Patents

Literature

90results about How to "Increase EGR rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

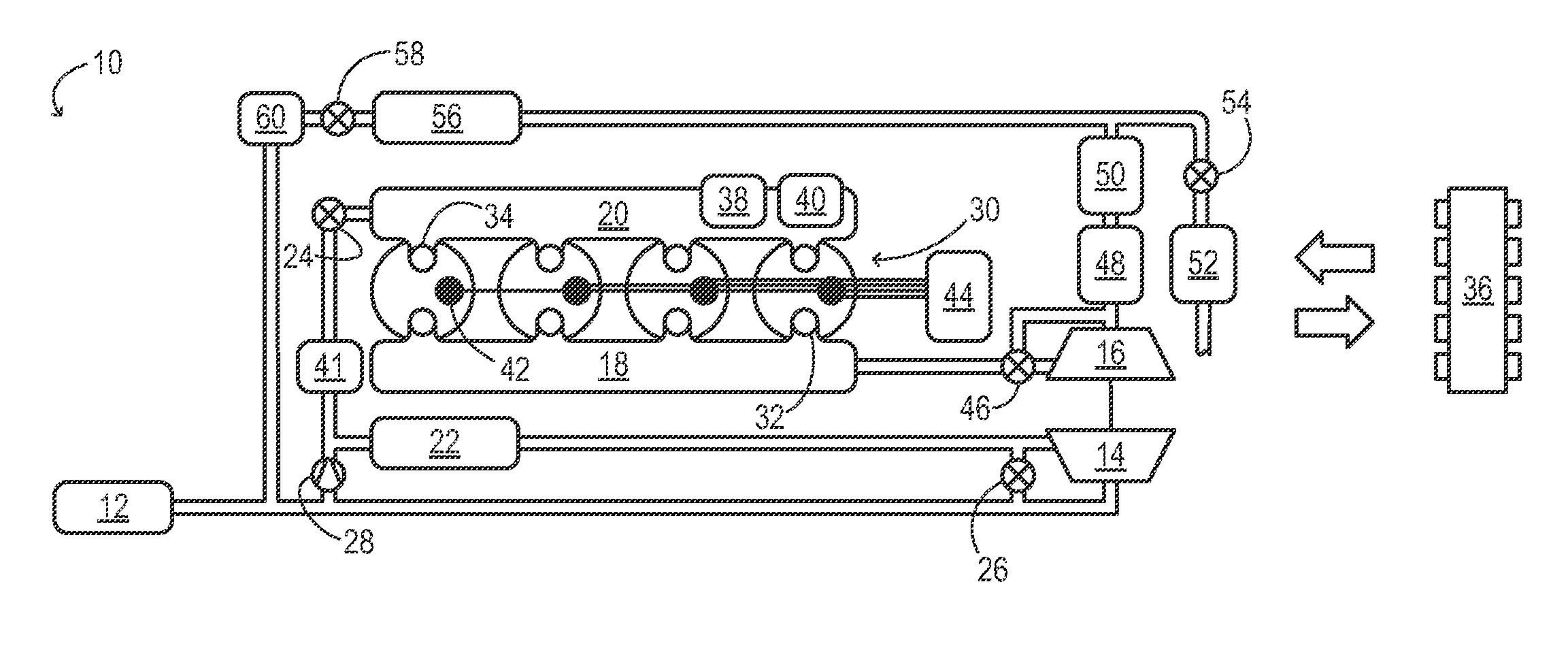

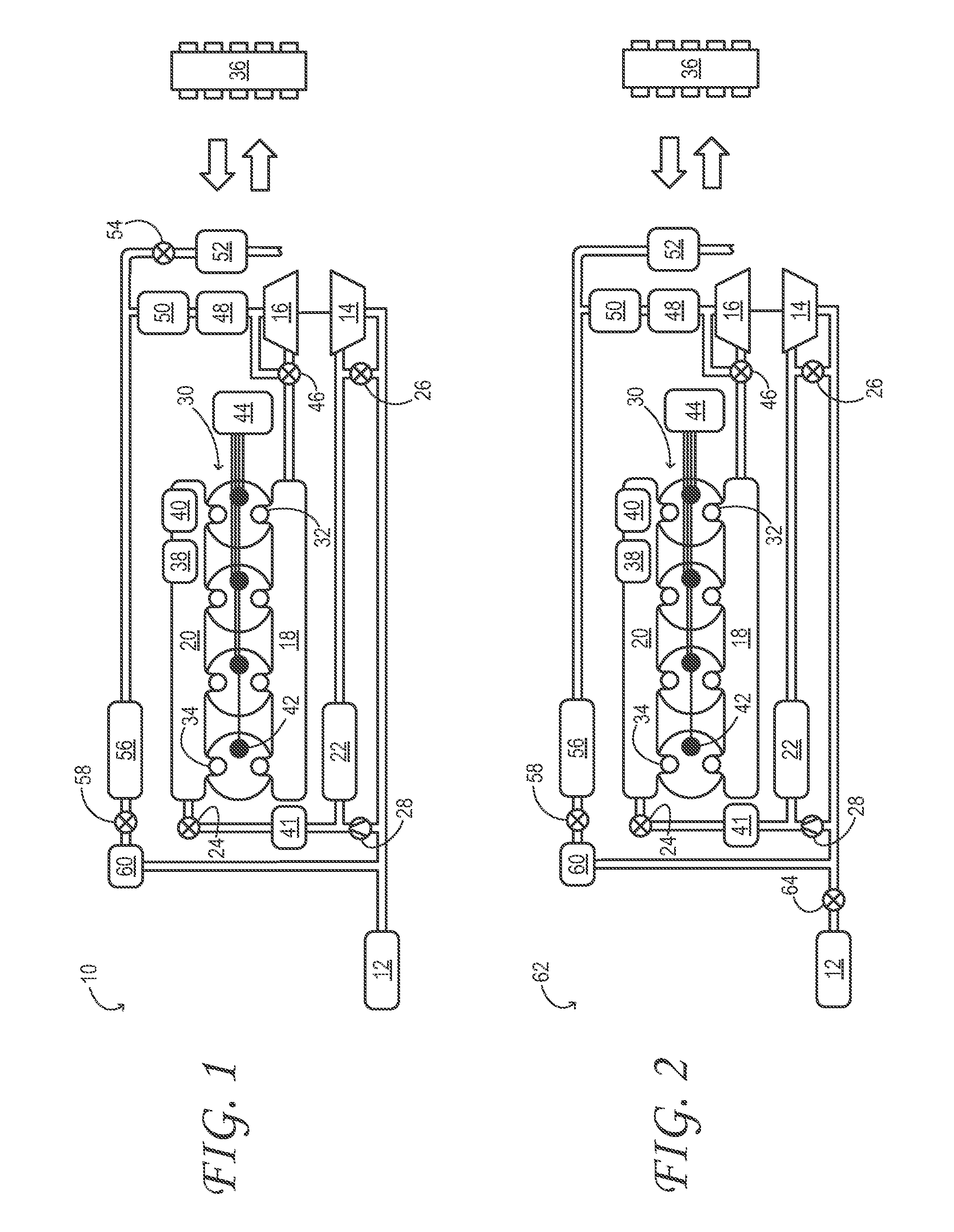

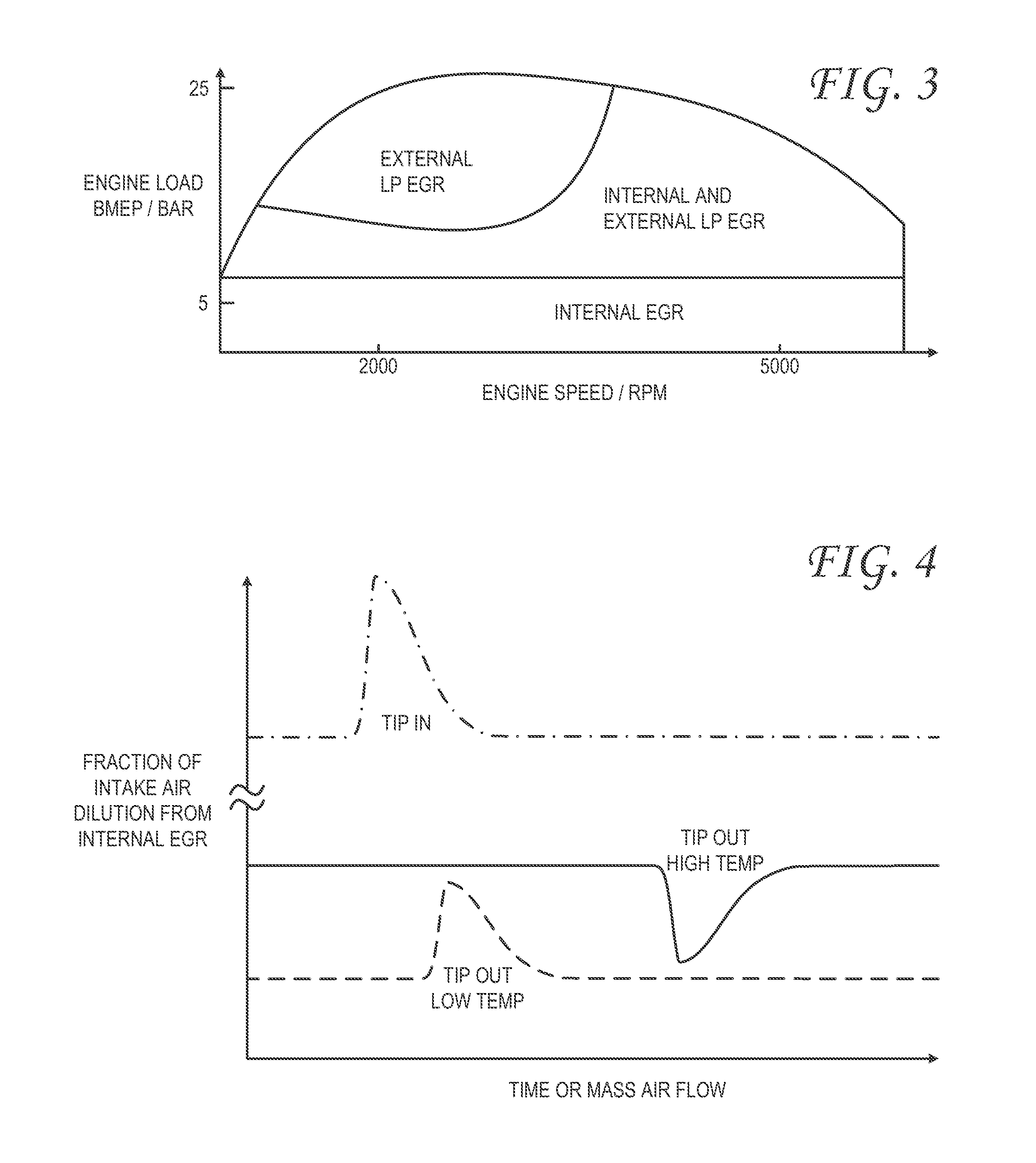

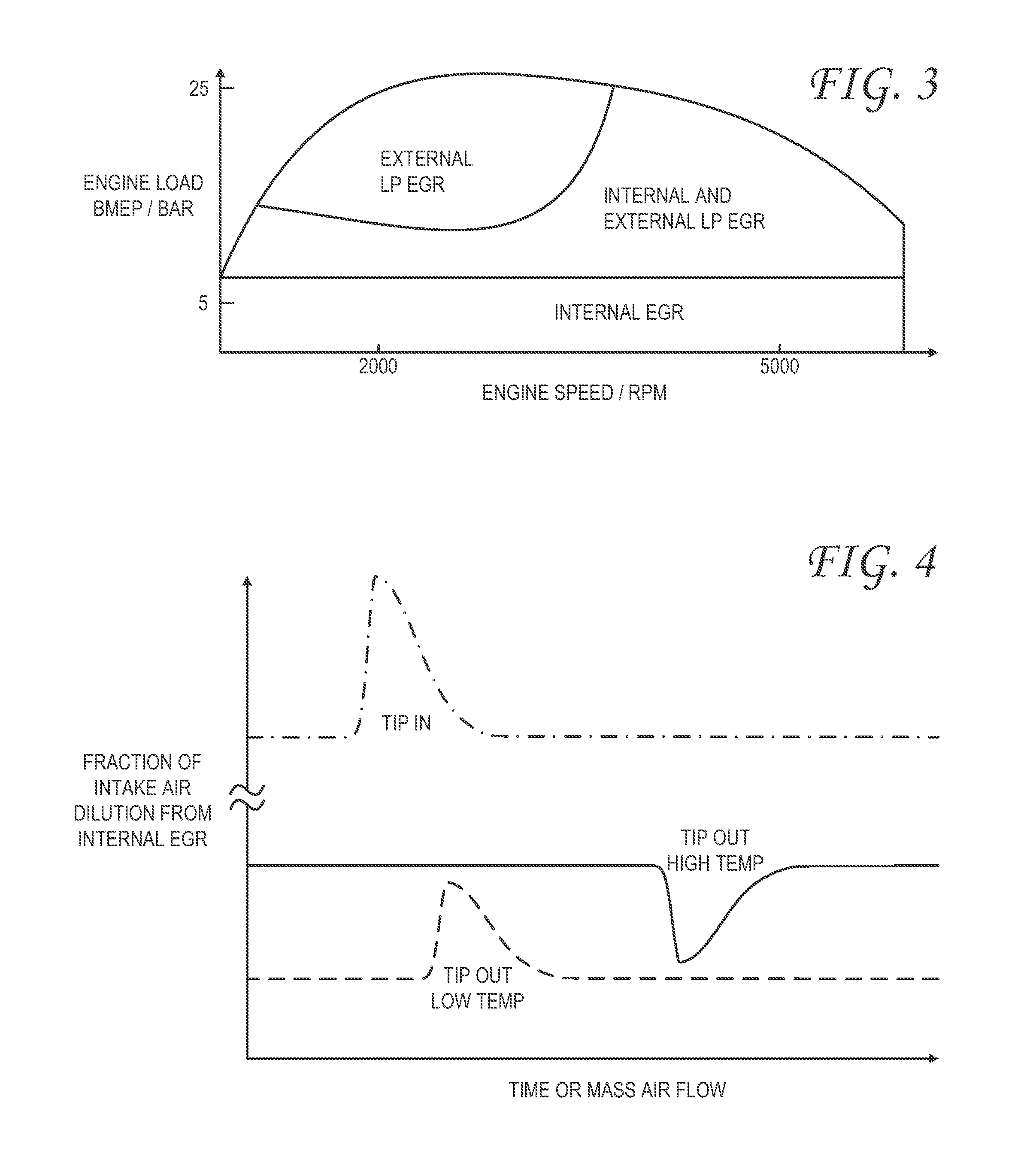

Combustion stability enhancement via internal egr control

ActiveUS20110239997A1High combustionHigh exhaust temperatureNon-fuel substance addition to fuelInternal combustion piston enginesCombustionAutomotive engineering

A method for controlling combustion in a cylinder of a turbocharged engine in which intake air is reserved upstream of the cylinder. The method comprises decreasing an internal EGR rate in the cylinder during a tip-out condition if the temperature of the intake air is above a threshold, and increasing the internal EGR rate in the cylinder during a tip-out condition if the temperature of the intake air is below the threshold.

Owner:FORD GLOBAL TECH LLC

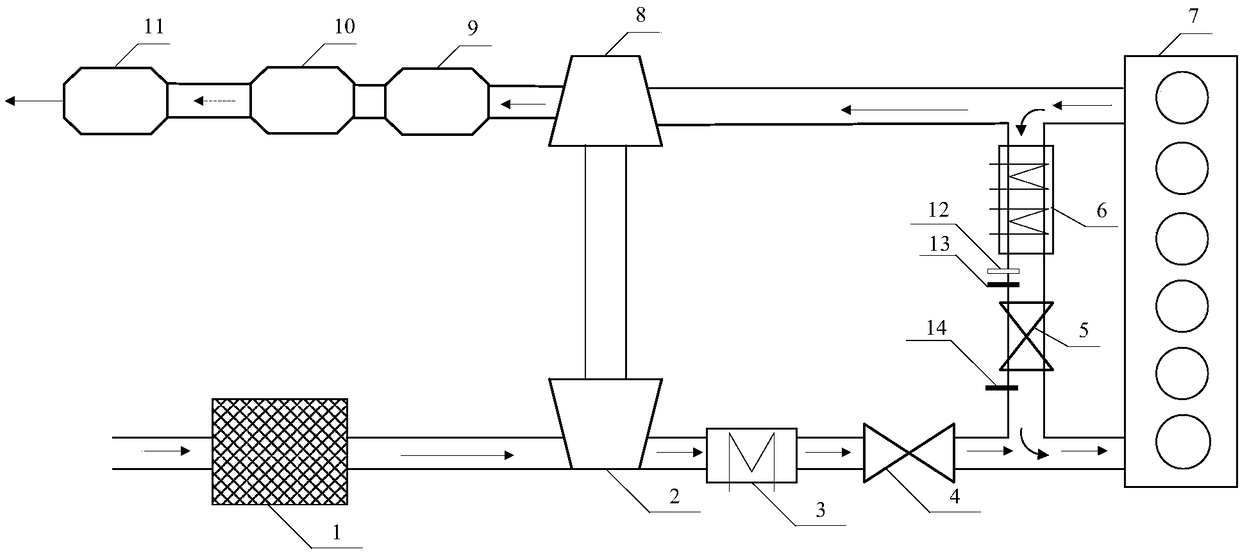

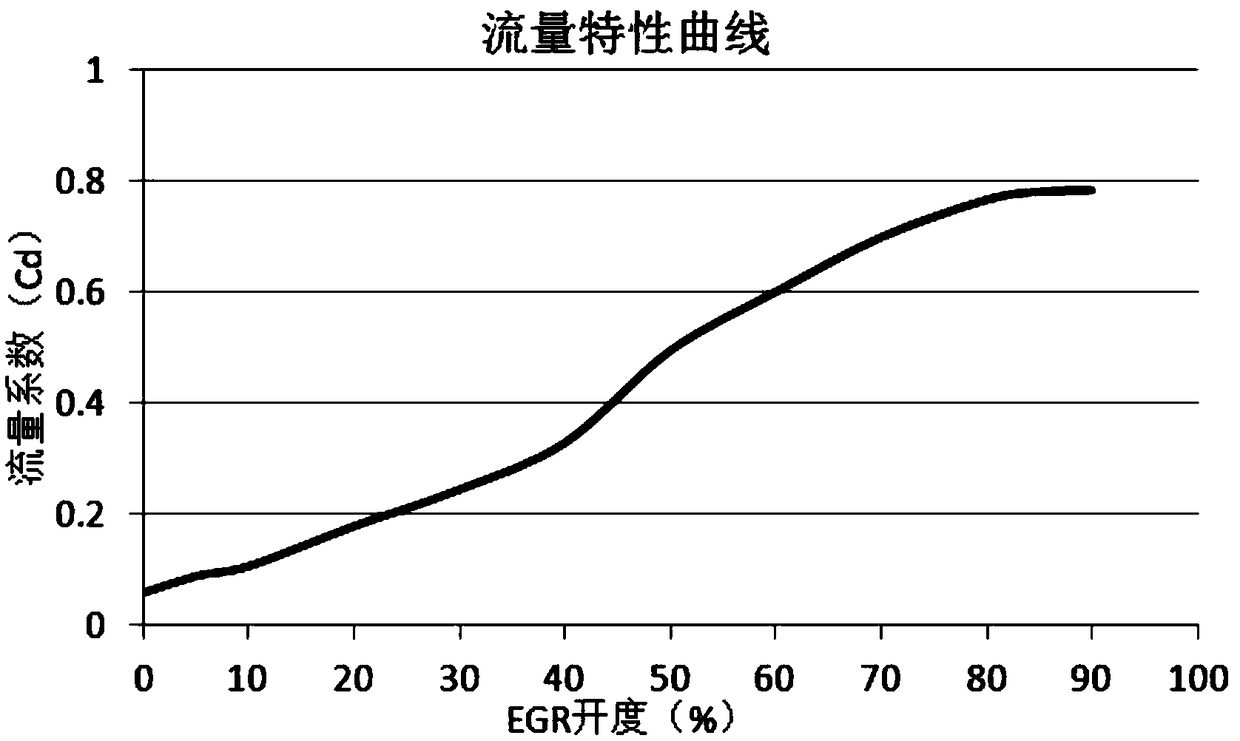

Exhaust gas flow measuring system and measuring method and closed loop control method

InactiveCN109209688AAccurate calculationIncreased pressure lossElectrical controlExhaust gas recirculationClosed loopEngineering

The invention provides an exhaust gas flow measuring system and measuring method and a closed loop control method. A temperature sensor, a first pressure sensor and a second pressure sensor are addedon the basis of an EGR system and an engine controller of the system. The engine controller calculates theoretical exhaust gas flow in different opening of an EGR valve according to relative data fedback by the temperature sensor, the first pressure sensor and the second pressure sensor. Flow coefficient of EGR valve under different opening can be obtained by using flow characteristics of the EGRvalve. Actual exhaust gas flow of the EGR valve under different opening is obtained by modifying the theoretical exhaust gas flow by the flow coefficient. According to the system, the flow can be calculated without components such as a Venturi Flowmeter, and therefore incorrect calculation of exhaust gas flow caused by unreasonable design of the Venturi Flowmeter can be avoided.

Owner:WEICHAI POWER CO LTD

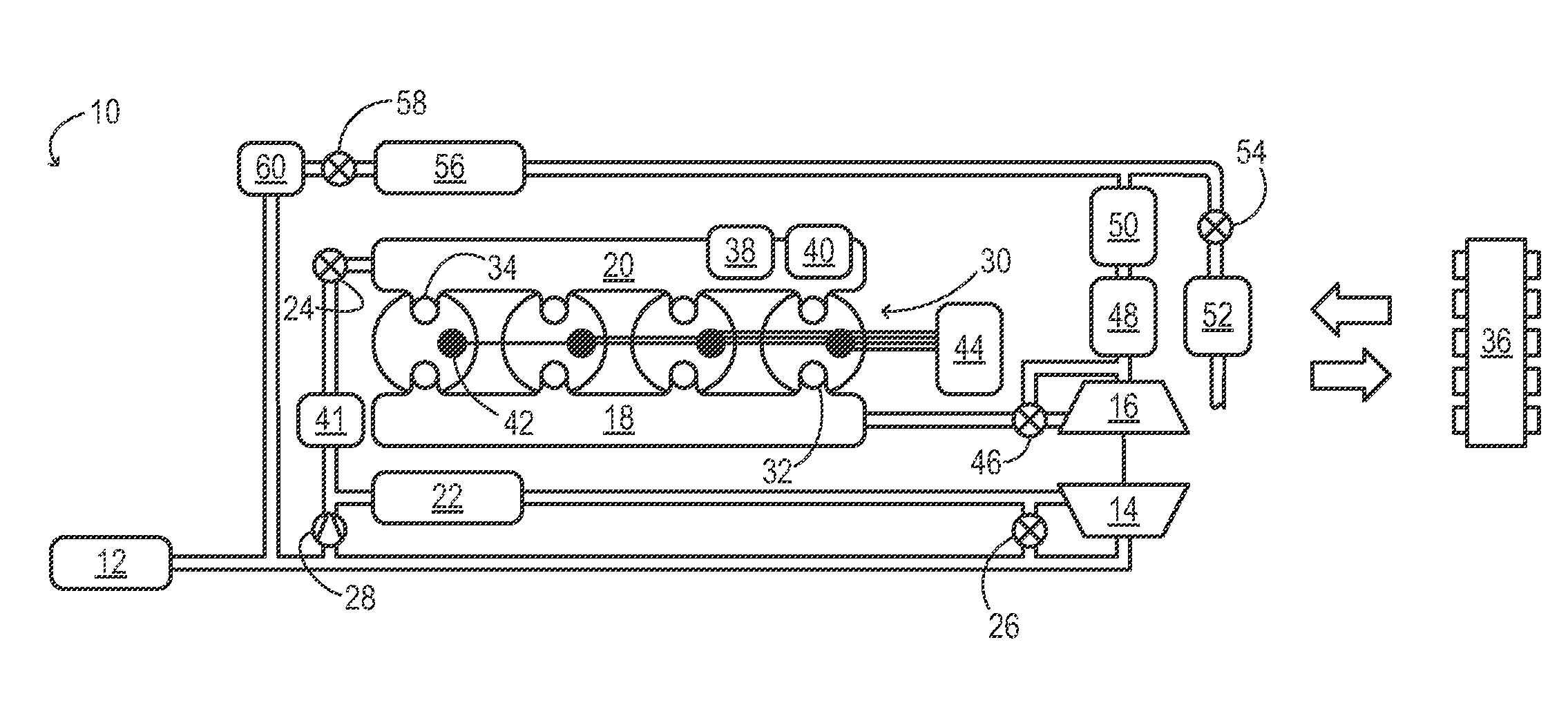

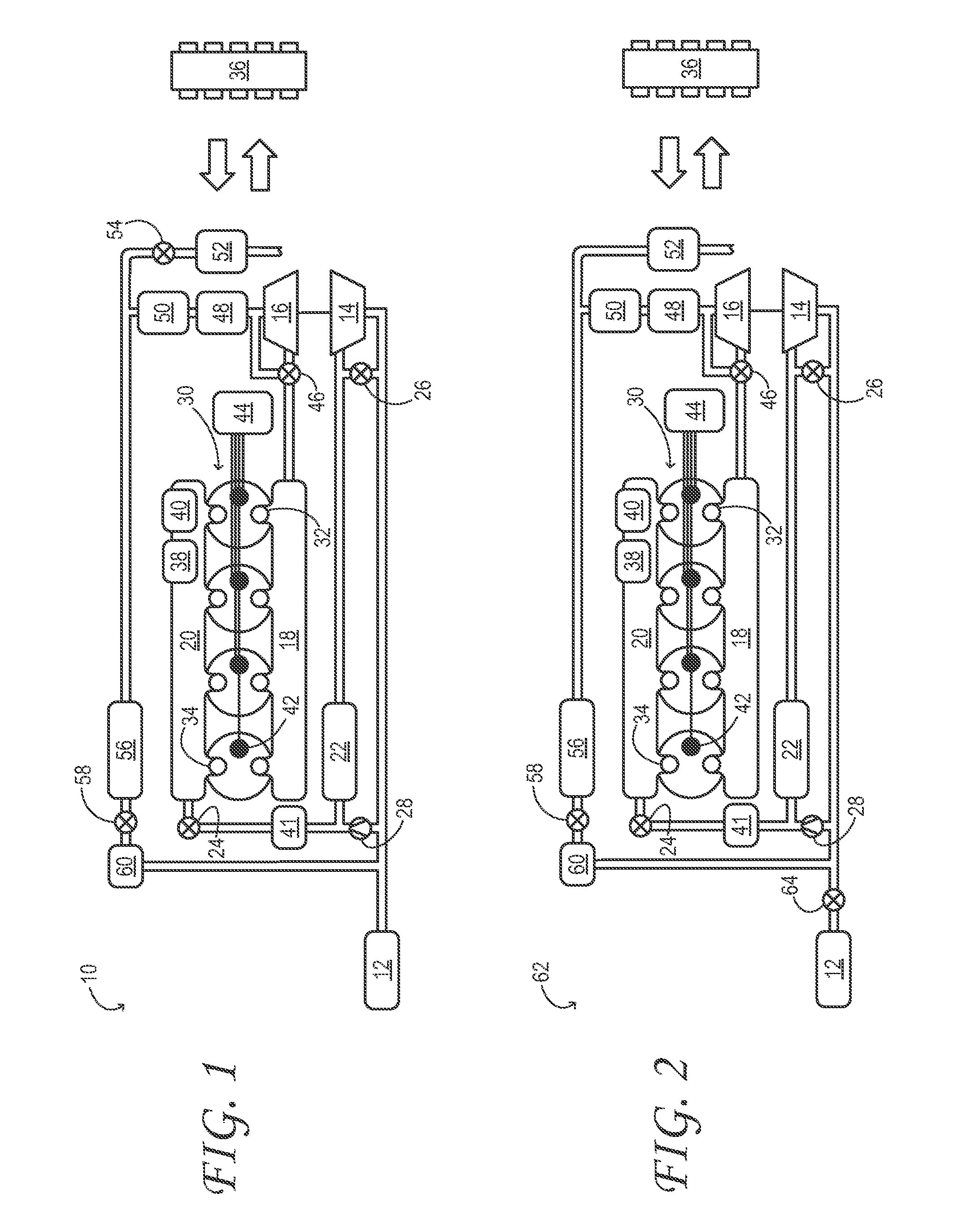

Systems and methods for egr control

ActiveUS20160040607A1Improve fuel economyHigh levelElectrical controlNon-fuel substance addition to fuelEngineeringCam

Methods and systems are provided for varying a location and rate of EGR delivered to an engine from a dedicated EGR cylinder. The dedicated EGR cylinder is configured with a plurality of exhaust valves controlled via a cam profile switching mechanism that allows the time and duration of opening of each exhaust valve to be varied. By selectively opening one exhaust valve at a time, exhaust from the dedicated EGR cylinder can be delivered to a pre-compressor location, a post-compressor location, or to the exhaust manifold, while bypassing all engine cylinders.

