Patents

Literature

1308results about How to "Promote atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

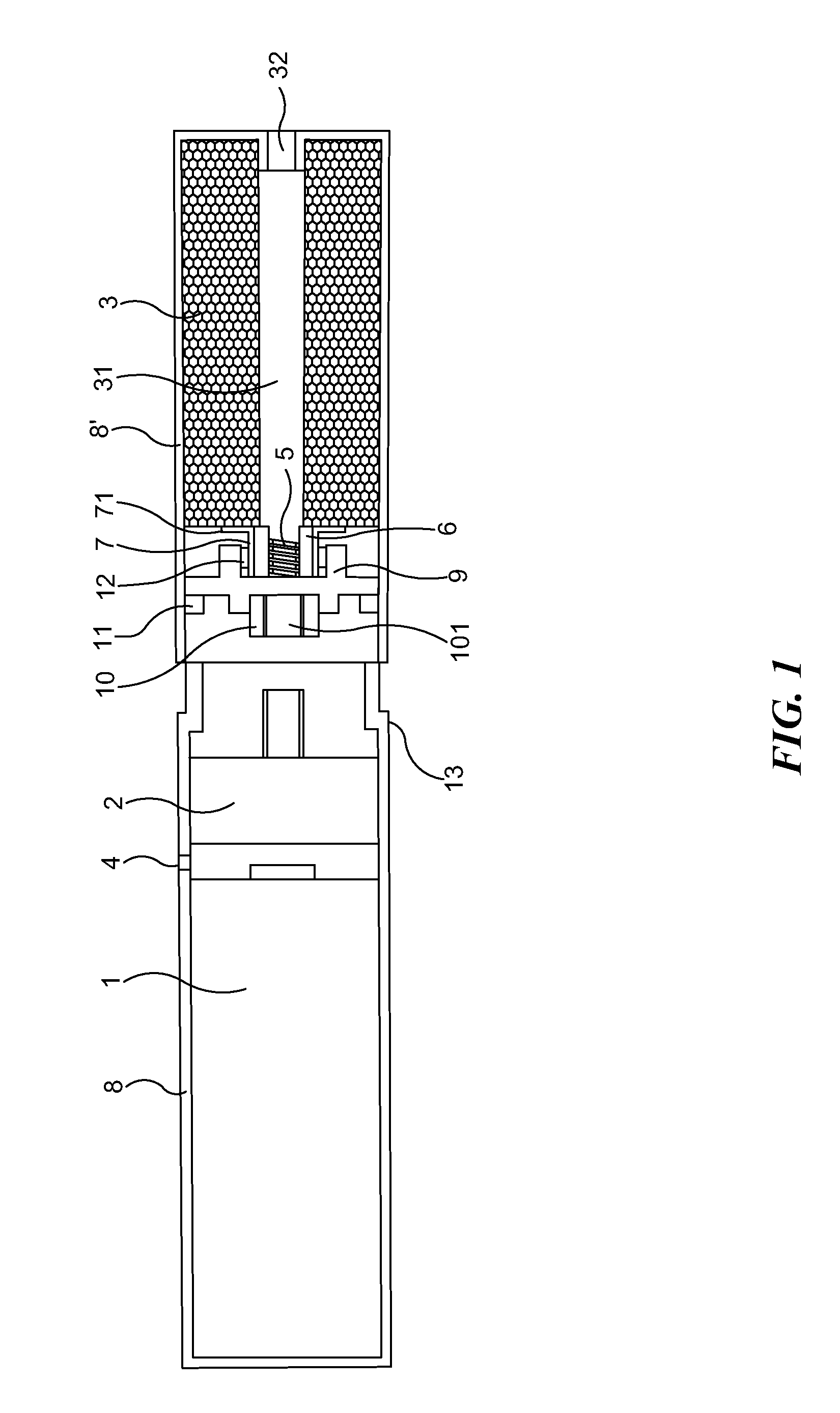

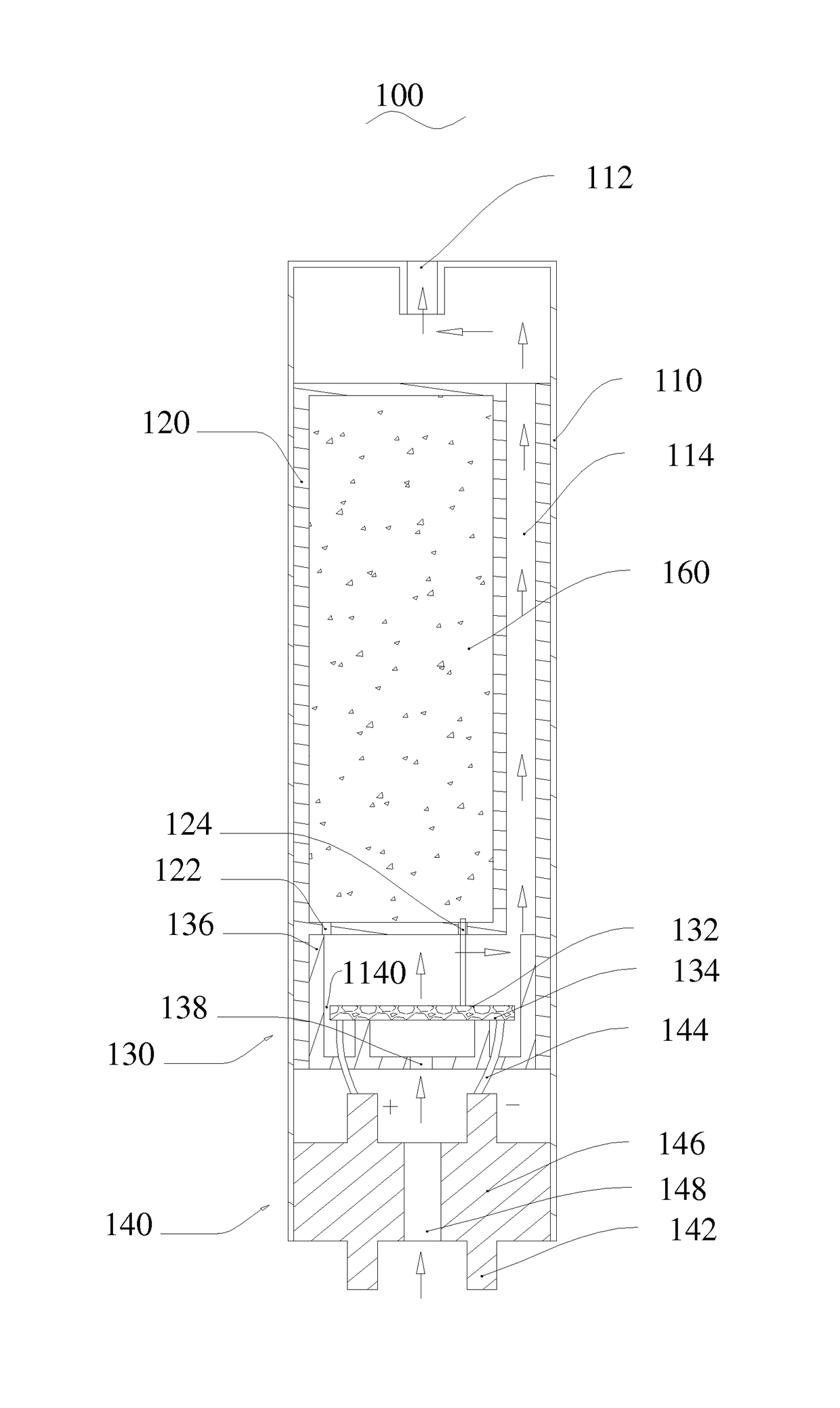

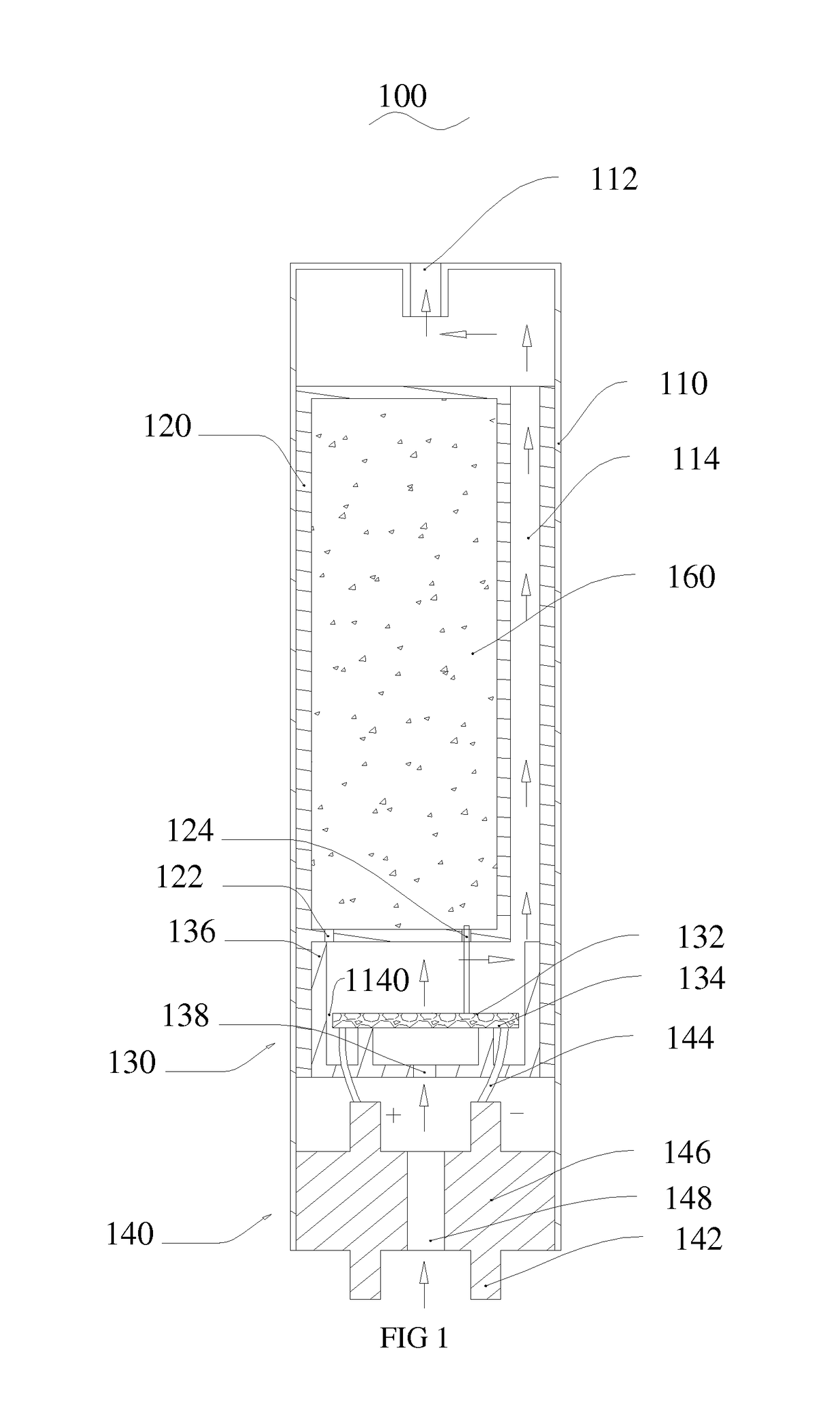

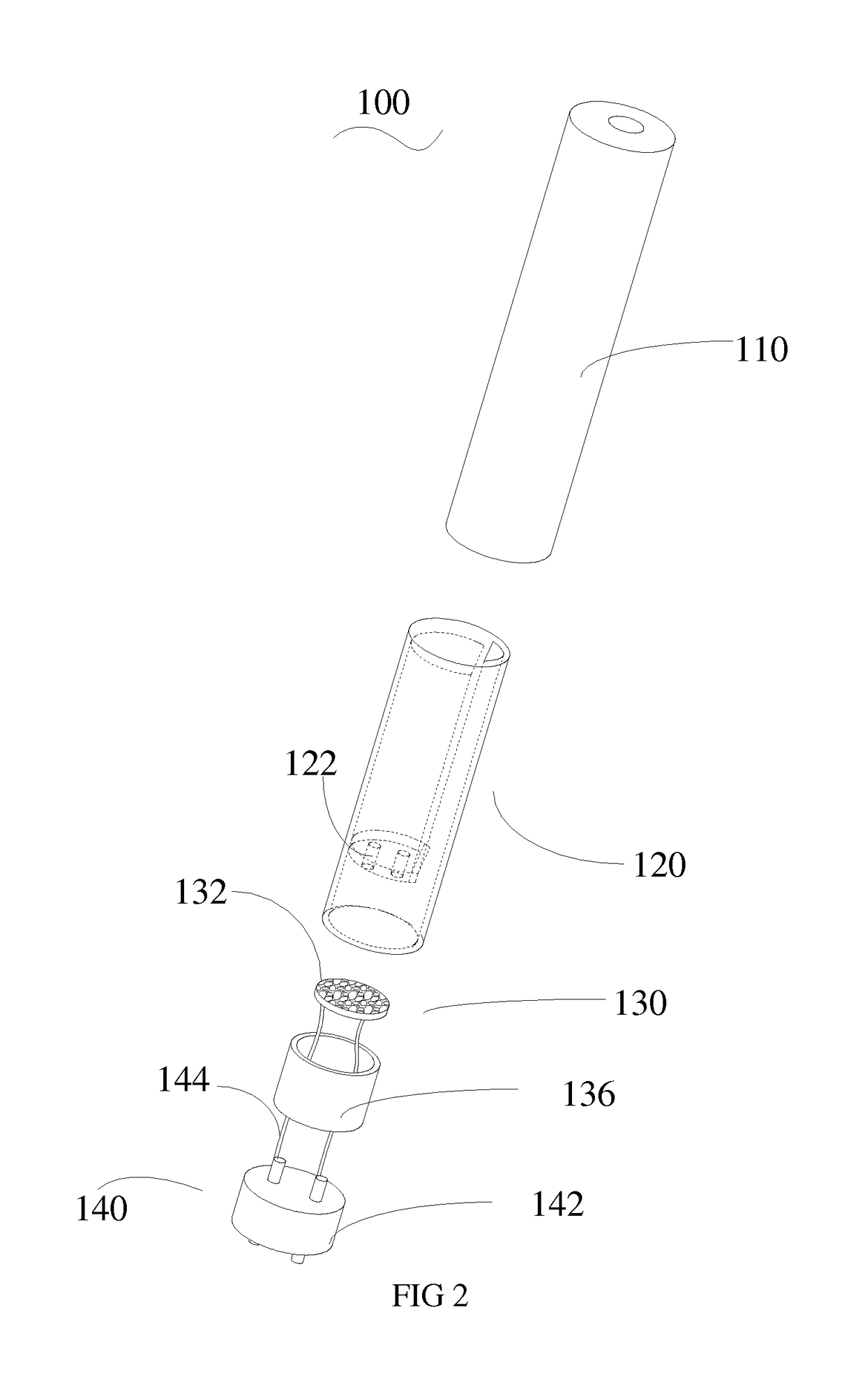

Atomizing electronic cigarette

InactiveUS20120111347A1Promote atomizationFully atomizedRespiratorsHeater elementsCore componentElectronic cigarette

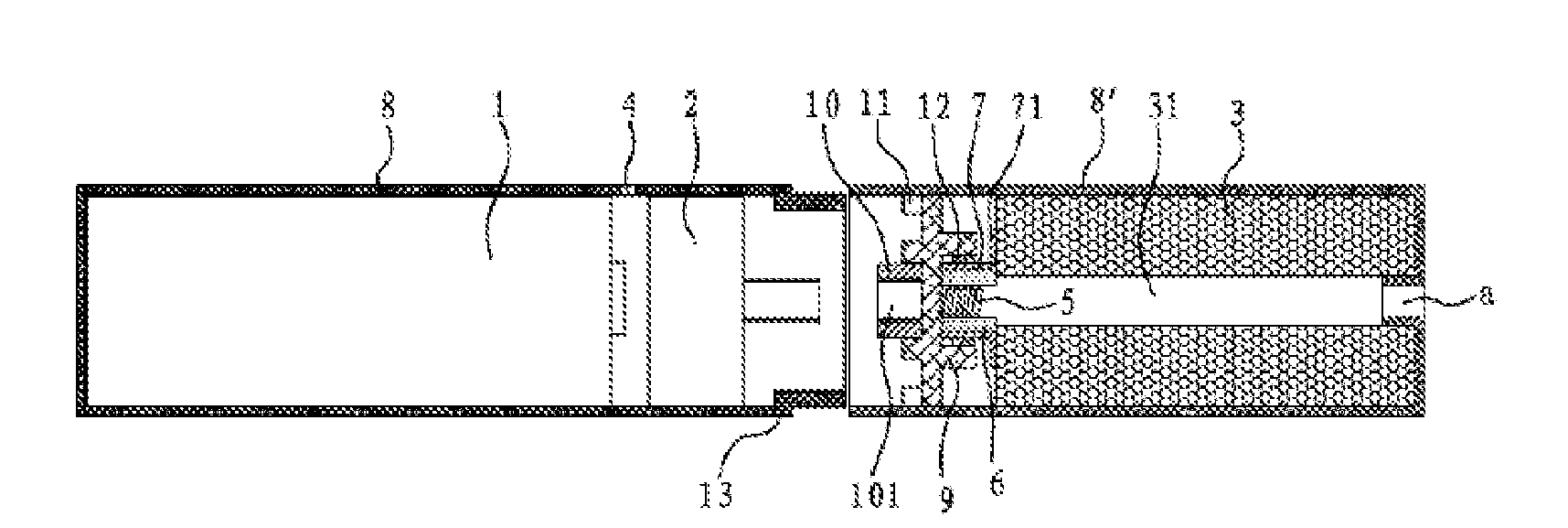

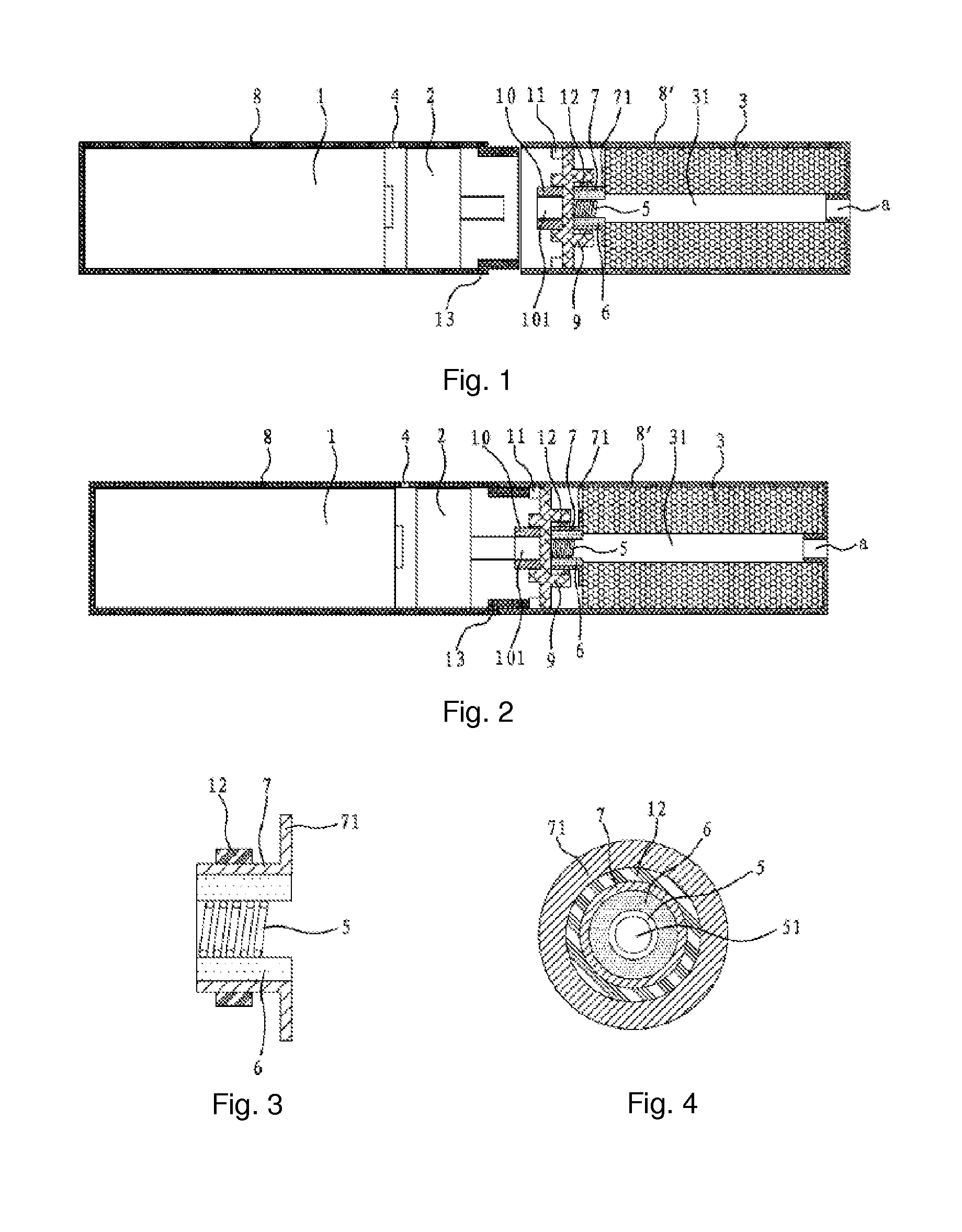

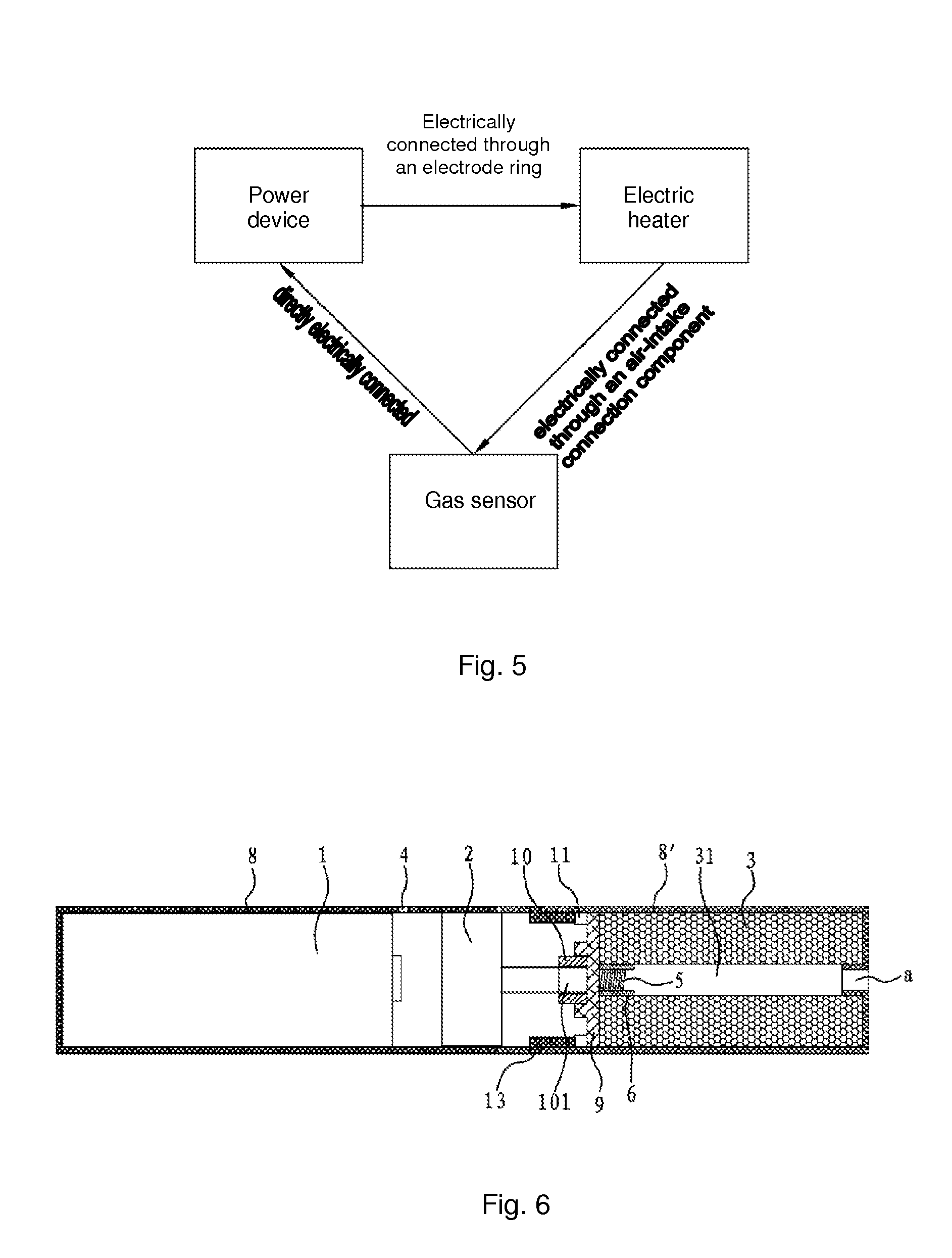

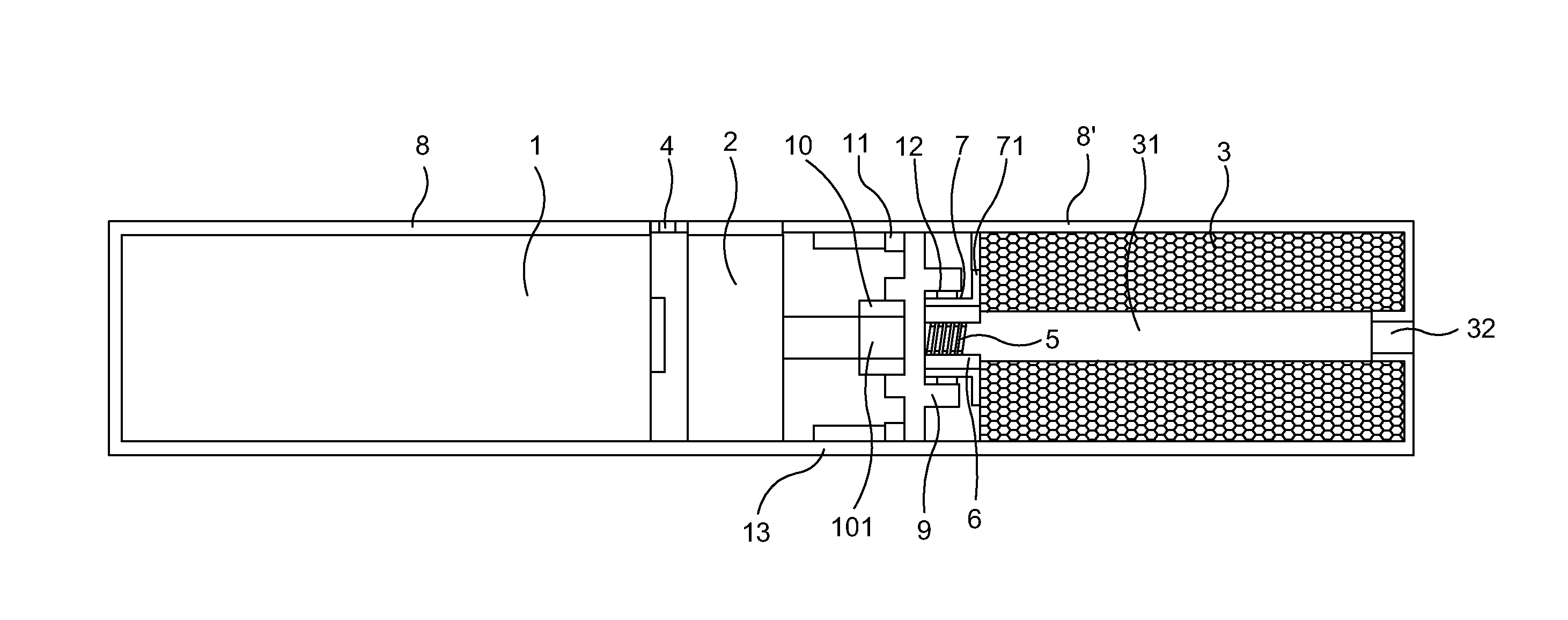

An electronic cigarette has a power device (1), a sensor (2), an atomizing core component and a liquid storage component (3). The atomizing core component includes an electric heater (5) and a liquid permeating component (6). The electric heater (5) has a through hole (51), the liquid storage component (3) has a channel (31), and the sensor (2) is connected with the through hole (51) and the channel (31) to form an airflow loop by the auxiliary air inlet. The liquid permeating component (6) is directly sleeved on the electric heater (5), so that the cigarette can adequately heat gasified smoke with uniform small drops. The electric heater (5) and the liquid storage component (3) are connected with the through hole (51) and the channel (31), so that the vapor generated by the atomizing process can be cooled.

Owner:FONTEM HLDG 1

Electronic cigarette

ActiveUS20120279512A1Promote atomizationEfficient productionRespiratorsHeater elementsEngineeringElectronic cigarette

