Patents

Literature

253results about How to "Improve electrical conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

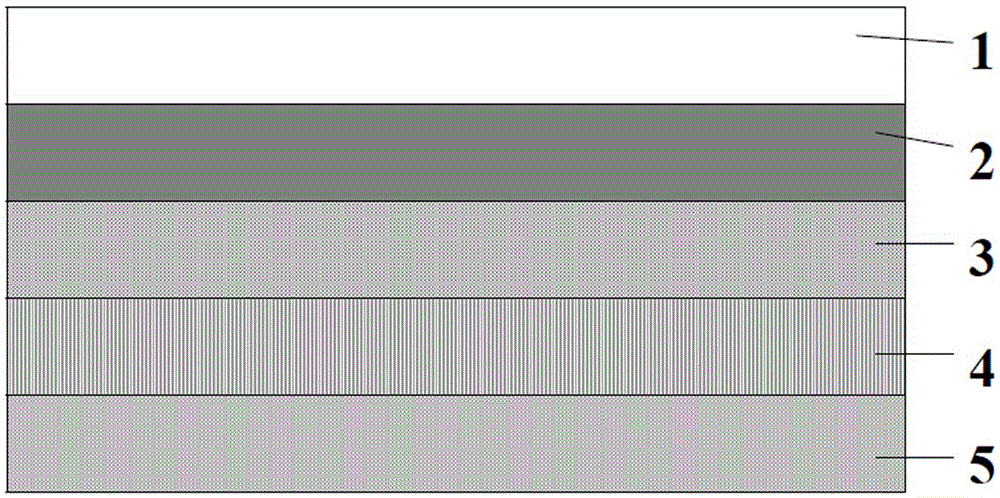

Solution processable material for electronic and electro-optic applications

ActiveUS20100012178A1Reduce work functionImprove electrical conductivityElectroluminescent light sourcesNanoinformaticsWork functionComposite material

An electro-optic device has a first electrode, a second electrode spaced apart from the first electrode, an active layer disposed between the first electrode and the second electrode, and an interfacial layer in contact with the active layer. The interfacial layer is a blend of a metal oxide and a second material that at least one of reduces a work function or increases an electrical conductivity of the interfacial layer according to an embodiment of this invention. A composition for electro-optic devices is a blend of at least one metal oxide and at least one salt in a ratio, by volume, of at least 1:0.1 and less than 1:1.2.

Owner:SOLARMER ENERGY INC

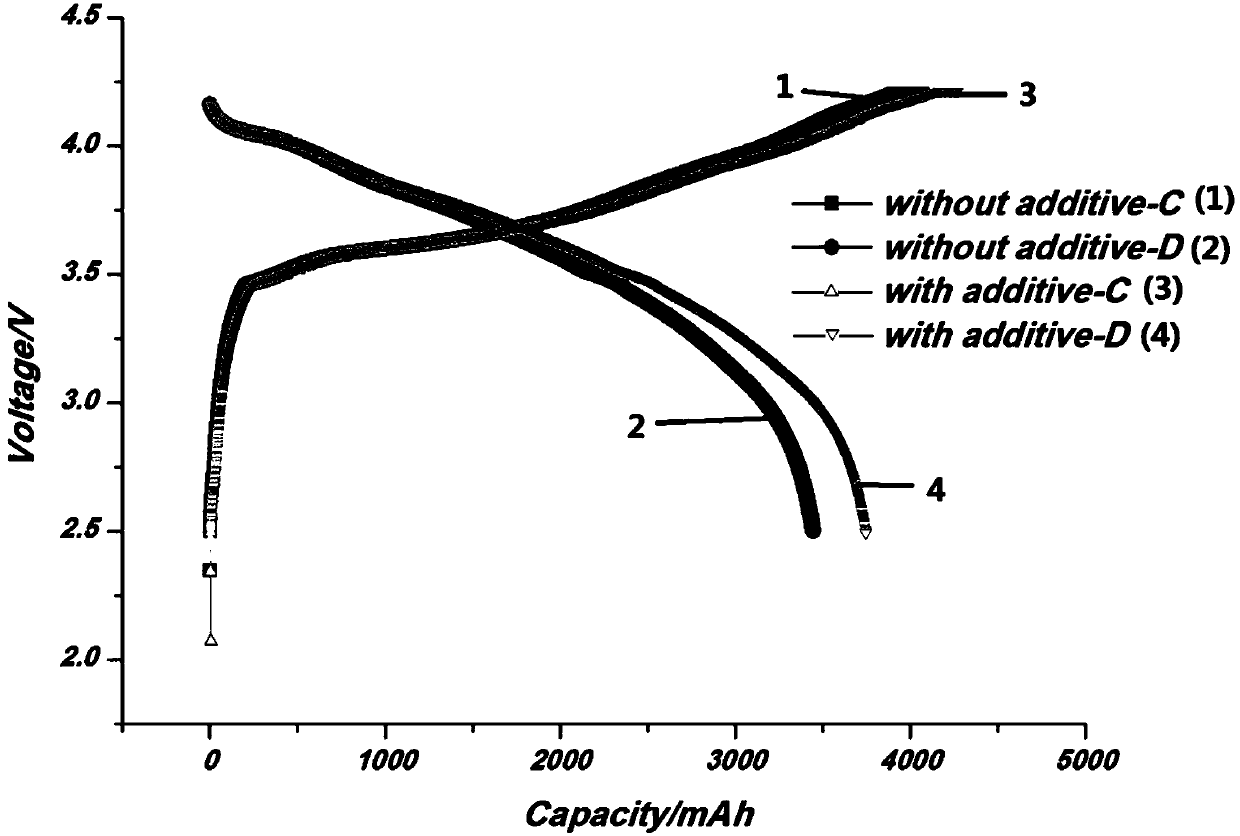

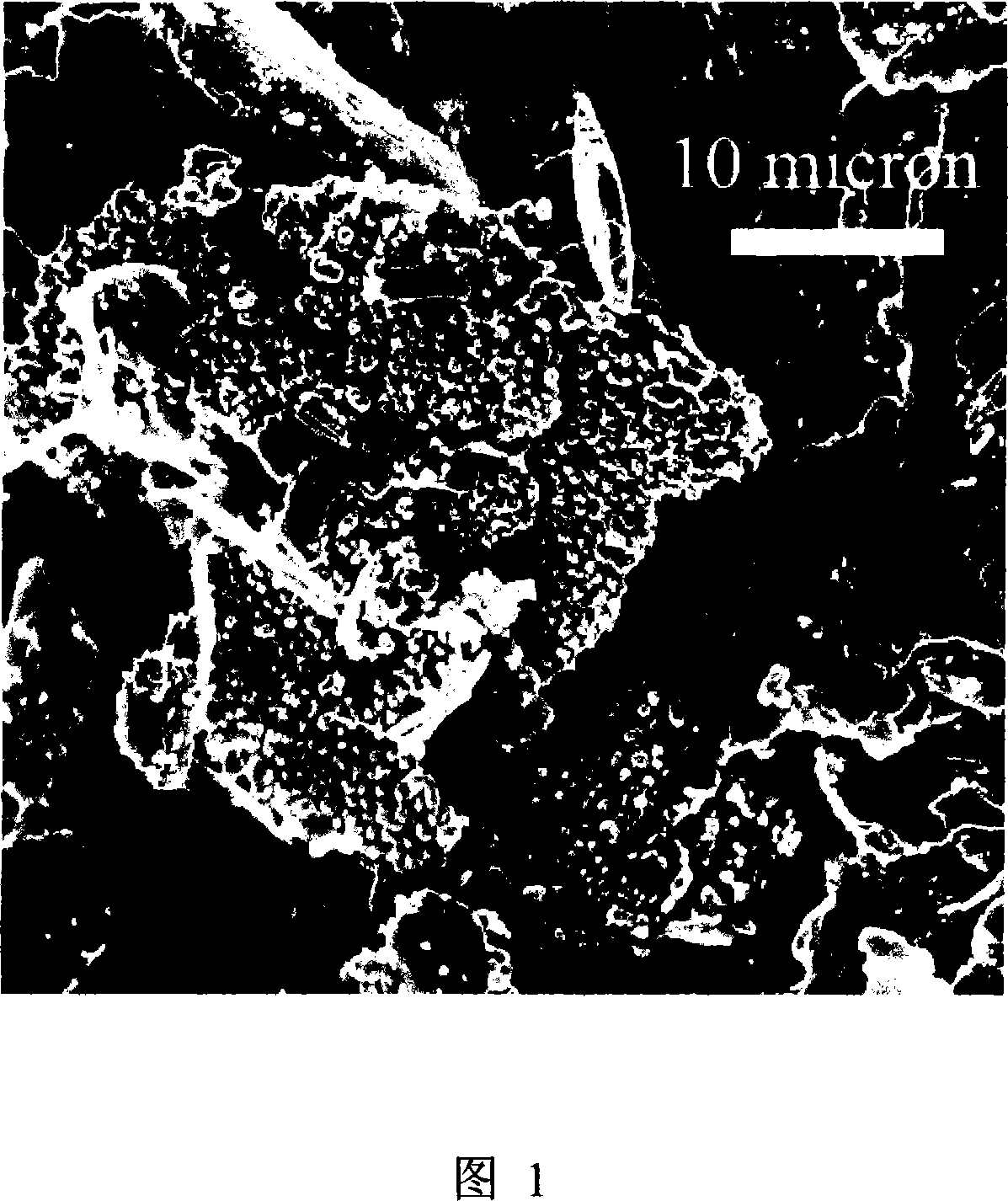

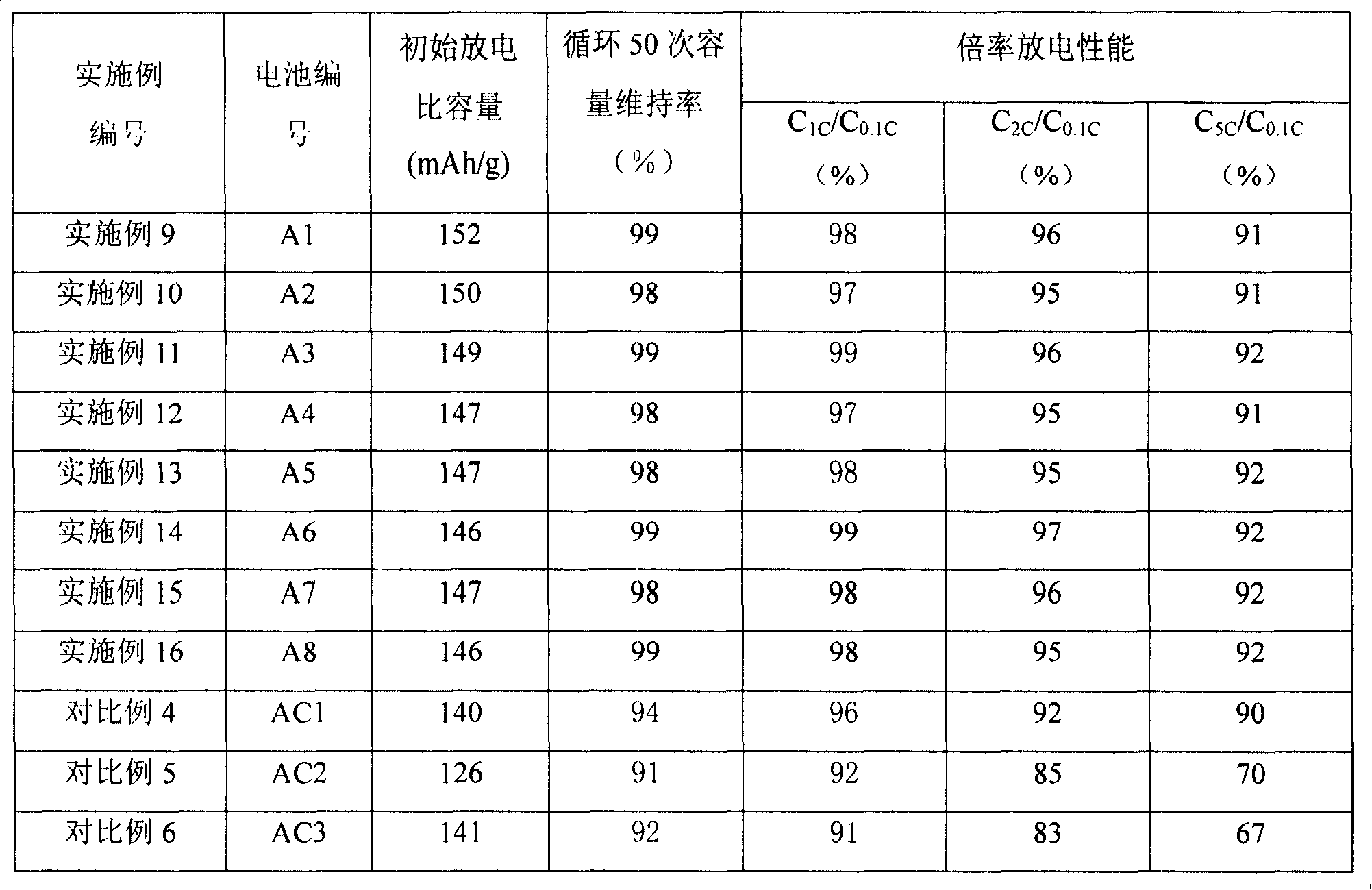

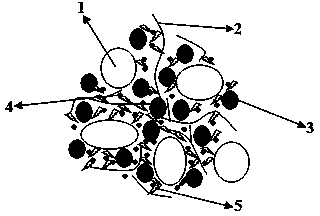

Lithium-supplementing additive as well as preparation method and application thereof

PendingCN107819113AImprove electrical conductivityIncrease profitCell electrodesSecondary cellsNanometreElectrically conductive

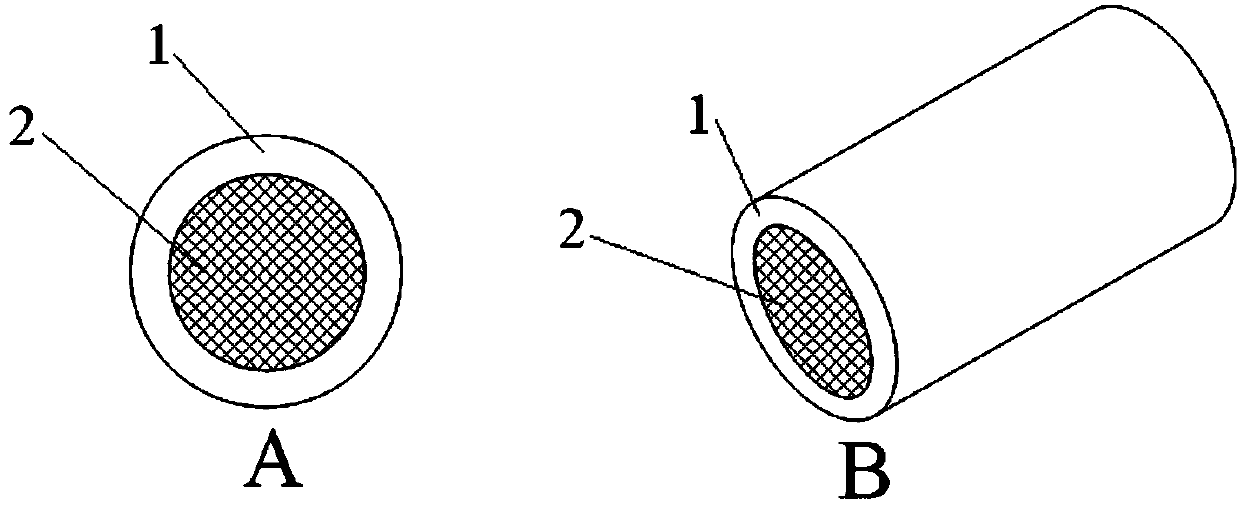

The invention discloses a lithium-supplementing additive as well as a preparation method and application thereof. The lithium-supplementing additive is of a core-shell structure, a core material is aconductive carbon material, a shell material is lithium oxide, lithium oxide is deposited on the surface of the conductive carbon material, and nano-scale lithium oxide particles form a nano-layer shell. According to the lithium-supplementing additive, lithium oxide is composited with the conductive carbon material and is utilized for supplementing lithium, and the conductive carbon material is utilized for conducting electrons, so that the utilization rate of lithium oxide is increased, and lithium can be well supplemented to an positive electrode or a negative electrode. Furthermore, after lithium is removed from the lithium-supplementing additive, the conductive carbon material can be used as an electrode conducting material, and no impurity is introduced. The lithium-supplementing additive is safe, environmentally friendly and non-toxic, and a foundation is laid for the preparation of high-capacity lithium ion batteries.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

