Patents

Literature

42results about How to "Improve heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

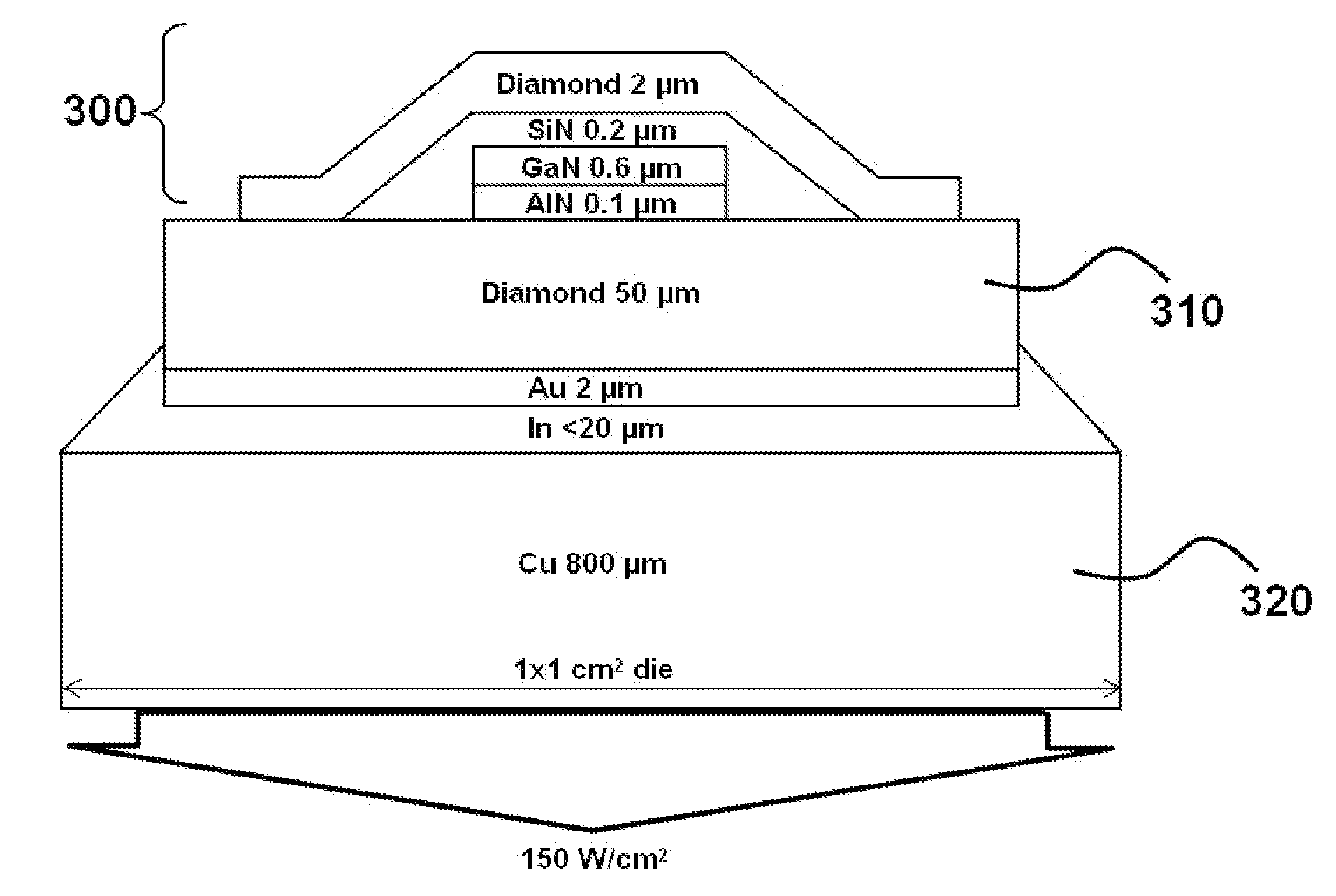

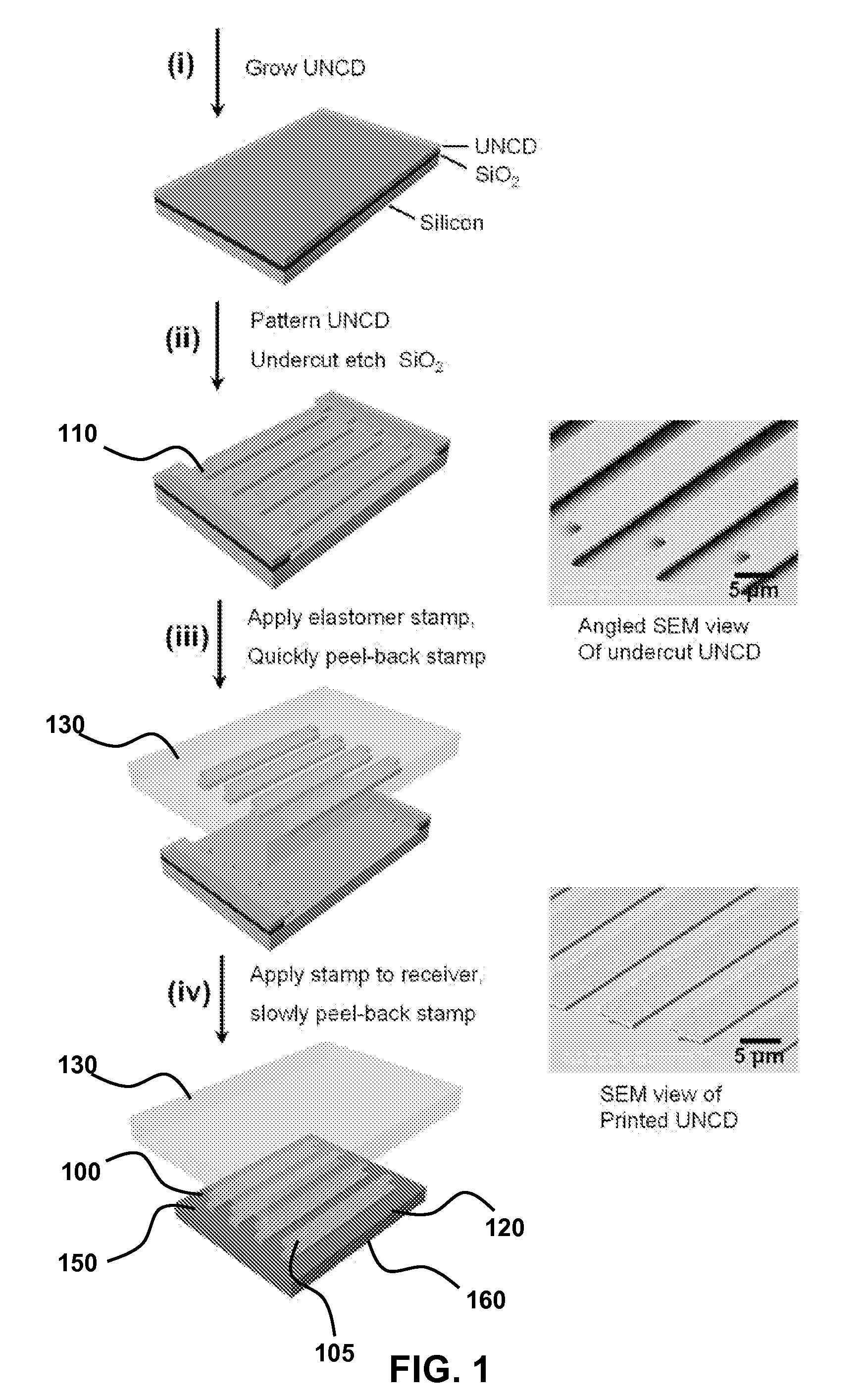

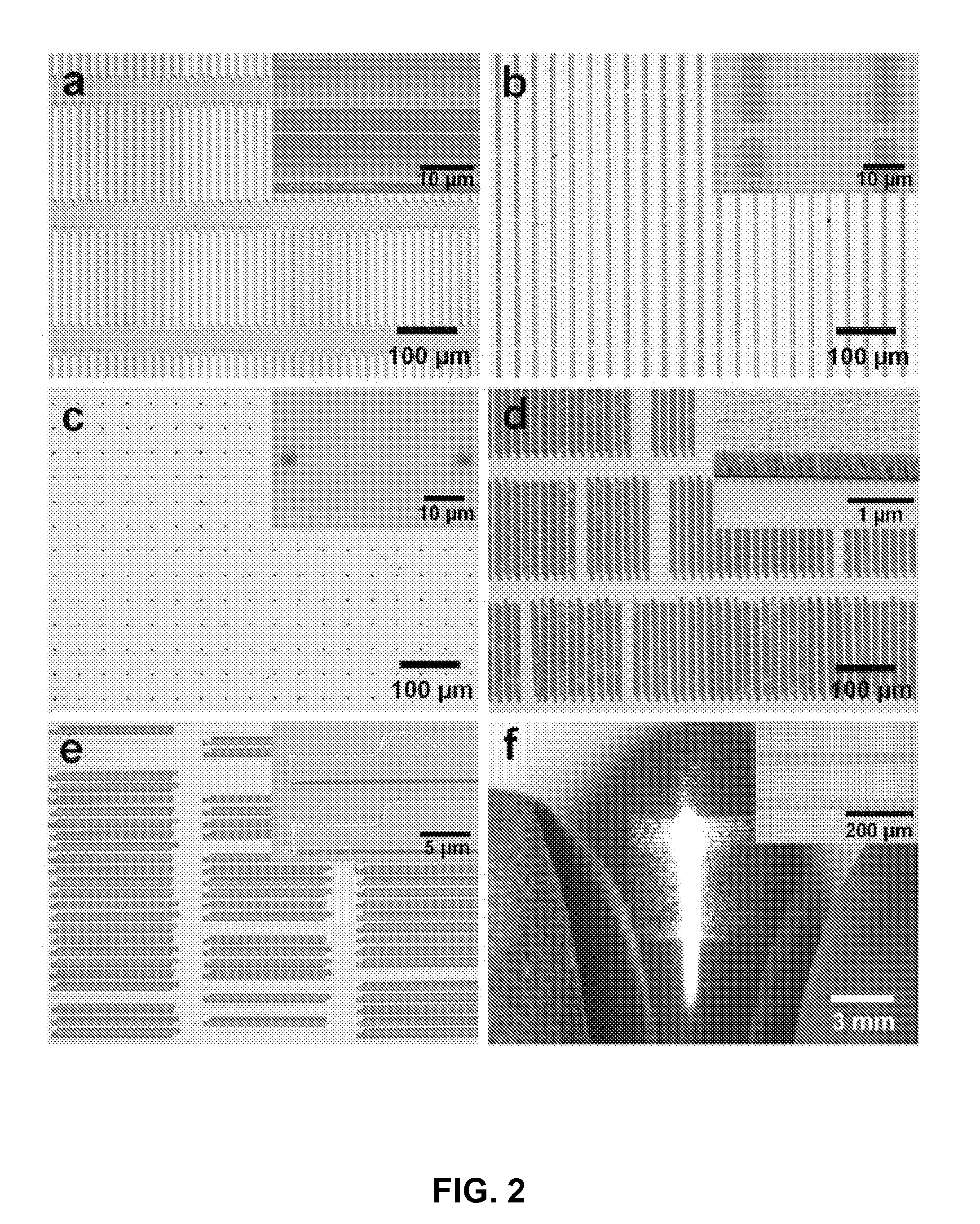

Printable, Flexible and Stretchable Diamond for Thermal Management

InactiveUS20100052112A1Improve heat transferReduce amountSemiconductor/solid-state device detailsSolid-state devicesFlexible electronicsHeat sink

Various heat-sinked components and methods of making heat-sinked components are disclosed where diamond in thermal contact with one or more heat-generating components are capable of dissipating heat, thereby providing thermally-regulated components. Thermally conductive diamond is provided in patterns capable of providing efficient and maximum heat transfer away from components that may be susceptible to damage by elevated temperatures. The devices and methods are used to cool flexible electronics, integrated circuits and other complex electronics that tend to generate significant heat. Also provided are methods of making printable diamond patterns that can be used in a range of devices and device components.

