Patents

Literature

362results about How to "Increase effective volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

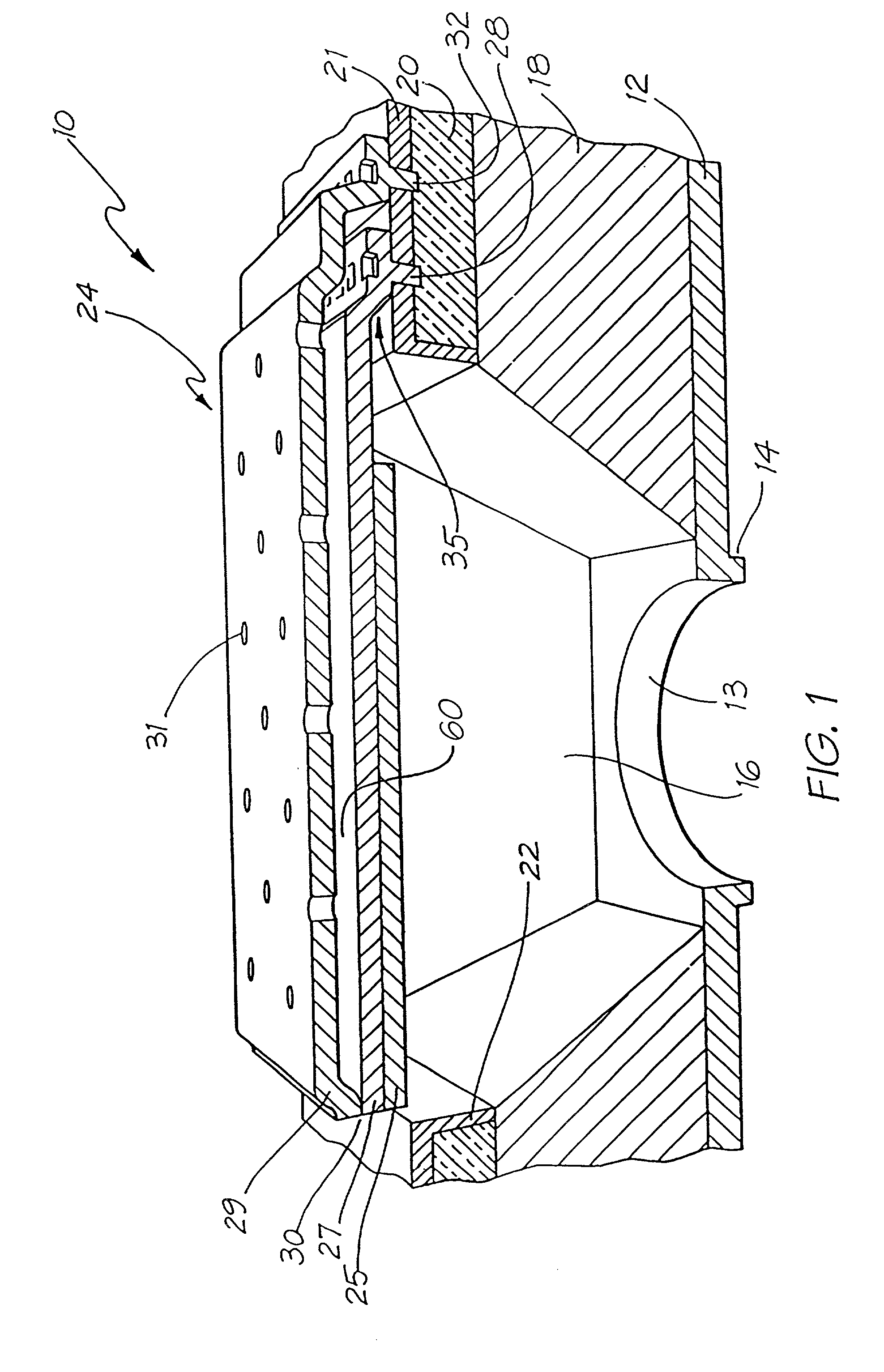

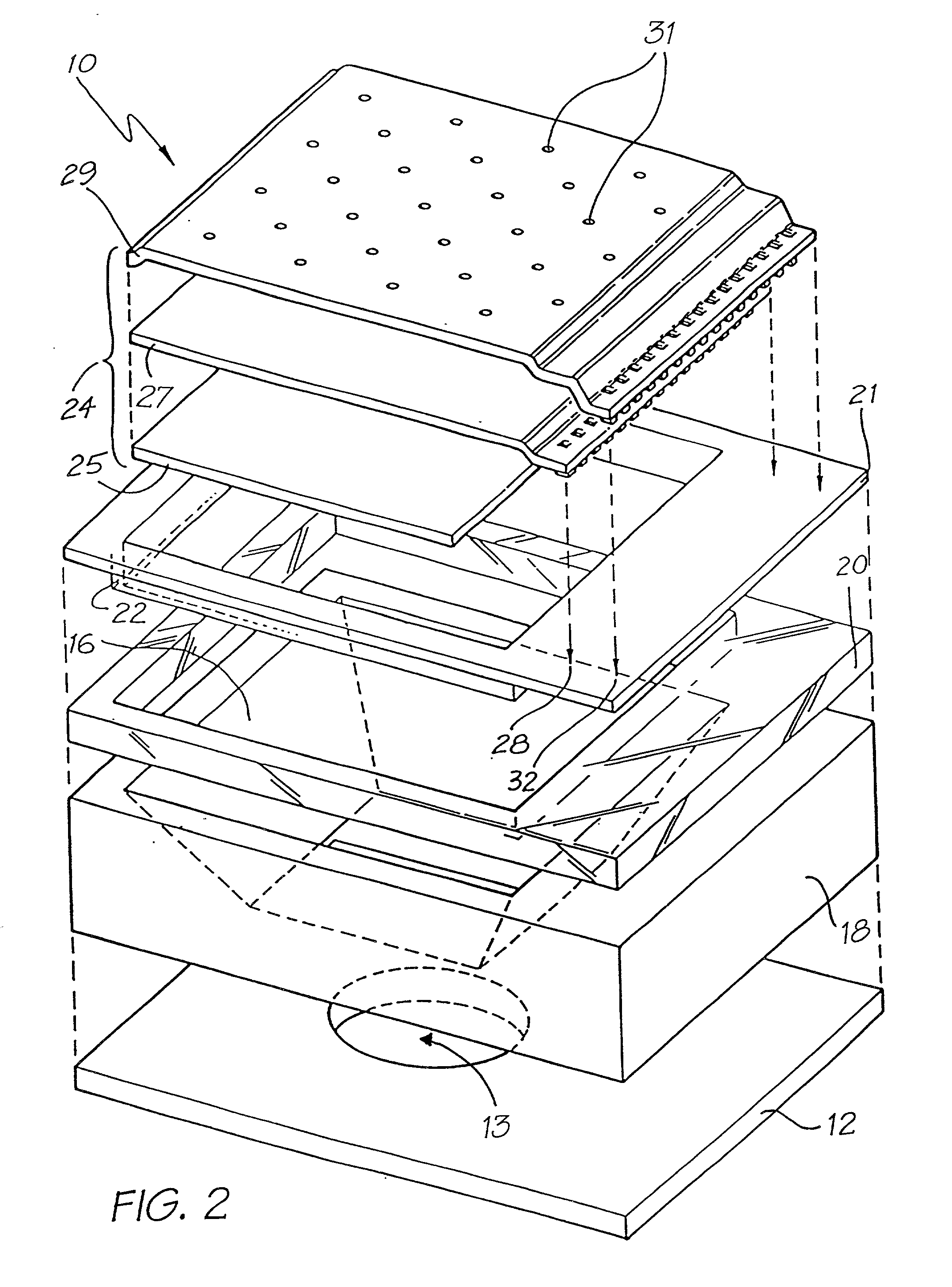

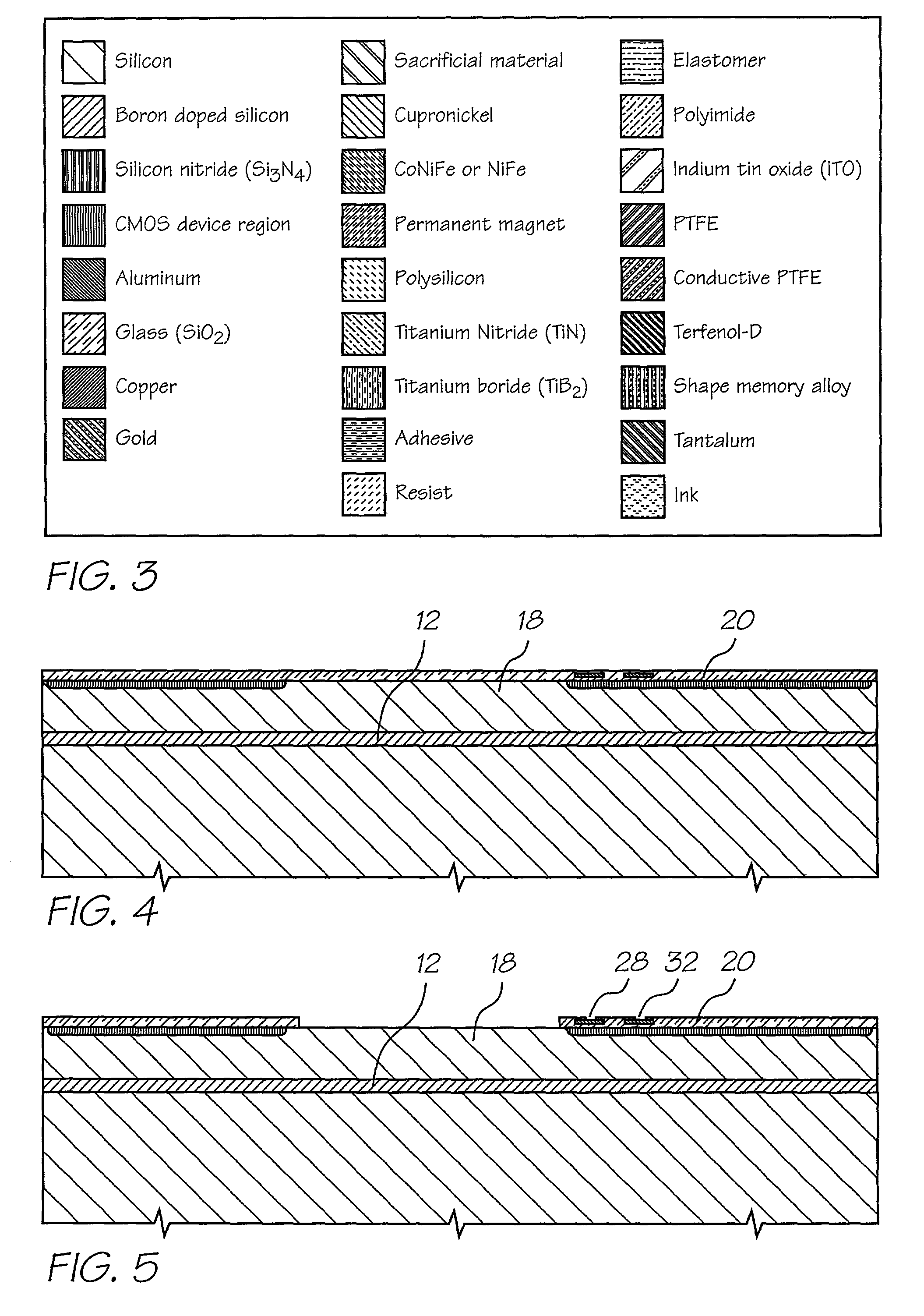

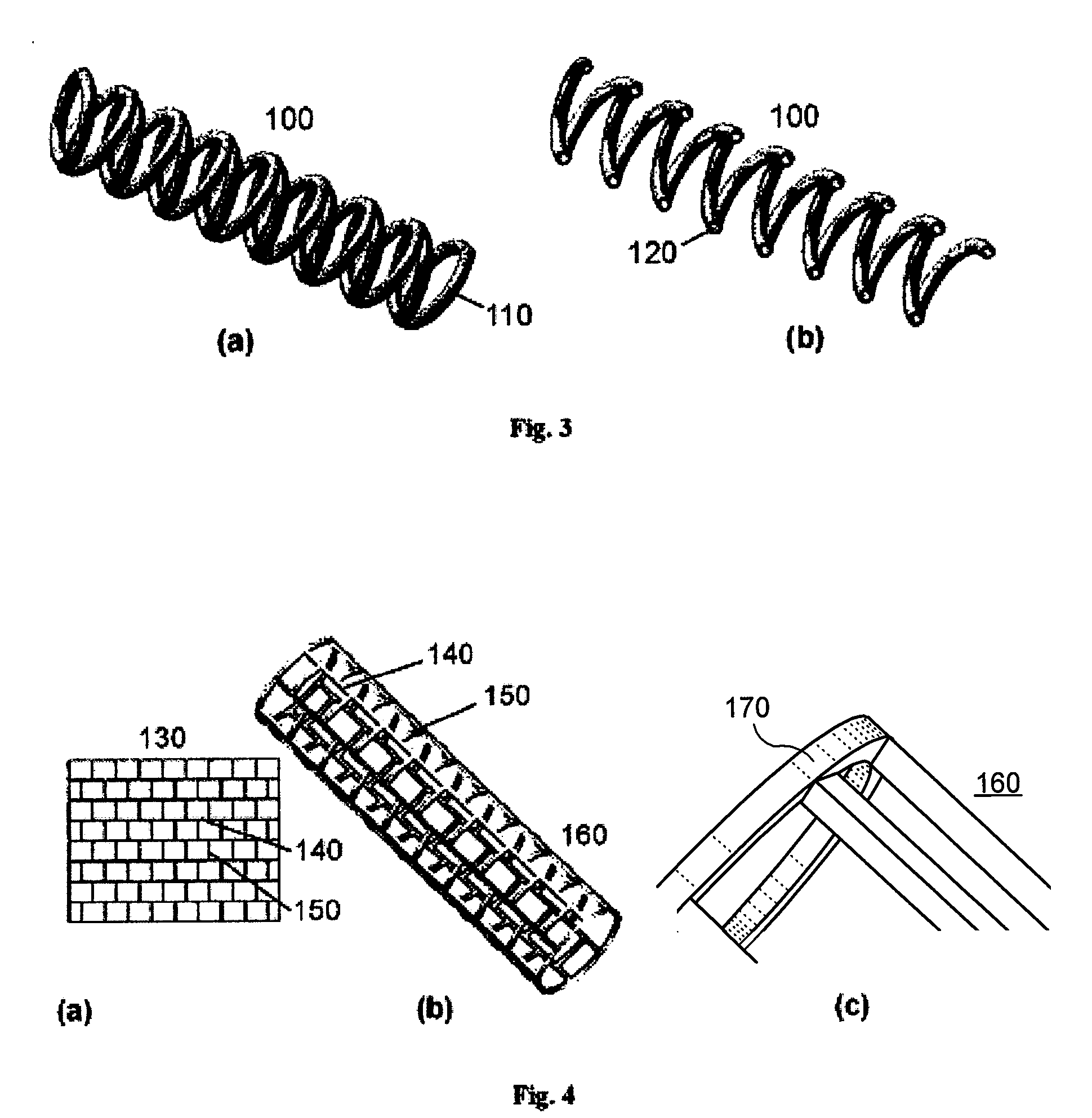

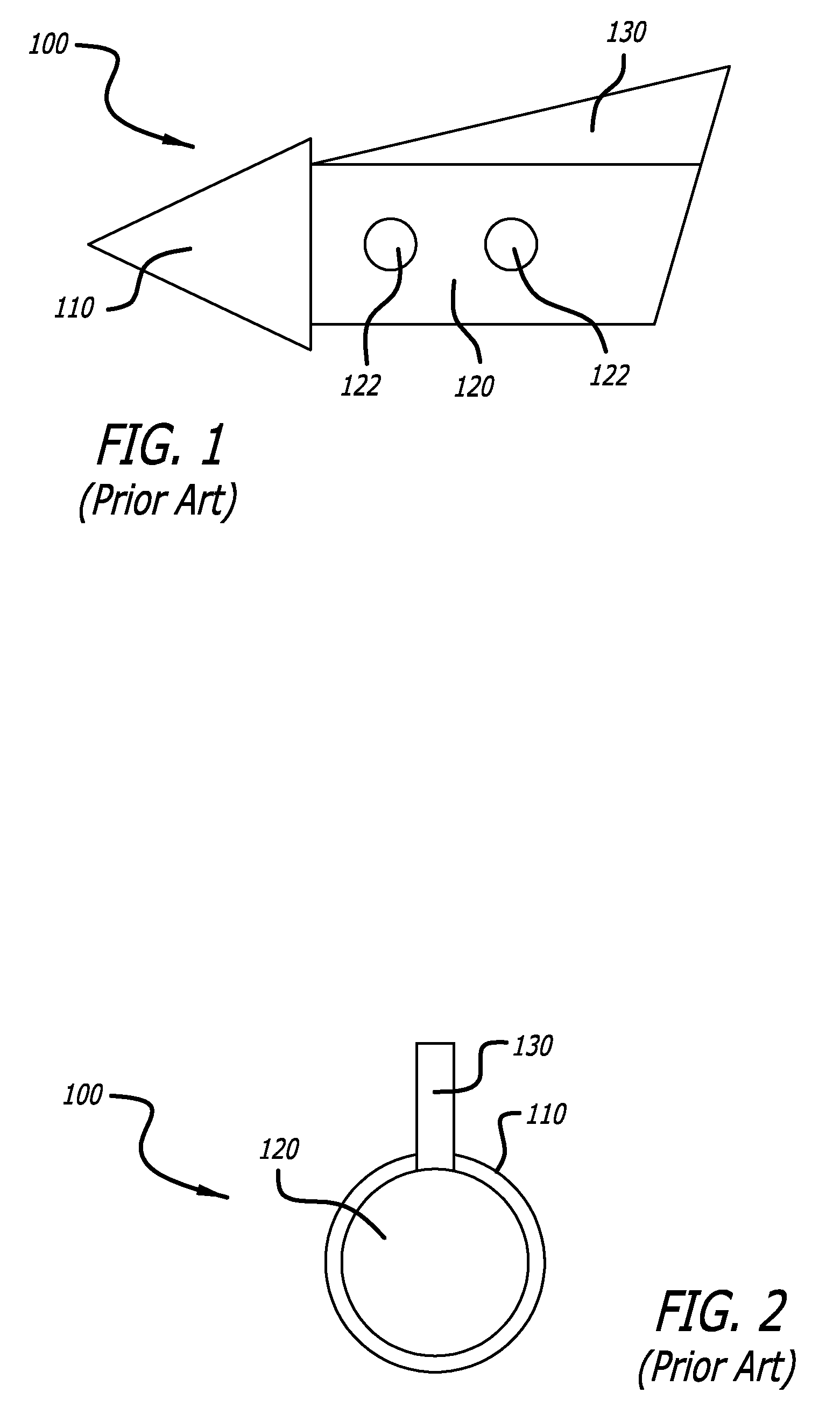

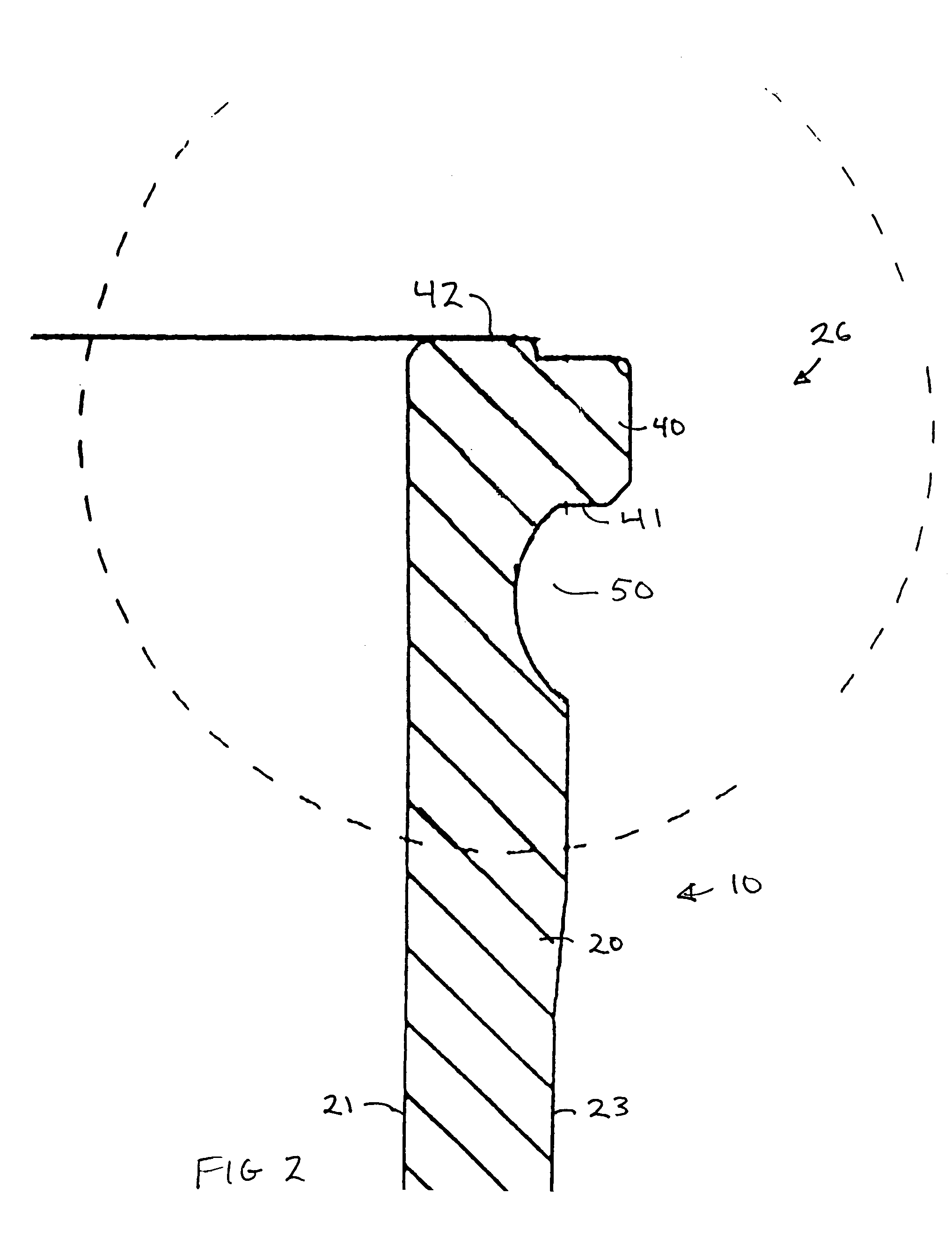

Ink jet mechanism with thermoelastic bend actuator having conductive and resistive beams

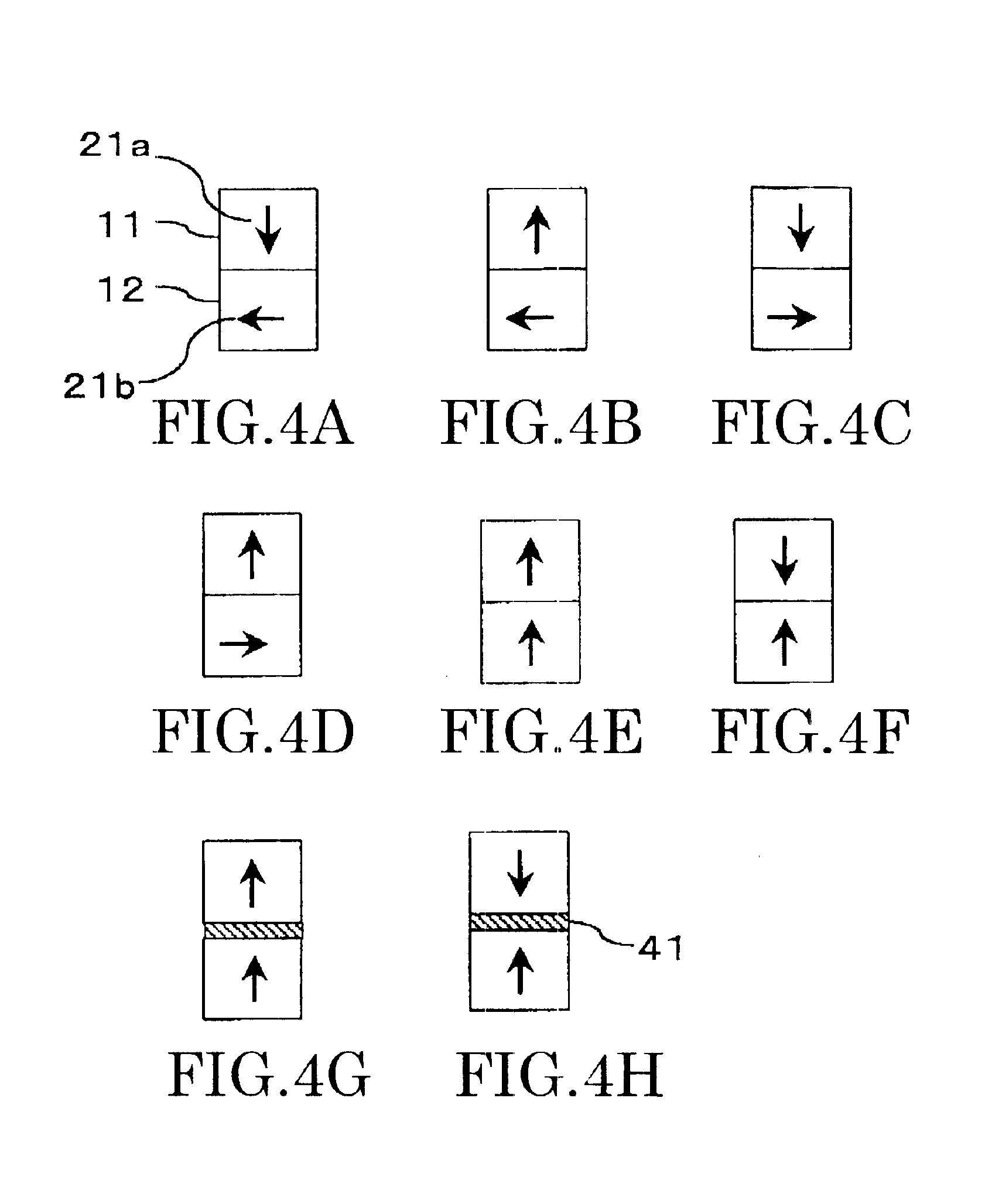

InactiveUS20010008406A1Effective volumeIncrease effective volumePrintingIndium tin oxideConductive materials

An ink jet printer uses a planar thermoelastic bend actuator to eject ink from a nozzle chamber. The thermal actuator includes a lower planar surface constructed from a highly conductive material such as a semiconductor metal layer interconnected to an upper planar surface constructed from an electrically resistive material such as Indium Tin Oxide (ITO), such that, upon passing a current between the planar surfaces, the thermal actuator is caused to bend towards an ink ejection port so as to thereby cause ejection of ink from the ink ejection port. The actuator is attached to a substrate and further includes a stiff paddle portion which increases the degree of bending of the actuator near the point where it is attached to the substrate. The surfaces are further coated with a passivation material as required.

