Patents

Literature

596 results about "Left valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On the left side of the heart is the mitral or left atrioventricular valve and on the right side the tricuspid valve is the conduit between right atrium and right ventricle.

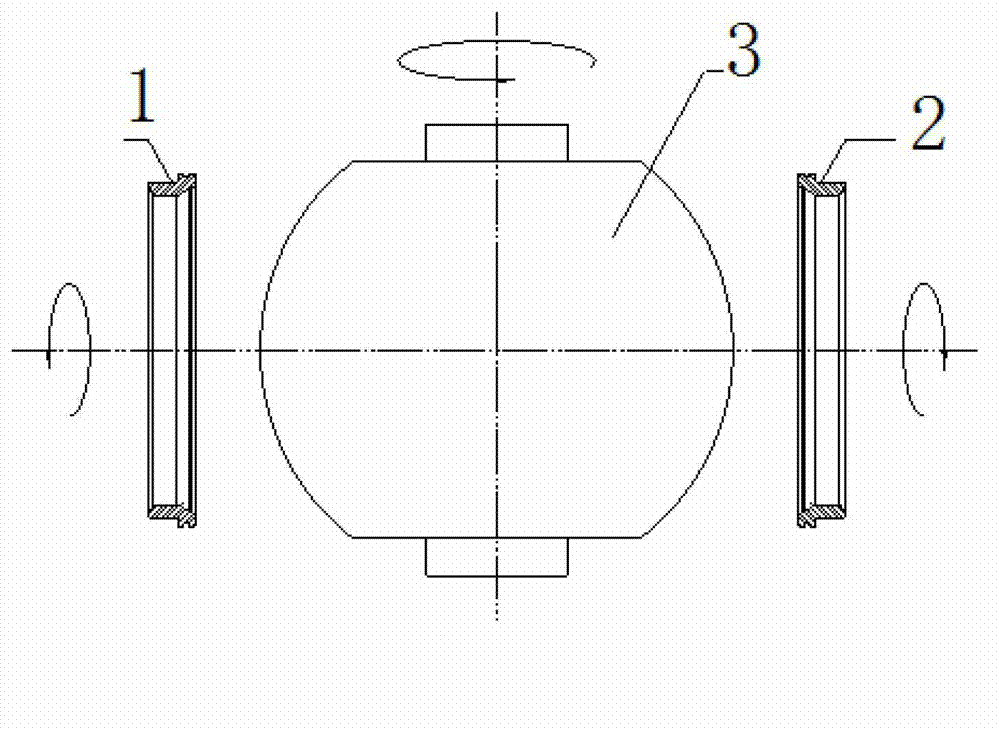

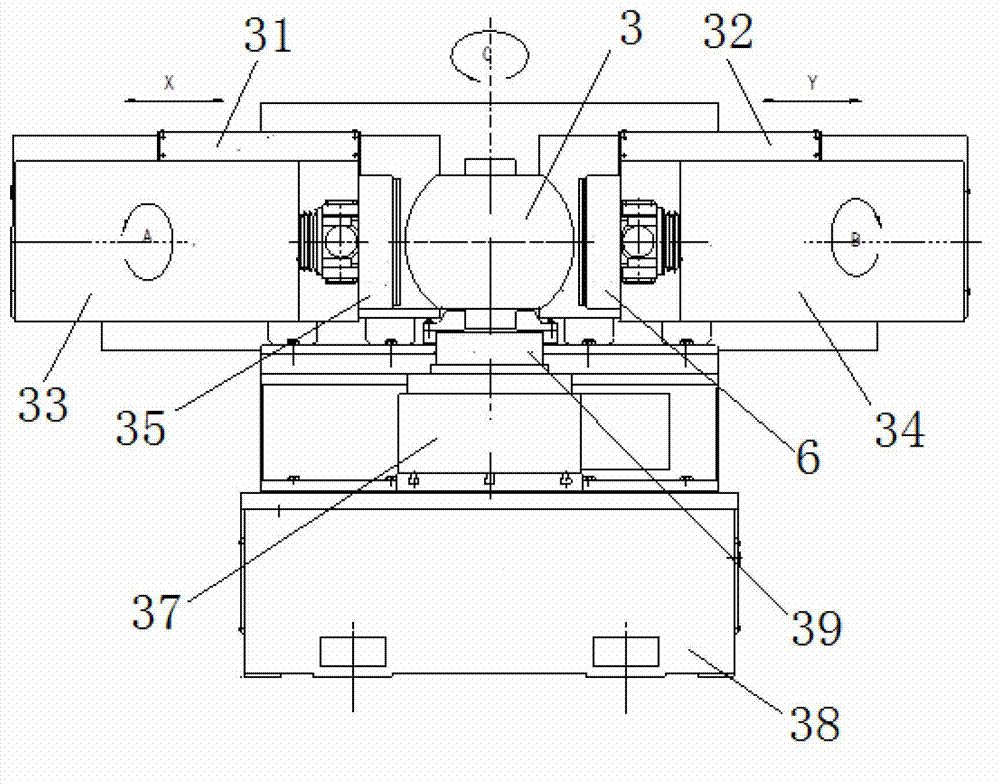

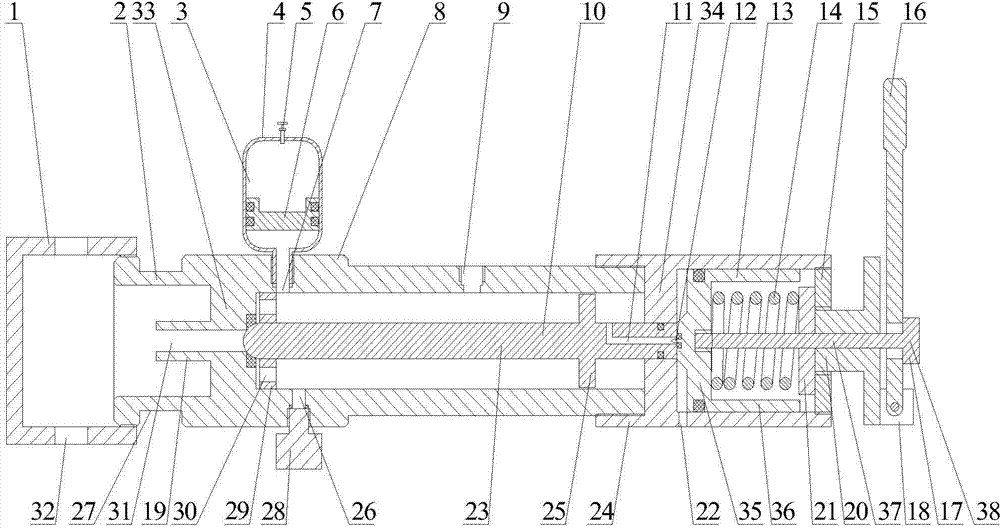

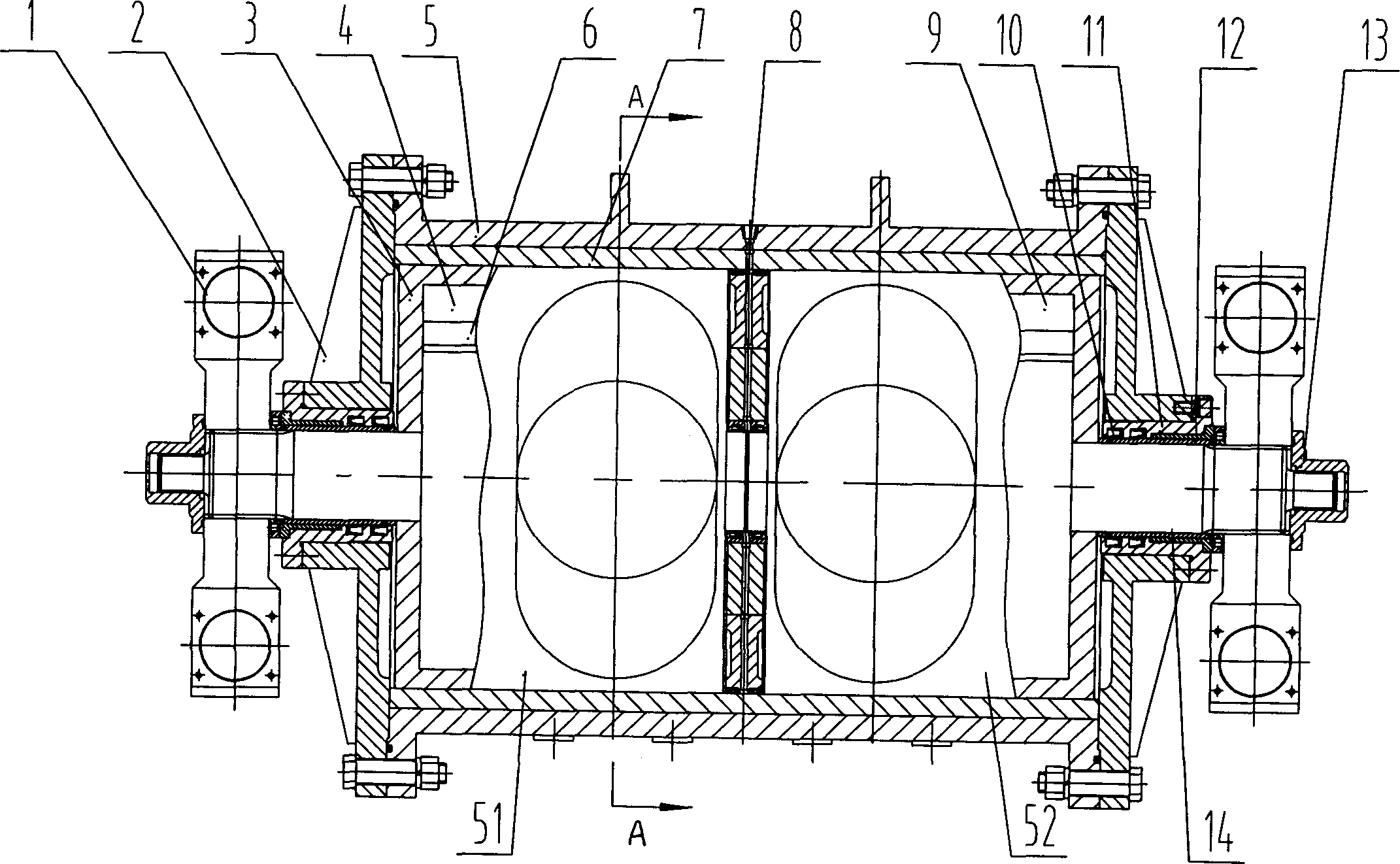

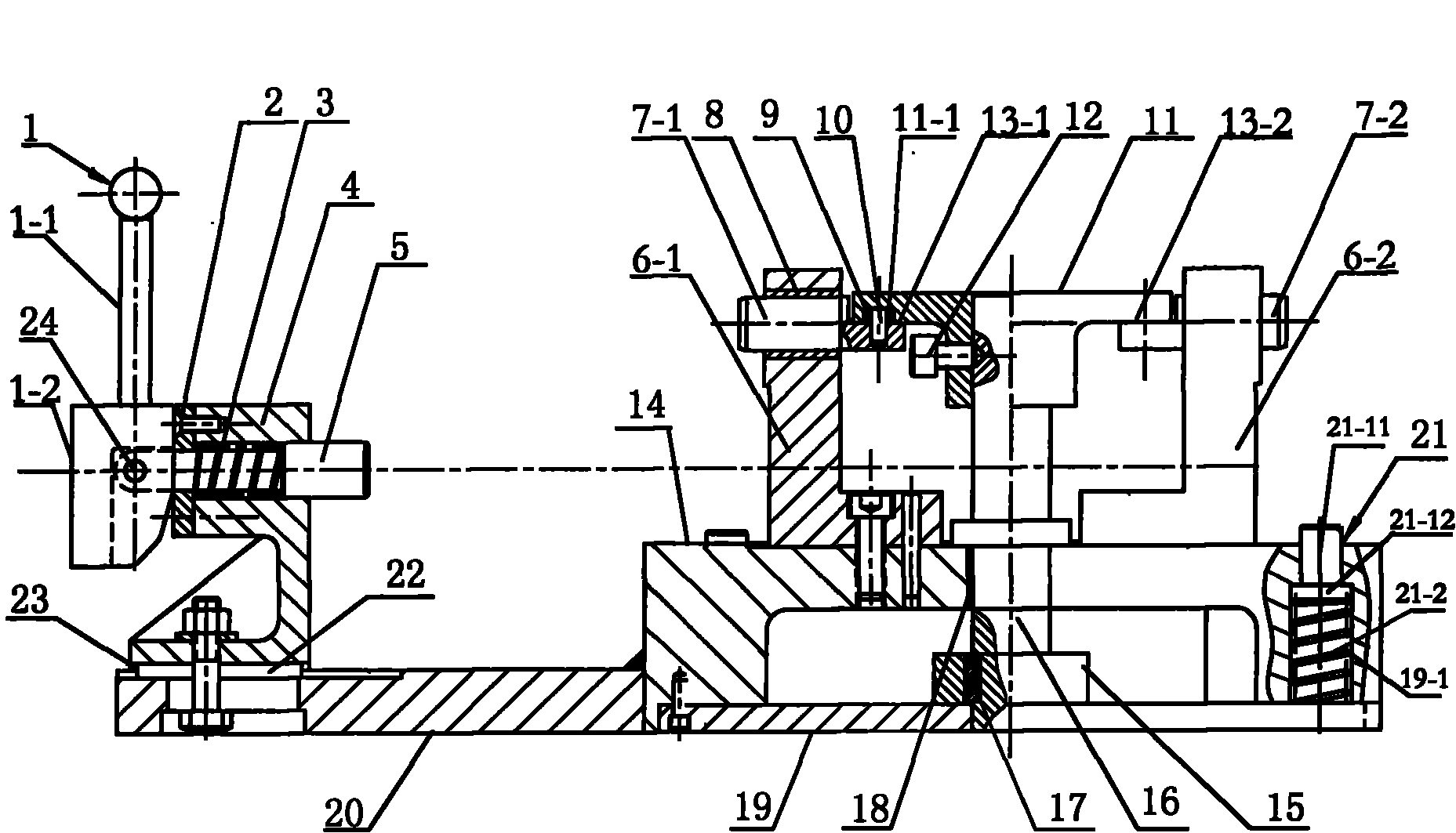

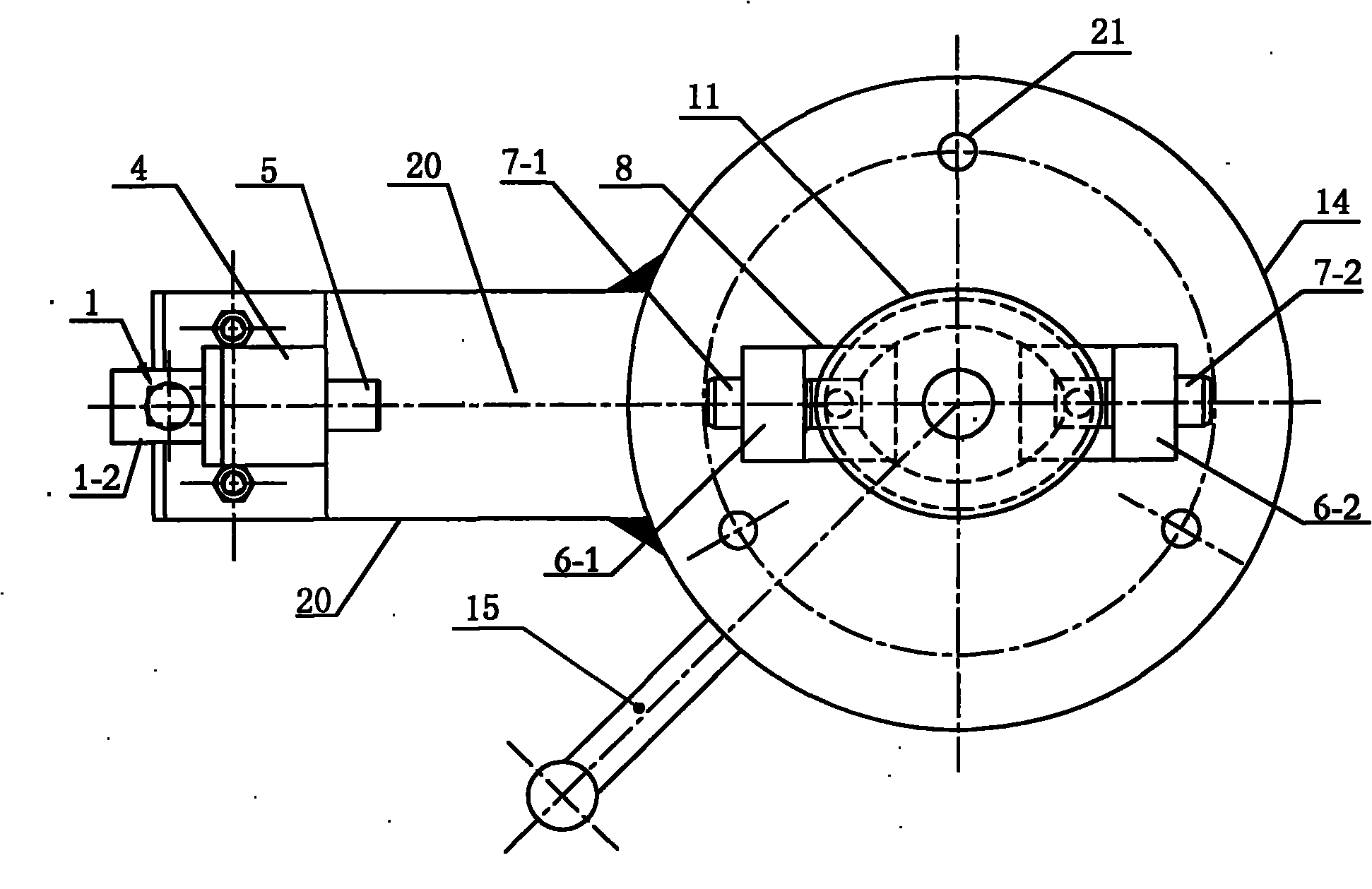

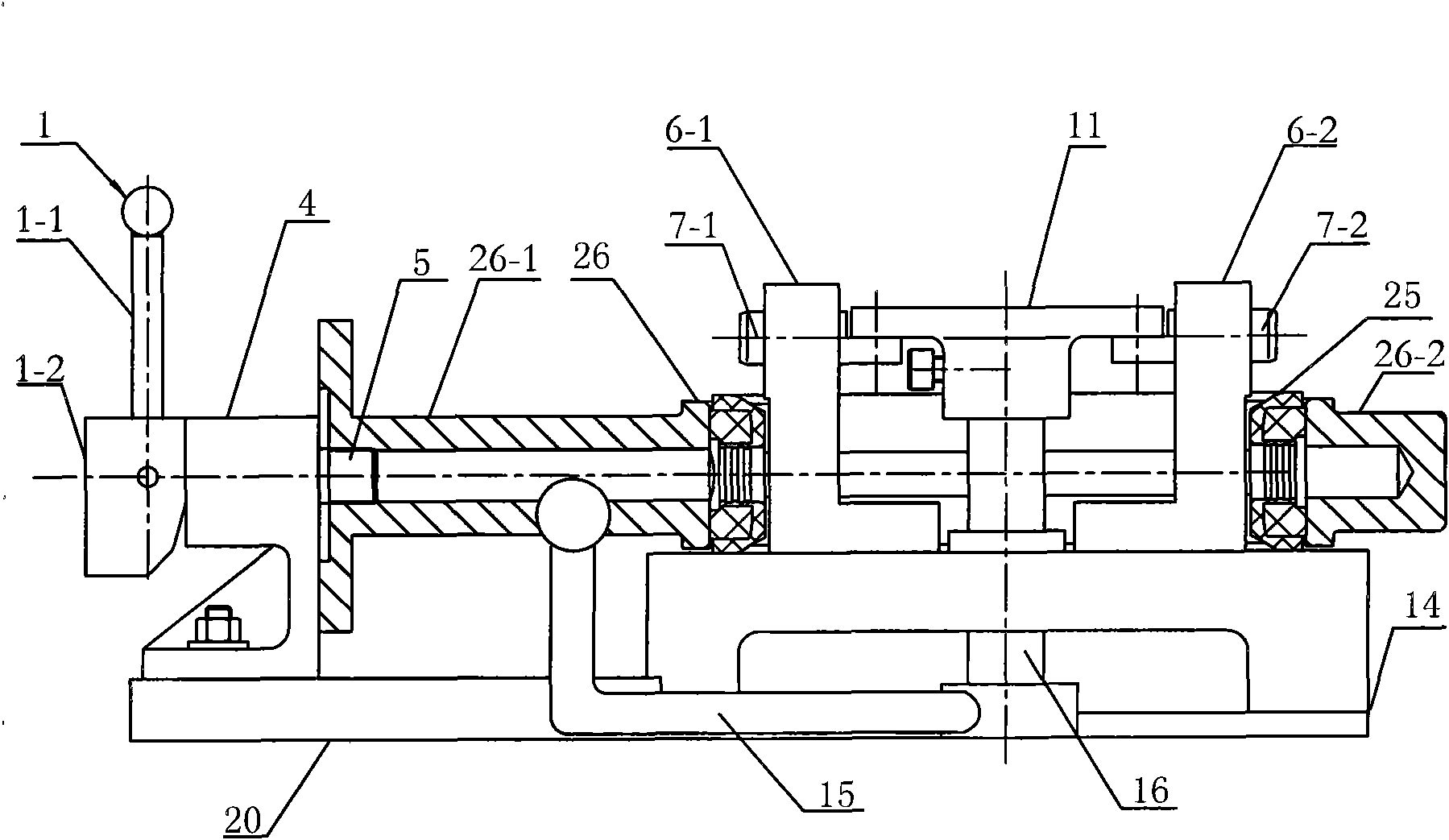

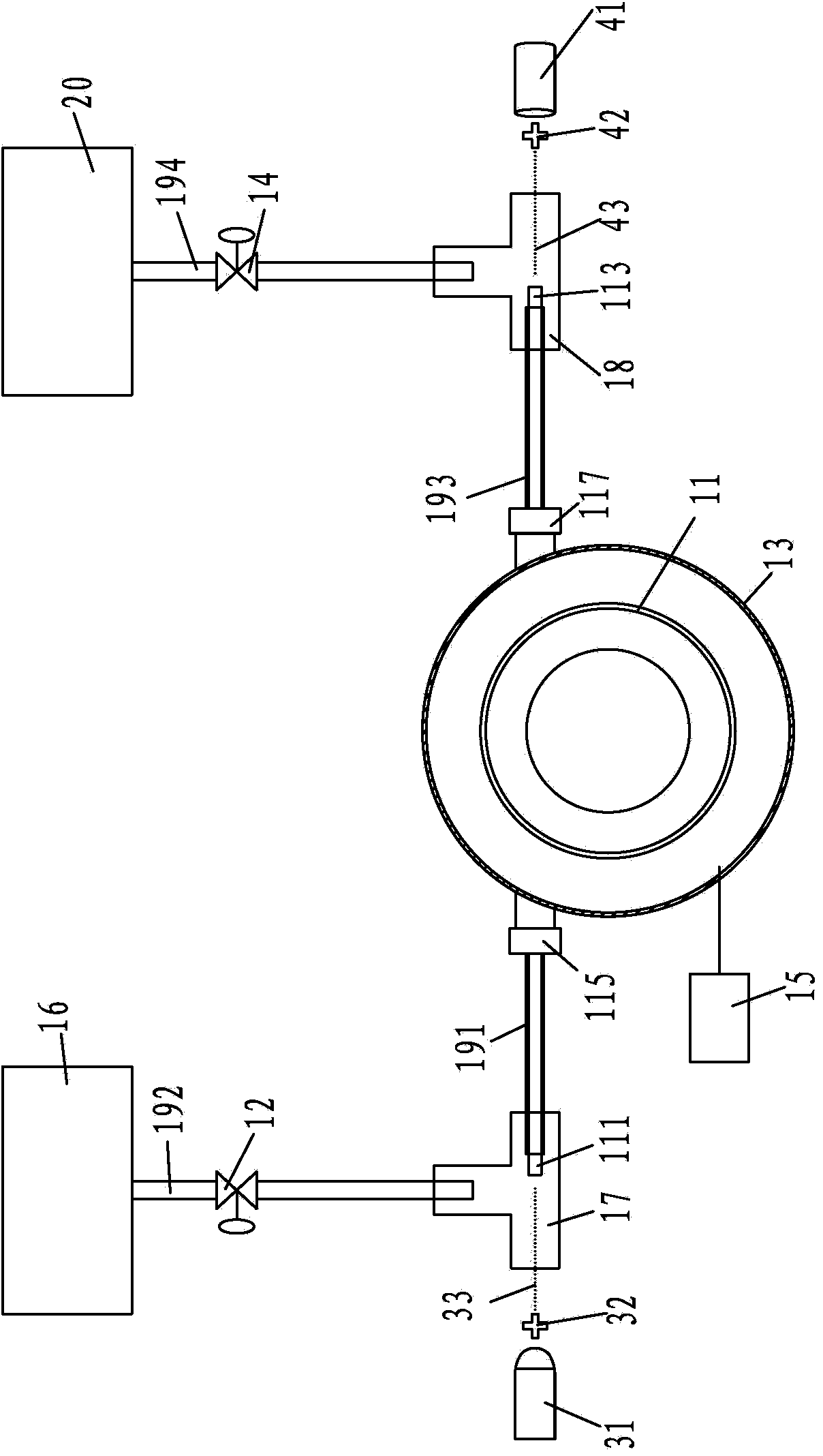

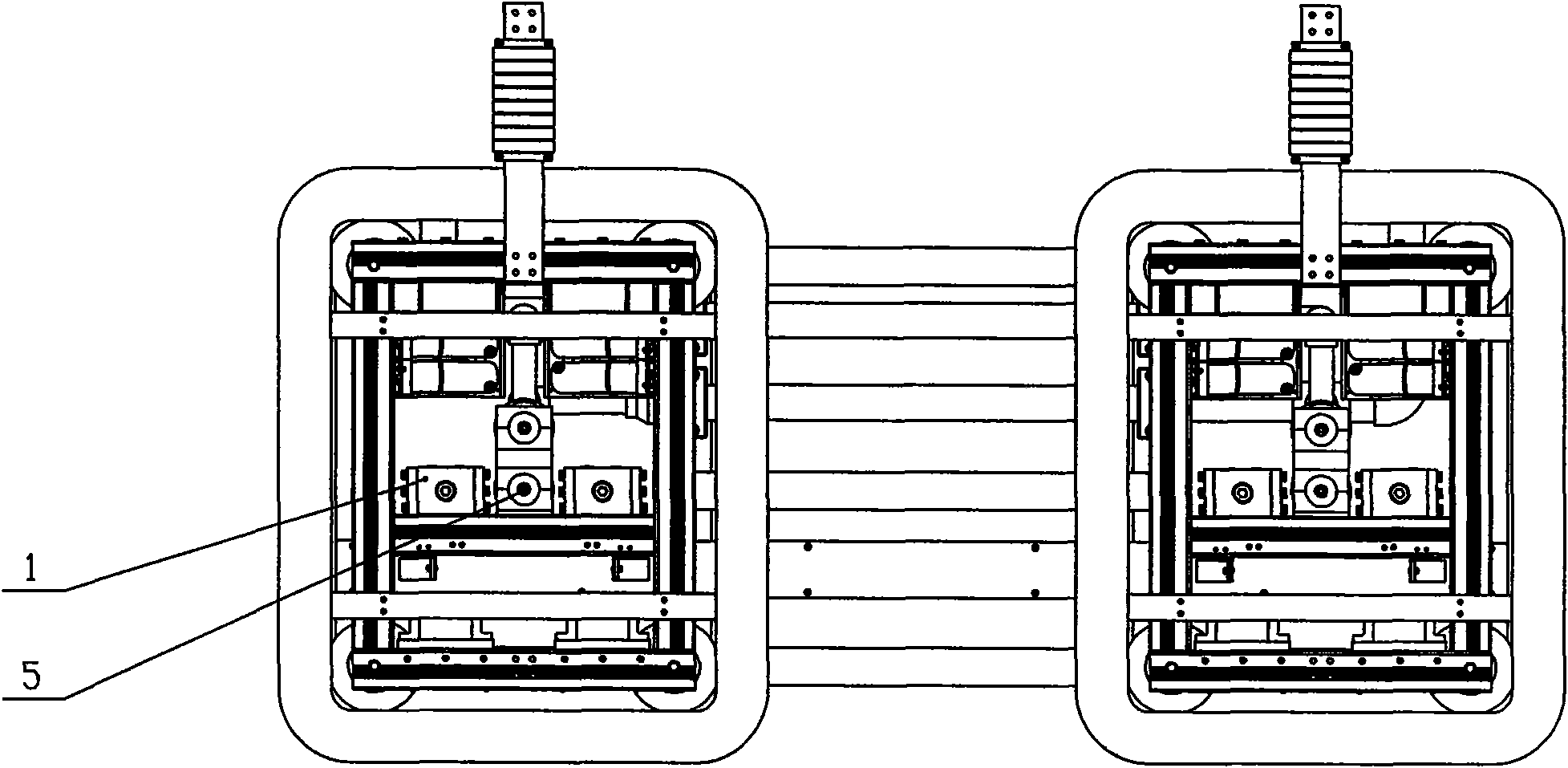

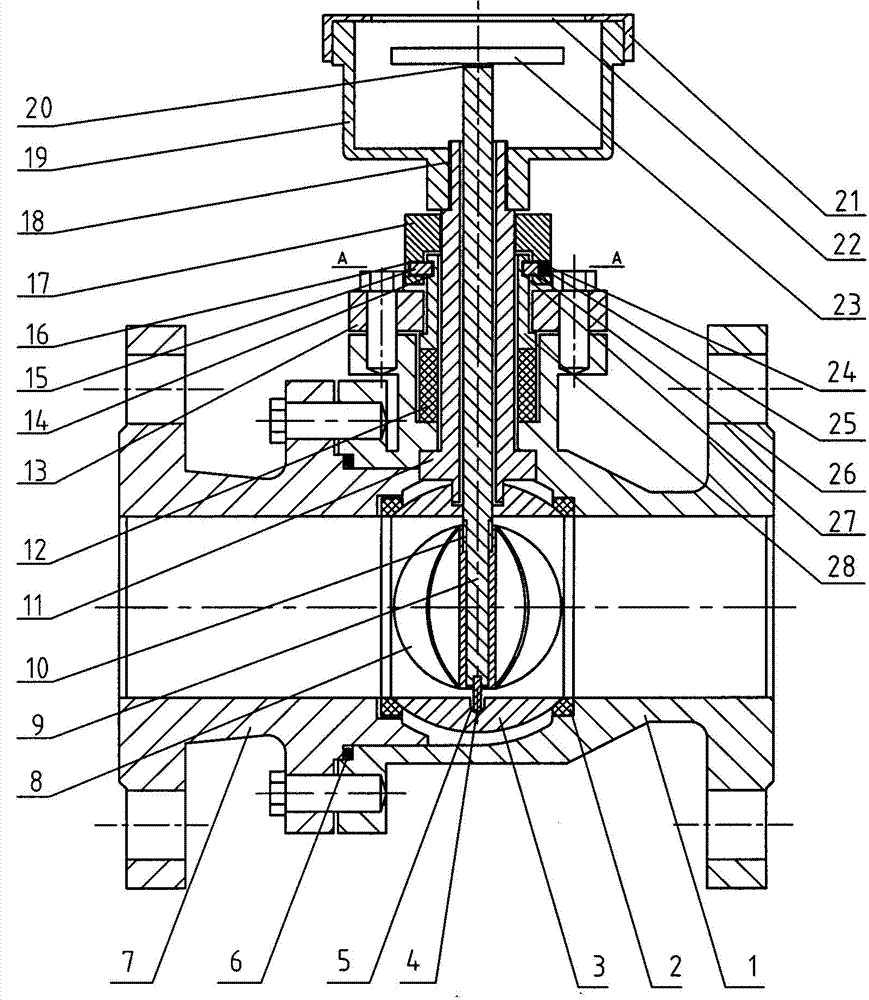

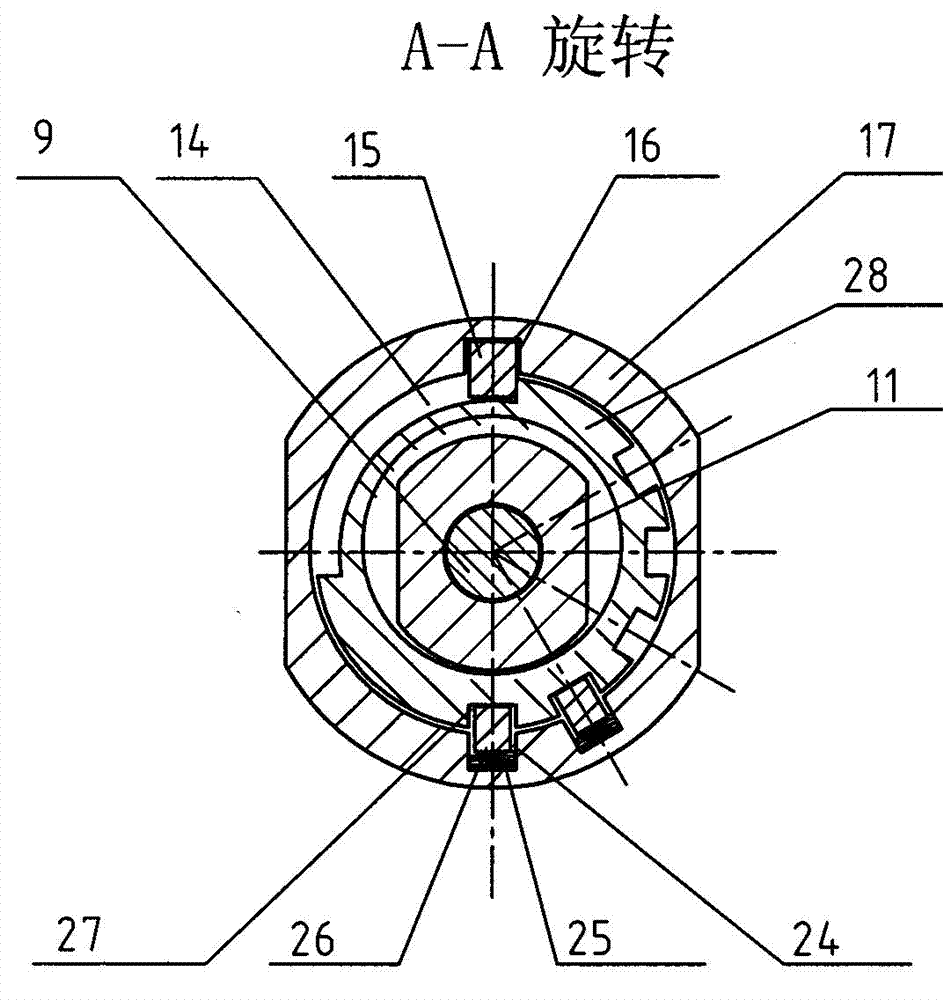

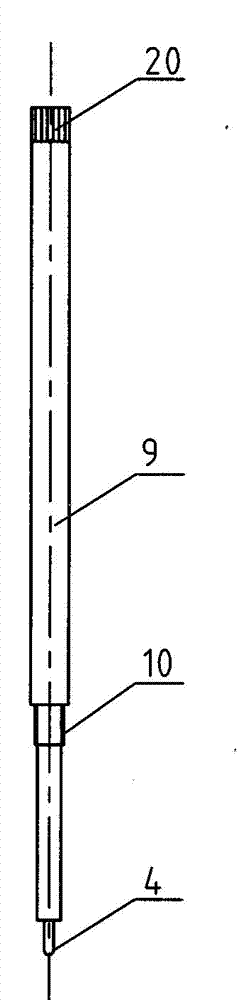

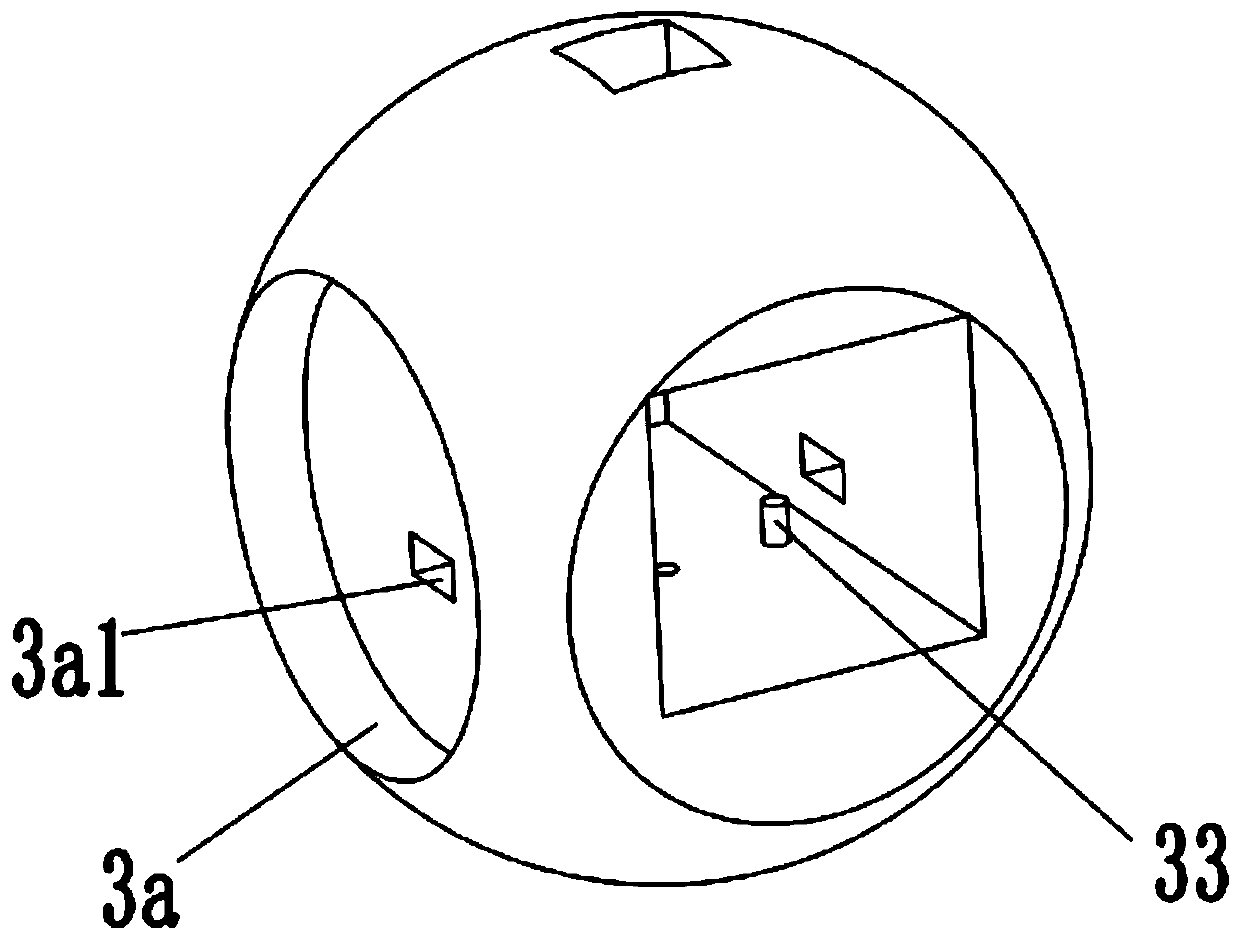

Numerical control spherical pair grinder and grinding method

InactiveCN102848301AImprove processing efficiencyProcessing quality is easy to guaranteeLapping machinesWork carriersNumerical controlPhysical hard work

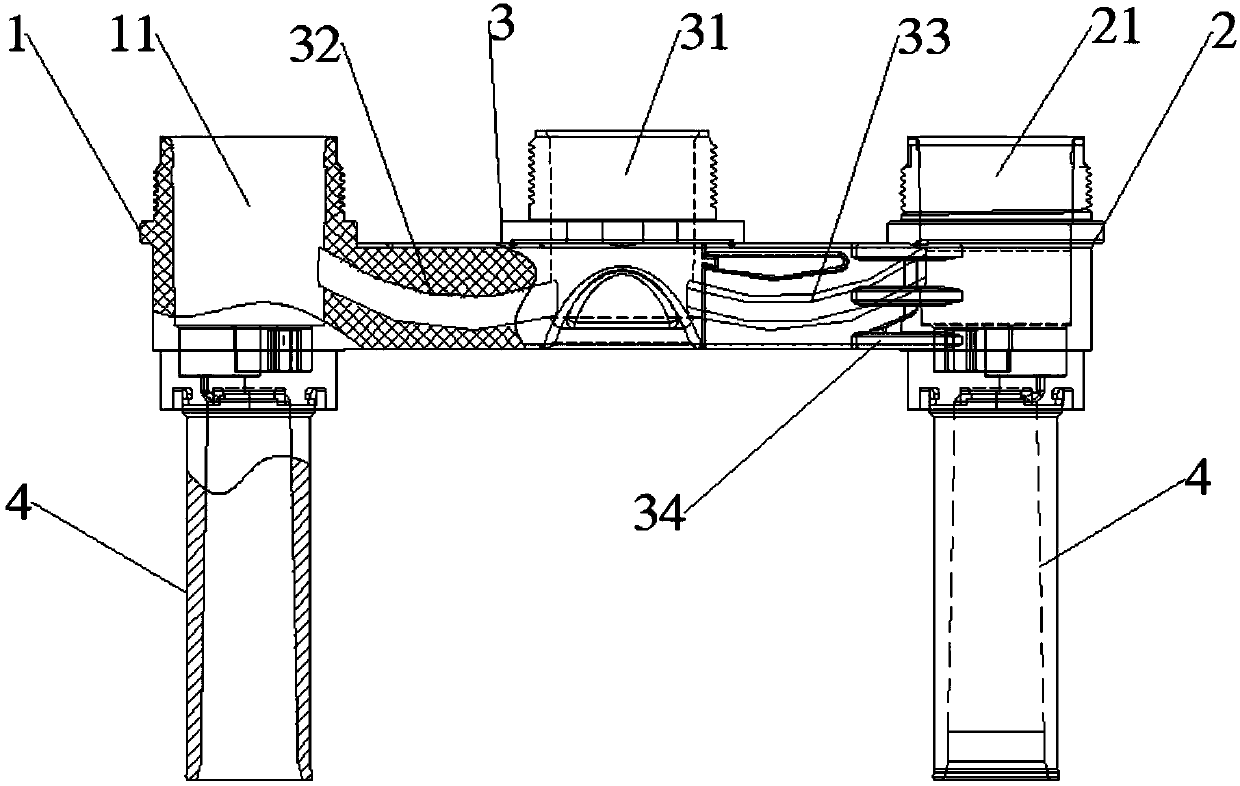

The invention relates to a numerical control spherical pair grinder and a grinding method and belongs to the field of machine manufacturing. In a machining process, a sphere rotates along an axis of the sphere, and valve seats of two sealing seats respectively rotate in a plane vertical to a rotating axis of the sphere; in a mutual grinding process, the valve seats of the two sealing seats are contacted with the sphere, and a grinding positive pressure is applied; and a grinding track is synthesized by two rotating movements. In the numerical control spherical pair grinder, a lathe bed is connected with a numerical control rotary table, a left numerical control slide plate and a right numerical control slide plate; the numerical control rotary table is connected with a sphere fixture; the left numerical control slide plate is connected with a left valve seat spindle box; the left valve seat spindle box is connected with a left valve seat fixture; the right numerical control slide plate is connected with a right valve seat spindle box; the right valve seat spindle box is connected with a right valve seat fixture; and the processed sphere is connected with the sphere fixture. The numerical control spherical pair grinder and the grinding method have the advantages that the machining effect is improved by more than five times, the machining quality is easily guaranteed, the machining speed can be improved, the precision of the grinded shape of the sphere and the sealing effect can be improved, and the heavy physical labor can be ridded.

