Patents

Literature

113results about How to "Meet the requirements of industrial applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

InactiveCN101280328AReduce consumptionReduce releaseFatty acid esterificationUnicellular algaeBiodiesel feedstockOil and grease

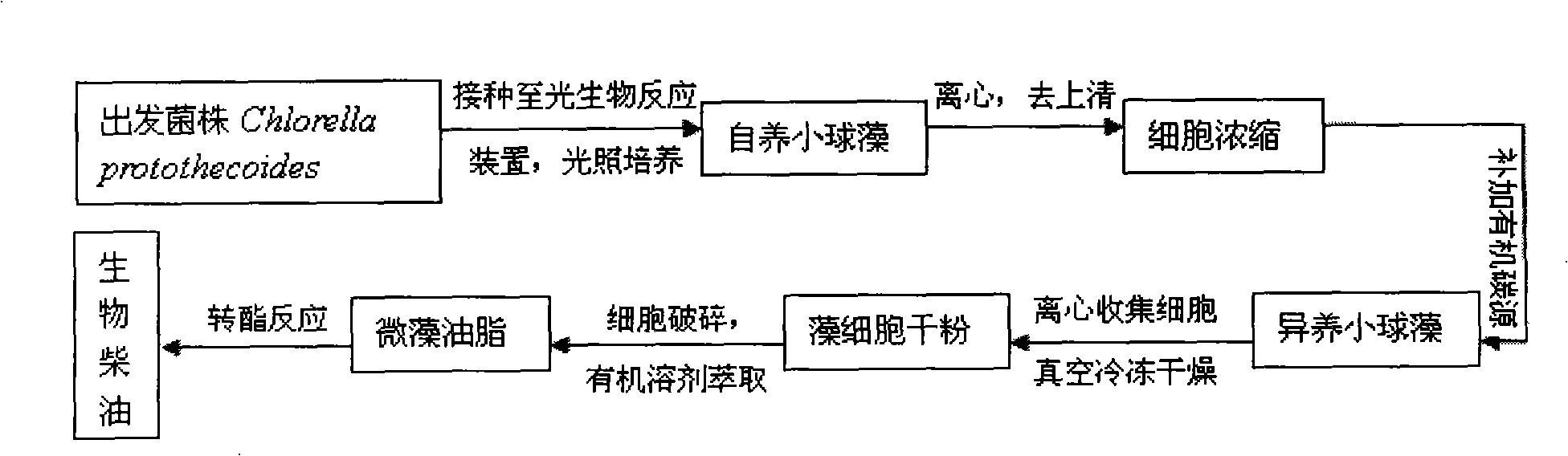

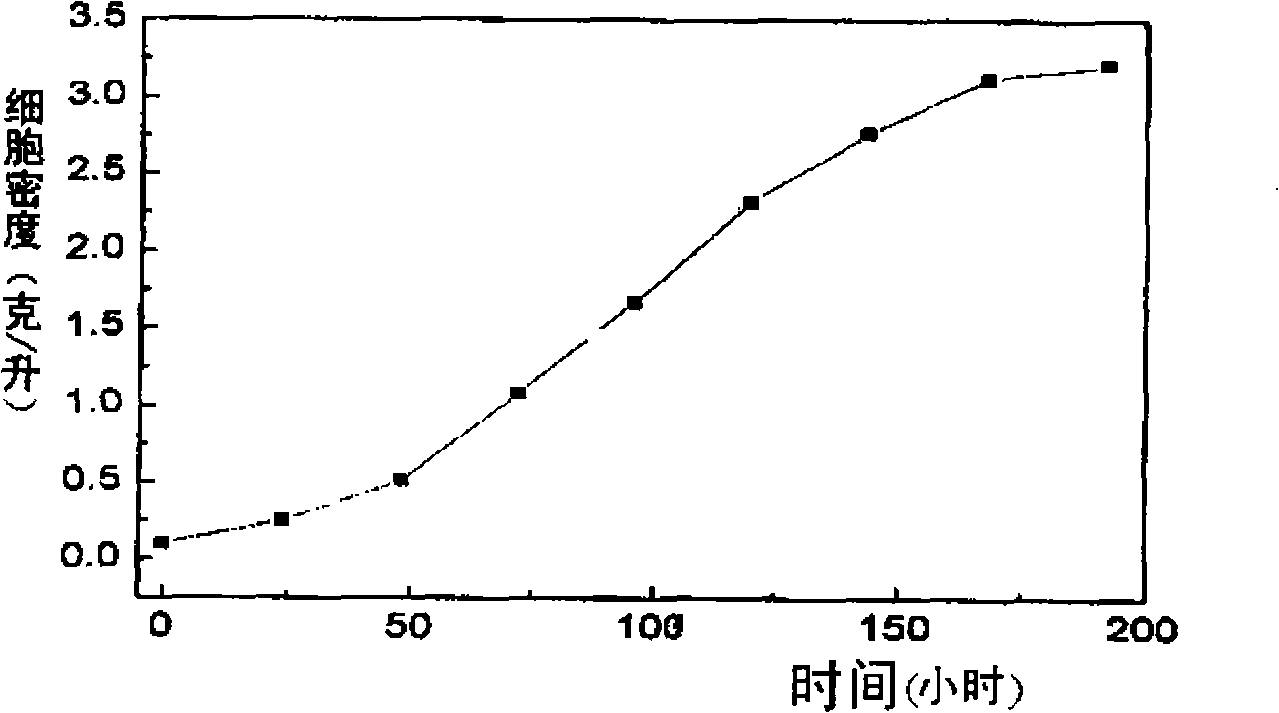

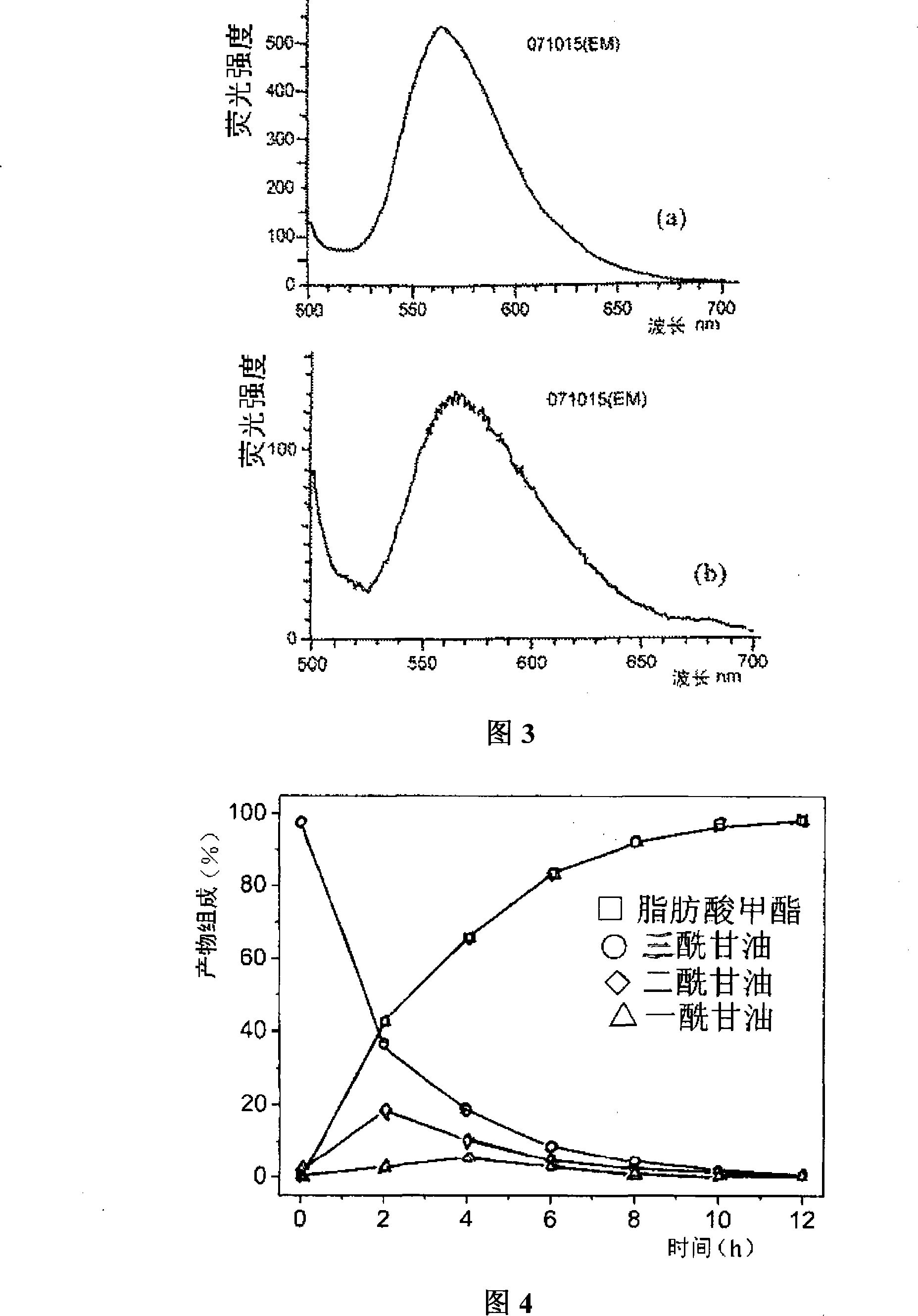

The invention discloses a method for producing biological diesel oil by two steps of culture of chlorellas, namely, autotrophy and heterotrophy, which belongs to the renewable biological energy field. Concentrated autotrophic algae is put into a fermentation tank to perform heterotrophic growth from the processes of autotrophic culture, cell concentration and fermentation pollution controlling of the chlorellas, to ensure the chlorellas to be synthesized into neutral fat. Effective feeding strategy is established to ensure the fat to be synthesized into optimal after the optimization of the fermentation conditions and the process control. The biomass can reach 108g.L-1, and the grease content can reach 52 percent of cell dry weight. After the culturing is finished, biological diesel oil can be prepared after extracting algal oil and transesterification reaction. The cell concentration technology adopted by the invention can effectively avoid the problem of light restriction during the high density culture process Not only is the carbon dioxide emission reduced, but also the organic carbon source consumption is reduced, thus the preparation cost of the biological diesel oil material is saved. The whole technical line is environmental friendly, high efficient, and can meet the industrial application requirements of the microalgae biological diesel oil.

Owner:TSINGHUA UNIV

Method for producing biodiesel by high-density fermentation of heterotrophic chlorella

InactiveCN101230364ALow raw material costOptimizing conditions for heterotrophic fermentationFatty acid esterificationUnicellular algaeBiodiesel feedstockBiodiesel

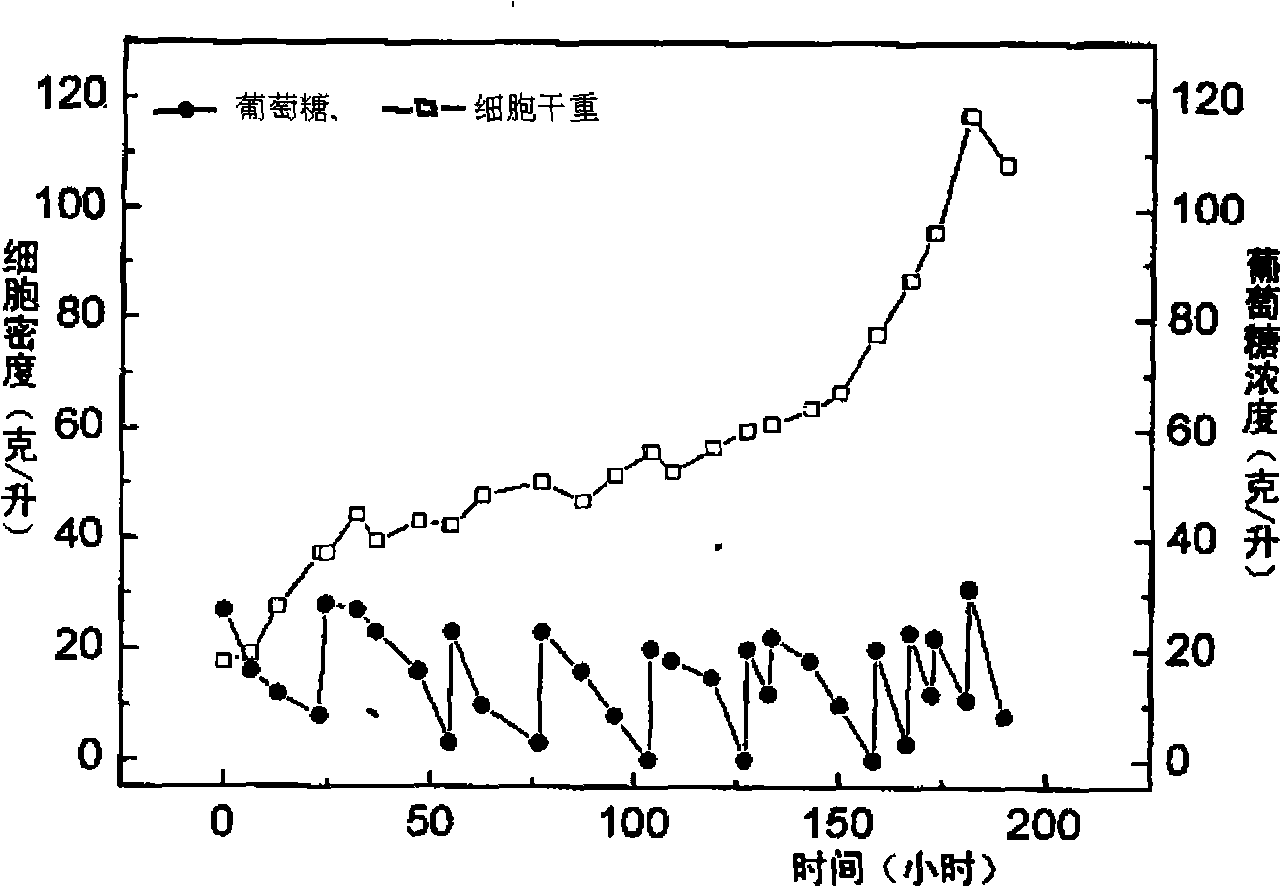

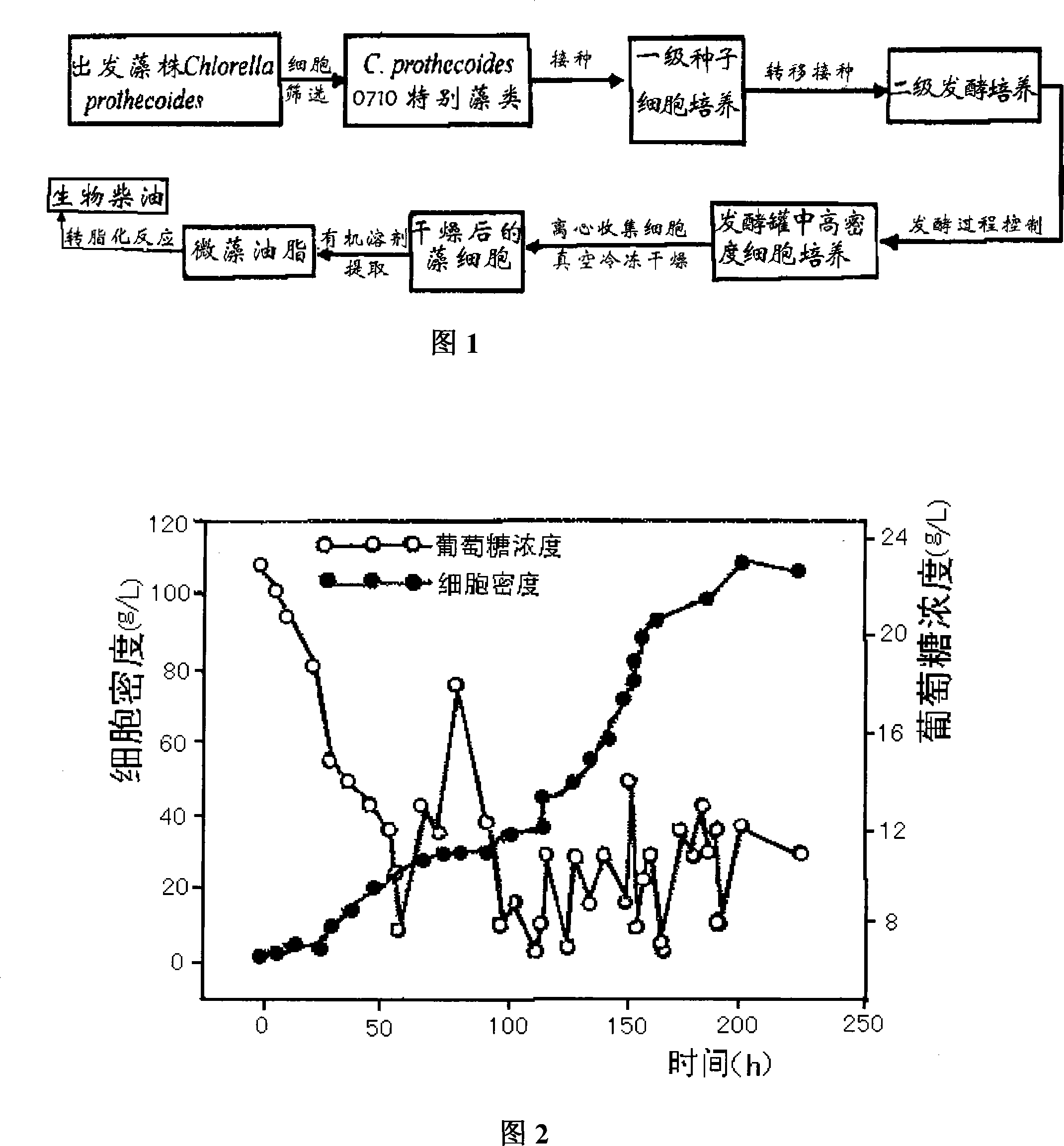

The invention discloses a method of producing bio-diesel by fermenting the heterotrophic chlorella in high density which belongs to the renewable biological energy field. The method uses the heterotrophic chlorella fermented in high density in the bio-reactor as a raw material, which screens the chlorella species having high growth rate and high oil content, directly inoculates into the bottle as the first-class germ to culture then transfers to the fermentation cylinder to undergo the second-glass high density fermentation; the reaction condition is then optimized, and the process is controlled; the culture containing the carbohydrate is dripped to provide the nutrition for the cell growth, therefore the heterotrophic chlorella cells cultured in high density with density of 108g / L and oil content of 61 percent are separated, collected and dried; the algae oil is extracted, and the bio-diesel is produced by transesterification reaction; the invention reduces the cost for the raw material of bio-diesel, and satisfies the demand of industrialized application of producing bio-diesel by heterotrophic chlorella cells, therefore the technique of the invention becomes an economical and effective way of making oils from bio-diesel materials.

Owner:TSINGHUA UNIV

Ceramic coating and preparation method thereof and method for preventing cracking of ceramic coating

ActiveCN101760057ALow costMeet the requirements of industrial applicationsCoatingsSilanesCeramic coating

The invention relates to a ceramic coating and a preparation method thereof, and a method for preventing cracking of the ceramic coating. The invention provides the ceramic coating, which comprises the following components: a component A which consists of a metal oxide sol, a coloring pigment, a lamellar pigment, an oriented auxiliary agent and water, wherein the grain diameter of the lamellar pigment is between 1 and 80mum, while the tablet diameter ratio thereof is between 5 and 100; and a component B which is prepared by mixing at least two alkoxy silanes with different hydrolysis rates, wherein the weight ratio of the component A to the component B is 2-3:1-2, and the solid content of the component A is between 20 and 45 by weight percent. The invention also provides the preparation method of the ceramic coating, and the method for preventing cracking of the ceramic coating.

