Patents

Literature

87results about How to "Good anti-corrosion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insulating mold coating and its uses

InactiveCN1800283AStrong adhesionGood anti-corrosion performanceFireproof paintsEpoxy resin coatingsPolymer chemistryMetal

The invention relates to a insulating coating whose constituents include film forming substance 15-65 weight parts, nano porous SiO2 3-20 weight parts, nano iron oxide yellow 1-12 weight parts, dyestuff 5-30 weight parts, gasket material 3-22 weight parts, auxiliary agent 0.4-8 weight parts, and dissolvent 6-30 weight parts.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Anticorrosion thermal insulation heat reflecting paint for storage tank and preparation method thereof

InactiveCN103849293AExcellent thermal insulation and heat reflection propertiesGood anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsThermal insulationChemistry

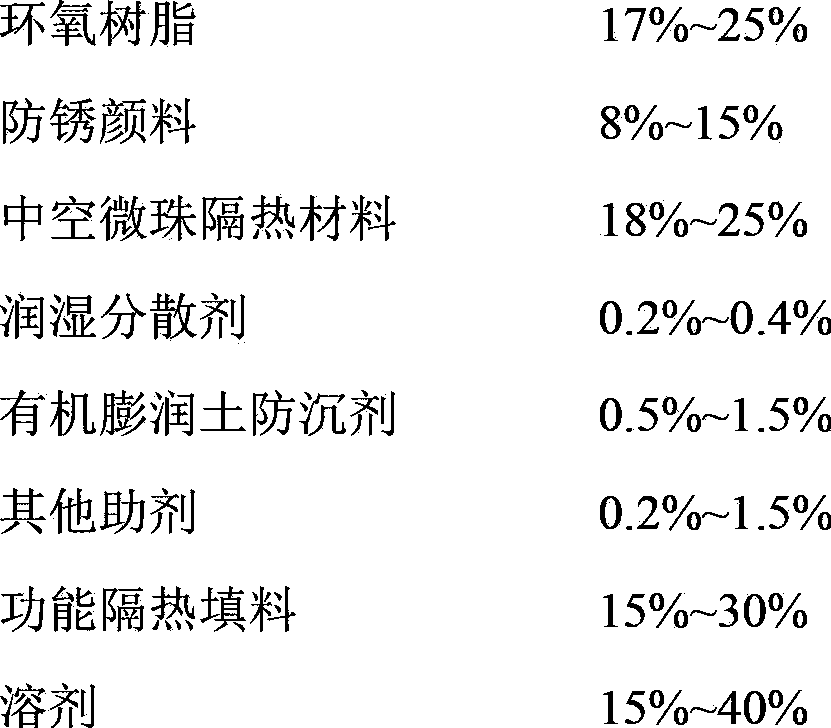

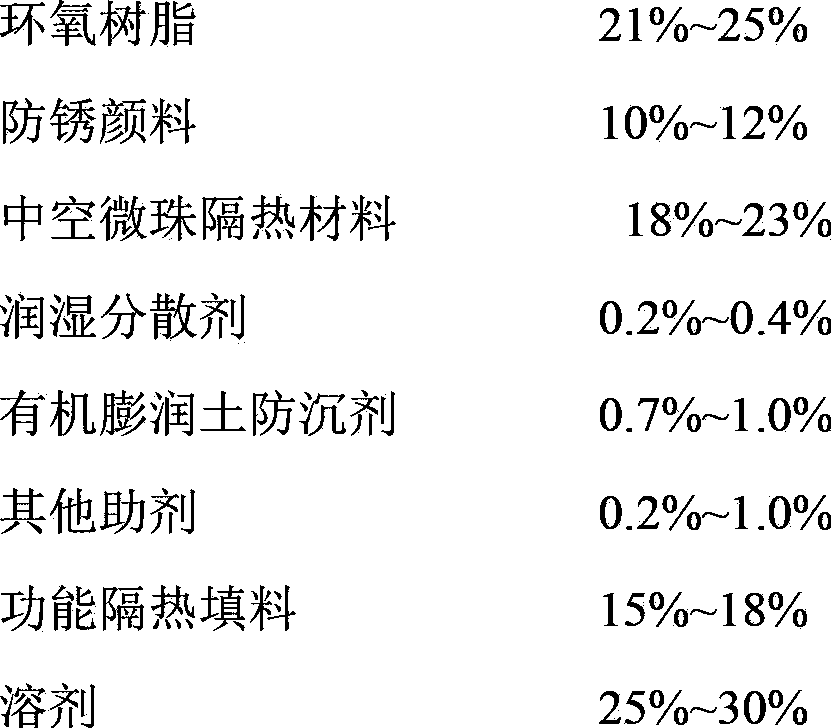

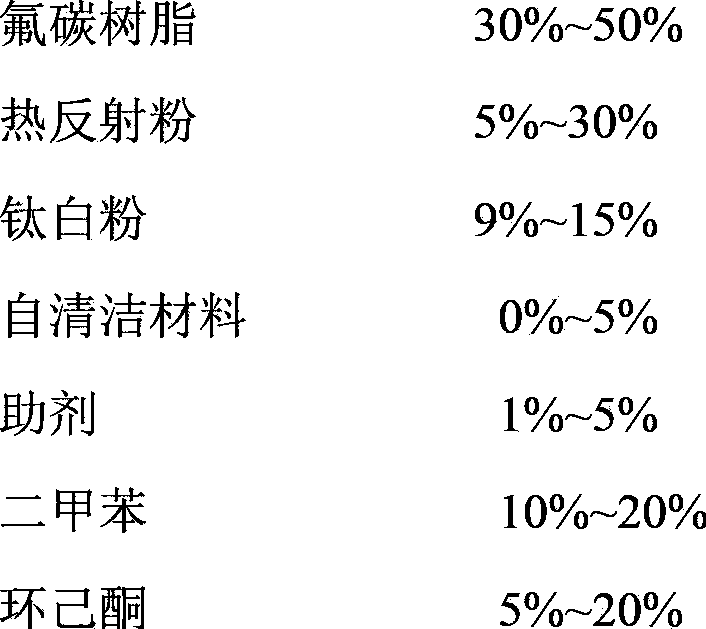

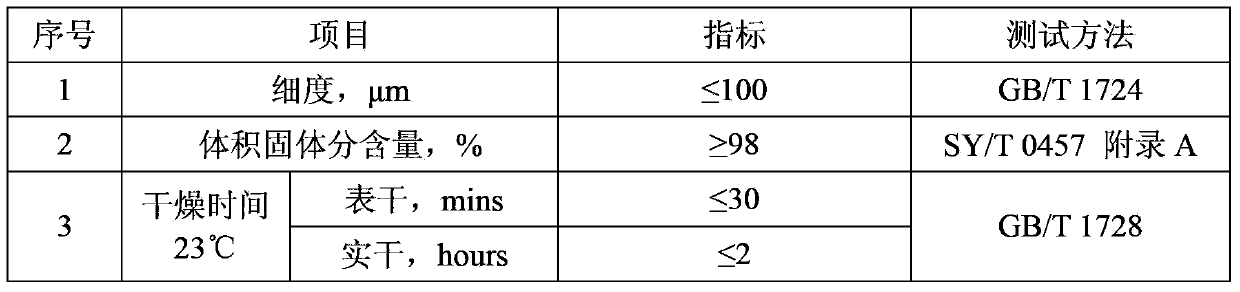

The invention discloses an anticorrosion thermal insulation heat reflecting paint for a storage tank and a preparation method thereof. The paint comprises primer and finishing coat, wherein the primer comprises a component A and a component B, the weight ratio of the component A to the component B is (2-8):1, the molar ratio of epoxy group of the component A to reactive hydrogen of the component B is 1:1, the component A and the component B are mixed for use, the finishing coat comprises another component A and another component B, the weight ratio of the component A to the component B is as shown in the specification, the molar ratio of content of hydroxy in the component A to content of NCO in the component B is 1:1, and the component A and the component B are mixed for use. The paint has excellent corrosion resistance, according to national standard, after a cold-roll steel sheet is coated with thermal insulation anticorrosion paint and is maintained, a neutral salt spray test is carried out on the steel sheet for 1000 hours, and then the test shows that the sample does not have corrosion phenomena like blistering and peeling off, so that the paint has a good effect in protecting the surface of the steel from being corroded, and also has good chemical resistance.

Owner:上海华谊精细化工有限公司上海开林造漆厂

Dissolvent-free polyurethane weather-proof anticorrosive coating for storage tank

ActiveCN103421420AReduces coating bubble problemsGood anti-corrosion performanceLiquid surface applicatorsAnti-corrosive paintsAnoxomerSolvent free

The invention relates to a dissolvent-free polyurethane weather-proof anticorrosive coating for a storage tank. The coating is composed of a component A and a component B, wherein the component A comprises the following components by weight percentage: 20-60 percent of hydroxide radical, 0.3-1.0 percent of dispersant, 0.5-2.0 percent of antifoamer, 0.2-0.6 percent of leveling agent, 2.0-5.0 percent of dehydrator, 0.5-1.0 percent of anti-settling agent, 0.1-1.0 percent of curing accelerator, 1.0-3.0 percent of ultraviolet absorbefacient, 0.5-2.0 percent of photostabilizer, 0.2-1.0 percent of antioxidant, 5.0-20 percent of aluminum dihydrogen tripolyphosphate, 10-25 percent of titanium dioxide, 10-20 percent of barium sulfate and 4.0-6.0 percent of zeolite power, wherein the component hydroxide radical is polyester polyether polylol obtained by chemically modifying castor oil; the component B is a hexamethylene diisocyanate curing agent; the weight ratio of the component A to the component B is 100:25-100:50. Via the selection of the terminal hydroxyl compound and the curing agent in the component A, bubbles in the anticorrosive coating are reduced. The coating has good anticorrosive performance, and besides, the super-high performance of UV aging resistance and salt and fog resistance is suitable for the outer wall construction of the storage tank.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Alkyl lubricating grease used for surface protection of steel wire rope and preparation method thereof

InactiveCN102994198AImprove adhesion performanceGood anti-corrosion performanceLubricant compositionAmmonium polyphosphatePetroleum

The invention relates to alkyl lubricating grease used for surface protection of a steel wire rope and a preparation method thereof. The alkyl lubricating grease comprises the following components by weight: 52.0-78.0% of base oil, 10.0-35.0% of microcrystalline wax, 8.0-30.0% of thickener, 0.25-0.6% of alkyl diphenylamine, 1.5-3.0% of petroleum barium sulfonate and 1.5%-3.0% of lanolin calcium soap. The sum of the weight percentages is 100%. The moving viscosity of the base oil under 100 DEG C is 10.0-40.0 mm2 / s, the thickener is ammonium polyphosphate (APP) or amorphous poly alpha olefin (APAO), and the dropping melting point of the microcrystalline wax is 65-85 DEG C. The APP or the APAO is utilized as the thickener, dropping point of the alkyl lubricating grease is improved, adhesion performance of the alkyl lubricating grease is improved, and antirust performance and anti-corrosion performance of the alkyl lubricating grease are excellent.

Owner:天津市津冠润滑脂有限公司

Anticorrosive high-rigidity ceramic coating

InactiveCN101845264AGood anti-corrosion performanceGood corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsCeramic coatingTitanium

The invention relates to an anticorrosive high-rigidity ceramic coating. The coating comprises the following components in percentage by weight: 20 to 40 percent of epoxy resin, 30 to 50 percent of submicron ceramic powder, 5 to 10 percent of titanium pigment, 15 to 20 percent of epoxy resin curing agent and 1 to 5 percent of high polymer dispersant. The coating of the invention can provide effective protection for the surfaces of metals such as an aluminum alloy and the like. The coating has excellent anticorrosive performance and mechanical performance, wherein the mechanical performance is that the rigidity is 4H and the adhesive force is 1 level. The rigidity of an ordinary epoxy coating is 2H. The coating is more applicable for the fields of aerospace, ocean shipping, chemical engineering and the like.