Owner:FORD GLOBAL TECH LLC

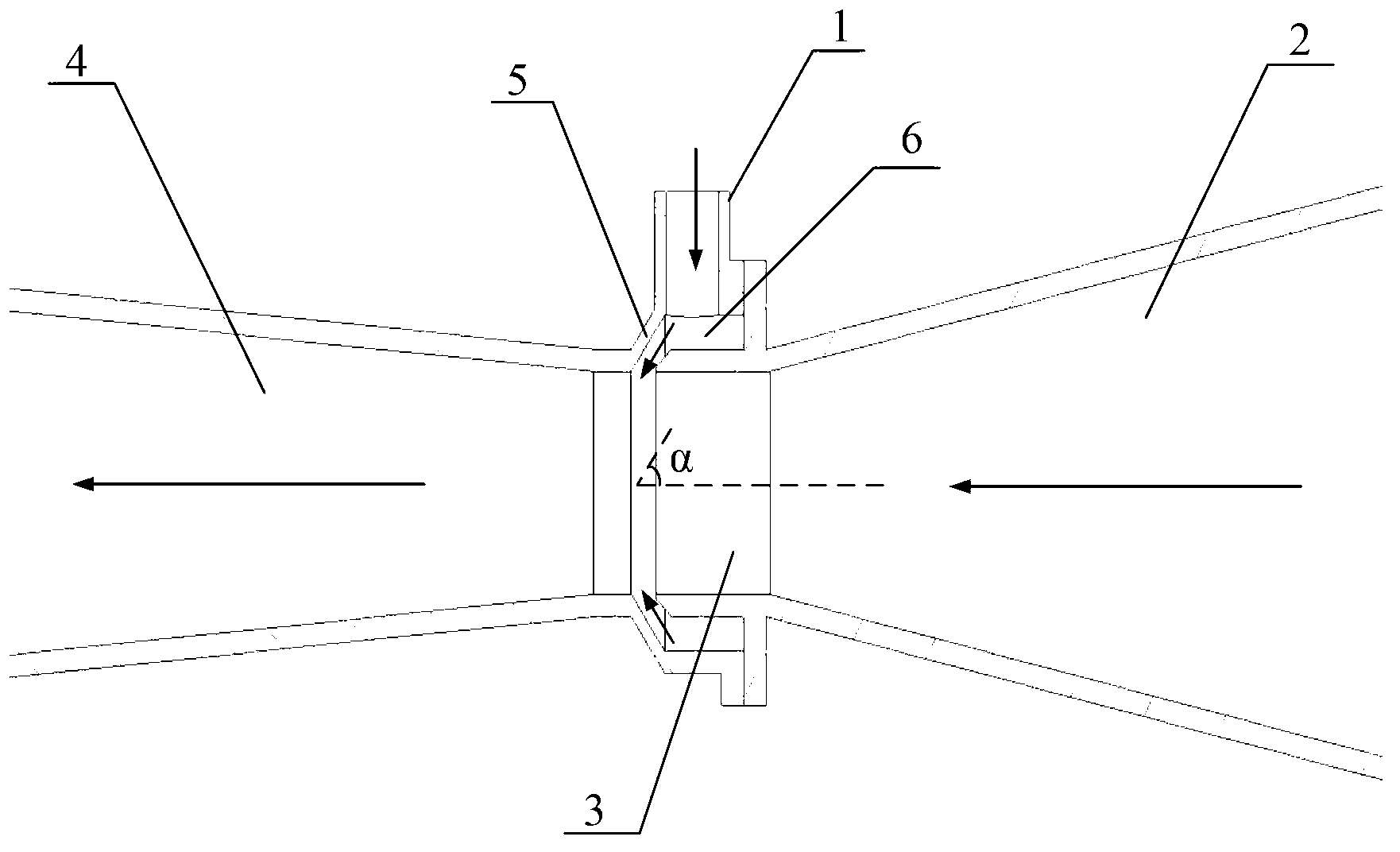

Low-pressure EGR introduction device capable of realizing high EGR rate and low-pressure EGR introduction method

InactiveCN104791148AIncrease EGR rateInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gasAutomotive engineering

The invention discloses a low-pressure EGR introduction device capable of realizing high EGR rate and a low-pressure EGR introduction method. Recycled exhaust gas is led out through the upper side and lower side of a turbine, passes through only one EGR valve and an EGR cooler, and then enters the upper side of an air compressor. According to the scheme, two paths of EGR exhaust gas are introduced into the upper side of the air compressor through one electric control valve, so that a low-pressure EGR scheme is obtained. Under the high-rotating speed condition, exhaust gas can be introduced from the upper side of the turbine. Under the low-rotating speed condition, exhaust gas can be introduced from the lower side of the turbine. Compared with a high-and-low-pressure double-circuit EGR system, the device and method have the advantages that high EGR rate can be realized, requirements for EGR under high-and-low rotating speed and load conditions can be met, and emission of NOx of an engine can be effectively reduced; meanwhile, two paths of EGR exhaust gas share one EGR valve and one EGR cooler, structure is simple, weight is reduced, packaging complexity is reduced, and manufacturing cost is low.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

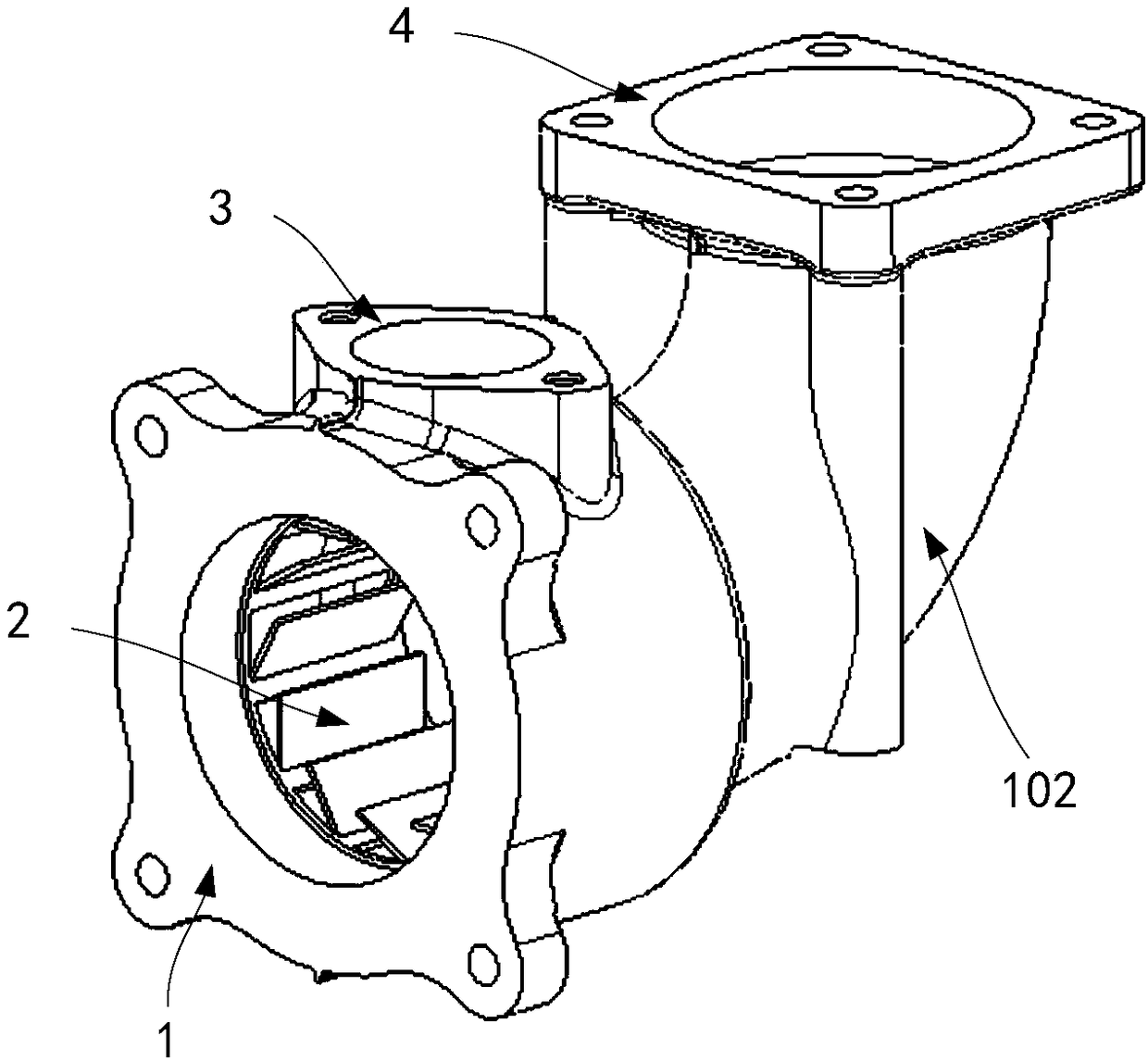

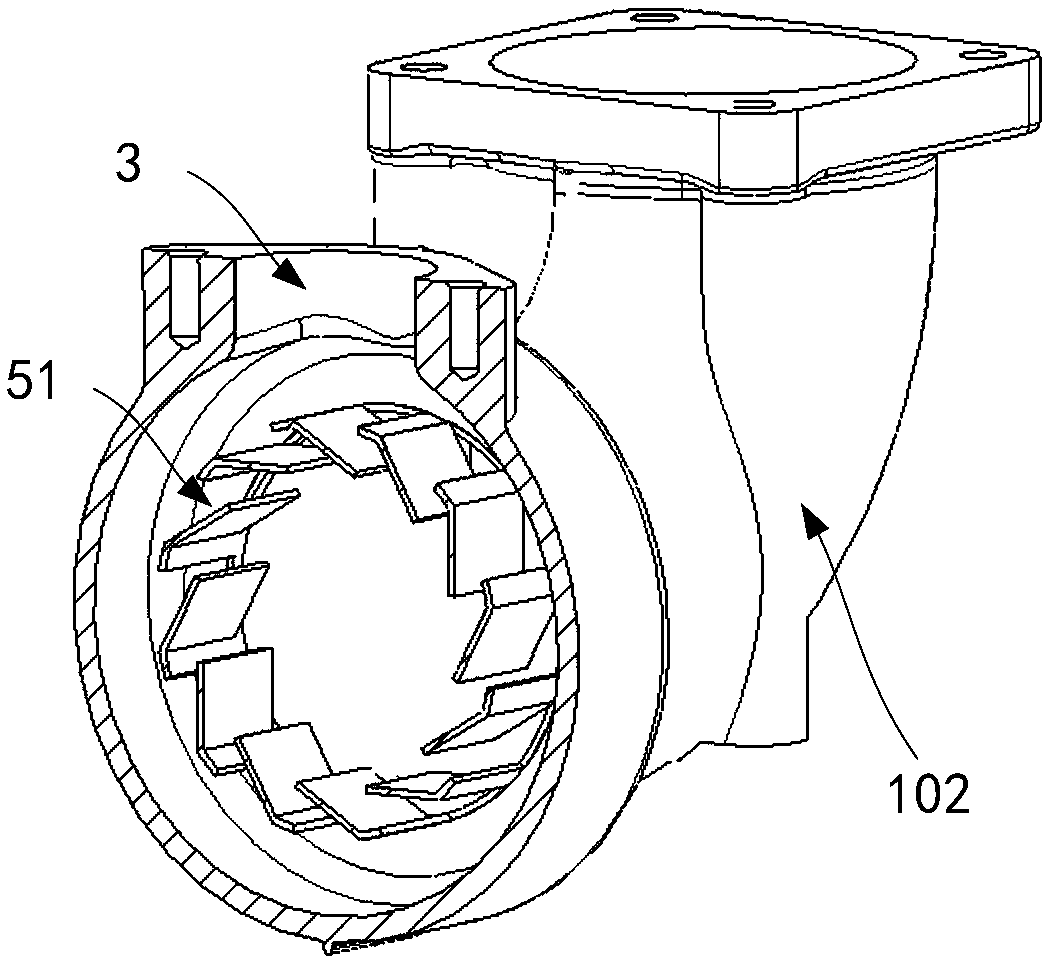

EGR (exhaust gas recirculation) air mixing device and fuel engine with EGR system

ActiveCN103306858AWell mixedIncrease EGR rateInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

The invention provides an EGR (exhaust gas recirculation) air mixing device and a fuel engine with an EGR system. The EGR air mixing device comprises an EGR inlet pipe and a Venturi mixer, wherein the Venturi mixer comprises a contraction section, a throat section and a diffusion section; the diffusion section is provided with a connector; the EGR inlet pipe is communicated with the connector of the diffusion section; the throat section is integrated with the diffusion section; the throat section is embedded into the connector of the diffusion section; an annular gap in the circumferential direction of the throat section is formed in the embedding position; the annular gap forms a certain angle with an axial line of the throat section; and the contraction section is hermetically connected with the diffusion section at the connector of the diffusion section. According to the EGR air mixing device, the annular gap is formed between the throat section and the diffusion section, and EGR air is guided into an air inlet pipe from the gap to be mixed with inlet air, so that the fact that the EGR air can be fully mixed with fresh air can be guaranteed, the EGR rate uniformity of each cylinder is improved, and the EGR rate of the fuel engine is effectively increased.

Owner:WEICHAI POWER CO LTD

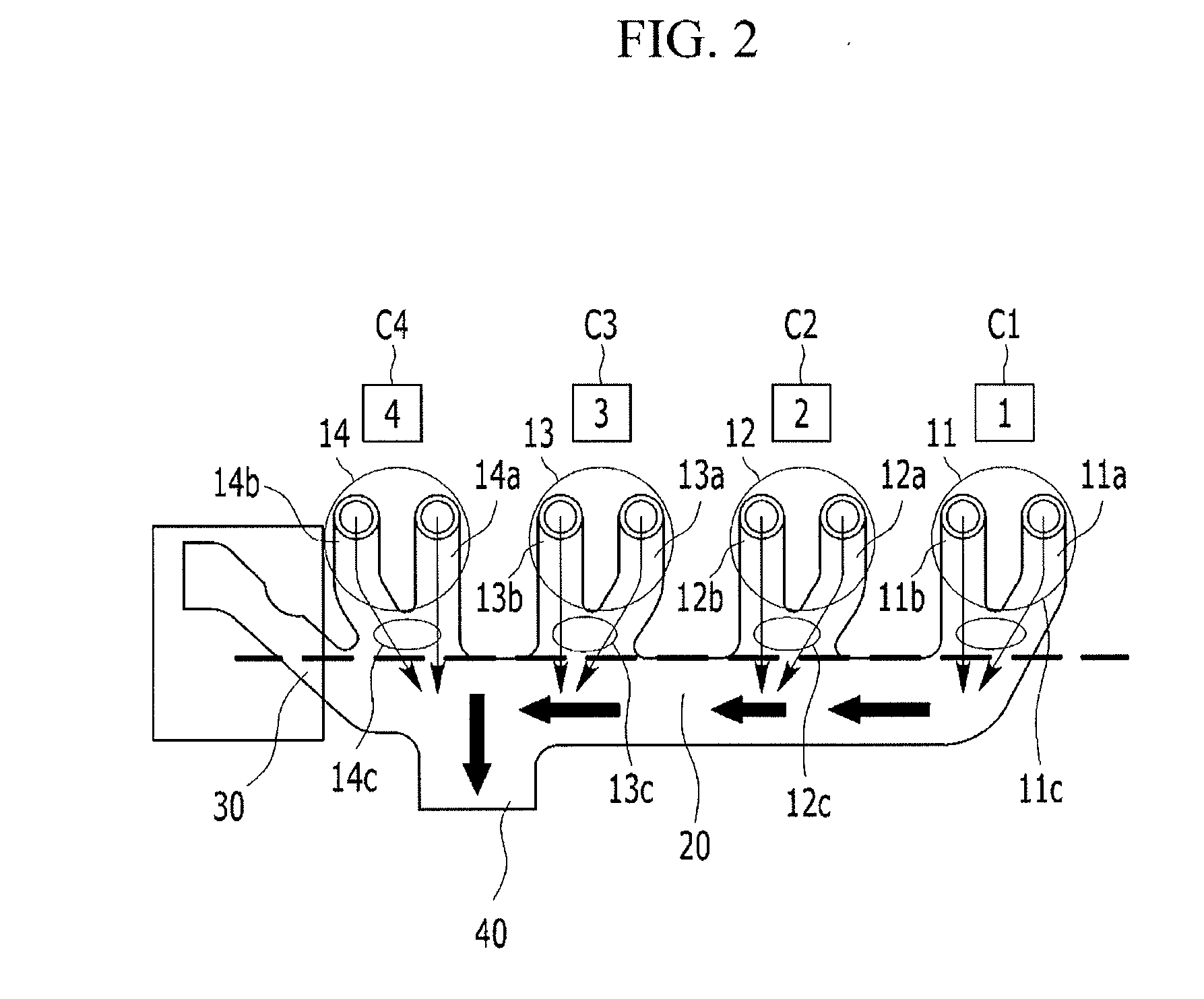

Exhaust port structure of cylinder head

InactiveUS20130086891A1Reduce weightIncrease EGR rateNon-fuel substance addition to fuelExhaust apparatusLine tubingCylinder head

An exhaust port structure of a cylinder head includes a connection pipe communicating with a plurality of exhaust ports of the cylinder head and an exhaust hole connected to the connection pipe and performing a function of an exhaust manifold, wherein the connection pipe has an EGR line integrally formed and connected thereto and each of the exhaust ports is formed with the same shape or a symmetrical shape, and the present invention can reduce the weight of the cylinder head and the manufacturing cost and improve the EGR rate and T / C efficiency.

Owner:HYUNDAI MOTOR CO LTD +1

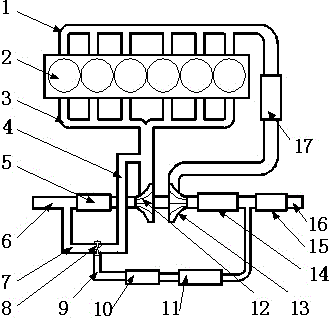

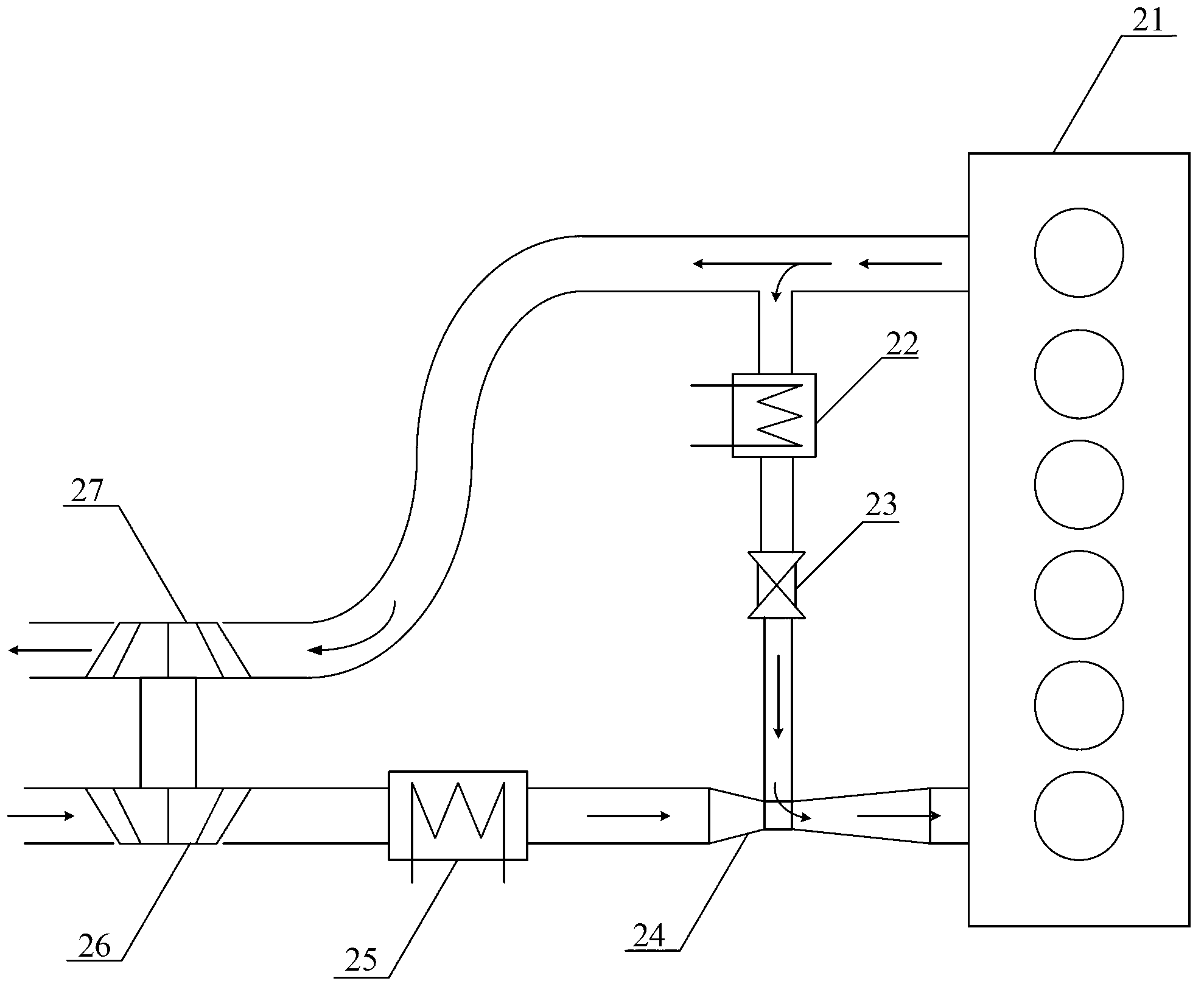

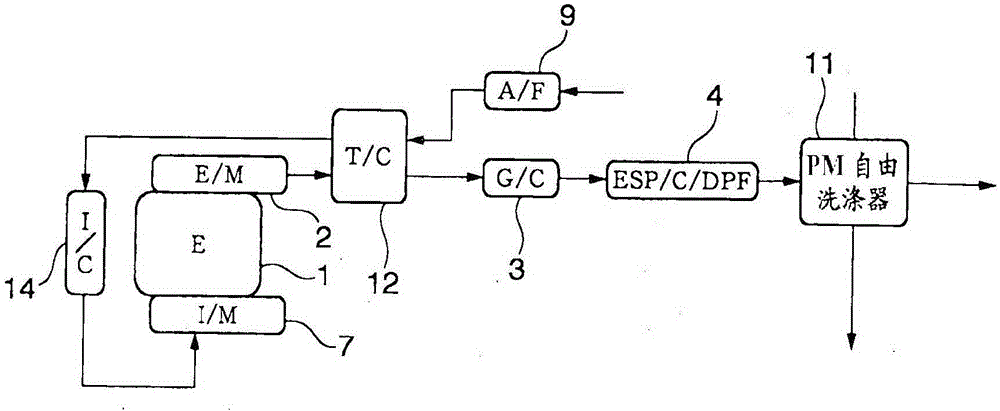

Waste gas recirculation system for spark ignition type supercharged engine and use method of waste gas recirculation system

ActiveCN105508088AReduce fuel consumptionIncrease fuel consumptionElectrical controlExhaust gas recirculationIntercoolerProcess engineering

The invention provides a waste gas recirculation system for a spark ignition type supercharged engine. The waste gas recirculation system comprises a gas inlet pipeline, a throttle valve, a gas inlet manifold, a supercharger, an exhaust pipeline, an exhaust manifold, a waste gas posttreatment device, a first intercooler, a bypass valve, a first EGR valve, a first pipeline with a first port and a second port, a second intercooler connected with the bypass valve in parallel, a second EGR valve, a second pipeline with a fourth port and a third port communicated with the first pipeline, and a multiport valve communicated with the first pipeline and the second pipeline; the first port is communicated with the exhaust pipeline between the exhaust manifold and the waste gas posttreatment device; the second port is communicated with the gas inlet pipeline between the throttle valve and the gas inlet manifold; the fourth port is communicated with the gas inlet pipe at the upstream of the supercharger, the multiport valve is controlled to enable the first pipeline to convey waste gas, the bypass valve is controlled to enable the multiport valve to be communicated with the second port, or the waste gas is conveyed to the gas inlet manifold by the first port and the fourth port. The waste gas recirculation system improves EGR rate and improves oil consumption.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

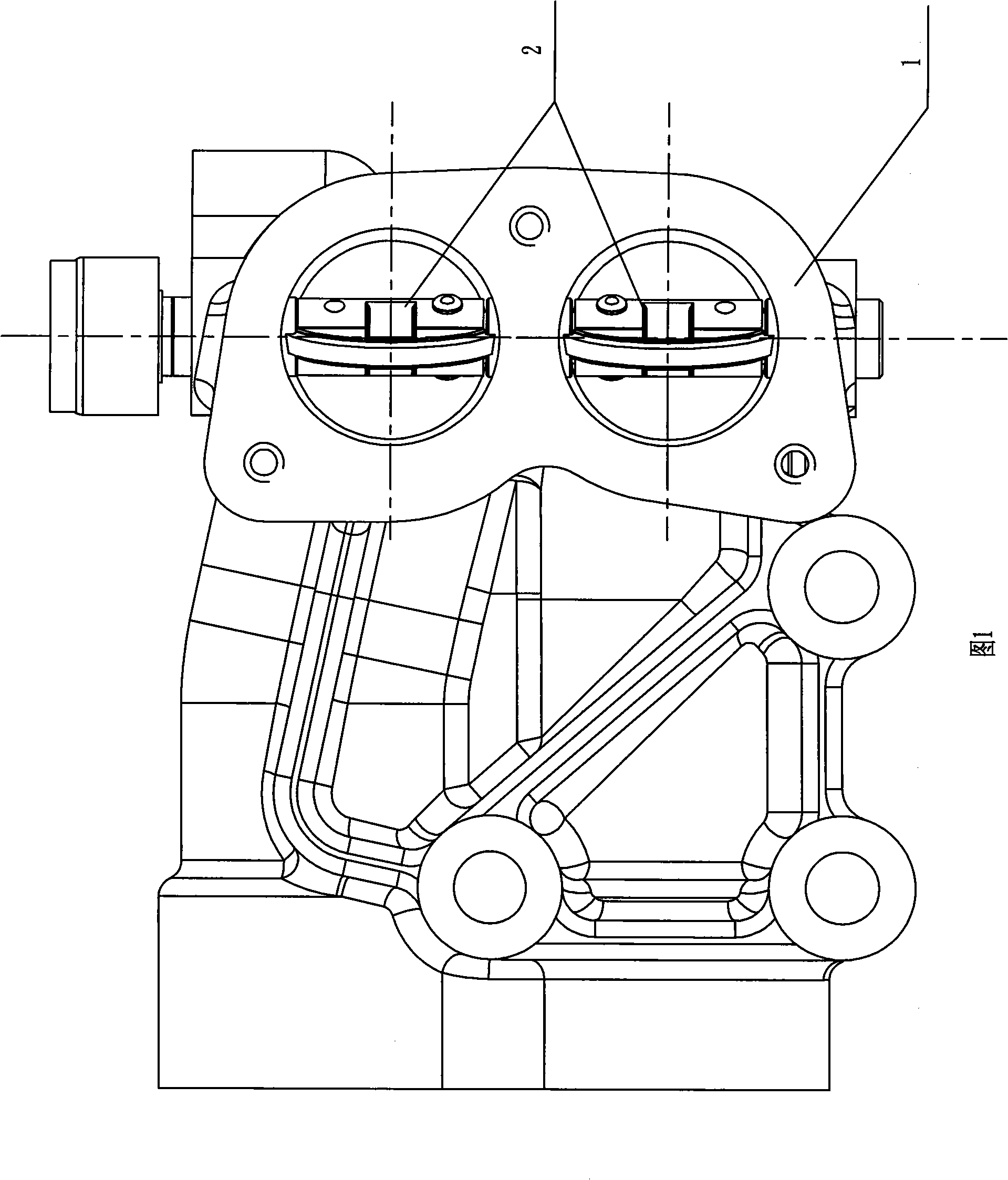

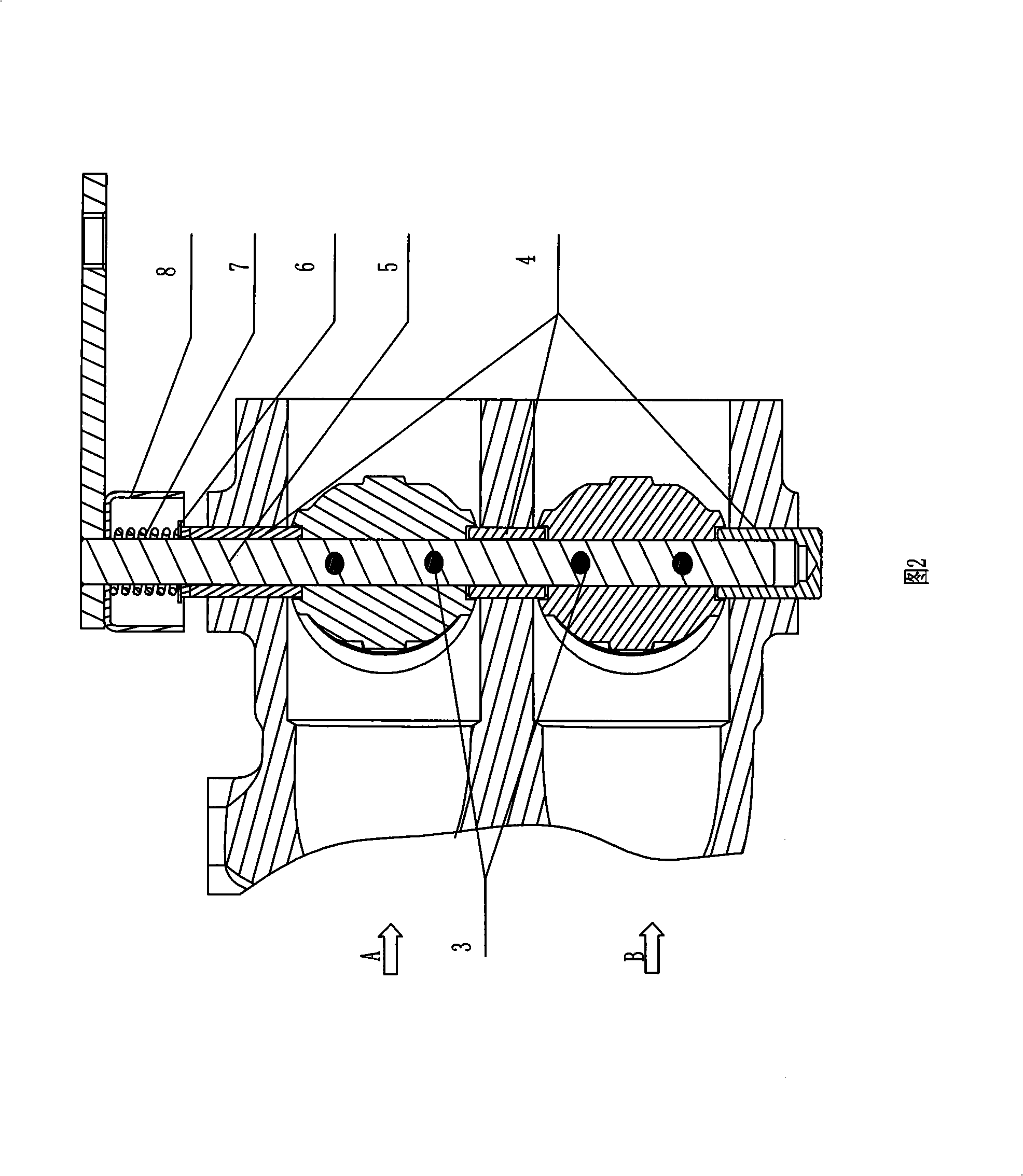

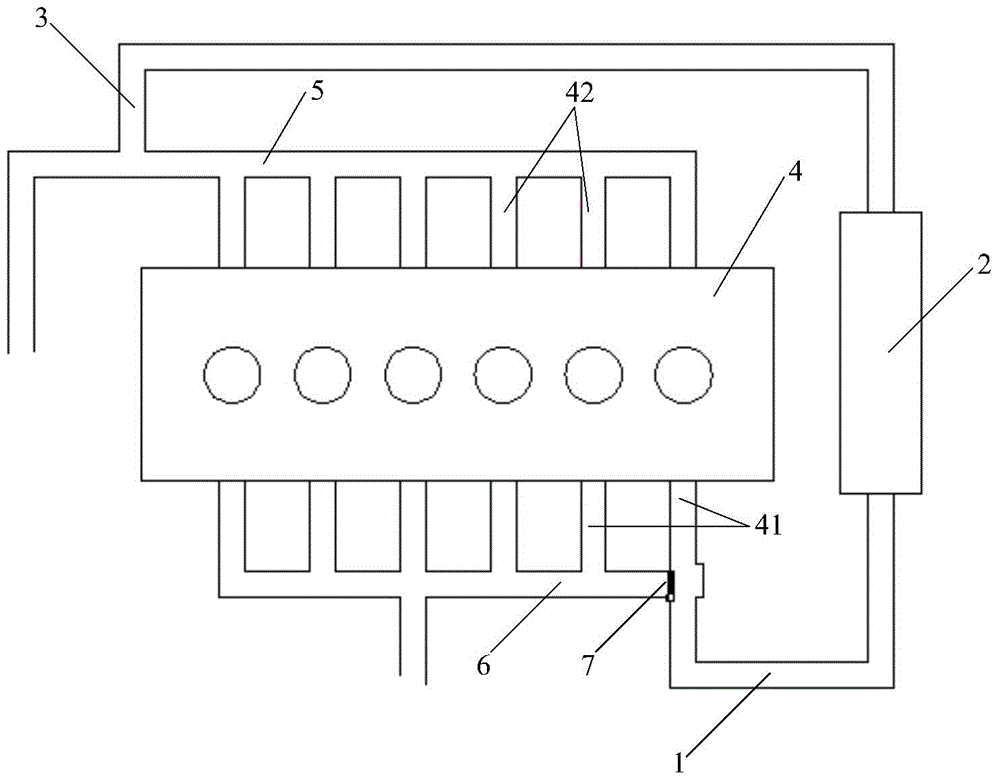

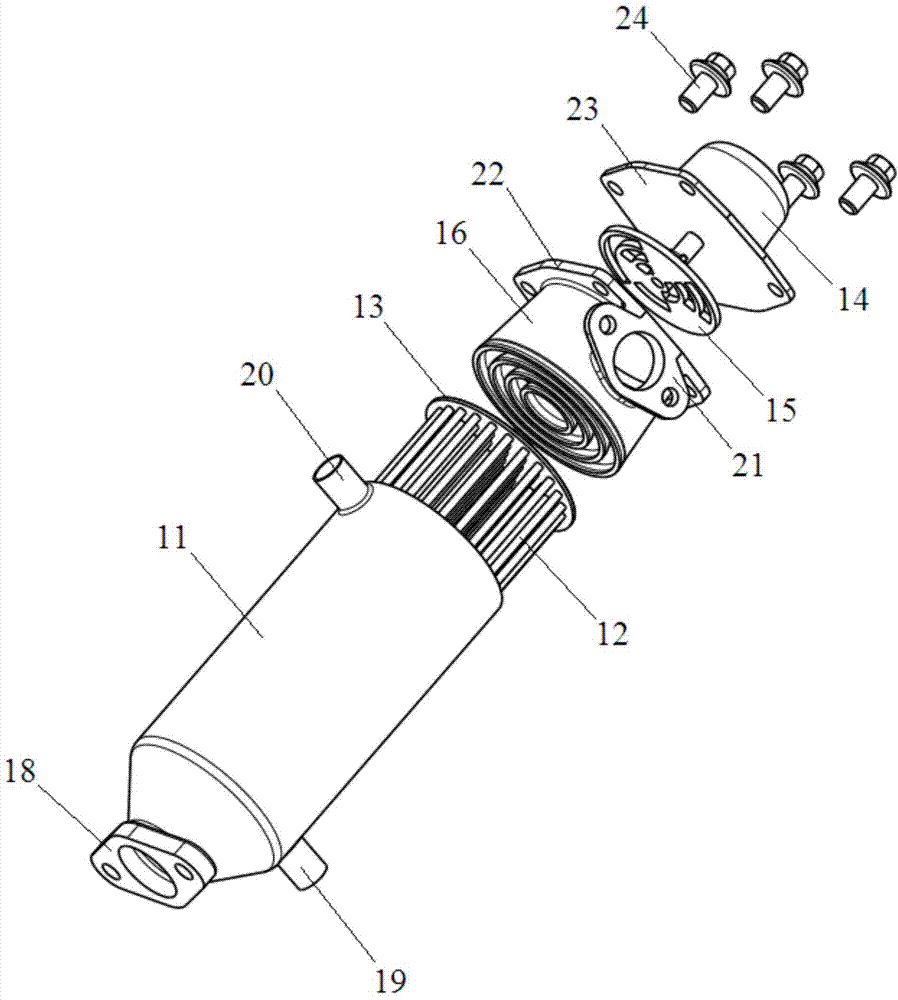

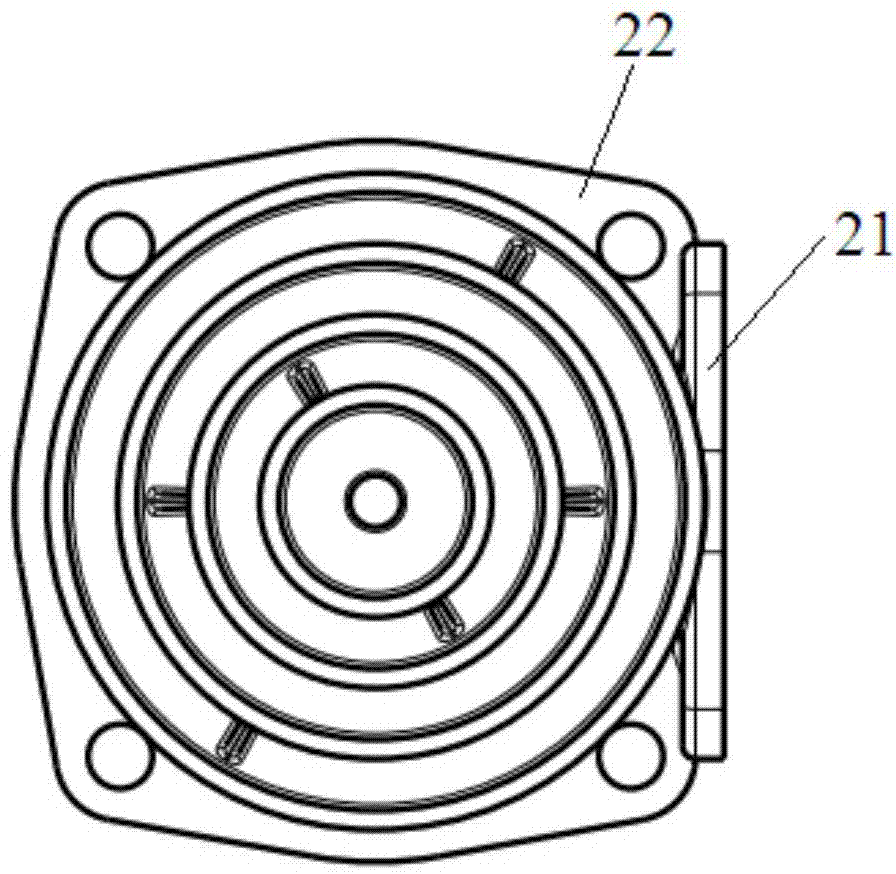

Double-channel butterfly valve structure

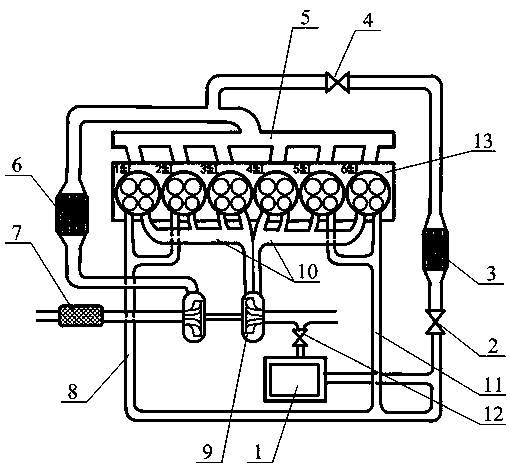

InactiveCN101349222AFlexible rotationAvoid stickingNon-fuel substance addition to fuelInternal combustion piston enginesDrive shaftPulse energy

The invention relates to a structure of a dual channel butterfly valve arranged on a hot end, in particular to a hot end dual channel EGR valve which is mounted on a six cylinder diesel engine. The hot end dual channel EGR valve is characterized in that two waste gas channels are arranged on the body of the EGR valve, a drive shaft assembly is mounted in the EGR valve body, two EGR valve plates are fixed on a drive shaft of the drive shaft assembly via rivets, a sealing gasket, a pressing spring and a protective sleeve are arranged on the drive shaft of the drive shaft assembly, the pressing spring tightly compresses the sealing gasket, and is arranged in the protective sleeve. The drive shaft is equipped with an adjusting sleeve which is used to adjust the clearance between the two EGR valve plates. The dual channel butterfly valve can sufficiently utilize the exhaust pulse energy of the six cylinder diesel engine, and realizes higher EGR rate to purify the diesel engine, and thereby enabling the engine to be easier to realize recycling of waste gas, and meeting high requirements of discharge regulations.