Owner:上海金力泰化工股份有限公司

Medium oil type hydrocracking catalyst and its preparing process

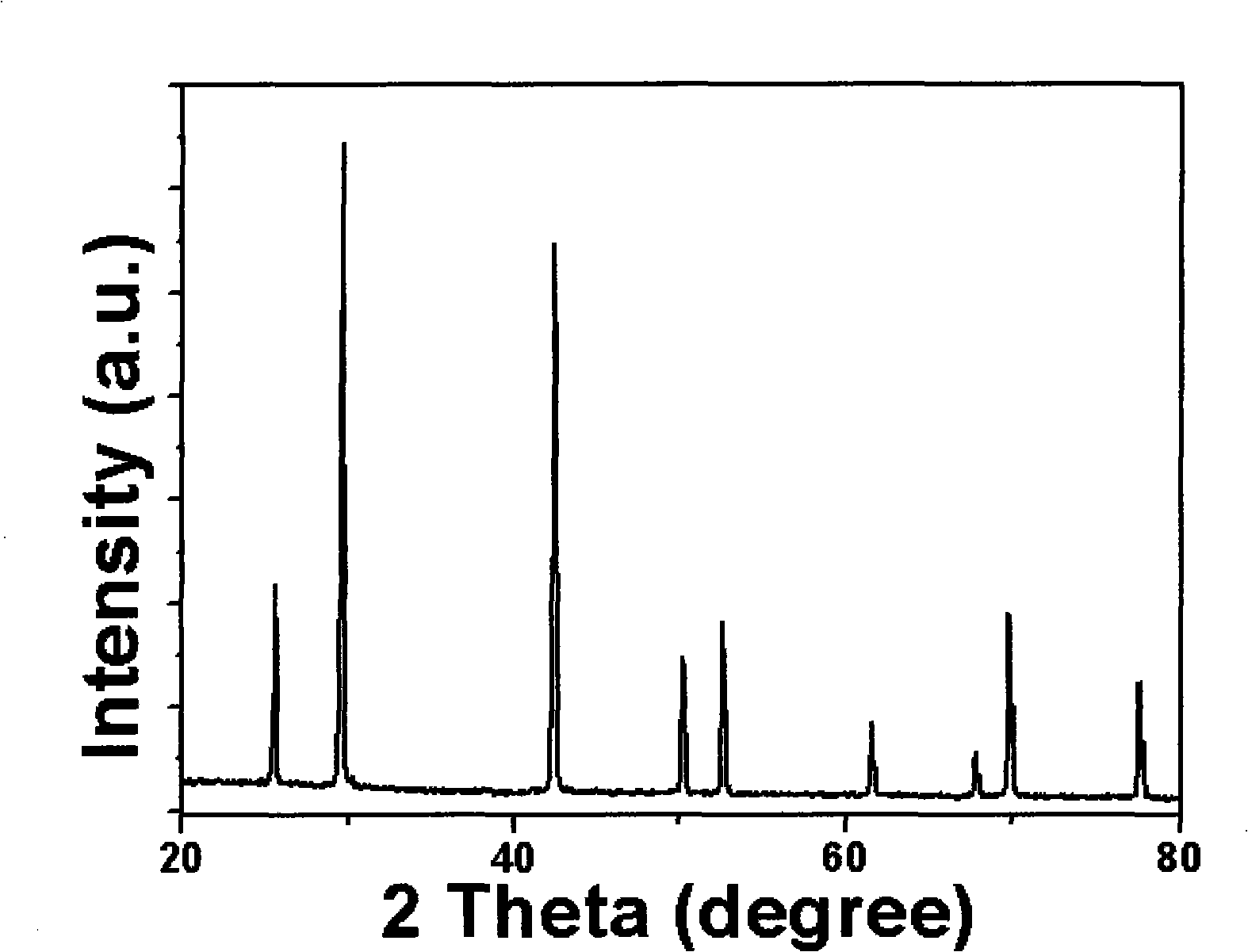

ActiveCN1566283AHigh crystallinityLow cell parametersHydrocarbon oil crackingMolecular sieveAluminium

The invention relates to a medium oil type hydrocracking catalyst and its preparing process, wherein the catalyst employs non-shaped silicon aluminium as carrying agent, and the particularity modified type Y molecular sieve is used as the acidic component, the molecular sieve possesses high degree of crystallization, low unit cell parameter, strong nitrogen resistant property and good destroying capability. The hydrocracking catalyst employing the molecular sieve has strong nitrogen resistant capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

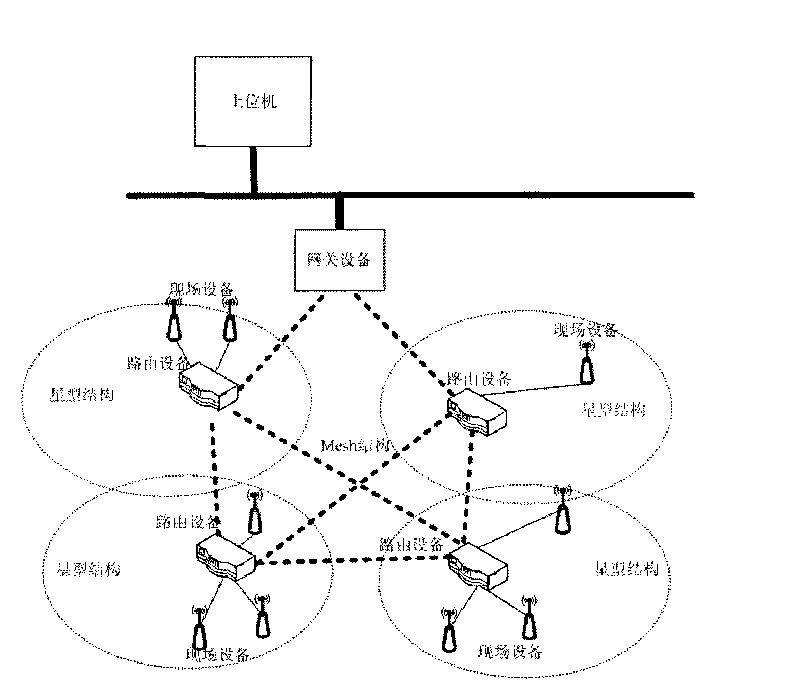

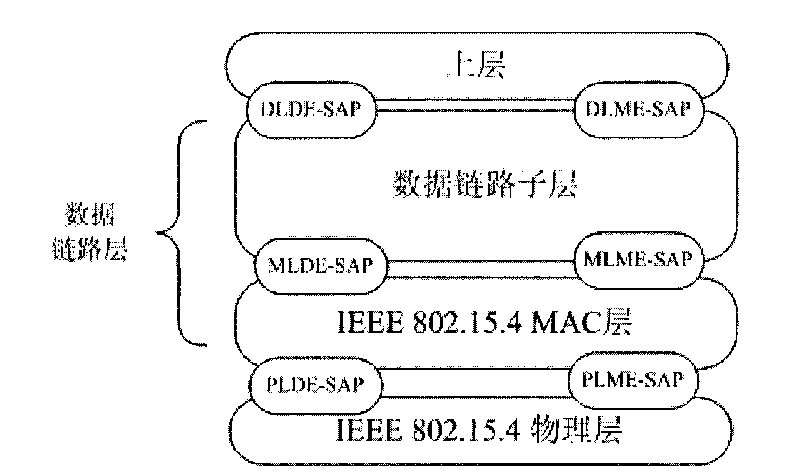

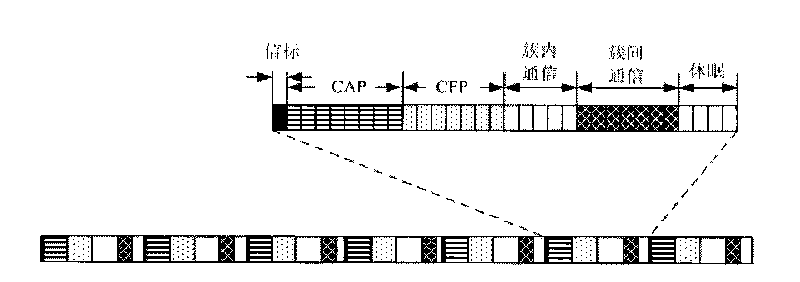

Industrial wireless communication method based on IEEE802.15.4

InactiveCN101754423ASimple structureImprove reliabilityNetwork topologiesWireless network protocolsWireless communication protocolWeb structure

The invention relates to an industrial wireless communication method based on IEEE802.15.4, comprising the following steps: building various devices in the industrial wireless network into web-and-star-shaped mixed topological structure; establishing an industrial wireless communication protocol stack model based on the IEEE802.15.4; defining a superframe structure based on the IEEE802.15.4 based on the topological structure and the protocol stack model; defining a frame structure based on the protocol stack model; realizing industrial wireless communication process based on the protocol model, the superframe structure and the frame structure. In the method of the invention, the web-and-star-shaped mixed topological structure is adopted, and the star-shaped structure simplifies network structure, reduces maintenance and management difficulty and improves system flexibility; the web structure is adopted to improve network reliability; the advantages of the IEEE802.15.4 are fully made use of to improve system compatibility, protect existing investment and meet industrial application requirements by expansion.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

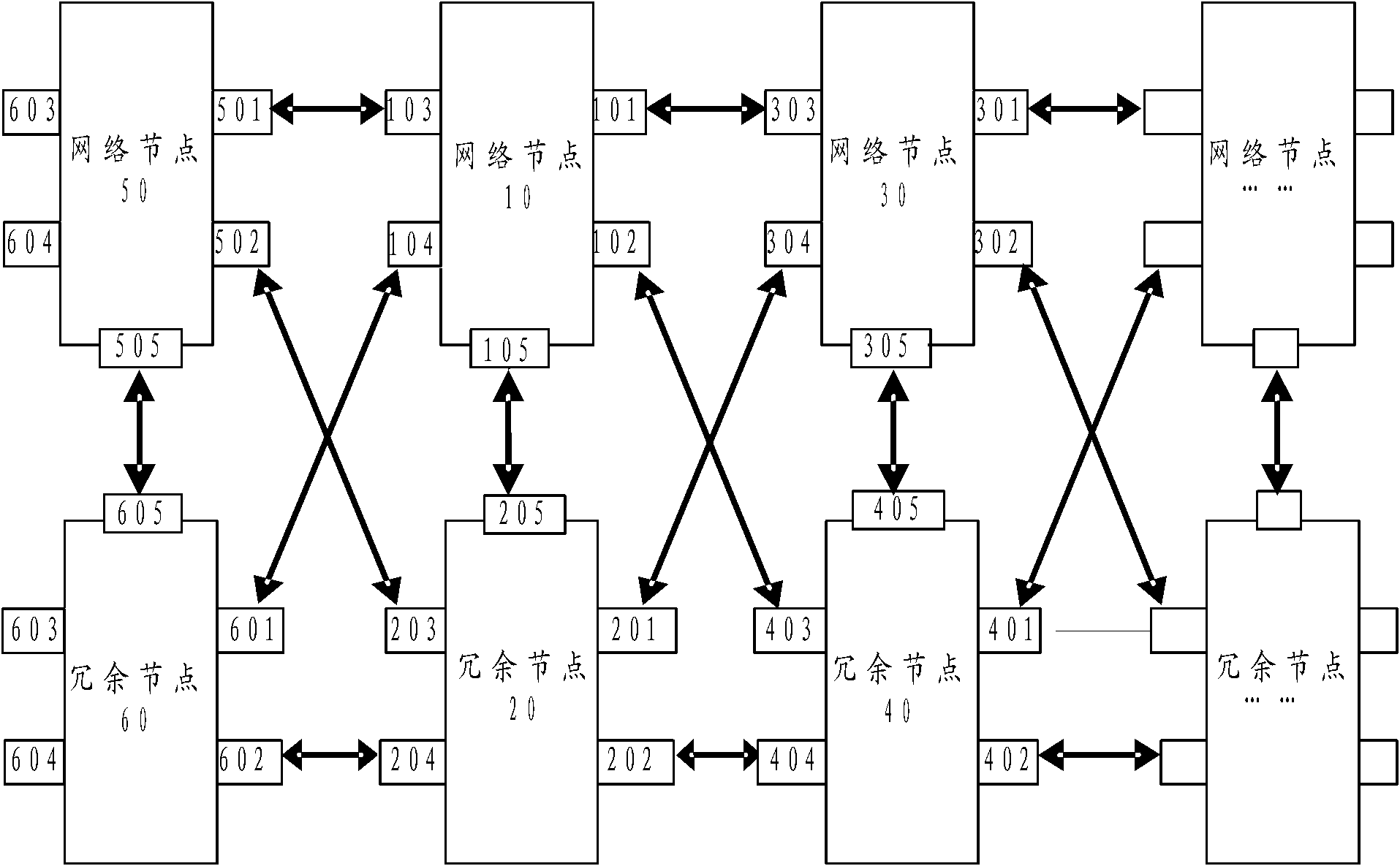

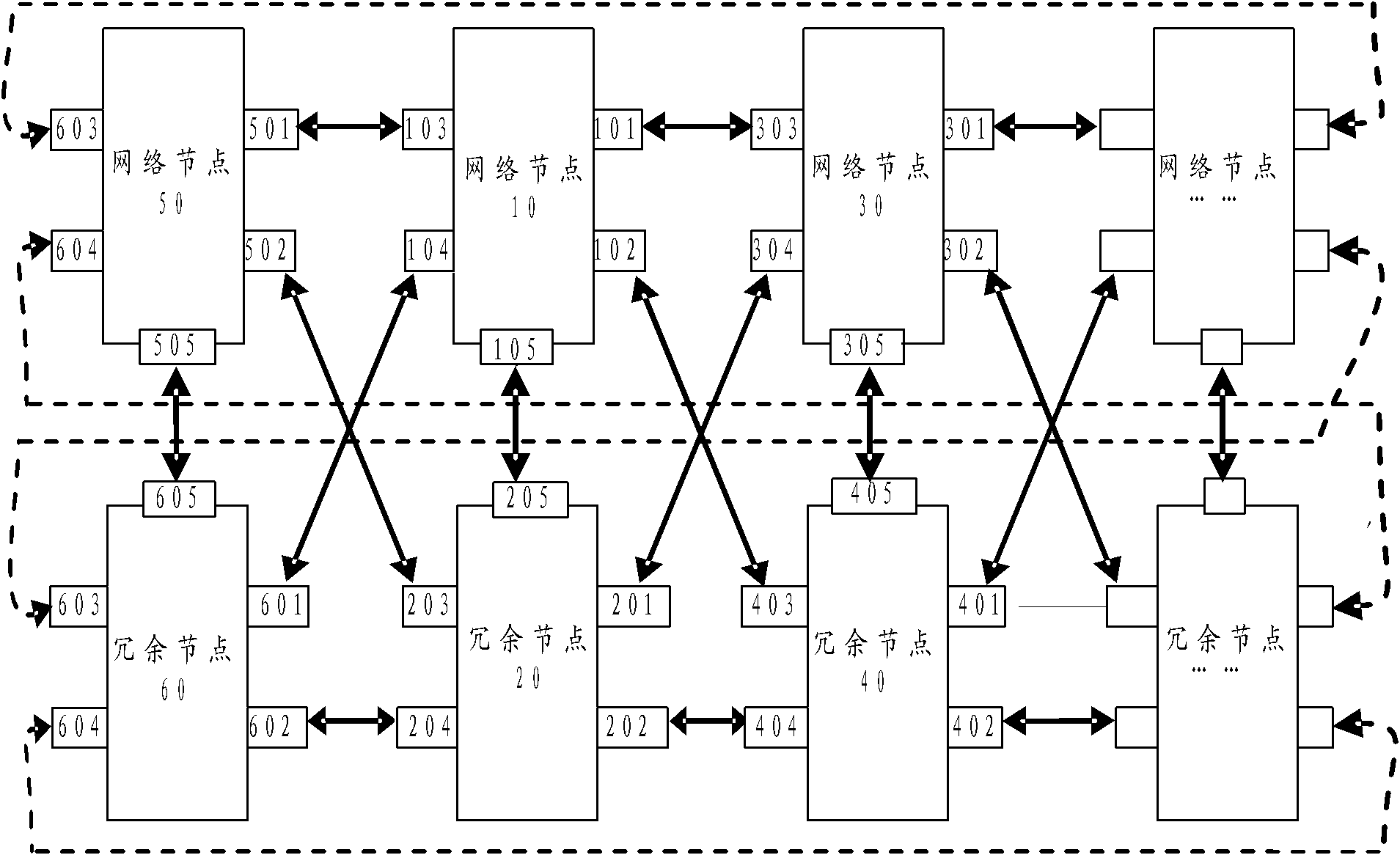

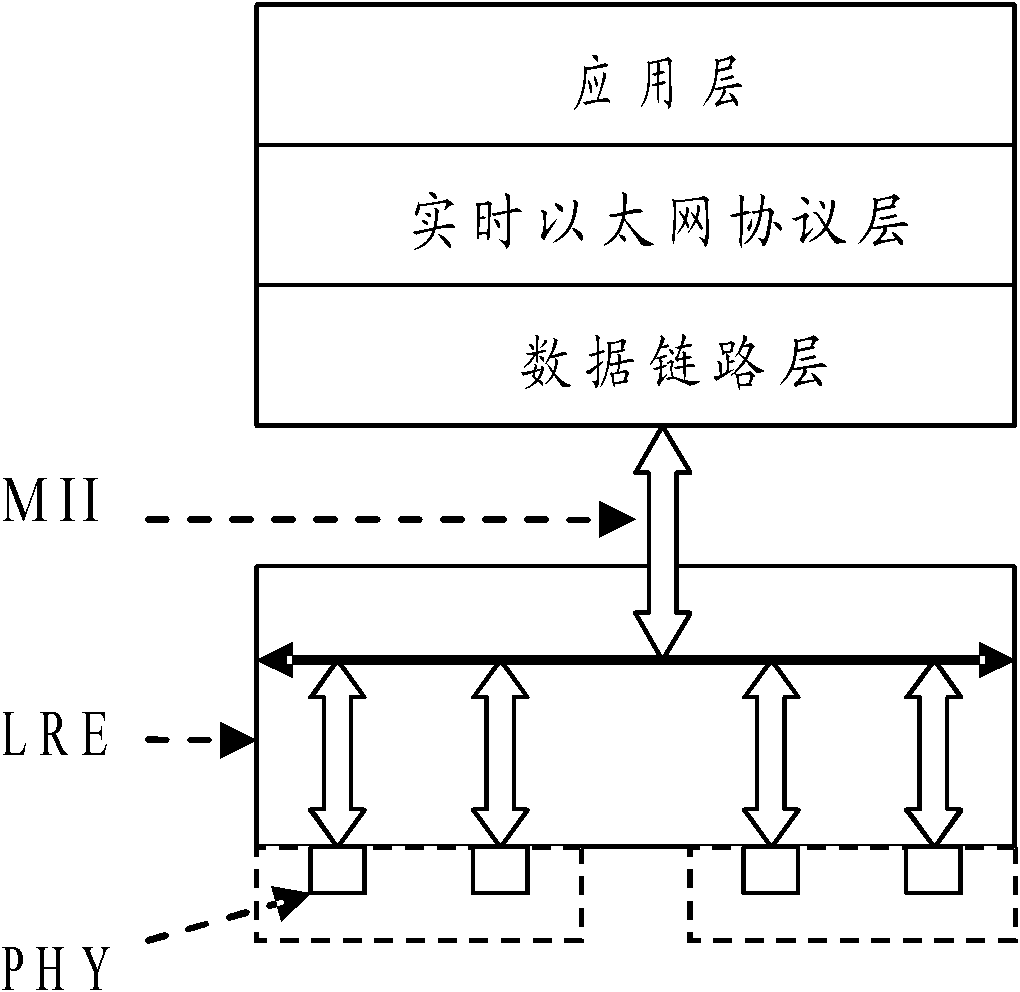

Hot standby redundancy network system and redundancy realization method

InactiveCN102082695ANormal operation does not affectGuaranteed uptimeError preventionData switching networksCross connectionLogical address

The embodiment of the invention discloses a hot standby redundancy network system and a redundancy realization method, which can be suitable for real-time Ethernet. The hot standby redundancy network system comprises at least two network nodes and redundancy nodes which are in one-to-one correspondence with the network nodes, wherein each network node and each redundancy node both comprise four network interfaces and one exchange interface, the four network interface are all provided with the same physical address and logic address, the four network interfaces make up two pairwise redundancy interface in pairs, the network nodes are connected with the corresponding redundancy nodes through the exchange interfaces to make up redundancy node pairs, and the network nodes of the adjacent redundancy node pairs are in cross connection with the redundancy nodes though the network interfaces. With the scheme, the failure rate of the real-time Ethernet is insensitive to the increase of the number of the network nodes, the data message format of the real-time Ethernet does not need to be modified, the failure rate of the real-time Etherent can be obviously reduced, and the redundant degree and the usability of the real-time Etherent can be greatly increased.

Owner:SUPCON GRP +1

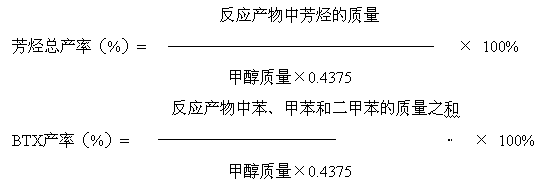

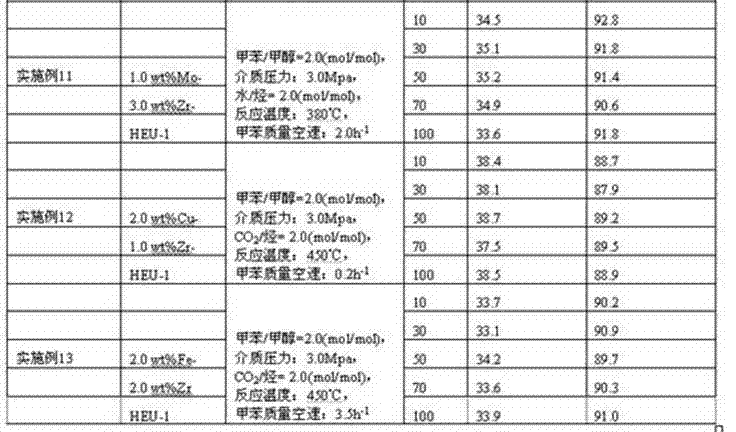

Method for improving the selectivity and reaction stability of arene prepared in methanol aromatization manner

InactiveCN103288582AThe production is conducive toHigh yieldHydrocarbon from oxygen organic compoundsBulk chemical productionMolecular sievePtru catalyst

The invention relates to a method for improving the selectivity and reaction stability of an arene product prepared in a methanol aromatization manner, and is used for preparing the arene in the methanol aromatization manner through the catalysis of a molecular sieve under the action of a carbon dioxide reaction medium. The method comprises the following steps: under the action of the carbon dioxide medium, by taking methanol as a raw material, preparing the arene in the methanol aromatization manner through a molecular sieve based catalyst containing a metal additive under the conditions that the reaction temperature ranges from 340 to 540 DEG C, the methanol reaction airspeed is maintained for 0.1 to 5.0 hours, the reaction pressure ranges from 0.1 to 5.0MPa and the molar ratio of the carbon dioxide to the methanol is 0.5-5.0 (mol / mol). According to the method, a large quantity of excess greenhouse gases, namely the carbon dioxide, serve as the reaction medium; the molecular sieve containing the metal additive serves as the catalyst, so that the selectivity and reaction stability of the arene in a methanol aromatization product are improved effectively. Thus, the method meets the requirement of an industrial application basically.