Owner:BEIJING QINGFENGDA PRECISION TECH

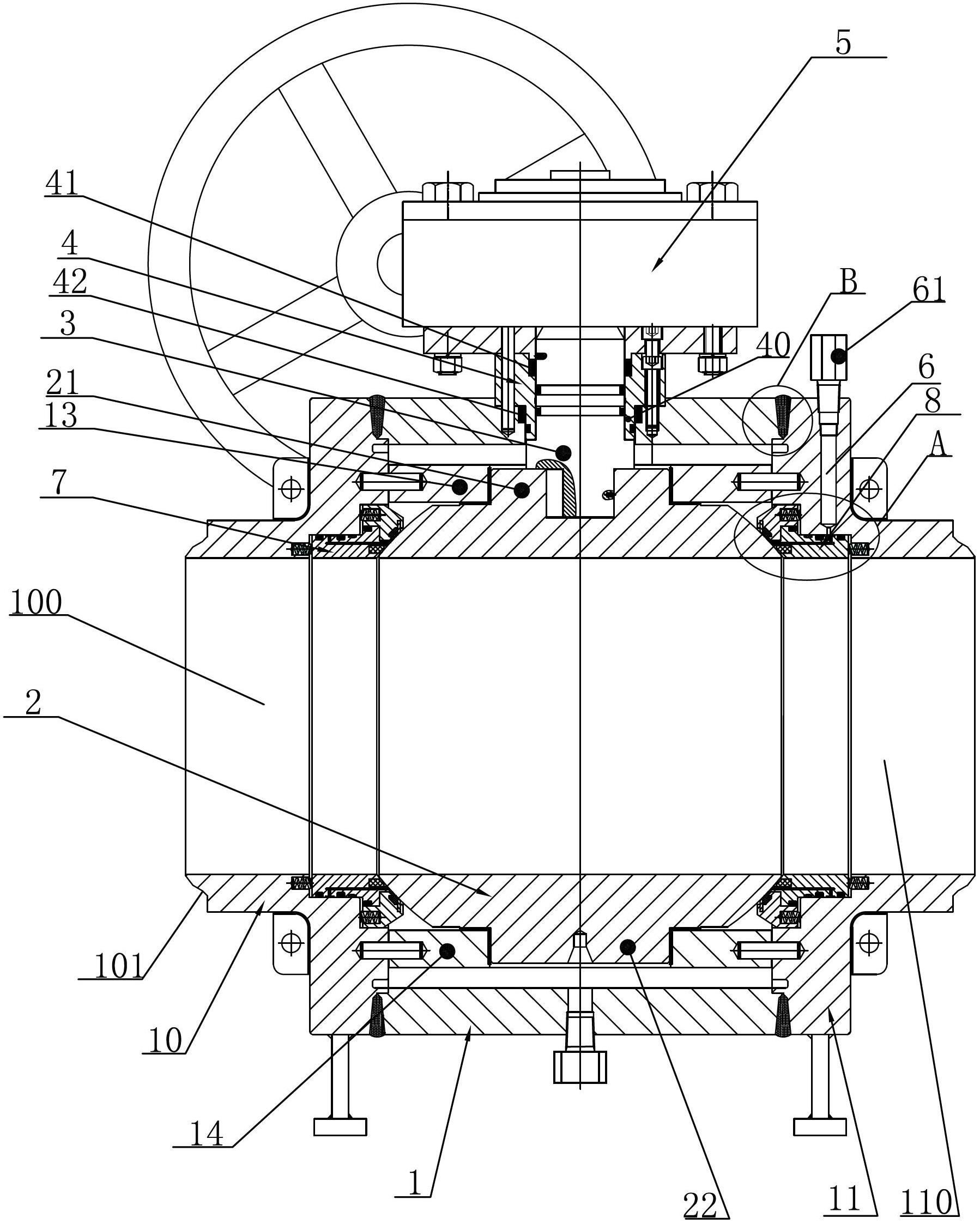

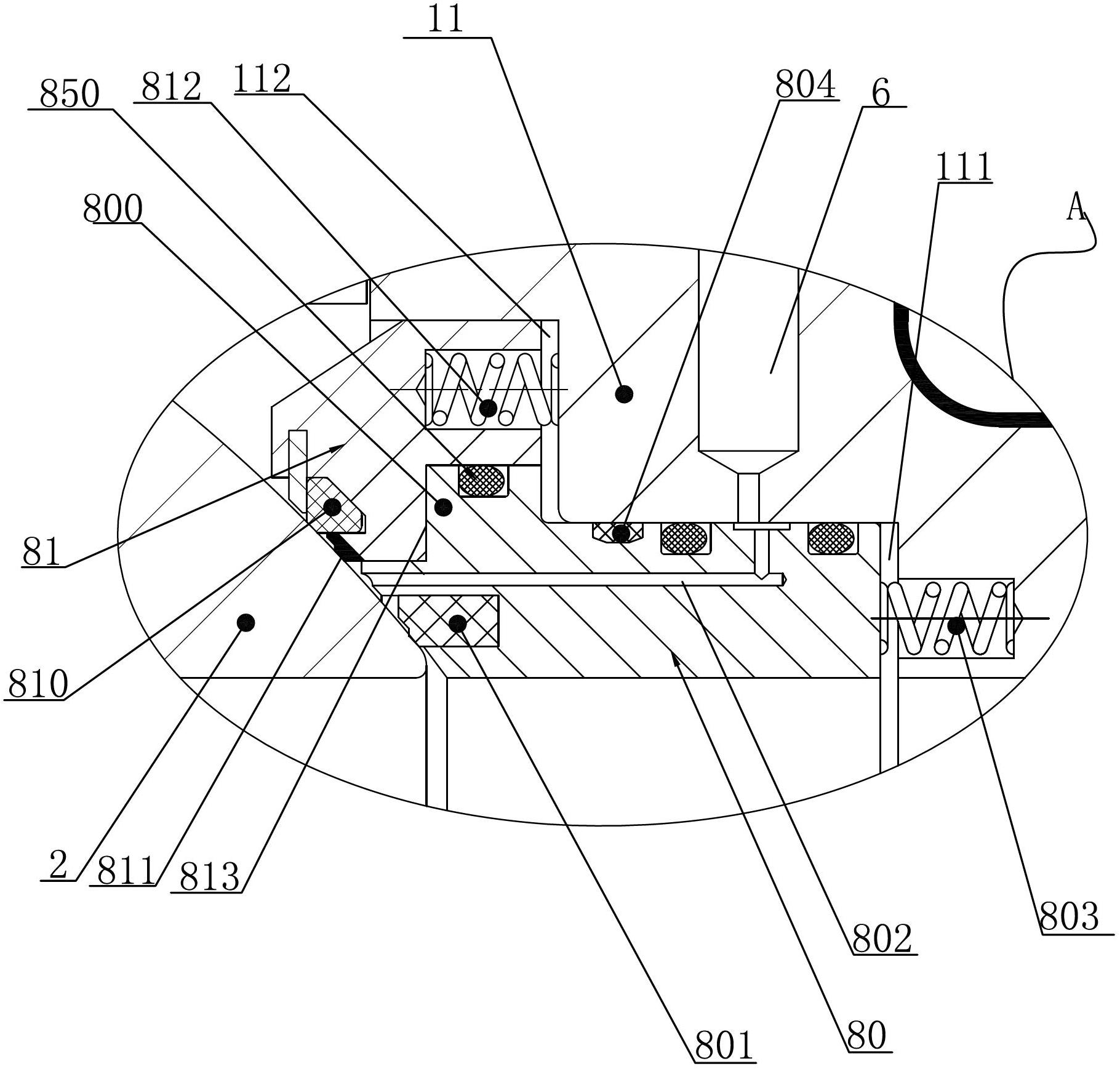

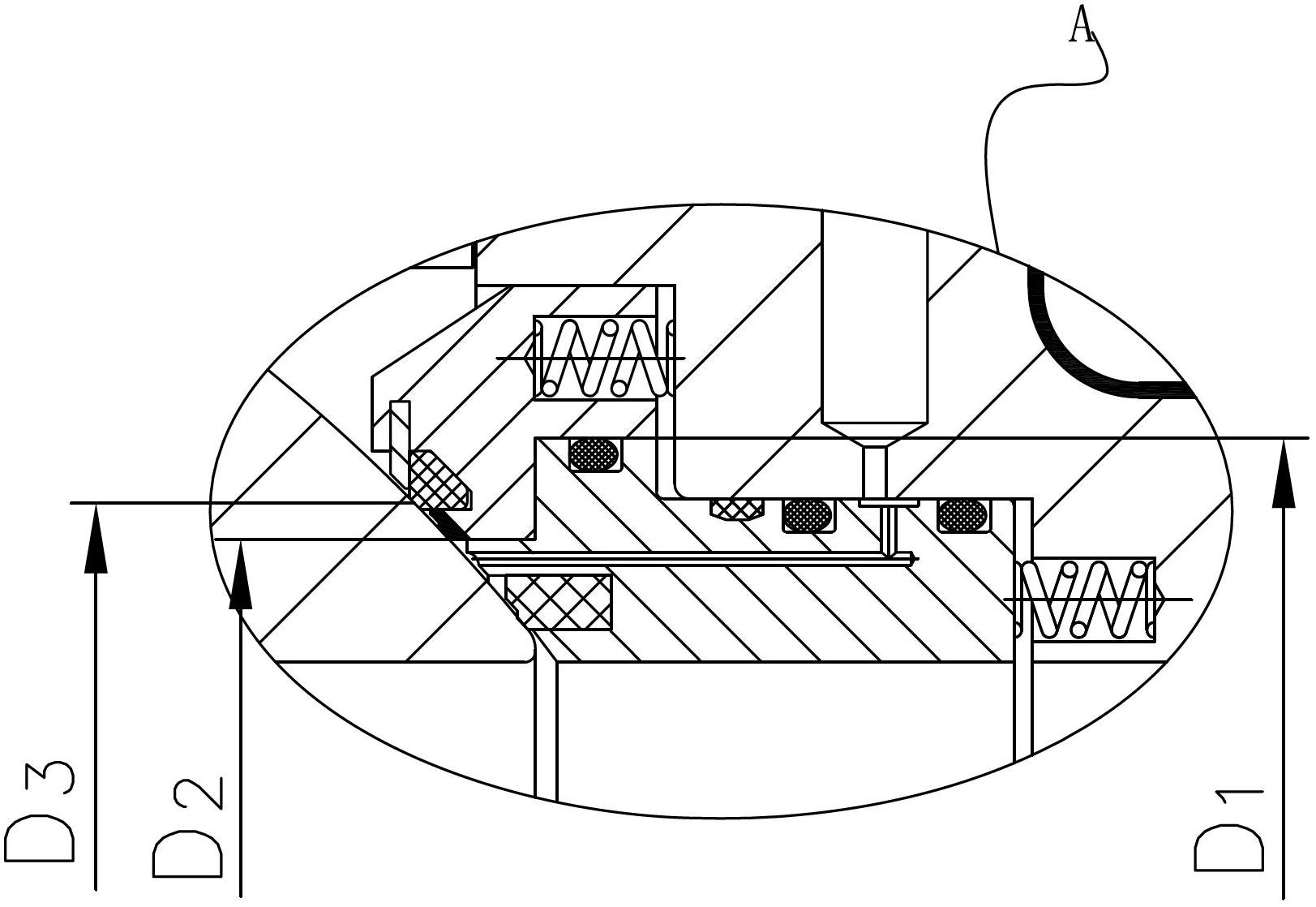

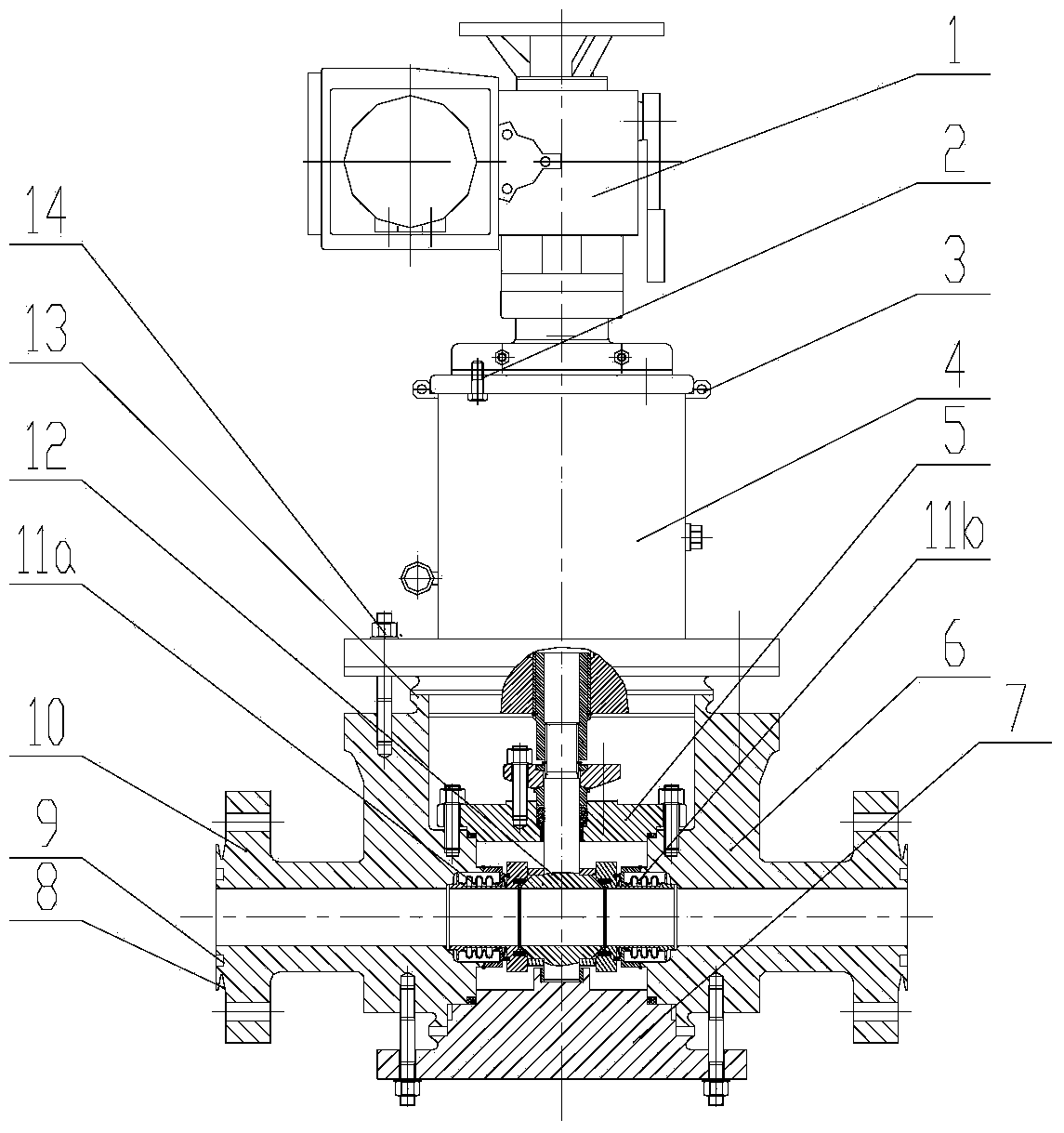

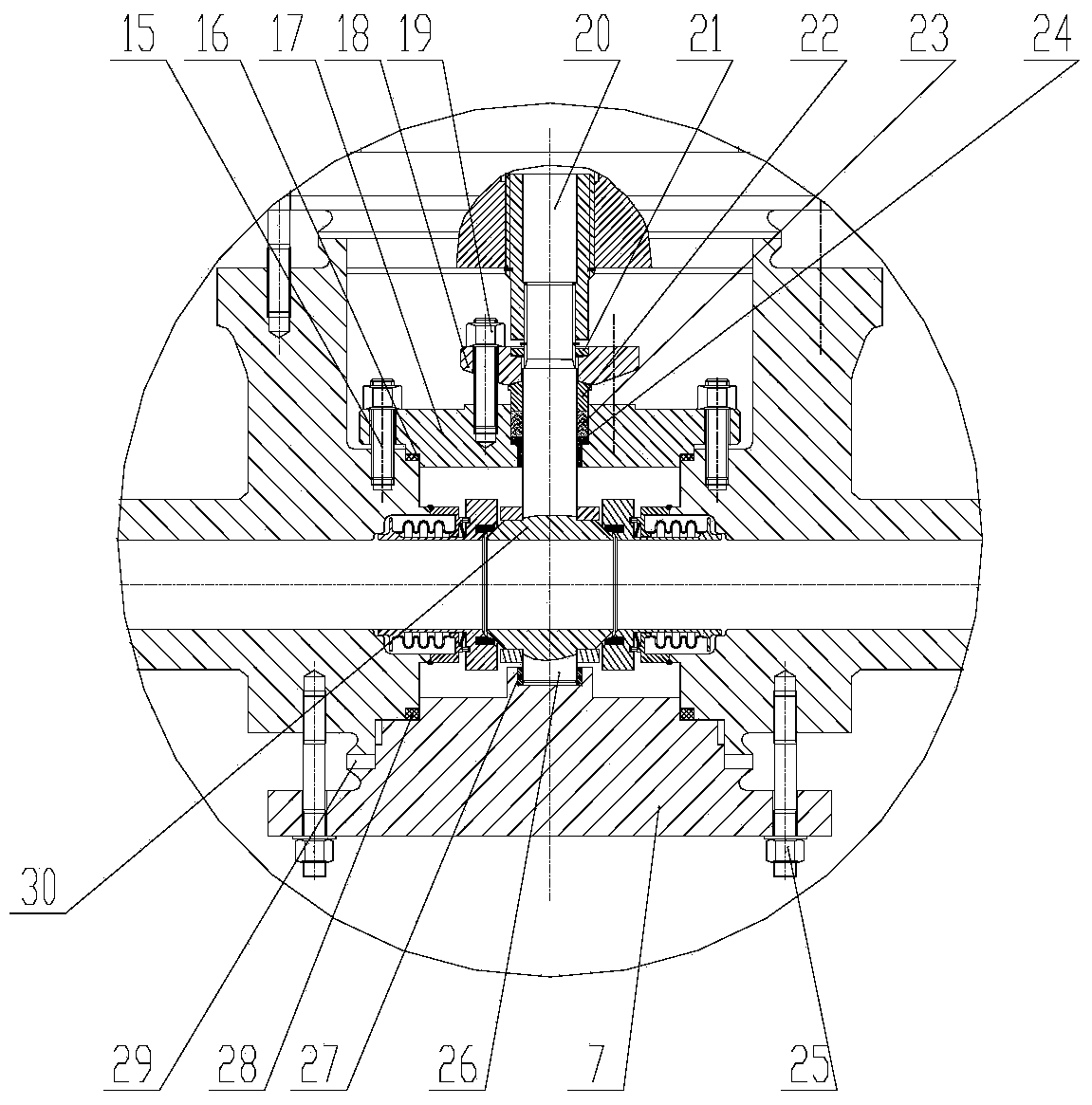

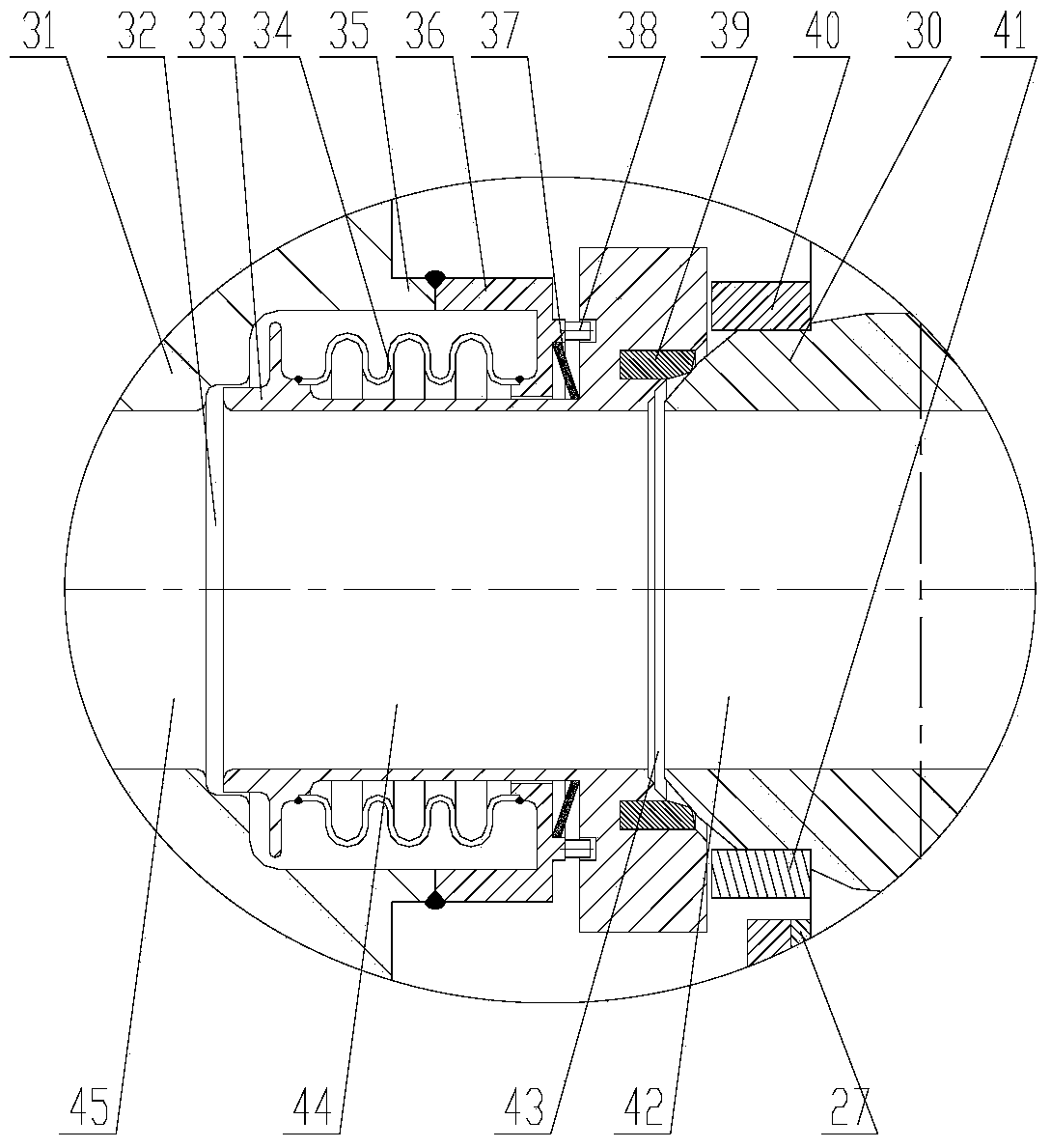

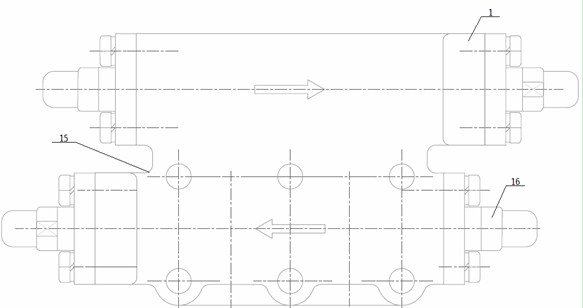

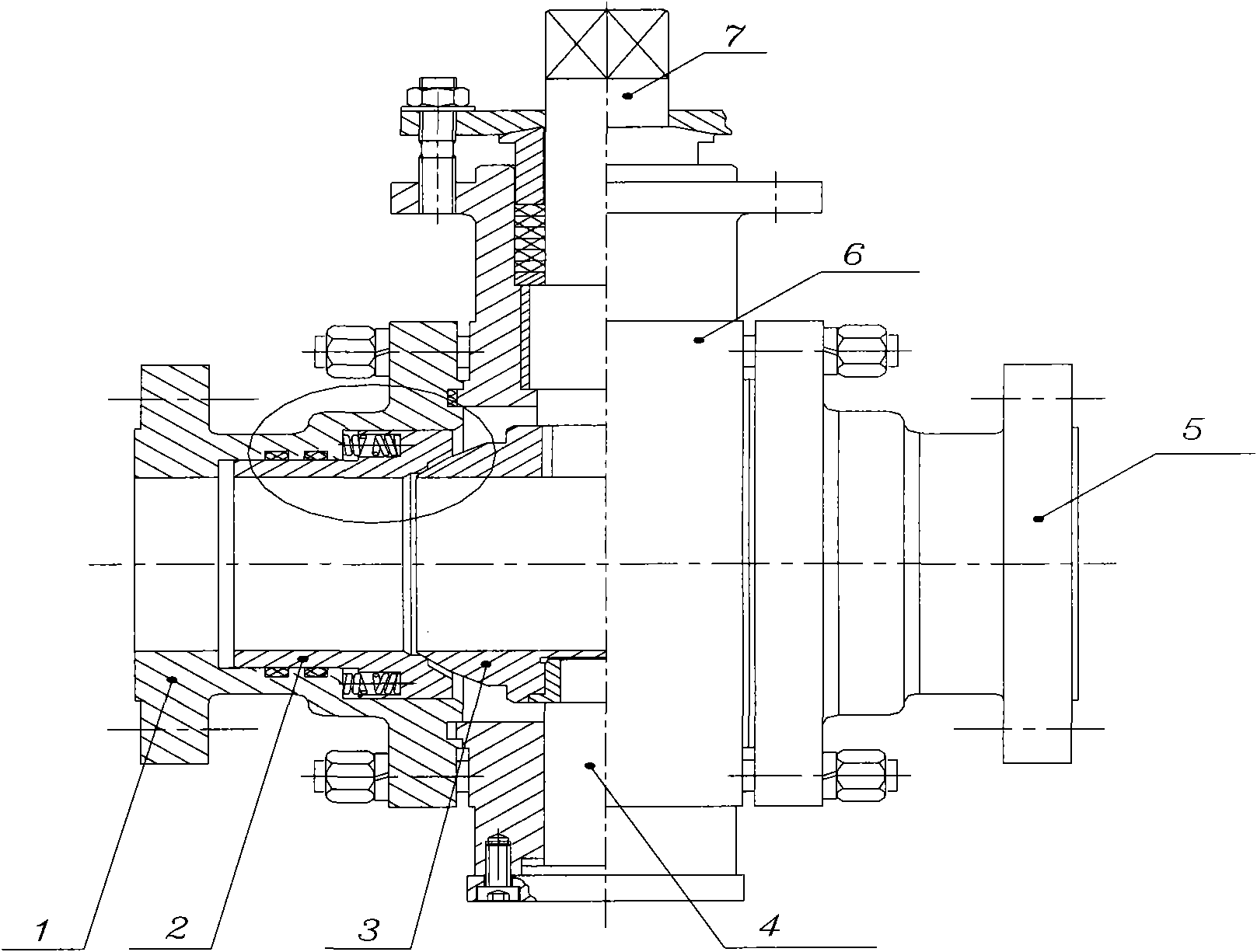

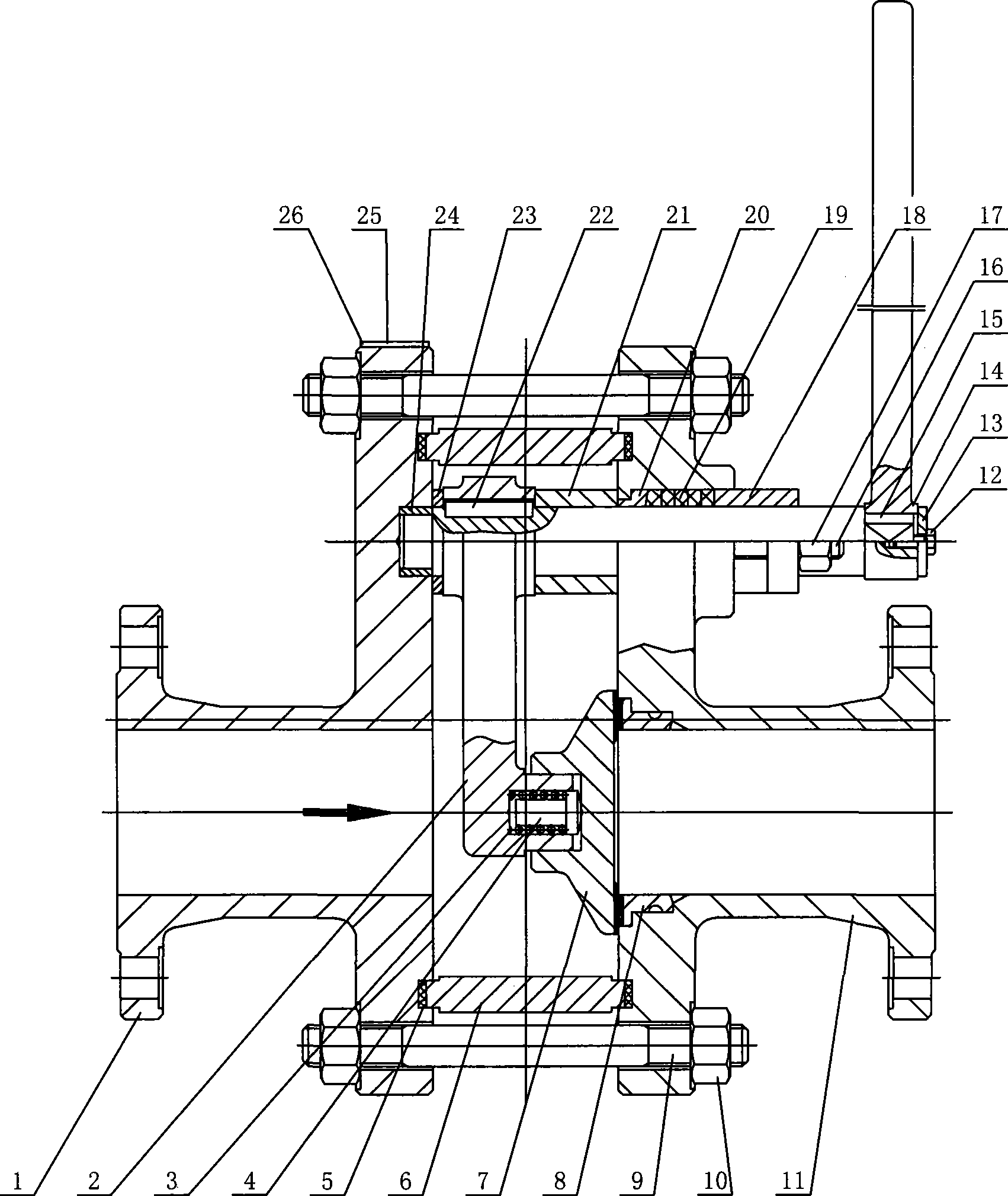

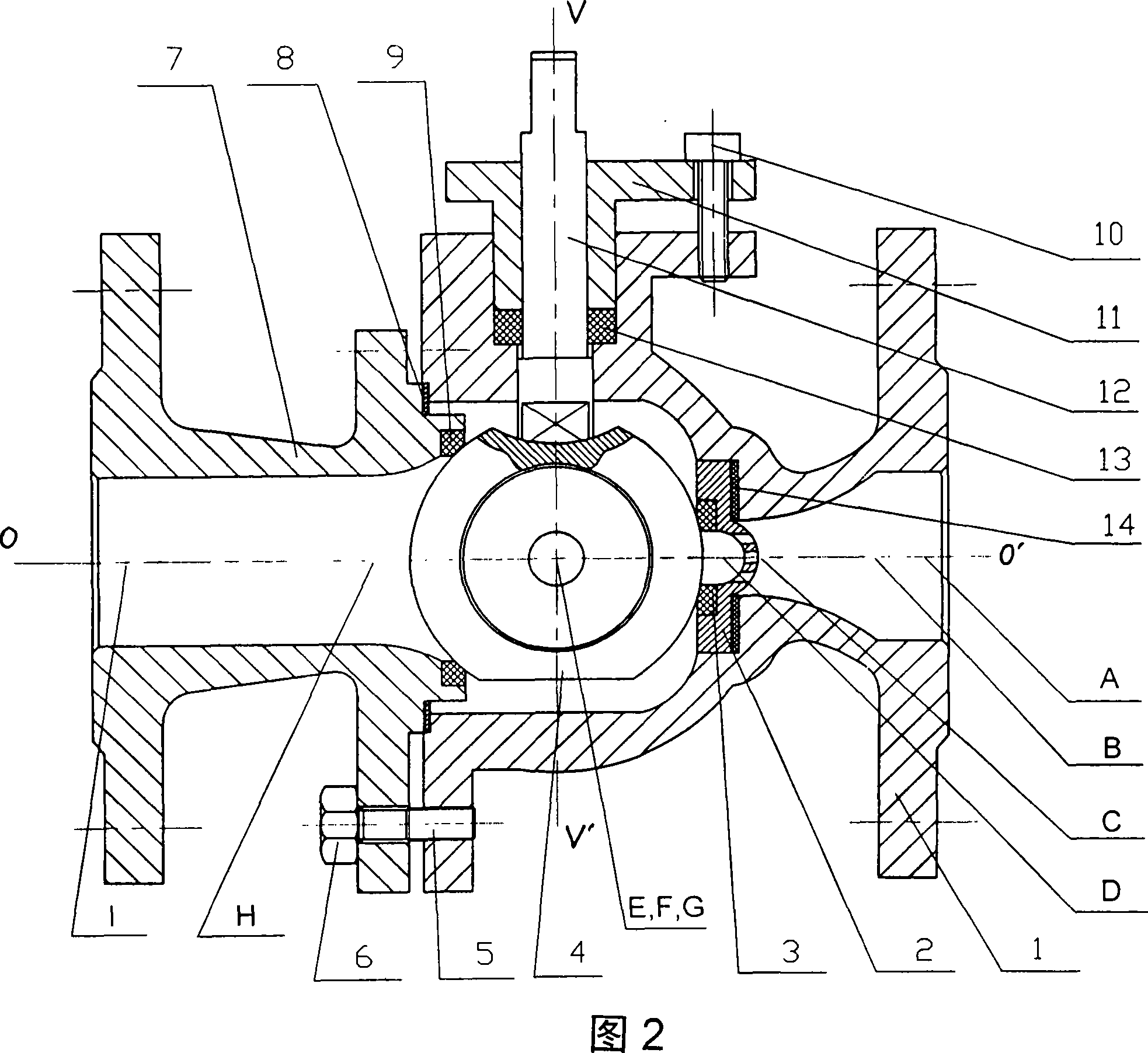

Heavy-calibre ball valve

InactiveCN102679008AAvoid spreadingEliminate potential safety hazardsPlug valvesValve housingsFire - disastersEngineering

The invention relates to a ball valve, in particular to a heavy-calibre ball valve. The heavy-calibre ball valve comprises a valve body, valve base assemblies, a ball body, a valve rod and a drive device, wherein a fireproof sealing device is arranged between the valve rod and the valve body; the valve body comprises a main valve body which is provided with a valve cavity and left and right valve bodies which are arranged on two sides of the main valve body; the left and right valve bodies are welded on two sides of the main valve body; the left and right valve bodies are provided with welding beveled edges which enable the valve to be welded on a pipeline relative to the end part of the other end welded with one end