Patents

Literature

70 results about "Gas chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is one of the four fundamental states of matter, along with solids, liquids, and plasma. Under ordinary conditions, the gas state is between the liquid and plasma states. A gas may consist of atoms of one element (e.g., H 2, Ar) or of compounds (e.g., HCl, CO 2) or mixtures (e.g., air, natural gas).

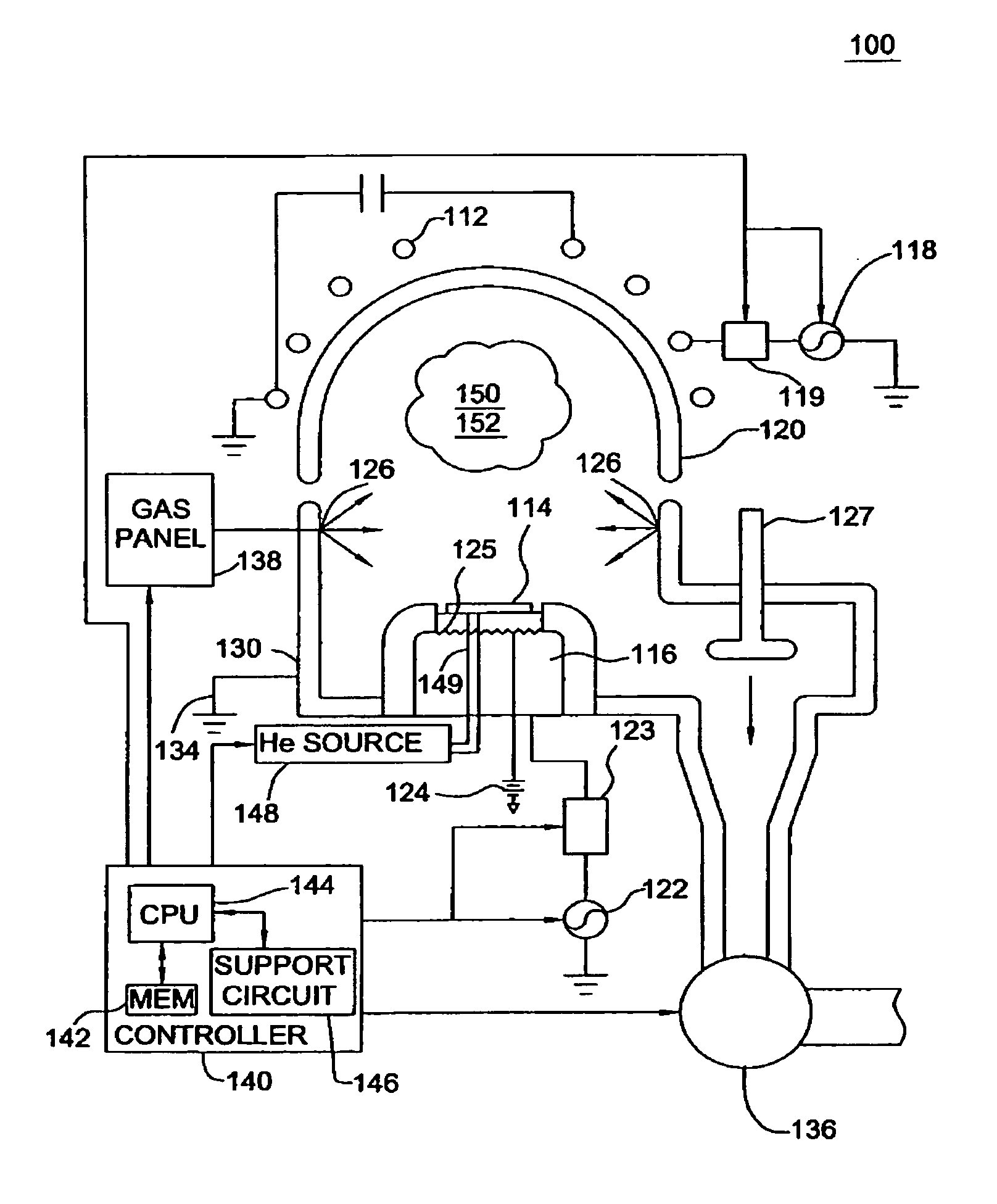

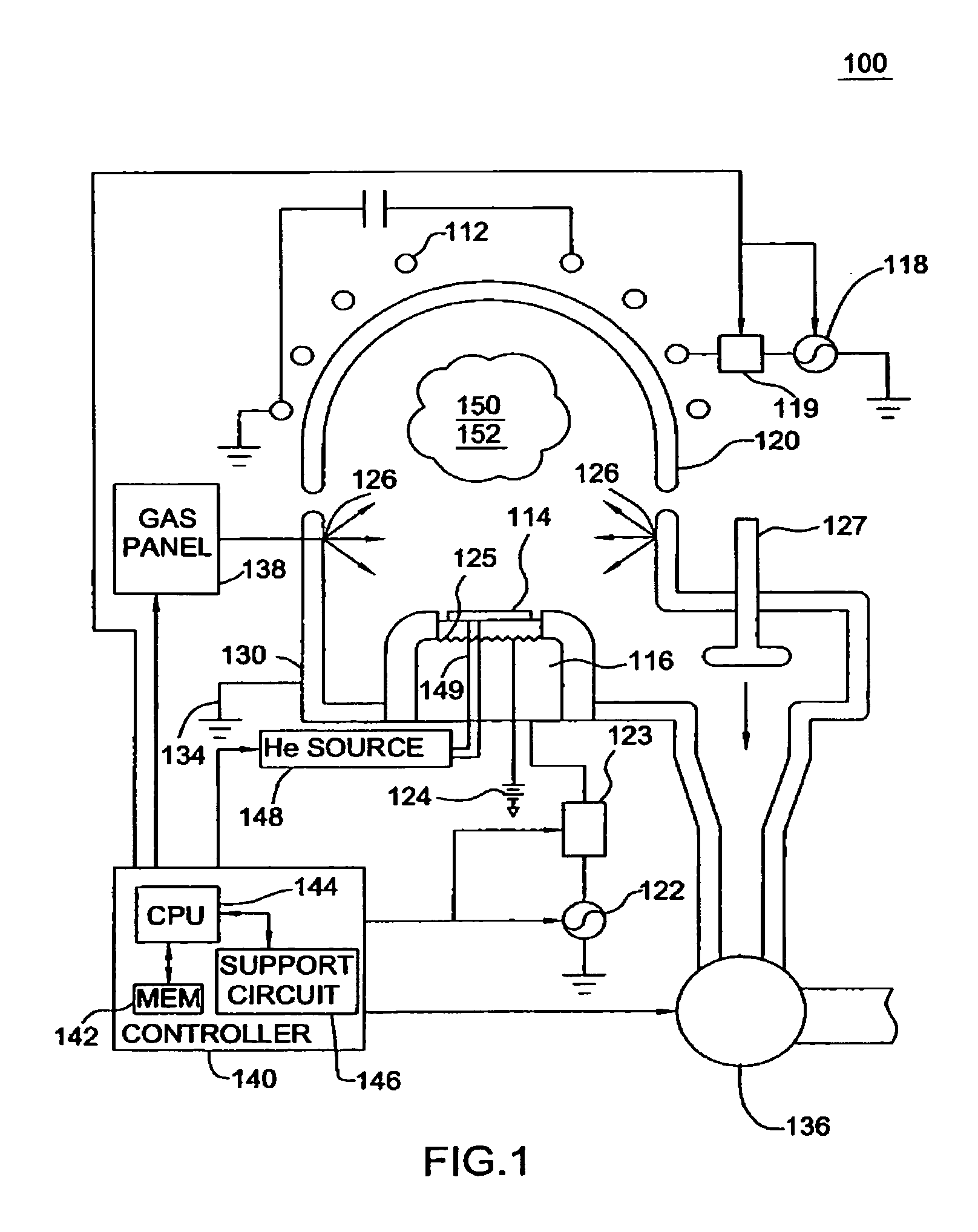

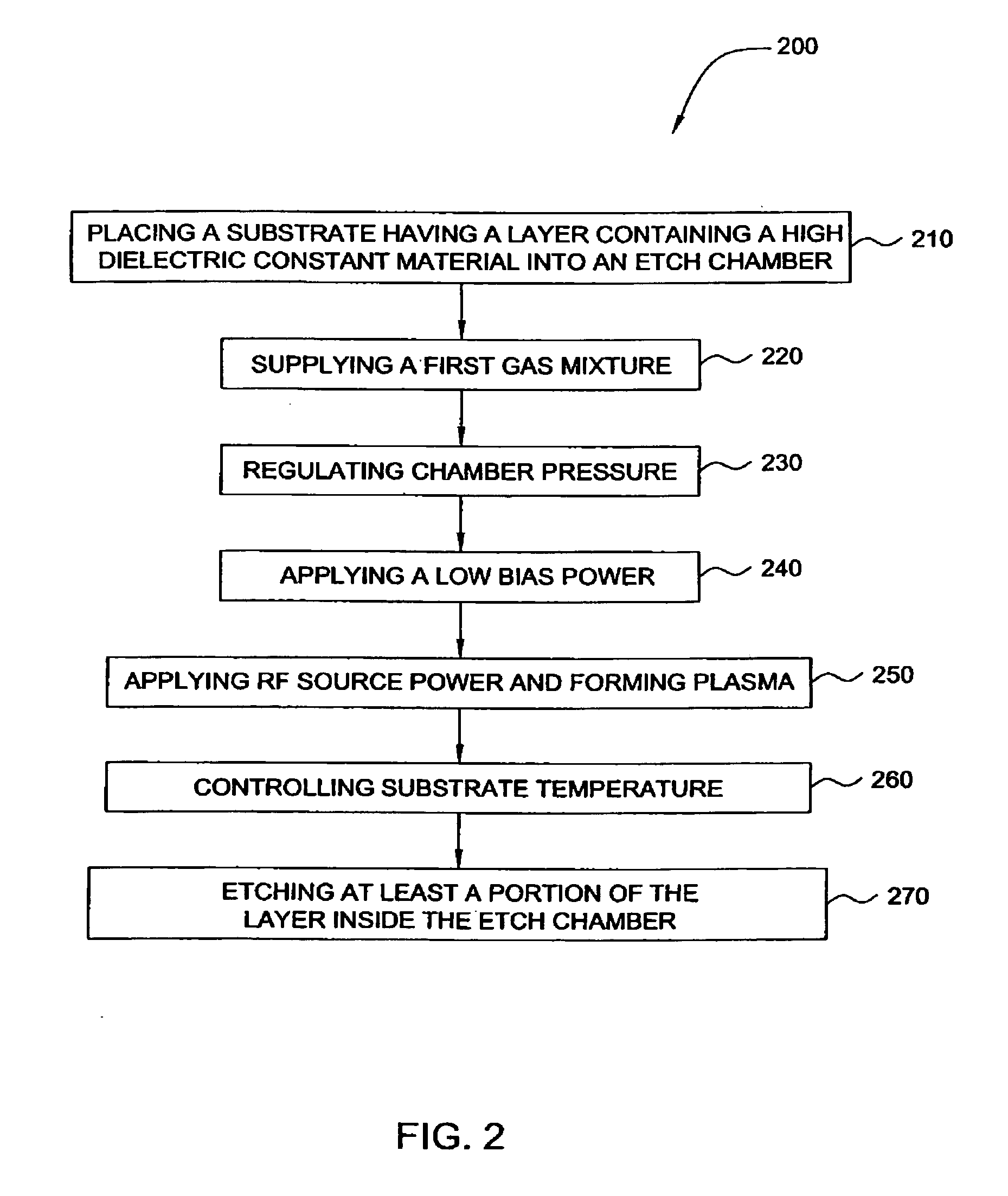

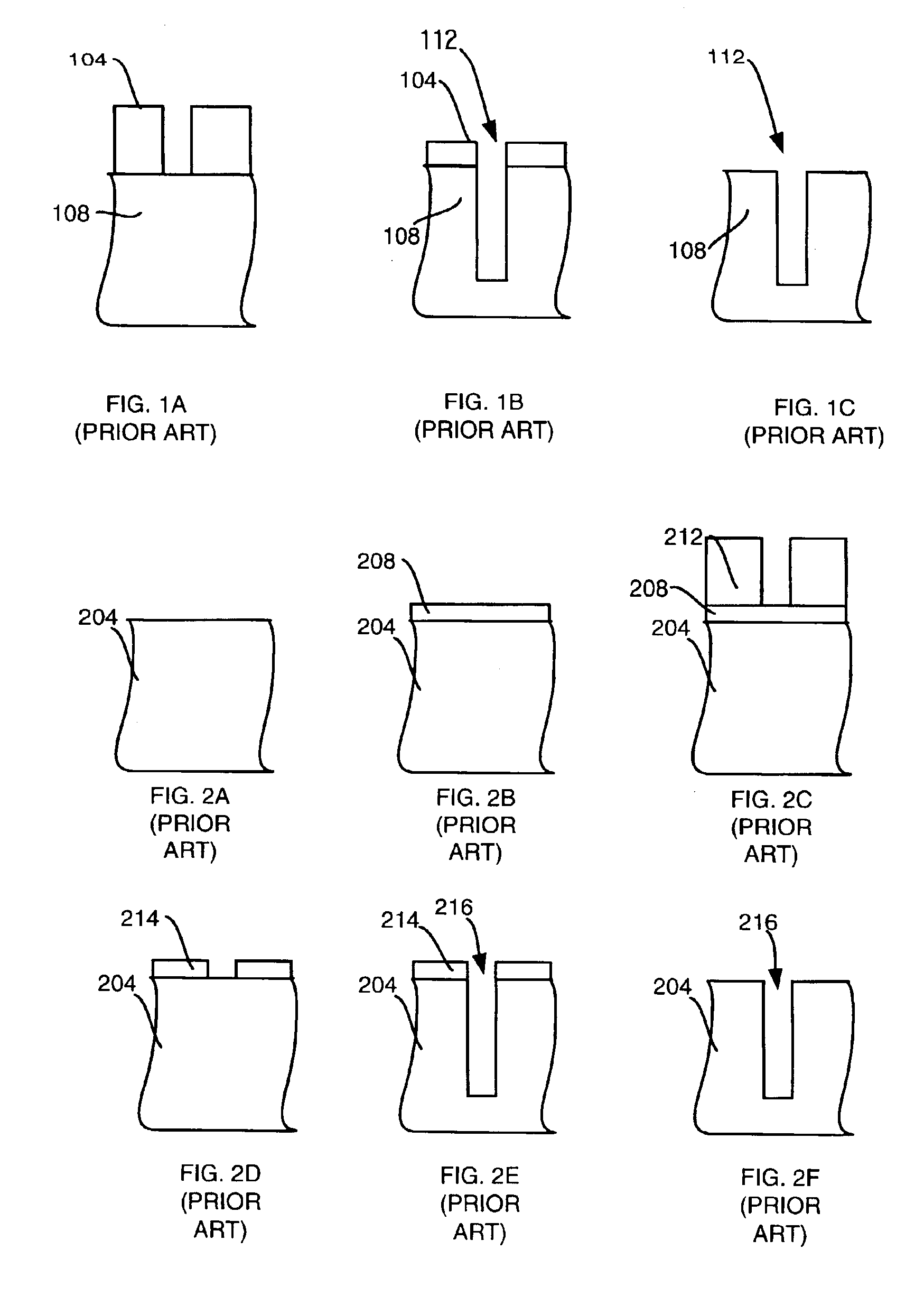

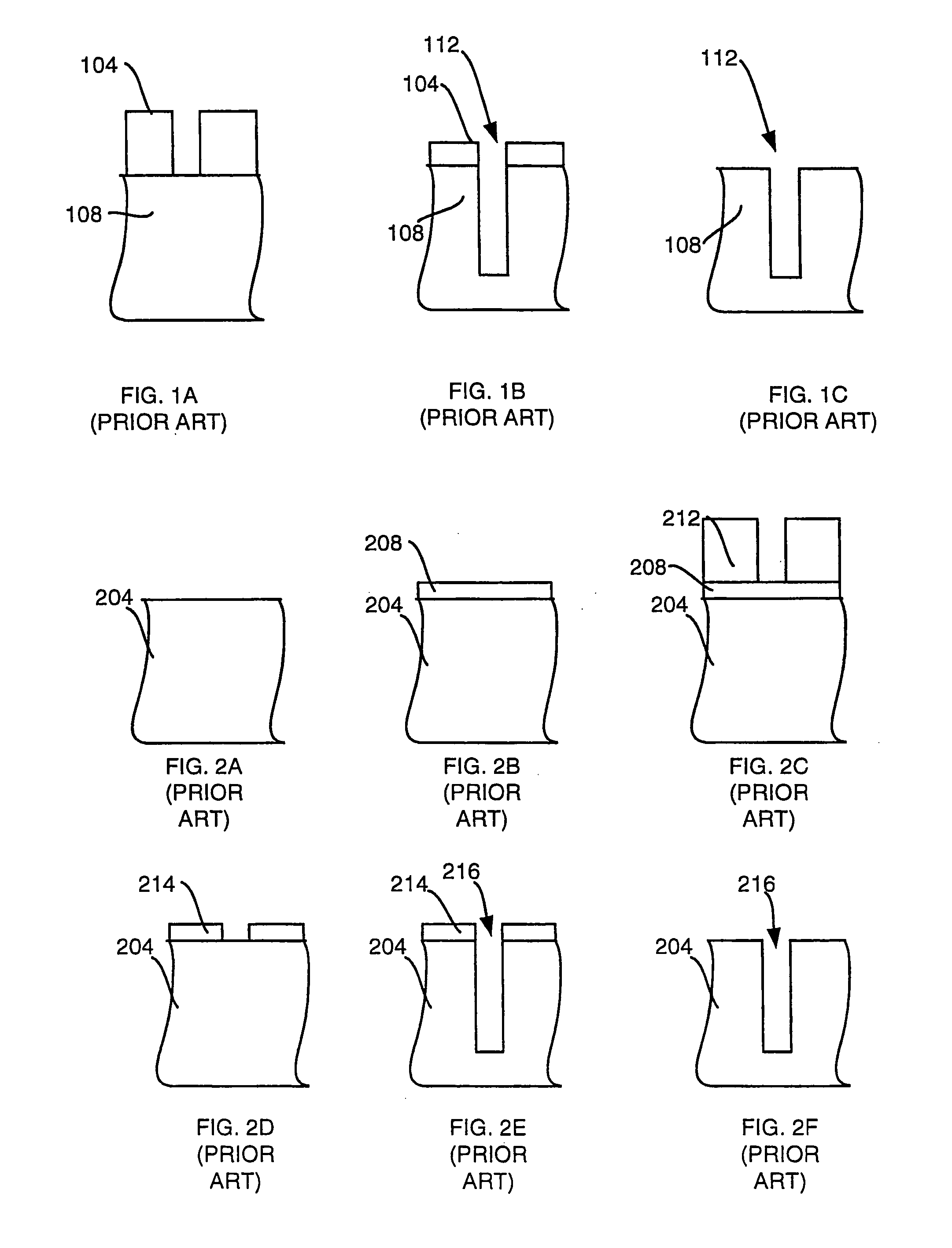

Etching high-kappa dielectric materials with good high-kappa foot control and silicon recess control

InactiveUS20060252265A1High selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingDielectricHalogen

An apparatus and a method for etching high dielectric constant (high-κ) materials using halogen containing gas and reducing gas chemistries are provided. One embodiment of the method is accomplished by etching a layer using two etch gas chemistries in separate steps. The first etch gas chemistry contain no oxygen containing gas in order to break through etching of the high dielectric constant materials, to dean any residues left from previous polysilicon etch process resulting in less high-κ foot, and also to control silicon recess problem associated with an underlying silicon oxide layer. The second over-etch gas chemistry provides a high etch selectivity for high dielectric constant materials over silicon oxide materials to be combined with low source power to further reduce silicon substrate oxidation problem.

