Patents

Literature

171 results about "Potential harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An intrinsic property of anything with the potential to cause harm. Harm includes ill health and injury, damage to property, plant, products or the environment, production losses, or increased liabilities.

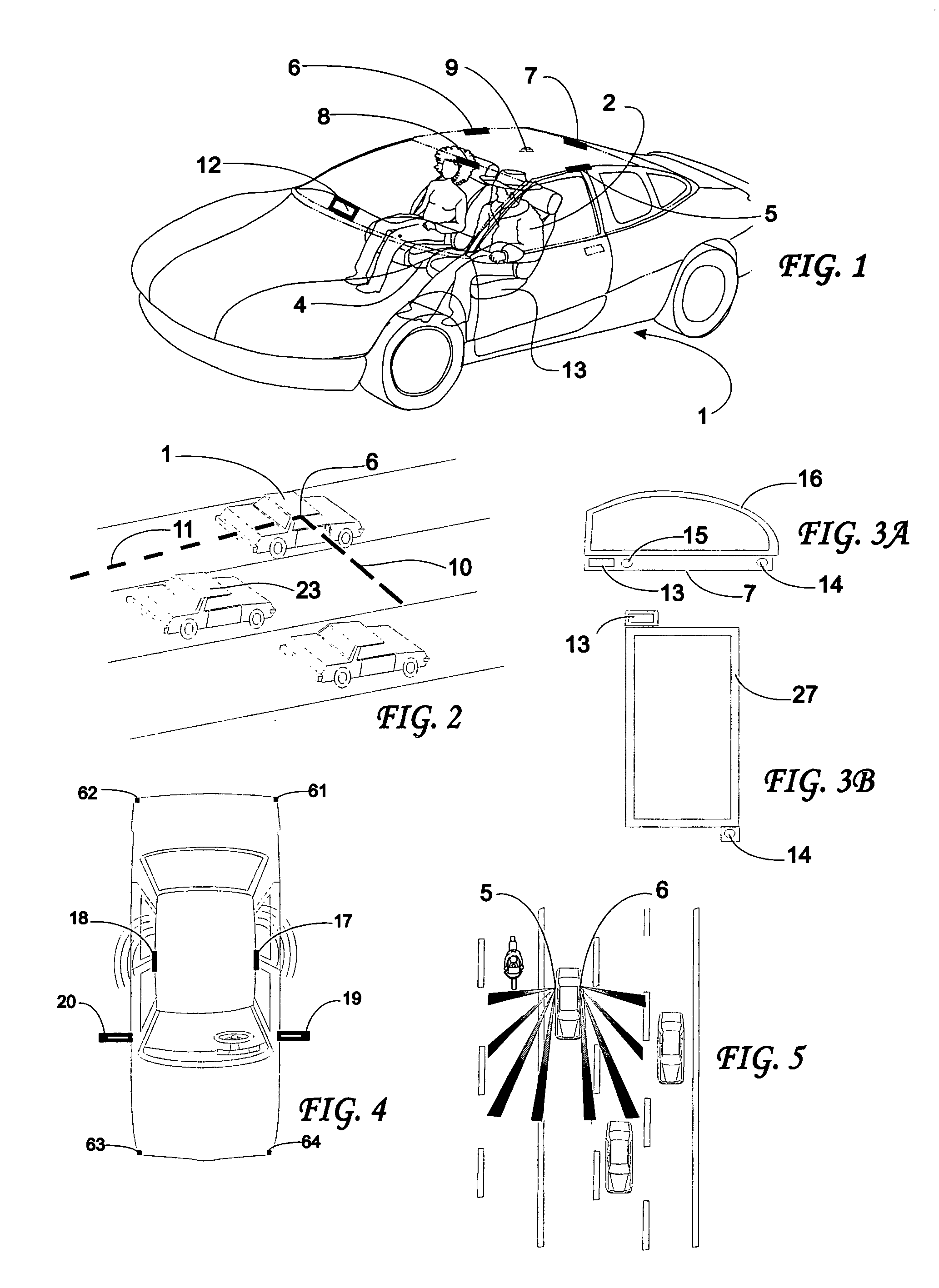

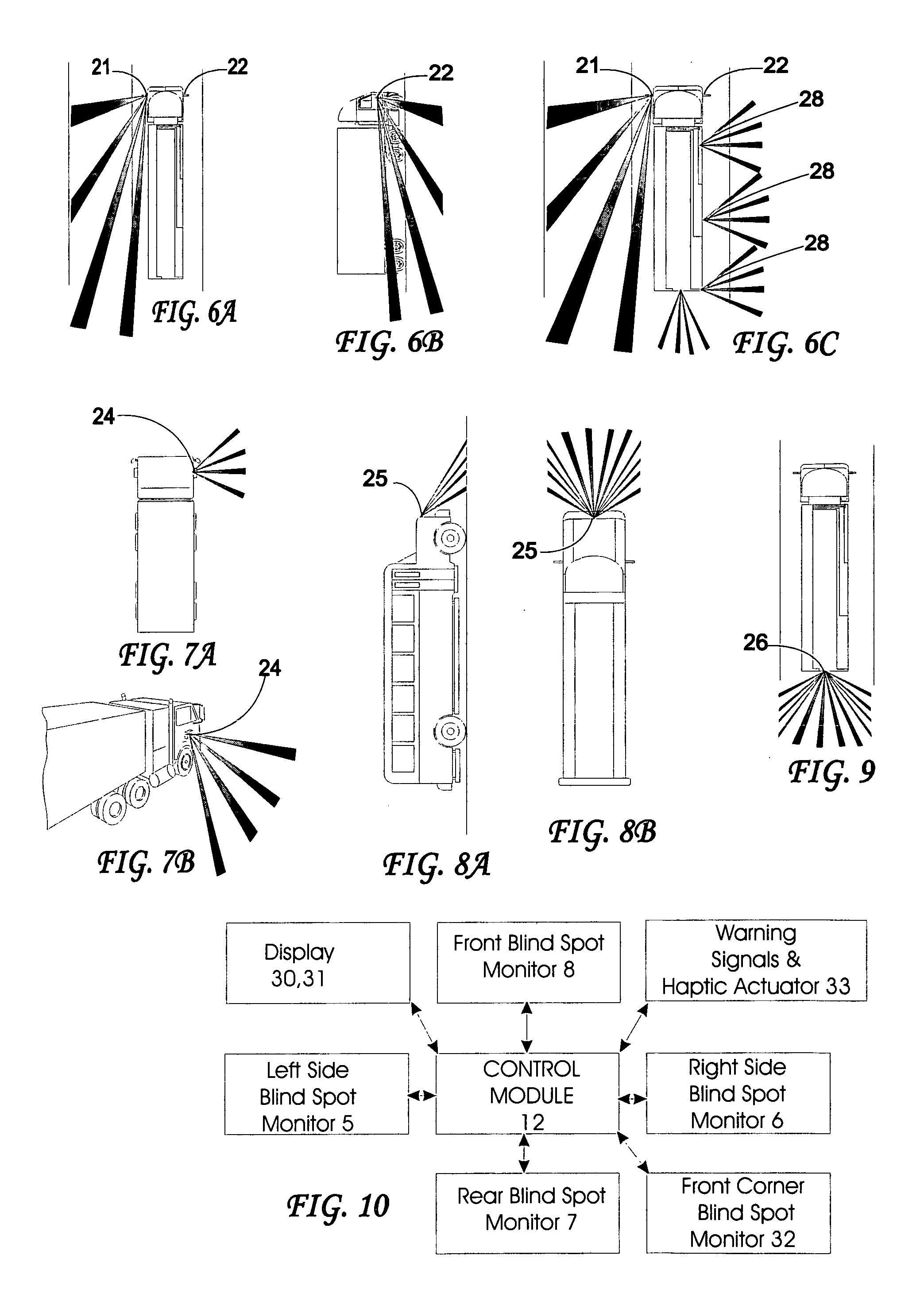

Vehicular impact reactive system and method

InactiveUS20050278098A1Reduce number and severityDigital data processing detailsAnti-collision systemsEngineeringReactive system

System and method for reacting to an expected impact involving a vehicle including an anticipatory sensor system for determining that an impact involving the vehicle is about to occur prior to the impact and an impact responsive system coupled to the sensor system and actuated after its determination of the expected impact. The sensor system includes wave receivers spaced apart from one another, each receiving waves generated by, modified by, or reflected from a common object exterior of the vehicle. The impact responsive system attempts to reduce the potential harm resulting from the impact and can be a protection apparatus which protects a vehicular occupant or a pedestrian, such as one including an airbag and an inflator for inflating the airbag.

Owner:AMERICAN VEHICULAR SCI

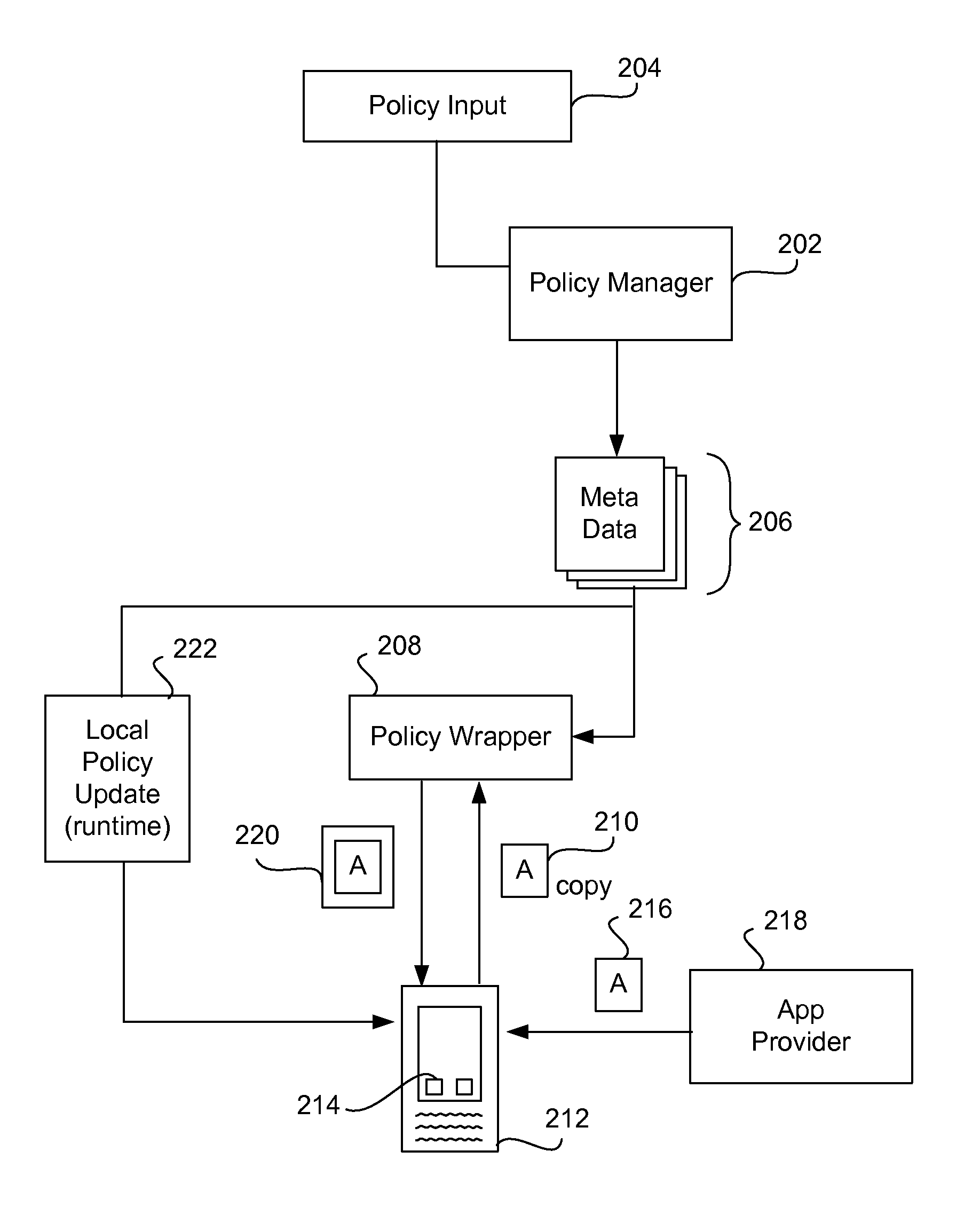

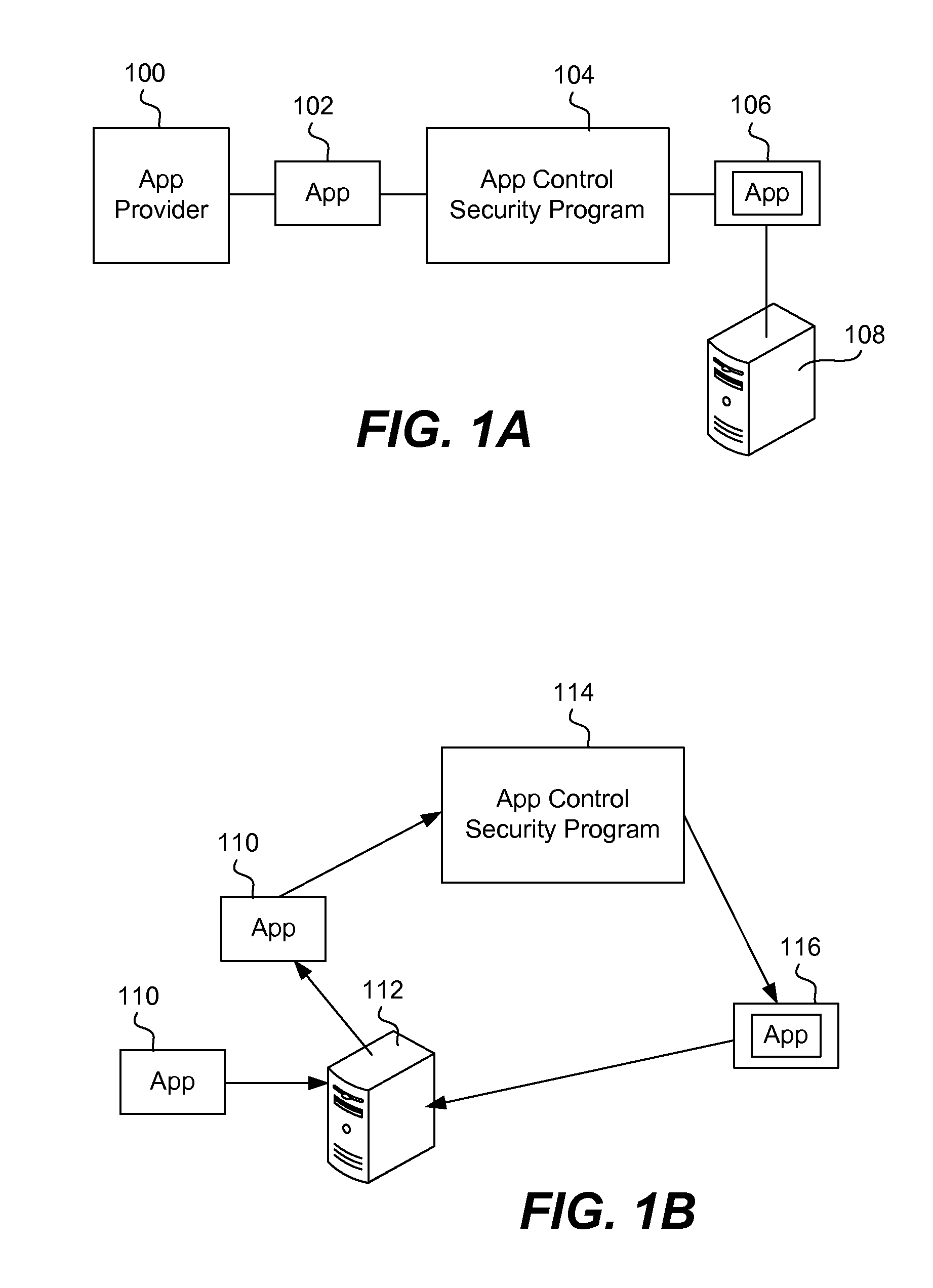

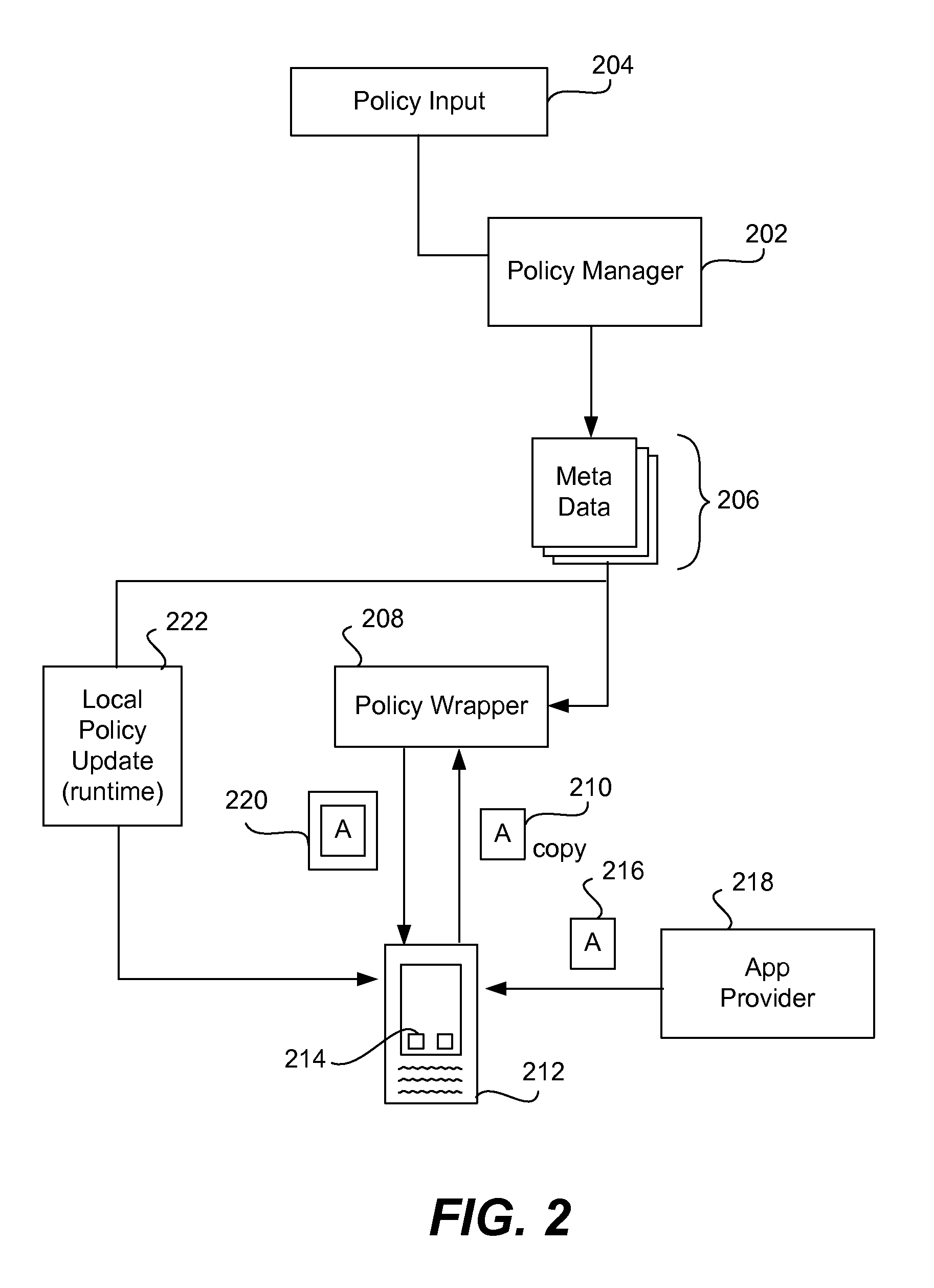

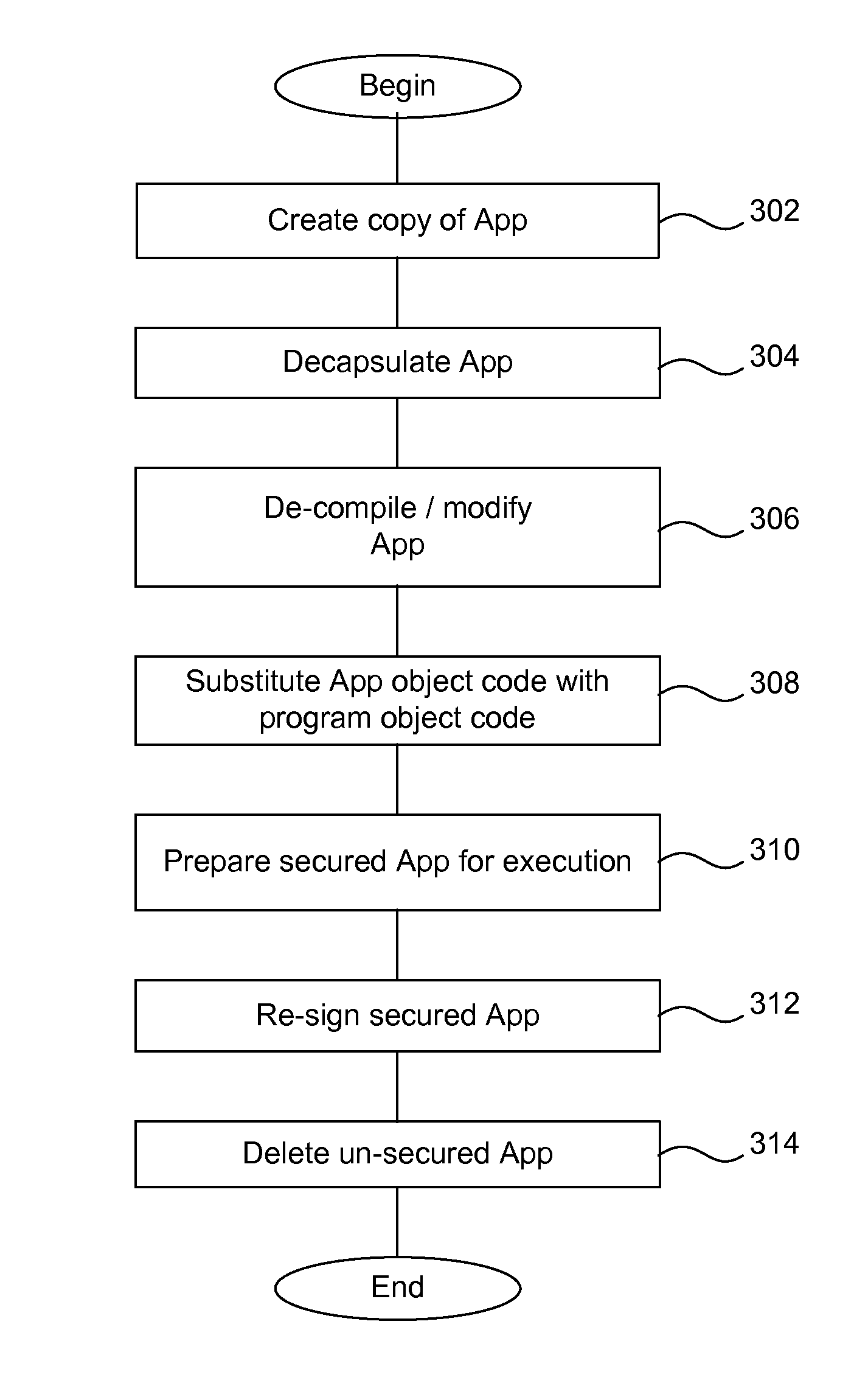

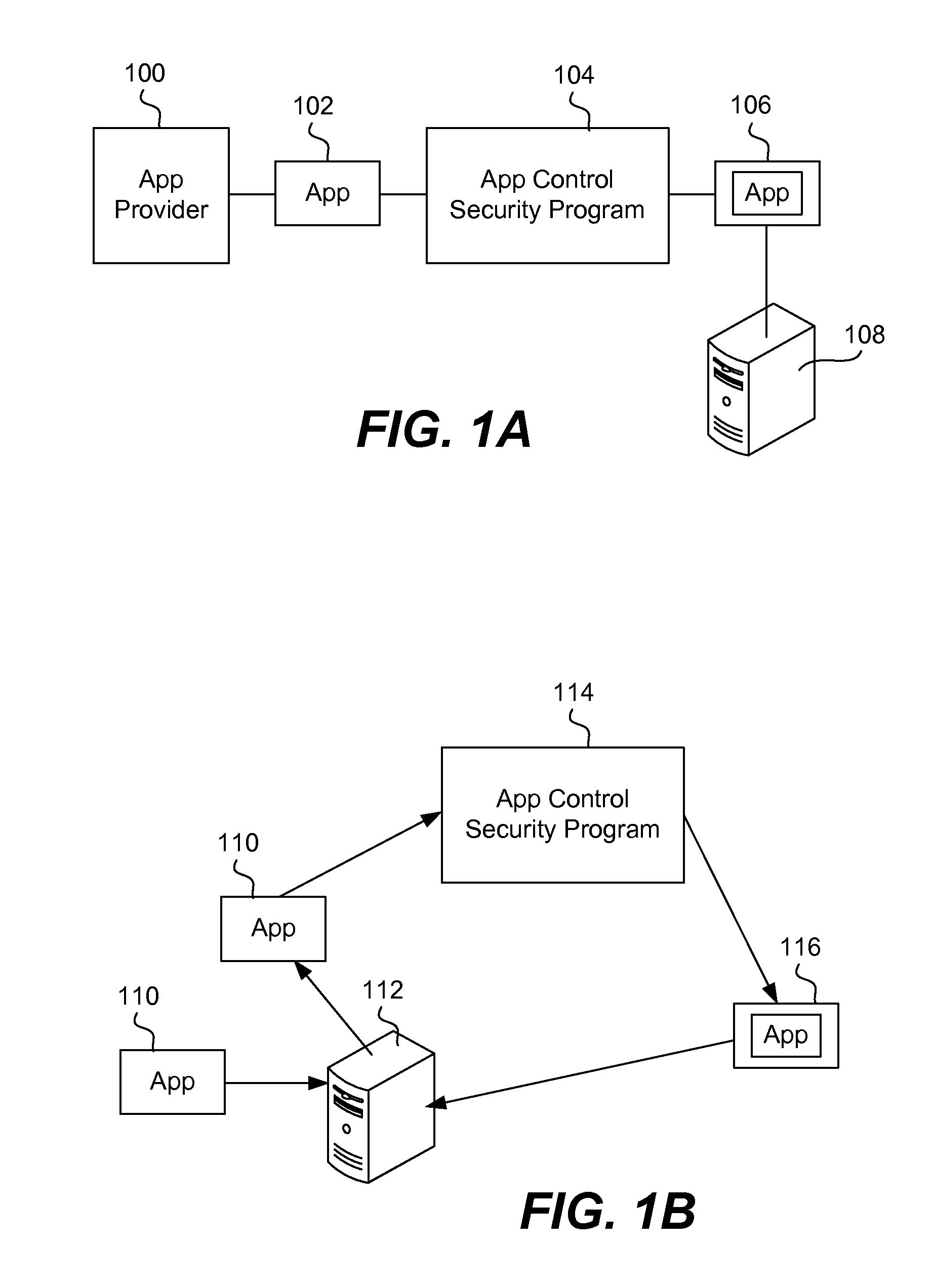

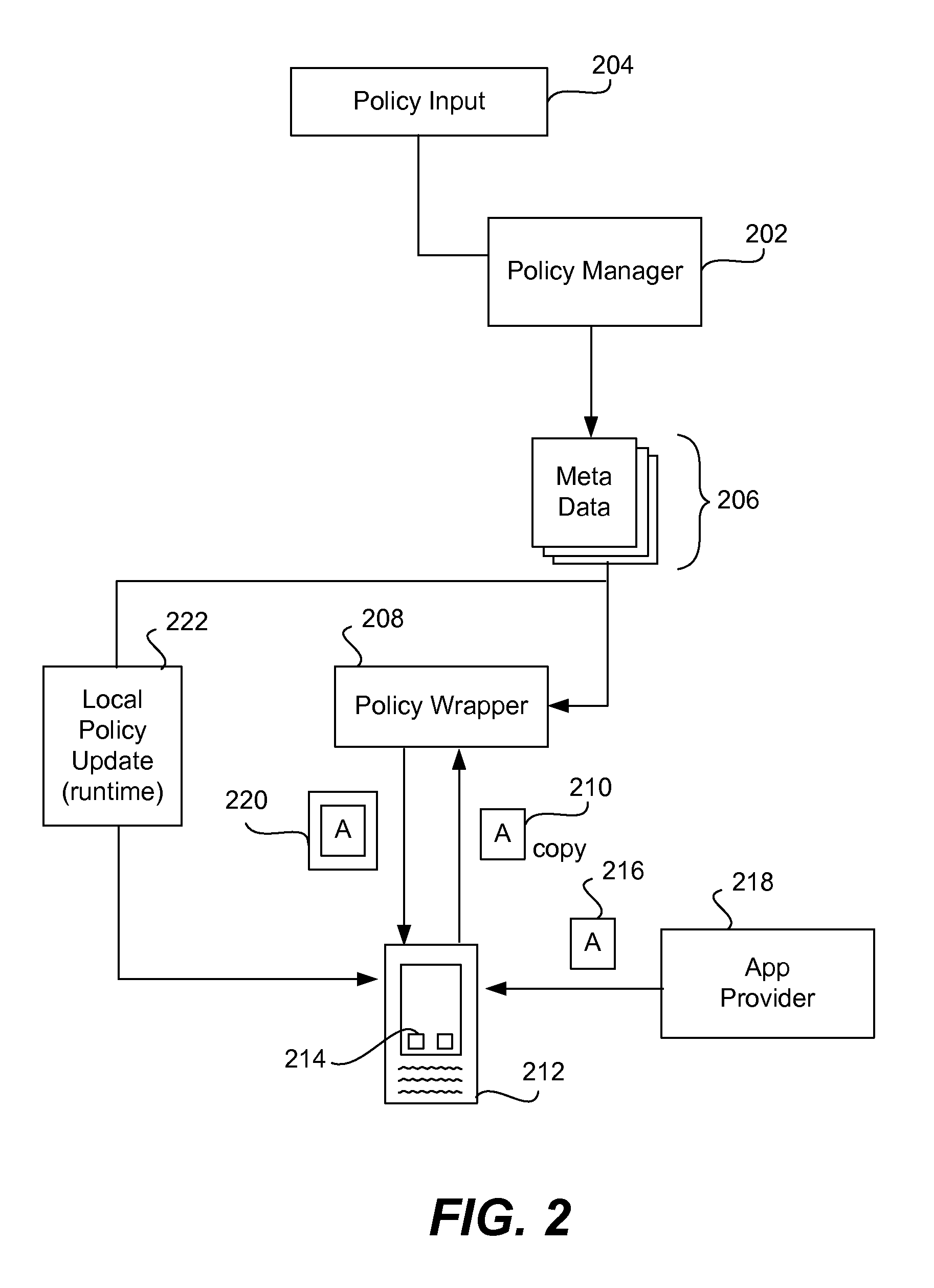

Secure execution of unsecured apps on a device

ActiveUS20120246731A1Minimize damageMinimize data lossDigital data processing detailsAnalogue secracy/subscription systemsPotential harmEnforcement

Devices are pre-deployed with an app security mechanism to ensure that apps that are downloaded onto the device do not cause data loss, data leakage, or other harm to the device. A user can start using the device and downloading apps in a conventional or typical manner and be assured that security measures are being taken to minimize potential harm for unsecured and secured apps. An app security enforcement layer or engine operates with, for example, a Type 2 hypervisor on the device, and ensures that any calls by the apps to the operating system of the device are generally safe. Measures such as enhancing or modifying the call, obfuscating the call, or terminating the app may be taken to protect the operating system. These actions are taken based on a policy that may be either interpreted or compiled by the enforcement engine with respect to app execution. The security measures are generally transparent to the user of the device.

