Patents

Literature

241results about How to "Good surface treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

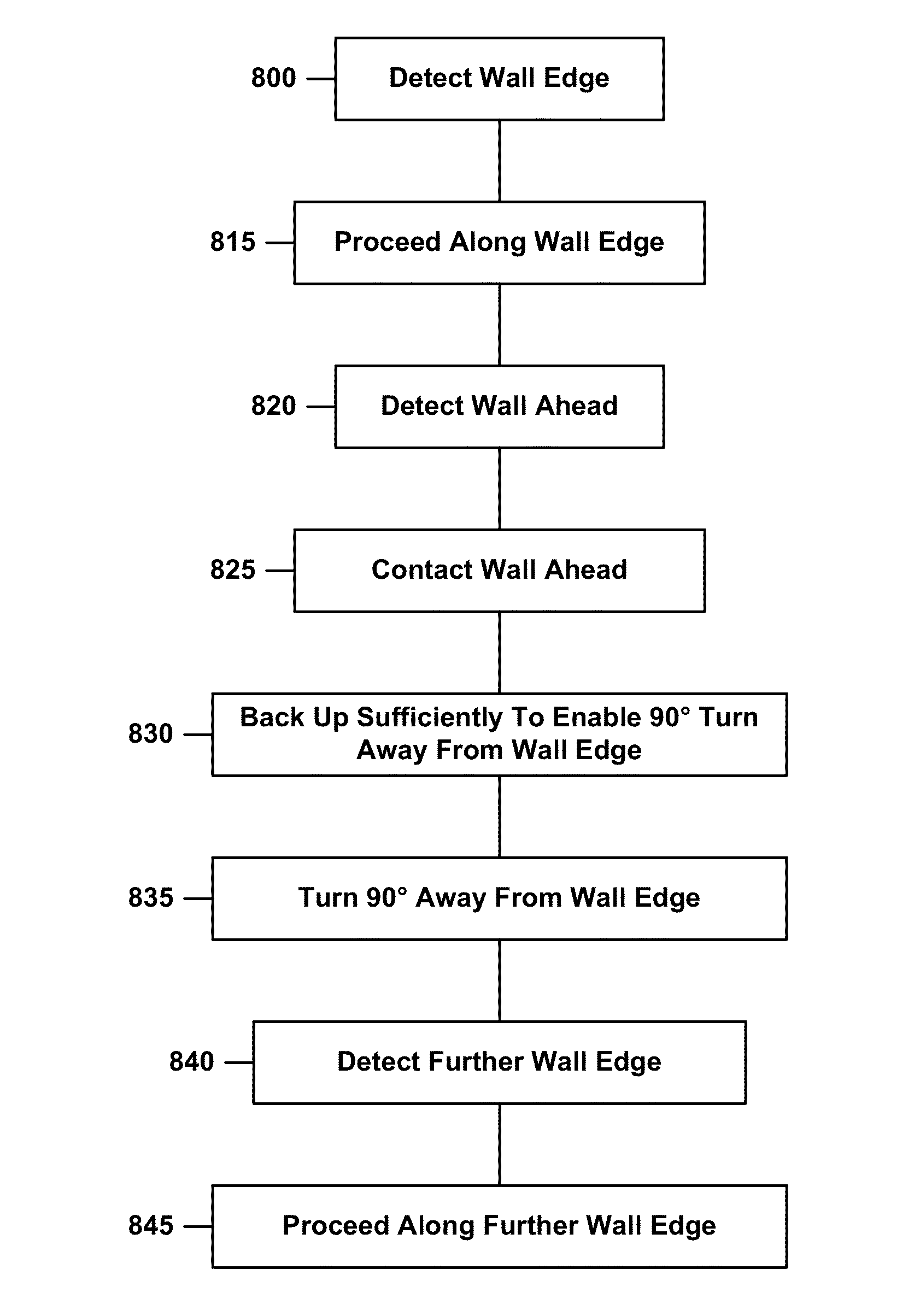

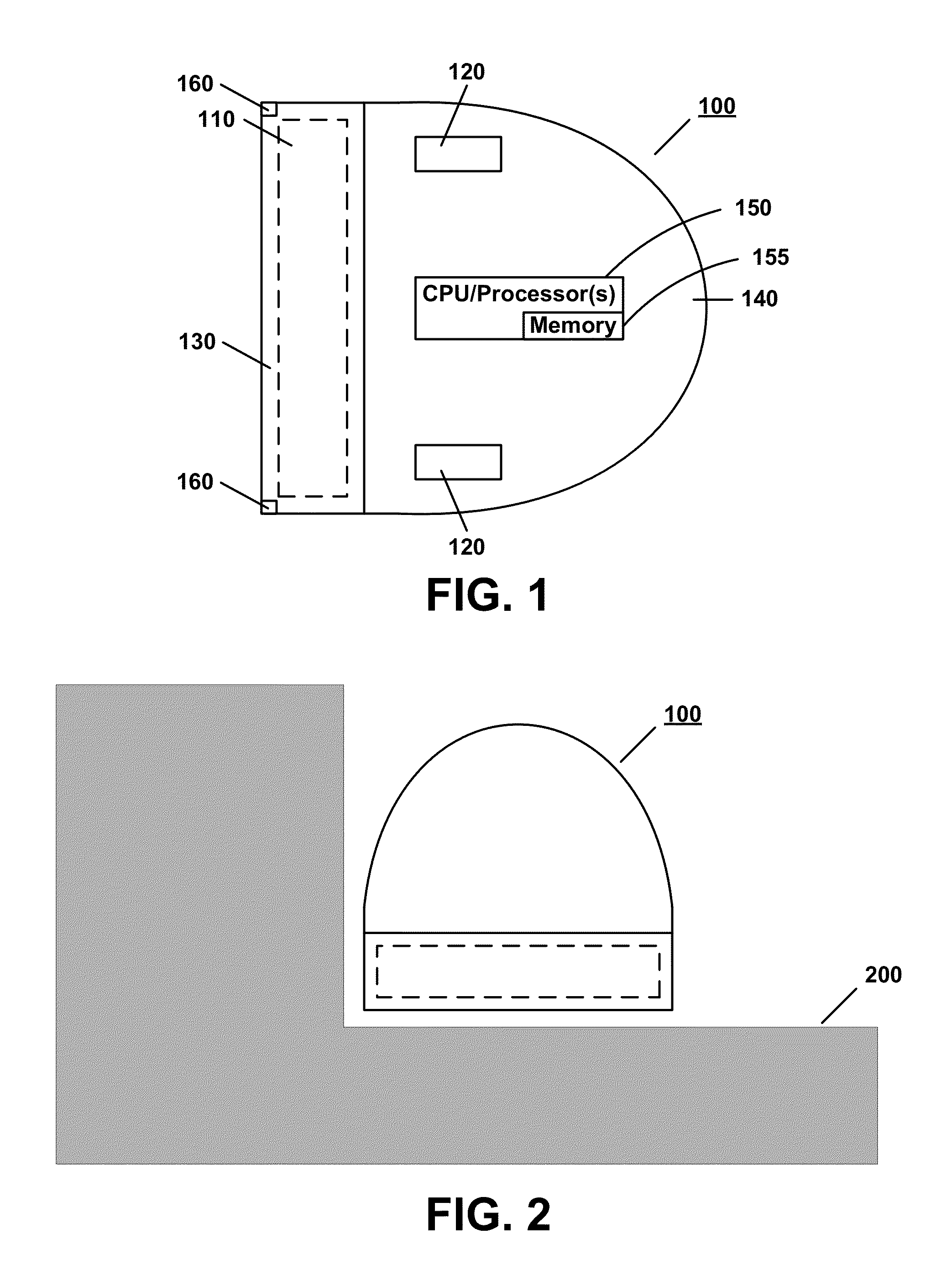

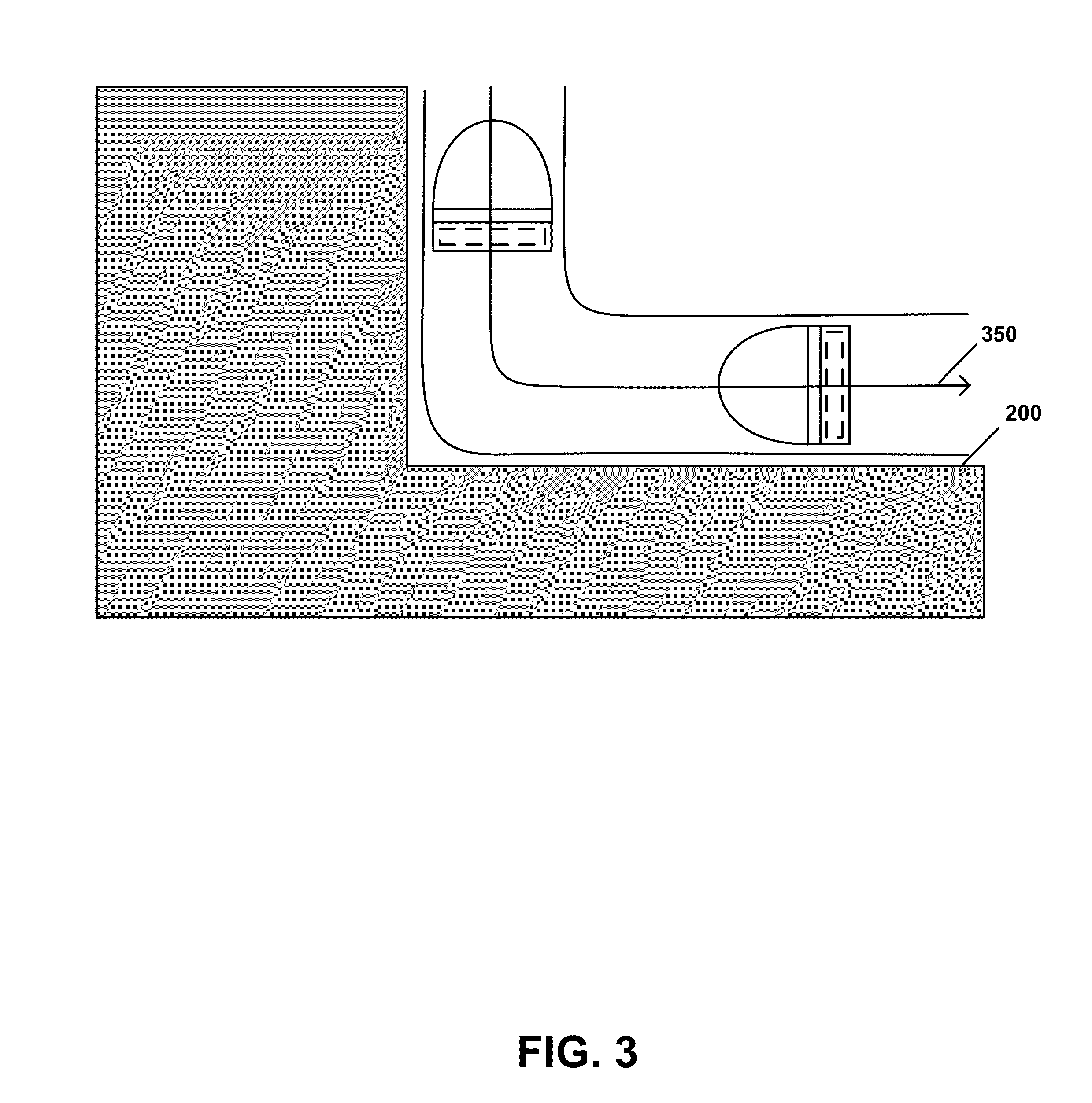

Method and apparatus for traversing corners of a floored area with a robotic surface treatment apparatus

ActiveUS8855914B1Good surface treatmentEfficient surface treatmentAutomatic obstacle detectionTravelling automatic controlObstacle avoidanceEngineering

A robotic surface treatment apparatus treats corners of rooms more effectively through intricate guidance of the apparatus through inside and outside corners. In one aspect, contact and / or non-contact sensors provide information to one or more on-board processors on the apparatus to enable selective overriding of obstacle avoidance program code and allow the apparatus to get closer to walls to facilitate treatment. In another aspect, the sensors provide information to the on-board processors to control backup motion of the apparatus to cover previously-missed areas when turning corners. In yet another aspect, the apparatus is shaped to have its treatment mechanism positioned more closely to the front of the apparatus to enable treatment more closely to walls near corners. In one embodiment, the robotic surface treatment apparatus is a robotic vacuum. The vacuum may have its cleaning brush positioned near a flat front portion of the apparatus.