Owner:中国第一汽车集团公司无锡柴油机厂

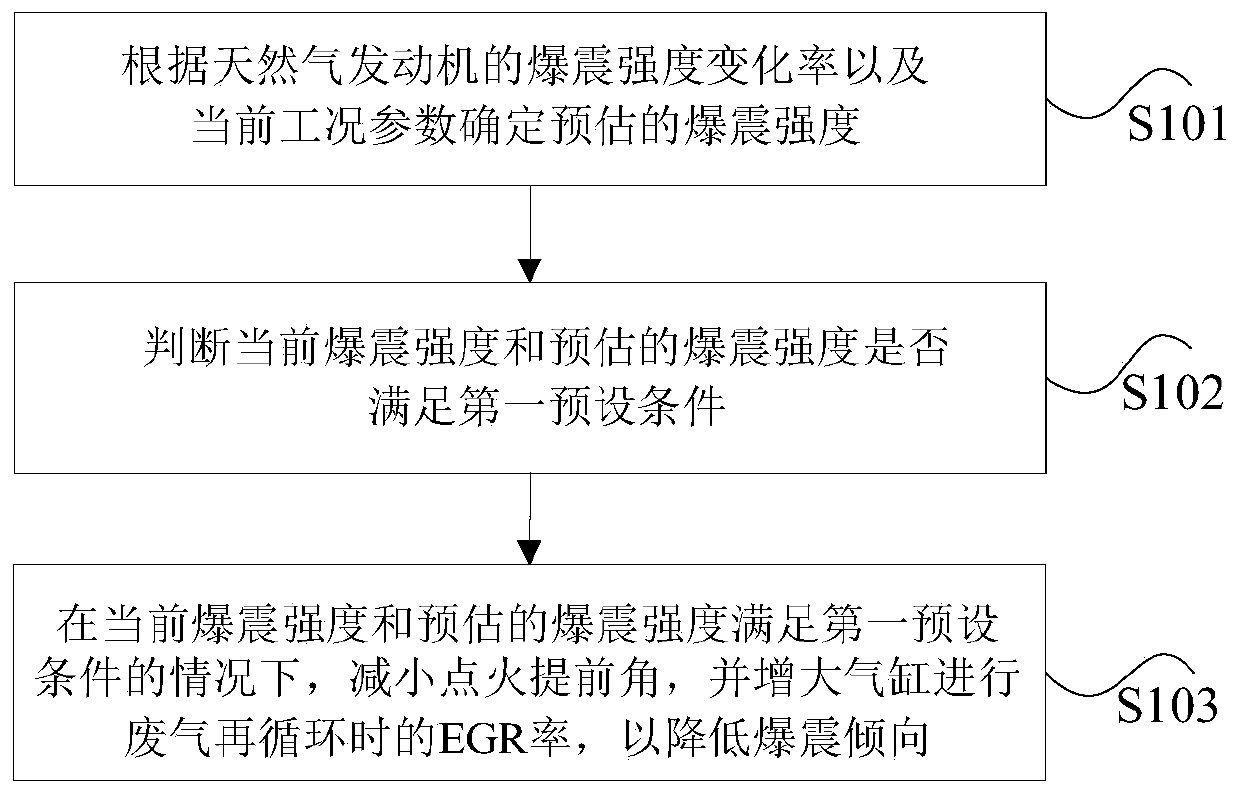

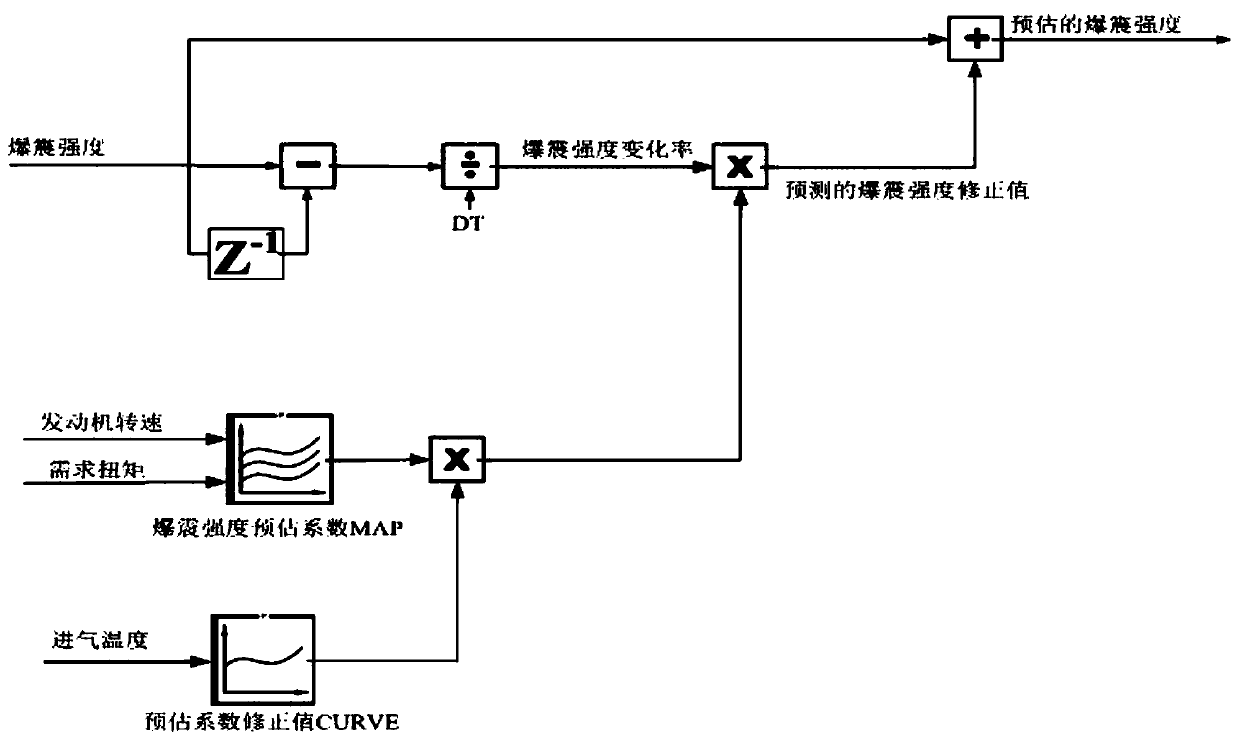

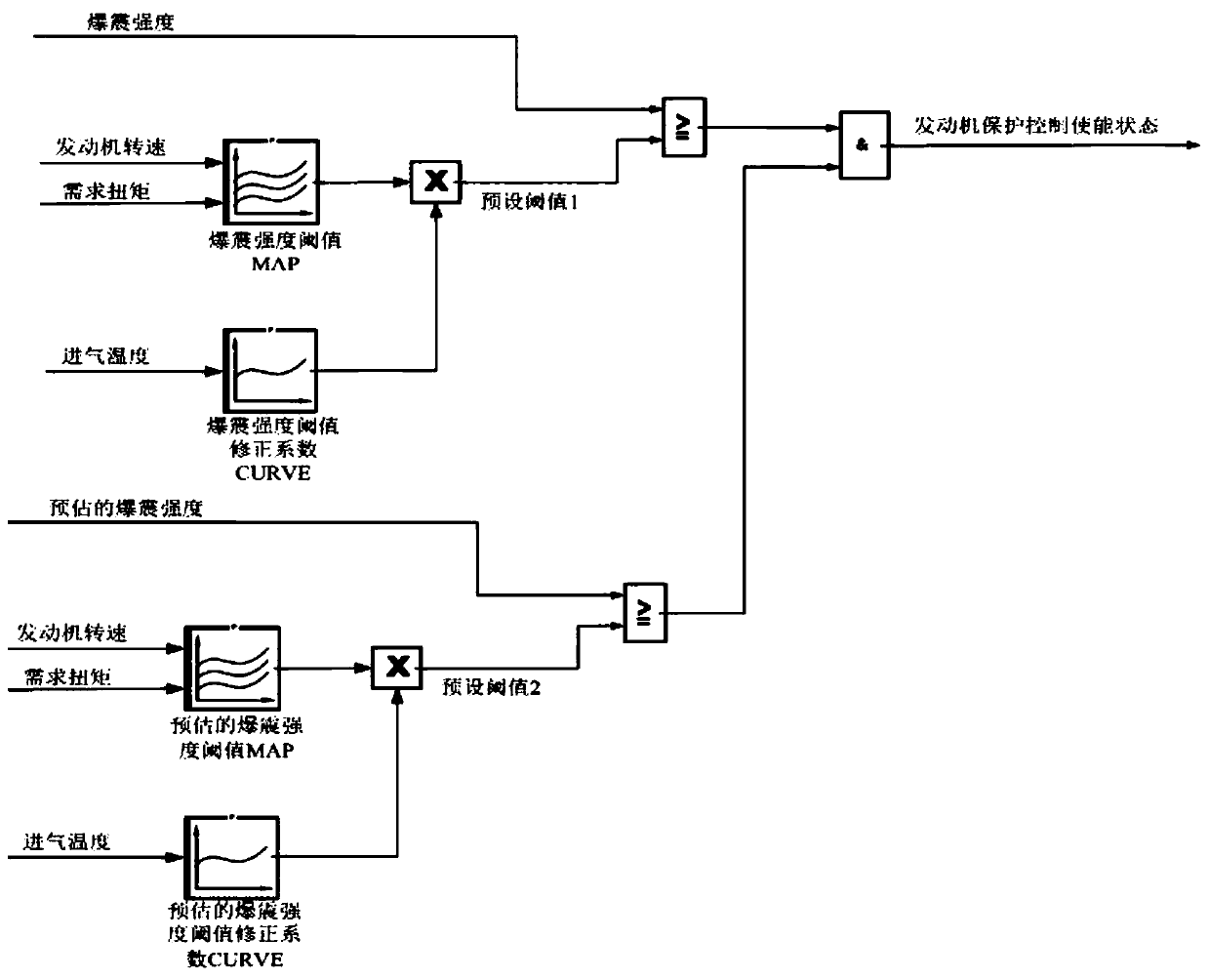

Control method and device of natural gas engine, storage medium and processor

ActiveCN111396210AIncrease EGR rateDecrease the ignition advance angleElectrical controlInternal combustion piston enginesThermodynamicsExhaust fumes

The invention discloses a control method and device of a natural gas engine, a storage medium and a processor. The method comprises the following steps: determining the estimated knock intensity according to the knock intensity change rate of the natural gas engine and the current working condition parameter; judging whether the current knock intensity and the estimated knock intensity meet a first preset condition or not; and when the current knock intensity and the estimated knock intensity meet the first preset condition, reducing an ignition advance angle, and increasing the EGR rate of acylinder during exhaust gas recirculation, so that the knock tendency is reduced. Through the application, the problems in the related art that knocking tendency is weakened by adjusting the ignitionadvance angle after the engine knocks and the knocking tendency is difficult to reduce before knocking are solved.

Owner:WEICHAI POWER CO LTD

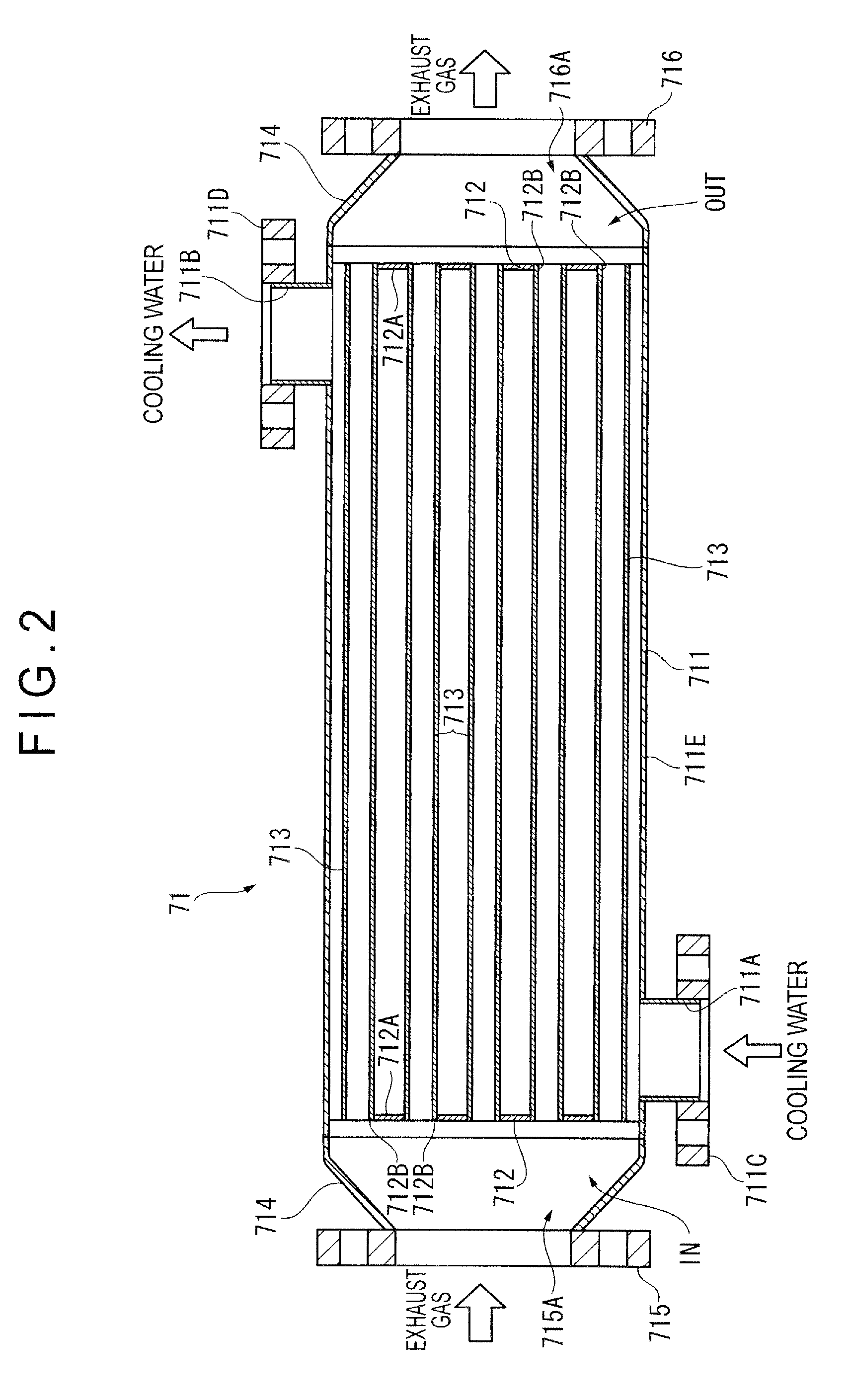

Exhaust gas recirculation system

InactiveUS20090020106A1Avoid it happening againImprove cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelExhaust valveExhaust fumes

An exhaust gas recirculation system having an exhaust line connected to an exhaust manifold of an engine; an intake line connected to an intake manifold of the engine; and an EGR line that intercommunicates the exhaust line and the intake line, in which a part of exhaust gas exhausted from the exhaust line is delivered to the intake line via the EGR line to be recirculated in the engine, is provided with a liquid cooling heat exchanger made of a corrosion-resistant material at downstream of an intersection with the EGR line in the intake line.

Owner:KOMATSU LTD

Exhaust gas purification device for diesel engine using heavy-oil or lower quality fuel

InactiveCN103261595ANO

<sub>x</sub>

reduceSuppress generationNon-fuel substance addition to fuelInternal combustion piston enginesElectricityFuel oil

Owner:USUI KOKUSAI SANGYO KAISHA LTD

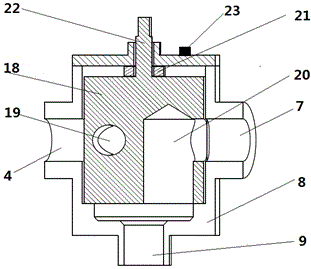

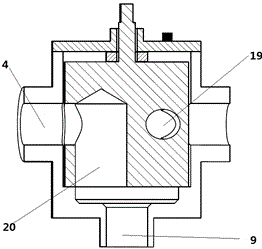

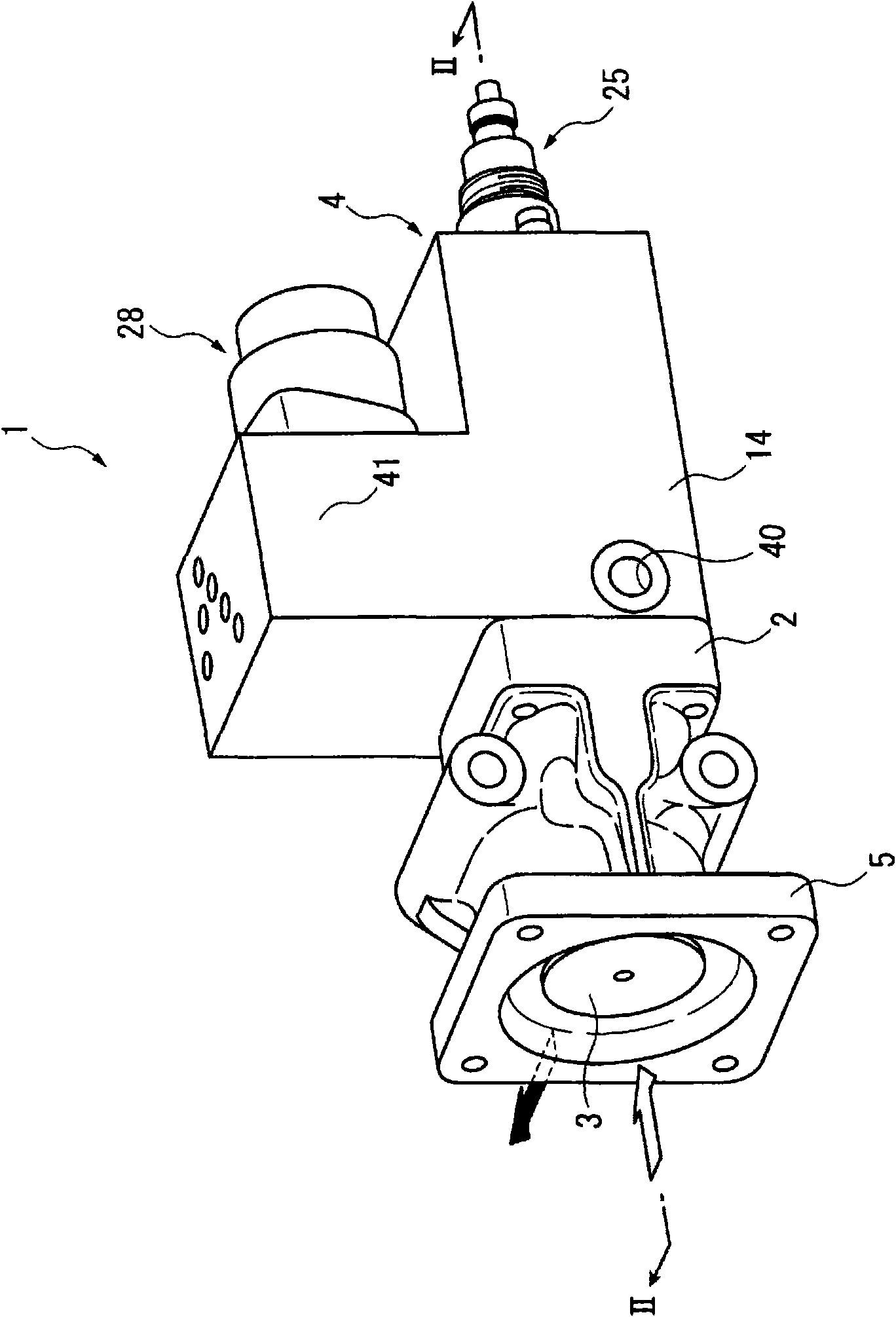

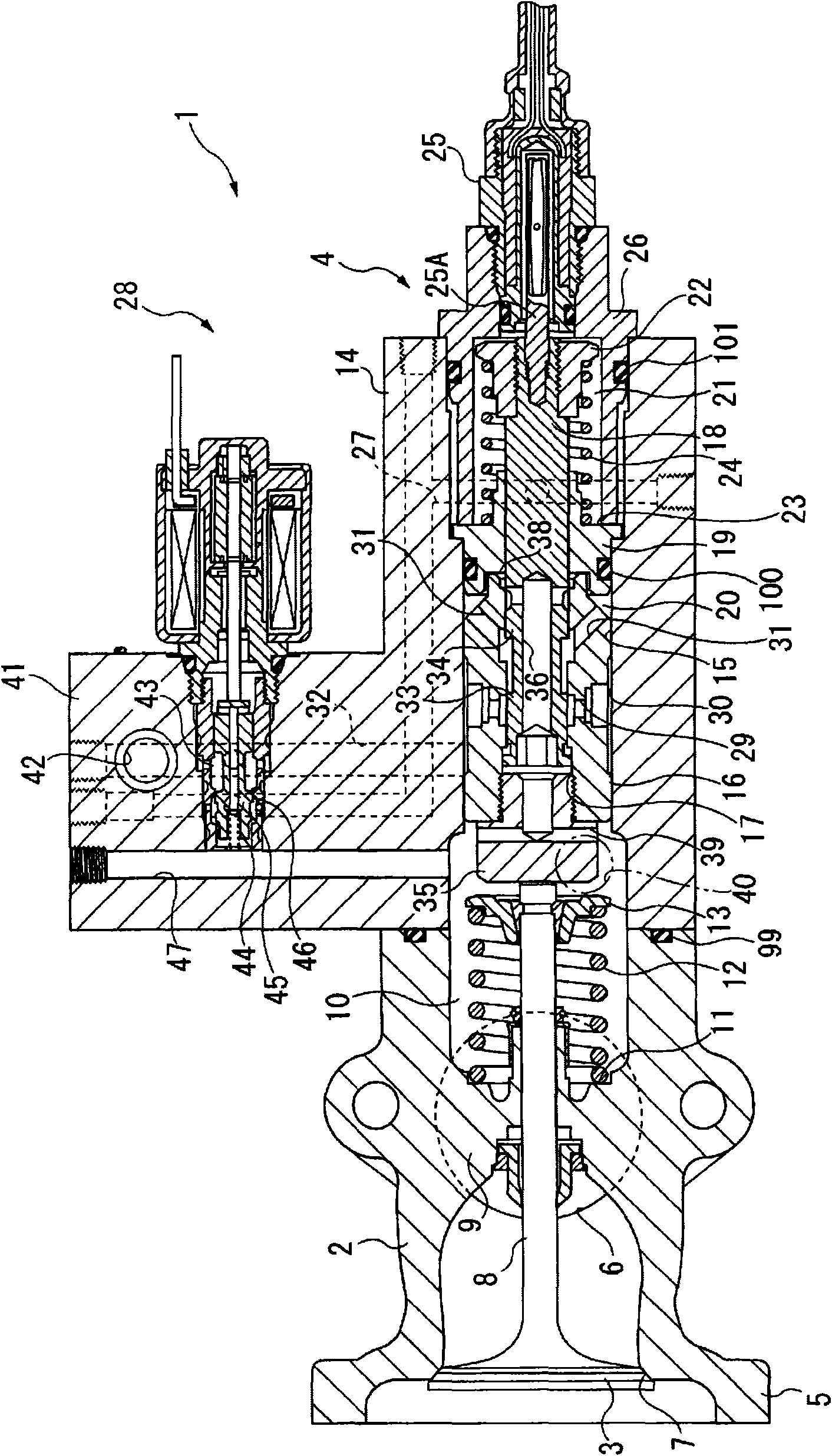

Egr valve device

InactiveCN101573527AControl flowMiniaturizationOperating means/releasing devices for valvesNon-fuel substance addition to fuelServo actuatorControl theory

The present invention provides an EGR valve device (1) that includes a valve housing (2) of which inside exhaust gas passes through, a poppet valve (3) as a valve body accommodated in the valve housing (2), and a hydraulic servo actuator (4) for driving the poppet valve (3) to be opened and closed. The hydraulic servo actuator (4) is provided by a three-port ( Figure 2 ) or four-port servo valve.

Owner:KOMATSU LTD

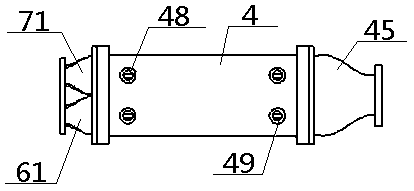

Controllable EGR system using integrated dual-channel EGR cooler

ActiveCN110500208ALarge adjustment rangeMeet needsInternal combustion piston enginesExhaust gas recirculationPulse energyEngineering

The invention relates to a controllable EGR system using an integrated dual-channel EGR cooler. The system involves the integrated cooler and a double-channel structure formed by two exhaust manifolds, wherein the integrated cooler comprises two cold channels and two heat channels which are independent from one another, each exhaust manifold is connected with air inlet ends of one cold channel, one heat channel and a turbine through three air channels, the air outlet ends of the cold channels and the air outlet ends of the heat channels are connected with the air inlet end of a device air outlet cavity arranged in the integrated cooler, and the air outlet end of the device air outlet cavity and the air outlet end of an air compressor are connected with an engine after sequentially througha mixer and an air inlet manifold. According to the system, the EGR temperature and the EGR rate can be adjusted through a cold EGR and heat EGR combined mode, so that the adjusting capacity is high,and the EGR can be driven by utilizing exhaust pulse energy, so that the EGR rate and the driving capacity are improved.

Owner:DONGFENG COMML VEHICLE CO LTD

EGR mixing device and internal combustion machine

ActiveCN108150316ASimplify the intake structureSmall pressure resistanceExhaust gas recirculationMachines/enginesCombustion chamberDifferential pressure

The invention provides an EGR mixing device. The device comprises an EGR mixing pipe communicating with an air inlet pipe and a combustion chamber, an EGR mixing cavity is formed in the inlet segmentof the air inlet pipe of the EGR mixing pipe, a waste air inlet communicating with the EGR mixing cavity is formed in the side wall of the EGR mixing pipe, a mixing cavity support is supported and erected in the EGR mixing cavity, an air inlet valve plate for blocking the waste air inlet is supported and erected on the mixing cavity support, the air inlet valve plate comprises a first closing sidepushed by input air in the air inlet pipe to be closed and a second opening side pushed by input air of the waste air inlet to be opened. Fresh air and waste air are mixed in the EGR mixing cavity, the waste air inlet is blocked or opened through the air inlet valve plate on the mixing cavity support, when the waste air inlet is blocked, backflow caused by the fact that air pressure in the air inlet pipe is larger than that of the waste air inlet is avoided, the air inlet structure of an EGR pipeline is simplified, the pressure difference between the fresh air and the waste air is used for blocking the waste air inlet, the pressure resistance of the EGR pipeline is small, and the EGR rate is improved. The invention further provides an internal combustion machine.

