Patents

Literature

1670results about "Physical paper treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly (vinyl alcohol) - based formaldehyde-free curable aqueous composition

A formaldehyde-free curable aqueous composition containing polyvinyl alcohol, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition may be used as a binder for non-woven products such as fiberglass insulation. The non-woven products are formed by contacting the formaldehyde-free curable aqueous composition with fibrous components and the mixture is cured to form a rigid thermoset polymer providing excellent strength and water resistance of the cured nonwoven product.

Owner:ARCLIN USA

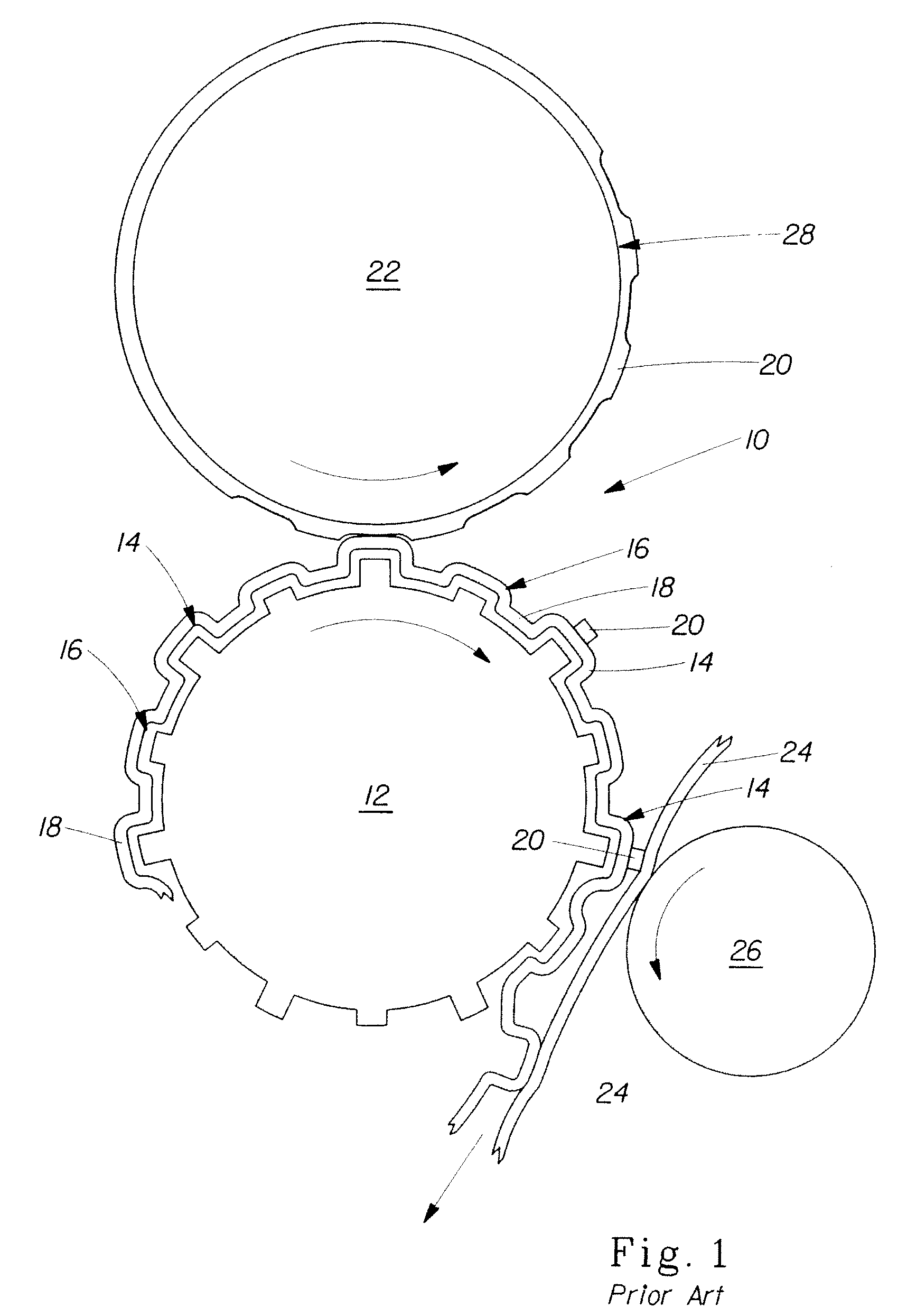

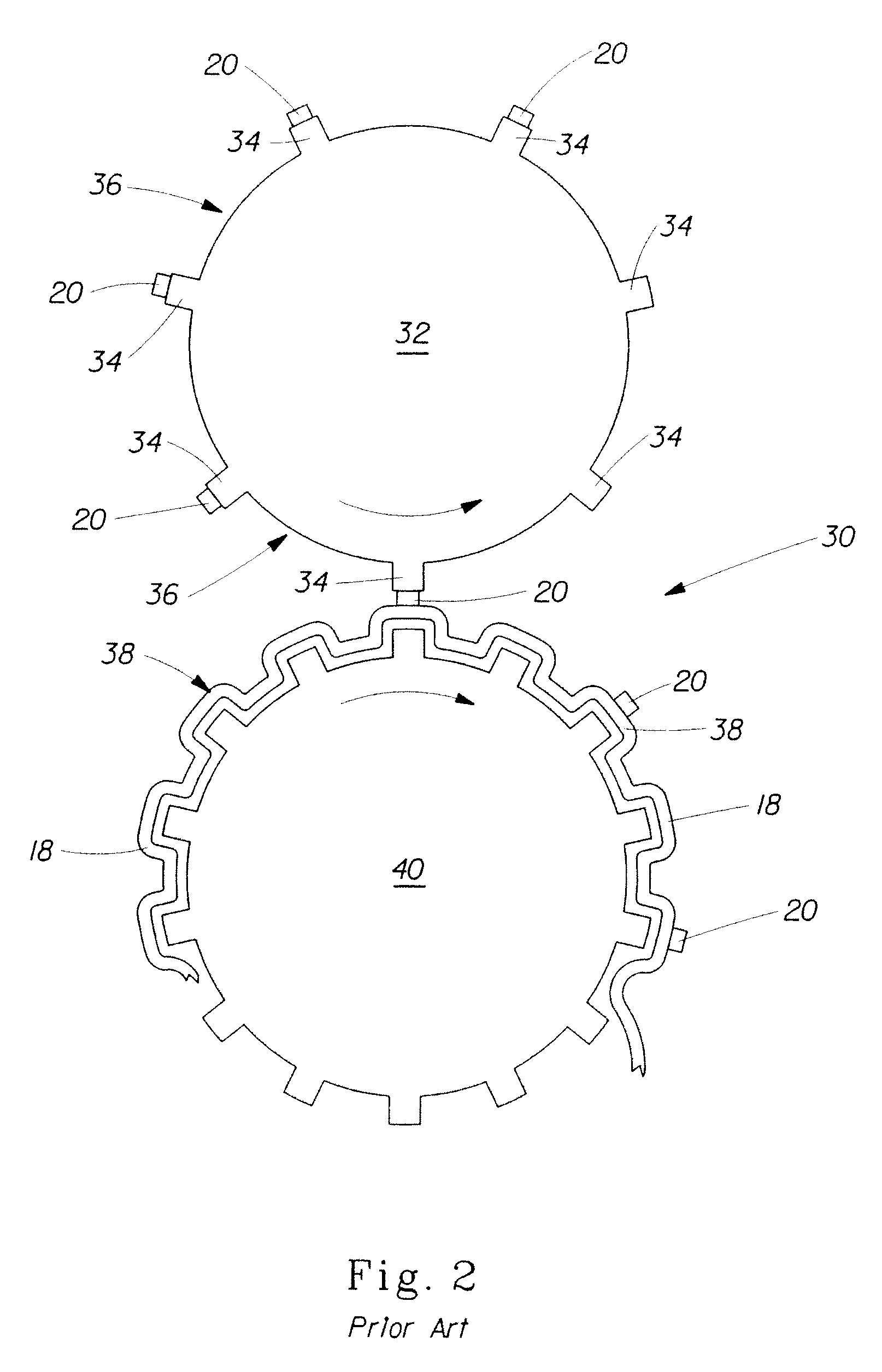

Nonwoven fabric for separator of non-aqueous electrolyte battery and non-aqueous electrolyte battery using the same

InactiveUS6200706B1Uniform and efficient productionImprove various performanceOrganic electrolyte cellsPaper/cardboardSurface roughnessEngineering

The object of the present invention is to provide a nonwoven fabric for separators of non-aqueous electrolyte batteries which is superior in adhesion to electrodes, causes no breakage of the separator and neither slippage nor space between electrode and the separator at the time of fabrication of battery, provides superior battery processability such as rollability with electrodes, causes no internal short-circuit due to contact between electrodes caused by shrinking or burning of the nonwoven fabric even when electrodes generate heat owing to external short-circuit, whereby ignition of the battery can be inhibited, has no pin holes and is superior in retention of electrolyte and penetration of electrolyte, and which can give non-aqueous electrolyte batteries superior in capacity, battery characteristics and battery storage characteristics. Specifically, the nonwoven fabric for separators of non-aqueous electrolyte batteries according to the present invention has a thickness non-uniformity index (Rpy) of 1000 mV or less or a center surface average roughness SRa of 6 mum or less in whole wavelength region as measured using a tracer method three-dimensional surface roughness meter.

Owner:MITSUBISHI PAPER MILLS LTD

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS20040250969A1Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

