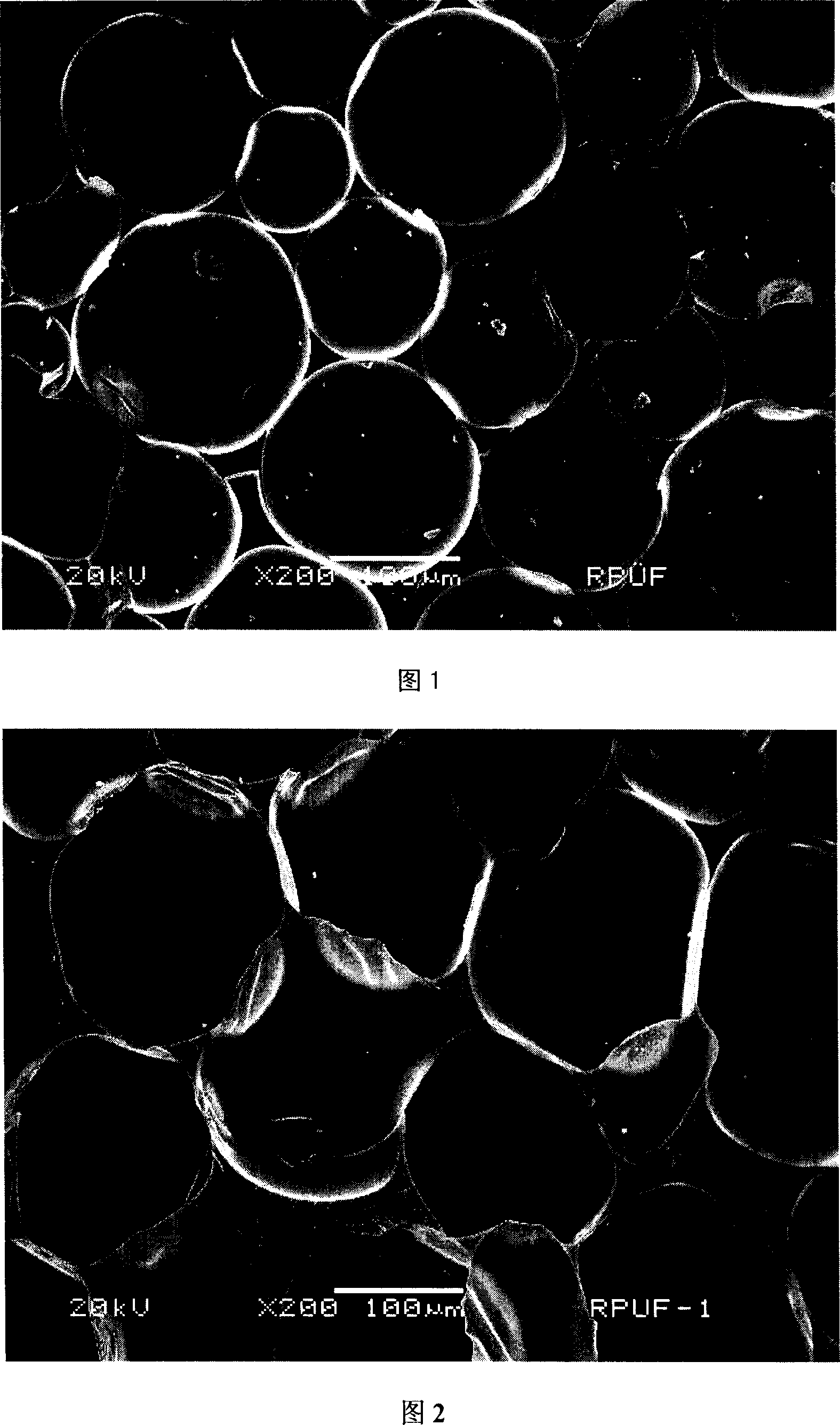

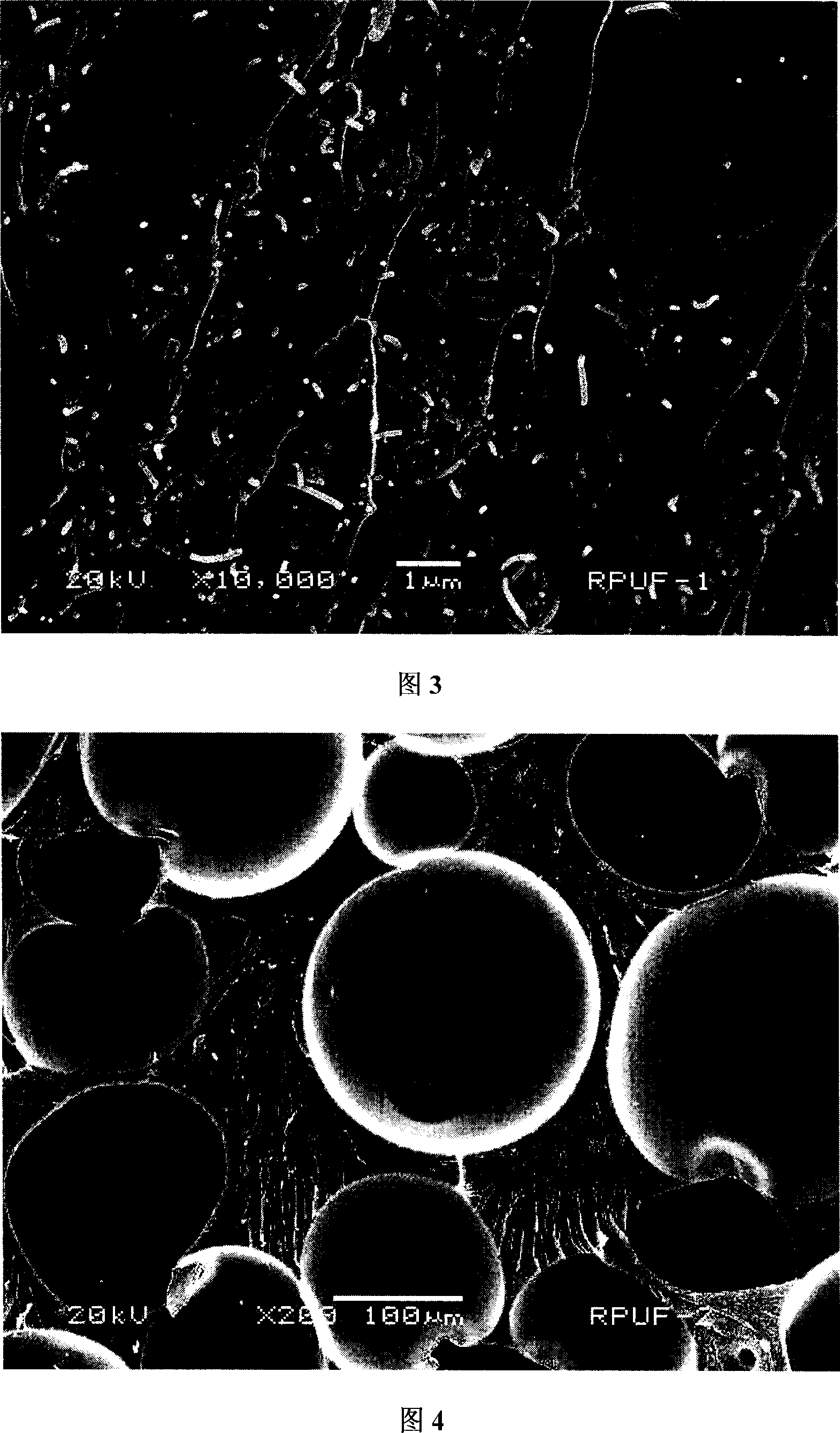

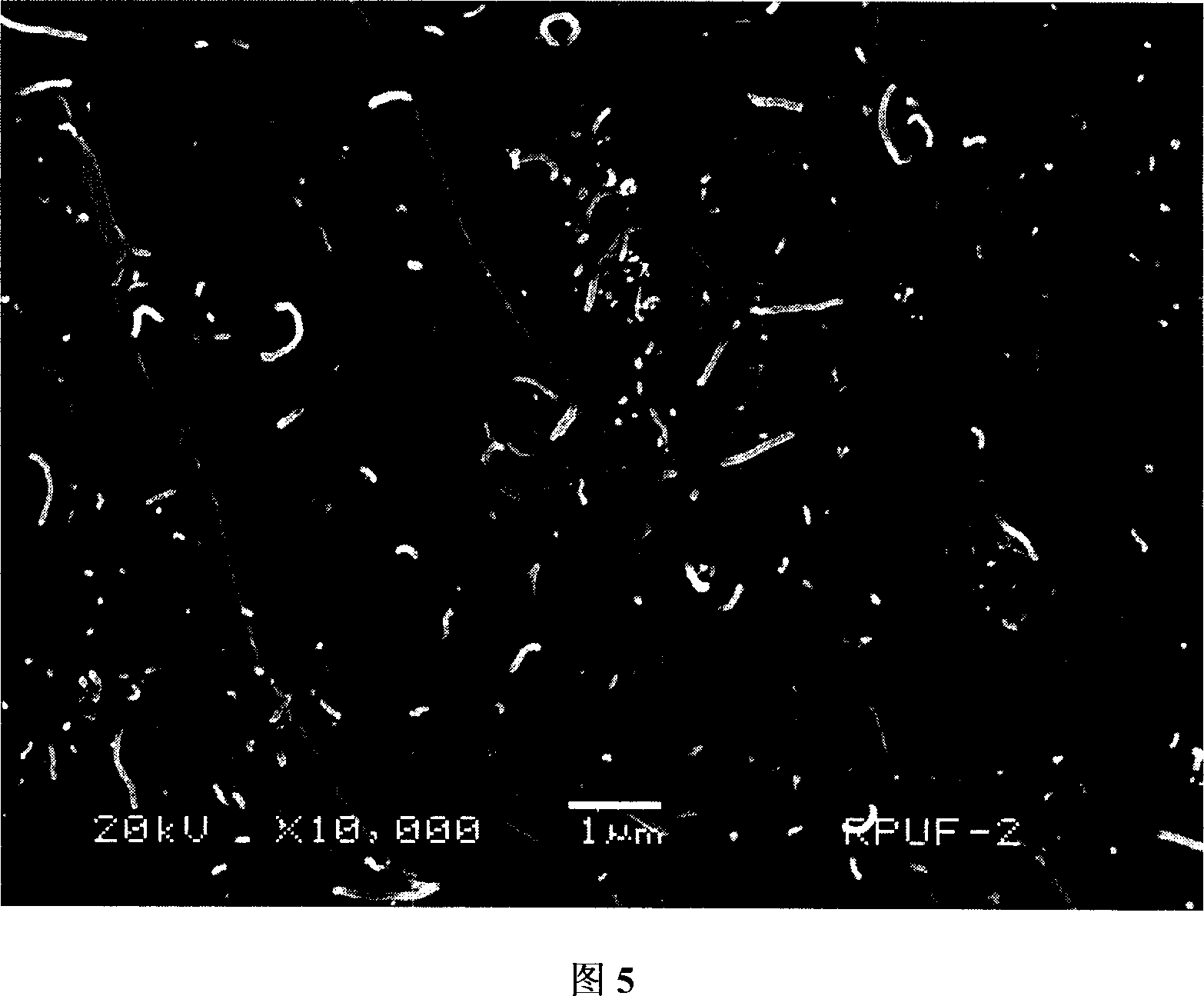

Preparation of hard polyurethane conductive foam plastic for carbon nanotube filling

A technology of rigid polyurethane and carbon nanotubes, applied in the field of new polymer materials, can solve the problems such as no reports of CNTs/polyurethane foam composite materials, and achieve the effect of improving electrical conductivity and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The examples given below are specific descriptions of the present invention. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Those skilled in the art according to the above-mentioned SUMMARY OF THE INVENTION Some non-essential improvements and adjustments to the present invention still belong to the protection scope of the present invention.

[0043] Density 0.25g / cm 3The formula of the embodiment 1~10 of the rigid polyurethane foam of left and right is shown in Table 3

[0044] The formula of table 3 embodiment 1~10

[0045] implement

example

Polyether polyol

carbon nanotubes

Organotin

water

silicone oil

share

share

share

share

share

share

share

1

100

140

0

0.1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com