Online rapid TCP calibrating method and device capable of achieving six freedom degrees

A calibration method and technology with degrees of freedom, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of the influence of calibration accuracy, the inability to achieve calibration of Z-axis angle errors, and the fast update speed, so as to improve the accuracy of assembly operations and reduce Downtime for maintenance, effect of increased automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

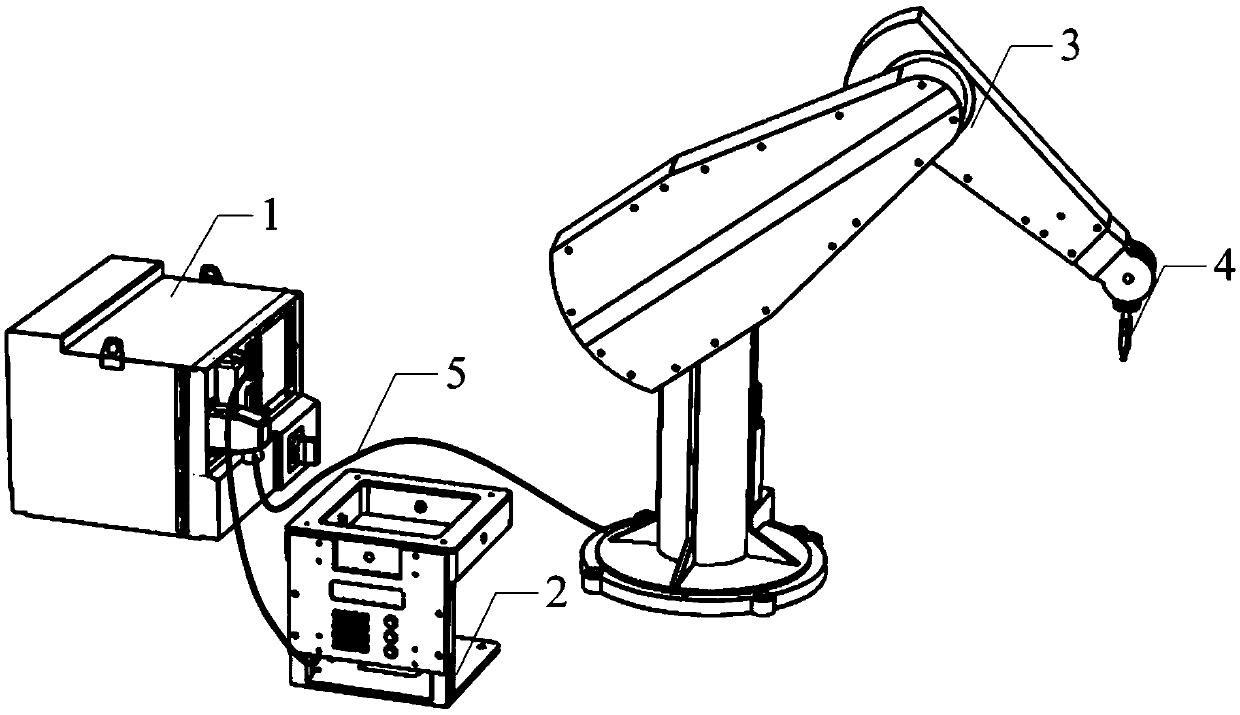

[0080] Such as figure 1 As shown, a TCP online rapid calibration device that can realize six degrees of freedom is composed of a control cabinet, a TCP calibration device, a robot, an end tool, and a control bus; the control cabinet is connected to the TCP calibration device and the robot through the control bus, and the end tool is installed on the robot.

[0081] The terminal tool of the present embodiment selects two-finger air gripper for use.