of the main valve body; a flow-in channel and a flow-out channel communicated with the valve cavity are formed in in the left and right valve bodies; a left valve base assembly matched with the ball body is arranged on one side inside the flow-in channel toward the valve cavity; and a right valve base assembly matched with the ball body is arranged on one side inside the flow-out channel toward the valve cavity. The welded type combined valve body is adopted and welded on the pipeline, so that a working medium is effectively prevented from leaking and fire is prevented from spreading during the fire disaster; and meanwhile, the weight of the valve can be lightened and the maintenance fee of a flange disc can be saved without using a flange disc.

Owner:BAOYI GROUP

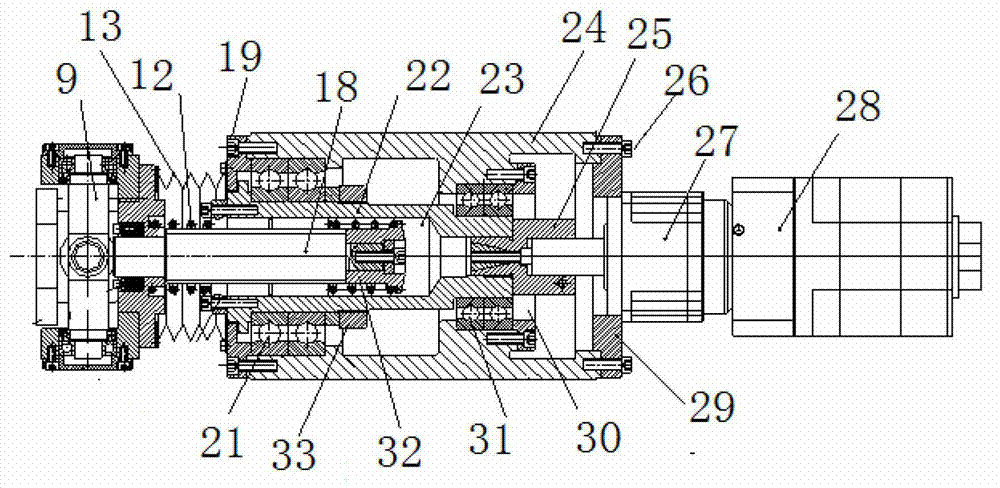

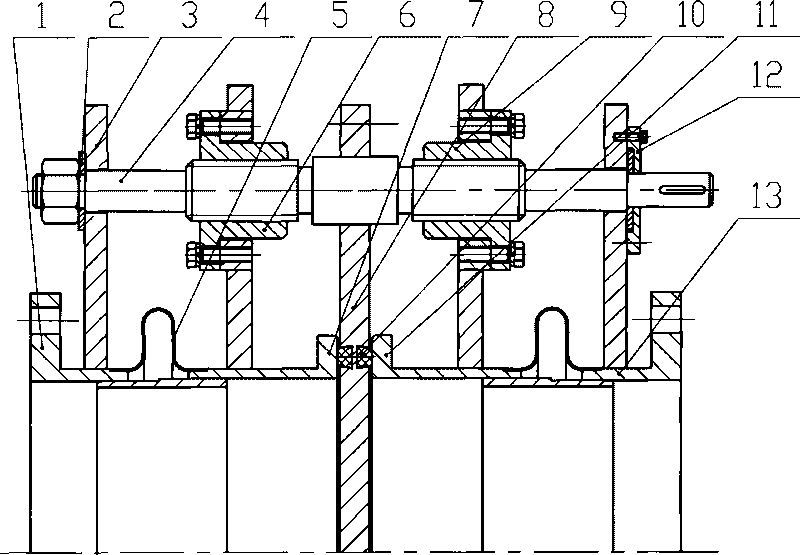

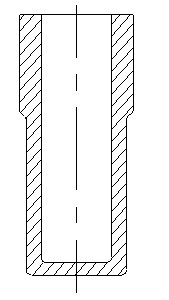

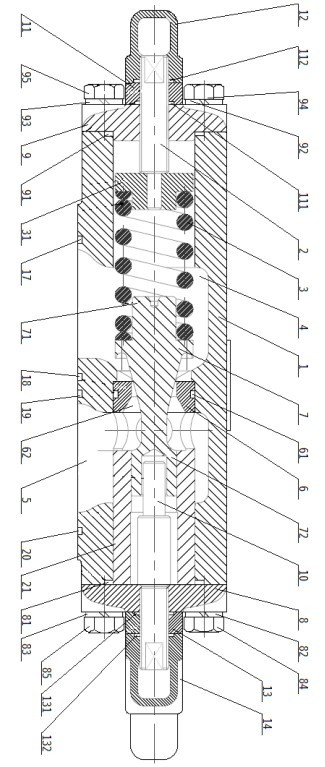

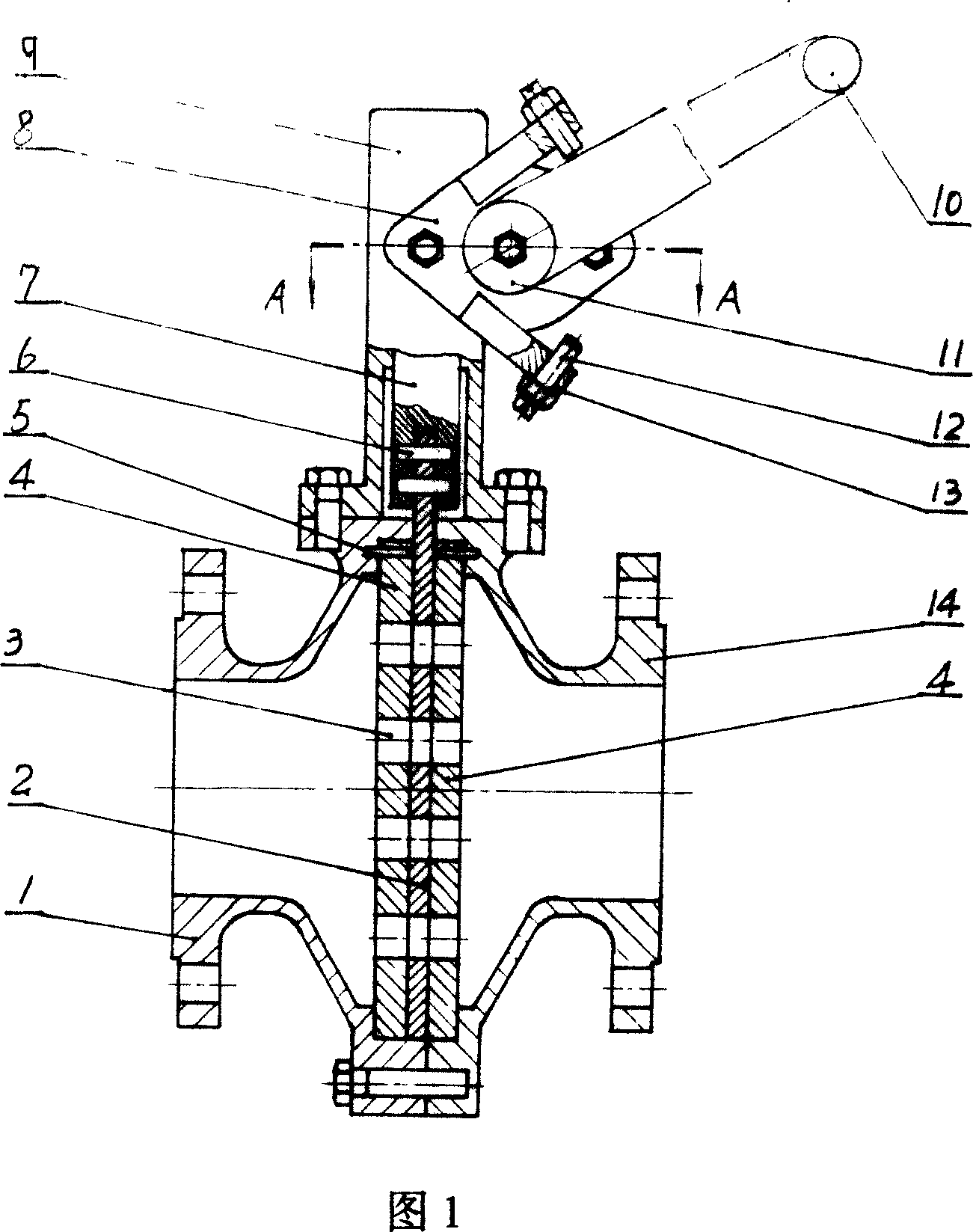

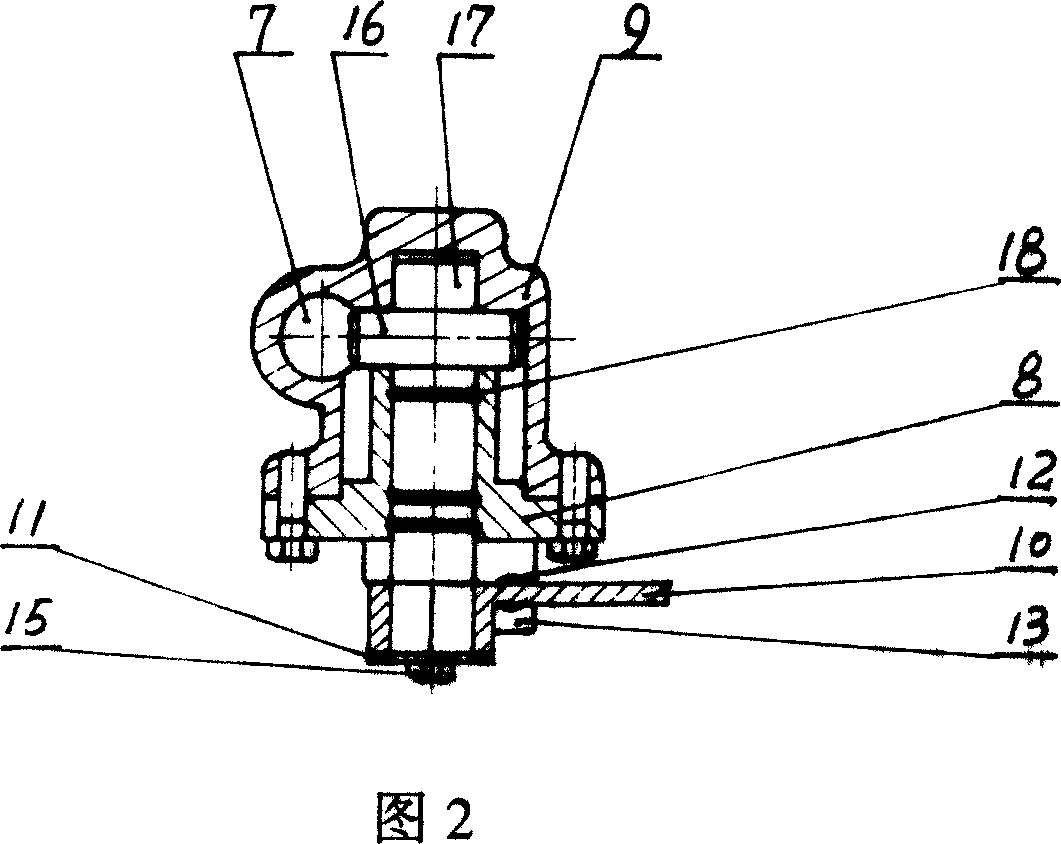

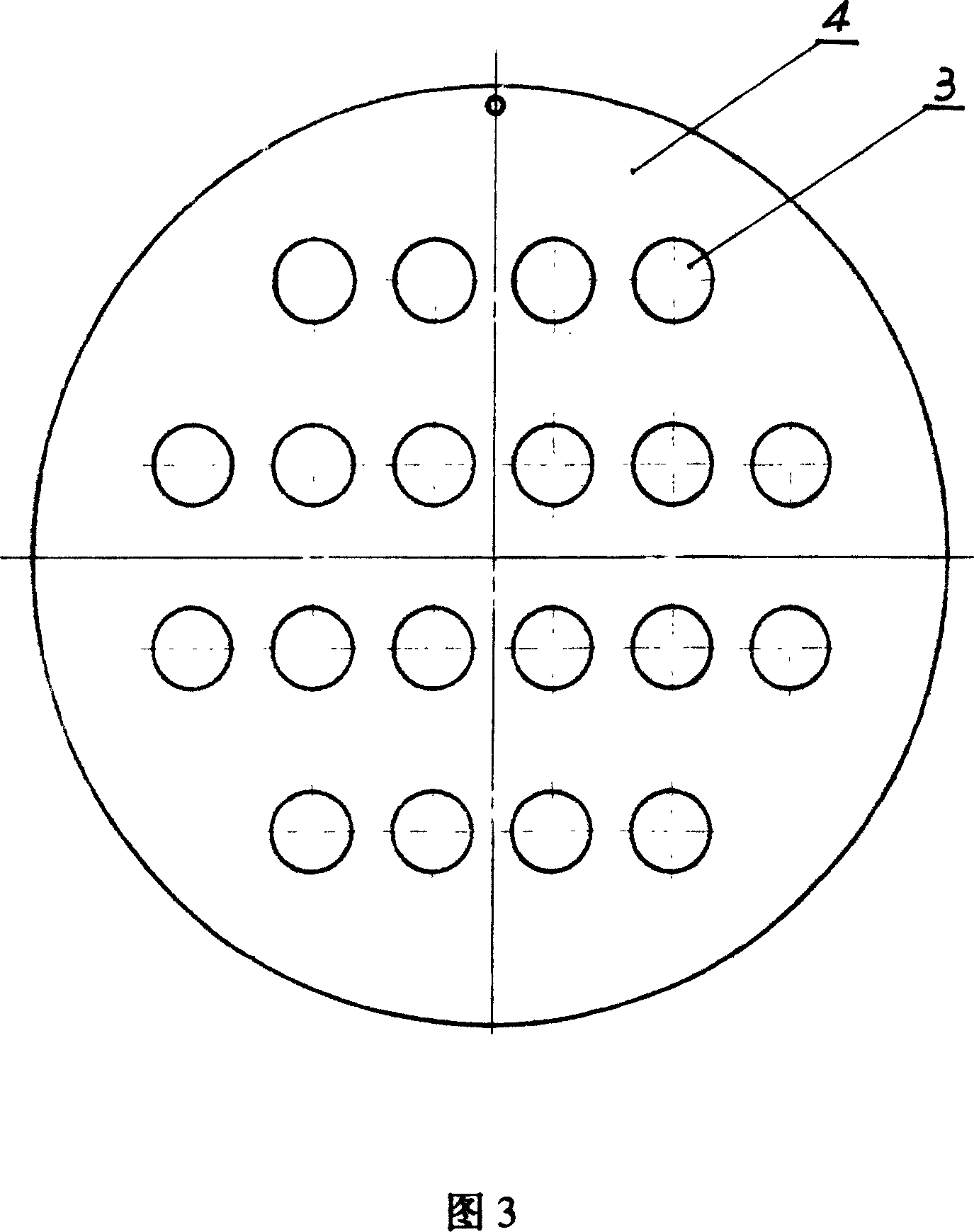

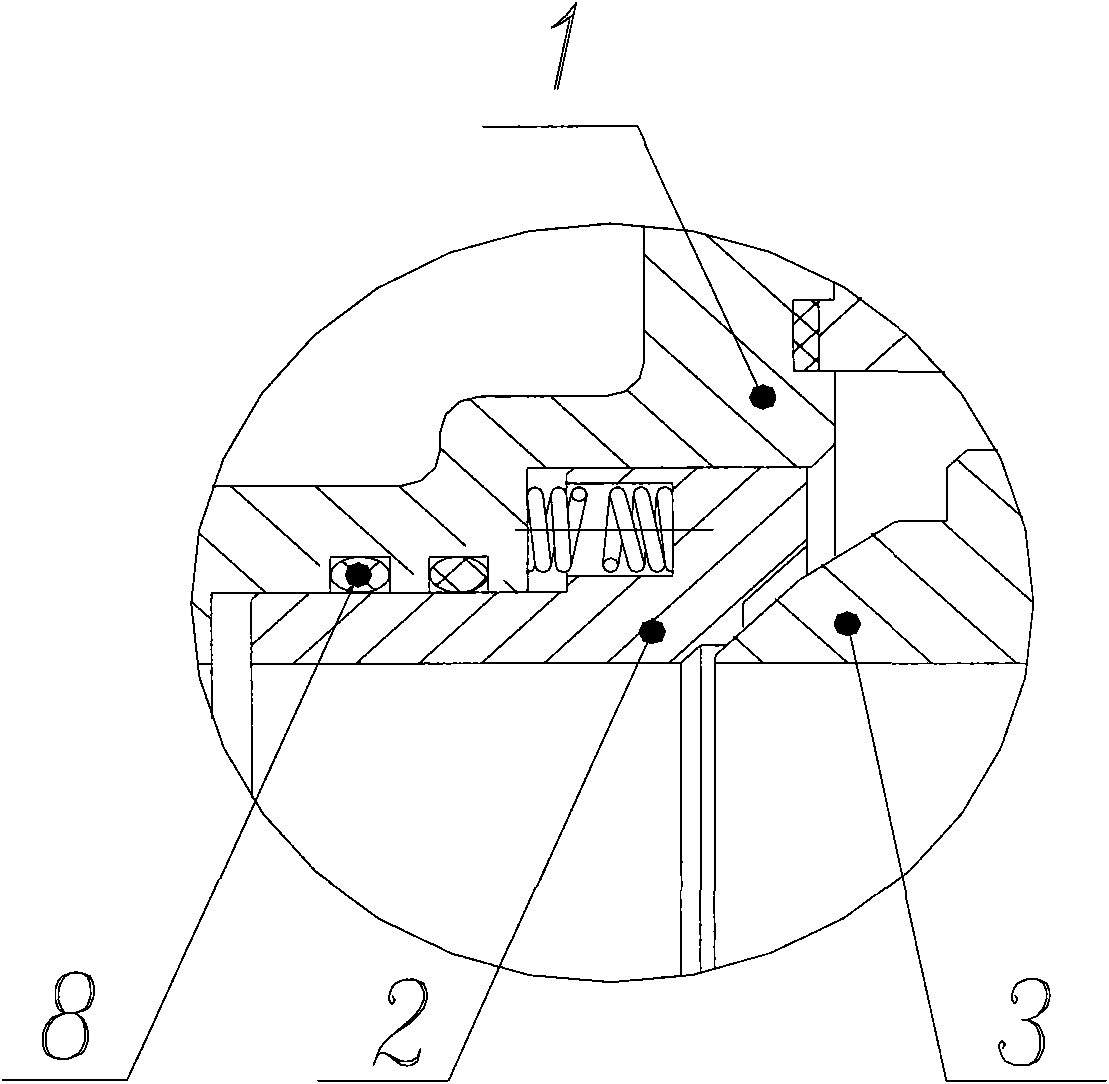

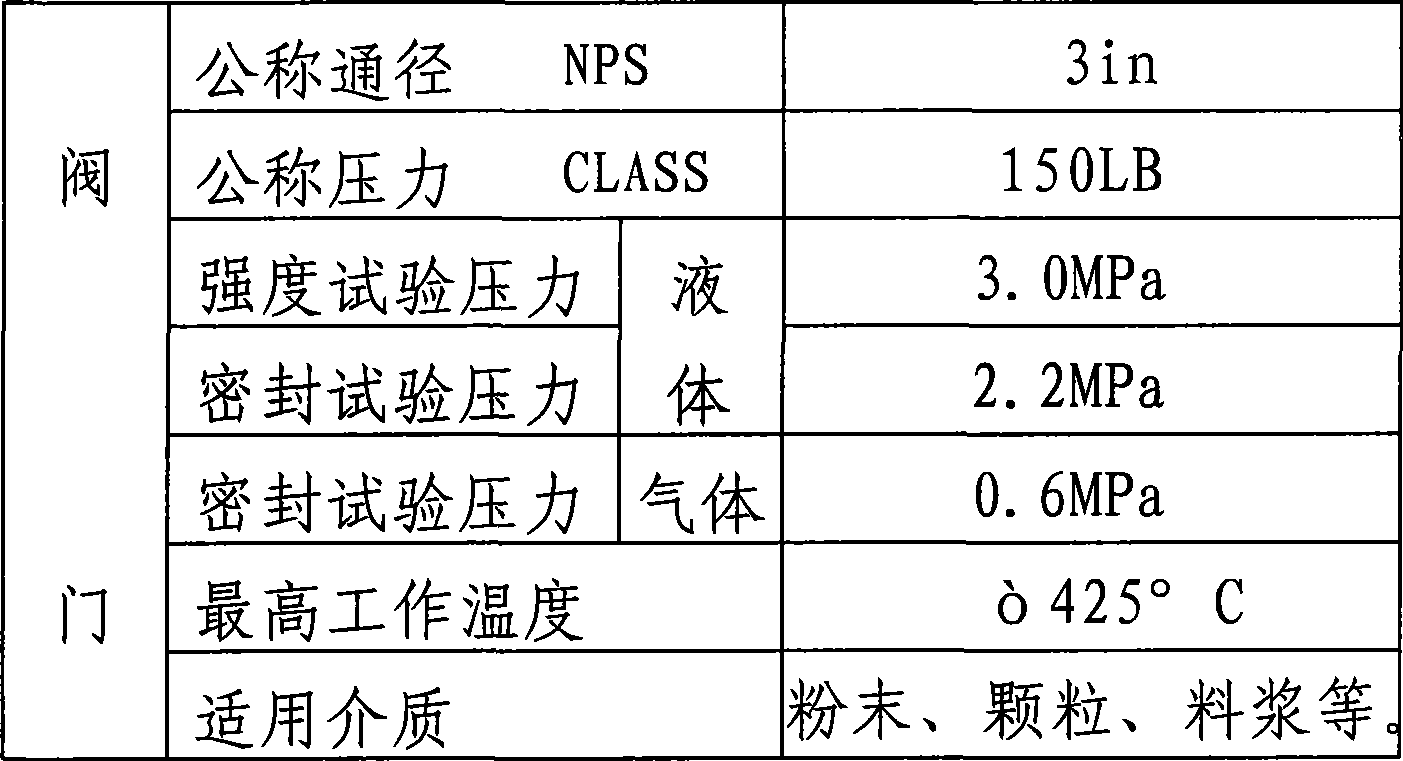

Flushing preventing valve with single hydraulic prop

InactiveCN103541748AImprove technical levelImprove disaster prevention and resilienceProps/chocksRemote controlAbsorbed energy

