Flushing preventing valve with single hydraulic prop

A single hydraulic prop and anti-collision technology, applied in props/supports, mining equipment, earth-moving drilling, etc., can solve the problems of large number of valve bodies, large impact ground pressure, single function, etc., to achieve multiple functions and major control. The occurrence of accidents, the effect of less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

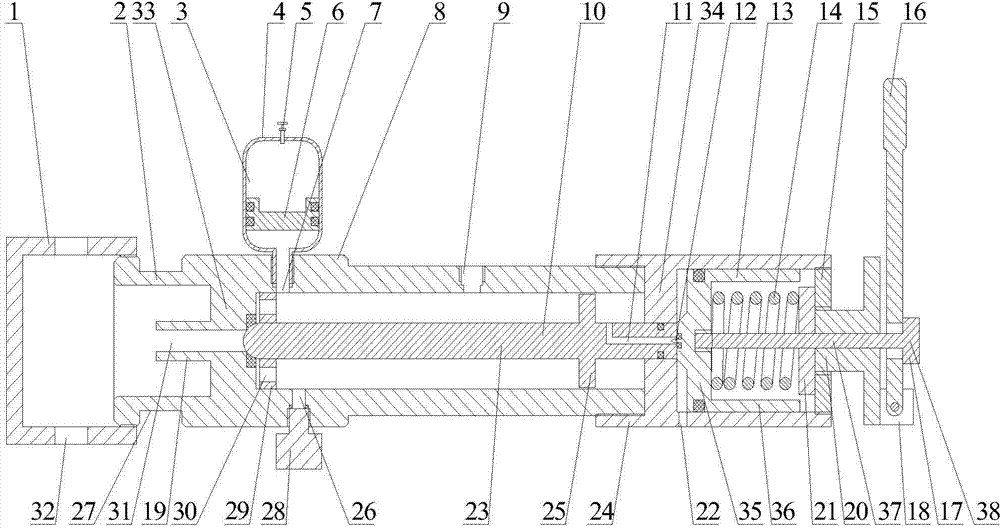

[0026] Such as figure 1As shown, a single hydraulic prop anti-shock valve includes cylindrical left and right valve bodies arranged horizontally and having openings at both ends. The left valve body 2 is arranged on the left side of the right valve body 24; The left and right dividing plates with through holes are respectively arranged in the body, and the left and right valve body parts are divided into two parts, and the right dividing plate 34 in the left valve body 2 is in contact with the right dividing plate in the right valve body 24; The left valve body 2 and the right valve body 24 on the right side of the partition plate 33 are provided with a control valve core 23 inside, and the control valve core 23 includes a push rod 10, a throttle support piston 29, a buffer piston 25, a guide body 13 and a spring 14 , the push rod 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com