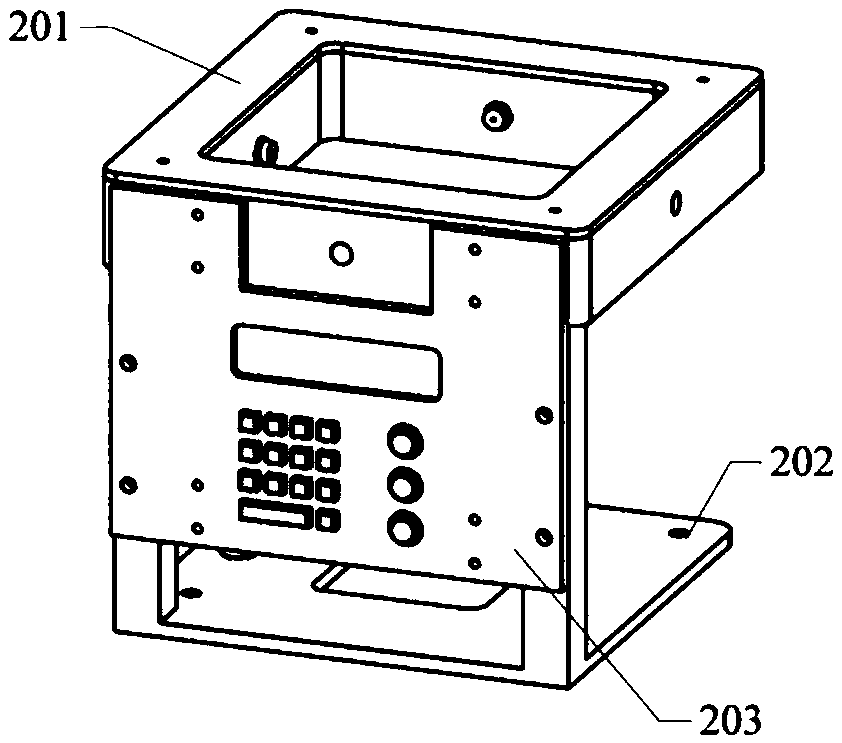

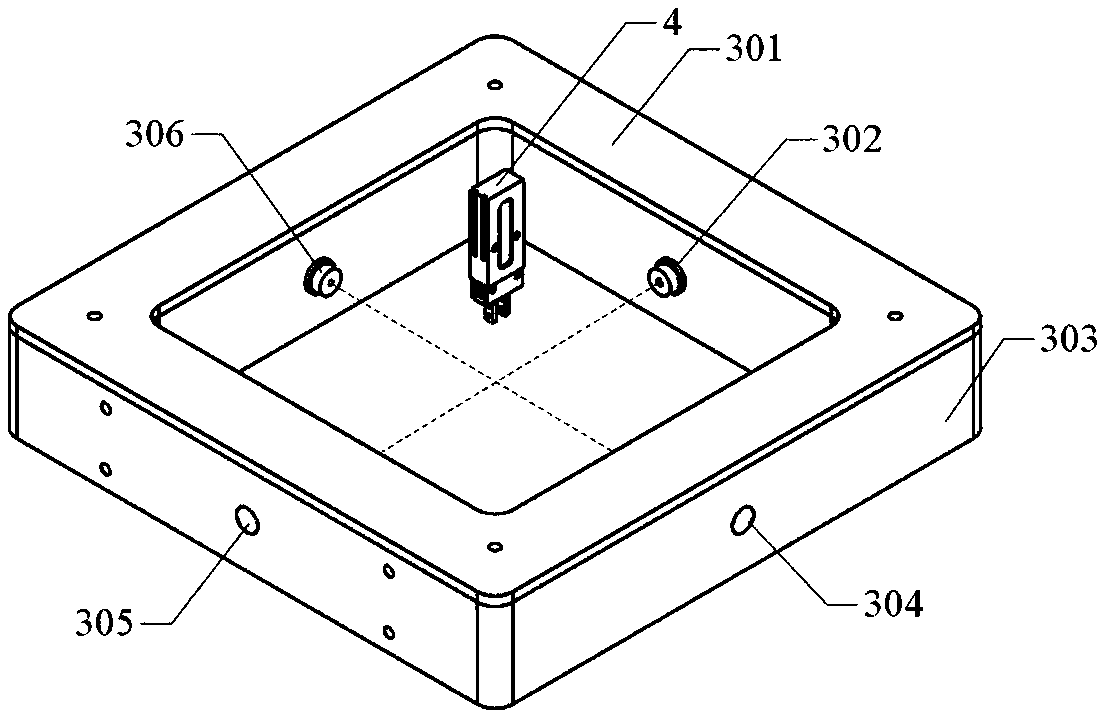

[0082] Such as figure 2 As shown, the TCP calibration device includes a TCP detection device, a calibration controller and a mounting base. The TCP detection device is fixedly installed on one side of the robot through the mounting base, and the measurement plane is parallel to the XOY plane of the robot's base coordinate system;

[0083] The laser rays of the through-beam photoelectric sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com