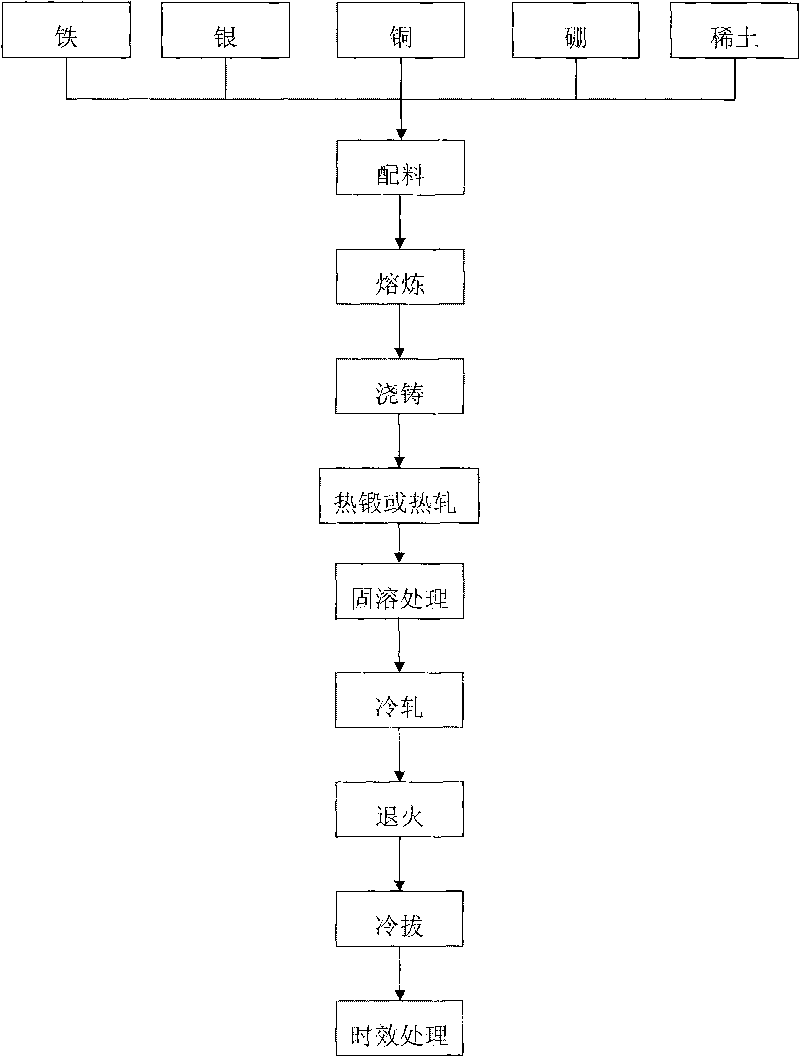

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Silver coating fabric making method

InactiveCN1570211AImprove electrical conductivityImprove flexibilityTextile decorationSuperimposed coating processNitrogen gasMetallic Nickel

A preparation method for silver plated fabric belongs to the field of the vacuum plating and electroplating technology. The preparation process comprises: employing the chemical fabric or the terylen non-woven cloth for the matrix; plating the silver or stainless steel on the matrix by ion plating method under the protection of the nitrogen gas or argon gas; continuously plating nickel, copper or silver on the surface of the matrix by the electroplated plastics technology; flushing, drying, trimming, measuring, cutting, and packing. The silver plated fabric can be continuously produced in high yield and with good quality, low cost and good shielding property.

Owner:夏芝林

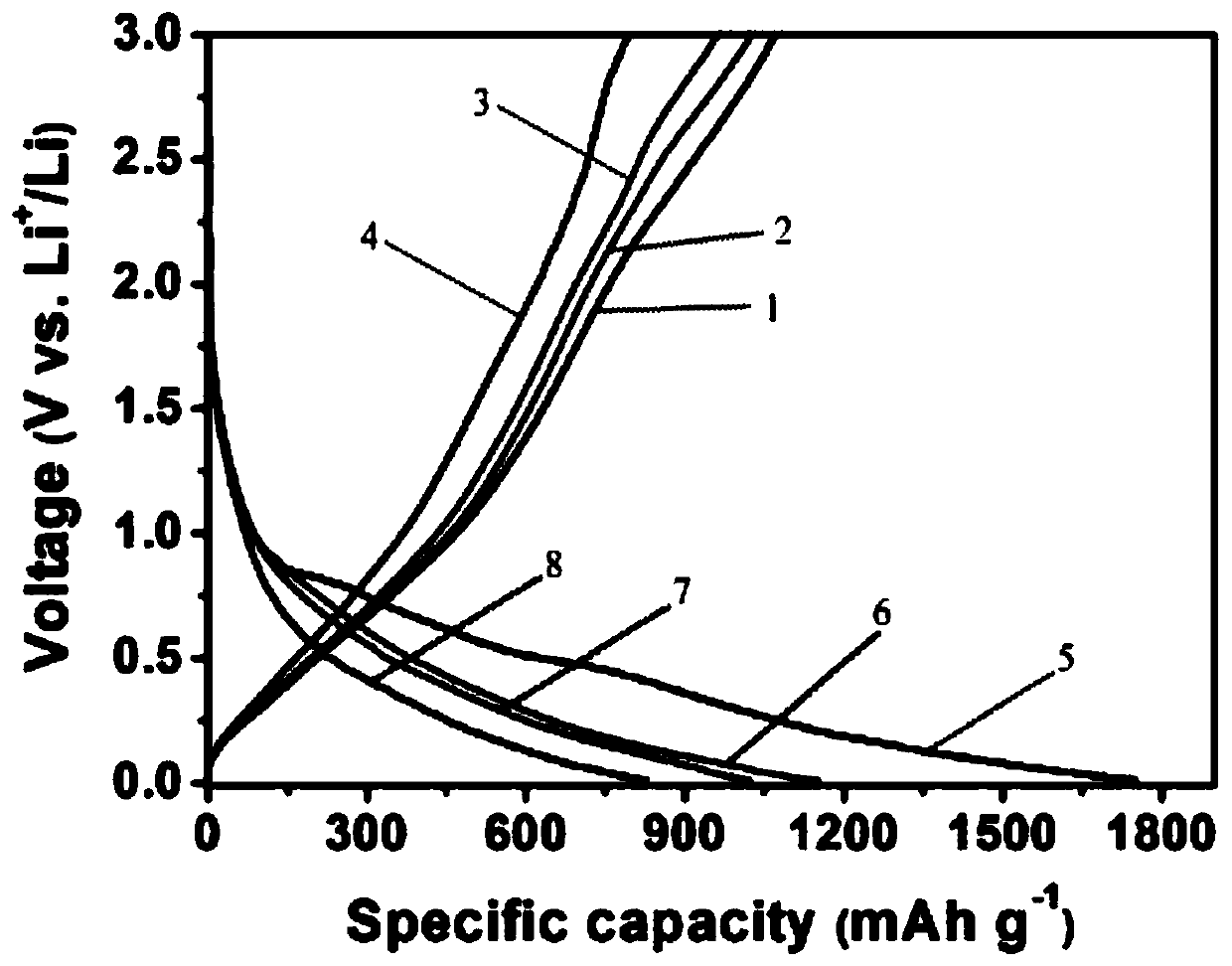

Lithium cell anode active substance, anode dressing and its preparing method

InactiveCN101071859AHigh platform capacityImprove electrical conductivityElectrode manufacturing processesBall millAdhesive

