Patents

Literature

59results about How to "Increase turbulent kinetic energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

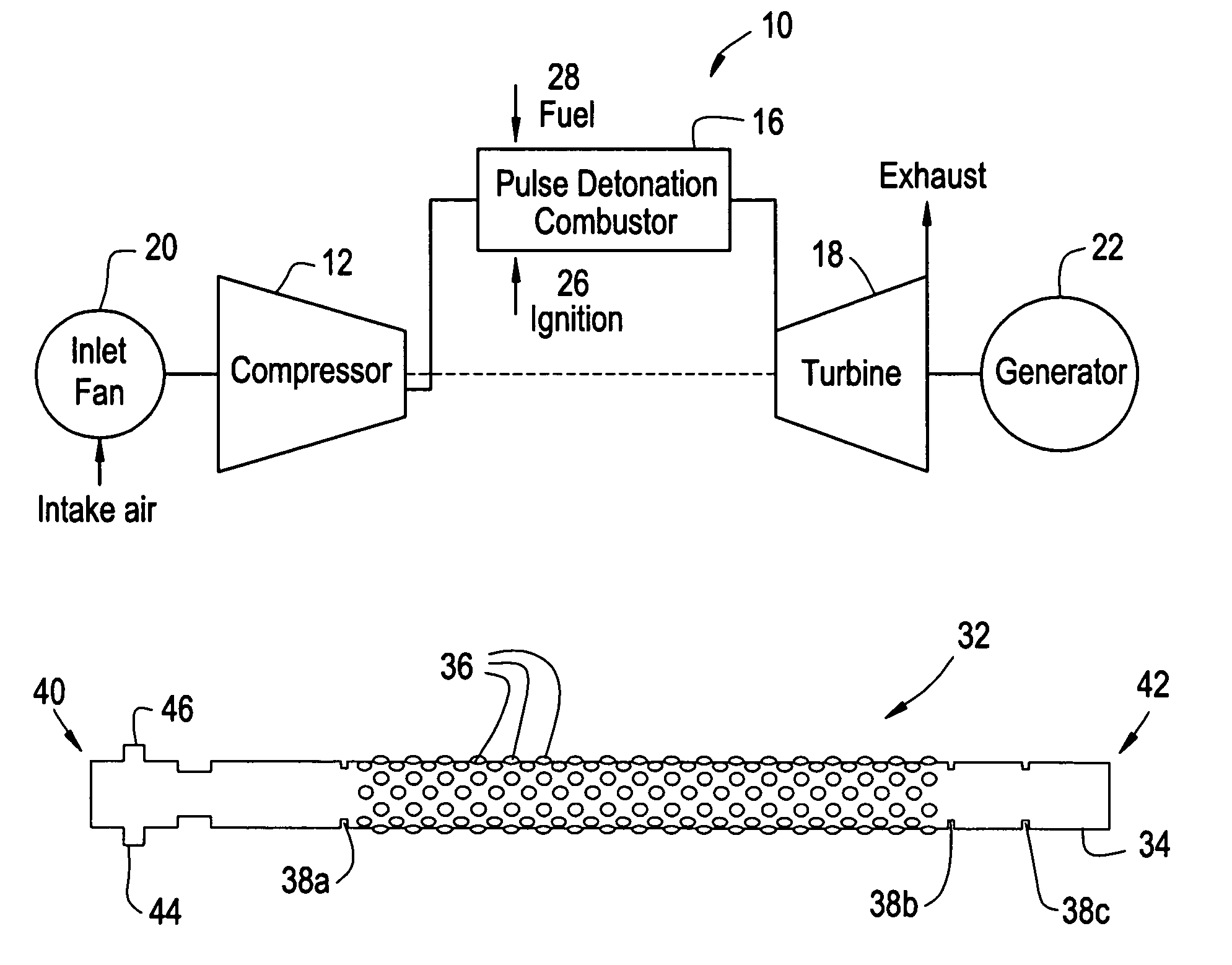

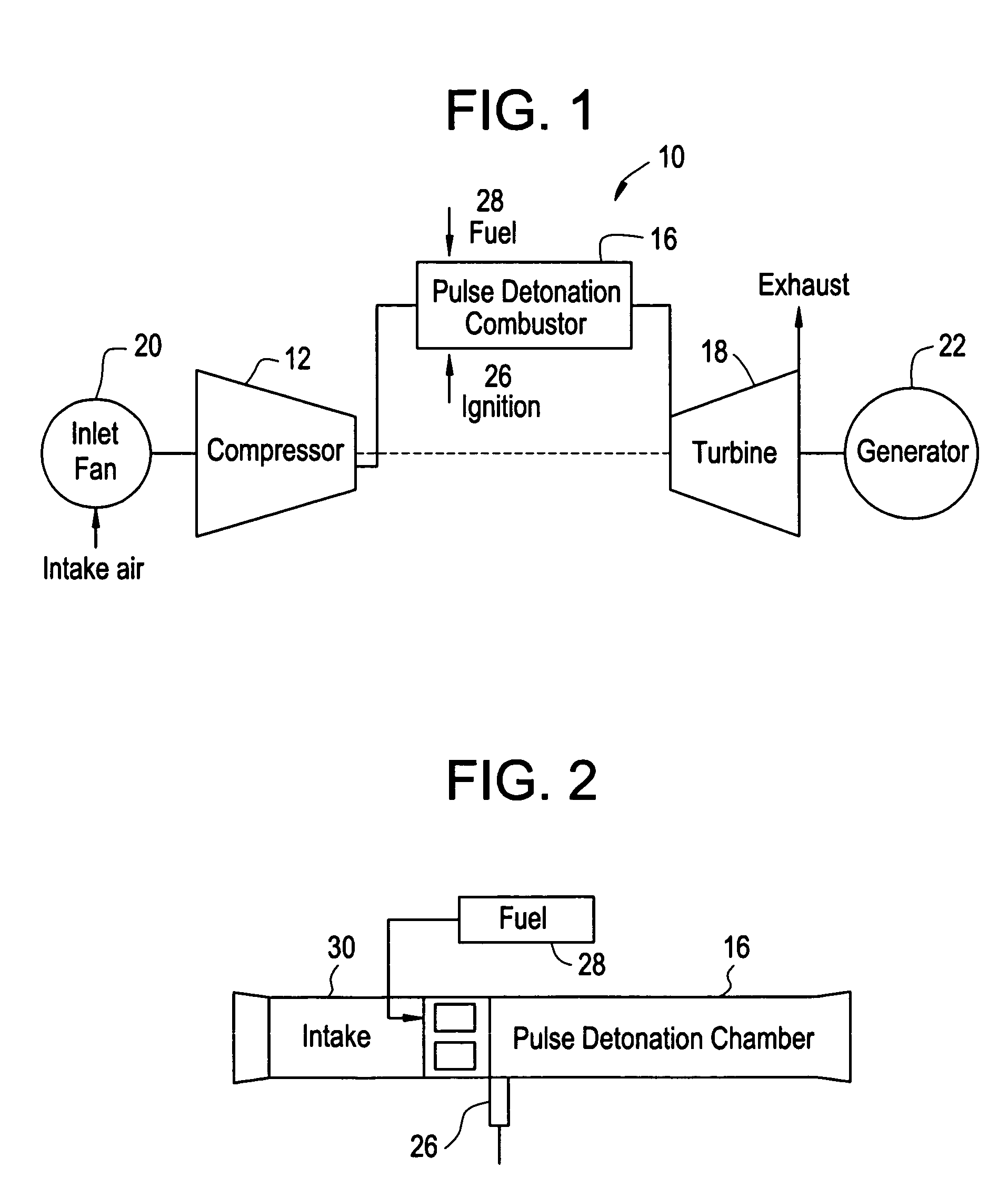

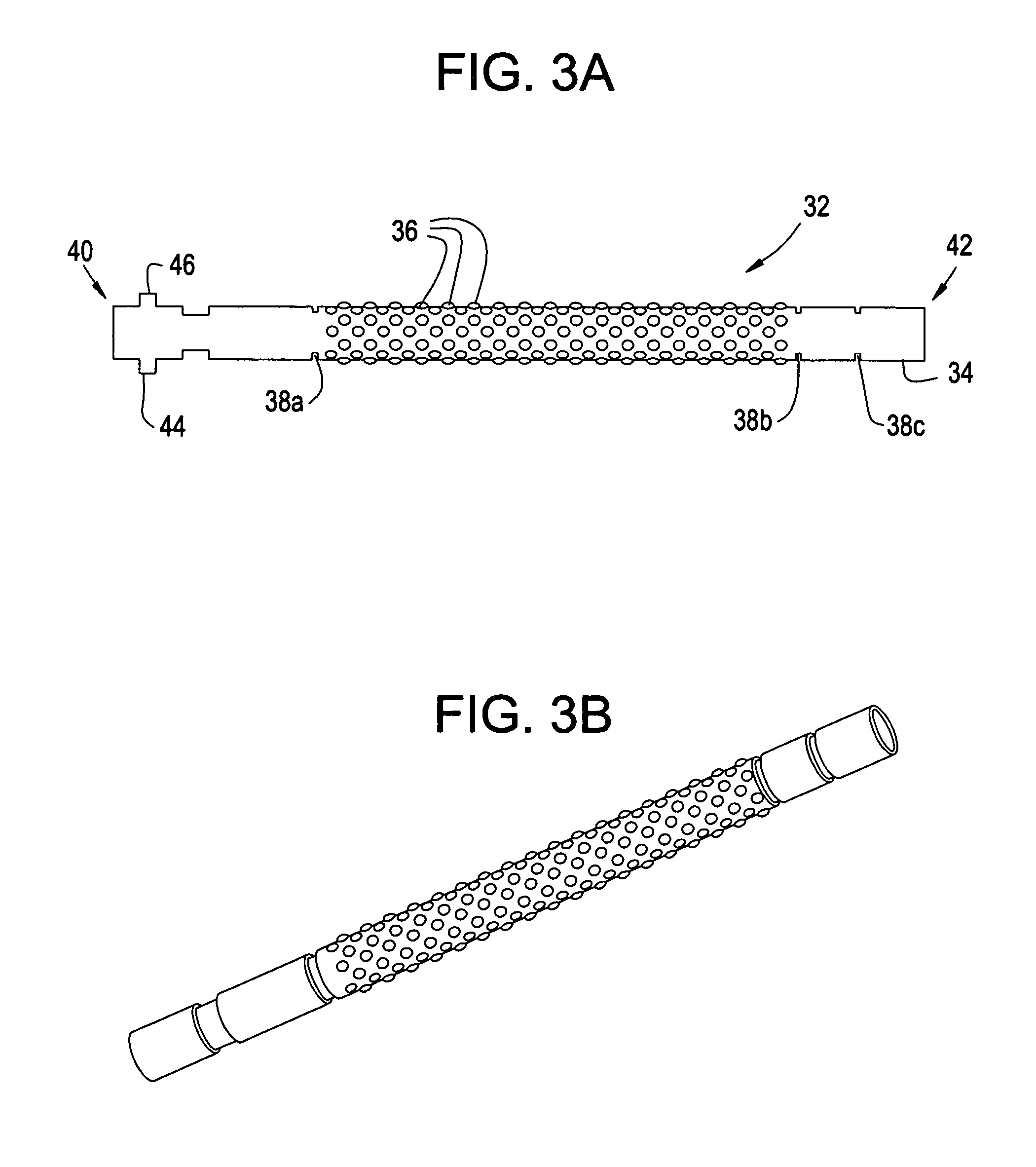

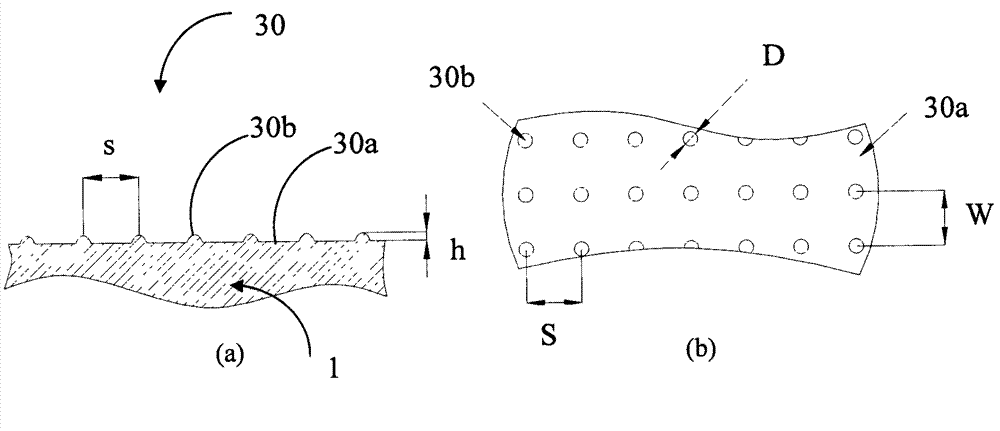

Shaped walls for enhancement of deflagration-to-detonation transition

ActiveUS7669405B2Increased turbulenceIncrease turbulent kinetic energyTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustorDeflagration to detonation transition

A detonation chamber for a pulse detonation combustor including: a plurality of dimples disposed on at least a portion of an inner surface of the detonation chamber wherein the plurality of dimples enhance a turbulence of a fluid flow through the detonation chamber.

Owner:GENERAL ELECTRIC CO

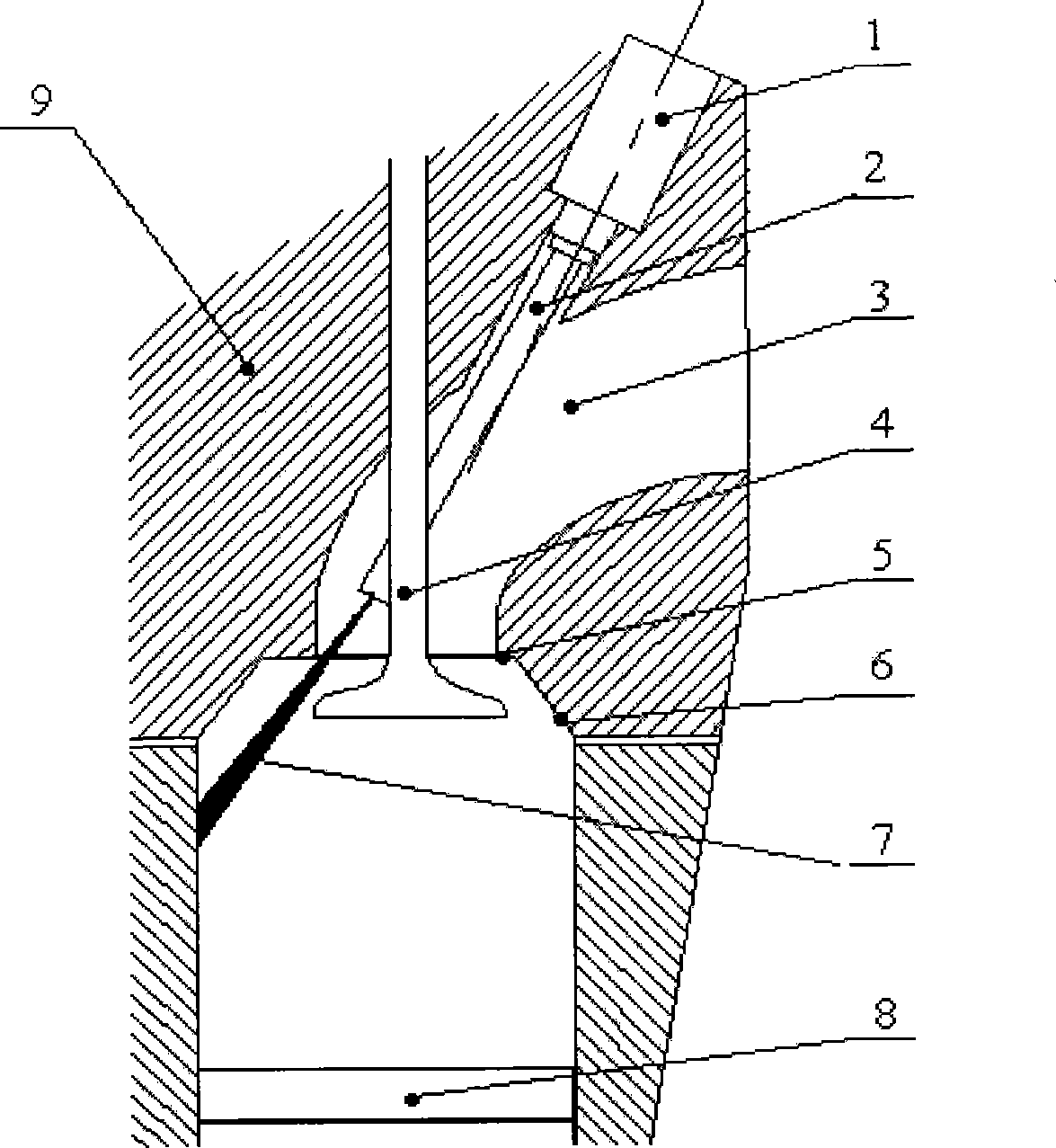

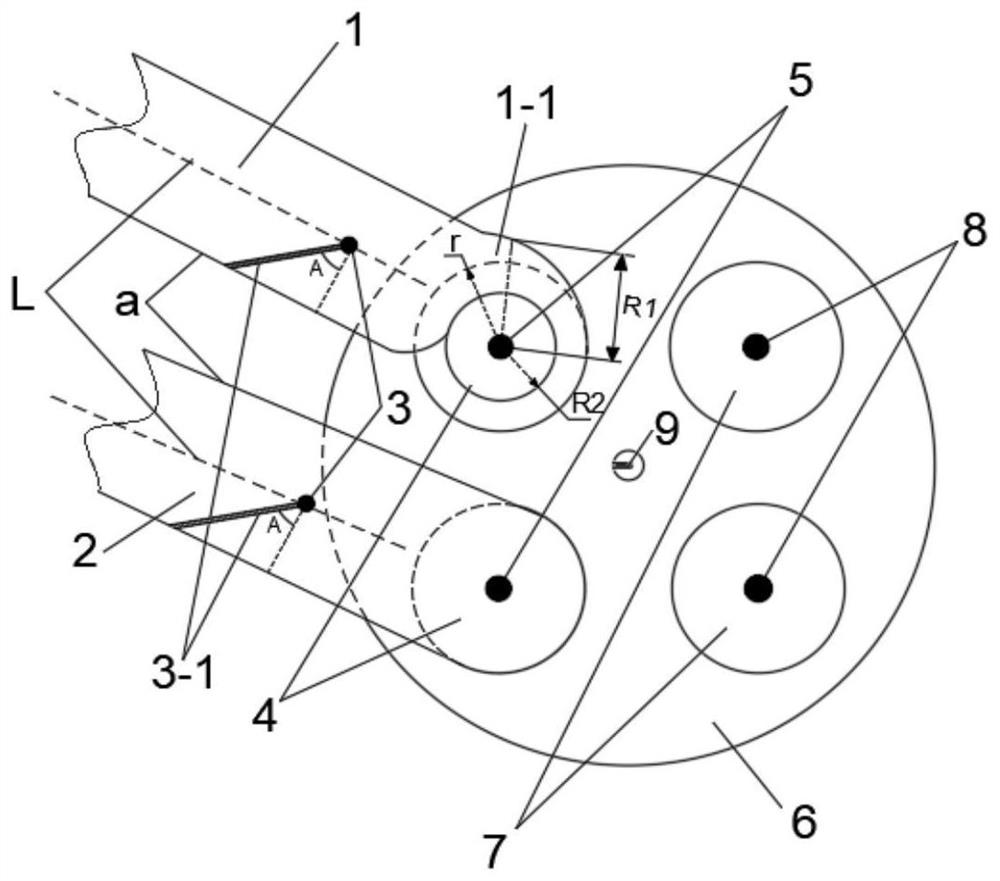

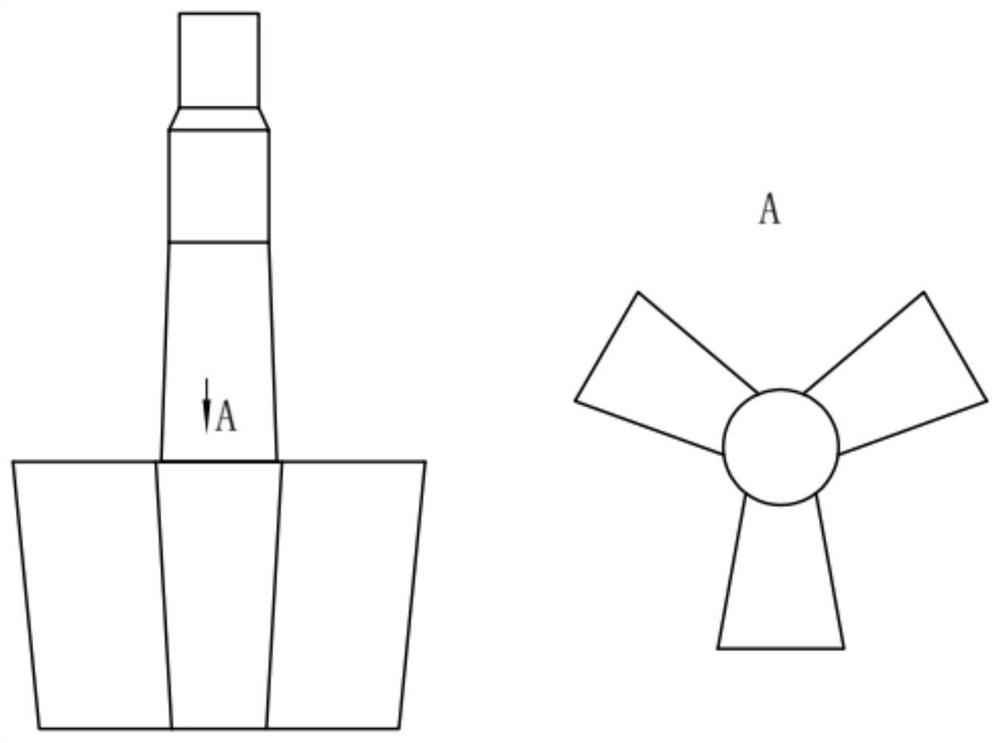

Gas jet device of electric control jet lean-burn natural gas engine and jet control method

InactiveCN101545418AExtended Stable Operation Lean LimitStable and reliable fireInternal combustion piston enginesFuel supply apparatusInlet valveElectric control

The invention provides a gas jet device of an electric control jet lean-burn natural gas engine and a jet control method. The gas jet device comprises a large flow natural gas nozzle, the nozzle is arranged on a cylinder cover or an air intake manifold, the lower part of the nozzle is provided with a draft tube, the inside diameter of the draft tube is the same as the inside diameter of a nozzle outlet, the center line of the draft tube and the center line of an intake valve are two spatial straight lines which are not mutually parallel or intersected, and post gas pulse in the air intake process passes through an annular gap between the intake valve and a valve seat and is directly sprayed into a cylinder. Through the gas jet control method, mixed gas concentration layers are formed from the top down in the cylinder to ensure reliable combustion of the engine; and the jet pulse is directly sprayed into the cylinder to convert self kinetic energy into turbulent energy in the cylinder so as to quicken the combustion process of the natural gas engine and expand the lean-burn limit of stable running of the engine, thereby improving the dynamic property, economical efficiency and emission performance of the natural gas engine.

