Patents

Literature

839 results about "Transesterification reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

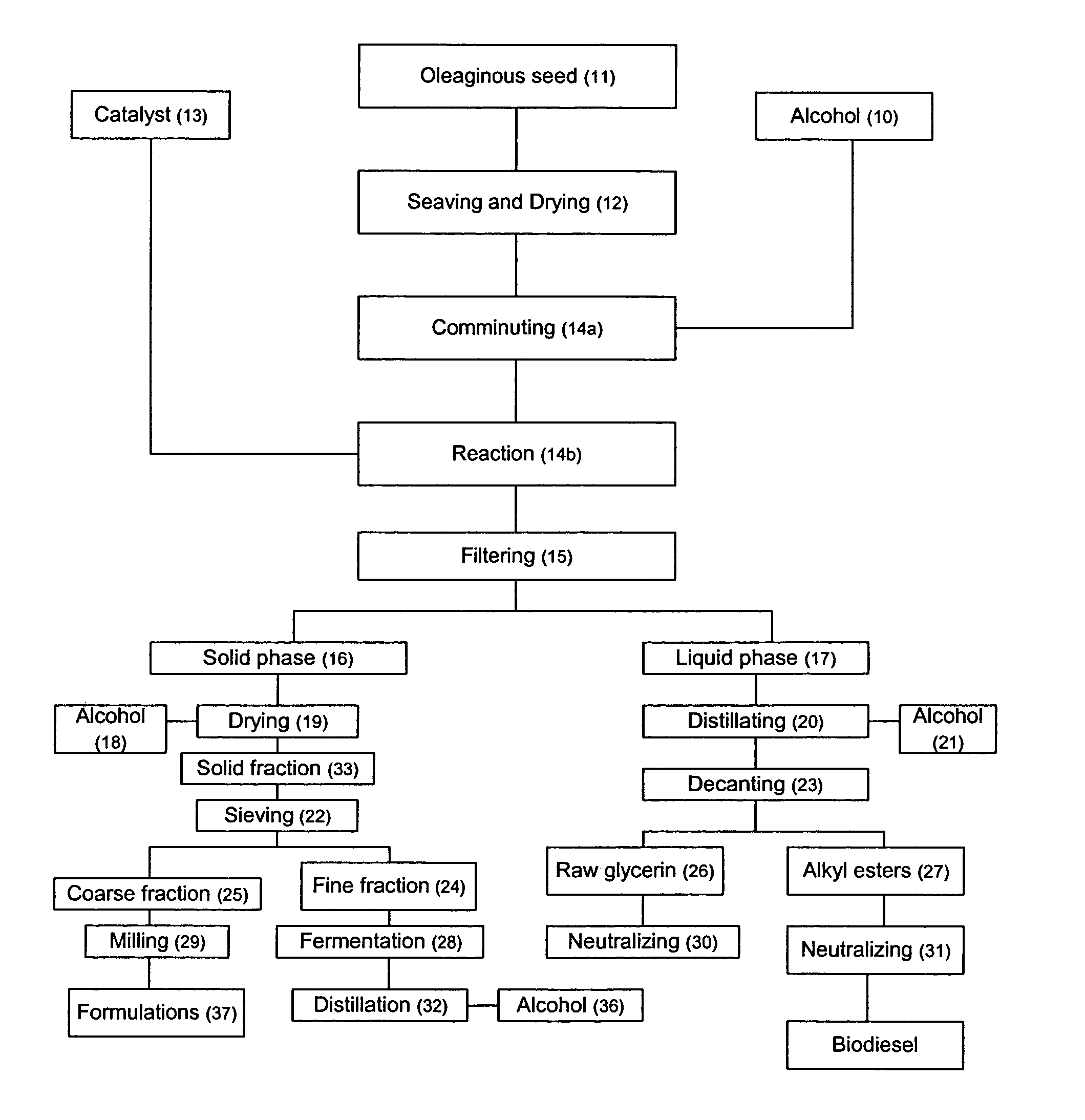

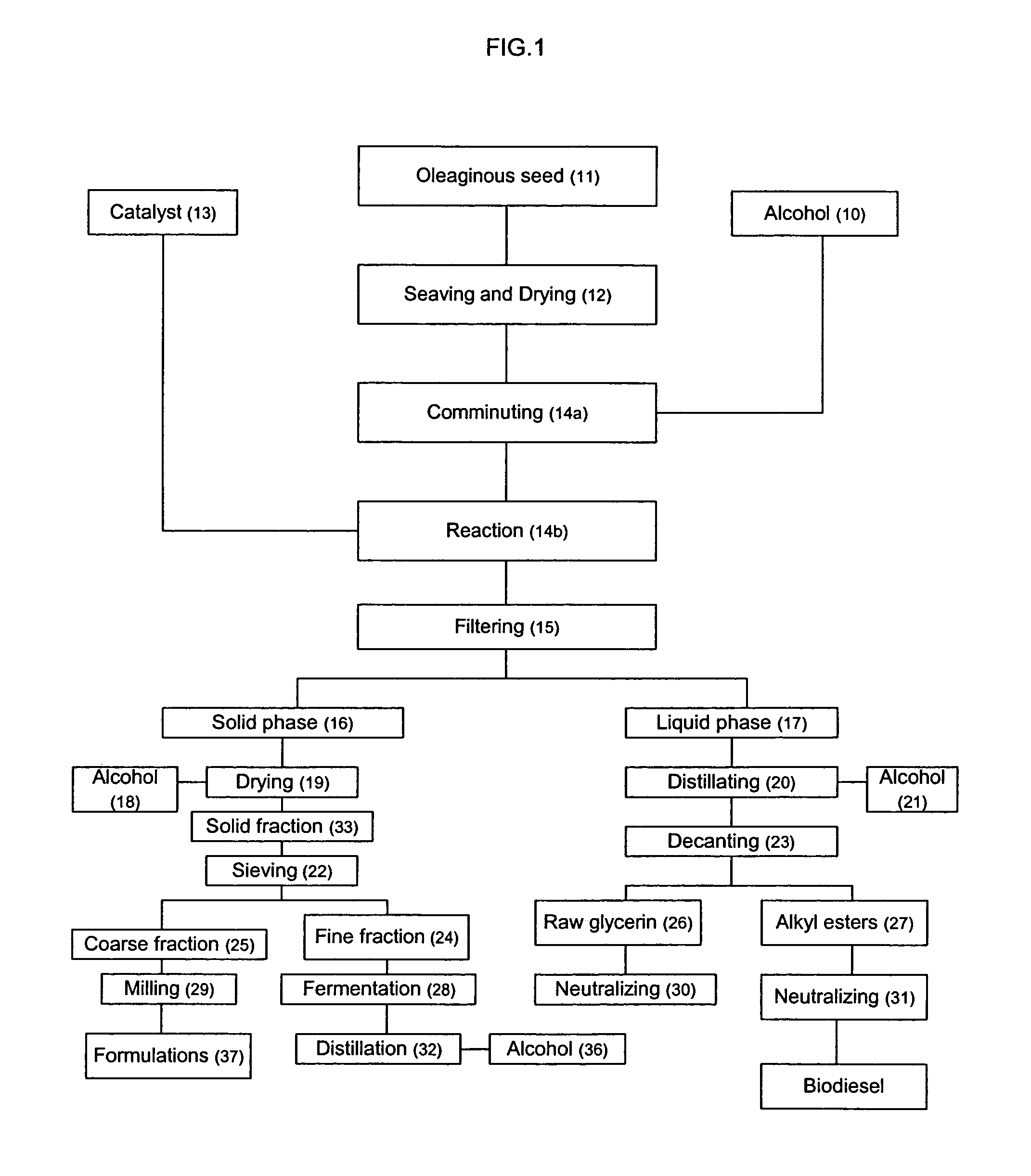

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

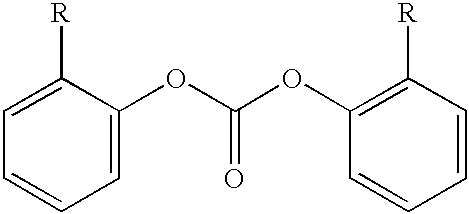

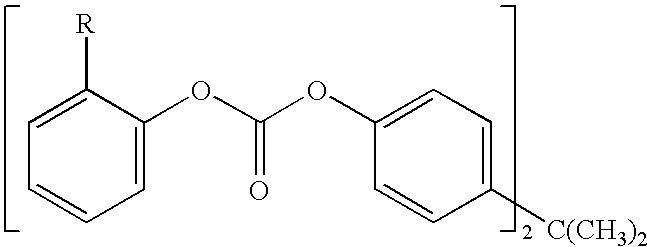

Method for end-capping polycarbonate resins and composition for use in same

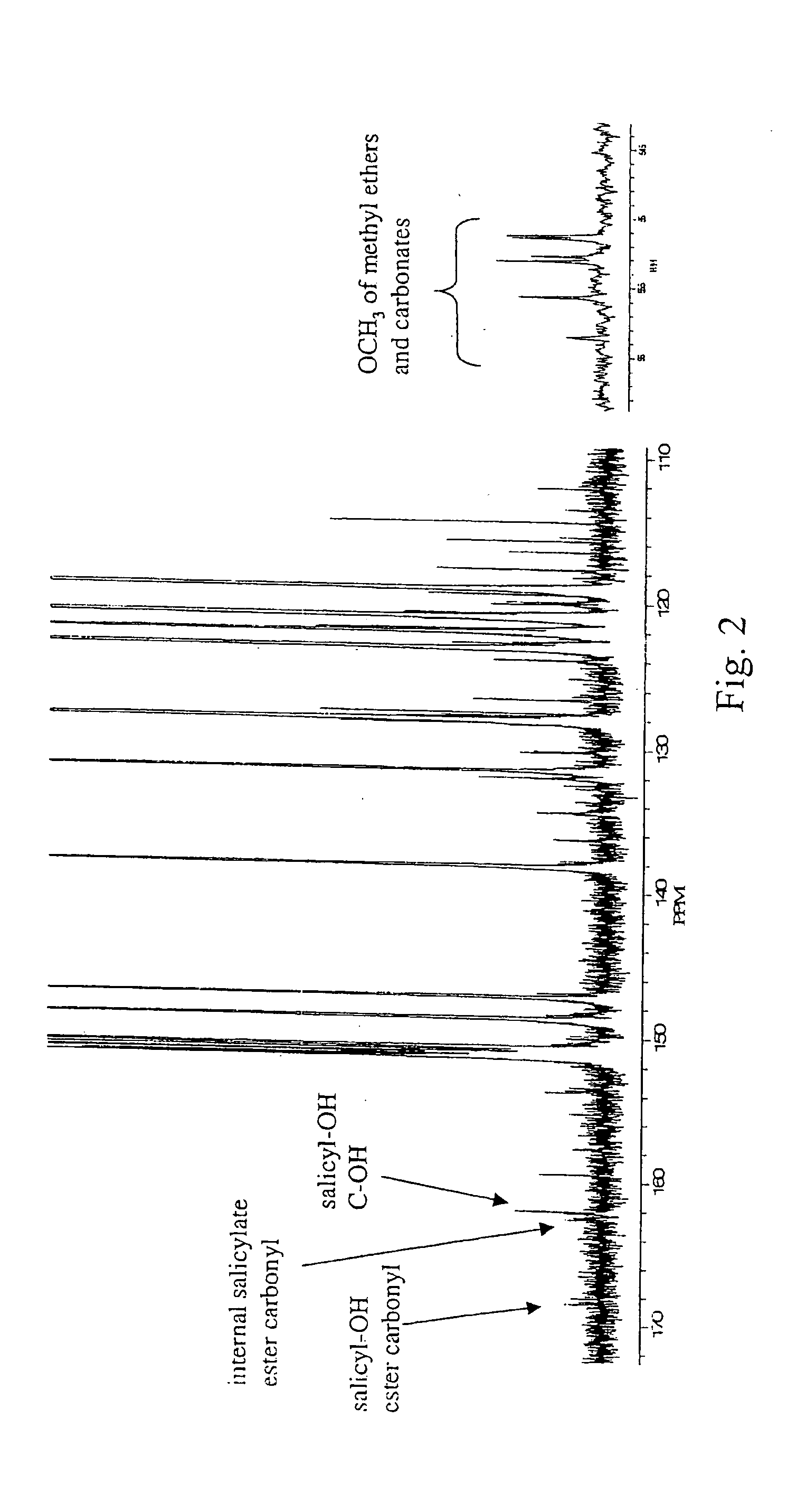

A method for end-capping polycarbonate resins, comprising the step of processing a mixture comprising a polycarbonate having free hydroxyl-end groups and an end-capping reagent in a melt transesterification reaction to produce a polycarbonate resin, wherein the end-capping reagent comprises a mixture of: (a) at least one species of a symmetrical activated aromatic carbonate, and (b) at least one species of an optionally-substituted phenol, whereby said end-capping reagent reacts with at least some of the free hydroxyl end-groups of the polycarbonate to produce an end-capped polycarbonate resin.