Owner:SILVERBROOK RES PTY LTD +1

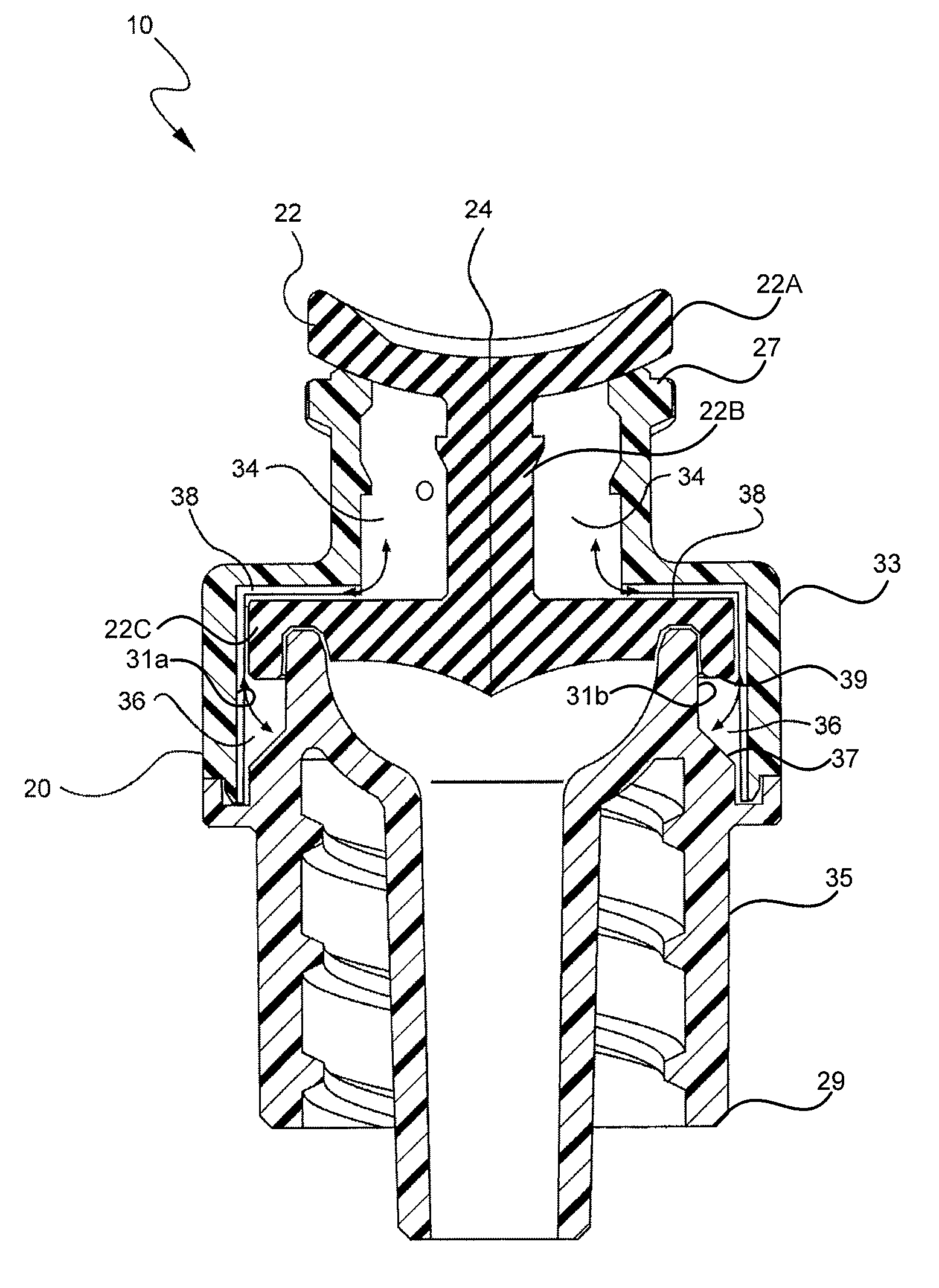

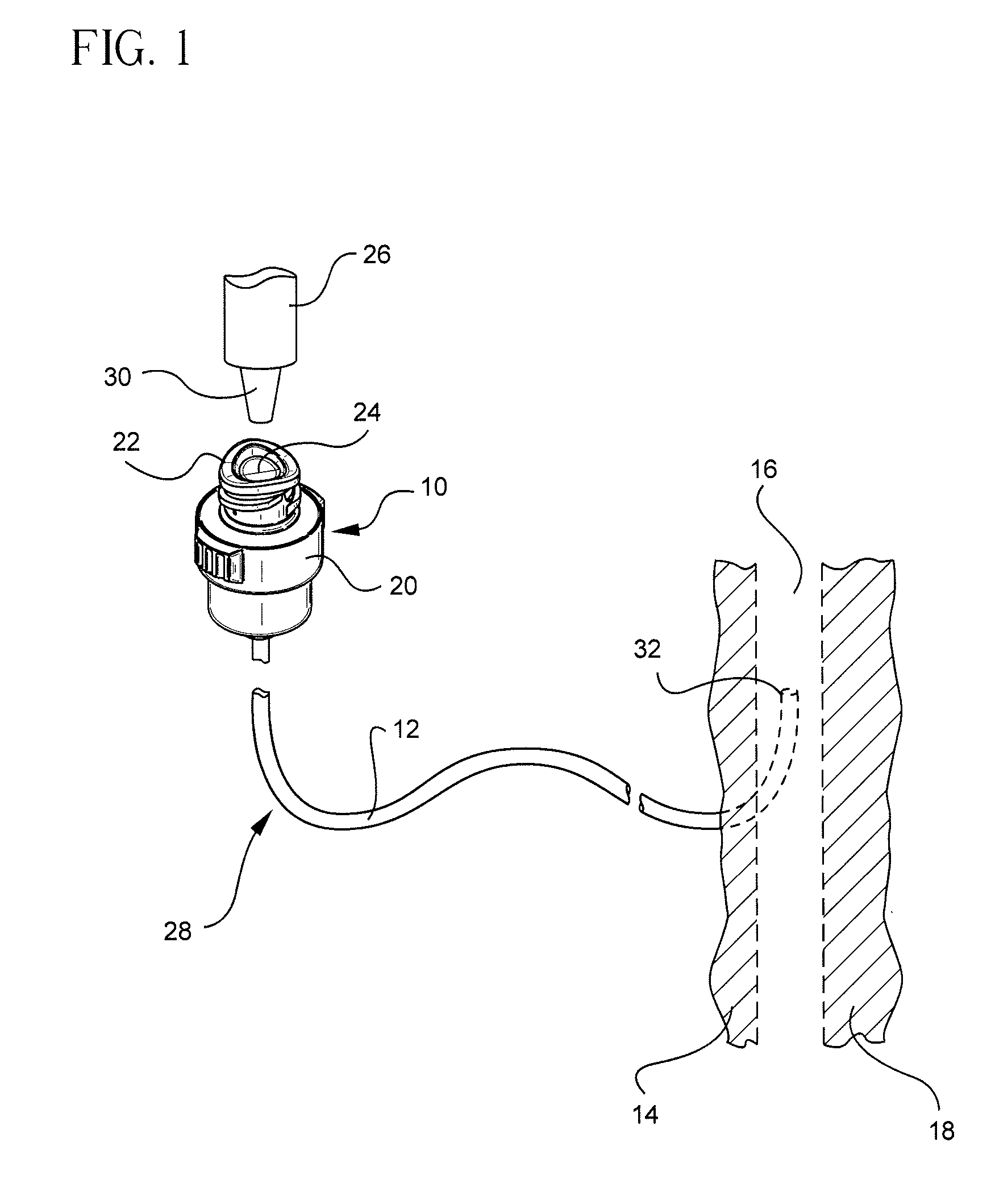

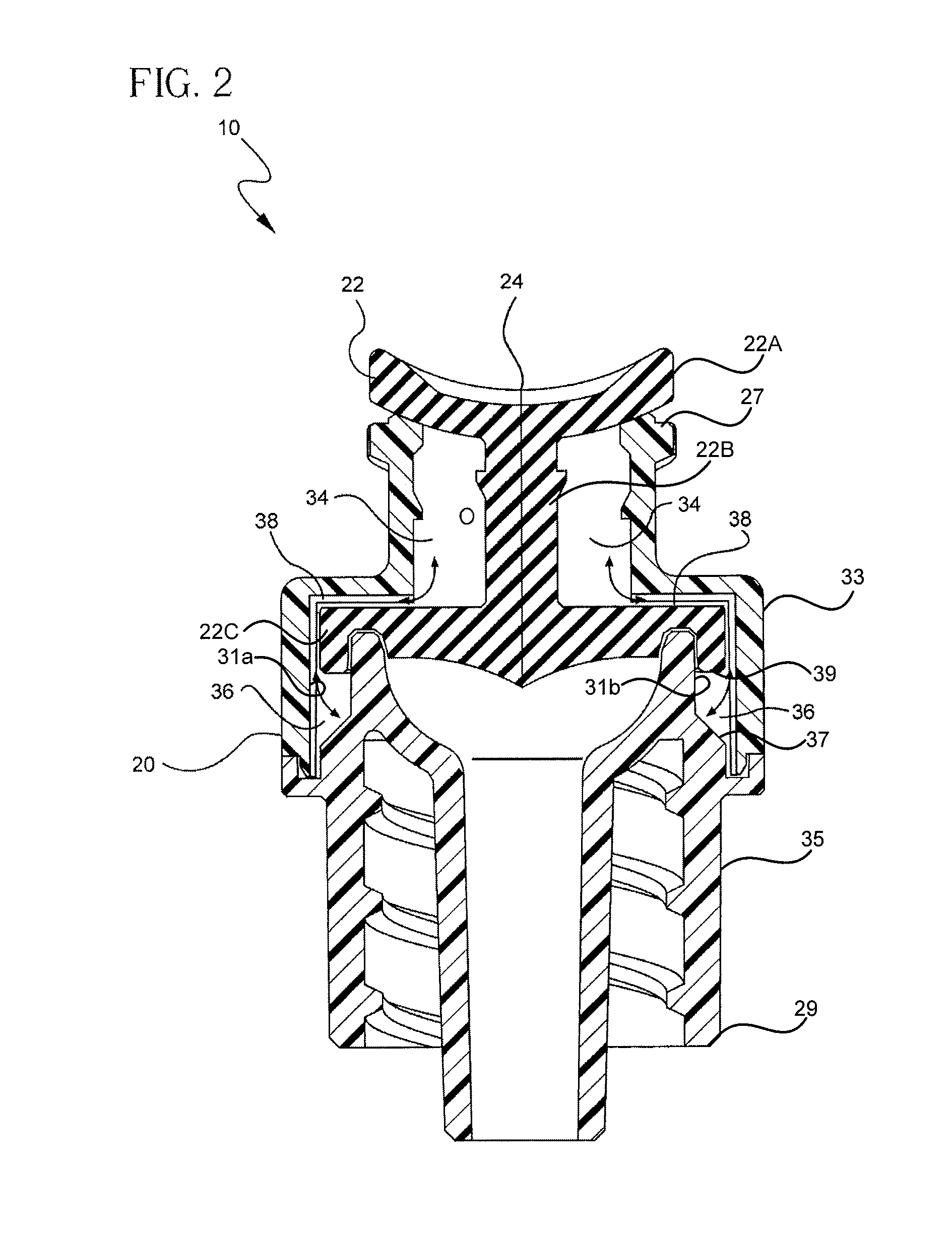

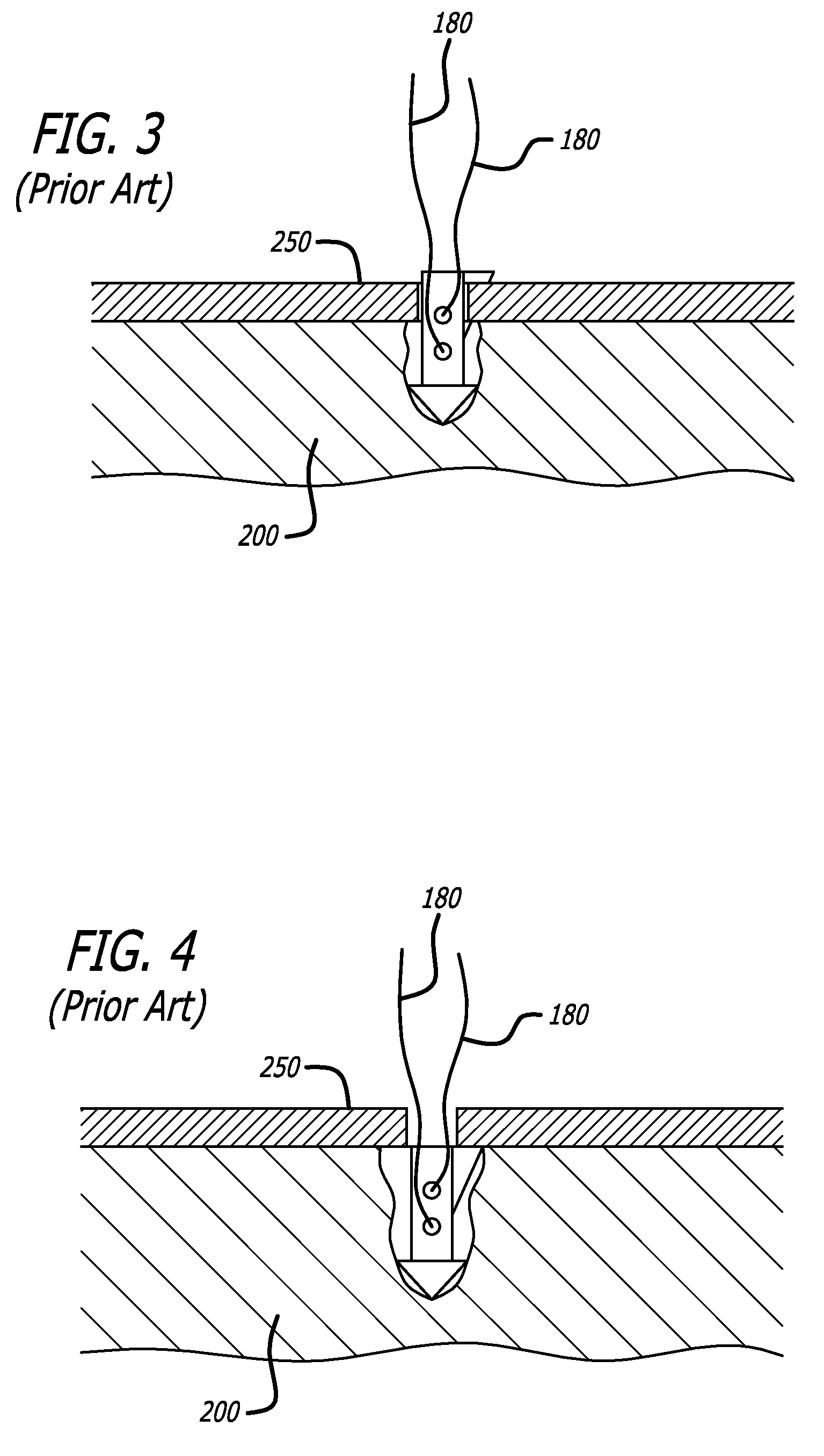

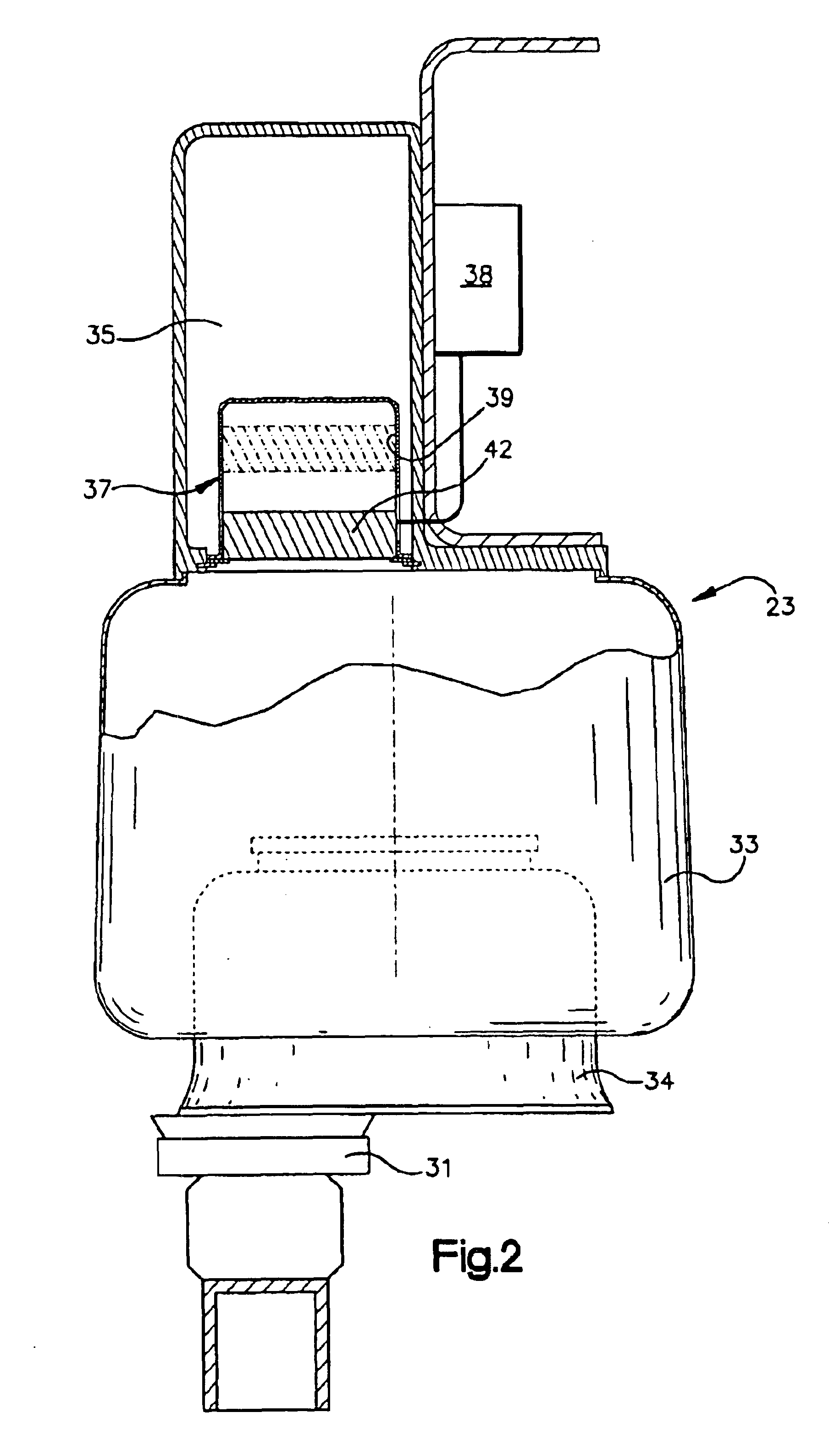

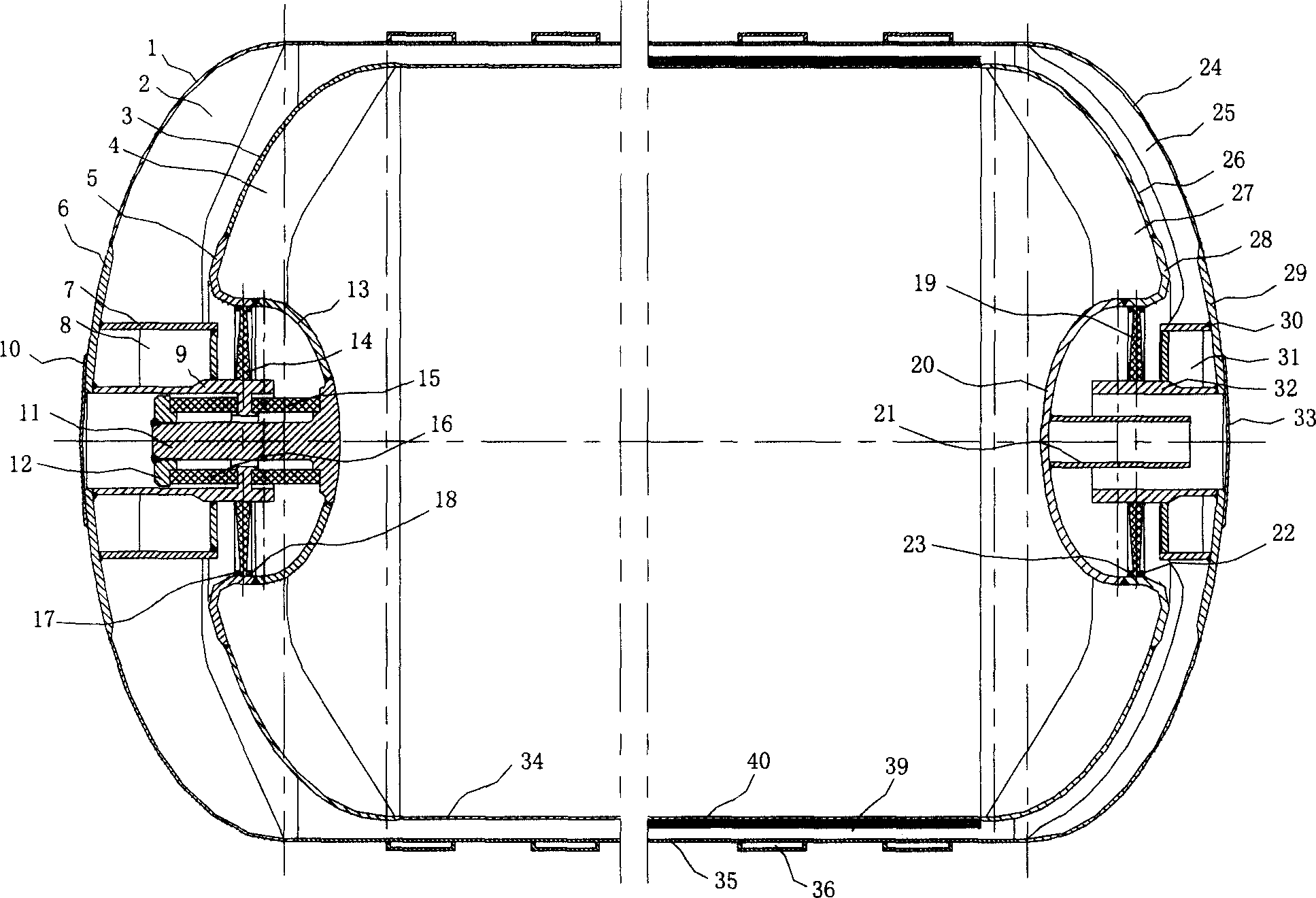

Vascular access device gas displacement

ActiveUS8366676B2Increase effective volumeIncrease volumeInfusion syringesCheck valvesVascular Access DevicesGas chamber

A vascular access device may include a gas chamber housed between a body and a septum, and a receptacle in communication with the gas chamber. A method of displacing gas in a medical device may include transferring gas between a gas chamber of a vascular access device and a receptacle housed within the vascular access device.

Owner:BECTON DICKINSON & CO

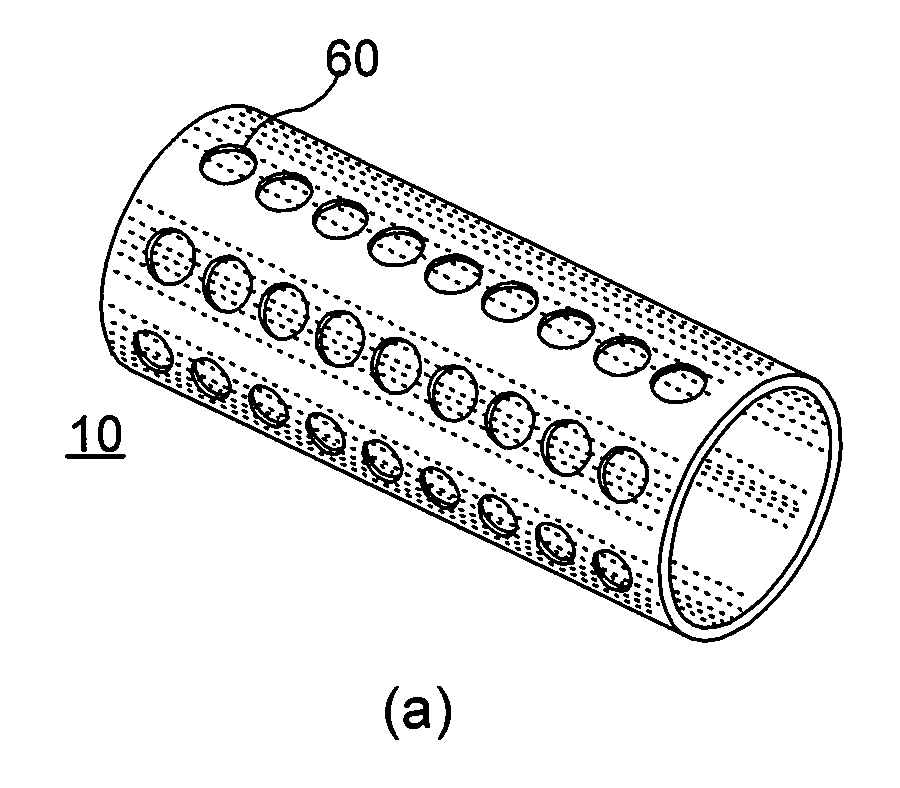

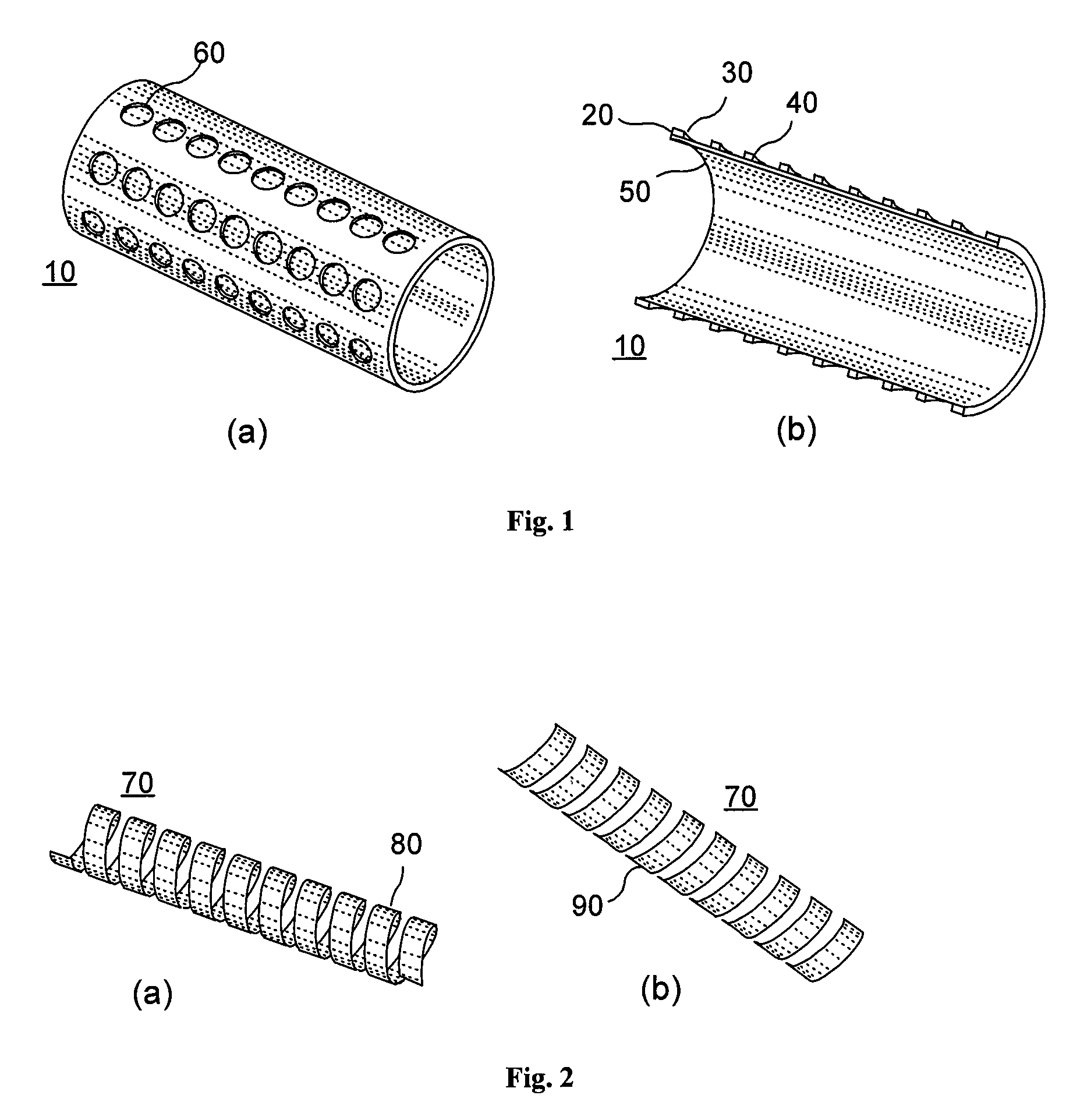

Reservoir implants and stents

InactiveUS20080195196A1Increase effective volumeStentsBlood vesselsInsertion stentBULK ACTIVE INGREDIENT

Exemplary embodiments of the present invention related to medical implants, such as e.g. stents are provided. For example, the implant can comprise at least one hollow space or lumen within the structural material or structure of the device, other than a pore or pore system, which may be used as a reservoir for a specific amount of active ingredient to be released after implantation into the body.

