Patents

Literature

36results about How to "Efficient and stable reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

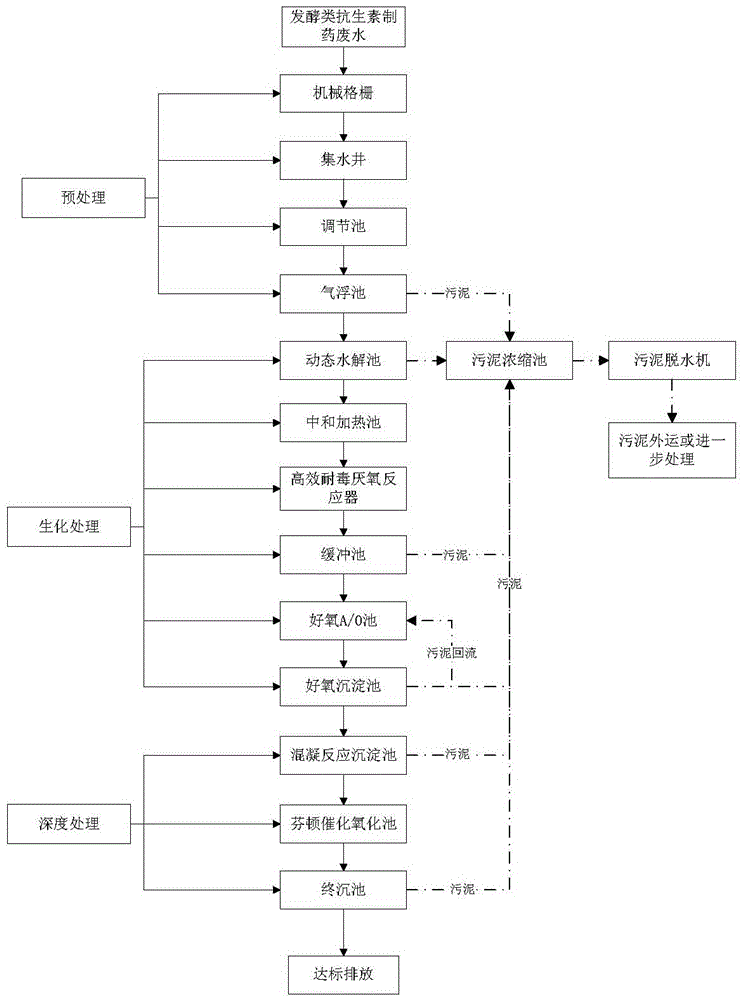

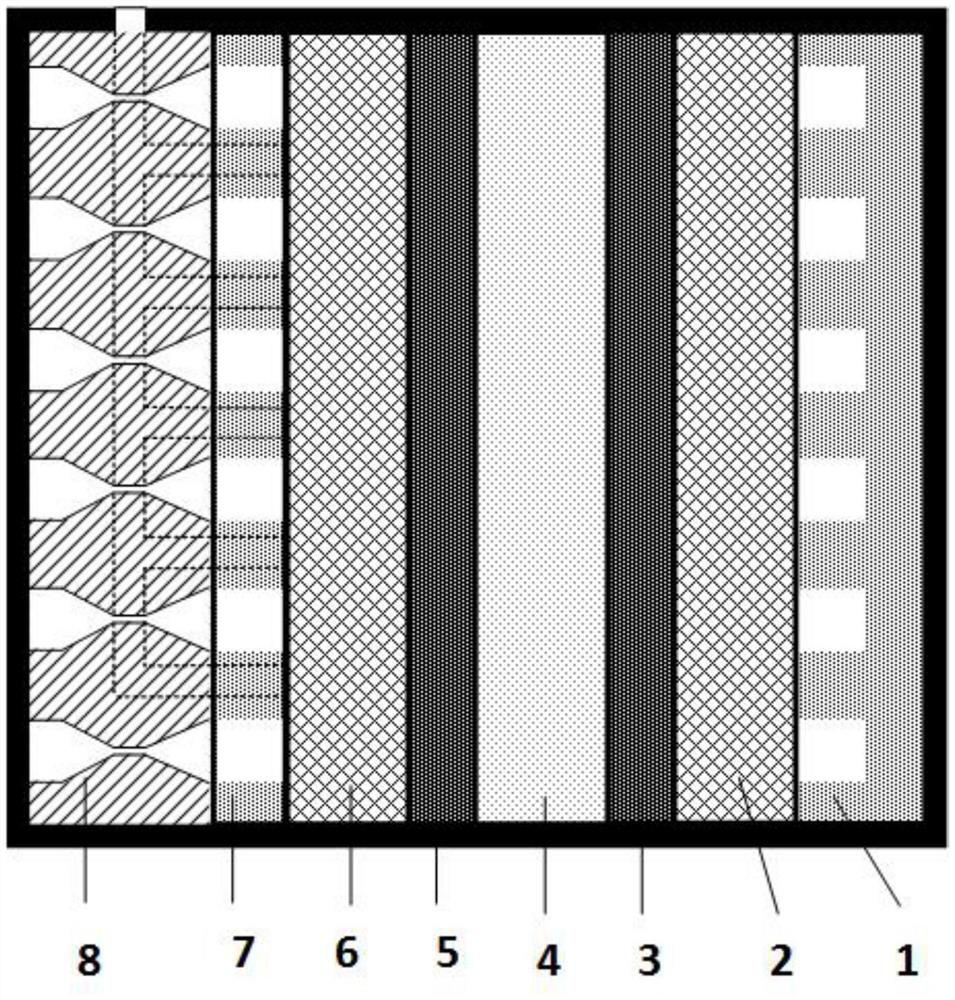

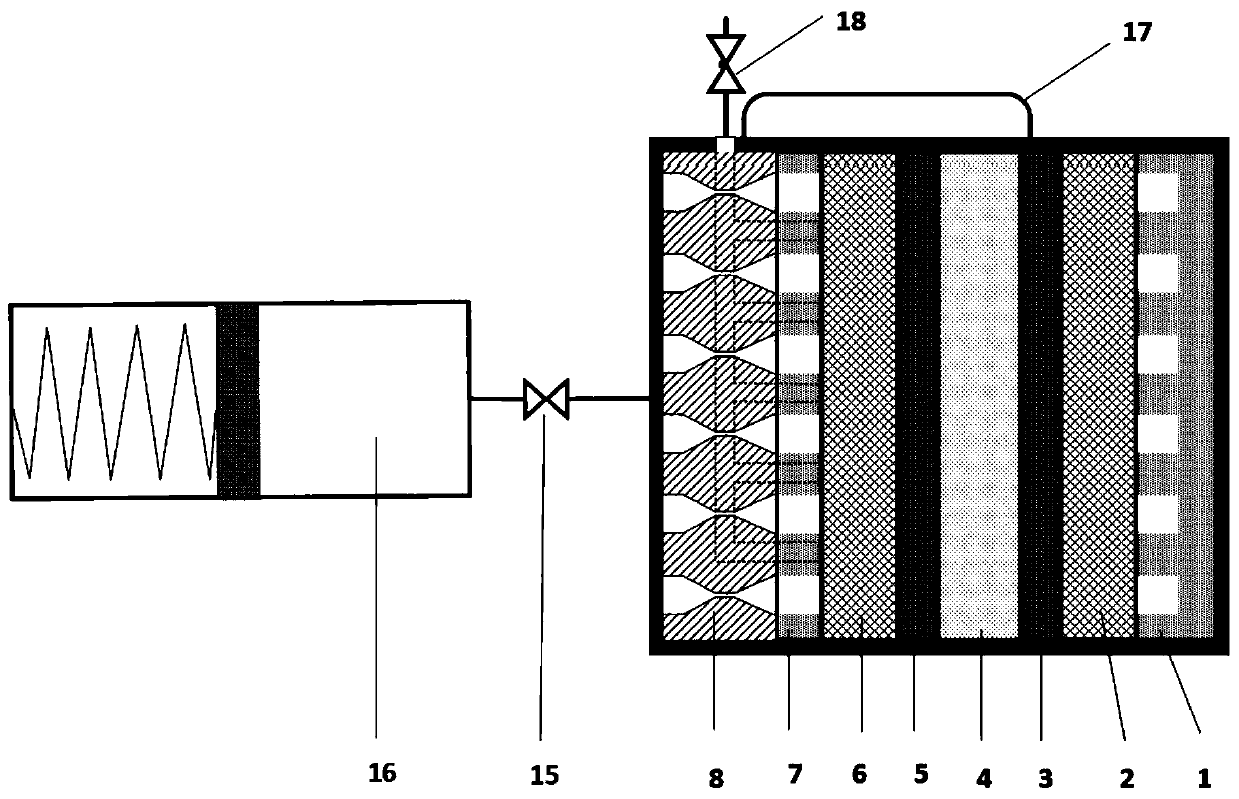

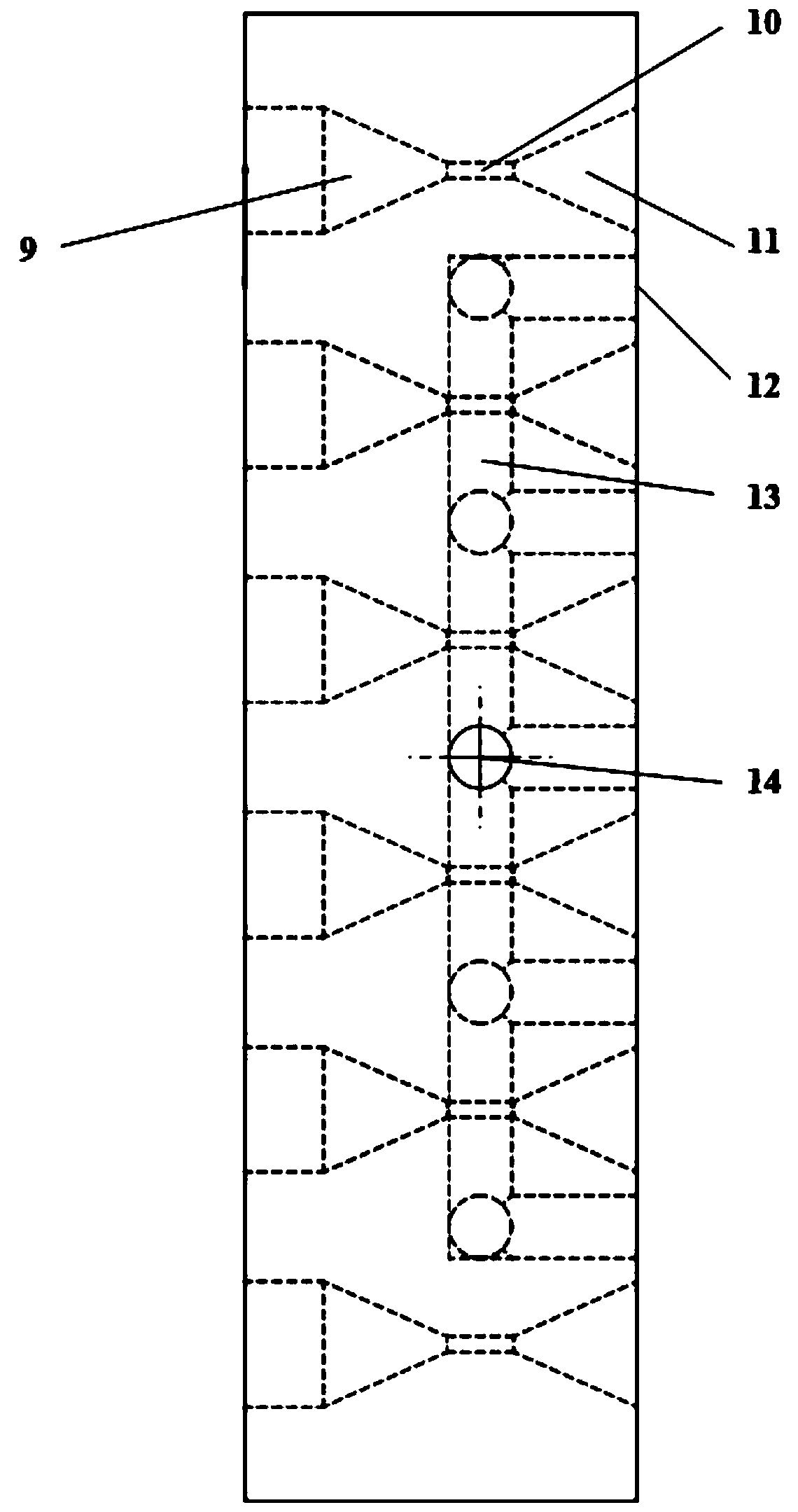

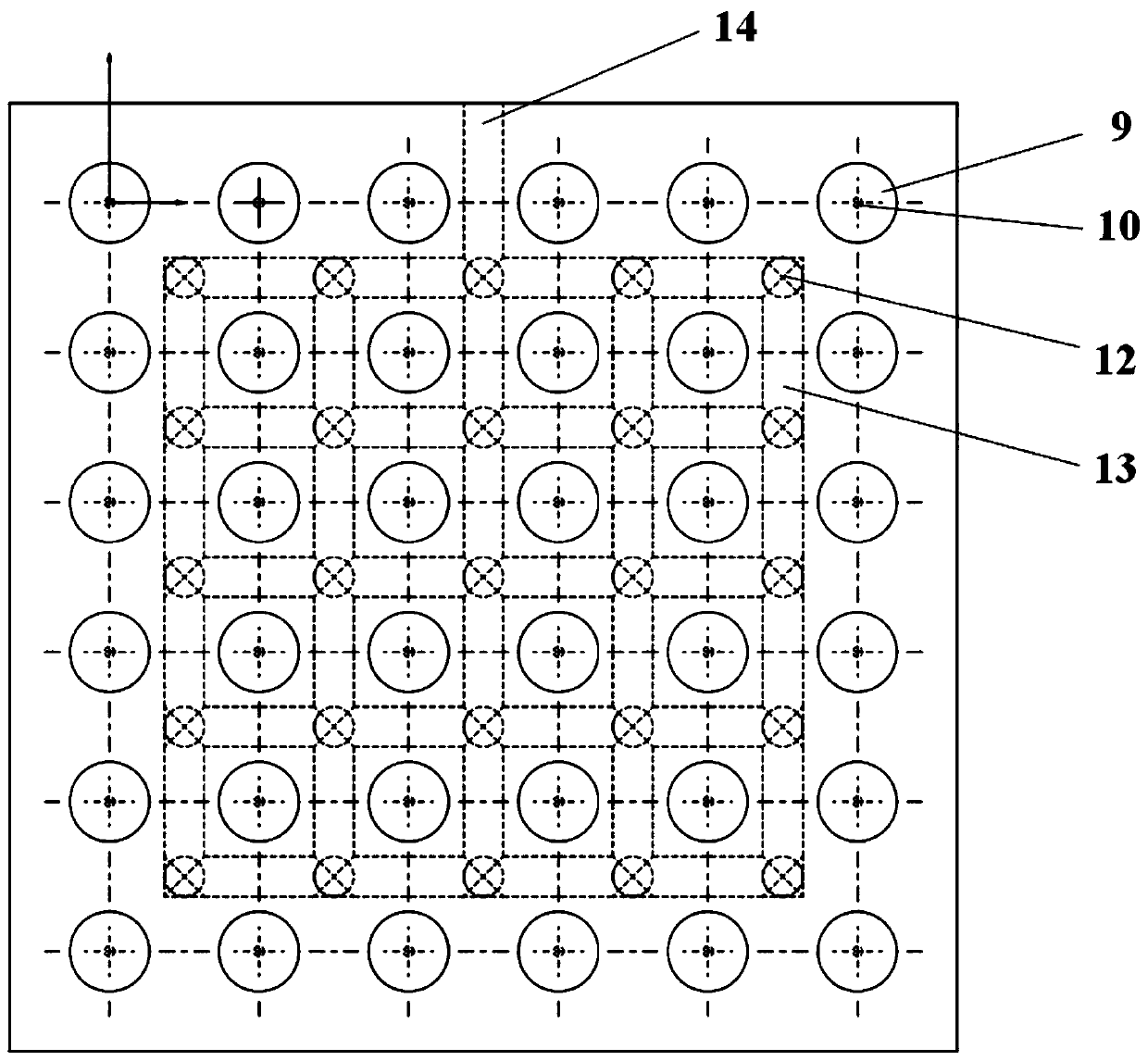

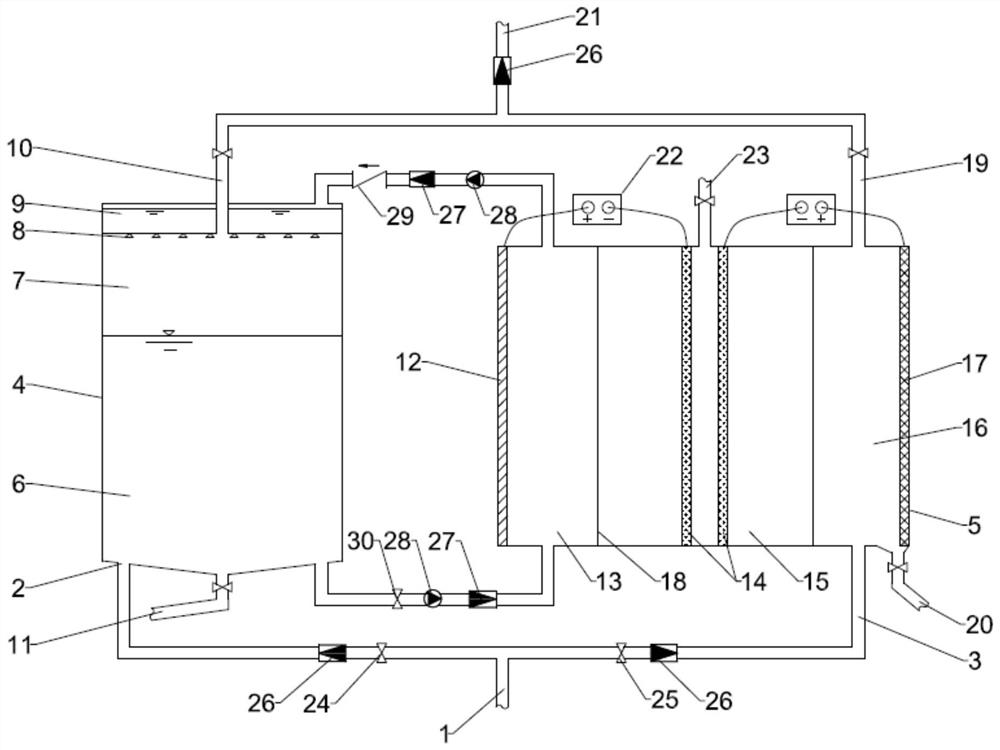

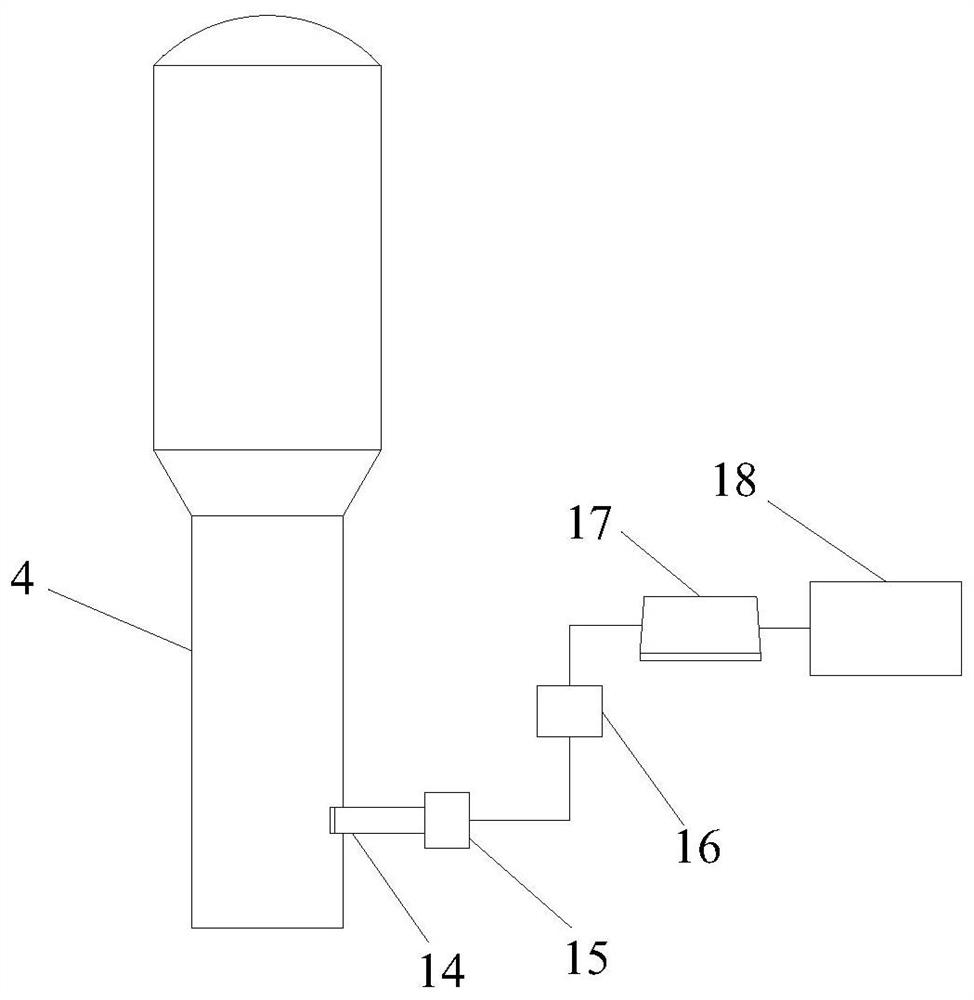

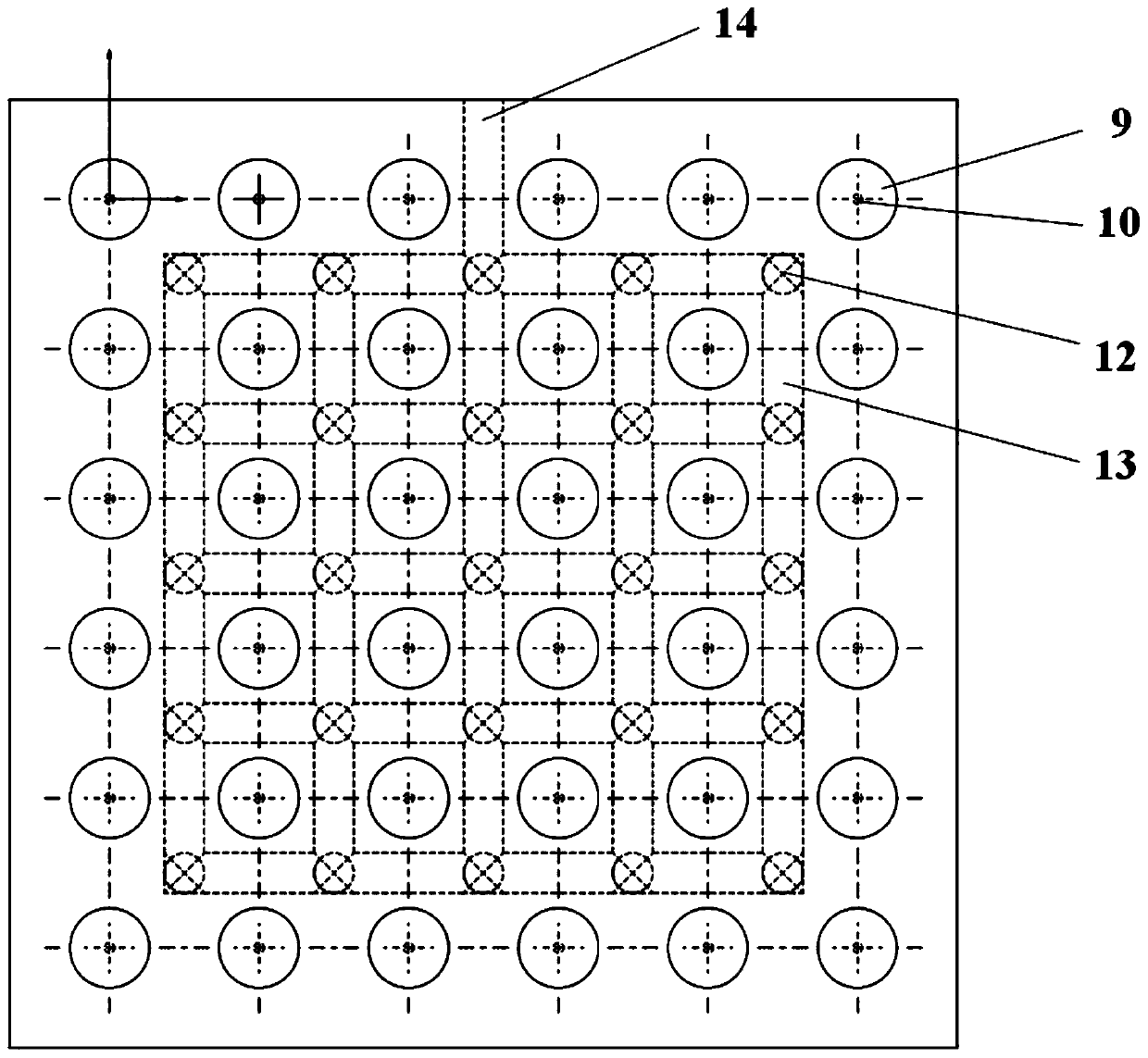

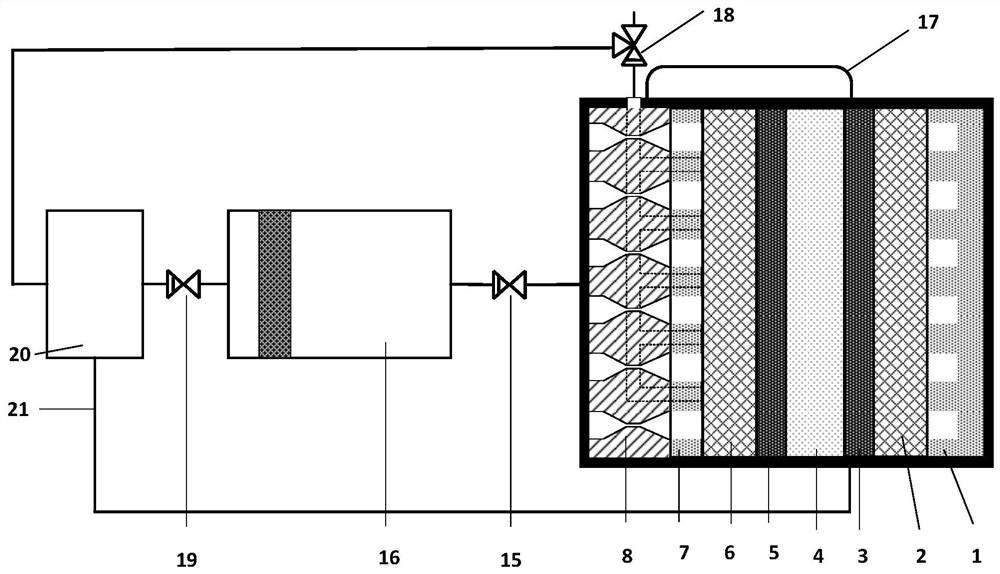

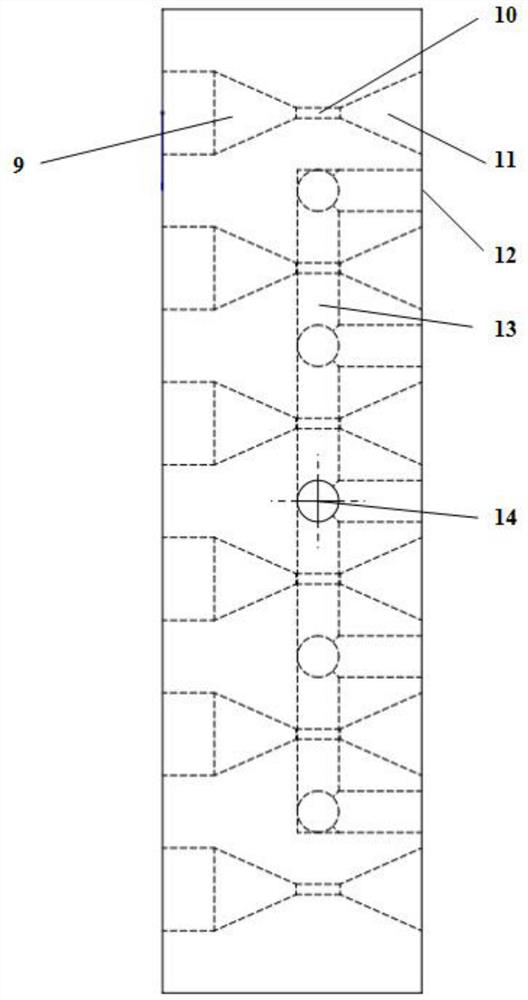

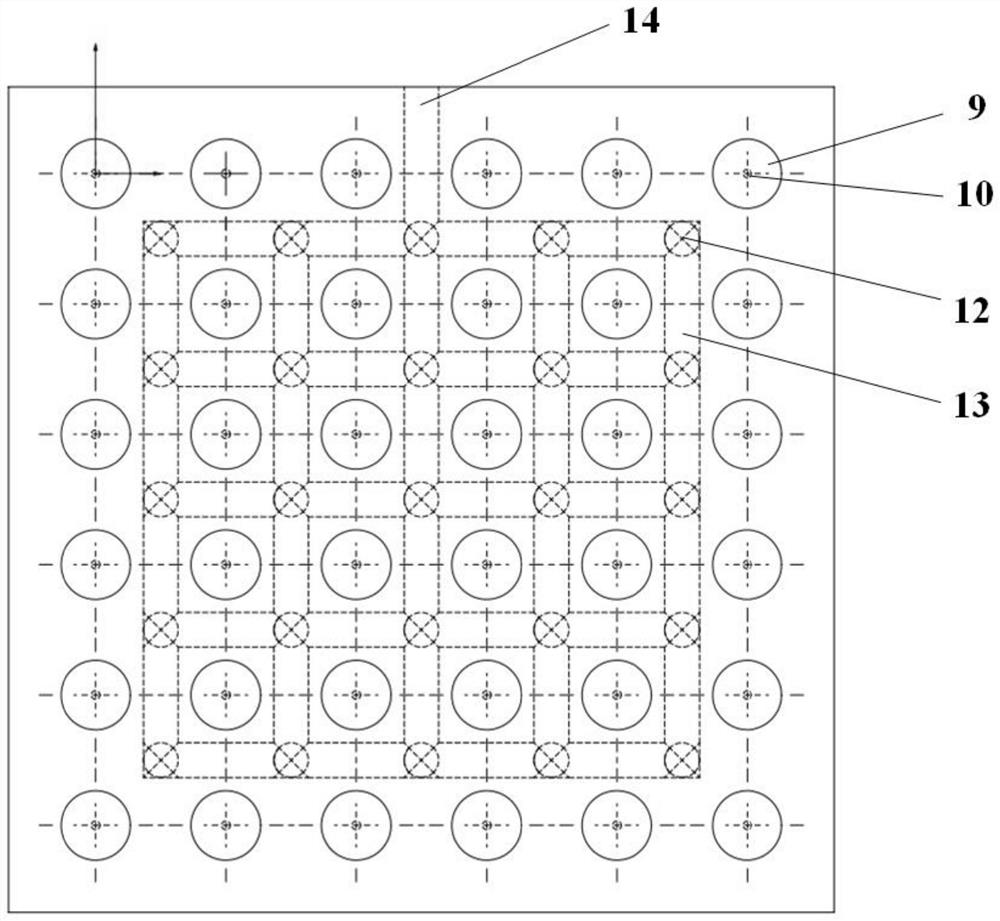

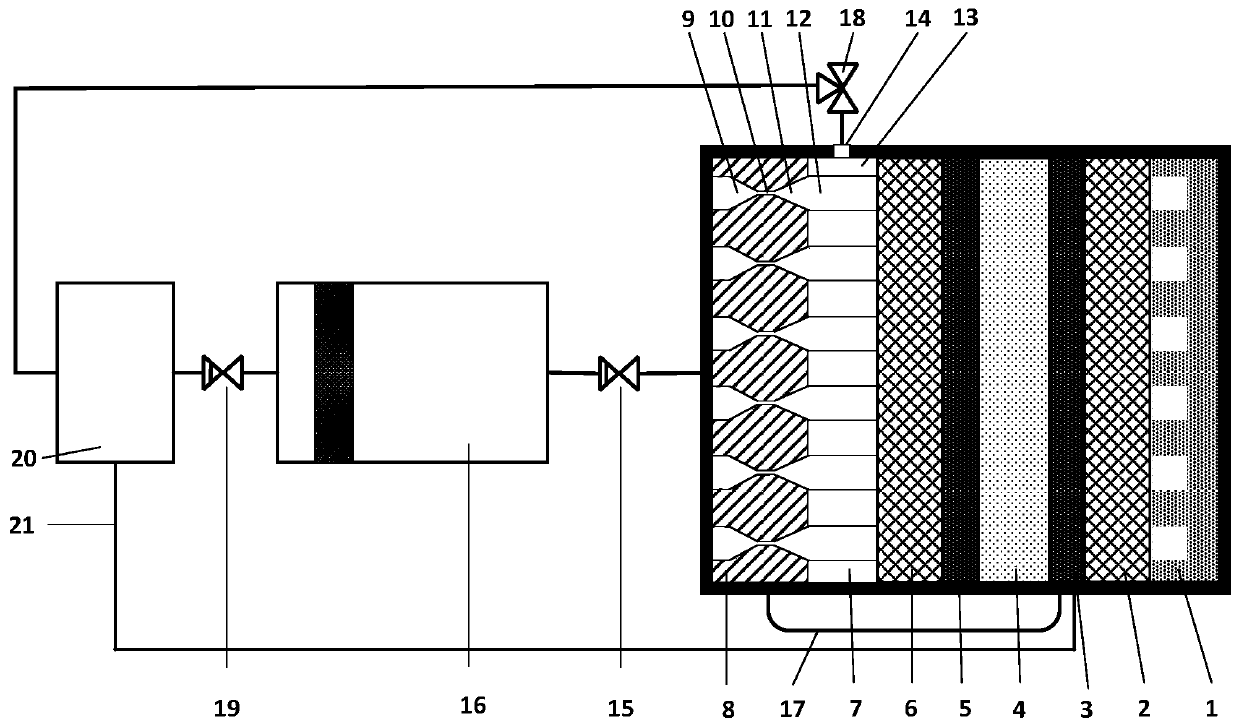

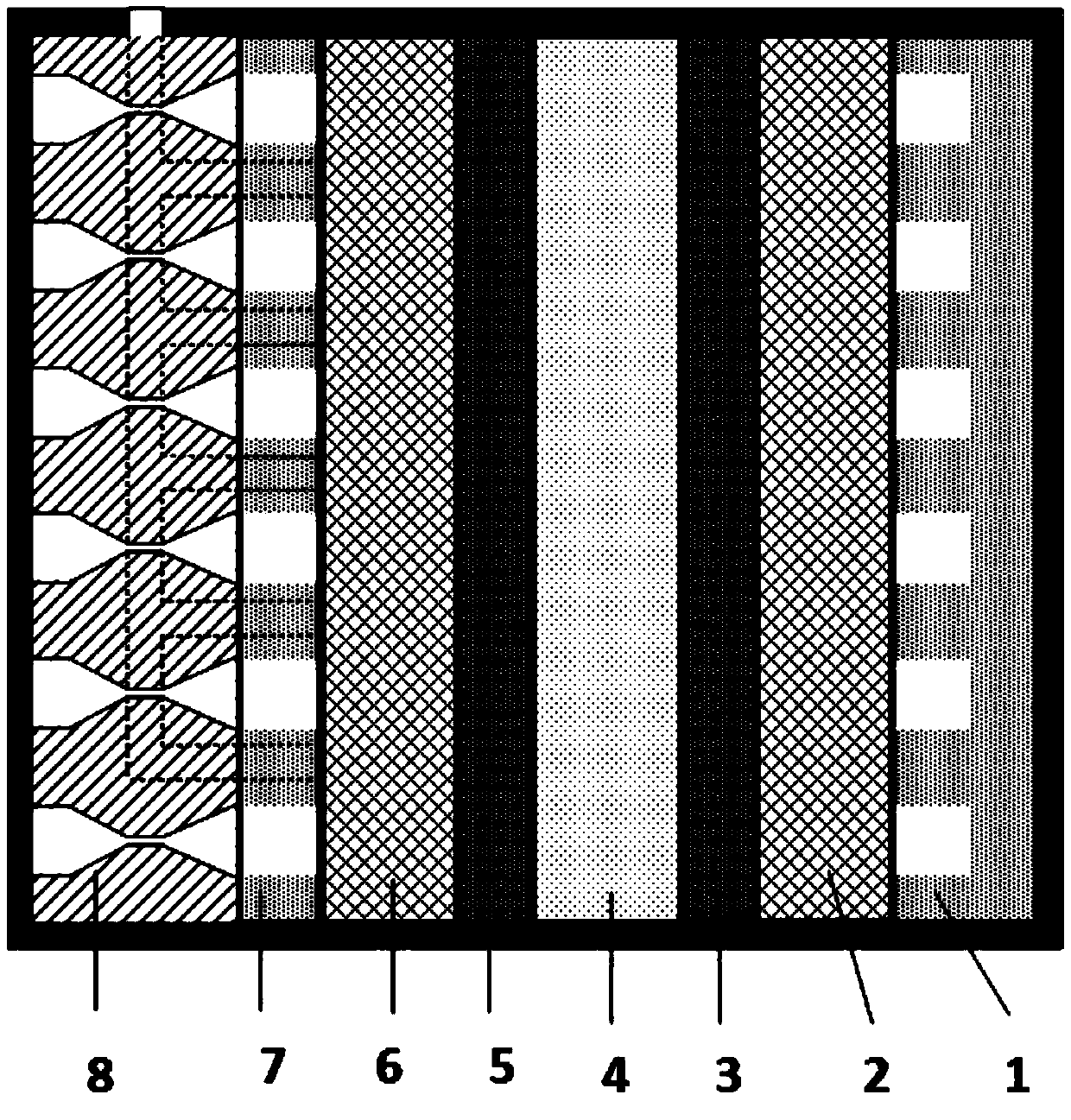

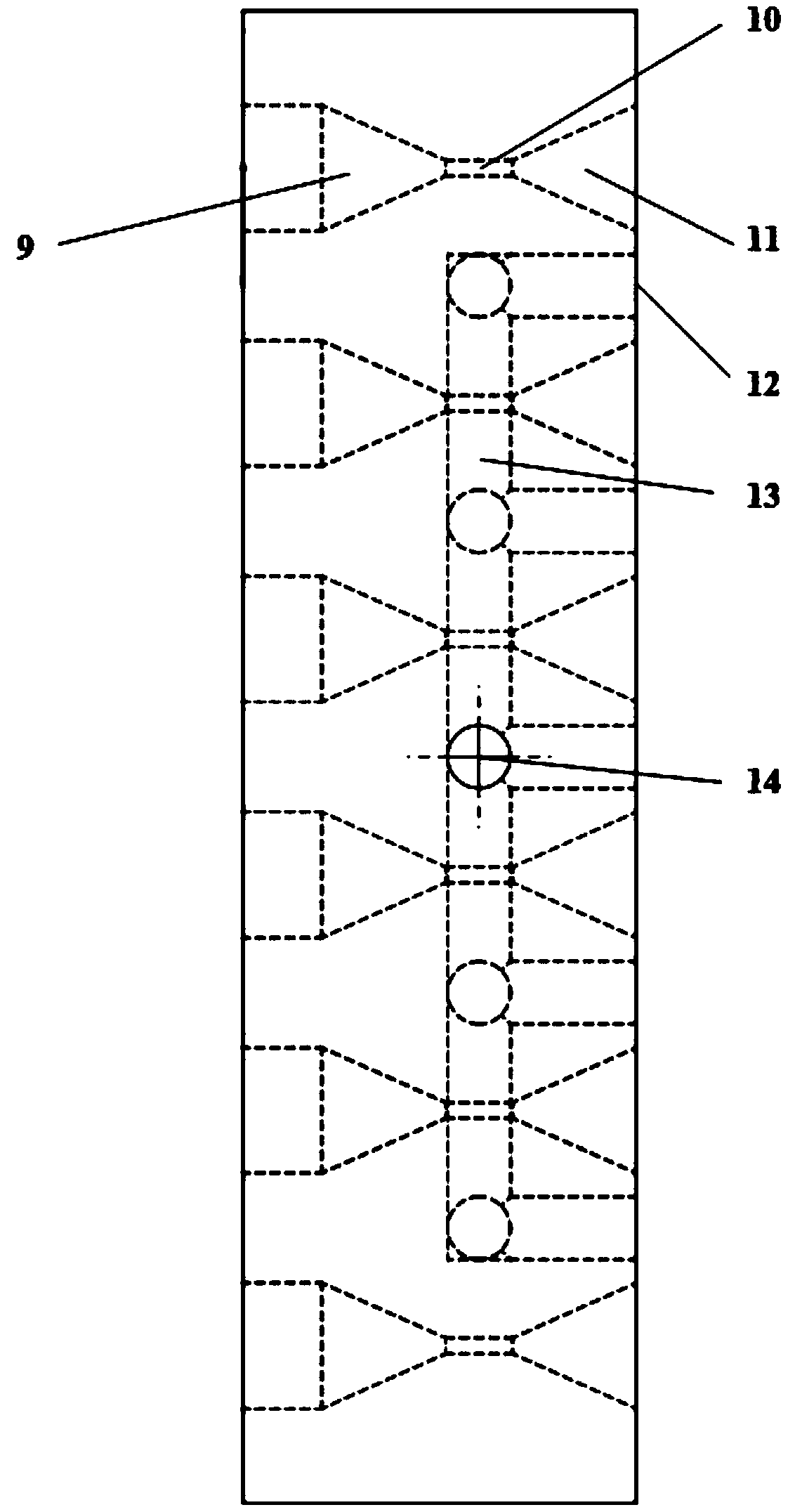

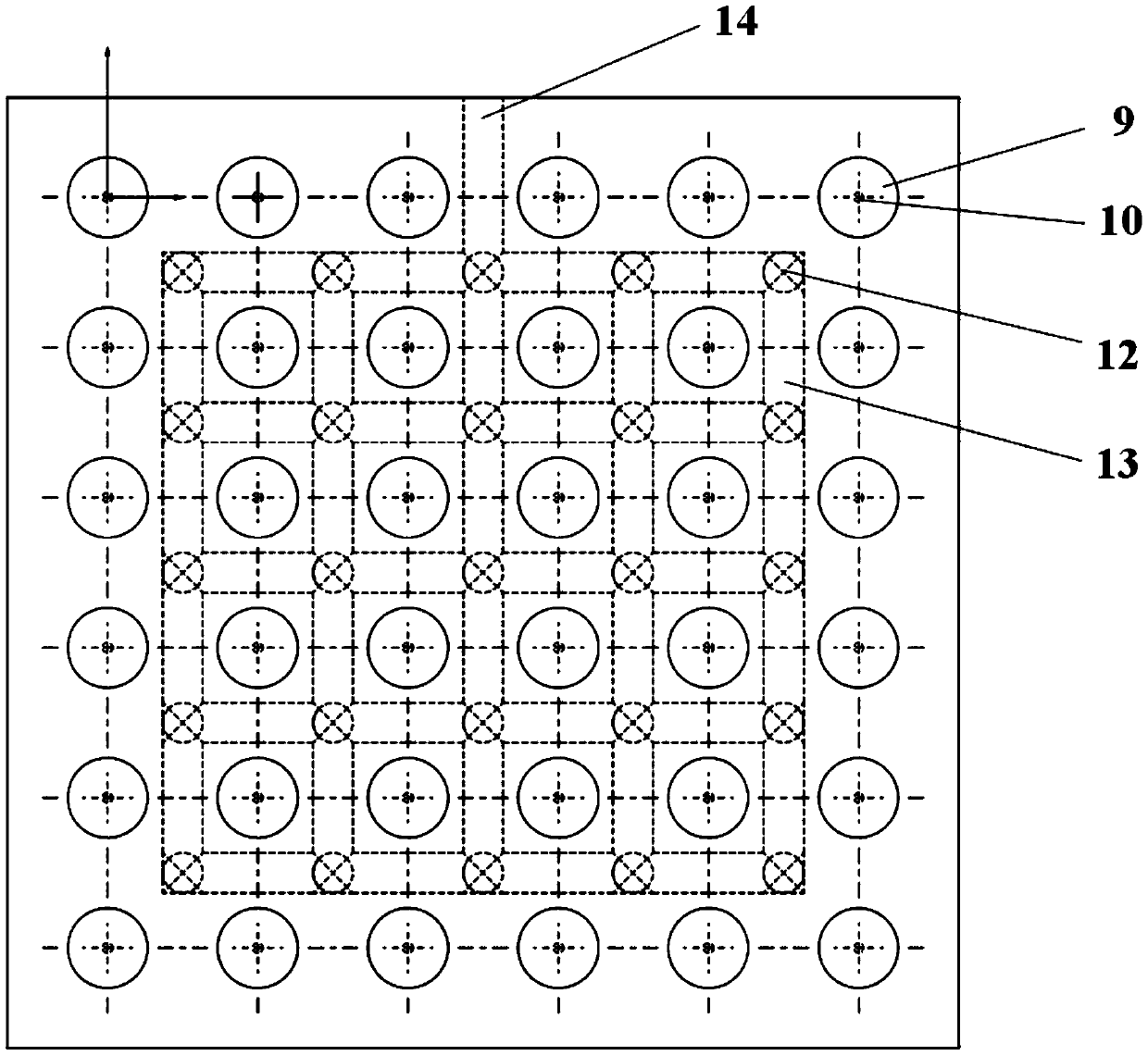

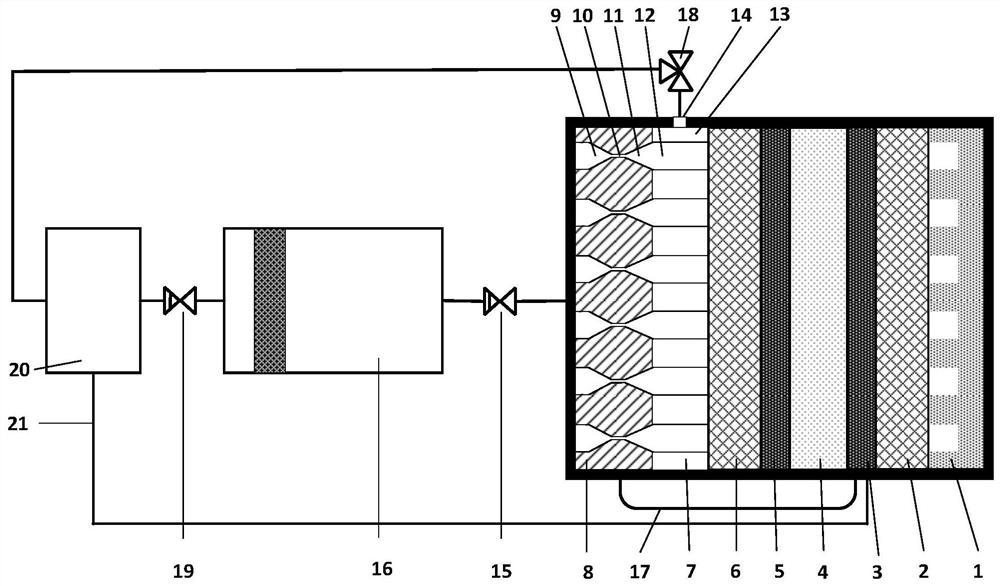

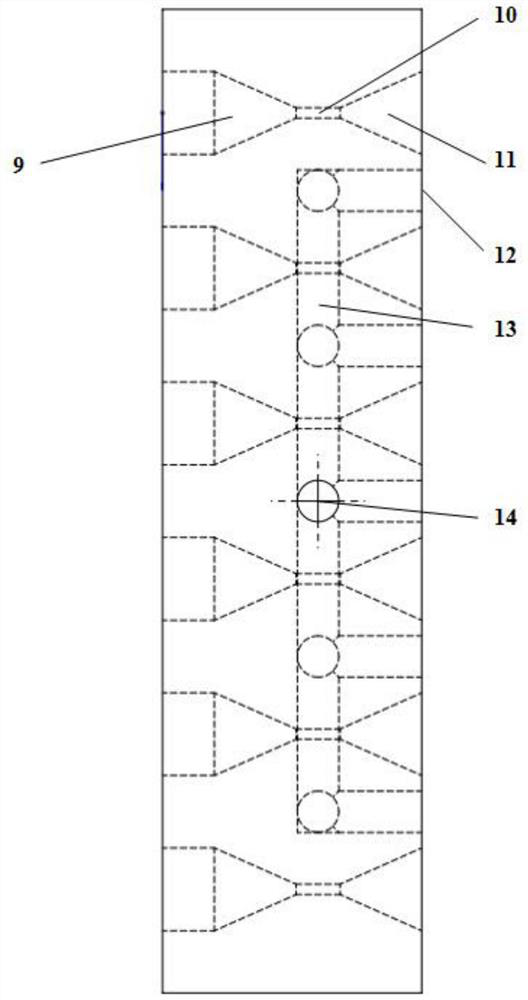

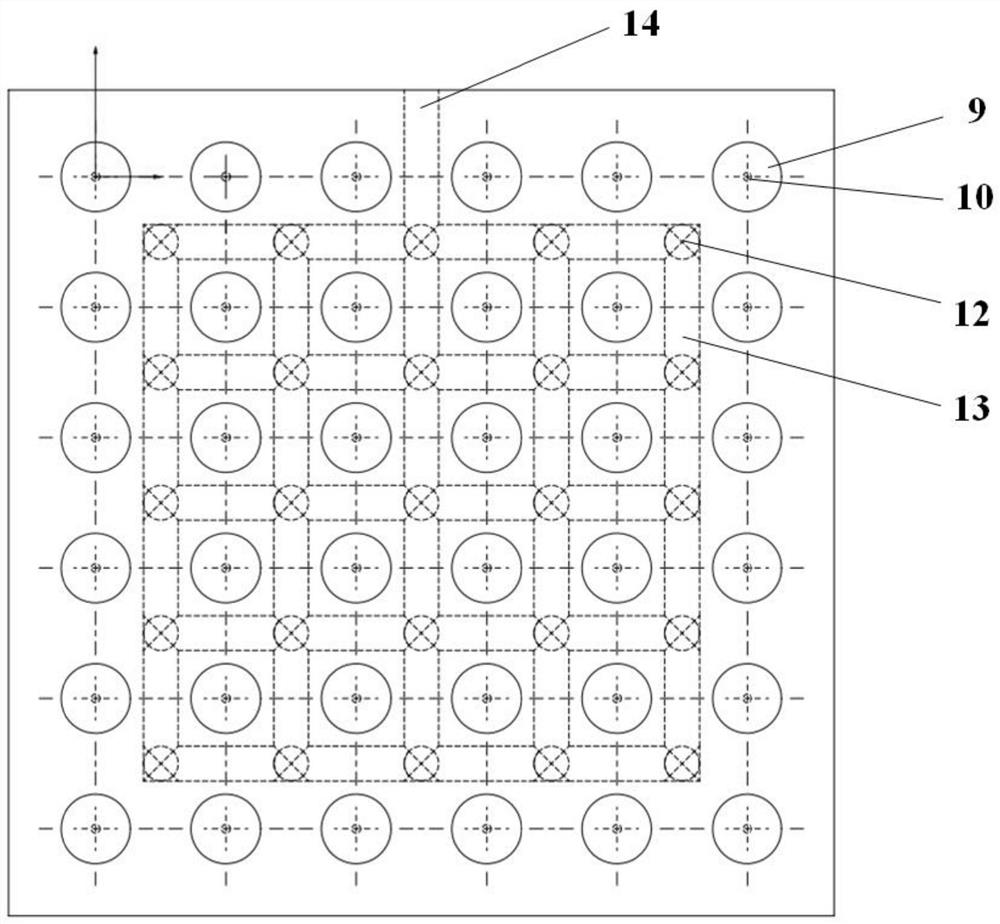

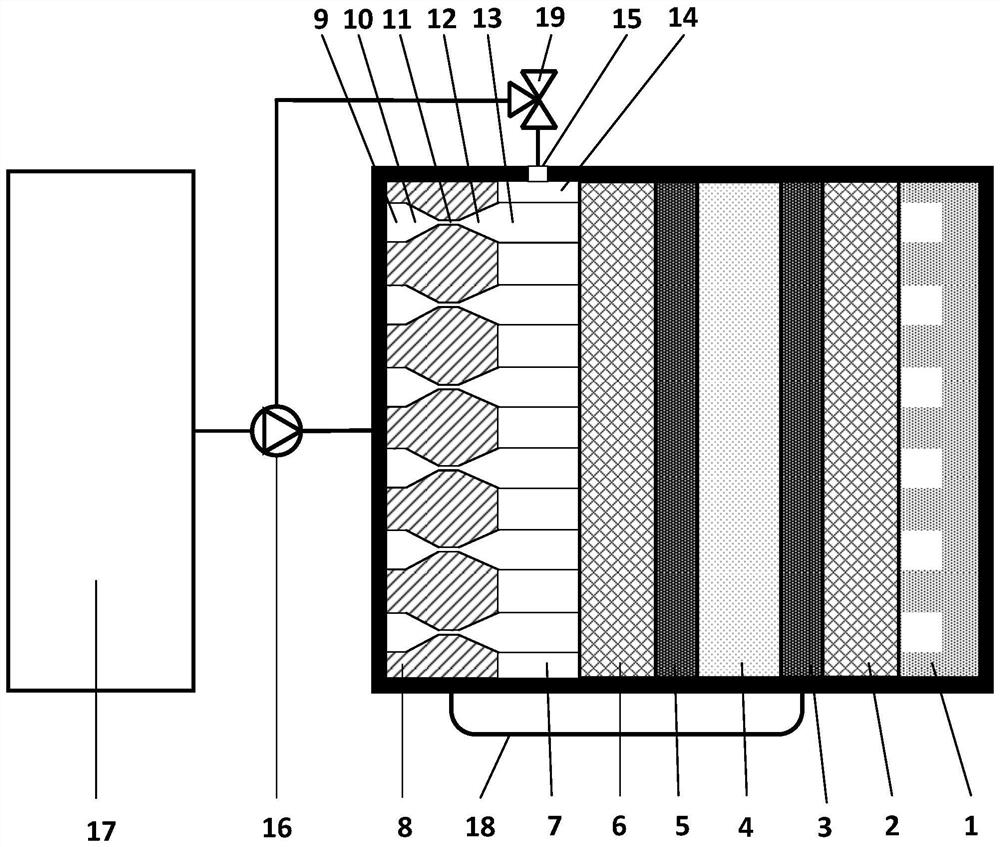

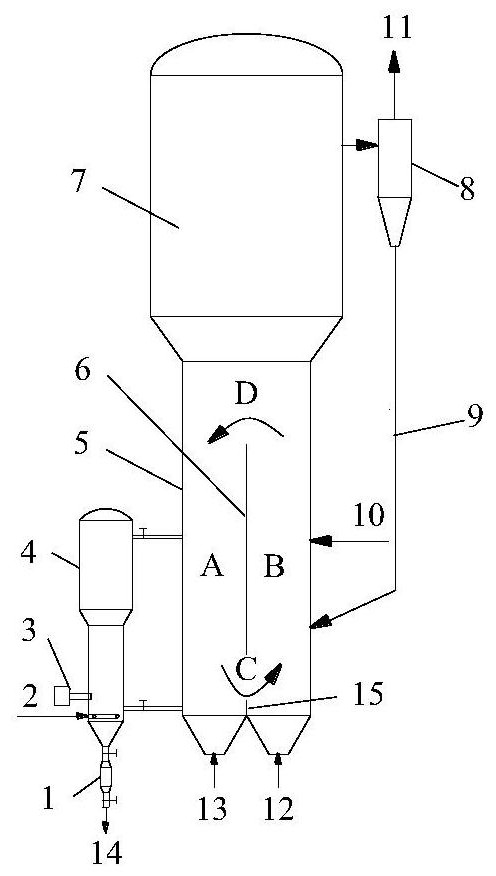

Comprehensive treatment system for fermented antibiotic pharmaceutical wastewater

InactiveCN106698856AImprove stabilityImprove anaerobic efficiencySludge treatment by de-watering/drying/thickeningWater treatment compoundsWater treatment systemMedicine

The invention relates to a pharmaceutical wastewater treatment system and in particular relates to a comprehensive treatment system for fermented antibiotic pharmaceutical wastewater. The system can be used for pre-treatment, biochemical treatment and advanced treatment of fermented antibiotic pharmaceutical wastewater, so that the stability of the anaerobic system is improved, the anaerobic investment is reduced, the anaerobic efficiency is improved, and moreover, in the advanced treatment stage, hardly degraded pollutants are removed through Fenton catalytic oxidation reaction, so that the wastewater is discharged by reaching the standard.