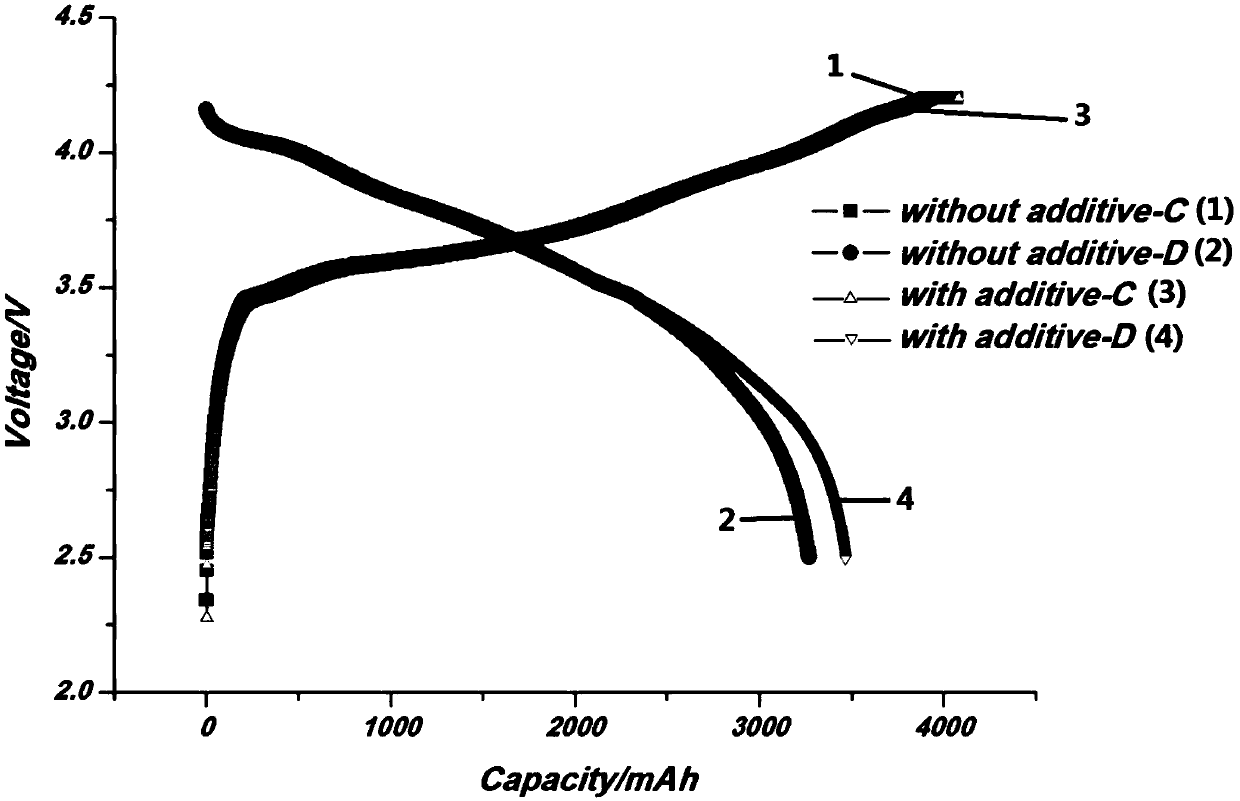

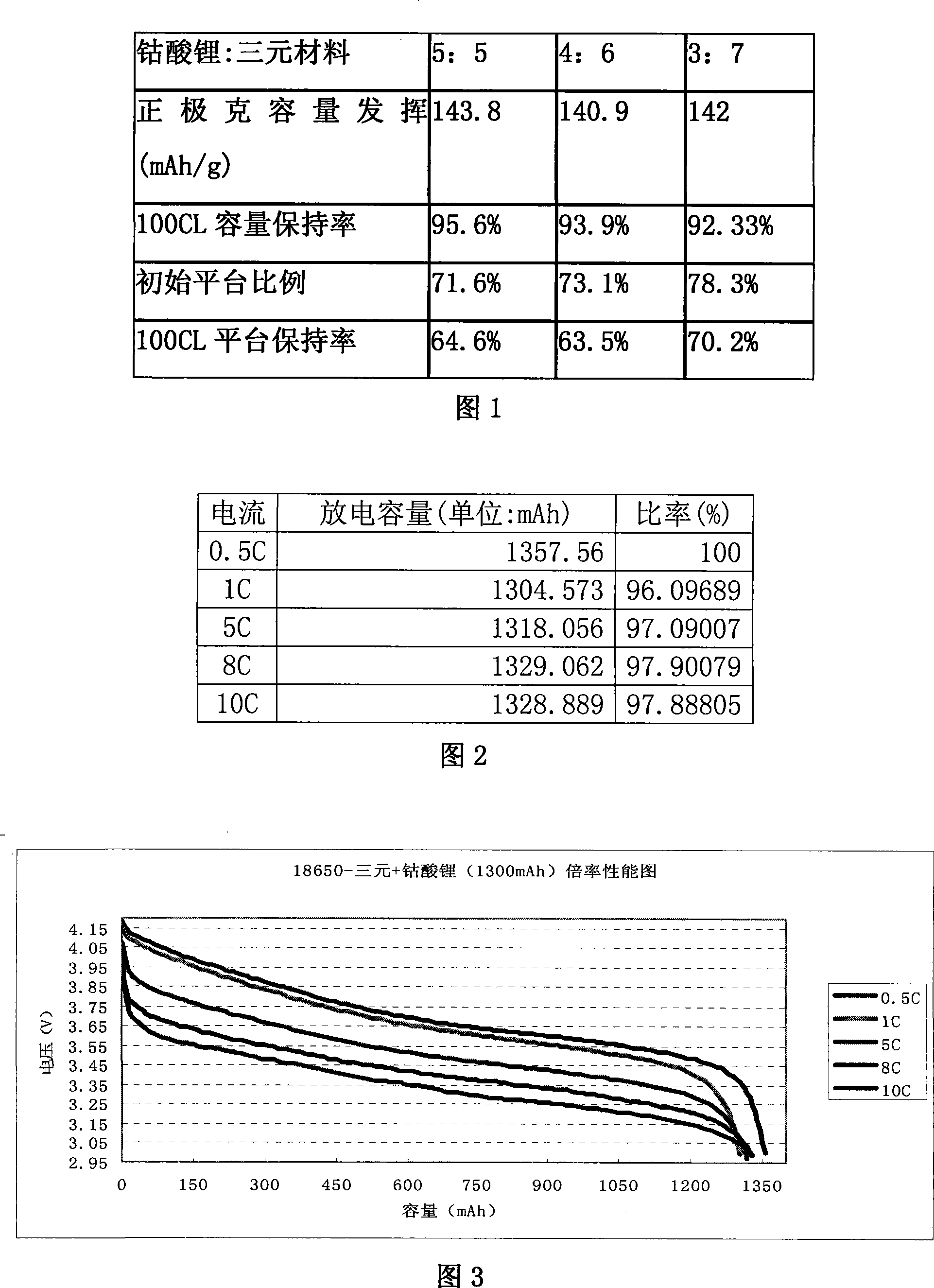

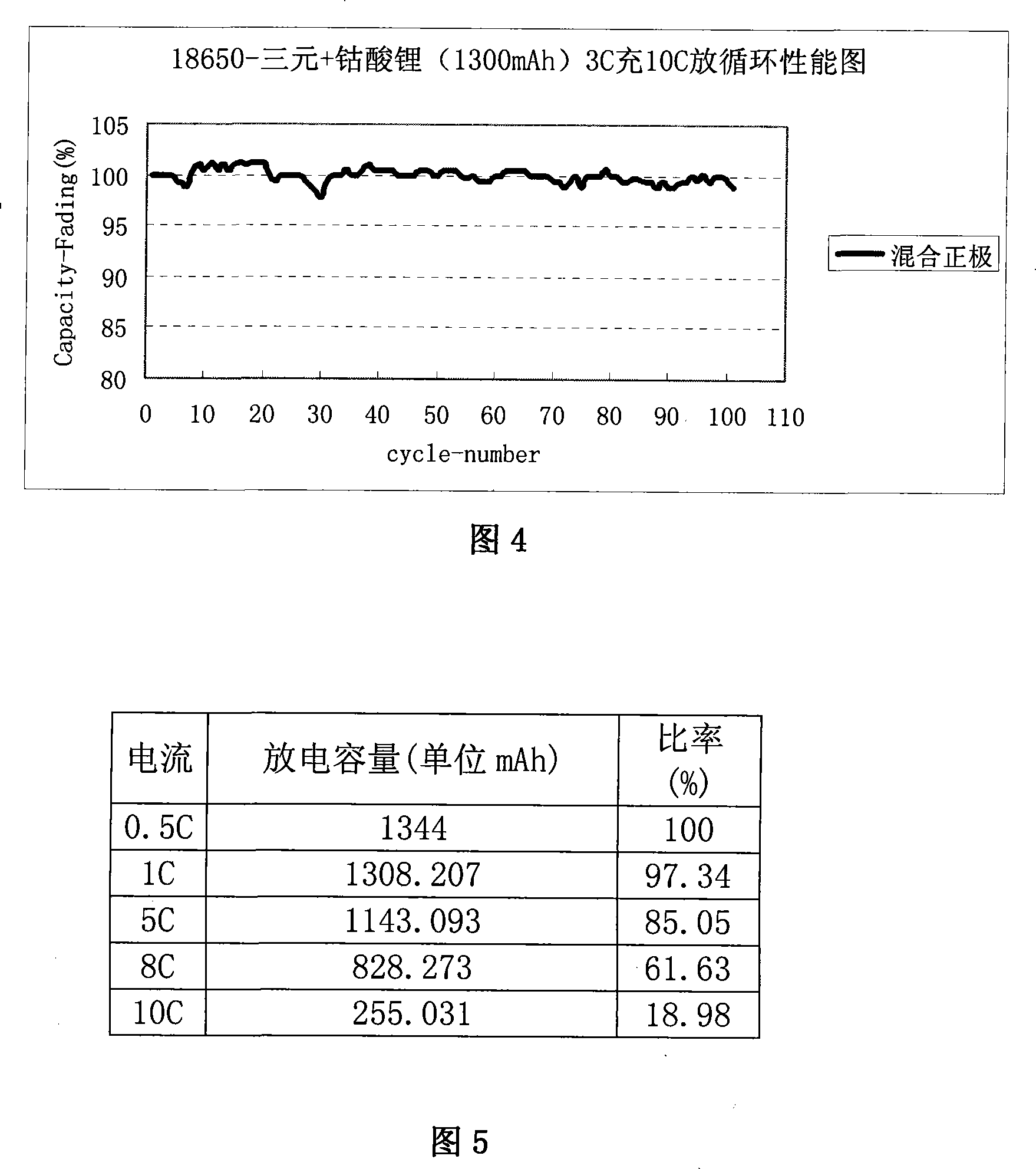

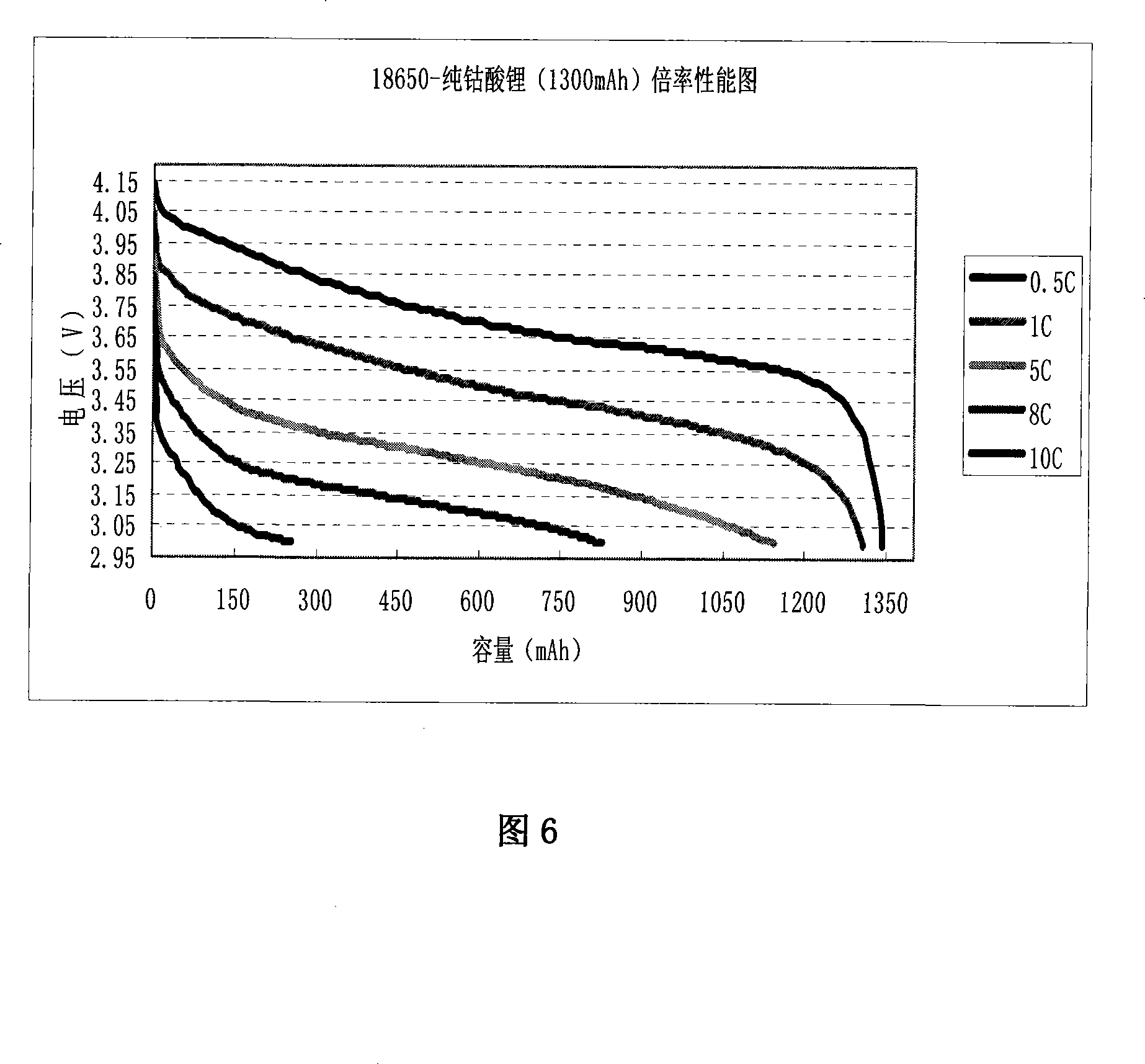

The invention is a lithium battery anode active matter, and anode dressing and the preparing method thereof. And the anode active matter comprises trinary material LiNixCoyMn1-x-yO2 and lithium cobaltate; the anode dressing comprises anode active matter, graphite conductive agent, charcoal black conductive agent, and adhesive; and the preparing method comprises: 1. ball-milling: a. ball-milling the trinary material, lithium cobaltate and graphite conductive agent in proportion; b. after a, adding the charcoal black conductive agent into ball-mill tank in proportion; and blending: a. taking the adhesive in proportion and blending with organic solvent, and when blending until no bubbles, stilling and serving; b. adding mixed material and other additives to colloid and blending thickly; and c. filtering for coating.

Owner:SHENZHEN B&K TECH

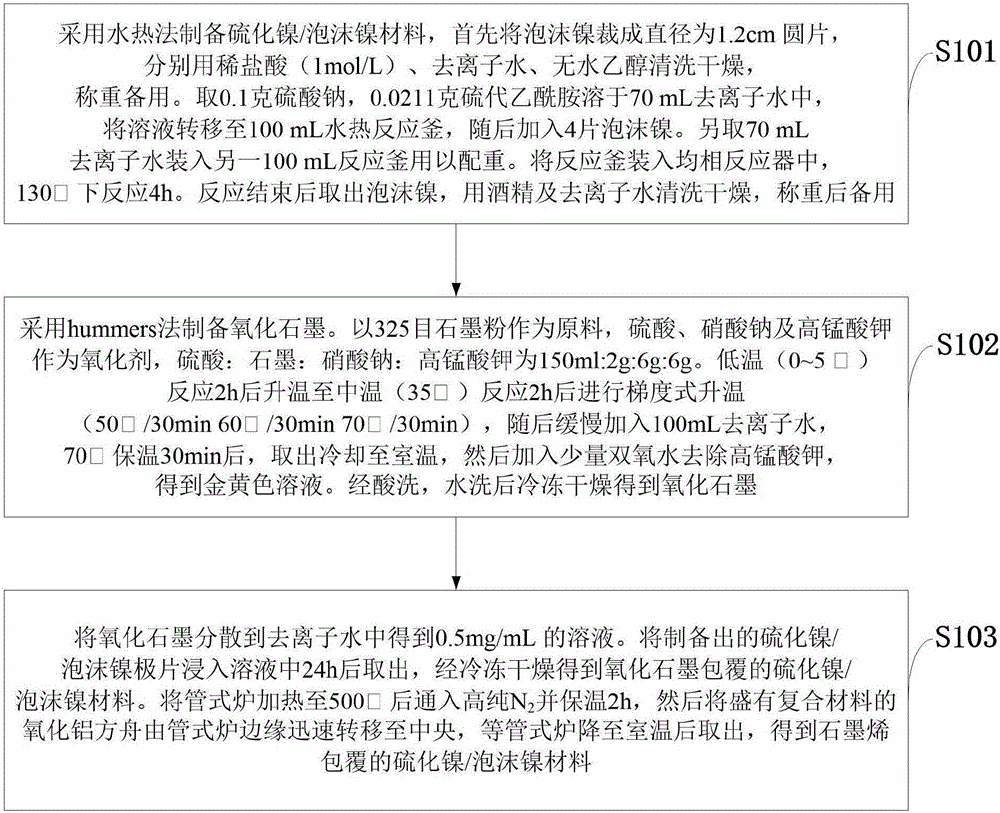

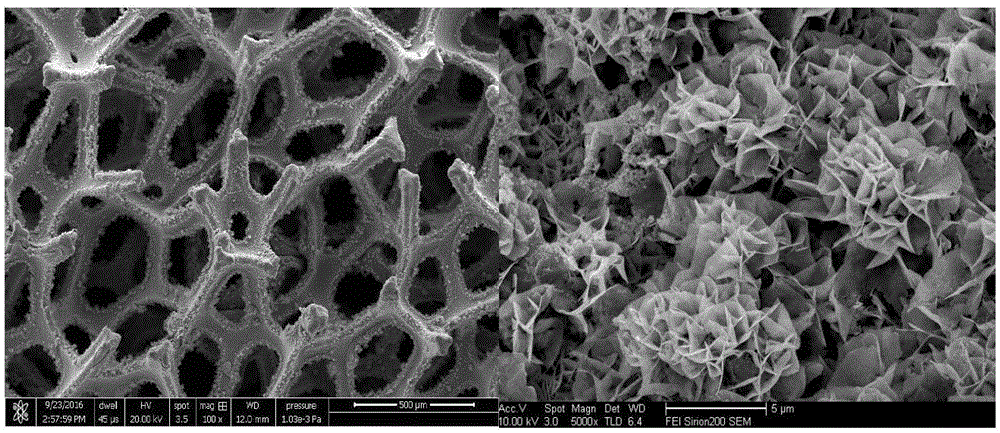

Method for preparing graphene wrapped 3D flowerlike nickel sulfide/foamed nickel material

InactiveCN106784719AAvoid structural collapseImprove electrical conductivityCell electrodesSecondary cellsCvd grapheneStructural stability

The invention discloses a method for preparing a graphene wrapped 3D flowerlike nickel sulfide / foamed nickel material. The method comprises the following steps: preparing a nickel sulfide / foamed nickel composite material by using a hydrothermal method, and performing vulcanization treatment on the surface of the foamed nickel by taking thioacetamide as a sulfur source so as to grow flaky nickel sulfide uniformly on the surface of the foamed nickel; wrapping the surface of the nickel sulfide / foamed nickel with a layer of graphene oxide through physical adsorption; performing thermal expansion and reduction on the adsorbed graphene oxide by using a rapid thermal expansion method, thereby obtaining the graphene wrapped composite material. The method is wide in nickel sulfide material source and simple in preparation process, the lithium extraction and insertion efficiency can be improved, and the electrochemical properties of the material can be improved; the conductivity and the structural stability of the material are improved, and the internal resistance of the material can be reduced; the electric conductivity of the material is improved, and effective pores can be provided for extraction and insertion of lithium ions due to C vacancy generated in the reduction process of the graphene.

Owner:SHANDONG UNIV OF TECH

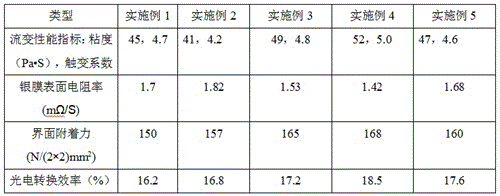

Mixed electrode slurry for crystalline silicon solar cells

InactiveCN105655010AIncrease contact areaImprove electrical conductivityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCarbon nanotubeCrystalline silicon

The invention belongs to a photocell electrode material and discloses a mixed electrode slurry for crystalline silicon solar cells. The mixed electrode slurry is prepared from, by weight, 40-60 parts of silver powder, 5-10 parts of zinc powder, 10-20 parts of silver coated nickel alloy powder, 1-5 parts of a lithium iron phosphate and carbon nanotube composite material, 1-8 parts of glass powder, 0.5-2 parts of a silane coupling agent, 10-15 parts of butyl carbitol acetate, 1-3 parts of zinc naphthenate, 0.1-0.5 part of hydroxymethyl cellulose and 0.25-1 part of hydrogenated castor oil. The invention further discloses a preparation method of the mixed electrode slurry. The mixed electrode slurry prepared by means of the preparation method does not contain lead, completely meets the requirements of environmental protection, is applied to the production of the solar cells and can form a strong attachment force on the surfaces of the solar cells, and the photoelectric conversion efficiency of the cells is high. In addition, the mixed electrode slurry is simple in process and low in cost and thus has a wide application prospect.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

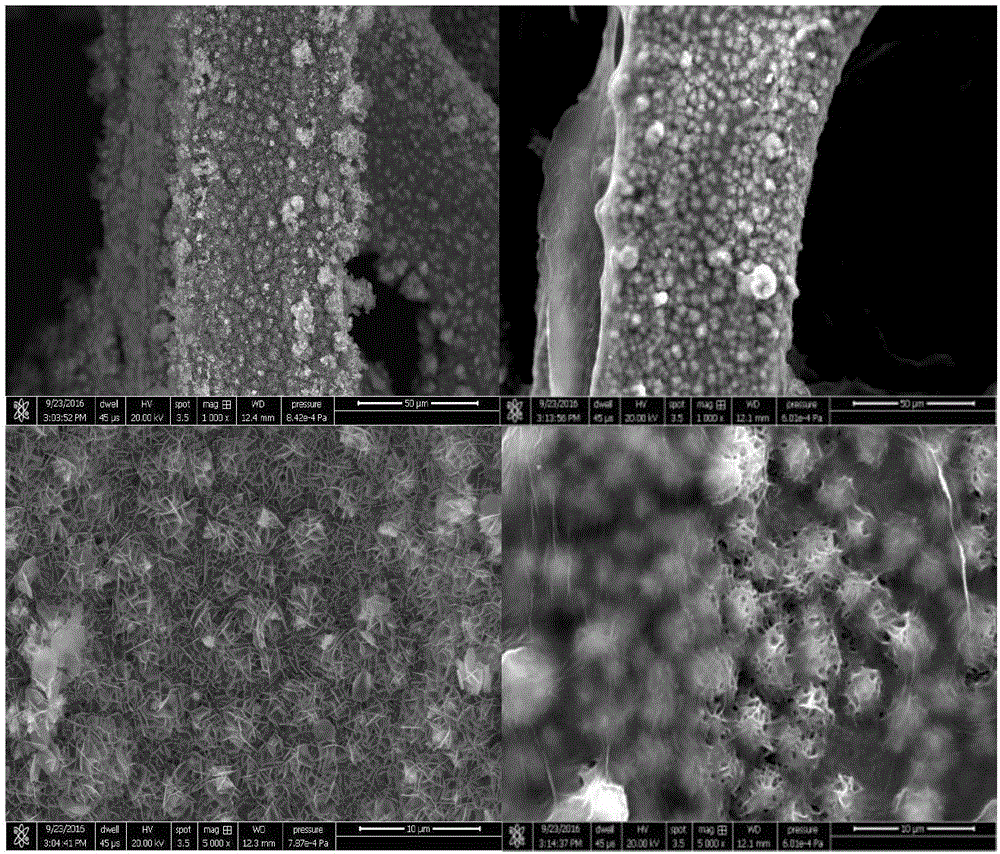

Micrometer silver-copper granule containing nano level surface structure and preparation and application thereof

InactiveCN101214547ALower surface sintering or melting temperatureImprove electrical conductivitySolventNanometre

The invention discloses a micron silver-copper particle with a nanometer-grade surface structure and a preparing method and usage for the particle. The invention takes silver powder, sliver copper clad powder or silver-copper mixed power with micron dimensions as a carrying stroma; firstly disperses the silver powder, the sliver copper clad powder or the silver-copper mixed power body into a solvent, then uses a reducing compound to reduce silver salt into nanometer silver power and precipitate on the surface of the carrying stroma; and finally filters and dries to acquire the micron silver-copper particle with a nanometer-grade surface structure which can be used as fillings for preparing an electromagnetic shielding paint or an conductive adhesive. The invention utilizes a principle of chemical reducing to change the surface topography layout of the sliver-copper particle with nanometer-grade to lead the silver-copper particle to contain a nanometer-grade surface structure, thus reducing the surface sintering or melting temperature and improving the overall conductive performance.