Owner:SABIC GLOBAL TECH BV

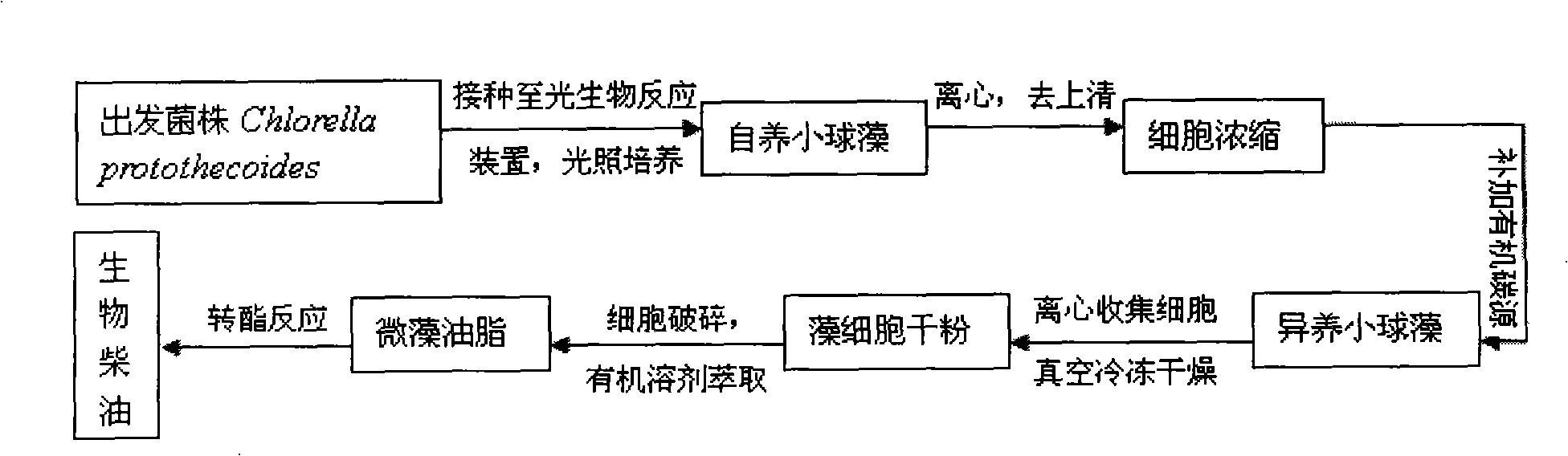

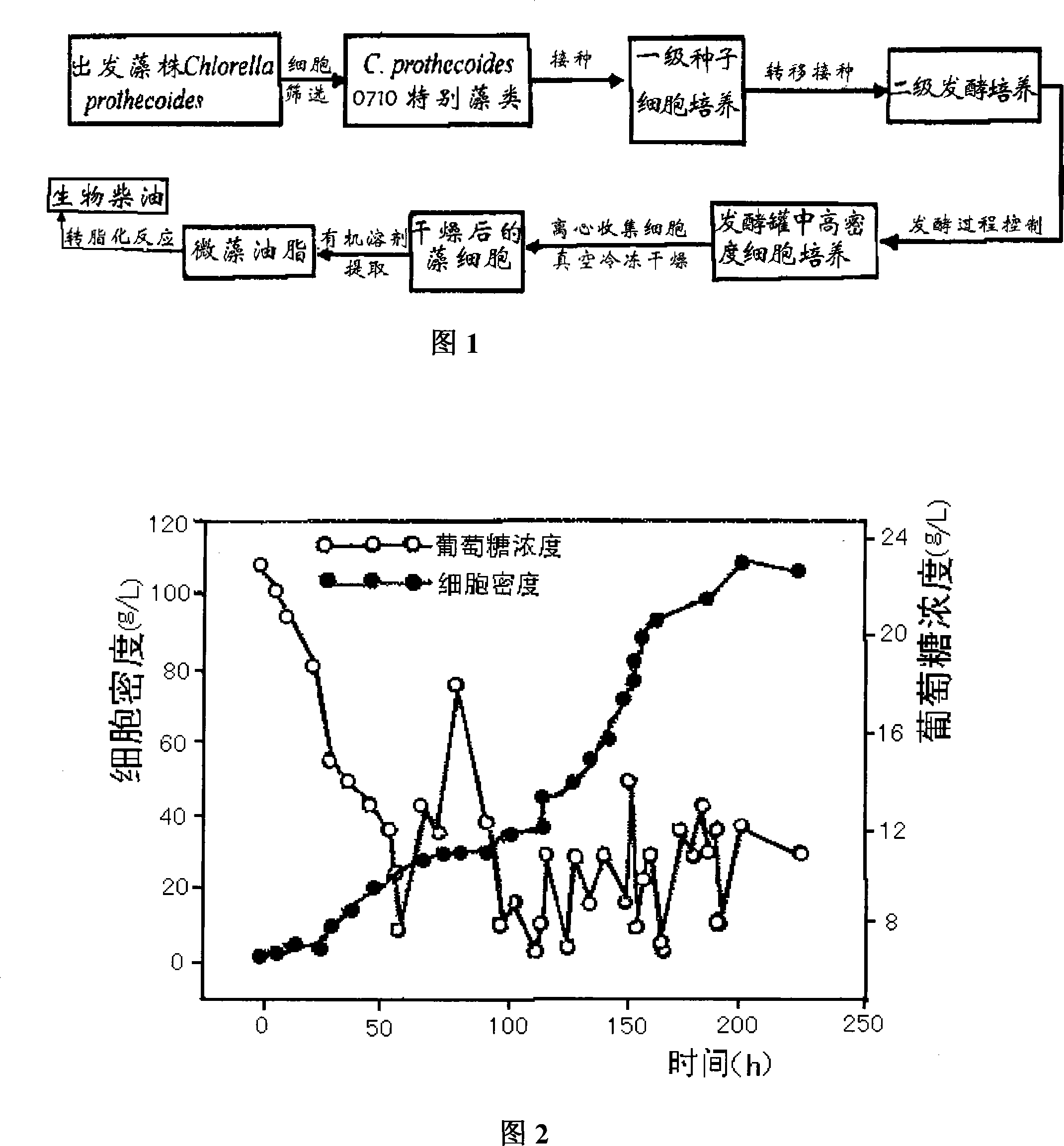

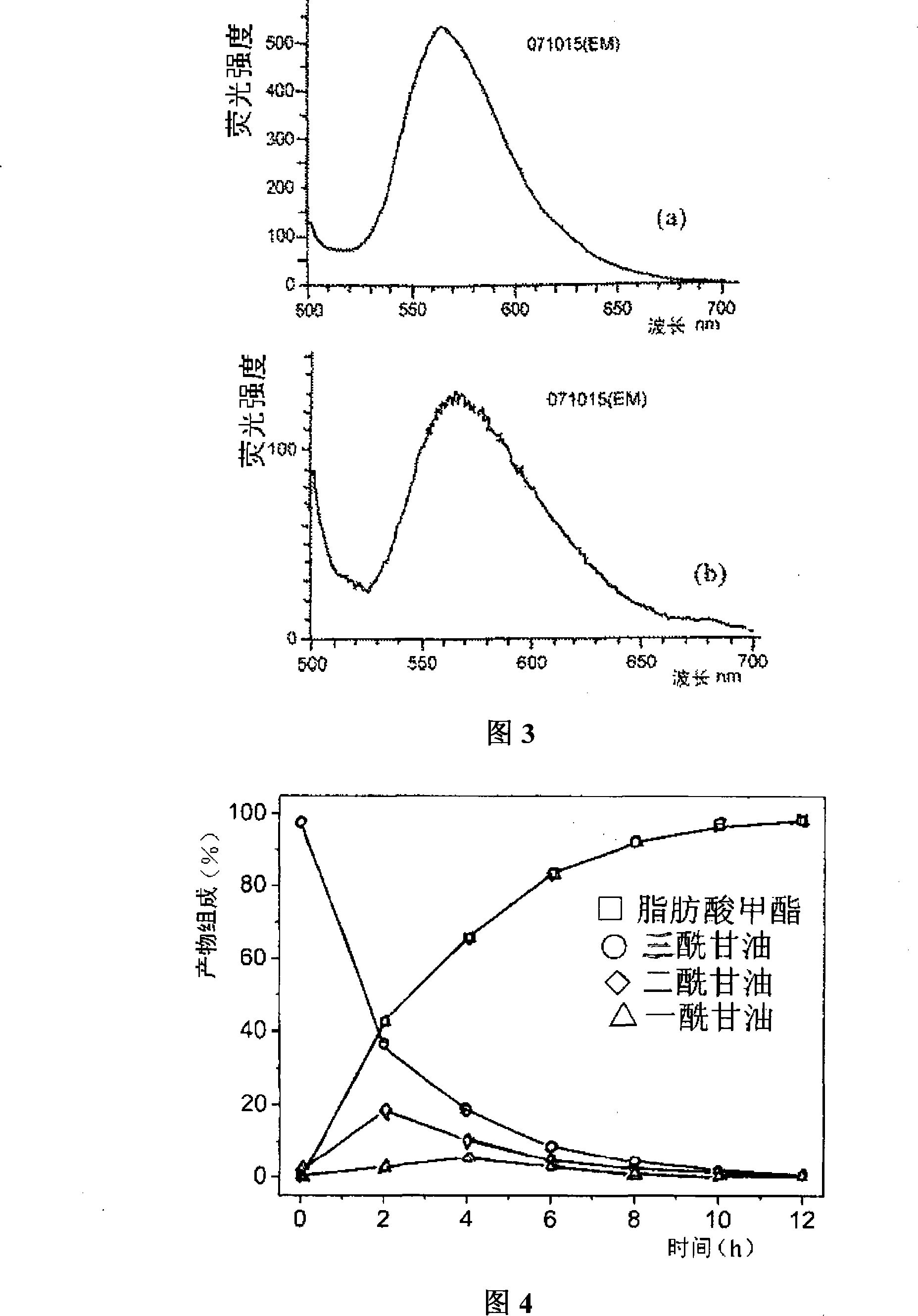

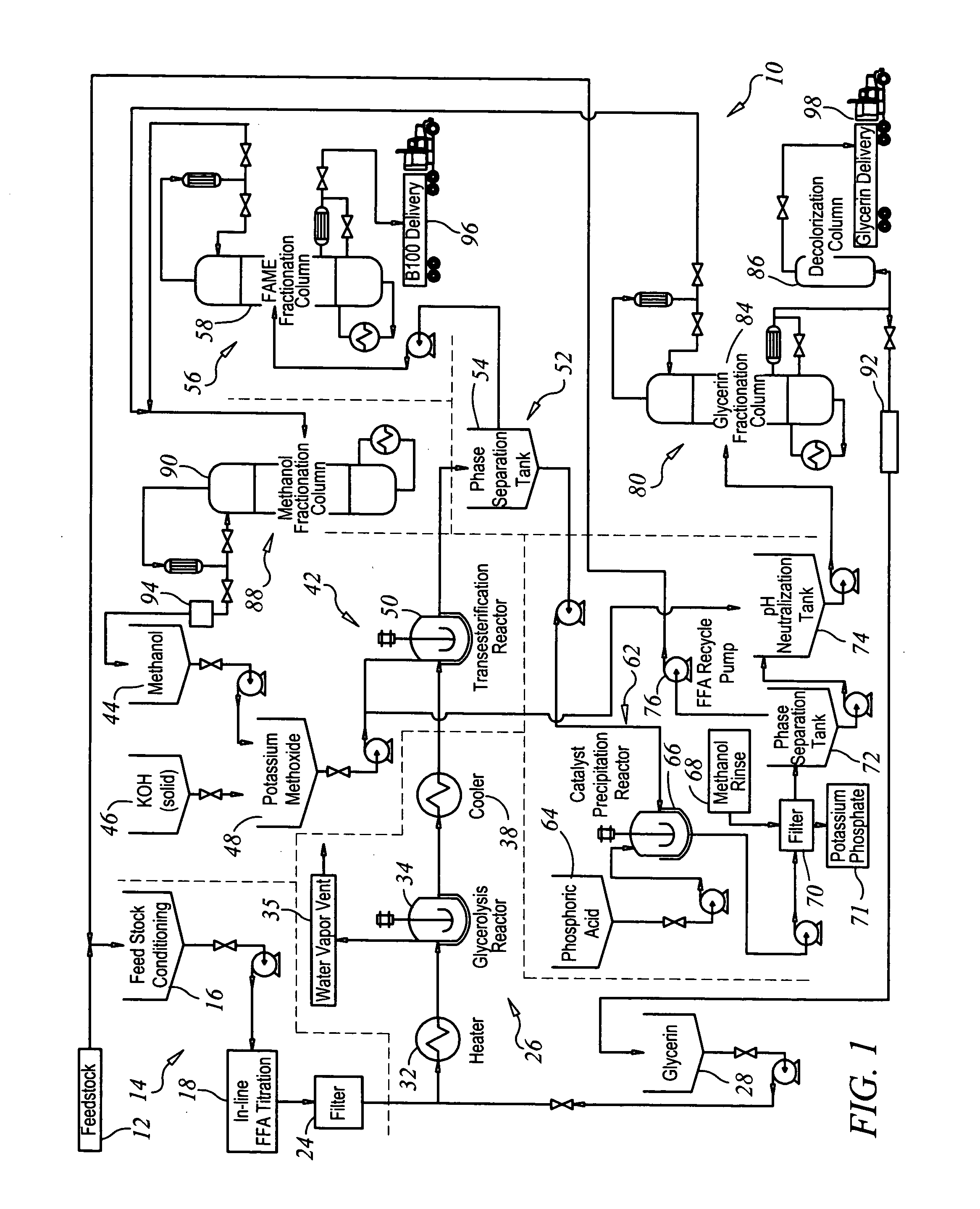

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

InactiveCN101280328AReduce consumptionReduce releaseFatty acid esterificationUnicellular algaeBiodiesel feedstockOil and grease

The invention discloses a method for producing biological diesel oil by two steps of culture of chlorellas, namely, autotrophy and heterotrophy, which belongs to the renewable biological energy field. Concentrated autotrophic algae is put into a fermentation tank to perform heterotrophic growth from the processes of autotrophic culture, cell concentration and fermentation pollution controlling of the chlorellas, to ensure the chlorellas to be synthesized into neutral fat. Effective feeding strategy is established to ensure the fat to be synthesized into optimal after the optimization of the fermentation conditions and the process control. The biomass can reach 108g.L-1, and the grease content can reach 52 percent of cell dry weight. After the culturing is finished, biological diesel oil can be prepared after extracting algal oil and transesterification reaction. The cell concentration technology adopted by the invention can effectively avoid the problem of light restriction during the high density culture process Not only is the carbon dioxide emission reduced, but also the organic carbon source consumption is reduced, thus the preparation cost of the biological diesel oil material is saved. The whole technical line is environmental friendly, high efficient, and can meet the industrial application requirements of the microalgae biological diesel oil.

Owner:TSINGHUA UNIV

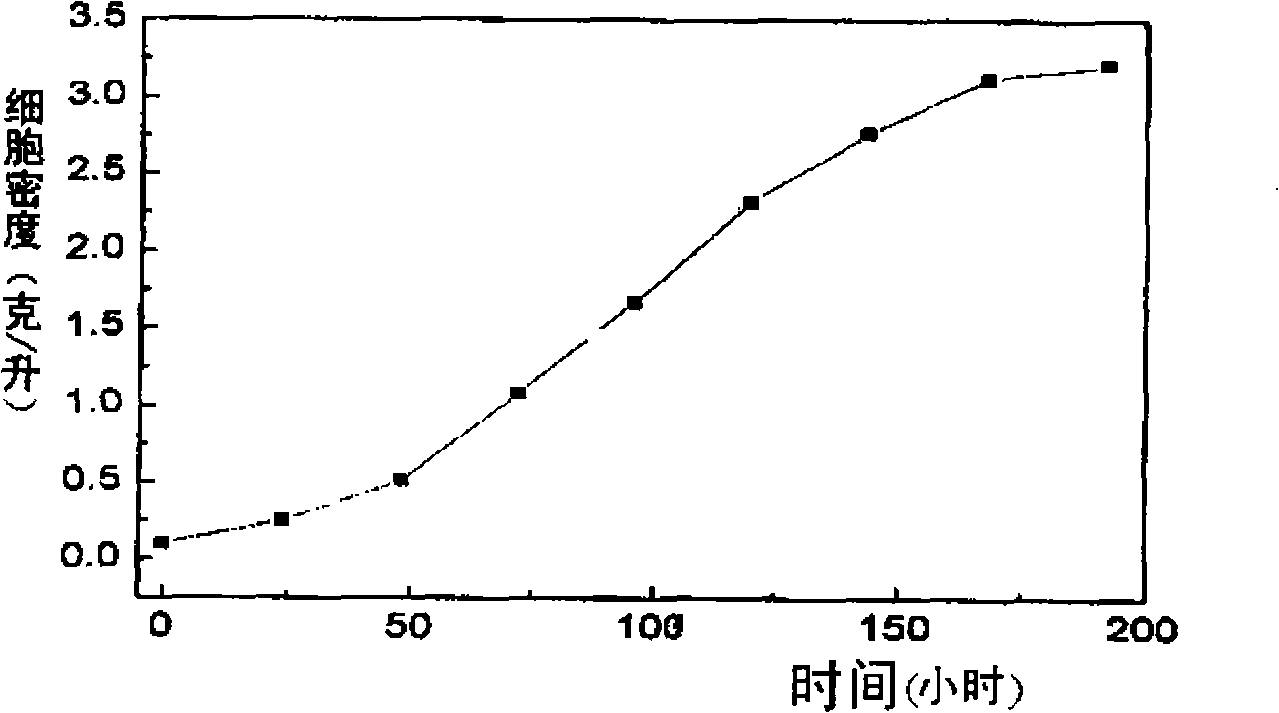

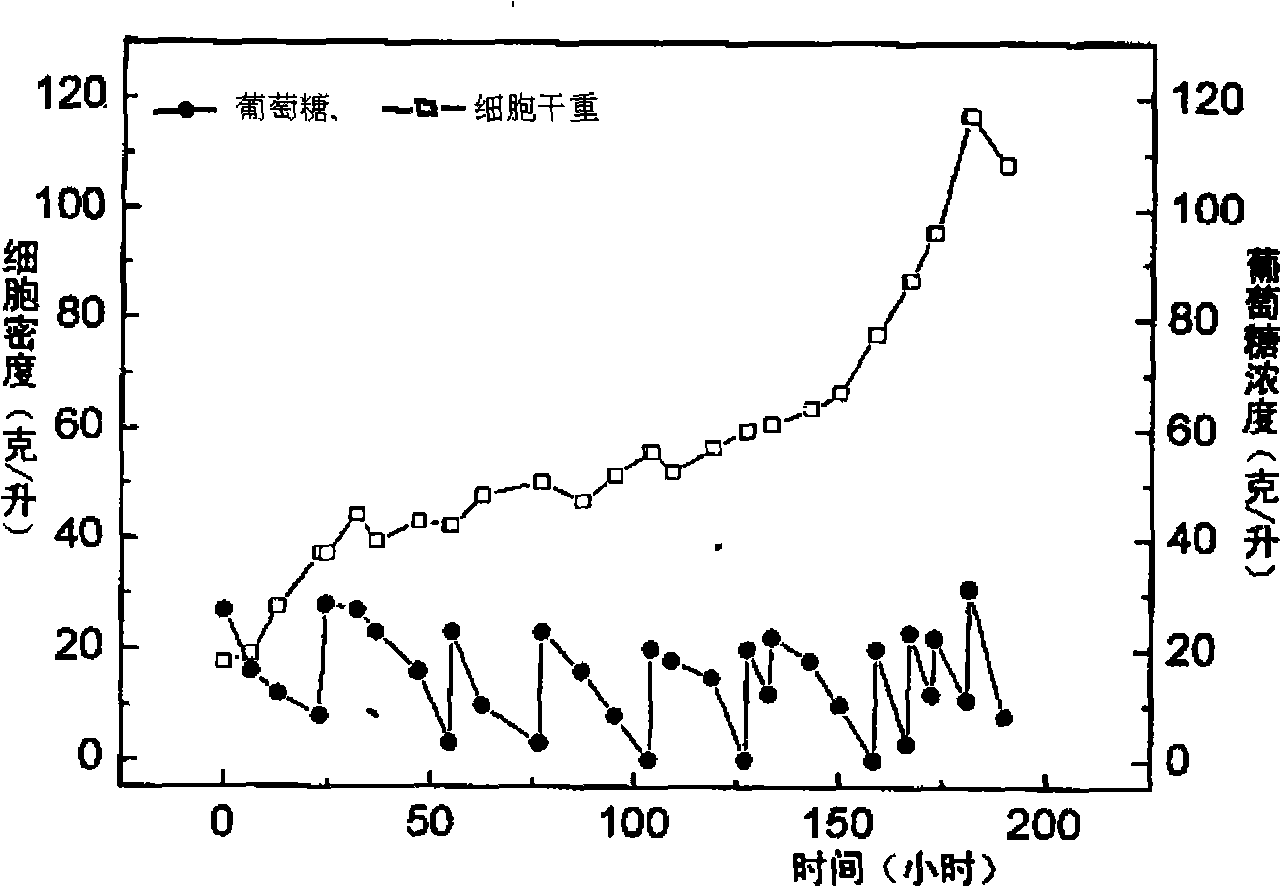

Method for producing biodiesel by high-density fermentation of heterotrophic chlorella

InactiveCN101230364ALow raw material costOptimizing conditions for heterotrophic fermentationFatty acid esterificationUnicellular algaeBiodiesel feedstockBiodiesel

The invention discloses a method of producing bio-diesel by fermenting the heterotrophic chlorella in high density which belongs to the renewable biological energy field. The method uses the heterotrophic chlorella fermented in high density in the bio-reactor as a raw material, which screens the chlorella species having high growth rate and high oil content, directly inoculates into the bottle as the first-class germ to culture then transfers to the fermentation cylinder to undergo the second-glass high density fermentation; the reaction condition is then optimized, and the process is controlled; the culture containing the carbohydrate is dripped to provide the nutrition for the cell growth, therefore the heterotrophic chlorella cells cultured in high density with density of 108g / L and oil content of 61 percent are separated, collected and dried; the algae oil is extracted, and the bio-diesel is produced by transesterification reaction; the invention reduces the cost for the raw material of bio-diesel, and satisfies the demand of industrialized application of producing bio-diesel by heterotrophic chlorella cells, therefore the technique of the invention becomes an economical and effective way of making oils from bio-diesel materials.

