Patents

Literature

43results about How to "Efficient gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

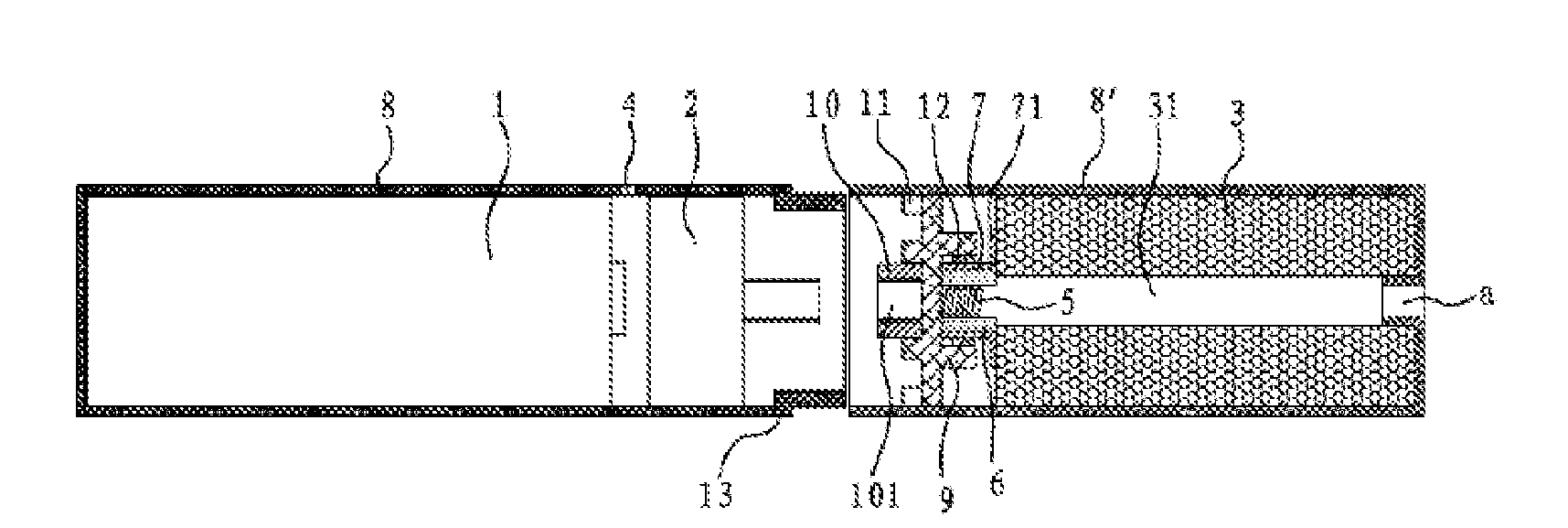

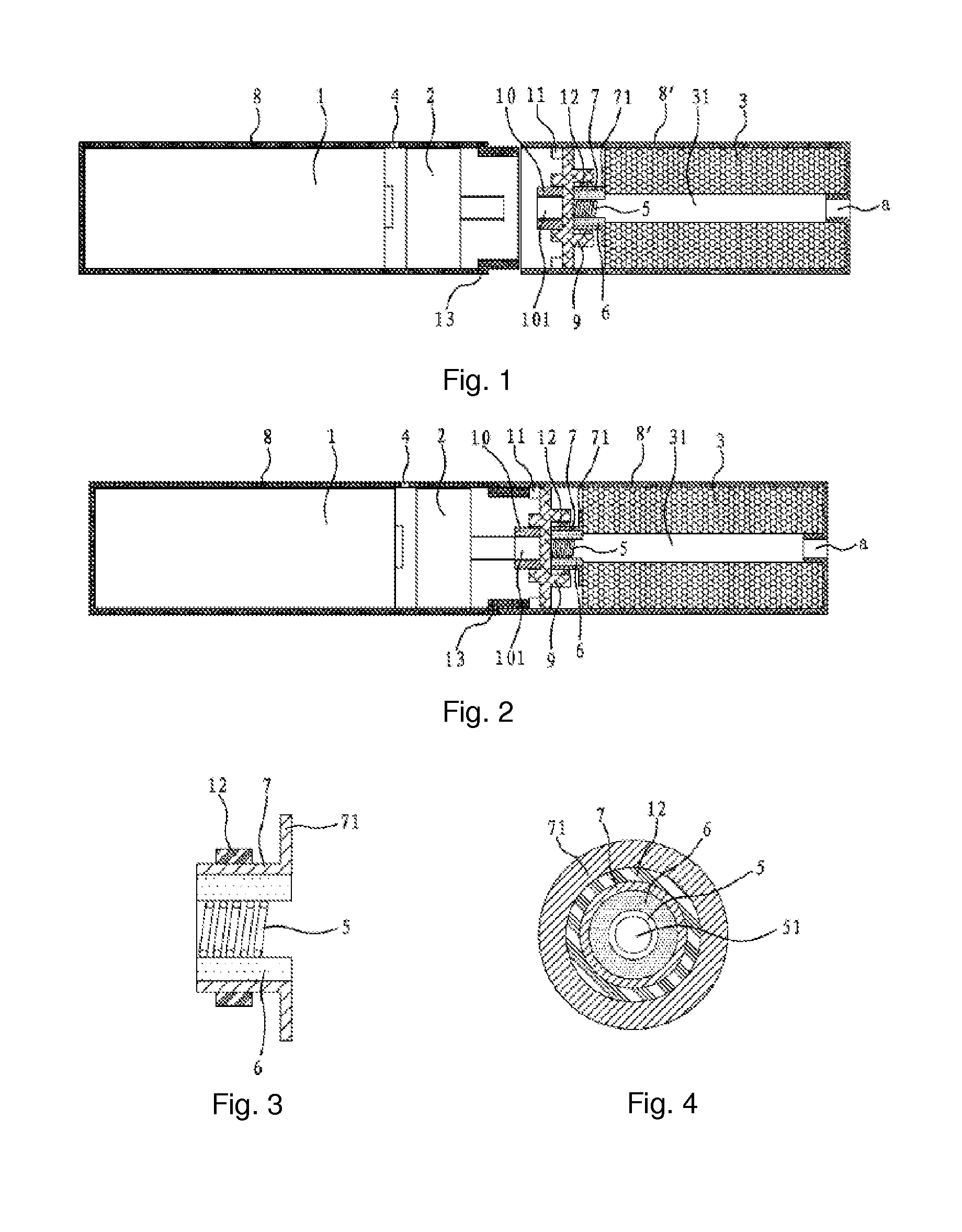

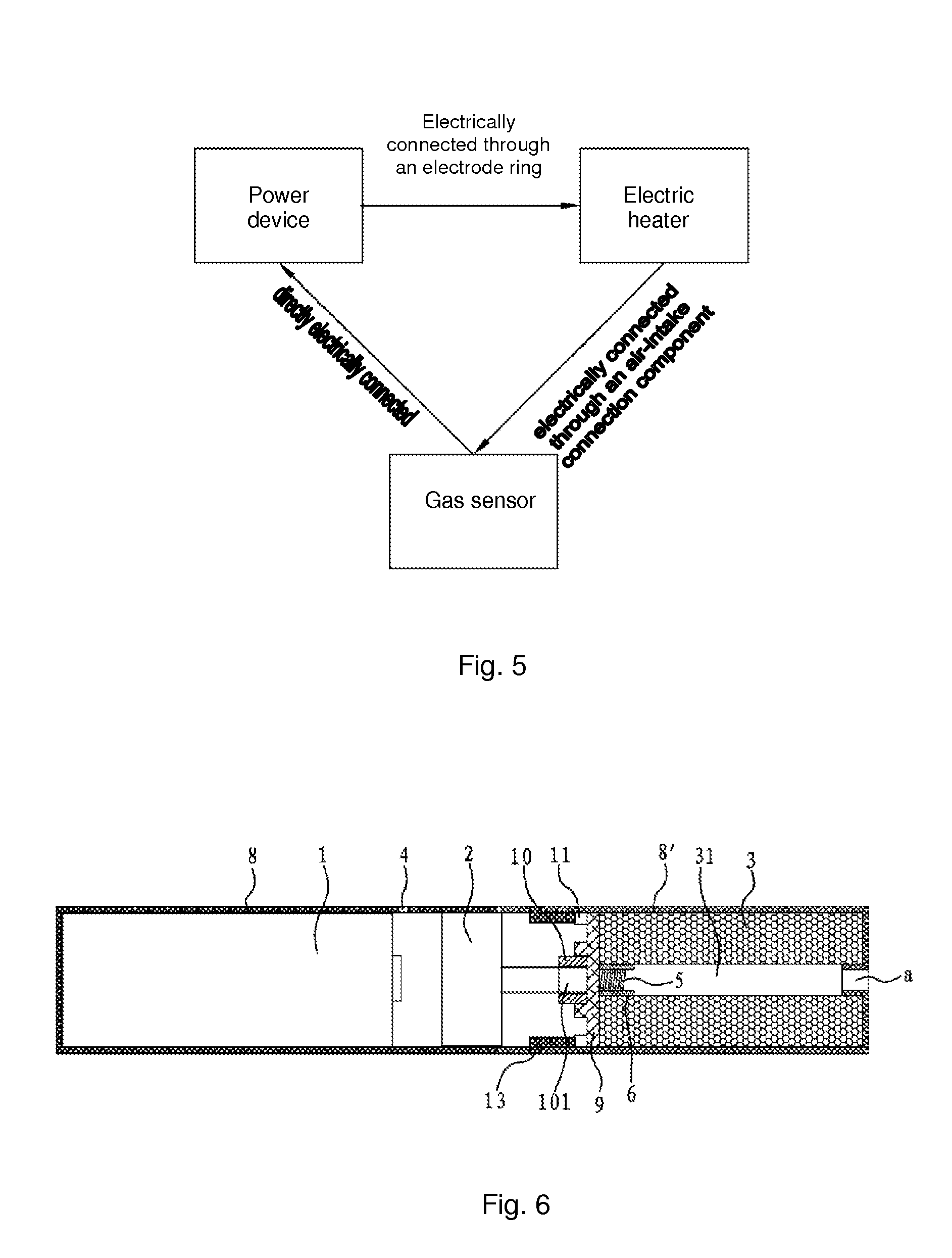

Atomizing electronic cigarette

InactiveUS20120111347A1Promote atomizationFully atomizedRespiratorsHeater elementsCore componentElectronic cigarette

An electronic cigarette has a power device (1), a sensor (2), an atomizing core component and a liquid storage component (3). The atomizing core component includes an electric heater (5) and a liquid permeating component (6). The electric heater (5) has a through hole (51), the liquid storage component (3) has a channel (31), and the sensor (2) is connected with the through hole (51) and the channel (31) to form an airflow loop by the auxiliary air inlet. The liquid permeating component (6) is directly sleeved on the electric heater (5), so that the cigarette can adequately heat gasified smoke with uniform small drops. The electric heater (5) and the liquid storage component (3) are connected with the through hole (51) and the channel (31), so that the vapor generated by the atomizing process can be cooled.

Owner:FONTEM HLDG 1

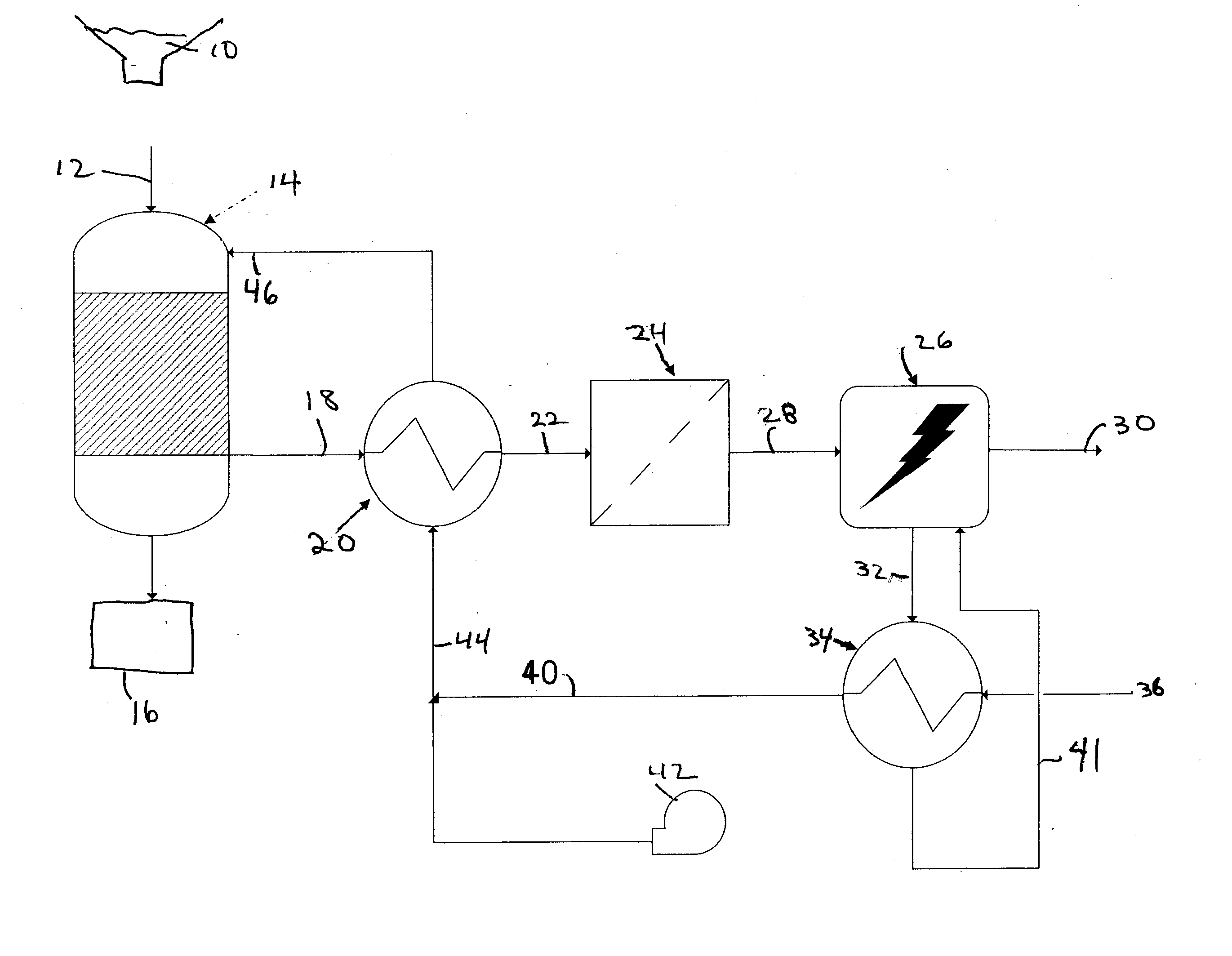

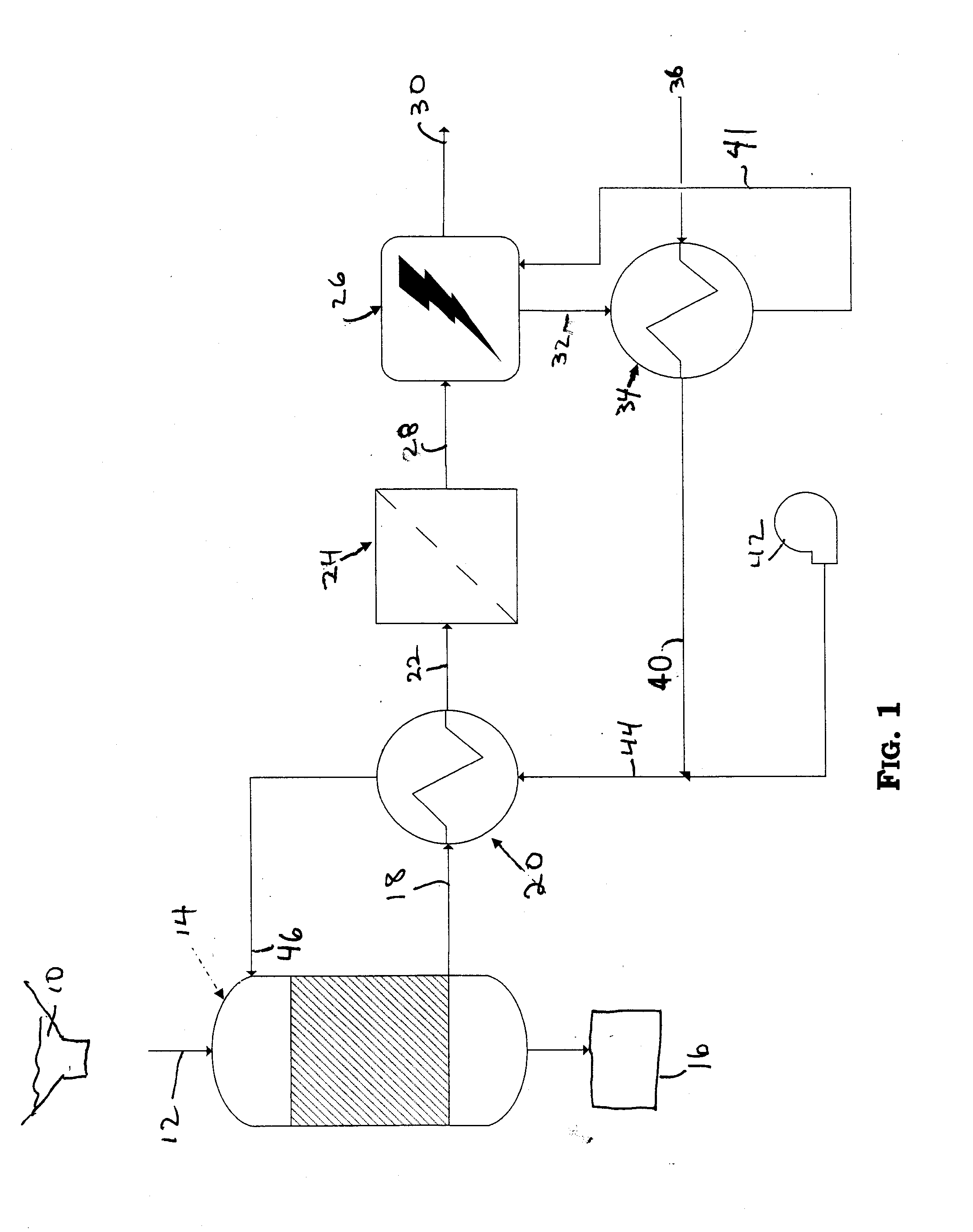

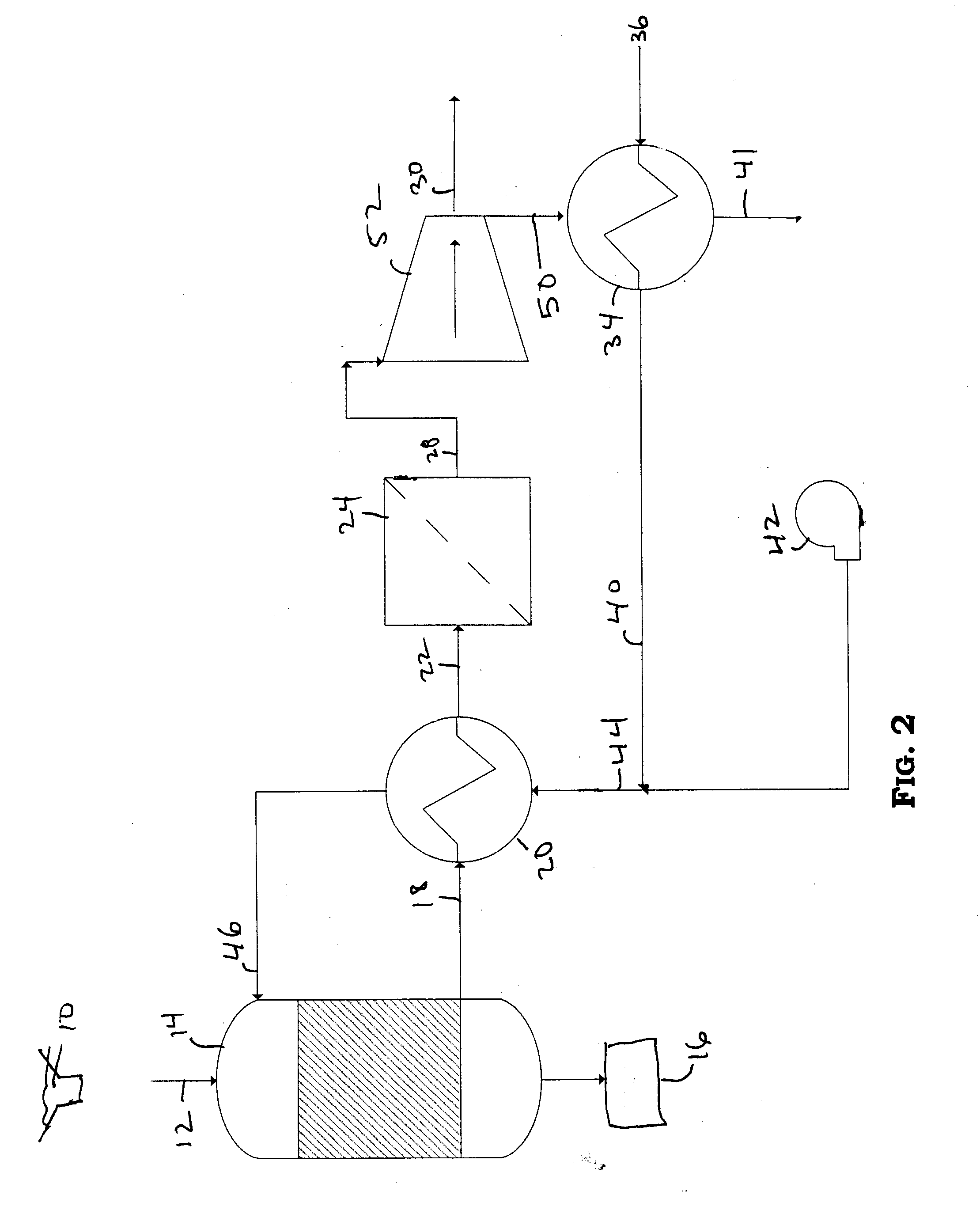

Method for improving gasification efficiency through the use of waste heat

InactiveUS20070220810A1Enhance energy densityEfficiently gasifyProductsReagentsProcess engineeringEnergy density

A method for recycling the waste heat generated from an external process, which is fuelled by syngas, into a gasification process to enhance the energy density of the syngas produced as well as the overall gasification efficiency of the system. A method is provided for utilizing the waste heat contained in a stream exiting in the syngas fueled process to vaporize water and produce steam. The steam is then upgraded by first exchanging energy with the hot syngas exiting the gasifier and then within the gasifier itself to a temperature where significant steam gasification of the biomass occurs. The process within the gasifier is driven by introducing a small amount of air into the gasifier such that some biomass is directly combusted to provide the heat required by the process.

