Micrometer silver-copper granule containing nano level surface structure and preparation and application thereof

A technology of surface structure and micron silver, which is applied in the field of micron silver-copper particles and its preparation, can solve problems such as inability to sinter filler particles, achieve stable and reliable product performance, easy process flow, and reduce surface sintering or melting temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] At room temperature, 1 kilogram of flaky pure silver powder (99.5%) with an average particle size of 30 microns and 2 grams (0.5%) of 3,4-dihydroxyphenylpropionic acid. In 10 liters of ethanol solution, stir at a speed of 100 rpm for 30 minutes, then add 17 grams of silver nitrate and 4 grams of sodium borohydride; continue to stir for 60 minutes at a speed of 100 rpm. The silver powder is filtered out, the solvent is removed from the powder liquid through a centrifuge at 500 rpm, and the excess solvent is removed by a vacuum pump to obtain a micron flake silver powder with a nano surface structure.

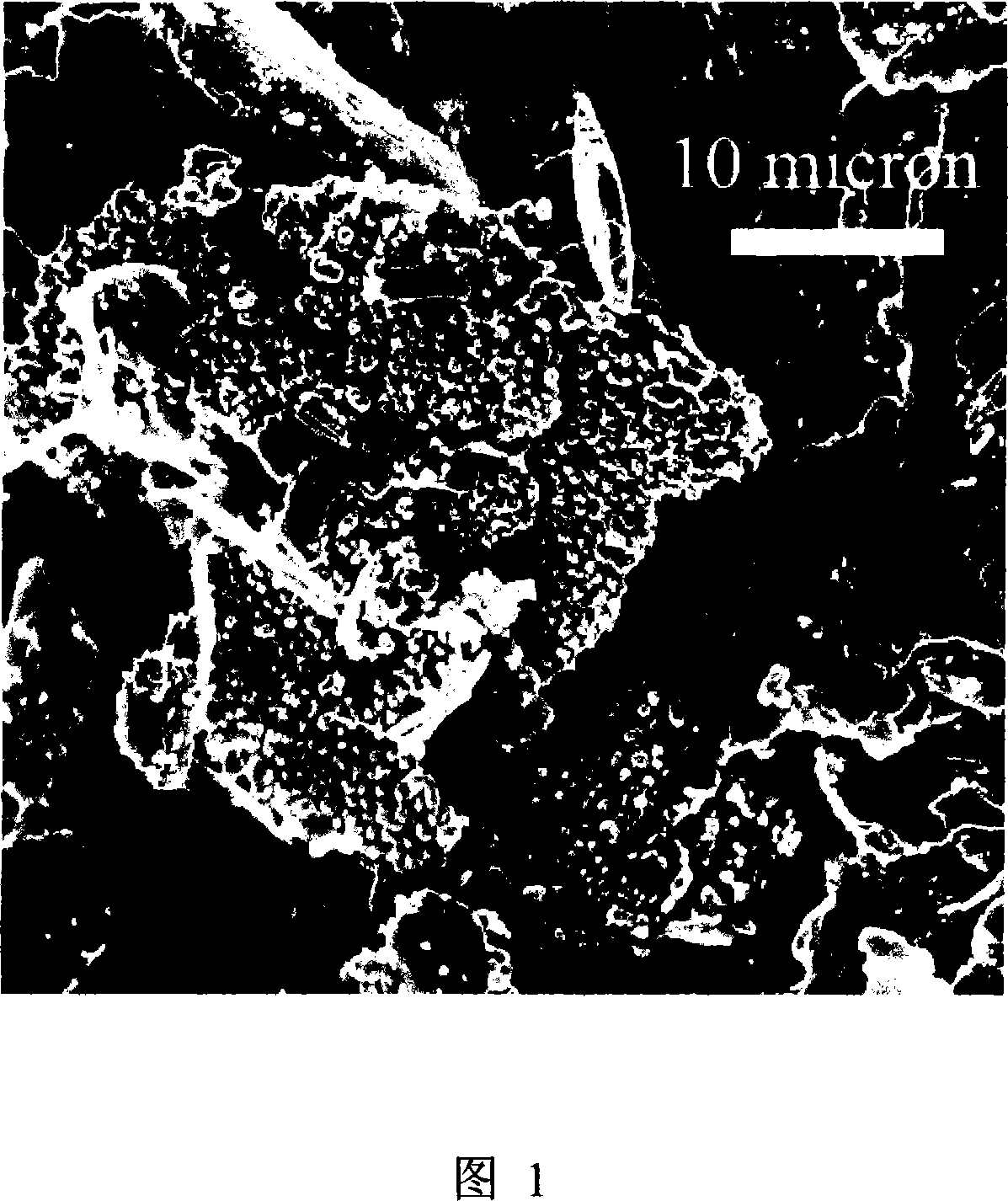

[0025] As shown in Figure 1, the tiny particles displayed on the surface of the micron silver powder are nano silver powder produced by this process.

Embodiment 2

[0027] At room temperature, 20 kg of flake-shaped silver-coated copper powder (the mass ratio of silver: copper is 5: 5) with an average particle size of 24 microns was stirred in 200 liters of ethanol solution for 30 minutes. Then add 560 grams of silver chloride powder, 780 grams of citric acid; continue to stir for 120 minutes at a speed of 100 rpm. The powder liquid is filtered through filter paper and drained to obtain micron flake silver-coated copper powder with nanometer surface structure.

Embodiment 3

[0029] At room temperature, 5 kilograms of flaky pure silver powder (99.5%) with an average particle size of 30 microns were dispersed in 50 liters of ethanol solution, stirred for 30 minutes, while 500 milliliters of ethanol solution containing 22 grams of acetaldehyde and 85 grams of nitric acid were added dropwise. 500 milliliters of ethanol solutions of silver, continue to stir 120 minutes with the speed of 100 revs / min. The powder liquid is filtered through filter paper and drained to obtain micron flake silver powder with nanometer surface structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com