Owner:JOHN CRANE INC +2

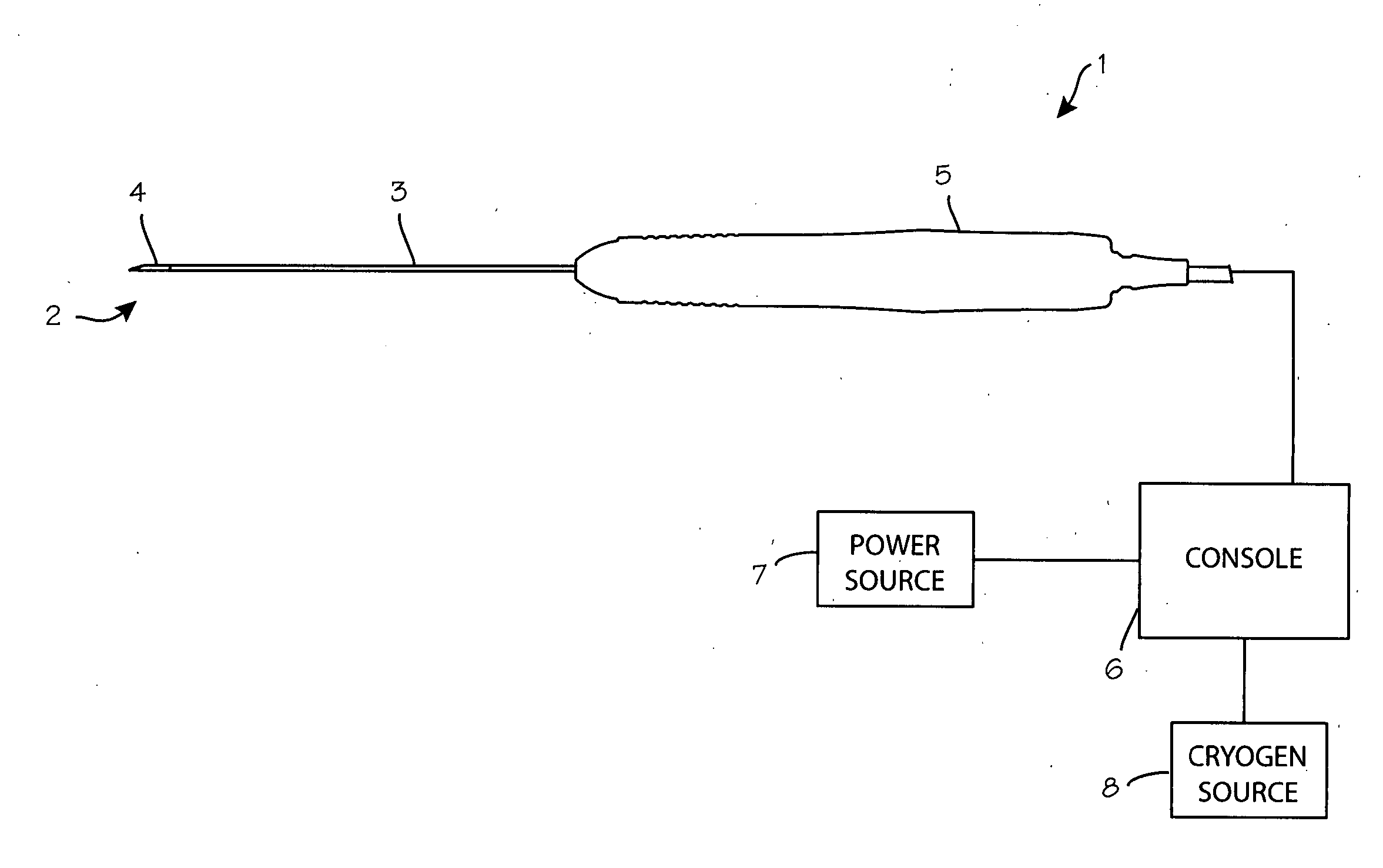

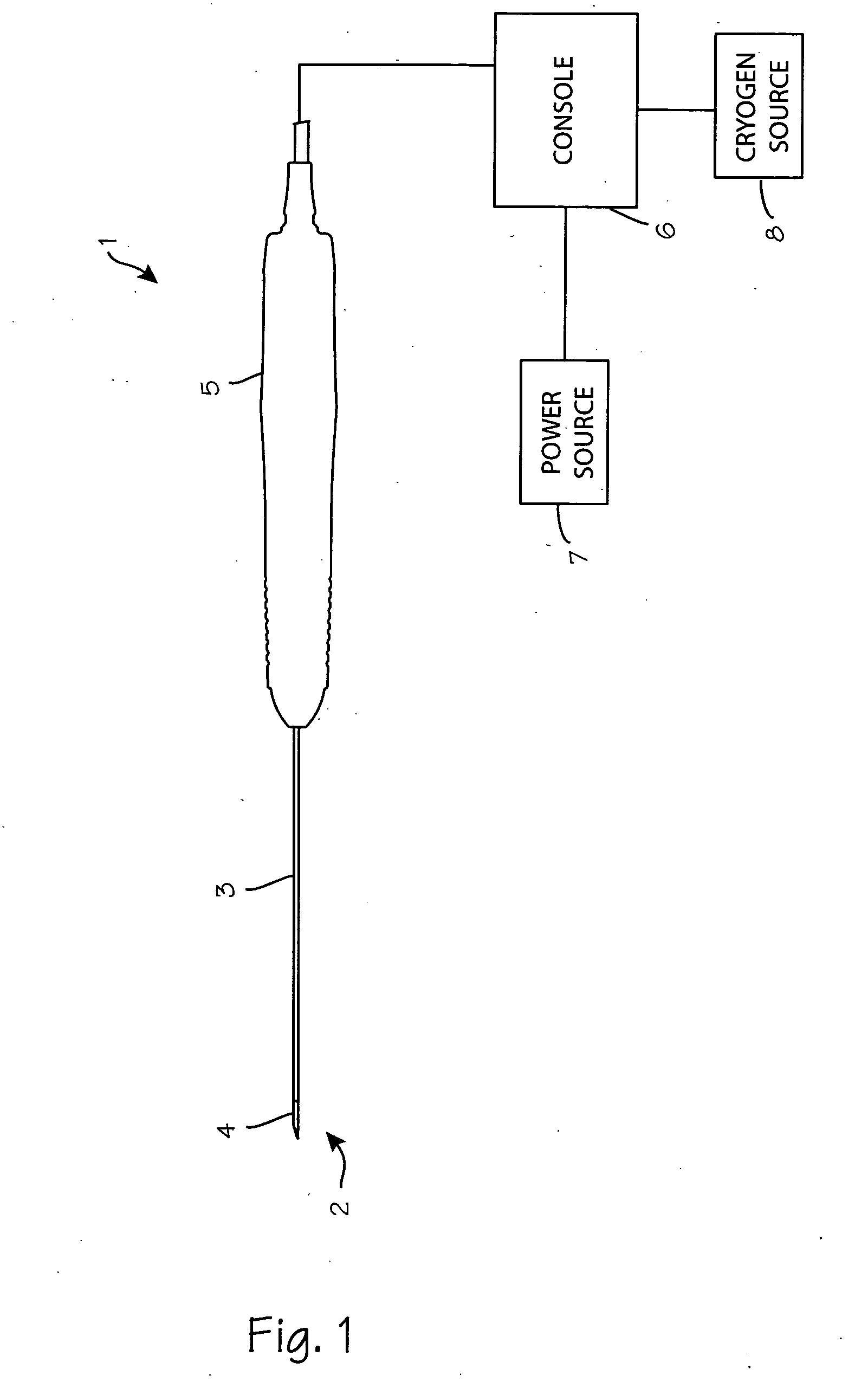

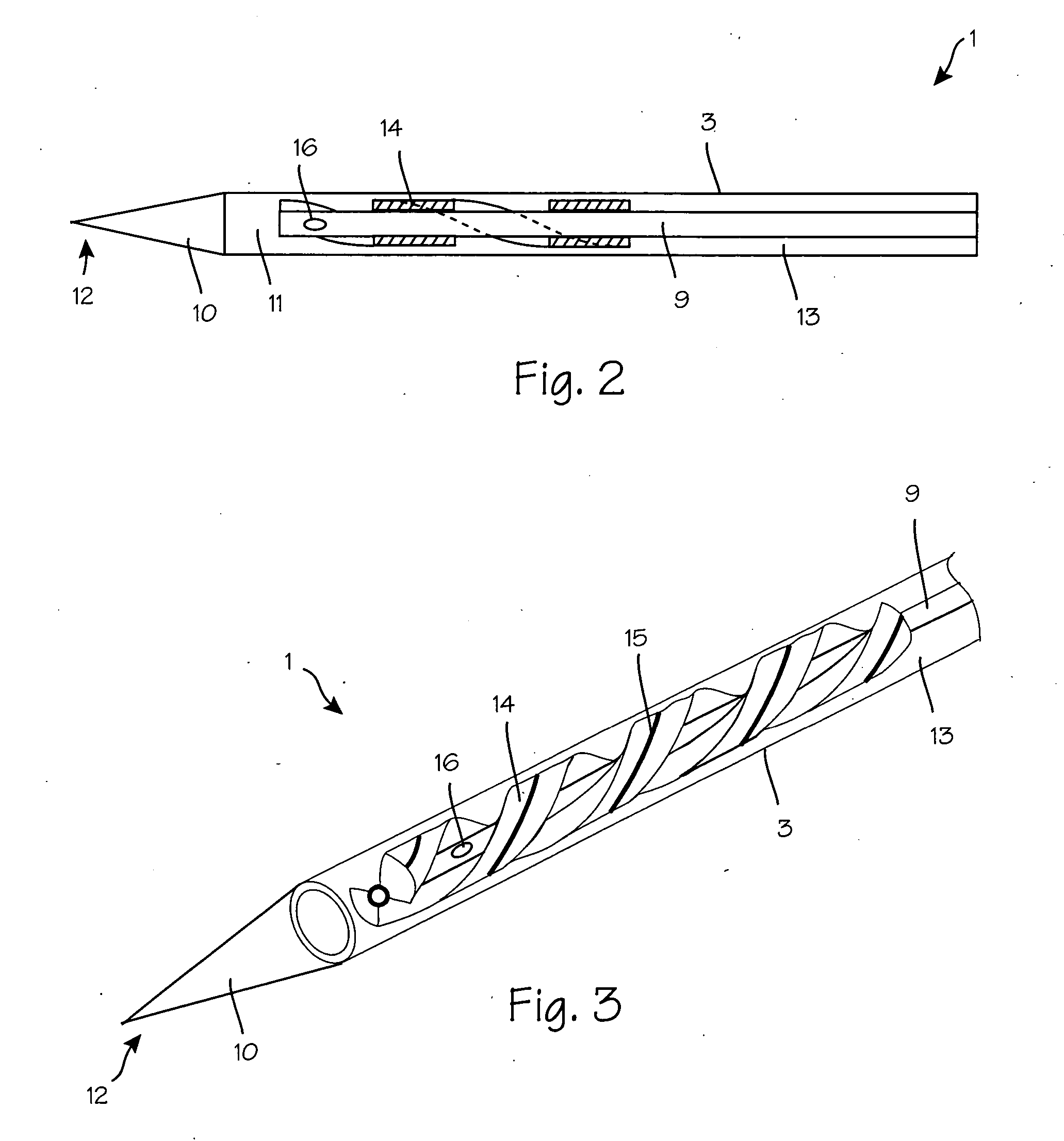

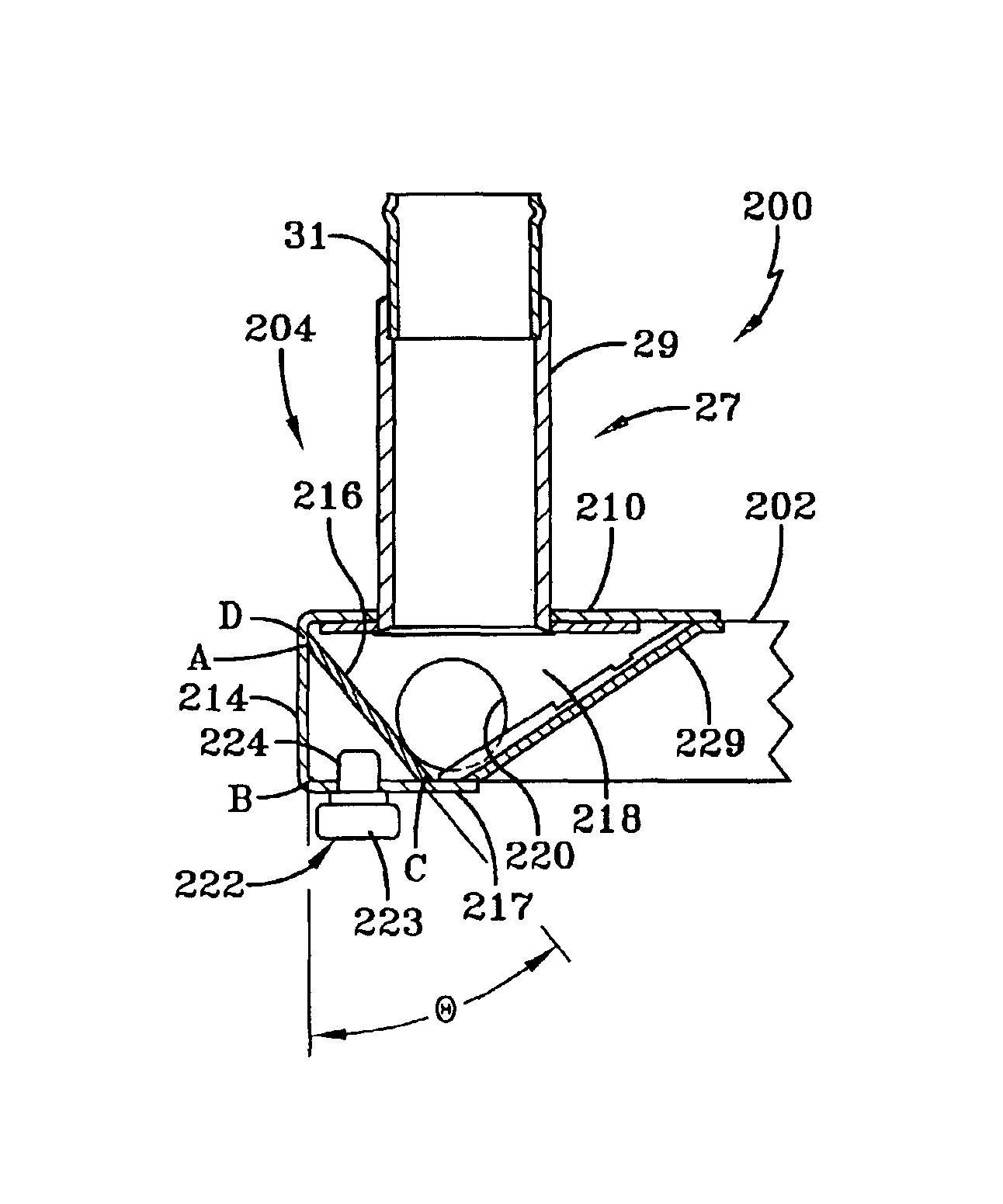

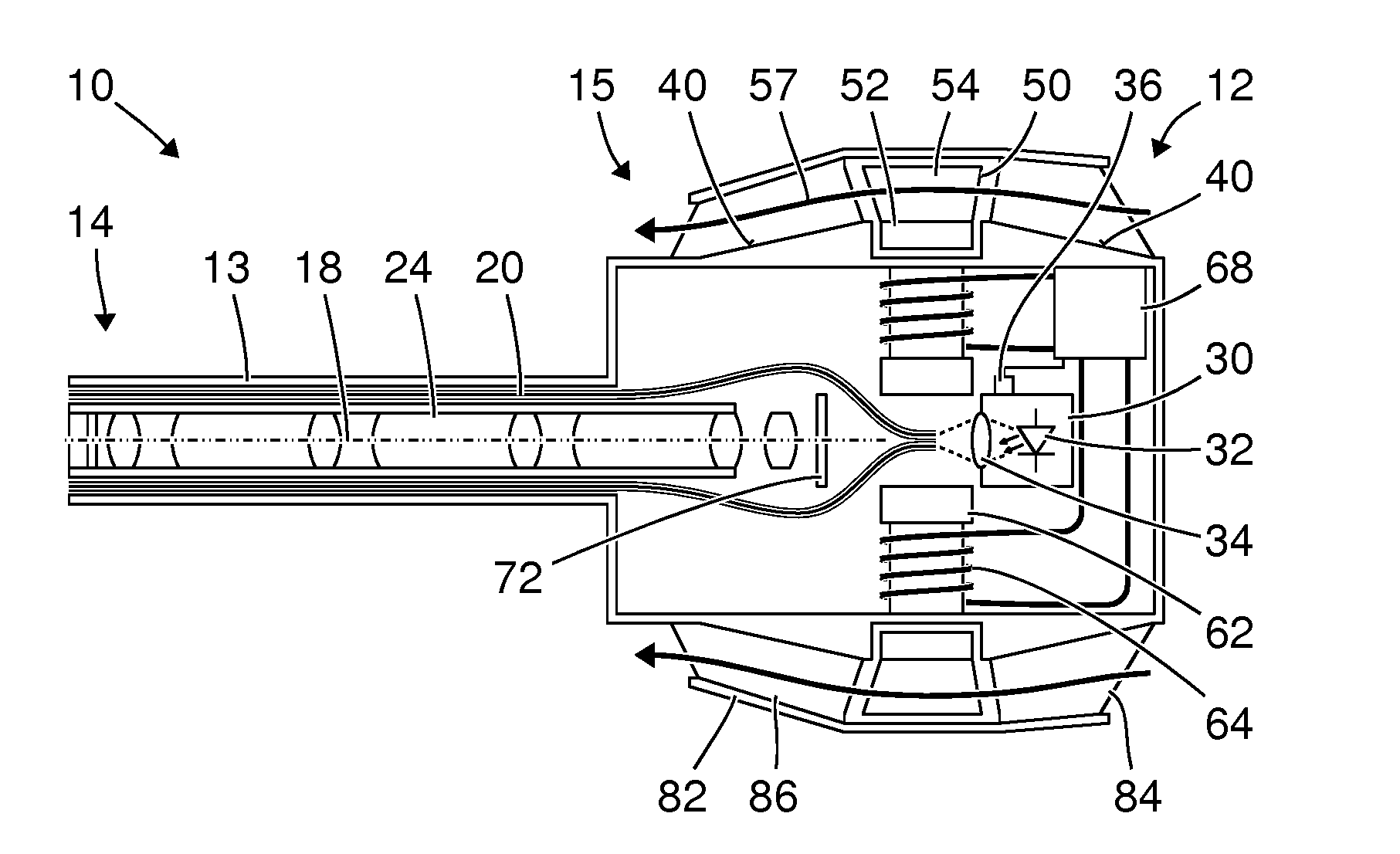

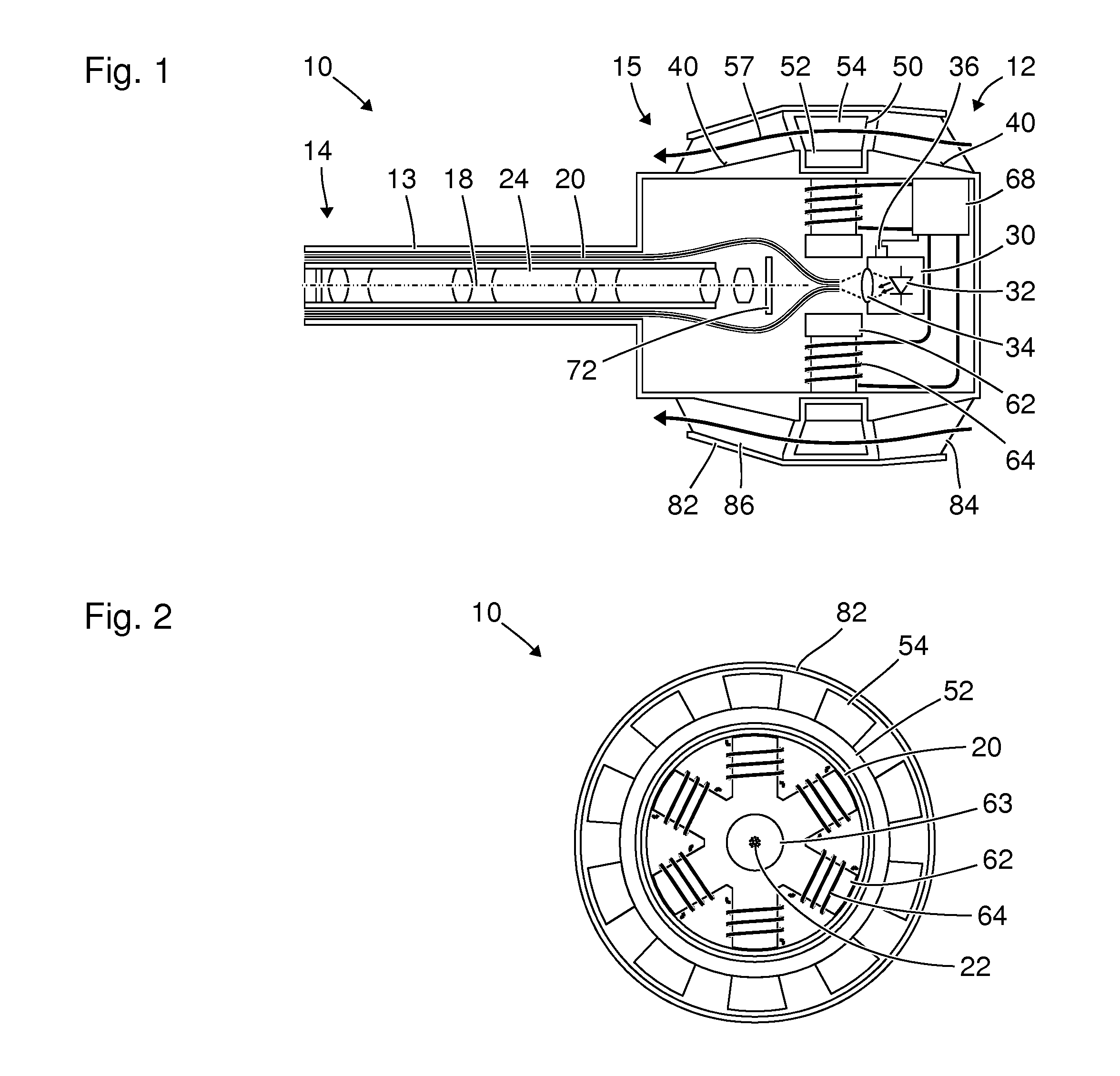

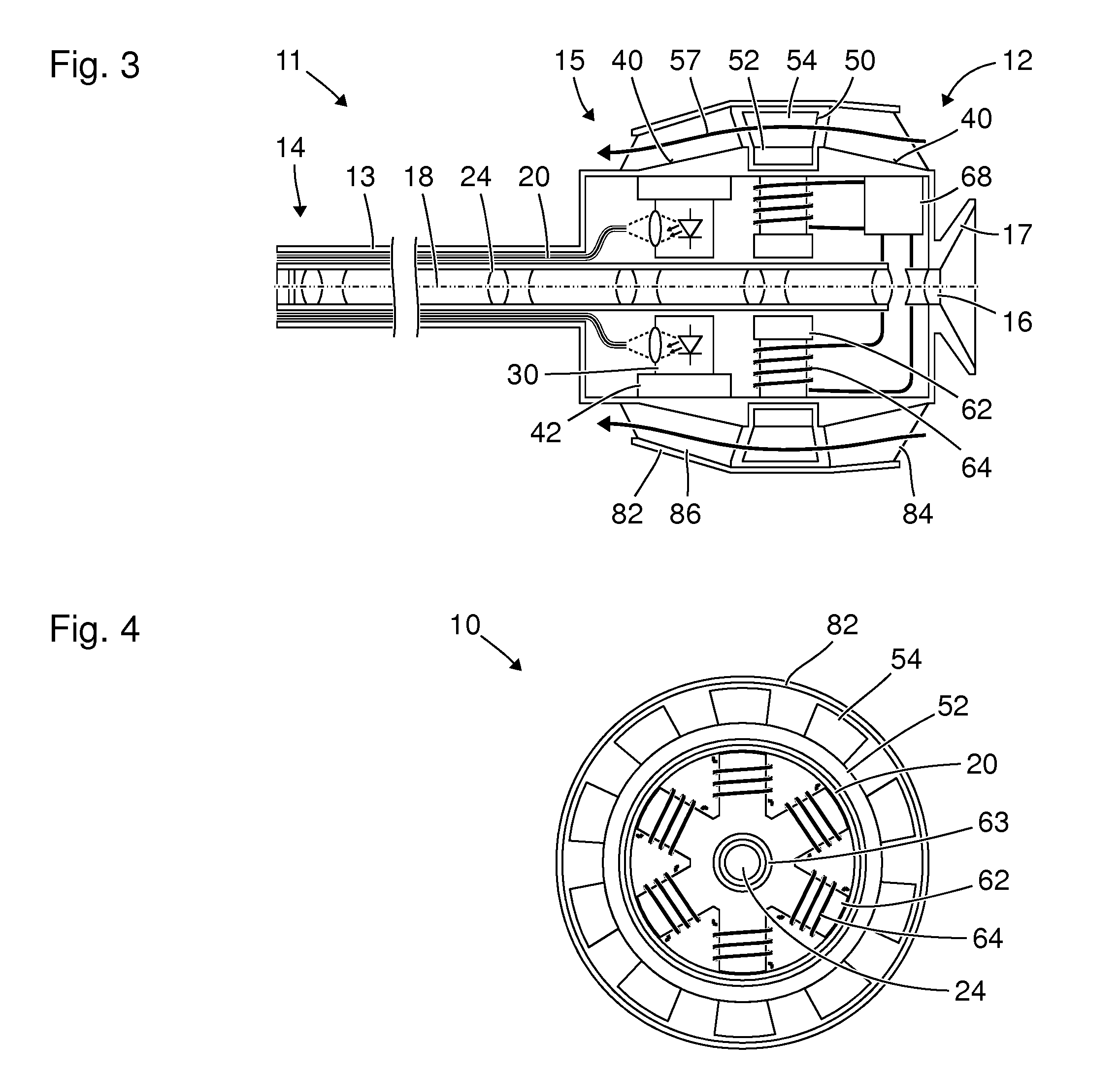

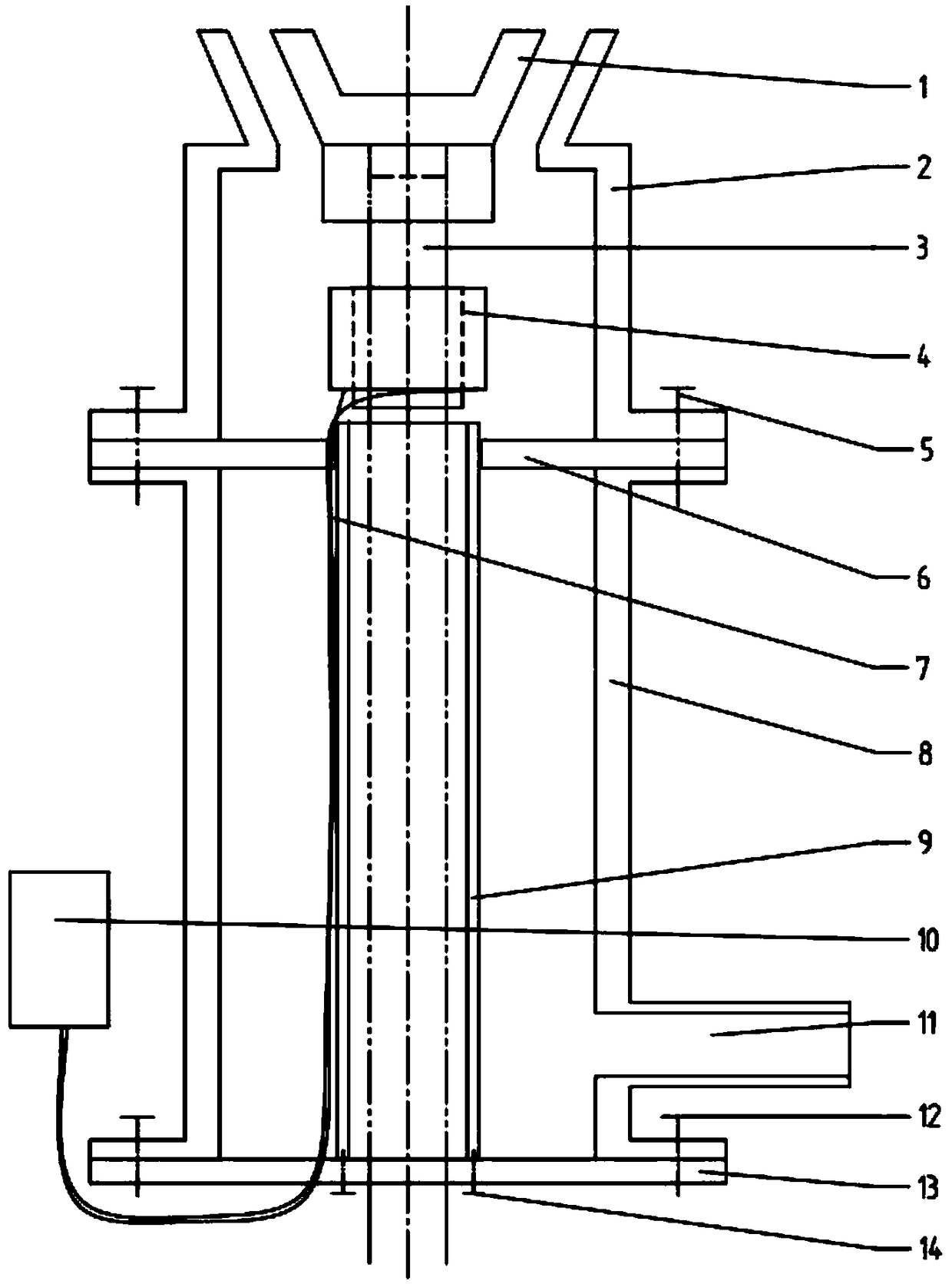

Cryoprobe for low pressure systems

InactiveUS20070149959A1Improve heat transferRapid heat transferSurgical instruments for coolingEngineeringHeating element

A cryoprobe for use in cryosurgery and other applications comprising a rigid outer tube, an inner coolant inlet tube a short rigid penetrating segment extending distally from the distal end of the outer tube and a helical-shaped baffle having a heating element disposed about the outer surface of the inlet tube. The baffle is adapted to produce turbulent fluid flow improving heat transfer and is able to warm target tissue during rapid freezing and thawing cycles.

Owner:SANARUS TECHNOLOGIES

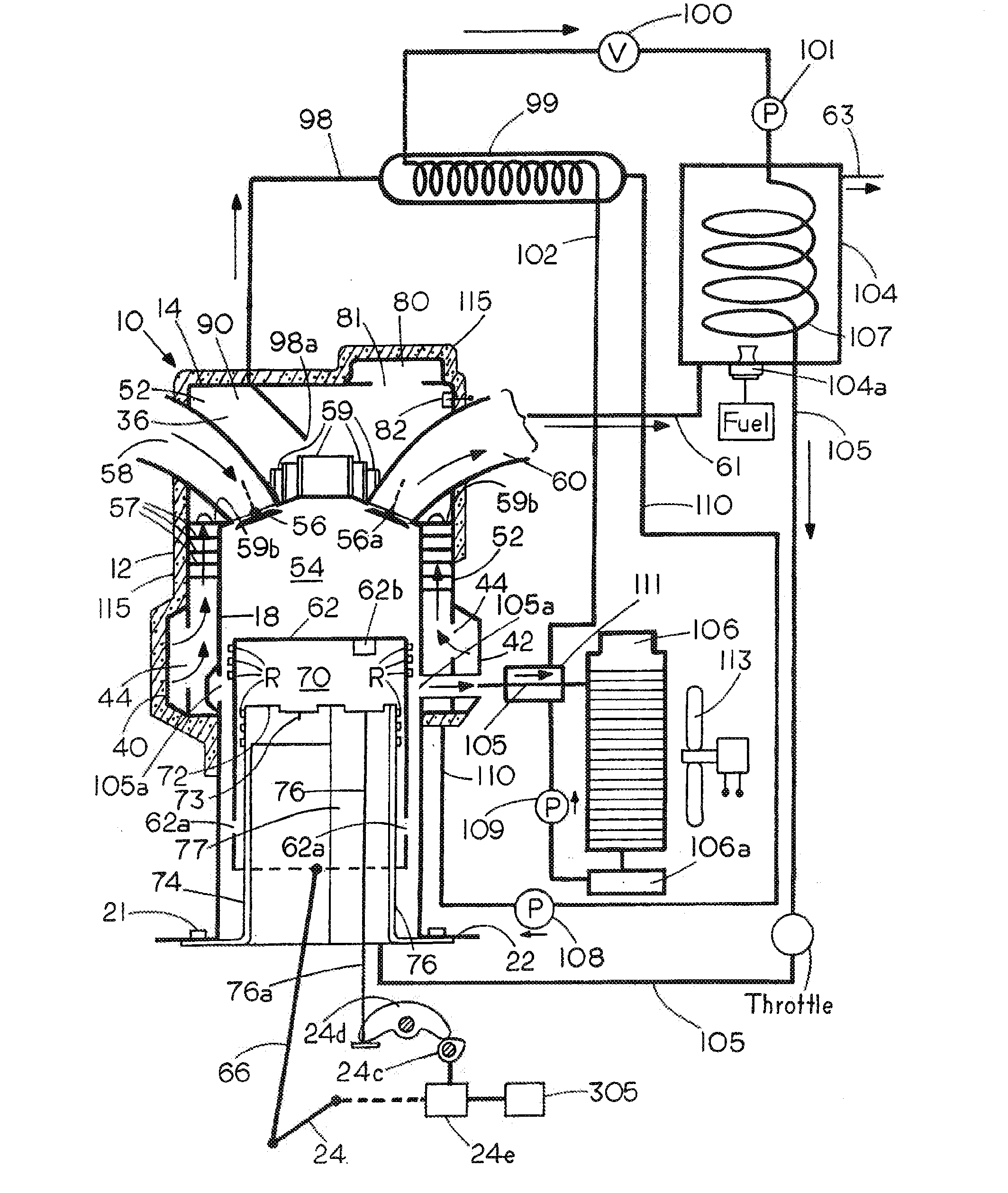

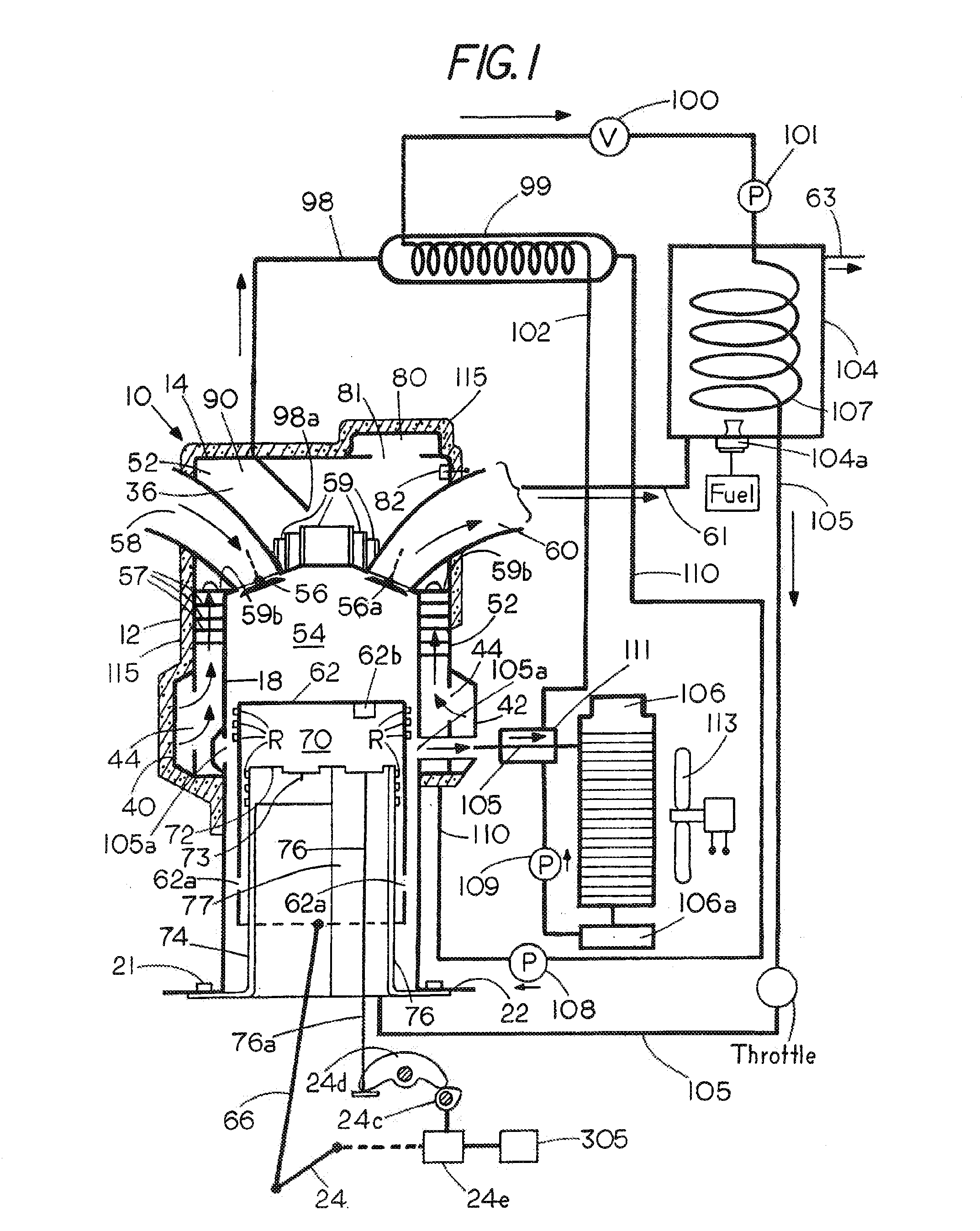

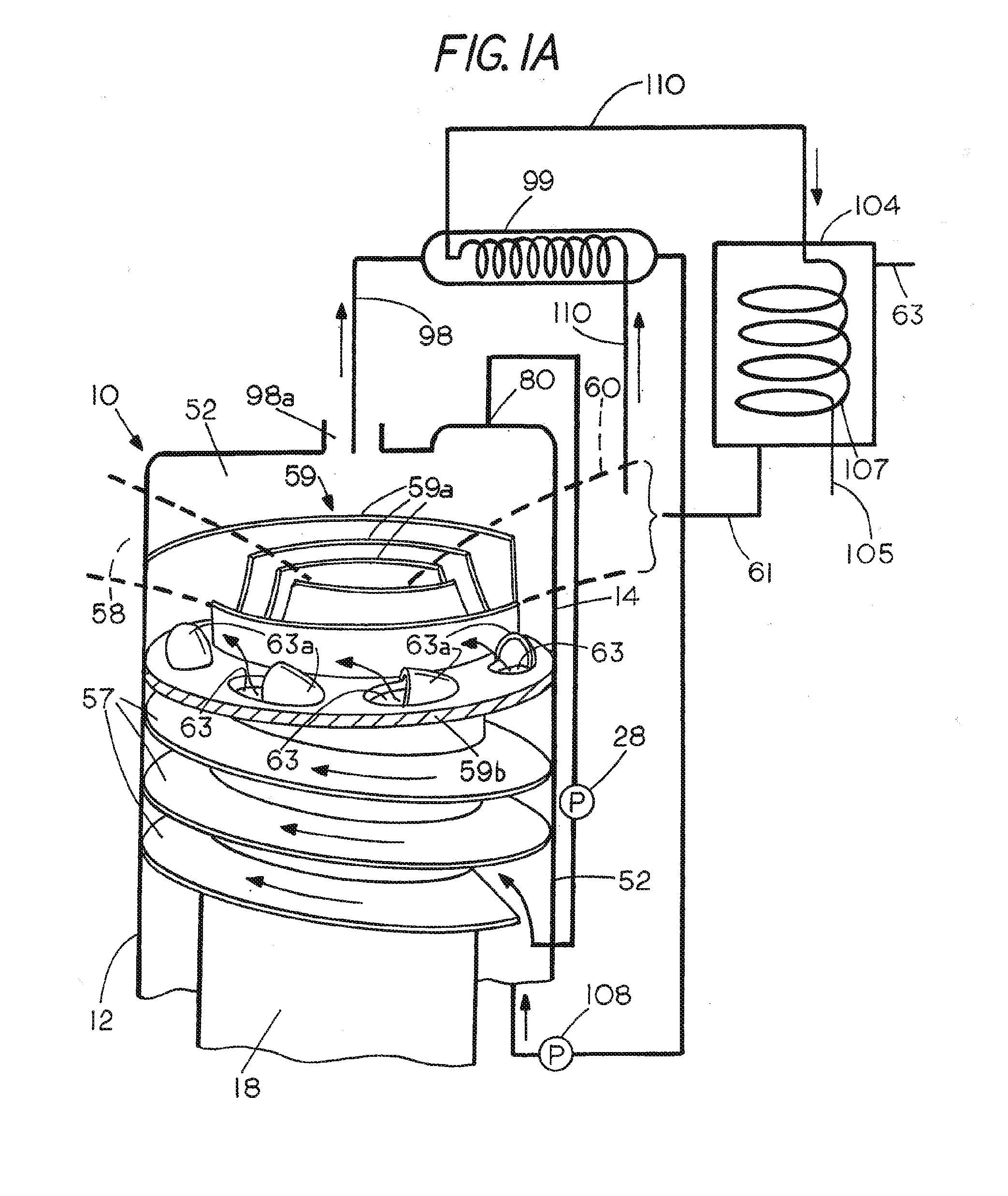

High Efficiency Dual Cycle Internal Combustion Steam Engine and Method

ActiveUS20100300100A1Efficient and improve heat transferImprove heat transferReciprocating combination enginesInternal combustion piston enginesBoiling pointWorking fluid

The coolant in the cooling jacket of a dual cycle internal combustion steam engine is intentionally maintained at an elevated temperature that may typically range from about 225° F.-300° F. or more. A non-aqueous liquid coolant is used to cool the combustion chamber together with a provision for controlling the flow rate and residence time of the coolant within the cooling jacket to maintain the temperature of the coolant at a selected elevated temperature that is substantially above the boiling point of water but below the boiling point of the coolant. The coolant is passed from the jacket through a heat exchanger in a first circuit to transfer heat to a vaporizable working fluid such as water and is then returned. An optional second intrajacket perturbation circuit within the engine can be used to disrupt and disperse pockets of vapor that may tend to form before damaging hot spots can develop around the combustion chamber. A cooling jacket design is tailored to extract heat at the highest possible temperature from each heat transfer zone as by having the coolant follow a circuitous helical pathway to achieve more efficient and improved heat transfer from the combustion chamber to the cooling medium.

Owner:THERMAL POWER RECOVERY

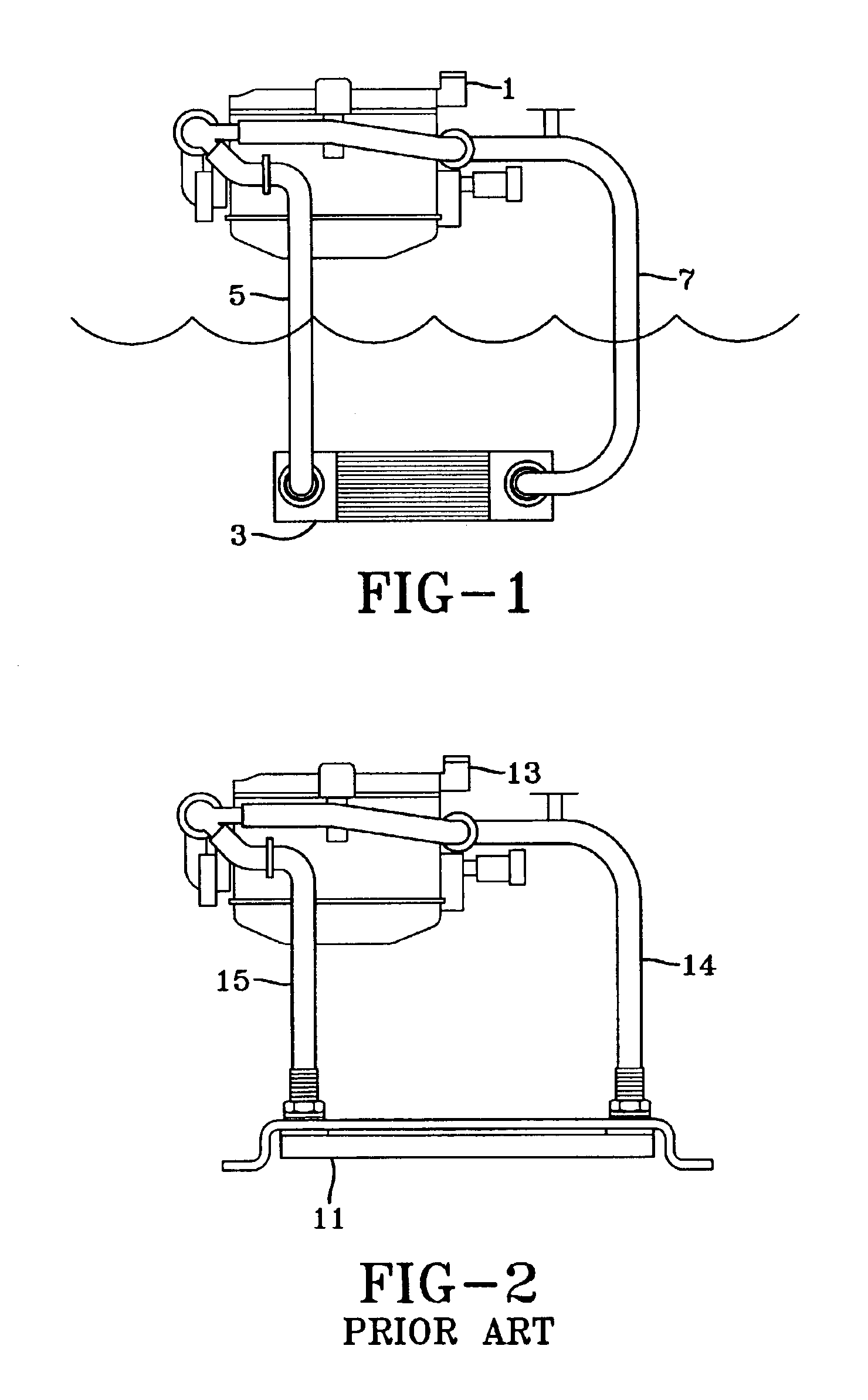

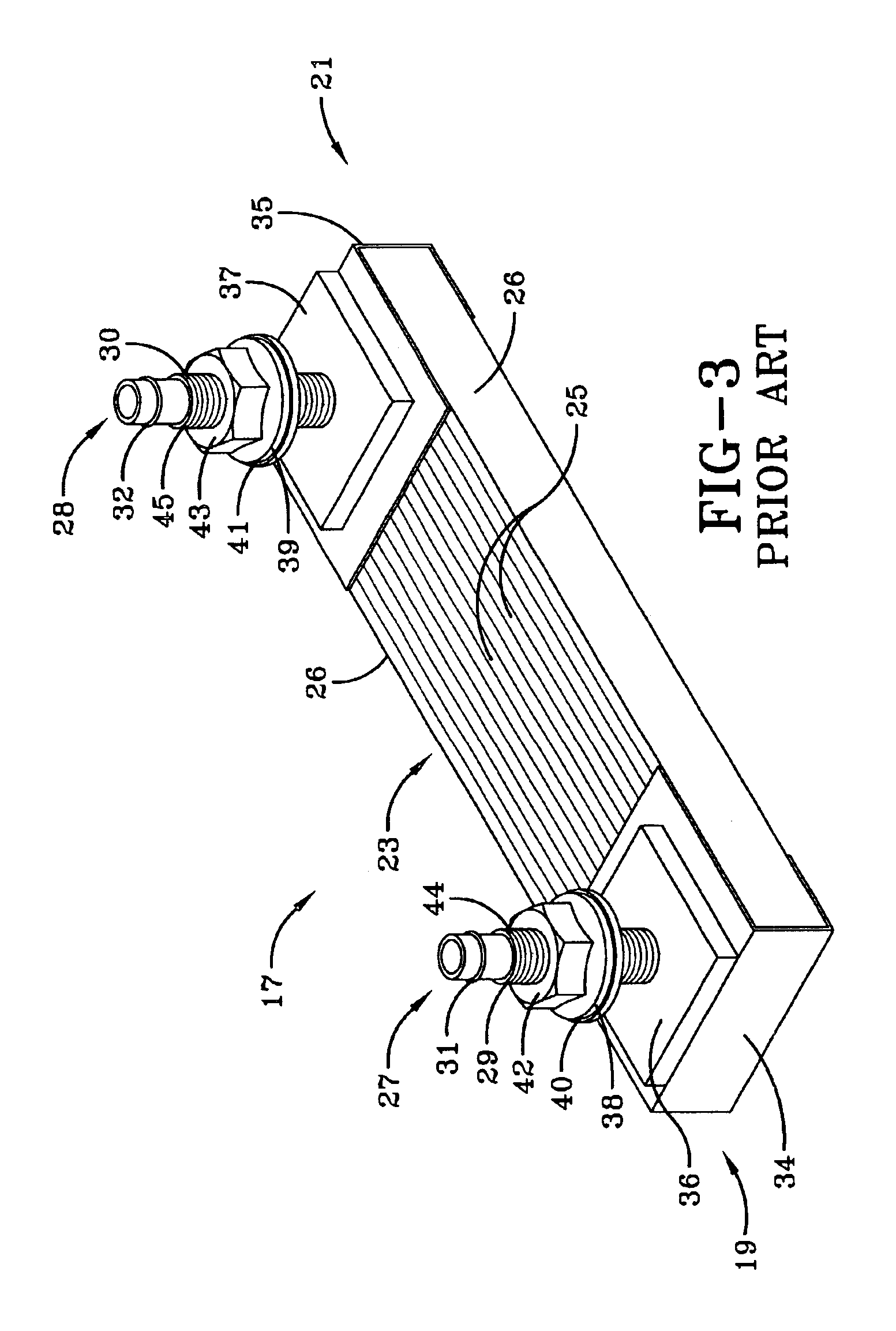

Keel cooler with fluid flow diverter

ActiveUS6896037B2Enhance heat exchangeImprove heat transferAuxillariesMachines/enginesChillerEngineering

A keel cooler having a standard header with an internal beveled bottom wall, with orifices on the inner wall of the exterior tubes extending into the header, the orifices being in the natural flow path of the coolant flow. The orifices are sufficiently large so as not to restrict the flow of coolant. A fluid flow diverter is additionally provided in the header of the keel cooler for facilitating coolant flow towards both the interior tubes and also towards the exterior tubes.

Owner:DURAMAX MARINE

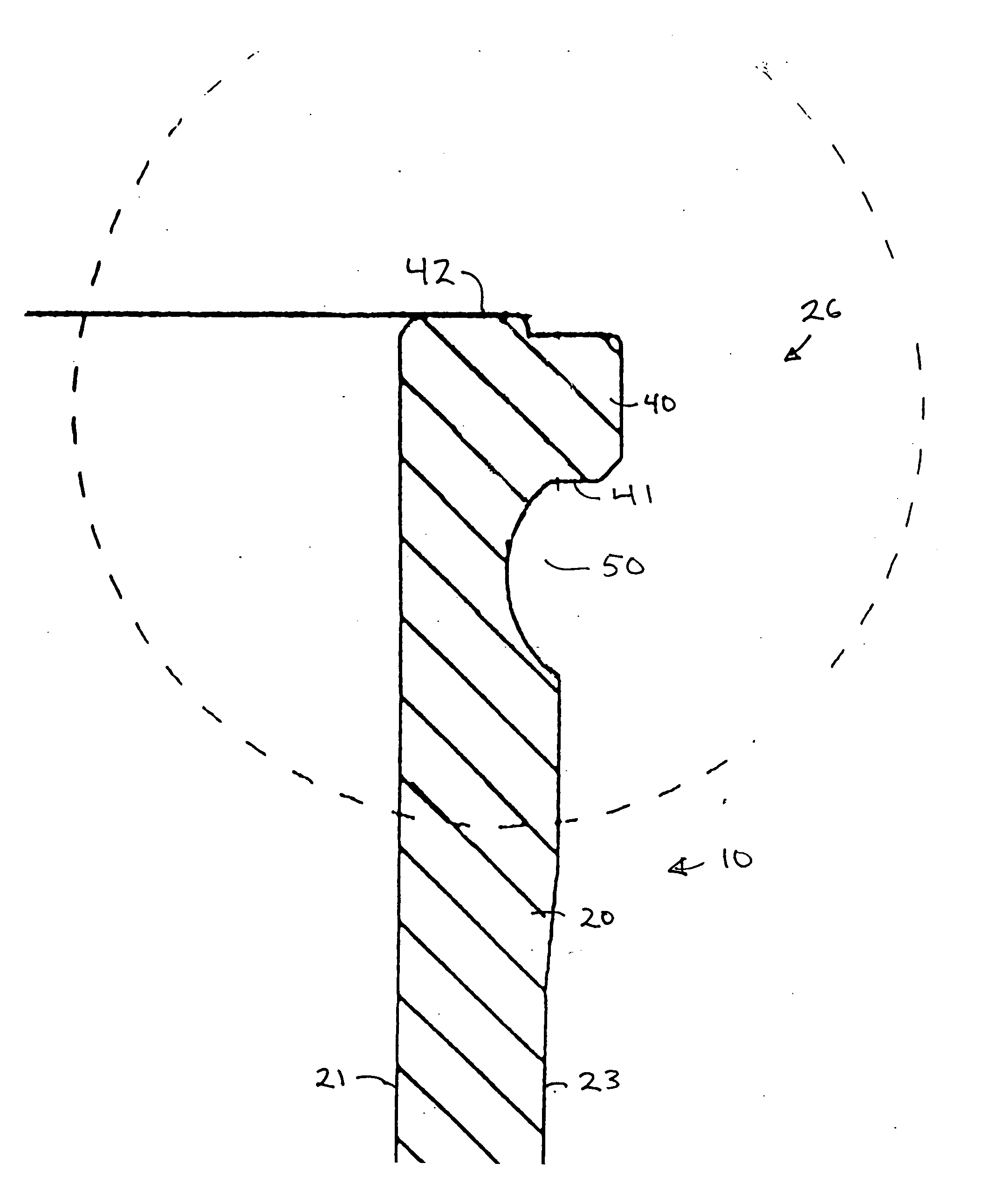

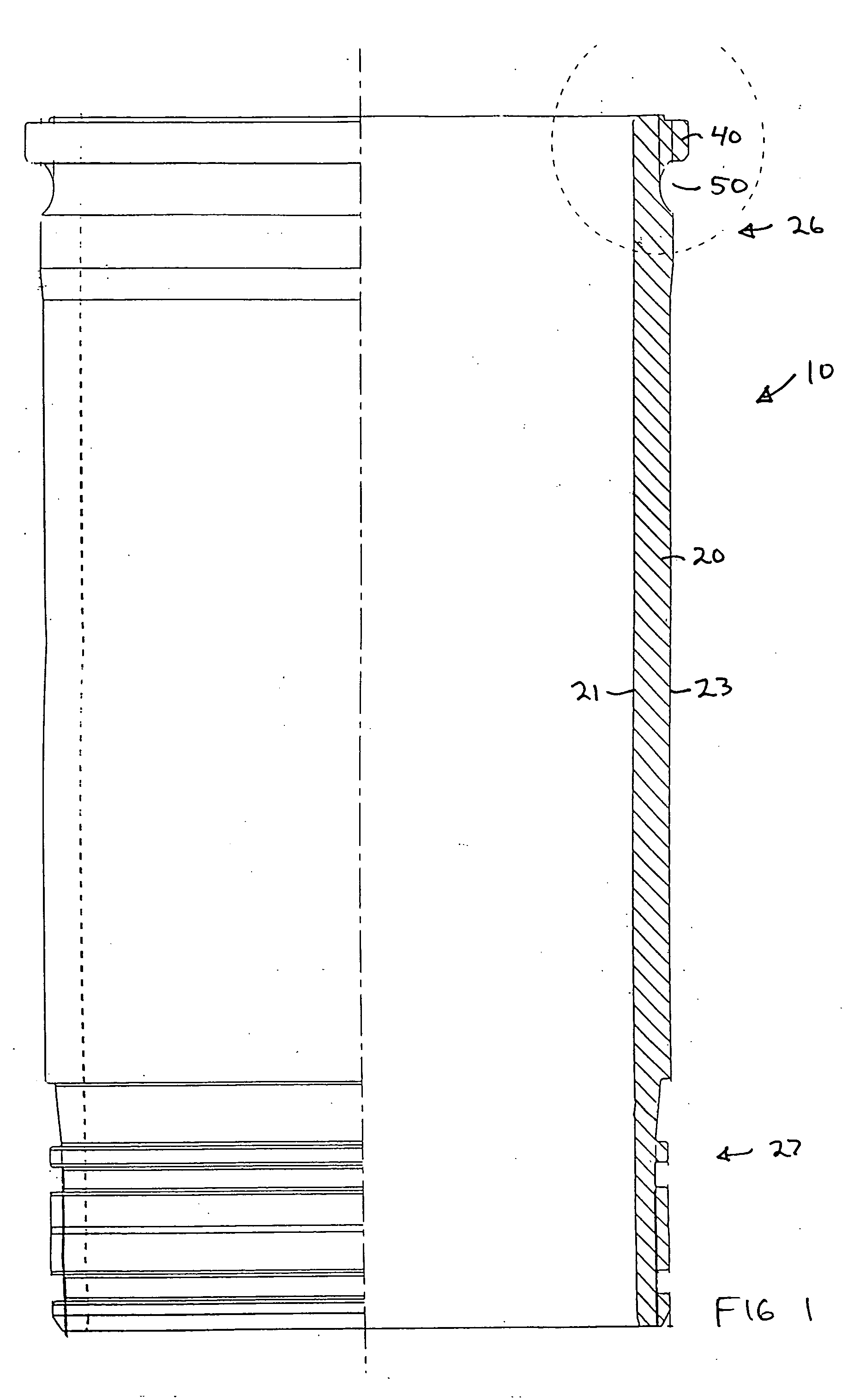

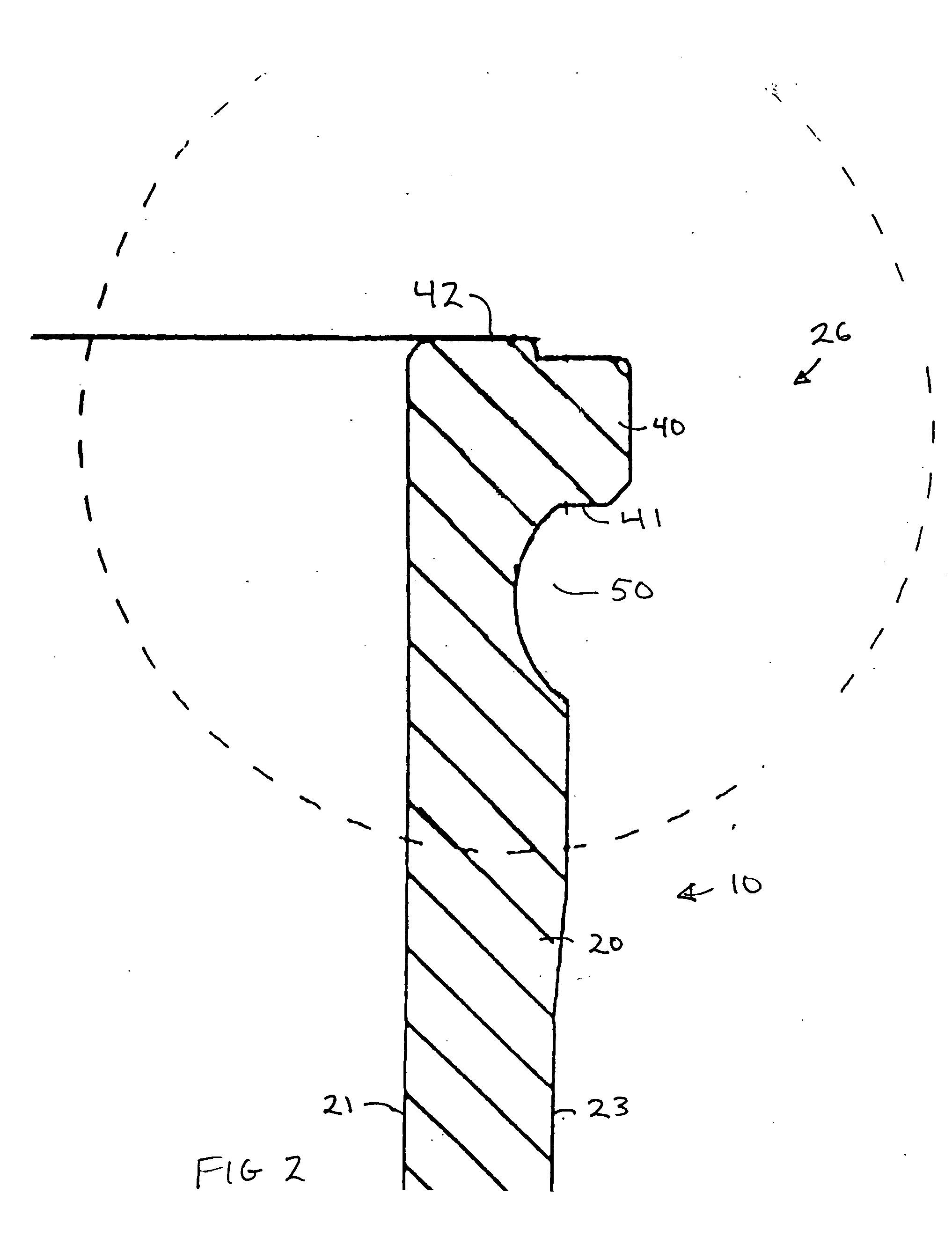

Cylinder liner

InactiveUS20060219192A1Improve heat transferExtend effective volumeCylinder headsMetal-working apparatusEngineeringDiesel engine

A ductile repair cylinder liner for a diesel engine, the cylinder liner having an additional cooling groove with a parabolic varying cross-section machined into the outer surface of the cylinder liner immediately below the radially extending locating flange for the liner.