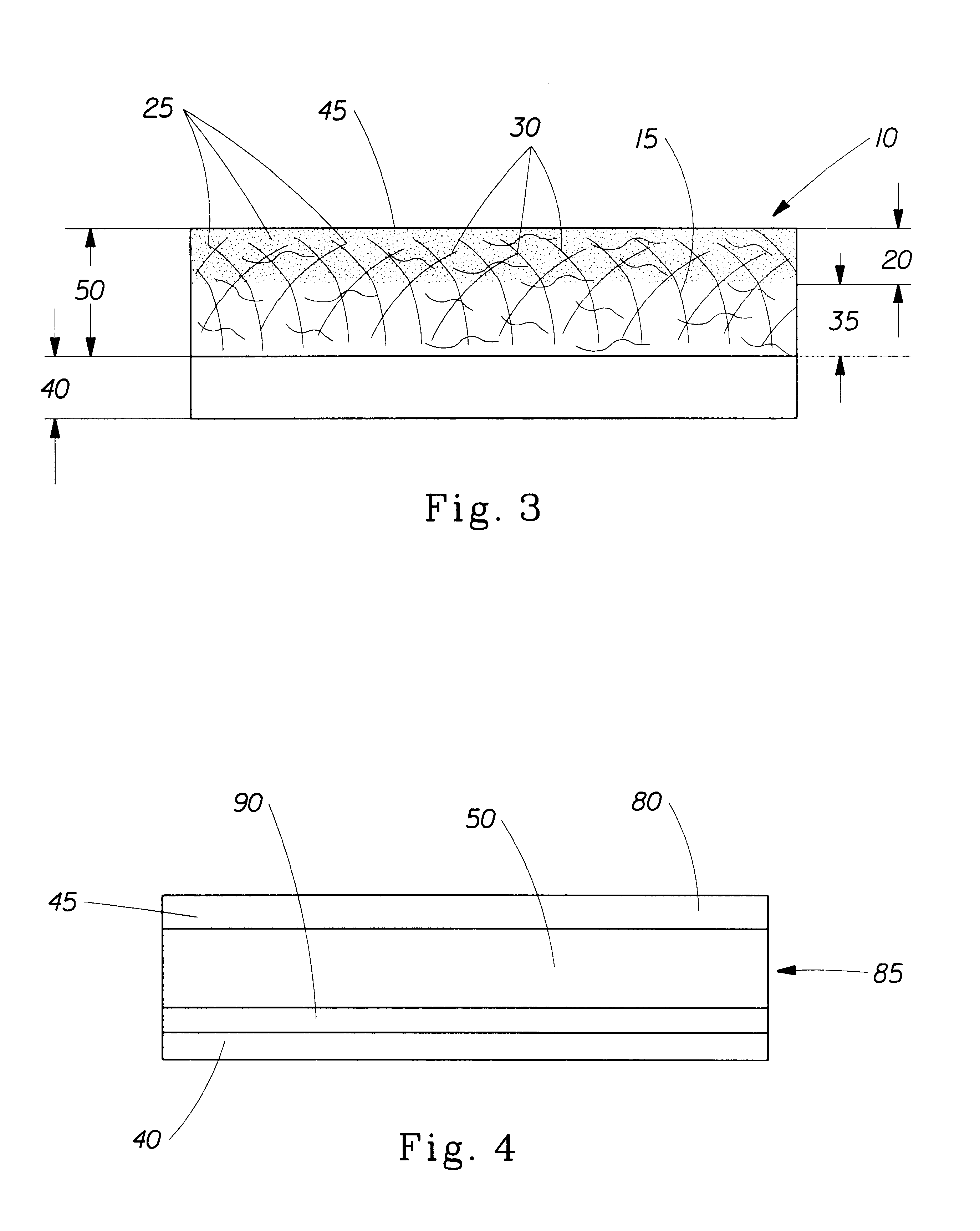

Continuous solid state web coating process and webs produced thereby

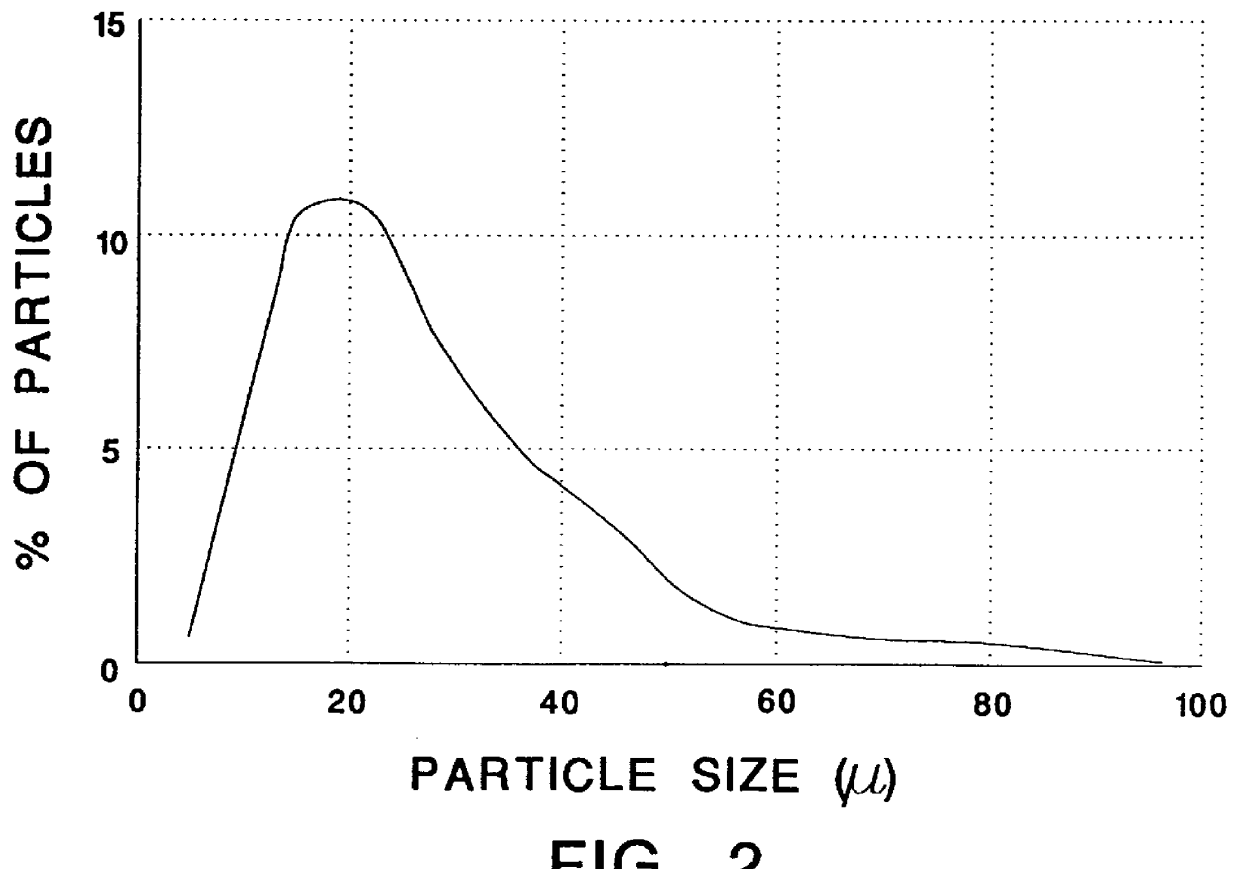

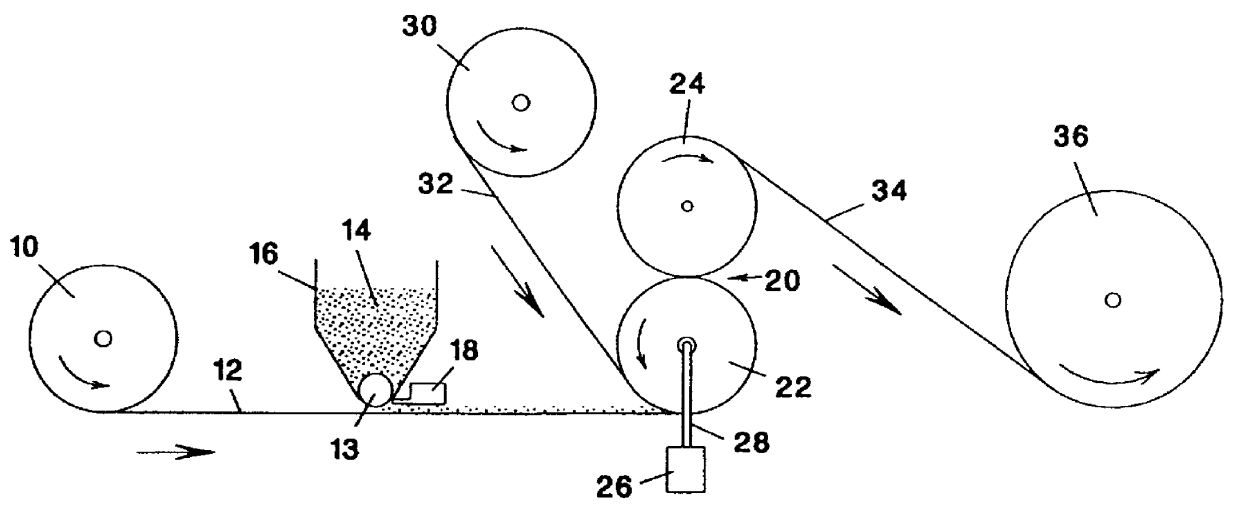

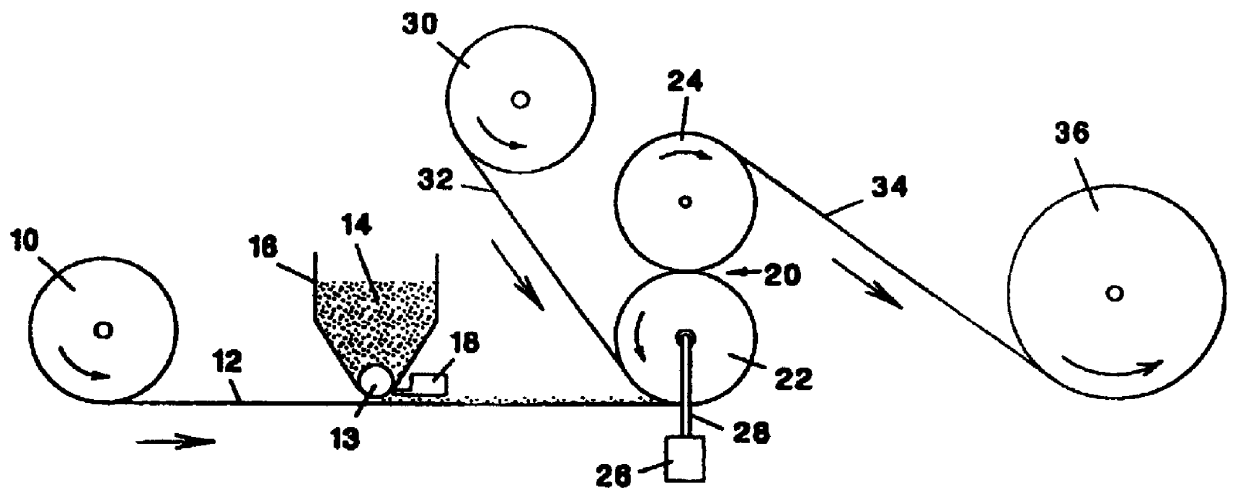

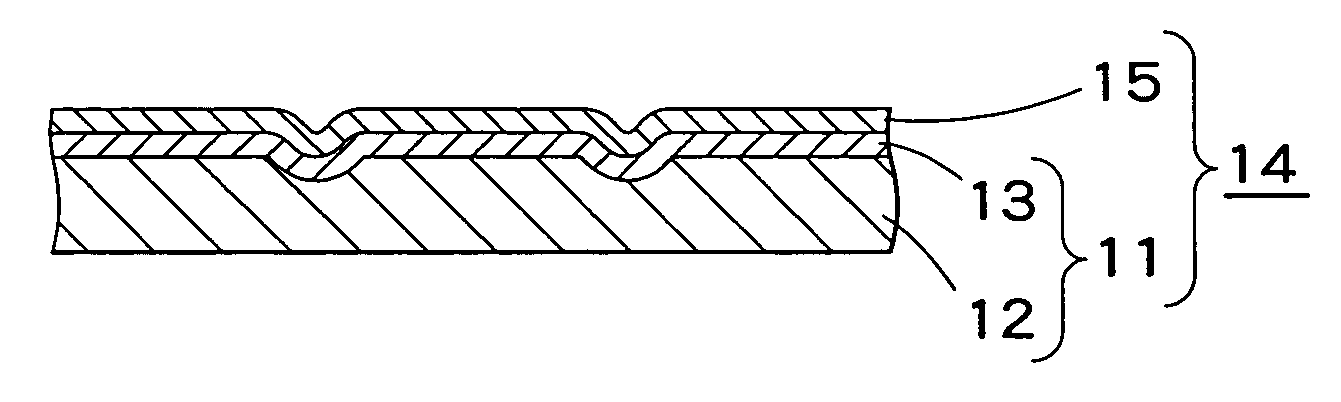

InactiveUS6077588AImprove cohesionLarge particle sizeNon-fibrous pulp additionInking apparatusParticulatesMetallurgy

One or more particulate active agents are fused to the surface of a substrate web by mixing the particulate agents with a particulate binder having a particle size not exceeding an average diameter of approximately 40 microns and coating the composite mixture onto the surface of the substrate. Thereafter, the coated substrate is heated to a temperature equal to or greater than the Vicat softening temperature of the binder and compressed within the nip of a pair of pressure rolls to achieve fusion. If desired, a top layer may be placed upon the coated composite prior to the compression step. Also disclosed are various products manufactured by the process.

Owner:KX TECH LLC (DW US)

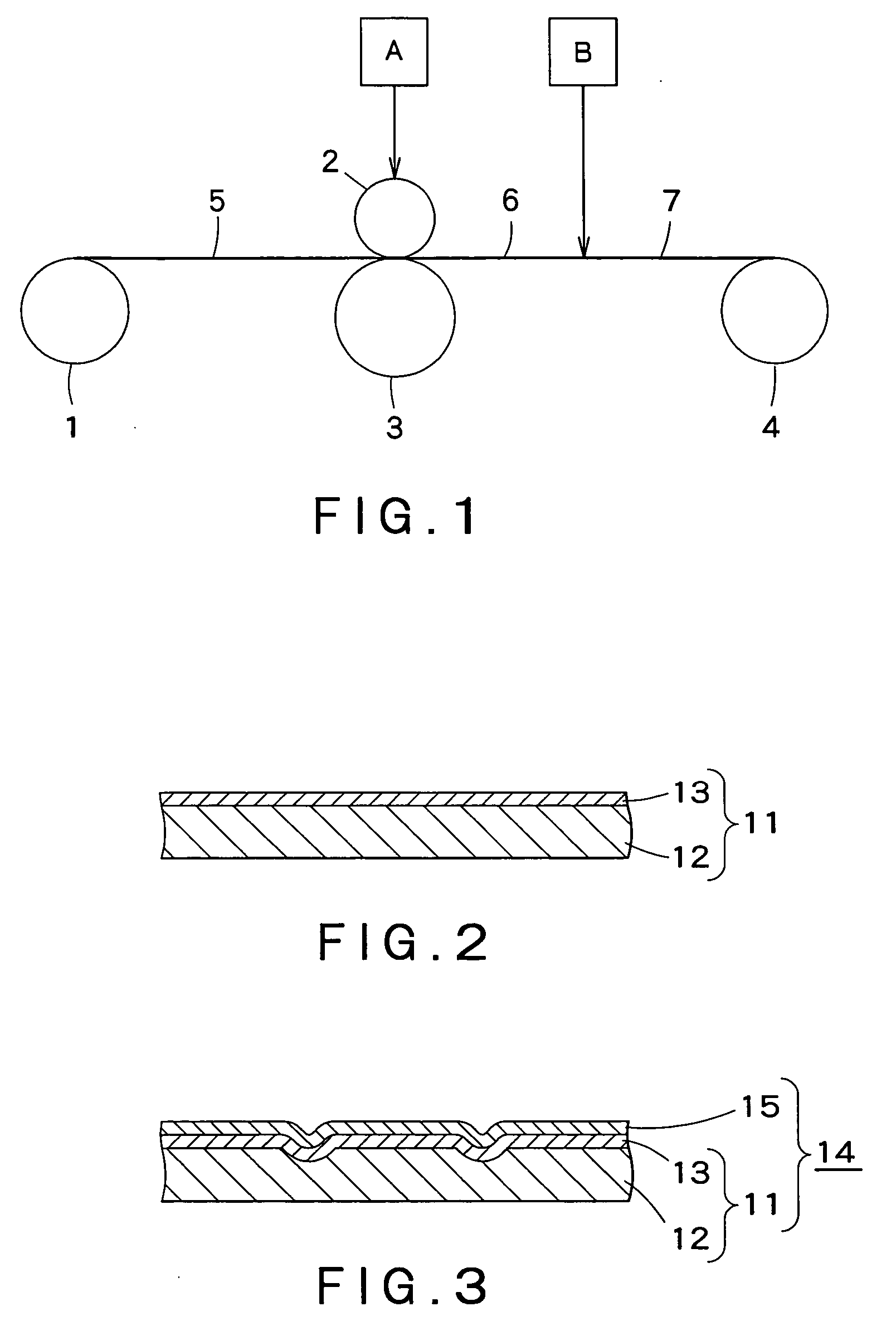

Embossed release paper for synthetic leather production and support therefor, and synthetic leather using the release paper and process for producing the synthetic leather

InactiveUS20070116929A1Excellent embossabilityExcellent releasabilityPaper coatingPaper/cardboardAdhesiveHeat resistance

This invention provides an embossed release paper for synthetic leather production, which has embossability, heat resistance and durability and, at the same time, has excellent separability from a two-pack curing type PU adhesive and can be used in all of synthetic leathers such as PU, PVC, and semisynthetic leathers, and a process for producing the same. The embossed release paper for synthetic leather production comprises at least paper as a support and an ionizing radiation cured film provided on the paper. The upper part of the cured film has been embossed. The ionizing radiation cured film has been formed by applying an ionizing radiation to a coating liquid having a specific composition to cure the coating liquid.