Owner:APPLIED MATERIALS INC

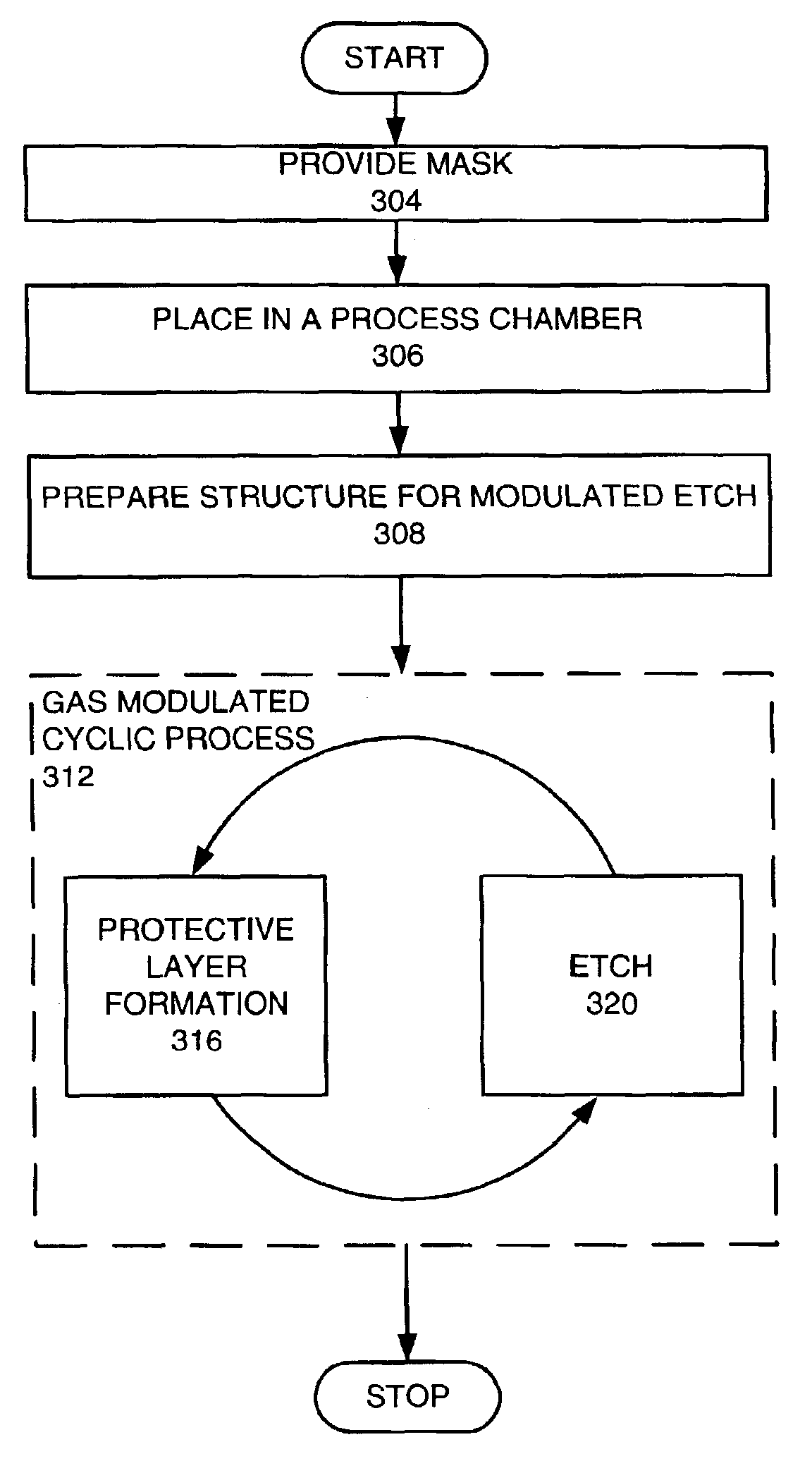

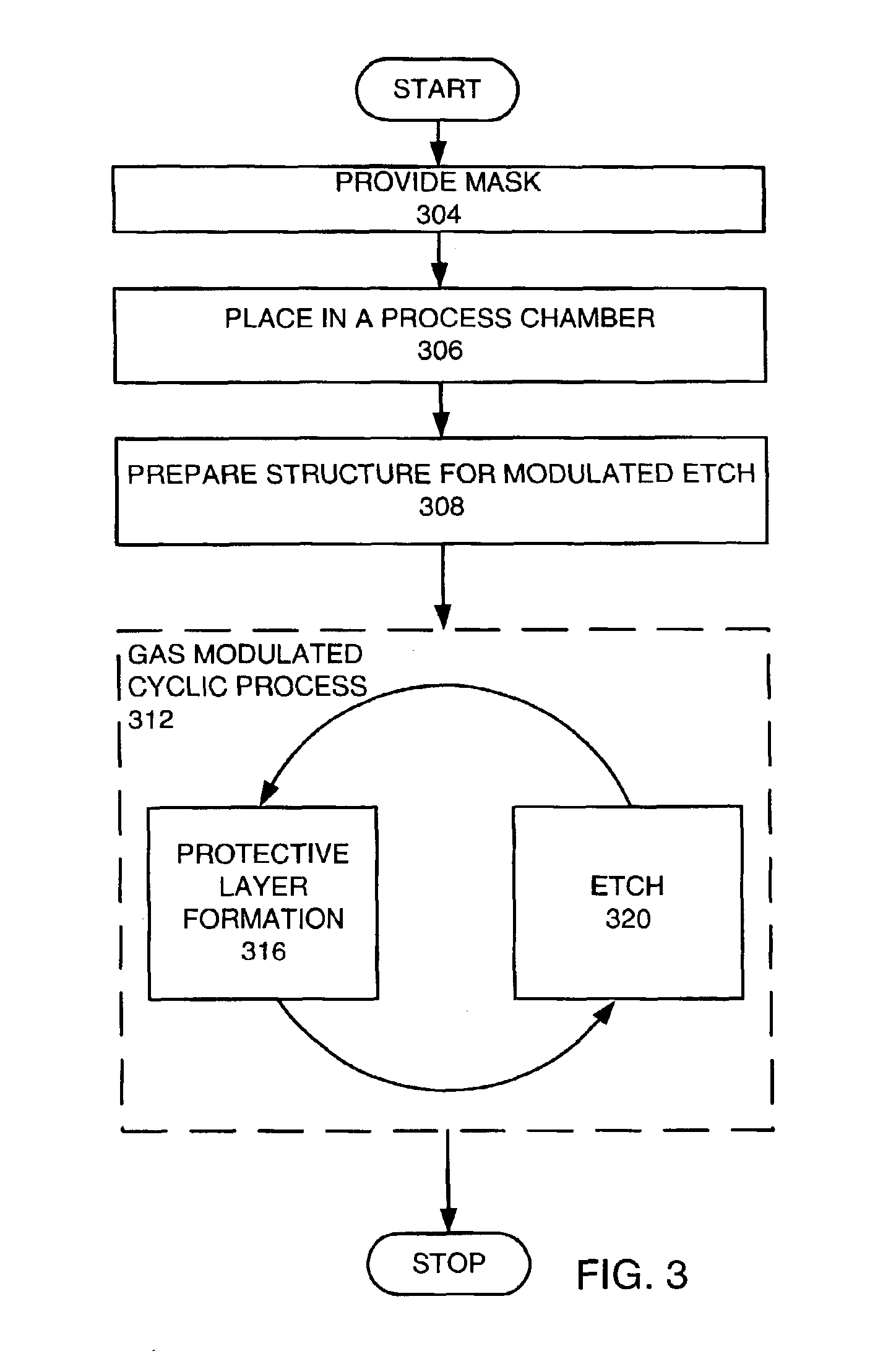

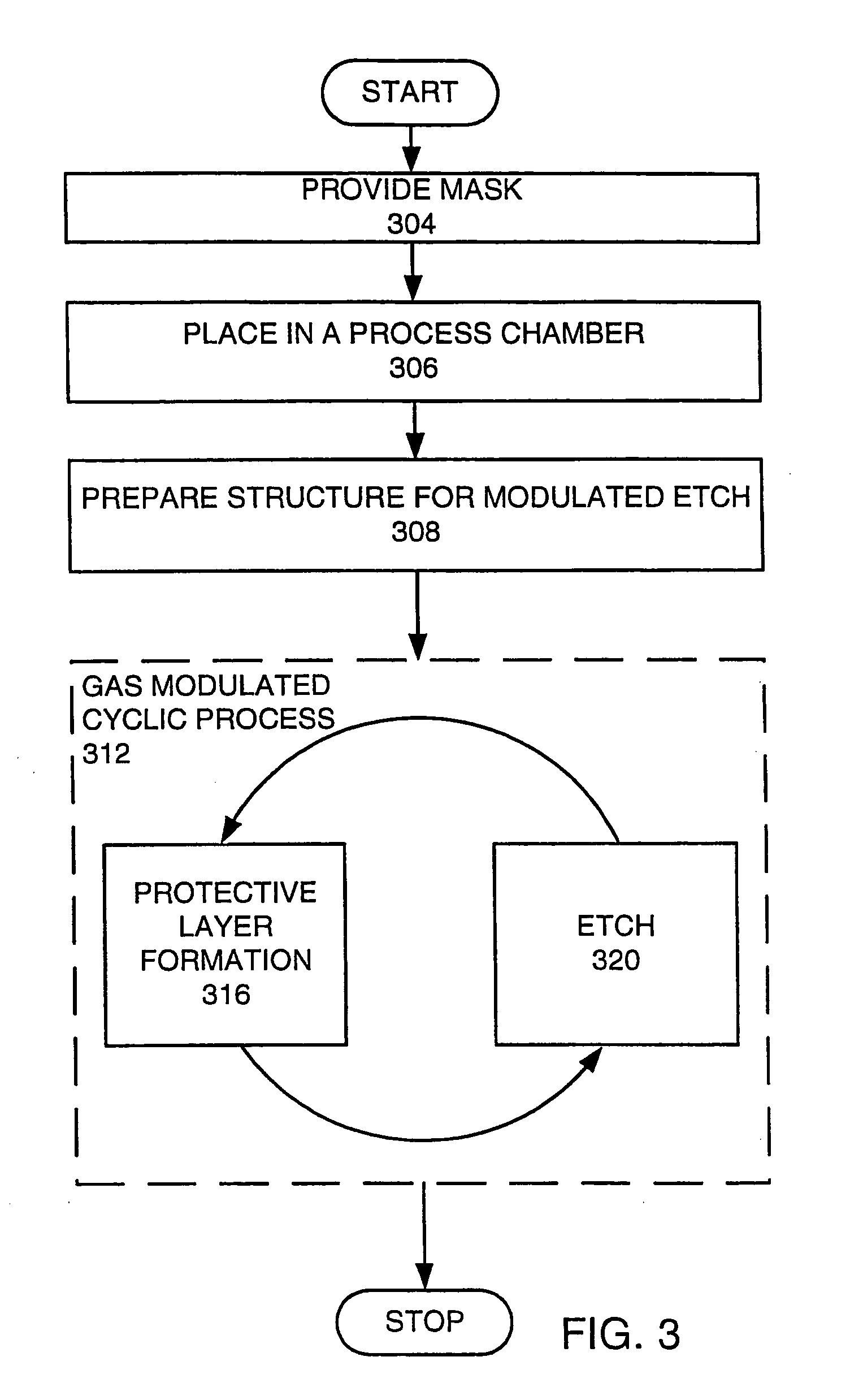

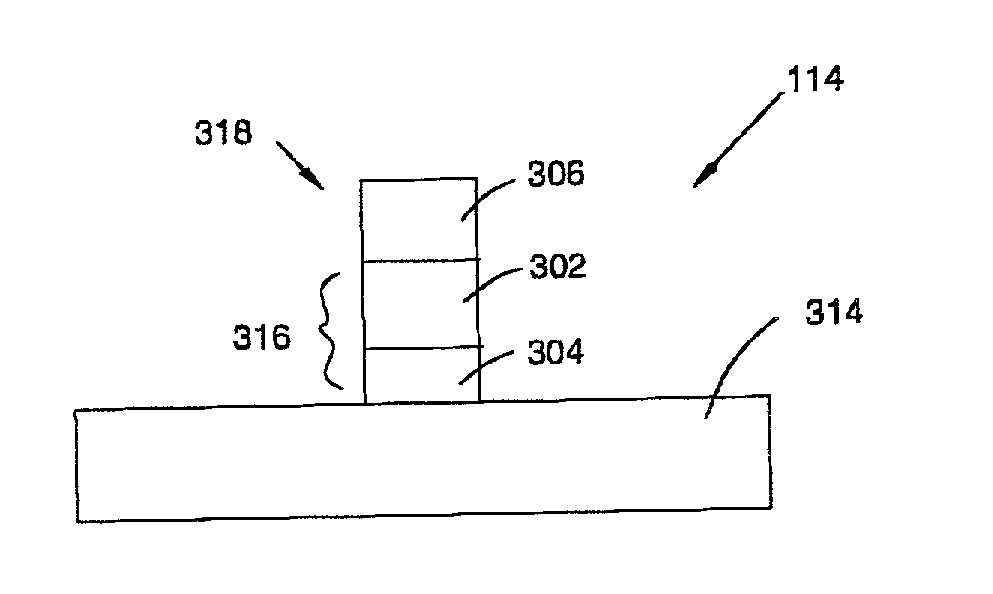

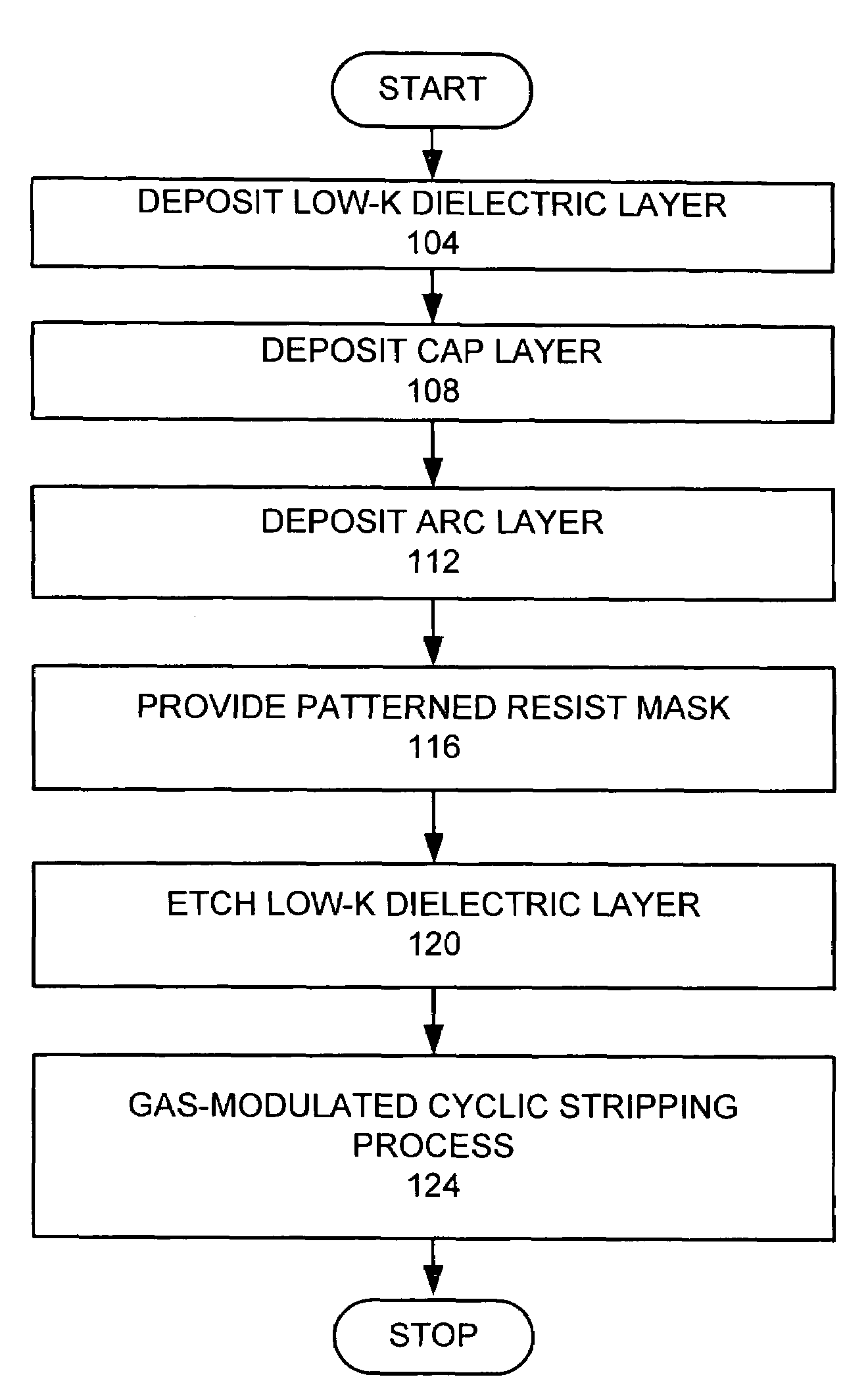

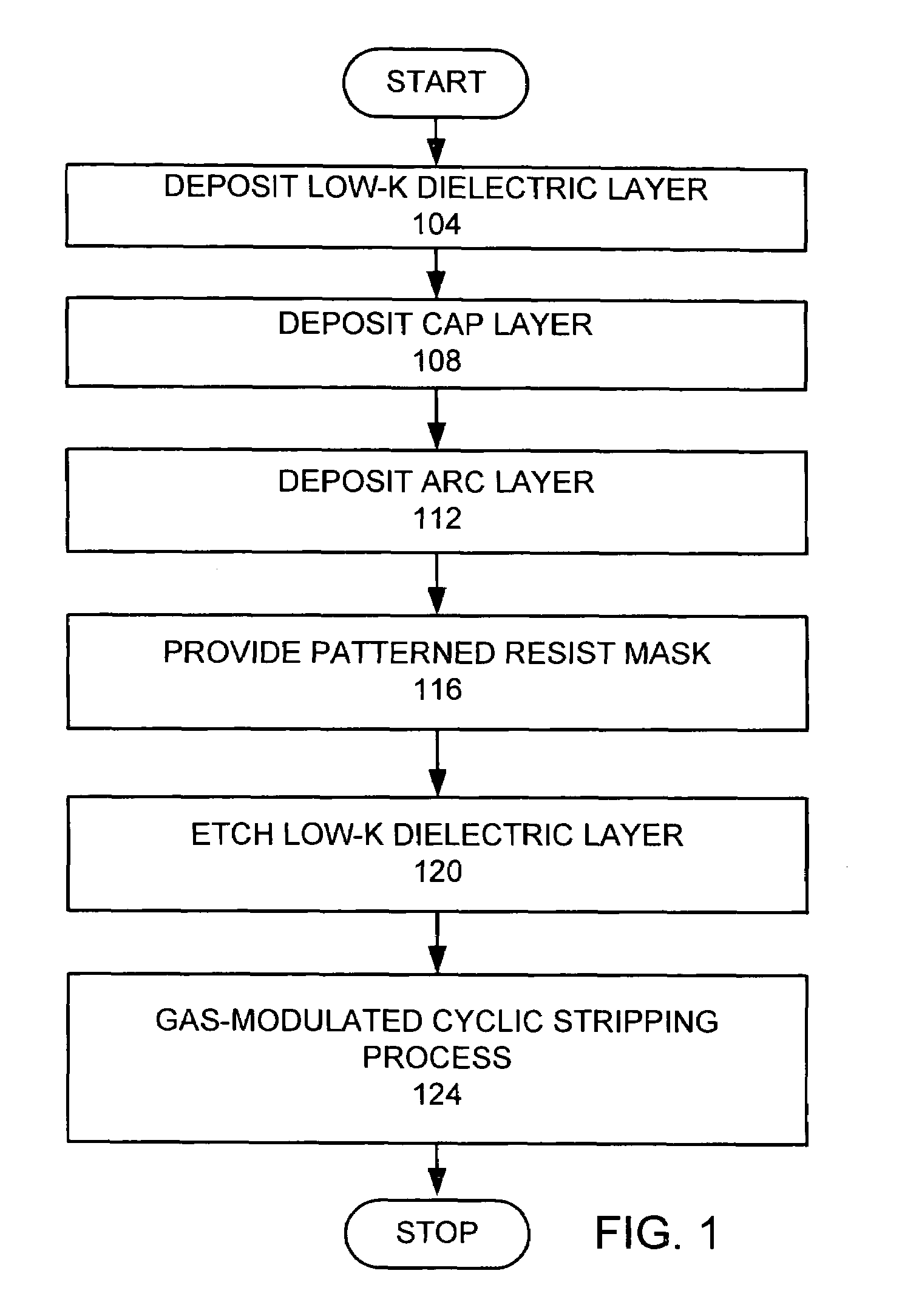

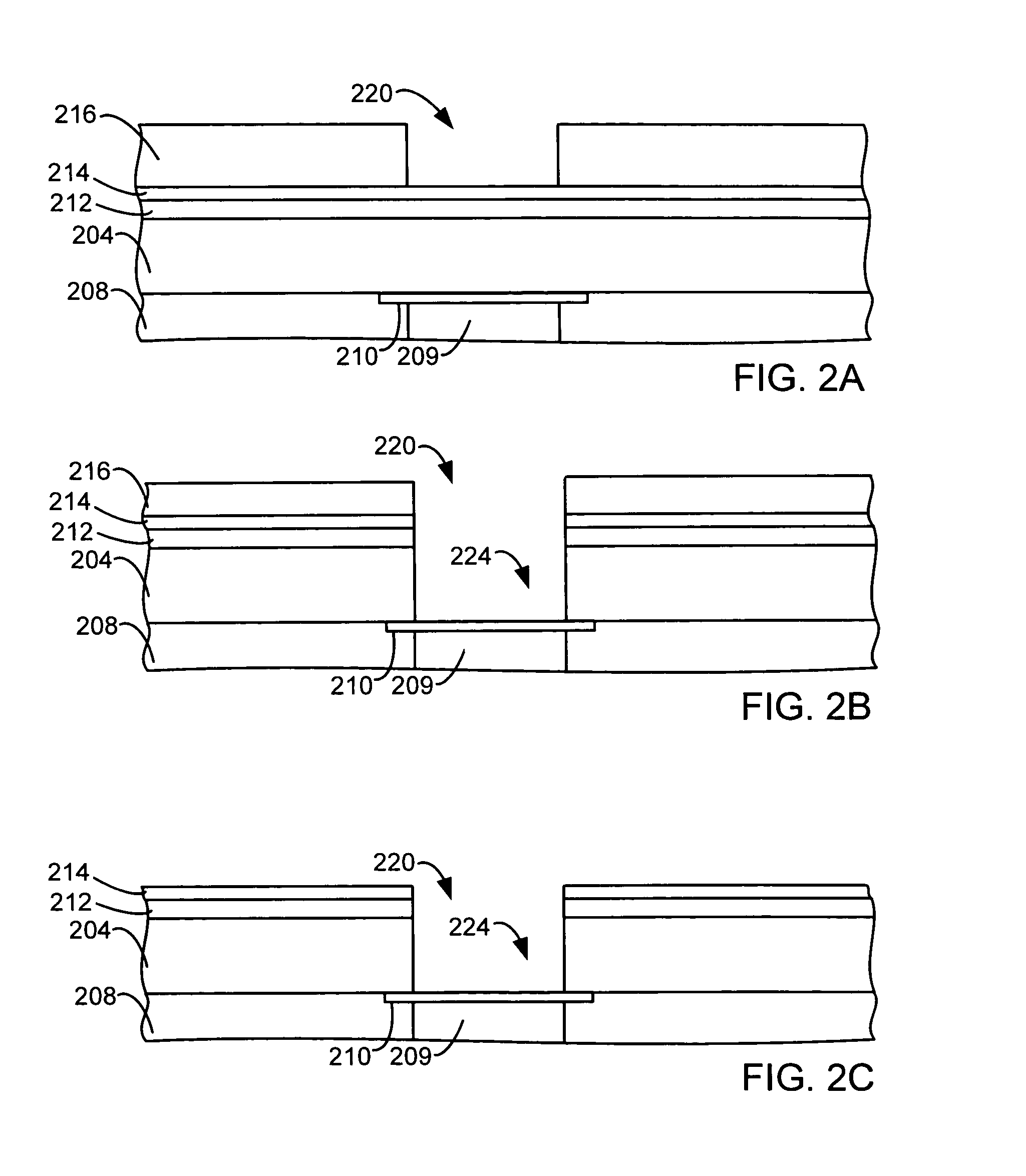

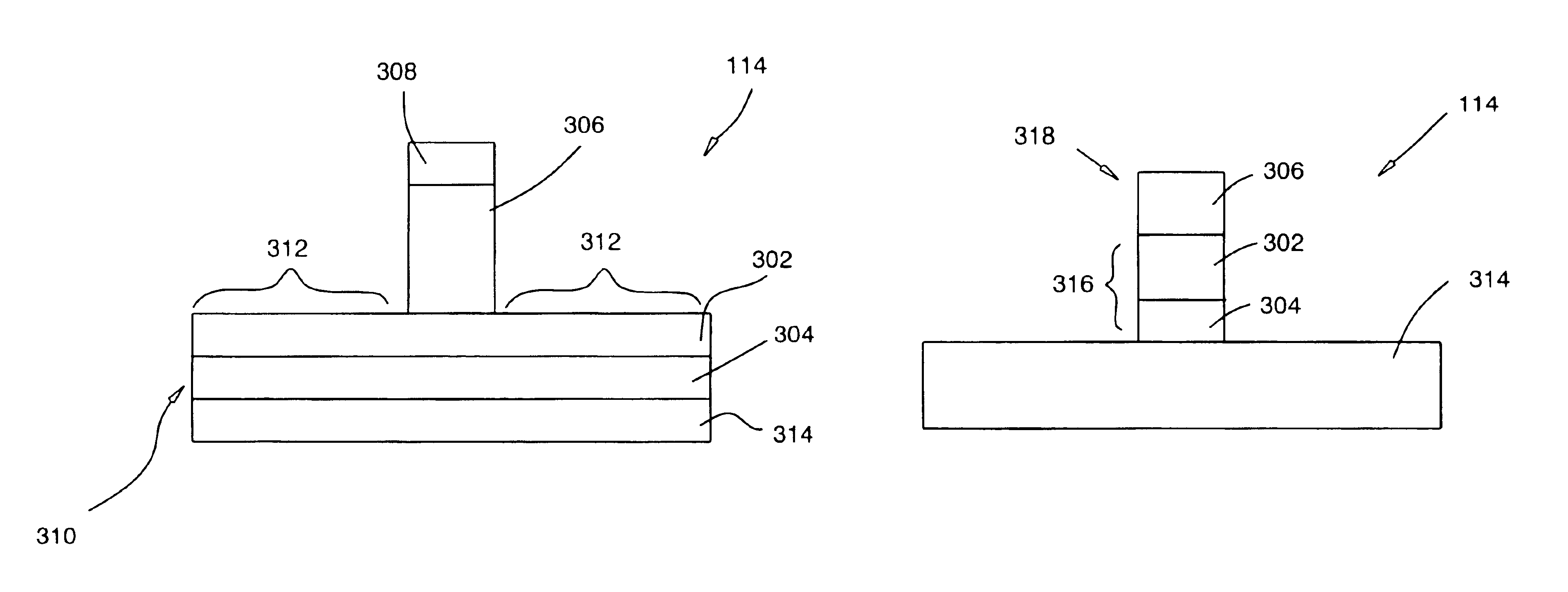

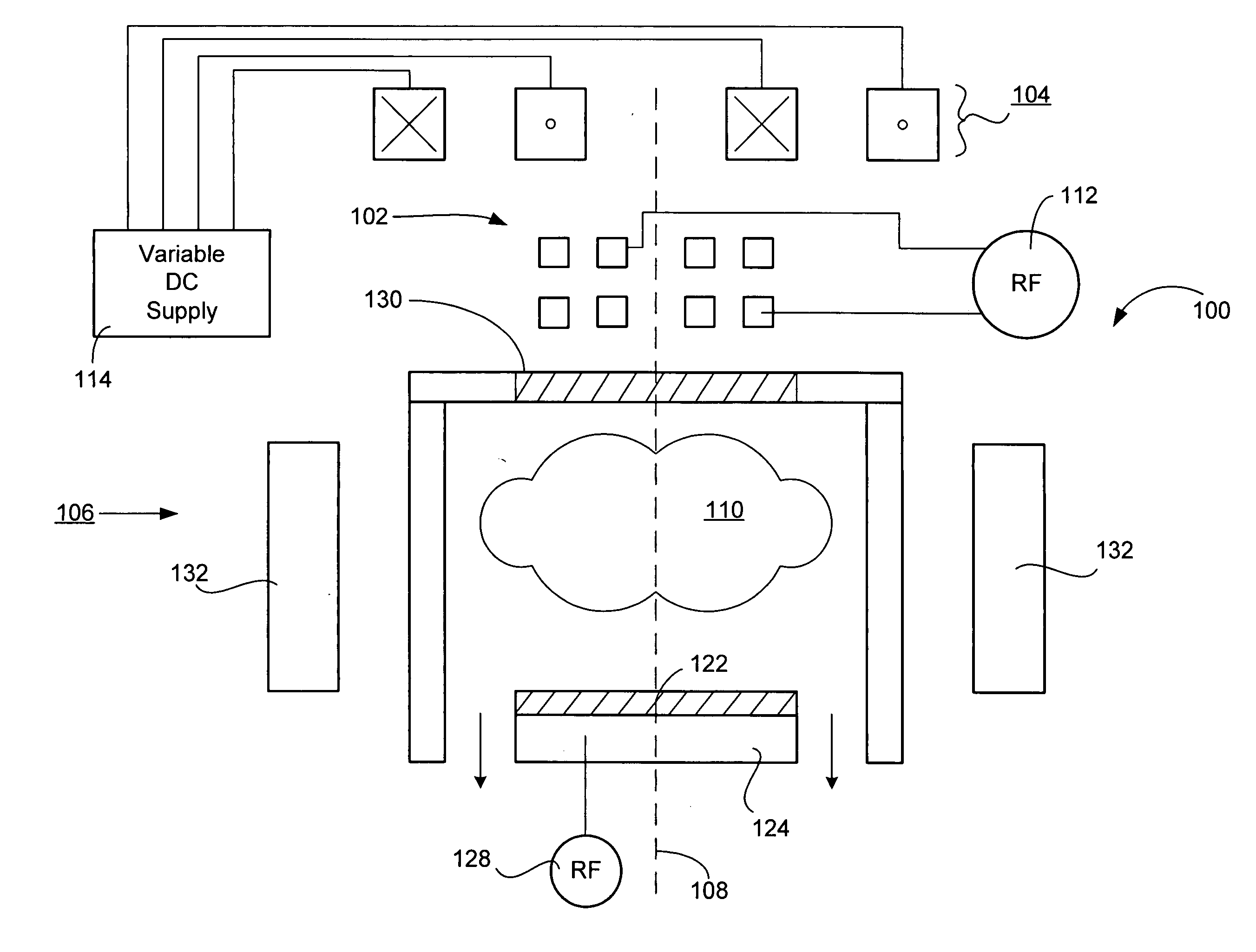

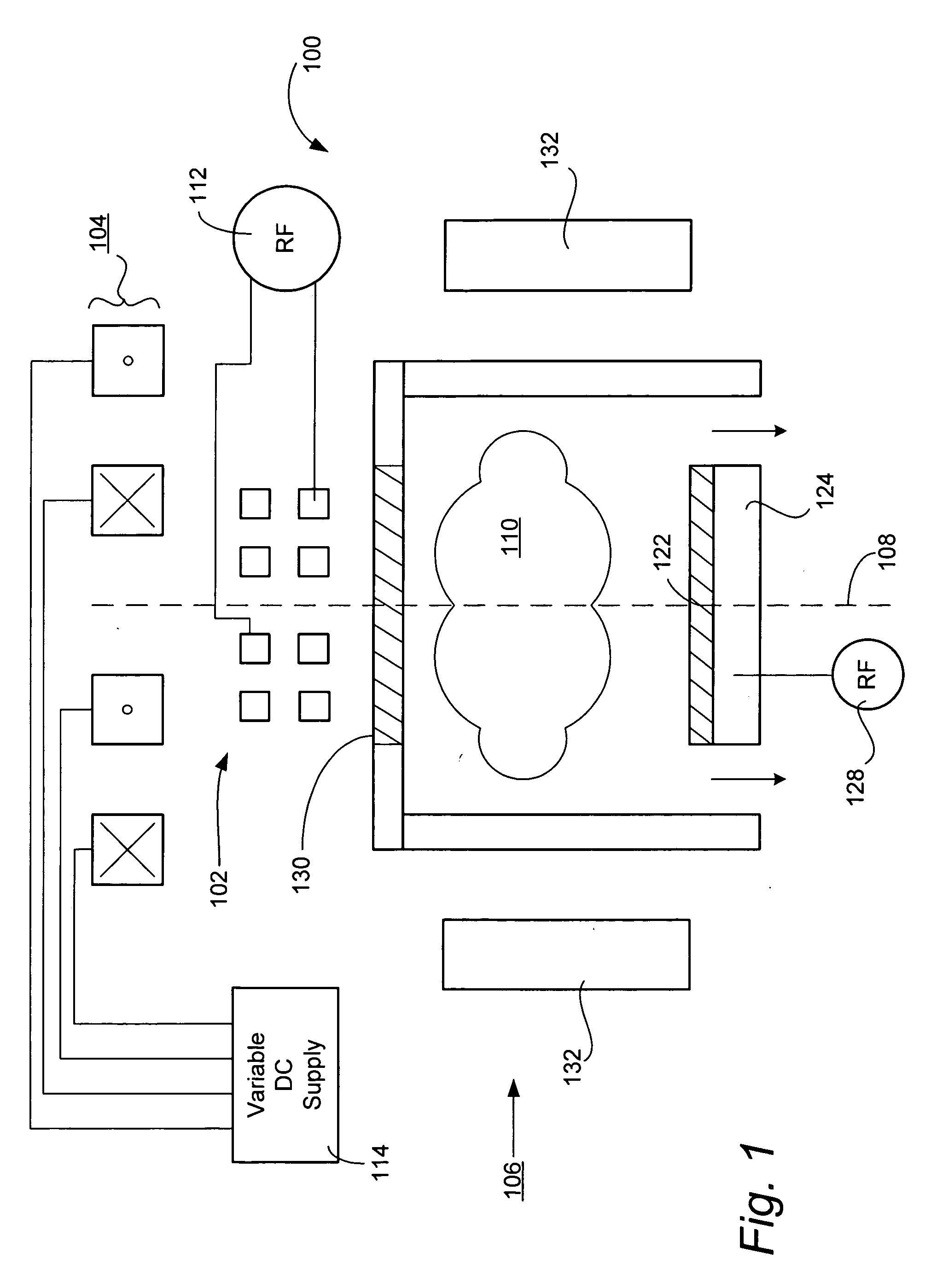

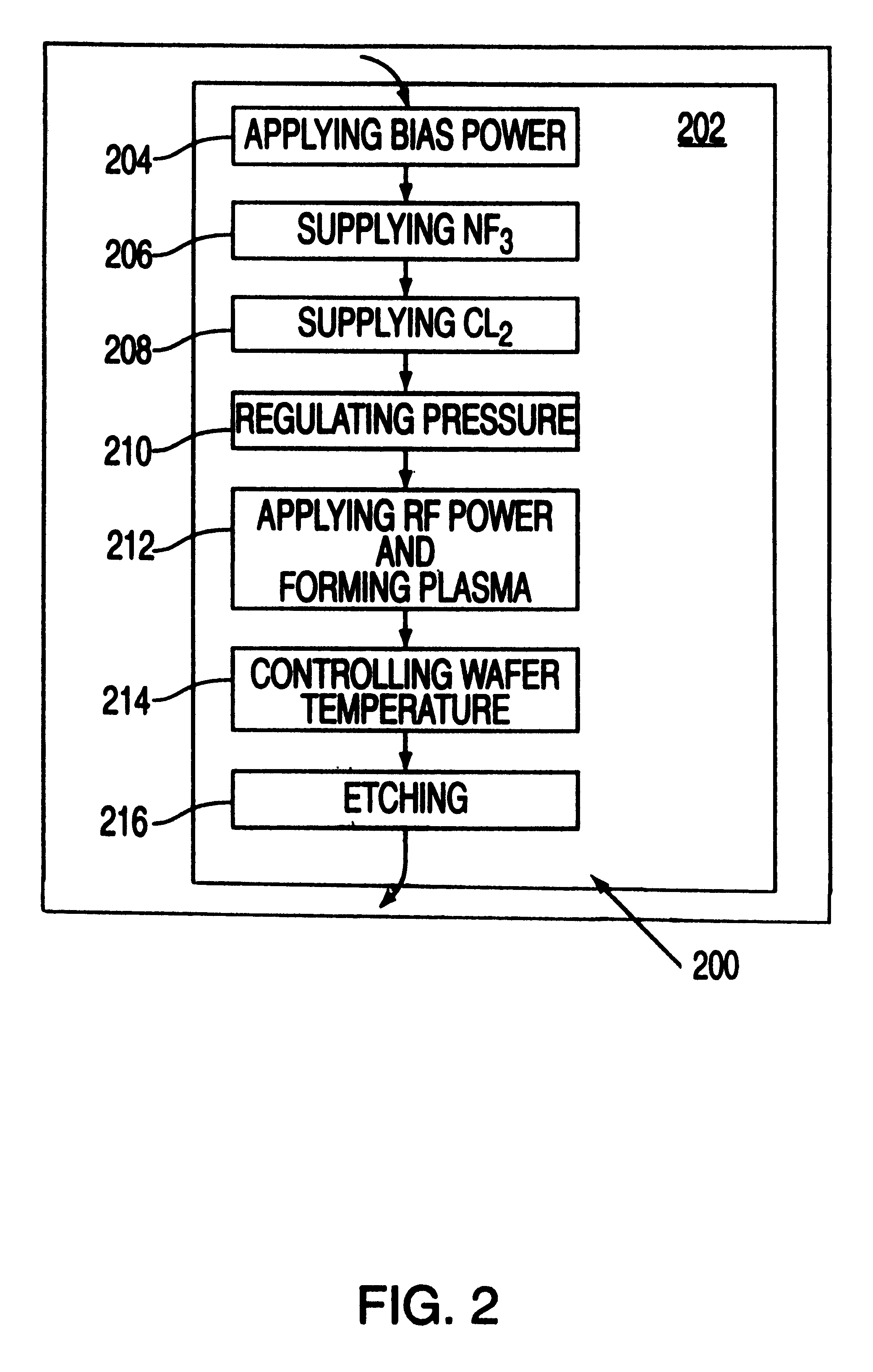

Method for plasma etching using periodic modulation of gas chemistry

InactiveUS6916746B1Decorative surface effectsSemiconductor/solid-state device manufacturingCyclic processGas chemistry

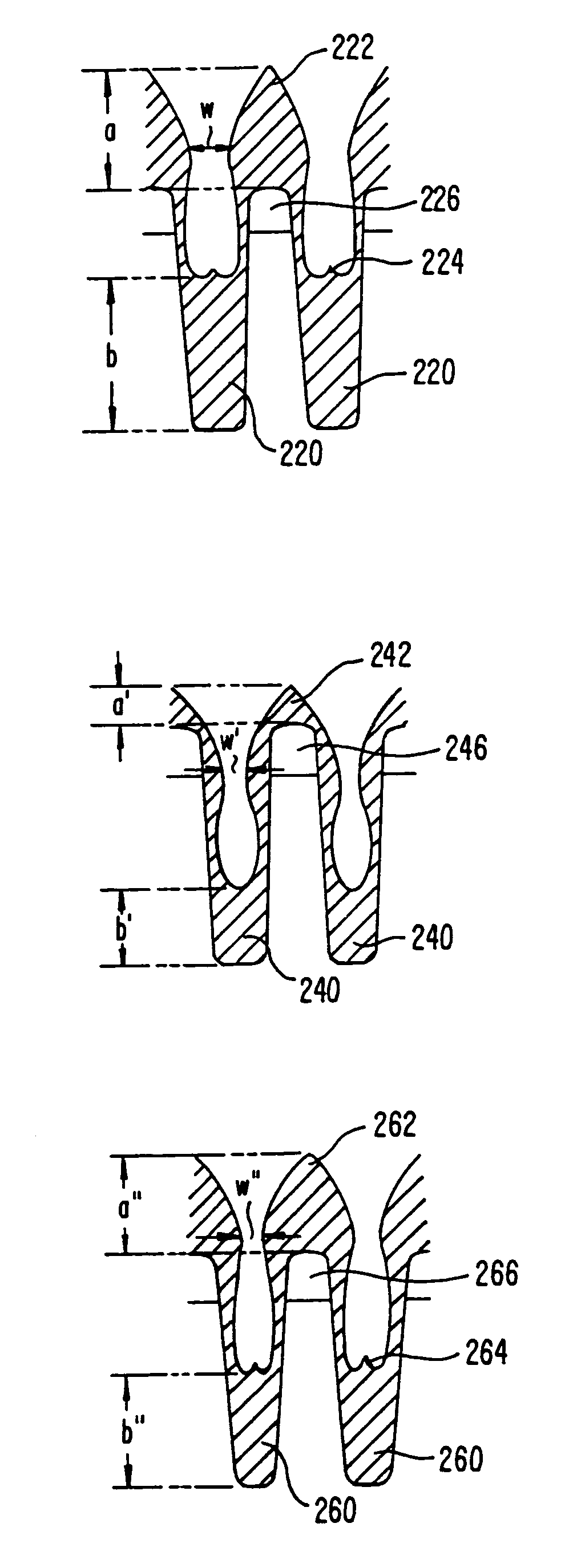

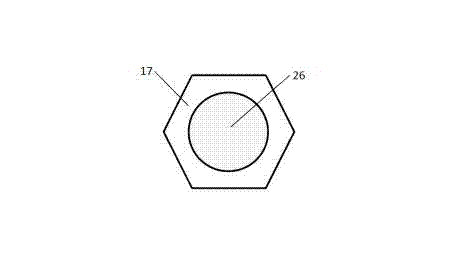

A method for etching a layer over a substrate is provided. A gas-modulated cyclic process is performed for more than three cycles. Each cycle comprises performing a protective layer forming phase using first gas chemistry with a deposition gas chemistry, which is performed in about 0.0055 to 7 seconds for each cycle and performing an etching phase for the feature through the etch mask using a second gas chemistry using a reactive etching gas chemistry, which is performed in about 0.005 to 14 seconds for each cycle. The protective layer forming phase comprises providing the deposition gas and forming a plasma from the deposition gas. Each etching phase comprises providing a reactive etching gas and forming a plasma from the reactive etching gas.

Owner:LAM RES CORP

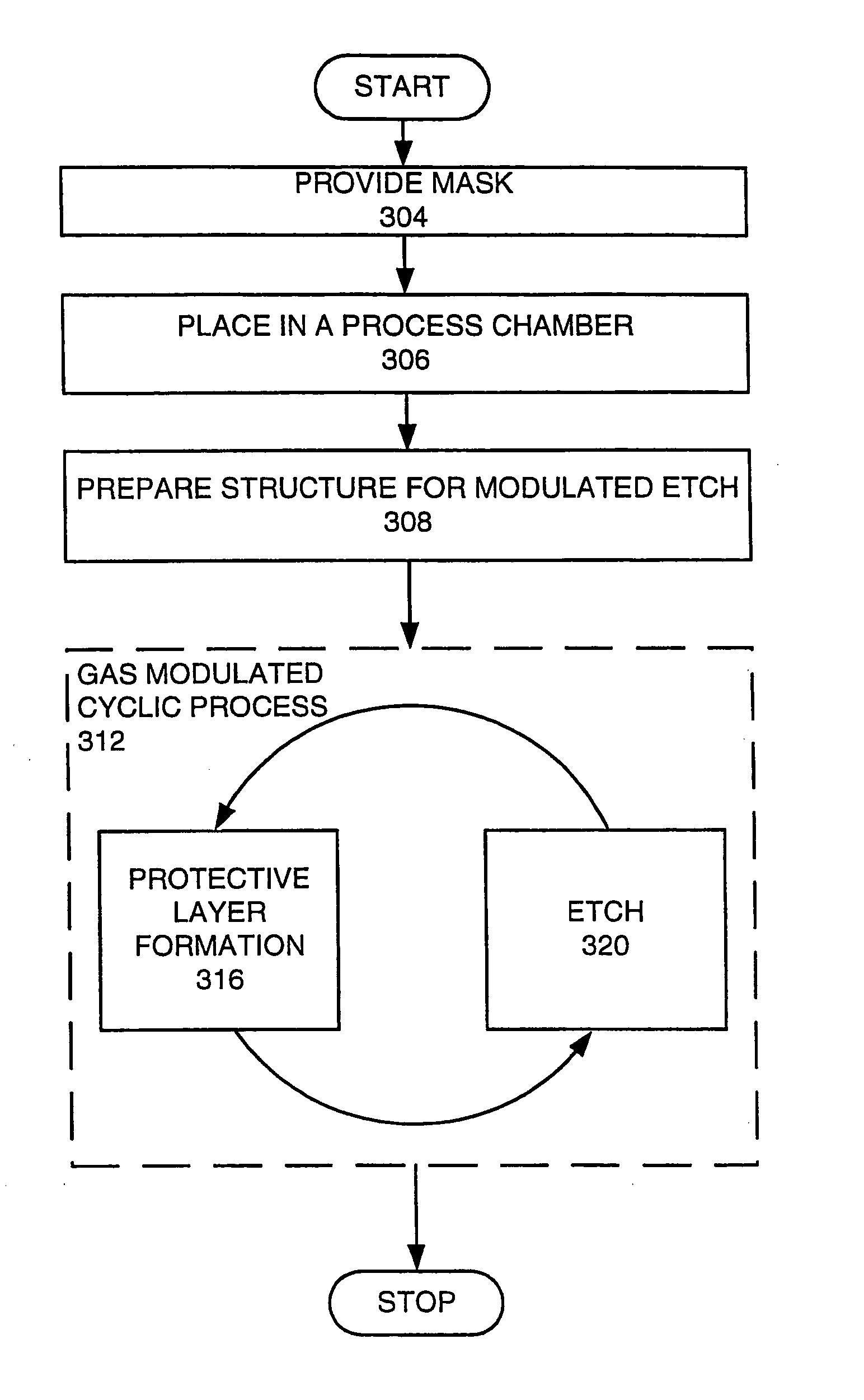

Method for plasma etching using periodic modulation of gas chemistry

A method for etching a layer over a substrate is provided. A gas-modulated cyclic process is performed for more than three cycles. Each cycle comprises performing a protective layer forming phase using first gas chemistry with a deposition gas chemistry, which is performed in about 0.0055 to 7 seconds for each cycle and performing an etching phase for the feature through the etch mask using a second gas chemistry using a reactive etching gas chemistry, which is performed in about 0.005 to 14 seconds for each cycle. The protective layer forming phase comprises providing the deposition gas and forming a plasma from the deposition gas. Each etching phase comprises providing a reactive etching gas and forming a plasma from the reactive etching gas.