Owner:HARBIN HACHUAN POWER TECH

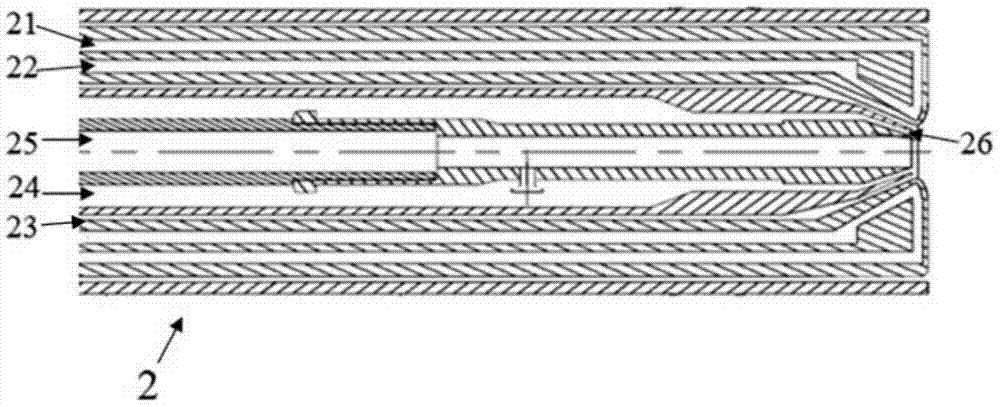

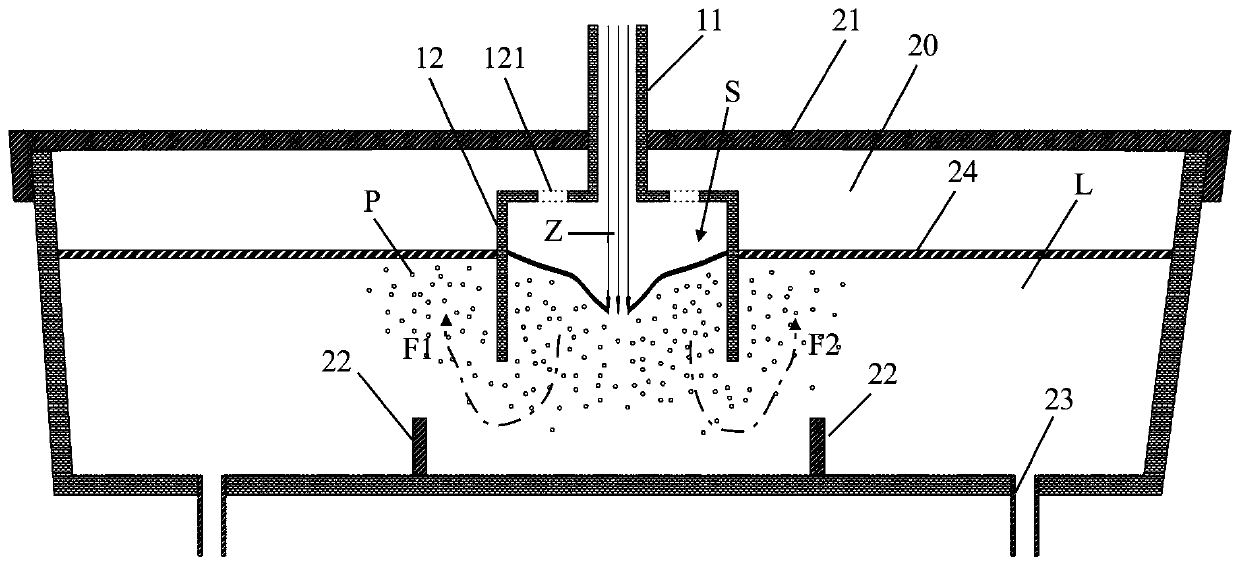

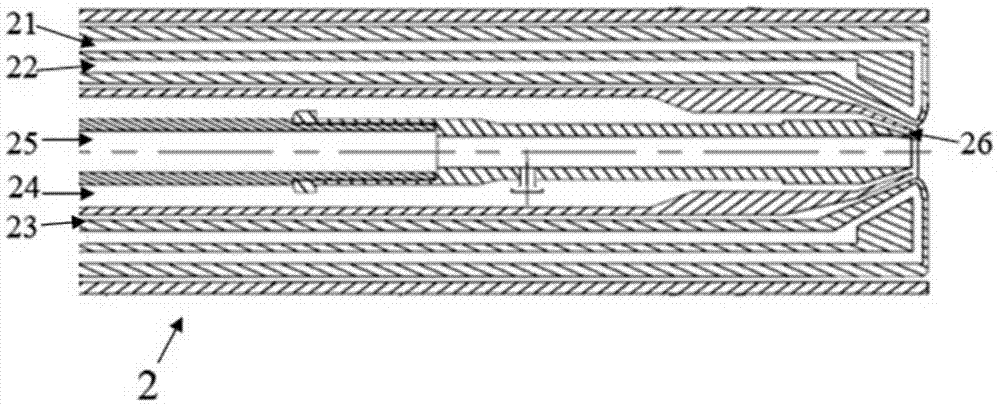

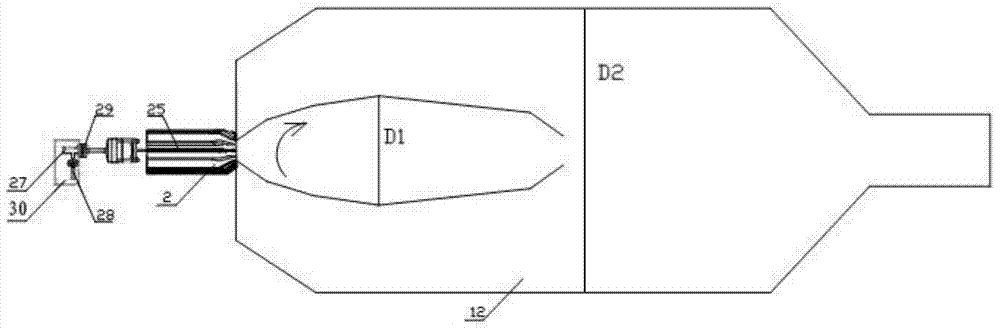

Dry-pulverized-coal gasification combined burner

ActiveCN103497785AIncrease the degree of mixingIncrease turbulent kinetic energyGranular/pulverulent flues gasificationNitrogenWater cooling

The invention discloses a dry-pulverized-coal gasification combined burner comprising a pulverized coal burner and an igniting burner. The pulverized coal burner sequentially comprises a first water-cooling jacket, a pulverized coal channel, a first oxidant channel and an inner barrel from outside to inside. The pulverized coal channel is directly adjacent to the first oxidant channel, and contracts toward the axial direction of the pulverized coal burner, at a position, adjacent to a flame-forward end. The first water-cooling jacket comprises a first water-inflowing channel, a window-type water-cooling groove and a first water-outflowing chanel, and the first water-inflowing channel is communicated with the first water-outflowing channel through the window-type water-cooling groove which is spirally wound at the flame-forward end of the pulverized coal burner. The igniting burner is arranged in the inner barrel and comprises a second water-cooling jacket, a second oxidant channel, a fuel channel, an igniter and a center nitrogen channel. By the arrangement, an ignition process is simplified, and reliability of ignition and operation of pulverized coal is improved; flame diameter is effectively controlled, a membrane water-cooling wall is prevented from being damaged by flames, and reliability of a gasification furnace is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