Owner:ZEROPOINT CLEAN TECH

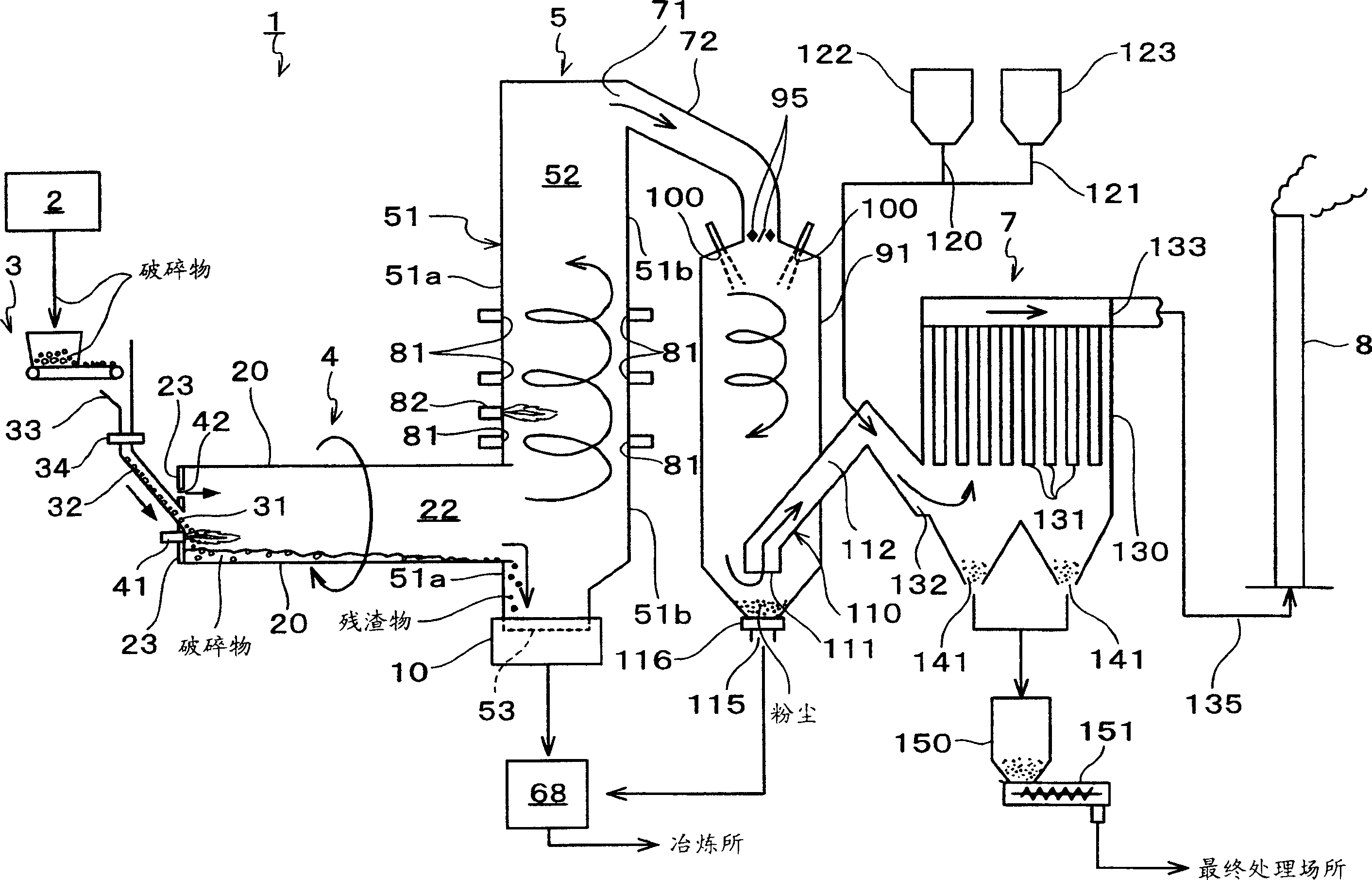

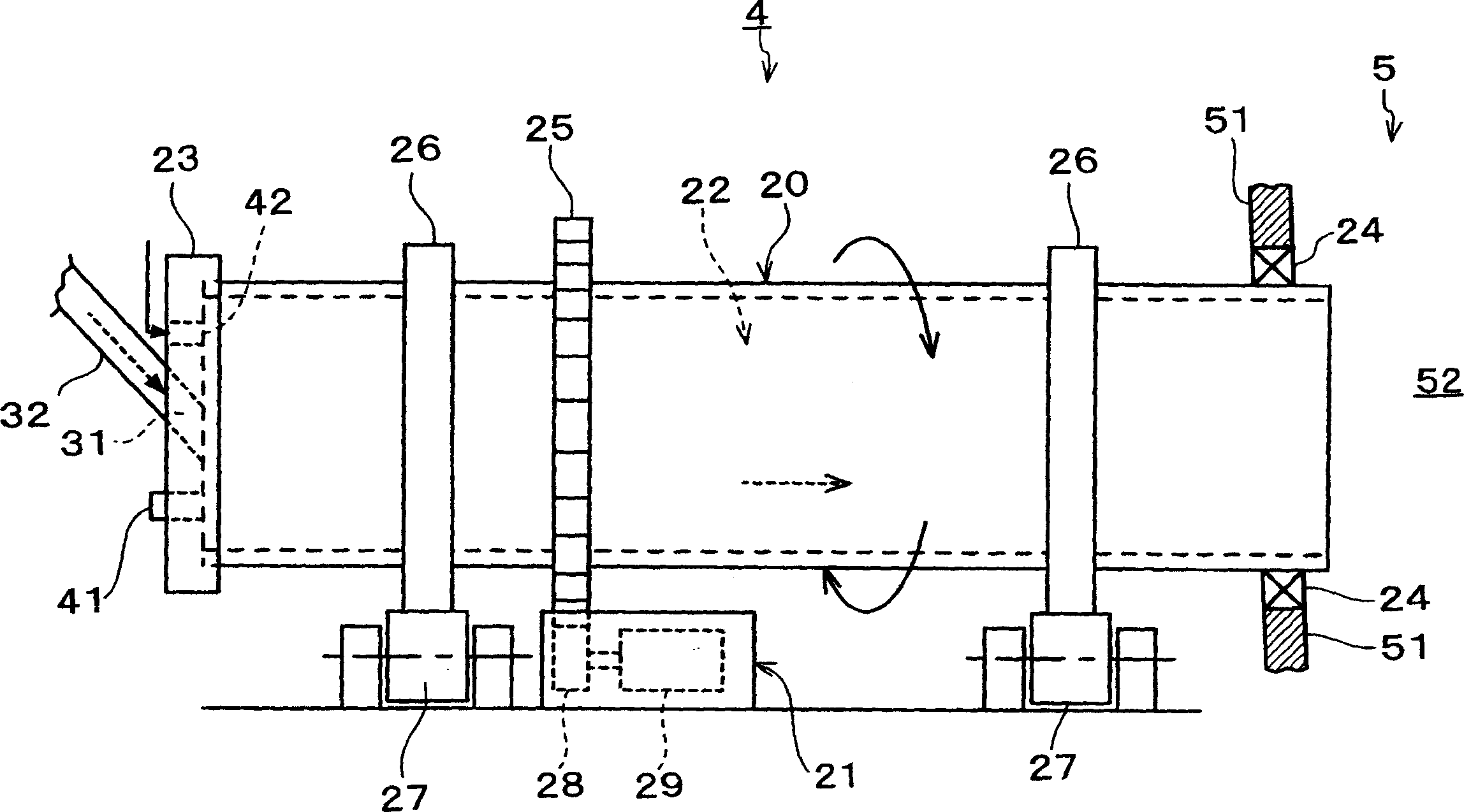

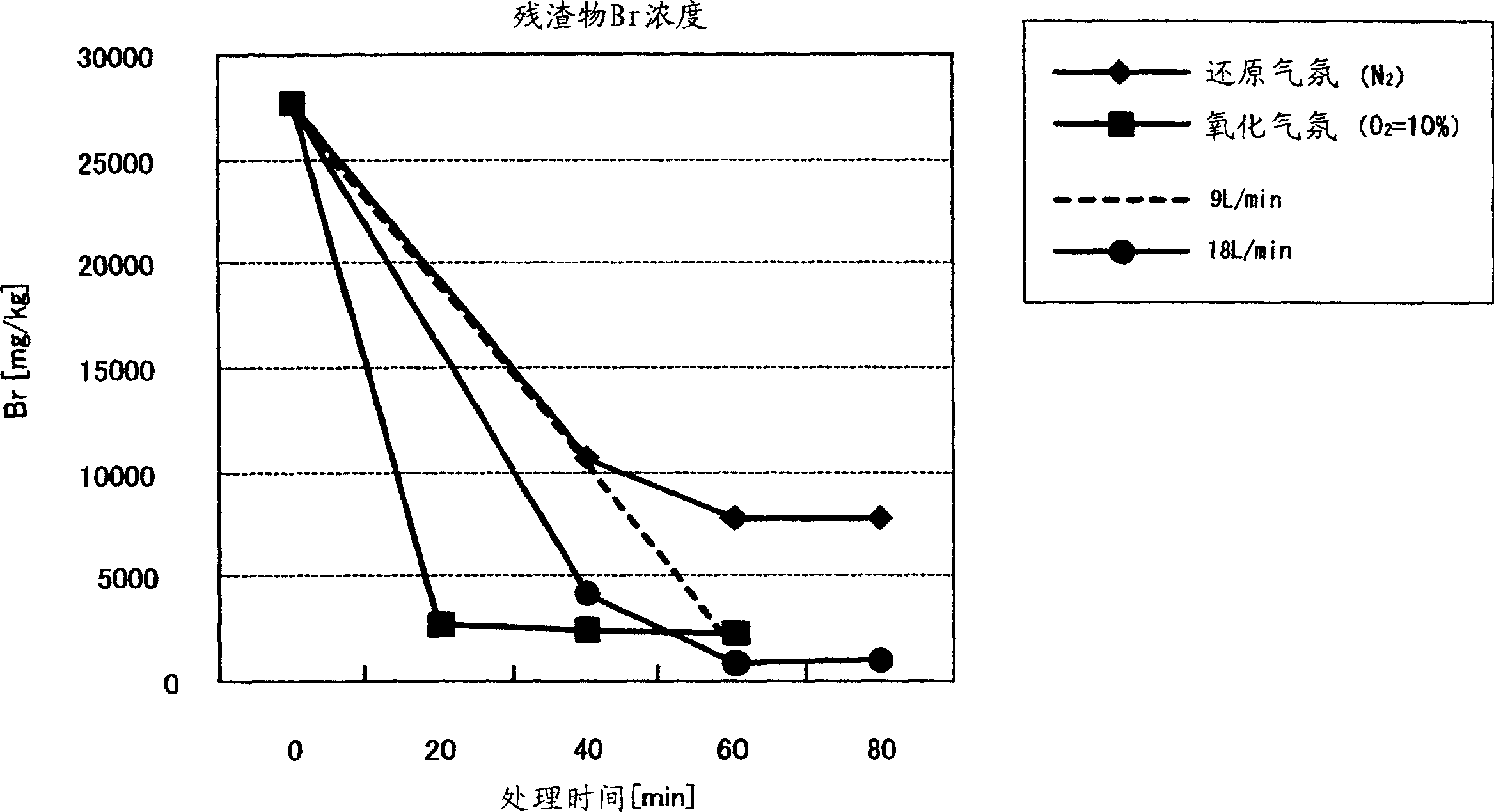

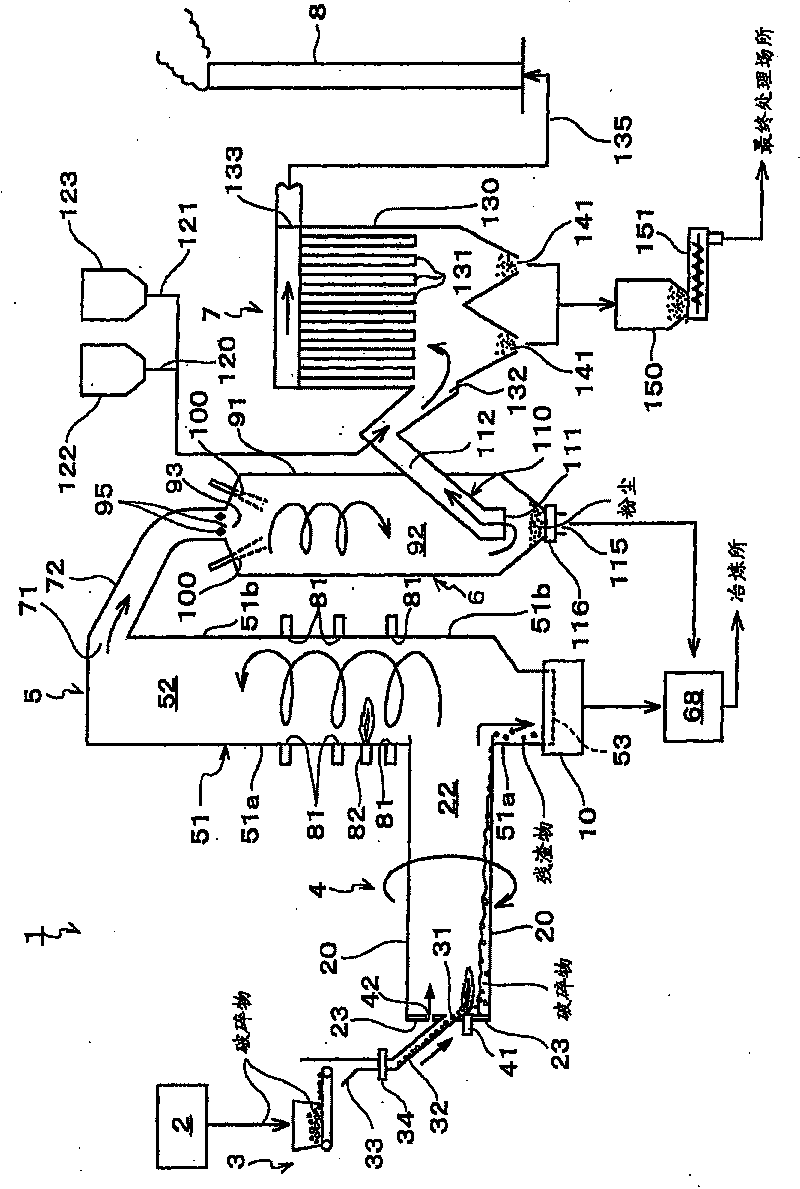

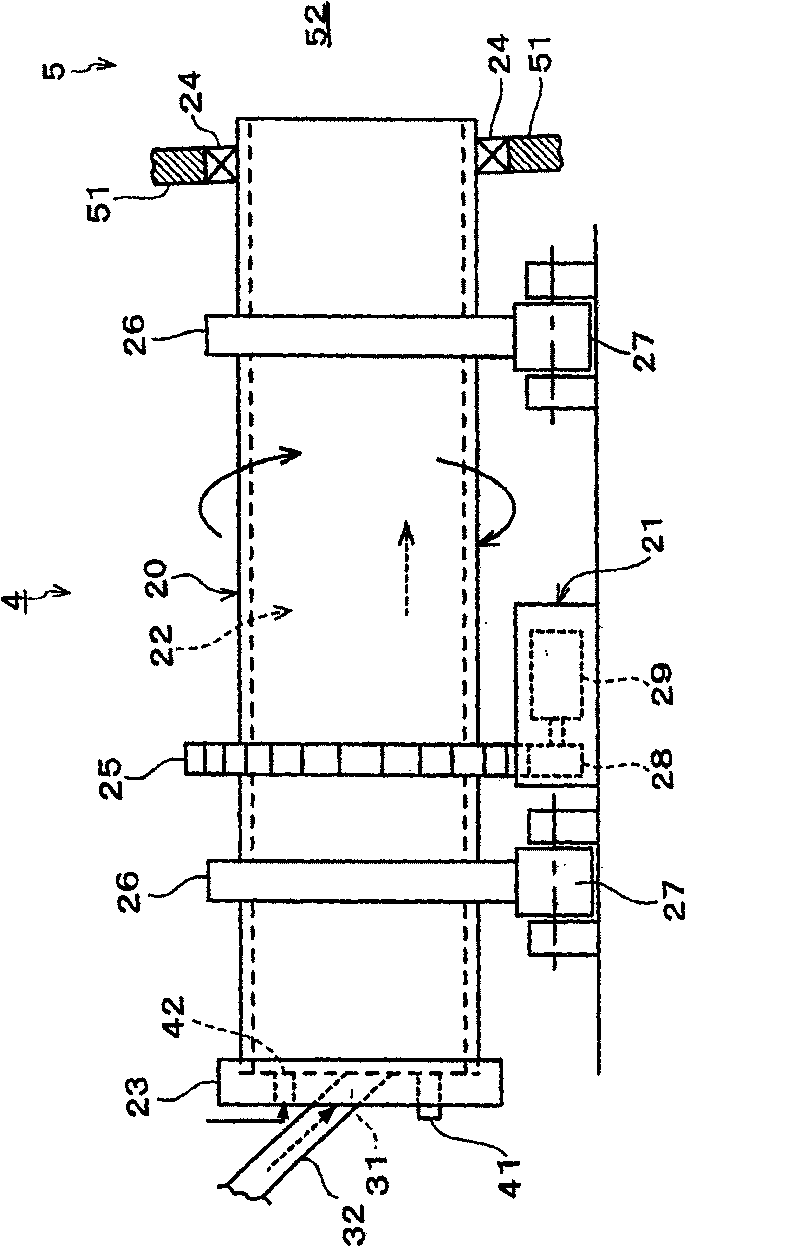

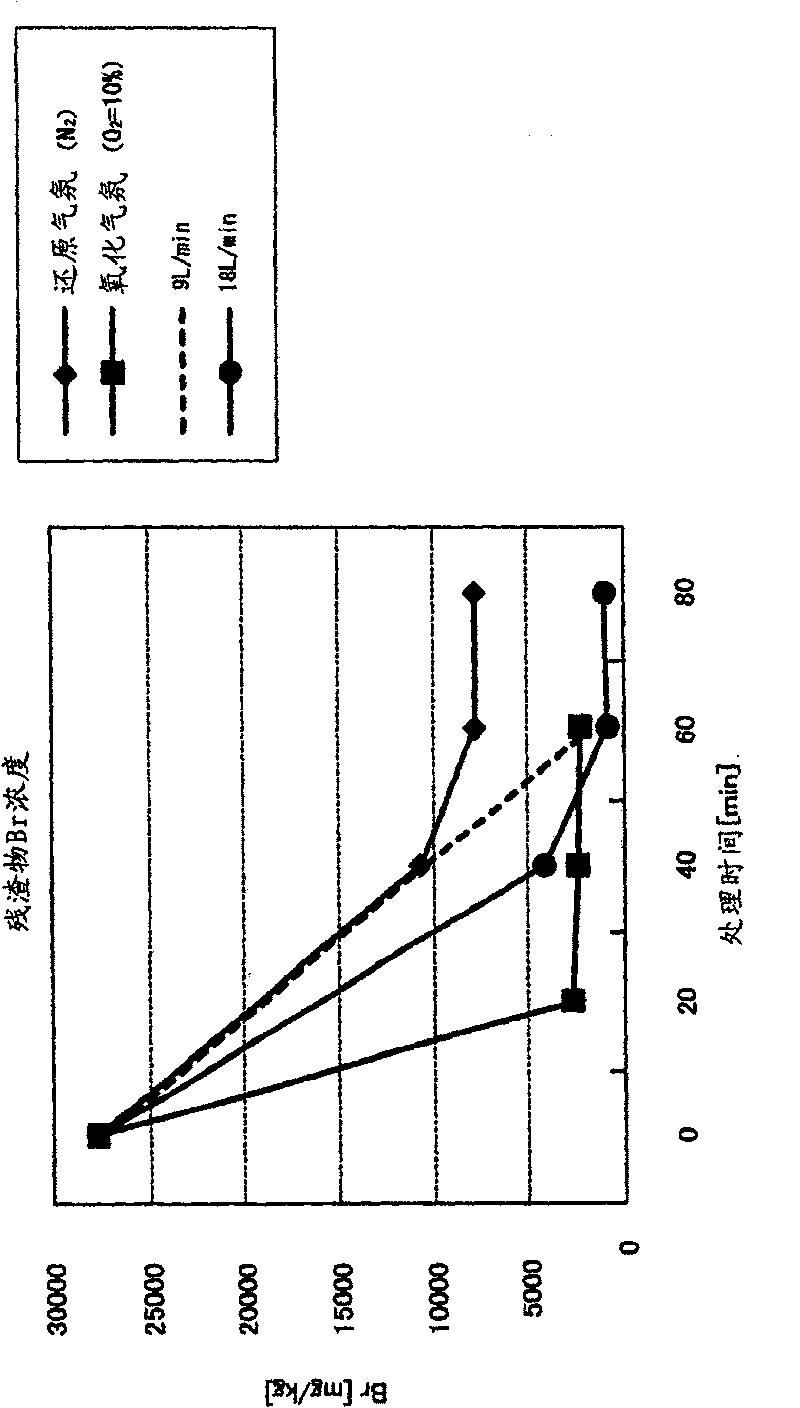

Castoff processing method and system

ActiveCN1834537AEfficient combustionEfficient gasificationProcess efficiency improvementIncinerator apparatusWaste processingHazardous substance

The invention relates to a waste processing method and a waste processing system which can avoid discharging harmful material as dioxins and effectively attain the slag of value metal. Wherein, the method for recycling value metal comprises: burning the waste, recycling the slag that containing value metal, and fully burning generated gas , and cooling said burning gas with the cooling speed that avoiding generating dioxins. With said method, the invention can gasify the resin component in the waste via burning waste, to obtain the slag of value metal in short time.

Owner:DOWA METALS & MINING CO LTD

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

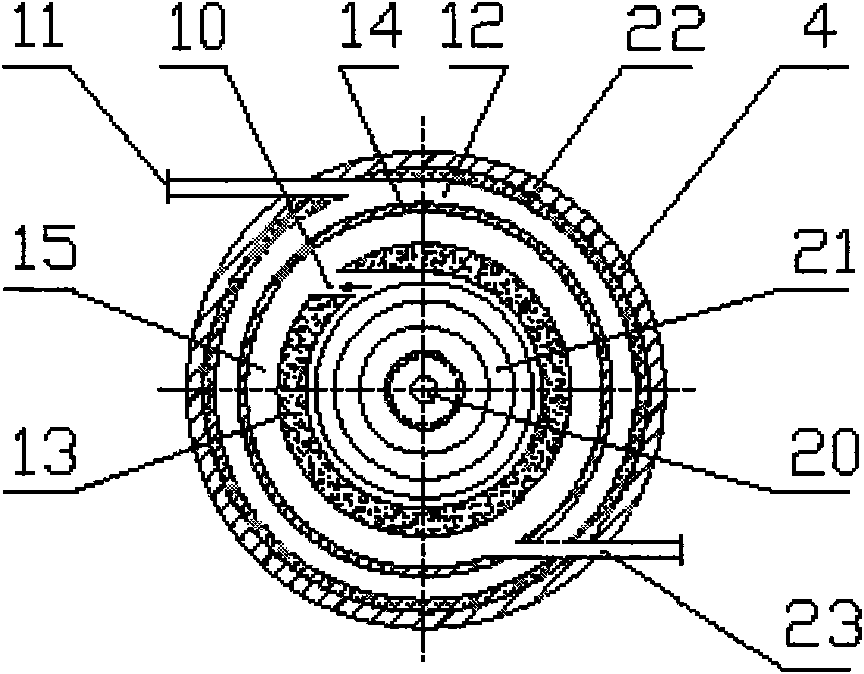

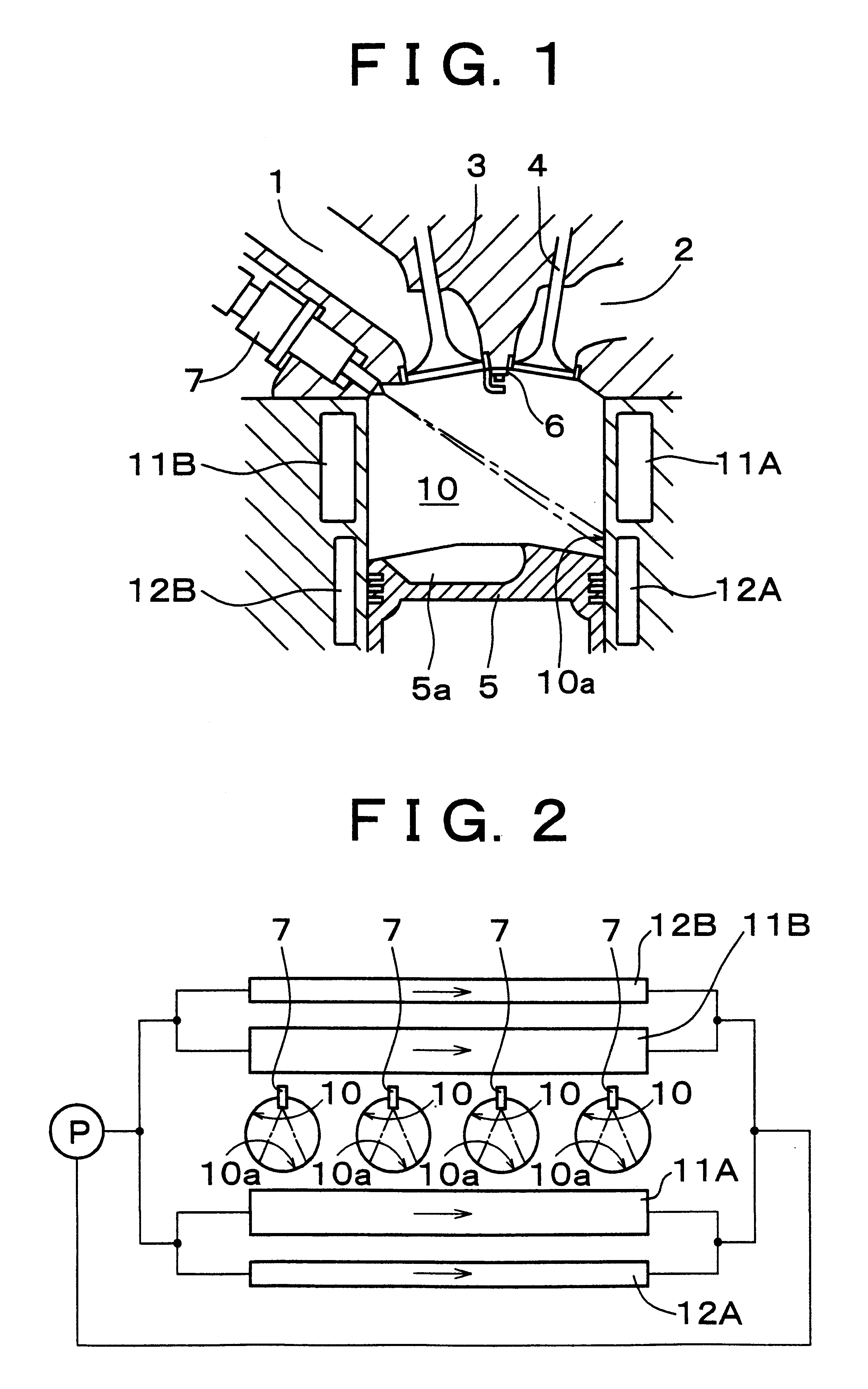

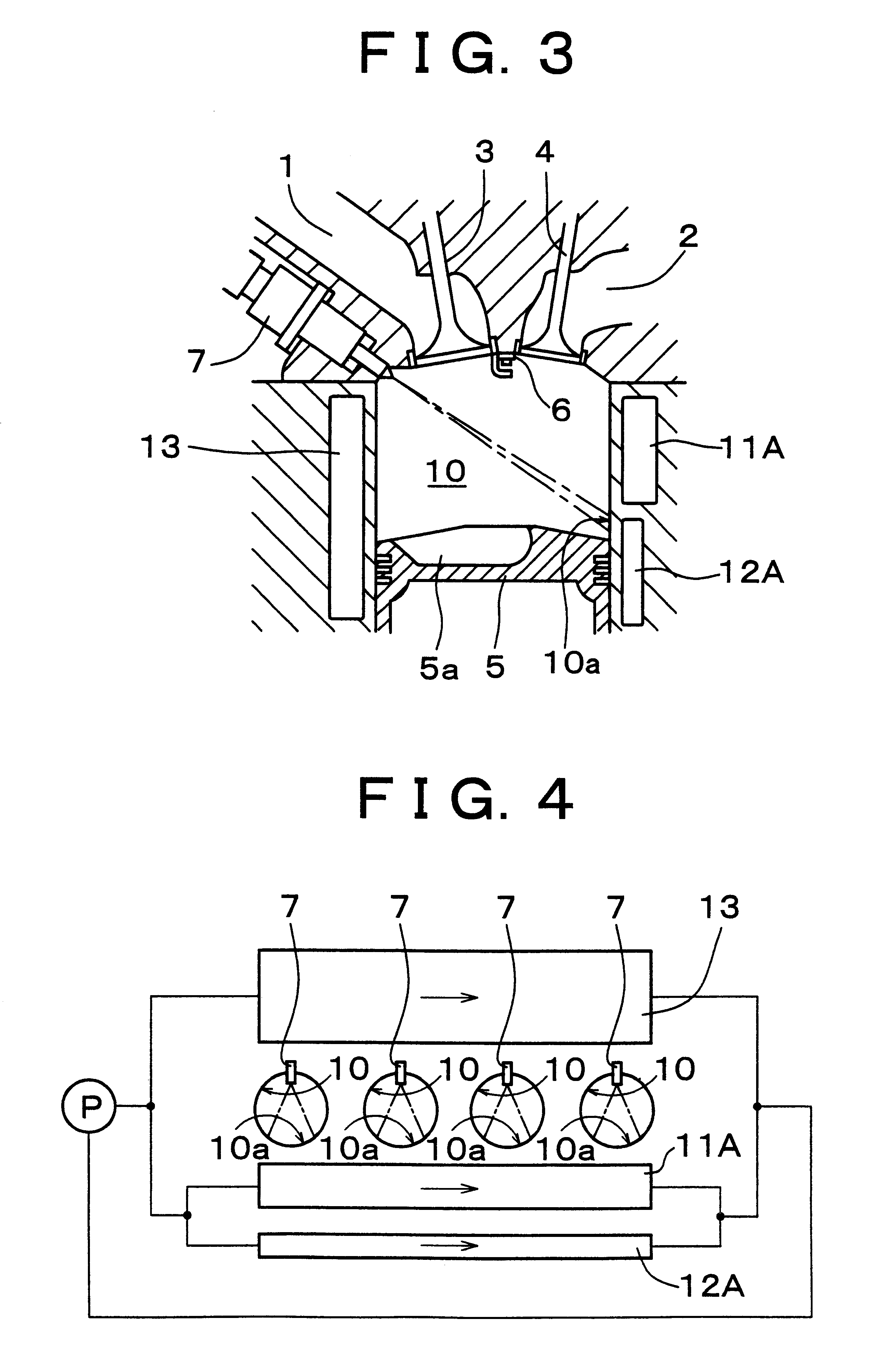

Direct-fuel-injection-type spark-ignition internal combustion engine and method of controlling the internal combustion engine

InactiveUS6349697B1Avoid temperature dropAvoid it happening againLiquid coolingElectrical controlExternal combustion engineEngineering

A direct-fuel-injection-type spark-ignition internal combustion engine has a fuel injection valve which directly injects fuel into a cylinder. A nozzle hole of the fuel injection valve directs fuel toward an impingement portion of the cylinder bore located opposed to the nozzle hole in a lower section of the cylinder bore so that fuel can be injected into a cavity formed in a top face of a piston from an upper section of the cylinder bore during the latter half of a compression stroke. A cooler located at least in the neighborhood of the impingement portion in the lower section of the cylinder bore has a lower cooling capacity than a cooler located in the neighborhood of the upper section of the cylinder bore. Thus, fuel injected during the latter half of an intake stroke that adheres to the cylinder bore can be effectively gasified.

