Preparation method of phosphorus-containing halogen-free environmentally-friendly flame-retardant polyester polyol

A flame retardant polyester and polyol technology, which is applied in the preparation of phosphorus-containing halogen-free environment-friendly flame retardant polyester polyol, and in the field of polyester polyol preparation, can solve the problem of human injury, reduced flame retardant performance, and volatility in confined spaces. The concentration of internal organic matter exceeds the standard and other problems, so as to achieve the effect of less by-products, fewer reaction steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

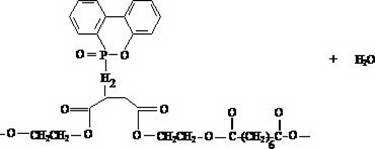

Method used

Image

Examples

Embodiment 1

[0029] In a 500ml reaction flask equipped with a stirrer, nitrogen protection and condensing reflux device, add 174.36g, 0.81mol LDOPO and 93.6g, 0.81mol maleic acid, raise the temperature to slowly rise to 100-105°C, start stirring and nitrogen, and react After 180 minutes, add 117.95, 0.81moL adipic acid and 113.83g, 1.83moL ethylene glycol. After completely melting, slowly raise the temperature to 150-155°C to carry out esterification and dehydration reaction. After the dehydration is completed, raise the temperature to 200-210°C ℃, carry out transesterification reaction, after 180 minutes of reaction, check the acid value and hydroxyl value every 30 minutes.

[0030] The theoretical hydroxyl value of the phosphorus-containing polyester polyol synthesized in this embodiment is: 56mgKOH / g;

[0031] The theoretical average molecular weight (number average) of the phosphorus-containing polyester polyol synthesized by the present embodiment is: 2000;

[0032] The theoretical p...

Embodiment 2

[0035] In a 500ml reaction flask equipped with a stirrer, nitrogen protection and condensing reflux device, add 134.3g, 0.62mol LDOPO and 72.12g, 0.62mol maleic acid, heat up to 105-110°C slowly, start stirring and nitrogen, and react After 100 minutes, add 155g, 1.06moL of adipic acid and 38.6g, 0.43moL of 1,4-butanediol. After completely melting, slowly raise the temperature to 155-160°C for esterification and dehydration reaction. After the dehydration is completed, raise the temperature to 210-220°C, carry out transesterification reaction, after 150 minutes of reaction, check the acid value and hydroxyl value every 30 minutes, after the acid value and hydroxyl value pass the test, cool down to below 100°C, and discharge the material for packaging.

[0036] The theoretical hydroxyl value of the phosphorus-containing polyester polyol synthesized in this embodiment is: 224mgKOH / g;

[0037] The theoretical average molecular weight (number average) of the phosphorus-containing ...

Embodiment 3

[0041]In a 500ml reaction flask equipped with a stirrer, nitrogen protection and condensing reflux device, add 202.3g, 0.94mol LDOPO and 108.7g, 0.94mol maleic acid, raise the temperature to slowly rise to 110-115°C, start stirring and nitrogen, and react After 130 minutes, add 87.17g, 0.60moL of adipic acid and 43.17g, 0.48moL of 1,4-butanediol. After complete melting, slowly raise the temperature to 155-160°C for esterification and dehydration reaction. After the dehydration is completed, raise the temperature to 225-235°C, carry out transesterification reaction, after 120 minutes of reaction, check the acid value and hydroxyl value every 30 minutes, after the acid value and hydroxyl value pass the test, cool down to below 100°C, and discharge the material for packaging.

[0042] The theoretical hydroxyl value of the phosphorus-containing polyester polyol synthesized in this embodiment: 11.2mgKOH / g;

[0043] The theoretical average molecular weight (number average) of the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical hydroxyl value | aaaaa | aaaaa |

| Theoretical hydroxyl value | aaaaa | aaaaa |

| Theoretical hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com