Owner:TONGJI UNIV

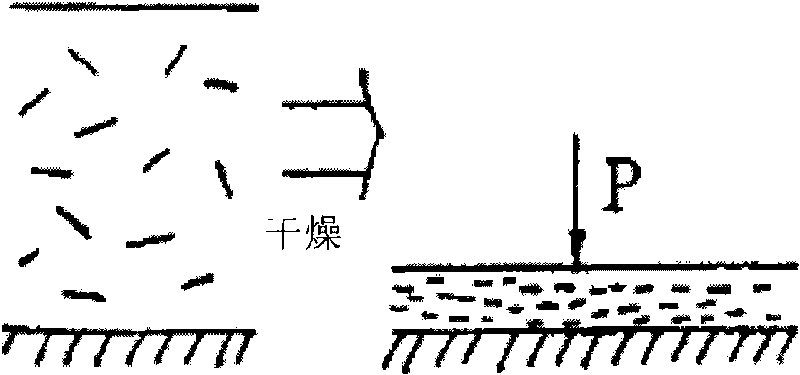

Iron-based powder porous surface heat-exchanging tube and manufacture method thereof

ActiveCN101251351ALower sintering temperatureGuaranteed bonding strengthHeat transfer modificationTubular elementsMechanical propertyMaterials science

The invention discloses an iron-based powder porous surface heat exchange tube and a preparation method thereof. The heat exchange tube is formed by a tube base body and a porous surface layer; the porous surface layer takes fine grained power of iron or an iron alloy as the main composition, contains a low melting point alloy element and is formed by sintering; the porous surface layer can be positioned at any side of the inner side and the outer side of the tube, the other corresponding side can be a smooth surface or a structure provided with an enhanced condensing characteristic. The preparation method is that: an organic bonding agent and metal powder of an iron-based alloy are evenly mixed; the mixture is coated on the outer surface or the inner surface of the tube; the coated tube is dried; the tube is sent into a sintering furnace to decompose the organic bonding agent; the tube is sintered under the temperature not higher than the regular normalizing or annealing heat treatment temperature of the material; the speed of temperature reduction is controlled to assure the structure and the mechanical property required by the heat exchange tube. The heat exchange tube and the preparation method have the advantages that: the sintering temperature is lower, the mechanical performance of the tube material is basically unchanged, and the heat exchange tube has high efficiency and low cost, and can meet the requirement of the industrialized application.

Owner:EAST CHINA UNIV OF SCI & TECH

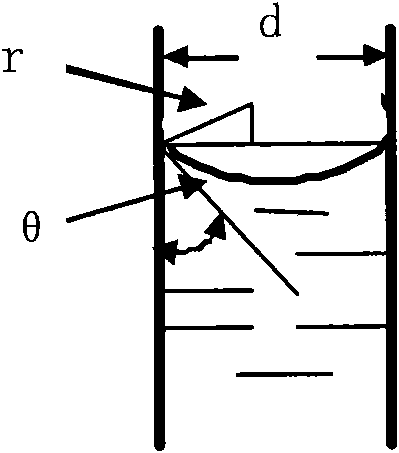

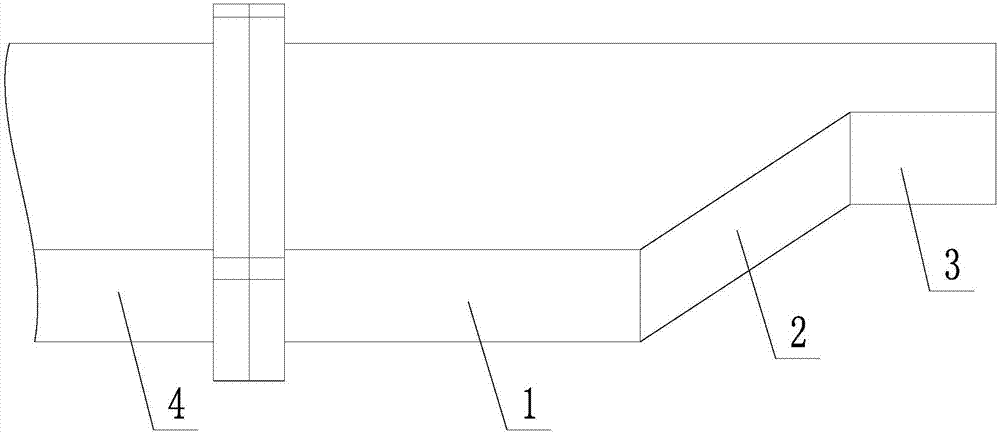

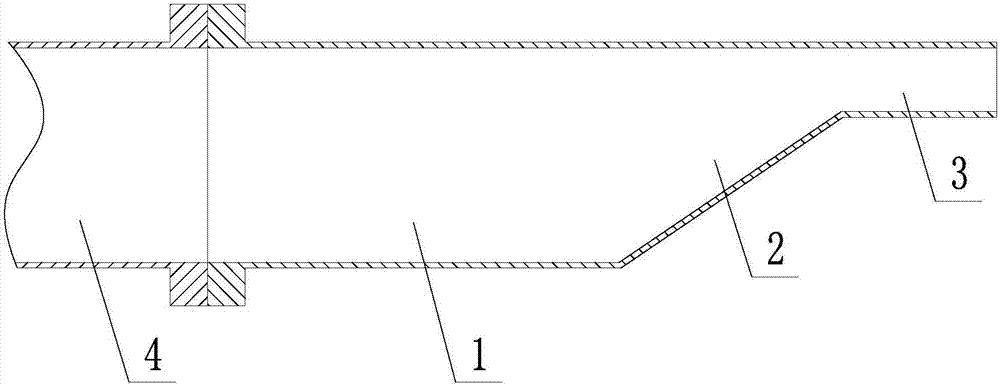

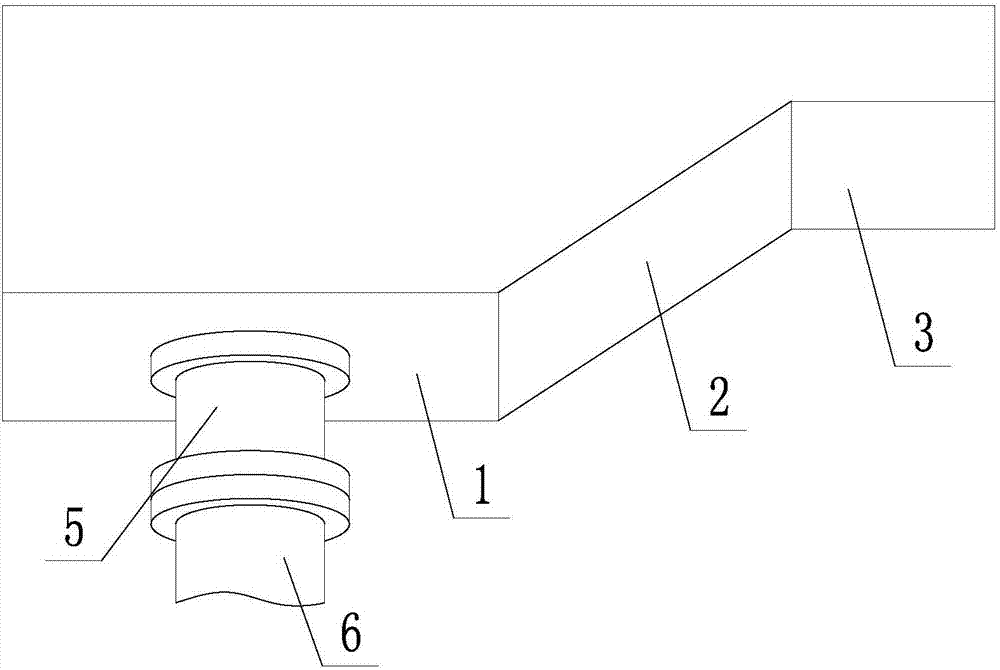

Rock surface fracturing microwave focusing radiator

InactiveCN107035316AImprove absorption efficiencyGuaranteed cracking effectDisloding machinesDrilling machines and methodsMicrowaveCoaxial cable

A rock surface fracturing microwave focusing radiator comprises a standard waveguide section, an impedance matching section and a compression radiation section. The standard waveguide section is used for allowing microwaves transmitted by a microwave source to be connected and is connected with the compression radiation section through the impedance matching section which forms impedance matching between the standard waveguide section and the compression radiation section. The compression radiation section radiates the focused microwaves outwards. The standard waveguide section and the compression radiation section both adopt uniform section rectangular metal cavities, and the impedance matching section adopts a variable section rectangular metal cavity. The wide edge sizes of the standard waveguide section, the impedance matching section and the compression radiation section are matched with the wave length of the microwaves transmitted by the microwave source. The longitudinal narrow edge size of the impedance matching section is in linear transition from large to small. The large size end of the impedance matching section is connected with the standard waveguide section, and the small size end of the impedance matching section is connected with the compression radiation section. The standard waveguide section has two microwave connection structure forms, the first microwave connection structure form is that the microwaves are connected through a rectangular waveguide or annular device, and the second microwave connection structure form is that the microwaves are connected through a coaxial converter and a coaxial cable.

Owner:NORTHEASTERN UNIV

Preparation of red strontium sulphide long afterglow material

InactiveCN101328405AEasy to controlWell mixedLuminescent compositionsSolubilitySurface-active agents

The invention discloses a method for preparing a red strontium sulphide long afterglow material, comprising a hydrothermal coprecipitation method which comprises the following steps that: (a) water-solubility strontium salt, water-solubility europium salt, water-solubility dysprosium salt, carbamide and water are weight according to the mol ratio of 1: between 0.01 and 0.05: between 0.01 and 0.05: between 4 and 6: between 28 and 32 and are put inside a container to be stirred and dissolved, the mixture is insulated in a sealing state at a temperature of between 80 and 160 DEG C for 5 to 24 hours so that a precursor is obtained; (b) the precursor is subject to filtering and annealing at a temperature of between 900 and 1200 DEG C in the reaction environment for 0. 5 to 2 hours so that the red strontium sulphide long afterglow material is prepared; the water-solubility strontium salt is strontium nitrate or strontium chloride or strontium acetate, the water-solubility europium salt is europium nitrate, europium chloride or polyimide, the water-solubility dysprosium salt is dysprosium nitrate or dysprosium chloride or dysprosium acetate, and a surface active agent is added according to the mol ratio of the water-solubility strontium salt to the surface active agent of 1: between 0.0001 and 0.0003. The method is widely applied to the fields such as building decoration, traffic transportation, military facilities, fire emergency service and goods for everyday consumption.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-voltage repetitive pulse generating apparatus and method for electric pulse breakage

InactiveCN106452159AReduce usageReduce equivalent inductancePulse generation by energy-accumulating elementVoltage amplitudeComputer module

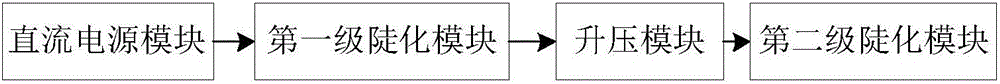

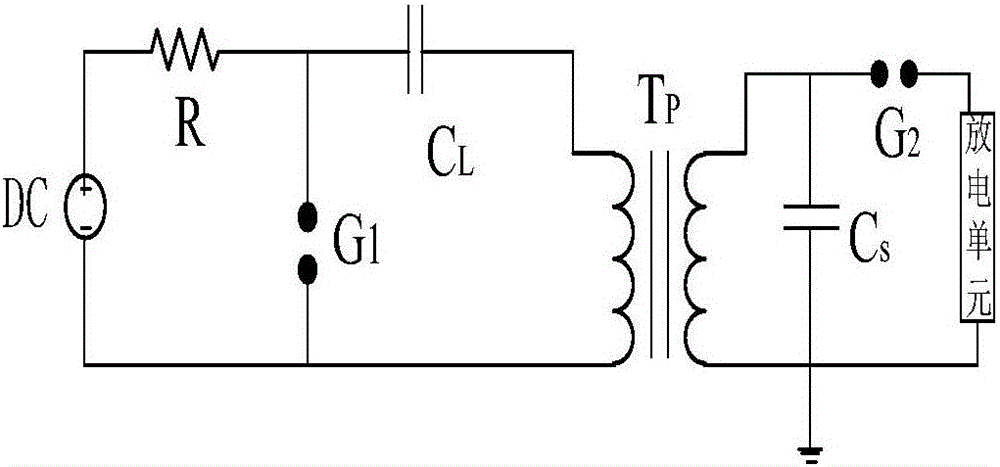

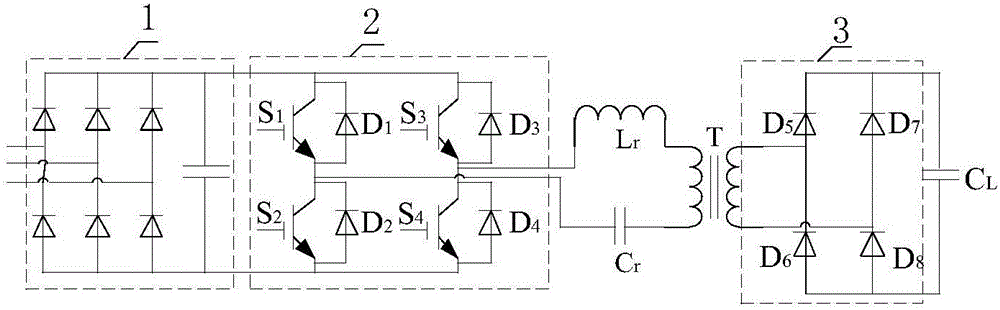

The invention discloses a high-voltage repetitive pulse generating apparatus and method for electric pulse breakage. The apparatus is composed of a direct-current power supply module, a first-stage steepening module, a boost module, and a second-stage steepening module. The direct-current power supply module is used for outputting a direct-current voltage. The first-stage steepening module connected with the direct-current power supply module converts a direct-current voltage into a pulse voltage with the period at a microsecond level. The boost module connected with the first-stage steepening module amplifies the pulse voltage with the period at a microsecond level. And the second-stage steepening module connected with the boost module carries out steepening processing on the amplified pulse voltage with the period at a microsecond level, so that the pulse voltage having a large output amplitude and a rising edge at a nanosecond level. The first-stage steepening module and the second-stage steepening module carry out steepening processing on the pulse voltage and the boost module amplifies the pulse voltage, so that the apparatus having a simple structure is easy to operate for long time. Using the high-voltage repetitive pulse generating apparatus, the high-voltage pulse having the rising edge within 400 ns, the voltage amplitude of 200kV, the frequency of 5Hz, and the single-shot energy of 900J can be provided; and thus breaking work of various rocks and polycrystalline silicon bars can be completed by cooperation with a discharging electrode.

Owner:HUAZHONG UNIV OF SCI & TECH

Dust-removal mercury-removal filter bag for bag-type dust remover and preparation method of filter bag

The invention discloses a dust-removal mercury-removal filter bag for a bag-type dust remover. The dust-removal mercury-removal filter bag is bag which is loaded with a mercury-removal catalyst and made of high-temperature filtration fiber; and the mercury-removal catalyst is a mixture of manganese oxide and cobalt oxide. The invention further discloses a preparation method of the dust-removal mercury-removal filter bag; the filter bag is loaded with the mercury-removal catalyst and applied to the bag-type dust collector; the catalyst can be used for oxidizing elemental mercury in coal-fired flue gas into bivalent mercury (Hg2+), so that absorption or adsorption of a flue gas pollutant purifying device is facilitated. The dust-removal mercury-removal filter bag is applied to controlling mercury emission of a coal-fired power plant, so that adsorbent is substituted by catalytic oxidation; on the basis of keeping the smoke dust removal effect, the removal efficiency of the elemental mercury is bigger than 30%, so that the flue gas mercy removal effect of the coal-fired power plant can be satisfied.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