Owner:TOYOTA JIDOSHA KK

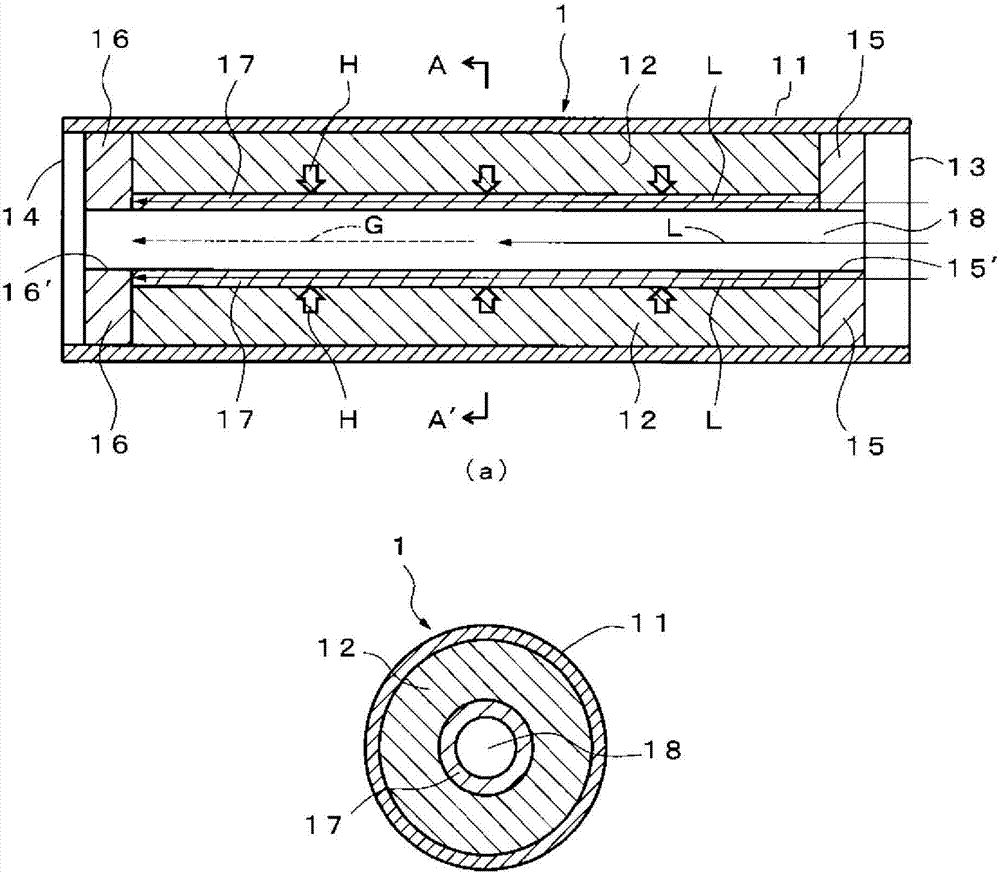

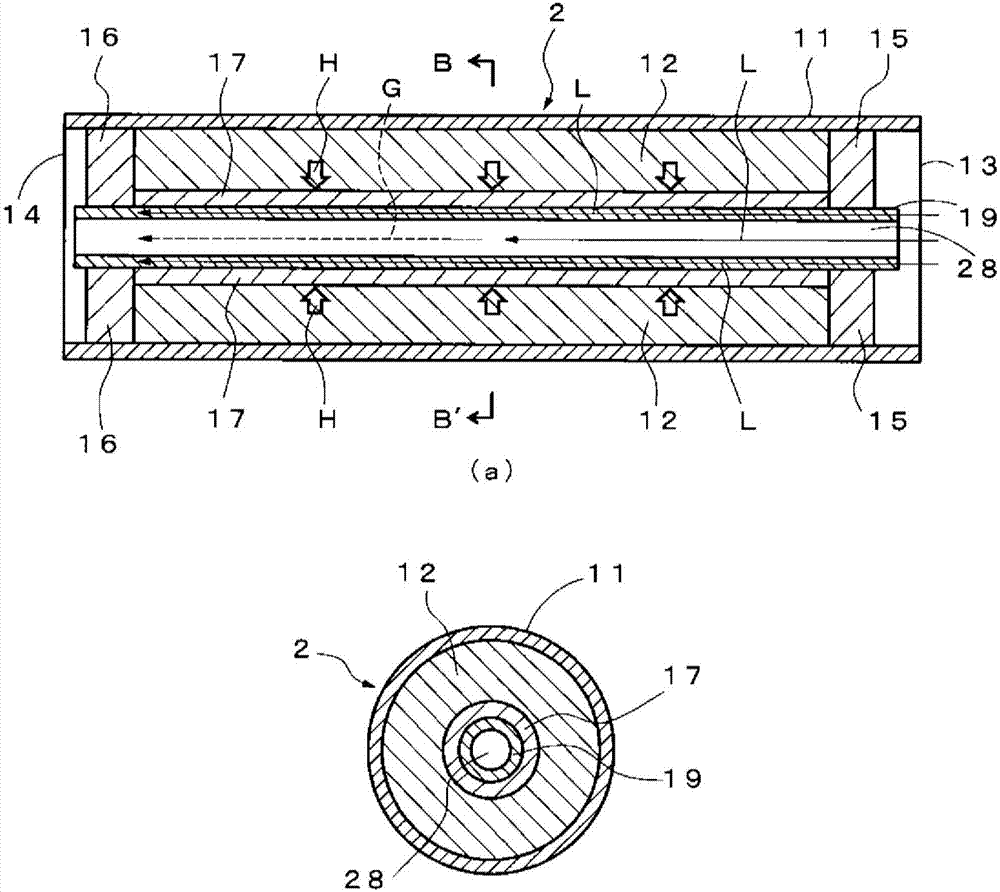

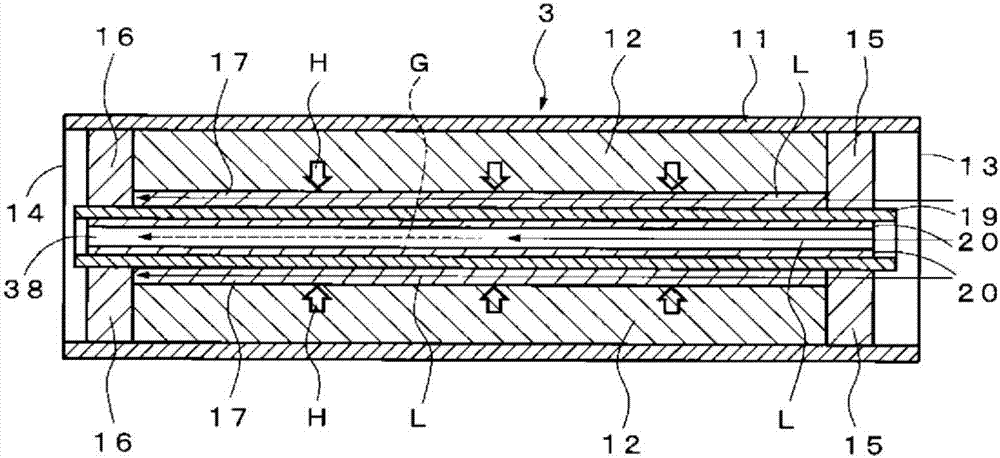

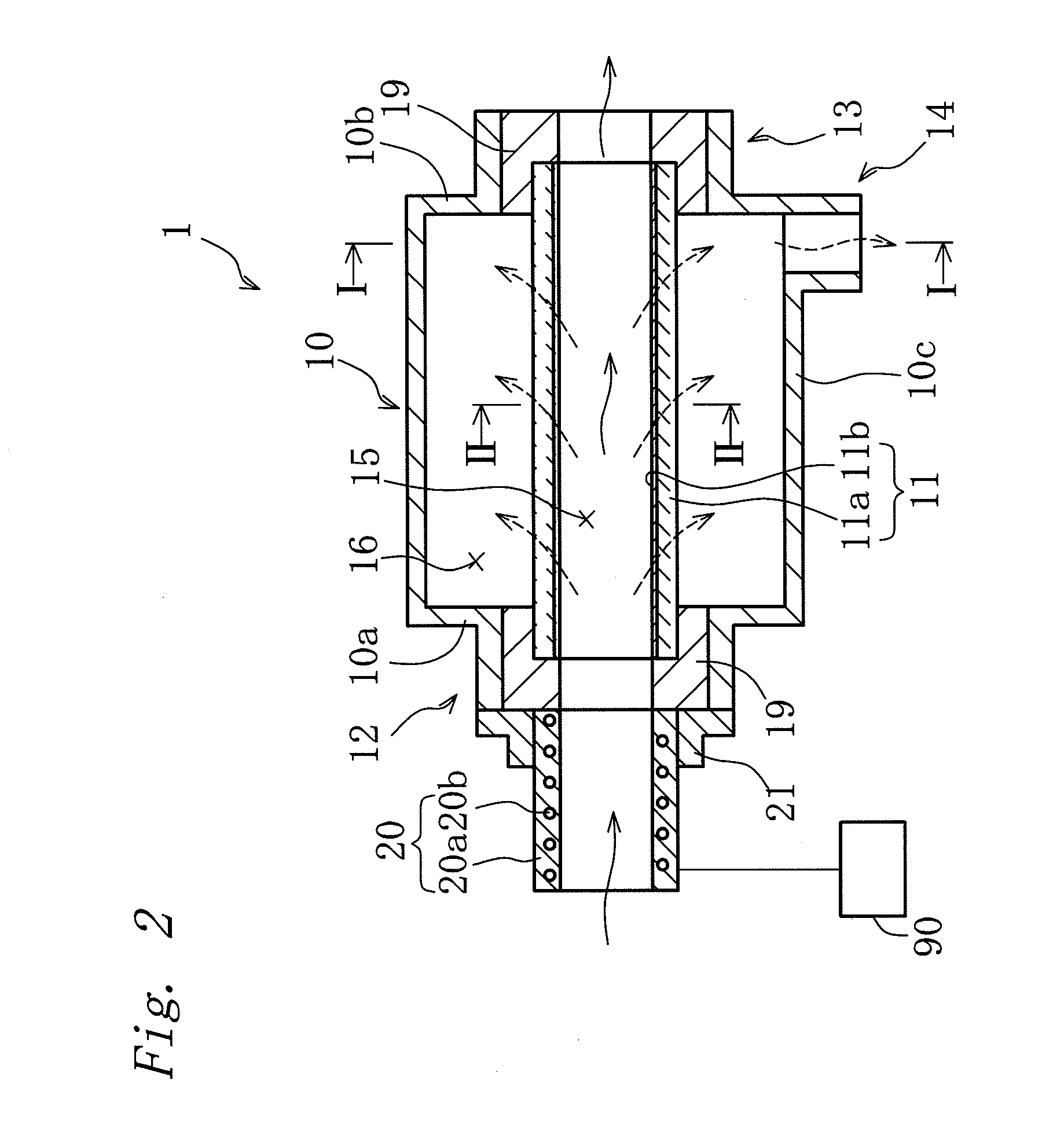

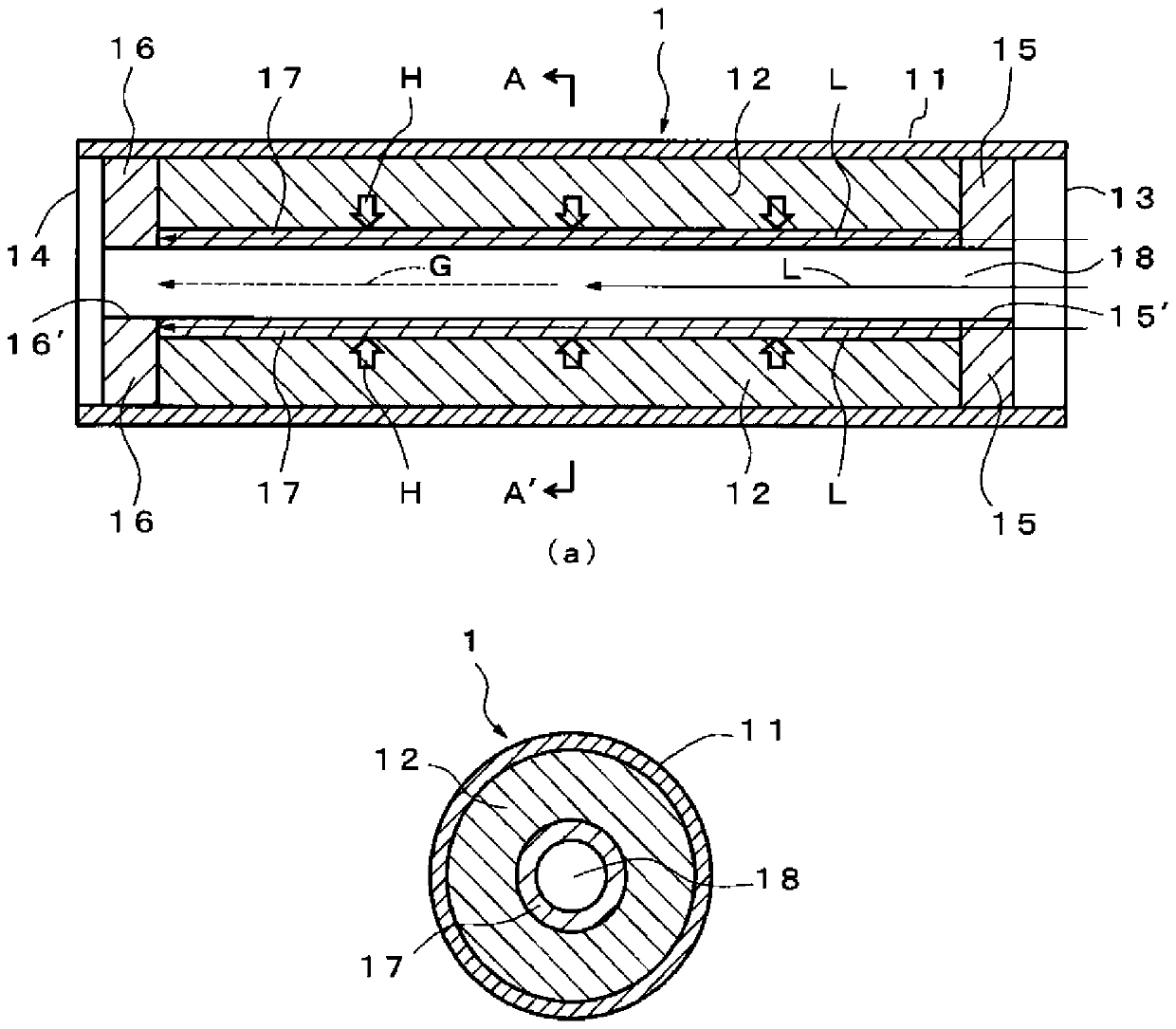

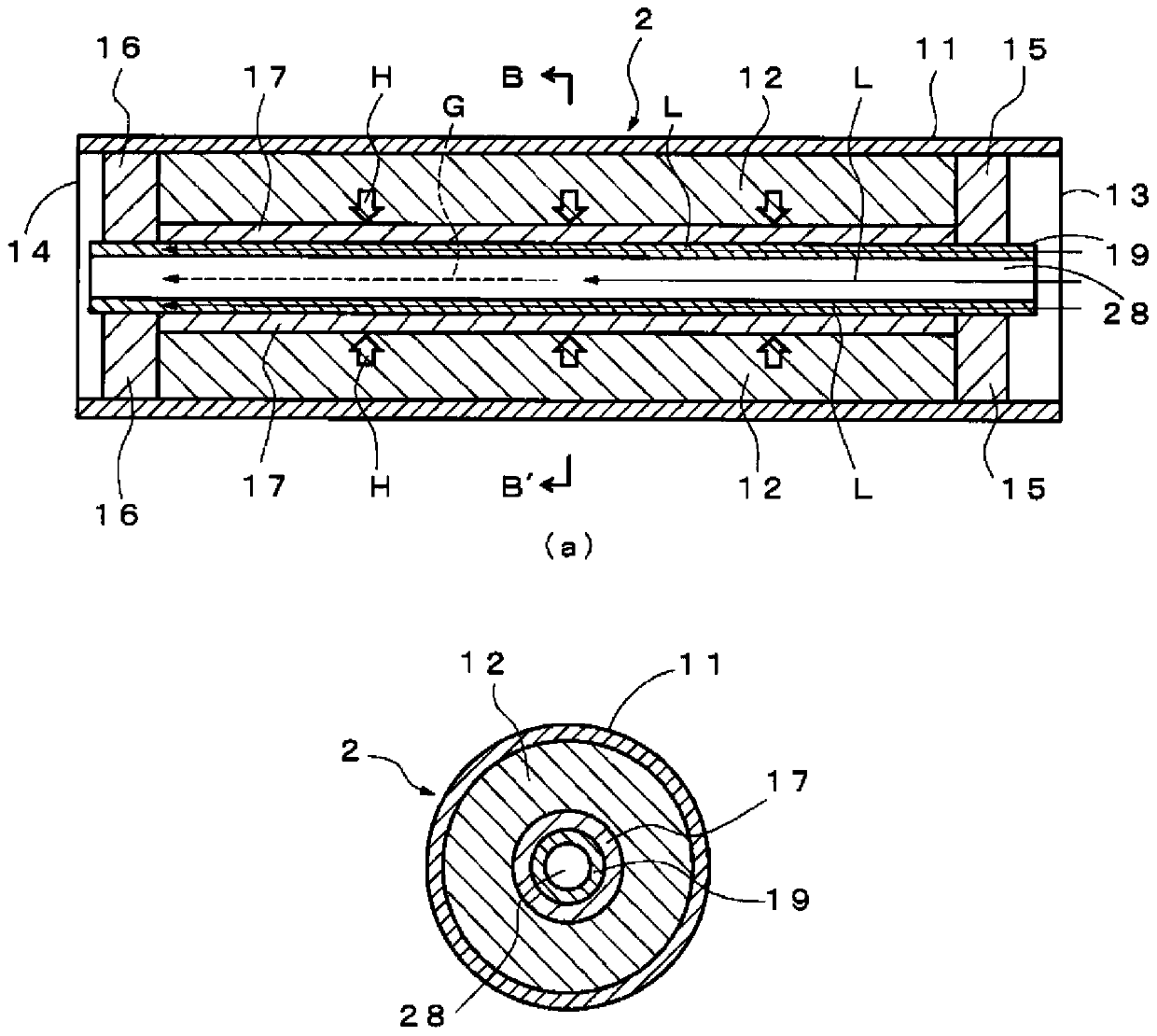

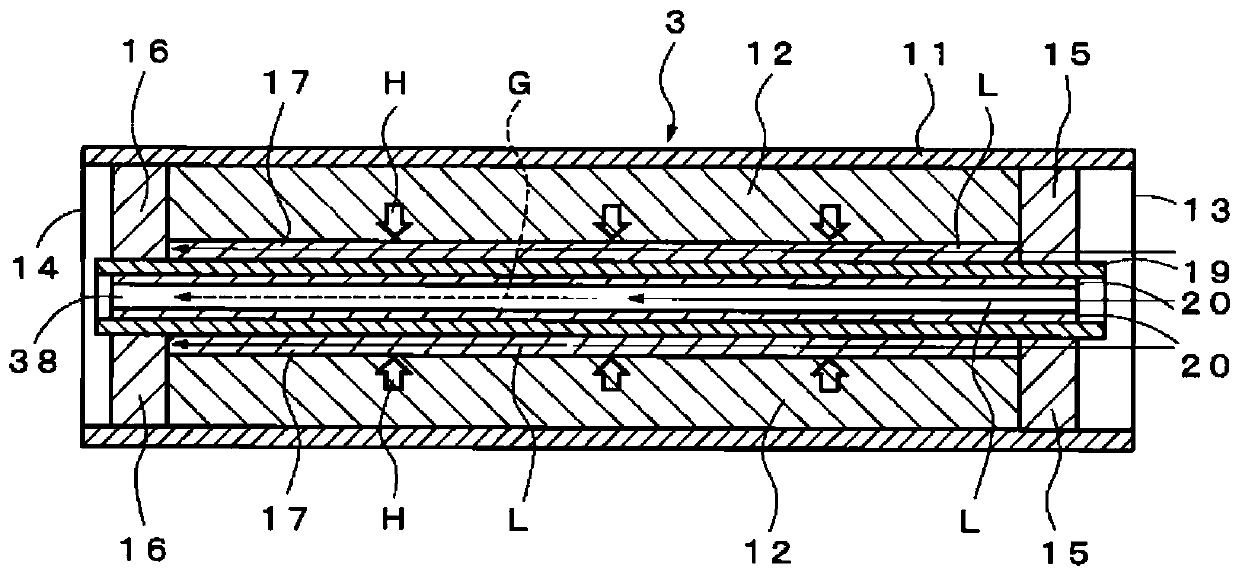

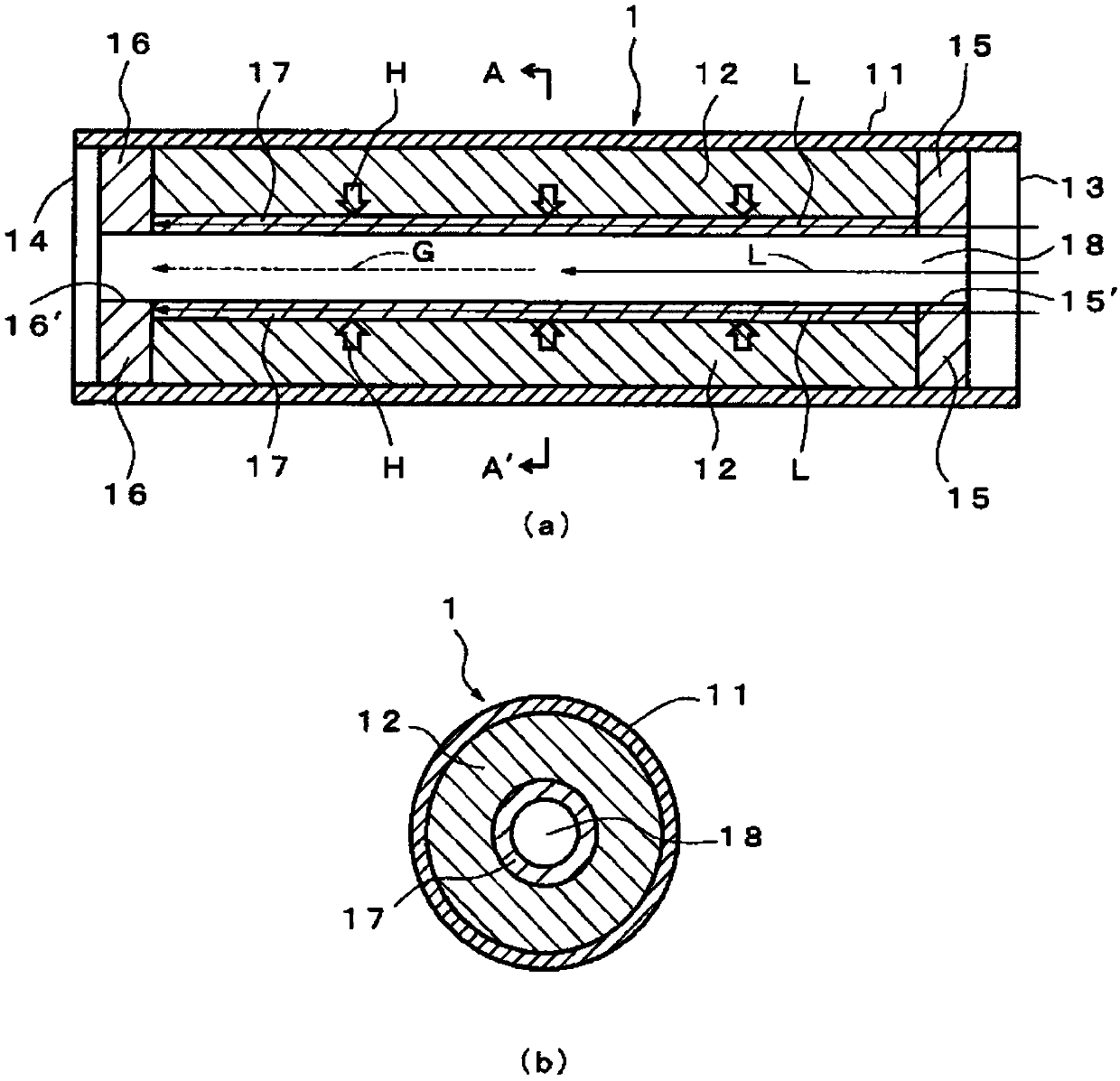

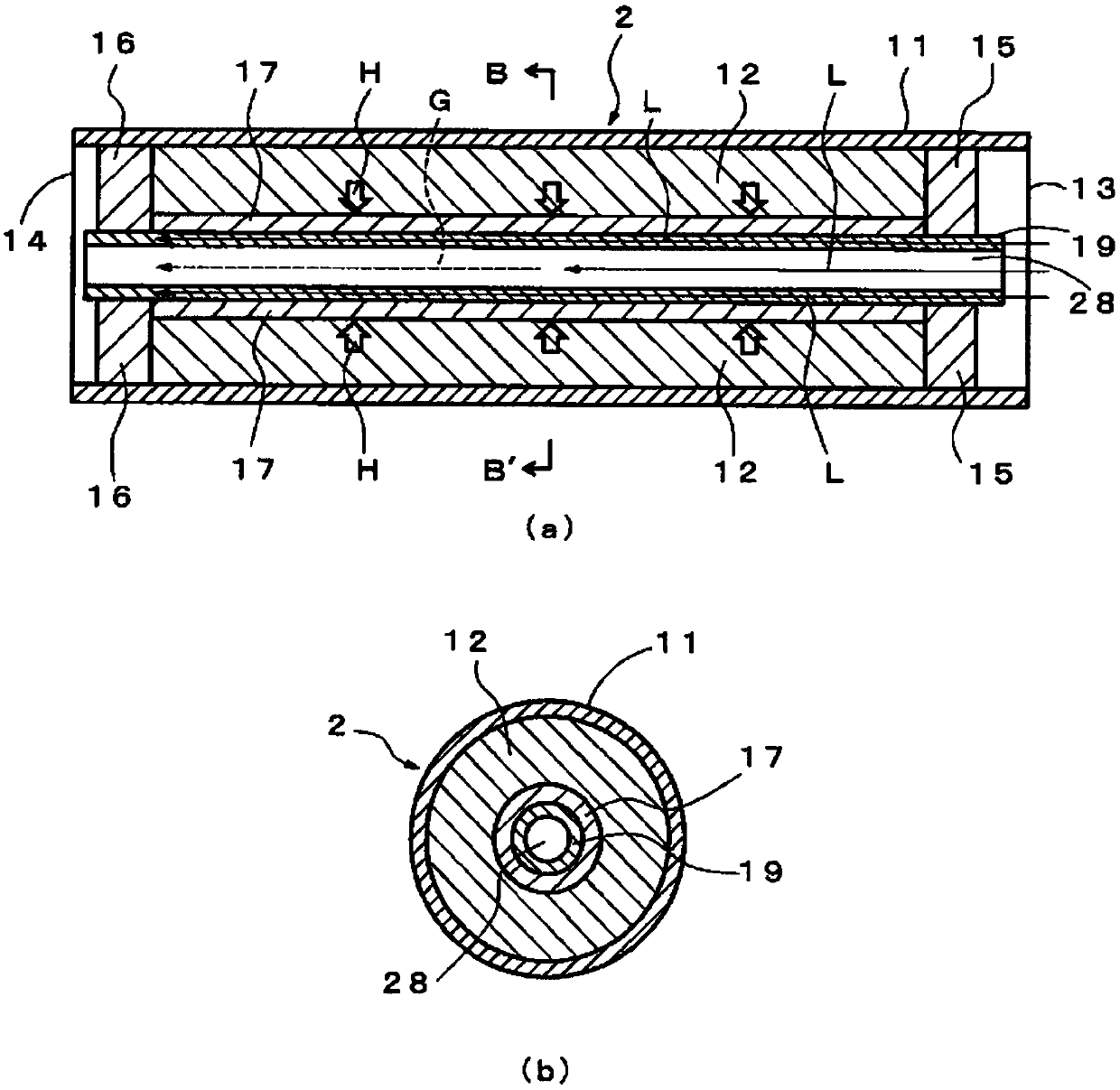

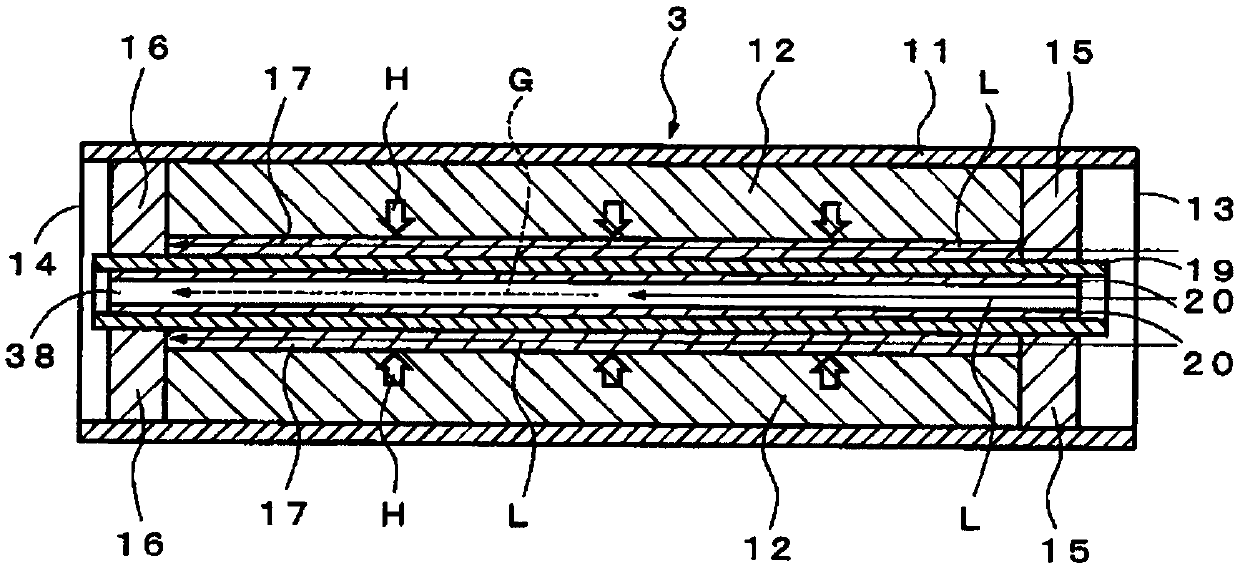

Heat storage container and heat storage device provided with heat storage container

ActiveCN107110613ASimple structureExcellent heat storage densityHeat storage plantsHeat-exchange elementsProcess engineeringHeat storage material

Provided is a heat storage system that is capable of improving the calorific quantity and the heat transport amount using a simple configuration, a heat storage container, and a heat storage device in which the heat storage container is used. A heat storage system in which is used a heat storage container having a tubular body, a chemical heat storage element accommodated in the tubular body, and a flow channel that penetrates the tubular body in the longitudinal direction, wherein: the heat storage system has a diffusion layer for transporting, from the flow channel toward the chemical heat storage element, a liquid that functions as a reaction medium with the chemical heat storage element; the liquid is transported in the flow channel; the liquid is transported to the diffusion layer; the liquid transported to the diffusion layer reacts with the chemical heat storage element, and the chemical heat storage material generates heat; and the liquid is vaporized by the heat to become a heat transporting fluid.

