Method for controlling wear monitoring of yaw brake friction plate of wind power generator set

A technology for wind turbines and yaw brakes, which is applied in the control of wind turbines, wind turbines, and wind power generation, etc., can solve the difference in the wear rate of the yaw friction plates of the unit, the different yaw frequency and angle of the unit, and the yaw control. It can reduce the loss, reduce the time of downtime and maintenance, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

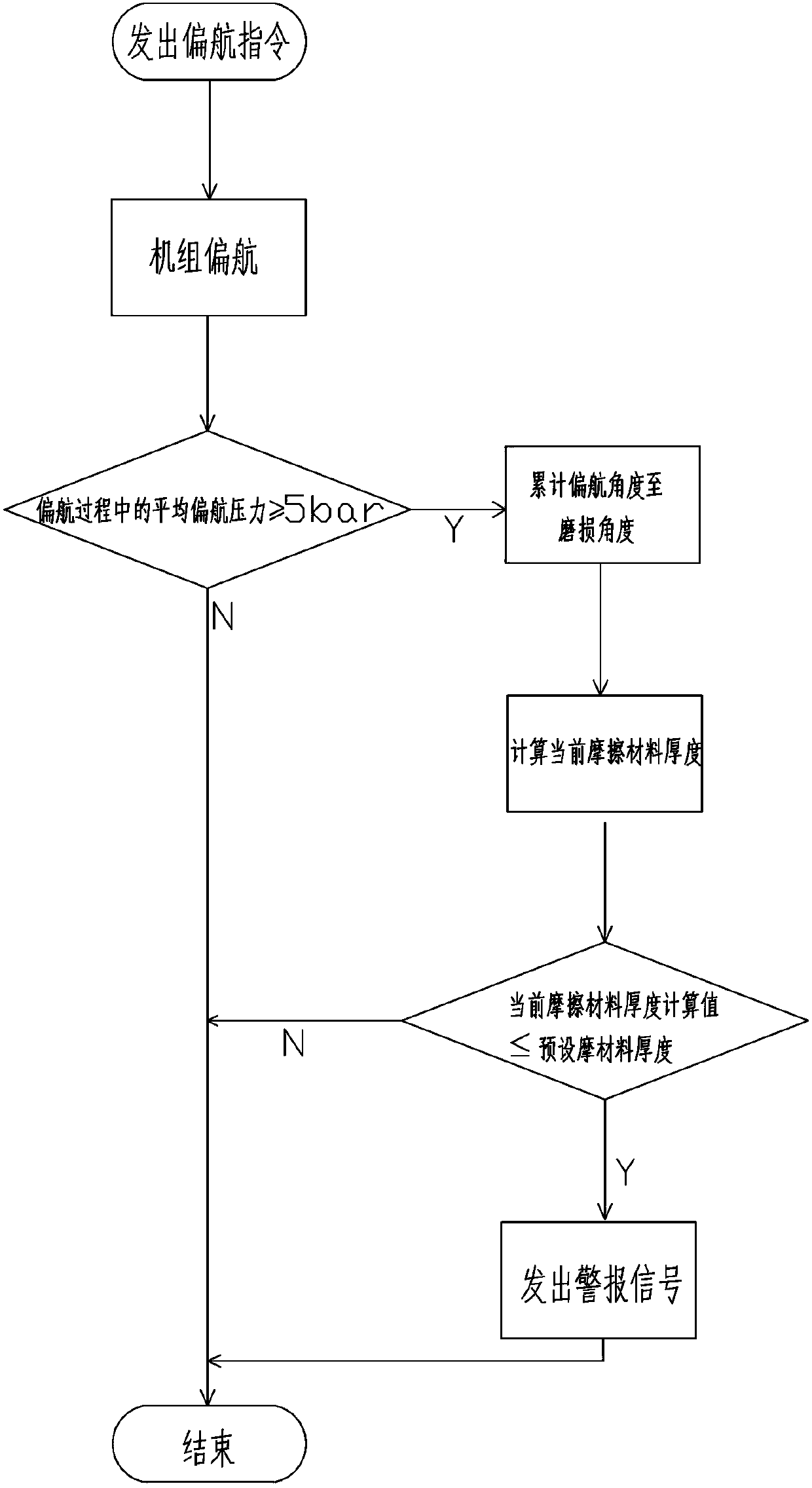

[0021] Such as figure 1 As shown in the present invention, a control method for monitoring the friction lining wear of the yaw brake of a wind power generating set, the control method is as follows:

[0022] Step 1: First set the friction material alarm thickness of the yaw friction plate (a safe value used to prevent the brake disc from being damaged due to the exhaustion of the friction material). When the wind turbine yaws, if the average yaw during the yaw process If the residual pressure is greater than or equal to 5bar, the yaw angle is accumulated to the wear angle, and the yaw angle is collected by a yaw proximity switch or a yaw encoder.

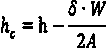

[0023] Step 2: at least calculate the friction material thickness of the current yaw friction plate by using the wear angle.

[0024] Step 3: Compare the current friction material thickness of the yaw friction plate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com