Owner:TSINGHUA UNIV

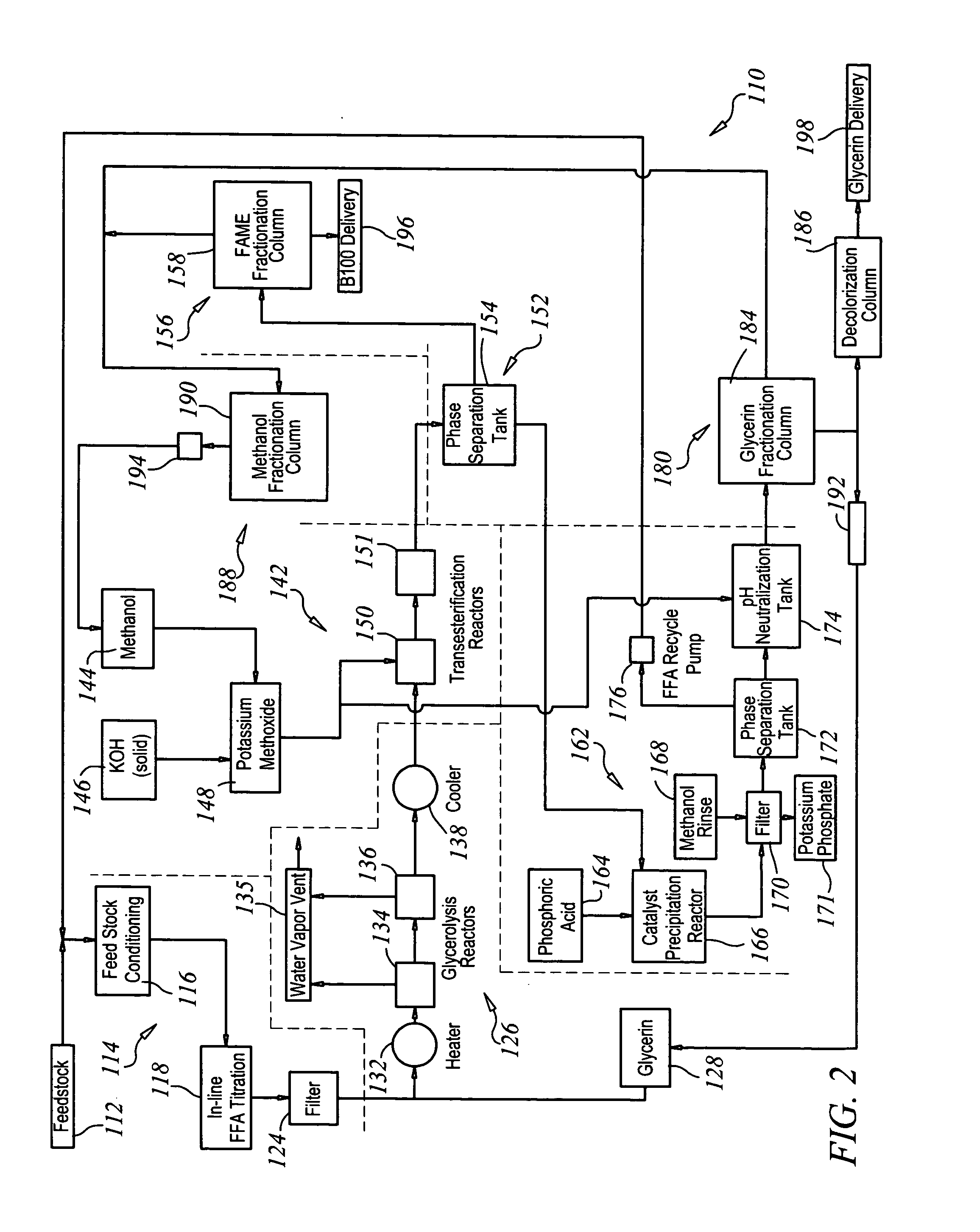

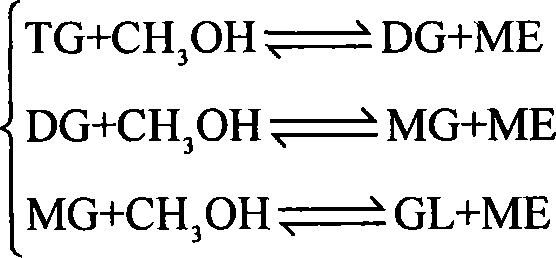

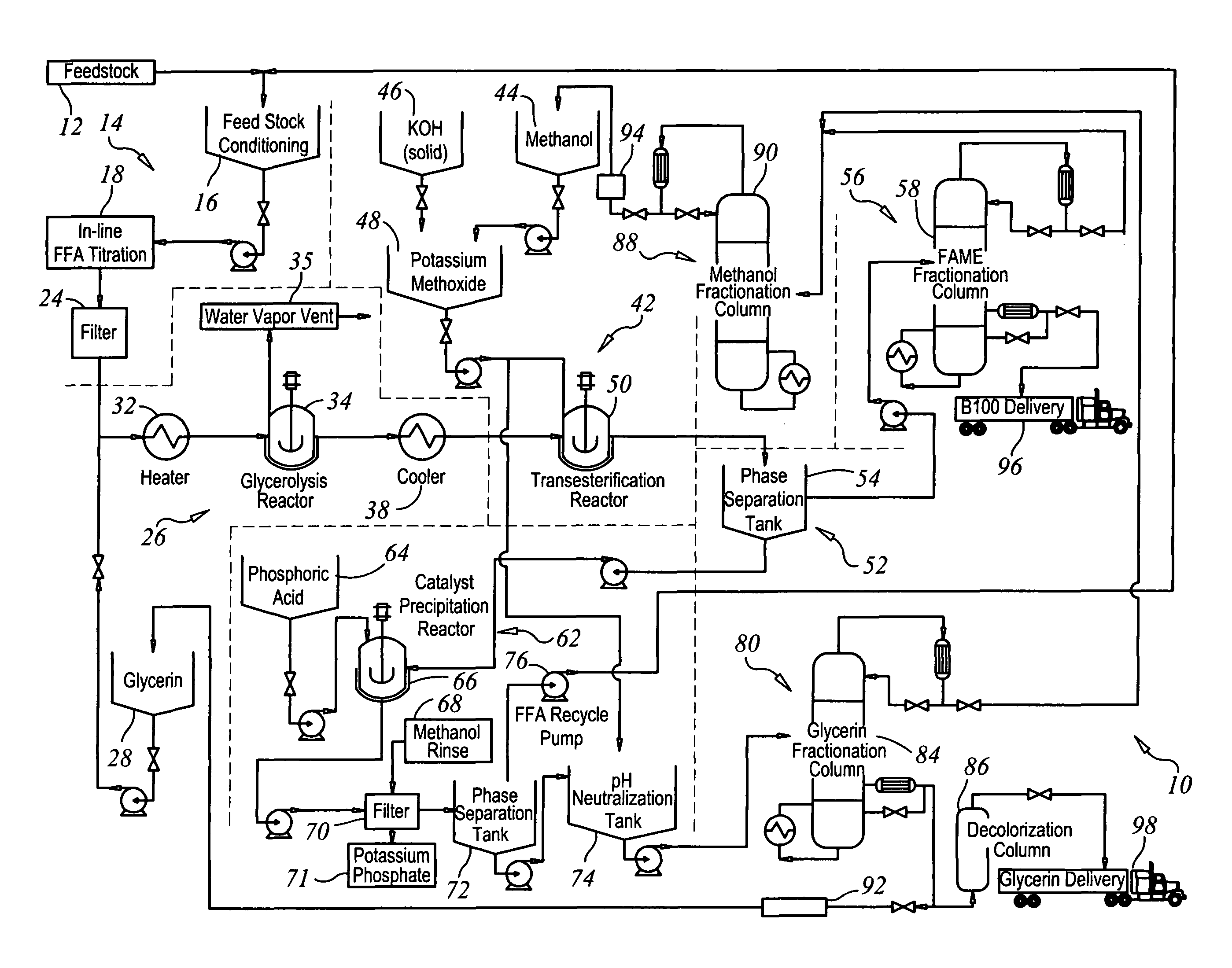

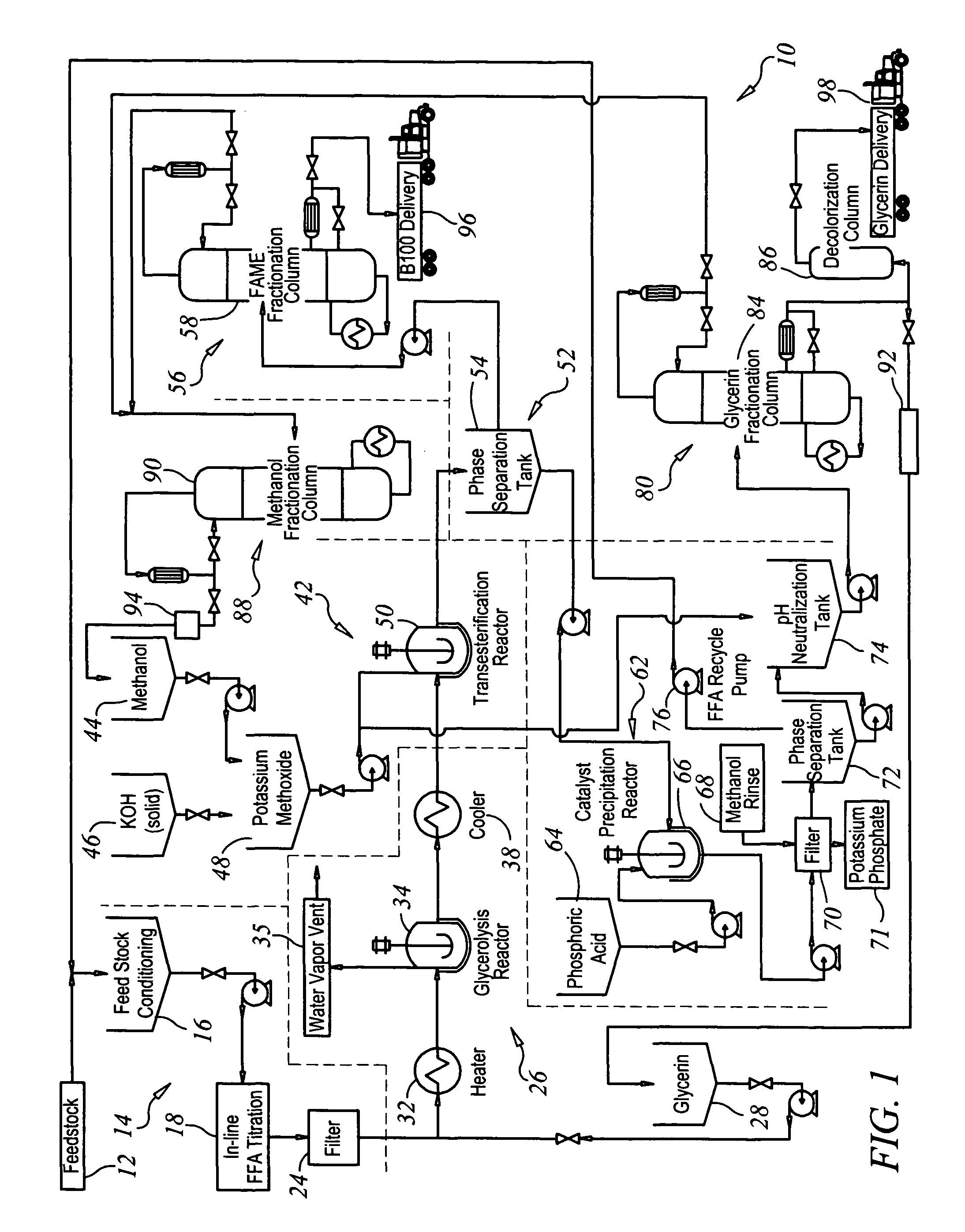

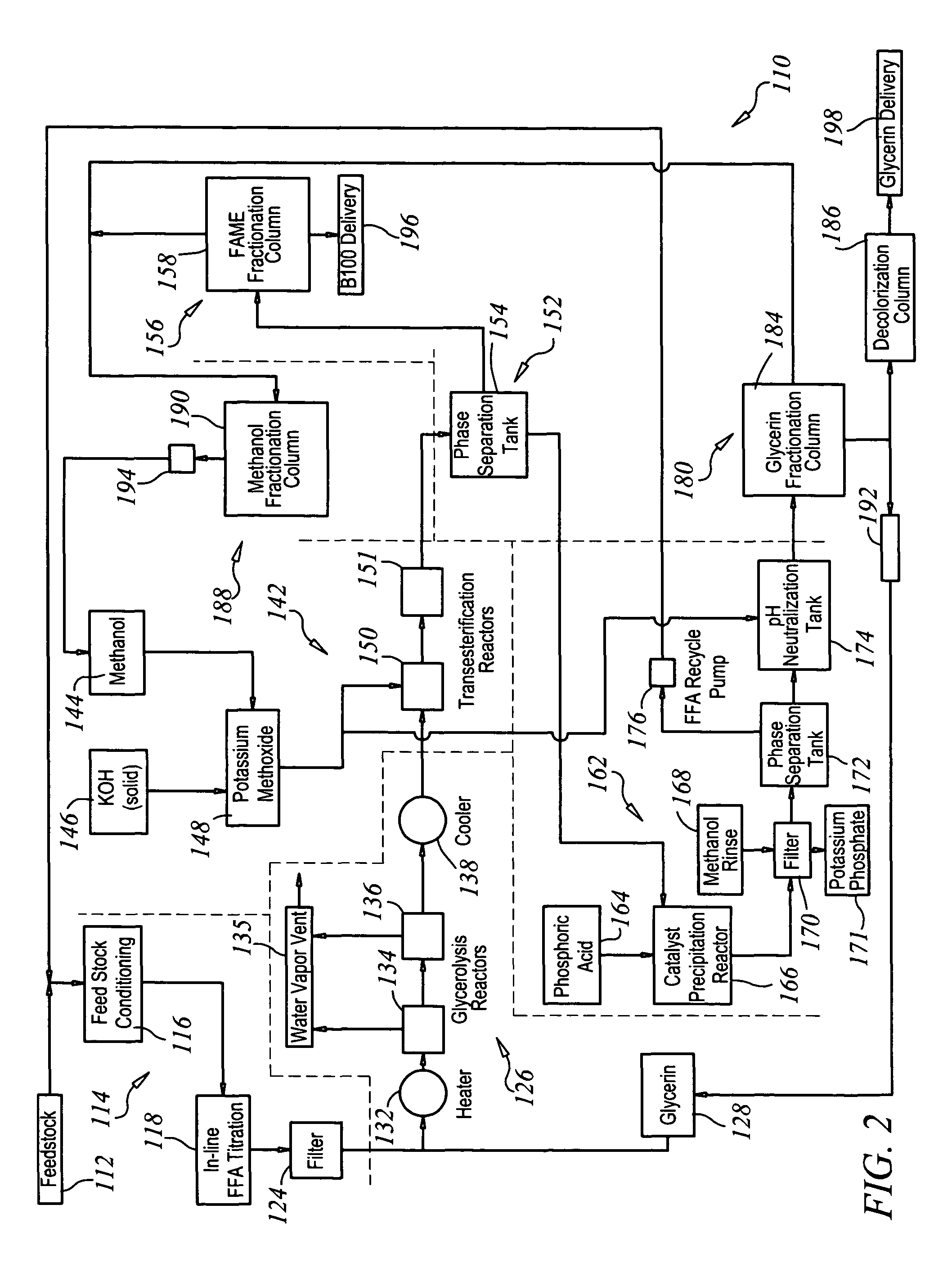

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277429A1Increase wasteLow costFatty oils/acids recovery from wasteFatty acid esterificationGlycerolGlycerolysis

A system and method for converting a high free fatty acid grease feedstock to biodiesel. The process comprises a glycerolysis reaction to convert free fatty acids to glycerides and a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin in the absence of solvents. In preferred embodiments, both glycerin and methanol are recycled. The process can process a feedstock containing up to 100 percent free fatty acid content to produce biodiesel and glycerin with minimal waste generation.

Owner:REG SENECA LLC +1

Production of esters of fatty acids and lower alcohols

InactiveUS20080051599A1Impurity can be harmfulBroad processingFatty acid esterificationFatty acids production/refiningTrans esterificationPtru catalyst