Owner:FURUKAWA ELECTRIC CO LTD

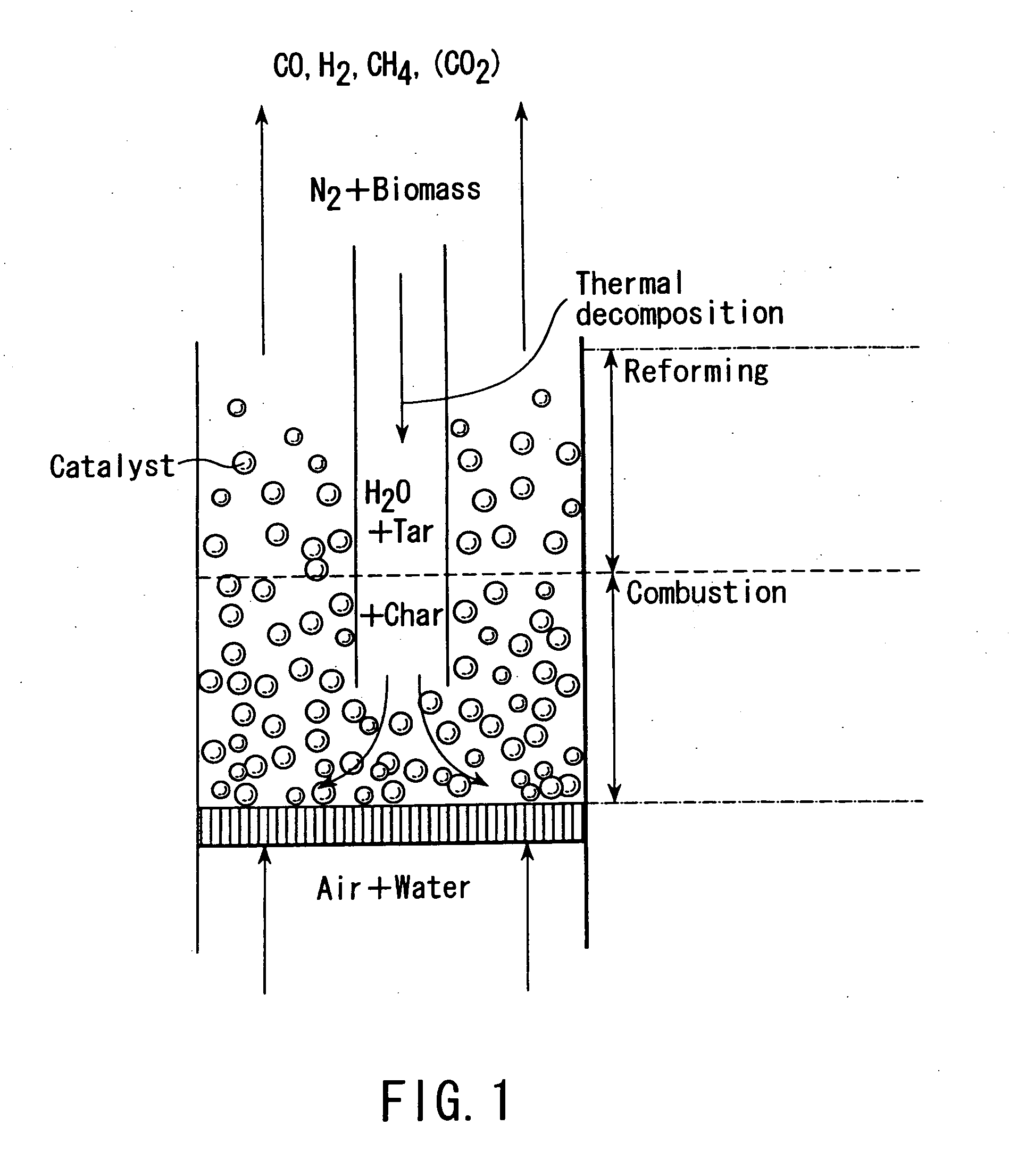

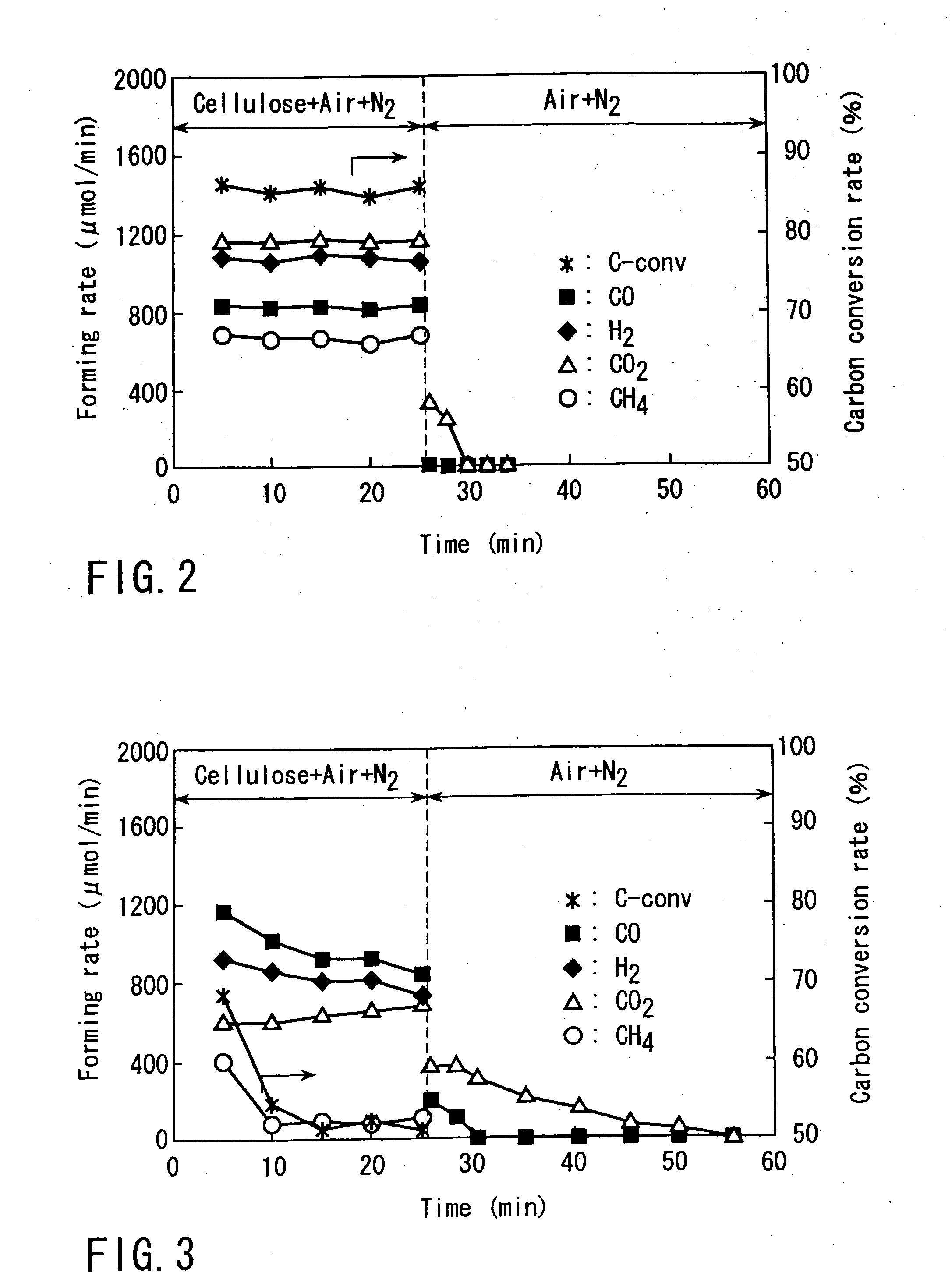

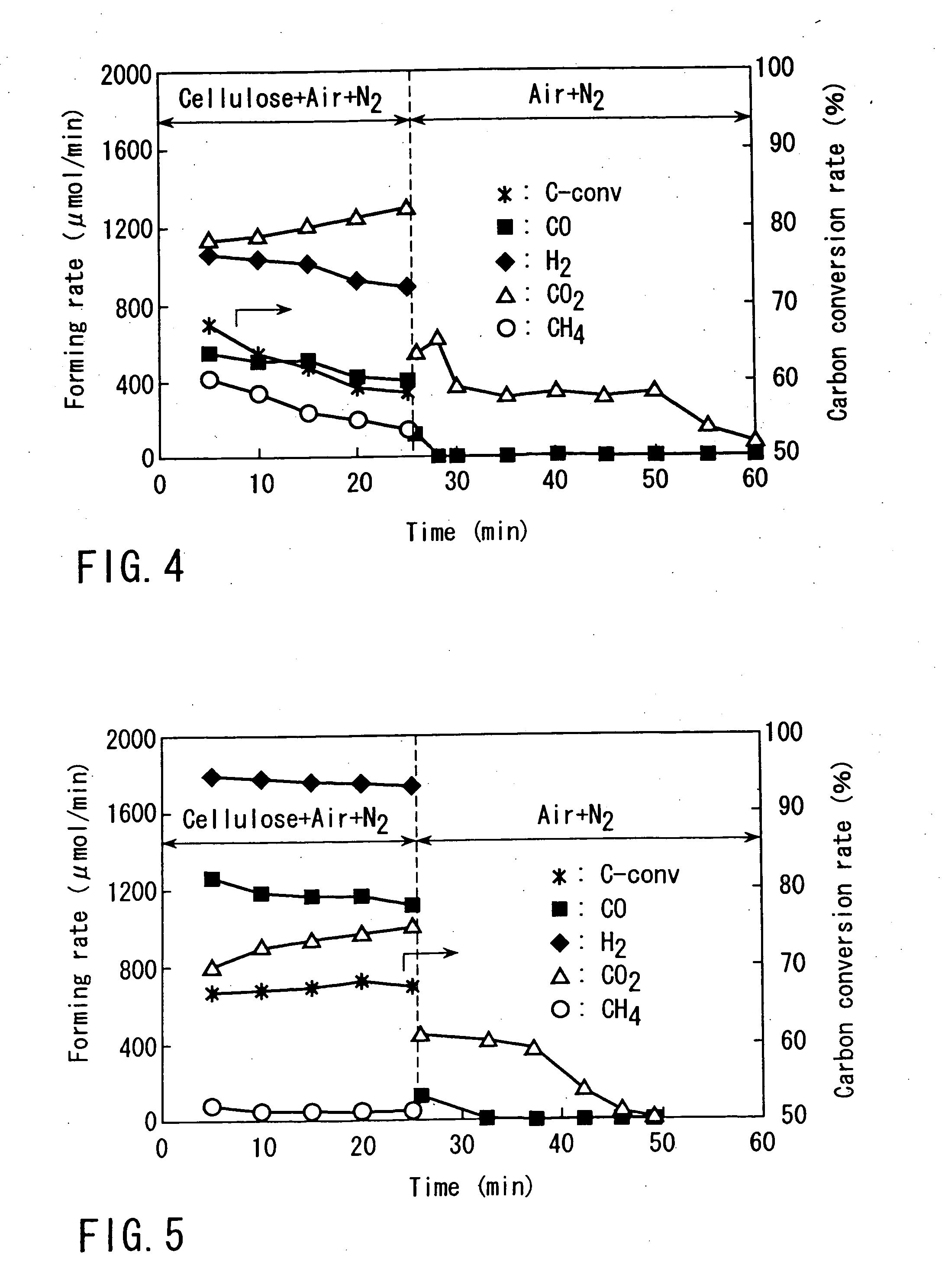

Method for gasifying biomass and catalyst used for said method

Disclosed is a method of gasifying a biomass, comprising heating a fluidized bed reactor loaded with a catalyst represented by Rh / CeO2 / M, where M represents SiO2, Al2O3 or ZrO2, to temperatures lower than 800° C. introducing biomass particles into the fluidized bed reactor from an upper portion thereof, introducing air and steam into the fluidized bed reactor from a lower portion thereof, and allowing the biomass particles to react at the surface of the Rh / CeO2 / M catalyst so as to manufacture hydrogen and a syngas.

Owner:TOHOKU UNIV

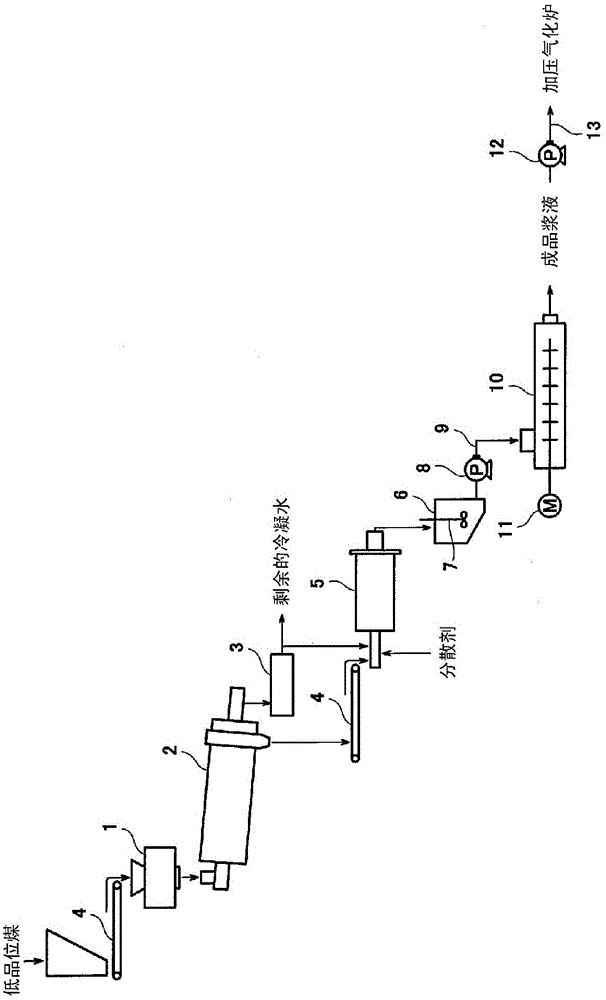

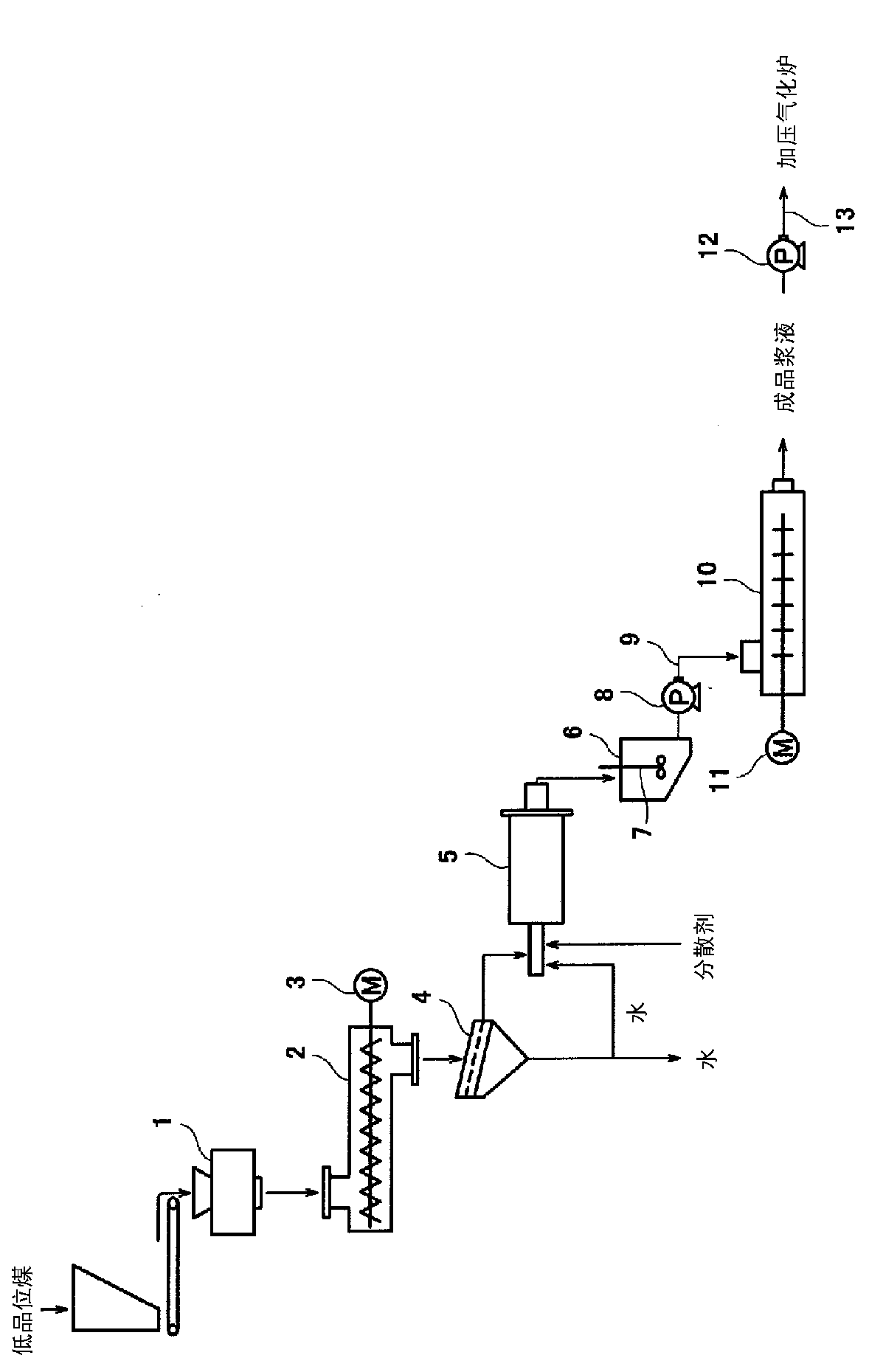

Low-grade coal slurry production method, low-grade coal slurry production device, and low-grade coal gasification system

ActiveCN103298918AEasy to manufactureLow viscosityGasification processes detailsLiquid carbonaceous fuelsCondensed waterProcess engineering

The purpose of the present invention is to provide: a production method and production device with which it is easy to produce a low-grade coal slurry having a high slurry concentration and a low viscosity, and which is appropriate for gasification using a pressurized gasification furnace; and a gasification system provided with such a production device. This low-grade coal slurry production method has: a first step for heating and drying coarsely ground low-grade coal, and recovering condensed water emitted from the low-grade coal as steam; and a second step for adding a dispersant and the condensed water obtained during the first step to the heated and dried low-grade coal, and forming a slurry using the wet-grinding method. In addition, this low-grade coal slurry production device has: a drying device for heating and drying the coarsely ground low-grade coal; a condensed water recovery device for recovering condensed water emitted from the low-grade coal as steam through the heating and drying; and a wet-grinding device for adding the condensed water and the dispersant to the heated and dried low-grade coal, and forming a slurry.

Owner:KAWASAKI HEAVY IND LTD

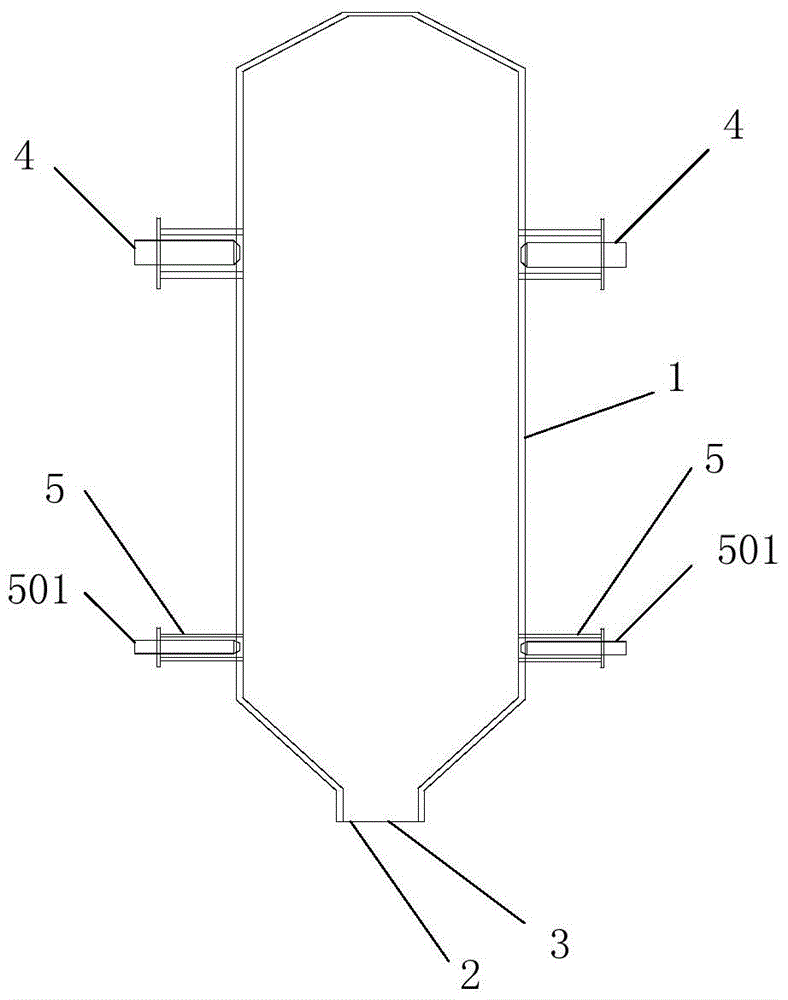

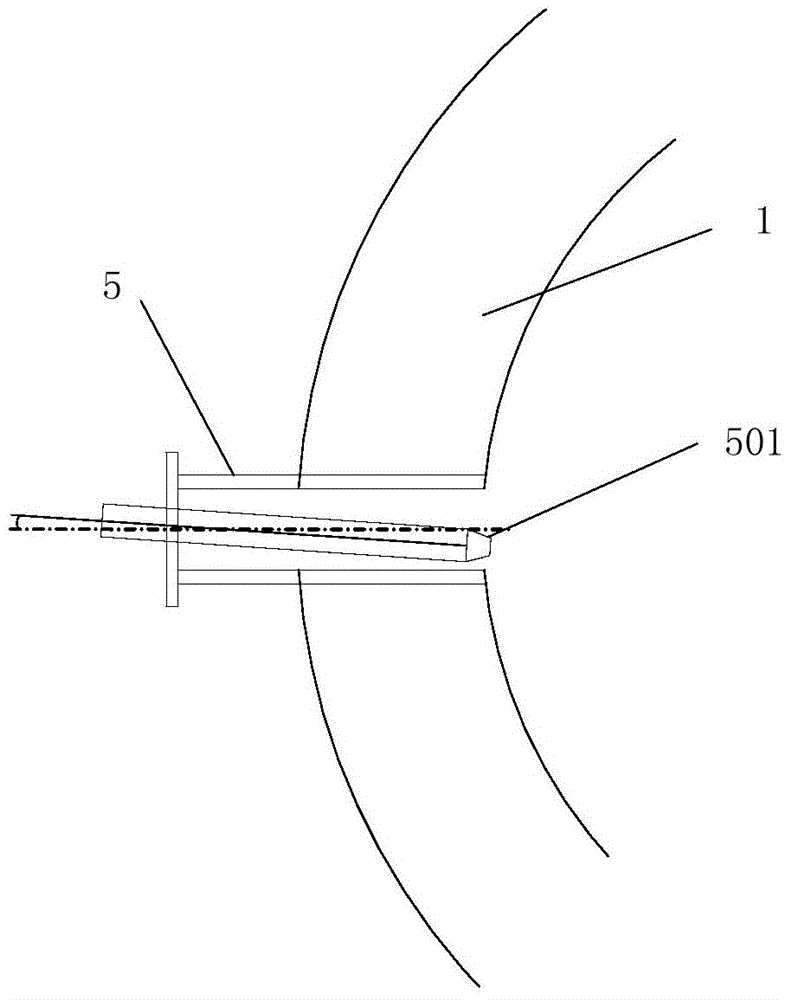

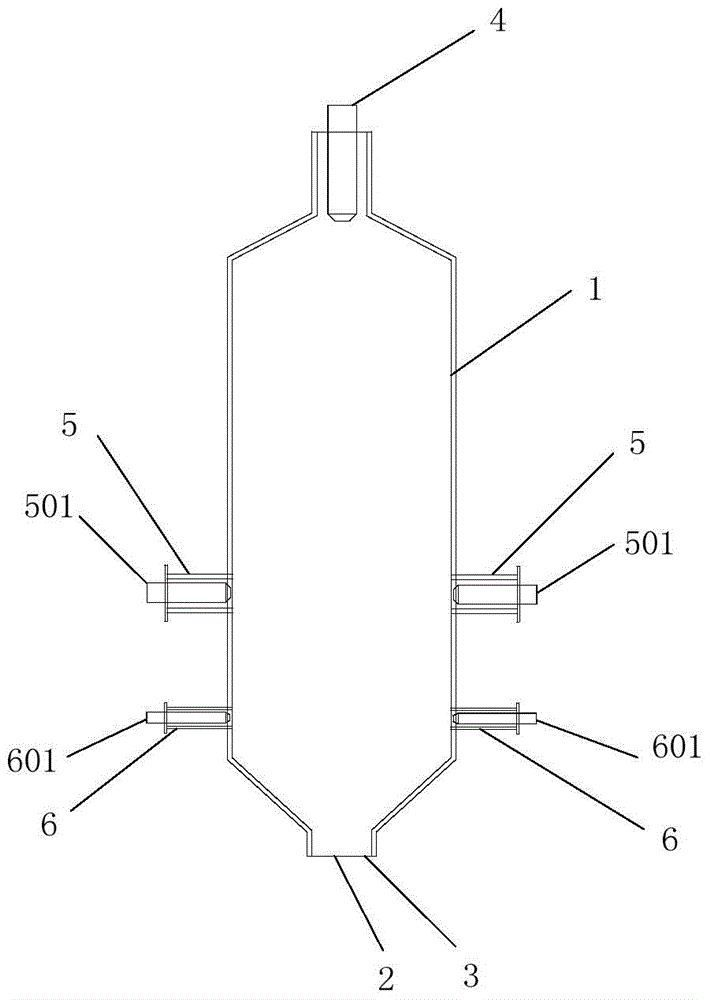

Separator

InactiveUS20100078371A1Facilitates gasificationFacilitate separationSemi-permeable membranesMembranesFiltrationWaste management

A separator separates fuel components from oil diluted by fuel in a crossflow filtration method. The separator includes a tubular separator main body; a separation member provided in the separator main body to partition an inside of the separator main body into a first area and a second area, and further to allow the fuel components contained in the oil to permeate and thus separate the fuel components; an oil inlet provided to the separator main body and feeding the oil to the first area; an oil outlet provided to the separator main body and discharging the oil from the first area; a fuel outlet provided to the separator main body and discharging the fuel components from the second area; and a heater provided to an upstream side of the separation member and heating the oil before the oil reaches the separation member.