Owner:CINVENTION AG

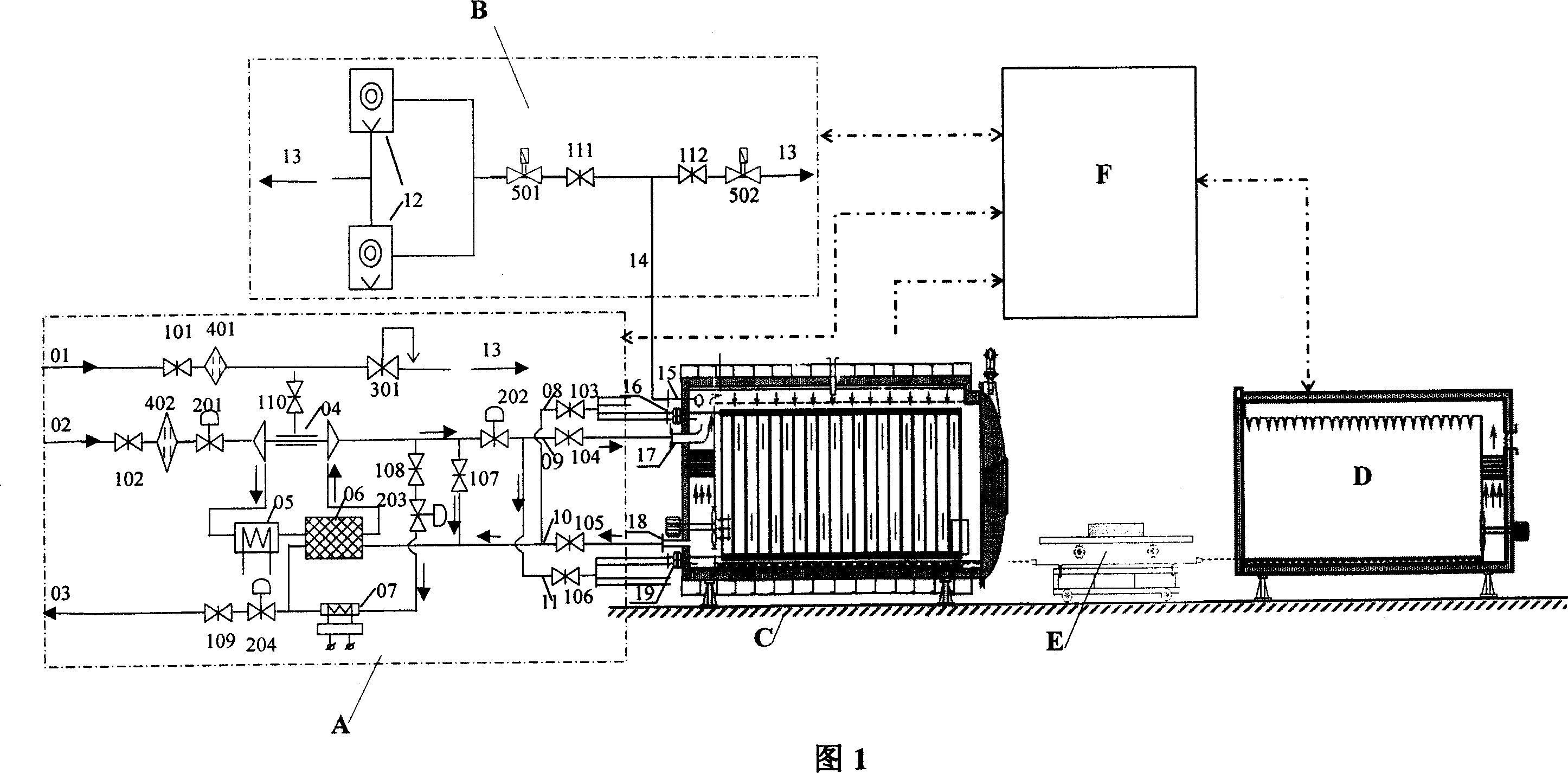

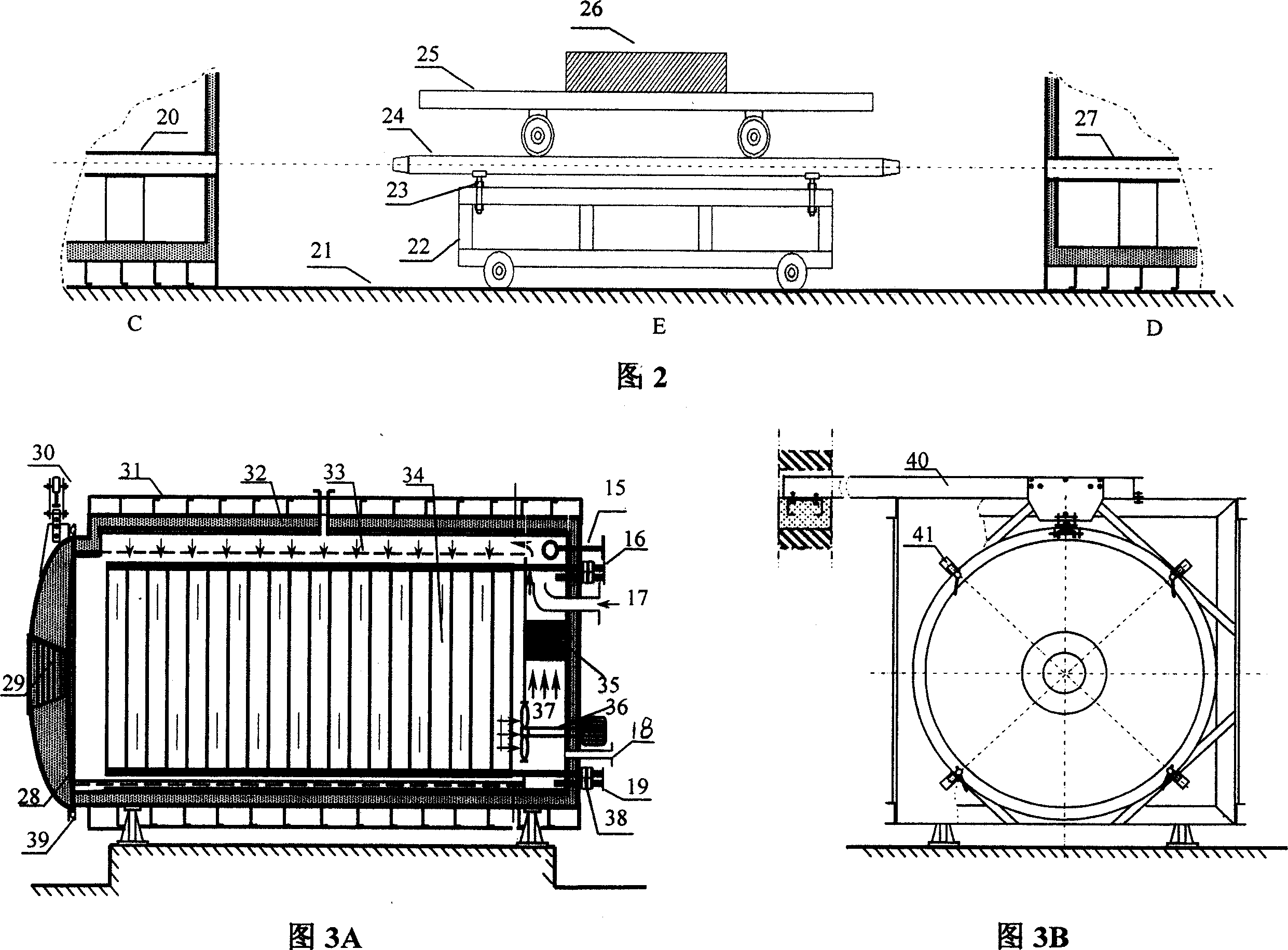

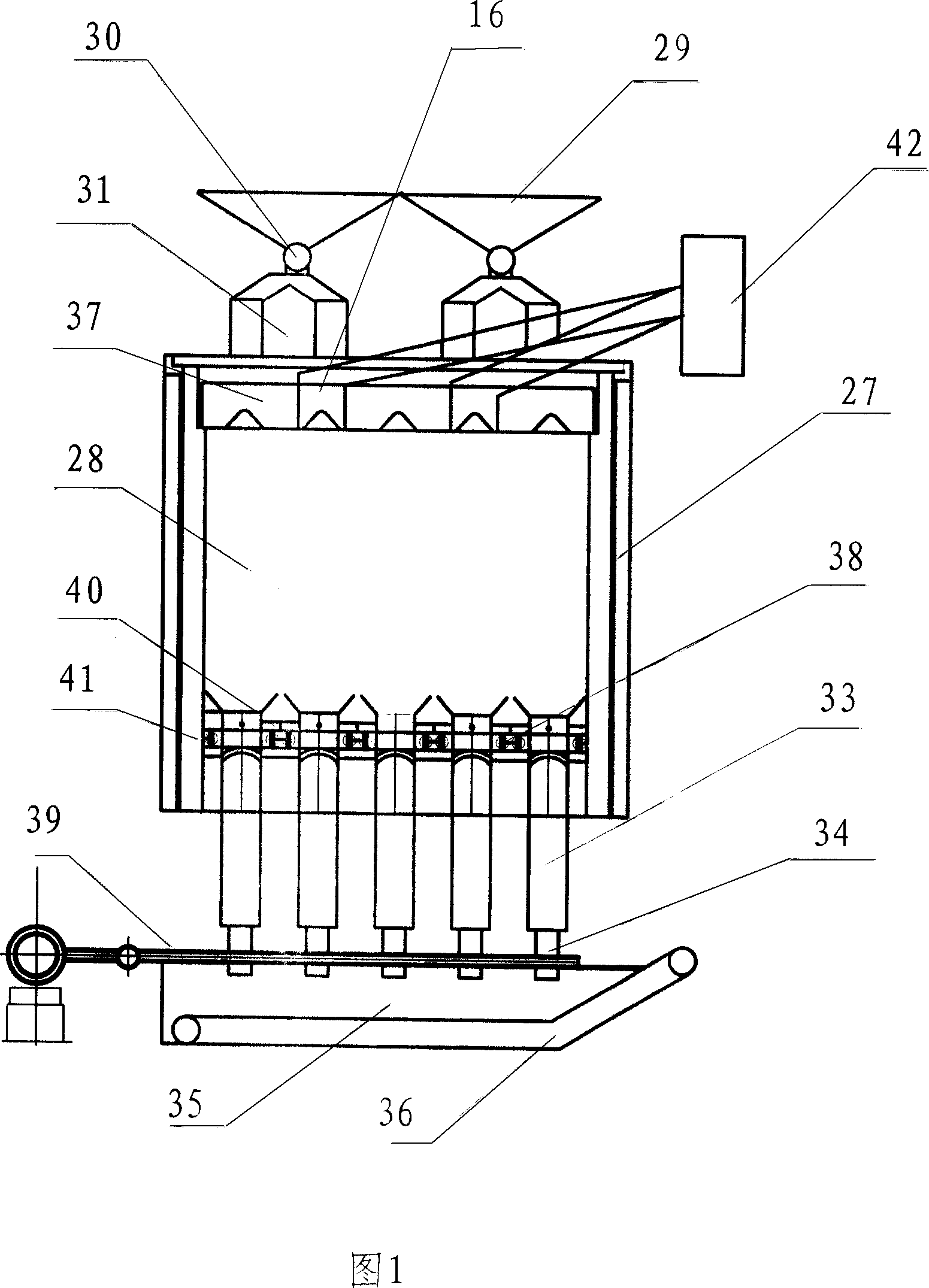

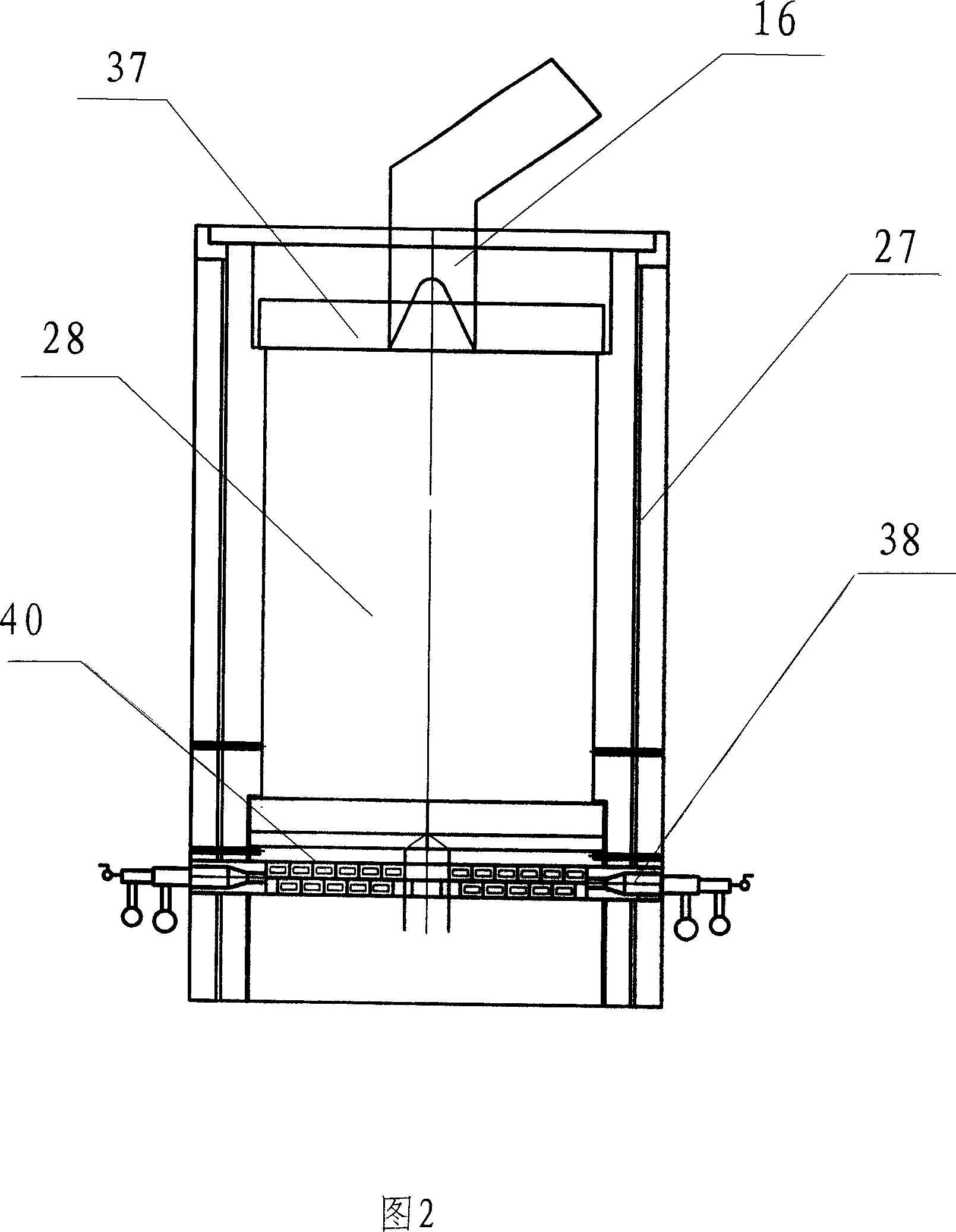

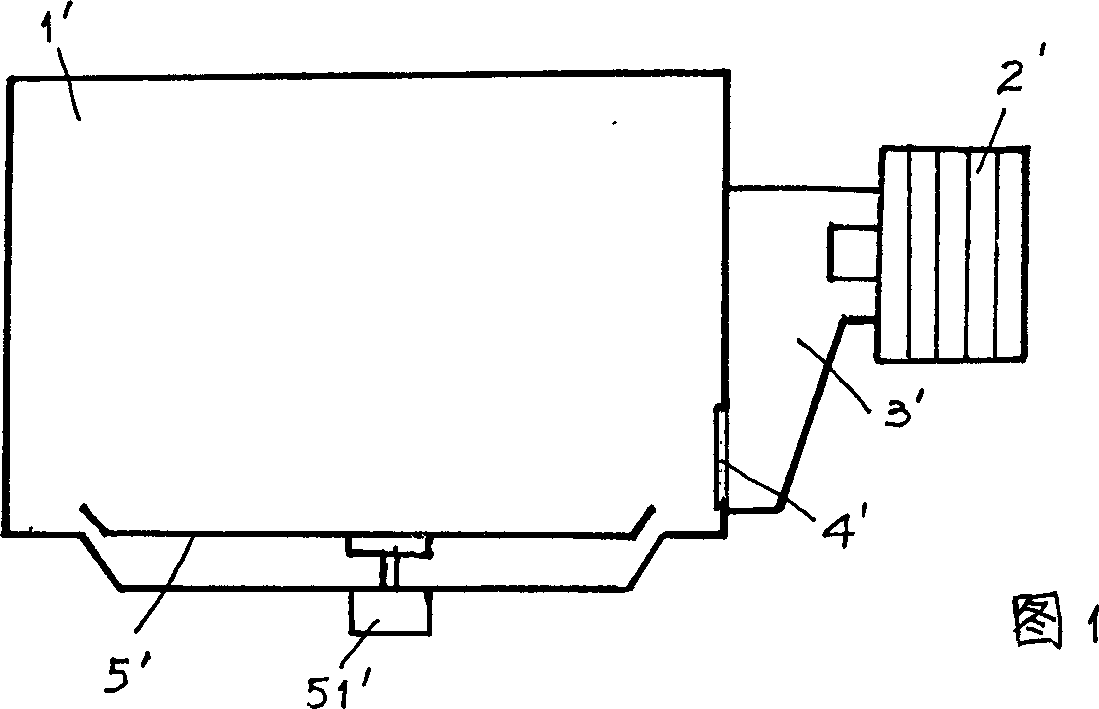

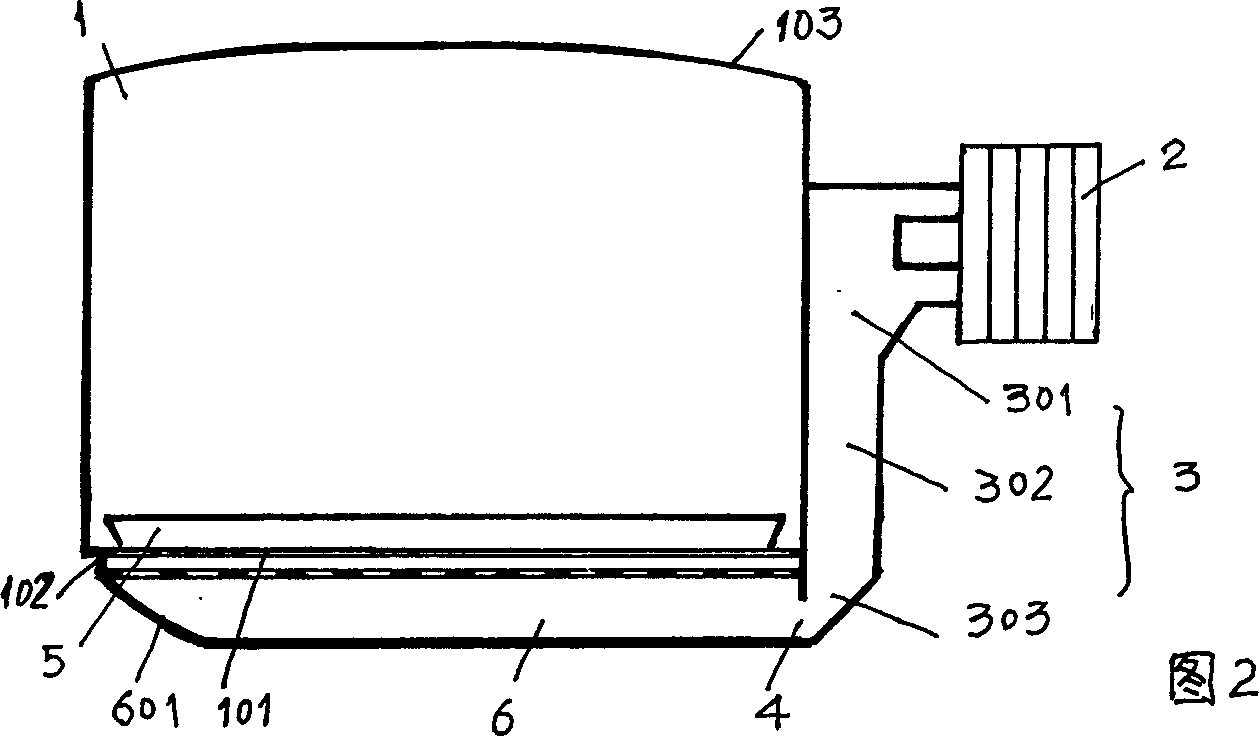

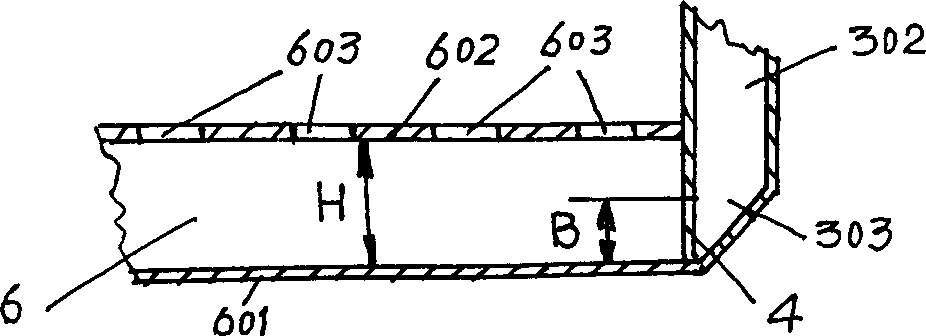

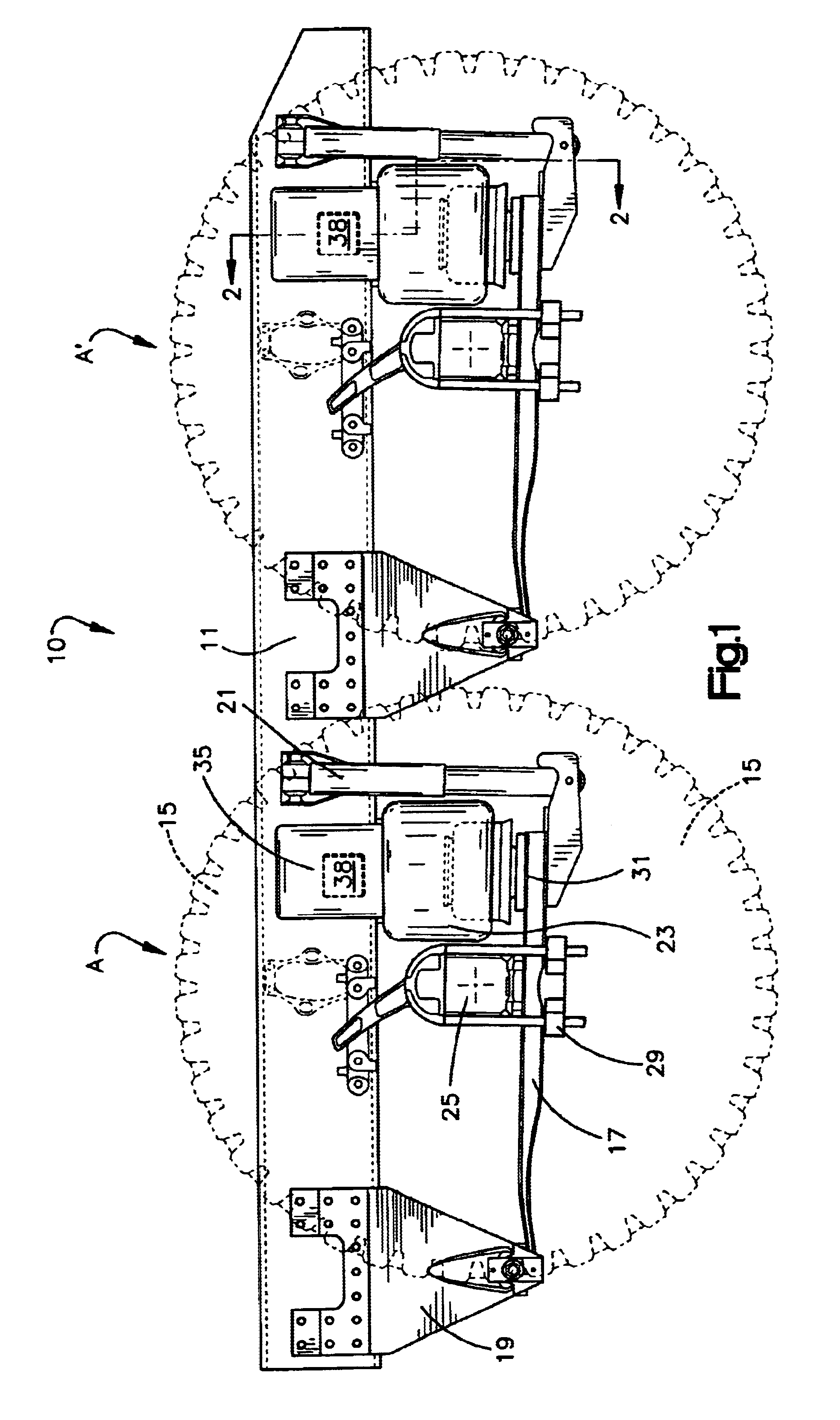

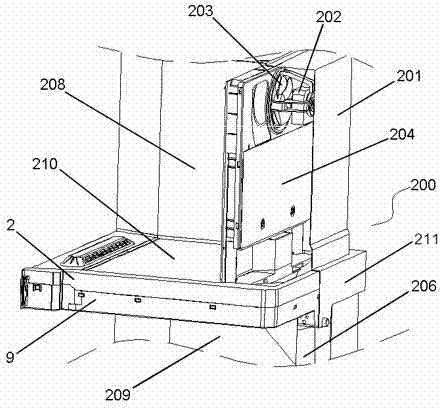

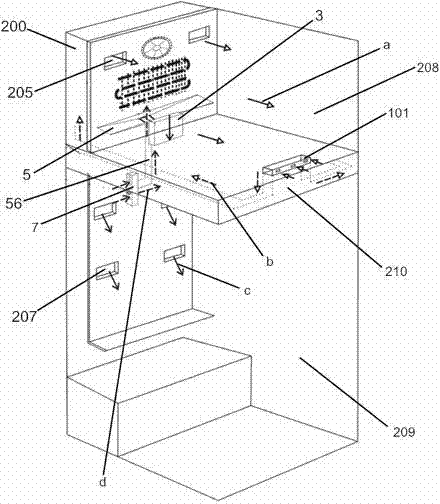

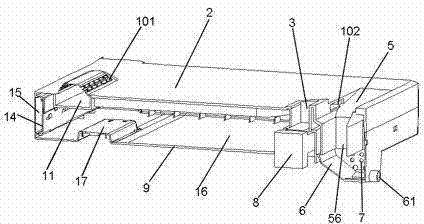

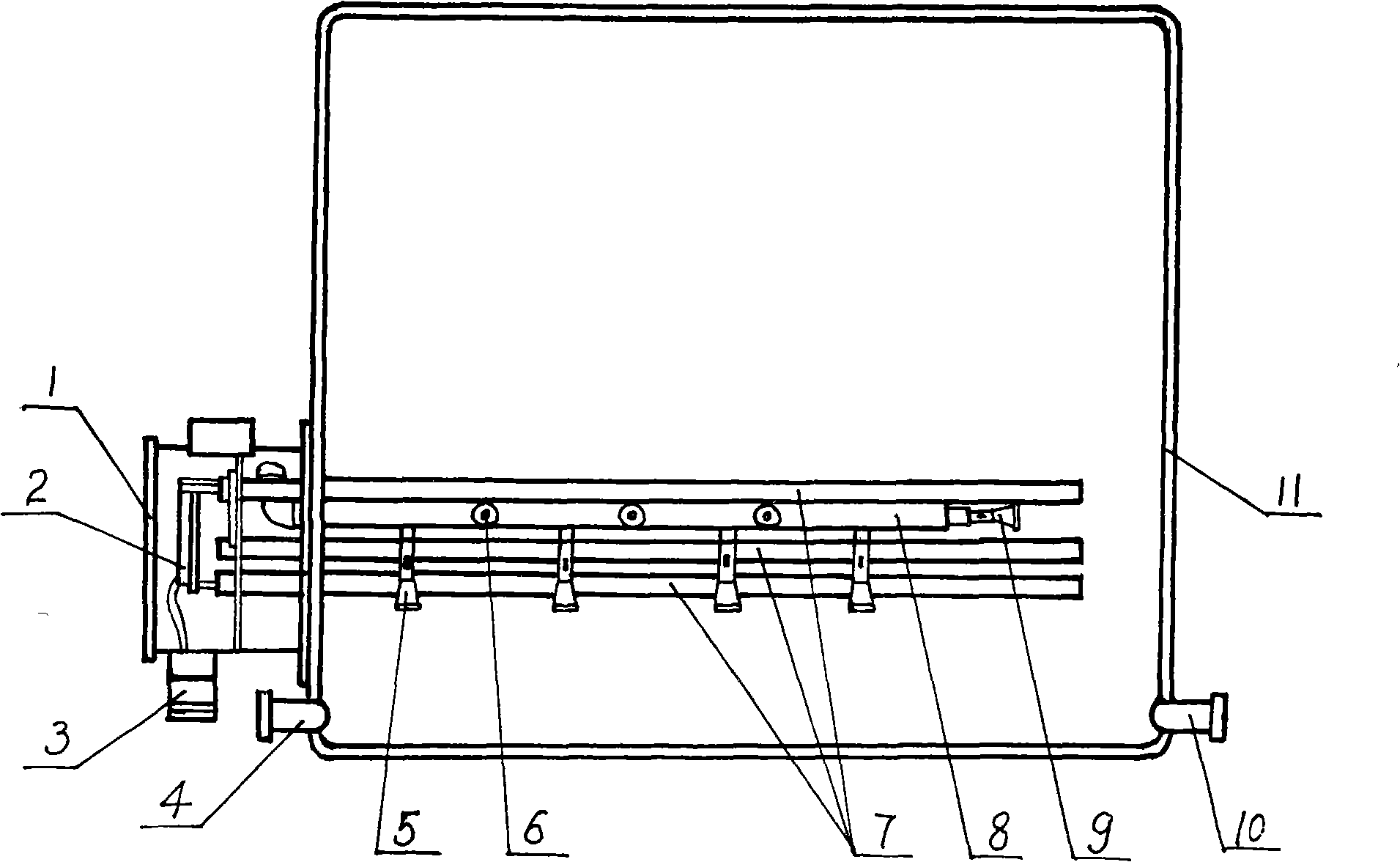

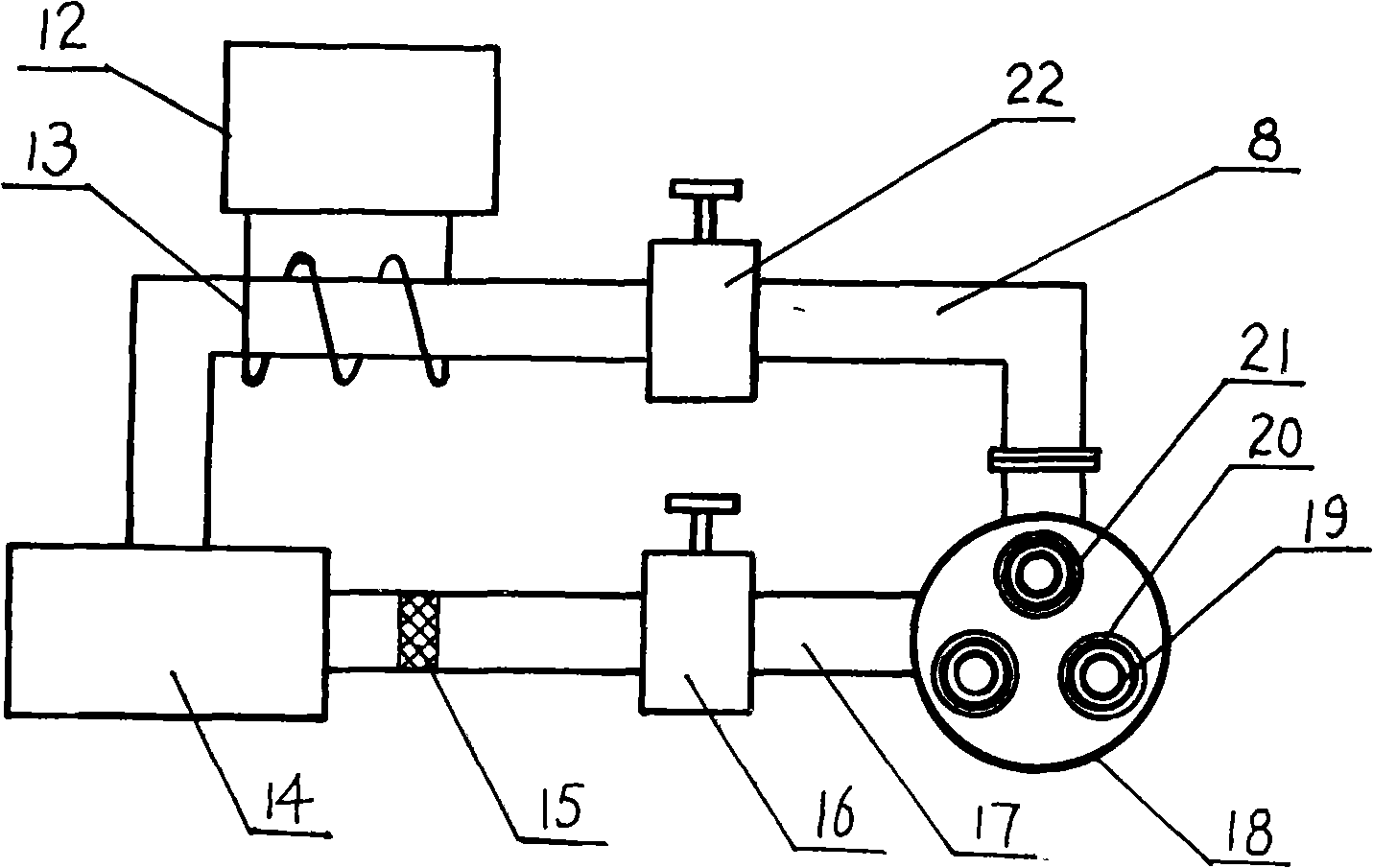

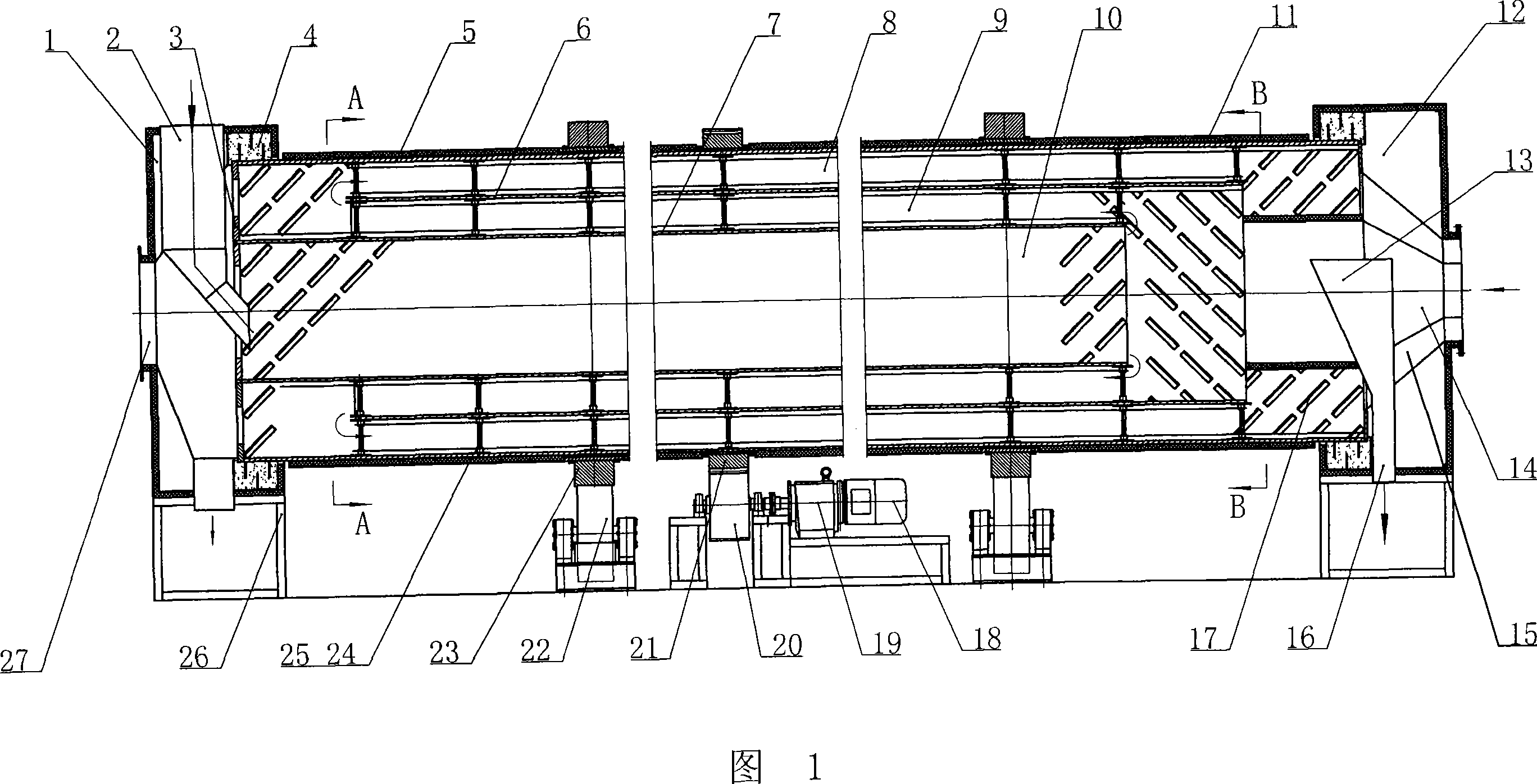

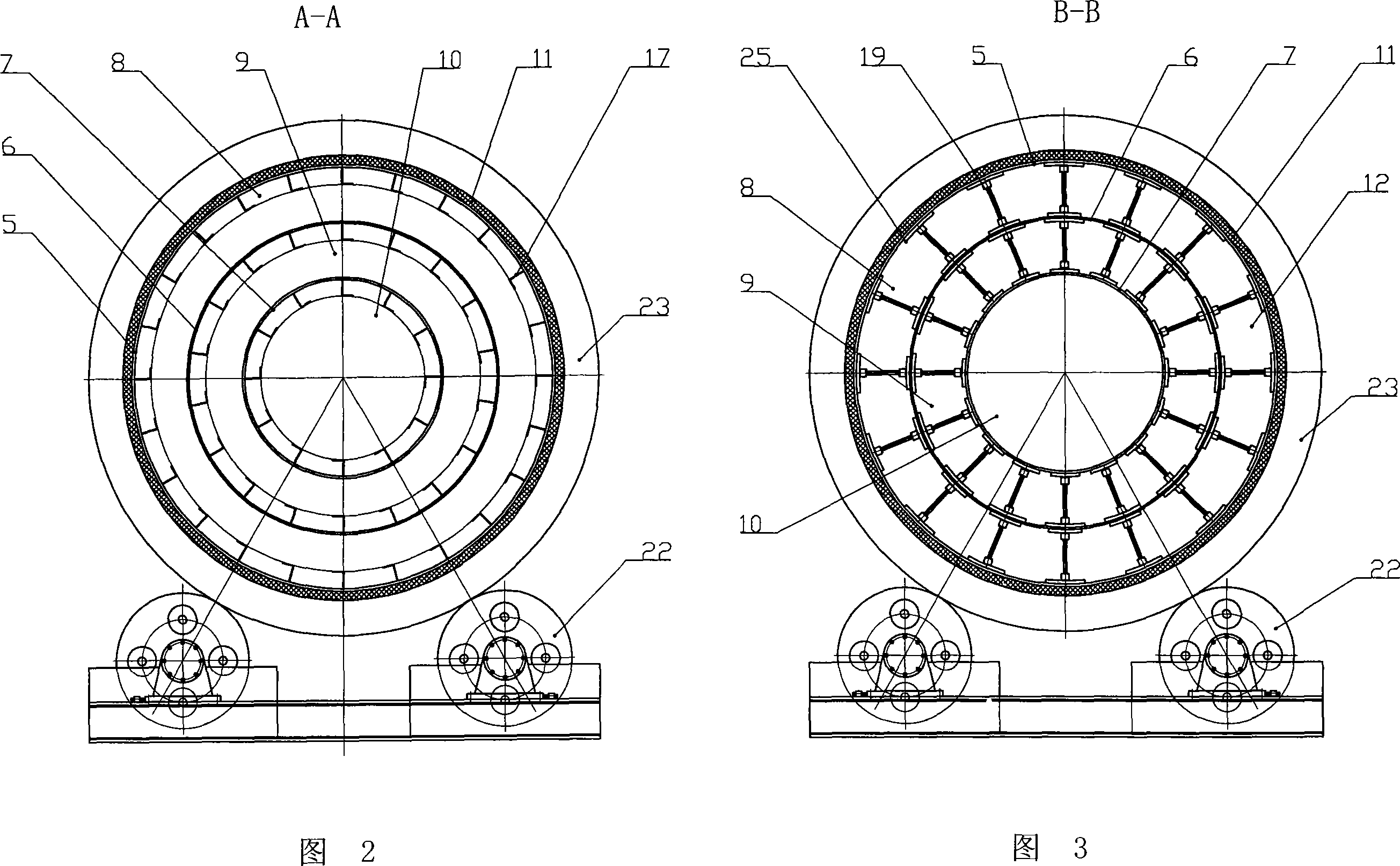

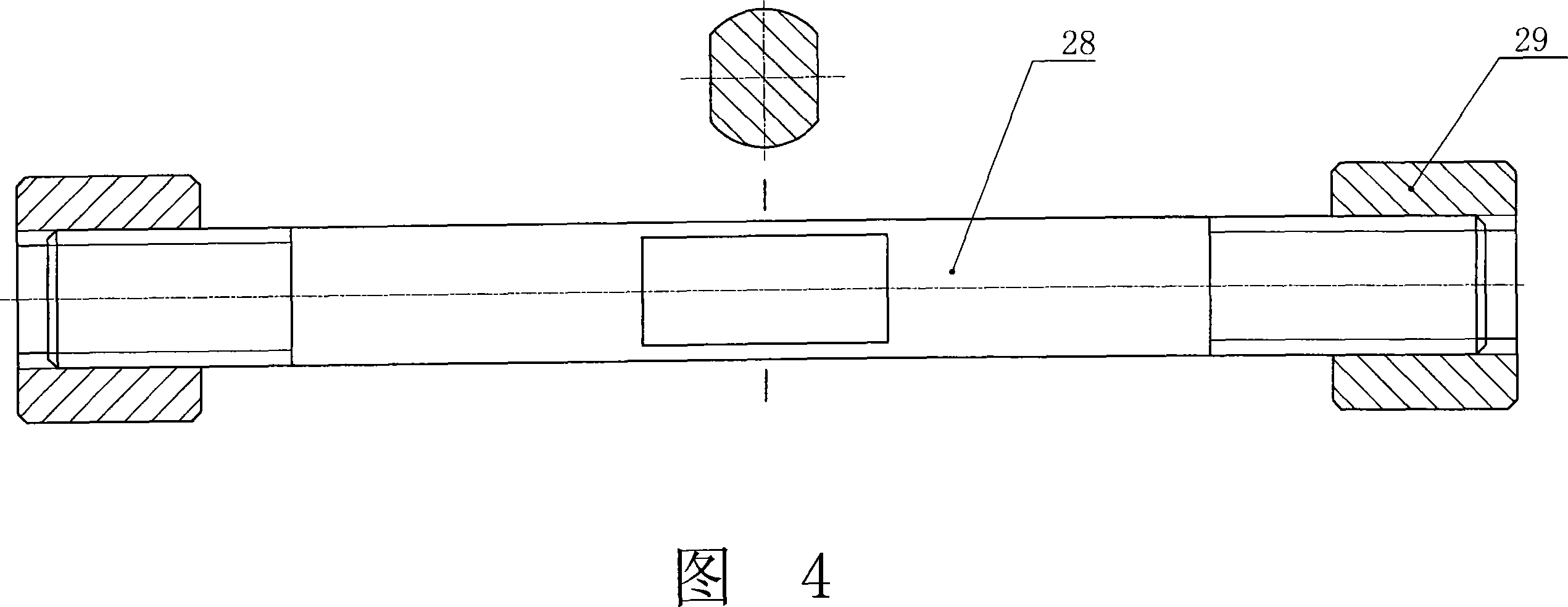

Test apparatus of large-scaled environment simulation

This invention relates to one large integral environment analogue experiment device, which comprises high temperature cabinet, air cooling system, vacuum system, rapid conversion track set and remote test and control system, wherein, the cabinet and temperature cabinet adopts gate to gate parallel distribution; the two cabinet sets rapid conversion track in charge for test parts rapid conversion; the air cooling system and vacuum system is in charge for temperature cabinet cool volume and to lower inside pressure; the temperature cabinet is in constant box structure composed of cooling board recycling system for analogue.

Owner:BEIHANG UNIV

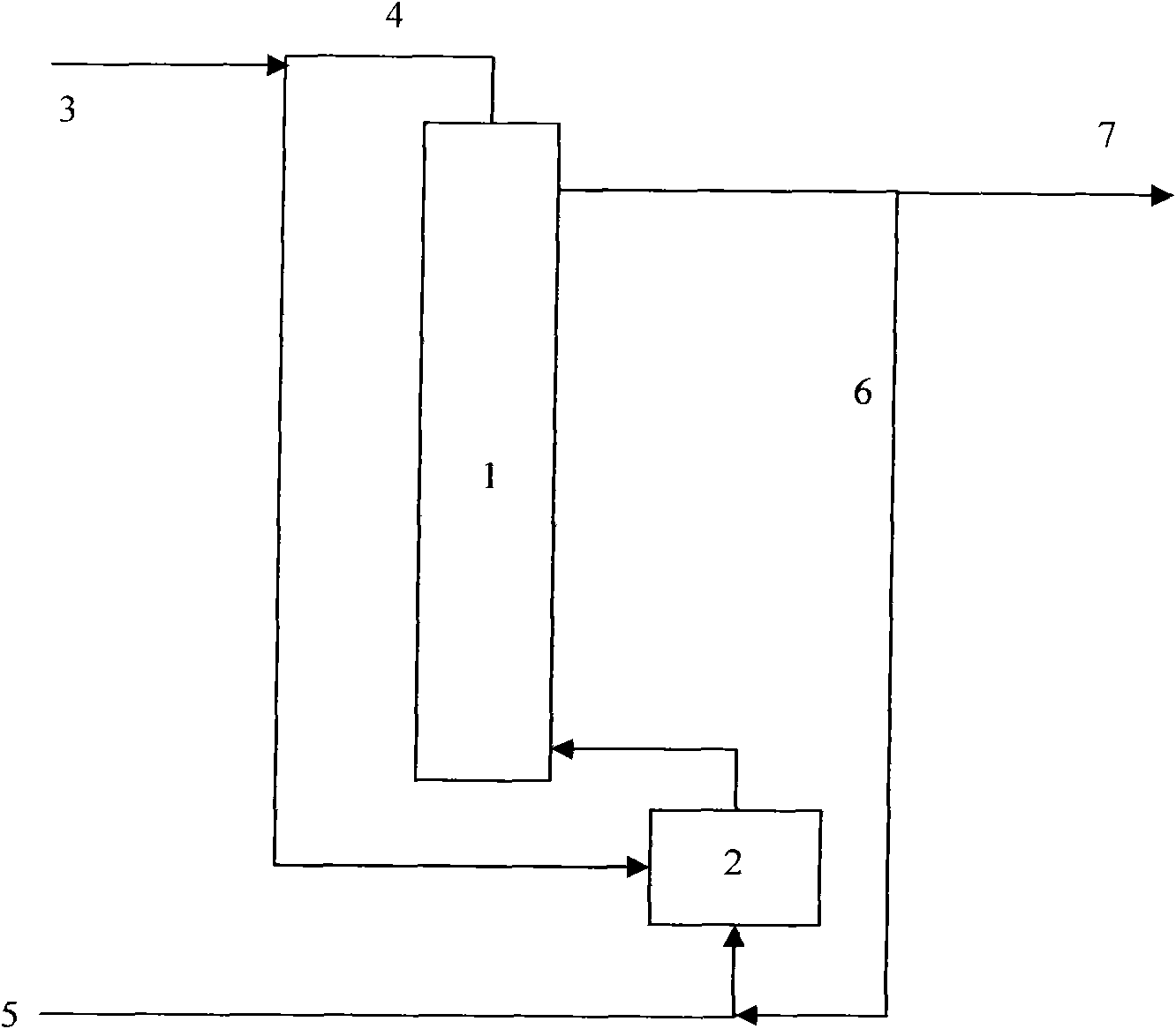

Method for enhancing gas-liquid mass transfer of ebullated bed hydrogenation reactor

ActiveCN102049220AIncreased contact surface areaImprove mass transfer efficiencyChemical/physical processesMicrobubblesHydrogenation reaction

The invention discloses a method for enhancing the gas-liquid mass transfer of an ebullated bed hydrogenation reactor, which comprises the following processes of: introducing fresh raw oil, circulating oil and hydrogen into a microbubble generator arranged in front of the reactor, fully mixing to make the hydrogen dispersed in a liquid-phase material in the form of microbubbles, and performing hydrogenation and cracking reaction in the ebullated bed reactor. The method can improve the utilization rate of the hydrogen, reduce the volume ratio of the hydrogen to the oil, save operating cost andpromote the depth of the hydrogenation and cracking reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Suture anchoring devices and methods for use

ActiveUS20130268001A1Reduce stenosisIncrease effective volumeSuture equipmentsSurgical instrument detailsDiseaseSuture anchors

A system and associated method for manipulating tissues and anatomical or other structures in medical applications for the purpose of treating diseases or disorders or other purposes. An implant for attachment of soft tissue to bone, an insertion tool for anchoring suture anchors to bone, and a method for anchoring a suture anchor to bone.

