Graphene high-performance anticorrosive paint and preparation method and product thereof

An anti-corrosion coating and graphene technology, applied in anti-corrosion coatings, coatings, etc., can solve the problem of engineering materials losing their protective effect, and achieve the effects of excellent compactness, delaying moisture, and prolonging shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

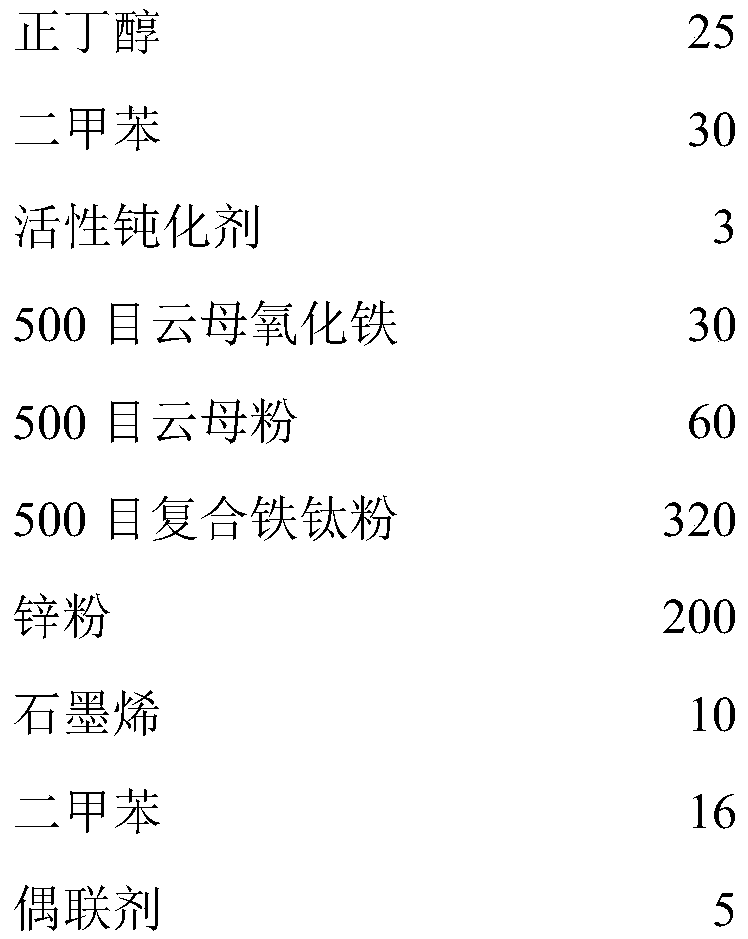

[0061] A graphene high-efficiency anticorrosion coating comprises the following components according to its parts by weight:

[0062] A component (main paint)

[0063]

[0064]

[0065] B component (curing agent)

[0066]

[0067] The preparation method of above-mentioned anticorrosion coating, specifically as follows:

[0068] (1) Mix small molecule epoxy resin, macromolecule epoxy resin, graphene, and nano-titanium, and obtain a resin matrix under the action of a modifier and a catalyst;

[0069] (2) Then put the wetting and dispersing agent, defoamer, passivator, anti-settling agent and paint solvent into the dispersion tank and stir, and disperse at a speed of 2000rpm for 30 minutes until the fineness is ≤30μm;

[0070] (3) Add mica iron oxide, mica powder, mica composite iron-titanium powder, graphene, zinc powder and other composite anti-rust pigments and fillers in sequence and stir for 30 minutes at a speed of 2000 rpm until the fineness is ≤70 μm;

[0071]...

Embodiment 2

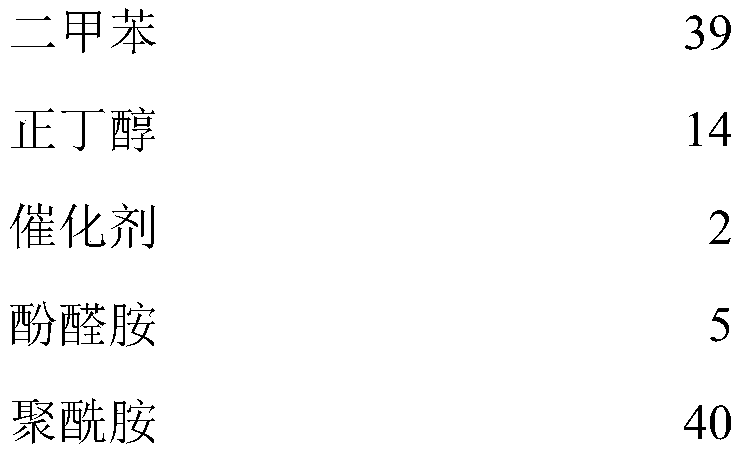

[0075] A graphene high-efficiency anticorrosion coating comprises the following components according to its parts by weight: A component (main paint)

[0076]

[0077] B component (curing agent)

[0078]

Embodiment 3

[0080] A graphene high-efficiency anticorrosion coating comprises the following components according to its parts by weight:

[0081] A component (main paint)

[0082]

[0083] B component (curing agent)

[0084]

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com