Owner:TOYOTA BOSHOKU KK

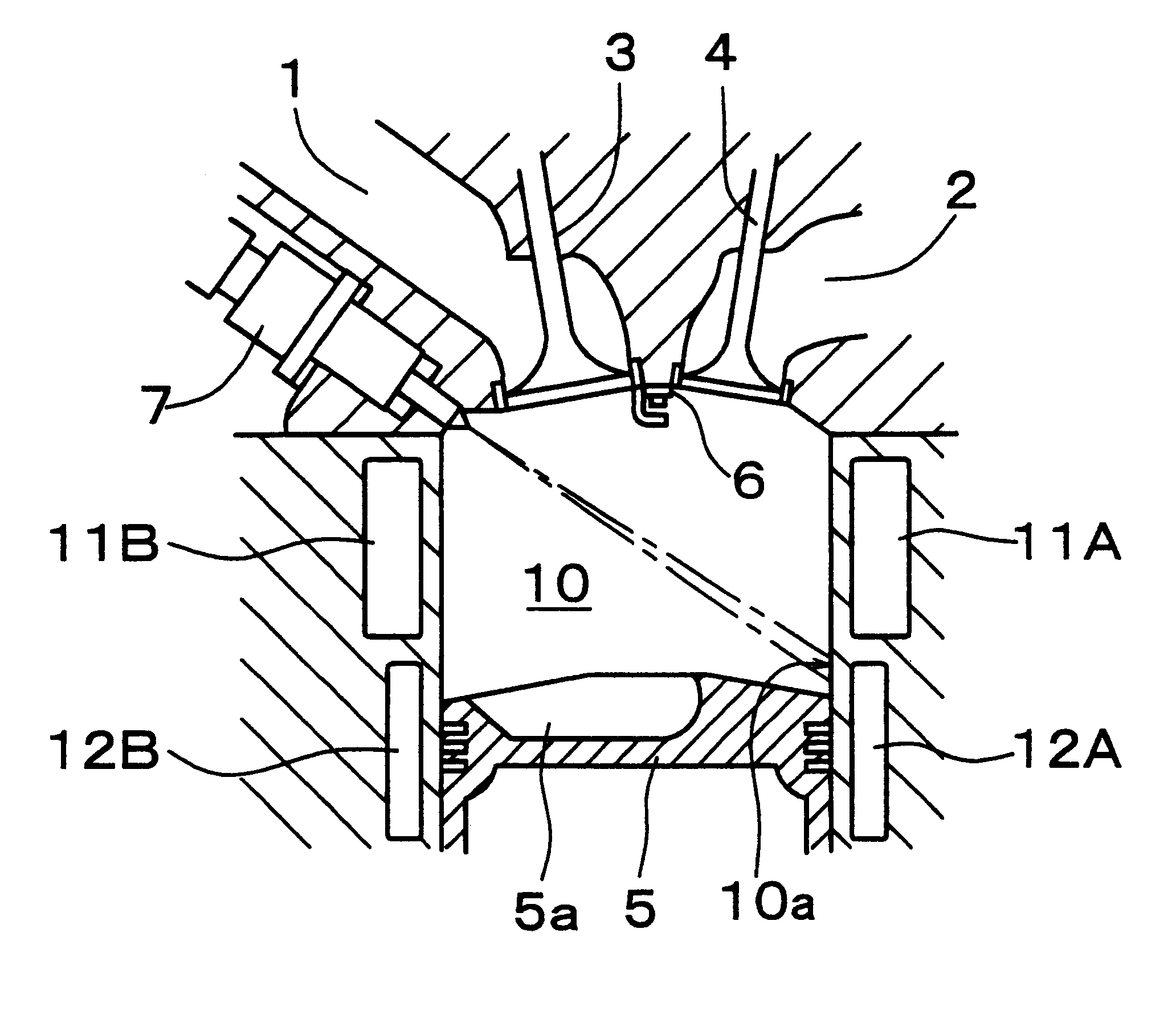

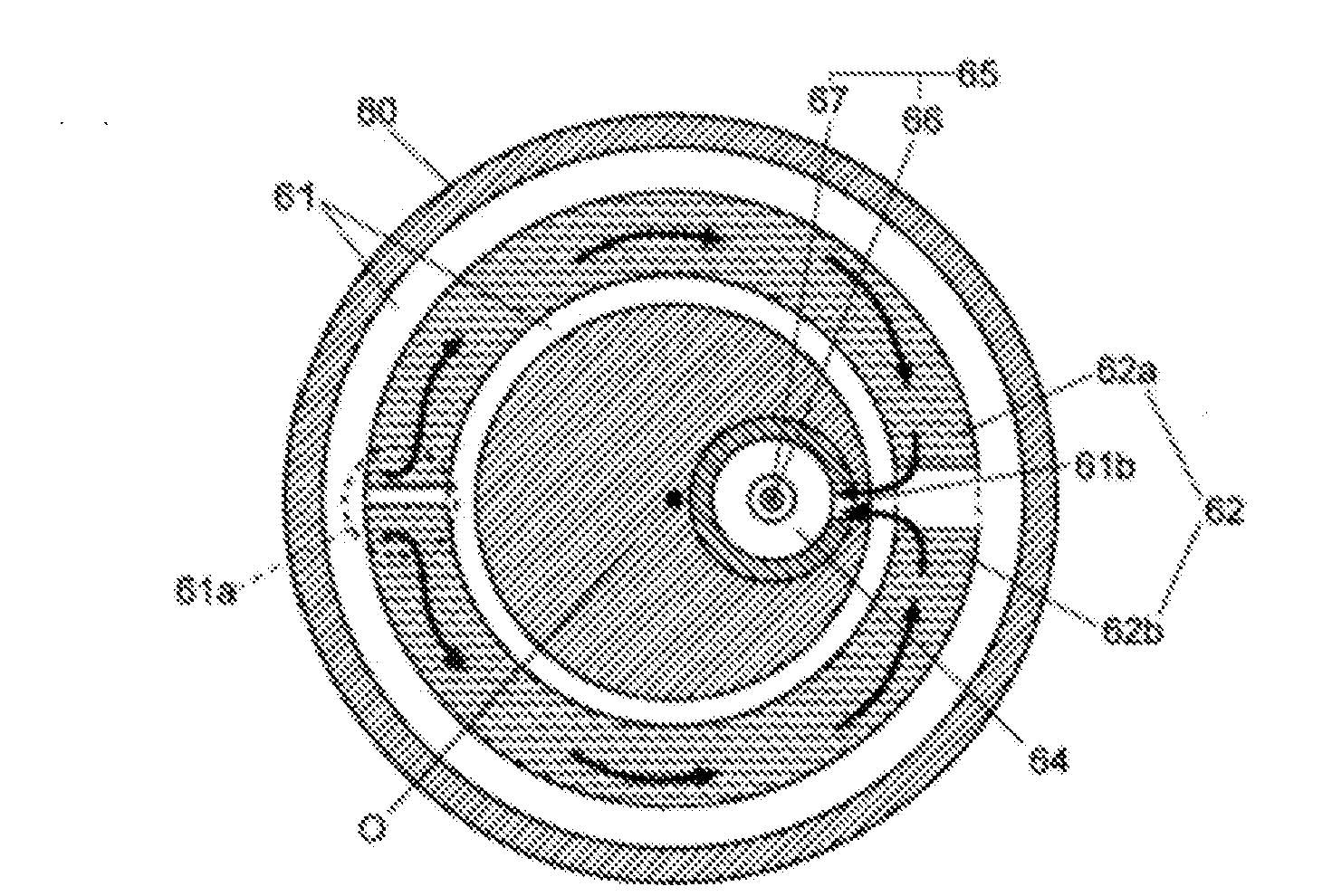

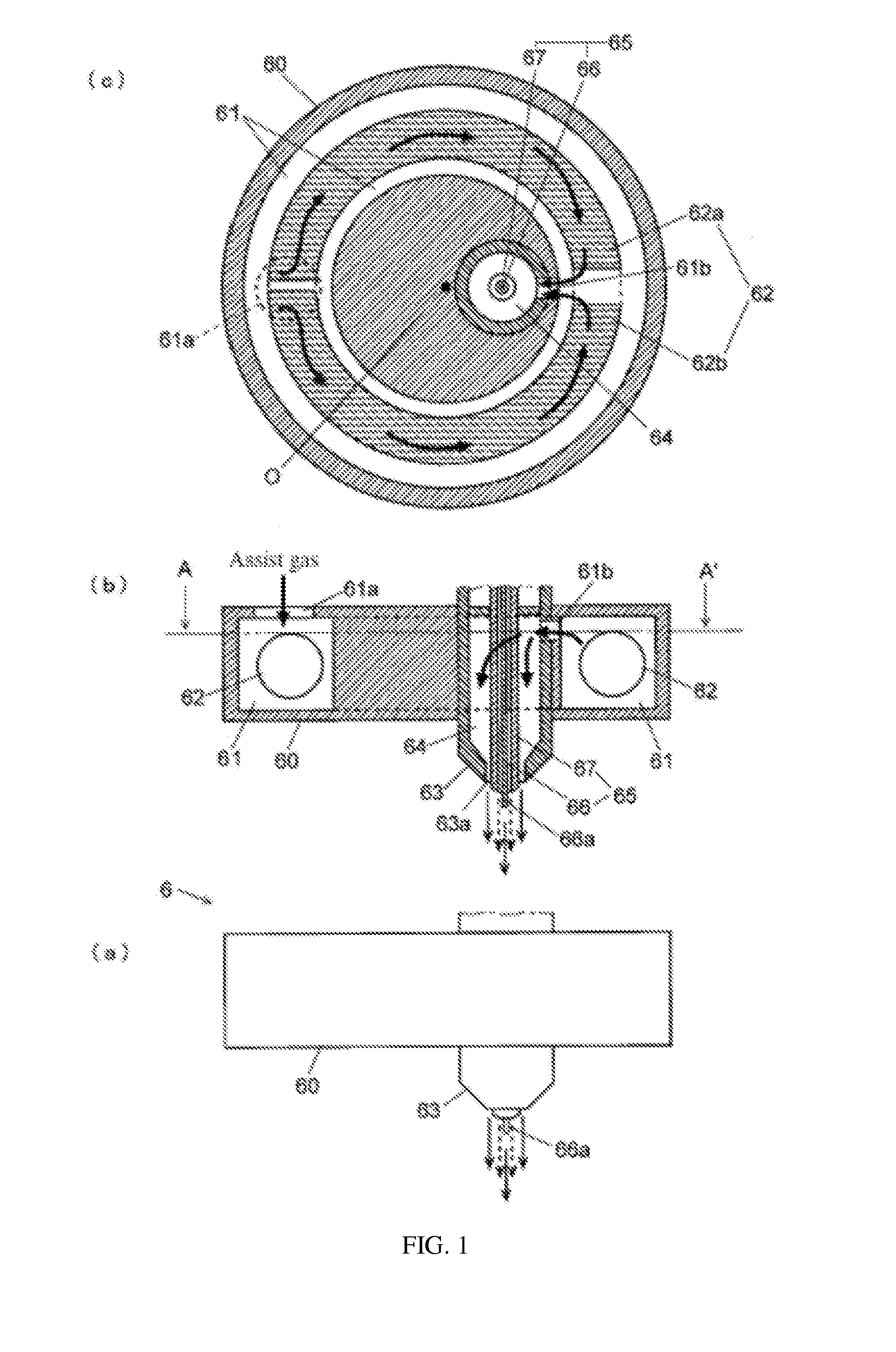

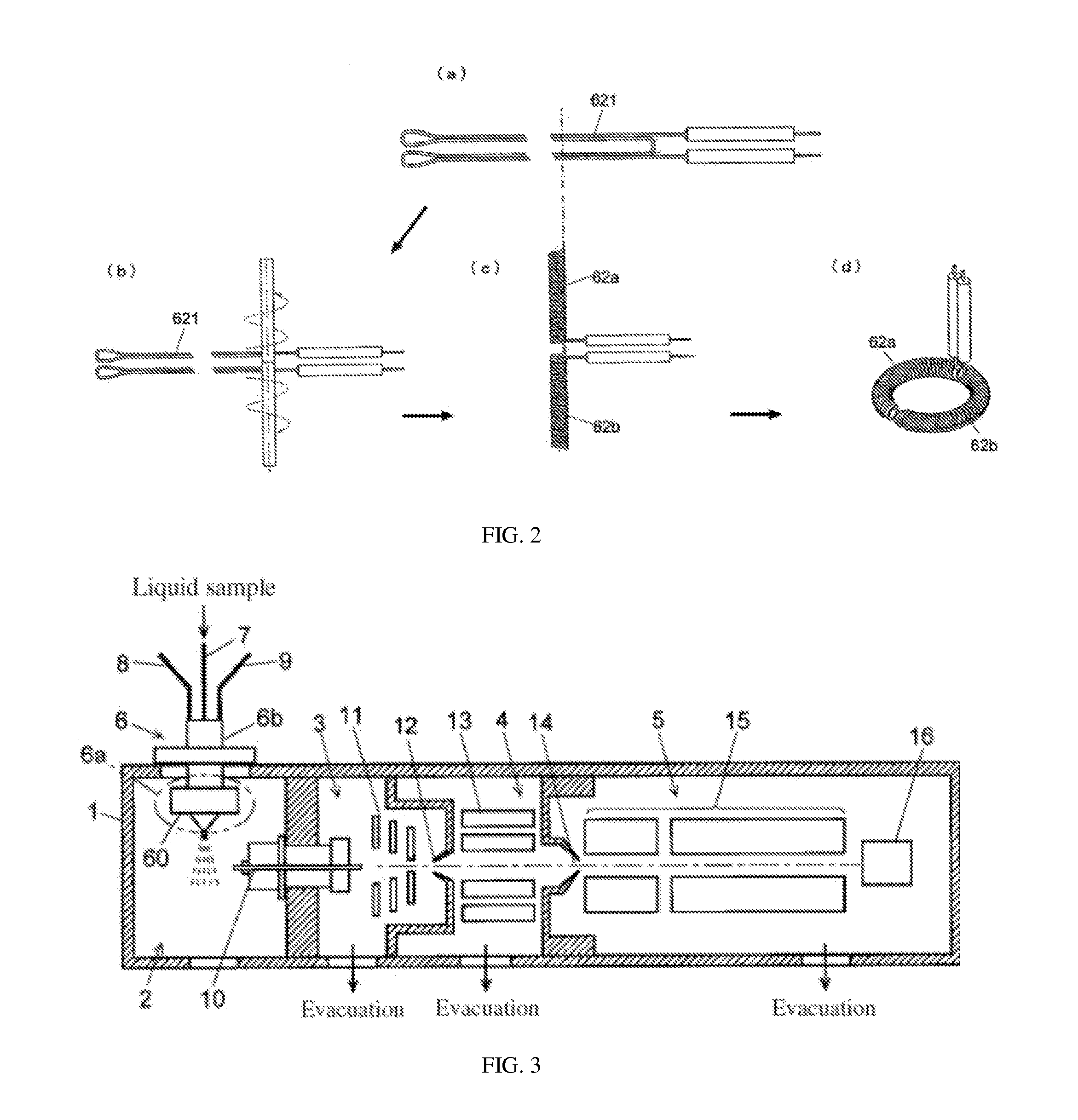

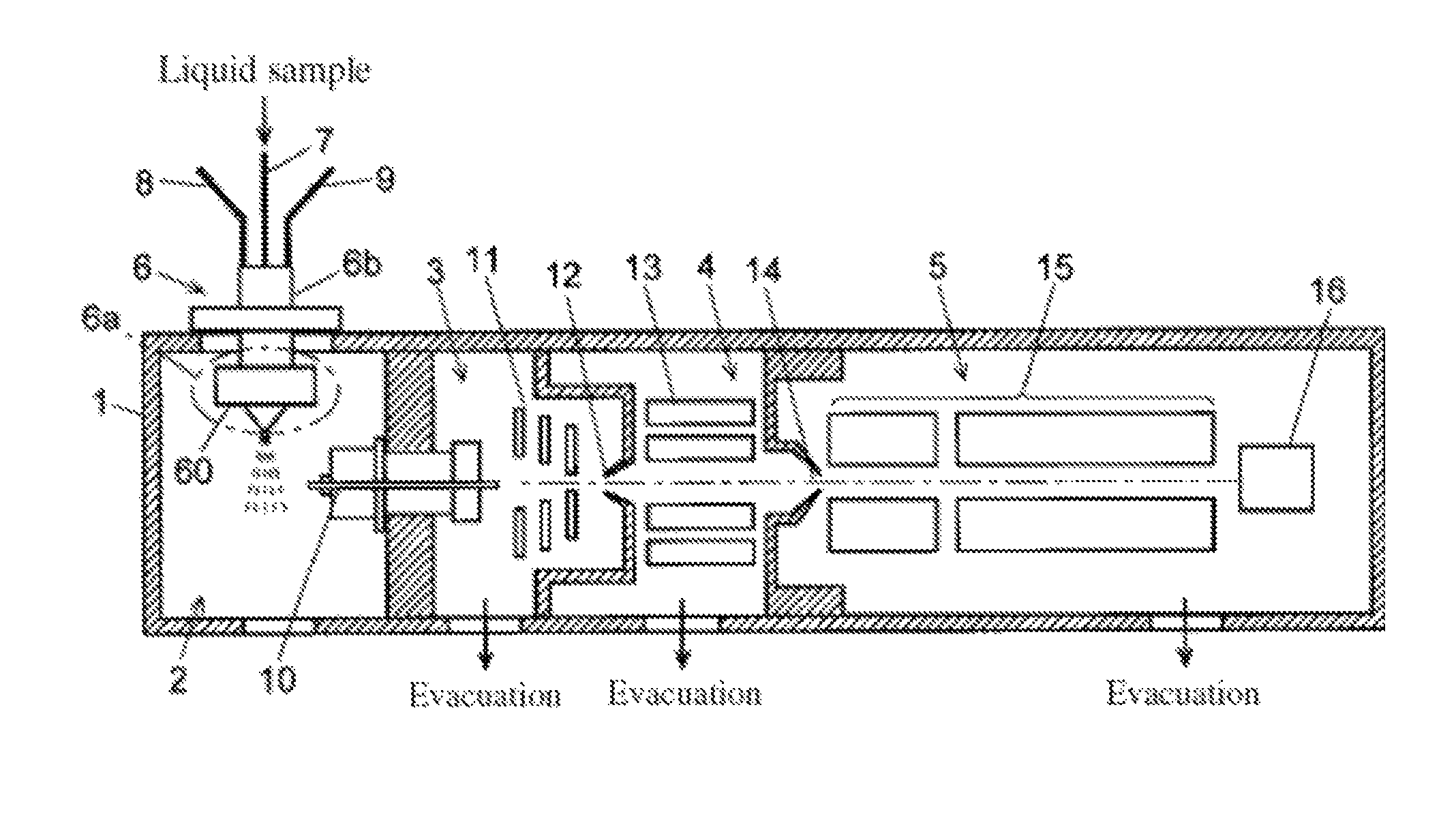

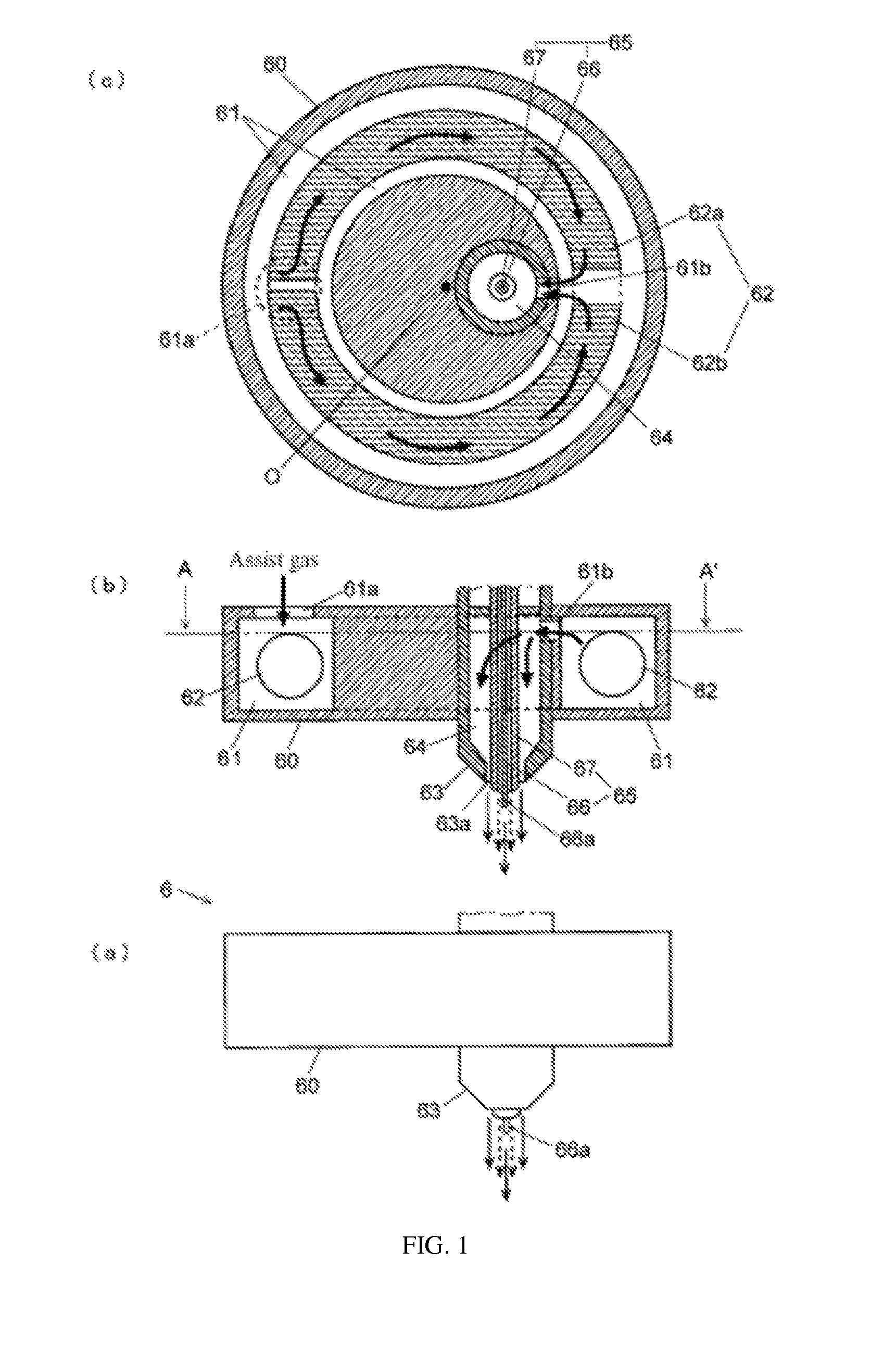

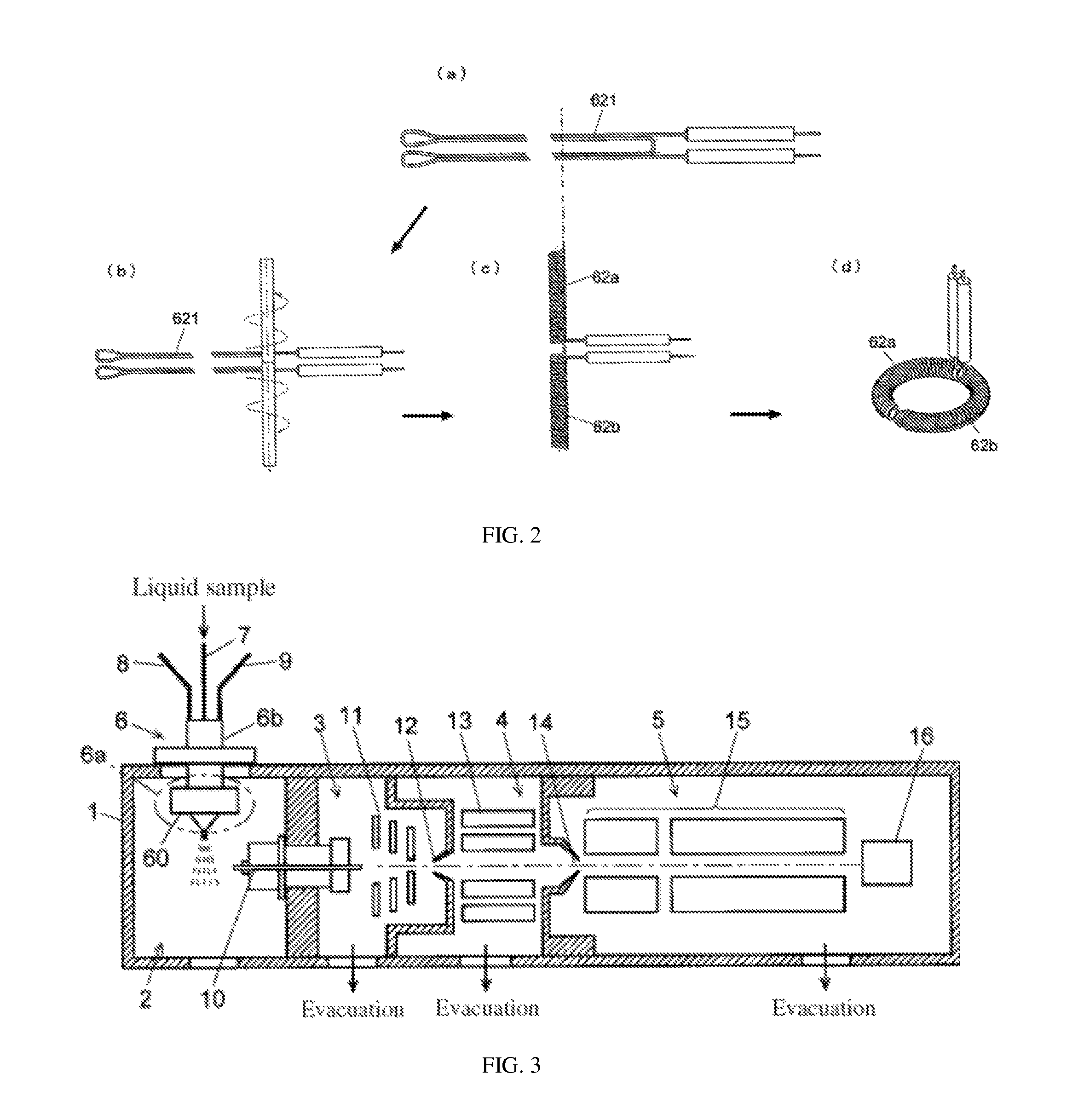

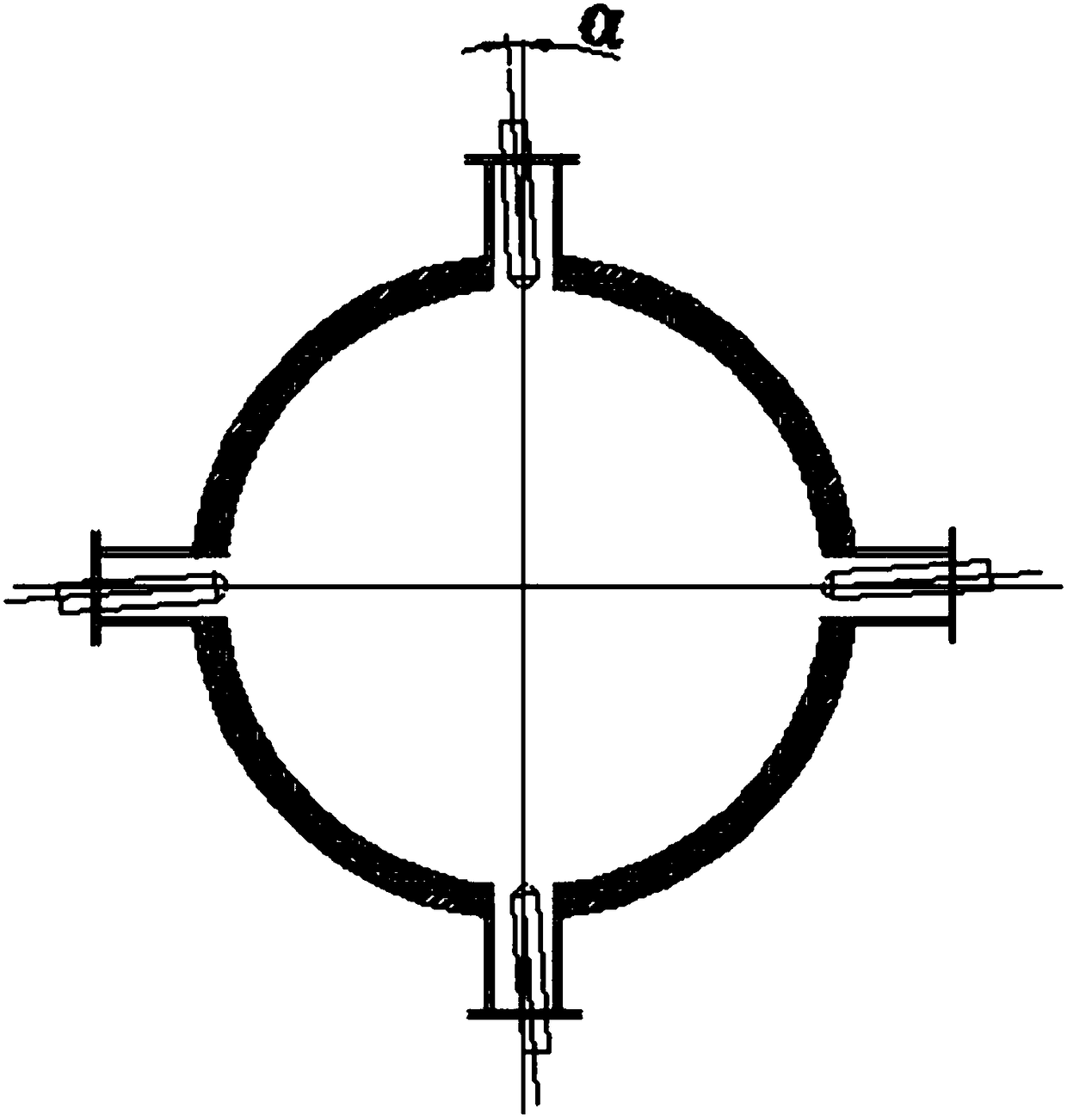

Ionization probe

ActiveUS20150060566A1Small sizeTemperature safetyLiquid surface applicatorsParticle separator tubesGas-discharge lampThermal insulation

In the ionization probe, an assist gas nozzle, coaxial with a nozzle, is provided around a nozzle that discharges a liquid sample. A housing inside which is formed an annular assist gas channel is provided around the assist gas nozzle. A gas inlet for introducing gas into the assist gas heating channel and gas outlet for feeding gas from channel to assist gas nozzle are provided at opposite locations across the center of the channel. Gas introduced into the assist gas heating channel is heated by a substantially annular heater, and high temperature gas is discharged through gas discharge hole of the assist gas nozzle. The heater and the channel through which high temperature gas flows are arranged solely at the tip part of the ionization probe, so thermal insulation of the probe base part can be easily accomplished.