Owner:LAM RES CORP

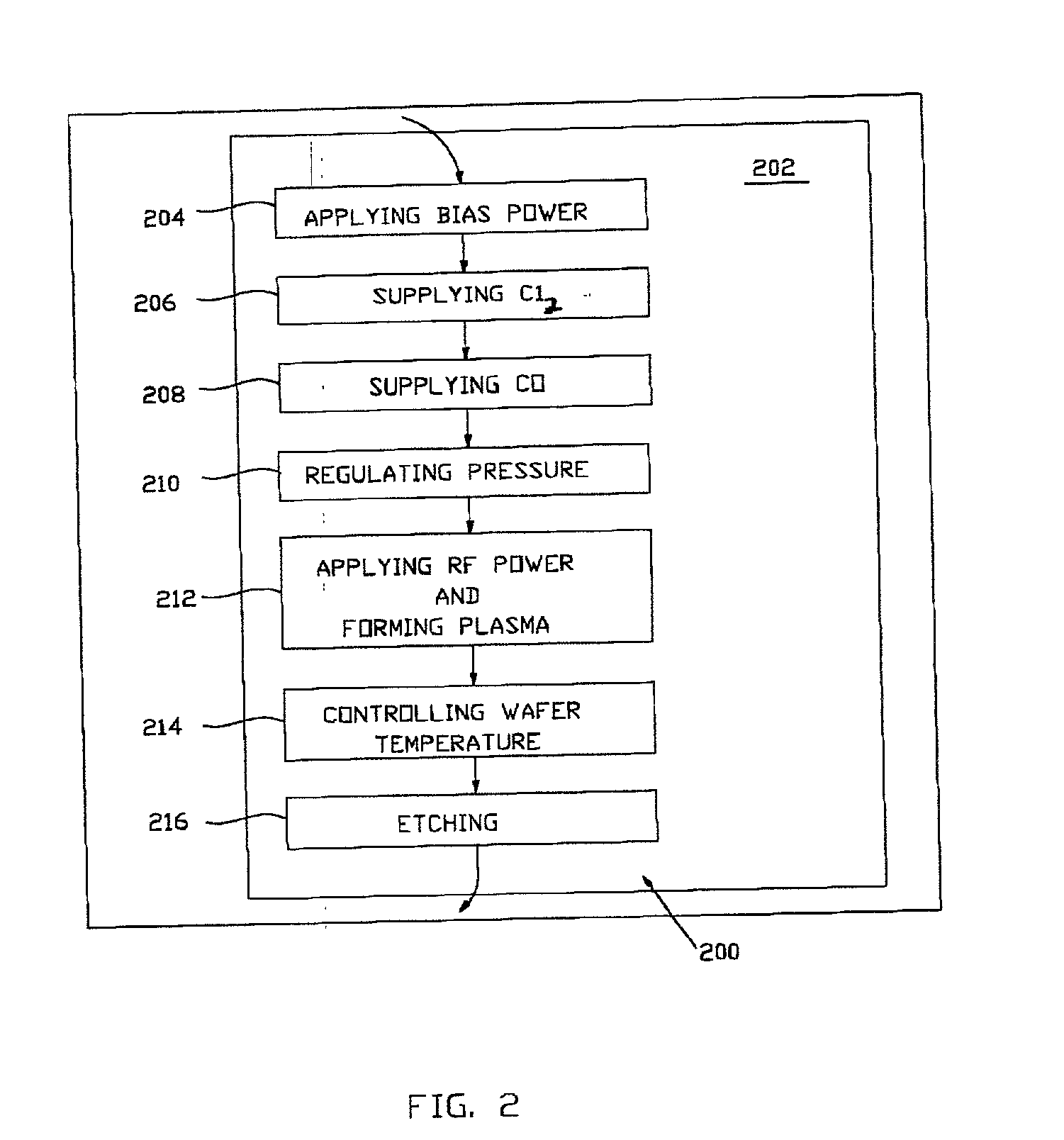

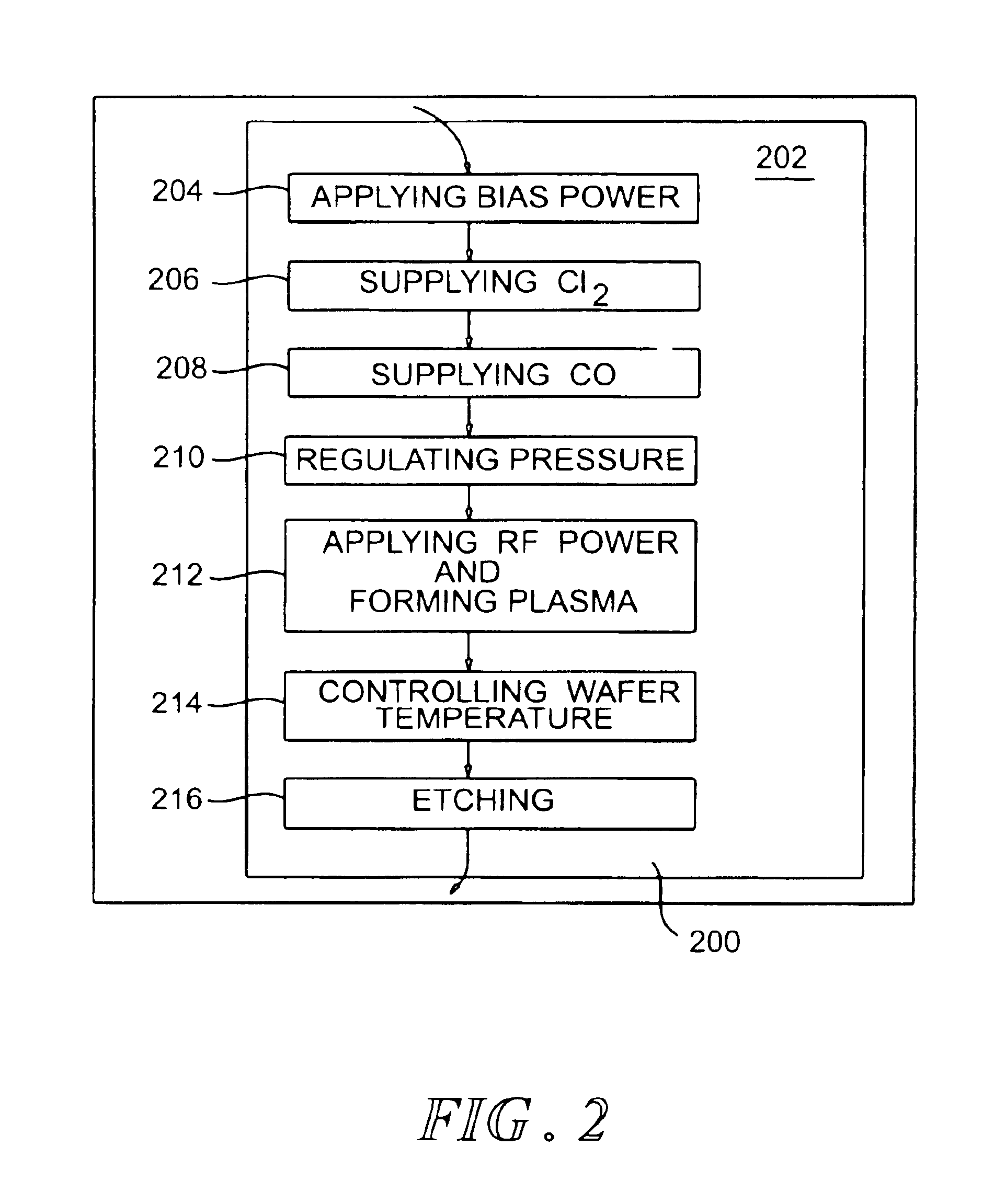

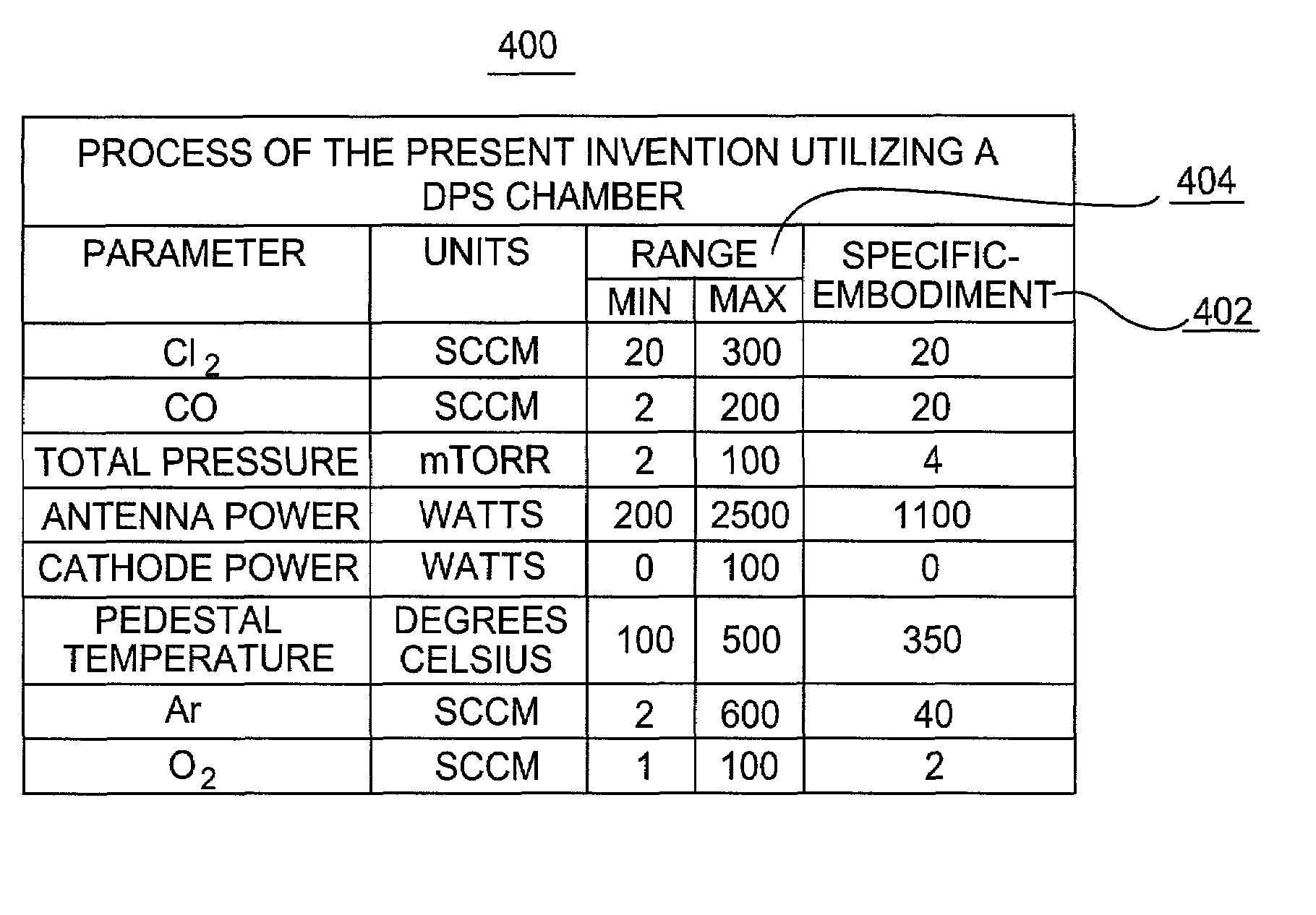

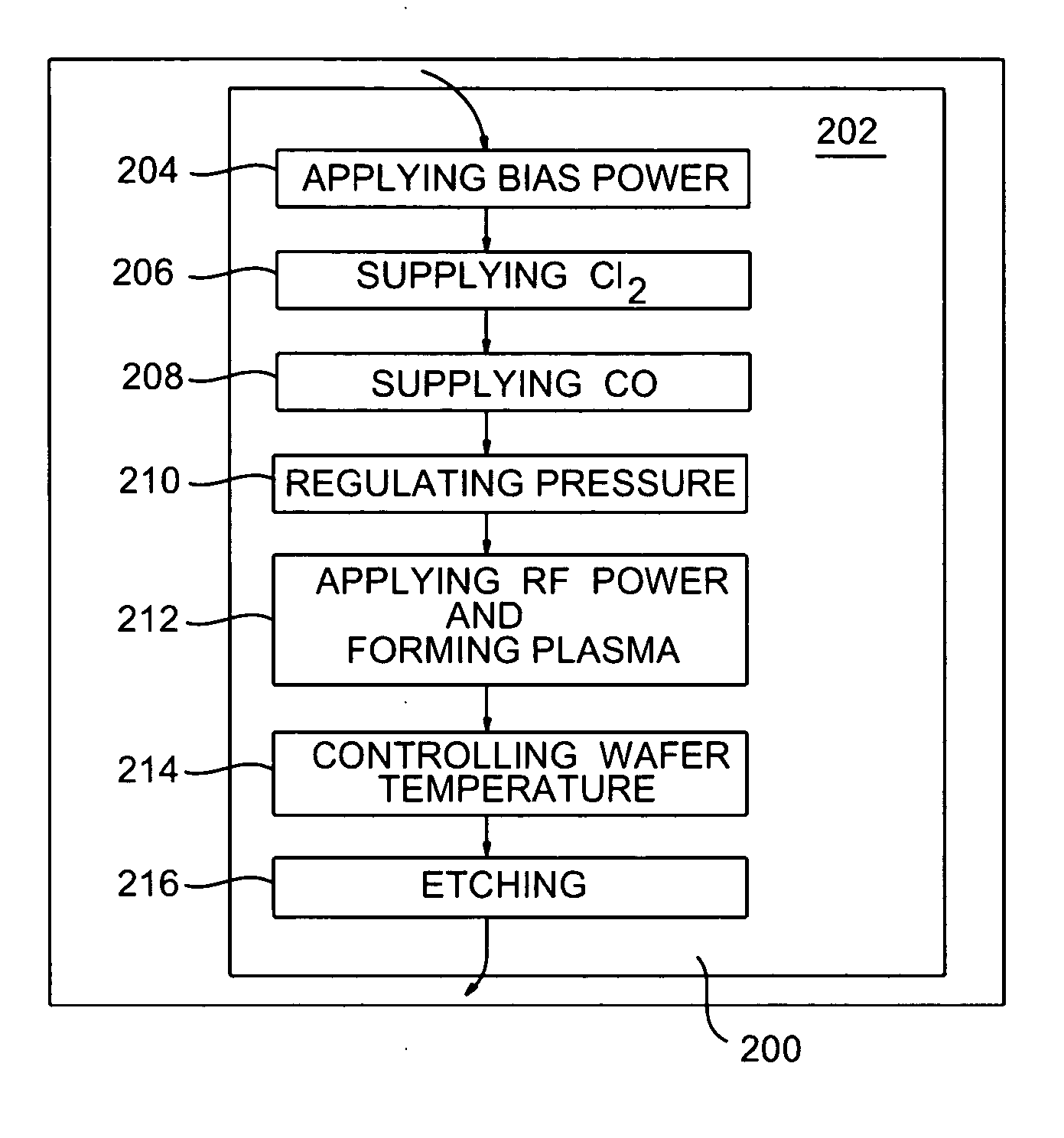

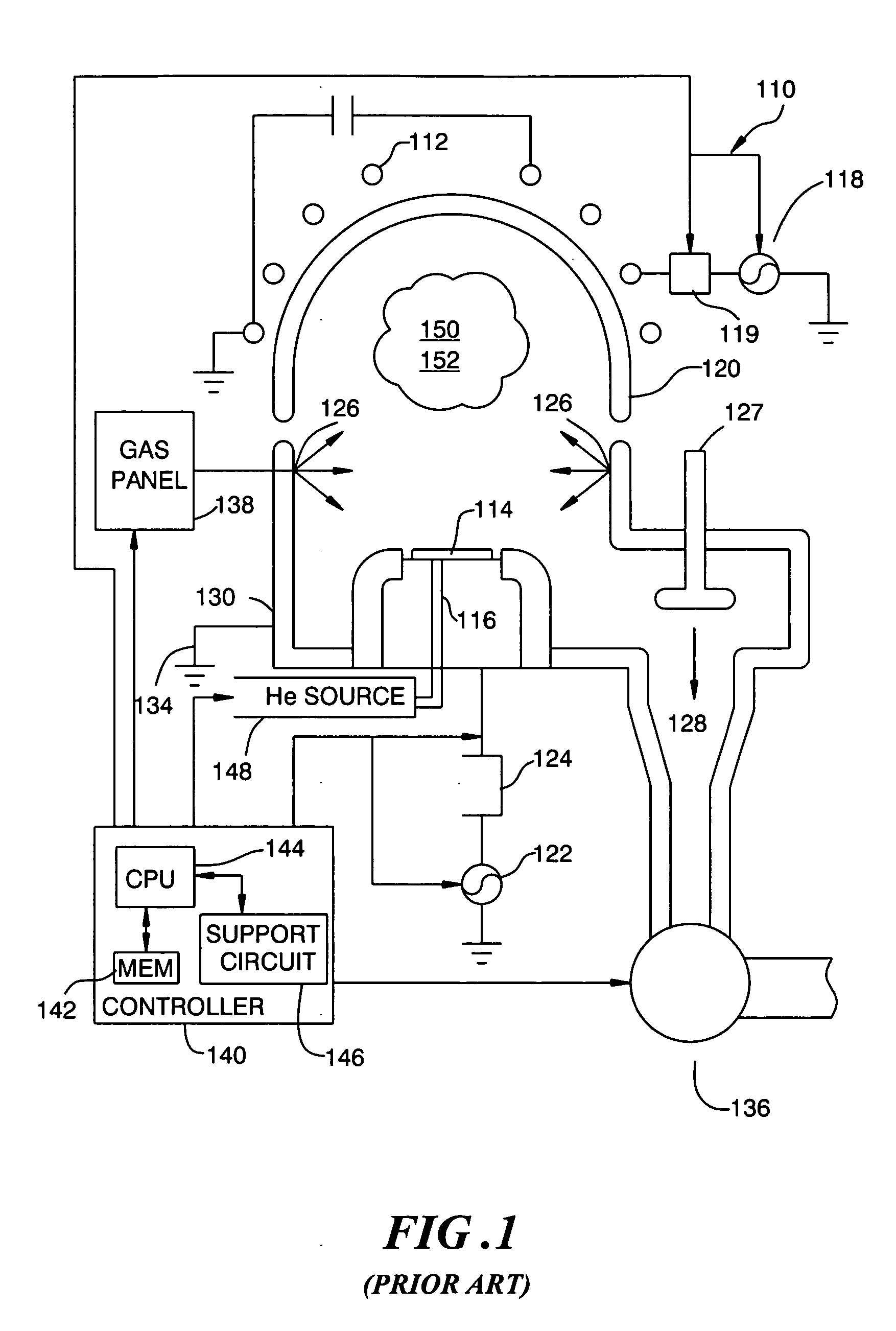

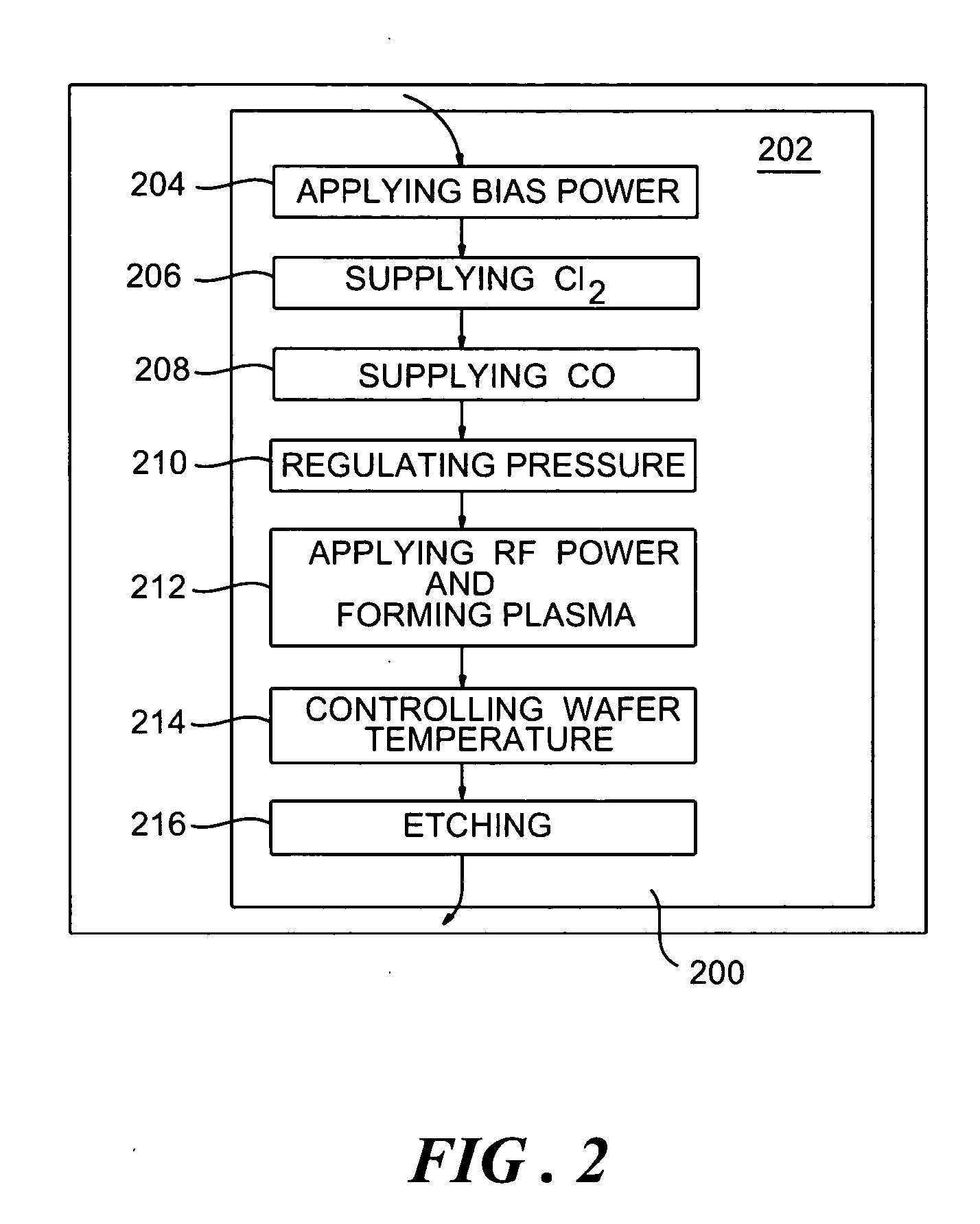

Method of plasma etching of high-K dielectric materials with high selectivity to underlying layers

InactiveUS20030170986A1Easy to understandSemiconductor/solid-state device manufacturingChamber pressureDielectric permittivity

A method of etching high dielectric constant materials using halogen gas and reducing gas chemistry. An embodiment of the method is accomplished using a 20 to 300 sccm of chlorine and 2 to 200 sccm of carbon monoxide, regulated to a total chamber pressure of 2-100 mTorr to etch a hafnium oxide layer.

Owner:APPLIED MATERIALS INC

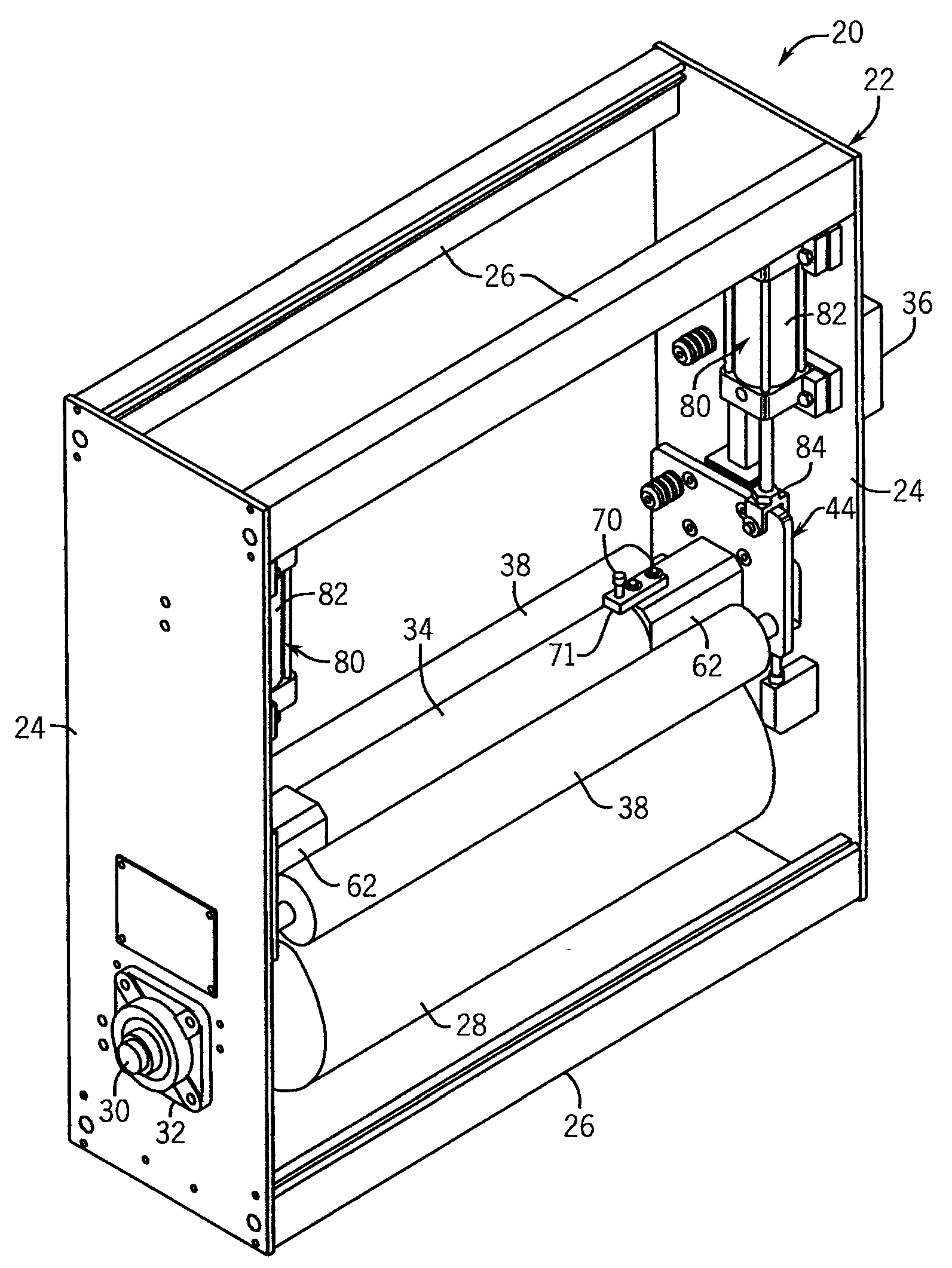

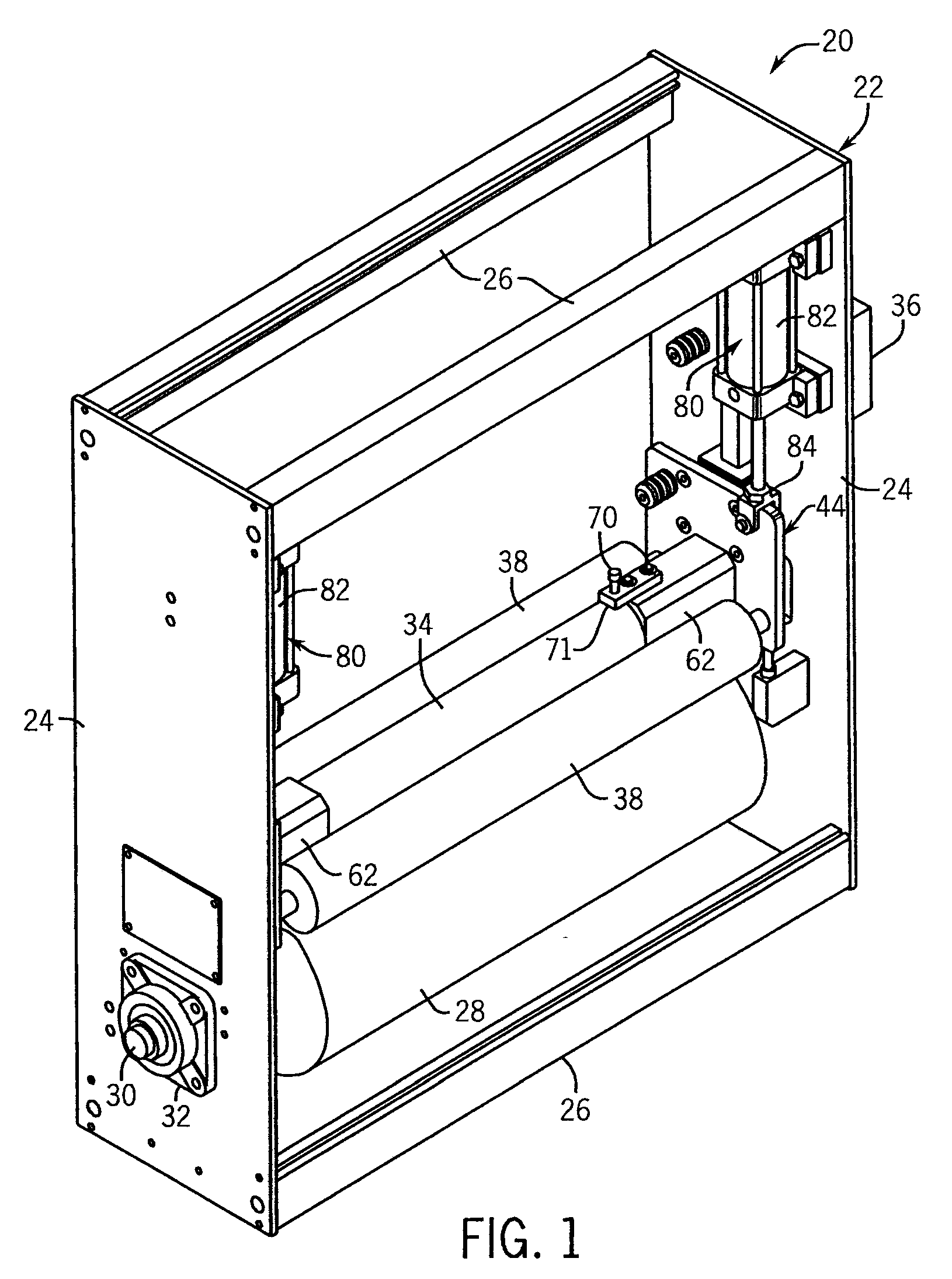

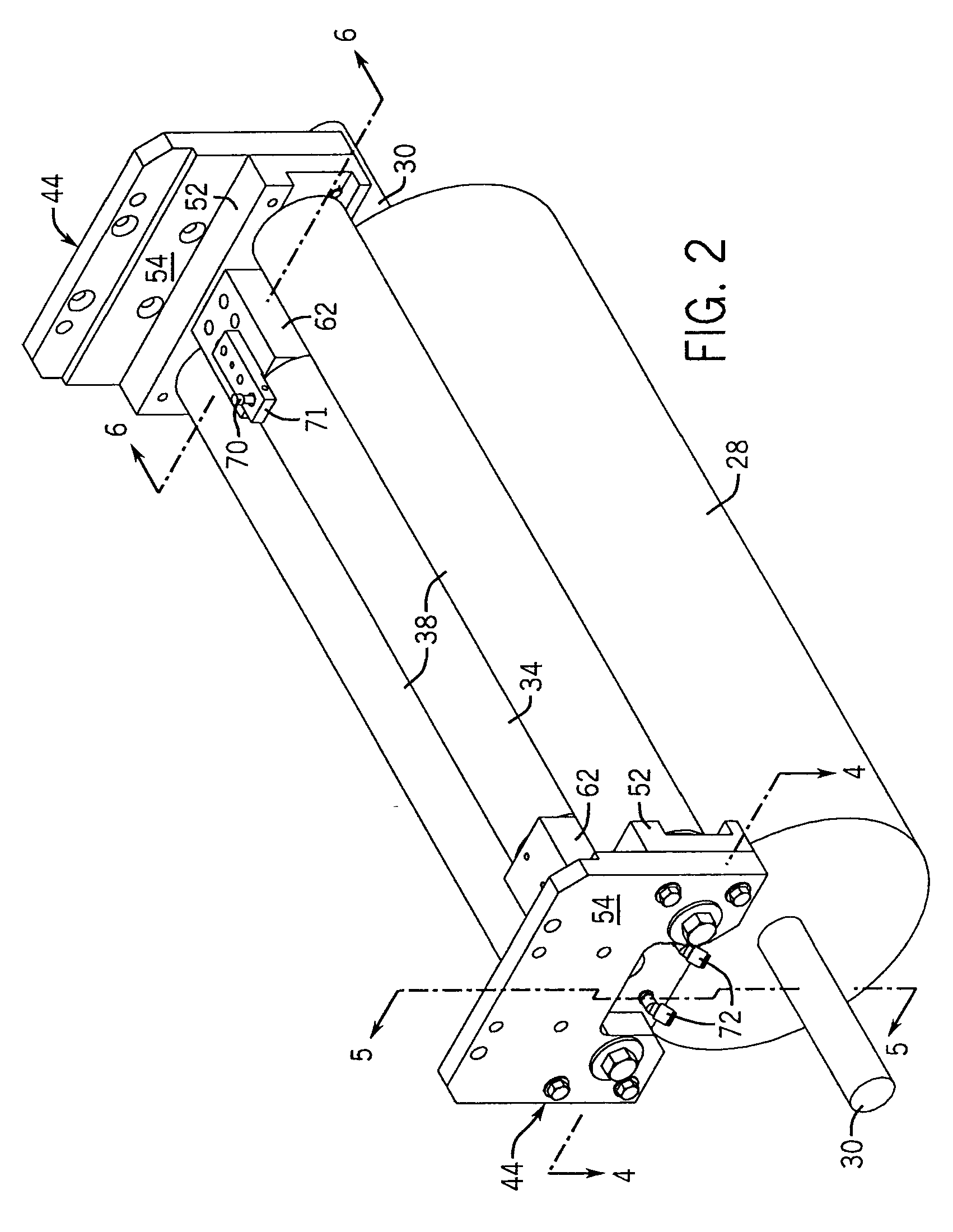

Atmospheric Treater With Roller Confined Discharge Chamber

ActiveUS20090120782A1Good surface treatmentQuality improvementDuplicating/marking methodsPhysical paper treatmentEngineeringAtmospherics

A continuous feed discharge surface treater for treating web materials has a discharge chamber where ionization of a process gas occurs defined and contained by one or more rollers. Enhanced chemical coronas and plasmas are achieved by limiting depletion of the gas chemistry from the discharge chamber and dilution or contamination from mixing with drawn in ambient air. Atmospheric coronas can also be achieved in which minimal or no ozone is exhausted from the treater. Various roller and electrode assemblies, including both fixed and rolling electrodes, can be employed.

Owner:ENERCON INDS

Method for plasma stripping using periodic modulation of gas chemistry and hydrocarbon addition

InactiveUS7294580B2Increasing the thicknessReduce thicknessDecorative surface effectsSemiconductor/solid-state device manufacturingResistPhysical chemistry

A method for etching a feature in a low-k dielectric layer through a photoresist etch mask over a substrate. A gas-modulated cyclic stripping process is performed for more than three cycles for stripping a single photoresist mask. Each cycle of the gas-modulated cyclic stripping process comprises performing a protective layer formation phase and a stripping phase. The protective layer forming phase using first gas chemistry with a deposition gas chemistry, wherein the protective layer forming phase is performed in about 0.005 to 10 seconds for each cycle. The performing the stripping phase for stripping the photoresist mask using a second gas chemistry using a stripping gas chemistry, where the first gas chemistry is different than the second gas chemistry, wherein the etching phase is performed in about 0.005 to 10 seconds for each cycle.

Owner:LAM RES CORP

Method of plasma etching of high-K dielectric materials with high selectivity to underlying layers

InactiveUS6806095B2Semiconductor/solid-state device manufacturingChamber pressureDielectric permittivity

A method of etching high dielectric constant materials using halogen gas and reducing gas chemistry. An embodiment of the method is accomplished using a 20 to 300 sccm of chlorine and 2 to 200 sccm of carbon monoxide, regulated to a total chamber pressure of 2-100 mTorr to etch a hafnium oxide layer.

