Cerium/molecular sieve catalyst used for selective catalytic reduction of nitrogen oxides and preparation method thereof

A nitrogen oxide and selective catalysis technology, applied in the field of catalysis, can solve the problems of poor selectivity at high temperature, hazards to the ecological environment and human health, narrow operating temperature window, etc., and achieve the effect of easy coating, no poisonous effect, and simple use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

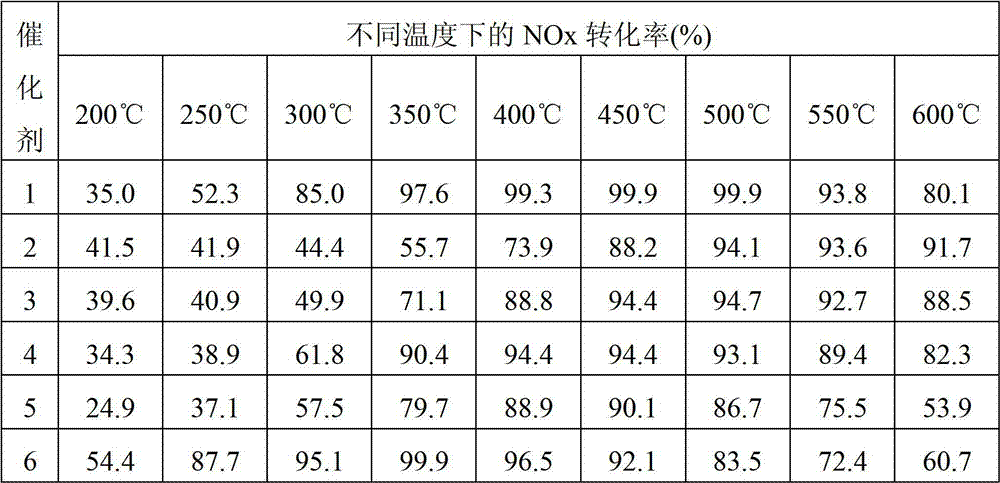

Embodiment 1

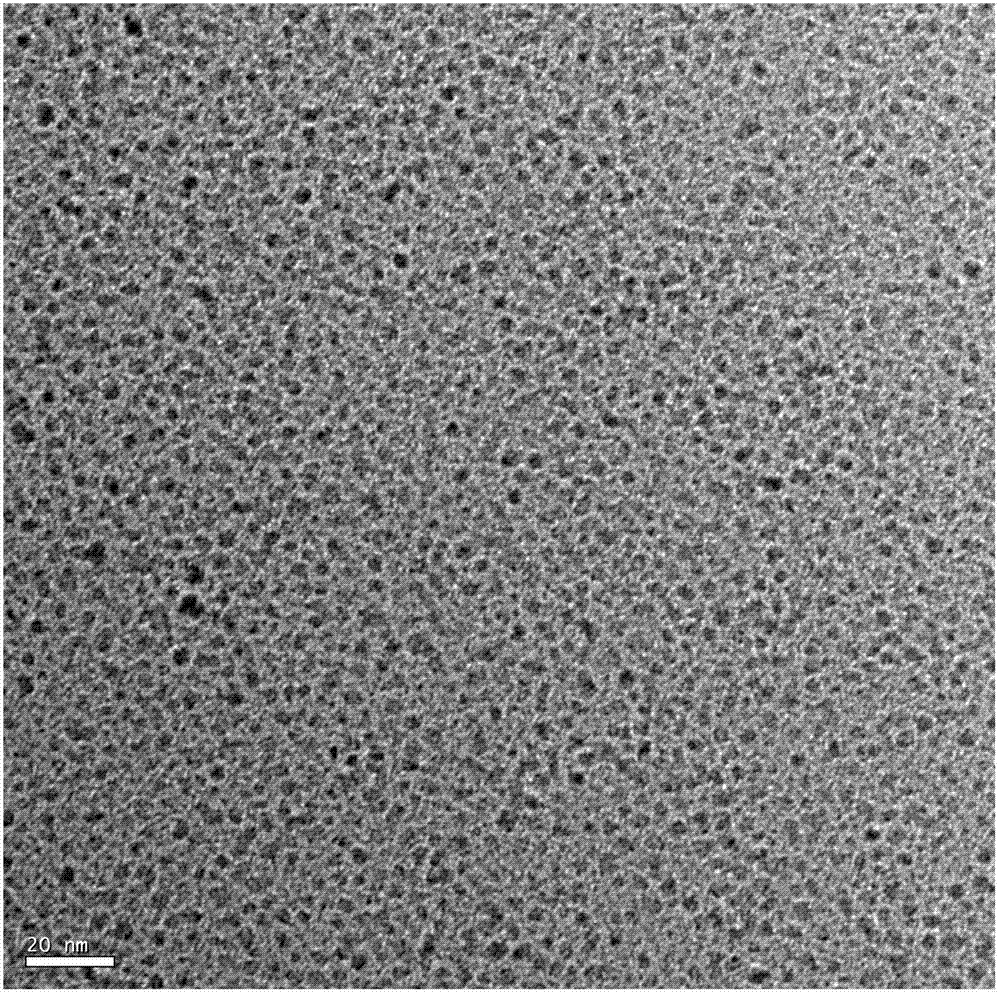

[0033] (1) Preparation of cerium oxide nanoparticles

[0034] Mix ethanol and oleic acid in a beaker, add NaOH solution, stir evenly, weigh cerium ammonium nitrate and dissolve it in water, add the above solution dropwise, transfer to the reaction kettle, and conduct a hydrothermal reaction at 120°C to obtain CeO 2 Nanoparticles;