Owner:VORWERK & CO INTERHOLDING GMBH

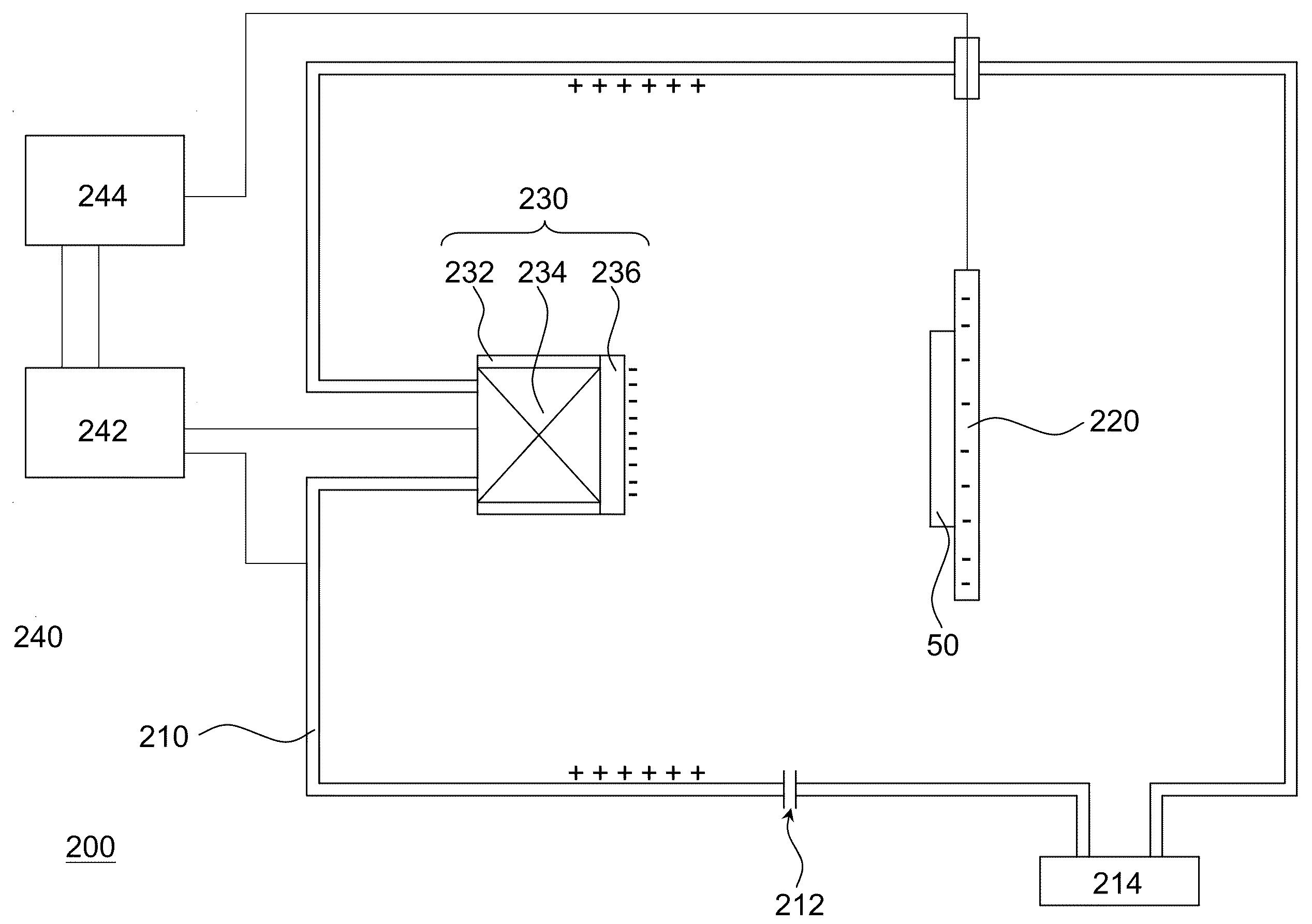

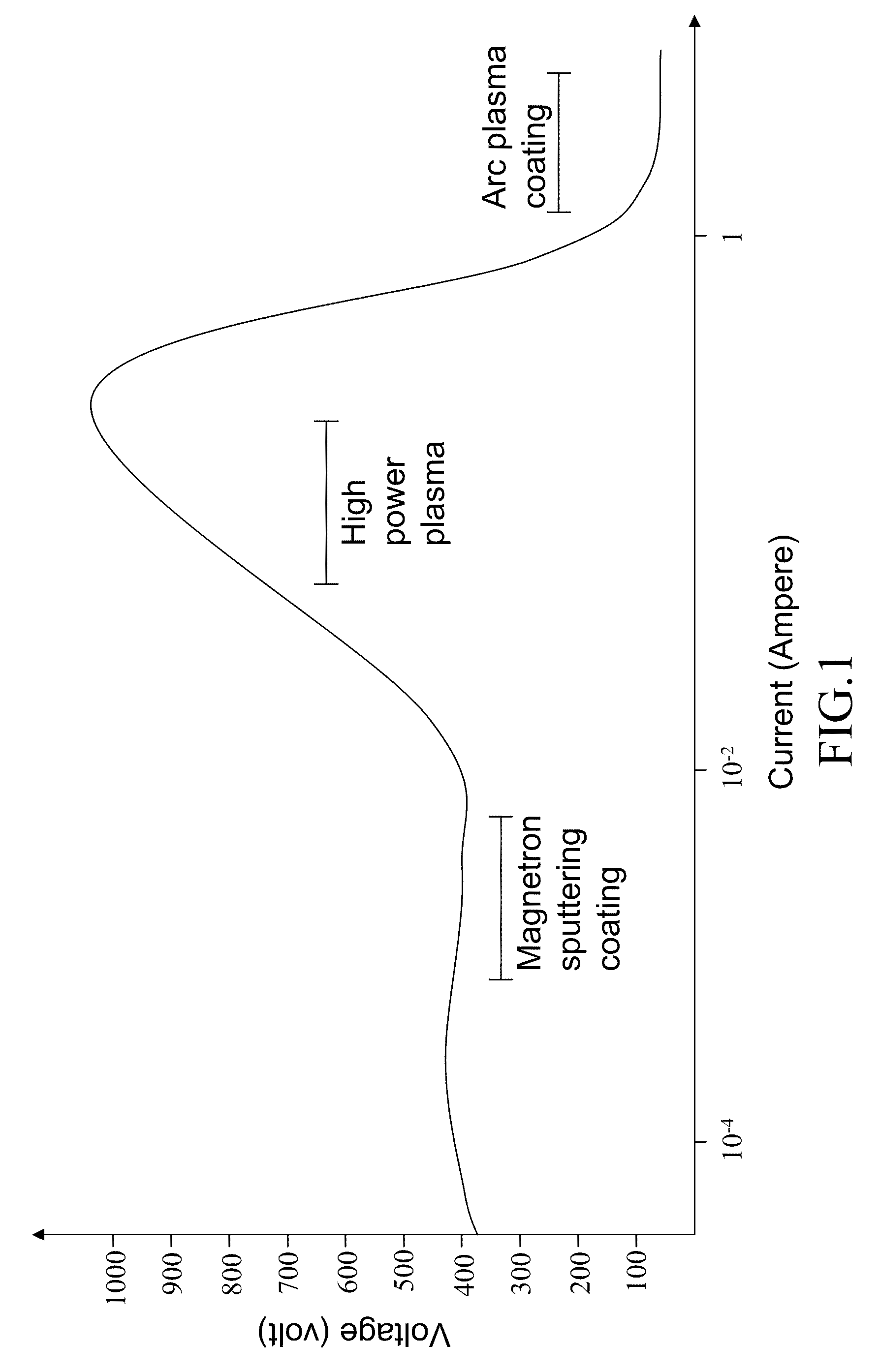

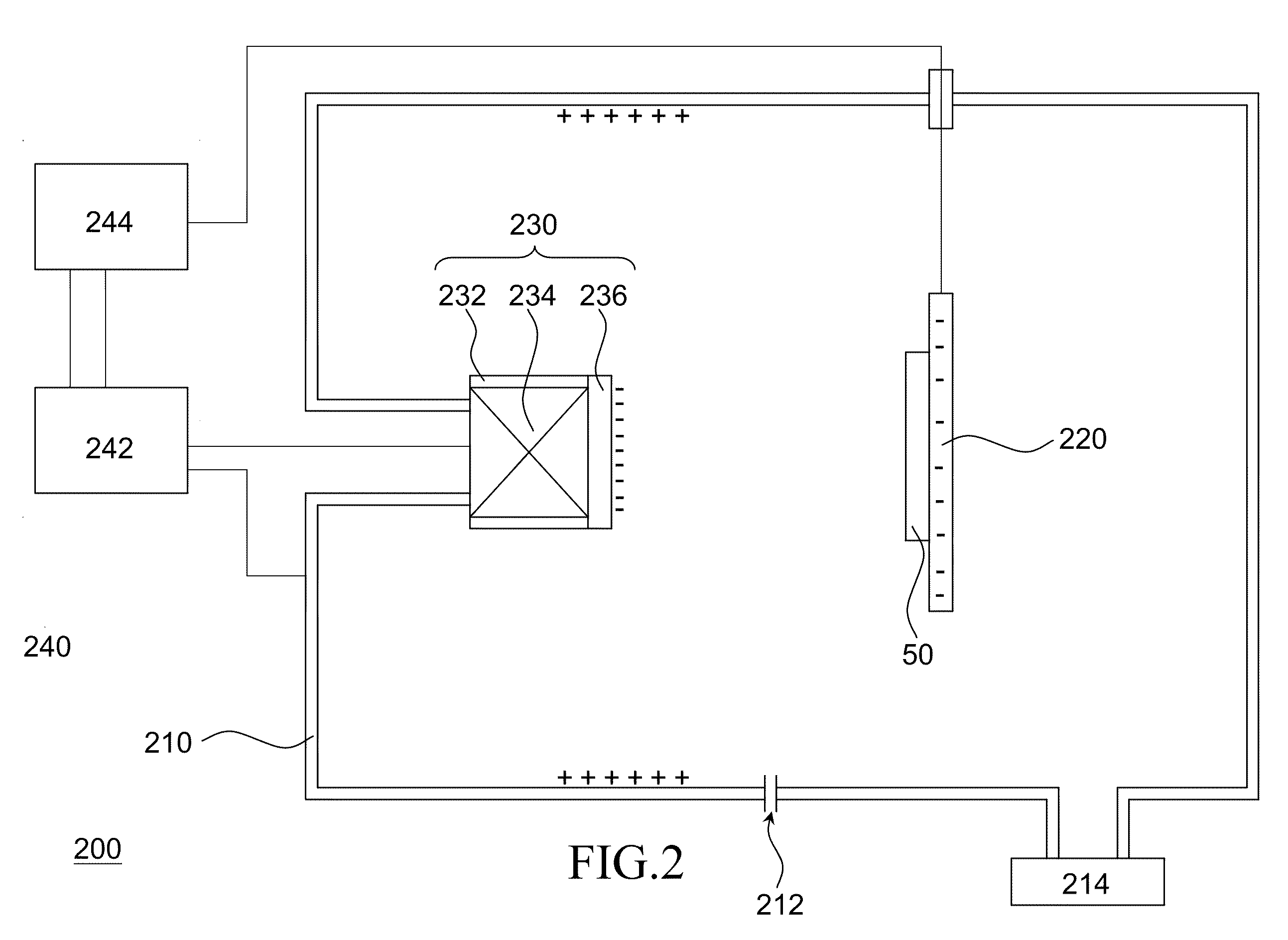

High-power pulse magnetron sputtering apparatus and surface treatment apparatus using the same