Owner:SHANGHAI UNIV +1

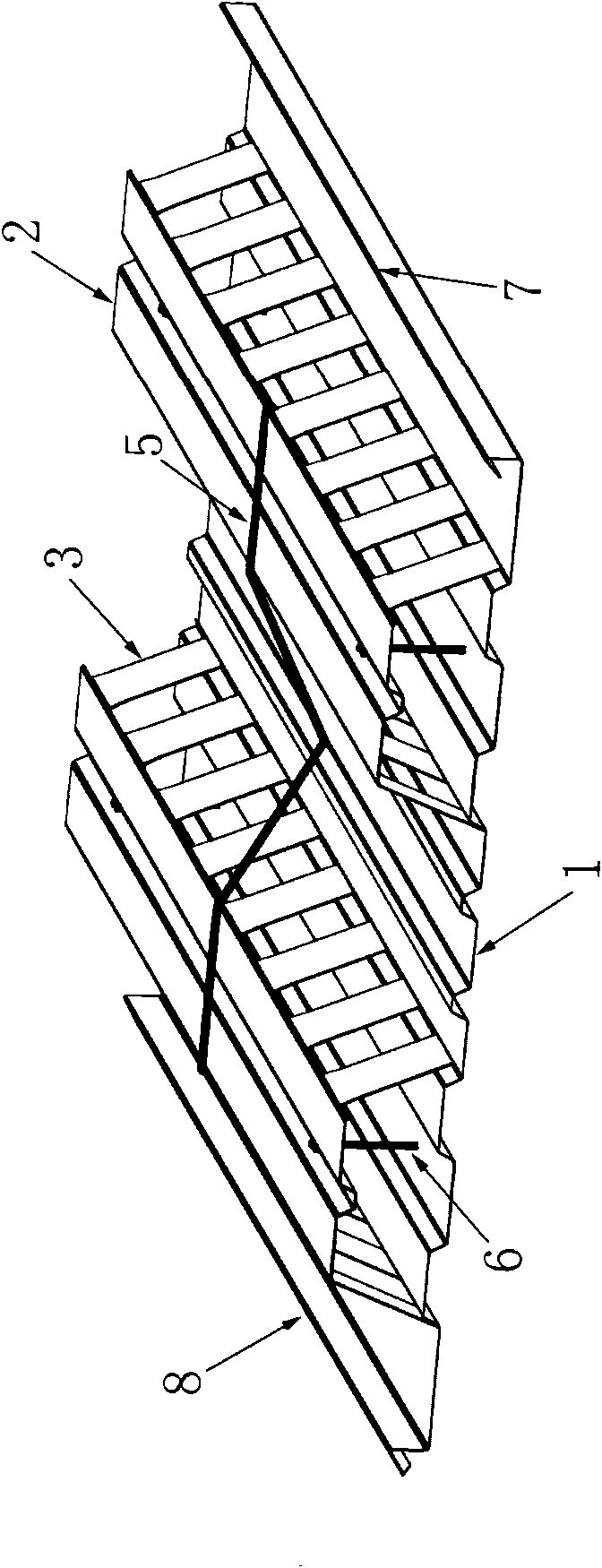

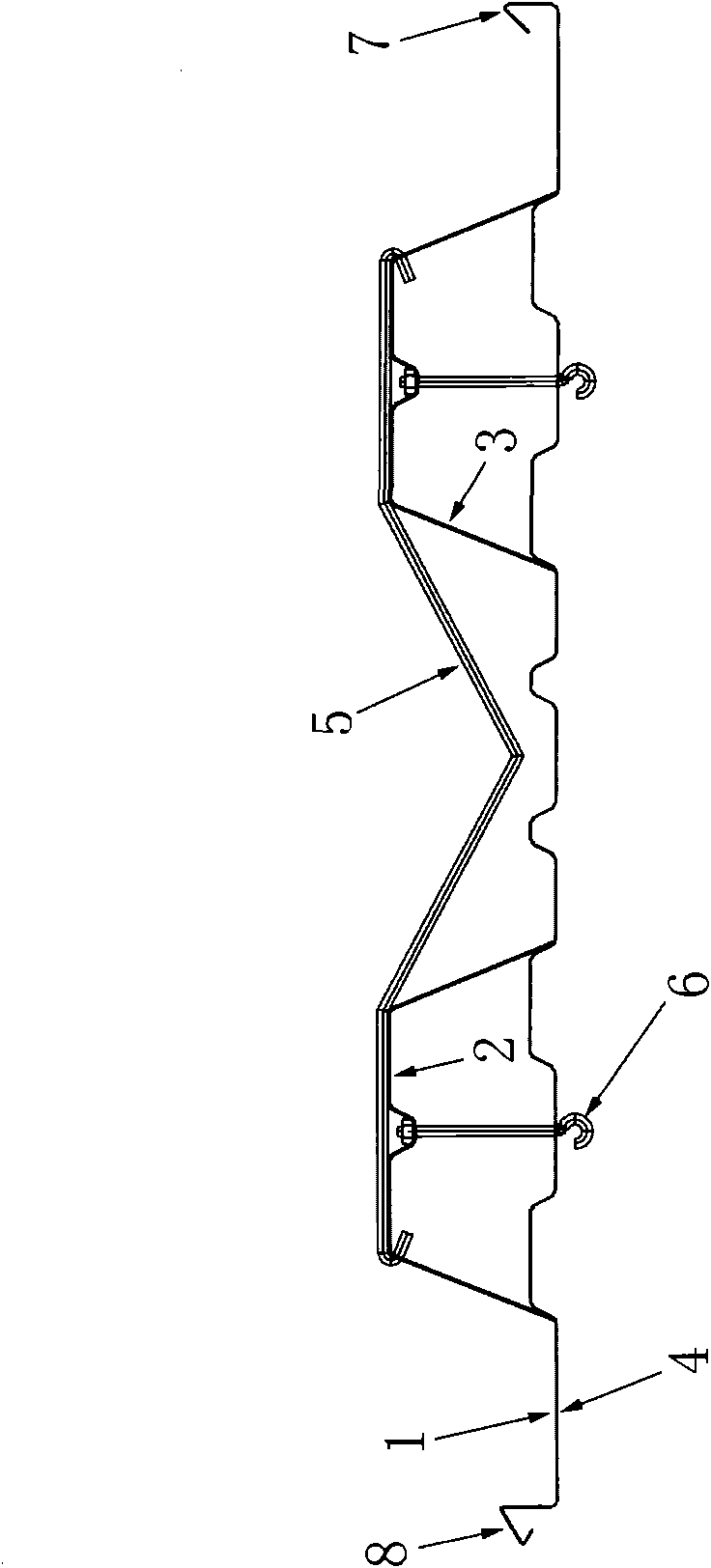

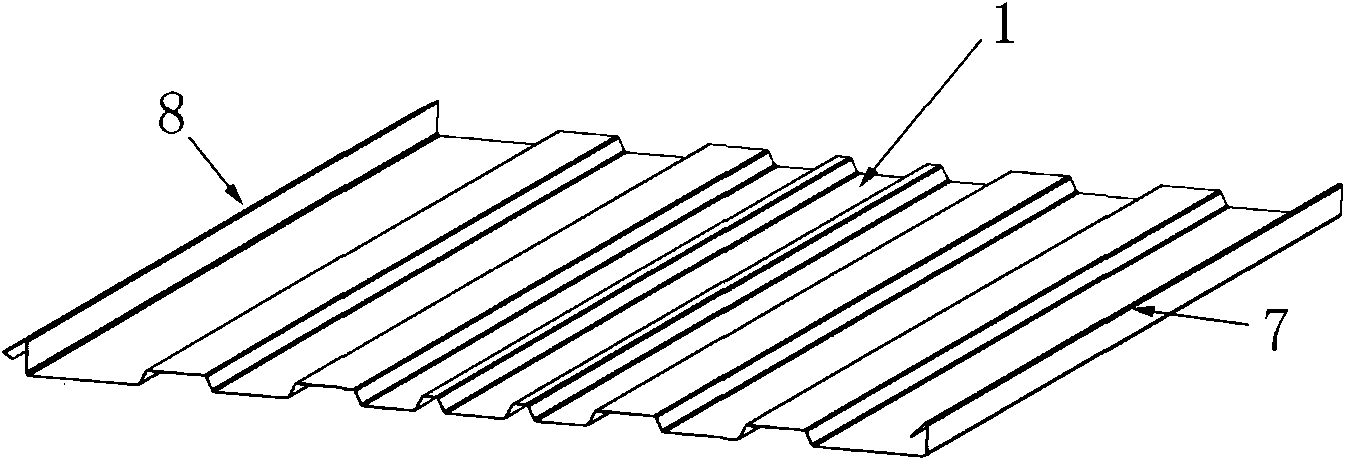

Profiled steel sheet

ActiveCN101565983AGood fire resistanceGood anti-corrosion performanceBuilding roofsConstruction materialSteel platesJoint working

The invention discloses a profiled steel sheet and aims at providing a profiled steel sheet having strong joint working capability together with concrete, approximately equal bending resistance moment at front and back effective cross sections as well as good fire resistance and corrosion resistance. The profiled steel sheet comprises a bottom plate (1), a top plate (2), ventral plates (3), a steel bar bracket (5) and a suspended ceiling hook (6). The ventral plates (3) are arranged at the two sides of each top plate (2). A cavity with lateral surfaces communicated with outside is formed by the enclosure of the top plate (2), the ventral plates (3) and the bottom plate (1). The two ends of the steel bar bracket (5) are suspended from the edge of the top plate (2). The suspended ceiling hook (6) penetrates through the bottom plate (1) and is fixed on the top plate (2). When a plurality of profiled steel sheets are paved side by side, a longitudinal edge (7) extends into and is mutually meshed with a longitudinal edge (8). The profiled steel sheet can be used for steel structural buildings and can form a composite floor plate after concreting thereon.

Owner:陕西有色建设有限公司

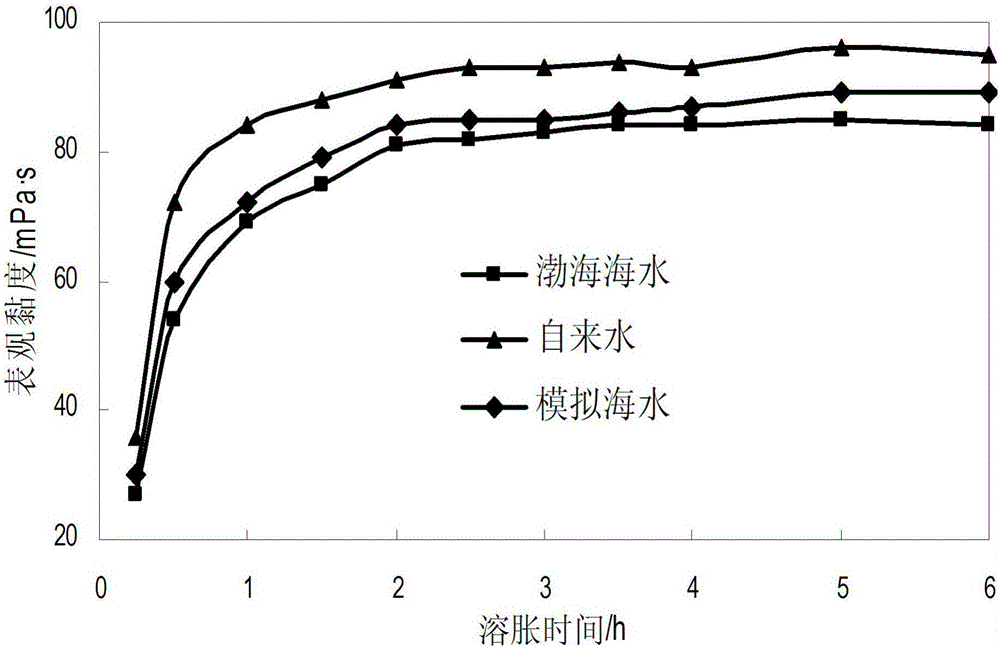

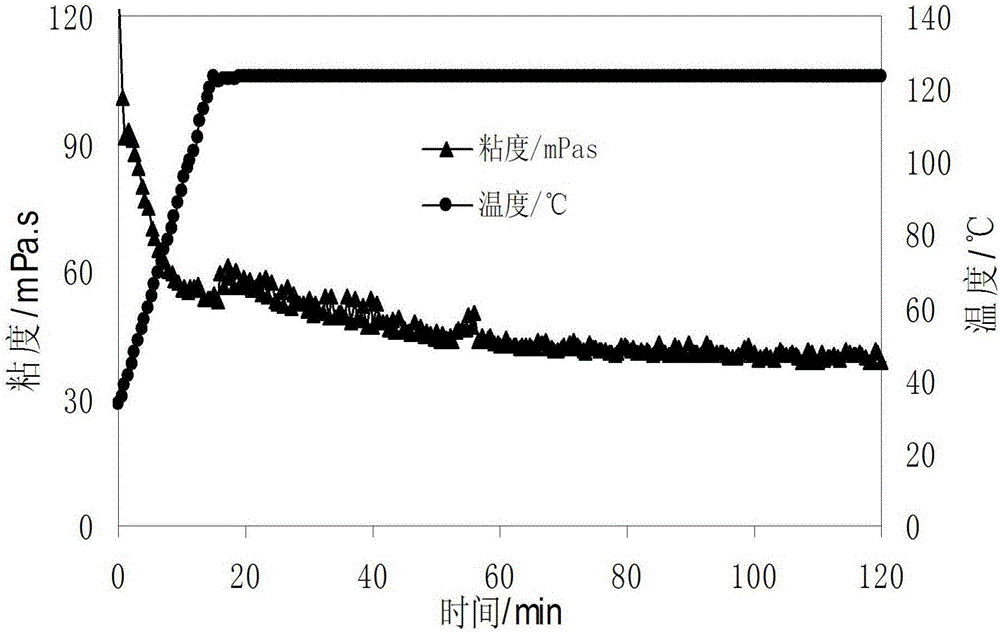

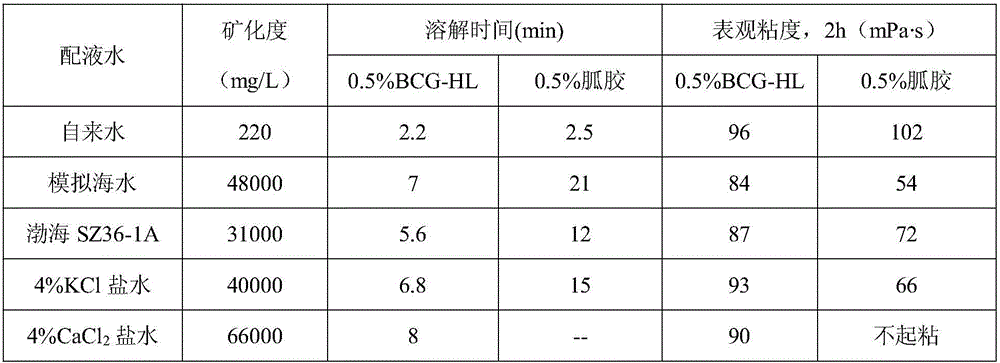

Temperature-resistant salt-resistant quick-dissolving thickening agent used for seawater-based fracturing fluid and preparation method thereof

ActiveCN106190088AStrong anti-bacterial abilityGood anti-corrosion performanceDrilling compositionIonSeawater

The invention discloses a temperature-resistant salt-resistant quick-dissolving thickening agent used for a seawater-based fracturing fluid and a preparation method thereof. The temperature-resistant salt-resistant quick-dissolving thickening agent comprises the following components in percentages by mass: 6% to 8% of acrylic acid, 5% to 6% of sodium hydroxide, 18% to 23% of acrylamide, 1% to 2% of an isolation monomer, 3% to 4% of a functional anion monomer, 3% to 5% of a functional cationic monomer, 4% to 6% of an association intermediate, and 0.4% to 0.8% of an ammonium persulfate-sodium bisulfite redox system or 0.6% to 1.0% of azobisisobutyronitrile which is used as an initiator, with the balance being deionized water. The preparation method for the temperature-resistant salt-resistant quick-dissolving thickening agent comprises the following steps: 1, synthesis of the association intermediate; 2, synthesis of a thickener colloid; and 3, colloid postprocessing. The thickening agent provided by the invention has the following advantages: salt resistance is excellent; the degree of mineralization of a solution has little influence on the rate of swelling; the viscosity-increasing capacity in seawater is strong; antibacterial stability of the solution is strong; the solution has excellent temperature resistance and shearing resistance; and the content of an insoluble substance is extremely small and can not be measured with a conventional method, so the damage of residues on reservoir strata is almost eliminated.