Owner:FONTEM VENTURES

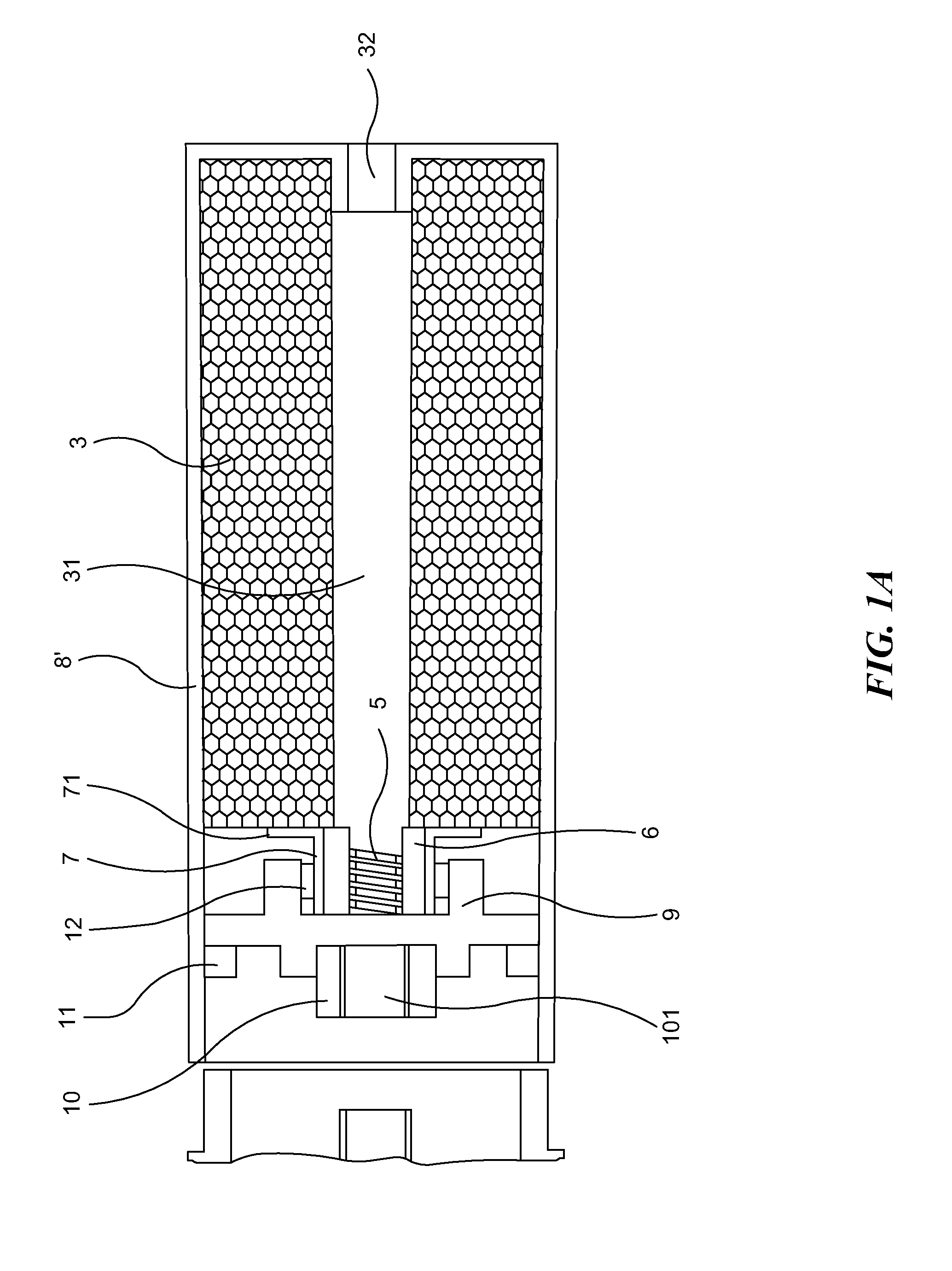

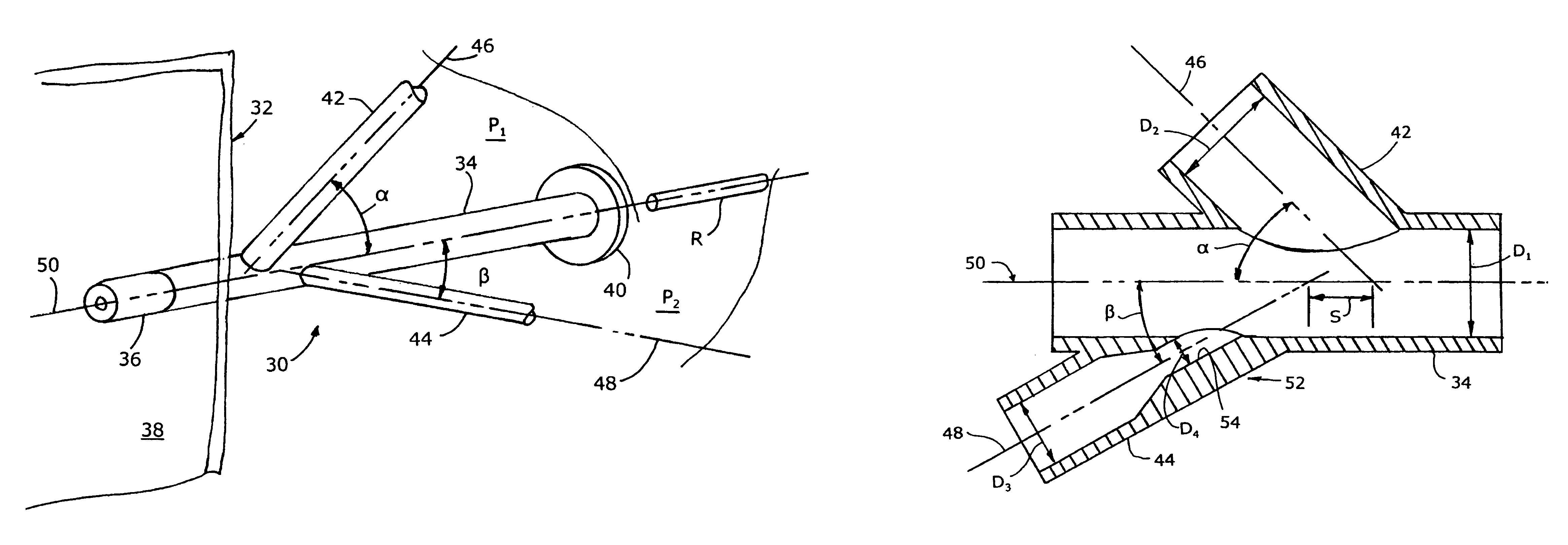

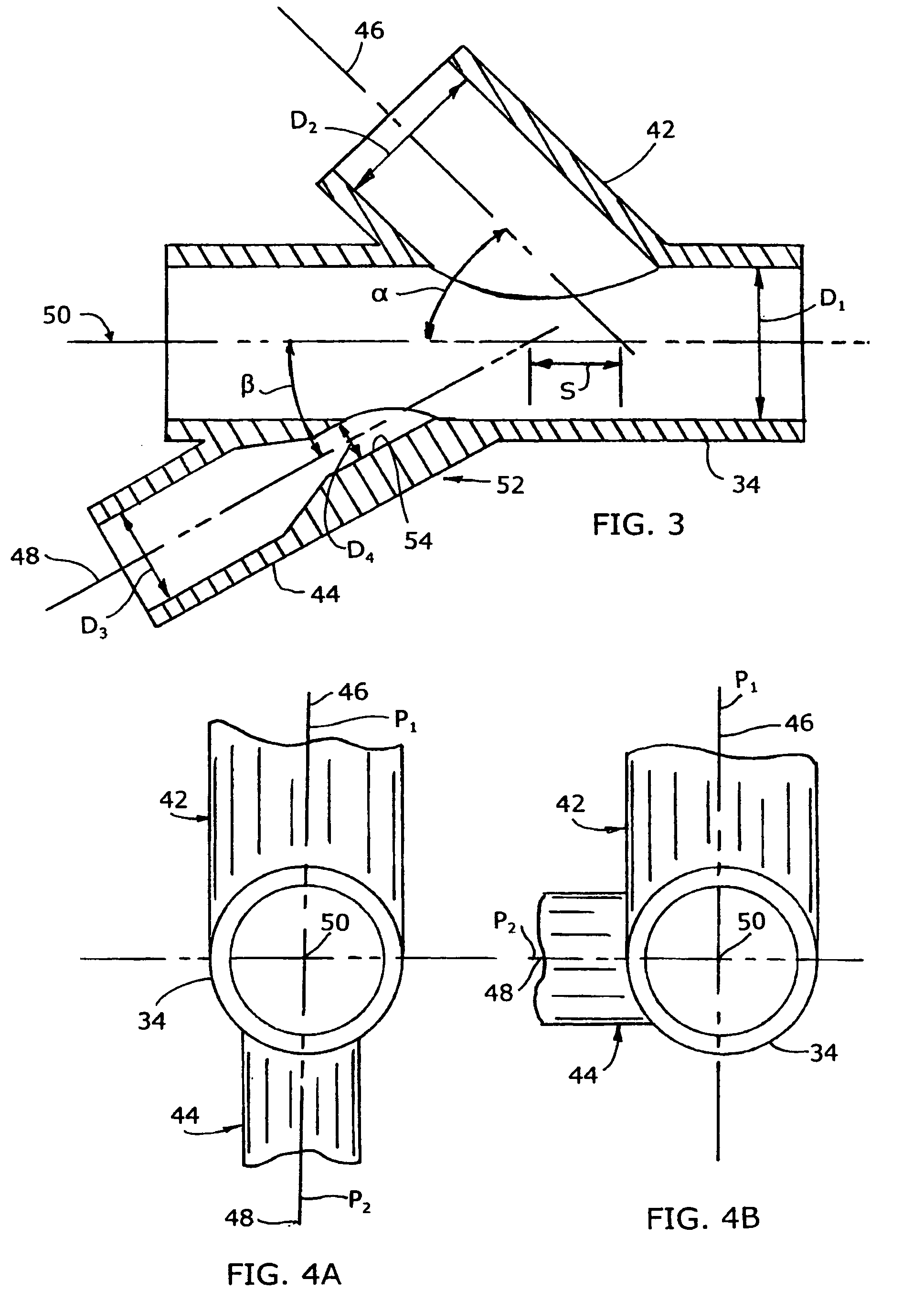

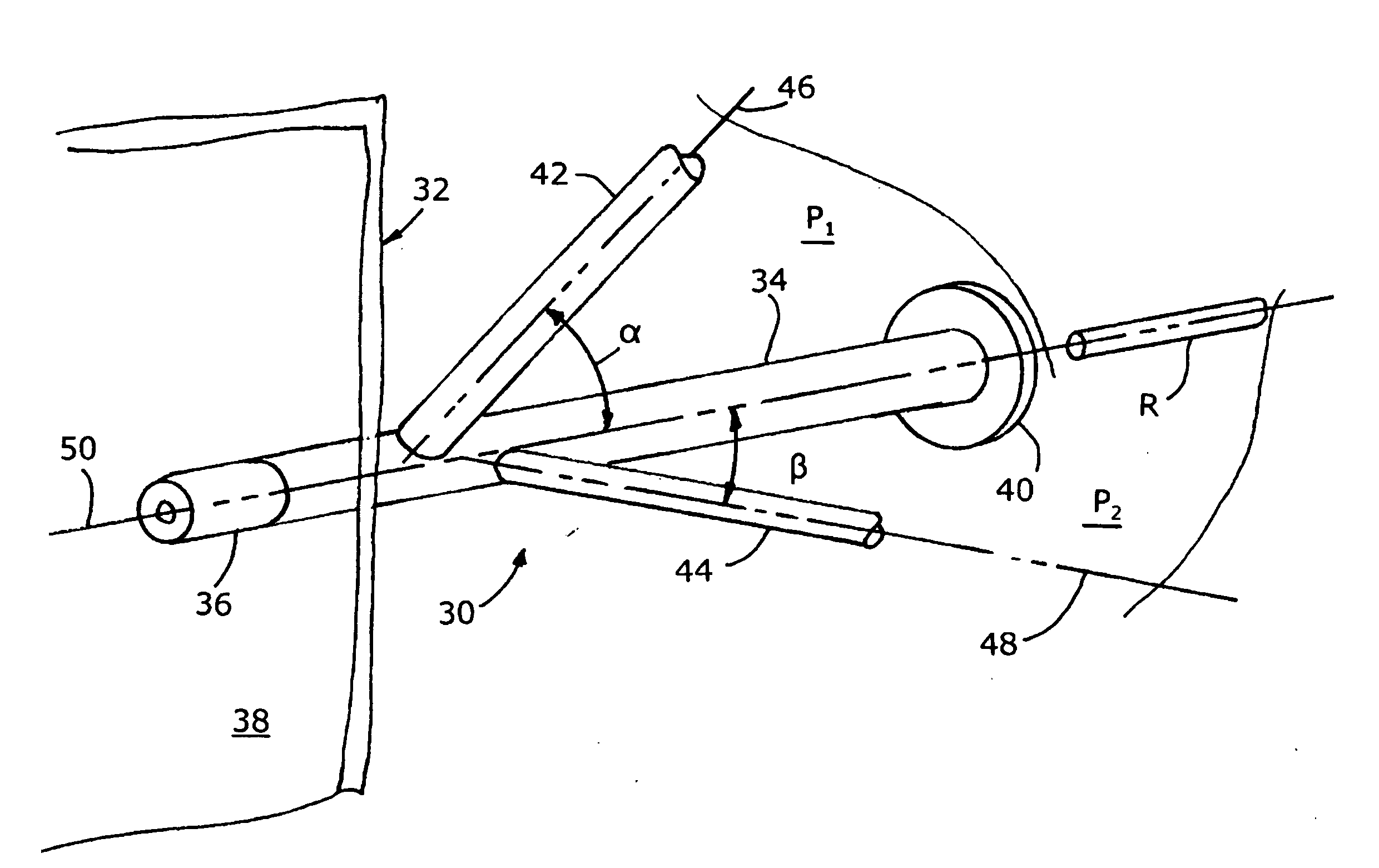

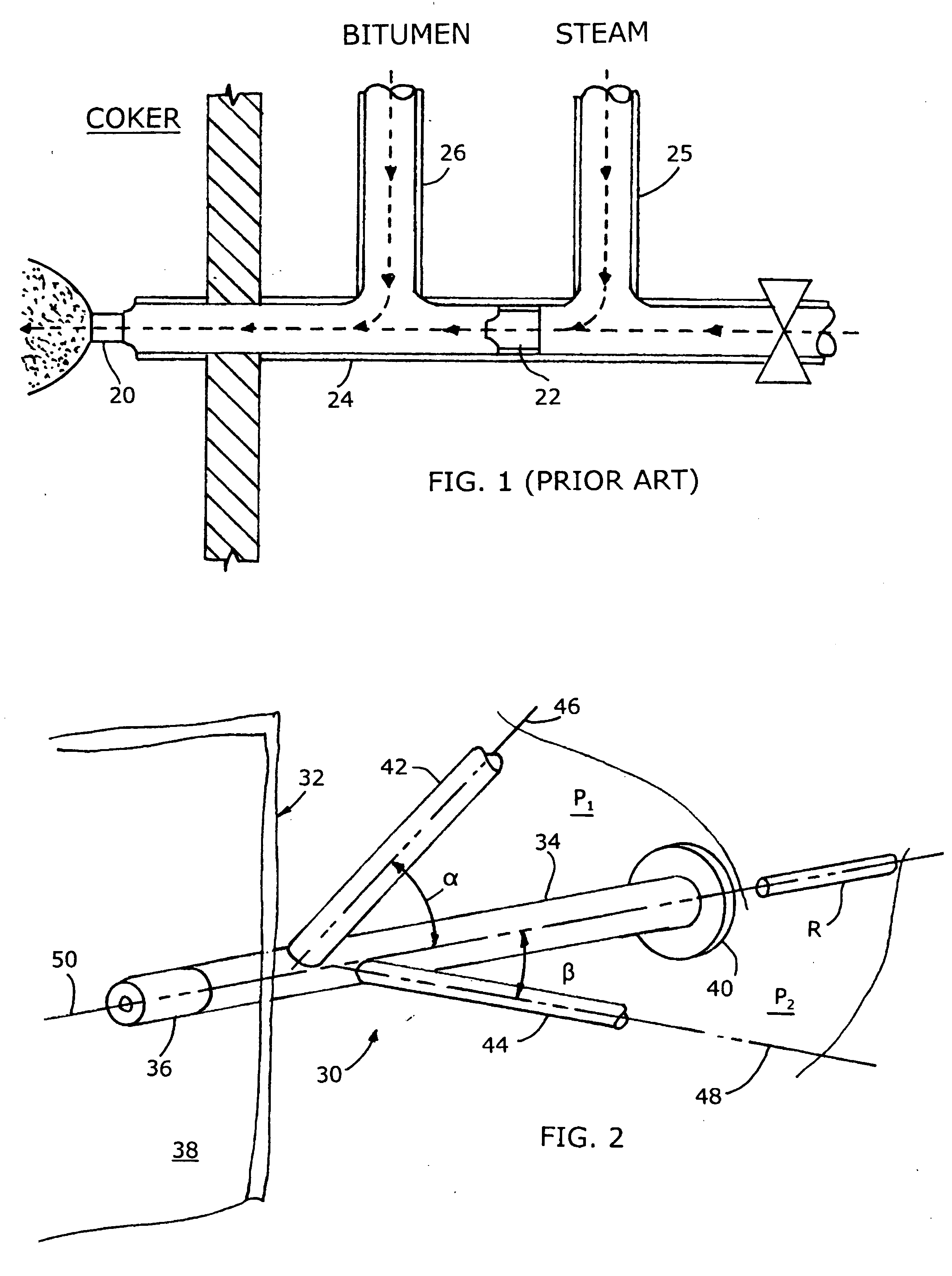

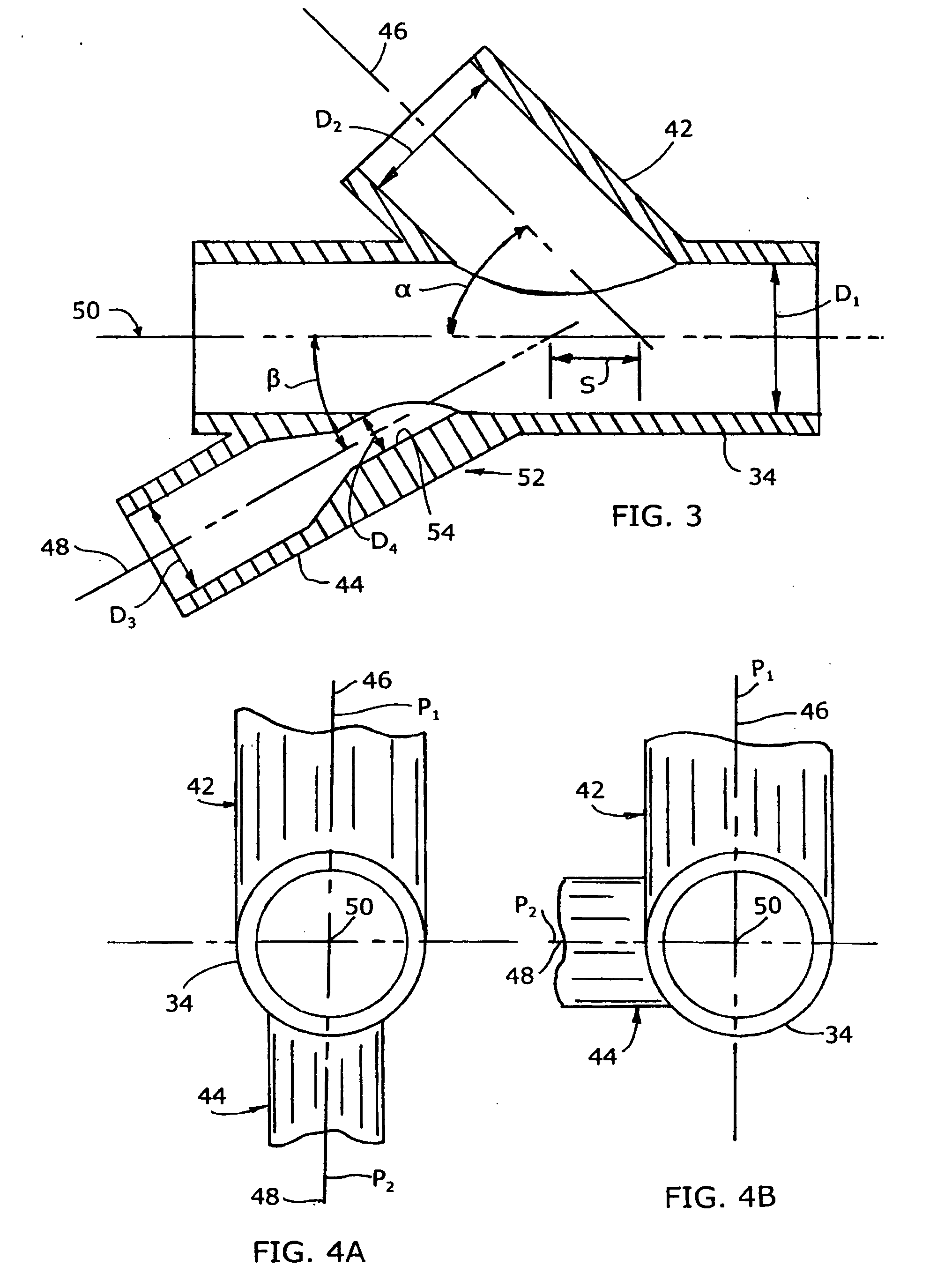

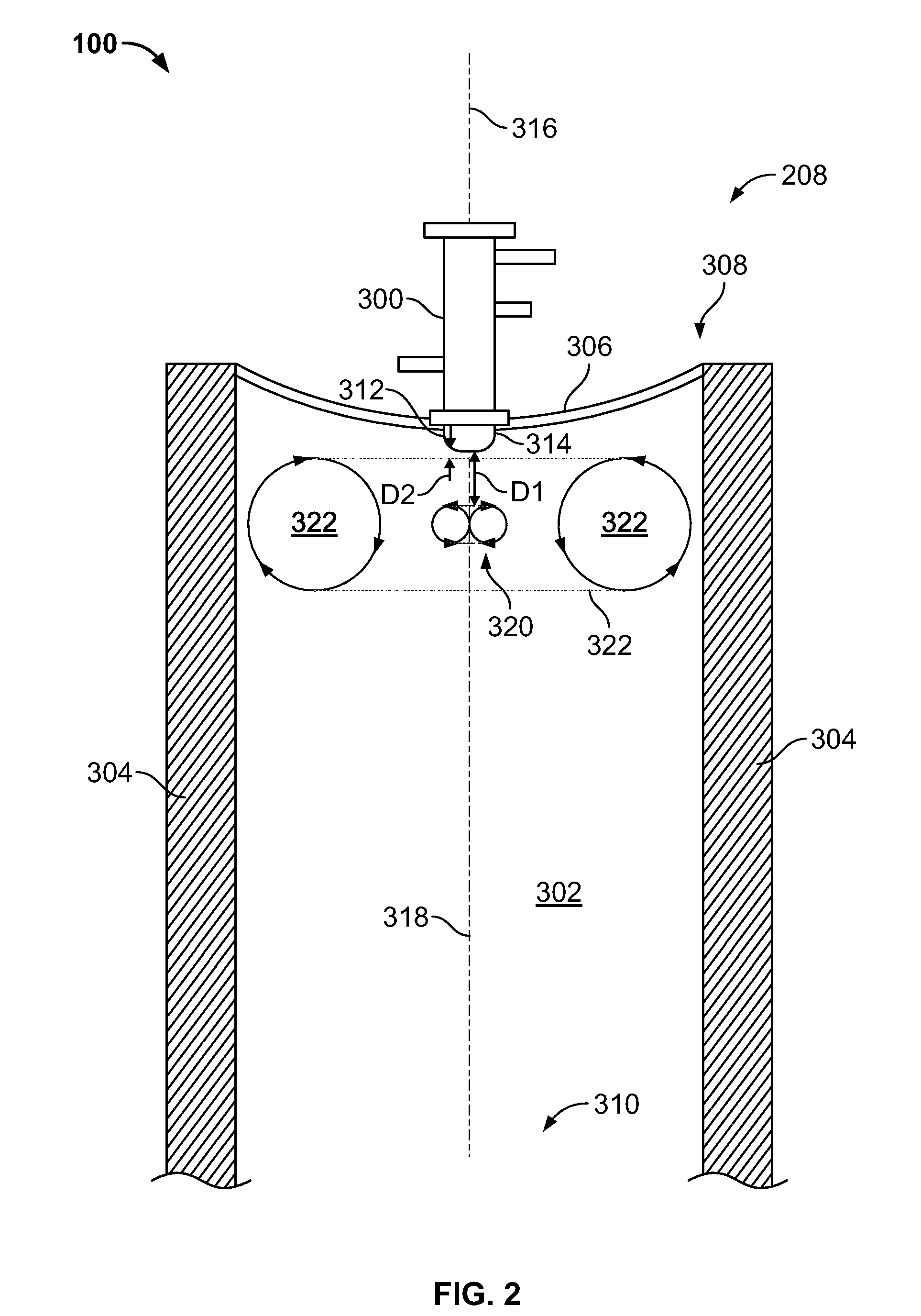

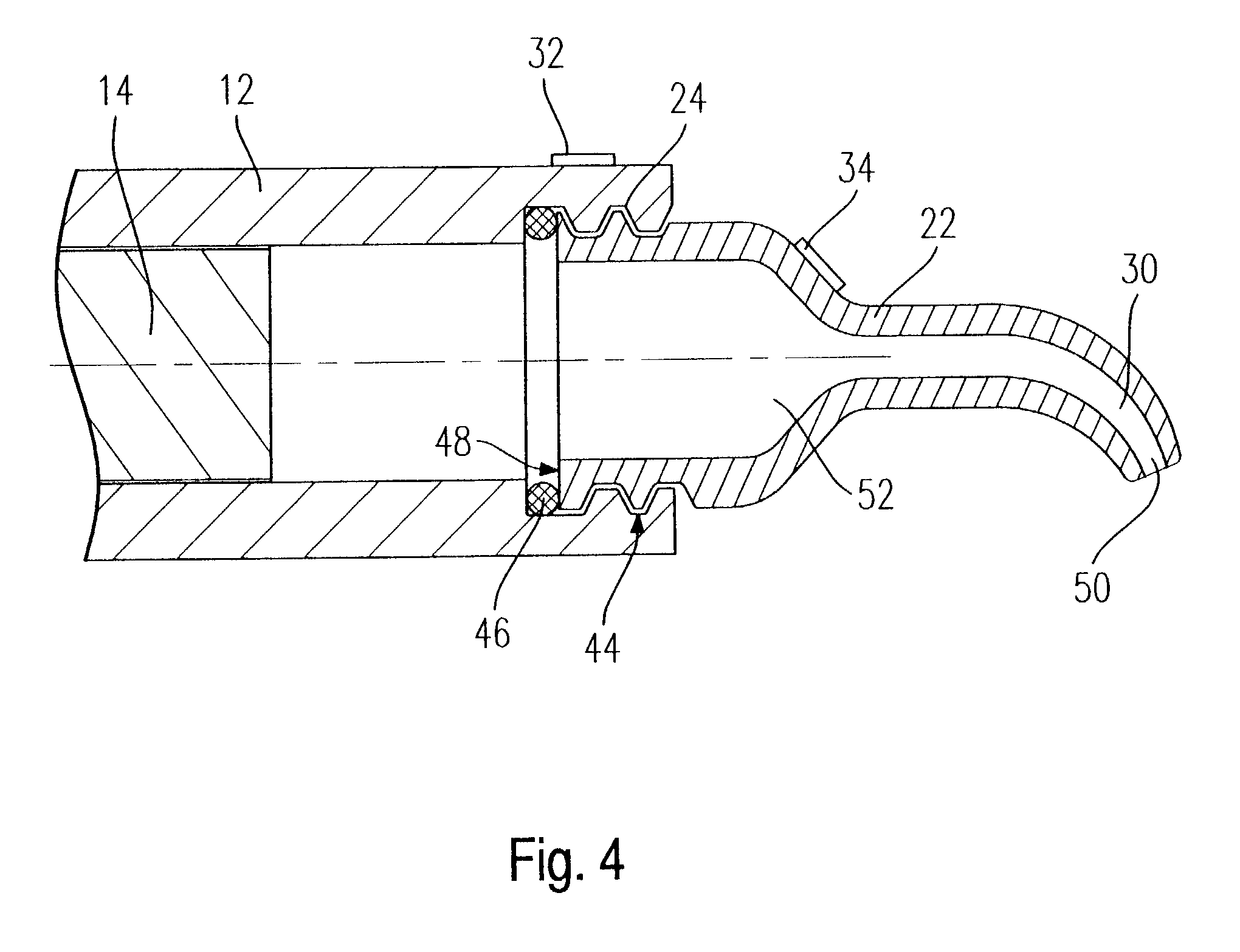

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

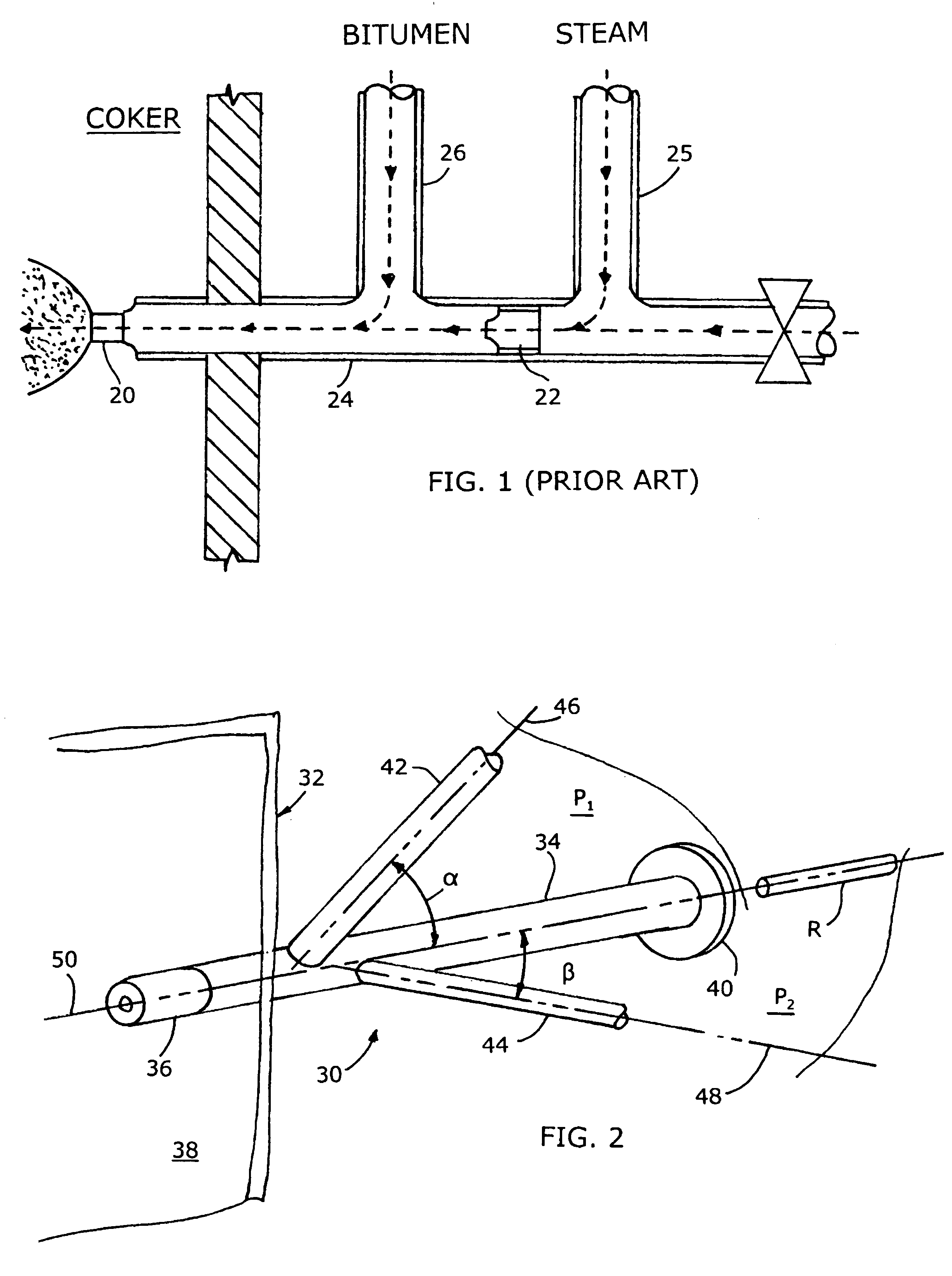

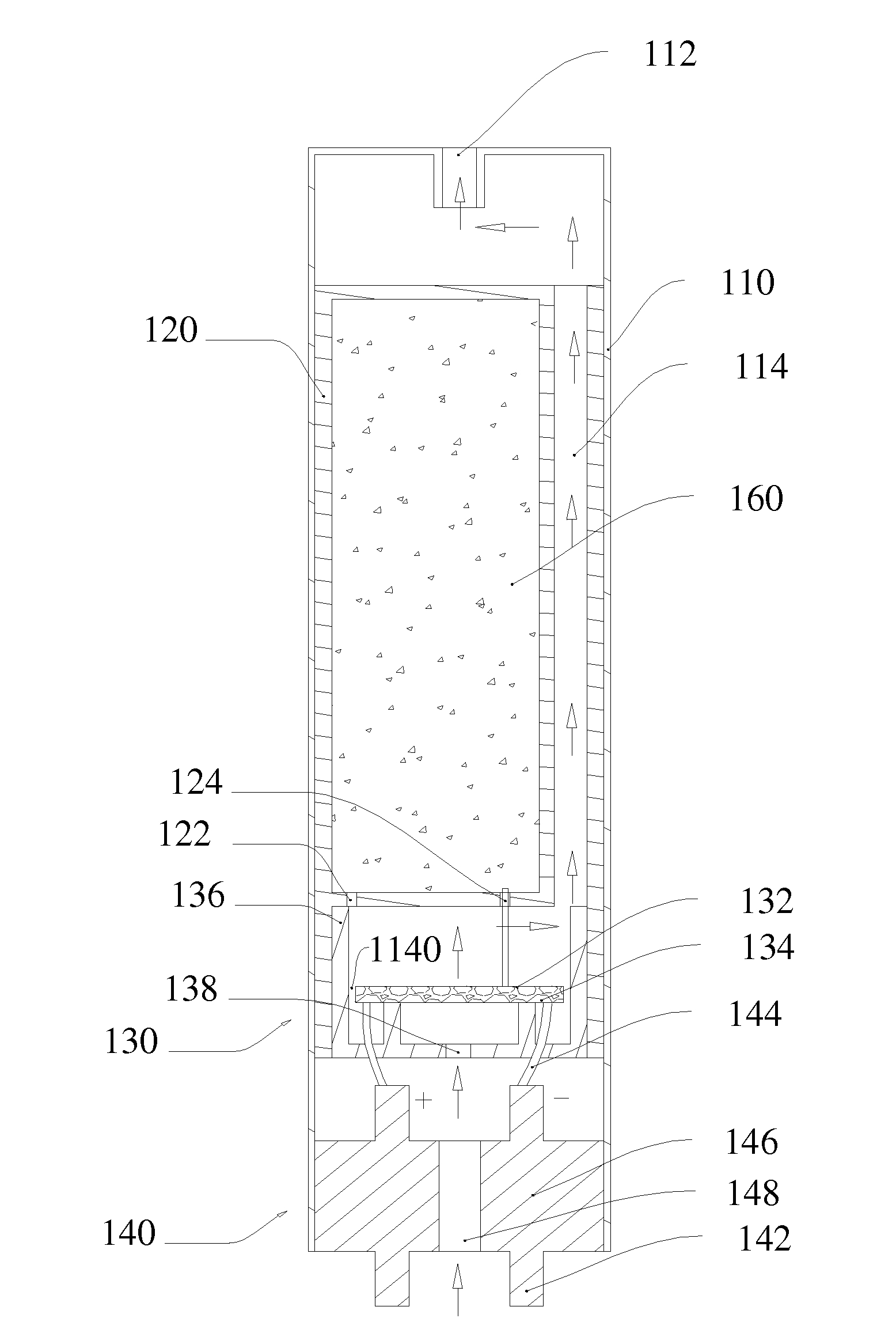

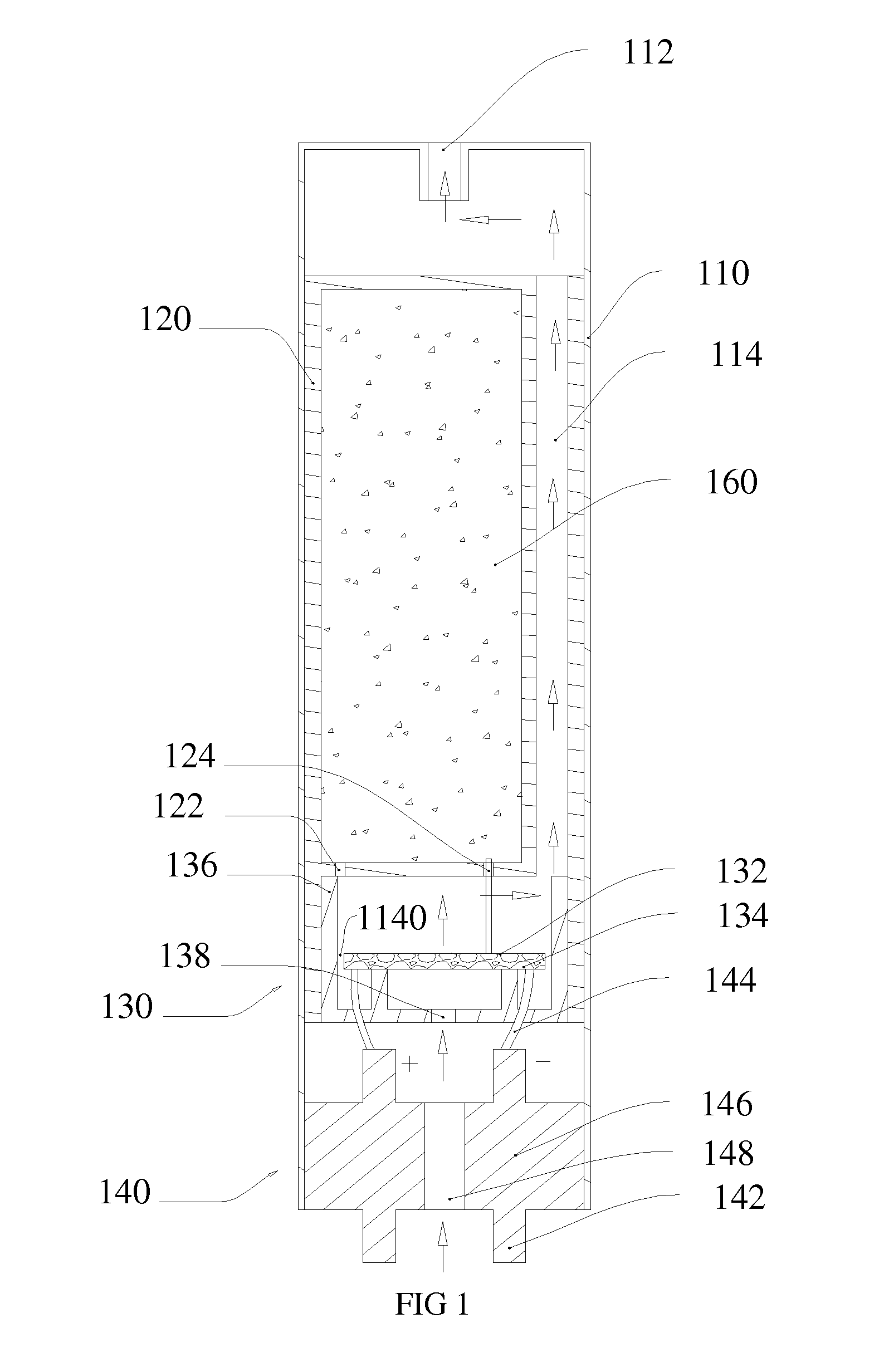

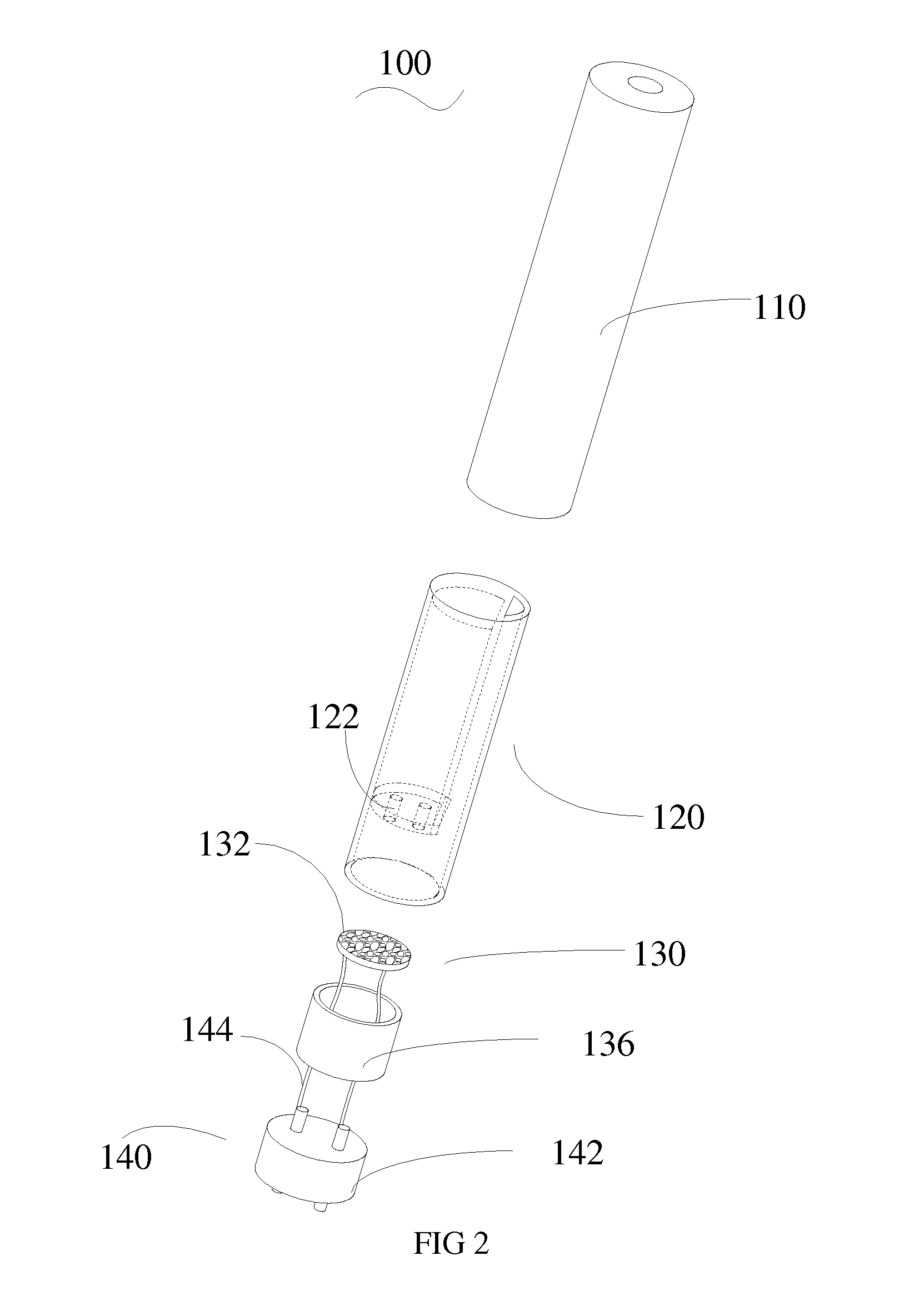

Electronic cigarette

ActiveUS20150090279A1Easily inhale smokeProne to feverTobacco pipesTobacco devicesEngineeringElectronic cigarette

An electronic cigarette is provided, which includes: a housing, a liquid reservoir, and an atomizer assembly. The housing has a chimney formed therein; the liquid reservoir is used for storing liquid; the atomizer assembly received in the housing. The atomizer assembly includes a heating plate capable of absorbing liquid. An outer surface of the heating plate is in contact with the air in the chimney.