InactiveUS20110011737A1High coatingImprove adhesionCellsElectric discharge tubesSputteringReactive gas

A magnetron sputtering apparatus suitable for coating on a workpiece is provided. The magnetron sputtering apparatus includes a vacuum chamber, a holder, a magnetron plasma source and a high-power pulse power supply set, wherein the magnetron plasma source includes a base, a magnetron controller and a target. A reactive gas is inputted into the vacuum chamber, and the holder supporting the workpiece is disposed inside the vacuum chamber. The magnetron plasma source is disposed opposite to the workpiece, wherein the magnetron controller is disposed in the base, and the target is disposed on the base. The high-power pulse power supply set is coupled to the vacuum chamber, the magnetron plasma source and the holder, and a high voltage pulse power is inputted to the magnetron plasma source to generate plasma to coat a film on the surface of the workpiece.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Steel Sheet for Hot Press Forming Having Excellent Heat Treatment and Impact Property, Hot Press Parts Made of It and the Method for Manufacturing Thereof

InactiveUS20080286603A1High strengthHigh yield strengthHot-dipping/immersion processesPig casting plantsSheet steelUltimate tensile strength

Disclosed is a steel sheet that exhibits an ultra-high strength after hot press forming followed by rapid cooling, and an enhanced yield strength after painting. The steel sheet has a composition comprising 0.1% to 0.5% by weight of C, 0.01% to 1.0% by weight of Si, 0.5% to 4.0% by weight of Mn, 0.1% by weight or less of P, 0.03% by weight or less of S, 0.1% by weight of soluble Al, 0.01% to 0.1% by weight of N, 0.3% by weight or less of W, and the balance Fe and other inevitable impurities. Further disclosed are a hot-pressed part made of the steel sheet and a method for manufacturing the hot-pressed part. The hot-pressed part achieves a high increment in yield strength after heat treatment for painting while ensuring an ultra-high tensile strength. Furthermore, the hot-pressed part exhibits superior adhesion to a coating layer, good surface appearance and improved corrosion resistance after painting.