Owner:BLUE CEDAR NETWORKS INC

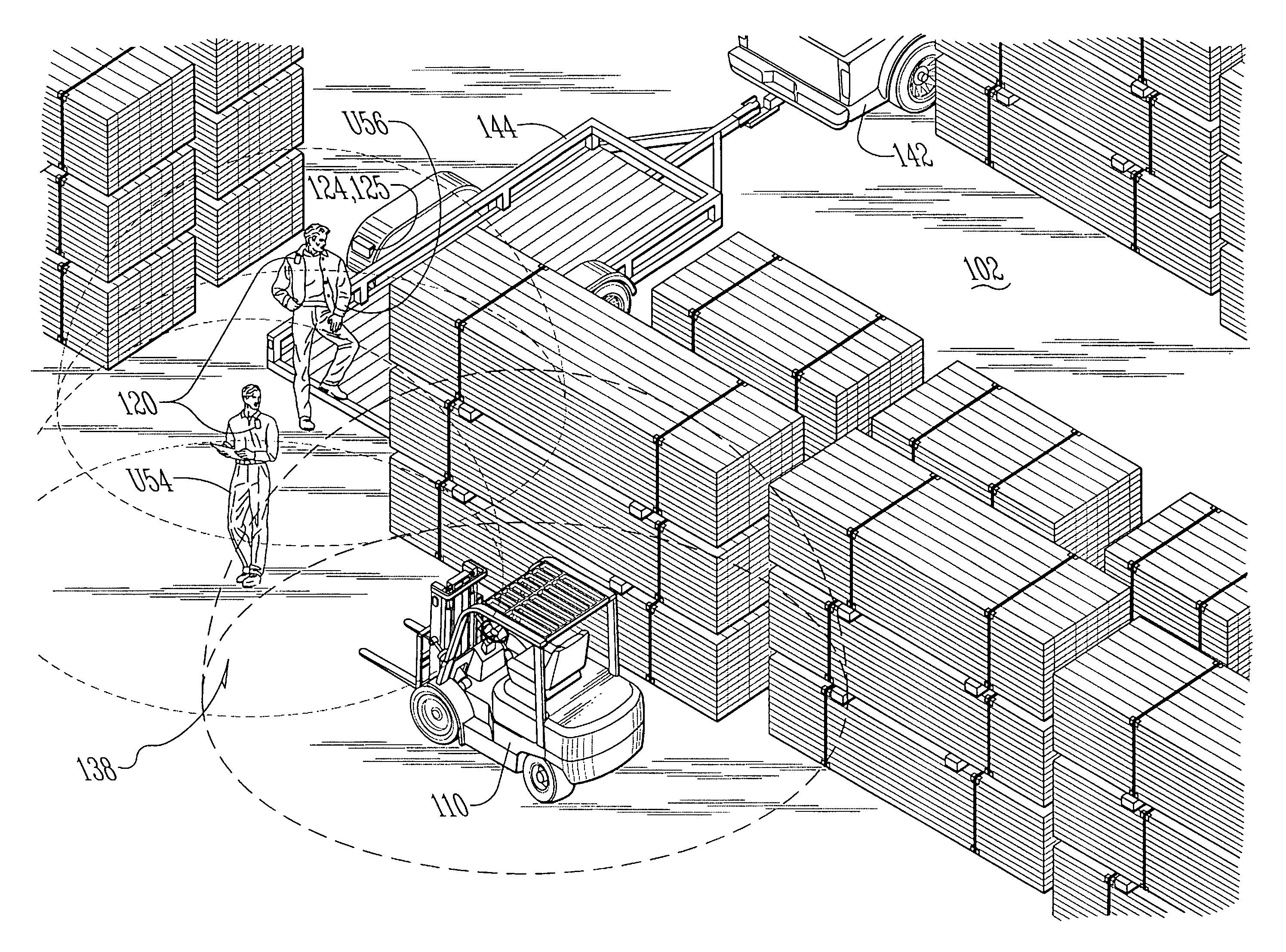

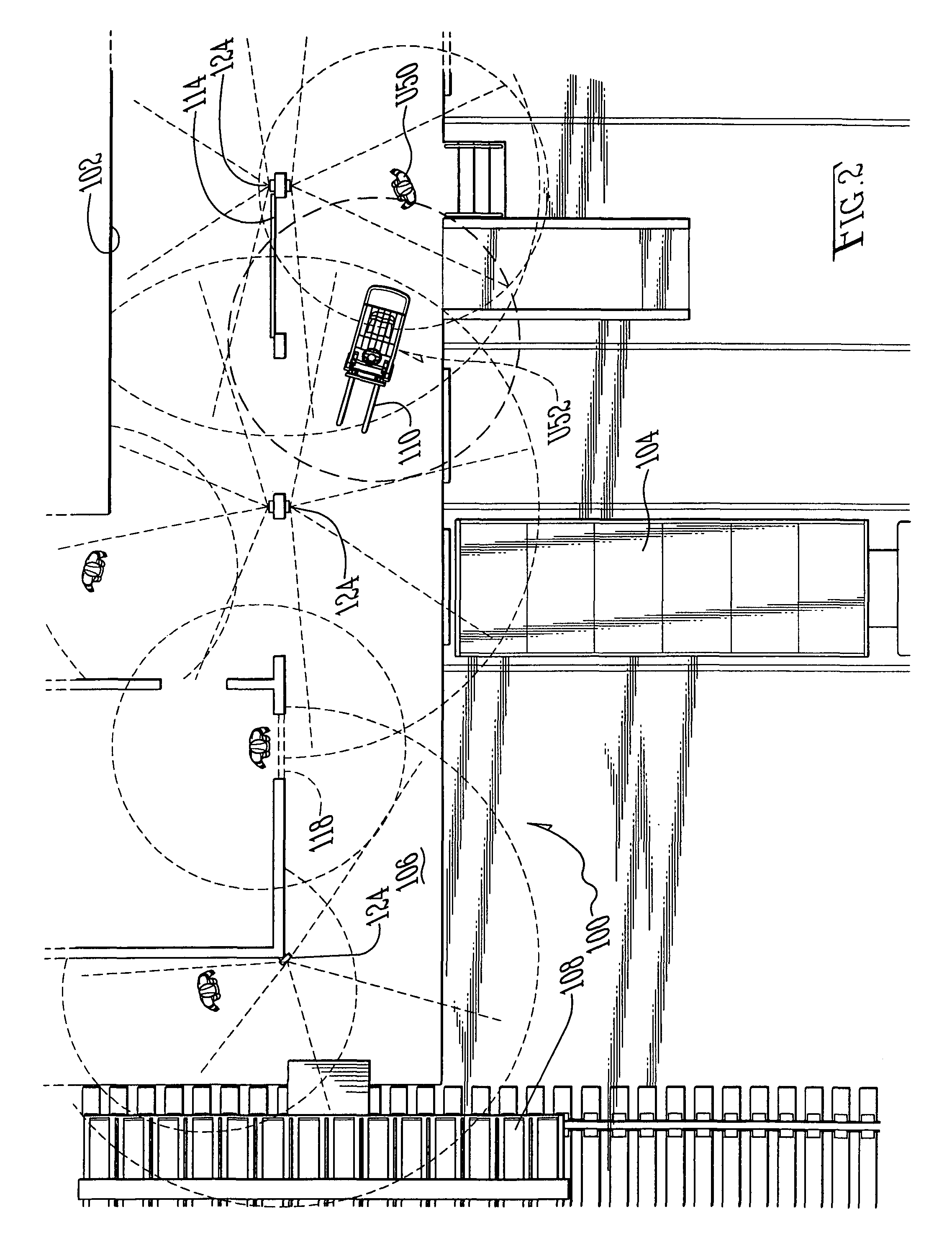

Traffic signal system for congested trafficways

ActiveUS9424749B1Improve the level ofEliminate detectionControlling traffic signalsControl with pedestrian guidance indicatorTraffic signalEngineering

A traffic signal system for congested trafficways has a plurality of stationary alarm light / sensor-reader combinations and mobile alarm light / sensor-reader combinations monitoring each other and monitory tags placed on individuals, machines, and hazards to provide real time alarms to not only pedestrians but also machine operators, who are potentially approaching harm's way, or have the better ability to avert potential harm. Different forms of alarms are provided to indicate different kinds of alarm conditions and to reduce complacency to alarms, and thus improve effectiveness.