The invention provides a flushing preventing valve with a single hydraulic prop, and belongs to the technical field of roadway supporting of a coal mine. The flushing preventing valve has a flushing preventing function, can quickly absorb impact energy, and has a function of lifting and lowering the prop, a function of preventing flushing and absorbing energy in a static-pressure and dynamic-pressure manner and a remote control function. The flushing preventing valve comprises a left valve body and a right valve body, wherein a left division plate and a right division plate are arranged in the left valve body and the right valve body; a control valve element is arranged in the left valve body and the right valve body and comprises an ejector rod, a throttling supporting piston, a buffering piston, a guiding body and a spring; a through hole of the left division plate is blocked by the left end of the ejector rod; the right end of the ejector rod is arranged in a through hole of the right division plate; the throttling supporting piston and the buffering piston are respectively arranged on the left side and the right side of the ejector rod; a prop liquid injecting opening is formed in the side wall of the left valve body; the guiding body is arranged in the right valve body and consists of a chassis and a guiding barrel; an ejector pin is arranged on the left end surface of the chassis; a right valve body bonnet is arranged at the right end of the right valve body; and a handle fixing seat is arranged on a pressure-adjusting rotating wheel and is hinged to the handle.

Owner:LIAONING TECHNICAL UNIVERSITY

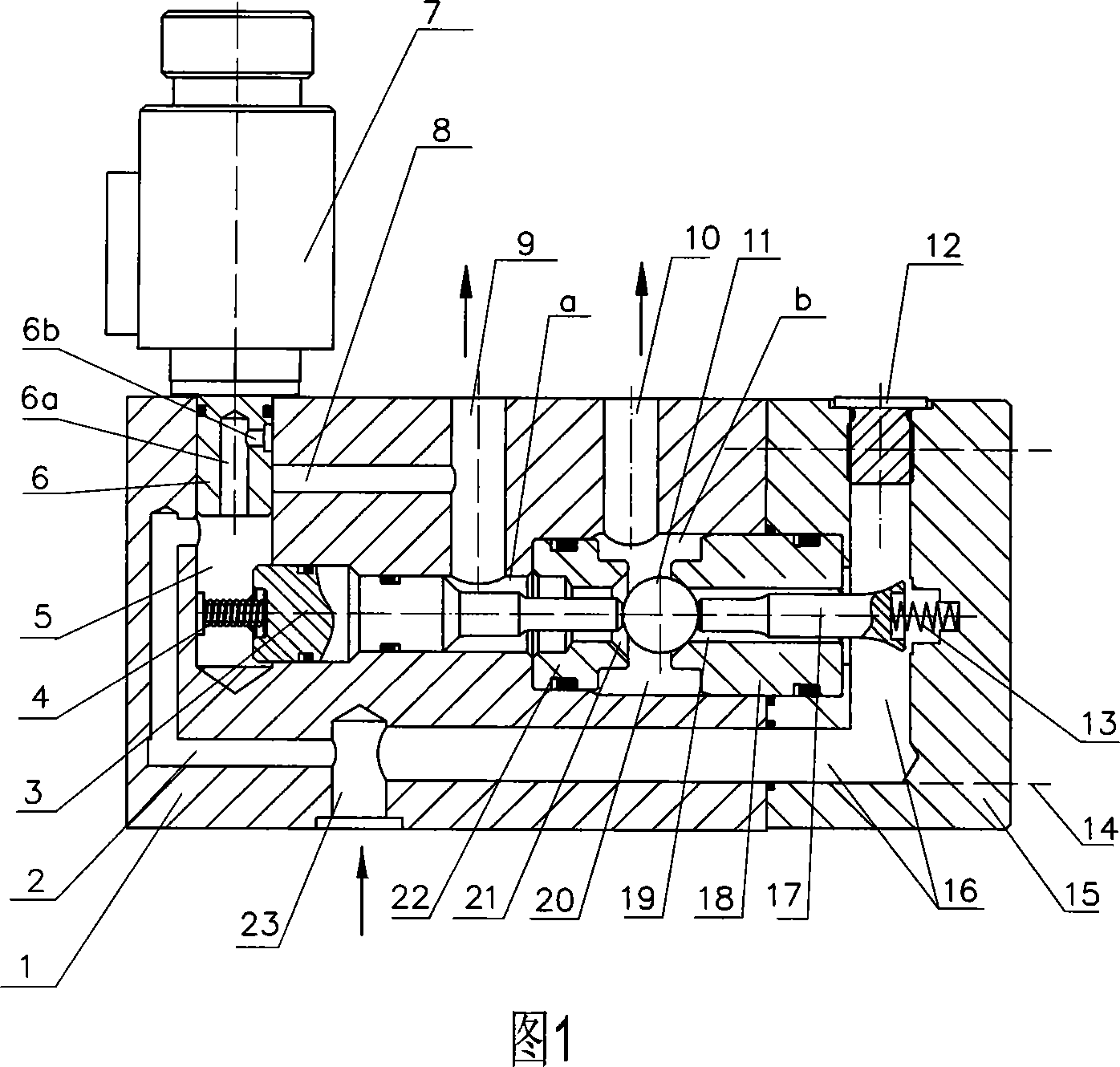

Gate valve

The invention provides a gate valve, which comprises a left valve body, corrugated pipes, a valve plate, seal rings, a screw rod, a left nut, a right nut, a right valve body, a left valve seat and a right valve seat. A corrugated pipe is welded between the left valve seat and the left valve body; seal rings are arranged in a groove of the valve plate; the valve plate is fixed on the middle part of the screw rod; the left end of the screw rod is arranged on the left valve seat through the left nut; the right end of the screw rod is arranged on the right valve seat through the right nut; another corrugated pipe is also welded between the right valve seat and the right valve body; a bearing plate is arranged on the left valve body; the screw rod passes through the bearing plate and then is fixedly connected with the left valve body through a limit plate; a bearing plate is arranged on the right valve body; and the screw rod passes through the bearing plate and then is fixedly connected with the right valve body through the limit plate and a gland. The gate valve has the advantages that: when the gate valve moves, the valve plate does not move; the sealing reliability is greatly improved because the seal rings on two sides of the valve plate is uniformly stressed; the service life of the product is prolonged; and production is conveniently organized and the management is convenient.

Owner:JIANGSU SHENTONG VALVE

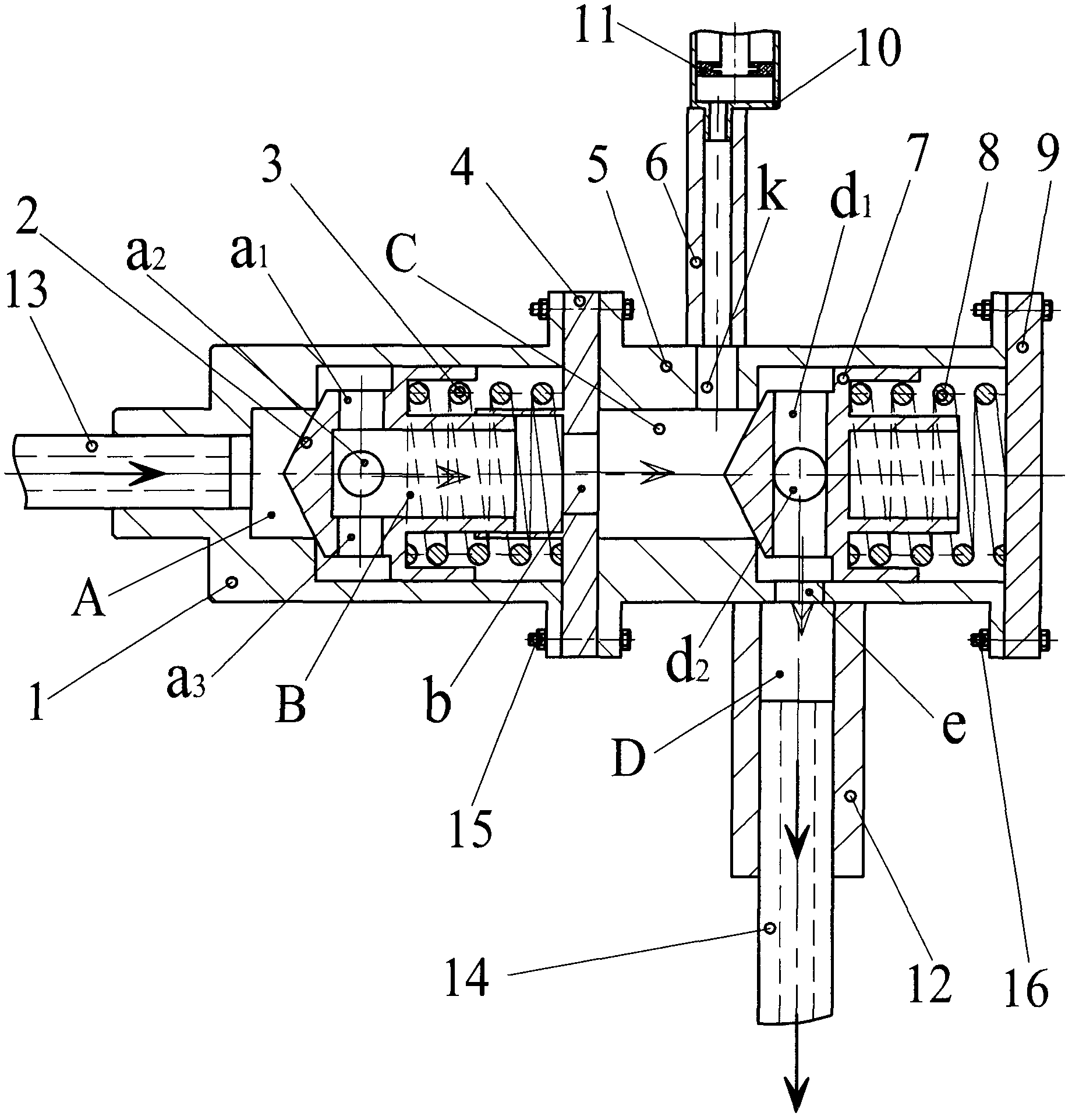

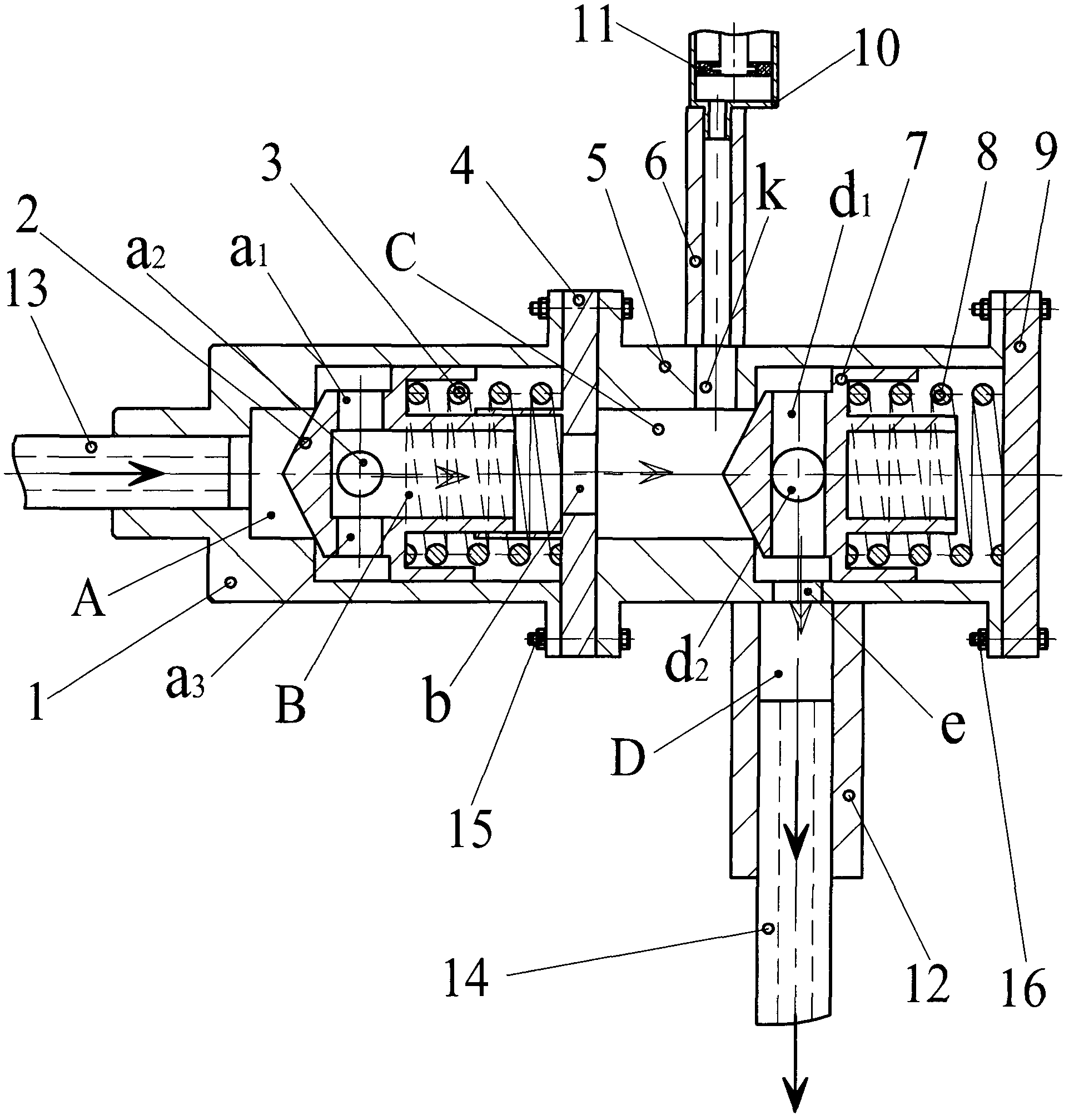

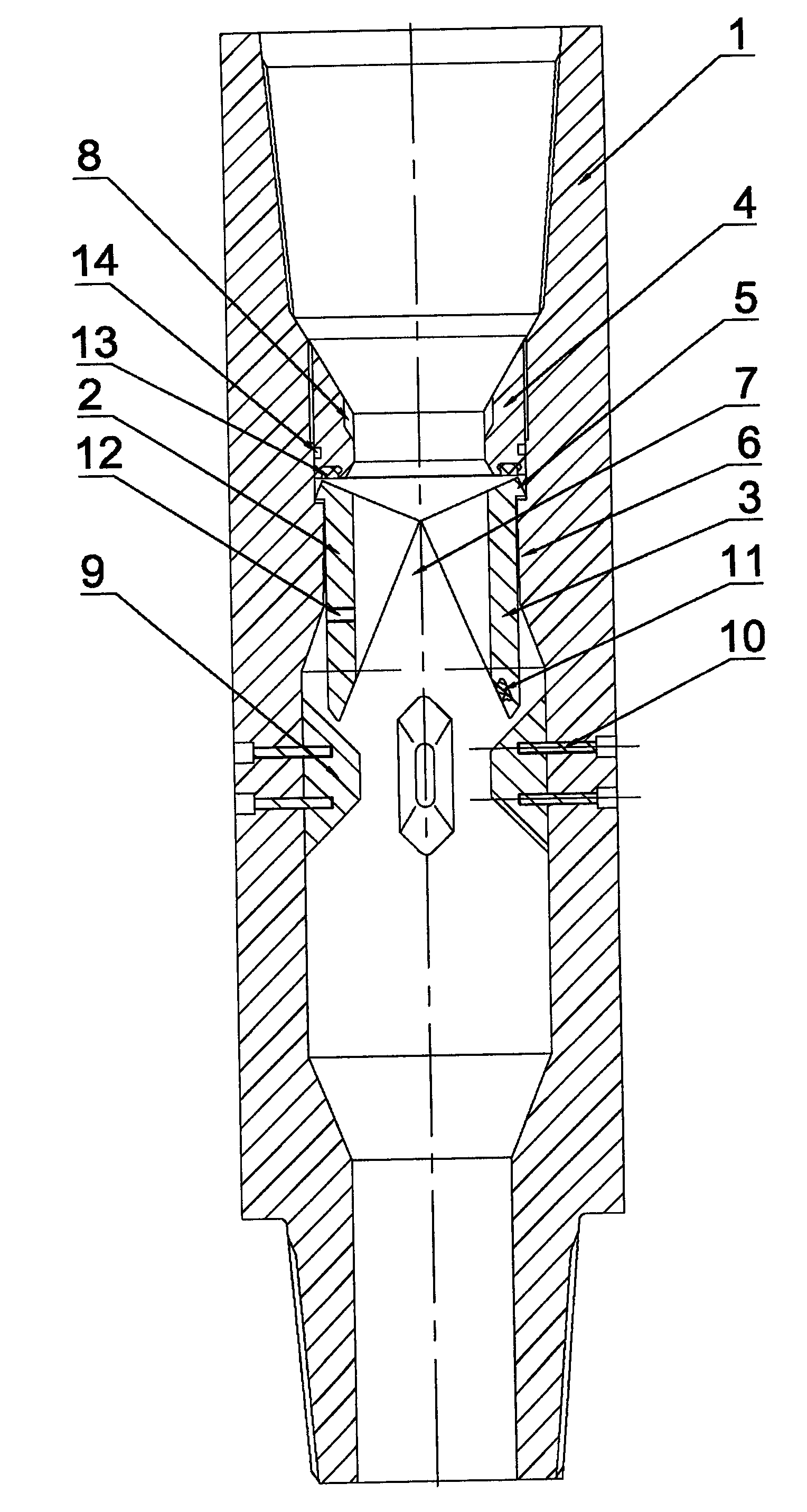

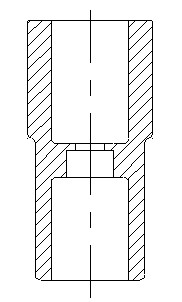

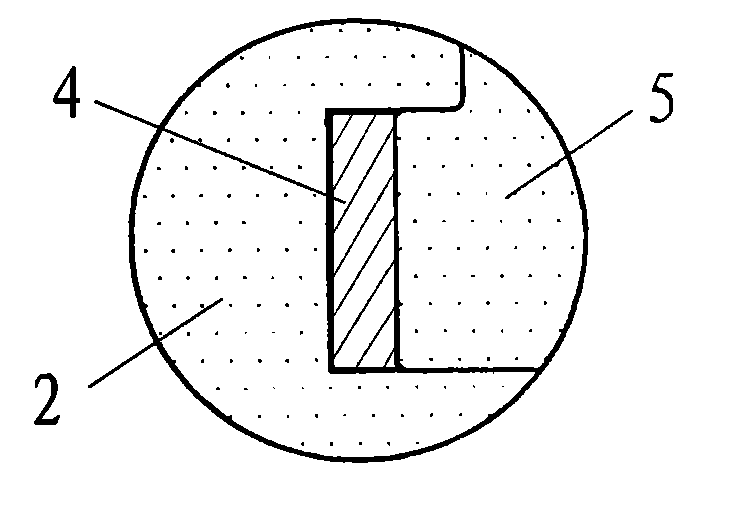

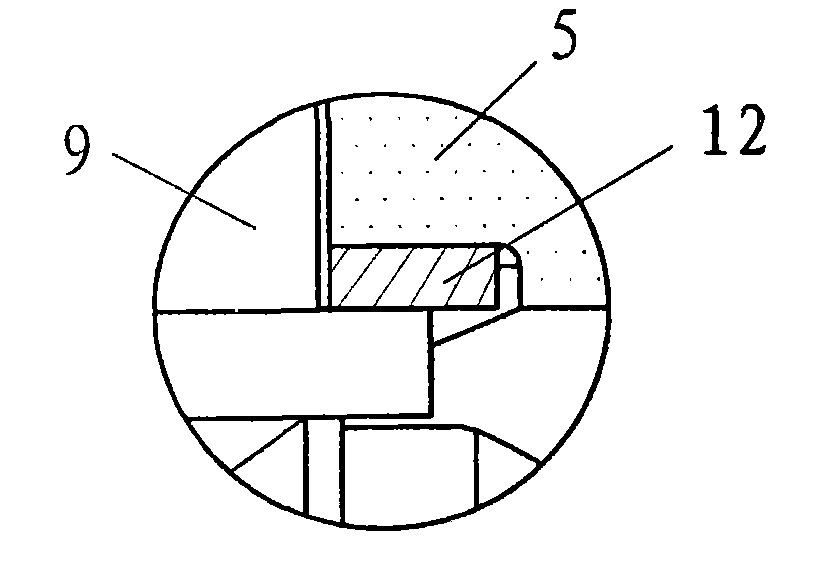

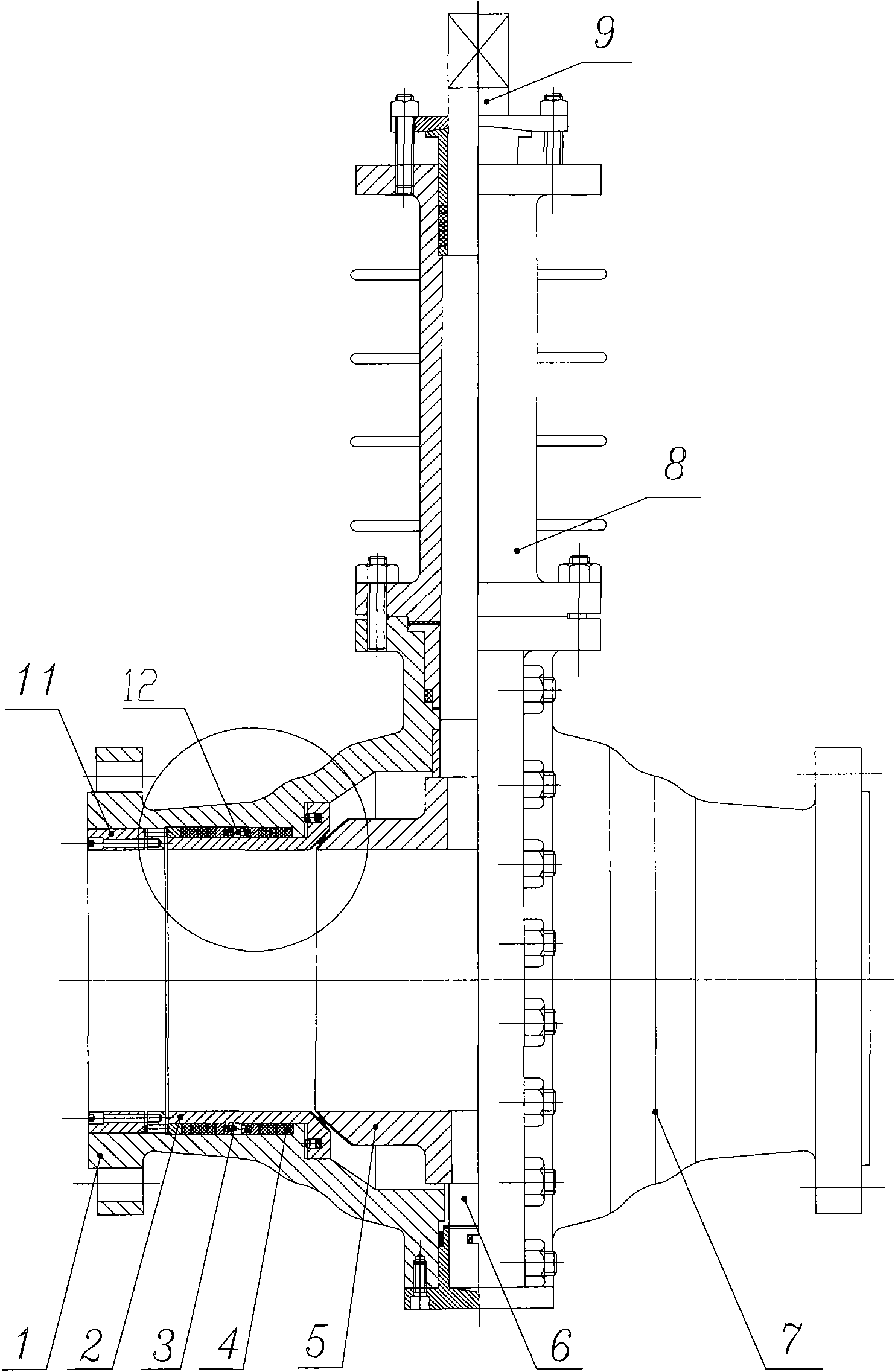

Anti-backflow and blockage-proof negative pressure drainage device

ActiveCN102526819APrevent retrograde infectionSpeed up the flowSuction devicesCause blockageInlet valve

The invention relates to an anti-backflow and blockage-proof negative pressure drainage device, which comprises a liquid inlet valve spool (2), a liquid drainage valve spool (7), left and right valve bushes (1 and 5), left and right valve bonnets (4 and 9), a needle barrel connecting tube (6), a liquid outlet connecting tube (12), a left spring (3) and a right spring (8). The liquid inlet valve spool (2) which only allows body liquid to flow rightwards is disposed in the left valve bush (1), the liquid drainage valve spool (7) which only allows the body liquid to flow to a right lower direction is arranged in the right valve bush (5), and the needle barrel connecting tube (6) and the liquid outlet connecting tube (12) are respectively connected with the right valve bush (5) via glue; and the body liquid can be led out via vertical movement of a piston (11) in a needle barrel (10) and then is drained to a container. The anti-backflow and blockage-proof negative pressure drainage device has the advantages that the device is smooth in drainage, not easy to cause blockage and high in drainage efficiency, can prevent backflow of the body liquid under the condition that negative pressure is instable or is removed suddenly, avoids possibility of infection caused by backflow of the body liquid, and is convenient in use and easy to be controlled by medical staffs and family members of patients.