Owner:DAI NIPPON PRINTING CO LTD

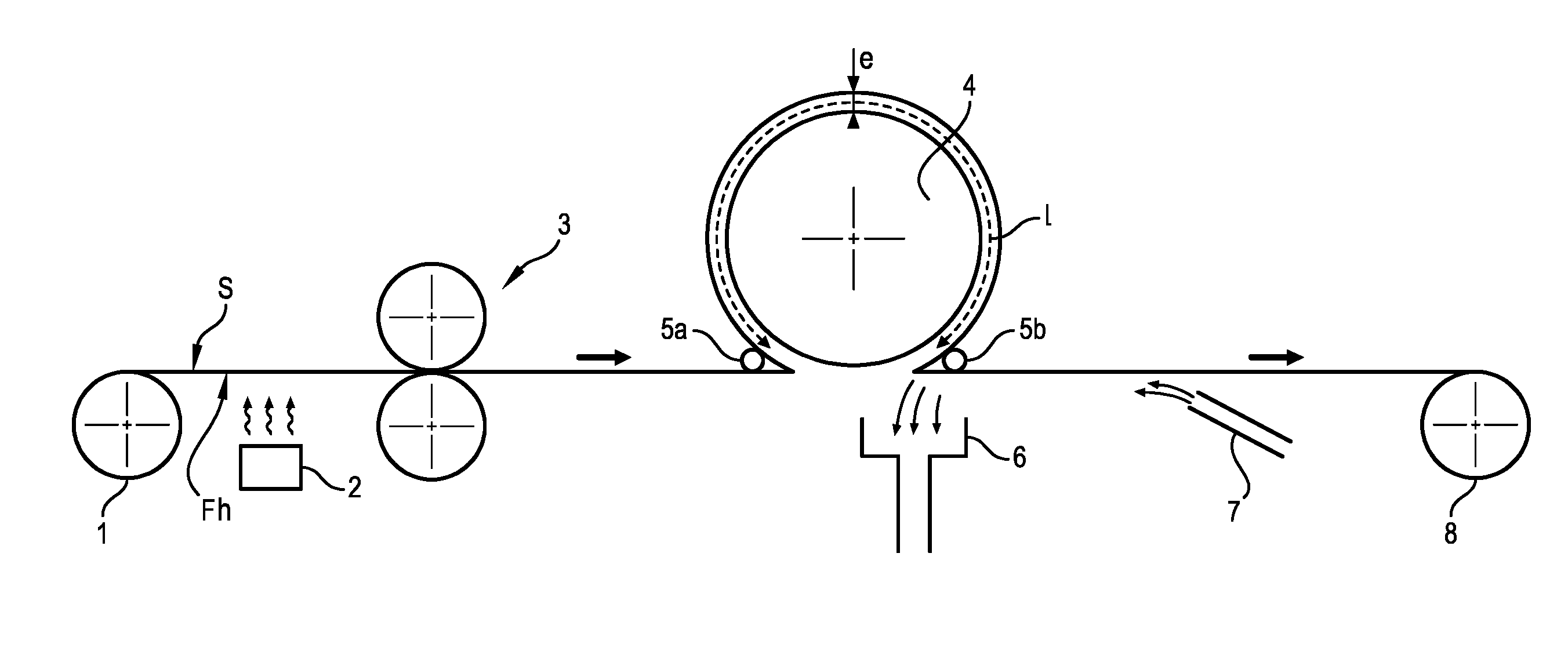

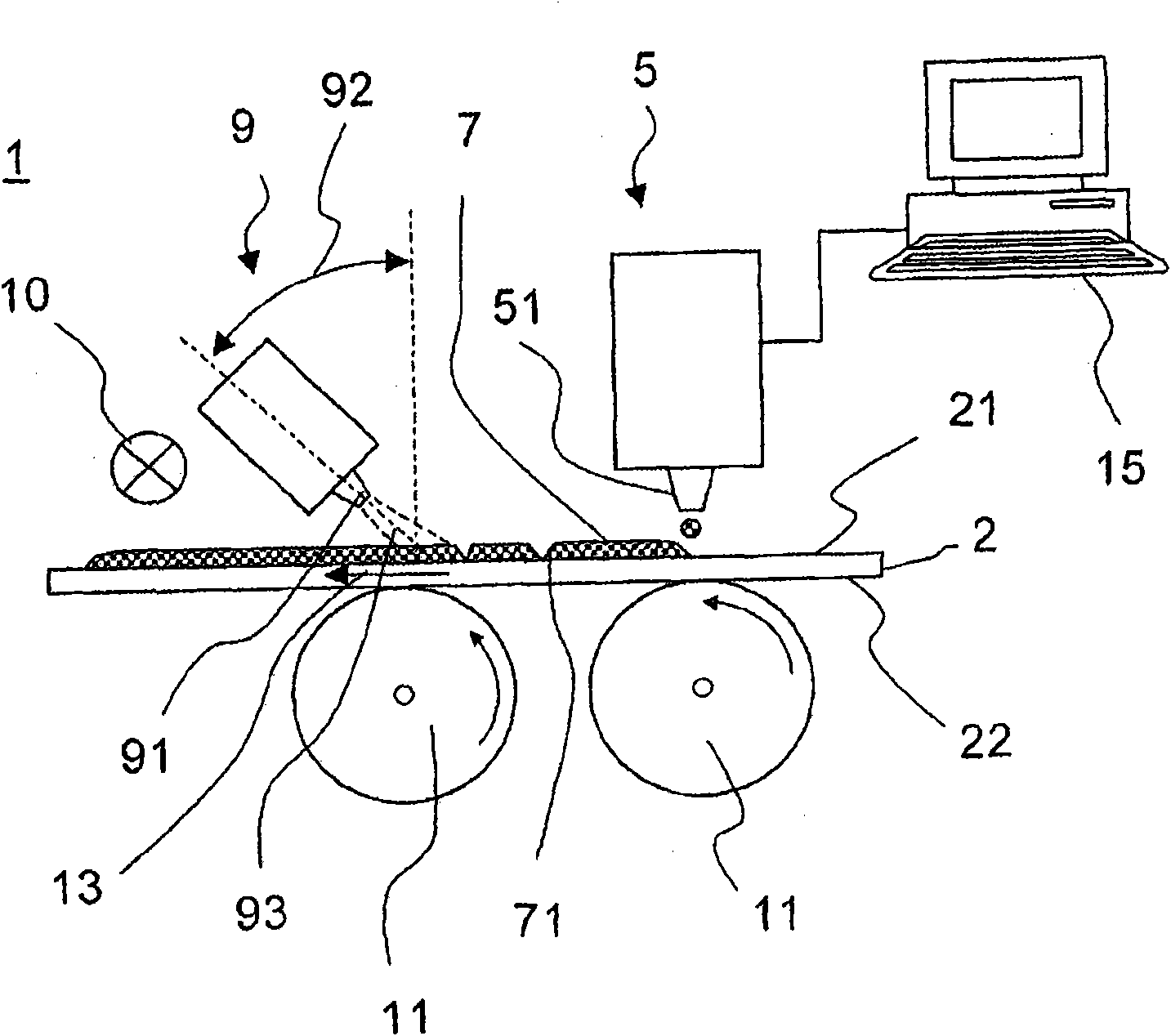

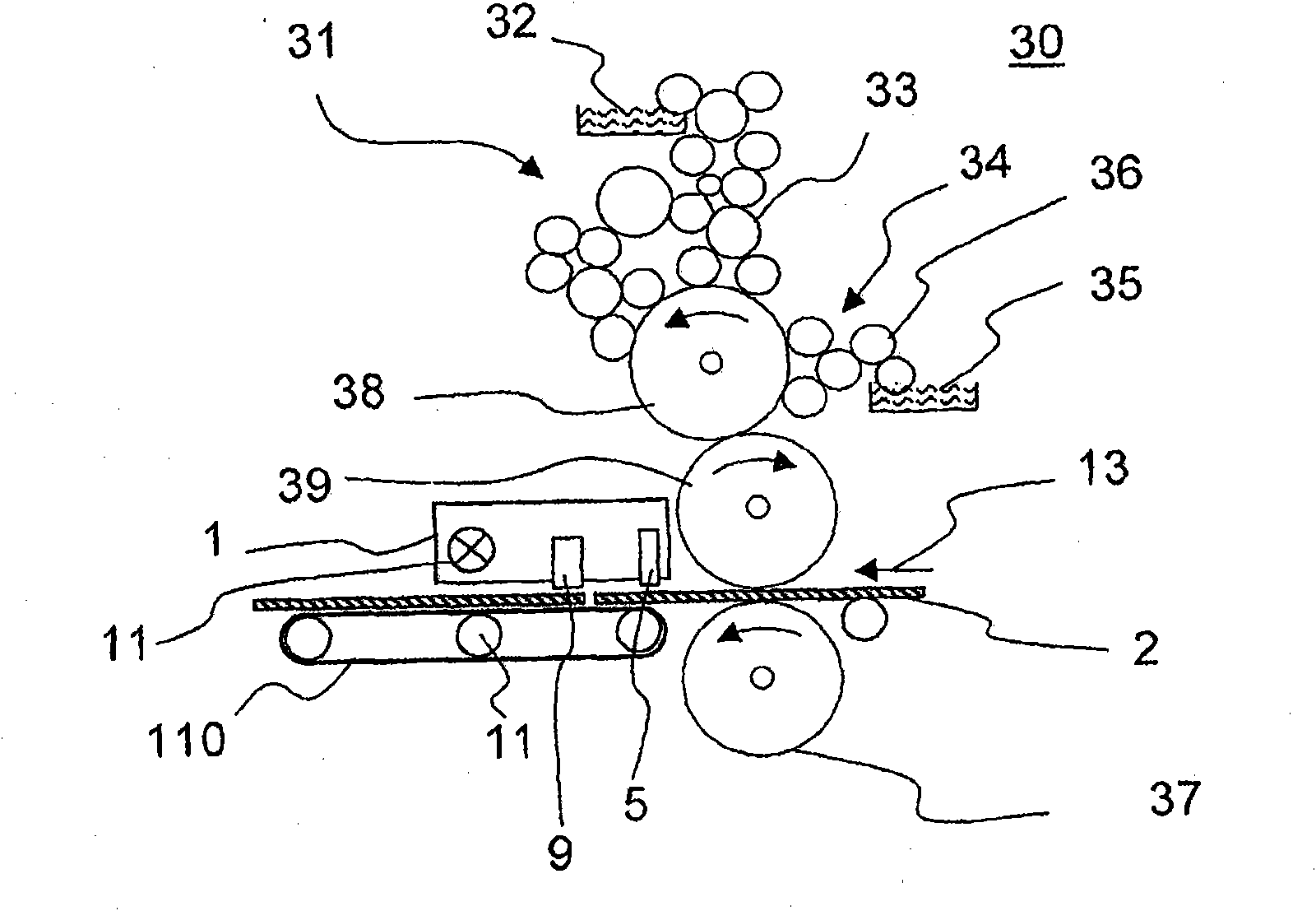

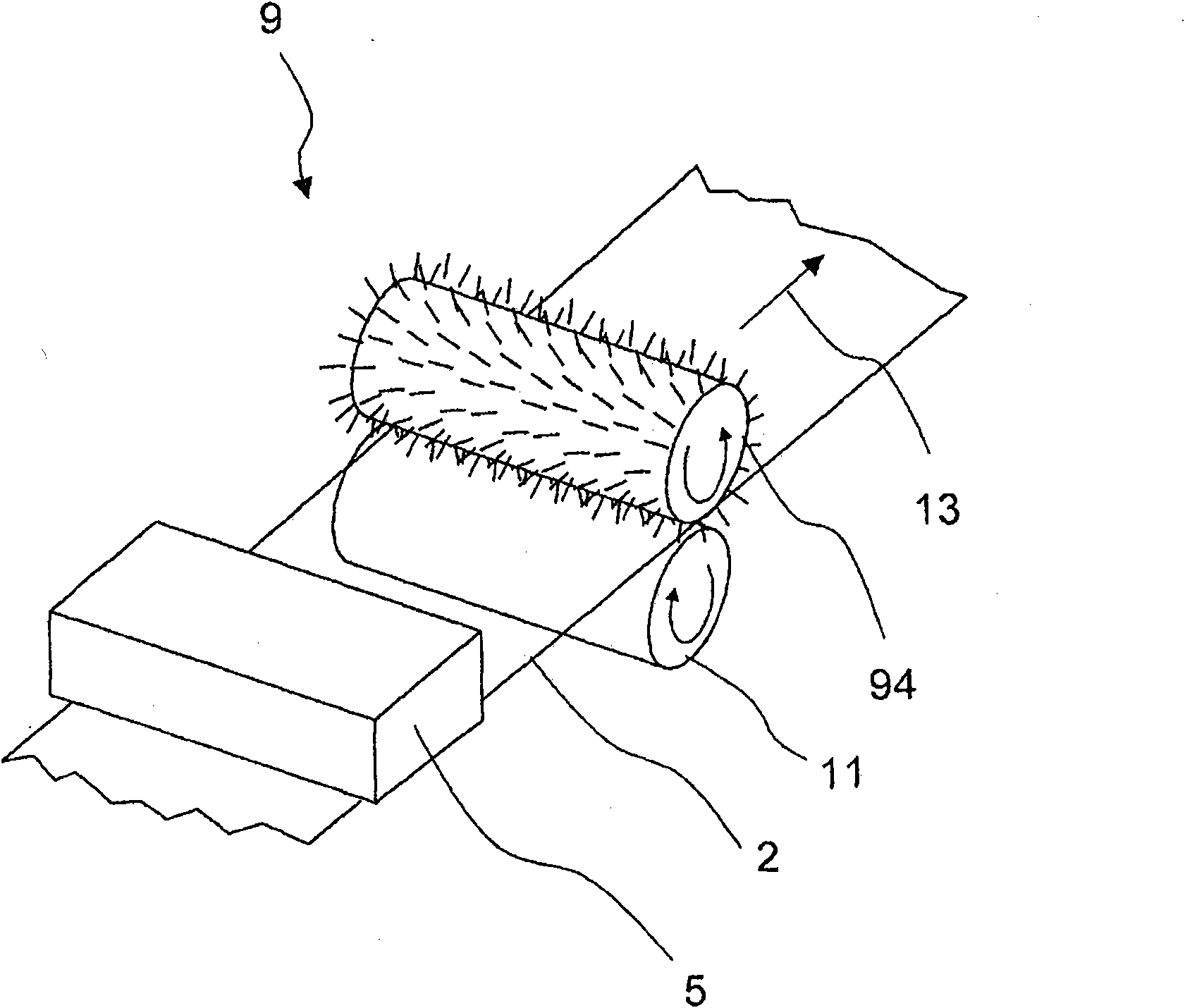

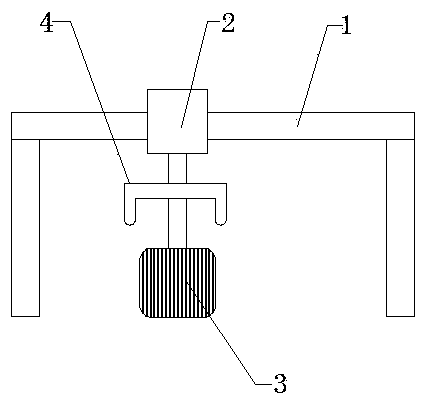

Machine and treatment process via chromatogenous grafting of a hydroxylated substrate

ActiveUS20130236647A1DissipationWater-repelling agents additionNon-macromolecular organic additionGraft reactionPulp and paper industry

The invention relates to a machine for chromatogenous grafting treatment of a scrolling substrate (S) having a hydroxylated face (Fh), comprising:an application device (3) of a grafting reagent on the hydroxylated face (Fh) of the substrate,a heating roller (4) for the development of the grafting reaction on the hydroxylated face (Fh) of the substrate, said roller (4) being provided with a bar-end system (5a, 5b) for applying a face of the substrate (S) against said heating roller (4),an extraction device (6) of the hydrochloric acid produced during the grafting reaction,an application device (7) of an air knife on the treated face of the substrate for eliminating the residual grafting reagent.The invention also relates to a chromatogenous grafting process used in said machine.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Absorbent sheet exhibiting resistance to moisture penetration

ActiveUS7300547B2Reduce feelingsReduce wetted areaNatural cellulose pulp/paperMechanical working/deformationWaxFiber

An absorbent paper sheet is treated with an aqueous wax dispersion such that the sheet includes a fused wax and emulsifier residue in an amount of from about 1 to about 20 weight percent of the sheet based on the combined weight of the fiber, wax residue and an emulsifier residue in the sheet. The fused wax emulsion operates to make at least one surface of the sheet laterally hydrophobic, exhibiting a moisture penetration delay of at least about 2 seconds and less than about 40 seconds as well as a typical contact angle with water at one minute of at least about 50 degrees. There is thus provided absorbent products which exhibit both absorbency and resistance to moisture penetration. The treated sheet further exhibits microbial barrier properties, impeding transfer of bacteria, for example, through the sheet. There are produced tissue products which resist moisture penetration from propelled liquids as well as sequester sorbed liquids in the interior of the tissue.

Owner:GPCP IP HLDG LLC

High strength material using cellulose micro-fibril

InactiveUS20050067730A1Reduce amountHigh strengthFibreboardCellulosic pulp after-treatmentFiberPolymer science

The present invention relates to a high strength material and a high strength molded article comprising 65 to 100 wt. % of cellulose microfibrils; and products comprising these. The material, which is lightweight and has a very high strength, can be used for various purposes and can be produced by recycling wastepaper, used cloth and the like. Furthermore, by appropriately selecting the type and / or amount of binder, the material comprising microfibrils as a main component can be decomposed by microbes or the like after being dumped as waste, and is thus friendly to the global environment.

Owner:KYOTO UNIV

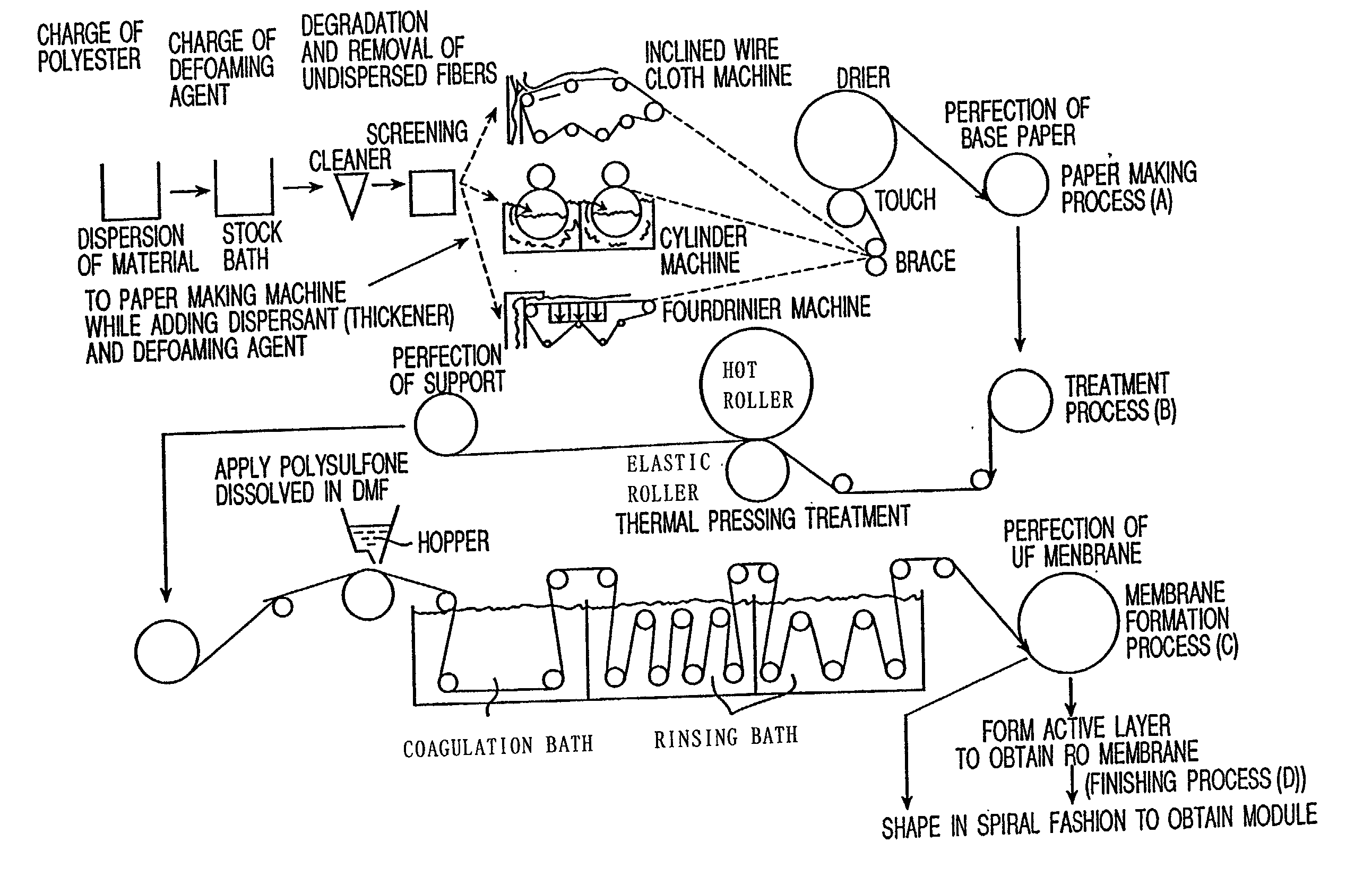

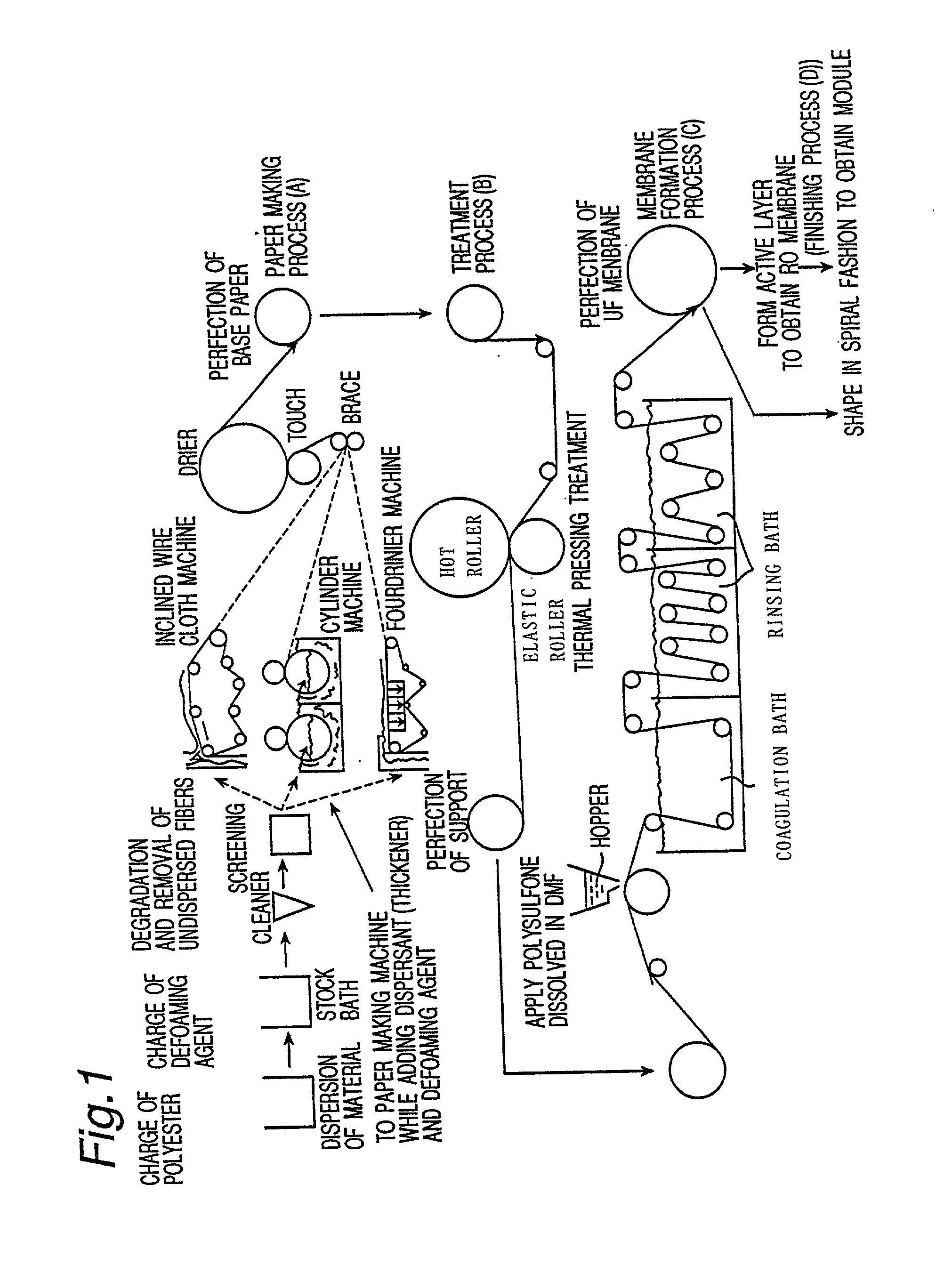

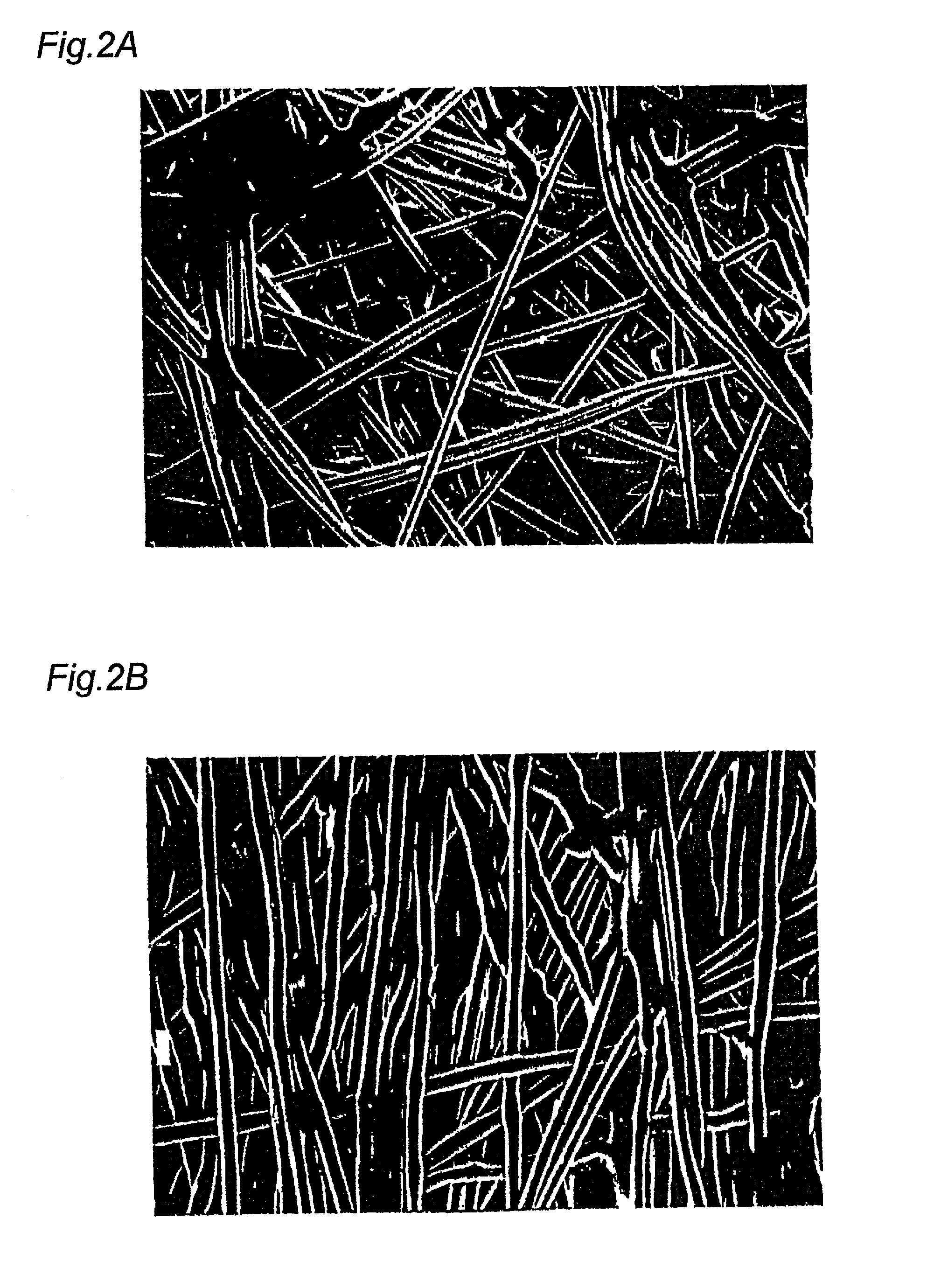

Semipermeable membrane support and process of preparation thereof

InactiveUS20020056535A1Avoid bendingQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperFiberSemipermeable membrane

Owner:AWA PAPER MFG +1

Process for coating a substrate

The invention relates to a process for the coating of a wooden, wood-like and / or cellulose-containing substrate comprising the steps of: a) applying a press coating to the substrate; b) applying heat and pressure to the coated substrate to cure the press coating and to obtain a substrate with a smooth coating film, with the pressure being such that the substrate is not substantially compressed; c) applying a top coat on the substrate after the curing of the press coating; and d) curing said top coat. As a result of this process, the amount of unreacted double bonds in the coated substrate is at a low level.