Owner:REED AMANDA +1

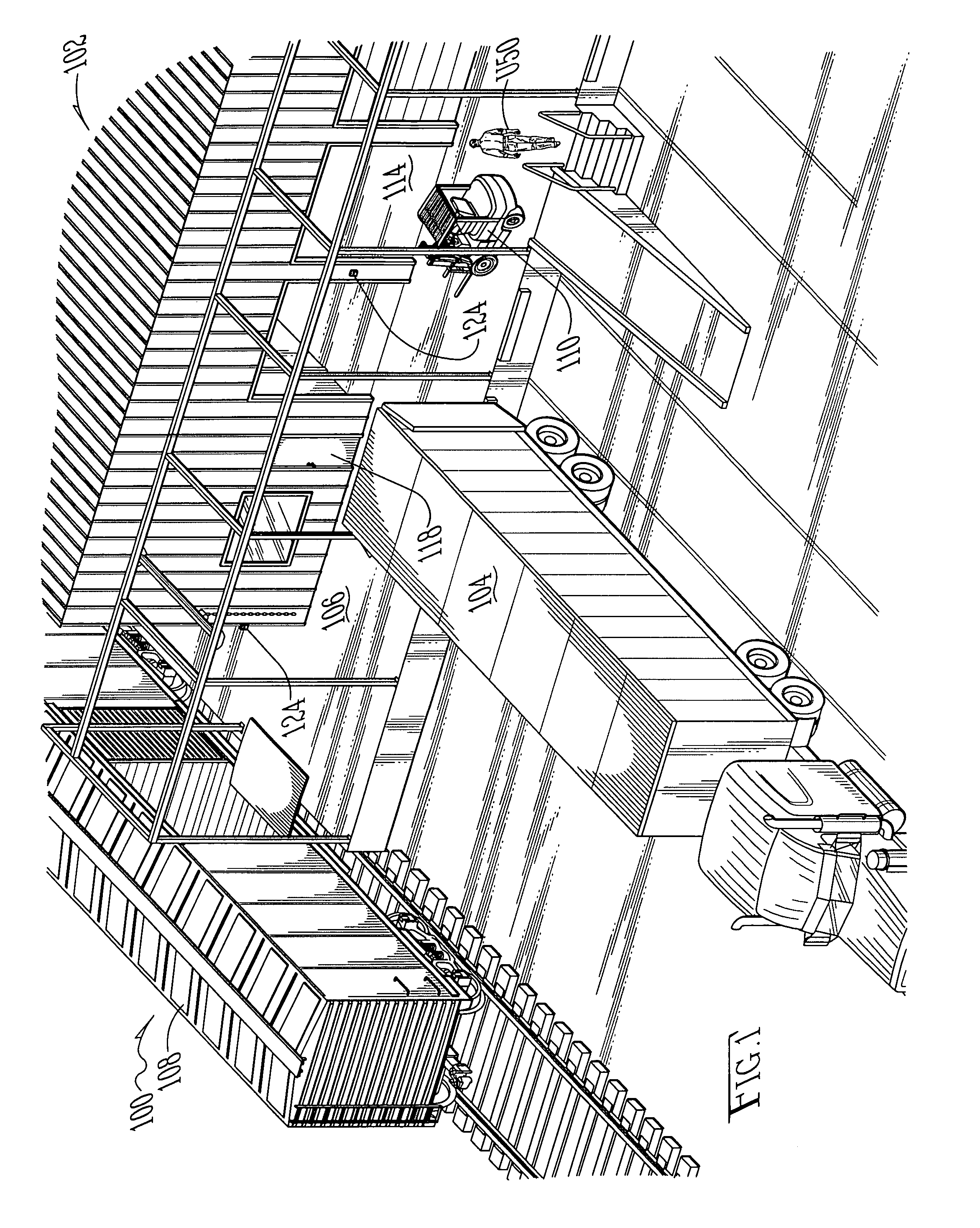

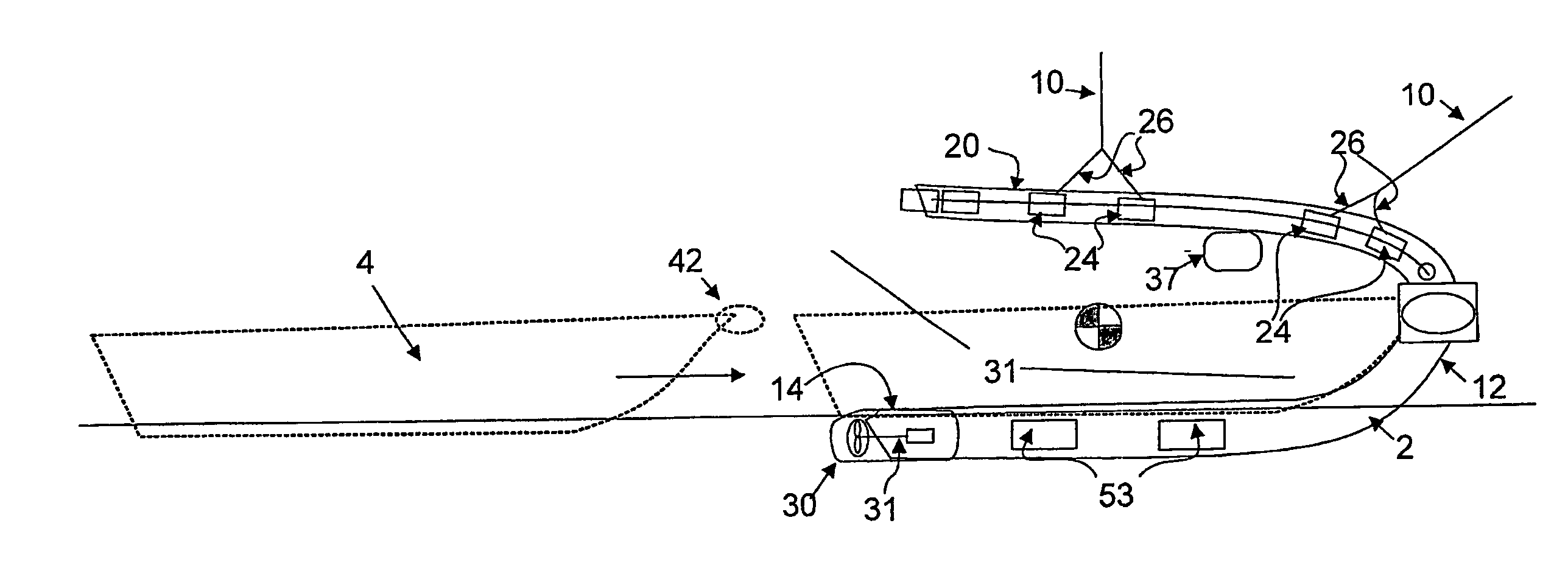

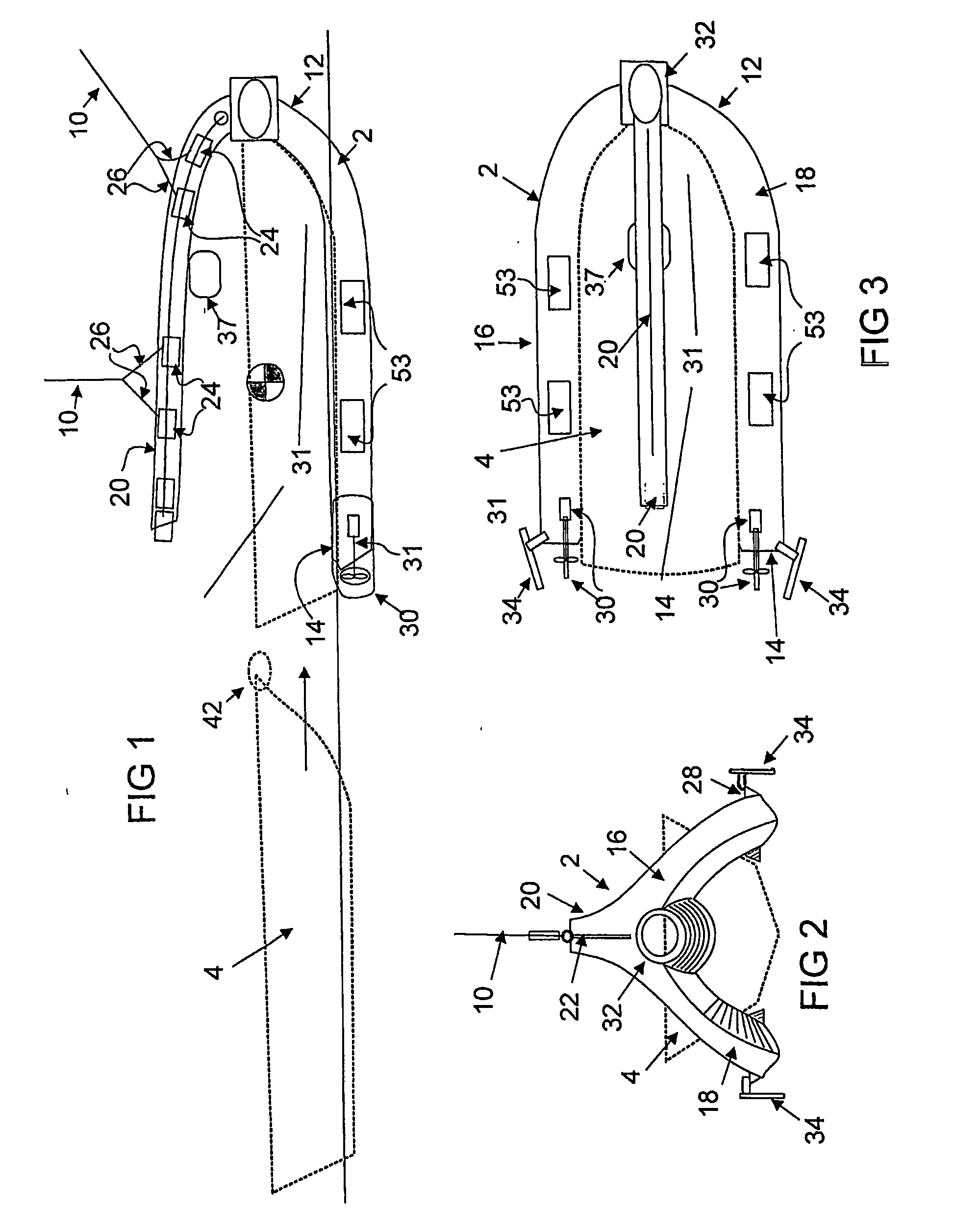

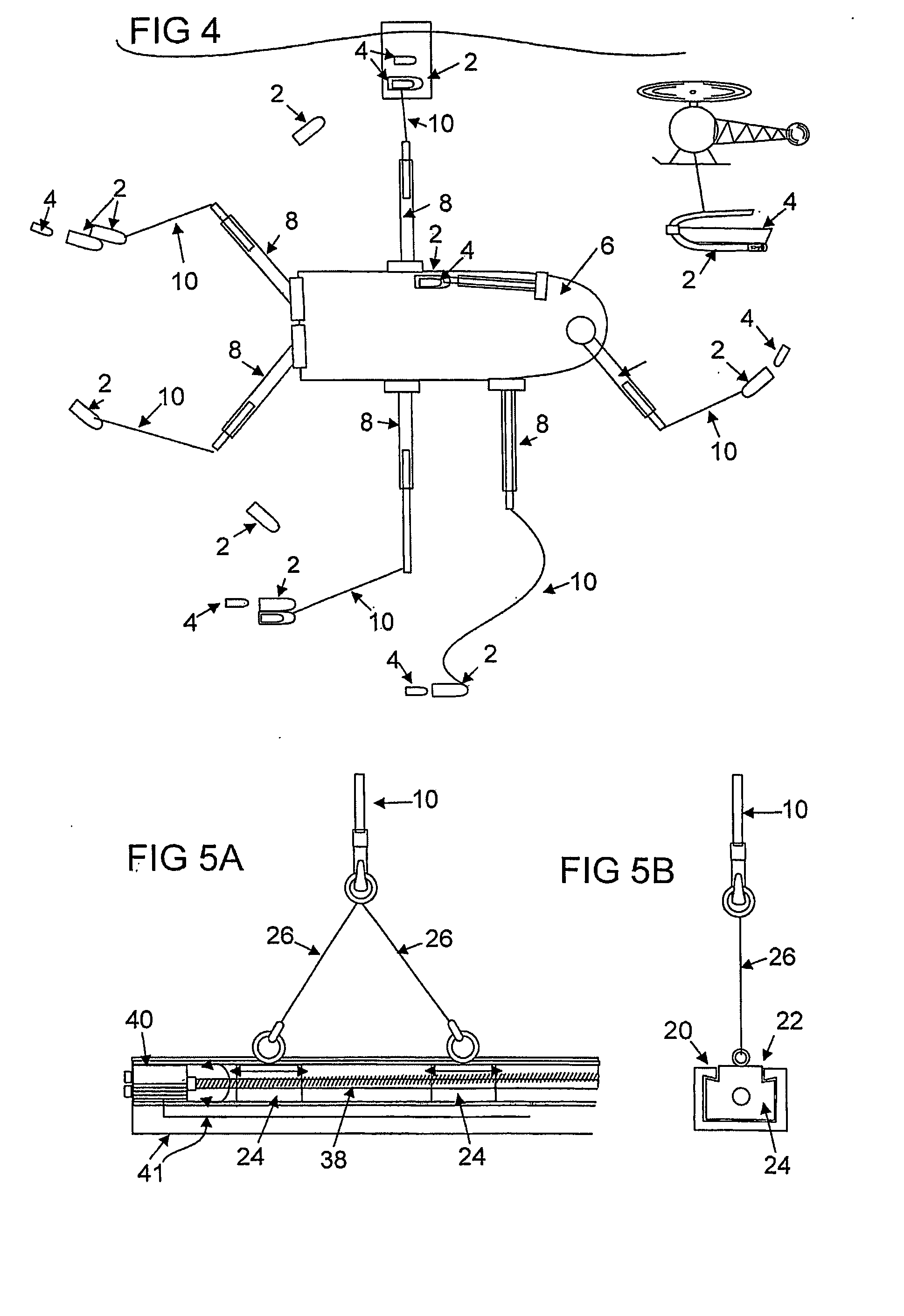

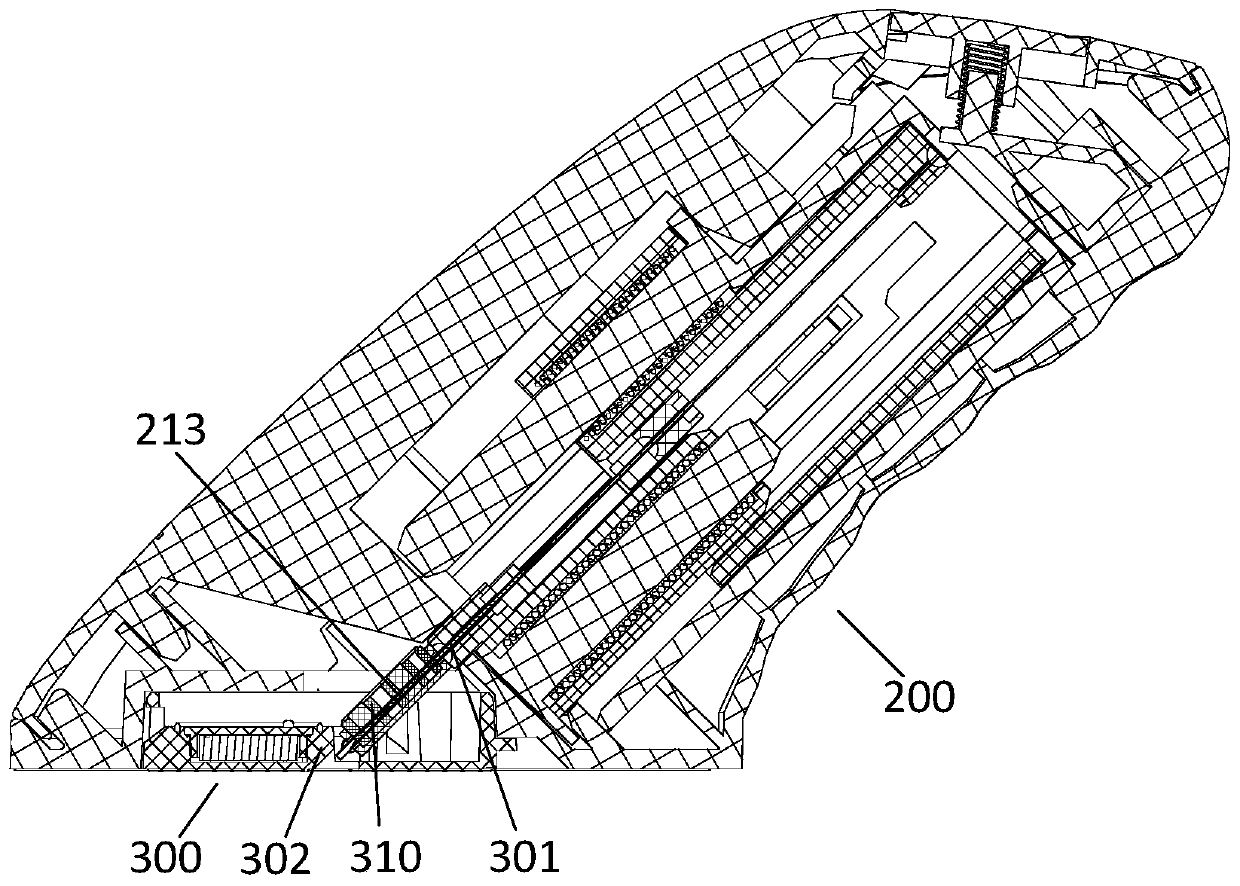

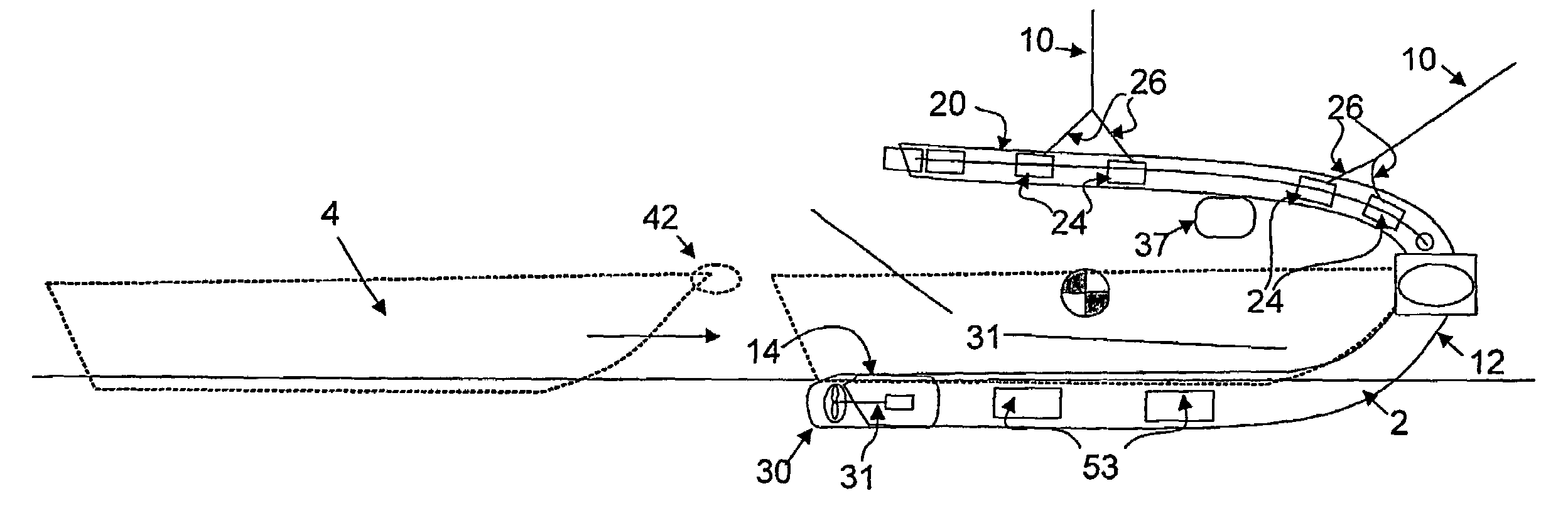

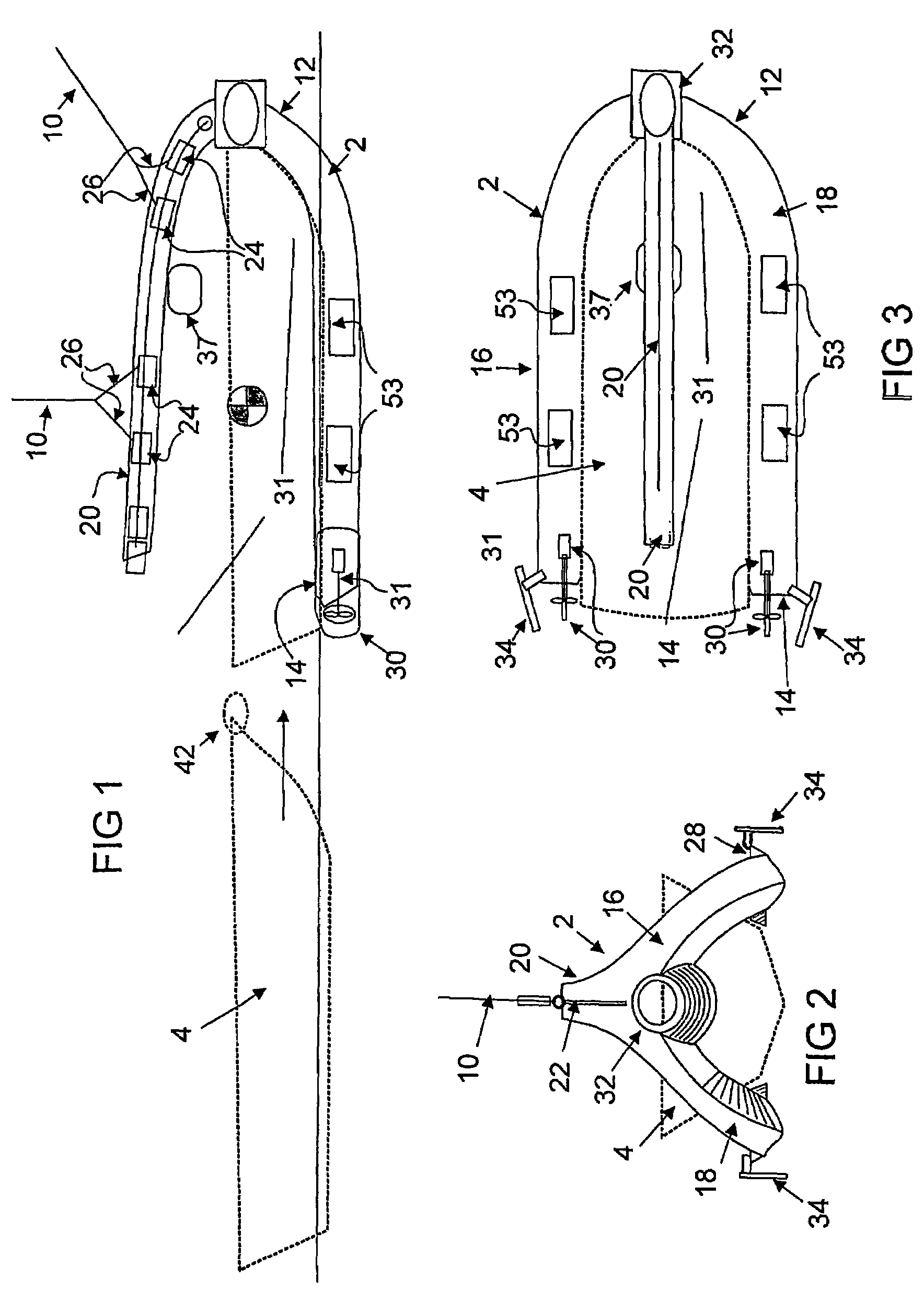

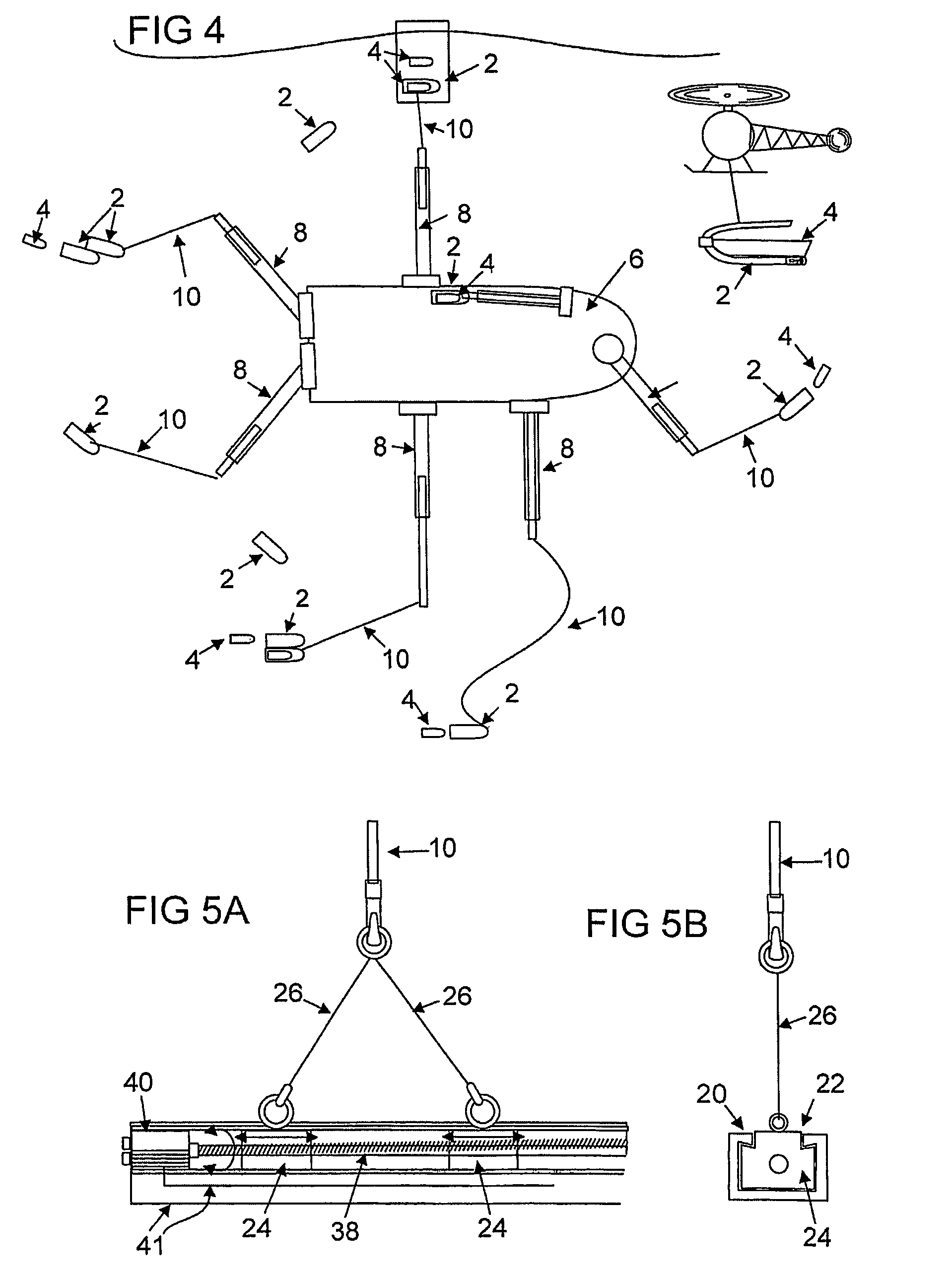

Marine payload handling craft and system

InactiveUS20060191457A1Easy to carryMinimizing motionsTowing/pushing equipmentCargo handling apparatusMarine engineeringOrbit

A marine handling craft and system is intended for use in deploying, inspecting and receiving vessels and payloads to and from locations on, under, over or near water and wet soils in potentially turbulent aquatic or atmospheric conditions. The marine handling craft may operate as a robot, or deployed from a crane or boom on a mother ship or other platform or helicopter so that it can transport and mate and dock at various locations, such as supply ships or autonomous marine vessels, at a stand off distance to limit potential harm to valuable assets. A sliding fastener and track are included on the marine handling craft so that it can be tethered and lifted by a single line or cable, and so can be manipulated by a single crane or helicopter. The utility of the handling craft is not limited to the transport of payloads and it may function as a stand-alone vessel for various remote sensing purposes. Smart communication between the marine handling craft and other vessels or other nodes in a distributed computer network facilitates simultaneous, hierarchical and multi-tasking control of the craft and permits verification and inspection of payloads, which might otherwise cause damage when proximate to more valuable assets.

Owner:ADVANCED MARITIME SUPPORT TECH

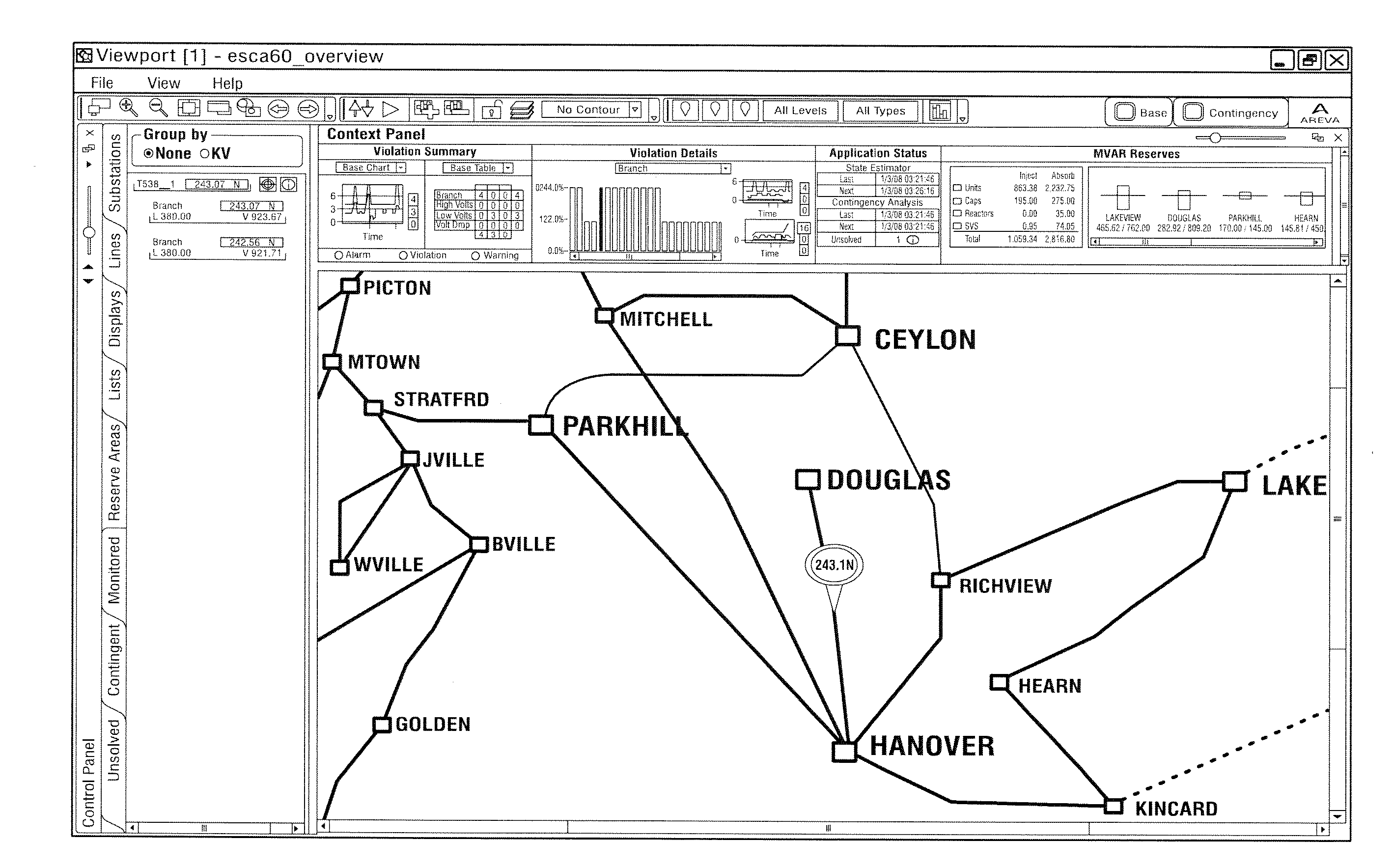

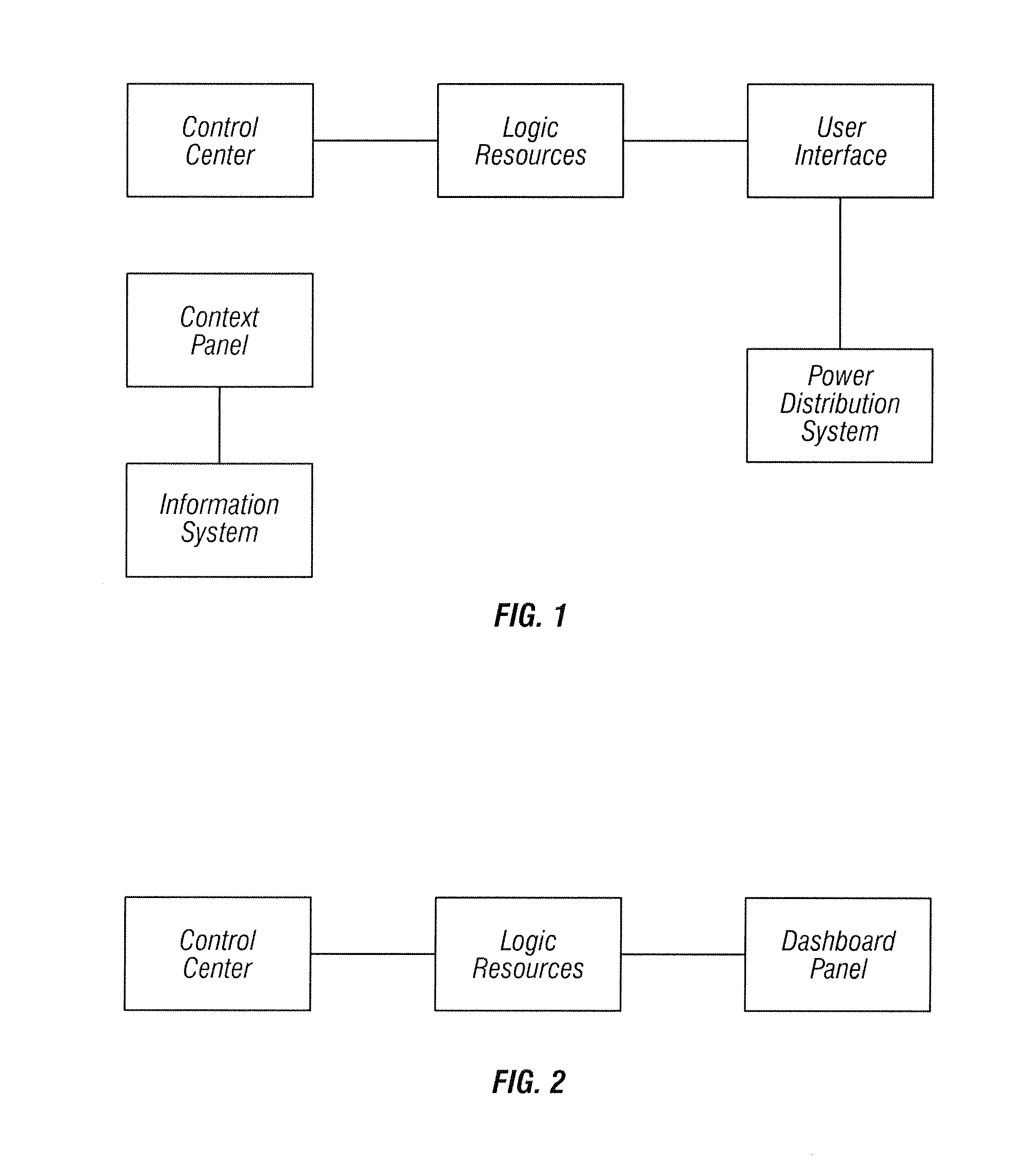

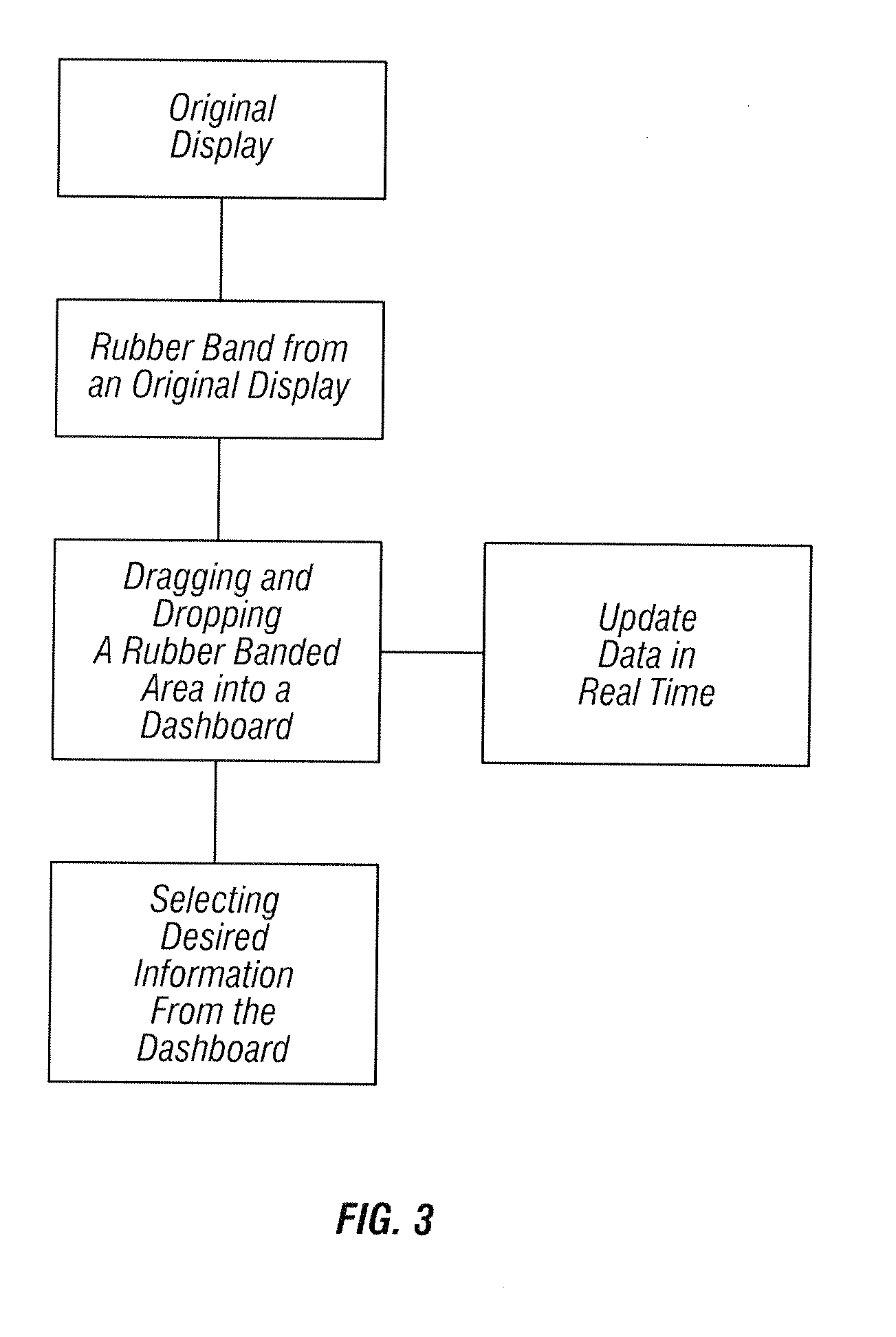

Energy management system that provides a real time assessment of a potentially compromising situation that can affect a utility company

An energy management system has a control center at a utility company and logic resources that provide a real time assessment of a potentially compromising situation that can effect the utility company. At least one situational dashboard panel is provided. The logic resources enable users to dynamically create their own dashboards from large overviews, regional schematic displays and station one-line displays that assist in assessing the potentially compromising situation of the utility company.