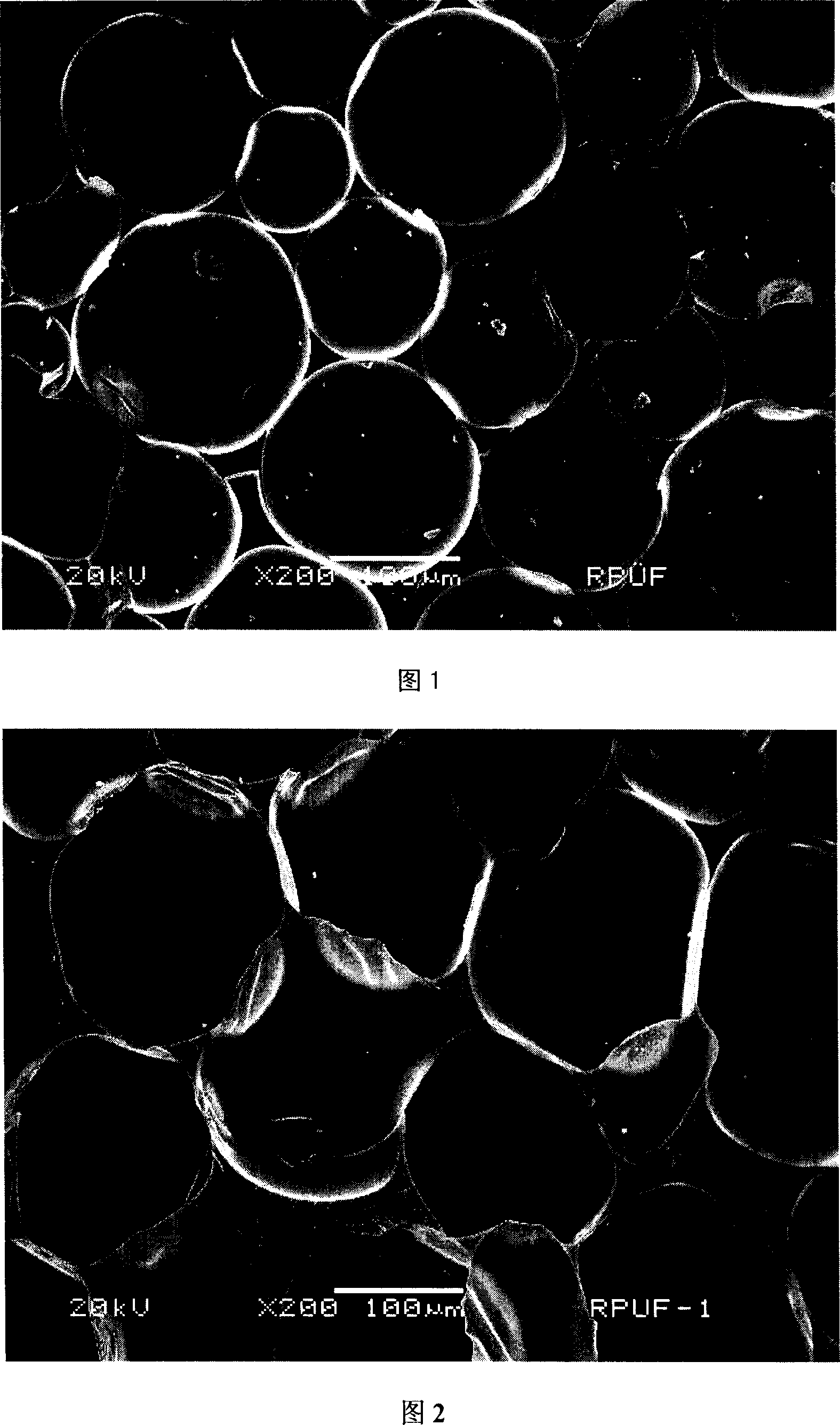

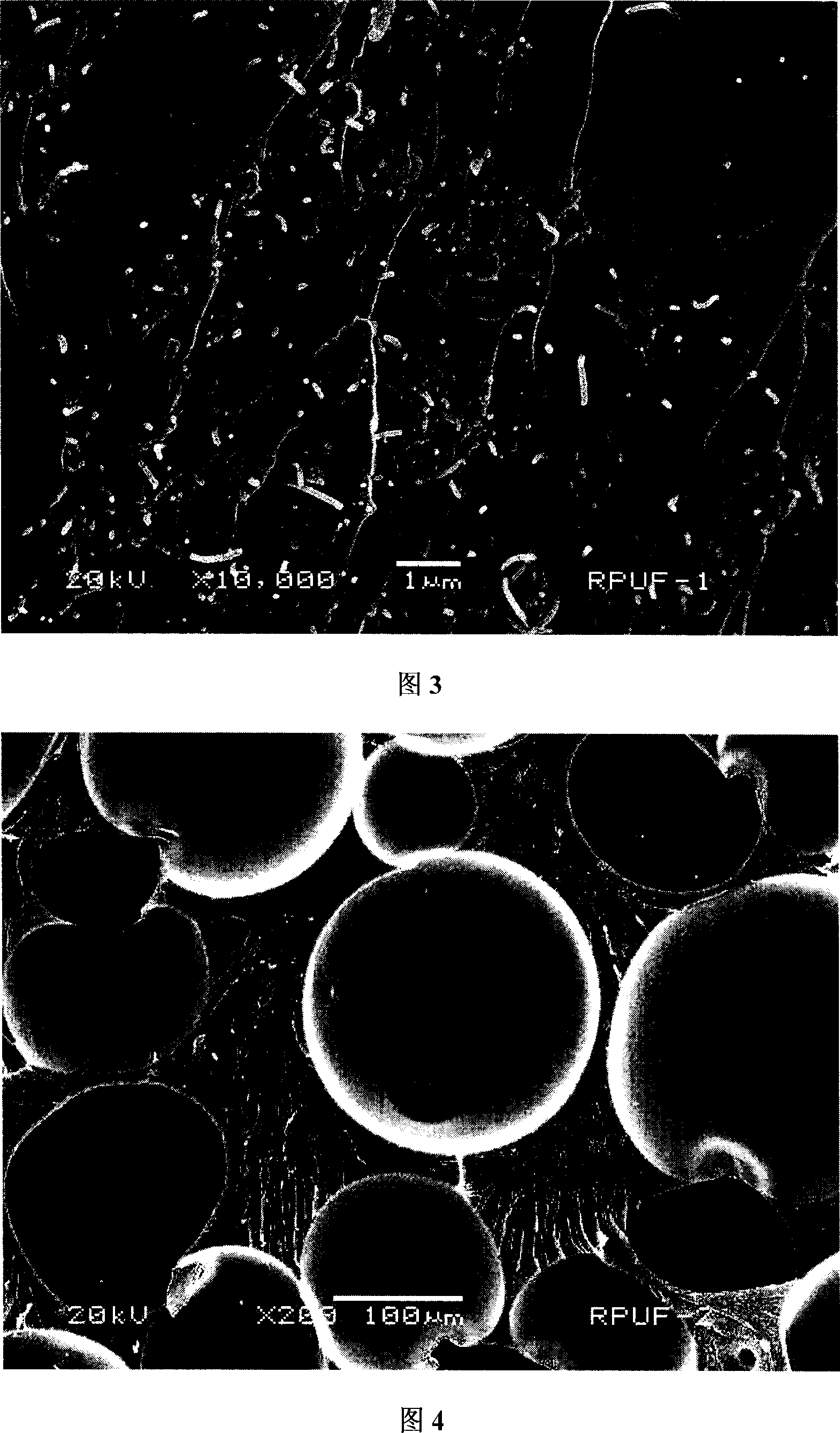

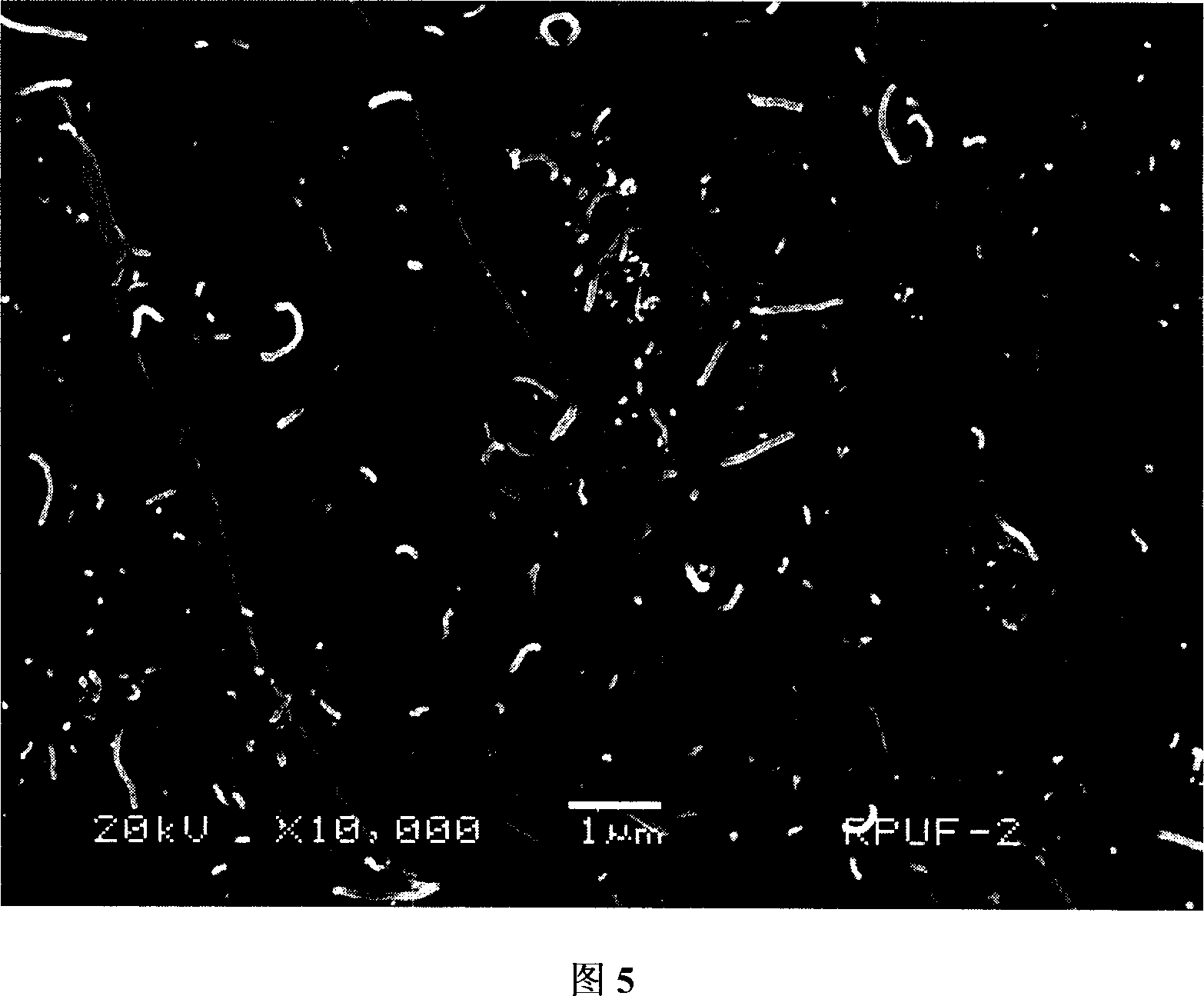

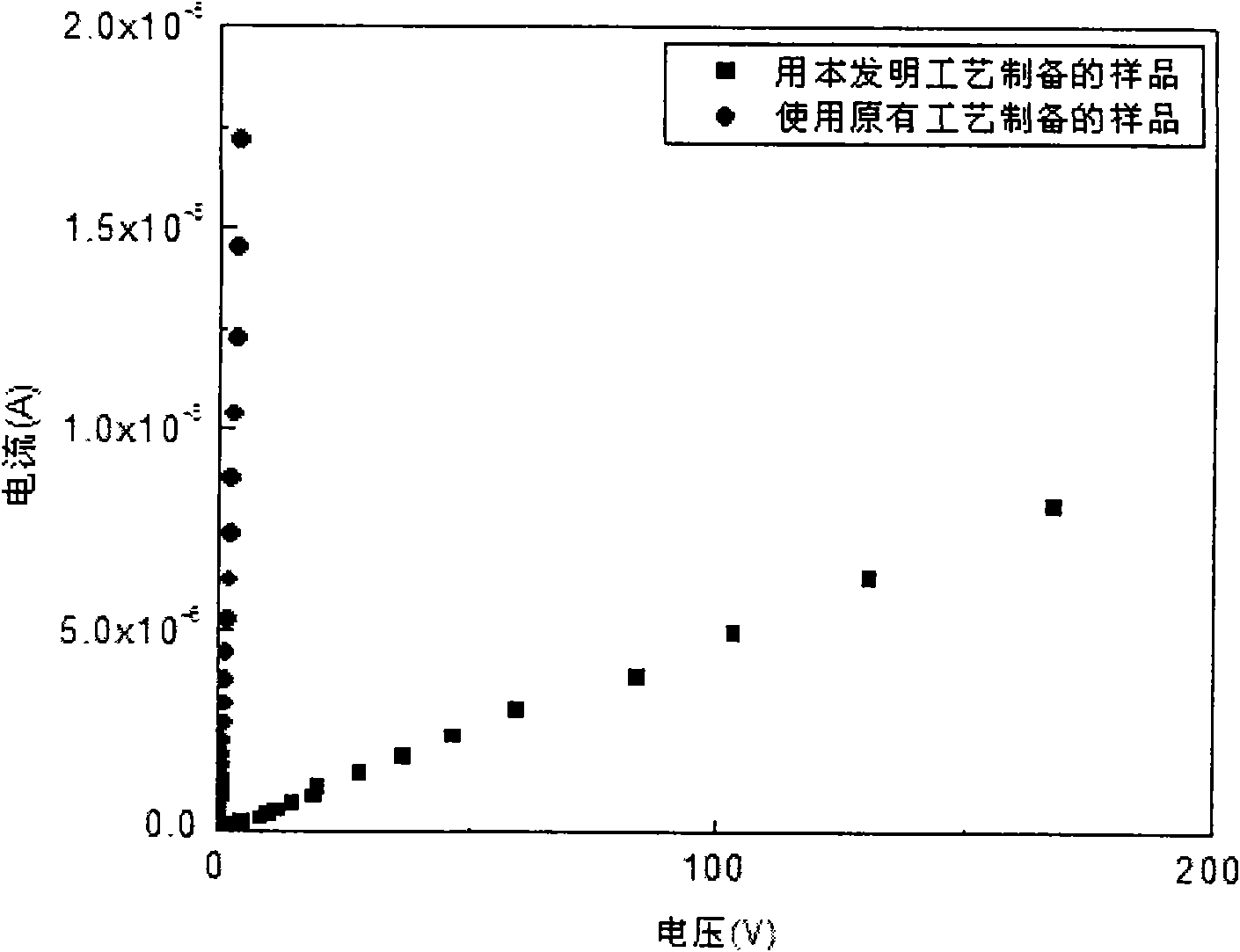

Preparation of hard polyurethane conductive foam plastic for carbon nanotube filling

InactiveCN1970598AImprove electrical conductivityImprove mechanical propertiesIsocyanateCarbon nanotube

The invention discloses a making method and device of carbon nanometer pipe with high-density conductive hard-polyurethane foam plastic, which comprises the following steps: oxidizing the surface of carbon nanometer pipe; adopting distilled water as diluent; vibrating and grinding through ultrasound; dispersing carbon nanometer pipe in the polyether polyol; evaporating water in the system; obtaining the composite liquid of carbon nanometer pipe and polyether polyol; blending with organic tin, silicon oil and water according to certain proportion through mechanic stirring device evenly; mixing with certain quantity of isocyanate completely; casting in the mould; closing mould lid; ripening; obtaining the product.

Owner:SICHUAN UNIV

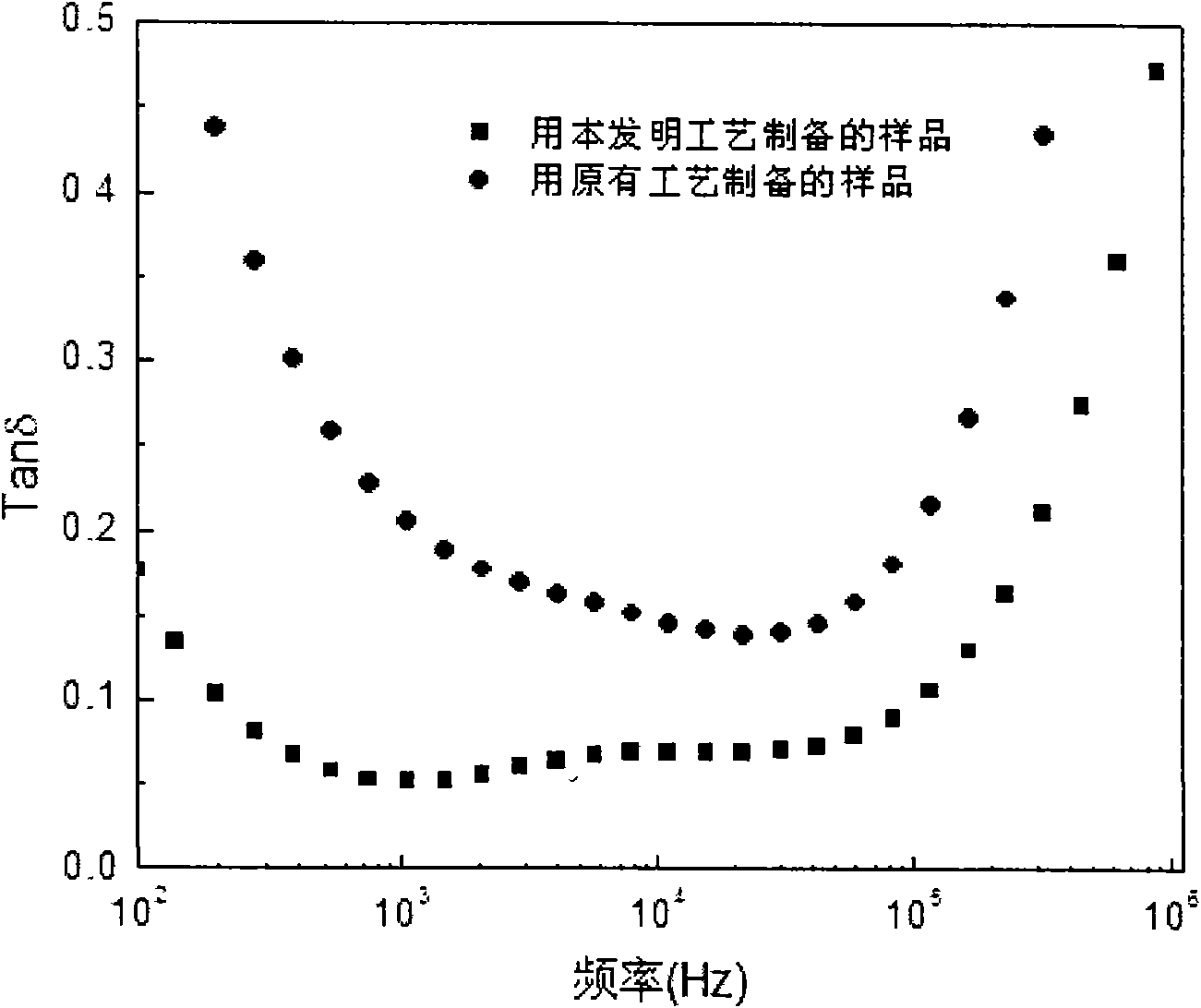

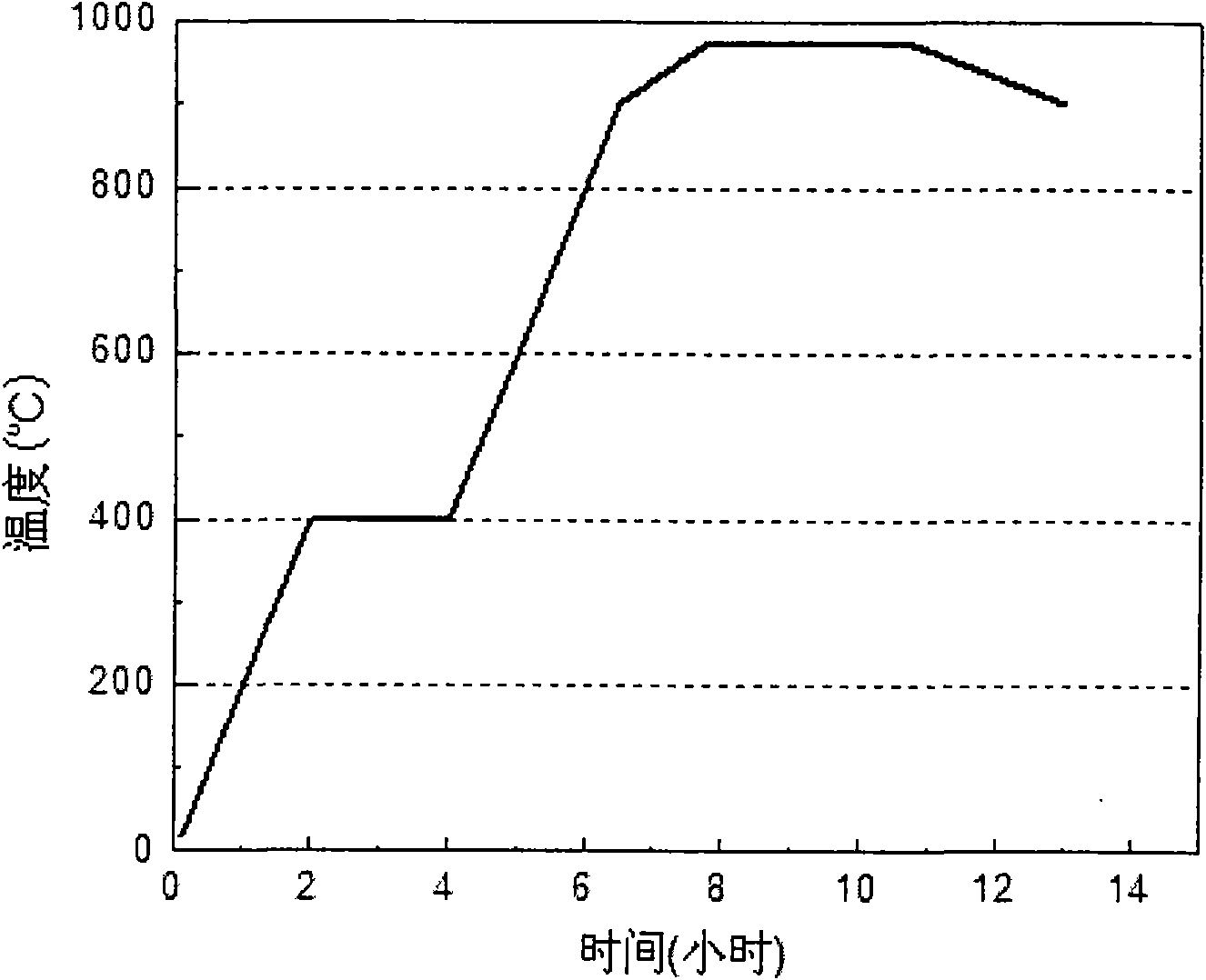

Method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics

ActiveCN101671174ASolve the problem of too much conductivitySuitable for industrial applicationsCeramic sinteringChemical reaction

The invention relates to a method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics, belonging to the technical field of high dielectric ceramic materials. The calcium copper titanate ceramics are prepared from initial raw materials of CaCO3 or CaO, CuO and TiO2, wherein after being mixed, the raw materials are processed by mix grinding and then processed by presintering at the temperature from 800 DEG C to 950 DEG C after mix grinding, hard blocks after presintering are cracked to be ground, and the powdered materials after presintering and grinding are prepared into green bodies with predetermined shapes; and the green bodies are heated to the sintering temperature ranging from 960 DEG C to 990 DEG C from room temperature, and heat preservation is carried out for 1 to 24 hours at the sintering temperature, thereby realizing the sintering densification of the ceramics. The preparation method controls performance parameters by controlling technological parameters, and structural changes and chemical reactions in a sintering process. The ceramic materials prepared by the method can meet the requirement on industrial application; and simultaneously, compared with the prior art, the preparation method can obviously reduce the energy consumption, is environment-friendly and reduces the production cost.

Owner:TSINGHUA UNIV

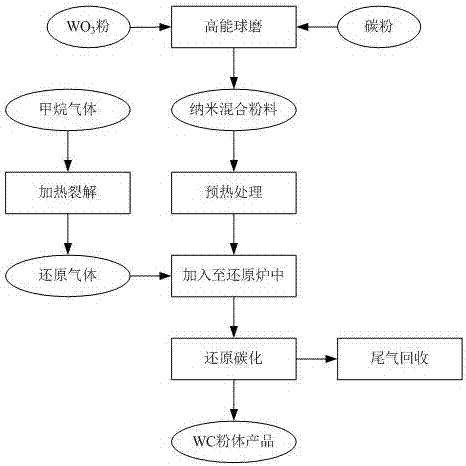

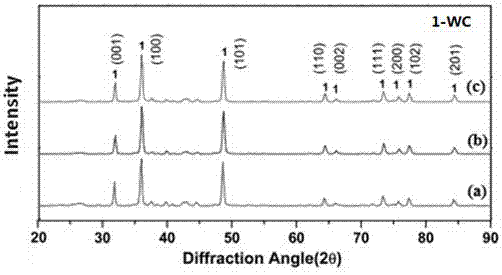

Method for preparing WC (wolfram carbide) powder by utilizing CH4 to reduce and carbonize WO3

ActiveCN107089662AWide variety of sourcesLow costMaterial nanotechnologyTungsten/molybdenum carbideActivated carbonHydrogen

The invention provides a method for preparing WC (wolfram carbide) powder by utilizing CH4 to reduce and carbonize WO3. The method effectively utilizes methane to directly reduce and carbonize WO3 nanopowder to obtain a WC powder product. The source of the methane gas is wide and the cost is low. Highly activated carbon and hydrogen of methane pyrolysis directly participate in reduction and carbonization reaction, WO3 can be reduced and carbonized under a low-temperature environment of 600 DEG C to 800 DEG C for 30 to 90 minutes, and thereby the WC powder product is prepared. The reduction and carbonization temperature is low, the time is short, the energy consumption and cost of production can be remarkably reduced, the method is used for implementing the large-scale low-cost industrial production of WC powder, moreover, the prepared WC powder has small average grain size, large specific surface area, good mechanical properties and good sphericity, the requirement of industrial application can be effectively met, and the WC powder can be used for preparing high-performance ultrafine-grain hard cemented carbide and highly activated wolfram carbide catalyst.