Owner:POHANG IRON & STEEL CO LTD

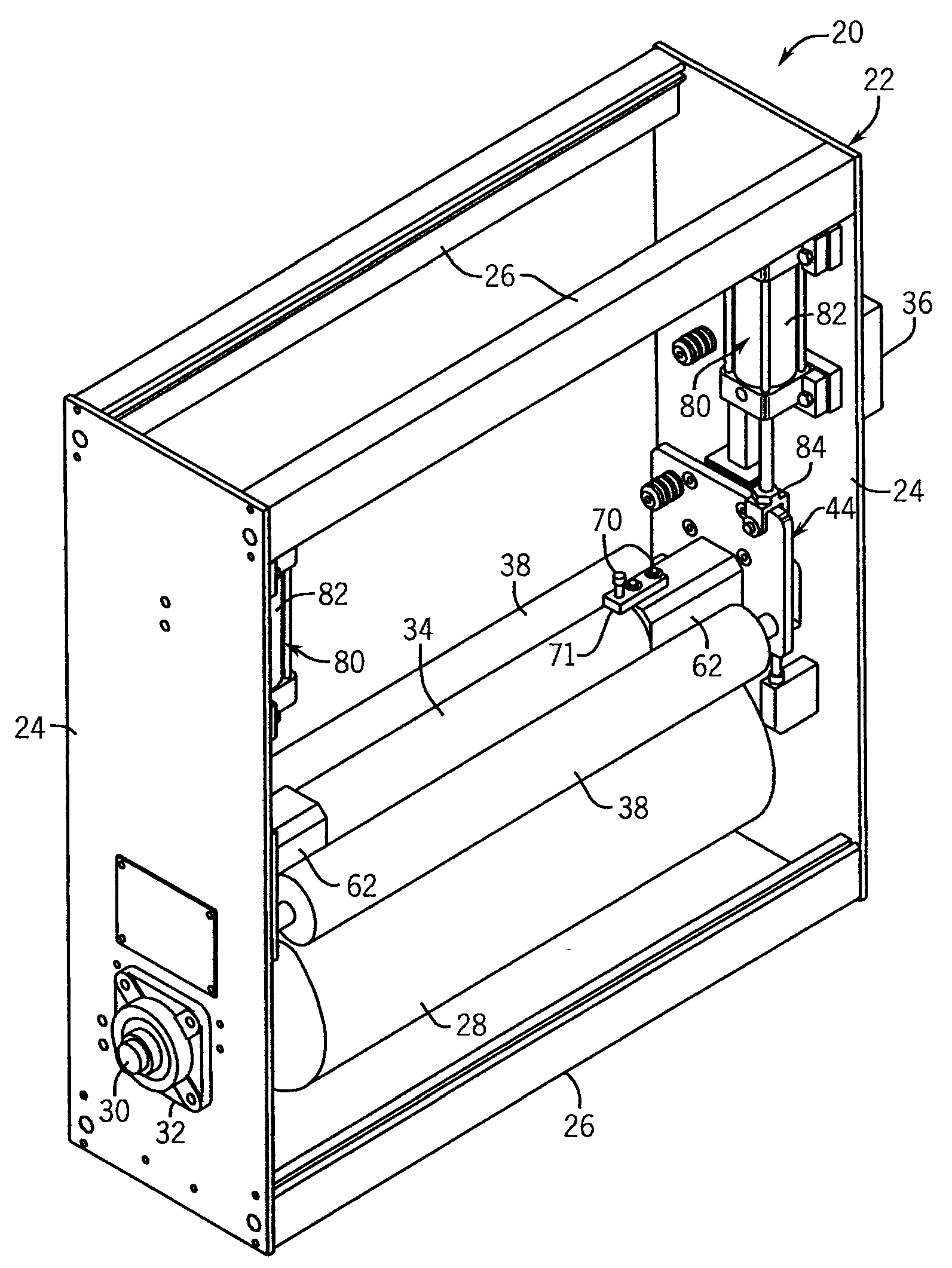

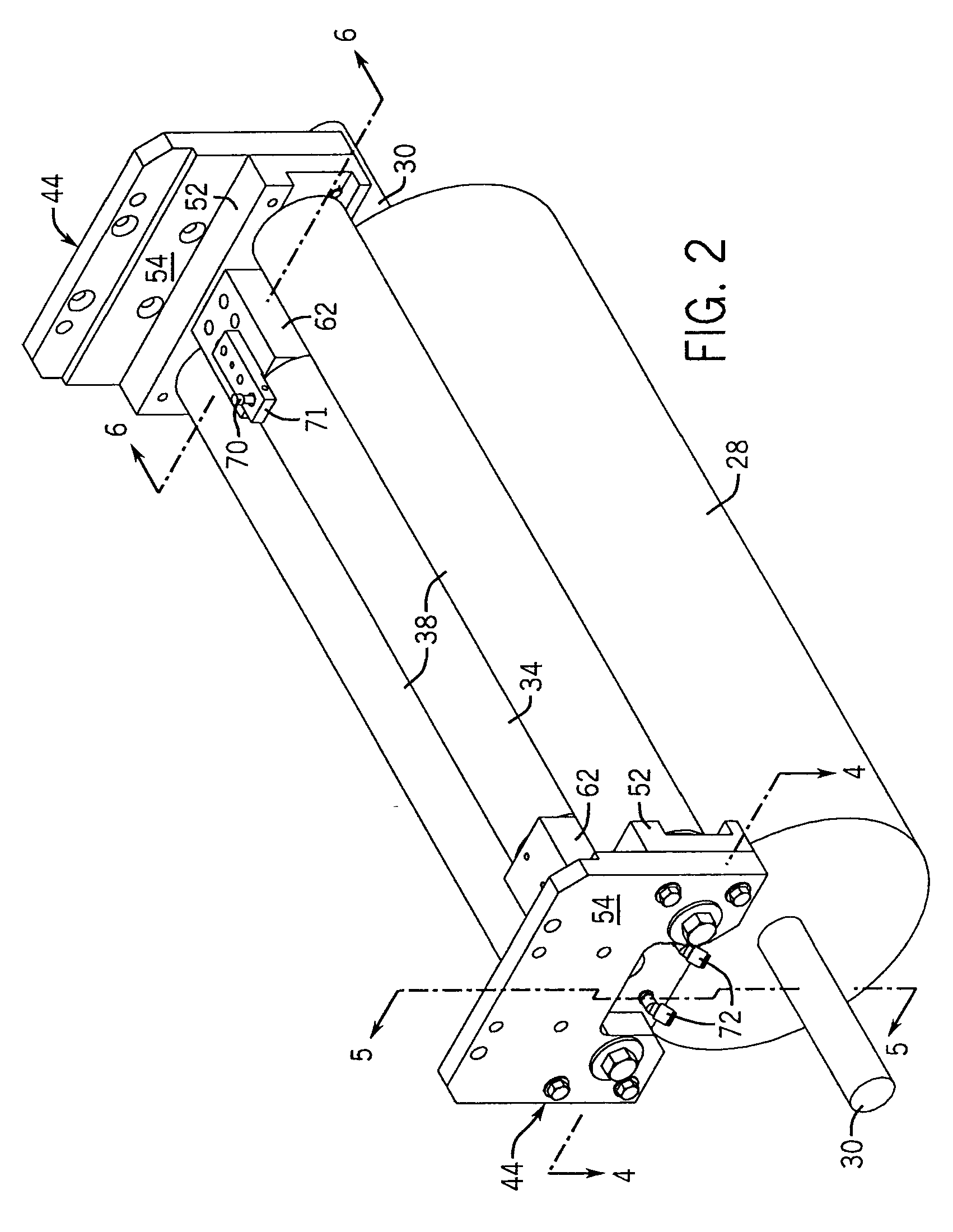

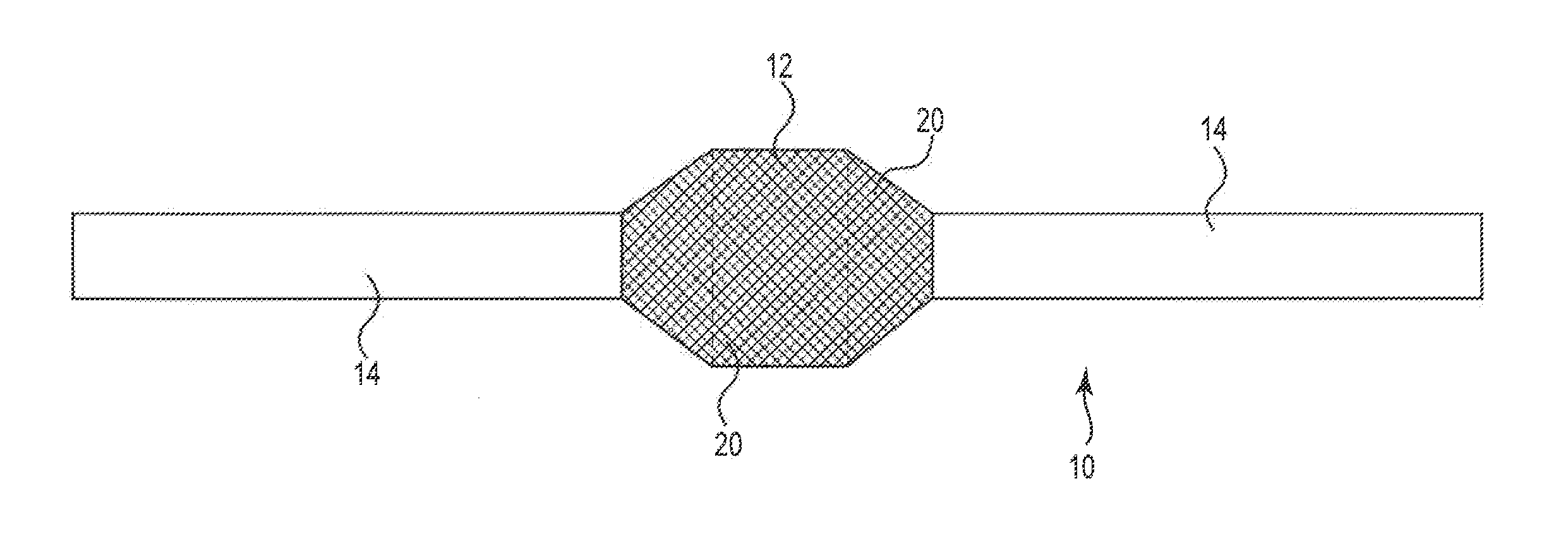

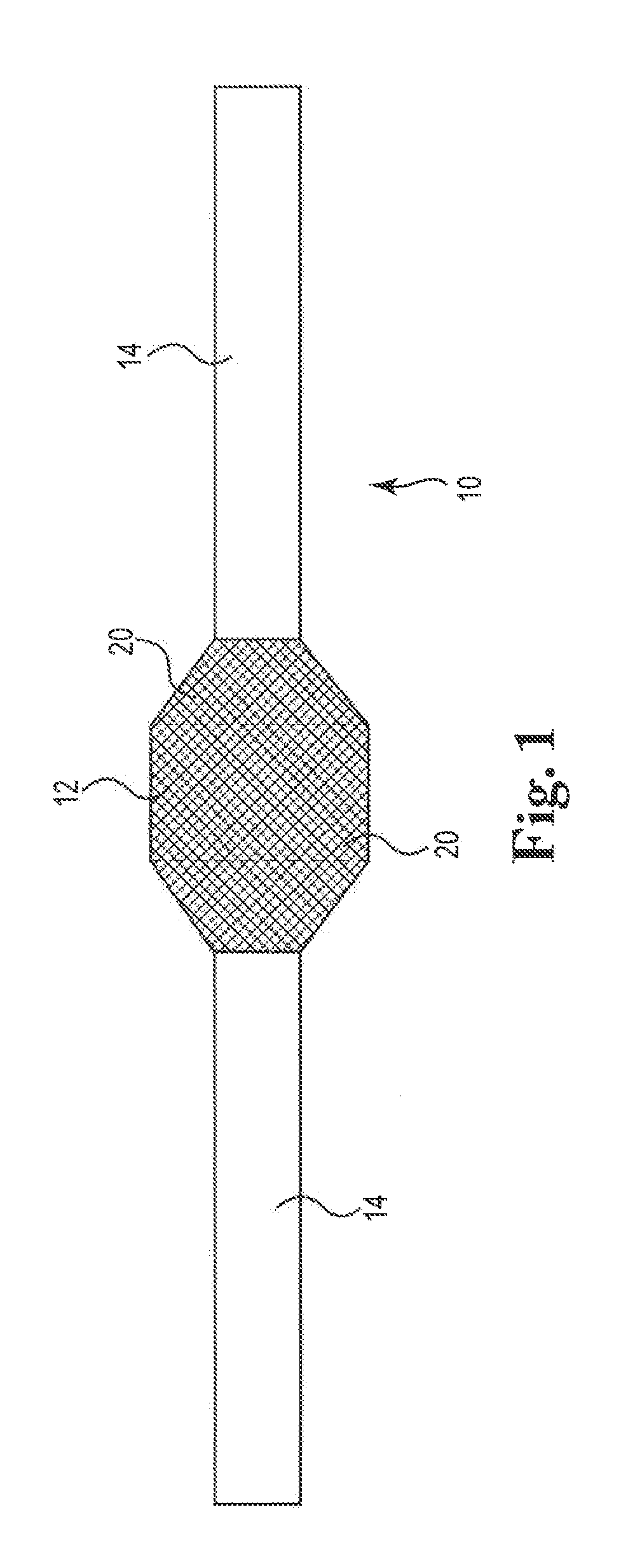

Atmospheric Treater With Roller Confined Discharge Chamber

ActiveUS20090120782A1Good surface treatmentQuality improvementDuplicating/marking methodsPhysical paper treatmentEngineeringAtmospherics

A continuous feed discharge surface treater for treating web materials has a discharge chamber where ionization of a process gas occurs defined and contained by one or more rollers. Enhanced chemical coronas and plasmas are achieved by limiting depletion of the gas chemistry from the discharge chamber and dilution or contamination from mixing with drawn in ambient air. Atmospheric coronas can also be achieved in which minimal or no ozone is exhausted from the treater. Various roller and electrode assemblies, including both fixed and rolling electrodes, can be employed.

Owner:ENERCON INDS

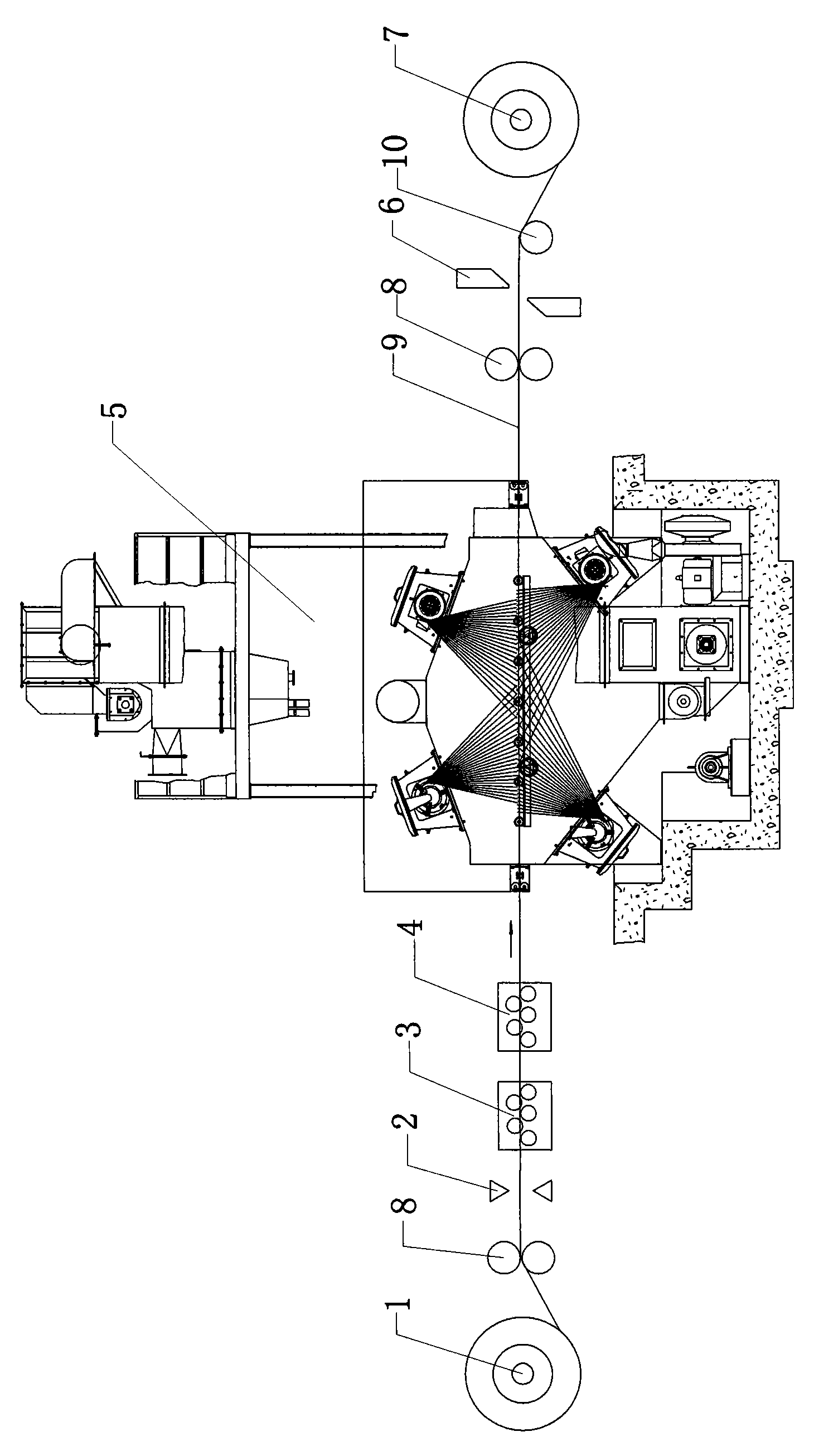

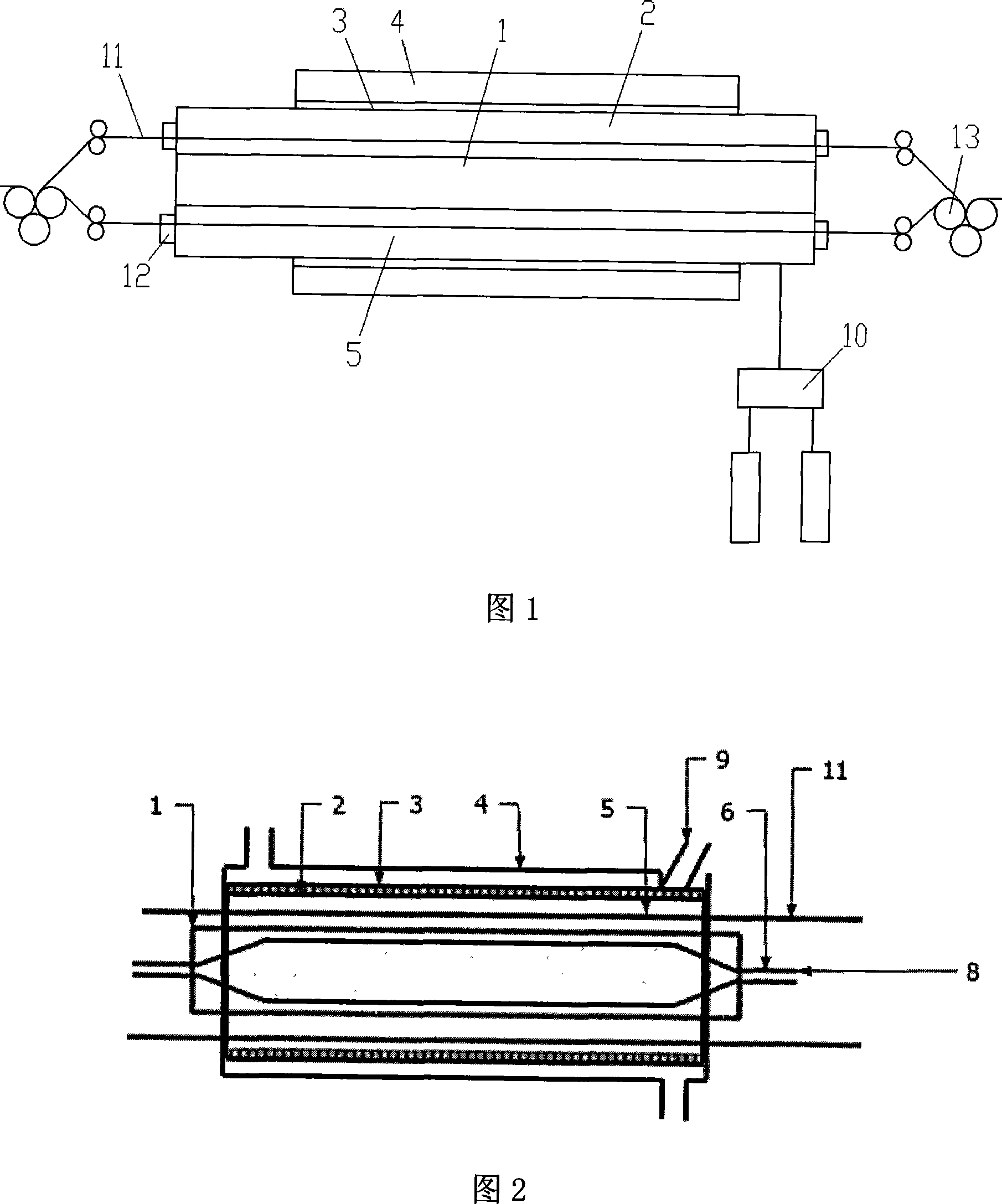

Method and device for surface processing of steel belt

InactiveCN101633111AGood effectImproves fatigue strength and corrosion resistanceWork treatment devicesOther manufacturing equipments/toolsPopulationSurface finishing

The invention relates to a method and a device for surface processing of a steel belt. The physical method instead of the chemical method adopted in the prior art processes the surface of the steel belt. The method mainly comprises the following steps of: uncoiling of the steel belt, mechanical scale removal, flattening, shot blasting and cleaning, coiling. Corresponding to the steps, the device comprises an uncoiling machine, a welding machine, a multi-roll type scale remover, a flattening machine, a shot blasting cleaning machine, a shearing machine and a coiling machine, which are arranged from front to back in sequence; and conveying rolls for conveying the steel belt are arranged between the uncoiling machine and the welding machine and between the shot blasting cleaning machine and the shearing machine respectively. The device has the advantages of simple structure, good surface processing effect, high cleaning efficiency, safety and environmental protection, low cost, small floor area, long service life of the steel belt and easy population.

