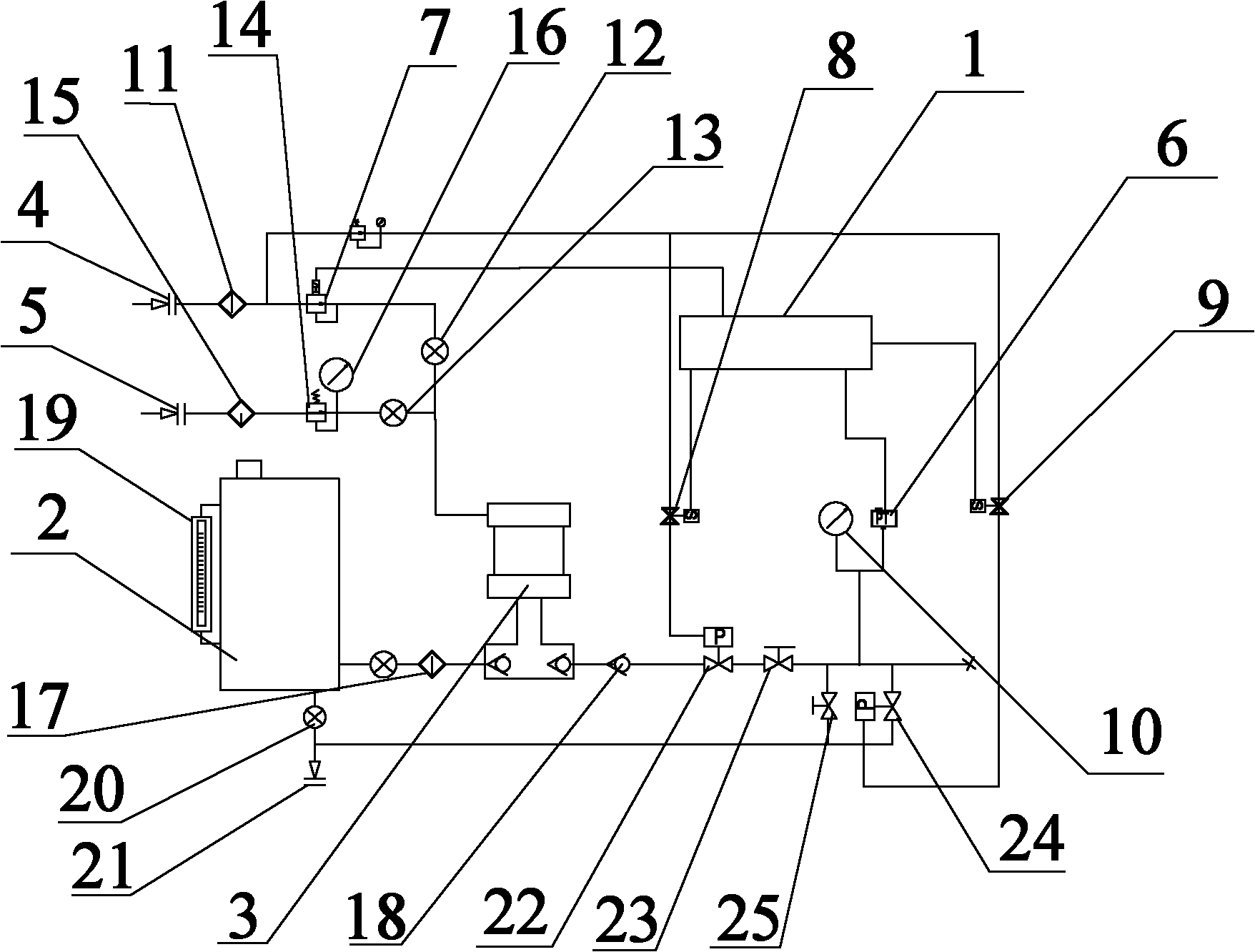

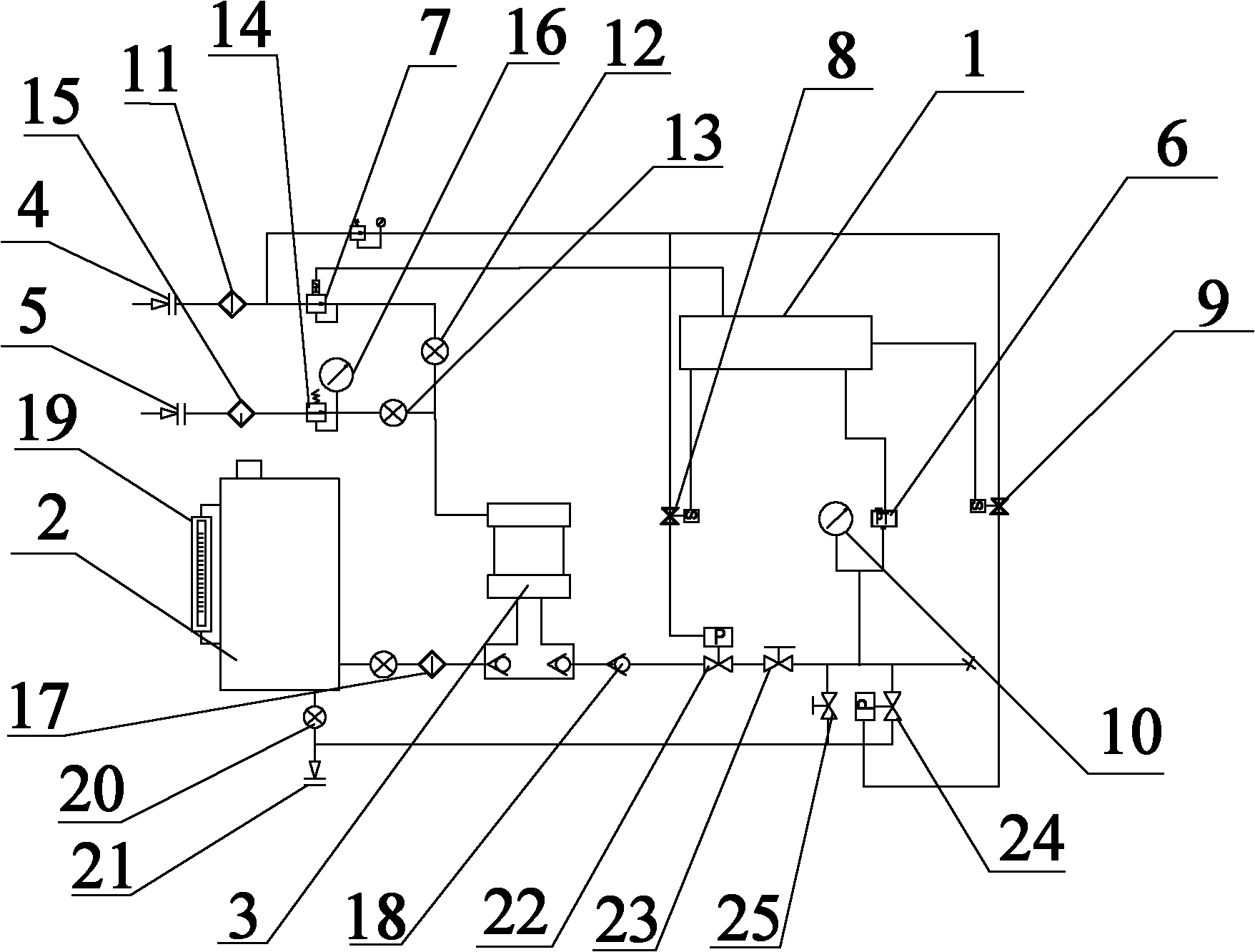

High pressure safety valve detection system

ActiveCN102323158AHigh precision calibrationReduce downtime for maintenanceMaterial strength using tensile/compressive forcesControl systemSolenoid valve

The invention relates to a high pressure safety valve detection system which comprises a control system and a water tank; the control system is respectively connected with a pressure sensor, an electric pressure-regulating valve, a first solenoid valve, and a second solenoid valve; the pressure sensor is connected with a double-needle pressure gauge; the first solenoid valve and the second solenoid valve are in parallel connection, and are connected to a first air filter; two ends of the first air filter are respectively connected with a first driving air inlet and the electric pressure-regulating valve; the other end of the electric pressure-regulating valve is connected with a first governing valve; the first governing valve is connected with a booster pump and a second governing valve; the second governing valve is connected with a manual pressure-regulating valve; a pressure gauge is mounted on the manual pressure-regulating valve; the manual pressure-regulating valve is connected with a second air filter; the second air filter is connected with a second driving air inlet. The beneficial effects of the invention are that: high-precision calibration of the high pressure safety valve is realized; the automation level is high; all operations of the operators can be performed only at a measurement and control bench after all is in order; the labor intensity is decreased, and the safety hidden danger is reduced.

Owner:北京海德利森科技有限公司

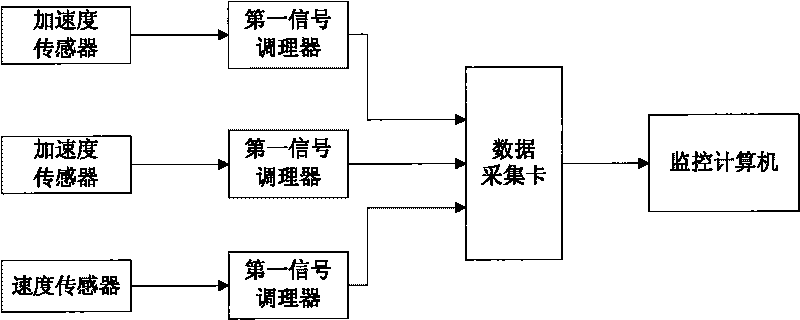

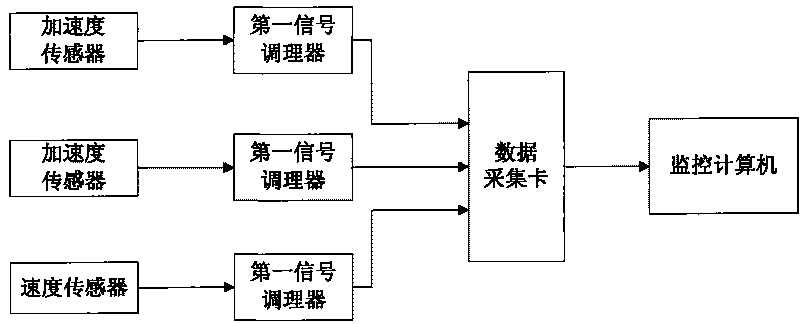

System and method for diagnosing faults of numerical control machine

InactiveCN101697072AReduce downtime for maintenanceImprove operational efficiencyProgramme controlComputer controlHardware structureNumerical control

The invention relates to a system and a method for diagnosing faults of a numerical control machine. The system comprises two acceleration sensors and one speed sensor which are used for obtaining vibration signals generated by the numerical control machine, two first signal conditioners used for conditioning and outputting signals output by the acceleration sensors, a data acquisition card used for gathering signals which are output after being conditioned, a monitoring computer connected with the output end of the data acquisition card and used for calculating and analyzing the vibration signals generated by the numerical control machine and diagnosing faults of the numerical control machine. The method comprises the following steps: (1) obtaining vibration signals; (2) conditioning the signals; (3) gathering data; and (4) analyzing the signals. The device has simple hardware structure and realizes the diagnosing and analyzing function mainly based on software, thereby being convenient to update and maintain. The fault time of the machine is reduced, thereby enhancing the operation efficiency of the machine in processing.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

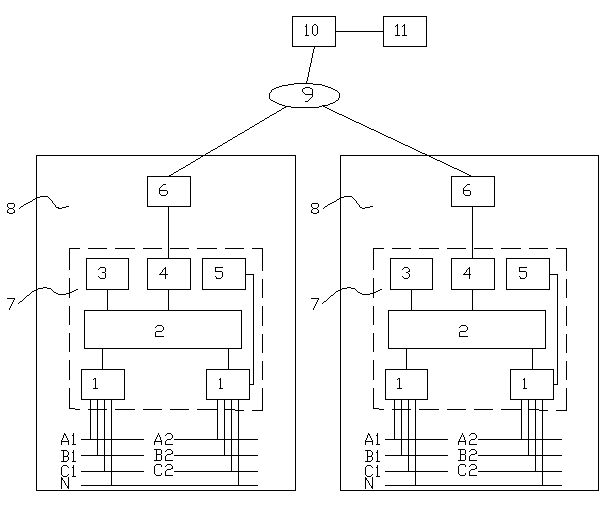

Operating data monitoring and alarming system of converting stations

InactiveCN101902077AOptimize schedulingWith metering functionProgramme controlTransmission systemsInternet communicationComputer terminal

The invention relates to an operating data monitoring and alarming system of converting stations, aiming at providing the operating data monitoring and alarming system of the converting stations with excellent real time performances, remote detection function and high intelligentization degree. The operating data monitoring and alarming system of the converting stations comprises information collectors, information concentrator, an operating maintenance server and an on-duty computer terminal; the information collectors are mounted at the converting stations and used for collecting various operating data of the converting stations; the information concentrators are mounted at the converting stations and connected with the information collectors; the operating maintenance server is in communication connection with the information concentrators of the converting stations by a wireless communication network; and the operating maintenance server is in communication connection with the on-duty computer terminal by the internet. The alarming, the failure analysis and the electric quantity statistic are carried out by the wireless network; one machine has a plurality of purposes; the failure maintenance time is reduced; the electric quantity scheduling is favorable; and the power supply quality is improved.