Owner:CHONGQING UNIV

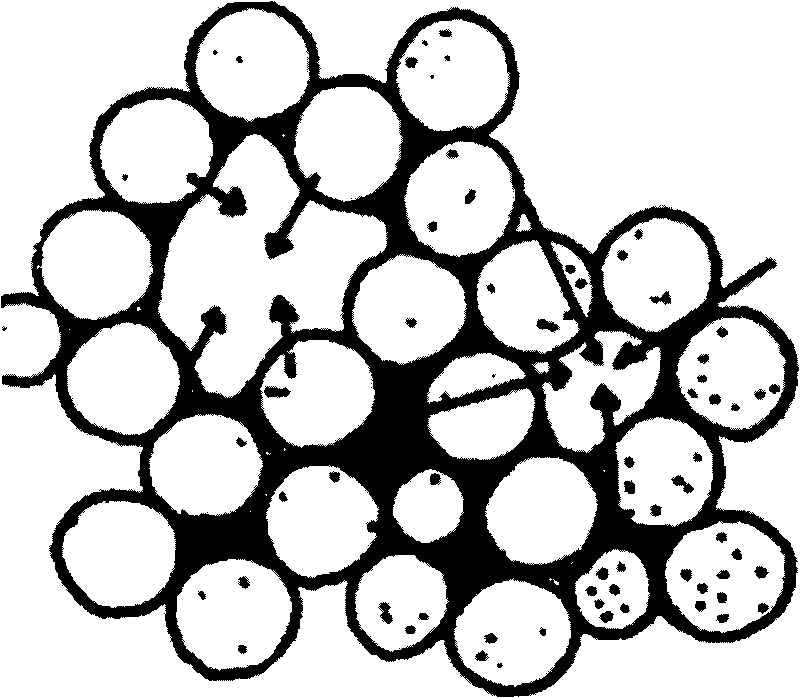

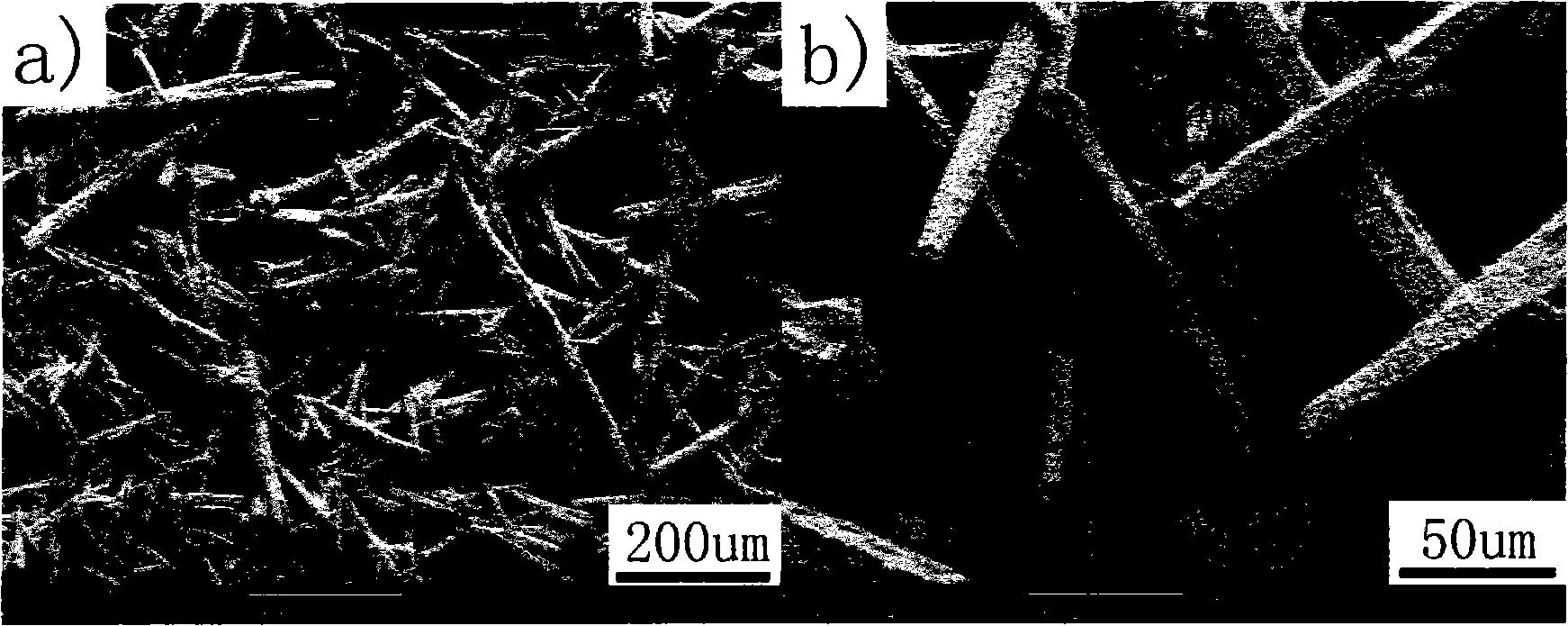

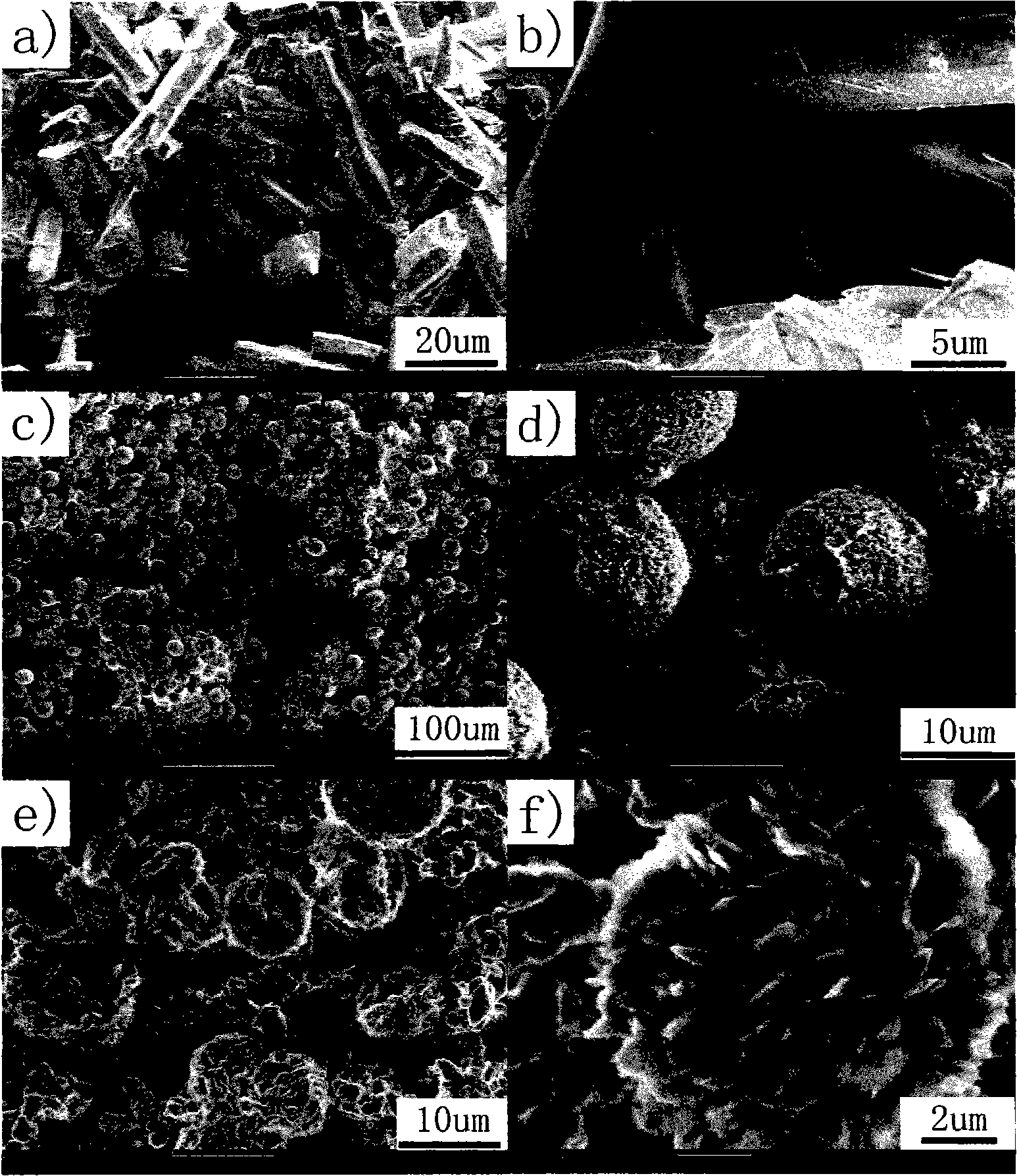

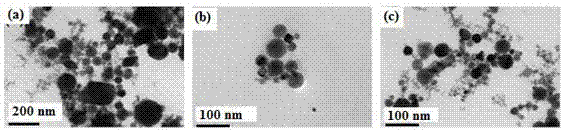

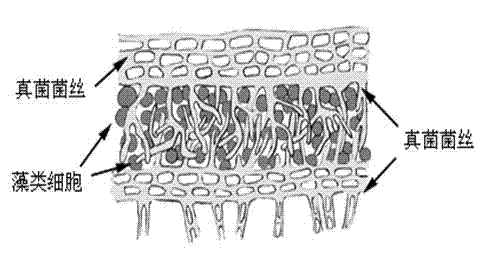

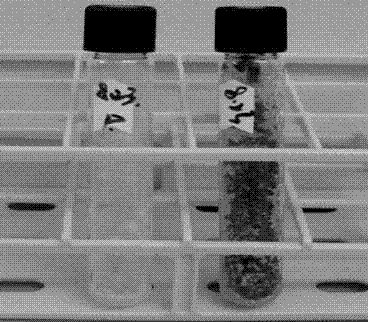

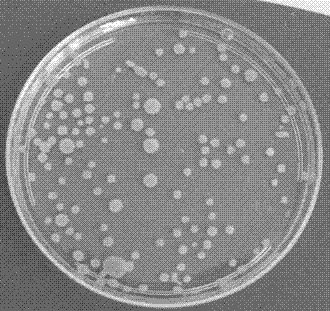

Harvesting method of microalgae mediated by fungus

InactiveCN102391953AControl the cost of collectionEconomic gainUnicellular algaeMicroorganism based processesHigh densityFiltration

The invention provides a harvesting method of microalgae mediated by fungus. The method is characterized by comprising the following steps: (1) transferring microalgae; (2) culturing the microalgae in high density; (3) culturing spores of fungus capable of balling; (4) adding fresh spore suspension into a microalgae culture medium; (5) forming a fungus-mediated large-grained fungus-algae homobium; and (6) harvesting the large-grained bacillus-algae homobium by a filtration method. According to the method, the fungus strain capable of balling is introduced and cultured in a mixing way in the microalgae culture medium to be harvested, so that the aim of symbiosis and balling of fungus and microalgae can be achieved, and the fungus-mediated large-grained fungus-algae homobium can be harvested by virtue of a simple filtration method.

Owner:NANCHANG UNIV

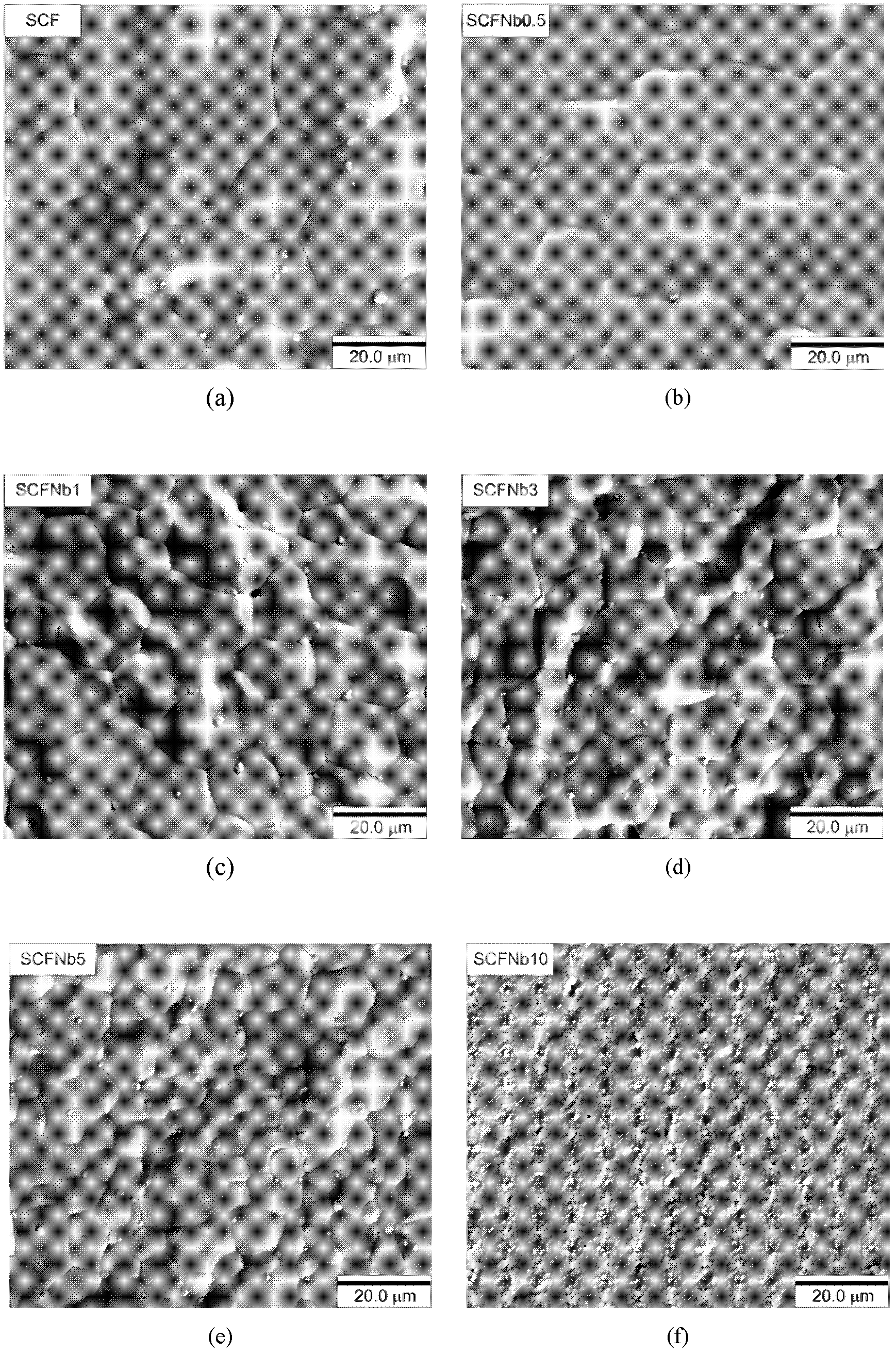

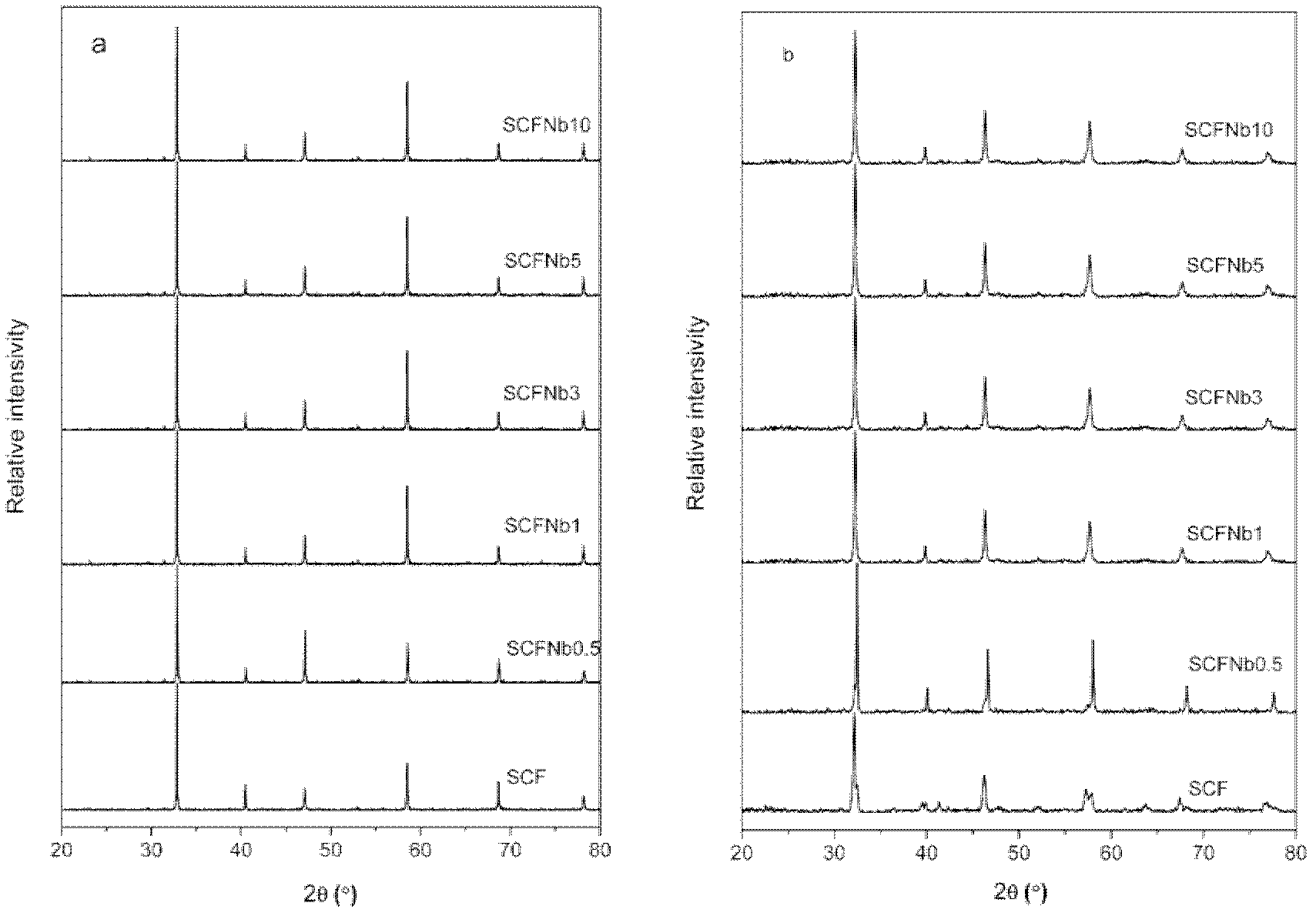

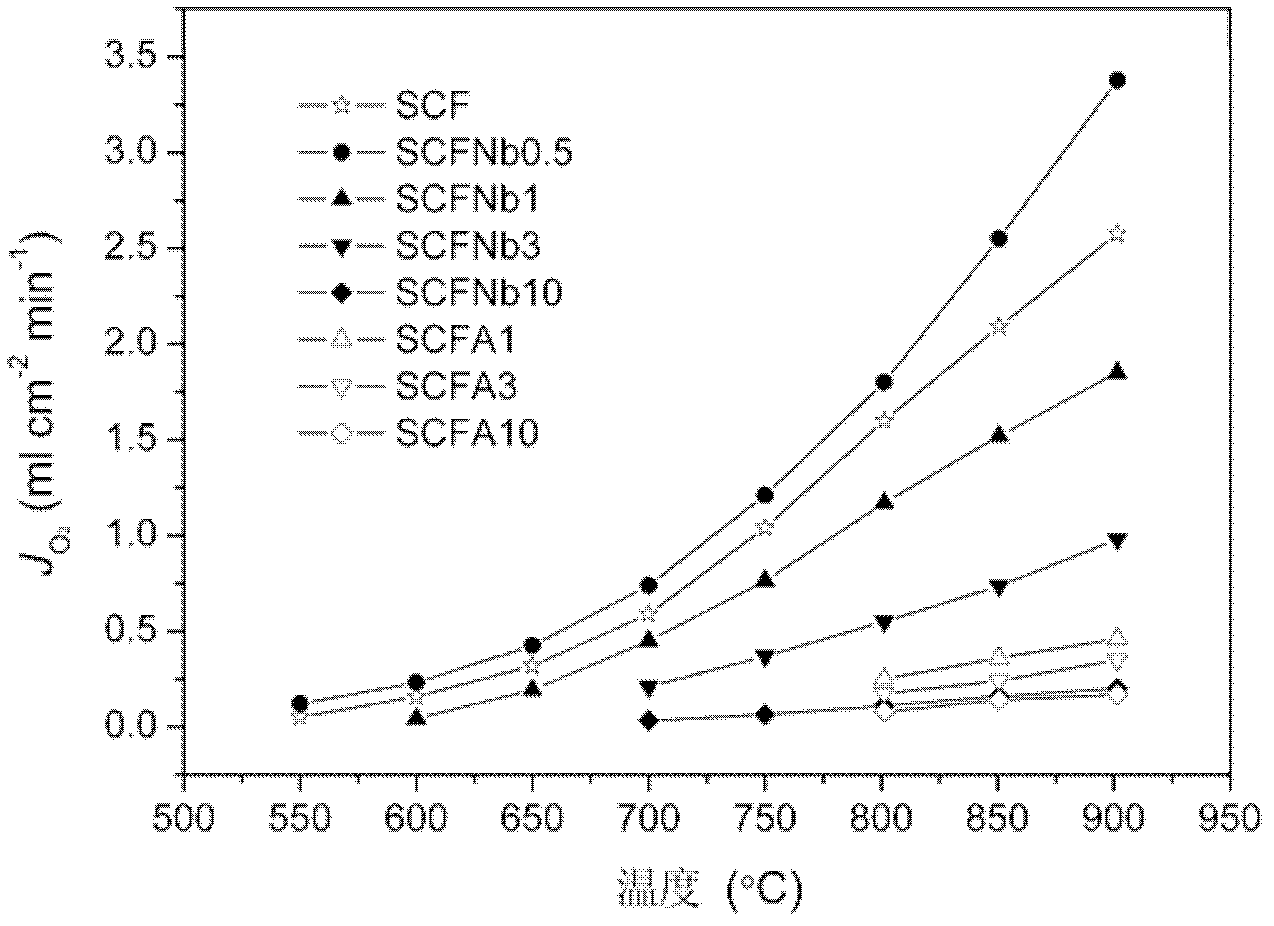

Oxide-doped medium-low temperature mixed conducting oxygen-permeable membrane material and its preparation method

The invention relates to an oxide-doped medium-low temperature mixed conducting oxygen-permeable membrane material and its preparation method. The material provided by the invention is a composition of a perovskite oxide and a simple metal oxide. The general formula of the perovskite oxide is C1-xC'xDyD'1-yO3-delta, wherein x is less than 1 and greater than or equal to 0; y is less than 1 and greater than or equal to 0; delta is less than 0.5 and greater than minus 0.5; C and C' both contain any one element selected from La, Pr, Nd, Sm, Gd, Ba or Sr; D and D' both contain any one element selected from Cr, Mn, Fe, Co, Ni, Cu, Zn or Bi. The simple metal oxide is one component selected from the group consisting of vanadium oxide, niobium oxide, thallium oxide, chrome oxide or molybdena. The weight of the doped simple oxides accounts for 0.01-15% the gross weight of the composition. According to the oxygen-permeable membrane material provided by the invention, the stability of a host material can be greatly raised at low oxygen partial pressure by a few doped simple oxides, and high oxygen permeable capability of the material can be maintained. The preparation method provided by the invention endows the material with more excellent medium-low temperature performance, is applicable to be operated at low oxygen partial pressure for a long time, and meets the requirement of large-scale industrial application.

