Three return journey barrel type drying machines

A kind of dryer and cylinder-type technology, which is applied in the field of a large number of material drying devices, can solve the problems of easy deformation and dislocation, axial displacement, etc., and achieve the effect of overcoming stress deformation, reducing occupied space, and increasing the output of dry products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

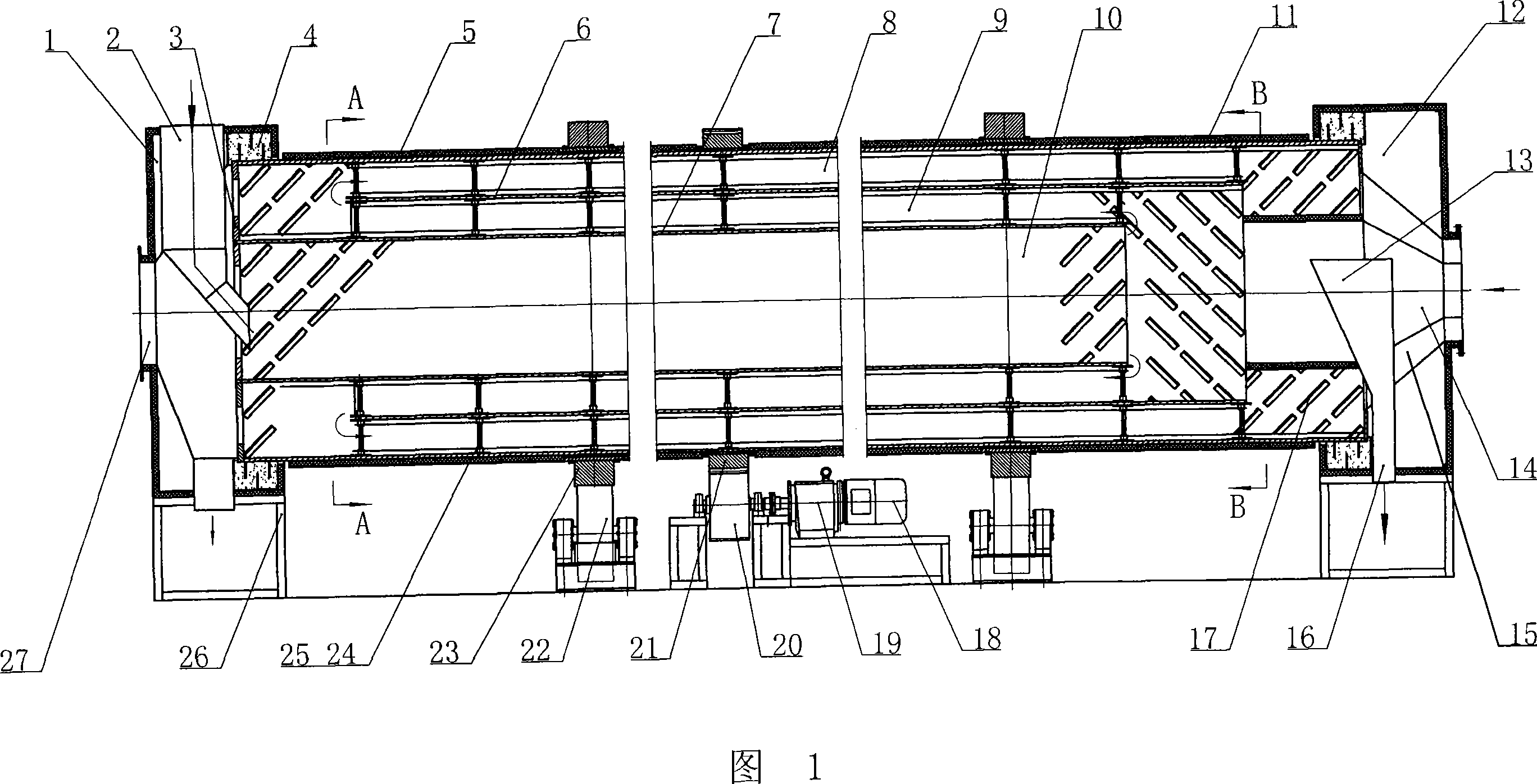

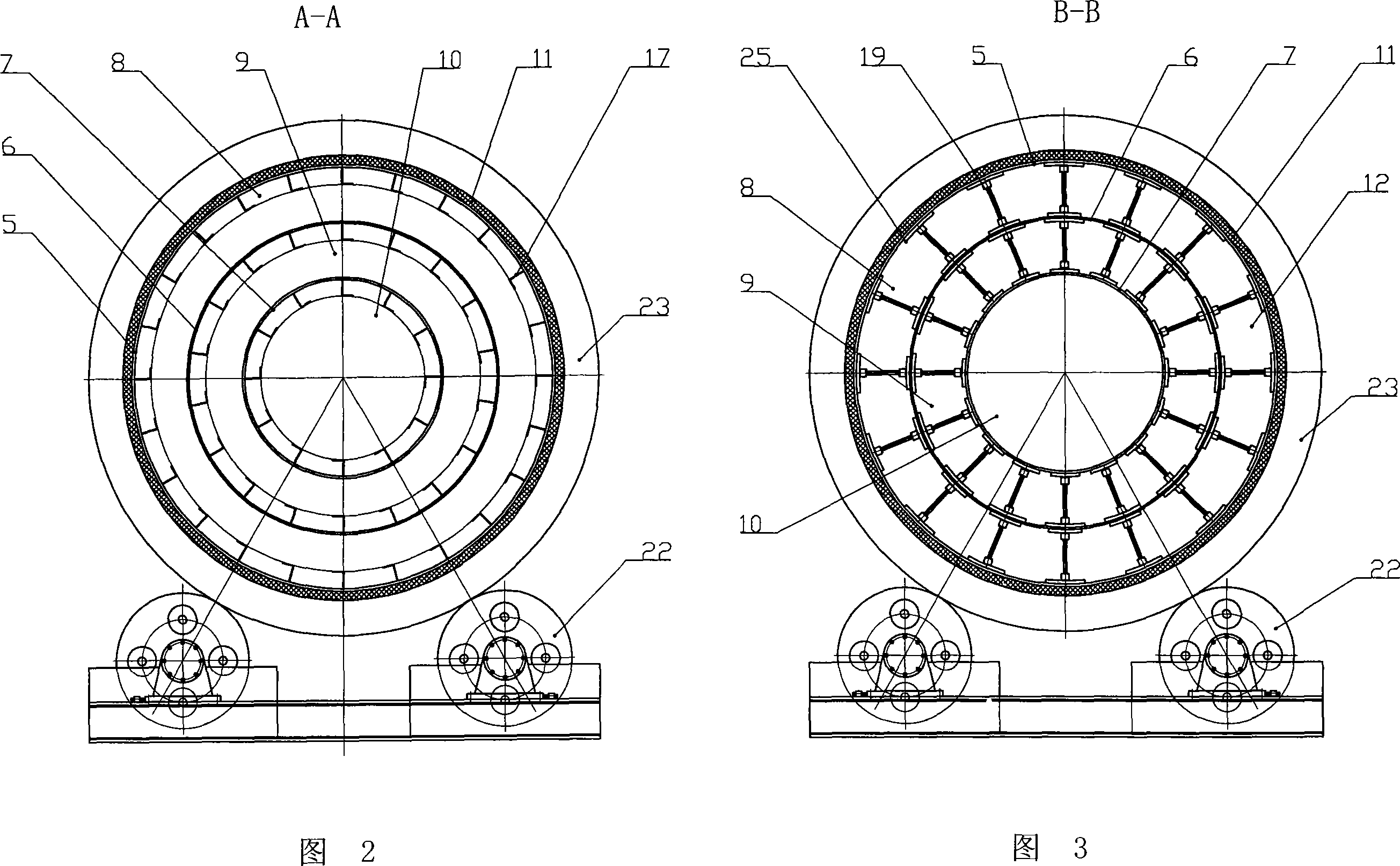