Owner:ZHEJIANG XINNENGLIANG TECH CO LTD

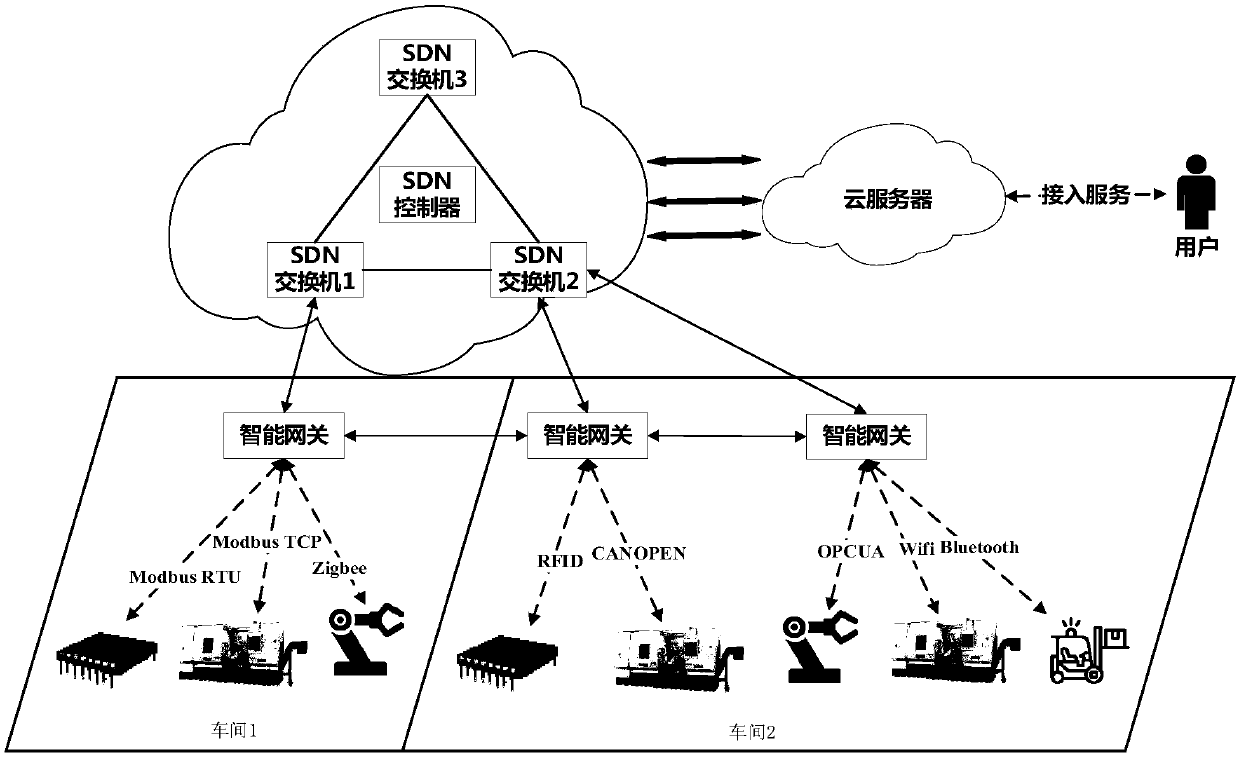

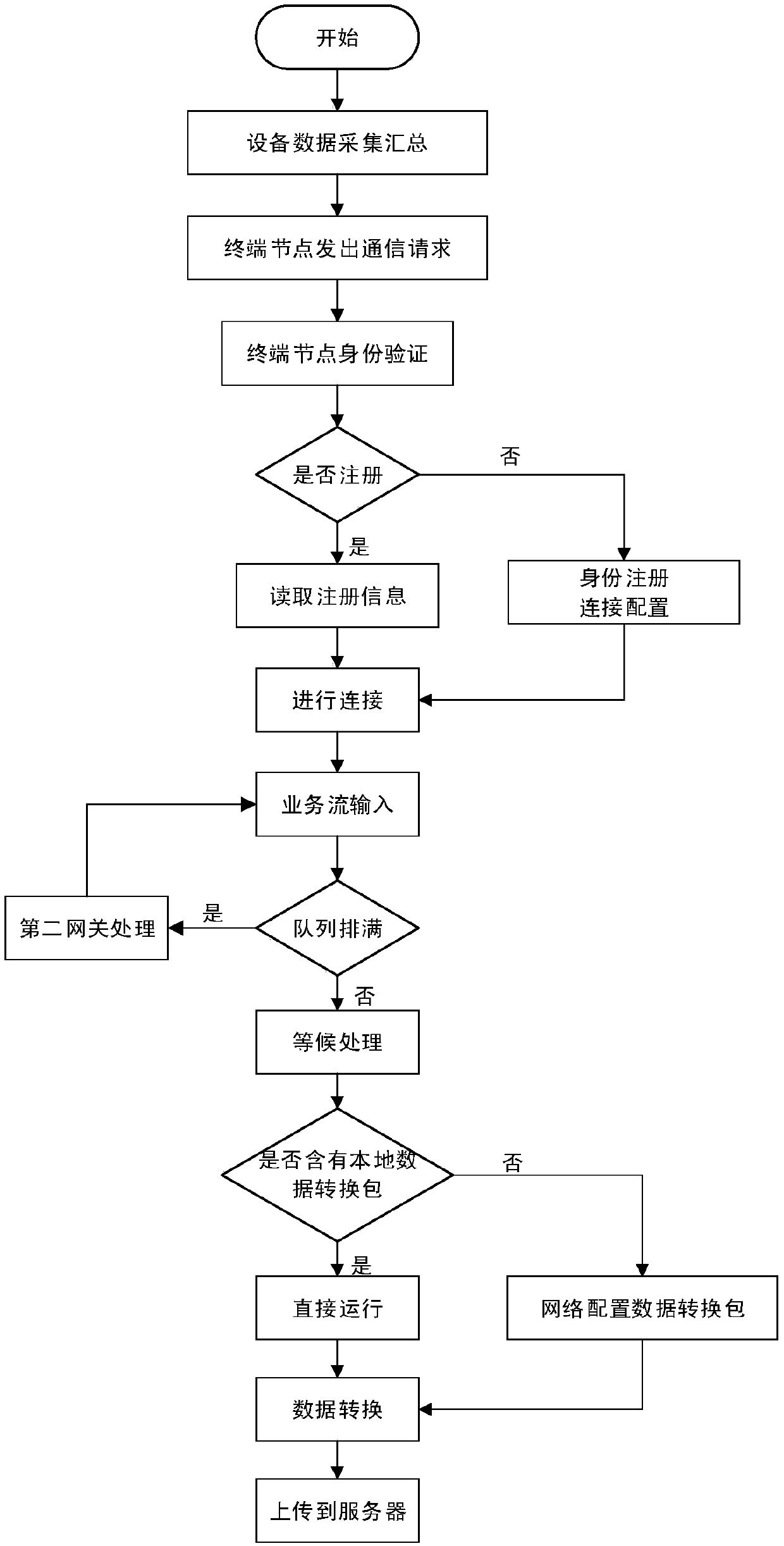

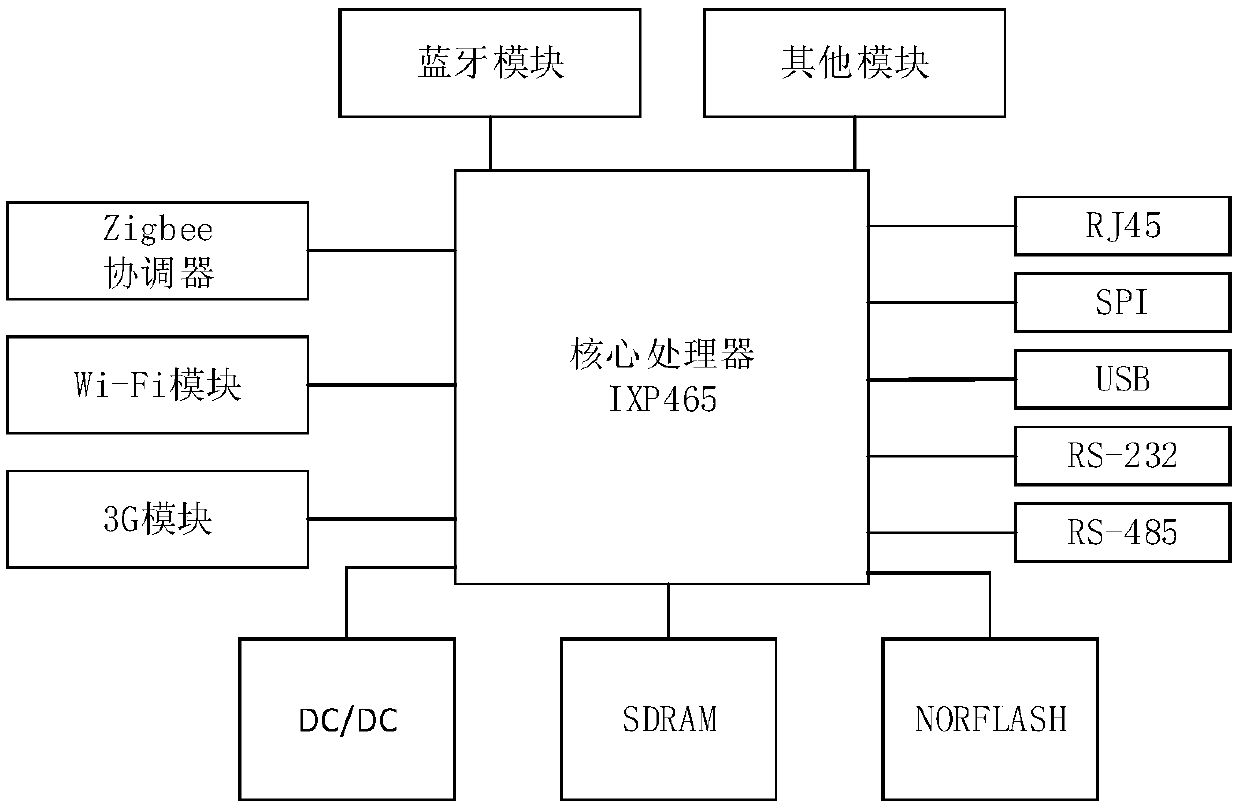

Software-defined network (SDN) based multi-mode data interaction system and method for intelligent production line

ActiveCN109639467AFlexible and convenient collectionSimple hardware structureData switching networksInteraction systemsDistributed intelligence

The invention discloses a software-defined network (SDN) based multi-mode data interaction system and method for an intelligent production line. The system comprises an equipment layer, a conversion layer, a network layer, and a server layer, wherein the equipment layer comprises underlying equipment, sensors and data acquisition nodes, and is used to acquire equipment operation information and carry out data summarization; the conversion layer comprises distributed intelligent gateways, and is used for data format conversion and interaction with the network layer; the network layer is erectedthrough an SDN, and is used for dynamic configuration of a conversion protocol of the conversion layer and data transmission path optimization; and the server layer stores different protocol conversion installation packages through establishment of a database, and is used for storage of acquired data and access of user services. The system disclosed by the invention has the advantages that an equipment control plane and a data plane are decoupled based on the SDN, so that network traffics can be flexibly controlled; and a wired network is mixed with a wireless network, so that a data acquisition network system is more flexible and convenient, and is more applicable to the current production line situation.