Owner:李伟强

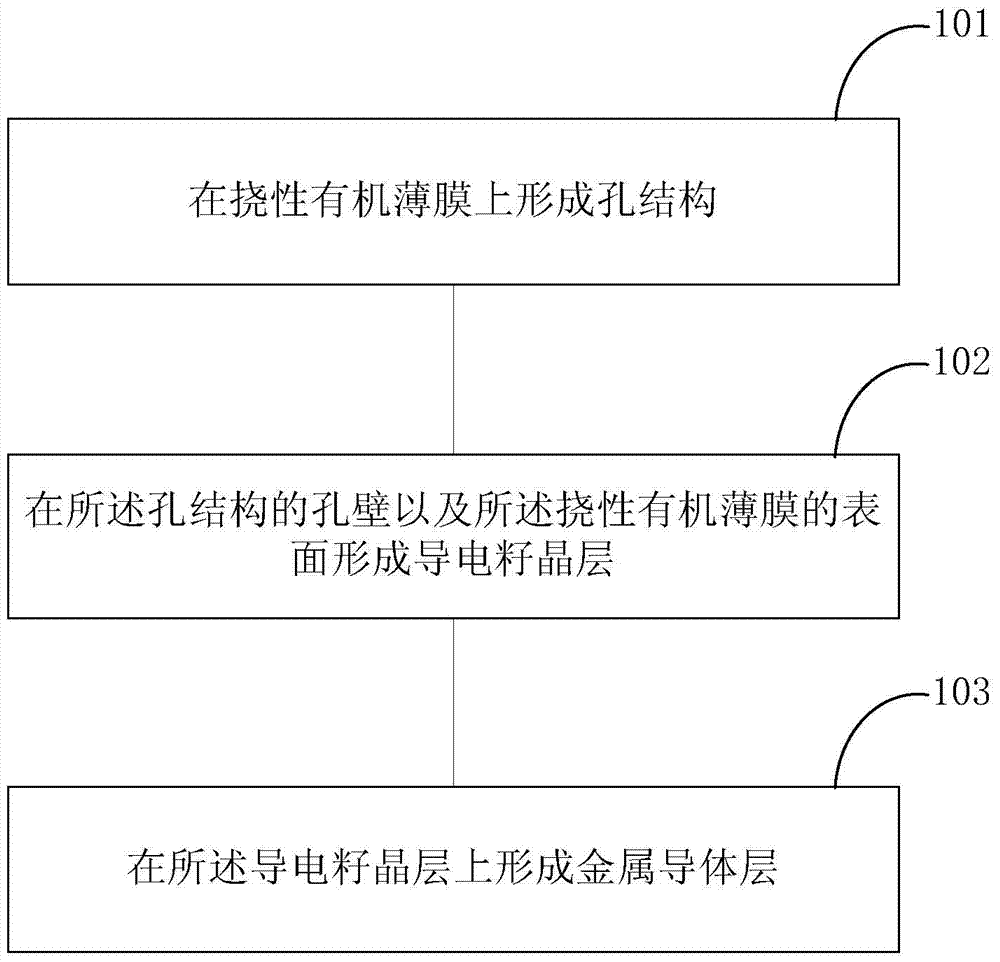

Method for manufacturing flexible copper-clad plate with metalized through hole

InactiveCN104219899ASimple processImprove electrical conductivityPrinted element electric connection formationSeed crystalEngineering

The invention discloses a method for manufacturing a flexible copper-clad plate with a metalized through hole. The method comprises the following steps of forming a hole structure on a flexible organic film; forming conductive seed crystal layers on the wall of the hole structure and the surface of the flexible organic film; and forming metal conductor layers on the conductive seed crystal layers. By the method, the working procedure for manufacturing the flexible copper-clad plate with the metalized through hole can be simplified, and the conductive performance of the metalized through hole in the flexible copper-clad plate is improved.

Owner:RICHVIEW ELECTRONICS CO LTD

Graphene-carbon black composite conductive coating, preparation method and application thereof

ActiveCN105820634AIncrease the number ofImprove electrical conductivityElectrically-conductive paintsCvd grapheneChemistry

The invention discloses a graphene-carbon black composite conductive coating, a preparation method and an application thereof. The graphene-carbon black composite conductive coating prepared by a solution blending method contains a graphene-carbon black dispersion solution, first aqueous resin and a first dispersant, by taking 100 weight parts of the first aqueous resin as a reference, the content of the graphene-carbon black dispersion solution is 80-350 weight parts, and the content of the first dispersant is 3-10 weight parts. The conductive coating can be used for electric heating, electromagnetic shielding, printed electronic circuits, membrane switches and lithium batteries. According to the invention, conductivity of the conductive coating is increased; the carbon black and the resin have good compatibility, mechanical properties are increased, cost is low, and the aqueous resin is environmentally friendly and pollution-free, and provides theoretical basis and practical base for practical application of the conductive coating.

Owner:MATERIAL & IND TECH RES INST BEIJING

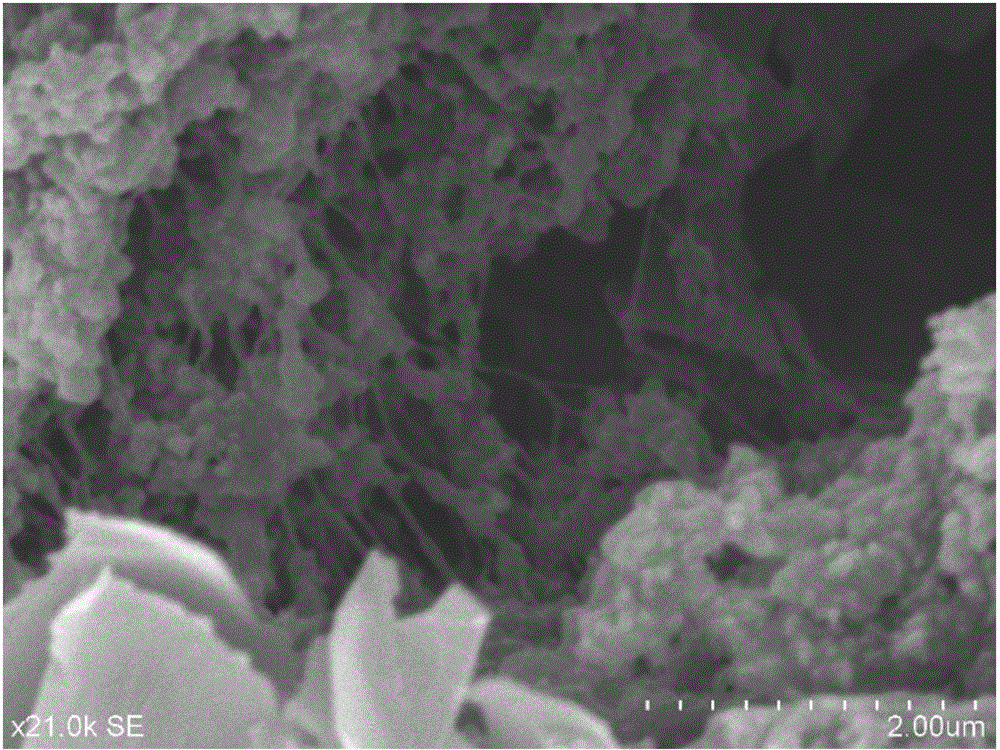

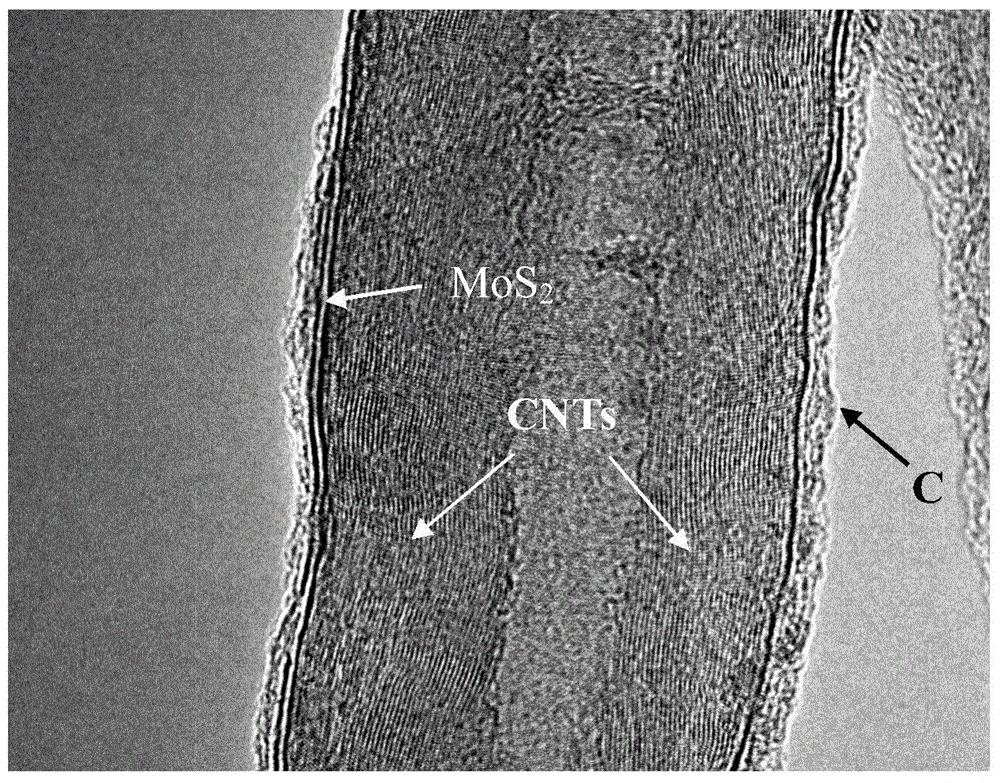

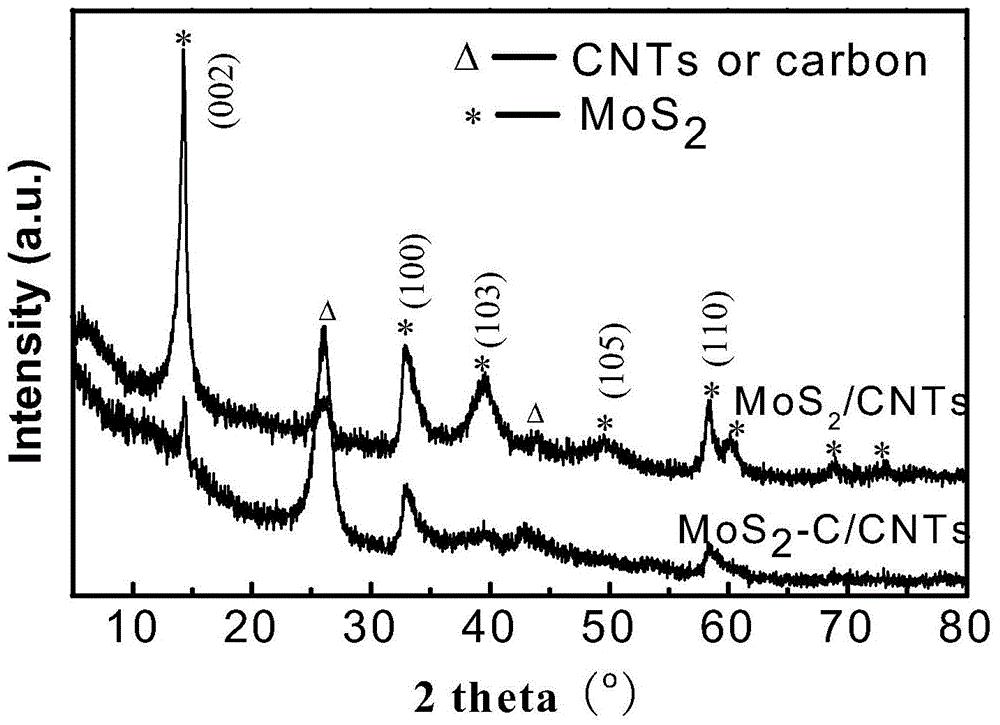

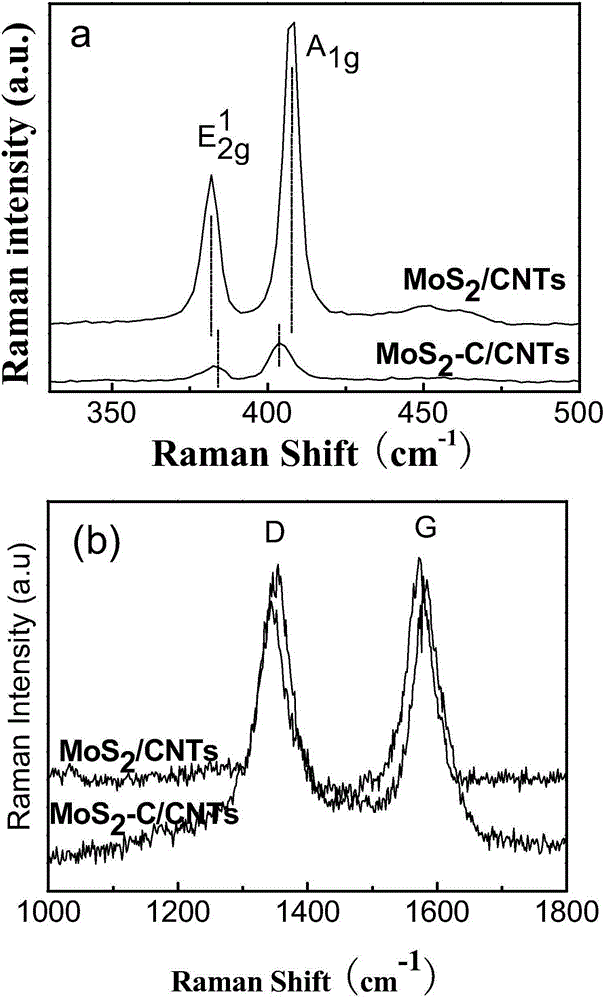

Composite nanotube composed of molybdenum disulfide-carbon-carbon nanotube and preparation method thereof

ActiveCN103553134AImprove dispersionImprove electrical conductivityMaterial nanotechnologyCarbon compoundsAmorphous carbonMolybdenum disulfide

The invention discloses a composite nanotube composed of a molybdenum disulfide-carbon-carbon nanotube and a preparation method thereof. The method comprises the following steps: firstly, orderly dissolving ammonium tetrathiomolybdate and a carbon high-molecular polymer with surface activity into water; then adding a multiwalled carbon nanotube; centrifuging, drying and burning after carrying out ultrasonic dispersing, so as to prepare MoS2-C / CNTs. By using the surface activity of a carbon high-molecular polymer, the molybdenum disulfide is more evenly dispersed on the surface of the carbon nanotube; on the other hand, the conductivity of a compound is improved through the compound of amorphous carbon and molybdenum disulfide left on the surface of the carbon nanotube when a mixture is burnt at high temperature.