Owner:AKZO NOBEL NV

Wet-or dry-use biodegradable collecting sheet

InactiveUS20050136766A1Strength propertySynthetic resin layered productsPretreated surfacesCelluloseElectret

A biodegradable, cellulose-based collecting sheet that can be used in either a wet state or a dry state. The collecting sheet may be a double recreped cellulose substrate reinforced with a binder, such as a latex binder. Alternatively, or in addition to the binder, the collecting sheet may be coated with a dielectric material and electret treated to establish a charge on the dielectric material. Additionally, the collecting sheet may be embossed to provide more interstices and greater surface area to enhance the pick-up ability of the collecting sheet. The invention further includes a method of forming such a collecting sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

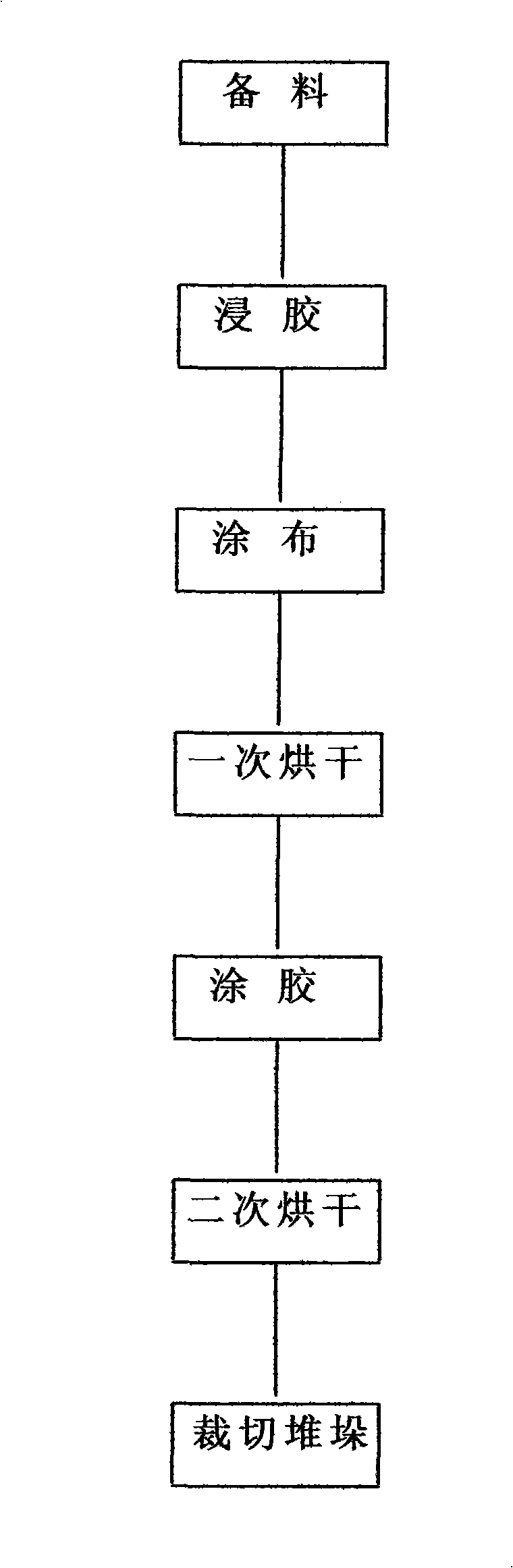

Production method of abrasion-proof decorating paper

InactiveCN101403207AReduce manufacturing costSimple production processNon-fibrous pulp additionSpecial paperMaterials preparationCLARITY

The invention discloses a production method of wear-resisting decorative paper, which is carried out sequentially by the steps of material preparation, gum dipping, coating, one-time drying, gluing and secondary drying, all processing work can be finished online by one-time operation and the production flow is simple: main characteristics thereof are as follows: the component formula of dipping glue, coating glue and surface glue solution is firstly created after a plurality of successful tests, which has obvious effect for improving the surface wear-resisting property, the overall wear-resisting evenness and stability, the anti-soil capability and the luster clarity of the wear-resisting decorative paper; the wear-resisting decorative paper produced by adopting the production method is especially suitable for being used as the surface decoration materials of compound floors or other decoration plates, can simplify production laying process, has obvious effect to improve the production efficiency of the compound floors and other decorative plates, save energy and reduce emission and cost, and has excellent environmental protection effect and large economic benefit.