Owner:WEICHAI POWER CO LTD

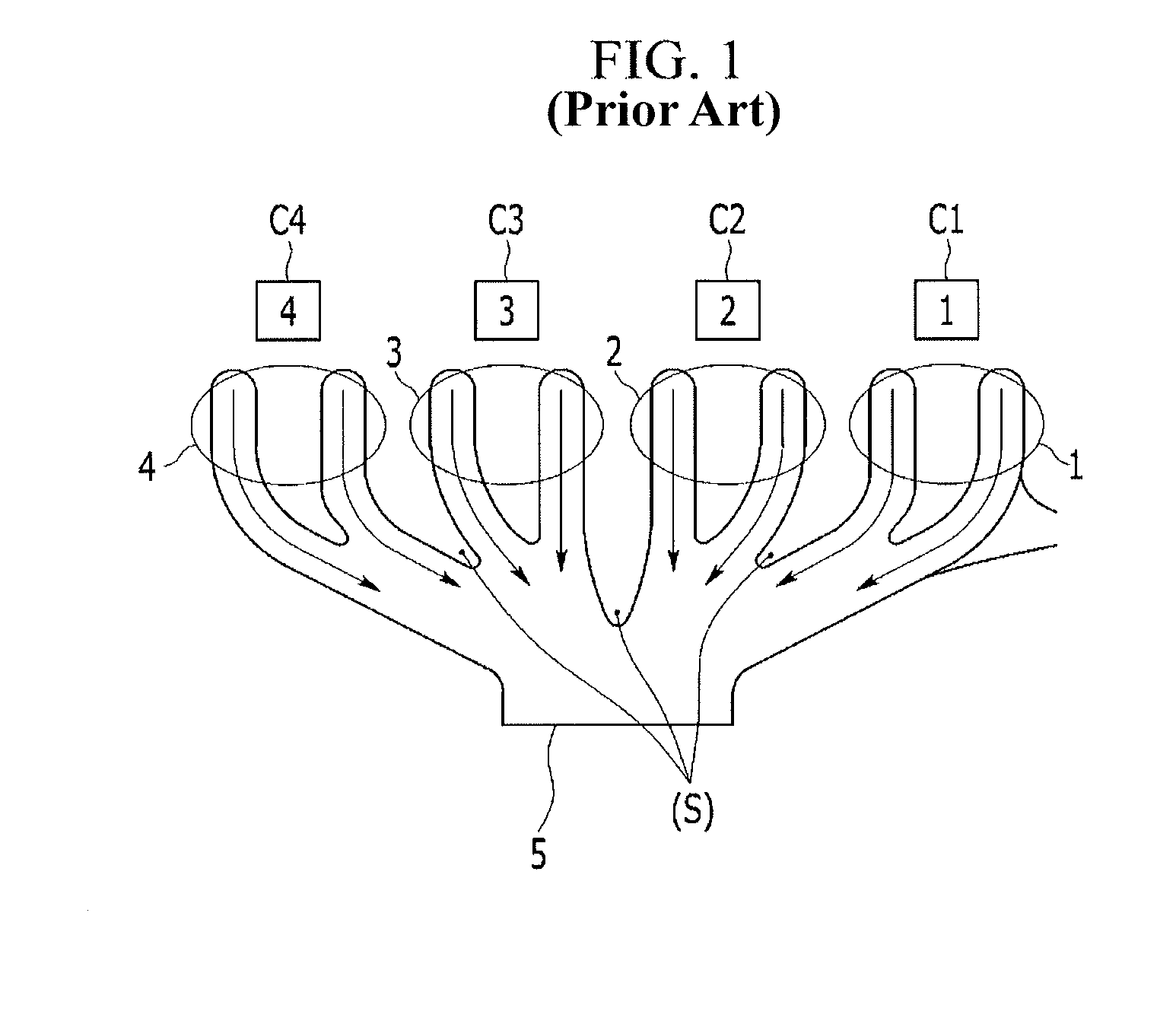

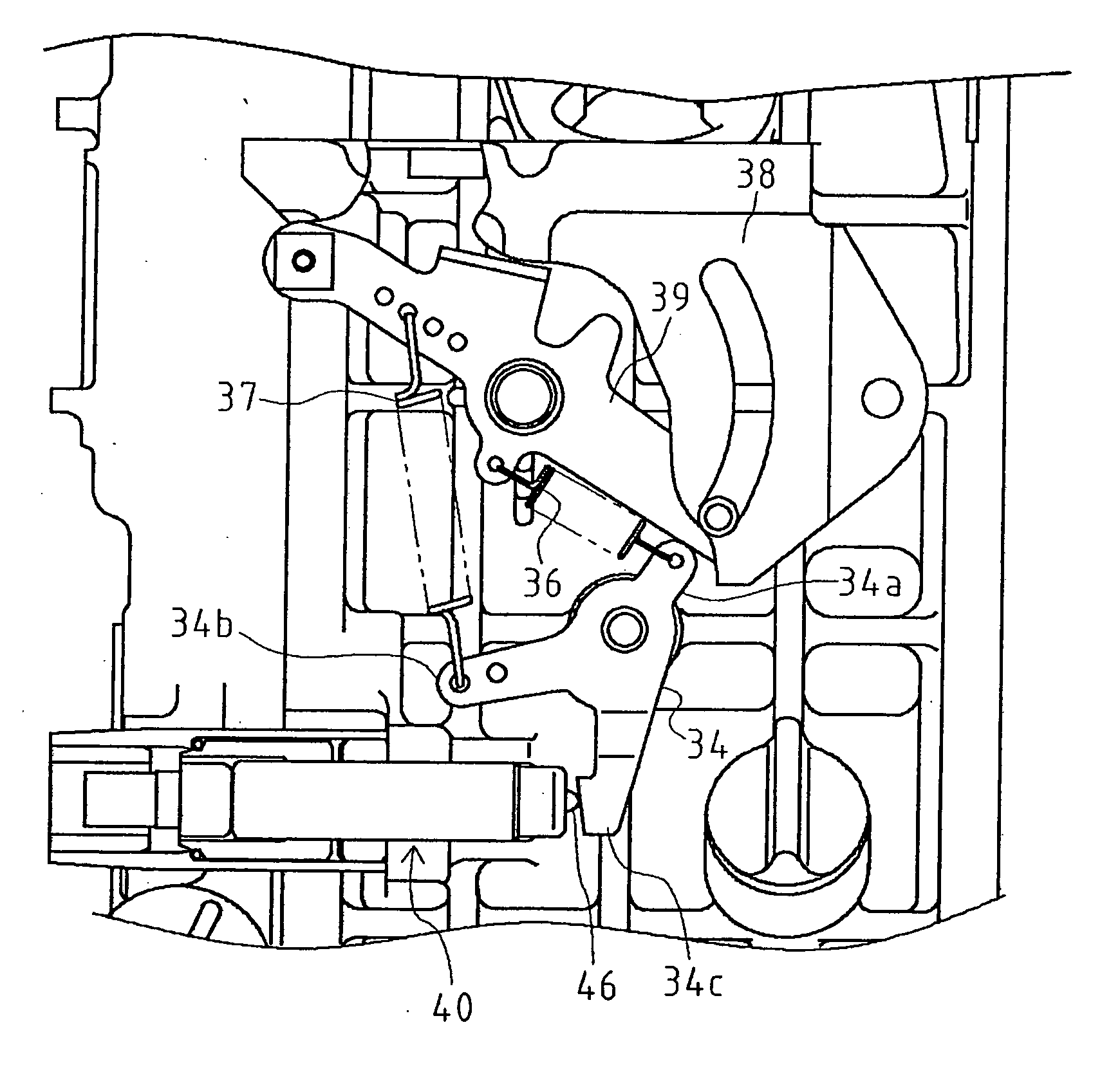

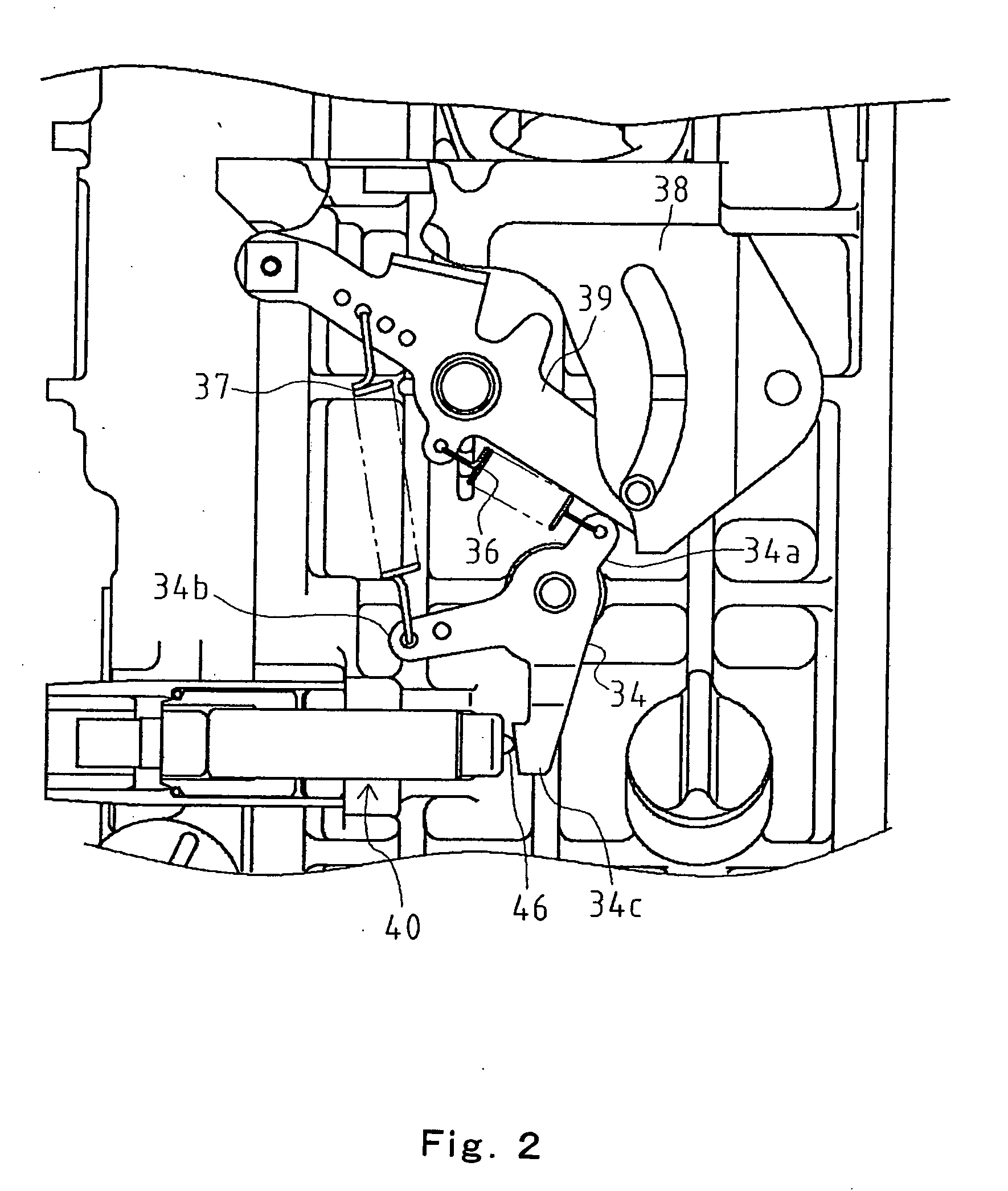

Exhaust gas recirculation device for engine

InactiveUS20070186899A1Reduce NOxReduce EGR rateInternal combustion piston enginesNon-fuel substance addition to fuelCylinder headExhaust fumes

An exhaust gas recirculation device for an engine having a cylinder head with a suction port and an exhaust port, provided with a mechanism for recirculating a portion of exhaust gas to the suction side of the cylinder head, comprises a connection hole is opened through a wall of the cylinder head disposed between the suction port and the exhaust port. The connection hole is bored vertically slantwise. The connection hole at the suction side is opened along the direction of swirls of sucked air. A throttle is disposed in at least either a suction flow passage communicating with the suction port or an exhaust flow passage communicating with the exhaust port so that the opening area of the suction flow passage or the exhaust flow passage can be adjusted by the throttle.

Owner:YANMAR CO LTD

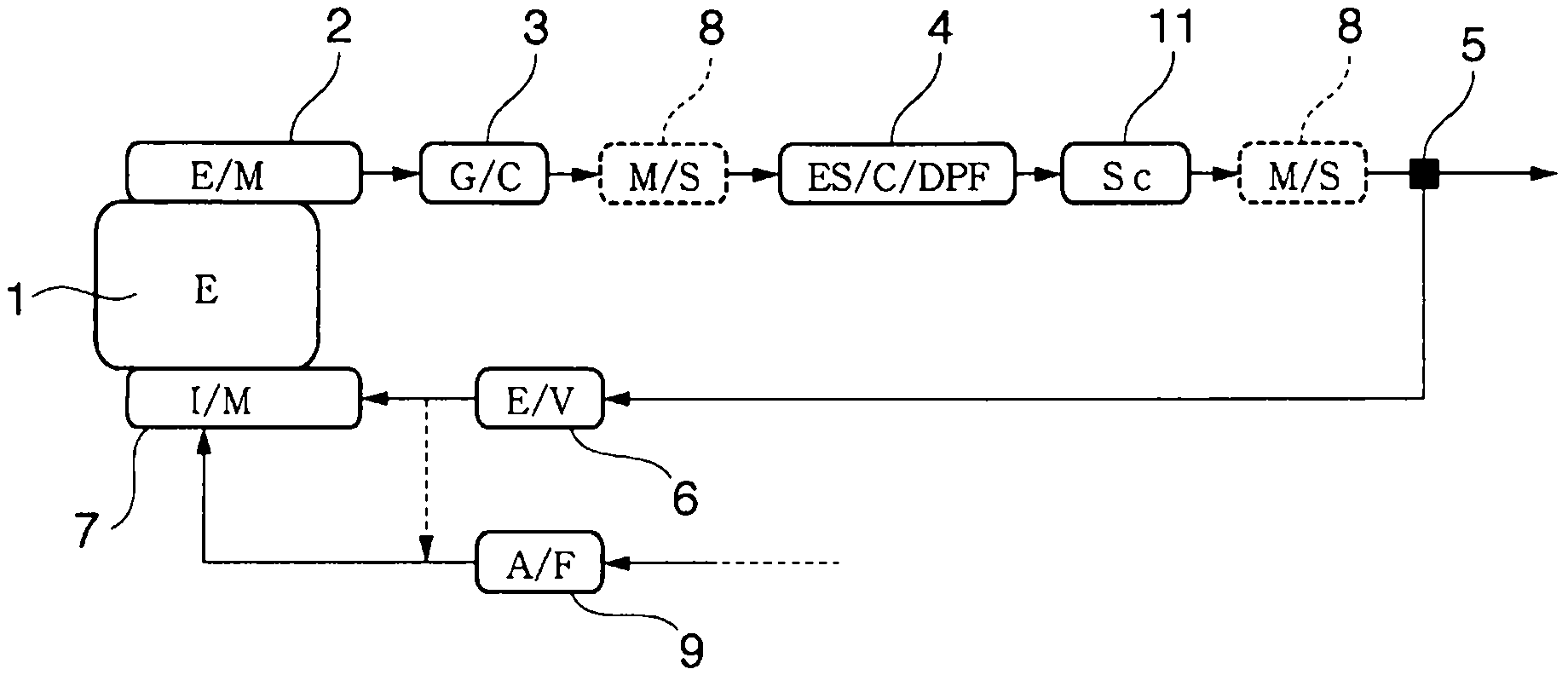

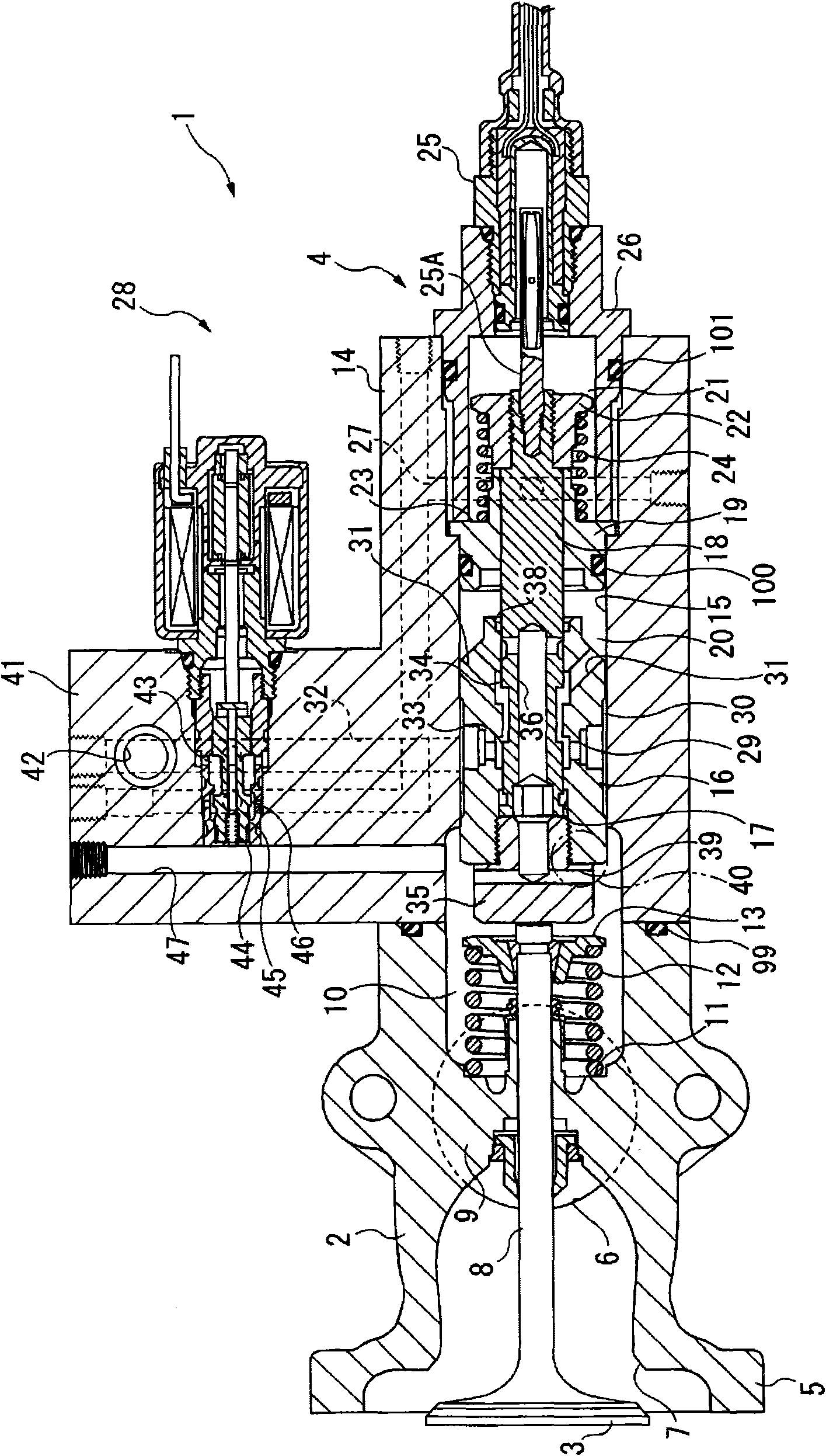

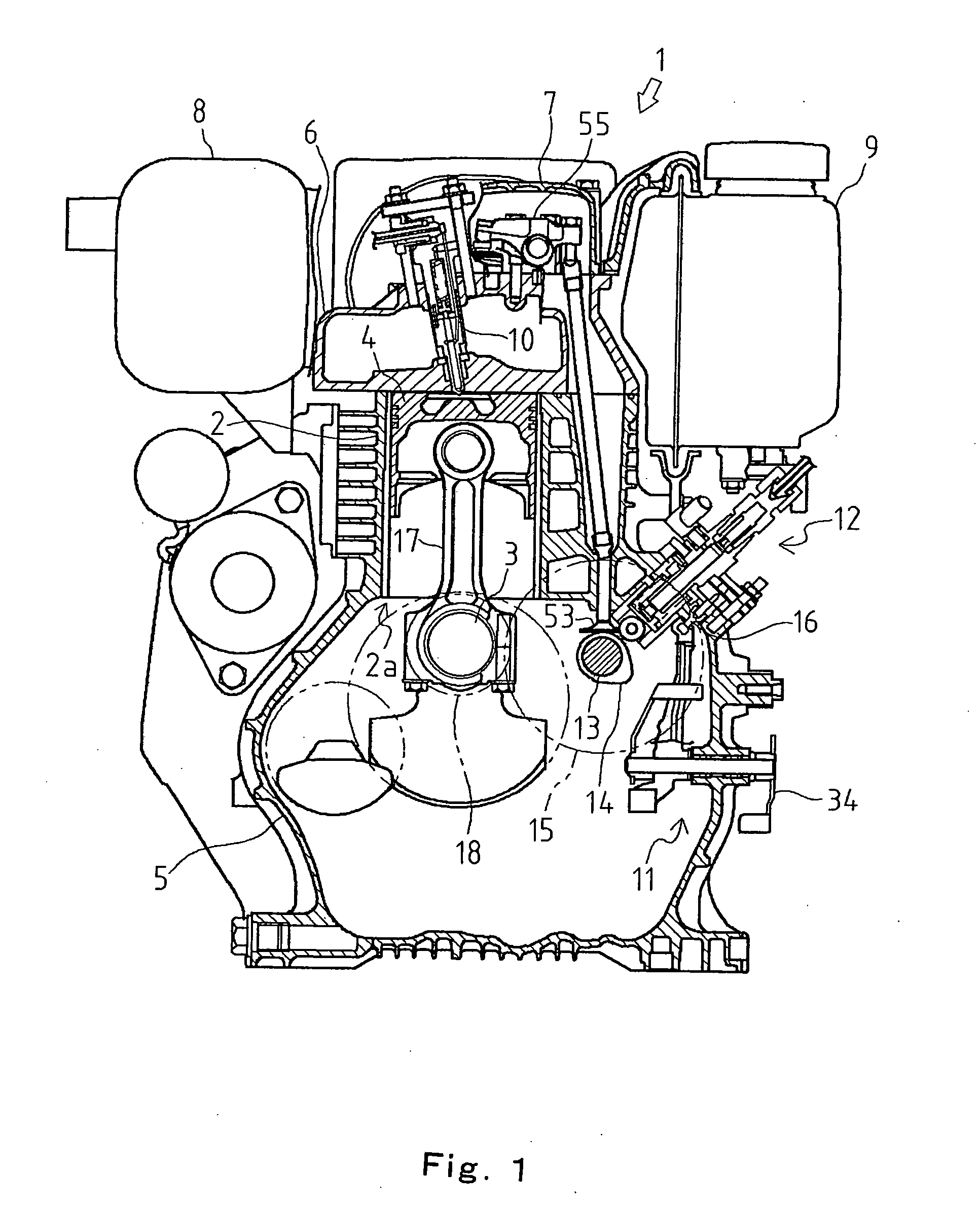

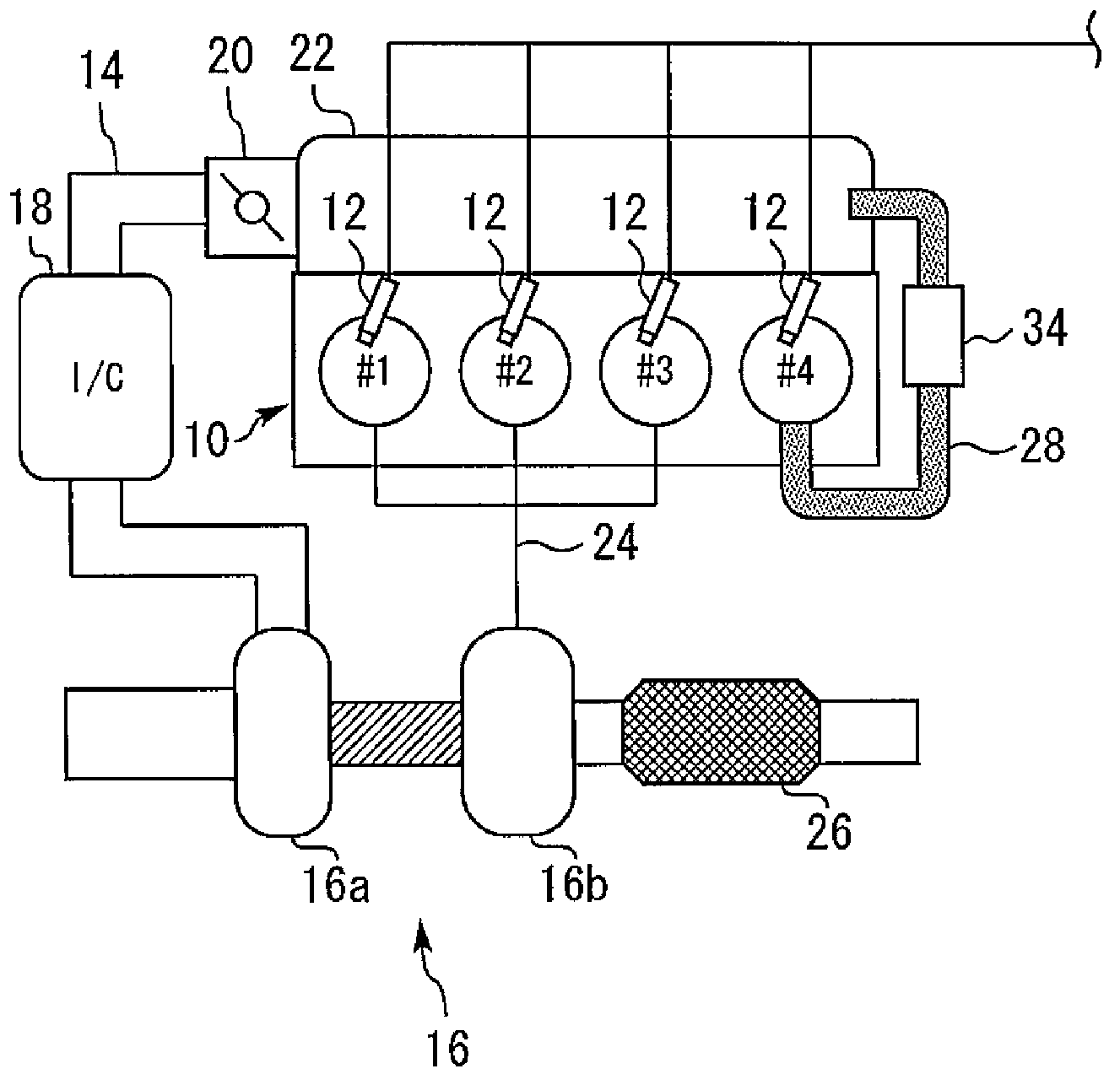

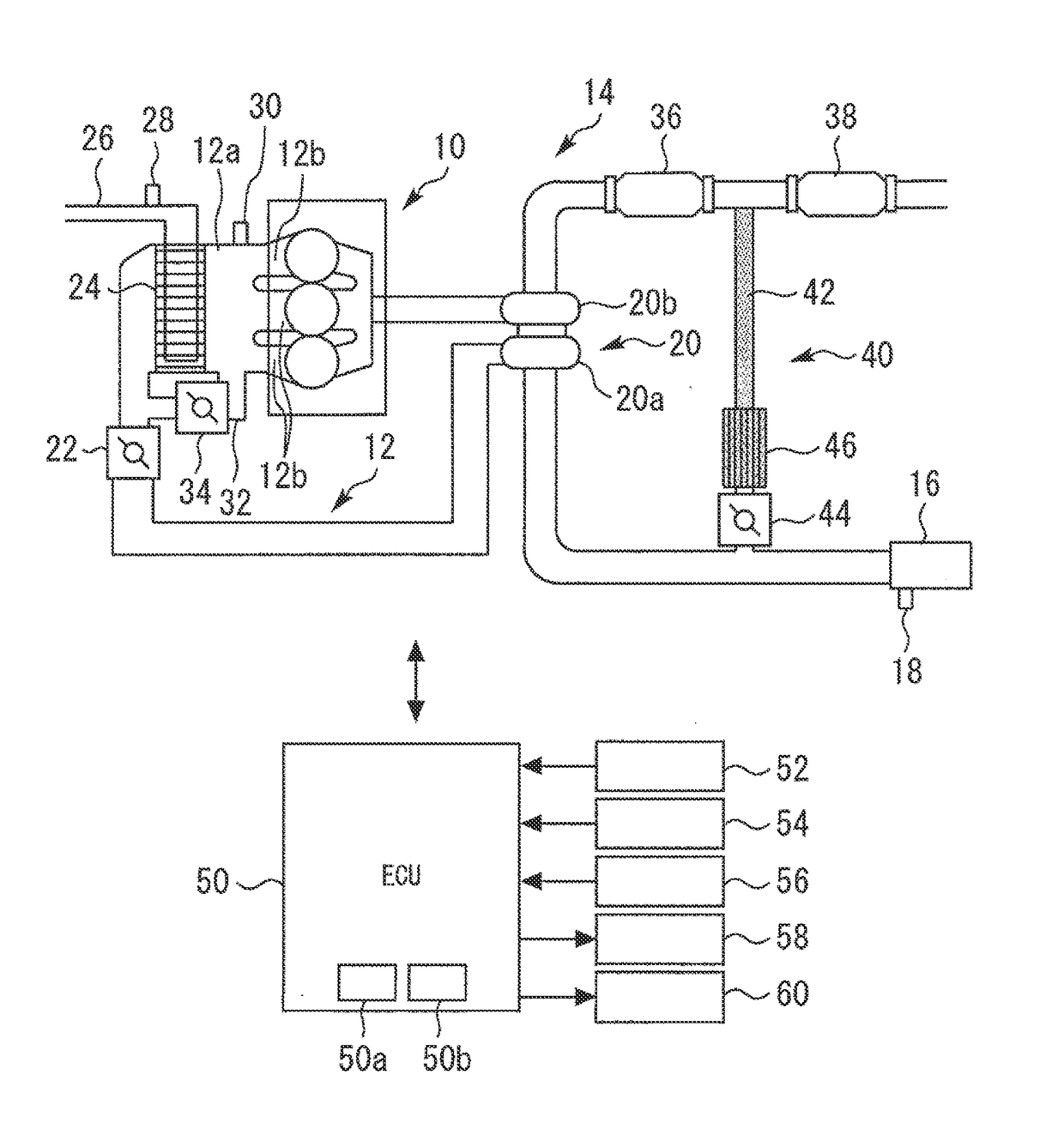

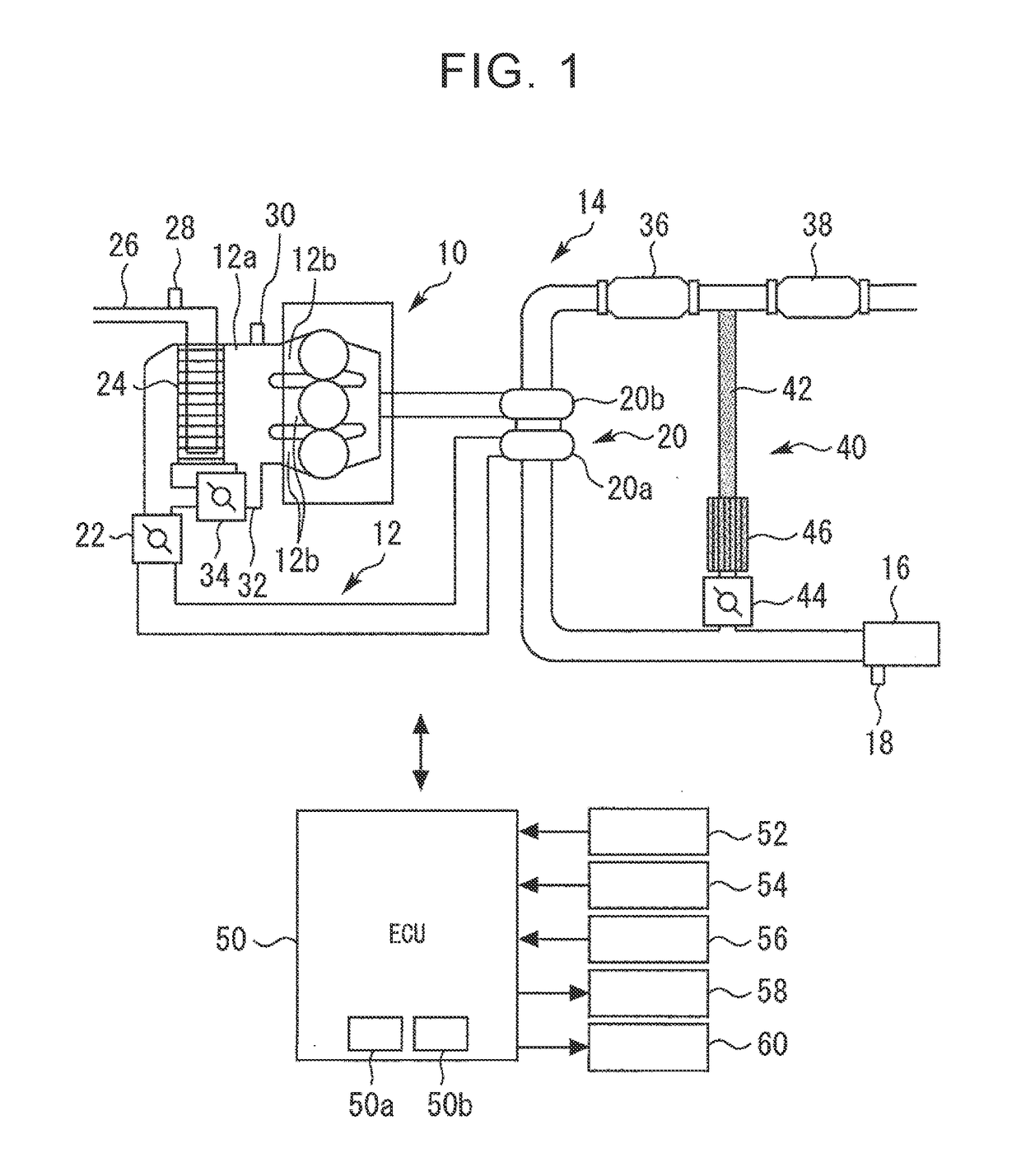

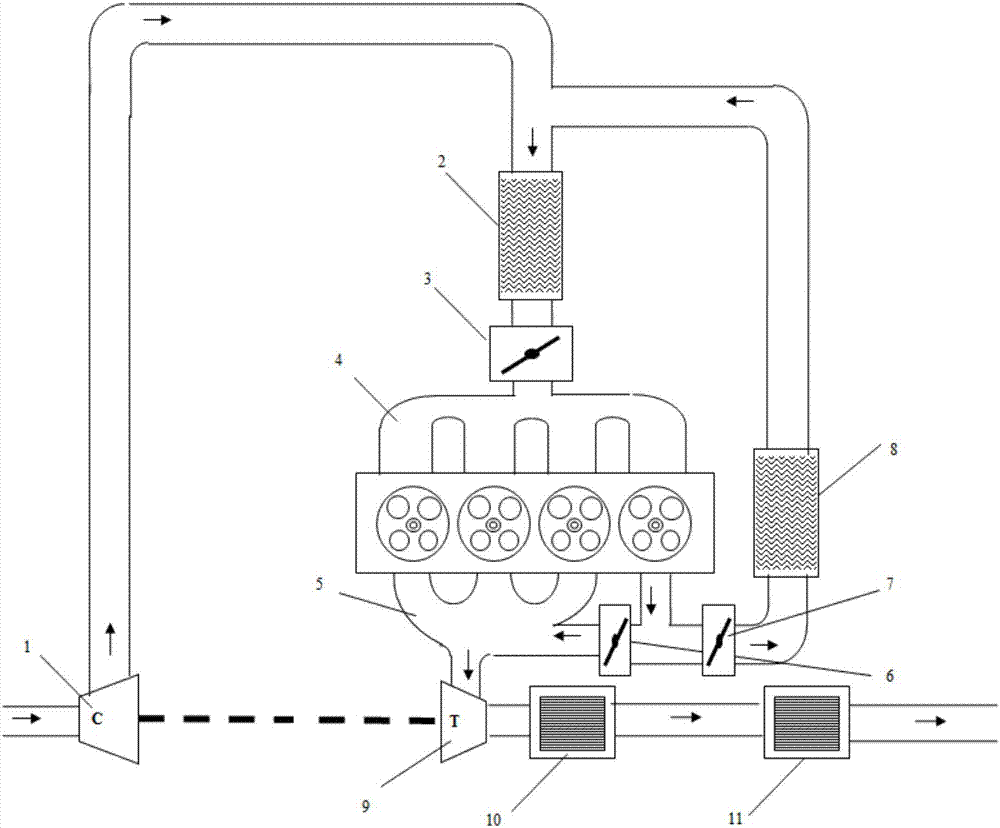

Internal combustion engine and control device for internal combustion engine

InactiveCN102906411AGuaranteed cooling effectIncrease EGR rateElectrical controlNon-fuel substance addition to fuelExternal combustion engineIntercooler

Provided are an internal combustion engine which is prevented from knocking even if the EGR ratio is increased, and a control device for the internal combustion engine. The system of the embodiment enables, as shown in figure 7, EGR gas to flow separately in a route (route (a)) which passes through an EGR passage (28) and a route (route (b)) which passes through an EGR passage (30). When caused to flow through the route (b), the EGR gas can be cooled by an intercooler (18). The intercooler (18) usually has a larger capacity than an EGR cooler (34) and therefore has high cooling ability. As a result, the system of the embodiment can cause the EGR gas to flow into a surge tank (22) with the heat of the EGR gas sufficiently dissipated.

Owner:TOYOTA JIDOSHA KK

Exhaust gas recirculation system for internal combustion engine

InactiveCN101956633AIncrease EGR rateShorten the lengthNon-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineInternal combustion engine cooling

The invention discloses an exhaust gas recirculation system for an internal combustion engine. The exhaust gas recirculation system comprises a cooling component, a gas compressor and a gas storage tank which are connected in turn; a gas inlet end of the cooling component is communicated with an exhaust pipe of the internal combustion engine; and a gas outlet end of the gas storage tank is communicated with a gas inlet of the internal combustion engine. The exhaust gas recirculation system has the advantages of simple and compact structure, low cost, stable and reliable work, quick exhaust gas recirculation response, capability of effectively reducing harmful emissions of the internal combustion engine, accurate control on recirculation exhaust gas amount and the like.