Owner:TELEFLEX LIFE SCI LTD

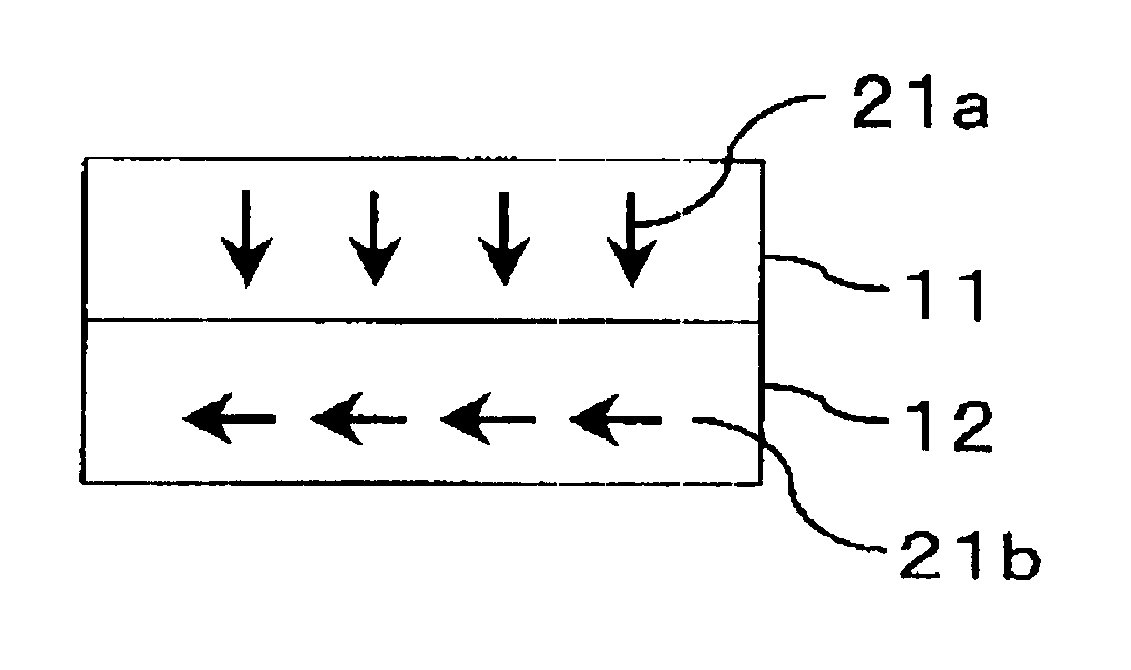

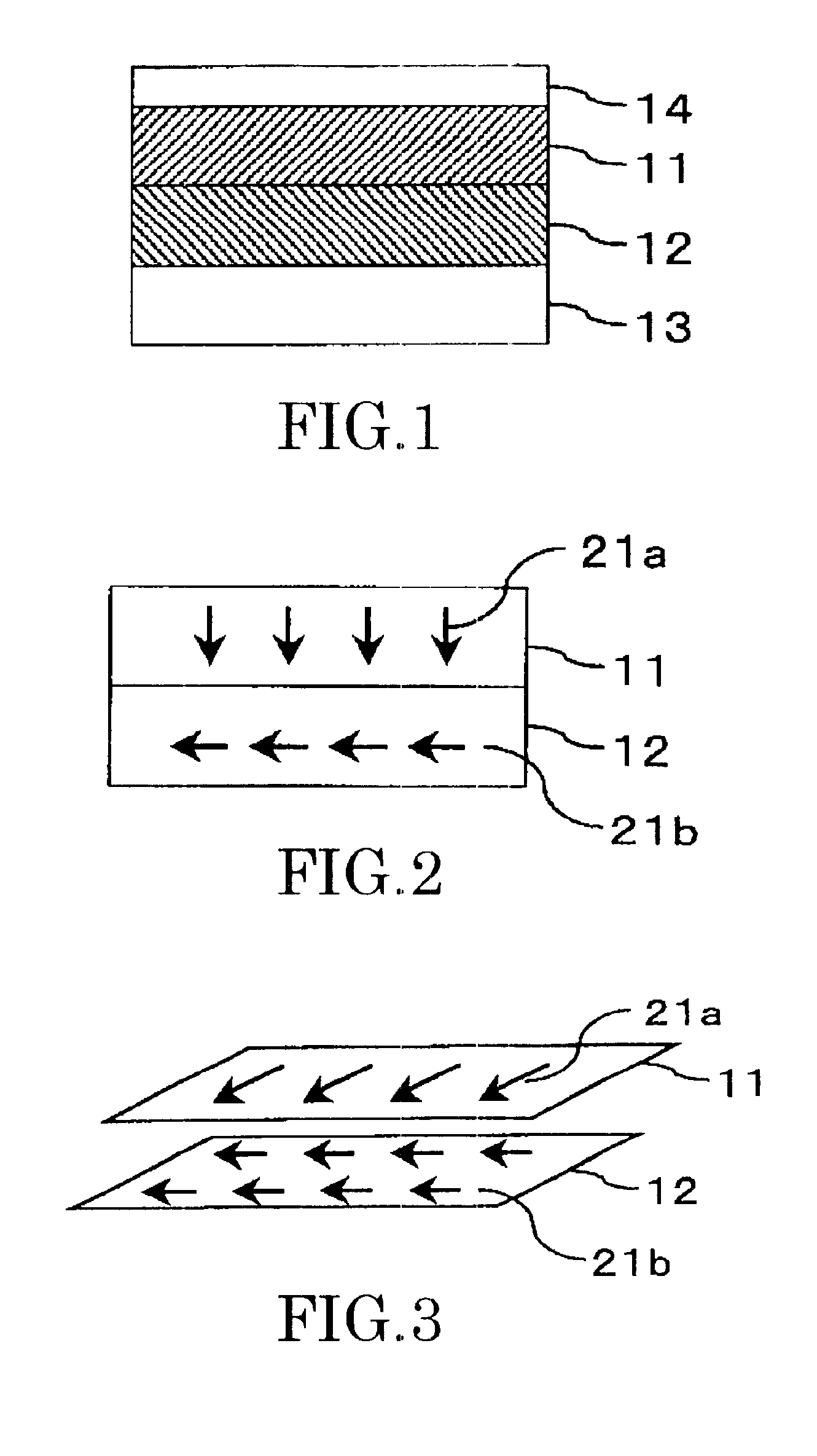

Magnetic recording medium including functional and recording layers orthogonally exchange coupled

InactiveUS6881495B2Increase effective volumeReduce fluctuationRecording by magnetic meansNanomagnetismRoom temperatureRecording density

Owner:KK TOSHIBA

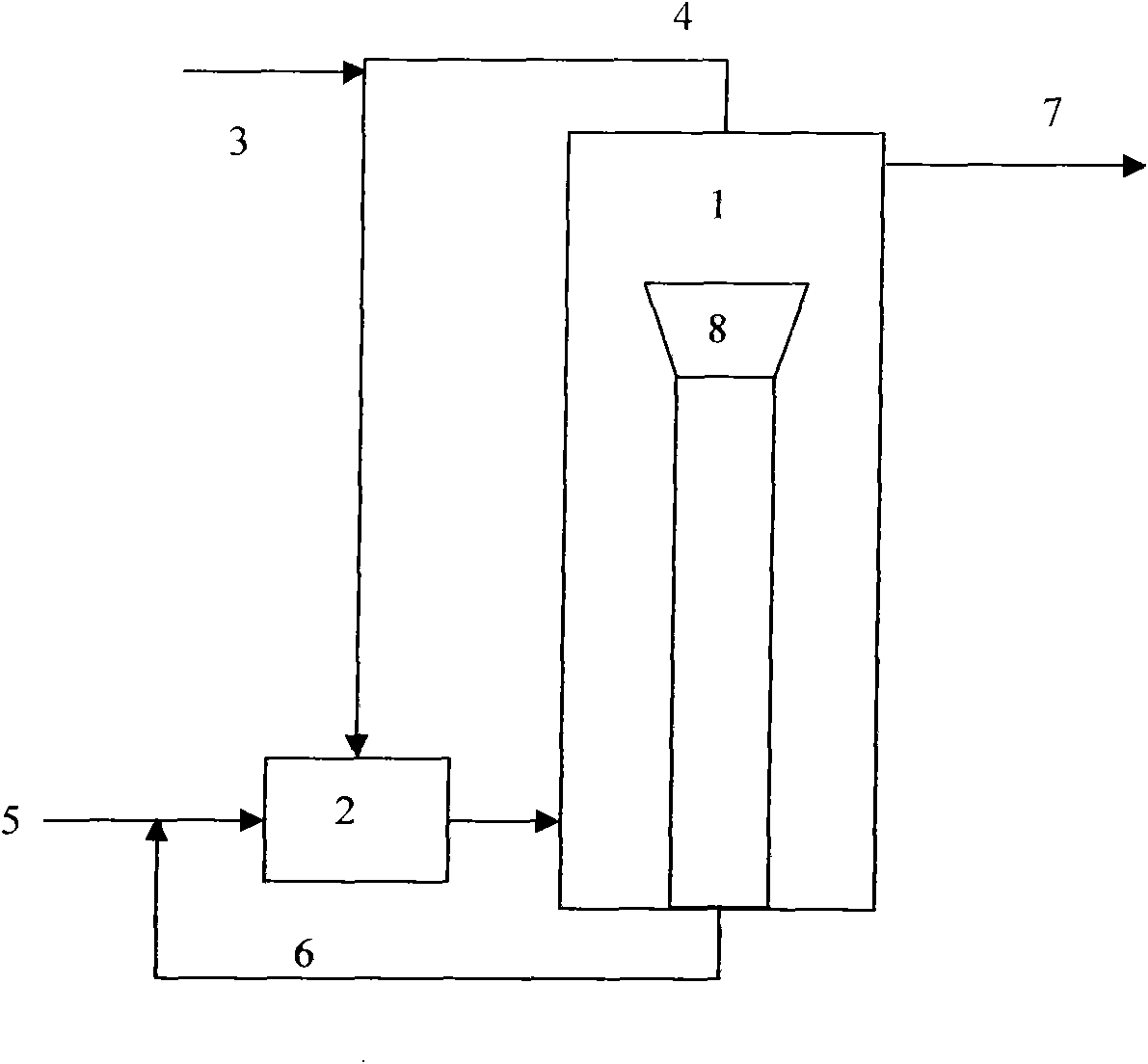

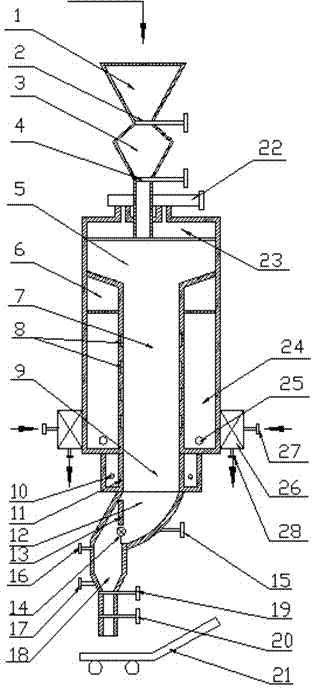

Low-temperature coal carbonization kiln

ActiveCN1966609AIncrease effective volumeHigh yieldRetortsDischarging devicesAutomatic controlCarbonization

The invention disclosed a kind of low temperature coal dry distillating square stove which includes stove body, coal cup, dant-pushing machine and branch admixer. On the top of the hearth there is installed the gas collecting umbrella, inside the stove it is cavity structure; on the bottom of the cavity there are installed several rows of emitting gas walls, every row of emitting gas wall is parallel to the interval between two side umbrella of the gas collecting umbrella; the consecutive emitting gas walls are pedestalled by arch wall; on both sides of the emitting gas walls there are two branch admixer respectively; the bottom of the stove connects the dant discharging box, the bottom of which connects the dant leading slot; the bottom of the dant leading slot is dant-pushing machine, the bottom of which is aqua sealing slot, in the slot there is scraper machine. The invention adopts the heating scheme of endo-burnning and calor internus which can heat uniformly. The gas collecting umbrella and accessory coalbox can make the material and gas-collecting uniformly while the dant-pushing machine can make the product uniform. The advantage of the invention: it can bring into full play of the producing ability and decrease the investment as well as increase the benefits; besides, it is easy to operate, it needs less people and can be controlled automatically.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

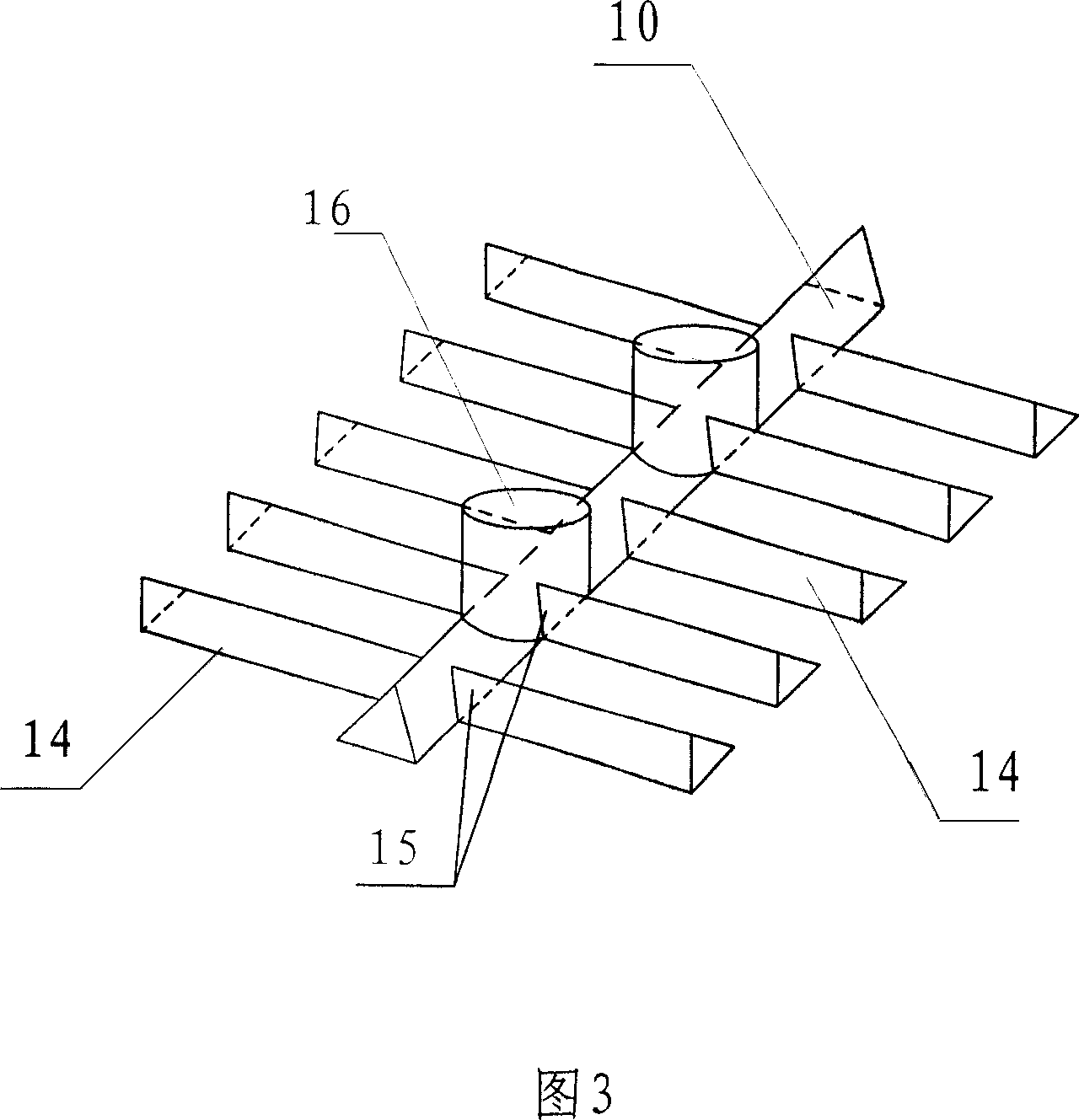

Uniform radiation microwave heating method and device

InactiveCN1826026AOvercome the defect of uneven microwave field distributionOvercome the defect of uneven distributionDomestic stoves or rangesLighting and heating apparatusImpedance ConverterRadiation heating

This invention relates to a heating method with uniform radiated microwaves and a device, in which, said method includes: a microwave device generates microwaves transmitted by a waveguide impedance converter and output to a corresponding couple cavity from the waveguide port to be reflected and scattered to output multiple microwave beams to the heating cavity uniformly from multiple couple holes on a sidewall of the couple cavity and these microwave beams enter into the heating cavity to radiate on the heated object, which greatly improves the un-uniform distribution of microwave energies in the heating cavity.

Owner:TSANN KUEN CHINA ENTERPRISE

Heat insulation cold closet for medical supplies

ActiveCN103723379AReduce thicknessIncrease effective volumeLighting and heating apparatusInsulation for cooling apparatusEngineeringEffective volume

The invention discloses a heat insulation cold closet. According to the heat insulation cold closet, due to the fact that a vacuum heat insulation panel layer and a rigid polyurethane layer are arranged in a polyurethane foamed plastic layer to form a composite head insulation structure, the thickness of the heat insulation cold closet is reduced so that the effective volume of a heat insulation closet in the same shape can be greatly increased; furthermore, the coefficient of heat insulation of the heat insulation cold closet is smaller than or equal to 0.004W / mK, heat radiation, heat conduction and heat convection between the interior of the closet body and the outside environment can be effectively prevented, and the heat insulation closet can guarantee that the interior temperature is controlled below 2-8 DEG C for more than 120 hours. The heat insulation cold closet is mainly used for cold storage and refrigeration during transportation and storage of medicine such as vaccine, insulin, blood products, biological products and reagents.

Owner:SUZHOU ANTEK INDAL

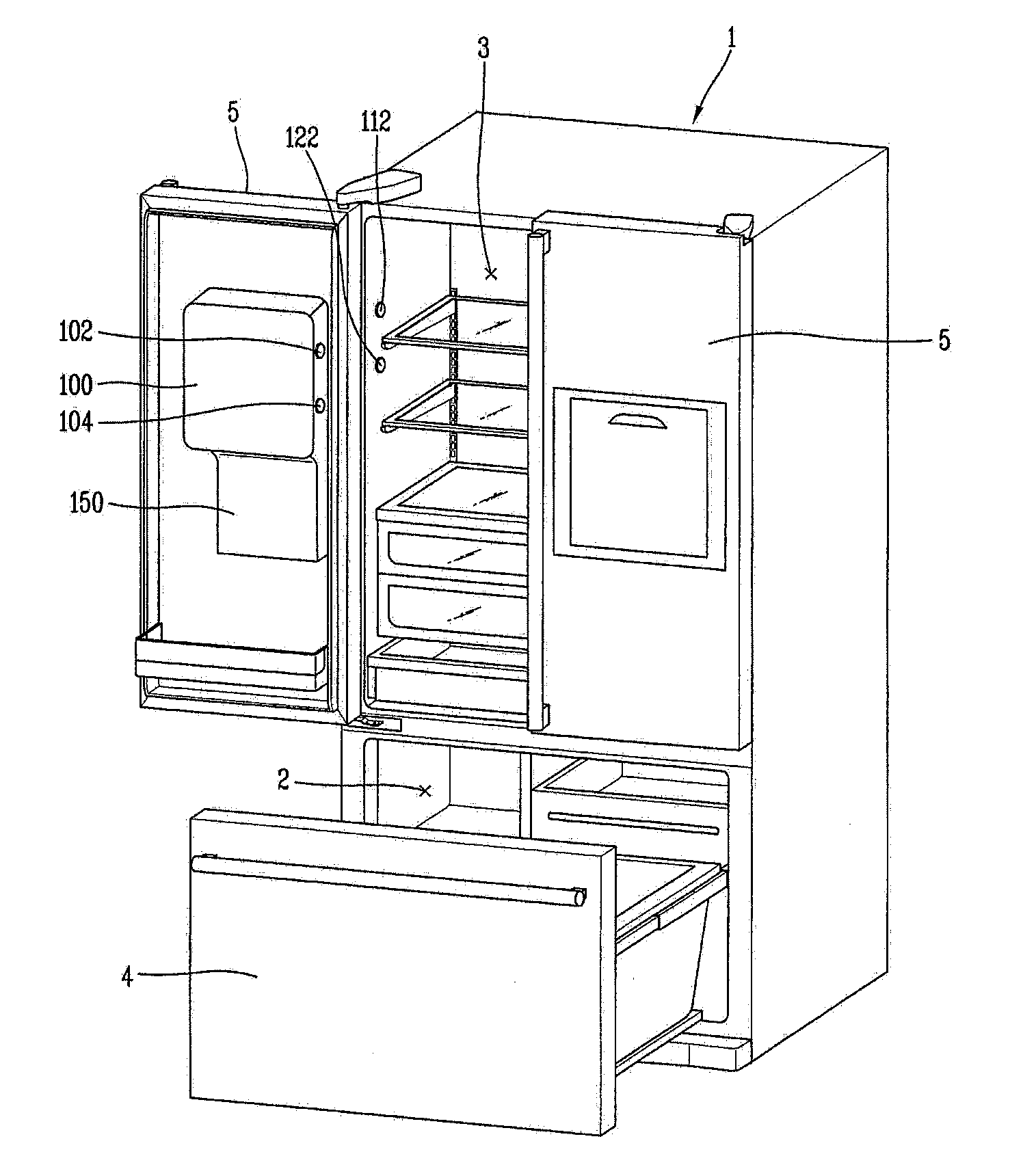

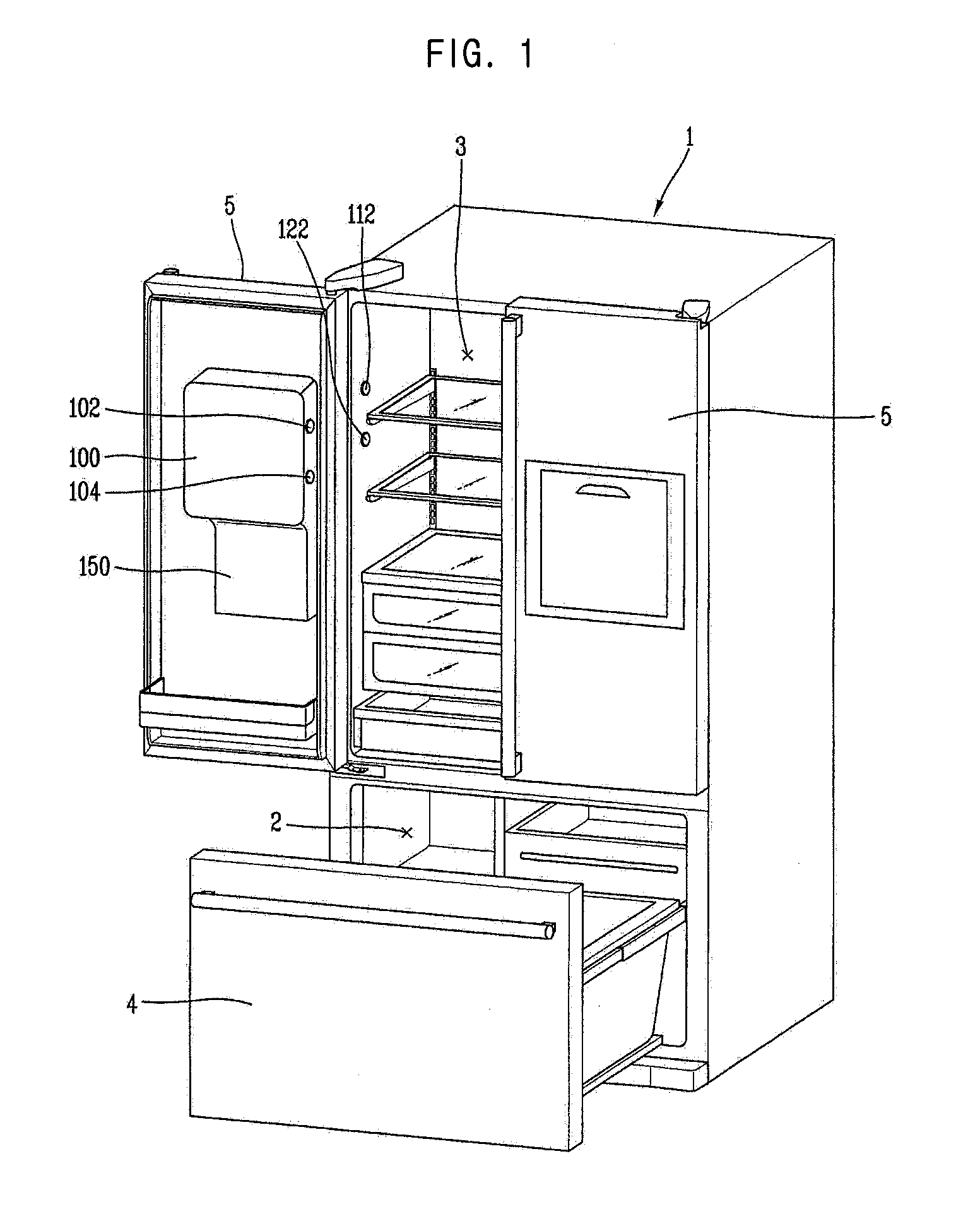

Refrigerator having ice transfer unit

InactiveUS20120023999A1Improve convenienceEffectively useLighting and heating apparatusIce productionFreezing chamberEngineering

A refrigerator includes: a refrigerator main body including a freezing chamber positioned at a lower portion thereof and a refrigerating chamber positioned at an upper portion thereof; an ice maker and an ice bank positioned at an inner side of the freezing chamber; an ice dispenser positioned at an inner side of the refrigerating chamber; a transfer flow path extending from the ice bank to the ice dispenser; an ice input unit supplying ice stored in the ice bank to the interior of the transfer flow path; and a blower blowing air to allow the ice supplied to the interior of the ice transfer flow path toward the ice dispenser.

Owner:LG ELECTRONICS INC

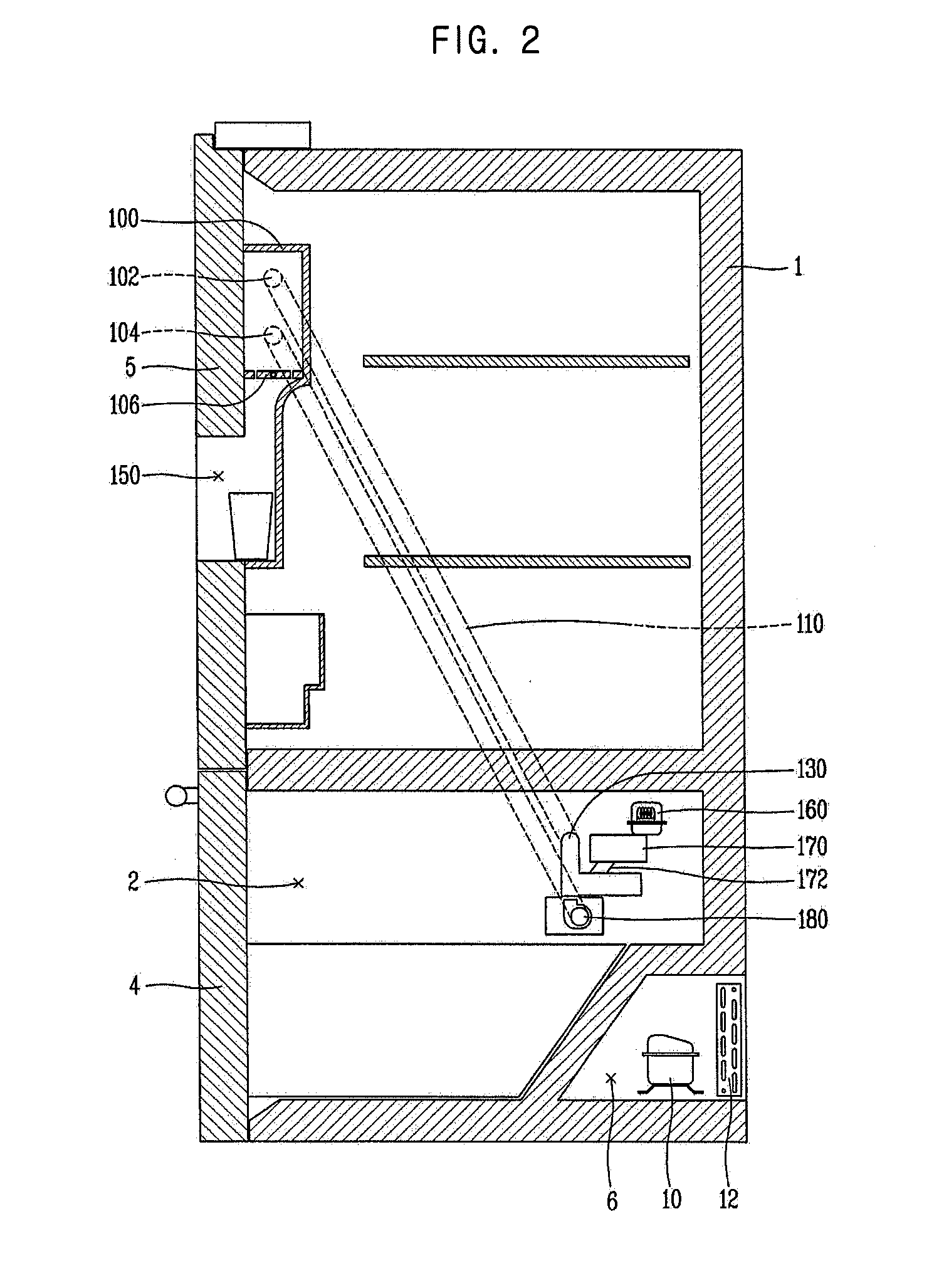

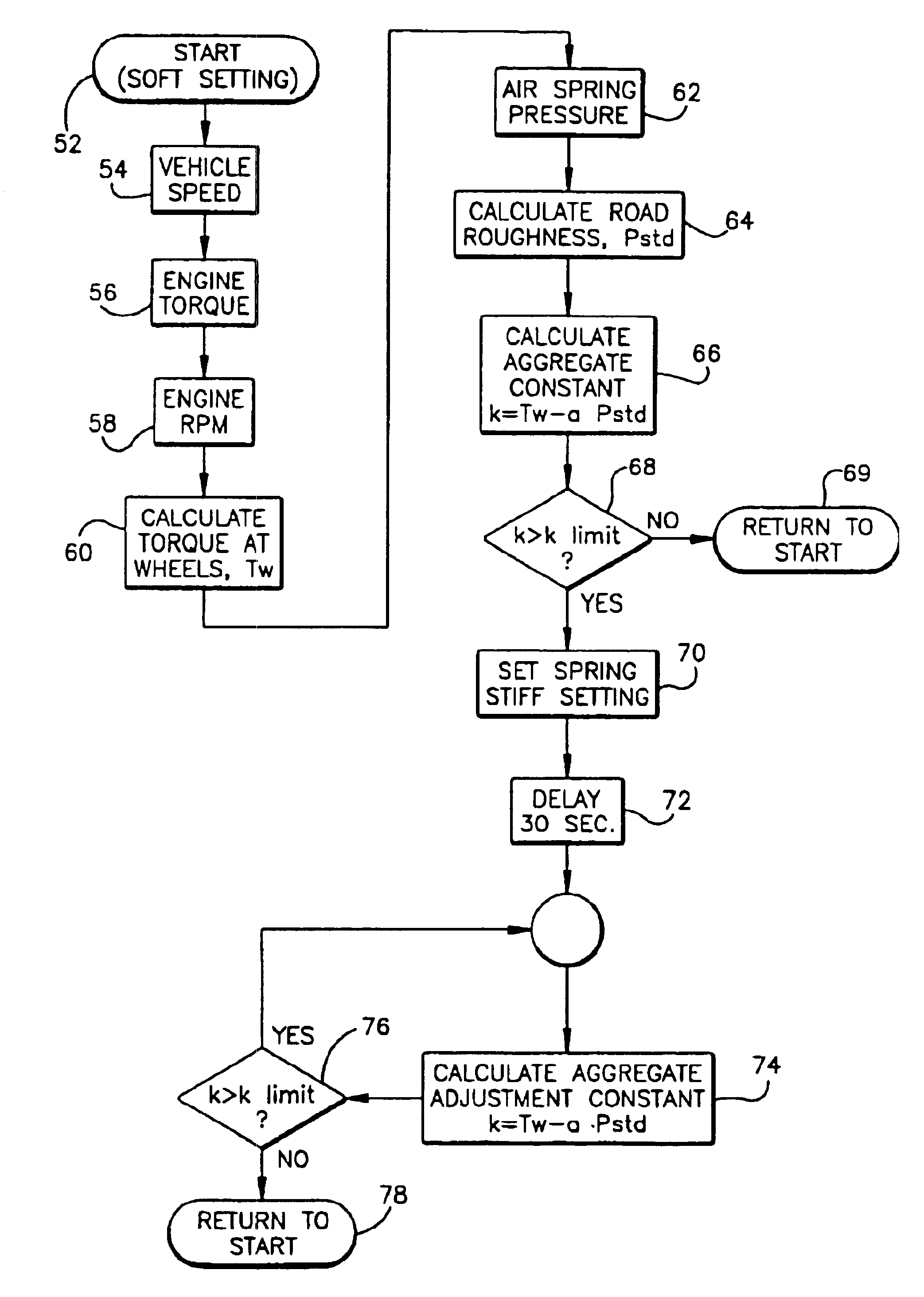

Air spring stiffness controller

InactiveUS6883810B2Improve rideIncrease effective volumeSpringsInterconnection systemsTruckAir suspension

A method and apparatus for adaptively damping relative motion between the wheels and the frame of a heavy duty truck having a frame suspended on wheels by a suspension system. An air spring is disposed between the frame and at least one of the wheels having a primary reservoir for holding air and a piston adapted to act upon the air in the reservoir to compress the air and thereby provide support for the frame. An auxiliary reservoir holds air and can be placed in fluid communication with the primary reservoir to increase an effective volume of air upon which the piston acts. A control valve selectively places the auxiliary reservoir in communication with the primary reservoir based on vehicle operating parameters. The control valve can be actuated mechanically by forces acting on the wheels or by a controller that controls the valve based on wheel torque and road roughness.

