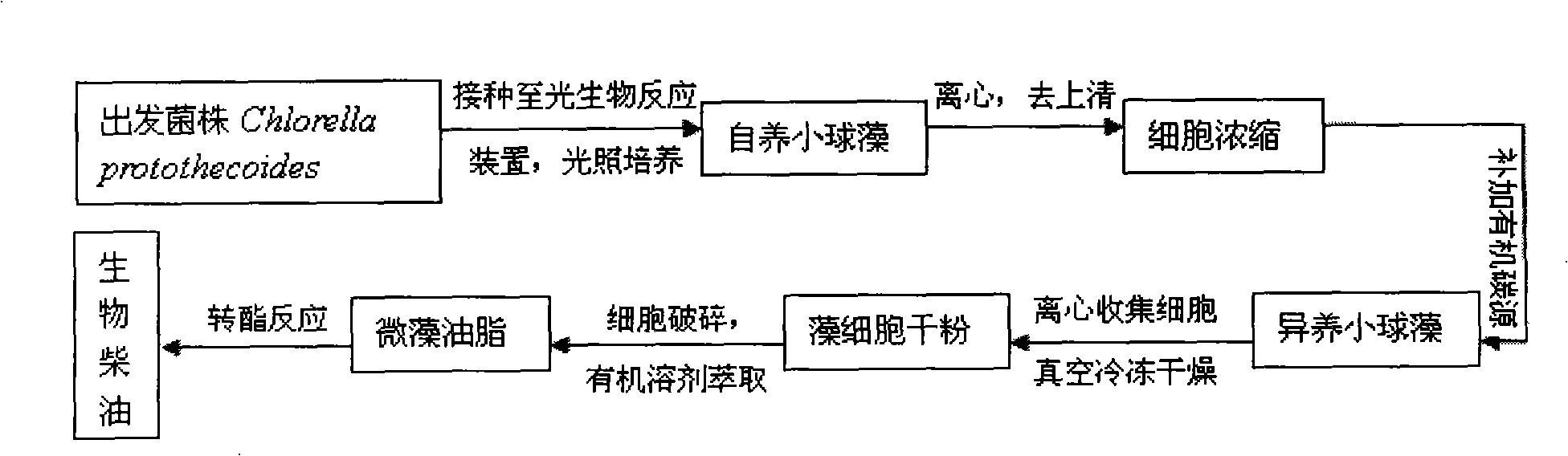

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

A technology of biodiesel and autotrophic cultivation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as increasing production costs, and achieve the effects of increasing production capacity, controlling raw material costs, and high fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Oil-bearing algae-freshwater green algae (Chlorella protothecoides) was purchased from the Algal Species Center of the University of Texas in the United States. For the research of bioenergy, the formula of its autotrophic medium is as follows:

[0033] K H 2 PO 4 : 0.6g.L -1 , K 2 HPO 4 : 0.4g.L -1 , MgSO 4 ·7H 2 O: 0.4g.L -1 , FeSO 4 ·7H 2 O: 1mg.L -1 , Glycine: 3g.L -1 , Vitamin B1: 0.03mg.L -1 , A5 trace element solution 1.5ml.L -1 , wherein A5 trace element liquid composition: H 3 BO 3 : 2.86g.L -1 , Na 2 MoO 4 2H 2 O: 0.039g.L -1 , ZnSO 4 ·7H 2 O: 0.222g.L -1 , MnCl 2 4H 2 O: 1.81g.L -1 , CuSO 4 ·5H 2 O: 0.074g.L -1 ;