Owner:华夏碧水环保科技股份有限公司

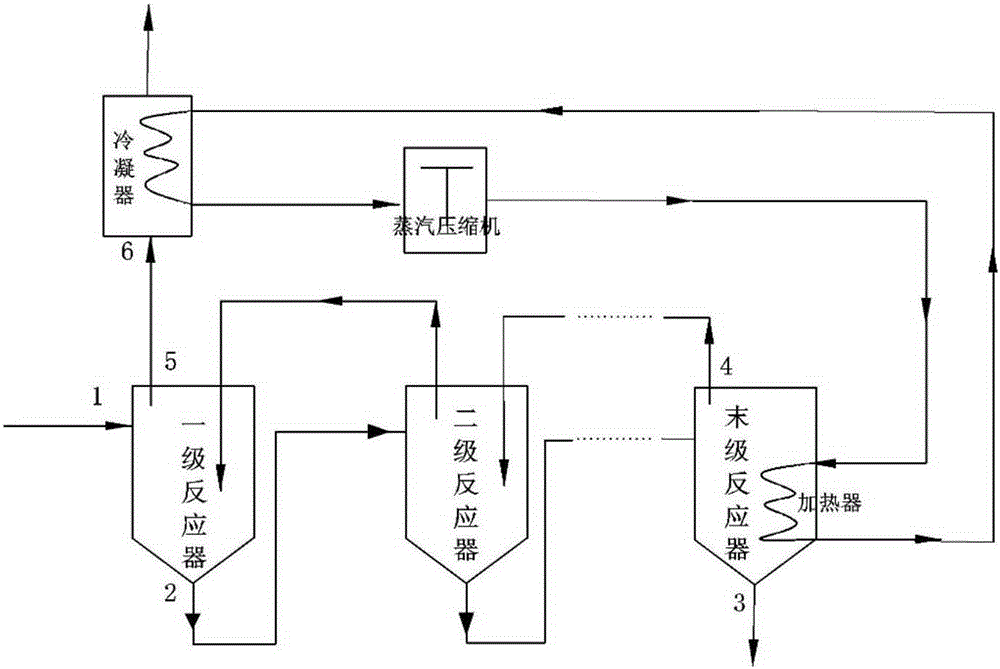

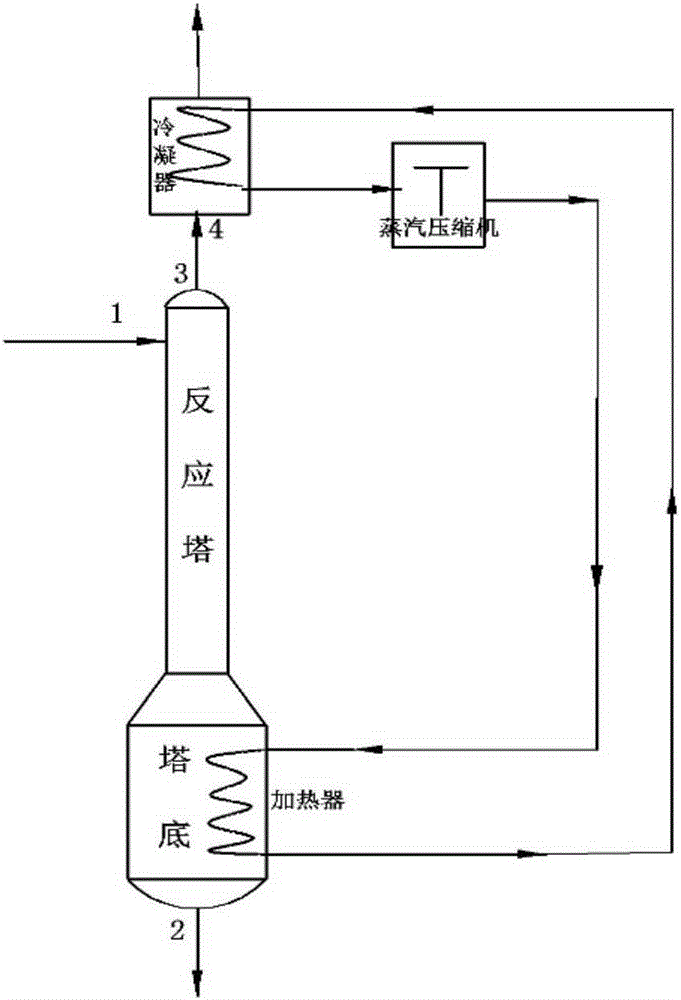

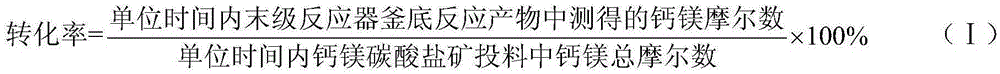

Calcium magnesium carbonate salt mine decomposition method

ActiveCN105347703AAchieve decompositionDecomposition is efficient and stableLime productionEvaporationAmmonium uranyl carbonate

The invention provides a calcium magnesium carbonate salt mine decomposition method which comprises the following steps: an ammonium salt solution is adopted to decompose calcium magnesium carbonate salt mine, the decomposition reaction is conducted in a series-connected multistage reactor or a tower-type reactor, heat carried by mixed gas generated by decomposition reaction of the ammonium salt solution and the calcium magnesium carbonate salt mine through heating are used as heat sources for recycling. According to the provided calcium magnesium carbonate salt mine decomposition method, through the introduction of the multistage countercurrent series-connected reaction kettle or the tower-type reactor, not only are the problems that a single-stage reaction kettle is large in water evaporation amount, the energy consumption is wasted, and ammonium carbonate is relatively low in concentration and unstable solved, but also the efficient and stable reaction of decomposition of the calcium magnesium carbonate salt mine by ammonium salt is realized, the energy consumption cost is reduced, and the method is energy-saving and economical.

