Fuel nozzle

A technology of fuel nozzles and injection holes, which is applied in the direction of fuel injection devices, charging systems, engine components, etc., to achieve the effects of improving flow coefficient, uniform mixture, and large diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

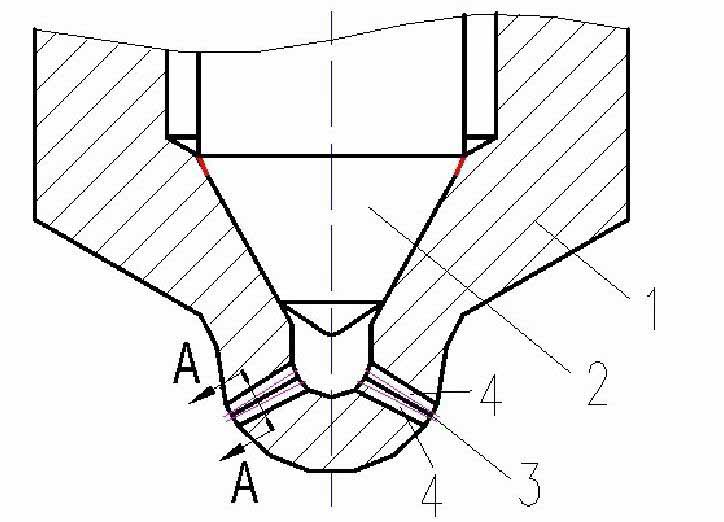

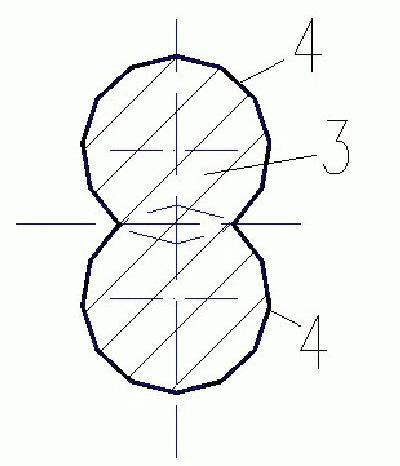

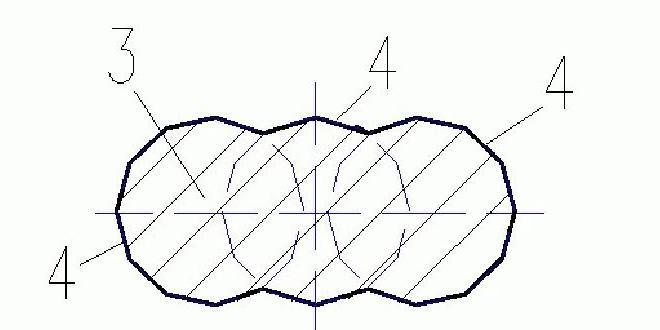

[0014] figure 1 A structure of a fuel nozzle is shown. This kind of fuel nozzle is composed of a needle valve body 1 and a needle valve 2, and a combination injection hole 3 is arranged on the head of the needle valve body 1, and each combination injection hole 3 is composed of at least two sub injection holes 4 gathered together. According to the matching requirements of combustion, there may be 1 to 16 combined injection holes 3 and 2 to 8 sub-injection holes 4 . The sub-spray hole 4 adopts a cylindrical small hole or a conical small hole. The combined nozzle hole 3 can have many different structural forms: the shape factor of the nozzle hole outlet is combined in different ways with the nozzle hole 4, and may have many different shapes.

[0015] figure 2 It is shown that the combined nozzle hole 3 is formed by the intersection of two sub-nozzle holes 4, and the area shown by the section line in the figure is the flow area of the combined nozzle hole 3 on the A-A secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com