Owner:VOLVO TRUCKS NORTH AMERICA

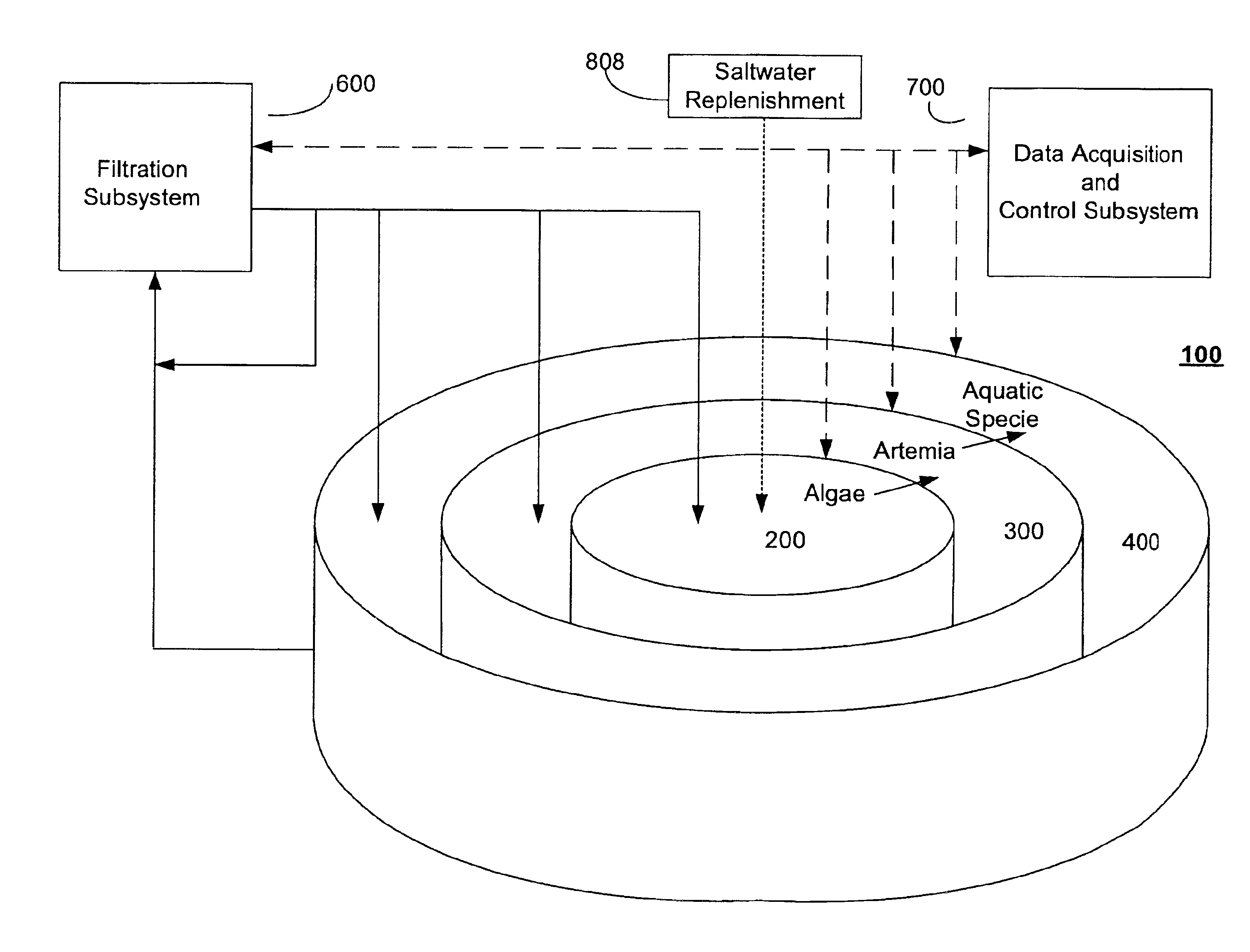

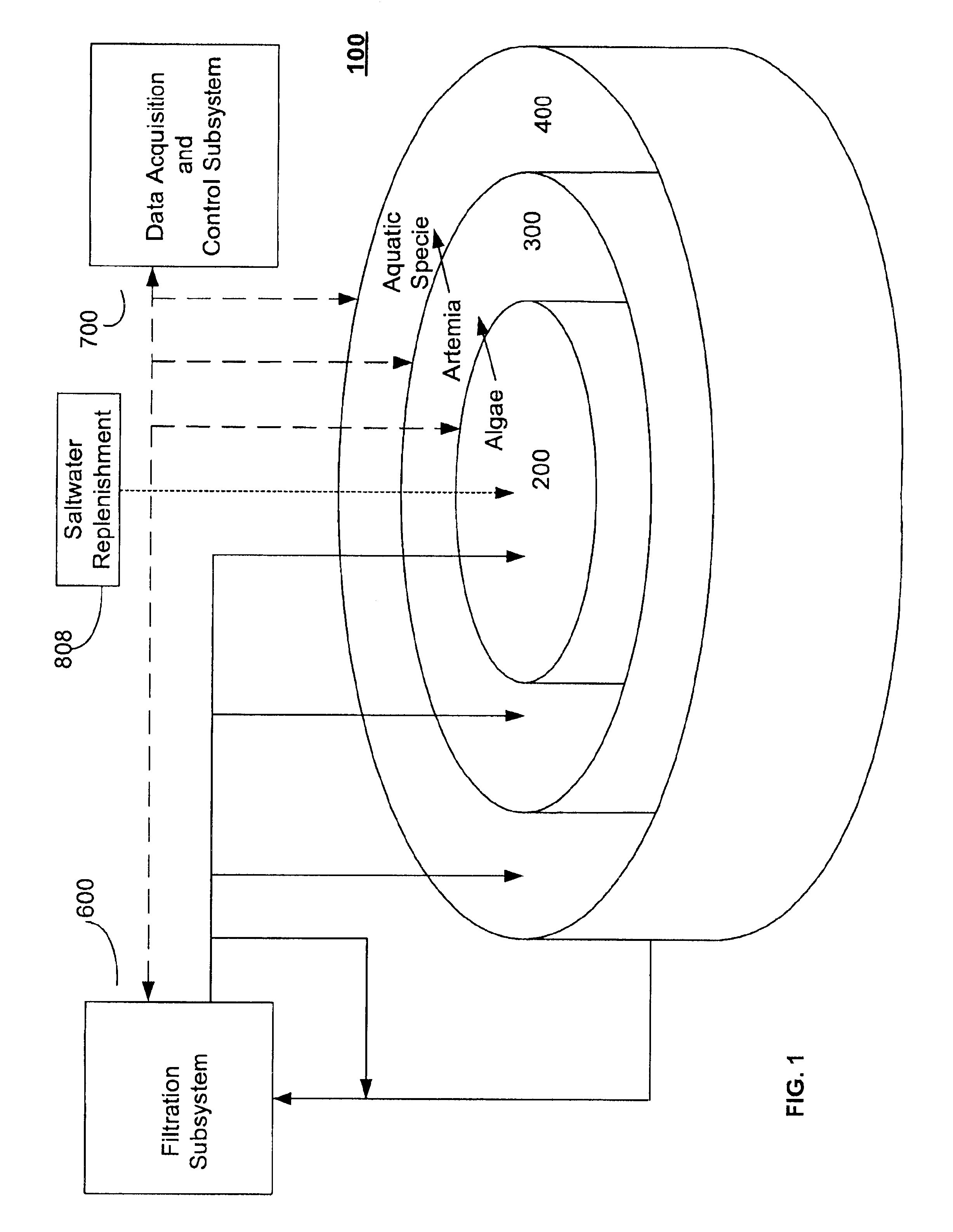

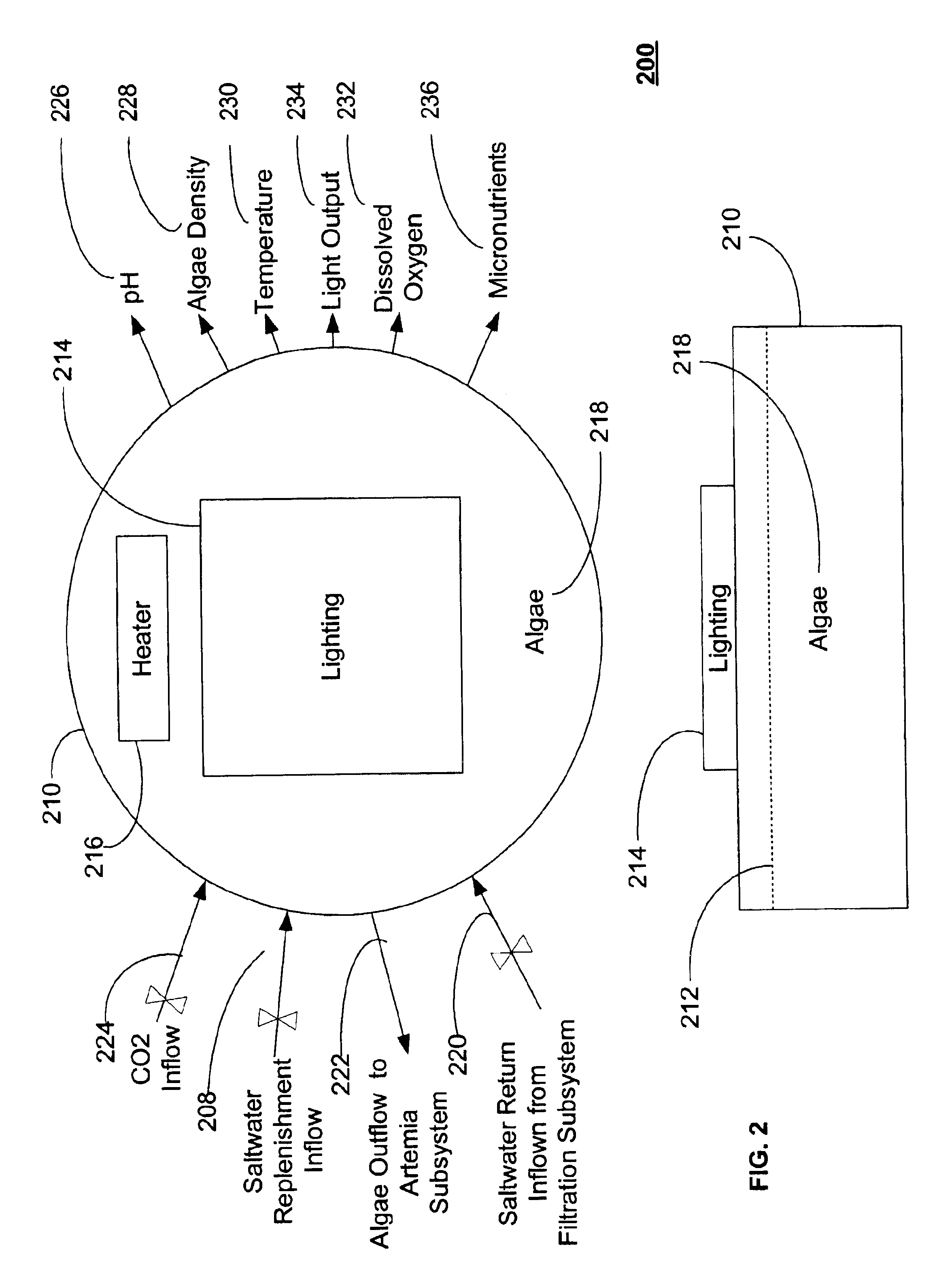

Aquaculture method and system for producing aquatic species

InactiveUS6851387B2Improve productivityReduce labor costsClimate change adaptationPisciculture and aquariaSaline waterAutomatic control

The invention provides a method and system for producing aquatic specie for consumer consumption within a closed aquaculture system. It provides for growing algae in artificial saltwater under controlled conditions in an algae subsystem, feeding the algae to adult artemia for producing small artemia in an artemia subsystem, feeding the algae and small artemia to immature aquatic specie for producing adolescent aquatic specie in an aquatic specie nursery subsystem, and feeding the algae and small artemia to the adolescent aquatic specie to for producing adult aquatic specie in an aquatic specie growout subsystem, which are then harvested. The invention also includes a data acquisition and control subsystem for automated control of the aquaculture system. A unique filtration subsystem accepts waste from the aquatic specie subsystem, pumps the waste through a series of filters, and returns the filtered saltwater to the algae subsystem, the artemia subsystem and the aquatic specie subsystem.

Owner:AUTOMATED SHRIMP HLDG CORP

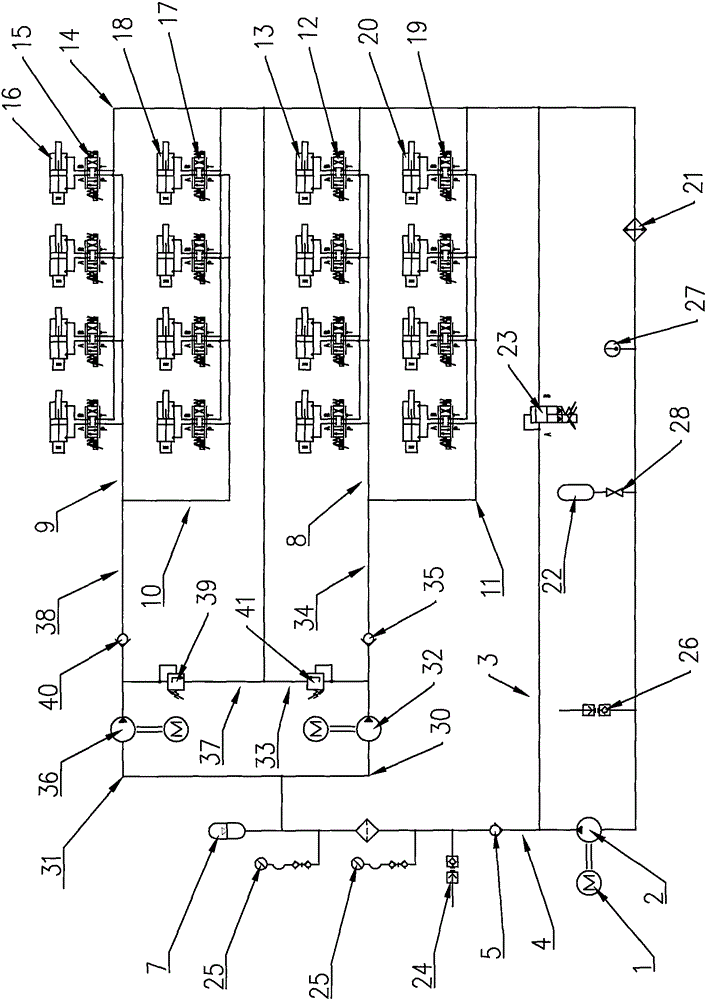

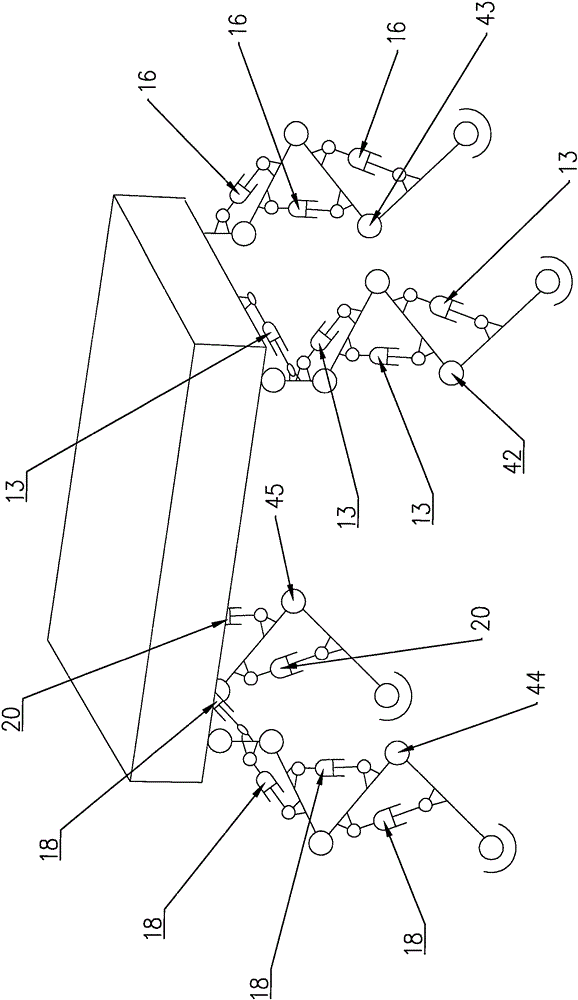

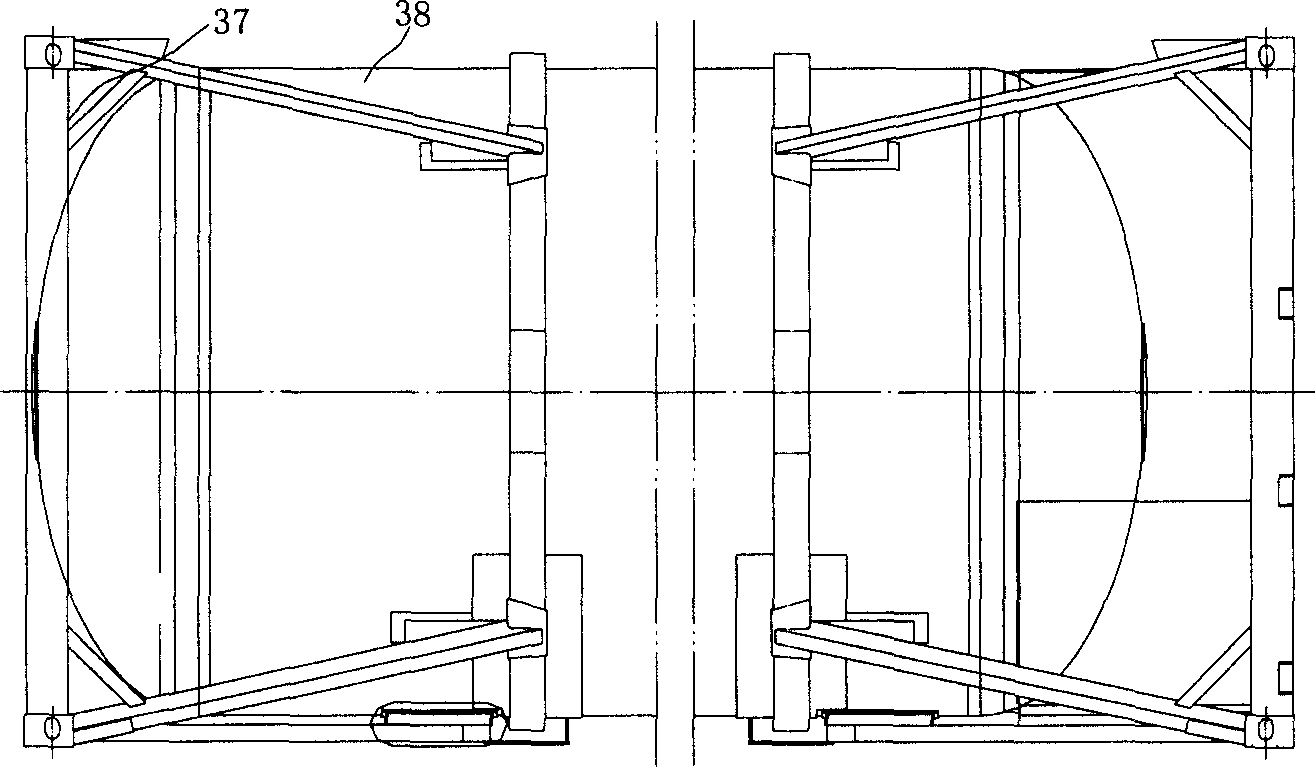

Electric servo hydraulic power source drive system of four-foot robot

ActiveCN105156382APlay a role in maintaining pressureEasy to check for faultsProgramme-controlled manipulatorServomotor componentsHydraulic pumpHigh pressure

An electric servo hydraulic power source drive system of a four-foot robot comprises a quantitative gear pump. The oil outlet of the quantitative gear pump is connected with the inlet of a high-pressure oil pipe. The outlet of the high-pressure oil pipe is connected with the inlet of a left oil supply pipe and the inlet of a right oil supply pipe. The left oil supply pipe is connected with a left hydraulic pump in series. The outlet of the left oil supply pipe is connected with the inlet of a left overflow pipe and the inlet of a left supercharging oil pipe. The middle of the left overflow pipe is connected with a left overflow valve in series. The outlet of the left supercharging oil pipe is connected with the oil inlet of a left front leg oil supply pipe and the oil inlet of a right rear leg oil supply pipe. The right oil supply pipe is connected with a right hydraulic pump in series, and the outlet of the right oil supply pipe is connected with the inlet of a right overflow pipe and the inlet of a right supercharging oil pipe. The middle of the right overflow pipe is connected with a right overflow valve in series. The outlet of the right supercharging oil pipe is connected with the oil inlet of a right front leg oil supply pipe and the oil inlet of a left rear leg oil supply pipe. According to the purpose, the electric servo hydraulic power source drive system of the four-foot robot is light, large in effective volume, constant in oil supplementing pressure, long in driving mileage, low in noise, long in service life, and stable and reliable in performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

High vacuum heat insulation low temperature liquefied gas storage tank

ActiveCN1683816AIncrease effective volumeReduce heat transfer areaVessel mounting detailsVessel manufacturingEngineeringHeat conducting

The high vacuum heat insulating low temperature liquefied gas storing tank includes frame and tank body. The tank body consists of outer casing, inner container and combined support structures connecting the outer casing and the inner container. The combined support structures are set between the inner sealing head and outer sealing head on two ends of the tank to bear the radial load and the axial load with great bearing force. The heat conducting area between the inner container and the outer casing is small, and the inner container has great effective loading volume.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

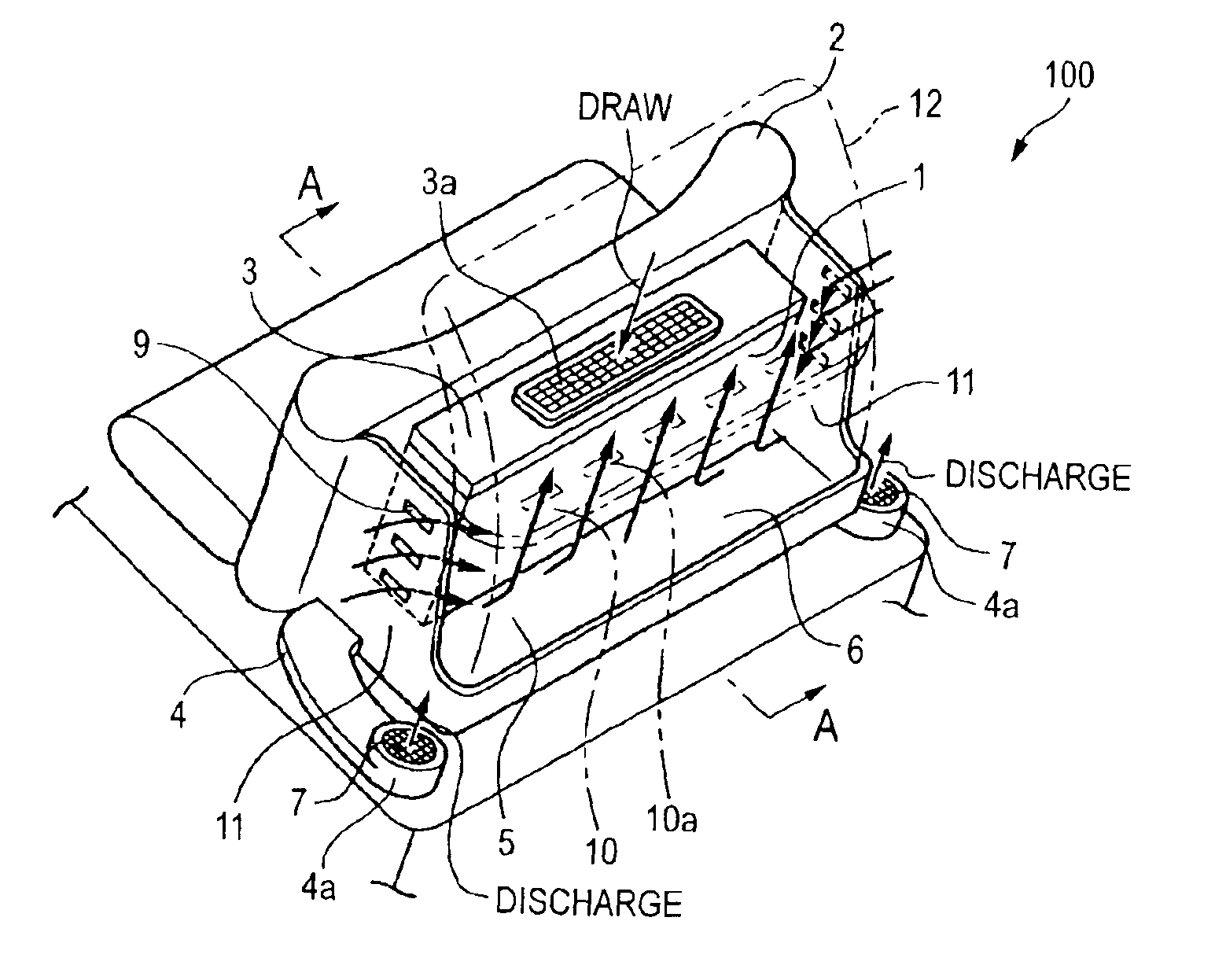

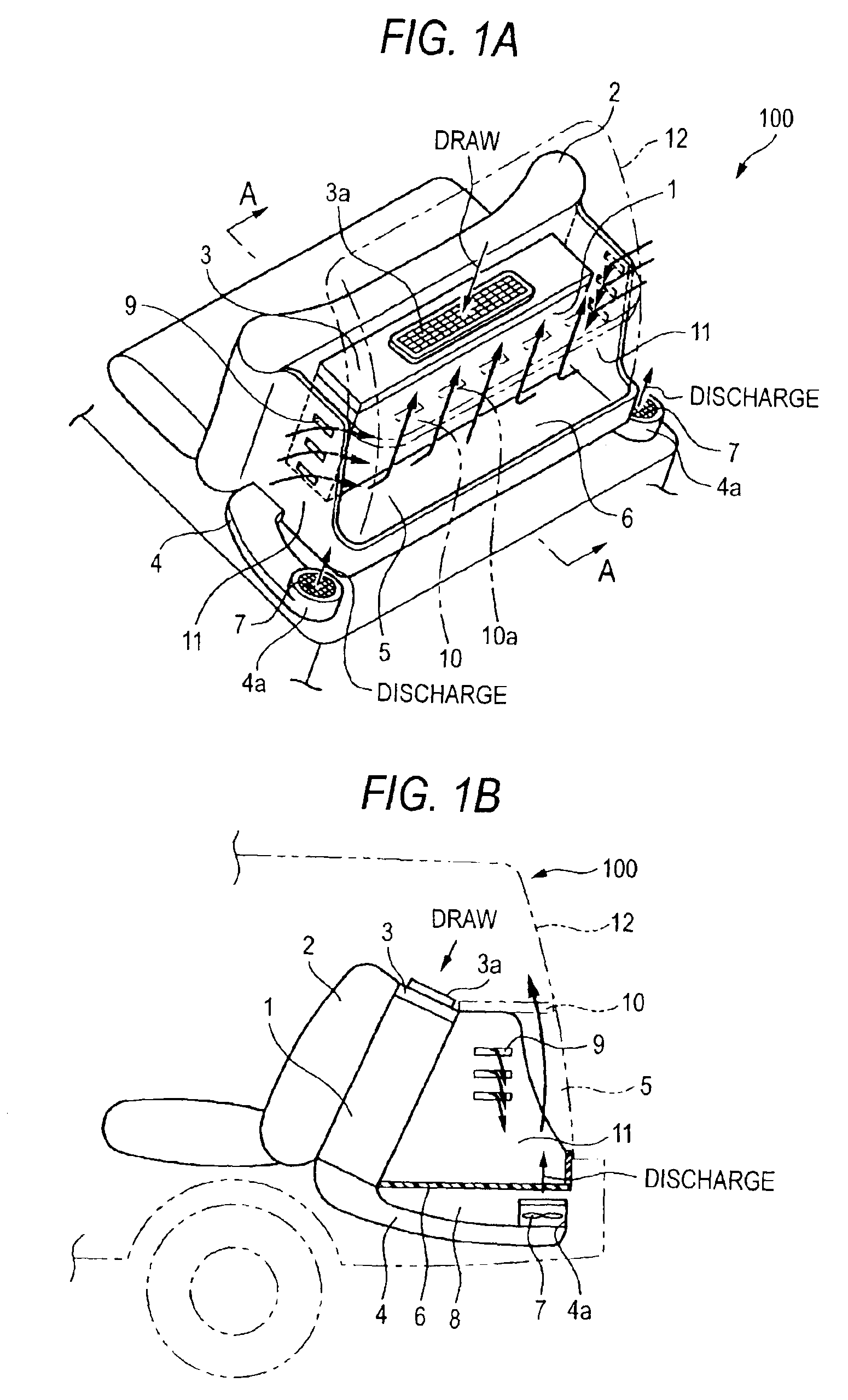

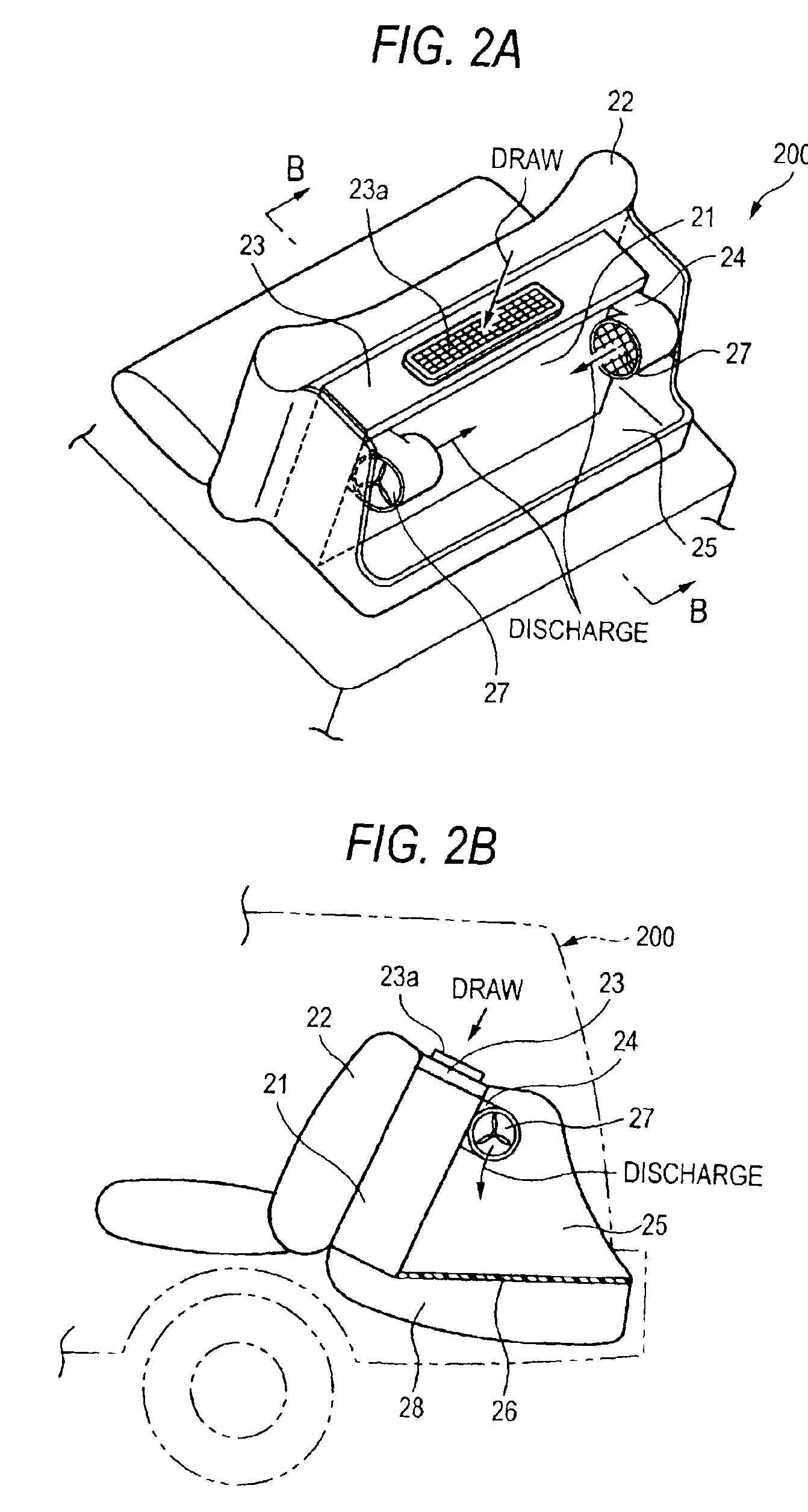

Arrangement of cooling apparatus

InactiveUS6931878B2Reduce noiseReduce noise levelDigital data processing detailsAnimal undercarriagesElectricityEngineering

An arrangement of a cooling apparatus installed in a vehicle for cooling with an air refrigerant an electricity storing apparatus for storing electricity generated in the vehicle, comprises an inlet port, a discharge duct and a fan. The inlet port let in therefrom the air refrigerant to the electricity storing apparatus. The discharge duct is disposed below a floor surface of a trunk of the vehicle for causing the air refrigerant discharged from the electricity storing apparatus to flow therethrough. The fan is situated in the discharge duct for discharging the air refrigerant. The fan is disposed outwardly of an interior material provided on a side of the trunk of the vehicle. The arrangement of a cooling apparatus can prevent the operating noise of a fan from entering a passenger compartment and which can facilitate the installation of luggage in a trunk.

Owner:HONDA MOTOR CO LTD

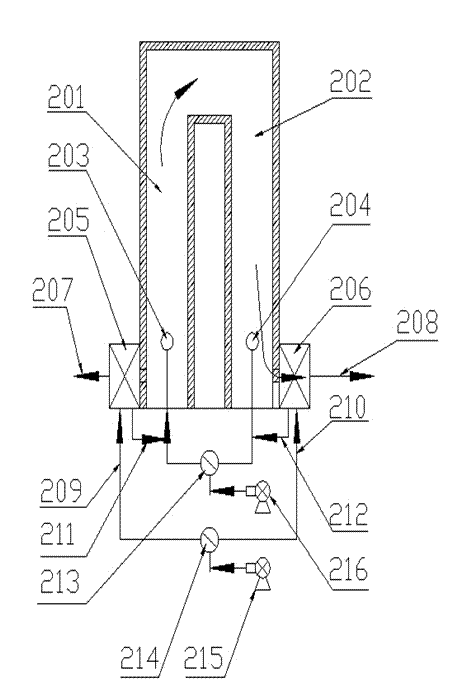

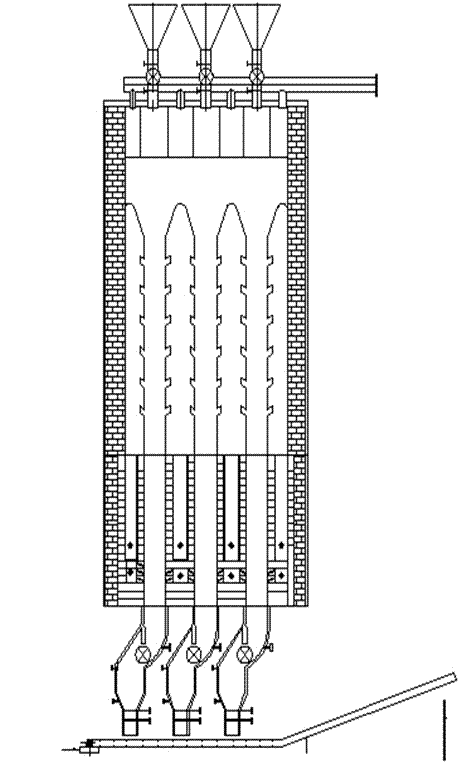

HY type dry distillation furnace

ActiveCN103923676ASolve the problem of low utilization efficiencyImprove utilization efficiencyIndirect and direct heating destructive distillationEnergy inputCombustion chamberHeat carrier

The invention discloses an HY type dry distillation furnace which is characterized by comprising a plurality of dry distillation subunits, wherein each dry distillation subunit comprises a charging device, an oil gas discharge device, a dry distillation device, a heating device and a coke discharge device; materials are subjected to dry distillation by using a combined radiation heat exchange and convection heat exchange mode in the furnace; gas generated in a dry distillation process is used as a dry distillation heat source, and the dry distillation heat can be self-balanced; the materials are directly heated by virtue of radiation of a furnace wall of a combustion chamber, and a heat carrier does not need to be subjected to secondary heating and long-distance conveying; a dry distillation gas outputting device is arranged in the furnace, so that the gas in the furnace flows smoothly; coke is discharged by a dry method. The dry distillation furnace is high in heat utilization efficiency, low in outlet gas quantity, low in water consumption, high in oil yield and large in daily treatment capacity capable of being more than 6,000 tons, and is suitable for low and medium-temperature dry distillation of the materials such as oil sand, oil shale, coal and the like, and suitable for oil refining and dry distillation of large particle materials and small particle materials of less than 15mm.

