Preparation method of flame-retardant 3D printing wood dust material

A 3D printing and flame-retardant technology, which is applied in the field of polymer chemical materials, can solve the problems affecting the application of wood, poor mechanical strength, and flammability of wood, and achieve the effect of not easy biological adhesion, high mechanical strength, and changing the properties of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

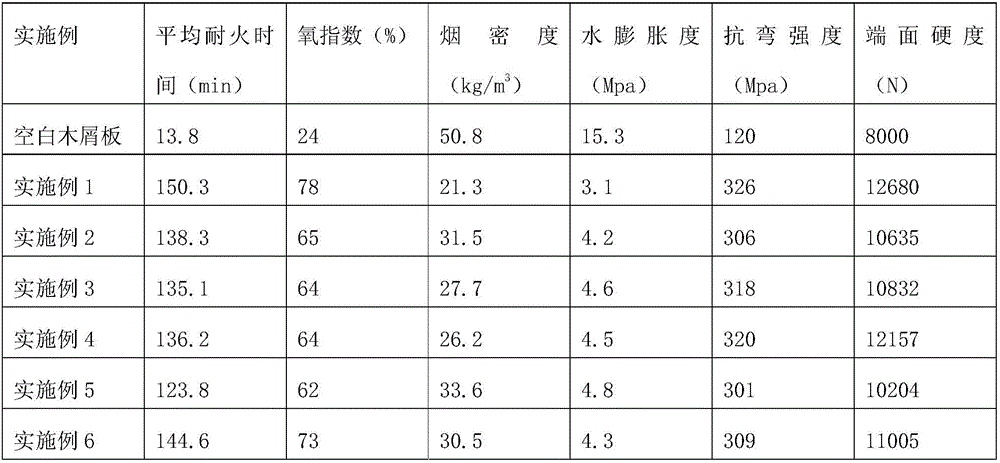

Examples

Embodiment 1

[0020] A kind of preparation method of 3D printing sawdust material, concrete steps are as follows:

[0021] 1. Put ordinary wood chips with a particle size of less than 1mmX1mmX1mm into the reactor, add benzene solvent to completely immerse it for 15 minutes, steam dry at 120°C, and vacuum to 100Pa to obtain wood chips with a water content of 7-12%;

[0022] 2. Use acetic anhydride to immerse the sawdust obtained in step 1, add acetic anhydride with a concentration of 40%, use benzene as a solvent, pressurize to 1MPa, react at 130°C for 8h, release the pressure and acetic anhydride, and vacuum to 100Pa to obtain The water content is 5-8% sawdust.

[0023] 3. Add benzene, KD-2 flame retardant, polyacrylonitrile-based carbon fiber and trimethylolpropane tris (3- aziridinyl propionate) bonding agent to the sawdust obtained in step 2, and heat it at 100° C. Mix and stir at 120°C to obtain a flame-retardant 3D printing wood chip material.

Embodiment 2

[0025] A kind of preparation method of 3D printing sawdust material, concrete steps are as follows:

[0026] 1. Put ordinary wood chips with a particle size of less than 1mmX1mmX1mm into the reactor, add toluene solvent to completely immerse it for 12 minutes, steam dry at 110°C, and vacuum to 150Pa to obtain wood chips with a water content of 8-13%;

[0027] 2. Use formic anhydride to immerse the sawdust obtained in step 1, add formic anhydride with a concentration of 30%, use toluene as a solvent, pressurize to 1MPa, react at 120°C for 10h, release the pressure, remove the formic anhydride, and evacuate to 150Pa to obtain The water content is 5-8% sawdust.

[0028] 3. Add toluene solvent, FRW flame retardant, glass fiber and trimethylolpropane tris (3- aziridinyl propionate) bonding agent to the sawdust obtained in step 2, and carry out at 100 ° C ~ 120 ° C Mix and stir to obtain a flame-retardant 3D printing wood chip material.

Embodiment 3

[0030] A kind of preparation method of 3D printing sawdust material, concrete steps are as follows:

[0031] 1. Put ordinary wood chips with a particle size of less than 1mmX1mmX1mm into the reaction kettle, add ethylbenzene solvent to fully immerse it for 10 minutes, steam dry at 100°C, and vacuum to 200Pa to obtain wood chips with a water content of 8-15%. ;

[0032] 2. Use acetic anhydride to immerse the sawdust obtained in step 1, add acetic anhydride with a concentration of 20%, ethylbenzene as a solvent, pressurize to 1MPa, react at 110°C for 8 hours, release the pressure and acetic anhydride, and vacuum to 200Pa to obtain Sawdust with a moisture content of 5-10%;

[0033] 3. Add ethylbenzene, ammonium dihydrogen phosphate-boric acid flame retardant, polyacrylonitrile-based carbon fiber and trimethylolpropane three (3- aziridinyl propionate) bonding agent to the sawdust obtained in step 2, Mix and stir at 100°C to 120°C to obtain a flame-retardant 3D printing wood chip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com