Owner:SHIMADZU CORP

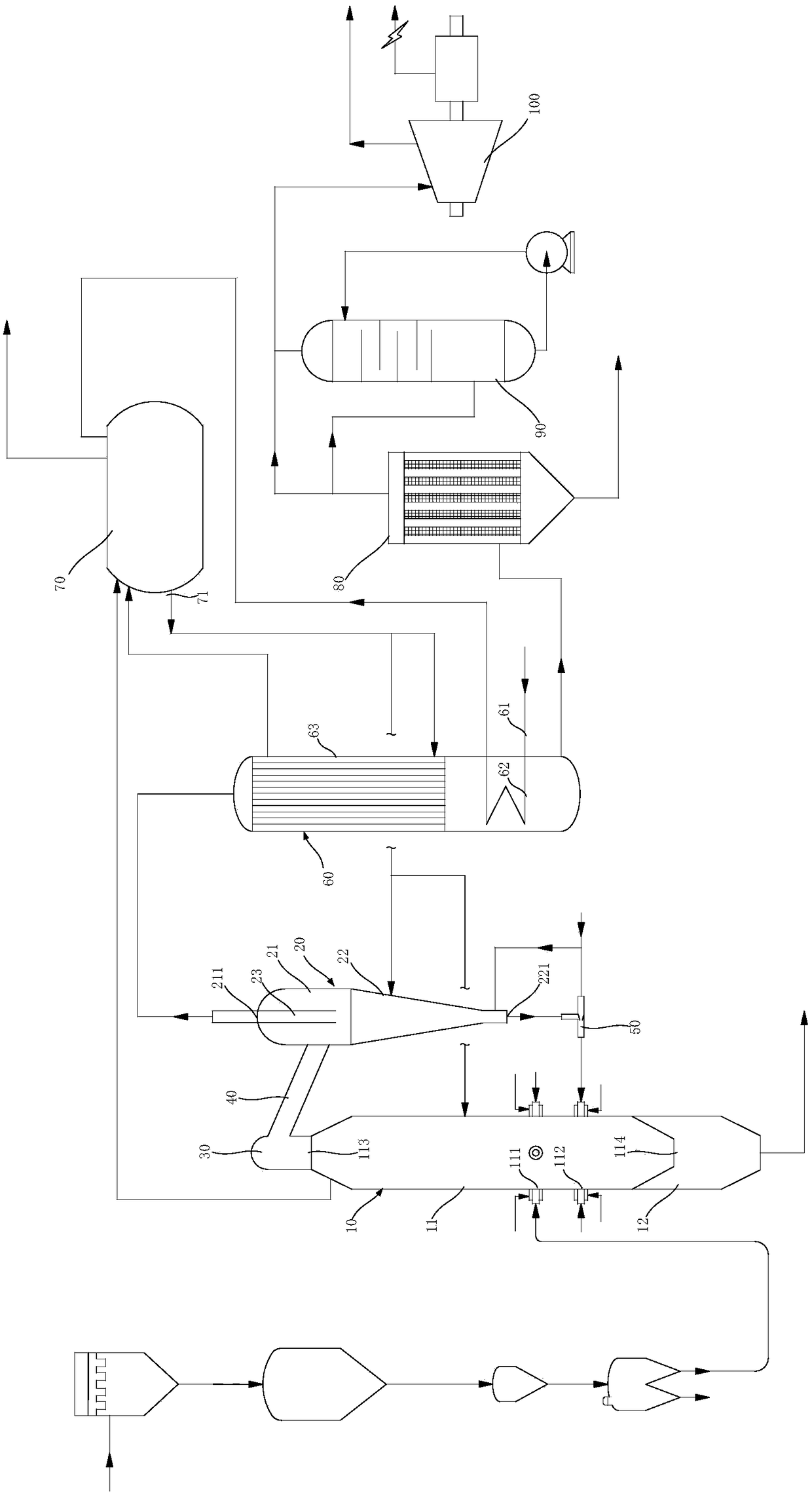

Clean and efficient garbage gasification and energy utilization system and garbage gasification and energy utilization method

PendingCN111662752AGuarantee continuous and stable operationReduce generationGasification processes detailsCombustible gas productionThermodynamicsProcess engineering

The invention relates to an urban garbage gasification and energy utilization system and method, specifically to a garbage material gasification and energy utilization system composed of a garbage gasification reaction device, a gasifying agent generation device, a fuel gas purification treatment device, a garbage crushing, drying and airtight feeding device, an airtight deslagging device, an oxidizing agent input device and the like, and an urban garbage gasification and energy utilization method. The system is characterized in that the gasifying agent generation device generates a hypoxic high-temperature gasifying agent which is required by garbage gasification and of which the temperature can be effectively controlled according to garbage materials and process requirements, garbage materials are directly contacted and acted with the hypoxic high-temperature gasifying agent to generate a gasification reaction, and the garbage gasification reaction device provides a space structure and reaction conditions of the gasification reaction. According to the gasification and energy utilization requirements, while the gasification reaction is maintained and the fuel gas is generated andoutput, the hypoxia high-temperature gasifying agent can be output as high-temperature heat energy, so that clean and efficient gasification and energy utilization are realized; and the system and themethod have the characteristics of high gasification and energy efficiency, no dioxin generation, suitability for urban garbage containing hydrocarbon components and the like.

Owner:陈晓辉

Ionization probe

ActiveUS9254497B2Efficient gasificationEasily thermally insulatedComponent separationMass spectrometersGas-discharge lampThermal insulation

In the ionization probe, an assist gas nozzle, coaxial with a nozzle, is provided around a nozzle that discharges a liquid sample. A housing inside which is formed an annular assist gas channel is provided around the assist gas nozzle. A gas inlet for introducing gas into the assist gas heating channel and gas outlet for feeding gas from channel to assist gas nozzle are provided at opposite locations across the center of the channel. Gas introduced into the assist gas heating channel is heated by a substantially annular heater, and high temperature gas is discharged through gas discharge hole of the assist gas nozzle. The heater and the channel through which high temperature gas flows are arranged solely at the tip part of the ionization probe, so thermal insulation of the probe base part can be easily accomplished.

Owner:SHIMADZU CORP

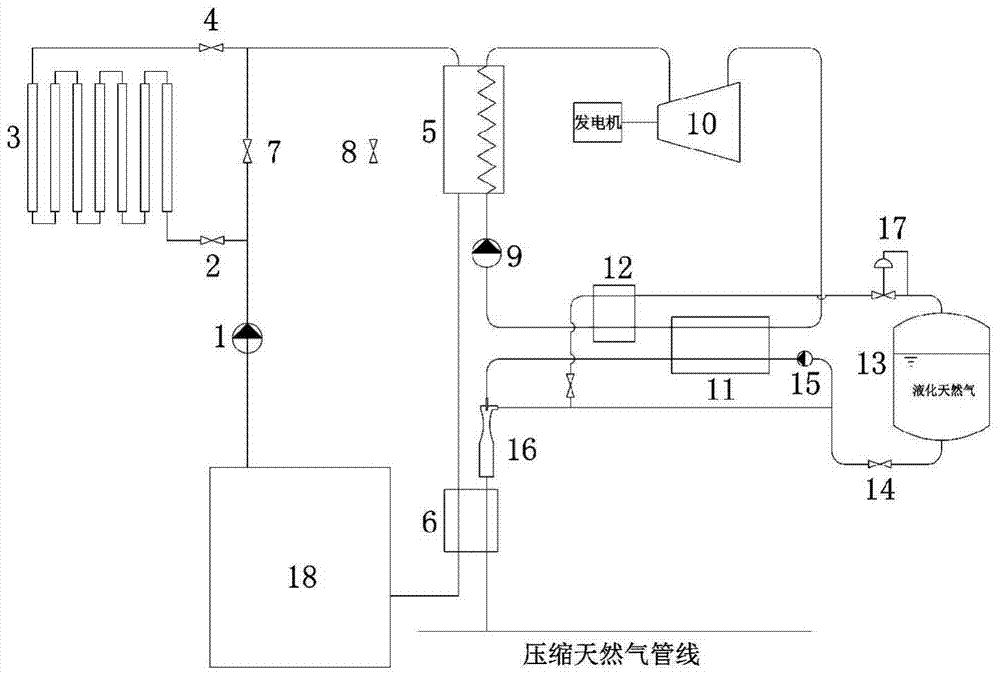

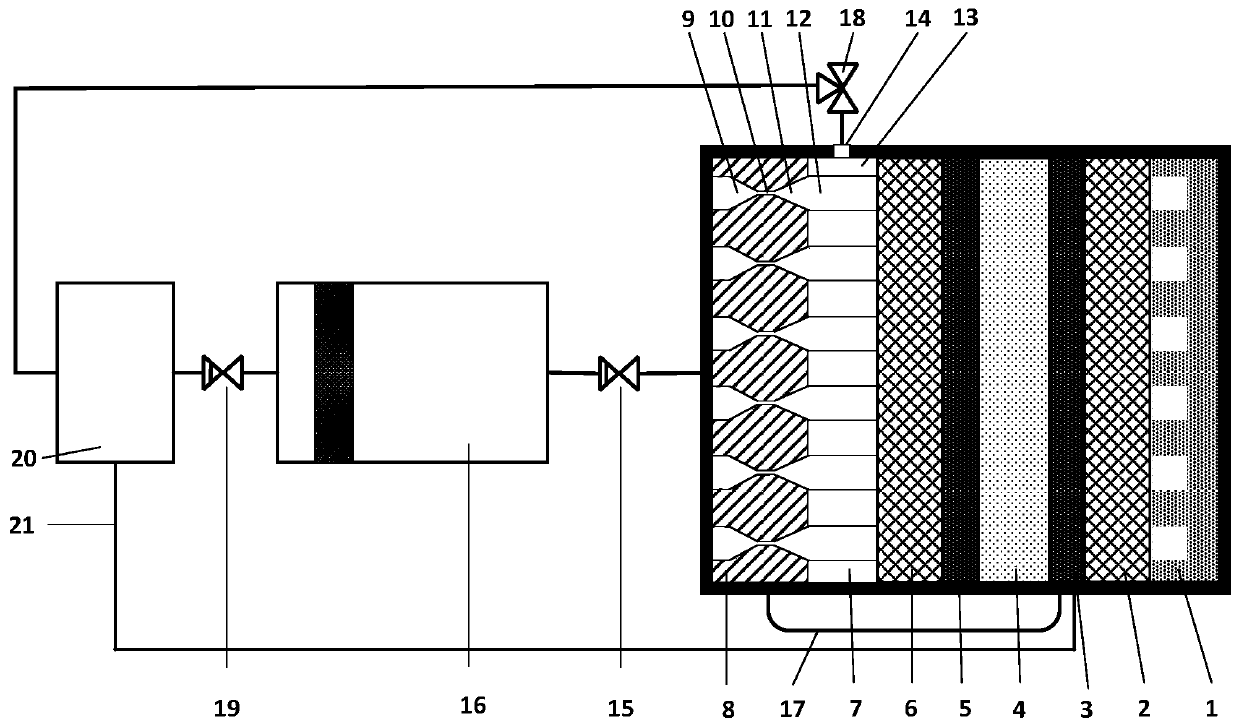

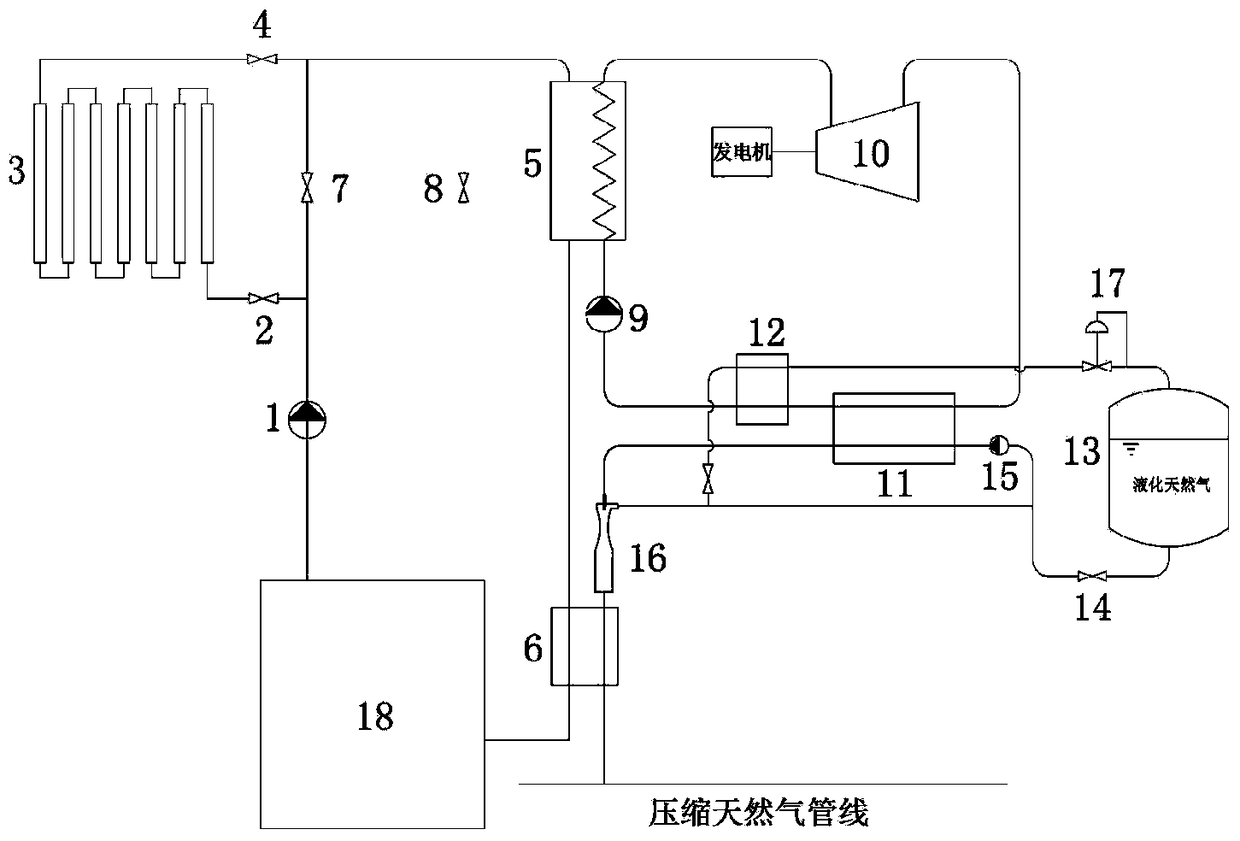

Liquefied natural gas gasification system and method based on circulating solar power generation

InactiveCN104747389AEfficient gasificationSave fossil energyFrom solar energyMachines/enginesOrganic Rankine cycleLiquefied natural gas

The invention provides a liquefied natural gas gasification system and method based on circulating solar power generation. The liquefied natural gas gasification system comprises a heat collection and storage unit, a power generation unit and a natural gas gasification unit, wherein the heat collection and storage unit is connected with the power generation unit through a first heat exchanger, the power generation unit is connected with the gasification unit through a third heat exchanger and a fourth heat exchanger, and the natural gas gasification unit is connected with the heat collection and storage unit through a second heat exchanger. In the gasification system, collected solar energy is utilized in a graded mode, high-temperature heat-transfer working media are used for power generation through an organic Rankine circulating system, waste heat is used for jet type liquefied natural gas gasification, liquefied natural gas gasification is achieved while renewable energy resources are used for power generation, the liquefied natural gas gasification speed is increased, and non-renewable energy resources are saved.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

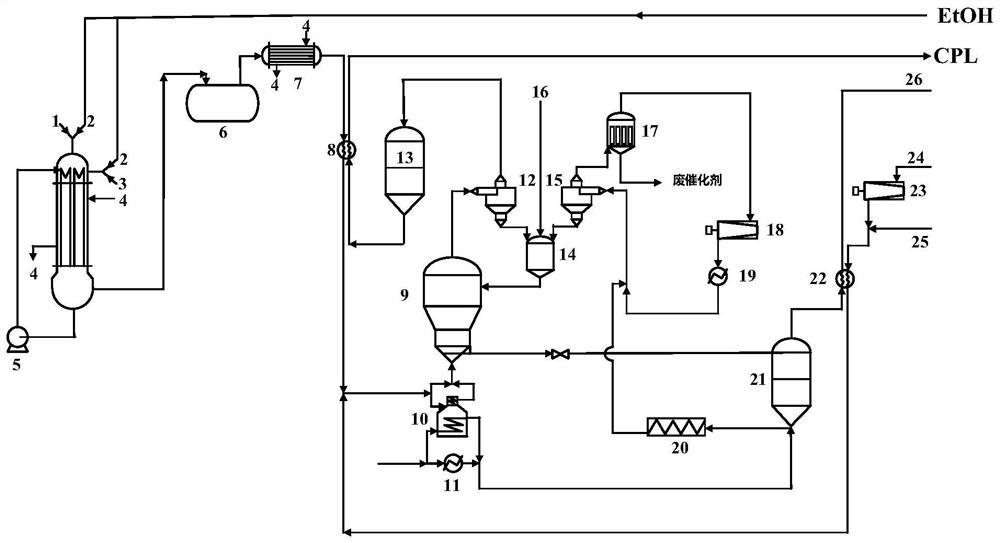

Production device and production method of caprolactam

PendingCN112079759AEfficient evaporationHigh Efficiency in Evaporation and GasificationLactams preparationLactams separation/purificationPtru catalystFluidized bed

The invention relates to the field of caprolactam production, in particular to a caprolactam production device and method, and the device comprises a cyclohexanone-oxime evaporation and gasification system, a mist separation system, a fluidized bed reaction system and a moving bed reaction system which are connected in series; the device further comprises a reaction solvent recycling system and acarrier gas recycling system. The method comprises the following steps: (1) evaporating and gasifying carrier gas, ethanol and cyclohexanone-oxime in a cyclohexanone-oxime evaporation and gasificationsystem; (2) feeding a gas-phase material flow obtained in the step (1) into a mist separation device to gasify cyclohexanone-oxime which is not completely gasified in a cyclohexanone-oxime evaporation and gasification system; (3) feeding the material flow obtained in the step (2) into a fluidized bed reaction system and a moving bed reaction system in sequence for gas-phase Beckmann rearrangementreaction; and (4) recovering ethanol and carrier gas in the material flow obtained in the step (3). By adopting the device and the method, the high conversion rate of cyclohexanone-oxime can be obtained, the problem of catalyst discharge is avoided, and the production is not interrupted.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

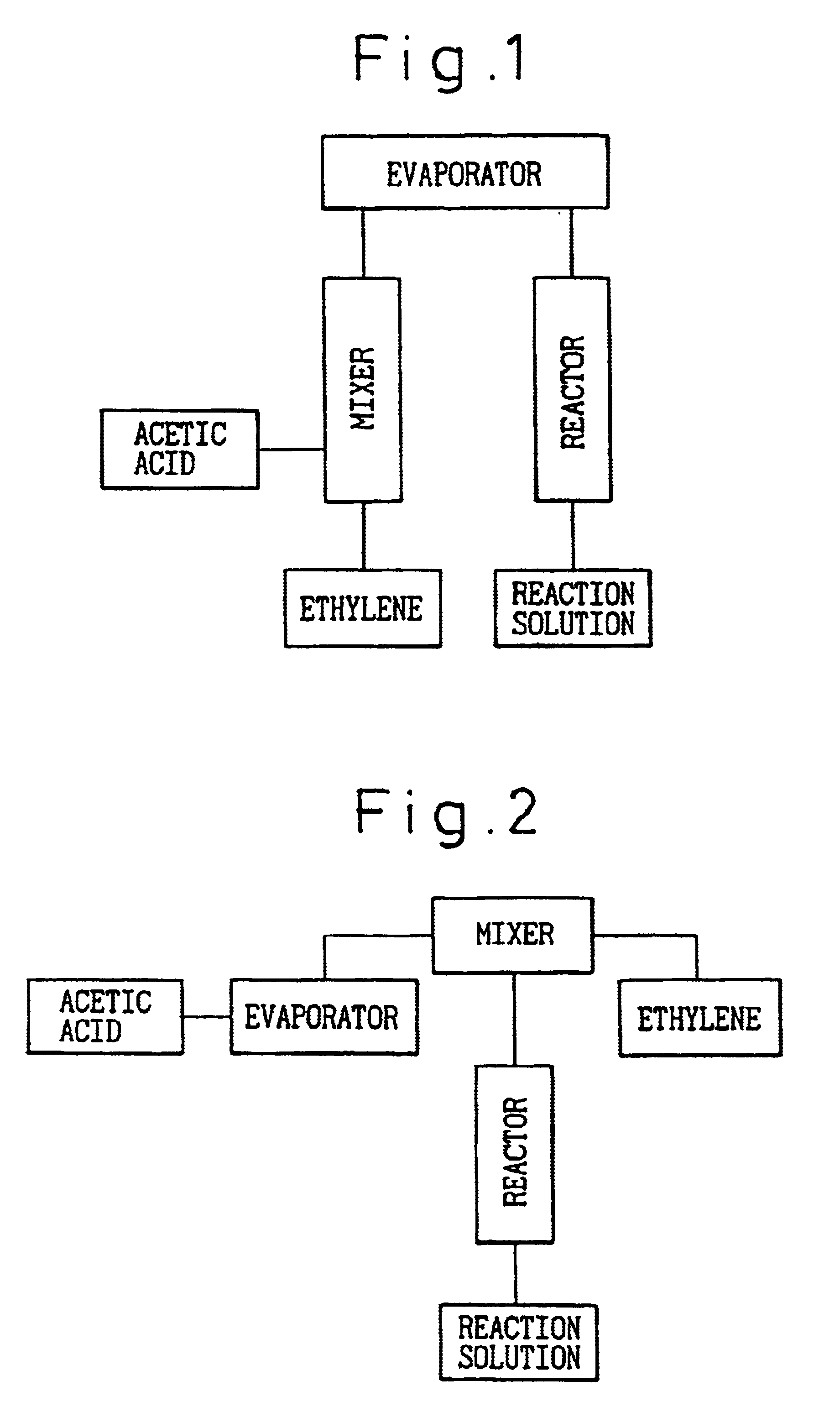

Process for producing mixed gas of lower olefin and lower aliphatic carboxylic acid, and process for producing lower aliphatic ester using the mixed gas

InactiveUS6818790B1Efficiently obtainedDifficult to gasifyOrganic compound preparationCarboxylic acid esters preparationGas phaseCarboxylic acid

A process for producing a lower aliphatic ester by catalytically reacting a lower olefin and a lower aliphatic carboxylic acid in a gas phase, where the lower aliphatic carboxylic acid is gasified at a relatively low temperature and thereby a mixed gas of the lower olefin and the lower aliphatic carboxylic acid is produced.