Owner:LONGYAN ZIYUN CHEM TECH

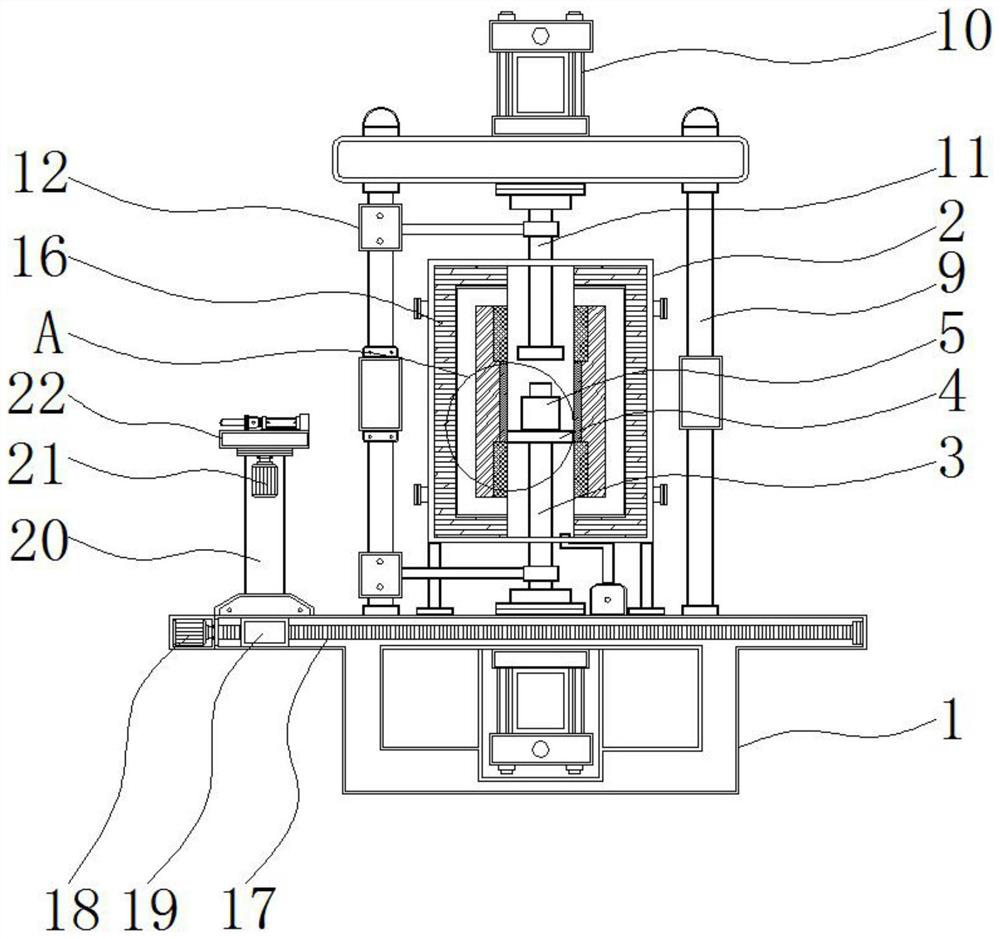

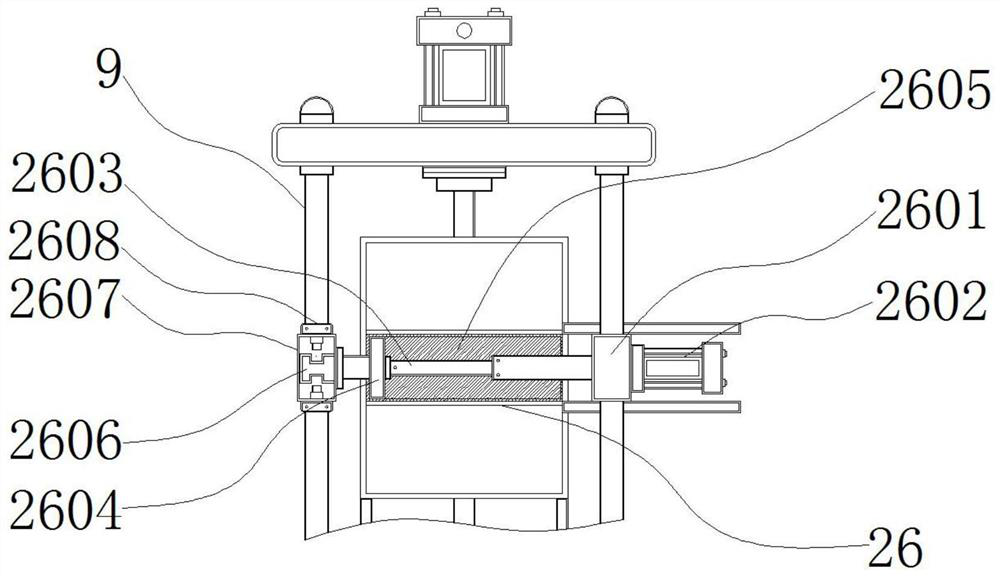

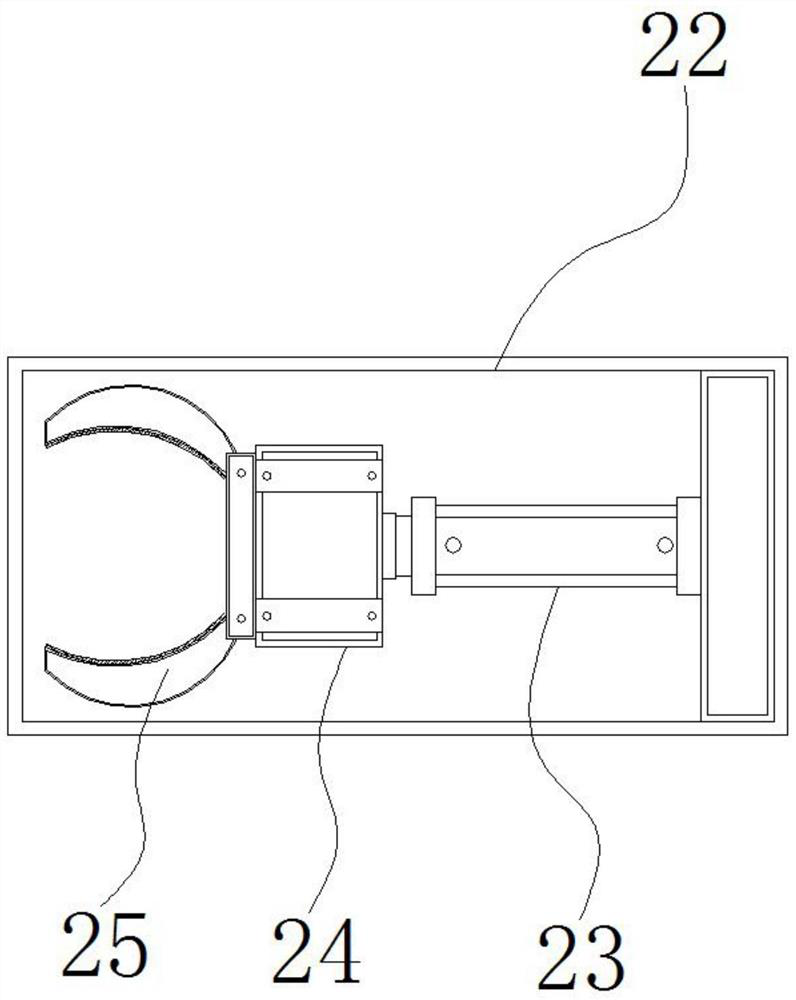

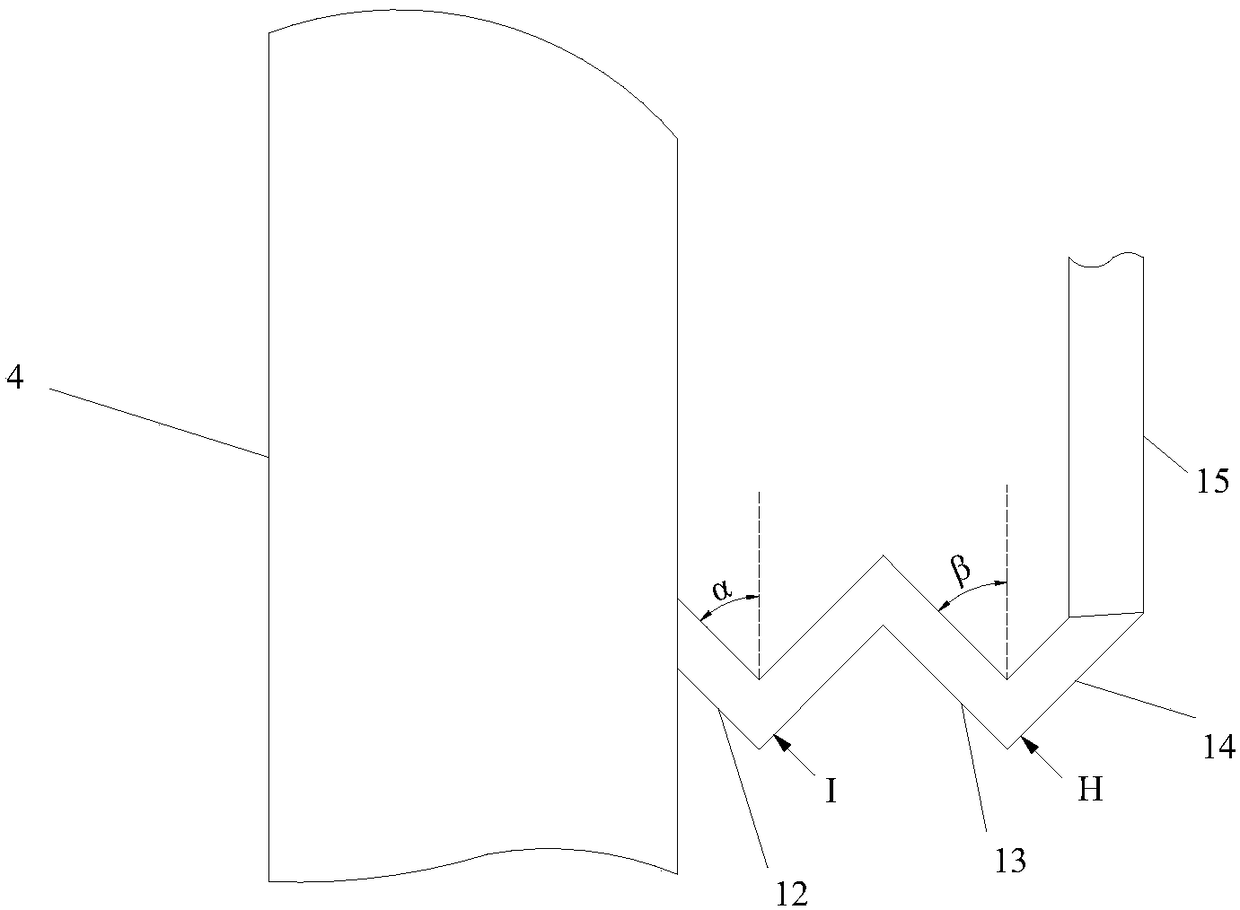

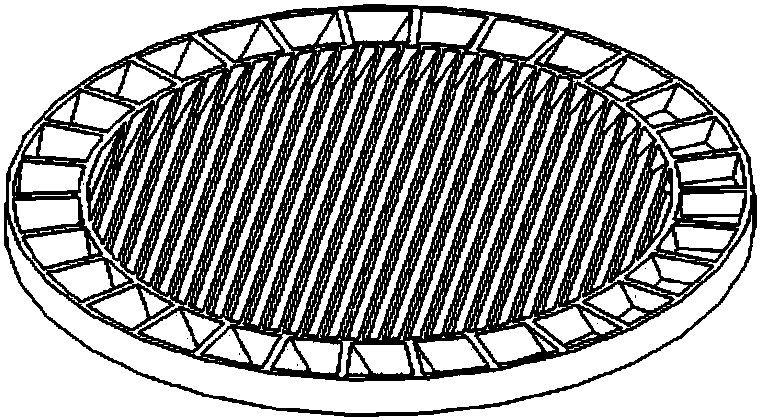

Oscillating hot-pressing sintering furnace with pressurizing auxiliary structure

The invention discloses an oscillating hot-pressing sintering furnace with a pressurizing auxiliary structure, and relates to the technical field of sintering furnaces. The oscillating hot-pressing sintering furnace specifically comprises a base and a sealing device, and a shell is arranged on the upper surface of the base. According to the oscillating hot-pressing sintering furnace with the pressurizing auxiliary structure, in the process of feeding a mold, a pneumatic block can be used for clamping the mold in an attached mode through a chuck, and slides to a tray along a lead screw througha moving rod and a sliding block, a second motor can drive a platform to rotate to an accurate direction, a first electric telescopic rod can immediately drive the clamped mold to be transferred to adesignated position on the upper surface of the tray for feeding treatment, and only the assembled mold needs to be placed at the mold position in the process, so that the operation is simple, follow-up correction by professionals is not needed, and potential safety hazards caused by misoperation are avoided; and the discharging process is similar, the chuck is driven by the first electric telescopic rod to discharge the sintered mold, manual touch is not needed in the process, and safety of workers is guaranteed.