Owner:HUNAN UNIV

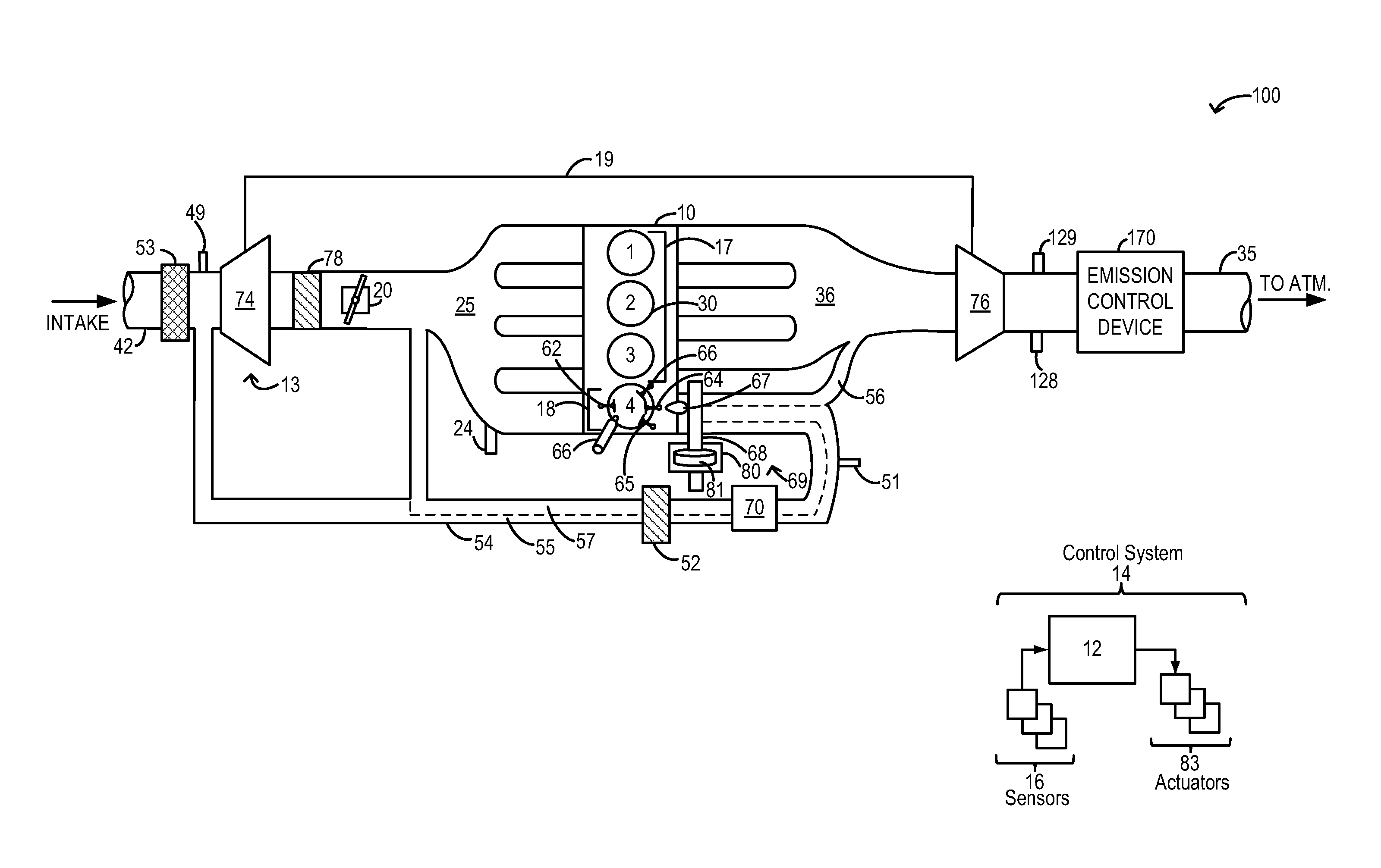

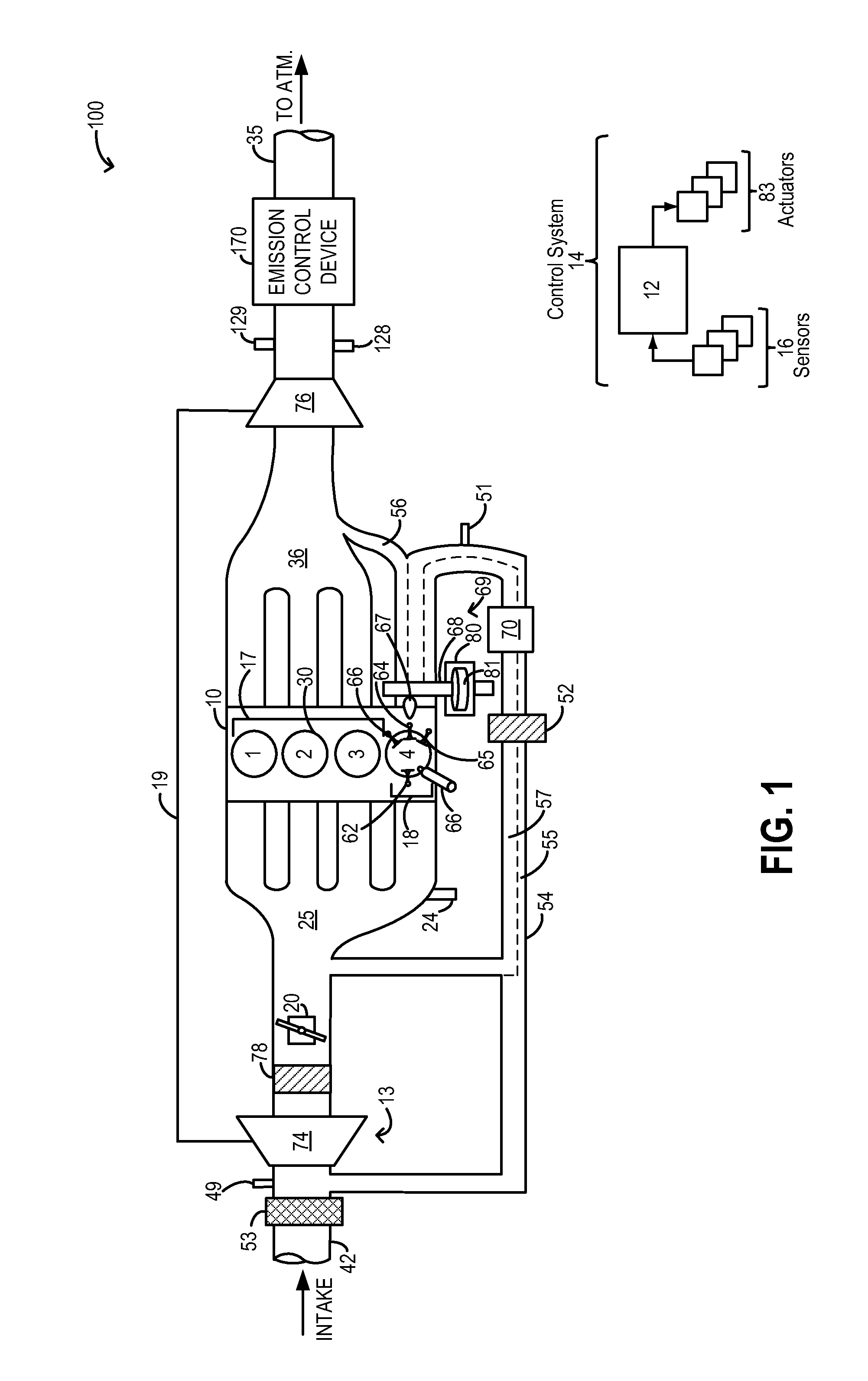

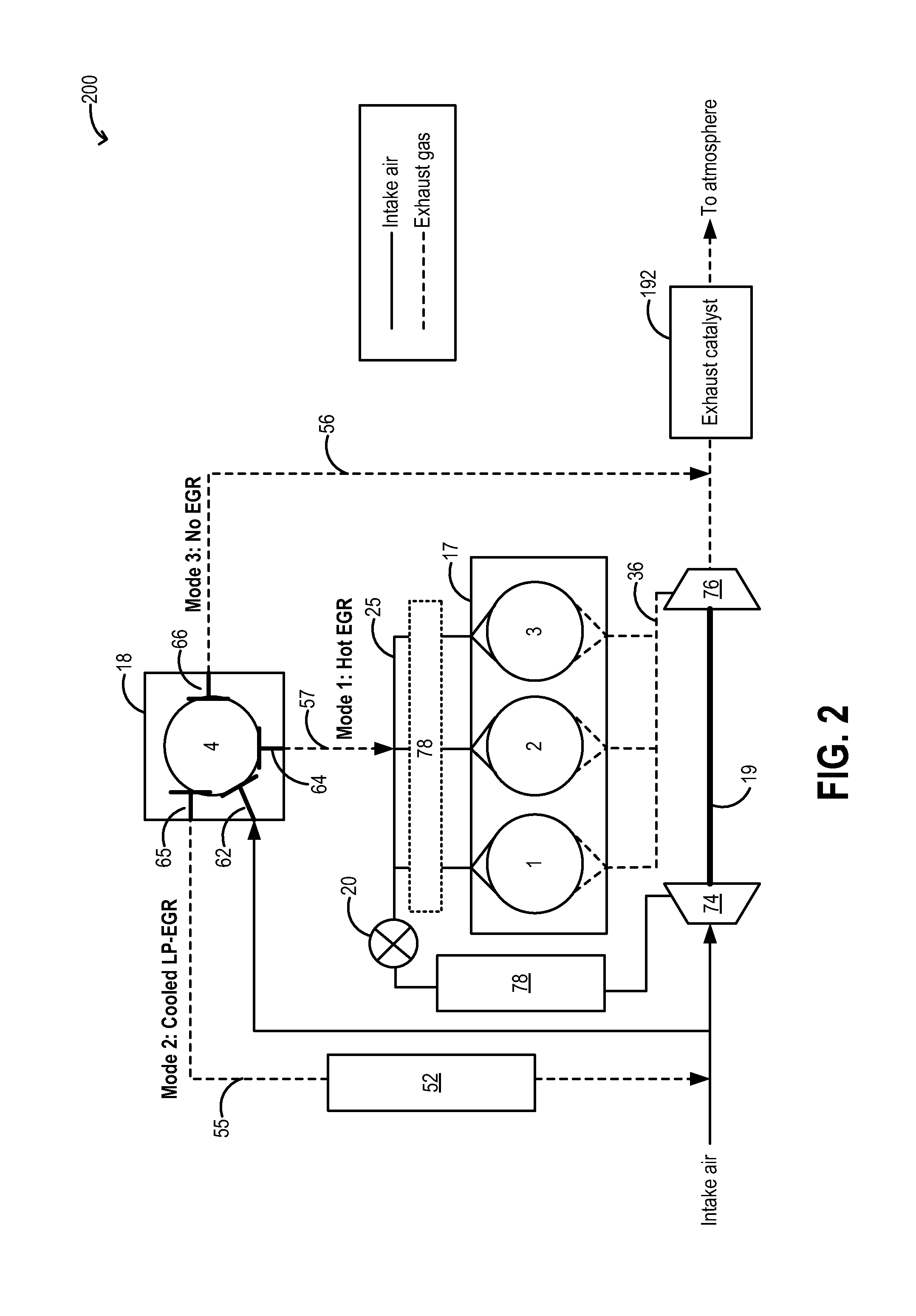

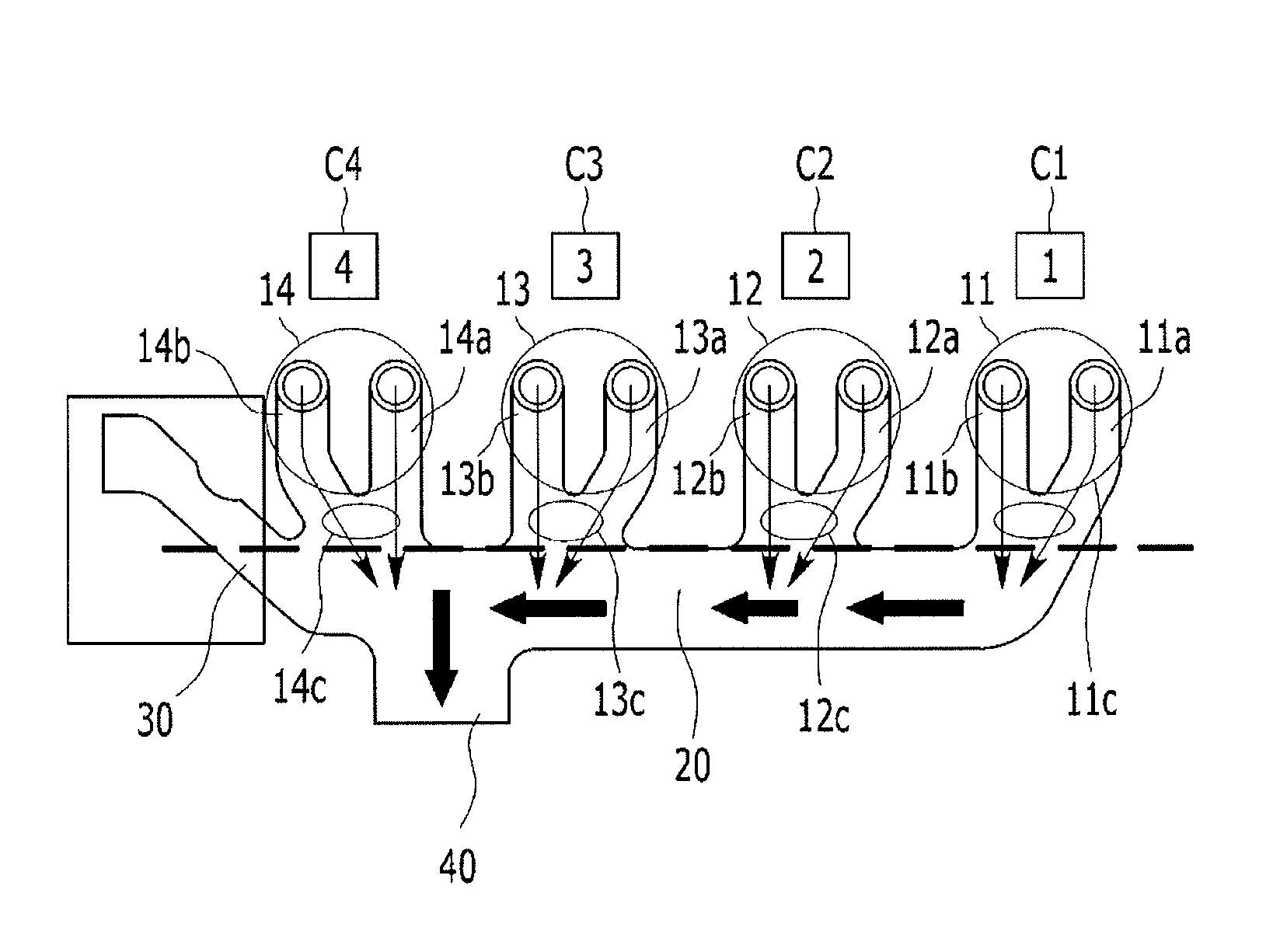

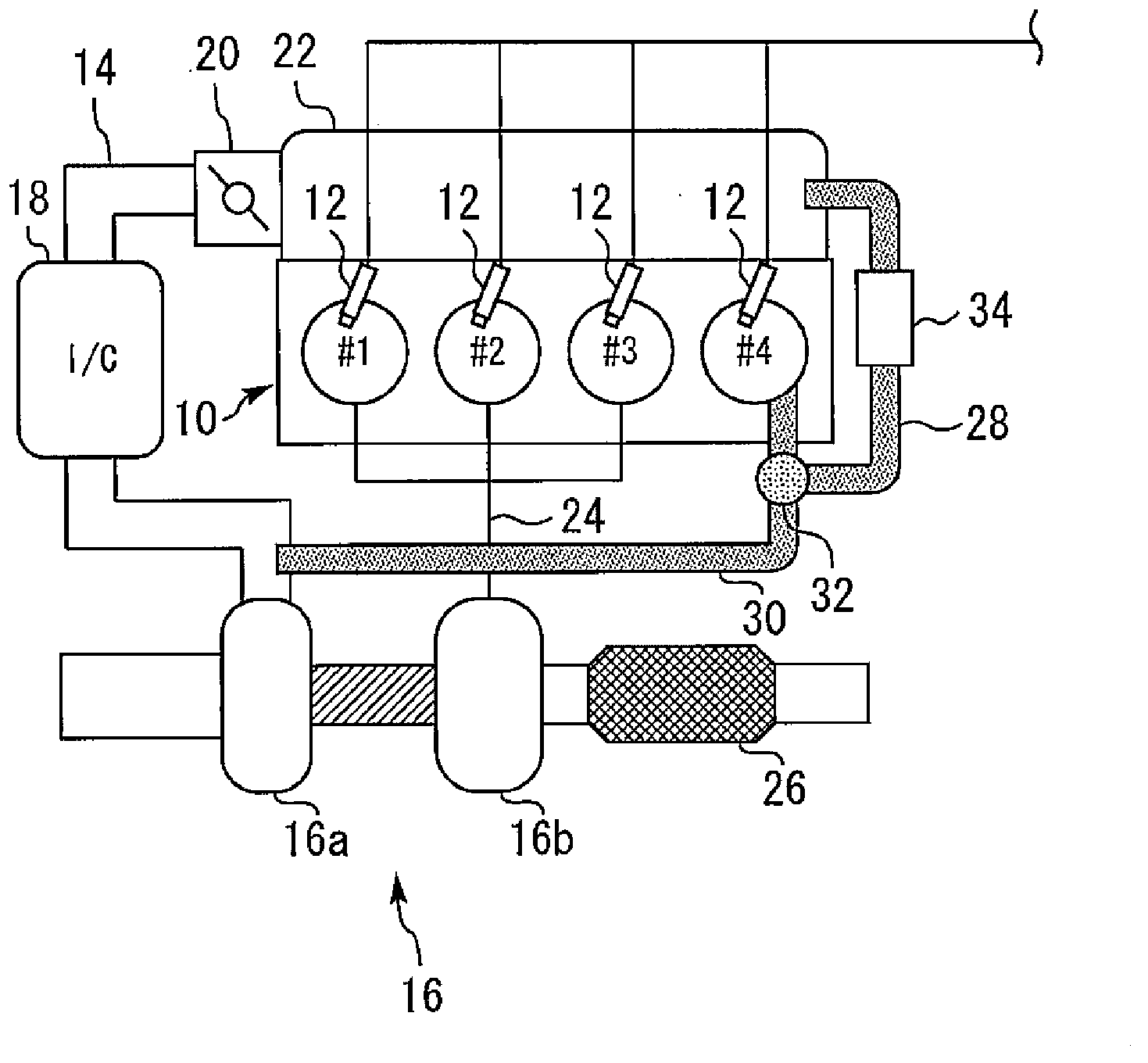

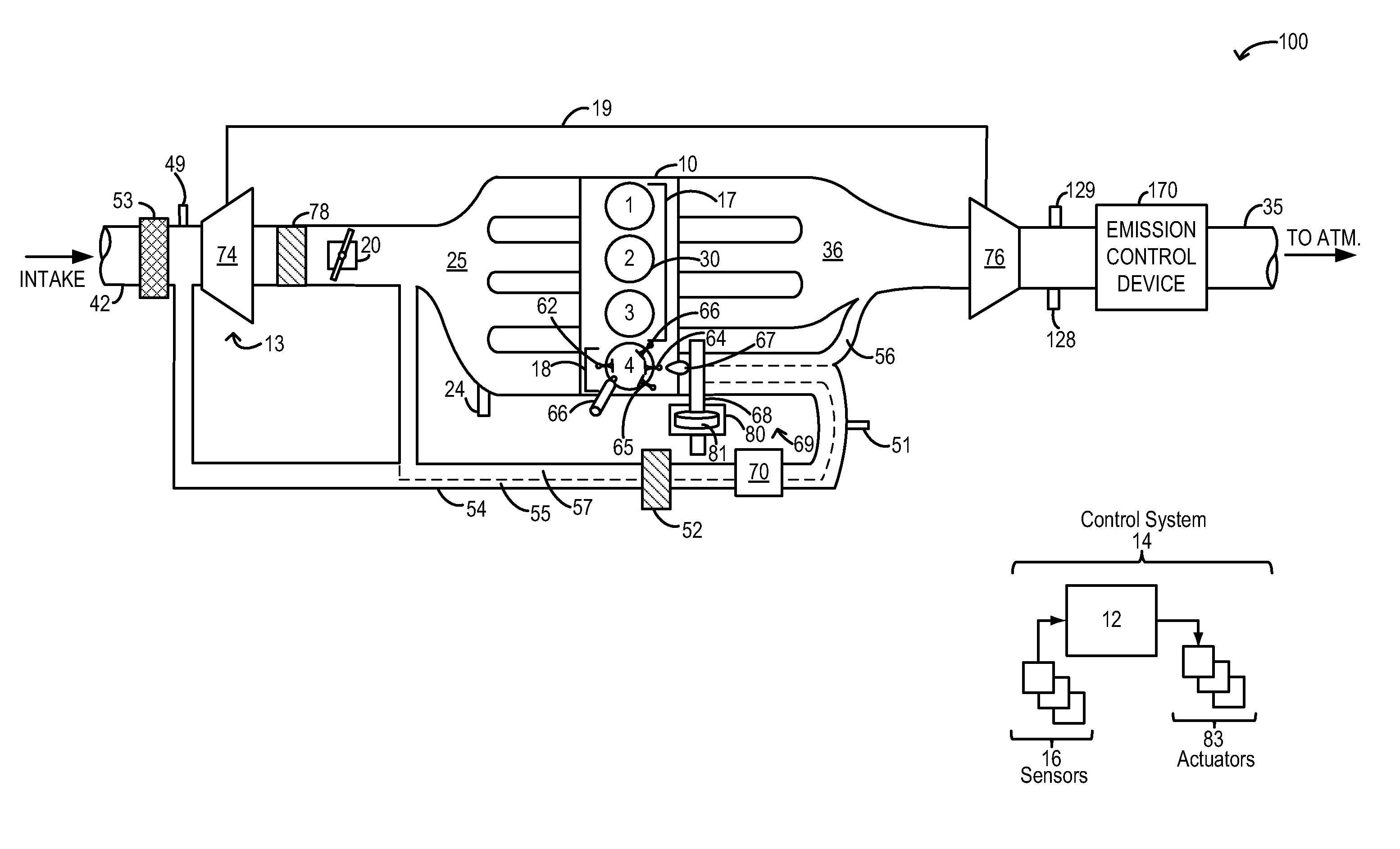

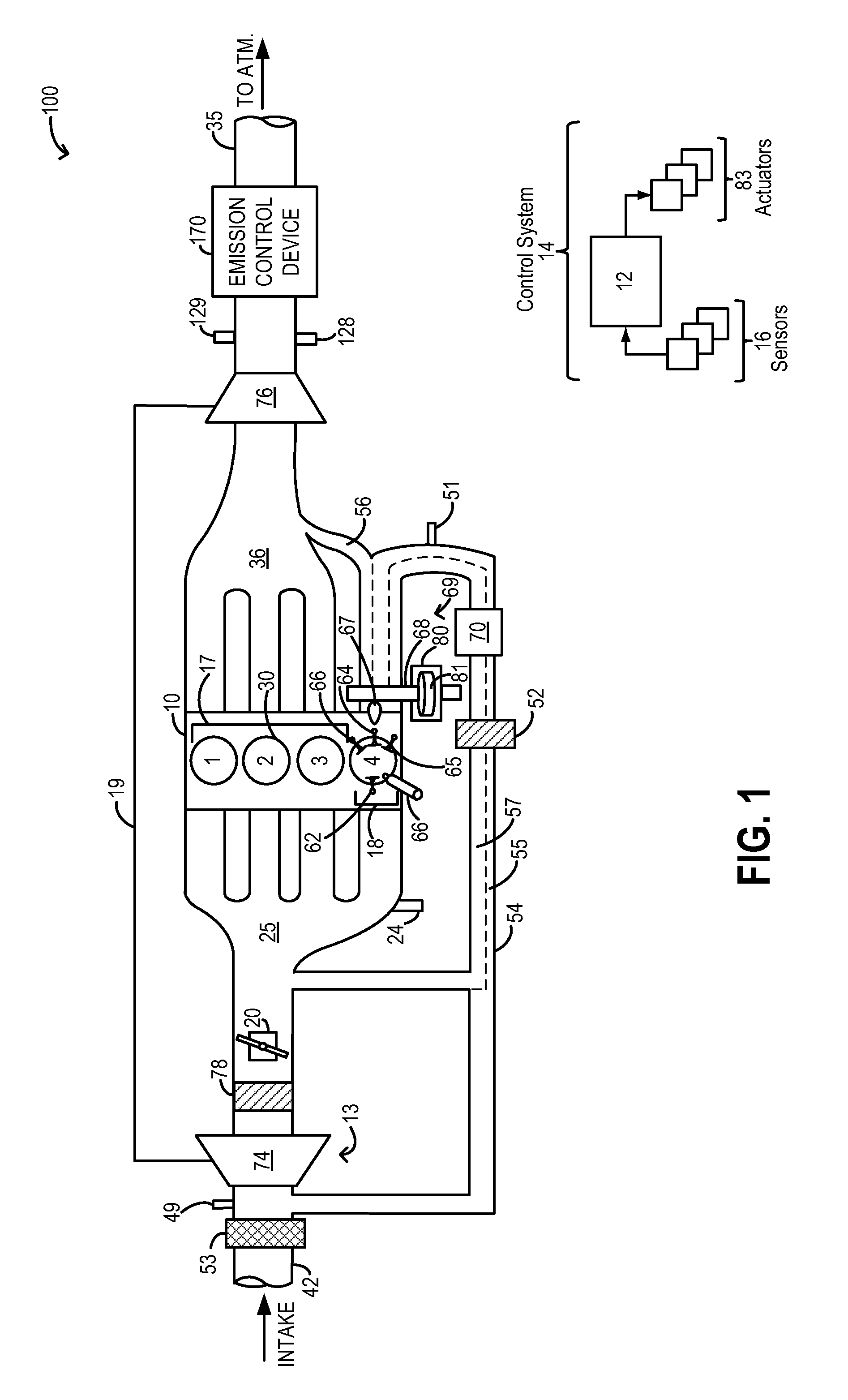

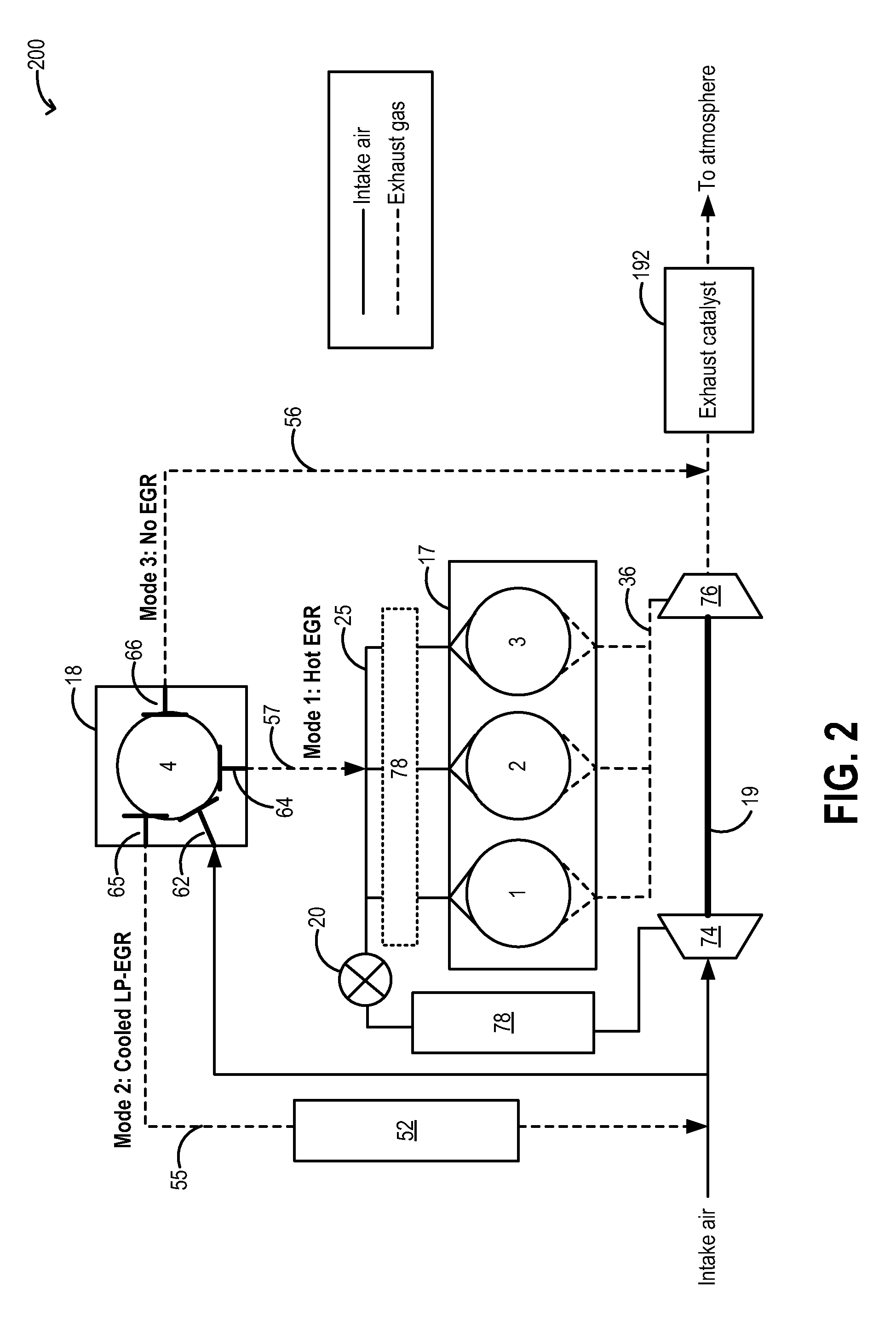

Systems and methods for EGR control

ActiveUS9534542B2Emission reductionReduce heatElectrical controlInternal combustion piston enginesExhaust valveEngineering

Methods and systems are provided for varying a location and rate of EGR delivered to an engine from a dedicated EGR cylinder. The dedicated EGR cylinder is configured with a plurality of exhaust valves controlled via a cam profile switching mechanism that allows the time and duration of opening of each exhaust valve to be varied. By selectively opening one exhaust valve at a time, exhaust from the dedicated EGR cylinder can be delivered to a pre-compressor location, a post-compressor location, or to the exhaust manifold, while bypassing all engine cylinders.