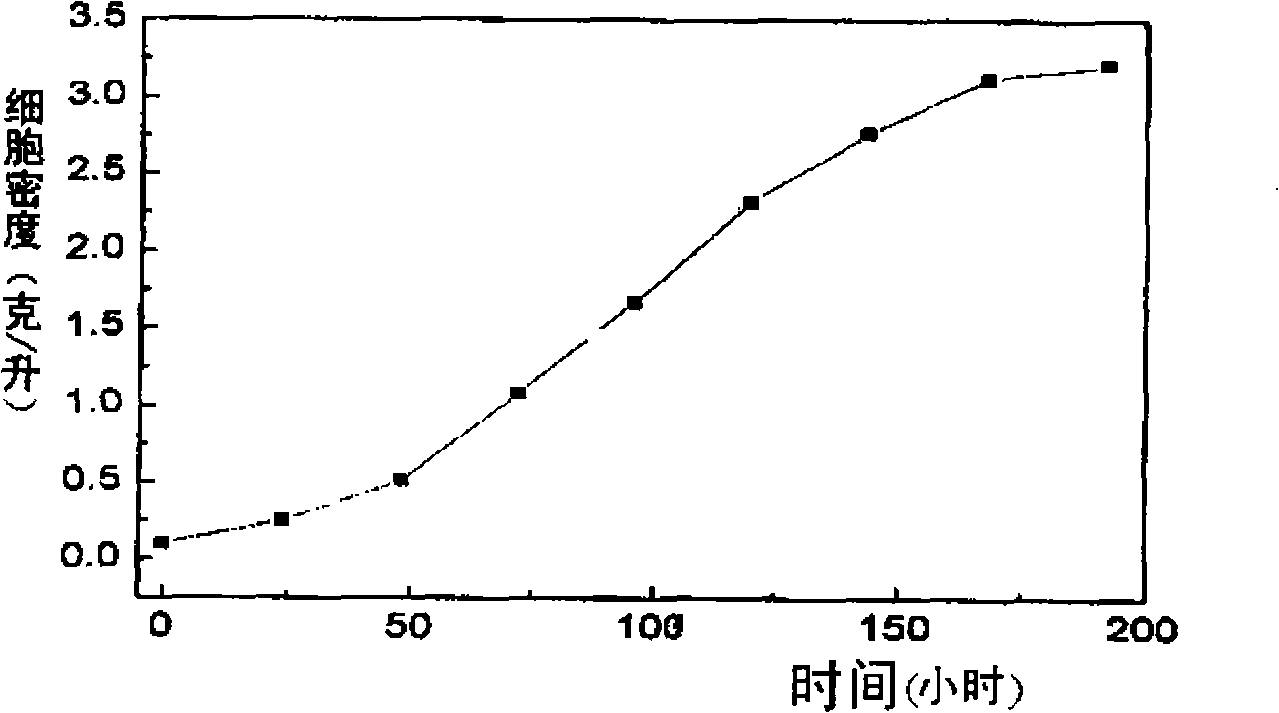

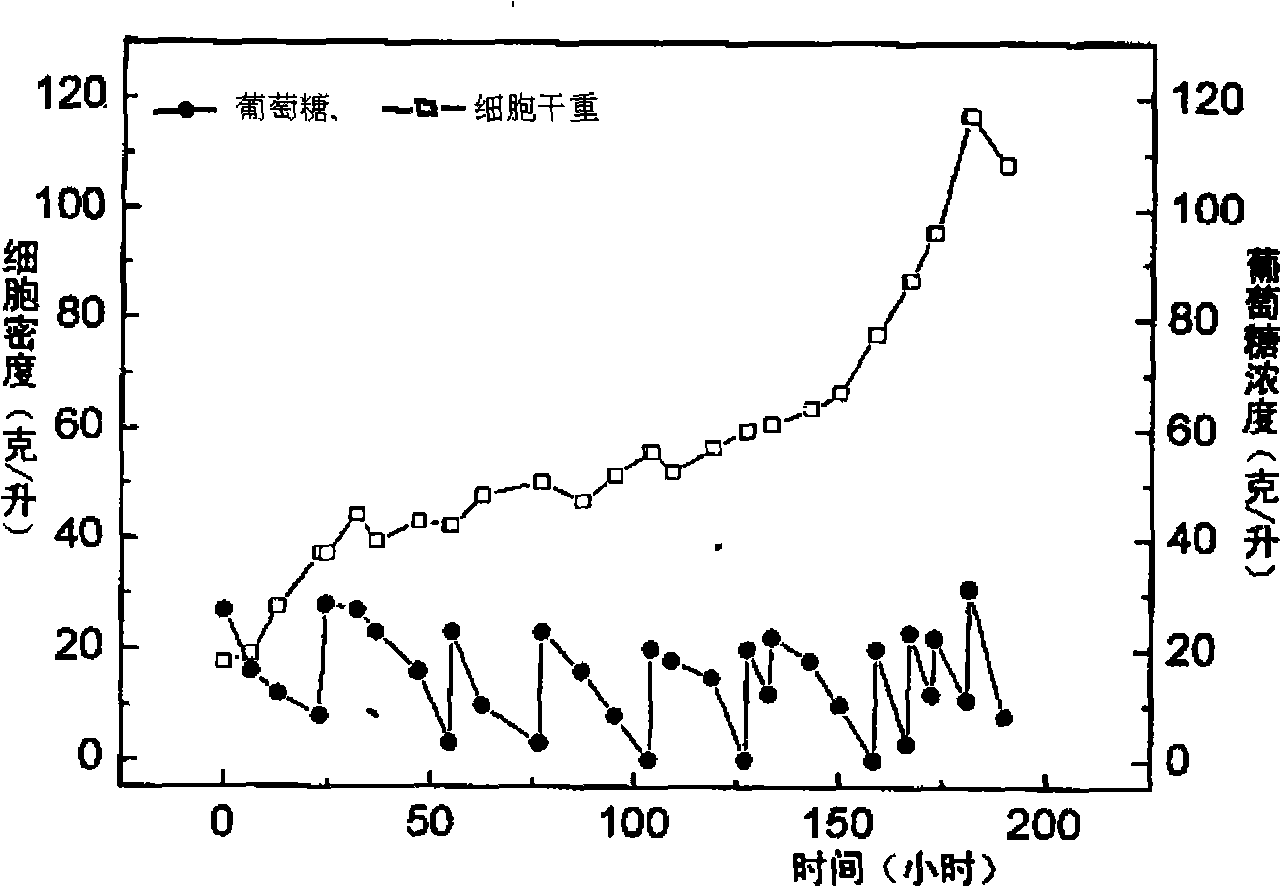

[0034] By the method described in step 1, inoculate a single colony of Chlorella grown on solid medium into a 1L aeration bottle, so that the initial cell density reaches 0.1g.L -1 , put a ventilated culture bottle in a light incubator at 25°C for cultivation, ventilate with air, and set the ventilation rate to 100 L / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com