Owner:张杰

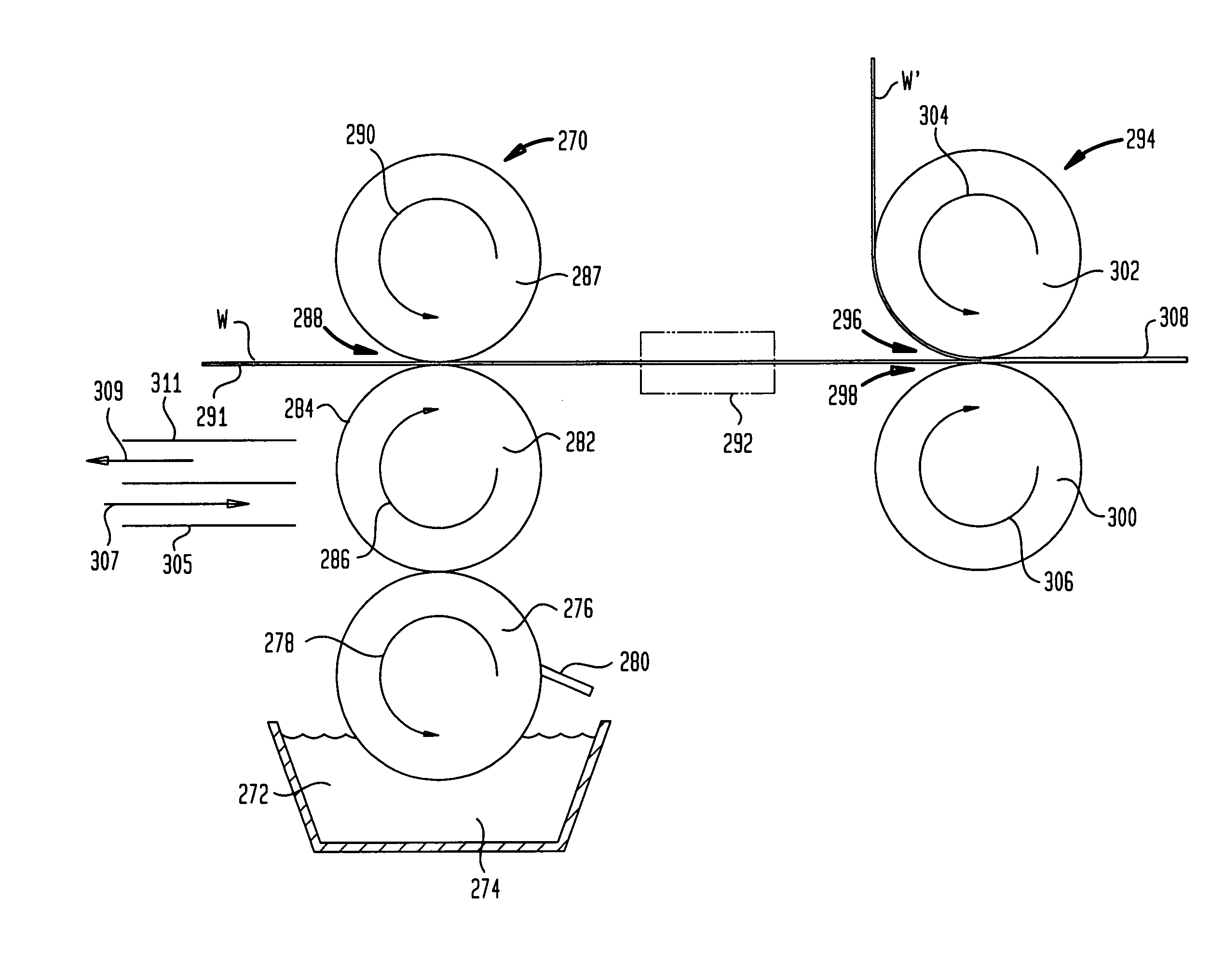

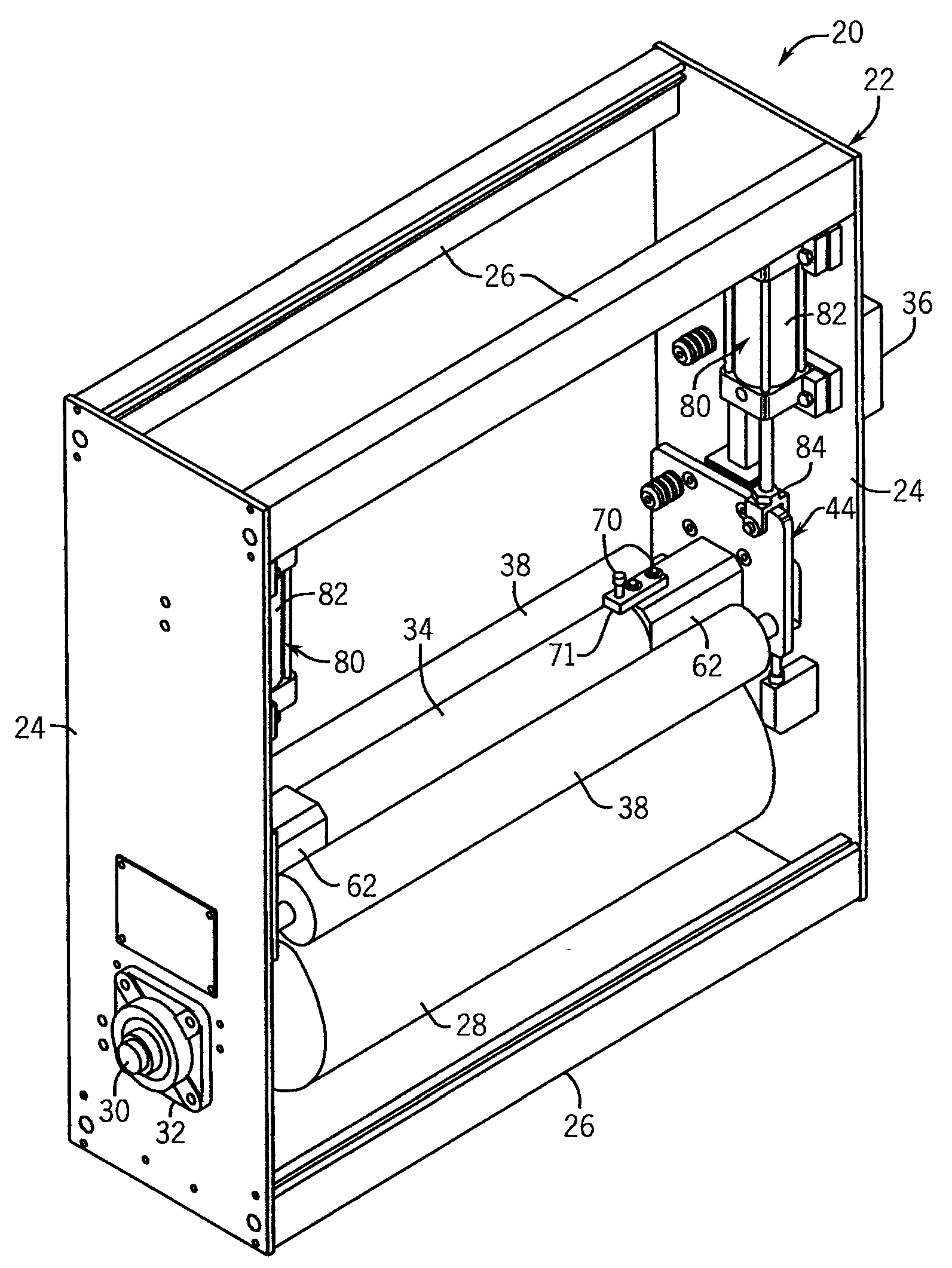

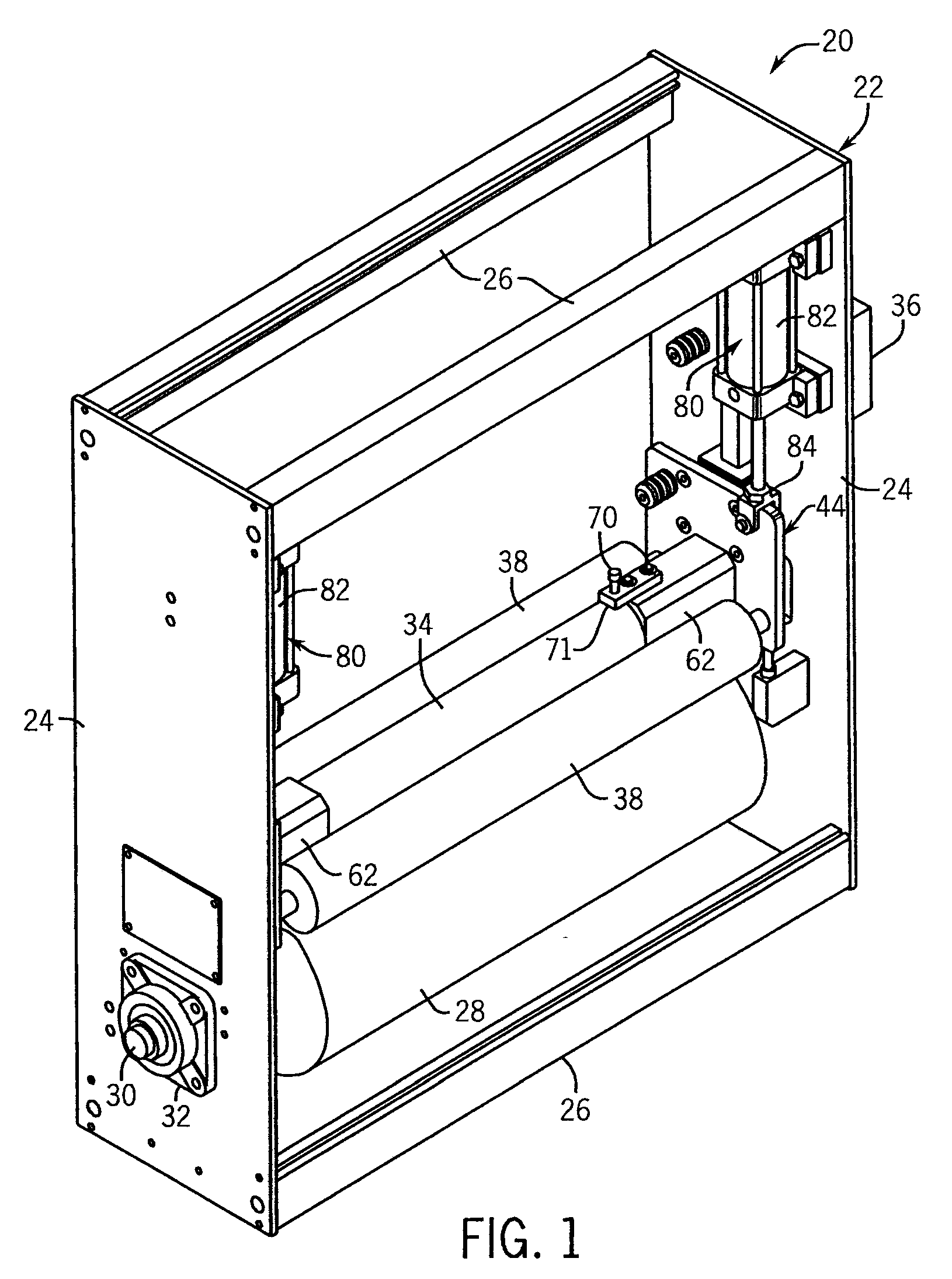

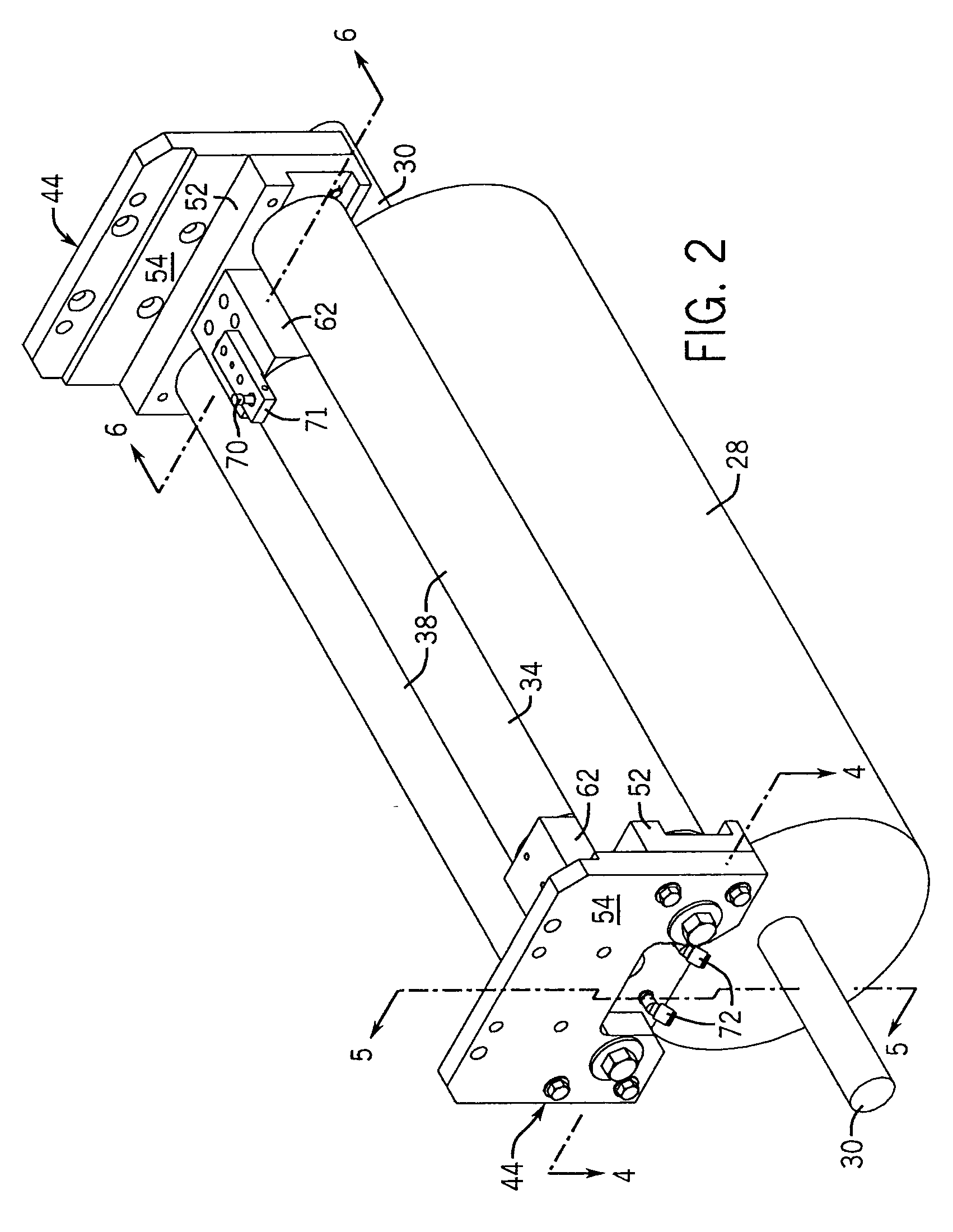

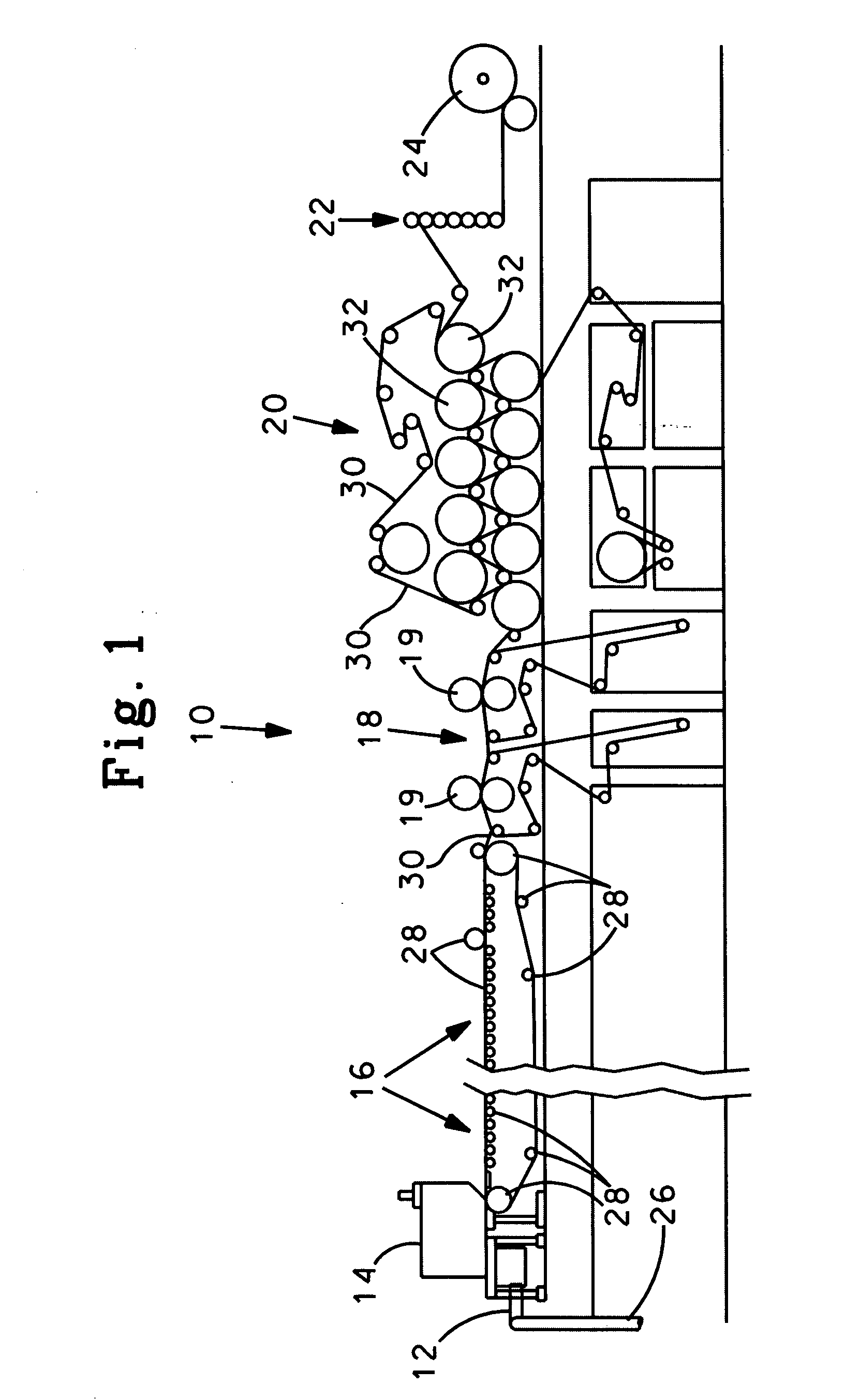

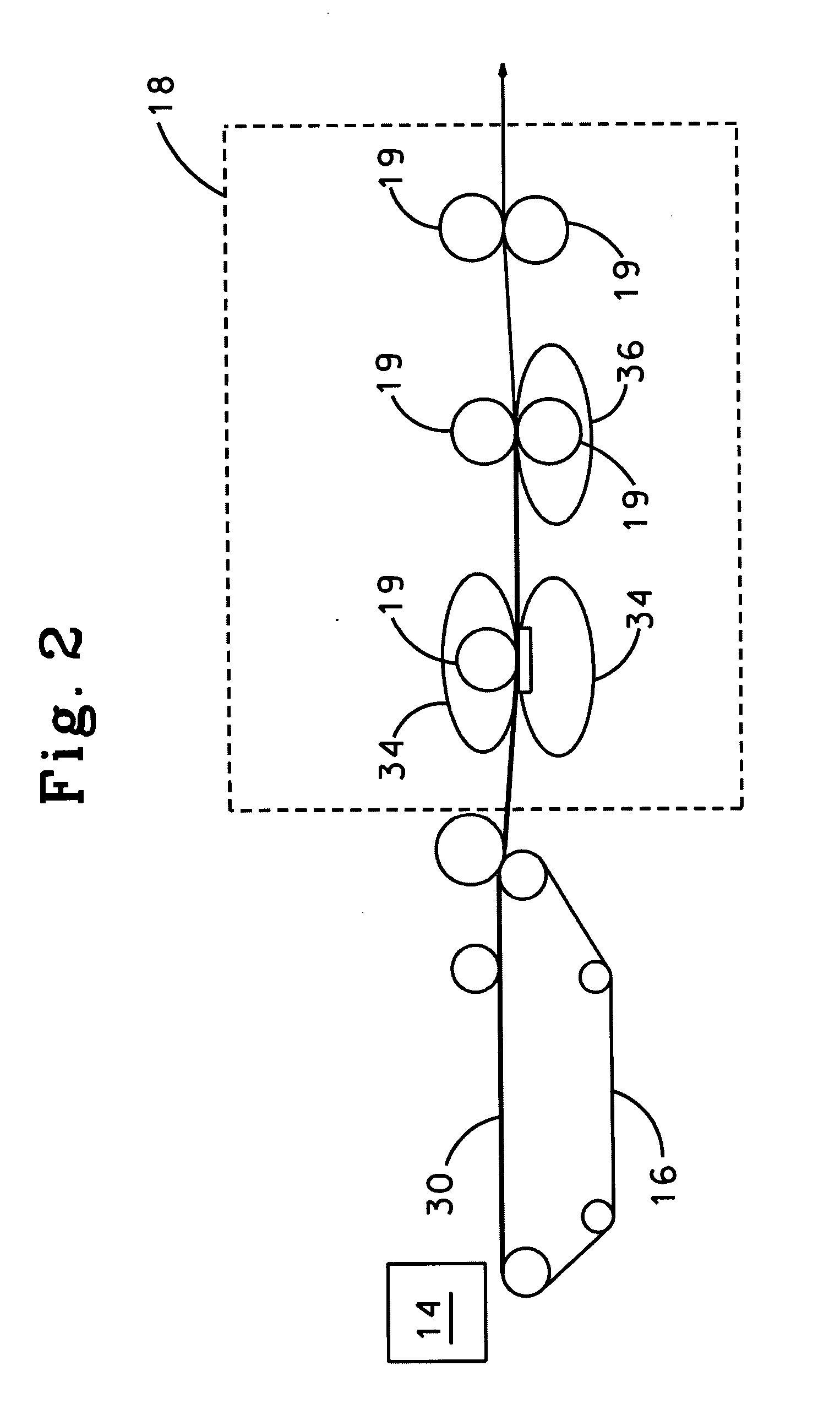

Atmospheric Treater With Roller Confined Discharge Chamber

ActiveUS20090120782A1Good surface treatmentQuality improvementDuplicating/marking methodsPhysical paper treatmentEngineeringAtmospherics

A continuous feed discharge surface treater for treating web materials has a discharge chamber where ionization of a process gas occurs defined and contained by one or more rollers. Enhanced chemical coronas and plasmas are achieved by limiting depletion of the gas chemistry from the discharge chamber and dilution or contamination from mixing with drawn in ambient air. Atmospheric coronas can also be achieved in which minimal or no ozone is exhausted from the treater. Various roller and electrode assemblies, including both fixed and rolling electrodes, can be employed.

Owner:ENERCON INDS

Separator for electrochemical device and method for producing the same

InactiveUS6905798B2Improves texture uniformityImprove thickness uniformityHybrid capacitor separatorsHybrid capacitor electrolytesPolymer scienceHeat resistance

The present invention provide a separator for an electrochemical device which comprises a wet nonwoven fabric comprising one or more kinds of fibrillated organic fibers which are at least partially fibrillated into a fiber diameter of 1 μm or less, and one or more kinds of unfibrillated organic fibers having a fineness of 0.5 dtex or less, which exhibits excellent heat resistance, electrolyte holding properties, internal short-circuit preventing property, and winding property, which results in a lowered internal resistance and prolonged life of an electrochemical device, and a method for producing the same and an electrochemical device.