Owner:湖南伊澍工业技术有限公司

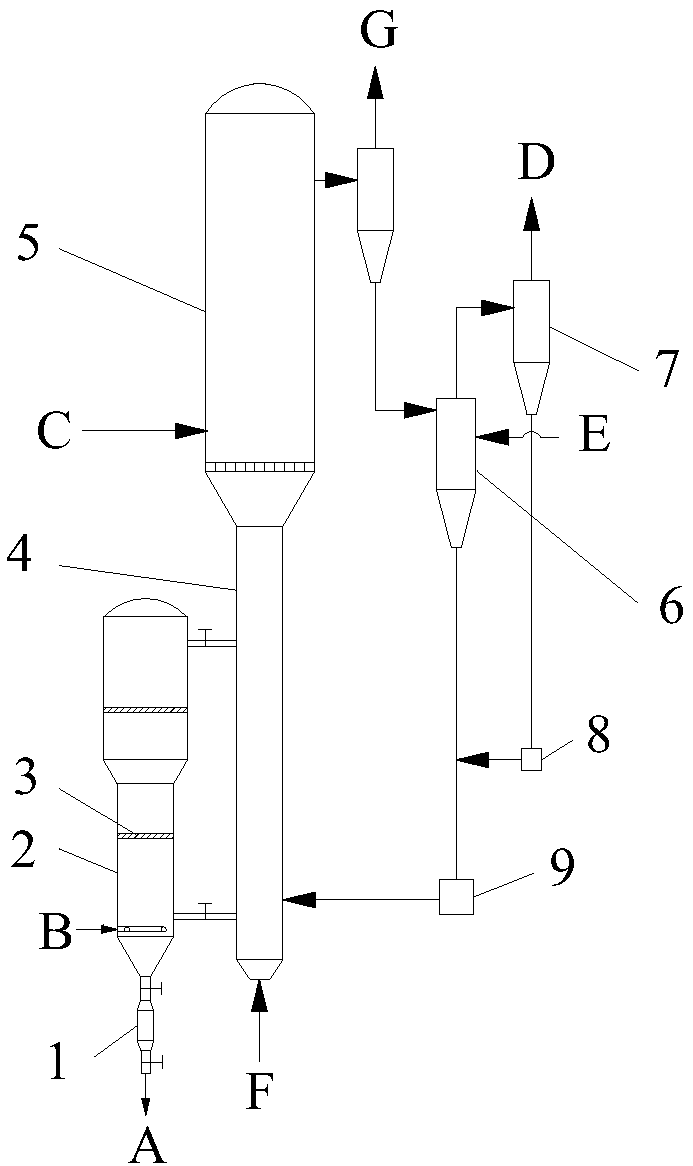

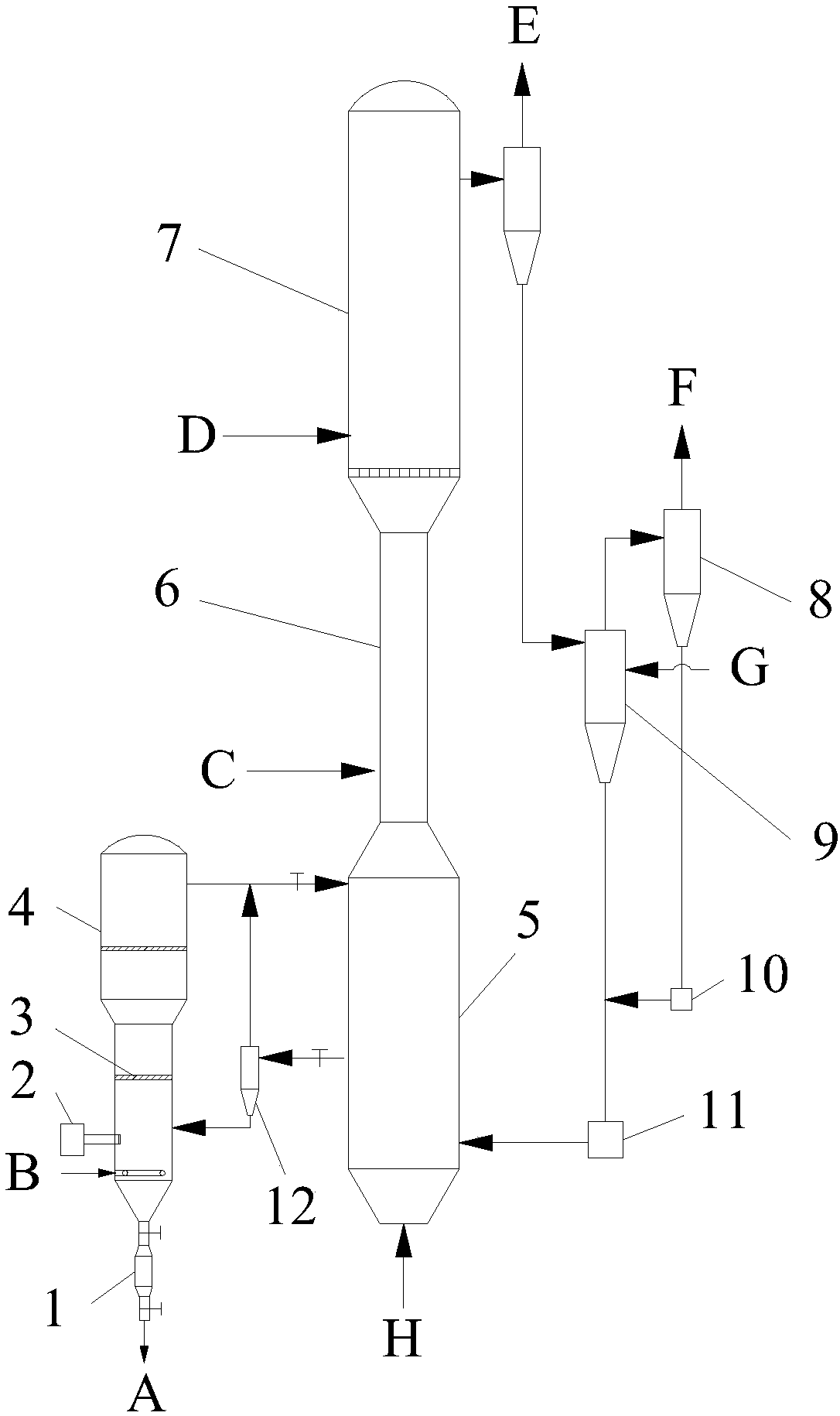

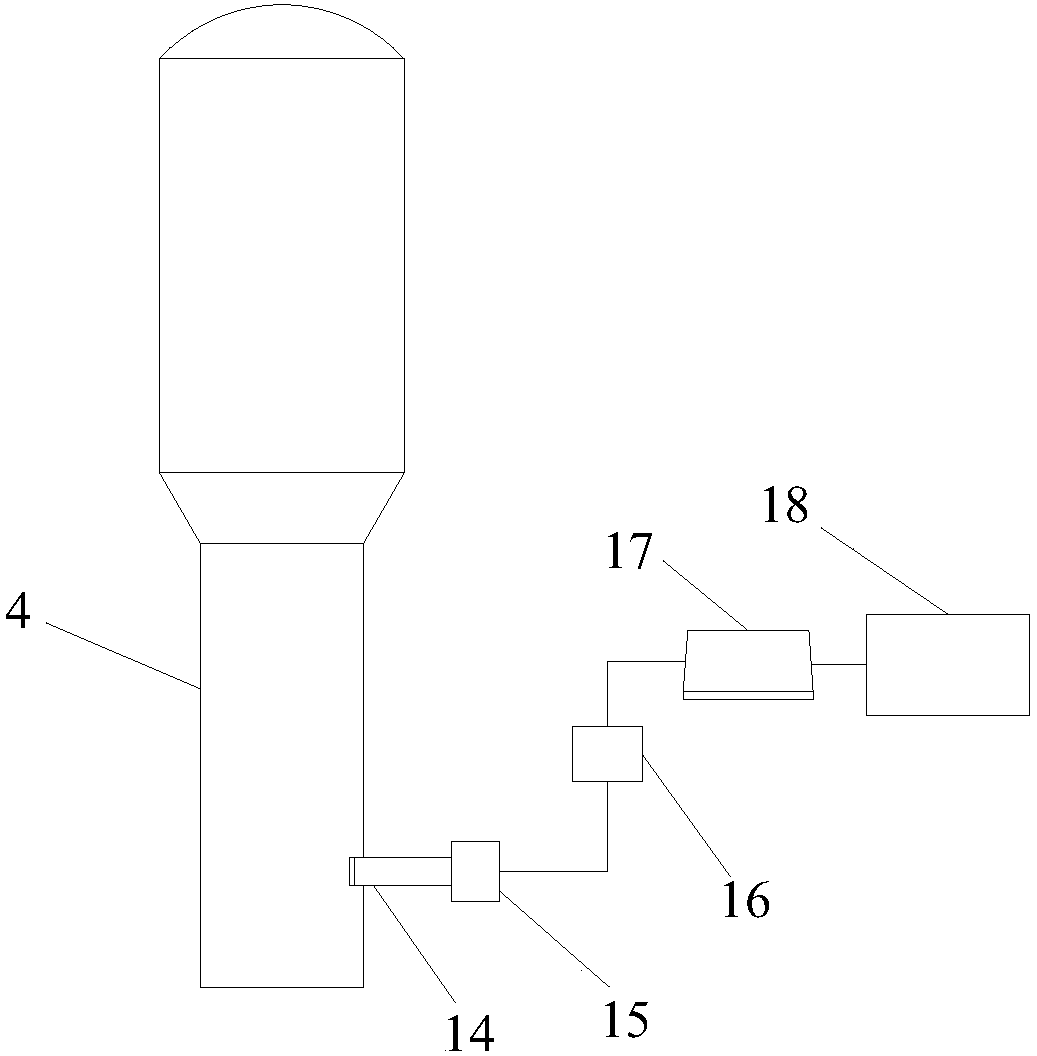

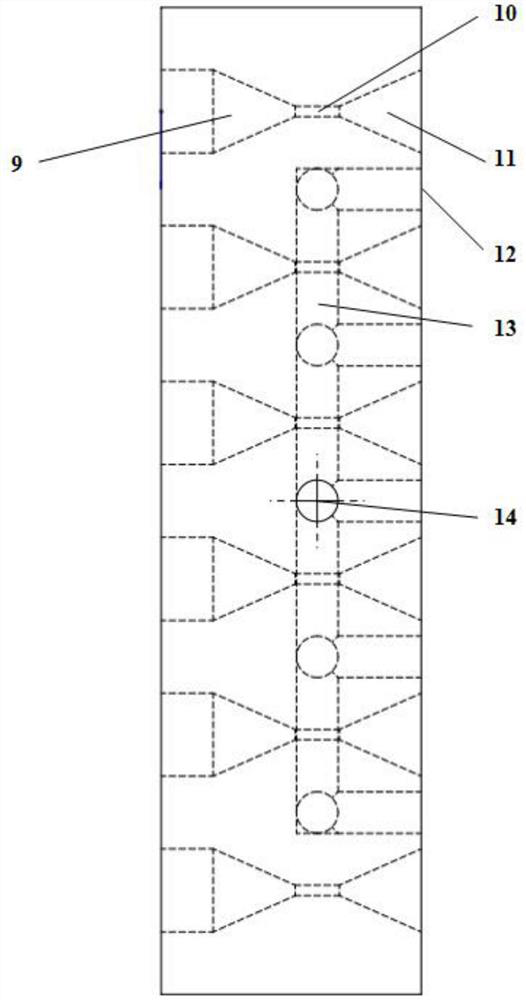

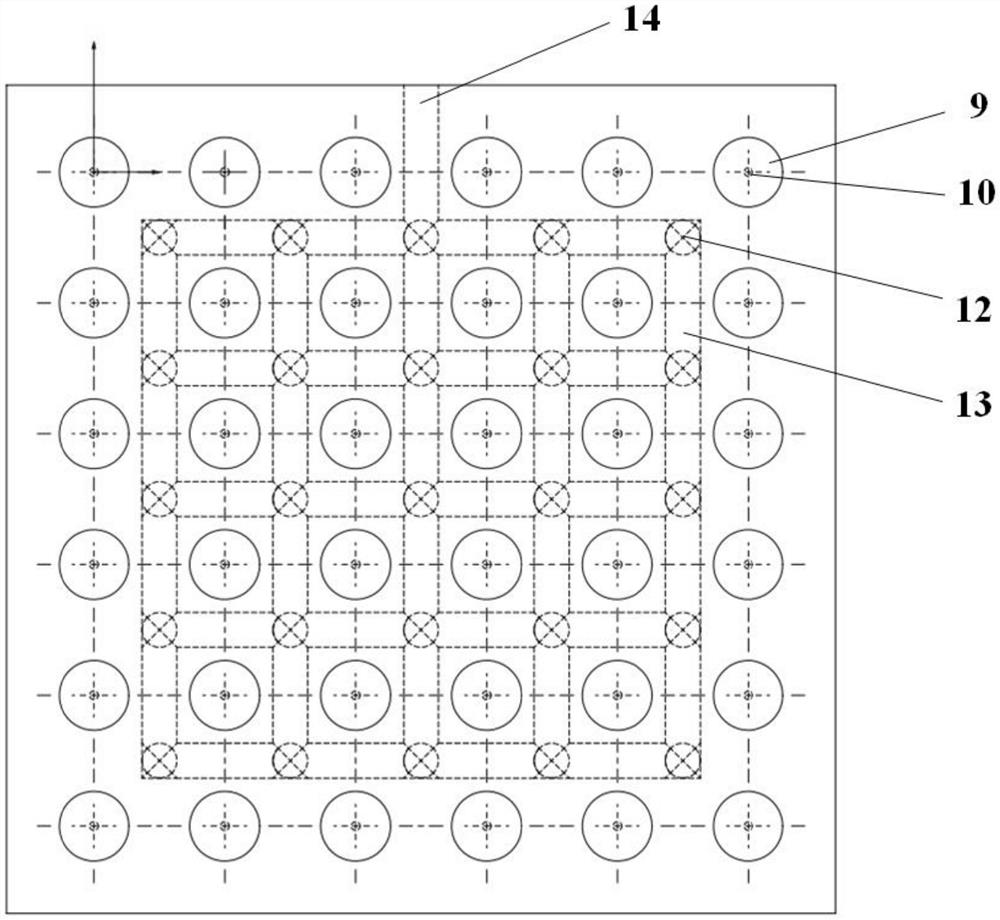

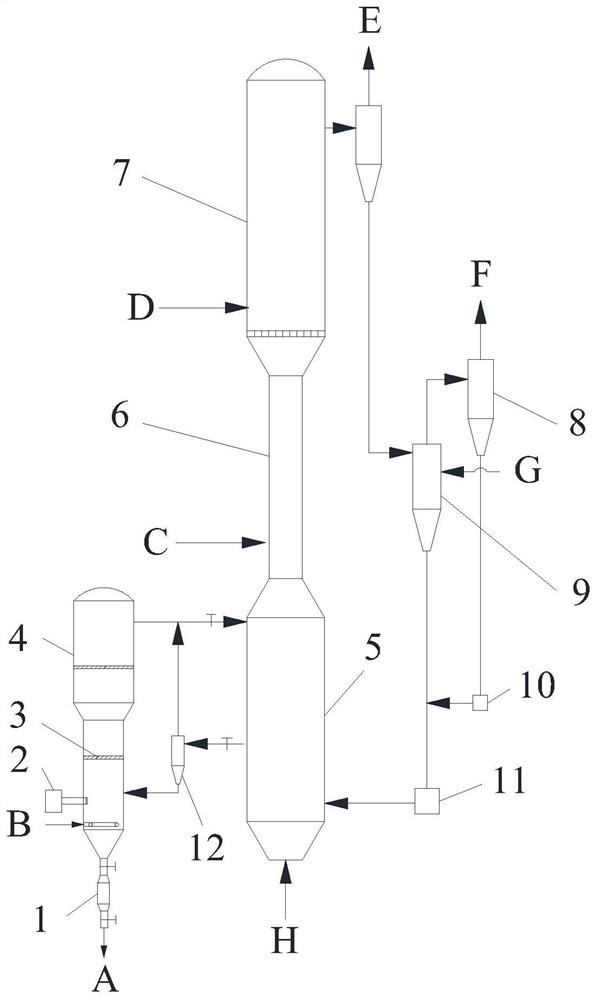

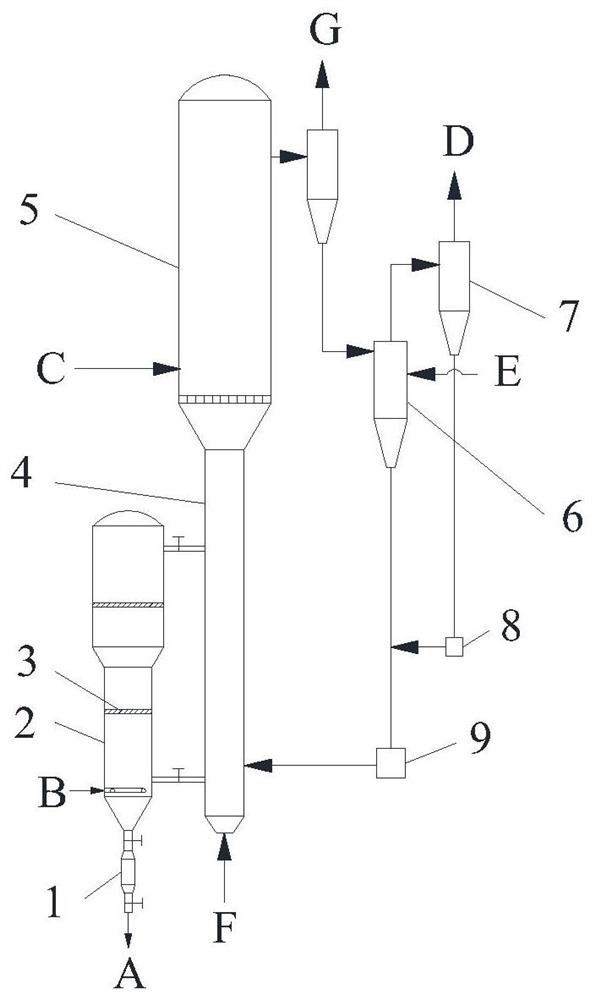

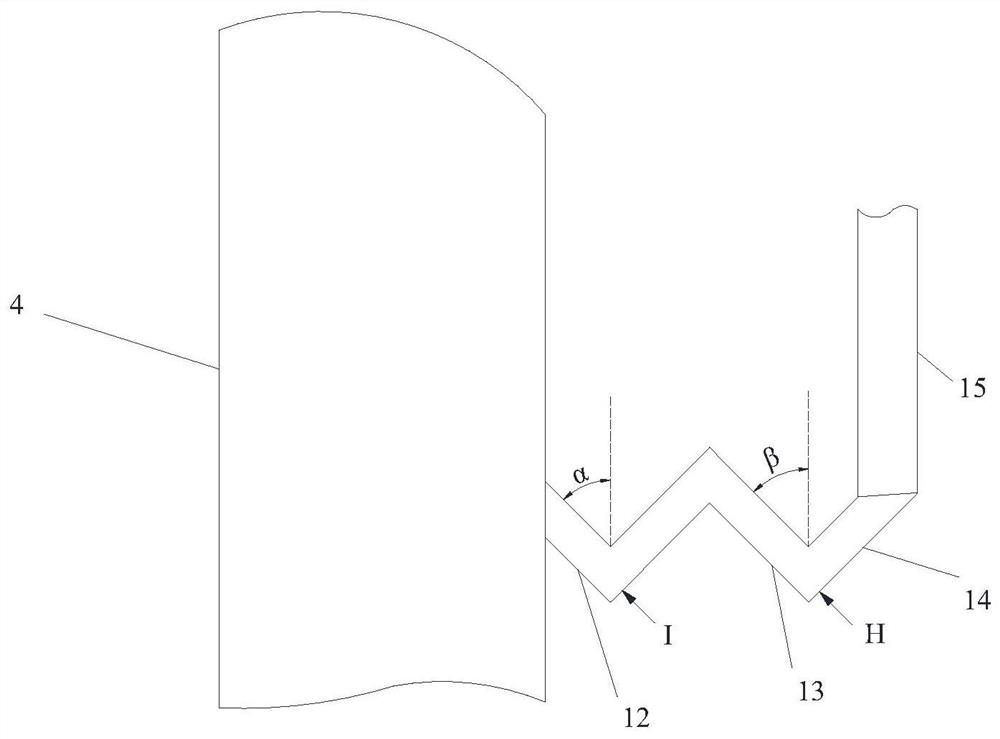

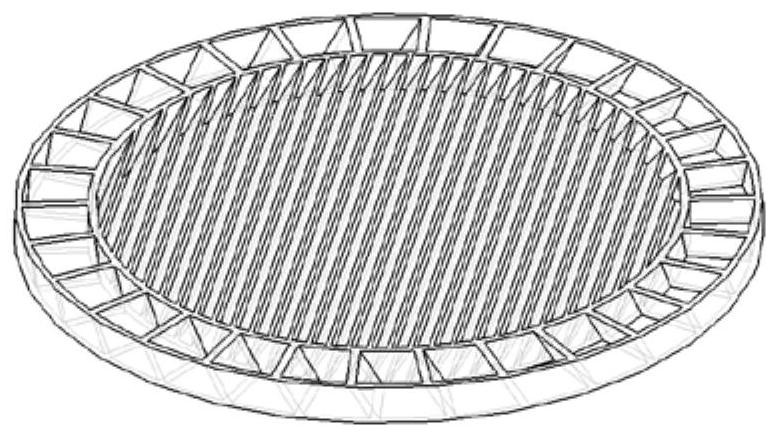

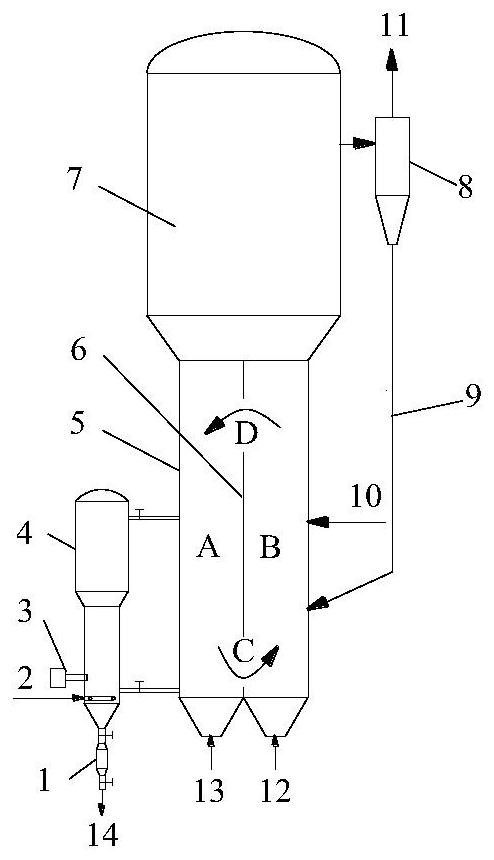

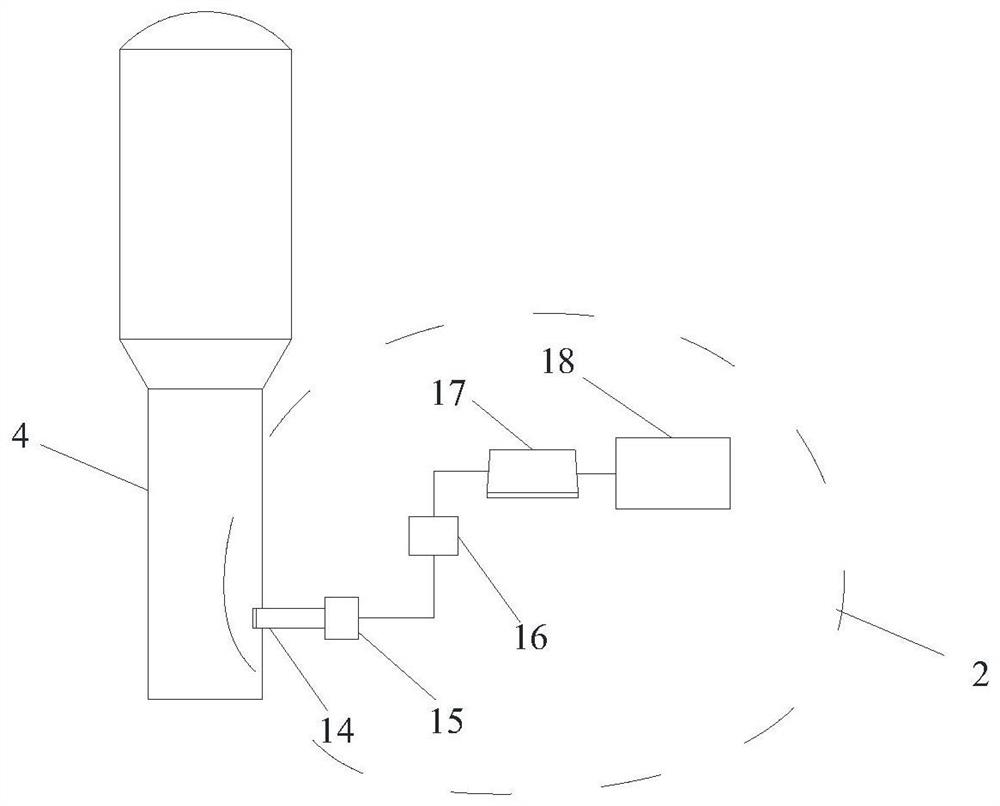

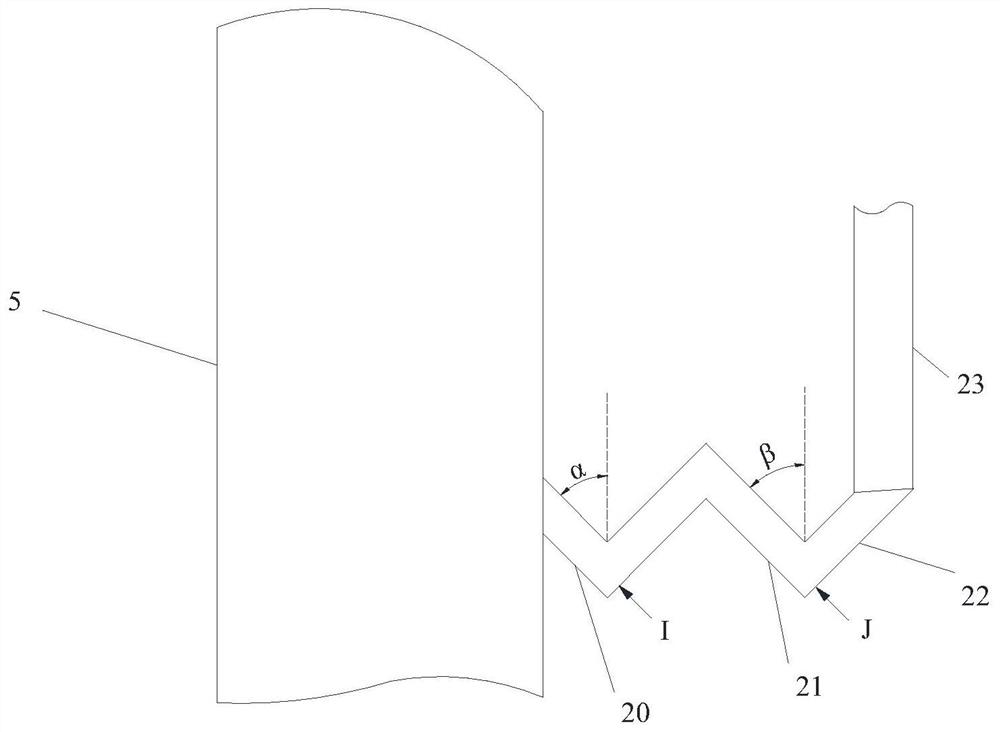

Reaction device and reaction method for grading conversion combined fluidized bed

ActiveCN109401794AIncrease cycle rateIncrease profitCombustible gas chemical modificationHydrocarbon from carbon oxidesSyngasCombustion

The invention relates to a reaction device and a reaction method for a grading conversion combined fluidized bed, and mainly solves the problems of low carbon conversion rate and gasification intensity, low methane yield, low treatment capacity, slagging difficulty and relatively low powdered coal utilization rate in the prior art. Through the technical scheme, according to the reaction device anda reaction method for the grading conversion combined fluidized bed, pyrolysis is carried out on a carbon-containing raw material of a supported catalyst in a pyrolysis furnace, tar gas is collectedafter being separated, partial combustion and a gasification reaction are carried out on semi-coke particles of the supported catalyst after pyrolysis as well as a gasifying agent and an oxidizing agent in a fine reactor, a further gasification reaction is carried out on subsequently generated synthesis gas and the carbon-containing particles without reacting completely in a coarse reactor, the carbon-containing particles after reaction and a part of the catalyst are returned into the pyrolysis