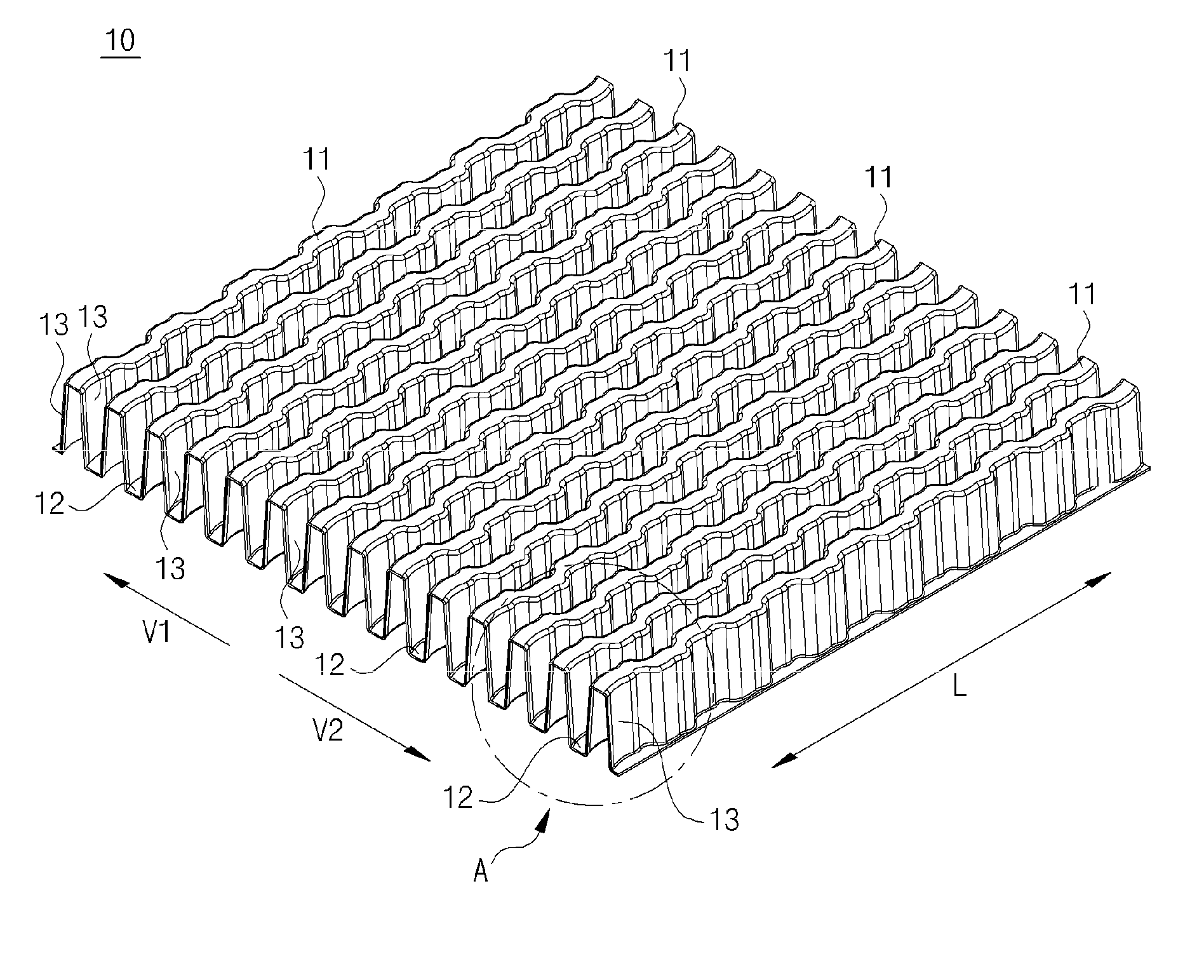

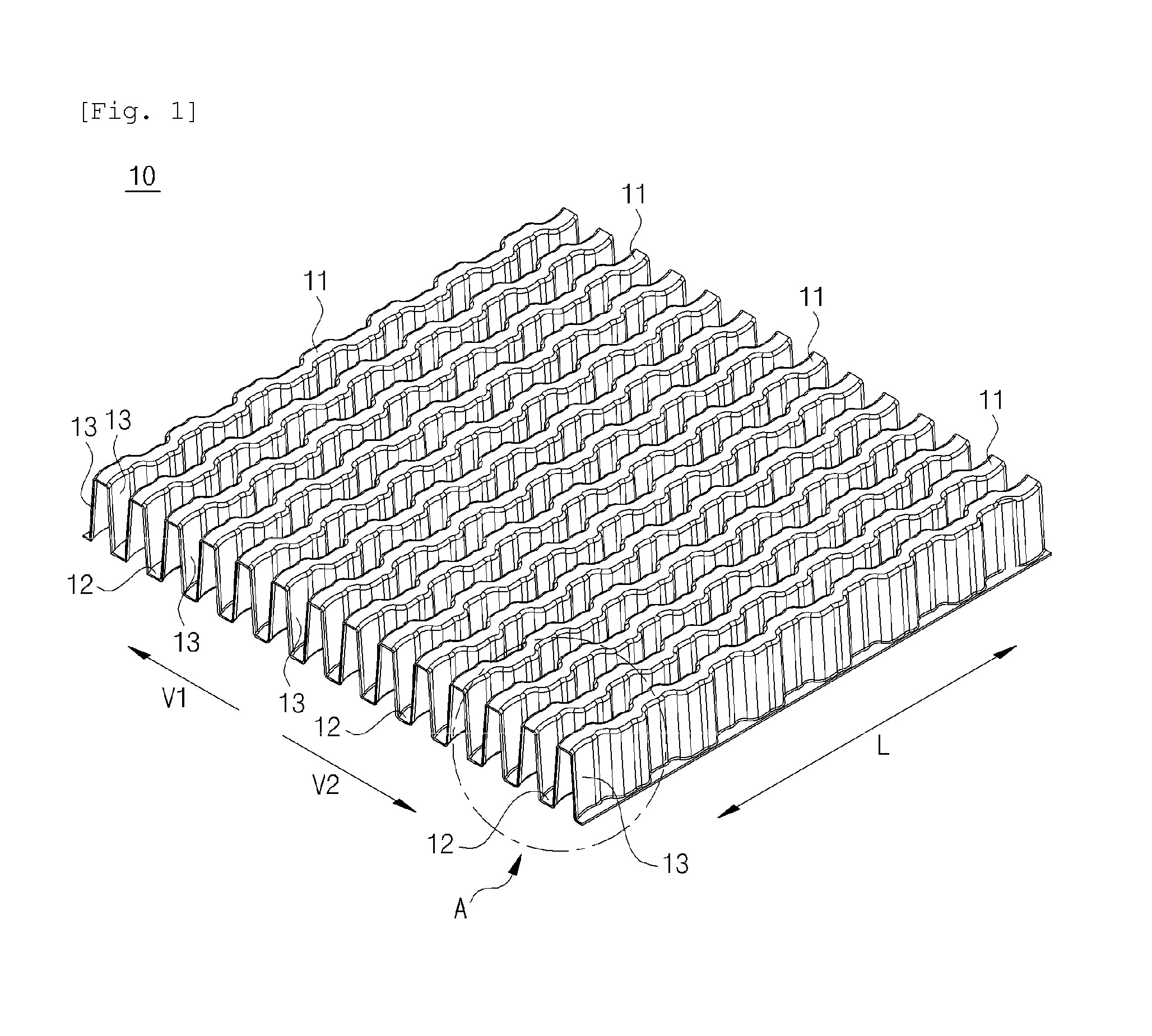

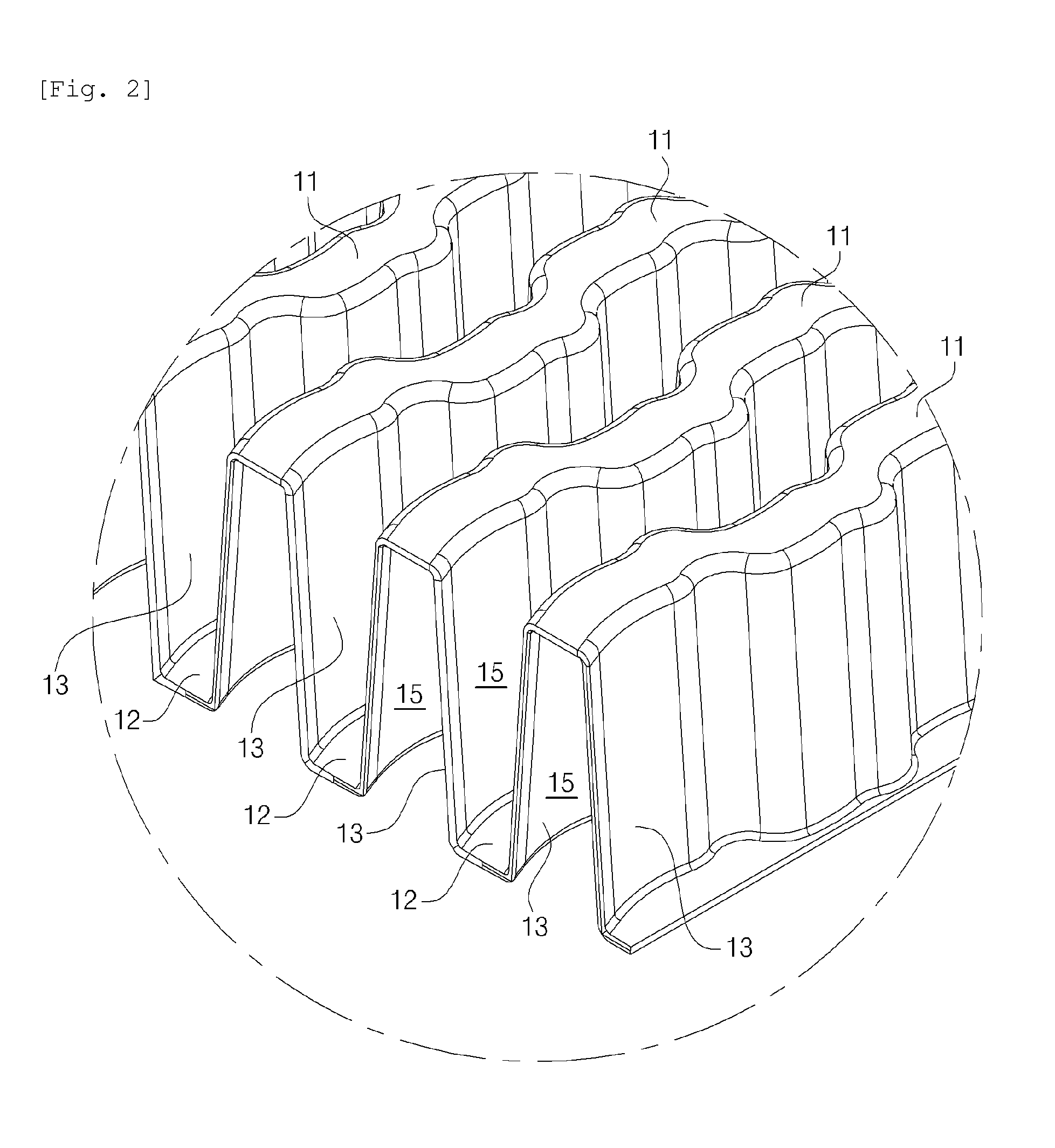

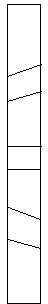

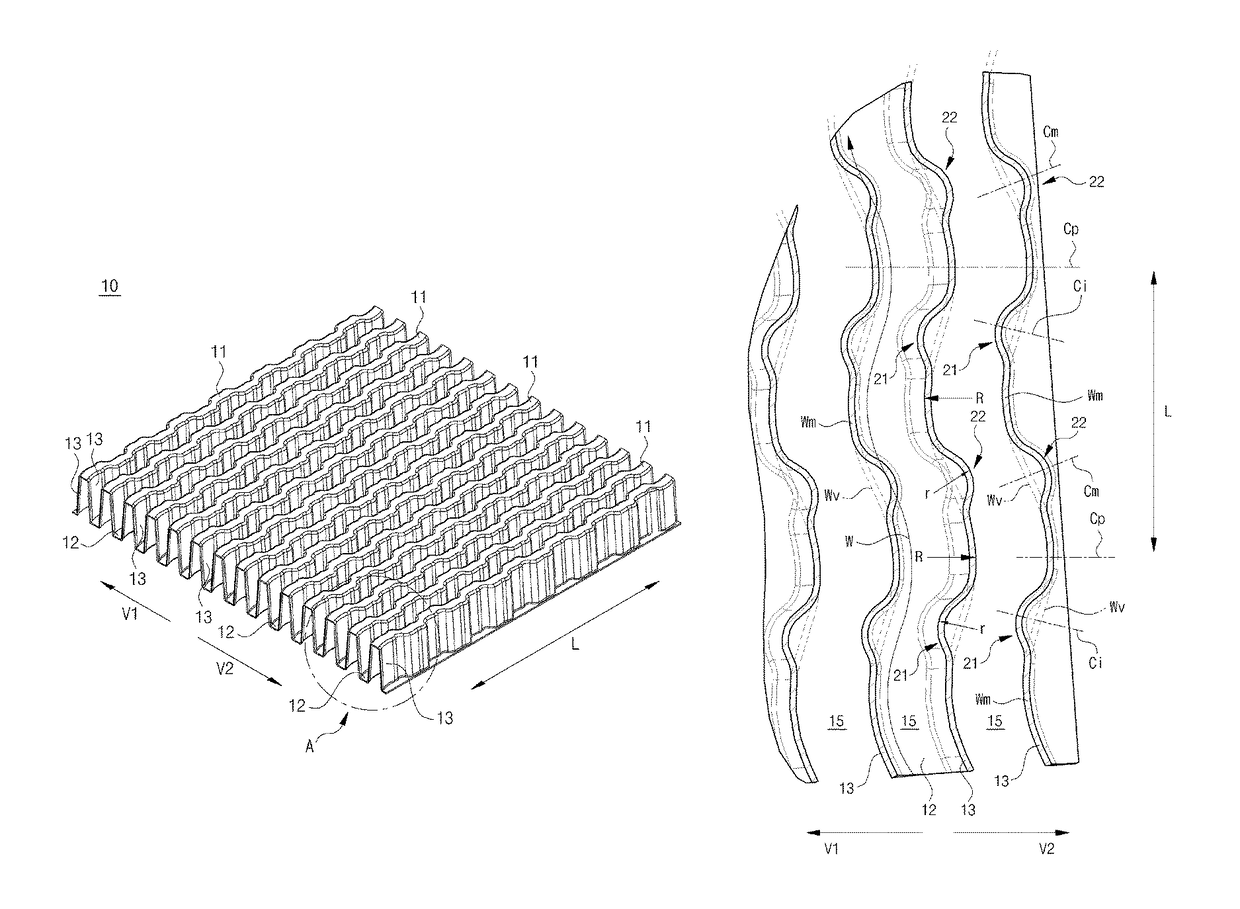

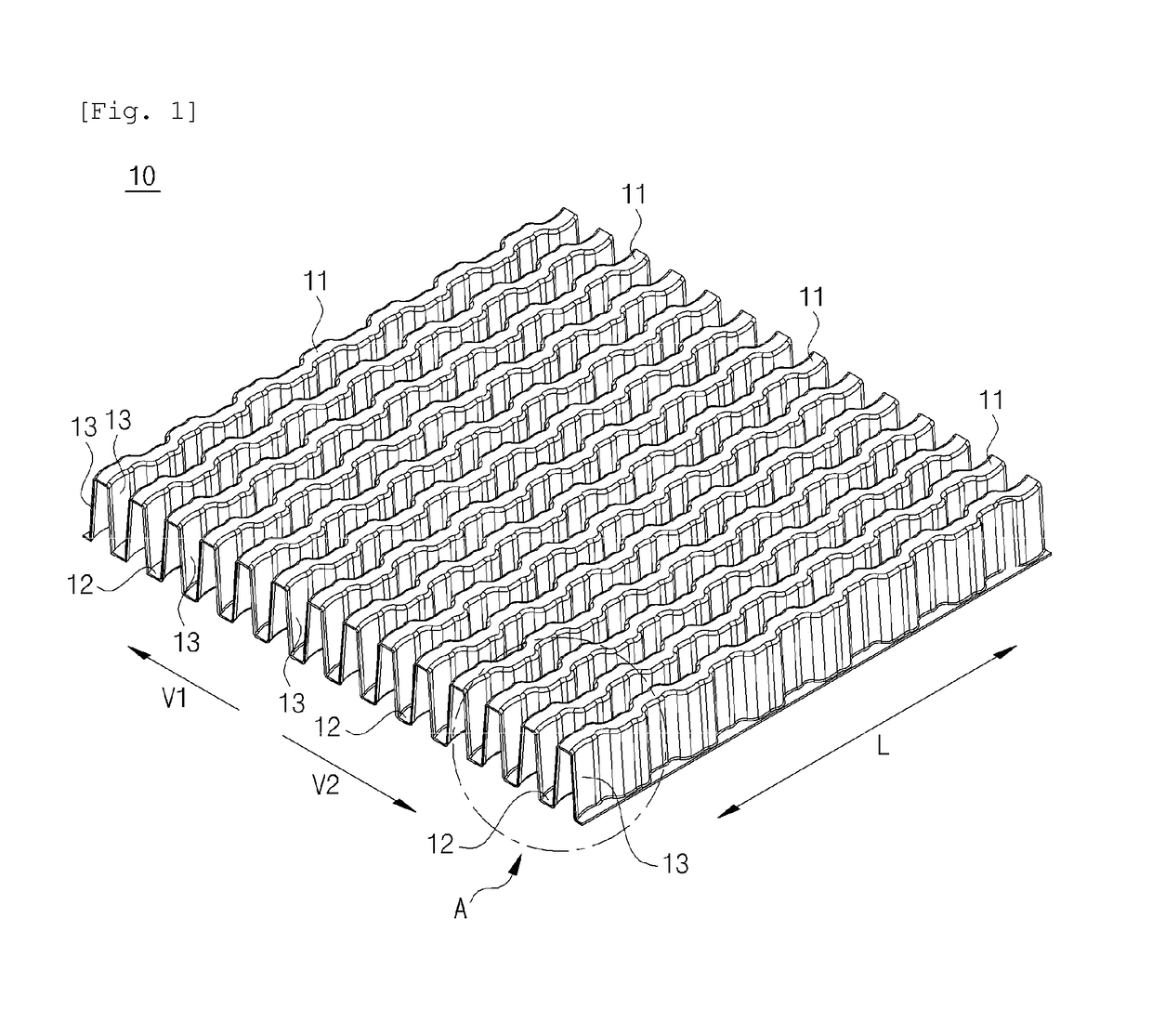

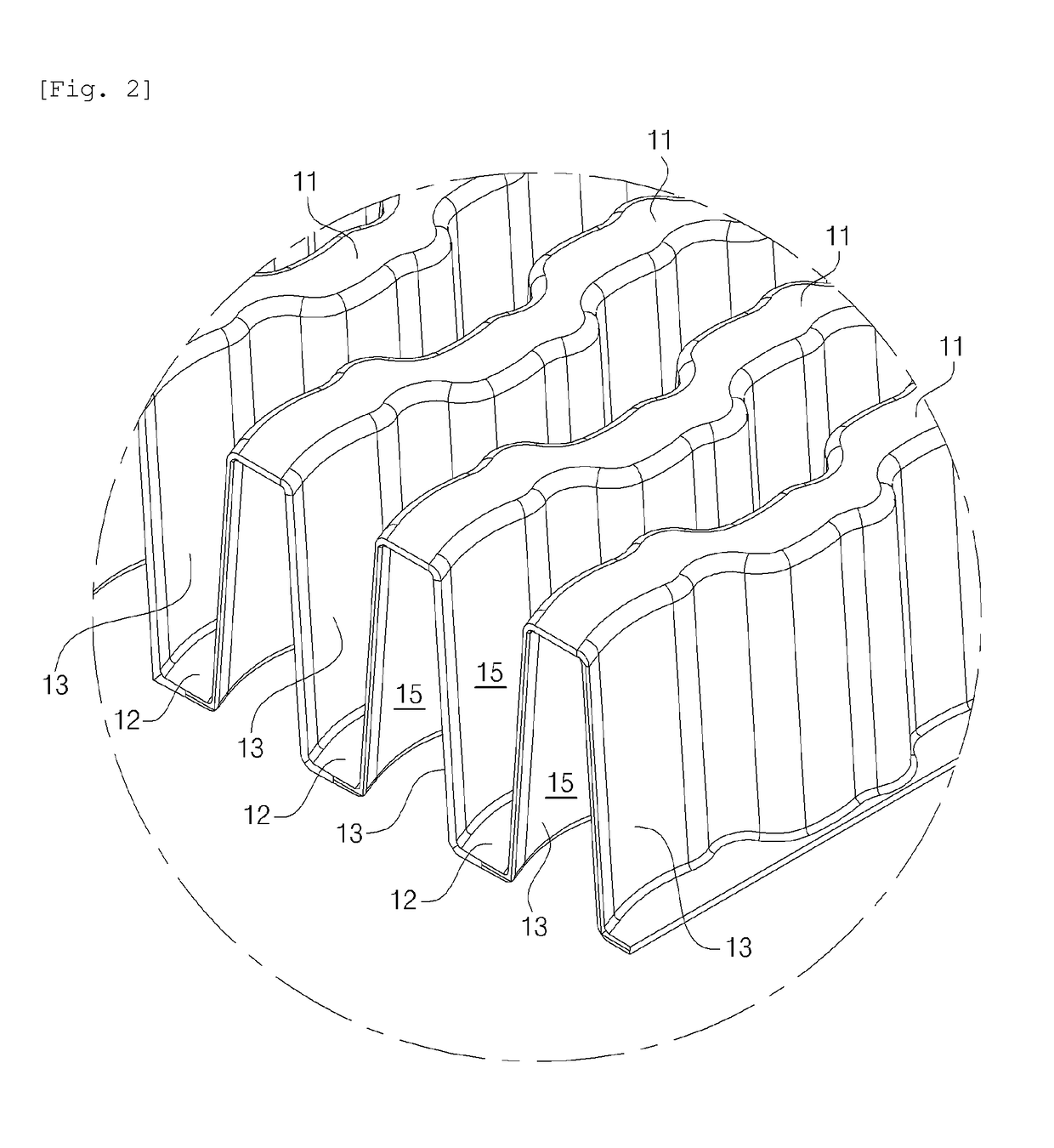

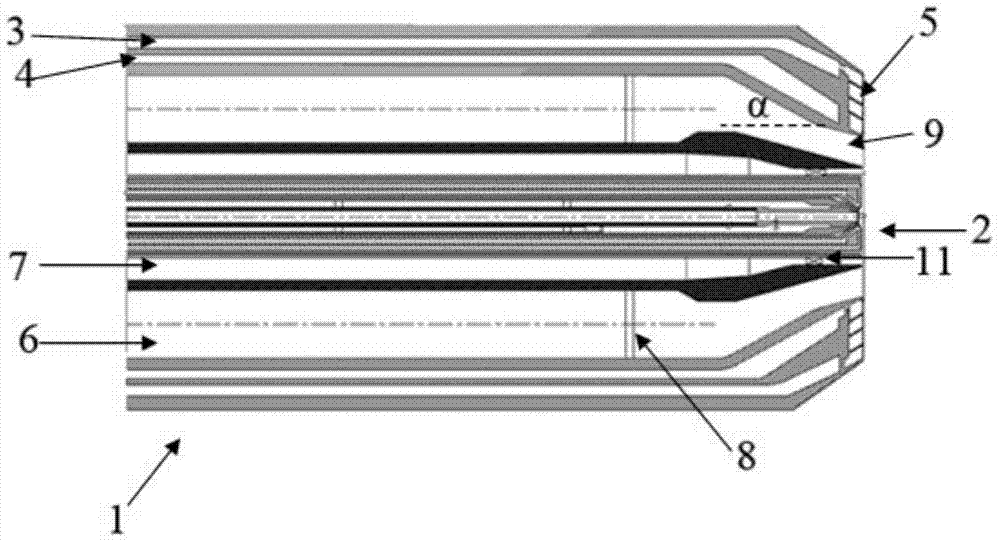

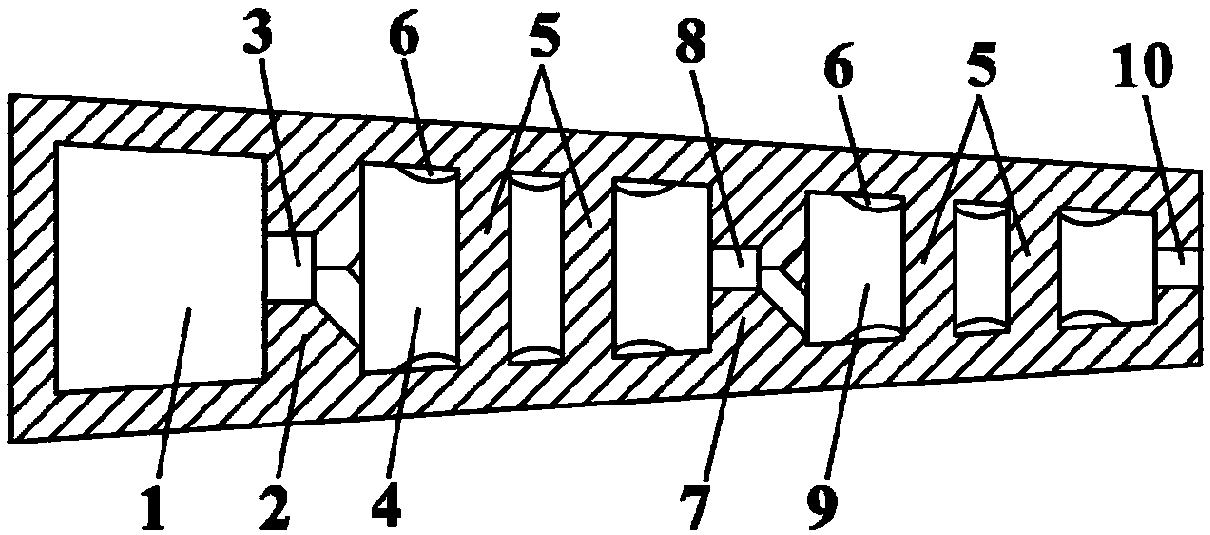

Wave fins

InactiveUS20140360707A1Increase turbulent kinetic energyImprove heat transfer efficiencyStationary tubular conduit assembliesHeat transfer modificationEngineeringHeat sink

Wave fins which are disposed inside a heat exchanger housing of a heat exchanger in order to cause a turbulent flow of fluid through direct contact with the fluid. The wave fins include a plurality of hills, a plurality of valleys and a plurality of sidewalls. The hills and valleys are connected to each other via the plurality of sidewalls. The sidewalls partition fluid passages between the hills and the valleys through which fluid passes. The hills, the valleys and the sidewalls form main waveforms that extend in a longitudinal direction so as to be waved in a first radius of curvature. One or more bent portions are formed on intermediate portions of the main waveforms, the bent portions being connected to remaining portions of the main waveforms so as to be bent at a second radius of curvature.

Owner:KORENS

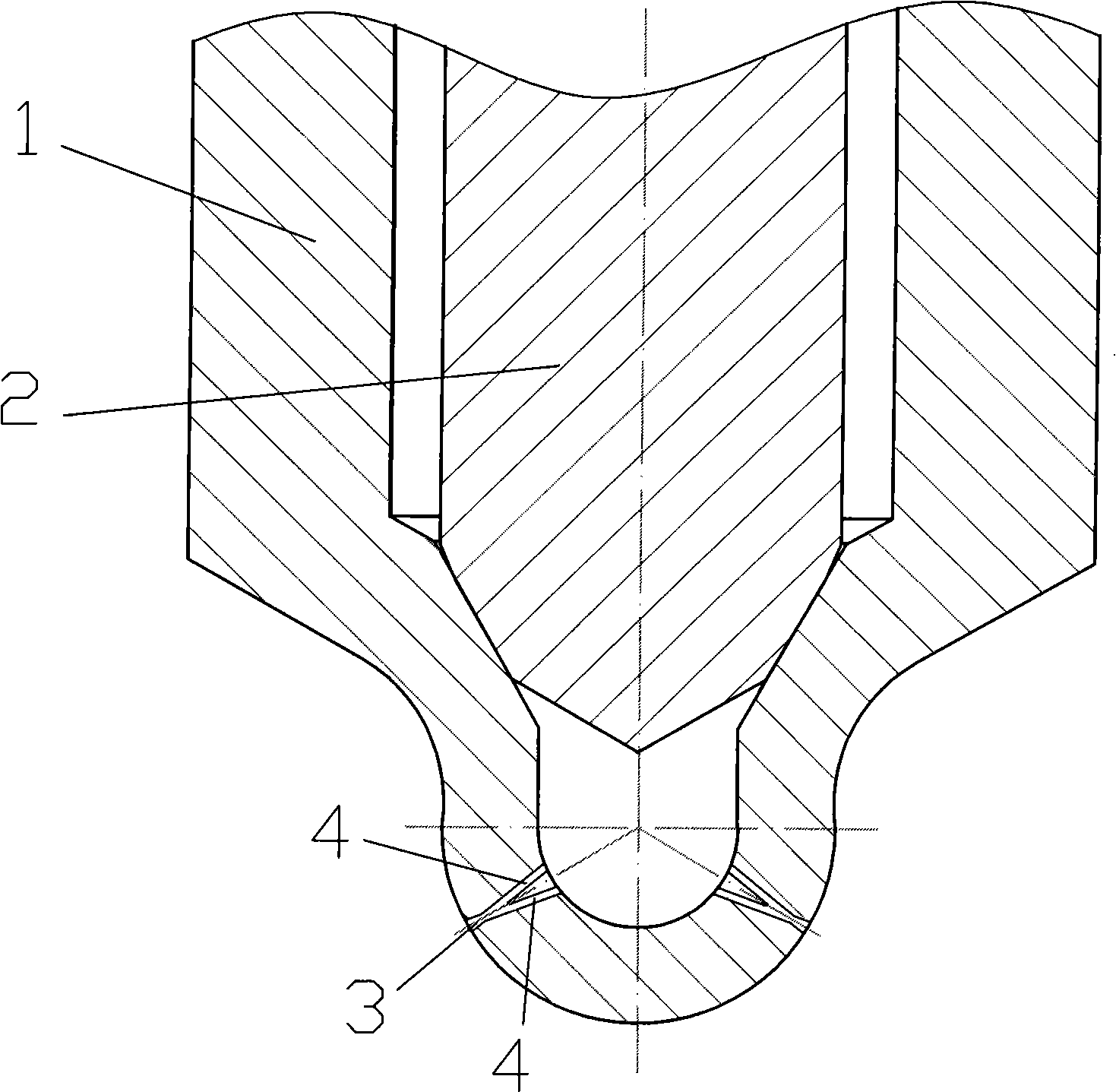

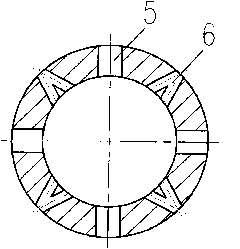

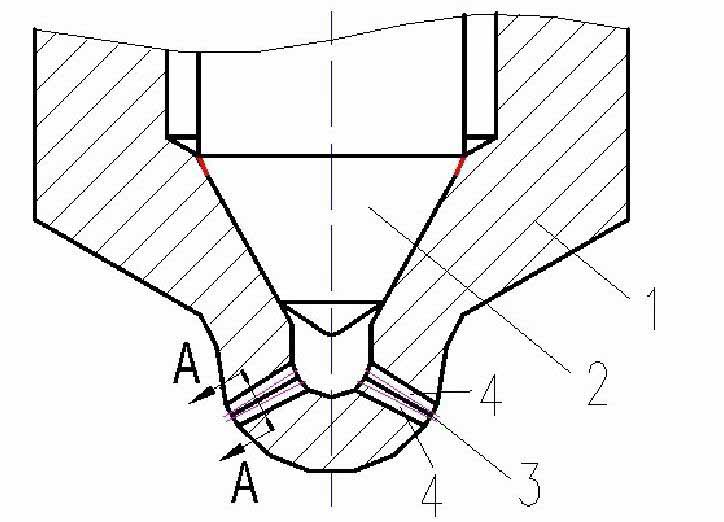

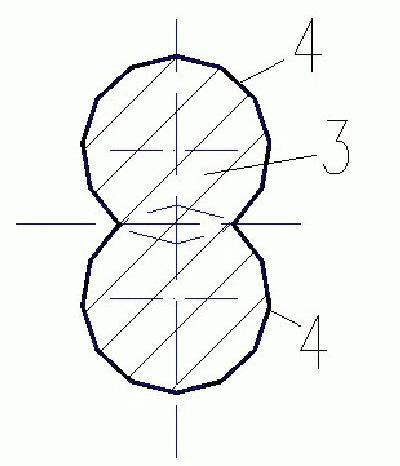

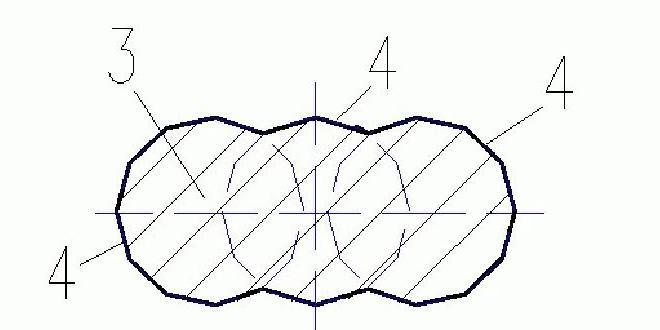

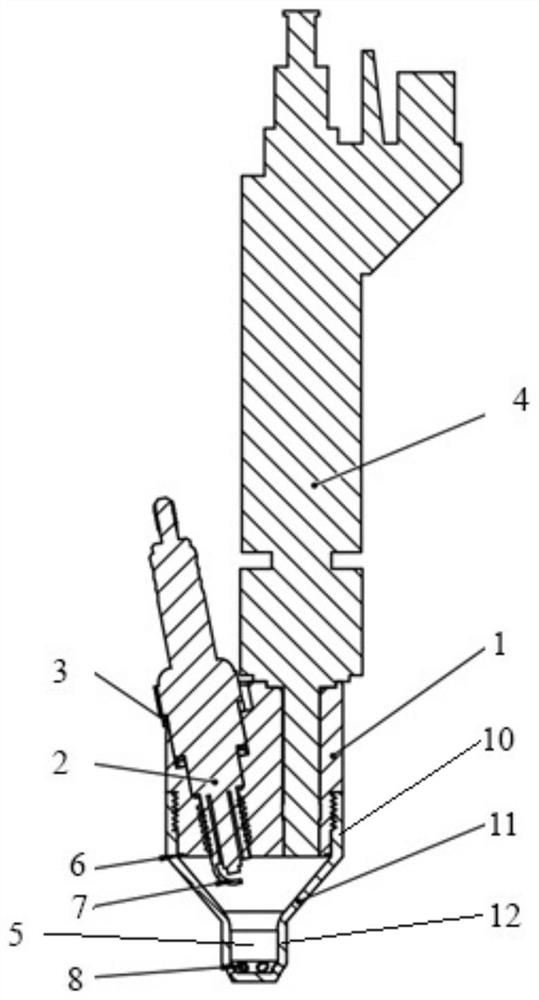

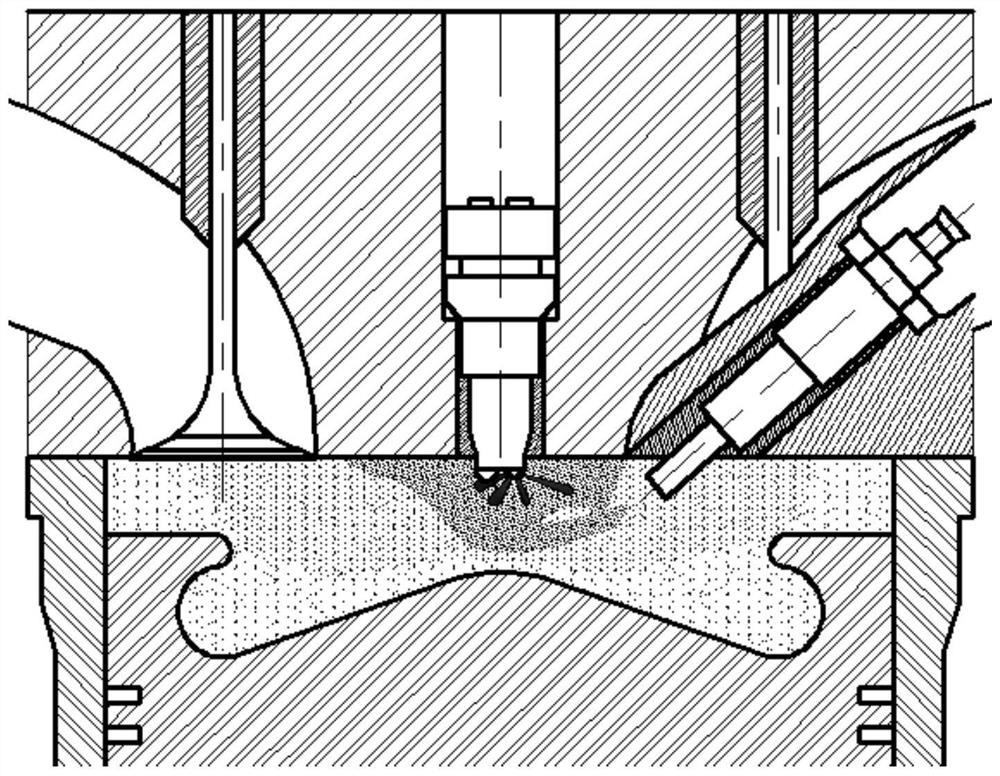

Crossing spray orifice type injection nozzle of internal combustion engine

InactiveCN101294533AIncreased turbulence intensityPromote atomizationFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention relates to a cross orifice typed injection nozzle for an internal-combustion engine and belongs to an oil injection device of a fuel system of the internal-combustion engine. The nozzle is a precision coupling formed by an injector valve body and an injector valve. The head of the injector valve body is provided with at least one cross sub-orifice and each cross orifice is formed by crossing and collecting of at least two sub-orifices. As the collection of fuel in the sub-orifices of the cross orifice can form intense disturbance, the turbulent kinetic energy is increased and the atomization is improved; as an outlet of the cross orifice is formed by the collection of the sub-orifices, the flow area of the outlet is less than the sum of the outlet areas of all the sub-orifices, the injection nozzle is characterized by improving discharge coefficient like an analogous V-shaped gradually shrinking orifice. In brief, the crossing of the sub-orifices increases the internal flow, improves the turbulent intensity, causes the cross orifice to improve atomization, improves the quality of the mixed gas and leads to rapid, sufficient and perfect combustion, thus being beneficial to the further improvement of the economic performance, discharging performance and kinetic performance of the motor.

Owner:DALIAN UNIV OF TECH

Combustion system of diesel engine

InactiveCN101825045AReduce quality problemsReduce heat loadInternal combustion piston enginesFuel injection apparatusCombustion systemCombustion chamber

The invention relates to a combustion system of a diesel engine, which belongs to the field of injection and combustion of fuel of diesel engines. The combustion system mainly comprises a combustion chamber, wherein the combustion chamber is arranged at the top of a piston with the diameter smaller than 150mm; and a fuel beam of a fuel injector positioned in the center of a cylinder cover is matched with the combustion chamber. The fuel injector is formed by combining one or more circular injecting holes and combined injecting holes with different hole diameters and matched with a shallow basin type combustion chamber or a shallow omega type combustion chamber by utilizing oil beams with different penetration distances and different spreading angles. Because the combustion system is combined by adopting various injecting holes, the optimal matching between the fuel beams and the combustion chamber is easy for realization; the intense disturbance can be formed when the fuel in injecting sub-holes of the combined injecting holes are converged, the turbulence function is added, and the atomization is improved; and the combustion system which configures a combined injecting hole nozzle with large spray diffusance and a long penetration distance and a short penetration distance of the adjacent fuel beams on the combustion chamber greatly improves the air utilization ratio, promotes combustion, reduces discharge and heat transfer loss and improves economy.