Owner:MITSUBISHI PAPER MILLS LTD

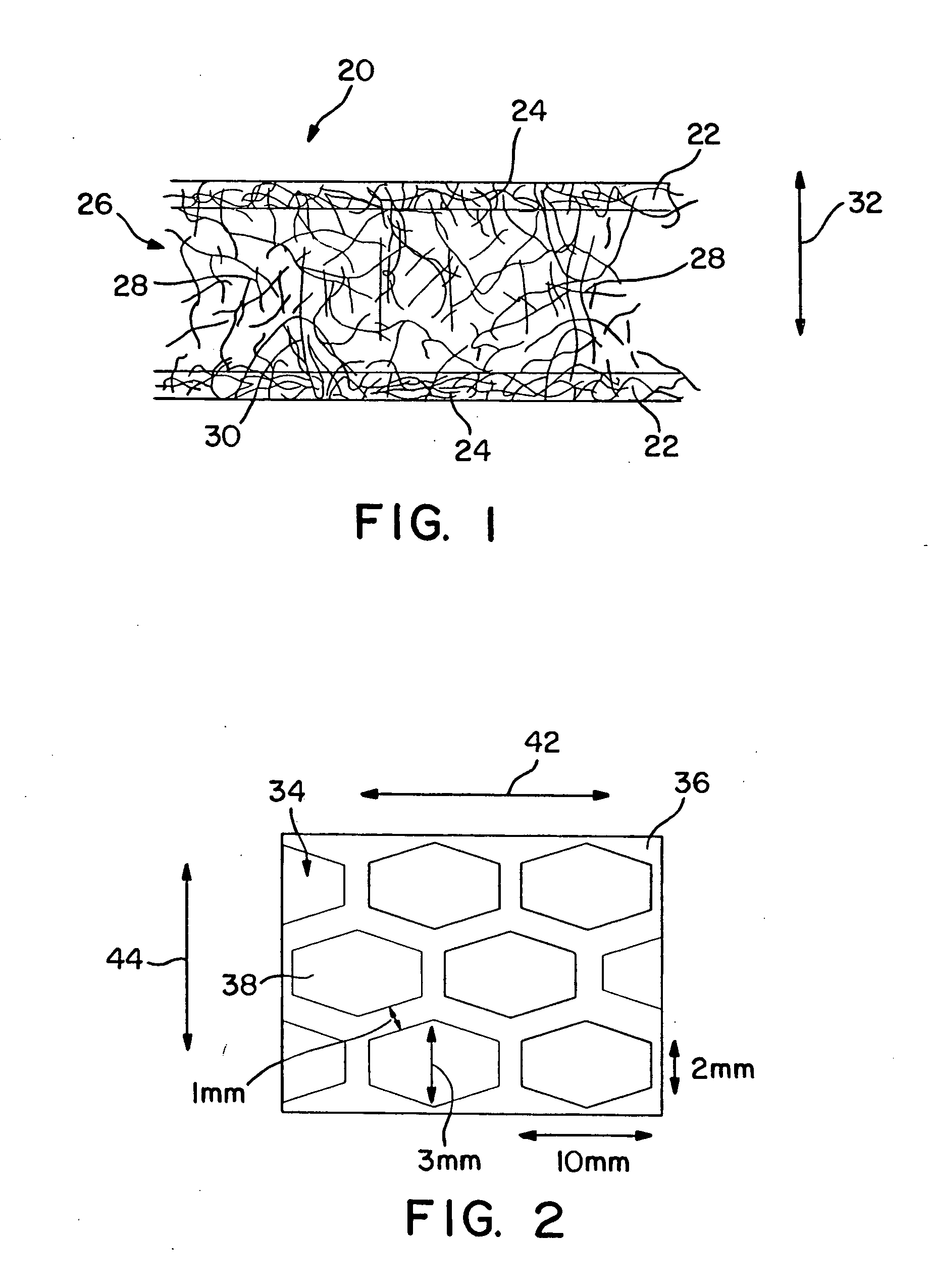

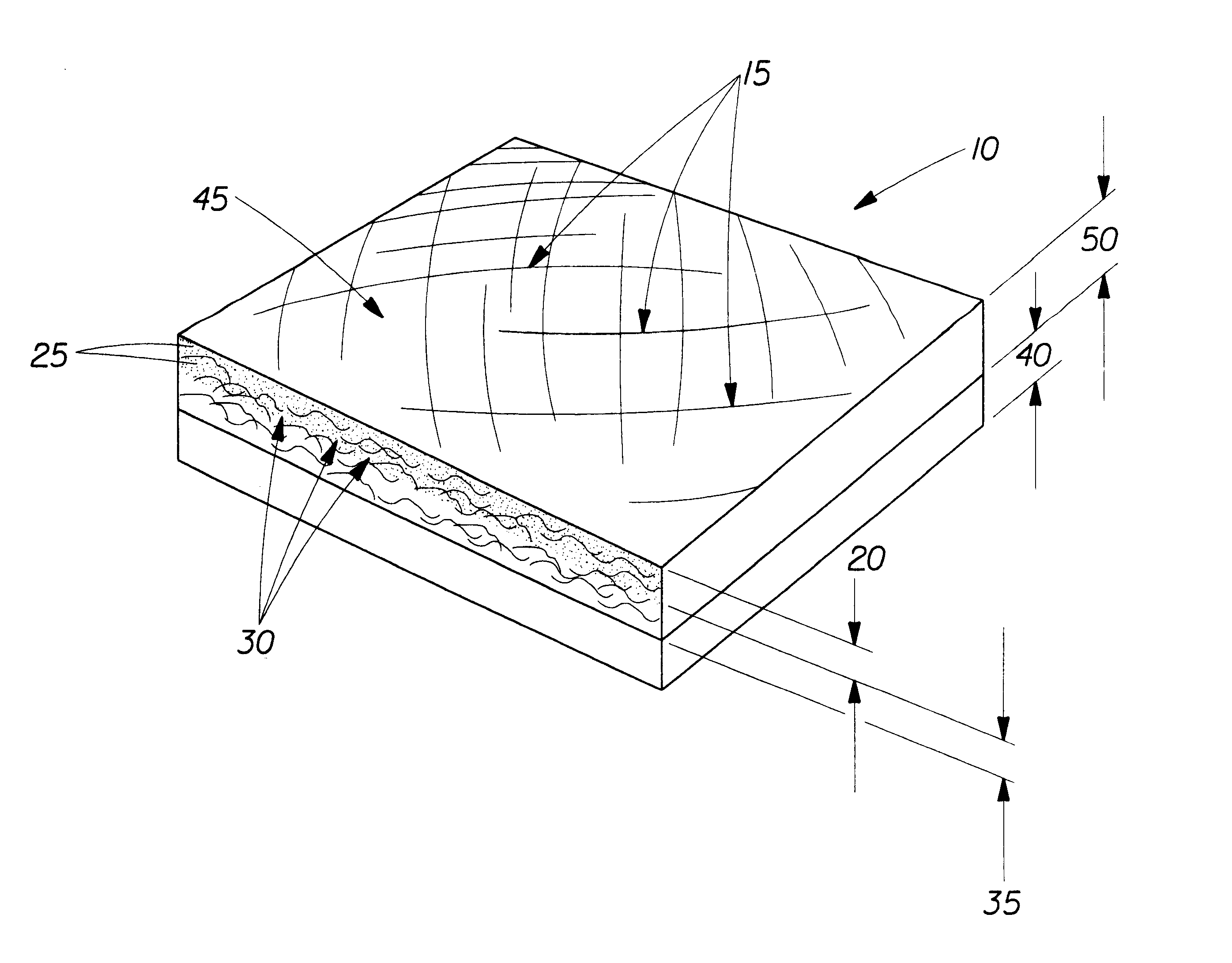

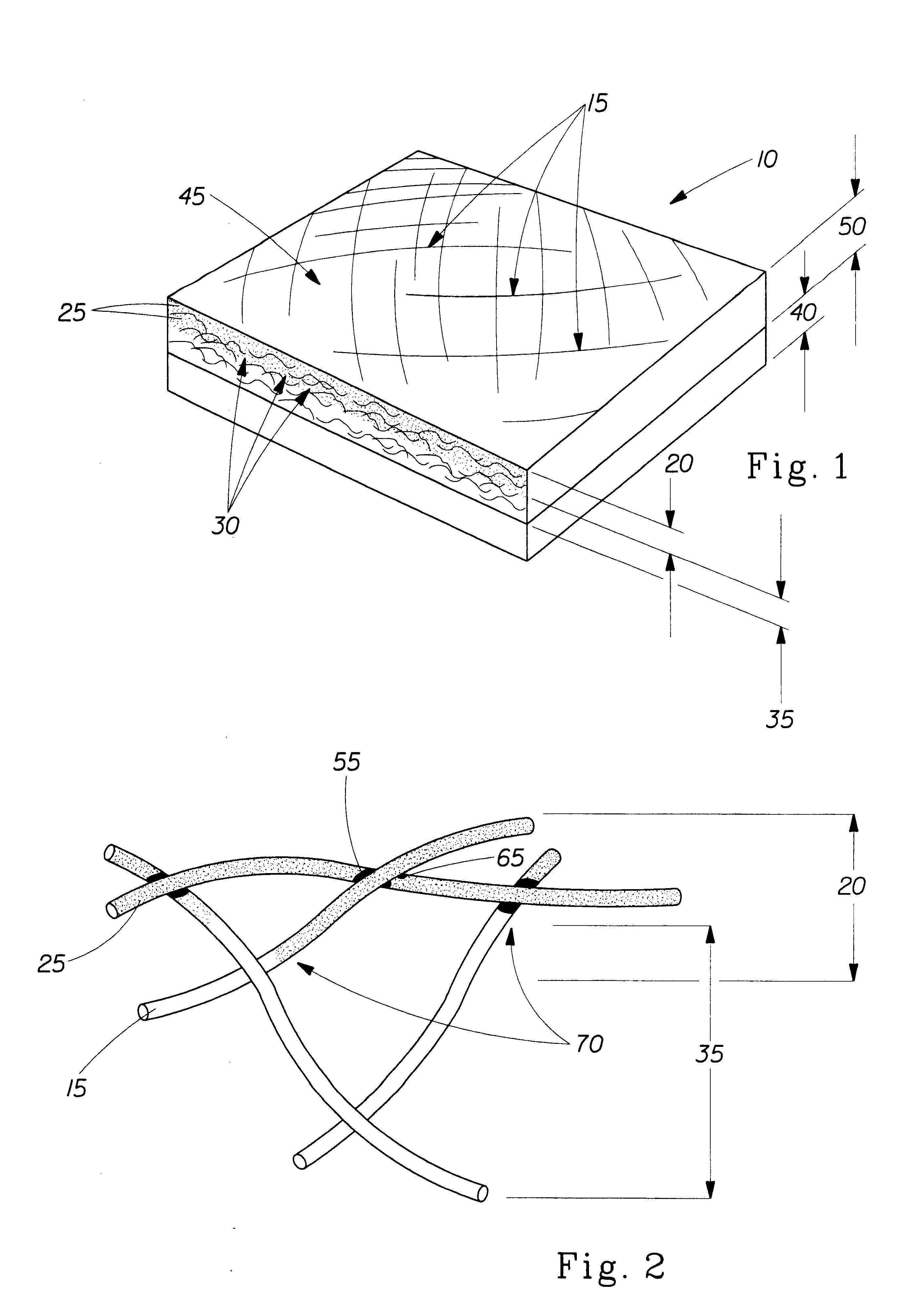

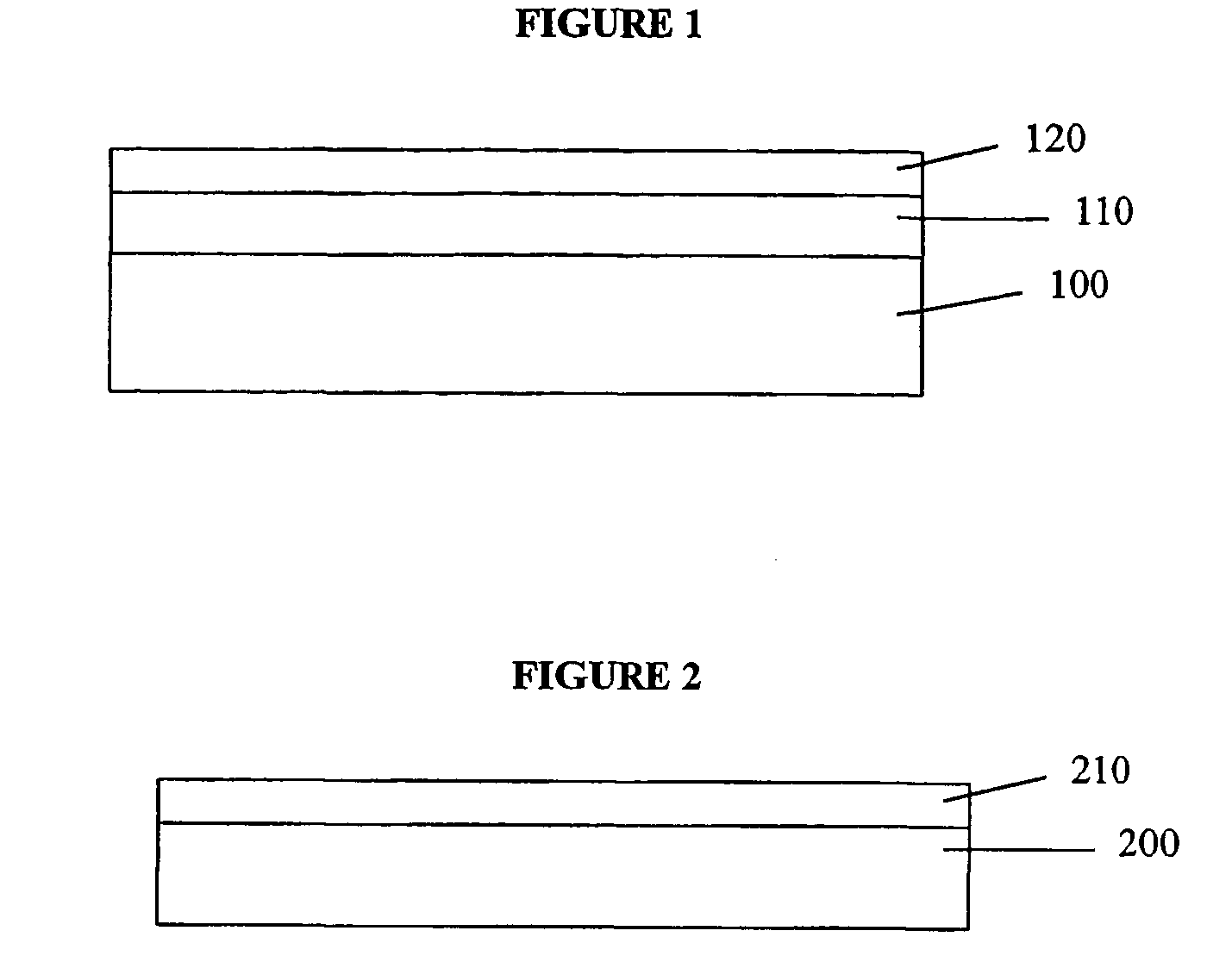

Multi-purpose absorbent and shred-resistant sheet material

InactiveUS6579816B2Cut surface smoothImprove propertiesReinforcing agents additionPaper/cardboardEngineeringAverage size

A shred-resistant and cut-resistant absorbent sheet material including an absorbent substrate and cut-resistant particles discontinuously distributed through the substrate. The absorbent substrate can comprise cellulosic material and the particles comprise polymeric materials having an average size of at least about 100 nanometers, and most preferably between 100 nanometers and 1000 nanometers. In one embodiment, the particles are provided in an amount of between about 10 percent to about 50 percent by weight of the sheet. The sheet material can be made using typical paper making processes. Heat and / or pressure are applied to the sheet material to cause the particles to at least partially flow, so as to bond to the absorbent substrate. The sheets can be provided as a layered structure with a slip-resistant base for home use in the preparation of foodstuffs.

Owner:PROCTER & GAMBLE CO

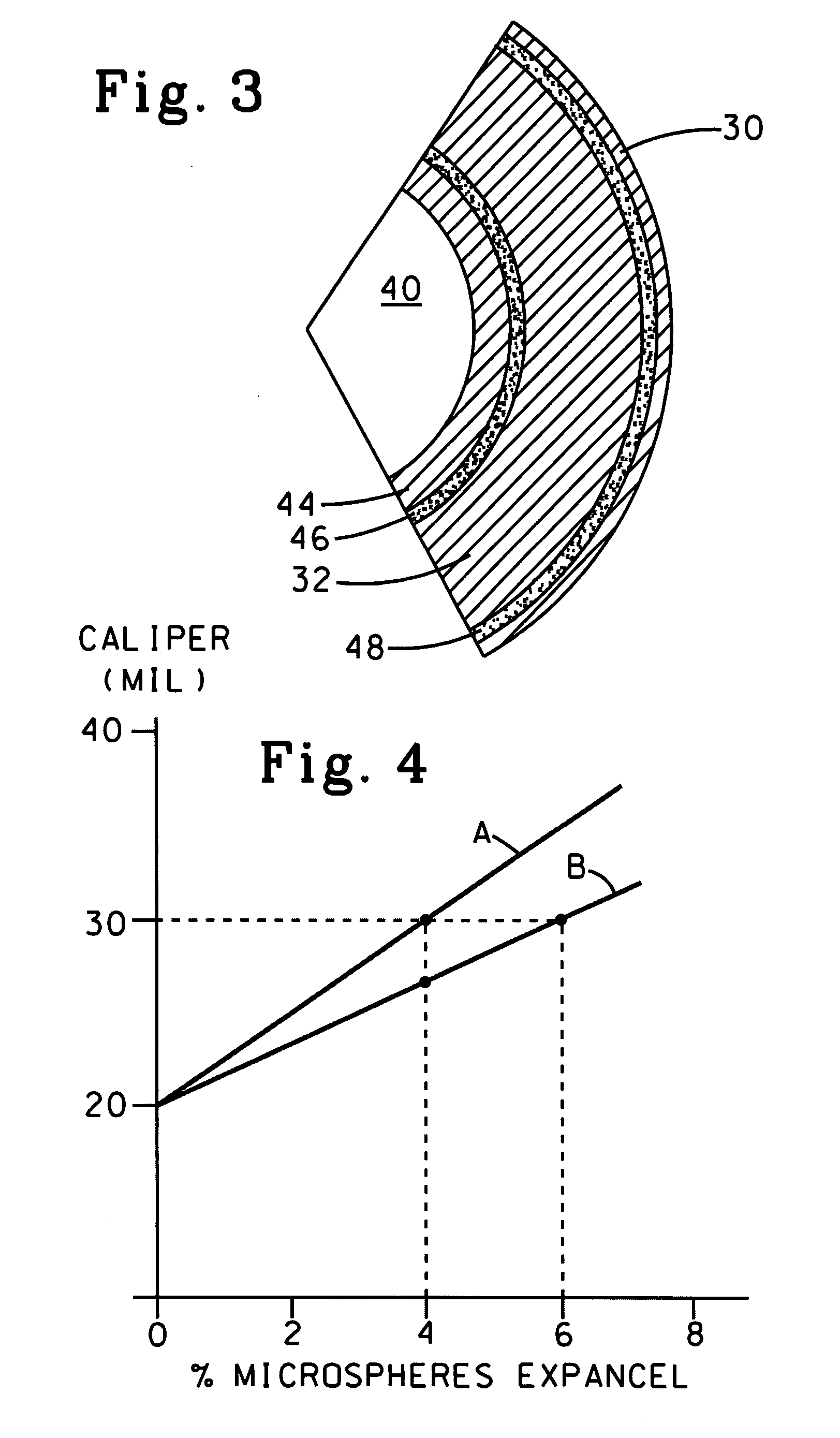

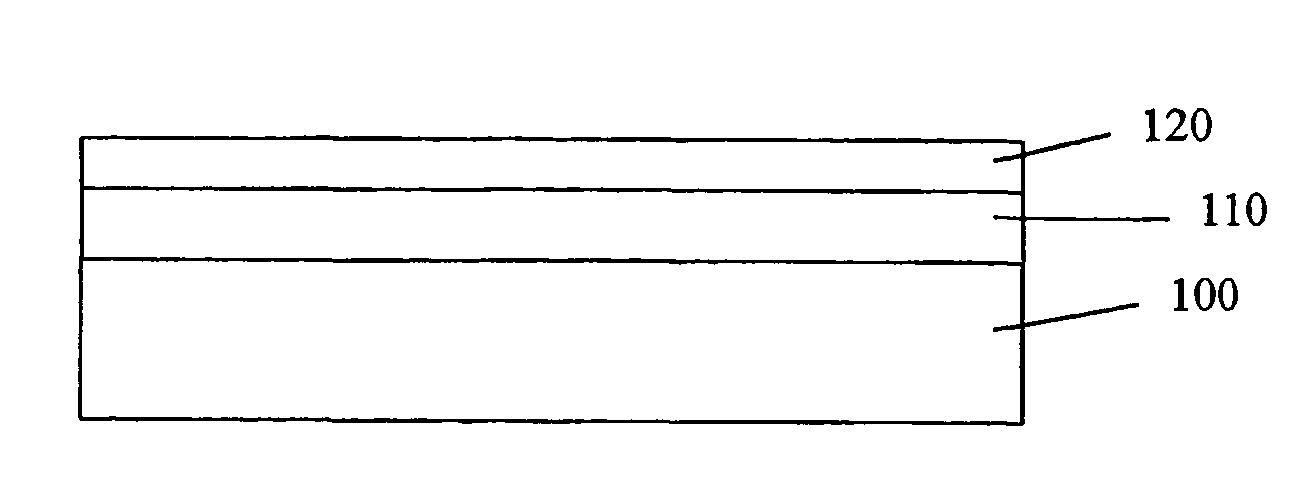

Paperboard material with expanded polymeric microspheres

InactiveUS20070256805A1Improve offset print performanceDecreased print mottle of printedNon-fibrous pulp additionNatural cellulose pulp/paperCoated surfaceMicrosphere

The present invention is related to a paperboard product having a basis weight in a range of 100 to 350 pounds per 3,000 square feet. The paperboard comprises at least one coated surface suitable for printing. The at least one coated surface comprising cellulosic fibers and from about 0.05 to about 0.5 wt. % dry basis expanded synthetic polymer microspheres based on total weight of the of cellulosic fiber dispersed thereof. The coated surface has a Parker smoothness less than about 2.0 and a Hagerty / Sheffield smoothness not less than about 20 Sheffield units.

Owner:INT PAPER CO

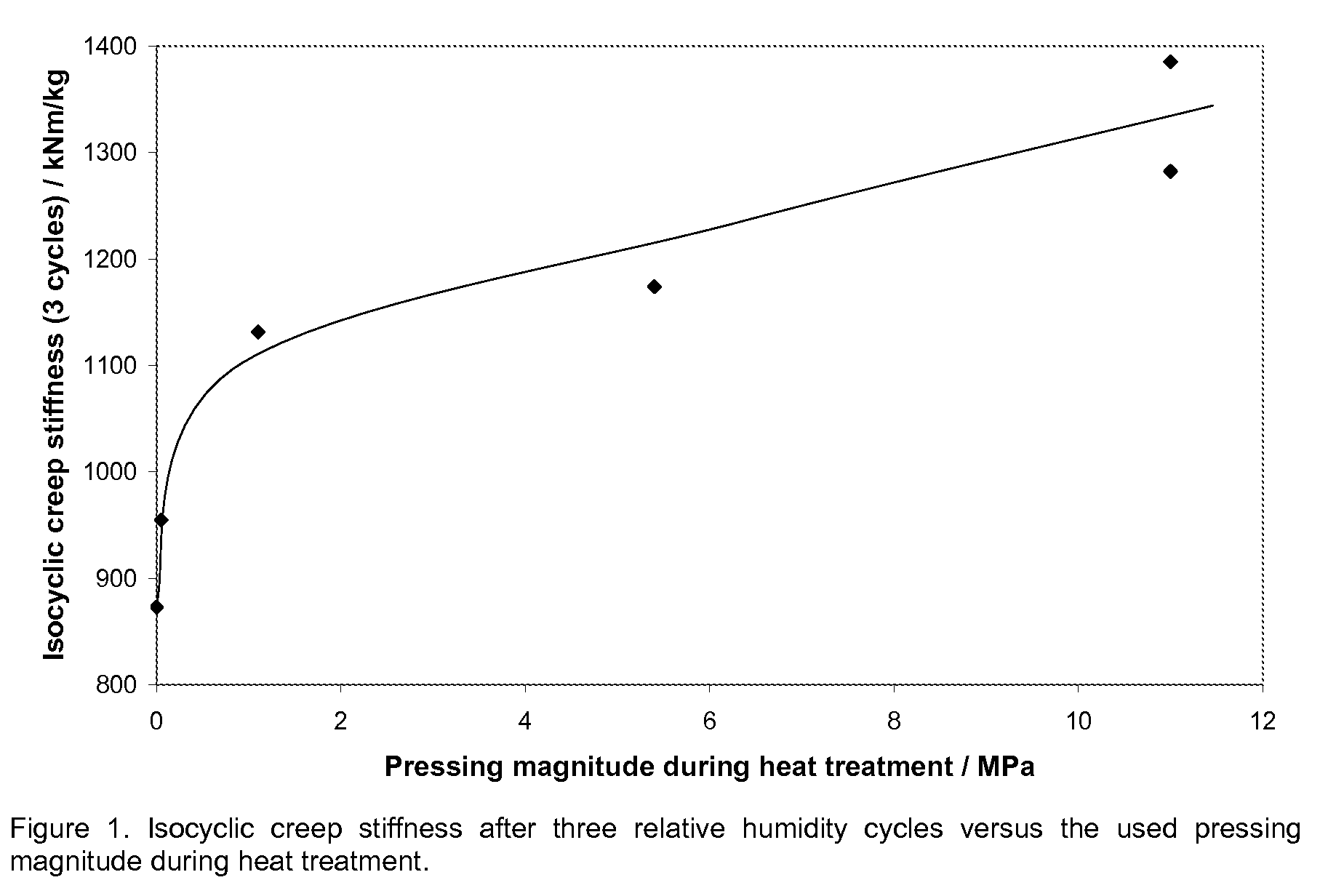

Method for manufacturing a composite material having reduced mechanosorptive creep, the composite material, use of the method and the composite material

A method for manufacturing a composite material having reduced mechanosorptive creep includes the following steps:a) mixing fibers of a lignocellulosic material with a thermoplastic material where the thermoplastic material is in fiber form; b) adding the mixture made in step a) onto a wet web, thus forming a composite material; and c) hot pressing of the composite material. The composite material having reduced mechanosorptive creep being the manufacturing result of the method, and the use of the method and the composite material are described.

