Fractional conversion combined fluidized bed reaction device and reaction method

A reaction device and combined flow technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of low slag discharge efficiency, small processing capacity, low methane yield, etc. Block, the effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

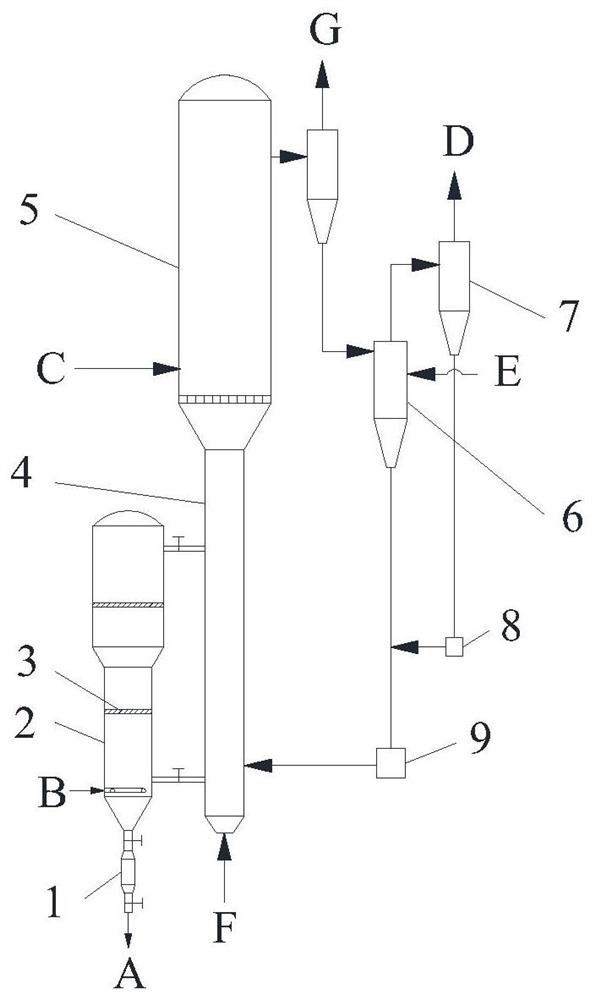

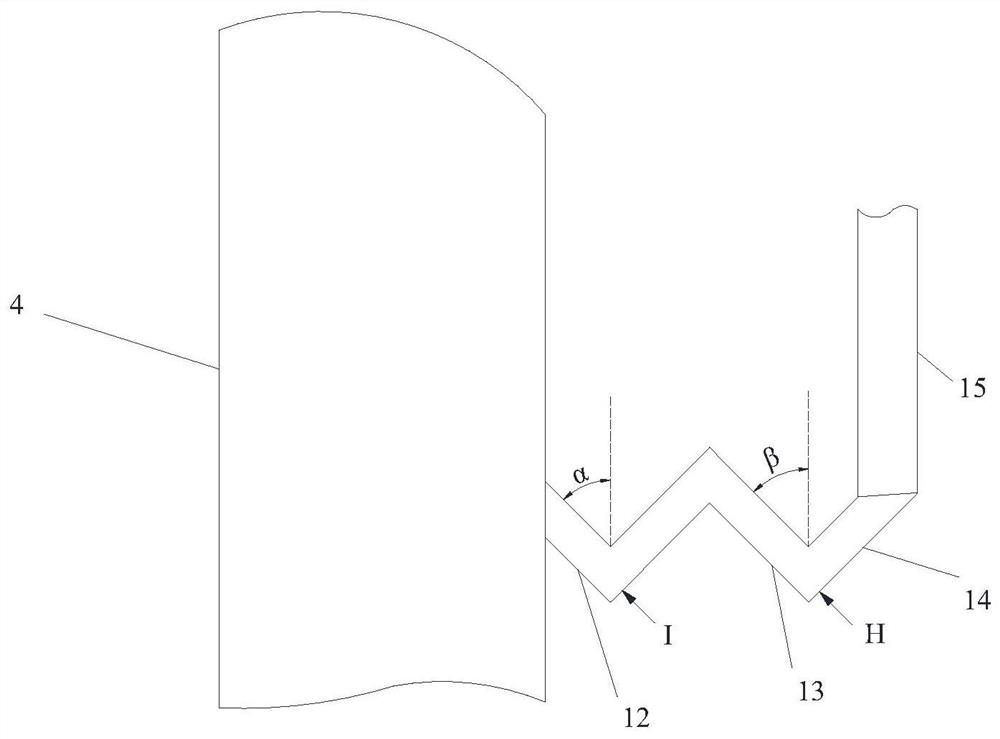

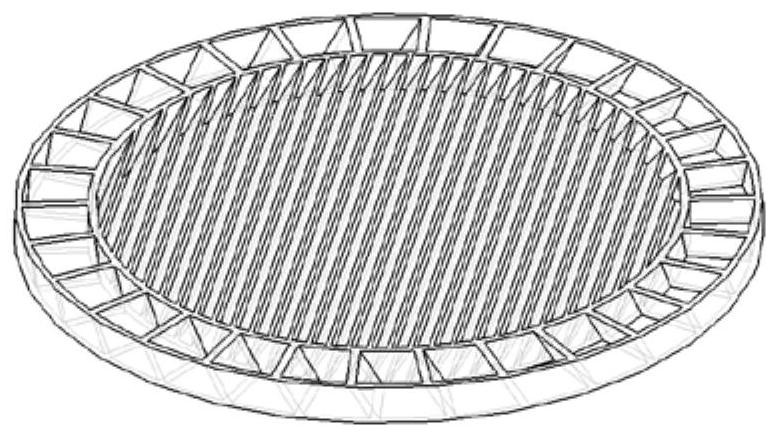

[0039] The reaction process is as follows: the catalyst and carbon-containing raw materials enter the pyrolysis furnace from the feed pipeline for pyrolysis, the tar gas is collected after separation, and the semi-coke particles loaded with the catalyst, gasification agent and oxidant are simultaneously released at a higher line rate after pyrolysis. Partial combustion and gasification reactions are carried out in the fine reactor with high speed and low particle concentration. After the reaction, the large-particle slag and some incompletely reacted carbon-containing particles are controlled by a valve and enter the classification slag discharge device. After particle classification, the classification Large particle slag is discharged from the bottom of the slagging device, while carbon-containing particles flow into the upper end of the fine reactor through the upper part of the grading slagging device to continue to participate in the reaction. The carbon-containing particl...

Embodiment 2

[0042] The reaction process is as follows: the catalyst and carbon-containing raw materials enter the pyrolysis furnace from the feed pipeline for pyrolysis, the tar gas is collected after separation, and the semi-coke particles loaded with the catalyst, gasification agent and oxidant are simultaneously released at a higher line rate after pyrolysis. Partial combustion and gasification reactions are carried out in the fine reactor with high speed and low particle concentration. After the reaction, the large-particle slag and some incompletely reacted carbon-containing particles are controlled by a valve and enter the classification slag discharge device. After particle classification, the classification Large particle slag is discharged from the bottom of the slagging device, while carbon-containing particles flow into the upper end of the fine reactor through the upper part of the grading slagging device to continue to participate in the reaction. The carbon-containing particl...

Embodiment 3

[0045]The reaction process is as follows: the catalyst and carbon-containing raw materials enter the pyrolysis furnace from the feed pipeline for pyrolysis, the tar gas is collected after separation, and the semi-coke particles loaded with the catalyst, gasification agent and oxidant are simultaneously released at a higher line rate after pyrolysis. Partial combustion and gasification reactions are carried out in the fine reactor with high speed and low particle concentration. After the reaction, the large-particle slag and some incompletely reacted carbon-containing particles are controlled by a valve and enter the classification slag discharge device. After particle classification, the classification Large particle slag is discharged from the bottom of the slagging device, while carbon-containing particles flow into the upper end of the fine reactor through the upper part of the grading slagging device to continue to participate in the reaction. The carbon-containing particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com