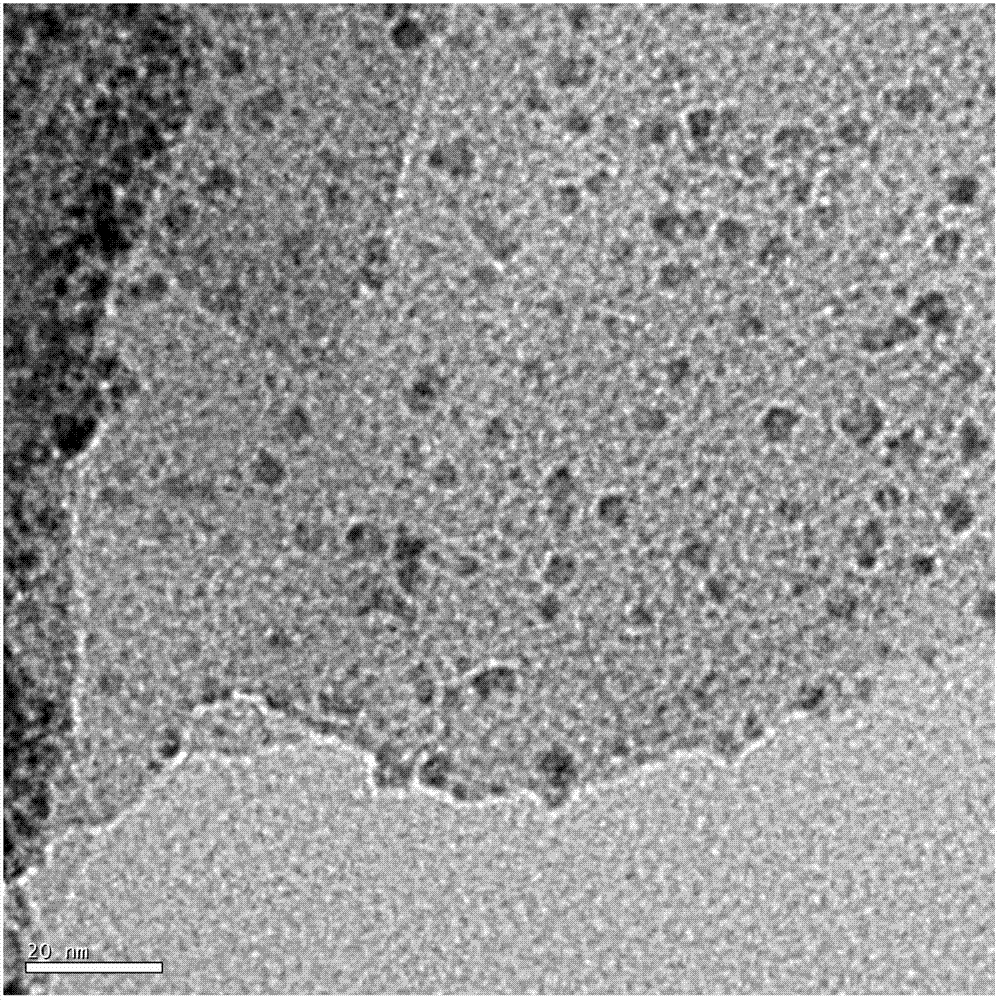

[0035] (2) Preparation of cerium / molecular sieve catalyst

[0036] Take by weighing 0.50g cerium oxide nanoparticles and disperse it in 15ml normal hexane, add 0.50g molecular sieve MCM56 (n(SiO 2 ) / n(Al 2 o 3 )=25), stirred for 1 day to make it uniform, heated at 50°C and stirred until the solution evaporated to dryness, dried the obtained sample at 100°C overnight, raised the temperature to 550°C at 1°C / min, and roasted in air for 1h to obtain A cerium / molecular sieve catalyst for nitrogen oxides, referred to as Catalyst 1. Finally, the catalyst is pressed into tablets, ground, and sieved to obtain 40-80 mesh particles for later use.

[0037...

Embodiment 2

[0040] (1) The preparation of cerium oxide nanoparticles is the same as in Example 1;

[0041] (2) Preparation of cerium / molecular sieve catalyst

[0042] Take by weighing 0.15g cerium oxide nanoparticles and disperse it in 15ml normal hexane, add 0.85g molecular sieve MCM56 (n(SiO 2 ) / n(Al 2 o 3 )=25), stirred for 1 day to make it uniform, heated at 50°C and stirred until the solution evaporated to dryness, dried the obtained sample at 100°C overnight, raised the temperature to 550°C at 1°C / min, and roasted in air for 1h to obtain A cerium / molecular sieve catalyst for nitrogen oxides, referred to as Catalyst 2. Finally, the catalyst is pressed into tablets, ground, and sieved to obtain 40-80 mesh particles for later use.

Embodiment 3

[0044] (1) The preparation of cerium oxide nanoparticles is the same as in Example 1;

[0045] (2) Preparation of cerium / molecular sieve catalyst

[0046] Weigh 0.25g cerium oxide nanoparticles and disperse it in 15ml normal hexane, add 0.75g molecular sieve MCM56 (n(SiO 2 ) / n(Al 2 o3 )=25), stirred for 1 day to make it uniform, heated at 50°C and stirred until the solution evaporated to dryness, dried the obtained sample at 100°C overnight, raised the temperature to 550°C at 1°C / min, and roasted in air for 1h to obtain A cerium / molecular sieve catalyst for nitrogen oxides, referred to as Catalyst 3. Finally, the catalyst is pressed into tablets, ground, and sieved to obtain 40-80 mesh particles for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com