Owner:ALSTOM TECH LTD

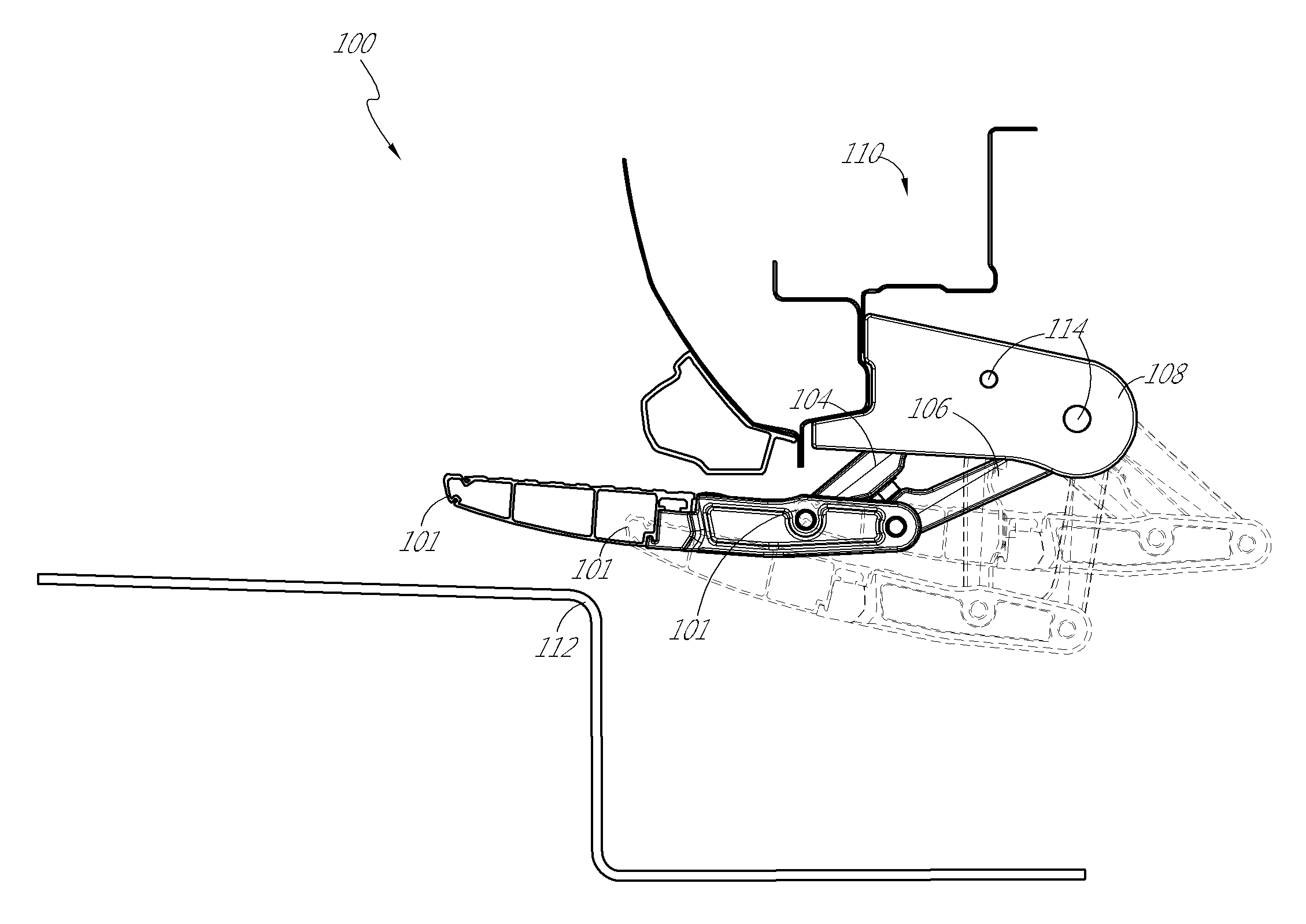

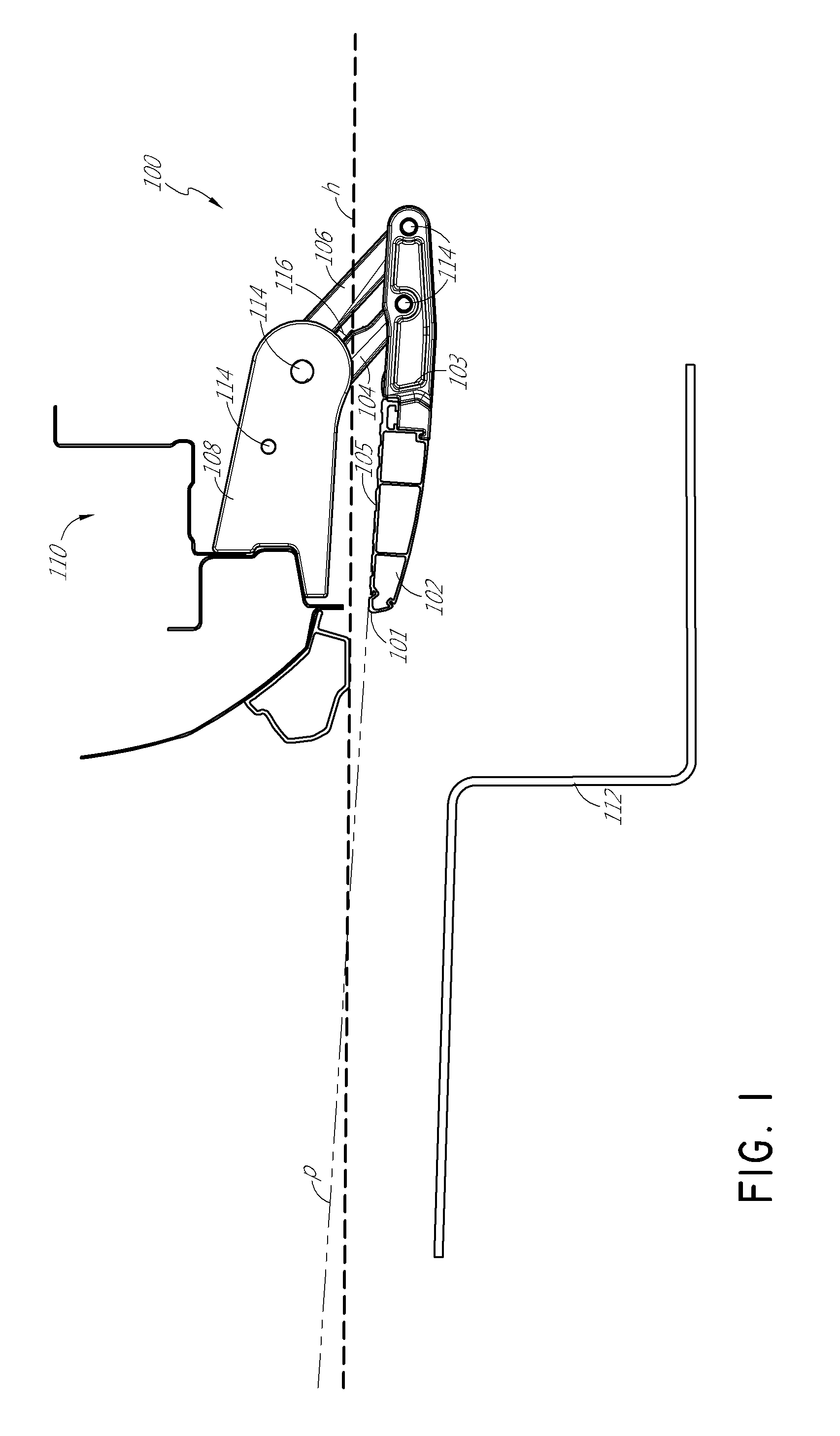

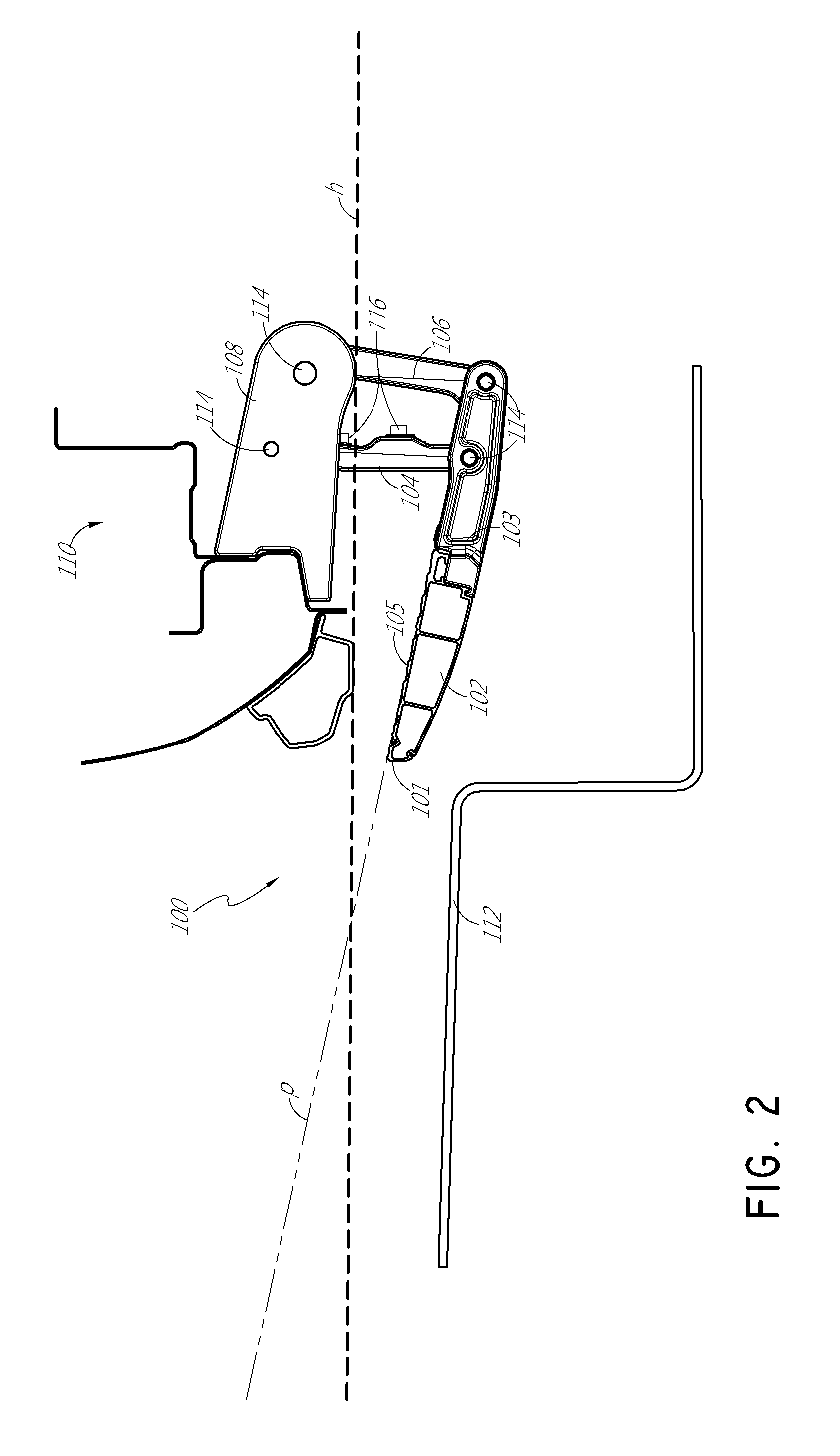

Horizontal retractable vehicle step

A horizontally moving retractable vehicle step is attachable to a vehicle, such as a low to the ground vehicle like a van. The horizontal vehicle step can provide access to different portions of the vehicle. Further, the horizontal vehicle step can act as a safety mechanism to reduce potential harm to a user in accidentally stepping in gaps between the vehicle and a curb.

Owner:LUND MOTION PRODS

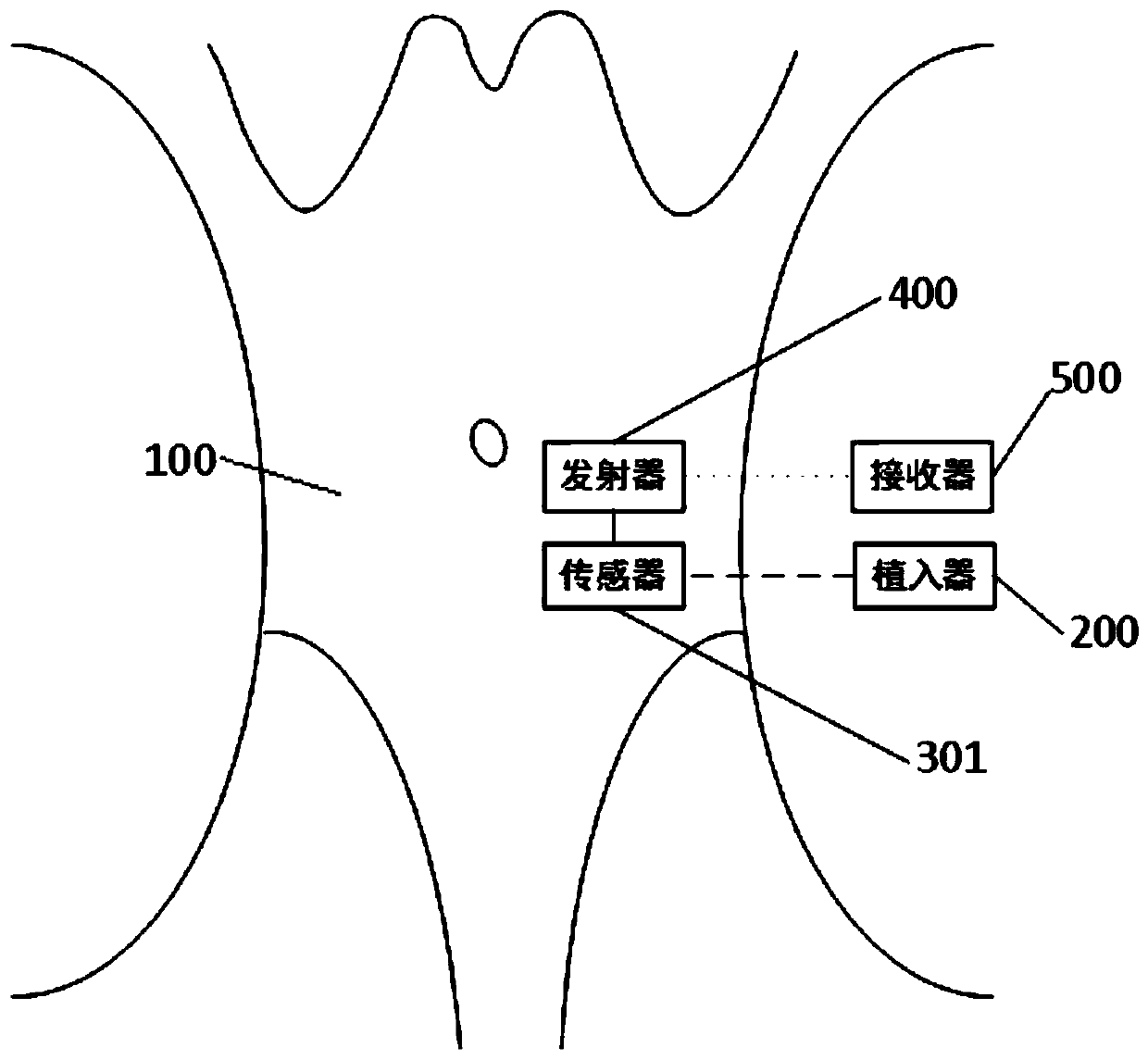

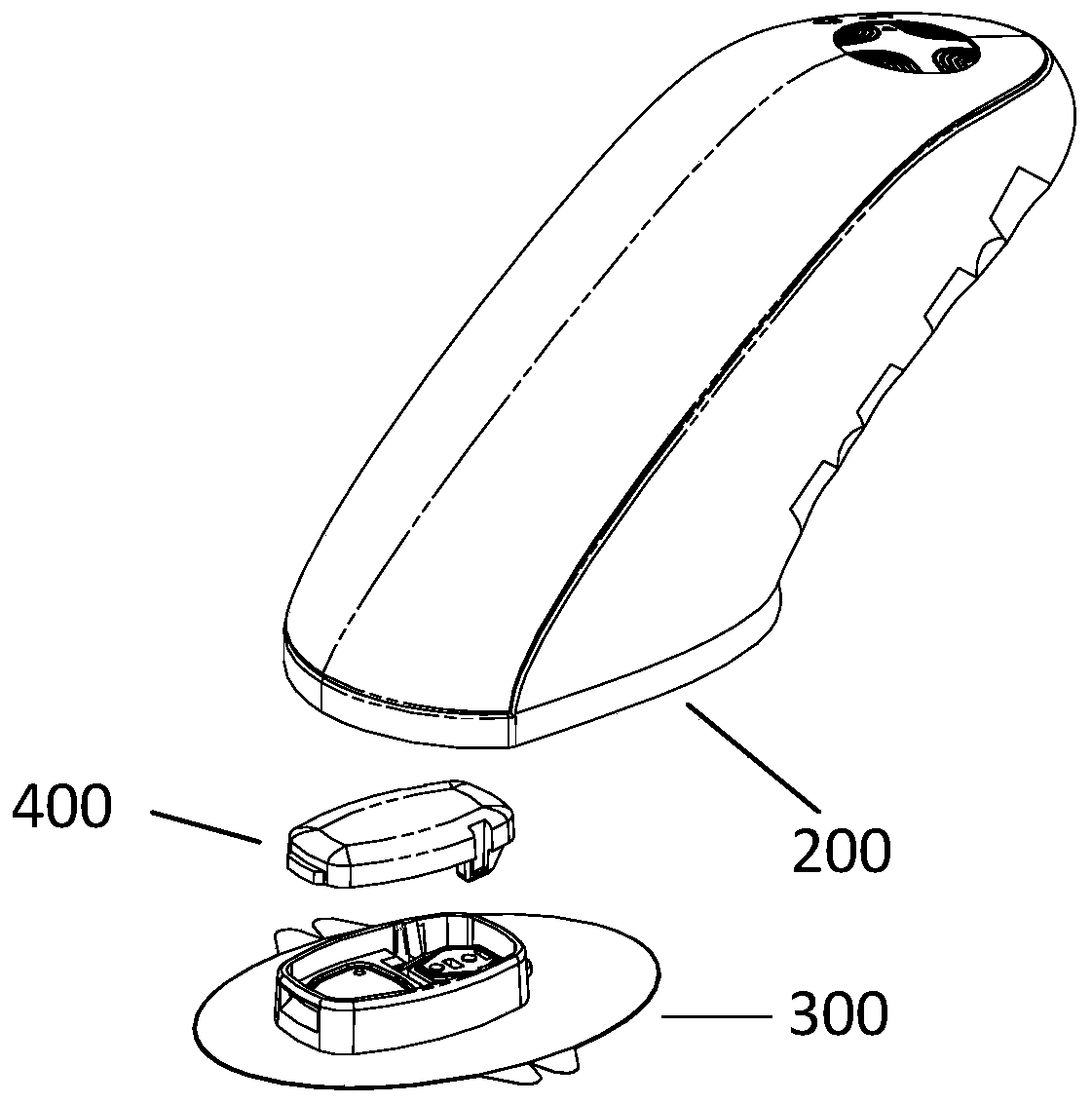

Receptor physiological parameter measuring system

PendingCN109998555ASolve the problem of multiple daily finger prick blood collectionSolve the problem of fingertip puncture blood collection multiple times a dayCatheterSensorsEngineeringSubcutaneous tissue

The invention discloses a receptor physiological parameter measuring system. The system comprises an implanter, a sensor base device and a transmitter, wherein the sensor base device is fixed on the skin of a receptor, the implanter is arranged on the sensor base device and is used for implanting a sensor part into the subcutaneous tissue of the receptor, and after the implanter is detached, the transmitter can be installed on the sensor base device, thereby performing dynamic physiological parameter monitoring within a certain period of time. Compared with the prior art, the receptor physiological parameter measuring system has the advantages that firstly, the pain of puncture of a patient can be reduced to the most extent, and physiological parameters are monitored within a certain period of time, so that the change of the physiological parameter level of the patient is known more accurately; secondly, after accessories of the system are reasonably combined, most of the accessories can be used repeatedly, thereby reducing the material waste, greatly reducing the use cost of a user, and reducing the potential harm to the environment.

Owner:SUZHOU DIASCIENCE MEDICAL CO LTD

Marine payload handling craft and system

InactiveUS7506606B2Easy to carryMinimizing motionsTowing/pushing equipmentCargo handling apparatusMarine engineeringTask control

A marine handling craft and system is intended for use in deploying, inspecting and receiving vessels and payloads to and from locations on, under, over or near water and wet soils in potentially turbulent aquatic or atmospheric conditions. The marine handling craft may operate as a robot, or deployed from a crane or boom on a mother ship or other platform or helicopter so that it can transport and mate and dock at various locations, such as supply ships or autonomous marine vessels, at a stand off distance to limit potential harm to valuable assets. A sliding fastener and track are included on the marine handling craft so that it can be tethered and lifted by a single line or cable, and so can be manipulated by a single crane or helicopter. The utility of the handling craft is not limited to the transport of payloads and it may function as a stand-alone vessel for various remote sensing purposes. Smart communication between the marine handling craft and other vessels or other nodes in a distributed computer network facilitates simultaneous, hierarchical and multi-tasking control of the craft and permits verification and inspection of payloads, which might otherwise cause damage when proximate to more valuable assets.

Owner:ADVANCED MARITIME SUPPORT TECH

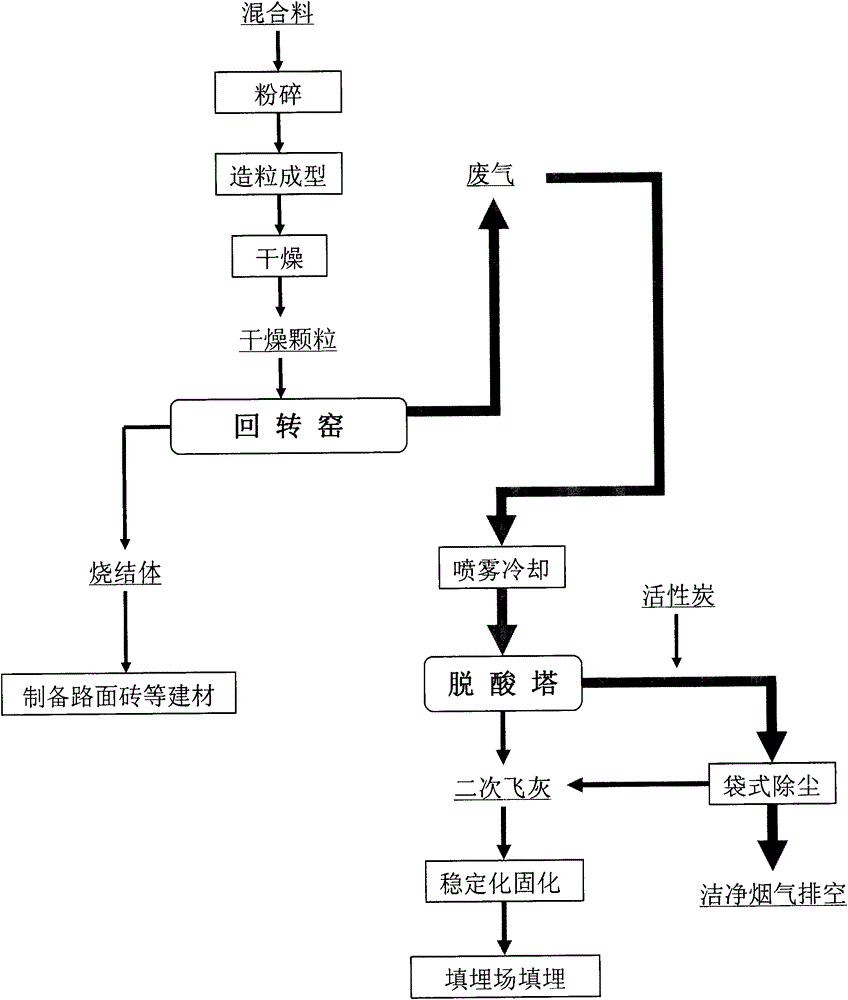

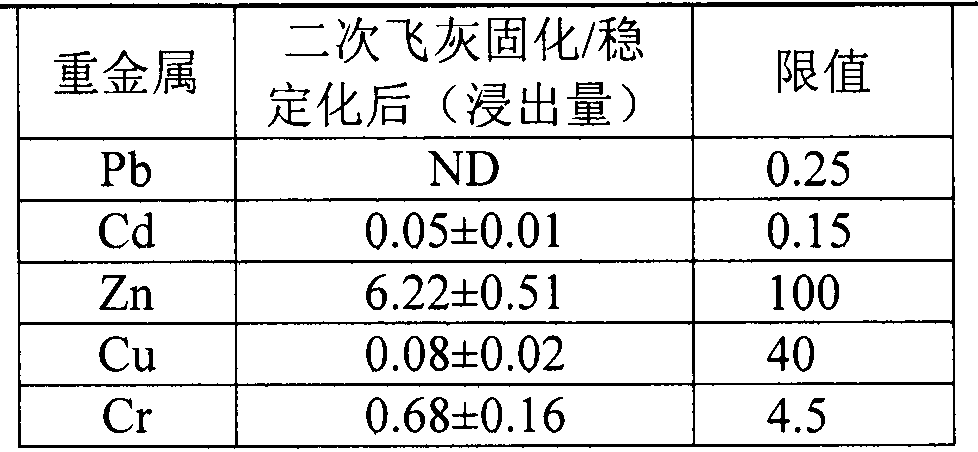

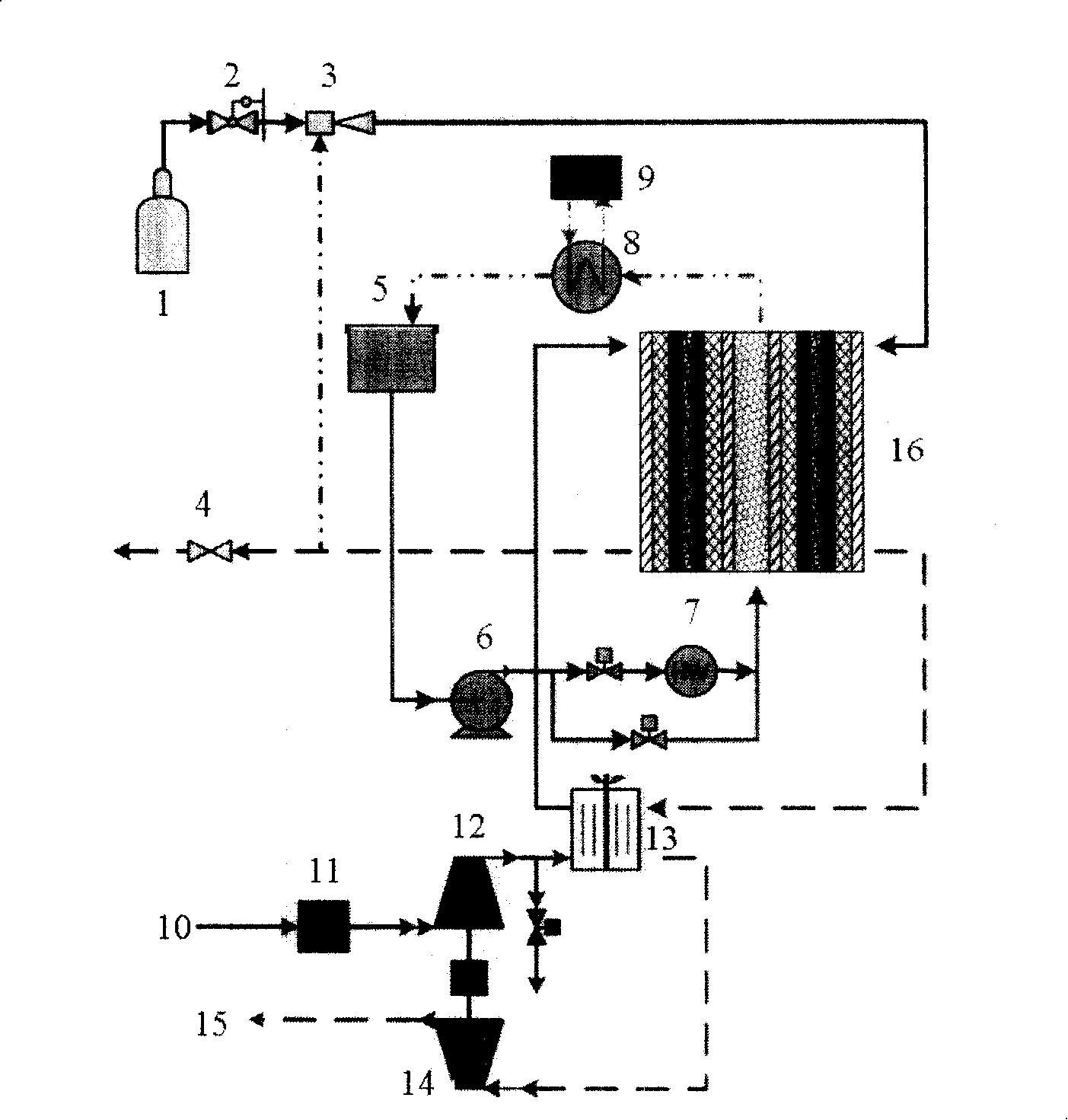

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

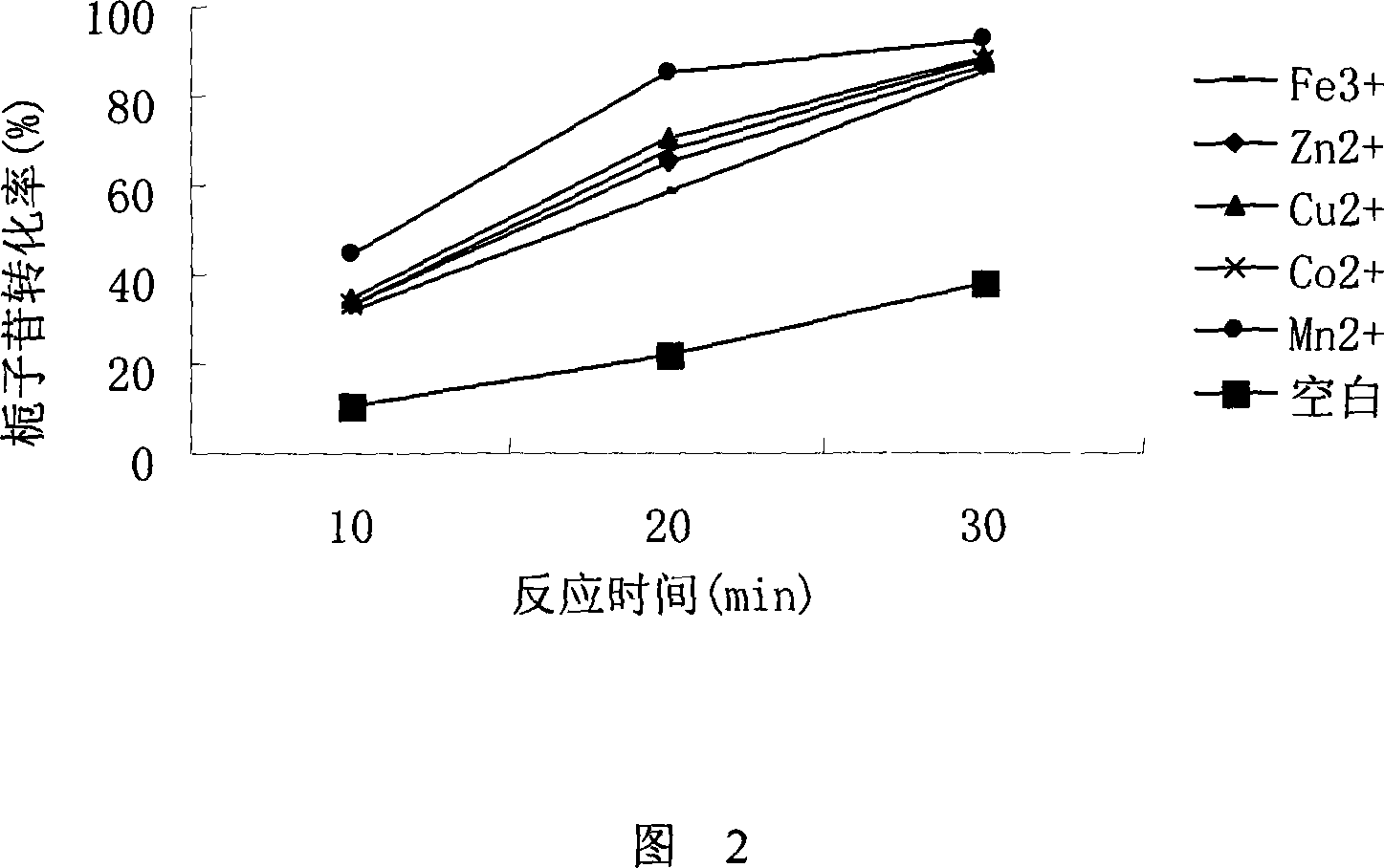

Method for producing natural blue pigment

InactiveCN101104745AIncrease health functionQuick responseNatural dyesFermentationFood industryAlglucerase

The invention provides a production method of a natural blue pigment, which comprises genipin prepared by reaction of beta-glucosidase catalyzing gargenoside, and natural gardenia blue pigment prepared by reaction between the genipin and amino acid in a proper condition. The production method is characterized in that metalloenzyme accelerator is added in the reaction of beta-glucosidase catalyzing gargenoside. Because the metalloenzyme accelerator is added in the reaction, the speed of enzymatic reaction can be accelerated and the reaction time is shortened, so that the production cost is saved, which is helpful for industrialized production. Meanwhile, metal ions added are all the trace elements that the human body needs, so the prepared pigment not only does not have the potential harm that the artificial pigment has, but oppositely has good health function, therefore the pigment can be applied in various fields like food industry.