Owner:王志强

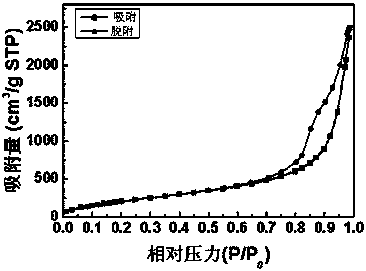

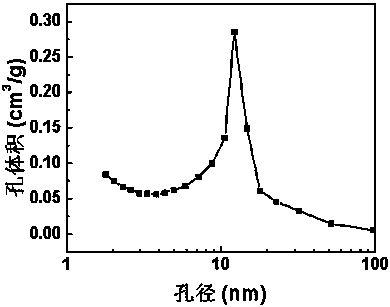

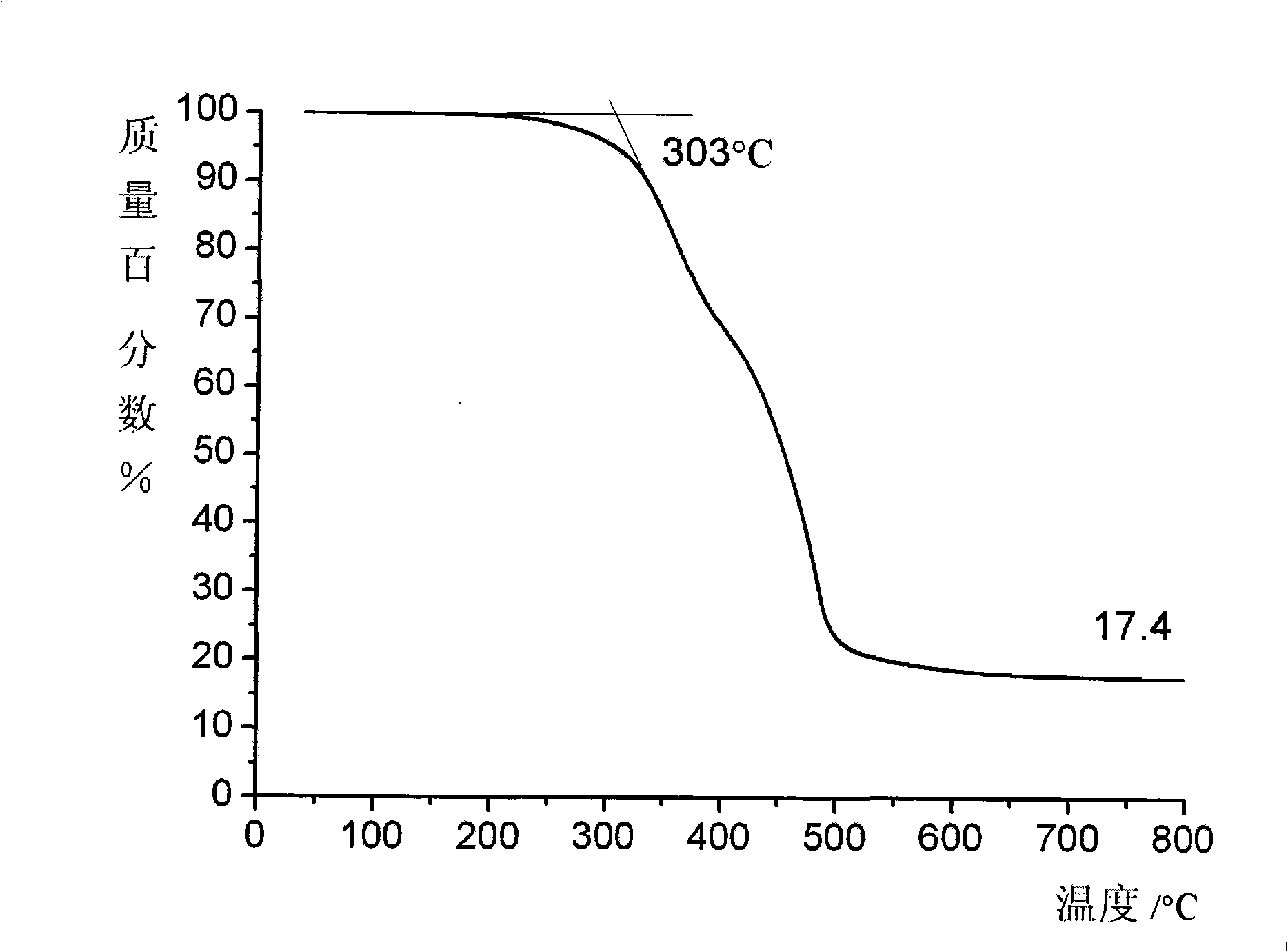

Preparation method of silica aerogel under atmospheric pressure

InactiveCN108423685ASimple and fast operationSimple processSilicon compoundsPolymer scienceHydrophobic silica

The invention discloses a method for preparing super-hydrophobic silica aerogel by atmospheric pressure drying. The method comprises the following steps: 1) preparing sol; 2) gelatinizing the sol; 3)aging gel; 4) exchanging a gel solvent; 5) carrying out surface hydrophobic modification; and 6) carrying out drying under atmospheric pressure. According to the preparation method of the silica aerogel, provided by the invention, tetraethoxysilane is used as a silicon source, ethanol is used as a solvent, acid and alkali are used as catalysts, and trimethylchlorosilane is used as a surface modifier, so that super-hydrophobic silica aerogel is prepared by atmospheric pressure drying. The prepared SiO2 aerogel with a super-hydrophobic three-dimensional network structure is tested to have a highspecific surface area, low density and good hydrophobicity at a room temperature. Therefore, the silica aerogel prepared through the method provided by the invention has excellent adsorption performance and has a good application prospect in the field of energy conservation. The preparation method of the silica aerogel under atmospheric pressure, provided by the invention, is simple in procedureand low in equipment requirements, can also shorten the process flow and reduce the cost, and is easy to industrialize.

Owner:ZHEJIANG UNIV OF TECH

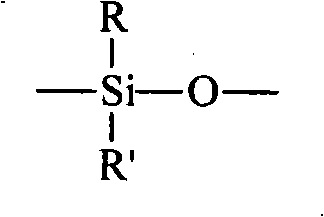

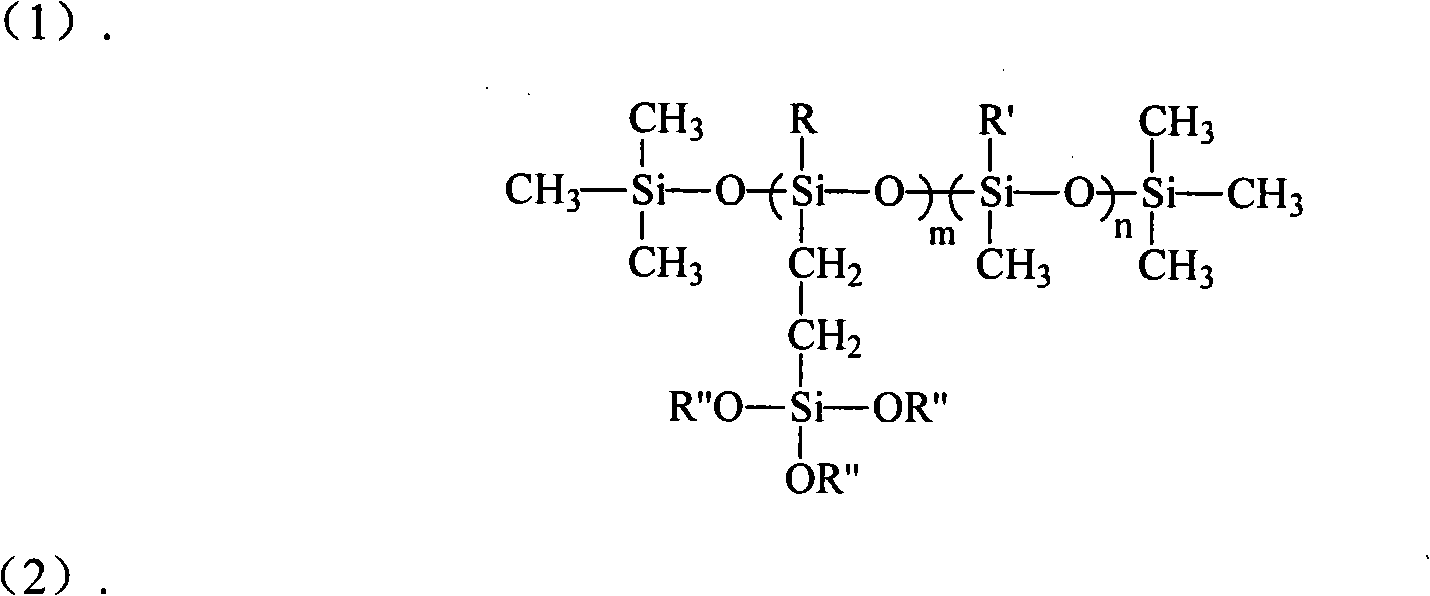

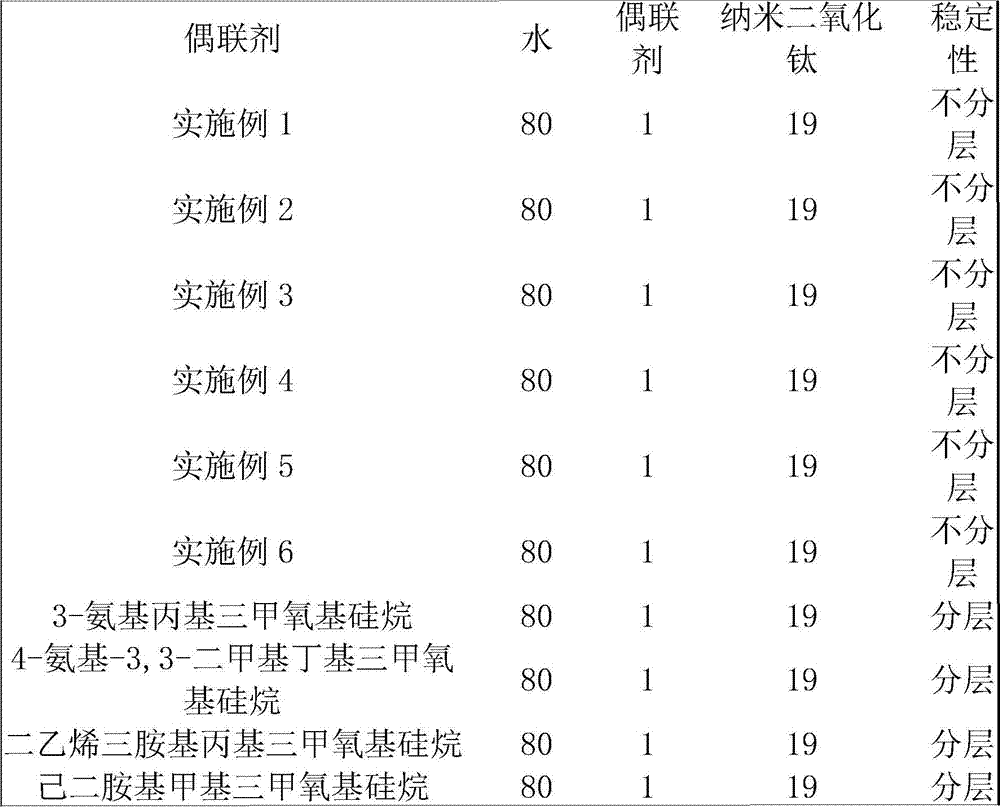

Multiple functionality degree polysiloxane coupling agent and preparation method thereof