Owner:DALIAN UNIV OF TECH

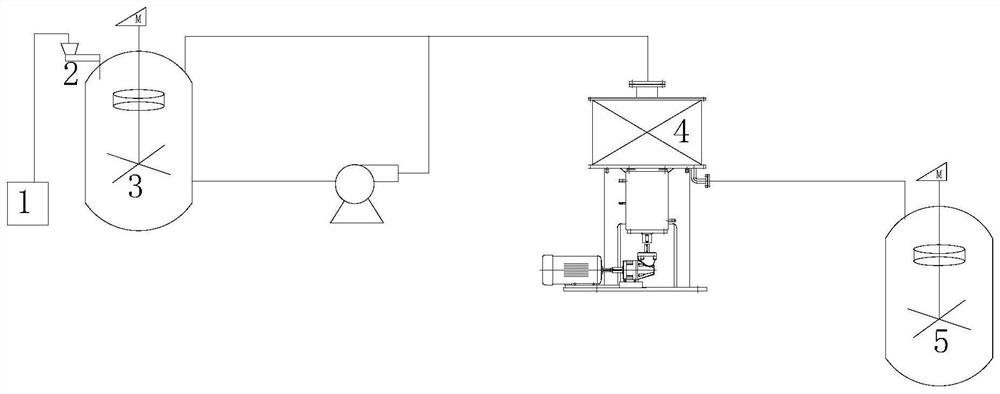

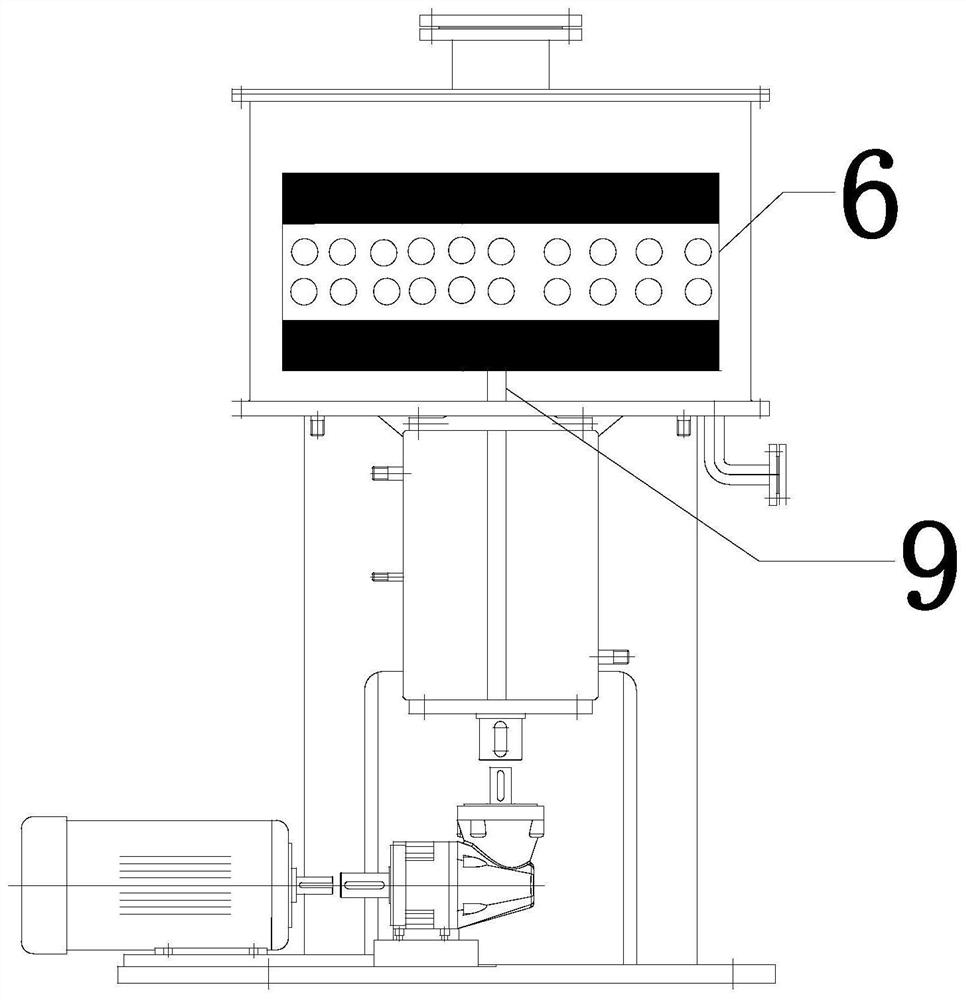

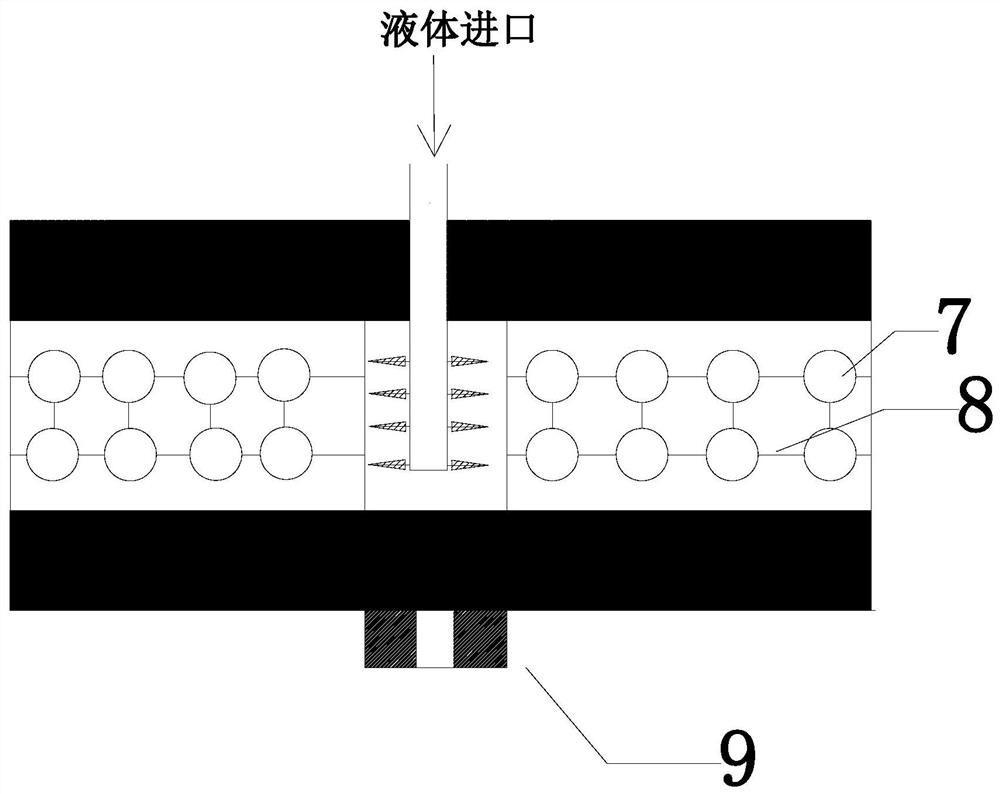

Device and method for preparing biodiesel

InactiveCN103881828ALarge mass transfer areaImprove exchange conversion rate effectFatty acid esterificationBiofuelsMotor driveBiodiesel

The invention discloses a device and a method for preparing biodiesel. The device comprises a pipeline system, a reaction system and a measurement system, wherein the pipeline system comprises a raw material circulating storage box, a material circulating pump, an inflow pipeline, a return pipeline, an adjustable butterfly valve, and an unadjustable butterfly valve, the reaction system comprises a hydrodynamic cavitation reactor, a hydrodynamic cavitation porous plate, a striking room, and a motor driving rotating nozzle, and the measurement system comprises an upstream pressure gage and a downstream pressure gage as well as a flowmeter. Based on the coupling hydrodynamic cavitation and rotating impinging stream technologies, the device realizes efficient preparation of biodiesel. Circulating fluid flows through throttling holes in the porous plate inside the cavitation reactor, so that the cavitation phenomenon increases the turbulence intensity of the fluid, and the mass transfer area of an alcohol phase and an ester phase is greatly increased; the rotating impinging stream technology strengthens the tangential force in collision and enhances the cavitation effect on the collision surface; the device runs safely, has low running cost, can greatly improve the preparation efficiency of biodiesel, and shortens the preparation time of the biodiesel.

Owner:JIANGSU UNIV

Fuel nozzle

InactiveCN102235283AImprove economyImprove emission effectFuel injection apparatusMachines/enginesCombustionEngineering

The invention discloses a fuel nozzle, belonging to a fuel spraying device of an internal-combustion engine fuel system. The fuel nozzle is composed of a needle valve body and a needle valve, wherein the head of the needle valve body is provided with at least one combined spray orifice; each combined spray orifice is composed of at least two sub spray orifices; the cross sections of the sub spray orifices are tangent; and the central lines of the sub spray orifices can be parallel or can be in different planes. Because fuel in the combined orifices can have intense disturbance, turbulence kinetic energy is increased so as to improve atomization; and atomization throughout distance is regulated by changing the injection direction of each sub spray orifice so as to improve flow coefficient. By the arrangement of the spray orifices, internal turbulence intensity is improved, atomization is improved, the throughout distance can be regulated, the spatial distribution range of sprayed mist is expanded, the quality of mixed gas is improved, and the effect of quick, sufficient and complete combustion can be achieved, therefore the economic performance, the emission performance and the power performance of the engine can be further improved.

Owner:DALIAN UNIV OF TECH

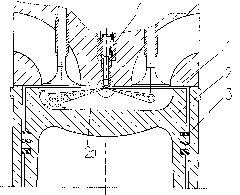

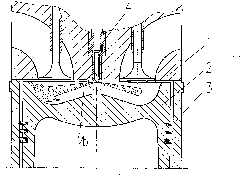

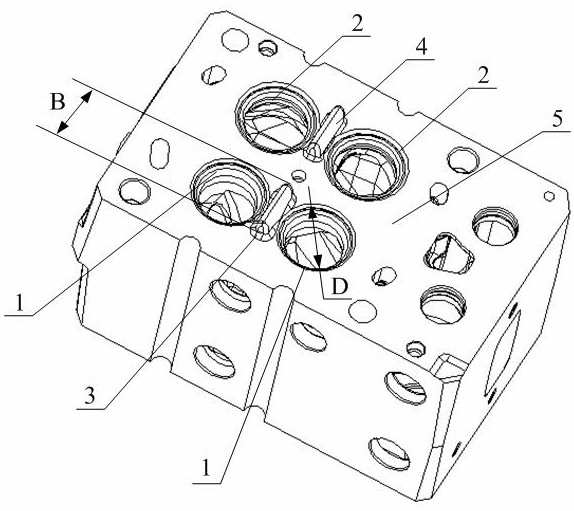

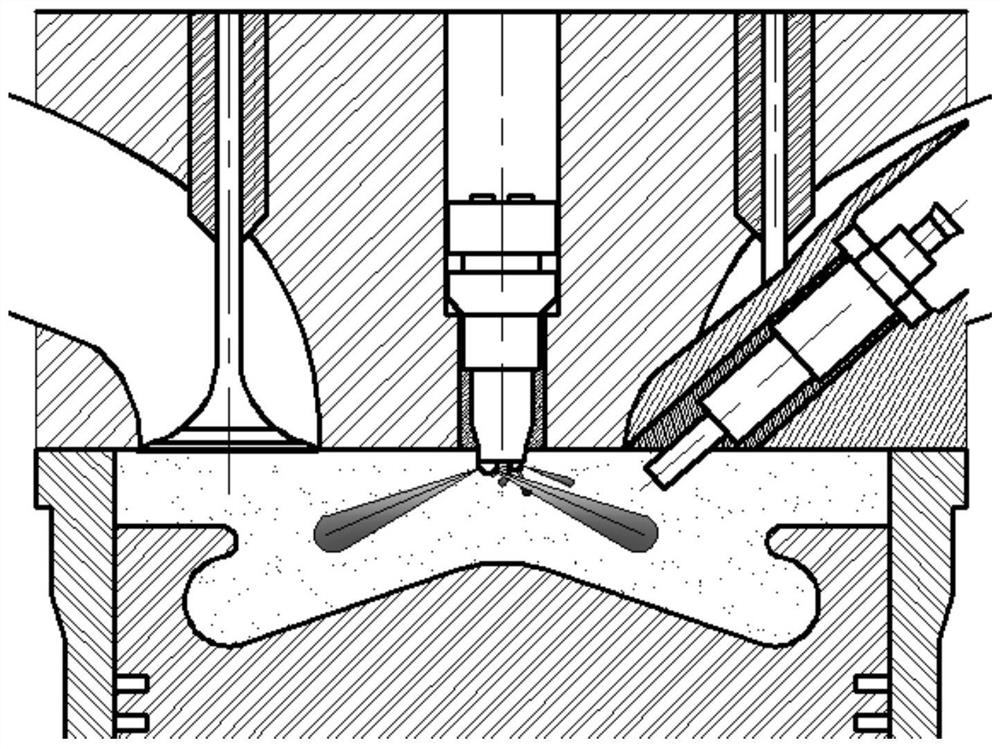

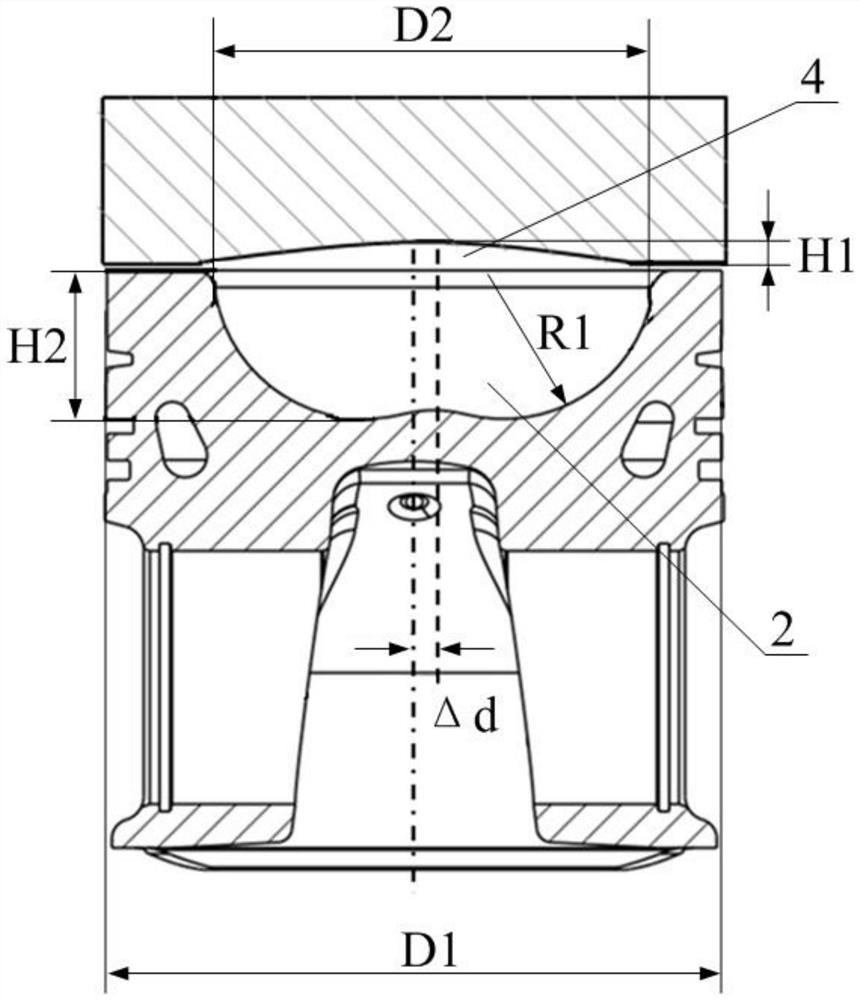

Heavy natural gas engine combustion system

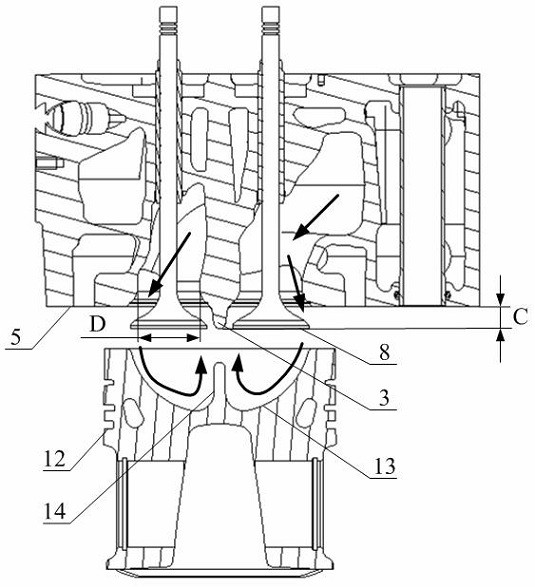

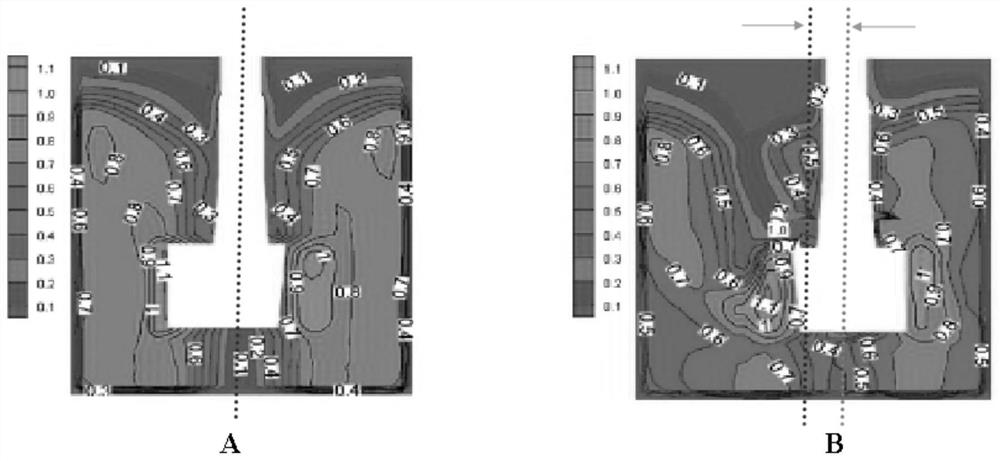

PendingCN113685264AImprove scalabilityPromote disseminationInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses a heavy natural gas engine combustion system. The system comprises an air cylinder and a cylinder cover covering the air cylinder, the cylinder cover is provided with a composite air inlet channel composed of a vortex air inlet channel and a straight tumble air inlet channel and communicates with the interior of the air cylinder through an air inlet gate provided with an air inlet valve, the air inlet valve is arranged on a valve seat, The air inlet gate is located in the whole valve seat, two exhaust passage inlets communicate with the interior of the air cylinder through exhaust valves arranged on the cylinder cover, a spark plug device is installed in the center of the bottom face of the cylinder cover, a steel piston is arranged in the cylinder cover, and the bottom face of the cylinder cover, the inner wall face of the air cylinder and the top face of the piston define a space which serves as a necking-down type combustion chamber, and gas supply and injection systems are respectively arranged on the two gas inlet channels or the bottom surface of the cylinder cover. The system is simple and compact in structure and convenient in manufacturing and assembly, low heat dissipation is achieved through the steel piston, meanwhile, inlet air flow can form oblique axis vortex around the central axis of the cylinder through the composite air inlet channel, turbulent kinetic energy in the cylinder is improved, and then heat efficiency is improved.

Owner:TIANJIN UNIV

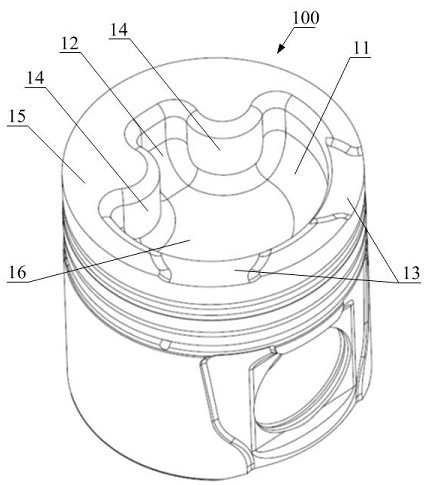

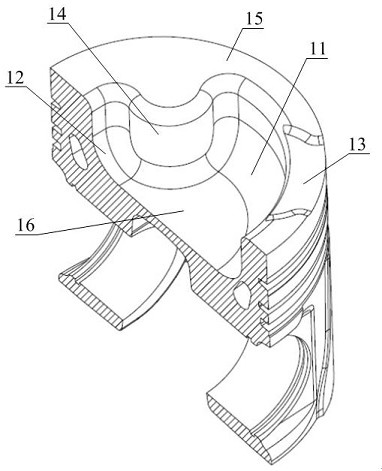

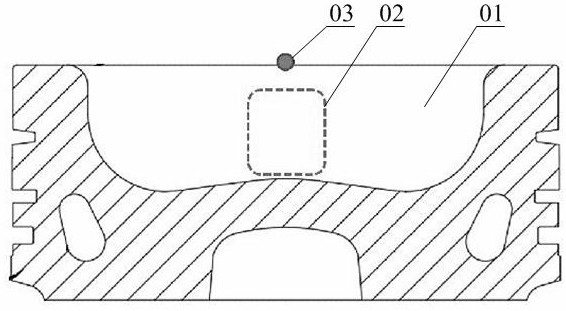

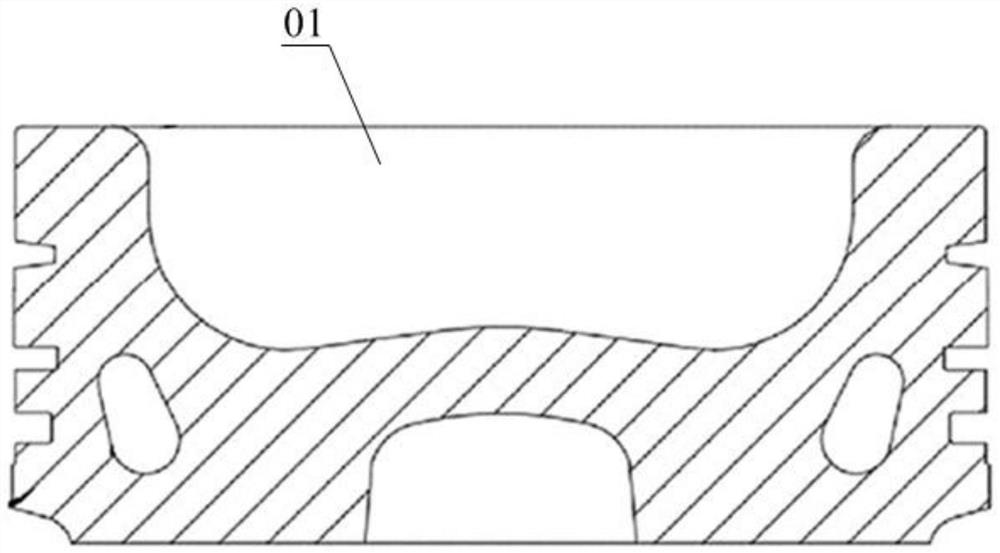

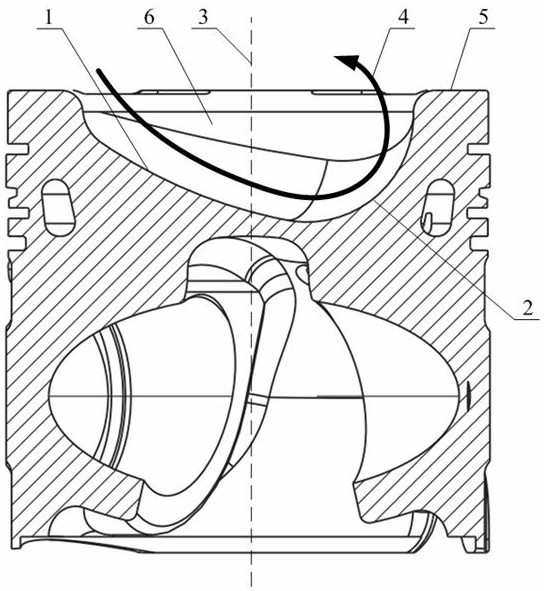

Combustion chamber and gas engine

ActiveCN112211715AIncrease turbulent kinetic energyBurn fasterInternal combustion piston enginesGaseous engine fuelsCombustion chamberExhaust valve

The invention discloses a combustion chamber which is applied to a gas engine. The combustion chamber comprises a piston upper top face located at the top of a piston and a combustion chamber pit sunken downwards relative to the piston upper top face, wherein two flow guide protruding parts protruding towards the inner side of the combustion chamber pit are arranged on the circumferential side wall in the combustion chamber pit, the two flow guide protruding parts are located below two air inlet valves correspondingly, the upper end faces of the flow guide protruding parts are connected with the piston upper top face, and the lower ends of the flow guide protruding parts are connected with the bottom face of the combustion chamber pit. The combustion chamber pit comprises a first flow guide pit located below the exhaust valve and a second flow guide pit located between the two flow guide protruding parts. The first flow guide pit is communicated with the second flow guide pit, and theside surface of the flow guide protruding part forms a smooth transition face between the first flow guide pit and the second flow guide pit. According to the combustion chamber, the tumble intensitycan be enhanced in the compression process, and tumble is violently broken into turbulent flow in the final stage of compression; and therefore the flame spreading speed is increased, and turbulent kinetic energy and heat efficiency are improved. The invention further discloses a gas engine.