Owner:EAST CHINA UNIV OF SCI & TECH

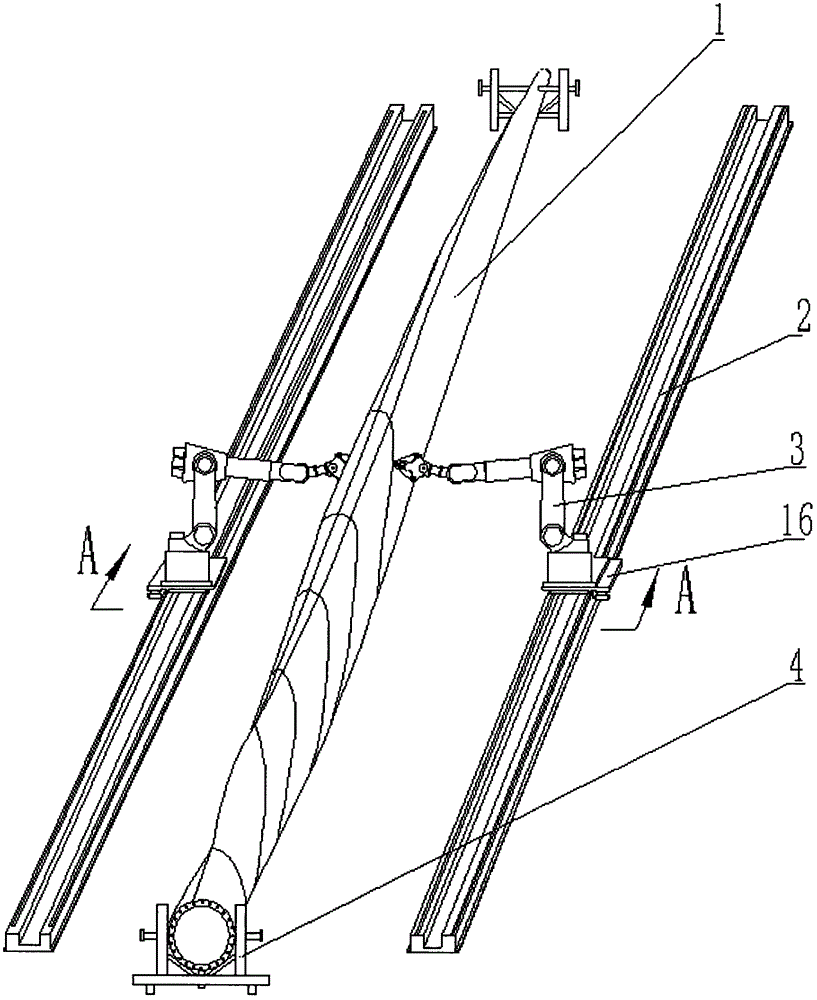

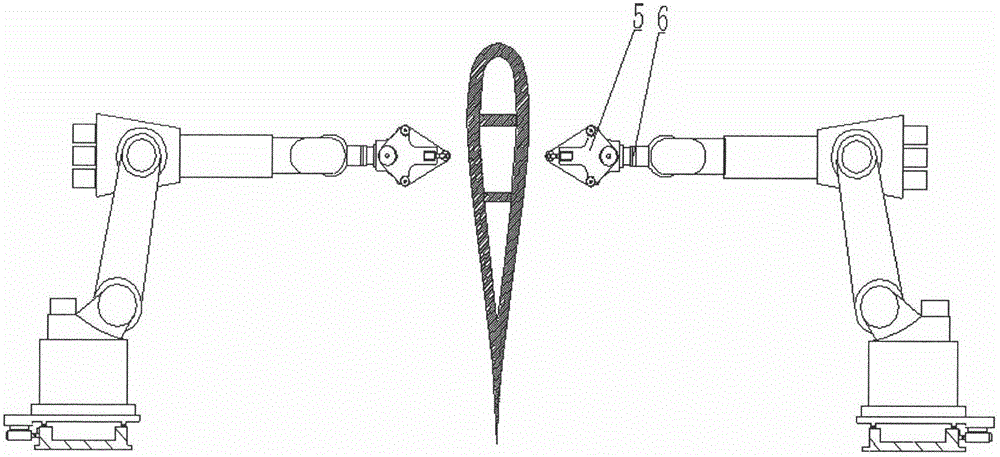

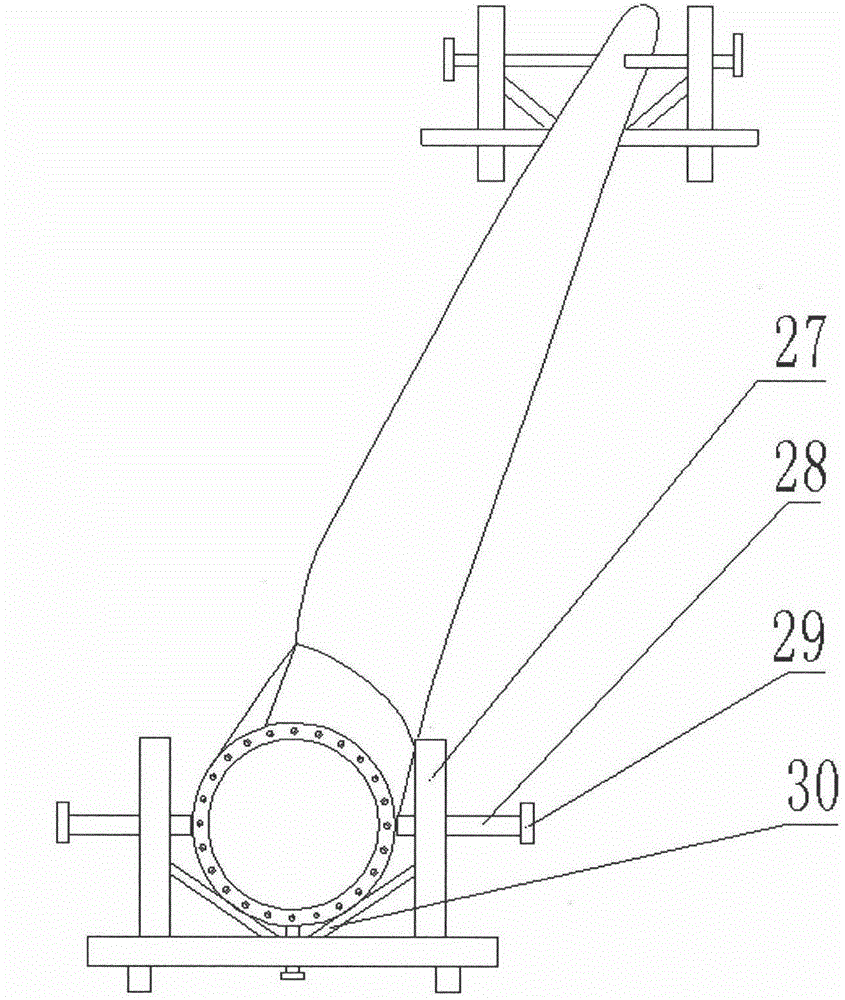

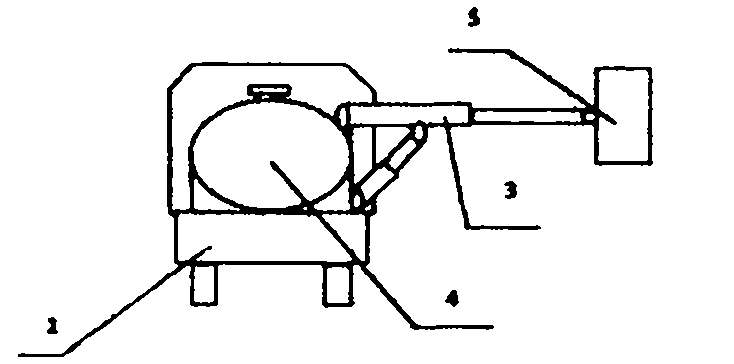

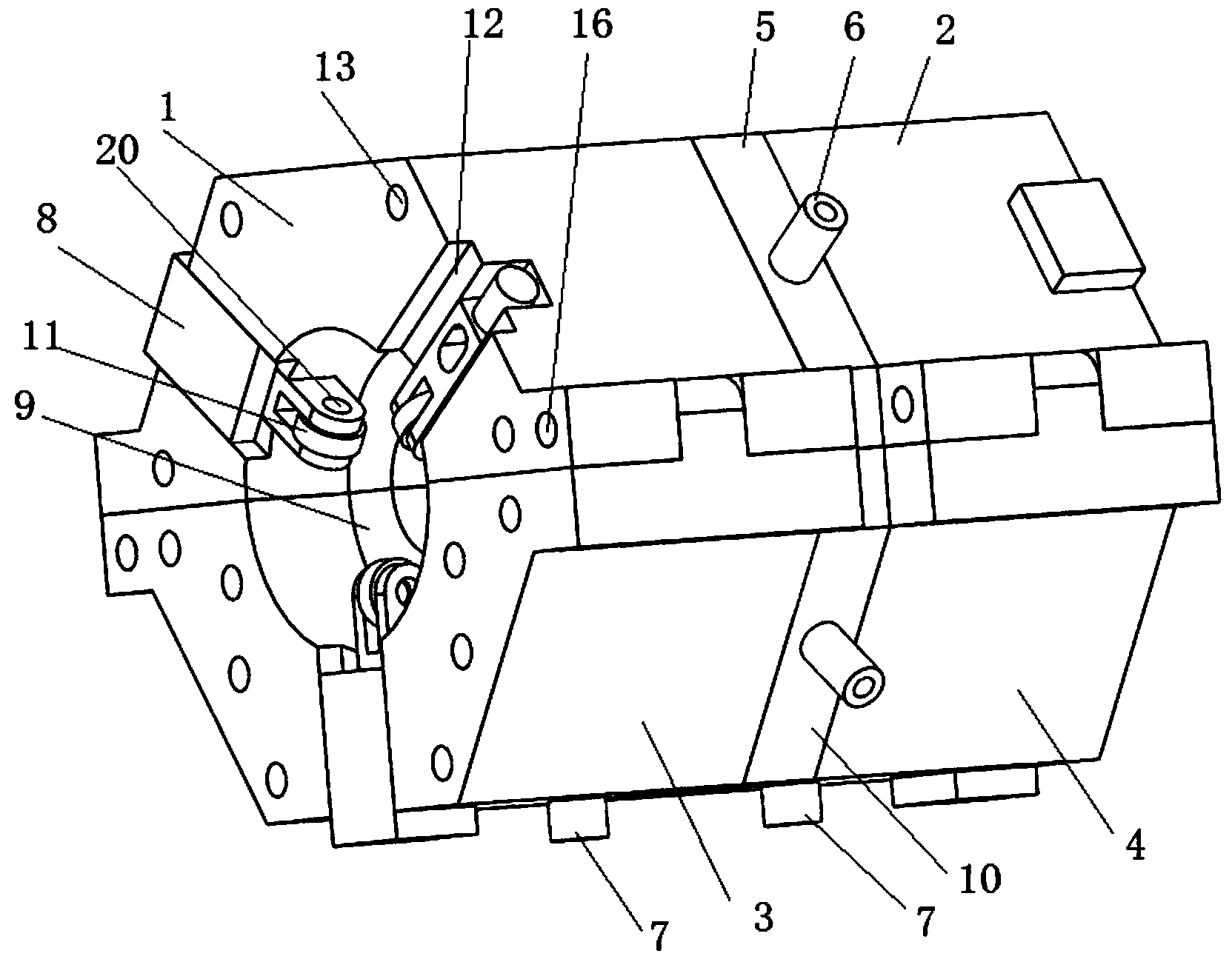

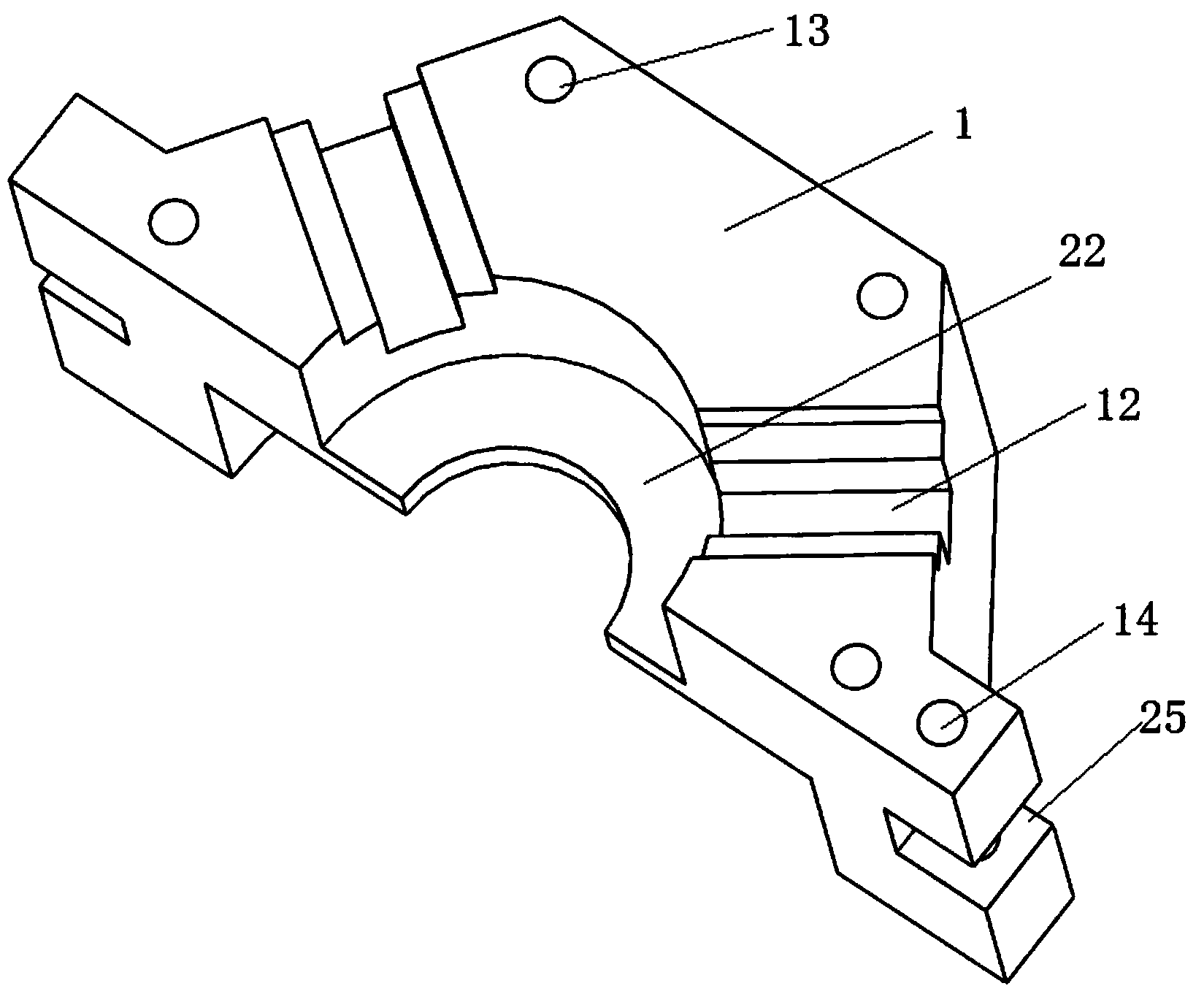

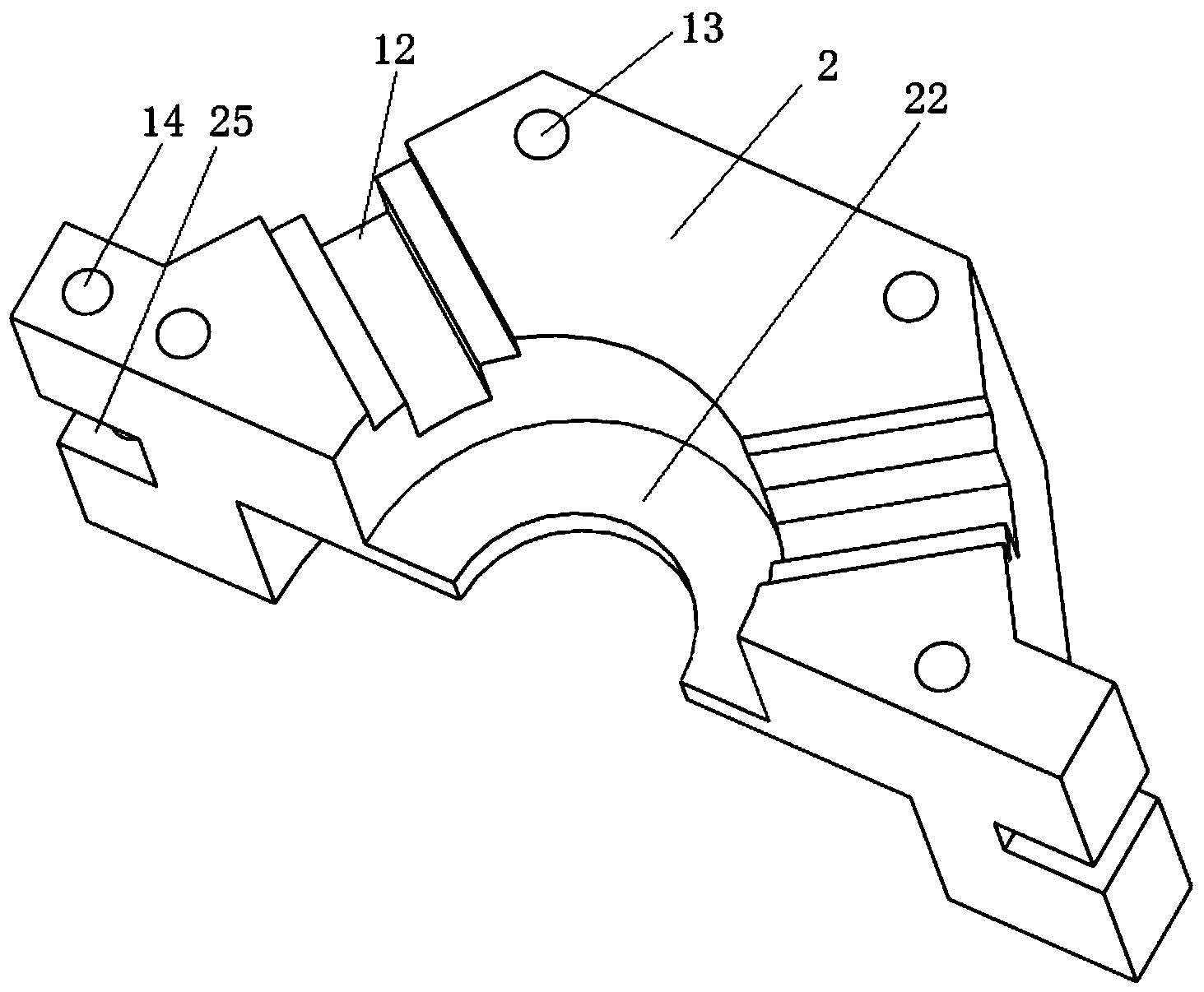

Curved surface mirror image grinding system

ActiveCN105252388ALow costImprove maintainabilityGrinding machine componentsBelt grinding machinesElectricityEngineering

The invention discloses a curved surface mirror image grinding system. The problems of excessively low efficiency, poor surface qualities, high labor intensity, severe dust harm and the like during manual grinding of wing-type curved surfaces of existing large wind power vanes are mainly solved. The curved surface mirror image grinding system comprises six-axis industrial robots, supports, sliding table devices and grinding devices; the industrial robots integrated with the grinding devices are arranged in dual directions in a mirror symmetry mode with the axis of a wind power vane workpiece as the center line and cooperate to carry out parallel control over the grinding devices to perform mirror symmetry grinding motions with different poses in working space, and dual-direction automatic mirror image grinding and polishing of the wind power vane curved surfaces can be achieved. The curved surface mirror image grinding system is ingenious in structural design; the grinding and polishing efficiency of the wind power vane curved surfaces is high; the ground and polished surface qualities are good; the production cost of the wind power vanes is greatly reduced; potential harm of grinding dust to people is eliminated; the good practical and popularizing value is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

