Conductive fabric and preparation method thereof

A conductive fabric and fabric technology, applied in plant fiber, textile, papermaking, fiber treatment, etc., can solve the problems of cupro ammonia fiber acid and alkali resistance, poor resistance to chlorine bleach, and unclear washing resistance, etc. To achieve the effect of poor washability, short reaction time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of conductive components: Dissolve polyvinyl alcohol completely in water, prepare a 1wt% polyvinyl alcohol aqueous solution, add 100mg of silver nanowires, and stir evenly to obtain a conductive material composed of polymers and 1wt% silver nanowires. components;

[0030] (2) Soak the washed 5cm×5cm×250μm pure cotton fabric in the conductive component prepared in step (1) for 3s, dry, repeat soaking and drying 10 times, so that the surface of the pure cotton fabric is loaded with enough silver nanometers Wire;

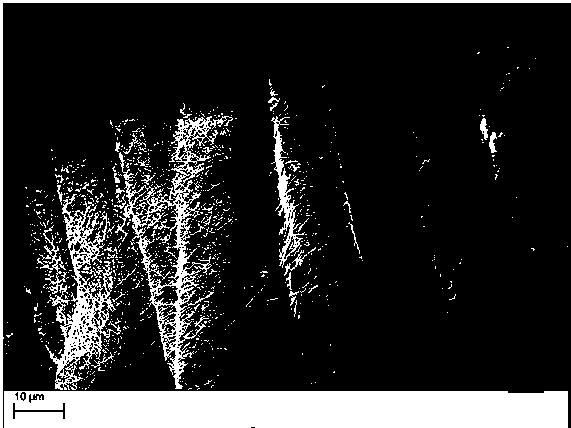

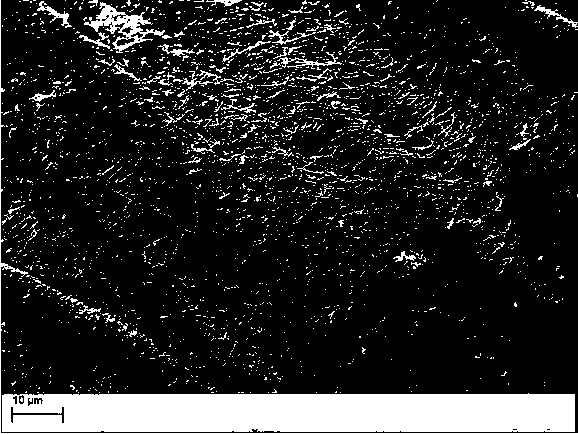

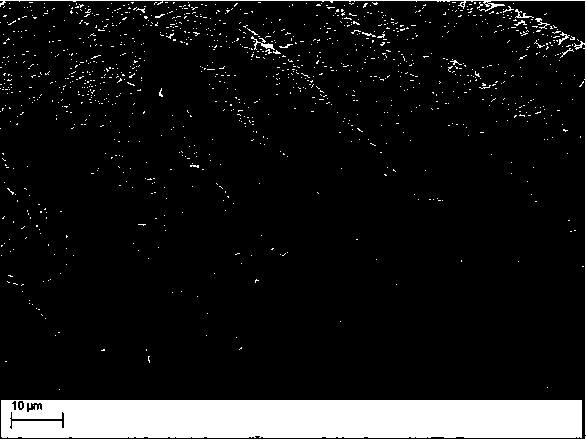

[0031] (3) Prepare a 1wt% glutaraldehyde solution, adjust the pH value to 1 with 1M hydrochloric acid, and make the conductive pure cotton fabric in step (2) (see figure 1 ), spray 1mL of glutaraldehyde solution on the surface, put it in an oven, and react at 80°C for 1h, so that the polyvinyl alcohol in the conductive component and the surface of the pure cotton fabric are fully cross-linked. Thoroughly wash with water to remove unreacted glut...

Embodiment 2

[0035] (1) Preparation of conductive components: Dissolve polyvinyl alcohol completely in water, prepare 1wt% polyvinyl alcohol aqueous solution, add 80mg silver nanowires, stir evenly, and obtain polymer and 0.8wt% silver nanowires conductive components;

[0036] (2) Soak the washed 5cm×5cm×250μm chitosan fabric in the conductive component prepared in step (1) for 3s, dry, repeat soaking and drying 8 times, so that the surface of the chitosan fabric is loaded with enough silver nanowires;

[0037] (3) Prepare a 1wt% glutaraldehyde solution, adjust the pH value to 7 with 1M sodium hydroxide, spray 2mL of the glutaraldehyde solution on the surface of the conductive chitosan fabric prepared in step (2), and put it in an oven , and react at 60° C. for 1 h, so that the polyvinyl alcohol in the conductive component and the surface of the chitosan fabric are fully cross-linked. Wash thoroughly with water to remove unreacted glutaraldehyde and polyvinyl alcohol on the surface of th...

Embodiment 3

[0040](1) Preparation of conductive components: Dissolve polyethyleneimine completely in ethanol to prepare a 10wt% polyethyleneimine ethanol solution, add 100mg silver nanowires, stir well, and obtain polymers and 1wt% silver nanowires Conductive components composed of wires;

[0041] (2) Soak the washed 5cm×5cm×250μm chitosan fabric in the conductive component prepared in step (1) for 10s, dry, repeat soaking and drying 5 times, so that the surface of the pure cotton fabric is loaded with enough silver Nanowires;

[0042] (3) prepare 0.5wt% glutaraldehyde solution, adjust the pH value to 7 with 1M hydrochloric acid, spray 5mL of glutaraldehyde solution on the surface of the conductive chitosan fabric prepared in step (2), put it in an oven, React at 80° C. for 1 h to fully cross-link the polyethyleneimine in the conductive component and the surface of the chitosan fabric. Thoroughly wash with water to remove unreacted glutaraldehyde and polyethyleneimine on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com