Owner:INNVENTIA

Coated paper including a pseudo-watermark, and a method of manufacture

InactiveUS6630055B1Reduce thicknessNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryWetting

The present invention relates to a method of manufacturing a coated paper having at least one mark resembling a watermark, the method being characterized in that said mark is made after the drying step which follows the last coating operation, by performing steps in which: a) a re-wetting solution is applied to at least one face of the coated paper, in one or more determined zones; and b) pressure and heat are applied in said re-wetted zone(s) of the coated paper so as to evaporate said solution and densify the coated paper in said zone(s) relative to the remainder of the paper. The present invention also provides a coated paper including at least one mark resembling a watermark, characterized in that one or more determined zones of the coated paper present a reduction in thickness relative to the remainder of the coated paper, the density per unit area in said zone(s) of the coated paper being identical to that in the remainder of the paper.

Owner:ARJO WIGGINS PAPIERS COUCHES

Multi-ply fibrous structures and processes for making same

InactiveUS20100030174A1Few applicationNon-fibrous pulp additionNatural cellulose pulp/paperFiberMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

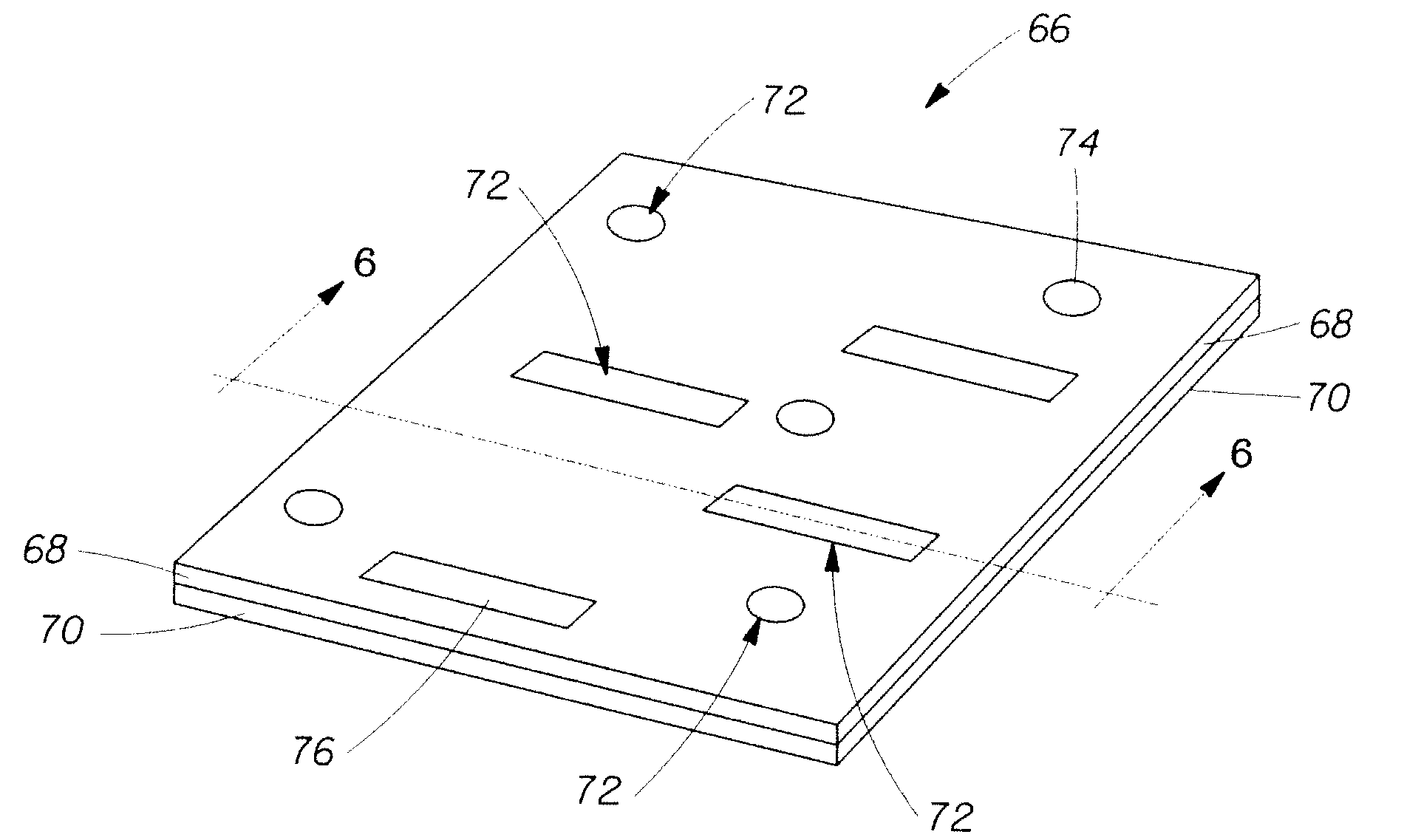

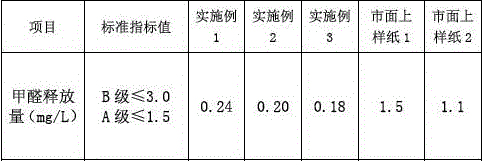

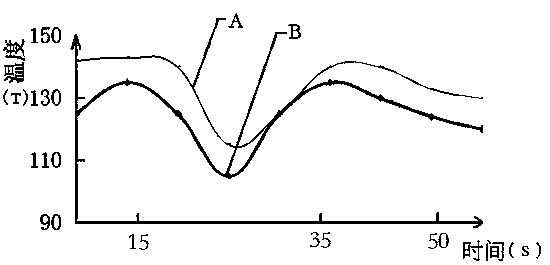

Production method of low-formaldehyde-releasing impregnating resin film paper

ActiveCN106498804AResolution timeGuaranteed surface physical and chemical propertiesPaper coatingPaper/cardboardPulp and paper industryHigh pressure

The invention provides a production method of low-formaldehyde-releasing impregnating resin film paper. The production method comprises the following steps: uncoiling raw paper and pre-treating; impregnating the raw paper into a urea formaldehyde resin impregnating solution; conveying the impregnated raw paper into a drying oven; drying at the temperature of 120 DEG C to 140 DEG C for 25s to 35s; cooling the resin film paper which is dried for the first time, coating double faces of the paper with an amine-aldehyde resin solution; conveying the coated resin film paper into the drying oven again, and drying at the temperature of 130 DEG C to 155 DEG C for 35s to 45s; after drying for the second time and cooling, conveying the resin film paper into a cutting machine, and cutting the resin film paper into needed length. According to the low-formaldehyde-releasing impregnating resin film paper provided by the invention, formaldehyde release can be effectively reduced, and the formaldehyde releasing amount is not increased after high-temperature and high-pressure attachment; the quality and applicability of the impregnating resin film paper can be improved.

Owner:GUANGDONG YAODONG FURNITURE BOARD +1

Stain-resistant and oil-resistant wallpaper and preparation method thereof

The invention discloses stain-resistant and oil-resistant wallpaper. The stain-resistant and oil-resistant wallpaper comprises a substrate layer, a stain-resistant layer and an oil-resistant layer, wherein the outer periphery of the substrate layer is coated with the stain-resistant layer, and the outer periphery, far away from the substrate layer, of the stain-resistant layer is coated with the oil-resistant layer; the oil-resistant layer is prepared from the raw materials: acrylic perfluoroalkyl ester, alkyd resin, polyester resin, perfluoroalkyl acrylate, butyl acrylate, hydroxyethyl acrylate, aluminum tripolyphosphate, nano zinc borate, potassium persulfate, hydroxymethyl cellulose, nano zinc oxide, nano titanium dioxide, diatomite, magnesium hydroxide, aluminum oxide, organobentonite, sericite powder, perfluorocarbon, ferric phosphate, sodium molybdate, sodium persulfate, chlorinated paraffin, silane coupling agent KH-560, dibutyltin dilaurate, octadecyl trimethyl ammonium chloride, polyethylene glycol, fluorosilicon oil, a thickener, an antifoamer, a curing agent and modifying auxiliaries. The invention further provides a preparation method of the stain-resistant and oil-resistant wallpaper. The prepared wallpaper has excellent stain resistance and oil resistance.

Owner:安徽易有墙纸有限公司

Flame-proof tarpaulin paper and preparation method thereof

InactiveCN101139809ACost-effective effectInhibit excessive water absorptionWater-repelling agents additionPaper/cardboardFiberOxygen

The invention belongs to the technical field of paper-making methods, and relates in specific to a non-fiber material that is added into paper pulp, in particular to cooperative utilization of paper impregnation materials in paper-making process. The invention relates to a flame retarding and moistproof paper as a paper cellular core material, as well as a relevant preparation method. The preparation method comprises a combined utilization mode of compounds of flame retardant and glutinous agent with high cost performance. Technical indexes of the paper are as follows: Oxygen index (OI): is more than or equal to 32; water content (percent): 6 to 14; quantitation (g / m2): in 50 to 120 or 130 to 450; transversal ring crush compression index (N is multiplied by m2 / g): anticipated as 2.5 to 5 or is more than or equal to 5. The paper-making method is characterized by impregnating flame retarding and fluid of glutinous agent (also named as sizing agent) on raw paper with a papermaking machine or / and a coating machine, and then, by being dried on a drying cylinder on the machine before being reeled and formed in a one-through way.

Owner:上海嘉龙纸业有限公司

Process for coating paper, paperboard, and molded fiber with a water-dispersible polyester polymer

ActiveUS7435483B2Increased reduced vapor permeationIncreased reduced sizingNon-fibrous pulp additionSpecial paperFiberPolyester

Disclosed are coated fiber-containing articles, including paper, paperboard, and molded fiber, and methods for preparing such articles. A preferred method comprises heating paperboard containing a polymeric binder to a temperature sufficient to remove at least some moisture from the paperboard; applying an aqueous dispersion or solution of at least one water-dispersible or water-soluble polymer to the paperboard product; heating the paperboard to at least partially cure the water-dispersible or water-soluble polymer; and cooling the paperboard to at least 160° F. to reduce the tackiness of the cured water-dispersible polymer.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

Method and apparatus for the application of plastics coatings

The invention relates to an apparatus for the application of coatings to surfaces of substrates in the form of paper, paperboard, or plastics foils, preferably for the finishing of print products. The apparatus encompasses a coating unit for the application of coating material in fluid form to the substrate surface, and equipment for smoothing of the film while it is still fluid after it has been applied by means of the coating unit to the substrate surface, where the equipment encompasses equipment for generating a gas stream orientated onto the substrate surface coated with the film, where the gas stream smooths the film with at least partial elimination of undesired structures in the film surface, e.g. depressions, elevations and craters, prior to the hardening of the coating material.

Owner:ACTEGA SCHMID RHYNER AG

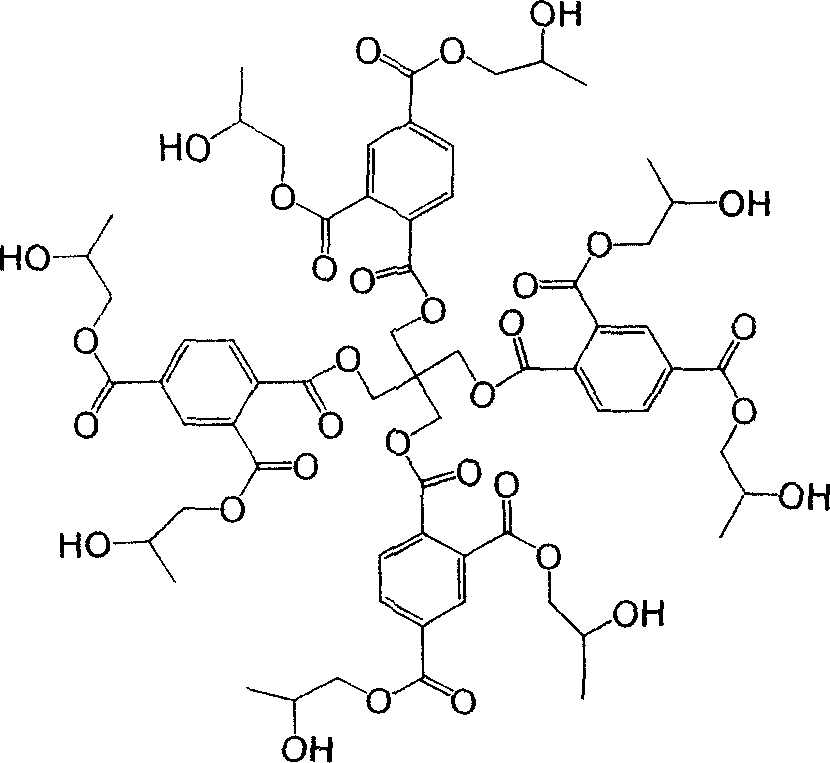

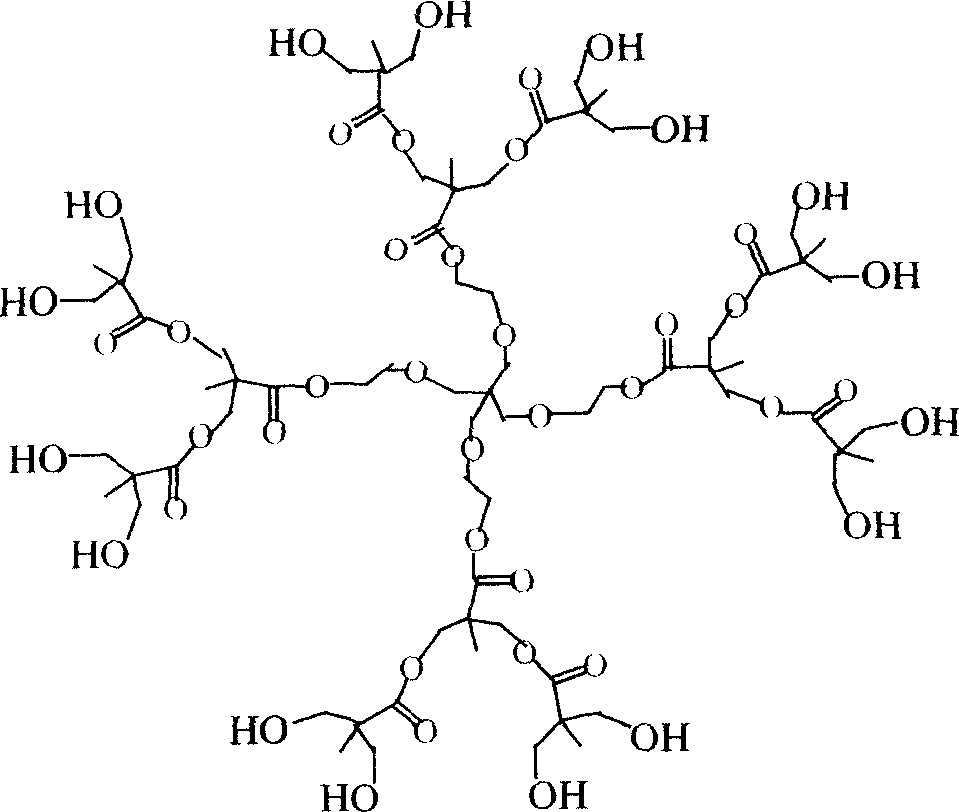

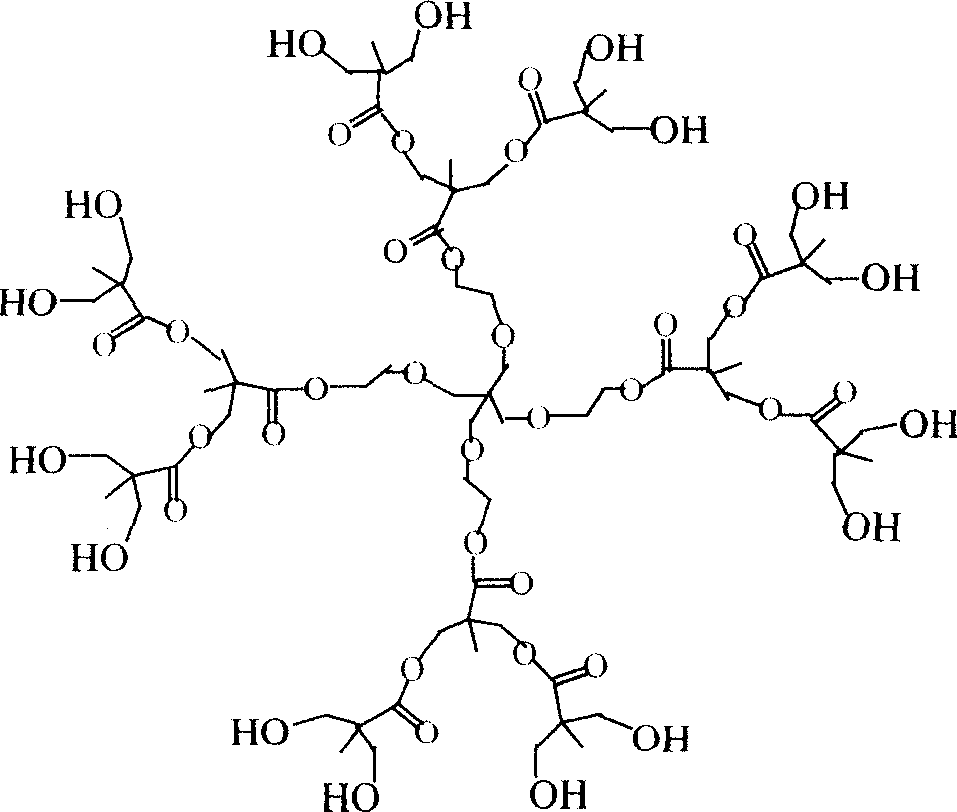

Method for preparing super branched polyacrylate fluorine and application in finishing agent for textile

InactiveCN1687180AWide variety of sourcesNovel preparation methodFibre treatmentPhysical paper treatmentEnd-groupDouble bond

The present invention relates to a fluorine-contained ultrabranched polyacrylate which can be used in water-proofing oil-proofing fabric finishing agent and its preparation method. Said method includes the following steps: using hydroxyterminated ultrabranched polyester as reaction substrate, adopting 'direct method' or 'indirect method' to modifying its hydroxyl end group into polymerizable active double bond, then adding perfluorinated acyl chlroide or esters, and making it and residual hydroxyl end group of said ultrabranched polyester implement esterification reaction; finally making part of its terminal group form into acrylate double bond and making its another part form into perfluoroalkyl so as to obtain the fluorine-contained ultrabranched polyacrylate. Then said fluorine-contanied ultrabranched polyacrylate and hydrocarbon (methyl) acrylate are undergone the process of emulsion copolymerization so as to obtain the water-proofing oil-proofing fluorine-contained fabric finishing agent emulsion.