Owner:HEFEI UNIV OF TECH

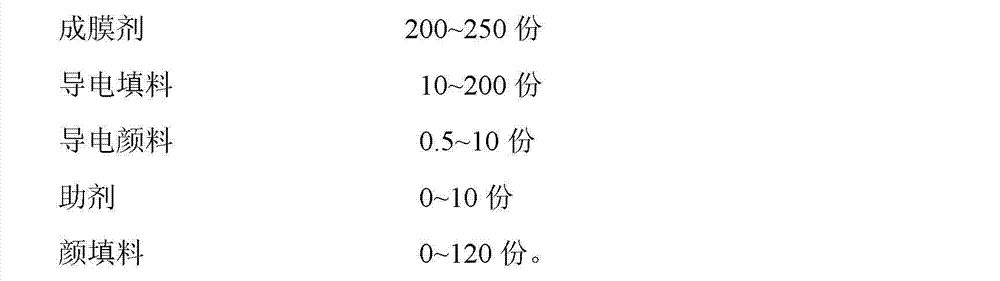

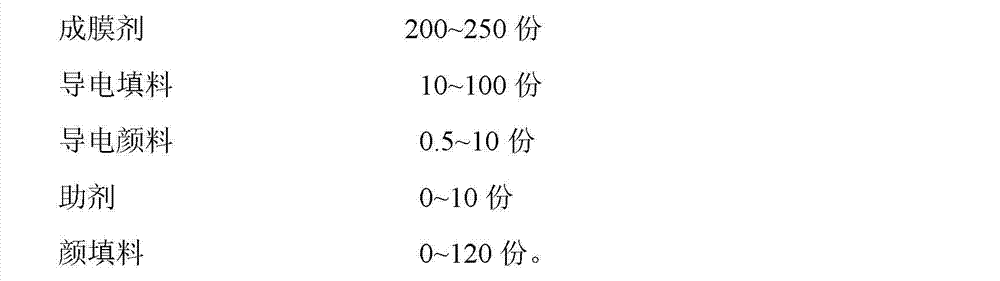

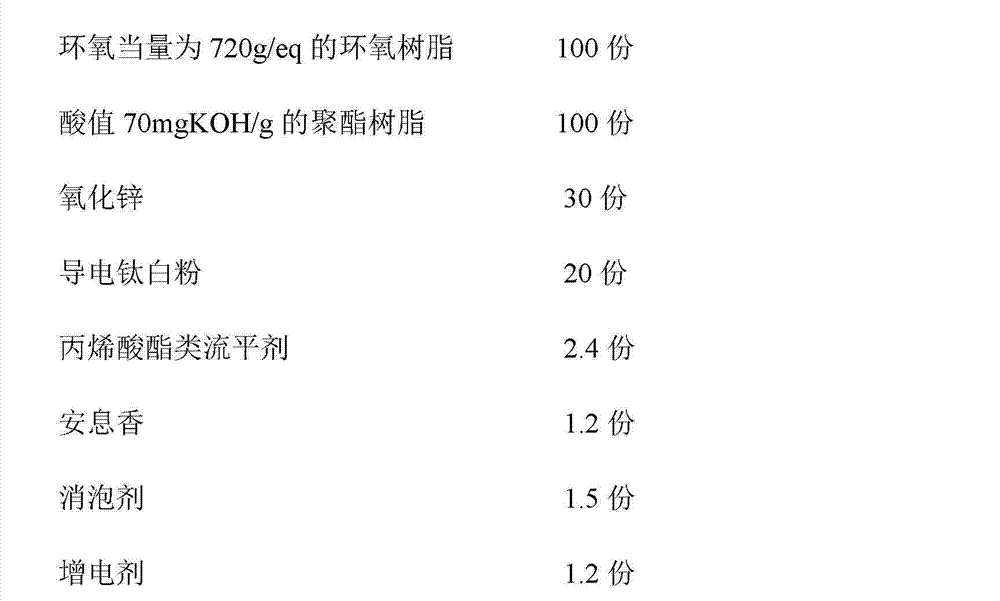

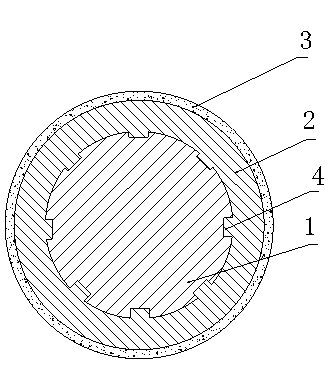

Low-temperature curing powder coating for coating medium-density fiber board and preparation method for coating

InactiveCN102898923AImprove electrical conductivityImprove powder feeding efficiencyPowdery paintsEpoxy resin coatingsMedium density fiberboardFiber

The invention discloses a low-temperature curing powder coating for coating a medium-density fiber board. The coating comprises 200 to 400 parts of conventional medium-density fiber board powder coating, 10 to 200 parts of conductive filler, and conductive pigment. The invention also discloses a preparation method for the powder coating. The powder coating for electrostatic coating can effectively overcome the defect that the conventional medium-density fiber board powder coating for electrostatic coating of the medium-density fiber board is difficult to coat.

Owner:CHINA NAT ELECTRIC APP RES INST +1

Copper-clad aluminum conductor

InactiveCN103021502AImprove electrical conductivityWide range of usesMetal/alloy conductorsCarbon-silicon compound conductorsJoint surfaceAluminium

The invention relates to a copper-clad aluminum conductor which comprises an aluminum core. The copper-clad aluminum conductor is characterized in that a copper cladding layer is arranged outside the aluminum core, and a graphite film layer is arranged outside the copper cladding layer. The section of the aluminum core is round or rectangular. The copper cladding layer is made from 99.97% pure refined copper. Joint surfaces of the aluminum core and the copper cladding layer are provided with grooves and ridges. The graphite film layer is made by chemical vapor deposition. The copper-clad aluminum conductor has the advantages that the lightweight aluminum and the high-conductivity graphene enable the copper-clad aluminum conductor to be light in weight and high in current carrying capacity, and accordingly the copper-clad aluminum conductor is more widely applicable.

Owner:SHANDONG XINHUI COPPER MATERIAL

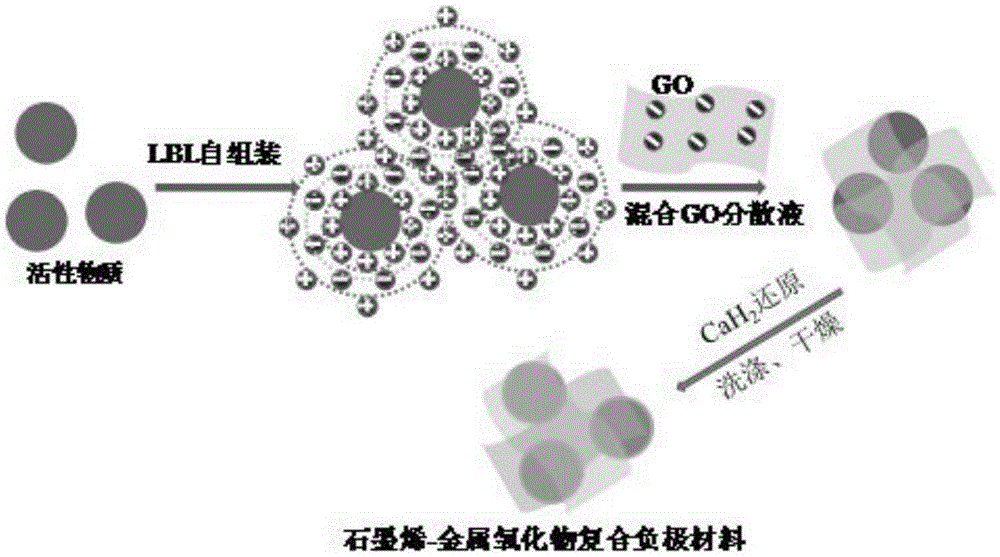

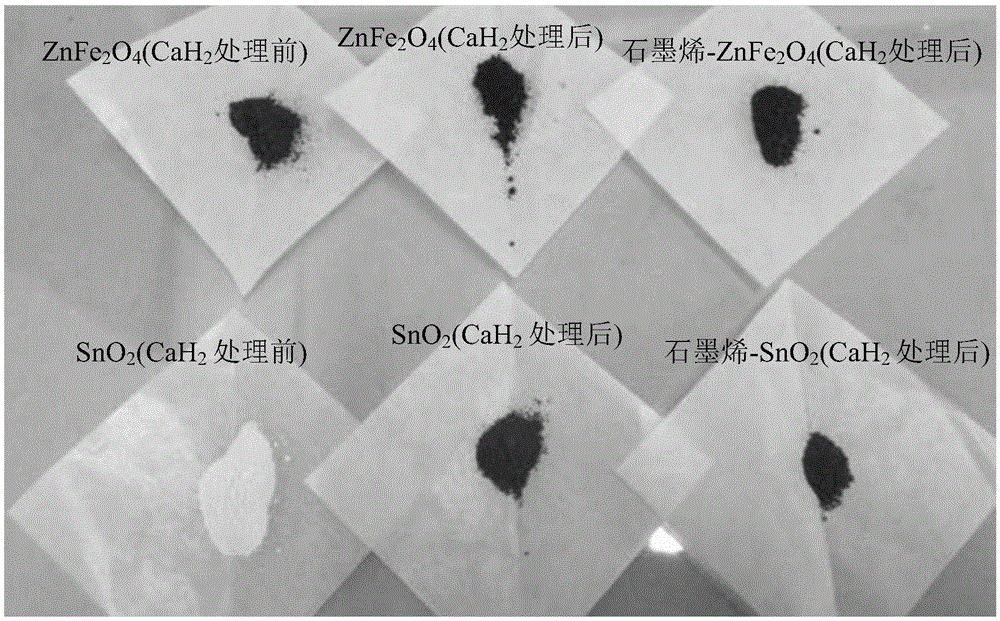

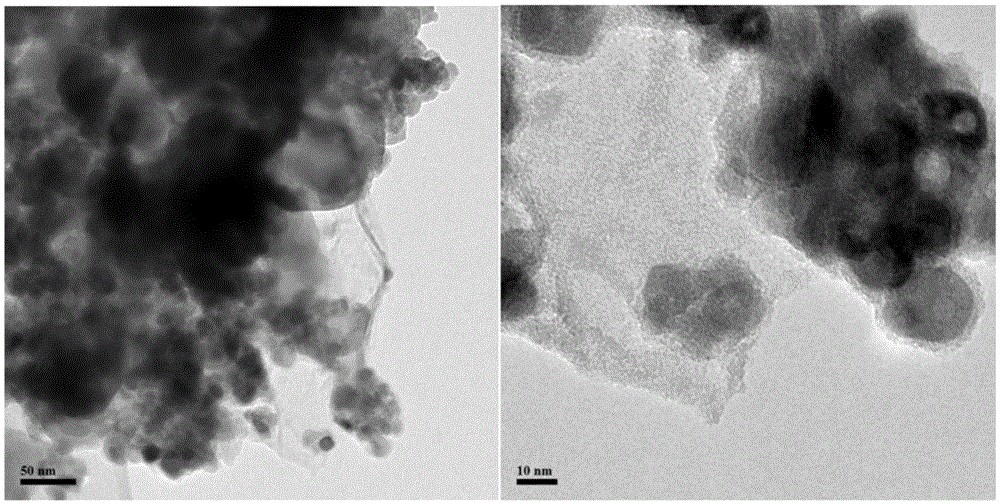

Graphene-metal oxide composite negative electrode material and preparation method therefor

ActiveCN105355877AImprove electrical conductivityGood electrical conductivityCell electrodesSecondary cellsOxygen deficiencyCvd graphene

The invention discloses a graphene-metal oxide composite negative electrode material and a preparation method therefor. The composite negative electrode material is mainly prepared from graphene and metal oxides. Graphene is employed as a three-dimensional network skeleton, metal oxides modified through layer-layer self assembly are employed as active substances, and a composite negative electrode material with oxygen deficiency is prepared. Compared with the prior art, the material can be prepared in conditions that the time is 3-10h and the temperature is 350-450 DEG C. The conductivity of the active substances is improved obviously, oxygen vacancy of the metal oxides can be increased greatly, and therefore the cycle performance of the composite material is improved greatly. In addition, the technology is simple, the repeatability is good, the cost is low, and the composite negative electrode material has a good large-scale application potential.

Owner:中炬高新材料股份有限公司

Transparent conducting film

InactiveCN104347155AImprove electrical conductivityImprove conductivityConductive layers on insulating-supportsCable/conductor manufacturePhysicsElectrically conductive

The invention provides a transparent conducting film, which comprises a substrate, a first conducting layer and a first lead electrode, wherein an inducing area and a lead area which is positioned on the edge of the inducing area are arranged on one surface of the substrate; the first conducting layer comprises grid-shaped first conducting patterns, the first conducting patterns are configured at the inducing area and the lead area and are mutually connected, and the first conducting patterns are formed by conducting wires; the first lead electrode is configured at the lead area, and the first lead electrode is electrically connected with the first conducting layer; the width of the conducting wires of the first conducting patterns which are positioned at the inducing area is smaller than that of the conducting wires of the first conducting patterns which are positioned at the lead area. According to the transparent conducting film provided by the invention, the width of the grid lines at the inducing area, i.e. a visual area is smaller than that of the grid lines at the lead area, i.e. a non-visual area; thus, when the first lead electrode is connected with the grid lines of the non-visual area, the conducting performance is greatly enhanced.

Owner:NANCHANG O FILM TECH CO LTD +2

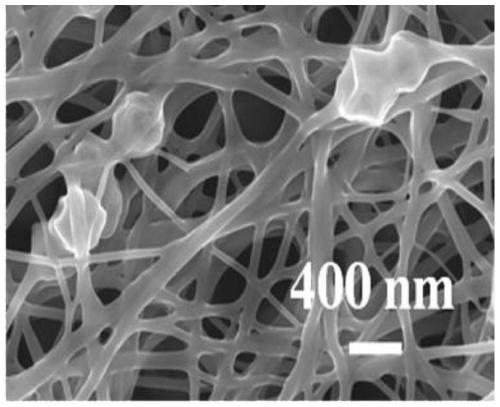

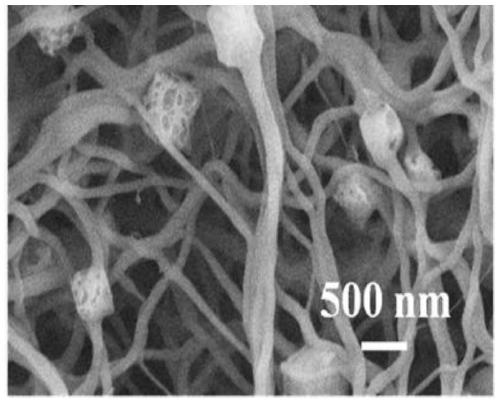

Preparation method of carbon nanofiber electrode material based on MOFs derived metal oxide

PendingCN111081995AHigh reversible specific capacityImprove electrical conductivitySecondary cellsNegative electrodesElectro conductivityLithium electrode

The invention discloses a preparation method of a carbon nanofiber electrode material based on an MOFs derived metal oxide, and belongs to the technical field of lithium ion battery negative electrodematerials. According to the preparation method, an N-N dimethylformamide solution formed by mixing MOFs particles and polyacrylonitrile fibers is adopted as a spinning precursor. The MOFs are connected to the polyacrylonitrile fibers in series through electrostatic spinning, so that a precursor film can be obtained; the MOFs derived metal oxide and carbon nanofiber composite material is preparedthrough subsequent pre-oxidation and carbonization treatment. The MOFs-derived metal oxide can maintain the unique frame structure of the precursor MOF material to be used as a lithium ion memory; thecarbon nanofibers can promote the rapid transfer of electrons so as to improve the conductivity of the electrode material; the metal organic framework (MOFs) derived material (metal oxide) with a unique structure is embedded into the carbon nanofibers, so that a three-dimensional conductive network structure can be formed; and used as a lithium ion battery negative electrode material, the three-dimensional conductive network structure shows relatively high reversible specific capacity and excellent cycle performance.