Owner:盐城市瑞华机电制造有限公司

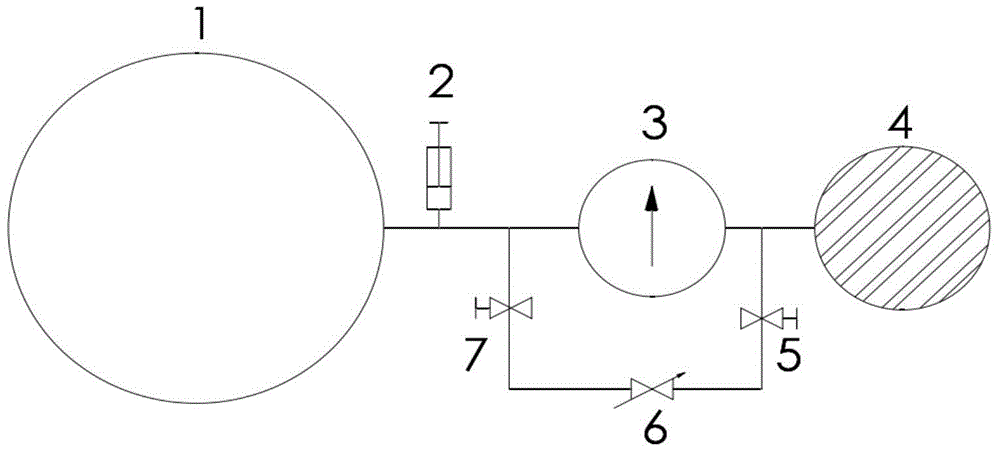

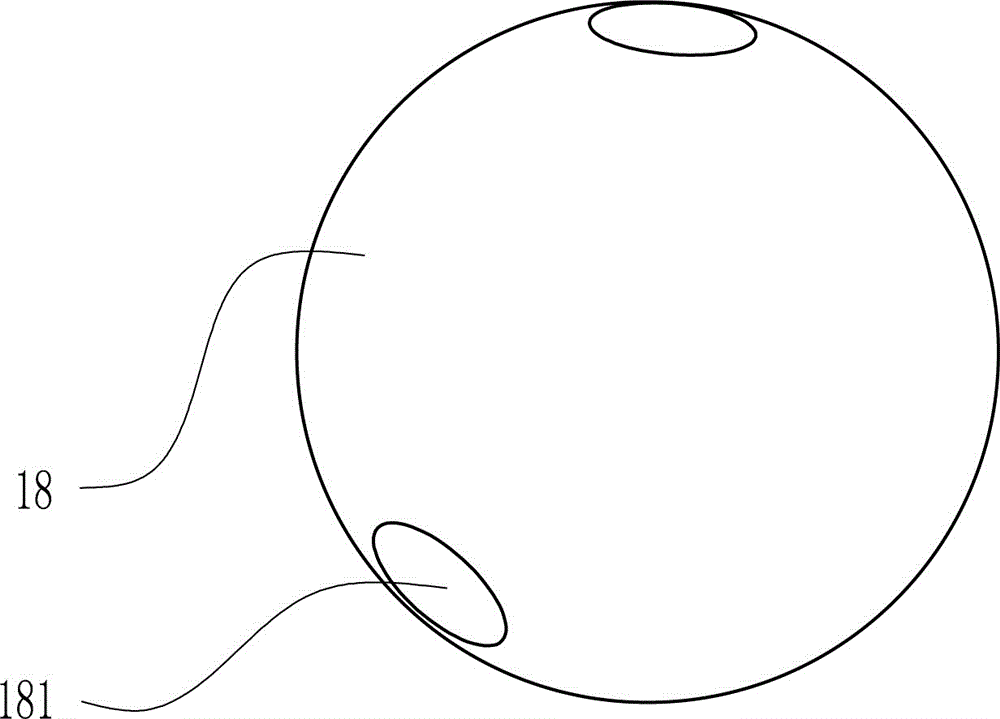

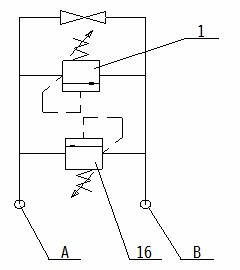

Container volume measurement device and measurement method based on secondary micro-variation allowance pressure principles

InactiveCN105115559AShort heat equilibration timeQuick measurementContainer/cavity capacity measurementVolume measurementsMeasurement device

The invention belongs to the technical field of equipment measurement and especially relates to a container volume measurement device and a measurement method based on secondary micro-variation allowance pressure principles. The measurement device comprises a measured container, wherein the measured container is connected to a differential pressure sensor and an isothermal reference container (4) by a pipeline; a precise piston is disposed between the measured container and the differential pressure sensor (3), and a left valve is connected between the differential pressure sensor and the precise piston; and a right valve is connected between the isothermal reference container and the differential pressure sensor. The measurement device is used for container volume measurement and can be used in rapid, accurate and nondestructive volume measurement of various kinds of containers with complicated structures.

Owner:63653 FORCES PLA

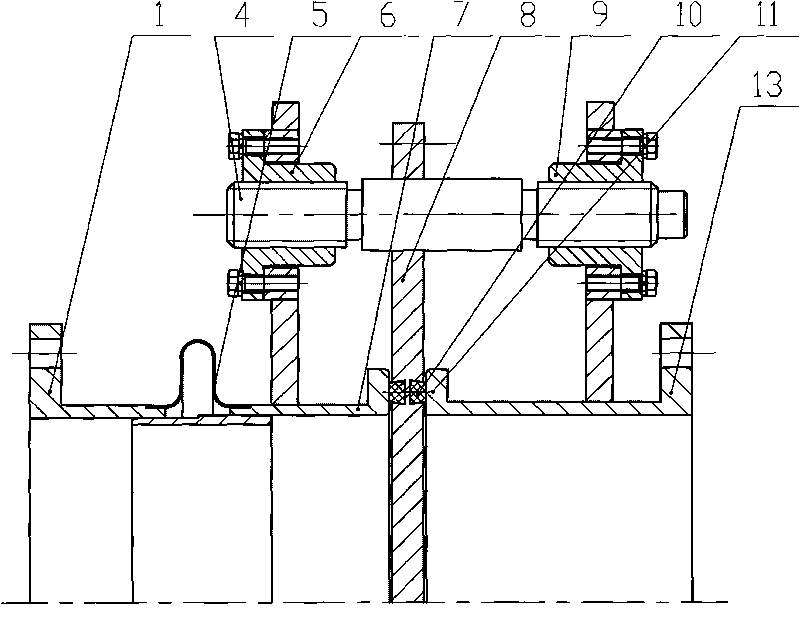

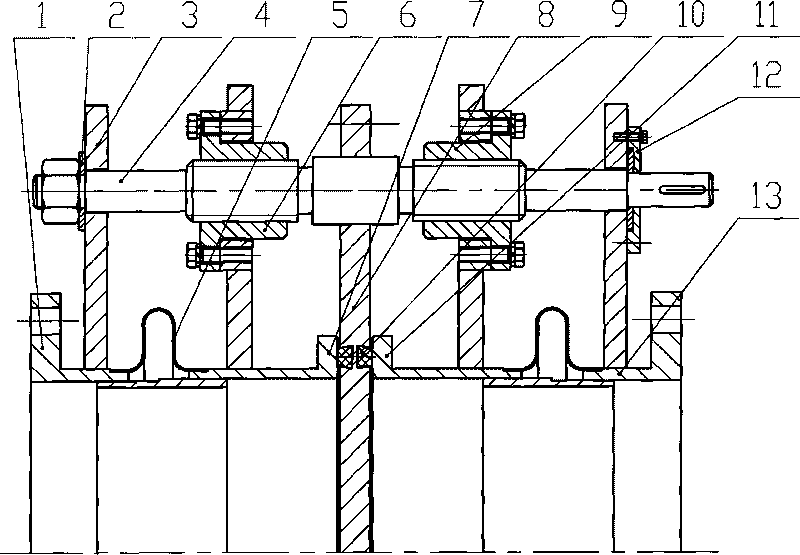

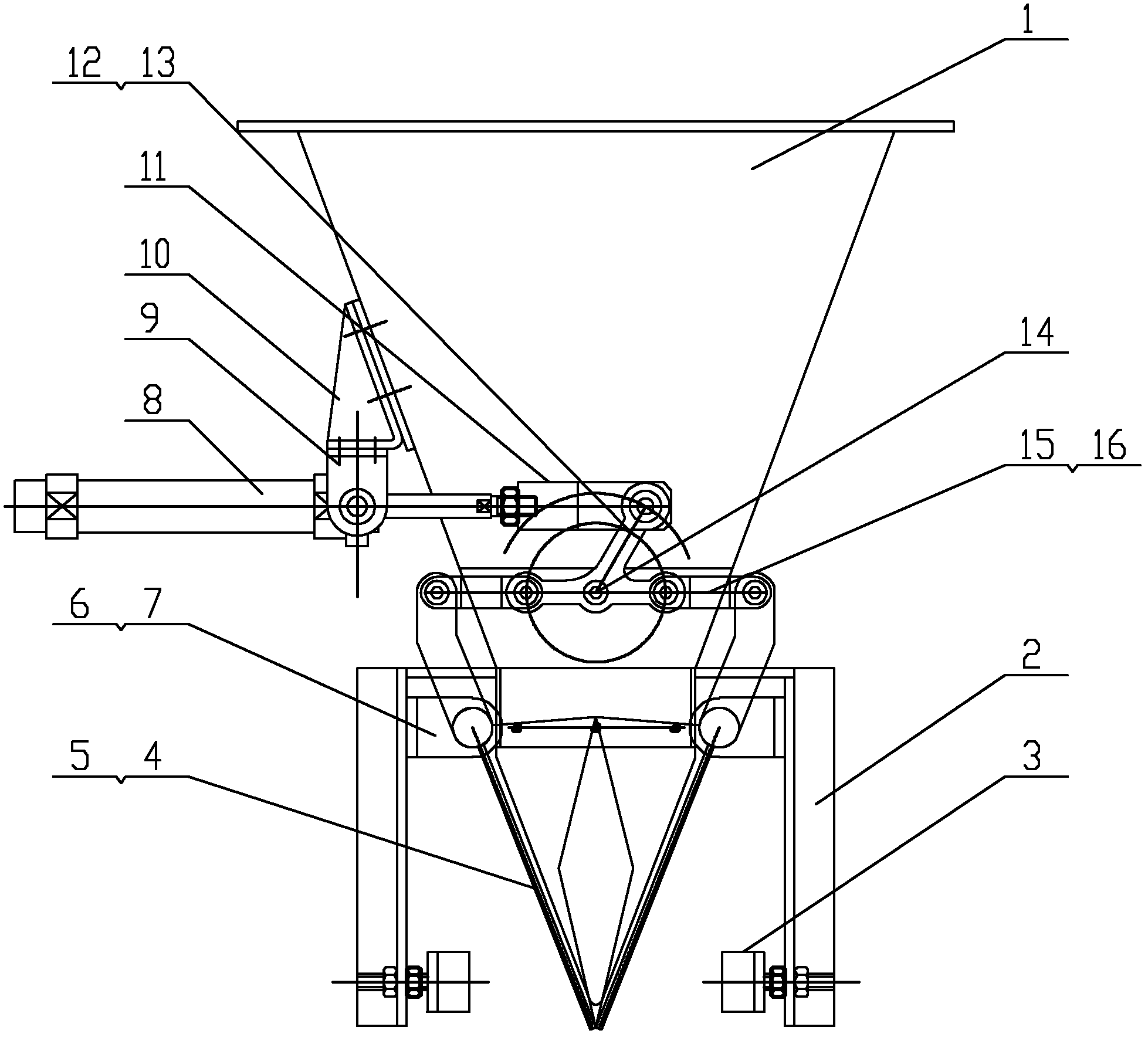

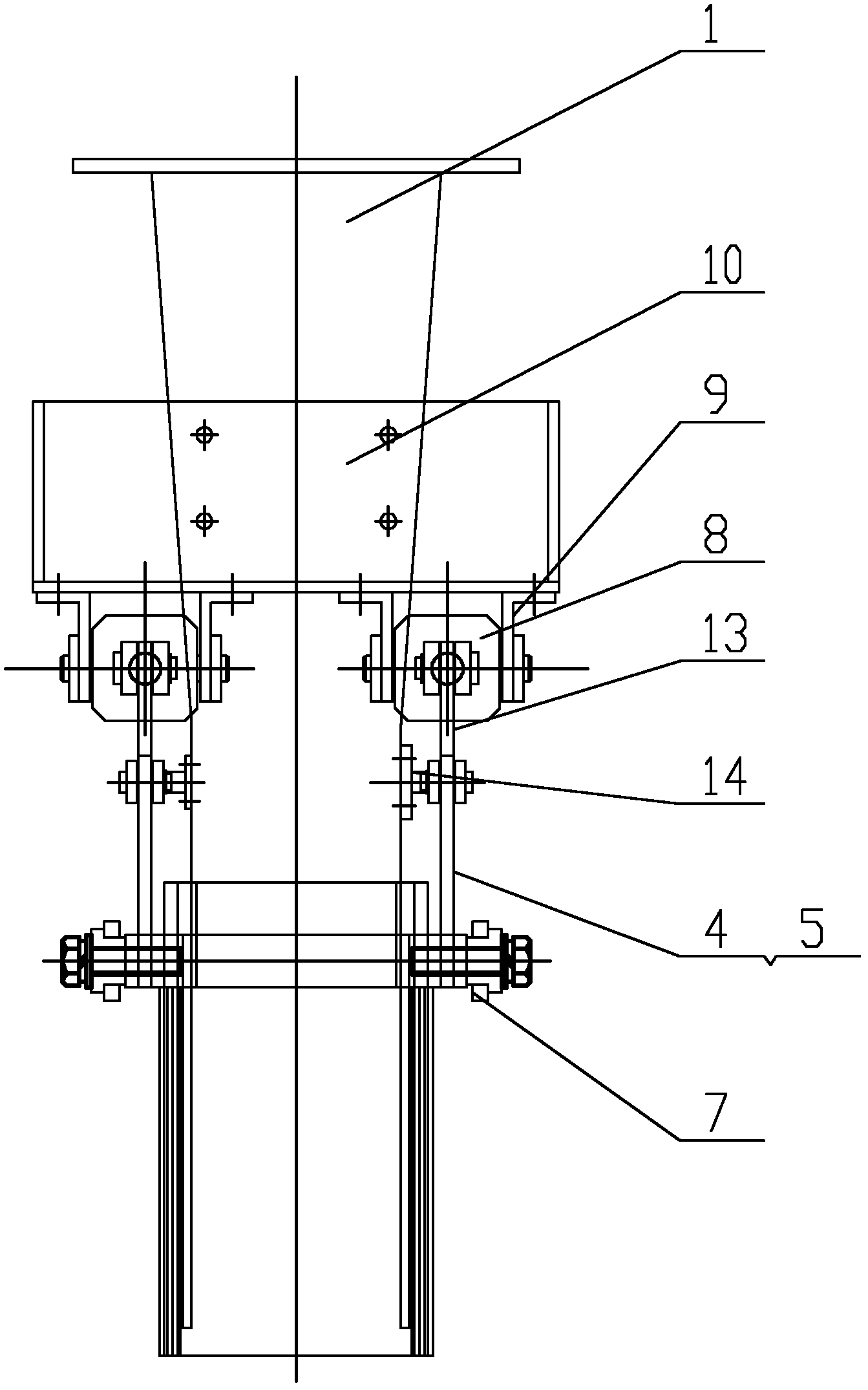

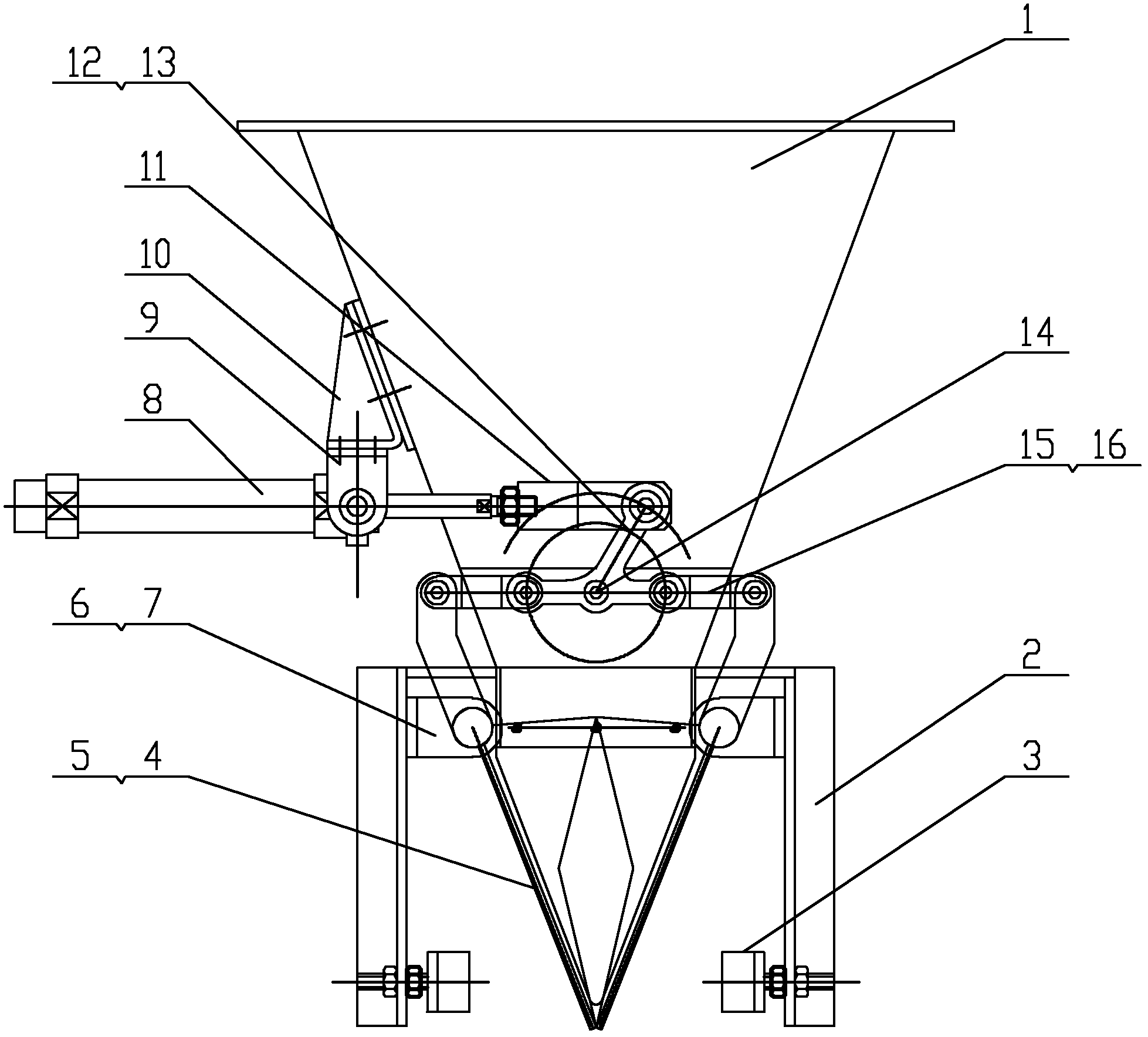

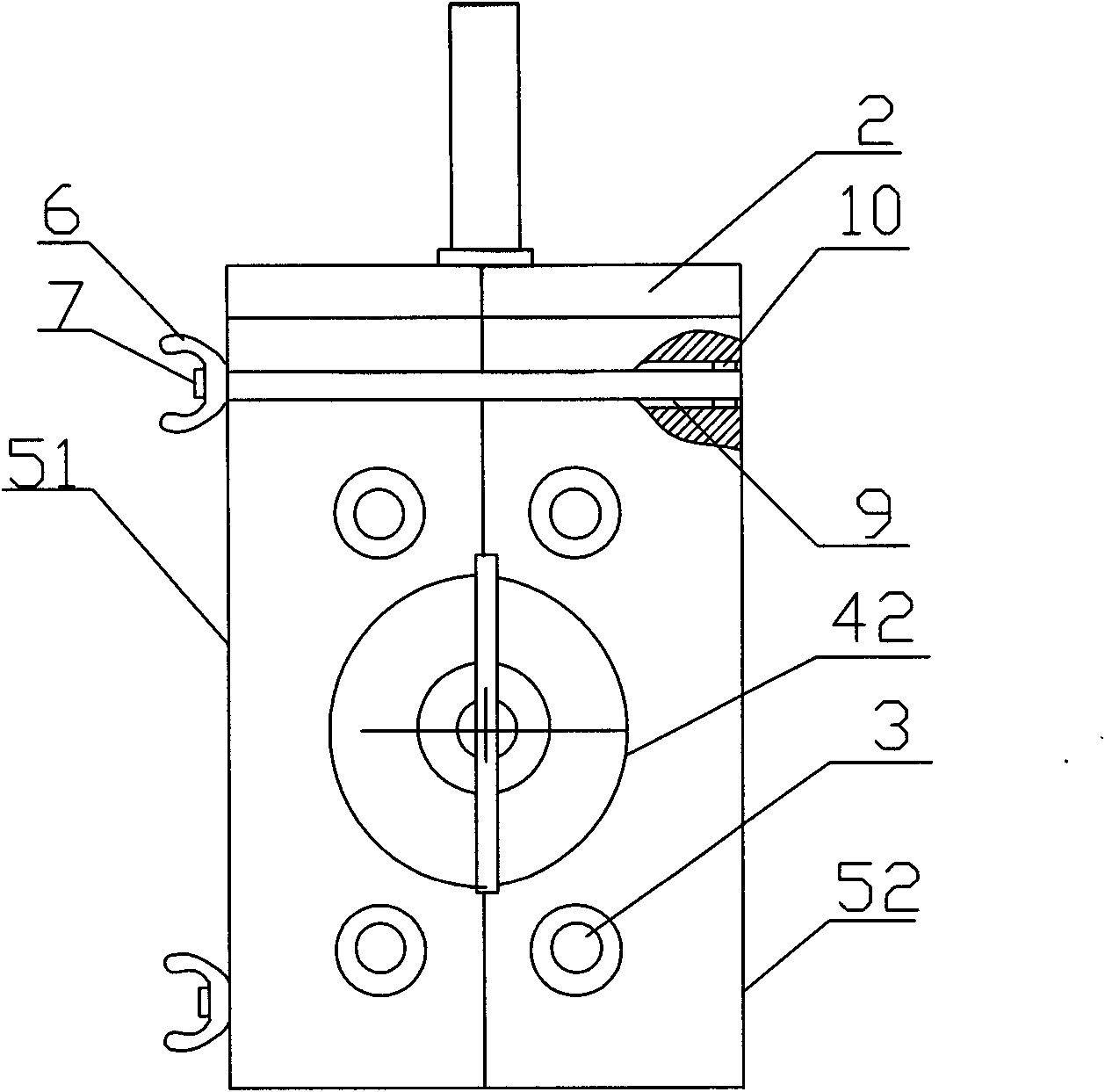

Bag clamping mechanism in automatic bagging machine

The invention relates to a bag clamping mechanism in an automatic bagging machine. For the bag clamping mechanism, bag clasping supports are welded on the lower end of a discharge hopper body; valve bearings are fixed on the bag clasping supports by bolts; a left valve and a right valve are respectively hinged on the valve bearings by bolts through a sliding bearing; the supports are arranged on the discharge hopper by bolts; cylinder mounting frames are arranged on the supports by bolts; cylinders are hinged on the cylinder mounting frames; cylinder connection pieces are connected on ends ofcylinder piston rods by threads; a center hole of a three-arm connection rod is sheathed on a rotating shaft; the rotating shaft is arranged on the discharge hopper body by bolts; the cylinder connection pieces are hinged with one end of the three-arm connection rod through a first pin shaft; and the other two ends of the three-arm connection rod are respectively connected with the left valve andthe right valve through a connection rod and a second pin shaft. The bag clamping mechanism has the advantages of simple, compact and reasonable structure, and is flexible and reliable in action, wherein, the left valve and the right valve work synchronously, thus being applicable to the automatic bagging equipment.

Owner:WUXI NAITE ELECTROMECHANICAL INTEGRATING TECH

Easy-to-clean extraction device for extracting nickel sulfate from used batteries

InactiveCN106730993AEasy maintenance and repairEasy to operateHollow article cleaningLiquid solutions solvent extractionSulfateLiquid storage tank

The invention relates to an extraction device, and in particular relates to an easy-to-clean extraction device for extracting nickel sulfate from used batteries. The invention aims at providing an easy-to-clean extraction device for extracting nickel sulfate from used batteries. To achieve the aim, the invention provides the easy-to-clean extraction device for extracting nickel sulfate from used batteries that comprises a left liquid storage tank, a left liquid inlet pipe, a left valve, an extraction tank, a left liquid sprayer, a stirrer, a cleaner, a right liquid sprayer, a right liquid inlet pipe, a right valve, etc. The left liquid inlet pipe is connected to the left liquid storage tank. The left valve is arranged on the left liquid inlet pipe. The extraction tank is arranged on the right side of the left liquid inlet pipe. A hole is provided in a left sidewall of the extraction tank. The easy-to-clean extraction device for extracting nickel sulfate from used batteries provided in the invention has the stirrer and the cleaner that match to achieve thorough cleaning.

Owner:南昌浩牛科技有限公司

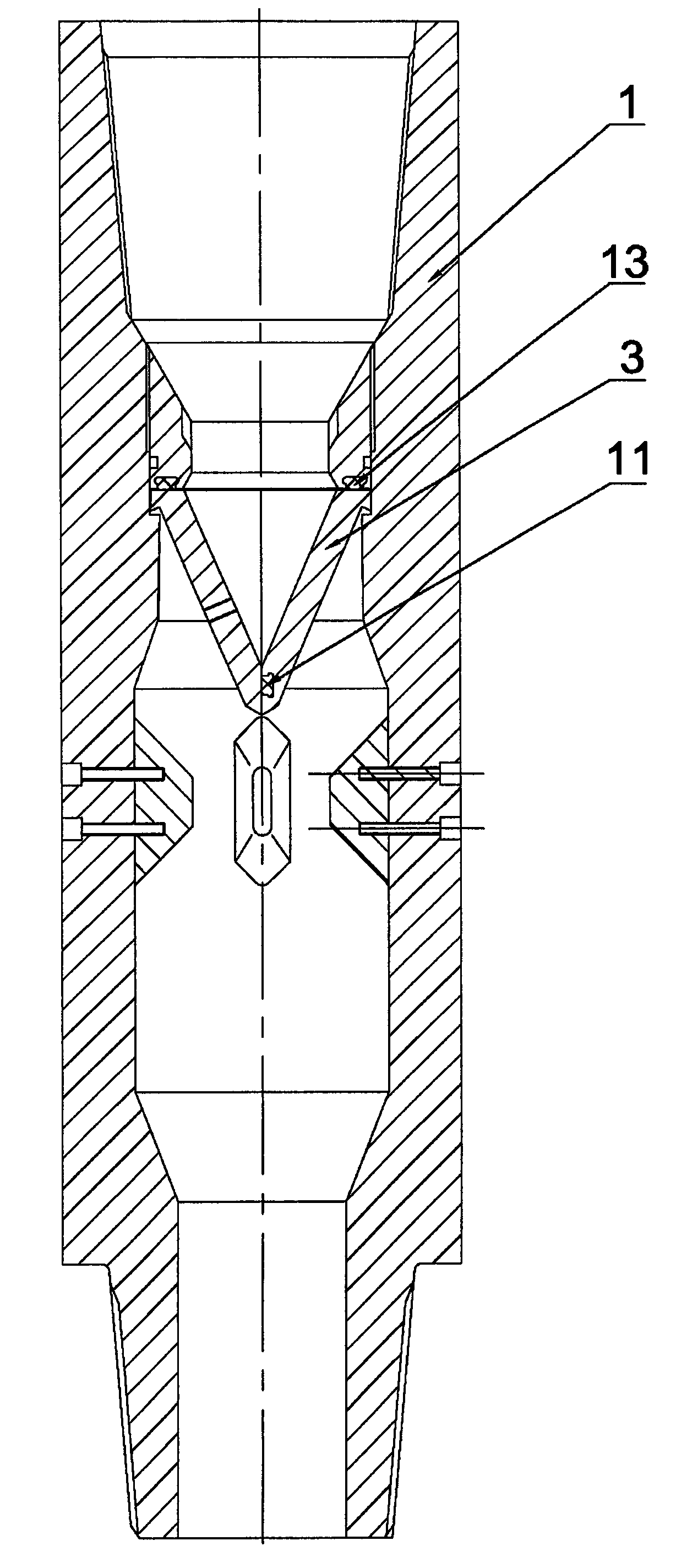

Inner blowout preventer of full-port drilling tool

ActiveCN101629480AImprove erosion resistanceNo erosionWell/borehole valve arrangementsSealing/packingSEMI-CIRCLEWell drilling

The invention relates to an inner blowout preventer of a full-port drilling tool. A valve body is internally provided with a passage and a lug boss; a left valve plate and a right valve plate are semi-circle conical; and the upper ends of the left valve plate and the right valve plate are respectively provided with outer flanges which are hung on the upper end surface of the lug boss and are in an open state so that the passage is in a through state. The invention has reasonable and compact structure and convenient use; and the conical valve plates can be fully opened in a positive cycle or static state to smoothen the passage of the drilling tool so as to reduce circulating pressure loss, basically have no erode to a valve core and carry out corresponding drilling operation by various instruments and tools with outside diameters smaller than a certain size. The inner blowout preventer of the full-port drilling tool can be automatically closed under the push of liquid dynamic power soas to take the blowout-preventing effect in case of blowouts in the drilling tool during the drilling operation, thereby not only extremely improving the processing rate during downhole accidents, but also improving the anti-erosion capability of the valve and further measuring the pressure of a vertical pipe.

Owner:中国石油集团西部钻探工程有限公司准东钻井公司

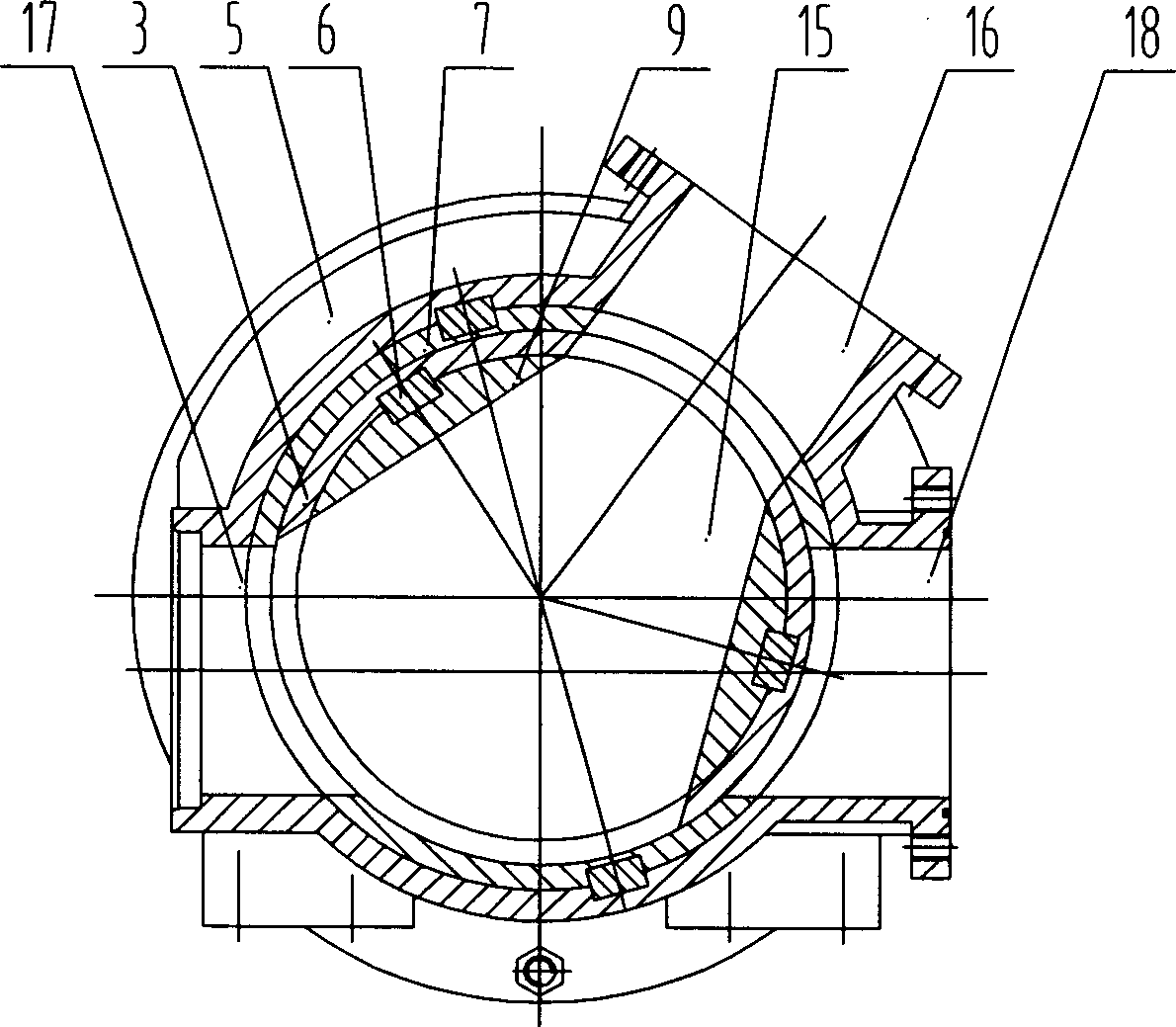

Distributing valve for concrete pump

InactiveCN1804398AIncrease the use volumeStir wellPositive displacement pump componentsPiston pumpsEngineeringHigh pressure

The invention discloses a distribution valve of concrete pump, which comprises a valve body, swing arms, two end caps, a left rotational valve and right rotational valve. Wherein, the end caps are arranged at the two ends of valve body; the valve body is divided into left valve chamber and right valve chamber; the left and right rotational valves are individually arranged inside the left and right valve chambers; the parts of valve relative to the left and right valve chambers have inlets, material adsorption inlets and outlets; the left and right rotational valves are individually connected to the swing arms at the outer side of two ends of valve body via the rotational axle; and said left and right rotational valves are cylinder which have through holes to connect the inlet and material adsorption inlet or material adsorption inlet and outlet. The invention has better material adsorption property which can meet the demand of high pressure pump.