Owner:FORD GLOBAL TECH LLC

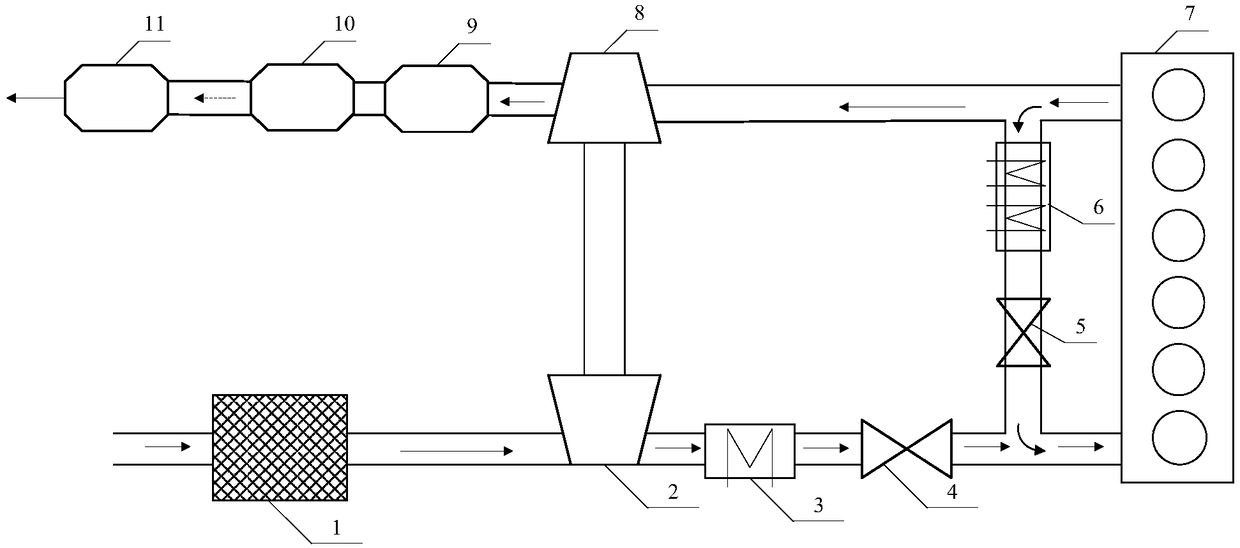

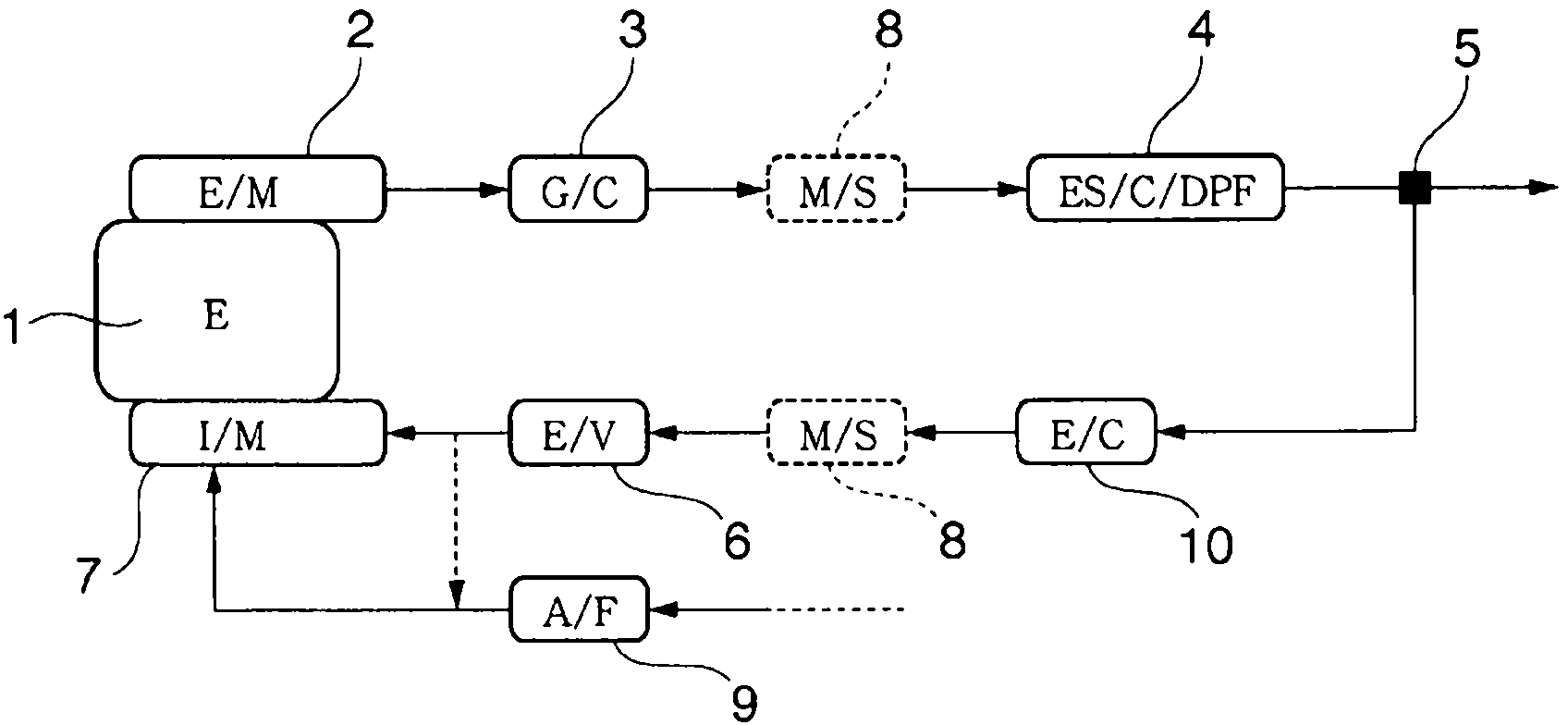

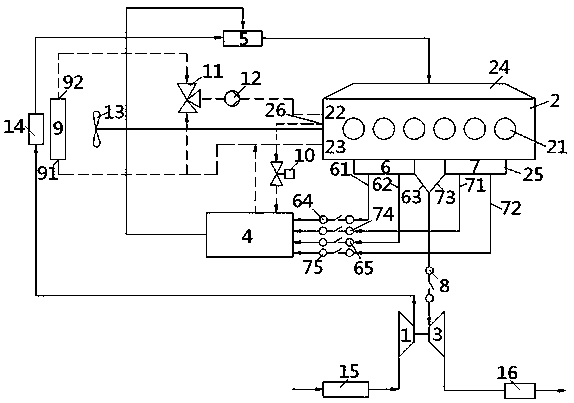

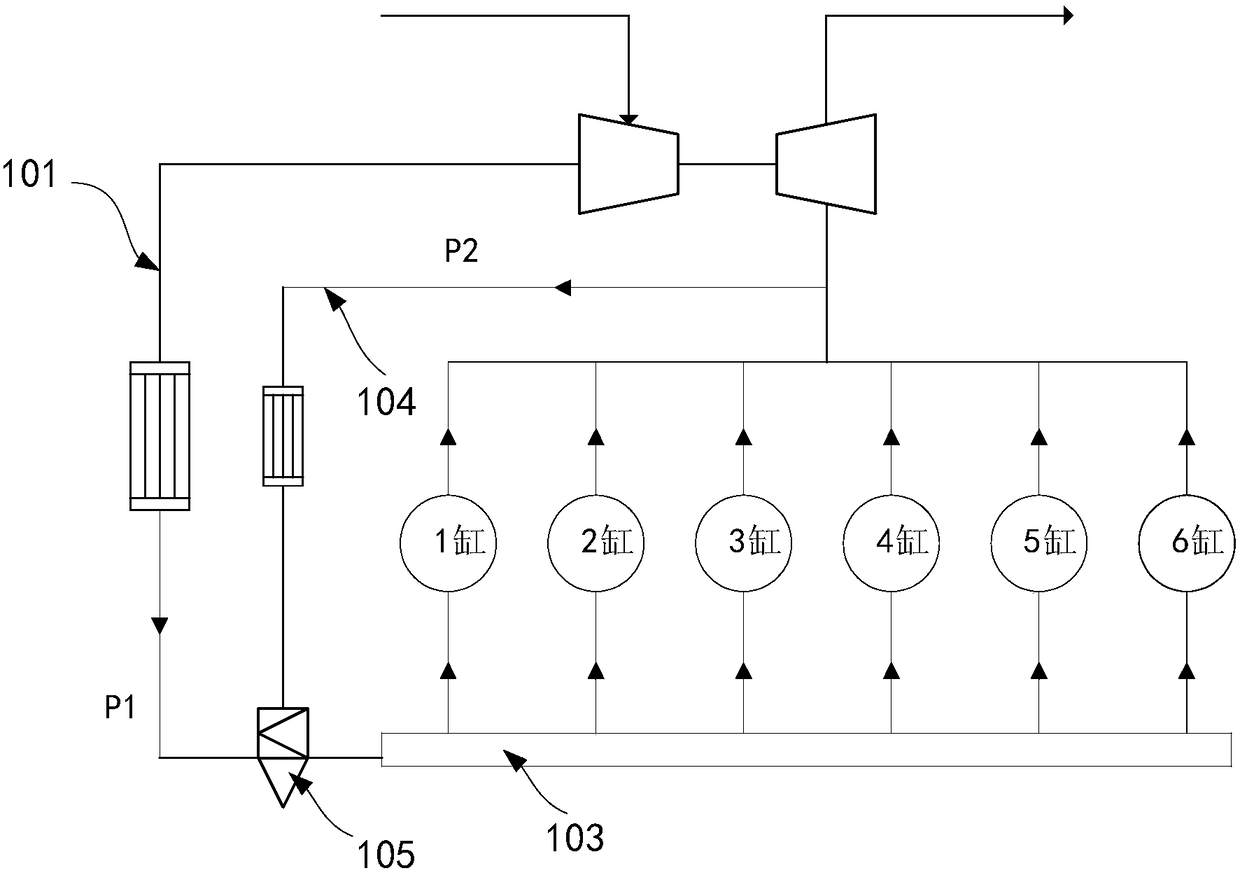

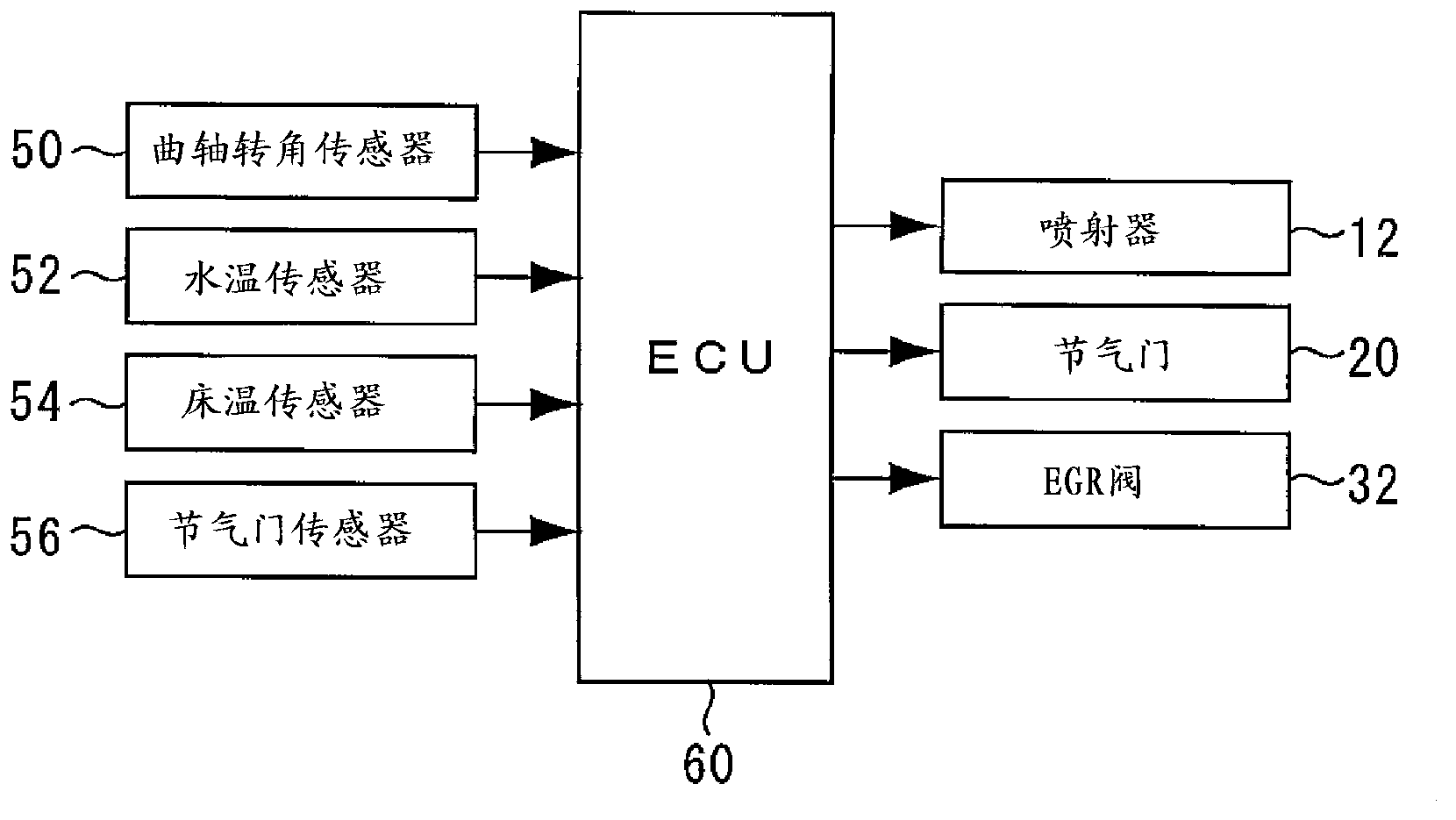

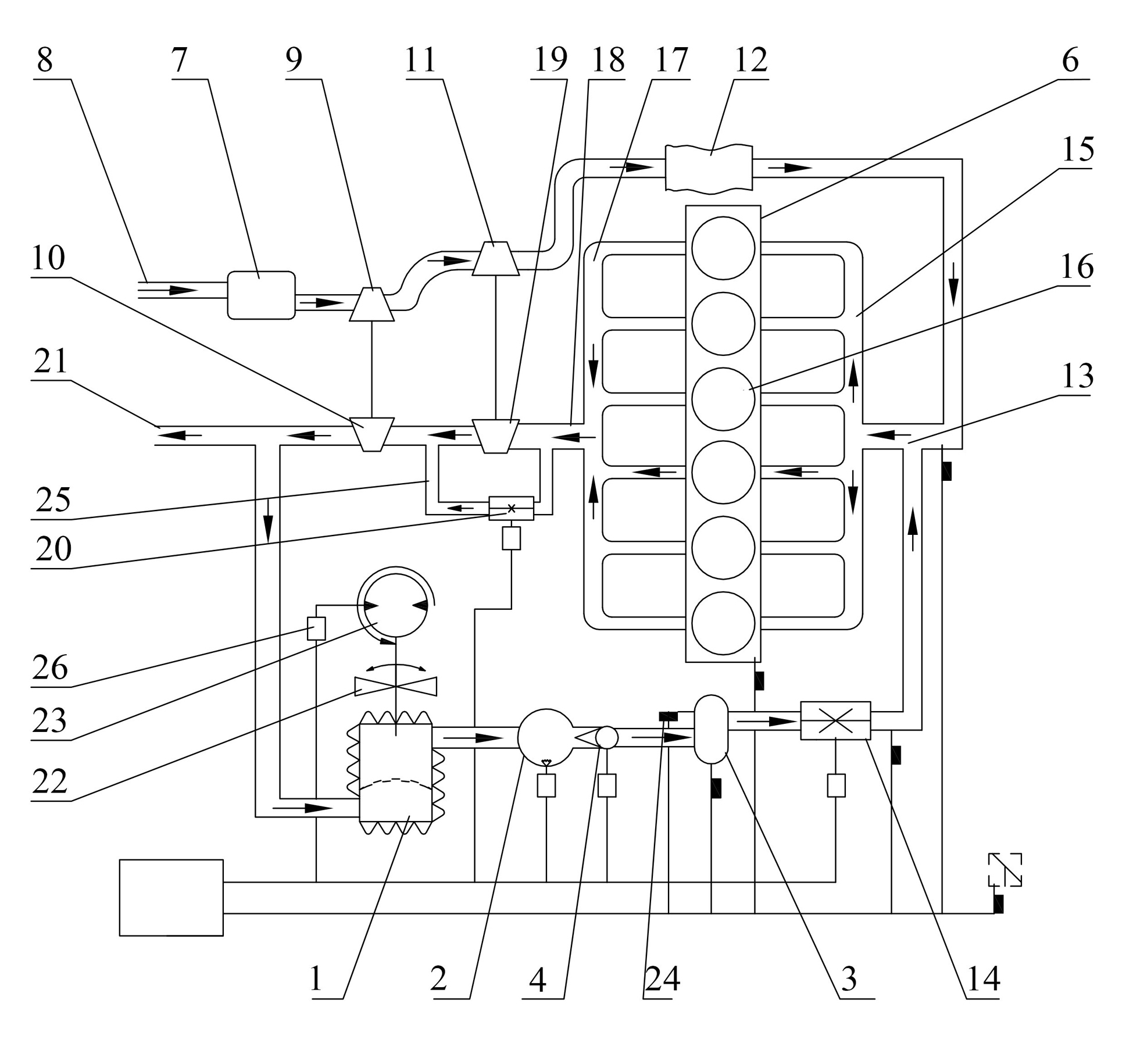

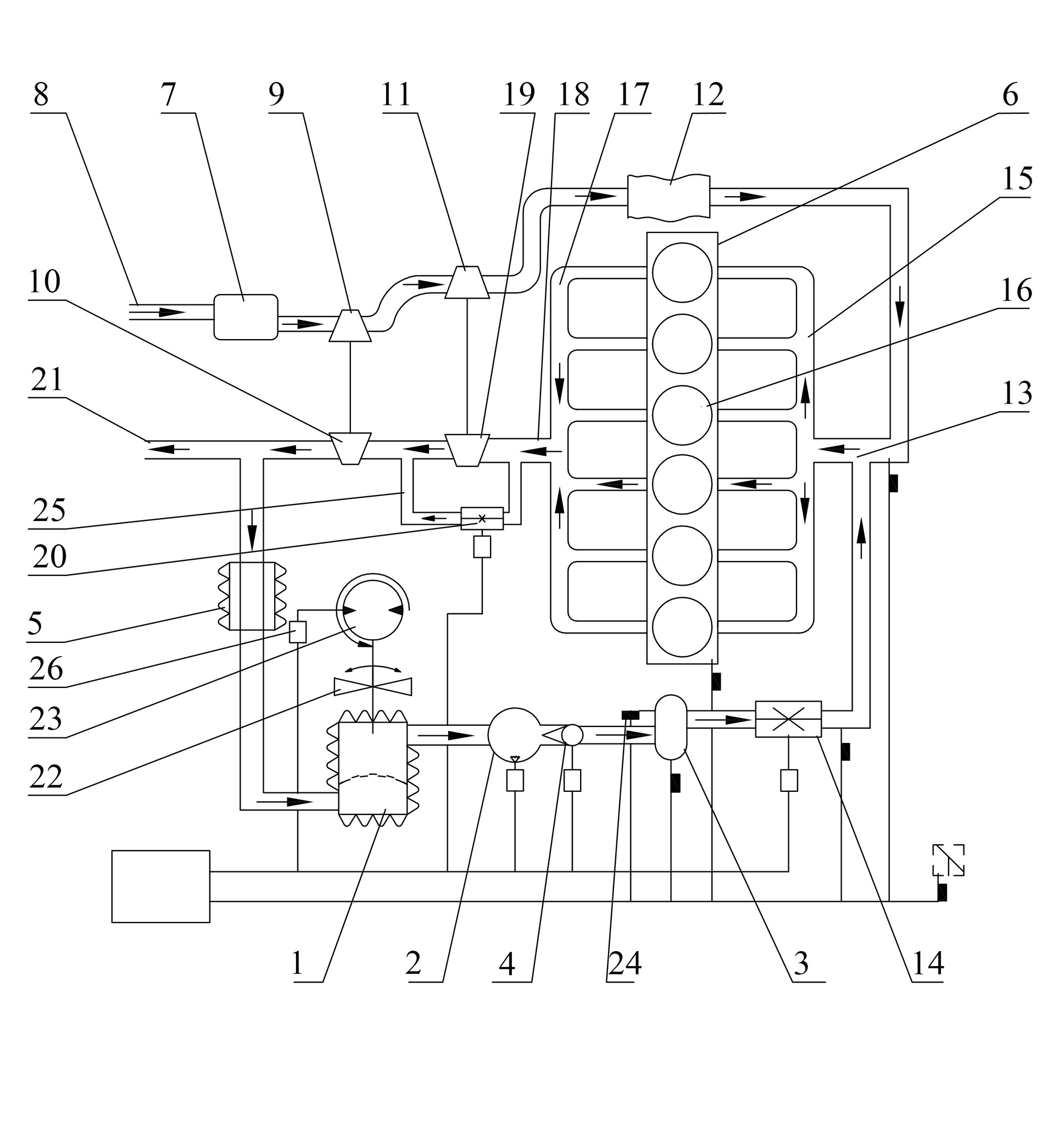

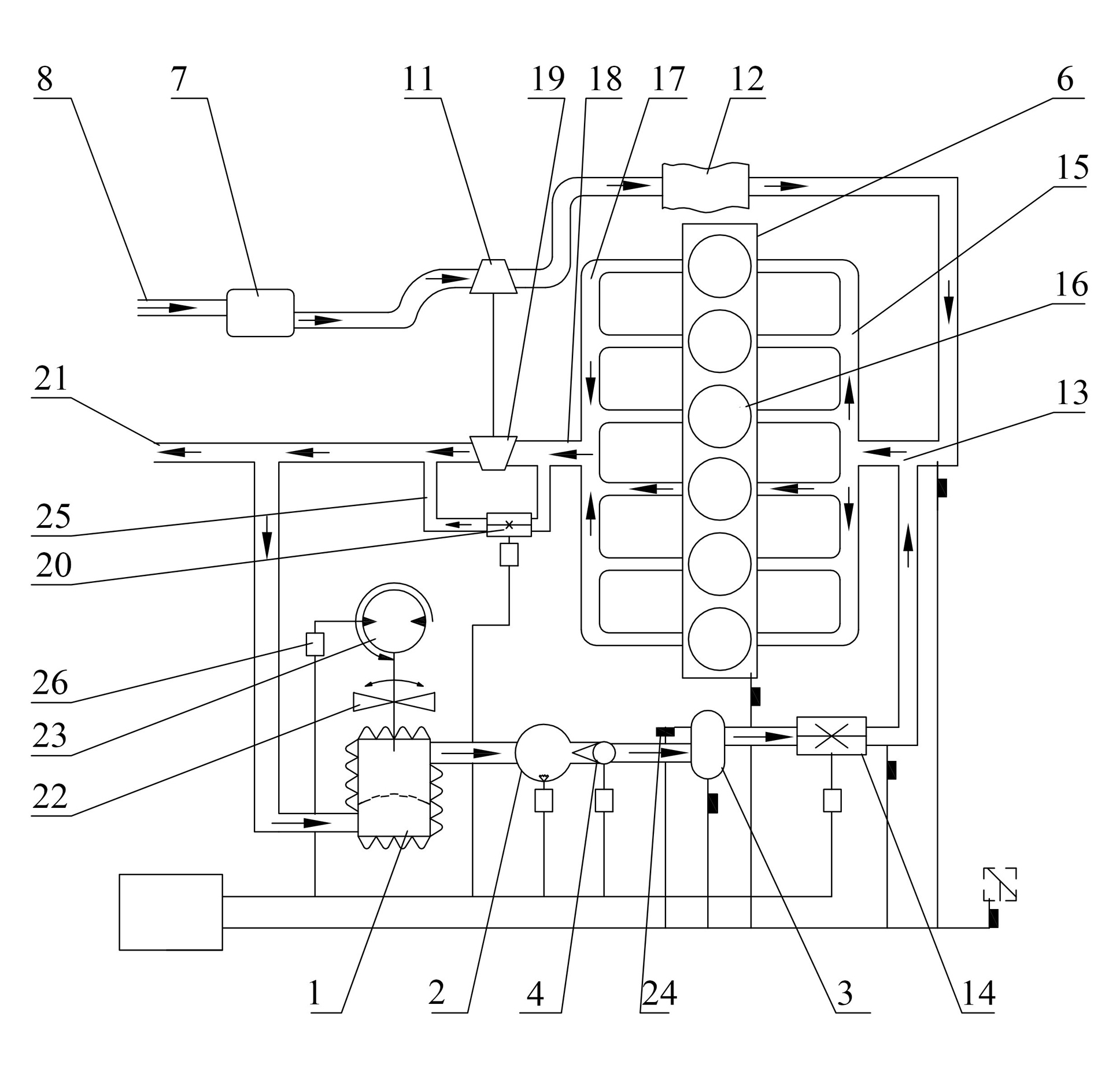

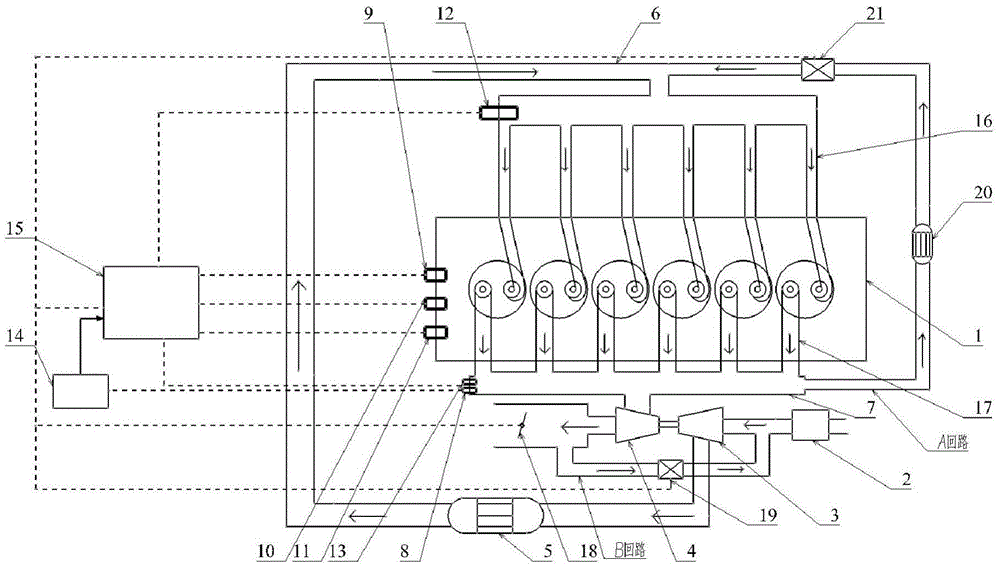

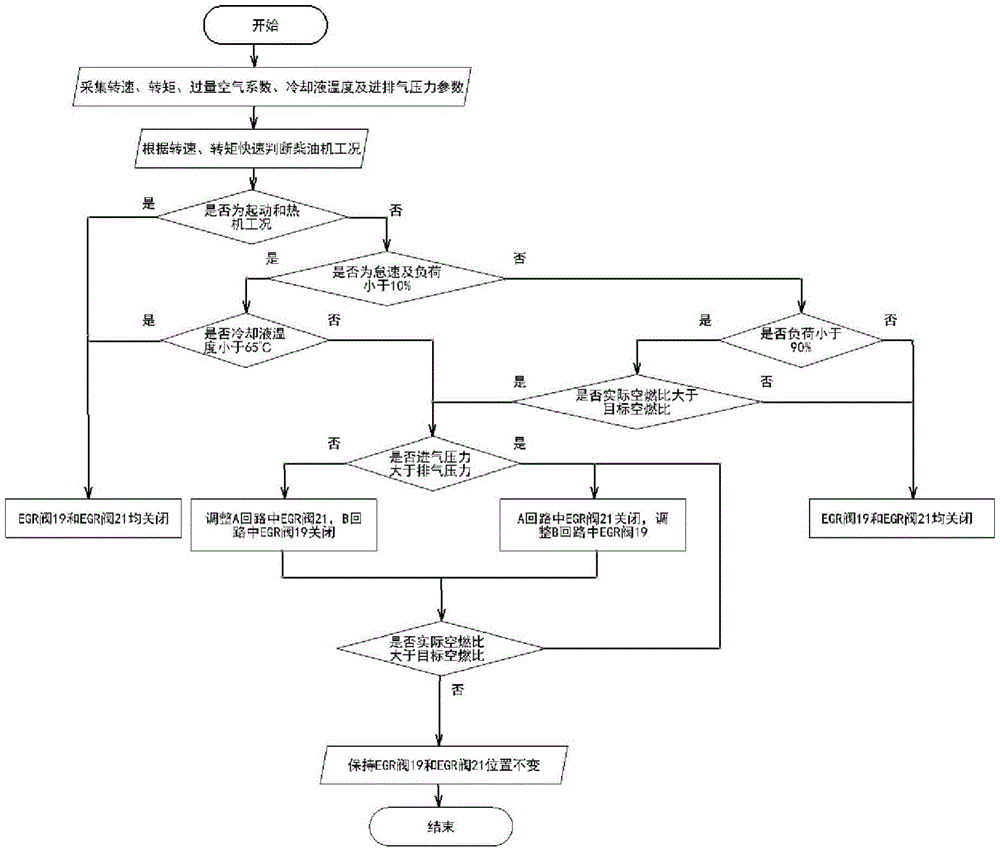

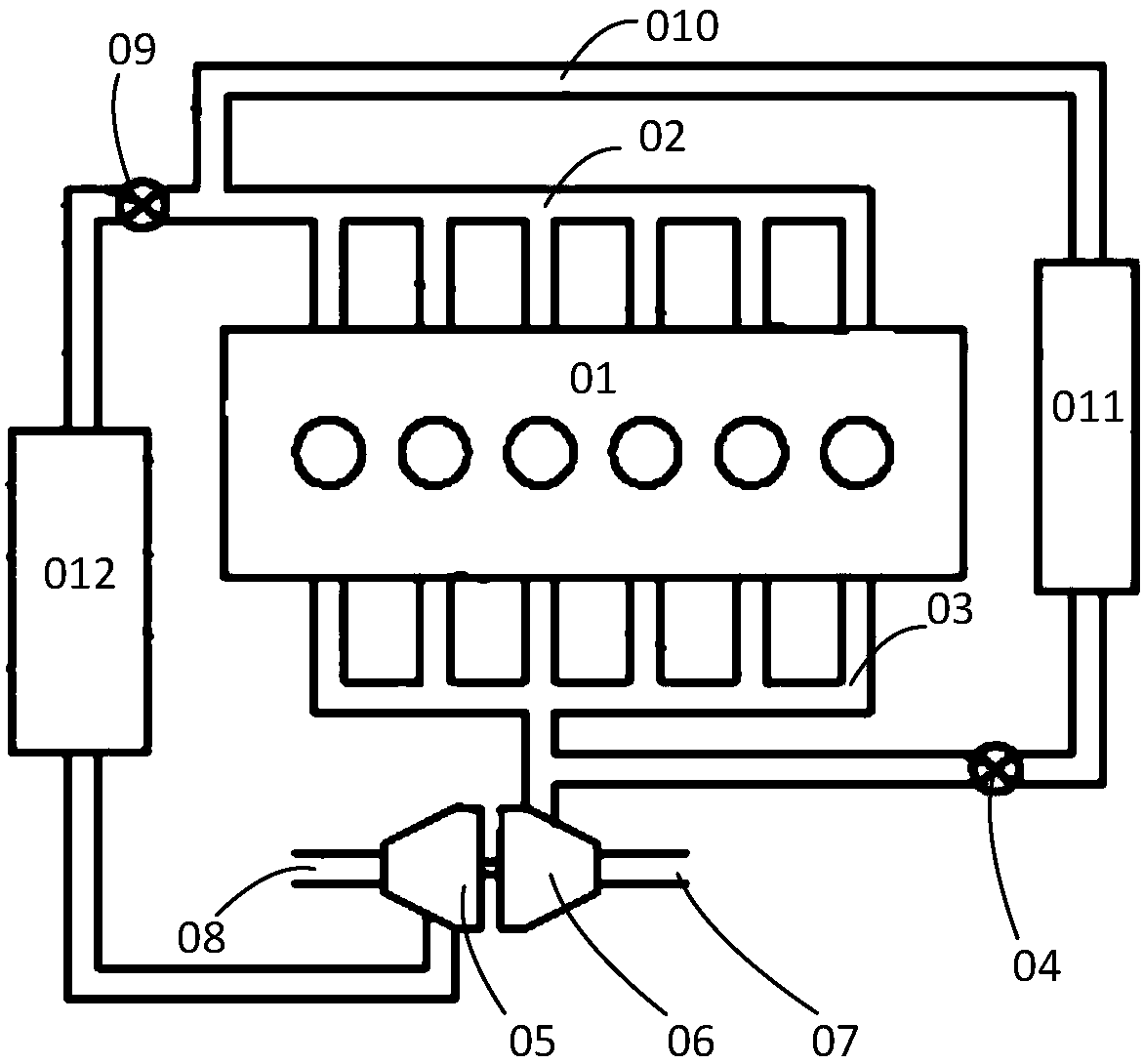

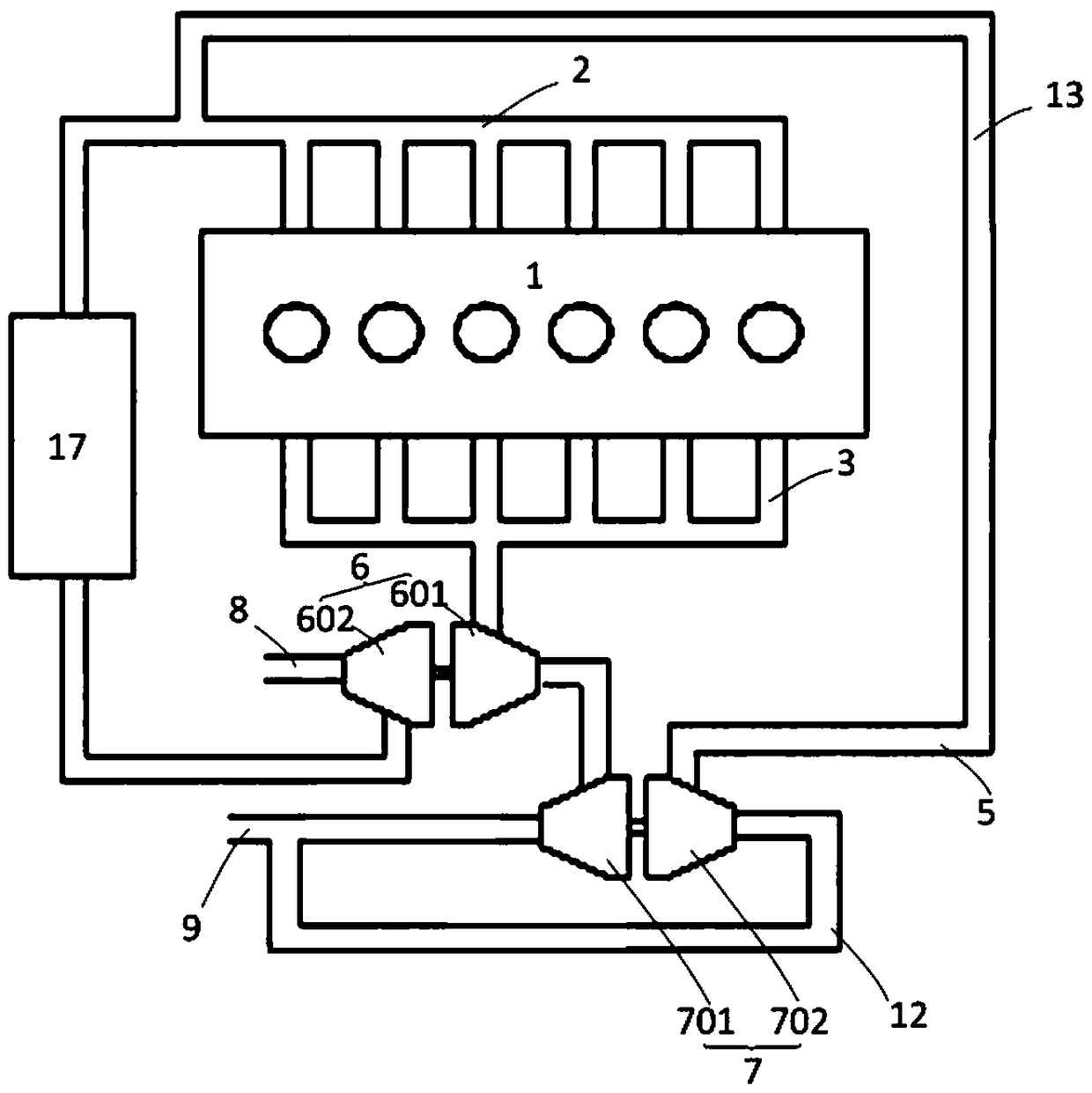

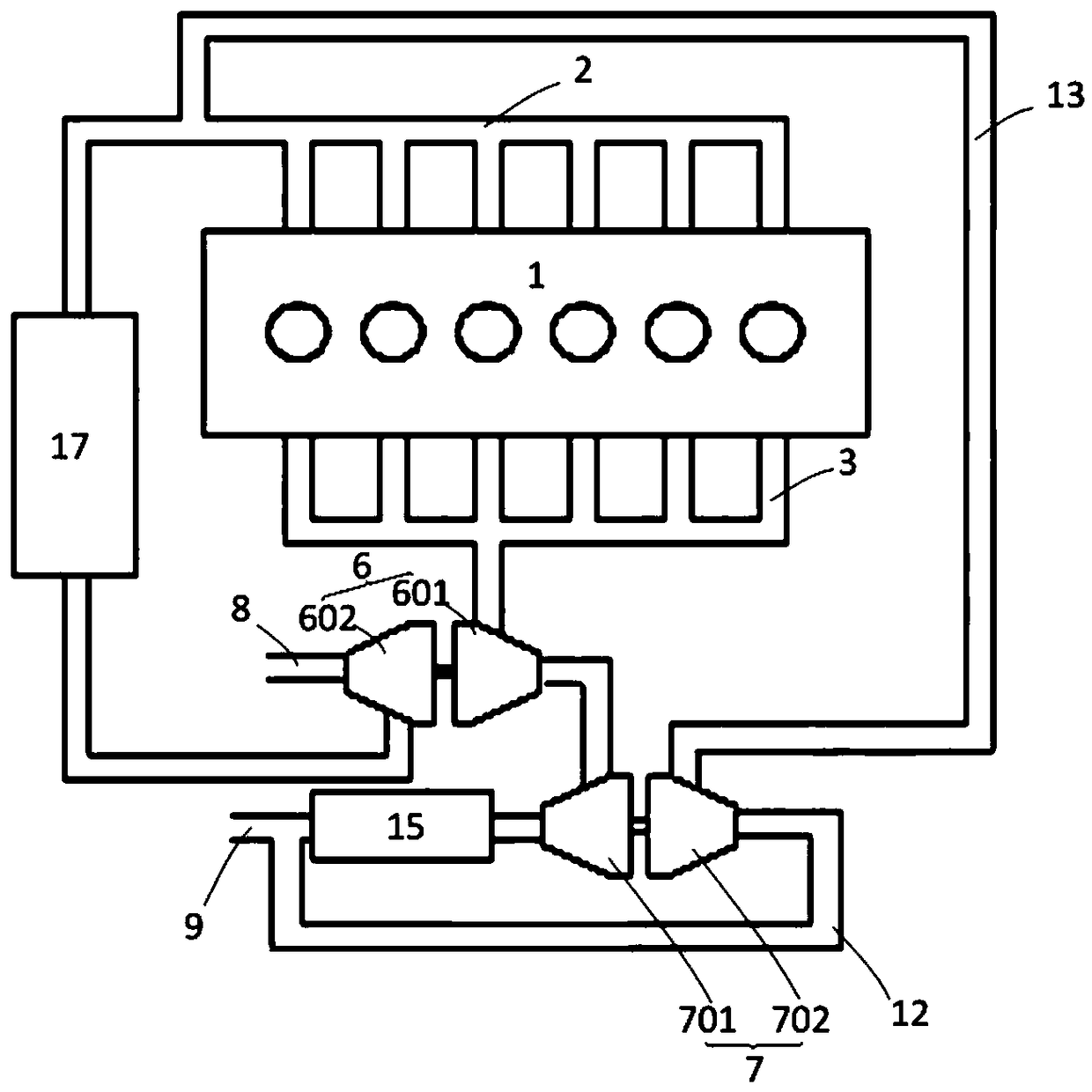

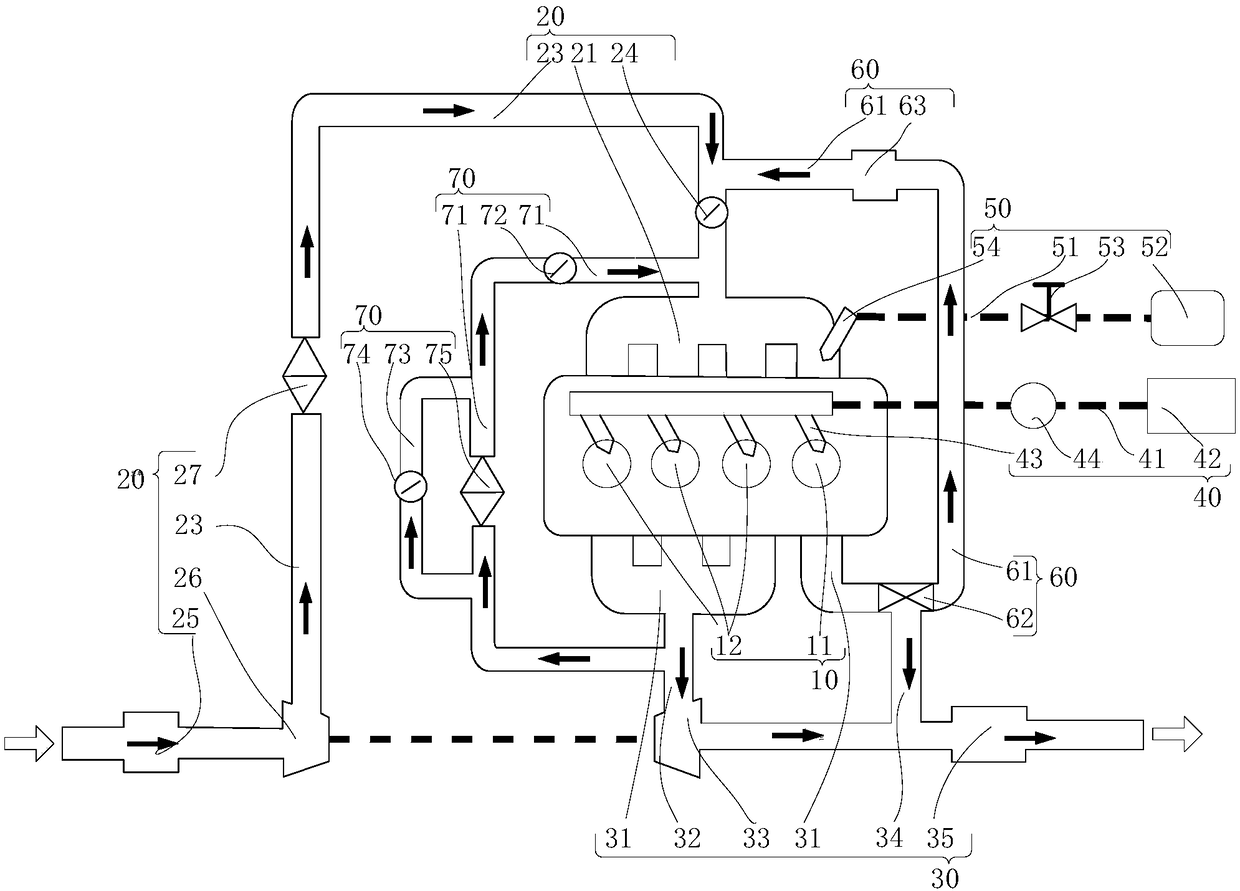

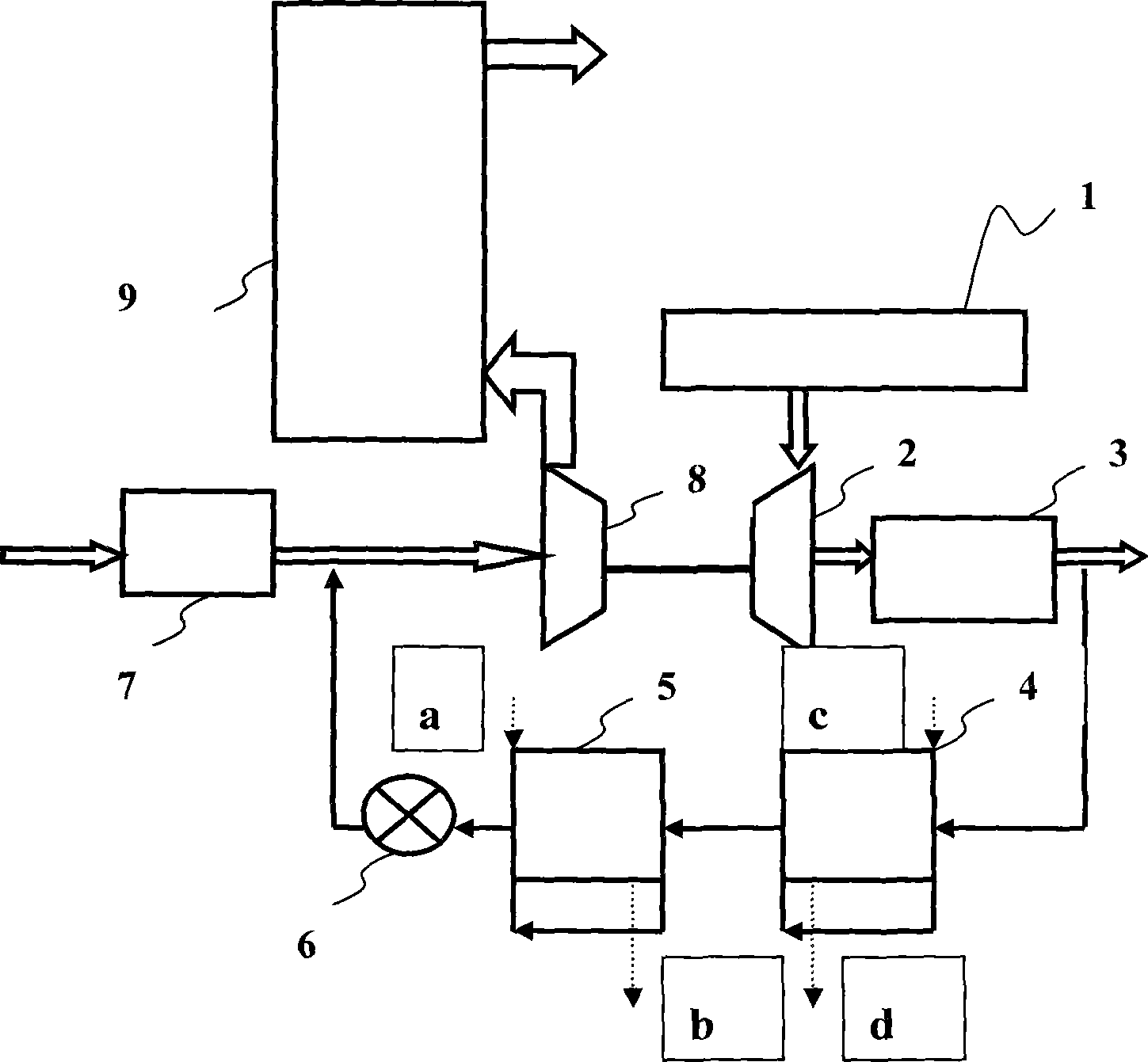

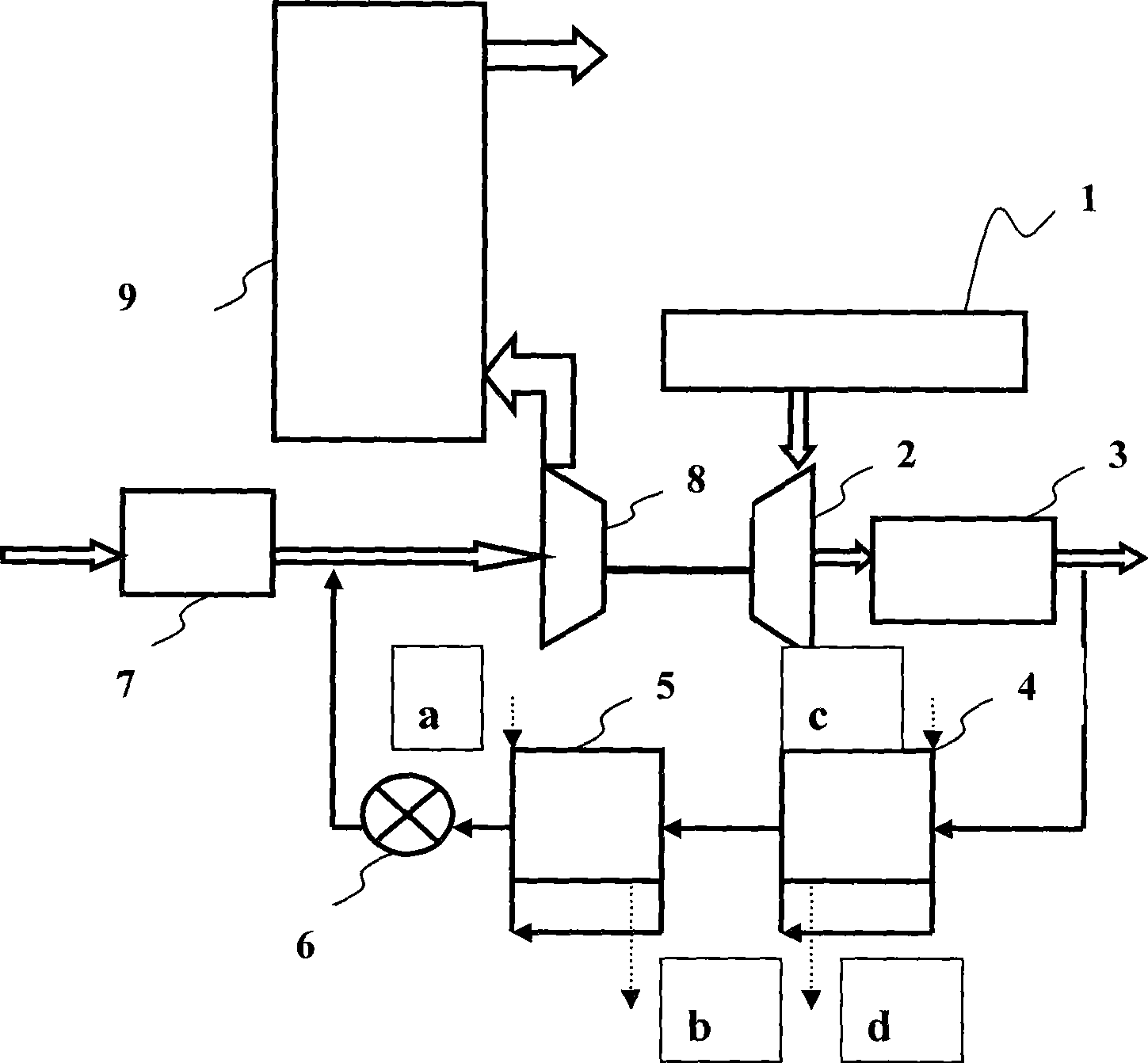

Control system and control method for reducing NOx emissions of diesel engine under all working conditions

InactiveCN105545501ALow powerReduced service lifeEngine controllersMachines/enginesAir filterIntercooler

The invention relates to a control system and a control method for reducing NOx emissions of a diesel engine under all working conditions. The control system comprises an engine, an air filter, an air compressor, a turbine coaxially connected with the air compressor, an intake intercooler, an intake manifold, an exhaust manifold, a gamma sensor and an intake tube pressure sensor which are arranged on the exhaust manifold, a coolant temperature sensor, a high-response torque sensor and a high-response rotational speed sensor which are arranged on the engine, an exhaust pipe pressure sensor arranged on the exhaust manifold, a single-chip microcomputer provided with an air-fuel ratio calculation program, an electronic control unit (ECU), a butterfly valve, two EGR valves and an EGR cooler. Corresponding signals are acquired through the sensors and transmitted to the electronic control unit, the electronic control unit judges a working condition according to the corresponding signals, and then the butterfly valve and the two EGR valves are controlled to change an air-fuel ratio. The control system disclosed by the invention is high in control accuracy; a high EGR rate can be realized on the basis of the system; and the purpose of reducing NOx emissions in a range of all working conditions can be achieved by taking the air-fuel ratio as a control object.