Owner:WEICHAI POWER CO LTD

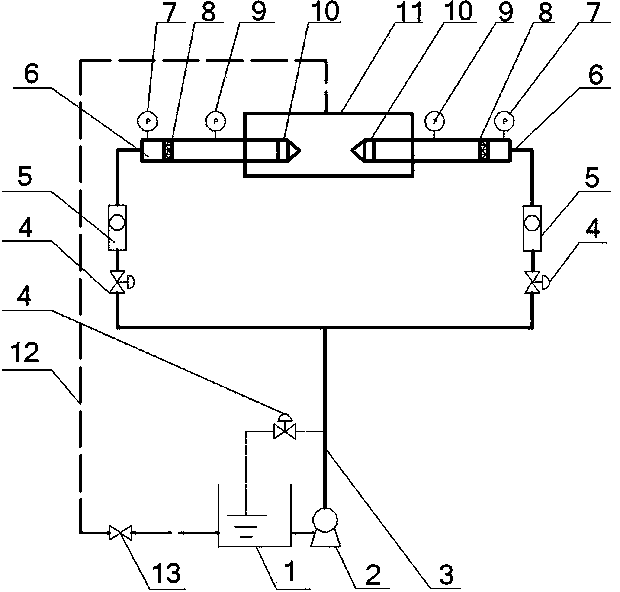

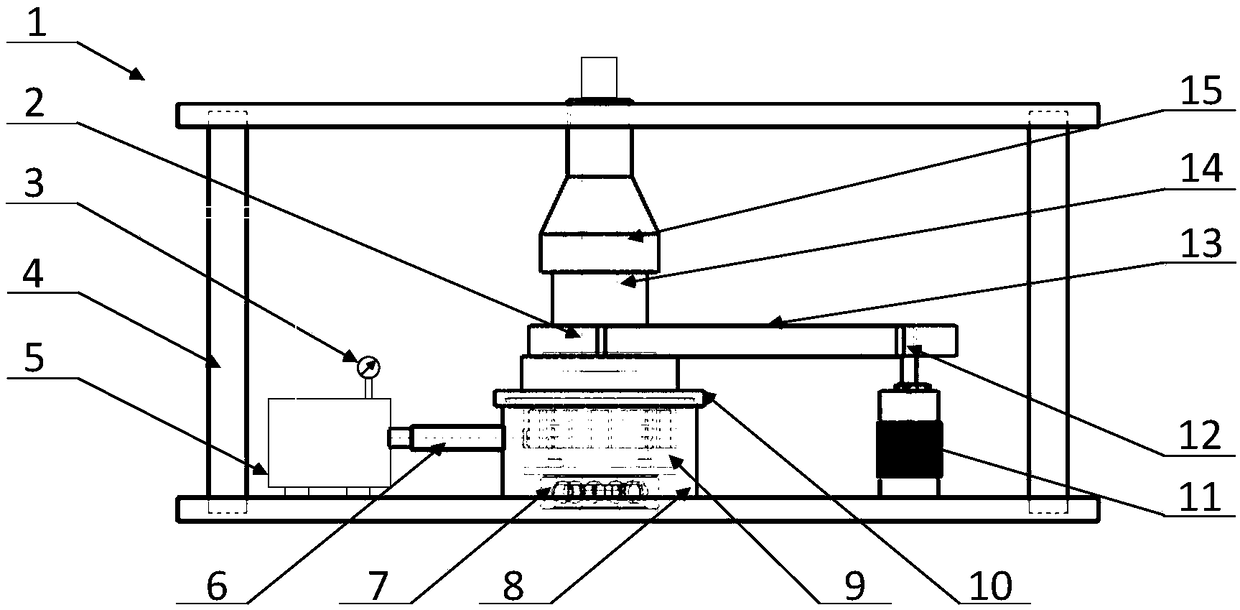

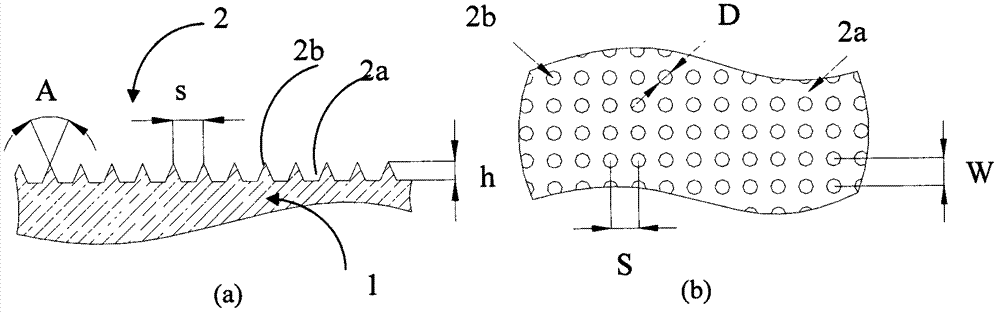

Pulsed abrasive flow polishing device and method

ActiveCN109352536AStable pressure waveLow failure rateEdge grinding machinesPolishing machinesMaterial hardnessEngineering

The invention relates to a pulsed abrasive flow polishing device and method, and provides a pulse generating device which can generate four different pressure forms. Different tooth forms and tooth spacings are designed, and different mechanical structures are used for generating stable sinusoidal pressure wave, triangular pressure wave, trapezoidal pressure wave and standard sine-cosine pressurewave, so that the effect of increasing the fluid turbulent kinetic energy is achieved, the uniform machining effect is achieved, additionally, different pressure forms are selected according to different material hardness and high-temperature oxidation effects during machining, the characteristics of different kinds of pressure wave are exerted, and the machining effects of high efficiency and economy are achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

System and process for continuously producing diazonium salt solution

ActiveCN112371072AReduce depositionExtended stayOrganic chemistryTransportation and packagingProcess engineeringSalt solution

The invention discloses a system and a process for continuously producing a diazonium salt solution. The system comprises conveying equipment, feeding equipment, a premixing kettle, a diazotization reactor and a finished product kettle which are connected in sequence, the diazotization reactor is a supergravity reactor, a multi-channel structure rotating bed is adopted, channels are arranged in astaggered mode, and connecting nodes between the channels are expanded to form a spherical cavity. The process adopts the system and comprises the following steps: (1) uniformly mixing aromatic amineand a diazotization reagent in the premixing kettle, continuously feeding the aromatic amine into the premixing kettle through conveying equipment and feeding equipment under continuous stirring, anddirectly and continuously conveying the diazotization reagent into the premixing kettle at the same time; and (2) continuously feeding and simultaneously continuously discharging the materials from the premixing kettle, enabling the discharged materials to partially flow back to the premixing kettle and partially enter the diazotization reactor, enabling the aromatic amine and the diazotization reagent to fully react, and continuously discharging the diazonium salt solution generated by the reaction to the finished product kettle.

Owner:ZHEJIANG DIBANG CHEM +1

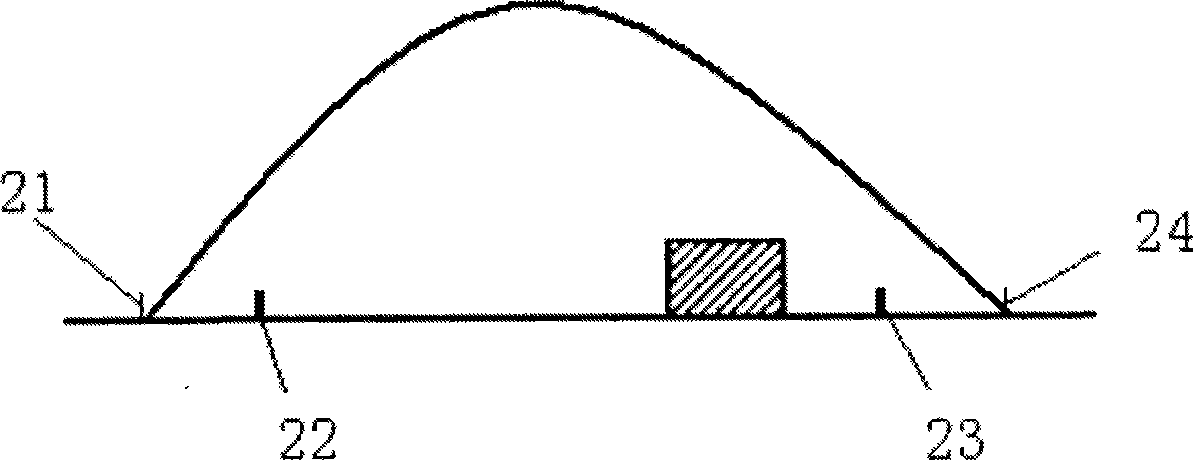

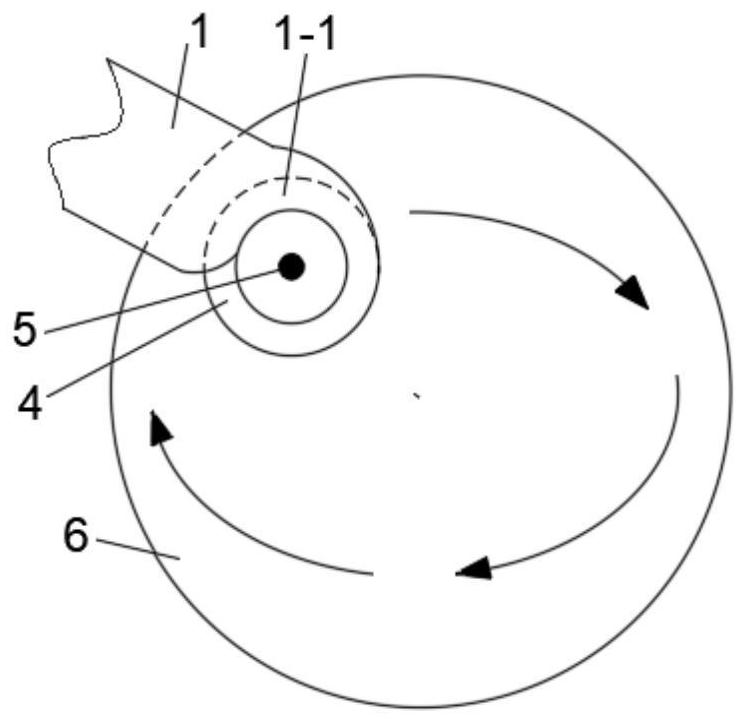

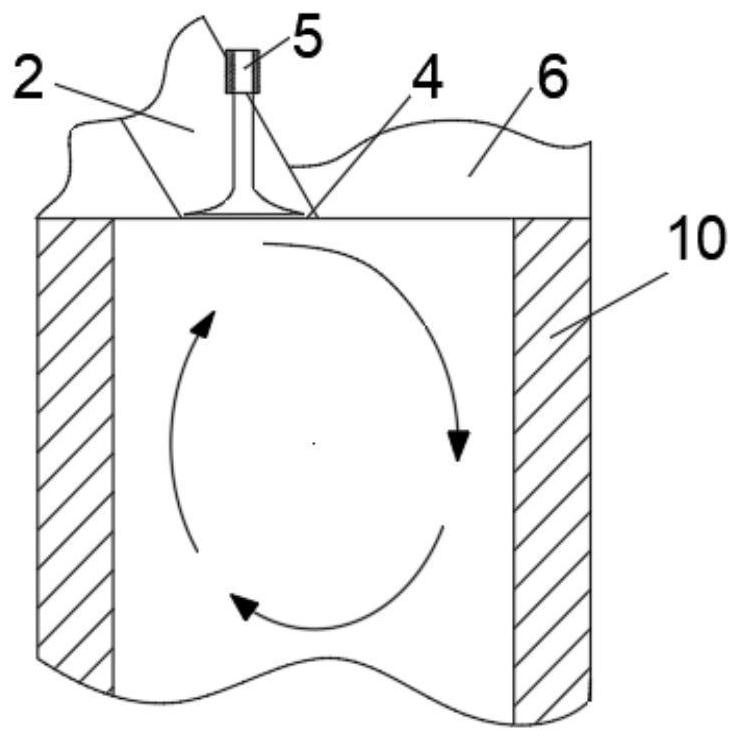

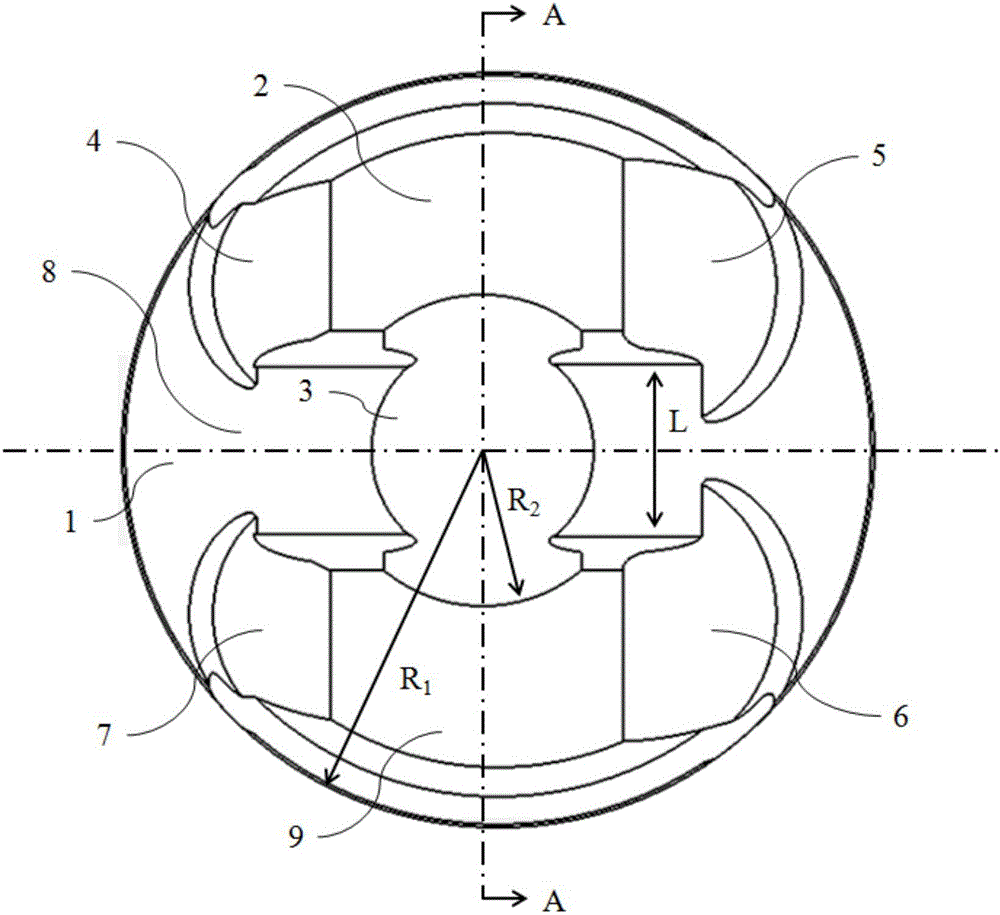

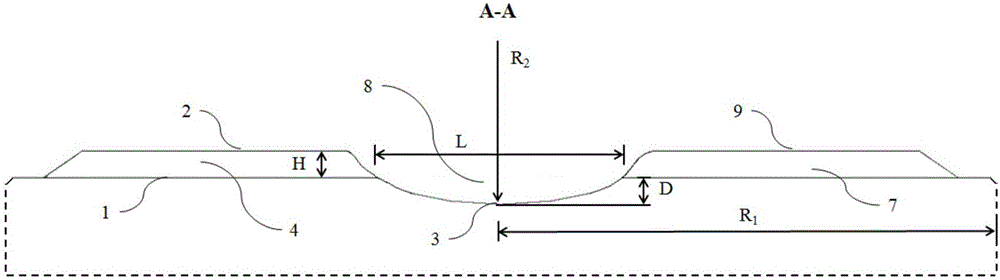

Rapid combustor of airflow hedging natural gas engine

The invention provides a rapid combustor of an airflow hedging lean-burn natural gas engine. The combustor is positioned on the top part of a piston, and the shape of the combustor is necking shallow ampullaceous; a circular groove is arranged on the top part of the piston; the circular groove is communicated with the shallow ampullaceous combustor through four uniformly distributed chutes; when the piston is close to a compression upper dead center, the airflow is erupted out at a high speed from the circular groove through the chutes and hits against with the rotating vortex formed in the intake process to damage the vortex structure in the shallow ampullaceous combustor and increase turbulent kinetic energy in a cylinder, thereby enabling the natural gas engine to generate rapid combustion, expanding stable operational lean-burn limit of the engine, and improving the dynamic property, economical efficiency and emission performance of the engine.

Owner:HARBIN ENG UNIV

Wave fins

InactiveUS9945619B2Improve heat transfer efficiencyIncrease turbulent kinetic energyHeat transfer modificationLaminated elementsEngineeringMechanical engineering

Wave fins which are disposed inside a heat exchanger housing of a heat exchanger in order to cause a turbulent flow of fluid through direct contact with the fluid. The wave fins include a plurality of hills, a plurality of valleys and a plurality of sidewalls. The hills and valleys are connected to each other via the plurality of sidewalls. The sidewalls partition fluid passages between the hills and the valleys through which fluid passes. The hills, the valleys and the sidewalls form main waveforms that extend in a longitudinal direction so as to be waved in a first radius of curvature. One or more bent portions are formed on intermediate portions of the main waveforms, the bent portions being connected to remaining portions of the main waveforms so as to be bent at a second radius of curvature.

Owner:KORENS

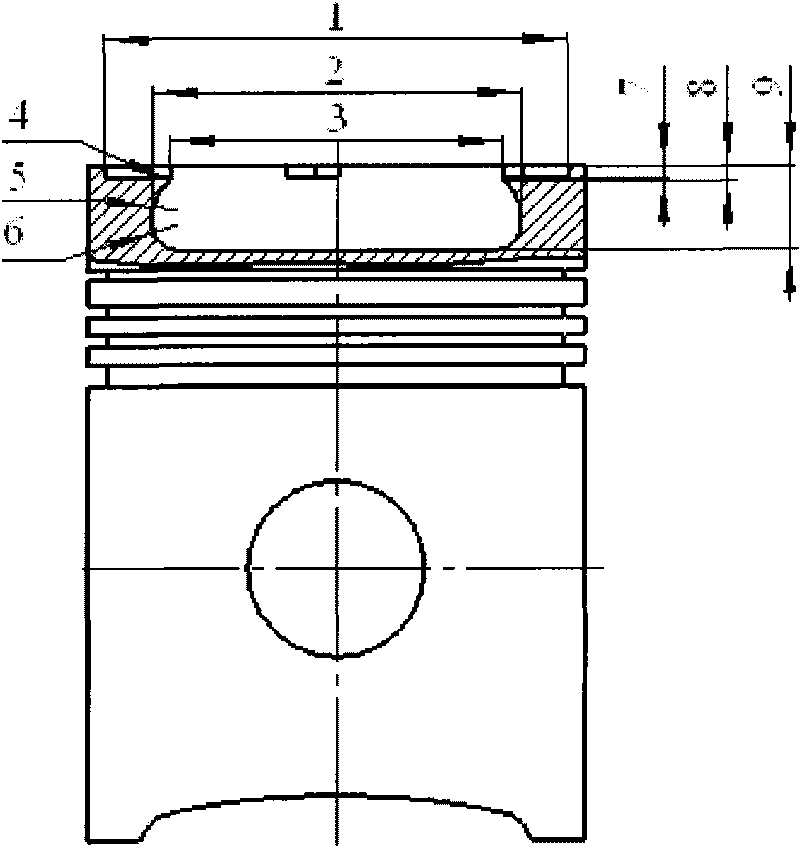

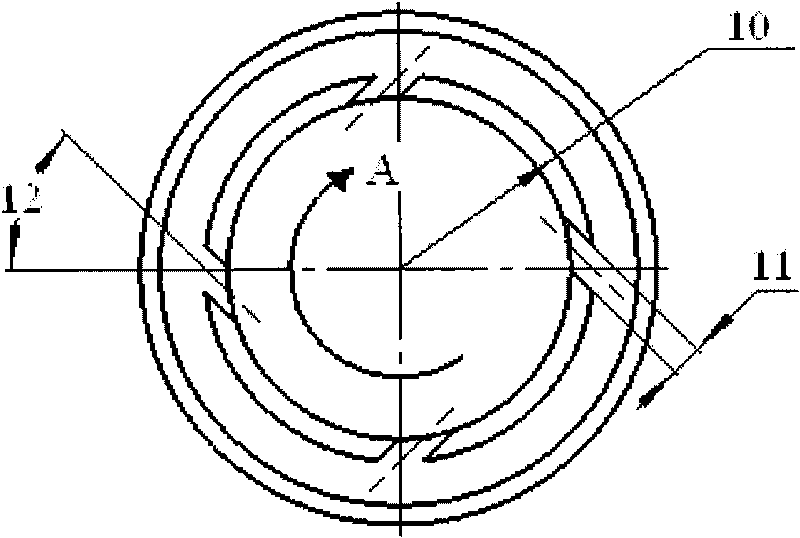

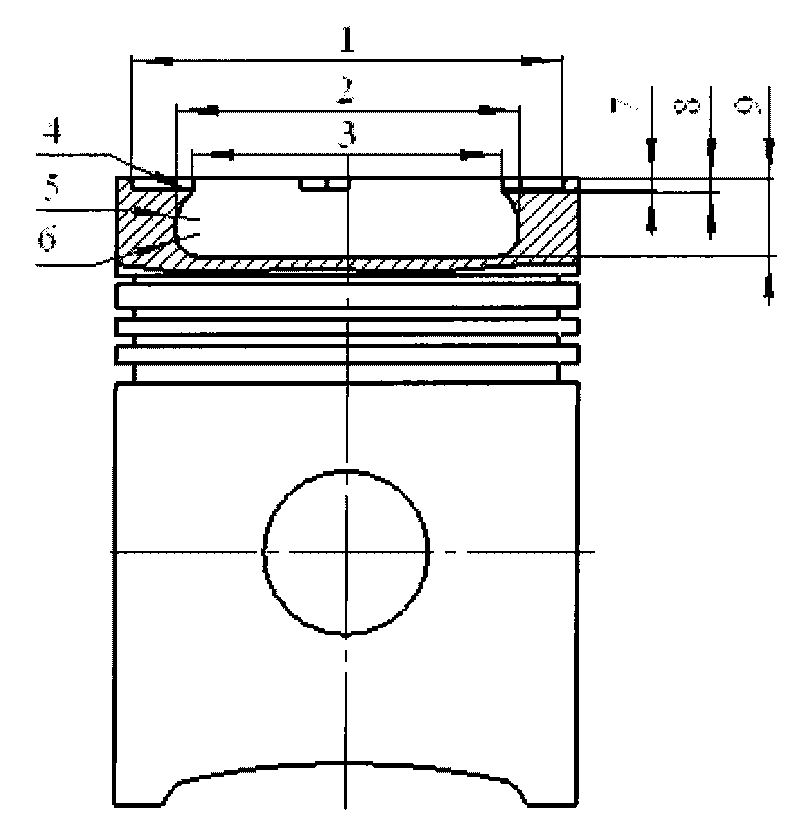

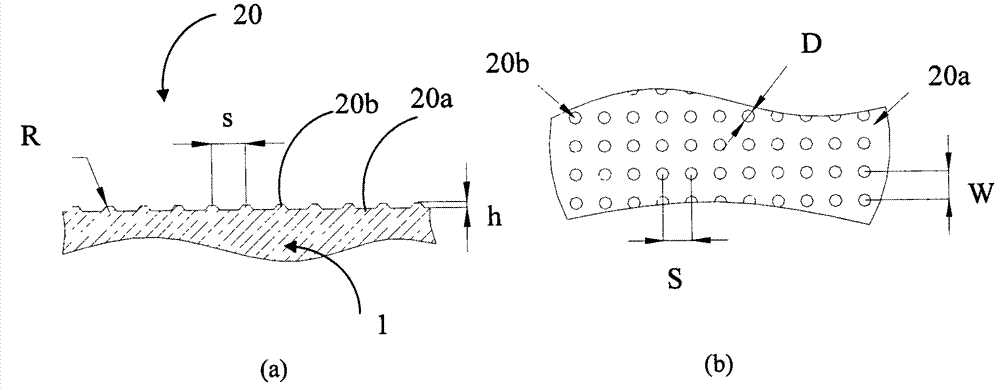

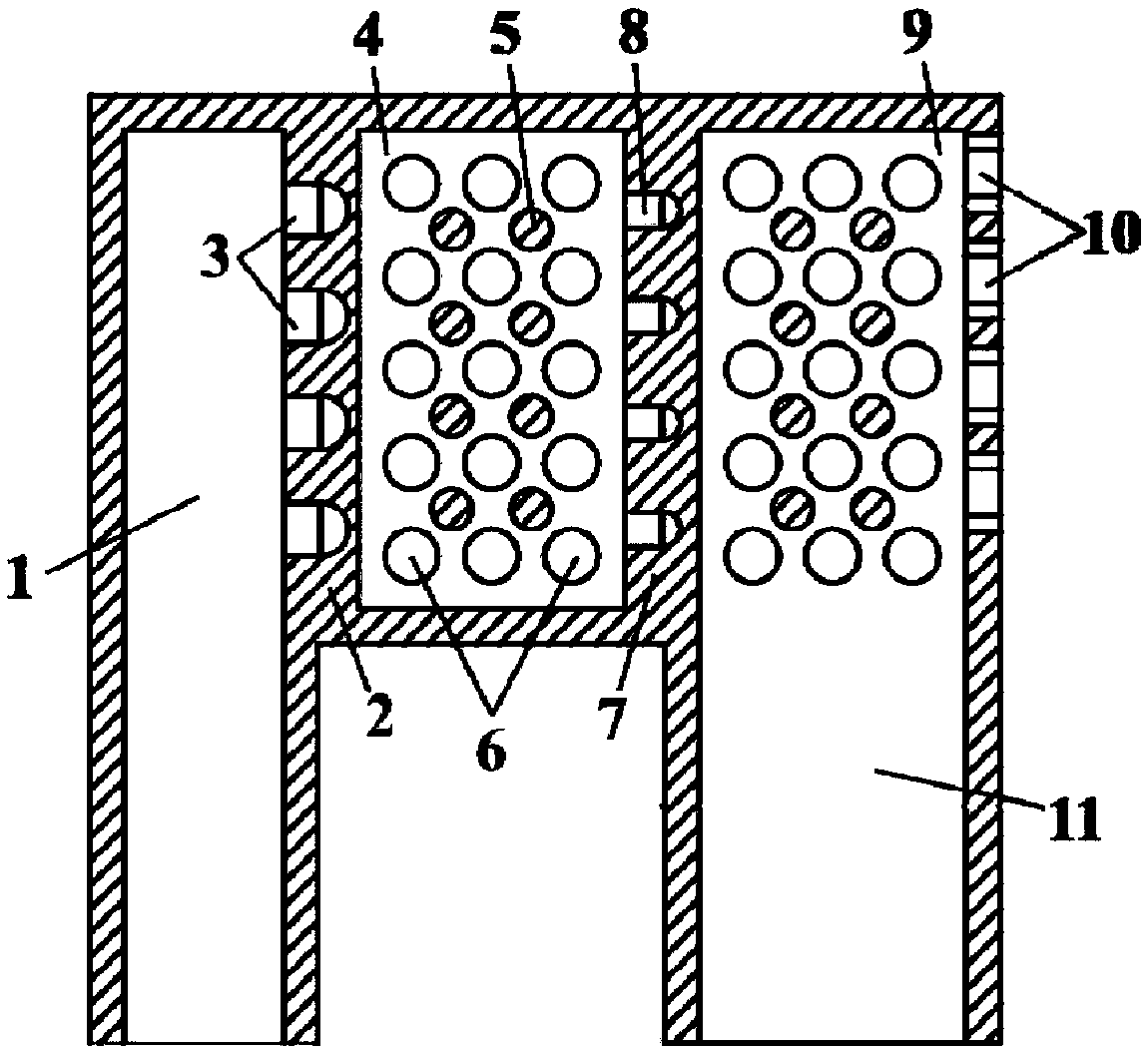

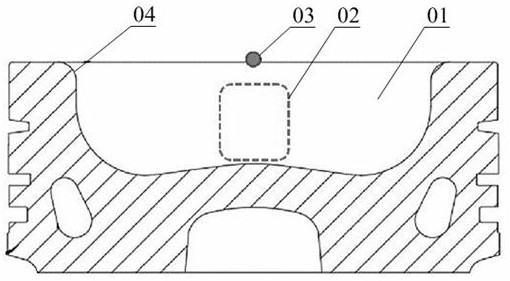

Piston with unsmooth top

ActiveCN102953859AReduce frictionPromote ruptureMachines/enginesPistonsCombustion chamberUltimate tensile strength

The invention discloses a piston with an unsmooth top. The piston comprises a piston matrix and the piston top, the piston top comprises a piston top base plane and a plurality of regularly arrayed piston top projections or pits, and the piston top projections or pits project outwards or recess inwards respectively. The piston has the advantages of simple structure and low manufacturing cost. When the piston and an engine cylinder are combined to form a combustion chamber, airflow can be distributed reasonably, tumble and break in a piston cylinder are accelerated, and turbulence intensity and turbulent kinetic energy are increased, so that gas mixture is combusted sufficiently in the engine cylinder, and further, combustion efficiency is improved, pollutant discharge is reduced, and fuel utilization rate is increased.