InactiveCN101260190AImprove heat resistanceSimple processPigment treatment with organosilicon compoundsPolymer sciencePtru catalyst

The invention discloses a multi-functionality polysiloxane coupling agent and a preparation method thereof. The preparation method, inside a system of weak polar solvent and under the action of platinum group catalyst, synthesizes the multi-functionality polysiloxane coupling agent at 50 to 120 DEG C by means of the silicon-hydrogen addition reaction between polysiloxane and trialkoxysilane through side group functional group or end group functional group; and the ratio between the mole numbers of the carbon-carbon double bond or the silicon-hydrogen bond in the polysiloxane and the mole number of the silicon-hydrogen bond or the carbon-carbon double bond in the trialkoxysilane ranges between 50:1 and 1:1. Each chain link of the multi-functionality polysiloxane comprises three alkoxyl groups or each end group contains three alkoxyl groups; therefore, the multi-functionality polysiloxane has better effect on the surface treatment of inorganic powder filler than multi-functionality polysiloxane of which each chain link only has one alkoxyl group; moreover, the heat resistance of the obtained multi-functionality polysiloxane is higher than that of the prior long-chain polyether-type silicane coupling agent.

Owner:SOUTH CHINA UNIV OF TECH

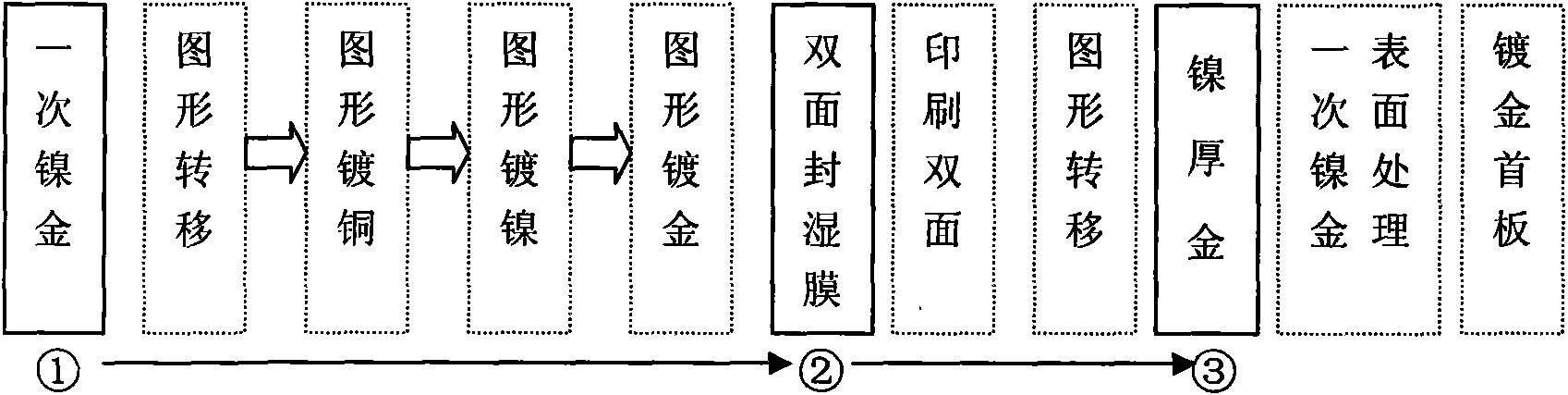

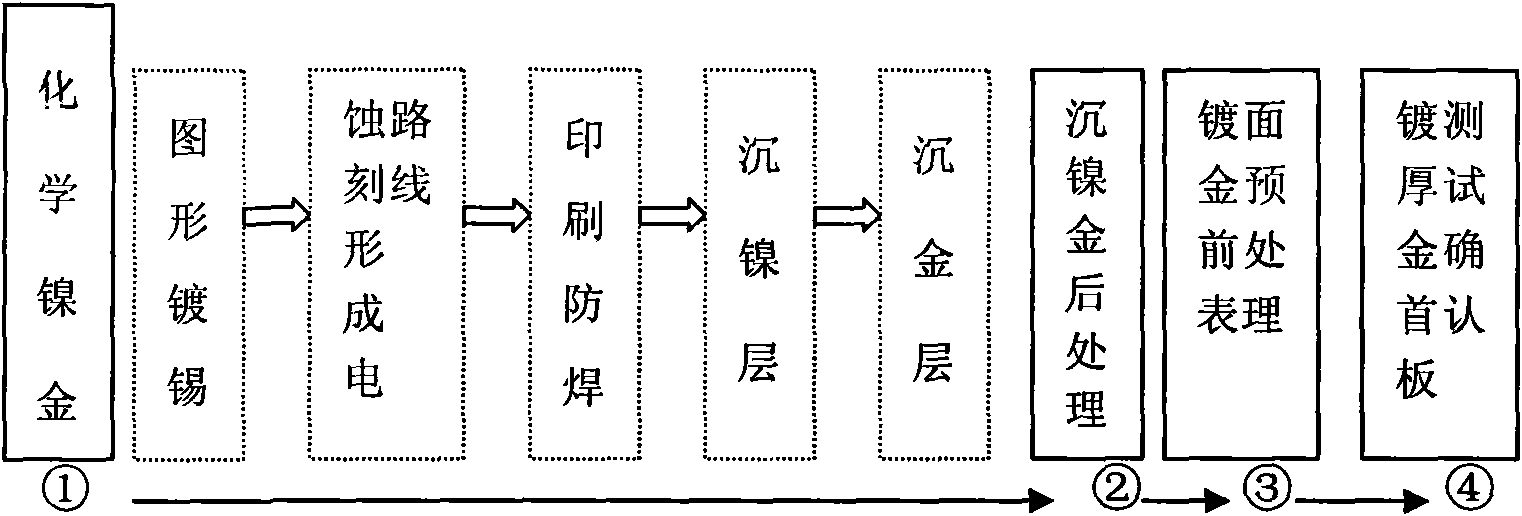

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427ANo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