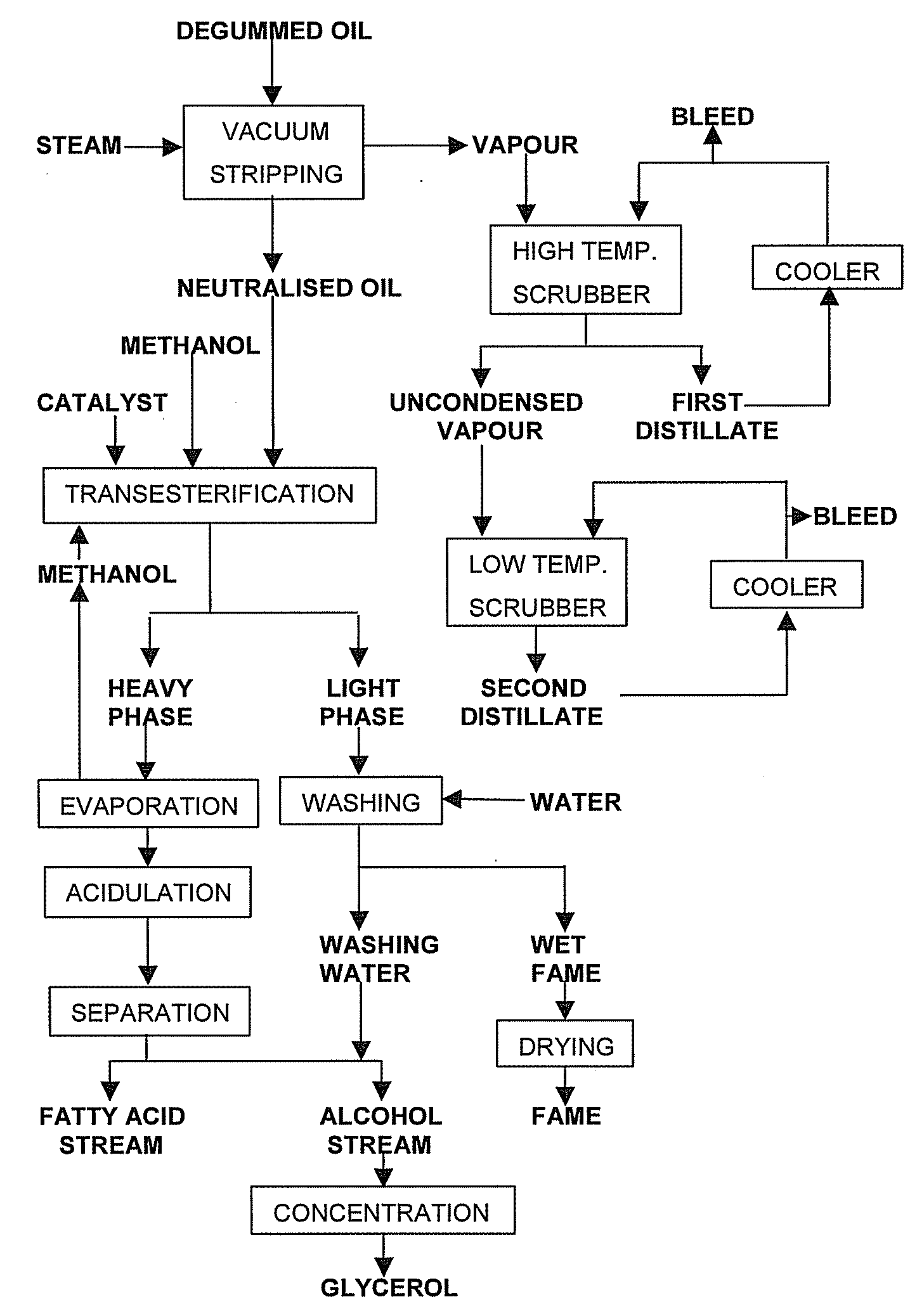

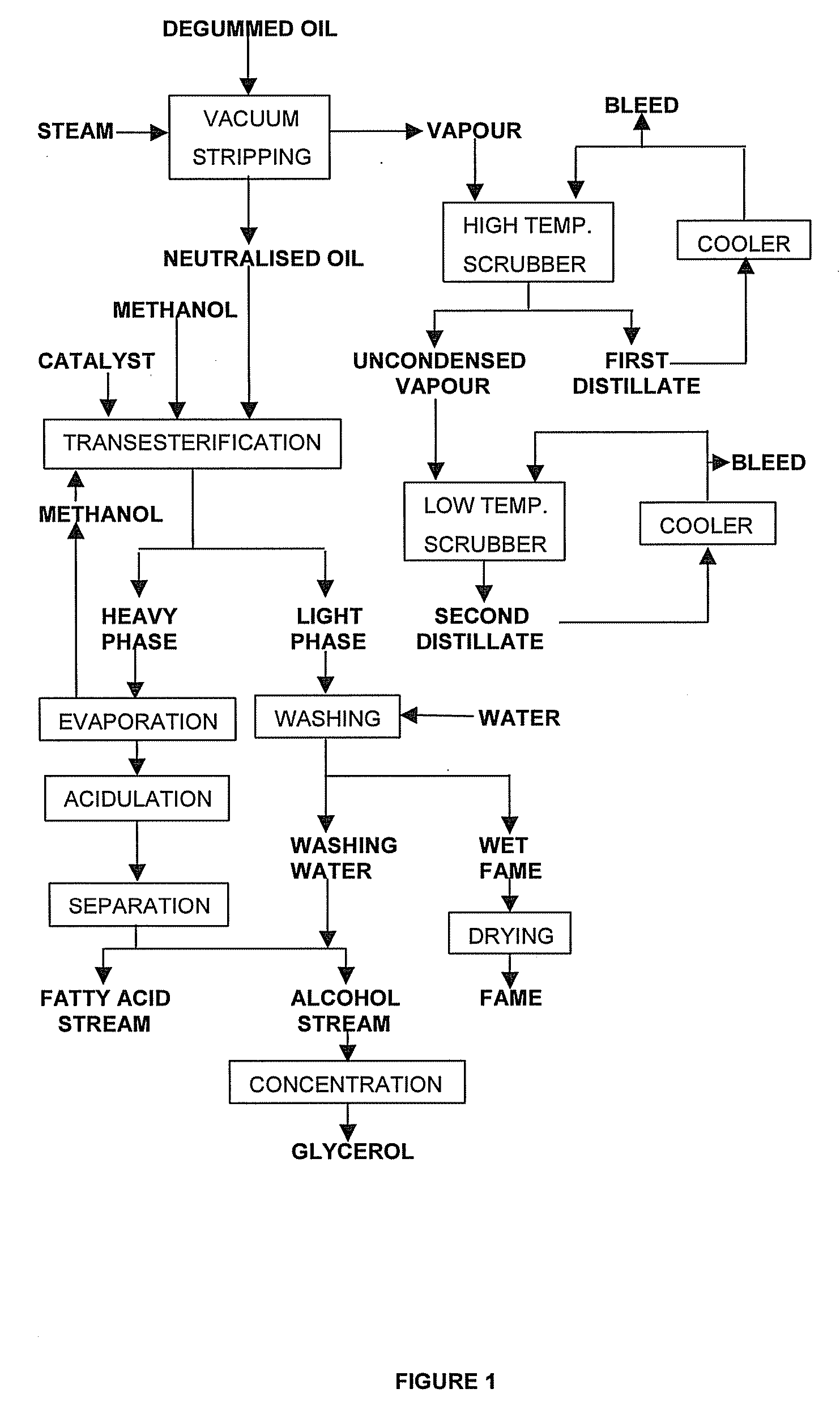

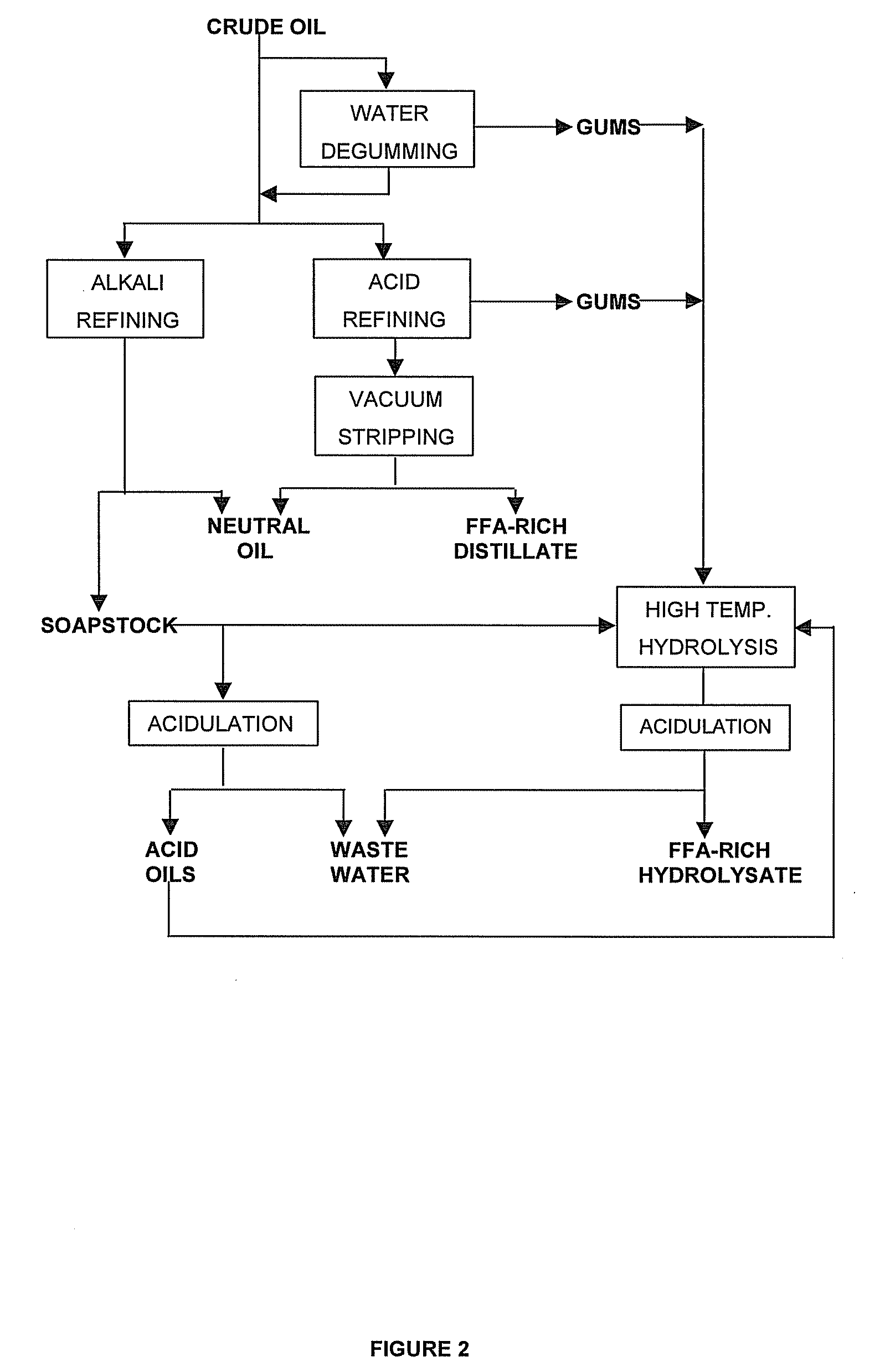

Process for the production of esters of fatty acids and C1-C5 alkyl alcohols comprising the steps of: (a) providing a fatty feed comprising a triglyceride oil or fat, partial glycerides and / or free fatty acids, (b) neutralising said fatty feed by vacuum stripping at a temperature from 200° C. to 280° C., thus providing a vapour stream and a residue, (c) collecting a distillate by scrubbing said vapour stream, (d) transesterifying said residue with a C1-C5 alkyl alcohol while using an alkaline catalyst, (e) separating the transesterification reaction mixture from step (d) into a fraction comprising C1-C5 alkyl esters of fatty acids and an alcoholic fraction (a) wherein at least part of free acids obtained as side products in step (a) and / or (c) and / or (e) are esterifyed with an alcohol using an acid catalyst, the product of this esterification being added to said fatty feed or said residue.

Owner:DESMET BALLESTRA OLEO

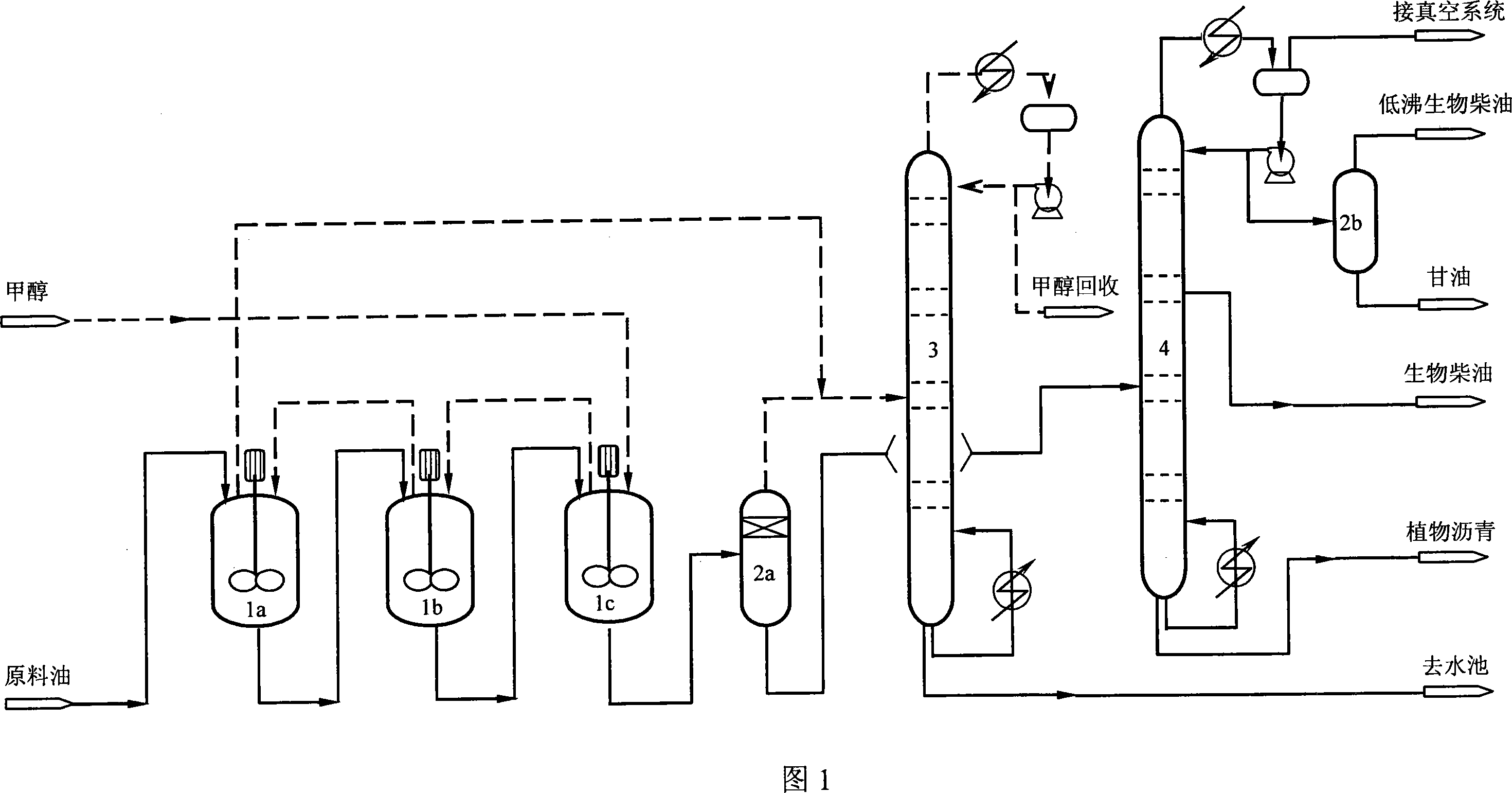

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

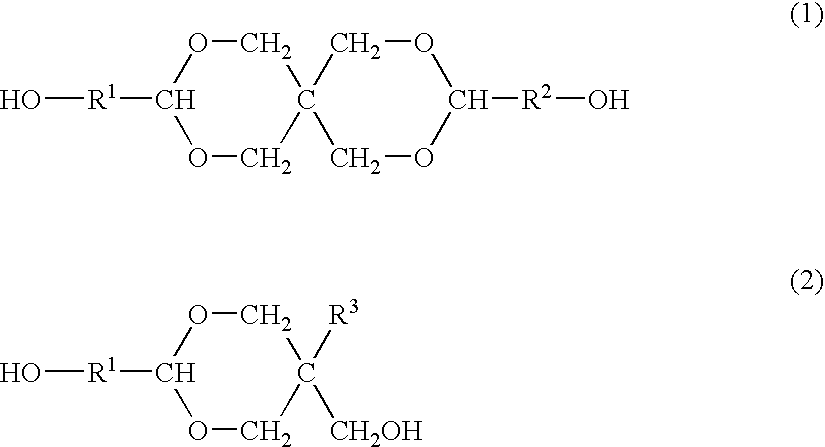

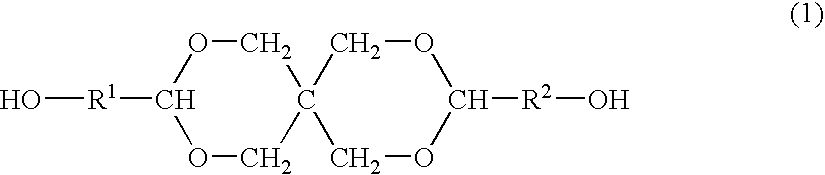

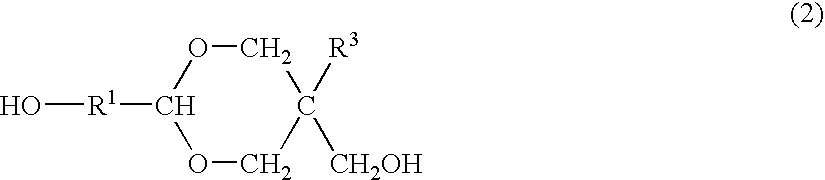

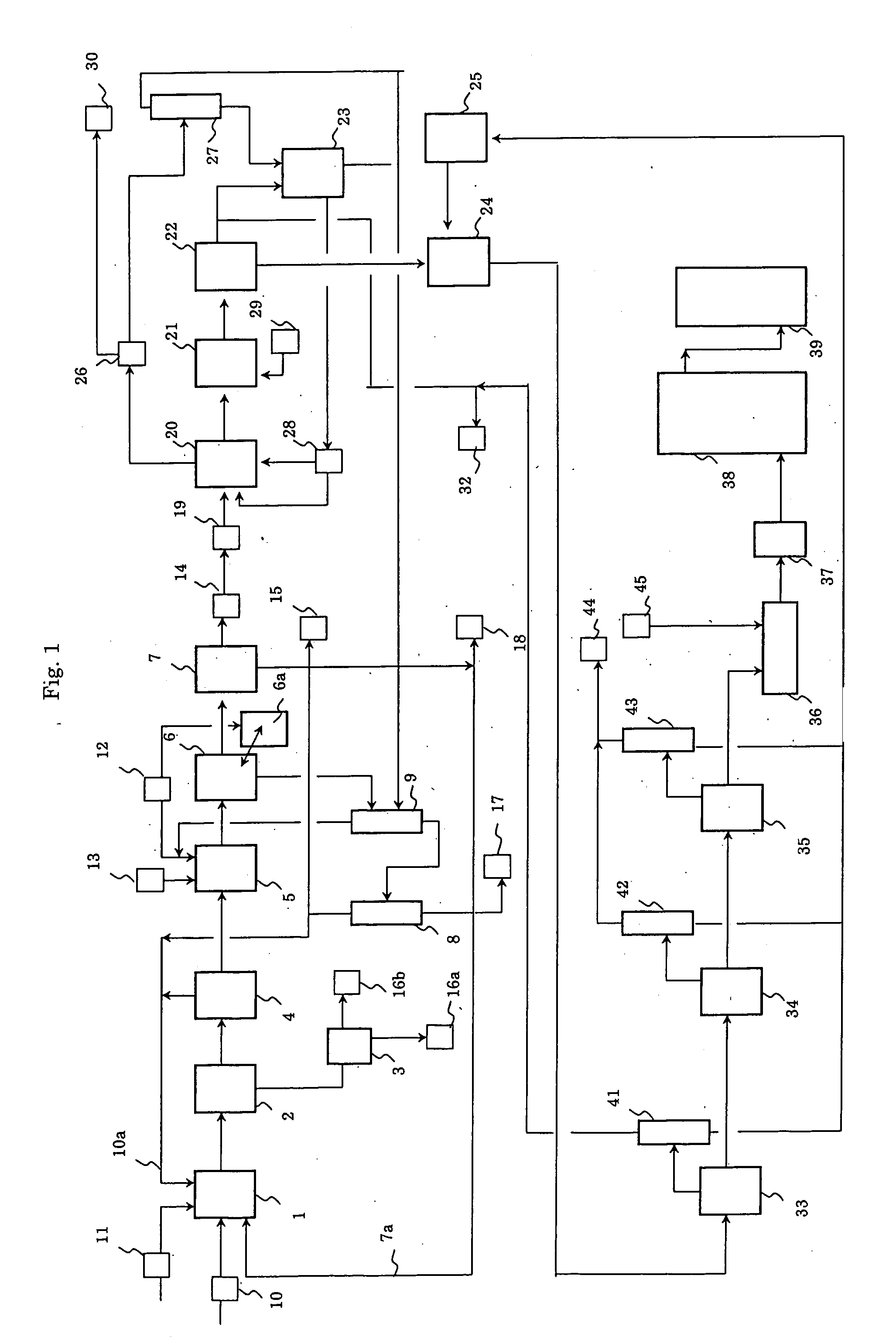

Process for producing polyester resins

The process of the present invention for producing a polyester resin comprising a dicarboxylic acid constitutional unit and a diol constitutional unit having a cyclic acetal skeleton comprises a step (1) of subjecting a diol (A) having a cyclic acetal skeleton and an ester (D) to transesterification reaction and a step (2) of mainly converting the resultant oligomer into a high polymer. The step (1) simultaneously satisfies the requirements (i) to (iv) as described in the specification. In the process of the present invention, the polyester resins having excellent moldability and mechanical properties are stably produced by a transesterification method which is less detrimental to environments.

Owner:MITSUBISHI GAS CHEM CO INC

Synthesis of higher polyol fatty acid polyesters by transesterification

InactiveUS6504003B1Process economyHigh degree of esterificationEsterified saccharide compoundsSugar derivativesPolyesterTrans esterification

A process for synthesizing polyol fatty acid polyesters comprising the steps of (1) mixing ingredients comprising (a) unesterified first polyol having hydroxyl groups, (b) second polyol esterified with fatty acids, (c) basic catalyst, and (d) emulsifying agent to form a mixture of ingredients; (2) reacting the mixture of ingredients at a temperature sufficient to obtain a transesterification reaction products and by-products; and (3) removing at least a portion of the by-products from the transesterification reaction mixture; and (4) further heating the transesterification reaction products and ingredients from step (3) at a temperature and for a time sufficient to esterify at least about 50% of the hydroxyl groups of the first polyol.