furnace, and slagging is carried out on ash at the bottom in an intermittent grading slagging manner; and the above technical problems are solved preferably, so that the reaction device and the reaction method can be applied to industrial production of coal grading conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

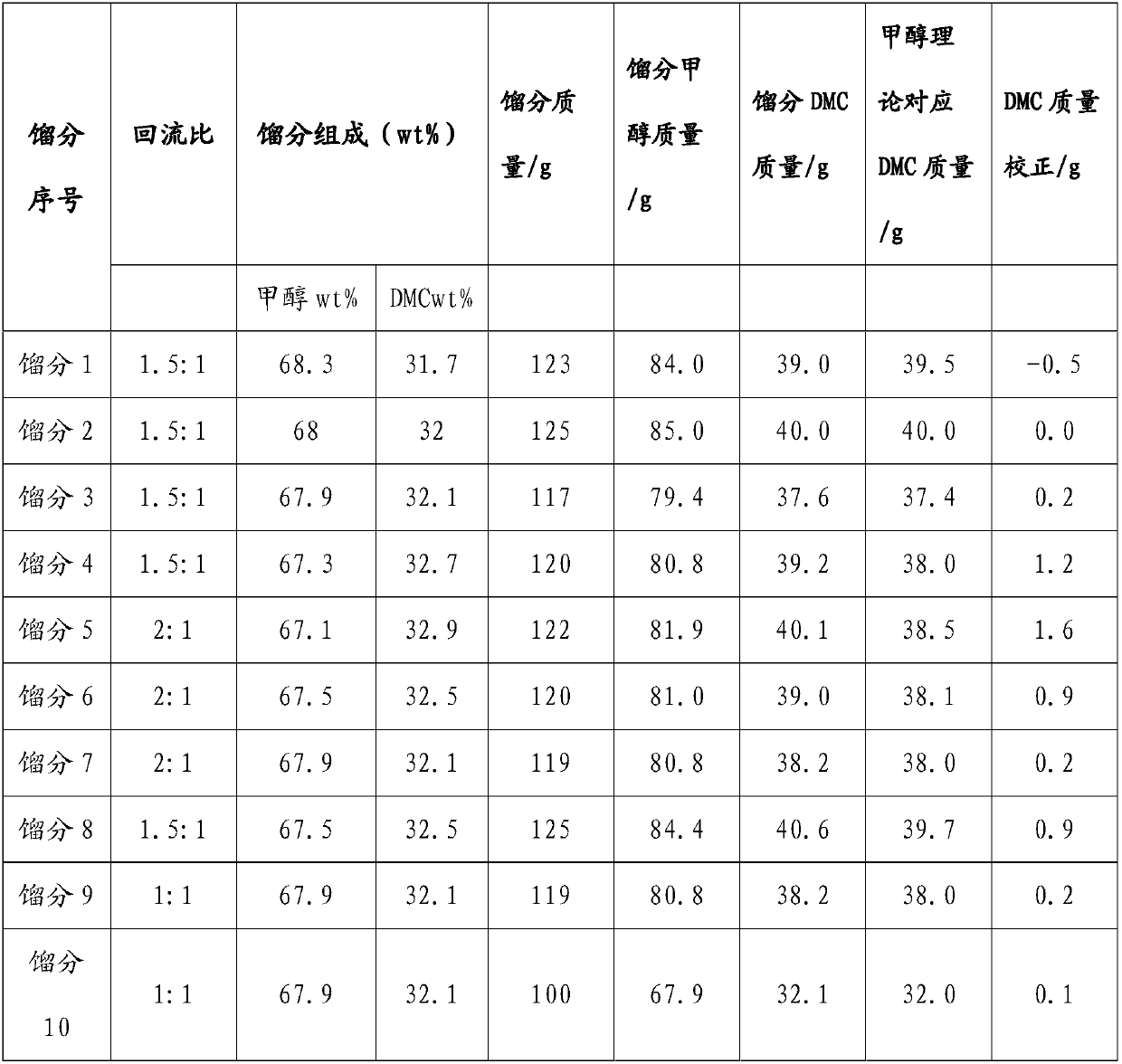

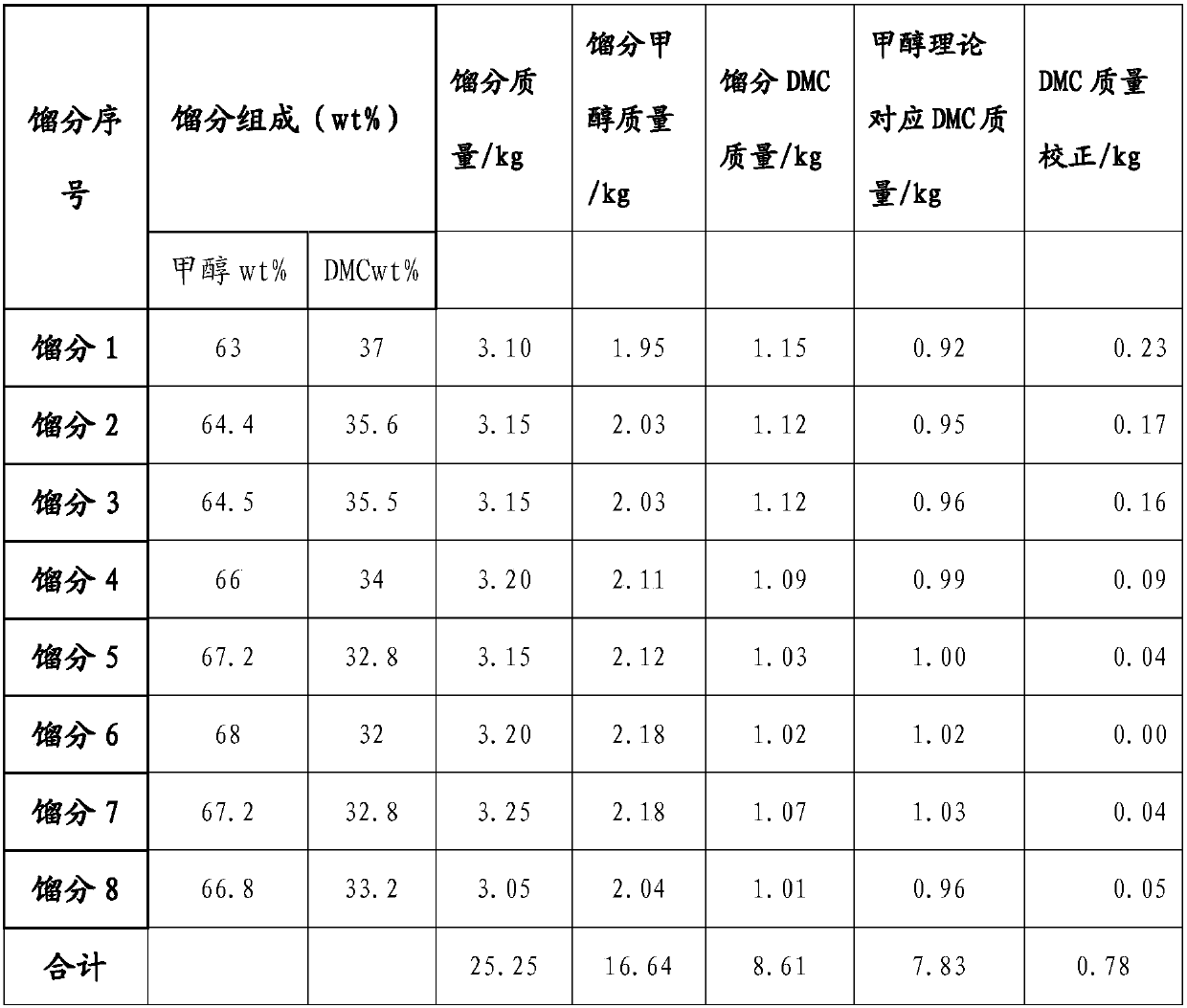

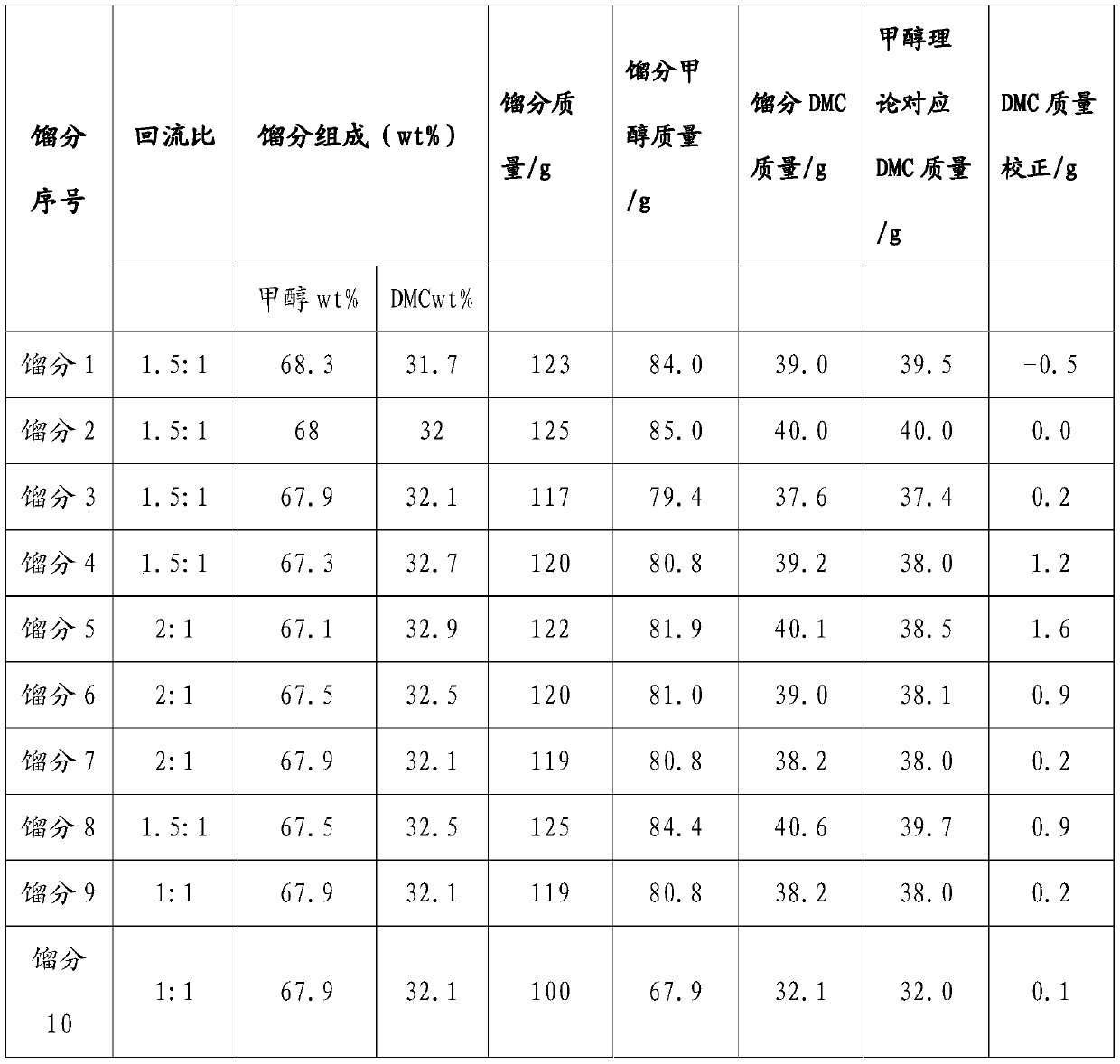

Polycarbonate polyol, and synthetic method and application thereof

ActiveCN109957101AOvercome stabilitySmooth responsePolyurea/polyurethane coatingsAlcoholCarbonate ester

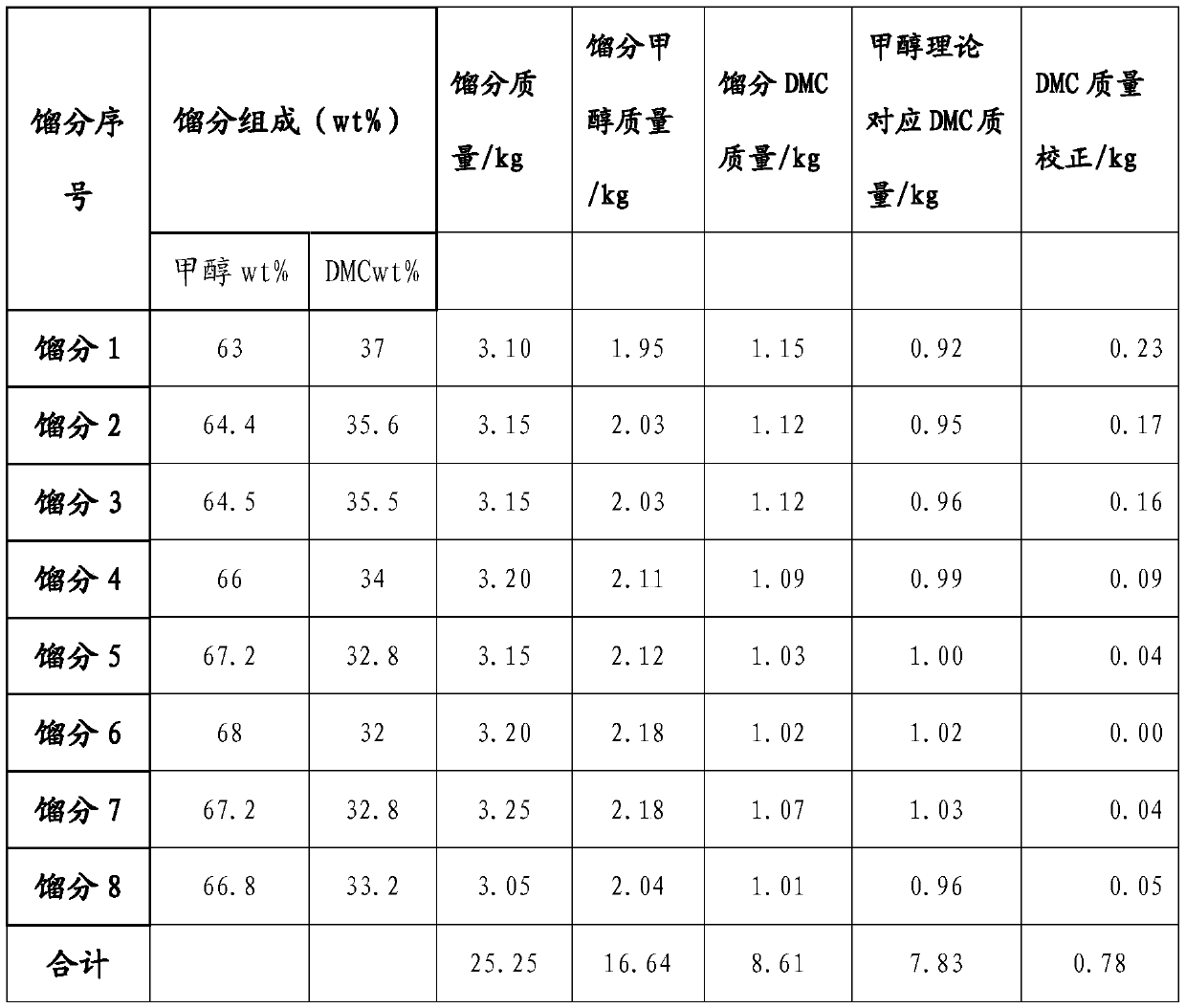

The invention provides a polycarbonate polyol, and a synthetic method and application thereof. The synthetic method comprises the following step that an ester exchange reaction is carried out on a rawmaterial A containing a mixture of polyhydric alcohol or polyol and lactone with carbonic ester to generate the polycarbonate polyol, wherein the raw material A is fed at one time, the carbonic esterwith a preset stoichiometric amount is fed into the reaction system in a continuous feeding manner, and an azeotrope of by-products and the carbonic ester is rectified in the reaction process. The mass percent of the carbonic ester in a fraction is sampled and monitored in the feeding process of the carbonic ester with the preset total stoichiometric amount, stability of the content of the carbonic ester in the composition of the extracted fraction is controlled, and / or the carbonic ester is supplemented or slightly added according to the change of the content of the carbonic ester in the fraction. The method provided by the invention can be used to rapidly and stably produce a product meeting the hydroxyl value requirement, and the post-treatment is simpler.