Owner:SAIC GENERAL MOTORS +1

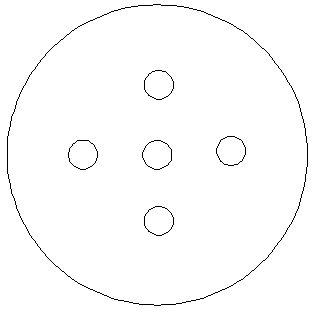

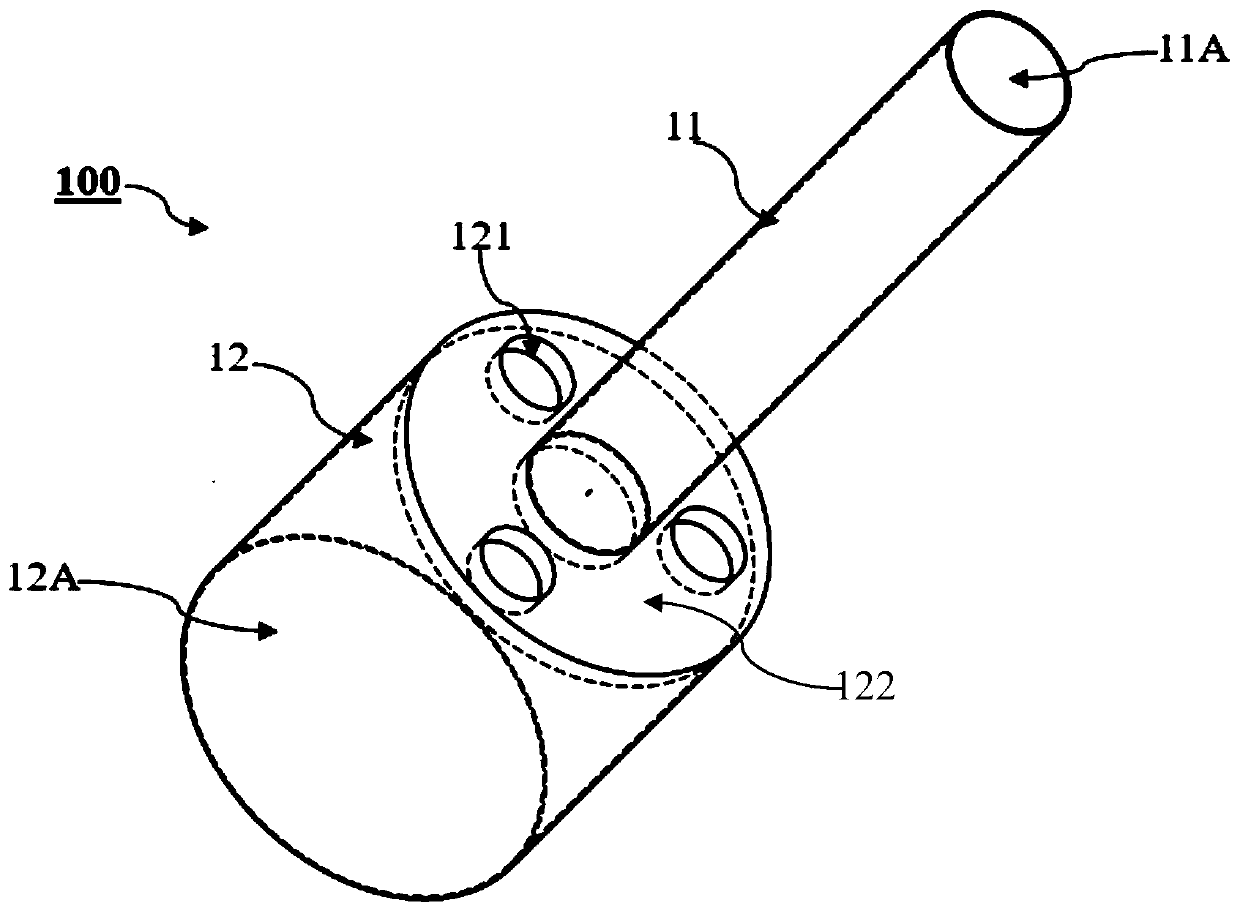

Long nozzle structure for free injecting flow of tundish and argon blowing smelting method

ActiveCN111299566ASteady upwelling motionGood removal effectMelt-holding vesselsProcess efficiency improvementEngineeringPipe

The invention relates to a long nozzle structure for free injecting flow of a tundish. The long nozzle structure comprises an upper pipe section and a lower pipe section, pipe holes are formed in theupper pipe section and the lower pipe section respectively, and the pipe hole in the upper pipe section communicates with the pipe hole in the lower pipe section; inner diameter of the pipe hole in the lower pipe section is larger than that of the pipe hole in the upper pipe section, an air hole is formed in the lower pipe section and communicates with the pipe hole in the lower pipe section. A traditional steel ladle long nozzle is divided into the thinner upper pipe section and the thicker lower pipe section, the inner top surface of the lower pipe section is higher than molten steel for a certain distance, and an argon absorbing space is formed between the lower pipe section and the molten steel liquid level. The molten steel forms free injecting flow under the gravity after flowing outfrom the upper pipe section, argon in the argon absorbing space is absorbed into the molten steel to form tiny argon bubbles, and the argon absorbing space is supplemented with argon automatically bythe aid of negative pressure. The phenomenon of bubble enlarging caused by the non-wetting condition in the argon blowing process of the nozzle can be inhibited, the problem of blockage of the air hole in the argon blowing process can be solved, and the structure is easy to maintain and can realize deep purification of the molten steel under the condition of lower cost.

Owner:NORTHEASTERN UNIV

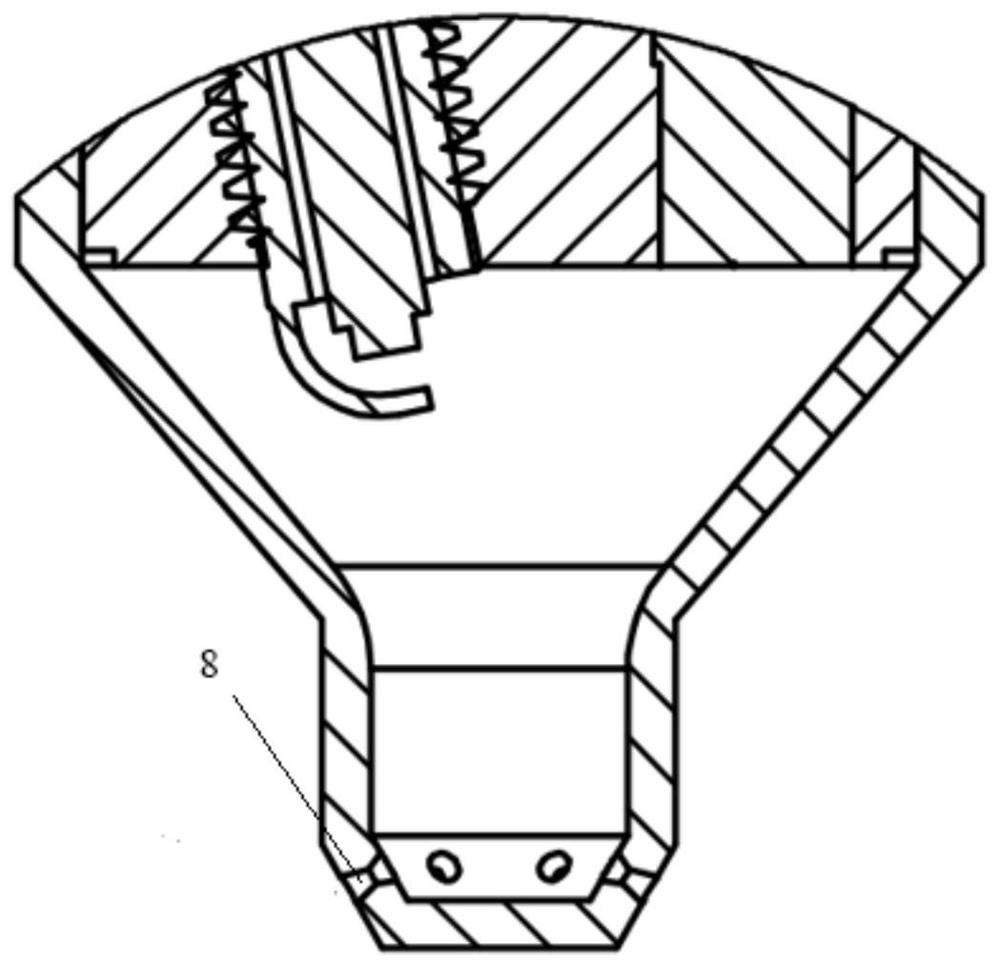

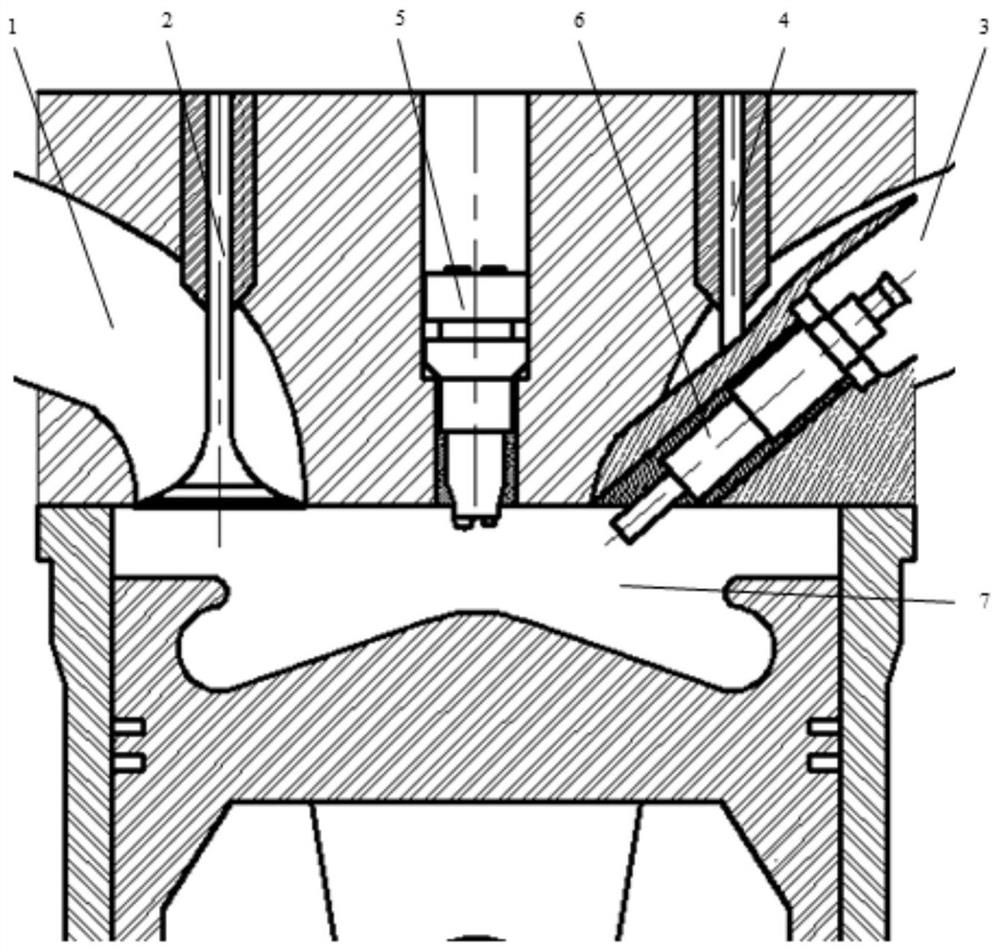

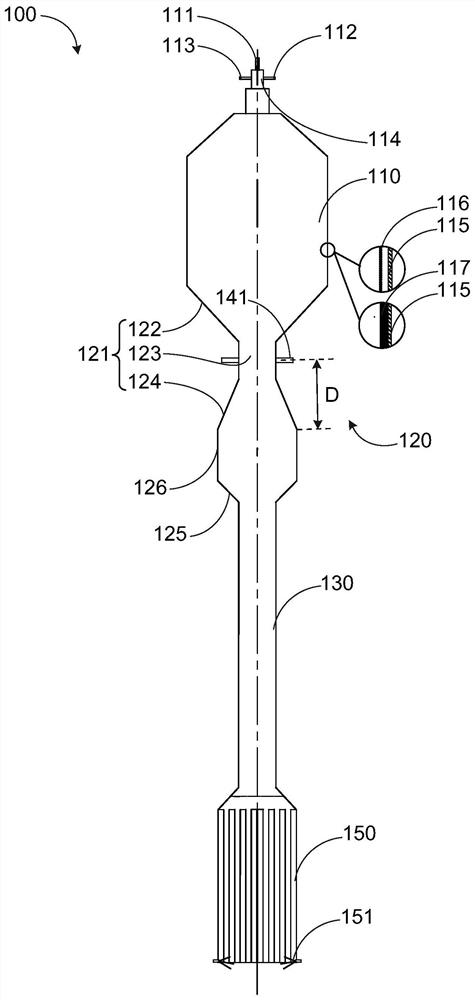

Gasoline engine ignition mechanism comprising supersonic jet orifice pre-combustion chamber

ActiveCN113685262AShortened lean burn limitImprove combustion effectInternal combustion piston enginesCombustion chamberJet flow

The invention relates to a gasoline engine ignition mechanism comprising a supersonic jet orifice pre-combustion chamber. The ignition mechanism comprises a cylindrical connecting piece, an oil sprayer mounting hole penetrating through the upper end face and the lower end face of the connecting piece, a spark plug mounting hole penetrating through the connecting piece, a pre-combustion chamber connected with the peripheral face of the connecting piece, a pre-combustion chamber oil sprayer matched with the oil sprayer mounting hole and a pre-combustion chamber spark plug matched with the spark plug mounting hole, wherein the pre-combustion chamber is formed by combining three sections, namely a first cylindrical sleeve body, a conical sleeve body and a second cylindrical cavity body from top to bottom in sequence, N uniformly distributed spray holes are formed in the lower part of the second cylindrical cavity body, and N is greater than or equal to 3; at least one of the spray holes is an over-expansion supersonic jet flow spray hole, and jet flow of the supersonic jet holes not only can shorten ignition delay, but also can prolong the lean combustion limit of a mixture in the main combustion chamber.

Owner:TIANJIN UNIV

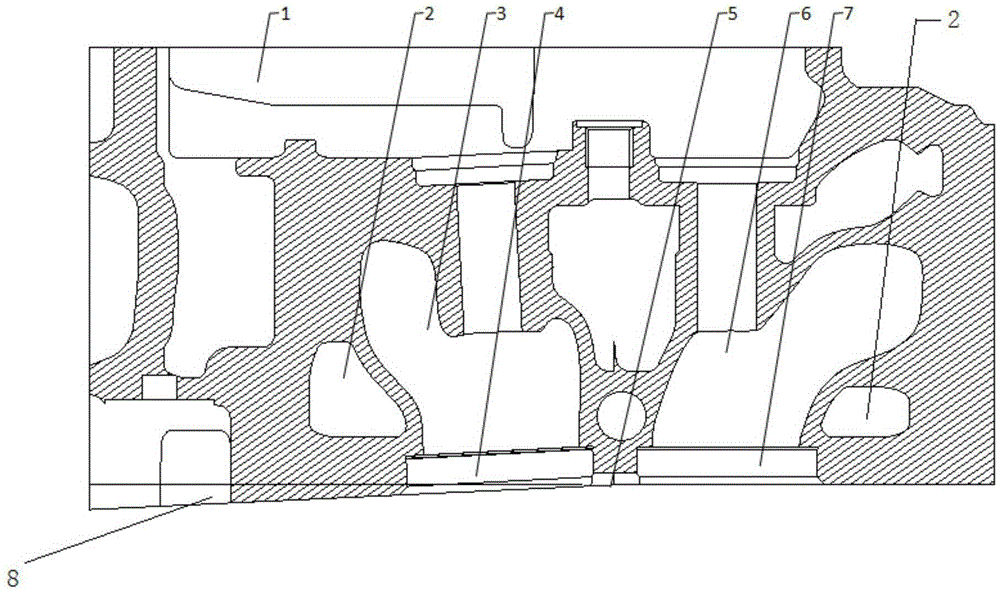

Diesel engine air cylinder cover

InactiveCN105402045AImprove performanceImprove efficiencyCylinder headsCylindersCombustionInlet channel

The invention provides a diesel engine air cylinder cover. The diesel engine air cylinder cover comprises an air cylinder cover (1), an air inlet door (7), an air outlet door (4), an air inlet channel (6), an air outlet channel (3) and an air cylinder cover bottom plane (5). The air inlet door (7) is arranged on the air cylinder cover bottom plane (5). The air inlet channel (6) is communicated with the air inlet door (7) and the air cylinder cover (1). The air outlet door (4) is arranged on the air cylinder cover bottom plane (5). The air outlet channel (3) is communicated with the air outlet door (4) and the air cylinder cover (1). The air cylinder cover bottom plane (5) is further provided with an inclined wedge surface (8) located on one side of the air outlet door (4). The center line of the air outlet door (4) is perpendicular to the inclined wedge surface (8). A cooling water cavity (2) is formed in the air cylinder cover (1). The temperature of the air cylinder cover and the air outlet door can be rapidly and effectively reduced, overheat and corrosion actions brought by high-temperature air can be weakened, and sufficient mixing of air and fuel can be facilitated; and the combustion quality is improved, the accumulated carbon content of exhausted gas is reduced, and the service life of the air cylinder cover is prolonged.

Owner:CHINA NORTH ENGINE INST TIANJIN

Combustion chamber and gas engine

ActiveCN113404586ASpread fastHigh thermal efficiencyInternal combustion piston enginesCylinder headsCombustion chamberEngineering

The invention discloses a combustion chamber and a gas engine. The combustion chamber is applied to the gas engine with at least two air inlet throats and at least two exhaust throats; the combustion chamber comprises a combustion chamber pit which is located at the top of a piston and is sunken downwards relative to the upper top surface of the piston, and the intersecting line of the combustion chamber pit and the longitudinal section of the piston is an arc line; a partition convex rib is arranged in the combustion chamber pit, and the partition convex rib extends upwards from the bottom of the combustion chamber pit and divides the combustion chamber pit into two flow guide pits; each flow guide pit comprises an incident flow guide part located below the corresponding air inlet throat and an emergent flow guide part located below the exhaust throat; and the joints of the wall surfaces of the flow guide pits and the partition convex ribs are smooth transition surfaces. Due to the fact that the combustion chamber pit is divided into the two flow guide pits by the partition convex rib, inlet air of the air inlet throats on the two sides forms two strands of large-scale tumble motion opposite in rotation direction in the combustion chamber, improvement of turbulent kinetic energy in the last stage of compression is facilitated, and rapid combustion of the engine is facilitated.

Owner:WEICHAI POWER CO LTD

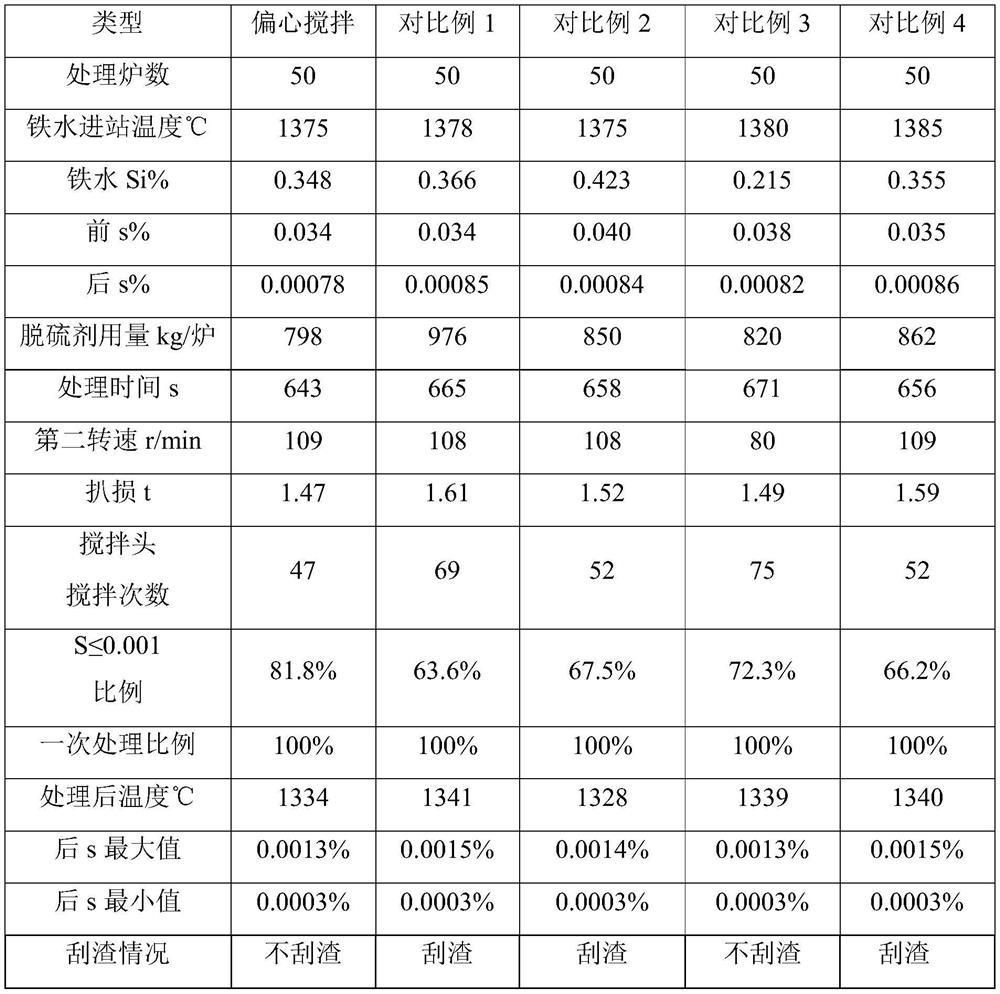

KR desulfurization method and desulfurization equipment thereof

The invention provides a KR desulfurization method. The KR desulfurization method comprises the steps of adding desulfurizer into molten iron contained in an iron ladle, and stirring; wherein the maximum inner diameter of the iron ladle is D, and the height of the iron ladle is H; the distance between the center of a stirring generation area in the vertical direction and the central axis of the iron ladle is 0.10 D to 0.30 D, and the distance between a plane where the bottom of the stirring generation area is located and the top surface of the molten iron is 3 / 5 H-4 / 5 H; and in the desulfurization process, a large amount of desulfurizer cannot be agglomerated.