Owner:NORTHEASTERN UNIV

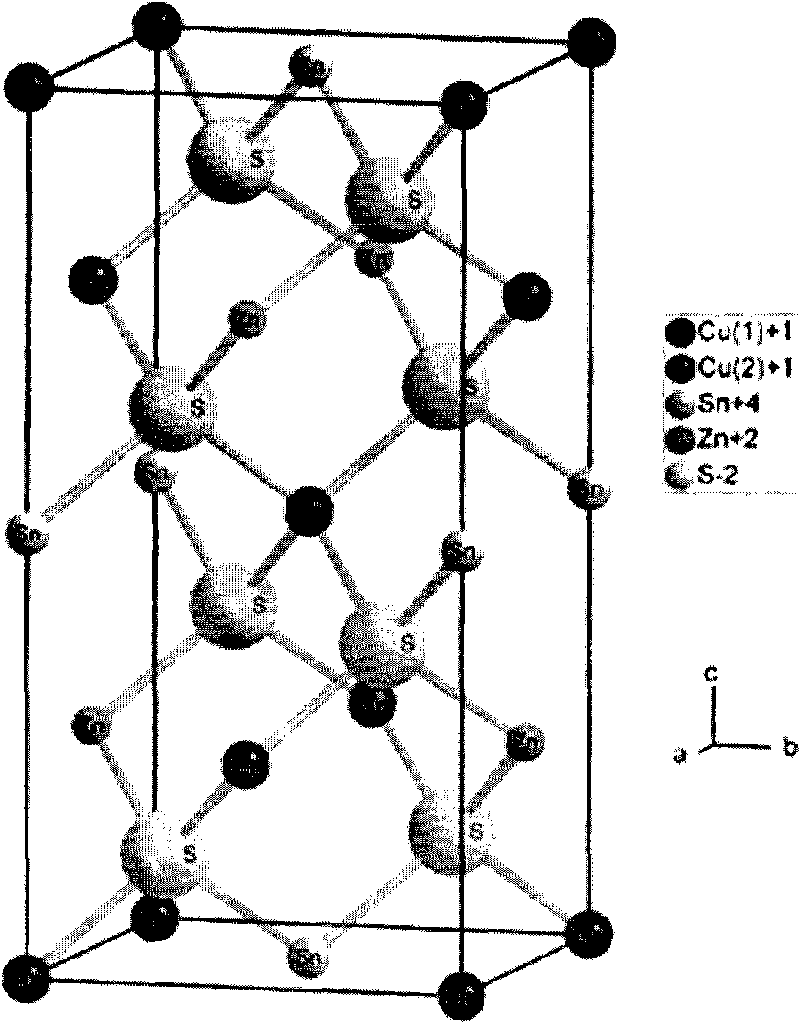

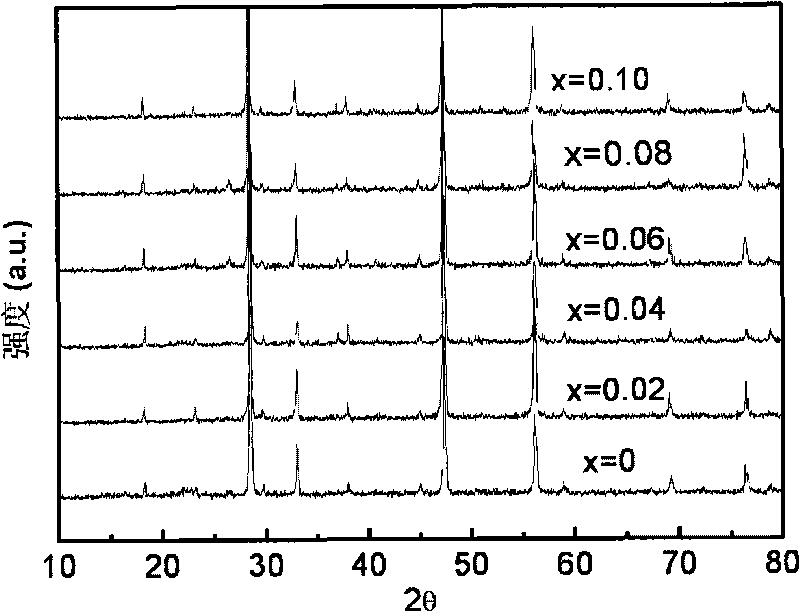

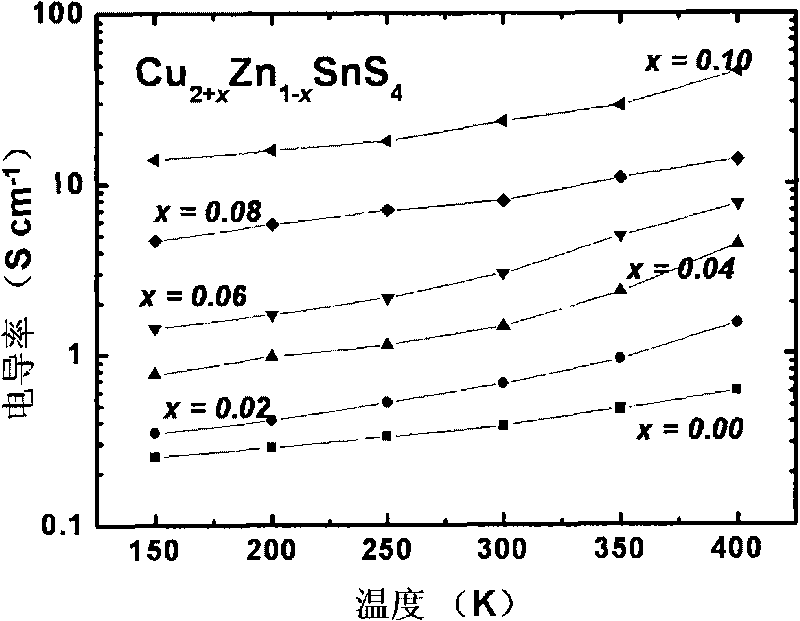

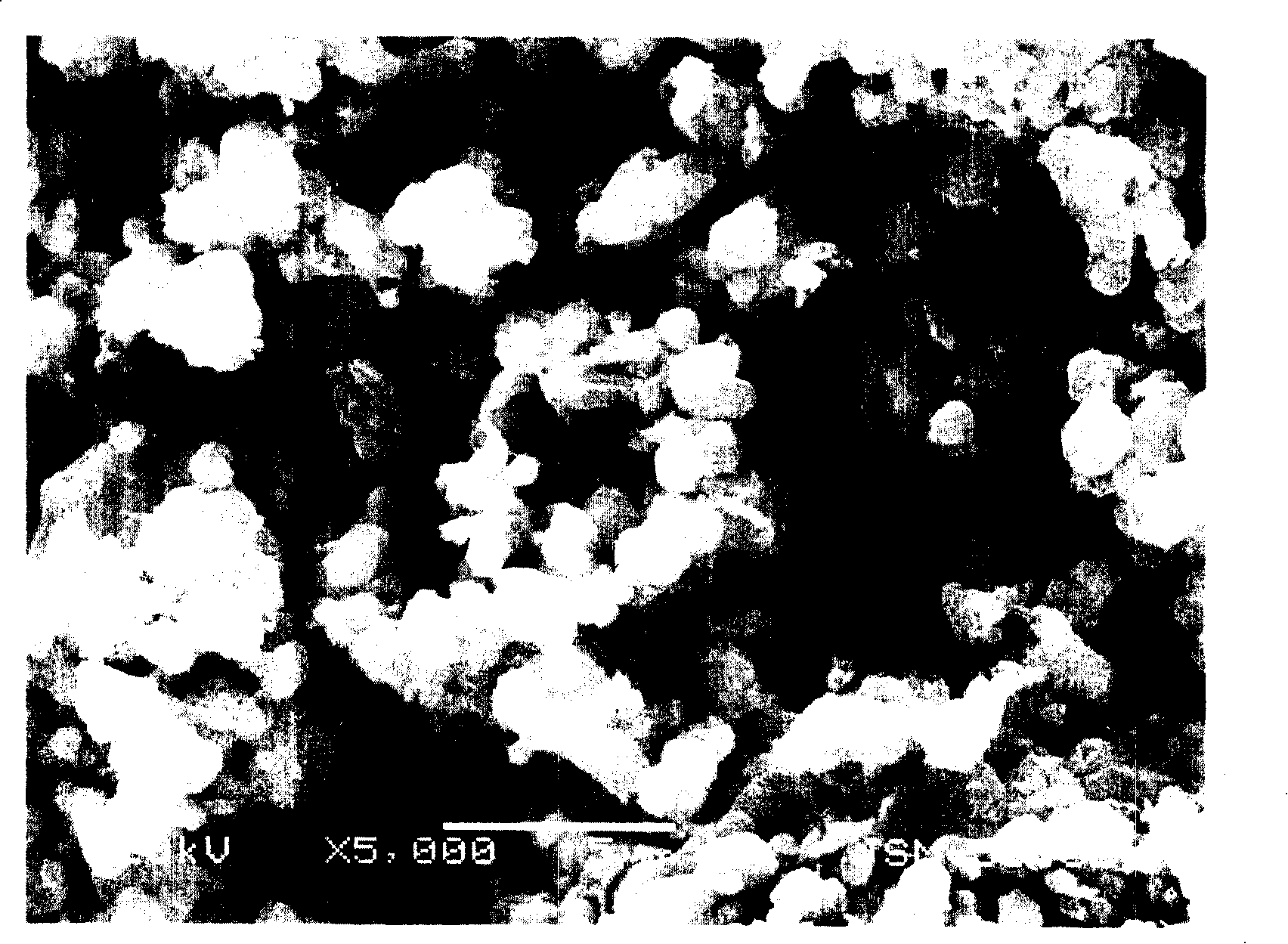

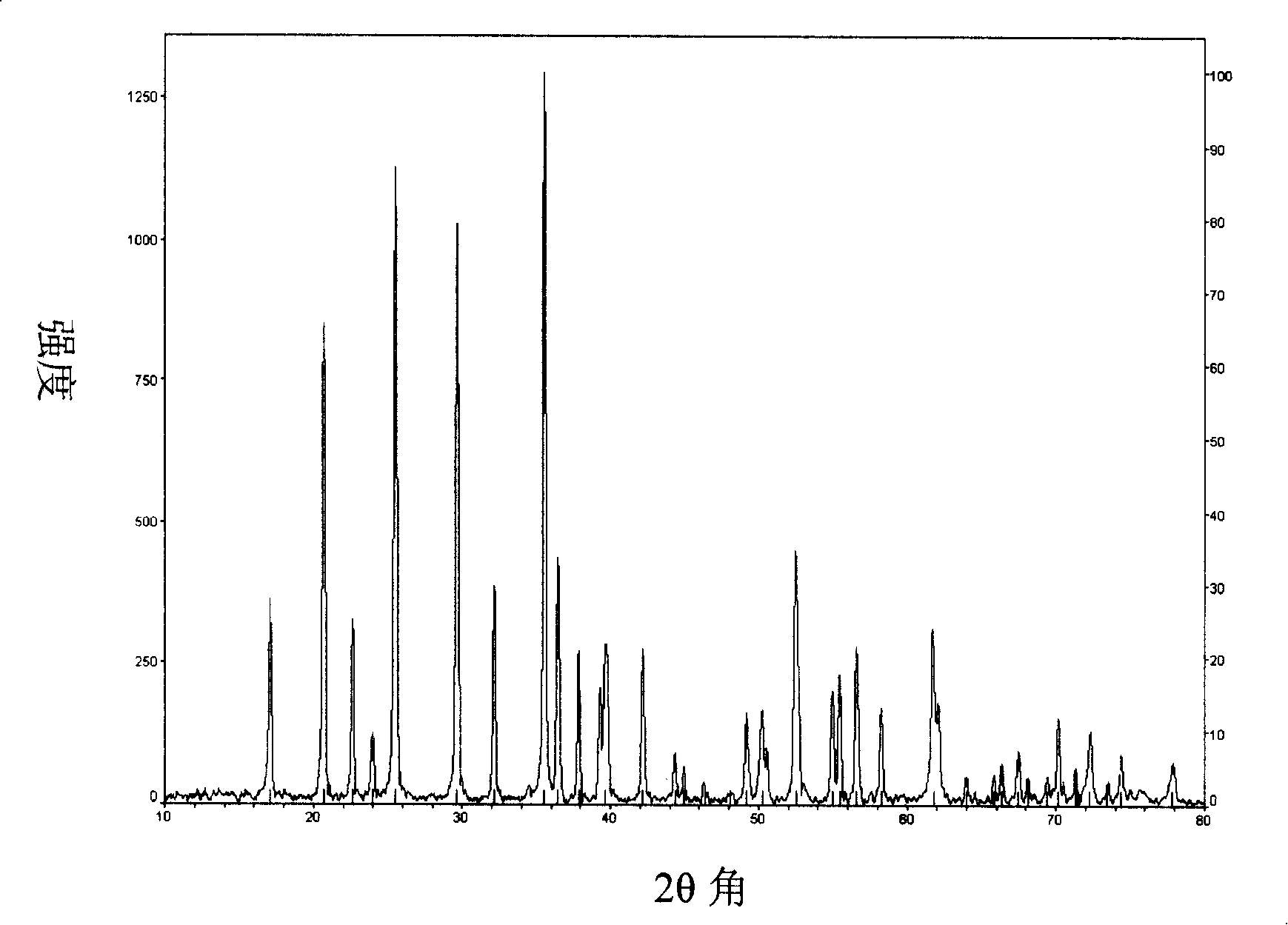

Compound capable of being used for thermoelectric material and preparation method thereof

InactiveCN101723669AImprove mobilityImprove electrical conductivityThermoelectric device junction materialsIonChemistry

The invention relates to a compound (A2BCQ4) capable of being used for a thermoelectric material and a preparation method thereof, wherein A is Cu, Ag or Au; B is any one of the divalent ions such as Zn, Cd, Hg, Fe, Ni, Pd and the like, or any one of the trivalent ions such as B, Al, Ga, In and the like; C is any one of the tetravalent ions such as Si, Ge, Sn, Pb and the like or any one of the trivalent ions such as B, Al, Ga, In and the like; and Q is S, Se and Te, or N, P, As and Sb. Properly speaking, the A2BCQ4 belongs to a tetragonal system, has a deformed blende superlattice structure and is similar to chalcopyrite (CuFeS2), and only half of Fe positions is occupied by B while the other half is occupied by C. The unique structure of the compound determines that the material of the type has considerable thermoelectric properties. The compound provided by the invention can be used for the thermoelectric material, has a unique design idea, low-price and readily available raw materials, and a simple preparation process, and the material has superior electric conductivity and superior thermoelectric properties and is a perfect novel thermoelectric candidate material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

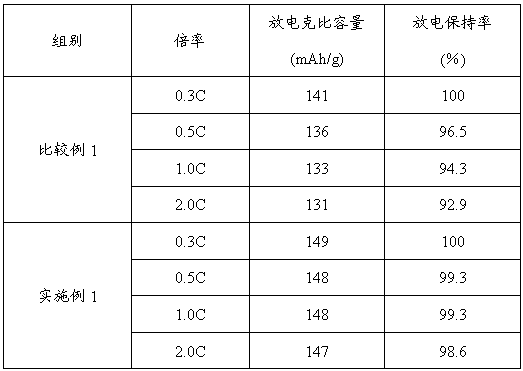

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

ActiveCN101209827AImprove conductivityImprove electrical conductivityCell electrodesPhosphorus compoundsLithium compoundAnode

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered and cooled to get a sintering product; wherein, the sintering method comprises the step: the mixture that contains lithium compound, iron compound, phosphorus compound and partial carbon source additive is sintered at a first constant sintering temperature, then a mixture of the product acquired at the first sintering temperature and the residual carbon source additive is sintered at a second constant sintering temperature, and the second sintering temperature is at least 100 DEG C higher than the first sintering temperature. The batteries made of the lithium iron phosphate prepared by the method of the invention have markedly improved discharge performance at high current.