Owner:SHOWA DENKO KK

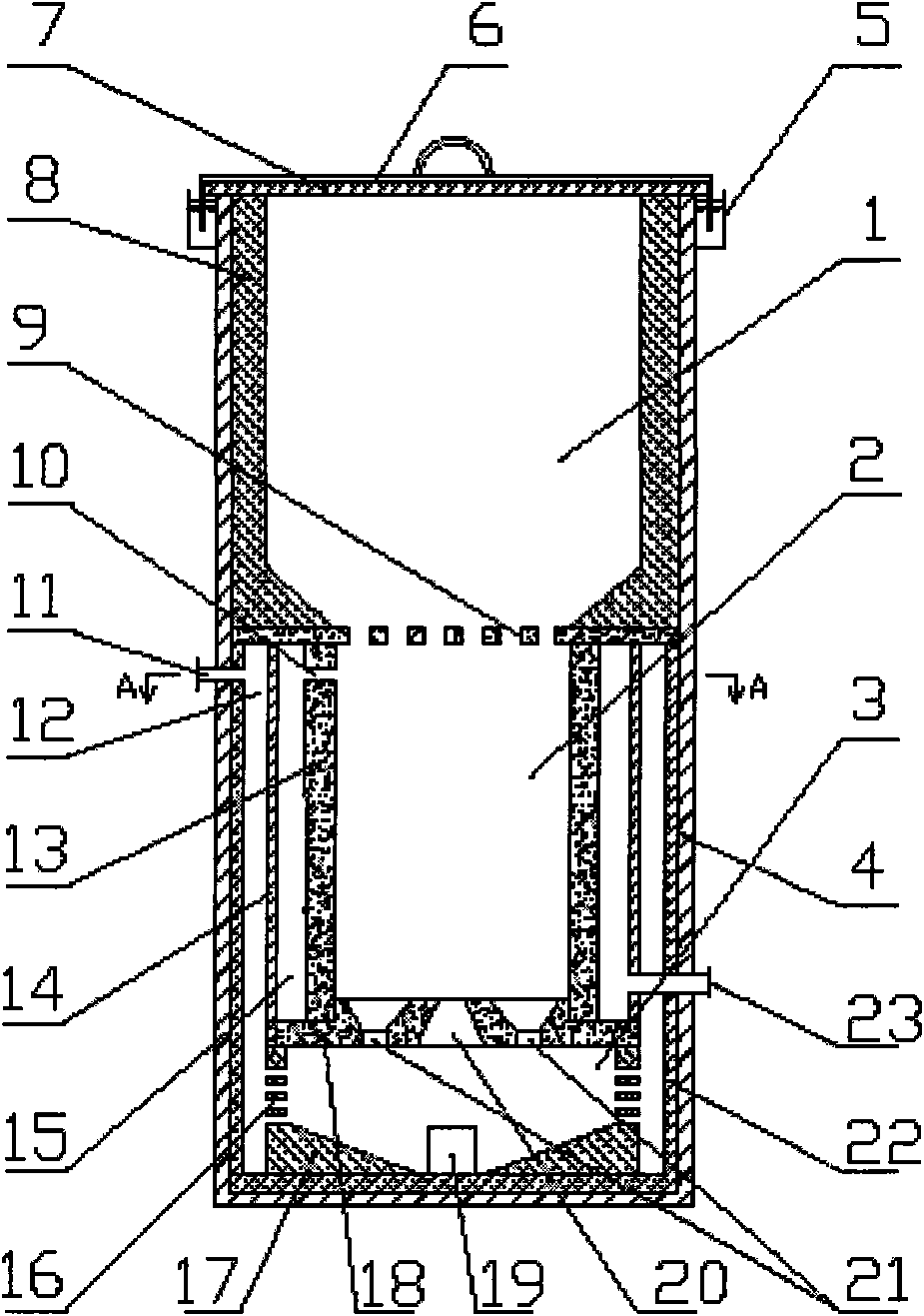

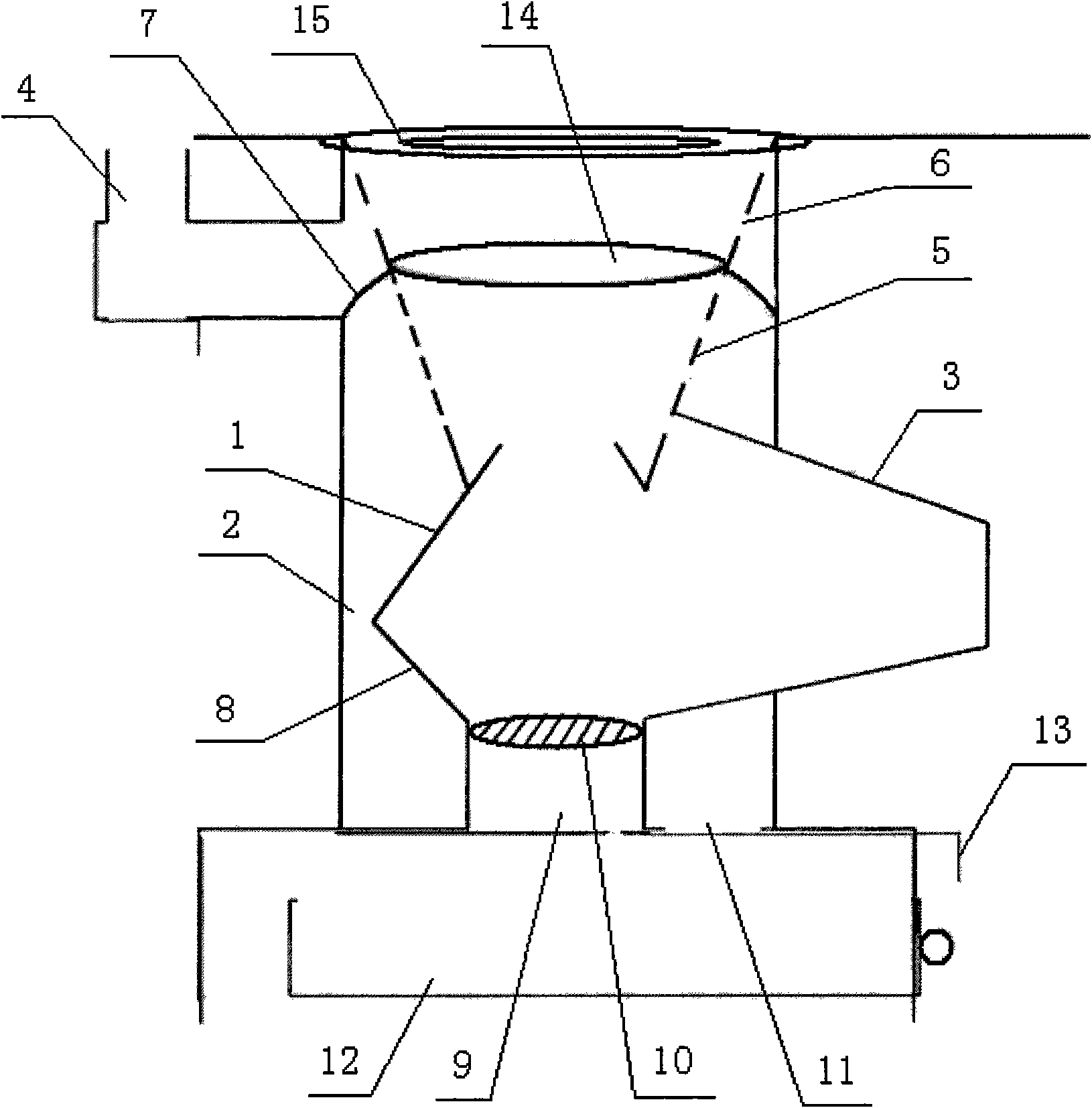

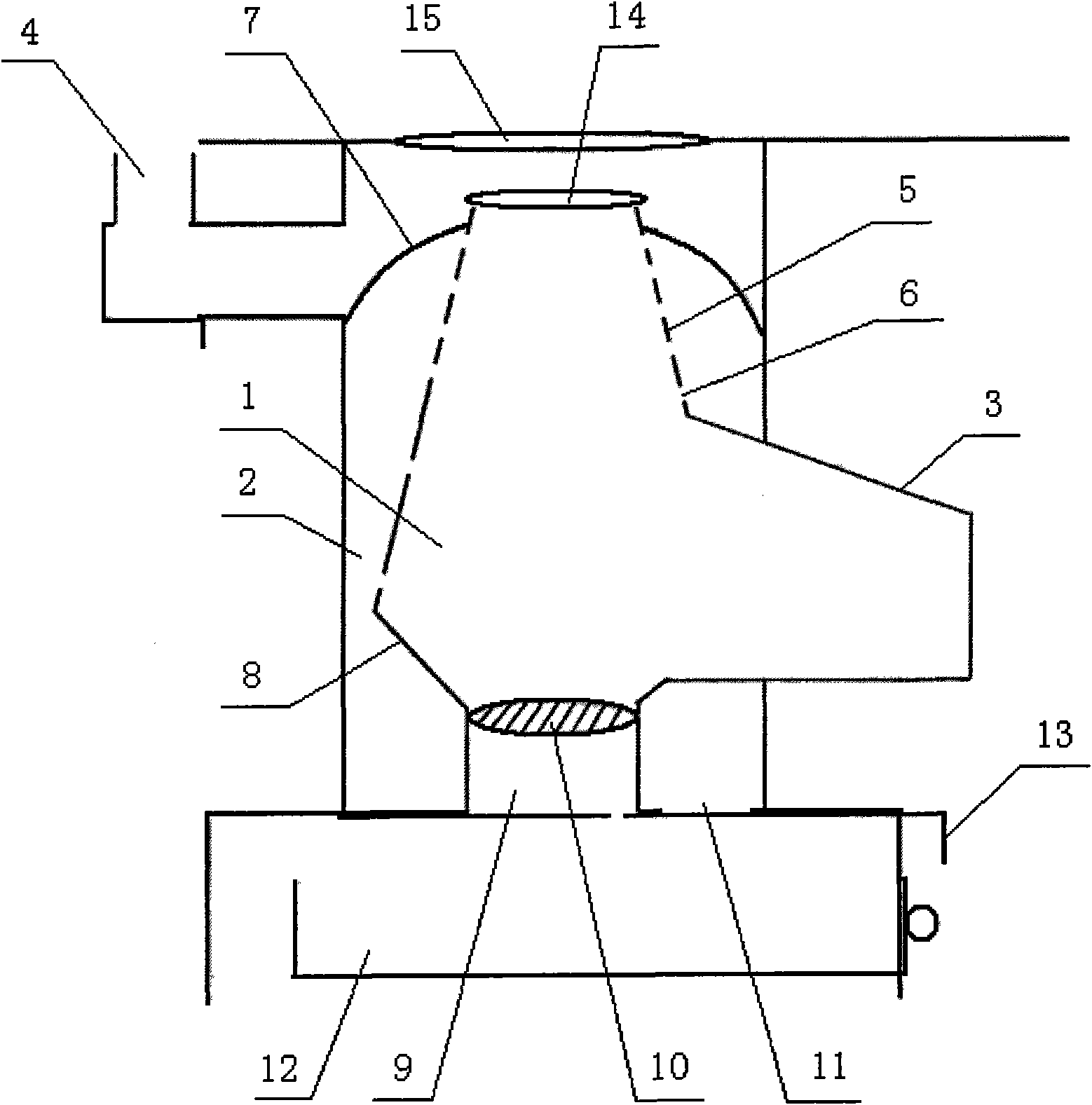

High-efficiency and energy-saving gasifier

InactiveCN101608135AIncrease profitEfficient gasificationChemical industryCombined combustion mitigationThermal energyCombustion

The invention discloses a high-efficiency and energy-saving gasifier, comprising a furnace body, a multi-cone furnace core, a feed port and an air vent; wherein the furnace core is formed by sealing connection of three cones, the upper cone is distributed with a plurality of pores, a clapboard is connected with the middle upper part of the upper cone of the furnace core in an enclosed way, the lower cone of the furnace core is connected with an air inlet I, furnace tooth is arranged at the upper end of the air inlet I, an air inlet II is opened at the lower end of the furnace body, the interior of a pedestal is opened with an air course, a slip air door is arranged at the joint of the furnace body and the pedestal, the air vent is arranged at the upper part of the furnace body, the feed port is connected with the furnace body and the furnace core, and the feed port is in folded plate type tank body structure. The invention has higher heat utilization and good gasifying and is more energy-saving, and combustion is more through.

Owner:徐同昕

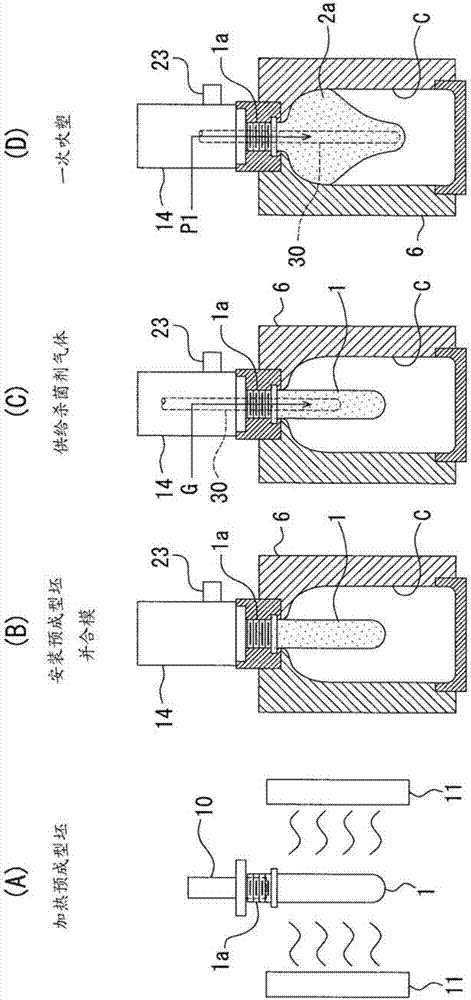

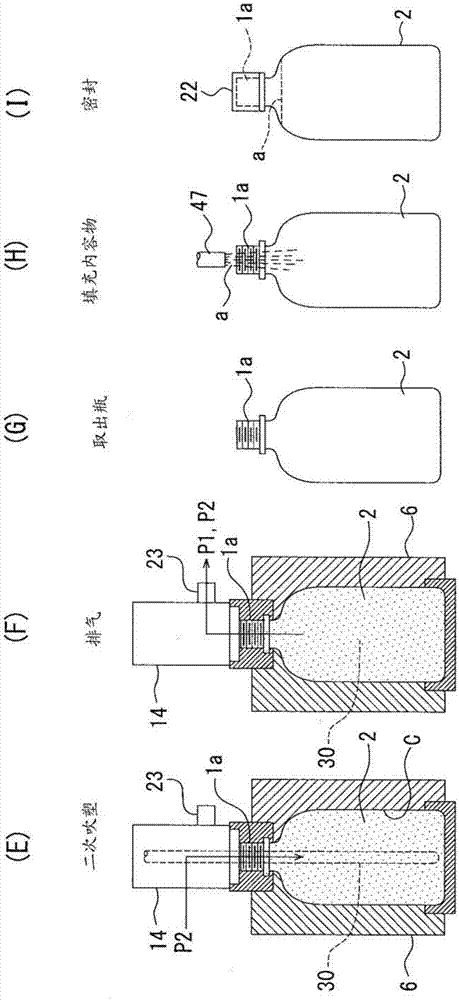

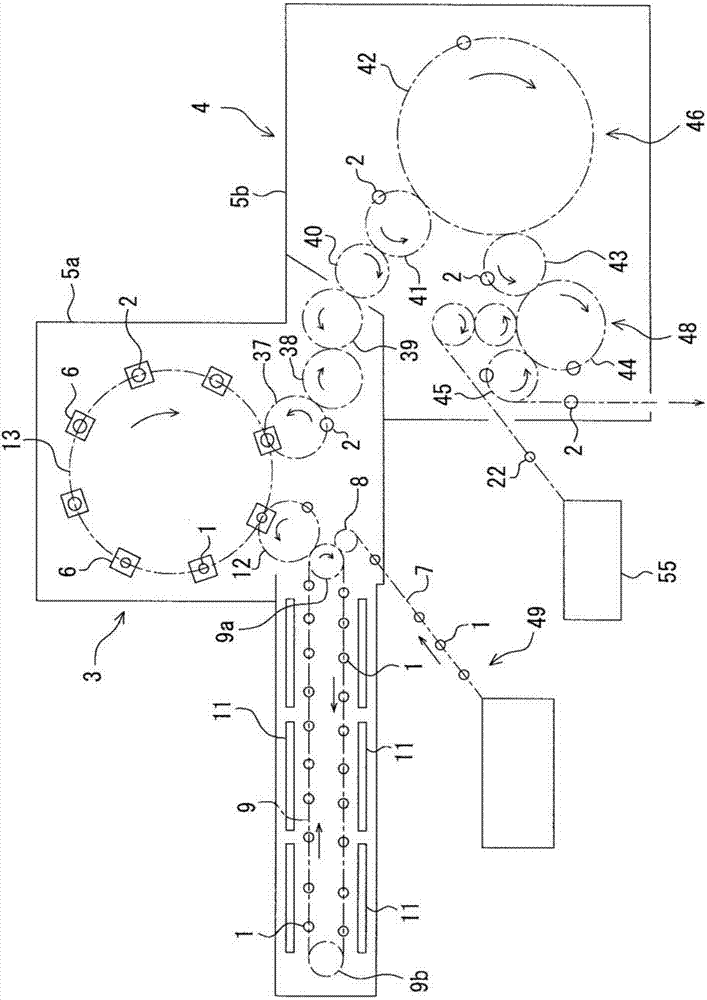

Method and device for molding sterile container, and method and device for sterile filling

ActiveCN107530946AImprove the bactericidal effectAvoid corrosionDomestic articlesBlow moldingPolymer science

The present invention sterilizes a container during the blow molding. A heated preform (1) is introduced into a mold (6), which is then closed. A mist or gas of a sterilizer or a mixture of these is blown into the preform (1). Air for blow molding is then blown into the preform (1) to expand the preform (1) to the dimensions of a finished container (2). The used air for blow molding is dischargedfrom inside the container (2) to remove the sterilizer from the inside of the container (2).

Owner:DAI NIPPON PRINTING CO LTD

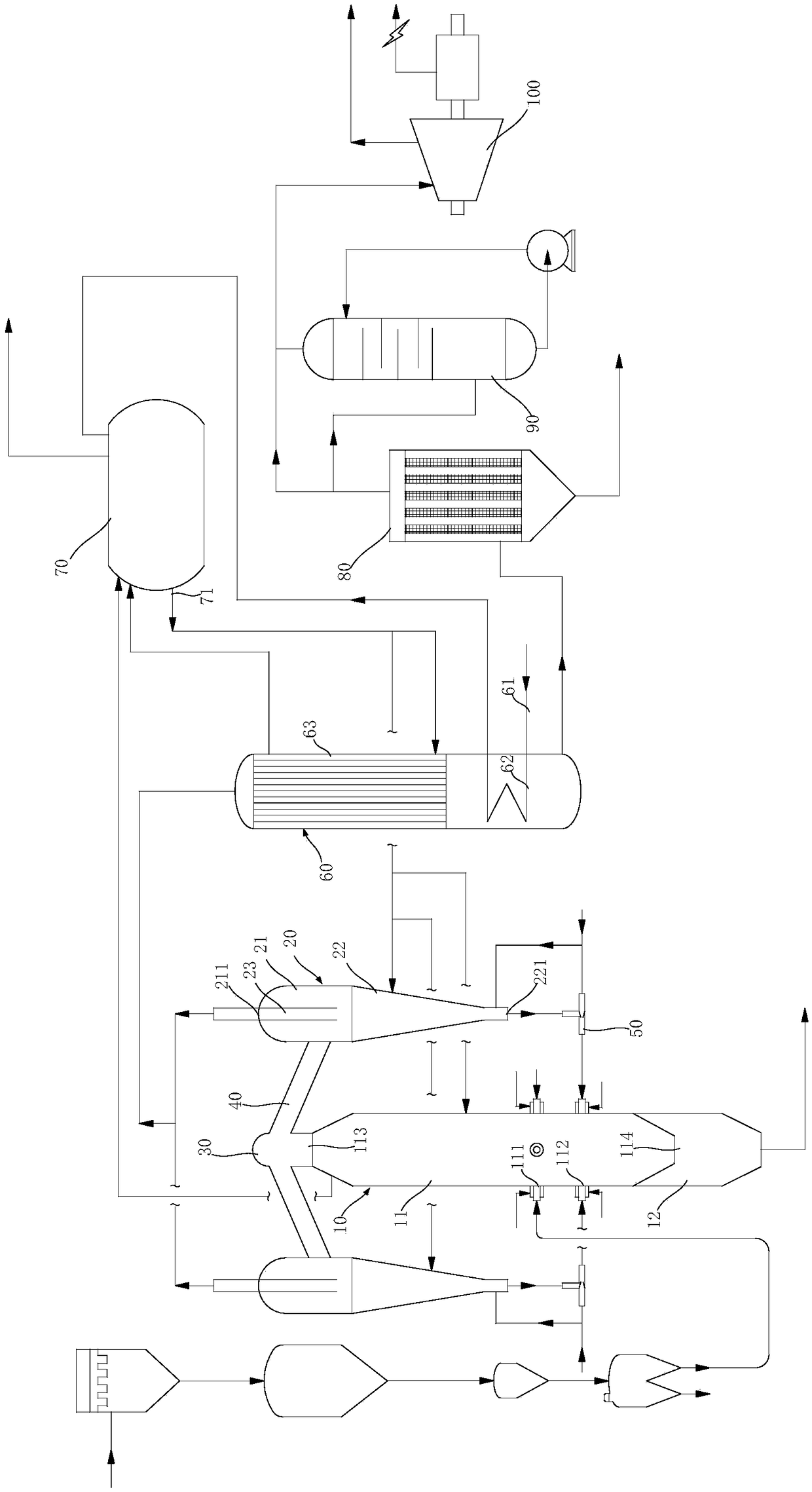

Preparation system of industrial gas and preparation method of industrial gas

PendingCN108517227ALow costAdaptableEnergy inputGasification processes detailsCyclonic separationSlag

The invention discloses a preparation system of industrial gas and a preparation method of industrial gas. The preparation system comprises a pulverized coal conveying unit, a entrained-flow gasifier,a convection waste heat boiler, a steam drum and a dust removing unit; the entrained-flow gasifer is provided with a gasification chamber, a cyclone separation chamber and a collection chamber; the side wall of the gasification chamber is uniformly provided with first nozzles; the top of the gasification chamber is provided with a first synthesis gas outlet, and the bottom of the gasification chamber is provided with a liquid slag outlet; the cyclone separation chamber is provided with a straight barrel section and a lower cone separation section, the first synthesis gas outlet is communicated with the straight barrel section, the top of the straight barrel section is provided with a second synthesis gas outlet, the bottom of the lower cone separation section is provided with a fly ash outlet, and the cyclone separation chamber is also provided with a cyclone riser leaded out from the straight barrel section; the side wall of the gasification chamber is uniformly provided with secondnozzles; the collection chamber is used for collecting the slag discharged from the liquid slag outlet so as to block the bottom of the gasification chamber from being communicated with the outside. The preparation system and the preparation method have lower investment, lower industrial gas cost, cleaner and stronger coal adaptability.