Owner:SHENZHEN SMOORE TECH LTD

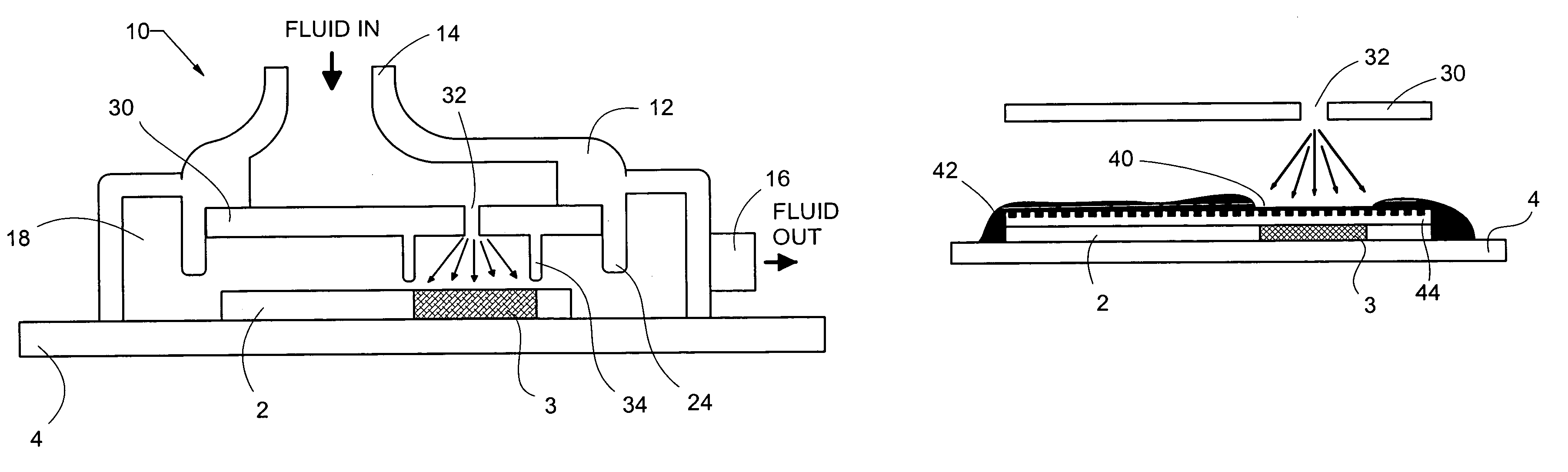

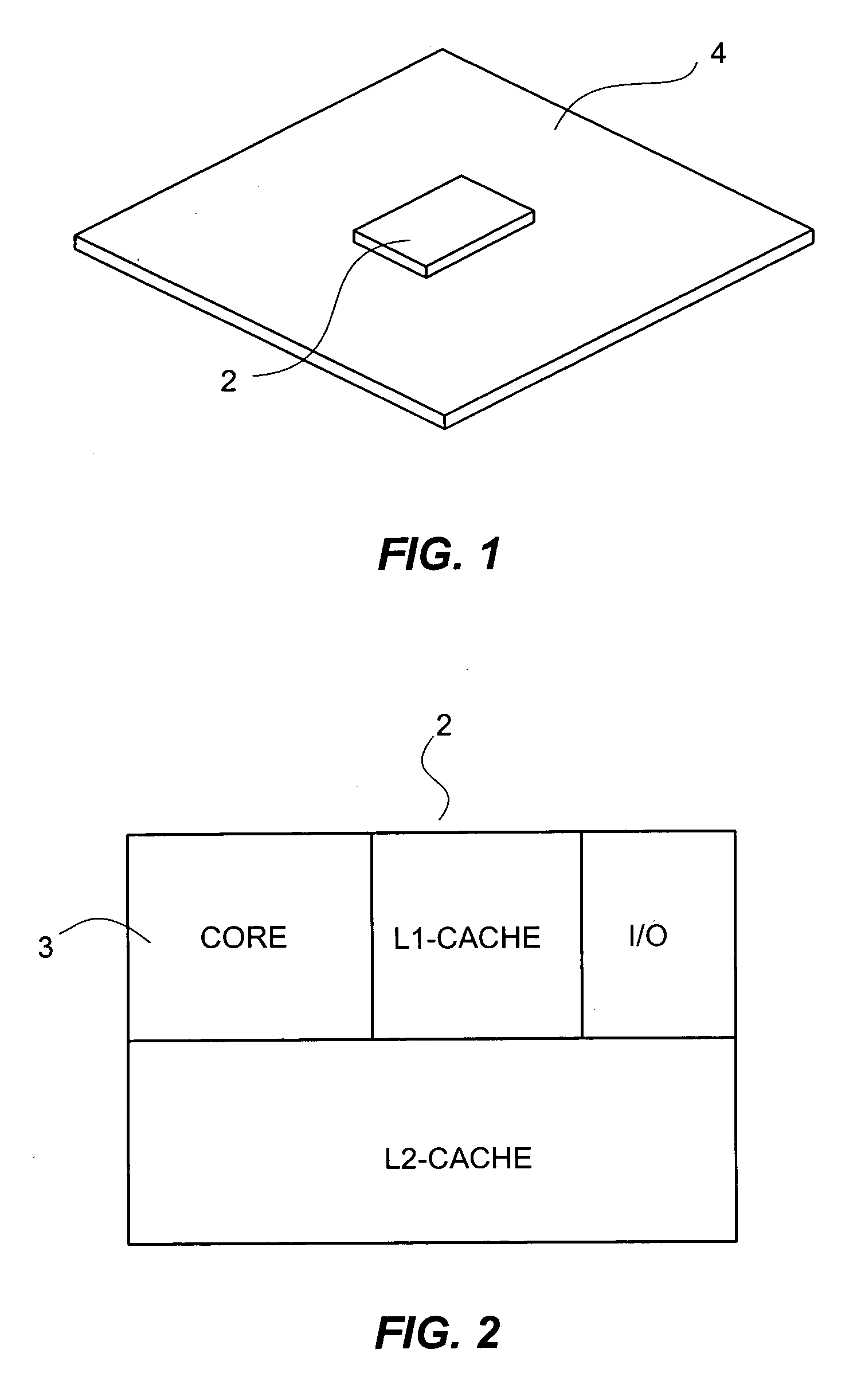

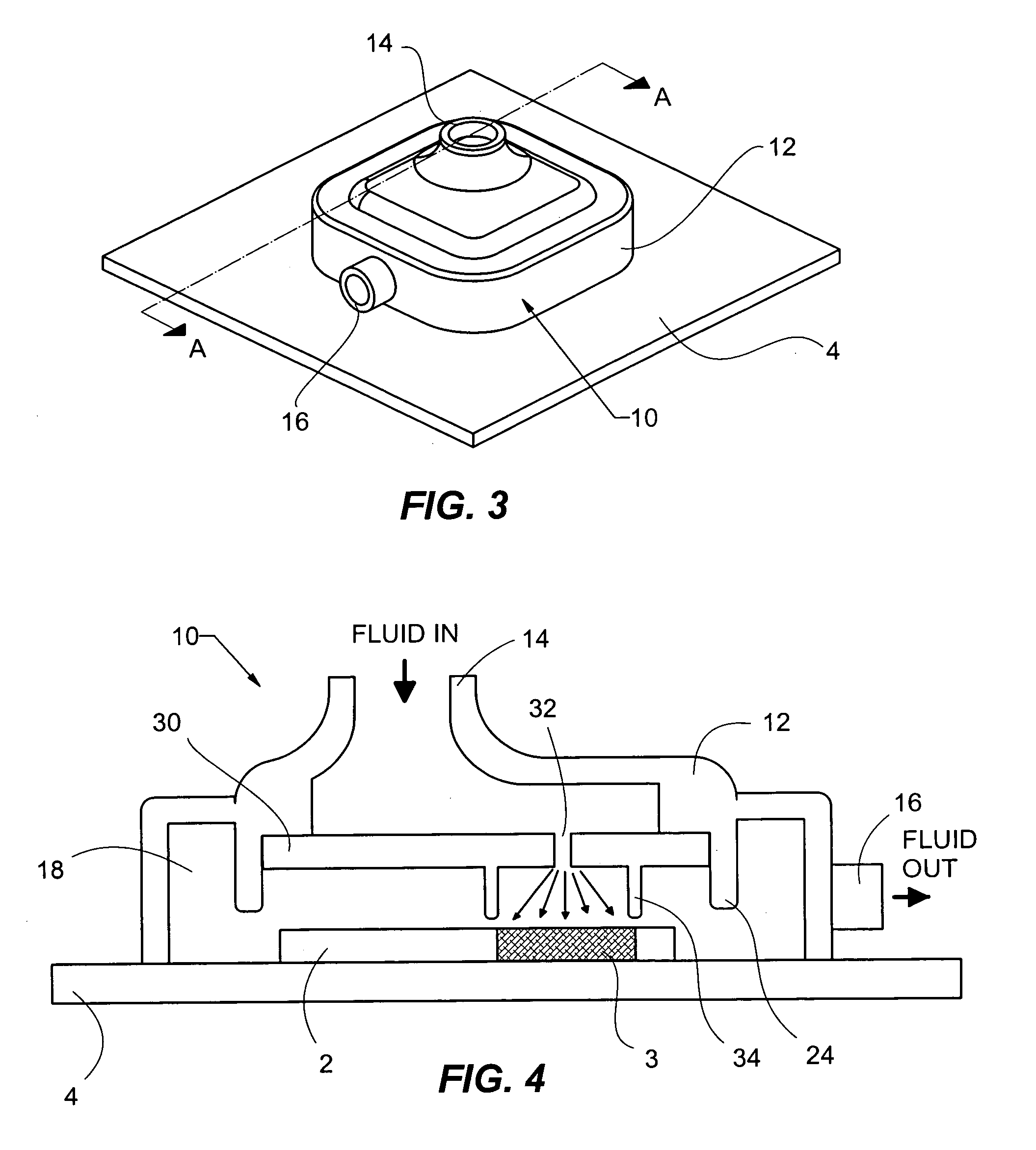

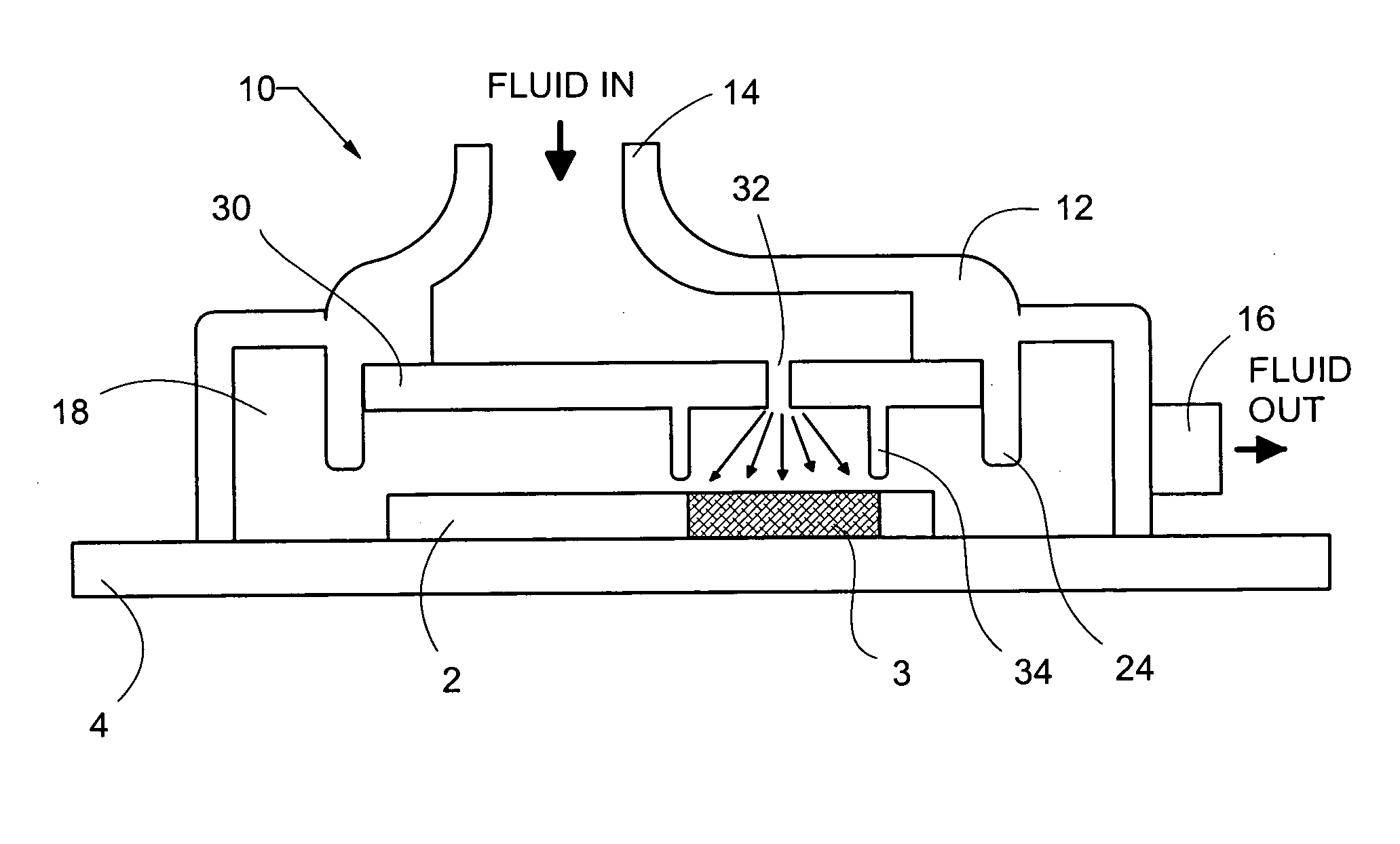

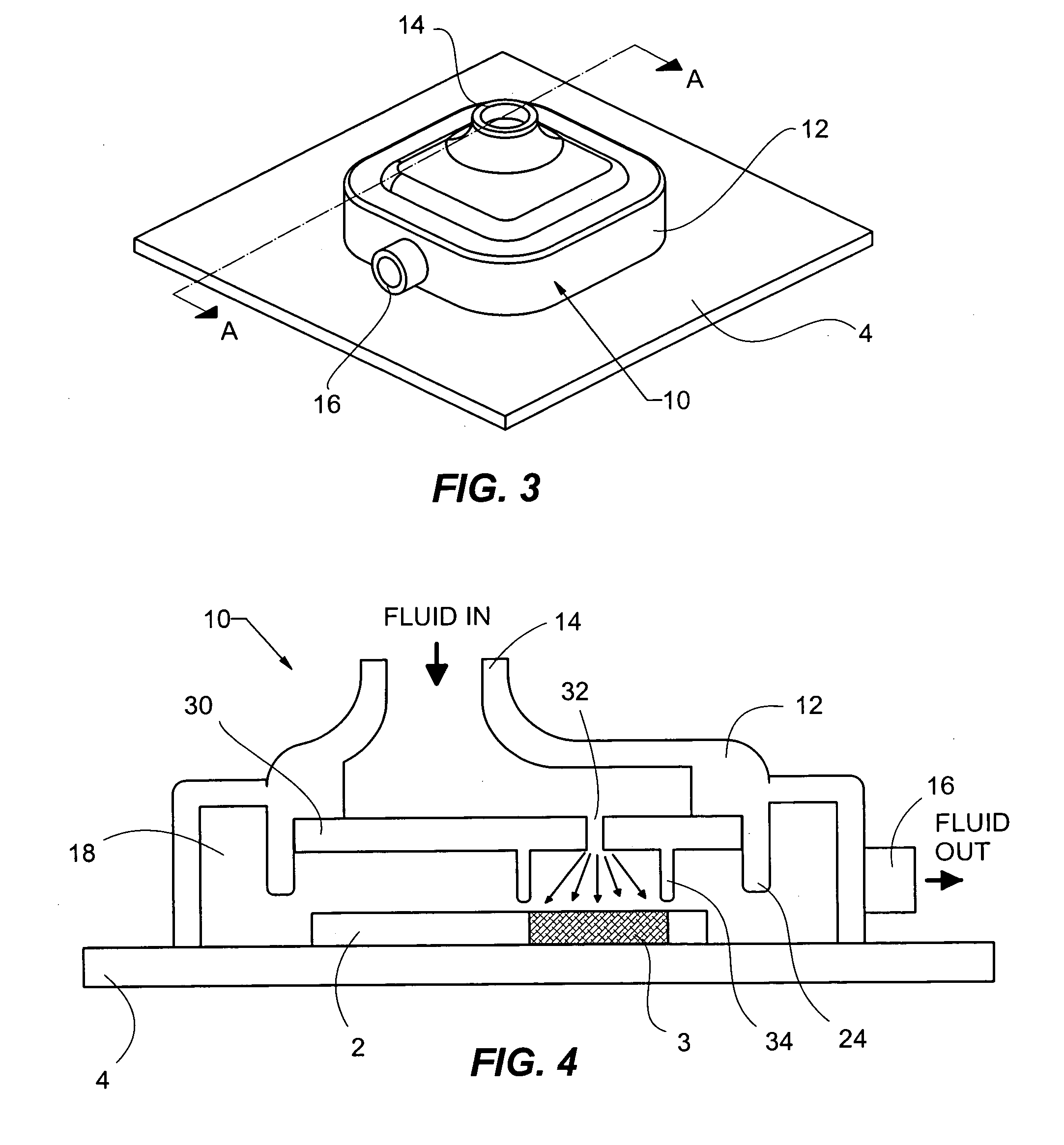

Etched open microchannel spray cooling

ActiveUS6952346B2Simple methodProvide flexibilityDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic componentSpray cooling

The present invention is a spray cooling thermal management device that cools an electronic component. Liquid coolant is dispensed upon a heated surface containing etched open microchannels.

Owner:PARKER INTANGIBLES LLC

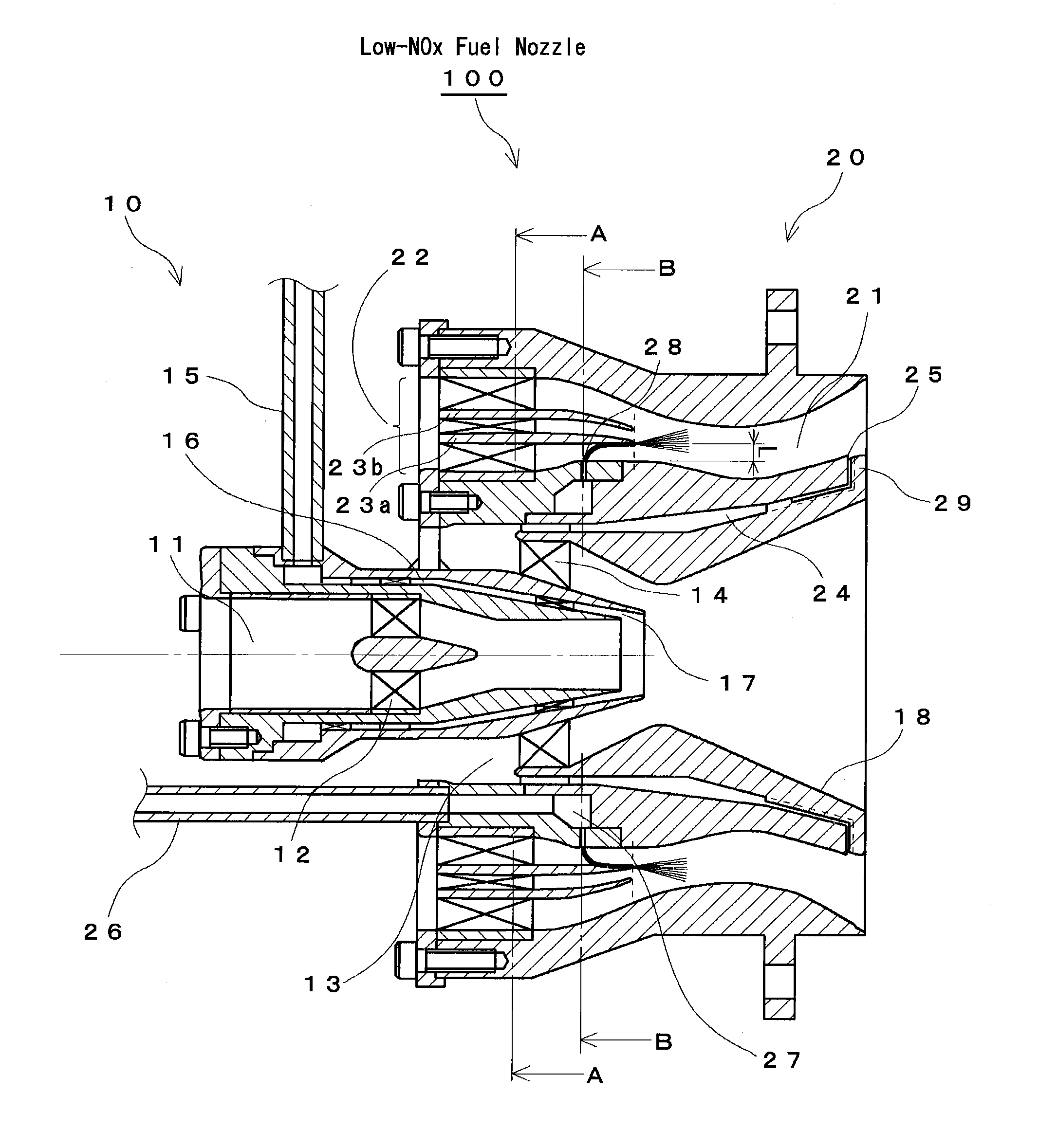

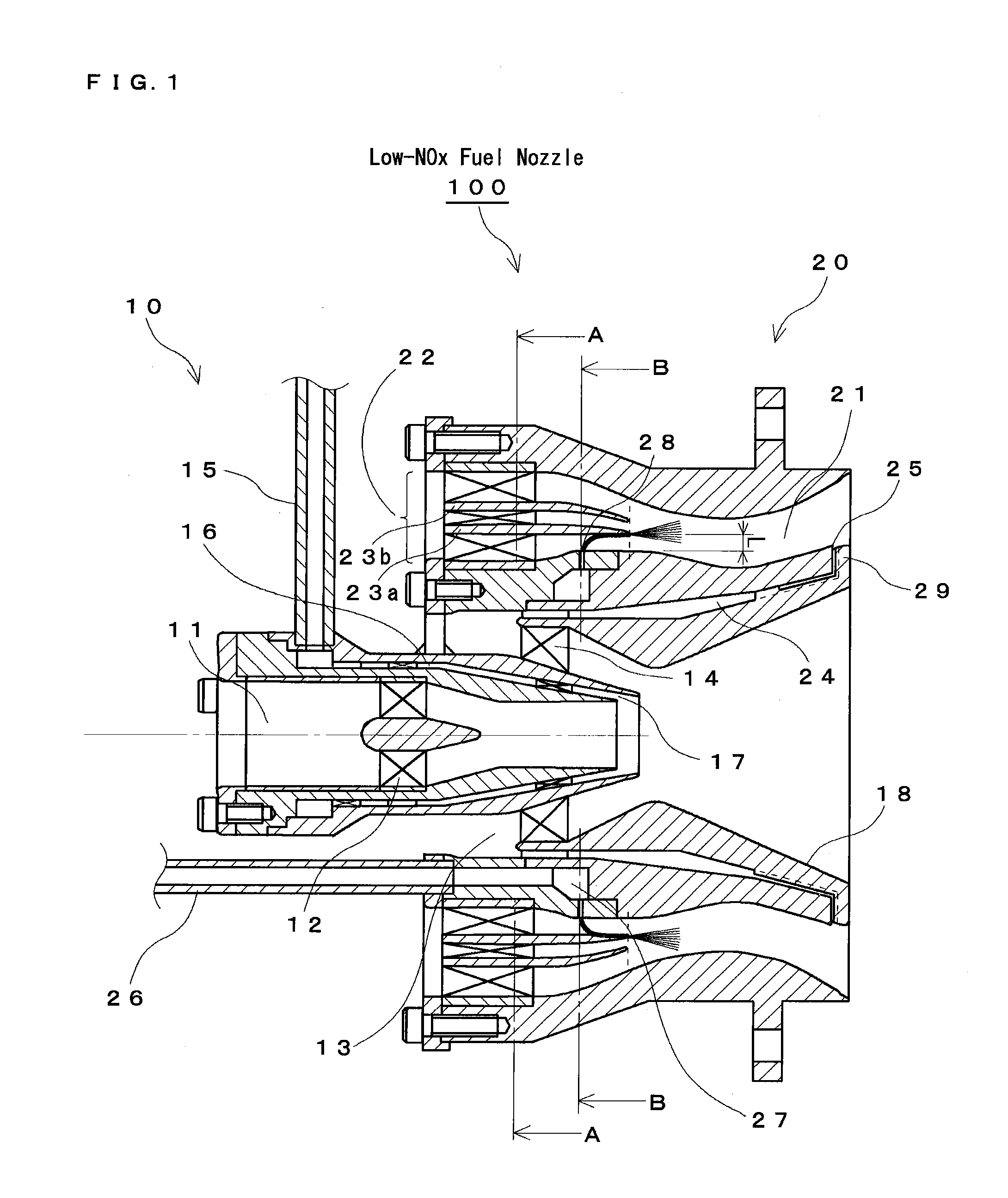

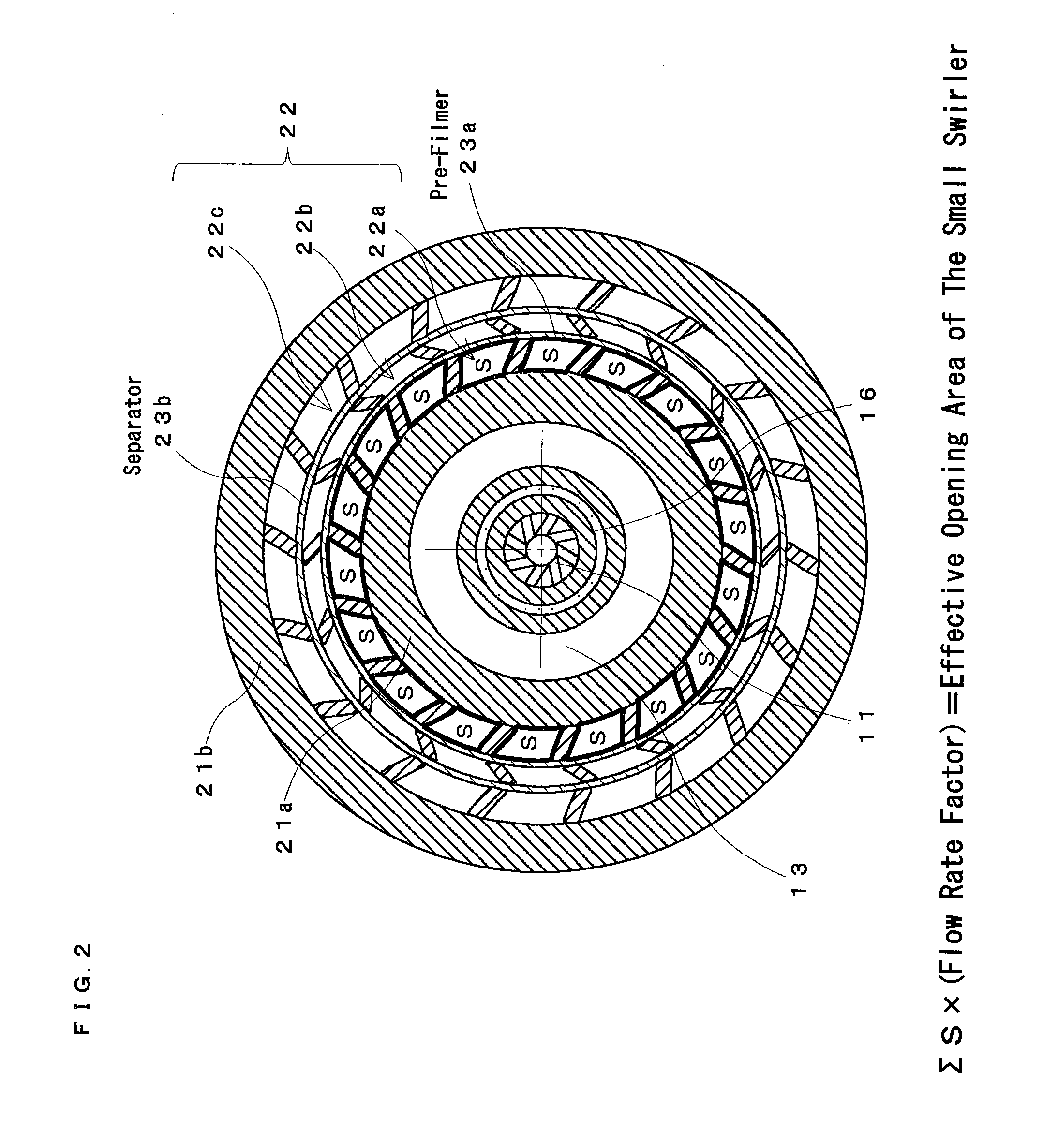

Staging fuel nozzle

ActiveUS20100308135A1Reduce amount of NOx generateHigh degree of atomizationBurnersTurbine/propulsion fuel supply systemsEngineeringFuel injection

A main swirler of a triple annular configuration that is partitioned by a pre-filmer and a separator is installed in an inlet port of a main air flow channel. The vicinity of the inner wall of the main air flow channel provided with a main fuel injection port is bulged radially outward from the innermost surface (innermost surface of a small swirler) of a main swirler. Further, a distance from the main fuel injection port and the pre-filmer is set such that an effective opening area between the pre-filmer and “the inner wall of the main air flow channel provided with the main fuel injection port” is equal to an effective opening area of the small swirler. The swirling directions of the swirlers of the main swirler are “clockwise”-“counter-clockwise”-“clockwise” respectively along the radial outward direction when the swirling direction of the innermost swirler is taken as “clockwise”.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