Owner:辽宁智越建设有限公司

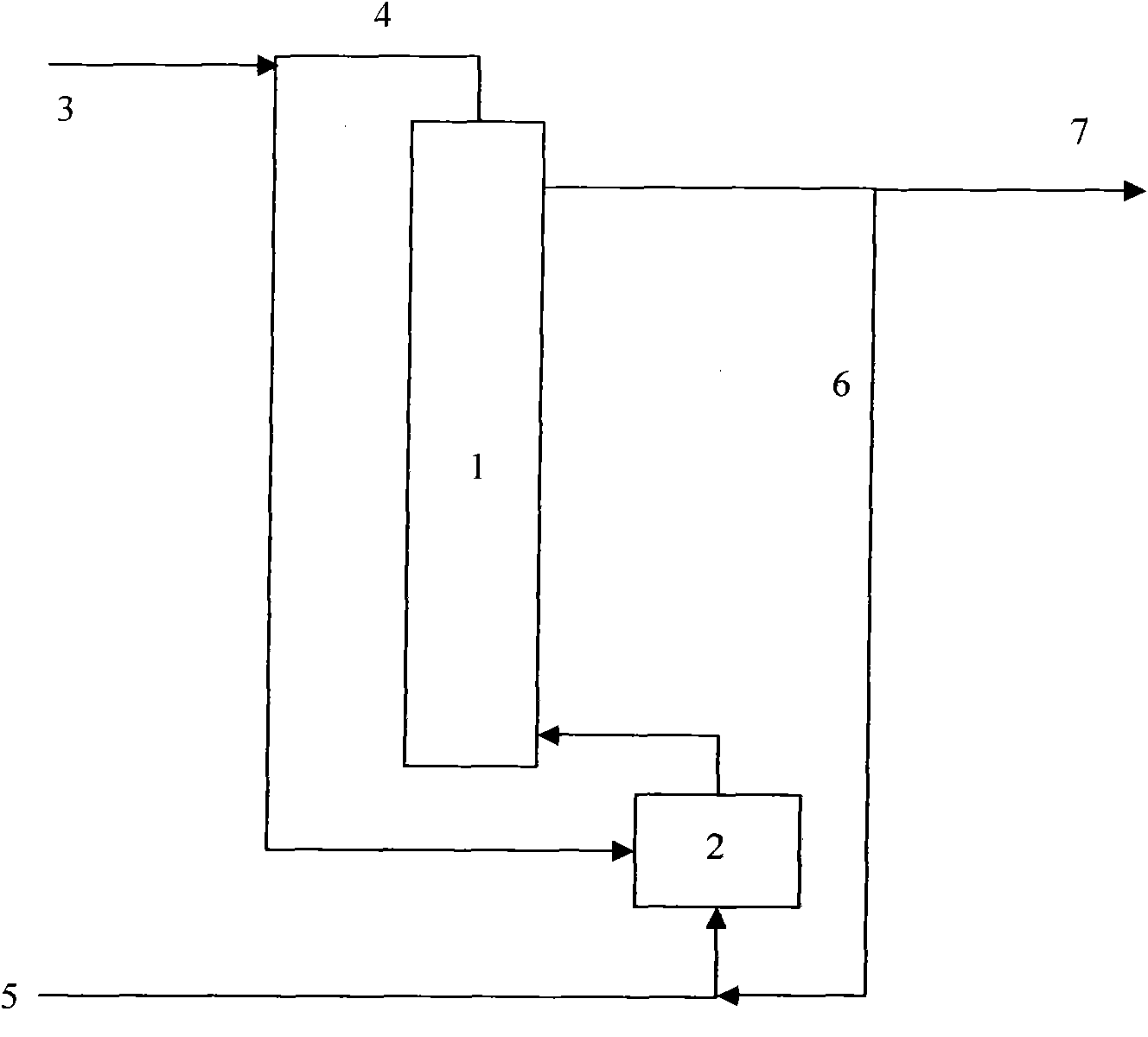

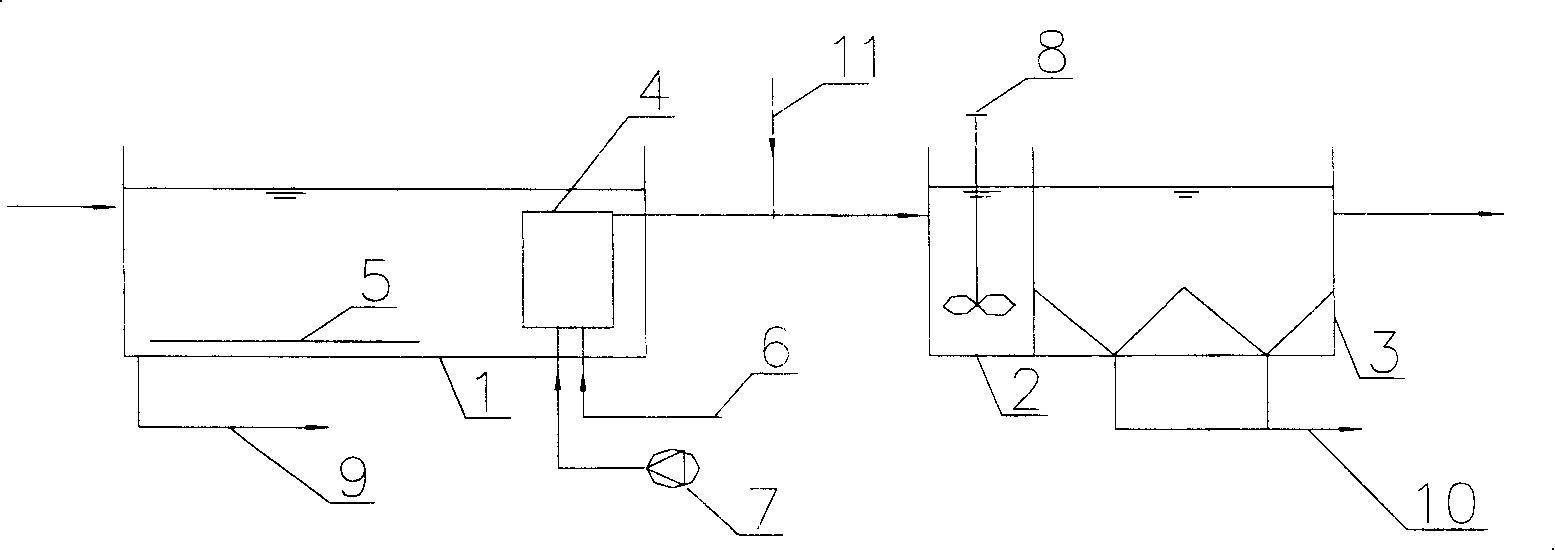

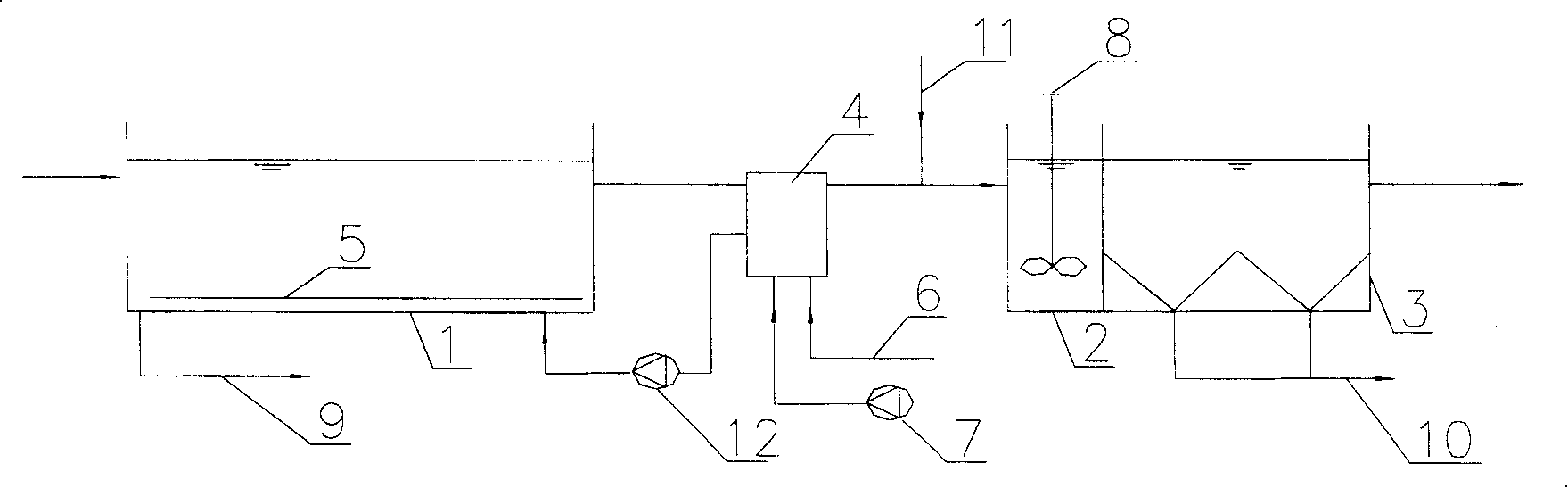

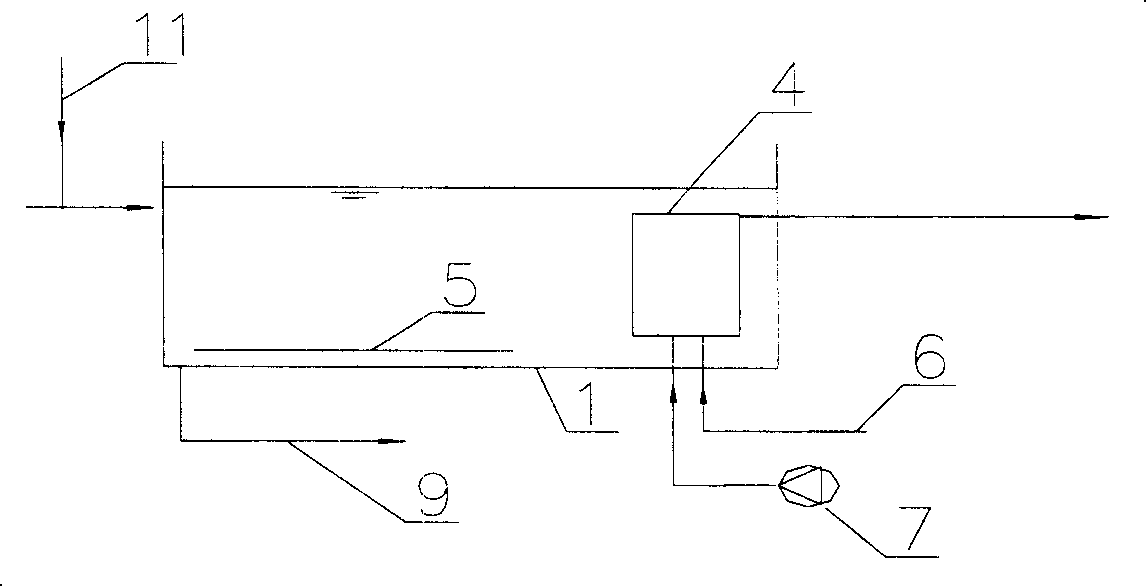

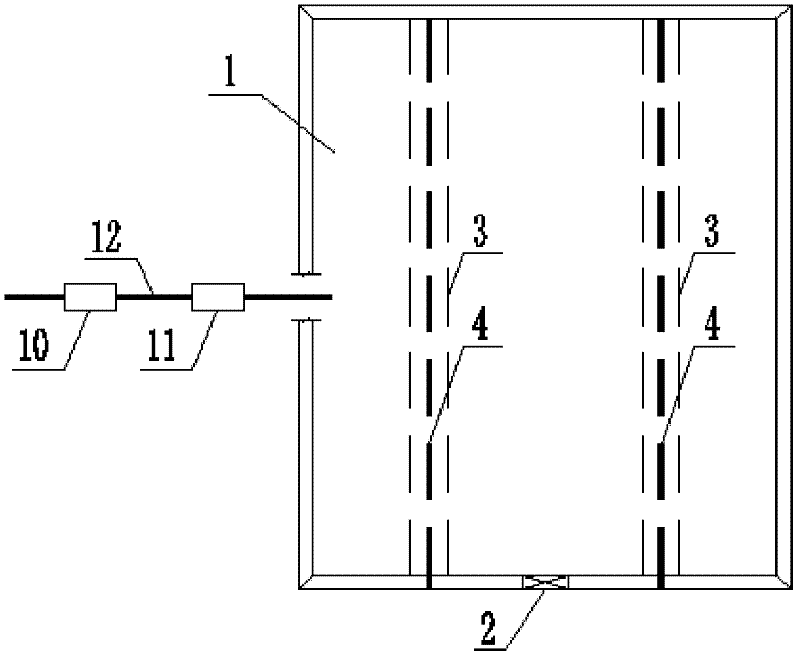

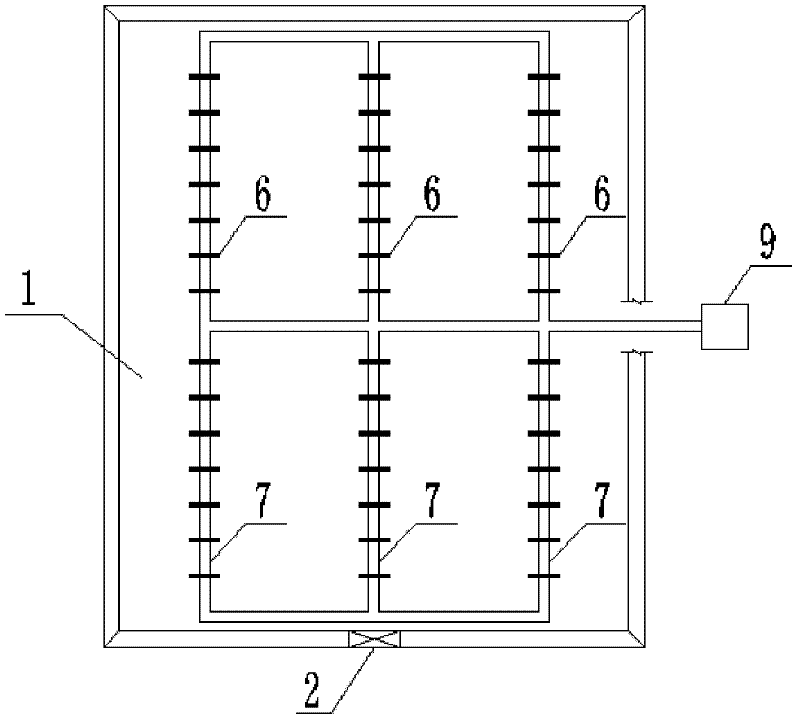

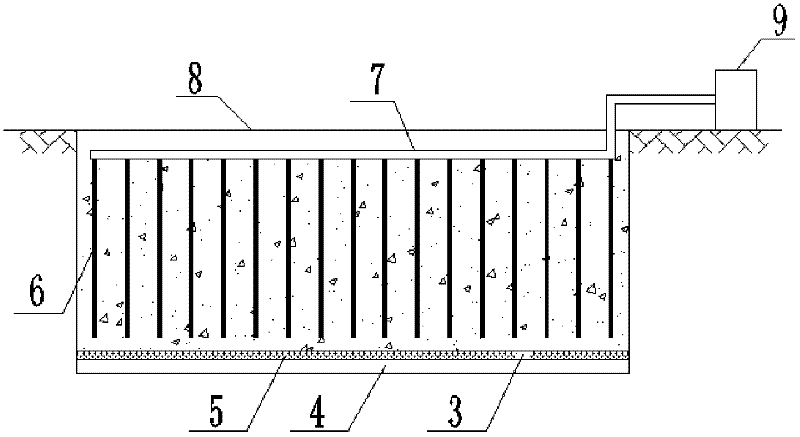

Sewage denitrogenation dephosphorylation treatment method by using biological film to filter

InactiveCN101168461ALow costEasy to operateSustainable biological treatmentBiological water/sewage treatmentSludgePhosphor

The invention relates to a sewage denitrification dephosphorization treatment method which uses biologic film to filter, wherein the invention arranges a biologic film filter in an aeration tank, which uses stainless steel or filter cloth as screen to replace traditional two deposit tanks to separate sludge and water. The invention is characterized in that the average aperture of stainless steel or filter cloth screen of the biologic film filter is 10-200mum, the screen is arranged with a biologic film to stop active sludge, the water flux at unit screen can reach more than 100l / h.m2, the highest filter resistance is controlled under 0.5m, the sludge of aeration tank can reach at least 2-3 times of general one, and the phosphor in the outlet water filtered by the biologic film filter is flocculated and deposited to reach denitrification and dephosphorization demands, the resistance of biologic filter is increased when serves some time, while the water flux is reduced, and the biologic film filter can come back to normal running after being blown reversely and washed reversely via a water pump.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

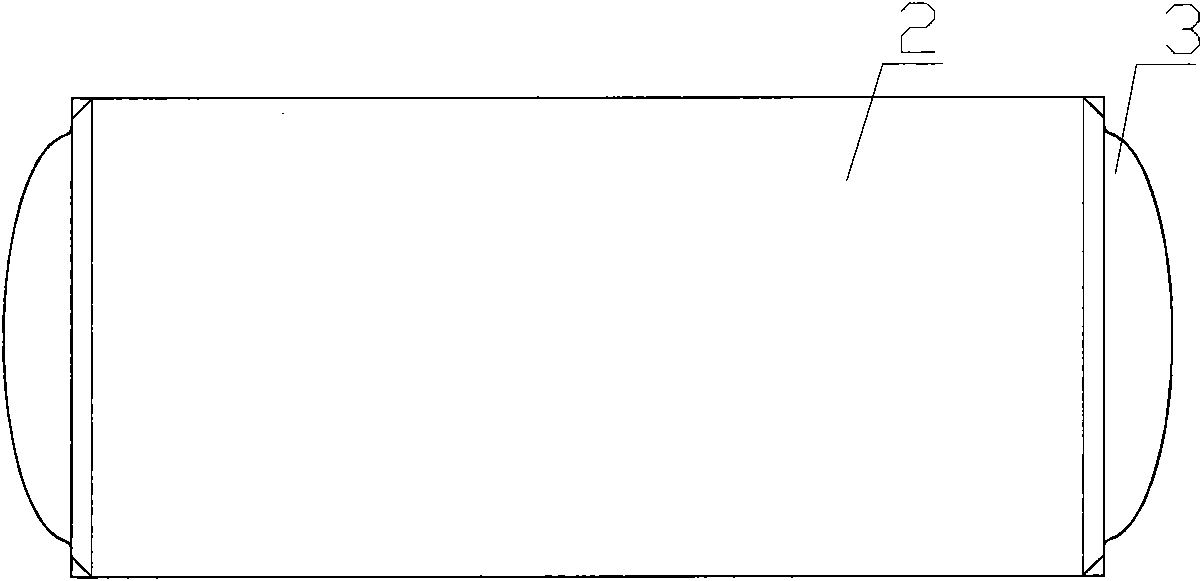

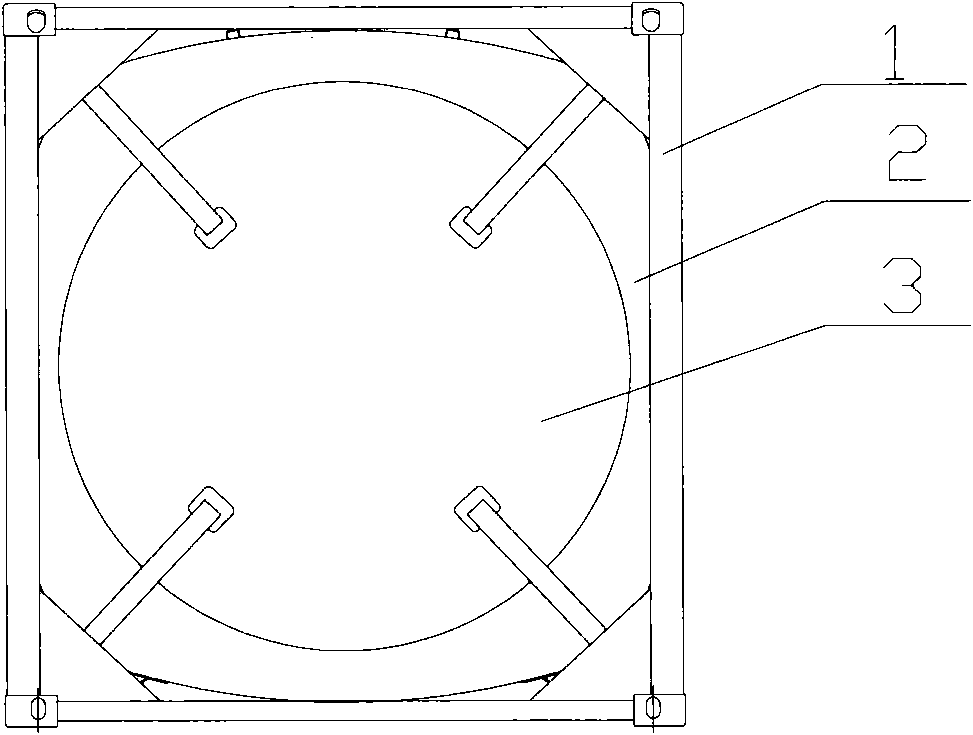

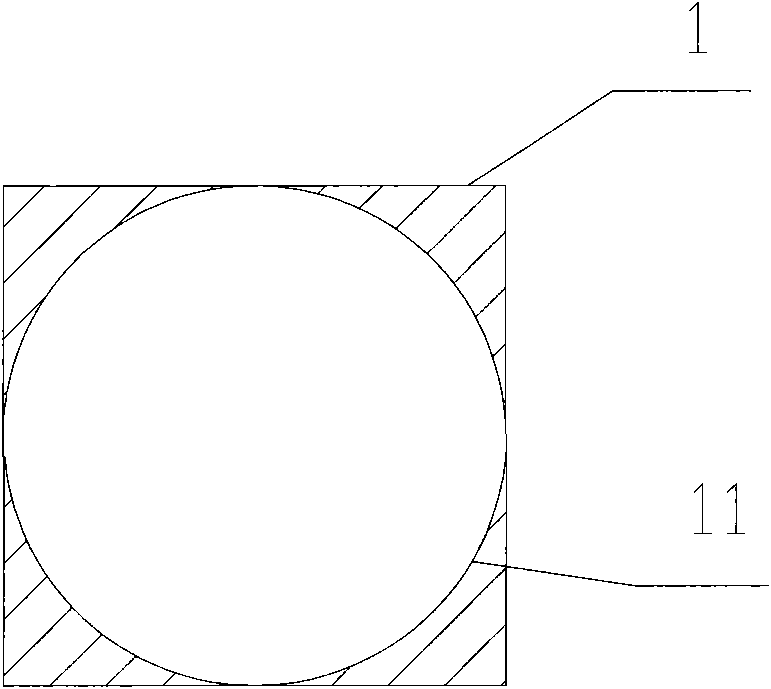

Tank container, tank body and processing method of tank body

ActiveCN101554948AImprove reliabilityLose weightLarge containersDomestic vesselsFuel tankTank container

The invention discloses a container tank body and a processing method thereof. The tank body is arranged in a frame with a square-shaped cross section and comprises a cylindrical main body part, end enclosures arranged at the two ends of the cylindrical main body part and fixedly connected with the cylindrical main body part, and a tank body strengthening device; the cylindrical main body part comprises a plurality of parts with an arc-shaped cross section, the parts are formed by the bending and welding of a same panel, and the cross section of the cylindrical main body part of the tank body is generally arranged between the square-shaped cross section of the frame and an inscribed circle of the square-shaped cross section. The invention also discloses a tank container comprising the tank body. As the cylindrical main body part is made by continuously bending a whole panel, the molding process is simplified so that the cylindrical main body part is only provided with one welding line, thereby remarkably lowering the leakage risk of the container tank body in use and improving the reliability of the container tank body in work; and the structure has quite strong self-anti-load capacity, thereby decreasing the number of the used tank strengthening devices and reducing own weight.

Owner:CRRC QIQIHAR ROLLING CO LTD

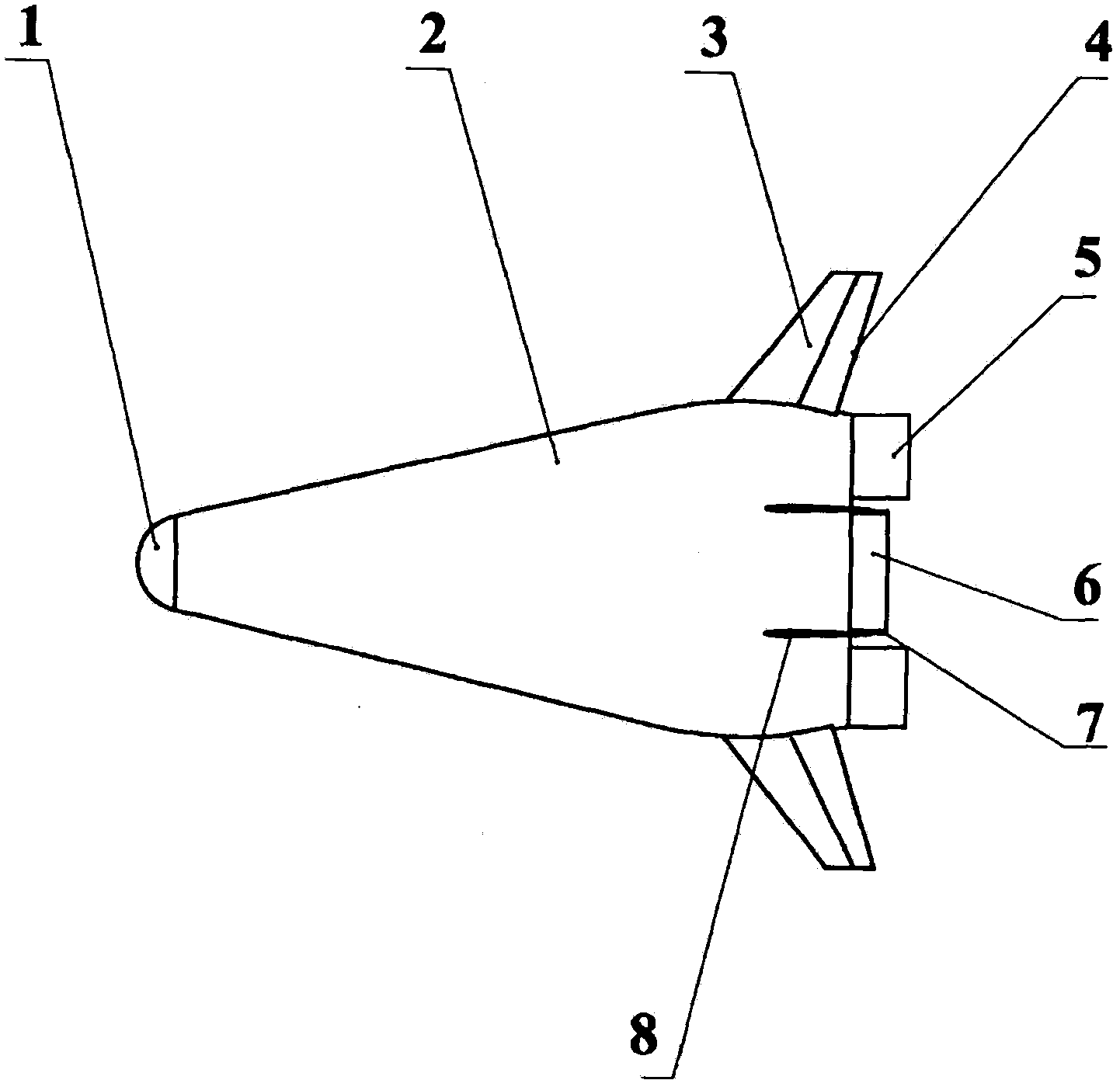

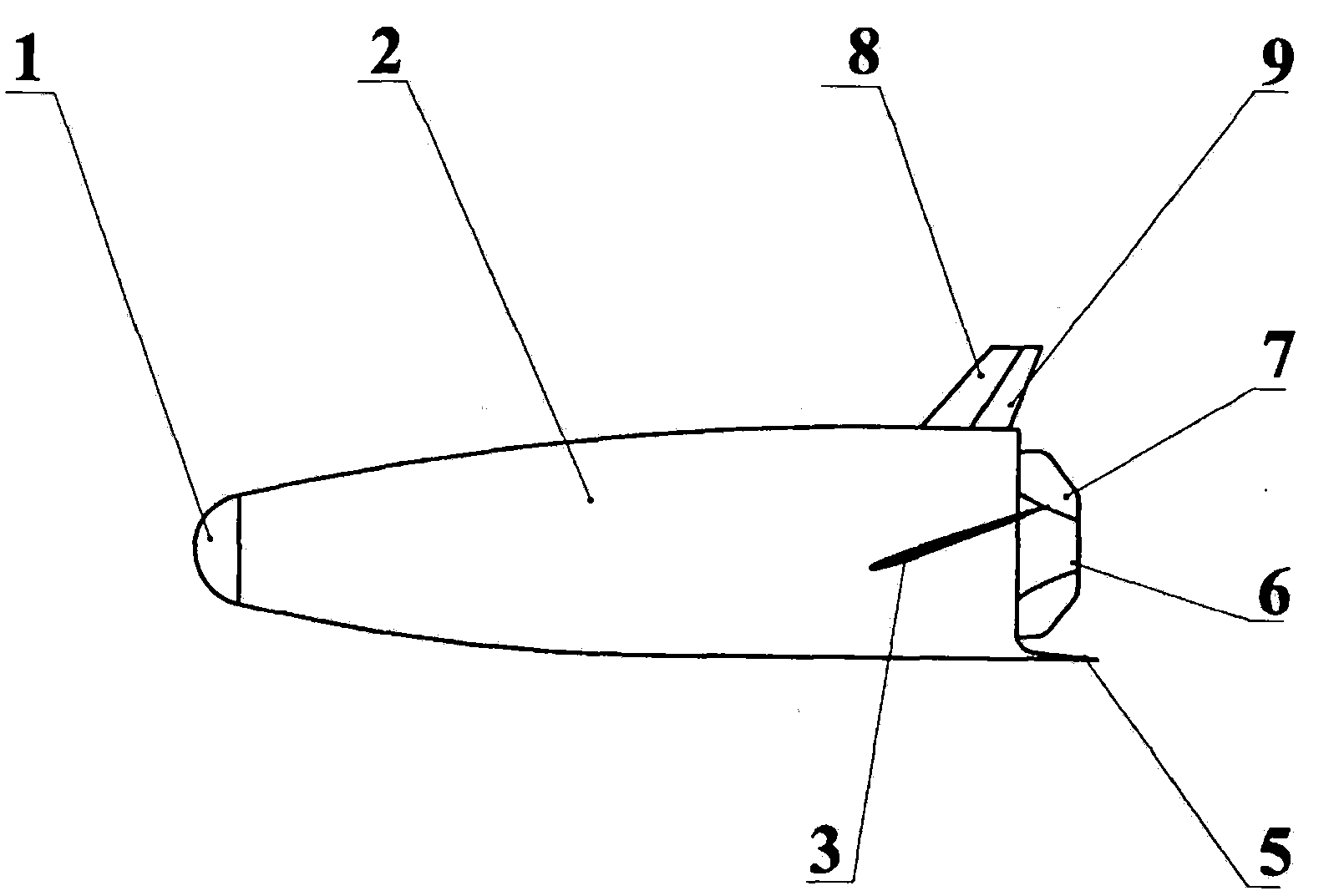

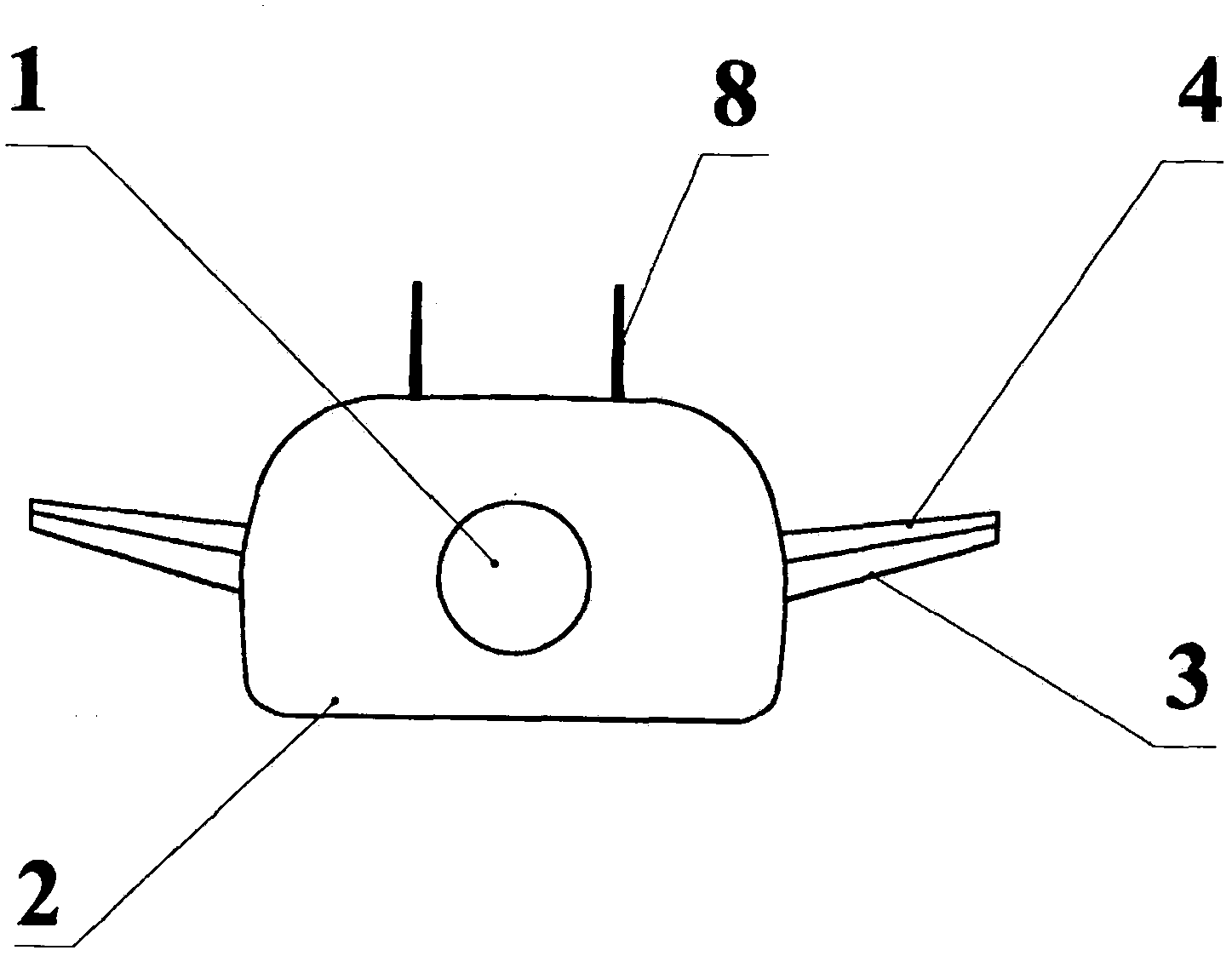

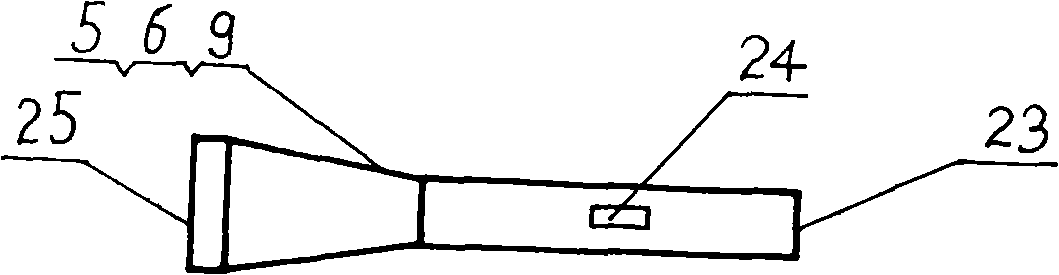

An Aerodynamic Layout of a Transatmospheric Reusable Vehicle

InactiveCN105659735BLow cost of launch usageShort launch lead timeSpace shuttlesLiquid hydrogenHigh lift

The invention discloses an aerodynamic layout of a transatmospheric reusable aircraft, which comprises a head, a fuselage, a horizontal wing, a vertical tail, a body flap and a liquid hydrogen / liquid oxygen linear plug-type nozzle rocket engine. The invention has no booster, and adopts a single stage to vertically launch into orbit from the ground; after completing the mission, it can return to the atmosphere and glide horizontally to land, and can be completely reused after recovery. Through reasonable aerodynamic configuration and optimized design, the aircraft has a high lift-to-drag ratio and good stability and maneuverability in a wide range of altitudes and speeds. At the same time, the fuselage has a large effective volume and needs to carry propulsion Dose less. The invention has low launching cost, short launching preparation period and high reliability. It can overcome the shortcomings of current space vehicles that cannot be completely reused, expensive to launch, and cumbersome to use and maintain. It can be used not only for military space missions, but also for commercial and civil space services.