Owner:SOUTH CHINA UNIV OF TECH

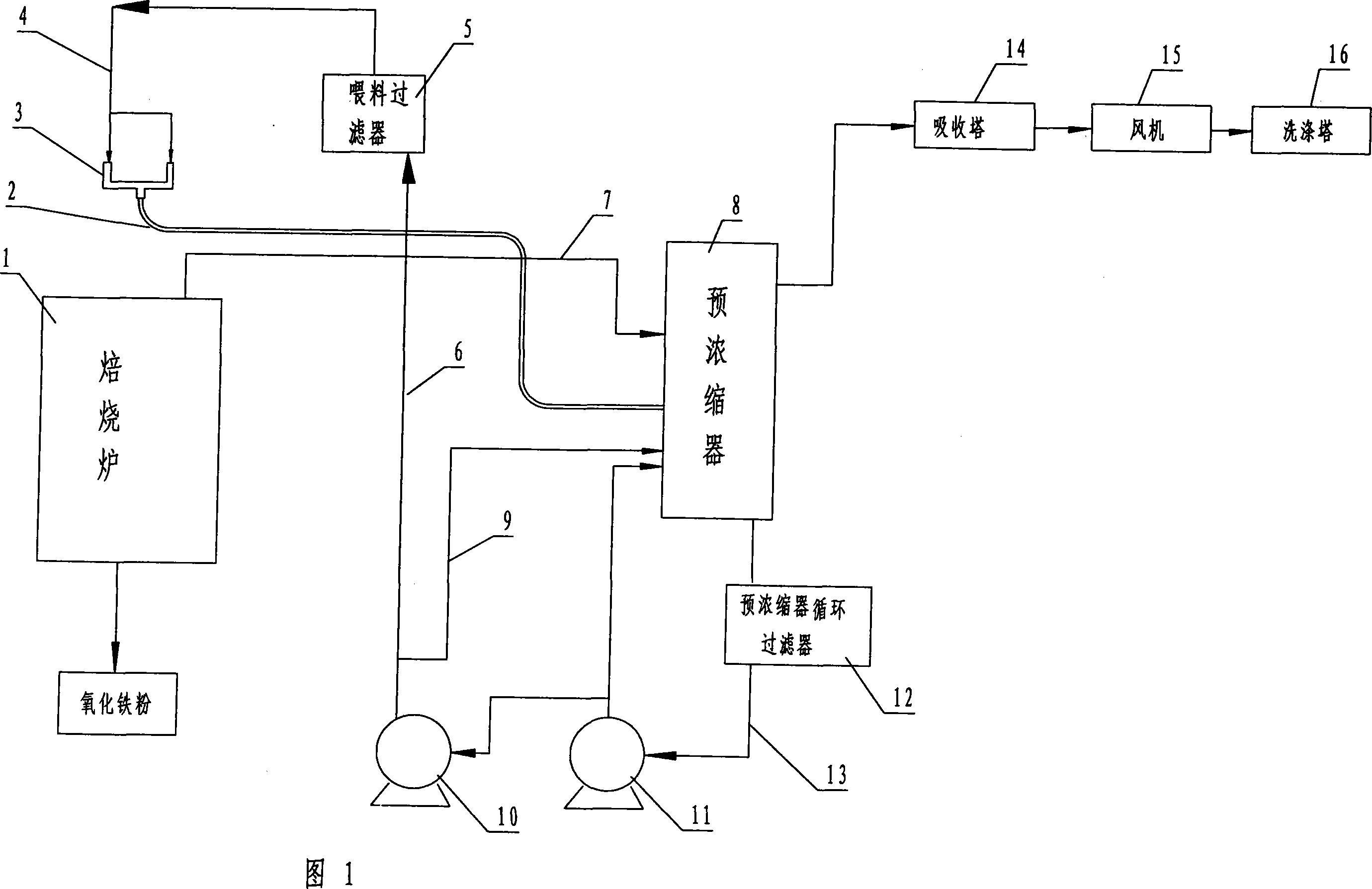

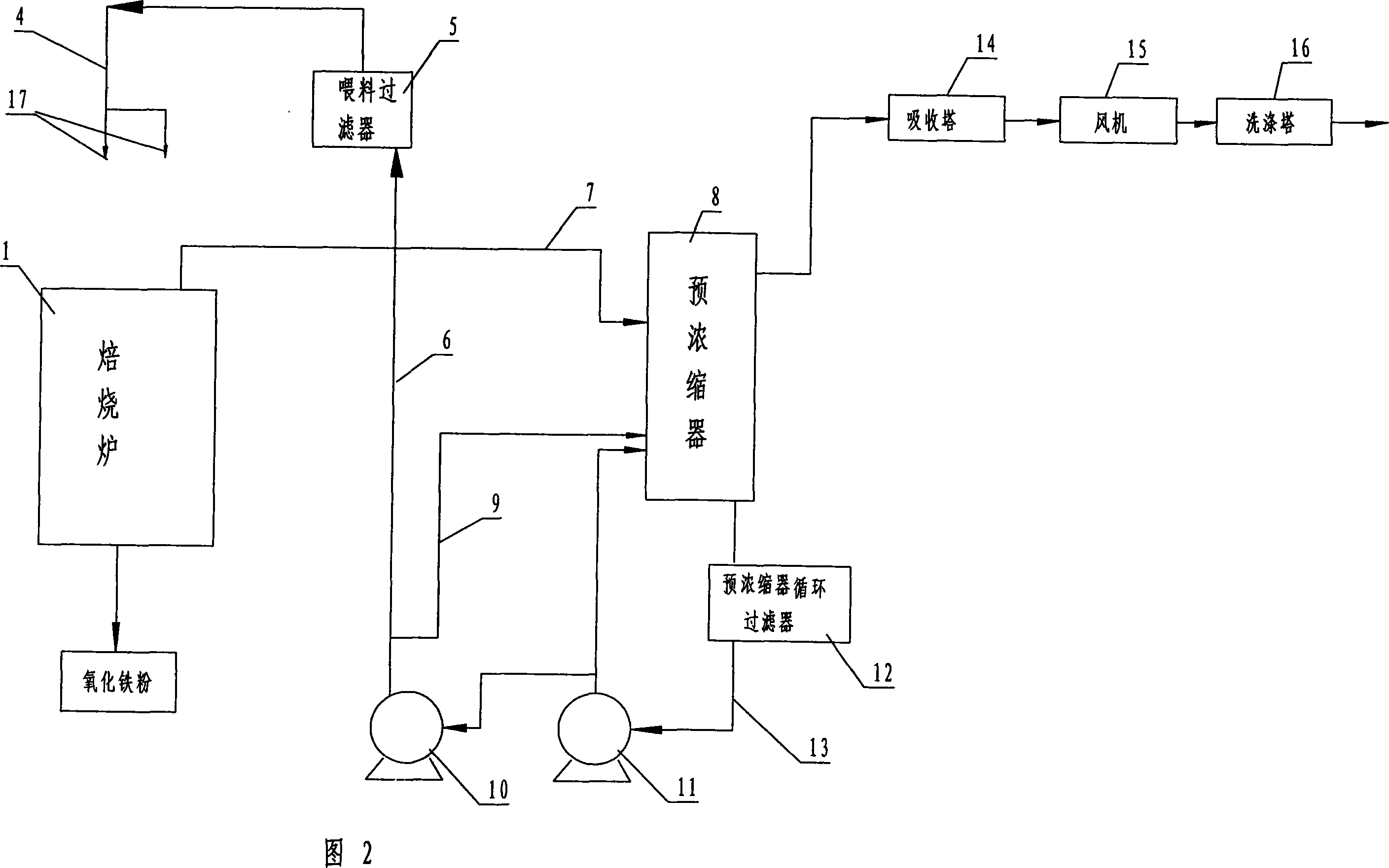

Technique for cleaning acid dirty of acid reactivating machine group inner loop type pipeline

InactiveCN101109088ASave manpower and material resourcesImprove cleaning efficiencyInner loopChemistry

A cleaning process for acid stain in the circulating pipe for an acid regeneration unit is provided, which pertains to the technical field of auxiliary equipment for steel rolling, is for solving the issue of high-efficiency washing for the acid stain in the pipe for an acid regeneration unit, and is characterized in that, the process takes use of the equipment of the acid regeneration unit and an added T joint to connect rubber pipes and form two parallelly connected alkali-liquor flushing and circulating circuits, takes the bottom of a pre-thickener of the acid regeneration unit as a bath for an alkali liquor, uses an negative-pressure blower of the acid regeneration unit to provide power for the flowing of the furnace gas, bakes the pre-heating gas at the furnace top by the acid regeneration unit, and the furnace gas exchanges heat with the alkali liquor. The advantages with the invention are: 1. that no external equipment is required to add, pipes and valves are not necessary to dismount, labor and materials are saved; 2. that high cleaning efficiency is achieved, 1 / 3 time in cleaning is saved comparing with former process; 3. that the acid stain can be thoroughly cleaned; the period between cleanings is prolonged for the pipes, which is 1.5 times as that before; 4. that as the acid stain is thoroughly cleaned, the fault in the feeding pump is evidently reduced, the service life is improved nearly 3 times.

Owner:HANSTEEL

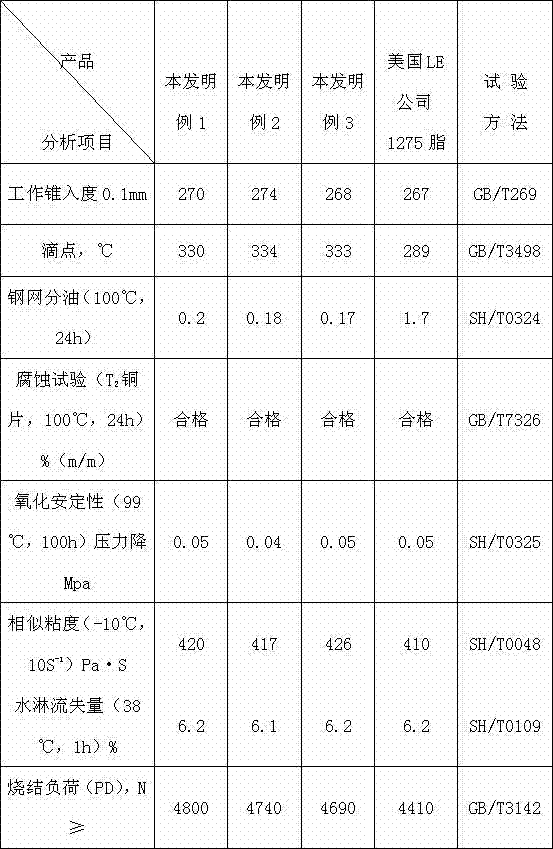

1206 lubricating grease

InactiveCN103897781AEnhanced pumpabilityGood reversibilityLubricant compositionBenzoic acidPhosphoric acid

The invention relates to a 1206 lubricating grease, comprising the following components by weight percent: 2-4% of aluminum isopropoxide, 4-6% of aminated bentonite, 3-5% of stearic acid, 1-3% of benzoic acid, 37-41% of viscous oil in refined naphthenic base, 29-43% of viscous oil in refined paraffin base, 1-3% of zinc dialkyl dithiophosphate, 1.6-2.9% of triazole fatty acid ammonium salt, 0.1-0.5% of a triazole derivative, 0.8-1.8% of tricresyl phosphate, 1.2-5% of polyisobutene and 0.7-1% of ethyl carbamate. Compared with the prior art, the 1206 lubricating grease is high in dropping point, large in sintering load data and relatively good in compression and wear resistance, and the more outstanding feature is as follows: the steel mesh is excellent in oil dividing, the embodiment 3 is 1 / 10 of the 1275 grease of LE company of America, and the embodiment 1 is not greater than 1 / 8; obviously, the pollution in the operation is smaller, the resource can be saved more, and the operation period of the equipment can be prolonged.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

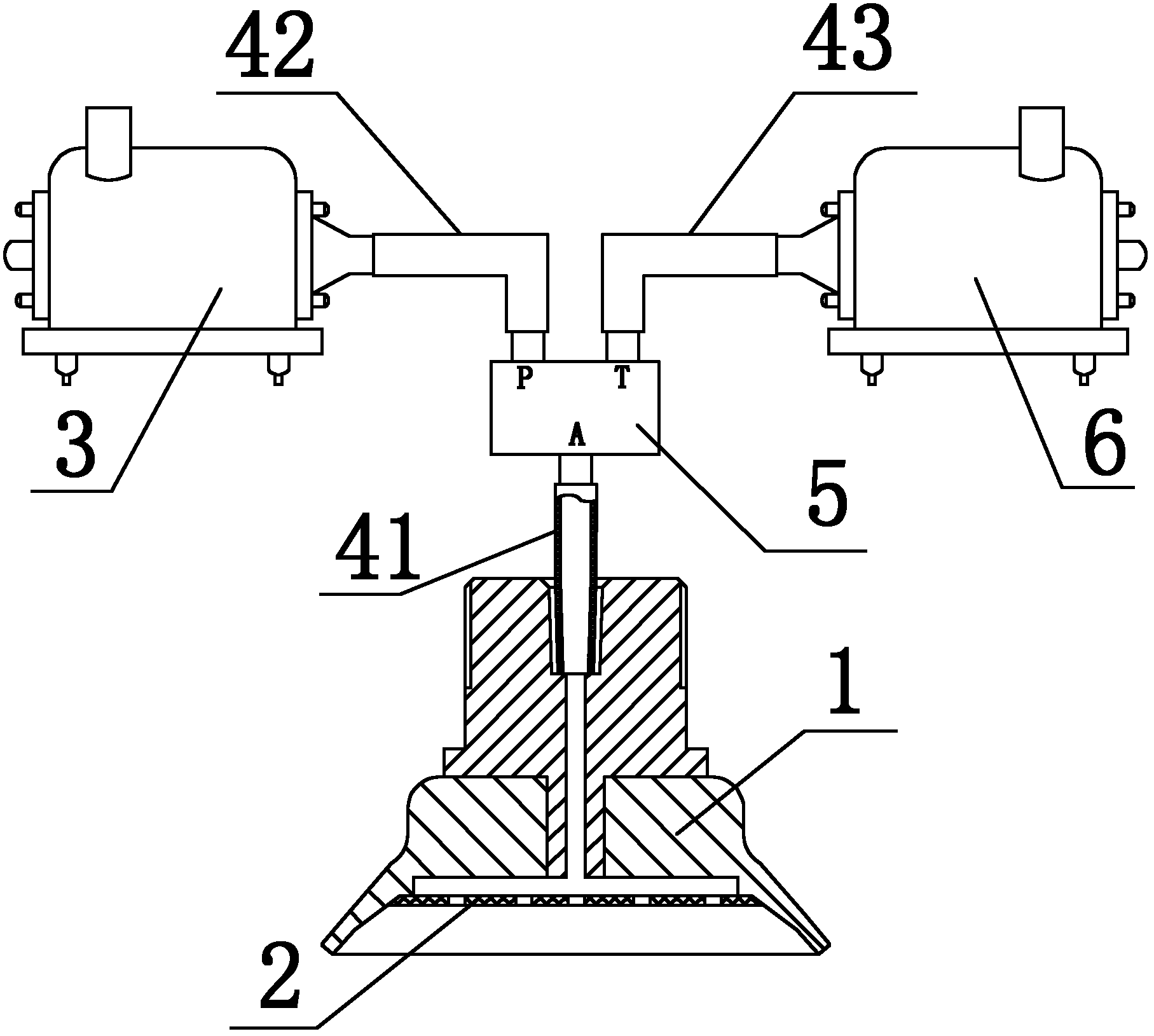

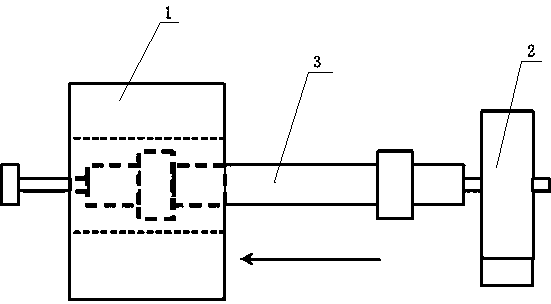

Online rapid TCP calibrating method and device capable of achieving six freedom degrees

ActiveCN109514549ARealize online precision maintenanceImprove assembly operation precisionProgramme-controlled manipulatorProduction lineSimulation

The invention discloses an online rapid TCP calibrating method and device capable of achieving six freedom degrees. The online rapid TCP calibrating device capable of achieving six freedom degrees comprises a control cabinet, a TCP calibrating device, a robot and an end-of-arm tool. The control cabinet is connected with the TPC calibrating device and the robot. The end-of-arm tool is installed onthe robot. The TCP calibrating device comprises a TCP detecting device, a calibrating controller and an installation base. The TCP detecting device is fixedly installed on one side of the robot through the installation base. A measuring plane is parallel to the XOY plane of a robot base coordinate system. According to on-off signals of correlation type photoelectric sensors, position and posture data of a flange are recorded, the angle and position deviations of the end-of-arm tool in the X-axis, Y-axis and Z-axis are calculated and compensated for; through repeated operation, the calibrationerror of the TCP is reduced, the operation precision of the robot is effectively improved, the halt maintenance time of the robot is shortened, and the automation degree of an industrial production line is improved.