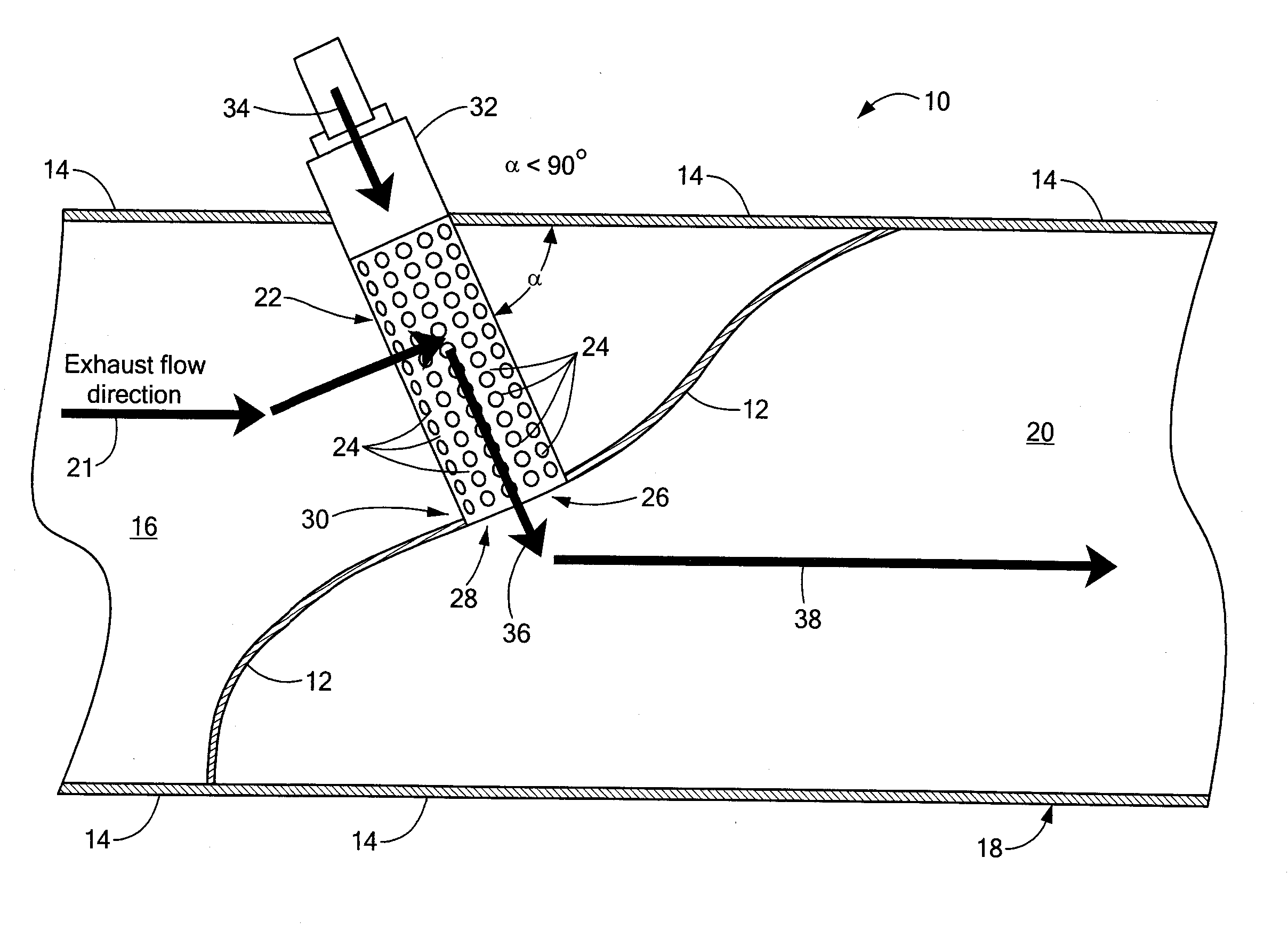

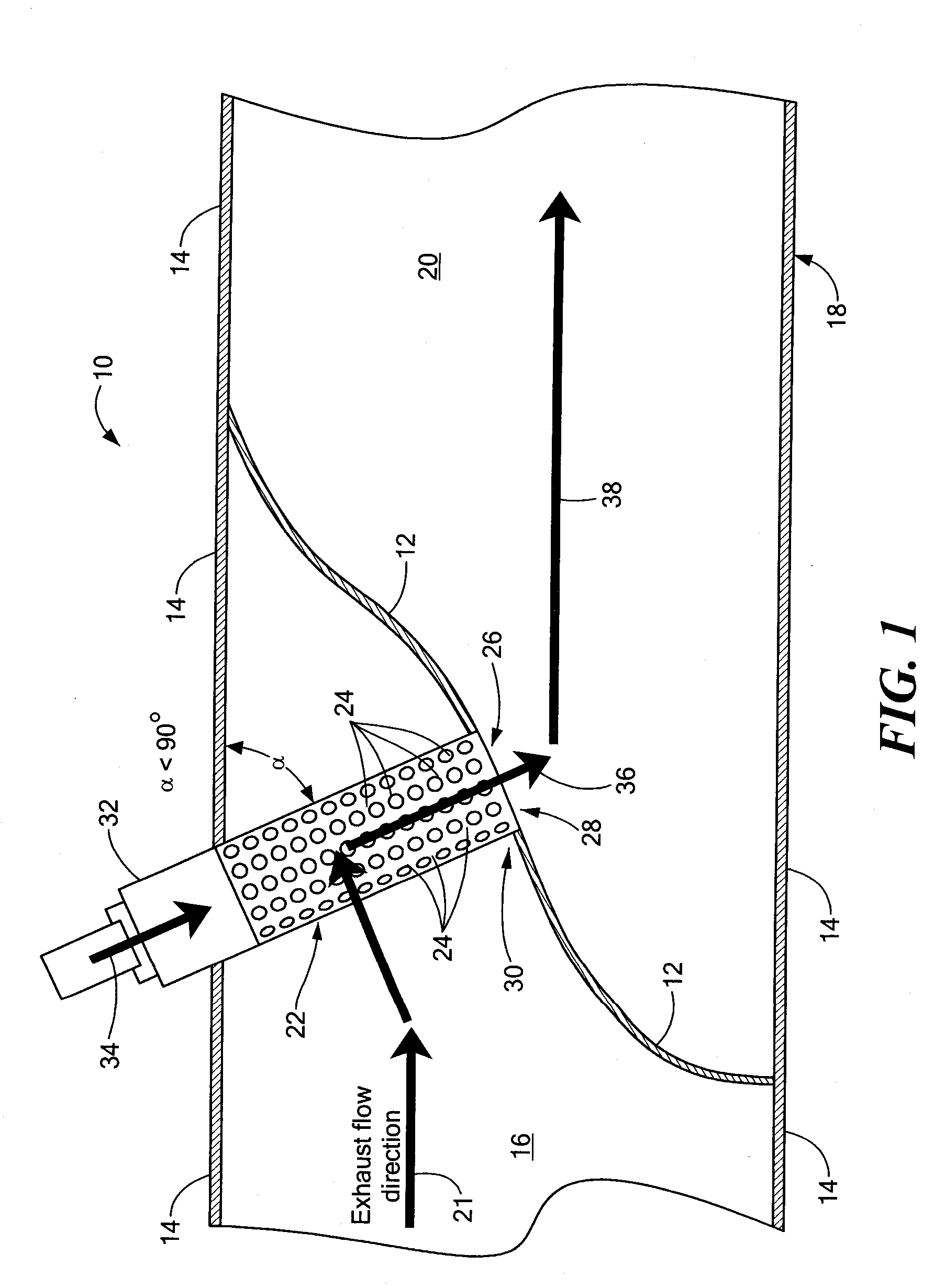

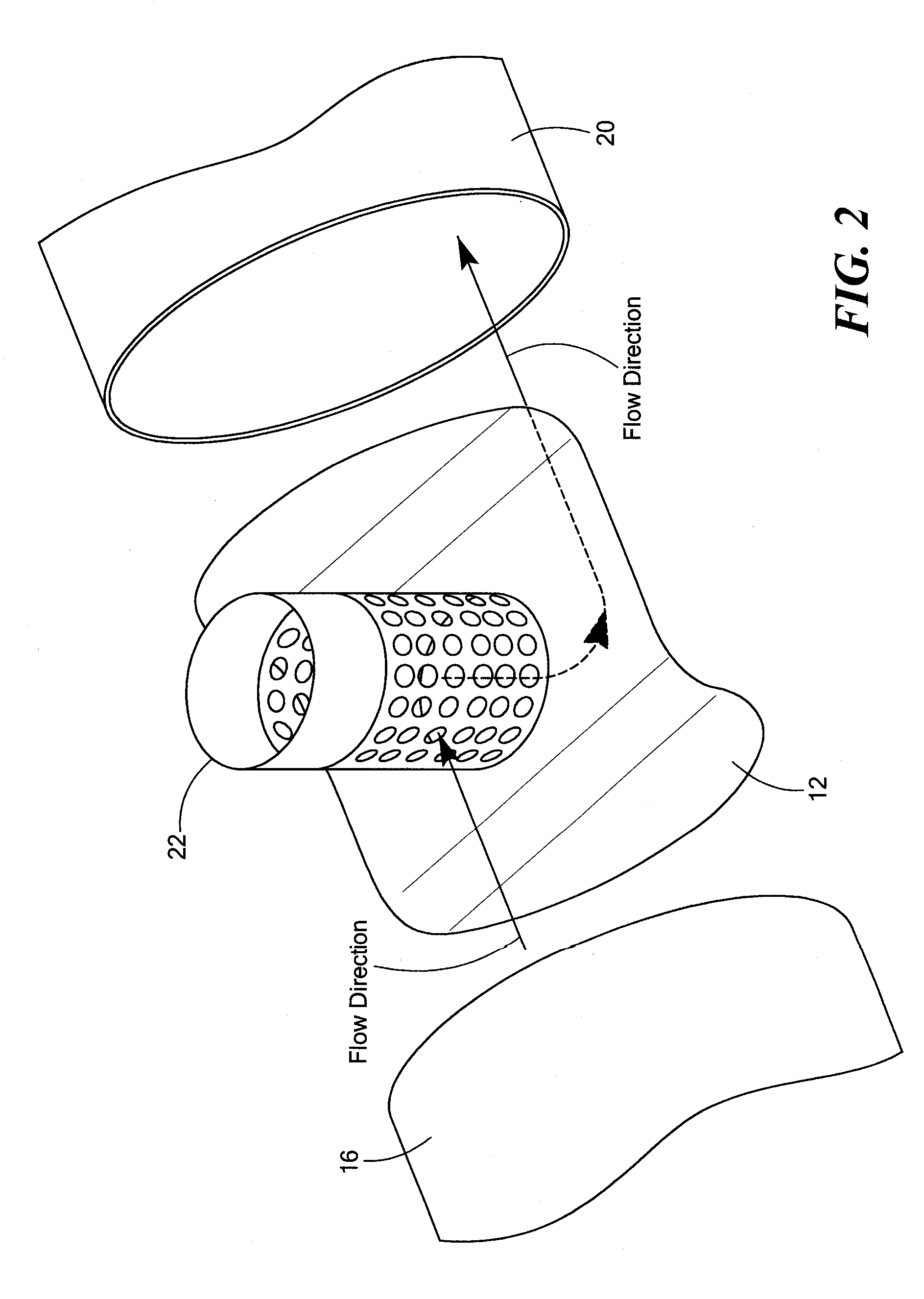

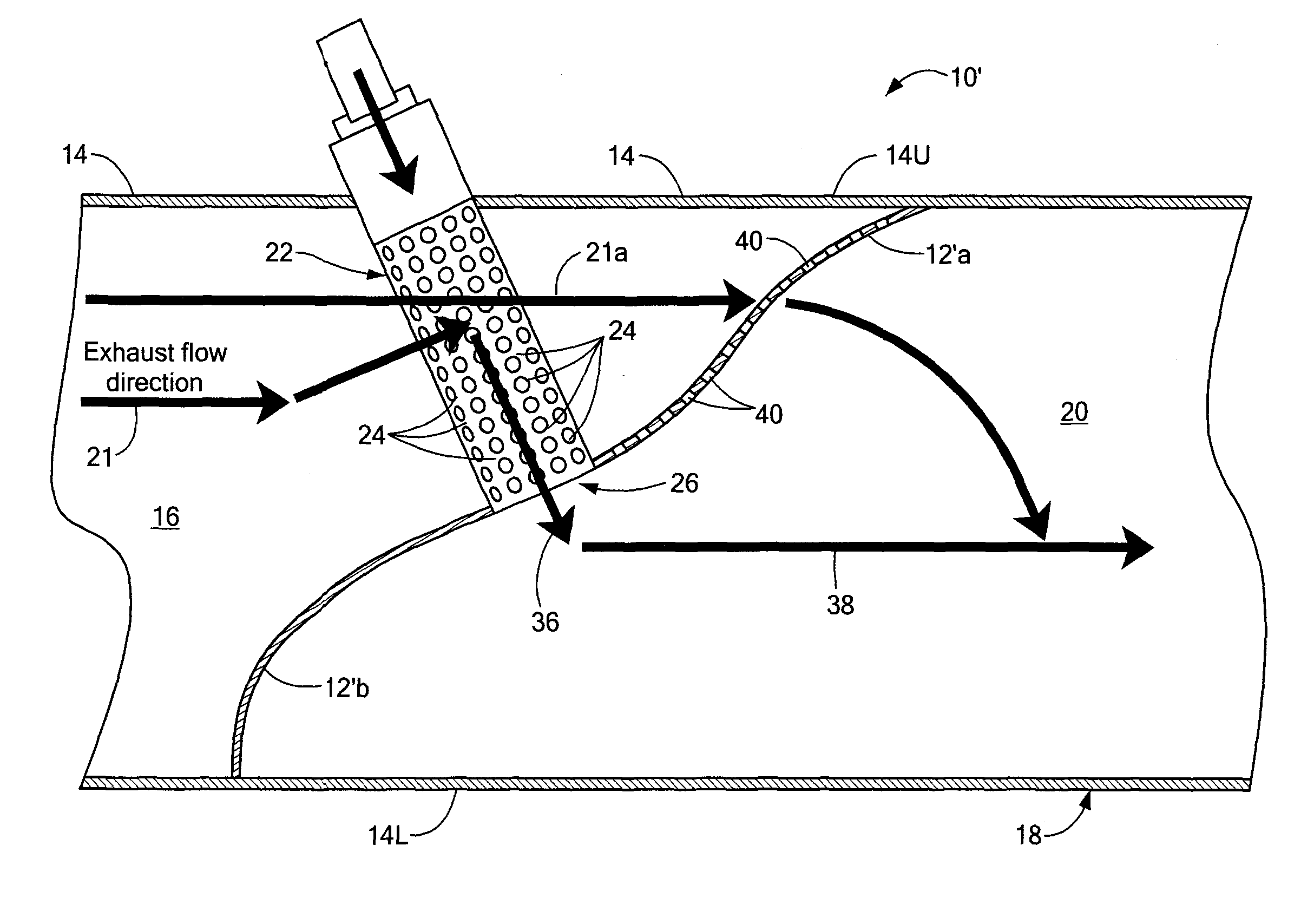

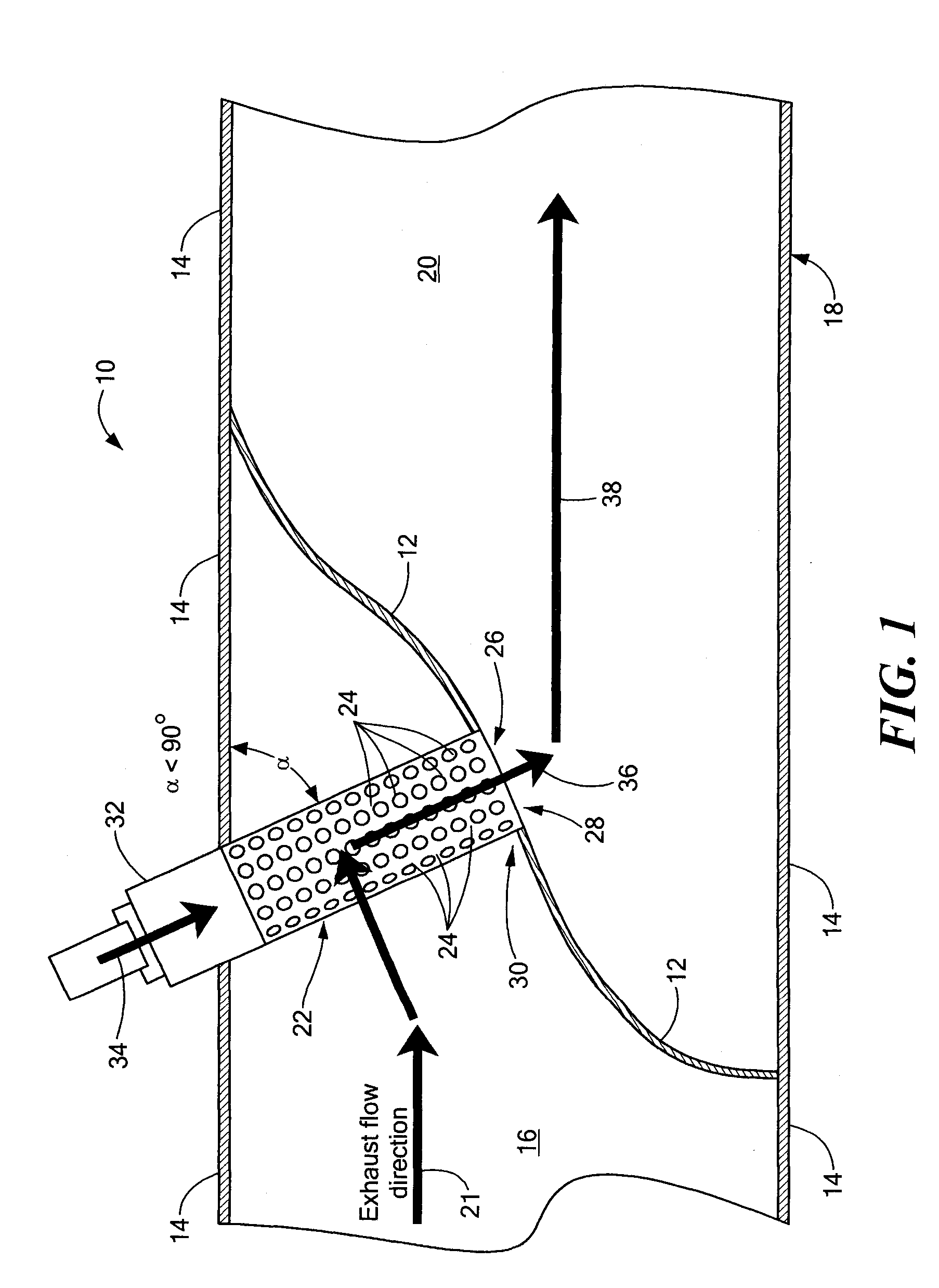

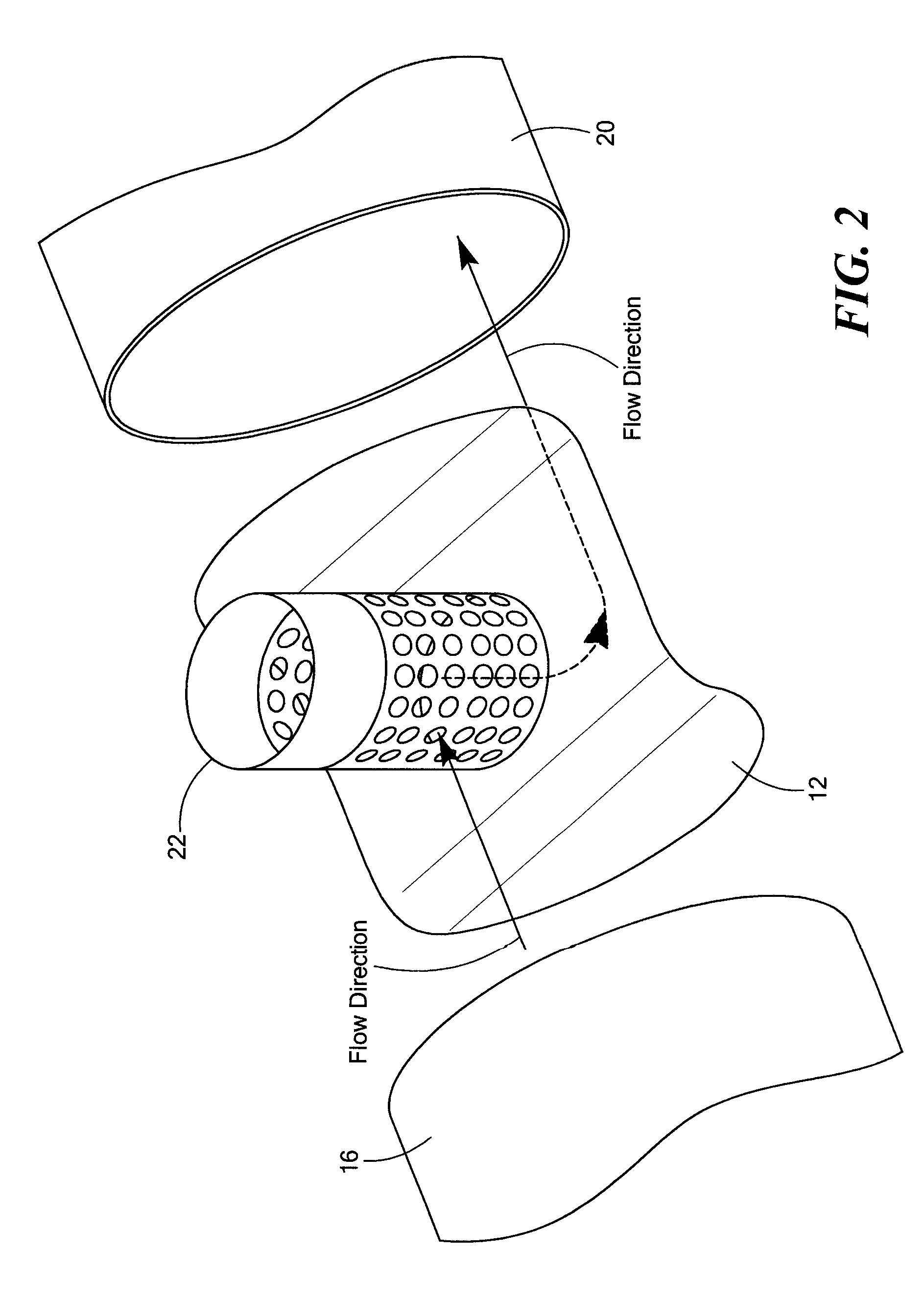

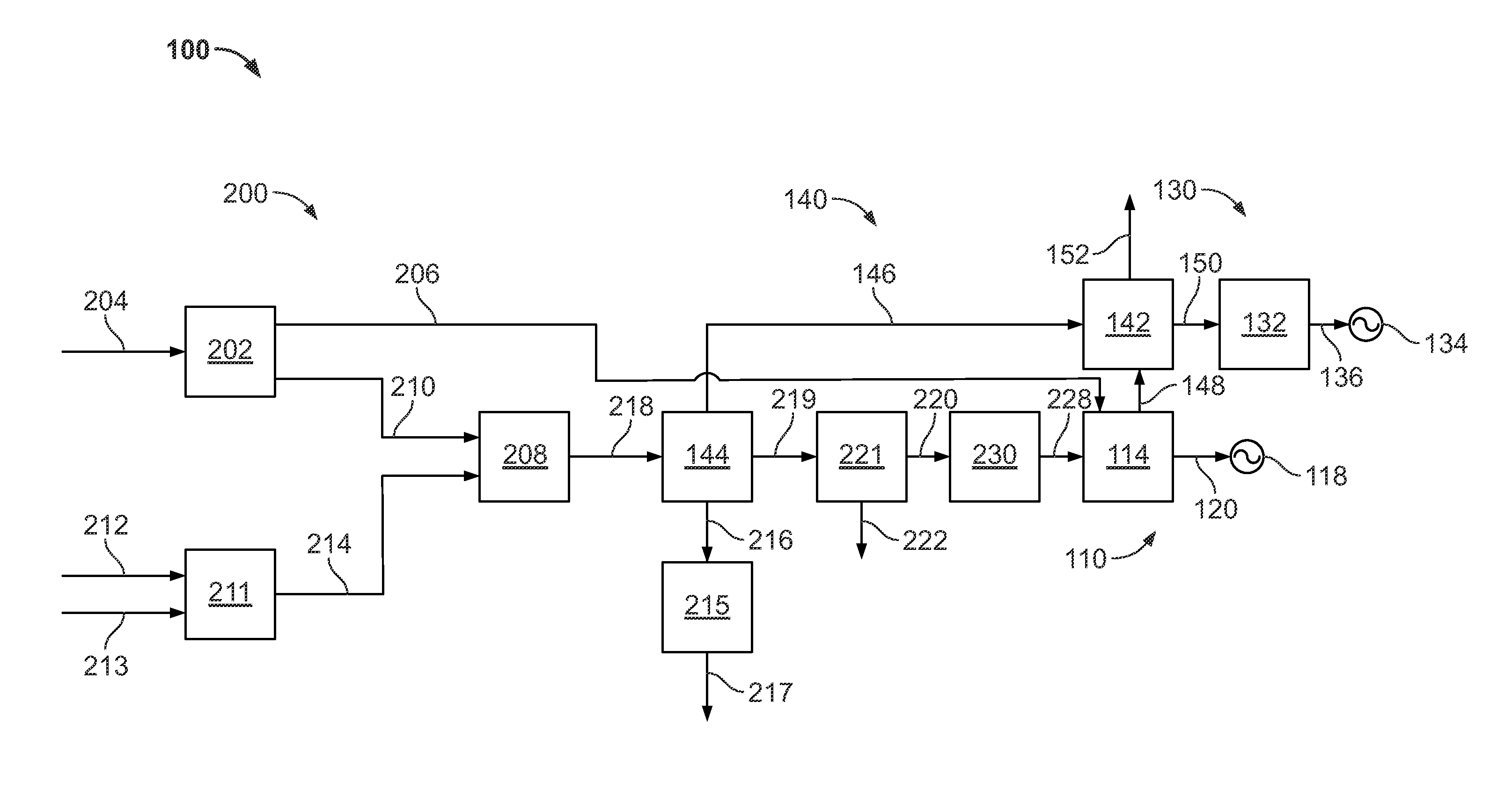

Selective Catalytic Reduction (SCR) Catalyst Injection Systems

ActiveUS20100005790A1Reduce pressureSpeed up the flowInternal combustion piston enginesSilencing apparatusExhaust gasExhaust fumes

A Selective Catalytic Reduction (SCR) injection system for mixing reductant with exhaust gasses. The system includes a plate disposed between walls of an entrance portion and an egress section of the exhaust pipe. The plate intercepts exhaust gasses entering the entrance section of the exhaust pipe and directs such exhaust gasses through apertures in a wall of a reductant-introducing conduit. The conduit has an outlet disposed in the egress section of the exhaust pipe. The wherein dimensions of the apertures in the wall and dimensions in the outlet of the conduit being selected to increase the velocity of the exhaust leaving the outlet of the conduit into the egress section of the exhaust pipe relative to the velocity of the exhaust gases in the entrance section.

Owner:FORD GLOBAL TECH LLC

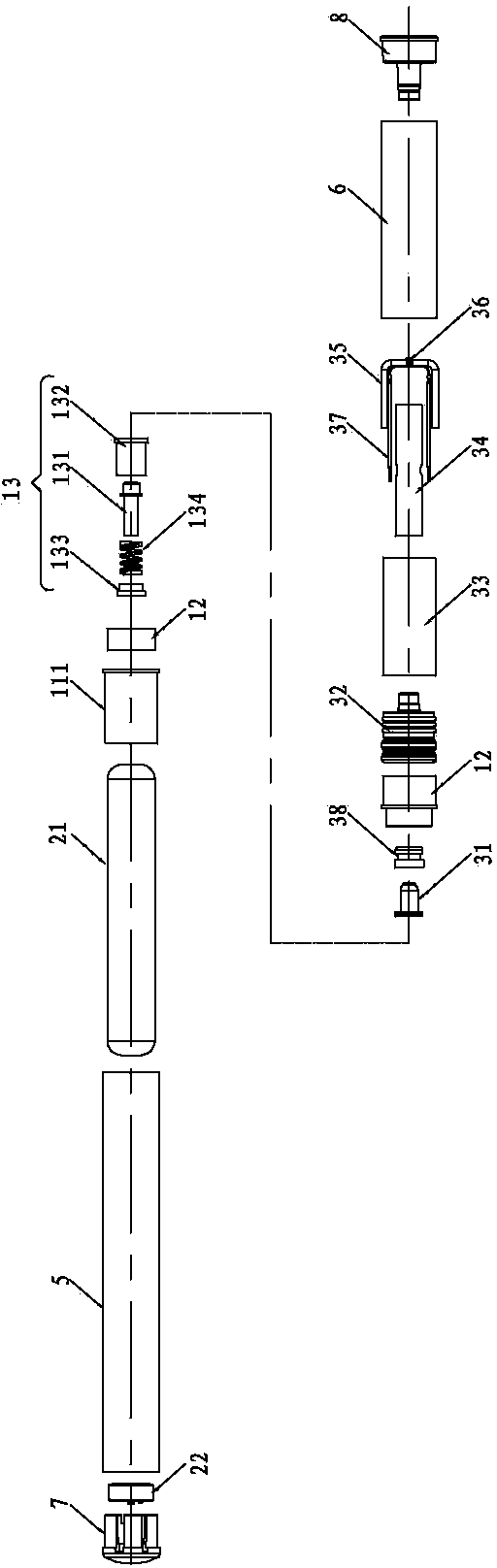

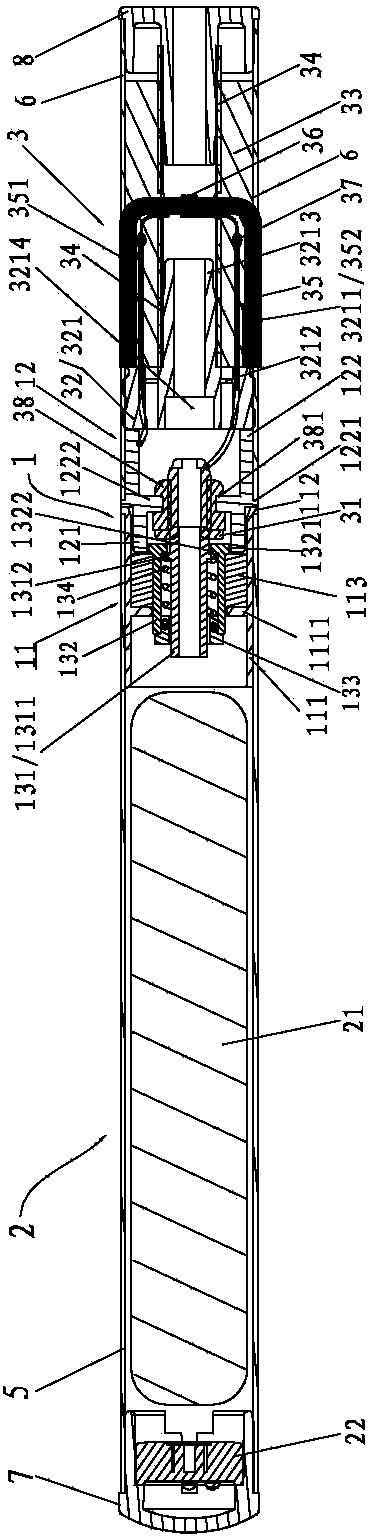

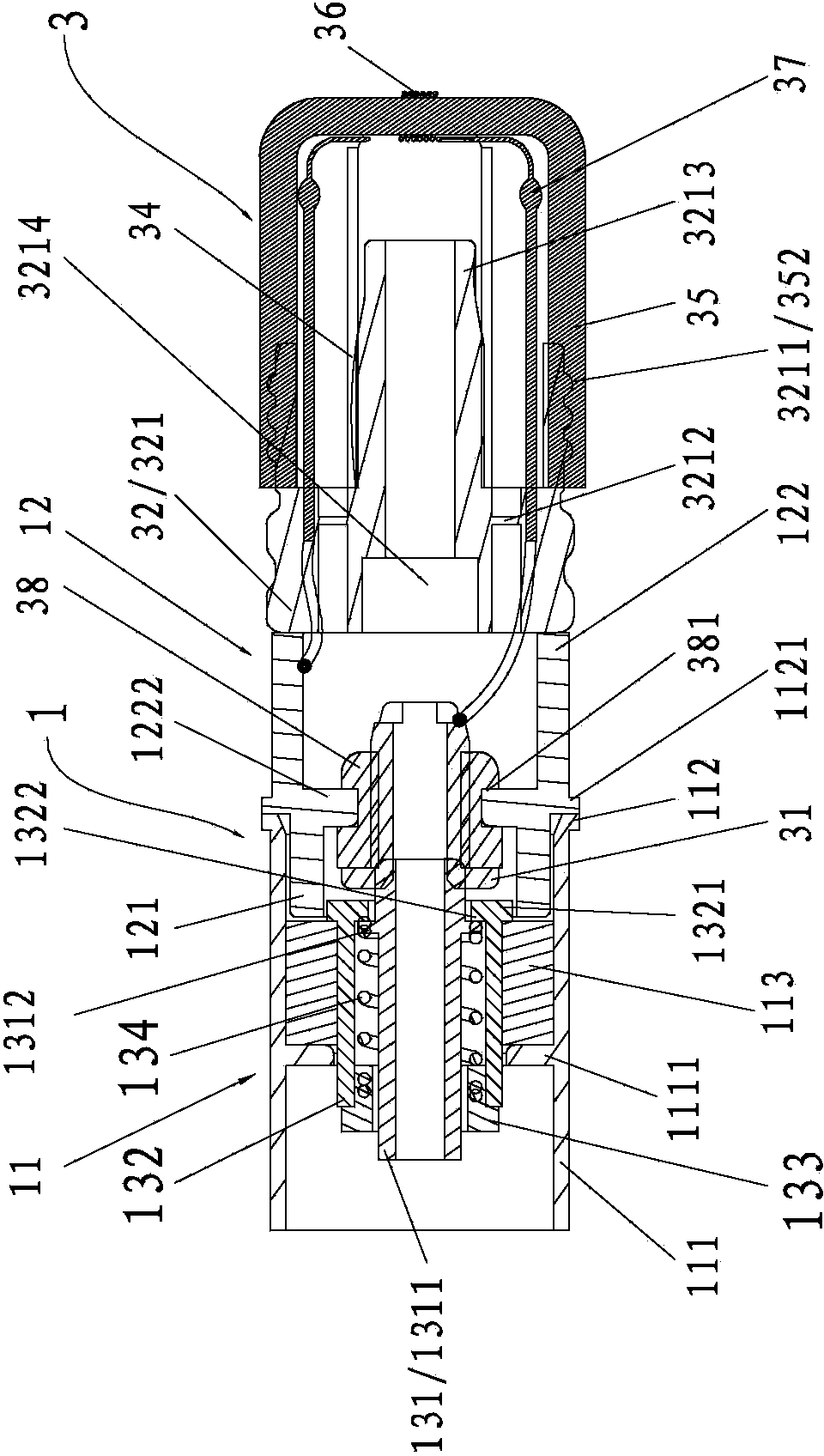

Magnetic force plug-in type electronic cigarette, manufacturing method, connecting assembly and atomization assembly

The invention relates to a magnetic force plug-in type electronic cigarette, a manufacturing method, a connecting assembly and an atomization assembly. The magnetic force plug-in type electronic cigarette comprises a power supply assembly and the atomization assembly, wherein the power supply assembly and the atomization assembly are connected with the two ends of the connecting assembly respectively. The connecting assembly is composed of a strong magnetic assembly and a metal assembly, wherein the strong magnetic assembly and the metal assembly are connected in a magnetic attraction mode and make contact with each other through convex edges which are arranged on the head portions and extend outwards in the radial direction, and the head extension end which is arranged in the axial direction along the head of a magnetic assembly abuts against an inner cavity of the strong magnetic assembly in a connected mode so that the strong magnetic assembly and the metal assembly can be coaxially assembled together in a magnetic attraction mode. The atomization assembly is composed of an atomizer positive pole needle, an oil removal silica gel seat, oil storage cotton, a heating wire fixing tube, an oil absorption rope provided with a heating wire and wires, wherein the wires are used for electrically connecting the heating wire with the atomizer positive pole needle and the negative electrode of the metal assembly respectively, and the atomizer positive pole needle, the oil removal silica gel seat, the oil storage cotton, the heating wire fixing tube, the oil absorption rope, the wires and the magnetic assembly are coaxially and sequentially assembled. The manufacturing method comprises the steps that the strong magnetic assembly is assembled, a control power supply assembly is assembled, the strong magnetic assembly is electrically connected a positive electrode and a negative electrode which are output by the control power supply assembly, the metal assembly is assembled, the atomization assembly is assembled, and the metal assembly is electrically connected with the atomization assembly.

Owner:林光榕

Selective catalytic reduction (SCR) catalyst injection systems

ActiveUS8033104B2Speed up the flowPromote atomizationInternal combustion piston enginesSilencing apparatusExhaust fumesExhaust pipe

A Selective Catalytic Reduction (SCR) injection system for mixing reductant with exhaust gasses. The system includes a plate disposed between walls of an entrance portion and an egress section of the exhaust pipe. The plate intercepts exhaust gasses entering the entrance section of the exhaust pipe and directs such exhaust gasses through apertures in a wall of a reductant-introducing conduit. The conduit has an outlet disposed in the egress section of the exhaust pipe. The wherein dimensions of the apertures in the wall and dimensions in the outlet of the conduit being selected to increase the velocity of the exhaust leaving the outlet of the conduit into the egress section of the exhaust pipe relative to the velocity of the exhaust gases in the entrance section.

Owner:FORD GLOBAL TECH LLC

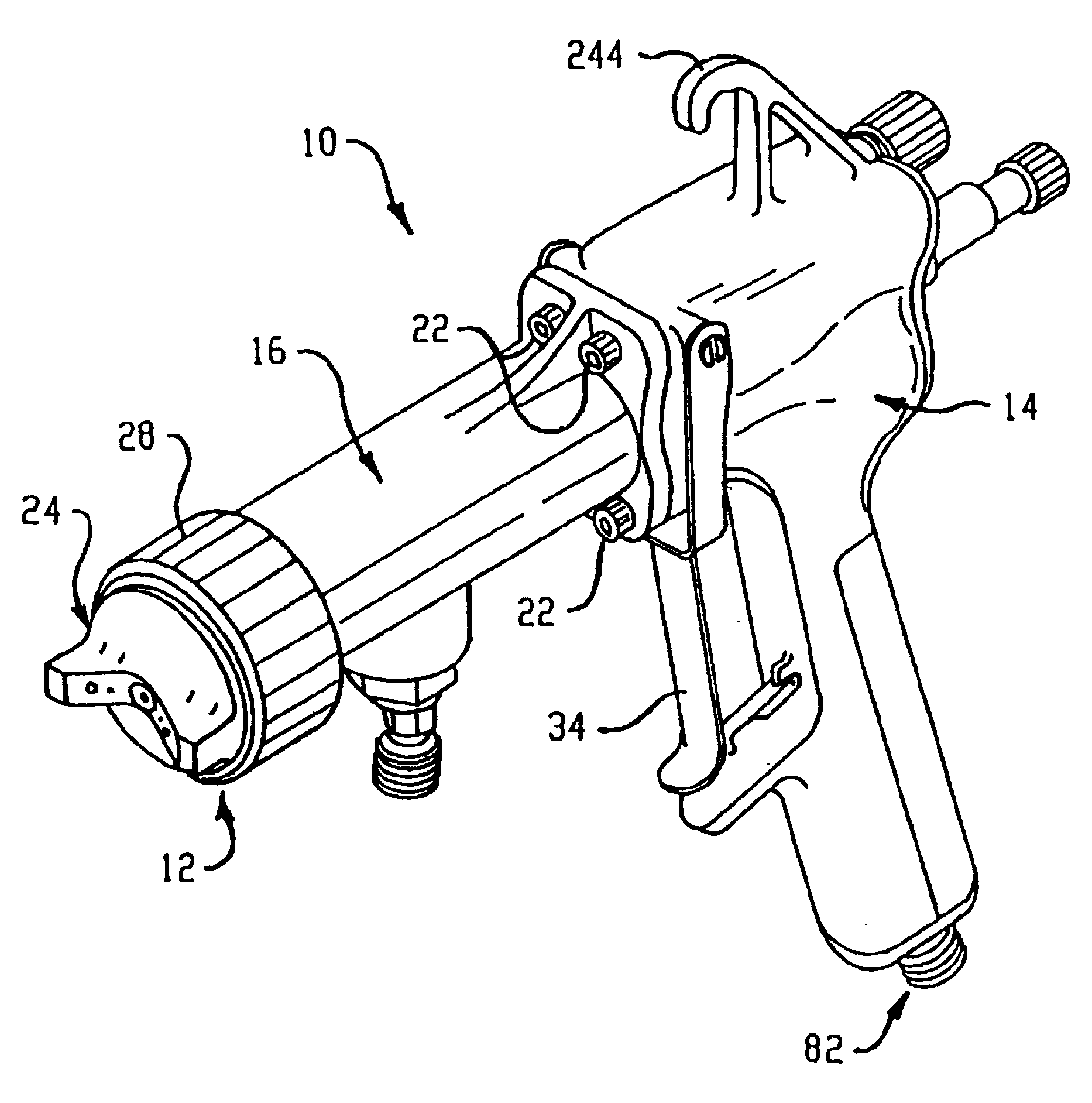

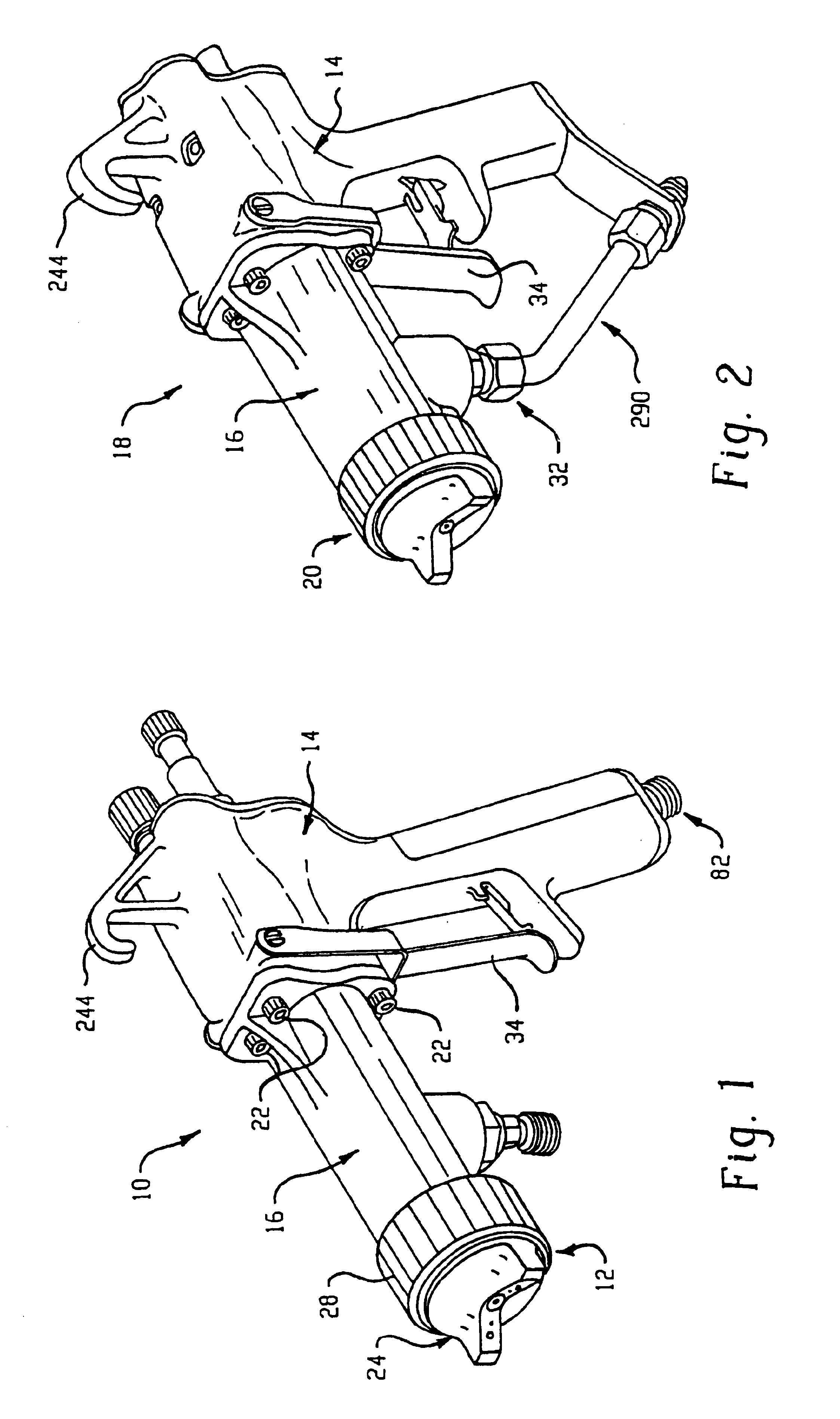

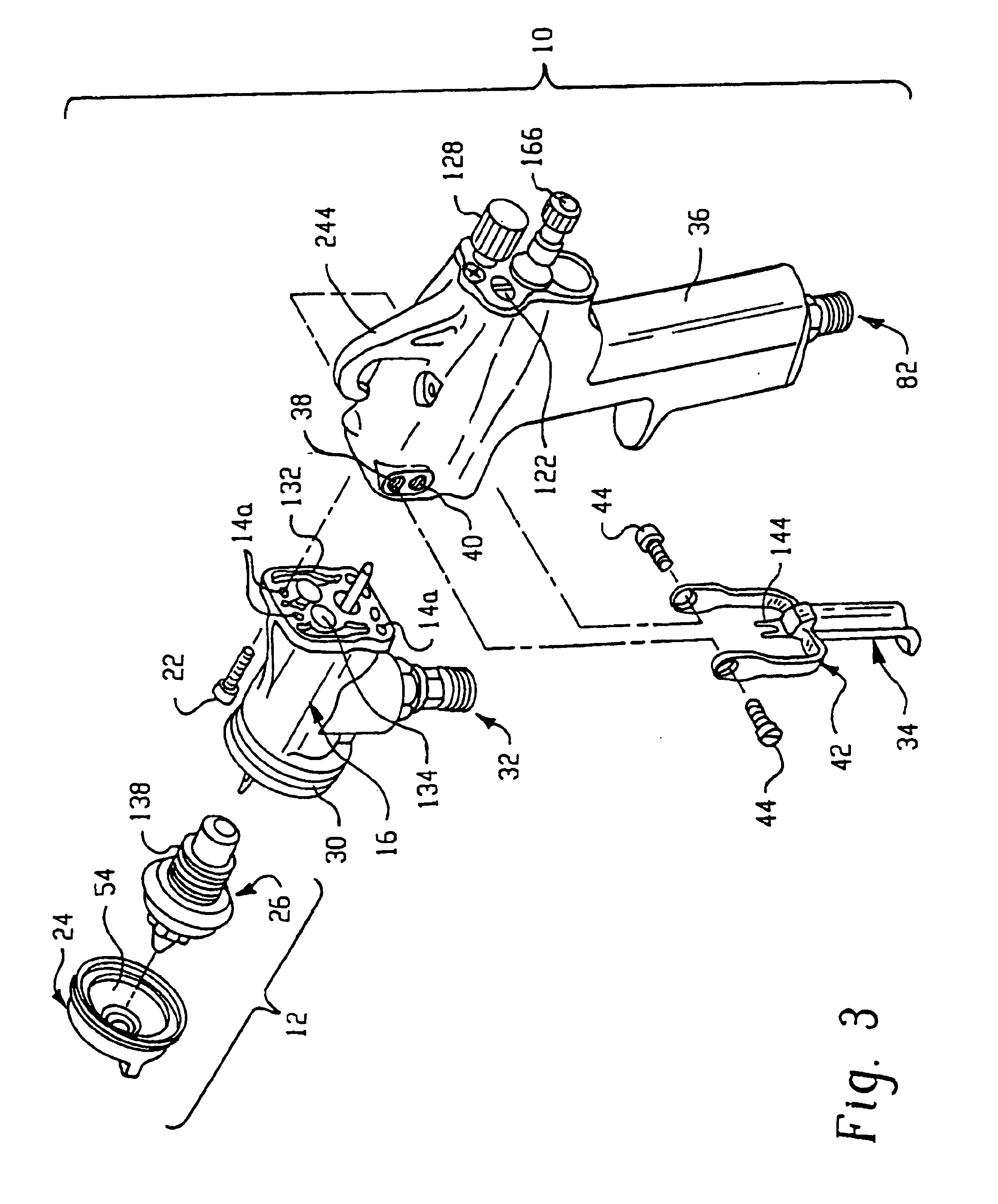

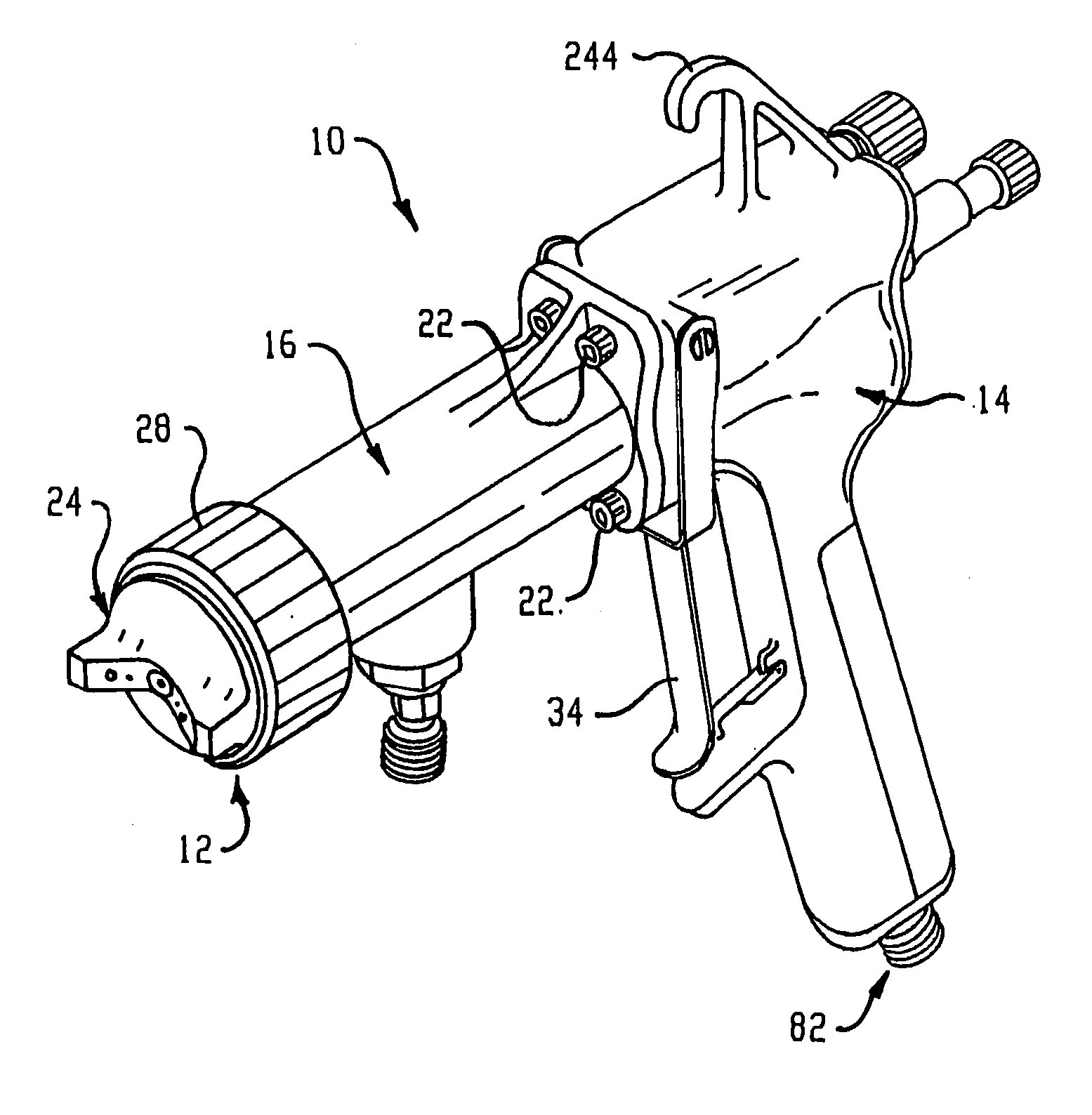

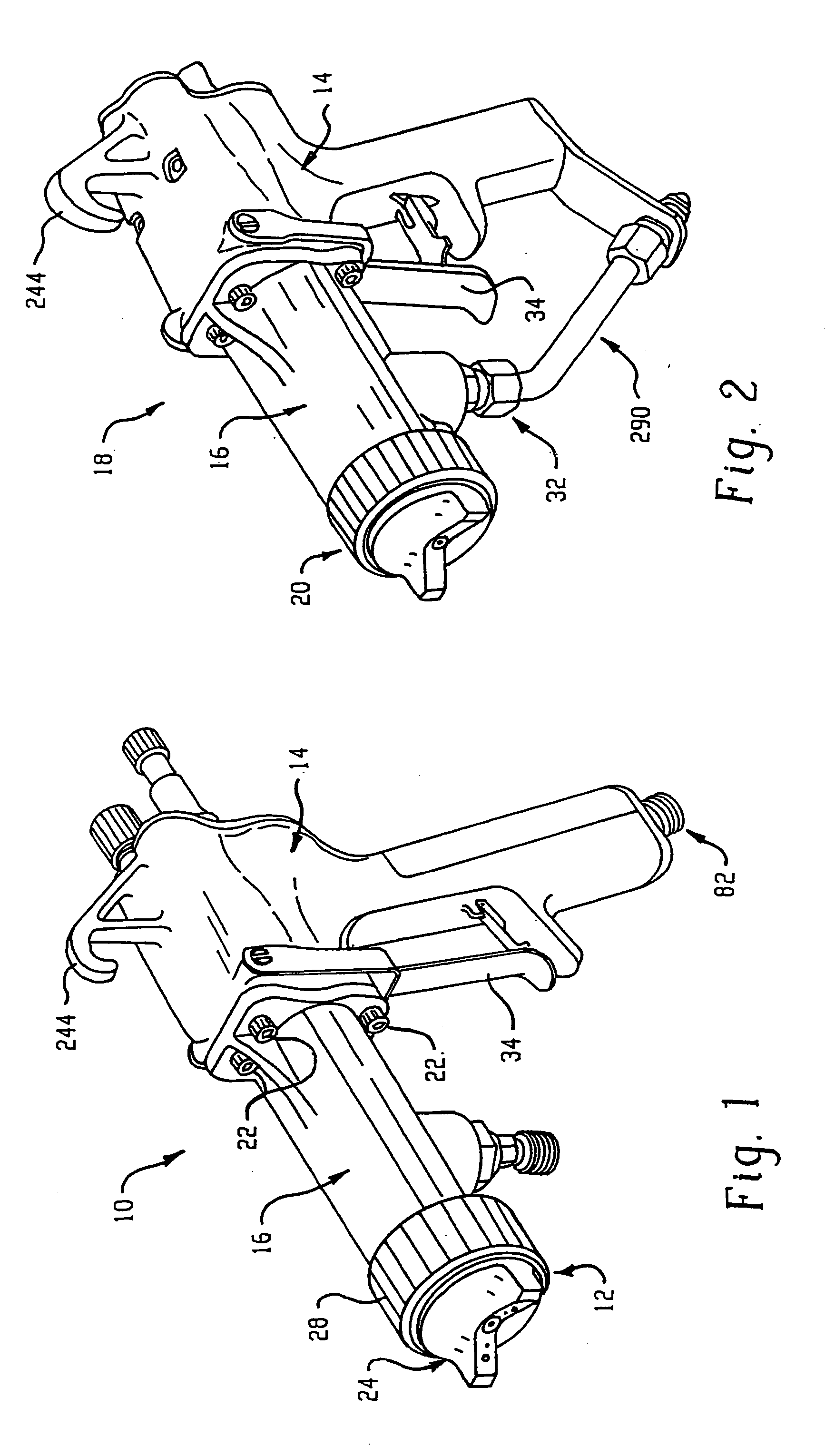

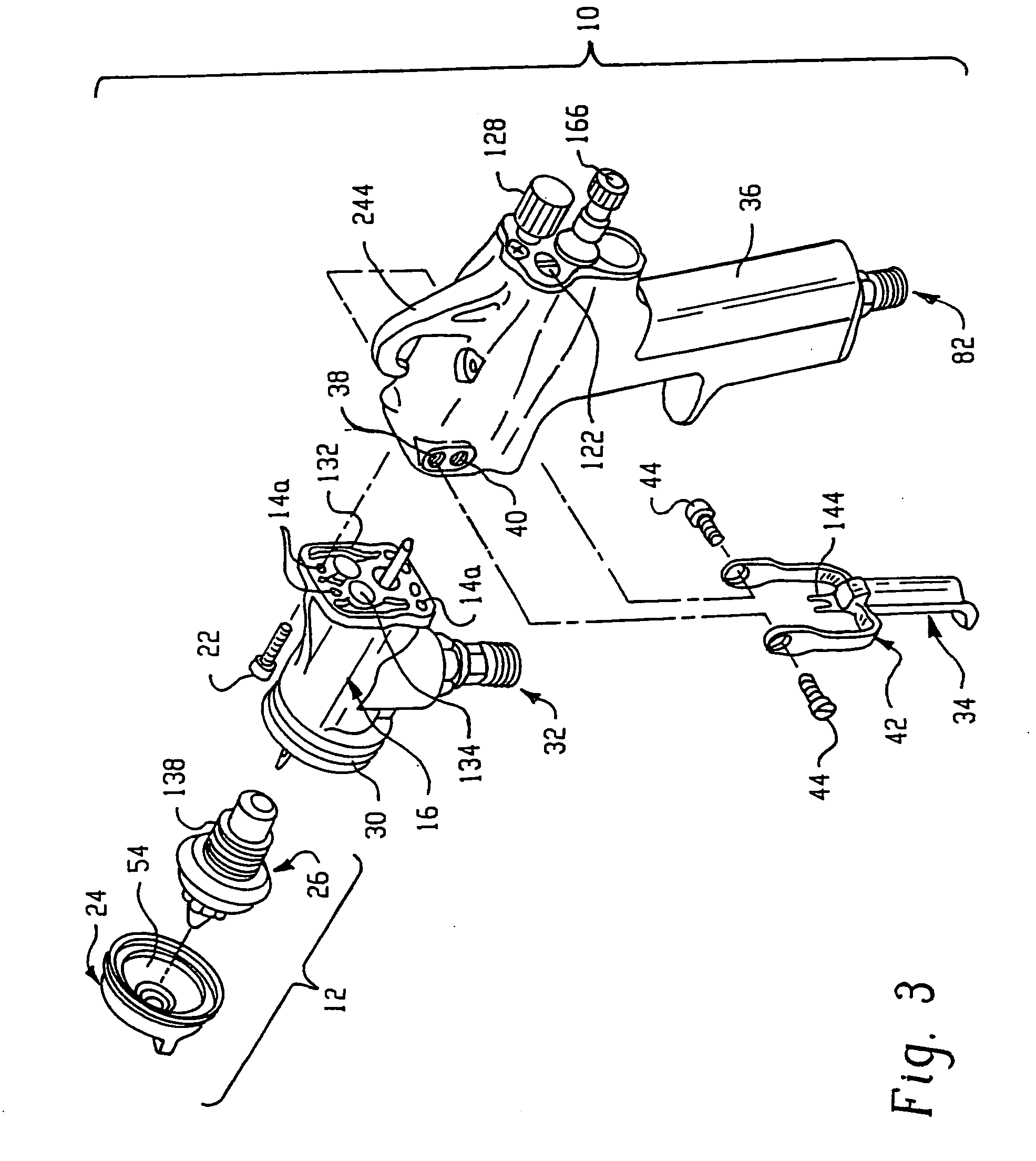

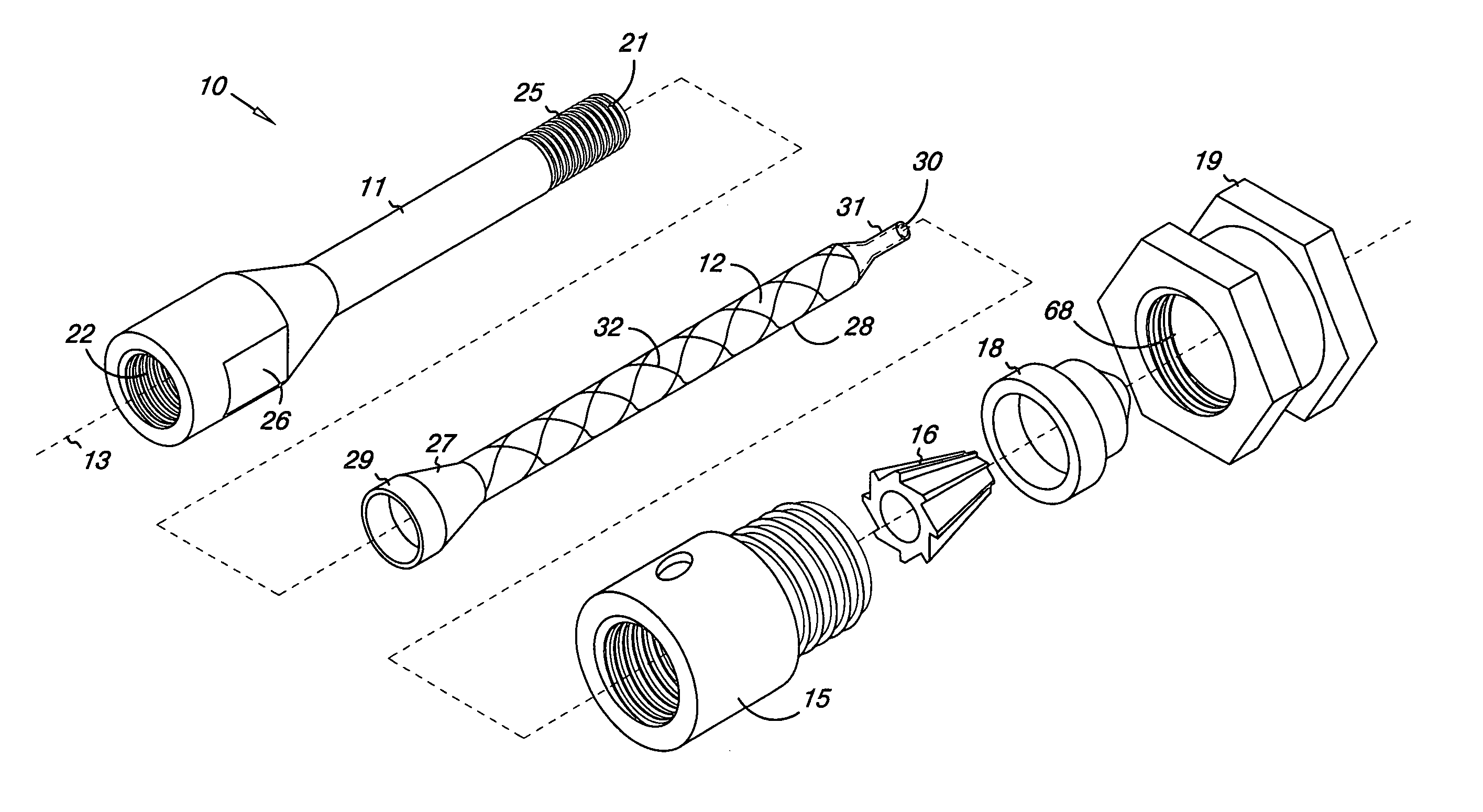

Spray gun having improved fluid tip with conductive path

InactiveUS6877681B2Reduce operator fatigueImprove ease of useBurnersSpraying power supplySpray nozzleEngineering

A modular spray gun that can be configured and built to operate using a selectable spray process. The modular spray gun includes a gun body, an extension and a selectable spray atomizing component. The basic gun body and extension are used to configure a spray gun that can operate as an air spray gun, an airless spray gun, an AAA gun or an HVLP spray gun. The modular extension can be selected to allow circulating or non-circulating operation. The modular extension also permits a variety of spray nozzle assemblies to be mounted thereon depending on the selected spray process to be used with the specific gun. The modular gun body allows selective connection of an atomizing air supply and additional components specific to a particular spray process. An indicator device and / or a relief valve is provided for spray guns using an HVLP spray process to provide an indication that the spray gun is in compliance with the maximum nozzle air pressure limit, usually less than 10 psi. A new air valve seal assembly is also provided. The modular gun design can accommodate electrostatic and non-electrostatic versions.