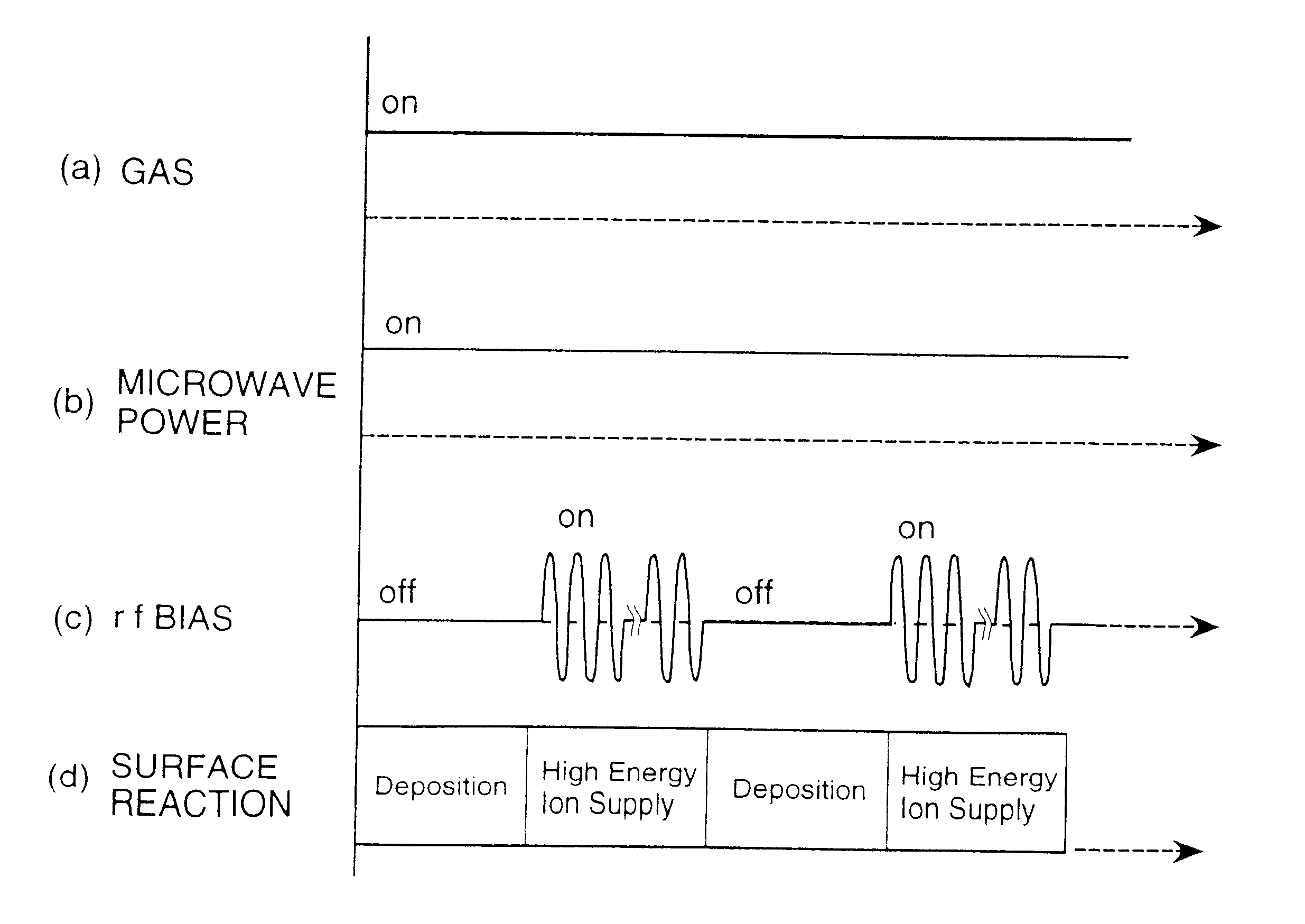

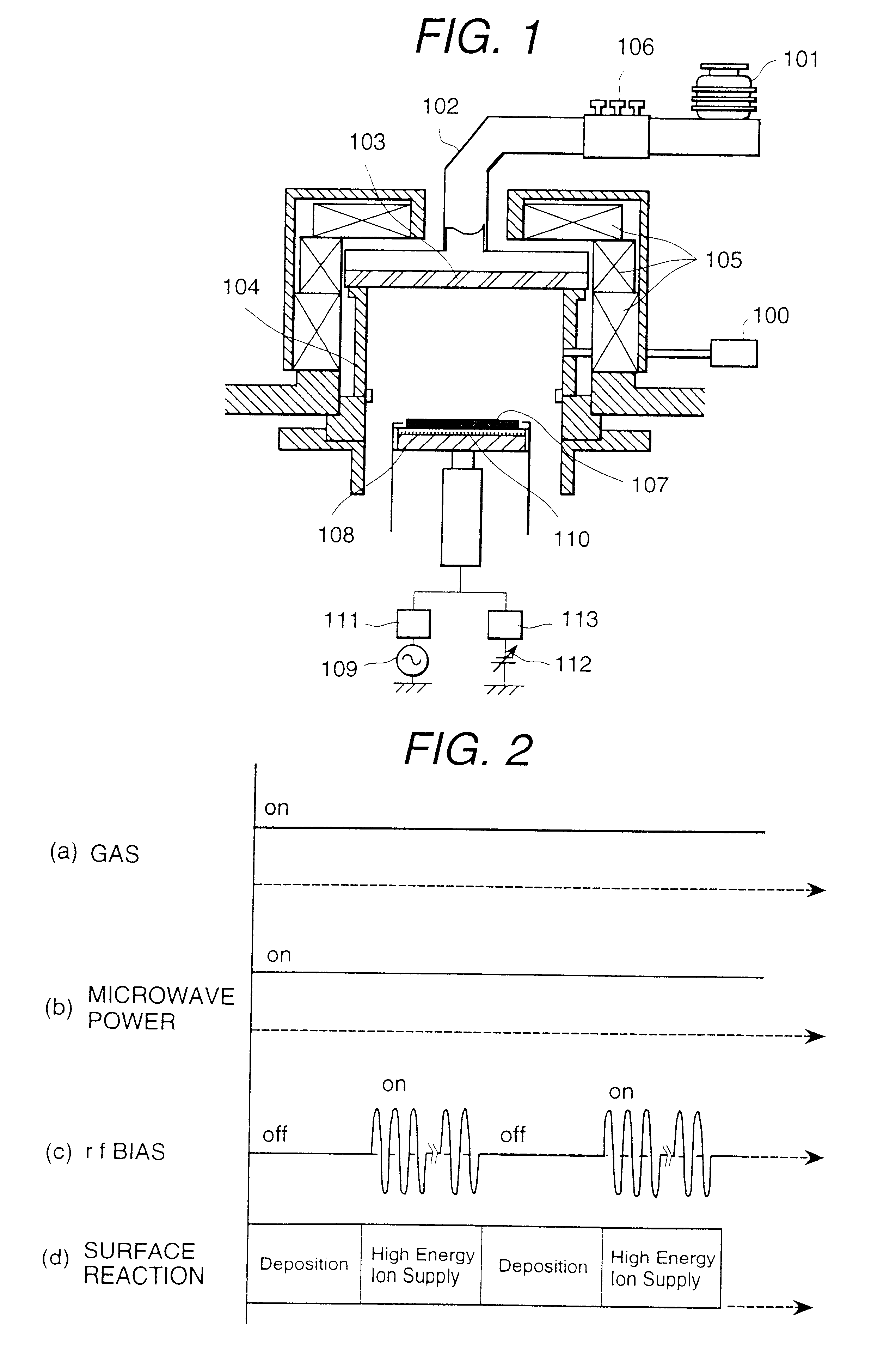

Method for processing surface of sample

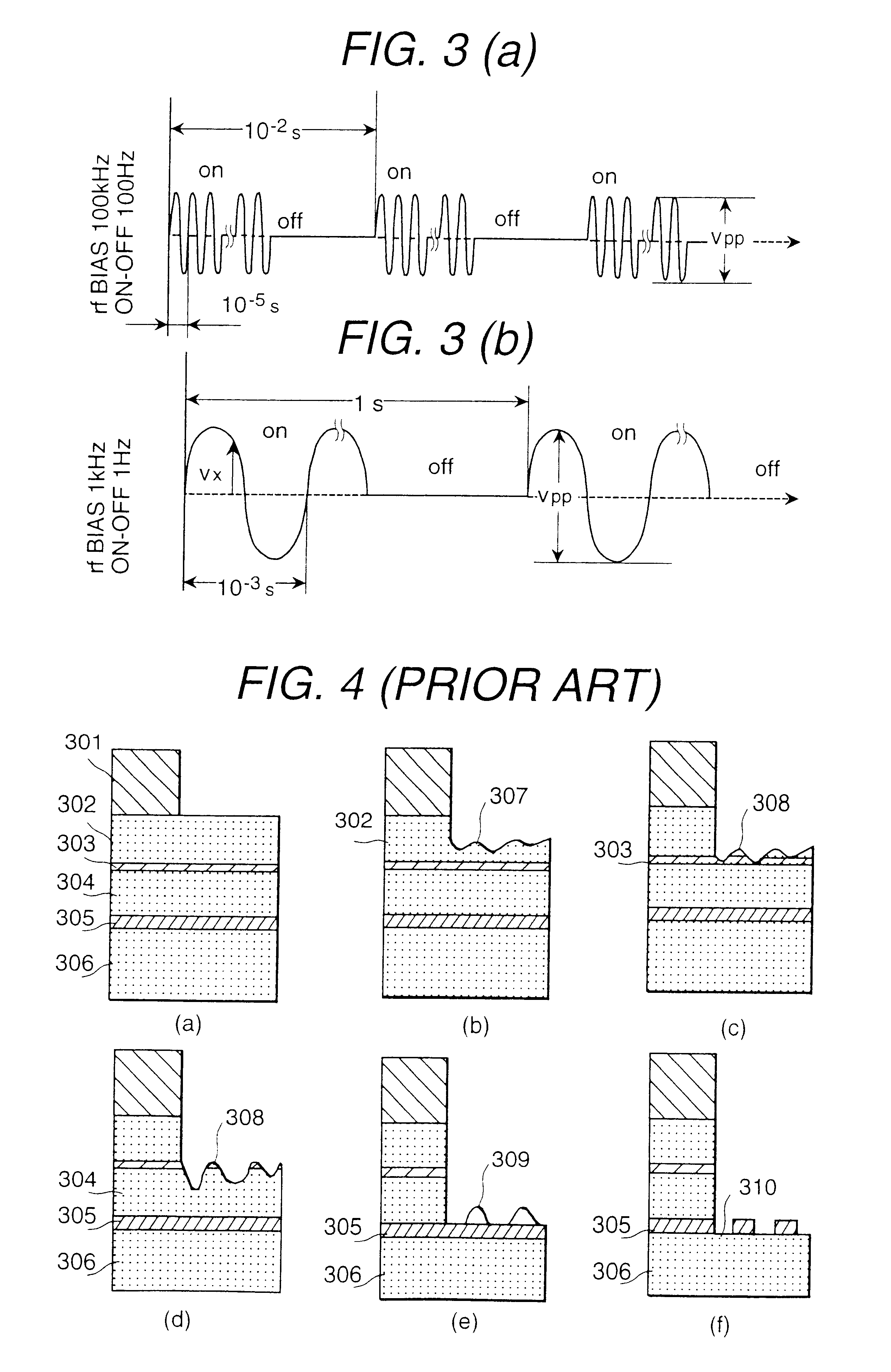

InactiveUS6660647B1Lower resistanceMinimize diffusionElectric discharge tubesDecorative surface effectsRadio frequencySemiconductor

A surface processing method of a sample having a mask layer that does not contain carbon as a major component formed on a substance to be processed, the substance being a metal, semiconductor and insulator deposited on a silicon substrate, includes the steps of installing the sample on a sample board in a vacuum container, generating a plasma that consists of a mixture of halogen gas and adhesive gas inside the vacuum container, applying a radio frequency bias voltage having a frequency ranging from 200 kHz to 20 MHz on the sample board, and controlling a periodic on-off of the radio frequency bias voltage with an on-off control frequency ranging from 100 Hz to 10 kHz.

Owner:HITACHI LTD

Liquid crystal polymers for flexible circuits

InactiveUS20020028293A1High operating requirementsReduce absorptionInsulating substrate metal adhesion improvementAfter-treatment detailsFlexible circuitsSolvent

A process for providing a metal-seeded liquid crystal polymer comprising the steps of providing a liquid crystal polymer substrate to be treated by applying an aqueous solution comprising an alkali metal hydroxide and a solubilizer as an etchant composition for the liquid crystal polymer substrate. Further treatment of the etched liquid crystal polymer substrate involves depositing an adherent metal layer on the etched liquid crystal polymer substrate. An adherent metal layer may be deposited using either electroless metal plating or vacuum deposition of metal such as by sputtering. When using electroless metal plating, a tin(IT) solution applied to the liquid crystal polymer provides a treated liquid crystal polymer substrate to which the application of a palladium(II) solution provides the metal-seeded liquid crystal polymer. The etchant composition comprises a solution in water of from 35 wt. % to 55 wt. % of an alkali metal salt, and from 10 wt. % to 35 wt. % of a solubilizer dissolved in the solution to provide the etchant composition suitable for etching the liquid crystal polymer at a temperature from 50° C. to 120° C. A flexible circuit comprising a liquid crystal polymer film having through-holes and related shaped voids may be formed using etchant compositions as previously described.

Owner:3M INNOVATIVE PROPERTIES CO

Blendable blasting media and method of reusing and discharging same

InactiveUS20050107005A1Easy to separateFacilitates cleaning and reuseBlast gunsAbrasive feedersEngineeringVolumetric Mass Density

An apparatus and method for applying a blasting media, comprised of at least first and second separate types of particles, to a surface to be treated. Each type of particle may comprise a core coated with a desired component, e.g. abrasive, absorptive, polishing, etc., and the components are selected so as to minimize the density variation of different types of media being combined with one another for the surface treatment. The different types of particles are mixed with one another prior to application to a surface to be treated. The mixing may occur in a mixing tank prior to use, in the media supply conduit prior to the nozzle, at the discharge outlet of the nozzle, or just prior to contacting the surface to be treated. By employing different types of particles, cleaning and reuse of the media is facilitated while also minimizing the amount of media consumed per unit area of wall to be treated. In addition, an operator is able to custom blend the media, during use at a jobsite, to maximize surface treatment, per pound of media, and minimize the generation of disposable waste.