Owner:WANHUA CHEM GRP CO LTD

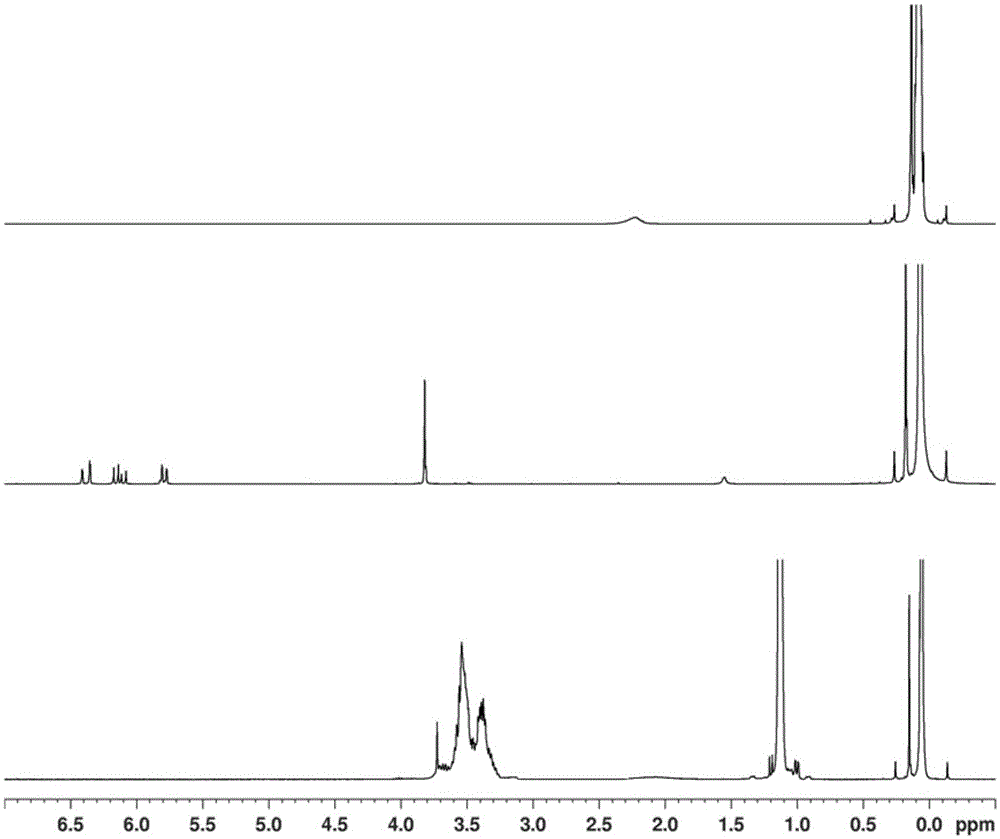

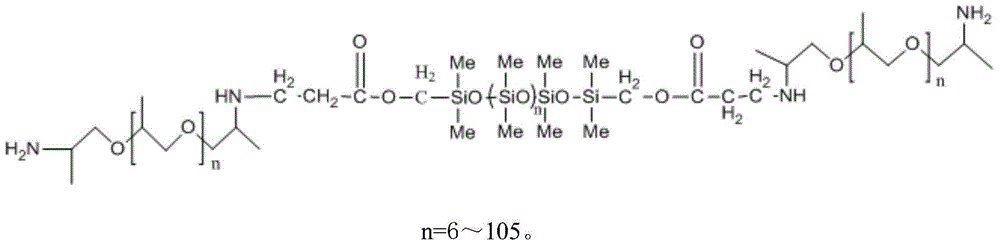

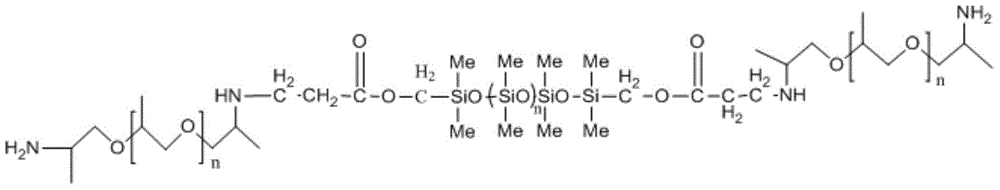

Thermoplastic elastomer mixed soft segment and preparation method thereof

The invention relates to a thermoplastic elastomer mixed soft segment and a preparation method thereof. The preparation method comprises the following steps: (1) reacting (acrylate-base methyl) dimethyl-acrylate-base silane with hydroxyl-terminated polydimethylsiloxane in an organic solvent to obtain acrylate-base methyl-terminated polysiloxane; and (2) dissolving amino-terminated polyether in a solvent B at room temperature, heating to 15-30 DEG C in an inert gas protective atmosphere, adding the acrylate-base methyl-terminated polysiloxane, and stirring for 12-24 hours while keeping the temperature to perform polymerization reaction, thereby obtaining the mixed soft segment. The polyether-polysiloxane mixed segment polymer product has stable properties, and can be easily characterized. The amine-olefine addition reaction is utilized to connect the polyether and polysiloxane; and the whole polymerization process has the advantages of stable and efficient reaction, high reaction degree (up to 100%), no need of any catalyst, and no byproduct generation.

Owner:SHANDONG UNIV

Method for promoting hydrolytic acidification process in anaerobic tank

InactiveCN104291440AHigh activityEfficient and stable reactionWater treatment parameter controlBiological treatment regulationChemistryTemperature treatment

The invention relates to a hydrolytic acidification method in an anaerobic tank. The hydrolytic acidification method comprises the following specific steps: adjusting the environment in a digestion tank in advance until a moderate pH value is achieved by adding an alkali; adding sodium thiosulfate into the digestion tank, and stirring with a stirrer while adding sodium thiosulfate so that the digestion tank is controlled to be in absolutely anaerobic state and the electrode potential is controlled to be at -75ev to -15ev; standing the digestion tank for 3-5 days and then adding ethanol into the digestion tank and continuously fermenting for 3-5 days; and finally introducing sewage into the digestion tank while controlling the digestion tank to be in absolutely anaerobic state, adjusting the pH value of the digestion tank to be 7.2-7.8 by virtue of continuously adding sodium hydroxide, heating the digestion tank to 50-55 DEG C in a gradient manner and carrying out high-temperature treatment on sewage in the digestion tank at the high temperature.

Owner:CHANGZHOU UNIV

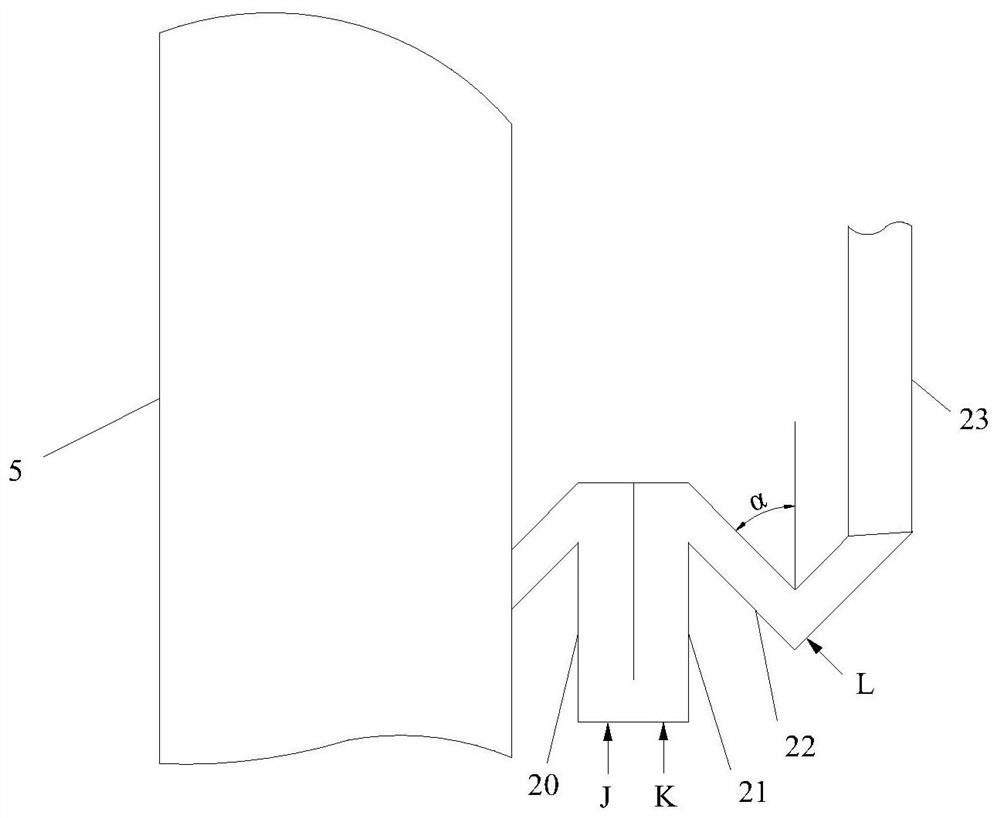

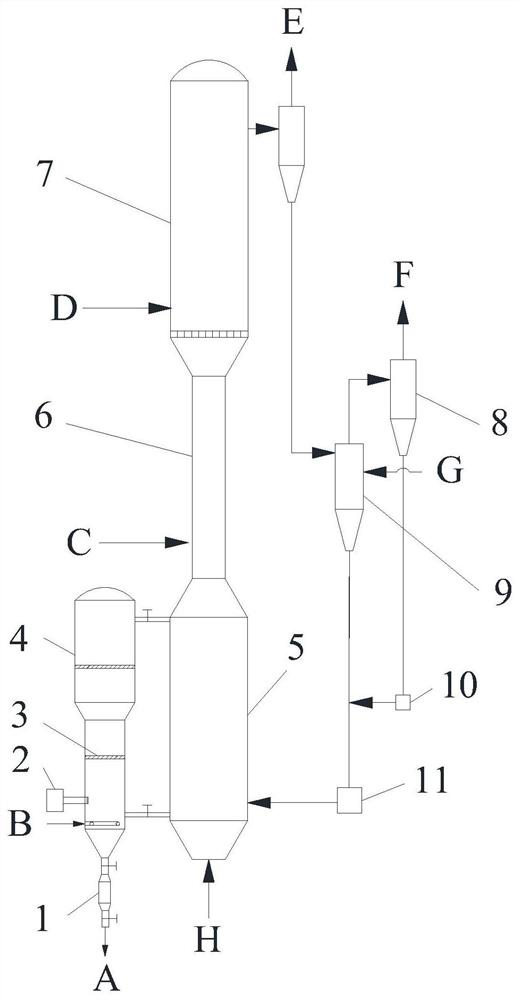

Coupled fluidized bed graded conversion reaction device and reaction method

ActiveCN109401795AEasy to getSave moneyCombustible gas chemical modificationHydrocarbon from carbon oxidesSlagMethane yield

The invention relates to a coupled fluidized bed graded conversion reaction device and a reaction method and mainly aims to solve the problems of low carbon conversion rates, low gasification intensities, low methane yields, hard slag discharge and low coal powder utilization rates in the prior art. By adopting the coupled fluidized bed graded conversion reaction device and the reaction method, acarbon-containing raw material with a catalyst is pyrolyzed in a pyrolyzation furnace, tar gases obtained after pyrolyzation are separated and collected, semicoke granules with the catalyst and a gasifying agent are respectively combusted and gasified in three reaction zones, reacted carbon-containing granules and a part of the catalyst are continuously fed back into the pyrolyzation furnace, ashslag at the bottoms of the reaction zones are firstly subjected to two-stage separation of a granule hydrocyclone separation device and a graded slag discharge device, and are secondly discharged outfrom the device according to acoustic emission monitoring feedback. By adopting the technical scheme, the technical problems are well solved, and the device can be applied to industrial production ofgraded conversion of coal.

Owner:CHINA PETROLEUM & CHEM CORP +1

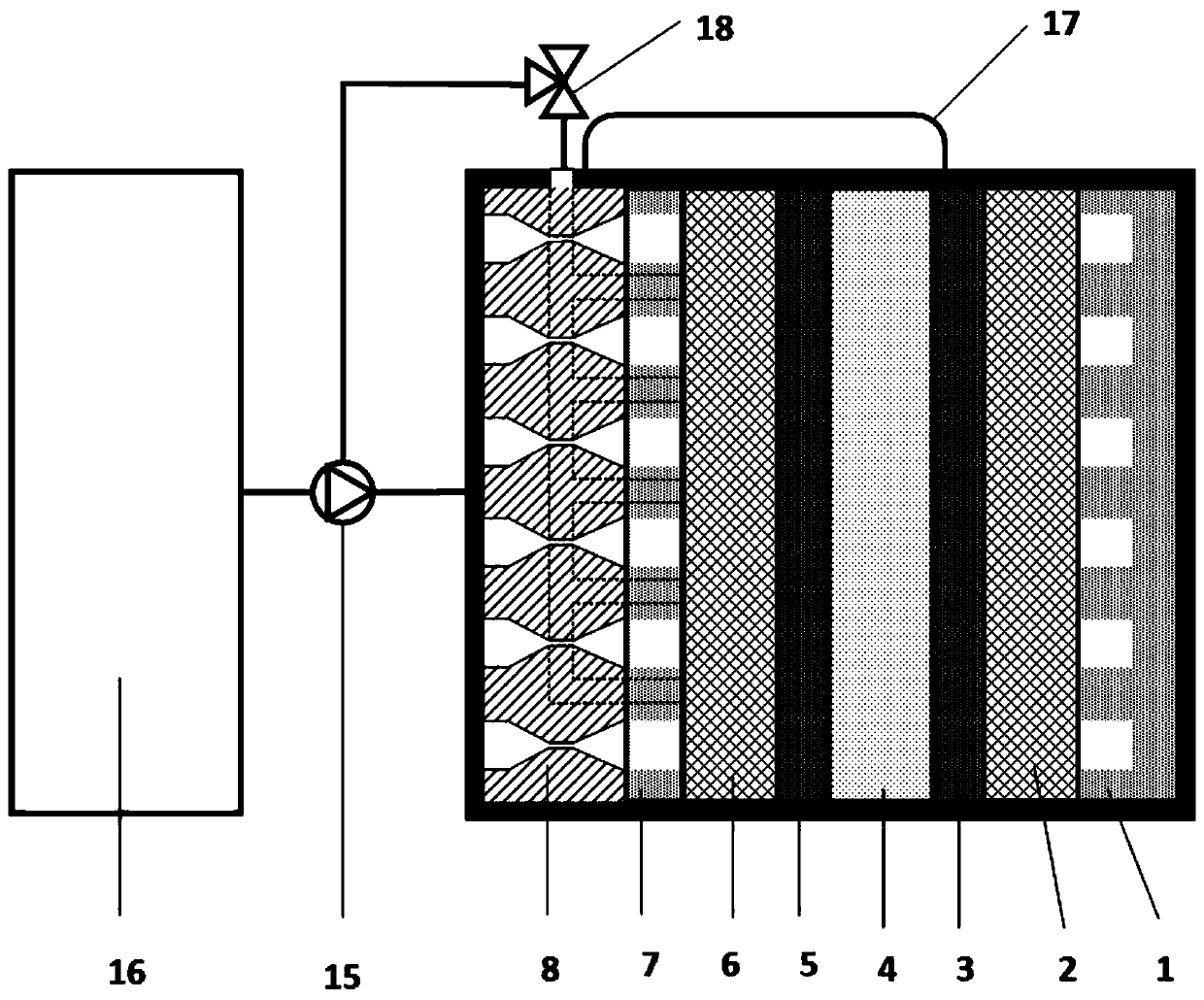

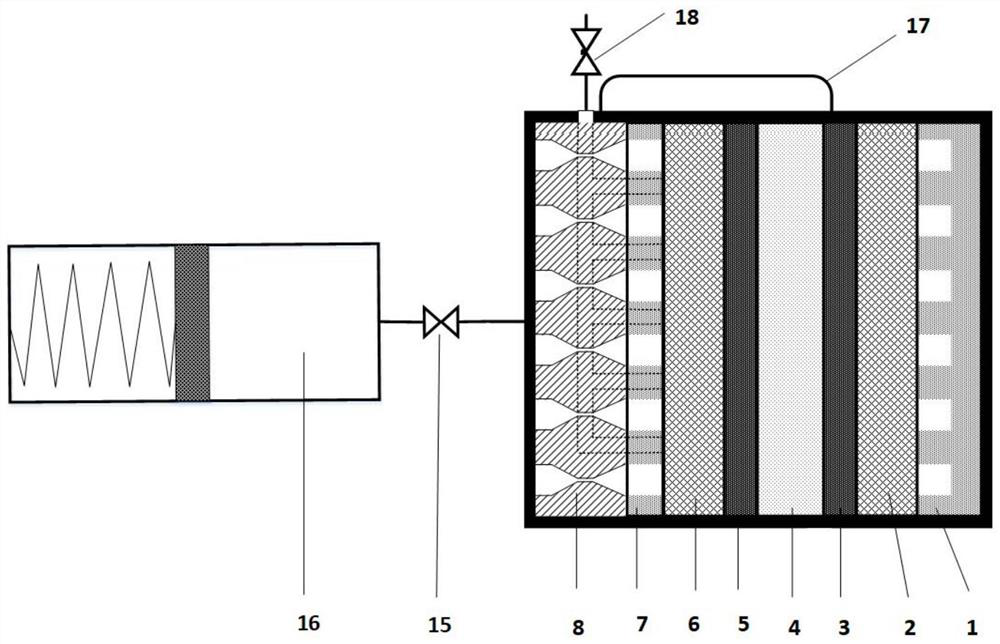

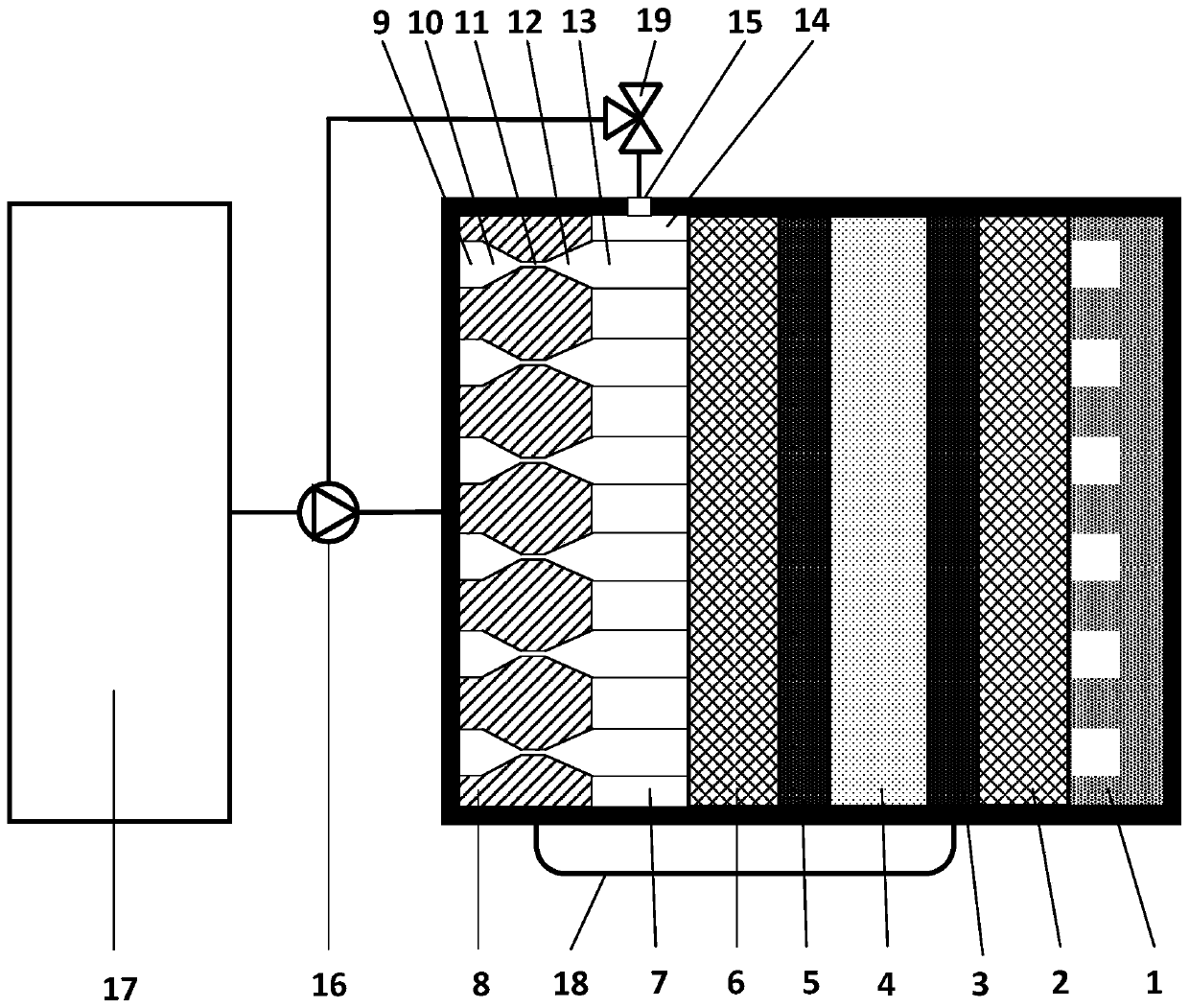

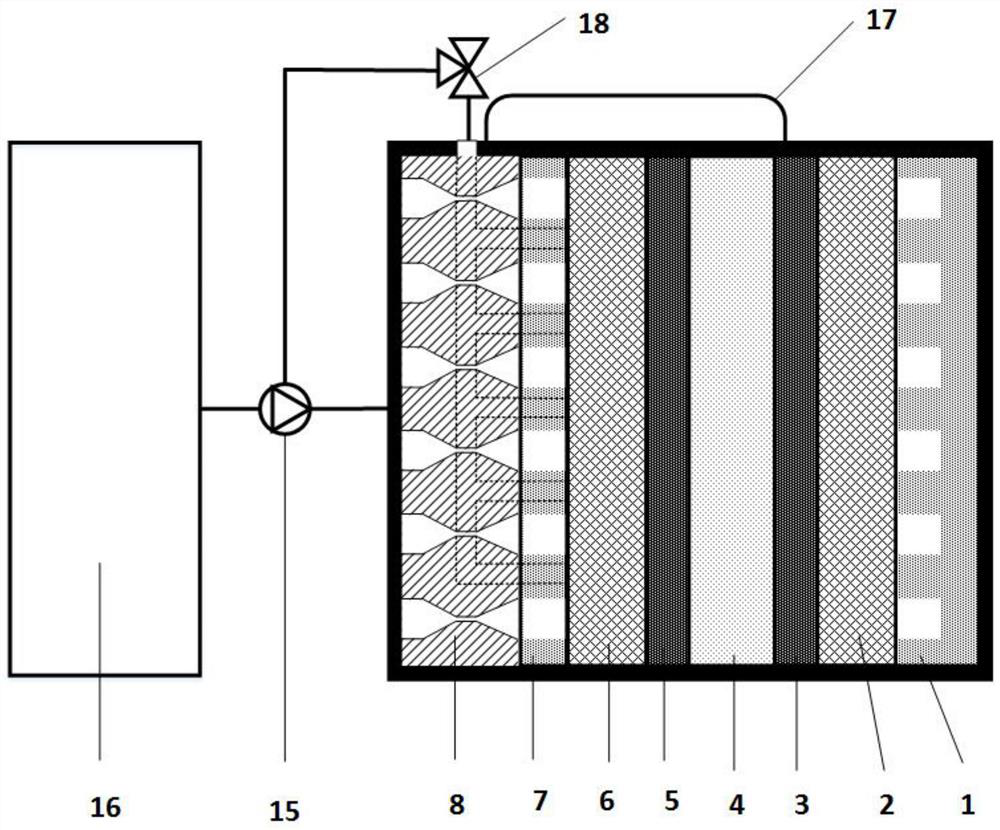

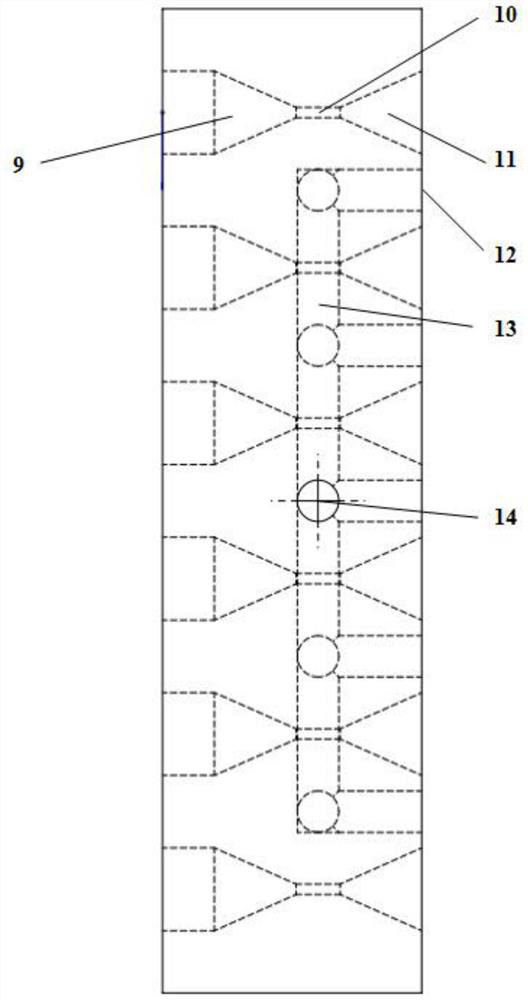

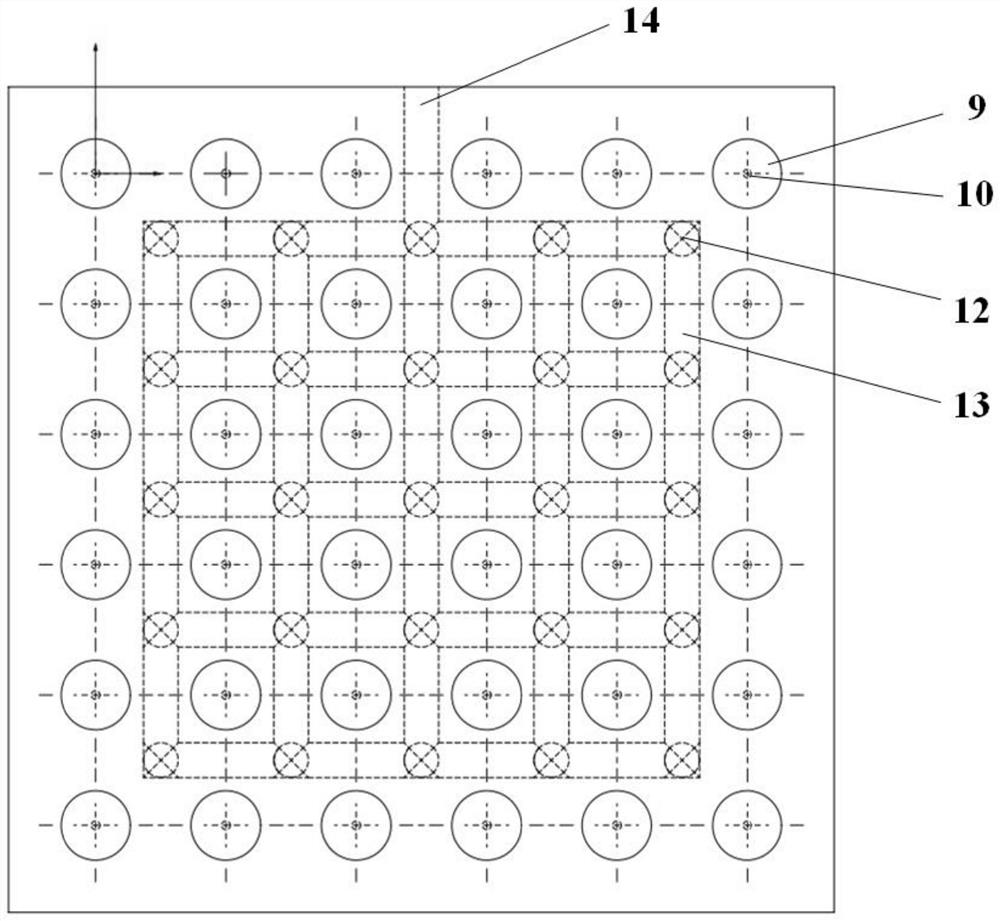

Low-power material separation and transmission direct methanol fuel cell and its working method

The invention discloses a low-power material separation and transmission direct methanol fuel cell and a working method thereof. A plurality of methanol evaporation pipelines and a plurality of carbondioxide flow paths are respectively arranged in a methanol evaporation region, and a methanol conveying pipeline and a carbon dioxide flow path are independently arranged; and the anode product carbon dioxide is directly discharged through the carbon dioxide flow path after being generated, so that the mixing of the carbon dioxide and a methanol vapor is reduced, the utilization rate of the methanol vapor is increased, and meanwhile carbon dioxide collection and utilization are facilitated. After the methanol vapor is generated, the methanol vapor directly enters a membrane electrode to participate in the reaction, so that the additional power consumption is reduced; a stable flow path is formed in the overall process from the inflow of methanol to the discharge of carbon dioxide, the fuel self-circulation structure largely solves the problems of uneven methanol vapor concentration, insufficient methanol reaction, and methanol and carbon dioxide mixing and the like, so that the battery reaction is more stable and efficient.