Owner:NANJING INST OF TECH

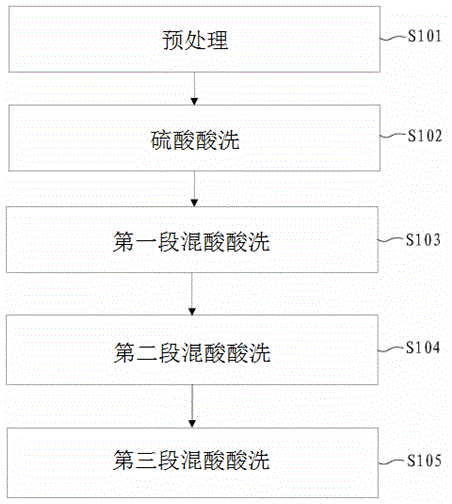

Acid pickling method for hot rolled 304 Austenitic stainless steel

The invention relates to an acid pickling method for hot rolled 304 Austenitic stainless steel. The acid pickling method comprises the steps of pretreatment, sulfuric acid pickling, mixed acid pickling for a first section, mixed acid pickling for a second section and mixed acid pickling for a third section. A mixed acid solution used in the steps of acid pickling for the three sections is formed by mixing nitric acid and fluorosilicic acid. According to the acid pickling method for the hot rolled 304 Austenitic stainless steel, the mixed acid solution formed by mixing nitric acid and fluorosilicic acid is adopted, H2SiF6 has a high ability to dissolve and corrode scale cinder and a metal matrix as HF, and therefore the acid pickling efficiency can be improved. In the acid pickling process, the activity of the acid solution is basically constant, and the service life of the acid solution is prolonged; in this way, the discharge amount of waste acid is reduced, and production cost and water treatment cost are reduced. In the mixed acid pickling process, fluoride sediment will not be generated, a pipeline will not be blocked, and the halt maintenance frequency is reduced.

Owner:WISDRI ENG & RES INC LTD

Process method for producing zirconium tetrachloride through fluidizing chlorination method

ActiveCN104058454AReduce manufacturing costDo not change frequentlyChemical industryZirconium halidesTetrachlorideSilicon tetrachloride

The invention relates to a process method for producing zirconium tetrachloride through a fluidizing chlorination method. The process method comprises the following steps: smashing zircon sand to 300-325 meshes, smashing petroleum coke to 100-200 meshes, smashing chemical heat supplementing agent to 200-400 meshes, firstly fully mixing the zircon sand and the petroleum coke powder, simultaneously adding the mixture and the heat supplementing agent into a fluidizing chlorination furnace, introducing chlorine to carry out chlorination reaction and keeping the temperature of the fluidizing chlorination furnace at 1100 DEG C, wherein the chemical heat supplementing agent is silica powder or silicon carbide or a mixture of the silica powder and the silicon carbide; the reaction formula of the chemical heat supplementing agent is SiC+2Cl2=SiCl4+C or Si+2Cl2=SiCl4; the main reaction formula of producing the zirconium tetrachloride through zircon sand chlorination is ZrSiO4+4C+4Cl2=ZrCl4+SiCl4+4CO. According to the method disclosed by the invention, the heating problem of a zircon sand fluidizing chlorination furnace can be solved, the production cost of the zirconium tetrachloride is reduced and a byproduct: an important chemical raw material silicon tetrachloride can be produced, so that the process method has the advantages of increasing the working efficiency, saving the energy and reducing the production cost.

Owner:内蒙古自治区浩森新材料开发有限公司

Process for producing high-molecular water-absorbent resin dust-free paper

InactiveCN102337701AEffective lockingReduce reverse osmosisNon-fibrous pulp additionSpecial paperReverse osmosisFluff pulp

The invention belongs to the papermaking technical field, more specifically relates to a process for producing the high-molecular water-absorbent resin dust-free paper. The process for producing the high-molecular water-absorbent resin dust-free paper takes fluff pulp wood pulp fiber, hot melt composite fiber and high-molecular water-absorbent resin (SAP) as the raw materials and the dust-free paper is composed of three-layer mixing layers. The process for producing high-molecular water-absorbent resin dust-free paper comprises the following steps: mixing the raw materials through a molding case, penetrating through hot air, wherein a heat bonding point between the hot melt fiber and wood pulp fiber formed by surface melting and flowing which are generated by the hot melt fiber during the heating process has the heat bonding effect, spraying latex on the double faces of the paper web and then drying by hot-air in a drying cylinder, rewinding to obtain the finished product. The present invention has the beneficial effects that the dust-free paper has good penetration performance and imbibition capability, is capable of effectively holding liquid, minimizing the reverse osmosis of liquid and maintaining the dry surface of the product, and has less dust and high tensile strength.