Owner:THE PROCTER & GAMBLE COMPANY

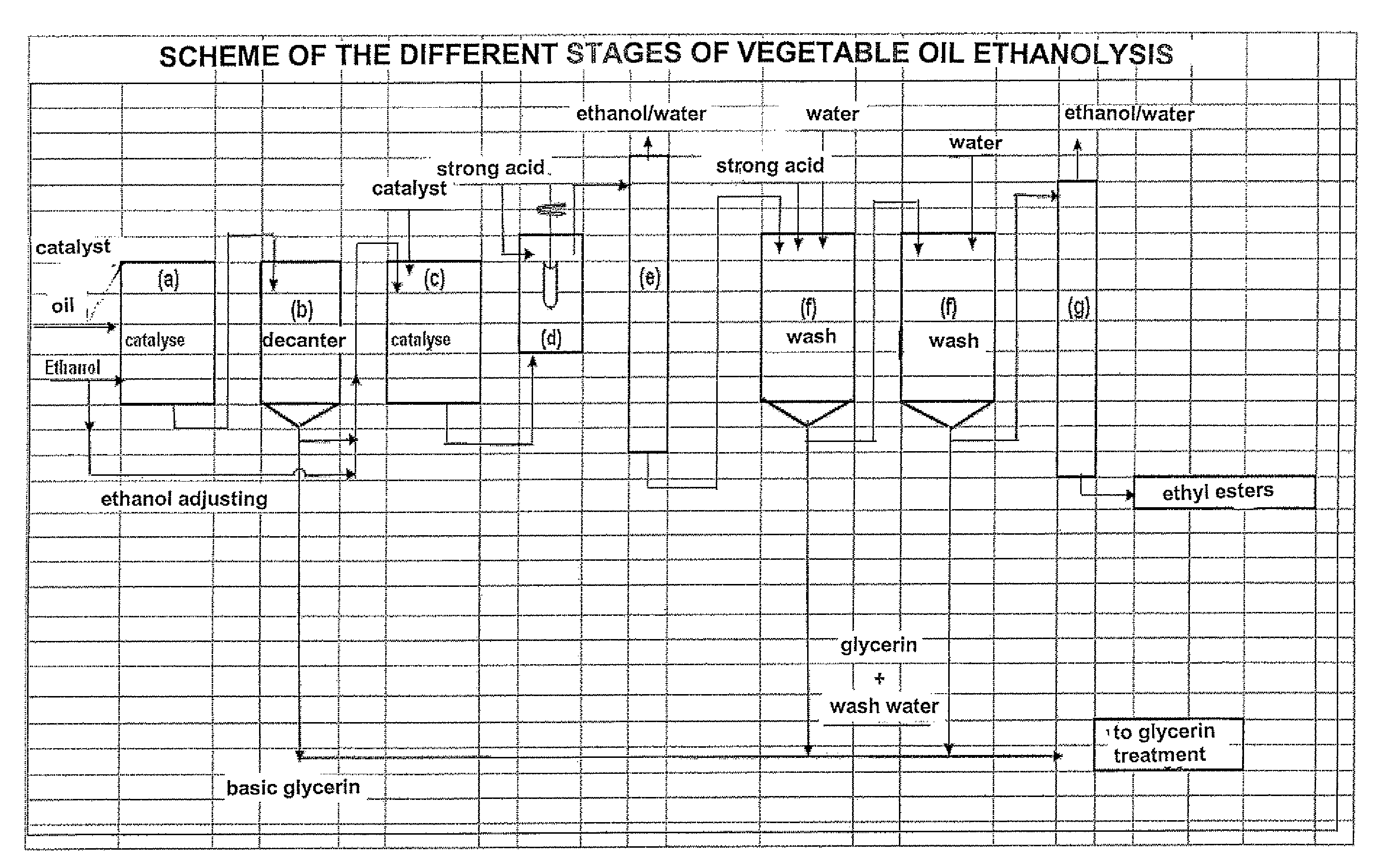

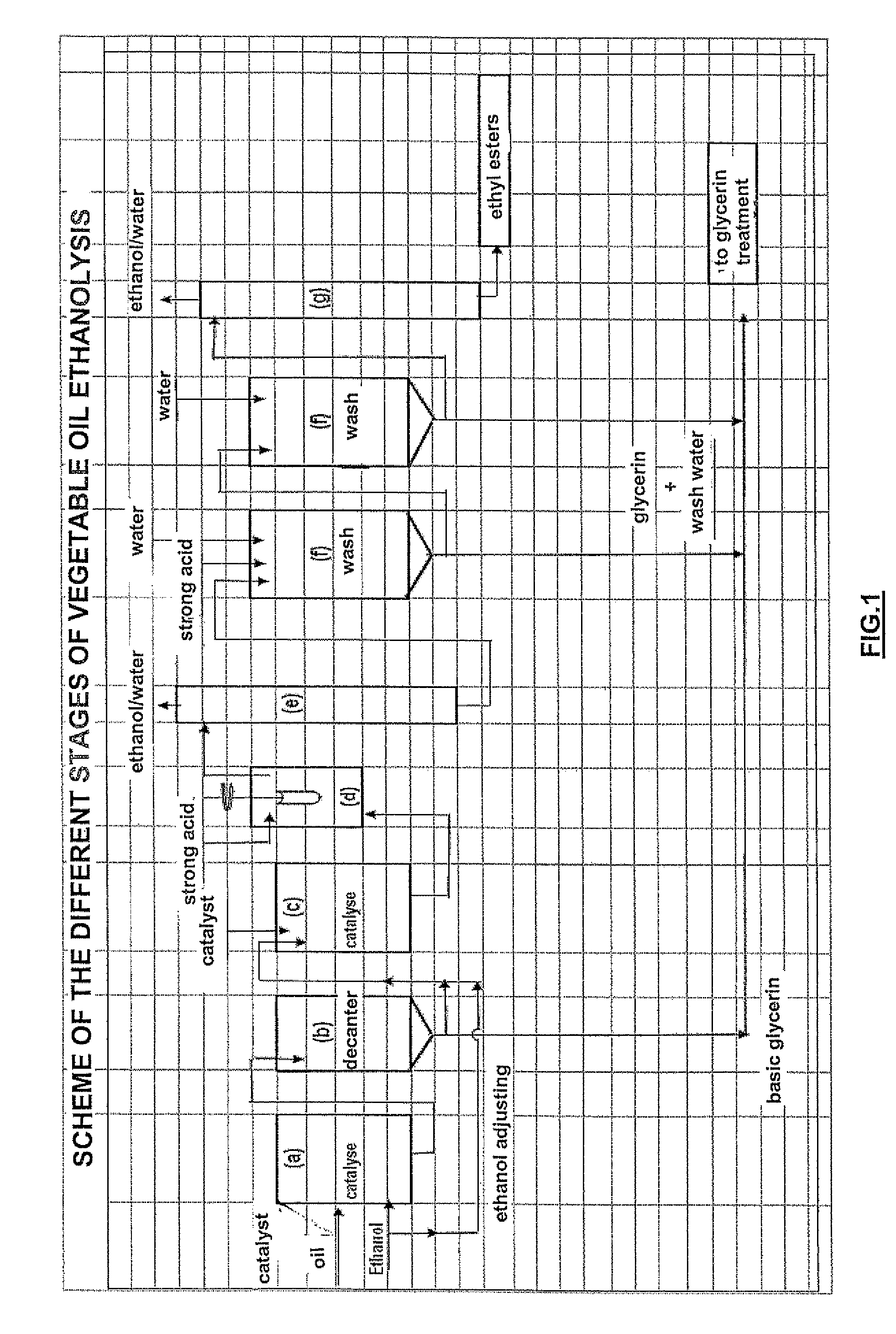

Refined method for manufacturing ethyl esters from fatty substances of natural origin

InactiveUS7652156B2Fatty oils/acids recovery from wasteFatty acid esterificationNatural sourceGlycerol ester of wood rosin

A method allowing, from natural fat or oils, vegetable or animal, or from other glyceride mixtures, to obtain in a quasi-quantitative way fatty acid ethyl esters that can be used as gas oil substitutes, comprises the succession of stages as follows:a stage (a) wherein the oil, the fat or the glyceride mixture is transesterified by ethanol using a soluble catalyst or a catalyst that becomes soluble during the reaction,a stage (b) wherein the glycerin formed is decanted and removed, without requiring an excess ethanol evaporation operation,a stage (c) wherein a second transesterification reaction is carried out so as to obtain a product whose ester content is at least 97% by mass,a stage (d) wherein controlled neutralization of the catalyst is carried out,a stage (e) wherein the excess ethanol is removed by distillation,a stage (f) wherein the ester undergoes purification by means of water wash sequences, anda stage (g) wherein the ester mixture is dried under reduced pressure.

Owner:INST FR DU PETROLE

Aromatic polycarbonate resin composition

InactiveUS6355767B1High impact strengthImprove hydrolysis resistanceTrans esterificationPolymer science

An aromatic polycarbonate resin composition comprising:(1) 10 to 90 wt % of an aromatic polycarbonate resin (component A) which is obtained from an ester exchange reaction between a diphenol and a dicarbonate ester and has a terminal hydroxyl group concentration of 10 to 70 mol % based on 100 molt of the total of all the terminal groups; and(2) 90 to 10 wt % of a thermoplastic graft copolymer resin (component B) which is obtained by grafting a vinyl cyanide monomer component and an aromatic vinyl monomer component to a diene-based rubber, the proportion of the vinyl cyanide monomer component to the copolymer resin being 10 to 27 wt % and the amount of a vinyl cyanide monomer contained in the copolymer resin being 200 ppm or less. According to the present invention, there is provided an aromatic polycarbonate resin composition which has excellent mechanical strength, particularly falling weight impact strength and improved hydrolysis resistance under a moist heat environment.

Owner:TEIJIN KASEK KK

Oil composition of conjugated linoleic acid

InactiveUS20070218183A1Reduce consumptionGood compatibilityFatty acid esterificationFood ingredientsPhytosterol estersEdible oil

A novel oil composition comprises an interesterified structured lipid component, the component being an interesterifcation reaction product of an amount of a medium chain triglyceride, an amount of a long chain domestic oil, and an amount of a conjugated linoleic acid material. The structured lipid component can be used in edible oil compositions. The oil compositions advantageously can contain an amount of a phytosterol ester component, up to about 12 weight percent of the total composition. The oil compositions disclosed herein have good stability and also have other properties useful for an edible oil composition.

Owner:BUNGE OILS INC

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS7806945B2Increase wasteQuality improvementFatty oils/acids recovery from wasteFatty acid esterificationGlycerolSolvent

A system and method for converting a high free fatty acid grease feedstock to biodiesel. The process comprises a glycerolysis reaction to convert free fatty acids to glycerides and a base catalyzed transesterification reaction to produce fatty acid methyl esters and glycerin in the absence of solvents. In preferred embodiments, both glycerin and methanol are recycled. The process can process a feedstock containing up to 100 percent free fatty acid content to produce biodiesel and glycerin with minimal waste generation.

Owner:REG SENECA LLC +1

Water stable compositions and articles comprising starch and methods of making the same

Thermoplastic polymer compositions comprising starch and articles made therefrom are water stable or may be rendered so. One method of making water stable thermoplastic compositions comprises the steps of mixing destructured starch with polyhydric alcohol and triglyceride, and forming a transesterification reaction product from at least a portion of the polyhydric alcohol and triglyceride.

Owner:THE PROCTER & GAMBLE COMPANY

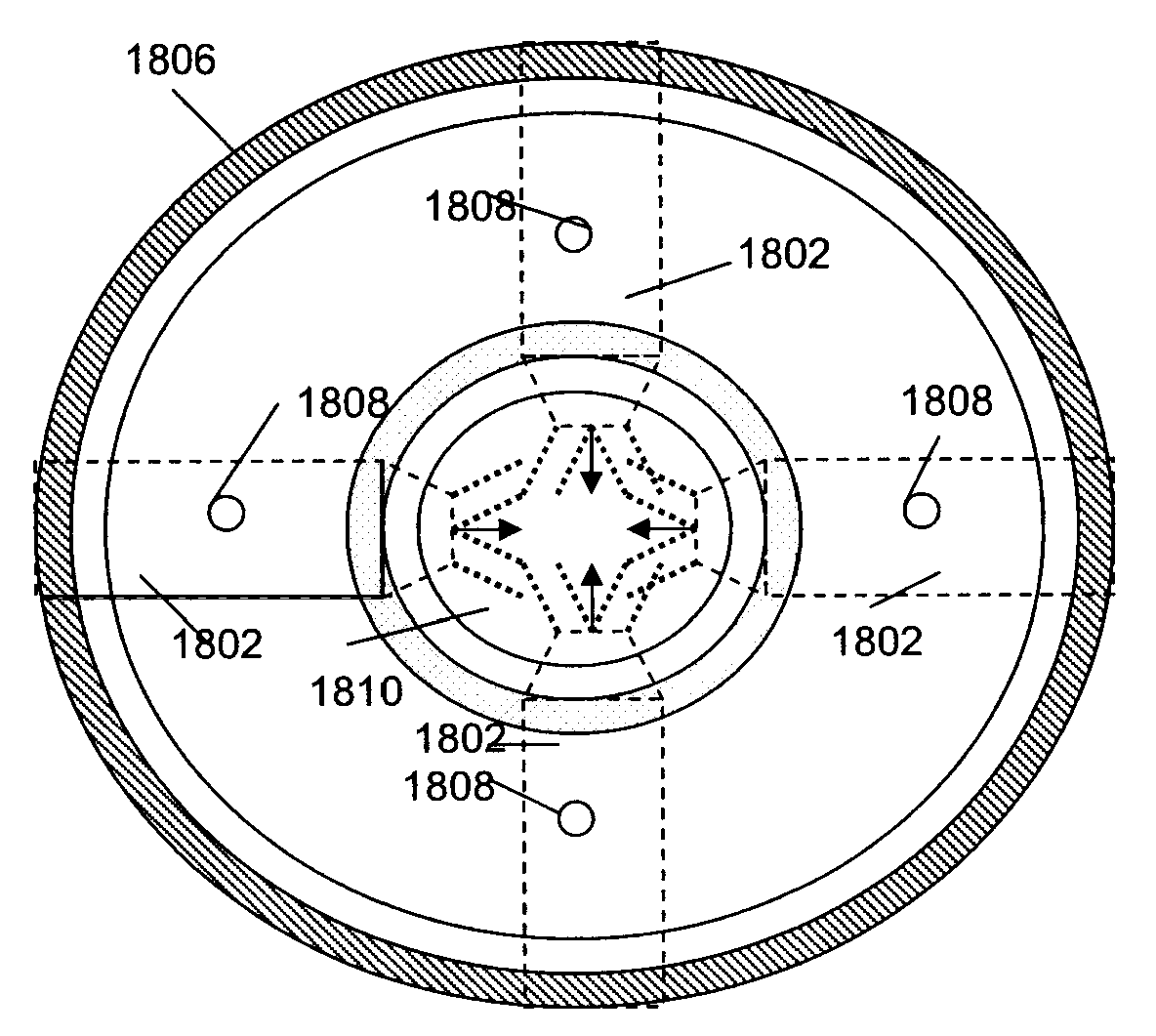

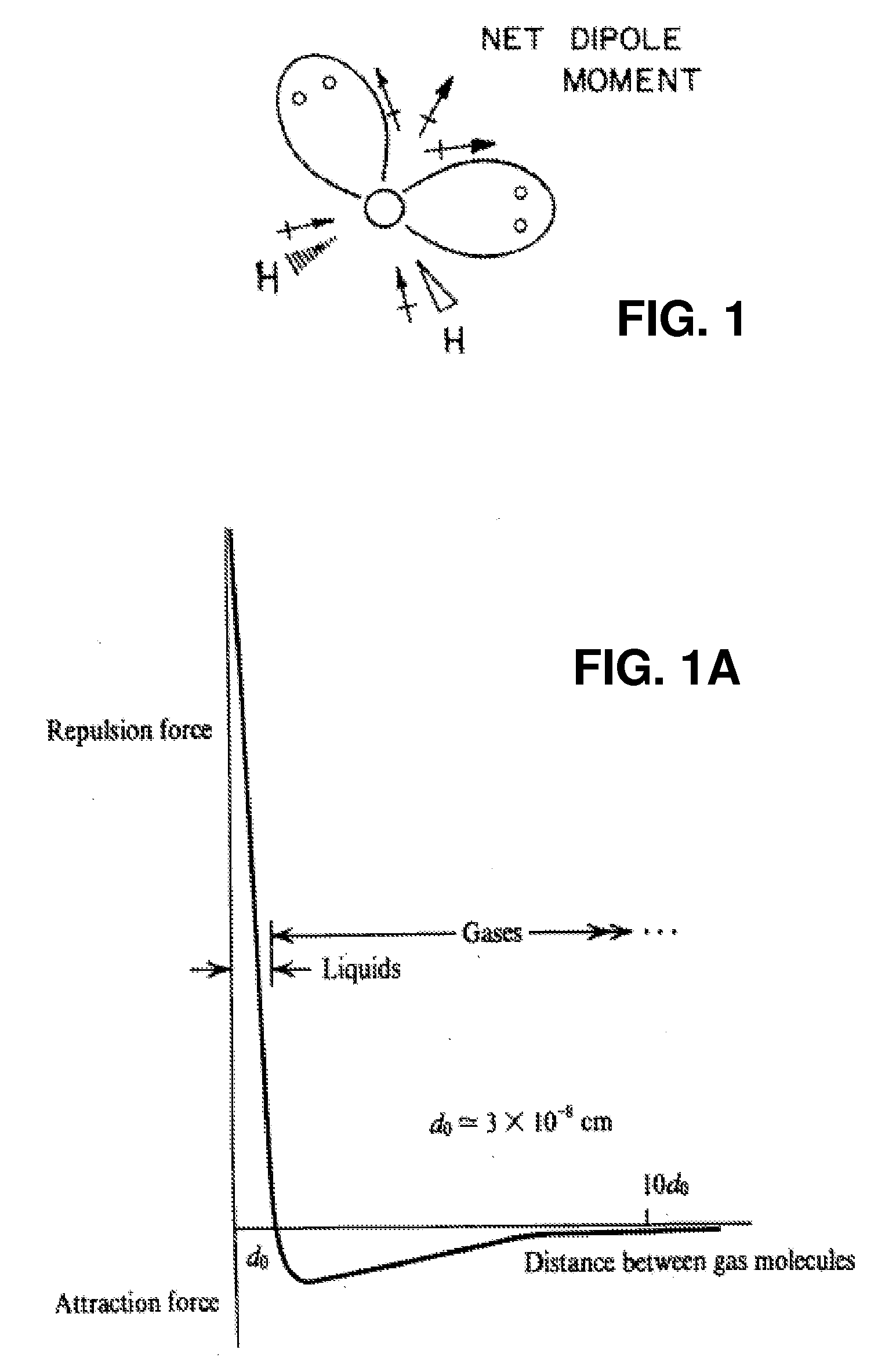

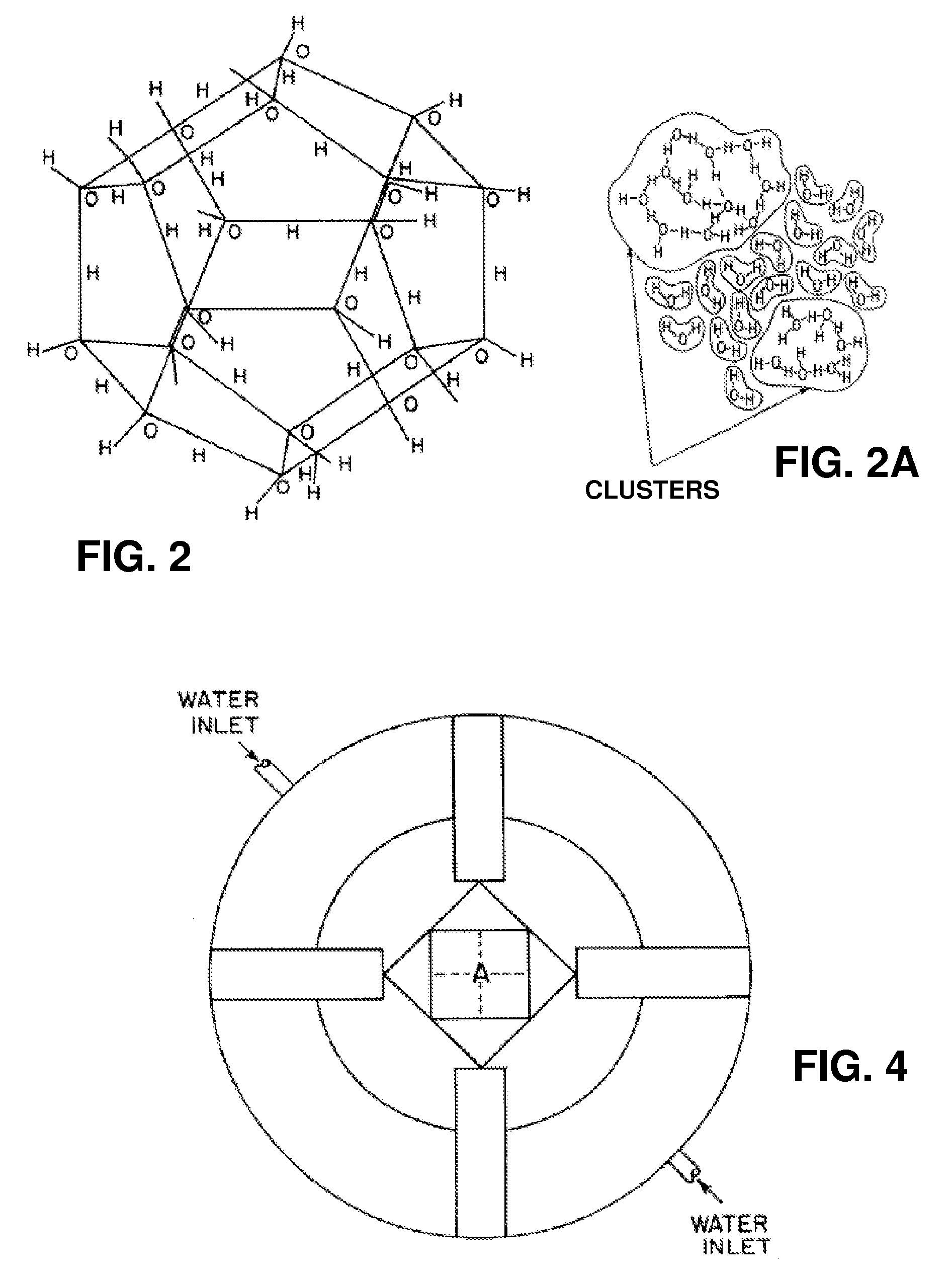

Device and method for combining oils with other fluids and mixtures generated therefrom

InactiveUS20090188157A1Amount of catalyst can be reducedHigh chemical activityCosmetic preparationsFlow mixersAlcoholBiodiesel

A device and method a provided for mixing and enhancing reaction between oil and a non-oil liquid by exploiting the formation, implosion and explosion of numerous cavitation bubbles within a cavitation device. Intense localized energy from the collapse of the cavitation bubbles subjects the mixture to intense heat and pressure, thereby accelerating reaction between the oil and non-oil liquid. In one embodiment, the non-oil liquid is an alcohol, and the cavitation device is used to enhance a transesterification reaction to convert the oil and alcohol into biodiesel in the presence of a catalyst.