Owner:SANY HEAVY IND CO LTD (CN)

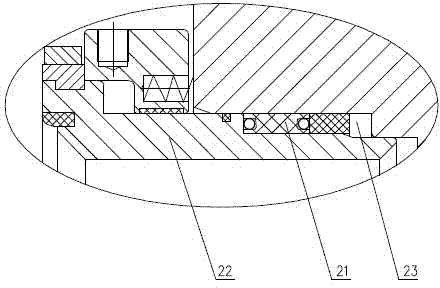

Installation fixture of press-seat butterfly valve seat

The invention relates to an installation fixture of a press-seat butterfly valve seat, which is composed of a cylindrical pedestal with a cavity for placing a valve body, a strip support plate arranged corresponding to the position and the length of an upper valve neck, a shaft-hole locating pin inserted into the shaft hole of the upper valve neck, a locating pin handle for pushing and pulling the shaft-hole locating pin, a bearing equipped with guide holes of the shaft-hole locating pin, a left valve seat locating pin and a right valve seat locating pin inserted in the shaft hole of the valve seat, a left support and a right support equipped with the guide holes of a valve seat locating pin respectively, a cam, a cam shaft connecting the cam, a rotating handle of the cam and three vertical elastic locating pins of the valve body. The axial line of the shaft-hole locating pin, the axial lines of the left valve seat locating pin and the right valve seat locating pin and a central line are in the same vertical plane; and the three vertical elastic locating pins of the valve body are alternately arranged on the end surface of the cylindrical pedestal at the position attaching to the inner wall of the valve body. The installation fixture has the beneficial effects of guaranteeing the coaxiality of the valve body and the shaft hole of the valve seat, saving labor cost, eliminating noise, improving operating conditions and environment and enhancing production efficiency.

Owner:TIANJIN GALAXY VALVE

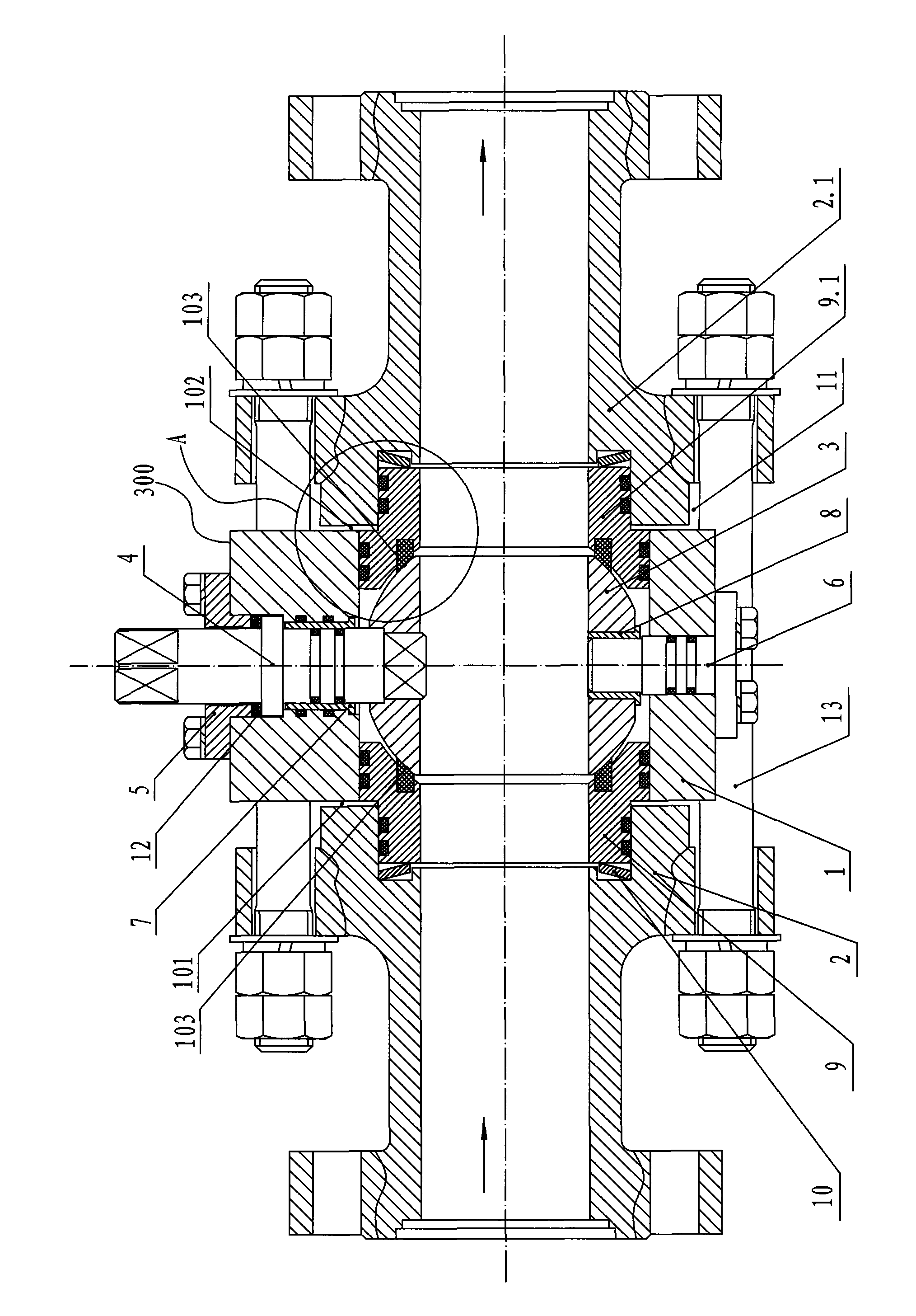

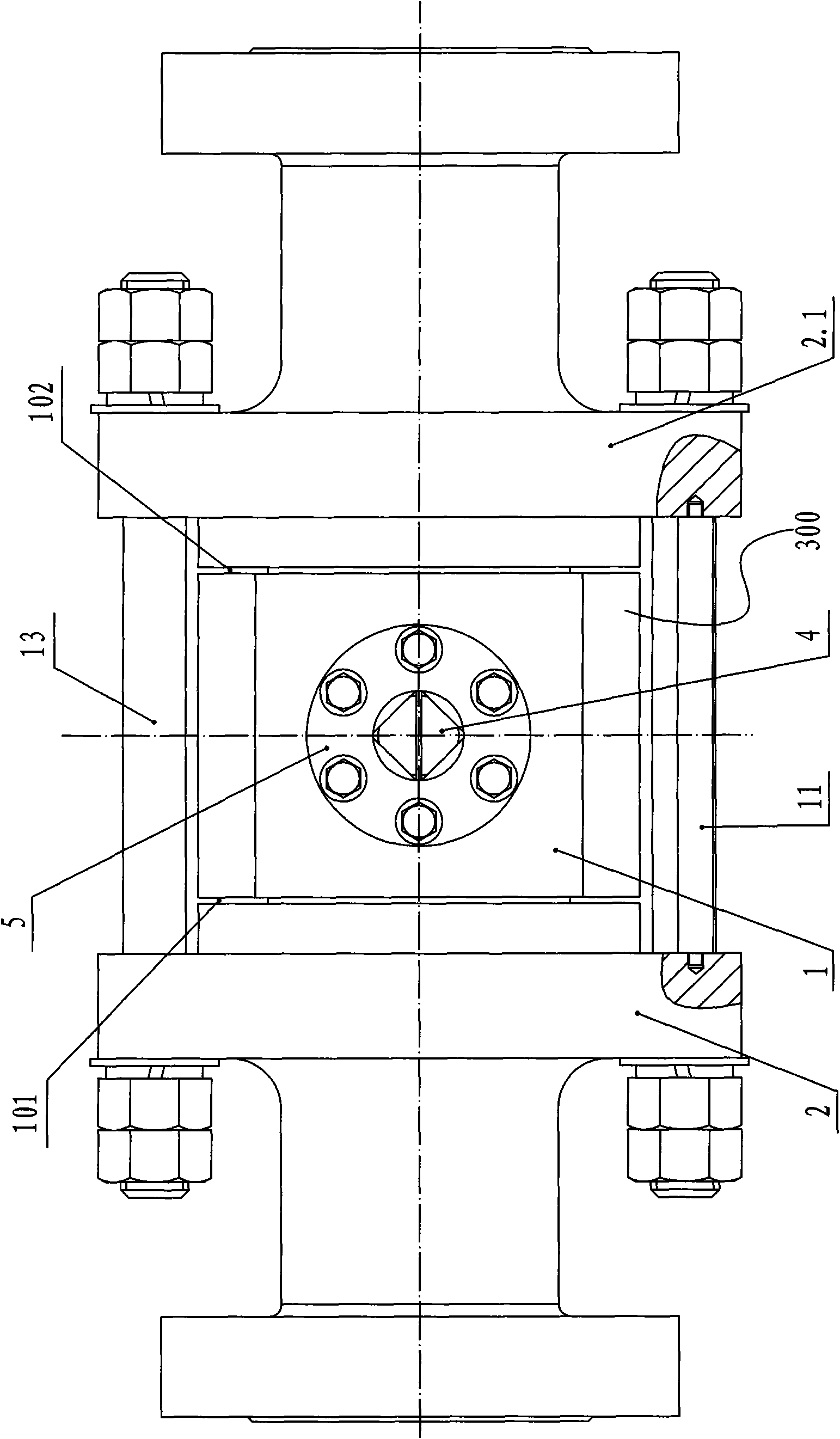

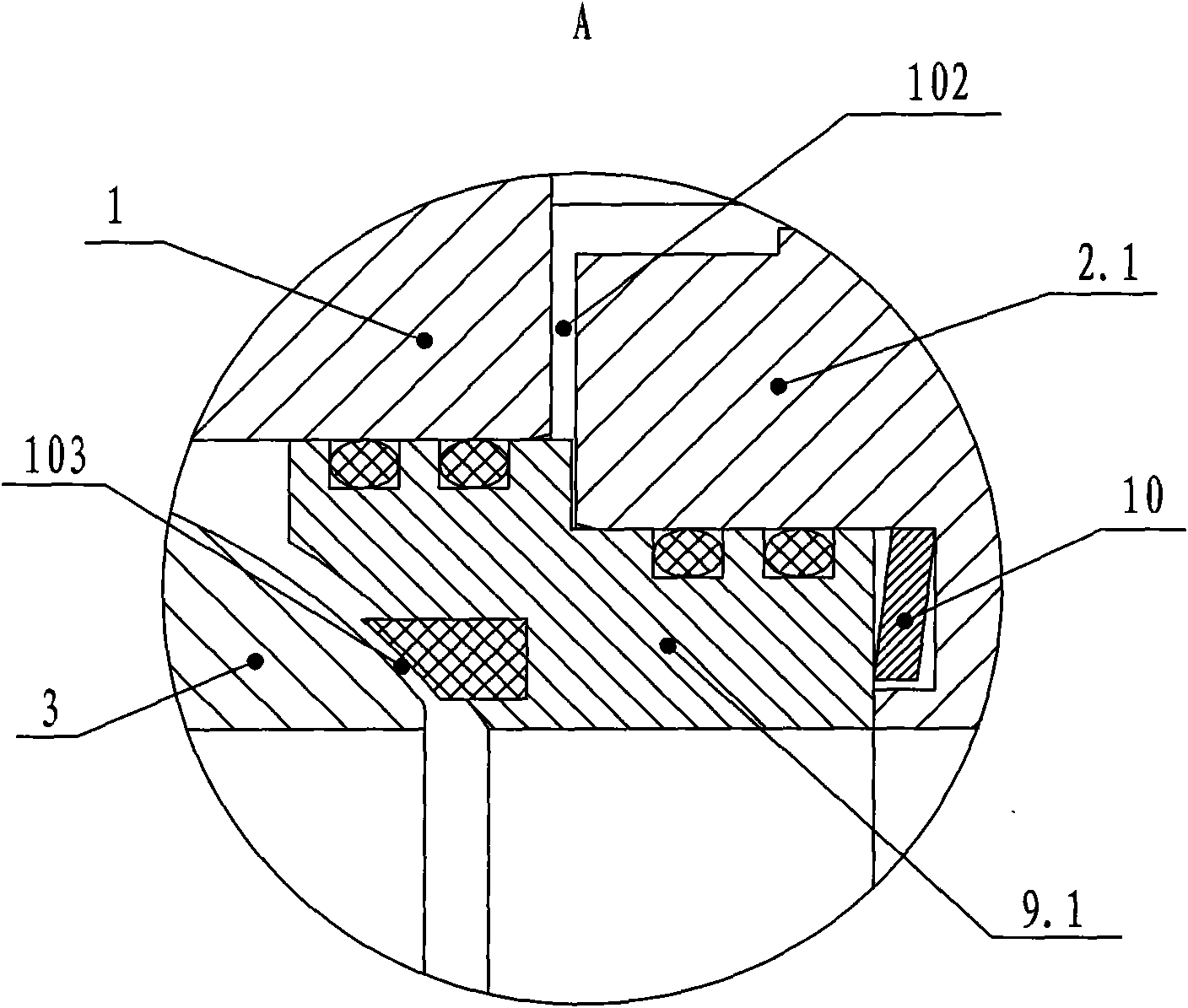

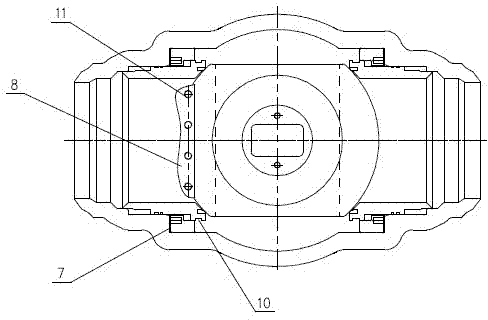

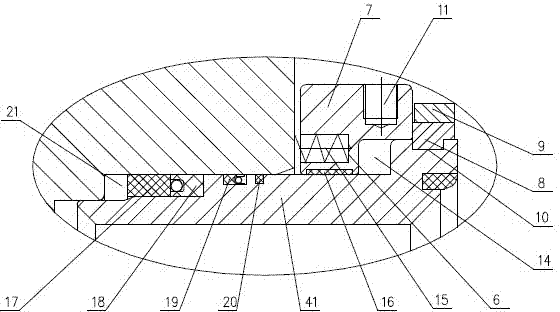

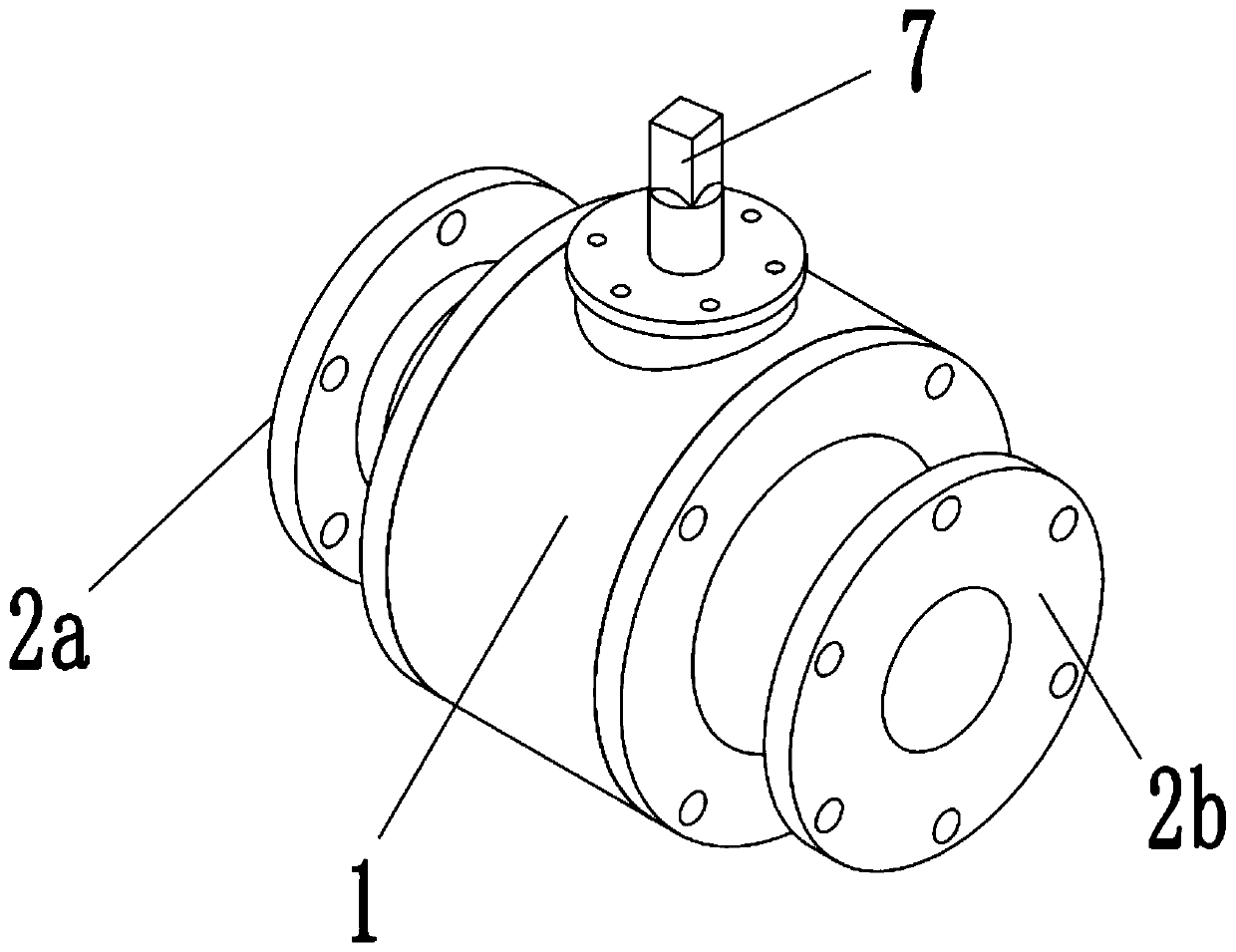

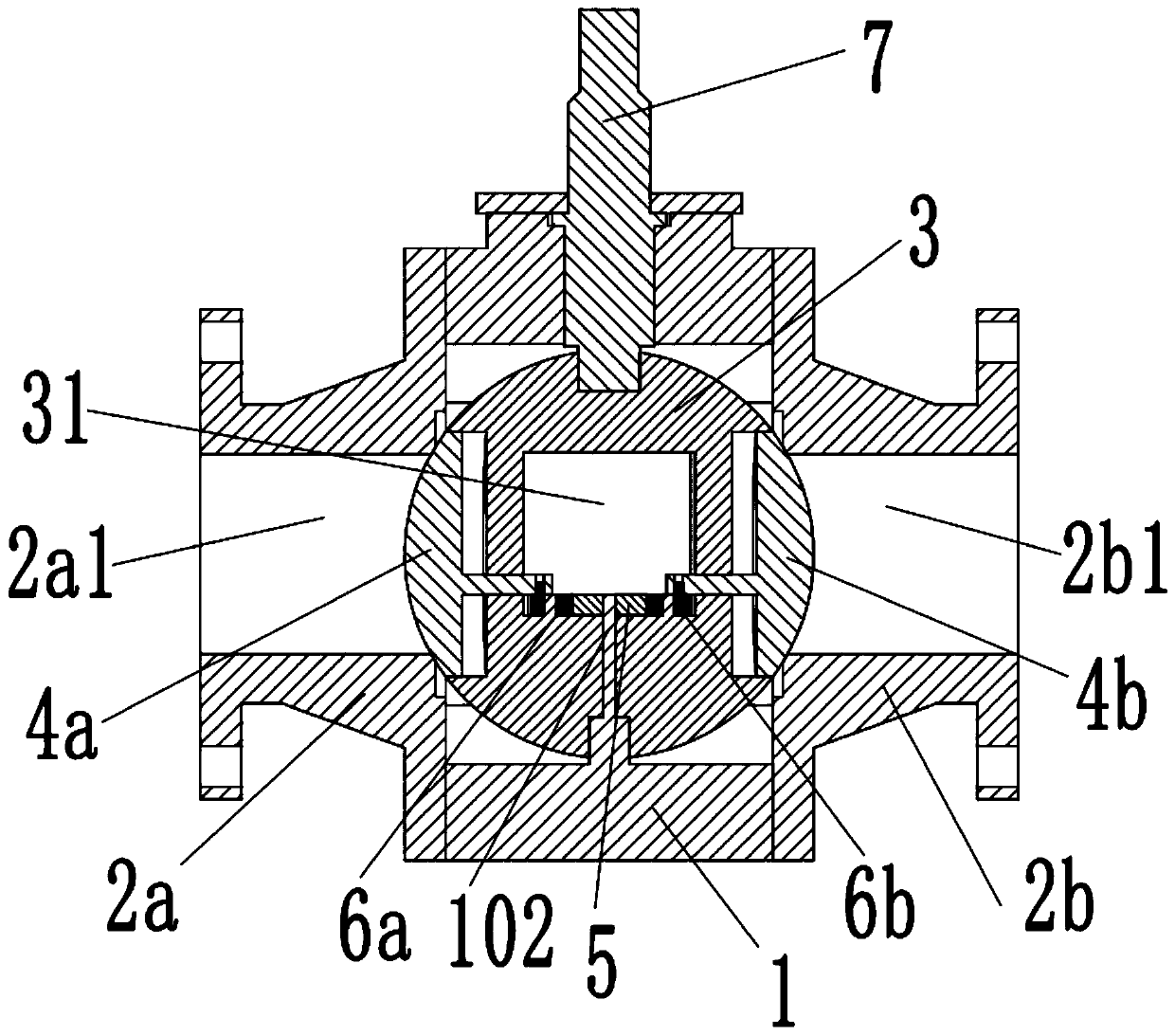

Ball valve

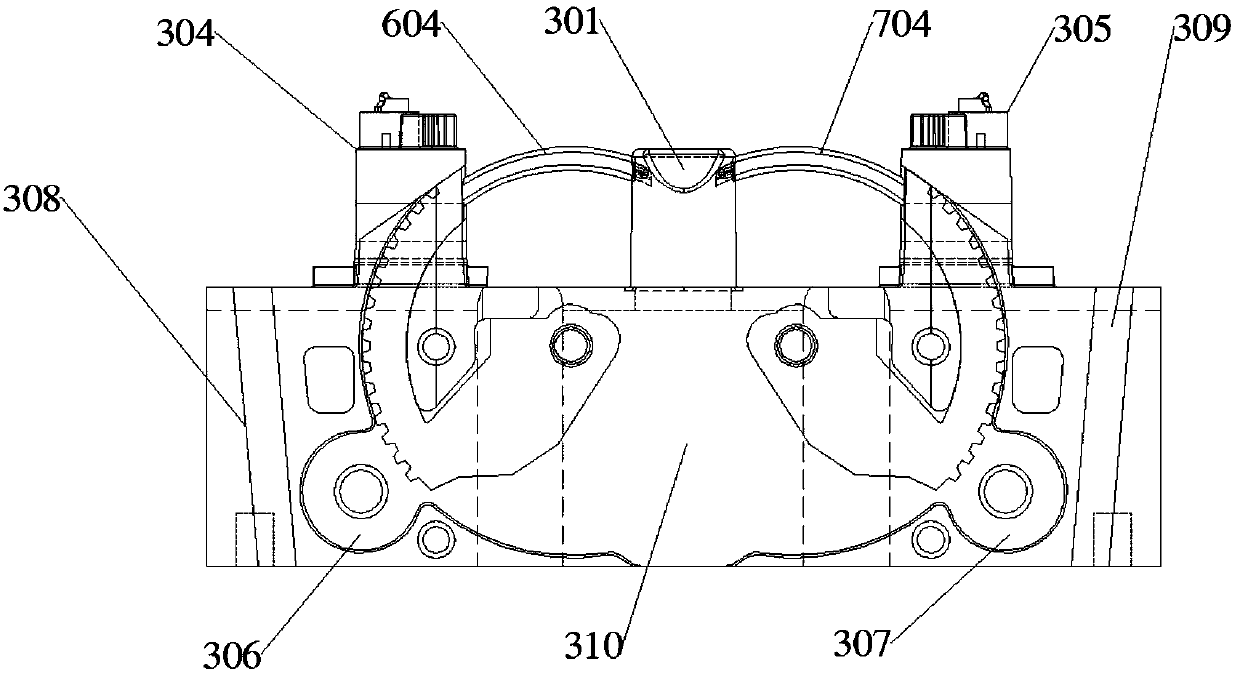

The invention relates to a ball valve. A main valve body assembly (300) comprises a main valve body (1), a ball body (3) which is positioned in the main valve body (1), an upper shaft (4) which is rotatably matched with the main valve body (1), a pressure cover (5) which is connected with the main valve body (1) and axially positions the upper shaft (4) and a lower shaft (6) which is connected with the main valve body (1), wherein the upper shaft (4) is fixedly connected with the upper end of the ball body (3), the lower end of the ball body (3) is rotatably connected with the lower shaft (6), the right end of a left valve seat is in slide connection with the left end of the main valve body (1), the left end of a right valve seat 9.1 is in slide connection with the right end of the main valve body (1), and the vertical distance between the right end face of a left auxiliary valve body (2) and the left end face of a right auxiliary valve body (2.1) is larger than the axial distance of the main valve body (1). Compared with the prior art, the invention has both of the advantages of a float ball valve and a fixed ball valve, and also has small operating torque, long service life and better sealing reliability.

Owner:星箭科技股份有限公司

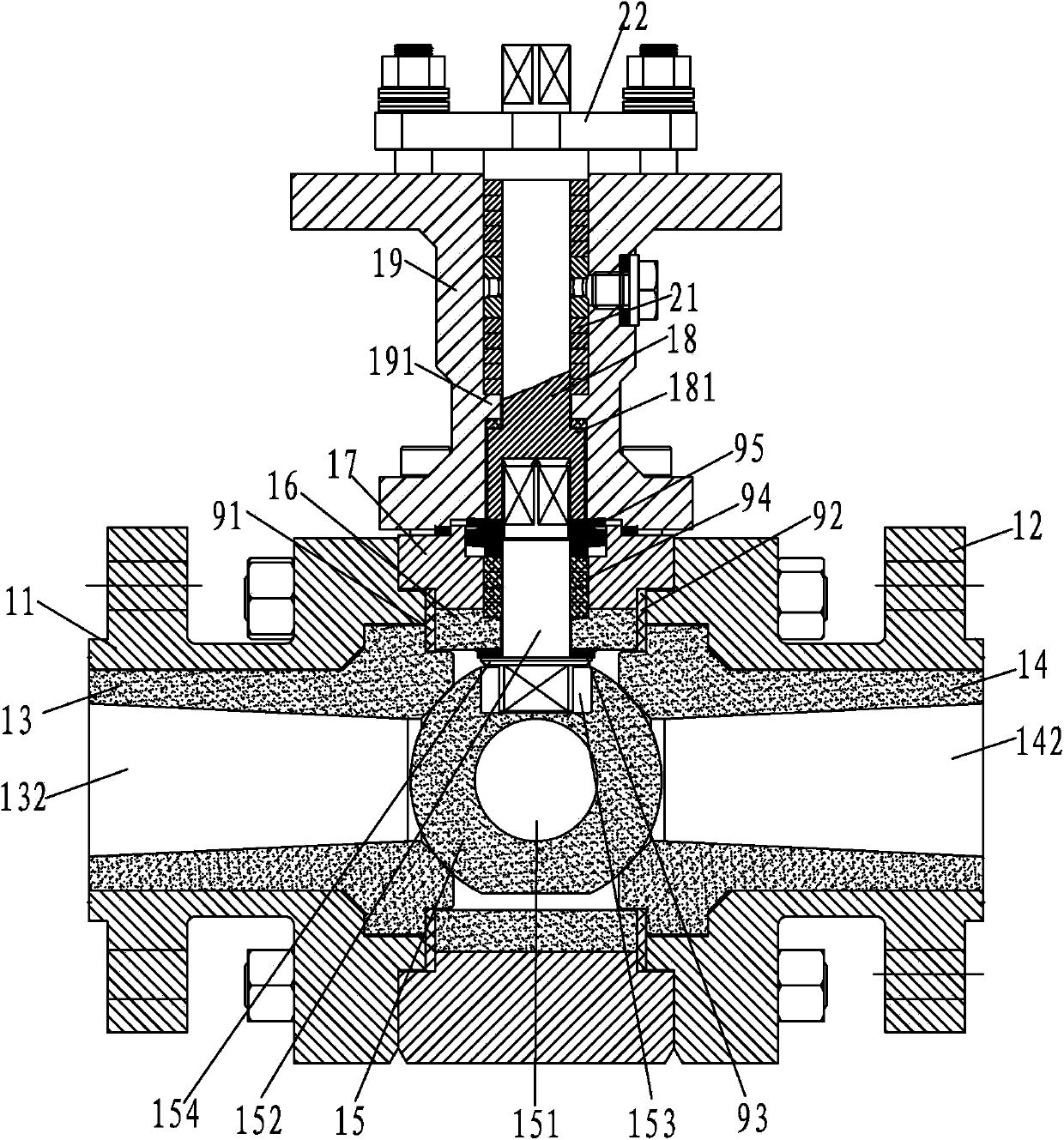

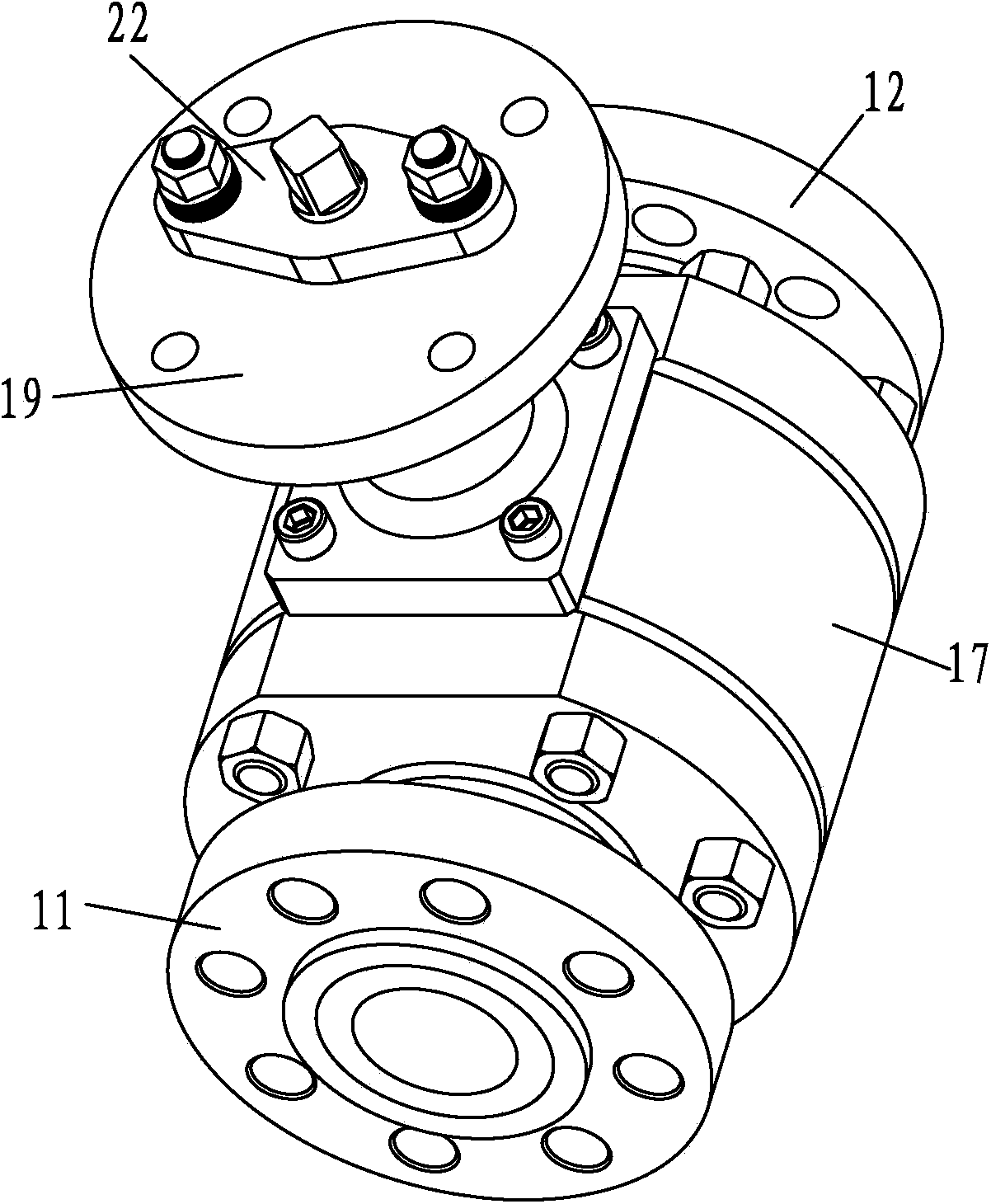

Ultralow-temperature tool-aid-type fixing ball valve and assembling method thereof

ActiveCN103801897AGuaranteed stabilityAvoid damagePlug valvesMetal working apparatusLeft valveScrew thread

The invention relates to an ultralow-temperature tool-aid-type fixing ball valve and an assembling method of the ultralow-temperature tool-aid-type fixing ball valve. The ultralow-temperature tool-aid-type fixing ball valve and the assembling method of the ultralow-temperature tool-aid-type fixing ball valve resolve the technical problems that an existing installation method of a valve seat adopts a thread screwing structure, the structure is difficult to screw and threads are damaged easily after multiple times of detachment and installation. A tool is used for putting a supporting ring, a left valve seat component and a right valve seat component into valve seat holes, a ball body is put into a valve cavity when the valve is in an open state, and the ball body is rotated by 90 degrees so that the valve can be in a closed state. A tool is used for opening the supporting ring to expose a positioning part of the left valve seat component and a positioning part of the right valve seat component, then the elastic supporting ring is fixed through a fixing process hole in the elastic supporting ring and the tool, and the tool used for opening the supporting ring is removed. A tool is used for clamping a positioning ring into the positioning parts of the valve seat through the tool, the split open positioning ring is fixed through a positioning plate, and then the tool used for fixing the elastic supporting ring is removed. Through the tool-aid structure and method, the installation method of the valve seat is changed, the traditional thread screwing type structure is changed into a stretchable installation structure, damage to the threads caused by multiple times of installation is avoided, multiple times of on-line detachment and installation on site can be achieved, and repairing is convenient.