Owner:NORDSON CORP

Electronic cigarette

ActiveUS9603389B2Increase surface areaPromote atomizationTobacco devicesInhalatorsElectronic cigaretteEngineering

An electronic cigarette is provided, which includes: a housing, a liquid reservoir, and an atomizer assembly. The housing has a chimney formed therein; the liquid reservoir is used for storing liquid; the atomizer assembly received in the housing. The atomizer assembly includes a heating plate capable of absorbing liquid. An outer surface of the heating plate is in contact with the air in the chimney.

Owner:SHENZHEN SMOORE TECH LTD

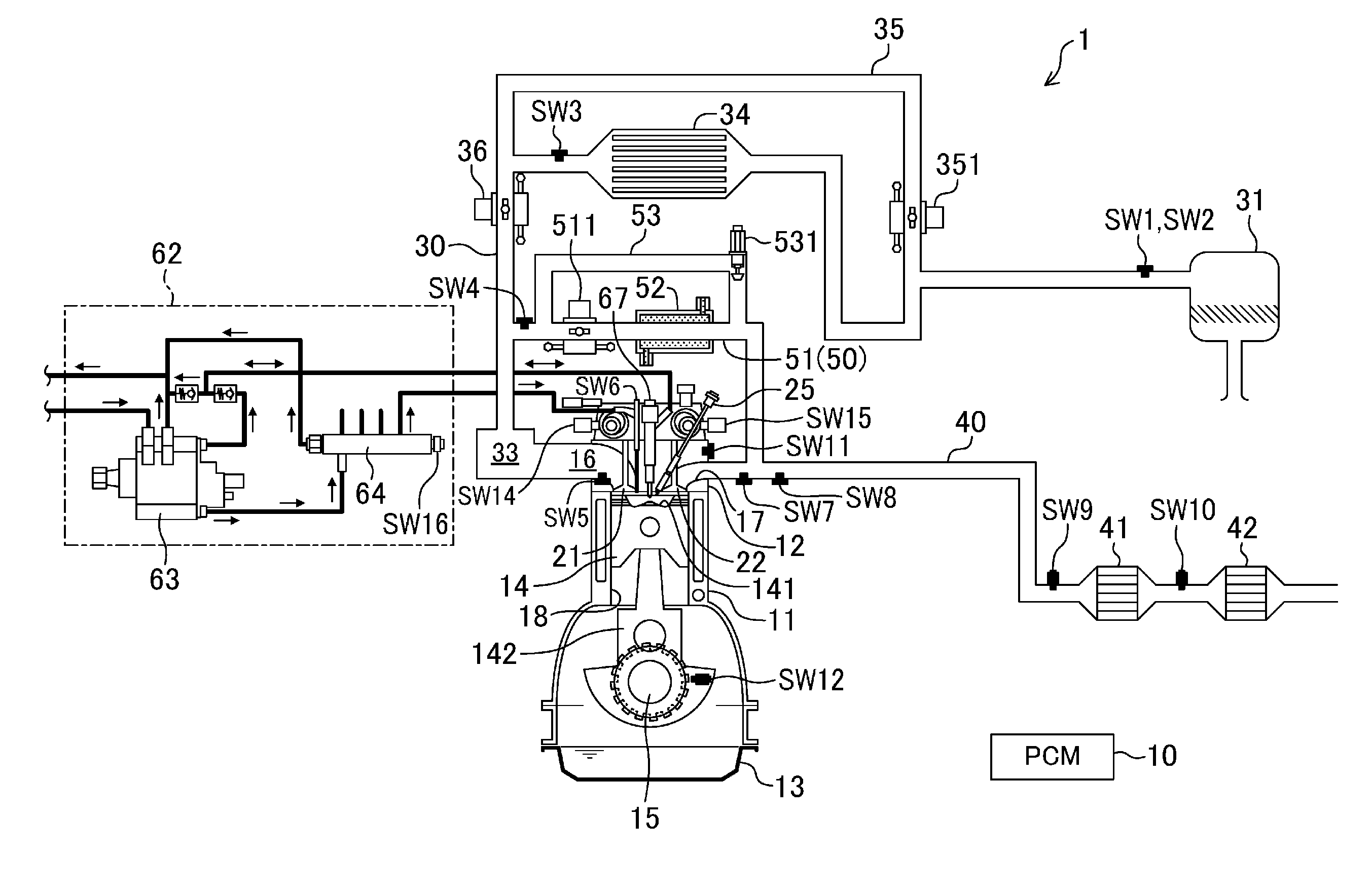

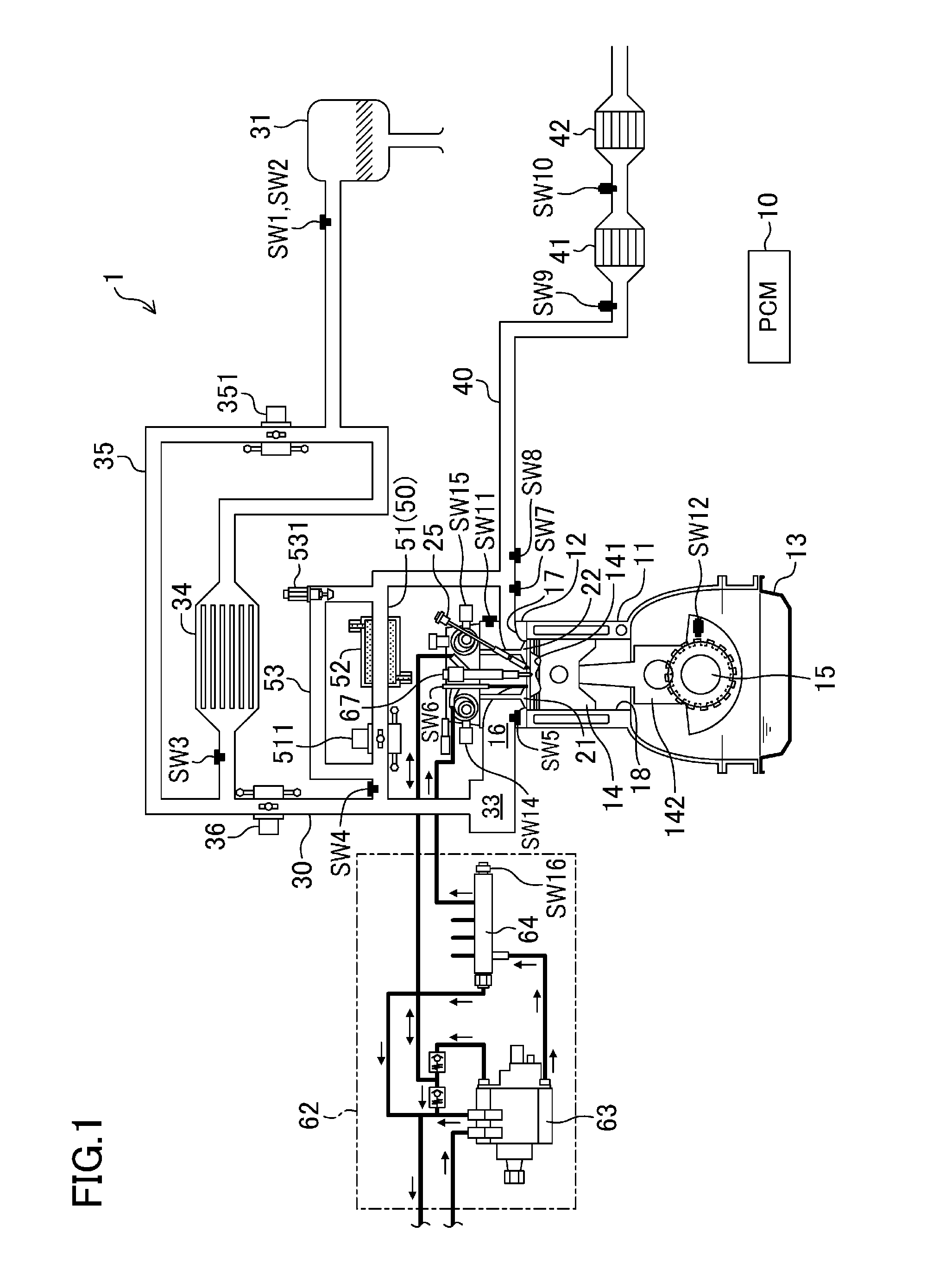

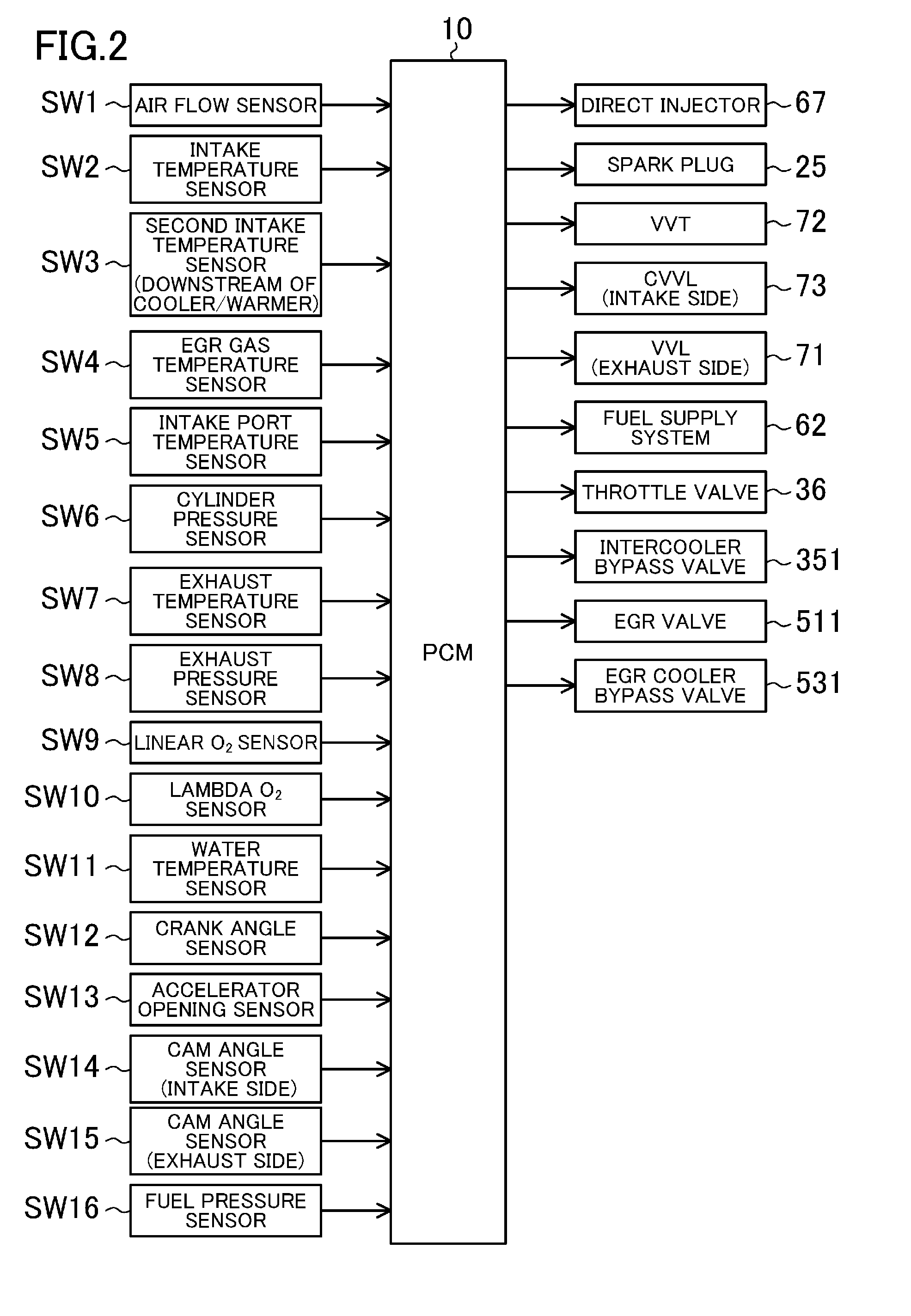

Spark-ignition direct-injection engine

ActiveUS20150114342A1Promote atomizationShorten the overall cycleElectrical controlInternal combustion piston enginesLow loadHigh load

A controller injects fuel into a cylinder at a high fuel pressure of 30 MPa or higher, at least in a period between a terminal stage of a compression stroke and an initial stage of an expansion stroke when an operating mode of an engine body is at least in a first specified sub-range of a low load range, and at least in a second specified sub-range of a high load range. The controller sets an EGR ratio in the first specified sub-range to be higher than an EGR ratio in the second specified sub-range, and advances start of fuel injection in the first specified sub-range to start of fuel injection in the second specified sub-range.

Owner:MAZDA MOTOR CORP

Polyurethane-polyacrylacid ester interpenetrating network polymer, preparation and use thereof

The invention relates to a polyurethane-polyacrylic ester interpenetrating network polymer and a preparation method and the application thereof. The following steps are comprised: self-emulsifying anionic polyurethane water dispersoid containing carbon-carbon double bonds are synthesized through a step addition polymerization method; the synthesized polyurethane water dispersoid is used as seeding emulsion and polymer surface active agent; in-situ emulsion polymerization is carried out on acrylic ester monomer in an emulsification system by using dropwise adding evocating agents, so that the pre-emulsifying acrylic monomers in the system can be polymerized and (or) cross-linked on the inner part and the surface of seeding emulsion particles, and then the polyurethane-polyacrylic ester interpenetrating network polymer emulsion can be obtained; after dried, emulsion powder which has good water resisting property and cohesiveness when re-dispersed in water is obtained; the polyurethane-polyacrylic ester interpenetrating network polymer not only can be used with inorganic cementing materials such as cement, white lime or plaster for manufacturing overcoating mortar, pointing-joint agents, plastering agents and building bonding agents, but also can be independently used as film forming binder for preparing dry powder emulsion coating.

Owner:SOUTH CHINA UNIV OF TECH

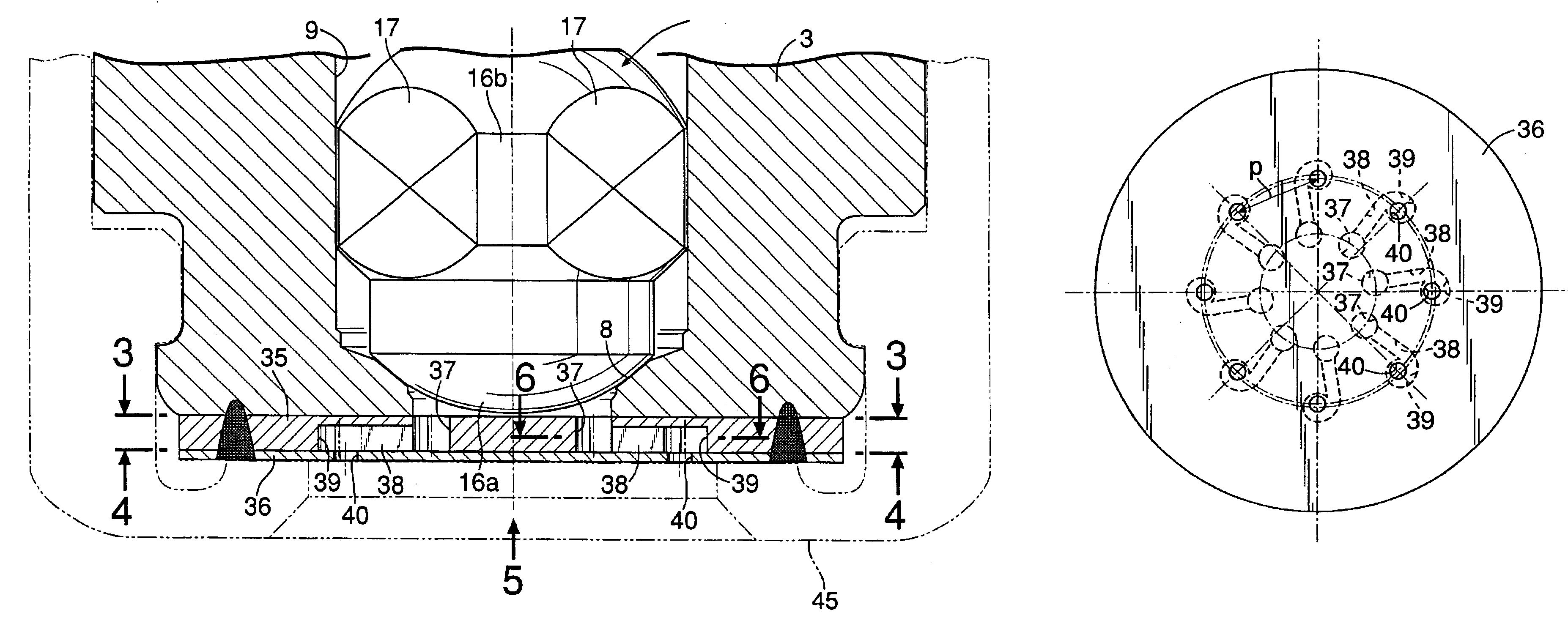

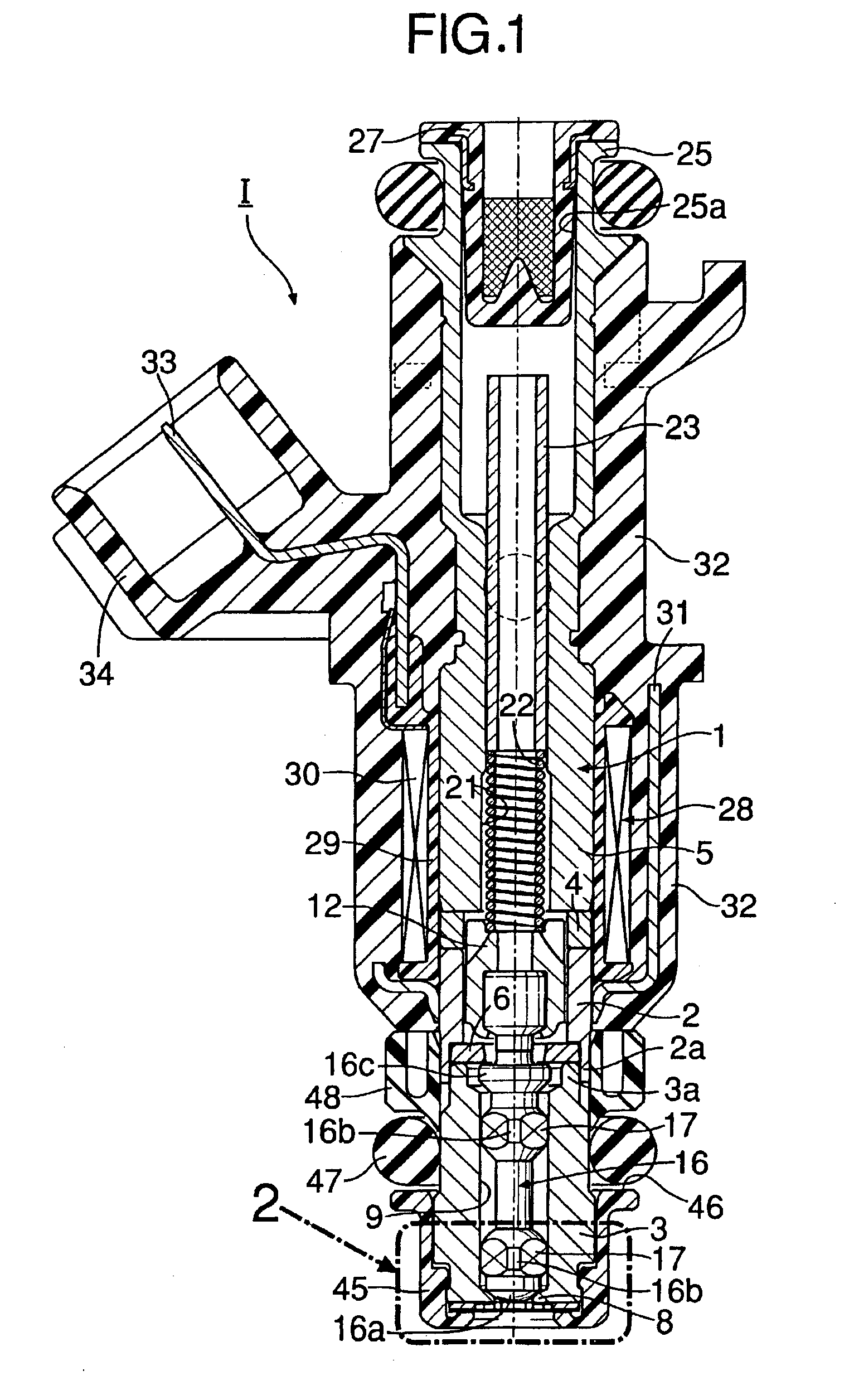

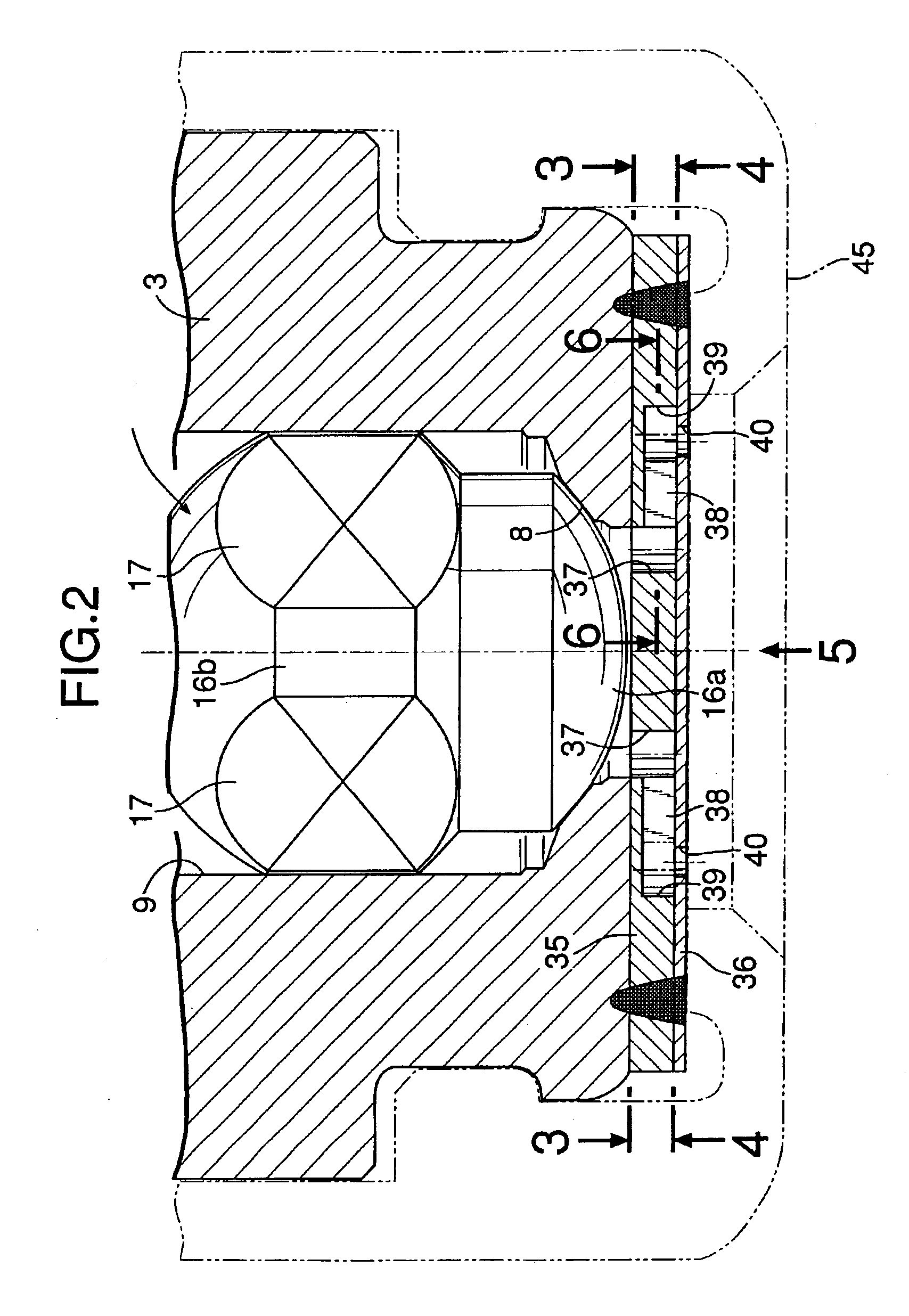

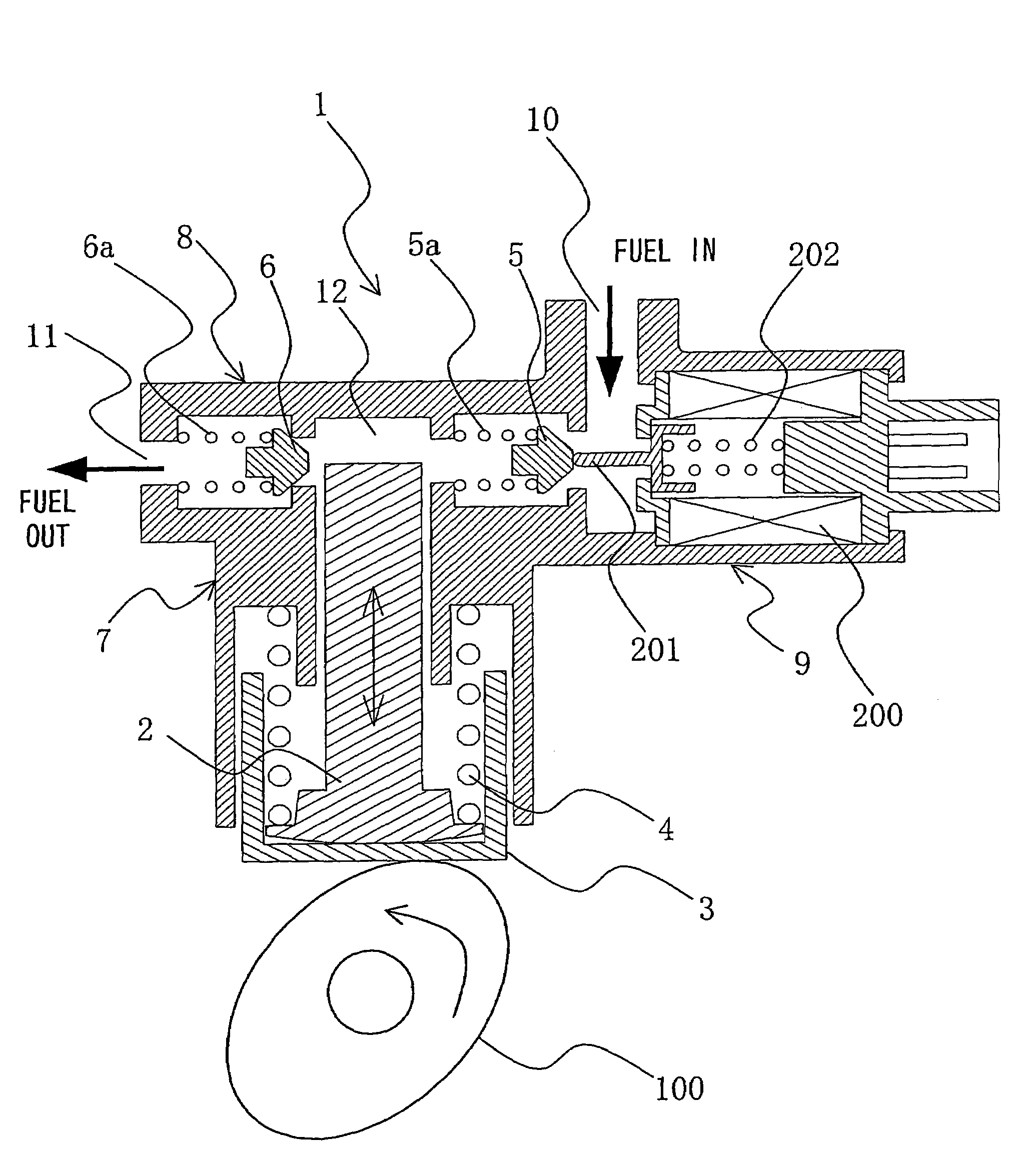

Fuel injection valve

ActiveUS6854670B2Promote atomizationHigh particle densityBurnersSpray nozzlesInjectorMembrane configuration

A fuel injection valve includes a valve seat member, and an injector plate which is coupled to a front end face of the valve seat member and has a plurality of fuel injection orifices disposed about an axis of the valve seat member to communicate with a valve seat. Swirling means for swirling a fuel injected from each of the fuel injection orifices is provided in at least one of the valve seat member and the injector plate. The plurality of fuel injection orifices are disposed so that liquid membrane portions of adjoining hollow conical fuel spray forms formed by the fuel injected from the fuel injection orifices collide with one another. Thus, the atomization of the injected fuel can be further promoted, and a coalesced fuel spray form having a fuel particle density higher in a central zone and lower in an outer peripheral zone can be formed.