Owner:NANNING QIAOHONG NEW MATERIALS

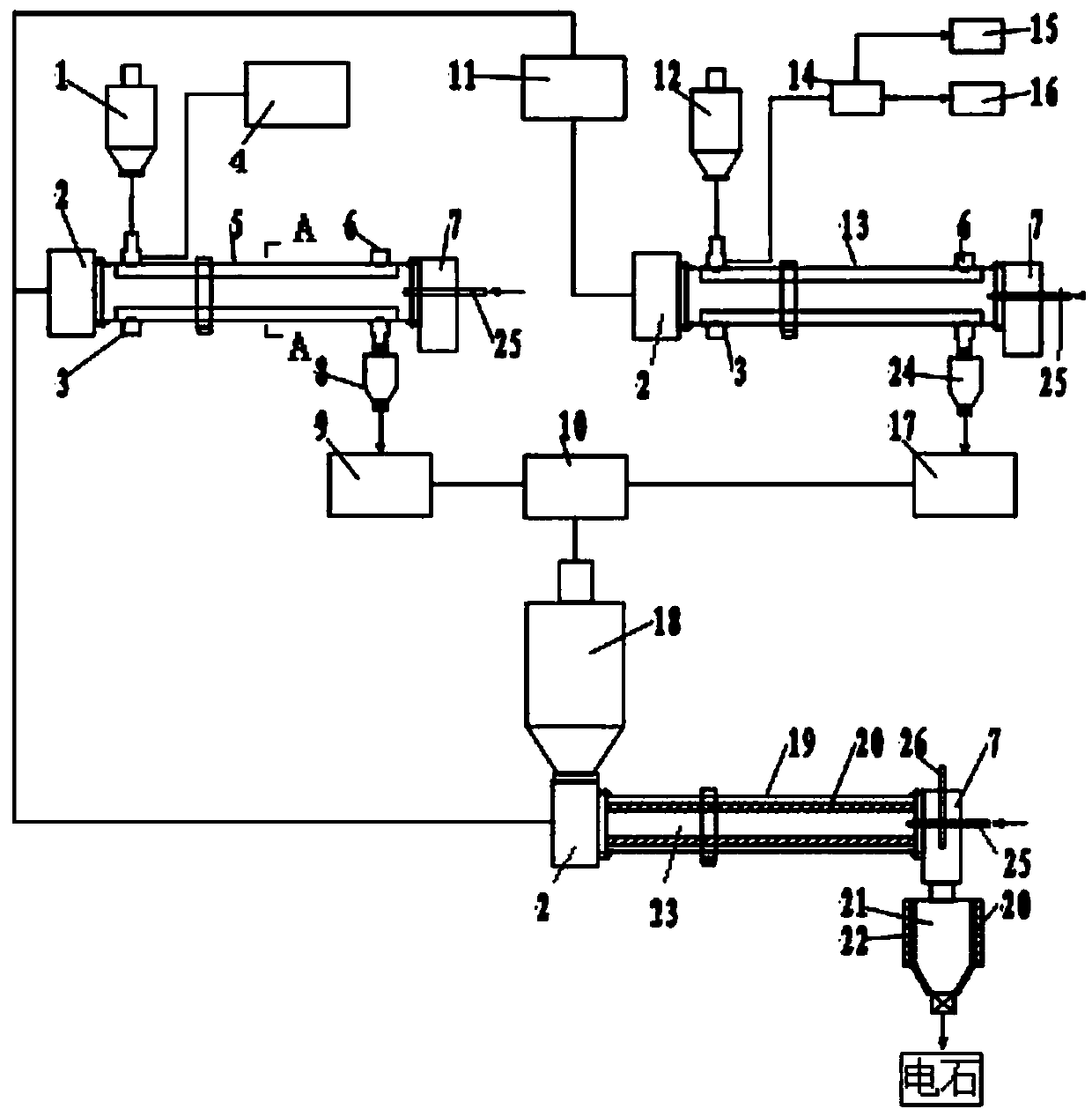

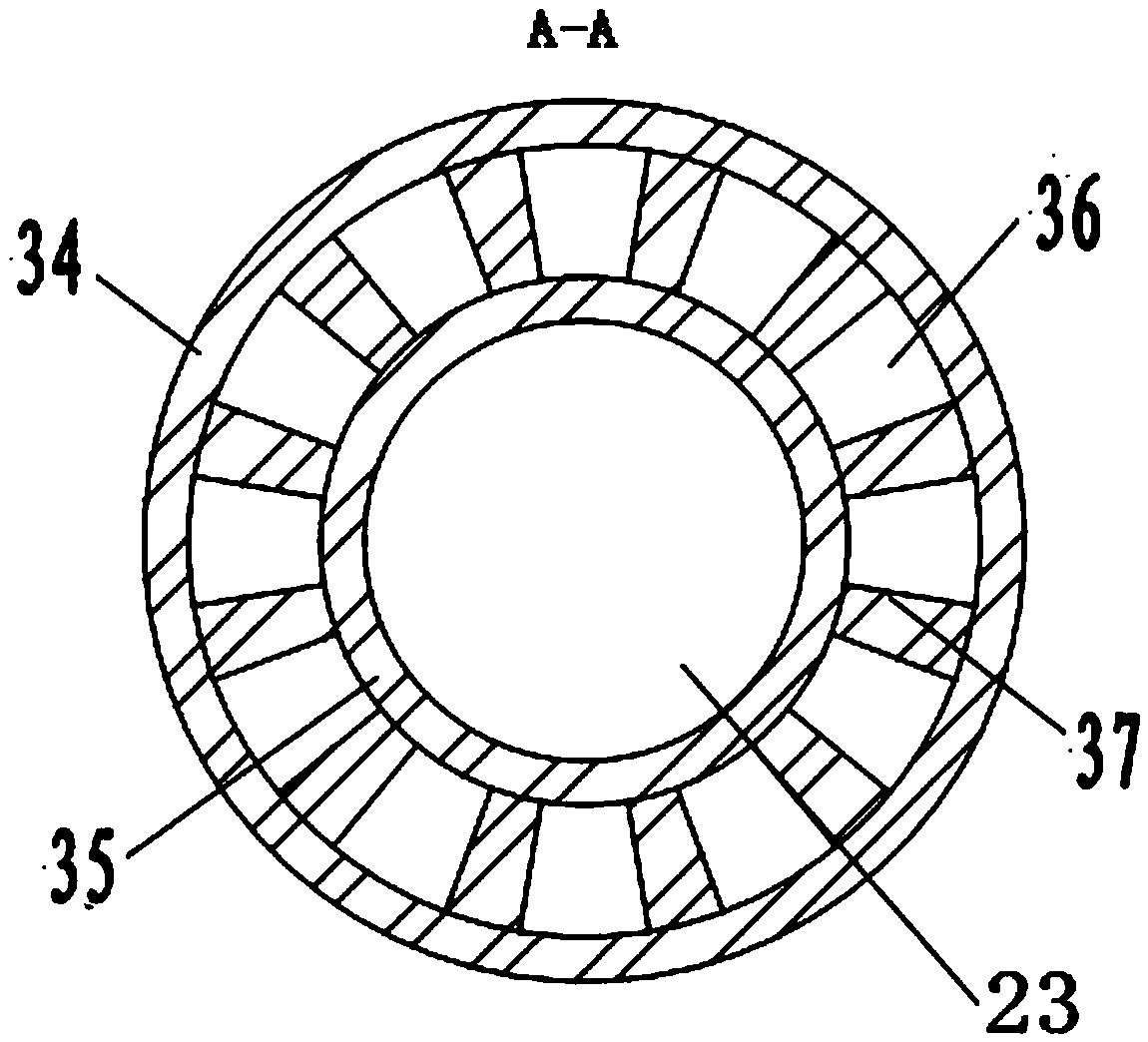

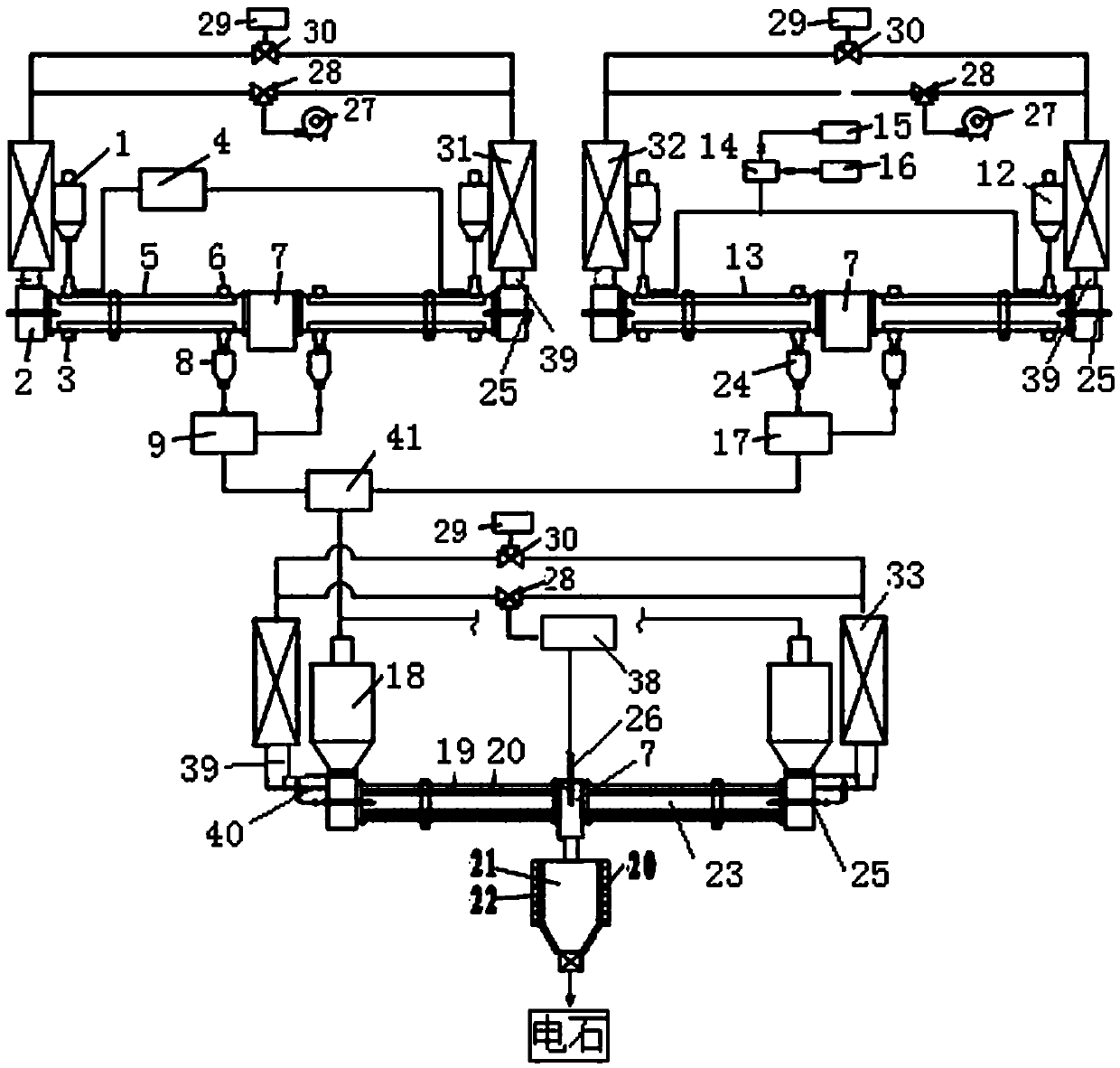

Lime-coke-calcium carbide production joint apparatus

ActiveCN105366964AReduce consumption costReduce manufacturing costCalcium carbideSpecial form destructive distillationCokeCalcium carbide

The present invention relates to a lime-coke-calcium carbide production joint apparatus. The production joint apparatus comprises a lime rotary kiln, a coking rotary kiln and a calcium carbide rotary kiln. The lime rotary kiln is provided with a limestone bin, a lime cooler and a lime bin; the coking rotary kiln is provided with a coal powder bin, a coke cooler and a coke powder bin; and the calcium carbide rotary kiln is provided with a calcium carbide raw material bin and a calcium carbide discharge bin. The lime bin and the coke powder bin are connected to the calcium carbide raw material bin through a mixing and ball-pressing device or a calcium carbide raw material powder conveyor, the calcium carbide raw material bin is connected to the kiln chamber of the calcium carbide rotating kiln through a kiln-end hood, and the kiln chamber is connected to the calcium carbide discharge bin through a firing hood. self-melting resistant material layers are separately coated on the kiln chamber of the calcium carbide rotating kiln and the inner wall of the calcium carbide discharge bin, and the calcium carbide discharge bin is provided with an induction heating coil. The lime-coke-calcium carbide production joint apparatus provided by the present invention makes full use of residual heat of the rotating kilns, reduces the heat loss in a production process, and comprehensively uses heat and materials, so that the energy consumption and production costs are lowered, and the emission of carbon dioxide is reduced.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method for removing impurities of vacuum chuck

InactiveCN102431787AGuaranteed StrengthAvoid cloggingCleaningMetal working apparatusEngineeringImpurity

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

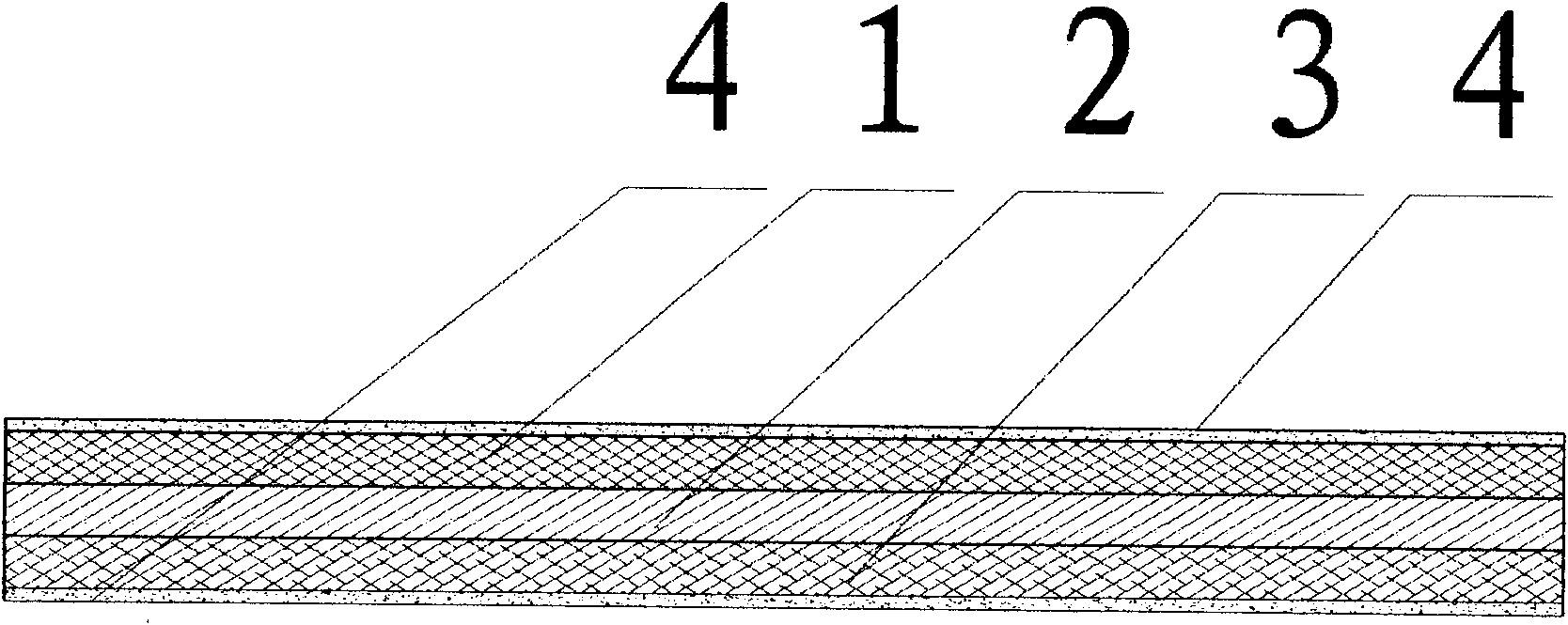

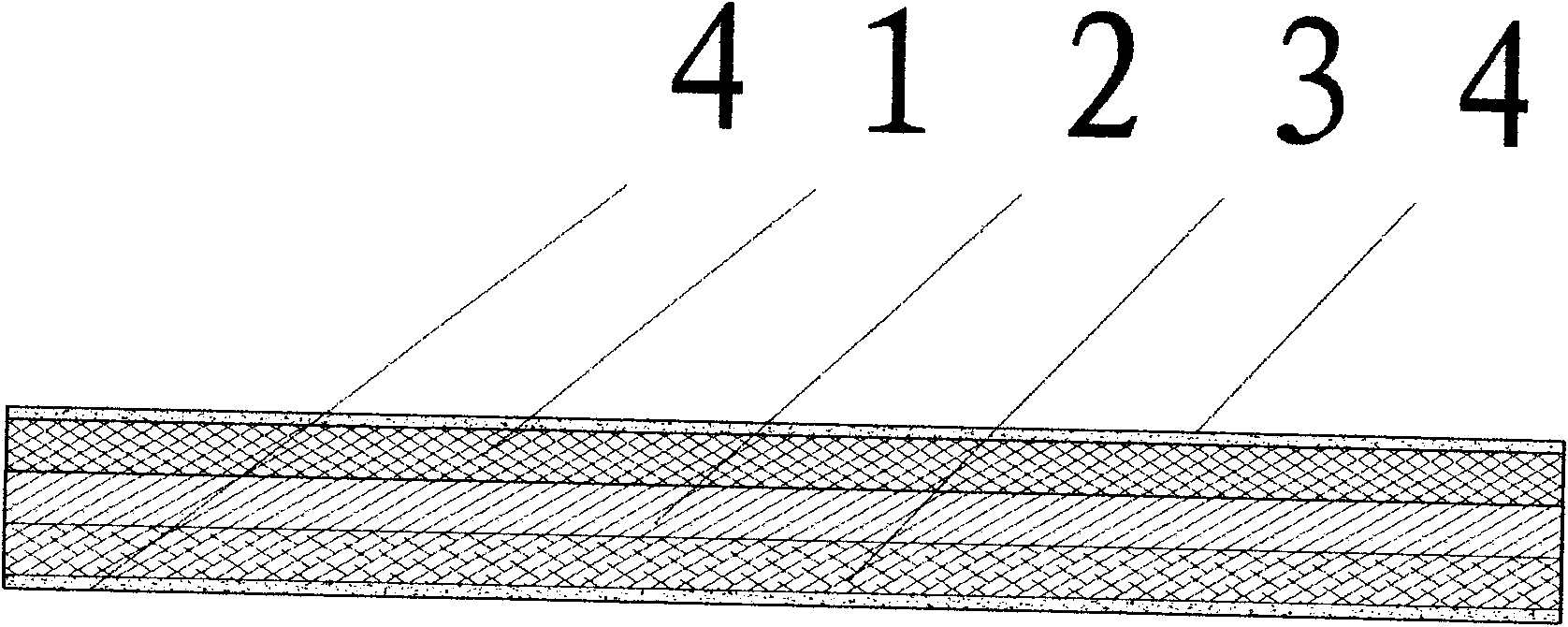

Metal flexible cloth for metal surface modification and preparation method thereof

The invention relates to a special metal flexible cloth for the preparation of a coating with high temperature and corrosion resisting and a preparation method thereof. The metal flexible cloth can be used for the protection of mechanical parts in fields, i.e. a power station, petroleum, aviation, food, plastic, and the like. The metal powder cloth is prepared by adding a forming agent and a bonding agent into the mixed power of metals, i.e. WC-Co, Ni, Cr, and the like, and the cloth patch can be bonded on a metal base body by an organic bonding agent to form a thicker protective layer with abrasion resistance, high temperature resistance and corrosion resistances by being metallurgically combined with the metal base body in a penetration brazing way. The coating has good heat conductivity, corrosion resistances and impact resistance, and wrapped parts can recover the original mechanical property of base materials through heat processing, thereby, the costing can be suitable for the recovery of pieces with heterogeneous surfaces and especially suitable for the recovery of a curved surface, a folded surface, a helical surface, and the like. The invention an solve the problems of the high temperature corrosion and the abrasion of parts with serious abrasion and heat resistance in mechanical equipment and power station equipment, decreases the times of stopping production for overhauling and enhances the economic benefits.