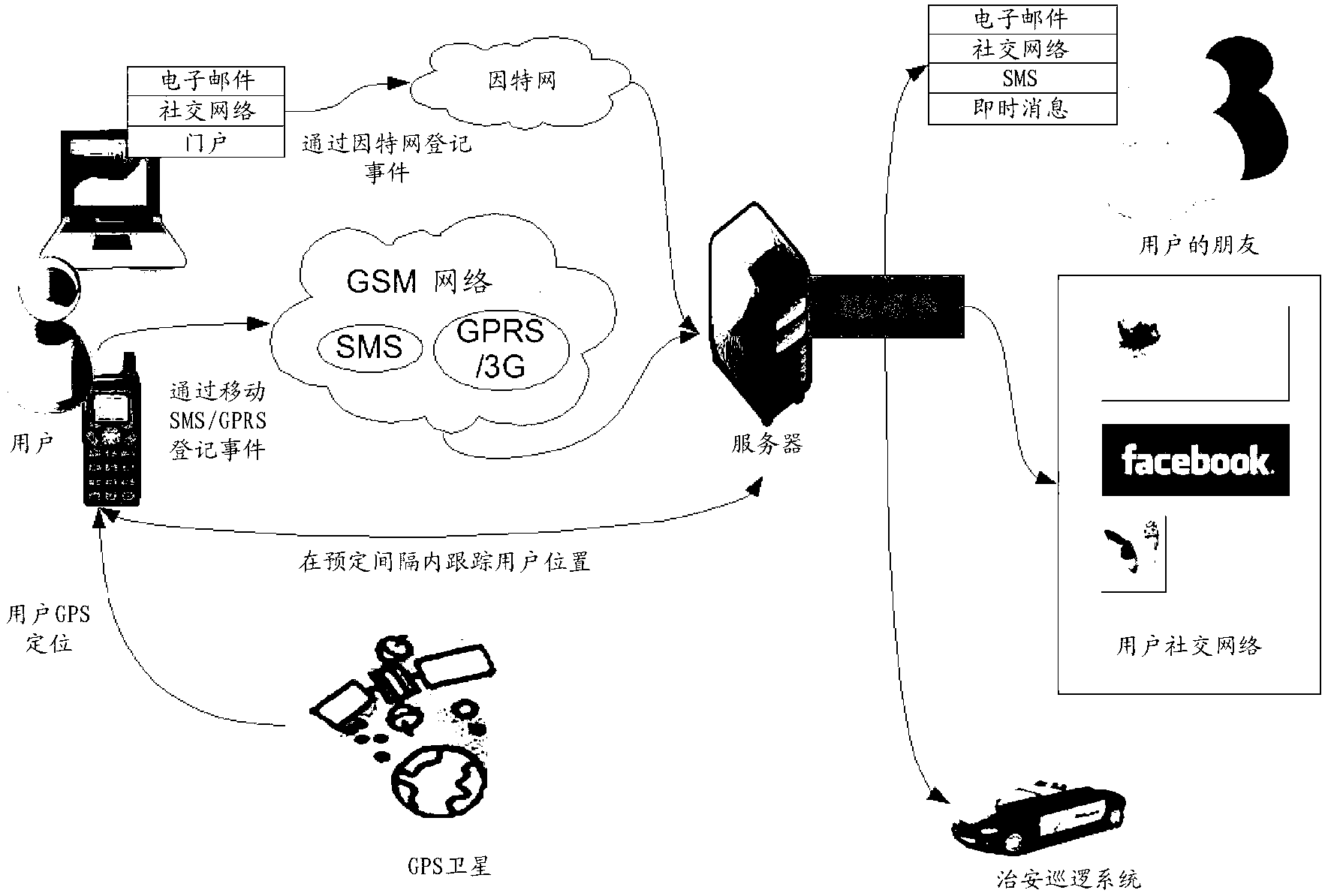

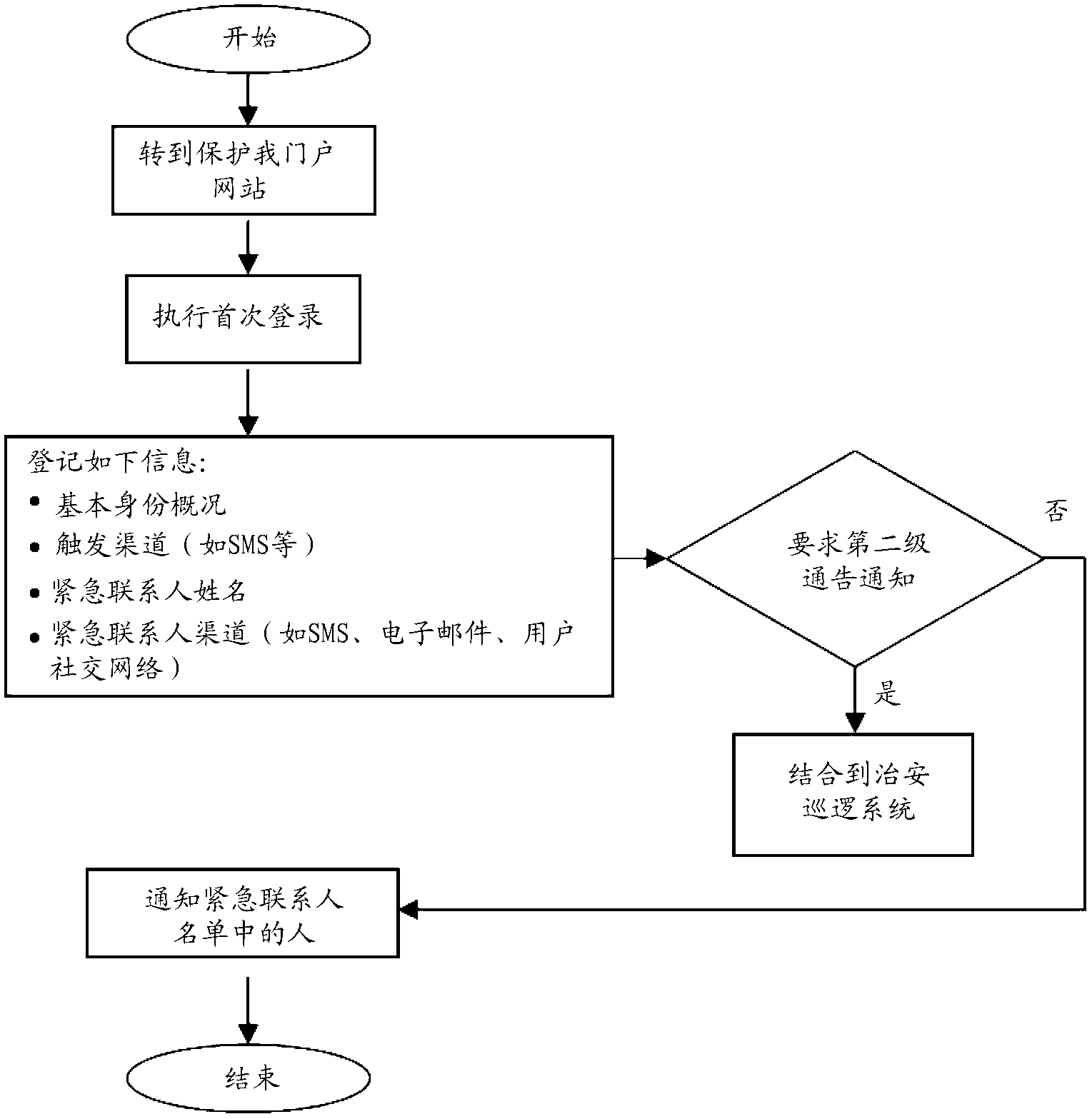

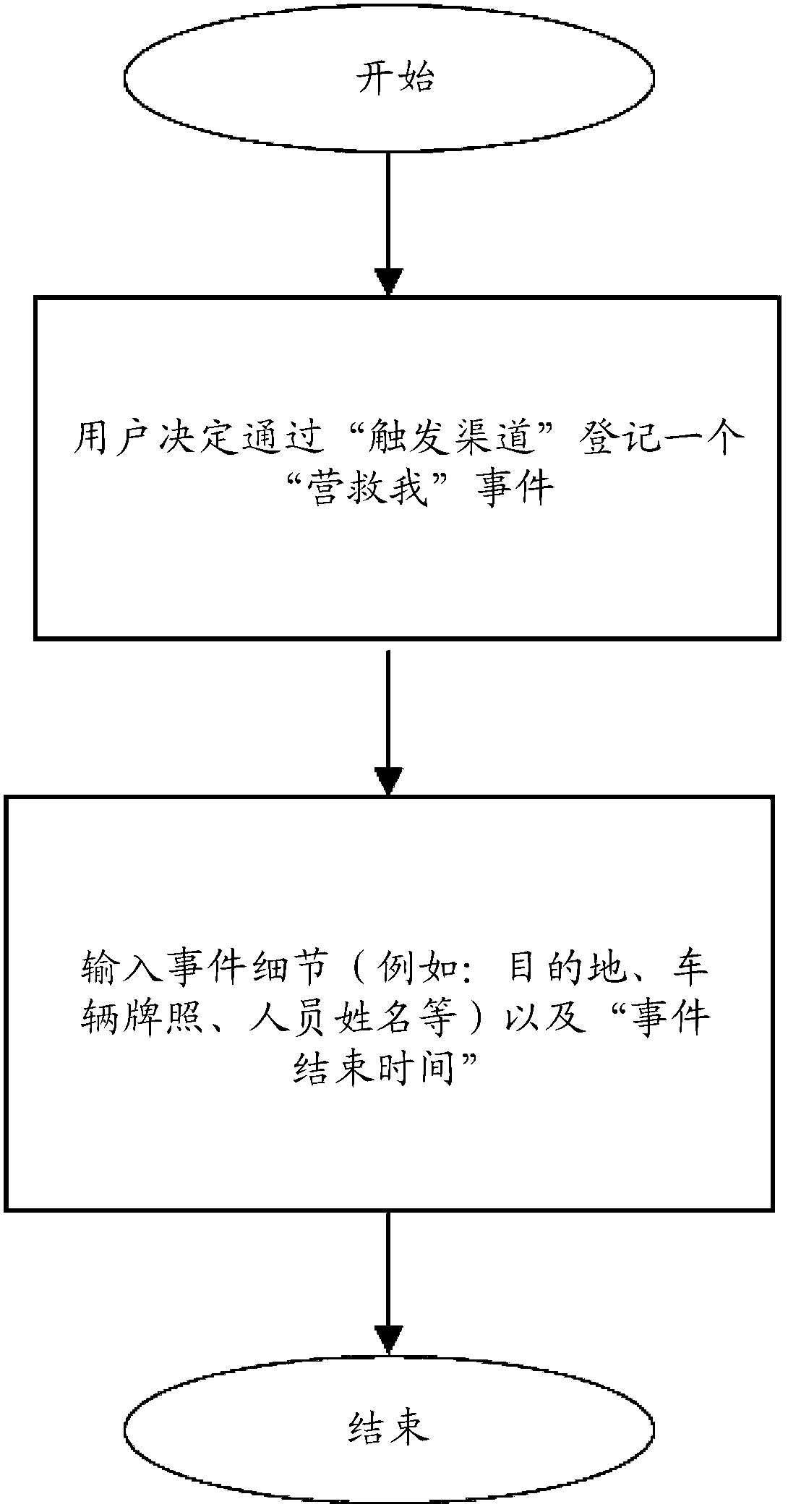

Personal protection system with automatic emergency contact notification based on registered events

InactiveCN102783193AEmergency connection handlingRoad vehicles traffic controlSocial network serviceProtection system

The concept rides on the believed of 'better be safe than sorry' where the subscriber will register an event with anticipated end-time which the individual deems is vulnerable to cause her any potential harm. The event is then stored in a database with sufficient information for any emergency tracking and notification. At the end of the anticipated end time, a message will be sent from the server to the subscriber's wireless device requesting for safety confirmation, failing which the system will automatically send an alert notification message to a group of predefined emergency contacts through various channels and medias. The emergency message will also be posted to the subscriber's own social network services for mass notification.; In addition, the subscriber has the option to trigger the location based tracking of his whole journey during the active event time if the individual wireless device is subscribed with the location base tracking system, such as global positioning system (GPS) service.

Owner:邱进祥 +1

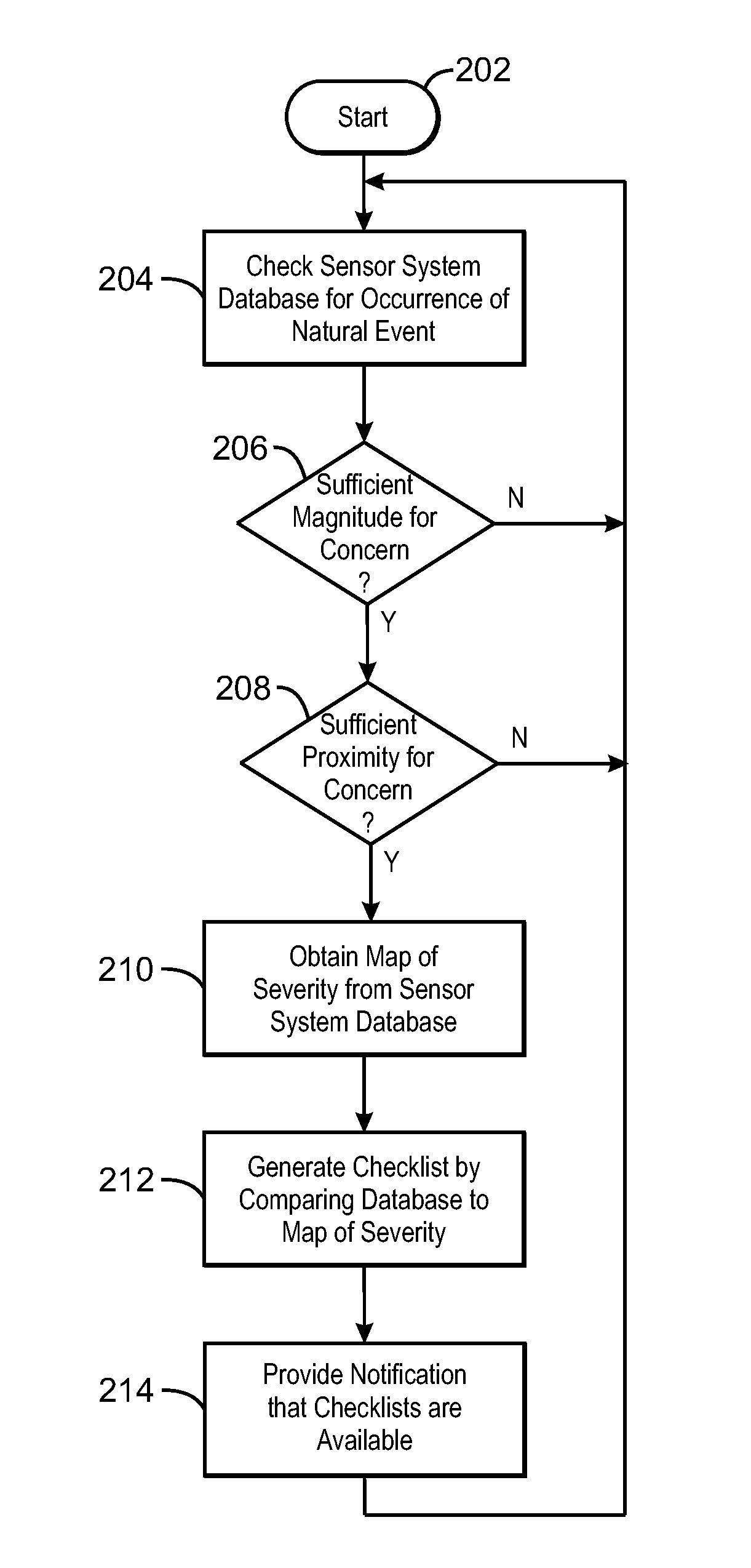

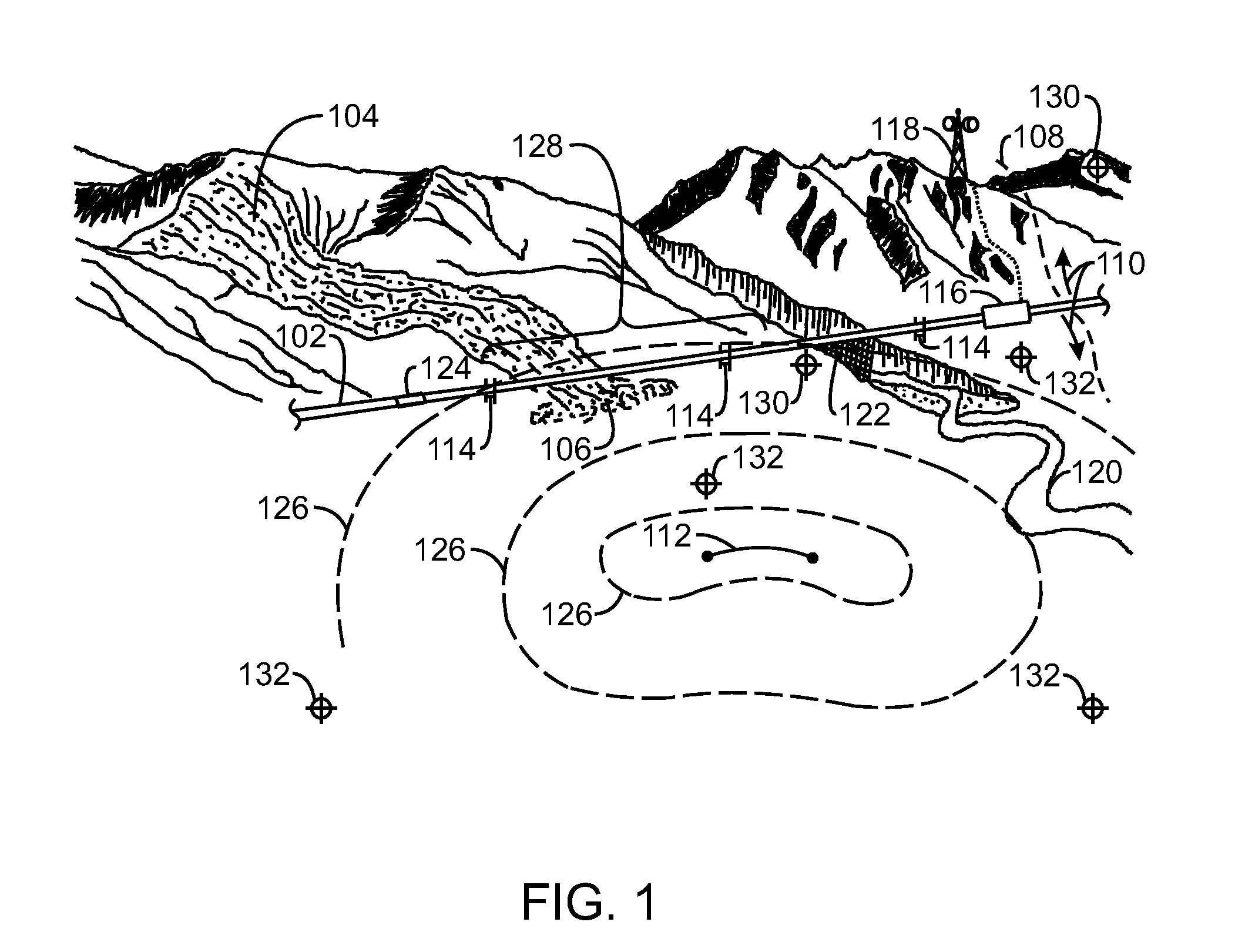

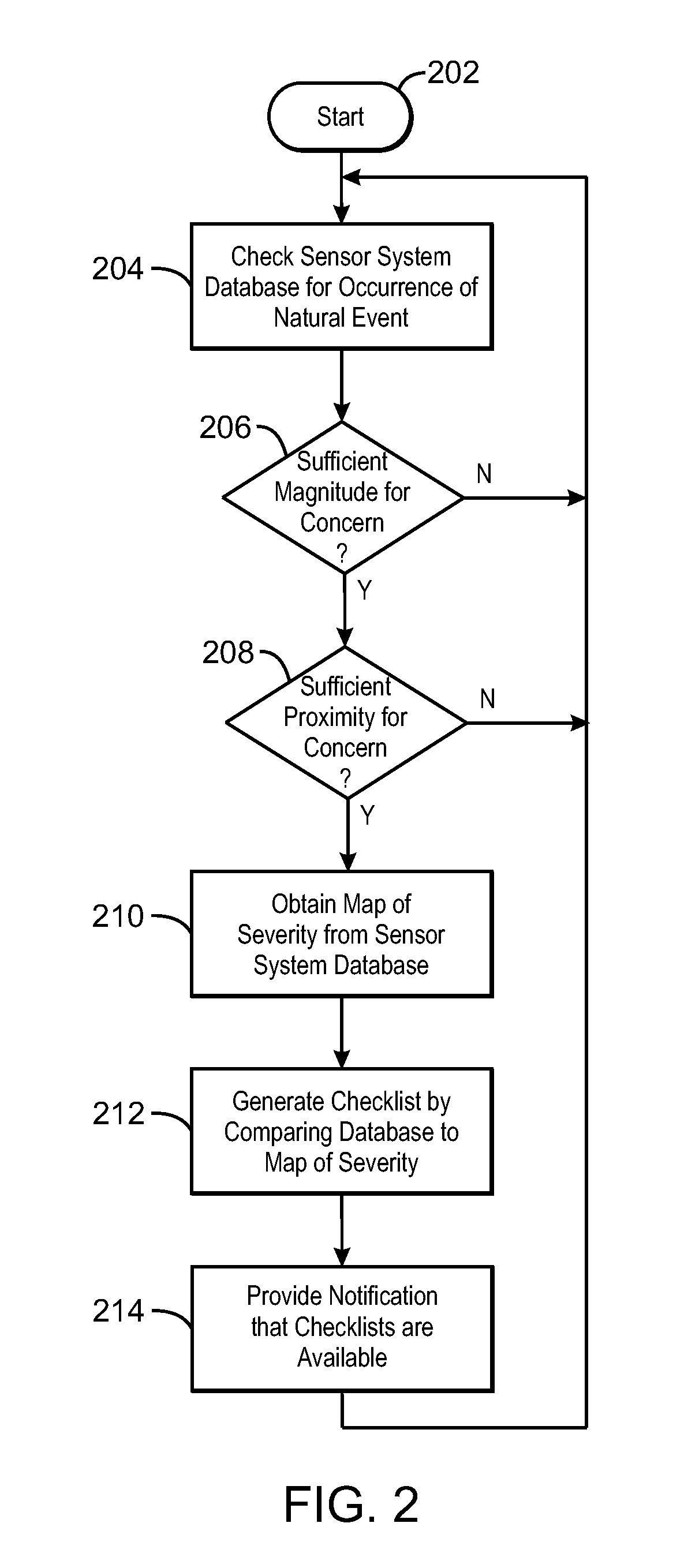

System and method for accessing potential damage to infrastructure items after natural events

Systems and methods for responding to a risk of damage caused by a natural event are presented. A method presented includes checking a sensor system database on a regular period for an occurrence of a natural event. If the natural event has occurred, a determination can be made as to whether the natural event is of sufficient strength and proximity to an infrastructure item to create a potential hazard to the infrastructure item. If so, a map of the severity of the natural event can be obtained from the sensor system database and compared to a database of infrastructure items. The database includes a fragility index associated with each infrastructure item. A customized checklist can then be generated for inspection of the infrastructure item.

Owner:ALYESKA PIPELINE SERVICE COMPANY

A special vehicle with white trunk

InactiveCN102283055AReasonable designImprove work efficiencySpraying apparatusPlant protectionPressure systemHigh pressure

The invention discloses a special vehicle for whitening tree trunks, and aims to provide a maintenance special vehicle for whitening the trunks of trees by replacing manual work with machinery. The special vehicle is composed of a car chassis, a pressure supply system, a telescopic arm, a liquid storage tank, a spraying device, and an operating table. The pressure supply system, the telescopic arm, the liquid storage tank and the operating table are installed on the chassis of the vehicle, the spraying device is installed on the telescopic arm, and the operating table is operated between the pressure supply system and the liquid storage tank. There is a high-pressure pipe connected between the table and each telescopic arm and the spraying device, and a liquid supply pipe is connected between the liquid storage tank and the spraying device; the telescopic arm can be adjusted in height, rotation angle, and telescopic arm length. In this way, the staff can realize mechanized operation by manipulating the console; the spraying device is composed of a semicircular liquid supply pipeline frame and a fixed seat; the liquid supply pipeline frame is installed on a fixed On the seat, it can be opened and closed freely; the inner side of the liquid supply pipeline frame is equipped with a spray head, and the surrounding and upper end surface of the liquid supply pipeline frame is equipped with a closing plate, so that when the semicircular liquid supply pipe When the road frame is closed, a relatively closed cylindrical space is formed; the design of the invention is reasonable, which fills the gap in the industry, and the mechanized operation replaces the manual operation, which improves the work efficiency, and the spraying liquid can be evenly sprayed on the trunk or penetrated Into the cracks of the bark, it is better than manual work, avoiding the direct contact opportunity between the staff and the whitening liquid, and preventing the potential harm of the spraying liquid to the human body.

Owner:范成玉

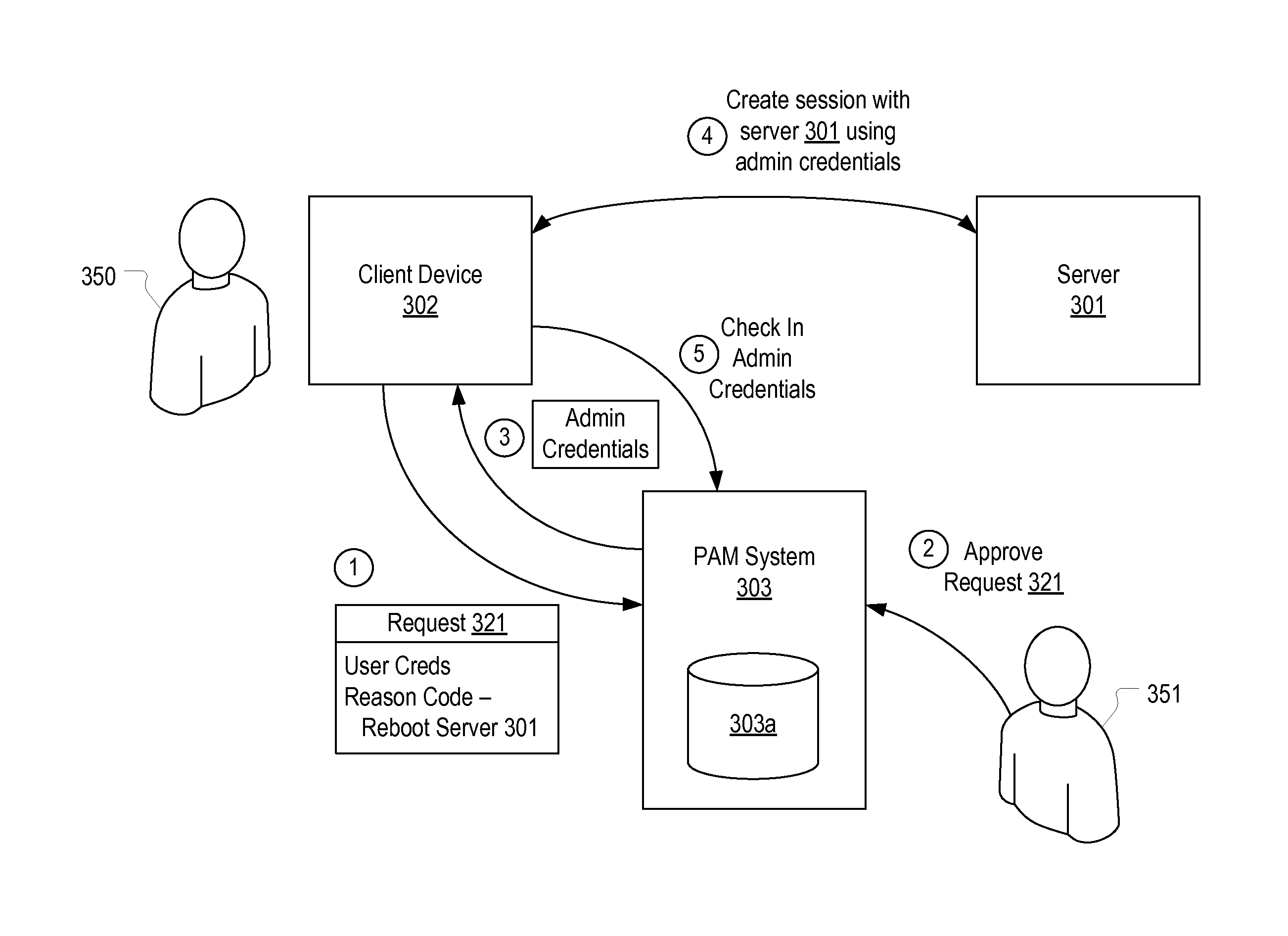

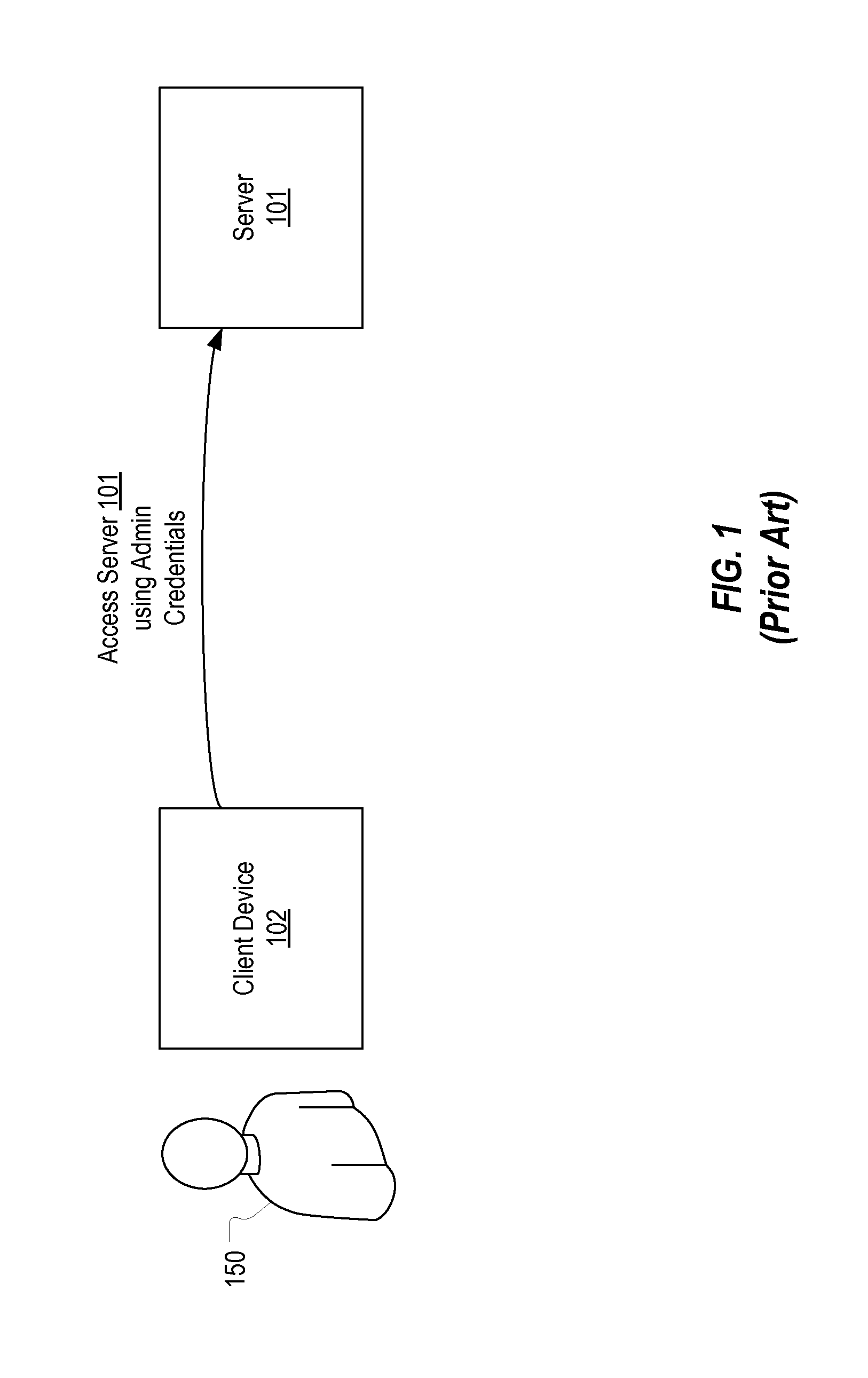

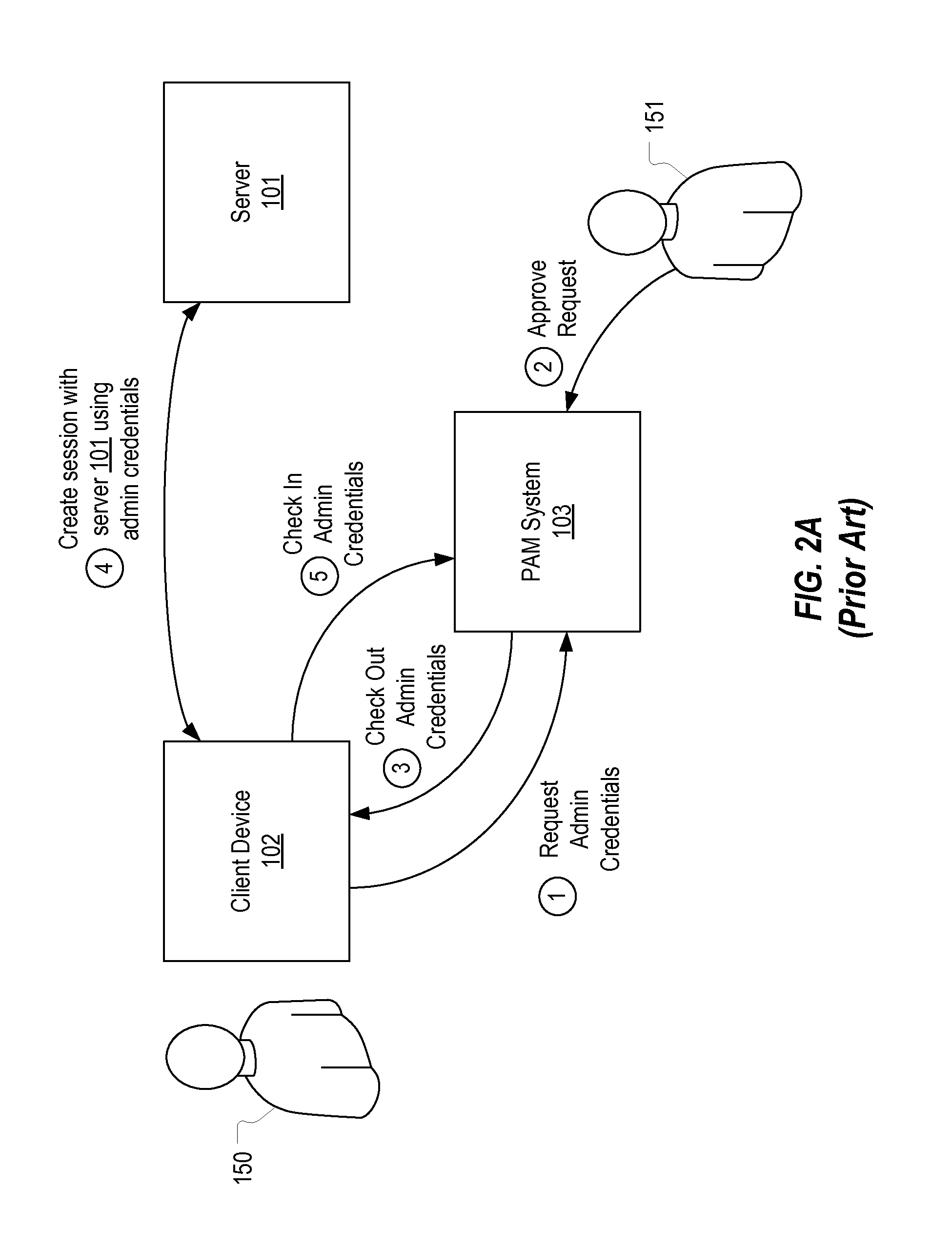

Detecting unauthorized risky or inefficient usage of privileged credentials through analysis of task completion timing

ActiveUS20160323288A1Mitigate any potential harm to the serverTransmissionTask completionPotential harm

A privileged account management system can maintain a database that defines a normal amount of time that it takes to perform a task associated with a reason code. When an administrator requests admin credentials for accessing a server, the administrator can provide a reason code which defines a task that the administrator intends to accomplish. A PAM system can maintain a database that defines, for each reason code, a normal amount of time that is required to accomplish the task associated with the reason code. The PAM system can then monitor an elapsed time over which the admin credentials are checked out to an administrator to determine whether the elapsed time exceeds the corresponding normal amount of time. If the elapsed time exceeds the normal amount, the PAM system can take appropriate action to mitigate any potential harm to the server.