Owner:IPD CORP

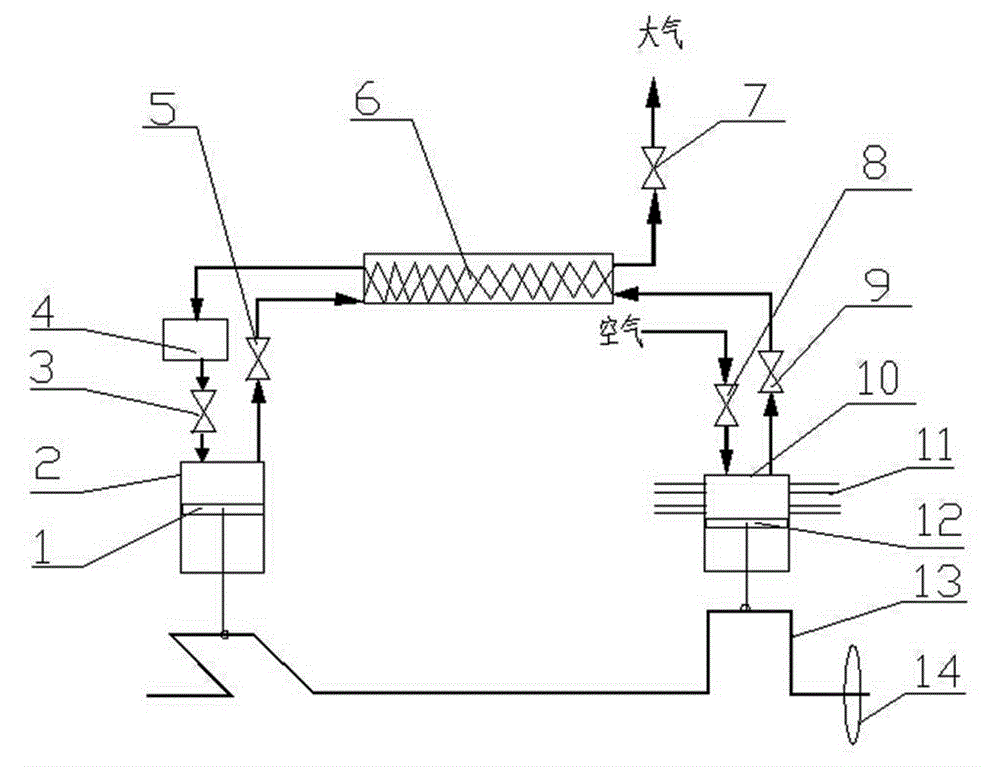

Opened circulating Stirling engine

InactiveCN104153910AHigh thermal efficiencyImprove reliabilityOpen-cycle gas positive displacement engine plantEngineeringPiston

The invention relates to an opened circulating Stirling engine comprising a hot-end cylinder, a hot-end piston, a regenerator, a cold-end cylinder and a cold-end piston. The regenerator is an one-way regenerator, the cold-end inlet and hot-end outlet of the one-way regenerator form a low-temperature medium channel, and the hot-end inlet and cold-end outlet form a high-temperature medium channel; the cold inlet of the cold-end cylinder is communicated with the air, and the cold outlet is communicated with the cold-end inlet of the one-way regenerator; the hot inlet of the hot-end cylinder is communicated with the hot-end outlet of the one-way regenerator, and the hot outlet is communicated with the hot-end inlet of the one-way regenerator; the cold-end outlet of the one-way regenerator is communicated with the air. The circulating medium adopts the one-way flowing manner, the heat exchanging manner is optimized, and the regenerating efficiency is improved; an absolute sealing device for a power piston and an expanding piston is omitted, the friction resistance is reduced greatly, and engine mechanical efficiency is improved; meanwhile, the medium is of the air, the operating pressure and temperature are low, expensive temperature-resistant material is omitted, cost is low, reliability is high, energy is saved, and environment is protected.

Owner:HEFEI UNIV OF TECH

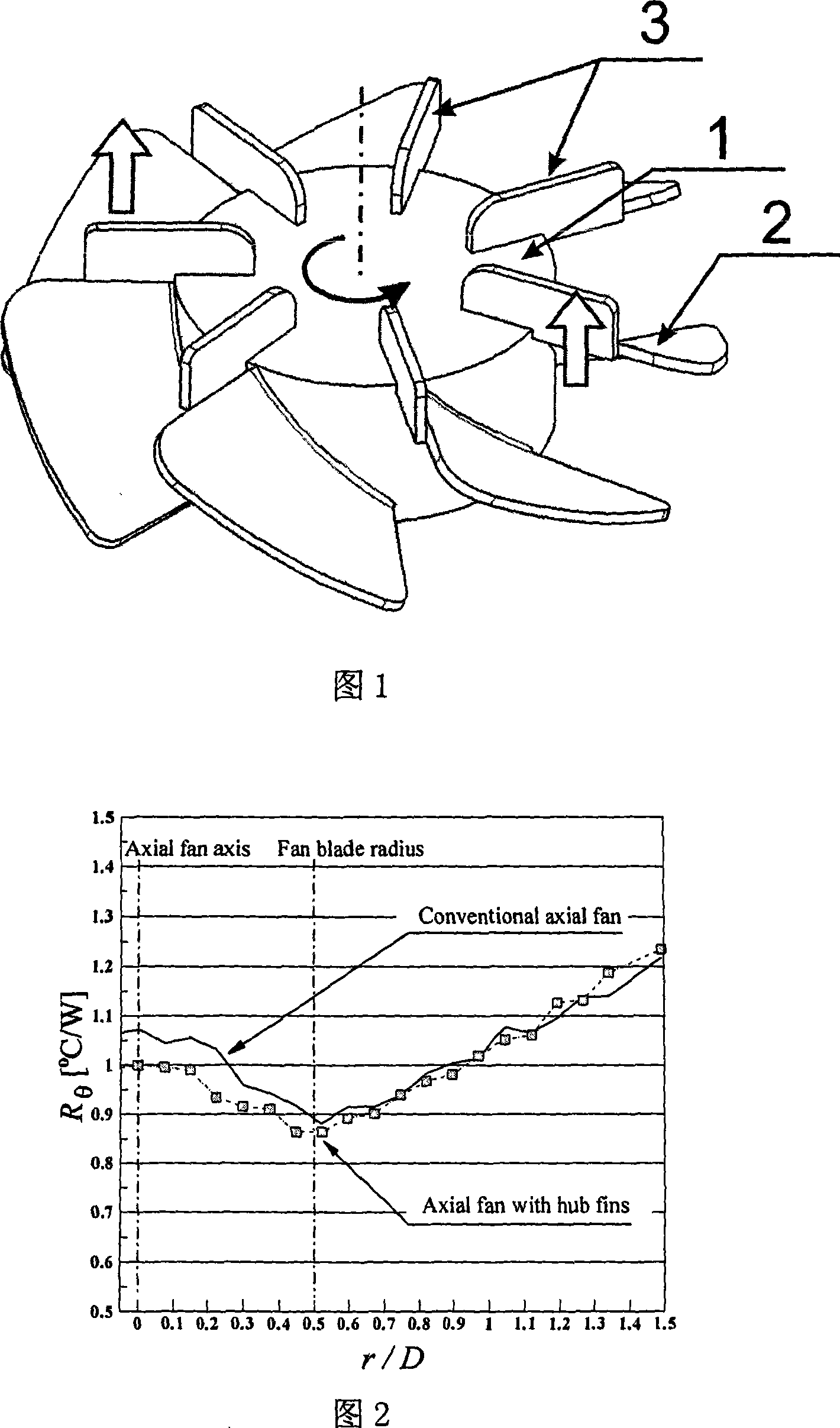

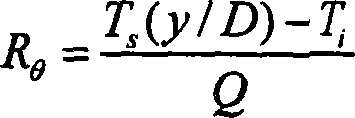

Axial fan for cooling electronic component

InactiveCN101220816AImprove heat transferImprove efficiencyPump componentsDigital data processing detailsEngineeringElectronic component

The invention provides an axial flow fan used for the heat dissipation of an electronic element, comprising a hub which is arranged at the center of a fan mainbody and main vanes which are fixed at the external side of the hub; the hub is also provided with attached vanes; one end of the attached vane is fixedly connected with the hub and the other end thereof is fixedly connected with the rear edge of the main vanes. The invention improves the heat exchange condition at the downstream area of the axial flow motor by adding a small vane on the central hub of the fan, thus greatly improving the efficiency of a radiator. Compared with a traditional fan, the central hub of the fan is provided with attached vanes, and the integration cooling performance of the impact baseplate of the invention is improved by about 10% compared with the traditional axial flow fan under the same input power.

Owner:XI AN JIAOTONG UNIV

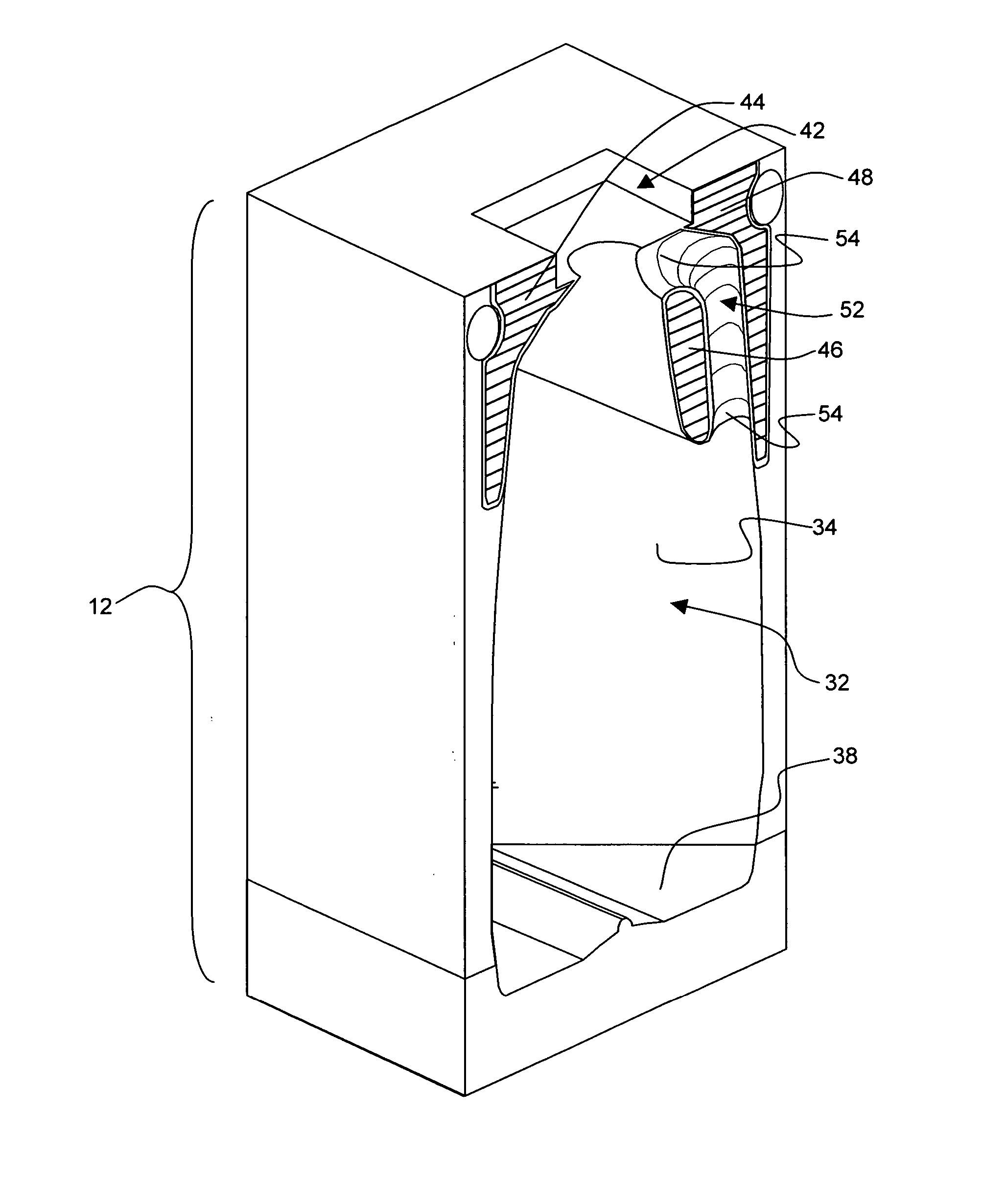

Cooling Of A Medical Instrument

A medical instrument includes a hermetically tight sheath, a heat source, a surface area thermally coupled to the heat source, a rotor arranged outside the hermetically tight sheath and serving to generate a flow of fluid at the surface, a magnet at the rotor, and means for generating a variable magnetic field in order to move the rotor. The means for generating a variable magnetic field is arranged inside the hermetically tight sheath.

Owner:KARL STORZ GMBH & CO KG

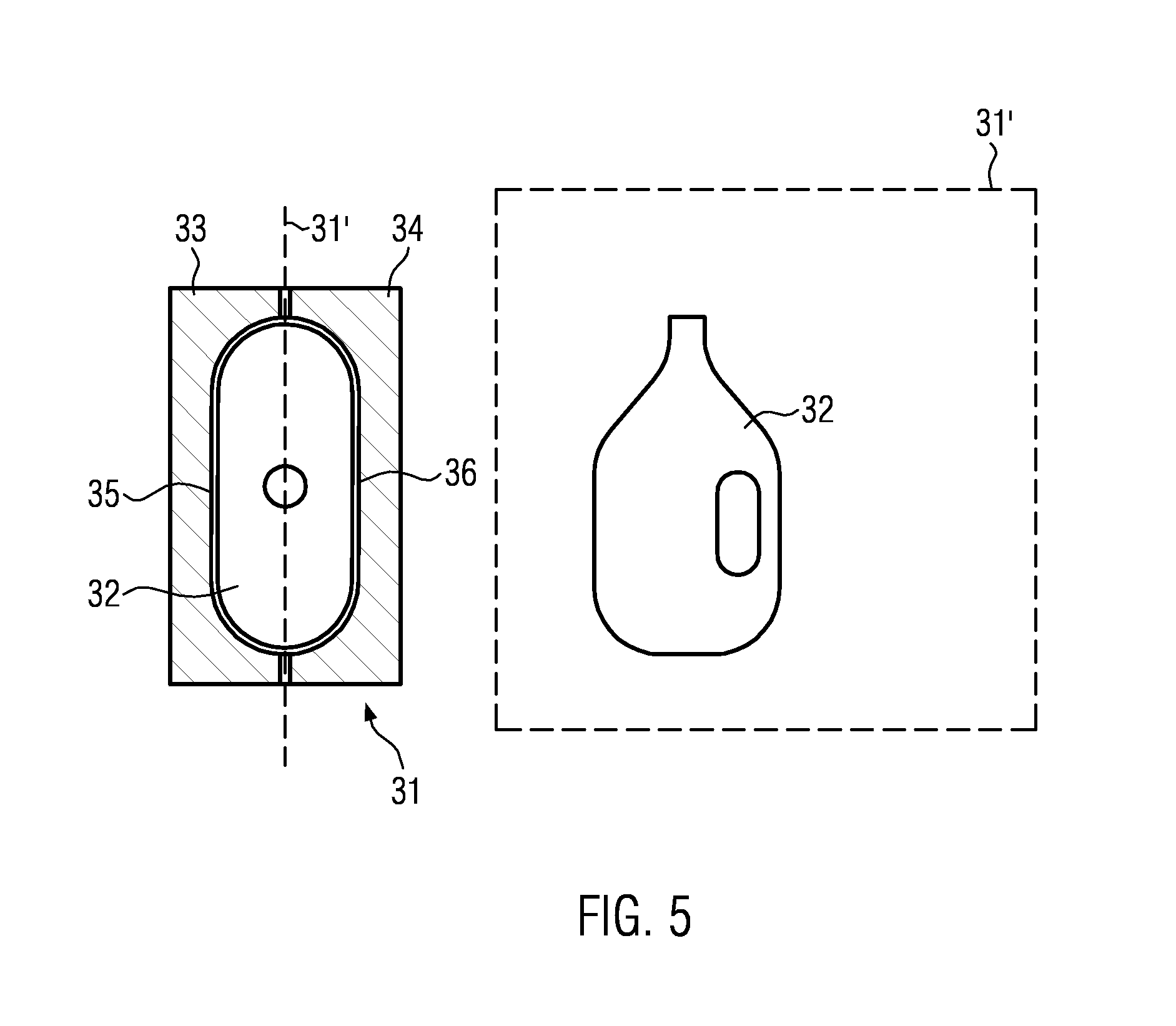

Apparatus for blow molding

InactiveUS20060182841A1Improve heat transferIncrease ratingsDomestic articlesMechanical engineeringHeat transfer

A molding tool for molding a substantially hollow article from a tubular parison comprises molding surfaces defining at least one cavity for forming a hollow portion of a molded article, the hollow portions having walls formed by expansion of the parison within the cavities and defining at least one solid area of the article to be molded attached to a wall of a hollow portion, the solid area comprising waste of the article as molded and the molding surfaces comprising surface undulations effective to improve the rate of heat transfer between the molding surfaces and the molding material comprising the solid areas. A mold assembly for molding hollow articles from tubular parisons comprises a molding tool in accordance with the invention. A blow molding machine comprises a mold assembly in accordance with the invention.

Owner:UNILOY MILACRON USA INC

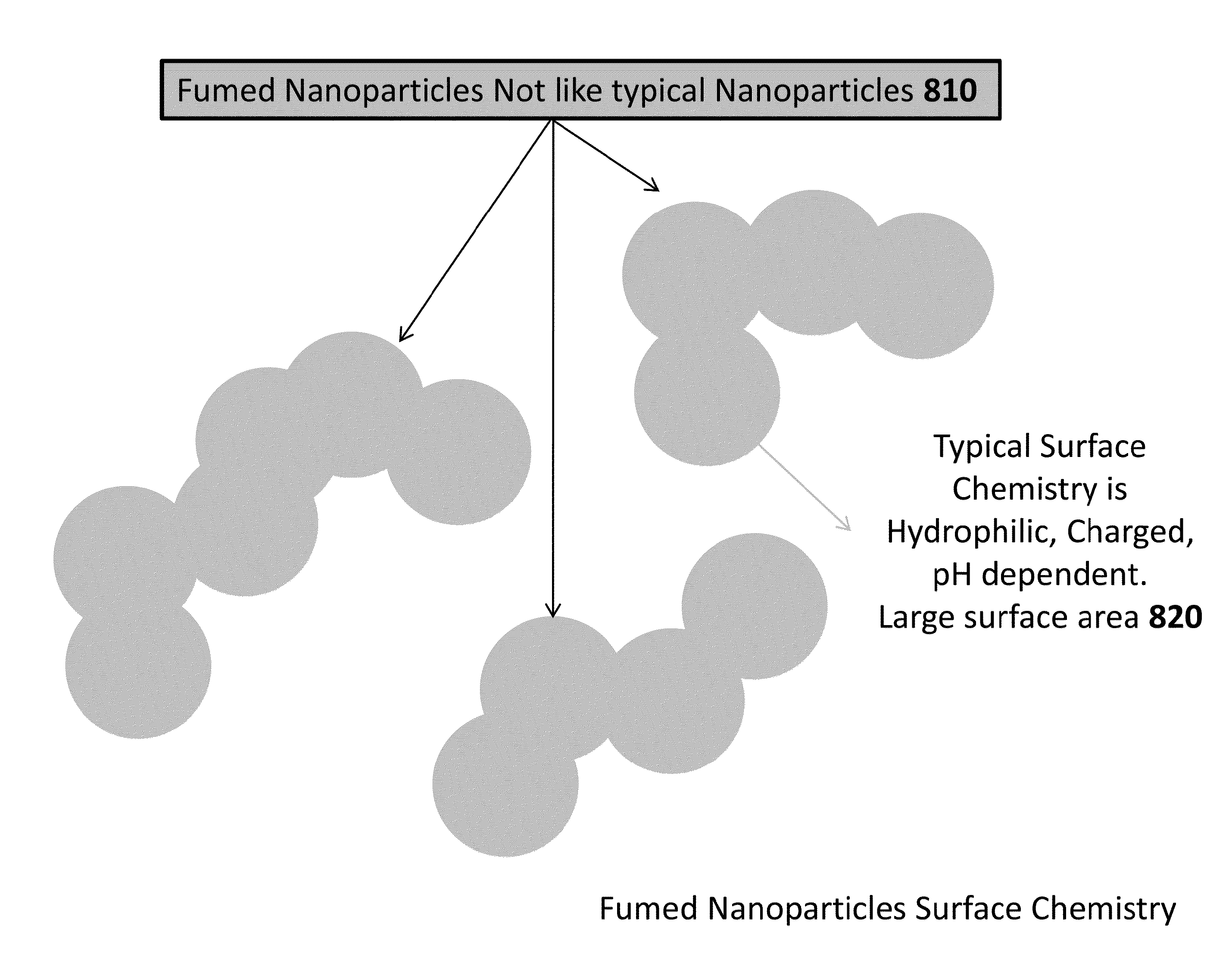

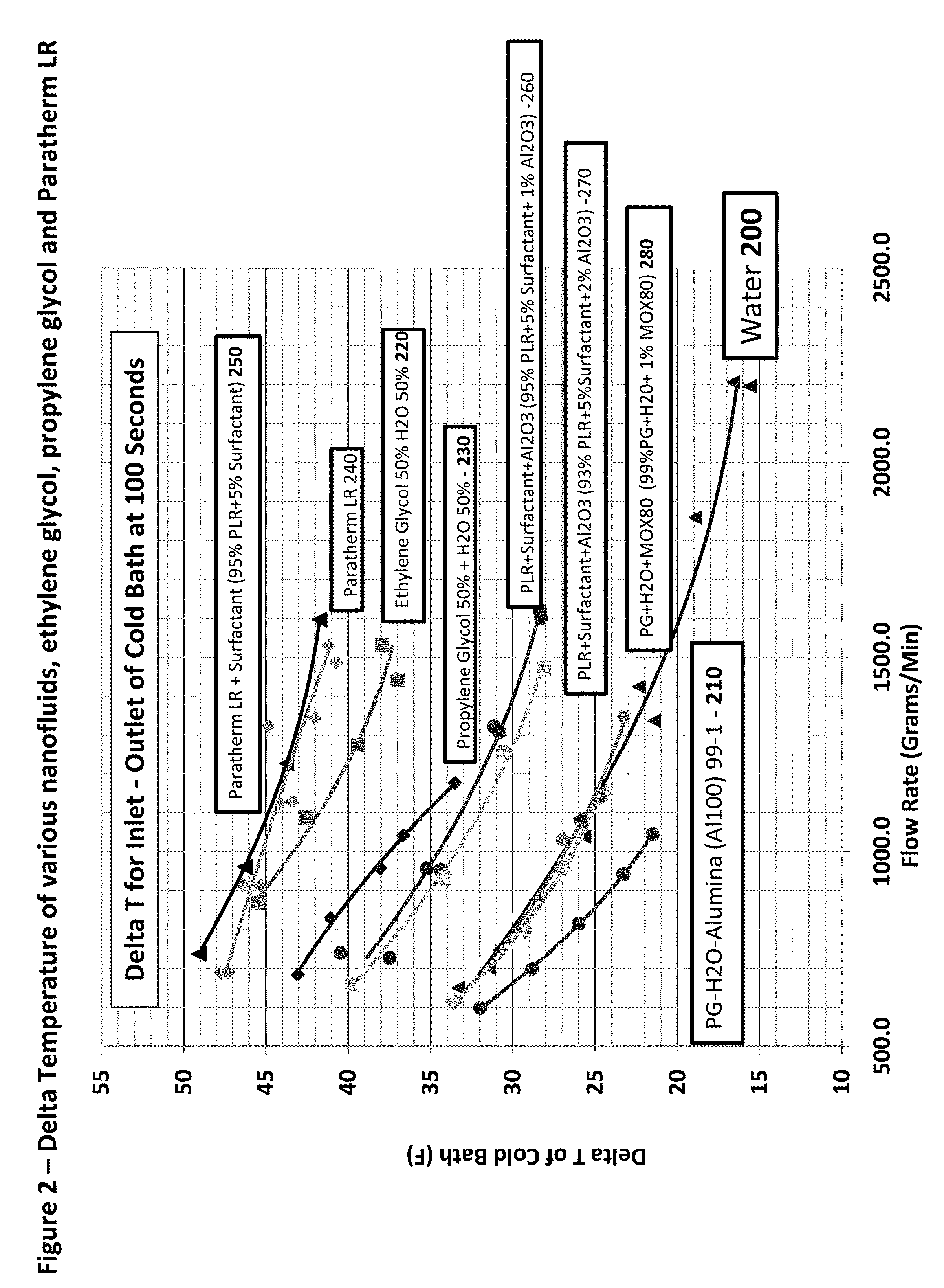

Method of making nanaofluids for ground souce heat pumps and other applications

InactiveUS20140197354A1Improve heat transferImprove heat transfer performanceMaterial nanotechnologyHeat-exchange elementsNanofluidHeat pump

A method on making a nanofluid using nanoparticles without the use of a surfactant to hold the nanoparticles in suspension.

Owner:ACTA TECH

Method for manufacturing blow molds

ActiveUS20140106105A1Improve heat transferGood heat transferLiquid surface applicatorsMolten spray coatingManufacturing engineering

A method for manufacturing segmented blow molds for plastic containers, where blow mold preforms are manufactured by flame-spraying at least one metal-containing and / or ceramic-containing layer on a negative model of at least one segment of the blow mold to be manufactured, and the at least one layer is then detached from the negative model, thereby providing a particularly simple and repeatable manufacturing of blow molds.

Owner:KRONES AG

Hydrogen production reactor using honeycomb SiC ceramic as catalyst carrier

ActiveCN110801785AGood orientationImprove flow uniformityHydrogenHydrogen/synthetic gas productionSteam reformingMethanol water

The invention discloses a hydrogen production reactor taking honeycomb SiC ceramic as a catalyst carrier. The reactor comprises an upper cover plate, a lower cover plate, an evaporation plate, a firstcatalytic combustion plate, a second catalytic combustion plate, a reforming chamber upper cover plate, a methanol steam reforming plate and a reforming chamber lower cover plate. Bolts pass througheach plate and are tightly connected; the upper and lower cover plates are provided with reactant inlet and outlet pipes; the evaporation plate is provided with a serpentine flow passage as an evaporation chamber; the first and second catalytic combustion plates are provided with parallelogram grooves as combustion chambers; the reforming chamber upper cover plate and the methanol steam reformingplate are provided with rounded rectangular through grooves, wherein the honeycomb SiC ceramics are arranged; reactants alternately pass through each plate and flow into corresponding cavities / groovesto realize hydrogen production reaction. The hydrogen production reactor can improve the orientation and flow uniformity of fluid flow, has the characteristics of high thermal conductivity, good thermal stability, stable chemical performance, large specific surface area and the like, improves the mass transfer and heat transfer performance in the reactor, reduces the pressure loss in the reactor,and enhances the loading capacity of a catalyst.