Owner:JIANGXI HENGDA HI TECH CO LTD

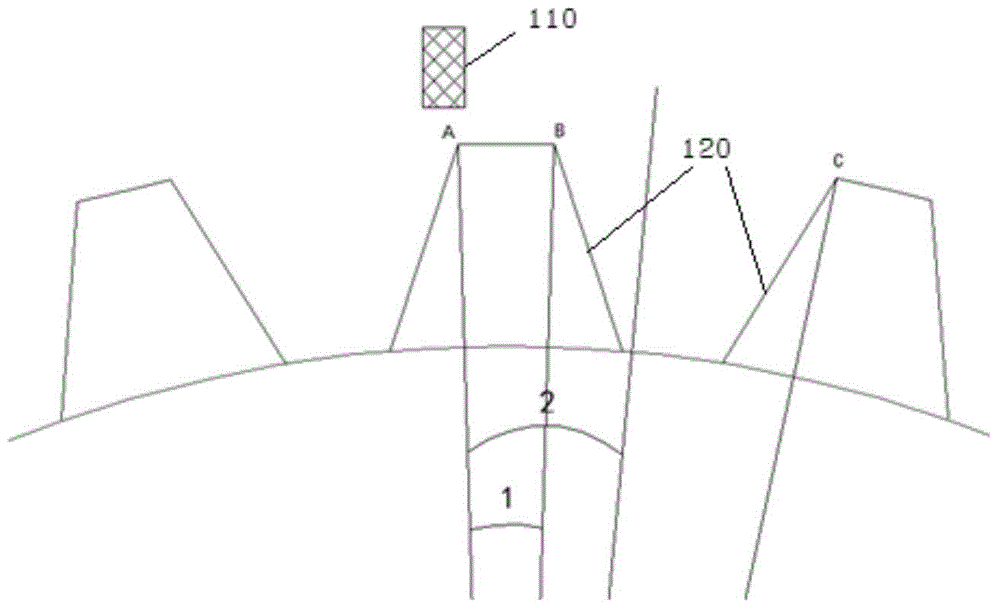

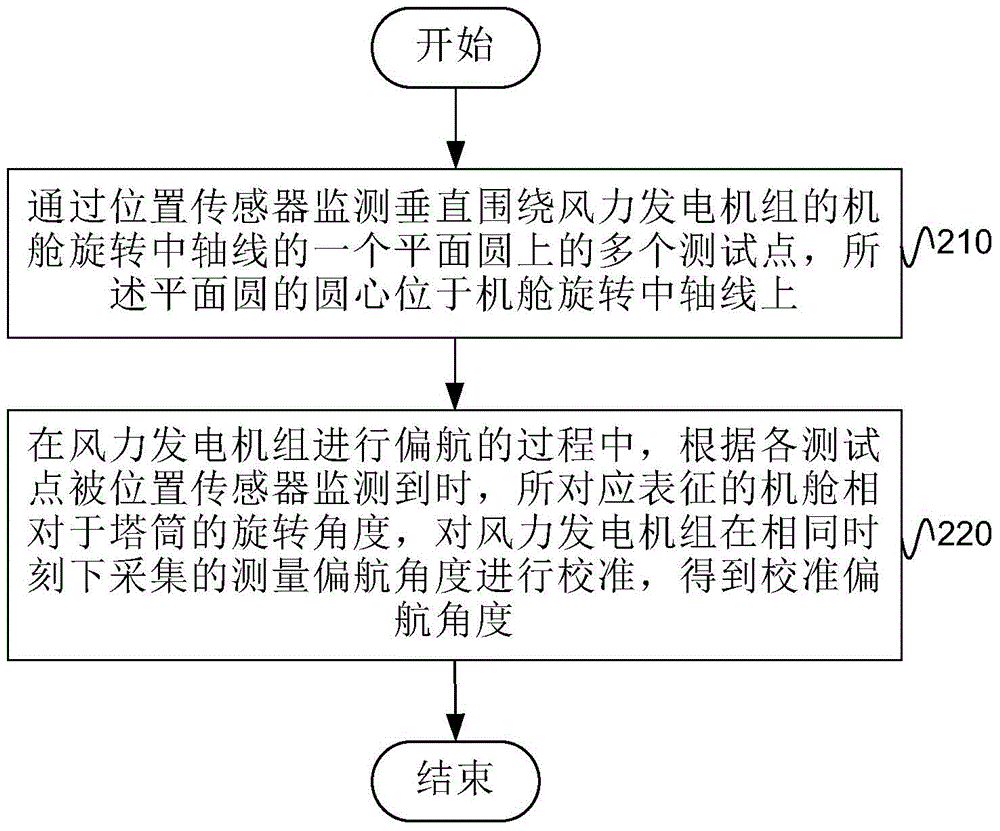

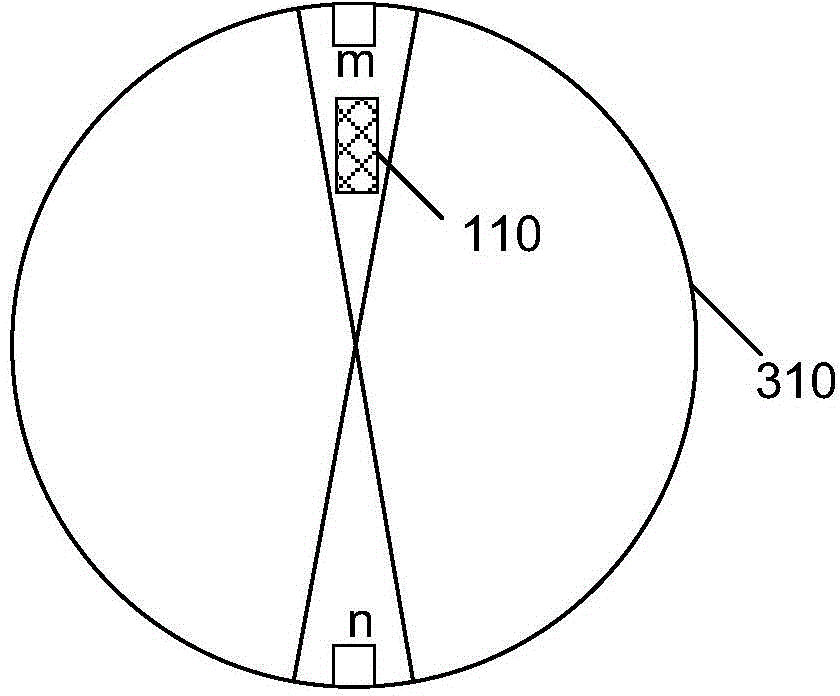

Calibration method and system for yaw angles of wind generating set

ActiveCN104948384AReduce downtime for maintenanceExtend your lifeWind motor controlMachines/enginesWind forceNacelle

The embodiment of the invention provides a calibration method and system for yaw angles of a wind generating set. The method includes the steps that a plurality of testing points on a plane circle vertical to a cabin rotation axle wire surrounding the wind generating set are monitored through a position sensor, and the circle center of the plane circle is located on the cabin rotation axle wire; in the yaw process of the wind generating set, according to the rotation angles, correspondingly represented when the testing points are monitored by the position sensor, of a cabin relative to a tower cylinder, measured yaw angles collected by the wind generating set at the same moment are calibrated, and the calibrated yaw angles are obtained. By means of the technical scheme, the yaw angles of the unit are controlled to be coincident with the torsion angle of a power cable in an actual yaw bearing, the halt maintenance time of the unit is further shortened, and the service life of the power cable of the unit is prolonged.

Owner:XINJIANG GOLDWIND SCI & TECH

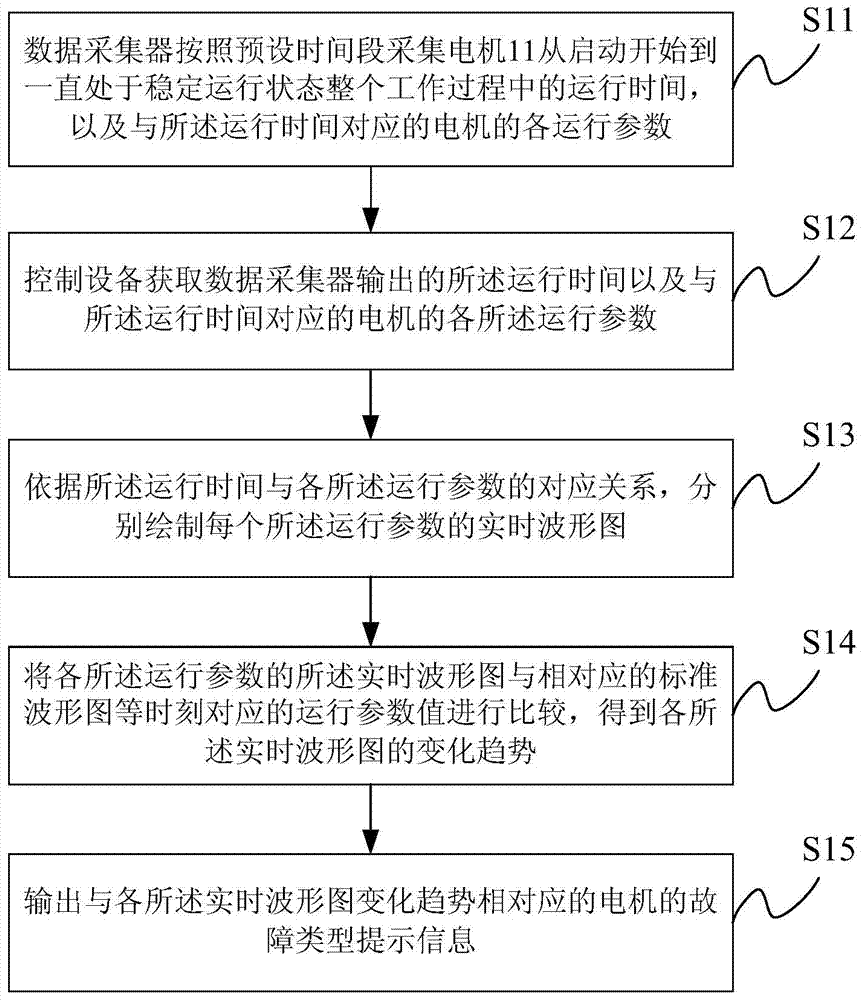

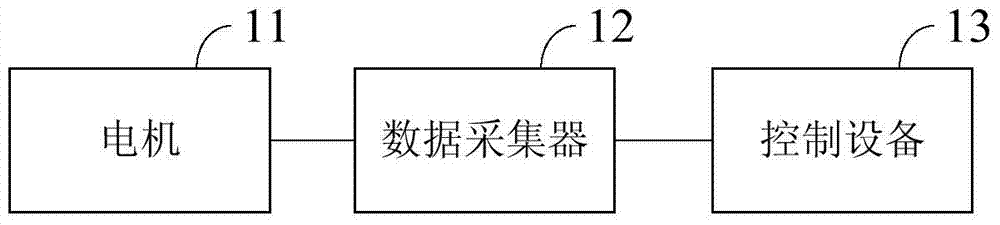

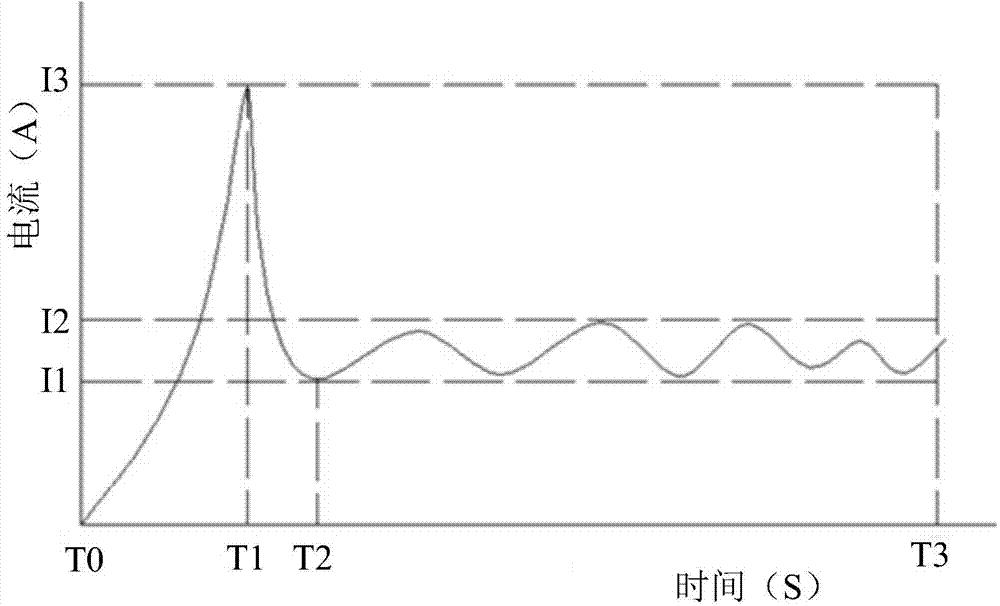

Monitoring method and monitoring system of motor

ActiveCN103888322AReduce downtime for maintenanceImprove reliabilityData switching networksData acquisitionMonitoring system

The invention provides a monitoring method and a monitoring system of a motor. The monitoring system comprises the motor, a data acquisition device and a control device, wherein the data acquisition device is respectively connected with the motor and the control device. Firstly, the motor running time acquired by the data acquisition device in the whole working process from starting to a continuous stable running state and motor running parameters corresponding to the running time are adopted to draw real-time oscillograms of the running parameters; then the real-time oscillograms and running parameter values constantly corresponding to standard oscillograms and the like during normal motor running are compared to obtain variation tendency of the real-time oscillograms. Due to the fact that the running parameters correspondingly change before motor faults occur, the motor faults can be anticipated according to the variation tendency of the real-time oscillograms, and workers can take corresponding protective measures in advance.

