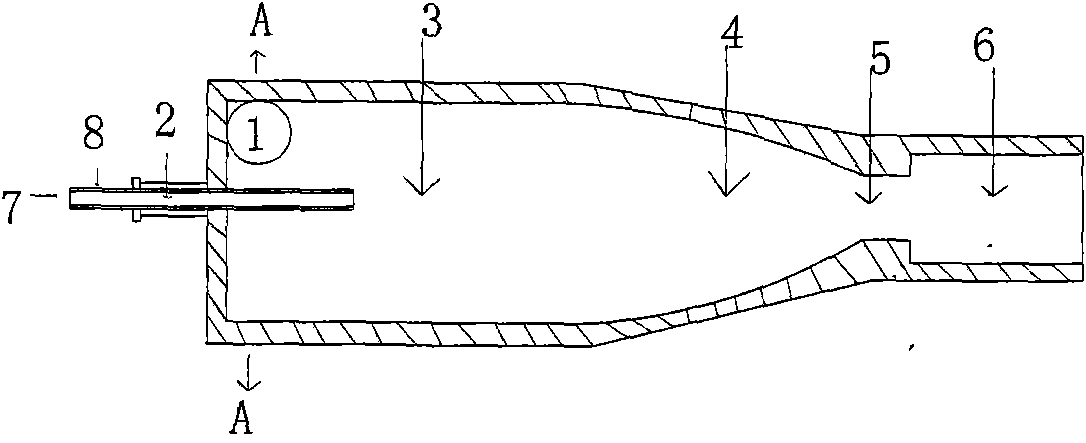

Novel soft carbon black reaction furnace

A soft carbon black and reaction furnace technology, applied in the direction of fibrous fillers, etc., can solve the problems of reduced performance of compound glue, affecting product quality, and reduced carbon black output, so as to reduce scouring destructive power, improve product quality, and carbon black The effect of more uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

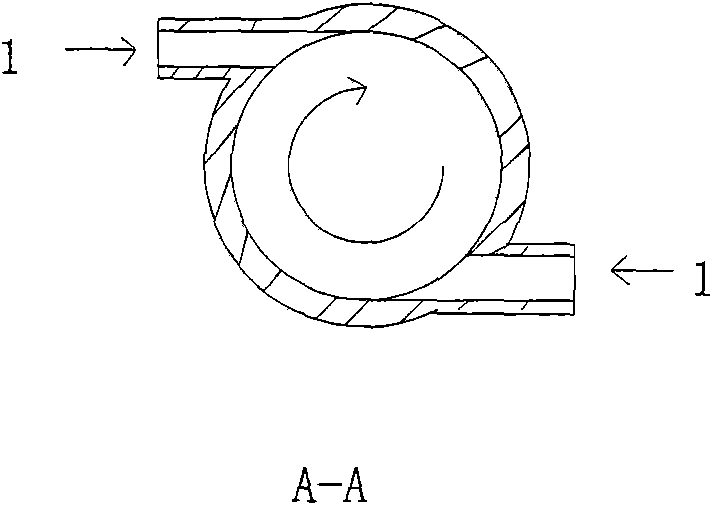

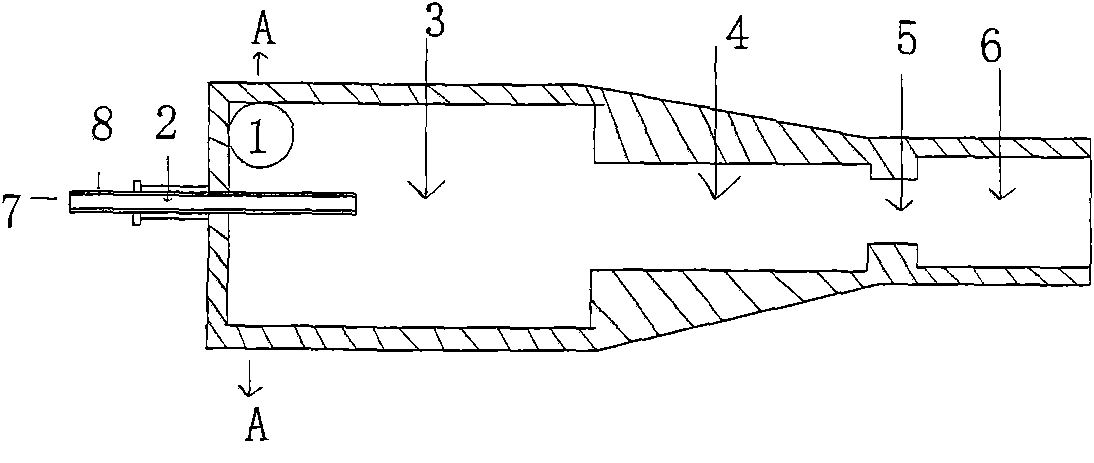

[0025] The air supplied by the main supply fan and preheated by the air preheater enters a pair of upper and lower tangential combustion chambers of the reaction furnace through the regulating valve and flow meter respectively, and is mixed with natural gas and burned to generate high-temperature waste gas Entering the reaction section, a high-speed swirling airflow is formed, which acts on the raw oil that is preheated by the raw oil preheater and sprayed out from the raw oil gun under the atomization of steam or compressed air. The raw oil is cut into oil droplets of hundreds of nanometers, a small part of the raw oil is burned to supplement the heat needed for cracking the other part of the raw oil, and most of the raw oil is instantly volatilized and cracked under high temperature. In the shrinking section, because the gas flow is restricted by the reaction furnace, the rotation rate increases rapidly, and the carbon-containing ions cracked into fragments collide violently ...

Embodiment 2

[0027]

Embodiment 3

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com