Owner:XI AN JIAOTONG UNIV

A kind of elemental sulfur-terpene copolymer/epoxy resin composition with self-healing properties and preparation method thereof

The invention discloses a self-healing elemental sulfur-terpene copolymer / epoxy resin composition and a preparation method thereof. The sulfur / terpene copolymer and epoxy resin are first dissolved in an organic reagent; then added to react Auxiliary, mix evenly, remove organic solvent under vacuum, pour into molding, and cure at 60-110°C for 2-4 hours to obtain a crude product; then cure the crude product at 120-150°C for 2-5 hours to obtain a self-healing Elemental sulfur-terpene copolymer / epoxy resin composition. The preparation process of the elemental sulfur-terpene copolymer / epoxy resin composition is simple and easy to operate, the reaction is efficient and stable, and it can be thermally repaired at 40-80° C. after being scratched.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Energy storage driving material separation and transmission direct methanol fuel cell and working method thereof

ActiveCN109830723AIncrease profitEasy to collect and useFuel cellsEvaporationNegative carbon dioxide emission

The invention discloses an energy storage driving material separation and transmission direct methanol fuel cell and a working method thereof. A methanol delivery pipeline and a carbon dioxide flow path are separately arranged. Carbon dioxide of an anode product is generated and then is directly discharged through the carbon dioxide flow path, which reduces the mixing of the carbon dioxide and a methanol steam, improves the utilization rate of the methanol steam, and facilitates the collection and the utilization of the carbon dioxide. After being generated, the methanol steam directly entersinto a film electrode to participate in a reaction so as to reduce extra power consumption. The heat exchange amount of a methanol working area and an evaporation area and a carbon dioxide emission amount are accurately controlled to further acquire the methanol steam with a constant flow which participates in a cell reaction, and then the working efficiency and the stability of the methanol fuelcell are improved.

Owner:XI AN JIAOTONG UNIV

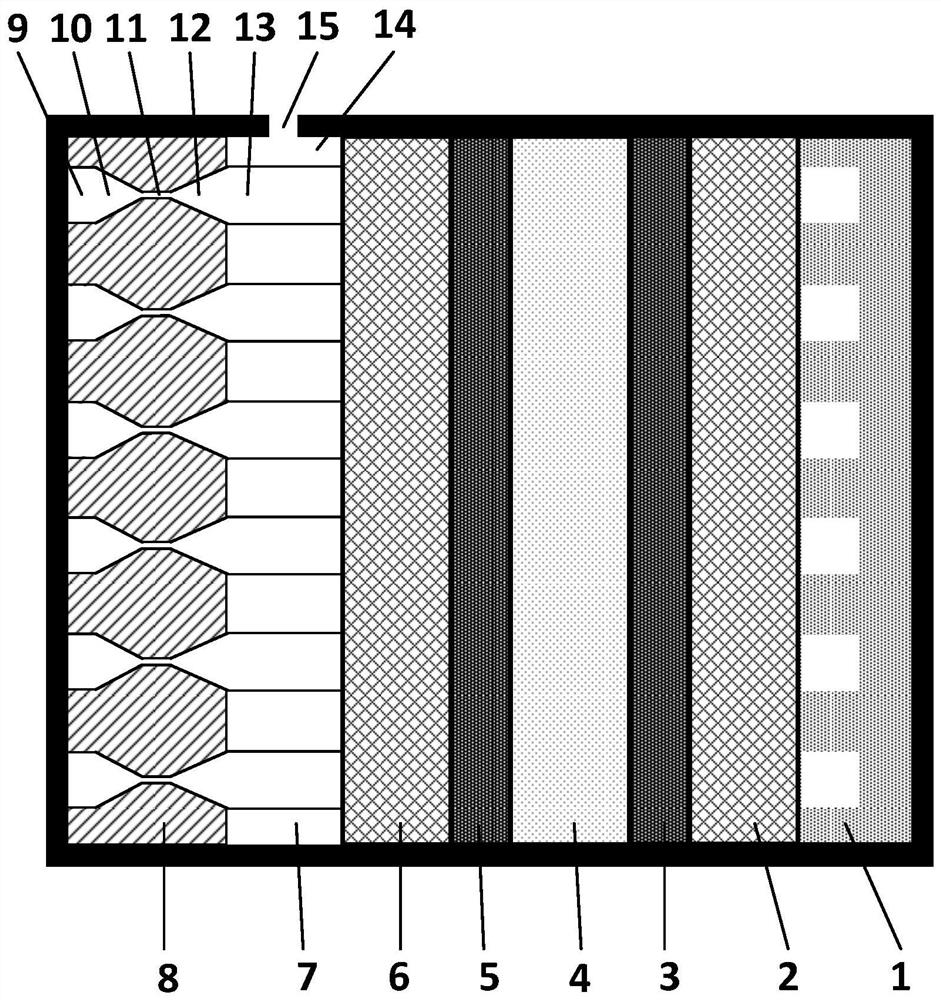

System and method for electrochemical desulfurization of organic solid waste anaerobic fermentation biogas

PendingCN112516766AImprove desulfurization efficiencyRealize continuous desulfurizationGas treatmentGas production bioreactorsElectrochemical responseChemical reaction

The invention discloses a system and a method for electrochemical desulfurization of organic solid waste anaerobic fermentation biogas. The system comprises an absorption tank, a cathode chamber of anelectrochemical reaction tank, anode chambers I and II, a proton exchange membrane, a cathode, anodes I and II and an external circuit. Synchronous desulfurization is realized through reaction of hydrogen sulfide and oxidation-state absorption liquid of the absorption tank and electrochemical reaction of the anode chamber II, generated elemental sulfur is recycled, and meanwhile, the reduced absorption liquid can be regenerated and circulated through the anode chamber I, so that the biogas desulfurization efficiency is improved. Independent absorption desulfurization or electrochemical desulfurization can be provided by controlling the gas amount, equipment failure and work interruption are avoided, and the continuity of desulfurization is guaranteed. According to the organic solid wasteanaerobic fermentation biogas electrochemical desulfurization system, solution regeneration and elemental sulfur recovery are achieved through electrochemistry, and the system is flexible and easy tooperate, efficient, stable, environmentally friendly and free of secondary pollution.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

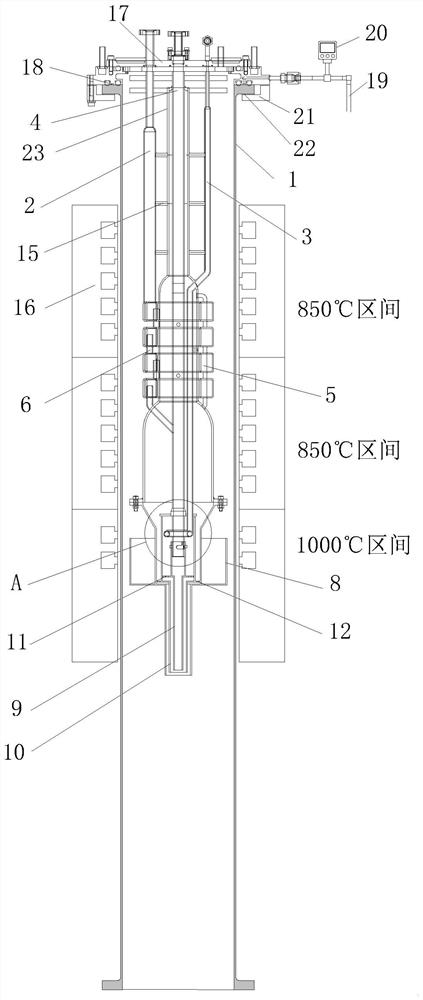

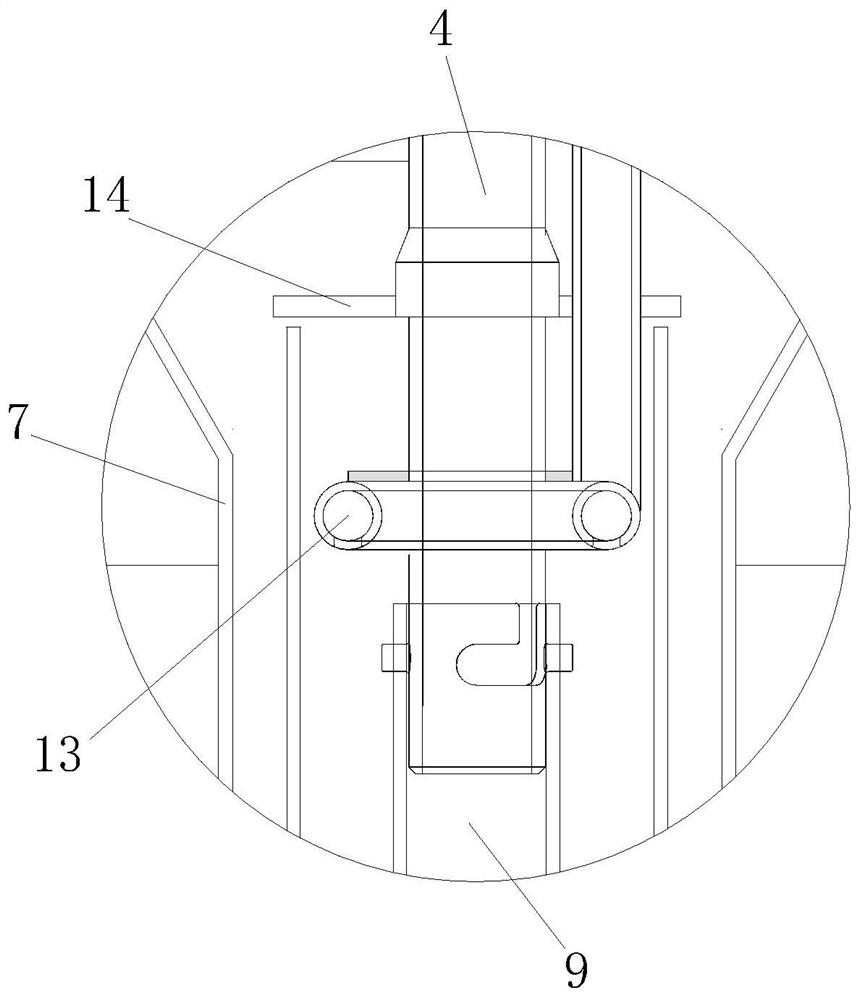

GaN single crystal manufacturing device

ActiveCN113026107AImprove intuitivenessIncrease the reaction contact areaPolycrystalline material growthFrom chemically reactive gasesPhysicsComposite material

The invention relates to the technical field of GaN single crystal preparation, and discloses a GaN single crystal manufacturing device which comprises a quartz reaction pipe, a connecting flange and a separating flange. A high-temperature electric furnace matched with the quartz reaction pipe is annularly arranged on the outer side of the quartz reaction pipe. A quartz guide inlet pipe, a quartz guide gas pipe, a quartz inner container, a quartz outer container, a quartz Ga groove, a quartz spiral reaction pipe, a quartz flange connecting pipe, a quartz stepped outer frame, an inner spray pipe and a middle spray pipe are arranged in the quartz reaction pipe; and a flange plate of the quartz inner container is clamped between two flange plates of the connecting flange. According to the manufacturing device of the GaN single crystal, an HVPE method and an MOCVD method are used in the same device to control the growth of the GaN single crystal, so that the situation that a gallium nitride crystal is cracked when the gallium nitride crystal grows thick or is cooled due to stress caused by a lattice constant and a thermal expansion number can be effectively avoided, and the grown gallium nitride is easy to strip from sapphire when being cooled. The manufacturing and production cost of the product is effectively reduced.

Owner:WUXI WUYUE SEMICON CO LTD

Coupled fluidized bed graded conversion reaction device and reaction method

ActiveCN109401795BIncrease cycle rateIncrease profitCombustible gas chemical modificationHydrocarbon from carbon oxidesPtru catalystSlag

The invention relates to a coupled fluidized bed staged conversion reaction device and reaction method, which mainly solves the problems of low carbon conversion rate and gasification intensity, low methane yield, difficult slag removal and low utilization rate of pulverized coal in the prior art . The present invention adopts a coupling fluidized bed graded conversion reaction device and reaction method, the carbon-containing raw material loaded with catalyst is pyrolyzed in a pyrolysis furnace, the pyrolyzed tar gas is collected after separation, and the semi-coke particles loaded with catalyst are combined with The gasification agent is combusted and gasified in the three reaction zones respectively. After the reaction, the carbon-containing particles and some catalysts continue to return to the pyrolysis furnace. After the two-stage separation of the device, it is discharged from the device according to the acoustic emission monitoring feedback, which better solves the above technical problems and can be applied to the industrial production of coal graded conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Material separation heat balance direct methanol fuel cell and working method thereof

ActiveCN109888323AEasy to collect and useReduce blendingFuel cell heat exchangeEvaporationHeat balance

The invention discloses a material separation heat balance direct methanol fuel cell and a working method thereof. A methanol delivery pipeline and a carbon dioxide flow path are independently arranged; an anode product carbon dioxide is directly discharged through the carbon dioxide flow path after being generated, so that the mixing of carbon dioxide and the methanol vapor is reduced, the utilization rate of the methanol vapor is increased, and meanwhile carbon dioxide collection and utilization are facilitated; after the methanol vapor is generated, the methanol vapor directly enters a membrane electrode to participate in the reaction, so that the additional power consumption is reduced; the waste heat generated in the operation process of the cell is used for heating a methanol evaporation area through a methanol evaporation heat exchange pipeline, and the cell anode working product carbon dioxide provides power for a pneumatic diaphragm pump, so that the methanol supply and evaporation process is realized on the premise of no extra power consumption; and the working efficiency and the stability of the methanol fuel cell are improved.

Owner:XI AN JIAOTONG UNIV

Product Driven Material Separation Transport Direct Methanol Fuel Cell and Method of Operation

The invention discloses a product driving material separation and transmission direct methanol fuel cell and a working method thereof. A methanol delivery pipeline and a carbon dioxide flow path are separately arranged. The carbon dioxide of an anode product is generated and then is directly discharged through the carbon dioxide flow path, which reduces the mixing of the carbon dioxide and a methanol steam, improves the utilization rate of the methanol steam, and facilitates the collection and the utilization of the carbon dioxide. After being generated, the methanol steam directly enters intoa film electrode to participate in a reaction so as to reduce extra power consumption. A fuel cell body is connected to a carbon dioxide buffer tank through a heat exchange pipeline, an anode productoutlet is externally connected with the carbon dioxide buffer tank, and power is provided for a piston in a methanol storage tank through the coordinated management of a fuel cell anode product and cell waste heat, and the supply of a methanol fuel is achieved without additional power consumption.

Owner:XI AN JIAOTONG UNIV

Heat and mass balanced direct methanol fuel cell and working method thereof

ActiveCN109888342AEasy to collect and useEfficient and stable reactionFuel cell heat exchangeGeneration processFuel cells

The invention discloses a heat and mass balanced direct methanol fuel cell and a working method thereof. According to the heat and mass balanced direct methanol fuel cell, methanol and a product are conveyed separately, the fuel cell forms a stable forward transmission flow path in the whole process from flow-in of liquid phase methanol to discharge of carbon dioxide, therefore, fuel can directlyand uniformly enter an anode, the problems that a methanol reaction is insufficient, and methanol steam concentrations are not uniform due to mixing of methanol and carbon dioxide are solved, stable and efficient running of an anode-side reaction is further benefited, and cell efficiency is improved; pressure intensity generated in the generation process of the product carbon dioxide is utilized to push the liquid state methanol to enter the fuel cell, so that additional pump work is lowered; waste heat generated in a reaction region in the cell running process is transmitted to a methanol evaporation region and used for assisting methanol evaporation; and the methanol evaporating and utilizing process is more efficient and saves more energy.

Owner:XI AN JIAOTONG UNIV

A material separation and transmission direct methanol fuel cell and its working method

The invention discloses a material separation and transfer direct methanol fuel cell and a working method thereof. For the material separation and transfer direct methanol fuel cell, the anode side adopts a new type downstream transmission structure, a liquid phase pure methanol is heated and evaporated through a methanol evaporation pipeline to generate methanol vapor, the methanol vapor flows directly into that anode diffusion layer through the methanol vapor channel, a reaction product is refluxed directly to a carbon dioxide buffer isolated from the methanol vapor channel in the fuel product separation zone and discharged directly into the atmosphere, the methanol and product are transported separately, and the whole process of the fuel cell from liquid methanol flowing to carbon dioxide discharge forms a stable downstream flow path, which is conducive to the stable and efficient operation of the anode-side reaction and improved cell efficiency.

Owner:XI AN JIAOTONG UNIV

Low-power material separation and transmission direct methanol fuel cell and working method thereof

ActiveCN109921074AEasy to collect and useReduce blendingFuel cell controlElectrical batteryEvaporation

The invention discloses a low-power material separation and transmission direct methanol fuel cell and a working method thereof. A plurality of methanol evaporation pipelines and a plurality of carbondioxide flow paths are respectively arranged in a methanol evaporation region, and a methanol conveying pipeline and a carbon dioxide flow path are independently arranged; and the anode product carbon dioxide is directly discharged through the carbon dioxide flow path after being generated, so that the mixing of the carbon dioxide and a methanol vapor is reduced, the utilization rate of the methanol vapor is increased, and meanwhile carbon dioxide collection and utilization are facilitated. After the methanol vapor is generated, the methanol vapor directly enters a membrane electrode to participate in the reaction, so that the additional power consumption is reduced; a stable flow path is formed in the overall process from the inflow of methanol to the discharge of carbon dioxide, the fuel self-circulation structure largely solves the problems of uneven methanol vapor concentration, insufficient methanol reaction, and methanol and carbon dioxide mixing and the like, so that the battery reaction is more stable and efficient.

Owner:XI AN JIAOTONG UNIV

A thermal mass balance direct methanol fuel cell and its working method

The invention discloses a thermal mass balance direct methanol fuel cell and its working method. In the thermal mass balance direct methanol fuel cell, the methanol and the product are transported separately, and the fuel cell as a whole forms a stable downstream transport in the overall process from liquid methanol inflow to carbon dioxide discharge. The flow path enables the fuel to enter the anode directly and evenly, which solves the problems of methanol and carbon dioxide mixing, insufficient methanol reaction, and uneven concentration of methanol vapor, which is more conducive to stable and efficient operation of the anode side reaction and improves battery efficiency; The pressure generated by the carbon dioxide generation process pushes liquid methanol into the fuel cell, reducing additional pump work; the waste heat generated in the reaction zone during battery operation is transferred to the methanol evaporation zone to assist methanol evaporation; the process of methanol evaporation and utilization is more efficient and energy-saving .