Owner:APPLIED MATERIALS INC

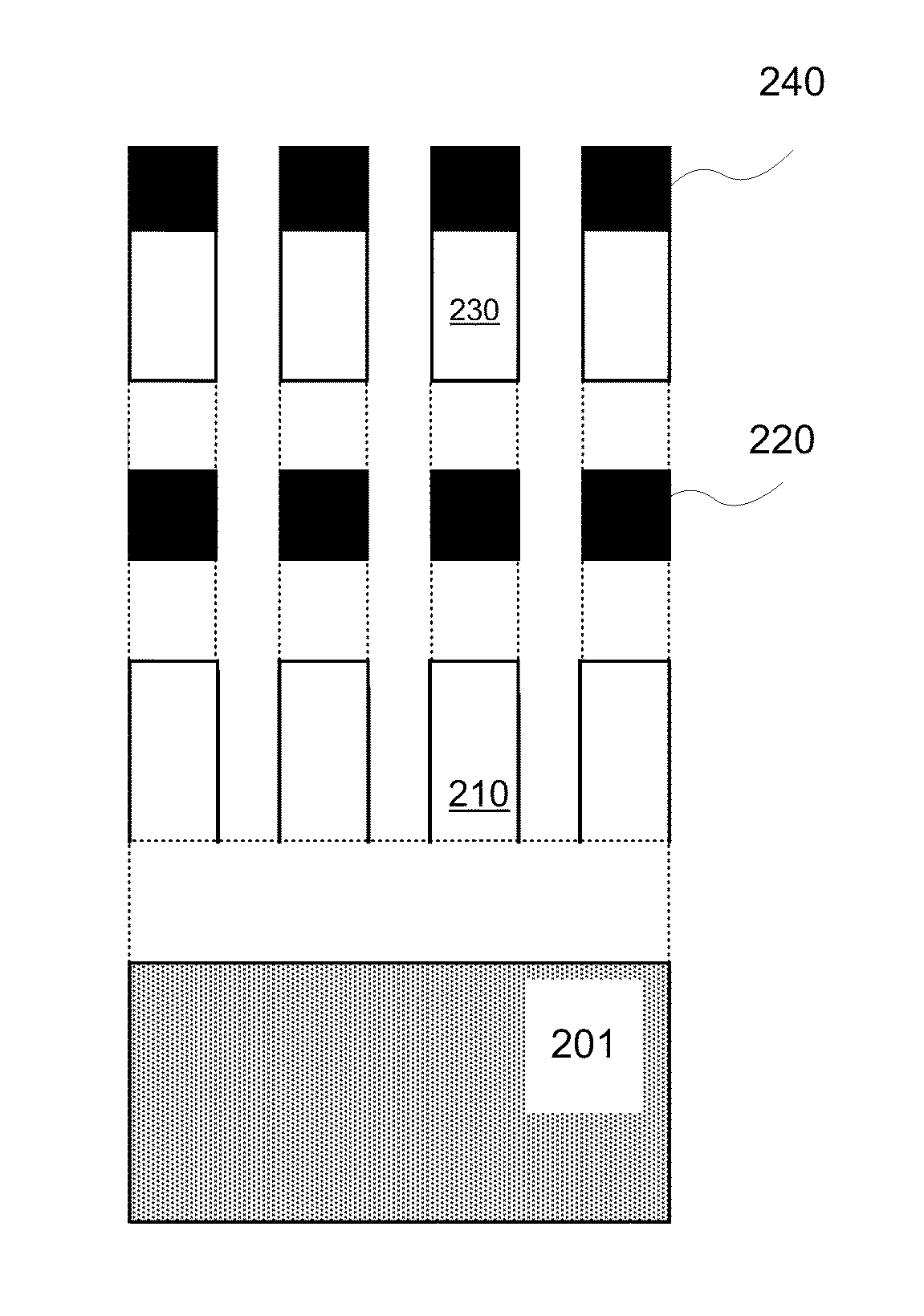

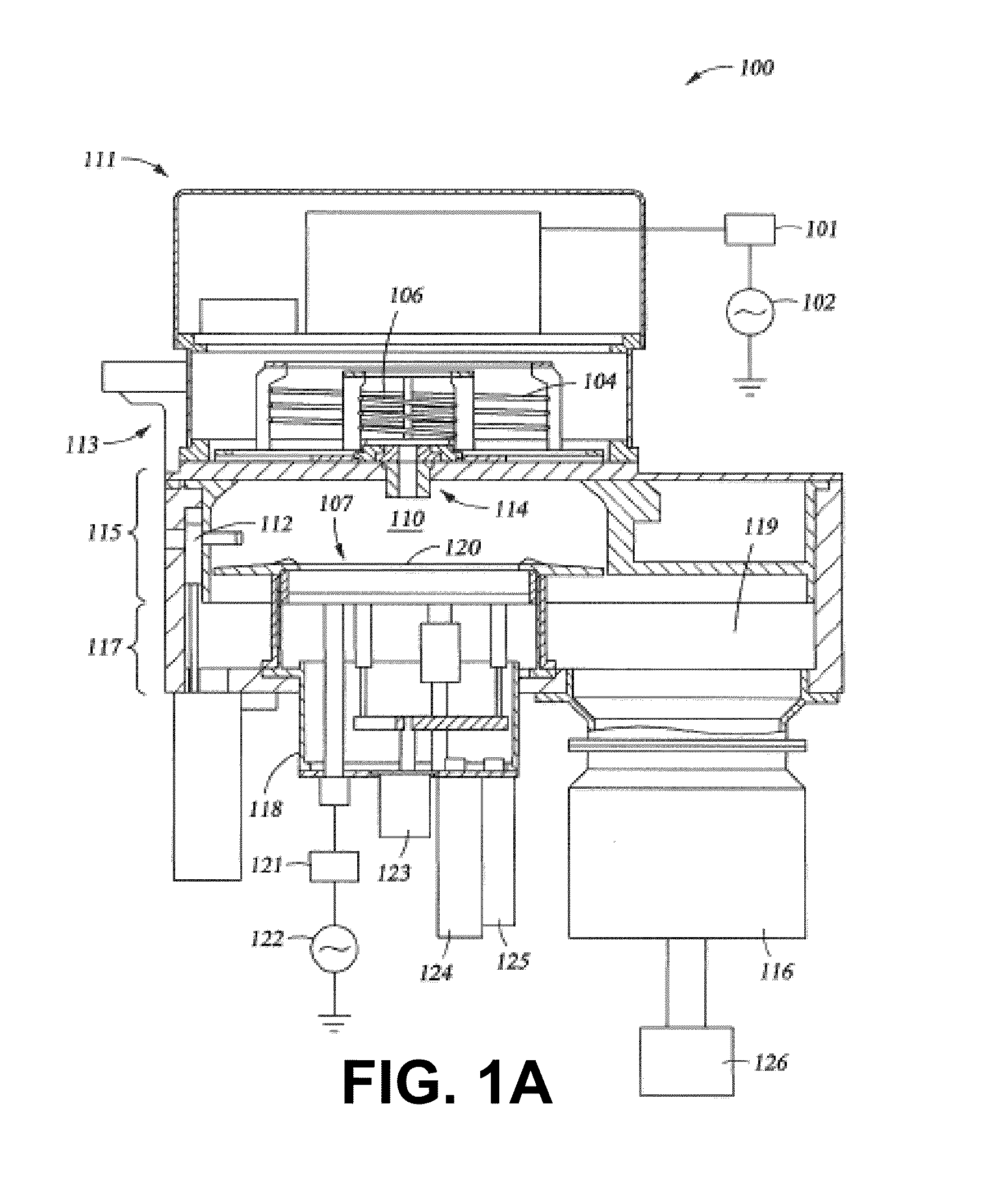

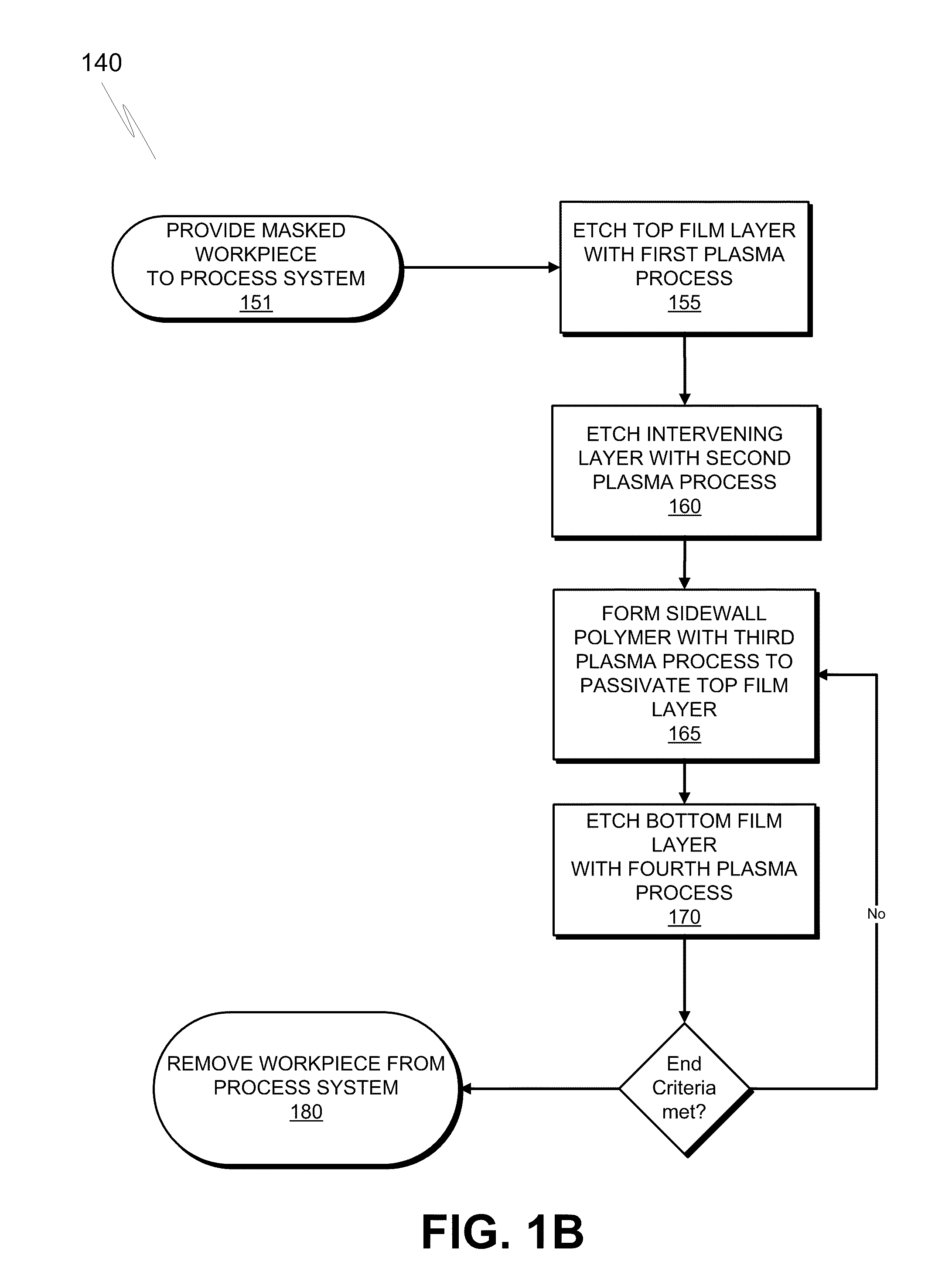

Multi-film stack etching with polymer passivation of an overlying etched layer

InactiveUS20110045672A1Reduce erosionElectric discharge tubesSolid-state devicesProduct gasSemiconductor

A method and apparatus for plasma etching a workpiece, such as a semiconductor wafer, including a thin film stack having a top film disposed over a bottom film with an intervening middle film there between. Etch selectivity between the top and bottom films may be as low as between 1:1 and 2:1 and a first carbon-lean gas chemistry is used to etch through the top film, a second carbon-lean gas chemistry is used to etch through the middle film, and the bottom film is etched through by alternating between depositing a polymer passivation on the top film using a carbon-rich gas chemistry and an etching of the bottom film with a third carbon-lean gas chemistry, which may be the same as the first carbon-lean gas chemistry.

Owner:APPLIED MATERIALS INC

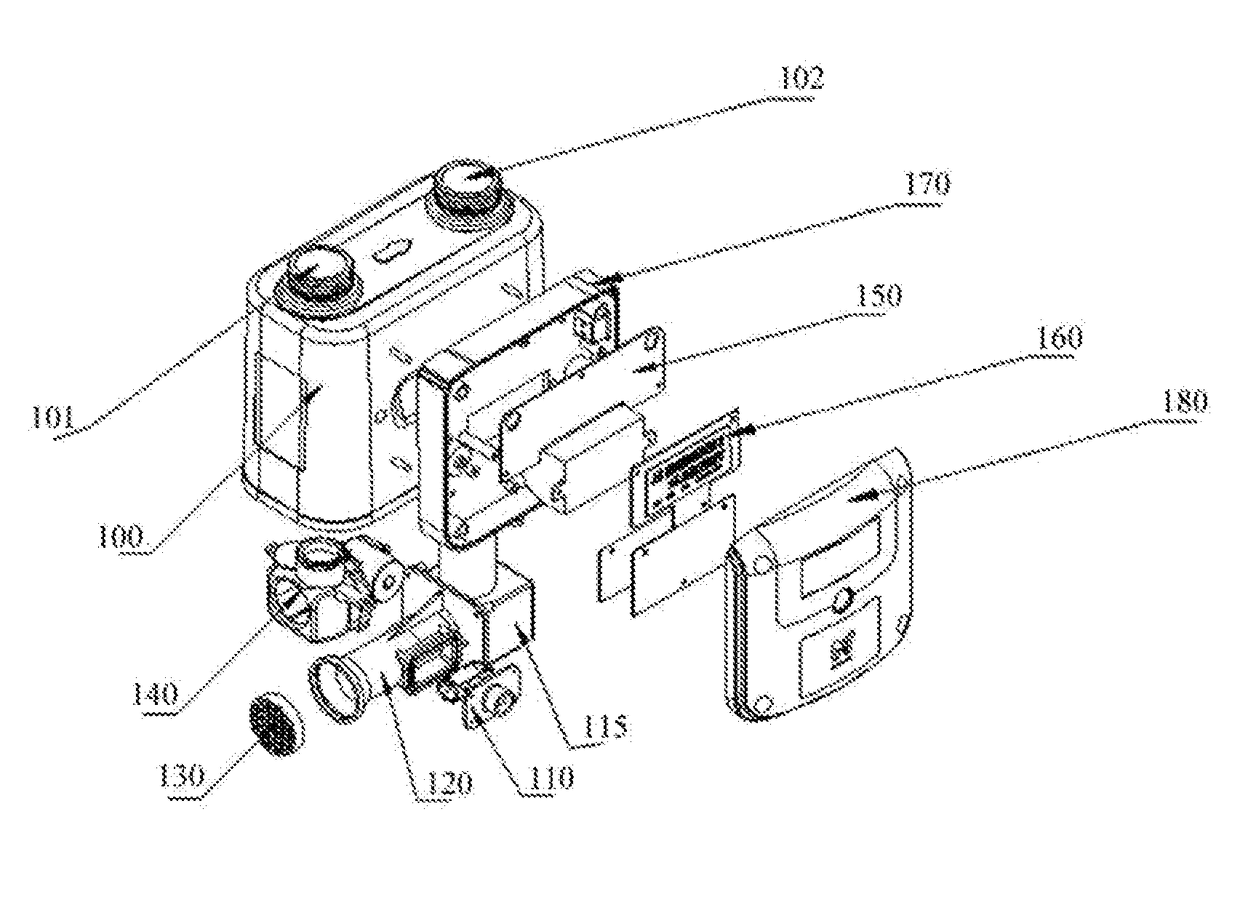

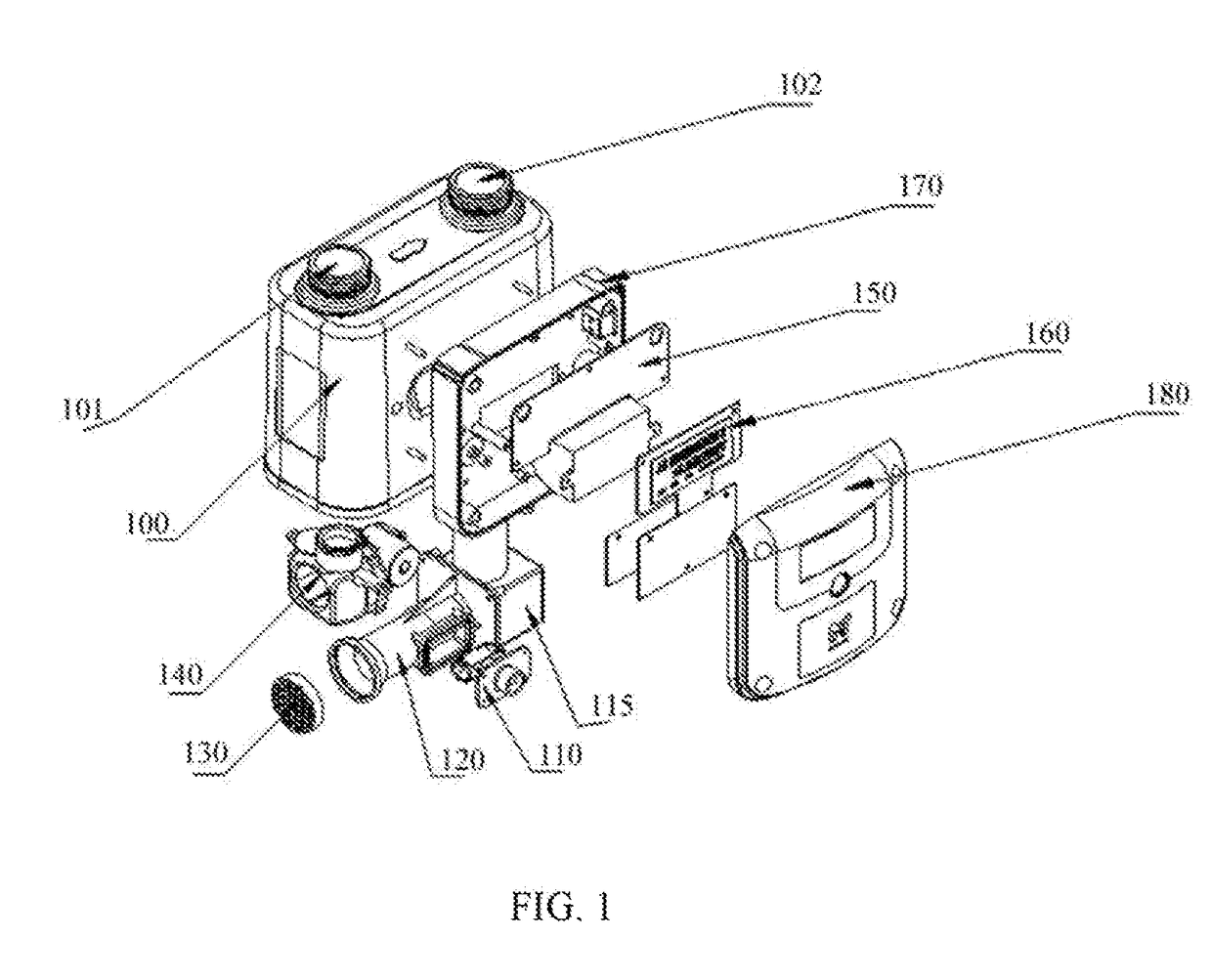

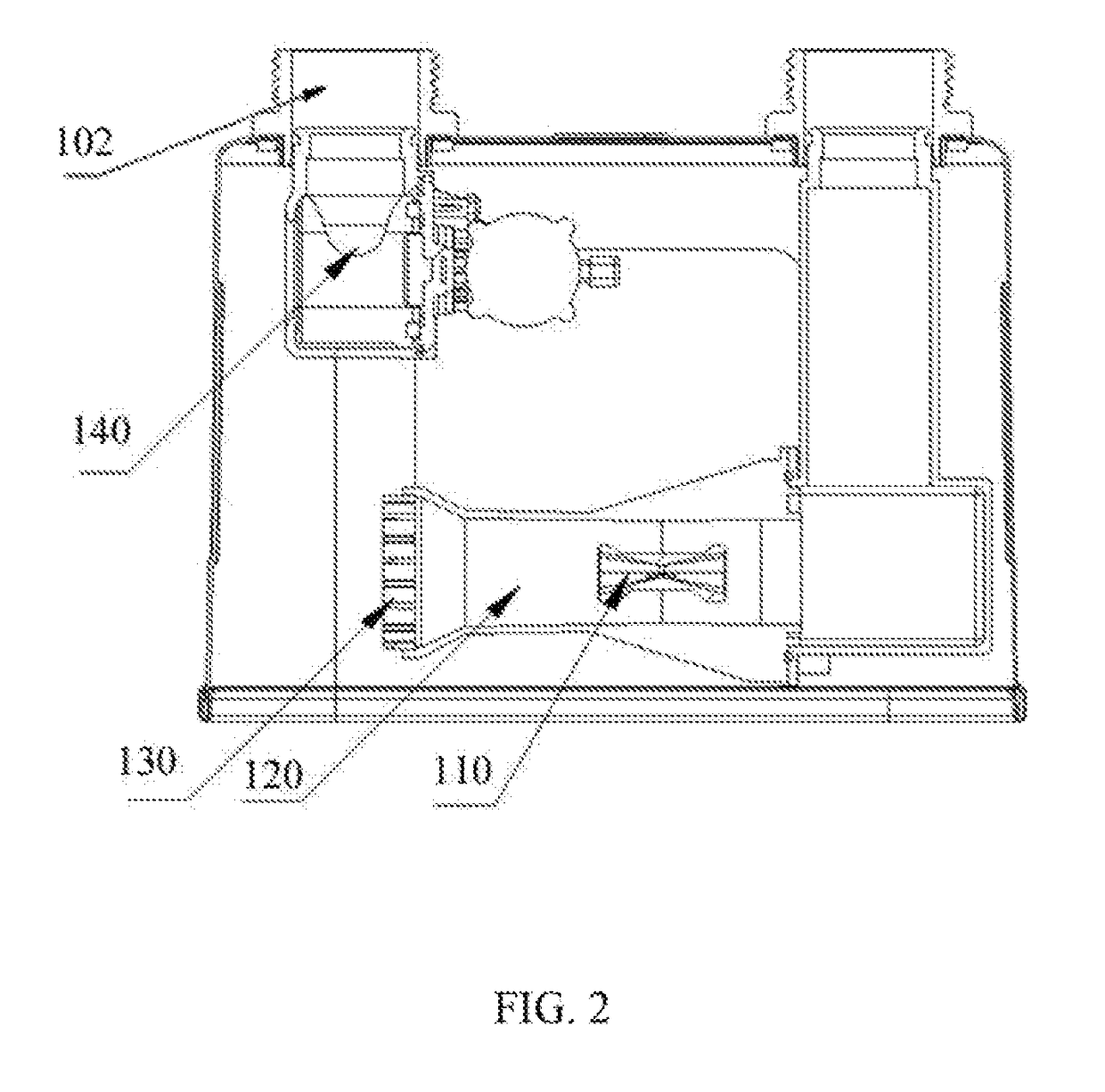

Utility mass flow gas meter

ActiveUS20170241822A1Improve flow stabilitySpeed up the flowTariff metering apparatusVolume meteringChemical safetyMetrology

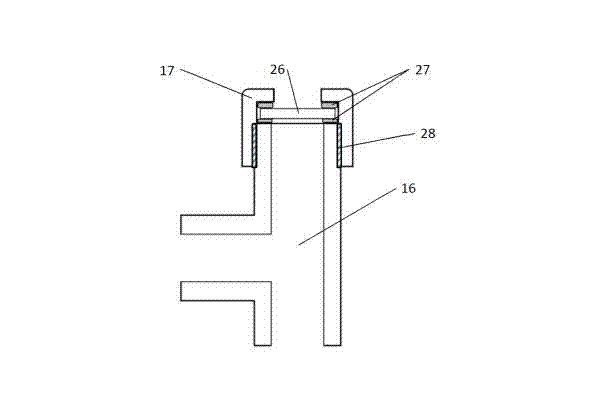

An electronic utility gas meter using MEMS thermal mass flow sensor to measure gas custody transfer data in city gas metering application is disclosed in the present invention. The meter is designed to have its mechanical connectors identical to those of the current diaphragm gas meters while the insertion metrology unit guided channel is placed coaxially in the main flow channel inside the meter body with gas flow conditioning apparatus. The mechanical installation of the electronic utility gas meter then can be fully compatible with the current mechanical utility gas meters, which allows a seamless replacement. The electronic utility gas meter provides gas metrology that significantly improves the accuracy of the city gas metering, and provides additional benefits for data safety, enhanced gas chemical safety, billing alternatives and full data management either locally or remotely.

Owner:M TECH INSTR HLDG

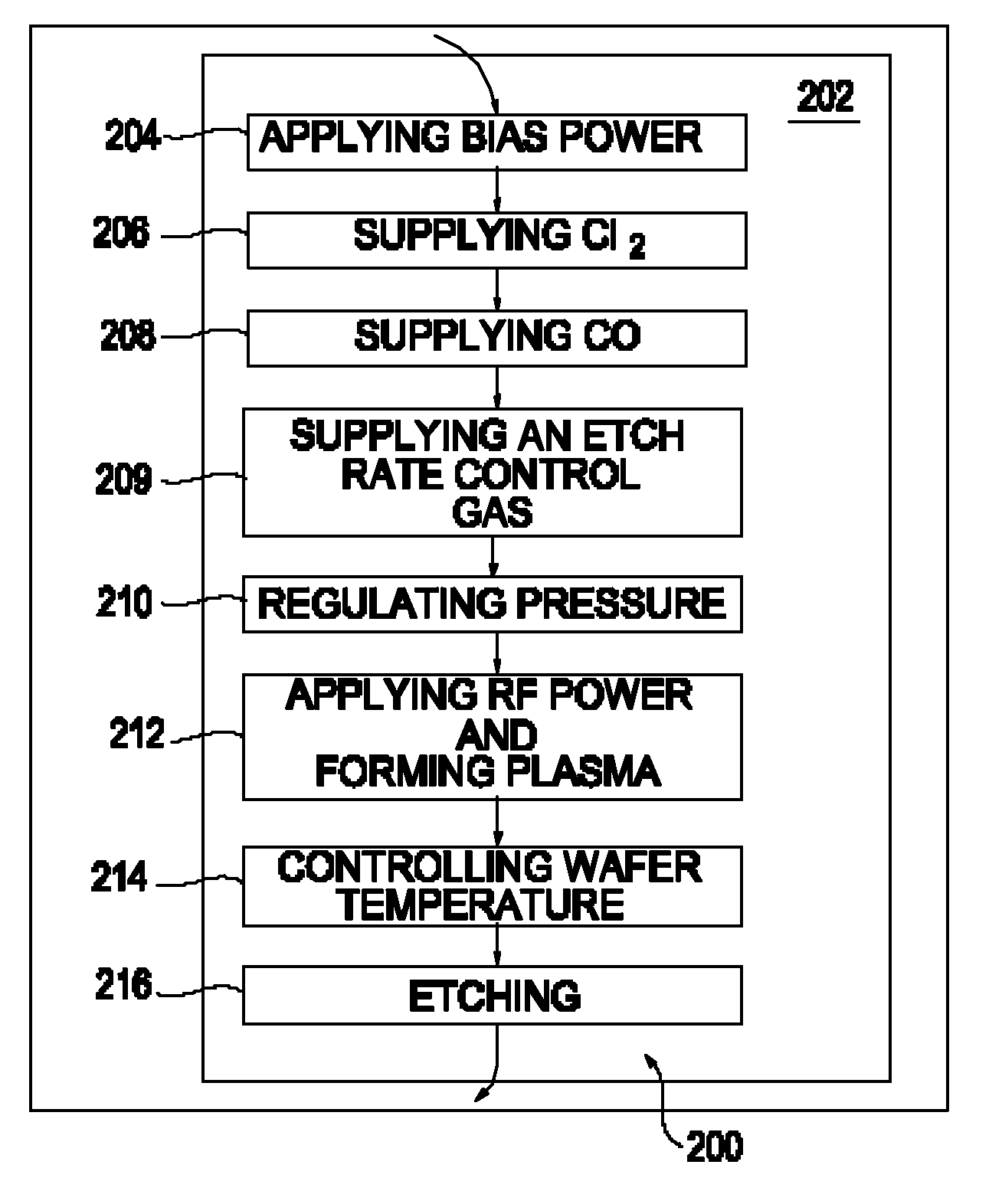

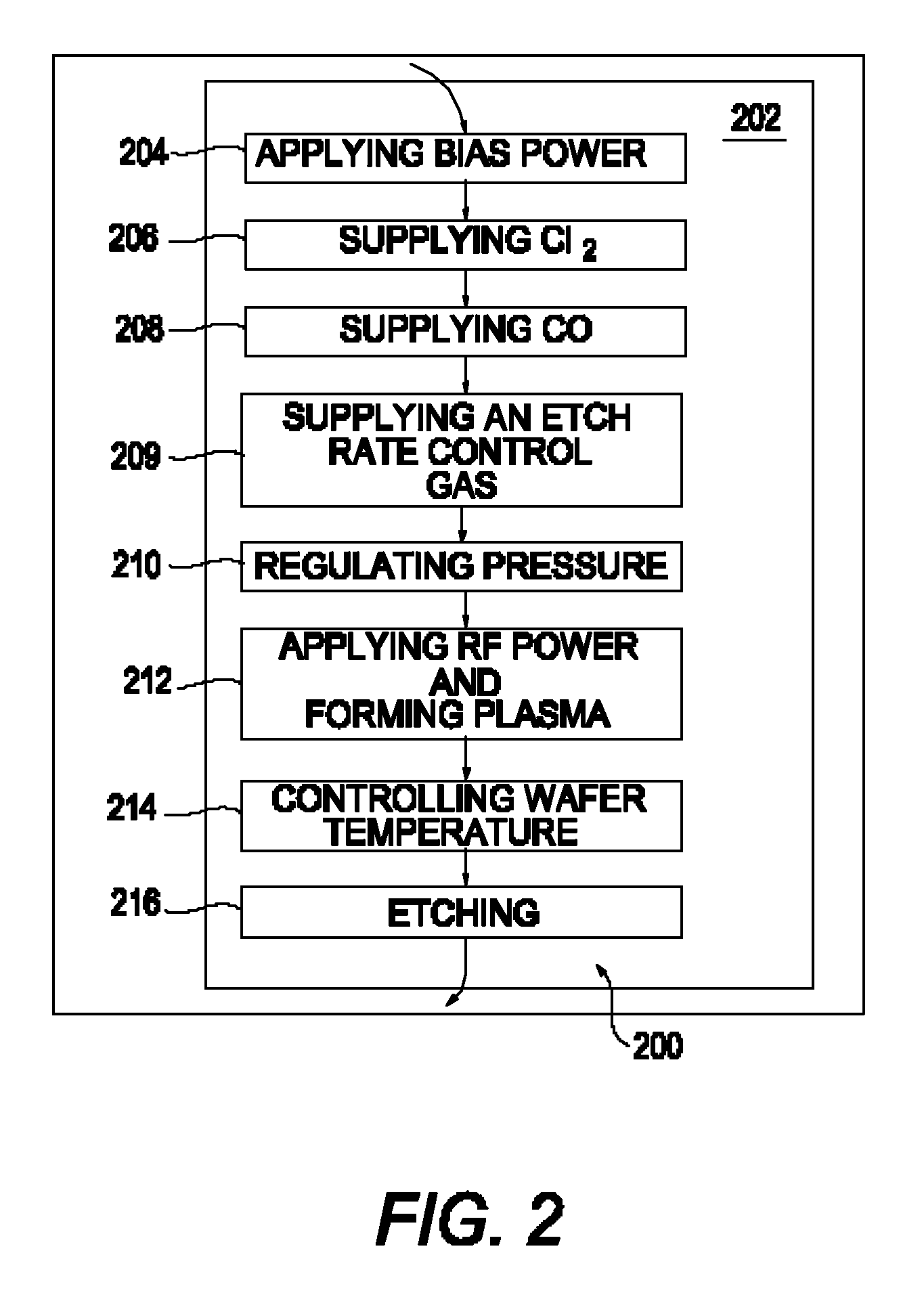

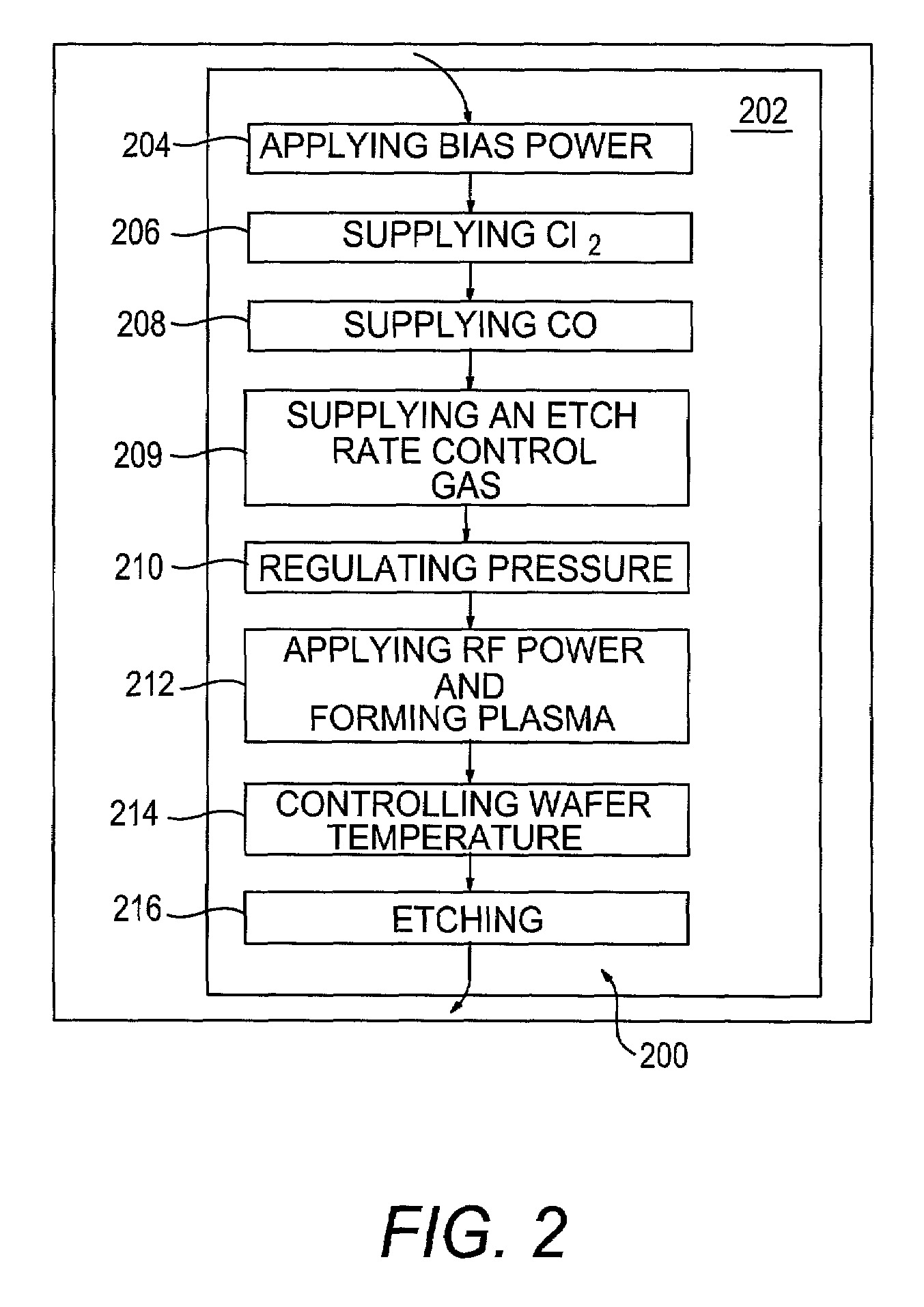

Method of plasma etching of high-k dielectric materials

InactiveUS20070077767A1Decorative surface effectsSemiconductor/solid-state device manufacturingMaterials scienceGas chemistry

A method of etching high dielectric constant materials using a halogen gas, a reducing gas and an etch rate control gas chemistry.