Owner:湖南华菱涟源钢铁有限公司

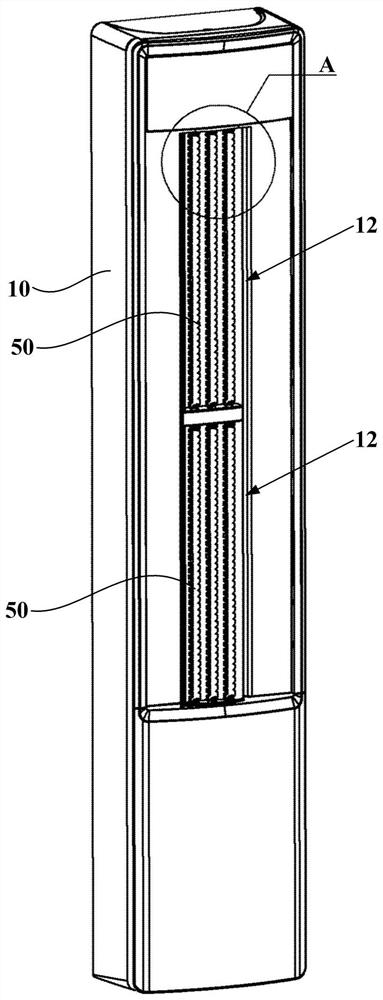

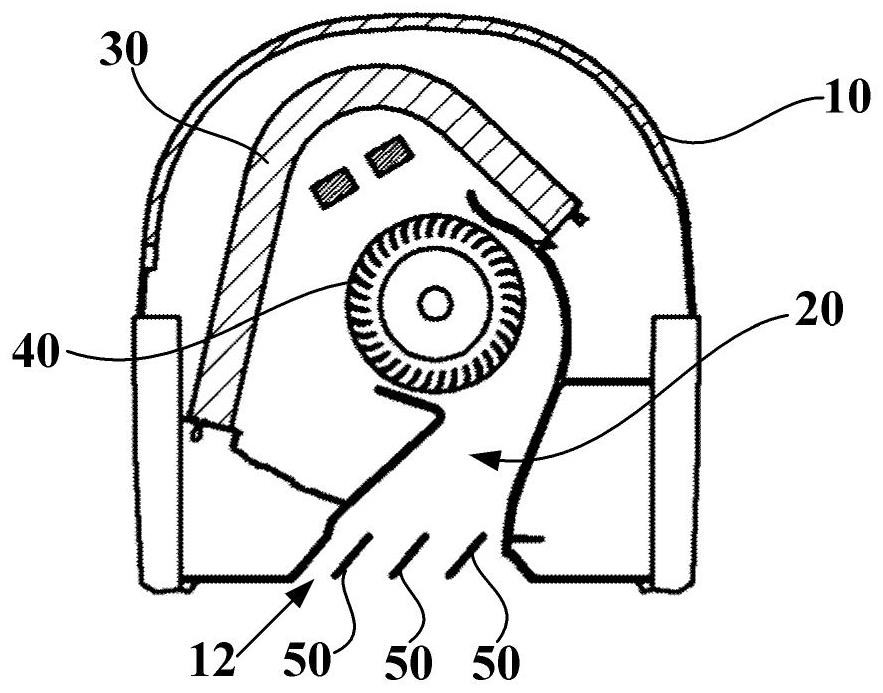

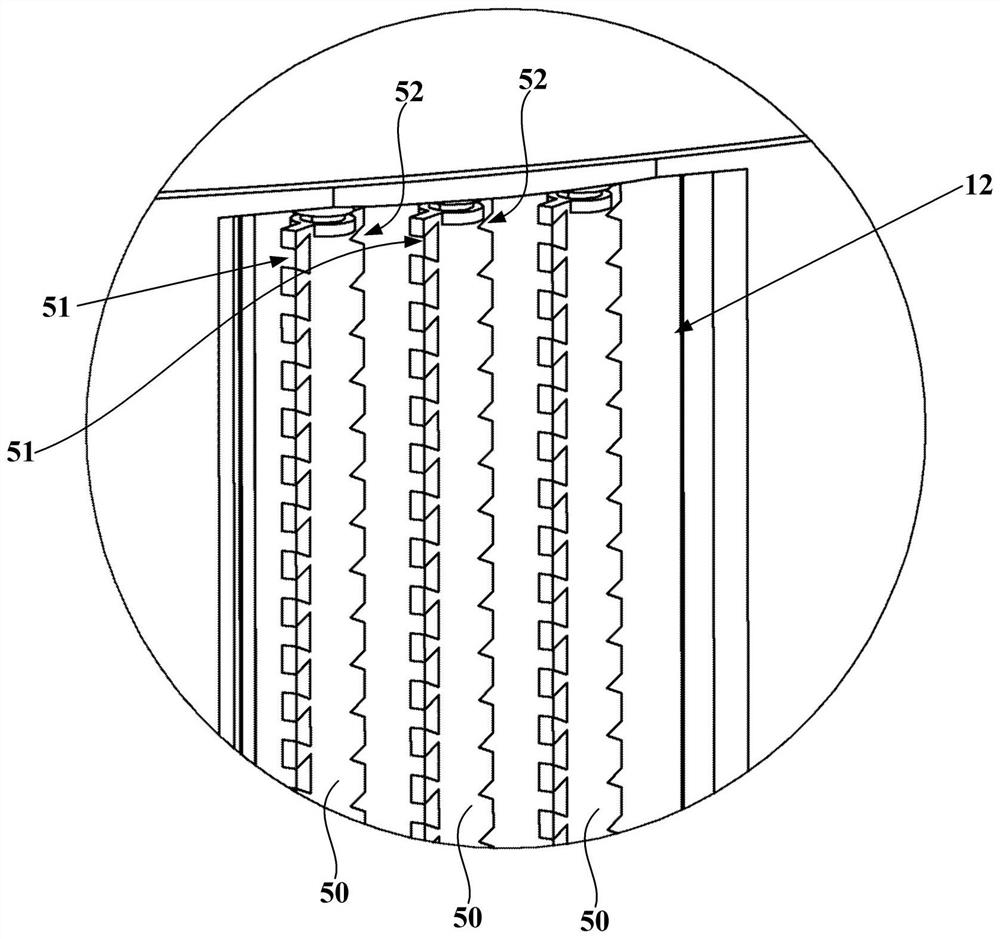

Air conditioner indoor unit and air guide assembly thereof

PendingCN114060921AGuaranteed StrengthImprove reliabilityLighting and heating apparatusAir conditioning systemsStructural engineeringMechanical engineering

The invention provides an air conditioner indoor unit and an air guide assembly thereof. The air guide assembly is used for being installed at an air outlet of the air conditioner indoor unit so as to guide the air outlet direction of the air outlet, the air guide assembly comprises a plurality of swing blades, each swing blade can be installed at the air outlet in the mode of rotating around the rotating axis of the swing blade, a plurality of notches are formed in the edges of at least two adjacent swing blades, and when the swing blades rotate to be in a coplanar state, the notches of every two adjacent swing blades are opposite in a one-to-one mode so as to be spliced into a plurality of air dissipation openings. The wind-feeling-free effect of air supply airflow of the air conditioner is improved, and the air supply airflow is closer to natural wind.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Dry-pulverized-coal gasification combined burner

ActiveCN103497785BIncrease the degree of mixingIncrease turbulent kinetic energyGranular/pulverulent flues gasificationNitrogenWater cooling

The invention discloses a dry-pulverized-coal gasification combined burner comprising a pulverized coal burner and an igniting burner. The pulverized coal burner sequentially comprises a first water-cooling jacket, a pulverized coal channel, a first oxidant channel and an inner barrel from outside to inside. The pulverized coal channel is directly adjacent to the first oxidant channel, and contracts toward the axial direction of the pulverized coal burner, at a position, adjacent to a flame-forward end. The first water-cooling jacket comprises a first water-inflowing channel, a window-type water-cooling groove and a first water-outflowing chanel, and the first water-inflowing channel is communicated with the first water-outflowing channel through the window-type water-cooling groove which is spirally wound at the flame-forward end of the pulverized coal burner. The igniting burner is arranged in the inner barrel and comprises a second water-cooling jacket, a second oxidant channel, a fuel channel, an igniter and a center nitrogen channel. By the arrangement, an ignition process is simplified, and reliability of ignition and operation of pulverized coal is improved; flame diameter is effectively controlled, a membrane water-cooling wall is prevented from being damaged by flames, and reliability of a gasification furnace is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

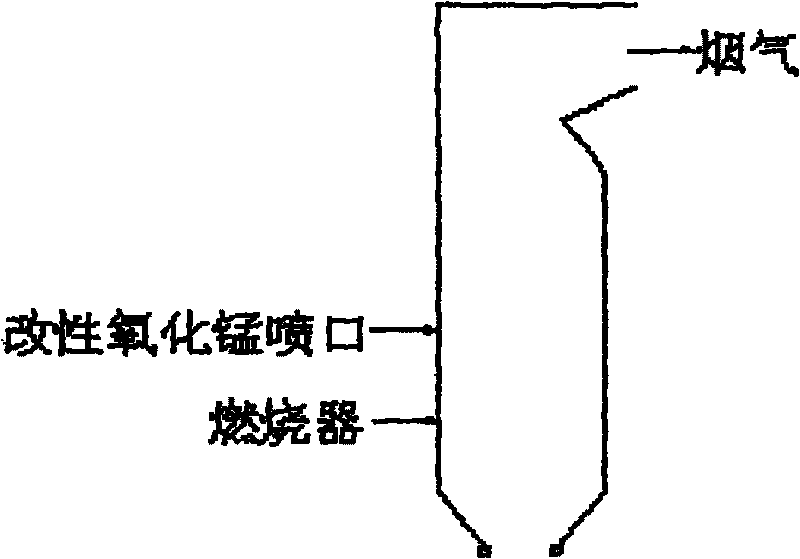

Boiler in-furnace desulfurization, denitration solid mercury integrated method

InactiveCN101209395BLess investmentIncrease turbulent kinetic energyDispersed particle separationAir quality improvementParticulatesNitrogen oxides

The invention discloses an integrated technique of desulfidation, denitration and mercury solidification in a boiler stove, and the invention injects modified MnO2 (manganese dioxide) into a boiler furnace and synthetically removes sulfur dioxide, nitrogen oxide and mercury by using the strong oxidizing property of manganese oxide; meanwhile, as the reaction of removing various infectants with modified MnO2 (manganese dioxide) is favorable for the conglobation of micro dust particles, the method can also reduce the exhaustion of inhalable particulates of PM2.5 from boilers.

Owner:TONGJI UNIV

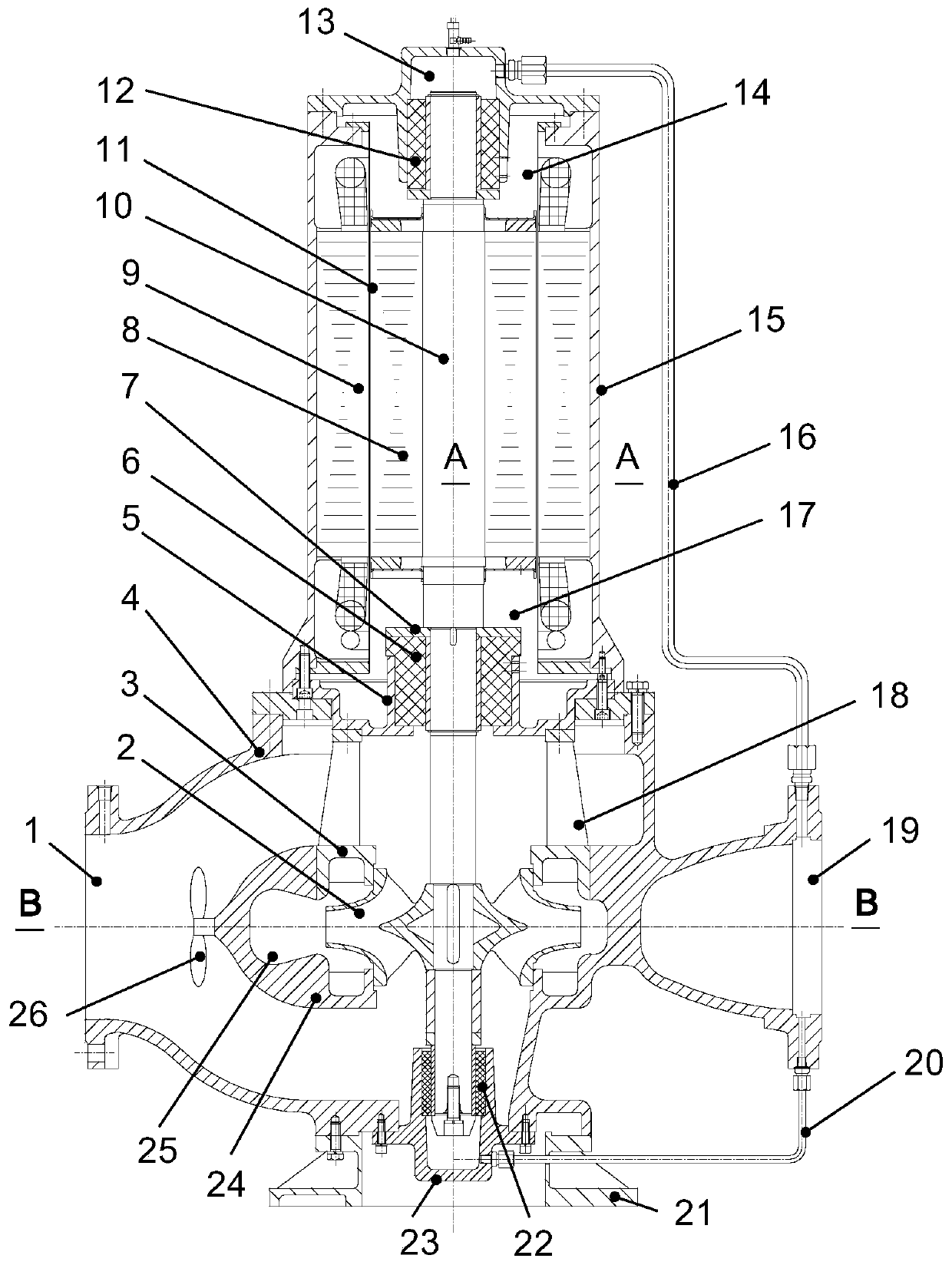

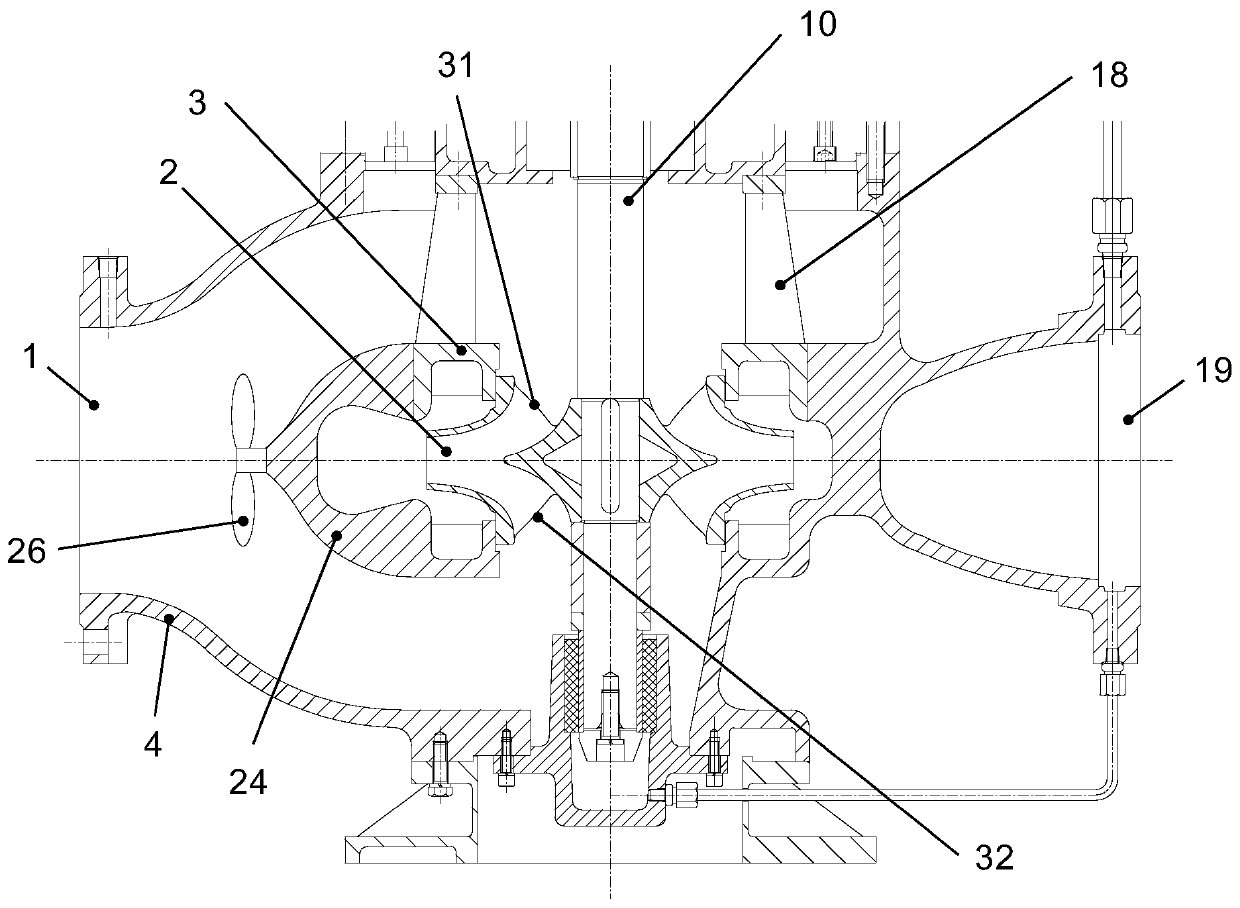

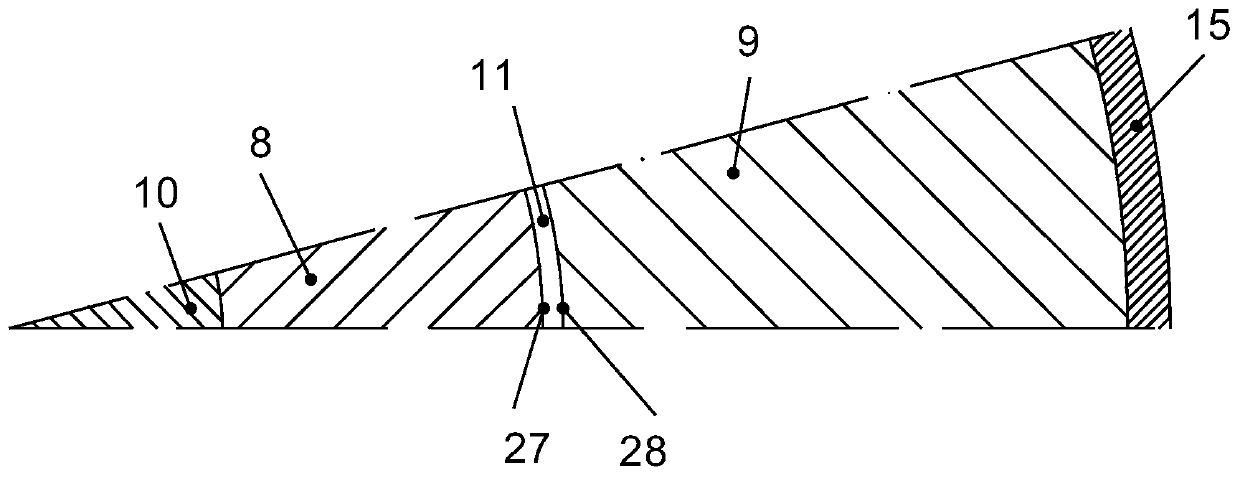

A double-body double-suction canned pump

ActiveCN106246559BImprove flow conditionsReduce loadPump componentsPump installationsImpellerWhole body

A dual-pump body dual-suction type shield pump includes a pump inlet, a pump body, a dual-suction impeller, a bearing support, a thrust disc, a motor roller, a motor stator, a main shaft, a circulating water pipe, a pump outlet, an auxiliary bearing, a rotor shield casing, a stator shield casing and a dual-suction impeller suction inlet; an internal pump body is arranged in the pump body, the dual-suction impeller is arranged in the internal pump, and an outlet section of the internal pump body and an outlet section of the pump body are formed into a whole body; an auxiliary impeller is arranged at one side near the pump inlet of the outer wall of the internal pump body; a sealing section is arranged on the upper end of the dual-suction impeller; and the sealing section and the internal pump body form a three-dimensional space of a water pumping chamber. A large operation flow can be obtained on the premise of keeping high lift, and the operation range of the shield pump can be expanded; and meanwhile, automatic balance of axial water thrust can be achieved through the dual-pump body, the load of the thrust disc can be relieved, and the reliability of the shield pump can be improved.