Owner:四川奥赛德材料科技有限公司

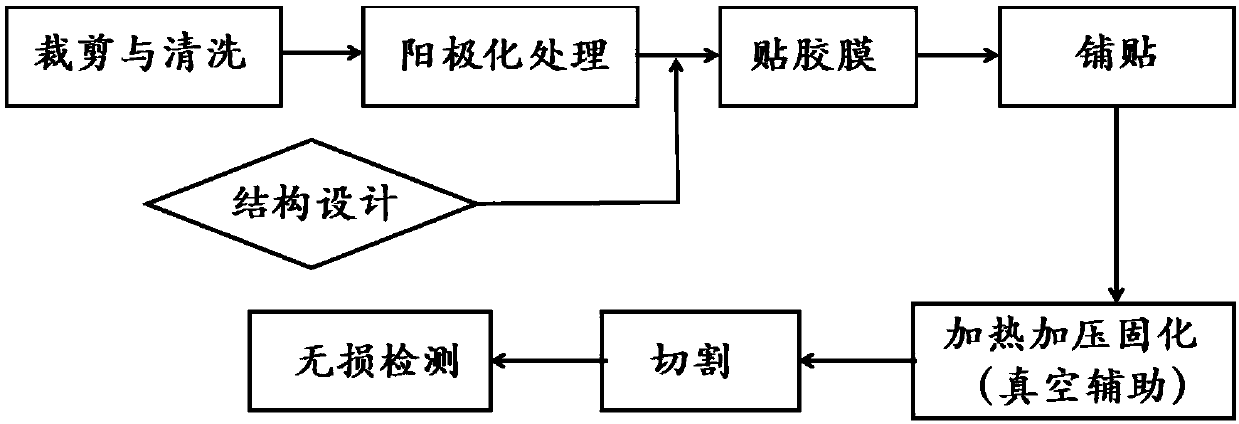

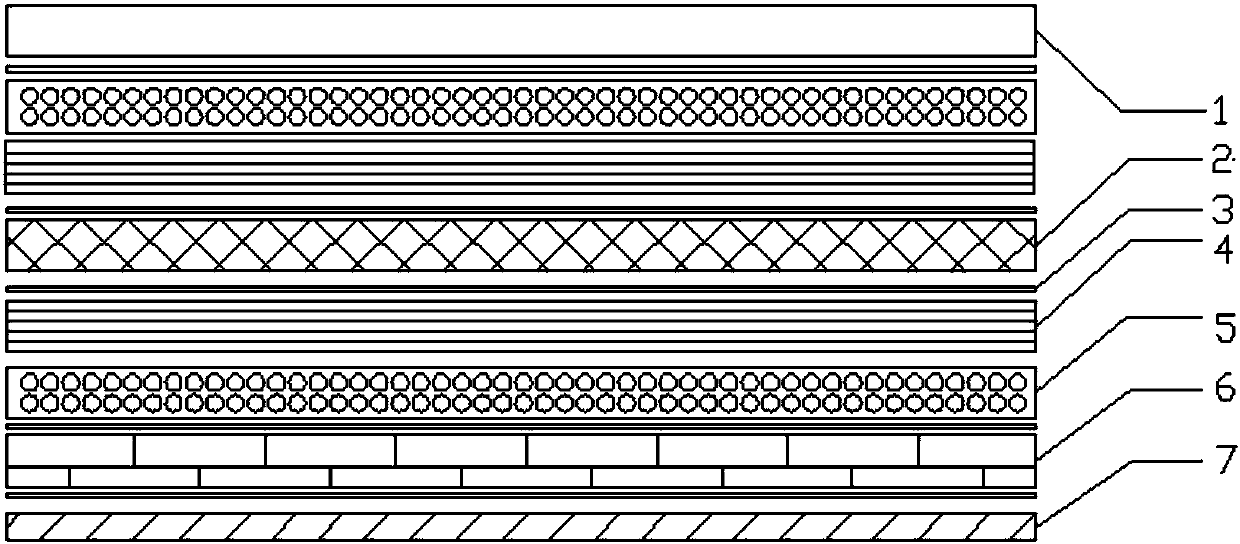

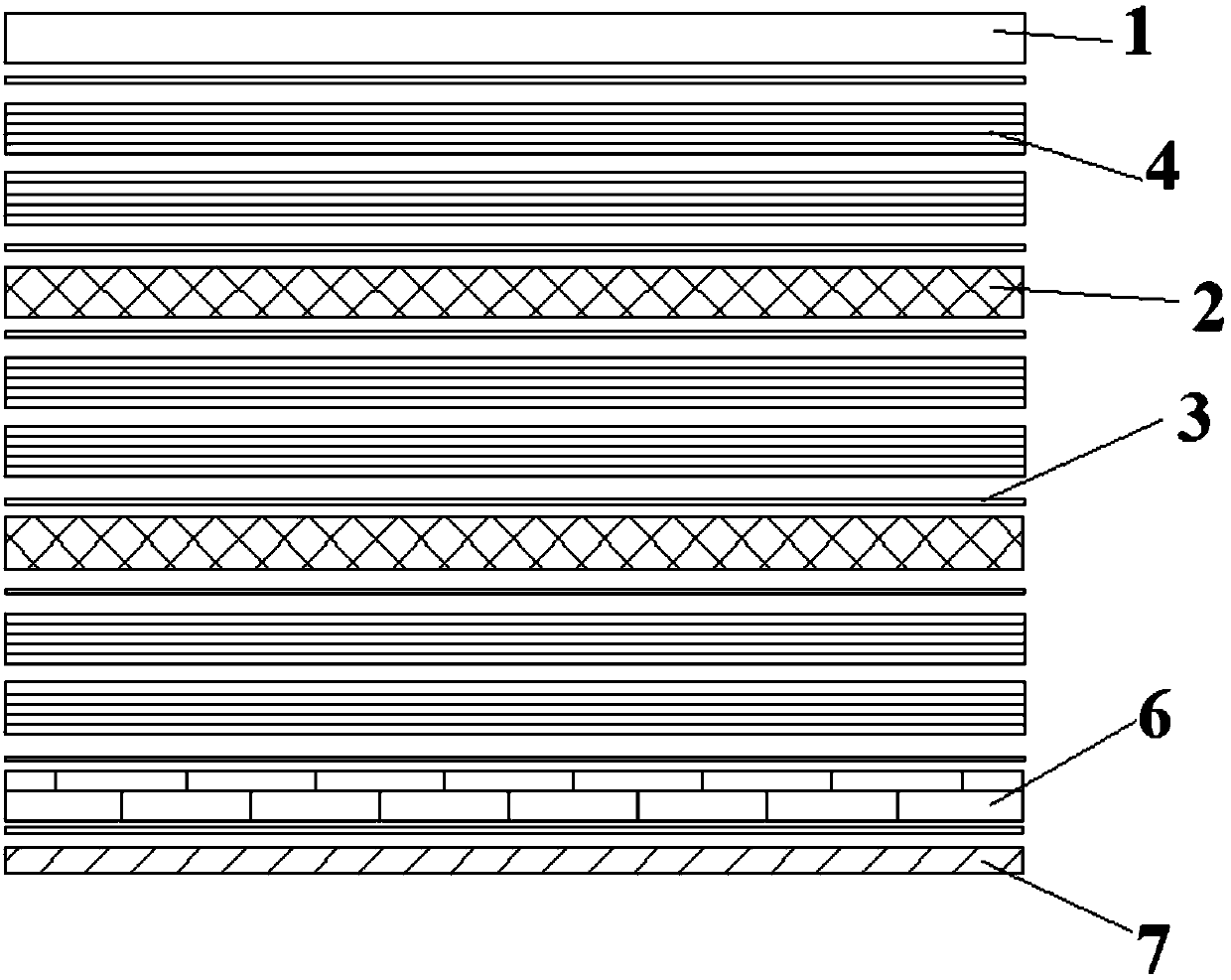

Super hybrid laminated composite structure and preparation method thereof

ActiveCN107825805AImprove lack of stiffnessGood anti-corrosion performanceLayered product treatmentSynthetic resin layered productsCar doorNondestructive testing

The invention discloses a preparation method of a super hybrid laminated composite structure. The super hybrid laminated composite structure comprises the following steps of: S01, performing cutting and cleaning; S02, performing anodizing; S03, performing attachment of glue film; S04, performing laying and attachment according to structural design of a fiber layer, a metal layer, a honeycomb layerand a non-woven composite punched felt layer; S05, performing heating and pressure curing; S06, performing cutting; and S07, performing non-destructive testing. The invention also discloses the superhybrid laminated composite structure which is obtained by the preparation method. According to the super hybrid laminated composite structure and the preparation method of the super hybrid laminatedcomposite structure, the original and excellent performance of the fiber and metal board layers can be ensured, and meanwhile high rigidity is obtained; in addition, no inner decorative layers are needed to be arranged after a vehicle door is molded, the production efficiency is improved, and the requirements for the comfort degree is further improved.

Owner:NANJING INST OF TECH

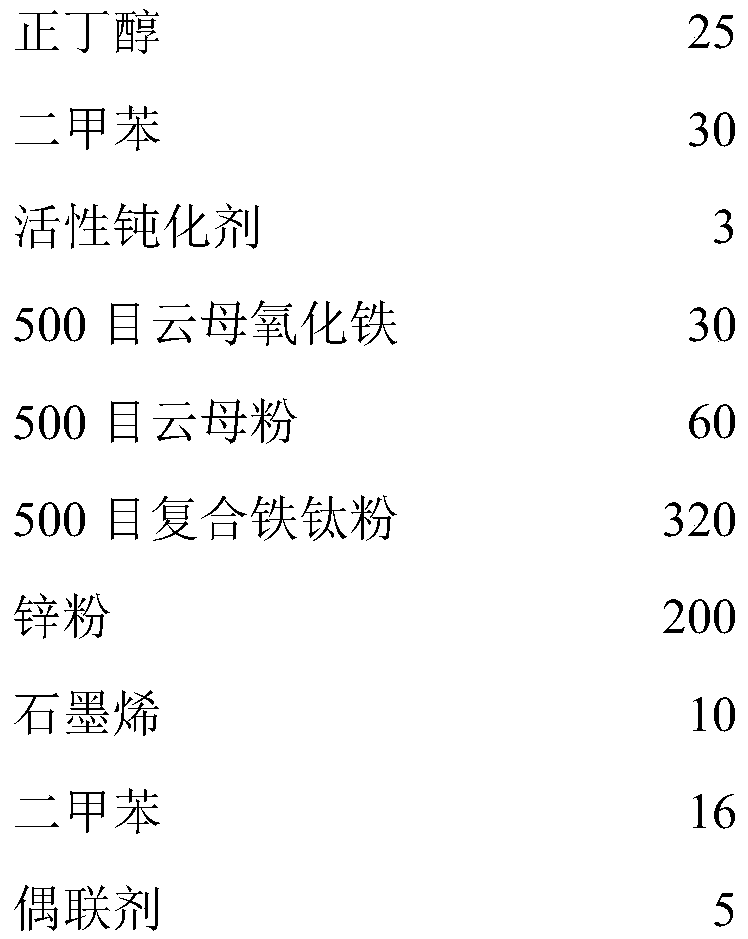

Graphene high-performance anticorrosive paint and preparation method and product thereof

InactiveCN110128943AGood anti-corrosion performanceExcellent compactnessAnti-corrosive paintsSolventGraphene

The invention discloses a graphene high-performance anticorrosive paint with long-acting anticorrosive performance and a preparation method and a product thereof. The graphene high-performance anticorrosive paint is prepared from the following raw materials (by weight): 250-300 parts of a resin matrix, 2-10 parts of a wetting dispersant, 1-5 parts of an antifoaming agent, 25-40 parts of an anti-settling agent, 40-70 parts of a paint solvent, 550-700 parts of rust-proof pigments and fillers, 5-20 parts of a viscosity regulator, 4-10 parts of a coupling agent, and 90-110 parts of a curing agent,wherein the resin matrix comprises a block copolymer of modified small-molecular epoxy resin and modified macromolecular epoxy resin. The graphene high-performance anticorrosive paint provided by theinvention has good permeability and adhesion and excellent anticorrosive performance; shelf life of the anticorrosive coating is greatly prolonged; and good economic benefits and ecological benefitscan be formed.