Owner:APPLIED MATERIALS INC

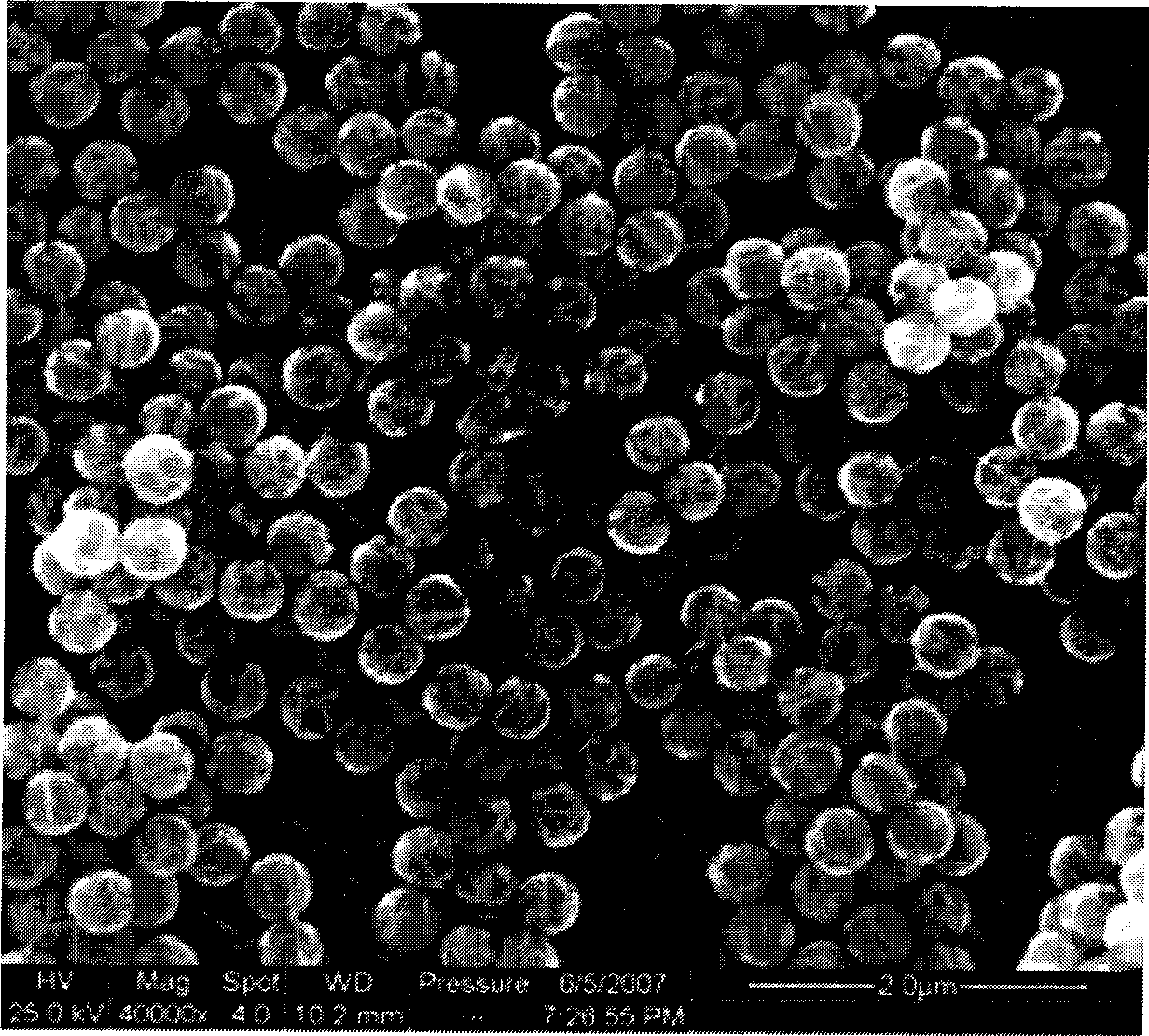

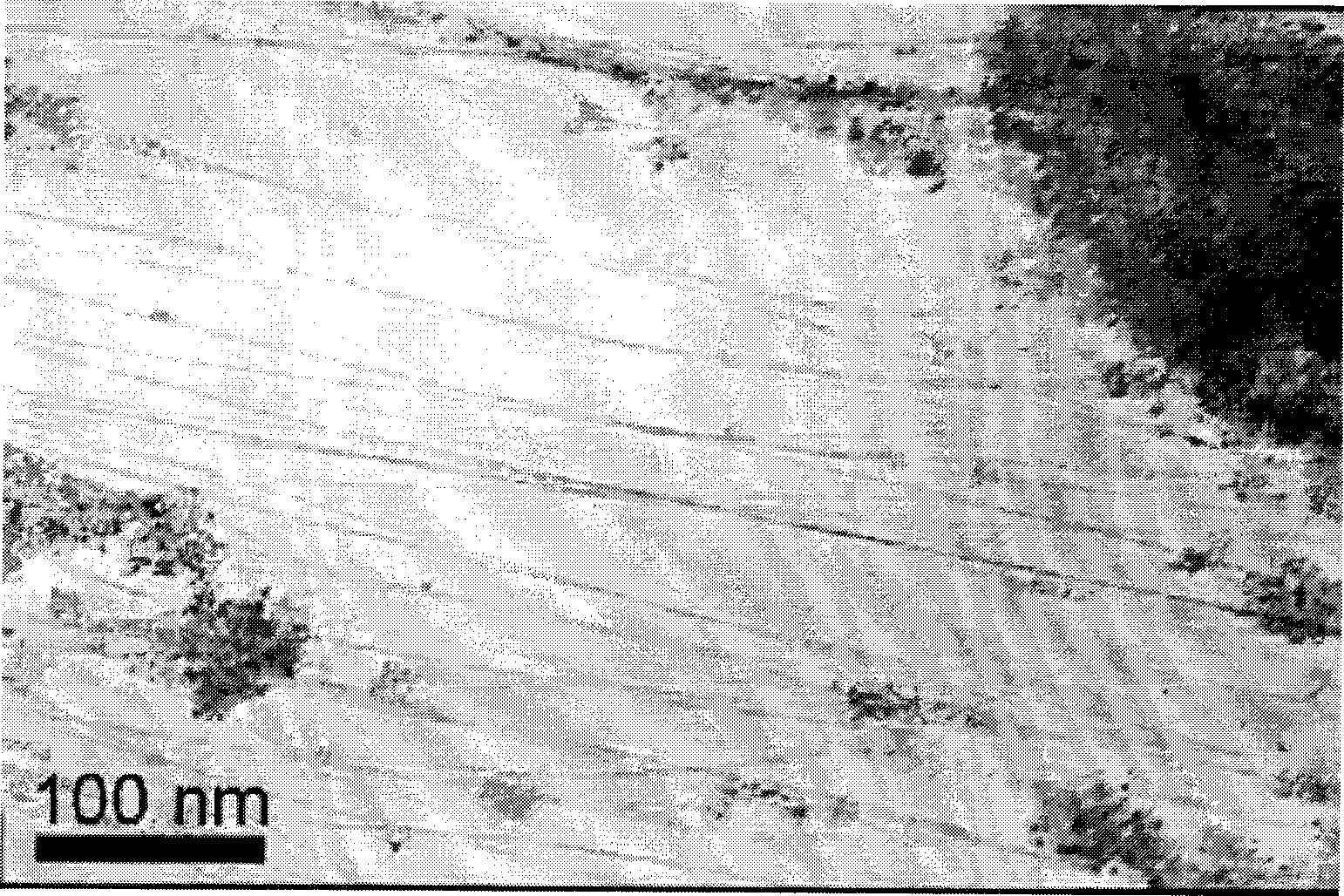

Semi-conductor type single-walled carbon nano tube and preparation method thereof

The invention discloses a semiconductor-typed single-walled carbon nano tube and a preparation method thereof, belonging to the carbon nano tube technical field. The carbon atoms on the tube wall of the single-walled carbon nano tube are replaced by doping atoms which comprise nitrogen atoms, boron atoms, oxygen atoms or sulfur atoms. The preparation method thereof comprises: at the reaction temperature, in an inert environment and under the catalysis of a catalyst which is positioned on substrate, the reaction gas is deposited on the substrate by chemical vapor deposition, so as to obtain the carbon nano tube; the reaction gas comprises carbon source and doped source which come from the same substance or different substances; after the chemical vapor deposition, a semiconductor-typed single-walled carbon nano tube is prepared. Compared with the prior art, the invention has the advantages of simple equipment, easy operation, low raw material cost and strong product repeatability, and can obtain single-walled carbon nano tubes which are all semiconductor-typed.

Owner:PEKING UNIV

Silicon dioxide-polysilicon multi-layered stack etching with plasma etch chamber employing non-corrosive etchants

ActiveUS20140213062A1Electric discharge tubesSemiconductor/solid-state device manufacturingSingle chamberSilicon dioxide

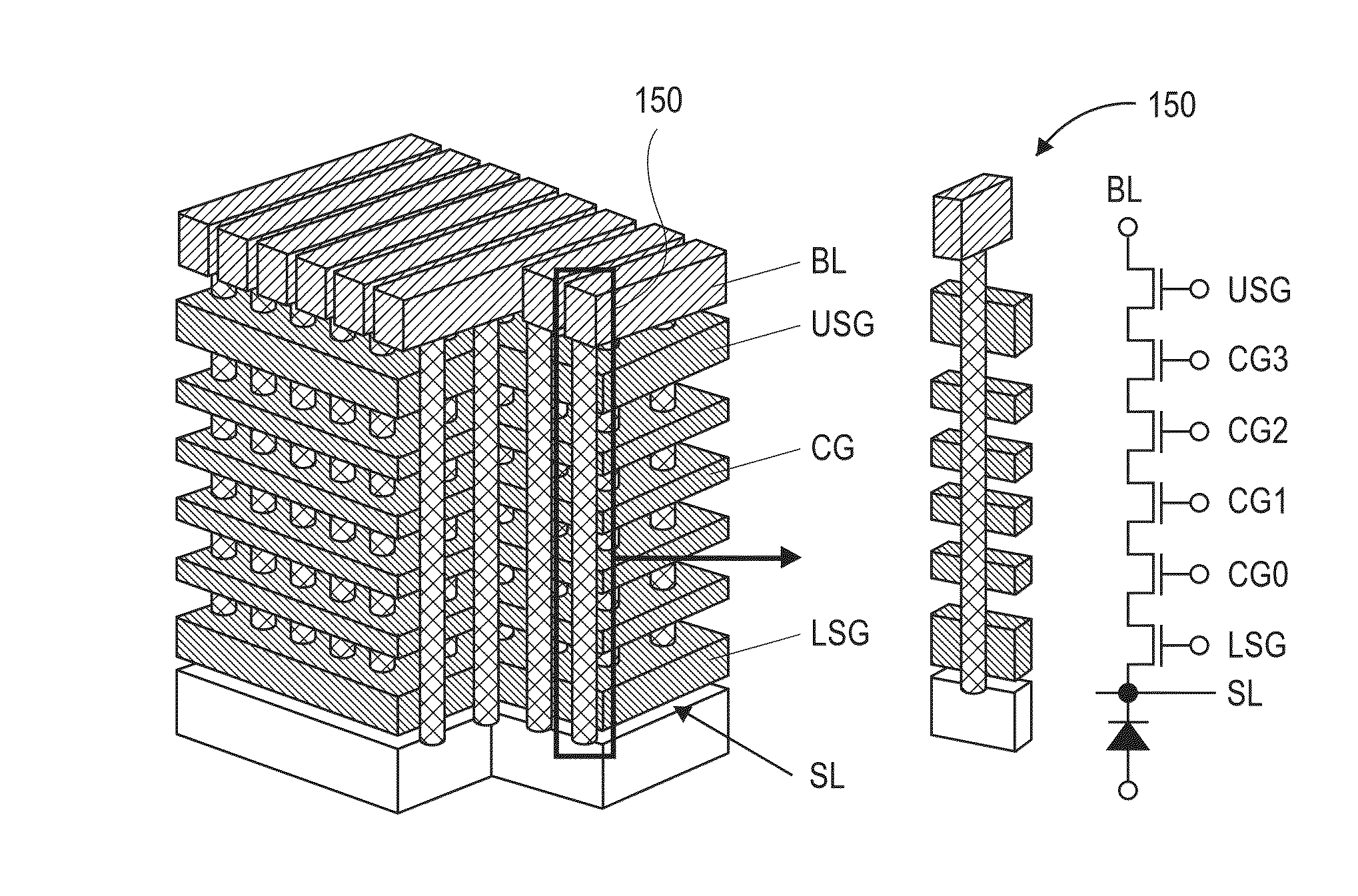

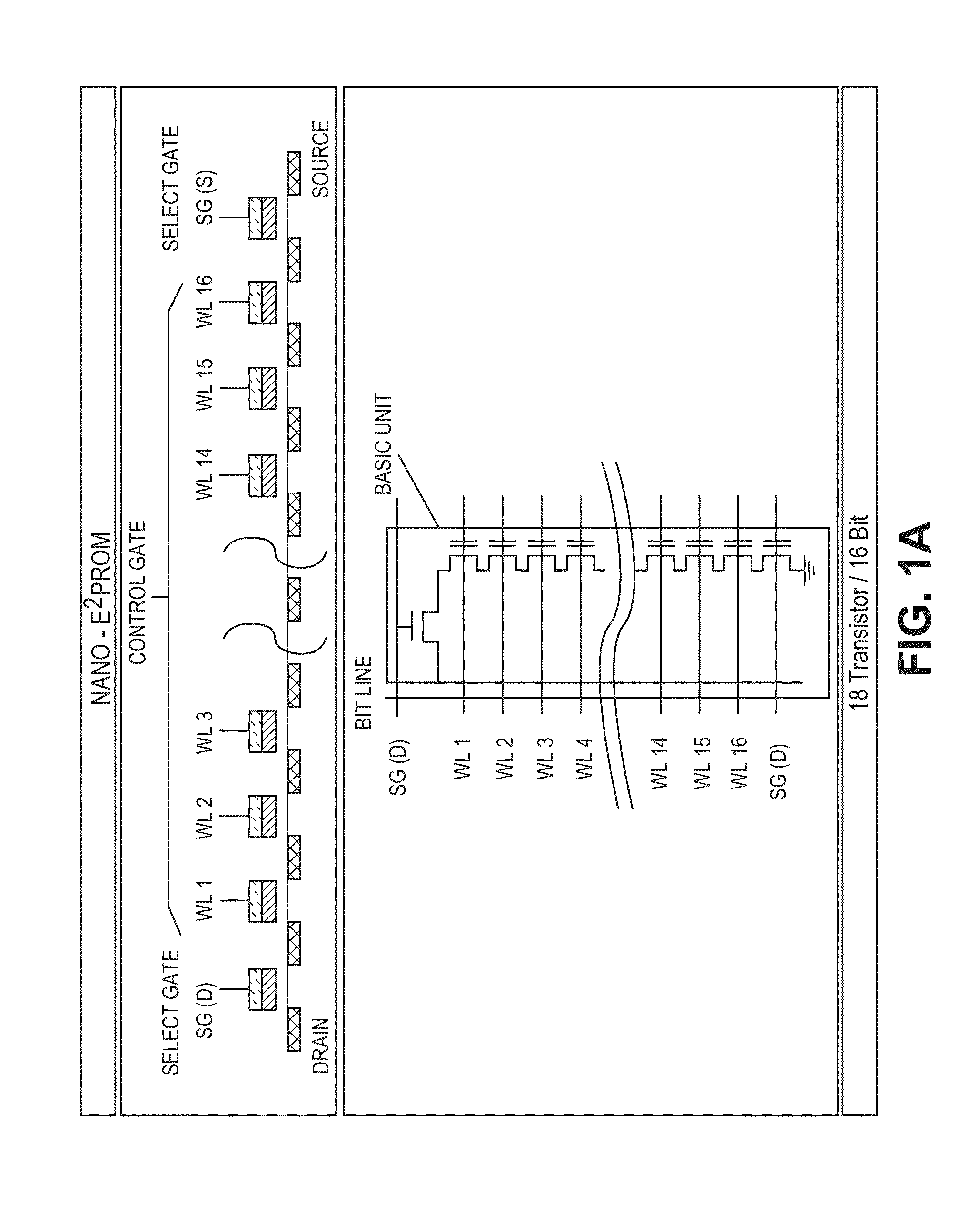

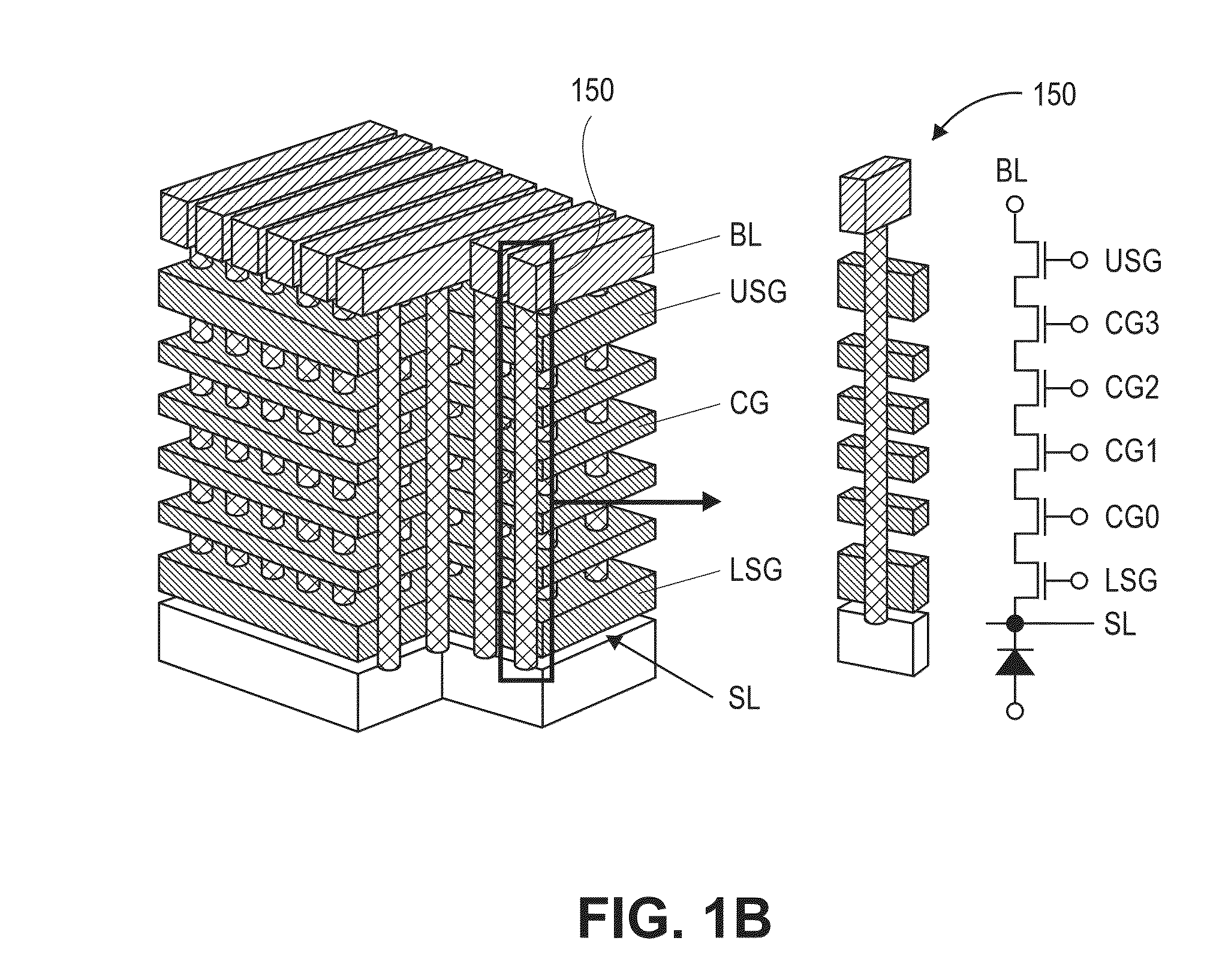

Multilayered stacks having layers of silicon interleaved with layers of a dielectric, such as silicon dioxide, are plasma etched with non-corrosive process gas chemistries. Etching plasmas of fluorine source gases, such as SF6 and / or NF3 typically only suitable for dielectric layers, are energized by pulsed RF to achieve high aspect ratio etching of silicon / silicon dioxide bi-layers stacks without the addition of corrosive gases, such as HBr or Cl2. In embodiments, a mask open etch and the multi-layered stack etch are performed in a same plasma processing chamber enabling a single chamber, single recipe solution for patterning such multi-layered stacks. In embodiments, 3D NAND memory cells are fabricated with memory plug and / or word line separation etches employing a fluorine-based, pulsed-RF plasma etch.

Owner:APPLIED MATERIALS INC

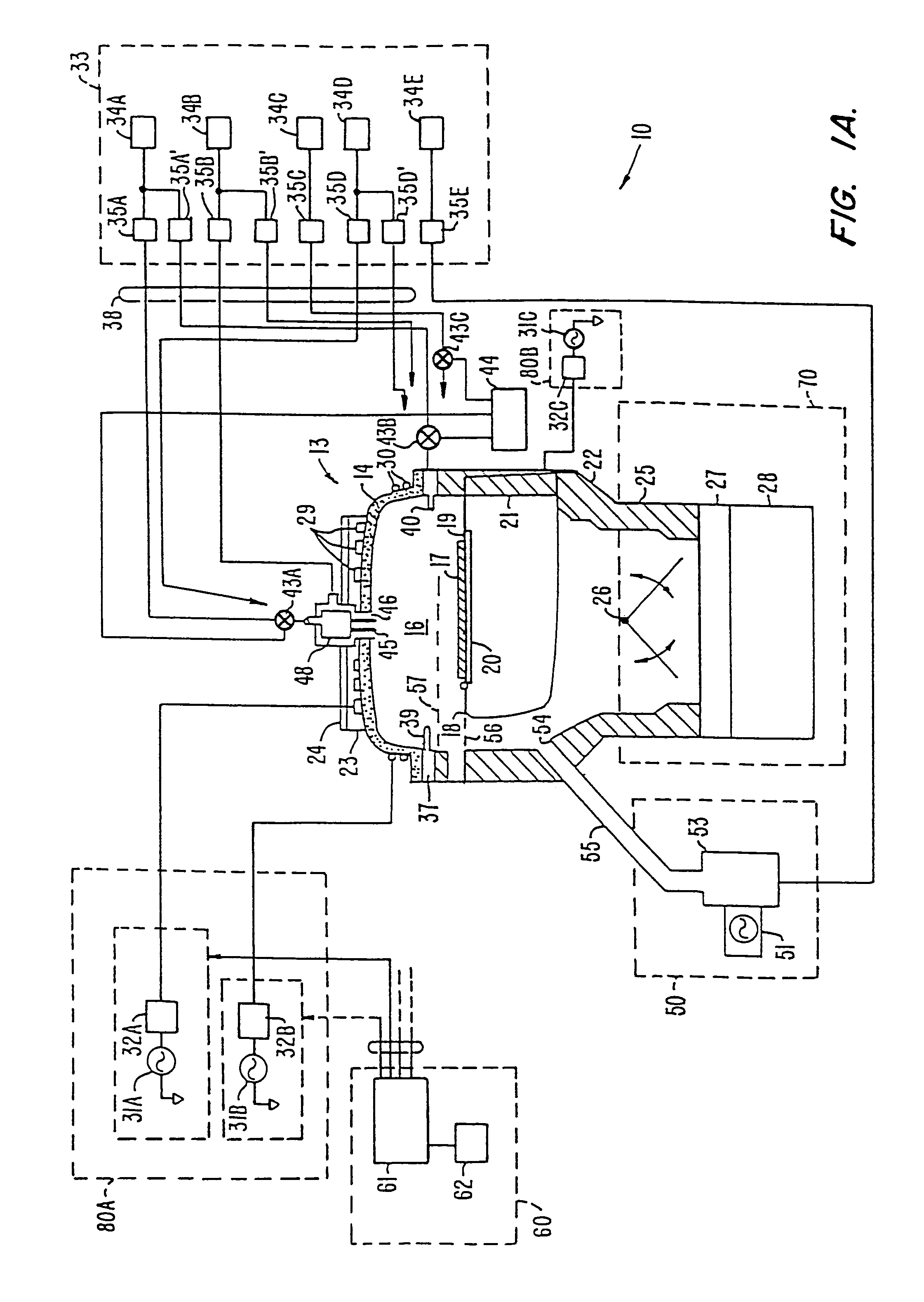

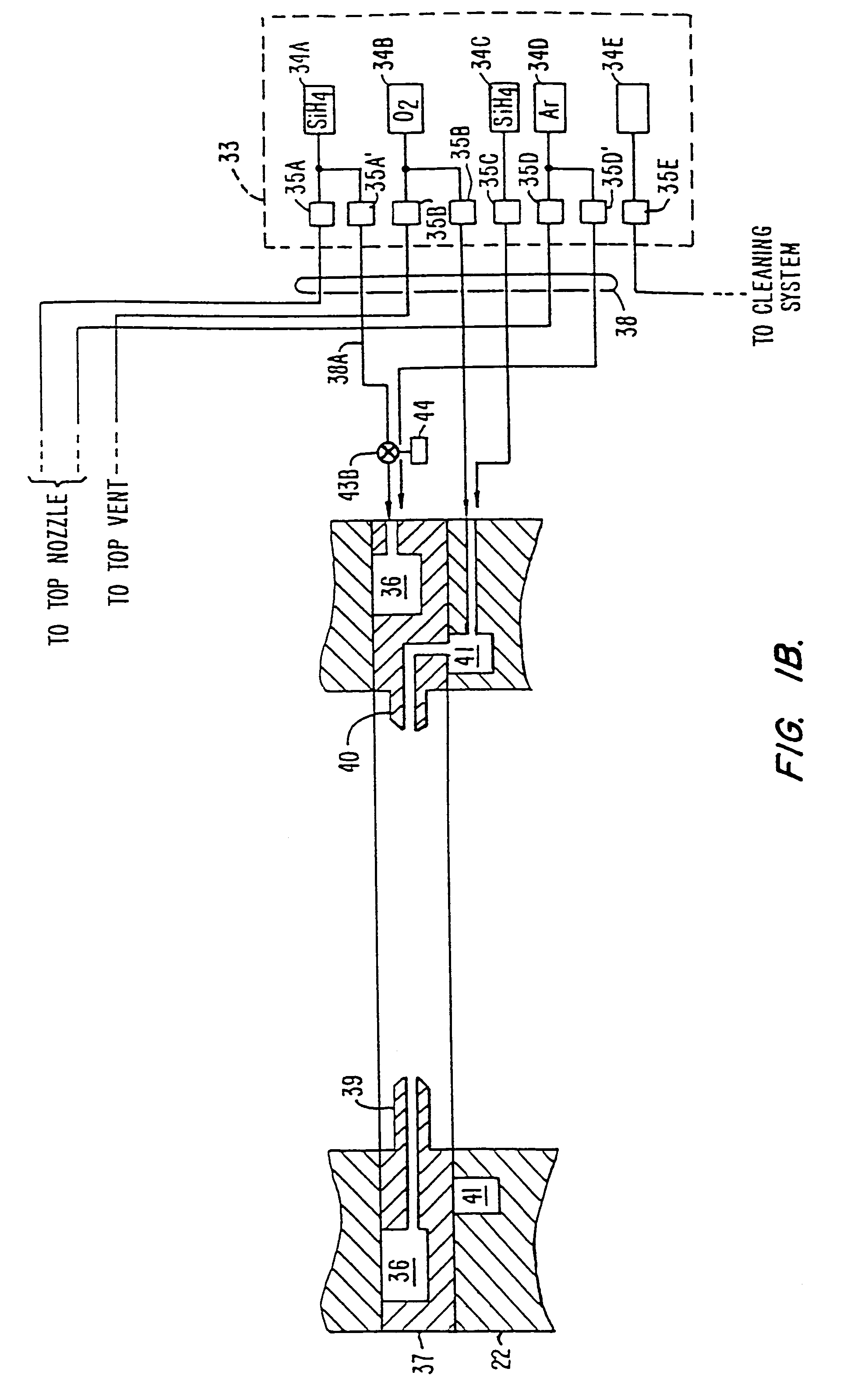

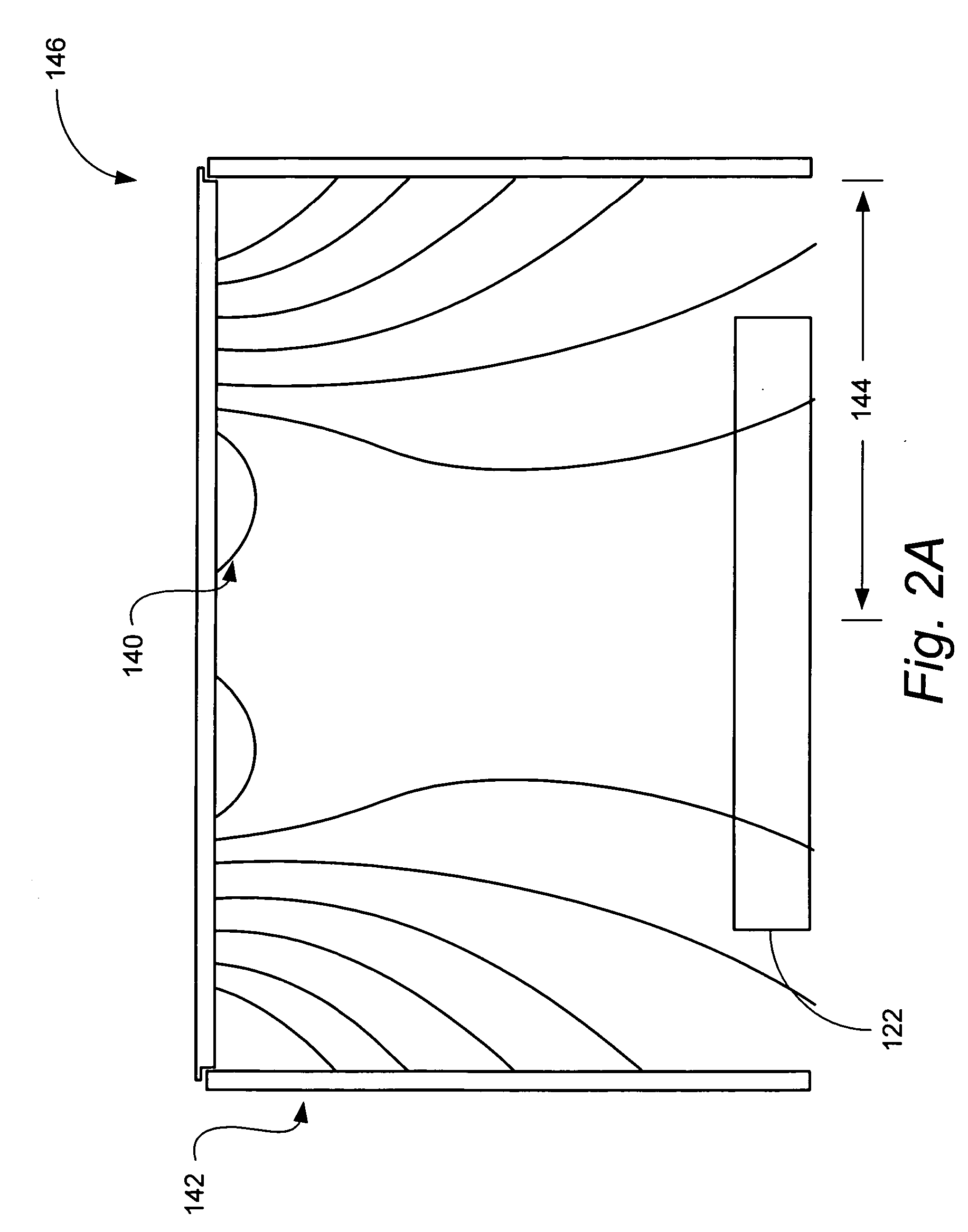

Gas chemistry cycling to achieve high aspect ratio gapfill with HDP-CVD

A method and apparatus are disclosed for depositing a dielectric film in a gap having an aspect ratio at least as large as 6:1. By cycling the gas chemistry of a high-density-plasma chemical-vapor-deposition system between deposition and etching conditions, the gap may be substantially 100% filled. Such filling is achieved by adjusting the flow rates of the precursor gases such that the deposition to sputtering ratio during the deposition phases is within certain predetermined limits.