Owner:ZHEJIANG UNIV

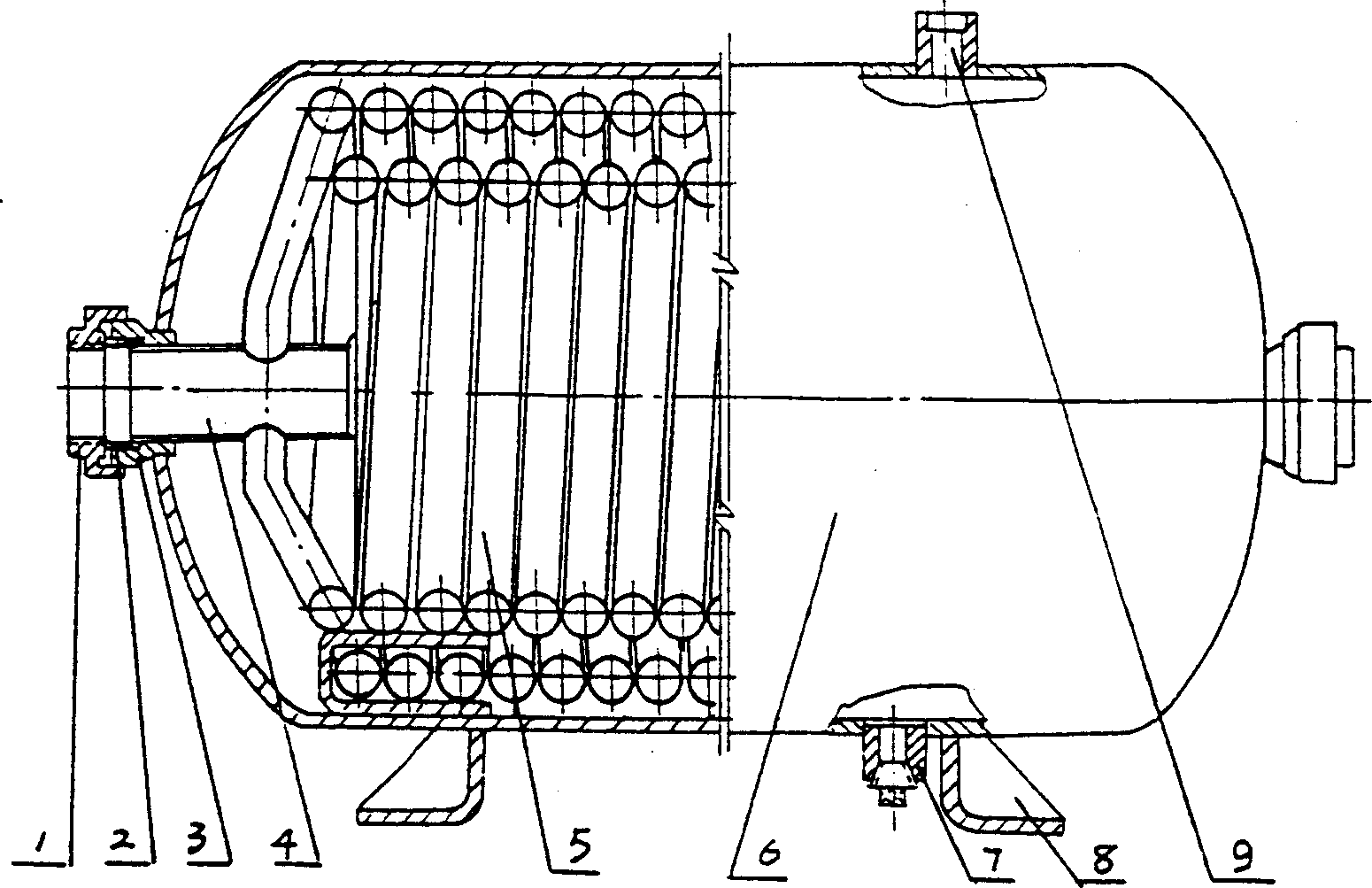

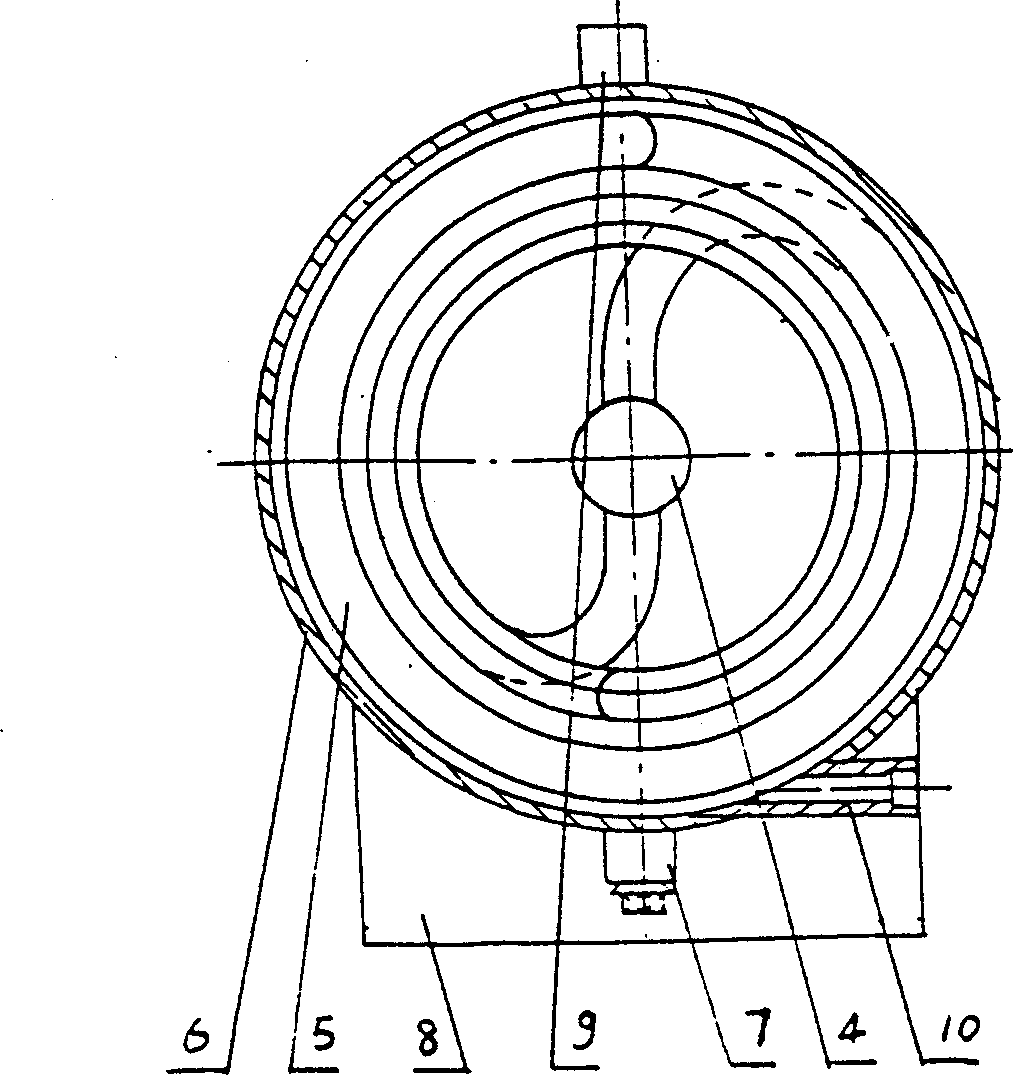

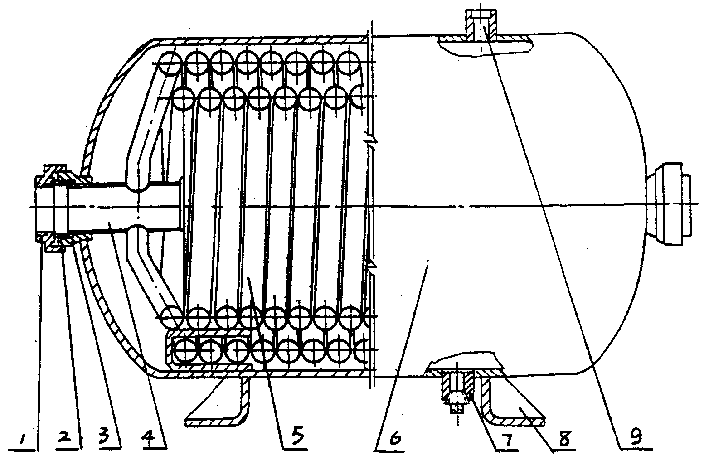

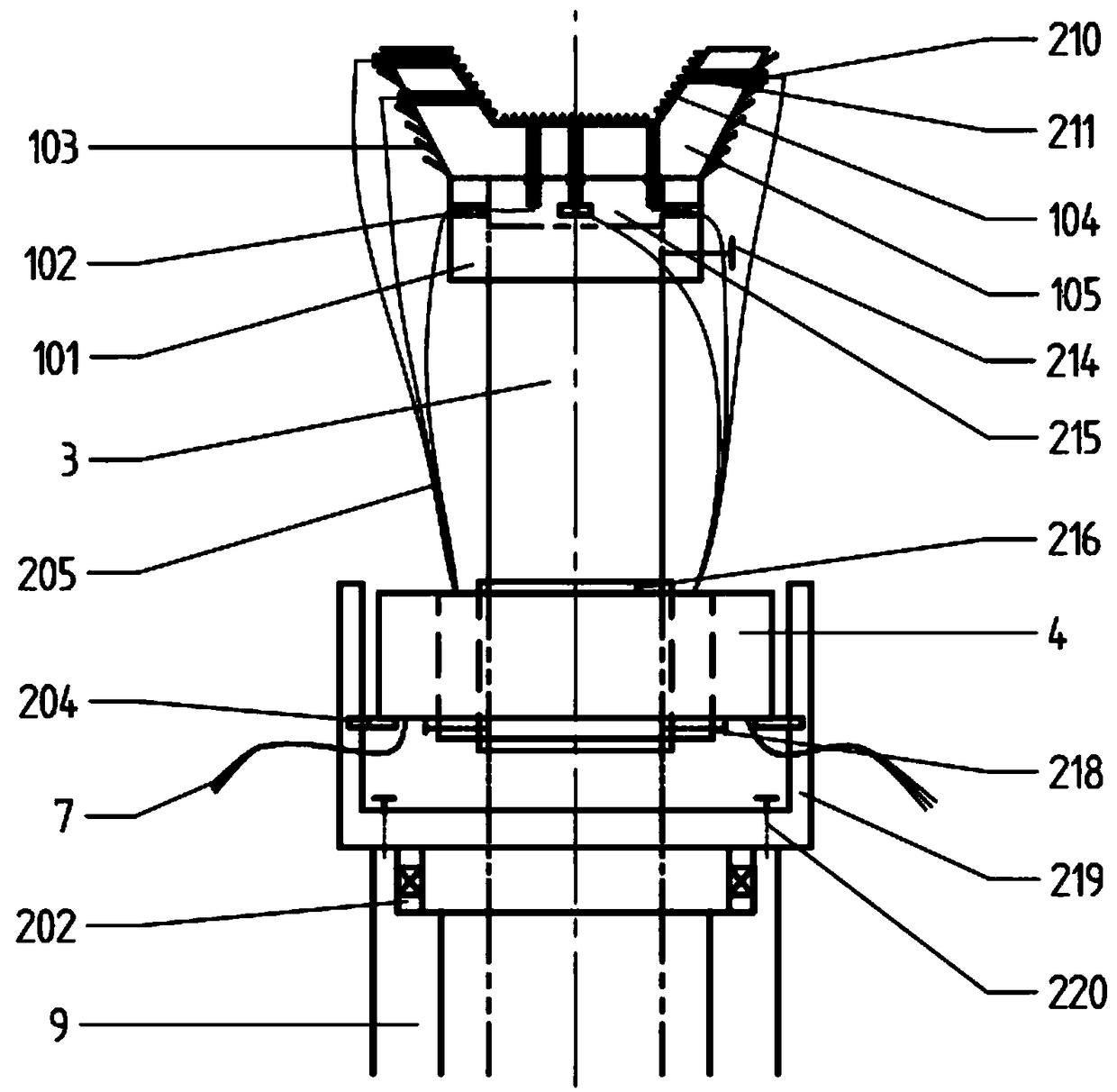

Sea water fresh water two-purpose spiral-tube condenser

InactiveCN1488913ASuitable for heatingSuitable for coolingStationary tubular conduit assembliesFresh waterPulp and paper industry

The present invention relates to a sea-water and fresh-water dual-purpose spiral tube condenser equipment. It mainly comprises header clamping cap, clamping ring, header positioning seat, header, spiral tube, shell body, liquor-discharging valve, supporting seat, steam inlet pipe seat and liquor outlet pipe seat. Said invented shell body is a hollow closed cylinder body whose two ends are made into the form of sphere, and said two ends are respectively equipped with one header. The spiral tubes with two different diameters are made by gapless parallelly-coiling smooth titanium alloy tubes and mutually cover-superposed coaxially, two ends of the spiral tube are welded together with headers, and fixed in the shell body. The refrigerant is sea-water or fresh-water. Said invention is compact in its structure and is convenient in installation.

Owner:SHANGHAI JIAO TONG UNIV

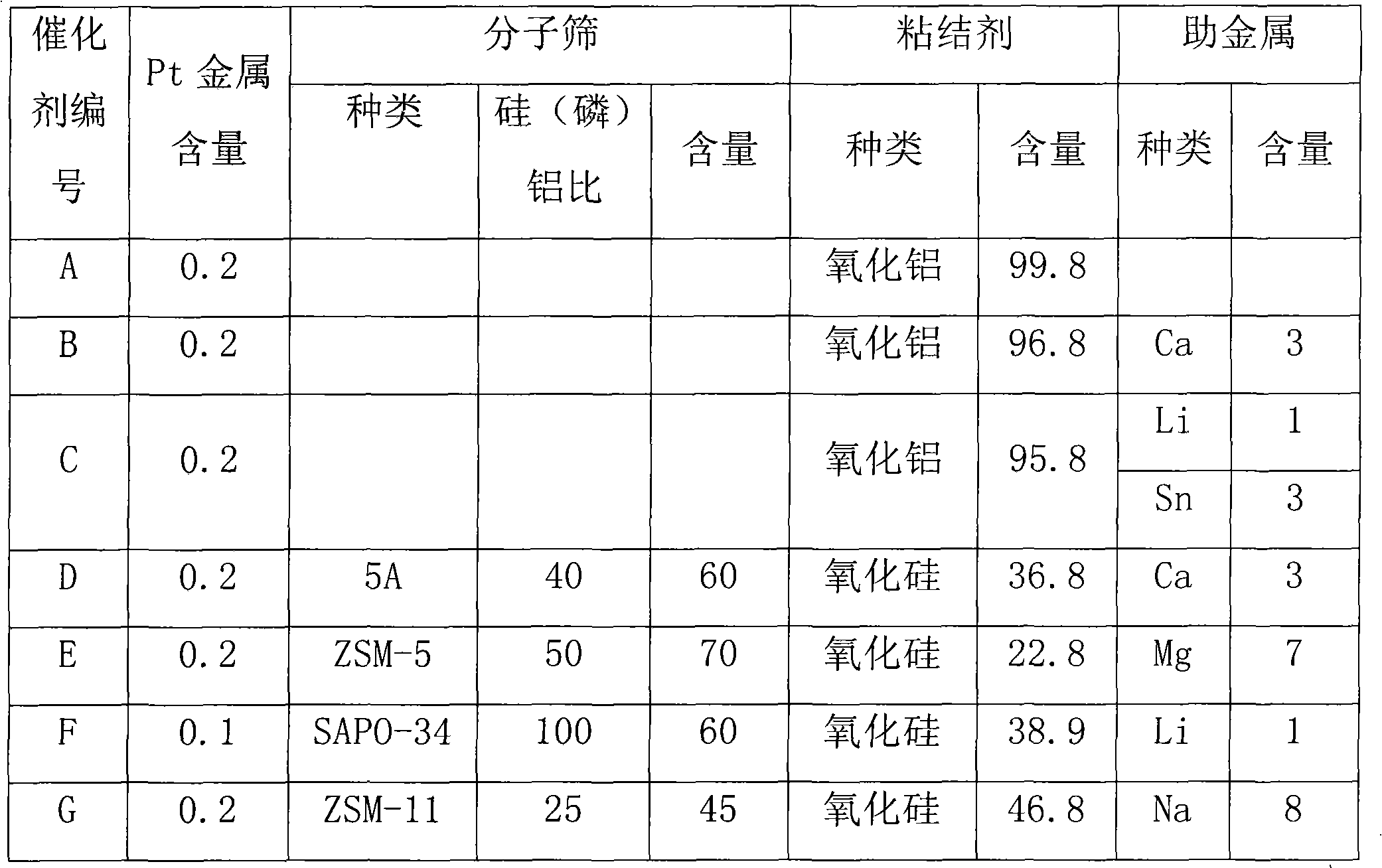

Selective hydrogen combustion catalyst for use in internal heating of petroleum hydrocarbon cracking stock and use thereof

ActiveCN101869835AImprove conversion rateImprove heat transferCatalytic crackingMolecular sieve catalystsChemistryMolecular sieve

The invention discloses a selective hydrogen combustion catalyst for use in the internal heating of a petroleum hydrocarbon cracking stock and use thereof. The catalyst comprises at least one of noble metal platinum and an alkali metal and / or alkaline-earth metal, various molecular sieves with a diameter of less than or equal to 6 and a regular duct structure and an adhesive. In the presence of the catalyst of the invention, a mixed material of the petroleum hydrocarbon cracking stock, the hydrogen and the oxygen can realize a hydrogen combustion internal heating process through a catalyst bed layer so as to raise the temperature of the petroleum hydrocarbon cracking stock and a diluting agent to a temperature required for subsequent cracking reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

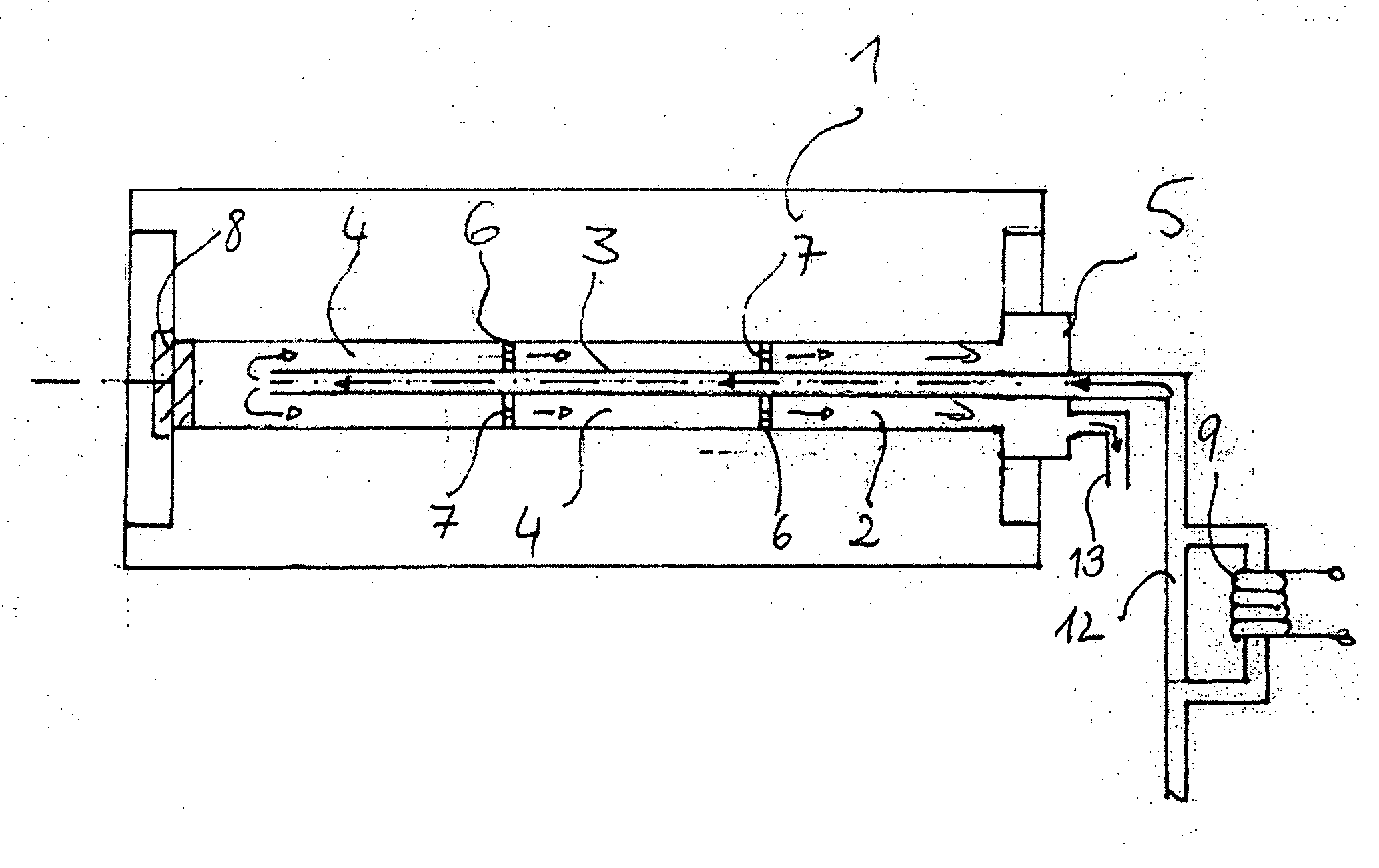

Device and method for controlling the temperature of a rotating body

InactiveUS20070193463A1Manufacture precision of be lowImprove heat transferRotary pressesPrinting press partsEngineeringPrinting press

A cylinder of a printing press is provided with an axial bore in which a fluid supply line is supported by spacers forming a return duct having an annular cross section, so that the inlet and the outlet of the fluid are at the same end of the cylinder.

Owner:MANROLANAD AG

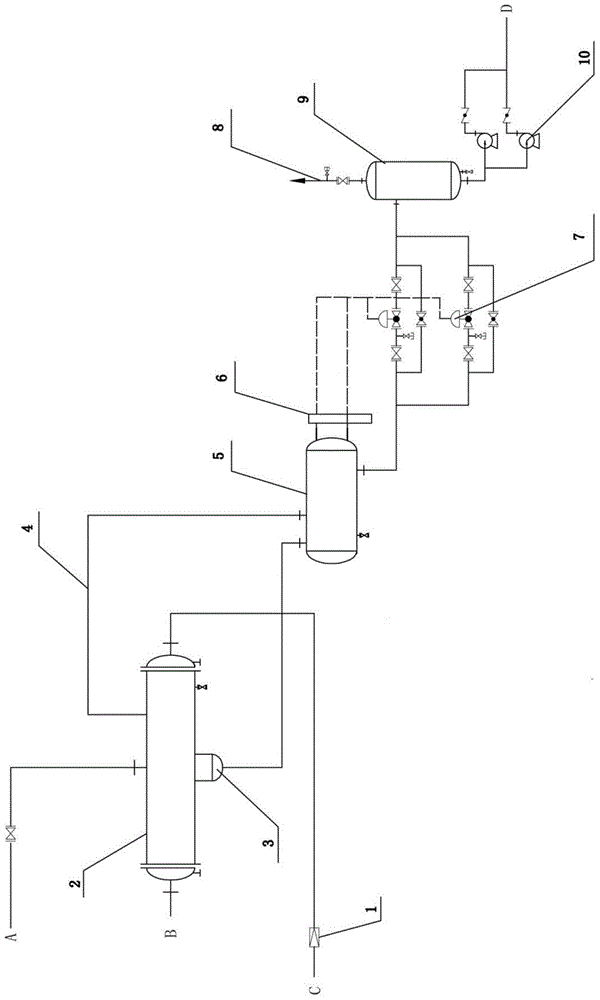

Low temperature ethylene torch heating system

ActiveCN104101232BImprove heat transferLow costStationary tubular conduit assembliesIncinerator apparatusTorchNational standard

The invention provides a low-temperature ethylene torch heating system, which mainly includes a low-temperature ethylene heating vaporizer, a saturated water condensation tank and a condensate recovery tank. Steam, low-temperature ethylene and steam exchange heat in the low-temperature ethylene heating vaporizer; the heated ethylene and the treated condensate all meet national standards, and the quality is up to standard, safe and reliable. In addition, the present invention has simple process, low cost, and heat transfer effect Good, safe and reliable, environmental protection advantages.

Owner:天津奥利达环保设备有限公司

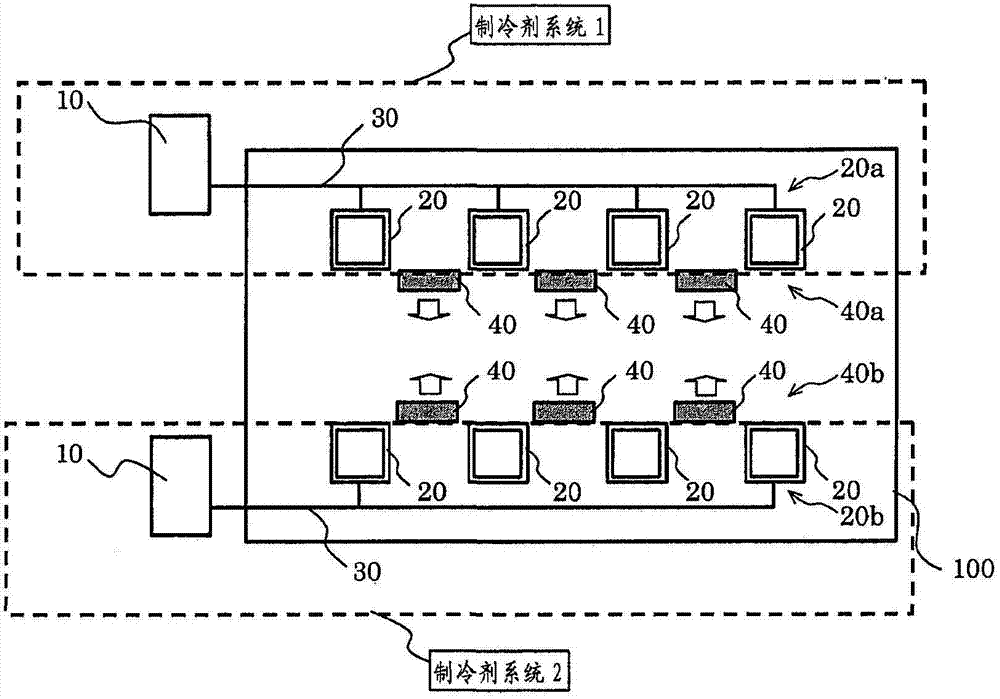

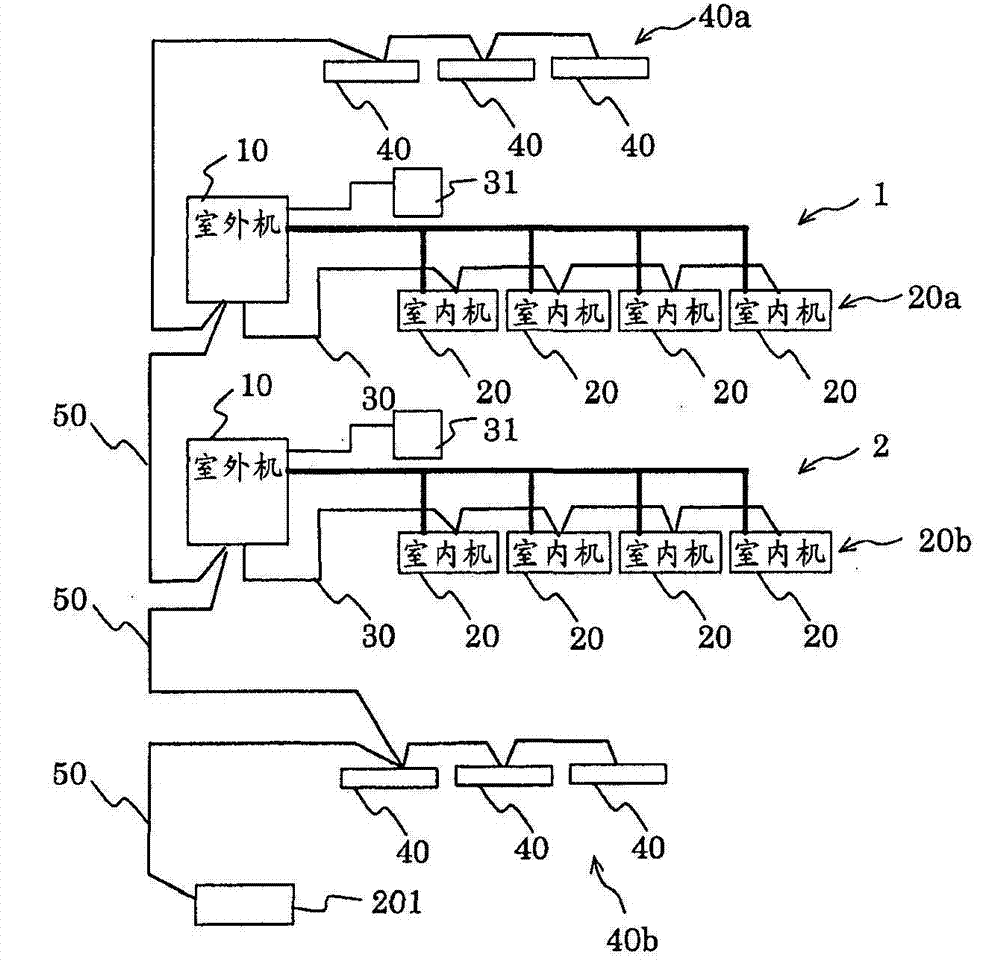

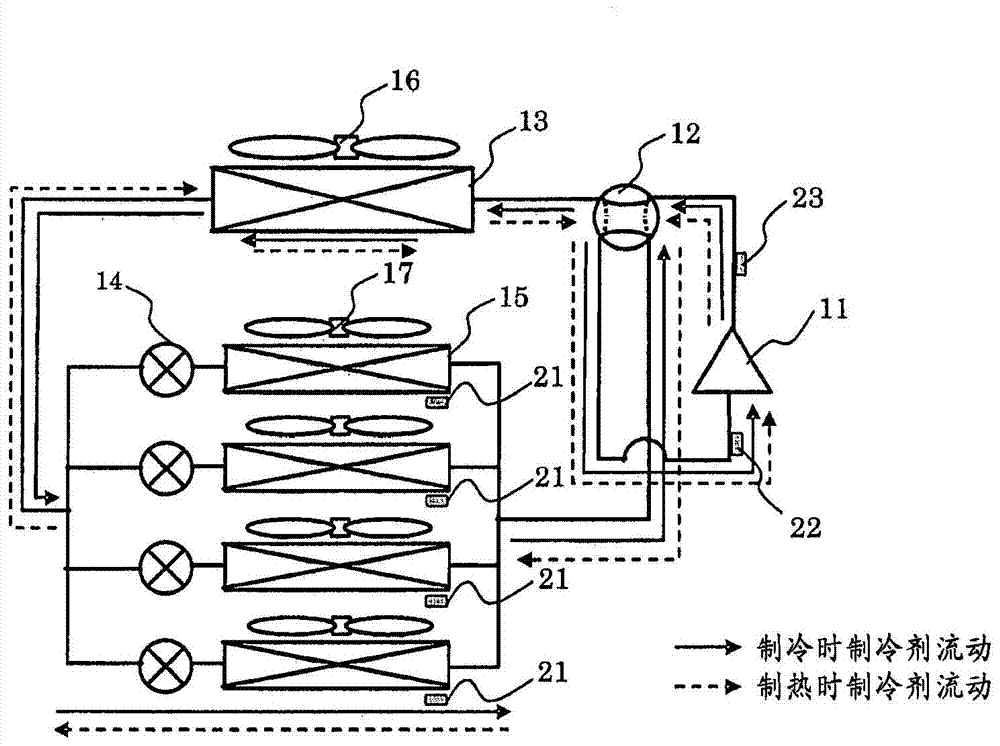

Air conditioning device

ActiveCN104285107AImprove operational efficiencyLow costMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringAir conditioning

An air conditioning device is provided with: refrigerant systems (1, 2) having an outdoor unit (10) and indoor units (20) and air conditioning the same room (100); and a circulator (40) for making temperature distribution in the room uniform. A load on each of the refrigerant systems (1, 2) being operated is determined, and when it is determined on the basis of the result of the determination of the loads that an increase in the operational efficiency can be expected, the air conditioning device is operated as follows: the operation of a refrigeration system which is determined as being subjected to a low load is stopped; integrated system operation is performed, the integrated system operation being that in which operation is integrated into a refrigeration system which is determined as being subjected to a high load; and discharge air which is blown from the indoor unit (20) of the refrigeration system which is determined as being subjected to a high load is conveyed by the circulator (40) to the air conditioning zone of the refrigeration system determined as being subjected to a low load.