Owner:AQUAPHOTONICS INC

Method for manufacture of esters by transesterification

InactiveUS7696376B2Fatty oils/acids recovery from wastePreparation by ester-hydroxy reactionPtru catalystSolid acid

A method for the manufacture of an ester by transesterification allows the transesterification reaction to proceed within a short reaction time and under a pressure of the order of normal pressure. It was found that transesterification proceeds when a starting material ester and an alcohol are brought into contact with a catalyst comprising (A) an amorphous zirconium oxide and (B) an oxide of a Group II element, an oxide of a Group V element, and / or an oxide of a Group IV element other than zirconium and hafnium. In this method, it is preferred that the starting material ester in a liquid-phase state and the alcohol in a vapor-phase state be brought into contact with a solid acid catalyst comprising the above components (A) and (B), the starting material ester be an oil or fat, and the alcohol be methanol or ethanol. An oxide of titanium, silicon, germanium, or tin is the preferred oxide of the Group IV element other than zirconium and hafnium.

Owner:JAPAN ENERGY CORP

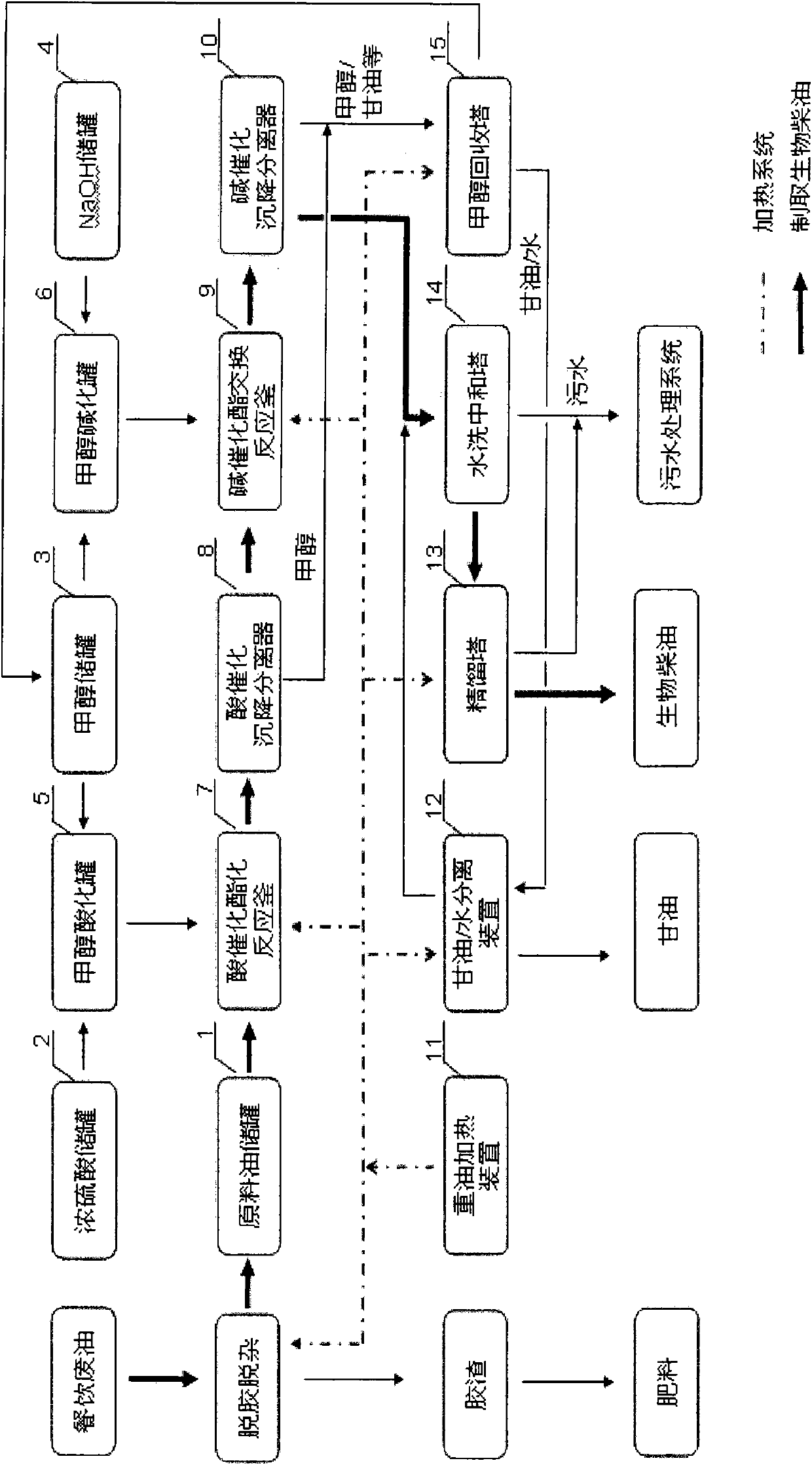

Method for preparing biodiesel by utilizing food waste recycling oil

ActiveCN101906355AReduce manufacturing costImprove pollutionFatty acid esterificationBiofuelsBiodieselGlycerol

The invention relates to a method for preparing biodiesel by utilizing food waste low-cost high-efficiency recycling oil, which is realized by four steps of dining waste oil degumming and impurity removing treatment, acid catalytic esterification reaction, base catalytic transesterification reaction and biodiesel refining. The final product is colourless biodiesel, and all performance indexes can reach the European and American biodiesel quality standard. The invention has the advantages of low production cost, high conversion rate and less pollutant discharge and overcomes the defect of preparation by a single method. When the biodiesel is produced, by-products comprise glycerol and methanol.

Owner:北京昊业怡生科技有限公司

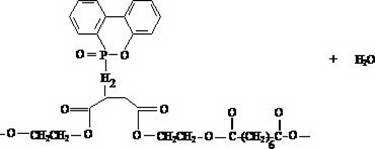

Preparation method of phosphorus-containing halogen-free environmentally-friendly flame-retardant polyester polyol

The invention provides a preparation method of phosphorus-containing halogen-free environmentally-friendly flame-retardant polyester polyol. The method comprises the steps that with DOPO being starting material, firstly, the DOPO reacts with dibasic acid or dibasic acid anhydride to generate a DOPO complex intermediate; secondly, esterification dehydration reaction is performed on the generated intermediate, small-molecules polyol and dibasic acid or dibasic acid anhydride at 150 DEG C-160 DEG C; after the dehydration reaction is over, the temperature is raised to 200 DEG C-250 DEG C for transesterification, wherein the reaction time is 1 h-3 h, and in this way, the polyester polyol is obtained. The prepared polyester polyol is not conventional polyester polyol but the polyester polyol containing the phosphorus element, has the reactivity with isocyanate and can be used for permanent flame retardant modification of polyurethane products. As the phosphorus element is introduced to the polyester polyol, the polyester polyol contains phosphorus and is free of halogen, environmentally friendly and capable of inflaming retarding.

Owner:XUCHUAN CHEM SUZHOU

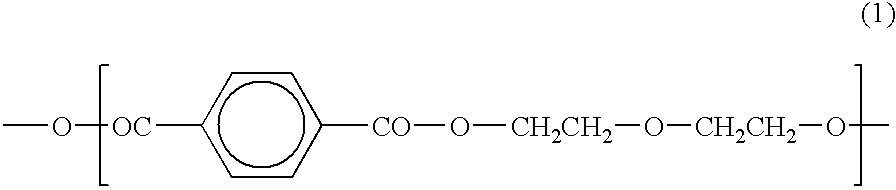

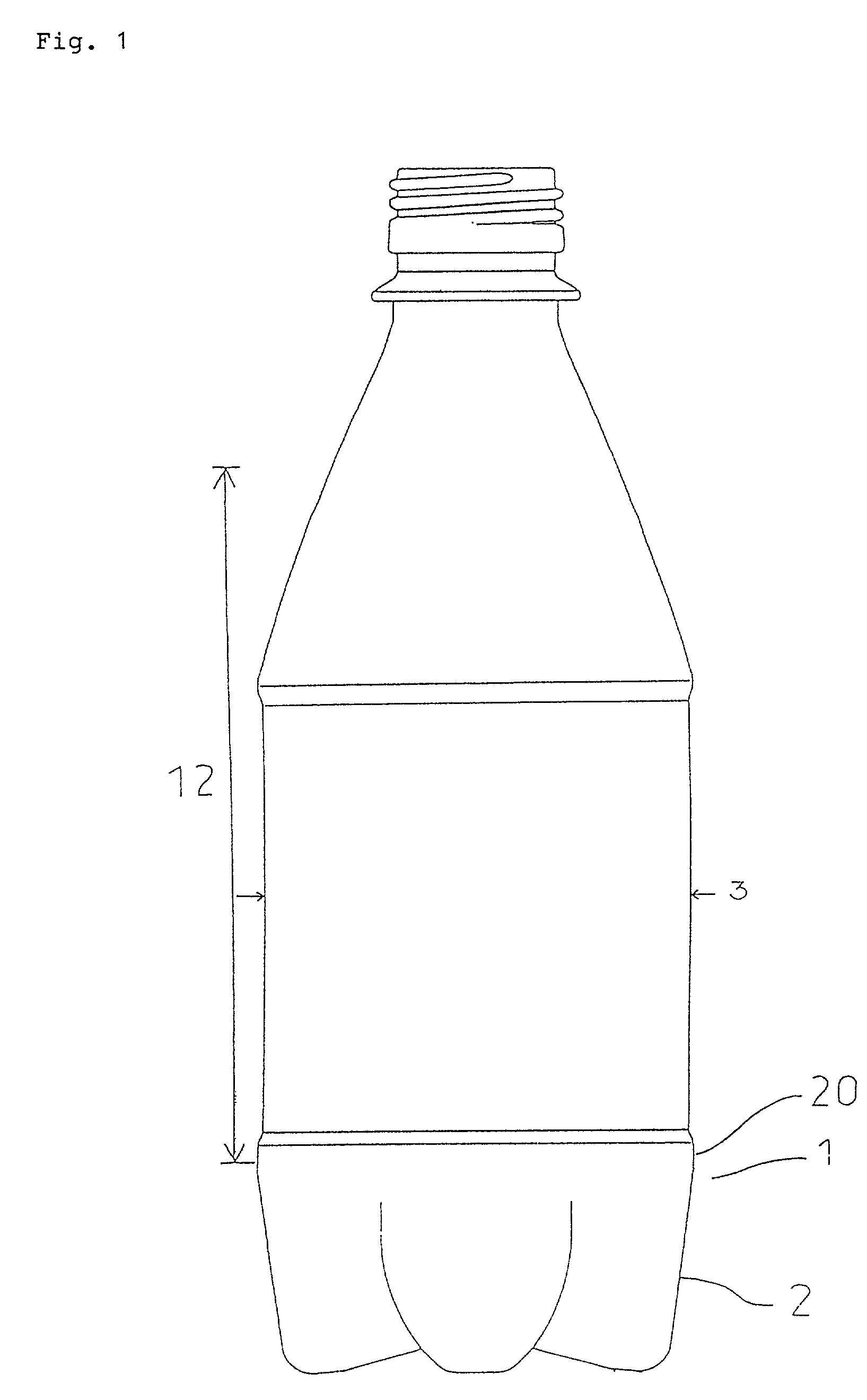

Polyester resin composition and a bottle therefrom

The present invention relates to a resin composition comprising polyethylene terephthalate and polyethylene naphthalate and a process for preparing the composition. The present invention relates also to a bottle produced from the composition and a process for the preparation of the bottle. The resin composition according to the present invention is prepared by melt-kneading (A) polyethylene terephthalate with (B) polyethylene naphthalate in a proportion of the ethylene naphthalate unit to a total of (A) and (B) of from 5 to 15 mole %, with a kneading extruder in a ratio of an extruder output rate to a screw rotation speed of 0.1 to 1.4 kg / hr.rpm. The present composition gives a bottle superior in transparency and in resistance to heat and pressure despite that it has a transesterification of 20% or lower.