Owner:NANJING UNIV OF TECH

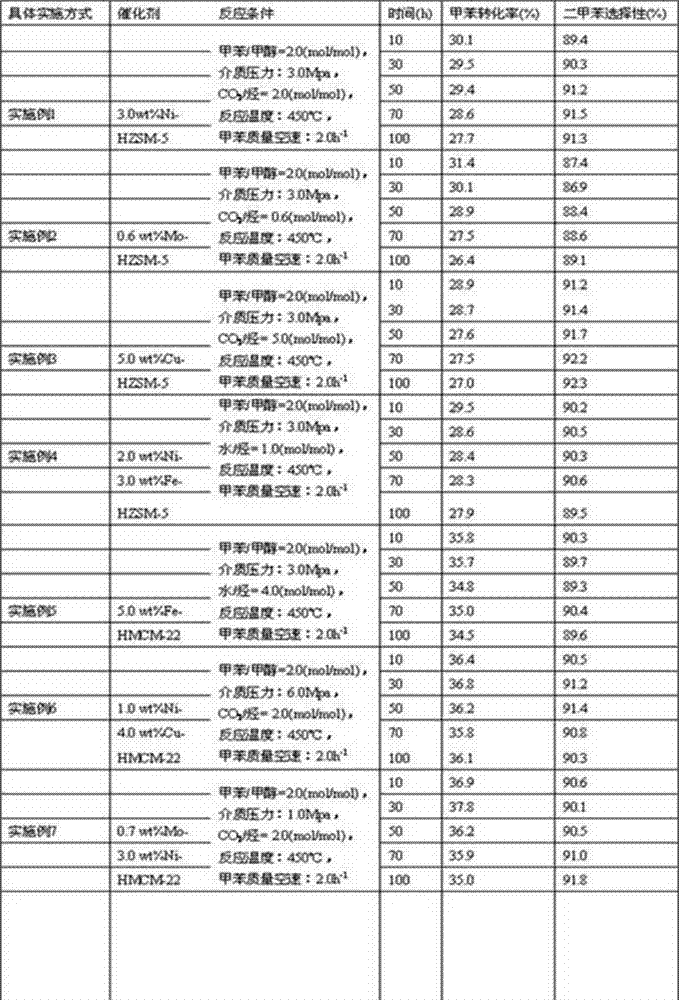

Method for improving reaction stability for synthesizing xylene through toluene and methanol alkylation

InactiveCN102951993AAvoid inactivationImprove reaction stabilityHydrocarbon by hydrocarbon and non-hydrocarbon condensationBulk chemical productionMolecular sieveEnvironmental chemistry

The invention relates to a method for improving reaction stability for synthesizing xylene through toluene and methanol alkylation. The method is used for realizing preparation of the xylene through the toluene and methanol alkylation via molecular sieve catalysis under the condition that carbon dioxide or water vapor is used as a reaction medium. The method comprises the following steps of: taking mixture of the toluene and the methanol according to a ratio of the toluene to the methanol which is equal to 1.0-4.0 (mol / mol) as a raw material under the condition that carbon dioxide or water vapor is used as the reaction medium; keeping toluene reaction air speed at 0.1-3.5 h<-1> at reaction temperature of 380-540 DEG C; keeping pressure of the reaction medium at 1.0-6.0 MPa; keeping the ratio of the carbon dioxide to hydrocarbon at 0.5-5.0 (mol / mol) or the ratio of the water to the hydrocarbon at 1.0-4.0 (mol / mol); and realizing synthesis of the xylene through the toluene and methanol alkylation via the molecular sieve shape-selective catalyst containing a metal auxiliary agent. According to the method, a large amount of redundant greenhouse gas carbon dioxide is used as the reaction medium, and the problem of poor reaction stability in the conventional toluene and methanol alkylation process is solved while the xylene is prepared at high yield, so that the reaction stability reaches the standard of industrial application.

Owner:TONGJI UNIV

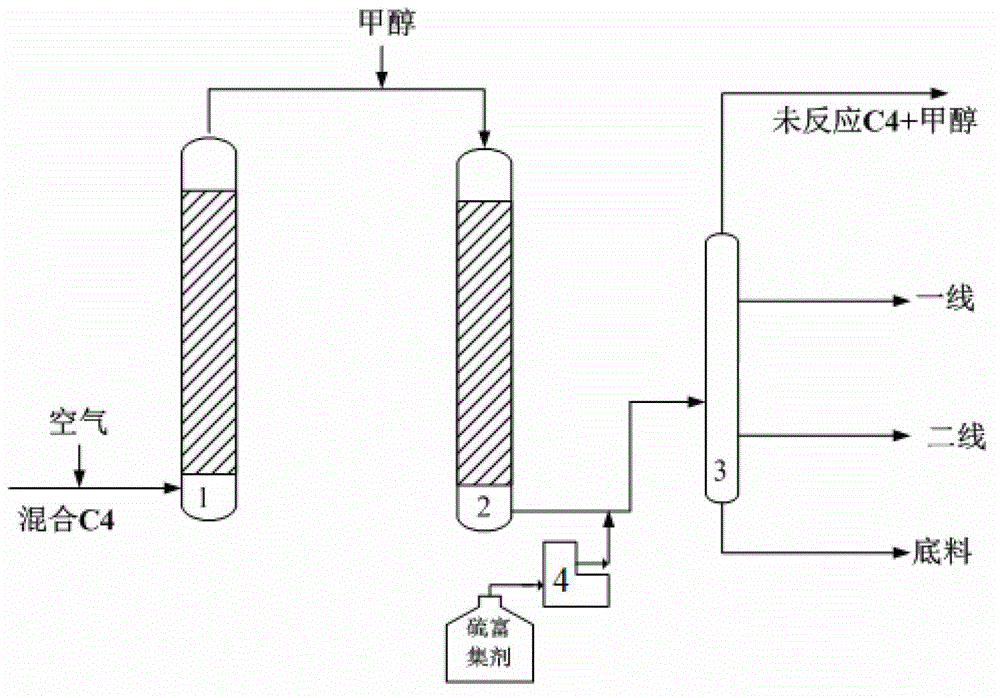

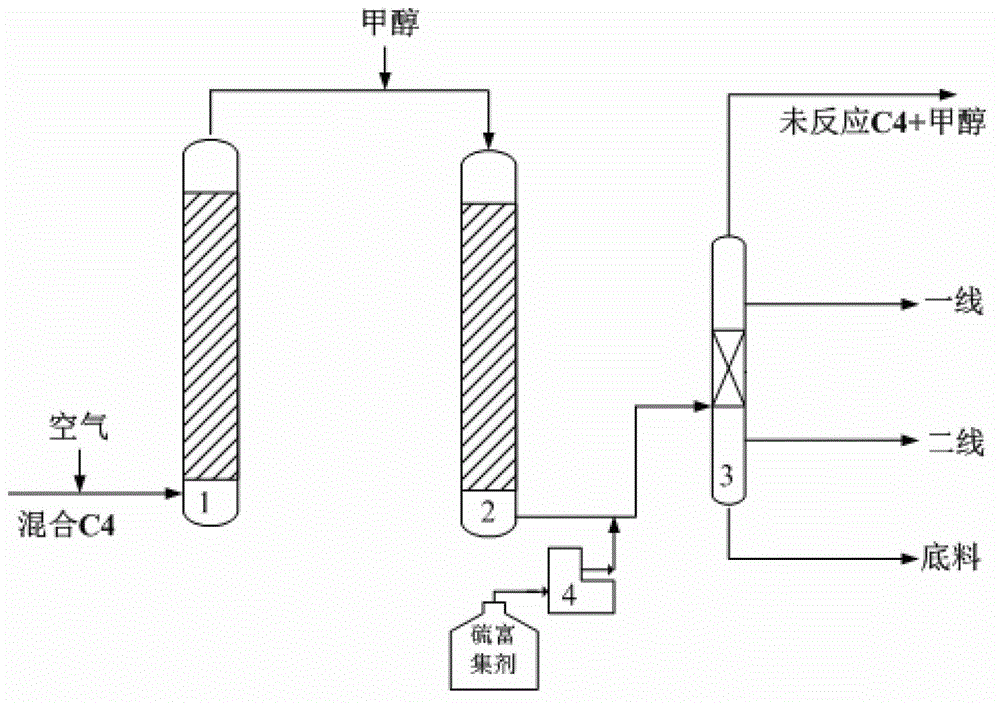

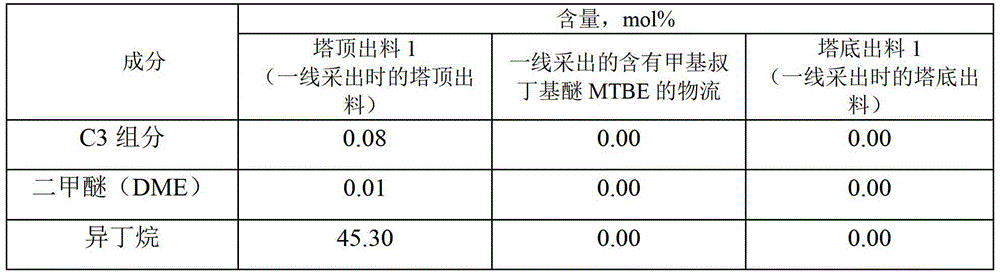

Methyl tert-butyl ether crude product purification method and methyl tert-butyl ether production method

ActiveCN104370708AReduce energy consumptionLow investment costEther separation/purificationChemical industryPurification methodsSulfide

The invention provides a methyl tert-butyl ether crude product purification method and a methyl tert-butyl ether production method, the method comprises distillation separation of a methyl tert-butyl ether-containing solution in a distillation ctower, the methyl tert-butyl ether-containing solution contains methanol, sulfides, mixture C4 and methyl tert-butyl ether; before the distillation separation, the sulfides capable of being oxidized, in the methyl tert-butyl ether-containing solution, are oxidized; distillation conditions are controlled for collecting of the methanol and the mixture C4 from the top of the tower, the oxidized sulfides and / or the sulfides which are not oxidized are collected from the bottom of the tower, and a methyl tert-butyl ether-containing material flow is collected from a side line. According to the method, super low sulfur methyl tert-butyl ether (MTBE) and low sulfur unreacted C4 can be produced only by use of a catalytic distillation or an azeotropic distillation device in the prior art, the method has the advantages of simple desulfurization process, low operation energy consumption, low investment of equipment and maintenance costs, and is very suitable for industrial application.

Owner:BEIJING ENERGY ENG TECH

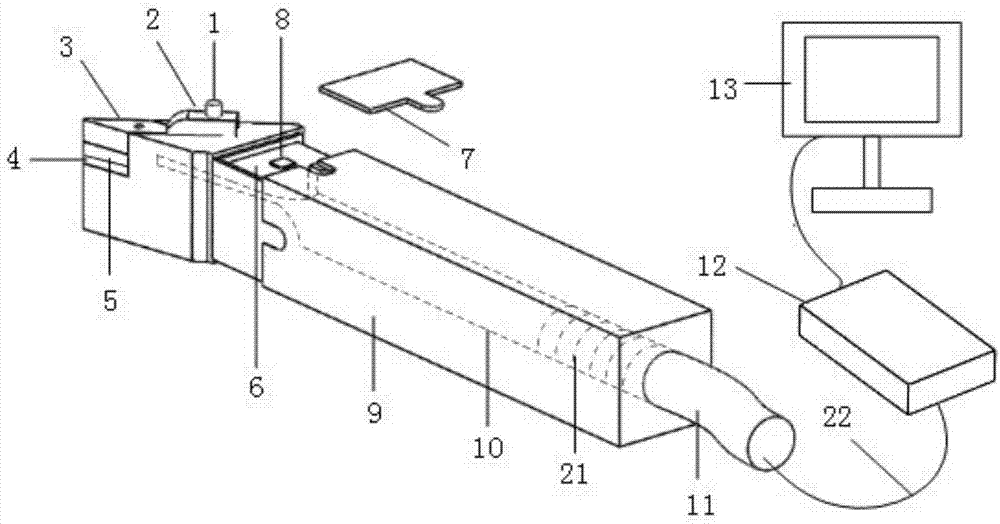

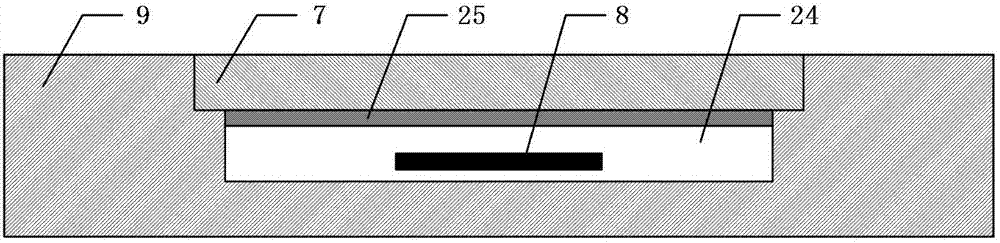

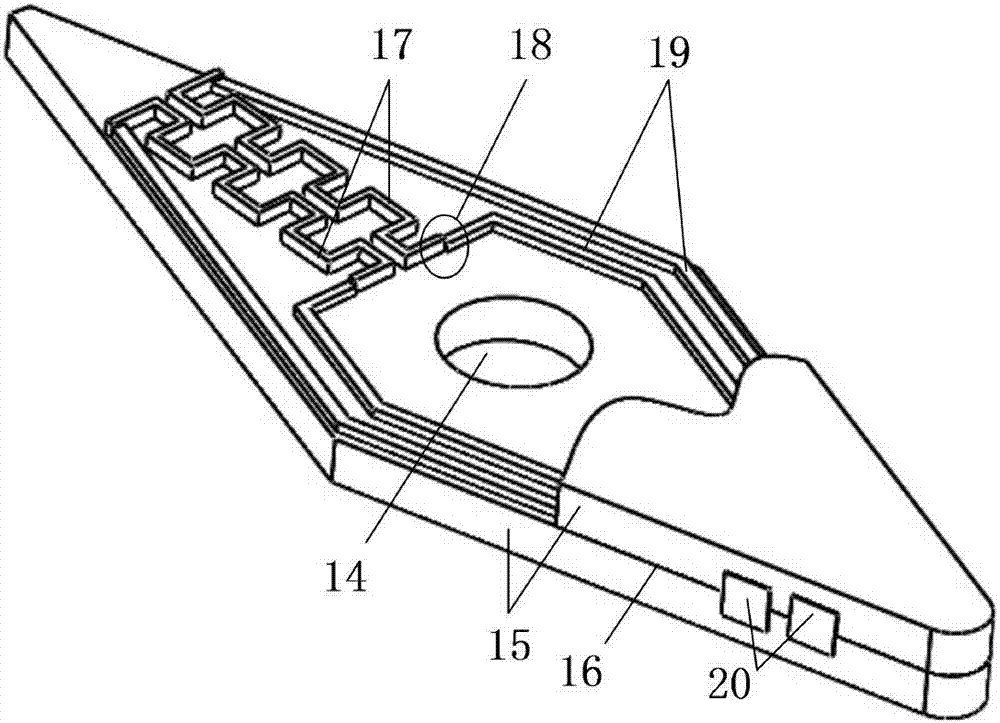

Cutting force measurement device based on manganese-copper alloy micro-nano sensitive units

ActiveCN107322368AOverall stiffness does not affectImprove device compatibilityMeasurement/indication equipmentsMicro nanoSignal processing circuits

Provided is a cutting force measurement device based on manganese-copper alloy micro-nano sensitive units. A cutting force measurement unit is arranged between a blade and a cutter pad. The shape and dimension of the cutting force measurement unit are matched with those of the blade and the cutter pad. The cutting force measurement unit is of a sandwich structure and comprises an upper aluminum oxide insulating layer, a lower aluminum oxide insulating layer and a middle component layer. Sensitive resistors based on a manganese-copper alloy material are integrated in the middle component layer. One ends of copper electrodes and one ends of lead circuits communicate with the sensitive resistors based on the manganese-copper alloy material, and the other ends of the copper electrodes and the other ends of the lead circuits communicate with metal welding plates on the side faces of the cutting force measurement unit, so that the sensitive resistors based on the manganese-copper alloy material are connected with a fixed resistor in a signal processing circuit to form a Wheatstone measurement bridge. The cutting force measurement unit adopts am MEMS technology for processing. The cutting force measurement device based on the manganese-copper alloy micro-nano sensitive units has the advantages of good compatibility, high universality and high measurement precision.