Owner:QUEST SOFTWARE INC

Atomizing cleaning head for overhead transmission line

ActiveCN104226623AEfficient cleaning functionEasy to replaceCleaning using liquidsApparatus for overhead lines/cablesComputer modulePotential harm

The invention discloses an atomizing cleaning head for an overhead transmission line. The atomizing cleaning head comprises a cylindrical member formed by connecting a plurality of module structures, wherein two sealing elements which are arranged longitudinally in parallel are fixed on the middle part of the inner cavity of the cylindrical member; a hole through which the transmission line needing to be cleaned passes and which is hermetically formed in the transmission line in a sleeving manner is formed in the center of each sealing element; a cavity is formed between the two sealing elements; a plurality of atomizing nozzles which are communicated to the outside of the cylindrical member are arranged along the circumferential direction of the cavity; a recycling nozzle which is communicated to the outside of the cylindrical member is arranged at the bottom of the cavity; compression walking mechanisms which can be compressed onto the transmission line and can move along the transmission line are arranged in the inner cavities at the two ends of the cylindrical member. Through adoption of a modular structural design form, the atomizing cleaning head is simple in overall structure, is reliable, is convenient to replace, and is low in manufacturing cost; during cleaning, the atomizing cleaning head is not in direct physical contact with the transmission line, so that potential damage to the surface of the transmission line is avoided, residual cleaning liquid can be recycled while atomizing cleaning is realized, and potential harm to the environment is avoided.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Manufacturing method of cigarette inside lining direct plating laser paper

InactiveCN101037852AReduce dosageEliminate hazardsPaper coatingPhysical paper treatmentLymphatic SpreadEngineering

A method for manufacturing a direct plating lined laser paper of cigarettes is disclosed, which main technological process comprises the steps of coating the base paper surface with a coating layer, laser molding the base paper after the coating, then aluminum plating the base paper, and then brushing and coating a layer to obtain said direct plating lined laser paper of cigarettes. The present invention simplifies the technological process by taking out adhesive and thin film in a metastasis process, and then saves the using amount of metal aluminum in contrast to aluminum foil compound, and lowers the energy consumption and manufacturing cost; furthermore, eliminates the potential harm of residual additive of the original paint to environment and human, by utilizing waterborne coatings.

Owner:湖北盟科纸业有限公司

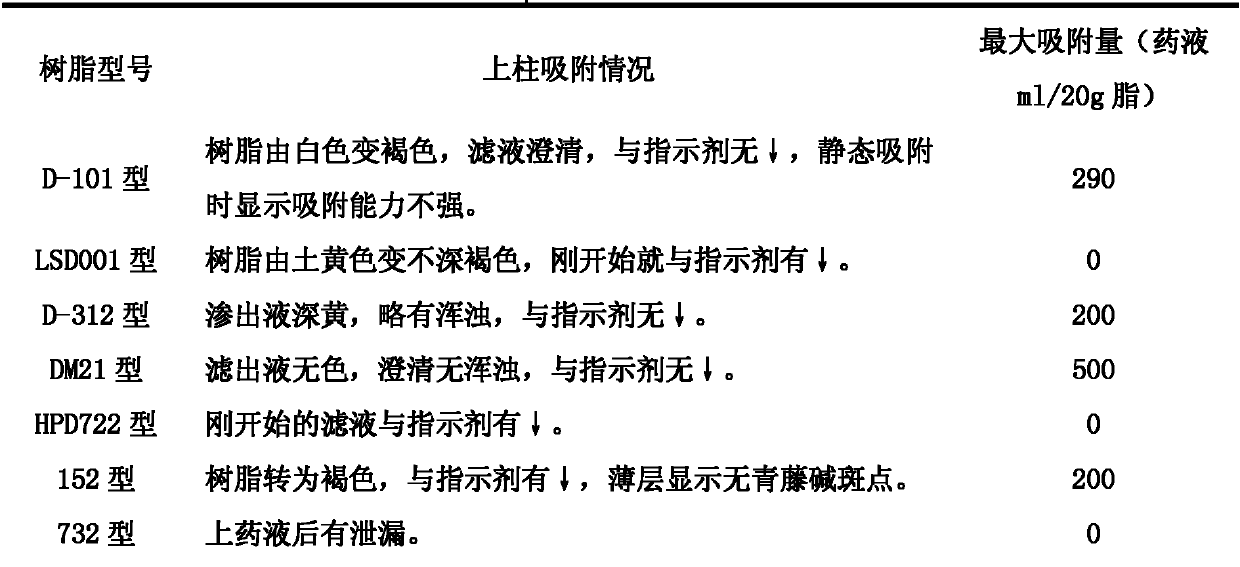

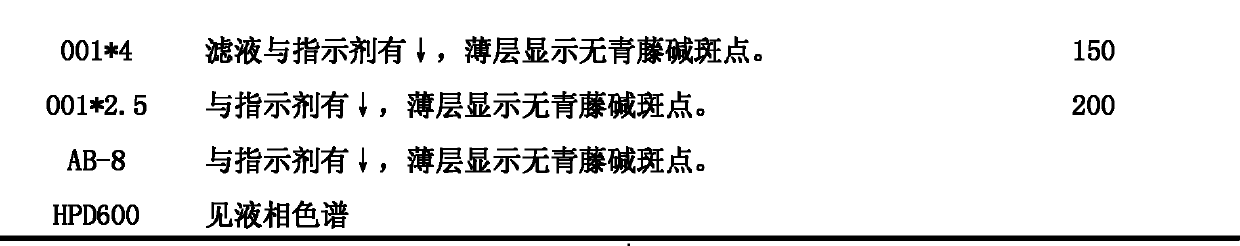

Method for preparing sinomenine hydrochloride by using non-organic solvent

The invention provides a preparation method of sinomenine hydrochloride. The method comprises the steps of: A) extraction: wetting caulis sinomenii coarse powder by using hydrochloric acid (HCl), installing a percolator, adding HCl for impregnation and percolation to obtain percolate; B) eluting treated cation exchange resin or 152 resin on the percolate by using ammonia water-ethanol solution or HCl with concentration being 3-10 percent, desalting, condensing and drying to obtain sinomenine hydrochloride crude products; and C) taking the sinomenine hydrochloride crude products, heating the crude products in ethanol or purified water for back flowing, condensing filtrate, cooling, crystallizing, filtering and using ethanol to wash a filter cake to obtain the sinomenine hydrochloride. Since the method adopts an absorbing process through the cation exchange resin or large-pore absorbing resin to replace the traditional extraction process through high-toxicity benzene and chloroform, the extraction rate is high, the method is simpler and convenient to operate, the harm and the pollution caused by high quantity of high-toxicity organic solvent to operator health and the environment can be avoided, the treatment process of the organic solvent is reduced, the environmental protection is further facilitated, the investment in environmental protection facilities of a factory is reduced and the environmental-friendly production is facilitated. The sinomenine hydrochloride prepared by adopting the method through extraction and separation can be used as a raw material for pharmaceutical preparations, the purity is higher, solvent residue does not exists and the potential harm to human bodies is reduced.

Owner:HUNAN ZHENGQING PHARM GRP CO LTD +1

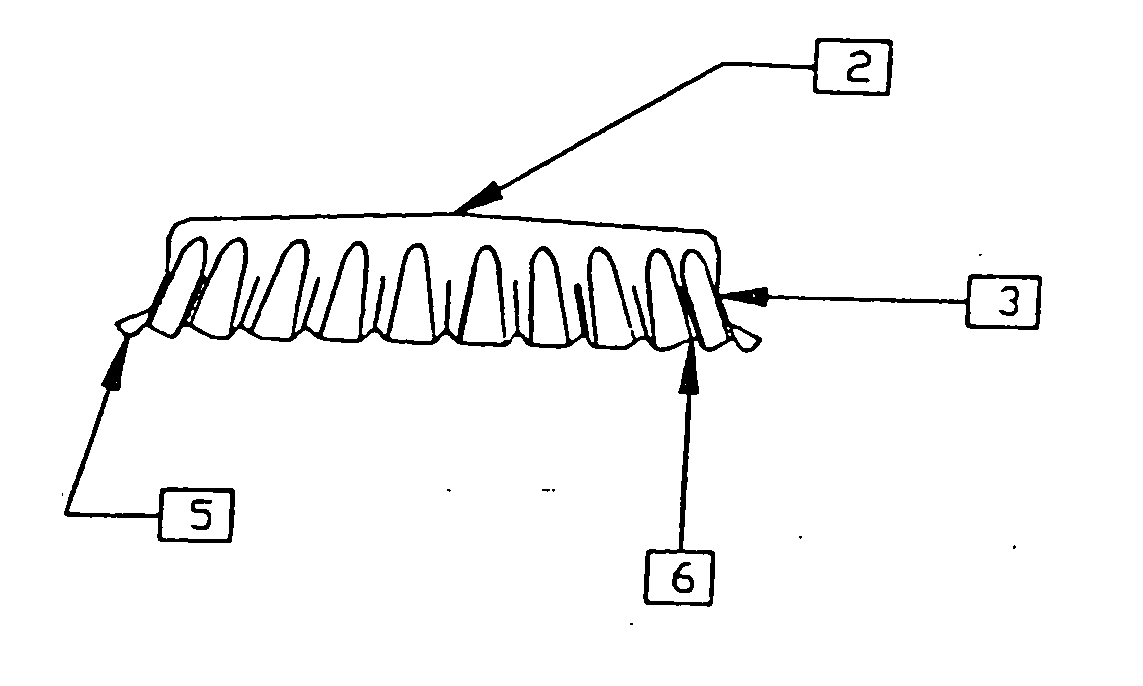

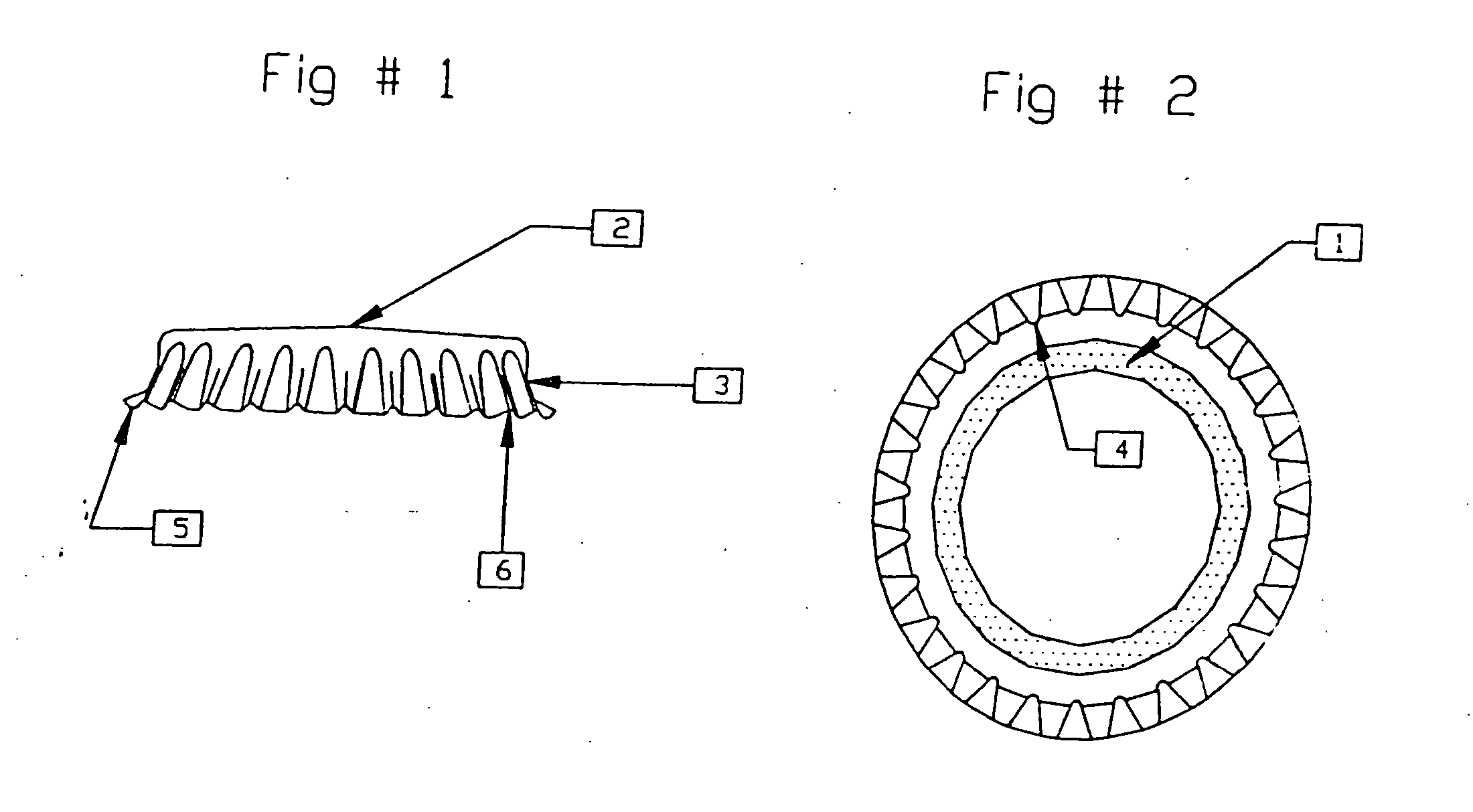

Crown closure

The present invention relates to a crown closure with 27 grooves that is opened or removed by applying a rotating force or a removal twist with a torque of from about 2 in lb to 9 in lb. The crown closure has a smaller contact surface between the grooves and the lip of the container that reduces friction and requires less force to open and therefore advantageously diminishes any potential harm the hands of those opening the closure.

Owner:TAPON CORONA DE C V

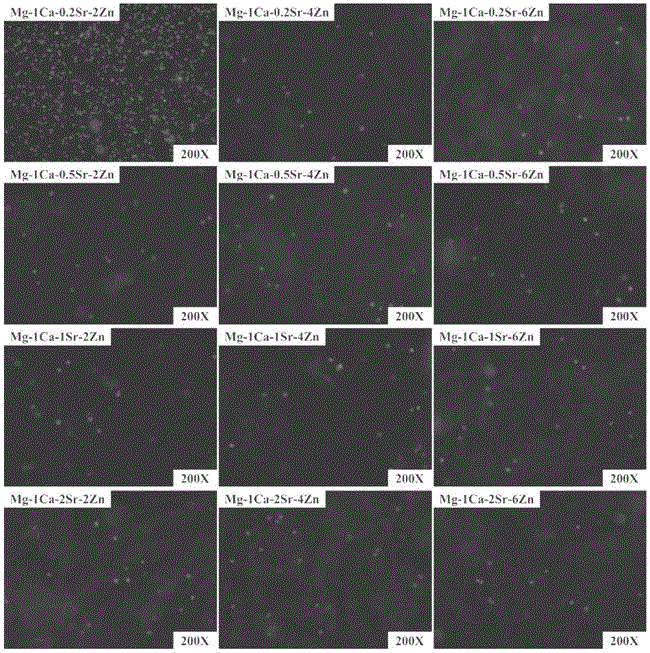

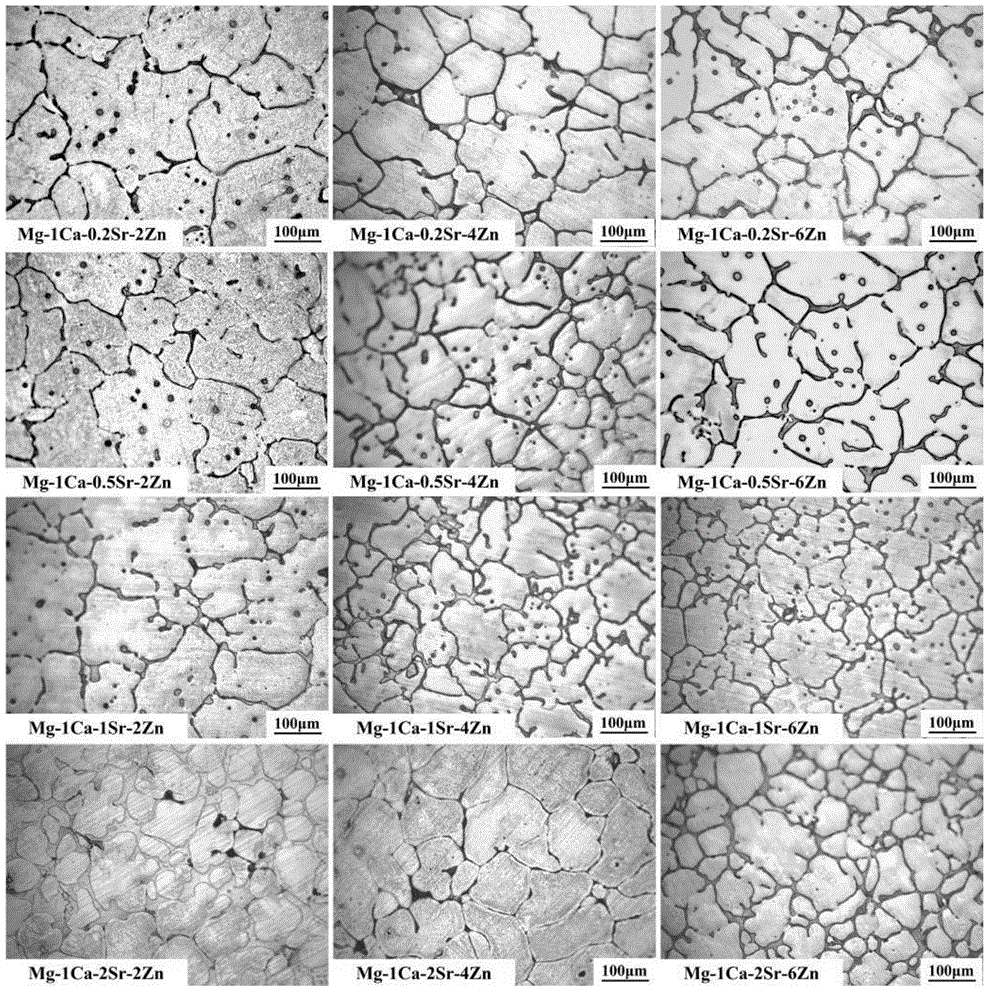

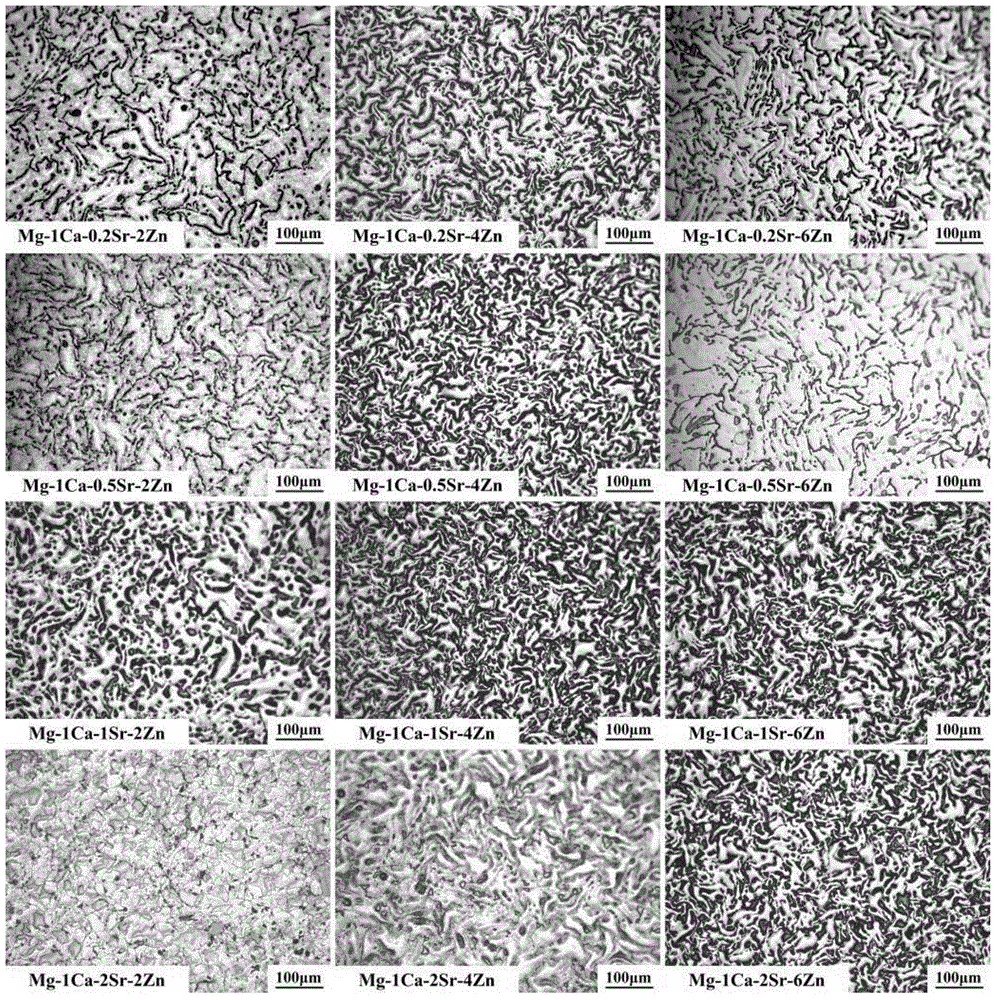

Mg-Ca-Sr-Zn magnesium alloy as well as preparation method and application thereof

The invention discloses an Mg-Ca-Sr-Zn magnesium alloy as well as a preparation method and application thereof. The Mg-Ca-Sr-Zn magnesium alloy consists of Mg, Ca, Sr and Zn in percentage by mass, wherein the content of Ca is 0-5% but not 0, the content of Sr is 0-5% but not 0, the content of Zn is 0-10% but not 0, and the remnants are Mg. Due to cooperation of component design and preparation process, the purposes of conditioning and controlling the mechanical property and the decomposition velocity of medical implants can be achieved, optimal mechanical property and corrosion resistance can be achieved, relatively good biocompatibility can be achieved, the Mg-Ca-Sr-Zn magnesium alloy has the main characteristic of relatively high cell survival rate, relatively high ALP activity and good erythrocyte and hemoglobin compatibility, and the cell survival rate is not remarkably reduced along with the culture time; metal elements essential for human bodies are adopted, no harmful element or element with potential harm is used, and the alloying element Sr can promote osteogenesis and inhibit bone resorption, so that along with decomposition of the Mg-Ca-Sr-Zn magnesium alloy, tissue heal can be promoted while Sr is partially released.