Owner:NISHIHARA SHUN ICHI +3

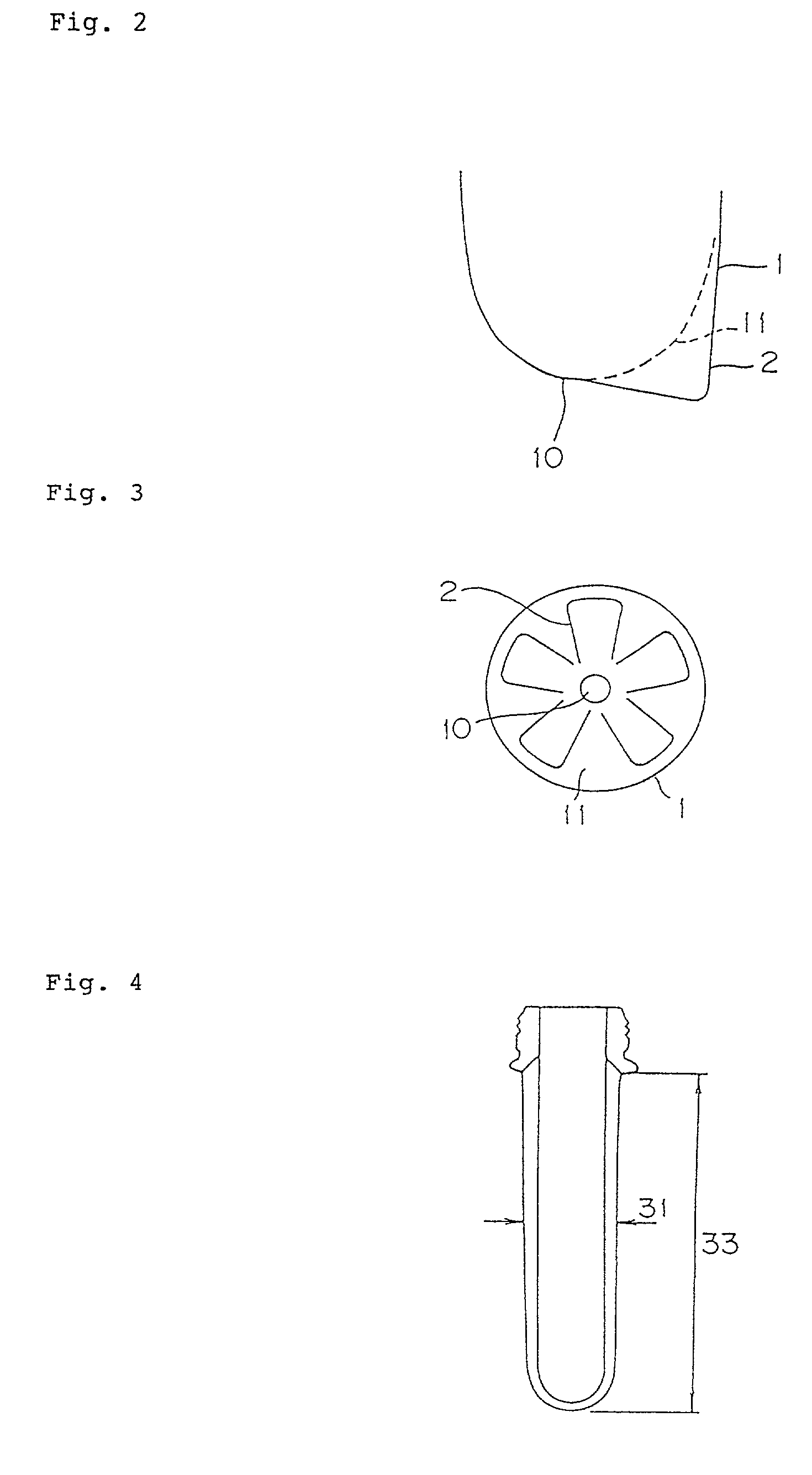

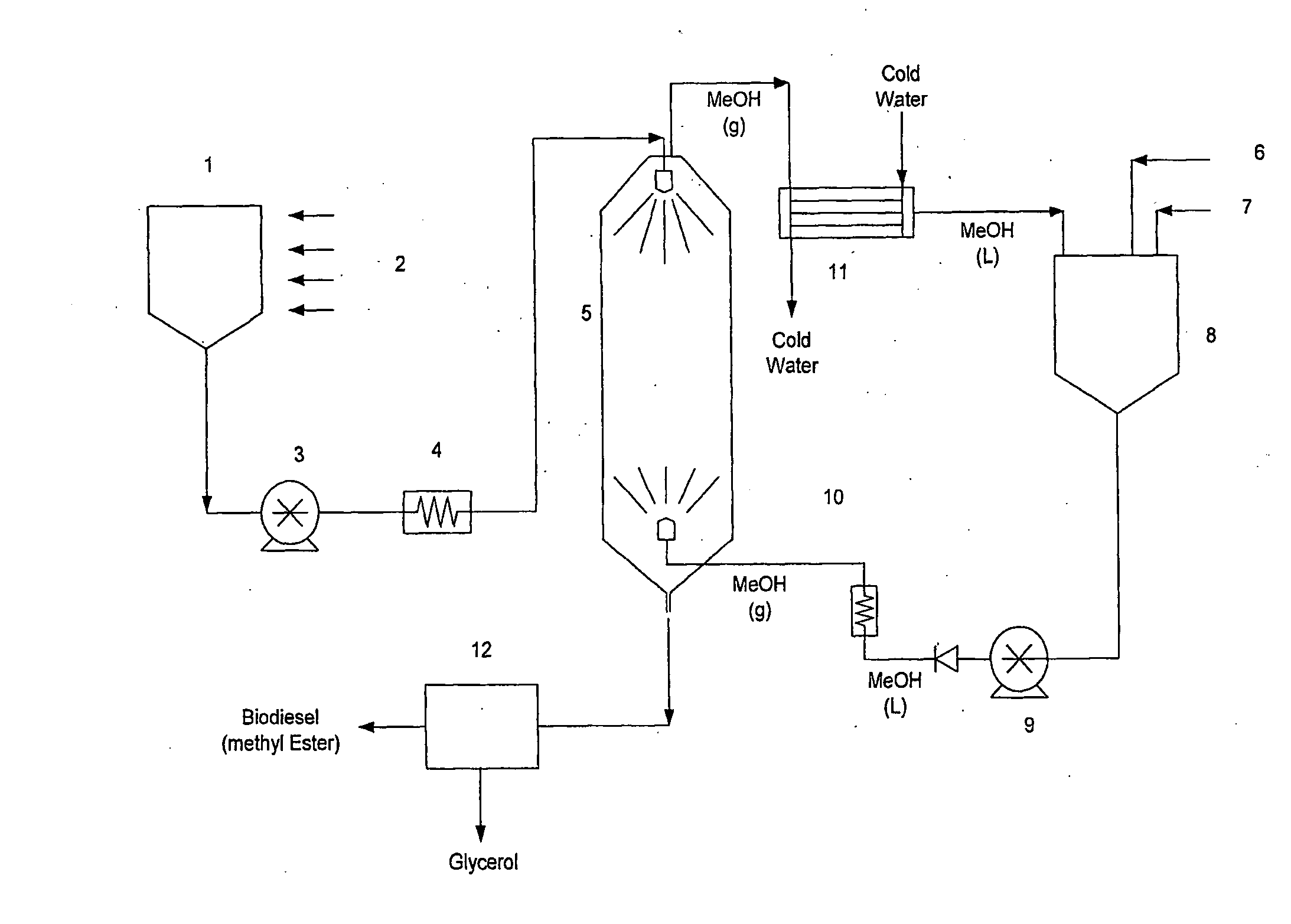

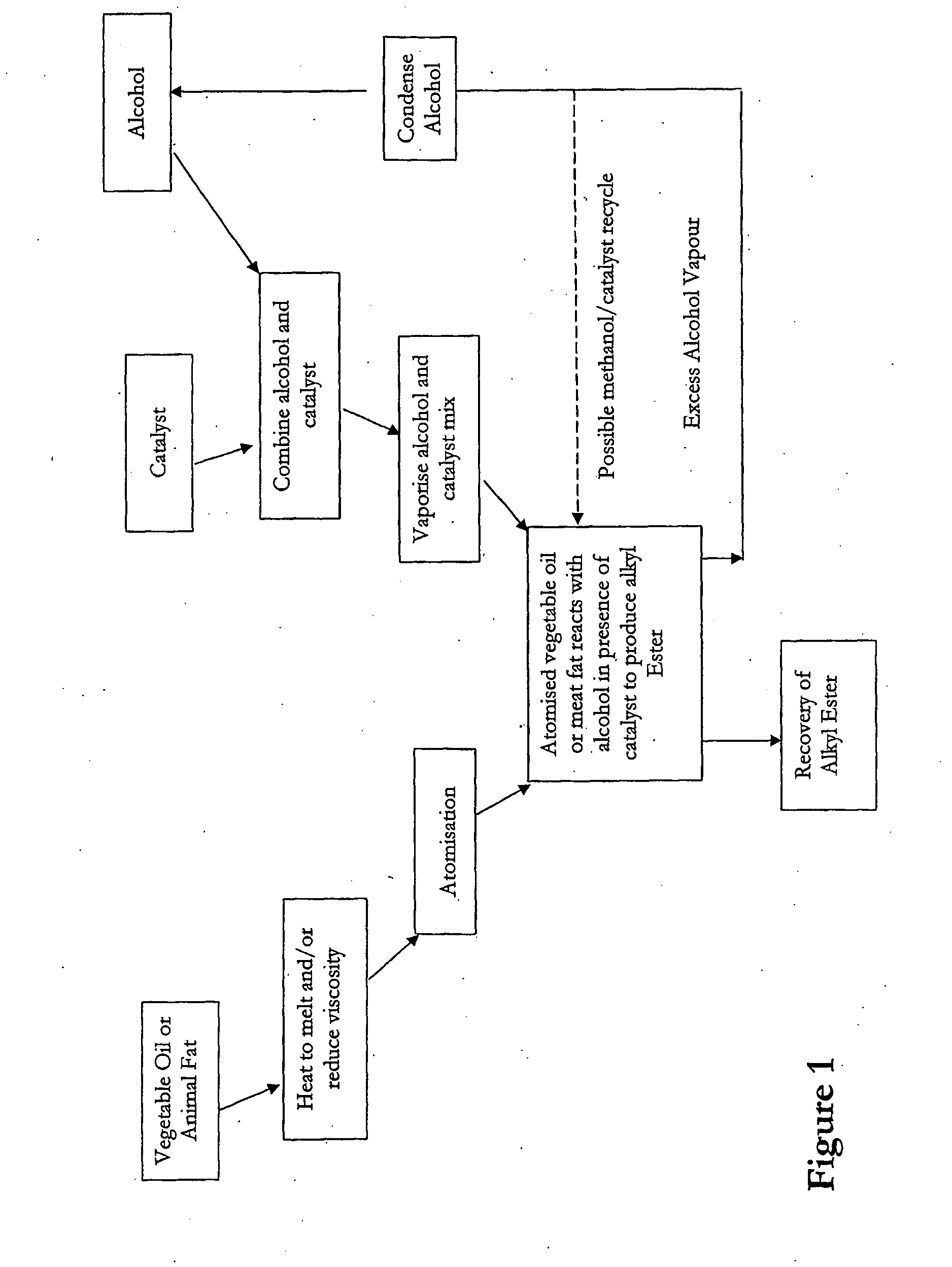

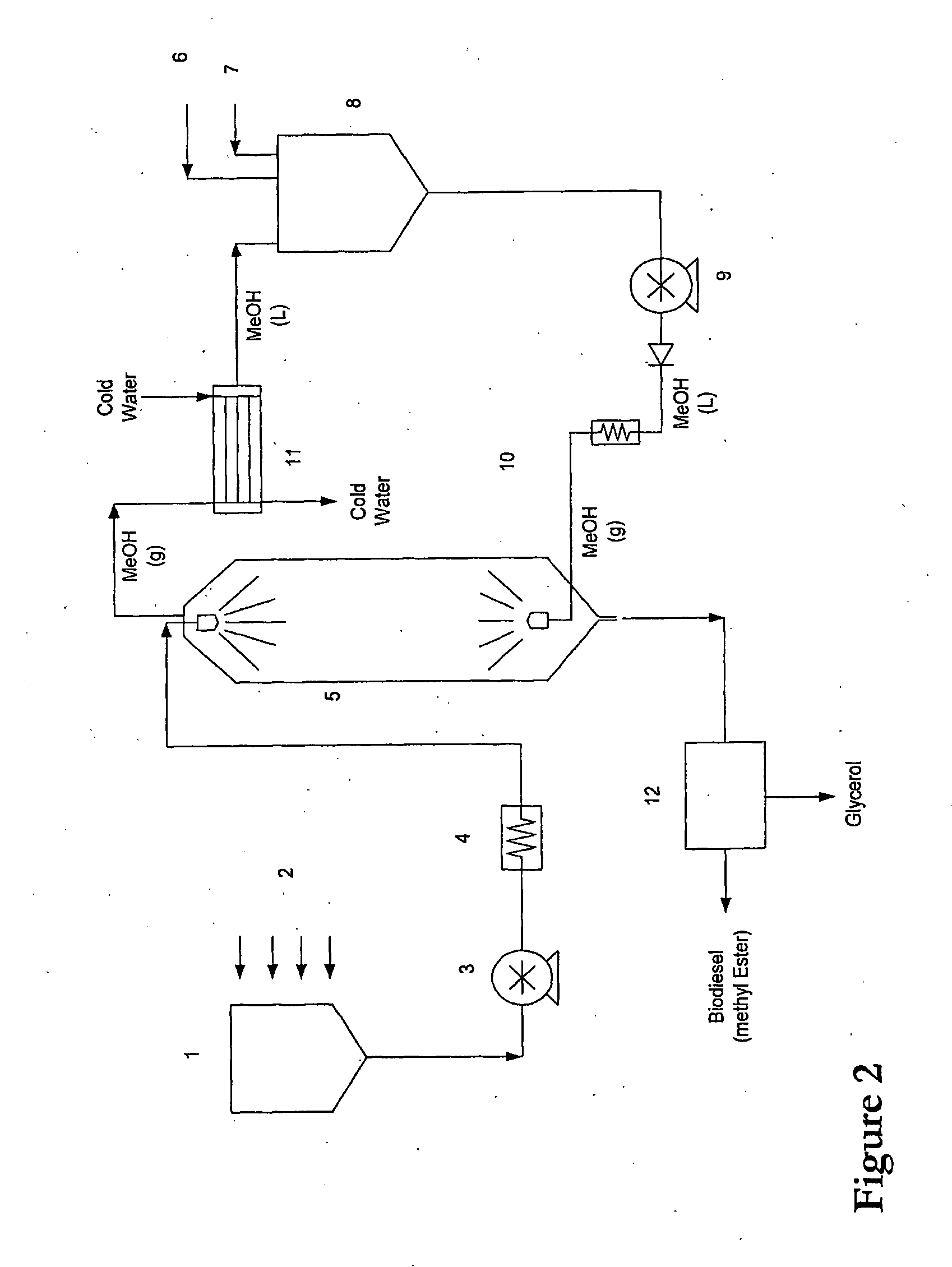

Method of Biodiesel Production

InactiveUS20090038209A1Physical/chemical process catalystsFatty acid esterificationBiodieselVegetable oil

The invention relates to a process of producing biodiesel via transesterification reaction where the feed of vegetable oil and / or animal fat is atomised prior to the reaction. The process is suitable for continuous production of biodiesel.

Owner:AUCKLAND UNISERVICES LTD

Methods and compositions for dust control and freeze control

ActiveUS7398935B2Avoid dustAvoid it happening againOther chemical processesCentrifugesTransesterificationDust control

Dust control and / or freeze control compositions and methods of using the compositions are provided. In an embodiment, the present invention provides methods of utilizing the dust control and / or freeze control products. For example, the method can comprise preventing the agglomeration of particulate material comprising coal and the adhesion thereof to surfaces in subfreezing weather. The method can also comprise preventing dust formation from particulate material handling processes. The dust control and / or freeze control compositions can comprise one or more glycerin by-products derived from a biodiesel manufacturing process. The dust control and / or freeze control compositions can also comprise one or more glycerin by-products of transesterification reactions involving triglycerides.

Owner:ECOLAB USA INC

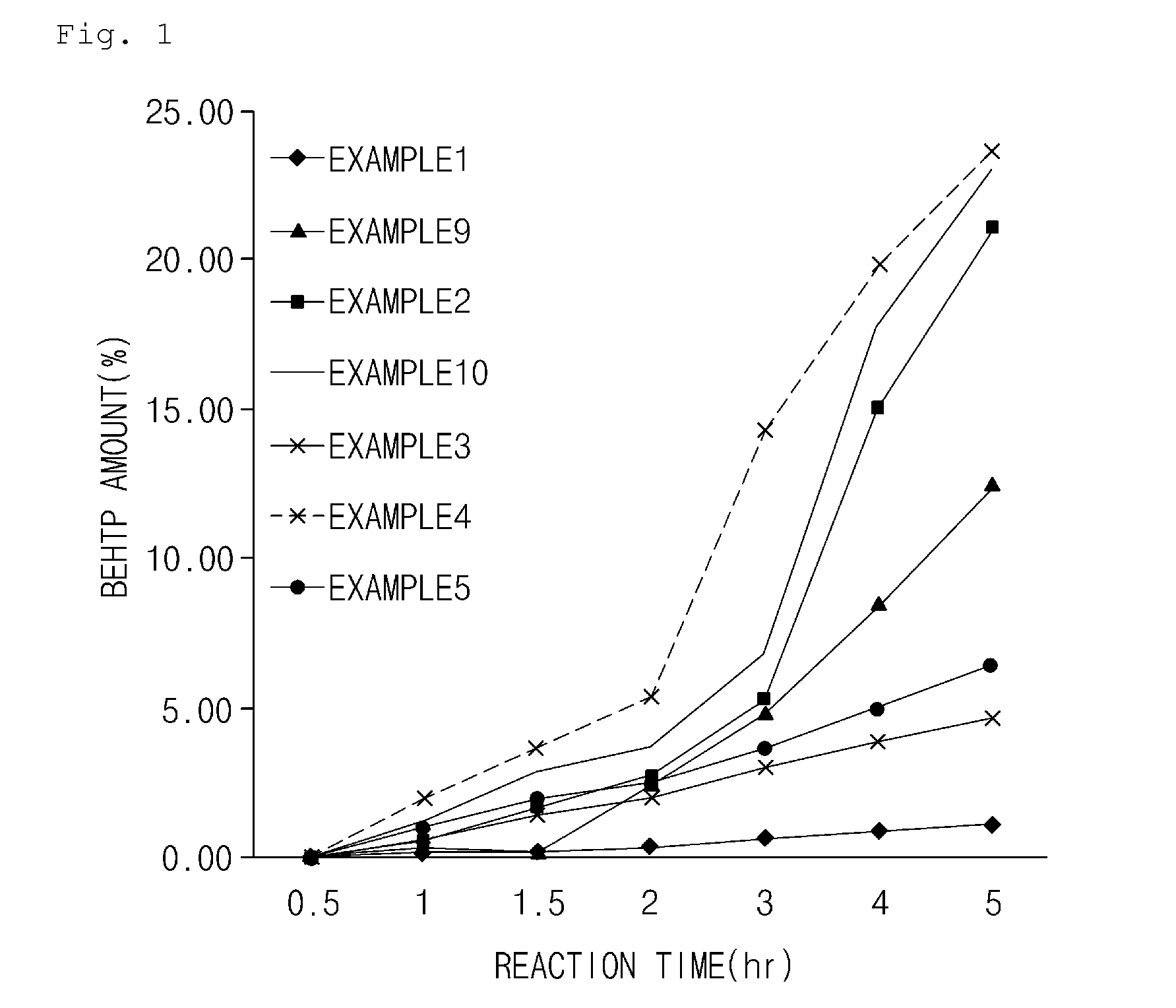

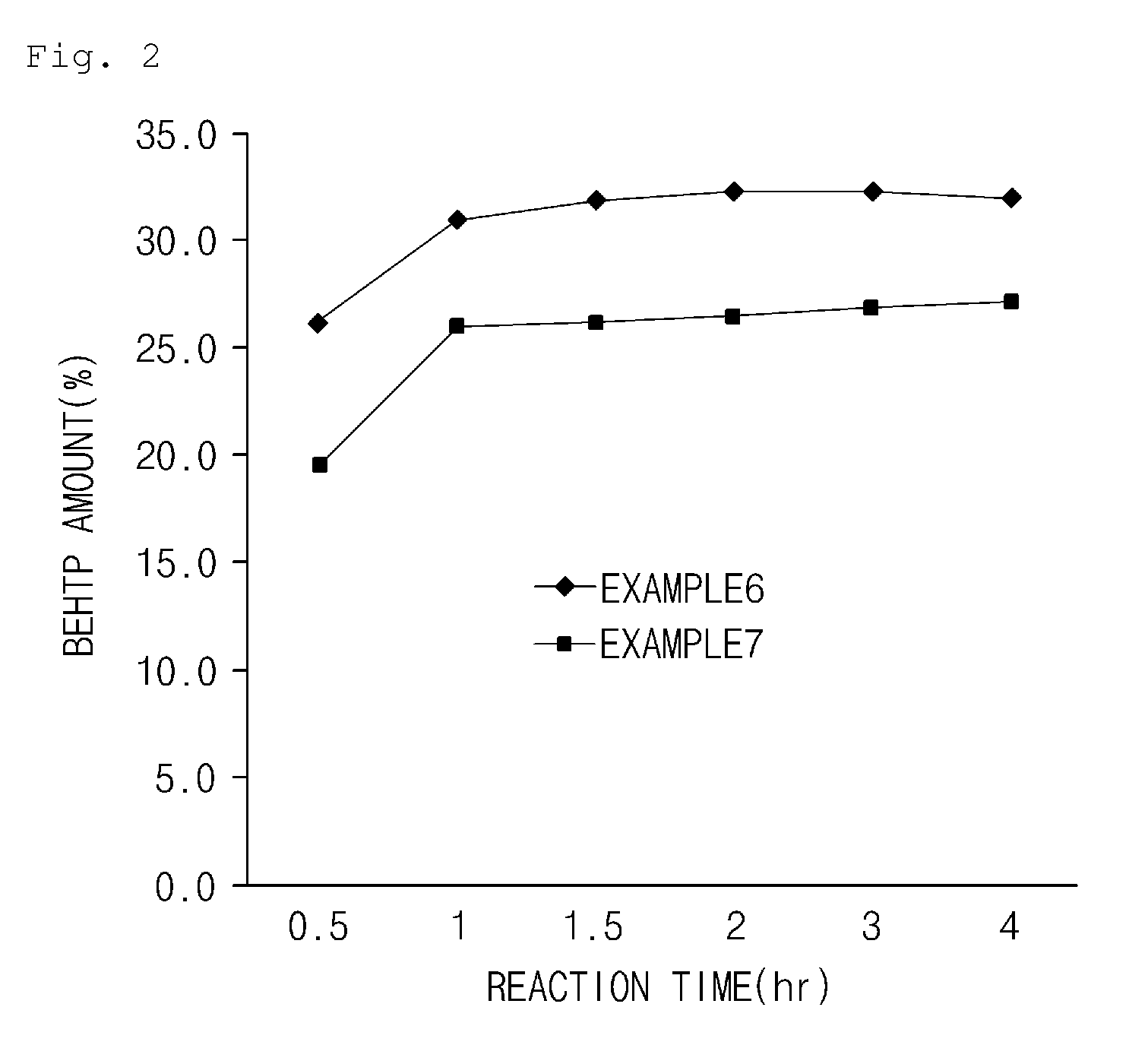

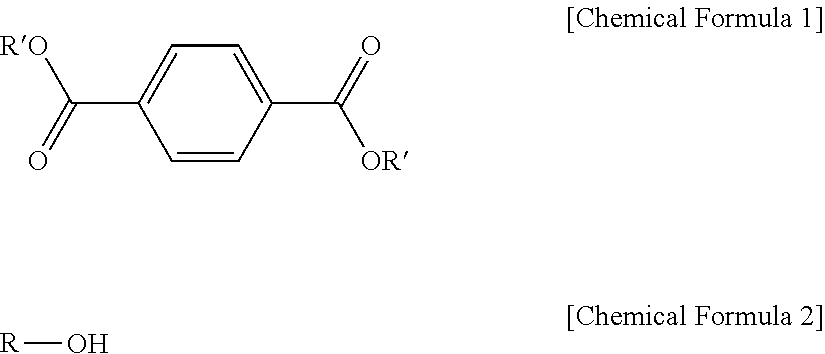

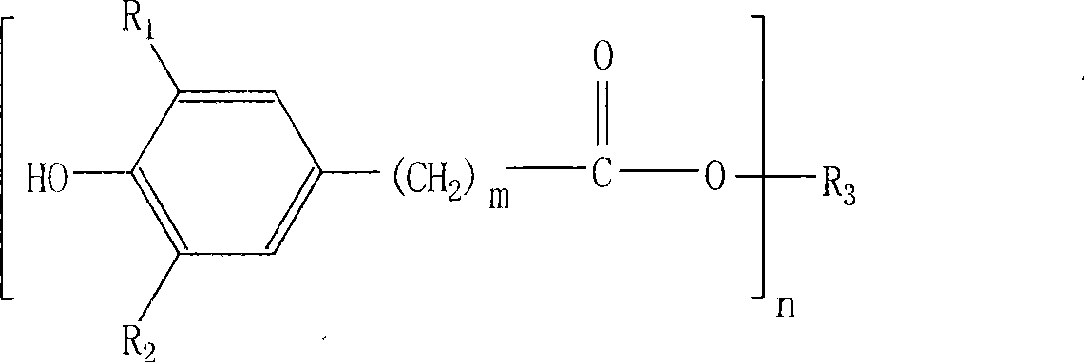

Method of preparing ester plasticizer and ester plasticizer prepared therefrom

ActiveUS20140336320A1High purityHigh yieldPreparation by ester-hydroxy reactionOrganic compound preparationAlcoholPlasticizer

Provided is a method of preparing an ester plasticizer, more particularly, a method of preparing an ester plasticizer including conducting a transesterification reaction of a compound of Chemical Formula 1 with a first alcohol of Chemical Formula 2.According to the preparation method according to an embodiment of the present invention, an ester plasticizer having high purity, yield, and process efficiency as well as excellent plasticizer properties such as processability and absorption rate may be easily prepared even under no catalyst.