Owner:FANGZHENG VALVE GRP

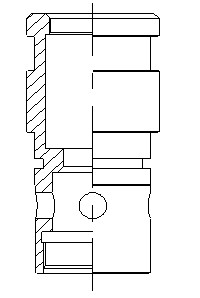

Production technology for left valve barrel of colliery three-purposed hydraulic valve

The invention relates to a production technology for a left valve barrel of a colliery three-purposed hydraulic valve, comprising the steps of discharging round steels, and heating up the round steel to 1120-1200 DEG C; removing scales by a punching machine, and blanking; reversely squeezing at a high temperature on a press machine; punching away wads of high-temperature reversely squeezed forge pieces by the punching machine; forging again by the press machine in a closed manner; carrying out heat treatment on the forging excess heat; finely turning by a numerically controlled lathe, processing and clamping by a milling machine; and finishing the manufacture to obtain finished products. In the invention, the press machine is used for finely forging the profile of the left valve barrel of the colliery three-purposed hydraulic valve, so that massive production is convenient. The technology of the invention is used for displacing a traditional old technology, so that steel materials are saved; the production efficiency is improved by three times; and the production cost is reduced. By using the technology in the invention, the production cost of the left valve barrel of each DZF colliery three-purposed hydraulic valve can be reduced ** Yuan; in each year, 6-7 million of three-purposed hydraulic valves for collieries are produced in China, so that ** Yuan of social resources can be saved.

Owner:SHANDONG UNIV

Safety level electric ball valve

ActiveCN103470804APrevent leakageMeet external sealing requirementsSpindle sealingsPlug valvesNuclear powerEngineering

The invention relates to the technical field of a valve, in particular to a safety level electric ball valve for a pebble-bed high-temperature reactor. The ball valve comprises a valve body, a left valve seat assembly, a valve ball, a right valve seat assembly, a blind flange, a magnetic actuator and an electric device. The electric ball valve adopting the technical scheme has the advantages that the dynamic sealing of a valve rod and a valve seat is changed into the static sealing, and the reliable sealing on high-temperature, high-pressure and high-radioactivity helium atmosphere at the pressure boundary part of the reactor in the service life of a pebble-bed high-temperature nuclear power station can be met.

Owner:CHINERGY CO LTD

Safety complex function valve and two-way valve composed by same

ActiveCN101907190AAchieve free spinsImprove sealingEqualizing valvesSafety valvesComposite functionEngineering

The invention relates to a safety complex function valve. A valve bush is arranged between the left valve cavity and the right valve cavity in the valve body; a valve core is arranged in the valve bush; the valve core and the valve bush form a conical seal fit; both ends of the valve core are respectively provided with a spring, an adjusting screw and an emergency push rod; both ends of the valve body are respectively fixed with a left valve cap and a right valve cap through bolts; and the left valve cap and the right valve cap are respectively provided with a left cap nut and a right cap nut. The two-way valve comprises a valve body and a reversing valve body, wherein the structure of the reversing valve body is identical to that of the valve body rotated for 180 degrees. A sealing element is respectively arranged between the valve bush and the valve body, between the valve cap and the valve body, between the valve cap and the bolt, on both ends of the sealing nut, and between the valve body and the reversing valve body in the two-way valve. The invention not only can adjust the pressure in two directions, but also can communicate the cavities in forward and backward directions in an emergency; and thus, the invention has the advantages of high safety, favorable sealing effect, wide application range of flow, strong flexibility and simple structure.

Owner:WUHAN MARINE MACHINERY PLANT

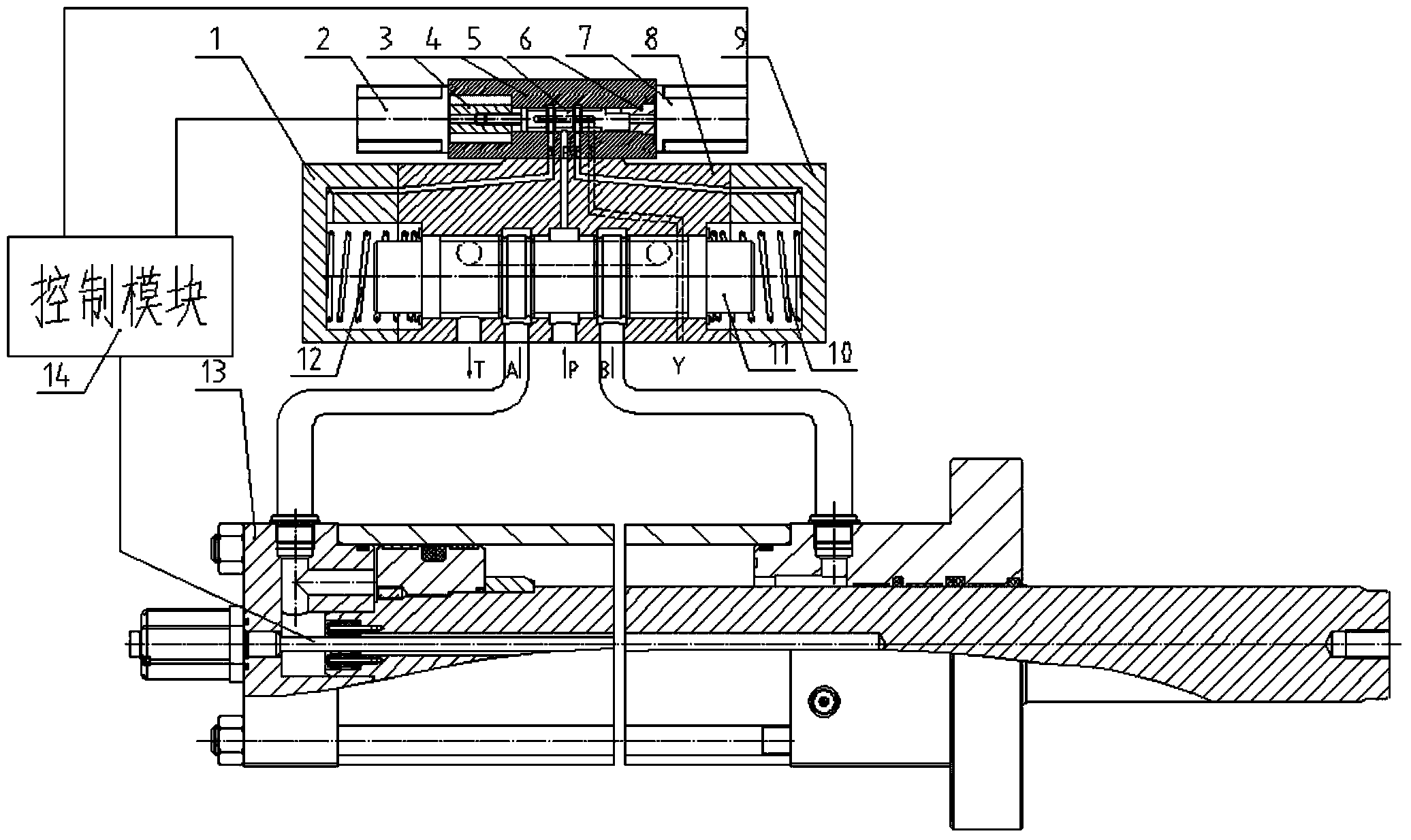

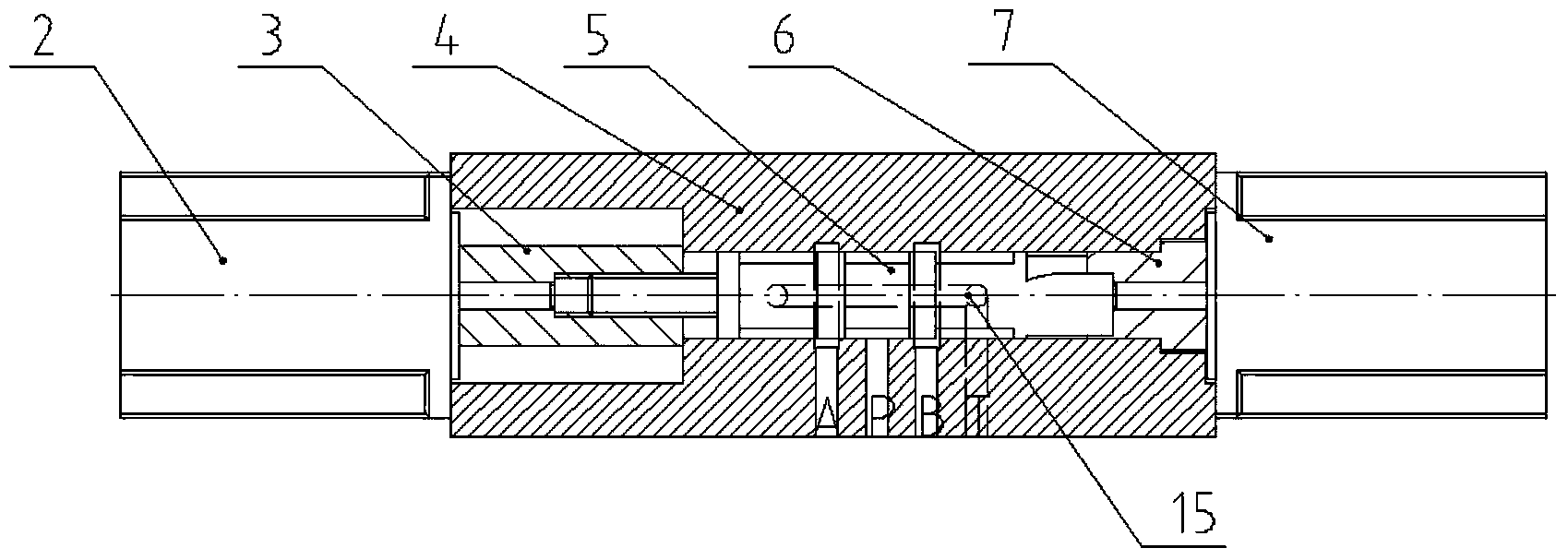

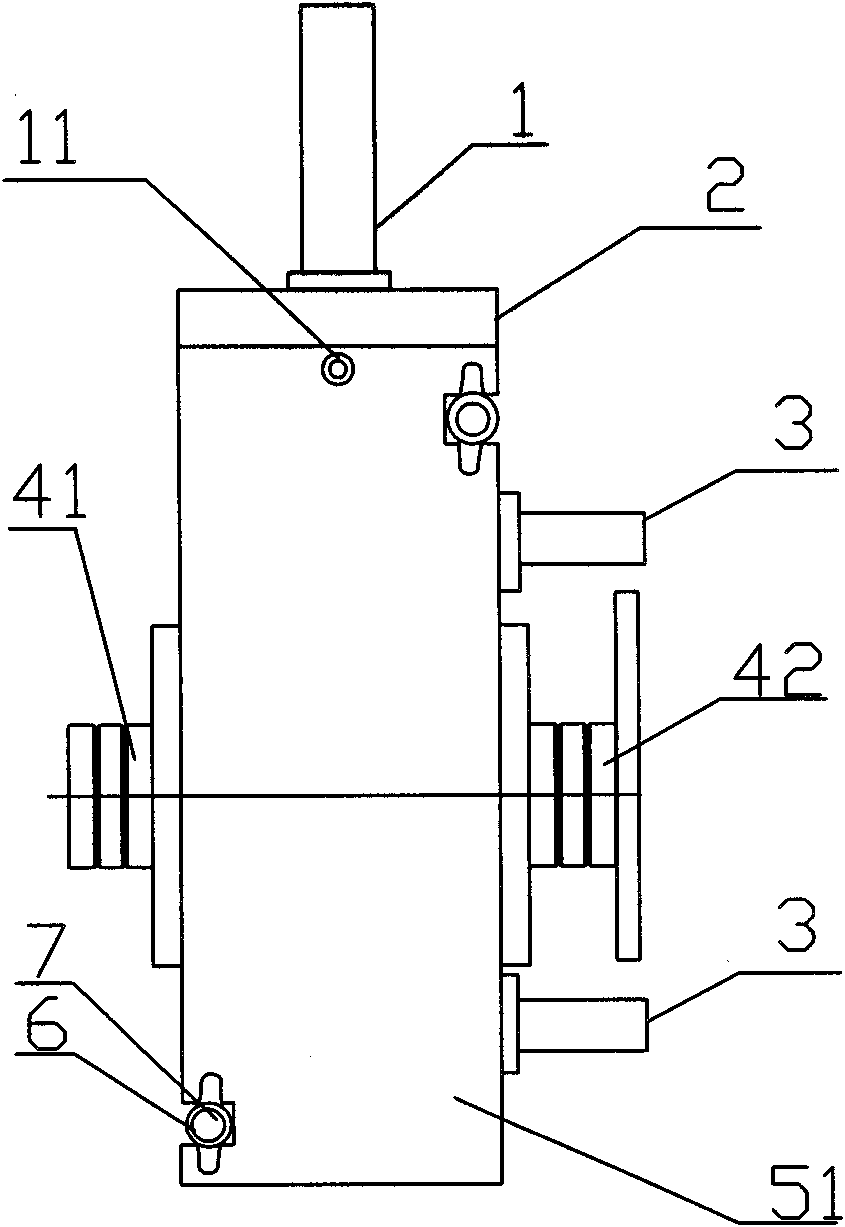

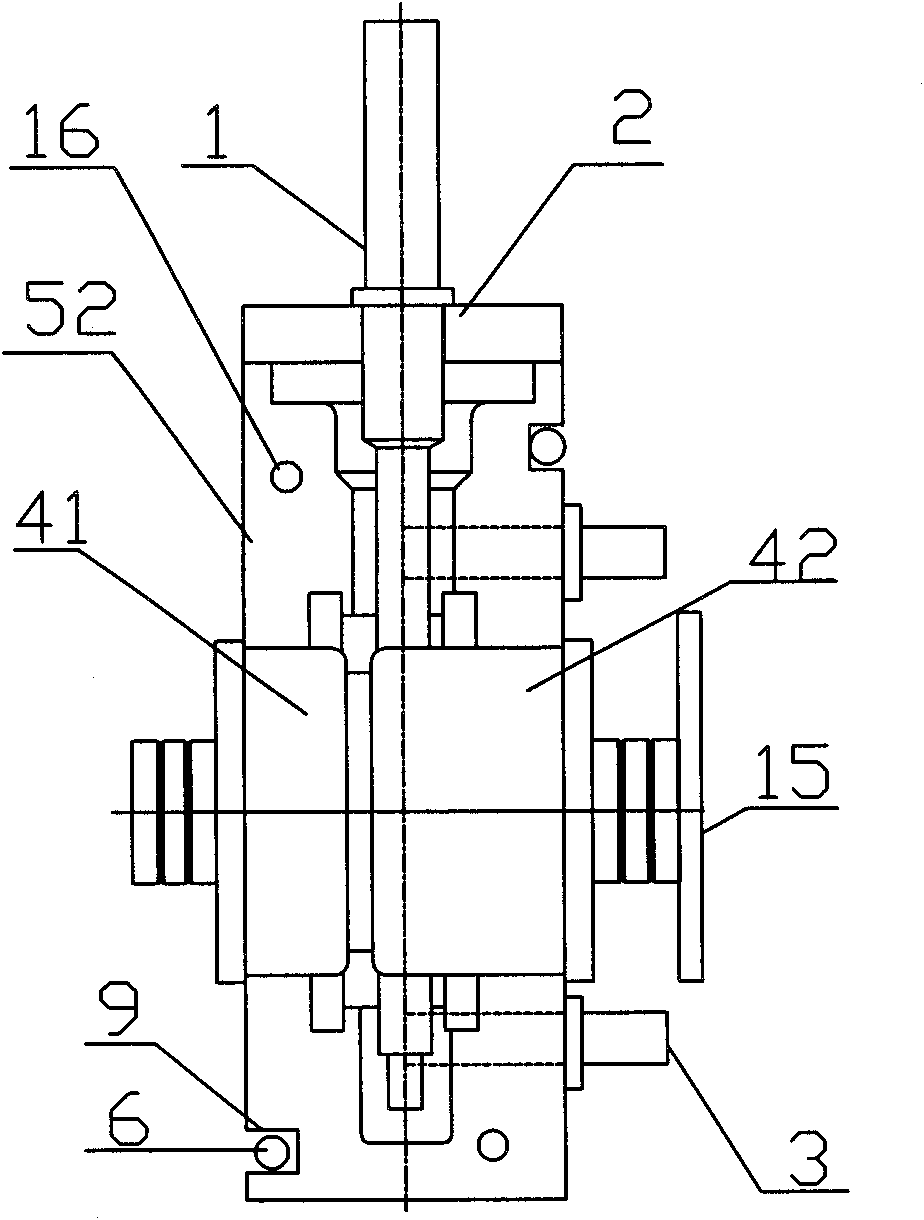

Electrical feedback large-scale servo hydraulic cylinder driven by double motors

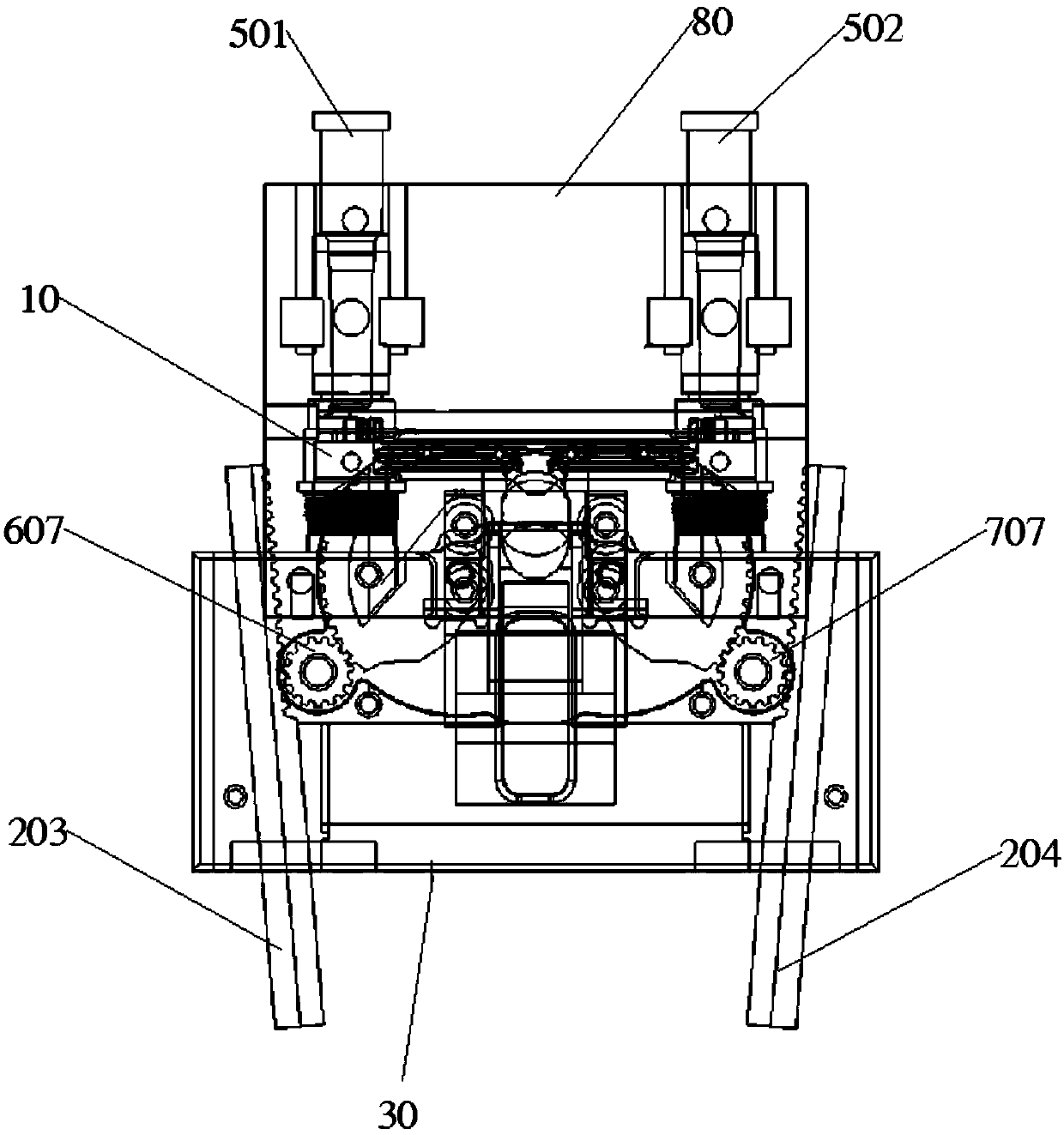

ActiveCN103775441ALarge thrustEasy to controlServomotor componentsFluid-pressure actuator componentsElectricityHydraulic cylinder

The invention discloses an electrical feedback large-scale servo hydraulic cylinder driven by double motors. The electrical feedback large-scale servo hydraulic cylinder comprises a hydraulic cylinder, a pilot valve and a glide valve, wherein the pilot valve comprises a pilot valve body, a pilot valve core is arranged in the pilot valve body, a pilot valve first oil opening, a pilot valve second oil opening, a pilot valve third oil opening and a pilot valve fourth oil opening are sequentially formed in the pilot valve body from the left side to the right side, the pilot valve core can leftwards and rightwards move in the axial line direction of the pilot valve core via a slide moving mechanism through being driven by a driving motor and a feedback motor, the glide valve comprises a glide valve body, a glide valve core, a left valve cover, a right valve cover, a left spring and a right spring, the glide valve core is assembled in the glide valve body, the left valve cover is matched and connected with the left end of the glide valve body, the right end cover is matched and connected with the right end of the glide valve body, the left spring is arranged at the left end of the glide valve core, and the right spring is arranged at the right end of the glide valve core. When the electrical feedback large-scale servo hydraulic cylinder is adopted, the quantization control can be easily realized.

Owner:TIANJIN UNIV

Negative-pressure liquid feeding device based on liquid core wave guide pipe

ActiveCN103454221AAvoid cross contaminationAvoid interferenceMaterial analysis by optical meansLiquid coreEngineering

The invention provides a negative-pressure liquid feeding device based on a liquid core wave guide pipe. The negative-pressure liquid feeding device comprises a liquid core wave guide pipe, a vacuum chamber, a vacuum pump, a left connector and a right connector, wherein the vacuum pump is communicated with an inner cavity of the vacuum chamber; a main body part of the liquid core wave guide pipe is arranged in the vacuum chamber; a sample feeding end and a detection end of the liquid core wave guide pipe stretch out of the vacuum chamber; the sample feeding end of the liquid core wave guide pipe is sleeved with a first sample feeding capillary pipeline; the first sample feeding capillary pipeline is connected with the left connector; the left connector is connected with a second sample feeding capillary pipeline for connecting a sample position; the second sample feeding capillary pipeline is provided with a left valve; the detection end of the liquid core wave guide pipe is sleeved with a first sample discharging capillary pipeline; the first sample discharging capillary pipeline is connected with the right connector; the right connector is connected with a second sample discharging capillary pipeline for connecting a waste discharging device; the second sample discharging capillary pipeline is provided with a right valve. The negative-pressure liquid feeding device based on the liquid core wave guide pipe can prevent a sample solution from being crossly polluted and has the advantages of small volume, low power consumption, easiness in modularization and small detection result error.

Owner:BEIJING JITIAN INSTR CO LTD

Valve body wax mold of tri-eccentric butt-clamped metal sealing butterfly valve

InactiveCN102107258AHigh dimensional accuracyHigh surface finishFoundry mouldsFoundry coresSurface finishWax

The invention relates to a valve body wax mold of a tri-eccentric butt-clamped metal sealing butterfly valve. The valve body wax mold is characterized by consisting of a front mold shell, a rear mold shell, a left valve body path core, a right valve body path core, a shaft hole core, a plurality of installation hole cores, a baffle plate and a fastening member; the front mold shell and the rear mold shell which are fixed together form a valve body cavity which is matched with the shape of the valve body and comprises a valve body path part cavity, a shaft hole upper end face part cavity, a shaft hole part cavity and an installation hole plate part cavity; the left valve body path core and the right valve body path core pass through the left sides and the right sides of the front mold shell and the rear mold shell so as to be penetrated and fixedly inserted into the path part cavity together; the shaft hole core is inserted into the shaft hole part cavity; the plurality of installation hole cores are respectively inserted into the installation hole part cavity; the baffle plate is covered on the shaft hole end face part of the valve body cavity; and a pouring hole is formed corresponding to shaft hole end face part. The valve body wax mold of the tri-eccentric butt-clamped metal sealing butterfly valve has the advantages of increasing the size precision and the surface finishment of the valve body, reducing the manufacturing cost and improving the production efficiency.

Owner:天津市大站阀门总厂

Fast valve specially for fire flighting

InactiveCN101046257ASave operating timeEasy to operateOperating means/releasing devices for valvesSlide valveWater flowLeft valve

The fast valve specially for fire fighting includes one right valve body, one left valve body, one valve seat inside the valve bodies, one valve plate matching the valve seat and one handle connected to the valve plate. The valve seat and the valve plate are set radically inside the valve bodies and fitted mutually via plates, and have through holes corresponding to each other. Normally, water flows through the through holes, and shifting the valve plate to stagger the through hole in the valve seat and that in the valve plate can cut off water flow. The shift stroke of the valve plate is equal to the diameter of hole or only 20-25 % shift stroke of common gate valve, so that the valve has fast operation. In addition, the valve may be operated conveniently through one long tool.

Owner:杨清强

Plastic faucet body and manufacturing die thereof

ActiveCN107631069AReduce assembly componentsImprove sealingDomestic plumbingDomestic articlesEngineeringLeft valve

The invention discloses a plastic faucet body and a manufacturing die, which belong to the technical field of machinery and aim to provide the plastic faucet body with good sealing performance. The plastic faucet body comprises a left water inlet pipe and a right water inlet pipe, wherein a left valve seat installation groove is formed in the left water inlet pipe, a right valve seat installationgroove is formed in the right water inlet pipe, a connecting cross beam is arranged between the left water inlet pipe and the right water inlet pipe, a water outlet is formed in the connecting cross beam, a middle waterway is formed in the connecting cross beam, the middle waterway communicates with the left water inlet pipe, the middle waterway communicates with the right water inlet pipe, the middle waterway communicates with the water outlet, the middle waterway comprises a left water inlet way and a right water inlet way, and the left water inlet way and the right water inlet way are in curved or U shapes. The plastic faucet body can be used for assembling various cold water and hot water mixed faucets and has the advantage of good sealing performance, and additionally, the plastic faucet body is integrally formed, so that the procedure is simplified, the cost is reduced, and the production efficiency is improved.

Owner:XIAMEN LOTA INT CO LTD +1

High-pressure high-temperature ceramic adjusting ball valve

InactiveCN103711927AReduce coefficient of frictionInevitable wear and tearPlug valvesValve housingsEngineeringHigh pressure

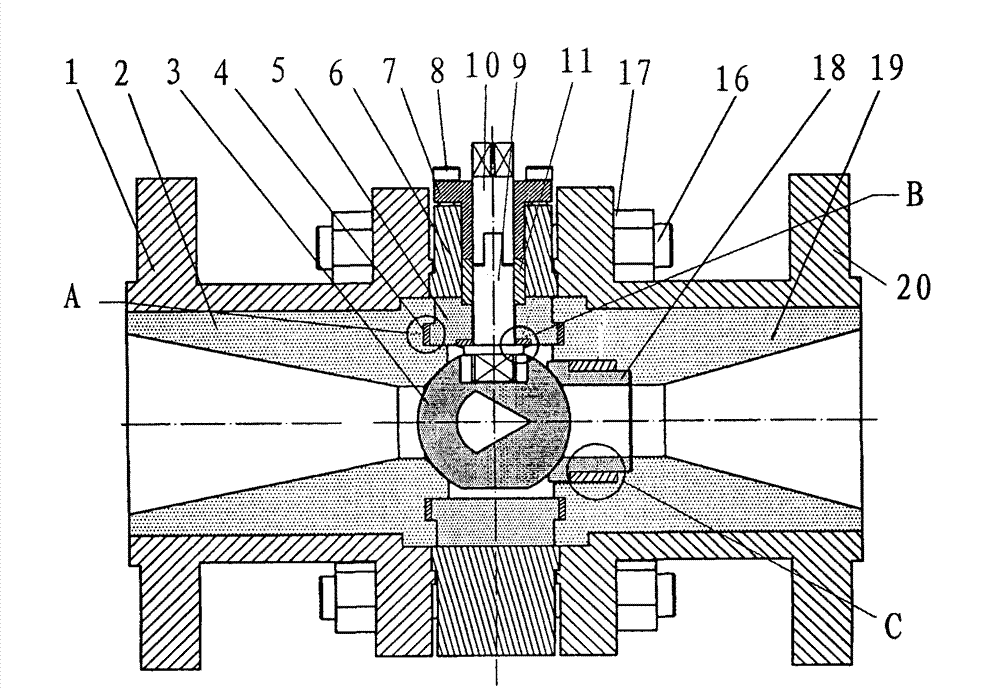

The invention discloses a high-pressure high-temperature ceramic adjusting ball valve which is reliable in sealing, resistant to high pressure and high temperature, resistant to corrosion and capable of automatically adjusting sealing performance to certain extent. The adjusting ball valve comprises a left flange (1) and a right flange (20), a valve body (6) and a valve body liner (5) are arranged between the left flange (1) and the right flange (20), and the left flange (1) and the right flange (20) are fastened by a bolt (16) and a nut (17). The adjusting ball valve is characterized in that a left valve seat (2) made of ceramic is arranged in the left flange (1), a right valve seat (19) made of ceramic is arranged in the right flange (20), a ball (3) made of a ceramic material, playing a role in opening or closing a passage and provided with a V-shaped groove is disposed between the left valve seat (2) and the right valve seat (19), and connected with a valve rod (9) and an output shaft (10), the valve body liner (5) is made of a ceramic material, and a tenon-shaped sealing structure is formed between the valve body liner (5) and the left and right valve seats (2,19).