Owner:XIAN WINWAY TOOLS

Sintering process of Cu-Ni alloy pipe with porous surface

The present invention provides sintering process of Cu-Ni alloy pipe with porous surface. The process includes the following steps: mixing polystyrene-base adhesive and Cu-Ni alloy powder, coating the mixture powder onto the inner and outer surface of the base pipe in the thickness of 0.1-0.5 mm, rotating the pipe horizontally in the speed of 30-100 rad / min to volatilize the volatile matter of the adhesive and to dry, sintering in a sintering furnace with introduced H2 or other reductive gas at 650-850 deg.c for 5-20 min, and cooling to 40-50 deg.c to obtain Cu-Ni alloy pipe with porous surface. The Cu-Ni alloy pipe produced with composite powder has high porosity, high pore uniformity and high base strength, and the sintering process may be used in producing long porous pipe and is suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

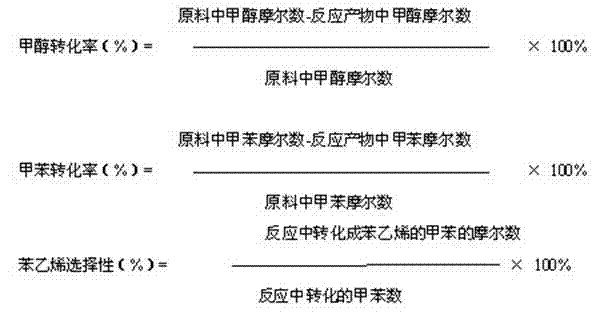

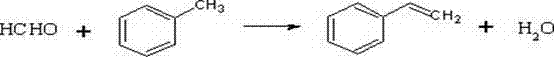

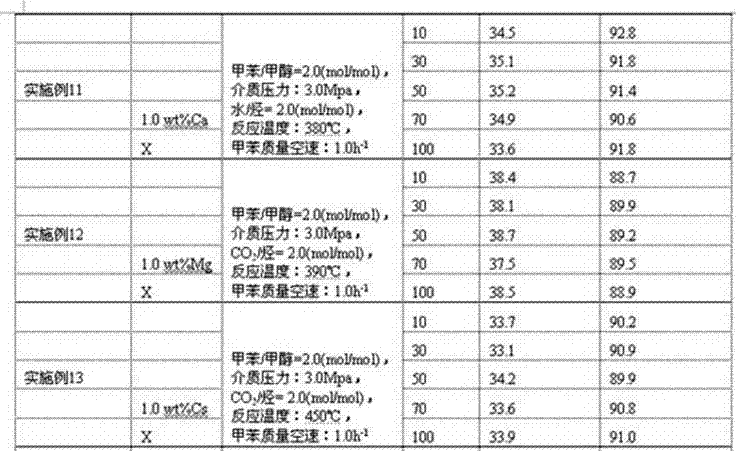

High-selectivity method for synthesizing styrene through methanol and toluene side chain alkylation

InactiveCN102964203AAvoid generatingHigh selectivityHydrocarbon by hydrocarbon and non-hydrocarbon condensationBulk chemical productionMolecular sievePtru catalyst

The invention relates to a high-selectivity method for synthesizing styrene through methanol and toluene side chain alkylation, namely a high-selectivity method for preparing styrene through toluene and methanol alkylation by use of an alkaline molecular sieve based catalyst under the condition of taking carbon dioxide as a reaction medium. In the method for synthesizing styrene through toluene and methanol alkylation by use of a molecular sieve based catalyst containing metal aid modification, in the presence of a carbon dioxide medium, the mixture of toluene and methanol at a molar ratio of 2.0-8.0 is used as a raw material, the reaction temperature is 350-540 DEG C, the toluene reaction airspeed is kept at 0.1-4.0 / h, the pressure of the reaction medium is kept at 0.1-6.0MPa, and the molar ratio of carbon dioxide to hydrocarbon is kept at 0.5-10.0. According to the invention, by taking a large amount of excessive greenhouse gas carbon dioxide as a reaction medium, the styrene is prepared with a high yield, and the problems of many side reactions and poor selectivity in the existing styrene synthesis technology through toluene and methanol alkylation are solved; and moreover, the reaction stability can be improved so that the catalyst stability and styrene selectivity in the styrene synthesis through toluene and methanol alkylation meet the requirements of industrial application.

Owner:TONGJI UNIV

Absorbent for removing mercury out of coal burning smoke and preparation method thereof

InactiveCN103566900AImprove mercury removal efficiencyLow costOther chemical processesDispersed particle separationSodium BentoniteAbsorption capacity

The invention relates to an absorbent for removing mercury out of the coal burning smoke. The absorbent is prepared from the following raw materials in parts by weight: 80 to 90 parts of bentonite, 4 to 6 parts of potassium iodate, 6 to 9 parts o chitosan, 3 to 5 parts of dilute sulfuric acid, 2 to 4 parts of sodium citrate, 2 to 4 parts of sodium tartrate, 4 to 5 parts of modified diatomite and an appropriate amount of water. According to the absorbent, bentonite is used as an absorbent base material, the absorption capacity is good, an antibactieral, deodorizing, moisture absorption and mildew preventing functions also can be realized, and organisms also can be catalyzed and decomposed; the absorbent is high in mercury removal efficiency, low in cost, free of secondary pollution and capable of meeting the industrial application requirement.

Owner:BENGBU HUAFANG FILTER

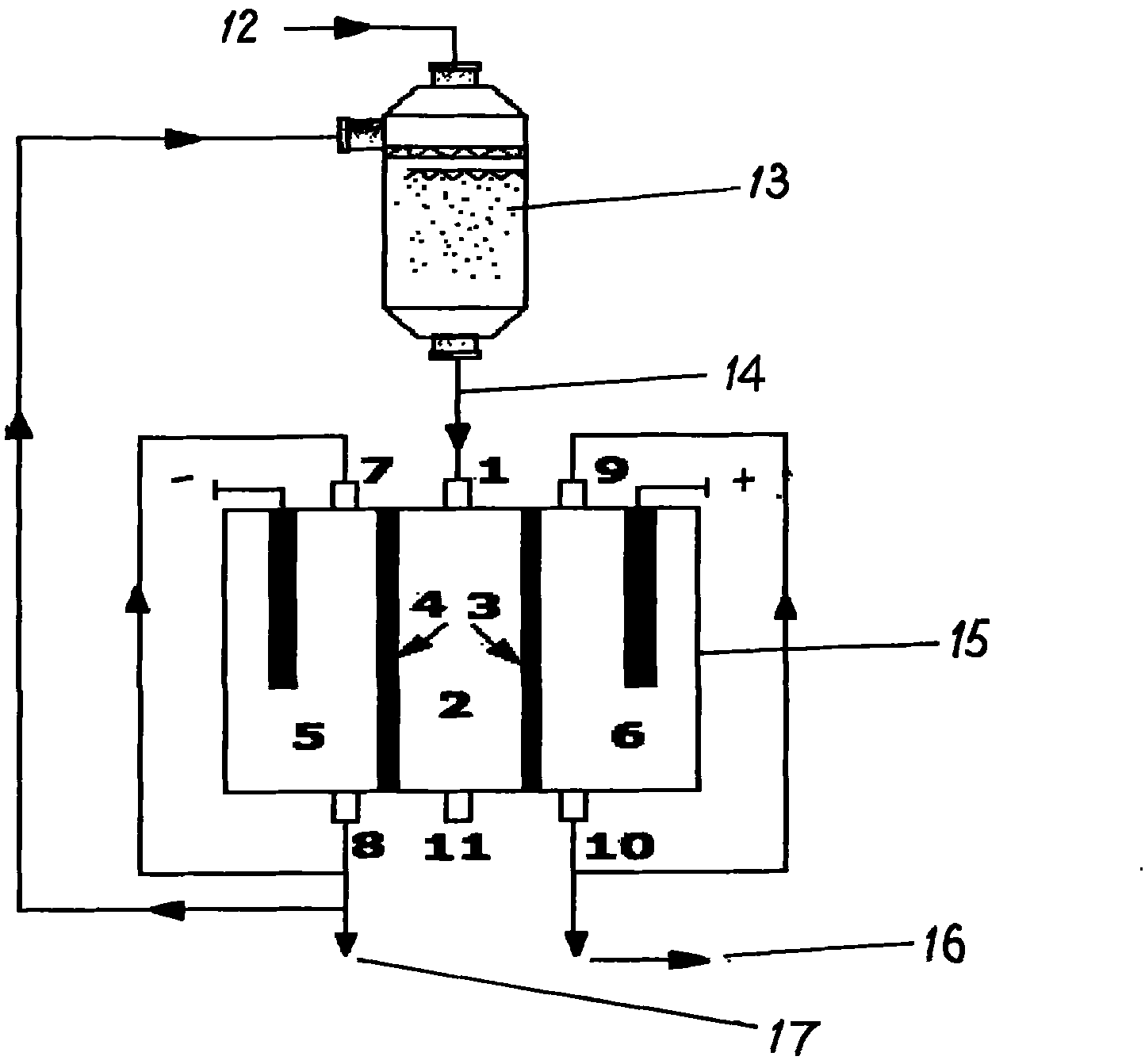

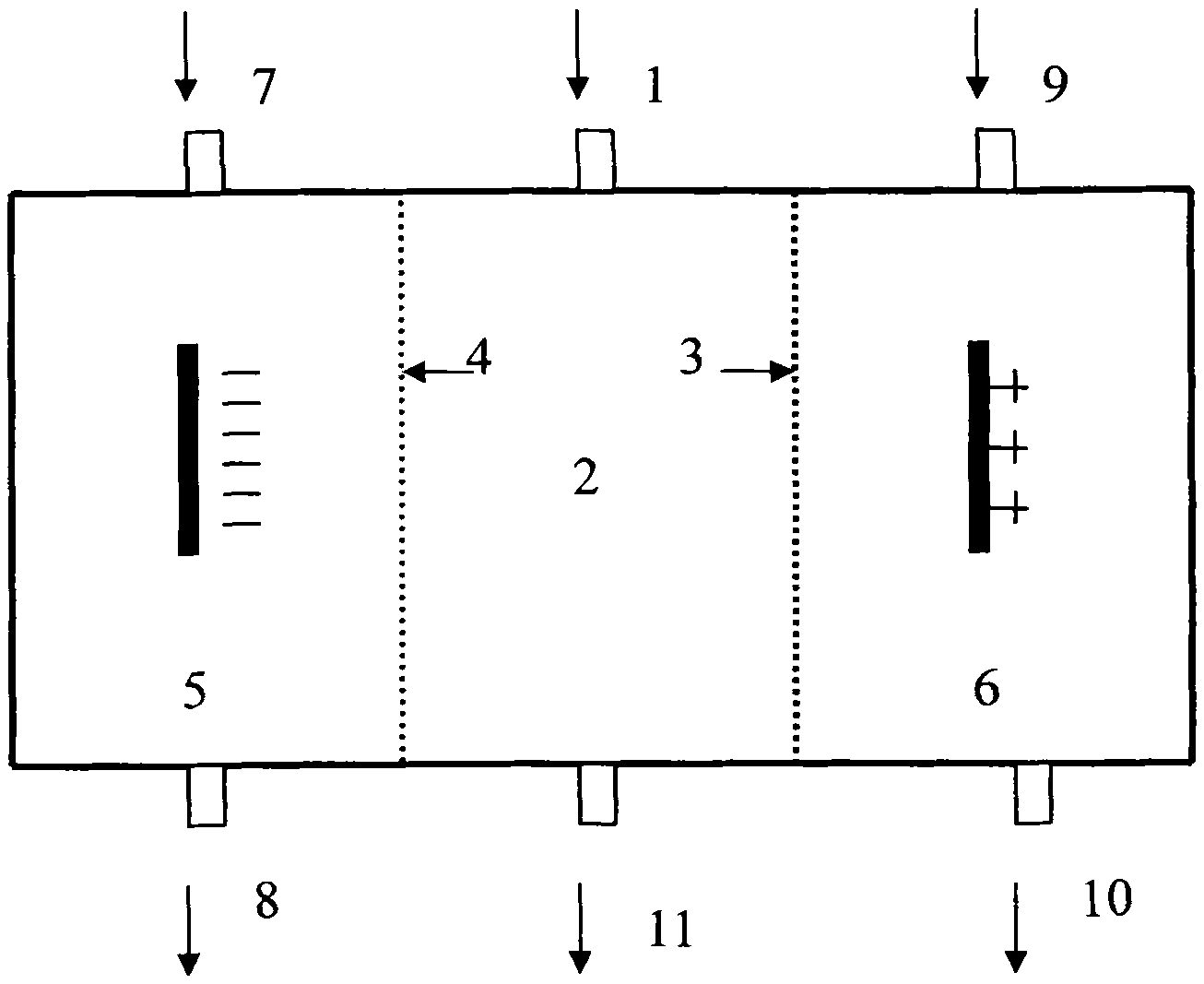

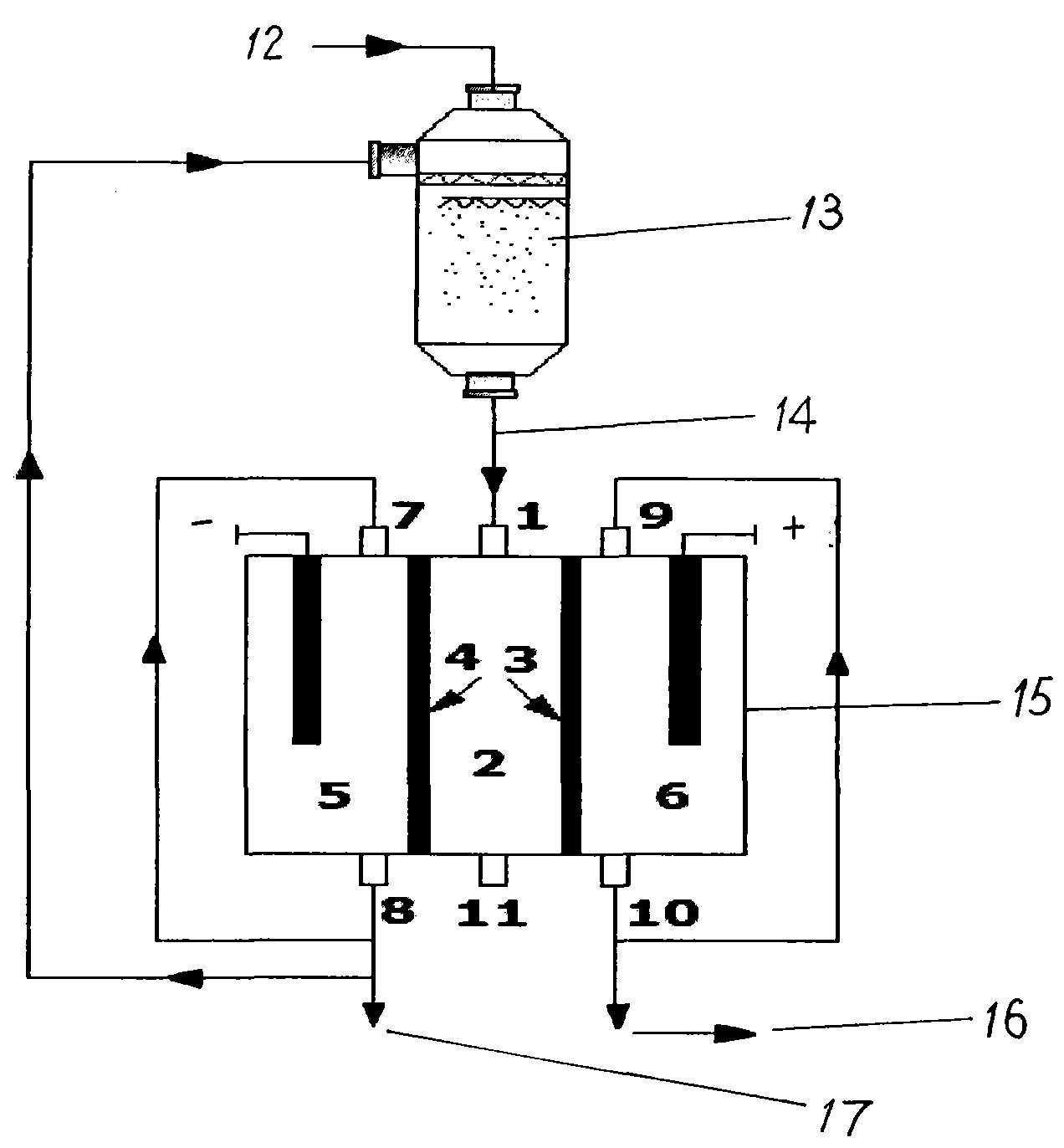

Electrolysis circulating flue gas desulfurization method utilizing reclamation semidry method

InactiveCN102101010AReduce the temperatureEfficient removalDispersed particle separationChemical industryElectrolysis

The invention relates to the technical field of chemical industry, in particular to an electrolysis circulating flue gas desulfurization method utilizing reclamation semidry method, wherein the desulfurization method provided by the invention is a desulfuration technique which is low in investment and operating cost and free from secondary pollution. In the technique, sodium hydroxide is utilizedas a desulfurizing agent, the semidry method is adopted for desulfurating waste gas and an electrochemical method is utilized to lead sodium sulfate which is a regenerated desulfurization product to generate the sodium hydroxide and high-purity sulfuric acid, wherein the sodium hydroxide is taken as the desulfurizing agent, and the sulfuric acid is sold as goods. The electrolysis circulating fluegas desulfurization method provided by the invention has the positive effects that the sulfur dioxide in the waste gas can be effectively removed; compared with a wet method, a desulfuration device is smaller, the investment is less, the cost is lower, the energy consumption of desulfuration can be reduced, and a great deal of desulfuration waste water and waste residue can not be generated; and compared with a dry method, the reaction speed is rapider, the desulfuration rate is higher, the requirement of industrialized application can be met, and the sulfur dioxide in flue gas is effectivelyrecycled.

Owner:SHANGHAI JIAO TONG UNIV +1

Microwave curing method for block

ActiveCN110936485AUniform temperatureDimensionally stable materialCeramic shaping apparatusChemistryMicrowave frequency

The invention provides a microwave curing method for a block. The method includes steps that (1) slurry is injected into a test mold, covered by a film, and is subjected to standing and pre curing for2-4 hours, and the temperature is controlled at 30-45 DEG C; (2) after pre curing, a steel wire is used to cut an uncured block, and then the film is utilized to re-cover and transferred to a microwave reaction chamber for 1-2 hours, the temperature is controlled at 50-70 DEG C, and the microwave frequency is 433-2450 MHz; and (3) after microwave heating and curing, the block is naturally cooledto room temperature, and curing is completed. The method is advantaged in that a microwave source with the specific frequency of 433-2450 MHz has the characteristics of deep acting depth, which can realize synchronous heating of the whole block inside and outside so that the temperature of each part of the block is uniform, and the stress damage caused by temperature difference is avoided, and themethod can realize fast curing of the block, improve production efficiency, and realize energy conservation and environmental protection.

Owner:GUANGXI ACAD OF SCI +2

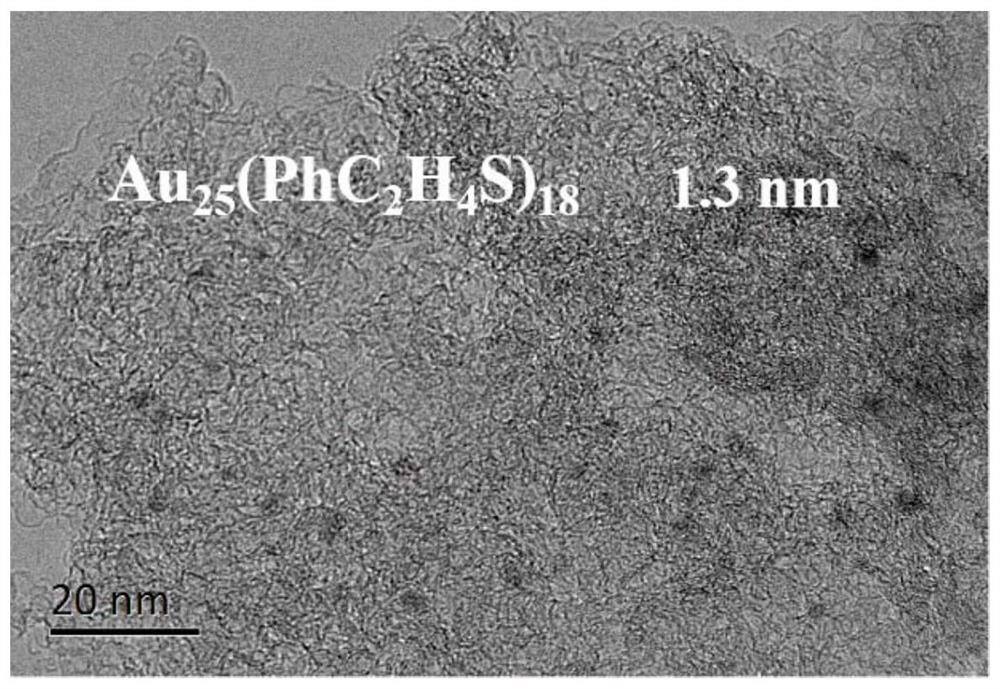

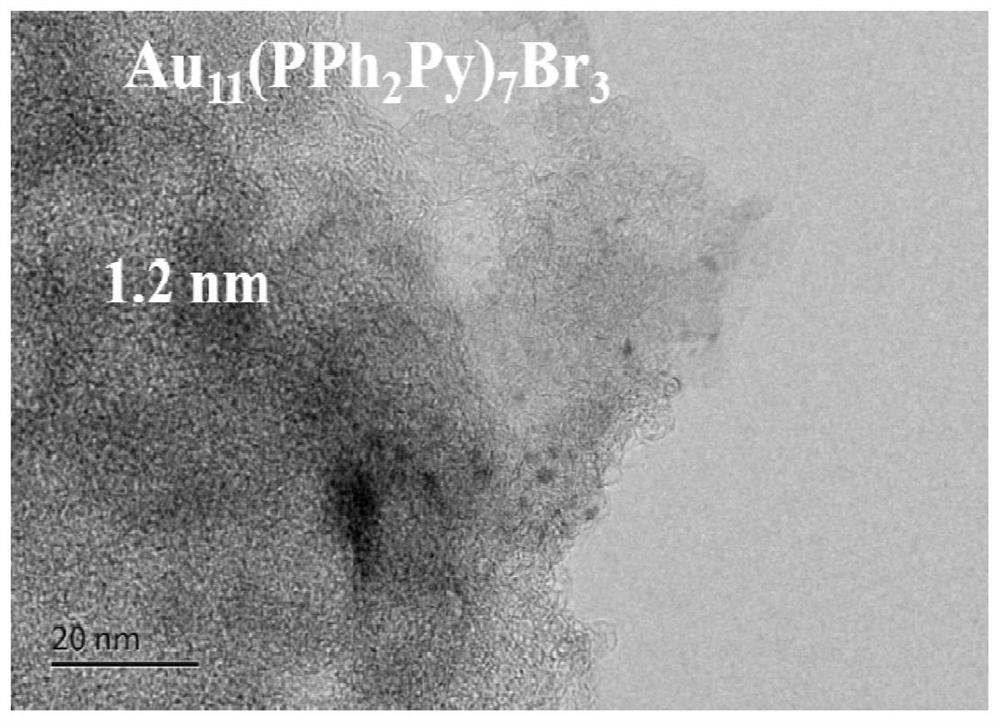

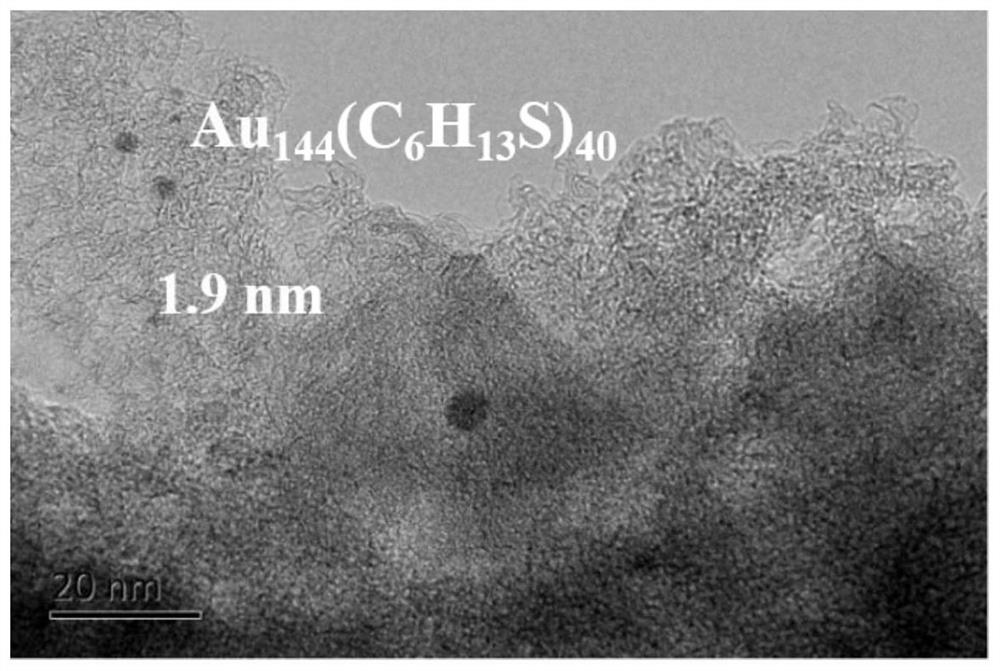

Preparation and application of noble metal atom cluster catalyst for acetylene hydrochlorination