Owner:YICHANG SANXIA ZHONGRUN NANO MATERIAL

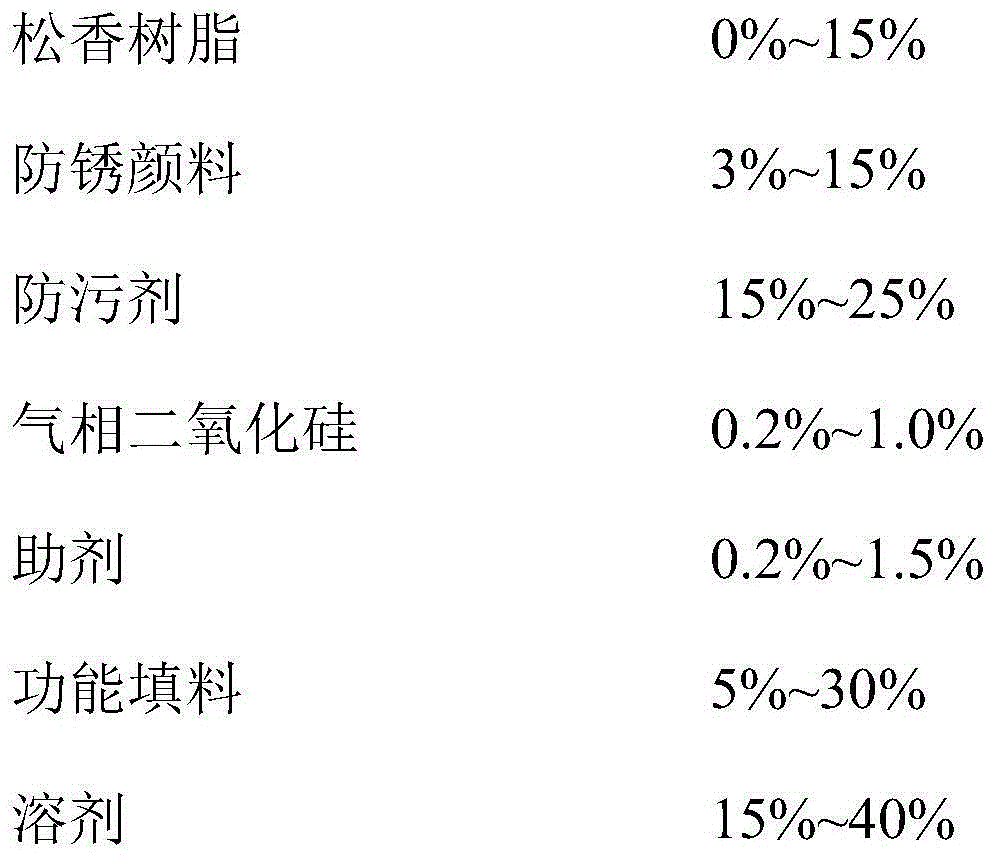

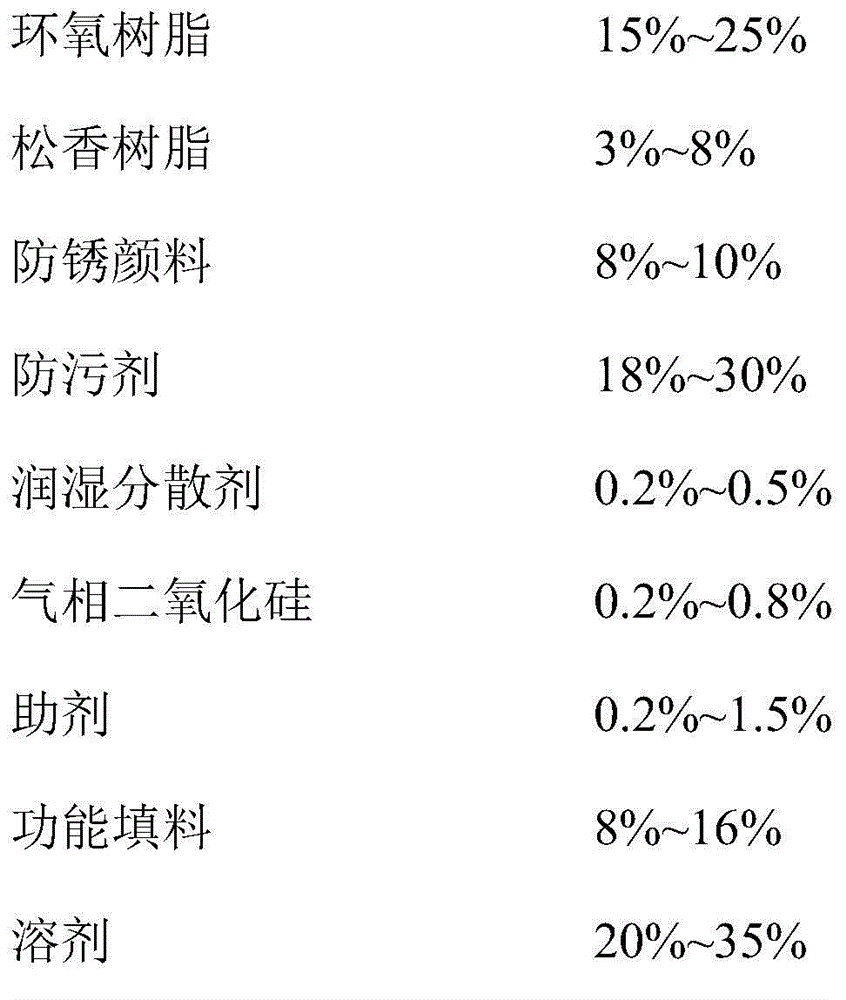

Contact type inshore fishing boat anti-fouling paint and preparation method thereof

InactiveCN104693970AGood antifouling performanceGood anti-corrosion performanceAntifouling/underwater paintsRosin coatingsSolventPesticide

The invention discloses contact type inshore fishing boat anti-fouling paint and a preparation method thereof. The contact type inshore fishing boat anti-fouling paint comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 10%-30% of epoxy resin, 0-15% of rosin resin, 3%-15% of anti-rusting pigments, 15%-25% of an anti-fouling agent, 0.2%-1.0% of fumed silica, 0.2%-1.5% of an aid, 5%-30% of functional pigments and 15%-40% of a solvent; the component B comprises the following components in percentage by weight: 60%-100% of an epoxy curing agent and 0-40% of a solvent. The contact type inshore fishing boat anti-fouling paint has the advantages that the anti-fouling paint does not contain internationally forbidden pesticide poisons such as organic tributyltin (TBT) and dichlorodiphenyltrichloroethane (DDT); the manufacturing and construction environments are relatively good, the poisons and resin emitted to ocean are reduced; the contact type inshore fishing boat anti-fouling paint is environmentally friendly and is non-toxic to the environment.

Owner:上海华谊精细化工有限公司上海开林造漆厂

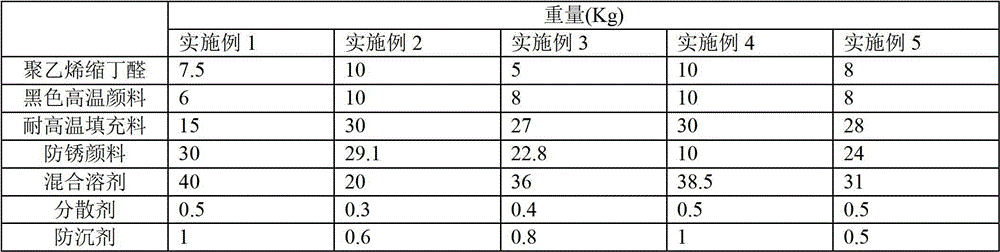

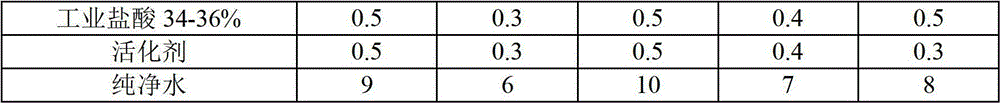

Low-cost high-temperature-resistant coating

InactiveCN102876156ALow costGood anti-corrosion performanceAnti-corrosive paintsSolventPolyvinyl butyral

The invention provides low-cost high-temperature-resistant coating, belonging to the technical field of coating. The low-cost high-temperature-resistant coating comprises components A and components B, wherein the components A comprise the following components in percent by weight: 5-10 percent of polyvinyl butyral, 6-10 percent of black high-temperature pigment, 15-30 percent of high-temperature-resistant filler, 10-30 percent of antirust pigment, 20-40 percent of mixed solvent, 0.3-0.5 percent of dispersing agent and 0.6-1 percent of anti-settling agent; and the components B comprise the following components in percent by weight: 40-60 percent of silicate ester, 30-50 percent of alcohol solvent, 0.3-0.5 percent of industrial hydrochloric acid, 0.3-0.5 percent of activating agent and 6-10 percent of purified water. By using inorganic silicate as raw materials, in combination with high-temperature-resistant pigment, the low-cost high-temperature resistant coating which can resist more than 600DEG C is developed; and the corrosion resistance is better than the corrosion resistance of the traditional organic silicon high-temperature-resistant coating.

Owner:JIANGSU HUAXIA PAINT MAKING

Water-based anti-corrosion paint and preparing method of water-based anti-corrosion paint

InactiveCN104962174AGood anti-corrosion performanceImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsEmulsion

The invention relates to water-based anti-corrosion paint, which is prepared from the following ingredients in parts by weight: 120 to 180 parts of water-based epoxy emulsion, 0.2 to 0.8 part of defoaming agent, 5 to 15 parts of dispersing agent, 0.5 to 1 part of thickening agent, 1.5 to 2 parts of flatting agent and 0.6 to 1.5 parts of anti-corrosion agent. The invention also relates to a preparing method of the water-based anti-corrosion paint. The water-based anti-corrosion paint has the excellent anti-corrosion performance, and can be widely used for anti-corrosion effects of material surface layers.

Owner:李福军

Zinc-rich steel structure anticorrosion coating

InactiveCN105482579AGood anti-corrosion performanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsAmmonium polyphosphateEther

The invention discloses a zinc-rich steel structure anticorrosion coating. The coating comprises, by weight, 20-30 parts of acrylic acid modified resin, 10-20 parts of bisphenol A epoxy resin, 5-10 parts of diphenol propane epoxy resin, 4-10 parts of nanometer zinc oxide, 15-20 parts of zinc powder, 2-8 parts of titanium dioxide, 8-15 parts of ammonium polyphosphate, 1-5 parts of pentaerythritol, 10-15 parts of a siloxane grafted polymer, 1-5 parts of expandable graphite, 1-3 parts of cyclohexanone, 5-10 parts of ethylene triamine, 0.1-0.3 parts of manganese acetate and 20-25 parts of deionized water. The coating is rich in zinc, is anticorrosive, and has very good anticorrosive performance; an ester bond, an epoxy group and other structures contained in the coating make the coating have good adhesion with a steel structure; and the coating also has the advantages of good waterproof property, excellent wear resistance, excellent impact resistance, and excellent mechanical performances.

Owner:青岛唐鹏钢结构工程有限公司

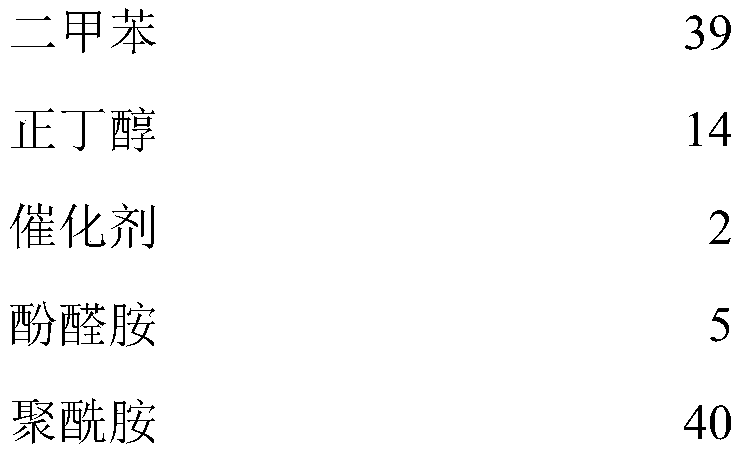

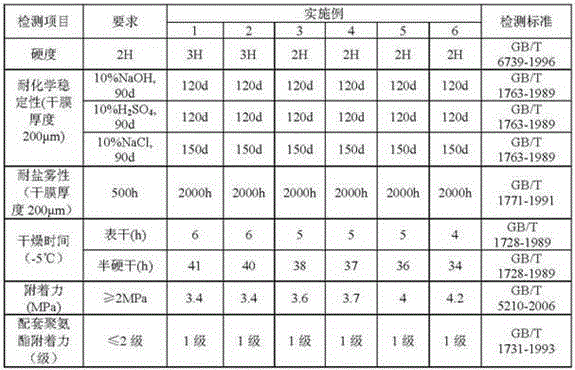

Low-temperature quick-curing epoxy coating and preparation method thereof

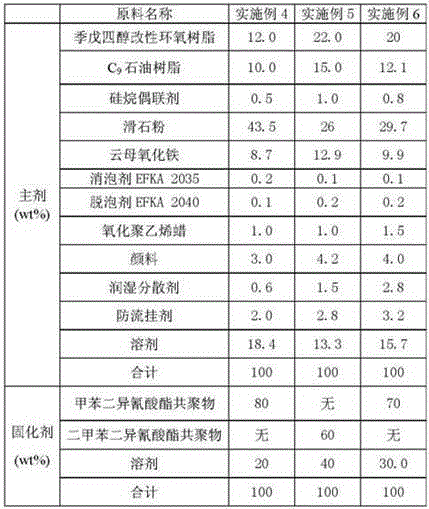

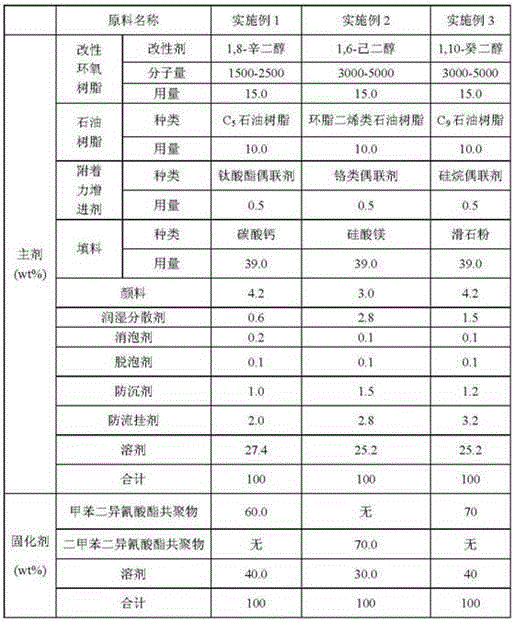

ActiveCN104559676AGood anti-corrosion performanceGood surface conditionAnti-corrosive paintsPolyurea/polyurethane coatingsSolventCorrosion resistant