Owner:MITSUBISHI ELECTRIC CORP

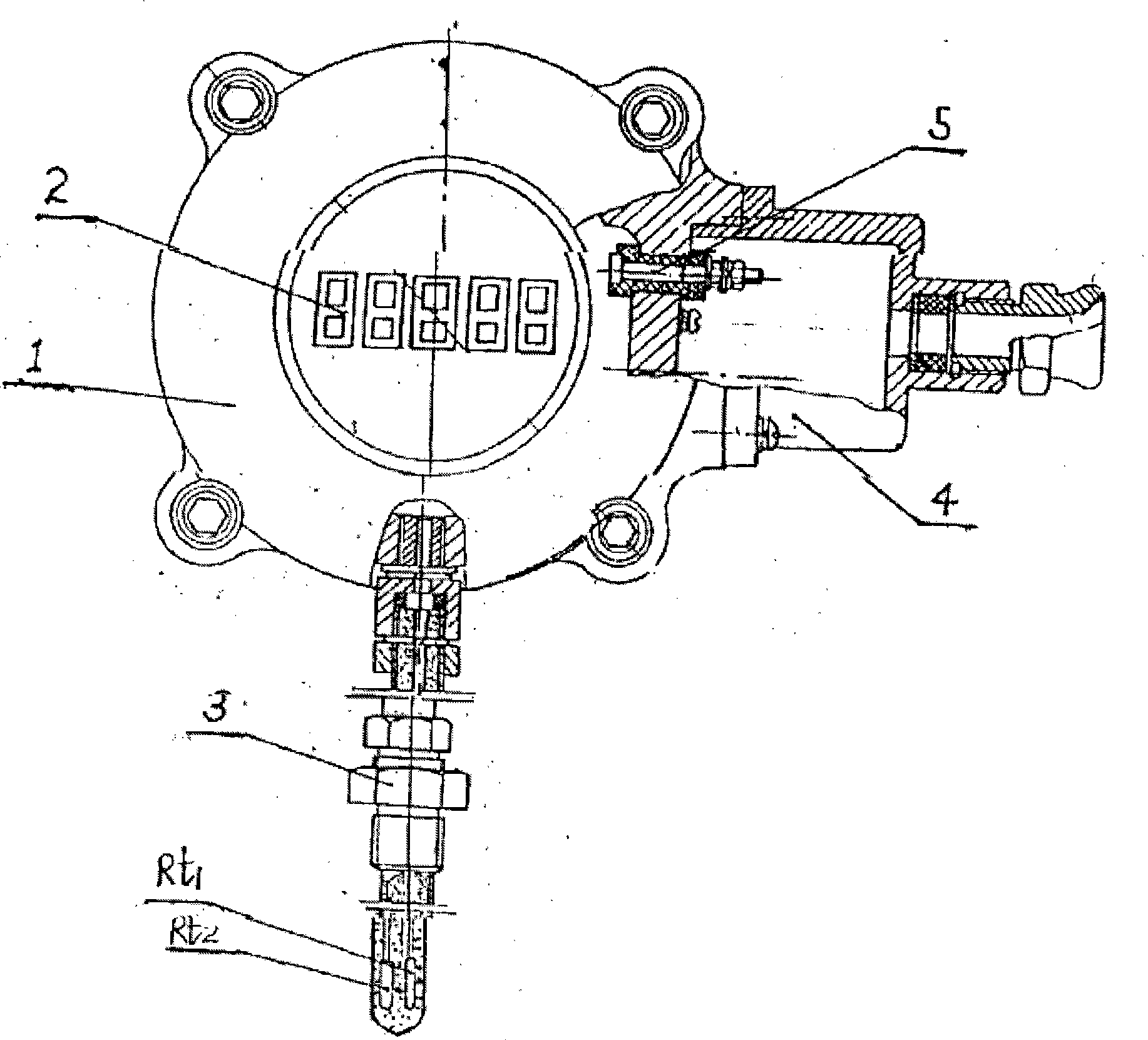

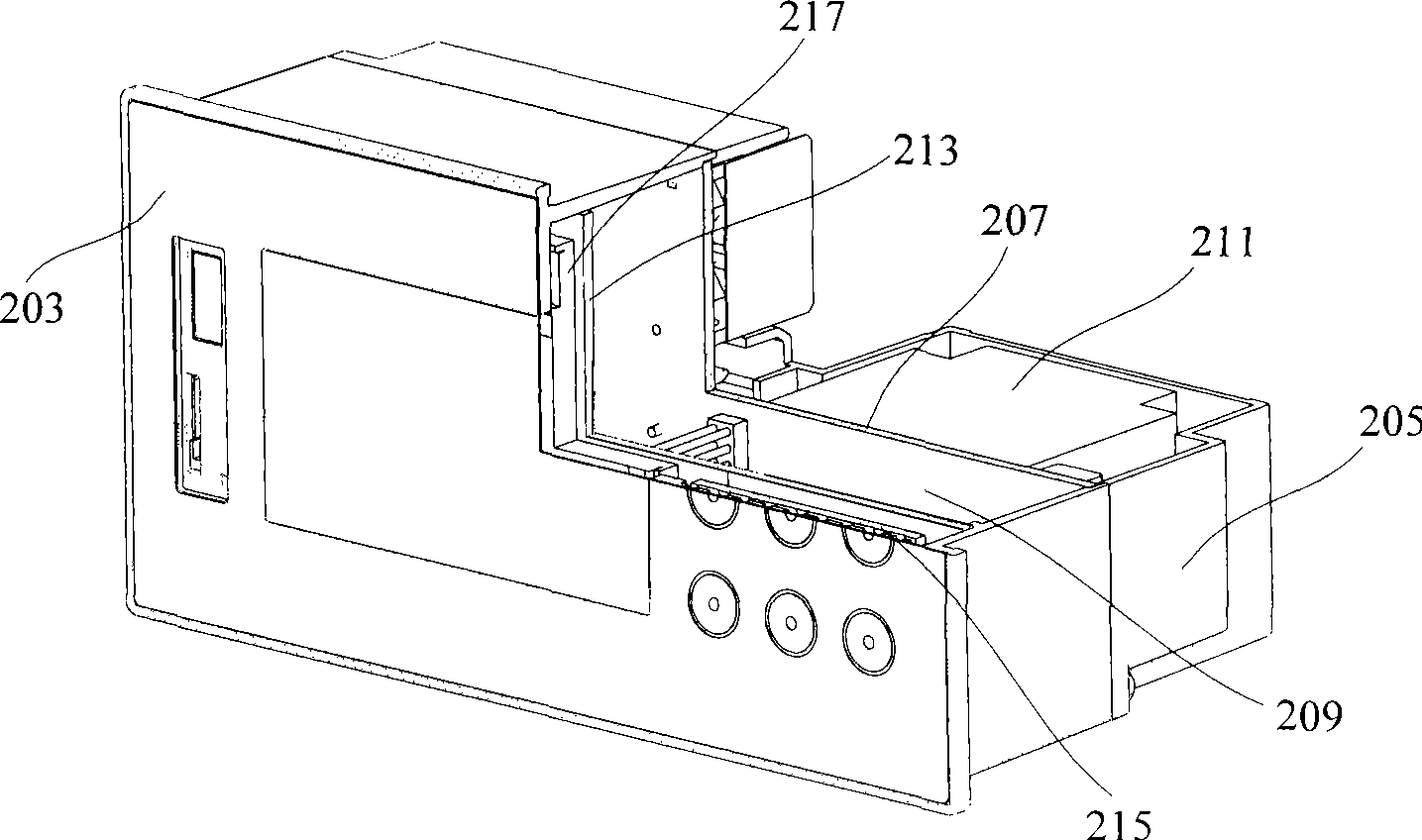

Instrument cabinet

ActiveCN101436437AAvoid interferenceImprove heat transferInstrument housingEngineeringElectrical and Electronics engineering

Owner:ZHEJIANG SUPCON INSTR

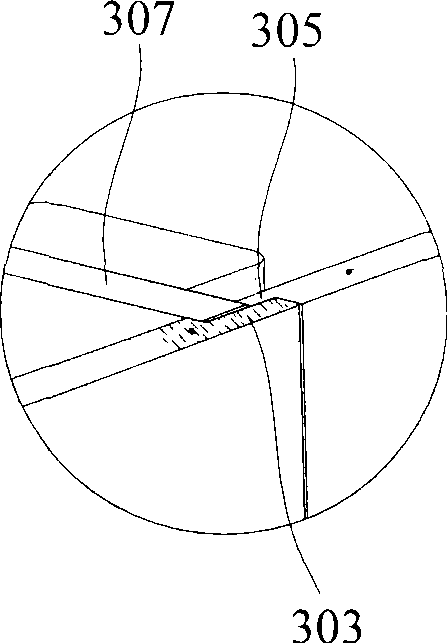

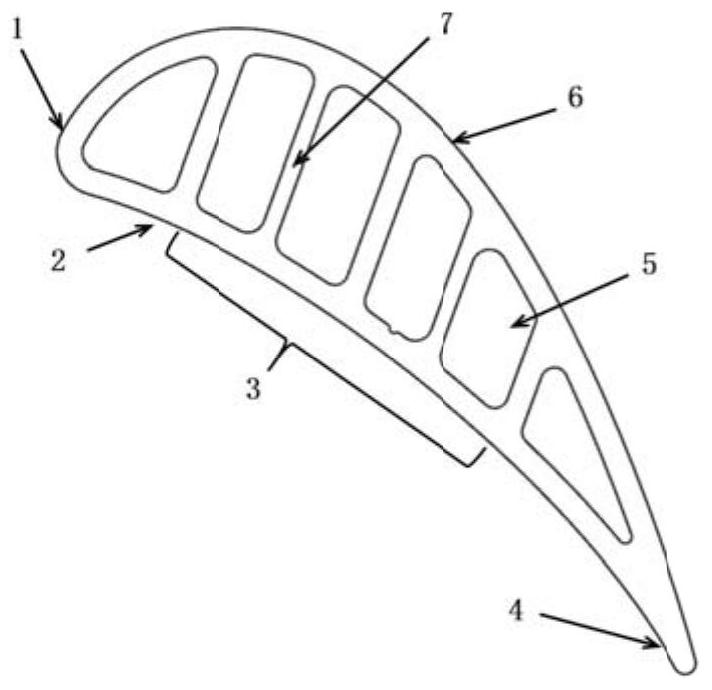

Turbine blade of gas turbine engine with V-shaped airflow differential plates

InactiveCN112282854AImprove structural strengthExtended service lifeBlade accessoriesMachines/enginesCold airThermodynamics

The invention discloses a turbine blade of a gas turbine engine with V-shaped airflow differential plates. The turbine blade comprises a blade body and a tenon, wherein the blade body is arranged on the end wall side of the tenon; the blade body comprises a blade front edge, a blade basin, a blade body middle chord area, a blade tail edge, a blade top and a blade back; a plurality of cooling cavities are formed inside the blade body; partition plates are arranged among the plurality of cooling cavities; a V-shaped airflow differential plate is arranged in each cooling cavity; air film holes are formed in the surface of the blade body; at least one blade top dust removal hole is formed in the blade top; cold air inlets are formed in an extension root of the tenon; cooling passages corresponding to the two cold air inlets, close to the front edge of the blade, of the extension root are combined into a flow path to communicate with the cooling cavities; and cooling passages correspondingto the two cold air inlets close to the tail edge of the blade are combined into a flow path to communicate with the cooling cavities. Therefore, the V-shaped airflow differential plates are fixed onto two adjacent partition plates, the structural intensity of the blade body can be favorably enhanced, and the blade can be kept at a low temperature level.

Owner:HARBIN INST OF TECH

Granulation system with thermal protection function

InactiveCN109371185AAids in heat protectionRealize transmissionRecycling and recovery technologiesTemperature monitoringStops device

The invention discloses a granulation system with a thermal protection function. The granulation system with the thermal protection function comprises a rotating shaft, an auxiliary cooling air supplyunit, a temperature monitoring unit and a granulating device, wherein the granulating device is fixed at the top of the rotating shaft. The granulation system is characterized in that the auxiliary cooling air supply unit provides cooling air for the temperature monitoring unit and the granulating device; the auxiliary cooling air supply unit comprises an air duct and an air inlet pipeline; the air duct is connected with a fan through the air inlet pipeline; the temperature monitoring unit and the granulating device are arranged in the air duct; the temperature monitoring unit comprises a plurality of thermocouples, a through aperture conductive slip ring, a rotation stopping piece and a rotation stopping device; and the plurality of thermocouples are arranged in the granulating device, the rotation stopping device is arranged below the granulating device, the through aperture conductive slip ring is arranged on the rotating shaft in a sleeving mode and is fixed on the rotation stopping device through the rotation stopping piece. The granulation system can be widely applied to the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

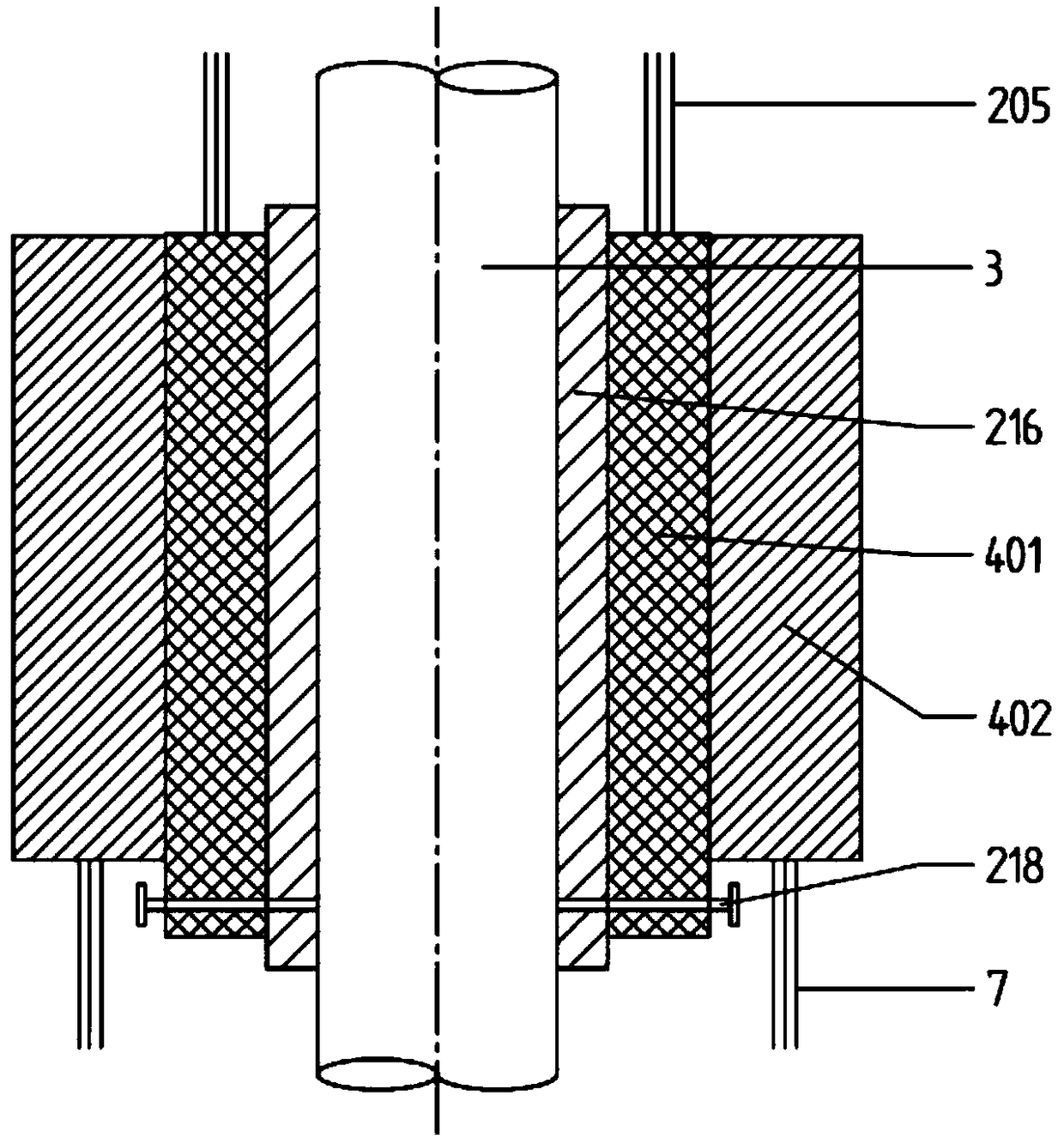

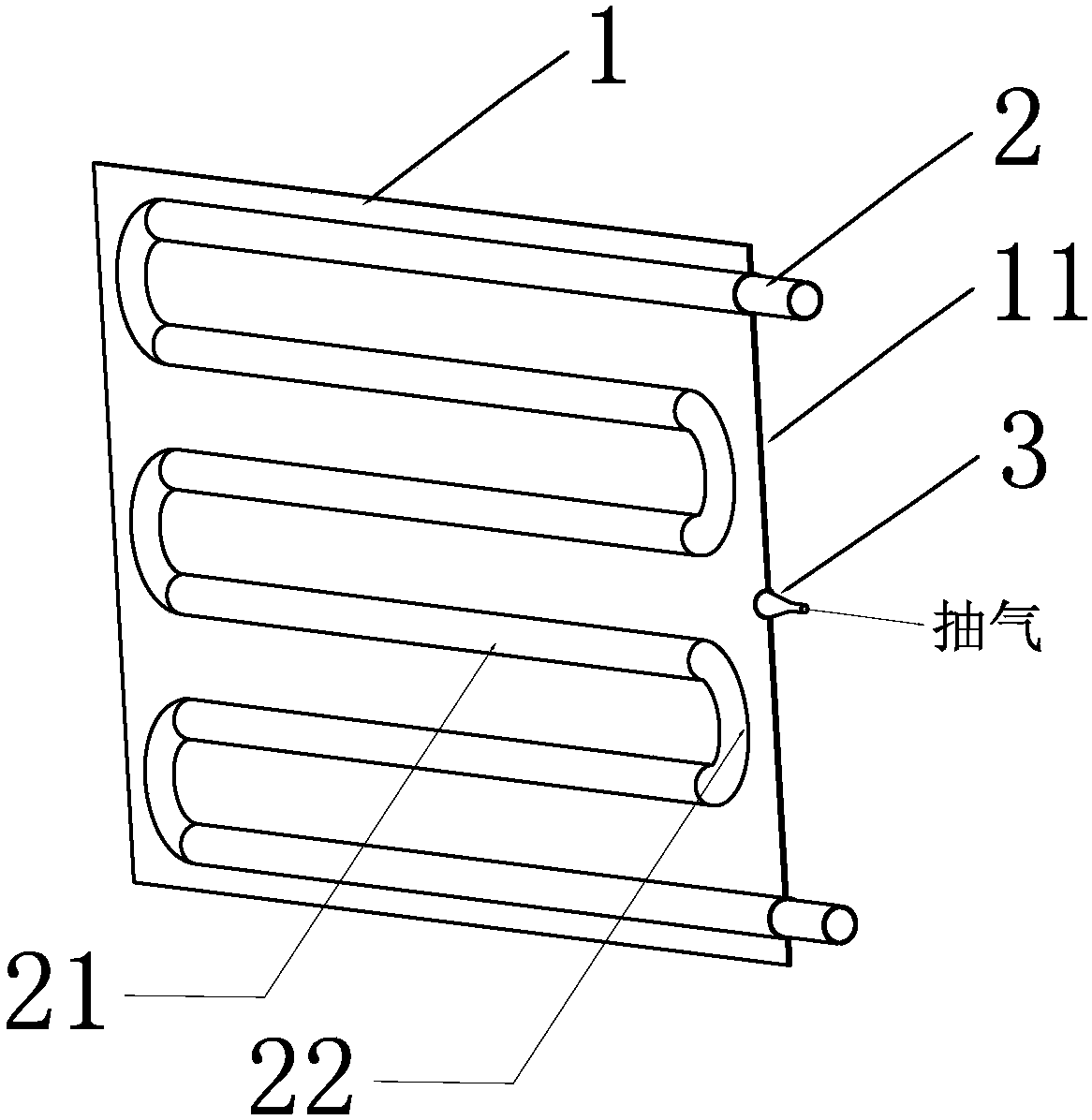

Bag and tube type vacuum attachment tube bundle and manufacturing method thereof

PendingCN108387129AImprove heat transferImprove corrosion resistanceCorrosion preventionHeat exhanger sealing arrangementEngineeringTubes types

The invention discloses a bag and tube type vacuum attachment tube bundle and a manufacturing method of the bag and tube type vacuum attachment tube bundle. The bag and tube type vacuum attachment tube bundle is characterized by comprising a heat exchange bag and an S-shaped heat exchange coiled tube, wherein the S-shaped heat exchange coiled tube is located on the same plane. The heat exchange coiled tube is arranged in the heat exchange bag, and a liquid inlet tube and a liquid outlet tube of the heat exchange coiled tube are exposed out of the heat exchange bag. The heat exchange bag comprises an air exhaust faucet. After the air in the heat exchange bag is extracted through the air exhaust faucet to form the vacuum, the front bag face and the rear bag face of the heat exchange bag areattached, and the front bag face and the rear bag face of the heat exchange bag and the outer side wall face of the heat exchange coiled tube are in close attachment. The bag and tube type vacuum attachment tube bundle has the beneficial effects that the heat exchange bag with high decay resistance covers the surface of the heat exchange coiled tube in a vacuum negative-pressure attachment mode when a tube material with high heat conductivity is adopted by the heat exchange coiled tube, and therefore the heat exchange coiled tube on a heat exchanger can keep high heat conductivity, and the decay resistance of the heat exchange surface is also enhanced. By the adoption of the vacuum negative-pressure attachment, the heat exchange coiled tube and the heat exchange bag can be completely attached with each other, no gaps exist between the heat exchange coiled tube and the heat exchange bag, a material which can conduct heat is adopted by the heat exchange bag, the heat dissipation area ofthe heat exchanger is increased, and therefore the service life of the heat exchanger can be prolonged, and the heat exchange efficiency is improved.

Owner:颜汉强

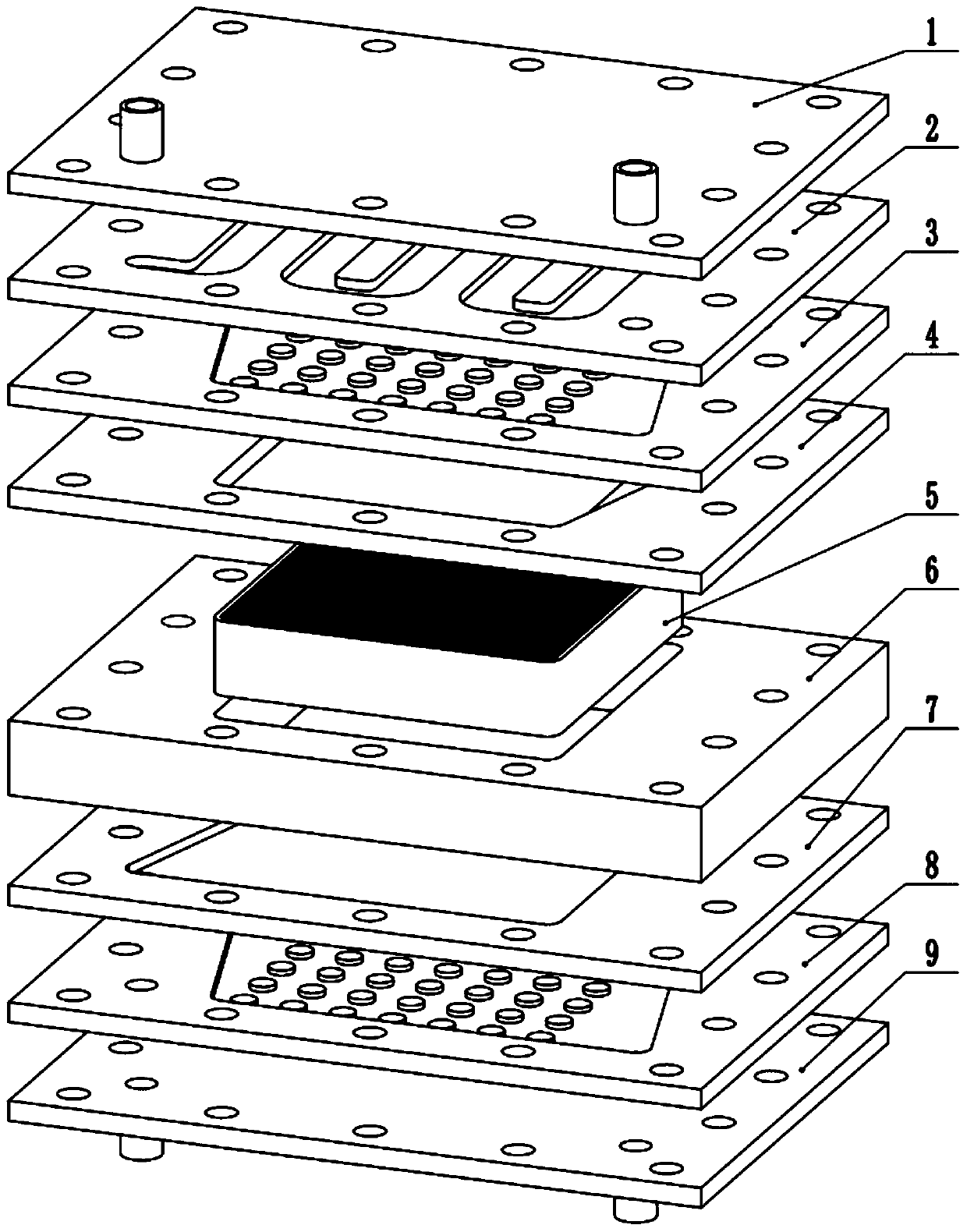

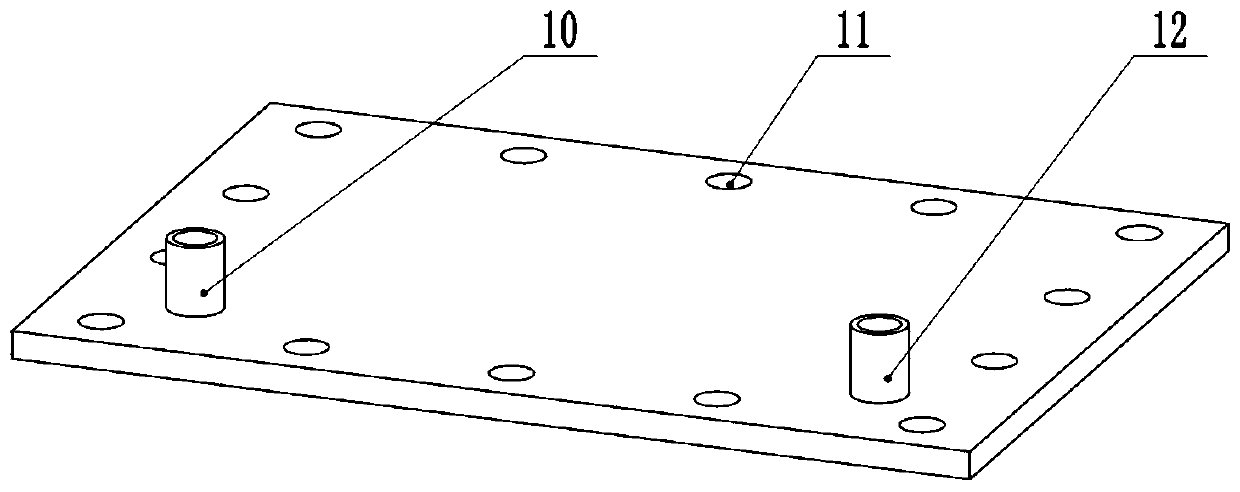

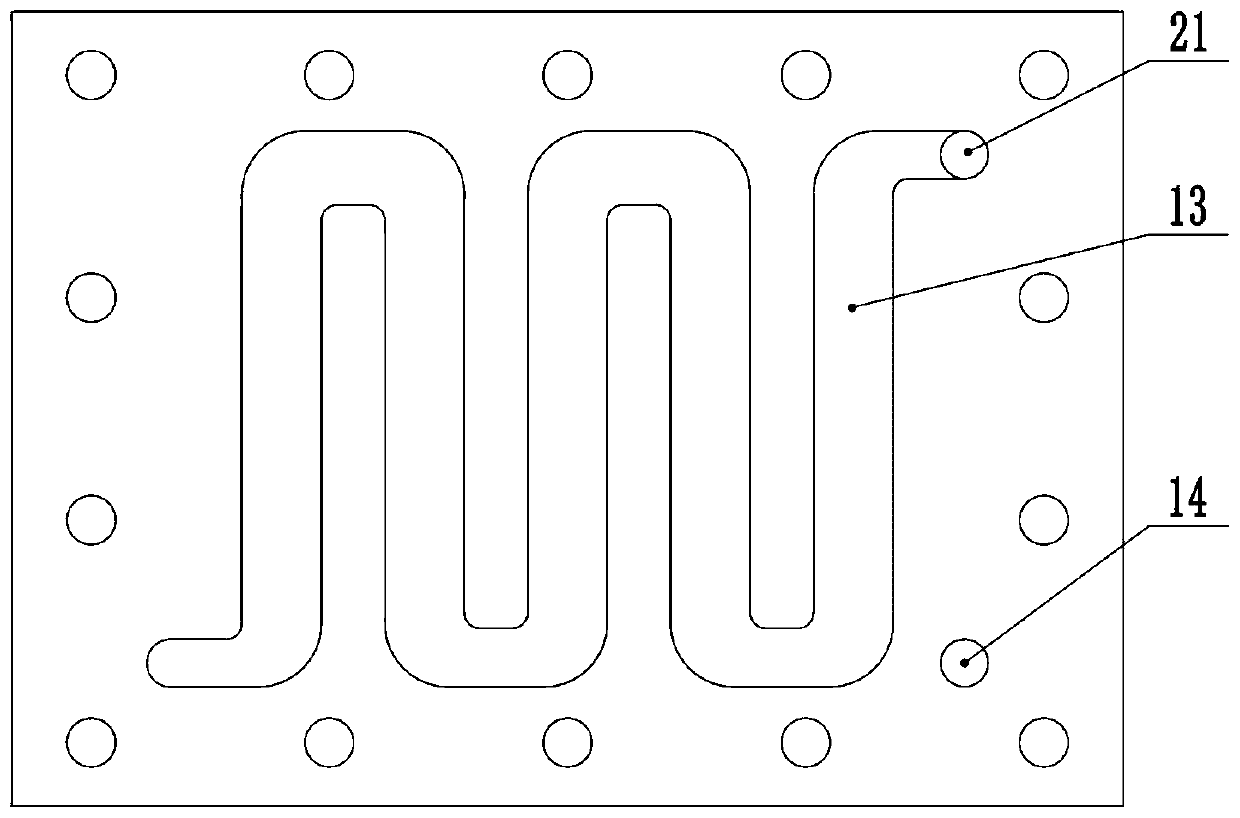

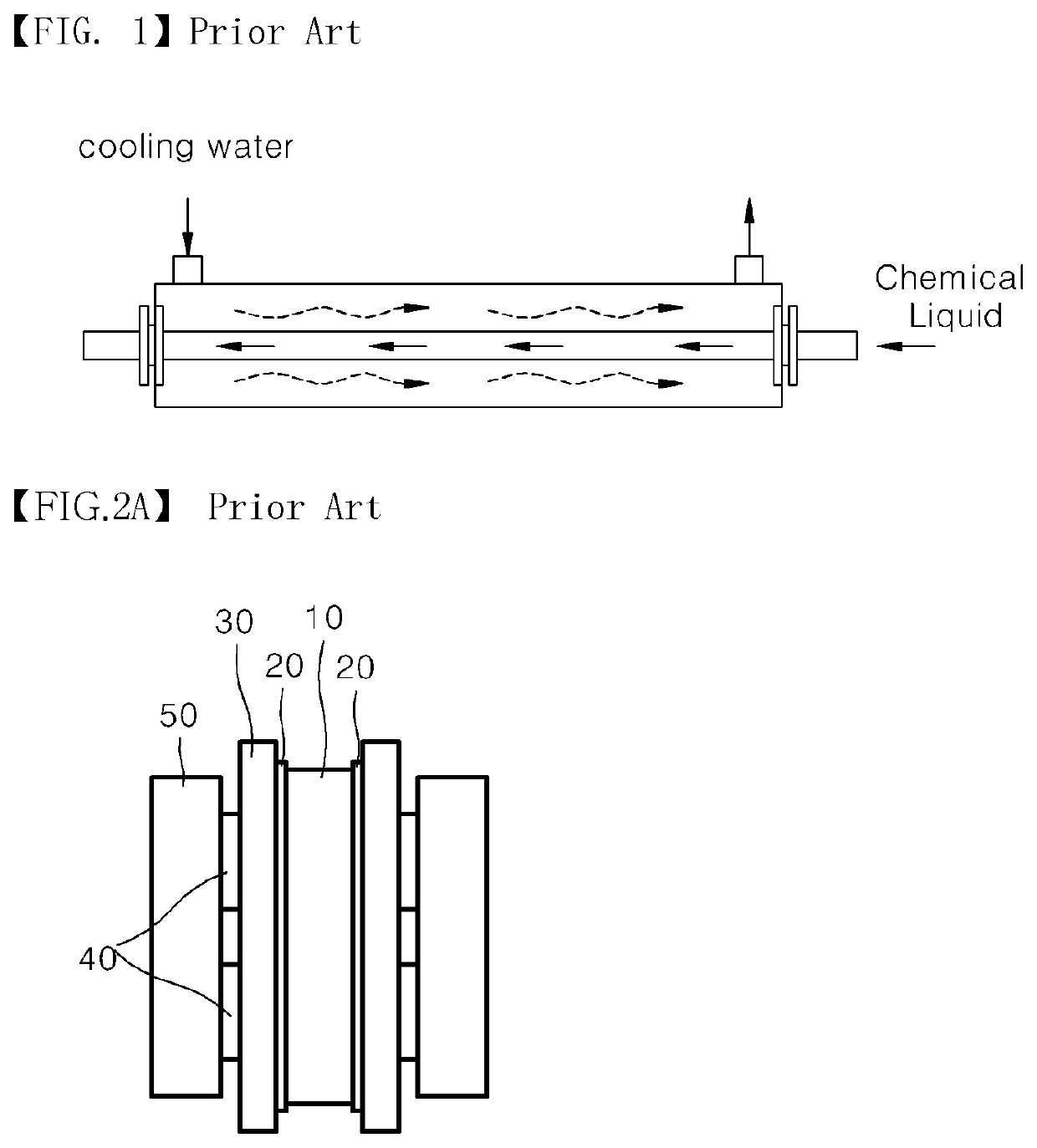

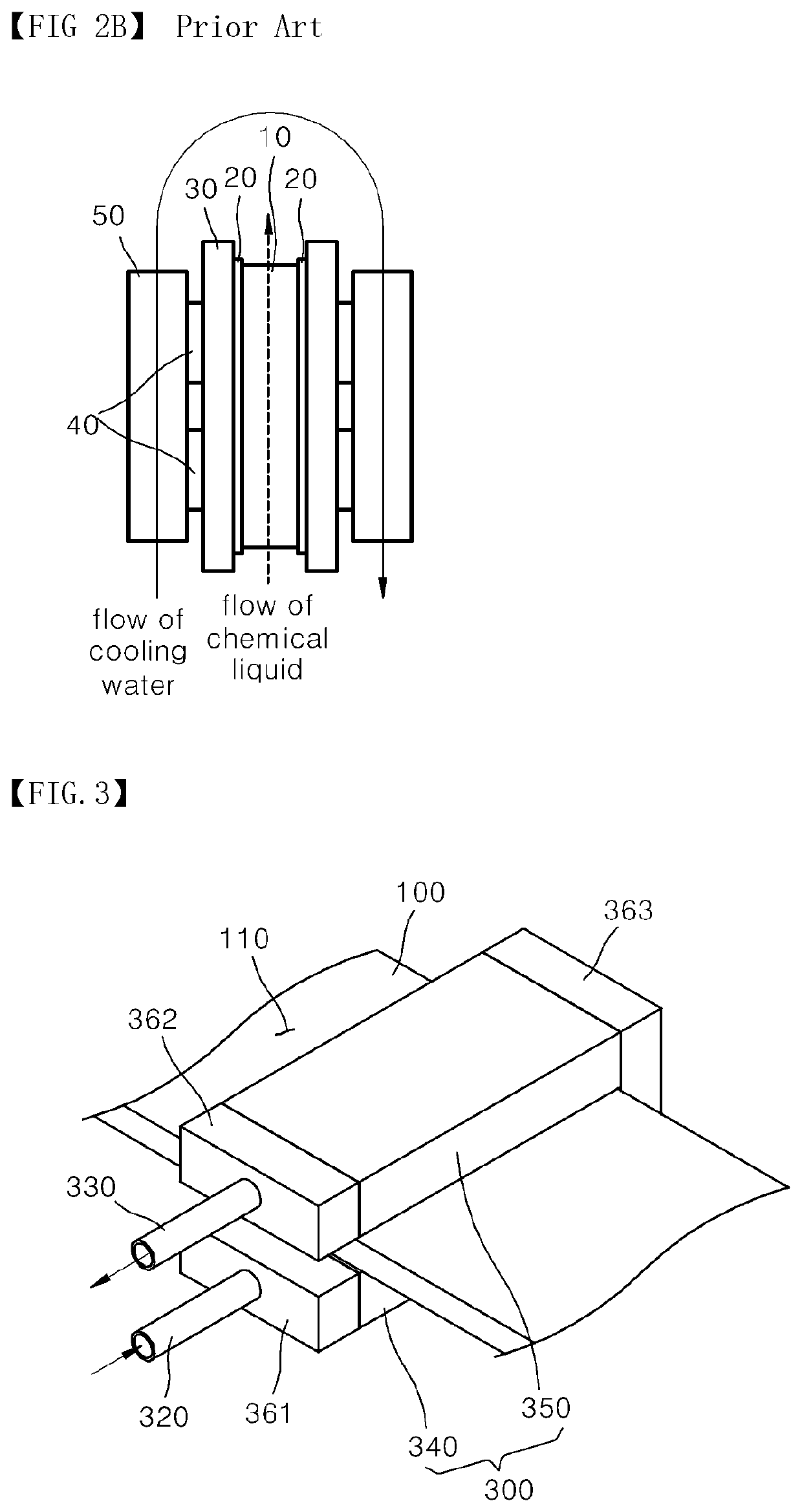

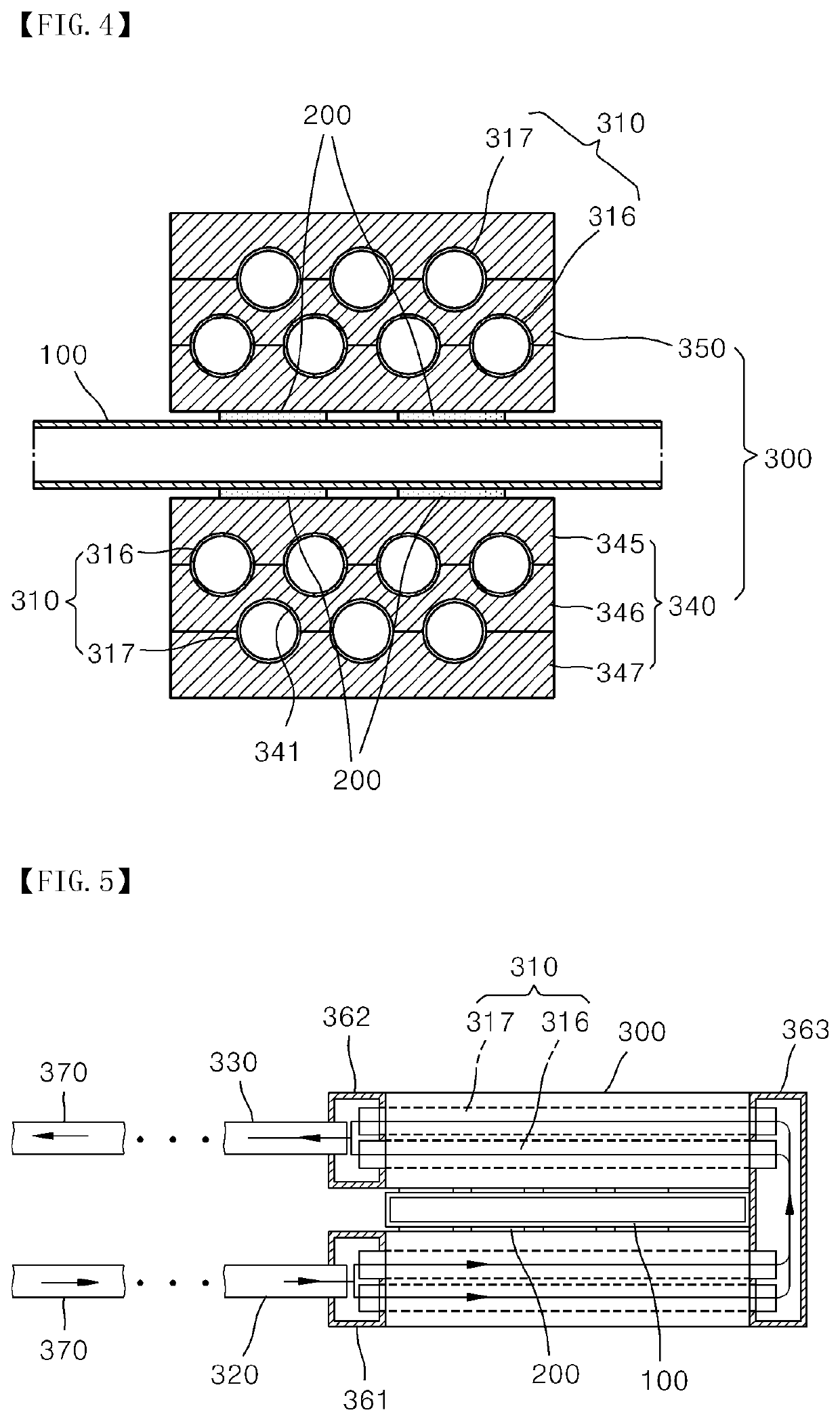

Temperature control device for chemical liquid used in semiconductor manufacturing process

PendingUS20210213482A1Improve heat transferUpgrade efficiencyLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringDeuteron radiation

A temperature control device for a chemical liquid used in a semiconductor manufacturing process. The device includes: a first heat sink having a cooling water flow path formed therein; a plurality of thermoelectric modules coming into contact with both side surfaces of the first heat sink, respectively; and a second heat sink coming into contact with the thermoelectric modules. The second heat sink includes first and second heat sink blocks, a chemical liquid inlet tube and a chemical liquid outlet tube connected to the first and second heat sink blocks, and a plurality of chemical liquid flow path tubes inserted into the insides of the first and second heat sink blocks in such a manner as to communicate with one another and with the chemical liquid inlet tube and the chemical liquid outlet tube, respectively, to flow the chemical liquid therealong.