Owner:PEKING UNIV

Decomposition catalyst and method for decomposing hydrogen peroxide in epoxidation reaction product through same

ActiveCN106140186AEliminates potential hazards of distillation separationsImprove securityOrganic chemistryWaterDistillationDecomposition

A decomposition catalyst is characterized by being prepared from, by mass, 1-20% of IV B-metallic oxide, 1-20% of VI B-metallic oxide, 1-20% of IB B-metallic oxide and 40-97% of III A-metallic oxide. By means of the catalyst, most part of hydrogen peroxide left in an epoxidation reaction product of 3-chloropropene and hydrogen peroxide is decomposed before distillation separation, potential harm of the excessive content of hydrogen peroxide in the epoxidation reaction product to the subsequent distillation separation process is effectively eliminated, and safety of producing epoxy chloropropane through epoxidation reaction of 3-chloropropene and hydrogen peroxide is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

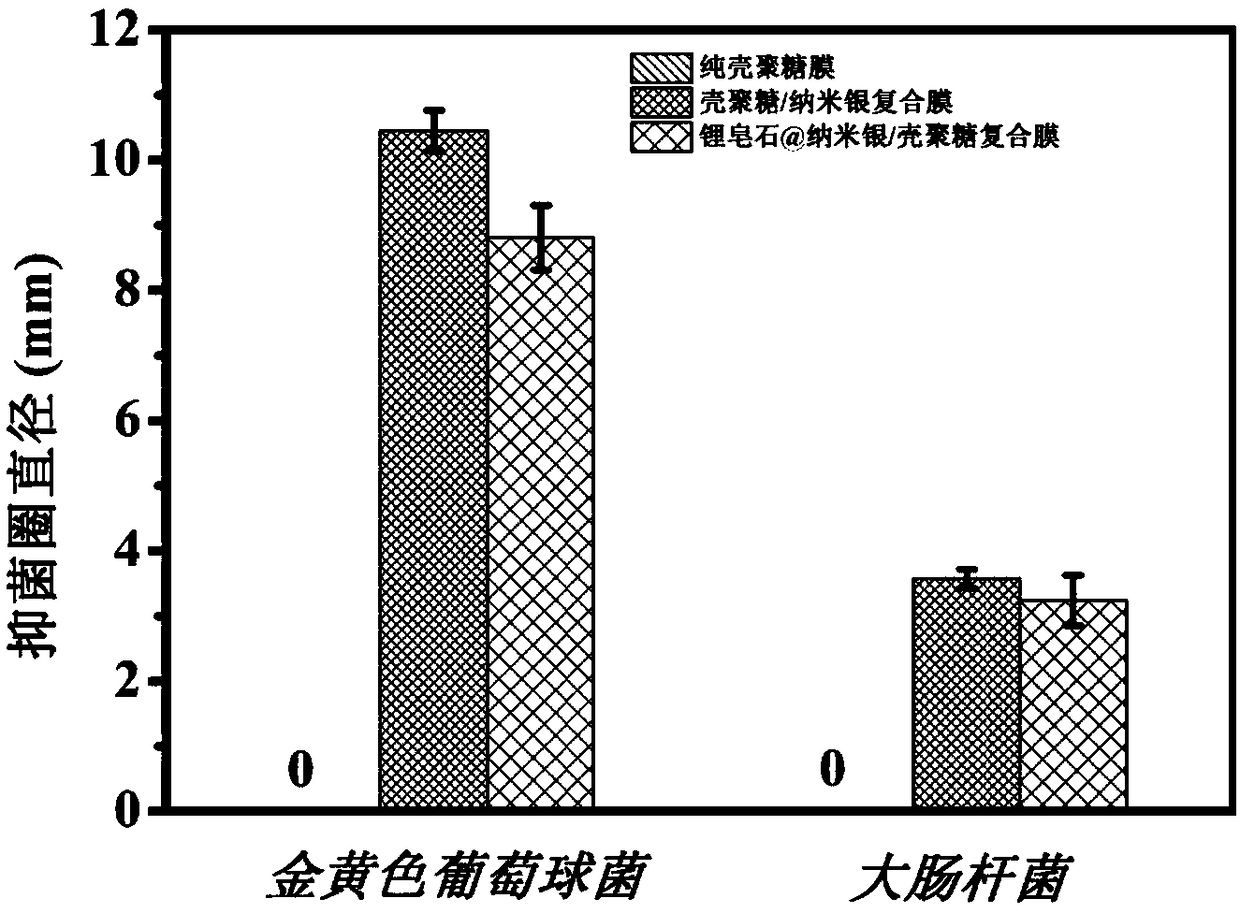

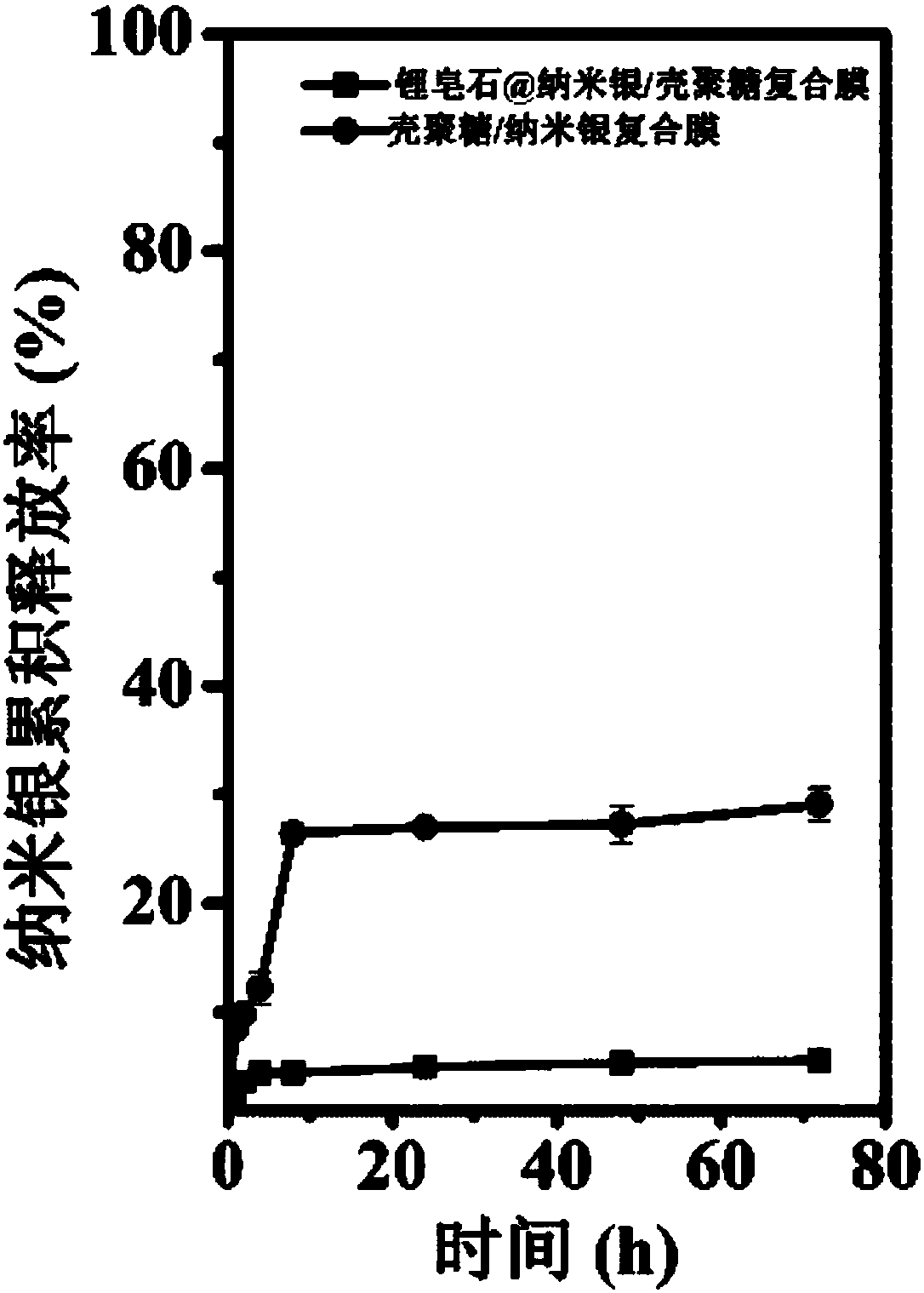

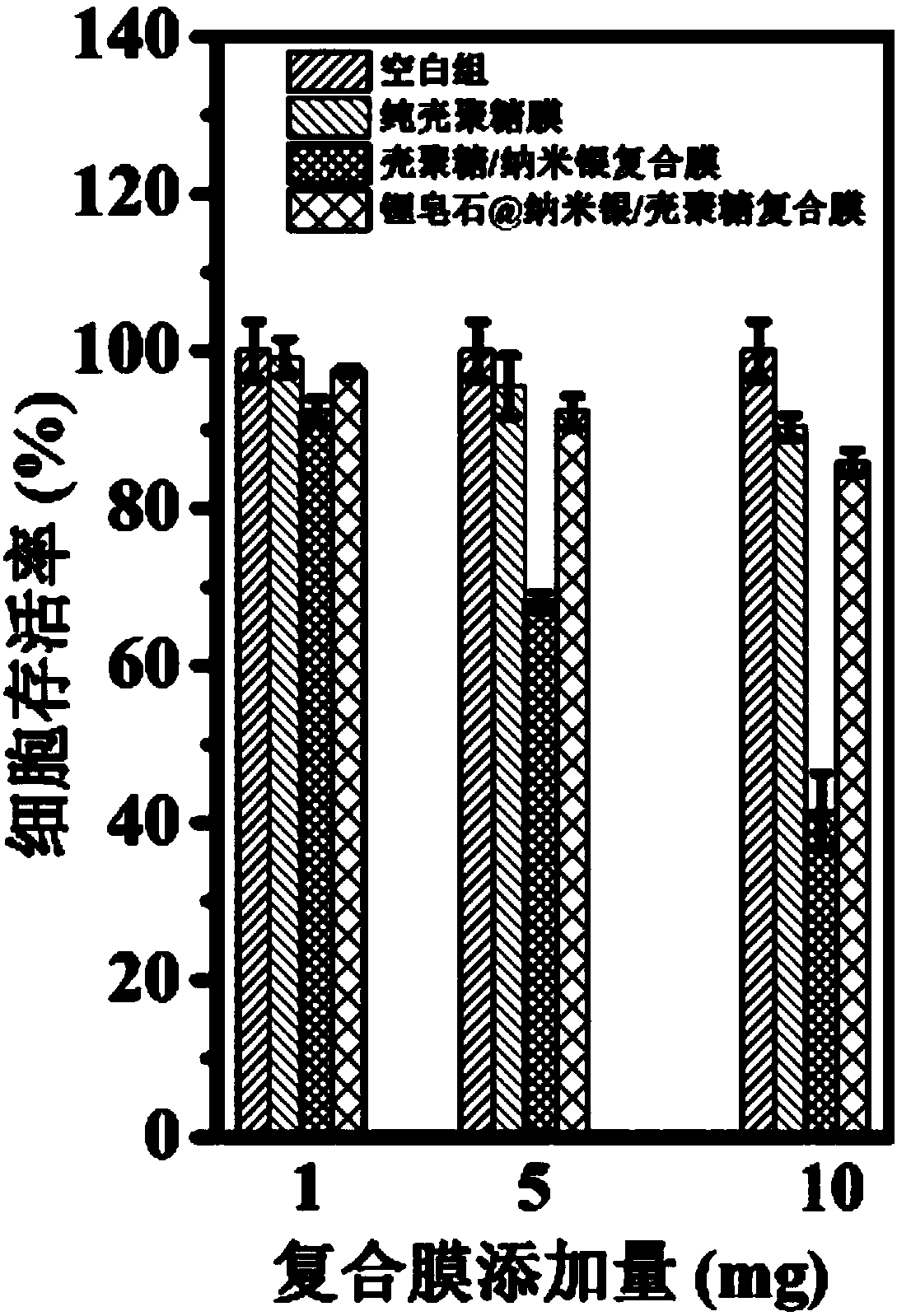

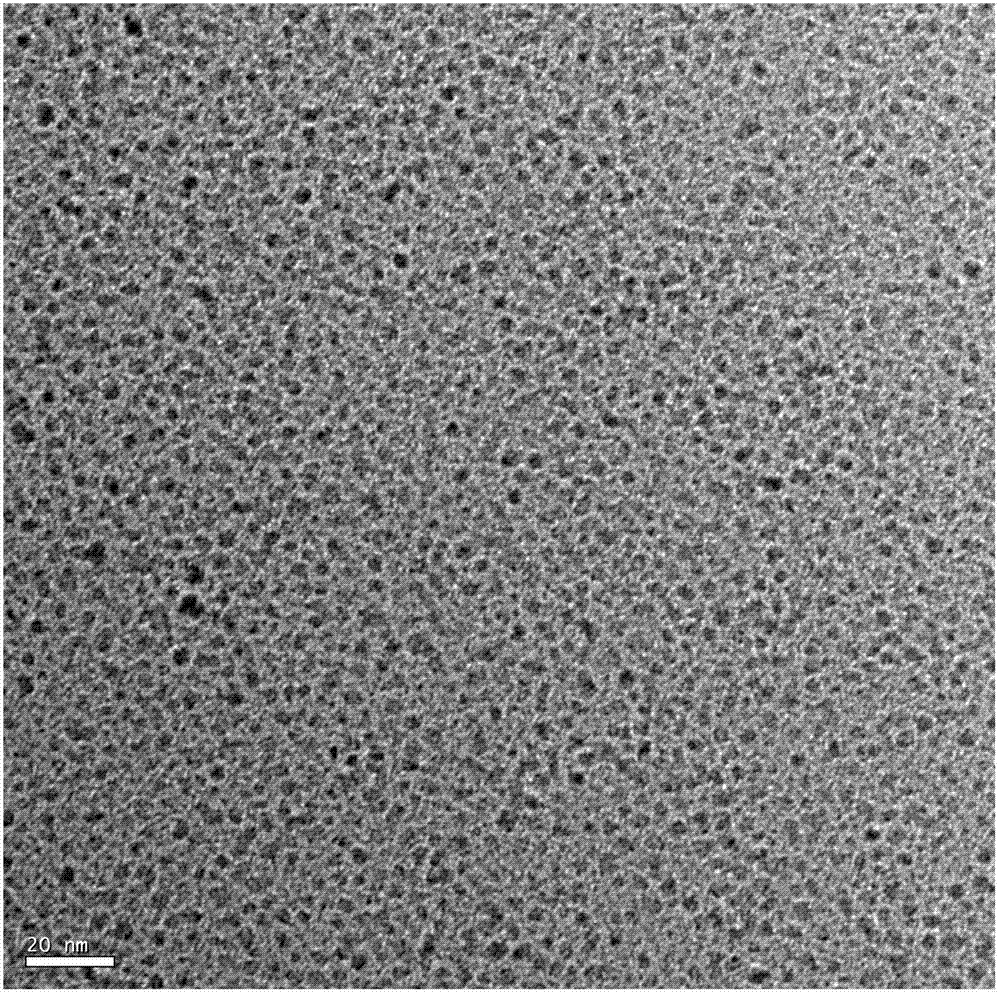

Hectorite immobilized nano silver/chitosan antibacterial composite membrane for food package, and preparation method and application thereof

The invention discloses a hectorite immobilized nano silver / chitosan antibacterial composite membrane for food package, and a preparation method and application thereof. According to the preparation method, chitosan quaternary ammonium salt is used as a reducing agent to prepare nano silver, the hectorite is used as a template to fix nano silver, so as to prepare a nano silver composite antibacterial agent; then the chitosan is used as a film substance, the hectorite is used as a membrane performance enhancer, glycerol is used as a plasticizer, the chitosan, the hectorite and the glycerol aremixed with the nano silver composite antibacterial agent so as to prepare the hectorite immobilized nano silver / chitosan antibacterial composite membrane for food package. According to the hectorite immobilized nano silver / chitosan antibacterial composite membrane for food package, the release proportion of nano silver is 1-8wt%. When the hectorite immobilized nano silver / chitosan antibacterial composite membrane for food package is applied to food package, nano silver particles for resisting bacteria are not leaked or go into food, so that the toxicity of the nano silver in food application is lowered remarkably, and the potential harm of the nano silver to human body is lowered.

Owner:SOUTH CHINA UNIV OF TECH

Cooling method and system for high temperature proton exchange membrane fuel cell battery

ActiveCN101212059AReduce energy consumptionTo achieve the purpose of evaporative heat transferFuel cell heat exchangeSolid electrolyte fuel cellsEvaporationEngineering

The invention relates to a fuel cell, in particular to a method applicable to cooling a fuel cell stack having a high-temperature proton exchange membrane and a system thereof. Under normal pressure, water with temperature more than 90 DEG C while less than 100 DGE C is filled in a cooling cavity of the fuel cell stack having the proton exchange membrane; generated heat of water and the cell is used for heat exchange, and the water is gasified to bring away waste heat of the battery. The system adopts the cooling method of water evaporation, which takes water as cooling medium and applies the latent heat of evaporation required in the process of water phase change to bring away the waste heat of the cell. Compared with the traditional fuel cell having a proton exchange membrane operating under 80 DEG C, the latent heat process of water cycle can greatly increase the heat transfer efficiency compared with the process of sensible heat transfer. By adjusting the output power and automatic coupling of the amount of cooled water, the target of evaporation and heat transfer is reached. Compared with the system which takes ethanol and other organics as evaporation and cooling medium, the invention has no potential harm on important components such as an electrode and the proton exchange membrane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for recycling titanium from sulfuric acid method titanium white acidolysis residue

The invention discloses a method for recycling titanium from sulfuric acid method titanium white acidolysis residue. The method comprises the following steps of: (1) washing the acidolysis residue produced when titanium white powder is produced by using a sulfuric acid method, and removing fine silt from the residue by using a cyclone; (2) preparing residue pulp of which the concentration is 20 to 30 percent, and regulating the pH of the residue pulp by using oxalic acid, wherein the final pH value is 6 to 7; and (3) adding No.2 oil serving as a foaming agent and ROB serving as a collecting agent, controlling the temperature to be between 20 and 40 DEG C, performing two-stage flotation to obtain titanium ore, drying, and thus obtaining a raw material for producing the titanium white powder, wherein the grade of the recovered titanium ore is more than 46 percent, and the recovery rate is more than 85 percent. The method has the advantages of recovering the valuable component in the residue, eliminating potential harm of the stored original acidolysis residue to the environment, protecting the environment and bringing huge social benefits.

Owner:云南昆欧科技有限责任公司

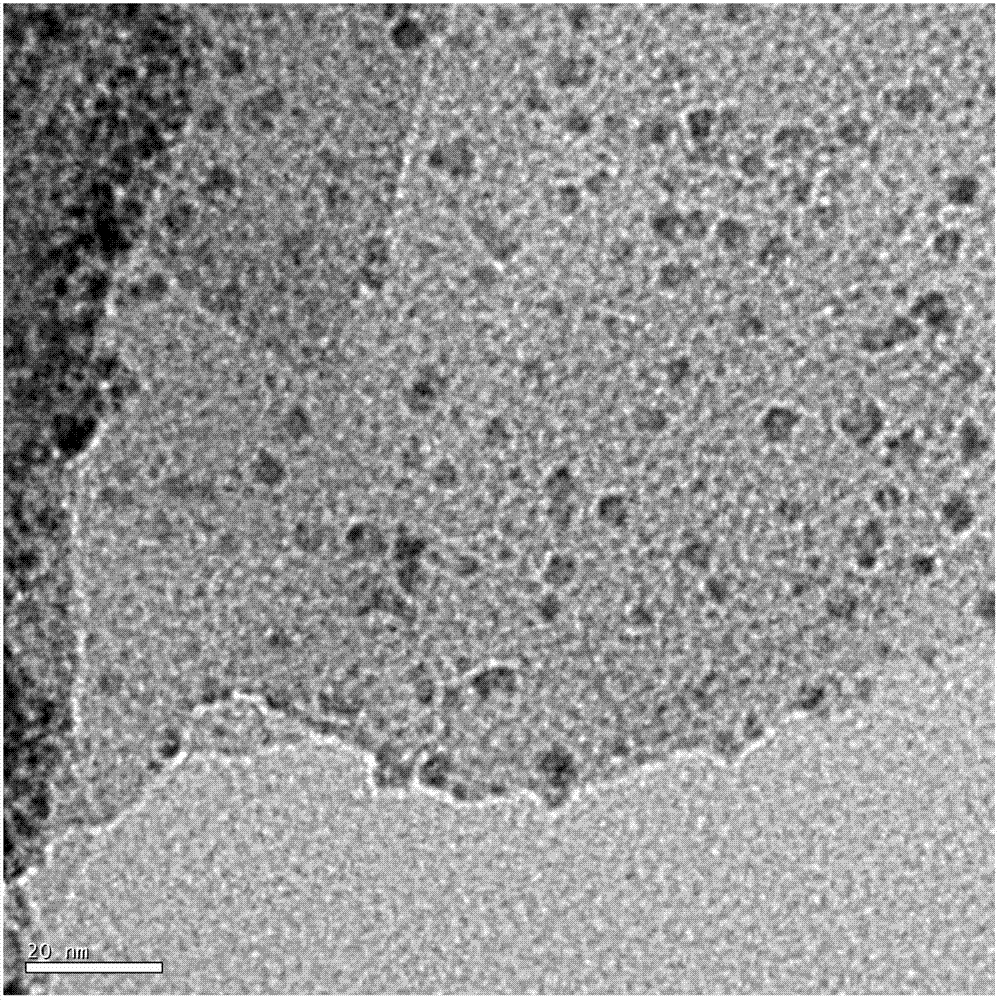

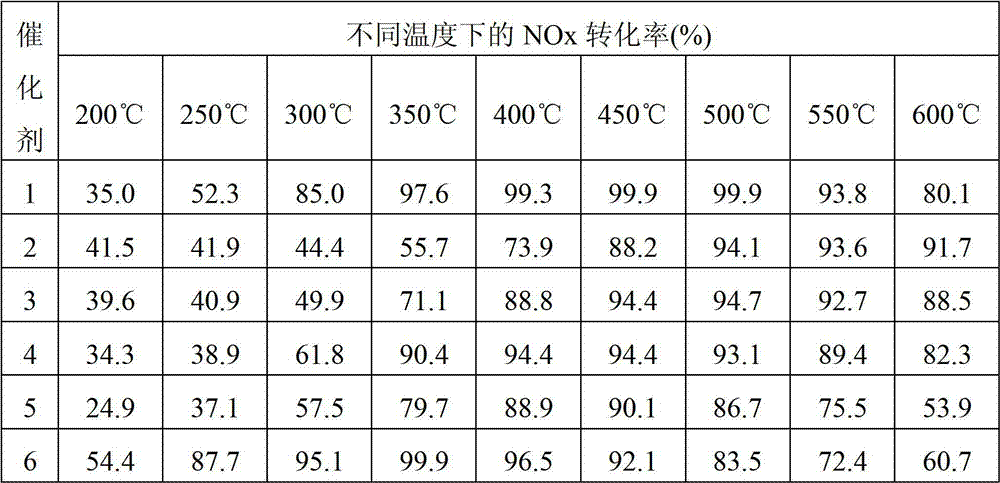

Cerium/molecular sieve catalyst used for selective catalytic reduction of nitrogen oxides and preparation method thereof

ActiveCN102814192ANon-toxicRaw materials are readily availableMolecular sieve catalystsDispersed particle separationEcological environmentSynthesis methods

The invention discloses a cerium / molecular sieve catalyst used for selective catalytic reduction of nitrogen oxides and a preparation method thereof. The invention overcomes the technical problems of a narrow operating temperature window, poor selectivity at a high temperature and potential harm to the ecological environment and human health of a vanadium-based catalyst system. The catalyst provided by the invention comprises a cerium oxide nanoparticle and a molecular sieve, wherein the molecular formula of the cerium oxide nanoparticle is CeO2, the molecular sieve is MCM56 (n(SiO2) / n(Al2O3)=15-30), and the mass ratio of the cerium oxide nanoparticle to the molecular sieve is 1:19 to 3:1. The invention also provides a preparation method for the catalyst. The preparation method comprises the following steps: synthesizing the cerium oxide nanoparticle by using a hydro-thermal synthesis method; and loading the cerium oxide nanoparticle on the molecular sieve MCM56 for removal of nitrogen oxides through NH3-SCR. The supported catalyst prepared by using the method has the advantages of uniformly dispersed active components, high activity, a wide temperature range and good stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

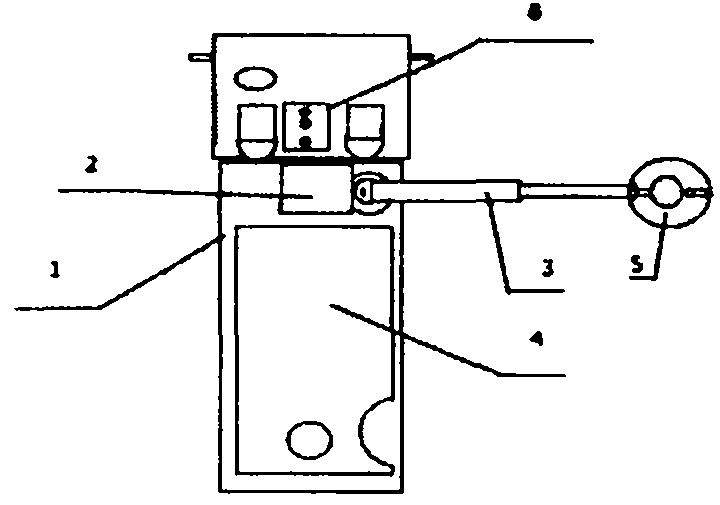

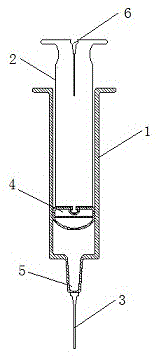

Disposable syringe

InactiveCN105597195ASimple structureEasy to produceInfusion syringesMedical devicesSyringe needlePotential harm

The invention provides a disposable syringe. The disposable syringe comprises a sleeve, a push rod, a syringe needle and a piston, wherein the piston is connected to the lower end of the push rod, and is arranged in the sleeve together with the push rod in a sleeving way; the front end of the sleeve protrudes to form a medicinal liquid supply port; the syringe needle is separately combined with the medicinal liquid supply port; the bottom of the push rod is provided with a cavity of which the shape and size correspond to the syringe needle. After use, the syringe needle can be pressed into the corresponding cavity in the bottom of the push rod, so that the syringe needle is prevented from being taken out easily, repeated use of the disposable syringe can be prevented effectively, and the health of patients is protected effectively; meanwhile, potential harm due to random placement of the syringe needle after use is avoided.

Owner:黄沛敏

Method for preserving ginseng or American ginseng

InactiveCN102018265AHigh hardnessReduce respirationClimate change adaptationFood preservationAMERICAN GINSENG ROOTPreservative

The invention relates to a method for preserving ginseng or American ginseng, which belongs to the field of the preservation of plants and overcomes the defects of harm or potential harm caused by the preservation of the ginseng or the American ginseng by using the conventional preservative to a human body and great loss of ginsenoside serving as a medicinal active ingredient. The method comprises the following steps of: cleaning fresh ginseng or American ginseng, putting the cleaned ginseng or American ginseng into almost boiling water for soaking for a short time, fishing the soaked ginseng or American ginseng out and cooling in the air; adding the cooled ginseng or American ginseng into preservative liquid, namely solution of chitosan liquor or solution of tea polyphenol liquor or solution of lysozyme liquor serving as a preservative for soaking, fishing the soaked ginseng or American ginseng out and draining the preservative liquid; and packaging the ginseng or the American ginseng, injecting the preservative into a ginseng or American ginseng bag and sealing the bag. The method has the advantages of avoiding harm to the human body, keeping high quality of ginseng and reducing the loss of ginsenoside in the storing process.

Owner:JILIN AGRICULTURAL UNIV

Processing technic of convenient potato food

The invention relates to a processing technic of potato convenient food, comprising the following steps of: selecting and storing, freezing by steps, peeling off and unfreezing, precision processing, squeezing, cutting off, air-curing, washing, steaming, inspecting and packaging. Prepared by cooked potato, the convenient food is convenient to eat and carry, and fresh in taste, can be added with various flavors as needed, has good nutrition and low cost, can be fried, roasted, boiled and stewed as a primary machining raw material and can be eaten hot or cold at once when opened. The invention overcomes shortcomings of traditional fried potato food, maintains nutrient components of potato overall, avoids potential harms of fried food to human body and is better suitable for fast speed way of life at present.

Owner:尚义县圣农蔬菜加工有限公司

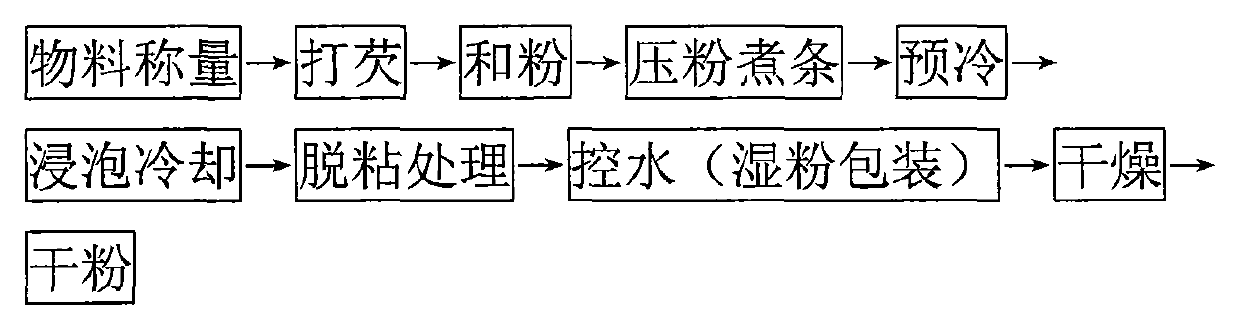

Alum-free potato type starch vermicelli and preparation method thereof

InactiveCN104187500AAvoid harmSolve the problems you want to solveFood preparationPolysaccharide/gum food ingredientsFood additiveAluminum Ion

The invention discloses alum-free potato type starch vermicelli and a preparation method thereof. The potato type starch vermicelli is processed by taking potato type starch as a main raw material and selecting artemisia sphaerocephala krasch seed glue which is a natural food additive to replace alum and serve as an additive by virtue of the processes of mixing, water adding, blending, pressing and cooking vermicelli, precooling, soaking cooling, unsticking treatment, water control, drying and the like. The preparation method is simple; alum is not added, so that potential harm, caused by aluminum ions, to a human body is avoided; the problems in long-term vermicelli processing are solved; the preparation method is wide in application range and can be suitable for vermicelli production by potato starch, sweet potato starch and cassava starch.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Secure execution of unsecured apps on a device

ActiveUS8955142B2More secure for app downloading and executionMinimize damageDigital data processing detailsAnalogue secracy/subscription systemsOperational systemSecurity Measure

Devices are pre-deployed with an app security mechanism to ensure that apps that are downloaded onto the device do not cause data loss, data leakage, or other harm to the device. A user can start using the device and downloading apps in a conventional or typical manner and be assured that security measures are being taken to minimize potential harm for unsecured and secured apps. An app security enforcement layer or engine operates with, for example, a Type 2 hypervisor on the device, and ensures that any calls by the apps to the operating system of the device are generally safe. Measures such as enhancing or modifying the call, obfuscating the call, or terminating the app may be taken to protect the operating system. These actions are taken based on a policy that may be either interpreted or compiled by the enforcement engine with respect to app execution. The security measures are generally transparent to the user of the device.

Owner:BLUE CEDAR NETWORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com