Owner:APPLIED MATERIALS INC

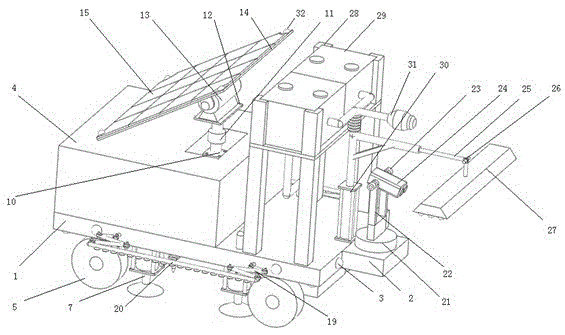

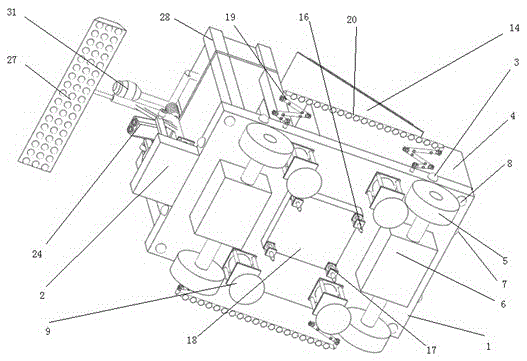

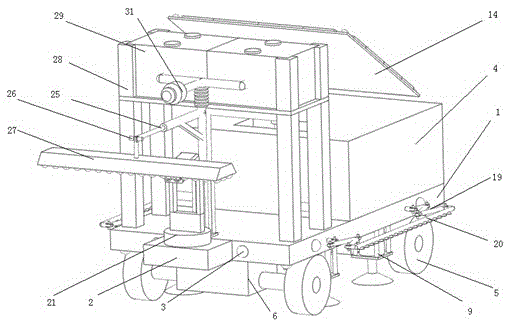

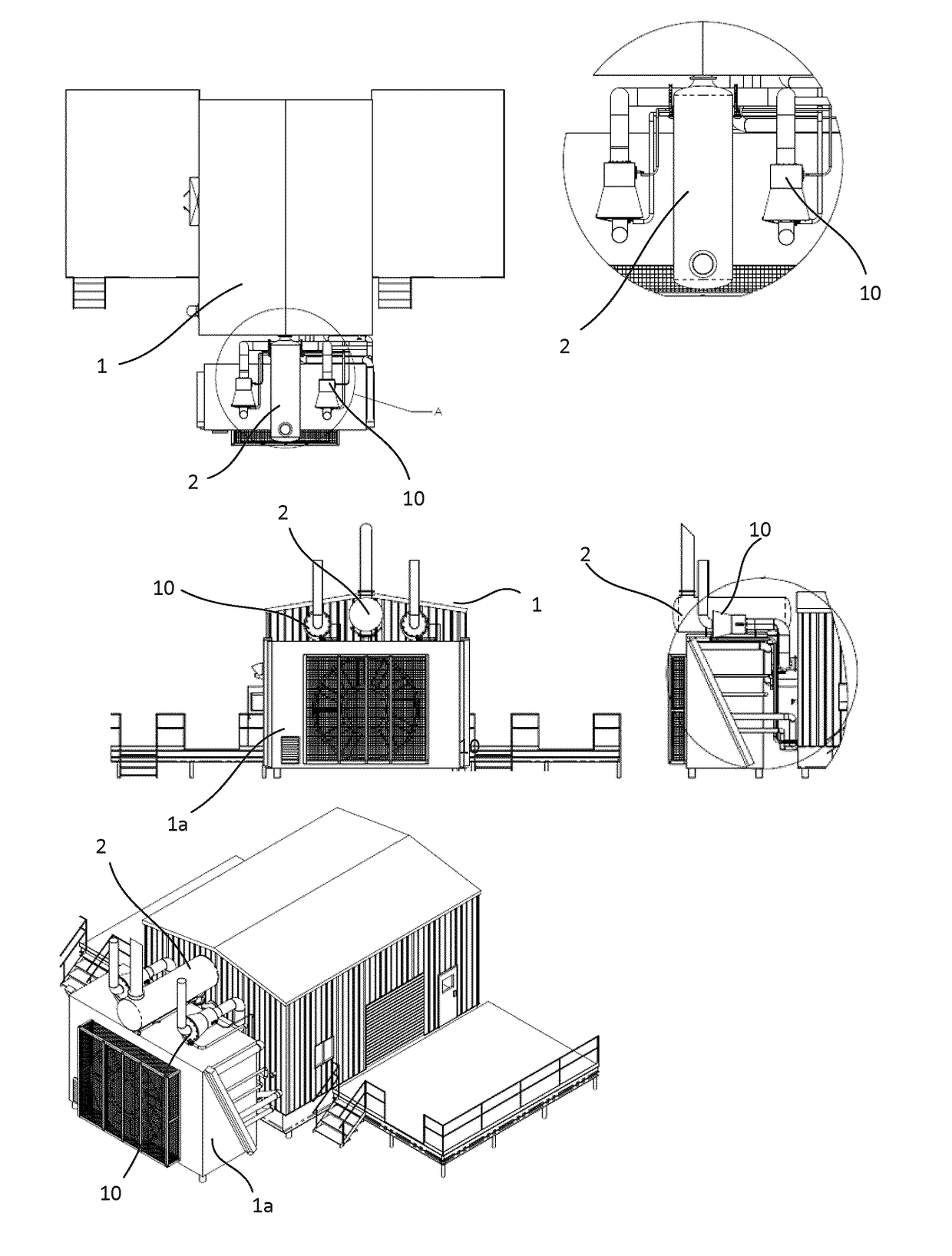

Solar energy robot for chemistry accident treatment and working method

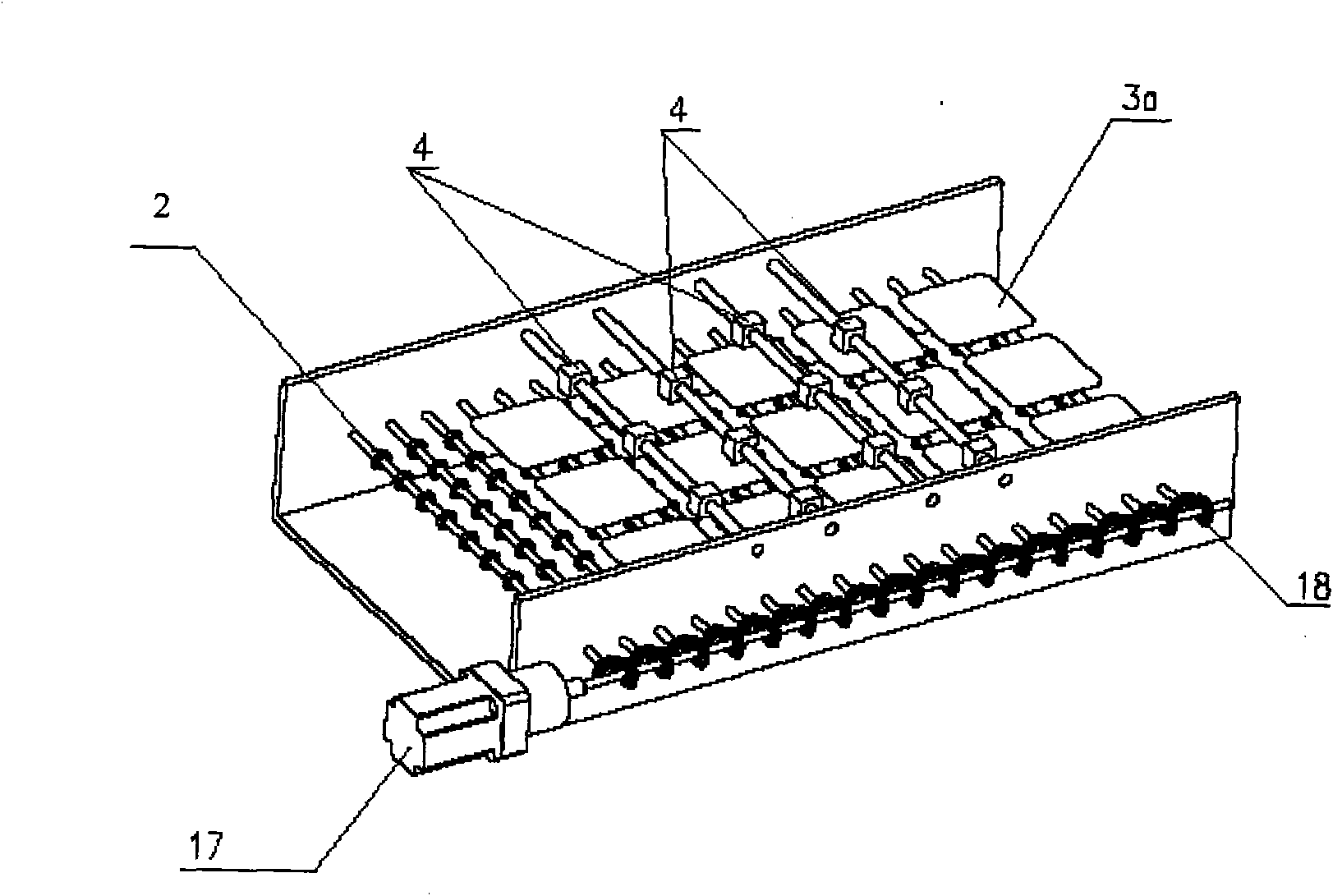

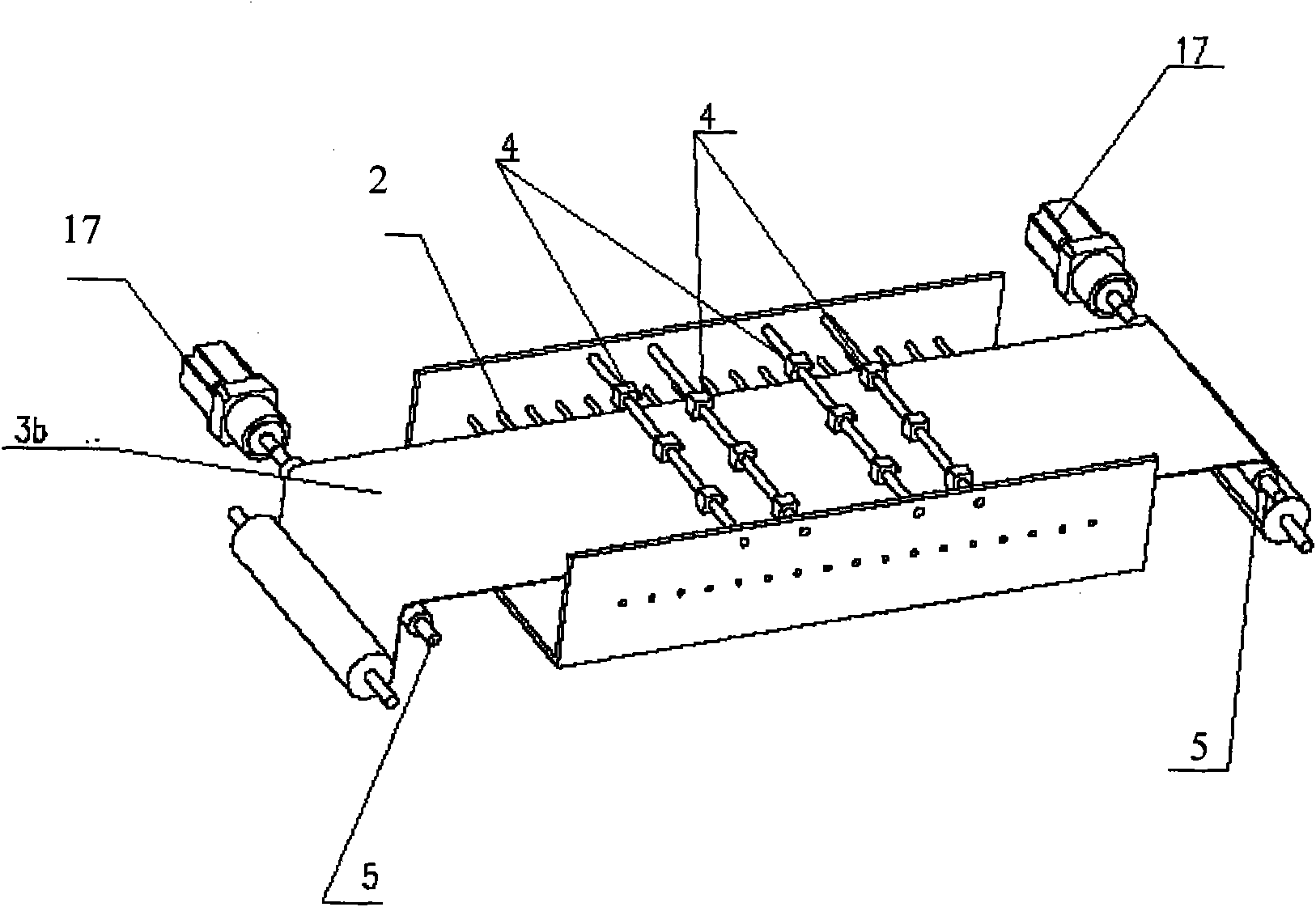

ActiveCN105459079AAvoid corrosionImprove terrain adaptabilityPhotovoltaic supportsGas treatmentSolar chemicalTherapeutic effect

The invention provides a solar energy robot for chemistry accident treatment. The robot comprises a main supporting plate, a front supporting plate, a control box, tyres, a tyre bracket, a signal transmitting receiver, a gas chemical detector, supporting cylinders, a battery plate cylinder, a battery plate rotating motor, a motor mounting plate, an angle adjustment motor, a solar energy mounting plate, a solar energy battery plate, a sampling straw, a telescopic cylinder, a sampling detecting device, folding spray pipes, vertical spray pipes, a camcorder lens rotating motor, a camcorder lens fixing frame, an angle controlling motor, a camcorder lens, a lateral cylinder, spray head adjustment motors, a spray head, a placing frame, liquid storing tanks, a main telescopic cylinder, a spray gun head and light intensity inductors. The solar energy robot disclosed by the invention can perform corresponding treatment on an accident zone according to the corresponding detecting result and the corresponding shooting result, the treatment effect is good, the treatment efficiency is high, an angle variable solar battery plate is adopted for providing electricity, and the solar energy battery plate can change along with the angle of light, so that the absorption efficiency of solar energy is high, and the service time is long.

Owner:JINLING INST OF TECH

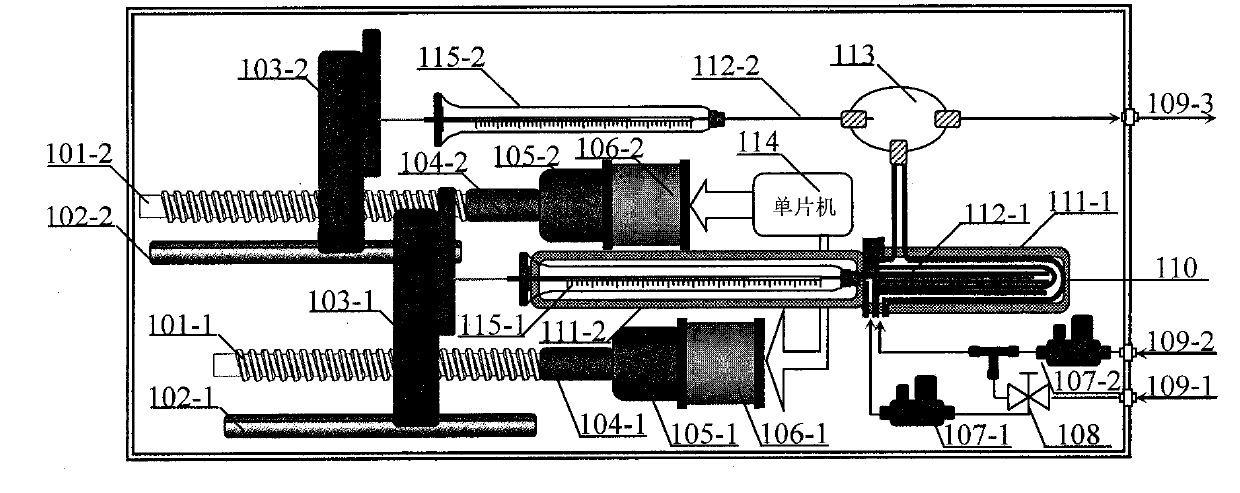

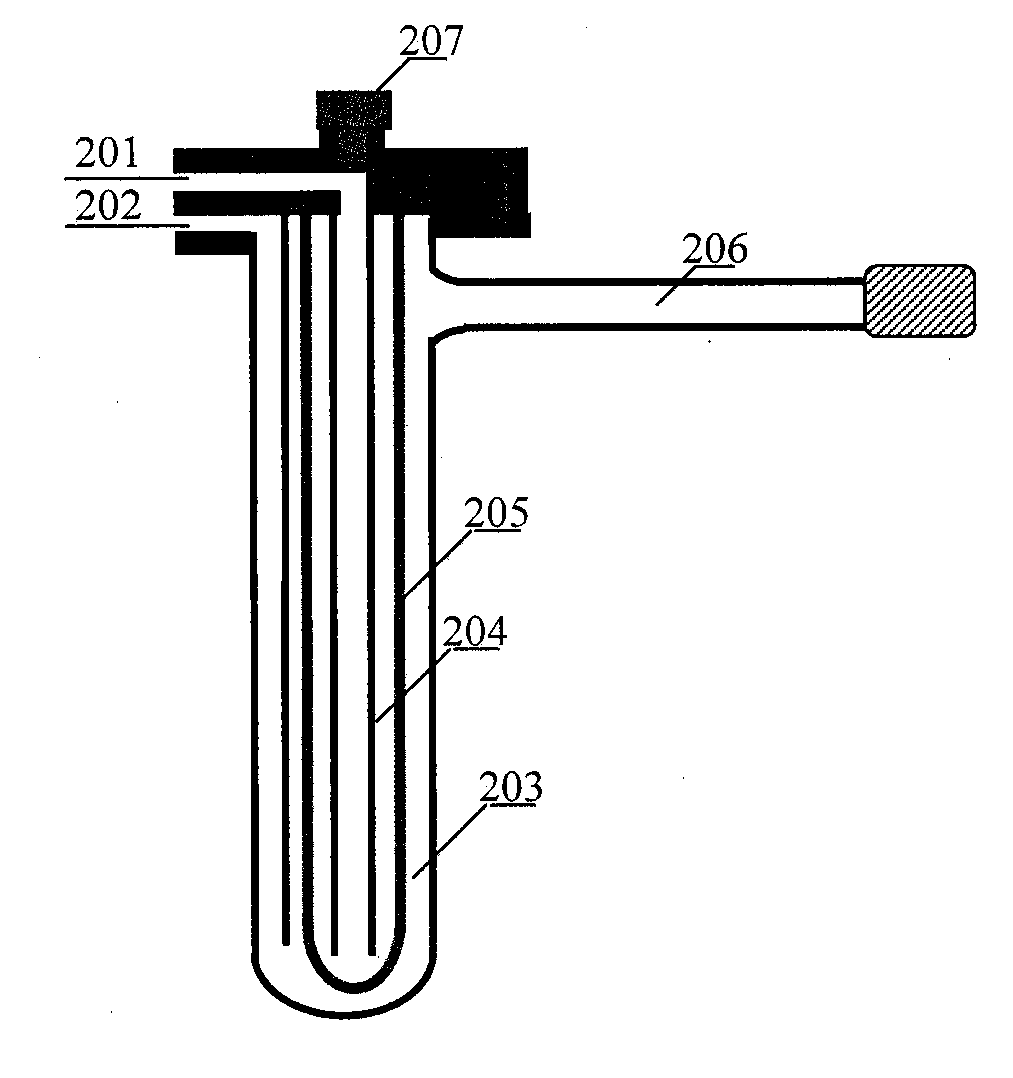

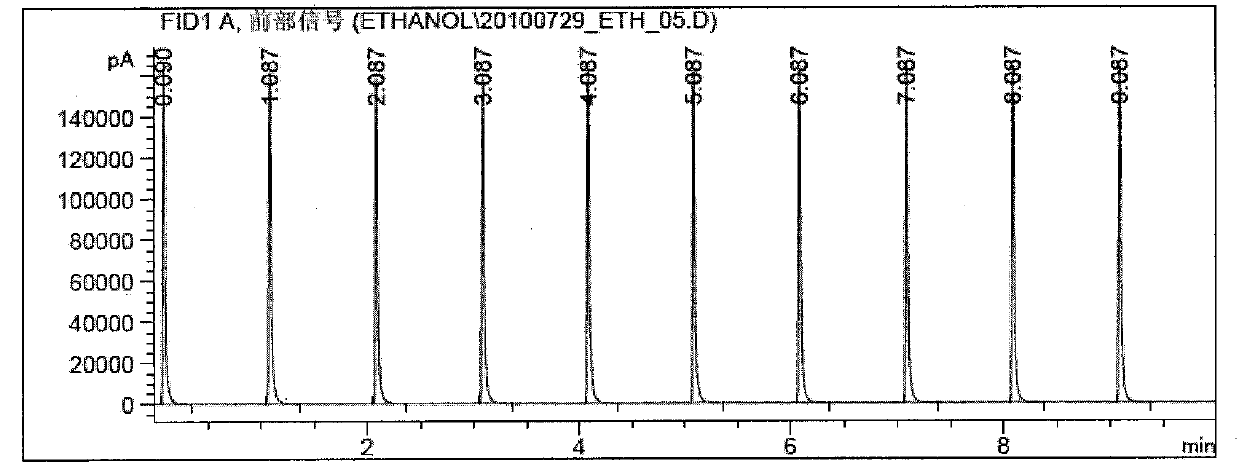

Multifunctional standard gas generator

ActiveCN105498640AThe result is accurateReliable resultsPreparing sample for investigationGas generation devicesHigh concentrationEvaporation

Owner:李圣彭

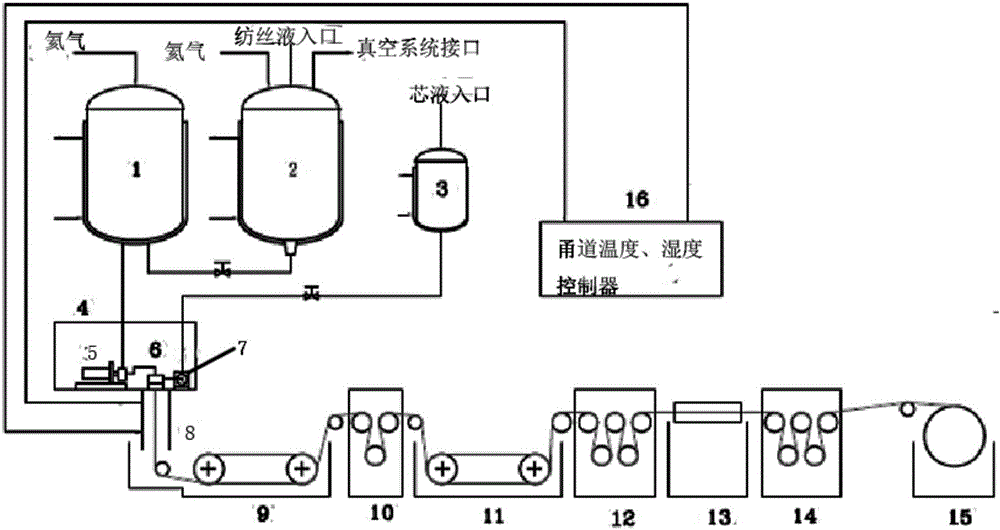

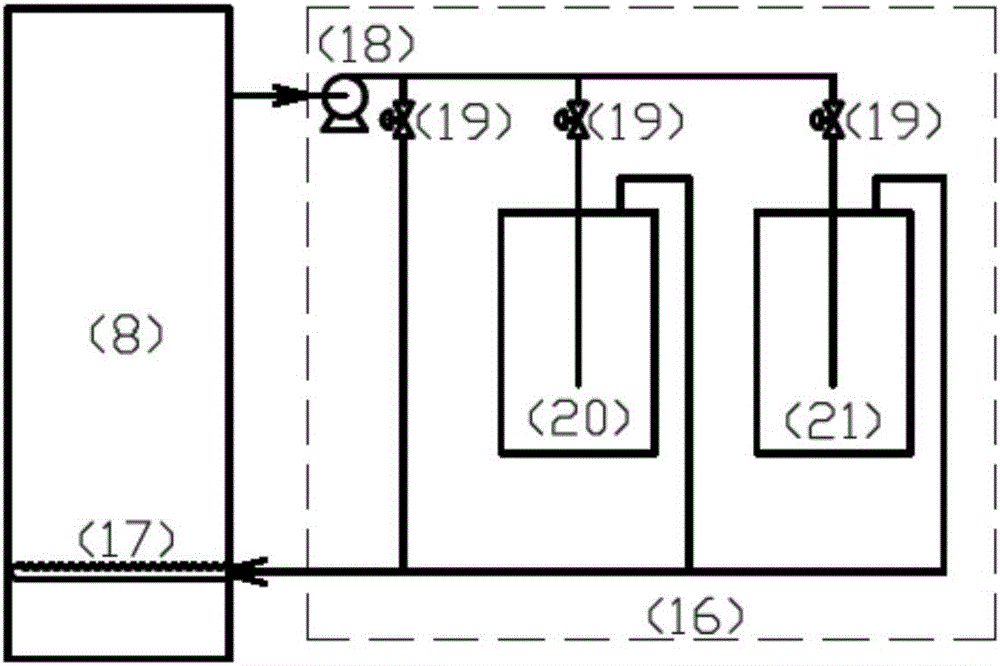

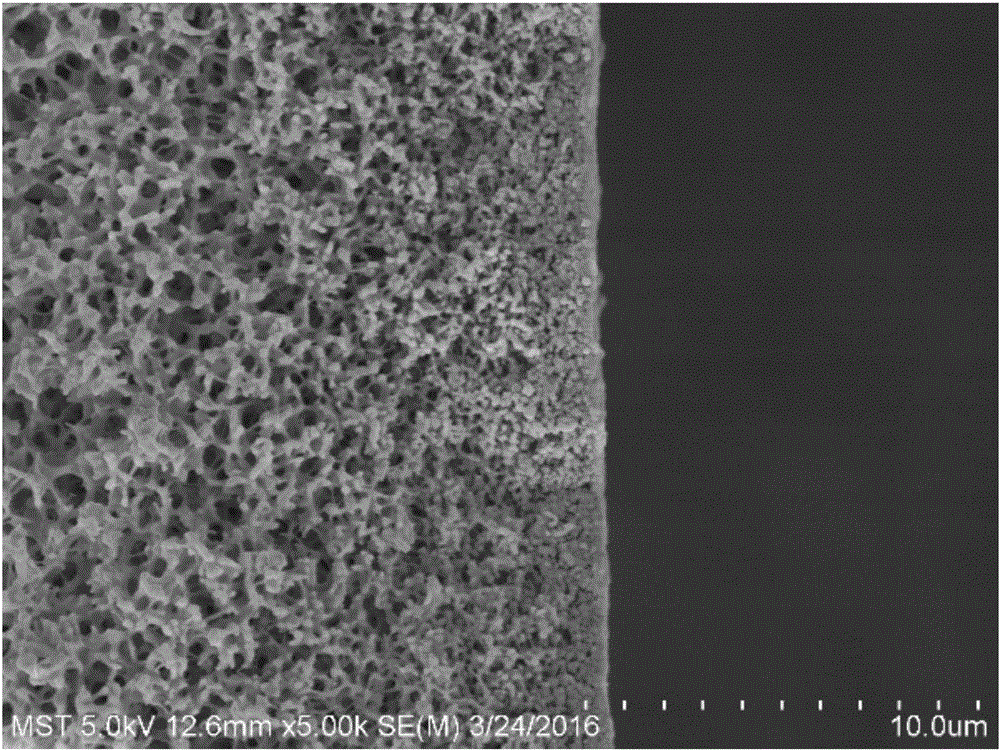

High-pollution-resistance type polyvinylidene fluoride (PVDF) hollow fiber ultrafiltration membrane, preparation method and device

ActiveCN106731897AThe outer surface has small poresGood flexibilityMembranesUltrafiltrationFiberUltrafiltration

The invention relates to a preparation device and a manufacturing method for a high-pollution-resistance type symmetrical polyvinylidene fluoride (PVDF) hollow fiber porous membrane. The device comprises a membrane liquid pretreatment apparatus, a spinning box, a gas passage, a passage atmosphere control system, a coagulating bath and a potcher, and a preparation process combining vapor phase gelation and immersion gelation is adopted. The device provided by the invention, designed with a reasonable passage and a reasonable passage atmosphere adjusting system, can realize adjustment of the temperature, humidity and chemical composition of gas in the passage. Nascent fibers extruded out of a spinning head are firstly subjected to vapor induced phase separation to preliminarily generate microporous phase separation so as to form a high-porosity surface, and a membrane filament with a high aperture ratio has an overall asymmetric cell-like structure after consolidation forming. The invention can achieve stage control of pore diameter distribution of a surface and a support layer, and a membrane pollution experiment shows that the overall asymmetric structure with good integrality and a surface separation layer with a high aperture ratio and narrow pore diameter distribution have higher pollution resistance.