Owner:BANG MIN CHEOL

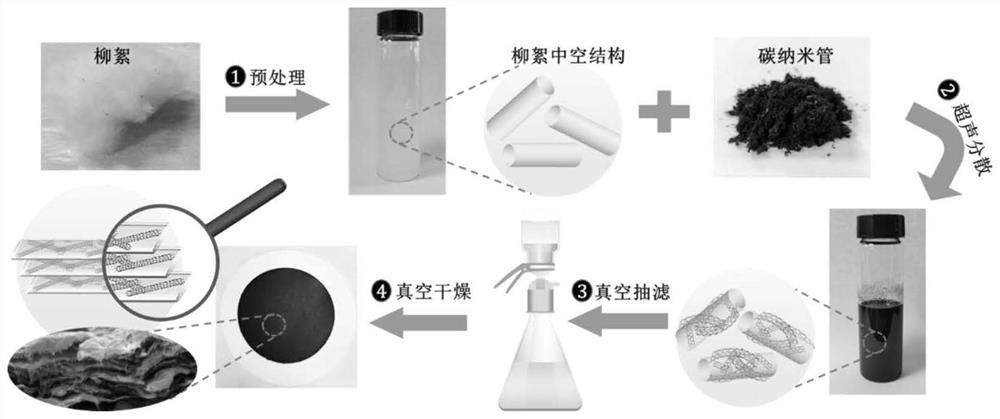

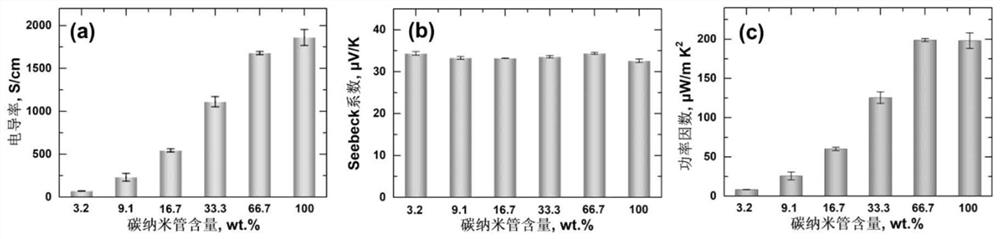

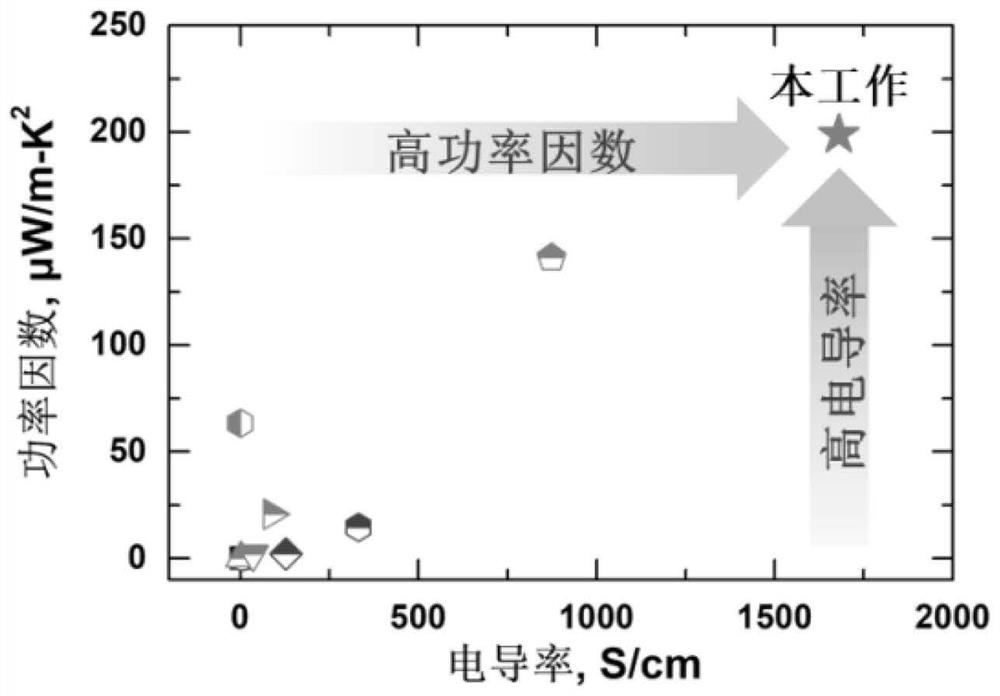

Green washing wearable thermoelectric self-powered sensing device and preparation method thereof

ActiveCN114383757AGood flexibilityImprove heat transferThermometer detailsBody temperature measurementCarbon nanotubeDopant

The invention discloses a green washing wearable thermoelectric self-powered sensing device and a preparation method thereof, and the method comprises the steps: adding a carbon nanotube into a catkin suspension, and carrying out the treatment to obtain a p-type carbon nanotube / catkin flexible composite film; adding an n-type dopant into an organic solvent, dropwise coating the p-type carbon nanotube / catkin flexible composite film with the n-type dopant, and carrying out patterning treatment to obtain an n-type carbon nanotube / catkin flexible composite film; coating the surfaces of the p-type carbon nano tube / catkin flexible composite film and the n-type carbon nano tube / catkin flexible composite film with silane; and then cutting into a long strip shape, and adopting electric series connection and thermal parallel connection to obtain the wearable thermoelectric self-powered sensing device. According to the invention, the p-type carbon nanotube / catkin thermoelectric film can be successfully transformed into the n-type through the n-type dopant, and the prepared thermoelectric device made of the full-biological composite material generates high output voltage of 4.17 V under the help of 280mV voltage provided by the boost converter and the power supply, and successfully lightens the LED lamp.

Owner:XI AN JIAOTONG UNIV

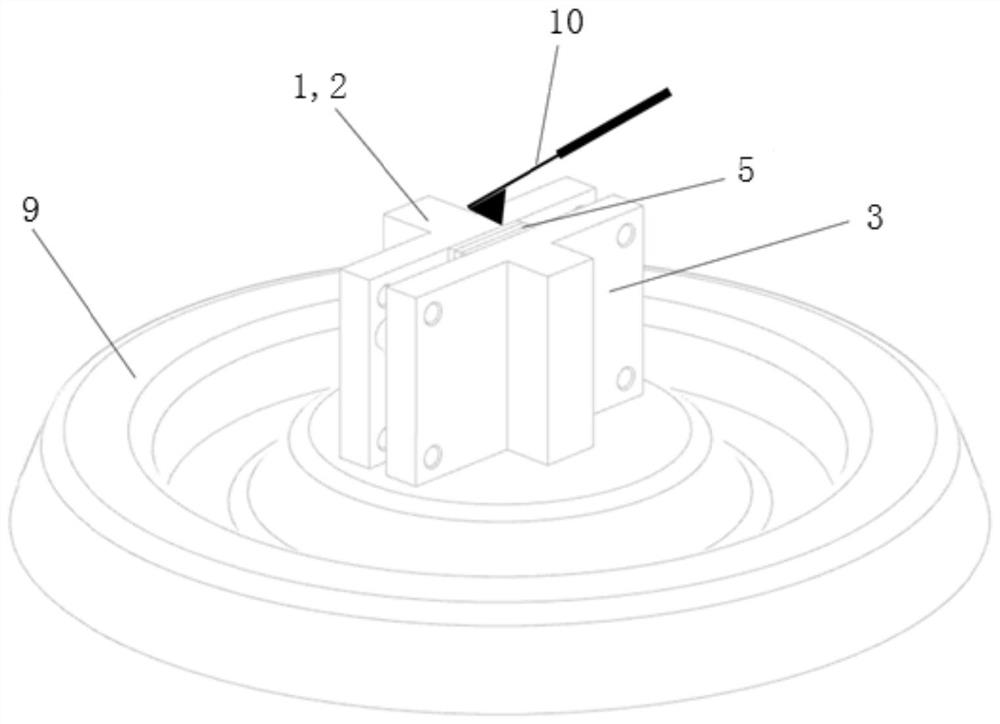

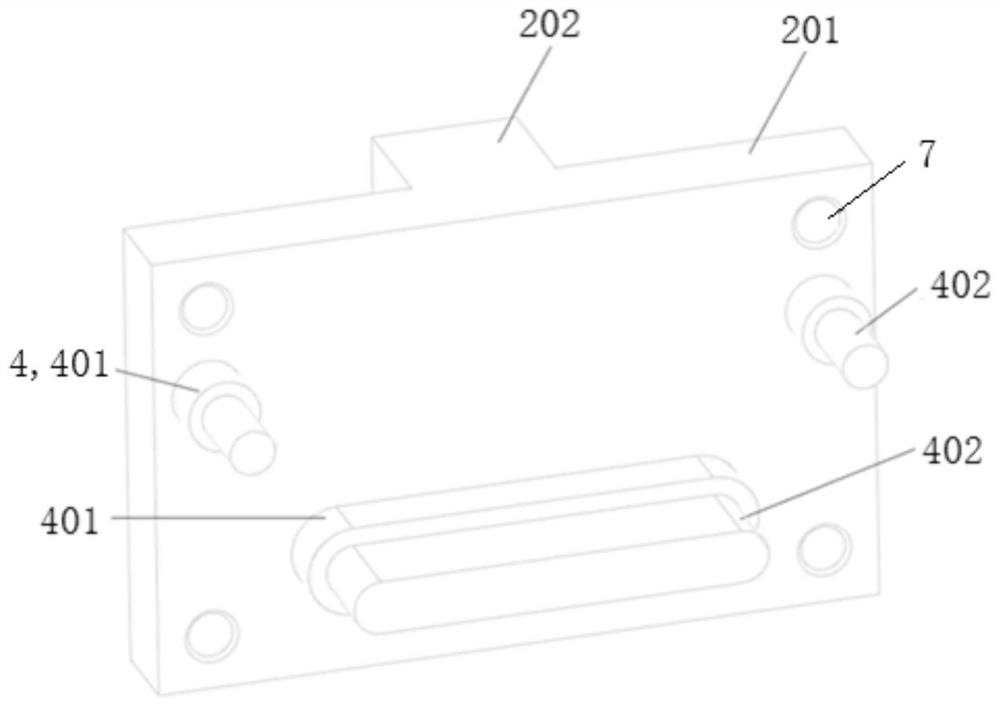

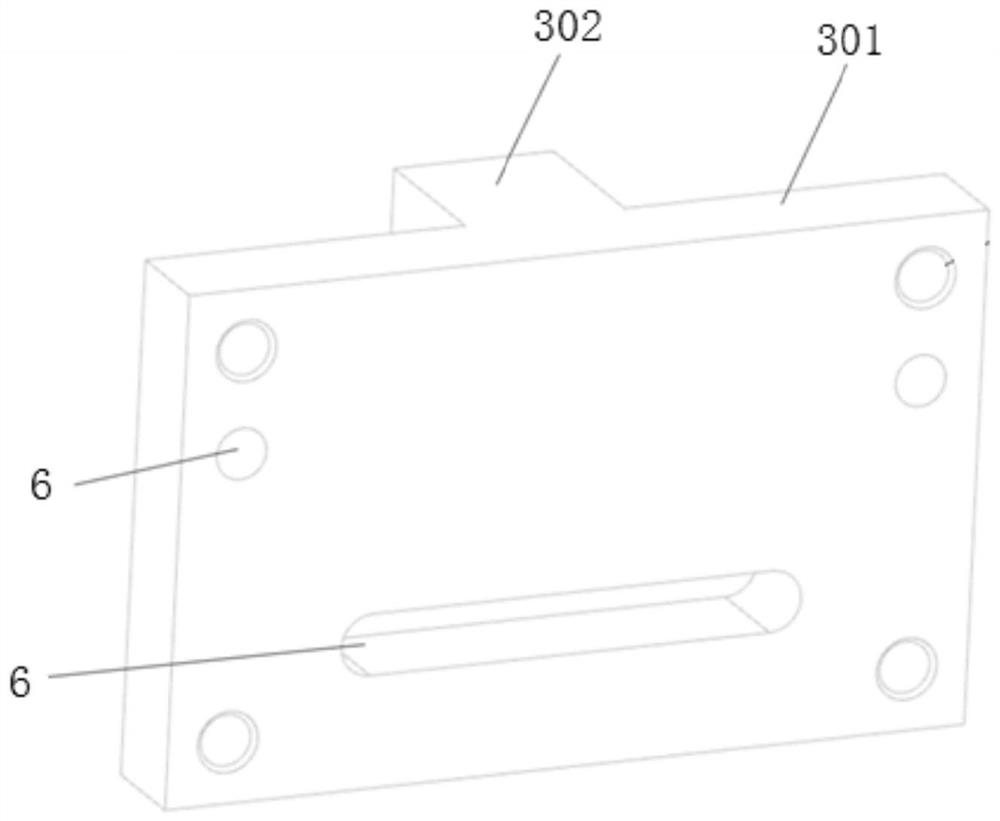

A device for observing the surface interface of variable temperature solid-state batteries by in-situ electrochemical atomic force microscopy

ActiveCN111337715BEasy to assembleSame pressureScanning probe microscopyTemperature controlAfm atomic force microscopy

The invention provides an in-situ electrochemical atomic force microscope for observing the surface interface of a variable temperature solid-state battery, including a battery fixture, the battery fixture includes a conductive plate and an insulating plate, the positive electrode of the solid-state battery is in contact with the conductive plate, and the negative electrode is in contact with the insulating plate. The feature is that the device also includes a temperature control device under the battery clamp, a protruding positioning device is provided on the side of the conductive plate facing the insulating plate, and a corresponding positioning device is provided on the side of the insulating plate facing the conductive plate. Positioning hole, after the positioning device is aligned with the positioning hole, the distance between the conductive plate and the insulating plate is equal to the thickness of the solid-state battery, preventing the solid-state battery from being over-extruded or unevenly stressed.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Energy storage device

InactiveUS20200144581A1Improve heat transferIncrease in numberCell seperators/membranes/diaphragms/spacersFinal product manufacturePhysicsChemistry

An electrochemical storage device comprising a container, a sheet of cathode material, a sheet of anode material and a separator material. The electrode sheets being wound in the container about a winding axis to provide a cylindrical electrochemical cell assembly having a curved sidewall and two end faces. At least one of the sheets of the anode or cathode material has a plurality of tabs that extend from one end face of the cylindrical electrochemical cell assembly. The tabs are arranged on said end face in a spiral about the winding axis.

Owner:DYSON TECH LTD

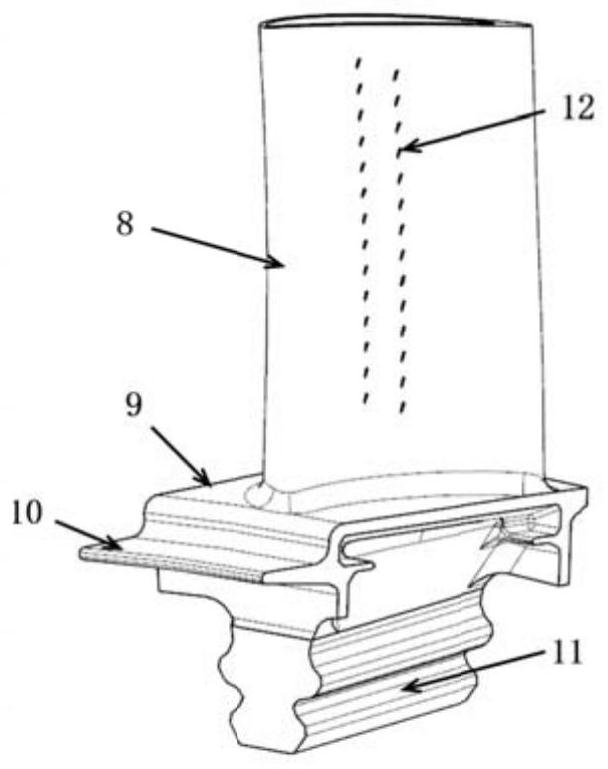

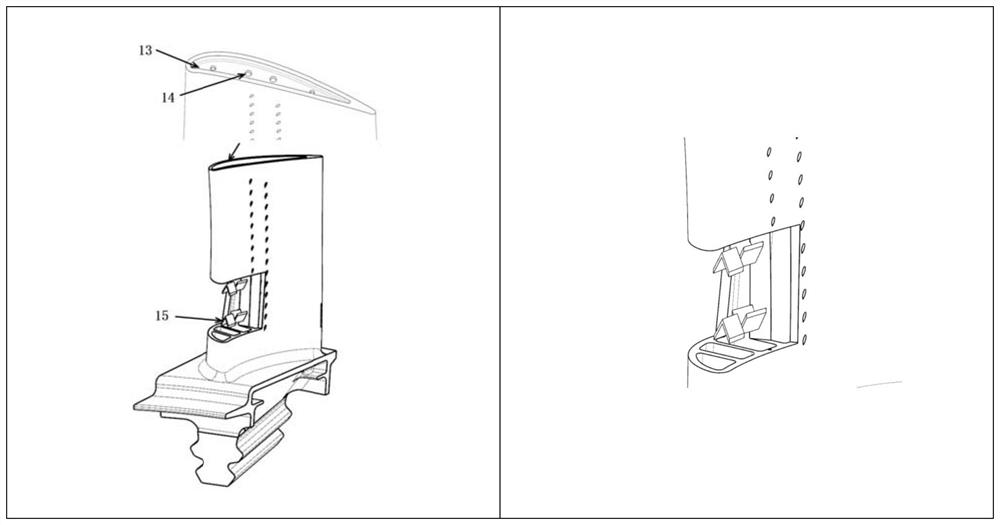

Turbine moving blade internal composite cooling structure

ActiveCN113266427AGuaranteed structural strengthImprove heat transfer performanceEngine fuctionsBlade accessoriesJet flowEngineering

The invention discloses a turbine moving blade internal composite cooling structure. The turbine moving blade internal composite cooling structure comprises a leading edge rotational flow cooling passage, a middle chord U-shaped cooling passage and a tail edge trapezoidal cooling passage, wherein the U-shaped cooling passage comprises a U-shaped cooling passage inlet section, a U-shaped cooling passage outlet section and a U-shaped cooling passage top turning area which are integrally formed, wherein the U-shaped cooling passage inlet section and the U-shaped cooling passage outlet section communicate through the U-shaped cooling passage top turning area, and the U-shaped cooling passage inlet section, the U-shaped cooling passage outlet section and the rotational flow cooling passage communicate through a plurality of jet flow holes which are formed in a staggered mode; a plurality of ball sockets / ball protrusions and air film hole structures are arranged on the surface of the whole cooling passage; and a plurality of fin structures are arranged in the U-shaped cooling passage and the tail edge trapezoidal cooling passage. According to the turbine moving blade internal composite cooling structure, through coupling of multiple structures, the structural strength of the blade is guaranteed, and the advantages of high heat transfer, low resistance, high adaptability and the like are achieved.