Owner:BYD CO LTD

Carbon-based material/polymer composite material and preparation method thereof

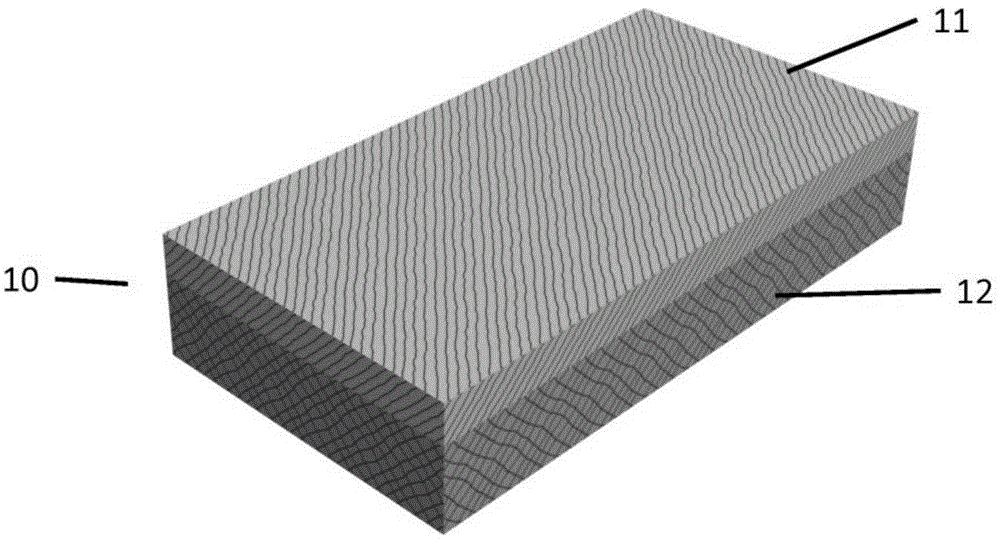

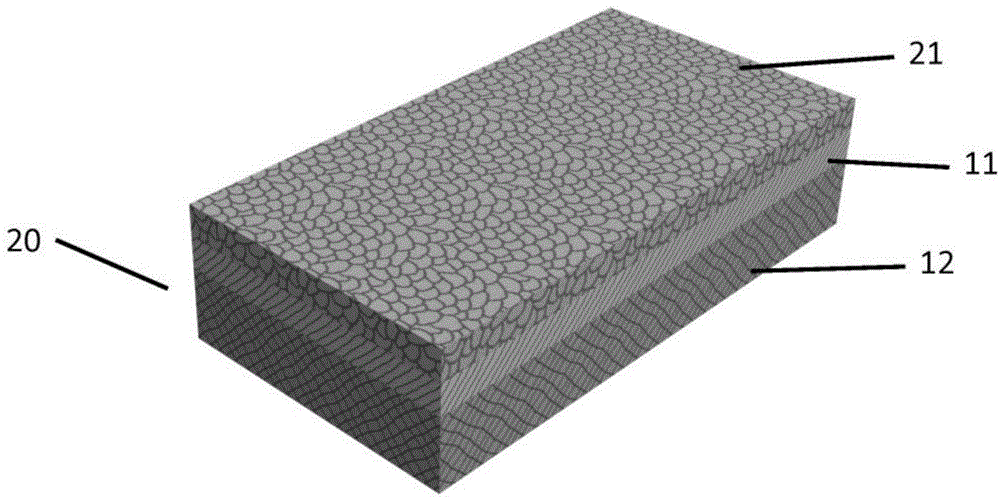

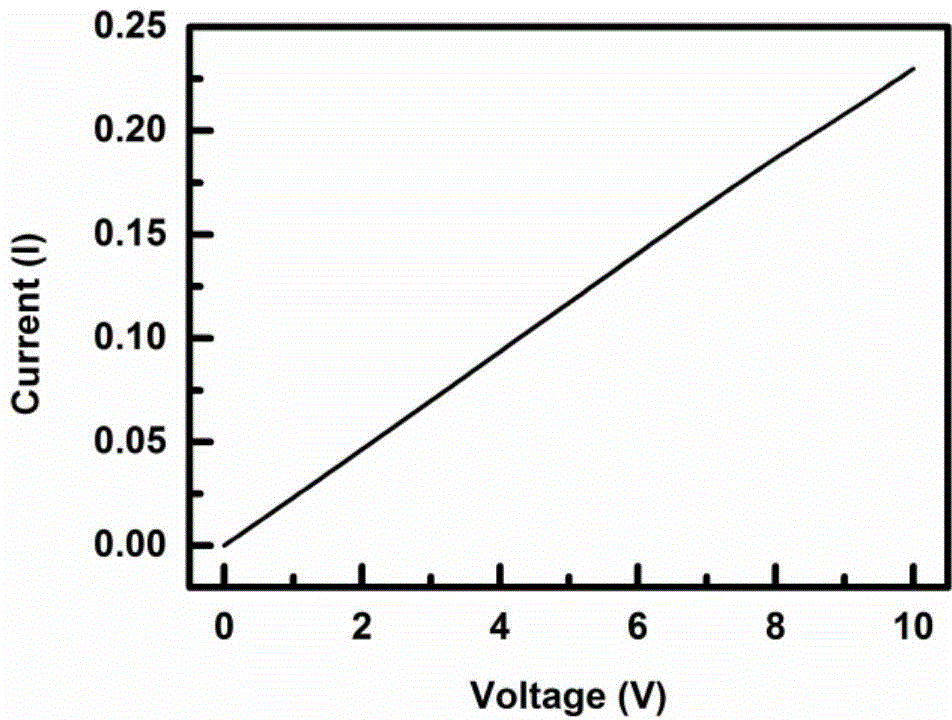

ActiveCN104924701AImprove conductivityImprove electrical conductivitySynthetic resin layered productsRubber layered productsElectrically conductivePolymer composites

The invention discloses a carbon-based material / polymer composite material and a preparation method thereof. The carbon-based material / polymer composite material comprises at least one flexible polymer layer and at least one conducting layer, wherein the conducting layer is arranged on the flexible polymer layer in a staggered layer mode, and the conducting layer is a carbon-based material / polymer composite material layer or a carbon-based material / polymer composite material layer and an organic conducting polymer layer, the carbon-based material / polymer composite material has good electrical conductivity, in addition, polymer materials are tightly filled between the carbon-based materials, therefore, the connection between the carbon-based materials is stable, the connection between the conducting layer and the polymer material layer is firm and better in the mechanical property, and the carbon-based material / polymer composite material is good in flexibility and capable of being used as a flexible electrode of accumulators such as a capacitor.

Owner:FUJIAN NORMAL UNIV

Method for preparing composite Cu-Fe-Ag nano material at original position with high intensity and high conductance

A method of preparing high intensity and high conducting in-situ nano-composite: Cu-Fe-Ag. The steps: (1) Prepare Cu-Fe-Ag by using medium freguency induction furnace to smelt, and dealt it with ultrasonic or strong electric pulse. Make the ingot casting by water-cold Cu-model: (2) Forge the ingot casting and then draw it multiple times in room temperature in order to made Fe-icrostructural elongate by stretch until it forms nano fiber. (3) Heat treatment it when its cold forming process strain quantum is 2 - 3 so the soild-solution of Fe and Al can separate out as natrium rice level particles; (4) In the following forming process , this particles join in distortion, and form the enhanced fiber which particles are smaller than before. This process can make the material enhanced more. The present invention mixes the thinning of as-cast microstructure and deformation together. It increases the electric while enhances the intensity of the materials, and also can obtain materials in large sectional dimension.

Owner:SHANGHAI JIAO TONG UNIV

Shielding and grounding foam tape with metal foil as base material and preparing method thereof

ActiveCN105111952AImprove electrical conductivityExcellent three-dimensional electromagnetic shielding functionNon-macromolecular adhesive additivesFilm/foil adhesivesPressure sensitiveMetal foil

The invention discloses a shielding and grounding conductive foam tape with a metal foil sheet as the base material. The tape comprises shielding and grounding conductive foam, a hot melting adhesive layer, the metal foil sheet base material, a conductive adhesive layer and a release material layer which are sequentially stacked from top to bottom. The invention further discloses a method for preparing the shielding and grounding conductive foam tape. Compared with products in the current market with conducive cloth or gauze as the base material, the shielding and grounding conductive foam tape with the metal foil sheet as the base material has the advantages that conductivity is high, electromagnetic shielding function is better, die cutting can be achieved more easily, and the phenomenon which can happen on the conductive cloth that broken filaments appear is avoided. Compared with the method according to which ordinary conductive pressure-sensitive adhesive is adopted for gluing foam to a base material, the shielding and grounding conductive foam tape with the metal foil sheet as the base material has the advantage that the rebound resilience of foam is higher, and the problem that the rebound resilience of the foam is poor due to the fact that the foam is stuck with glue during die cutting or using is solved.

Owner:SHENZHEN MEIXIN ELECTRONICS

Graphene-based water-based conductive ink prepared by one-step method and preparation method thereof

The invention relates to graphene-based water-based conductive ink prepared by a one-step method and a preparation method thereof. The preparation method comprises the steps: jointly adding 1 to 8 parts of expanded graphite, 10 to 30 parts of conductive filler, 10 to 50 parts of water-soluble resin, 20 to 80 parts of solvent and 1 to 10 parts of aid into a high-pressure homogenizer to perform high-pressure shear; grinding until the particle size of slurry is smaller than 80mu m to obtain the graphene-based conductive ink with excellent conductivity and good stability. By means of the method, expanded graphite peeling and intercalation of conductive particles among graphite flakes can be finished at the same time in a shearing and grinding process; thus, an integrated good conductive network is established. The method has the advantages of simpleness in operation, short consumed time, ability in avoiding stack among the graphene flake layers and avoiding a grinding medium, simpleness infollow-up processing and suitability for production. The prepared graphene-based water-based conductive ink has the advantages of good dispersion and high stability.

Owner:北京航科航天科技有限公司

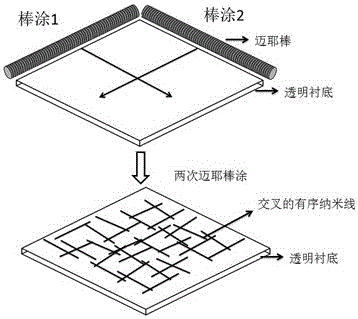

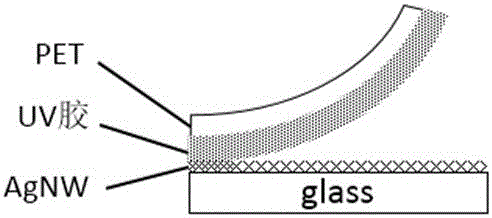

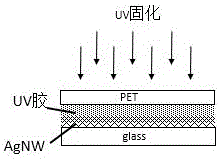

Preparation method for embedded multi-orientation metal nanowire transparent conductive film

ActiveCN106057359AImprove electrical conductivityPromote adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrically conductiveSurface modification

The invention discloses a preparation method for an embedded multi-orientation metal nanowire transparent conductive film. The preparation method comprises the following steps that S1. a metal nanowire solution is added in a temporary substrate and then metal nanowires are arranged in an orientation way, wherein the temporary substrate is made of hydrophilic material; S2. surface modification is performed on the temporary substrate so that the temporary substrate is enabled to be hydrophobic from being hydrophilic, and a surface modified substrate-metal nanowire film is obtained; and S3. embedding and stripping process is performed: the metal nanowires are embedded in cure adhesive by using the cure adhesive and the cure adhesive is stripped from the temporary substrate. The hydrophilic and hydrophobic performance of the temporary substrate is adjusted so that the embedded multi-orientation metal nanowire transparent conductive film having better conductivity, adhesiveness, flatness and stability is obtained.

Owner:SUN YAT SEN UNIV

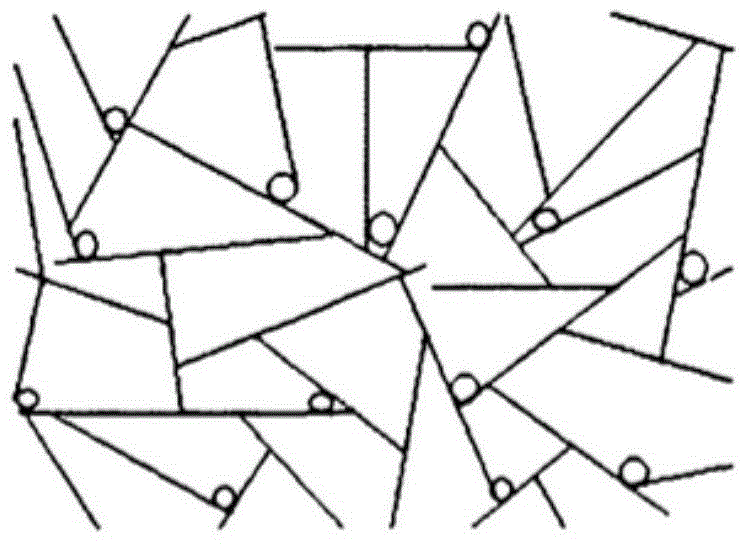

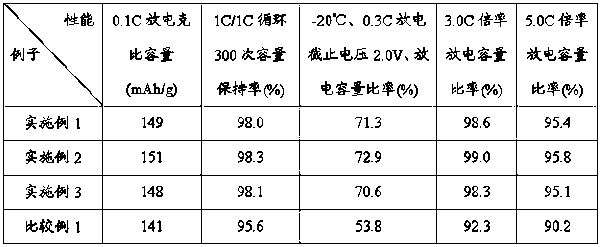

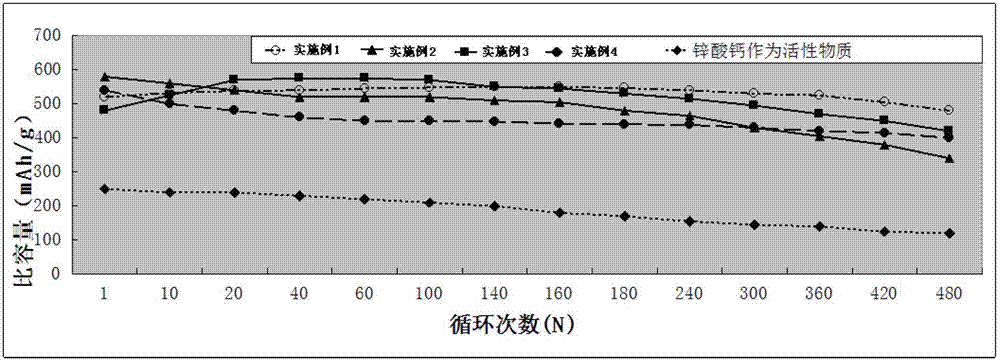

Composite conductive agent and dispersion method thereof as well as positive plate and lithium ion battery

ActiveCN103531814AImprove electrical conductivityImprove gram specific capacityCell electrodesSecondary cellsGramLithium electrode

The invention discloses a composite conductive agent and a dispersion method thereof as well as a positive plate and a lithium ion battery. The particles of the components of the composite conductive agent are in graded distribution from nanoscale to micron order, and the composite conductive agent comprises the following components in percentage by weight: 30-40% of a nanoscale spherical carbon particle conductive agent, 15-30% of a sub micron order graphite particle conductive agent, 10-20% of micron order conductive graphite and 20-30% of a nanoscale linear conductive agent. According to the invention, a three-dimensional network conductive structure is formed in the positive plate by adding the composite conductive agent in the preparation process of the positive plate and effectively mixing the composite conductive agent with anode material particles in the lithium ion battery, so that the conductive performance of the anode material is greatly improved to further improve the development of gram specific capacity of active substances and improve the liquid absorption performance of the positive plate, thereby remarkably improving the rate capability, the circulating performance and the low temperature performance of the lithium ion battery, and further ensuring that the lithium ion battery has more excellent safety performance to some extent.

