Flexible graphite grounding grid

A flexible graphite, grounding mesh technology, applied in the direction of connecting contact materials, etc., can solve the problems of accelerated corrosion of other metals, high price, poor electrical conductivity, etc., to achieve enhanced electrical conductivity, excellent anti-corrosion performance, and low contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

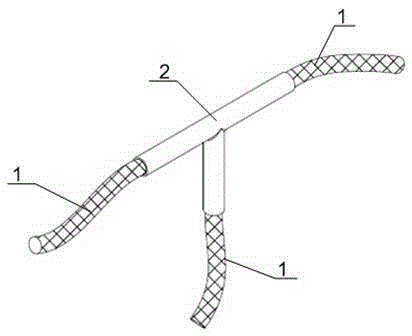

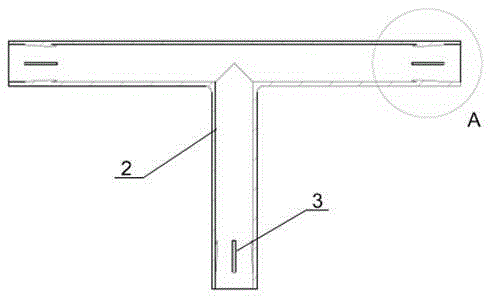

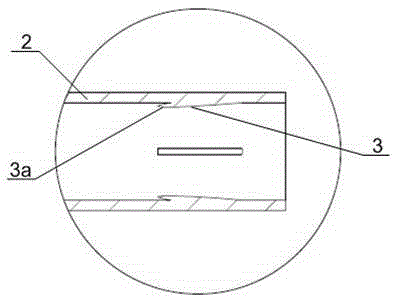

[0019] like Figure 1~3 As shown, the present invention provides a flexible graphite grounding grid, which includes a multi-section flexible graphite wire 1 and a metal sleeve 2 for crimping and connecting the flexible graphite wire 1, wherein one end of the flexible graphite wire 1 is pressed Connected and fastened in the metal sleeve 2, the multi-section flexible graphite wire 1 is connected into a whole through the metal sleeve 2.

[0020] Specifically, in the actual construction process, a grounding network may contain multiple grounding bodies, that is, multiple segments of flexible graphite conductors 1 in this application, and these grounding bodies are interconnected to form the entire grounding network. In this embodiment, each segment The graphite wires are connected through the metal sleeve 2, and according to different construction needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com