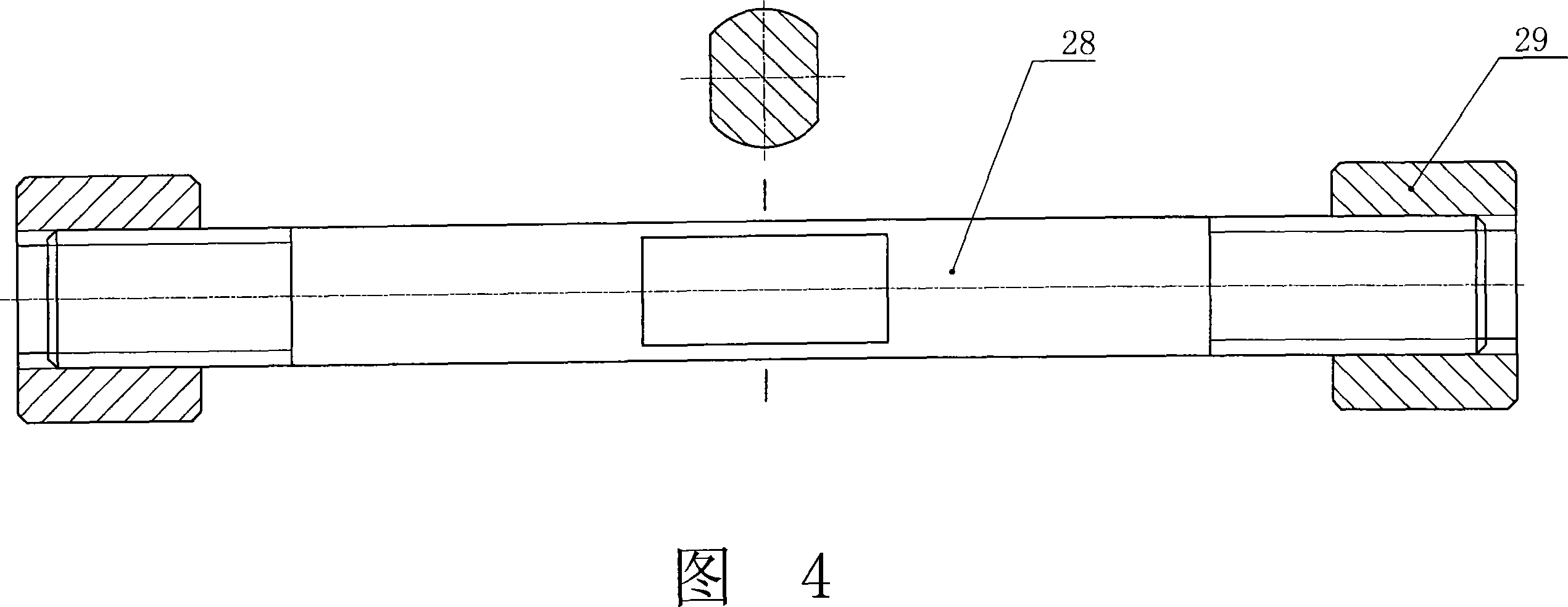

[0018]The specific structure of the present invention will be described in detail according to Figs. 1-4. Because the machine is improved on the basis of the structure of the traditional drum dryer, the specifications, models and manufacturing processes of its basic components should be determined in accordance with existing standards and relevant regulations, especially the structural design and use should be in line with safe production The requirements of measures and the provisions of relevant standards. The cylinder dryer includes a body composed of a bracket 26, a sealed box 1, 12, a cylinder with a rolling ring 23 and a ring gear 21 on the outer periphery, and a drive device, a support device, and a controller (not shown in the figure). . Wherein the driving device includes a common motor 18 assembled on a bracket 26, a speed reducer 19, a drive gear 20 connected by a shaft coupling, and a ring gear 21 meshed with it. In order to further improve the power distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com