Owner:江西格林德能源有限公司

Technology for dispersing carbon nanotubes in lithium ion battery slurry

InactiveCN103606650AImprove electrical conductivityImprove dispersion uniformityCell electrodesPolyvinylidene fluorideElectrically conductive

The invention relates to the technical field of lithium ion batteries and especially relates to a technology for dispersing carbon nanotubes in lithium ion battery slurry. The technology comprises the following steps of 1, carbon nanotube conductive paste preparation, 2, polyvinylidene fluoride glue solution preparation, and 3, lithium ion battery slurry preparation: (1), mixing the polyvinylidene fluoride glue solution and the carbon nanotube conductive paste, (2), adding lithium cobaltate into the mixture for the first time and (3), adding lithium cobaltate and the polyvinylidene fluoride glue solution into the mixture obtained by the step (2) for the second time. The technology improves carbon nanotube dispersion uniformity and solves the problem of too fast agglomeration of the carbon nanotubes and the problem of a too fast rate of lithium ion battery slurry settlement. The carbon nanotubes are uniformly dispersed in the lithium ion battery slurry so that the pole piece of the lithium ion battery is smooth in lithium ion battery slurry coating and thus the pole piece of the lithium ion battery does not have obvious granular feel and has good electroconductivity.

Owner:东莞市金源电池科技有限公司

Alkaline battery negative pole material and preparation method thereof

ActiveCN102931385AImprove electrical conductivityImprove efficiencyCell electrodesRare-earth elementElectrical battery

The invention discloses an alkaline battery negative pole material and a preparation method thereof. The negative pole material is doped zinc oxide, the content of the zinc oxide is 70%-99% by mole, a trivalent metal ion X<3+> is used as a main doping agent, and the content of the trivalent metal ion is 0.1%-29% of the mole number of the zinc oxide; and a rare-earth element M<3+> is used as an auxiliary doping agent, and the content of the rare-earth element is 0.01%-5% of the mole number of the zinc oxide. According to the alkaline battery negative pole material and the preparation method thereof, the doped zinc oxide is used as an active material to be applied to a nickel / zinc secondary battery, by means of the active material, a series of problems of deformation, dendrite and self-corrosion of a zinc negative pole are solved, simultaneously, electrical conductivity of the negative pole is improved, and electrochemical performances of the battery are improved, so that specific energy, specific power, charging receptivity are greatly improved, reversibility of the negative pole is improved, and the alkaline battery negative pole material and the preparation method are a revolution of traditional technologies.

Owner:HUNAN FENGRI ELECTRIC GROUP

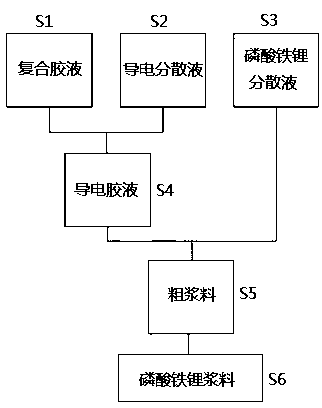

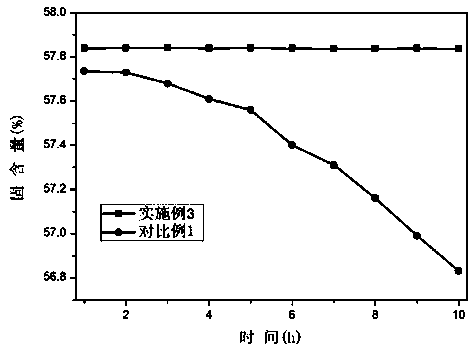

Lithium iron phosphate water-based positive electrode slurry and preparation method thereof

InactiveCN111244405AAvoid reunionImprove electrical conductivityCell electrodesSecondary cellsBatch productionChemical engineering

The invention discloses lithium iron phosphate water-based positive electrode slurry and a preparation method thereof. The water-based slurry comprises the following components in percentage by mass:40%-50% of lithium iron phosphate powder, 2%-6% of a conductive agent, 2%-5% of a water-based binder, 0.5%-2% of a dispersing agent and the balance of deionized water. The preparation method comprisesthe following steps of: S1, preparing a composite glue solution, S2, preparing a conductive dispersion liquid, S3, preparing a lithium iron phosphate dispersion liquid, S4, mixing and dispersing forthe first time, S5, mixing and dispersing for the second time, and S6, conducting vacuum defoaming and standing. The lithium iron phosphate water-based positive electrode slurry prepared by the methodis uniform in dispersion, good in consistency and stability and convenient to coat; meanwhile, the solvent selected by the slurry is a water-based solvent, so that the slurry is environment-friendly,pollution-free and low in cost; the preparation method is simple and convenient to operate, high in production efficiency and suitable for batch production.

Owner:SHENZHEN GPC ENERGY GRP CO LTD

Conductive fabric and preparation method thereof

InactiveCN108221368AImprove electrical conductivitySolve poor washabilityVegetal fibresNatural fibresElectrically conductiveChemistry

The invention discloses a conductive fabric and a preparation method thereof. The method comprises the steps: preparing a conductive component by mixing a silver nanowire with a polymer compound solution, immersing the fabric in the conductive component, and carrying out a crosslinking reaction on polymer compound and the surface of the fabric by using a crosslinking agent to prepare a fabric withexcellent conductivity. The fabric prepared by the method fully utilizes the crosslinking effect of the crosslinking agent on the polymer compound in the conductive component and the surface of the fabric, and fixes the silver nanowires on the surface of the fabric to hinder the stripping and peeling off during the washing process of the fabric, thereby preparing the conductive fabric having excellent washing resistance. The preparation process is simple, the reaction condition is mild, and the prepared conductive fabric not only has higher conductivity, but also has good washing resistance at the same time, thereby solving the problem that the conductivity of the conductive fabric prepared by a coating method is drastically decreased as the number of washing is increased. The conductivefabric can be practically applied in the fields of wearable electronic devices, smart clothing, electrode materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

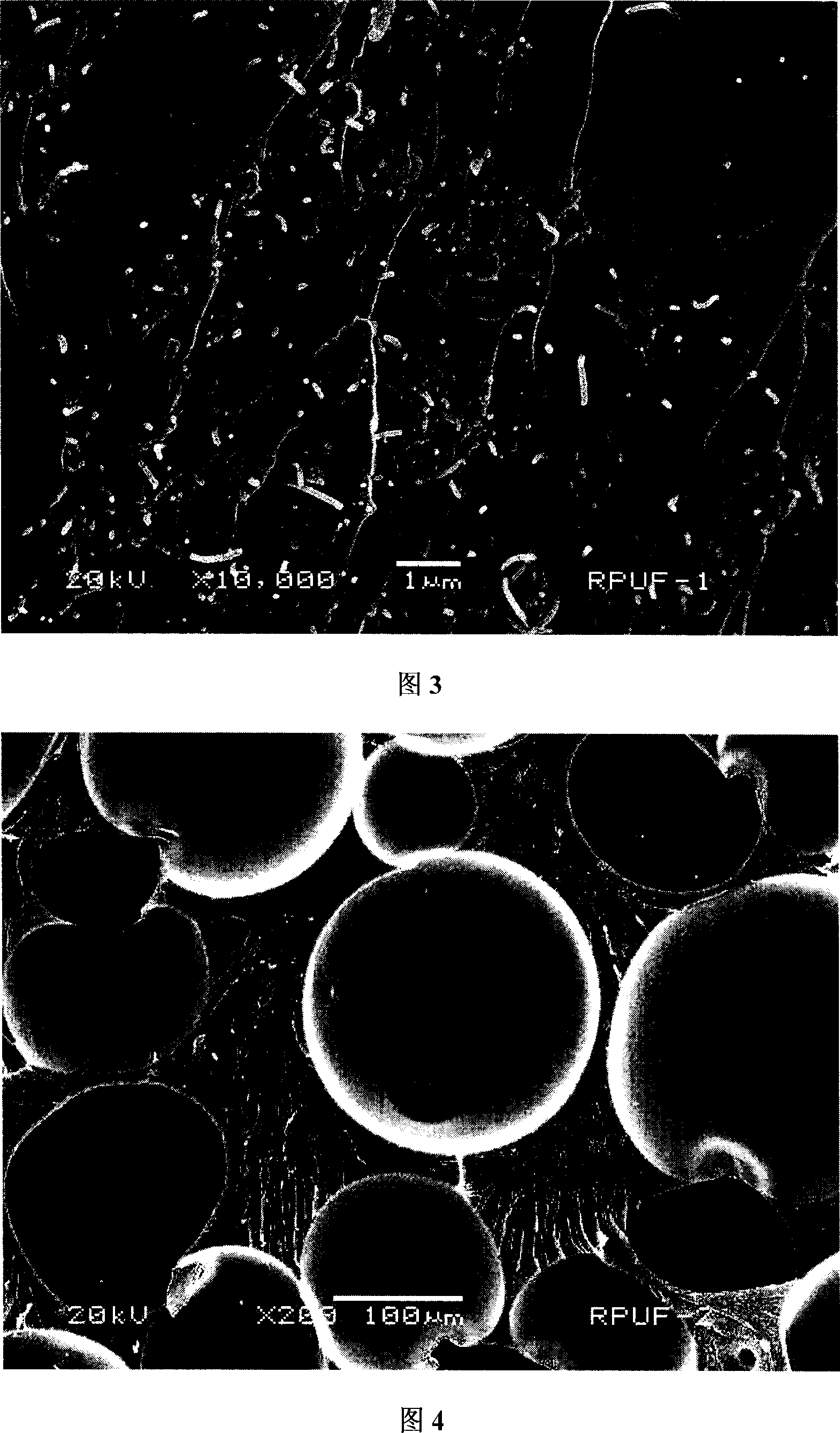

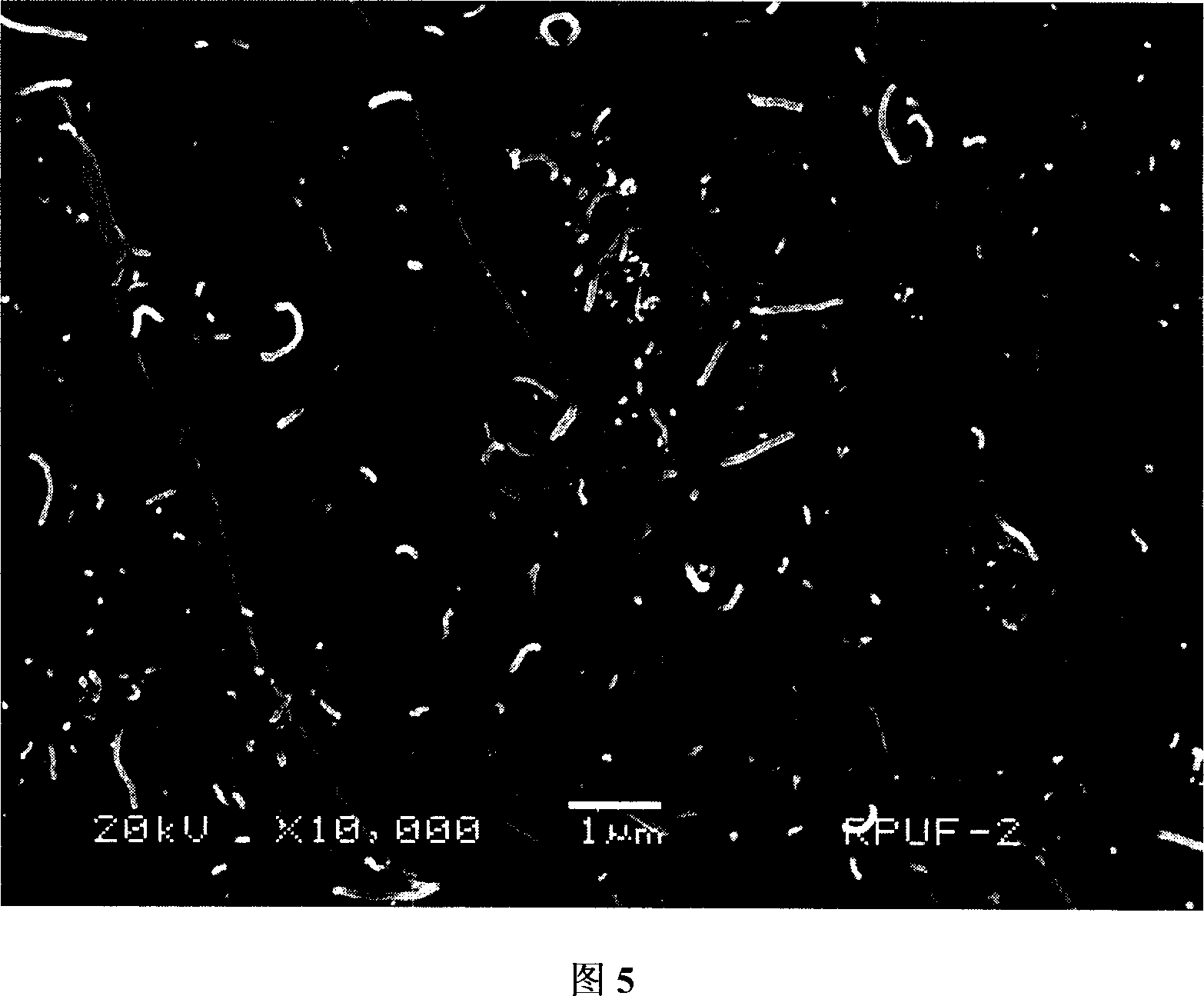

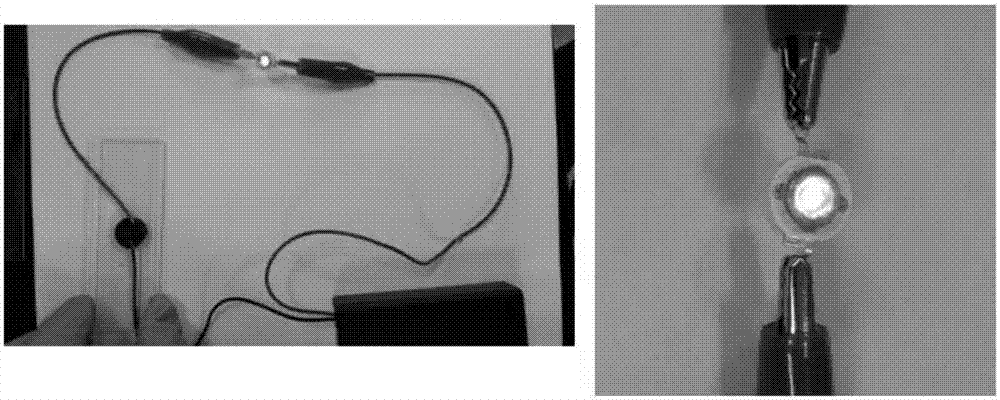

Preparation of hard polyurethane conductive foam plastic for carbon nanotube filling

InactiveCN1970598AImprove electrical conductivityImprove mechanical propertiesIsocyanateCarbon nanotube

The invention discloses a making method and device of carbon nanometer pipe with high-density conductive hard-polyurethane foam plastic, which comprises the following steps: oxidizing the surface of carbon nanometer pipe; adopting distilled water as diluent; vibrating and grinding through ultrasound; dispersing carbon nanometer pipe in the polyether polyol; evaporating water in the system; obtaining the composite liquid of carbon nanometer pipe and polyether polyol; blending with organic tin, silicon oil and water according to certain proportion through mechanic stirring device evenly; mixing with certain quantity of isocyanate completely; casting in the mould; closing mould lid; ripening; obtaining the product.

Owner:SICHUAN UNIV

Preparation method of PNAGA/PANI self-repairing conductive hydrogel

InactiveCN106866995AImprove electrical conductivityExcellent self-healing performanceChemistryIn situ polymerization

The invention discloses a preparation method of PNAGA / PANI self-repairing conductive hydrogel, belonging to the technical field of high polymer materials. The PNAGA / PANI self-repairing conductive hydrogel is prepared by the following steps: firstly synthesizing monomer N-acryloyl glycinamide, named as NAGA, and preparing a series of self-repairing hydrogel with different concentrations through photopolymerization; carrying out in-situ polymerization on aniline (ANI) in the self-repairing hydrogel, so as to prepare the self-repairing conductive hydrogel. Compared with other hydrogel, the PNAGA / PANI hydrogel not only has self-repairing or self-healing capacity, but also simultaneously has self-repairing or self-healing capacity and conductivity; and furthermore, the self-repairing performance of the hydrogel is influenced by the concentration of PNAGA, and the self-repairing degree of the hydrogel reaches the highest value along with the increase of the concentration of PNAGA. The self-repairing conductive hydrogel prepared by virtue of the preparation method is hopefully applied to flexible supercapacitors with the self-healing capacity.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com