Owner:YANTAI KINGWAY SCI & TECH

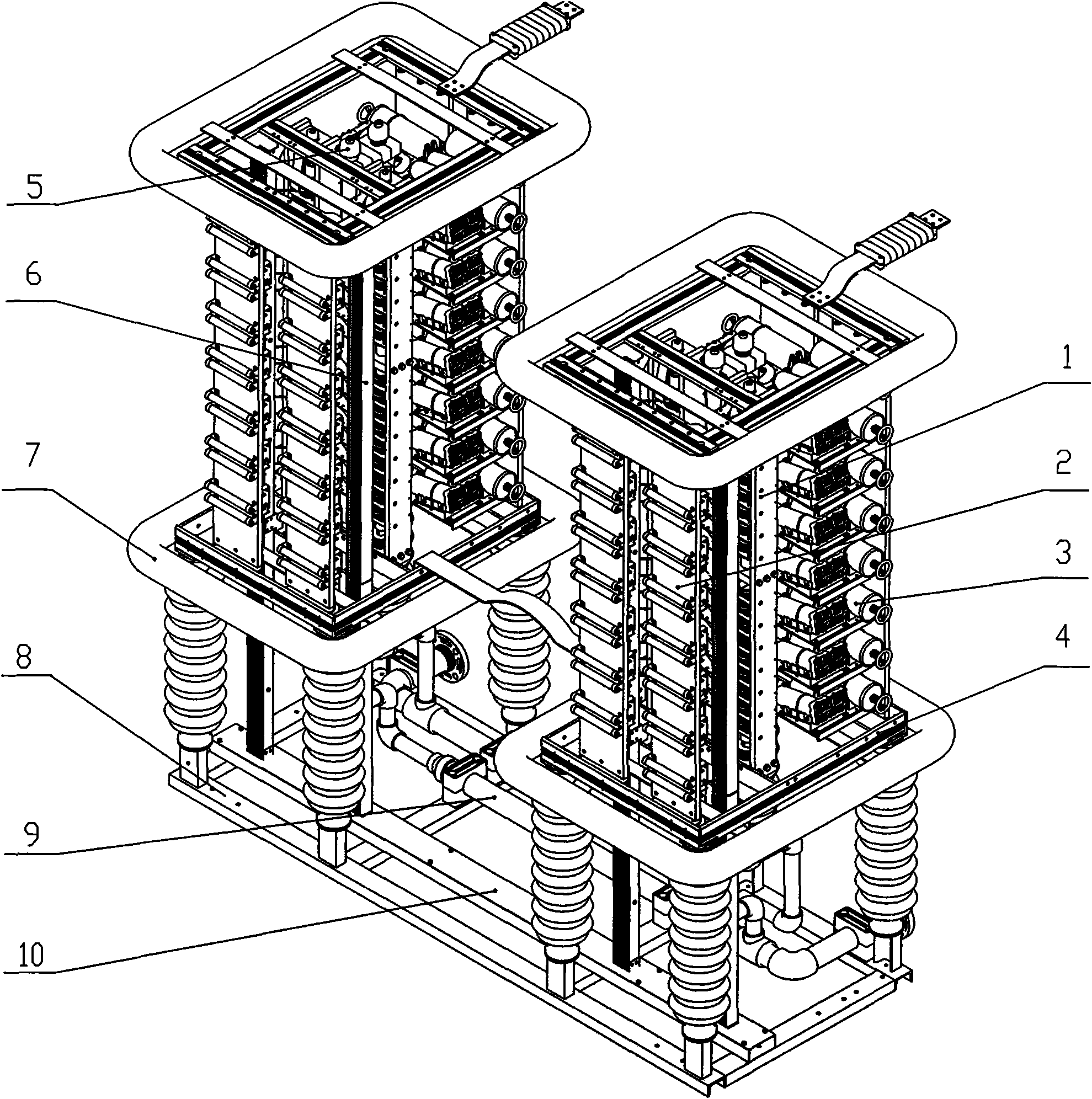

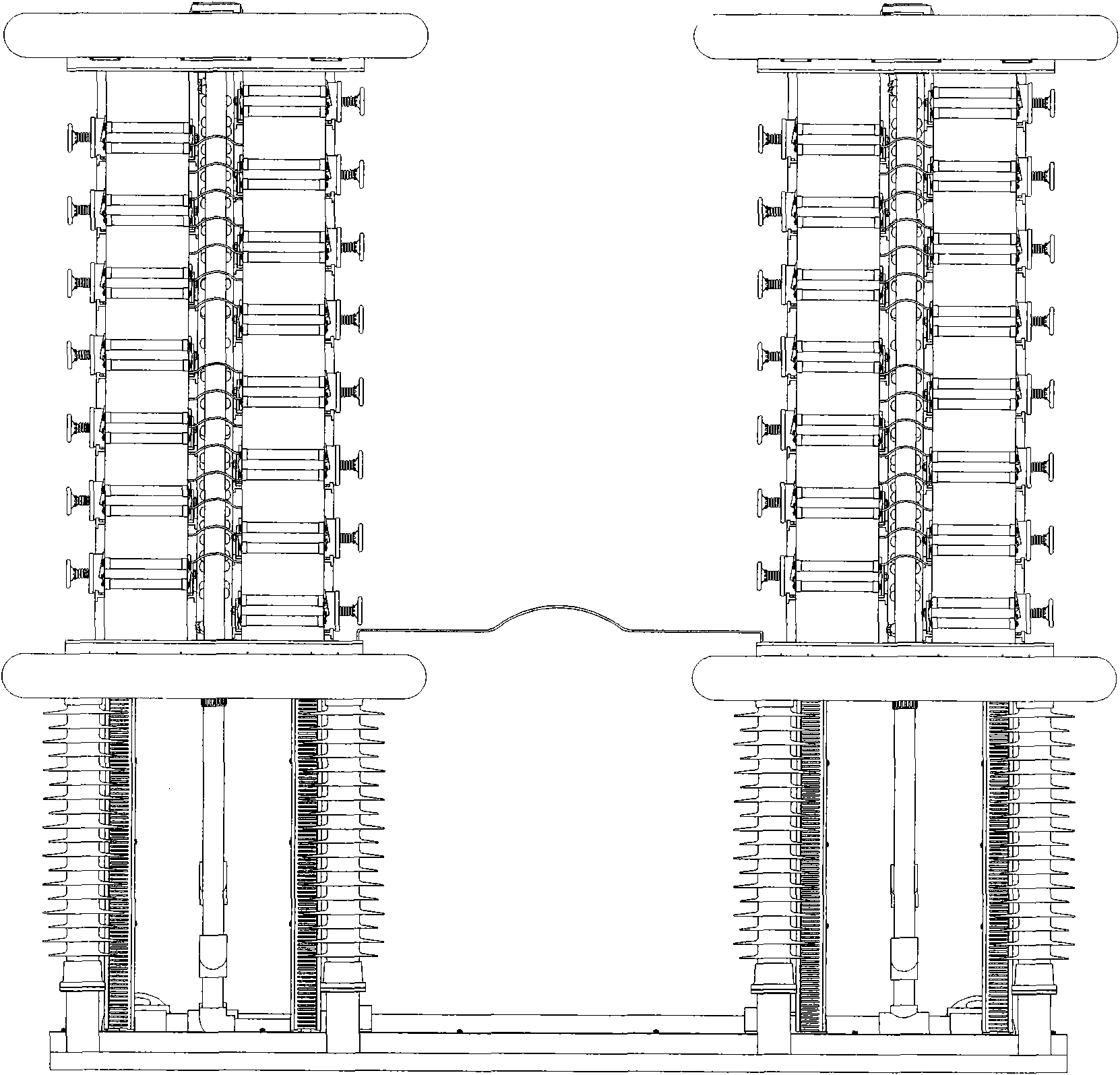

66kv optically-controlled water-cooling thyristor valve box

ActiveCN101651135AReasonable layoutSimple and exquisite appearanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceModular design

The invention relates to an optically-controlled water-cooling radiating thyristor valve box which is characterized in that the valve box is in a dual body vertical structure; a left valve unit and aright valve unit are connected in series to form a uniphase valve box; the left valve unit and the right valve unit are connected by a copper foil soft contactor; a water pipe unit of each valve unitis mounted in the middle of the valve unit, and a thyristors unit needing water cooling and a water-cooling resistance of a resistive-capacitive protective unit are mounted at two sides of the water pipe unit; other elements of the resistive-capacitive protective unit without needing of water cooling except the water-cooling resistance, a cabling channel unit, an equalizing ring unit are mounted at the periphery of the valve box. The water-cooling resistance and a damping capacitance are mounted on a resistive-capacitive bracket side by side in a concentrated layout manner. The resistive-capacitive protective unit uses modular design, and can assemble two eudipleural resistive-capacitive protective units by arranging the same water-cooling resistance and the damping capacitance on the resistive-capacitive bracket. The invention has the advantages of high reliability, small occupied area, separately arrangement of circuit and waterway and pure water cooling.

Owner:辽宁荣信兴业智能电气有限公司

High-temperature abrasive resistant ball valve with fixed ball and floating valve seat

The invention discloses a high-temperature abrasive resistant ball valve with a fixed ball and a floating valve seat. The ball valve has a left valve body (1) and a right valve body (7) which form a stuffing box with the floating valve seat (2) respectively. The stuffing box is filled with stuffing (4) and a high-temperature resistant spring (3) is arranged between stuffing (4) so as to form stuffing seal (12). The two floating valve seat (2) is caused to reach floating and sealing requirements in the left valve body (1) or the right valve body (7) in virtue of recurrent force of the embedded high-temperature resistant stuffing (4), the high-temperature resistant spring (3) and the auxiliary seal spring (13). In respect of material selection, the ball valve is made of a high-temperature material. The ball valve is made from a new material and by a new process and has a spray welding sealing surface made of a nickel-based alloy and a chrome-based alloy, thus improving hardness of the sealing surface (up to HRC68-72) and reaching remarkable effect of abrasive resistance, corrosion resistance and erosion resistance.

Owner:SINOPEC ENG +1

Abrasion-proof disk valve

InactiveCN101482184APlay a sealing rolePretightened seal specific pressure increasesSpindle sealingsSlide valveAutomatic controlLine tubing

The invention relates to a wear resistant disc valve, belonging to the technical field of automatic control. The invention is characterized in that an adjustable shaft sleeve is arranged on a valve rod; the valve rod is inserted into the stuffing box of a right valve body; a valve seat is welded on the right valve body; the valve rod is provided with a key, a rocker, an adjusting gasket, and a bearing in sequence; a spring, a top core, and a valve clack are arranged on the rocker; a shaft sleeve is arranged on the left valve body; a sealing gasket, a valve body and the left valve body are arranged on the right valve body, and are fixed by bolts and nuts; a stuffing ring, stuffing, and a stuffing gland bush are arranged on the stuffing box in sequence, and the stuffing is compressed by bolts and nuts. The valve rod is provided with a handle and is fastened by the gasket and bolts. The wear resistant disc valve has simple structure and safe and reliable performance, is convenient for debugging and maintaining the valve when in use, has good sealability, and is capable of ensuring the normal running of the valve under the working condition on a high temperature high pressure pipeline.

Owner:锡阀阀业(江苏)有限公司

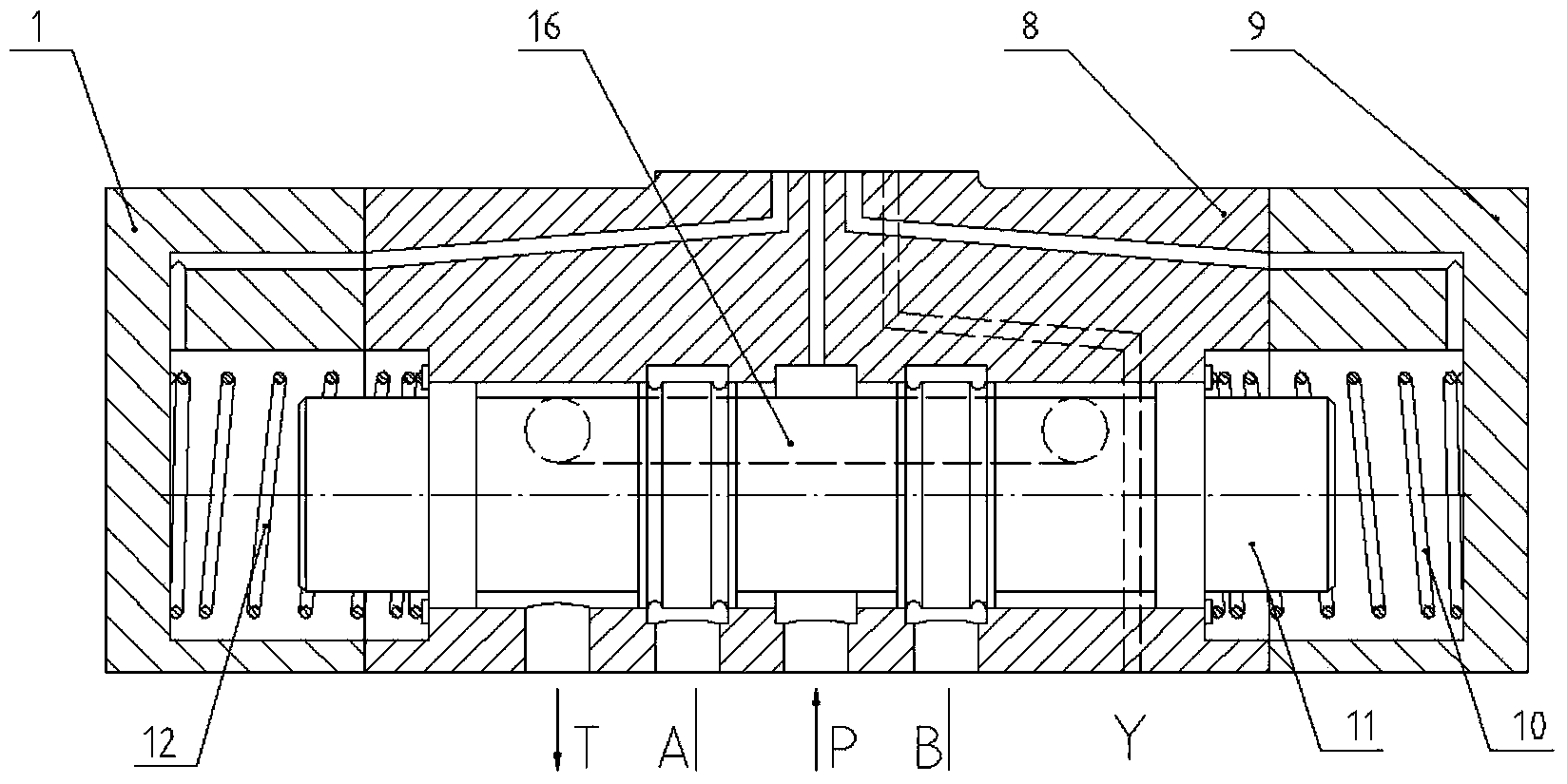

Electromagnetic pilot type high-pressure two-position three-port valve

ActiveCN101162059ASimple structureEasy to useOperating means/releasing devices for valvesMultiple way valvesInlet channelSteel ball

The invention relates to an electromagnetic pilot operated high pressure two-position three-way valve which is characterized in that a valve (1) is provided with a valve plug (3) and an elastic ejector rob (17) which is contacted with a steel ball (11); when an electromagnetic valve plug (6) retracts, a discharge port (8) is closed by the electromagnetic valve plug (6); a left valve chamber (5) is communicated with an inlet channel (2); as the end area of the valve plug (3) is larger than the area of a hole (19), a high pressure difference pushes the valve plug, a hole at the right side of a seal seat (18) is closed by a steel ball, and an discharging channel (10) is communicated with an emptying channel (9); when the electromagnetic valve plug (6) extends, the inlet channel (2) is closed, and the left valve chamber (5) and the discharge port (8) are communicated with air, here, the steel ball is pushed to the left side and sealed by the pressure difference, the discharging channel (10) is communicated with an inlet channel (16). The invention has the advantages of simple structure, convenient use, high control precision, application of high pressure.

Owner:BENGBU FANGZHENG GAS PURIFICATION EQUIP +1

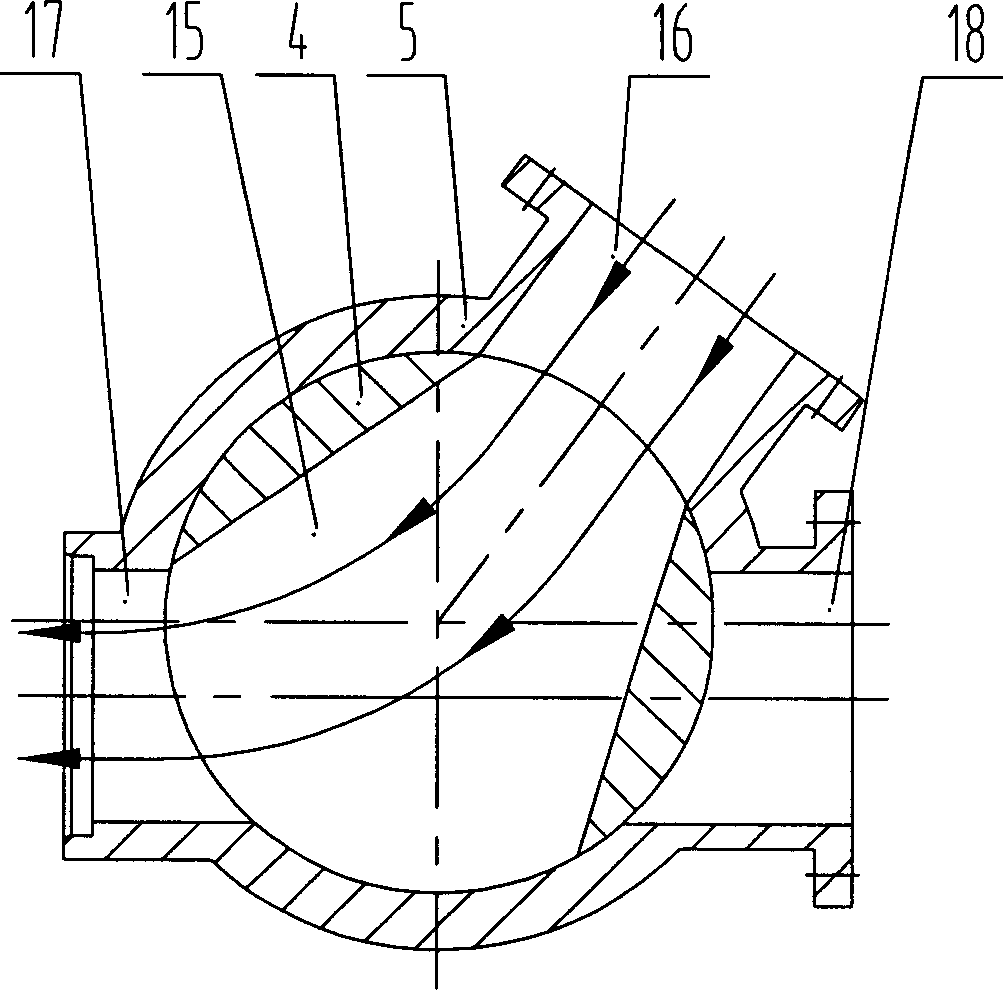

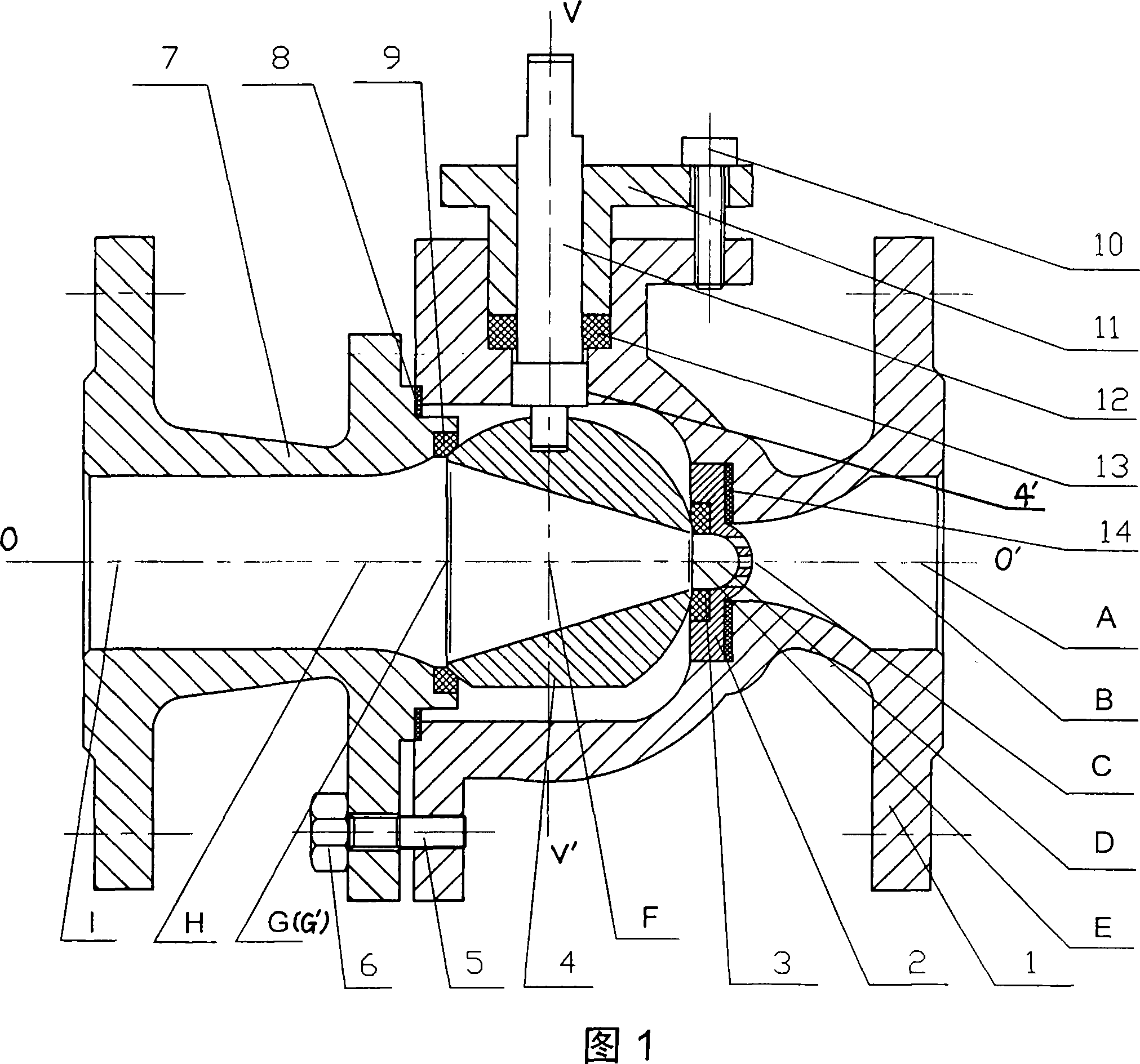

Ball valve

InactiveCN101059175ASpeed up the flowMitigate negative water hammer effectsPlug valvesValve housingsEngineeringLeft valve

A ball valve aims at achieving the stable regulation flow in ball valve regulating saturated water process, reducing the generating of phase transition and playing a role of anti-air cavity and reversing anti-negative waterhammer. The left valve body valve seat 9 is installed between the left valve body 7 and the ball body 4, the ball body 4 is opened with a conical through-hole through the valve cavity axial cord, the ball body 4 is installed in the inner cavity of right valve body, the upper end of the ball body 4 is opened with key groove 4'along the central line of ball body 4, the lower end of the valve bar 12 is installed in the key groove 4'and drives the ball body 4 rotating around the central line of ball body 4 as axial cord; the diffuser part of valve cavity of left valve body 7 starts with the left diffuser start point H and finishes with the left diffuser finishing point G, the inner surface of left valve body 7 valve cavity from the valve cavity input mouth I to the left diffuser start point H, the valve cavity of left valve body 7 is a conical surface from the left diffuser start point H to the left diffuser finishing point G, the valve cavity of right valve body 1 is conical surface from the right diffuser start point D to the right diffuser finishing point B, the valve cavity between the right diffuser finishing point B and the valve cavity mouth A of right valve body 1 is circular column surface.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Cut-off adjusting and metering valve

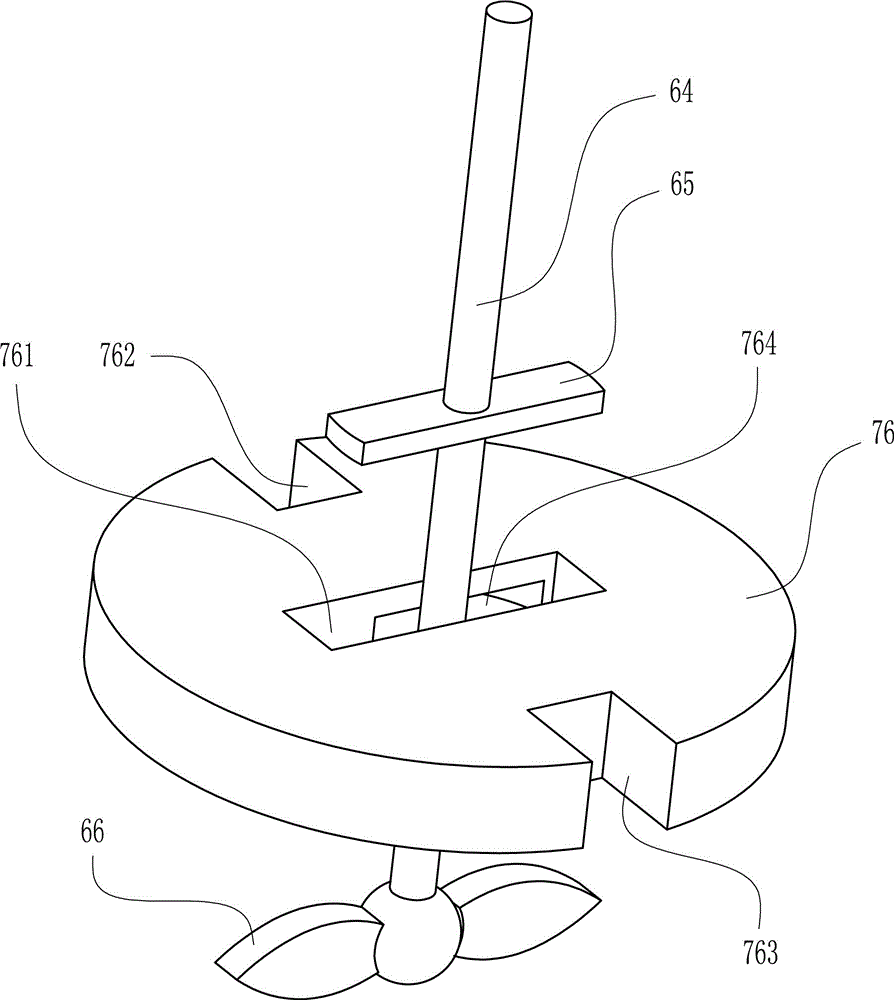

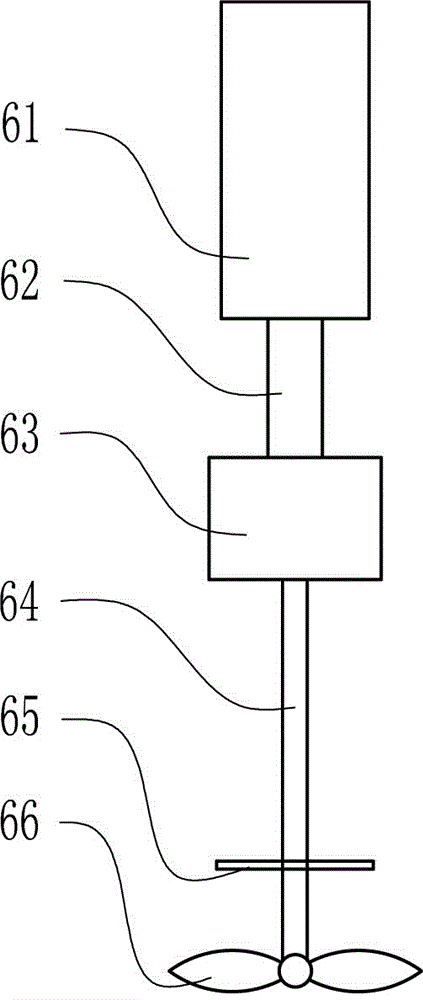

InactiveCN102788166AAccurate measurementRegulate heat balancePlug valvesPreventing unauthorised/accidental actuationImpellerControl engineering

The invention discloses a cut-off adjusting and metering valve, which overcomes the problems of single function and energy source waste of the existing valve. The cut-off adjusting and metering valve comprises a valve body, a spherical valve core, a hollow valve rod, an impeller and a rotary wing metering meter. The technical main points are that: the valve body is combined by a left valve body and a right valve body; the spherical valve core driven by the hollow valve rod is assembled inside a combined cavity of the left valve body and the right valve body; a limiting lock for controlling the hollow valve rod to rotate and driving the spherical valve core to open and close is arranged on the periphery of the hollow valve rod as to control the closing and opening angles of the spherical valve core; the lower part of a transmission rod sleeved inside the hollow cavity of the hollow valve rod is connected with the impeller; the top end of the transmission rod is connected with a meter core of the rotary wing metering meter; and the impeller drives the transmission rod to rotate and drives the meter core at the top end of the transmission rod to synchronously rotate and meter the flow. The cut-off adjusting and metering valve is reasonable in structural design, can intuitively and effectively adjust heat balance of a pipe network, ensures the metering accuracy, immediately and accurately finds out water loss phenomena such as running, emitting, dropping, leaking and the like of the pipe network, achieves various functions of cutting off, adjusting and metering, and achieves the energy-saving purpose.

Owner:董振友

High temperature high pressure ceramic valve

ActiveCN103470800AImprove high temperature resistanceImprove corrosion resistancePlug valvesValve housingsEngineeringHigh pressure

A high temperature high pressure ceramic valve comprises a left flange, a right flange, a left valve seat, a right valve seat, a sphere, a valve body lining and a valve body; the left flange and the right flange are sleeved outside the left valve seat and the right valve seat; centers of the left valve seat and the right valve seat are provided with flow channels; the sphere is arranged between the left valve seat and the right valve seat; a through hole is formed in the center of the sphere; a valve rod is connected to the upper end of the sphere; the valve body is clamped between the left flange and the right flange; the valve body lining is clamped between the left valve seat and the right valve seat; the valve body is sleeved outside the valve body lining; the left flange, the right flange and the valve body are mutually fixed; through holes are formed in the valve body lining and the valve body; the valve rod extends out from the through hole which is formed in the valve body; the left valve seat, the right valve seat, the sphere and the valve body lining are made of ceramic materials. The high temperature high pressure ceramic valve has the advantages of being high temperature resistant and corrosion resistant, enabling the high temperature resistant performance to be greatly improved and enabling the service life under poor working conditions to be prolonged.

Owner:YANTAI KINGWAY SCI & TECH

Wear-free ball valve

ActiveCN110159786ANo friction and wearExtended service lifePlug valvesOperating means/releasing devices for valvesDrive shaftEngineering

The invention relates to a ball valve comprising a valve body, a left valve deck, a right valve deck, a valve ball, a left valve clack, a right valve clack, a large gear, a left small gear, a right small gear and a drive shaft. The valve body is internally provided with a cavity body and a rotating shaft. The left valve deck and the right valve deck are fixedly installed at the two ends of the valve body correspondingly. The valve ball is arranged in the cavity body in a rotatable manner. The valve ball is internally provided with a left valve cavity, a right valve cavity and a rectangular circulation window. The left valve clack and the right valve clack are arranged in the left valve cavity and the right valve cavity correspondingly. The large gear is fixedly installed on the rotating shaft and located in the circulation window. The left small gear and the right small gear are connected with the left valve clack and the right valve clack correspondingly and are both engaged with thelarge gear. The drive shaft is used for driving the valve ball to rotate. According to the ball valve, in the opening process, no friction or wear is caused to the left valve clack and the right valveclack, and the service life can be prolonged.

Owner:ZHEJIANG XINDA VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com