The invention discloses a low-temperature quick-curing epoxy coating and a preparation method of the low-temperature fast-curing epoxy coating. The coating is prepared from a main agent and a curing agent, wherein the main agent comprises modified epoxy resins, petroleum resins, wetting dispersants, antifoaming agents, defoaming agents, anti-settling agents, anti-sag agents, adhesion promoters, pigments, fillers and solvents; the curing agent is toluene diisocynate copolymer or xylene diisocyanate copolymer and a solvent; the modified epoxy resins are double polycondensate of the modified bisphenol A and epoxy epichlorohydrin; a modifying agent is linear chain alkyl diol or pentaerythritol; and the linear chain alkyl diol has carbon atom number of 6-10. The coating can be quickly cured under a cold environment of below 5 DEG C; the preparation method is carried out in a cold area of below 10 DEG C, half-hardening and half-drying can be realized in two days and the coating is used for coating. The coating is high in corrosion resistant performance and high in adhesion force, and can achieve heavy corrosion protection of steel surfaces.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN +2

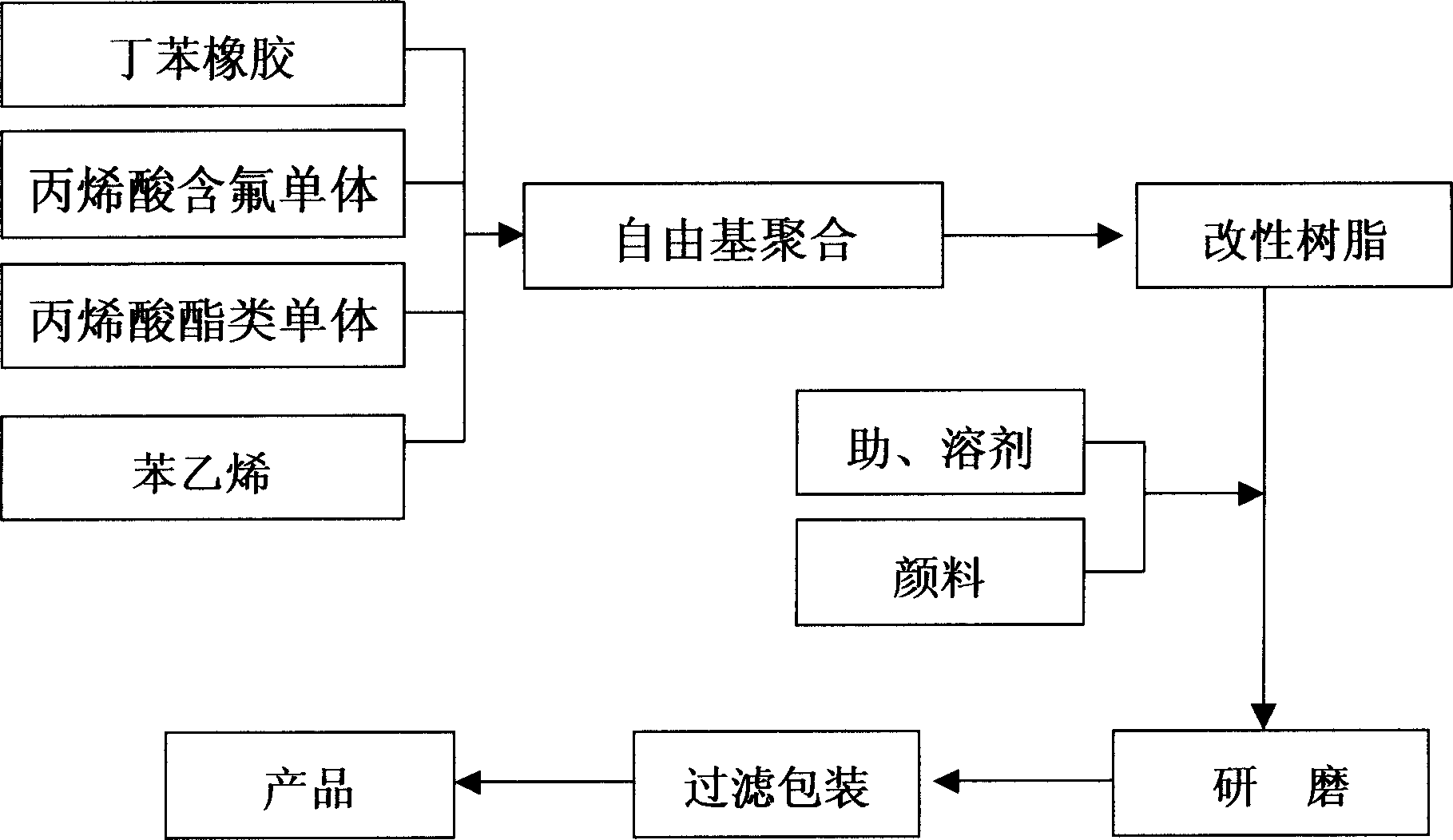

Process for preparing fluorocarbon protective paint of aluminium alloy anodization

The present invention relates to the preparation process of protective fluorocarbon paint for aluminum alloy anodization. The protective fluorocarbon paint has rubber modified fluorocarbon resin base material prepared with mixed monomer comprising fluoroacrylic monomer, acrylate monomer, styrene and styrene-butadiene rubber as well as mixed solvent and primer through mixing, heating, filtering and other steps. The rubber modified fluorocarbon resin base material is mixed with pigment, modifier, pigment moistening dispersant and thickener, and the mixture is ground in grinder and added with mixed solvent to regulate viscosity and obtain the protective fluorocarbon paint for aluminum alloy anodization.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

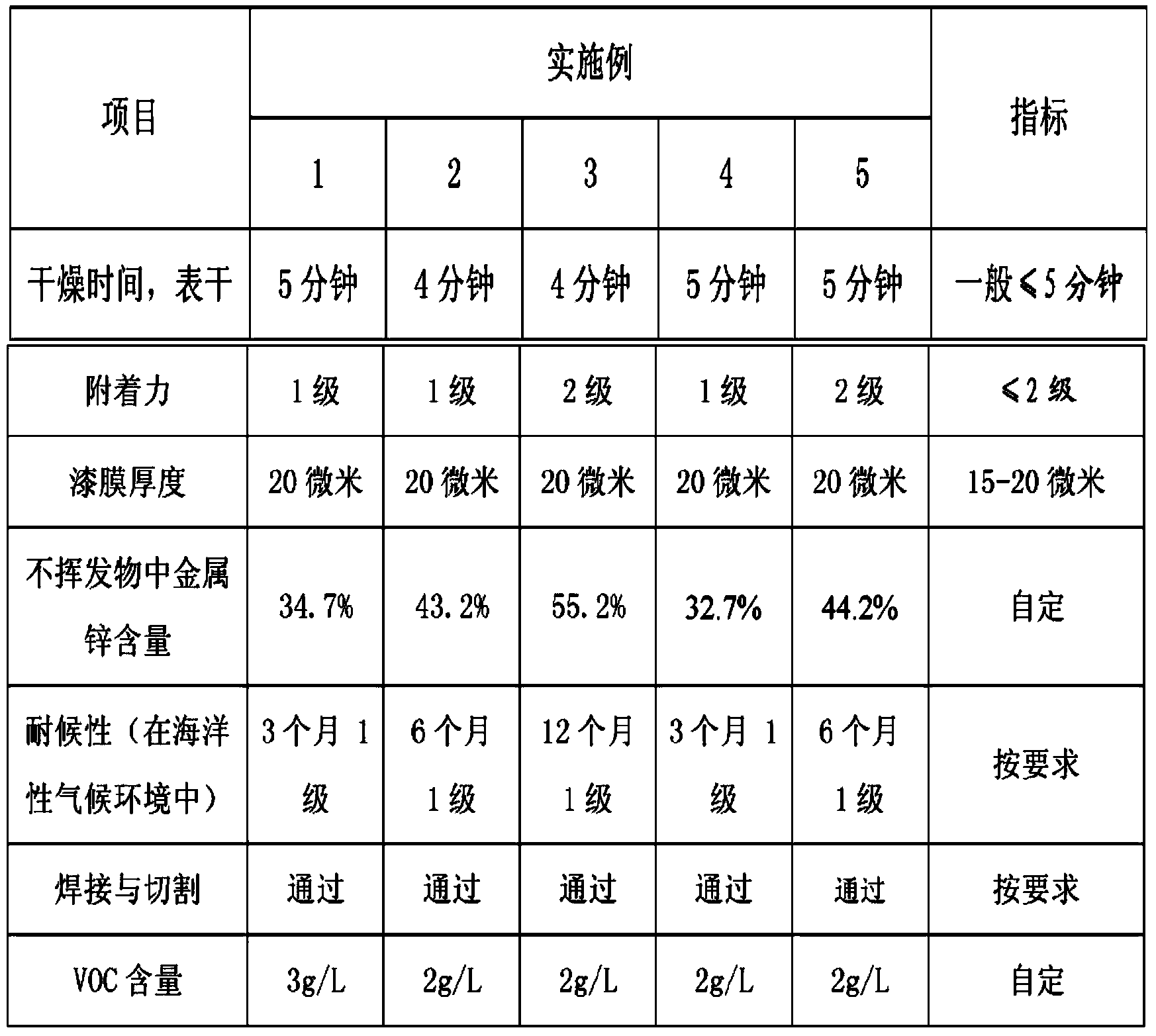

Waterborne inorganic zinc shop primer, and preparation and application thereof

InactiveCN103408974AGood anti-corrosion performanceImprove anti-corrosion performanceAlkali metal silicate coatingsAnti-corrosive paintsChemistryZinc

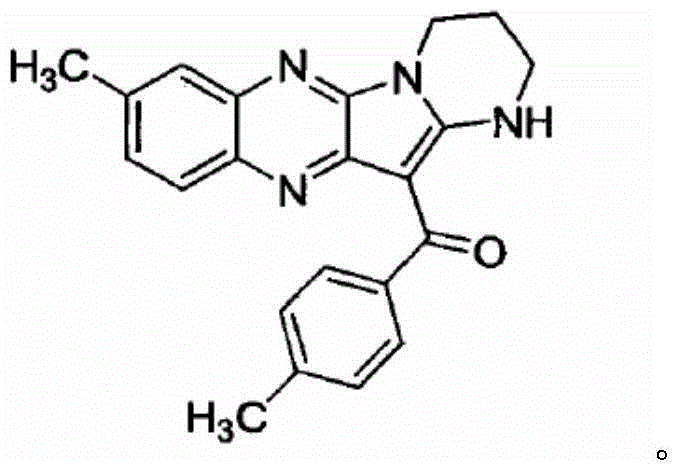

The invention discloses a waterborne inorganic zinc shop primer. The waterborne inorganic zinc shop primer is characterized by comprising a basic material and a curing agent, wherein the basic material comprises, by weight, 25 to 55 parts of zinc dust, 10 to 45 parts of a filling material, 5 to 20 parts of a pigment, 0 to 4 parts of rare earth oxide, 0.5 to 3 parts of a heterocyclic organic compound, 0.1 to 1 part of a surfactant, 18 to 38 parts of water, 0.2 to 2 parts of an anti-settling agent and 0.07 to 0.7 part of an antifoaming agent, the curing agent comprises, by weight, 15 to 30 parts of an inorganic polymer film-forming substance, 0 to 10 parts of an acrylic monomer, 3 to 8 parts of styrene, 0 to 5 parts of methyl acrylate, 0.5 to 2 parts of a dispersant, 14 to 35 parts of water, 0 to 0.05 part of an antifoaming agent and 0 to 0.15 part of a surfactant, and the fineness of the zinc dust is more than 800 meshes.

Owner:张家港保税区金企鹅贸易有限公司

Graphene modified heavy anticorrosion functional coating

InactiveCN107163712AGood anti-corrosion performanceImprove anti-corrosion abilityAnti-corrosive paintsParaffin waxN-Butyrate

The invention relates to the technical field of anti-corrosion paint production, in particular to a graphene-modified heavy-duty anti-corrosion functional paint. A graphene-modified heavy-duty anti-corrosion functional coating, comprising the following components by weight percentage: acetate: 15-30%; resin: 39-71% paraffin: 10-20%; auxiliary agent: 0.2-1%; surfactant : 1‑3%; curing agent: 0.5‑1.5%; graphene: 2‑4.5%; pigment: 1‑2%. This graphene-modified heavy-duty anti-corrosion functional coating has good anti-corrosion performance, can improve the anti-corrosion ability of buildings when used, effectively reduces economic losses, and meets the needs of use.

