Controllable EGR system using integrated dual-channel EGR cooler

An EGR cooler and dual-channel technology, applied in the field of EGR systems, can solve the problems of limited EGR temperature adjustment range, no vortex pre-throttling function, and inability to realize EGR rate, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

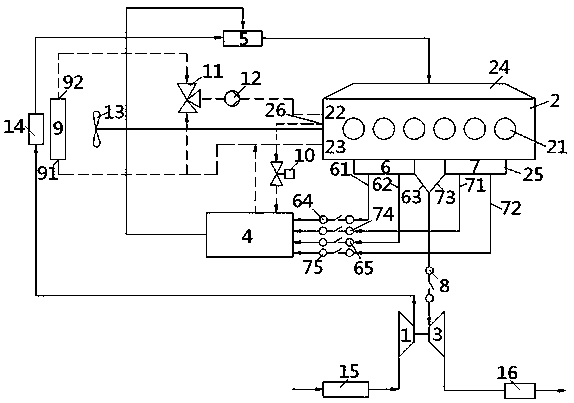

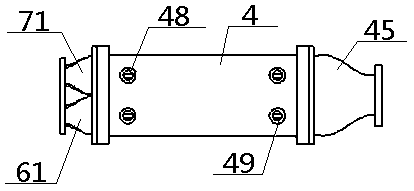

[0055] see Figure 1 to Figure 7 , a controllable EGR system using an integrated dual-channel EGR cooler, including a compressor 1, an engine 2, a turbine 3, an integrated cooler 4 and a mixer 5, and the compressor 1 is connected to the engine 2 through an intake manifold 24 The other end of the engine 2 is connected to the turbine 3 through the exhaust manifold 25; the inside of the integrated cooler 4 is provided with a cold one passage 41, a cold two passage 42, a hot one passage 43 and The second heat channel 44, the exhaust manifold 25 includes a first exhaust manifold 6 and a second exhaust manifold 7, and the first exhaust manifold 6 passes through the first A air passage 61 and the first B air passage respectively. Air channel 62, first third air channel 63 are connected with cold one channel 41, hot one channel 43, the intake end of turbine 3, and described second exhaust manifold 7 passes through second first air channel 71, the first third air channel respectively. ...

Embodiment 2

[0057] Basic content is the same as embodiment 1, the difference is:

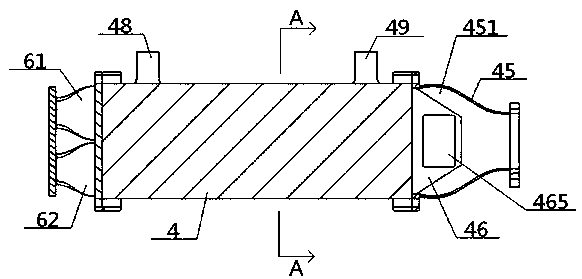

[0058] The integrated cooler 4 includes an air outlet cover 45 and an air outlet chamber 451 provided inside, and a first check valve 46 and a second check valve 47 are arranged inside the air outlet chamber 451; 1. The gas outlets of the first hot channel 43 communicate with the air outlet chamber 451 of the device through the first one-way valve 46, and the gas outlets of the second cold channel 42 and the second hot channel 44 communicate with the air outlet chamber 451 of the device through the second one-way valve 47. connected. The structures of the No. 1 one-way valve 46 and the No. 2 one-way valve 47 are consistent, and both include a valve housing 461 and a valve inner chamber 462 provided therein. Both sides of the valve housing 461 are provided with a left valve port 463 and a right valve port. Valve port 464, left valve port 463, right valve port 464 are respectively provided with corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com