Bag and tube type vacuum attachment tube bundle and manufacturing method thereof

A manufacturing method and vacuum technology, applied in the direction of tubular elements, damage protection, lighting and heating equipment, etc., can solve the problems of poor corrosion resistance, poor heat transfer performance, low heat transfer efficiency of heat exchangers, etc., and achieve high heat transfer performance. , The effect of enhanced corrosion resistance and increased heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

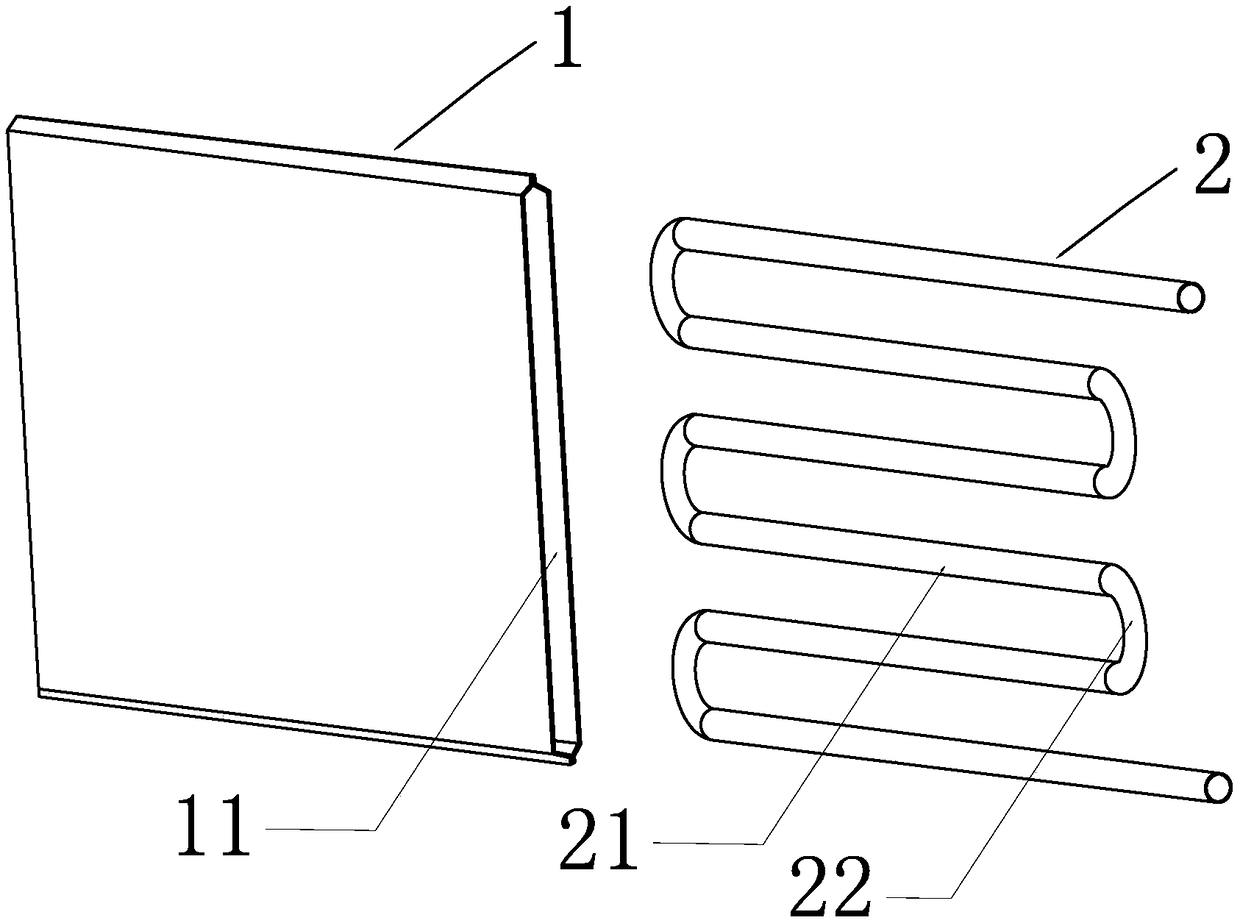

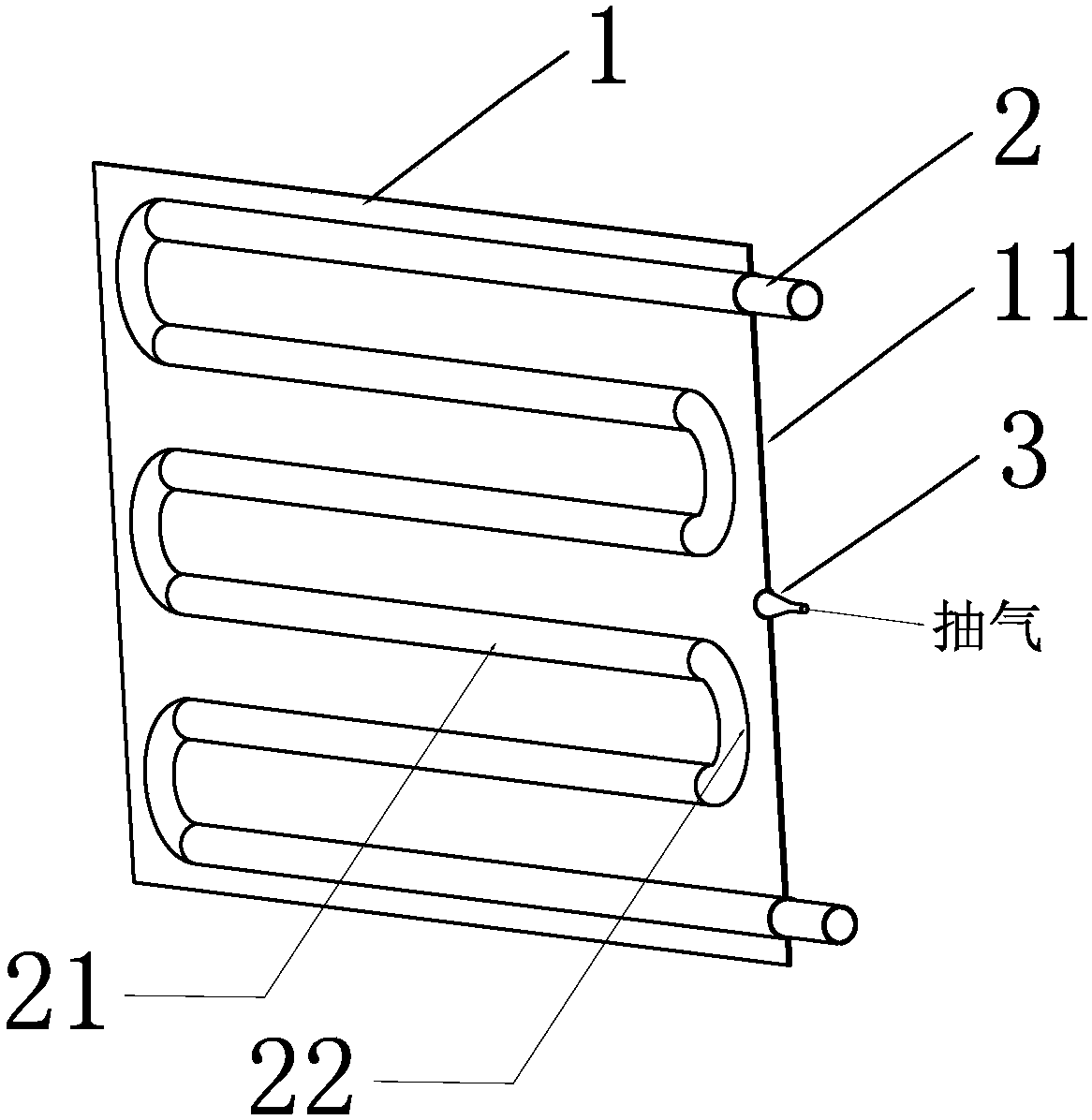

[0018] Such as figure 1 , 2 As shown, a bag-type vacuum-bonded pipe row and its manufacturing method: it includes a heat exchange bag 1 and an S-shaped heat exchange coil 2 in the same plane, and the heat exchange coil 2 is arranged on the heat exchange bag 1, and the nozzles at both ends of the heat exchange coil 2 are exposed outside the heat exchange bag 1. The heat exchange bag 1 is provided with a suction nozzle 3, and after the vacuum of the heat exchange bag 1 is extracted through the suction nozzle 3, The front and rear bag surfaces of the heat exchange bag 1 are in close contact with each other, and form a tight fit with the outer wall surface of the heat exchange coil 2 .

[0019] Preferably, the heat exchange bag 1 is composed of two metal sheets, and the surroundings of the two metal sheets are sealed to form a bag shape.

[0020] Preferably, the air suction noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com