Owner:重庆贻科科技有限公司

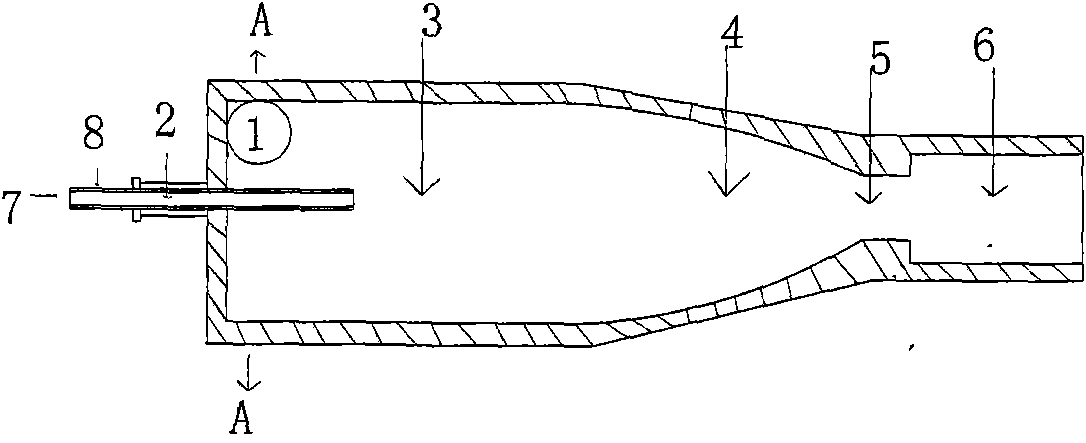

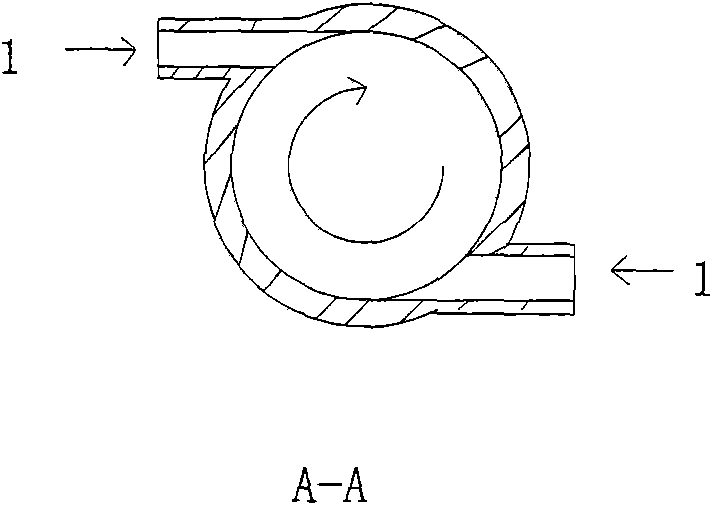

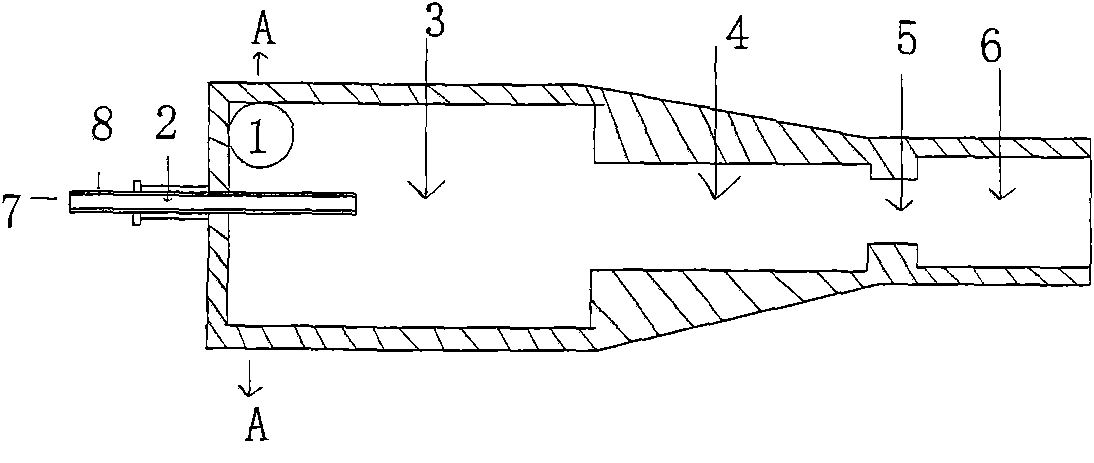

Novel soft carbon black reaction furnace

InactiveCN101891976AIncrease effective volumeLarge amount of processingPigmenting treatmentCombustion chamberReaction temperature

The invention relates to a device for producing soft carbon black. A necking section of a reaction furnace is designed into an arc smooth curve structure and is tangent with a reaction section. Raw material oil ejected from a raw material oil spray gun nozzle meets rotary high-temperature burning residual gas entering the reaction furnace from upper and lower tangent combustion chambers on two sides of the reaction furnace, a small part of the raw material oil is burnt to provide enough heat, and most of the raw material oil is cracked to generate the carbon black. The necking section adopts the smooth arc curve structure, and the reaction airflow can stably pass through the necking section in a rotary plug flow form by controlling air quantities of inlets of the two combustion chambers, so the 'back mixing' phenomenon is reduced, the frequent coking phenomenon of the soft carbon black due to large treatment quantity and low reaction temperature is avoided, the quality of the carbon black is improved, and the yield of the carbon black is improved.

Owner:LONGXING CHEMICAL STOCK CO LTD

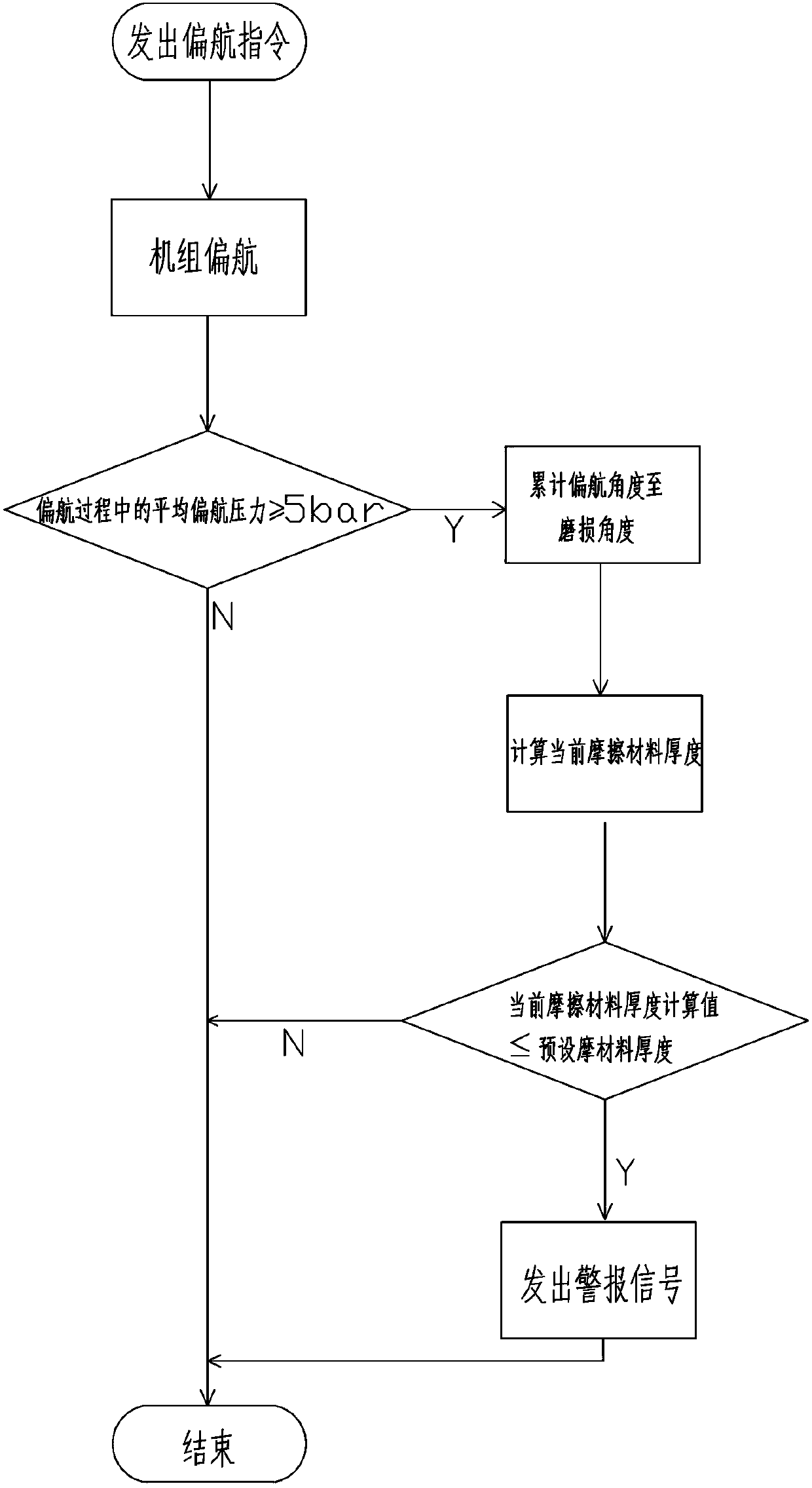

Method for controlling wear monitoring of yaw brake friction plate of wind power generator set

ActiveCN109058334AWide applicabilityReduce downtime for maintenanceWind motor controlMachines/enginesWind forceWind power generator

The invention relates to a method for controlling wear monitoring of a yaw brake friction plate of a wind power generator set. The following technical scheme is adopted: step 1, setting a warning thickness of a friction material of the yaw friction plate, and accumulating a yaw angle to a wear angle if an average yaw residual pressure in the yawing process is larger than or equal to 5 bar after the wind power generator set yaws; step 2, calculating and obtaining the thickness of the friction material of the current yaw friction plate by at least the wear angle; step 3, comparing the thicknessof the friction material of the current yaw friction plate with the set warning thickness of the friction material, and sending a warning signal by a monitoring system if the thickness of the currentfriction material is less than or equal to the set value to remind maintenance personnel to check and replace the yaw friction plate; and step 4, resetting a total yaw angle of a system after the yawfriction plate is replaced, thereby achieving control of the wear monitoring of a new yaw brake friction plate.

Owner:HUAYI WIND ENERGY CO LTD

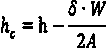

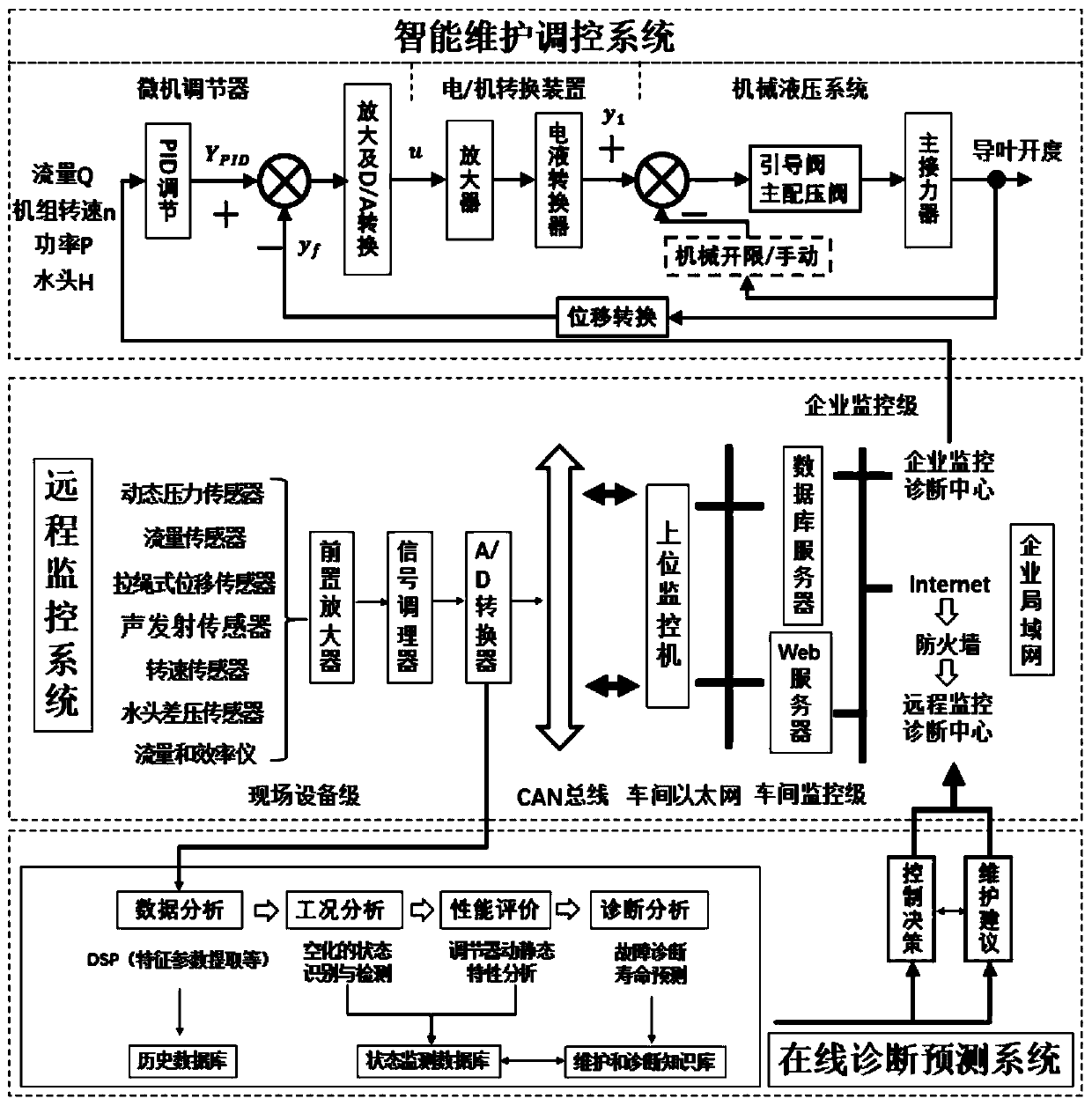

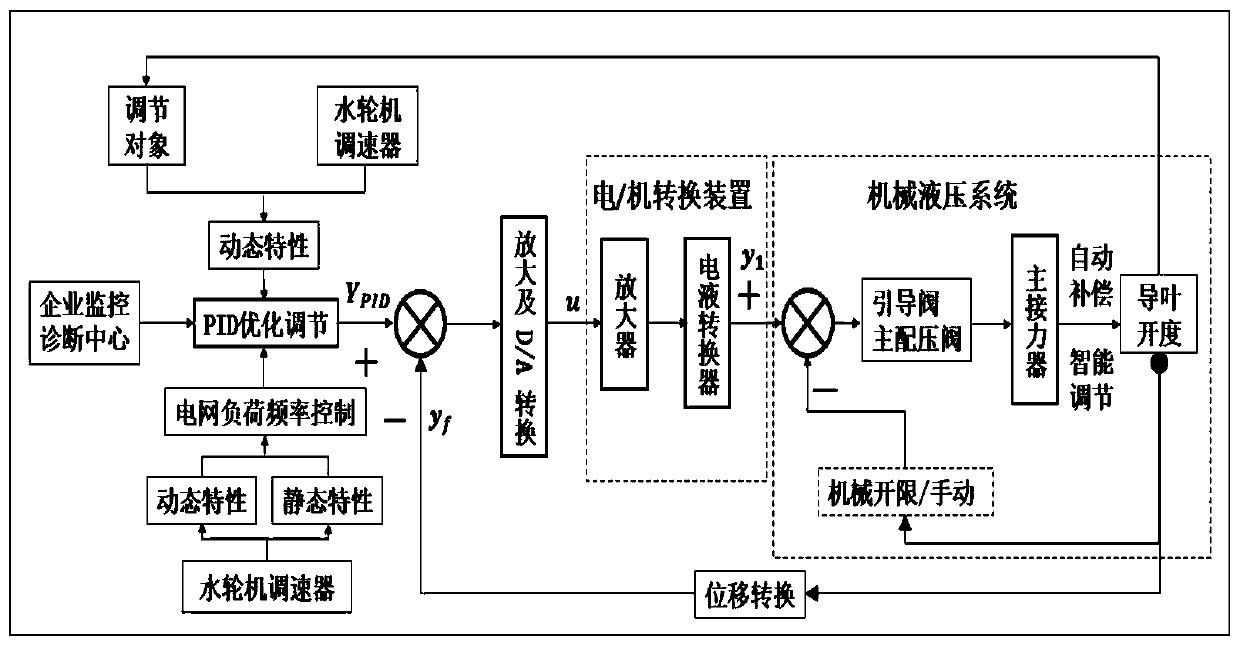

Remote monitoring, diagnosis and prediction and intelligent maintenance control system for hydraulic turbine

InactiveCN110206676ARealize systematic operation and maintenanceImprove operational efficiencyMeasurement devicesHydro energy generationDowntimeControl system

The invention discloses a remote monitoring, diagnosis and prediction and intelligent maintenance control system for a hydraulic turbine. The remote monitoring, diagnosis and prediction and intelligent maintenance control system for the hydraulic turbine comprises a remote monitoring system, an online diagnosis and prediction system and an intelligent maintenance control system. The system can realize accurate fault positioning, can carry out on-line monitoring and intelligent control under variable operating conditions for equipment, and can improve the operating efficiency. The remote monitoring, diagnosis and prediction and intelligent maintenance control system for the hydraulic turbine can realize the systematic operation and maintenance from the part to the whole. The online diagnosis and prediction system can carry out on-line diagnostic analysis and intelligent prediction for the equipment, which can effectively avoid excessive maintenance or insufficient maintenance. Moreover,the system can predict the development trend of the operating state of a unit and can effectively reduce the downtime maintenance probability of the unit.