Owner:南京久盈膜科技有限公司

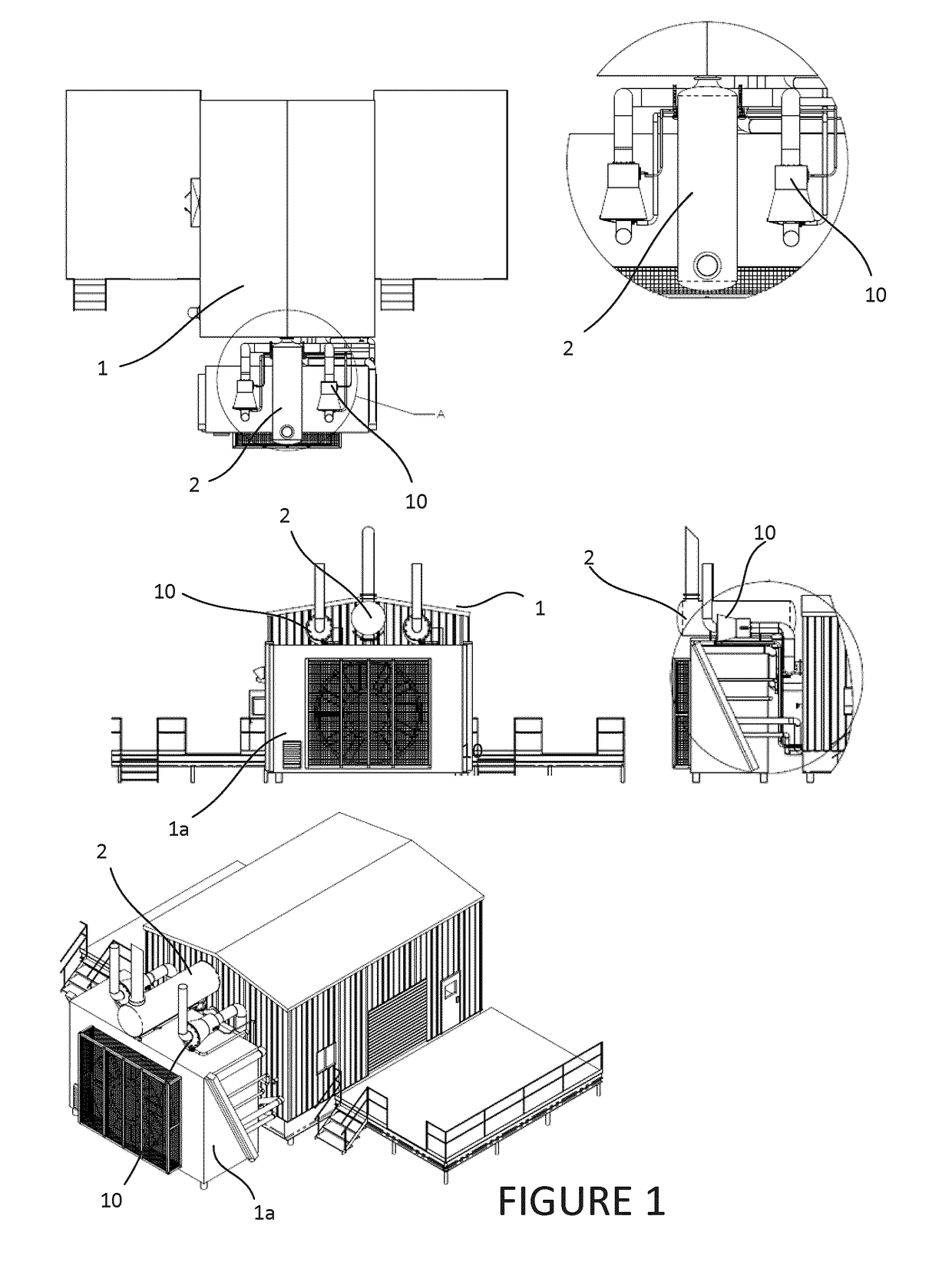

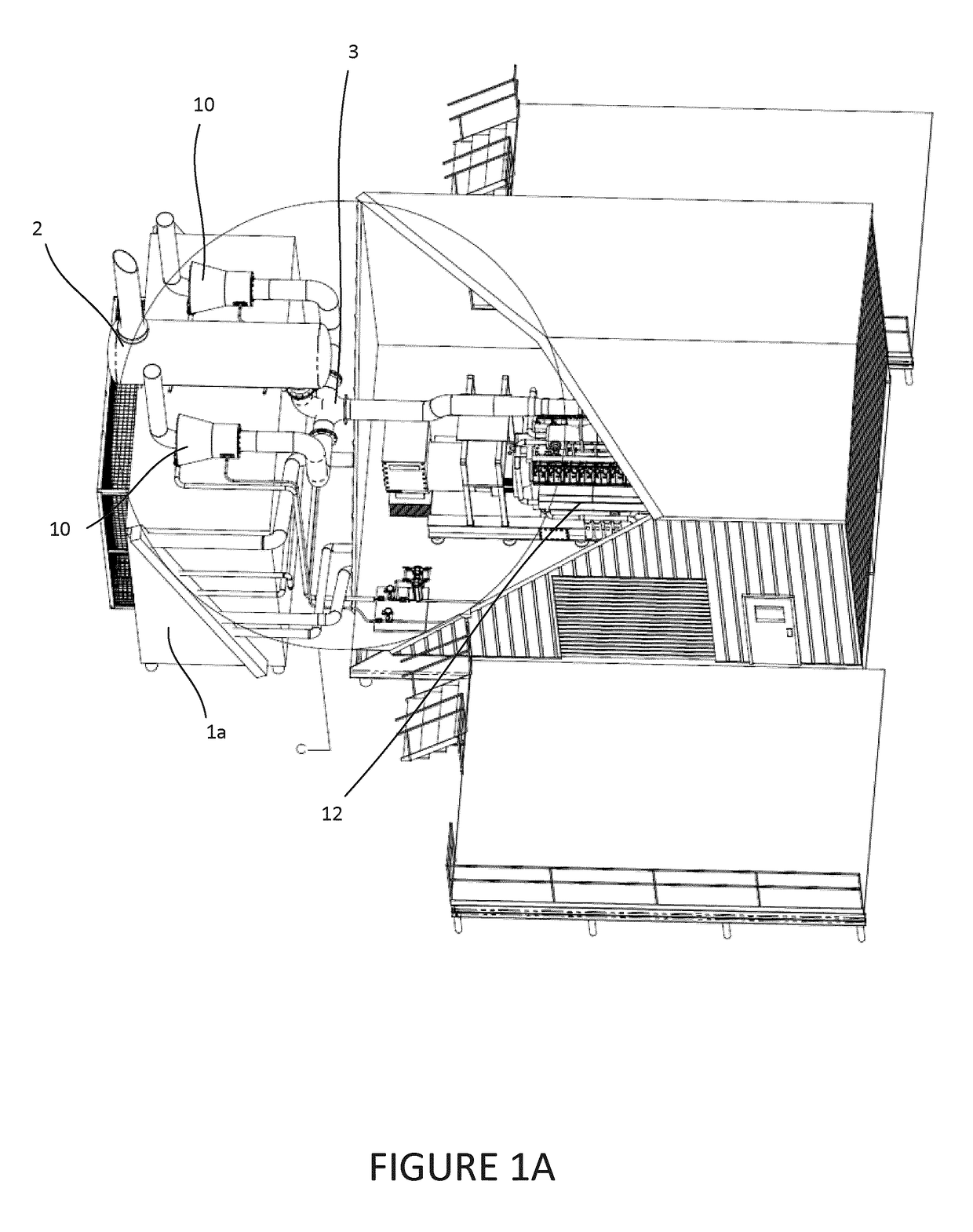

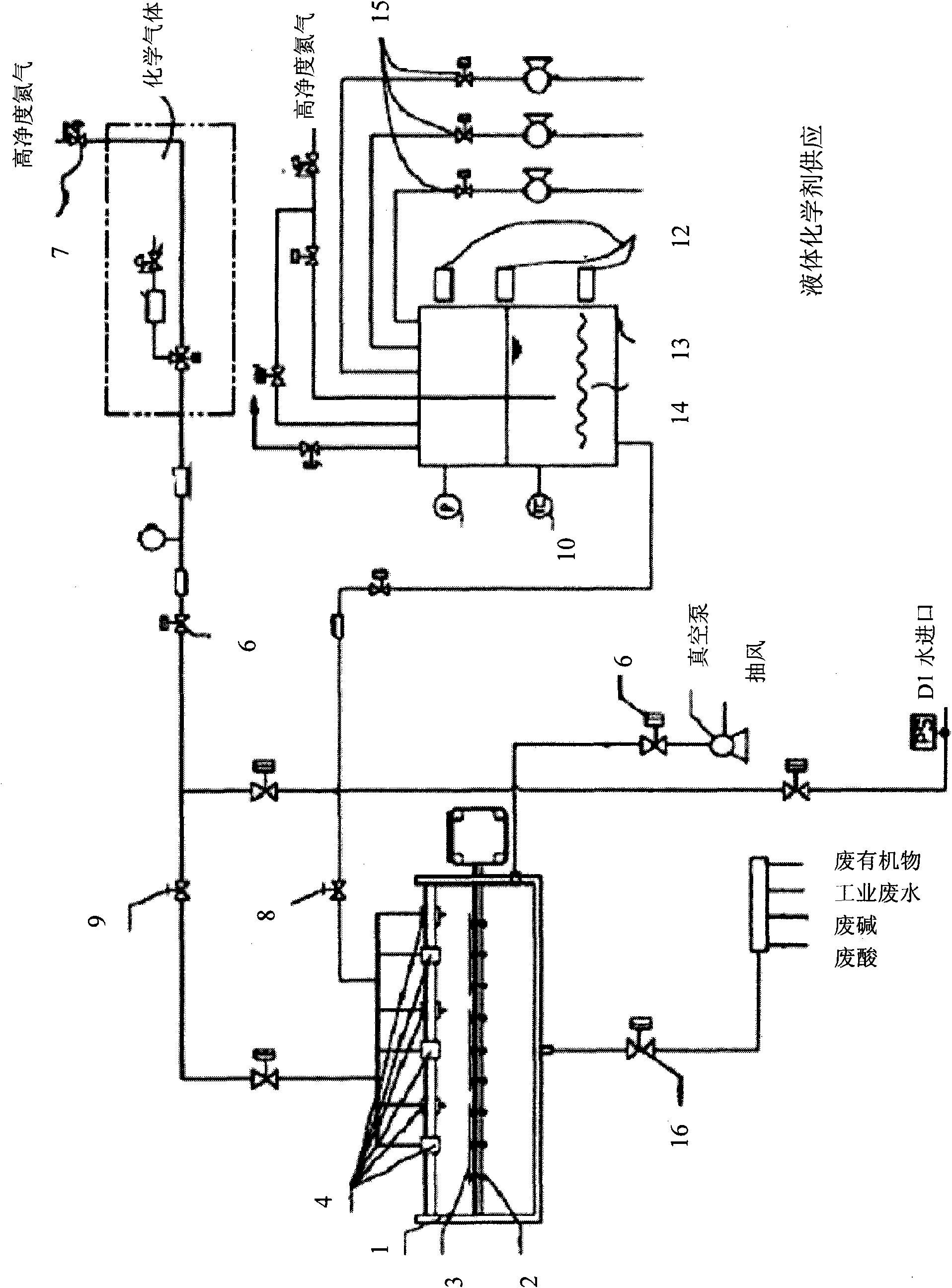

Apparatus, systems and methods for management of raw water and emissions utilizing heat and/or pressure energy within combustion gas sources

InactiveUS20180215632A1Quick interactionIncrease the areaWaste water treatment from quariesUsing liquid separation agentParticulatesAtmospheric air

The invention relates to methods, systems and apparatus for distributed management of raw water and internal combustion engine (ICE) gas emissions generated during industrial operations. One aspect of the invention at least partially utilizes a hot gas air knife to increase or partially increase surface area between a raw water and a hot gas in order to vaporize a proportion of the aqueous phase of the raw water and concentrate contaminants within a residual raw water concentrate. The water vapor generated by the vaporization process may be demisted, discharged directly to the atmosphere or alternatively condensed and captured for use. Another aspect relates to how the liquids and gasses interact to continuously flush the surfaces of the system which may help mitigate scaling issues. The invention may help facilitate rapid transfer of ICE combustion gas particulate and ICE combustion gas chemicals onto and into the raw water as it concentrates.

Owner:HORIZON OILFIELD SOLUTIONS

Method of plasma etching of high-K dielectric materials

InactiveUS7094704B2Decorative surface effectsSemiconductor/solid-state device manufacturingDielectric permittivityMaterials science

A method of etching high dielectric constant materials using a halogen gas, a reducing gas and an etch rate control gas chemistry.

Owner:APPLIED MATERIALS INC

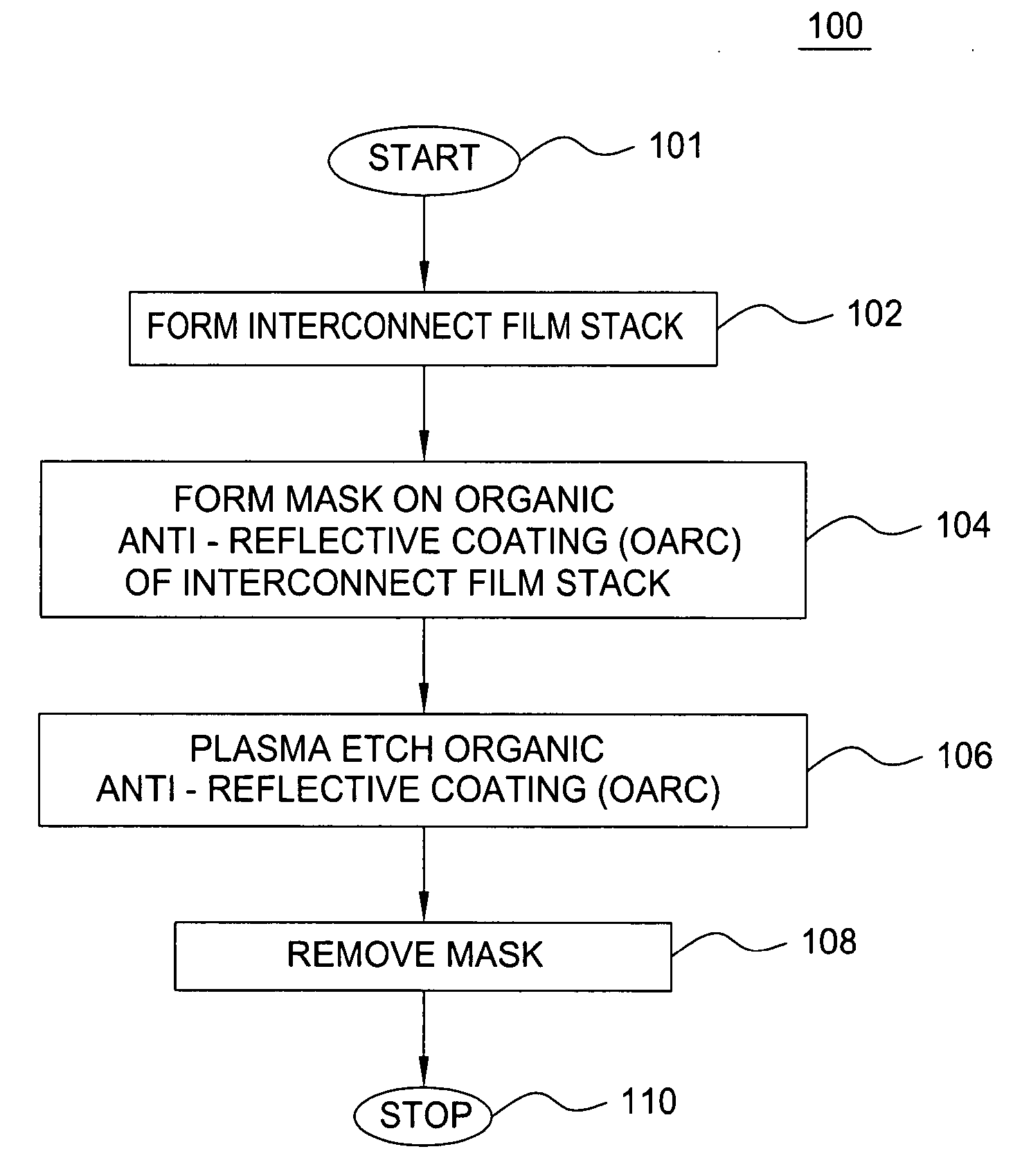

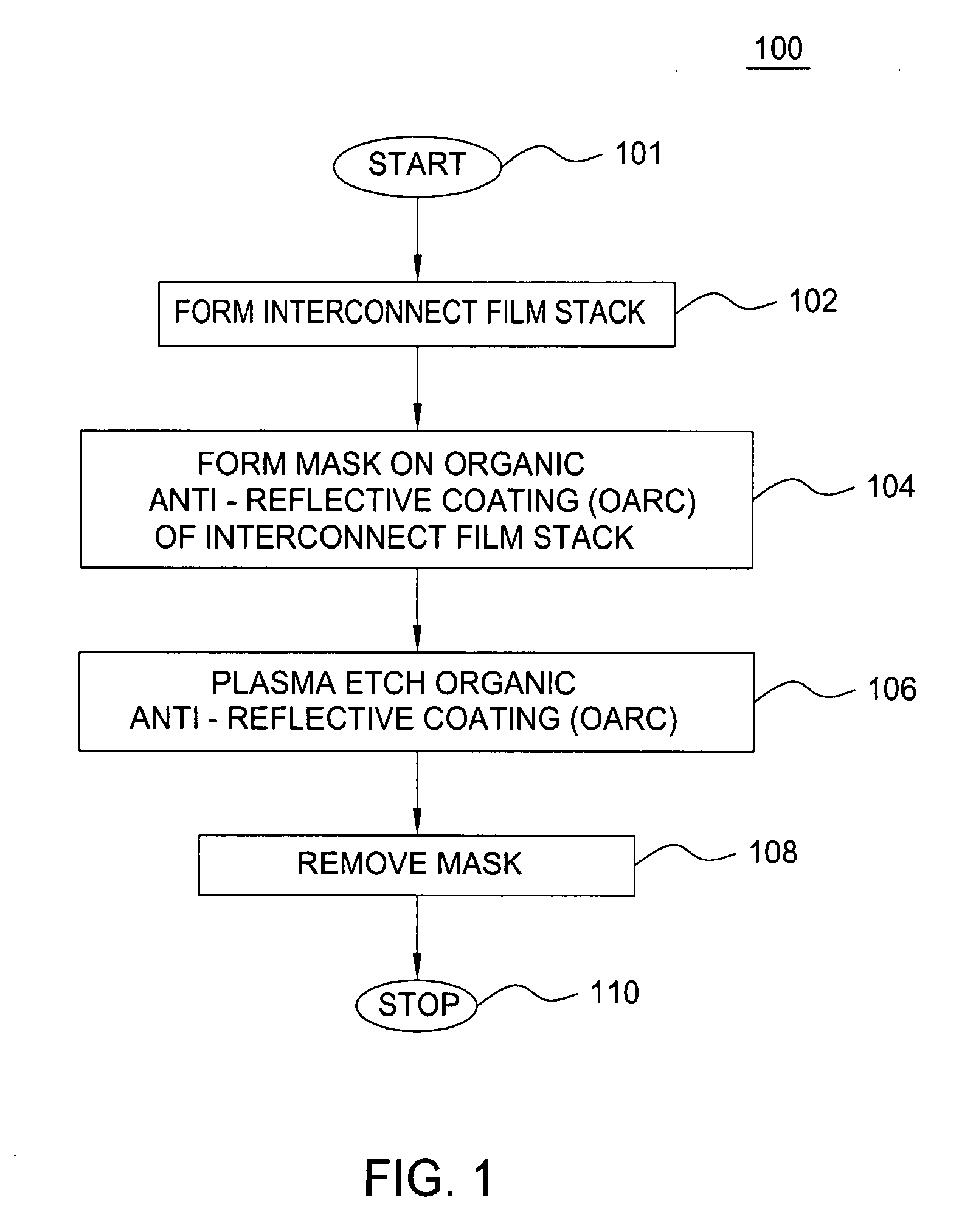

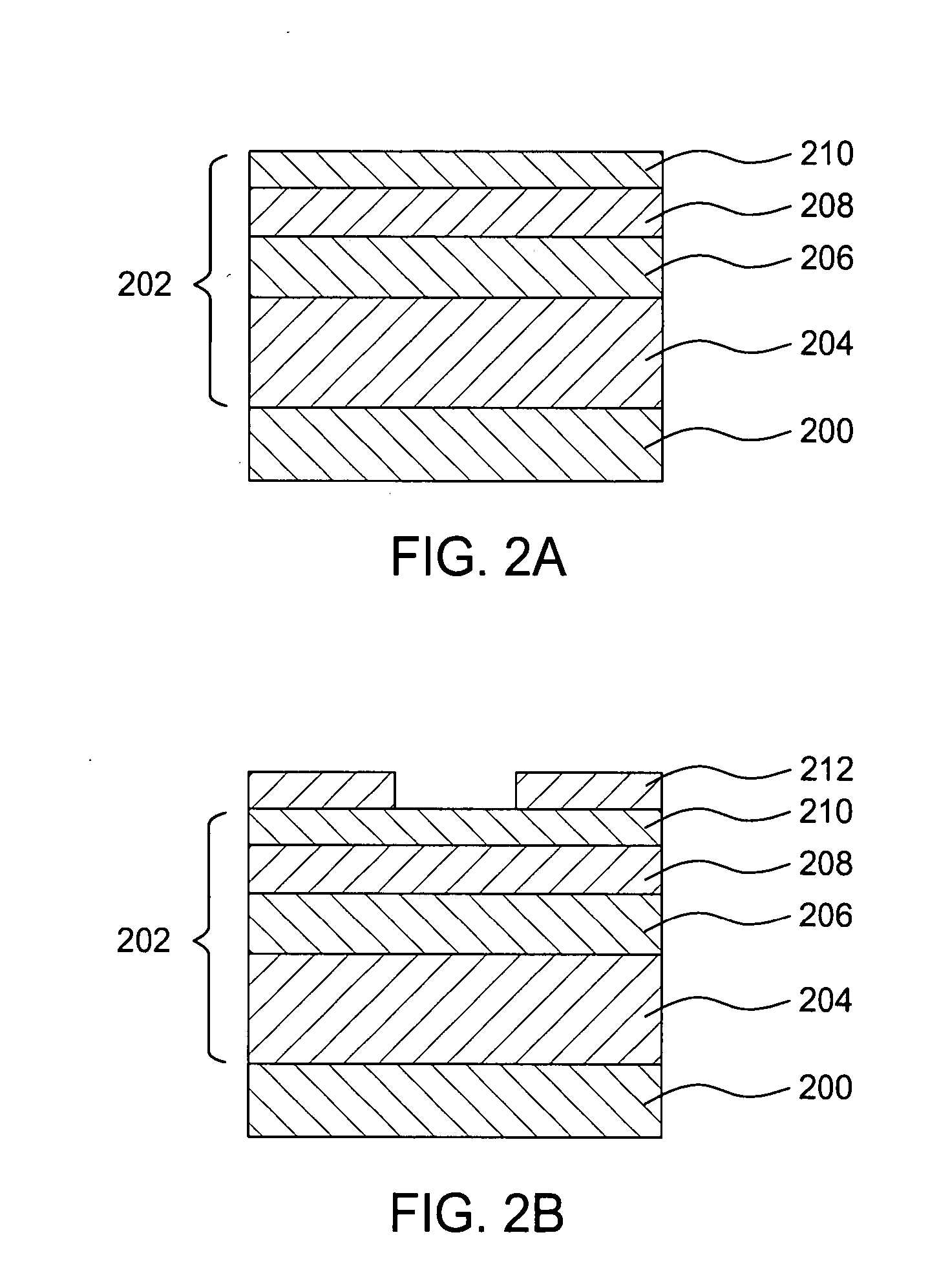

Method for etching an organic anti-reflective coating (OARC)

InactiveUS20050009342A1Improve etch selectivitySemiconductor/solid-state device manufacturingAnti-reflective coatingOxygen

A method for etching an organic anti-reflective coating (OARC) using a halogen-free gas chemistry is disclosed. The organic anti-reflective coating (OARC) is etched using a gas mixture comprising at least one of a hydrocarbon-containing gas and an oxygen-containing gas. The method provides high etch selectivity for the organic anti-reflective coating (OARC) over metal layers (e.g., copper (Cu), aluminum (Al), and the like) or dielectric layers (silicon dioxide (SiO2), and the like).

Owner:APPLIED MATERIALS INC

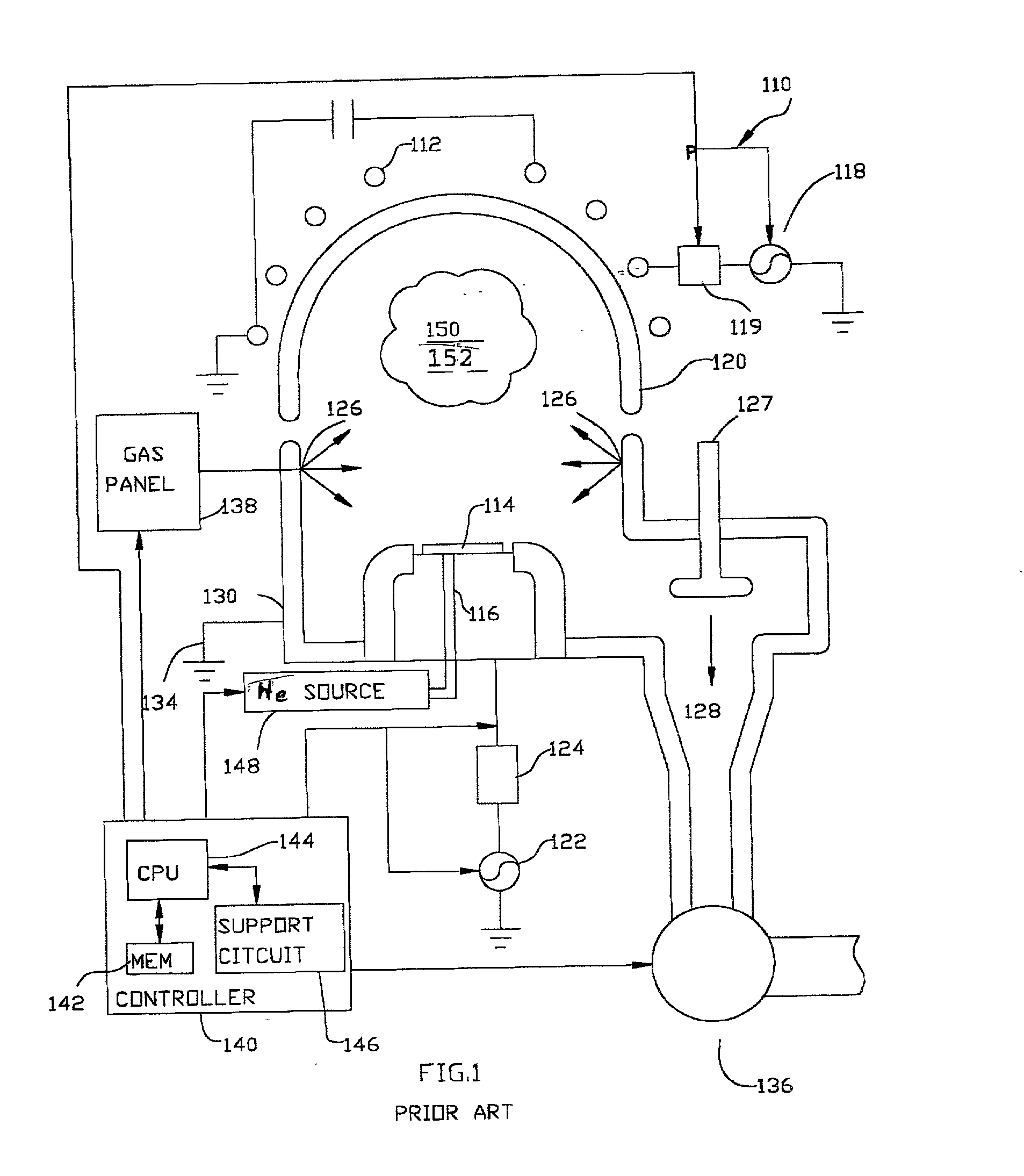

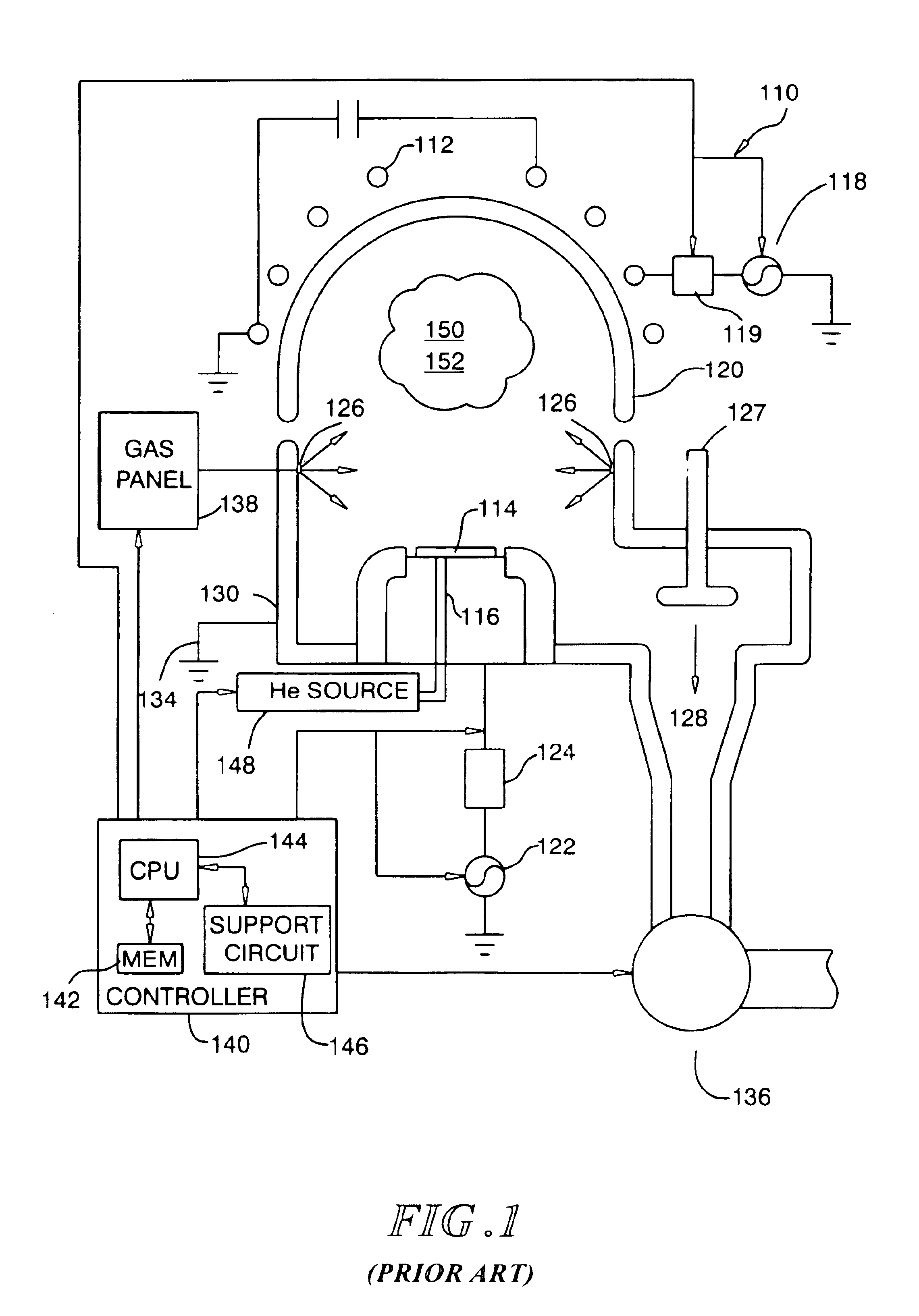

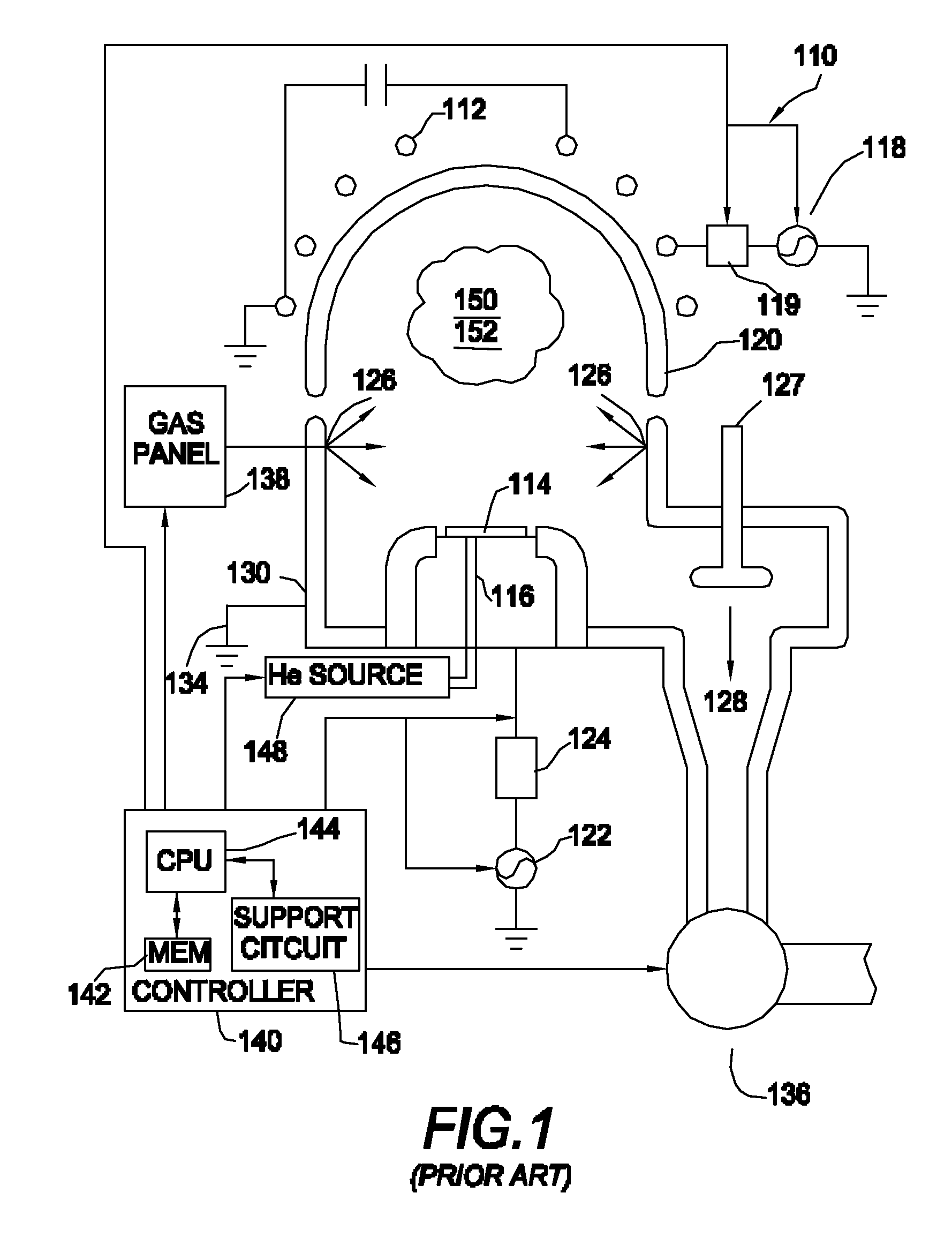

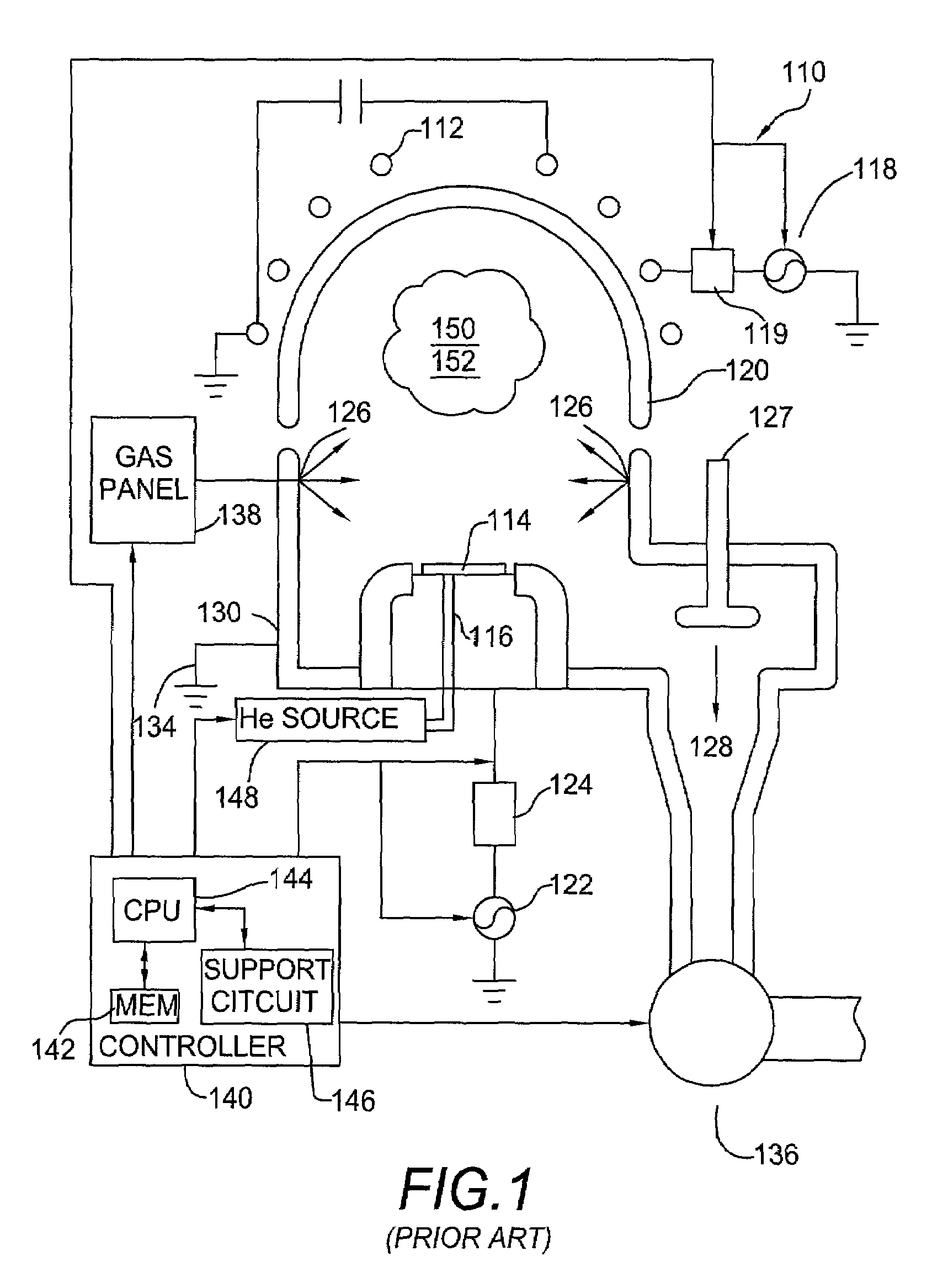

Materials and gas chemistries for processing systems

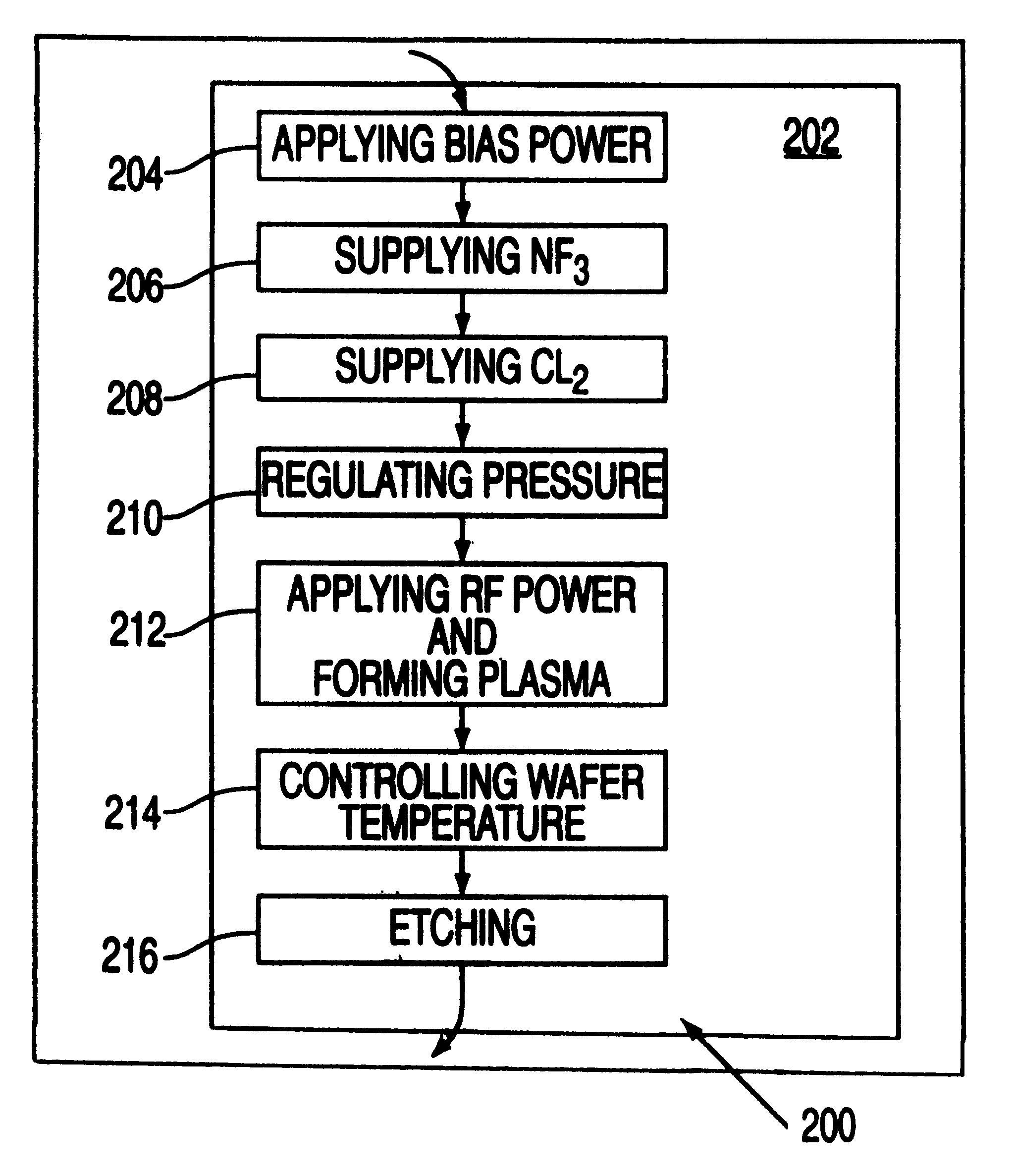

InactiveUS20060011583A1Speed up the processImprove uniformityLiquid surface applicatorsElectric discharge tubesReactive gasSingle chamber

A plasma processing system for processing a substrate, is disclosed. The plasma processing system includes a single chamber, substantially azimuthally symmetric plasma processing chamber within which a plasma is both ignited and sustained for the processing. The plasma processing chamber has no separate plasma generation chamber. The plasma processing chamber has an upper end and a lower end. The plasma processing chamber includes a material that does not substantially react with the reactive gas chemistries that are delivered into the plasma processing chamber. In addition, the reactant gases that are flown into the plasma processing chamber are disclosed.