Owner:XI AN JIAOTONG UNIV

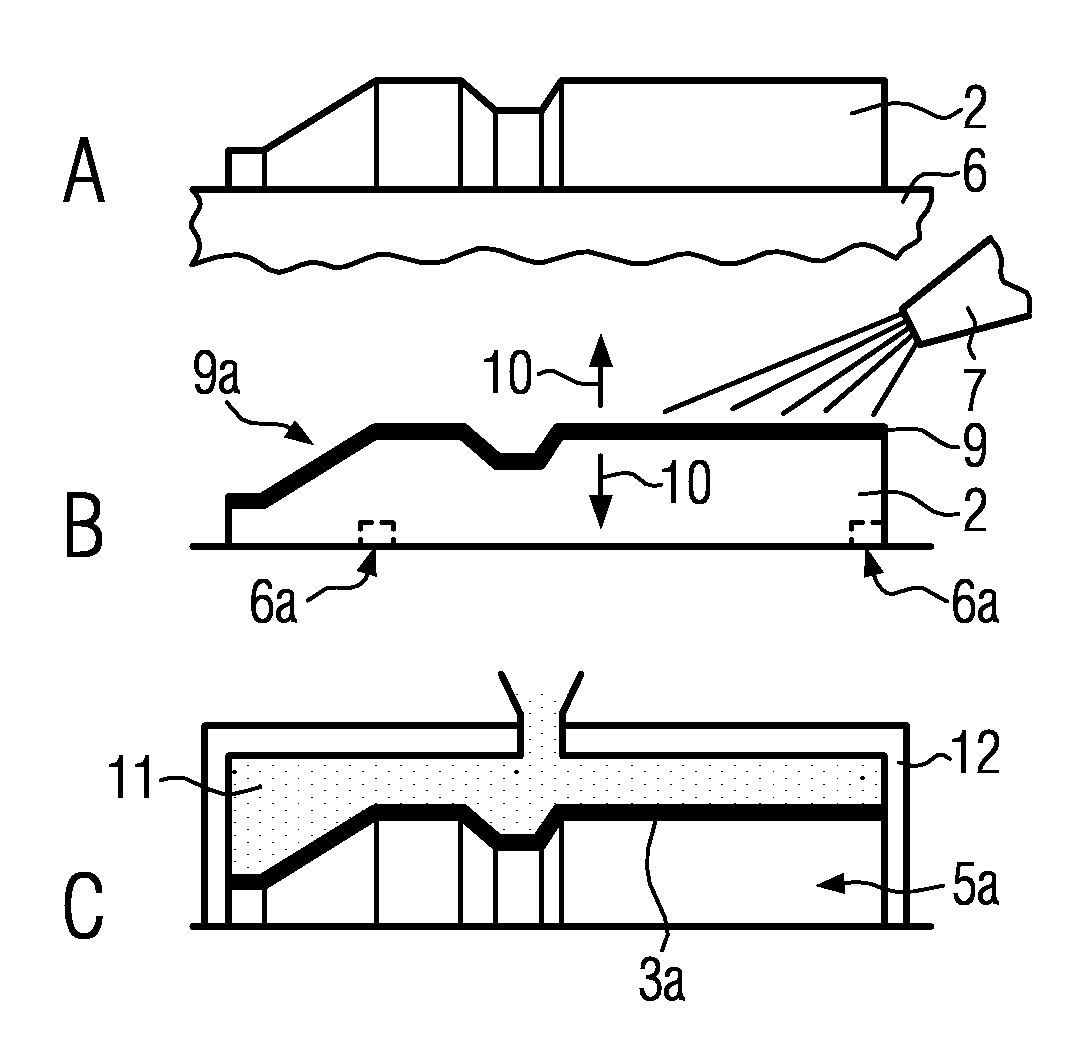

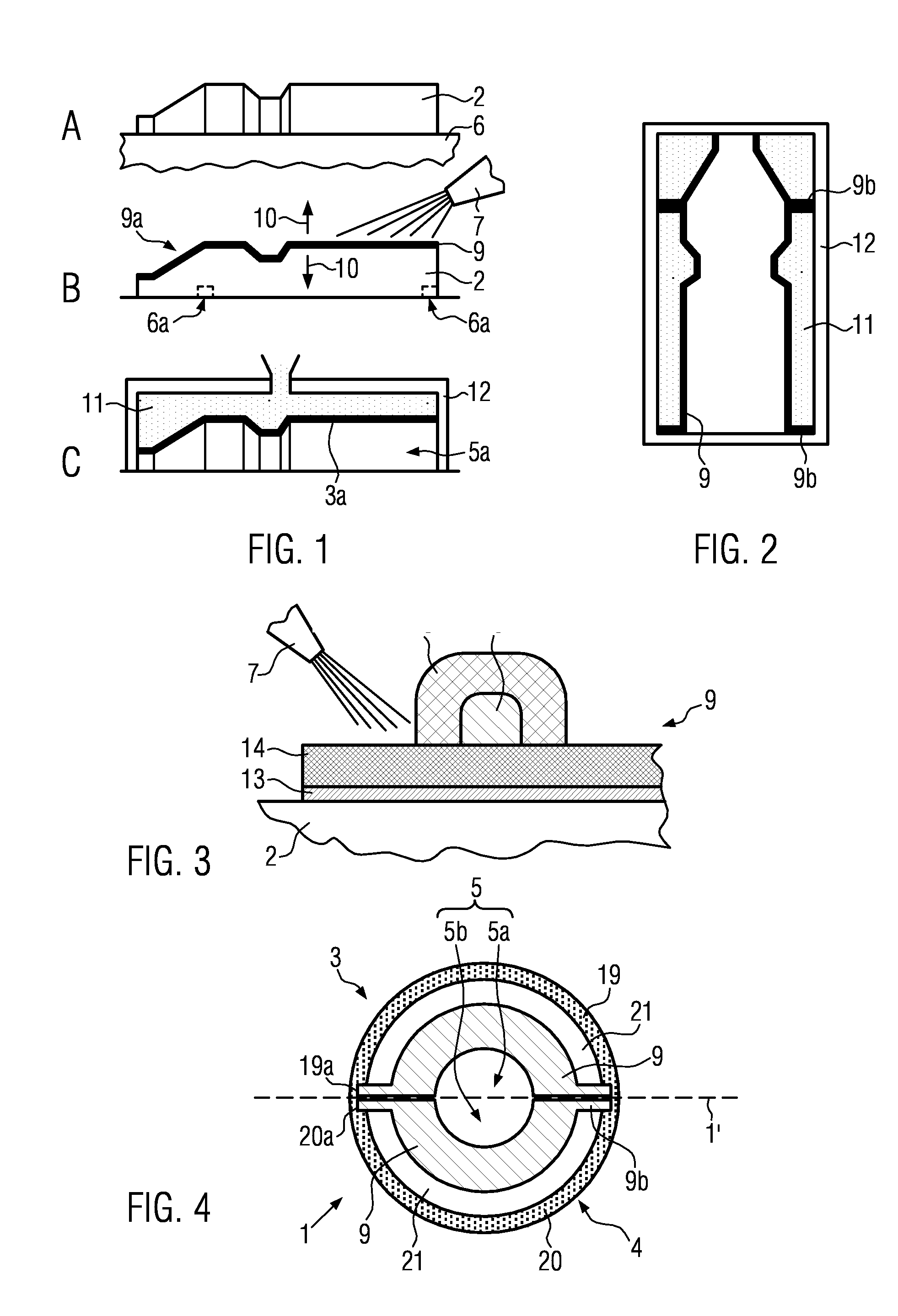

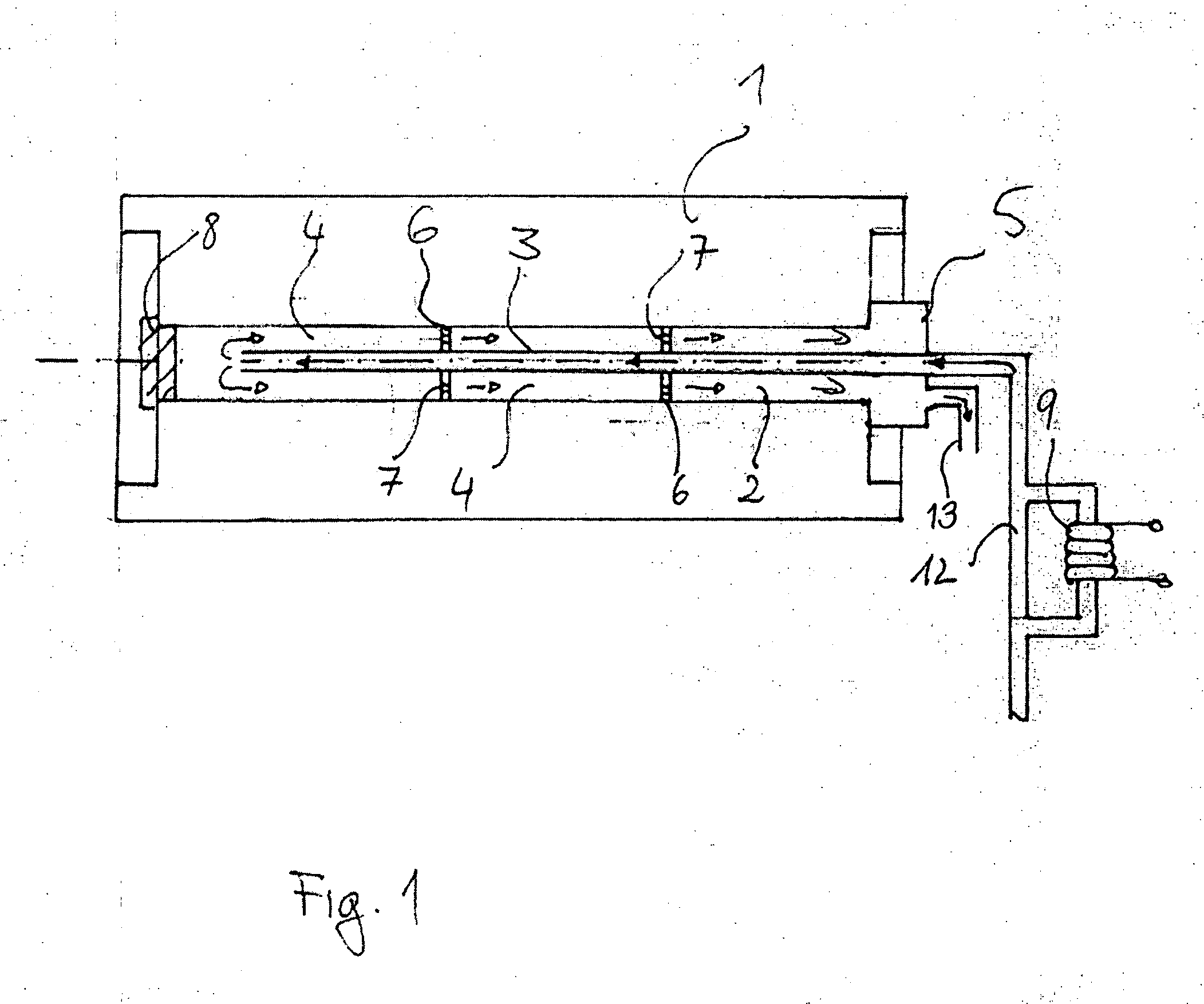

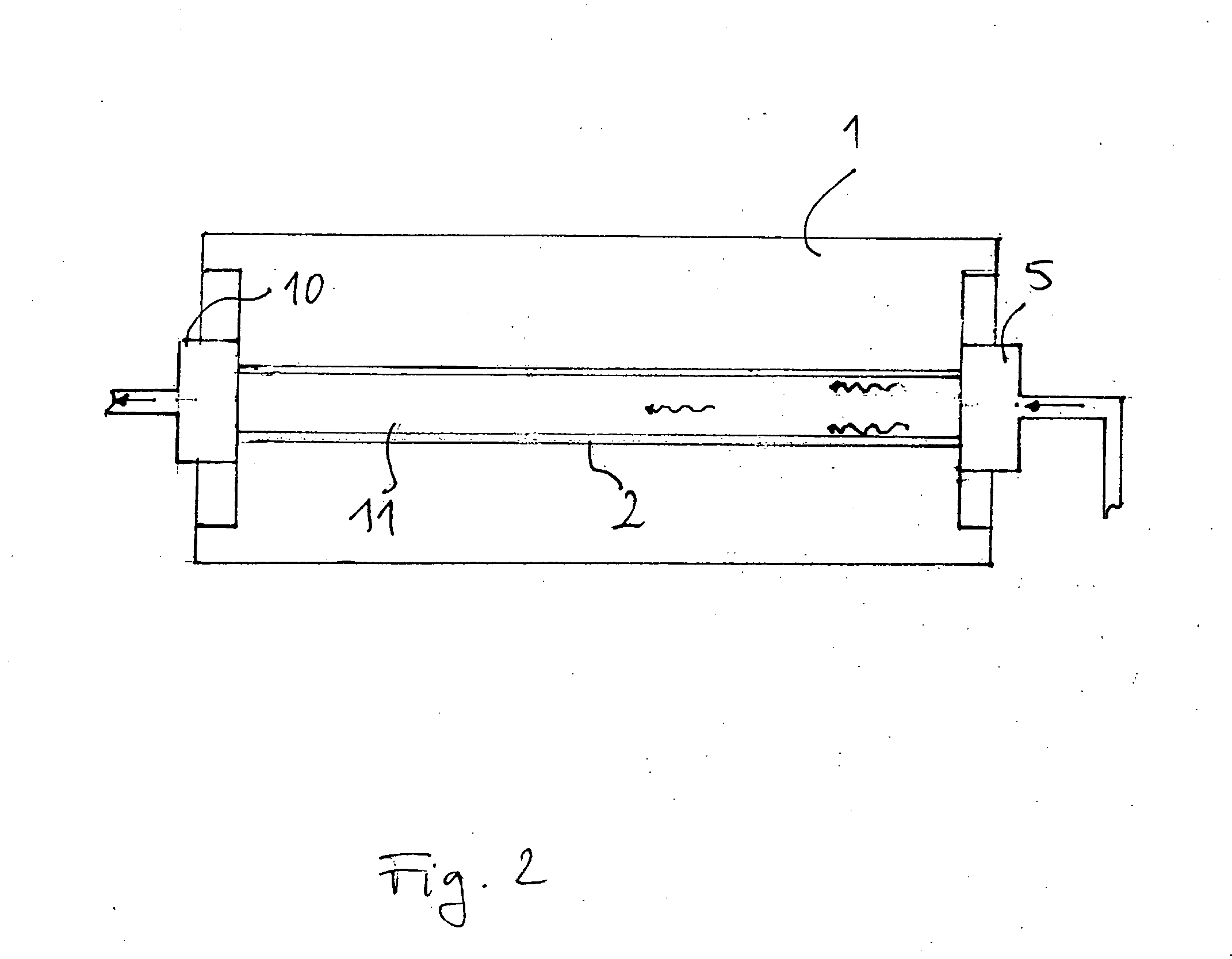

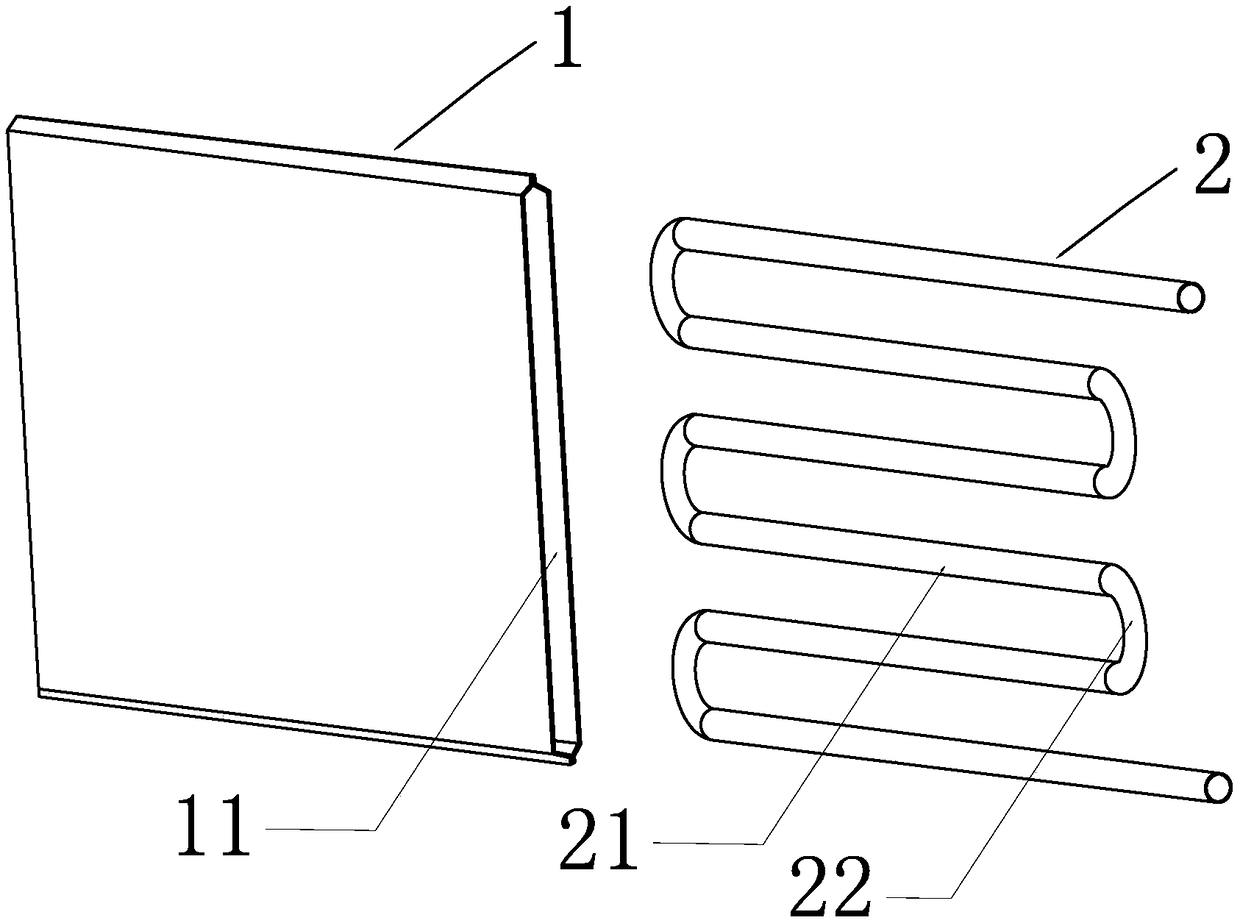

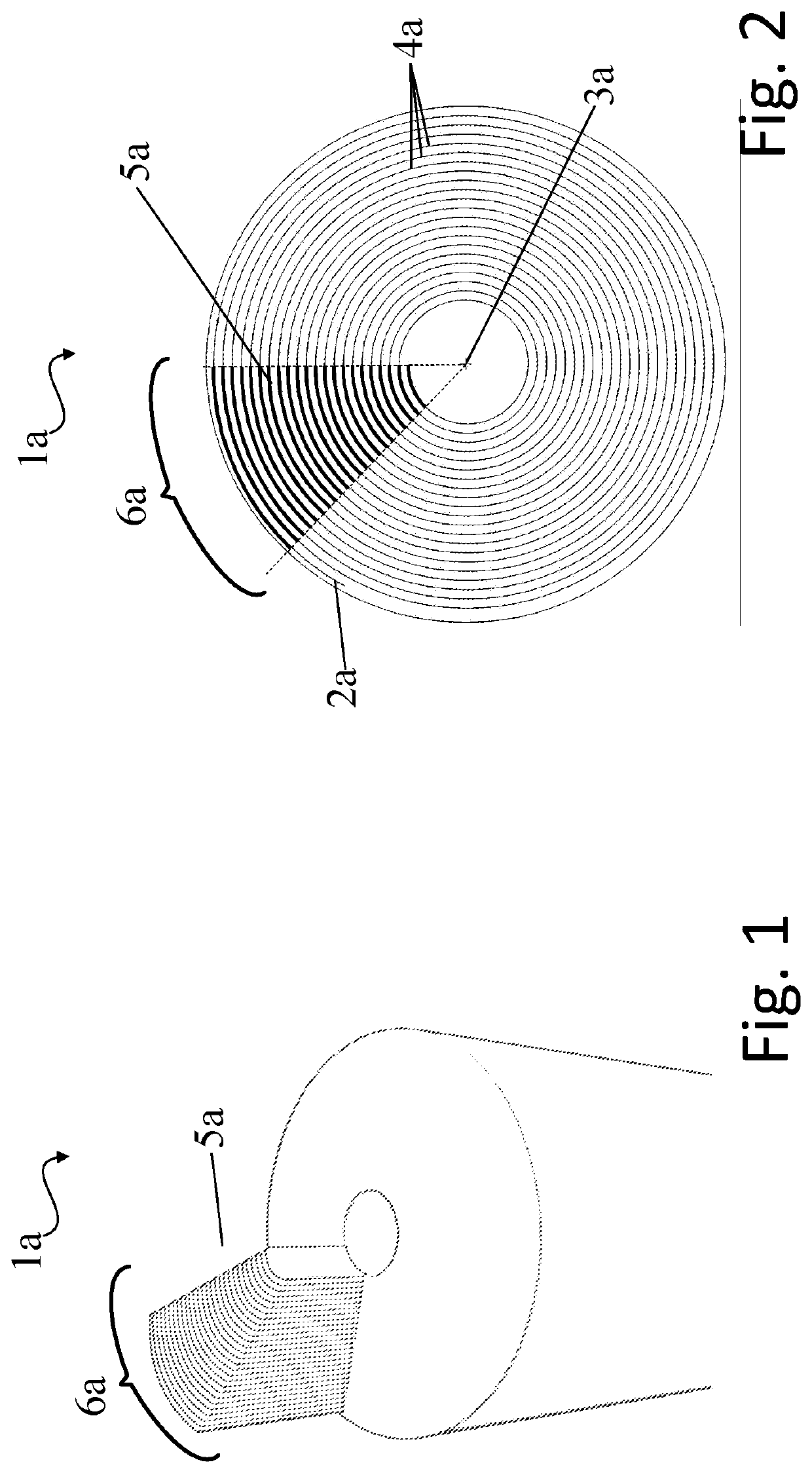

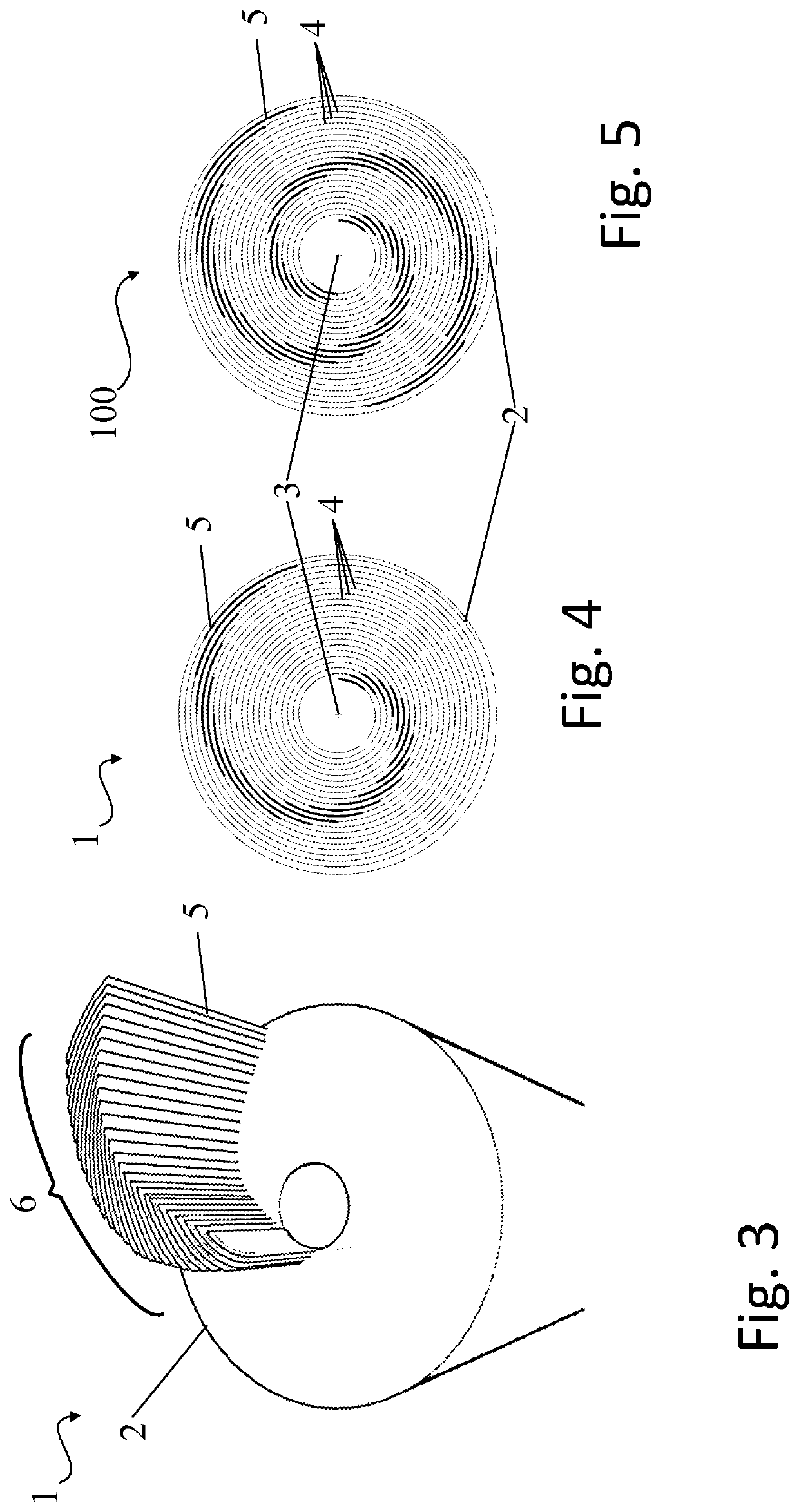

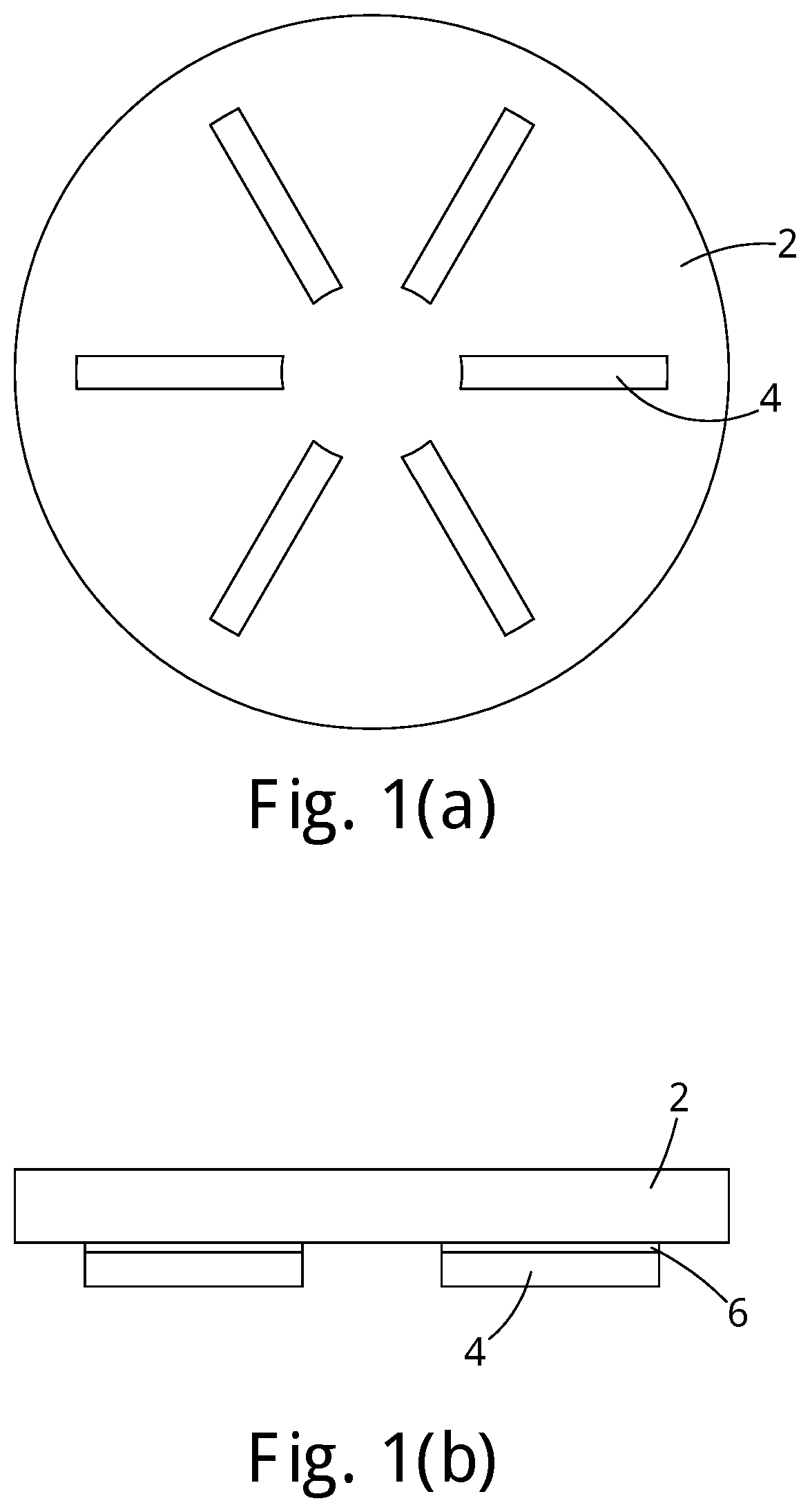

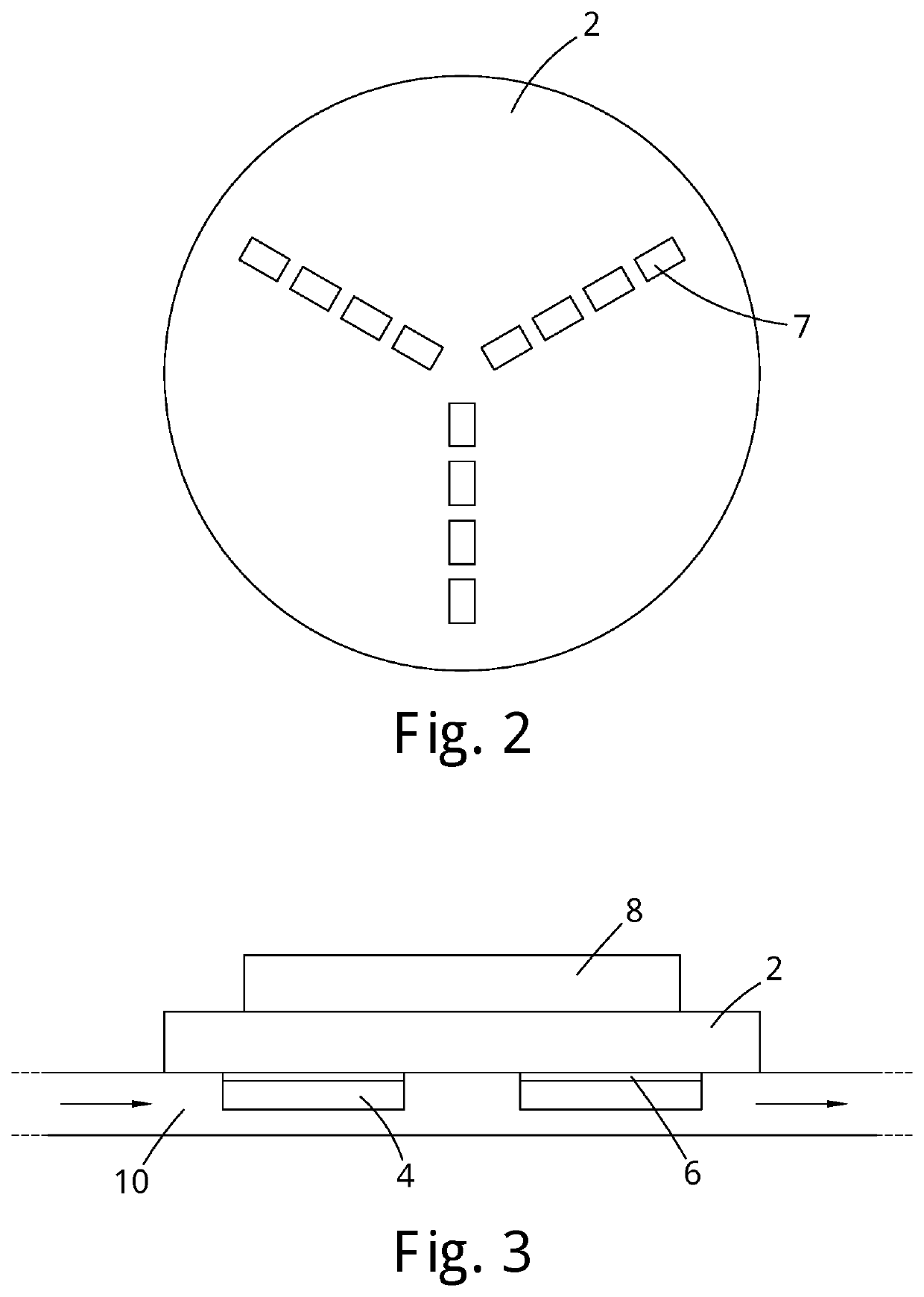

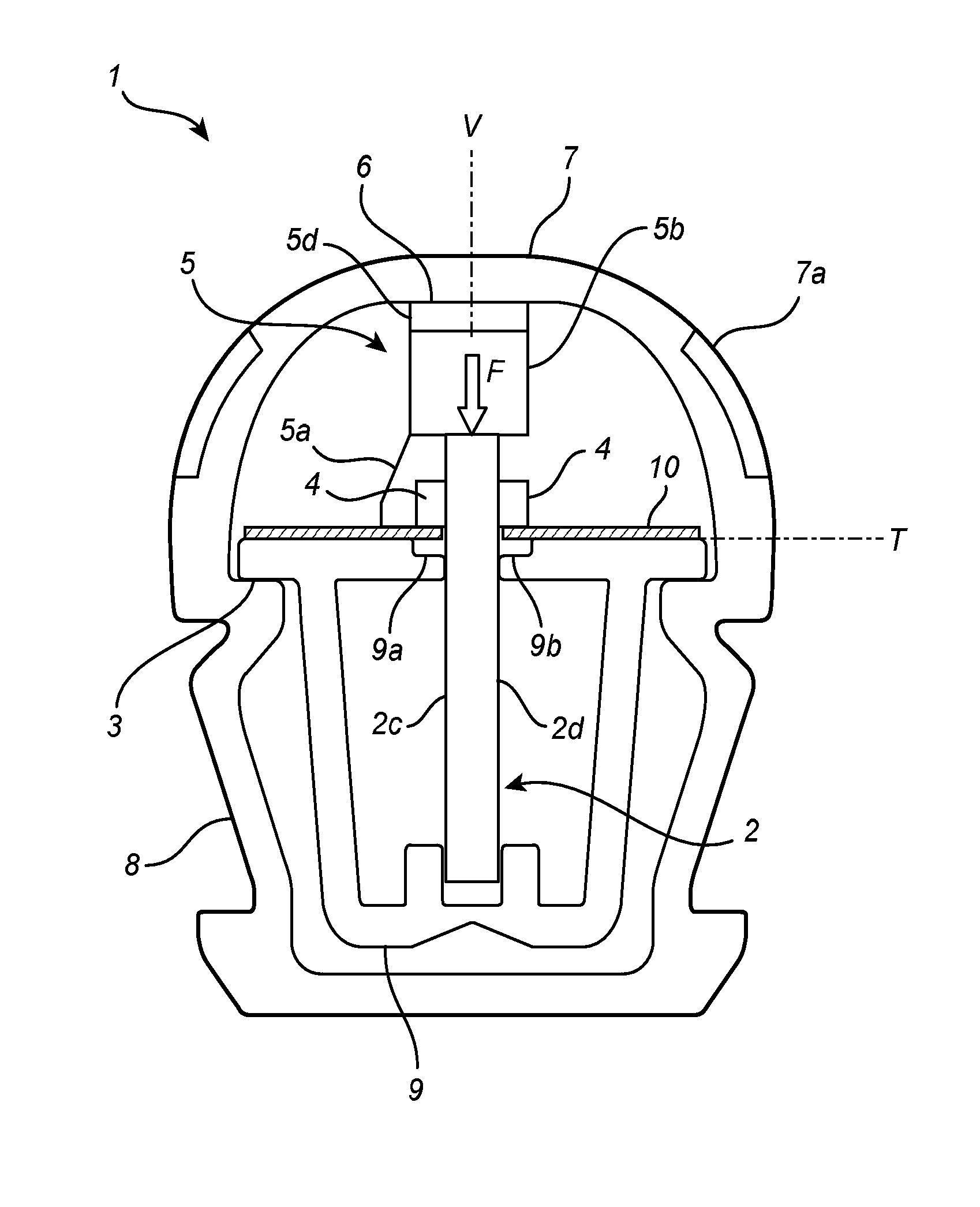

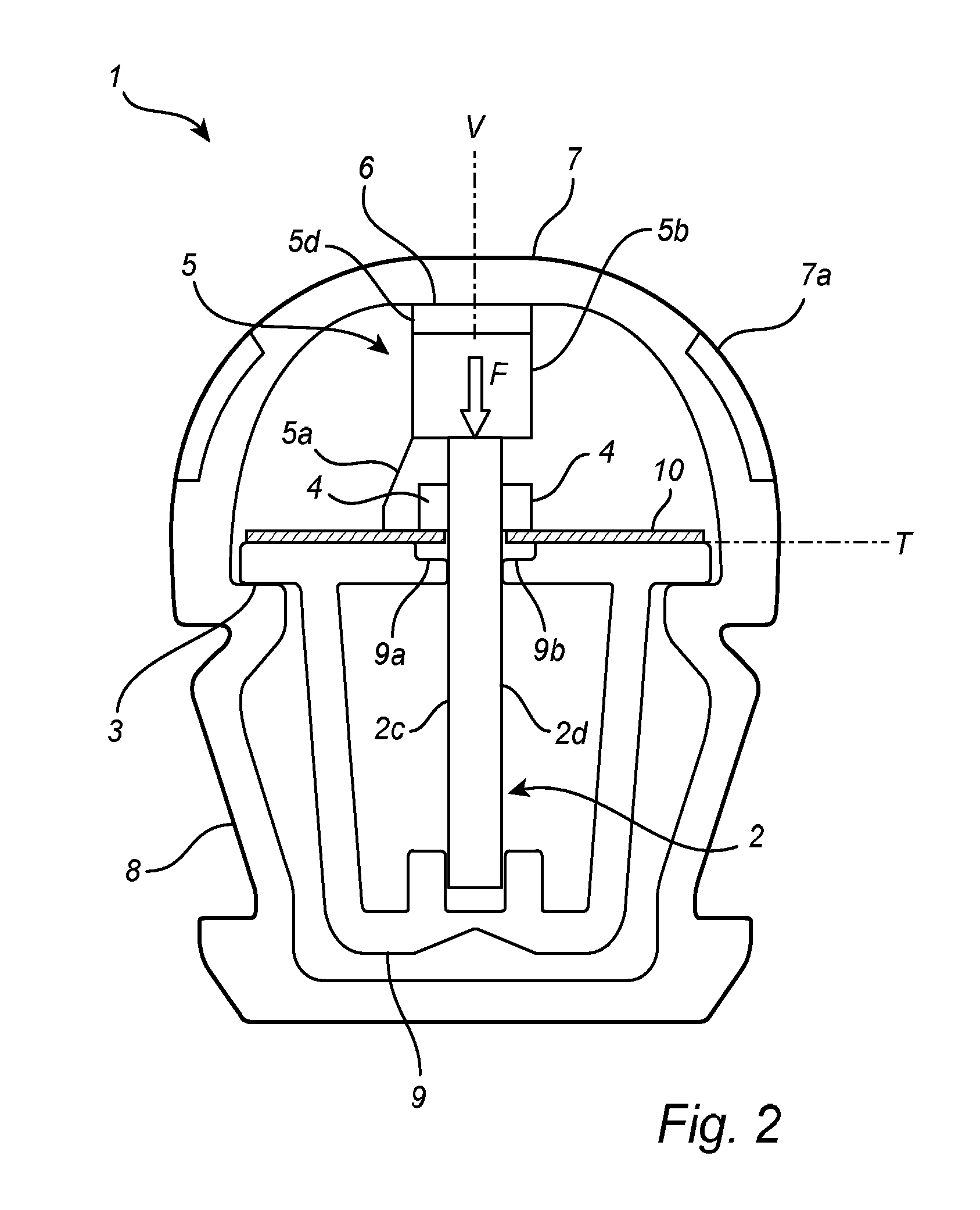

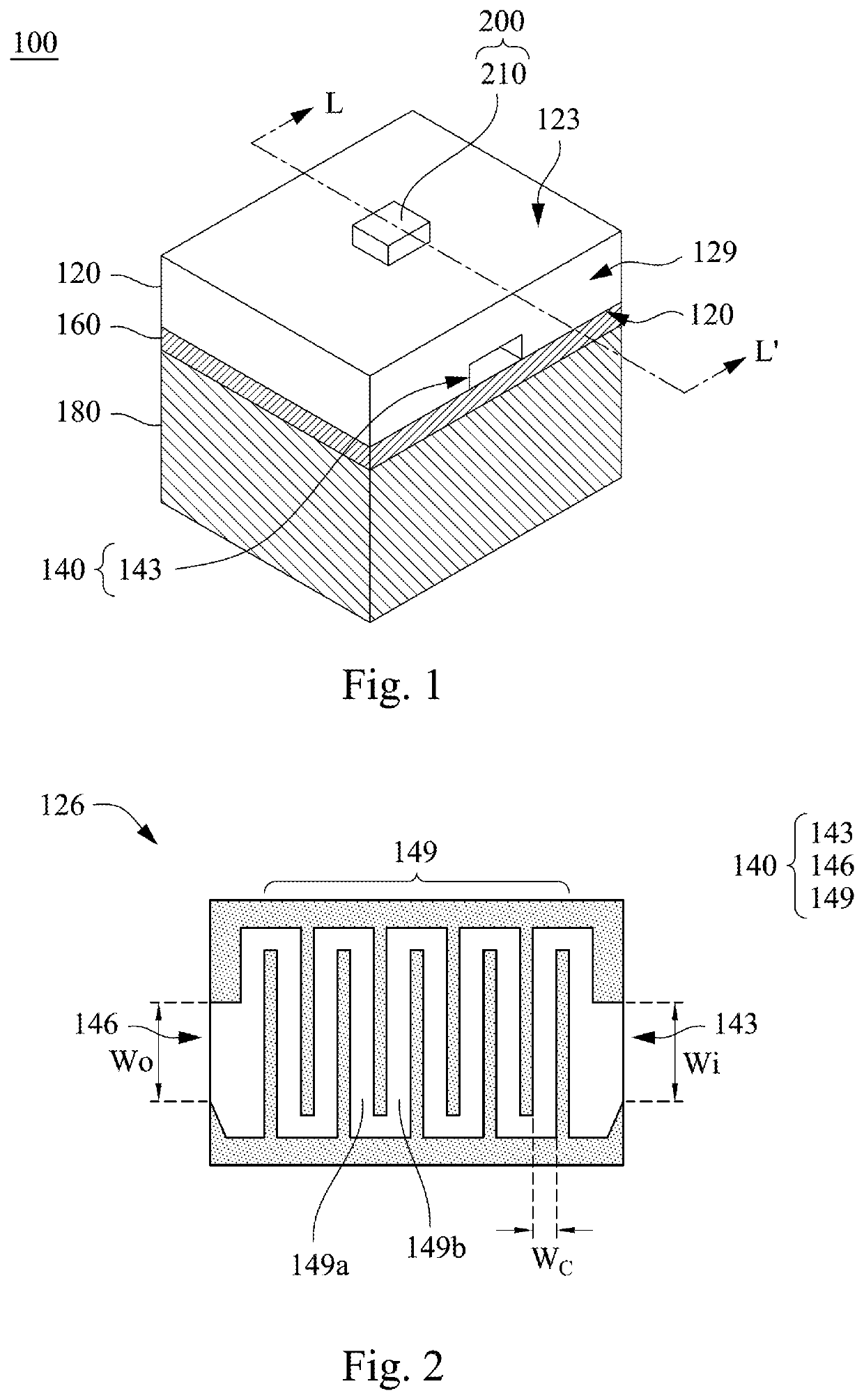

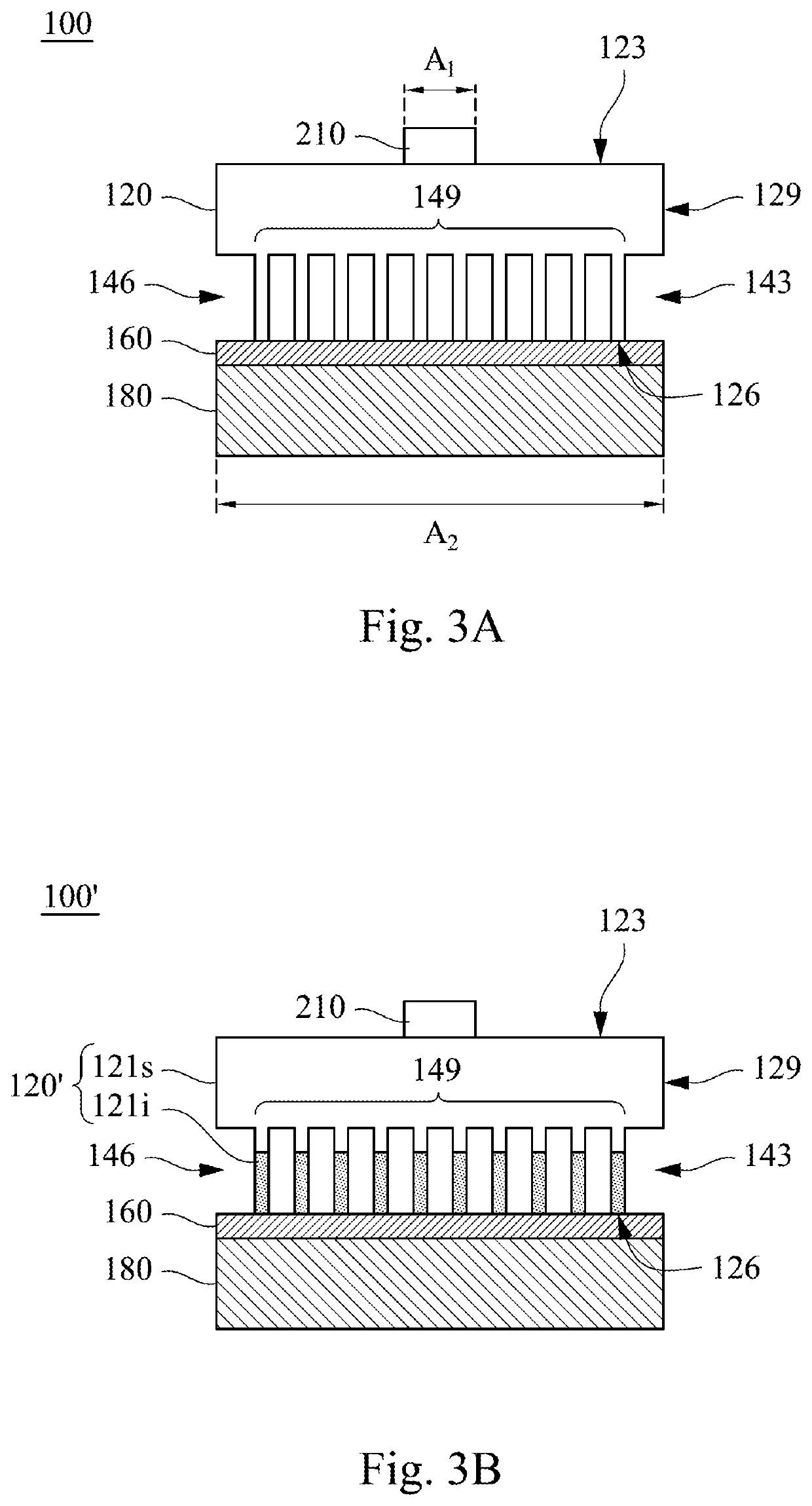

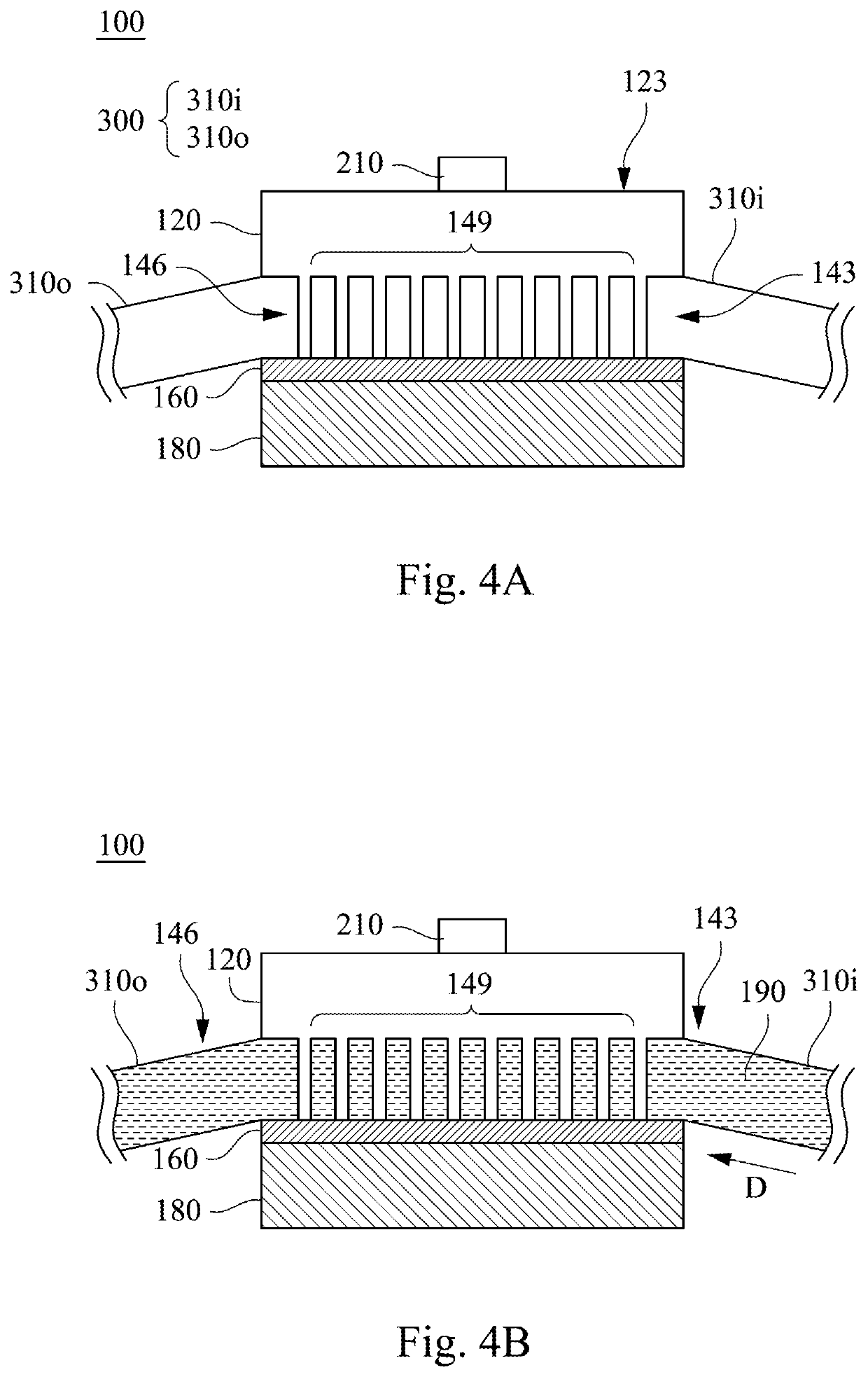

A heat sink comprising synthetic diamond material

ActiveUS20200088482A1Improve stiffnessImprove heat transferMirrorsSemiconductor/solid-state device detailsPhysicsSynthetic diamond

A heat sink comprising a heat spreader (2) made from synthetic diamond and having a front surface for mounting one or more components to be cooled like a laser disc (8) and a rear surface for direct fluid cooling (10). A plurality of ribs (4,7) is bonded to the rear surface of the heat spreader (2) to stiffen the heat spreader. Both the heat spreader and the plurality of ribs are formed of synthetic diamond material. The ribs (4,7) may be fixed to the heat spreader by braze bonds (6).

Owner:ELEMENT SIX TECH LTD

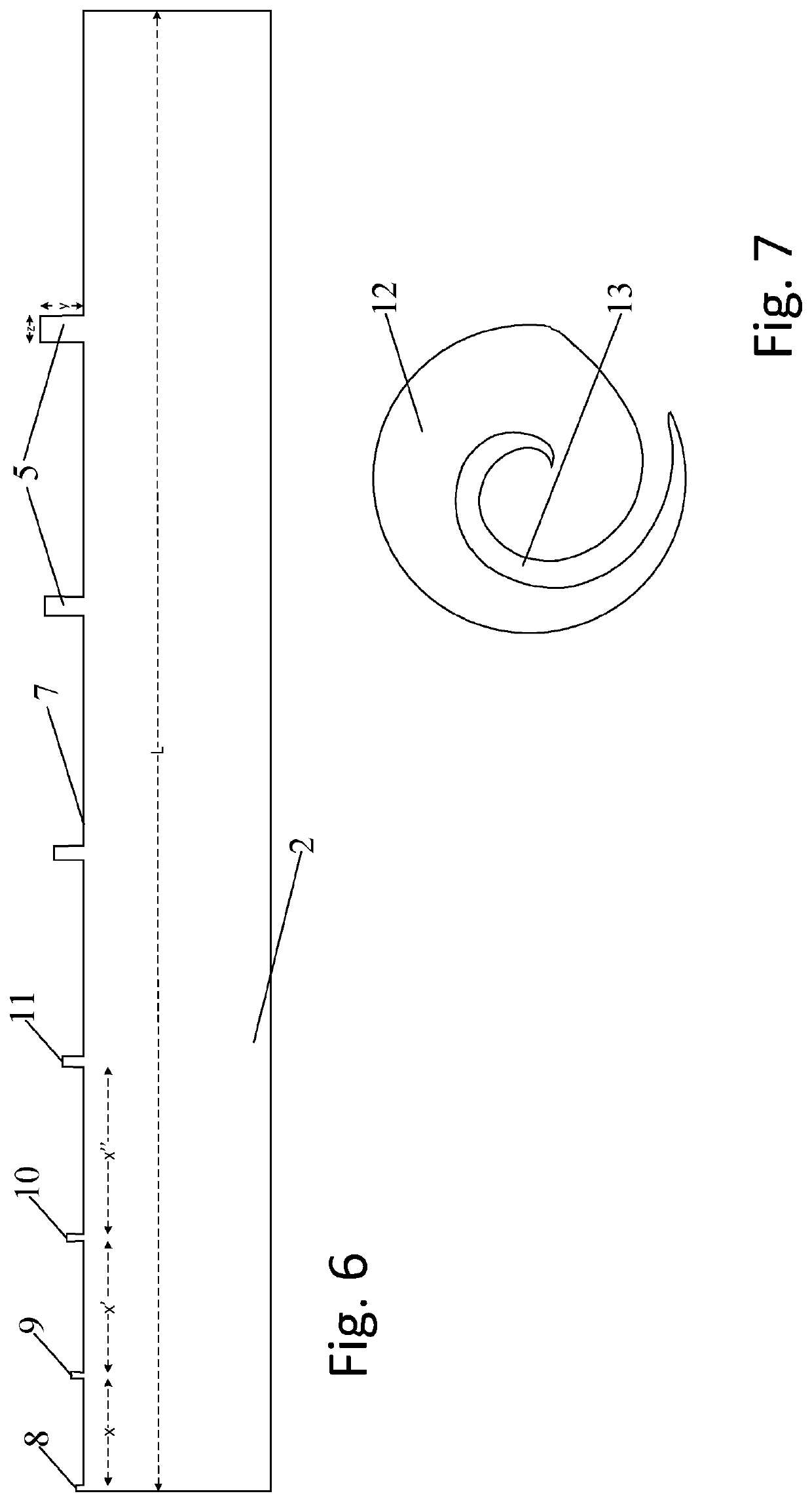

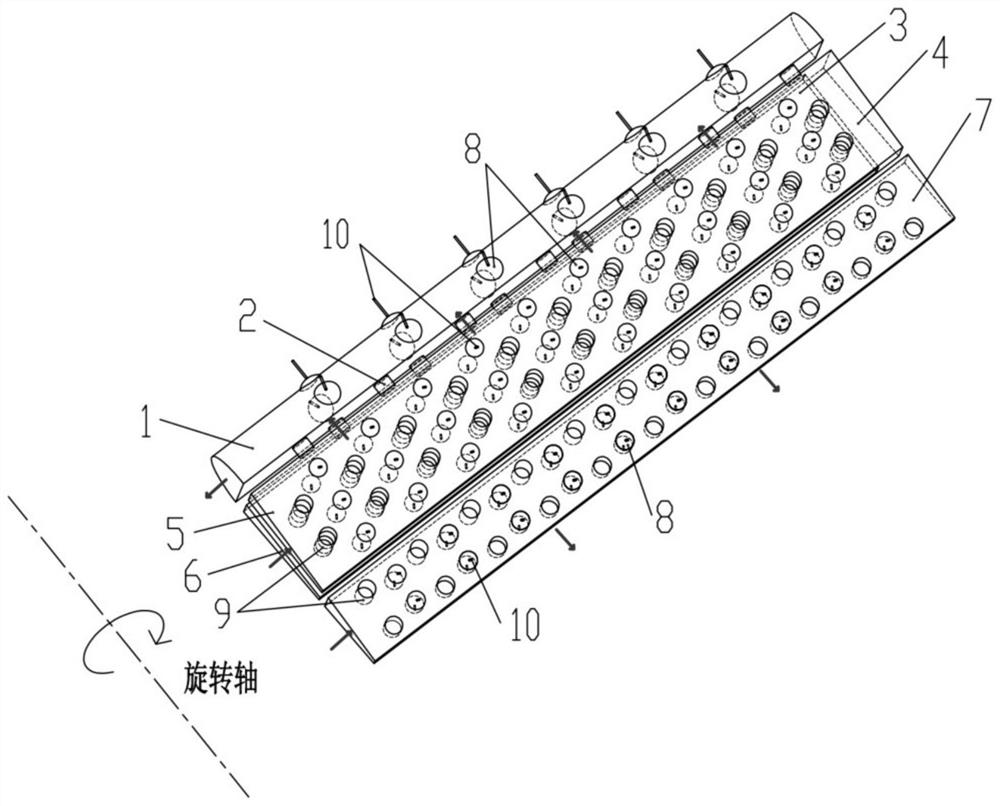

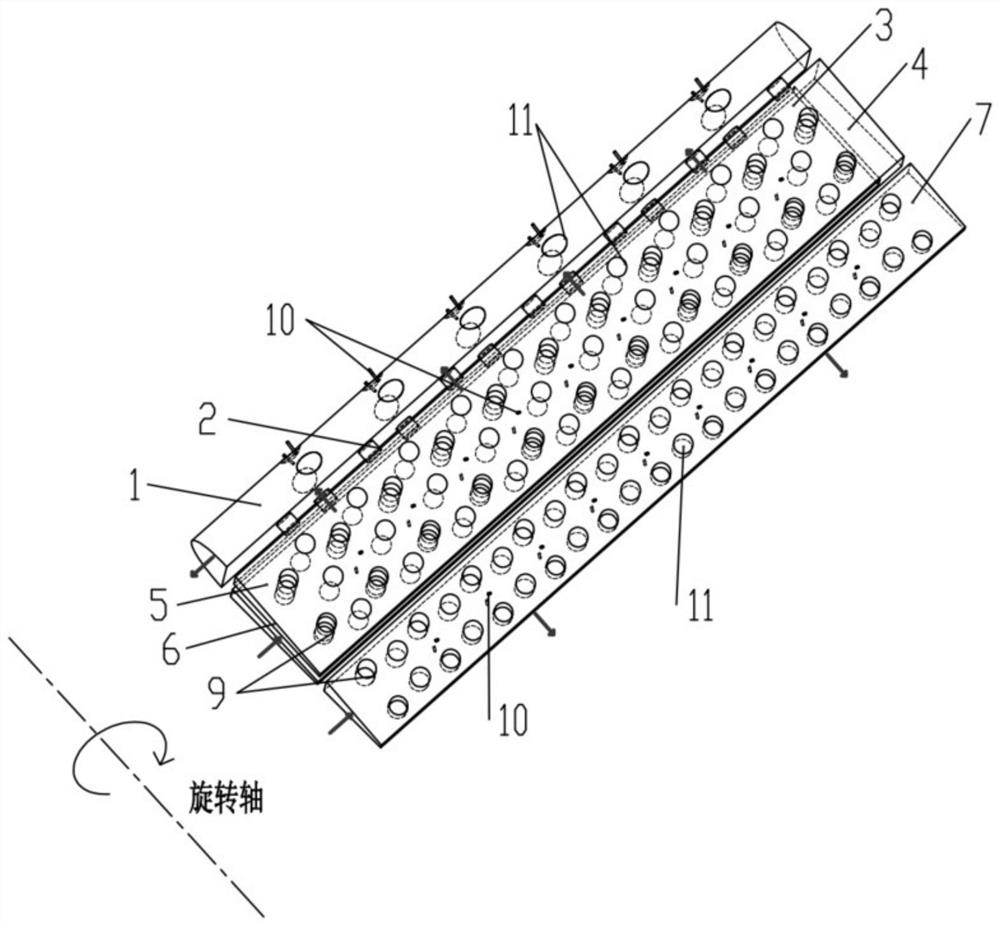

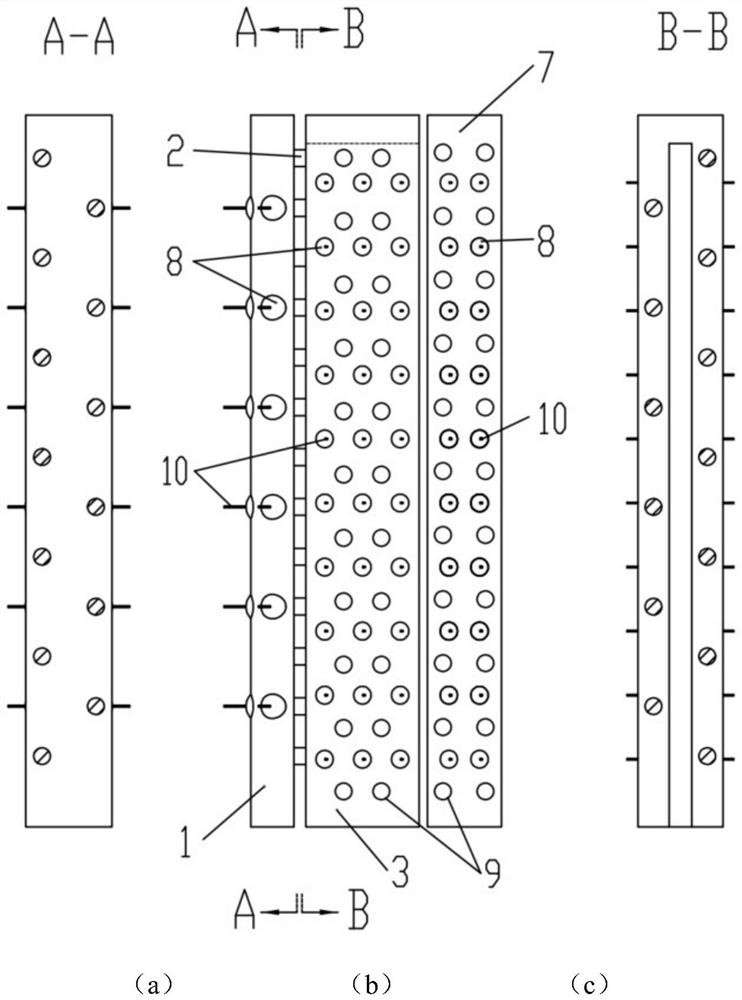

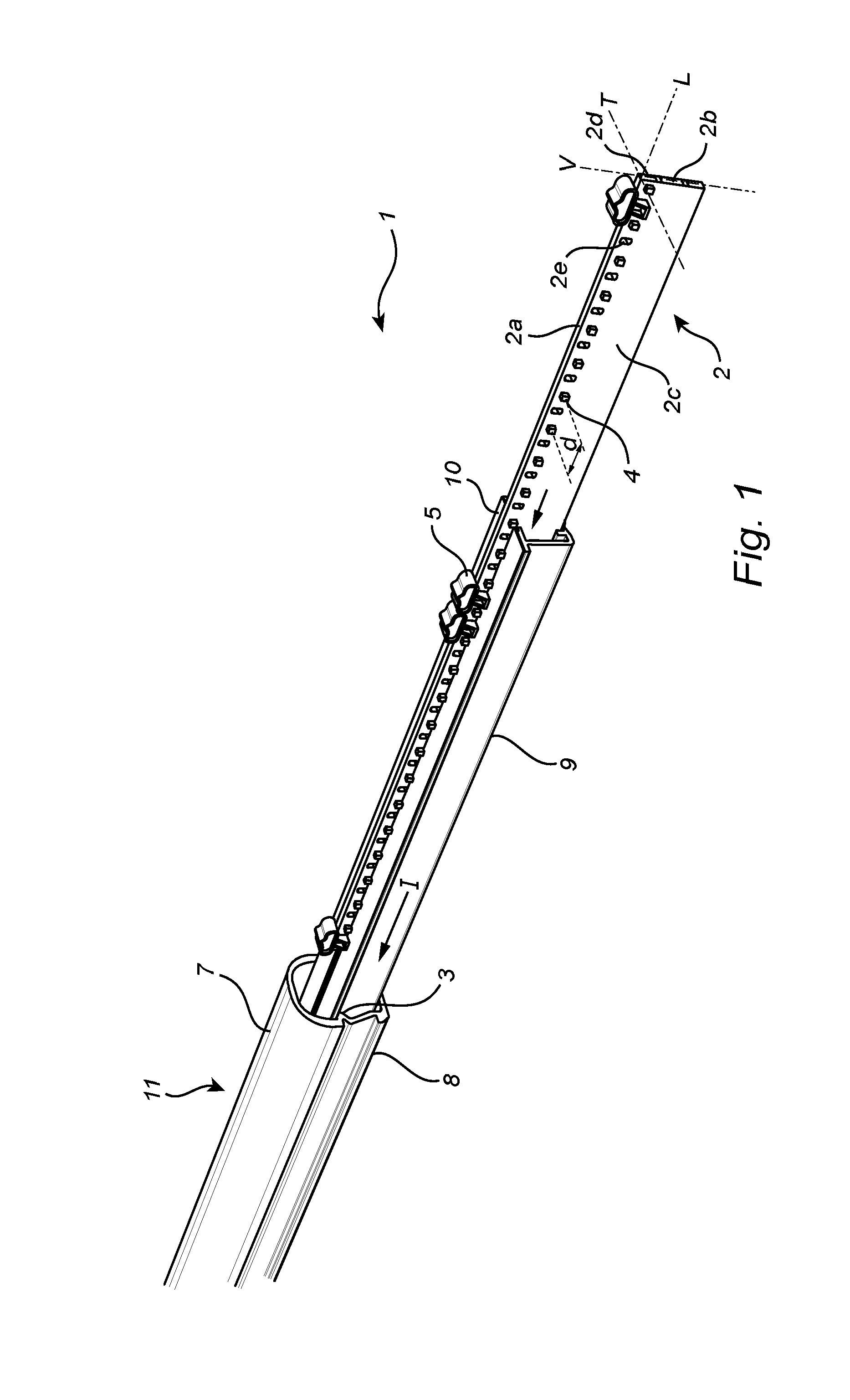

Lighting arrangement having a resilient element

ActiveUS20160223169A1Improve heat transferIncrease illumination efficiencyPoint-like light sourceElongate light sourcesLight sourceElectrical and Electronics engineering

A lighting arrangement (1)is disclosed. The lighting arrangement (1)has a circuit board (2),a support (3) for supporting the circuit board (2) and at least one light source (4) mounted on the circuit board(2). The lighting arrangement also has at least one abutment (6) which is fixed relative to the support (3) and at least one resilient element (5) which is sandwiched between the at least one abutment (6) and the circuit board (2), whereby the resilient element (5) presses against the circuit board (2).