Owner:EAST CHINA UNIV OF SCI & TECH

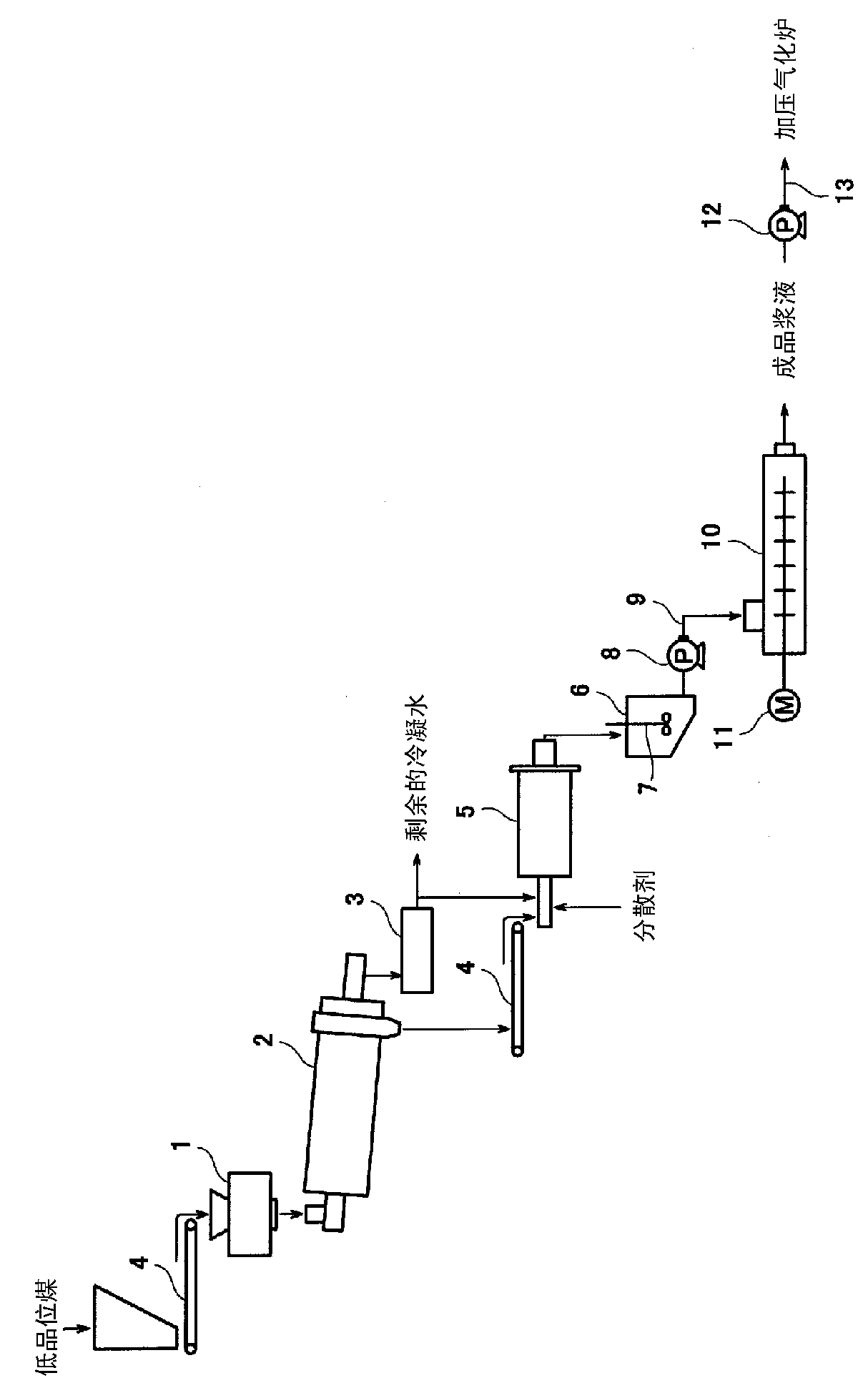

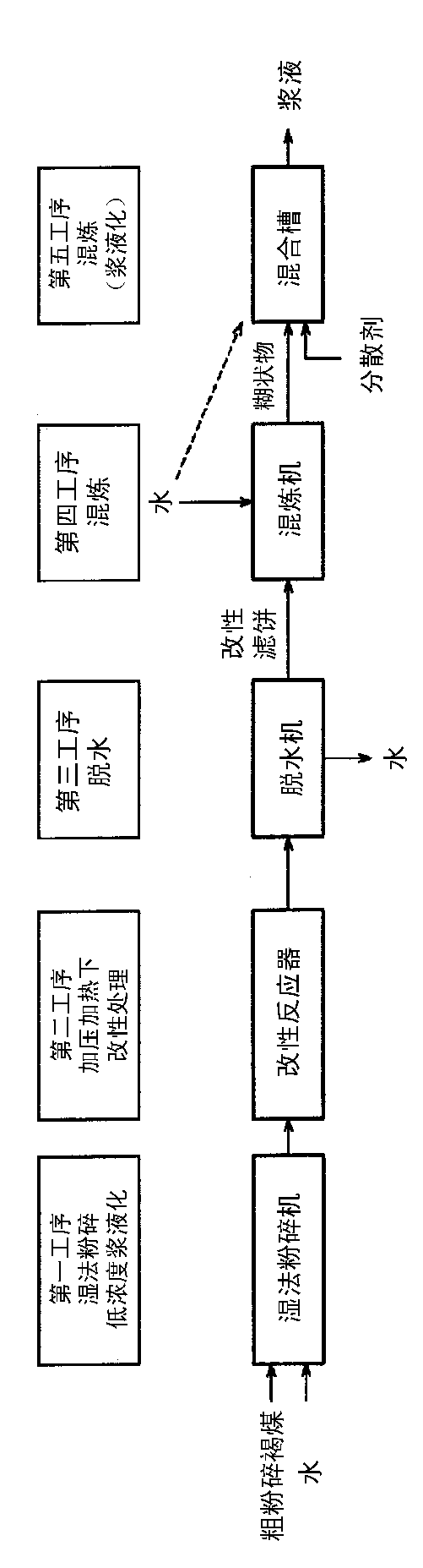

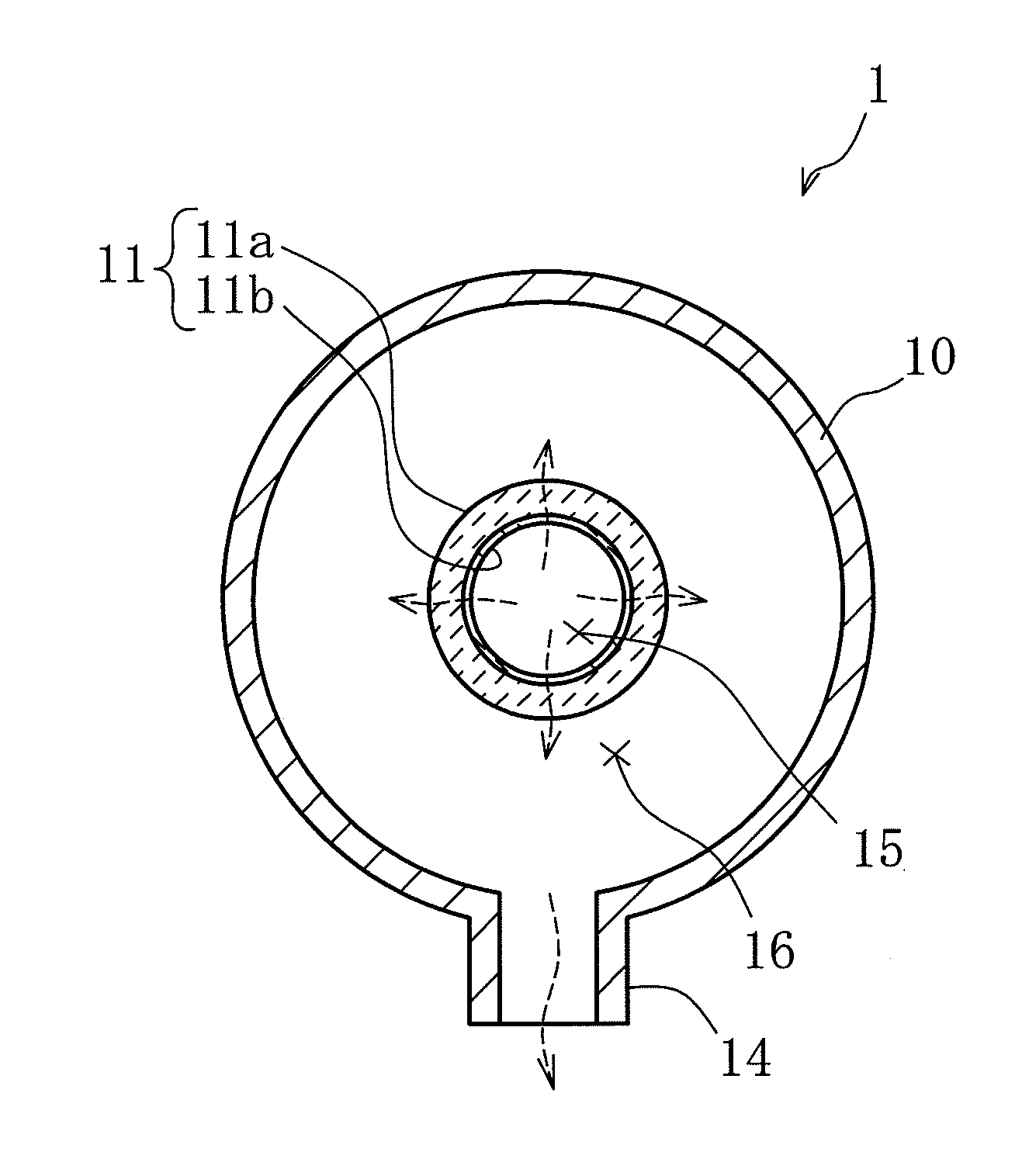

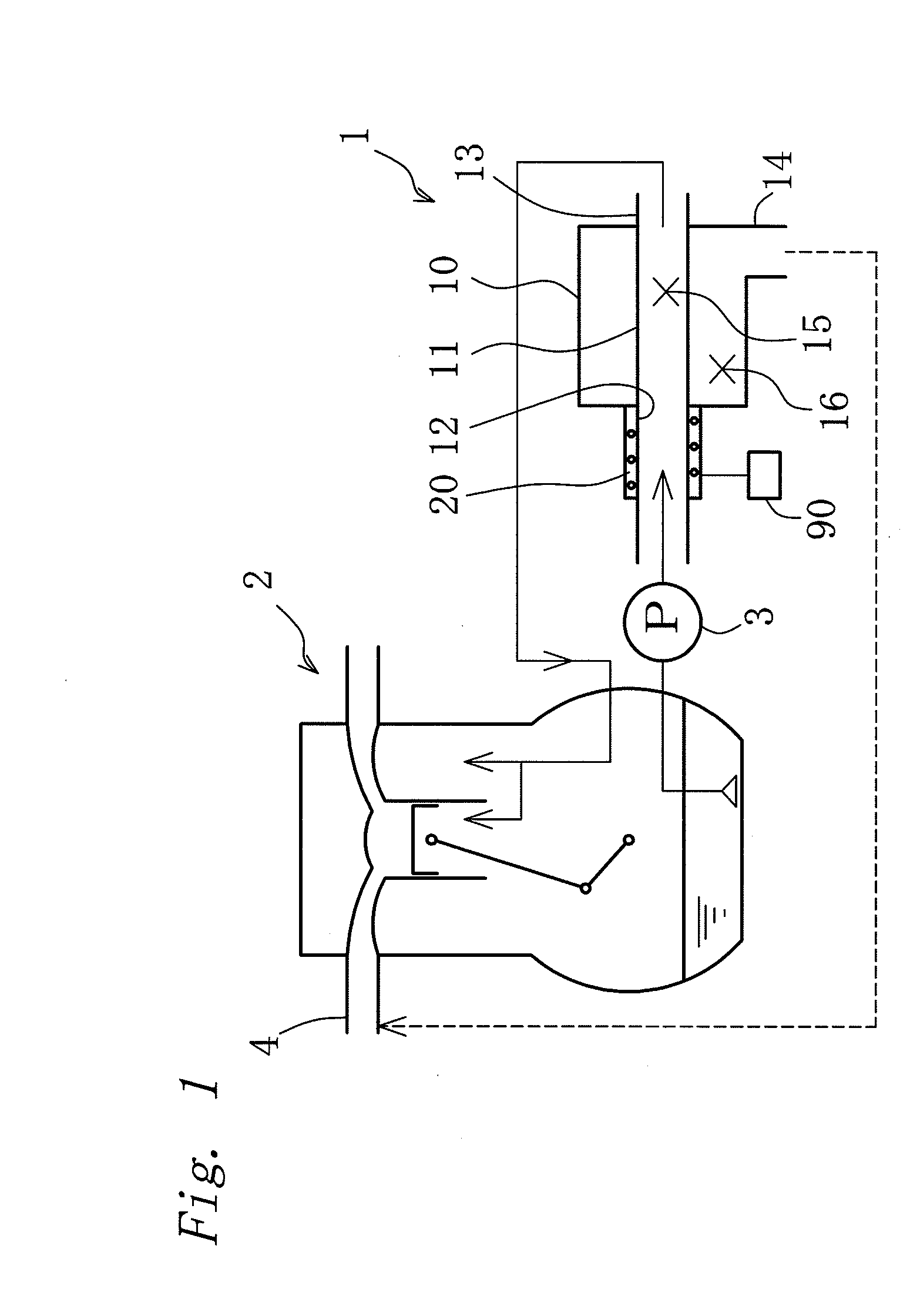

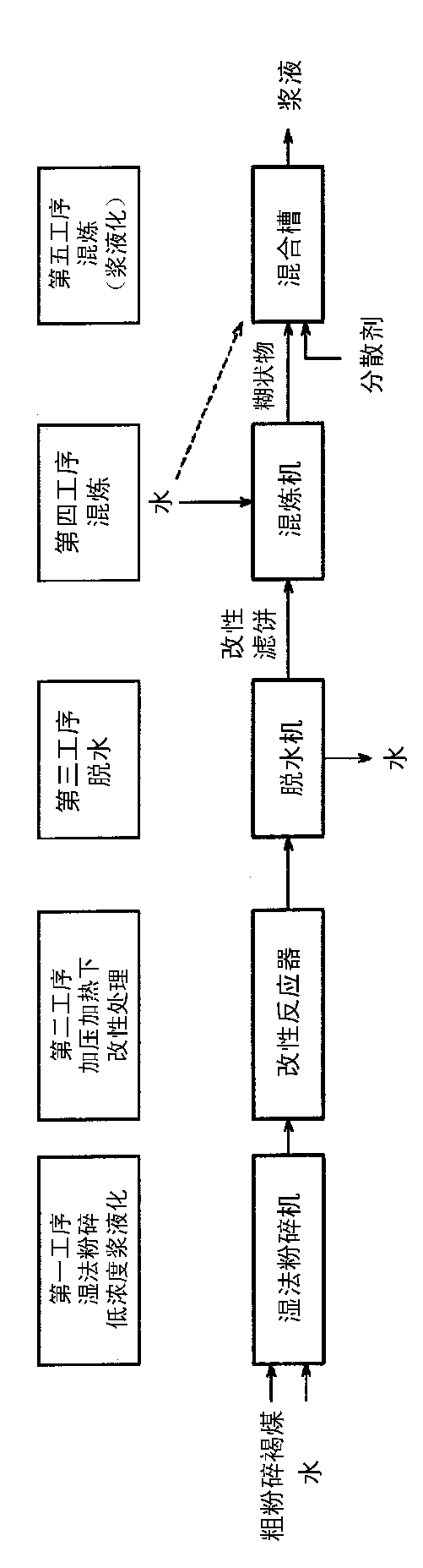

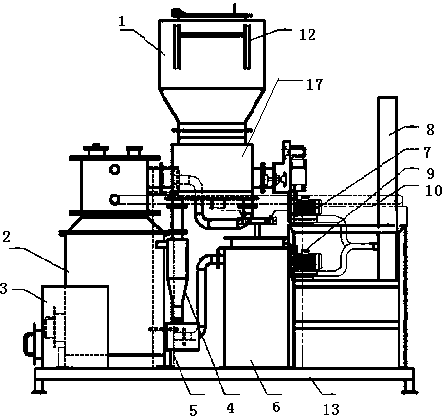

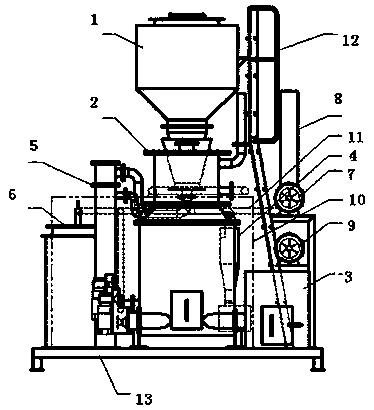

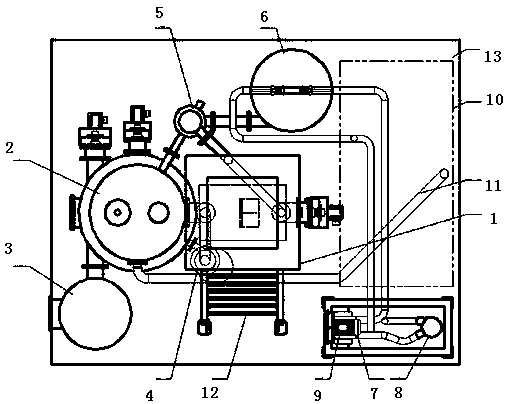

Method for manufacturing low-grade coal slurry, device for manufacturing low-grade coal slurry, and gasification system for low-grade coal

ActiveCN103298918BEasy to manufactureLow viscosityGasification processes detailsLiquid carbonaceous fuelsProcess engineeringCoal slurry

The purpose of the present invention is to provide: a production method and production device with which it is easy to produce a low-grade coal slurry having a high slurry concentration and a low viscosity, and which is appropriate for gasification using a pressurized gasification furnace; and a gasification system provided with such a production device. This low-grade coal slurry production method has: a first step for heating and drying coarsely ground low-grade coal, and recovering condensed water emitted from the low-grade coal as steam; and a second step for adding a dispersant and the condensed water obtained during the first step to the heated and dried low-grade coal, and forming a slurry using the wet-grinding method. In addition, this low-grade coal slurry production device has: a drying device for heating and drying the coarsely ground low-grade coal; a condensed water recovery device for recovering condensed water emitted from the low-grade coal as steam through the heating and drying; and a wet-grinding device for adding the condensed water and the dispersant to the heated and dried low-grade coal, and forming a slurry.

Owner:KAWASAKI HEAVY IND LTD

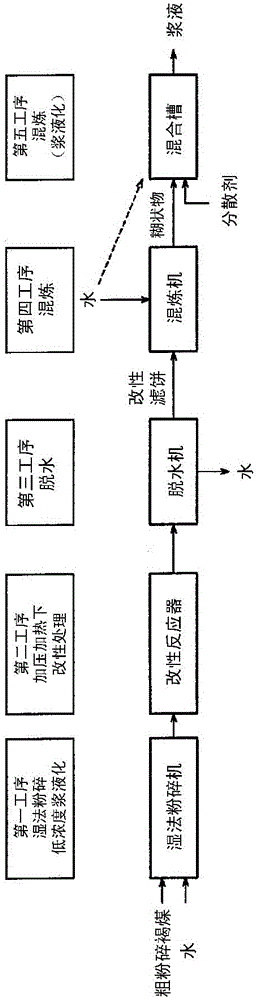

Low-grade coal slurry production method, low-rade coal slurry production device, and low-grade coal gasification system

ActiveCN103282469AEasy to manufactureLow viscosityGasification processes detailsLiquid carbonaceous fuelsWet grindingProcess engineering

The purpose of the present invention is to provide: a production method and production device with which it is easy to produce a low-grade coal slurry having a high slurry concentration and a low viscosity, and which is appropriate for gasification using a pressurized gasification furnace; and a gasification system provided with such a production device. This low-grade coal slurry production method has: a first step for performing a modification treatment on coarsely ground low-grade coal under high-temperature and high-pressure conditions; and a second step for adding water and a dispersant to the modification-treated low-grade coal, and forming a slurry from the low-grade coal using a wet-grinding method. In addition, this low-grade coal slurry production device has: a dry-grinding device for dry-grinding the low-grade coal; a high-temperature / high-pressure kneading device for performing a modification treatment on the dry-ground low-grade coal; and a wet-grinding device for adding the dispersant, and the water discharged from the low-grade coal during the modification treatment, and forming a slurry from the modification-treated low-grade coal.

Owner:KAWASAKI HEAVY IND LTD

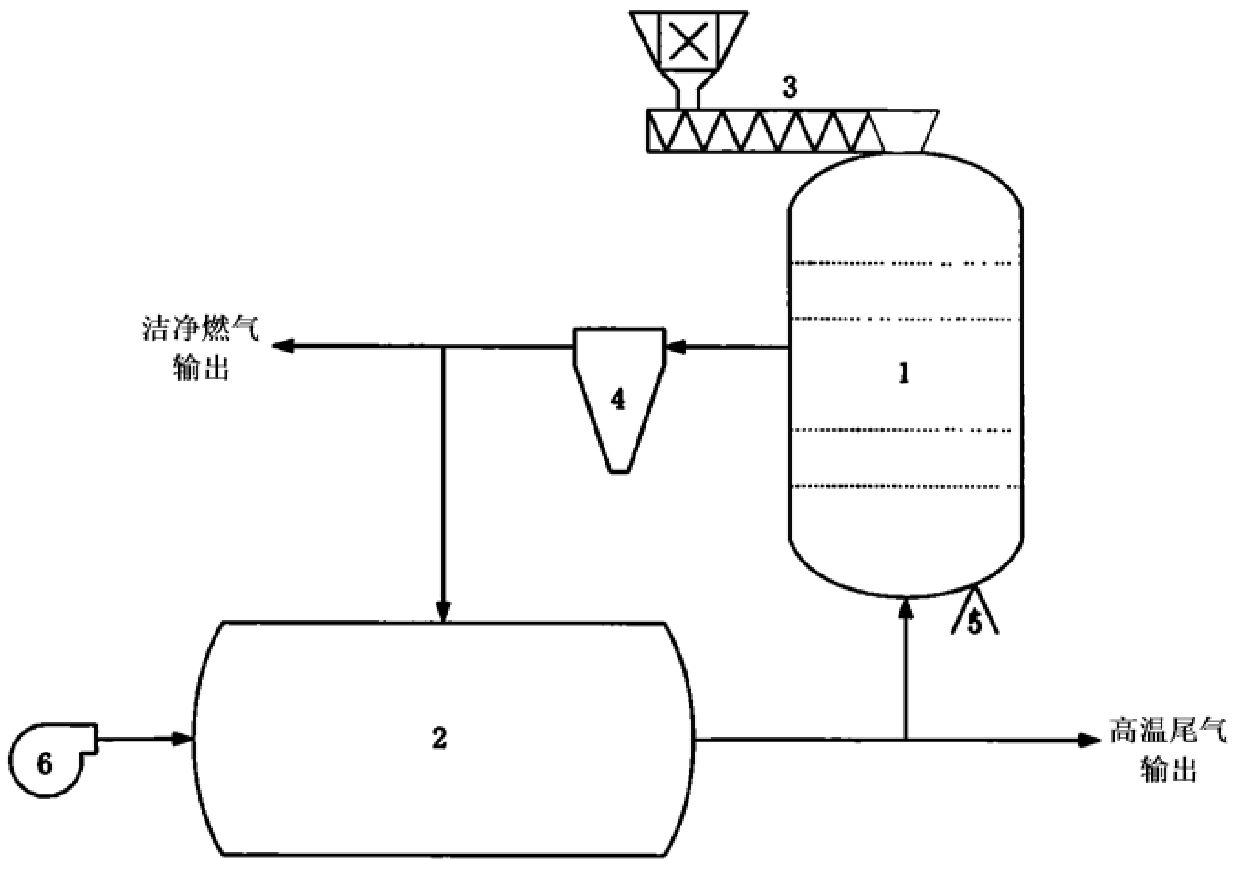

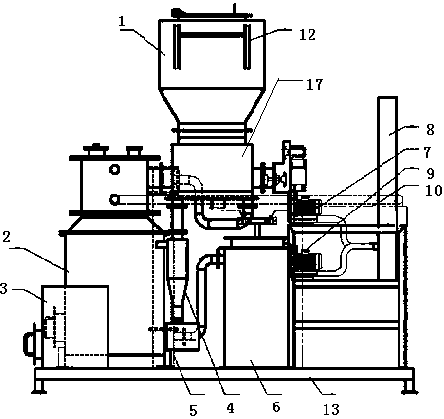

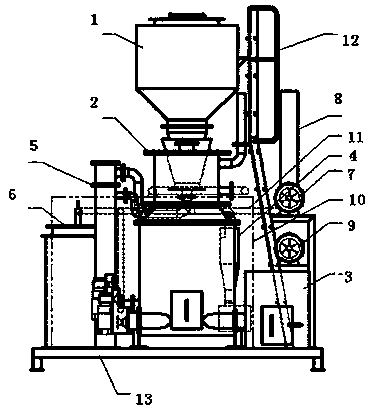

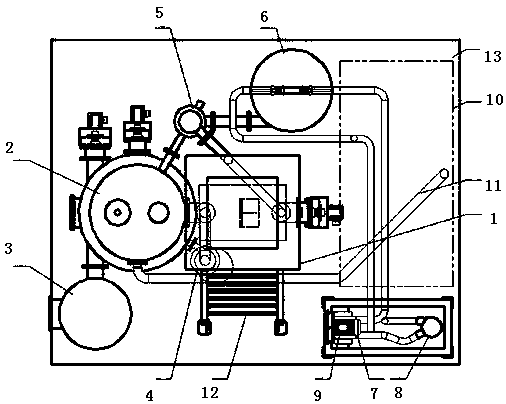

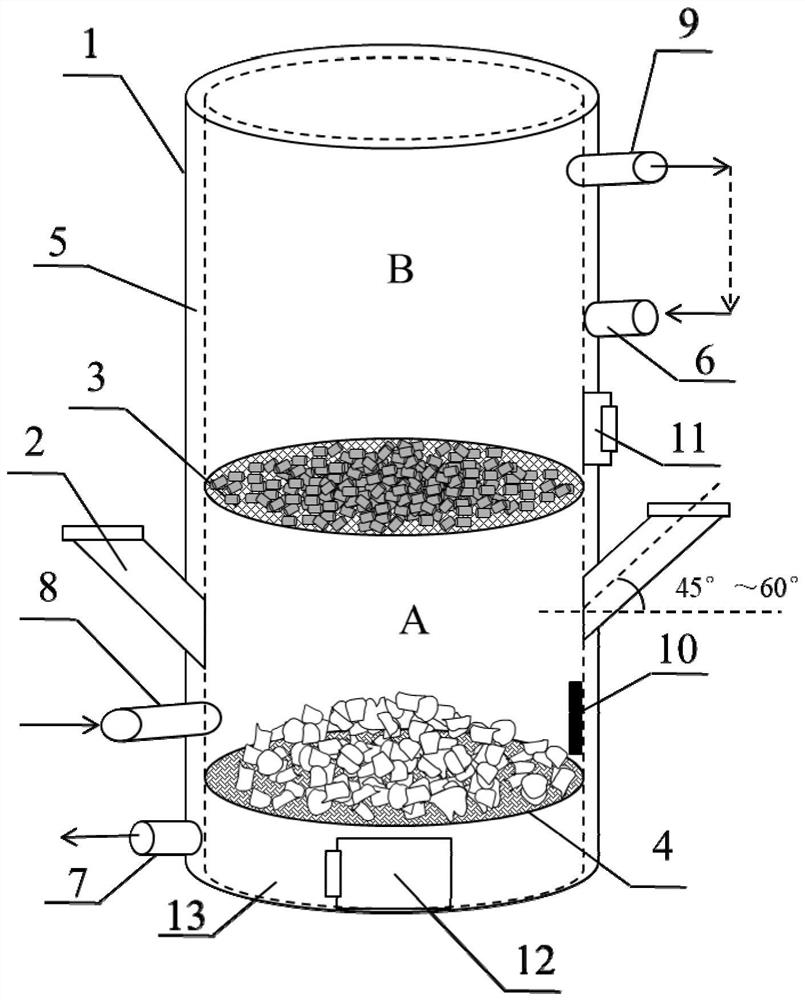

Integrated downdraft biomass gasification power generation system and method

ActiveCN110295065AImprove efficiencyIncrease profitEnergy inputGasification processes detailsActivated carbonGas generator

The invention discloses an integrated downdraft biomass gasification power generation system, belongs to the technical field of biomass gasification power generation, and particularly relates to an integrated downdraft biomass gasification power generation system and method. The system comprises a hopper, a reactor, a slag barrel, a cyclone dust remover, an air preheater, an activated carbon adsorber, a gas fan, a torch, an air fan, a gas generator set, a pipeline, a ladder and a base, and is characterized in that the hopper, the air preheater, the cyclone dust remover, the slag barrel and thereactor are coupled into a compact whole, so that the heat efficiency of the whole system is greatly improved. The system is suitable for gasifying straw particles, wood chips, crushed coconut shellsand other carbonaceous biomass materials to generate combustible gas, and the combustible gas is conveyed into a gas engine to be combusted to push the engine to drive a generator to generate electric energy. The system is compact in structure, high in universality, high in energy utilization rate, reliable, convenient to use and easy to operate.

Owner:青岛德瑞汇丰环保科技股份有限公司

An integrated downdraft biomass gasification power generation system and method

ActiveCN110295065BReduce moisture contentIncrease temperatureEnergy inputGasification processes detailsAir preheaterCyclonic spray scrubber

The invention discloses an integrated downdraft biomass gasification power generation system, belongs to the technical field of biomass gasification power generation, and particularly relates to an integrated downdraft biomass gasification power generation system and method. The system comprises a hopper, a reactor, a slag barrel, a cyclone dust remover, an air preheater, an activated carbon adsorber, a gas fan, a torch, an air fan, a gas generator set, a pipeline, a ladder and a base, and is characterized in that the hopper, the air preheater, the cyclone dust remover, the slag barrel and thereactor are coupled into a compact whole, so that the heat efficiency of the whole system is greatly improved. The system is suitable for gasifying straw particles, wood chips, crushed coconut shellsand other carbonaceous biomass materials to generate combustible gas, and the combustible gas is conveyed into a gas engine to be combusted to push the engine to drive a generator to generate electric energy. The system is compact in structure, high in universality, high in energy utilization rate, reliable, convenient to use and easy to operate.

Owner:青岛德瑞汇丰环保科技股份有限公司

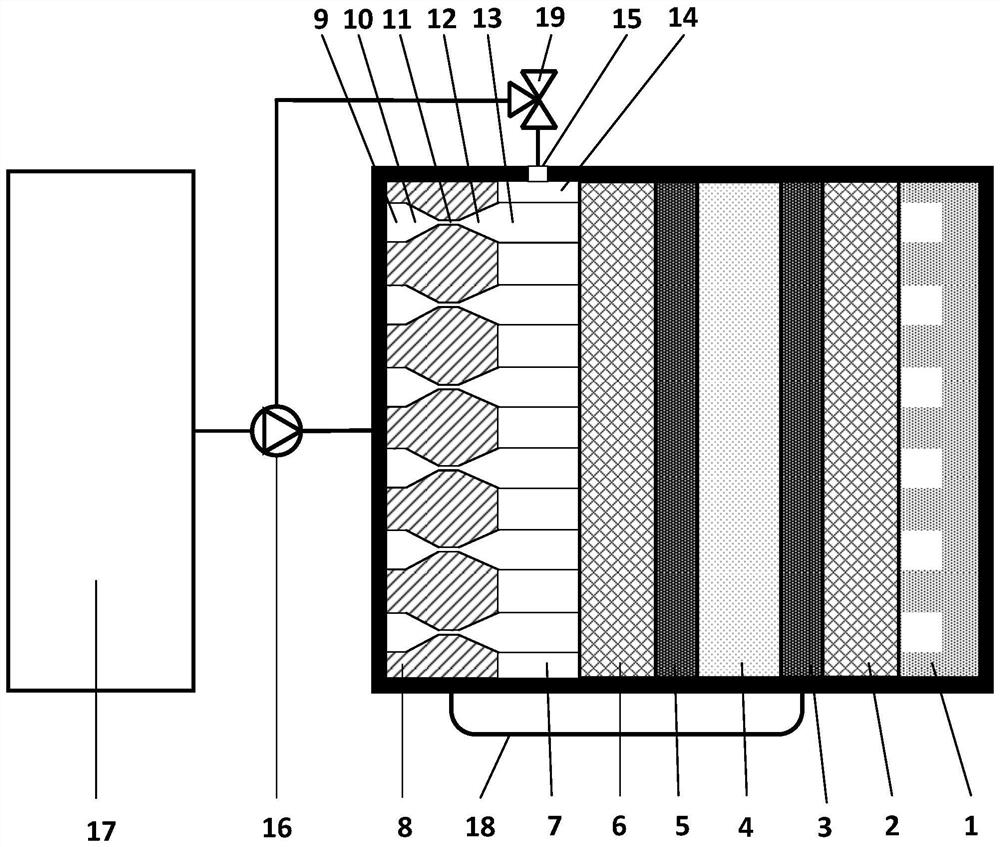

Heat and mass balanced direct methanol fuel cell and working method thereof

ActiveCN109888342AEasy to collect and useEfficient and stable reactionFuel cell heat exchangeGeneration processFuel cells

The invention discloses a heat and mass balanced direct methanol fuel cell and a working method thereof. According to the heat and mass balanced direct methanol fuel cell, methanol and a product are conveyed separately, the fuel cell forms a stable forward transmission flow path in the whole process from flow-in of liquid phase methanol to discharge of carbon dioxide, therefore, fuel can directlyand uniformly enter an anode, the problems that a methanol reaction is insufficient, and methanol steam concentrations are not uniform due to mixing of methanol and carbon dioxide are solved, stable and efficient running of an anode-side reaction is further benefited, and cell efficiency is improved; pressure intensity generated in the generation process of the product carbon dioxide is utilized to push the liquid state methanol to enter the fuel cell, so that additional pump work is lowered; waste heat generated in a reaction region in the cell running process is transmitted to a methanol evaporation region and used for assisting methanol evaporation; and the methanol evaporating and utilizing process is more efficient and saves more energy.

Owner:XI AN JIAOTONG UNIV

Castoff processing method and system

ActiveCN1834537BEfficient combustionEfficient gasificationProcess efficiency improvementIncinerator apparatusWaste processingSlag

The invention relates to a waste processing method and a waste processing system which can avoid discharging harmful material as dioxins and effectively attain the slag of value metal. Wherein, the method for recycling value metal comprises: burning the waste, recycling the slag that containing value metal, and fully burning generated gas , and cooling said burning gas with the cooling speed thatavoiding generating dioxins. With said method, the invention can gasify the resin component in the waste via burning waste, to obtain the slag of value metal in short time.

Owner:DOWA METALS & MINING CO LTD

A system and method for liquefied natural gas gasification based on solar cycle power generation

InactiveCN104747389BSimple structureReduce manufacturing costFrom solar energyMachines/enginesWorking fluidOrganic Rankine cycle

The invention provides a liquefied natural gas gasification system and method based on solar power cycle power generation. The gasification system includes a heat collection and heat storage unit, a power generation unit and a natural gas gasification unit, and the heat collection heat storage unit and the power generation unit pass through the first A heat exchanger is connected to the power generation unit, the power generation unit is connected to the gasification unit through the third heat exchanger and the fourth heat exchanger, and the natural gas gasification unit is connected to the gasification unit through the second heat exchanger The heat collection and heat storage units are connected. In the gasification system of the invention, the collected solar energy is used in stages, the high-temperature heat transfer working medium first generates electricity through the organic Rankine cycle system, and the waste heat is used for the gasification of jet liquefied natural gas. Gasification, which improves the gasification rate of liquefied natural gas and realizes the saving of non-renewable energy.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Organic solid waste semi-in-situ carbon sequestration gasification device and application thereof

PendingCN113881462AAvoid carbon deposits and other phenomenaAvoid the inconvenience of the reuse processProductsReagentsPtru catalystCombustible gas

The invention belongs to the field of energy treatment and utilization of solid wastes, and particularly relates to an organic solid waste semi-in-situ carbon sequestration gasification device. The device comprises a gasification furnace body, a heat supply interlayer, a semi-in-situ catalyst placing net and a movable fire grate, wherein the gasification furnace body comprises a solid waste feeder, a carbon dioxide inlet, a combustible gas outlet, a catalyst replacement port, an ash outlet, an ash bin and the like; the heat supply interlayer is communicated with the hot air inlet and the hot air outlet; the organic solid waste is converted into combustible gas by controlling the furnace temperature and the carbon dioxide amount. The device is simple and ingenious in structure, high in gasification efficiency and stable in carbon dioxide fixation. Compared with an in-situ gasification catalytic device, carbon deposition and coverage caused by mixing of a catalyst and fed materials are avoided, compared with a two-stage gasification catalytic device, the investment cost can be reduced, the problems of slow natural degradation, incineration emission pollution and the like of organic solid waste can be effectively solved, the treatment efficiency of the organic solid waste is improved, and increase of carbon dioxide is effectively inhibited.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A kind of gasification furnace and its application, gasification method of carbonaceous material

ActiveCN104498100BReduce usageReduce heat lossGasification processes detailsGasification apparatus detailsSyngasThermodynamics

The invention discloses a gasification furnace, its application and a method for gasifying carbonaceous substances. The gasification furnace includes a vertical furnace body, and a slag outlet, a synthesis gas outlet and at least one process burner are provided on the vertical furnace body. At least one flux nozzle chamber is fixed, and the flux nozzle installed in the flux nozzle chamber: the height of the axis of the flux nozzle chamber from the bottom of the vertical furnace body is less than or equal to the vertical furnace body 0.4 times the height. The gasification furnace provided by the invention can add flux from the bottom of the gasification furnace, which effectively ensures the liquid slag discharge at the slag outlet, improves the carbon conversion rate of the gasification furnace, reduces heat loss on the wall surface, and avoids The flux enters the fly ash, which improves the utilization rate of the flux.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Heat storage container and heat storage device including heat storage container

ActiveCN107110613BSimple structureExcellent heat storage densityHeat storage plantsHeat-exchange elementsEngineeringHeat storage material

There is provided a heat storage system and a heat storage container each capable of improving a heat generation amount and a heat transport amount with a simple configuration, and a heat storage device using the above heat storage container. A heat storage system using a heat storage container having a tubular body, a chemical heat storage material accommodated in the tubular body, and a flow channel that penetrates the tubular body in a longitudinal direction, the heat storage system having a diffusion layer for transporting liquid from the flow channel to the chemical heat storage material, the liquid functioning as a reaction medium of the chemical heat storage material, wherein the liquid is transported to the flow channel, the liquid is transported to the diffusion layer, the liquid transported to the diffusion layer reacts with the chemical heat storage material, the chemical heat storage material generates heat, and the liquid is vaporized by the heat to become heat transport fluid.

Owner:FURUKAWA ELECTRIC CO LTD

A heat balance material separation direct methanol fuel cell and its working method

ActiveCN109888343BImprove efficiencyGuaranteed uptimeFuel cell heat exchangeDiaphragm pumpFuel cells

The invention discloses a direct methanol fuel cell capable of realizing heat balance and material separation as well as a working method thereof. The direct methanol fuel cell is characterized in that methanol and a product are separately conveyed, a stable downstream transmission flow path is formed in the whole process of the fuel cell entirety from a moment that liquid-phase methanol flows through to a moment that carbon dioxide is discharged, the problems that methanol reaction is insufficient and methanol vapor concentration is nonuniform as methanol and carbon dioxide are mixed are solved, stable and efficient performance of a reaction at an anode side is better benefited, and cell efficiency is improved; extra heat produced in a fuel cell operation process is transmitted into a methanol evaporation region, and energy consumption is reduced while a fuel cell operating temperature is lowered; and a cell product carbon dioxide enters a pneumatic diaphragm pump under the action ofair pressure, a carbon dioxide flow divider valve drives the pneumatic diaphragm pump to stably convey the liquid phase methanol to the methanol evaporation region, and power is provided for the liquid phase methanol when entering the cell without extra power consumption.

Owner:XI AN JIAOTONG UNIV

Thermal storage system, thermal storage container, thermal storage device using thermal storage container, and warm air device using thermal storage device

InactiveCN109642776ASimple structureExcellent heat storage densityHeat storage plantsEnergy efficient heating/coolingThermal energy storageDesorption

Provided are a thermal storage system, thermal storage container, and thermal storage device using said thermal storage container that enable the amount of heat generated and amount of heat transported to be enhanced with a simple configuration. The thermal storage system uses a thermal storage container that comprises: a tubular body; an adsorbent material that is housed in the tubular body, generates heat through adsorption of a substance to be adsorbed, and absorbs heat through desorption of the subject to be adsorbed; and a channel penetrating through the tubular body in a long-axis direction. In the system, included is a diffusion layer for diffusing a liquid-phase substance to be adsorbed from the channel to the adsorbent material; the substance to be adsorbed is transported to the channel; the substance to be adsorbed is transported to the diffusion layer; some of the substance to be adsorbed having been transported to the diffusion layer is adsorbed onto the adsorbent material;the adsorbent material releases heat; and the remainder of the substance to be adsorbed is evaporated by the heat and becomes a heat transport fluid.

Owner:FURUKAWA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com