Owner:江苏晨光涂料有限公司

Antiseptic lubricating grease and preparation method thereof

InactiveCN104357142AEasy to prepareGood anti-corrosion performanceLubricant compositionSOYBEAN SEED OILChemistry

The invention discloses an antiseptic lubricating grease. The antiseptic lubricating grease consists of base oil, a densifier and additives, wherein the weight of the densifier accounts for 13-16% of that of the base oil, and the weight of the additives accounts for 1.5-2.3% of that of the base oil; the base oil is a mixture of silicon oil, soybean oil and peanut oil; the densifier is polyurea, polyacrylamide and epoxy resin; the additives are the mixture of benzoic acids, benzotriazole, MoSz, tricresyl phosphate and polymethacrylate. The silicon oil, the soybean oil and the peanut oil are used as the base oil of the lubricating grease disclosed by the invention, the polyurea, the polyacrylamide and the epoxy resin are added as the densifier, after heating and pressurizing, the chemical property is steady, the lubricating grease is not easy to corrode, and the benzoic acids, the benzotriazole, the MoSz, the tricresyl phosphate and the polymethacrylate which are added can improve the abrasion resistance and the inoxidizability of the lubricating grease.

Owner:WUXI FEITIAN GREASE

Asphalt phenolic waterproof material

InactiveCN103788670AGood anti-corrosion performanceGood waterproof performanceBuilding insulationsRosinMicrobial corrosion

The invention discloses an asphalt phenolic waterproof material. The asphalt phenolic waterproof material comprises the following components in parts by mass: 100 parts of petroleum asphalt, 10-25 parts of pine tar, 15-20 parts of ester gum, 1-2 parts of calcium chloride, 12-18 parts of rosin modified phenolic resin, 20-30 parts of pigment, 40-60 parts of solvent gasoline, 10-18 parts of aluminium paste, 30-40 parts of benzene, 6-8 parts of silicon dioxide, 8-10 parts of dimethylbenzene, 1-2 parts of butanol and 2-3 parts of ethanediamine; the product is excellent in corrosion resistance and has resistance to microbial corrosion; the time for surface drying is 2.2-3.2 hours; the time for hard dry is 20-22 hours; the asphalt phenolic waterproof material is high-temperature resistant and cold-resistant, has resistance to low temperature of 50 DEG C below zero and is incapable of defoaming and flowing within 4 hours at the temperature of 100-120 DEG C; the asphalt phenolic waterproof material is excellent in waterproof property, impermeable under 0.1-0.2MPa and excellent in anti-cracking property; and the product is high in bending resistance, excellent in weather resistance, high in compressive strength, applicable to extensive production and capable of continuously replacing the current material.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

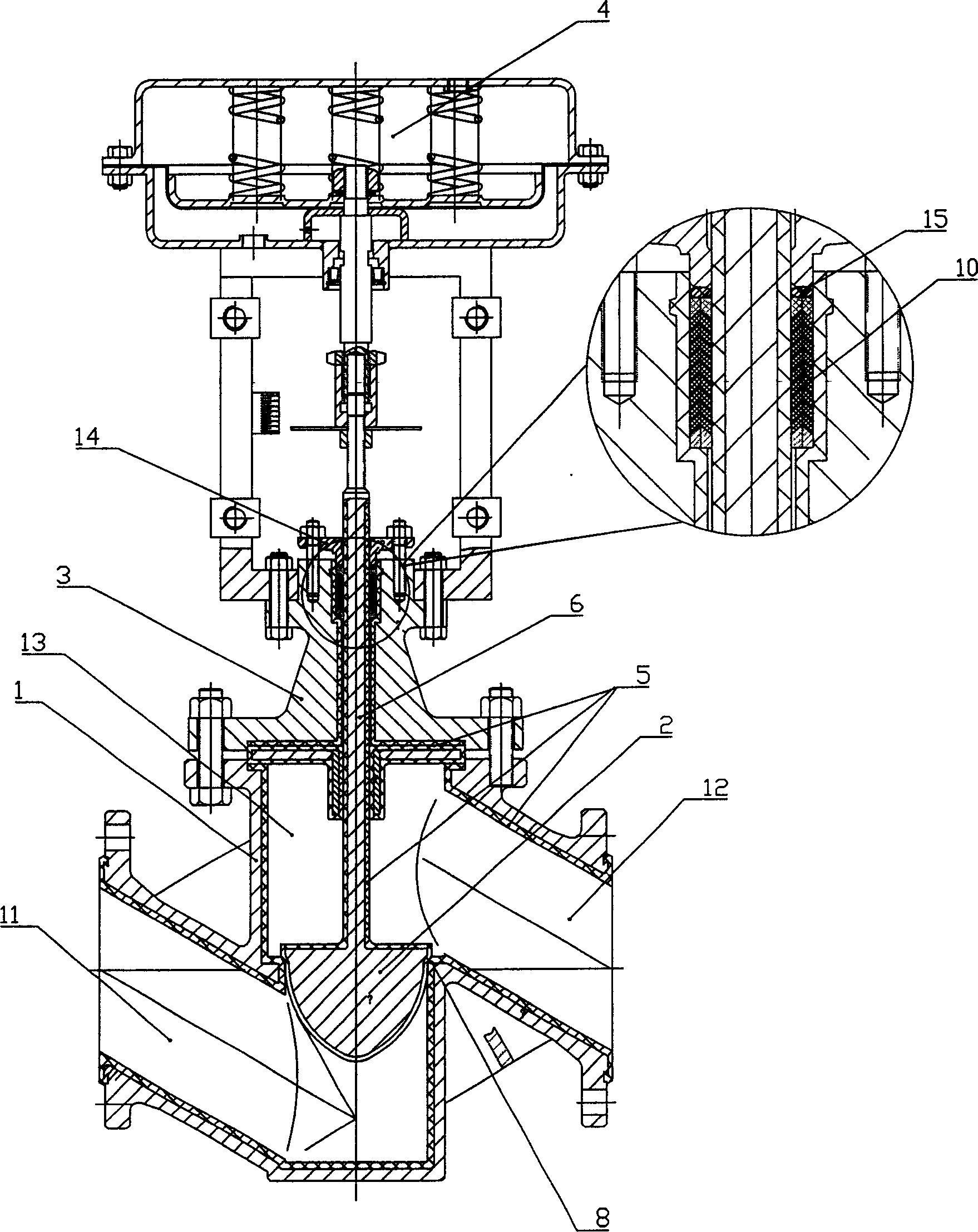

High efficiency smart fluorine-lined control valve

ActiveCN1834511AGood anti-corrosion performanceSimple structureSpindle sealingsLift valveEngineeringControl valves

The present invention discloses a high-effective intelligent fluorine-lined control valve. It includes valve body, valve cavity, inlet tube, outlet tube, valve cover and valve core. In the interior of valve cavity, between the inlet tube and outlet tube a valve seat is set, in the interior of valve cavity, inlet tube and outlet tube on the surface which can be contacted with the fluid an integrally-formed fluorine plastic layer is made, on the external surface of integral valve core and valve rod a fluorine plastic layer is integrally-formed, and on the valve cover an integrally-formed fluorine plastic layer is made in the position which can be contacted with fluid, and the described valve seat is a fluorine plastic layer integrally-formed ring-shaped fluorine plastic valve seat in the valve cavity.