Owner:XI AN JIAOTONG UNIV

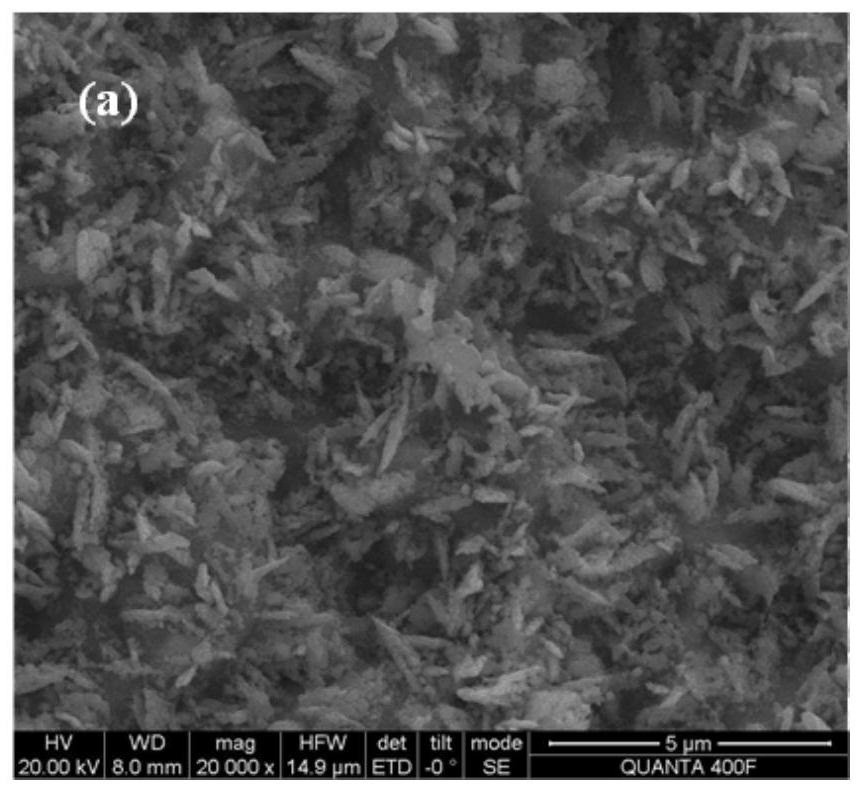

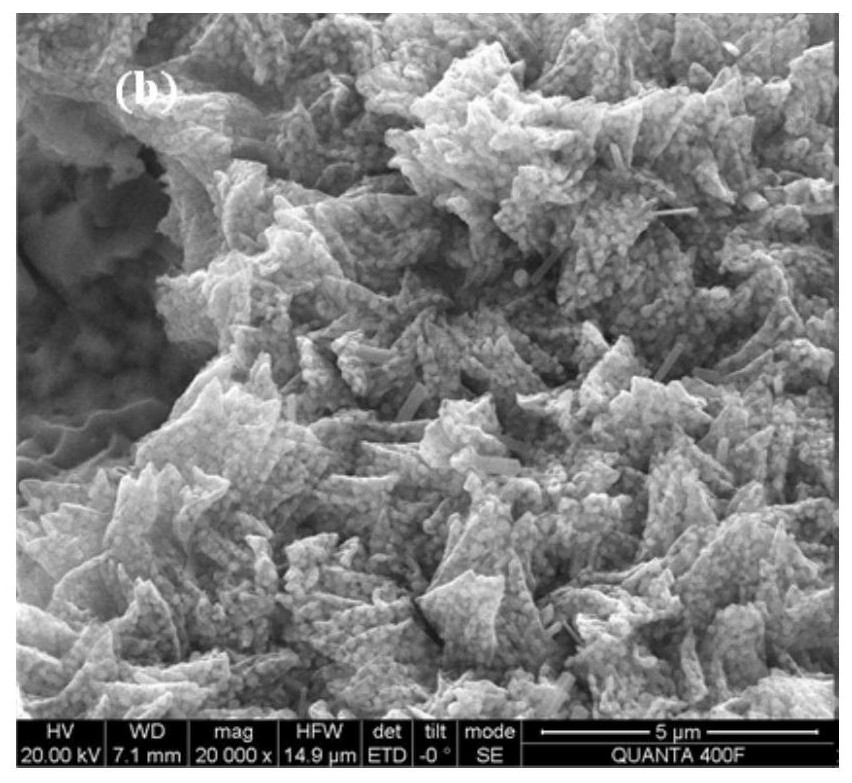

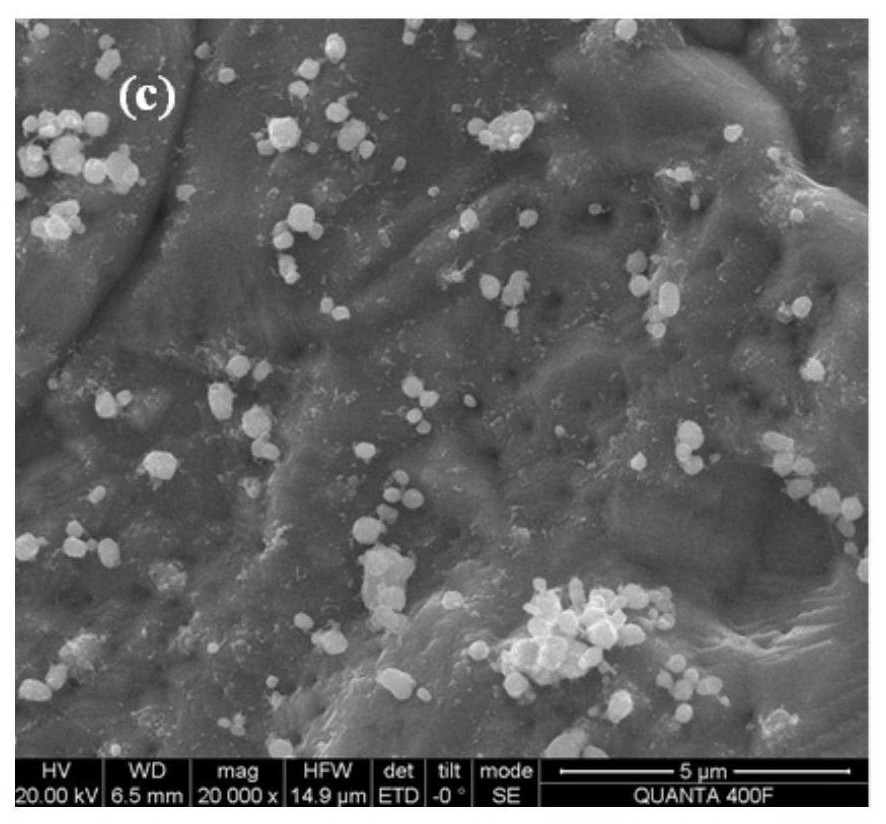

Foamed nickel loaded carbon embedded zero-valent iron cathode, preparation method and antibiotic degradation method

PendingCN114560538AEfficient degradationExtended service lifeWater contaminantsEnergy based wastewater treatmentCarbon layerPtru catalyst

The invention relates to a foamed nickel loaded carbon-embedded zero-valent iron cathode, a preparation method thereof and a method for degrading antibiotics. The foamed nickel loaded carbon-embedded zero-valent iron cathode is composed of an NF matrix and a carbon-embedded zero-valent iron catalyst loaded on the surface of the matrix. PMS can be activated under the action of an electric field to degrade antibiotics. The invention also provides a preparation method of the cathode material. The preparation method comprises the following steps: preparing an MOF-Fe precursor solution; preparing an MOF-Fe / NF precursor; and preparing the carbon-embedded zero-valent iron-loaded NF cathode. According to the carbon-embedded zero-valent iron-loaded foamed nickel cathode provided by the invention, the carbon-embedded zero-valent iron grows in situ on the surface of the NF matrix, the zero-valent iron is used as a catalyst, and the surface carbon layer not only can be used as an electron transmission channel to accelerate the catalytic reaction, but also can isolate the elemental iron from a complex external environment to effectively protect the elemental iron and prolong the service life of the electrode; the high-efficiency degradation of antibiotics can be realized, and the electrode can play a good role in complex and changeable environments, and can be suitable for industrial wastewater treatment with complex water conditions.

Owner:NORTHEASTERN UNIV

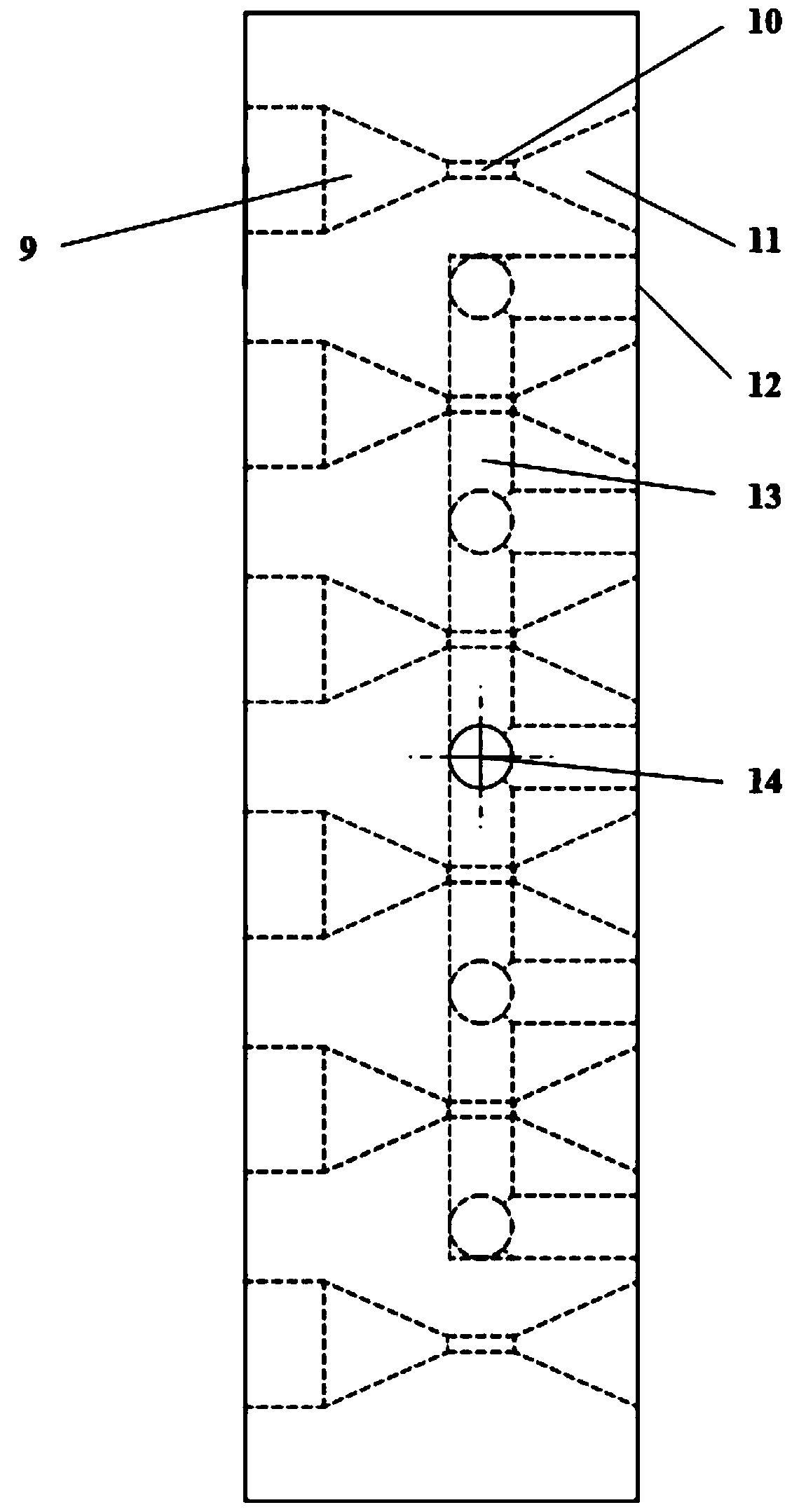

Fractional conversion combined fluidized bed reaction device and reaction method

ActiveCN109401794BIncrease cycle rateIncrease profitCombustible gas chemical modificationHydrocarbon from carbon oxidesSyngasPtru catalyst

The invention relates to a graded conversion combined fluidized bed reaction device and a reaction method, which mainly solve the problems of low carbon conversion rate and gasification intensity, low methane yield, small processing capacity, difficult slagging and pulverized coal existing in the prior art. The problem of low utilization. The present invention adopts a graded conversion combined fluidized bed reaction device and reaction method. Carbon-containing raw materials loaded with catalysts are pyrolyzed in a pyrolysis furnace, and tar gas is collected after separation. After pyrolysis, semi-coke particles loaded with catalysts are mixed with gas The oxidizing agent and oxidant are partially combusted and gasified in the fine reactor, and then the syngas and unfinished carbon-containing particles are further gasified in the coarse reactor, and the reacted carbon-containing particles and part of the catalyst continue to Returning to the pyrolysis furnace, the technical scheme of discharging the ash at the bottom through intermittent classification and slagging can better solve the above technical problems and can be applied to the industrial production of coal classification conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy storage-driven material separation and transmission direct methanol fuel cell and its working method

The invention discloses an energy storage driving material separation and transmission direct methanol fuel cell and a working method thereof. A methanol delivery pipeline and a carbon dioxide flow path are separately arranged. Carbon dioxide of an anode product is generated and then is directly discharged through the carbon dioxide flow path, which reduces the mixing of the carbon dioxide and a methanol steam, improves the utilization rate of the methanol steam, and facilitates the collection and the utilization of the carbon dioxide. After being generated, the methanol steam directly entersinto a film electrode to participate in a reaction so as to reduce extra power consumption. The heat exchange amount of a methanol working area and an evaporation area and a carbon dioxide emission amount are accurately controlled to further acquire the methanol steam with a constant flow which participates in a cell reaction, and then the working efficiency and the stability of the methanol fuelcell are improved.

Owner:XI AN JIAOTONG UNIV

A heat balance material separation direct methanol fuel cell and its working method

ActiveCN109888343BImprove efficiencyGuaranteed uptimeFuel cell heat exchangeDiaphragm pumpFuel cells

The invention discloses a direct methanol fuel cell capable of realizing heat balance and material separation as well as a working method thereof. The direct methanol fuel cell is characterized in that methanol and a product are separately conveyed, a stable downstream transmission flow path is formed in the whole process of the fuel cell entirety from a moment that liquid-phase methanol flows through to a moment that carbon dioxide is discharged, the problems that methanol reaction is insufficient and methanol vapor concentration is nonuniform as methanol and carbon dioxide are mixed are solved, stable and efficient performance of a reaction at an anode side is better benefited, and cell efficiency is improved; extra heat produced in a fuel cell operation process is transmitted into a methanol evaporation region, and energy consumption is reduced while a fuel cell operating temperature is lowered; and a cell product carbon dioxide enters a pneumatic diaphragm pump under the action ofair pressure, a carbon dioxide flow divider valve drives the pneumatic diaphragm pump to stably convey the liquid phase methanol to the methanol evaporation region, and power is provided for the liquid phase methanol when entering the cell without extra power consumption.

Owner:XI AN JIAOTONG UNIV

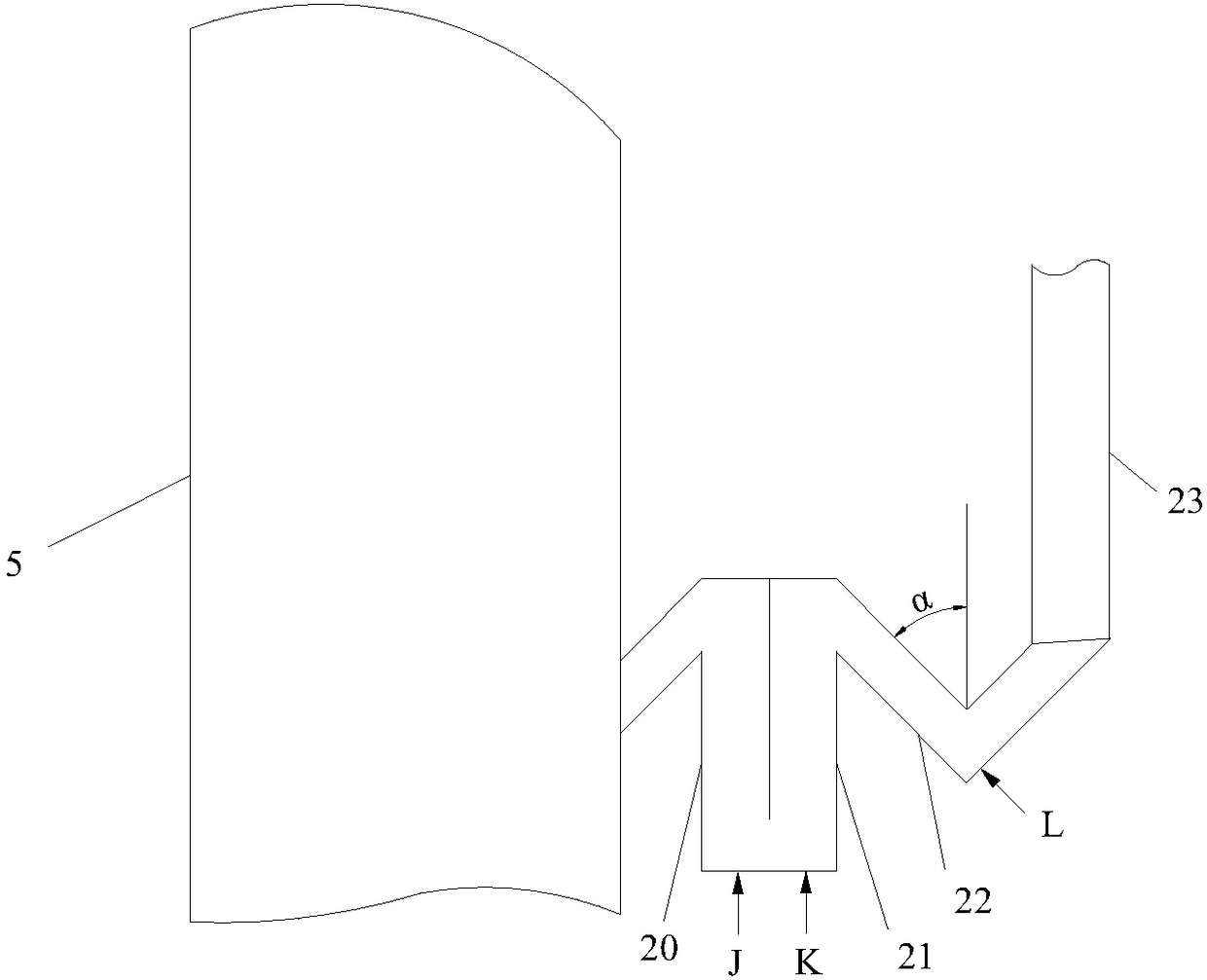

Differential fluidized bed reaction device and reaction method

ActiveCN112239680BIncrease profitOrderly discharge of slagGasification processes detailsGranular/pulverulent flues gasificationPtru catalystSlag

The invention relates to a differential velocity fluidized bed reaction device and a reaction method, which mainly solve the problems of low carbon conversion rate and gasification intensity, low methane yield, difficult slag discharge and low utilization rate of pulverized coal in the prior art. In the present invention, through a differential velocity fluidized bed reaction device and a reaction method, the carbonaceous raw material loaded with the catalyst enters the pyrolysis zone of the inner circulating fluidized bed reactor, and passes through the circulating return zone from the gasification zone. After the carbon-containing particles are rapidly mixed, they are rapidly pyrolyzed. The pyrolyzed semi-coke particles enter the gasification zone for mixing with the gasification agent and gasification reaction. Enter into the slag discharge combustion device, carry out the oxygen-enriched combustion reaction, the heat generated after the reaction supplements the heat demand of the reaction in the gasification zone, and the final generated low-carbon ash is accurately discharged under the monitoring of the acoustic emission detection system. The above-mentioned technical problems are better solved, and the method can be applied to the industrial production of coal graded conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficiency graded conversion combined fluidized bed reaction device and reaction method

ActiveCN109401796BIncrease cycle rateIncrease profitCombustible gas chemical modificationCatalystsPtru catalystSlag

The invention relates to a high-efficiency graded conversion combined fluidized bed reaction device and reaction method, which mainly solves the problems of low carbon conversion rate and gasification intensity, low methane yield, difficult slagging and low utilization rate of pulverized coal in the prior art question. The present invention adopts a high-efficiency graded conversion combined fluidized bed reaction device and reaction method, and the carbon-containing raw material loaded with the catalyst is pyrolyzed in the pyrolysis furnace, and the pyrolyzed tar gas is collected after separation, and the semi-coke particles loaded with the catalyst Combustion and gasification reaction with gasification agent in the first reaction zone, then enter the second reaction zone for gasification reaction, and then the generated syngas and unfinished carbon-containing particles are further gasified in the third reaction zone The reaction, the carbon-containing particles and part of the catalyst after the reaction continue to return to the pyrolysis furnace, and the ash at the bottom of the reaction zone is monitored by acoustic emission in the graded slag discharge device. The above-mentioned technical problems can be solved, and it can be applied to the industrial production of coal graded conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Direct methanol fuel cell capable of realizing heat balance and material separation as well as working method thereof

ActiveCN109888343ALower operating temperaturePromote methanol evaporationFuel cell heat exchangeChemistryCarbon dioxide

The invention discloses a direct methanol fuel cell capable of realizing heat balance and material separation as well as a working method thereof. The direct methanol fuel cell is characterized in that methanol and a product are separately conveyed, a stable downstream transmission flow path is formed in the whole process of the fuel cell entirety from a moment that liquid-phase methanol flows through to a moment that carbon dioxide is discharged, the problems that methanol reaction is insufficient and methanol vapor concentration is nonuniform as methanol and carbon dioxide are mixed are solved, stable and efficient performance of a reaction at an anode side is better benefited, and cell efficiency is improved; extra heat produced in a fuel cell operation process is transmitted into a methanol evaporation region, and energy consumption is reduced while a fuel cell operating temperature is lowered; and a cell product carbon dioxide enters a pneumatic diaphragm pump under the action ofair pressure, a carbon dioxide flow divider valve drives the pneumatic diaphragm pump to stably convey the liquid phase methanol to the methanol evaporation region, and power is provided for the liquid phase methanol when entering the cell without extra power consumption.

Owner:XI AN JIAOTONG UNIV

Material Separation Heat Balance Direct Methanol Fuel Cell and Its Working Method

ActiveCN109888323BEasy to collect and useReduce blendingFuel cell heat exchangeFuel cellsElectrical battery

The invention discloses a material separation heat balance direct methanol fuel cell and a working method thereof. A methanol delivery pipeline and a carbon dioxide flow path are independently arranged; an anode product carbon dioxide is directly discharged through the carbon dioxide flow path after being generated, so that the mixing of carbon dioxide and the methanol vapor is reduced, the utilization rate of the methanol vapor is increased, and meanwhile carbon dioxide collection and utilization are facilitated; after the methanol vapor is generated, the methanol vapor directly enters a membrane electrode to participate in the reaction, so that the additional power consumption is reduced; the waste heat generated in the operation process of the cell is used for heating a methanol evaporation area through a methanol evaporation heat exchange pipeline, and the cell anode working product carbon dioxide provides power for a pneumatic diaphragm pump, so that the methanol supply and evaporation process is realized on the premise of no extra power consumption; and the working efficiency and the stability of the methanol fuel cell are improved.

Owner:XI AN JIAOTONG UNIV

A kind of polycarbonate polyol and its synthesis method and application

ActiveCN109957101BOvercome stabilitySmooth responsePolyurea/polyurethane coatingsTrans esterificationCarbonate ester

The invention provides a polycarbonate polyol and its synthesis method and application. The synthesis method comprises the following steps: carrying out transesterification reaction between a raw material A containing a polyol or a mixture of a polyol and a lactone and a carbonate to generate the polycarbonate polyol. Carbonate polyol, the raw material A is fed at one time, and the carbonate of the stoichiometrically predetermined total amount of carbonate feed is put into the reaction system by continuous feeding, and the by-products and carbonate are rectified during the reaction. Azeotrope; Sampling and monitoring the mass percentage of carbonate in the fraction during the completion of the stoichiometrically predetermined carbonate feed total amount, controlling the stability of the carbonate content in the fraction composition and / or according to the The content of carbonate is changed to add or reduce carbonate. The method provided by the invention can quickly and stably produce products meeting the requirements of hydroxyl value, and the post-treatment is simpler.

Owner:WANHUA CHEM GRP CO LTD

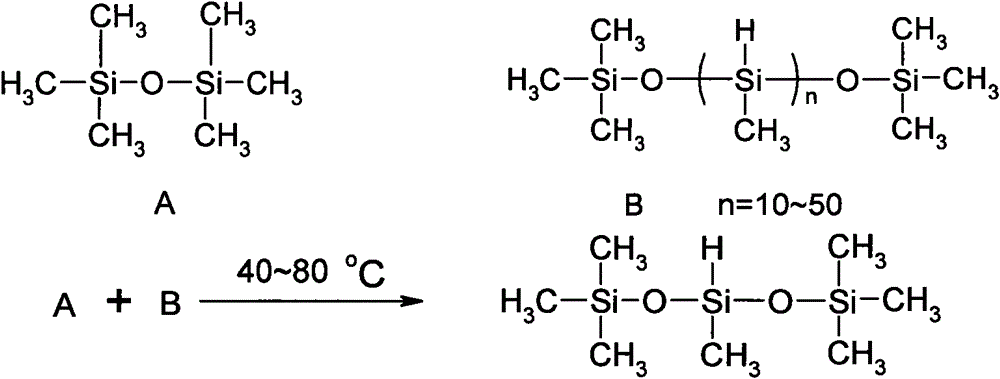

Method for synthesizing 1,1,1,3,5,5,5-heptamethyltrisiloxane by continuous catalysis of solid phase catalyst

ActiveCN101921287BEasy to separateEfficient and stable separationSilicon organic compoundsChemical recyclingRecyclable catalystHydrogen

The invention relates to a method for synthesizing 1,1,1,3,5,5,5-heptamethyltrisiloxane by continuous catalysis of a solid phase catalyst. Hexamethyldisiloxane and straight chain methyl hydrogen polysiloxane in a molar ratio of 3:1-2:1 are taken as raw materials, strongly acidic ion exchange resin is taken as the solid phase catalyst, the reaction temperature is 40 to 80 DEG C, a fixed bed reactor is adopted, the raw materials pass through the reactor filled with the ion exchange resin at a certain flow rate, the retention period is 5 to 10 hours, the conversion rate of the raw materials is ensured by the retention period of the reaction through controlling the flow rate of the reaction product, the continuous reaction production is realized, and the reaction product is subjected to low fraction and high fraction removal rectification to form the 1,1,1,3,5,5,5-heptamethyltrisiloxane product with the purity of over 99 percent. The method has the advantages of readily available raw materials, no three-waste emission, simple process, continuous production, high-efficiency and stable reaction, simple separation, recyclable catalyst, conversion per pass of the raw material straight chain methyl hydrogen polysiloxane of over 32 percent, good product quality and low production cost.

Owner:JIANGXI HITO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com