Direct current air temperature adjusting device based on composite graphene film auxiliary heat and manufacturing method

A technology of composite graphene and temperature regulating device, which is applied in the direction of electric heating device, heating method, air conditioning system, etc., can solve the problems that affect the development of composite graphene application in air conditioning and energy saving technology, uneven heating of tubular carbon fiber, and poor heating effect, etc. Achieve the effect that is conducive to widespread application, stable and reliable effect, and high cooling/heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

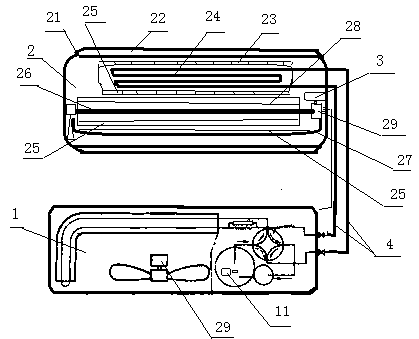

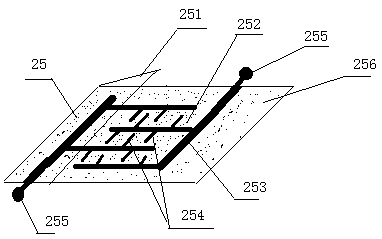

[0076]The refrigerating implementation mode of the present invention is the same as the refrigerating mode of the traditional air conditioner, and the description of the embodiment will not be carried out. The heating of the air conditioner of the present invention is implemented as follows: during implementation, first connect the DC power supply, start the air conditioner indoor unit 2, and make the air conditioner indoor unit be in the heating working mode. Flow fan 26 and composite graphene heating film 25, composite graphene heating film 25 begins to generate heat evenly after conducting electricity, adjust the temperature value of the temperature control module, the heat that composite graphene heating film 25 sends passes through the rotation of cross-flow fan fan 29 Heat The air is sent out of the air conditioner, causing the room temperature to rise and reach the set room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com