Owner:ZHEJIANG UNIV

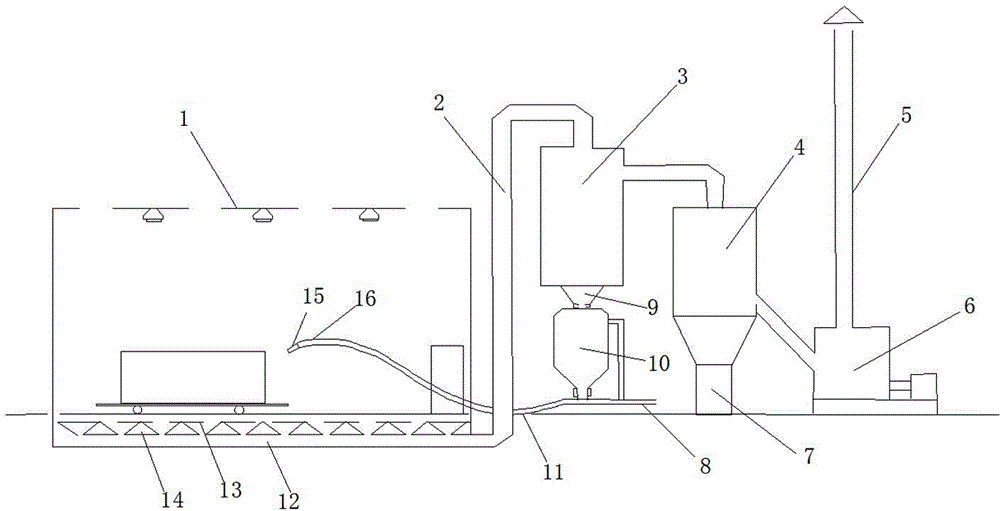

Sand-spraying dust-removing equipment

InactiveCN104907940AEasy to installInstallation economyAbrasive machine appurtenancesAbrasive blastingHoneycomb

The invention discloses sand-spraying dust-removing equipment. The sand-spraying dust-removing equipment comprises a sand-spraying chamber body, wherein the bottom part of the sand-spraying chamber body comprises a floor grid, a honeycomb recovery floor and a pill-transporting air pipe respectively from upper layer to lower layer. The sand-spraying dust-removing equipment also comprises a sand-lifting air pipe, a pill sorting machine and a dust remover, wherein one end of the sand-lifting air pipe is connected with the bottom part of the sand-spraying chamber body, and the other end of the sand-lifting air pipe is connected with the top part of the pill sorting machine; a sand storage hopper is arranged at the bottom part of the pill sorting machine; a sand-spraying tank is arranged at an outlet of the sand storage hopper; an outlet of the sand-spraying tank is connected to a compressed-air pipe; the outlet end of the compressed-air pipe is connected with one end of a rubber pipe, and the other end of the rubber pipe is connected with a spraying gun; a spraying nozzle is arranged at the outlet end of the spraying gun; the dust remover is connected with a fan; and a chimney is arranged at the top part of the fan. The sand-spraying dust-removing equipment disclosed by the invention has the advantages that a deep foundation is not needed, and the installation is convenient and economic; the equipment maintenance is simple, and the maintenance cost is low; the spraying gun is used for spraying sand or pills, the positioning is accurate, the impacting force is strong and the surface treating effect is better.

Owner:南通恒力重工机械有限公司

Bulk installation method of small steam turbine driving synchronous generator

ActiveCN103628936AGood effectExtended service lifeMachines/enginesEngine componentsEngineeringProtection system

The invention discloses a bulk installation method of a small steam turbine driving a synchronous generator. The bulk installation method comprises the following steps of installing the steam turbine, installing the generator and installing a regulating protection system, wherein the steam turbine is installed by the following steps of (a) foundation lineation, treatment and no-parallels installation of a base, (b) detection and installation of a bedplate bracket, a bearing box and a lower cylinder body, (c) installation of a condenser, (d) installation of a gland sealing sleeve, a guide vane ring, a partition, a partition sleeve and a steam chamber, (e) installation of a rotor, (f) first installation of a regulating steam valve on the upper half part of steam, and simultaneous installation of both, (g) check of parameters before the steam turbine is covered, (h) covering of the steam turbine and (i) secondary grouting; the generator is installed by the following steps of (a) installation of a bearing seat and (b) installation of a main body of the generator; the regulating protection system is installed by the following steps of (a) installation of a regulating system and (b) installation of a protection system. The bulk installation method has the beneficial effects that vibration and noise caused by equipment operation are greatly reduced, and the cost is reduced.

Owner:中国化学工程第四建设有限公司

Method for producing zirconium tetrachloride

InactiveCN104556226AControl reaction temperatureAvoid the tediousness of frequent parking and replacementHalogenated silanesZirconium halidesAutomatic controlReaction temperature

The invention relates to the technical field of chemical processes and in particular discloses a method for producing zirconium tetrachloride. The method comprises the following steps: respectively crushing zircon sand, petroleum coke powder and a chemical auxiliary agent; fully mixing the zircon sand and petroleum coke powder according to a ratio, adding the mixture into a boiling chloridizing furnace, and introducing chlorine for carrying out a chlorination reaction; regulating the amount of the added chemical auxiliary agent by virtue of an automatic control system, so that the temperature of the boiling chloridizing furnace is always preserved to 1100 DEG C. The chemical auxiliary agent accounts for 15-30 percent of the total weight of the zircon sand and petroleum coke powder; the weight ratio of the zircon sand to petroleum coke powder is 10:(1-2.5); and the chemical auxiliary agent refers to metal silicon, silicon carbide or a mixture of metal silicon and silicon carbide. According to the method disclosed by the invention, the reaction temperature can be constantly controlled, the complicated operation of frequently stopping and replacing is avoided, the production efficiency is improved, and the production cost is reduced.

Owner:赤峰盛森硅业科技发展有限公司

Wafer discharging method, wafer discharging auxiliary device, wafer discharging device and CMP equipment comprising wafer discharging device

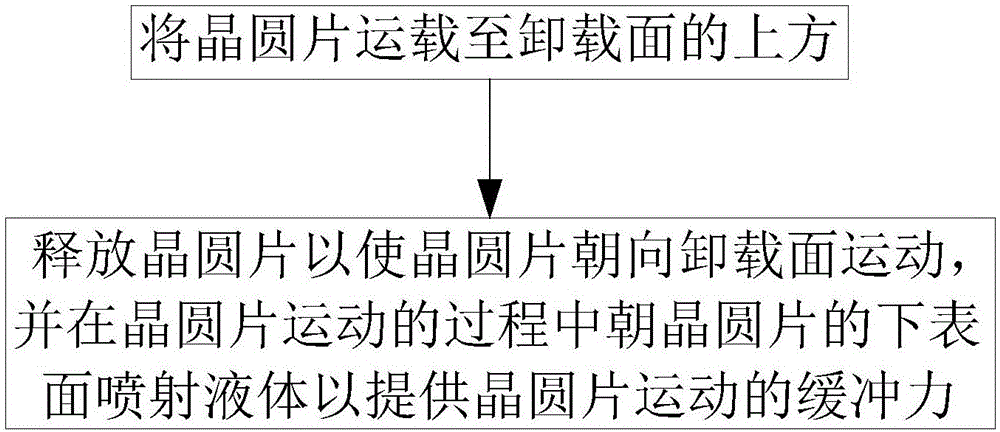

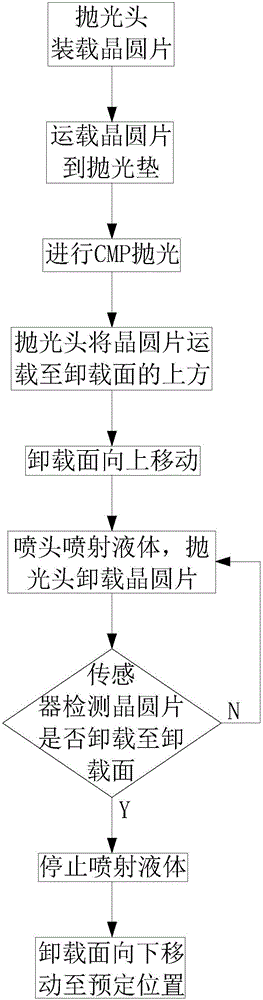

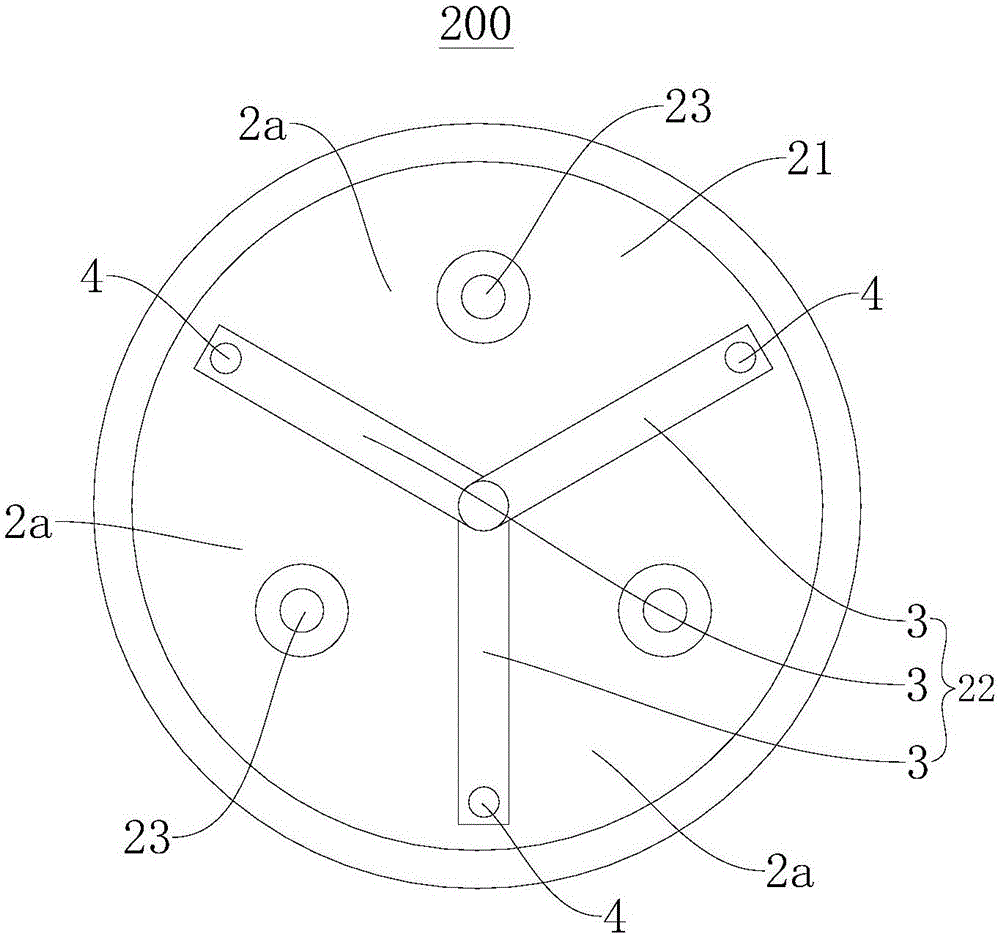

ActiveCN106625207AShock mitigationAvoid scratchesSemiconductor/solid-state device manufacturingLapping machinesEngineering

The invention discloses a wafer discharging method, auxiliary device and device, and CMP equipment comprising the wafer discharging device. The wafer discharging method comprises the following steps of conveying a wafer to the position above a discharge surface; releasing the wafer to enable the wafer to move towards the discharge surface; spraying liquid to the lower surface of the wafer in the moving process of the wafer to provide buffering force for the moving wafer. According to the wafer discharging method provided by the embodiment of the invention, the wafer can be prevented from being scratched and broken during wafer discharging; accordingly, the yield of wafers can be increased, the productivity and efficiency can be improved, the frequency of shutdown maintenance can be reduced, and the cost can be lowered.

Owner:HWATSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com