Owner:上海创科泵业制造有限公司 +1

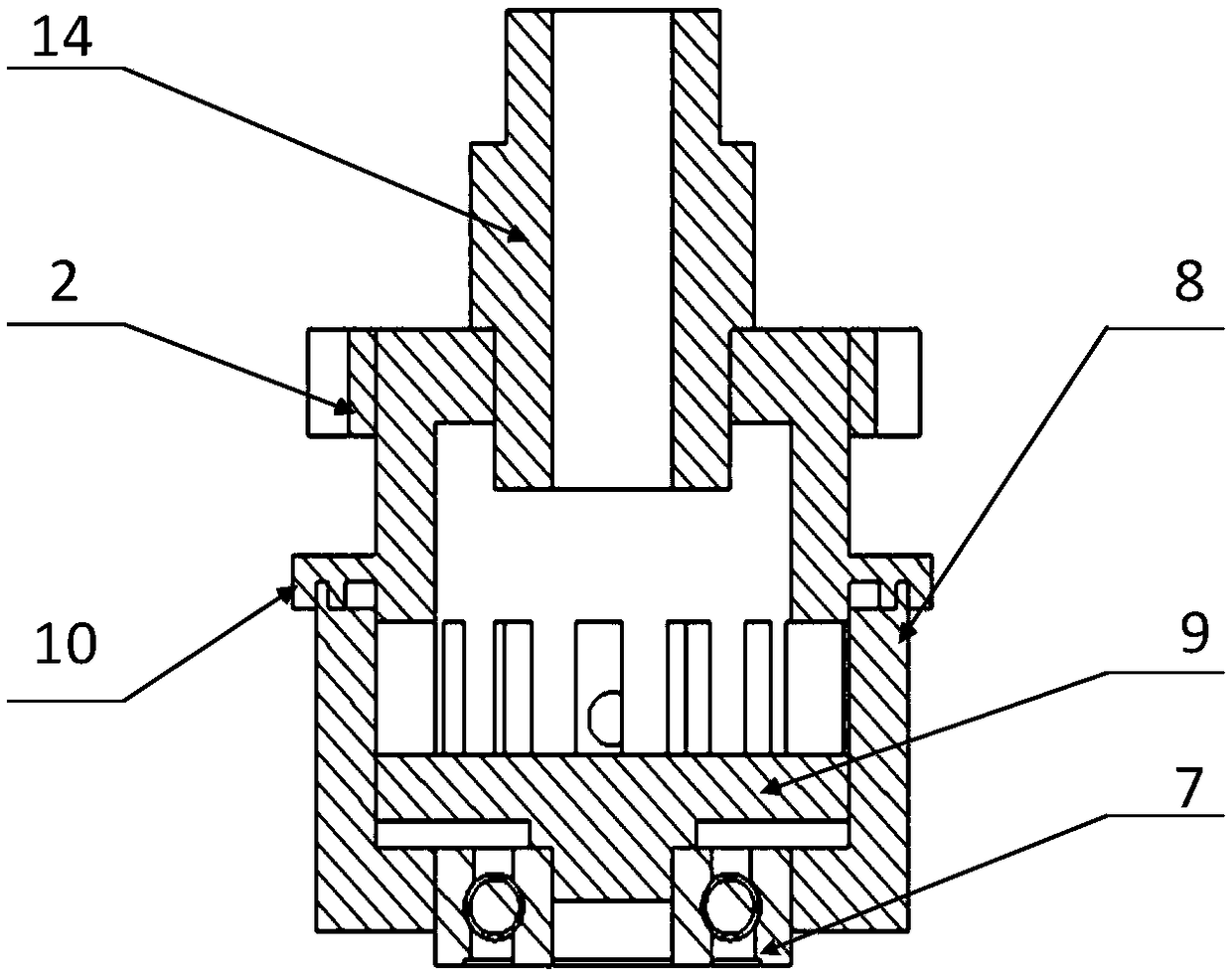

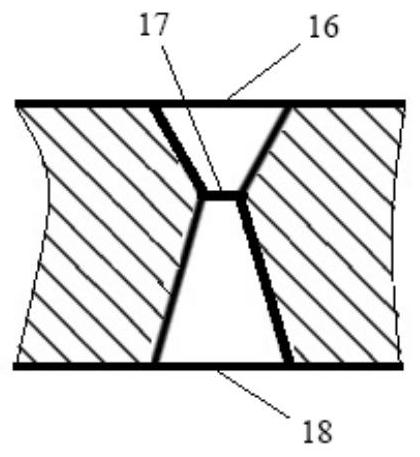

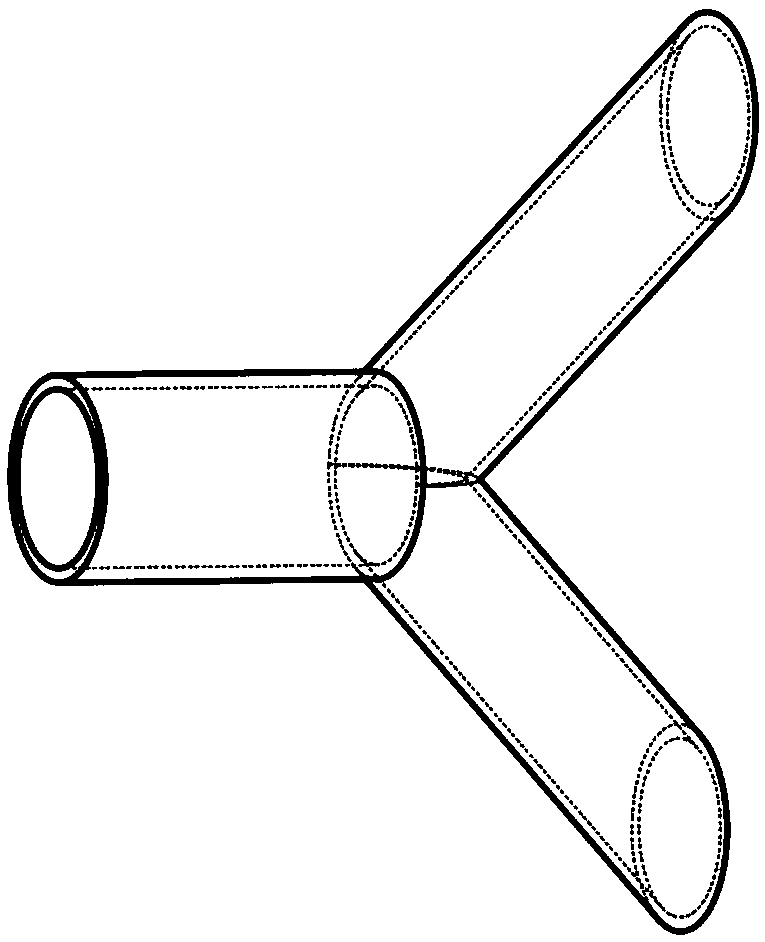

Novel trailing edge cooling structure with Y-shaped jet holes of turbine blade

ActiveCN108729955AImprove integrityEfficiencyBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention discloses a novel trailing edge cooling structure with Y-shaped jet holes of a turbine blade. The trailing edge of an integral trapezoidal structure is internally provided with a coolingworking medium supply cavity, a first cooling cavity, a second cooling cavity and an outlet section successively, wherein a first partition plate is arranged between the cooling working medium supplycavity and the first cooling cavity; a second partition plate is arranged between the first cooling cavity and the second cooling cavity; the plurality of uniformly distributed first Y-shaped jet holes are formed in the first partition plate; and the plurality of uniformly distributed second Y-shaped jet holes are formed in the second partition plate. During work, a working medium enters the second cooling cavity successively through the cooling working medium supply cavity and the first cooling cavity, and the working medium after heat exchange is recovered through the outlet section connected to the second cooling cavity. According to the novel trailing edge cooling structure with Y-shaped jet holes of the turbine blade provided by the invention, the trailing edge cooling effect can beenhanced obviously and the pressure loss is reduced.

Owner:XI AN JIAOTONG UNIV

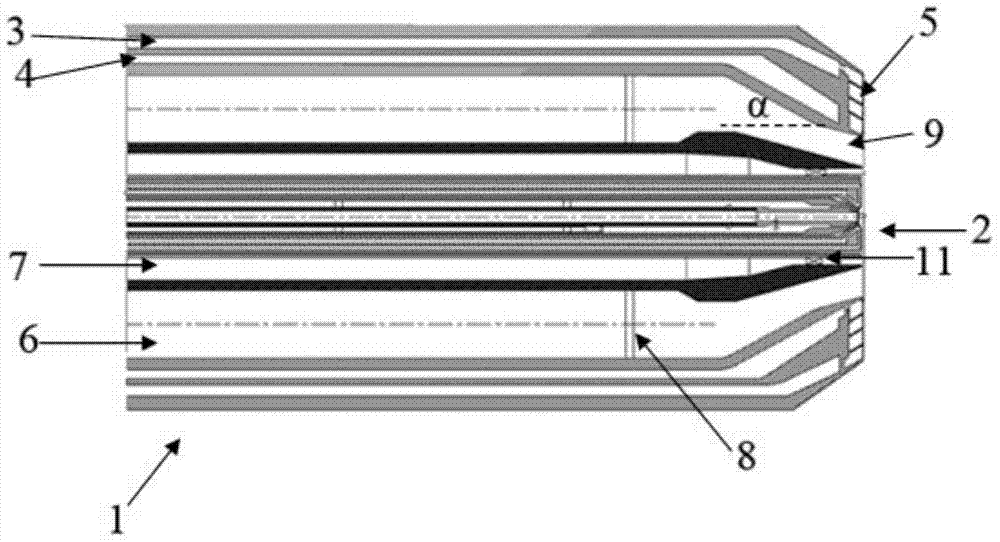

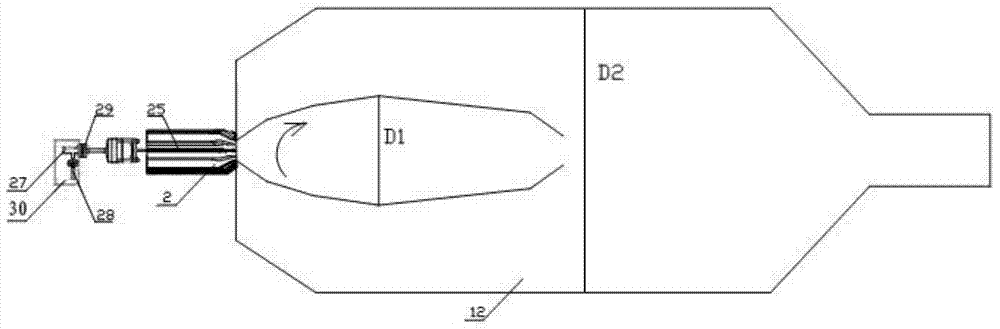

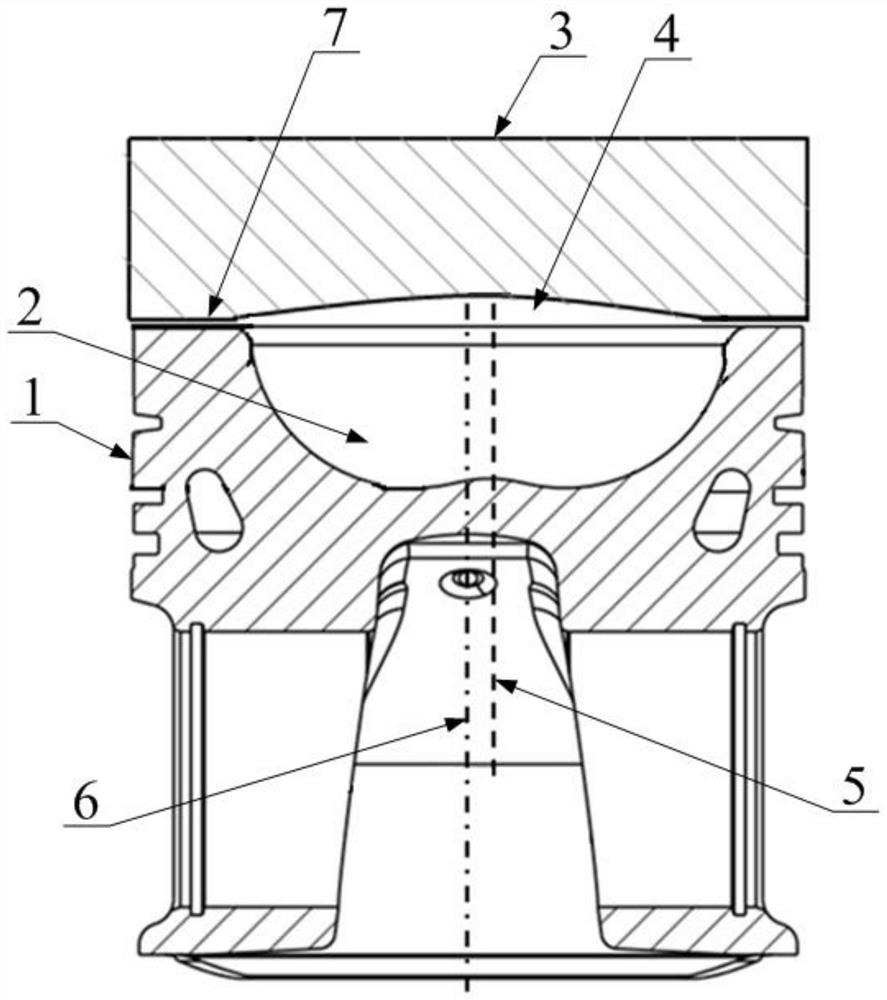

Combustion device and method for a dual-fuel engine based on a dual-needle valve injector

ActiveCN109184926BFlexible switchingReduce the temperatureInternal combustion piston enginesFuel supply apparatusCombustion chamberFuel oil

The invention relates to the field of dual-fuel engines, in particular to a dual-fuel engine combustion device and method based on a double-needle-valve oil atomizer. The dual-fuel engine combustion device based on the double-needle-valve oil atomizer comprises an air distribution system, a fuel supply system and a combustion chamber system. The air distribution system is located on an air cylinder cover. An air inlet part and an exhaust part are symmetrically distributed at the two ends of the air cylinder cover. The fuel supply system is located on the air cylinder cover and is right opposite to the lower combustion chamber system. The combustion chamber system is formed by connecting the air cylinder cover and an air cylinder through bolts. The dual-fuel engine combustion method based on the double-needle-valve oil atomizer comprises the steps that firstly, the dual-fuel engine is in a gas mode; and secondly, the diesel oil mode is switched when the dual-fuel engine is in starting and idling work conditions. Dual-fuel engine gas and fuel oil dual modes are rapidly and flexibly switched, mixed gas concentration layering in the dual-fuel engine gas mode is achieved, and accordingly power performance, economic efficiency and discharging performance of the fuel are improved.

Owner:HARBIN ENG UNIV

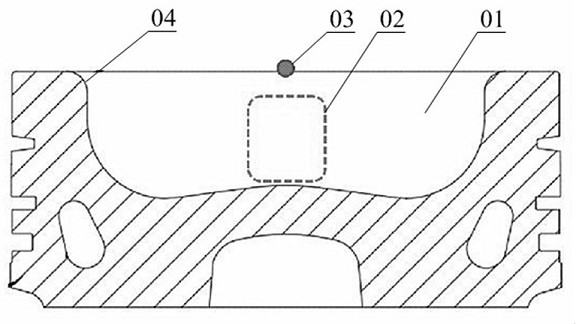

Combustion chamber and gas engine

PendingCN114810327AGood streamlined surface structureIncrease turbulent kinetic energyCombustion enginesPistonsCombustion chamberExhaust valve

The invention discloses a combustion chamber and a gas engine, the combustion chamber is used for the gas engine transformed from a diesel engine, the combustion chamber is combined with a weak tumble cylinder cover structure for use, and the combustion chamber comprises a cylinder cover bottom surface and a combustion chamber pit located at the top of a piston; the surface of the combustion chamber pit is a rotary smooth curved surface, the cylinder cover bottom face comprises a rotary arc-shaped cylinder cover pit located above the combustion chamber pit, and the center line of the combustion chamber pit is closer to the exhaust valve relative to the center line of the arc-shaped cylinder cover pit. The combustion chamber is of a good streamline curved surface structure, formation of tumble flow is facilitated, meanwhile, the combustion chamber pits and the arc-shaped cylinder cover pits are asymmetrically designed, energy loss in the tumble flow process can be reduced, turbulent kinetic energy in the combustion chamber is enhanced, the flame propagation speed is increased, and the heat efficiency of an engine is improved.

Owner:WEICHAI POWER CO LTD

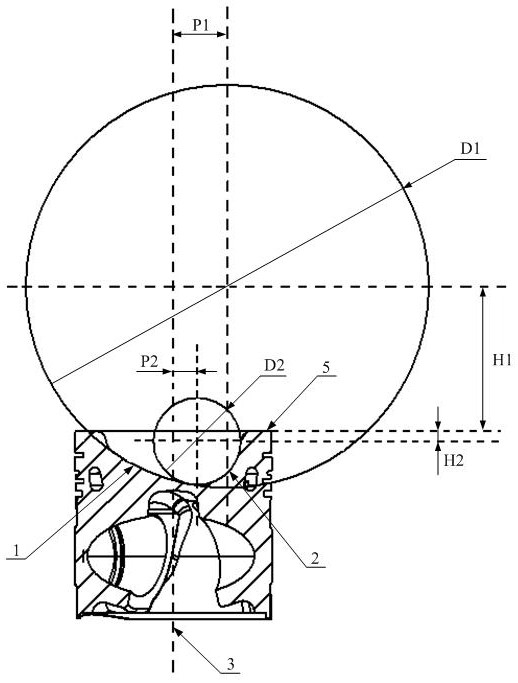

Tumble guide type high compression ratio piston of gasoline engine

InactiveCN106640403AIncrease turbulent kinetic energyControl generationMachines/enginesPistonsExhaust valveCombustion

The invention belongs to the technical field of pistons, and particularly relates to a tumble guide type high compression ratio piston of a gasoline engine. The piston comprises a piston top face, a first boss top face, a second boss top face, a hemispheric piston pit, a first exhaust valve evasion pit extending surface, a second exhaust valve evasion pit extending surface, a first inlet valve evasion pit extending surface, a second inlet valve evasion pit extending surface and a tumble channel. The first exhaust and inlet valve evasion pit extending surfaces and the first boss top face together form a boss which is higher than the piston top face. The second exhaust and inlet valve evasion pit extending surfaces and the second boss top face together form a boss which is higher than the piston top face. The first and second boss top faces are parallel to the piston top face. The grooved tumble channel is located between the first boss top face and the second boss top face, and the upper surface of the tumble channel and the piston top face are in the same plane. The hemispheric piston pit is located at the geometrical center of the piston. By means of the shape of the piston surface, the high compression ratio is maintained, and meanwhile the tumble strength and the combustion speed are not reduced; and atomization of fuel oil and generation of a gas mixture are controlled, and the tendency of the knock is inhibited.

Owner:CHINA FIRST AUTOMOBILE

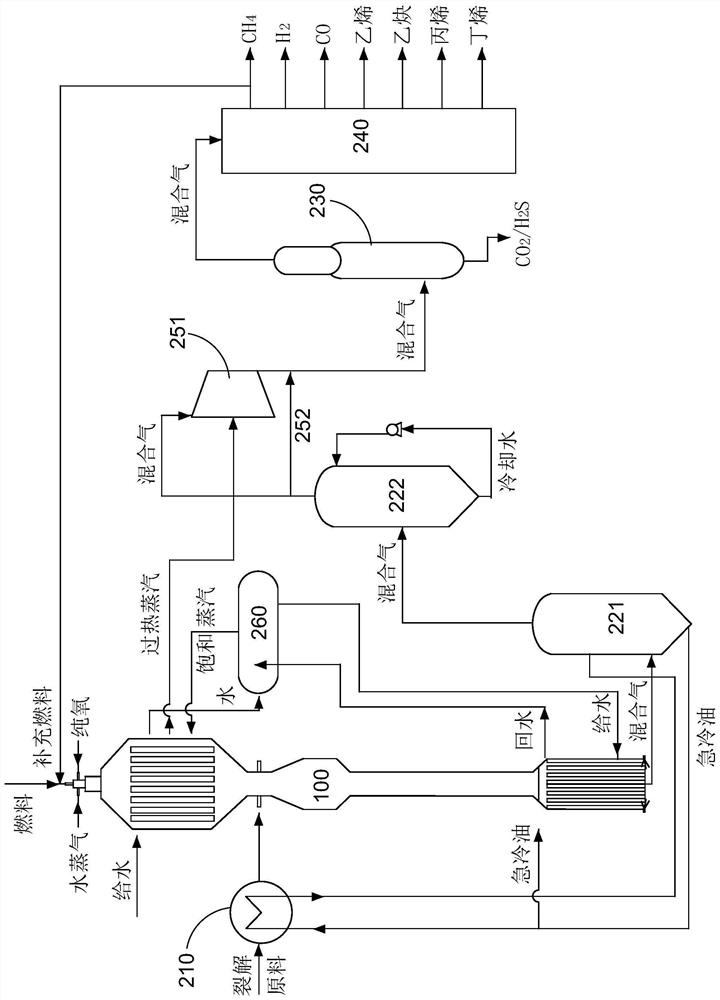

Reaction device, production system and production method for preparing low-carbon olefin

ActiveCN111826173AShorten the timeLow yieldDirect heating destructive distillationEnergy inputThermodynamicsCombustion chamber

The invention discloses a reaction device, a production system and a production method for preparing low-carbon olefin. The reaction device is a pressure reaction device and comprises a device body, the device body comprises a combustion chamber, a mixing chamber and a cracking chamber which are sequentially communicated, the mixing chamber comprises a Venturi section and a raw material inlet, andthe raw material inlet is formed in the lowest pressure position of the Venturi section. According to the reaction device, the independent mixing chamber is arranged, the raw materials are mixed withthe synthesis gas in the mixing chamber and directly exchange heat, and the cracking reaction is performed after the cracking temperature is reached so that the reaction time can be shortened, and the yield of the low-carbon olefin is increased; the mixing chamber is constructed to comprise the venturi section, and the raw material inlet is formed in the lowest pressure position of the venturi section so that turbulent flow with higher turbulence is formed, higher convective heat exchange strength is achieved, raw materials can be quickly mixed and subjected to heat exchange with synthesis gas, and shorter retention time can be achieved.

Owner:中国船舶集团有限公司第七一一研究所 +1

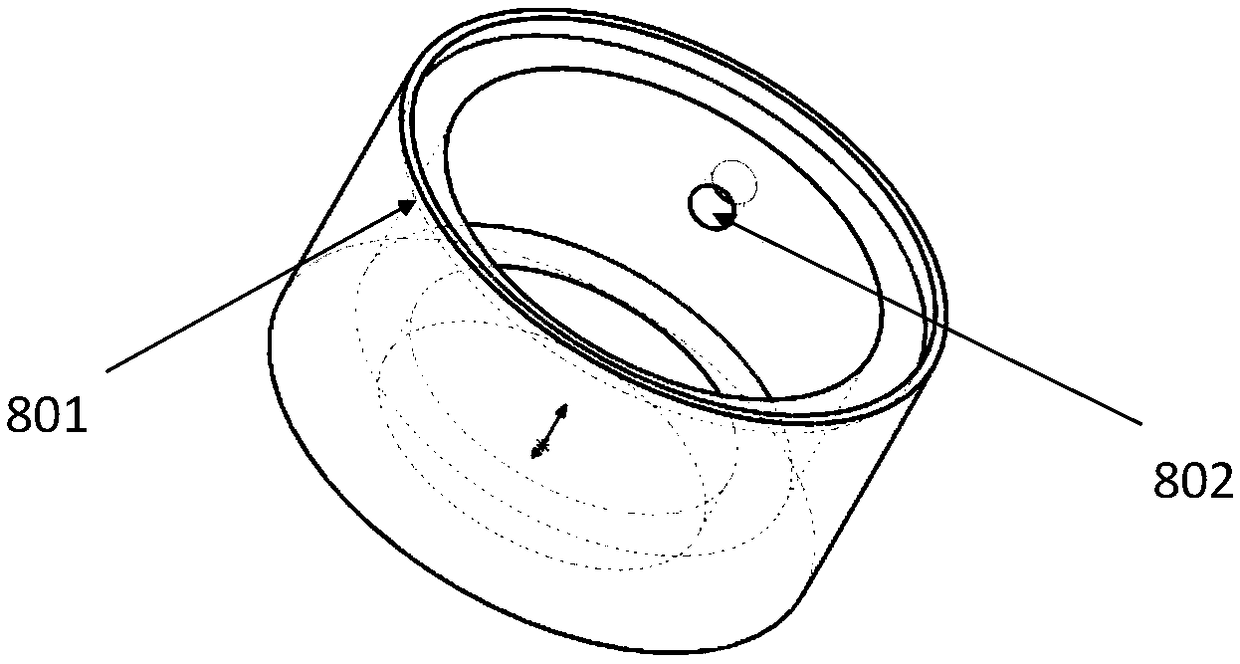

A combustion chamber and a gas engine

ActiveCN111486020BIncrease turbulent kinetic energySpread fastInternal combustion piston enginesPistonsCombustion chamberEngineering

The invention discloses a combustion chamber and a gas engine. The combustion chamber comprises a combustion chamber pit which is located in the top of a piston and concaves downwards relative to theupper top face of the piston, the combustion chamber pit comprises an airflow guiding pit and an airflow casting pit which are sequentially arranged, the bottom face of the airflow guiding pit is a tumble flow guide face, and the bottom face of the airflow casting pit is a tumble flow generation face; the tumble flow guide face gradually extends downwards from the upper edge of one side of the combustion chamber pit and is in smooth transition connection with the tumble flow generation face, and the tumble flow generation face is an inwards-concave curved face in smooth transition from the lower end of the tumble flow guide face to the upper edge of the other side of the combustion chamber pit. By means of the asymmetric combustion chamber pit structure, mixed gas rolls in the combustion chamber and forms tumble flow, so that turbulent energy of spark plug accessories is improved, transverse and longitudinal propagation speed of flames is increased, combustion characteristics of fuel gas are improved, and thermal efficiency of the gas engine is improved. The invention further discloses the gas engine comprising the combustion chamber.

Owner:WEICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com