Owner:HITACHI ASTEMO LTD

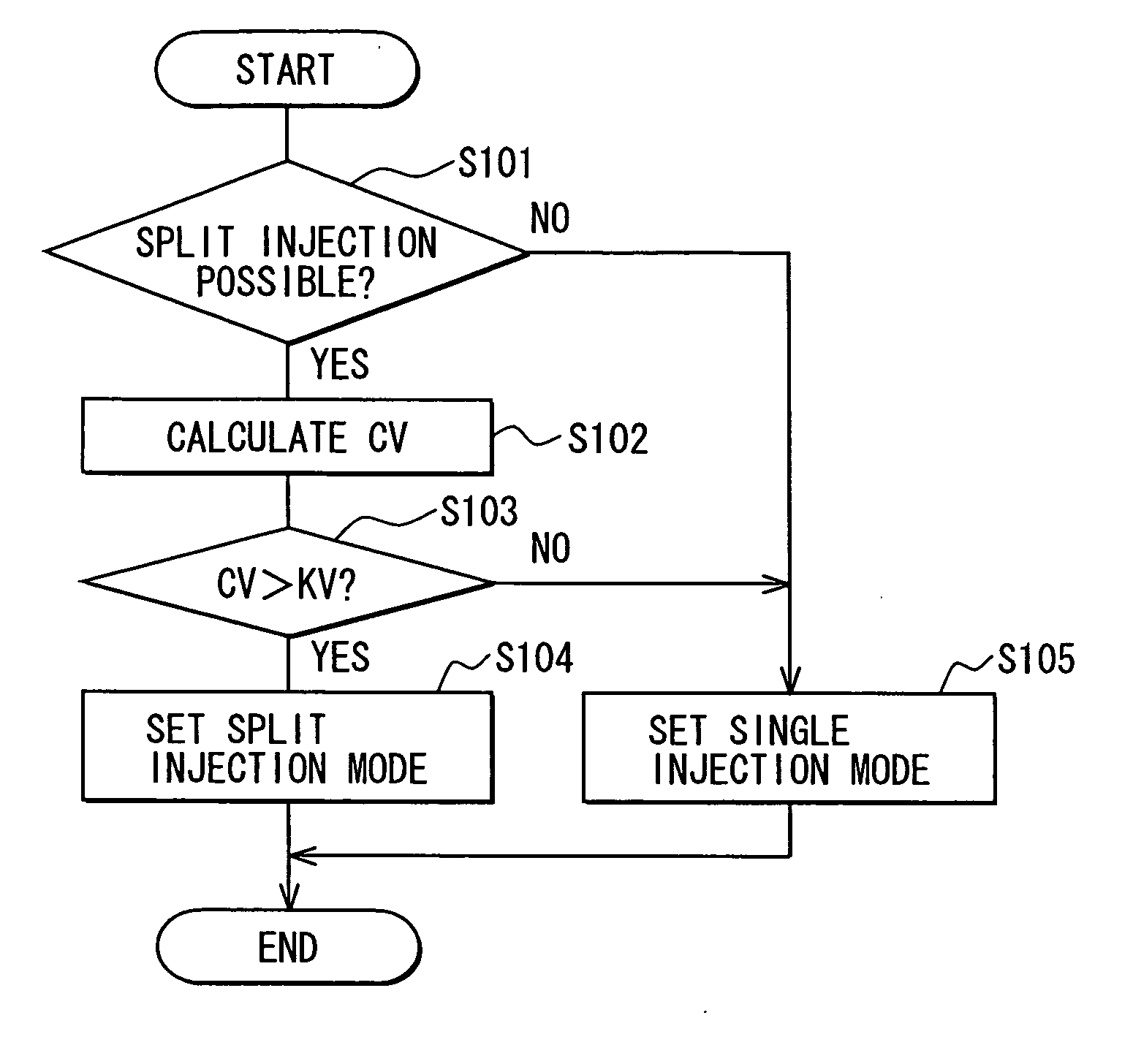

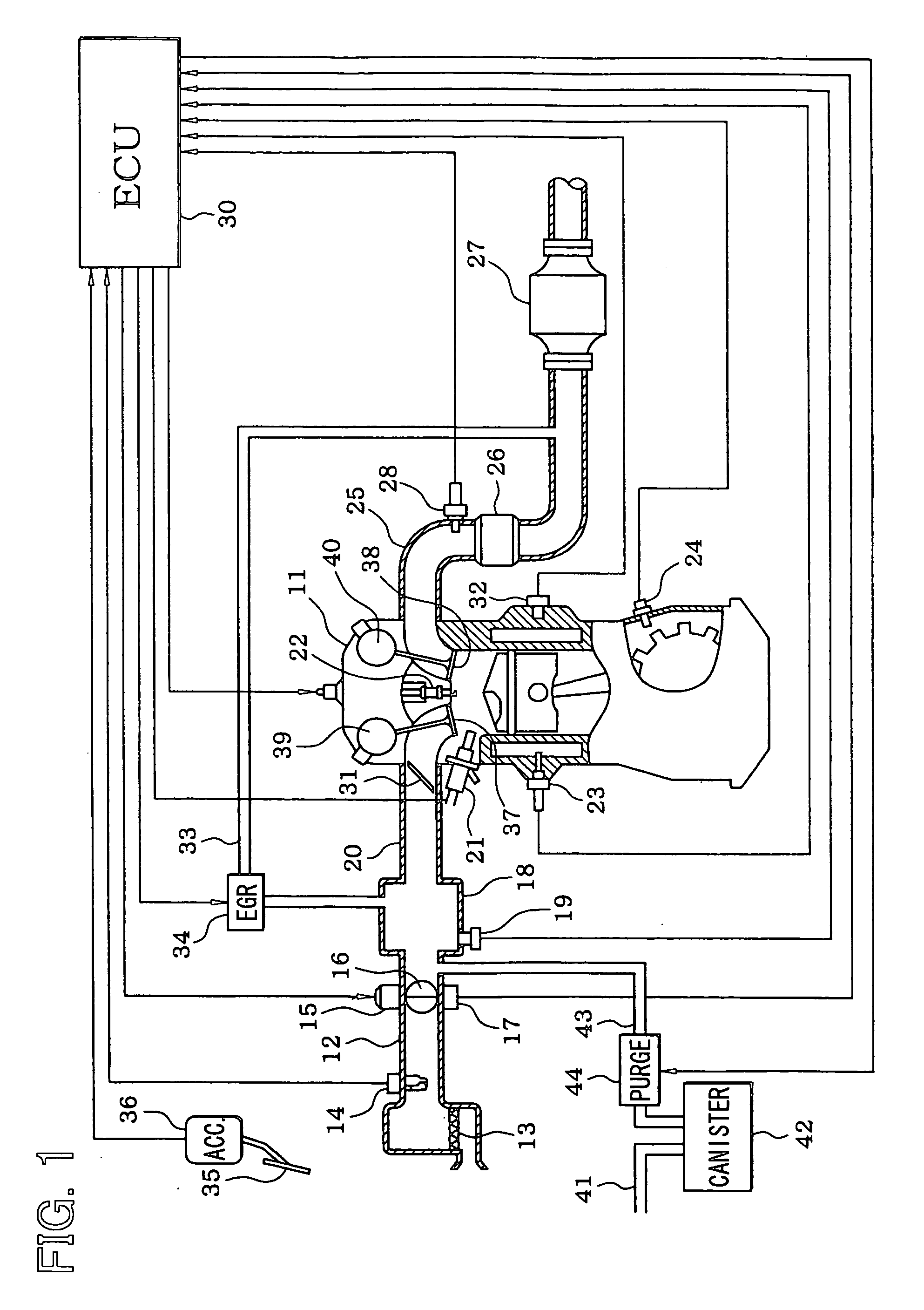

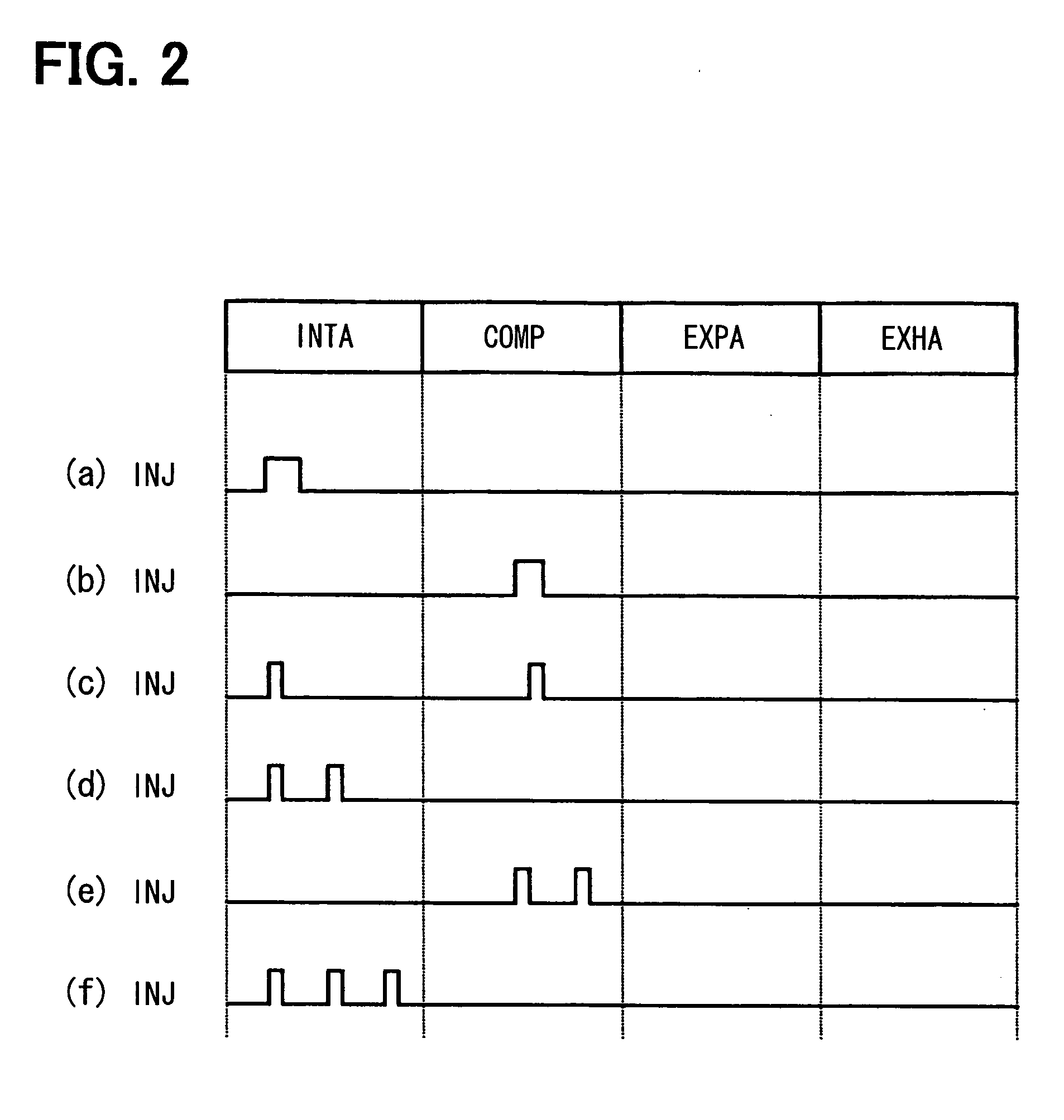

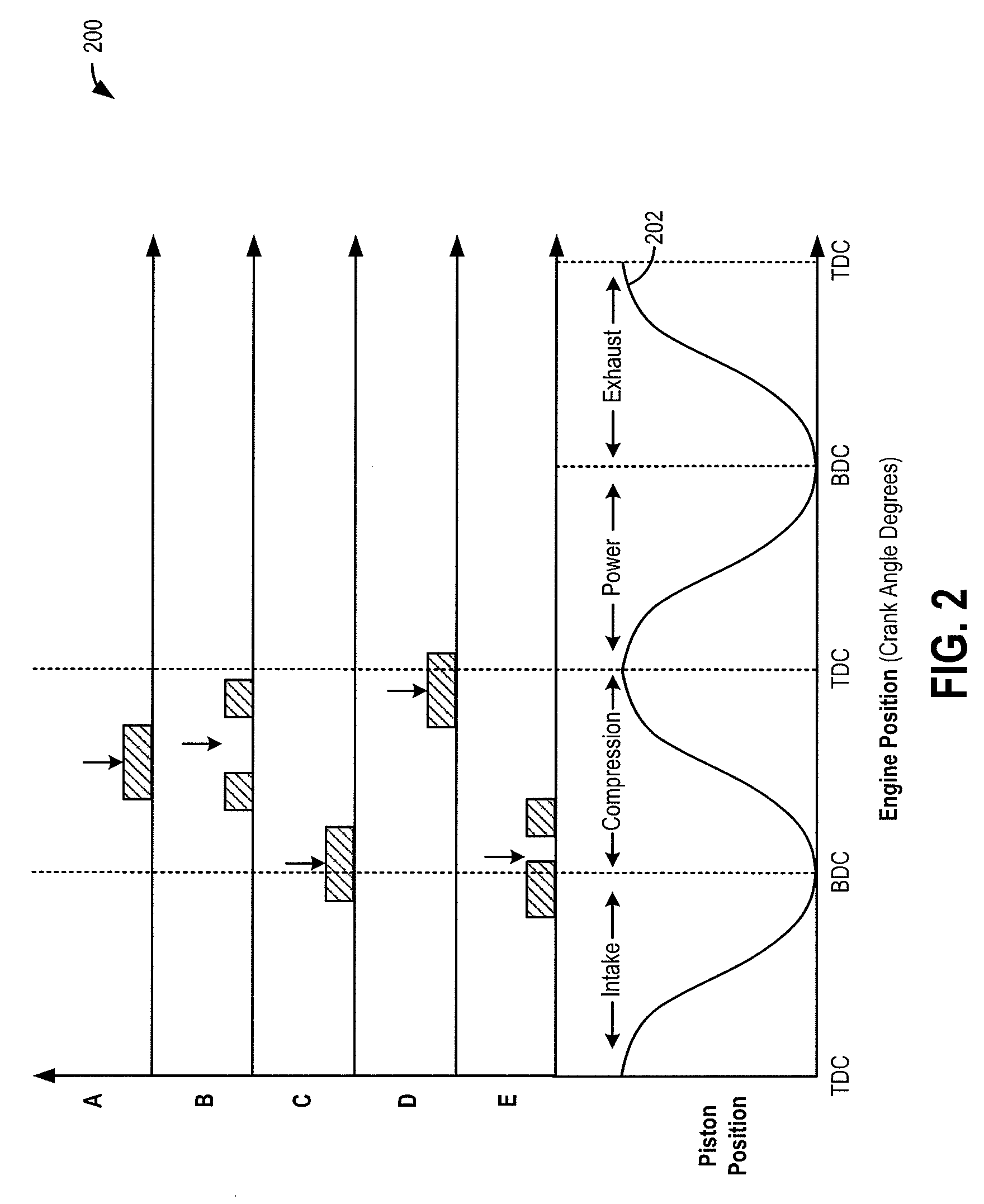

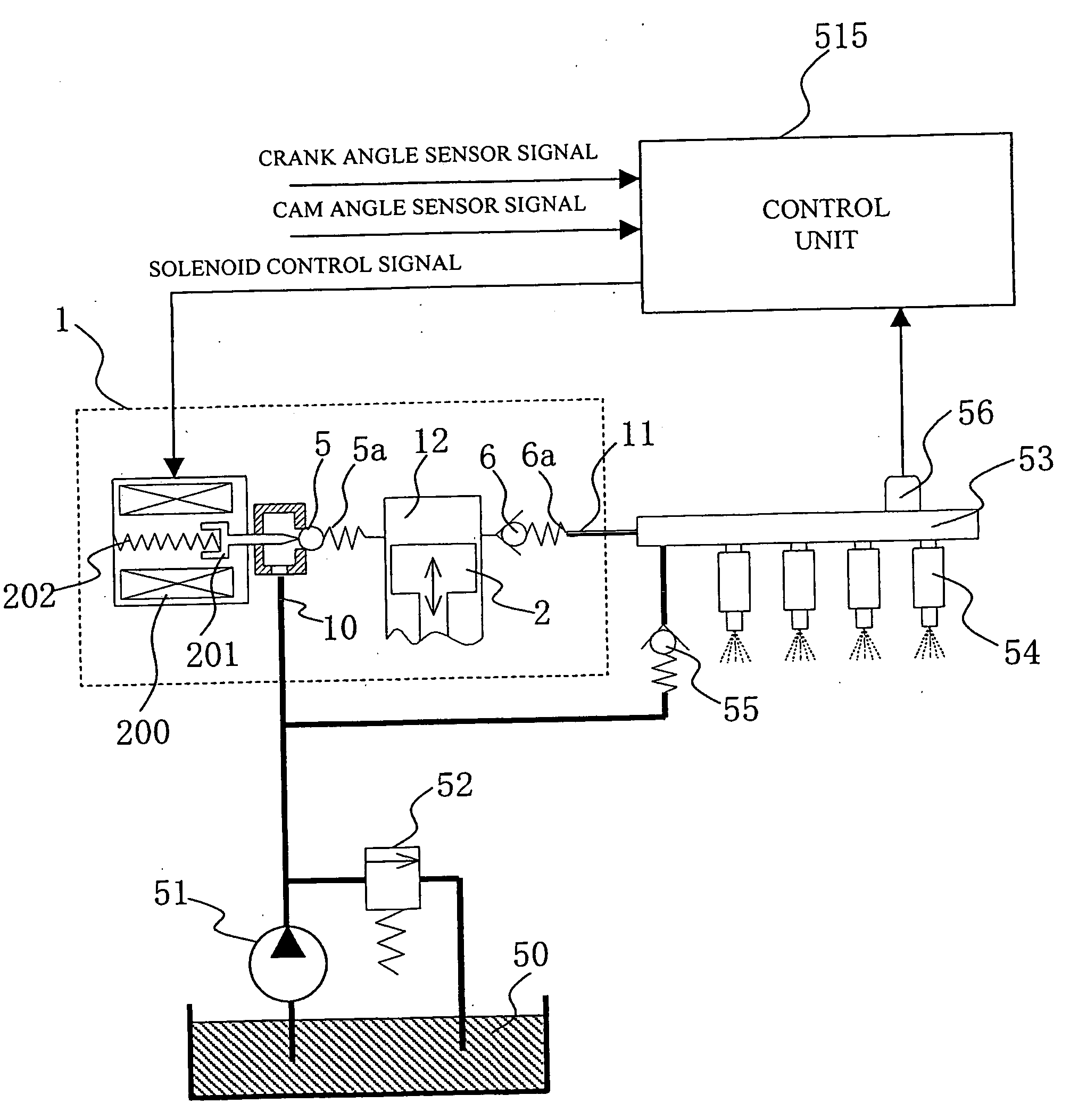

Fuel injection controller for in-cylinder injection engine

InactiveUS20060243243A1Improve the state of combustionEmission reductionElectrical controlInternal combustion piston enginesMultiple injectionCombustion

A fuel injection controller of an in-cylinder injection engine determines that a combustion state has deteriorated and executes a split injection for injecting fuel in split amounts into each cylinder in multiple injection events in a cycle of the cylinder if it is determined that a combustion fluctuation is greater than a predetermined determination value during operation of the engine. The fuel injection controller increases a ratio of an injection amount of the first injection event in the split injection and lengthens an injection interval between the injection events as the combustion fluctuation increases. Thus, a wet amount of the injected fuel is reduced to expedite atomization of the injected fuel and to homogenize an in-cylinder mixture gas. As a result, the combustion state is improved.

Owner:DENSO CORP

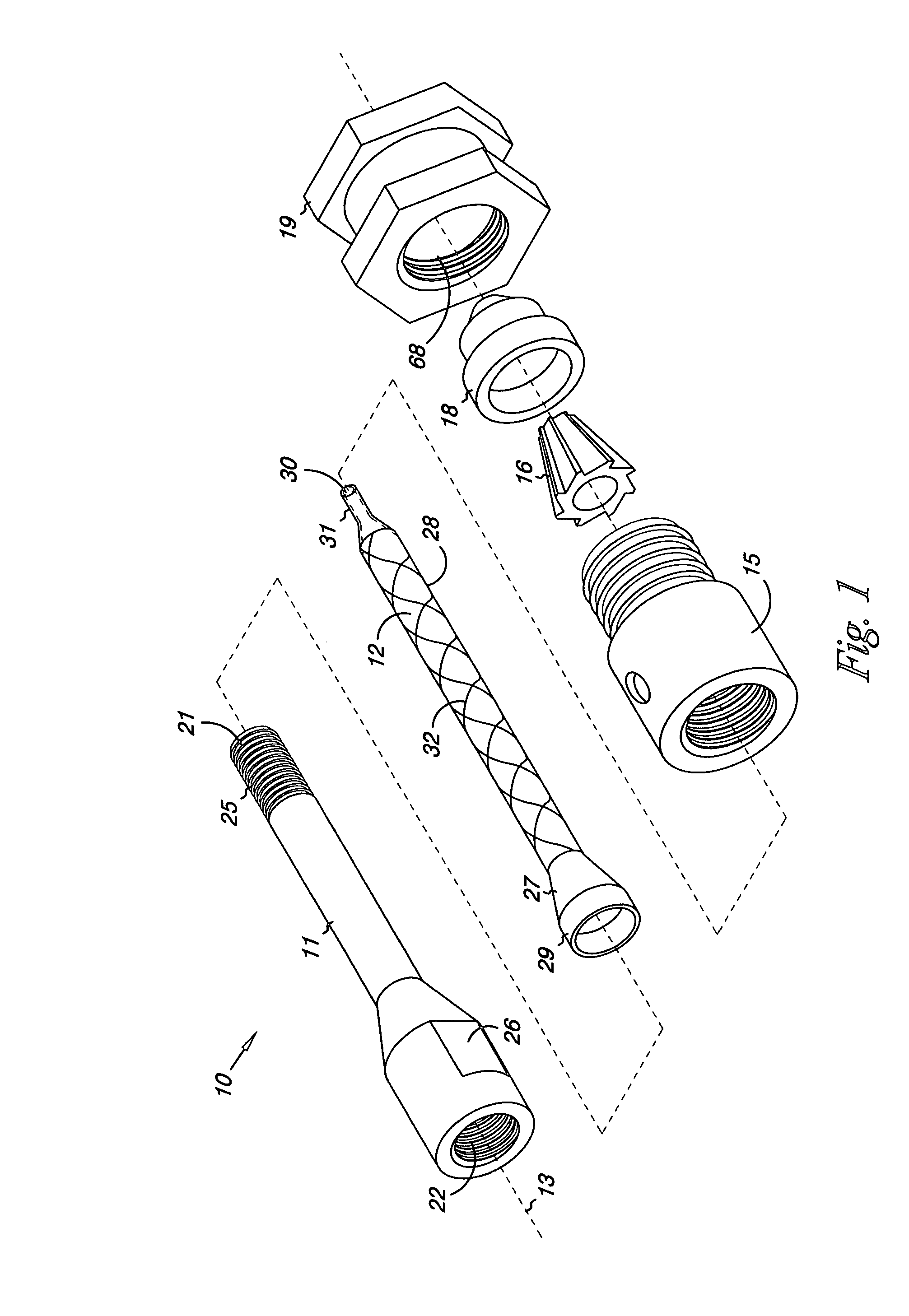

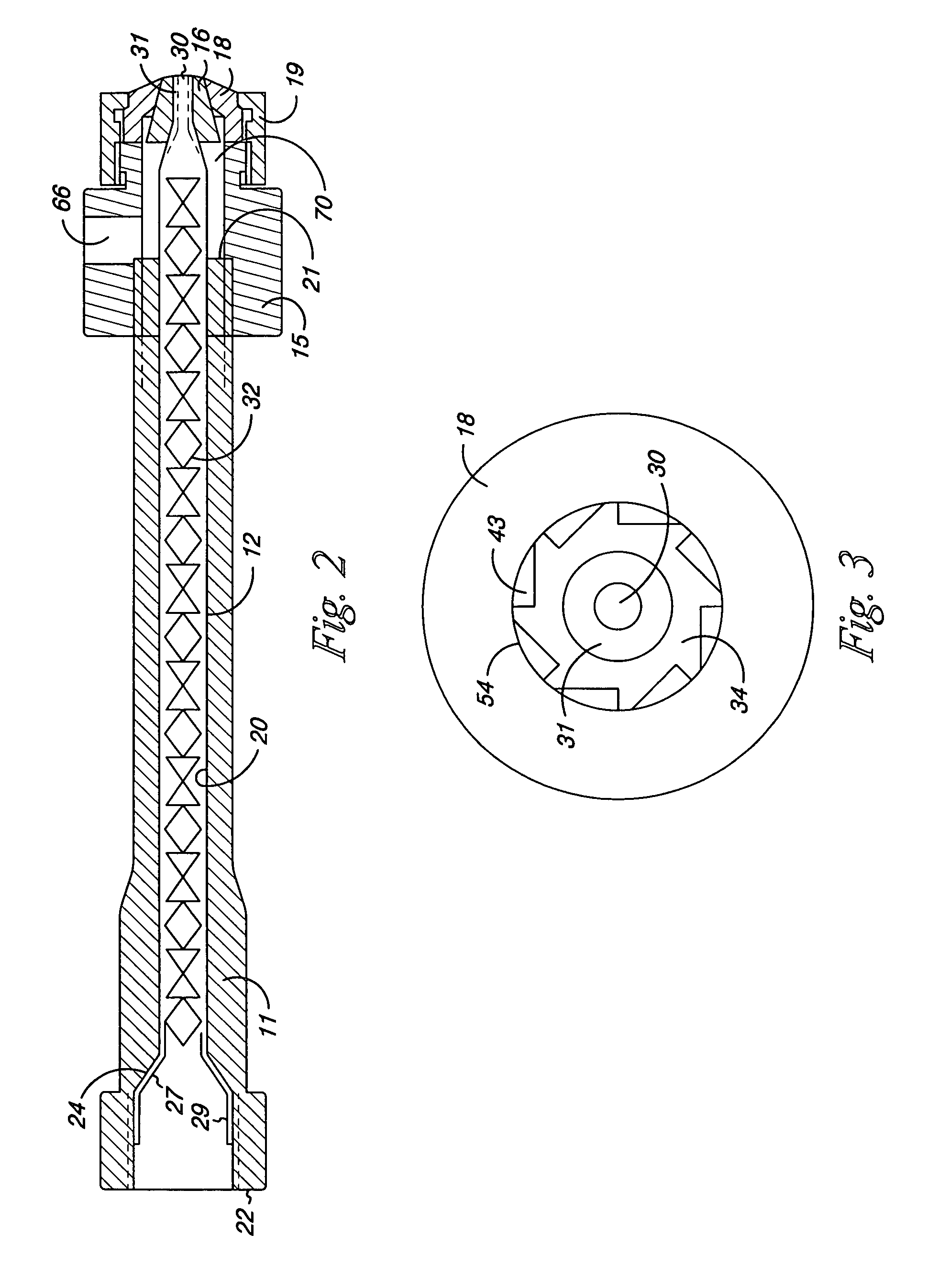

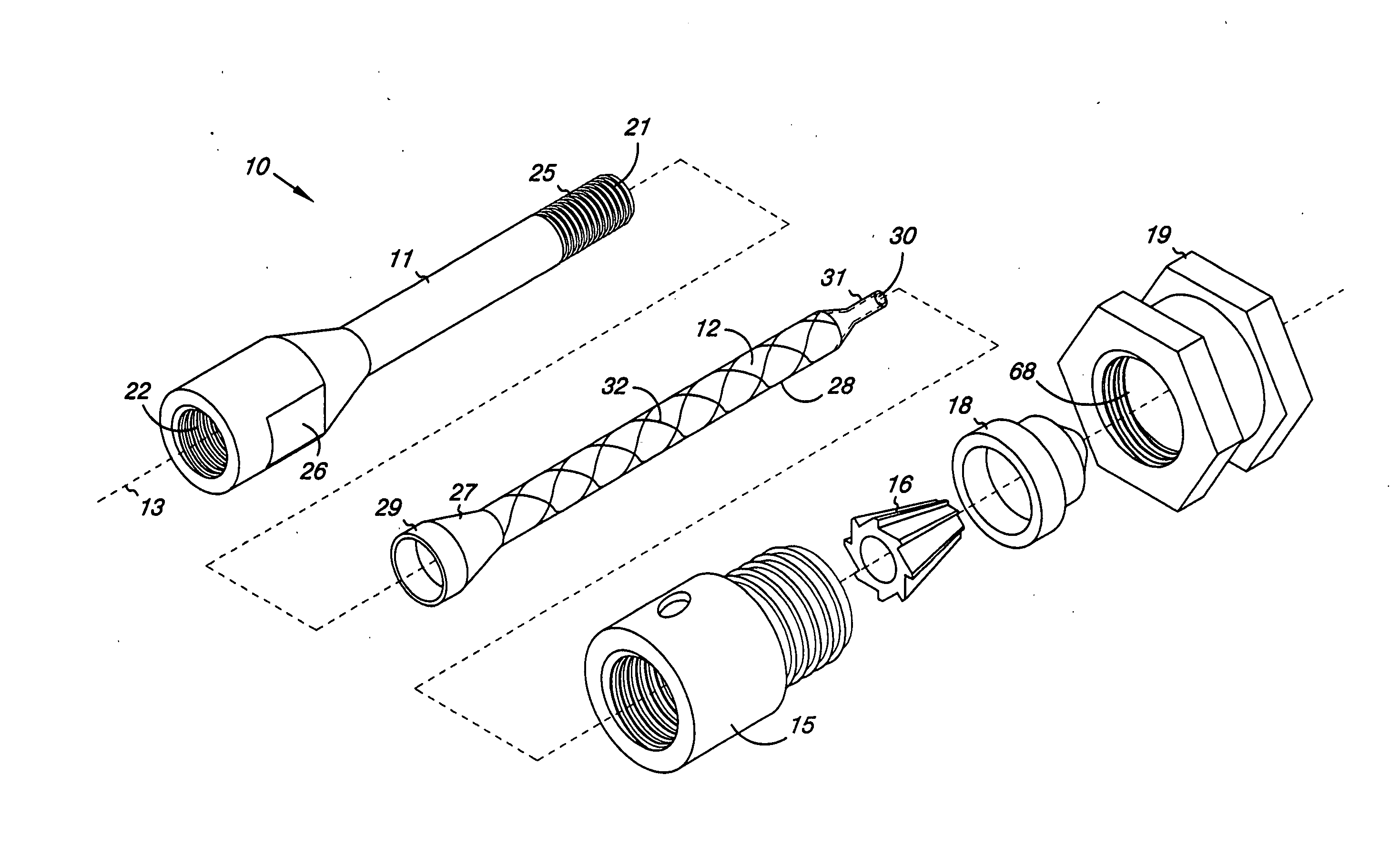

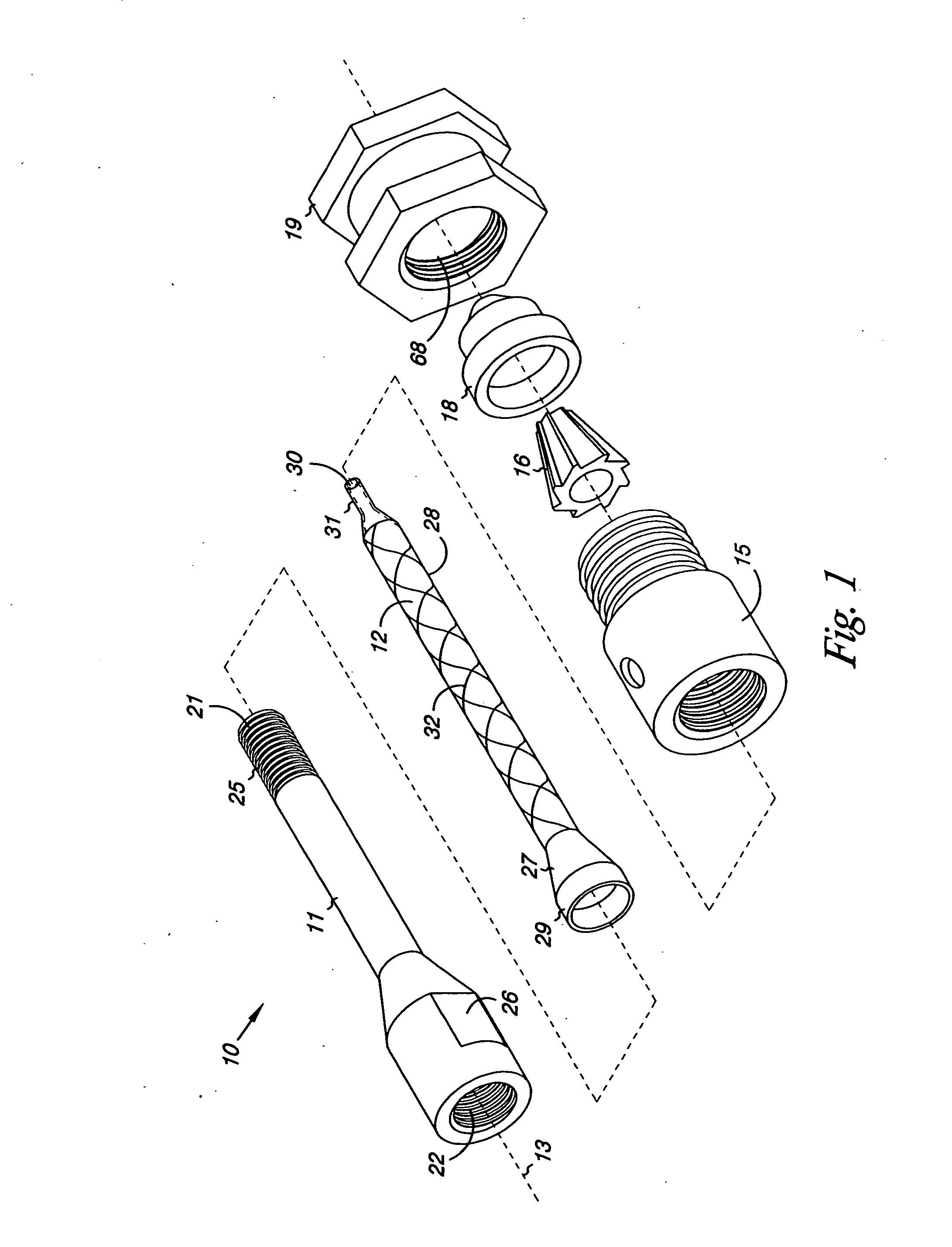

Modular fluid spray gun

InactiveUS20050189445A1Improve modularityPromote atomizationBurnersSpraying power supplySpray nozzleModular design

A modular spray gun that can be configured and built to operate using a selectable spray process. The modular spray gun includes a gun body, an extension and a selectable spray atomizing component. The basic gun body and extension are used to configure a spray gun that can operate as an air spray gun, an airless spray gun, an AAA gun or an HVLP spray gun. The modular extension can be selected to allow circulating or non-circulating operation. The modular extension also permits a variety of spray nozzle assemblies to be mounted thereon depending on the selected spray process to be used with the specific gun. The modular gun body allows selective connection of an atomizing air supply and additional components specific to a particular spray process. An indicator device and / or a relief valve is provided for spray guns using an HVLP spray process to provide an indication that the spray gun is in compliance with the maximum nozzle air pressure limit, usually less than 10 psi. A new air valve seal assembly is also provided. The modular gun design can accommodate electrostatic and non-electrostatic versions.

Owner:HARTLE RONALD J +2

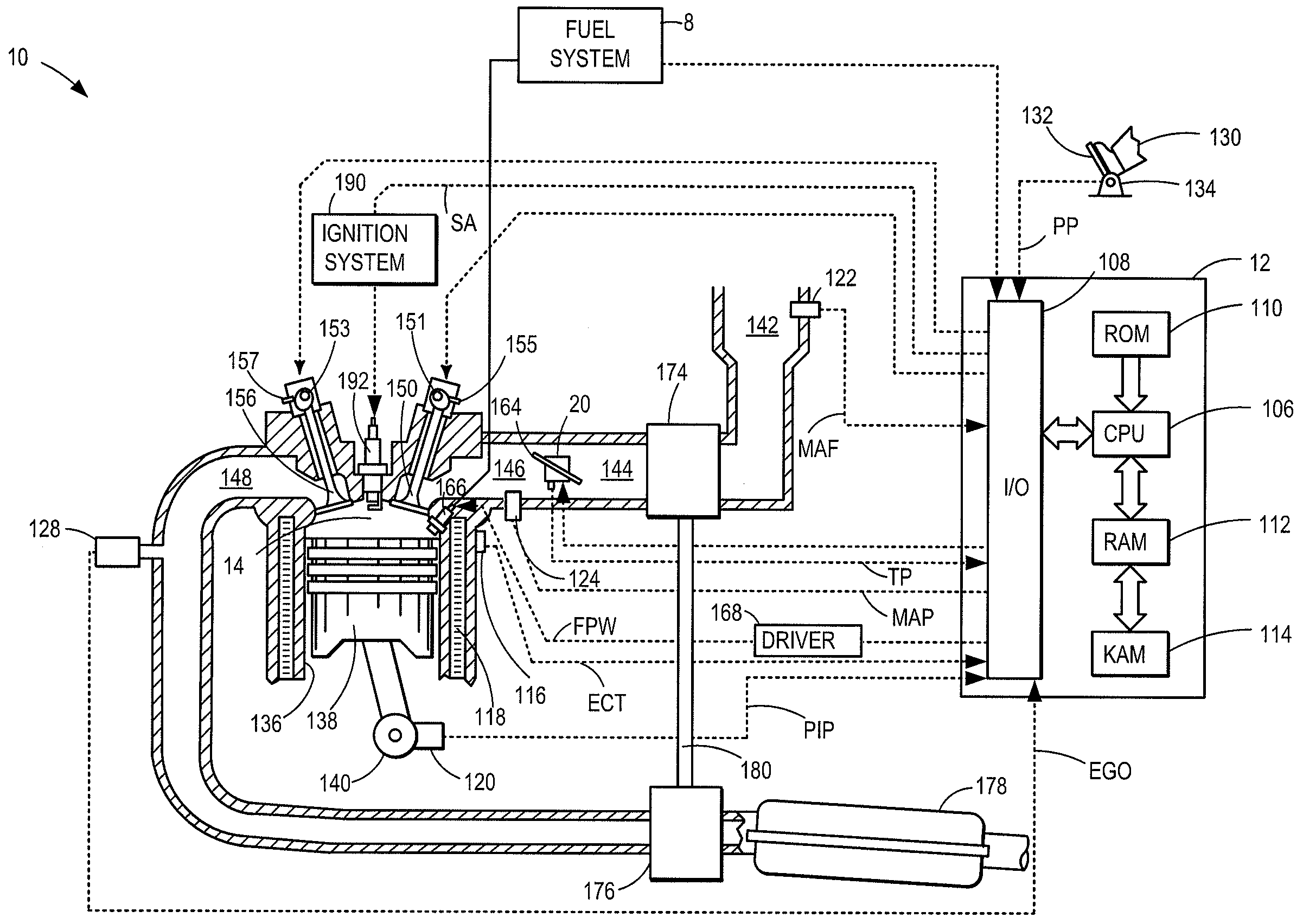

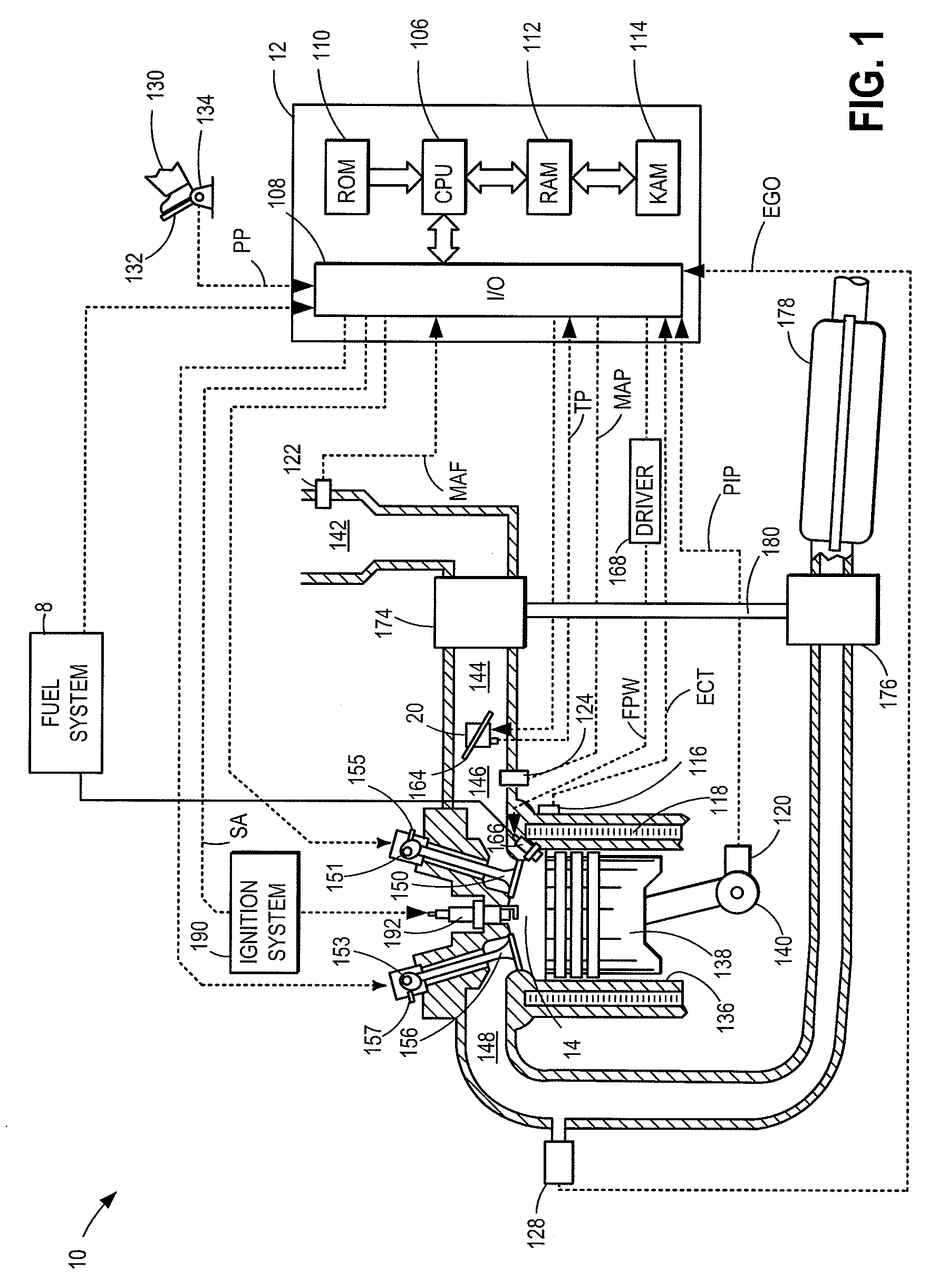

Fuel-Based Injection Control

ActiveUS20100294236A1Improve atomizationIncrease it fuel contentAnalogue computers for vehiclesElectrical controlInjectorFuel injection

Systems and methods of operating an engine, the engine including an injector configured to directly inject fuel into an engine cylinder. One example method comprises, during an engine cold start, performing compression direct fuel injection, and retarding a timing of the compression injection as a fuel alcohol content of the fuel increases.

Owner:FORD GLOBAL TECH LLC

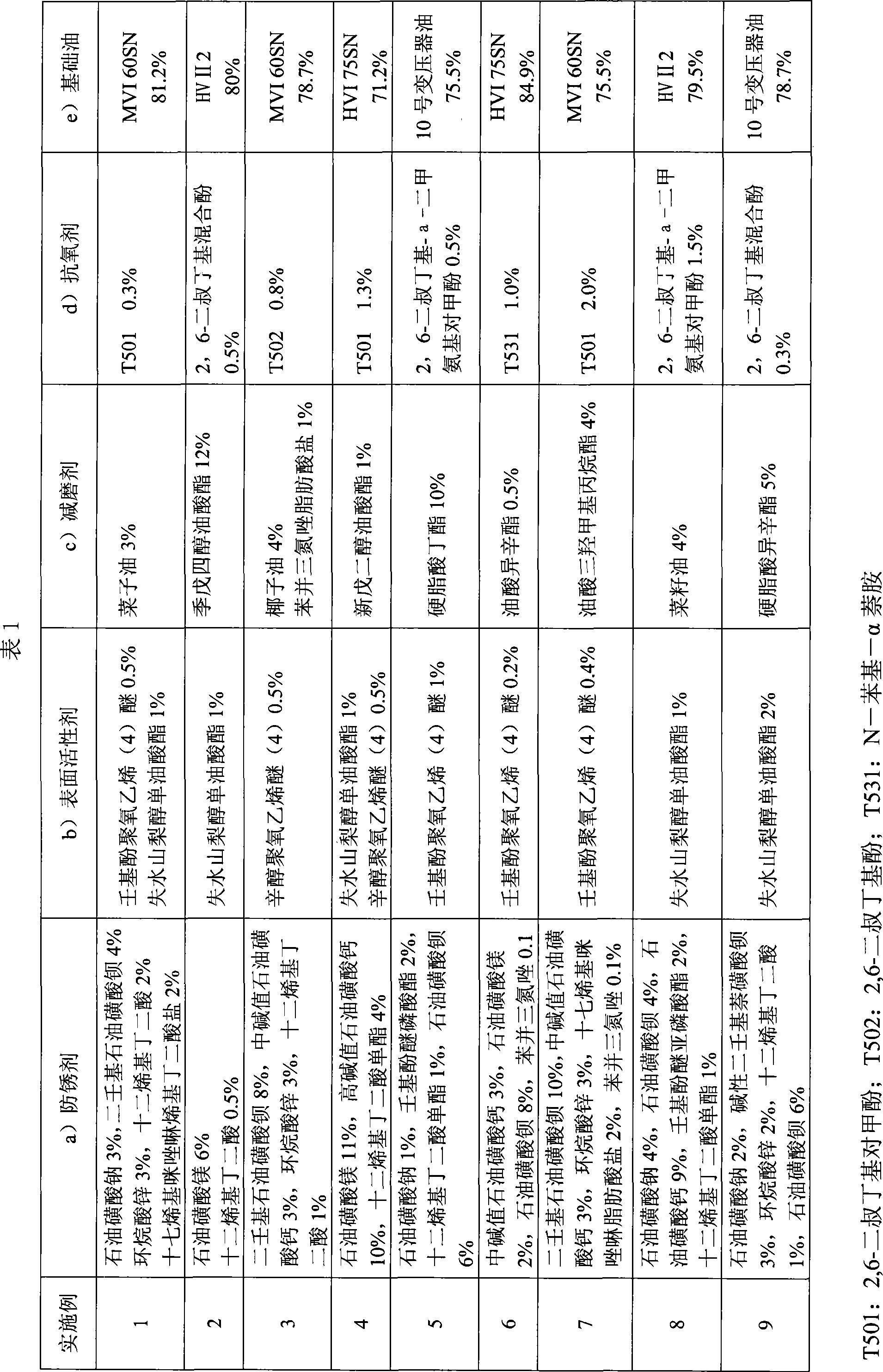

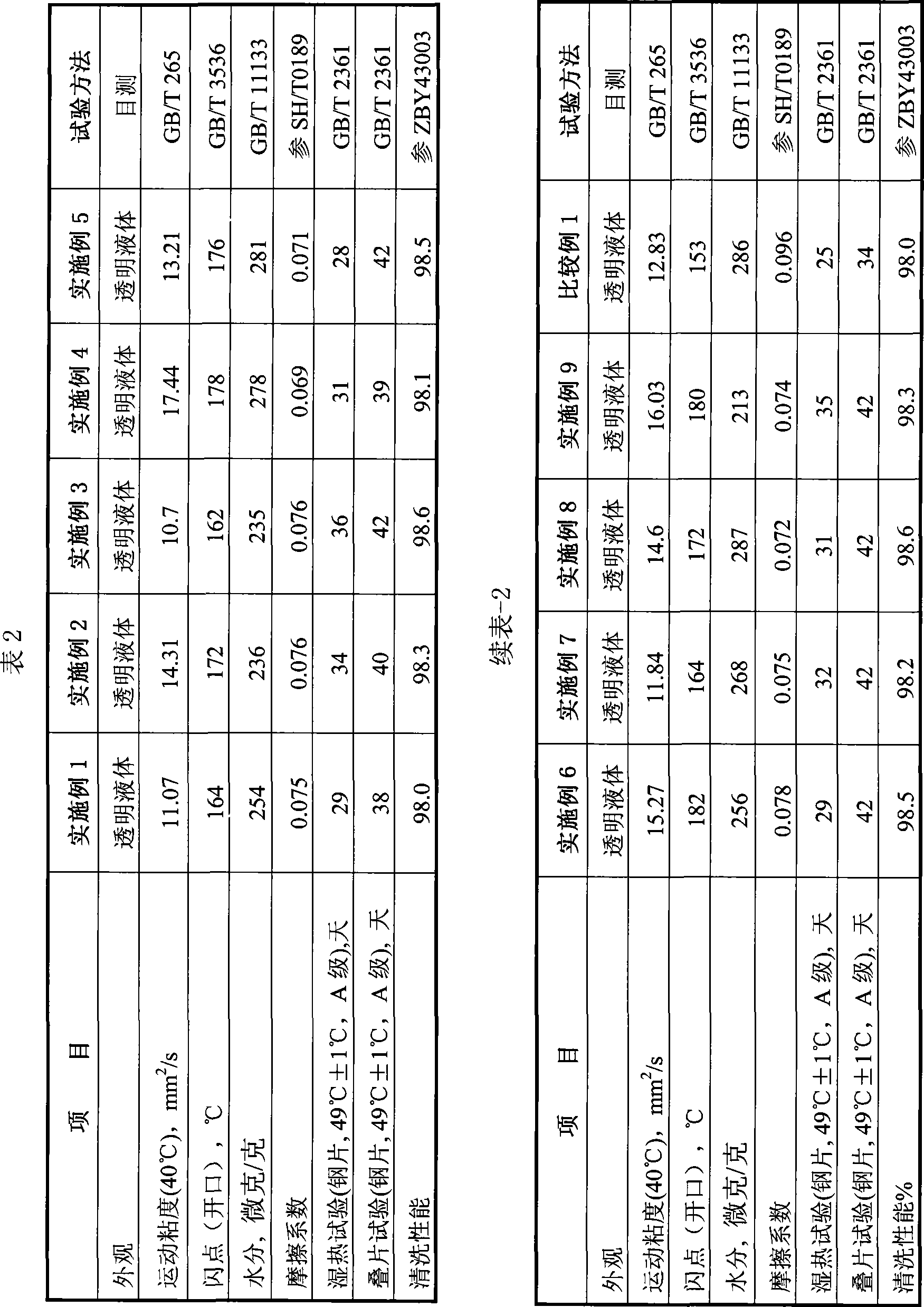

Electrostatic painting anticorrosive oil and production method thereof

ActiveCN101486945ADoes not affect post-processing effectsPost-processing effect is reducedAdditivesAntioxidantBase oil

The invention relates to electrostatic spraying anti-rust oil and a production method thereof, which essentially solves the problems of the prior art that the lubricating property of the anti-rust oil is poor; and interlayer sliding is caused due to larger tension during the reeling process of the steel plate, resulting in steel plate scratch and having impact on the surface quality of the steel plate. The electrostatic spraying anti-rust oil commendably solves the problems by using the technical proposal comprising components of weight percentages as follows: a) 5 to 30 percent of anti-rust agent, b) 0.1 to 5 percent of surface activator, c) 0.1 to 15 percent of anti-friction composition, d) 0.1 to 5.0 percent of antioxidant and e) 50 to 90 percent of base oil, and can be used for the electrostatic spraying rust resistance of the cold-rolled carbon steel plate, galvanized plate and aluminized zinc silicon plate of the steel enterprises.