Owner:LG CHEM LTD

Method for recycling pet bottle

InactiveUS20050004390A1Efficient preparationPreparation by ester-hydroxy reactionPlastic recyclingDepolymerizationBottle

A through process comprising depolymerization reaction of used PET bottles with EG, recovering DMT by ester interchange reaction with MeOH, obtaining terephthalic acid by hydrolysis of the recovered DMT, and manufacturing a PET polymer which can be used for manufacturing PET bottles again by using the terephthalic acid.

Owner:TEIJIN LTD

Method for preparing sucrose-6-acetic ester by enzymatic method

The invention discloses a method for preparing sucrose-6-acetic ester by an enzymatic method, and belongs to the technical field of biocatalysis. In the method, in a non-aqueous medium tertiary butanol-dimethyl sulfoxide system, sucrose and vinyl acetate are catalyzed by lipase to perform a transesterification reaction so as to synthesize the sucrose-6-acetic ester. The method has the advantages of mild reaction condition, high reaction selectivity, single reaction product, high conversion rate, product safety and the like, and provides a novel feasible way for preparing the sucrose-6-acetic ester by a biological method.

Owner:HANGZHOU XINFU TECH CO LTD

Method of improving mechanical strength of flexible polyurethane foams made from bio-based polyols, the polyol compositions utilized therein and the foams produced thereby

ActiveUS20120277338A1Improve rigidityReduce resiliency characteristicFatty acid esterificationOrganic compound preparationPolyesterPolyol

A method of improving the mechanical strength of polyurethane foams made from bio-based polyols, the polyol-containing compositions utilized in the method of the invention, and the polyurethane foams produced by the method of the invention are provided. The method of the invention involves the incorporation of aromatic polyester polyol in the polyol-containing composition used to manufacture the foams. In one embodiment, the aromatic polyester polyol is utilized in a polyol-containing composition which is employed in the manufacture of flexible polyurethane foam. In another embodiment, the aromatic polyester polyol transesterified with a natural oil-containing composition to form a transesterification reaction product that is utilized in a polyol-containing composition which is employed in the manufacture of flexible polyurethane foam. Flexible polyurethane foams of the invention exhibit substantial improvements in mechanical strength properties, such as tear strength, tensile strength and elongation relative to foams made from bio-based polyols such as soybean oil-based polyols.

Owner:STEPAN COMPANY

Process for co-preparing biodiesel by ultrasonic and microwave

The invention discloses a method for making biological diesel oil by the association of ultrasonic waves and microwaves. The method comprises the following steps: 1. raw oil has free fatty acids removed and undergoes dehydration treatment; 2. mixed liquor of the raw oil, low carbon alcohols and catalysts are put in a reactor and undergo transesterification reaction under the simultaneous actions of the ultrasonic waves and the microwaves; and the mol ratio of the raw oil to the low carbon alcohols is between 1:1 and 1:80, and the mass ratio of the catalysts to the raw oil is between 0.1:100 and 10:100, and the reaction temperature is controlled between 25 and 80 DEG C; 3. after reaction, remained methyl alcohols are evaporated, and reaction products undergo the standing stratification to extract coarse products of the biological diesel oil on the upper layer; 4. the coarse products of the biological diesel oil are purified to obtain the biological diesel oil with high quality. The method has the advantages of high yield, fast reaction speed, short reaction time, low energy consumption, low consumption of the catalysts, low product cost and environmental protection, etc., and is suitable for commercialized production.

Owner:UNIV OF JINAN

Method for extracting cholesterol from lanoline

This invention discloses a method for extracting high-purity cholesterol from lanolin. The method comprises: (1) dissociating cholesterol from lanolin by transesterification reaction; (2) performing short-path distillation to obtain cholesterol crude product; (3) purifying by silica gel column chromatography; (4) crystallizing to obtain refined cholesterol with purity higher than 95% and yield higher than 70%. The method has such advantages as high product consumption, little pollution, simple process and easy operation, thus is suitable for mass production.

Owner:ZHEJIANG UNIV

High-quality utilization method for waste oil

InactiveCN104711126ASimple processRealize high-quality utilizationFatty acid esterificationBase-materialsOil and greaseVegetable oil

The invention provides a method for preparing oil-based polyol ester by virtue of gutter oil and using the oil-based polyol ester as basic lubricating oil so as to add treatment and utilization channels for gutter oil and realize the high-quality utilization of gutter oil. The method for preparing the oil-based polyol ester by two-step transesterification reaction comprises the following steps: sequentially adding biomass-based raw materials, methanol and a catalyst into a reaction flask, and performing transesterification reaction to obtain biomass-based methyl ester; sequentially adding the biomass-based methyl ester, polyol and a catalyst into the reaction flask, and performing transesterification reaction to obtain biomass-based polyol ester. The biomass-based raw material comprise gutter oil, acid cottonseed oil and vegetable oil foots / soap, and can be utilized in a high-quality manner, and the prepared biomass-based polyol ester can be used as a raw material of biomass-based lubricating oil.

Owner:XINJIANG FUKE OIL PROD CO LTD

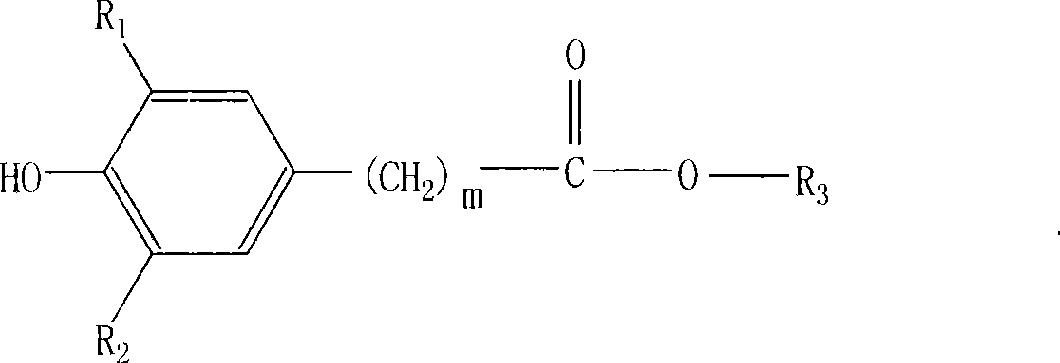

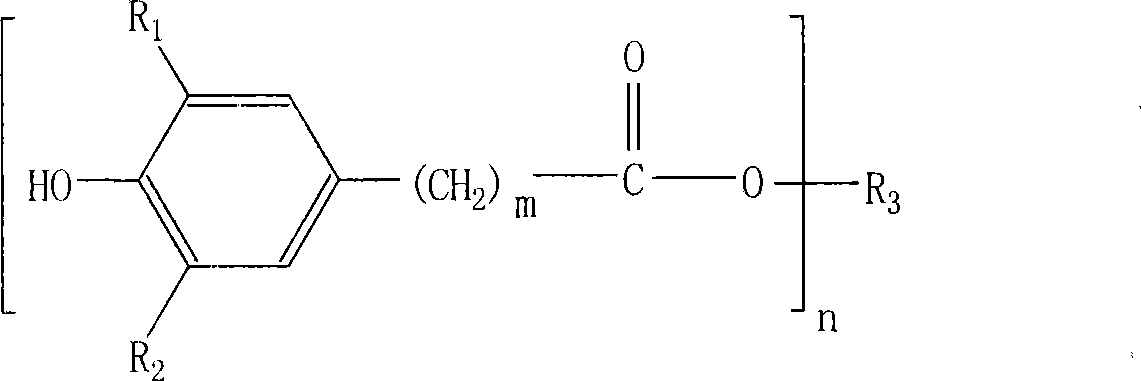

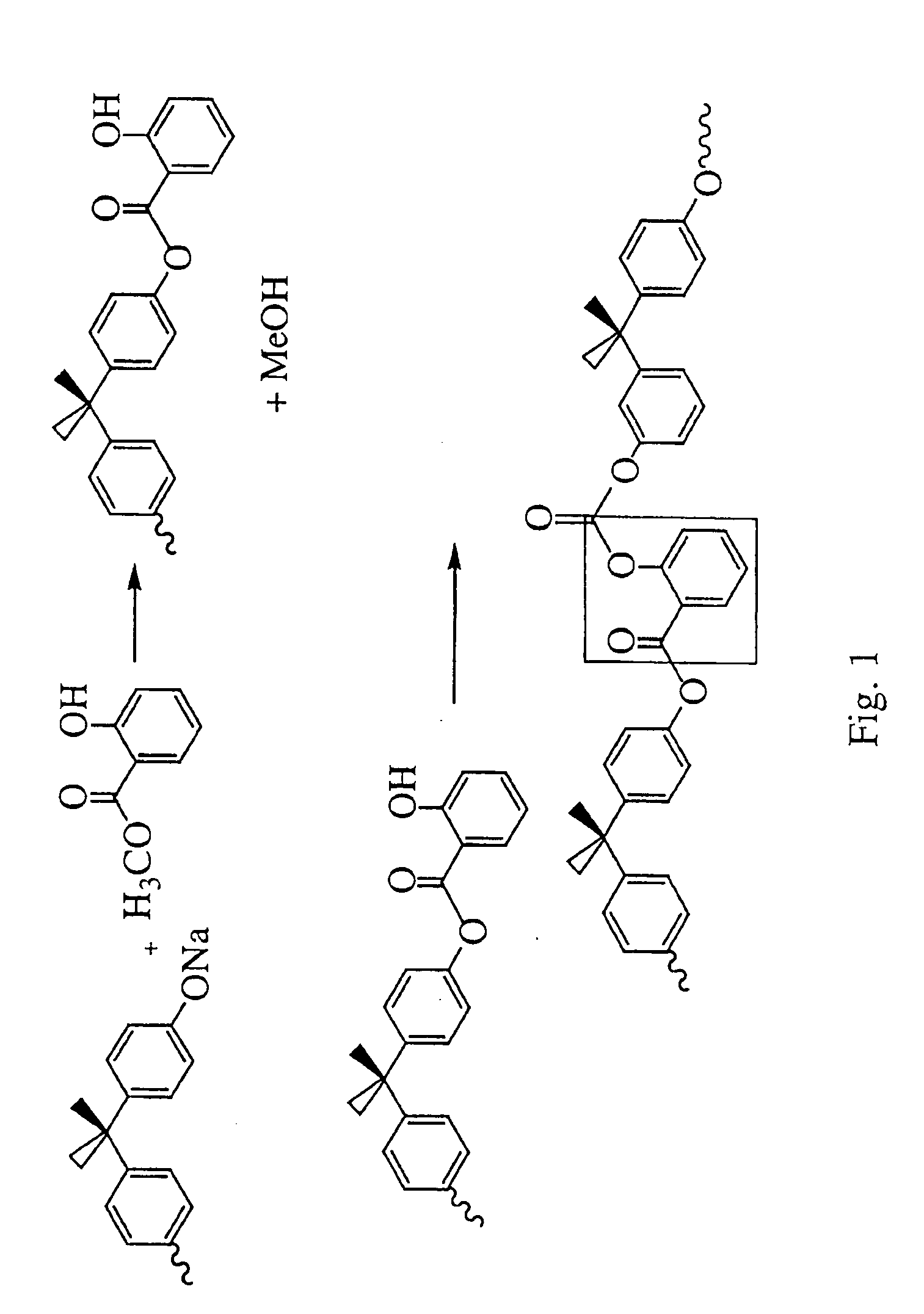

Novel synthesis method for hindered phenol anti-oxidants

ActiveCN101508644AHigh product conversion rateEfficient catalytic reactionPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsSolventCarboxylate

The invention provides a new method for the synthesis of hindered phenols antioxidants. Under the action of a composite catalyst, a compound II and a compound III are subjected to transesterification and byproducts-methanol is obtained via heating and decompression; the rate of conversion of the product is more than 98%, and the compound I of hindered phenols antioxidants is directly obtained without crystallizing and purifying reaction liquid by solvent. The composite catalyst is composed of a primary catalyst of carboxylates of organotin and a secondary catalyst of thioester compounds of phosphite ester. The primary catalyst can be recycled.

Owner:北京极易控股集团有限公司 +1

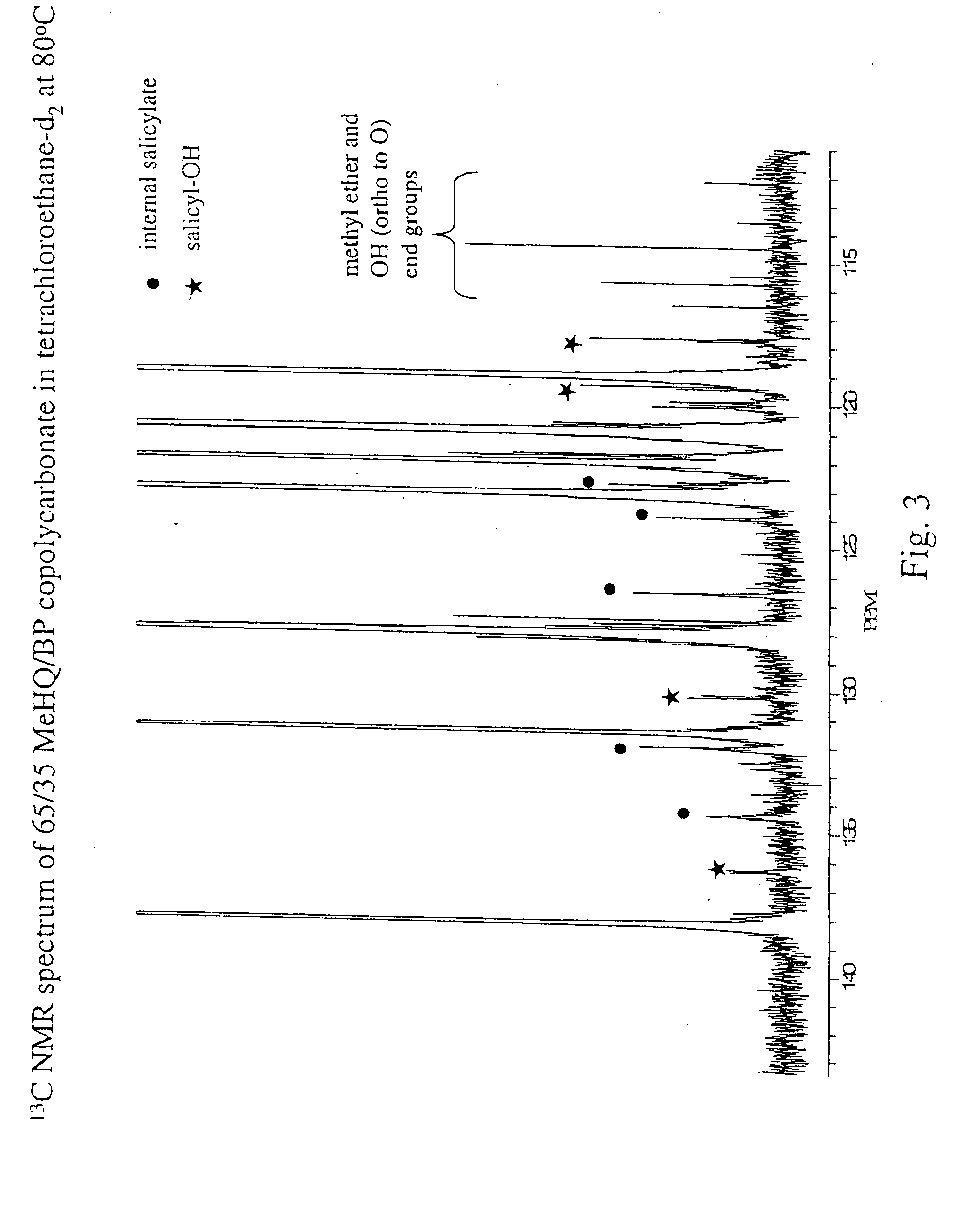

Liquid crystal polycarbonates and methods of preparing same

ActiveUS20050192424A1Liquid crystal compositionsOrganic-compounds/hydrides/coordination-complexes catalystsHydroquinone CompoundDiol

Liquid crystal polycarbonates are made by forming a reaction mixture containing (a) an activated diaryl carbonate; (b) at least two species of aromatic diols selected from among resorcinol, 4,4′-biphenol, hydroquinone, methylhydroquinone, 4,4′-dihydroxyphenylether, dihydroxynaphthalene, including in particular the 2,6, 1,5, and 2,7 isomers, 4,4′-dihydroxybenzophenone and 2,6-dihydroxyanthraquinone (anthraflavic acid); and (c) optionally bisphenol A in a maximum amount of 10 mole %; and processing the reaction mixture in a melt transesterification reaction to form a liquid crystal polycarbonate. While the product composition has the same overall characteristics as compositions made using diphenyl carbonate as the donor moiety for the carbonate linkage, they are analytically distinguishable because of limited incorporation of intermediate or end-cap residues derived from the activated diaryl carbonate.

Owner:SHPP GLOBAL TECH BV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com