Owner:SIGNIFY HOLDING B V

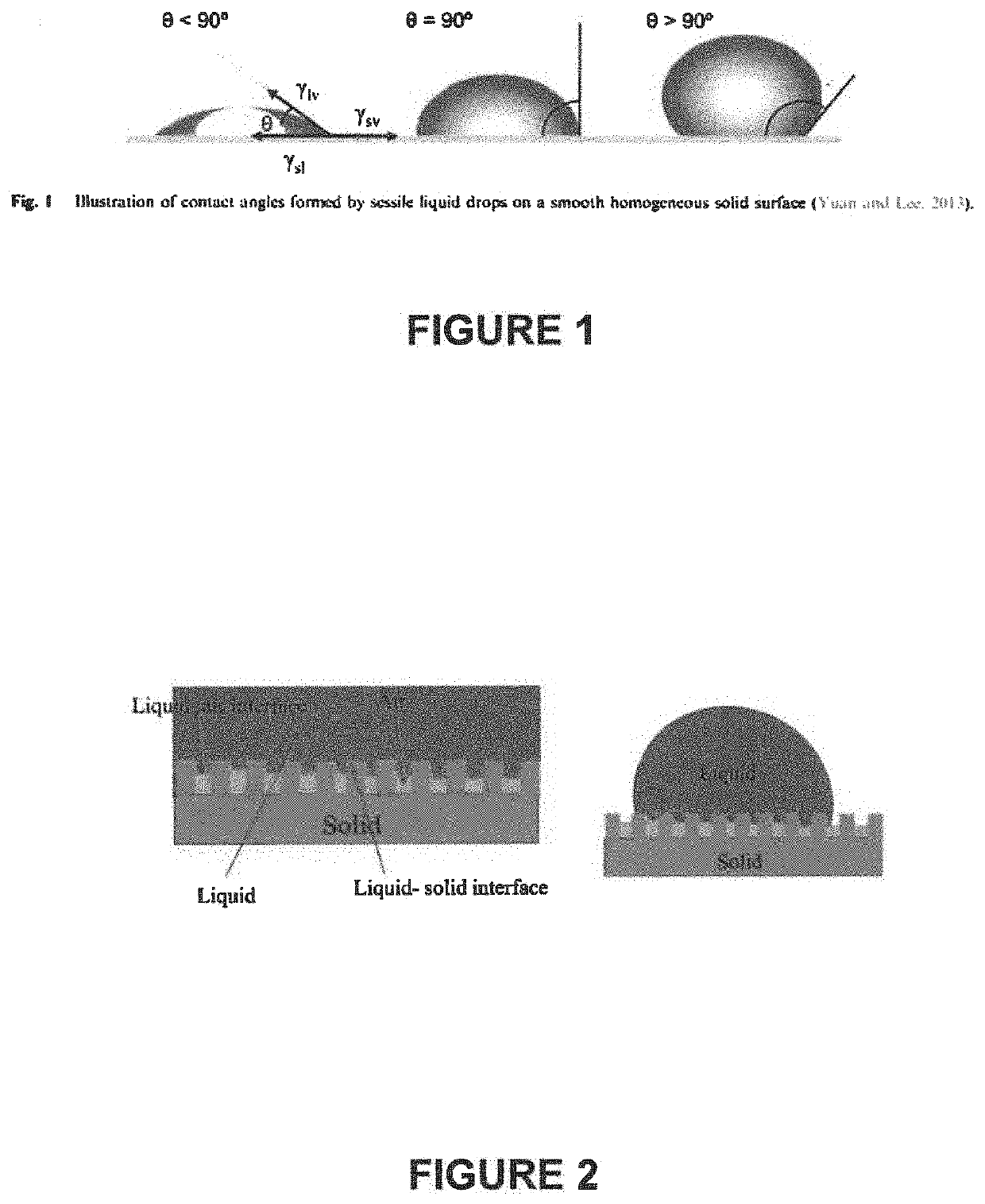

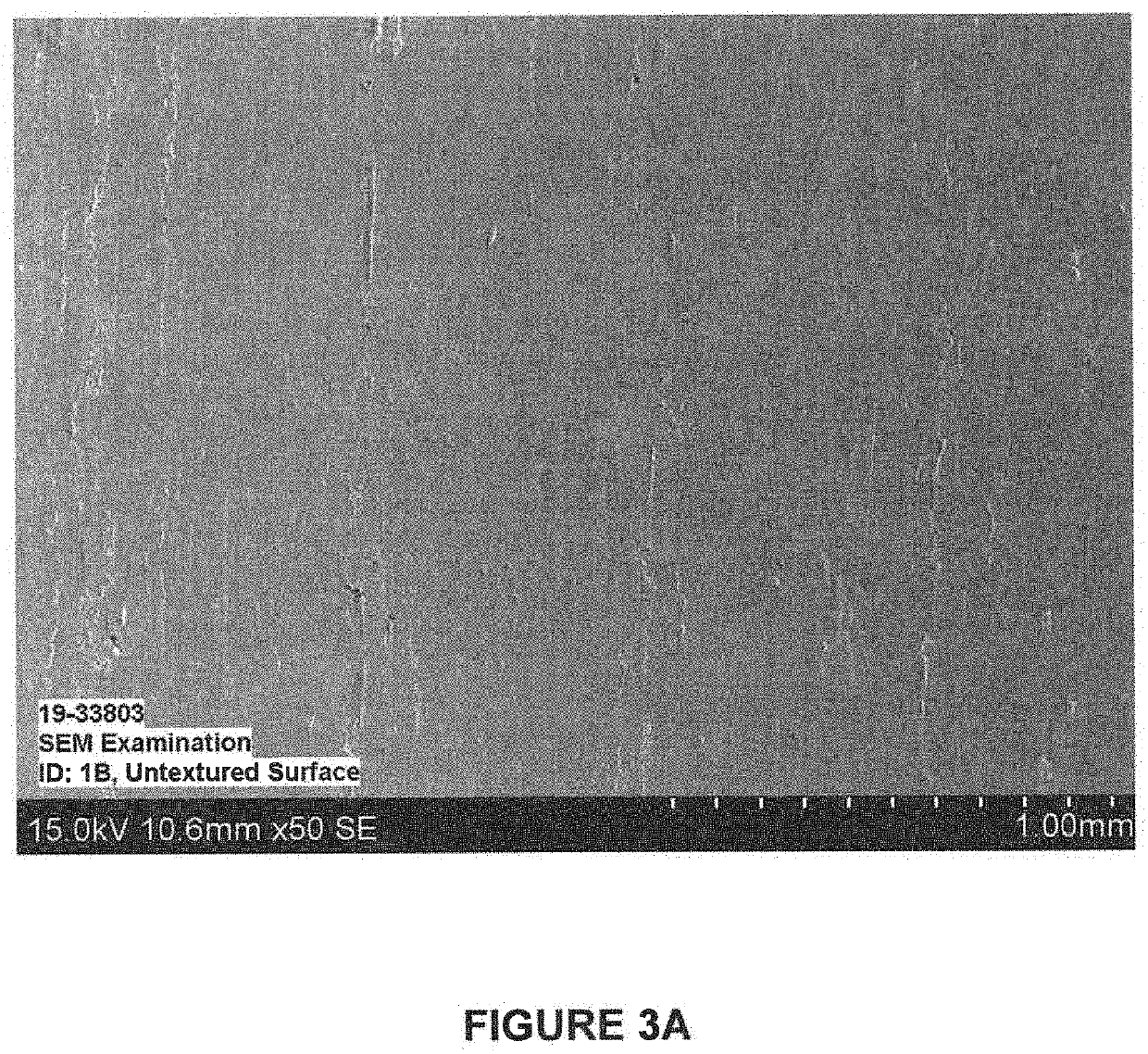

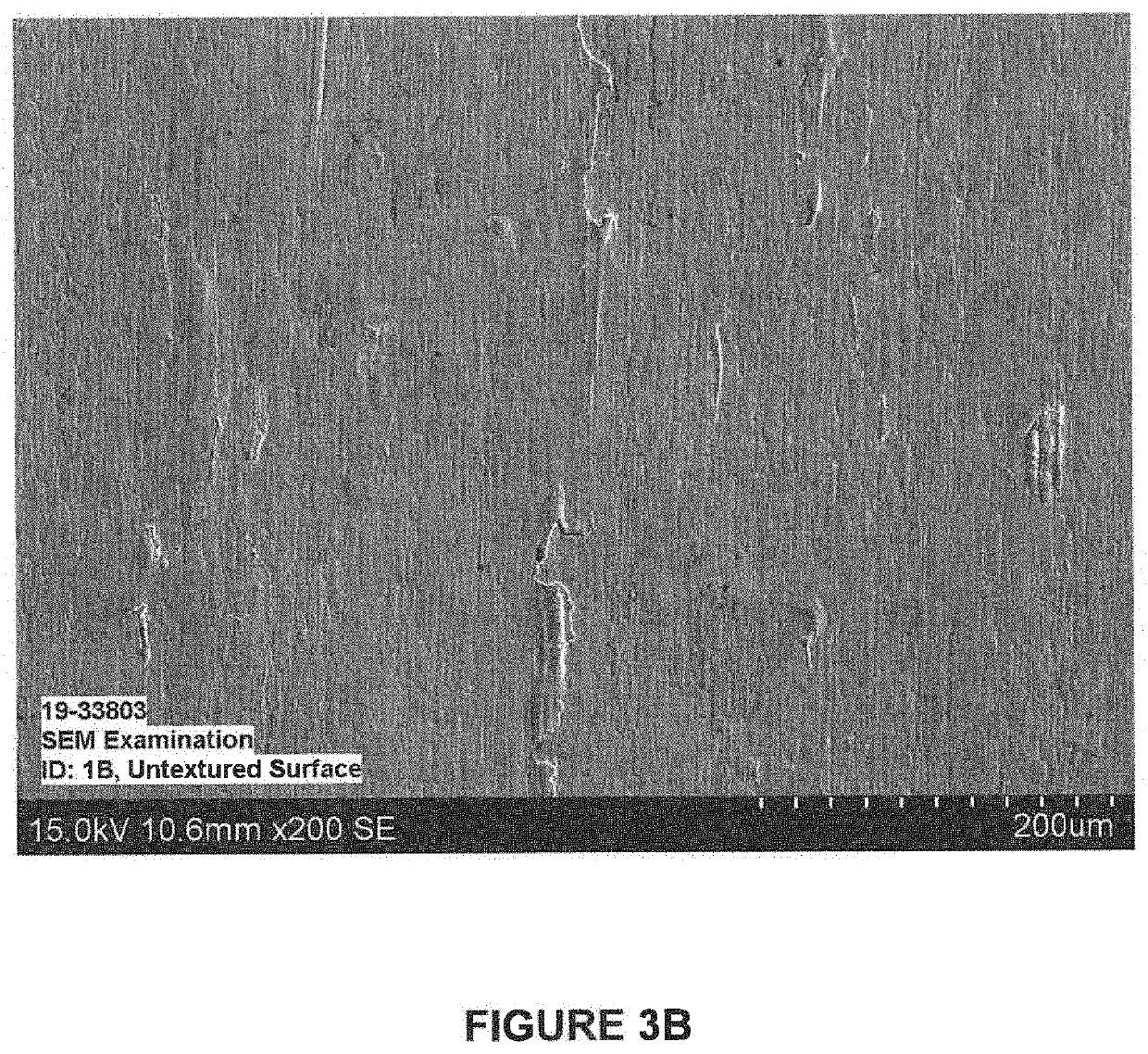

Tubing with Hydrophobic Surface

ActiveUS20200147669A1Lower heat transferImprove heat transferCoatingsHeat transfer modificationChemistryHydrophobic surfaces

A method of forming a heat exchanger tube, particularly suited for condensing applications, contemplates cold-rolling a metallic strip to emboss a hydrophobic surface texture, to thereby form an embossed surface on the metallic strip. The method includes roll forming the metallic strip to a tubular shape, with the embossed surface on the exterior of the tubular shape, and welding the edges of the roll-formed strip to form a heat exchanger tube. Cold-rolling to emboss a hydrophobic surface texture exhibiting a contact angle of at least about 75° is contemplated, with processing including heat-treatment to minimize degradation of the hydrophobic surface texture, and roll-forming to avoid deformation of the hydrophobic surface texture,

Owner:PLYMOUTH TUBE

Thermal dissipation structure for integrated circuits

ActiveUS20210013127A1Improve heat transferGood thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

A thermal dissipation structure for integrated circuits includes a semiconductor substrate, a thermal dissipation trench, a metal seed layer and a metal layer. The semiconductor substrate has a first surface and a second surface which is opposite to the first surface. Integrated circuits are located on and thermally coupled with the first surface. The thermal dissipation trench is formed within the second surface. The metal seed layer seals the thermal dissipation trench to define a thermal dissipation channel. The thermal dissipation channel includes an inlet and an outlet. The metal layer is an electroplated layer formed from the metal seed layer.

Owner:NATIONAL CHIAO TUNG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com