Owner:CHINA PETROLEUM & CHEM CORP

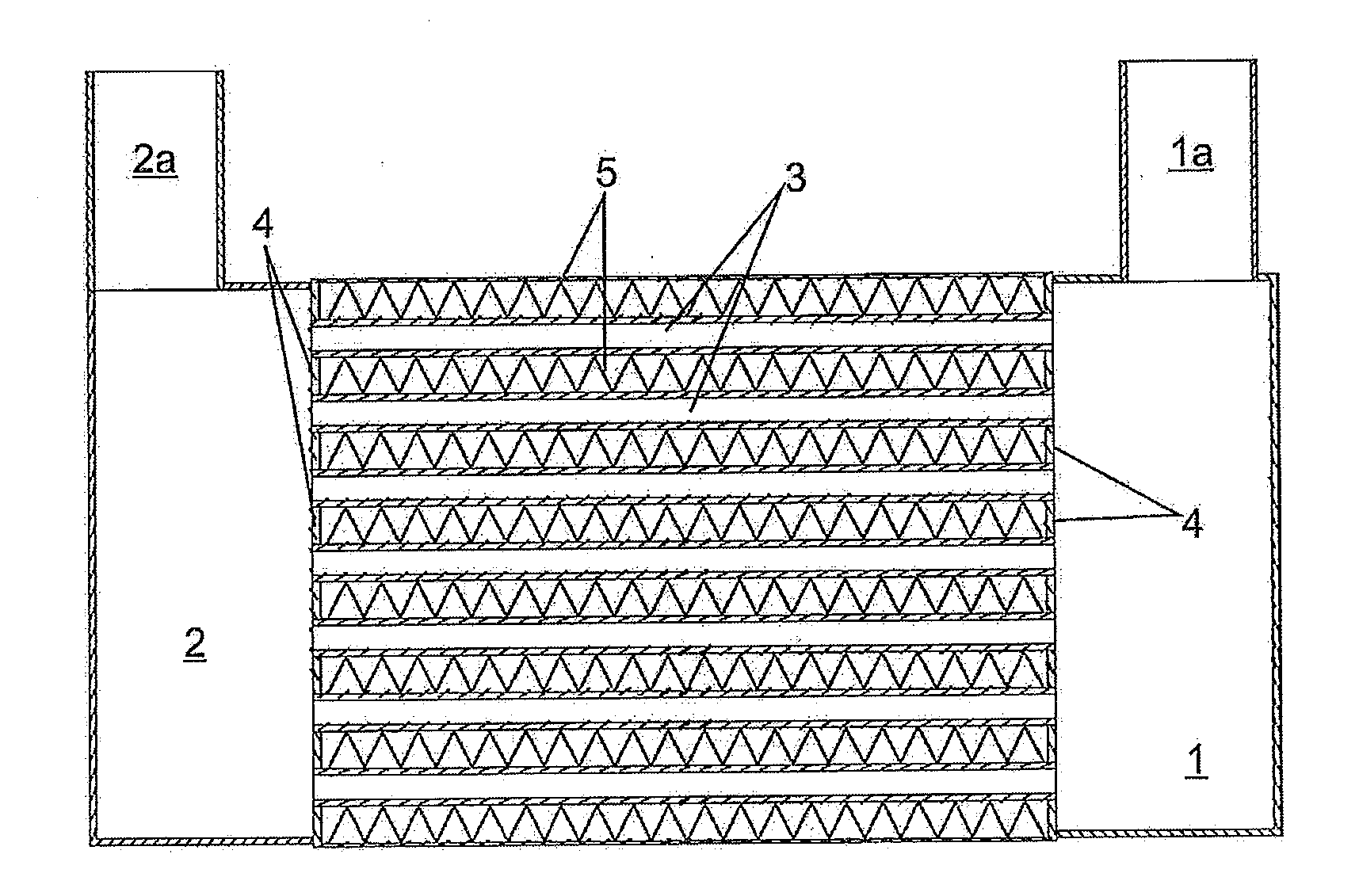

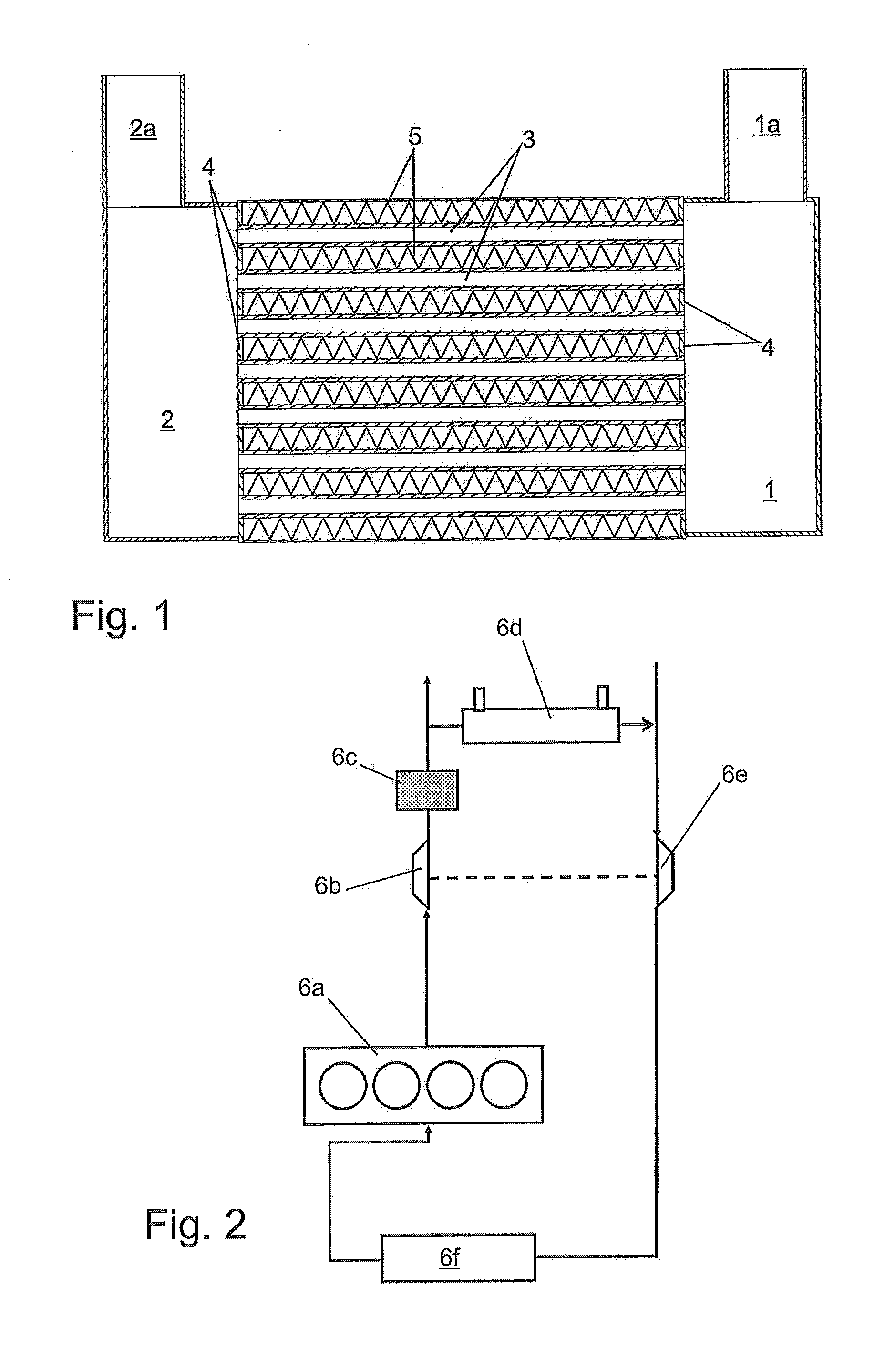

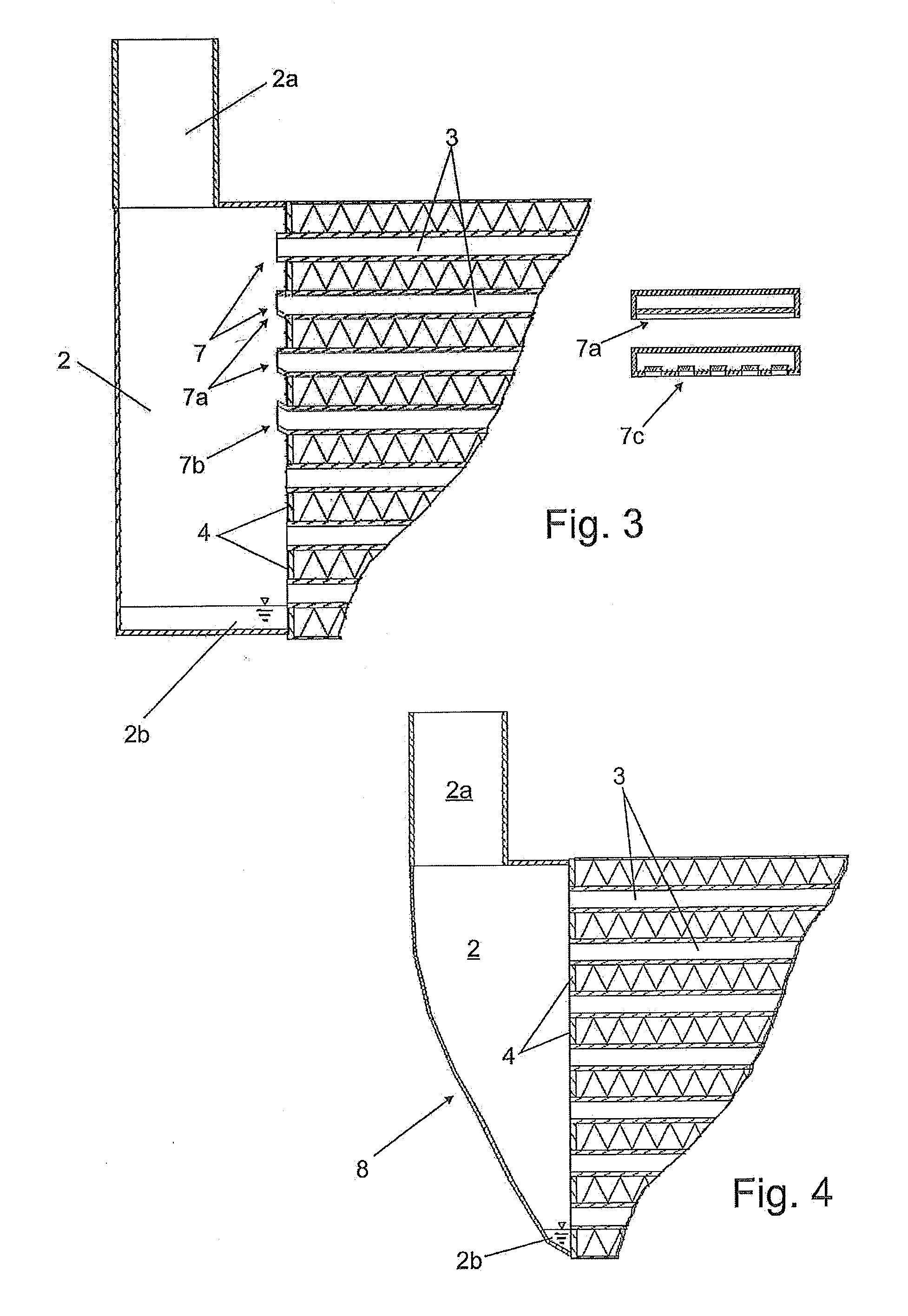

Heat exchanger

InactiveUS20100300647A1Promote atomizationReduce gas flowRecuperative heat exchangersMachines/enginesExternal combustion engineProcess engineering

A heat exchanger, in particular a charge air cooler or an exhaust gas cooler for an internal combustion engine, comprising a plurality of essentially parallel tubes and at least one collector box on the output side, the tubes each emptying into the collector box on the output side, and a gas flow flowing from the tubes into the collector box and from the collector box into an outlet of the collector box, a structure for interacting with the gas flow being provided at least one of the tubes or collector box, a condensation being transported to the outlet with the aid of the structure.

Owner:MAHLE INT GMBH

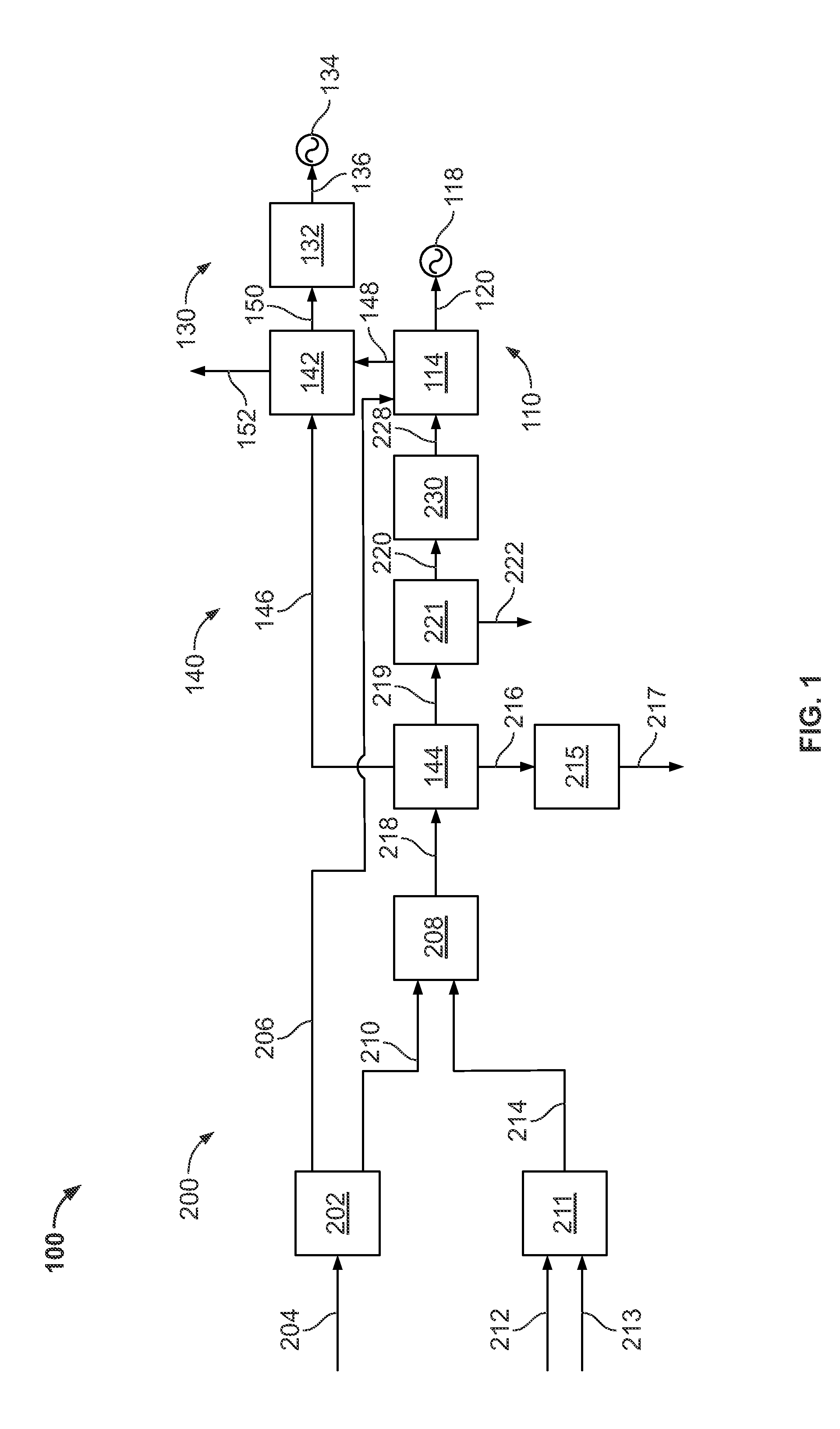

Method and apparatus to produce synthetic gas

ActiveUS20110036011A1Easy to operateEasy to evaporateValve members for heating/coolingPipe heating/coolingSyngasForming gas

A method of producing a synthetic gas (syngas) includes injecting a plurality of reactant streams into a gasification reactor via at least one injection device having a plurality of injection annuli, an inner portion that extends annularly about a centerline extending through the at least one injection device, and an outer portion extending substantially annularly about the inner portion. At least a portion of the outer portion is oriented obliquely with respect to the at least one injection device centerline. The method also includes mixing at least a portion of each of the streams together such that a plurality of recirculation zones is defined by the streams. The method further includes producing a syngas within the recirculation zones via mixing at least a portion of each of the streams. The injection device includes an inner portion that extends annularly about a centerline extending through the injection device. The device also includes an outer portion extending substantially annularly about the inner portion that includes at least one of at least one carbonaceous reactant injection port oriented obliquely with respect to the injection device centerline and at least one outer face oriented obliquely with respect to the injection device centerline.

Owner:AIR PROD & CHEM INC

Spray head and air atomizing assembly

InactiveUS6951310B2Promote atomizationHigh viscosityLiquid surface applicatorsSpray nozzlesEngineering

Owner:RUBBERMAID INDAL PRODS CORP

Air atomizing assembly and method and system of applying an air atomized material

A spray head and air atomizing assembly for providing atomizing air in an air sprayer or other delivery device in which the atomizing assembly includes converging, spiral atomizing fluid passageways. The invention also relates to a method and system for applying materials to a substrate using atomizing air as a vehicle for delivering a component to the application fluid or for conditioning the application fluid.

Owner:RUBBERMAID INDAL PRODS CORP

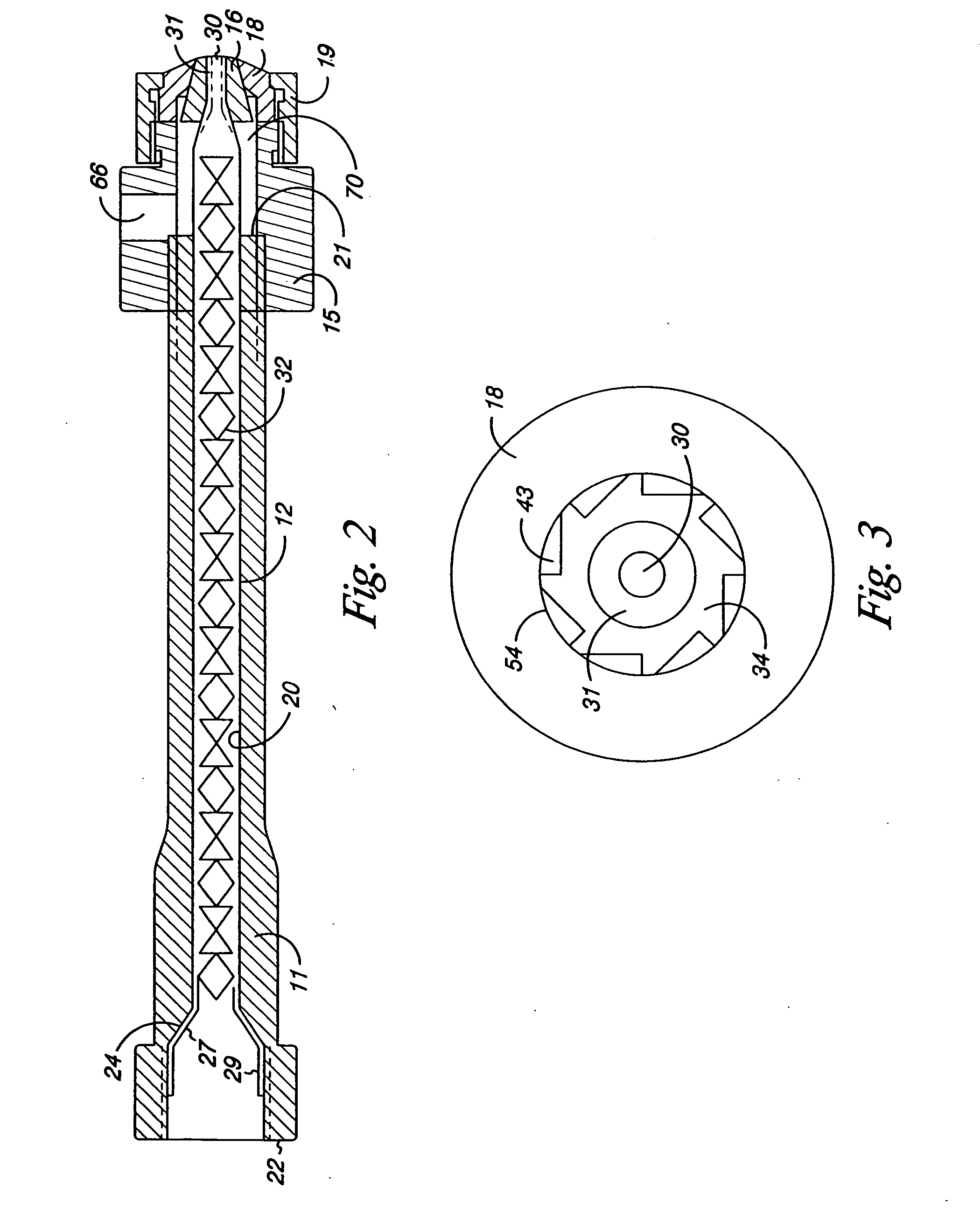

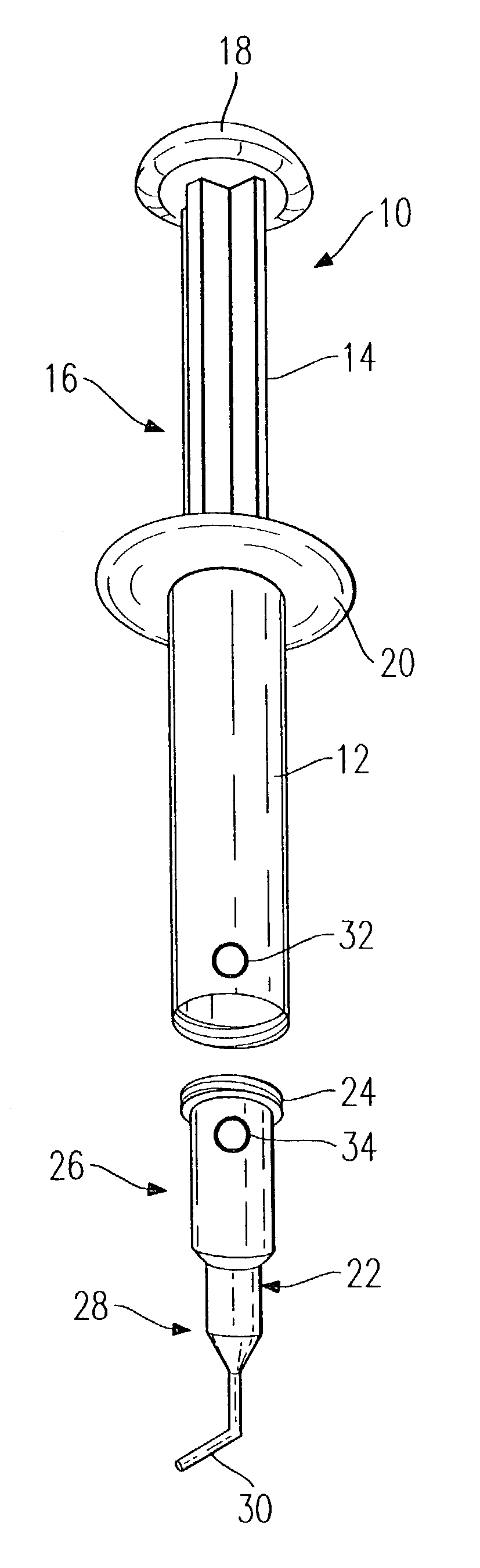

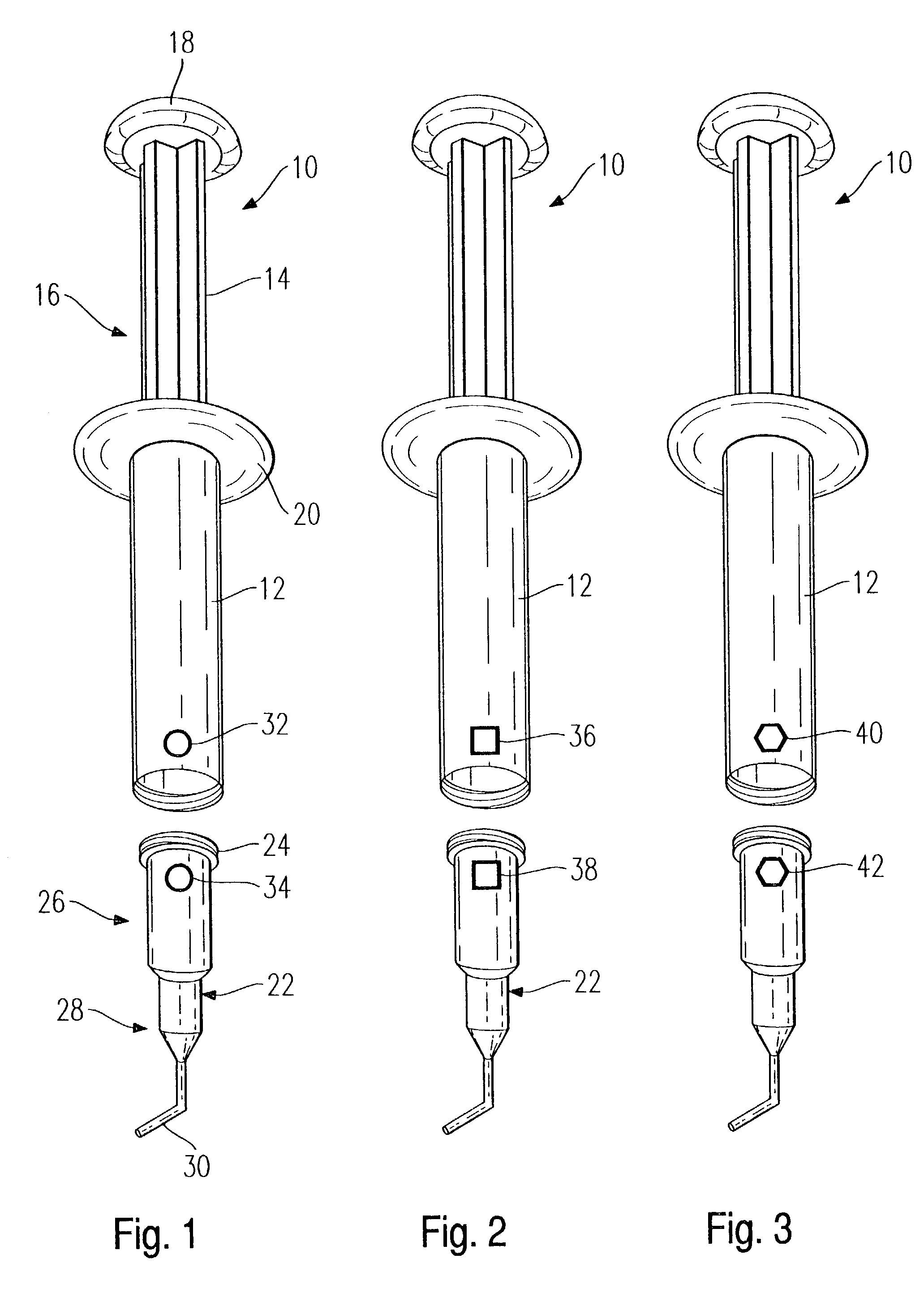

Container assembly for a substance to be applied

InactiveUS6981618B2Improve machine readabilityImprove atomizationLiquid surface applicatorsMedical devicesSyringeInjector

A container assembly for a substance to be applied is provided that includes a injector housing, an application tip, and a closure cap. The application tip and the closure cap are alternatively removably securable to the outlet end of the injector housing in a substantially fluid tight disposition. A first indicia is associated with the injector housing and a second indicia is associated with each of the application tip and the closure cap. The second indicia has an identity correspondence with the first indicia such that the presence of both the first indicia on the injector housing and the second indicia on the respective one of the application tip and the closure cap secured to the outlet end of the injector housing confirms that only the appropriate application tip or the appropriate closure cap has been secured to the injector housing.

Owner:IVOCLAR VIVADENT AG

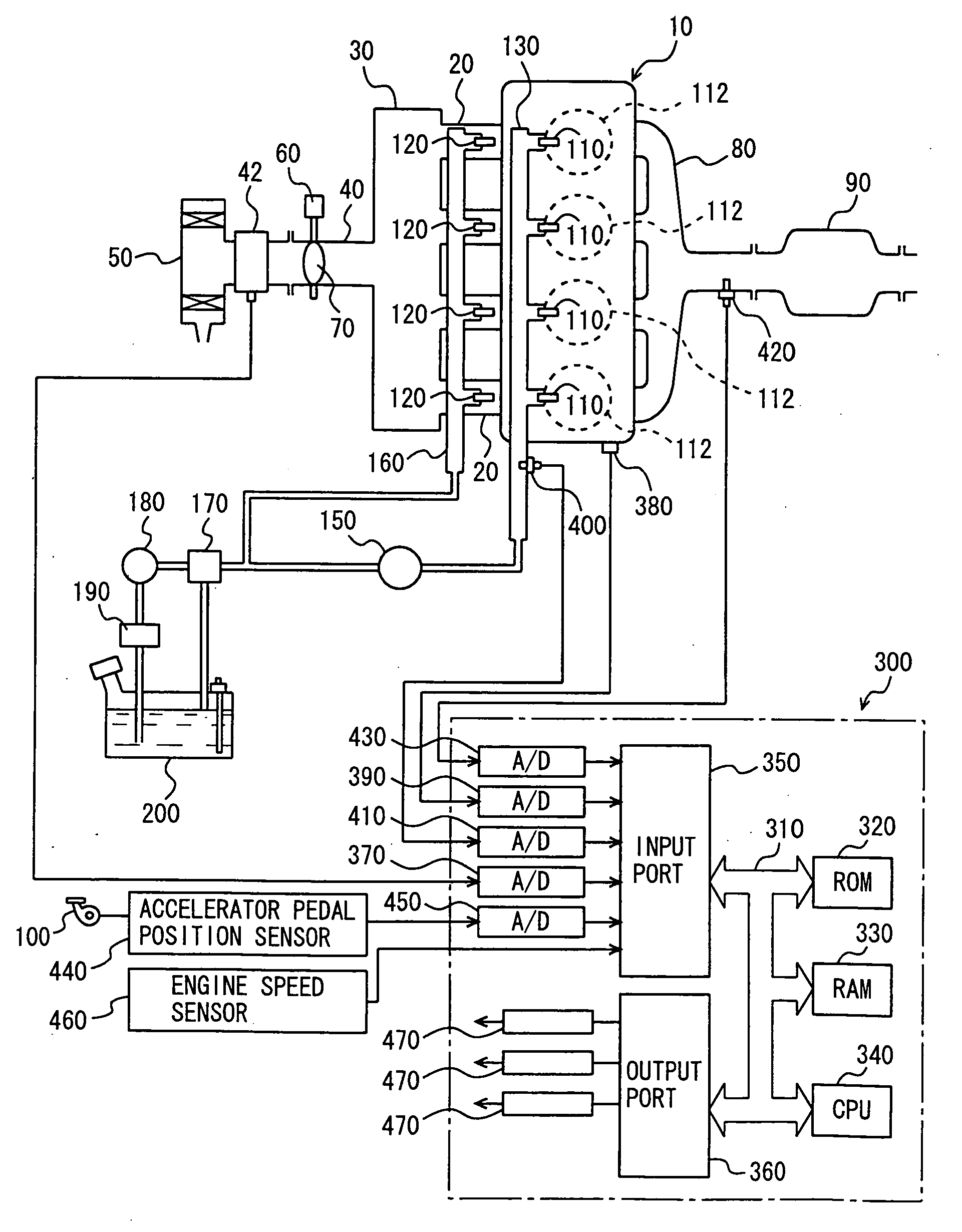

Control apparatus for internal combustion engine

InactiveUS20070000478A1Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionIdle speed