Owner:BAILEY ANDREW +3

Catalyst for synthesis of hydrocarbons from CO and H2 and preparation method thereof

The disclosed technology relates to nanotechnology, petrochemistry, gas chemistry, coal chemistry, in particular to a catalyst based on carbon nanotubes for synthesis of hydrocarbons from CO and H2 and a preparation method thereof. The carbon nanotubes fixed in the catalyst pellet pores improve mass and heat transfer in the catalyst pellet and the catalyst bed.

Owner:INFRA XTL TECH

System and method for performing single-side continuous chemical wet treatment by using mist chemical agent

InactiveCN101942661AImprove uniformityIncrease productionSpray nozzlesSemiconductor/solid-state device manufacturingSpray nozzleWater spray

The invention relates to a system and a method for performing single-side continuous chemical wet treatment by using atomized chemical agent. The system comprises an atomizer capable of generating atomized chemical agent by using heated gas chemical agent and liquid chemical agent, a plurality of chemical wet treatment cavity units, a plurality of deionized water spraying wet treatment cavity units, an isopropanol (IPA) drying treatment cavity unit and a transmission mechanism which delivers the materials to be treated into the processing unit cavities in turn; and the system also comprises a spraying knife which is provided with a plurality of atomized chemical agent spraying nozzles; a capillary is arranged in the middle of each spraying nozzle; and the atomized chemical agent is sprayed onto the surface of the material to be treated in sector shape through the spraying nozzle space around the capillaries. The system and the method make the single-side continuous chemical wet treatment simple and feasible, effectively solve the problem of cross contamination caused by the repeated use of chemical liquid of the traditional fixed chemical process tank, enhance the flat substrate and improve the uniformity, flexibility and yield of the chemical process treatment of the thin film substrate of the material to be treated.

Owner:倪党生

Process for producing synthetic liquid hydrocarbons and reactor for Fischer-Tropsch synthesis

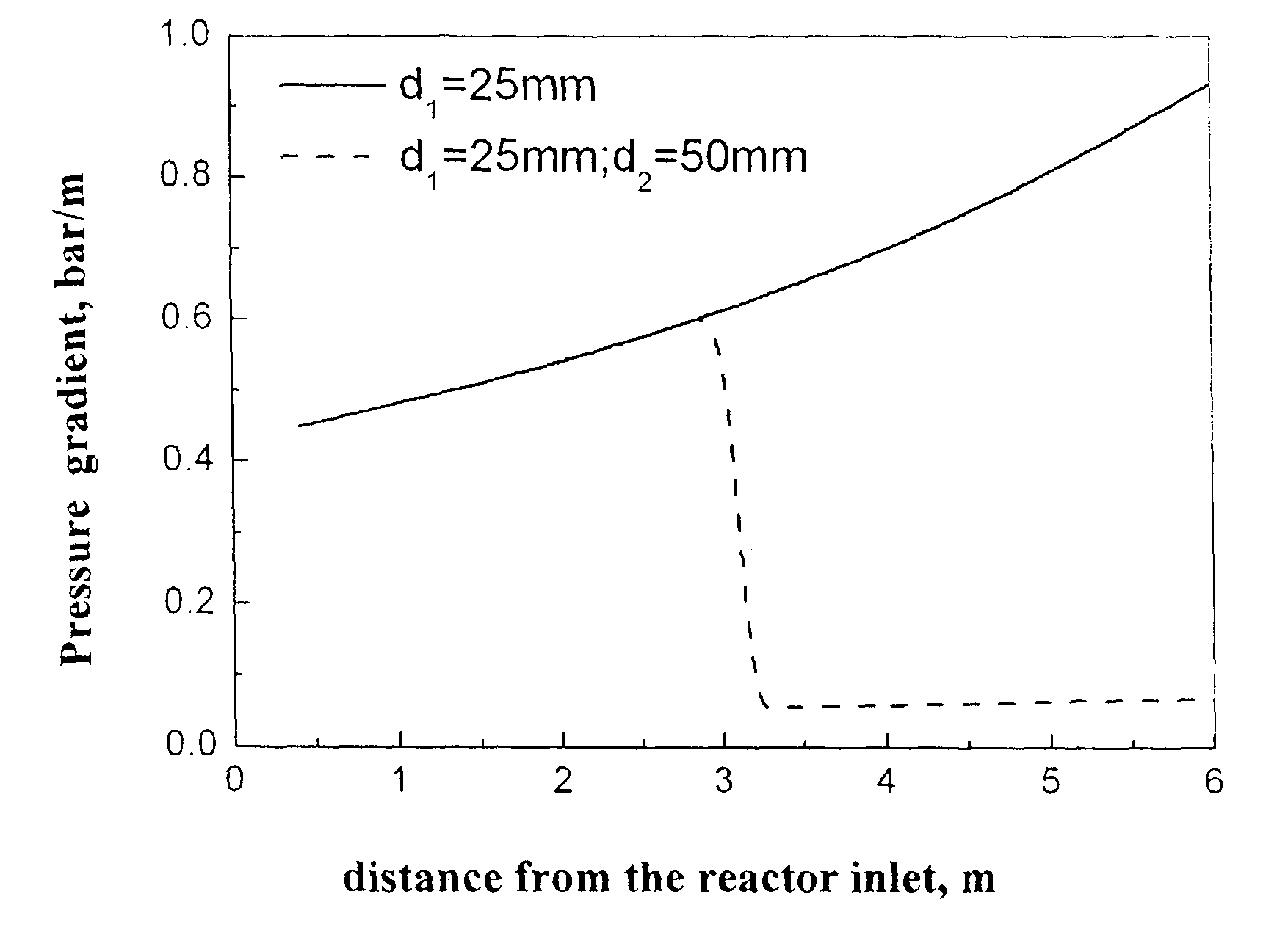

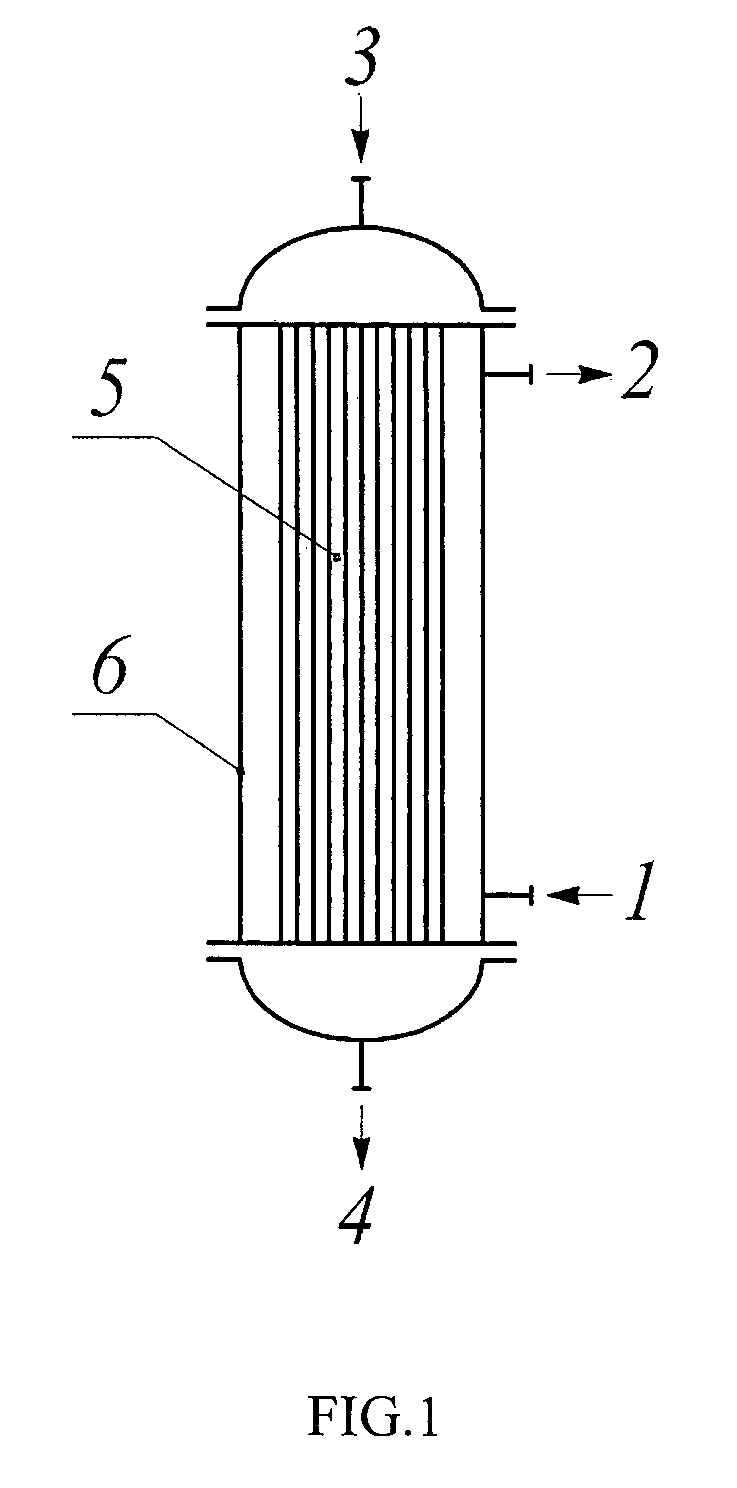

InactiveUS8524787B2Organic compound preparationOxygen compounds preparation by reductionLiquid productSyngas

The disclosure relates to petrochemistry, gas chemistry, coal chemistry, particularly to a synthesis of hydrocarbons C5 and higher from CO and H2 under the Fischer-Tropsch reaction; the invention relates to a process and a system for producing synthetic liquid hydrocarbons. A process for producing synthetic liquid hydrocarbons is provided by catalytic converting syngas under the Fischer-Tropsch reaction on a fixed catalyst bed in a vertical shell and tube reactor with coolant supply into shell wherein as soon as the syngas conversion degree achieves 60-80%, a pressure gradient along the tubes is reduced below 0.1 bar / m and this value is maintained during the whole process. A reactor for Fischer-Tropsch synthesis is provided comprising tubes with catalyst in a shell, the ratio of the tube diameter at the tube outlet to the diameter at the inlet is from 1.5 / 1 to 2.5 / 1. The invention gives a possibility to achieve the optimum temperature range in the catalyst bed; it improves heat and mass-transfer and shut out an accumulation of the liquid products in the bottom of the tubes.

Owner:INFRA XTL TECH

Catalyst for synthesis of hydrocarbons from co and h2 and preparation method thereof

InactiveUS20120214664A1Stable to overheatingIncrease heatMaterial nanotechnologyMolecular sieve catalystsCarbon nanotubeCoal chemistry

The disclosed technology relates to nanotechnology, petrochemistry, gas chemistry, coal chemistry, in particular to a catalyst based on carbon nanotubes for synthesis of hydrocarbons from CO and H2 and a preparation method thereof. The carbon nanotubes fixed in the catalyst pellet pores improve mass and heat transfer in the catalyst pellet and the catalyst bed.

Owner:INFRA XTL TECH

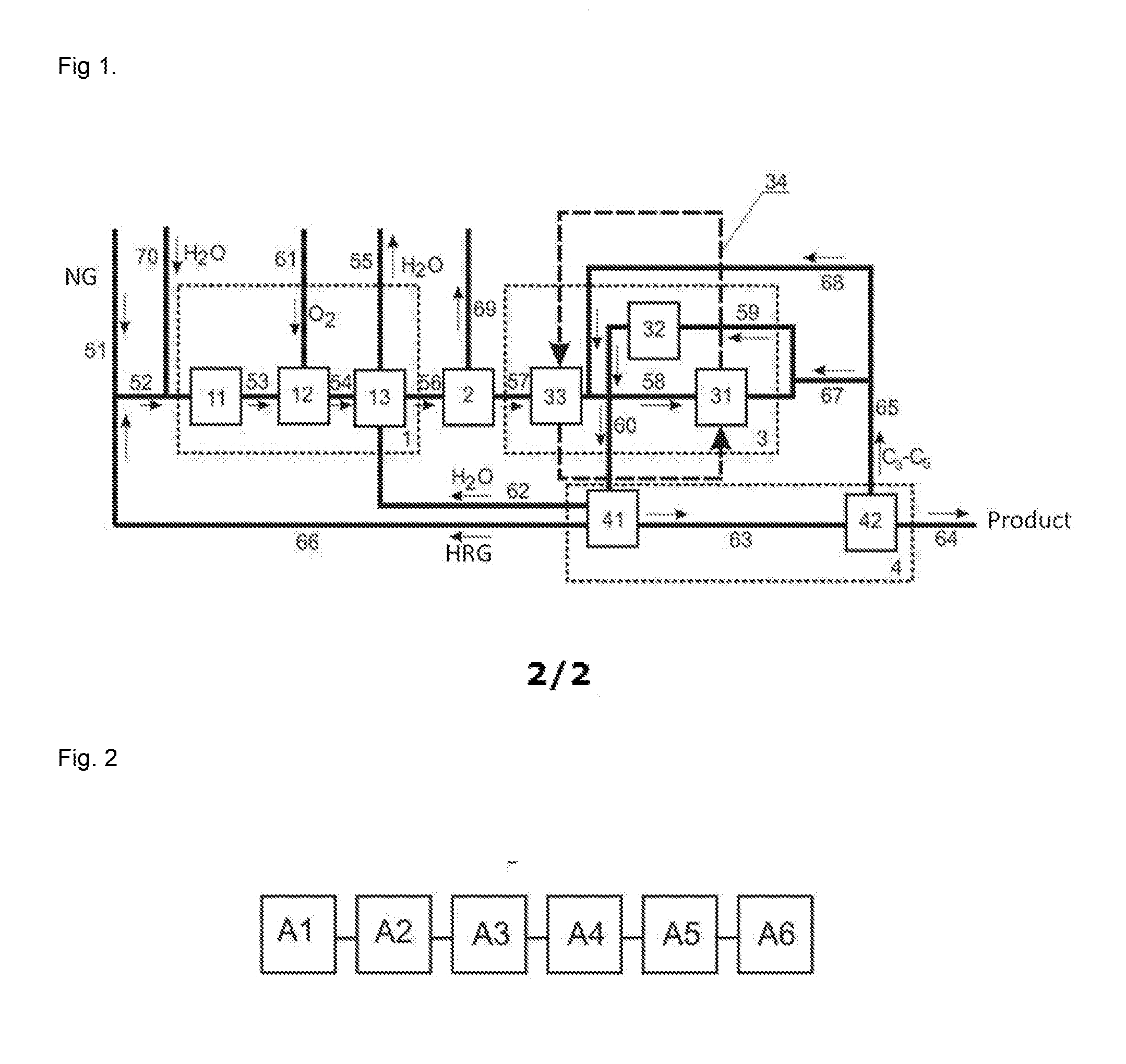

Methods for producing aromatic hydrocarbons from natural gas and installation for implementing same

The invention relates to the field of gas chemistry and, more specifically, to methods and devices for producing aromatic hydrocarbons from natural gas, which involve producing synthesis gas, converting same into methanol, producing, from the methanol, in the presence of a catalyst, a concentrate of aromatic hydrocarbons and water, separating the water, air stripping hydrocarbon residues from the water, and separating-out the resultant concentrate of aromatic hydrocarbons and hydrogen-containing gas, the latter being at least partially used in the production of synthesis gas to adjust the ratio therein of H2:CO 1.8-2.3:1, and can be used for producing aromatic hydrocarbons. According to the invention, the production of aromatic hydrocarbons from methanol in the presence of a catalyst is carried out in two consecutively-connected reactors for synthesizing aromatic hydrocarbons: in a first, low-temperature isothermal reactor for synthesizing aromatic and aliphatic hydrocarbons, and in a second, high-temperature adiabatic reactor for synthesizing aromatic and aliphatic hydrocarbons from aliphatic hydrocarbons formed in the first reactor, and the subsequent stabilization thereof in an aromatic hydrocarbon concentrate stabilization unit. At least a portion of the hydrogen-containing gas is fed to a synthesis gas production unit and is used for producing synthesis gas using autothermal reforming technology. The installation carries out the method. The achieved technical result consists in increasing the efficiency of producing concentrates of aromatic hydrocarbons.

Owner:UNIVERSAL FUEL TECH INC

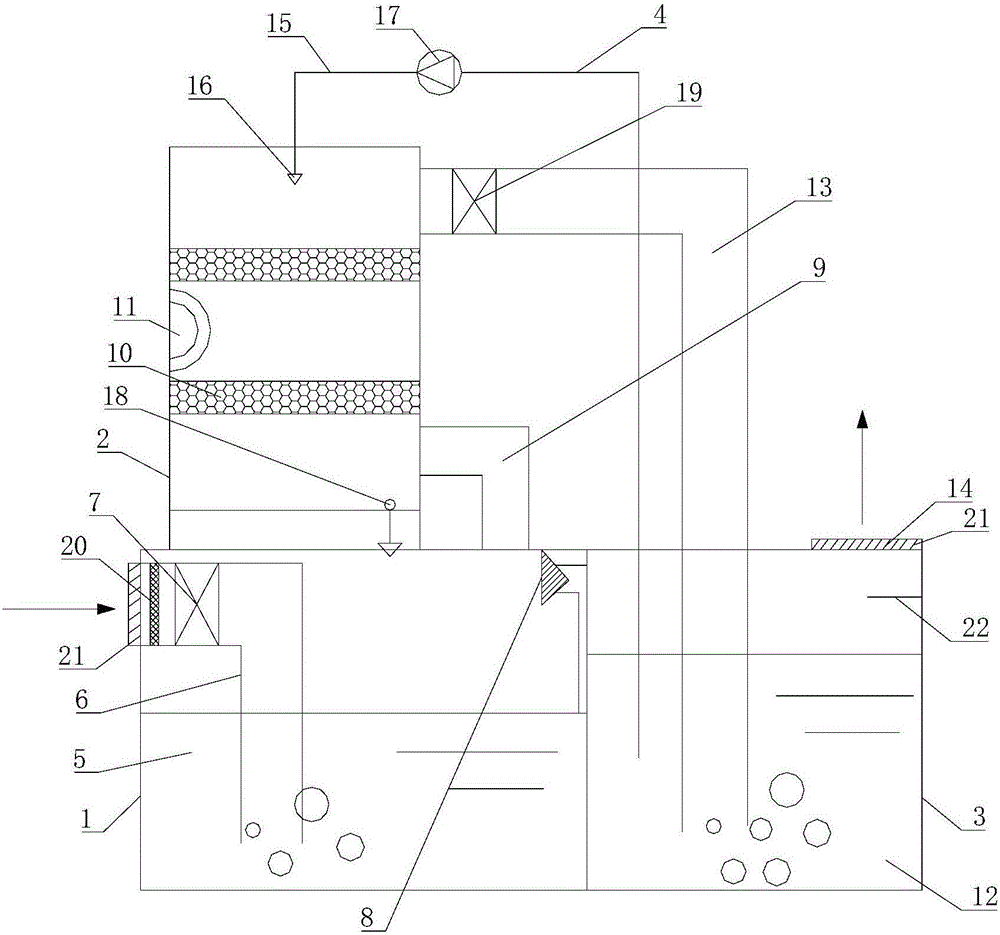

Air purifying device and air purifying method

InactiveCN106642353AImprove purification effectSimple processMechanical apparatusSpace heating and ventilation safety systemsPhoto catalyticAir purification

The invention relates to an air purifying device which comprises a first water purifying module, a photo-catalytic module, a second water purifying module and a spraying module, wherein the first water purifying module comprises a first purifying water tank and an air inlet pipe which is used for connecting water in the first purifying water tank with the exterior; a first axial flow fan is arranged in the air inlet pipe; a water atomizer is arranged on the upward side in the first purifying water tank; the photo-catalytic module is arranged above the first water purifying module; the upward side of the first purifying water tank is communicated with the downward side in the photo-catalytic module through a first air outlet pipe; at least one nanometer TiO2 diaphragm and an ultraviolet ray light source are arranged above the end part of the first air outlet pipe in the photo-catalytic module; the second water purifying module comprises a second purifying water tank and a second air outlet pipe; an air outlet is formed in the upper part of the second purifying water tank. The air purifying device has the advantages that the process of purifying fine particle pollutants PM2.5 and chemical gas pollutants in air is simple, the air purifying effect is good, the air purifying device has a function of continuously humidifying air, the cost is low and the air purifying device can be easily popularized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

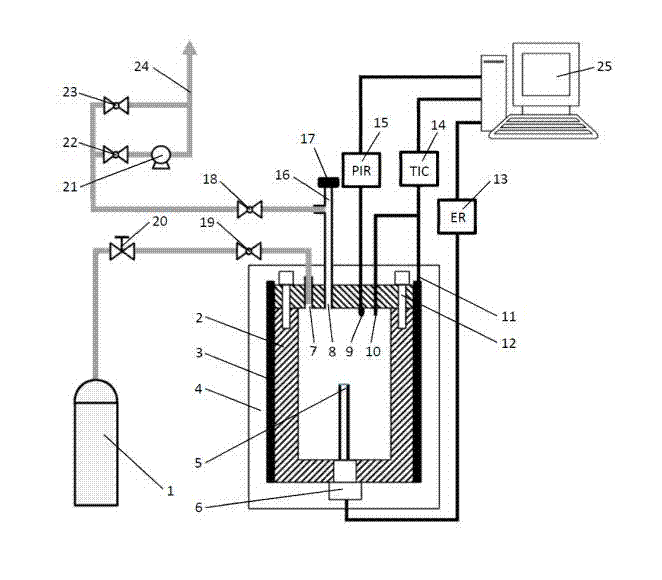

Gas chemical instability intelligent test device

The invention relates to a gas chemical instability intelligent test device, comprising a test container, an electronic ignition device, a temperature control module, a pressure control module, an energy recording module and a control terminal, wherein a gas inlet and a gas outlet are arranged at the top of the test container, a closed test space is formed in the test container by fixing bolts, an electric heater and a heat-insulation layer are sequentially arranged outside the test container and are connected with a pressure sensor and an in-container temperature sensor, and the in-container temperature sensor and a heater sensor regulate test temperature under the control of a temperature sensing control module. After ignition, gas chemical instability can be determined through recording of pressure in the test container. A T-shaped gas guide pipe is connected with the gas outlet, one end of the T-shaped gas guide pipe is connected with an explosion disk fixing nut, and the other end of the T-shaped gas guide pipe is connected with a gas outlet pipeline; and the gas outlet pipeline is provided with a direct exhaust branch and an exhaust branch with a vacuum pump. After reaction, the pressure of test gas in the test container rises up, and when the pressure is higher than a safe pressure value, an explosion disk is exploded automatically to release pressure.

Owner:王利兵

Plasma etching of silicon using a chlorine chemistry augmented with sulfur dioxide

InactiveUS6415198B1Easy to understandElectric discharge tubesDecorative surface effectsChamber pressureSilicon

A method of etching silicon using a chlorine and sulfur dioxide gas chemistry. An embodiment of the method is accomplished using a 20 to 300 sccm of chlorine and 2 to 100 sccm of sulfur dioxide, regulated to a total chamber pressure of 2-100 mTorr.

Owner:APPLIED MATERIALS INC

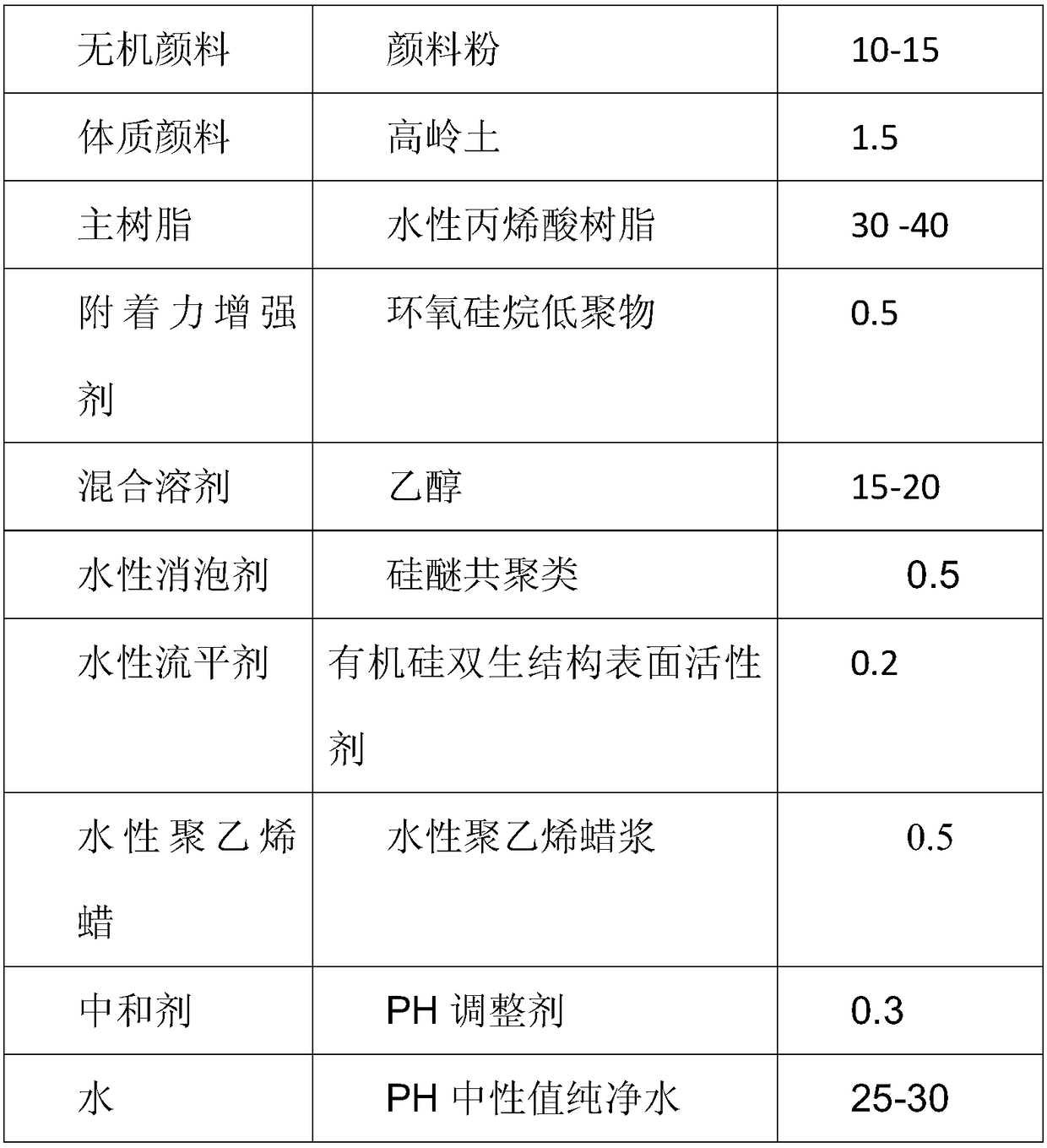

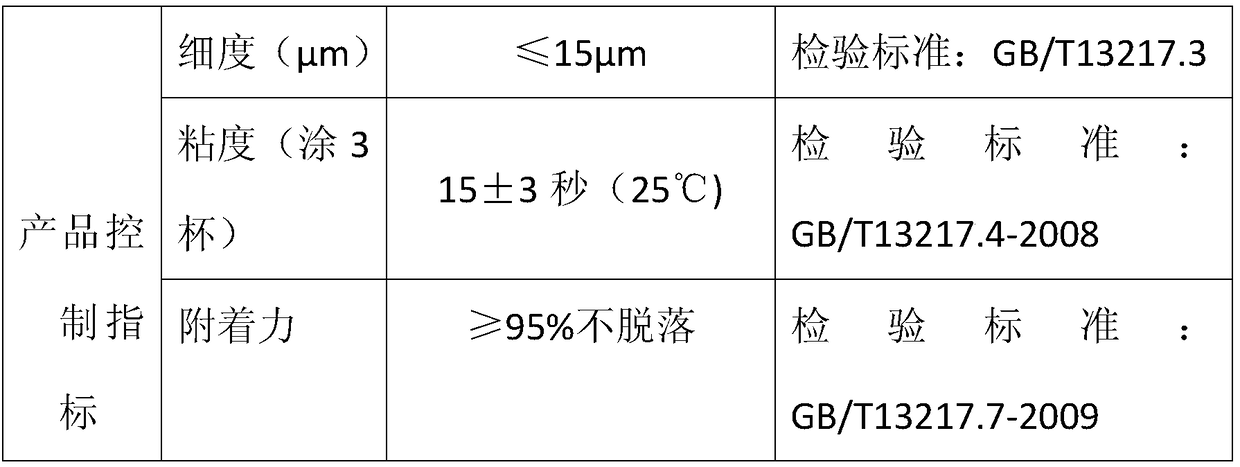

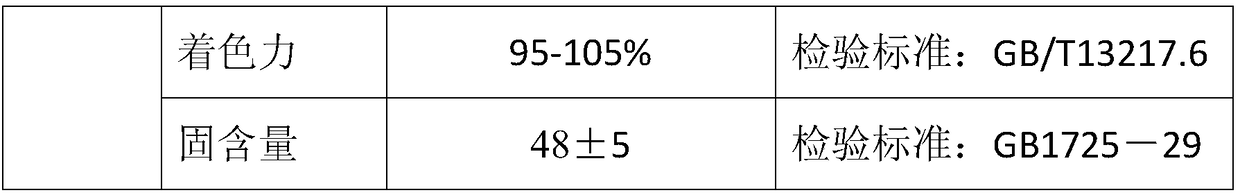

Water-based plastic gravure table printing ink

InactiveCN108753040AResidue reductionMeet the requirements of safety and environmental protectionInksWater basedAcrylic resin

The invention discloses water-based plastic gravure table printing ink. In order to solve the defects existing in the prior art, the specific procedure comprises the following steps that S1, materialsare prepared, specifically, resin materials comprise s-90 acrylic resin (Hanwha), 7159 emulsion (basf) and 7266 emulsion (basf); pigment materials comprise bronze red pr53:1 (Hangzhou lily), magentapr57:1 (Changzhou Beimei), bright red pr48:2 (Changzhou beimei), titanium dioxide 996 (longmang), permanent yellow py14 (Longkou taihang), 15:3 bocour blue (Zhengyan) and extra black 6500; assistantscomprise 180 defoaming agent (Tongxiang hongye), 1488 defoaming agent (tego), 104E leveling agent (gas chemistry), 760W dispersing agent (Digao), 0251 wax powder (Tianshi), dc-51 slipping agent (America Dow Corning), a fast drying agent (Guangzhou Duwei) and the like; solvents comprise deionized water, 95% ethyl alcohol, an environment-friendly ether solvent, ammonium hydroxide (28%), monoethanolamine and the like; and S2, the weight rate of the formula is that the weight rate of organic or inorganic pigment is 10-15, and the weight rate of extender pigment is 1-3.

Owner:广东天龙油墨有限公司

Method of plasma etching of high-K dielectric materials with high selectivity to underlying layers

InactiveUS20040173572A1Decorative surface effectsSemiconductor/solid-state device manufacturingChamber pressureDielectric permittivity

A method of etching high dielectric constant materials using halogen gas and reducing gas chemistry. An embodiment of the method is accomplished using a 20 to 300 sccm of chlorine and 2 to 200 sccm of carbon monoxide, regulated to a total chamber pressure of 2-100 mTorr to etch a hafnium oxide layer.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com