Owner:朱孝有

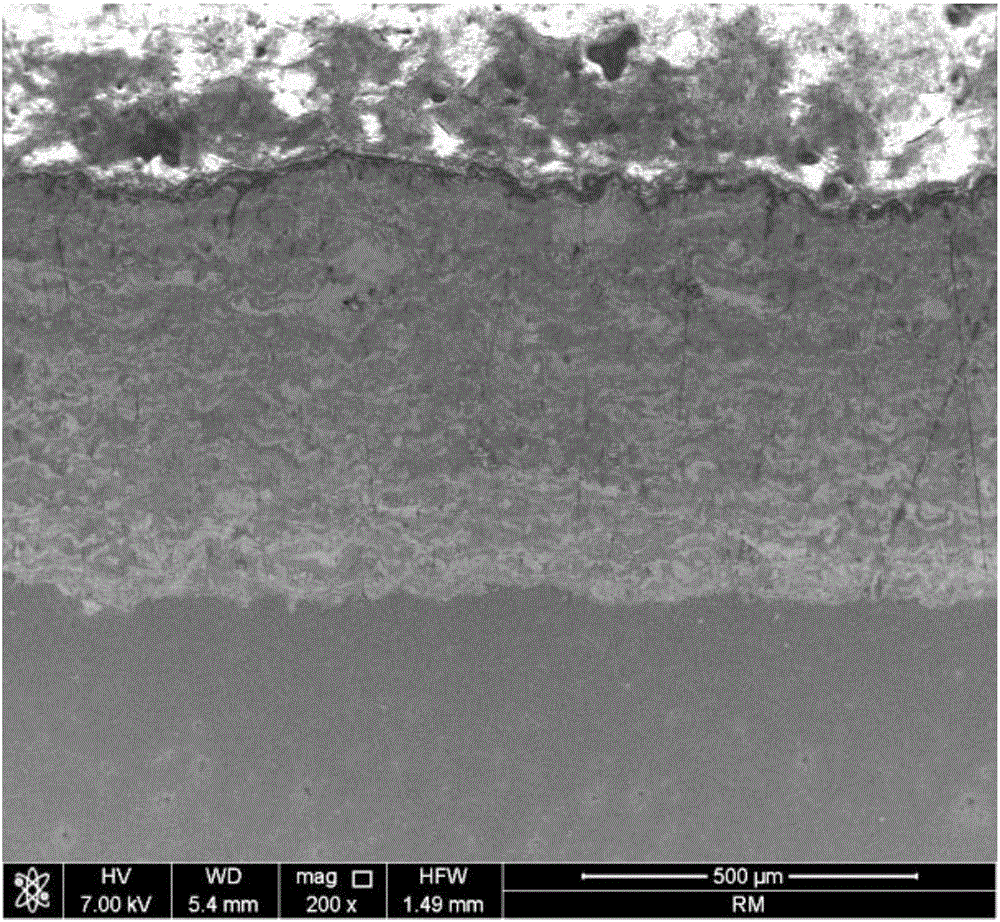

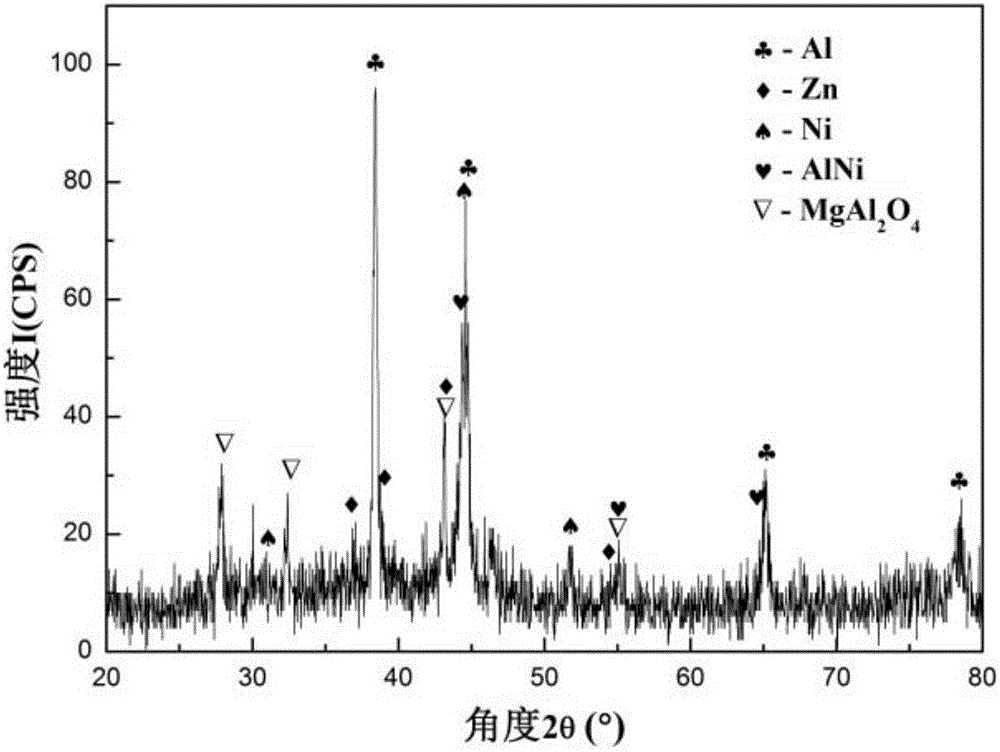

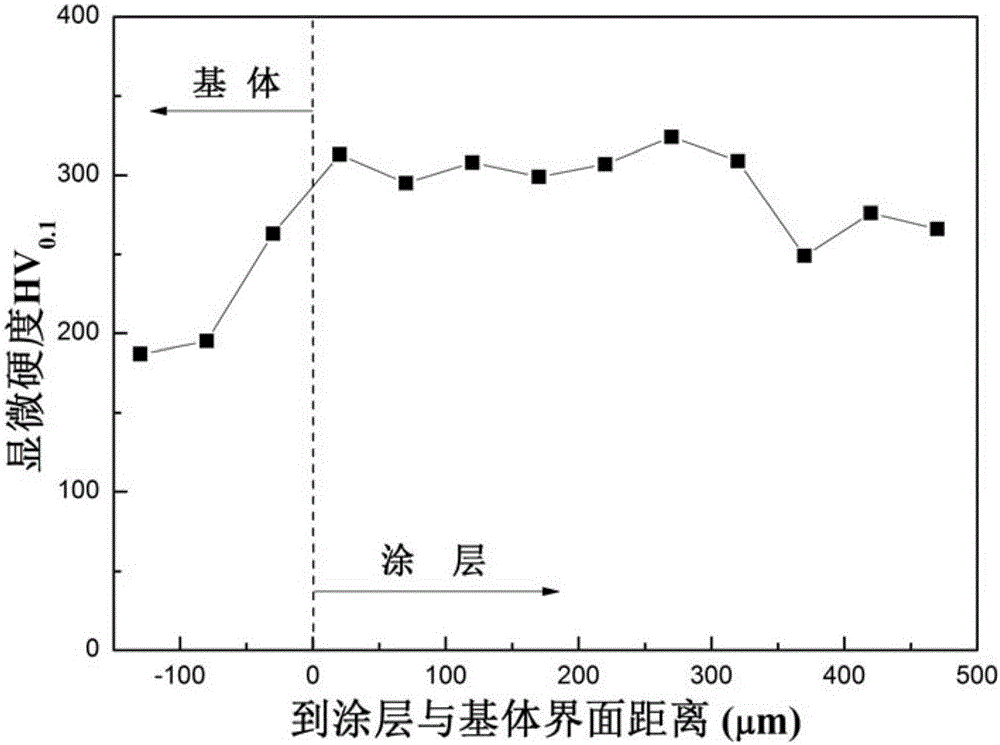

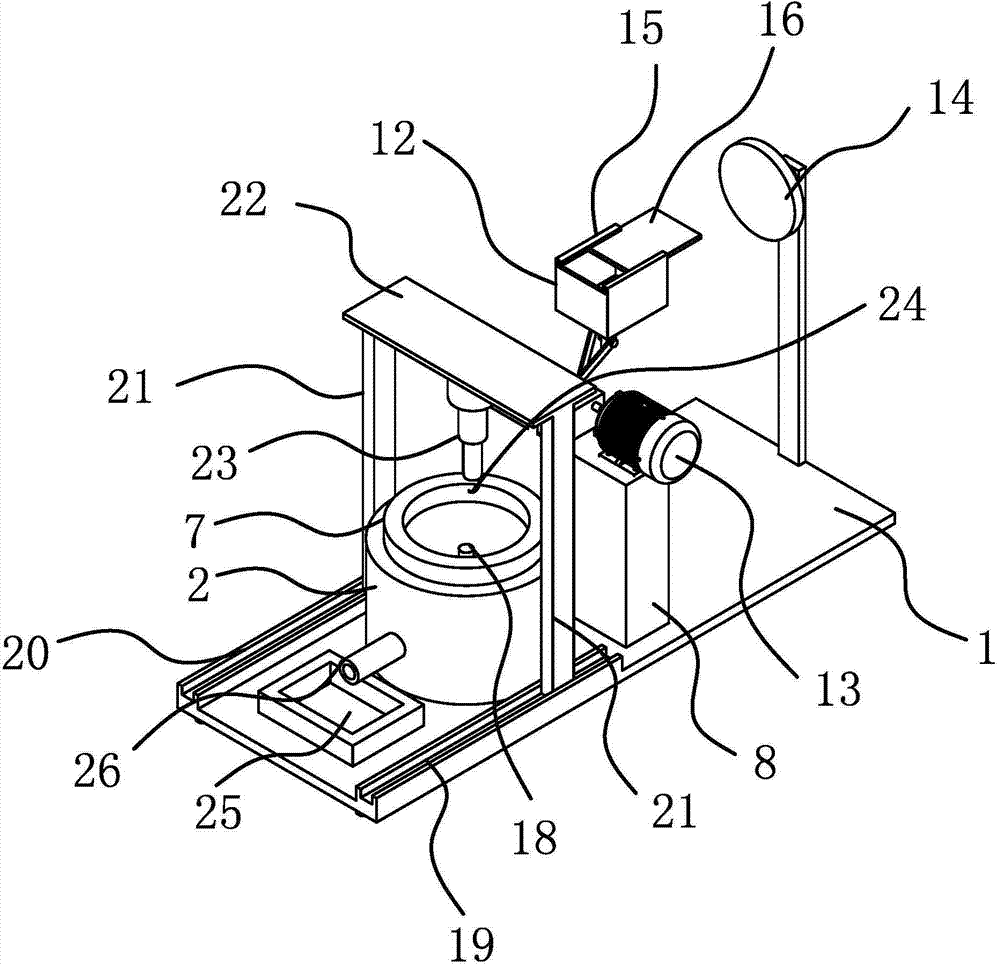

Cored wire for preparing anti-corrosion Al-Zn-Mg-Ni amorphous-nanocrystalline composite coating layer

ActiveCN106591767AReduce manufacturing costGood anti-corrosion performanceMolten spray coatingElectric arcAluminium

The invention discloses a cored wire for preparing an anti-corrosion Al-Zn-Mg-Ni amorphous-nanocrystalline composite coating layer. The cored wire is characterized in that the skin of the cored wire is a pure aluminum belt; a powder core is metal powder of Zn, Mg and Ni, and accounts for 38 to 44 percent of the mass of the wired; and the powder core is prepared from the following components in percentage by mass: 16 to 22 percent of Zn, 14 to 18 percent of Mg and 4 to 8 percent of Ni. The cored wire can be used for preparing an aluminum-based amorphous-nanocrystalline composite coating layer after being machined via a high-speed electric arc spraying technique; the coating layer consists of multiple phases of structures such as an amorphous phase, a nanocrystalline phase and a crystallization phase, and is excellent in corrosion resistance performance; and therefore, the corrosion resistance performance of the surface of a steel structural member can be effectively improved, and the service life can be prolonged.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Method of manufacturing corrosive-resistant single-body hydraulic supporter by salt bath nitriding

InactiveCN1924076AGood anti-corrosion performanceImprove fatigue strengthSolid state diffusion coatingCorrosion resistantChemistry

The invention discloses a corrosion resistant reinforcing method of disposed component in the salt bath of monomer hydraulic column, which comprises the following steps: removing oil and rust; washing through alkaline; cleaning; nitrogenizing in the salt bath; oxidizing in the salt bath; cooling; cleaning; immersing in the oil.

Owner:新汶矿业集团通力机械有限责任公司

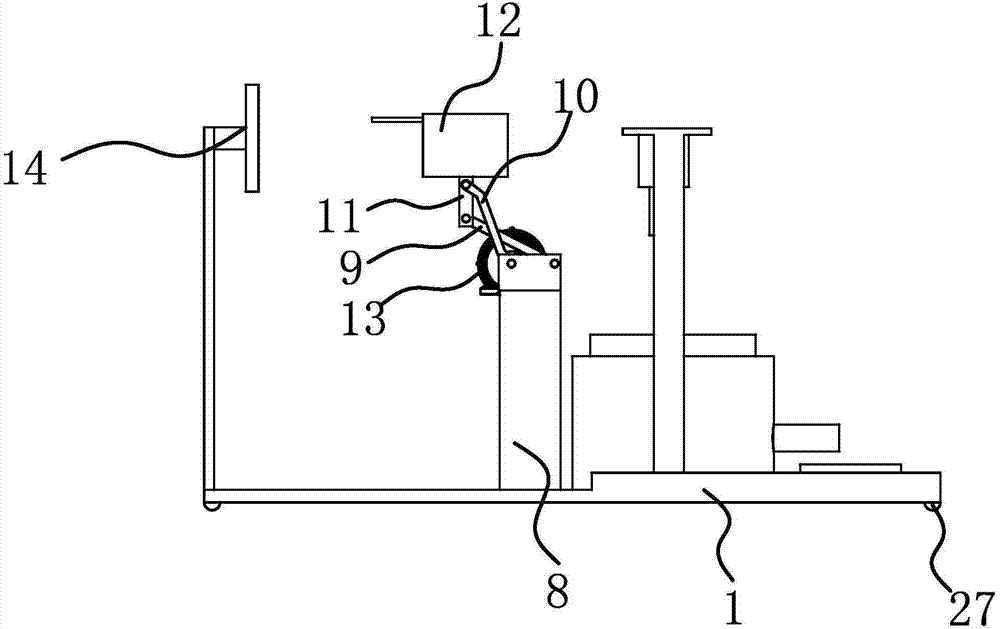

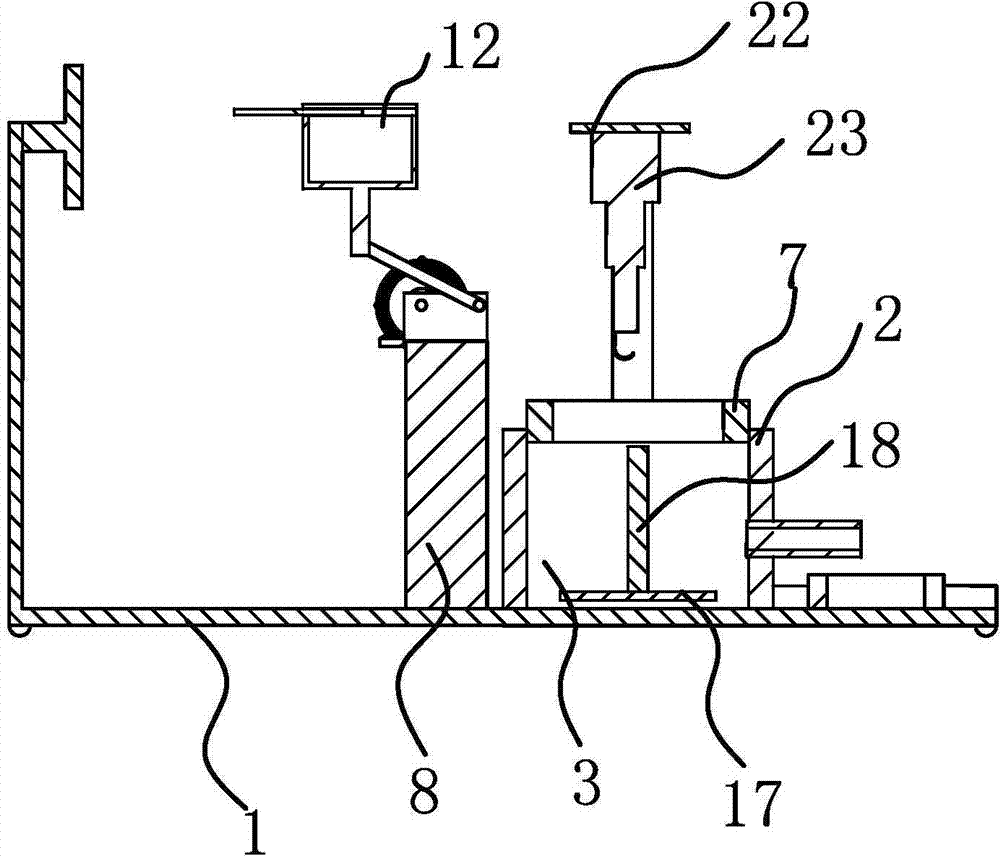

Vegetable pickling machine for pickling carrots

ActiveCN104839600AGood anti-corrosion performanceAvoid pickle rotFood preparationAgricultural engineeringMaterial storage

The invention provides a vegetable pickling machine for pickling carrots, belongs to the technical field of food machines and solves the technical problems that the anticorrosive performance of the existing vegetable pickling machine is poor and the like. The vegetable pickling machine comprises a bottom plate and a vegetable pickling jar, wherein a material storage chamber is provided in the vegetable pickling jar; the upper end surface of the vegetable pickling jar is provided with a feed inlet; the upper end of the vegetable pickling jar is further detachably connected with a cover plate; the center of the lower plate surface of the cover plate is fixedly connected with the upper end of a compression spring; the lower end of the compression spring is fixedly connected with a filter screen; the filter screen and the material storage chamber are coaxially arranged, and the distance between the outer edge of the filter screen and the side wall of the material storage chamber is 1mm; a cooling water passage is provided on the side wall of the vegetable pickling jar and the two ends of the cooling water passage are respectively a water inlet and a water outlet. The vegetable pickling machine for pickling carrots can improve the anticorrosive performance of the vegetable pickling machine.

Owner:安徽科惠商贸有限公司

Steel wire rope plastic coating technology

InactiveCN105178074AGood anti-corrosion performanceGood lubricityRope making machinesSurface finishingLow friction

The invention relates to a steel wire rope plastic coating technology. The technology comprises the following steps: (1) processing the surface of a steel wire before plastic coating; (2) dipping a plastic liquid, the plastic liquid being a mixed acid solution in which polytetrafluoroethylene solid content is 10-20 wt%; (3) and processing after plastic coating. A plastic-coated steel wire rope manufactured by the plastic coating technology is good in anticorrosion performance, and has good lubricating property and low friction coefficient.

Owner:WUXI WEISHUN METAL PROD

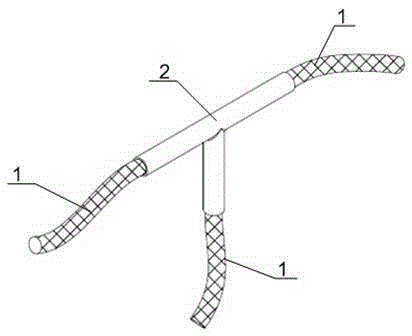

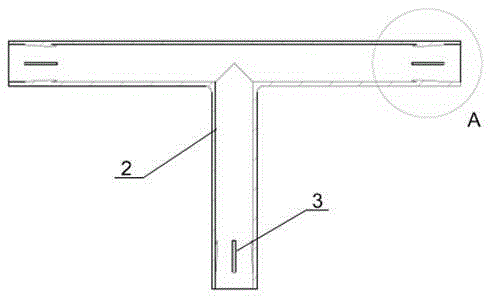

Flexible graphite grounding grid

InactiveCN105244640AGood anti-corrosion performanceReduce contact resistanceConnection contact member materialGrounding gridCorrosion

The invention discloses a flexible graphite grounding grid, which comprises a plurality of sections of flexible graphite lead wires, and a metal casing pipe used for crimping and connecting the flexible graphite lead wires, wherein one end of each flexible graphite lead wire is crimped and fastened in the metal casing pipe, and the plurality of sections of flexible graphite lead wires are integrally connected through the metal casing pipe. By adopting the flexible graphite lead wires to replace the original metal grounding bodies, the grounding grid has more excellent corrosion resistance; the plurality of flexible graphite lead wires are crimped and interconnected through the metal casing pipe, so that the flexible graphite lead wires are in tight contact with the inner side walls of the metal casing pipe and are not prone to fall off; and the flexible graphite grounding grid has smaller contact resistance at connecting points when compared with that of the traditional grounding grid adopting a welding and interconnecting method, and enhances the conductivity.