Owner:BEIHANG UNIV

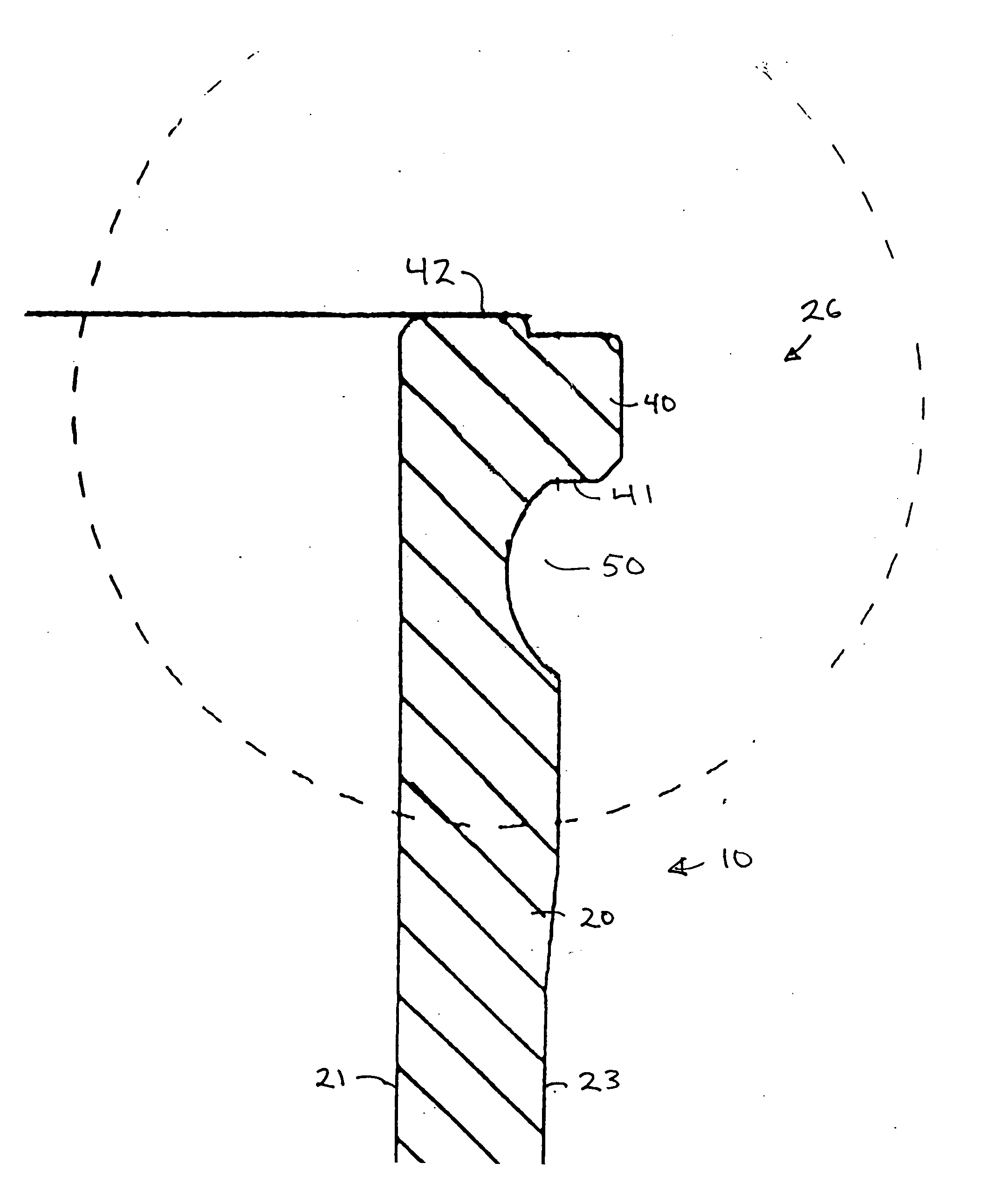

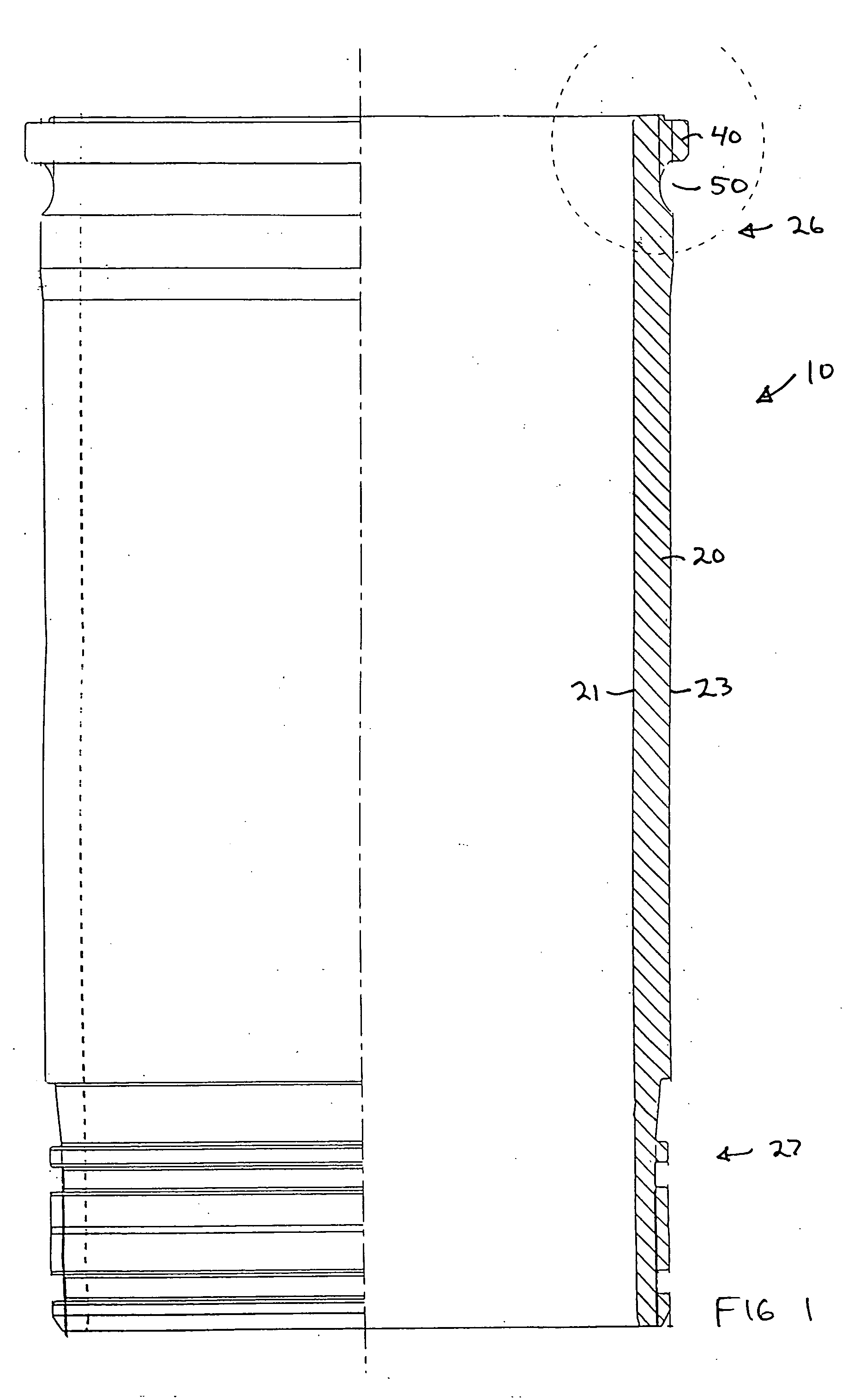

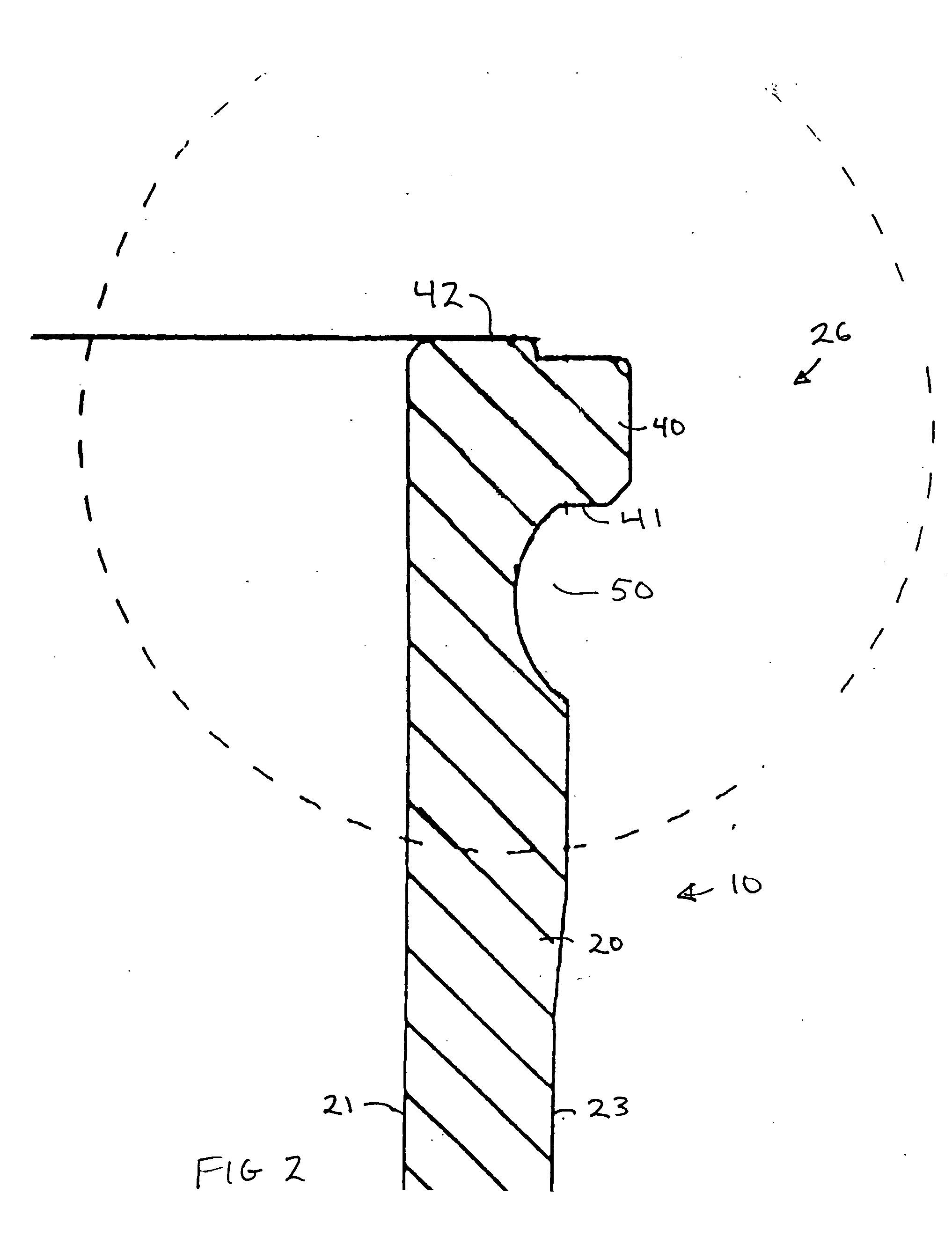

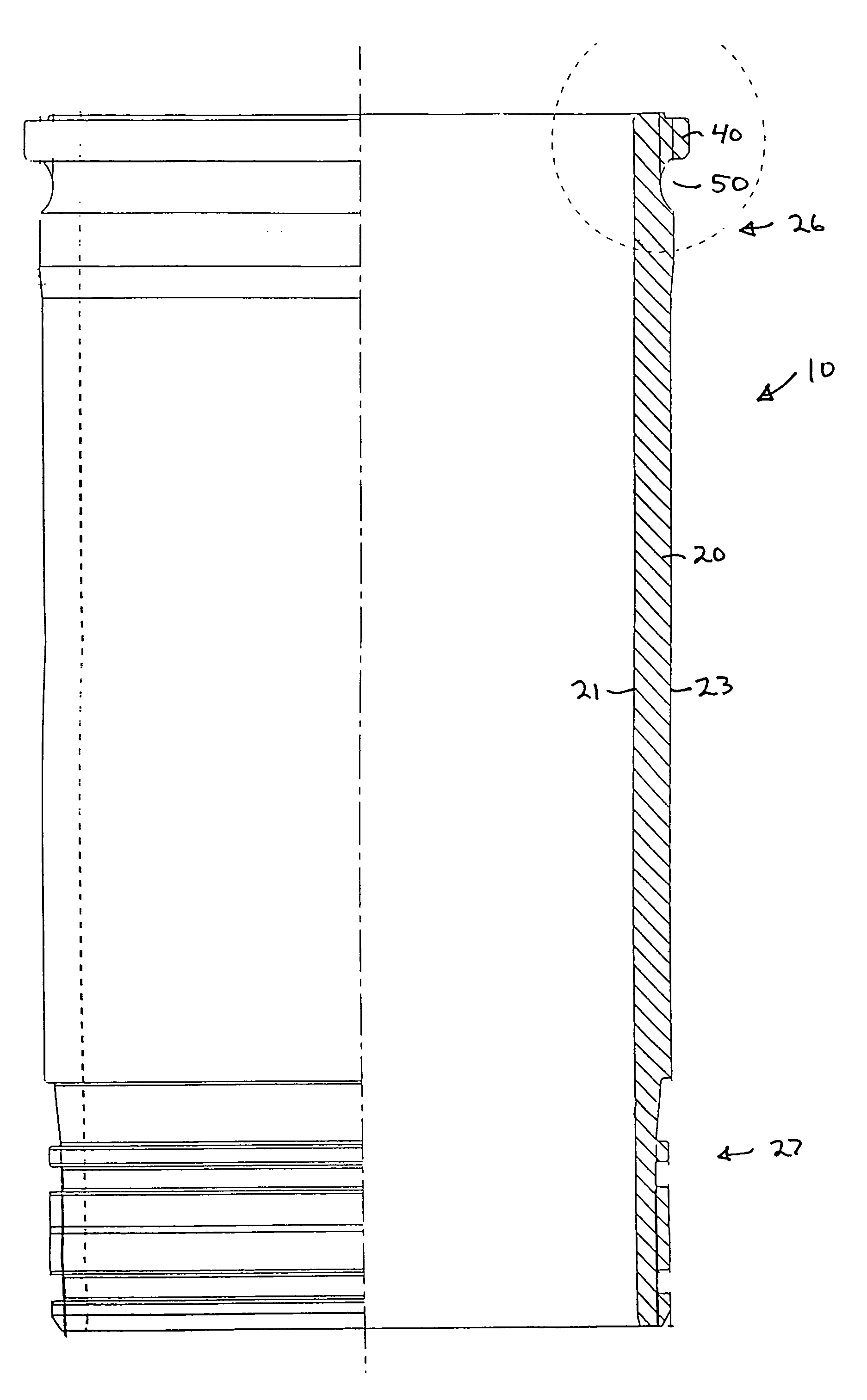

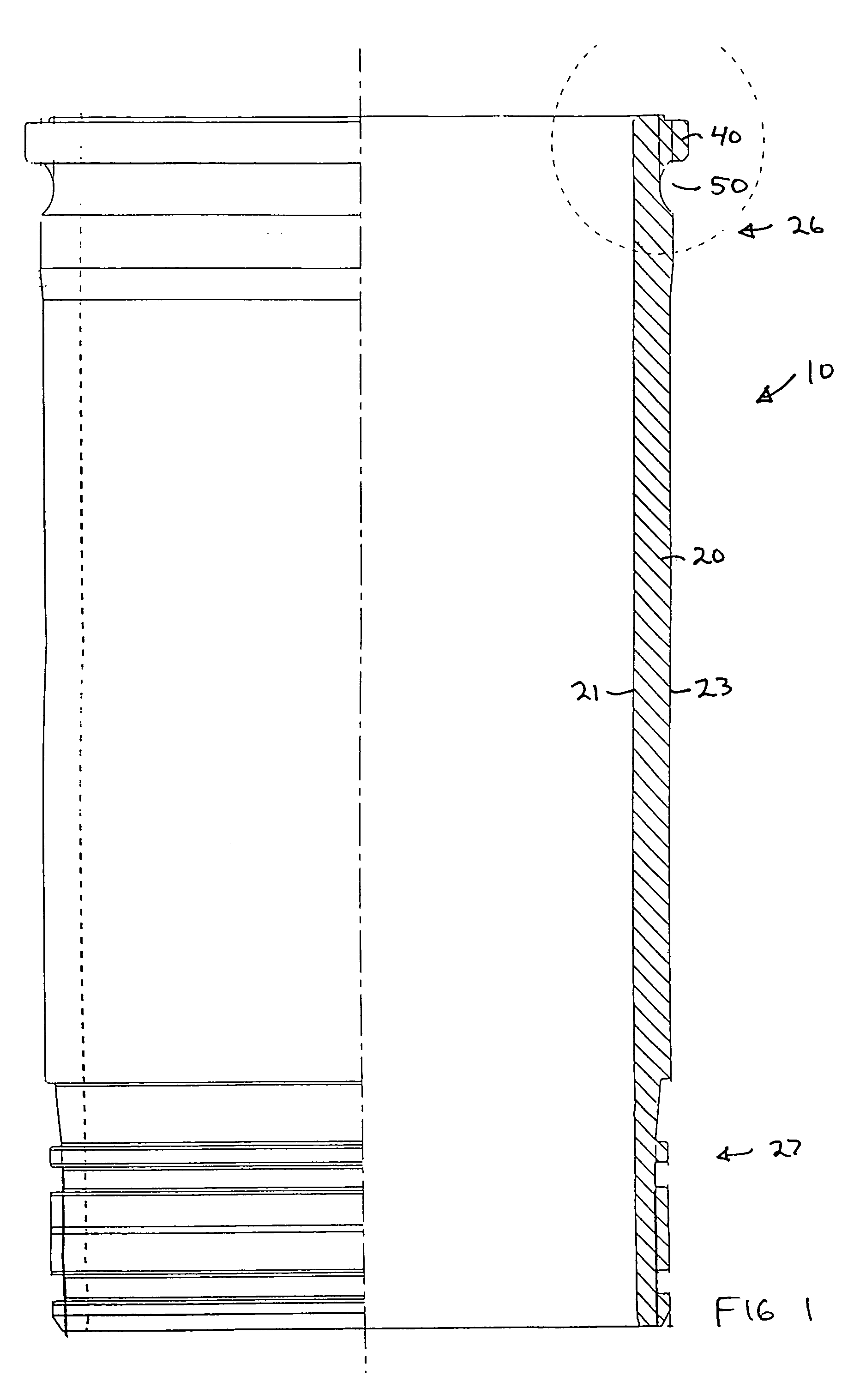

Cylinder liner

InactiveUS20060219192A1Improve heat transferExtend effective volumeCylinder headsMetal-working apparatusEngineeringDiesel engine

A ductile repair cylinder liner for a diesel engine, the cylinder liner having an additional cooling groove with a parabolic varying cross-section machined into the outer surface of the cylinder liner immediately below the radially extending locating flange for the liner.

Owner:IPD CORP

Air duct system for refrigerator

ActiveCN103575023AIncrease effective volumeImprove sealingLighting and heating apparatusCooling fluid circulationFreezing chamberCold store

The invention relates to the field of refrigeration equipment, in particular to an air duct system inside a refrigerator. The air duct system comprises a tank body, a tank linear, an evaporator and a fan. A middle air duct assembly comprises a casing and a freezing air return hose in the casing, and the casing is provided with a freezing air return inlet, a refrigeration air supplying inlet, a freezing chamber water collecting tank, a freezing air return outlet, a freezing chamber water discharging tank, a refrigeration air return opening and a ventilation door chamber. The freezing air return inlet is communicated with a freezing chamber, the refrigeration air supplying inlet is communicated with a freezing air duct, the freezing chamber water collecting tank is located below the evaporator, the freezing air return outlet is communicated with the freezing chamber, the freezing chamber water discharging tank is communicated with the freezing chamber water collecting tank, the refrigeration air return opening is communicated with the refrigeration chamber, the ventilation door chamber is communicated with the refrigeration air supplying inlet, and the freezing air return hose is communicated with the freezing air return inlet and the freezing air return outlet. According to the structure, the tightness of the air duct is effectively improved, a pipeline structure of the tank body is simplified, assembly is simplified, the electric ventilating door can be embedded in a middle air duct, and the space of the refrigeration chamber is not occupied.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

Energy-saving explosion-proof electric heater for pot

InactiveCN101492114ABreak the mode of temperature rise and viscosity dropSolve the many disadvantages that existLarge containersTank wagonsThermal energyEnergy transfer

The invention relates to an energy saving explosion prevention electric heater for pots, which is provided with a heating device which extends into a pot from the outside of the pot and a flow jet and heat transfer device, wherein the flow jet and heat transfer device consists of a flow jet pump and a flow jet pipe which is connected with the flow jet pump and extends into the pot. A liquid inlet of the flow jet pump is communicated with a liquid storage pot through a liquid suction pipe, and the part of the flow jet pipe extending out of the pot is provided with an electromagnetic scale preventing and scale removing device. The heating device consists of a plurality of electric heating components, and is arranged in a lower position in the liquid storage pot parallel to the flow jet pipe, wherein the electric heating components and the part of the flow jet pipe extending out of the pot are coated with an explosion prevention box, and the inside of the explosion prevention box is provided with a heating monitoring device. The energy saving explosion prevention electric heater can prevent the surface of the electric heater from scaling and coking effectively, and has the advantages of high heat energy transfer speed, high electric heat efficiency, long service life, obvious energy saving effect, good explosion prevention safety performance, convenient operation and maintenance, and the like.

Owner:NANYANG YITONG EXPLOSION-PROOF ELECTRIC CO LTD

Dehydration drying method capable of improving bearing capacity of dredged sediment stock dump

InactiveCN102392438AIncrease effective volumeImprove dehydration and drying speedSoil preservationPipingEngineering

The invention relates to a dehydration drying method capable of improving the bearing capacity of a dredged sediment stock dump. In the method, before dredged sediment enters a stock dump, a dehydrating agent and an modifying agent are added in a dredging pipe, a water outlet is arranged at one side of the stock dump, the upper side of the water outlet is abreast with the top of the stock dump, a plurality of parallel drainage ditches are arranged at the bottom of the stock dump at intervals, drain pipes are laid in the drainage ditches and slope towards the water outlet by a certain gradient, holes are formed on the peripheries of the drain pipes at regular intervals, plastic drainage boards are inserted to the bottom from the top of the stock dump, plastic water collecting pipes are laid on the top of the stock dump, then sealing films are laid, and the separated free water flows in the bottom drainage ditches via a sediment precipitation layer, flows through gravel, enters drain pipes and is discharged from the stock dump after being collected by the drain pipes. Compared with the prior art, the dehydration drying method can improve the bearing capacity of a dredge sediment stock dump, and shorten the occupation time of a temporary dredged sediment stock dump land.

Owner:SHANGHAI JIAO TONG UNIV

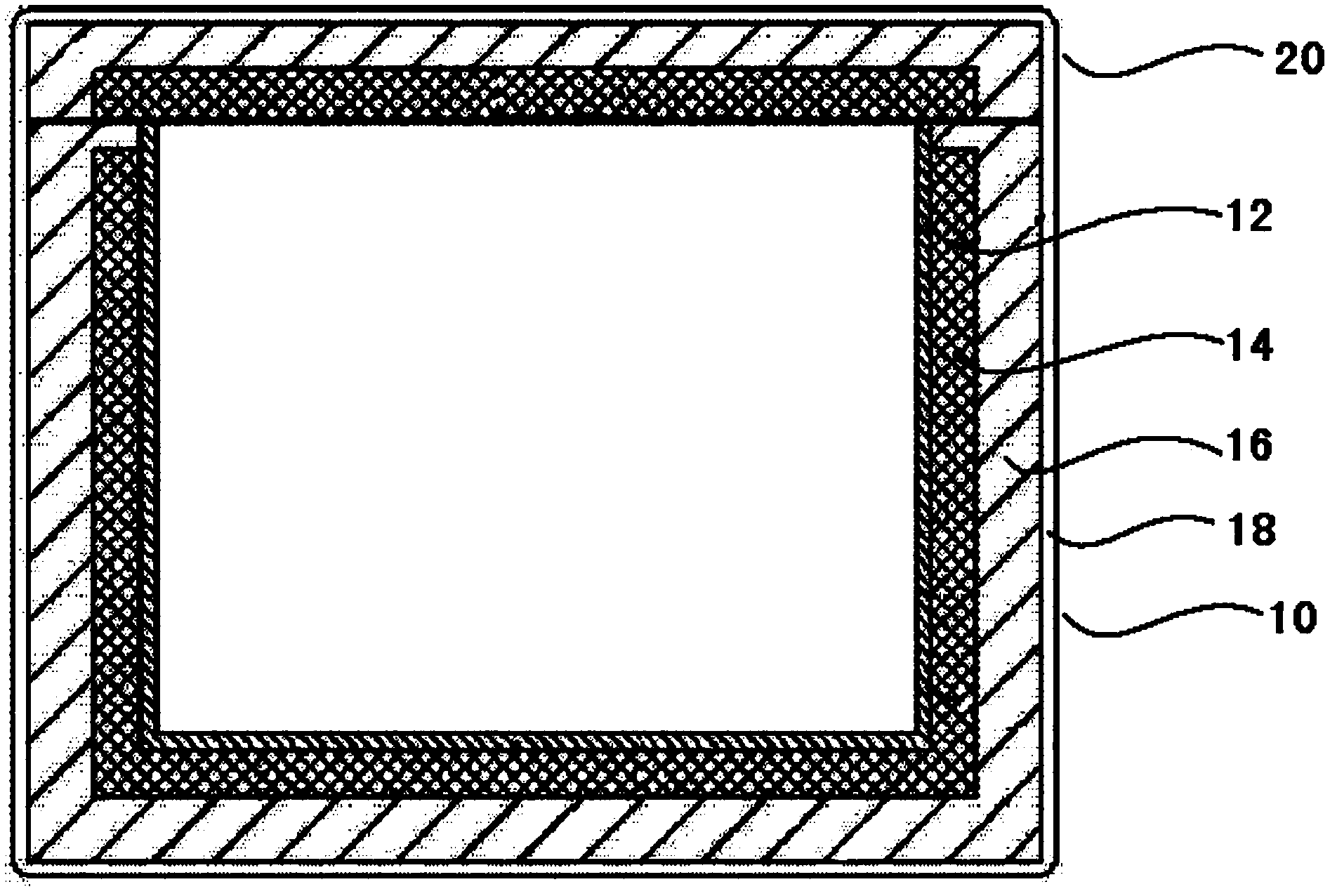

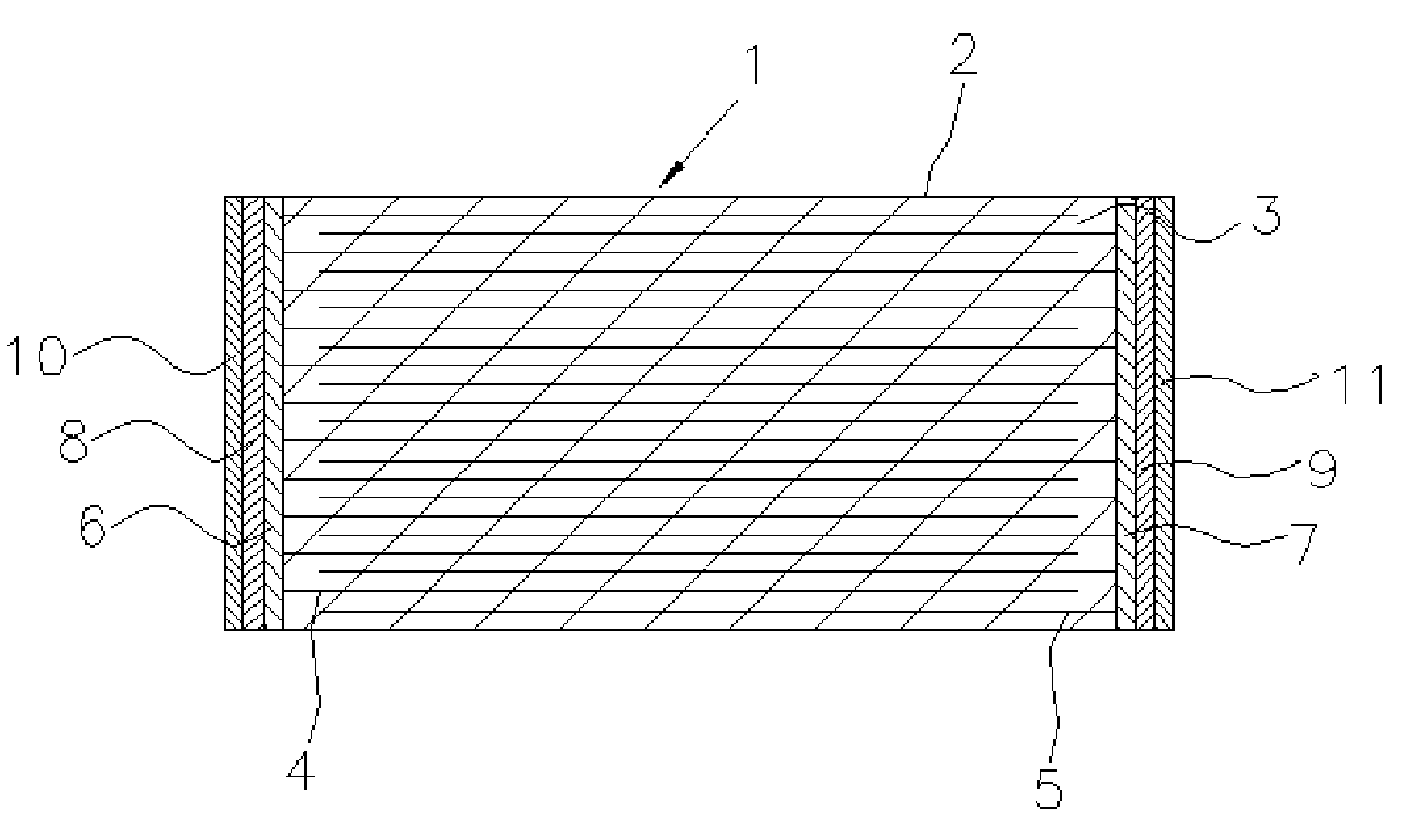

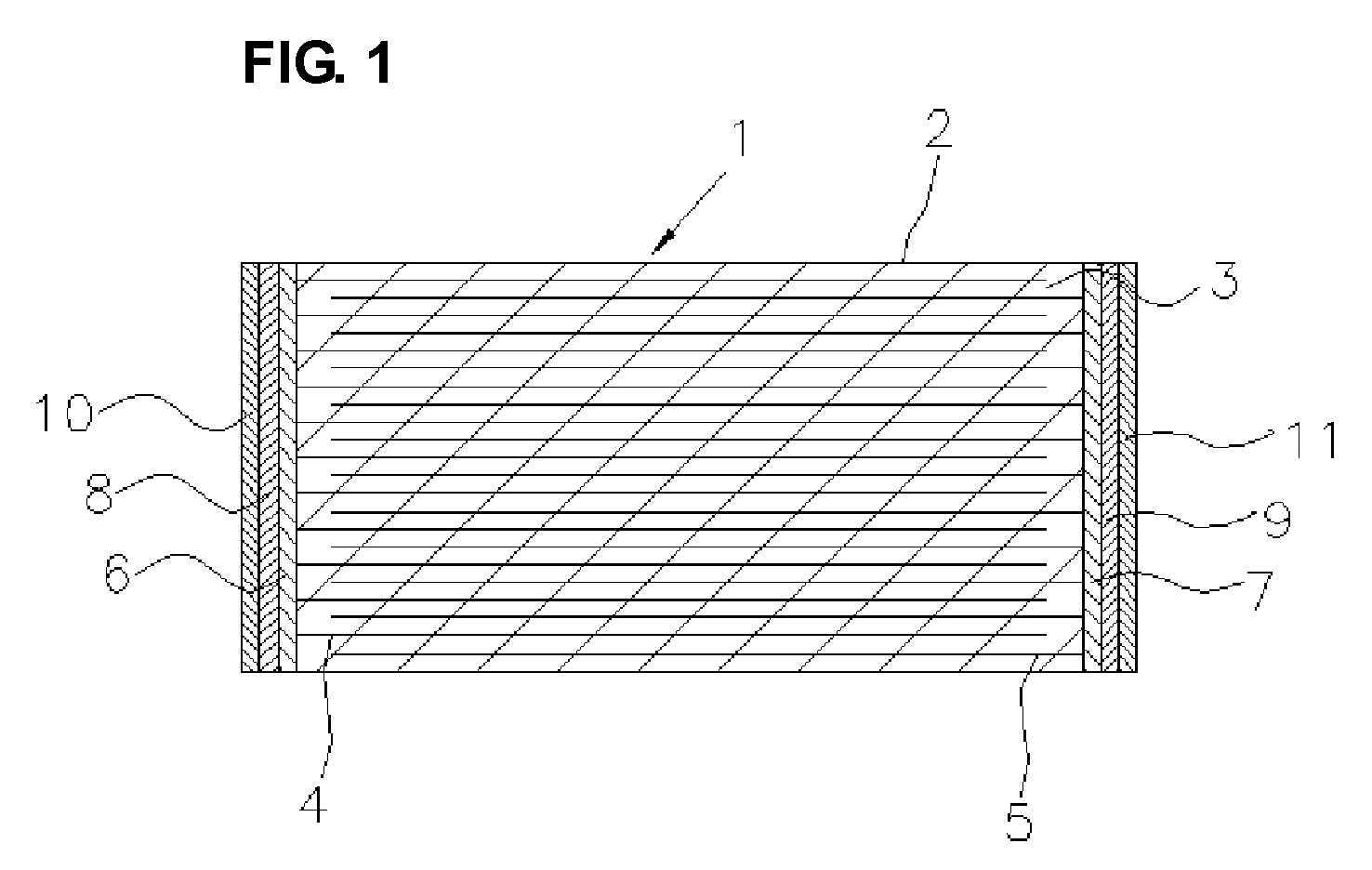

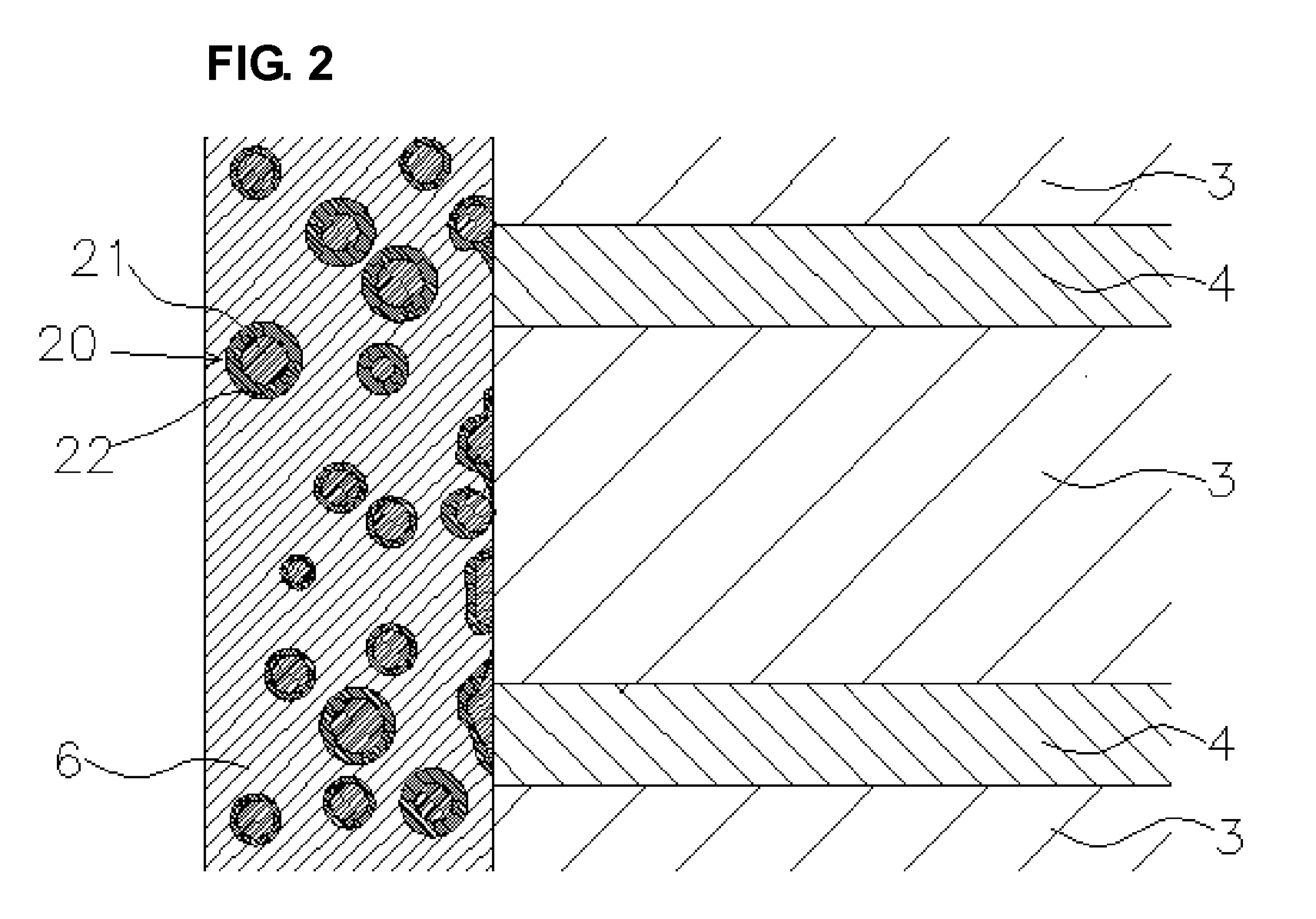

Ceramic electronic component and method for manufacturing the same

ActiveUS20090303655A1Improve reliabilityIncrease effective volumeFixed capacitor electrodesFixed capacitor dielectricMetallurgyGlass particle

A ceramic electronic component includes a ceramic body and a plurality of external electrodes disposed at a surface of the ceramic body. The external electrodes include a plating layer containing glass particles each coated with a metal film. The plating layer is formed by co-deposition of a plating metal and the metal-coated glass particles.

