Turbine moving blade internal composite cooling structure

A composite cooling and moving blade technology, applied in engine components, engine functions, machines/engines, etc., can solve problems such as difficult to achieve cooling effect, and achieve the effect of enhancing fluid turbulent kinetic energy, improving heat transfer level, and reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

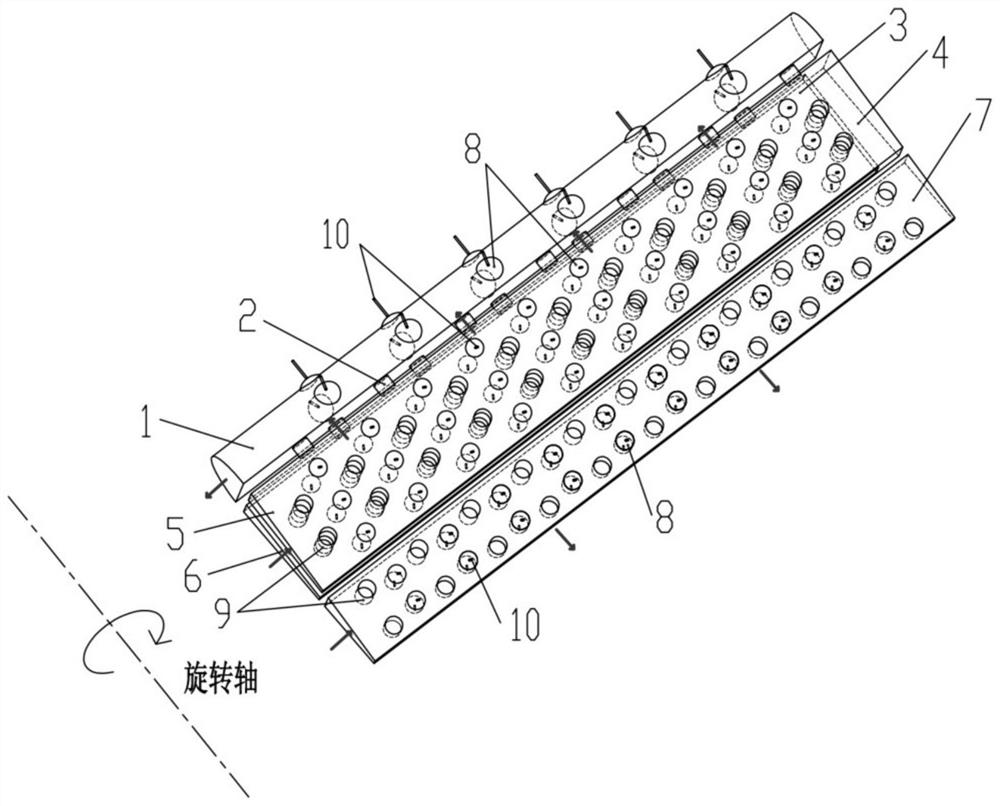

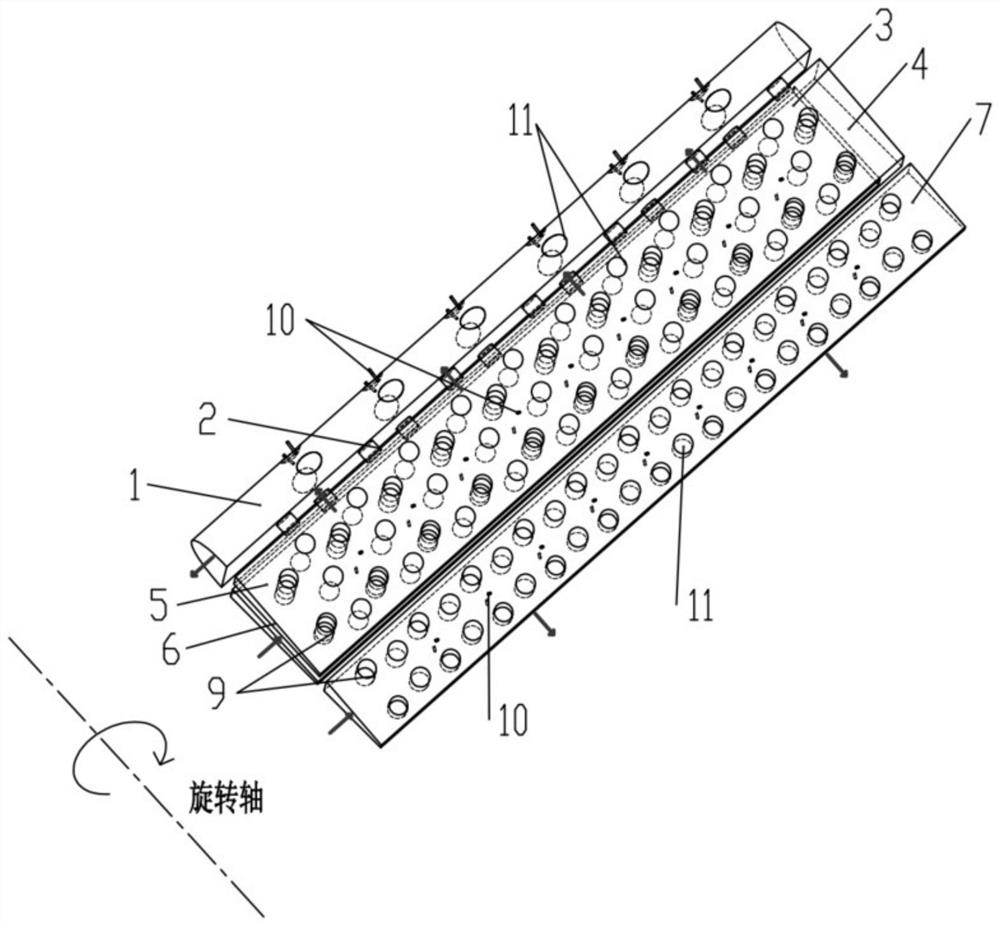

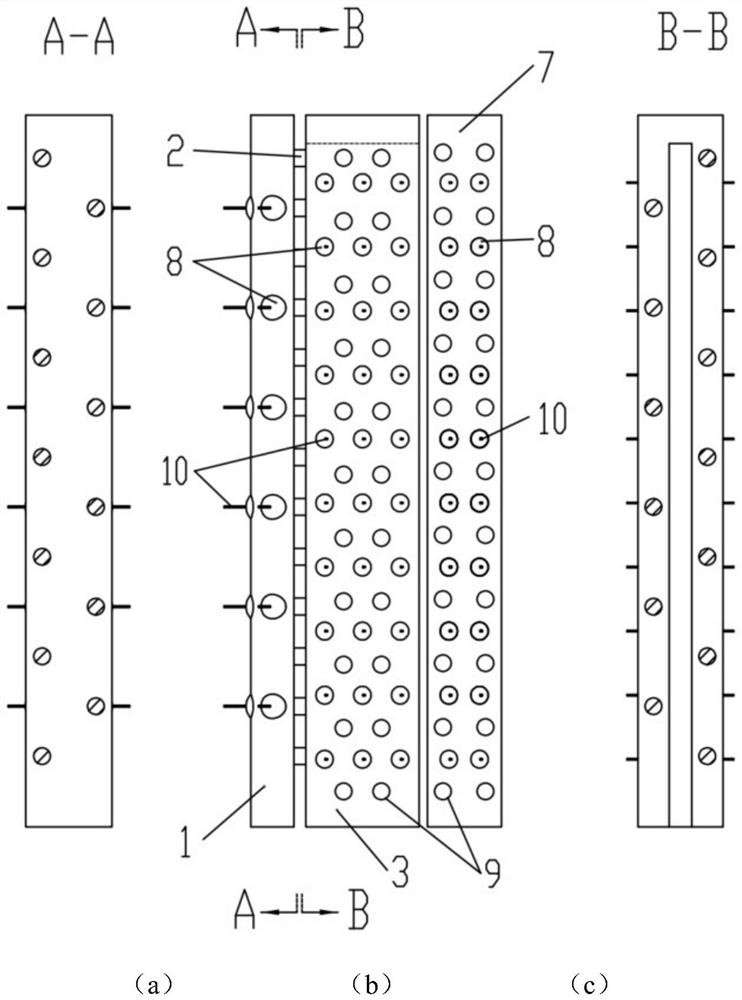

[0037] refer to Figure 1 to Figure 6 , a composite cooling structure inside a turbine blade provided by the present invention, comprising a swirl cooling channel 1, a U-shaped cooling channel 3 and a trailing edge trapezoidal cooling channel 7, a U-shaped cooling channel inlet section 5 of the U-shaped cooling channel 3 and The outlet section 6 of the U-shaped cooling channel communicates with the swirl cooling channel 1 through several jet holes 2 . The swirling flow cooling channel 1, the U-shaped cooling channel 3 and the trailing edge trapezoidal cooling channel 7 are arranged on the surface with a number of ball sockets 8 / ball convexes 11 and air film holes 10 structures, and the U-shaped cooling channel 3 and the trailing edge trapezoidal cooling channel 7 are arranged There are several fin 9 structures.

[0038] refer to Figure 3 to Figure 6, the shape of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com