Owner:STATE GRID CORP OF CHINA +3

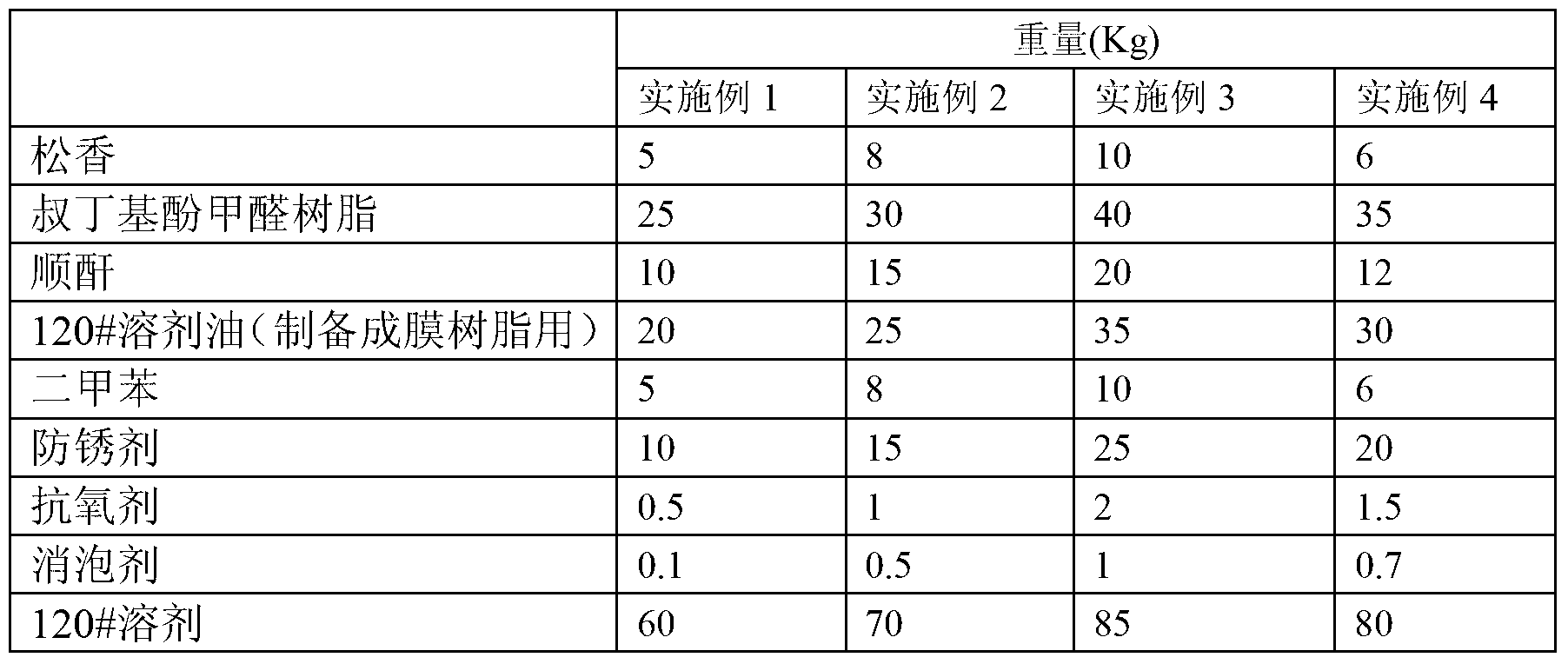

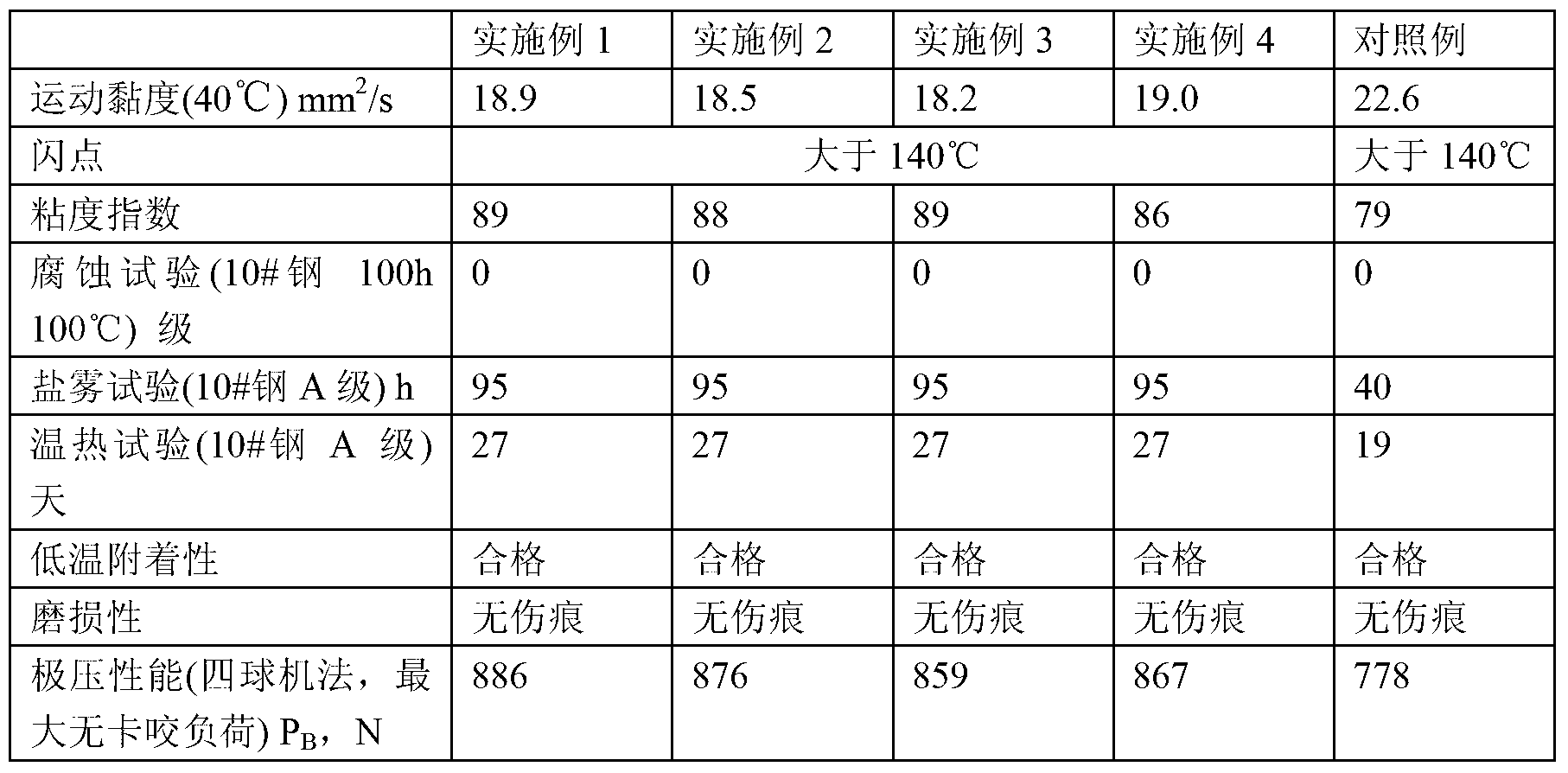

Hard-film rust-preventative oil

InactiveCN103265891AGood anti-corrosion performanceImprove anti-corrosion performanceRosin coatingsAnti-corrosive paintsSolventRosin

The invention provides a hard-film rust-preventative oil which is resistant to moisture, heat and salt mist and a preparation method thereof, and belongs to the technical field of rust-preventative oil. The hard-film rust-preventative oil comprises the following components in parts by weight: 20-30 parts of film-forming resin, 10-25 parts of a rust-preventative agent, 0.5-2 parts of an antioxidant, 0.1-1 parts of an antifoam agent and 60-85 parts of a 120# solvent, wherein the film-forming agent is prepared from the following raw materials in parts by weight: 5-10 parts of colophonium, 25-40 parts of tert-butyl phenol formaldehyde resin, 10-20 parts of cis-butenedioic anhydride, 20-35 parts of 120# solvent oil and 5-10 parts of dimethyl benzene. The durability in a salt mist test can last for 95 days, and the durability in a warm test can last for 27 days; and the hard-film rust-preventative oil has a good rust-preventative performance.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

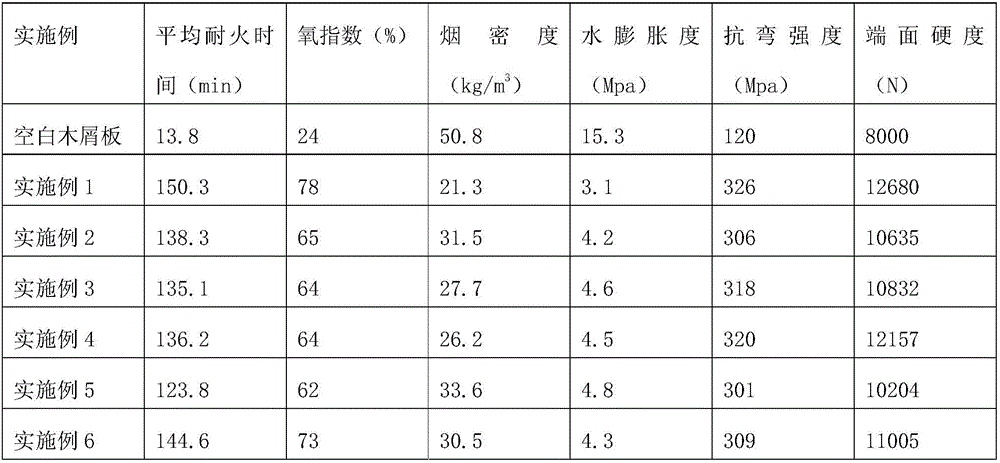

Preparation method of flame-retardant 3D printing wood dust material

InactiveCN106046829ANot easy to biofoulGood anti-corrosion performanceAdditive manufacturing apparatusSolventChemistry

The invention discloses a preparation method of a flame-retardant 3D printing wood dust material, comprising the steps: carrying out pretreatment, steam drying and vacuum pumping on common wood dust, submerging the wood dust with acid anhydride, and carrying out pressurizing and heating; after reaction ends, carrying out depressurizing, discharging of liquid, steam drying and vacuum pumping; and adding a solvent, a flame retardant, glass fibers and a cross-linking agent to obtain the flame-retardant 3D printing wood dust material. The preparation method has a simple production process, reduces processing steps and lowers production cost, and the prepared flame-retardant 3D printing wood dust material has superior properties and a wide range of application.

Owner:JIANGSU SOPO GRP +1

High-strength high-temperature-resistance high borosilicate glass

InactiveCN108455847AGood anti-corrosion performanceExtended service lifeBarium metaphosphateLanthanum

The invention discloses a high-strength high-temperature-resistant high borosilicate glass, and relates to the technical field of glass processing. The glass is prepared from the following components:112 parts of quartz sand, 35 parts of sodium borate, 34-38 parts of methyltrioxysilane modified boride silicon, 12 parts of dolomite, 14 parts of bauxite, 1.8 parts of barium metaphosphate, 0.12 parts of lanthanum trioxide, 5 parts of purple sand mud, 3 parts of boron oxide, 7 parts of calcium silicon slag and 1-3 parts of vanadium dioxide; The high-strength high-temperature-resistance high borosilicate glass has excellent anti-corrosion performance, high strength and high temperature resistance.

Owner:ANHUI DU HI TECH GLASS

Alloy-processing tool and coating agent thereof

InactiveCN101462148AGood anti-corrosion performanceGood lubricityFoundry mouldsFoundry coresAdhesiveFluoride calcium

The invention relates to a coating agent, which comprises the following components by weight portion: 100 portions of calcium fluoride, 0.7 to 3.3 portions of boric acid, and 5.5 to 11 portions of adhesive. The coating agent is used for protecting a processing tool during production of low-melting point alloys, and has the advantages of low cost and good protecting effect.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Infrastructure construction metal part alloy co-permeation and Dacromet composite anti-corrosive coating

ActiveCN105887006AGood anti-corrosion performanceHigh surface hardnessSolid state diffusion coatingAnti-corrosive paintsCerium(III) oxideOxide

The invention discloses an infrastructure construction metal part alloy co-permeation and Dacromet composite anti-corrosive coating which comprises an alloy co-permeation agent and a Dacromet coating solution, wherein the alloy co-permeation agent comprises zinc powder, aluminum powder, alumina powder, nickel powder, cerium (III) oxide powder and ammonium chloride, and is prepared by uniformly mixing the zinc powder, the aluminum powder, the alumina powder, the nickel powder and the cerium (III) oxide powder, heating the mixture to 150-200 DEG C, performing heat preservation for 30-50 minutes, cooling to the room temperature, and then uniformly mixing the cooled mixture with ammonium chloride; the Dacromet coating solution comprises a composition A and a composition B; the composition a zinc sheet, an aluminum sheet, deionized water and fatty alcohol-polyoxyethylene ether; the composition B comprises the following components in parts by mass: an amorphous complex molybdate compound, barium acid salt, hydrogen peroxide and 1-3 parts of polyethylene glycol; and the Dacromet coating solution is prepared by mixing the composition A with the composition B for uniform stirring, and then regulating the pH value of the obtained mixture to be 3.5-5.0 by adopting a pH regulator.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com