Atomizing electronic cigarette

a technology of electric cigarettes and atomizers, which is applied in the field of atomizing electric cigarettes, can solve the problems of poor atomization, too much moisture in the smoke, and many atomizing electronic cigarettes, and achieve the effects of convenient absorbing, convenient absorbing, and convenient gasification of liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

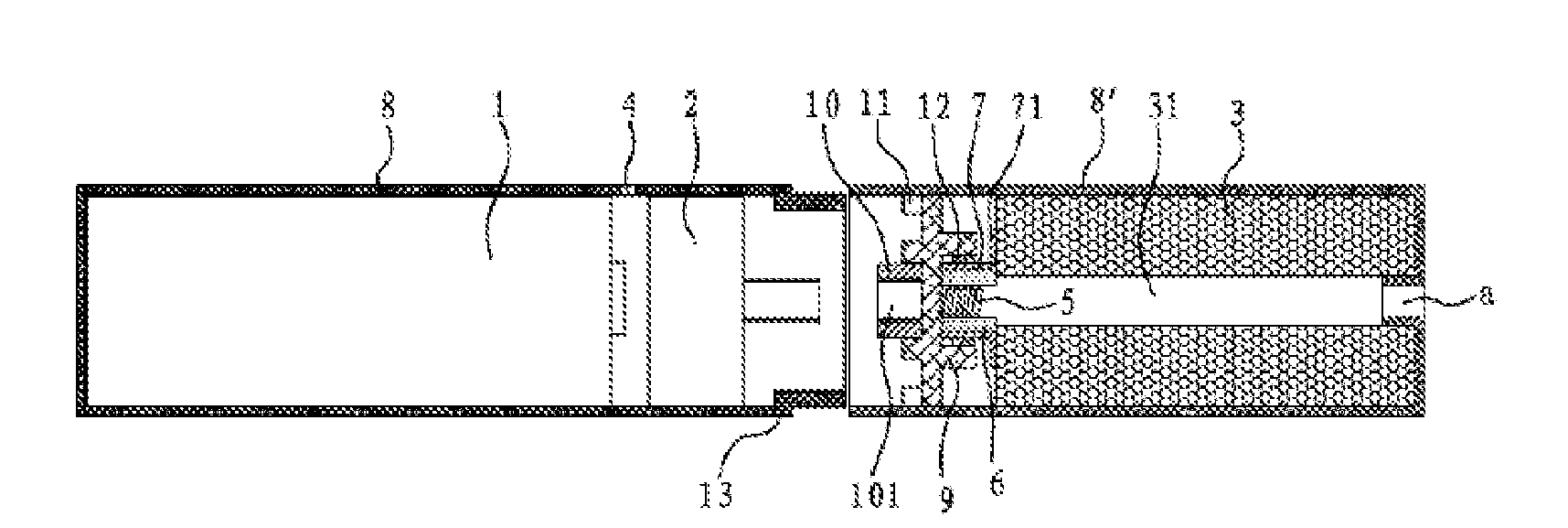

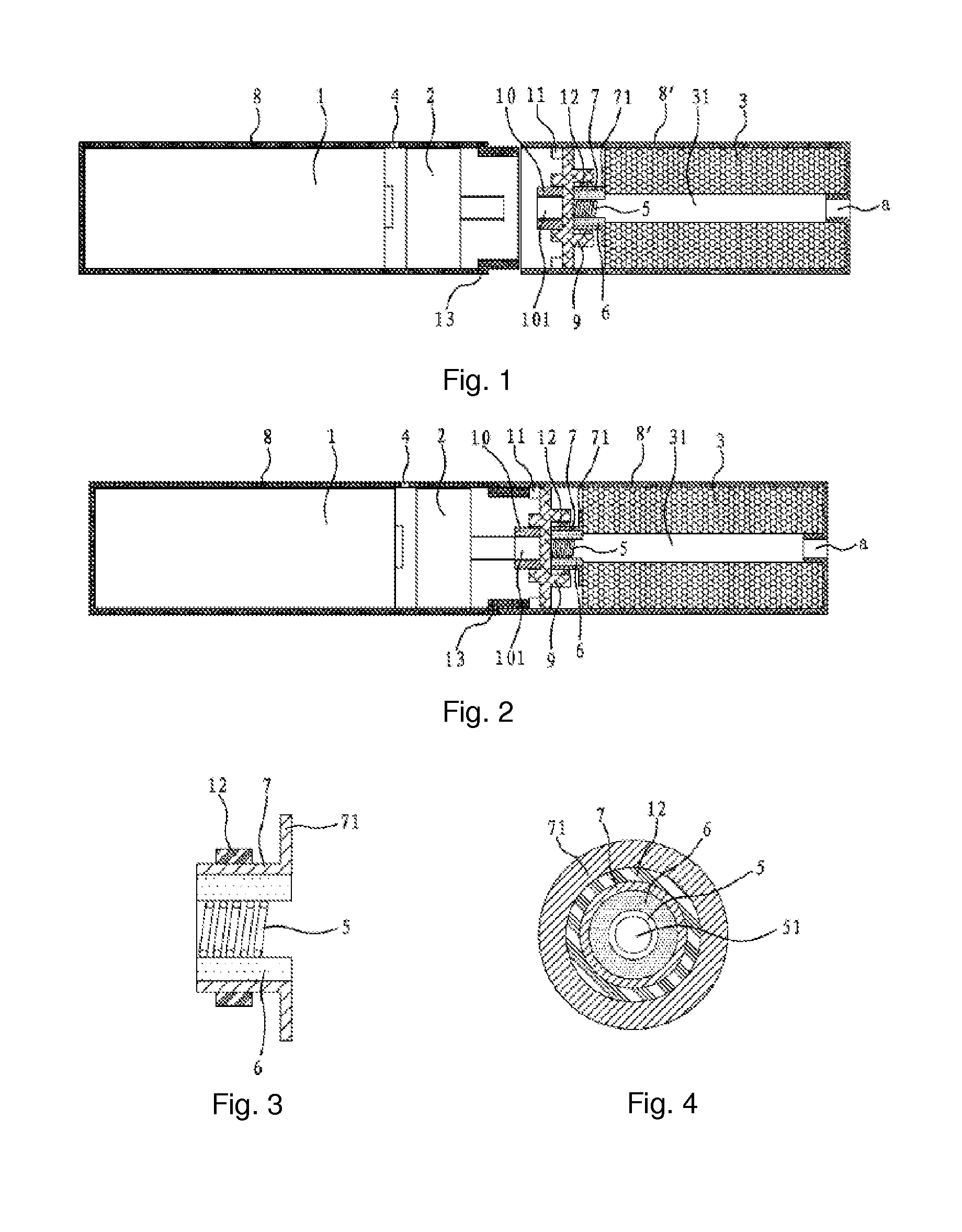

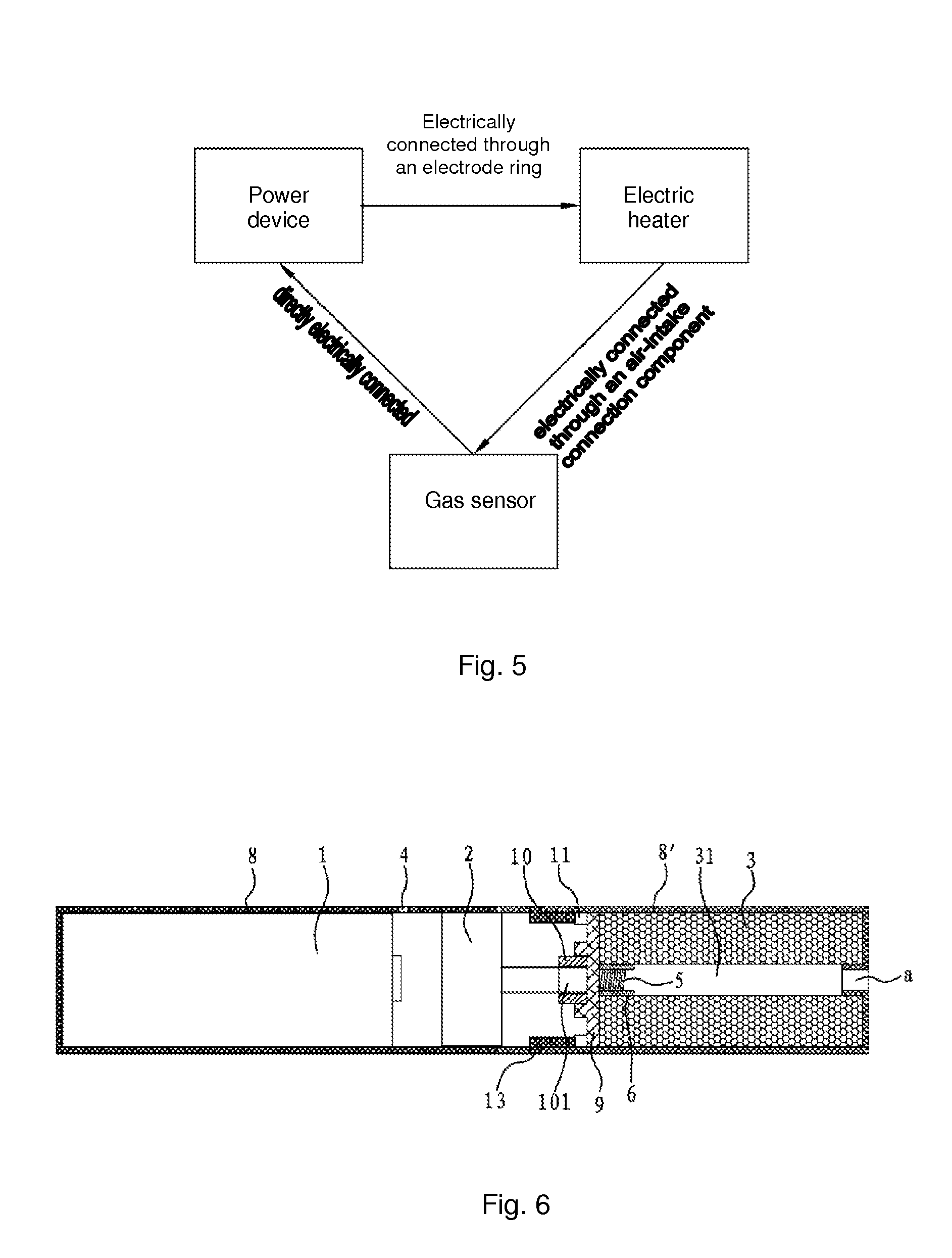

[0033]The invention will be described in detail below in conjunction with the drawings.

[0034]As shown in FIG. 1 to FIG. 5, the invention provides an improved atomizing electronic cigarette, comprising a power device 1, a sensor 2, an atomizing core component and a liquid storage component 3, further comprising a housing containing the above components. An auxiliary air inlet 4 is arranged on an area of the housing close to the sensor 2. The atomizing core component comprises an electric heater 5 and a liquid permeating component 6 sleeved on the electric heater 5. The electric heater 5 is of a hollow structure and has a through hole 51 through which gas flows. The liquid storage component 3 internally has a channel 31 through which the gas flows. The channel can be a hollow channel, a through-hole channel, an annular channel or a channel with local sparse mesh in cross section or combinations thereof, the purpose of which is to make the atomized gas that passes through the channel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com