Owner:MURATA MFG CO LTD

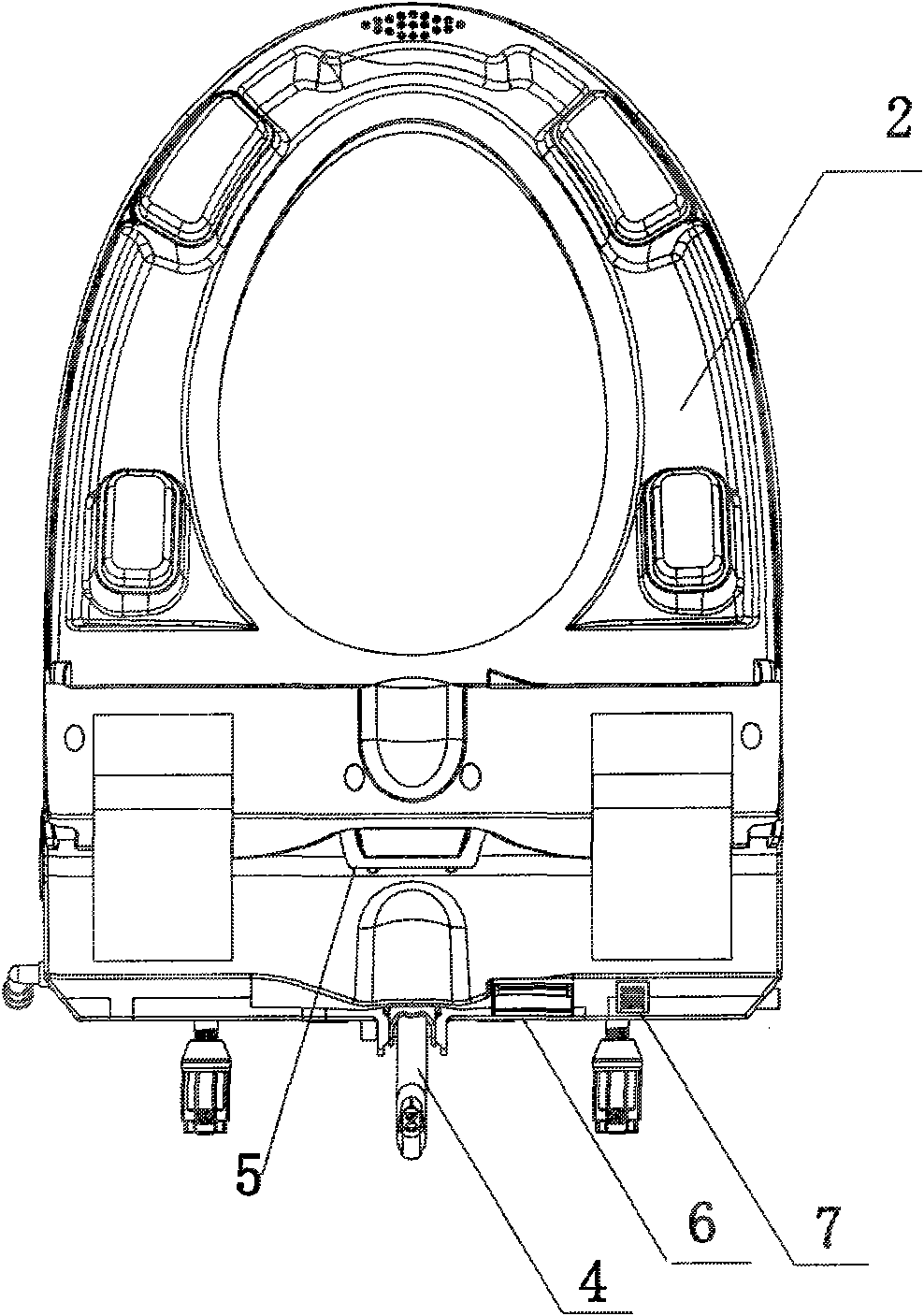

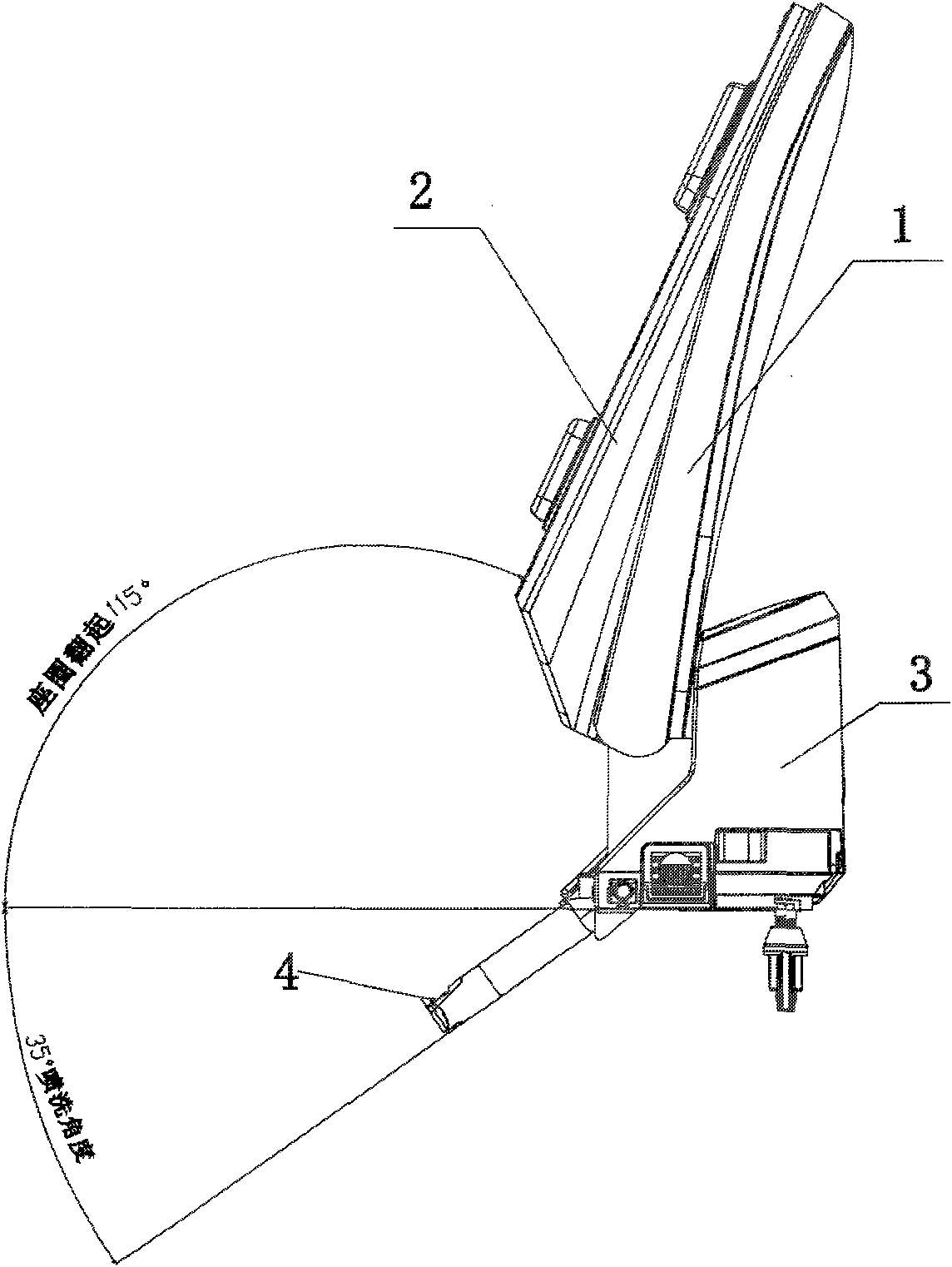

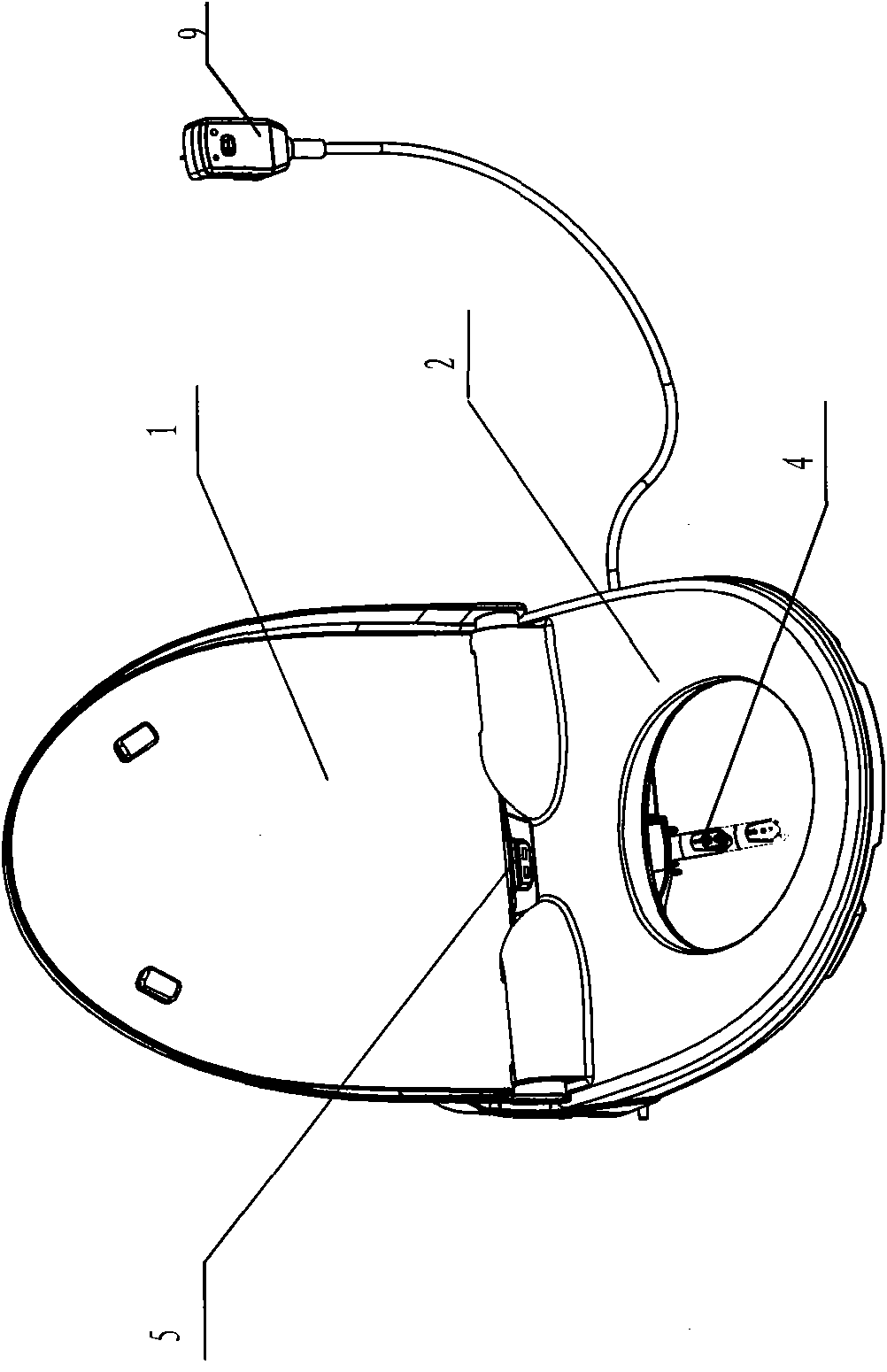

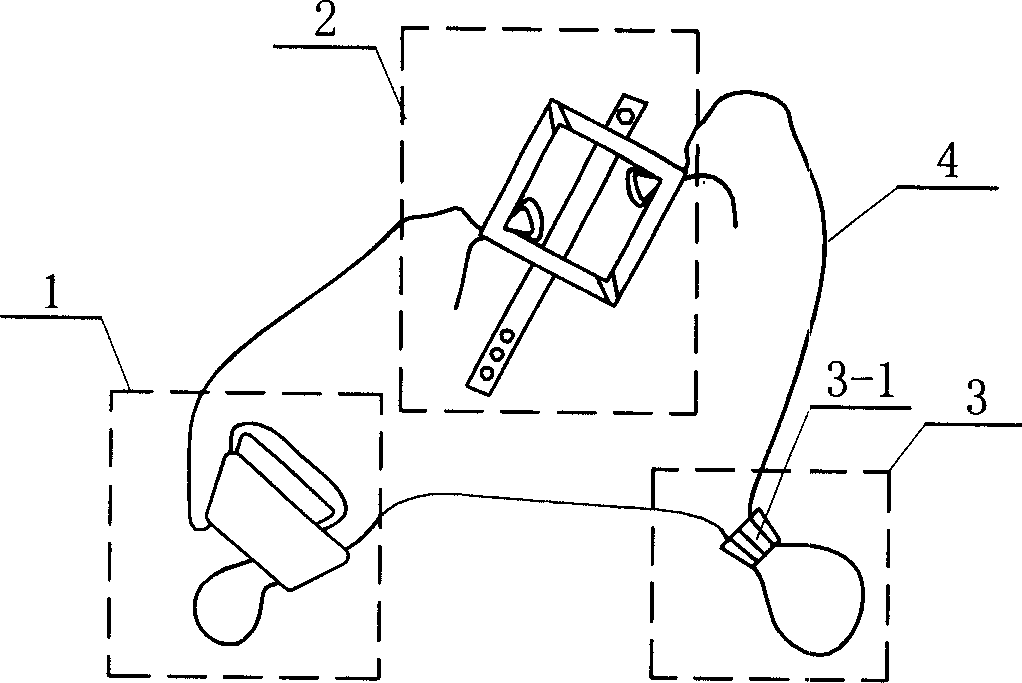

Electronic water closet with clysis function

The invention discloses an electronic water closet, which comprises a main machine (3) as well as a seat ring (2) and a seat cover (1) which are hinged with the main machine (3). A telescopic human body washing device (4) is arranged in the main machine (3) and below the seat ring (2). The human body washing device (4) comprises a sprayer (11), a spraying pipe (21) and a valve (31), wherein the sprayer (11) is provided with a clysis washing nozzle (12a), a hip washing nozzle (12b) and a female washing nozzle (12c). The spraying pipe (21) is provided with a first channel (22a), a second channel (22b) and a third channel (22c) which respectively supplies washing water to the clysis washing nozzle (12a), the hip washing nozzle (12b) and the female washing nozzle (12c). The valve (31) is provided with a valve body (32) and a valve seat (33) used for installing the valve body. The valve body (32) is internally provided with a valve cavity (38) communicated with a water pump (51). The valve cavity is selectively respectively communicated with the first, second and third channels (22a, 22b and 22c). The electronic water closet, by forming high density water column to be injected into and wash the inner 5-10cm of rectum, can effectively wet and soften internal hard object and is beneficial to relaxing the bowels and achieving clysis washing effect.

Owner:HANYU GRP CO LTD

Cylinder liner

InactiveUS7334546B2Improve heat transfer performanceEasy to manufactureCylinder headsMetal-working apparatusDiesel engineFlange

A ductile repair cylinder liner for a diesel engine, the cylinder liner having an additional cooling groove with a parabolic varying cross-section machined into the outer surface of the cylinder liner immediately below the radially extending locating flange for the liner.

Owner:IPD CORP

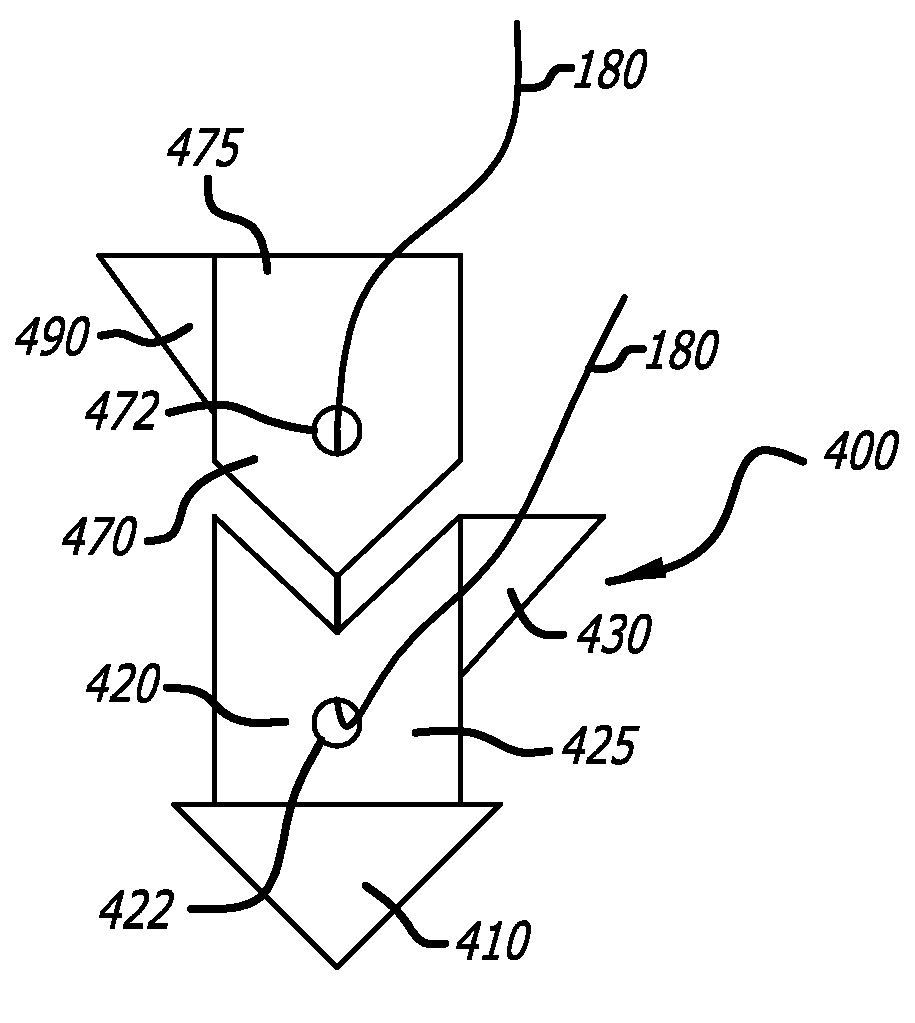

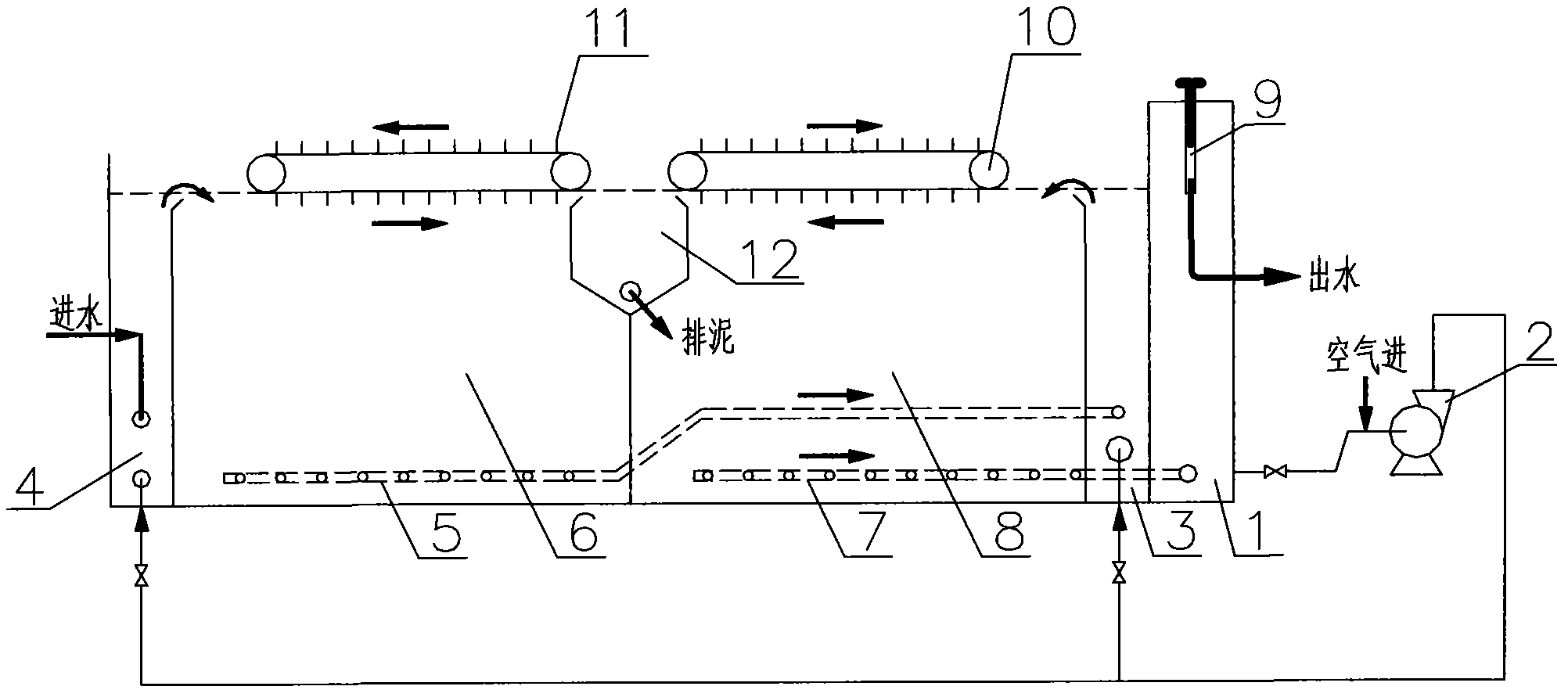

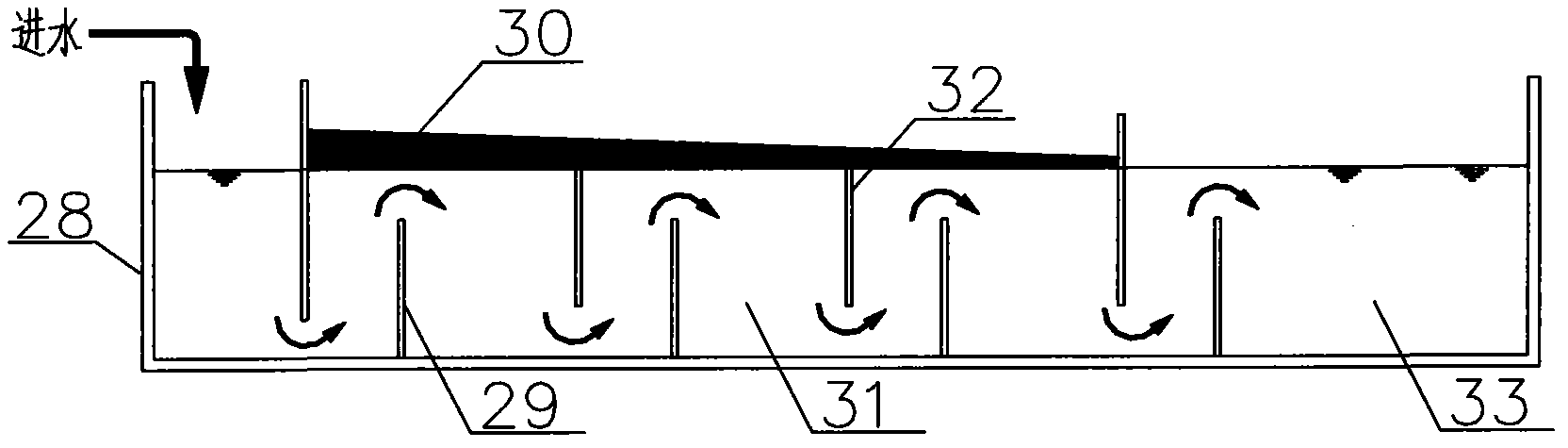

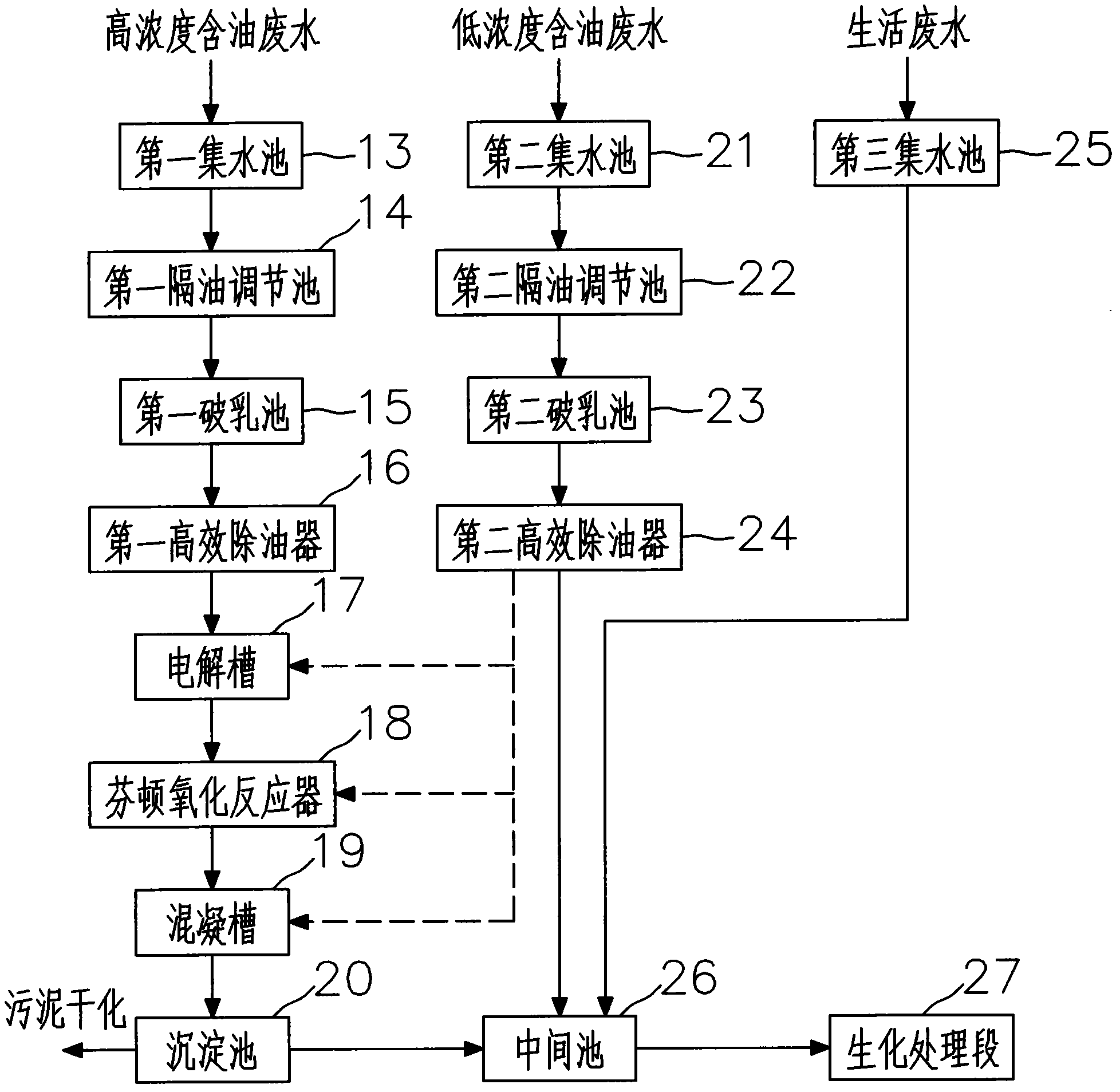

Oily wastewater pretreatment system and high-efficiency oil eliminator arranged in system

ActiveCN102701483APrevent emulsification from reducing the degreasing degree of purificationSimple structureFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationSludge

The invention belongs to the technical field of wastewater treatment and particularly relates to a high-efficiency oil eliminator and an oily wastewater pretreatment system with the high-efficiency oil eliminator. The high-efficiency oil eliminator comprises at least two stages of air floatation treatment devices. An air floatation treatment device at each stage is communicated with an adjacent air floatation treatment device along a water flowing direction. A sludge hopper is arranged on the side of each air floatation treatment device. A sludge scraper which is used for scraping floating sludge in the air flotation treatment device to the sludge hopper is arranged on the upper side of the air flotation treatment device at each stage. The oil eliminator additionally comprises an air dissolving water pump which is used for delivering air dissolving water to the air flotation treatment device through a water delivery pipe. The oily wastewater pretreatment system consists of a high-concentration oily wastewater pretreatment section and a low-concentration oily wastewater pretreatment section. The oily wastewater pretreatment system has the advantages that since a high-concentration and low-concentration oily wastewater quality-based treatment process route is adopted, the operating cost is low and the removal efficiency or degradation efficiency of pollutants is high; and the system is also suitable for pretreatment of all other kinds of high-concentration oily wastewater which is difficult to degrade, or is matched with process units.

Owner:安徽南风环境工程技术有限公司

Three return journey barrel type drying machines

InactiveCN101216241AAvoid stress deformationAvoid axial forceDrying chambers/containersDrying machines with non-progressive movementsHelical lineEngineering

An improved three-pass cylinder drying machine comprises a machine body composed of a bracket, a sealed tank and a cylinder body, and a driving device, a supporting device and a controller, wherein the axial line of the cylinder body of the machine body is parallel to the horizontal surface, an inner cylinder and an outer cylinder that are concentrically arranged are assembled together in a staggered way to form the cylinder body, the formed cavities are used as three drying and precipitation units, the adjacent wallboards of the inner, middle and outer cylinders are connected and positioned via regulating and supporting plates and reinforced buffer plates, a heat insulating cover is disposed at the outer periphery of the wallboard of the outer cylinder, three material homogenizing and spreading machines are respectively disposed at the inner surfaces of the inner, middle and outer wallboards in a screw propulsion way and has reversed helical lines, and gears at the outer periphery of the machine body are aligned with the center of gravity of the cylinder. The inventive three-pass cylinder drying machine effectively solves the shortcomings of the conventional cylinder drying machine, including high deformation and misplacement liability and high axial dislocation liability; and has the advantages of reasonable structural design, stable performance, large precipitation range for one time, high thermal efficiency, saved energy consumptionand wide application range.

Owner:沈阳清井环保机械工程有限公司

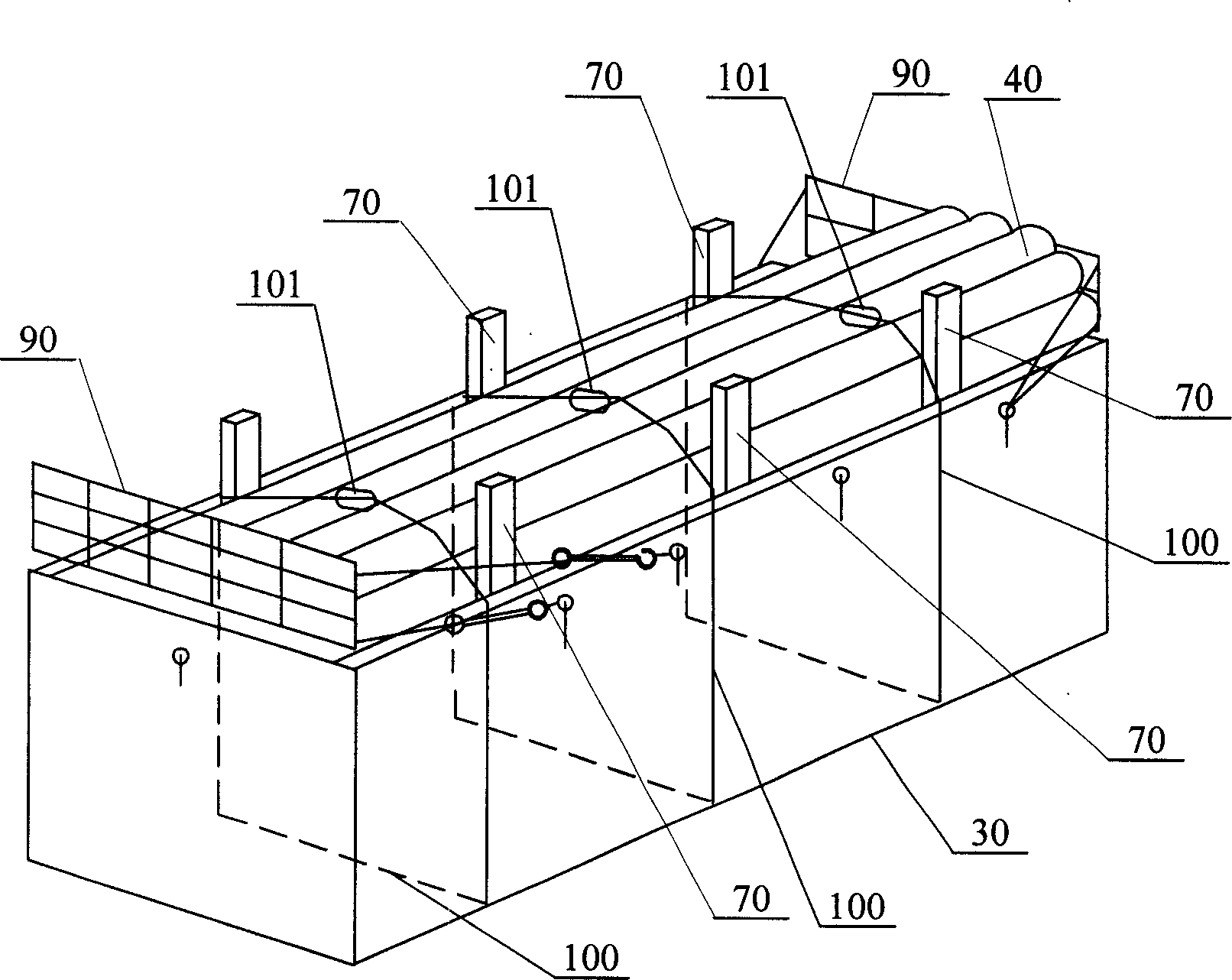

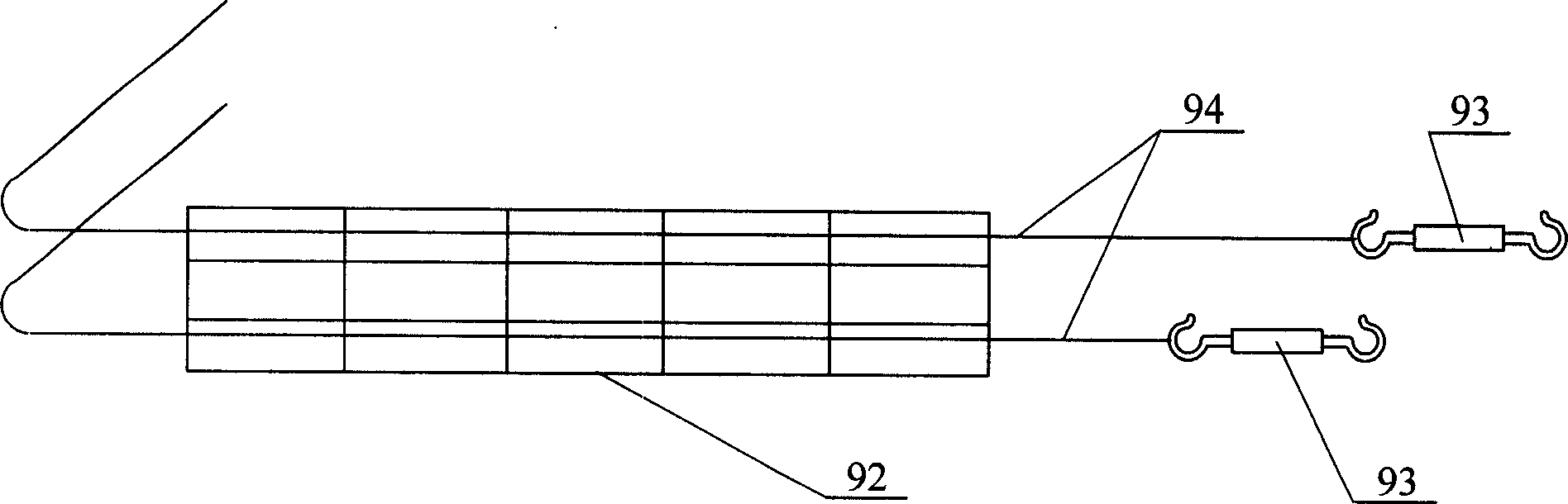

Rectangular materials transporting and fastening system

InactiveCN1817707AIncrease profitEliminate hidden dangers of transportation insecurityVehicle to carry long loadsWagons/vansEngineeringTruck

A reinforcing system for transporting long object features that the vertical posts are symmetrically fixed to the inner surfaces of both side board of truck, two end nets are arranged on both ends of long object, and the steel cables are tied between symmetrical posts for stabilizing the long object.

Owner:崔波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com