Owner:JILIN UNIV

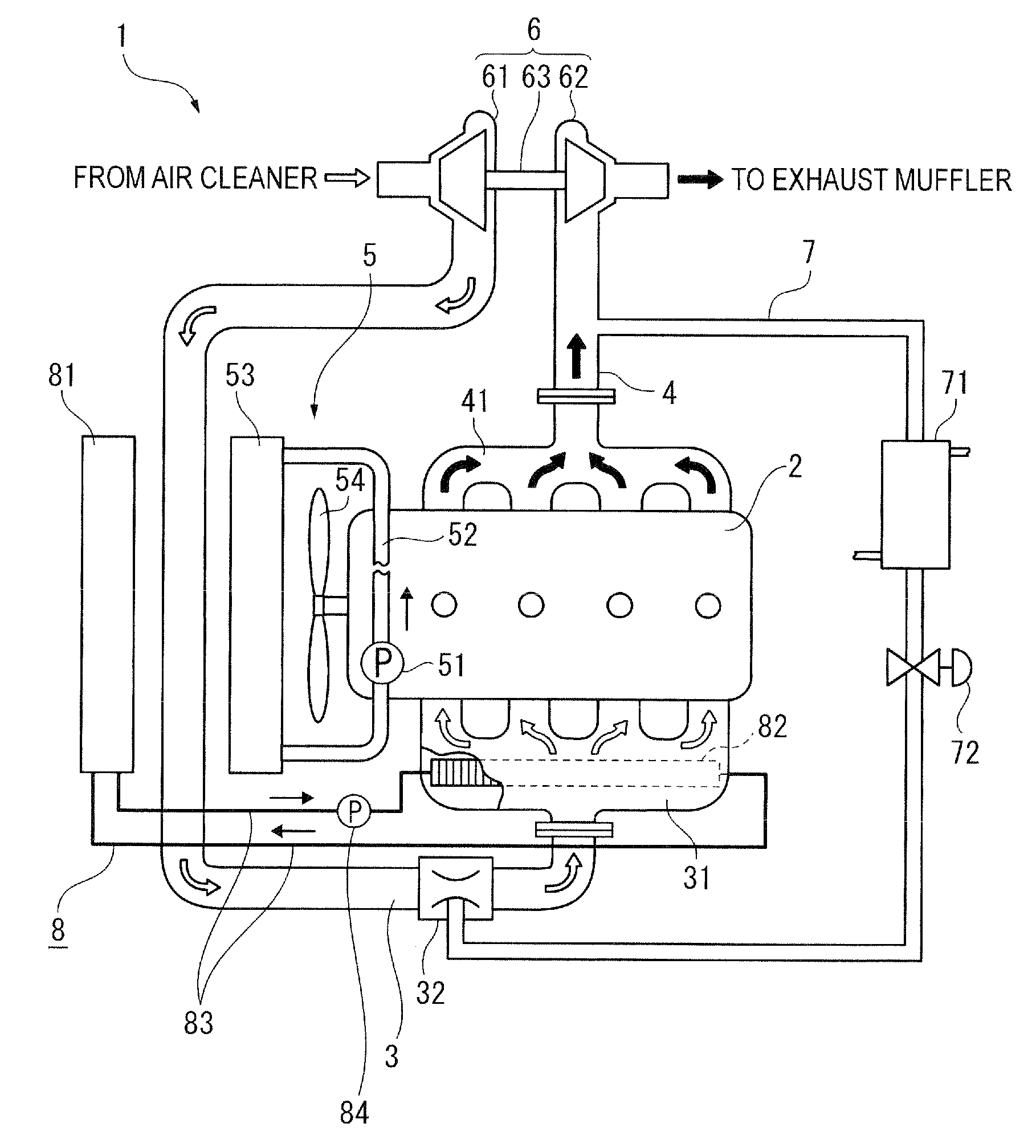

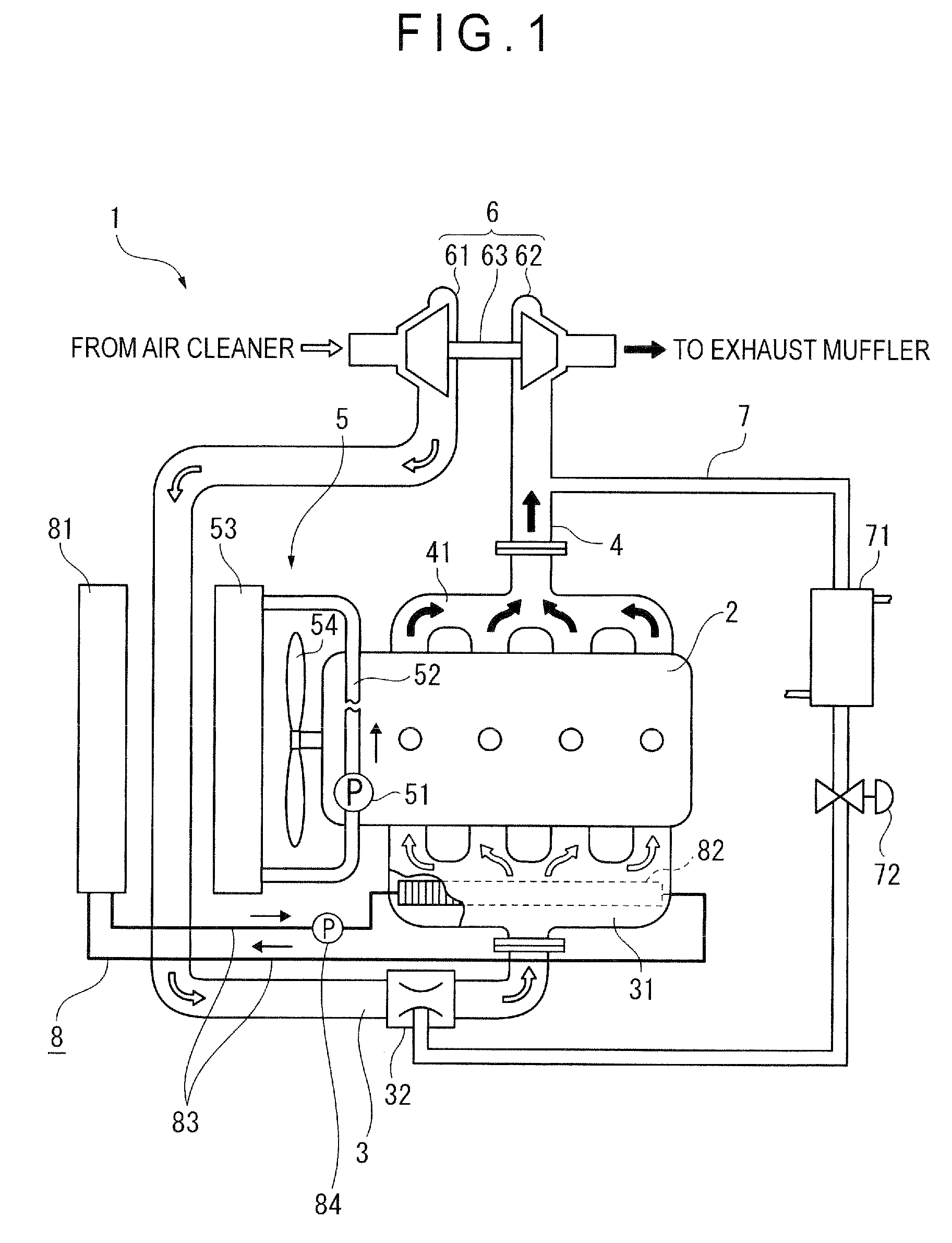

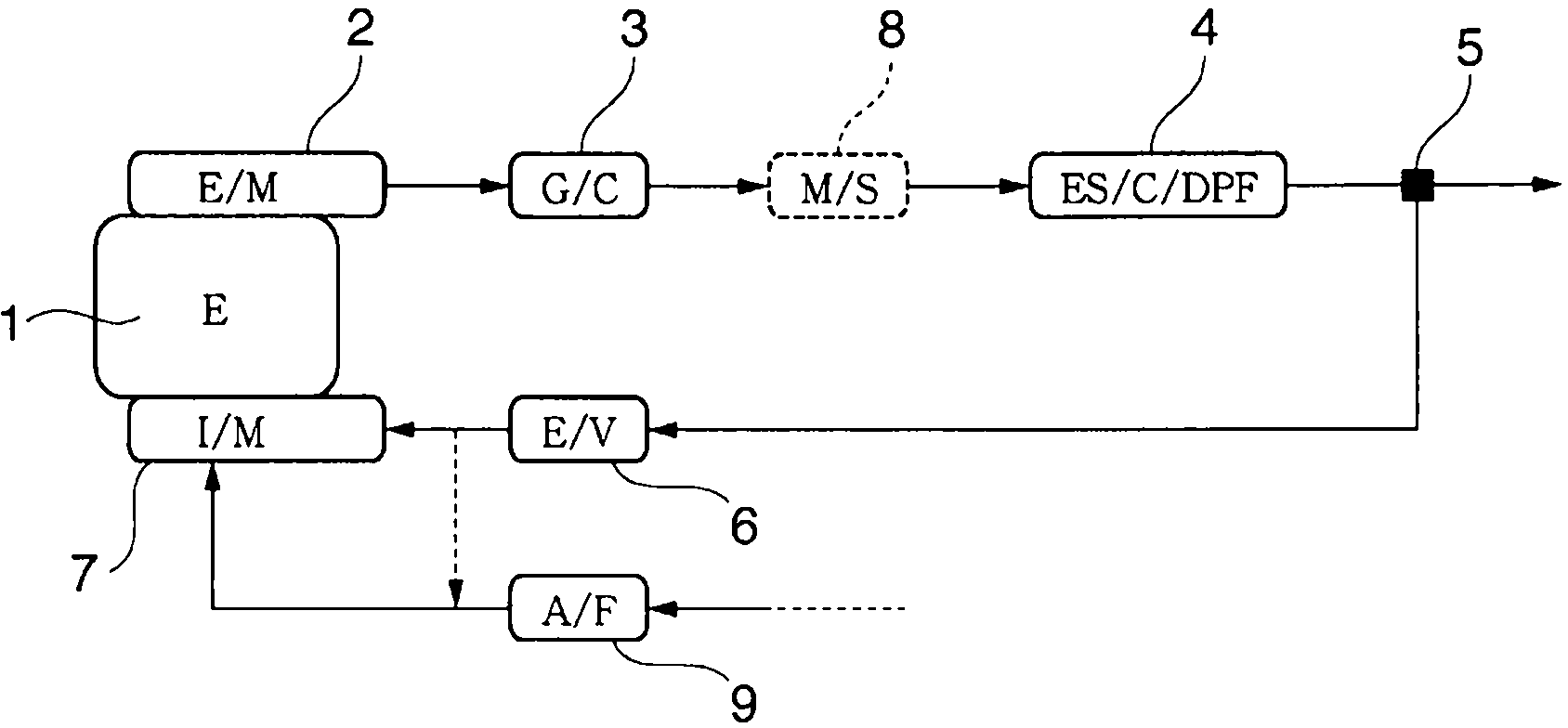

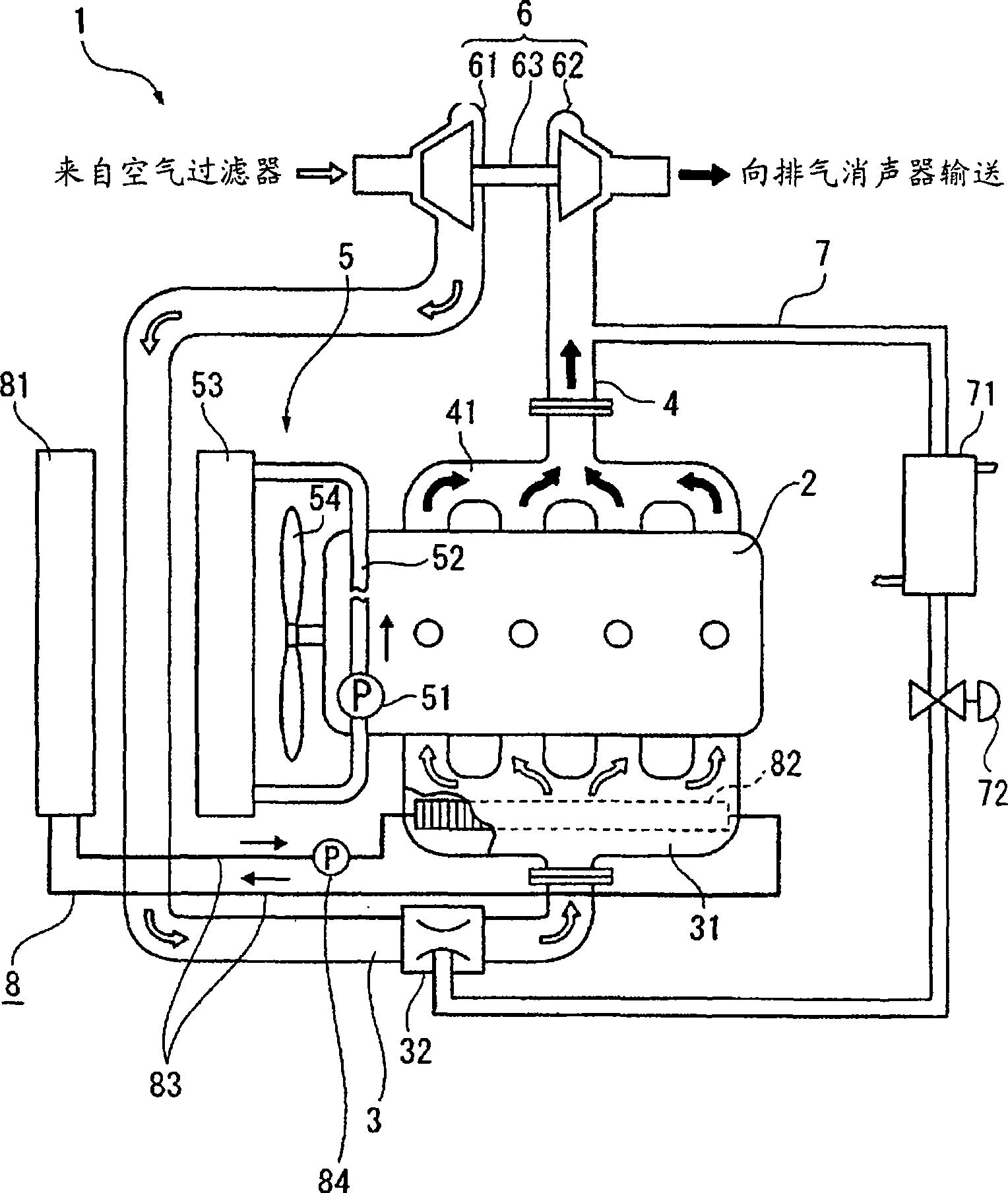

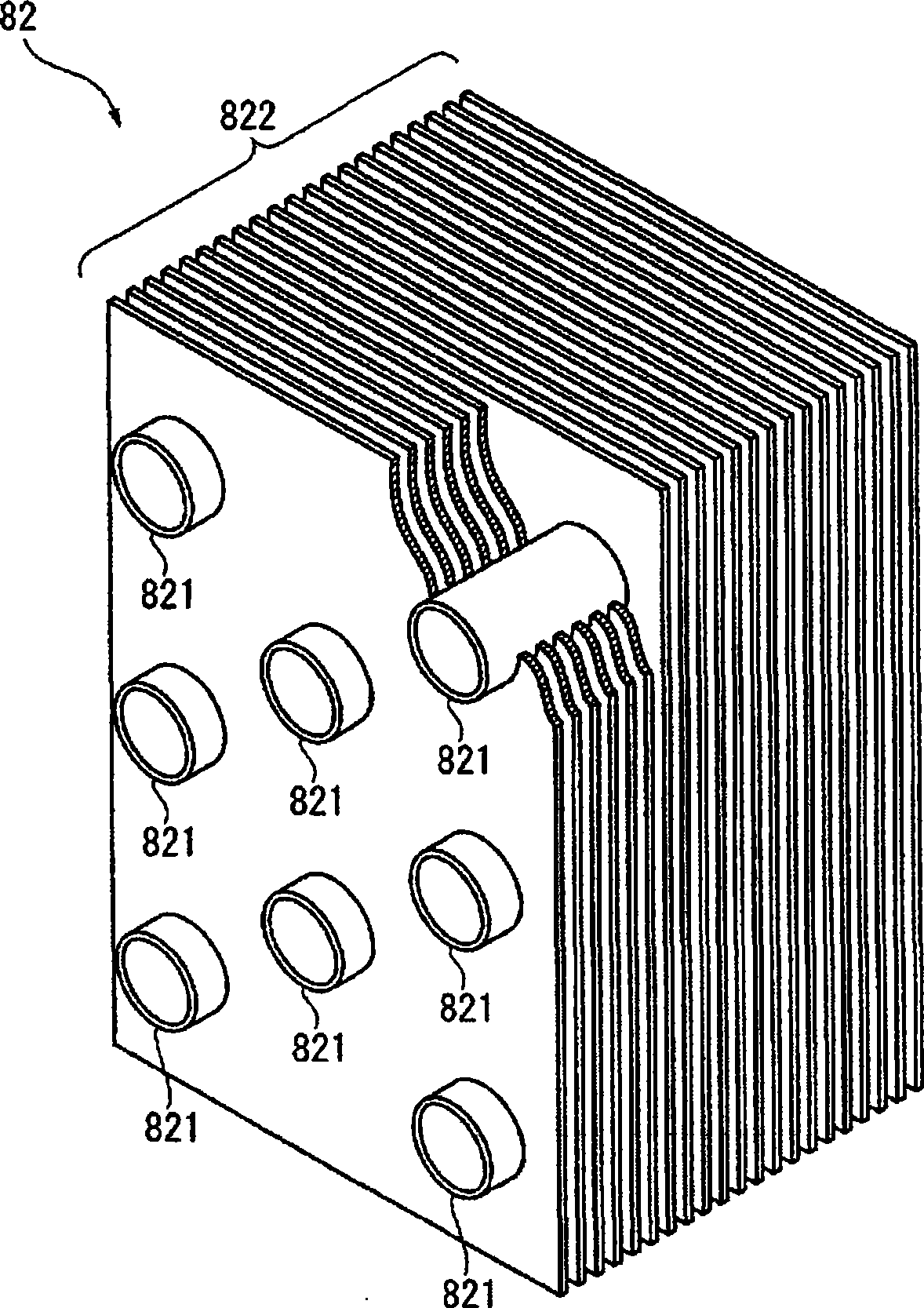

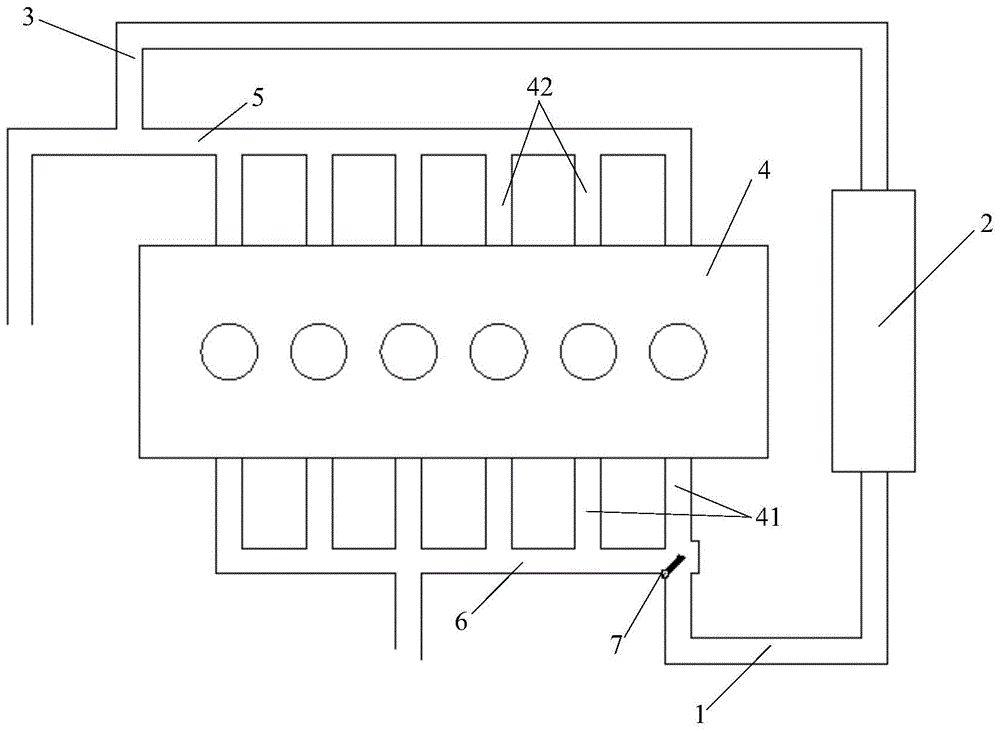

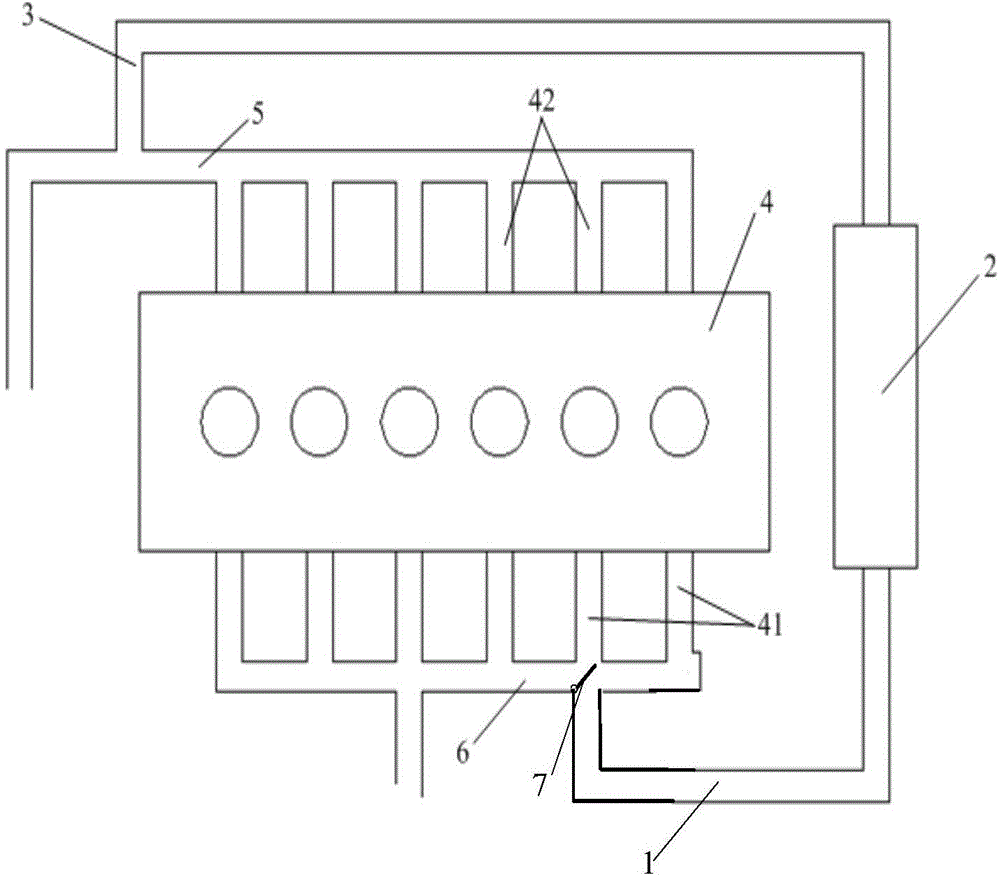

Exhaust gas recirculation system

InactiveCN101389850AImprove cooling effectLossy reduction effectNon-fuel substance addition to fuelInternal combustion piston enginesExhaust gas recirculationInlet manifold

An exhaust gas recirculation system comprises an exhaust line (4) connected with an exhaust manifold (41) of an engine (1), an intake line (3) connected with an intake manifold (31) of the engine (1), and an EGR line (7) short-circuiting the exhaust line (4) and the intake line (3). The exhaust gas recirculation system supplies a portion of the exhaust gas discharged from the exhaust line (4) to the intake line (3) through the EGR line (7) and recirculates the exhaust gas to the engine (1). A liquid-cooling type cooling means (8) equipped with a heat exchanger (82) composed of a corrosion-resistant member is provided on the downstream side of the connecting position of the EGR line (7) in the intake line (3).

Owner:KOMATSU LTD

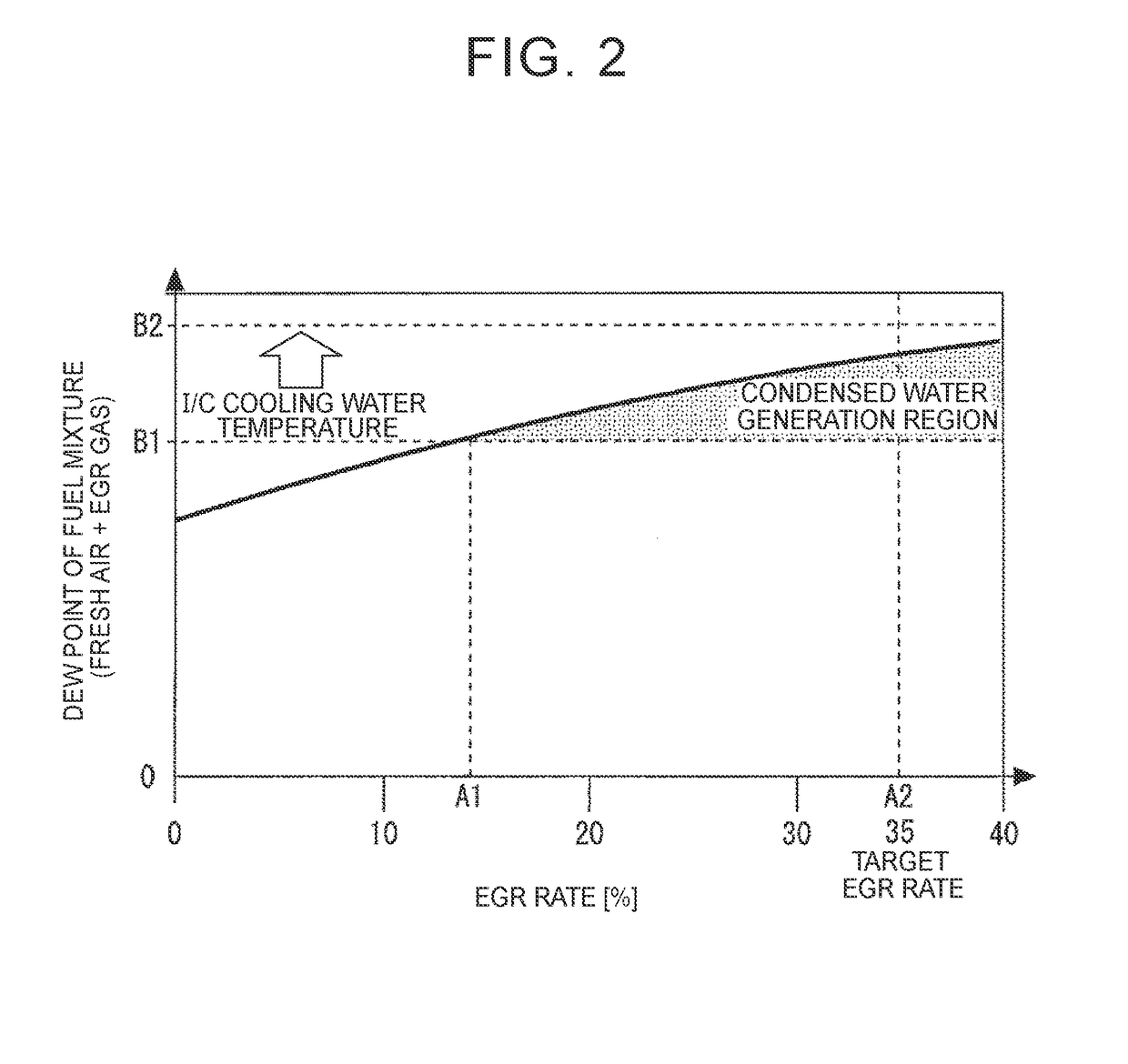

Control device for internal combustion engine and control method for internal combustion engine

ActiveUS20180245546A1Decrease in thermal efficiencyImprove thermal efficiencyElectrical controlInternal combustion piston enginesElectronic control unitIntercooler

An internal combustion engine includes an intercooler configured to cool an intake gas compressed by a compressor, a cooler bypass passage configured to bypass the intercooler, and a cooler bypass valve configured to open and close the cooler bypass passage, and an exhaust gas recirculation gas is introduced into an upstream side of the intercooler. An electronic control unit is configured to open the cooler bypass valve during use of a high exhaust gas recirculation rate region, and to close the cooler bypass valve during use of a low exhaust gas recirculation rate region.

Owner:TOYOTA JIDOSHA KK

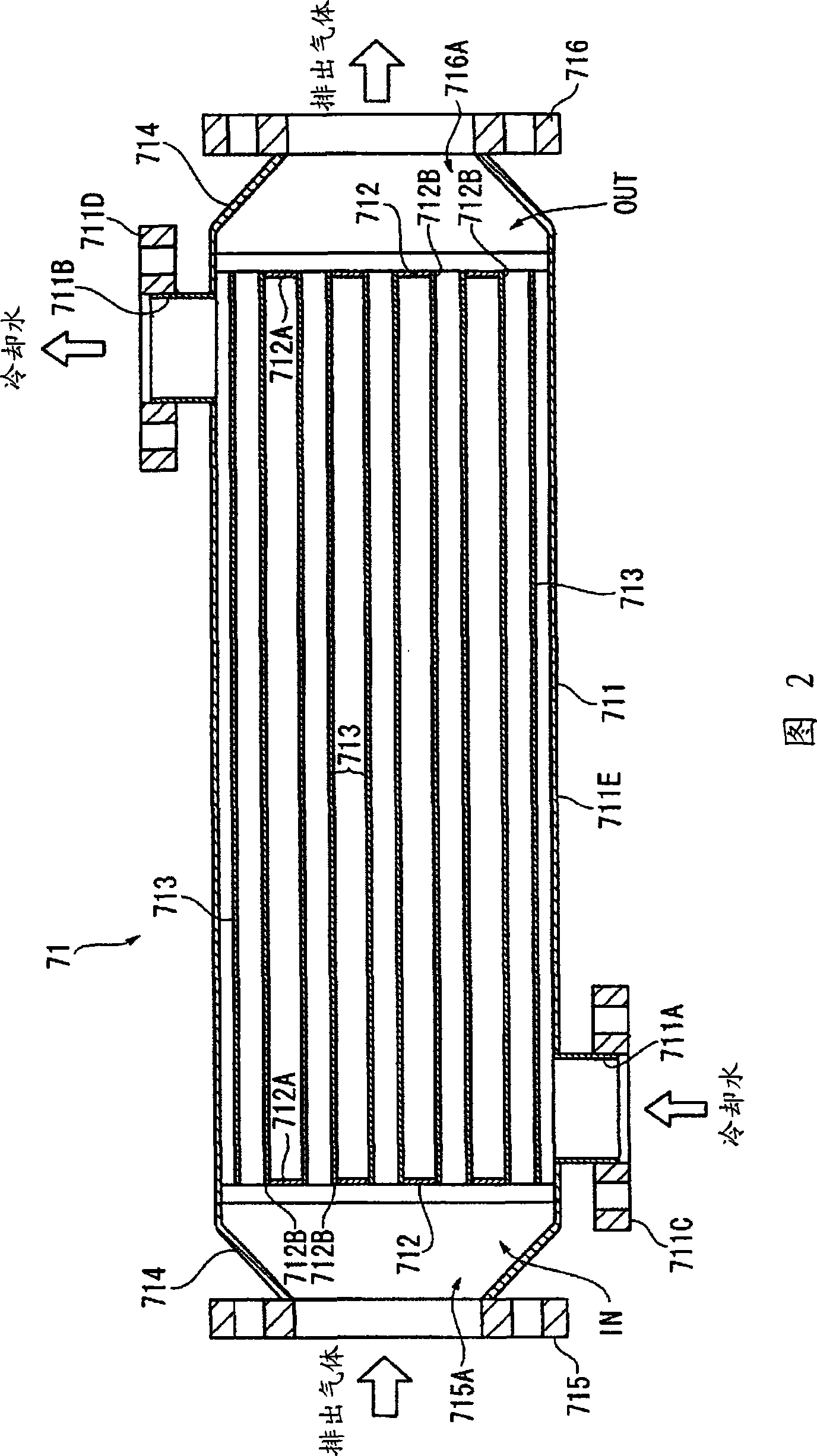

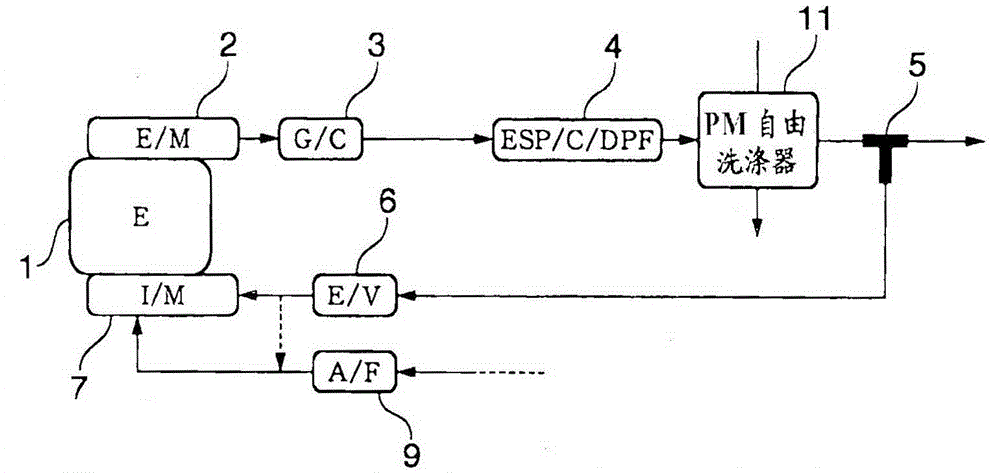

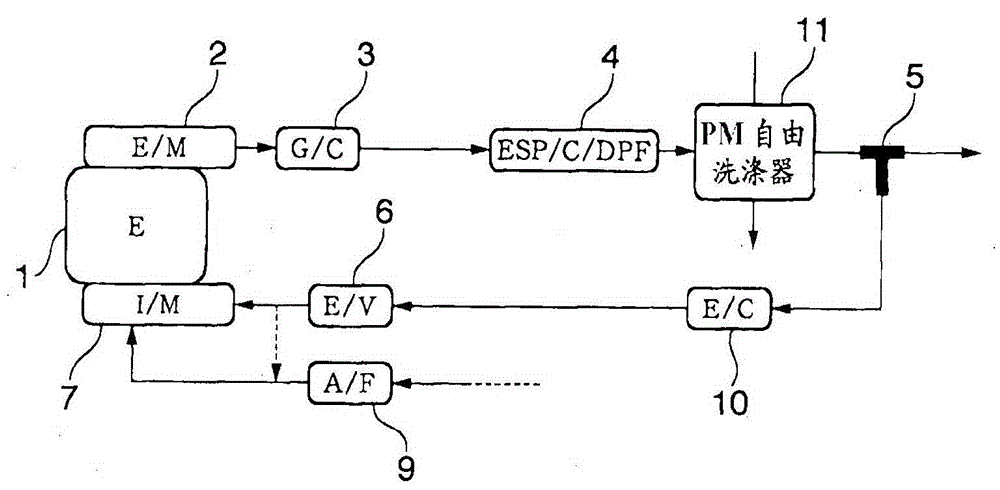

Exhaust gas purification device for marine diesel engine using low-quality fuel such as fuel oil containing high concentration of sulfur

InactiveCN105143619ASave man hoursSimple processCombination devicesGas treatmentHigh concentrationCyclone

Provided is an exhaust gas purification device for a marine diesel engine which enables treatment discharge water to be discharged into special marine areas, and enables waste treatment water to be discharged into areas other than special marine areas even when the vessel is moving, particularly in exhaust gas treatment in a marine diesel engine that uses fuel with a quality equal to or lower than that of fuel oil. In this exhaust gas purification device for a marine diesel engine using fuel with a quality equal to or lower than that of fuel oil, a gas cooler is provided in the exhaust gas path or an EGR gas path, an electrostatic cyclone exhaust gas purification device is provided downstream from the gas cooler, and a PM-free scrubber which dissolves / removes almost no PM is provided downstream from an electric dust-trapping means.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Exhaust gas recirculation system and engine

InactiveCN109356752AAvoid lostAvoid rising fuel consumptionInternal combustion piston enginesExhaust gas recirculationTurbochargerExhaust gas recirculation

The invention discloses an exhaust gas recirculation system and an engine. The exhaust gas recirculation system comprises a first turbosuperchager and a second turbosuperchager which are in series connection. An outlet of a power turbine of the second turbosuperchager is connected with an exhaust pipe, an inlet of a gas compressor of the second turbosuperchager communicates with the exhaust pipe through an EGR gas getting pipe, an outlet of the gas compressor of the second turbosuperchager communicates with a gas inlet manifold through a low-pressure EGR waste gas pipe, the system repeatedly uses waste gas energy to push power turbines of the two stages of turbosuperchagers, the waste gas use rate is improved, energy losses brought by front getting of waste gas of the turbosuperchagers canbe reduced, the first turbosuperchager can be matched with the efficient gas compressor, the oil losses are reduced, the exhaust temperature is improved, the conversion efficiency of a post-treatmentsystem is improved, meanwhile, the EGR gas pressure and waste gas amount can be improved, a gas inlet throttling valve is not needed, the conditions of pump gas losses, engine oil consumption increasing, particle discharge increasing and the like are avoided, and engine economy is improved.

Owner:WEICHAI POWER CO LTD

Waste gas recirculating system, motor vehicle, and control method of waste gas recirculating system

InactiveCN104895705AReduce lossesIncrease EGR rateInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesButterfly valve

The invention provides a waste gas recirculating system, a motor vehicle, and a control method of the waste gas recirculating system. The system comprises an EGR before-cooling pipeline, an EGR cooler, an EGR after-cooling pipeline, an engine, an air intake main pipe, an exhaust main pipe and an EGR butterfly valve, wherein at least one exhaust manifold of the engine is connected with the exhaust main pipe and the EGR before-cooling pipeline through the EGR butterfly valve. When the EGR butterfly valve is in a first state, at least one exhaust manifold is communicated with the EGR before-cooling pipeline; waste gas discharged by the at least one exhaust manifold enters the EGR cooler by the EGR before-cooling pipeline for cooling; the cooled waste gas is input into the air intake main pipe by the EGR after-cooling pipeline, and is led into the engine by the air intake main pipe. When the EGR butterfly valve is in a second state, at least one exhaust manifold is communicated with the exhaust main pipe, and the waste gas discharged by the at least one exhaust manifold is exhausted by the exhaust main pipe. The system can enhance the EGR rate and reduce the conditions of pumping loss and air inflow reduction of the engine.

Owner:WEICHAI POWER CO LTD

Outside waste gas recirculation system and operating method thereof

PendingCN108506119AStable combustionKnock suppressionElectrical controlInternal combustion piston enginesCombustionExhaust fumes

The invention provides an outside waste gas recirculation system and an operating method thereof. The outside waste gas recirculation system comprises an engine, a gasoline supply system, a single-cylinder EGR system, a multi-cylinder EGR system and a natural gas supply system. The engine comprises at least two cylinders, one of the cylinders is a combined combustion cylinder, at least one of thecylinders is a gasoline cylinder, and the combined combustion cylinder combusts a thick mixture of gasoline and natural gas; the gasoline supply system supplies gasoline to all the cylinders; the natural gas supply system supplies natural gas to the combined combustion cylinder; the single-cylinder EGR system is connected with an air vent of the combined combustion cylinder and air inlets of all the cylinders; and the multi-cylinder EGR system is connected with air vents of all the gasoline cylinders and the air inlets of all the cylinders. By means of the outside waste gas recirculation system and the operating method thereof, stable combustion with the EGR rate of 25%-50% is achieved, and oil consumption of the engine is reduced.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Engine with adjustable DEGR system

InactiveCN107387270AThe principle is simpleIncrease EGR rateExhaust apparatusExhaust gas recirculationEngineeringControl valves

The invention discloses an engine with an adjustable DEGR system, which includes an intake system and an exhaust system. The intake system includes a main intake pipe and an intake manifold connected to each cylinder respectively. The cylinders are divided into The first cylinder and the second cylinder, the exhaust system includes a first exhaust manifold communicated with the first working cylinder and a second exhaust manifold communicated with the second cylinder, the second exhaust manifold communicates Below is a control valve that controls the choice of exhaust gas to be routed to the supercharger turbine or the intake system. The engine with the adjustable DEGR system of the invention has a simple principle and is easy to realize in terms of structure, has high EGR rate, good fuel economy, good power performance, and has good application prospect.

Owner:CHERY AUTOMOBILE CO LTD

Combustion stability enhancement via internal EGR control

ActiveUS8733320B2High combustionIncrease temperatureNon-fuel substance addition to fuelInternal combustion piston enginesCombustionAutomotive engineering

A method for controlling combustion in a cylinder of a turbocharged engine in which intake air is reserved upstream of the cylinder. The method comprises decreasing an internal EGR rate in the cylinder during a tip-out condition if the temperature of the intake air is above a threshold, and increasing the internal EGR rate in the cylinder during a tip-out condition if the temperature of the intake air is below the threshold.

Owner:FORD GLOBAL TECH LLC

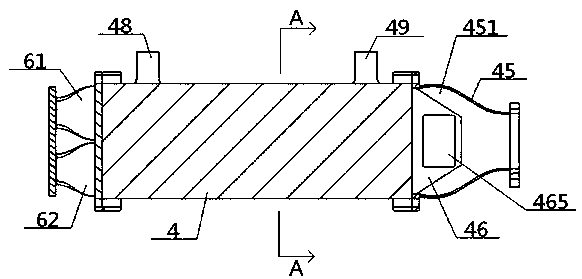

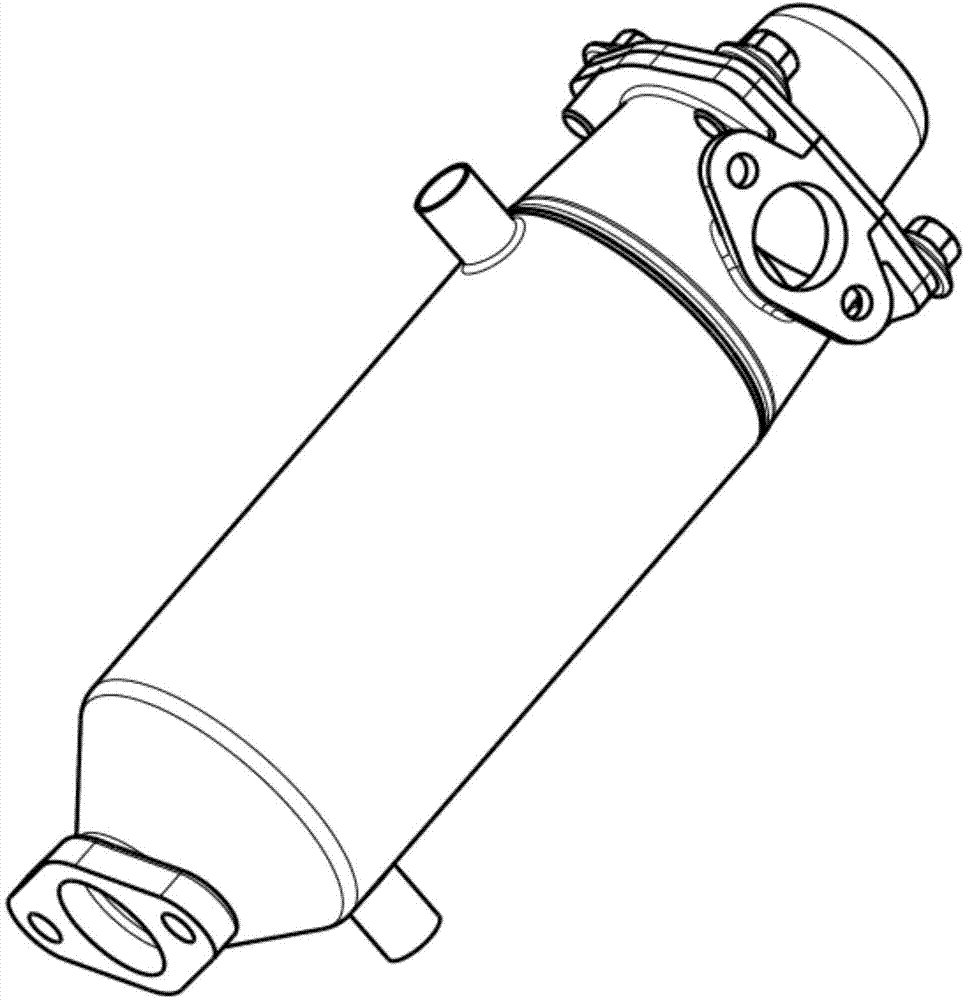

EGR (exhaust gas recirculation) cooler and engine

ActiveCN104847538AIncrease temperatureTemperature controlNon-fuel substance addition to fuelInternal combustion piston enginesPulp and paper industryExhaust gas recirculation

The invention discloses an EGR cooler comprising a shell, a heat exchange tube stack, an end cap and an adjusting device. The adjusting device comprises a rotary driving portion and a rotary plate in drive connection with the rotary driving portion, and the rotary plate is provided with a first waste gas via hole. The end cap comprises a cap body and an adjusting plate fixed to the cap body, the cap body is provided with a waste gas inlet communicated with the first waste gas via hole, multiple second waste gas via holes are formed in the adjusting plate and respectively communicated with multiple heat exchange tube bundles arranged in the heat exchange tube stack and unequal in heat exchange area, the rotary plate has a rotary stroke relative to the adjusting plate, and in the rotary stroke of the rotary plate, the first waste gas via hole is communicated with the second waste gas via holes in sequence. The EGR cooler is compatible to two operating conditions of low exhaust temperature and small EGR rate and high exhaust temperature and large EGR rate, temperature of cooled waste gas is more accurately controlled according to the different operating conditions, and arrangement of internal parts of an engine is facilitated. The invention further discloses the engine.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

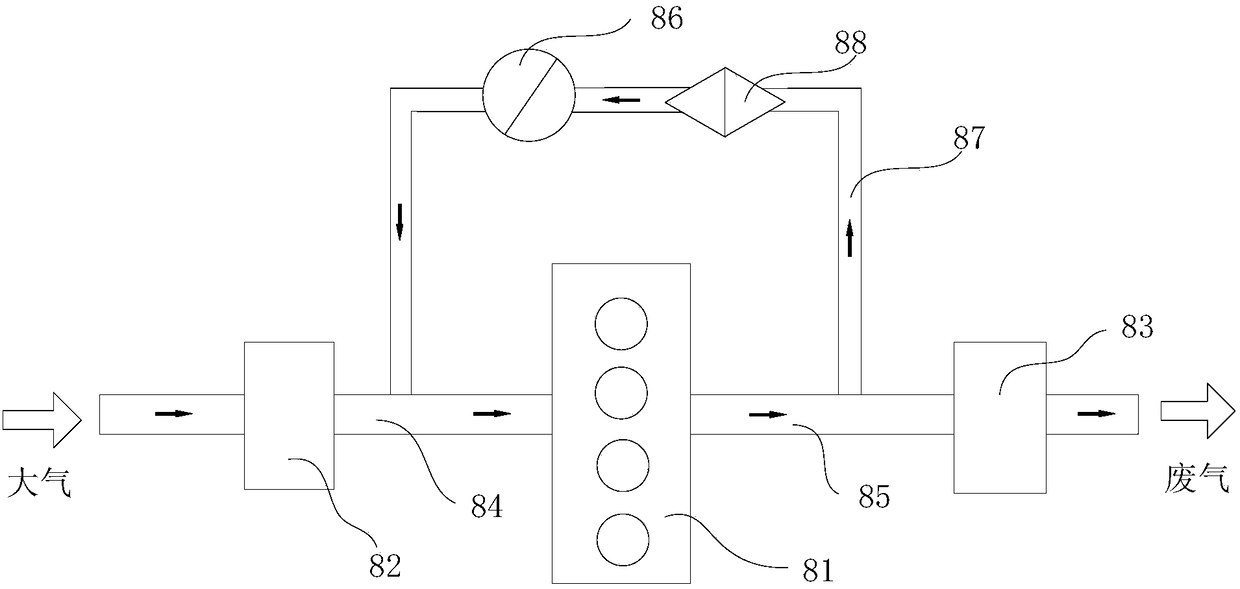

Low pressure EGR system

InactiveCN101368529BImprove cooling effectHomogeneous intakeNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberAir filter

The invention relates to a low-pressure EGR system; the waste gas is extracted from the backside of the particle trap by the EGR system and is forced to be cooled via the first stage cooler and the second stage cooler; the cooled waste gas is controlled and adjusted on the flow rate by the EGR valve to be mixed with the compression air discharged from the air filter in front of the compressor of the supercharger; then the mixed gas is imported into the intercooler and flows into the engine combustion chamber for combustion; wherein, a cooler shares part of the refrigerant of the air-conditioner system of the automobile to cool the EGR waste gas. Under the situation that no extra cooler is added, the cooling effect on the waste gas is improved greatly; the homogeneous intake is provided for the engine, so as to obtain higher EGR rate.

Owner:CHERY AUTOMOBILE CO LTD

EGR system and engine

InactiveCN110230556AIncrease EGR rateExhaust gas recirculationMachines/enginesExhaust gasAutomotive engineering

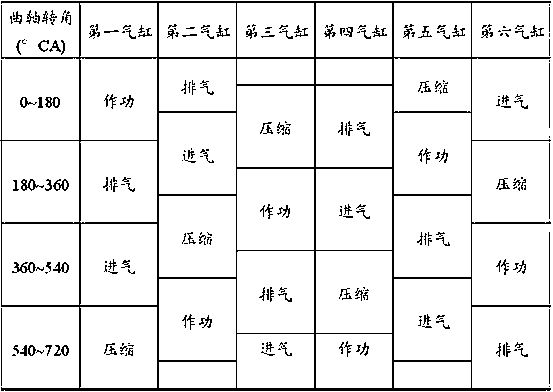

The invention discloses an EGR system and an engine. The EGR system is used for a multi-cylinder four-valve engine. Each cylinder of the engine is provided with a first exhaust passage and a second exhaust passage. The EGR system comprises an EGR gas pipe. A gas inlet of the EGR gas pipe is connected with the first exhaust passages of the at least two cylinders. The spaced crank angle of exhaust strokes of every two adjacent cylinders connected with the EGR gas pipe is greater than or equal to 180 degrees CA. A gas outlet of the EGR gas pipe is connected to a gas inlet pipe of the engine. According to the EGR system, the first exhaust passages of the two or more cylinders of the engine are connected to the EGR gas pipe; exhaust gas of the first exhaust passages is directly taken as an EGRgas source; meanwhile, the exhaust strokes of the adjacent cylinders are staggered, the offsetting and interference effect of exhaust pulses of the two adjacent cylinders is reduced; and accordingly,the exhaust pulses of the engine can be made full use of to improve the EGR gas taking efficiency, and then the EGR rate is increased.

Owner:WEICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com