Owner:上海瀛正科技有限公司

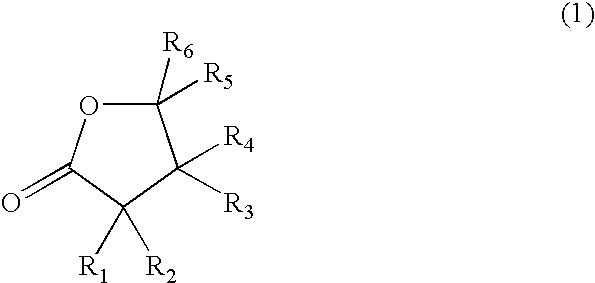

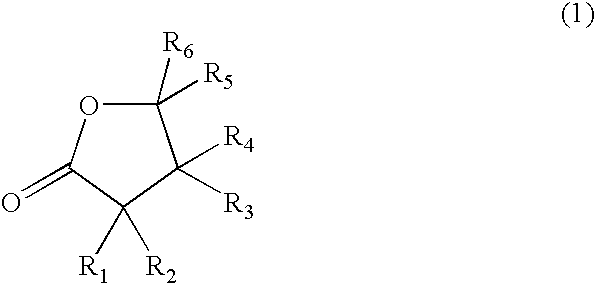

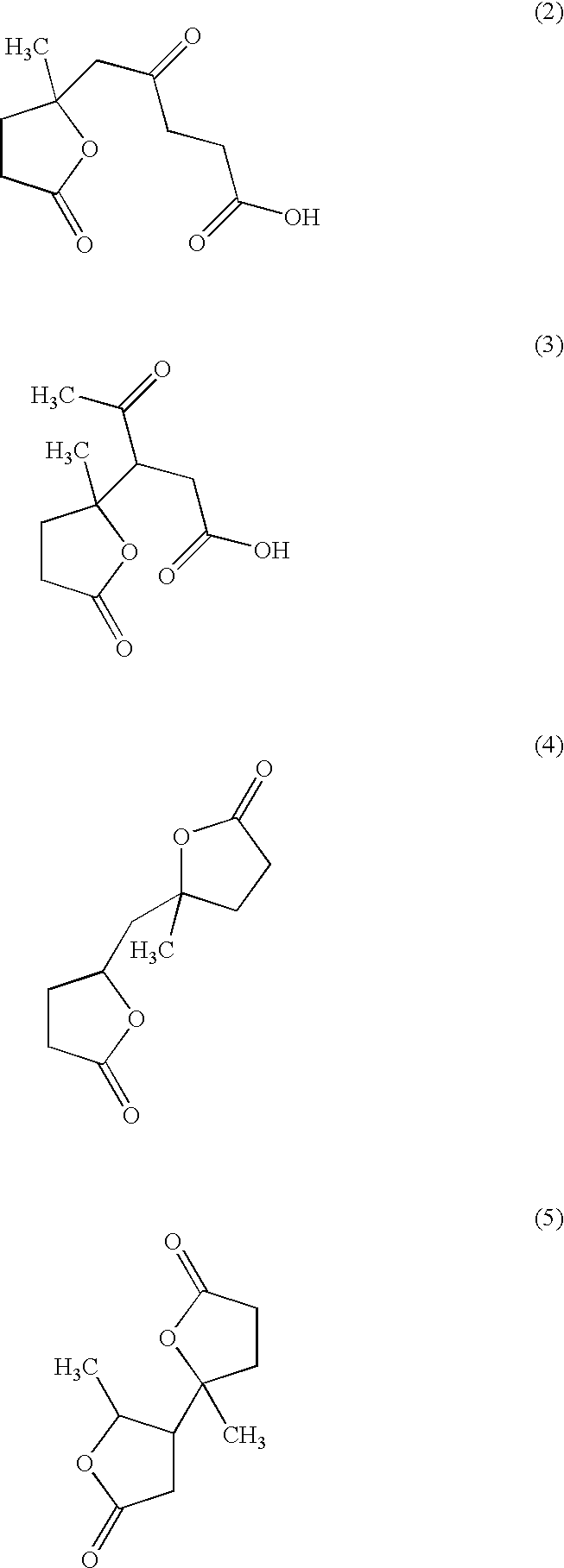

Process for organosolv pulping and use of a gamma lactone in a solvent for organosolv pulping

InactiveUS20070034345A1High boiling pointReduce stressPulp properties modificationPulp bleachingHydrogen atomOrganic group

The invention provides a process for organosolv pulping, wherein solid lignocellulosic feed material is heated at a temperature in the range of from 50 to 210° C. in a solvent to obtain a solid cellulosic fraction comprising at least 50 wt % of the cellulose present in the feed material and a liquid fraction, wherein the solvent comprises at least 10 wt % of a compound according to general molecular formula wherein R1 to R6 each represent, independently, a hydrogen atom or an organic group connected with a carbon atom to the lactone group. The invention further provides the use of a compound according to general molecular formula (1) in a solvent for organosolv pulping.

Owner:SHELL OIL CO

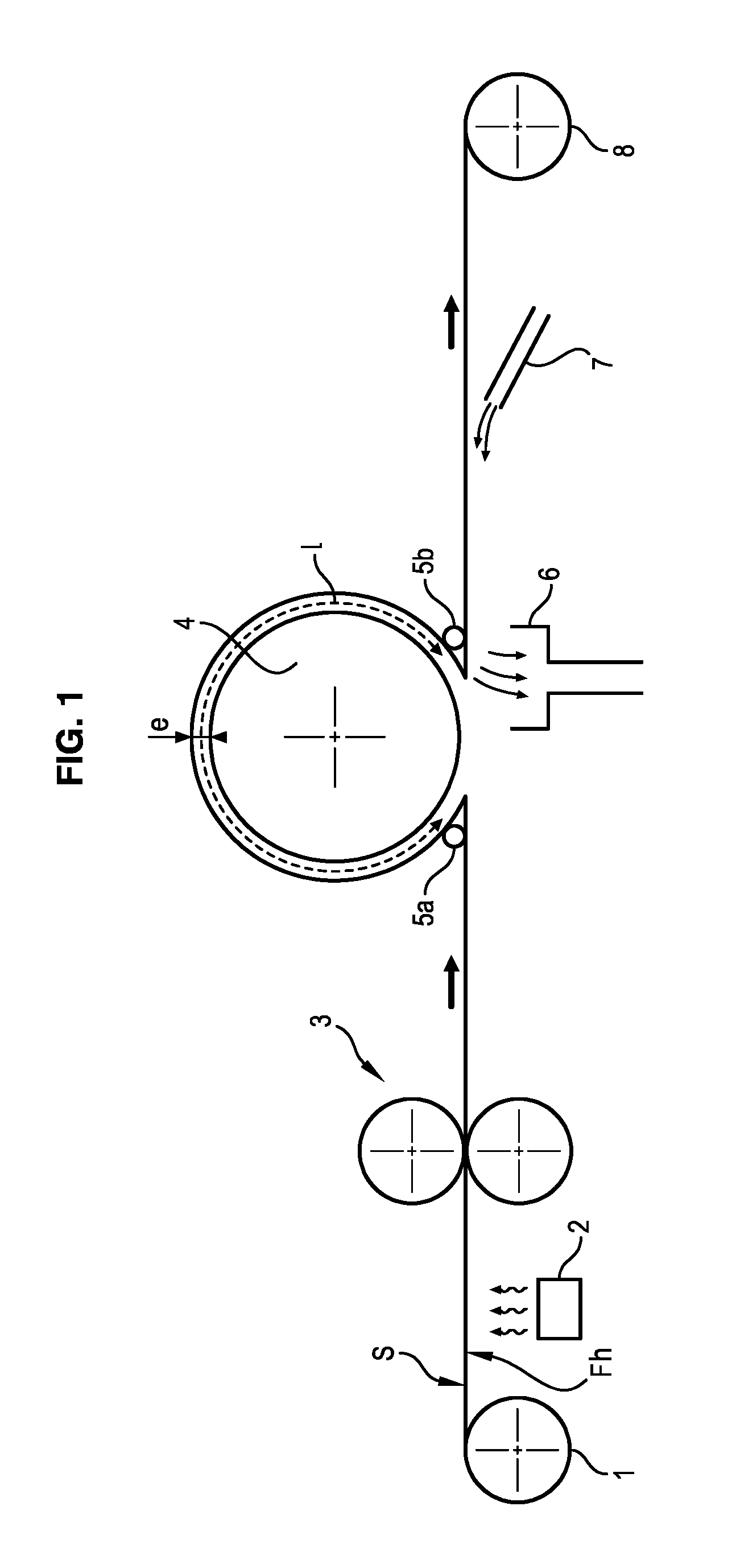

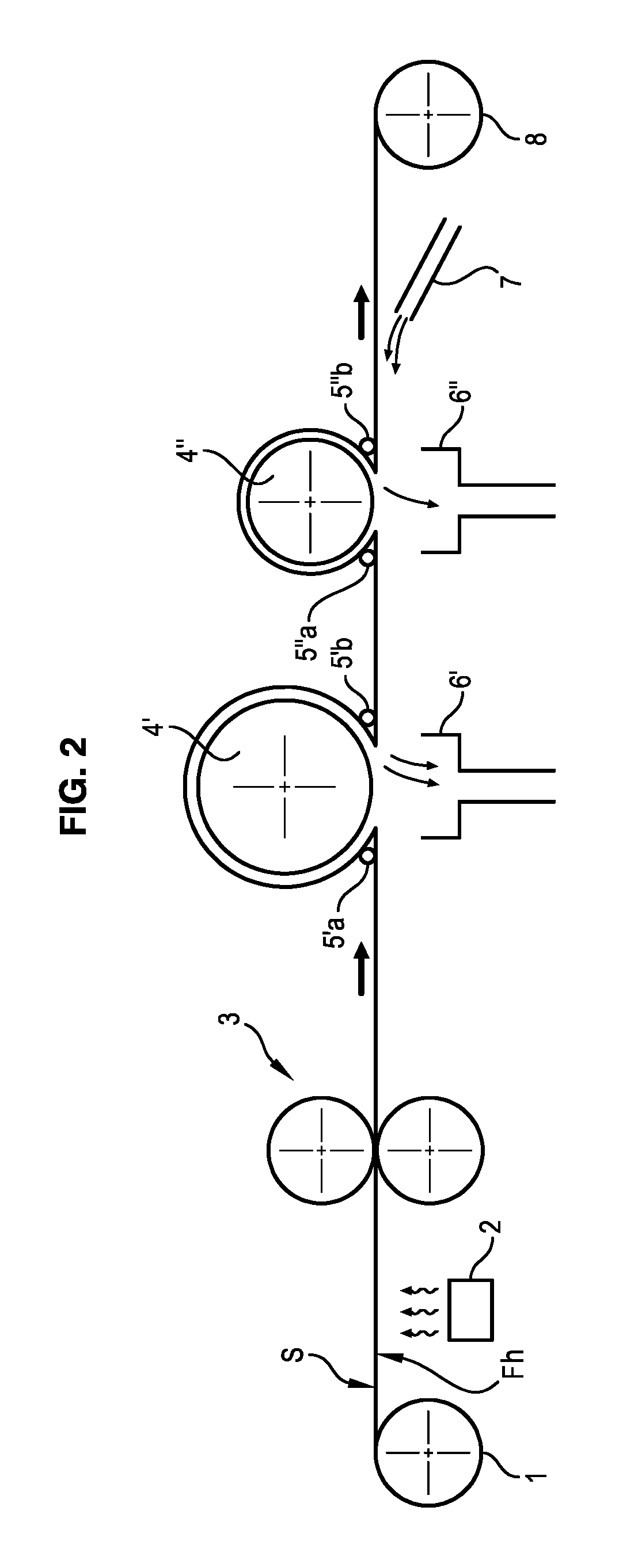

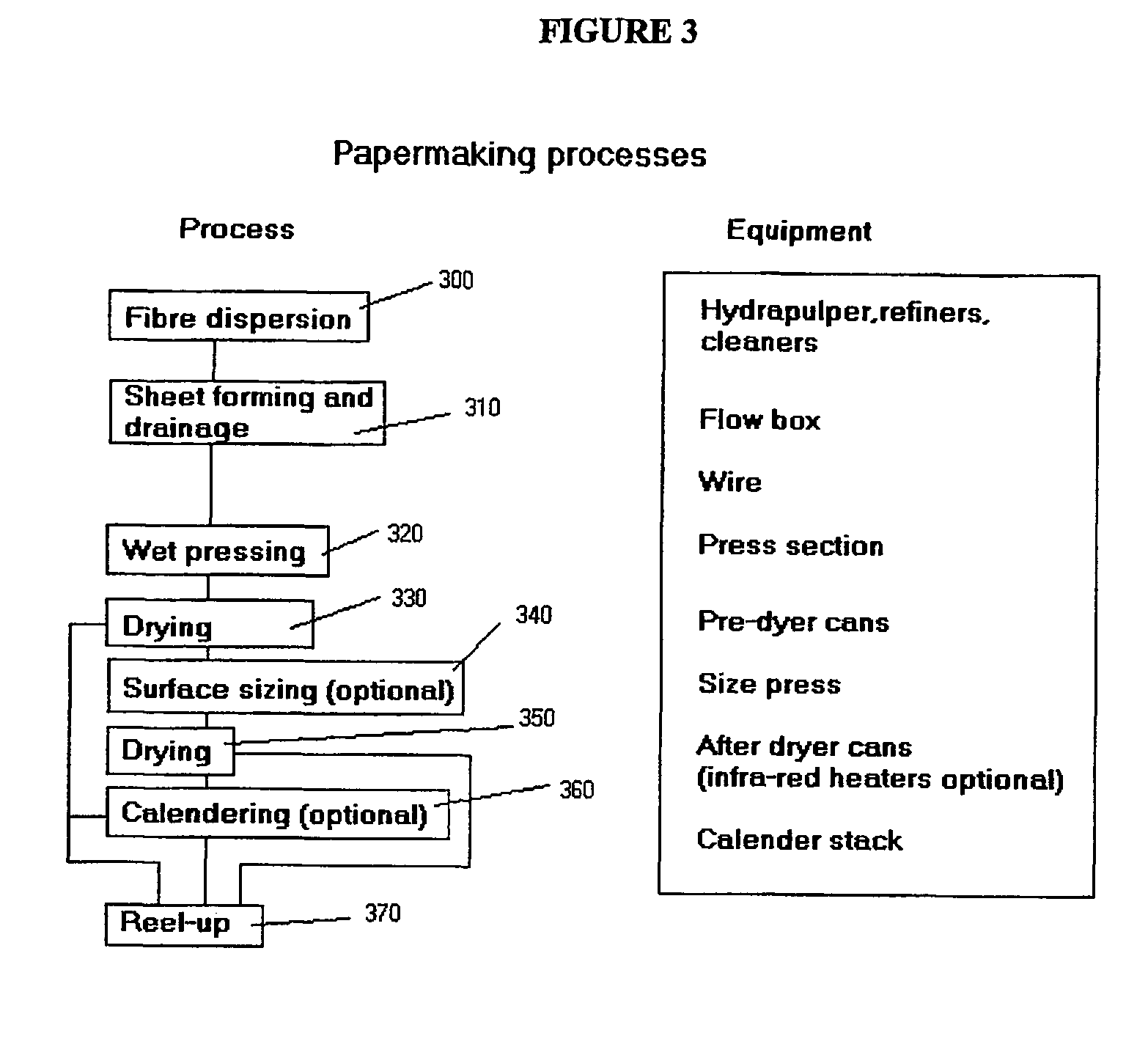

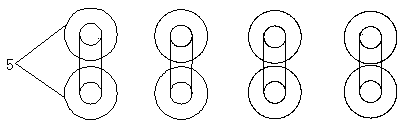

Method for producing a wet-laid nonwoven fabric

ActiveUS10443167B2Occurrence can be suppressedEasy to confirmSemi-permeable membranesPaper/cardboardPapermakingSlurry

A method for producing a wet-laid nonwoven fabric for a semipermeable membrane supporting body, the method comprising: performing papermaking according to a wet papermaking method by using a fiber slurry containing a synthetic fiber as a main constituent fiber; drying the fiber slurry; subsequently subjecting the dried sheet to hot press processing two times by using a heat calender apparatus, wherein the hot press process temperature in the second treatments is adjusted to be higher by 10° C. or more than the hot press processing temperature in the first treatment, while treating the dried sheet by using a hard nip heat calender apparatus equipped with a combination of a metal roll and a metal roll for at least one time of the hot press processing; and thereby obtaining a wet-laid nonwoven fabric for a semipermeable membrane supporting body.

Owner:HOKUETSU KK

Manufacturing method of impregnated bond paper for low formaldehyde furniture

ActiveCN105369687AIncrease crosslink densityPromote chemical reactionSpecial paperPaper/cardboardPulp and paper industryWetting

The invention discloses a manufacturing method of impregnated bond paper for low formaldehyde furniture. The method comprises the steps of raw paper selection and treatment, uncoiling, pre-wetting, impregnation, first time drying, gluing, preparation of coating glue, second time drying, deviation adjustment traction and cutting. The manufacturing method has the advantages that the quality of the impregnated bond paper prepared with the method is high, the content of formaldehyde is further reduced, the uniformity of impregnation and gluing of the impregnated bond paper is guaranteed in the manufacturing process, the flexibility of a glue layer and the sealing performance of the surface of the glue layer are guaranteed, and accordingly, the problems that the content of formaldehyde is high and the quality is not high in impregnated bond paper are fundamentally solved.

Owner:成都建丰新材料股份有限公司

Preparing technological process of laser aluminum plating paper

ActiveCN101324040AHigh glossGood film formingSpecial visual effect coatingsDecorative surface effectsSurface tension gradientAdhesive

The invention relates to a process method for preparing laser aluminium-plated paper, comprising the steps as follows: OPP film or PET film is coated with a disjuncting layer which is coated with an imaging layer that is mould pressed with laser patterns; the mould pressing layer is coated with adhesive; the OPP film or the PET film is stripped and enwound by a stripping machine, thus obtaining a paper substrate containing the disjuncting layer, the imaging layer and the mould pressing layer; the paper substrate is directly plated with aluminium in vacuum and the aluminium is plated on the disjuncting coating layer; the aluminium-plated layer is coated with a waterborne environmental-protective profile coating protection layer; the laser aluminium-plated paper is obtained by moisture reobtaining and resolved shearing; the process of the invention reasonably chooses resin solvent and adhesive on the basis of a plurality of tests, simultaneously, the process of the invention utilizes suitable tenacity endowed by the molecular structure when the resin and the adhesive are in a coating state, and the performance of the adhesion to optimize the proportion according to the principle of combined surface tension gradient distribution between layers, thus forming the coating layer with high blare, good film-forming performance, environmental-protection and excellent printing performance and good alkali solution permeability simultaneously.

Owner:青州金青云新材料有限公司

Poly (vinyl alcohol)—based formaldehyde-free curable aqueous composition

A formaldehyde-free curable aqueous composition containing polyvinyl alcohol, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition may be used as a binder for non-woven products such as fiberglass insulation. The non-woven products are formed by contacting the formaldehyde-free curable aqueous composition with fibrous components and the mixture is cured to form a rigid thermoset polymer providing excellent strength and water resistance of the cured nonwoven product.

Owner:ARCLIN USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com