ActiveCN112237945AThe synthesis method is simpleHigh yieldPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHalogen

The invention provides a noble metal atom cluster and a catalyst; the atom cluster is a noble metal atom cluster structure protected by an organic ligand, the structural formula is An(SR)m or An(PB)mCx, A is noble metal, B is an organic group coordinated with phosphorus (P), and C is halogen; SR is at least one of phenethyl mercaptan, 2-naphthalene mercaptan, hexanethiol or adamantane mercaptan, n=2-200, m=10-200 and x=2-20. Mercaptan and triphenylphosphine (diphenyl-2-pyridylphosphine) are used as protective agents, S and P atoms can well stabilize atom clusters and prevent the atom clustersfrom agglomeration, and the catalyst is excellent in stability, green, environment-friendly and recyclable, and has manipulation in industrial applications.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

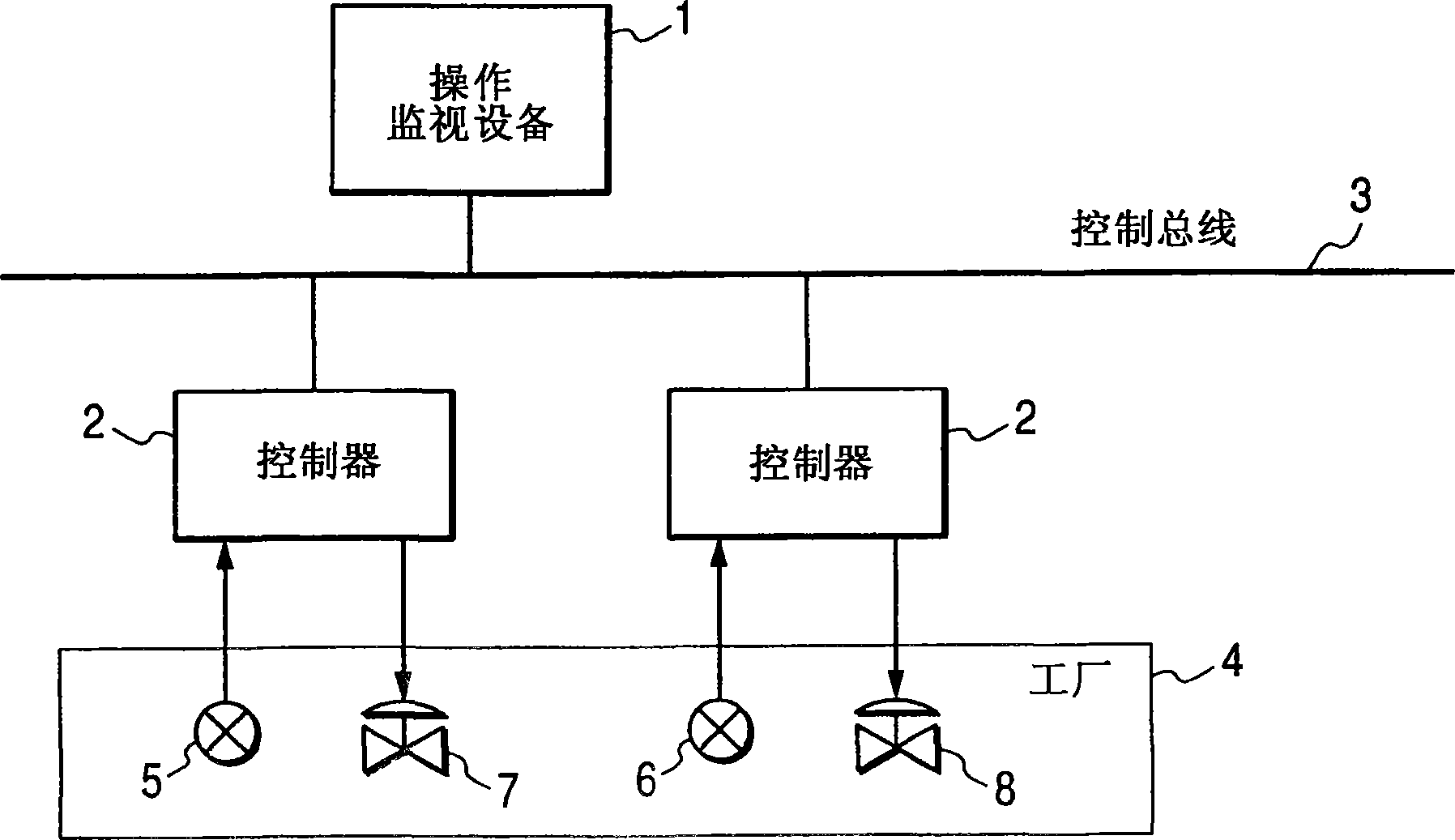

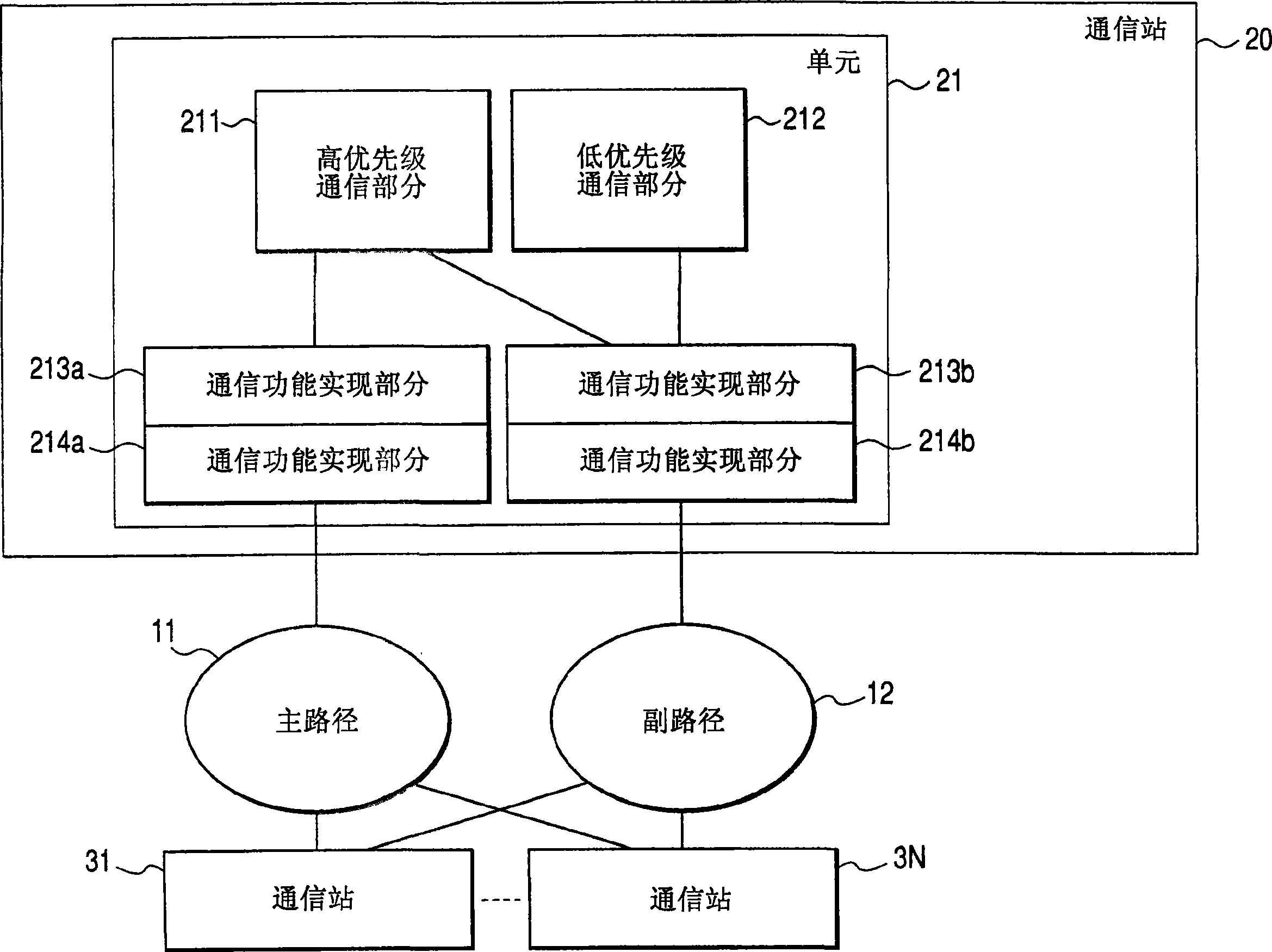

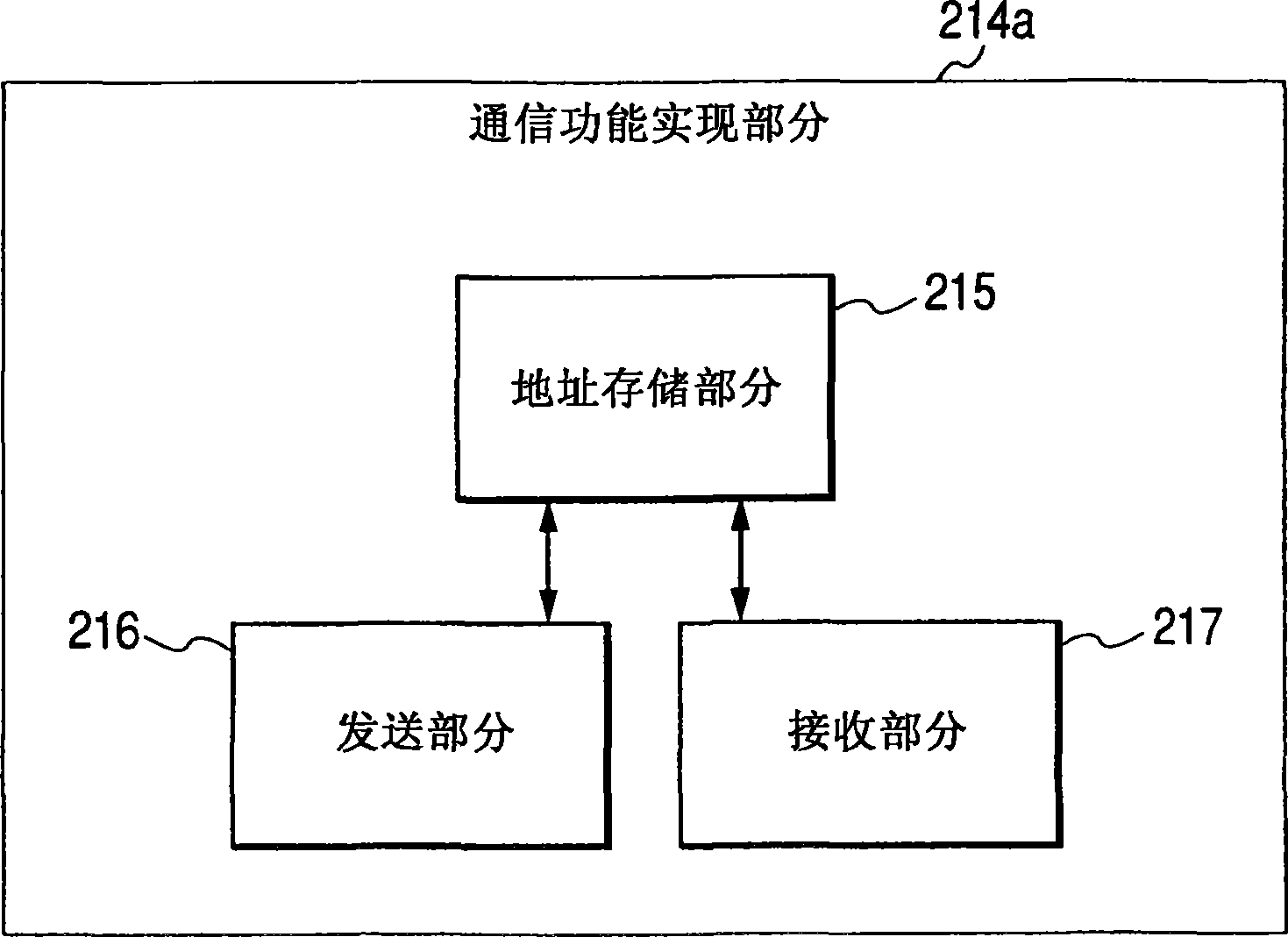

Communication control system

ActiveCN1894901AMeet the requirements of industrial applicationsImprove reliabilitySecuring communicationBus networksControl systemCommunication control

A communication control system is provided that performs communications satisfying a request for industrial applications and a request for open protocol communications at the same time. To this end, in the invention, a high-priority communication section performing critical communications to provide real time property and reliability, and a low-priority communication section performing communications based on an open standard protocol coexist in a same communication station.

Owner:YOKOGAWA ELECTRIC CORP

Production process of insulating ceramic for power equipment

The invention discloses a production process of an insulating ceramic for power equipment. The production process comprises the following steps: firstly, carrying out pretreatment on polygonatum odoratum; secondly, preparing a mixed raw material; thirdly, sintering and moulding, heating the mixed raw material to 80-120 DEG C within 40-50 minutes at a rate of 10 DEG C per minute, adding a sintering additive, and carrying out ball milling for 12-24 hours so that slurry with the solid phase content of 50-75vol is obtained, preparing the slurry into a transparent ceramic blank which is 1-3mm thick, heating the blank to 1400 DEG C in a high temperature box-type furnace at a rate of 2 DEG C / min, moulding in a perfusion mould, and carrying out heat preservation for 1.5-2.5 hours after moulding is carried out for 20-90 seconds, so that the insulating ceramic for the power equipment is obtained. The production process disclosed by the invention has the advantages that structural changes and chemical changes of the insulating ceramic material in a sintering process can be controlled by strictly controlling technological parameters, industrial application requirements can be met, and the production process can obviously reduce energy consumption compared with an existing process.

Owner:合肥羿振电力设备有限公司

Insulating ceramic for integrated circuit substrate and preparation method thereof

InactiveCN107382295ALow insulation resistanceImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesBarium titanateAdhesive

The invention discloses insulating ceramic for an integrated circuit substrate. The insulating ceramic consists of the following raw materials in parts by weight: 60-80 parts of willemite, 30-40 parts of barium titanate, 20-30 parts of burnt talc, 10-30 parts of titanium dioxide, 10-20 parts of silicon dioxide, 5-15 parts of silicon nitride, 3-8 parts of quartz powder, 5-10 parts of mica powder, 2-8 parts of boron carbide, 5-10 parts of sodium polyacrylate, 8-15 parts of phenolic resin, 3-8 parts of aluminum oxide, 2-6 parts of a compound additive, 1-5 parts of an adhesive and 100-120 parts of deionized water. The insulating ceramic for the integrated circuit substrate, disclosed by the invention, has the advantages of being low in insulation resistance value, good in insulation performance, long in service life, low in production cost and the like; meanwhile, according to a preparation method disclosed by the invention, via strictly controlling process parameters, the structural change and the chemical change of an insulating ceramic material in the sintering process can be controlled, and the requirements for industrial application can be met.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

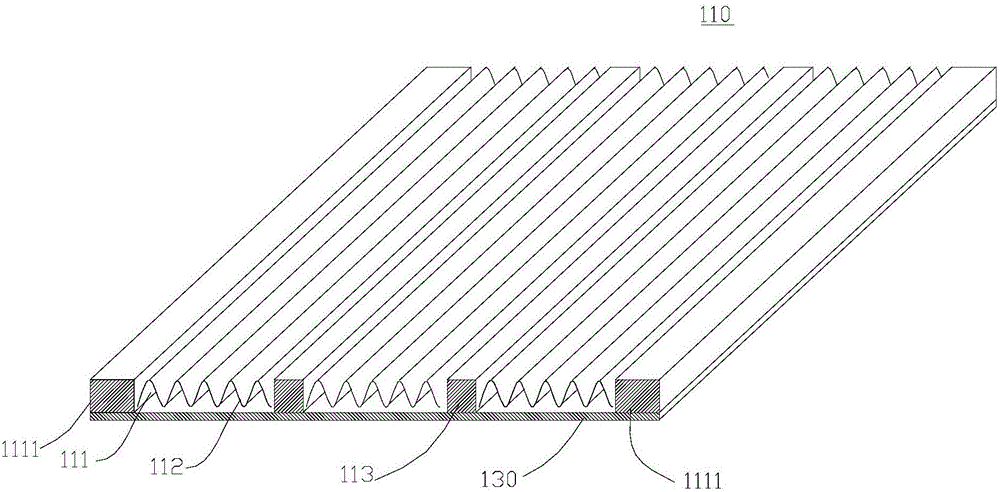

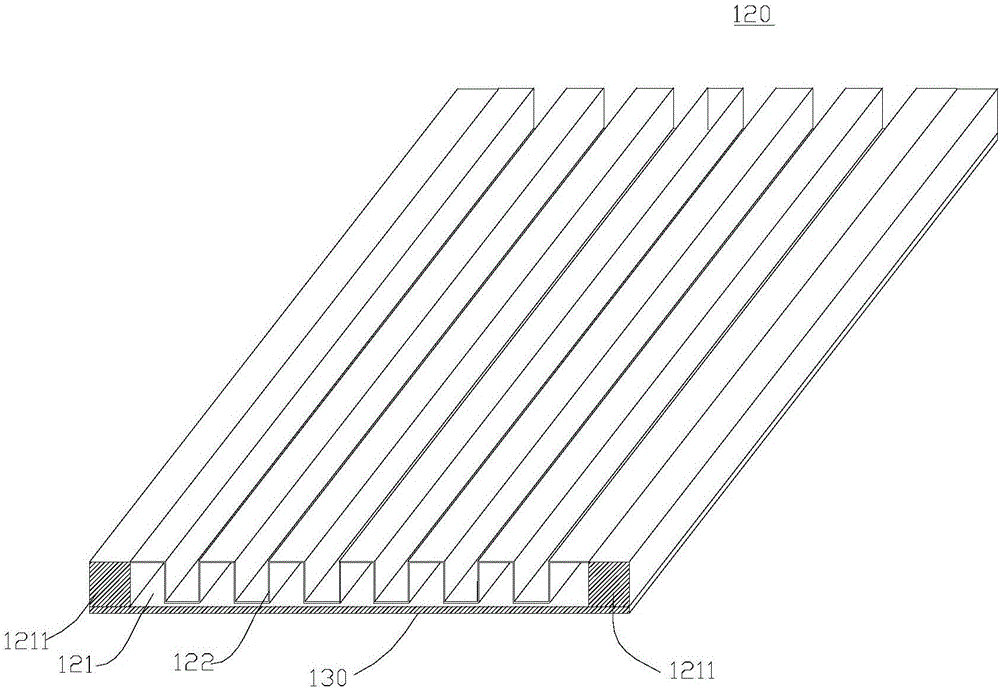

Reaction device and reaction equipment

InactiveCN106237939AIncrease production capacityMeet the requirements of industrial applicationsChemical/physical processesEngineering

Owner:CHENGDU SEPMEM SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com