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

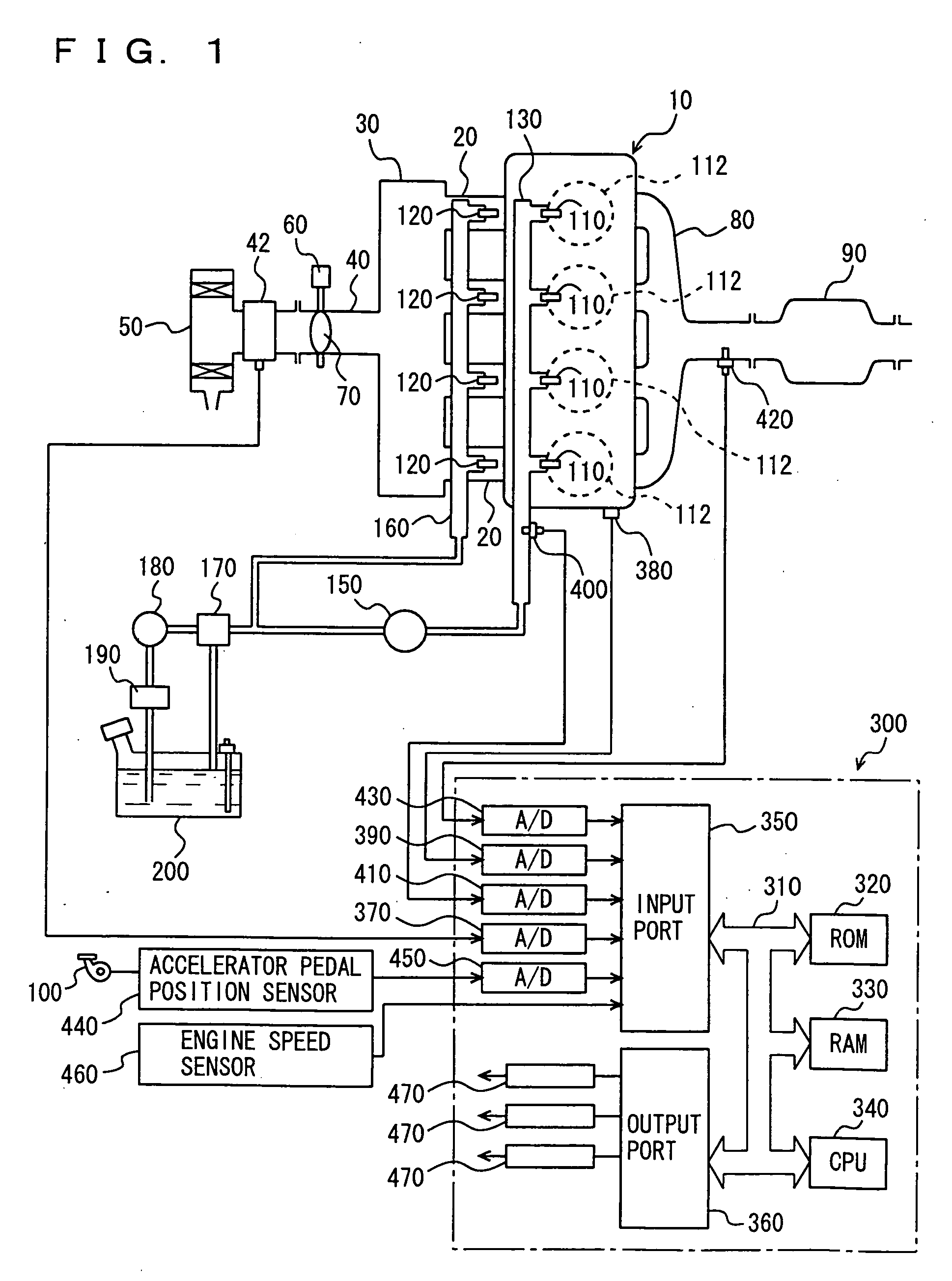

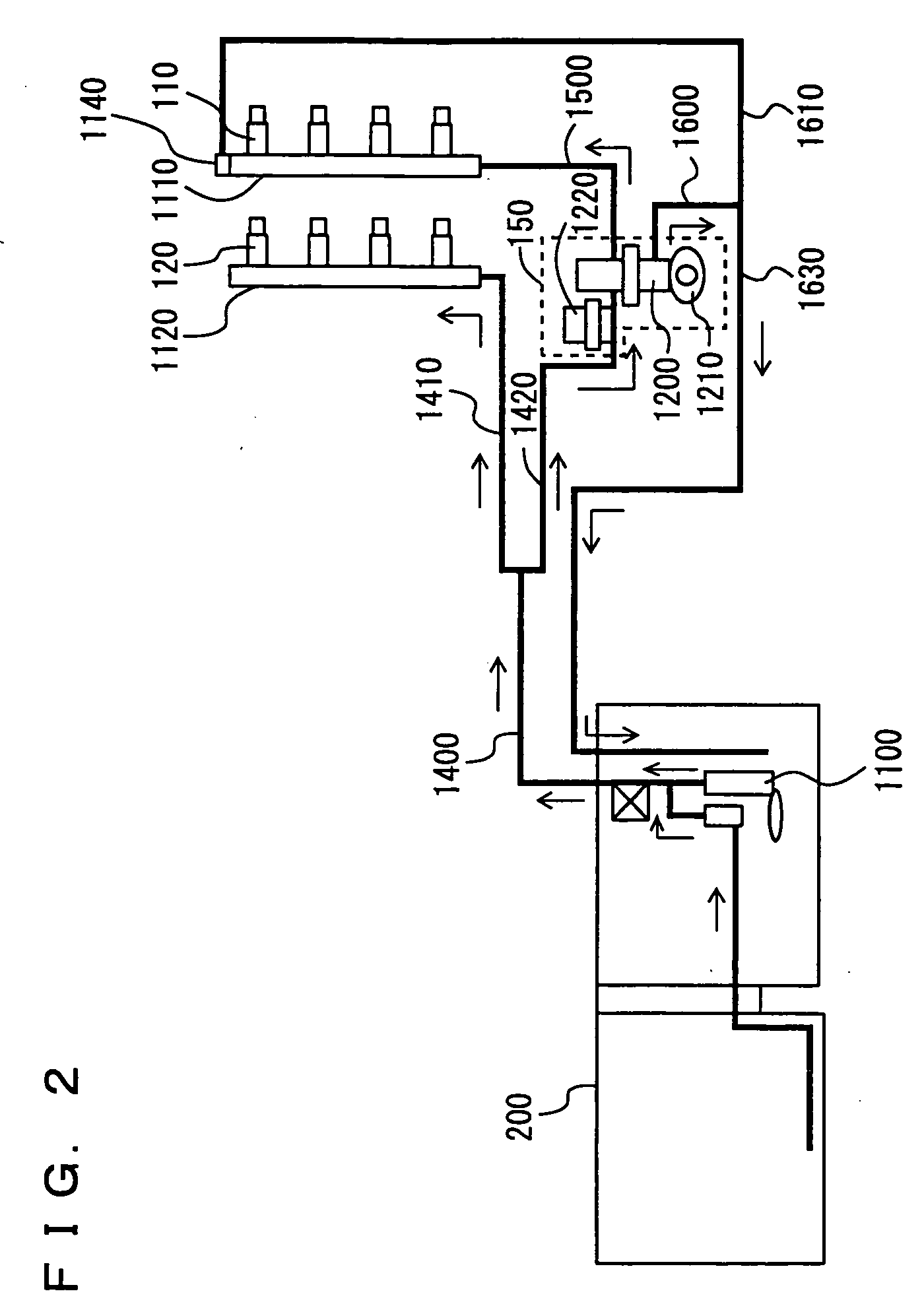

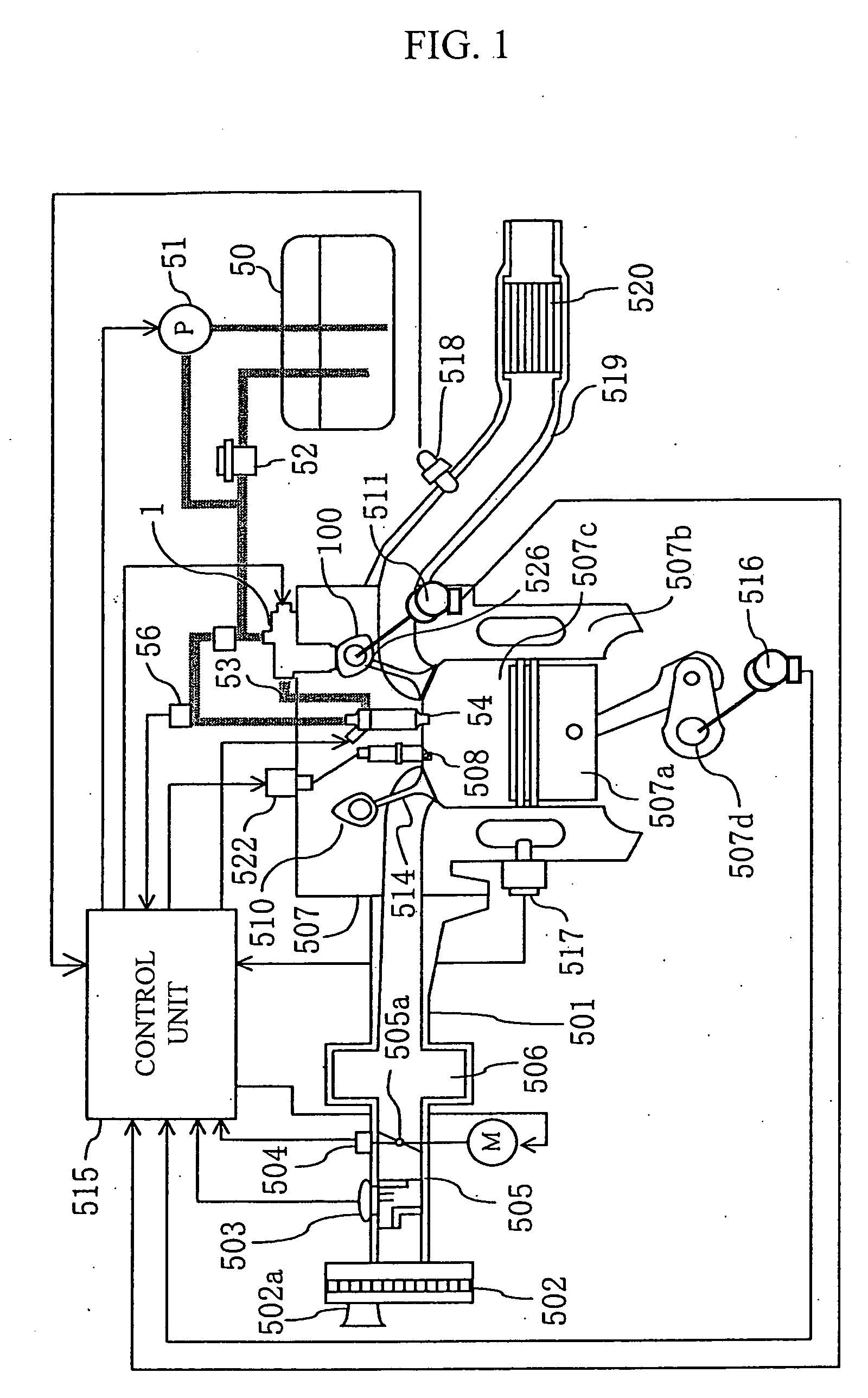

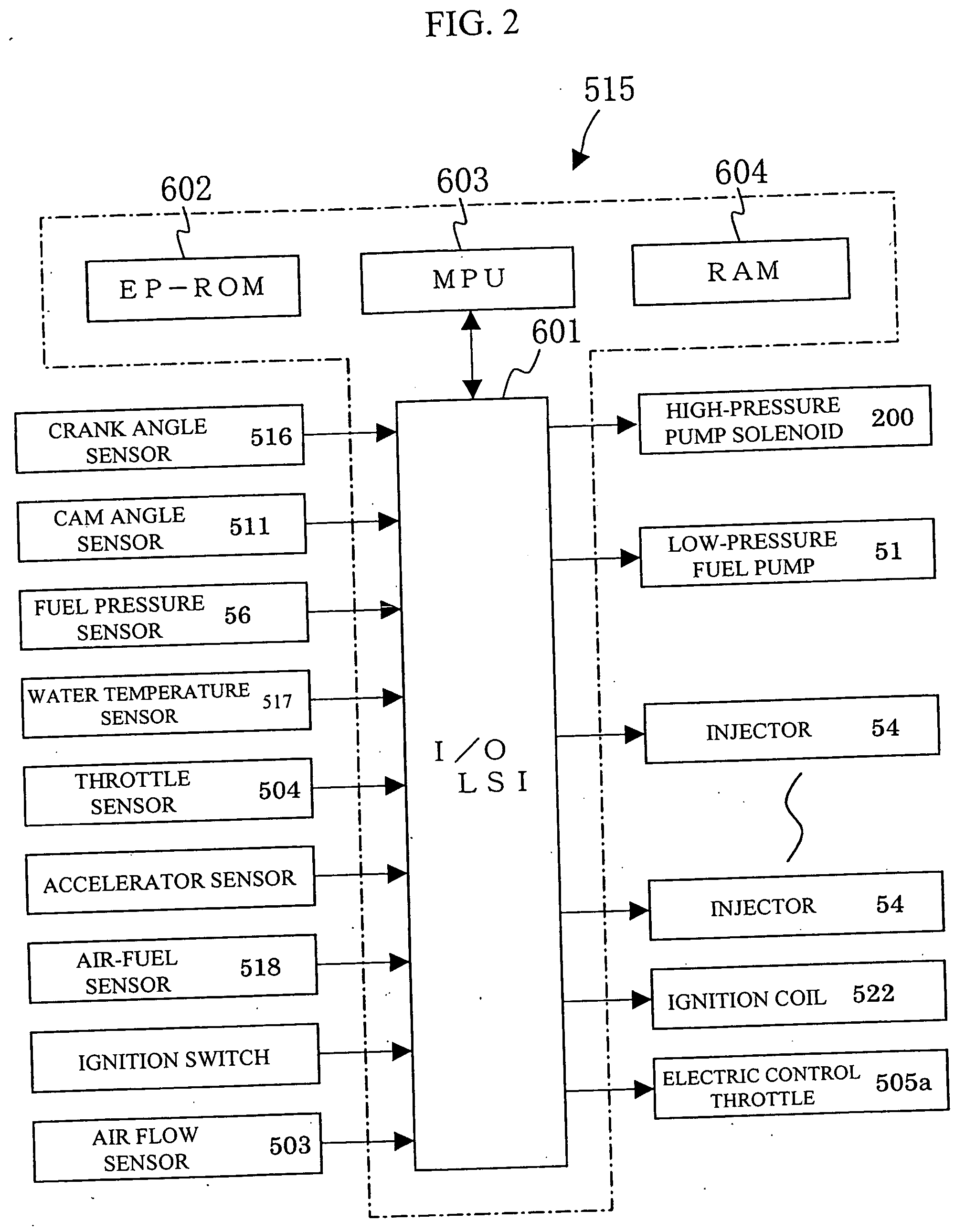

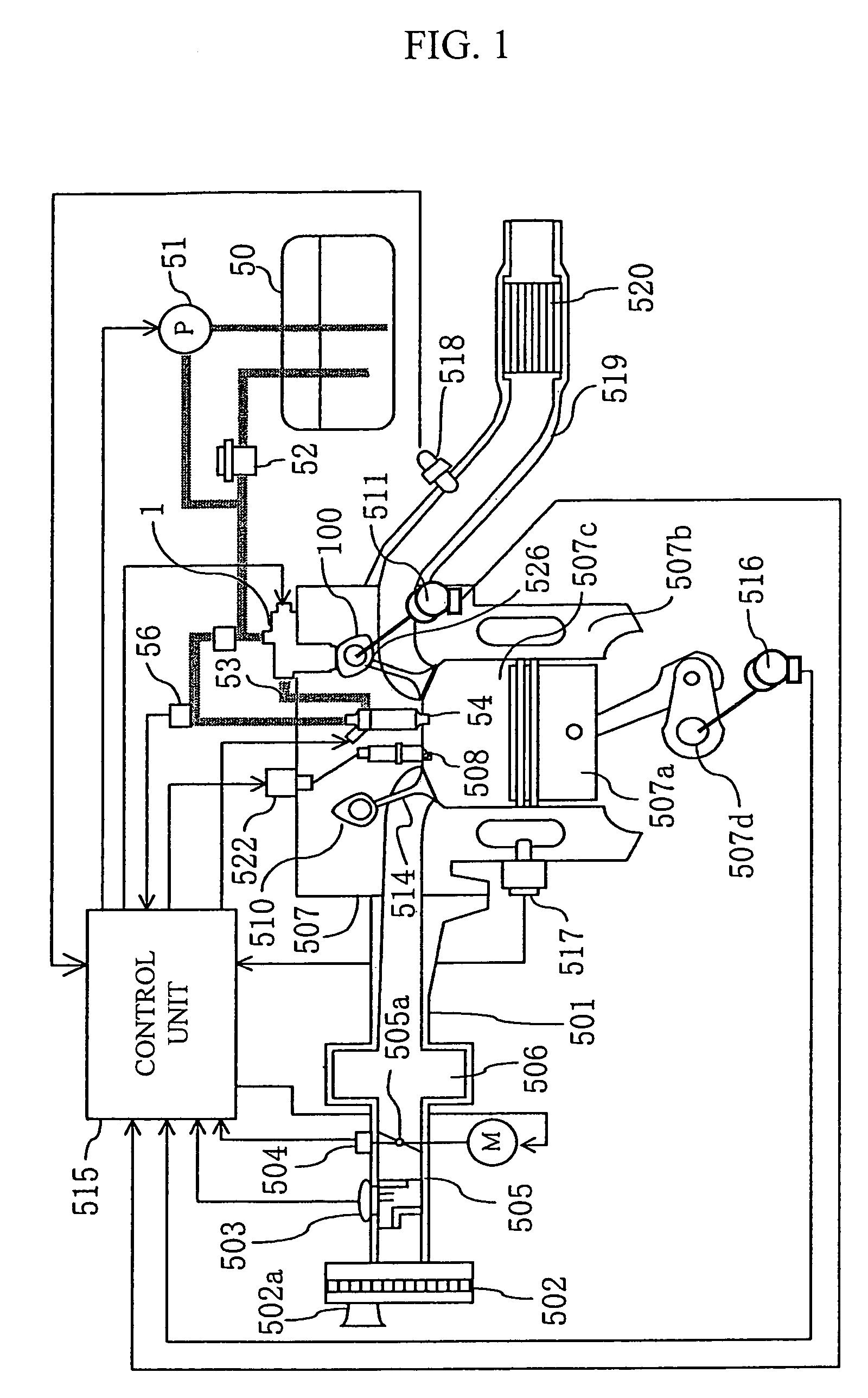

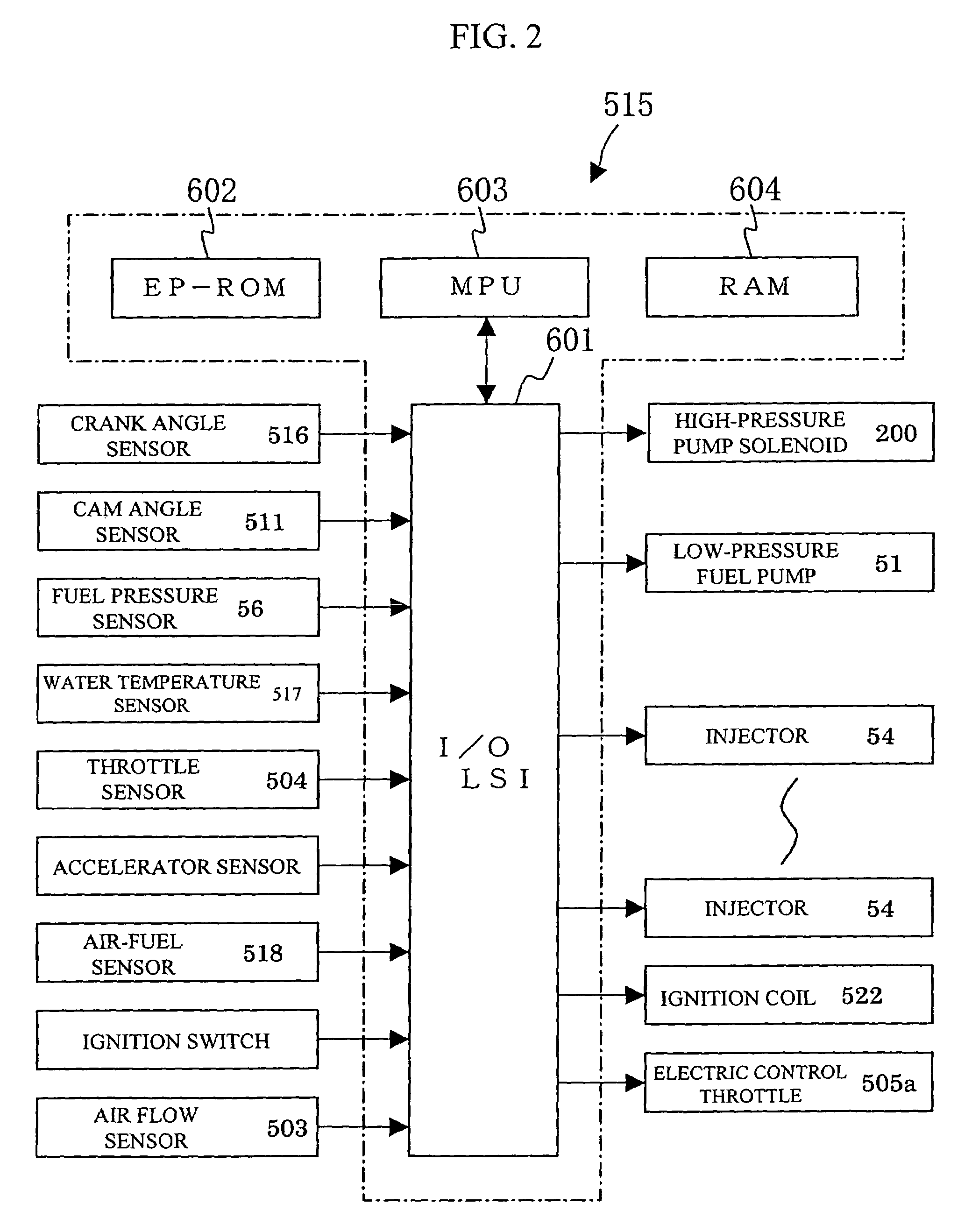

Control device of high-pressure fuel pump of internal combustion engine

InactiveUS20060147317A1Improve securityIncrease fuel pressureElectrical controlFuel injecting pumpsExternal combustion engineInternal combustion engine

A control device of a high-pressure fuel pump of an internal combustion engine capable of improving stability in controlling the drive of the high-pressure fuel pump by limiting the end timing of a drive signal of the high-pressure fuel pump and driving an actuator in a control effective range of the high-pressure fuel pump. The control device of the high-pressure fuel pump of the internal combustion engine has a fuel injection valve provided on a cylinder and the high-pressure fuel pump for pumping fuel to the fuel injection valve, wherein the high-pressure fuel pump comprises a pressure chamber, a plunger for pressurizing the fuel in the pressure chamber, a fuel valve provided in the pressure chamber, and the actuator for operating the fuel valve. The control device has means for calculating the drive signal of the actuator so as to realize the variable discharge of the high-pressure fuel pump. The means for calculating the drive signal has means for limiting the end timing of the drive signal of the actuator to a predetermined phase and / or means for limiting the output timing of the drive signal of the actuator to be within a predetermined phase range.

Owner:HITACHI ASTEMO LTD

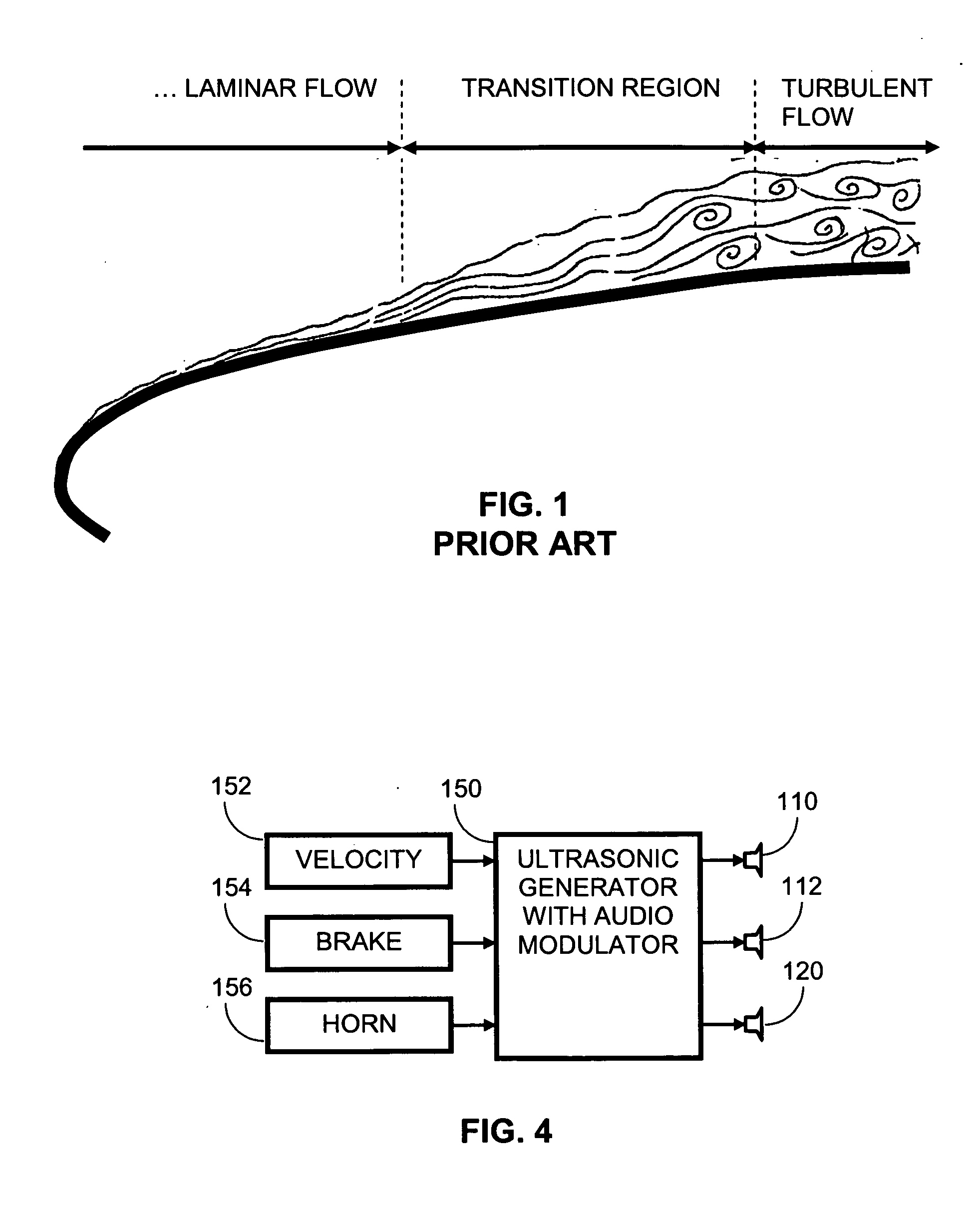

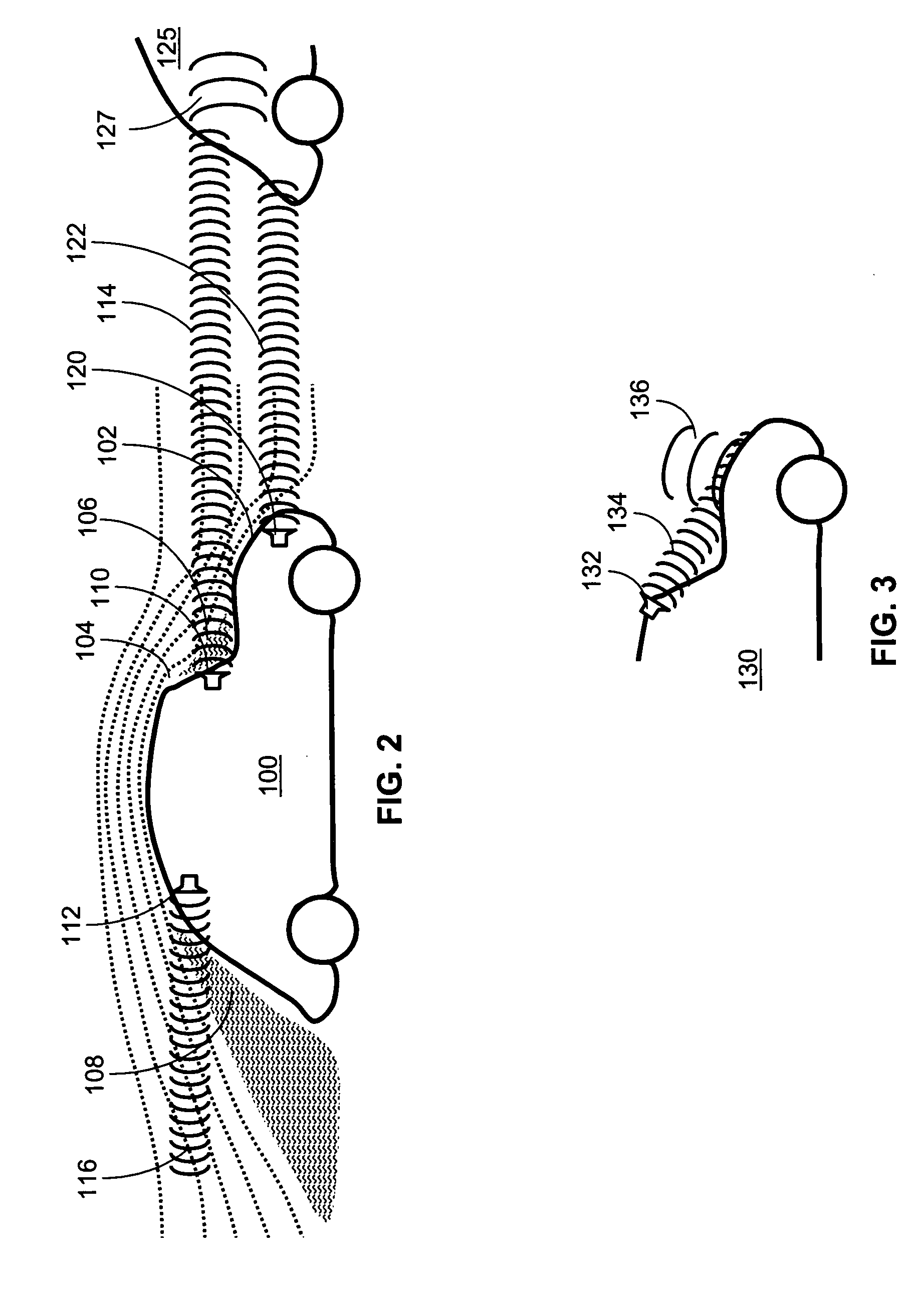

Active drag and thrust modulation system and methods

InactiveUS20050257776A1Good fuel atomizationPromote atomizationTyre partsInternal combustion piston enginesLeading edgeCombustion

A vehicle traveling through an environmental media such as air experiences drag. The drag is actively modulated by energy beams which may either increase or decrease the drag. The energy beams may provide either a chemical, acoustic or electromagnetic energy at a transition region between turbulent and laminar flows or at the leading edge of a laminar flow or in the direction of a crosswind in order to facilitate the respective increase or decrease in drag. If the vehicle is a sailing ship, areas of the sails are selectively roughened or widened to enhance the thrust derived from the wind. Furthermore, the keel or hull of the sailing ship may be modified to improve the hydrodynamic characteristics of the sailing ship. If the vehicle is an automobile, the tires or road surface may be selectively heated to improve the traction of the automobile. Furthermore, the energy beams may be used to facilitate atomization of the air / fuel mixture prior to combustion in an internal combustion engine thereby improving the thrust of provided to the vehicle. Energy beams may be used to generate virtual extensions of a vehicle to enhance traveling efficiency.

Owner:P TECH

Etched open microchannel spray cooling

ActiveUS20050185378A1Improve performancePotentially efficientDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic componentSpray cooling

The present invention is a spray cooling thermal management device that cools an electronic component. Liquid coolant is dispensed upon a heated surface containing etched open microchannels.

Owner:PARKER INTANGIBLES LLC

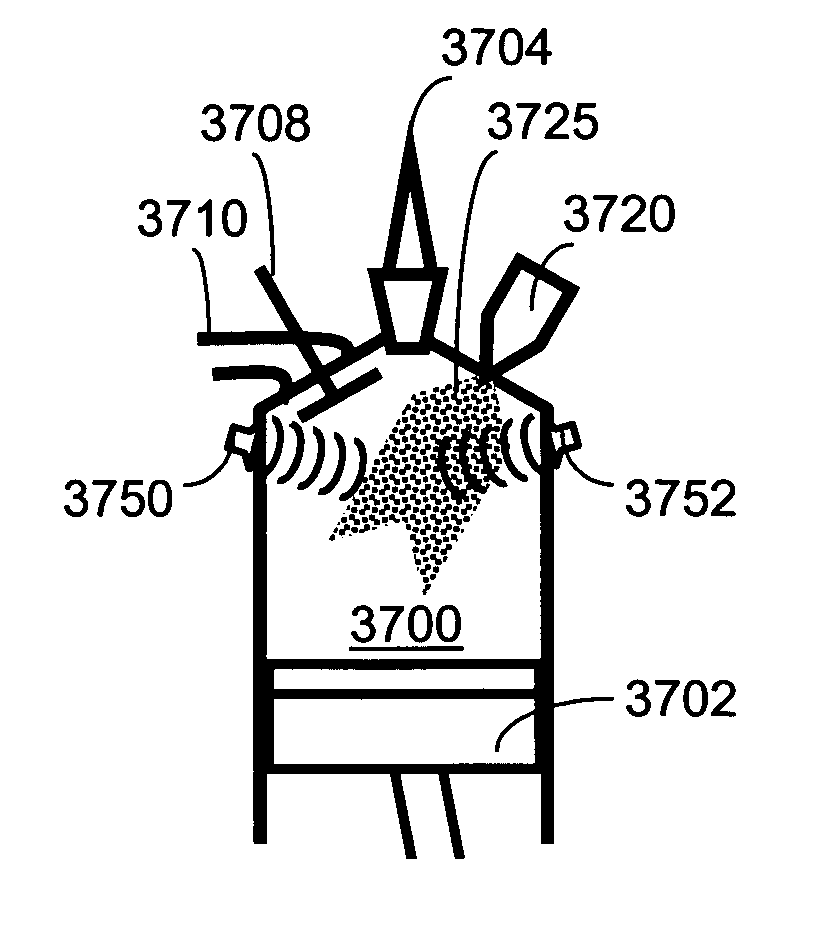

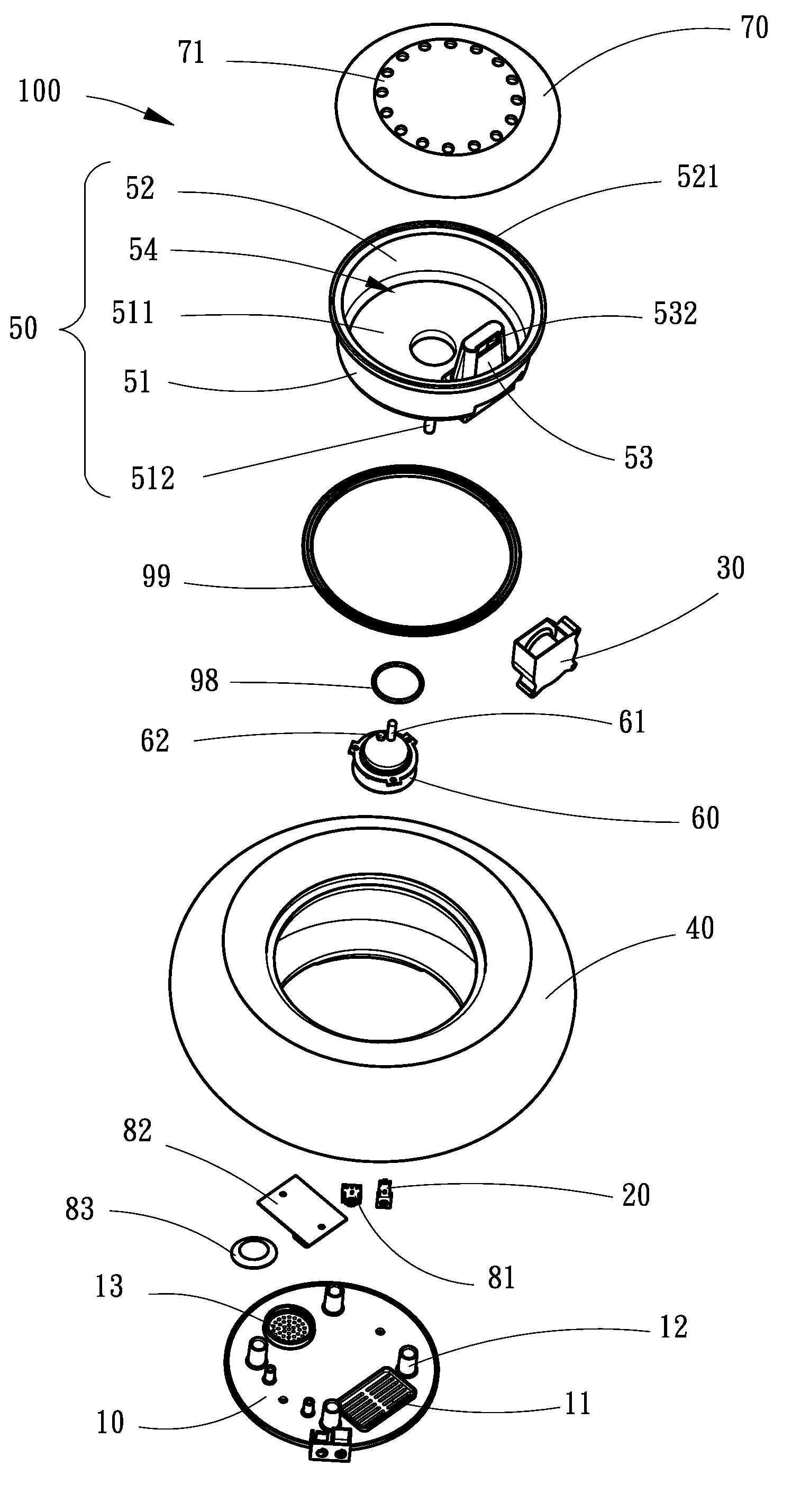

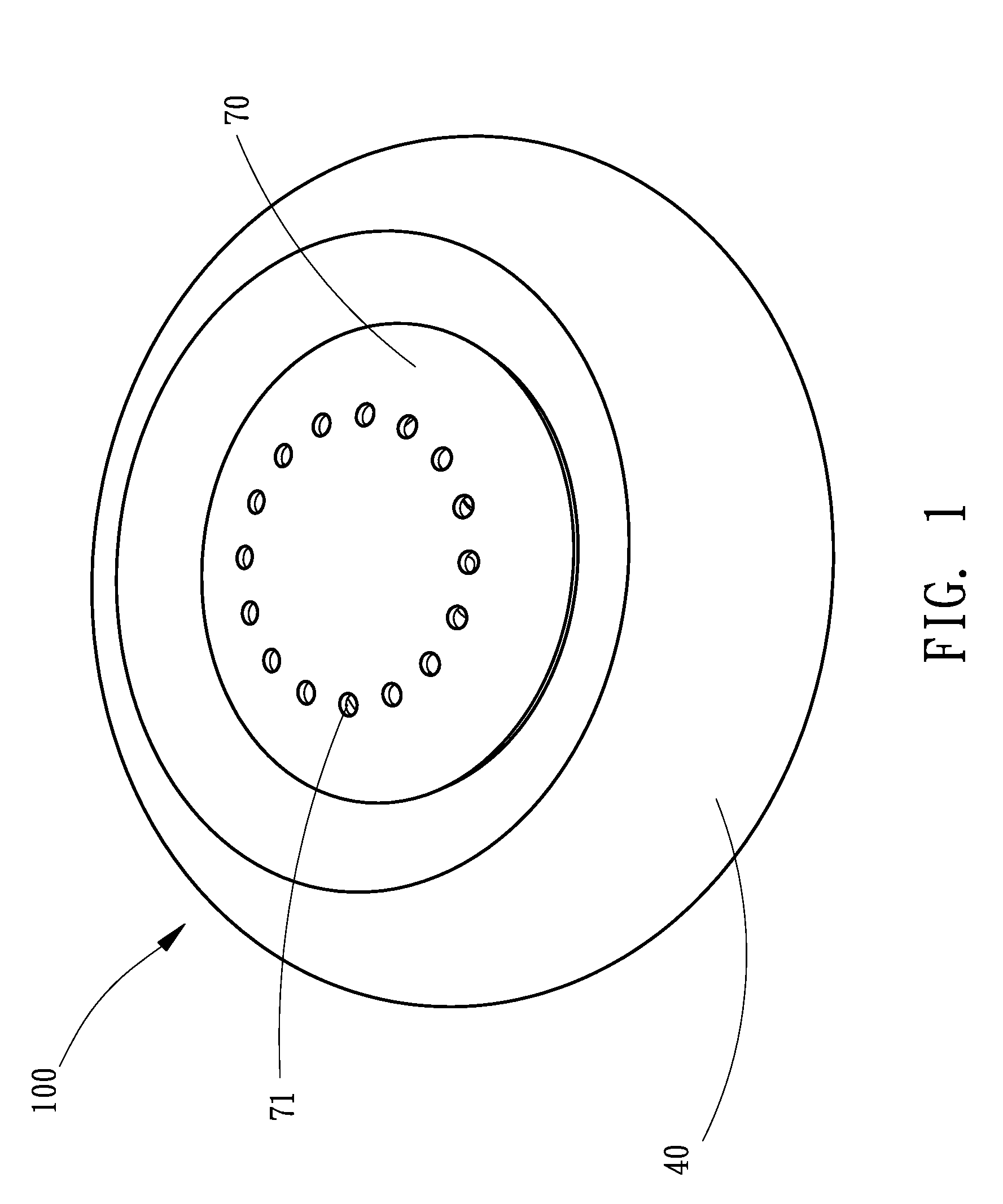

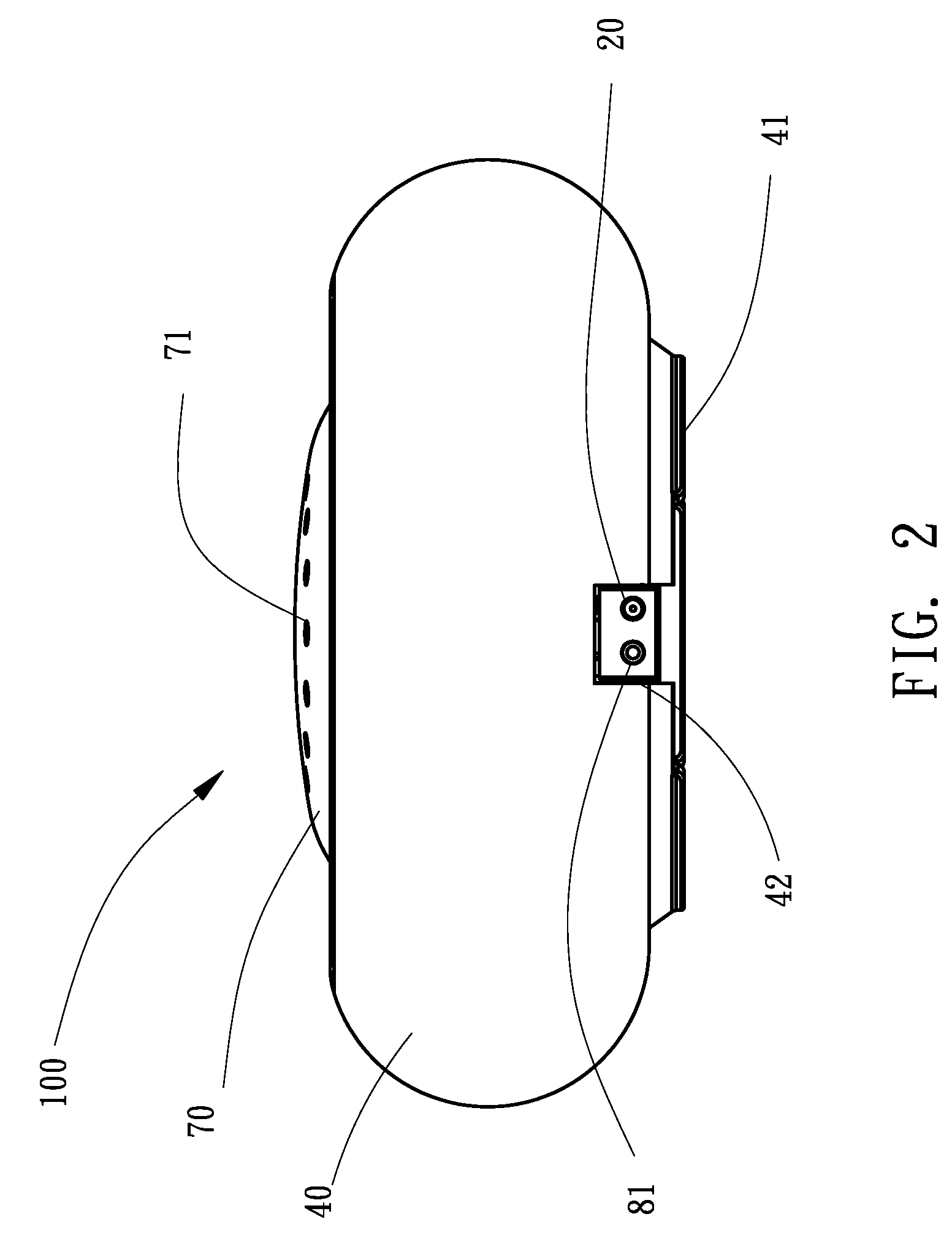

Aromatic nebulizing diffuser

InactiveUS8196903B2Promote atomizationPrevent splashUsing liquid separation agentMixing methodsEngineeringMechanical engineering

Owner:HSIAO MING JEN

Control device of high-pressure fuel pump of internal combustion engine

InactiveUS7299790B2Conducive to stable combustionAccelerate emissionsElectrical controlFuel injecting pumpsExternal combustion engineInternal combustion engine

A control device of a high-pressure fuel pump of an internal combustion engine capable of improving stability in controlling the drive of the high-pressure fuel pump by limiting the end timing of a drive signal of the high-pressure fuel pump and driving an actuator in a control effective range of the high-pressure fuel pump. The control device of the high-pressure fuel pump of the internal combustion engine has a fuel injection valve provided on a cylinder and the high-pressure fuel pump for pumping fuel to the fuel injection valve, wherein the high-pressure fuel pump comprises a pressure chamber, a plunger for pressurizing the fuel in the pressure chamber, a fuel valve provided in the pressure chamber, and the actuator for operating the fuel valve. The control device has means for calculating the drive signal of the actuator so as to realize the variable discharge of the high-pressure fuel pump. The means for calculating the drive signal has means for limiting the end timing of the drive signal of the actuator to a predetermined phase and / or means for limiting the output timing of the drive signal of the actuator to be within a predetermined phase range.

Owner:HITACHI ASTEMO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com