Owner:LYNN WILLIAM R

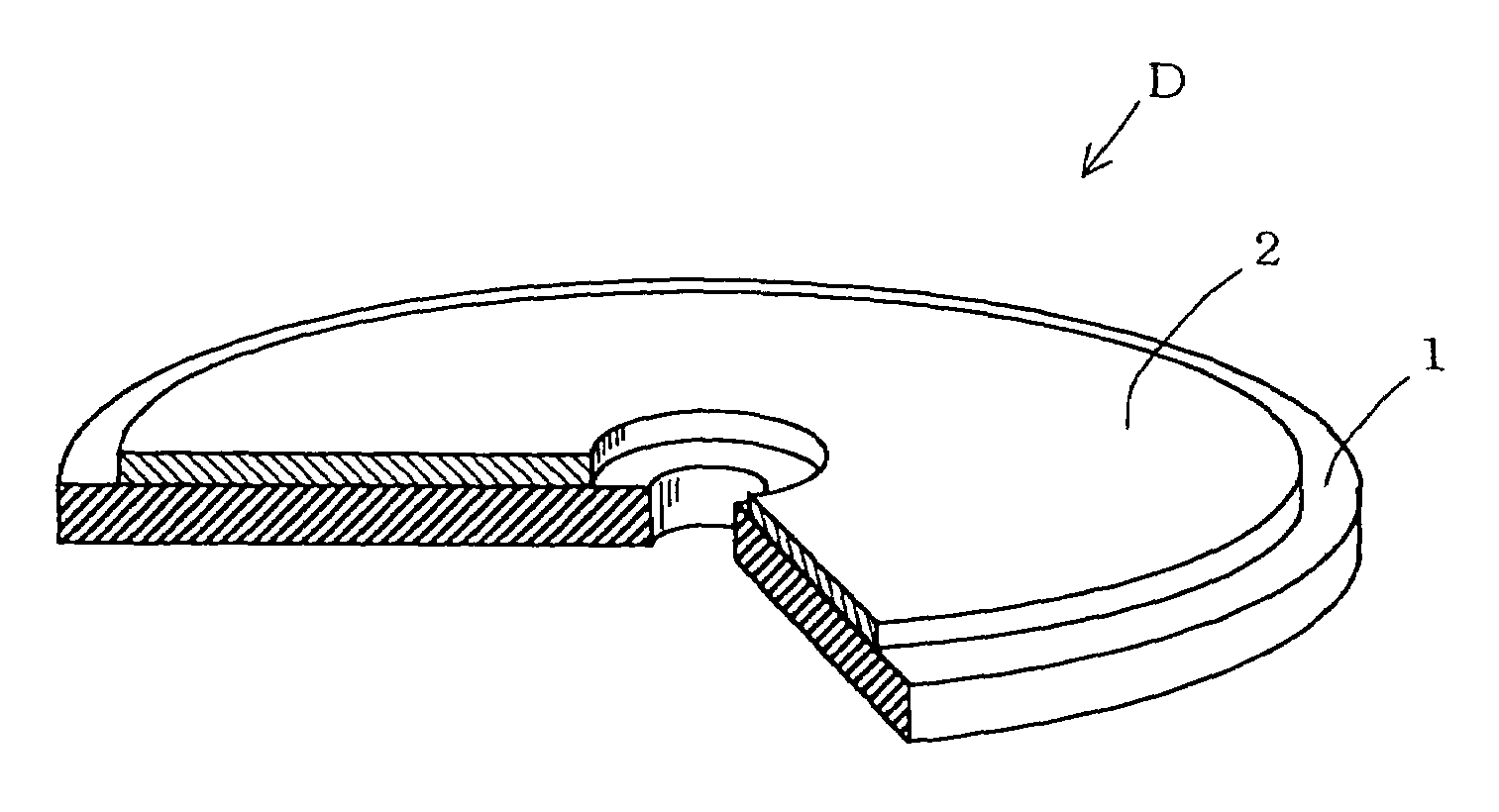

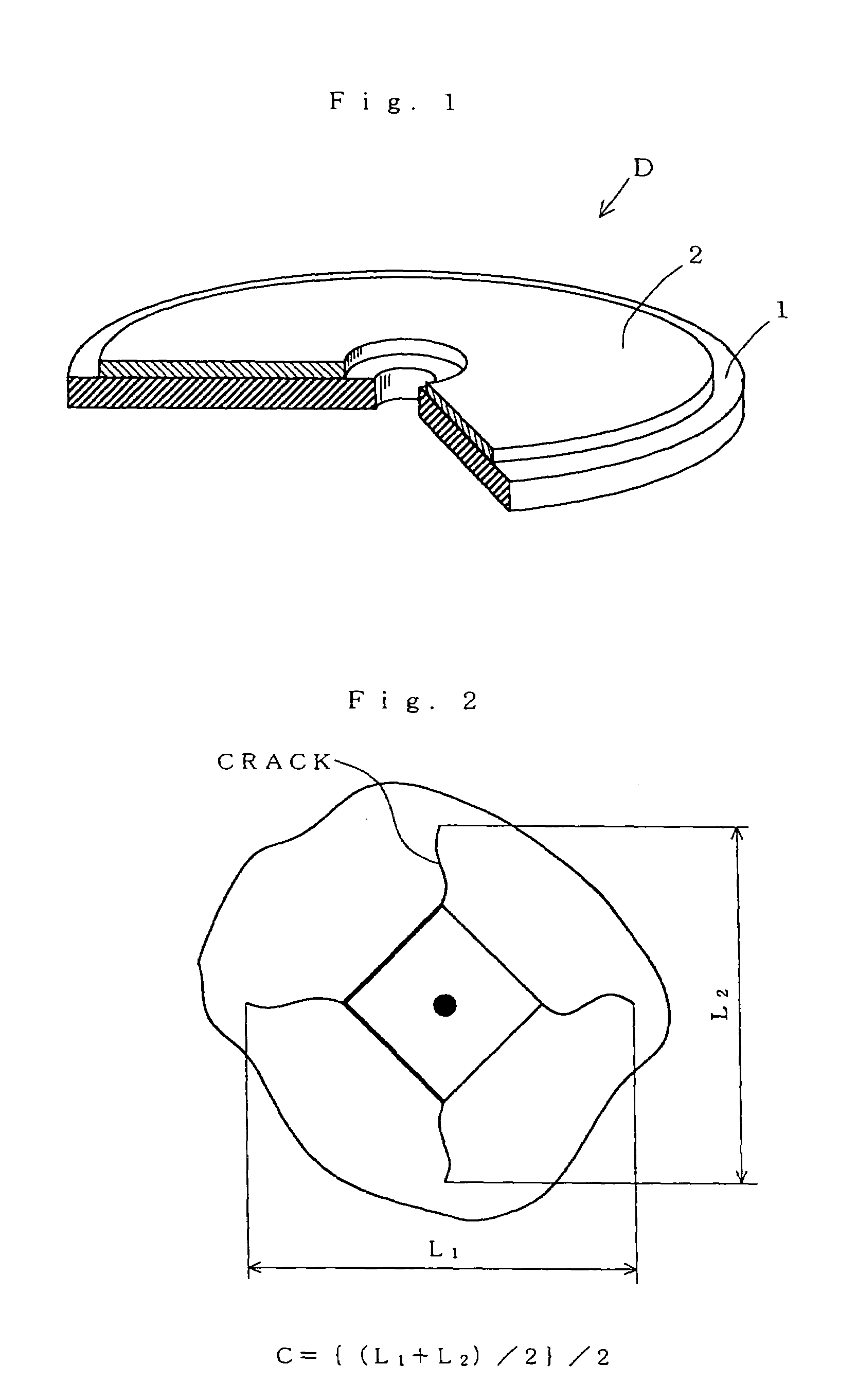

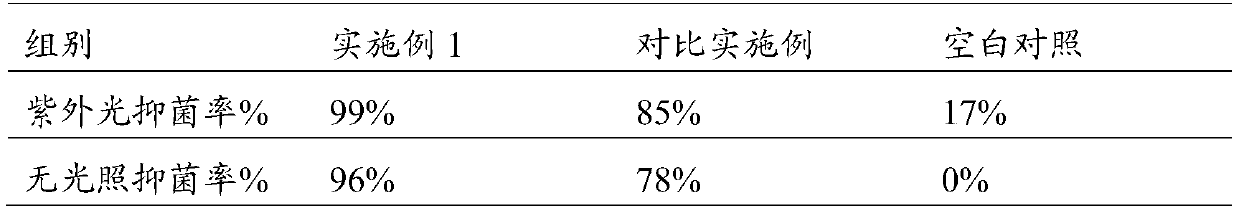

Glass composition and glass substrate

InactiveUS7192898B2Improve fracture toughnessLow alkali elutionMagnetic materials for record carriersBase layers for recording layersOptical communicationMetal

A glass substrate for use as the substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD or of an optical communication device, and a glass composition for making such a glass substrate, contains the following glass ingredients: 45 to 75% by weight of SiO2; 1 to 20% by weight of Al2O3; 0 to 8% by weight, zero inclusive, of B2O3; SiO2+Al2O3+B2O3 accounting for 60 to 90% by weight; a total of 0 to 20% by weight, zero inclusive, of R2O compounds, where R=Li, Na, and K; and a total of 0 to 15% by weight, zero inclusive, of TiO2+ZrO2+LnxOy, where LnxOy represents at least one compound selected from the group consisting of lanthanoid metal oxides, Y2O3, Nb2O5, and Ta2O5.

Owner:HOYA CORP

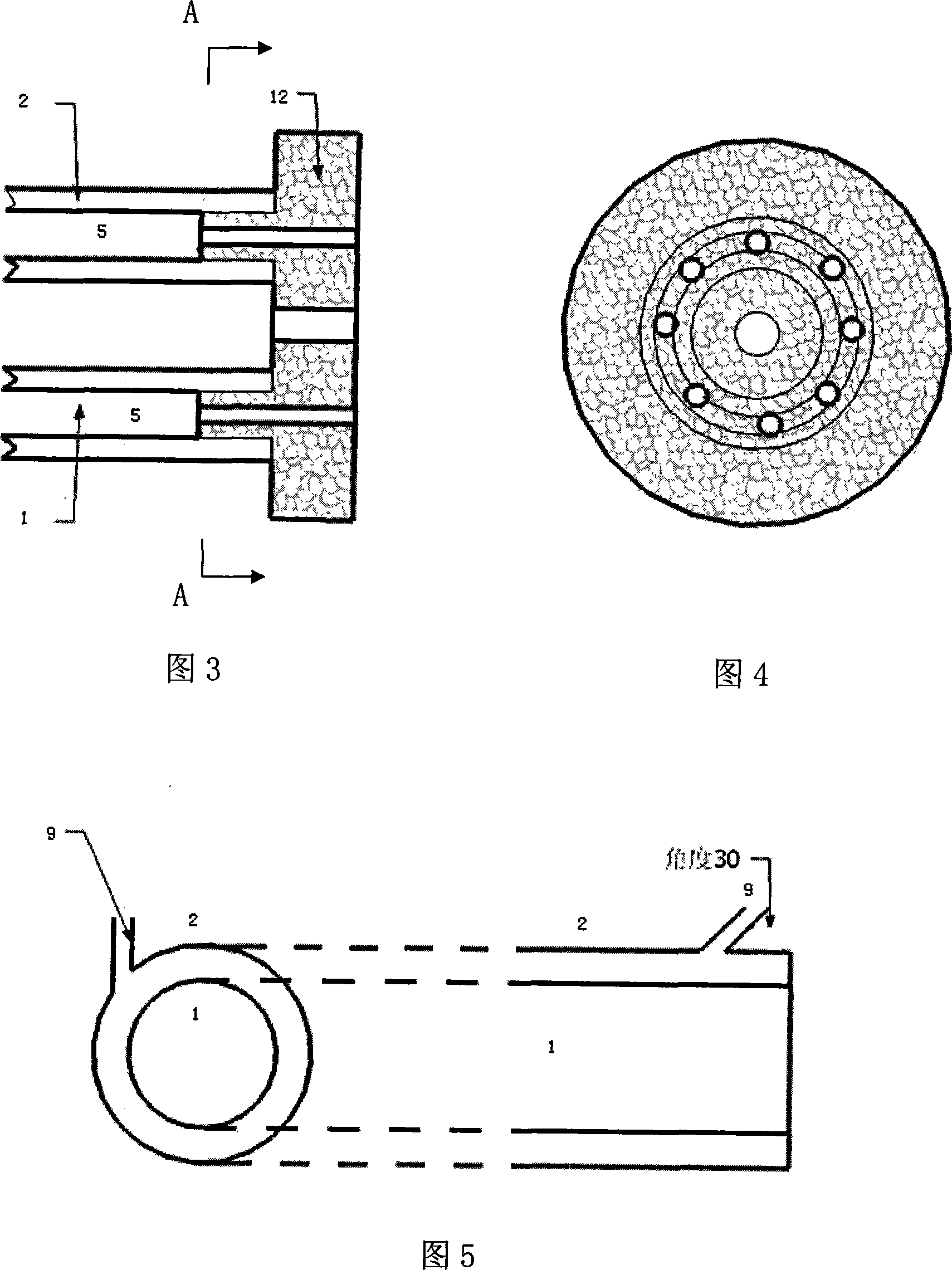

Atmosphere pressure plasma treatment fasciculus or fibre string surface device and method thereof

InactiveCN101096820AImprove surface structureImprove surface propertiesFibre typesUltrasonic/sonic fibre treatmentFiberPower parameter

The invention discloses an atmosphere pressure plasma dealing fiber tuft or fiber thread surface device and method, which is characterized by the following: arranging quartz liner pipe in coaxial cover; constructing gas discharging plasma zone with quartz outer tube; forming high pressure electrode with inner surface or outer surface of the quartz linear through vacuum deposition plated metallic film; cup-jointing stainless steel cloth and water coat sandwich on the outer surface of the quartz outer tube; constructing earth electrode; using coaxial quartz glass tube to construct asymmetric electrode structure of medium discharge resistance; keeping special laminar flow disperse for gas in sandwich; diminishing consumption of gas; decreasing treating temperature effectively. This invention can choose proper high pressure electrode form, gas component, power parameter and treating speed according to different fiber material, which can proceed highly effective, low consumption and environment protection treat for the surface of fiber tuft or fabric cord.

Owner:DONGHUA UNIV

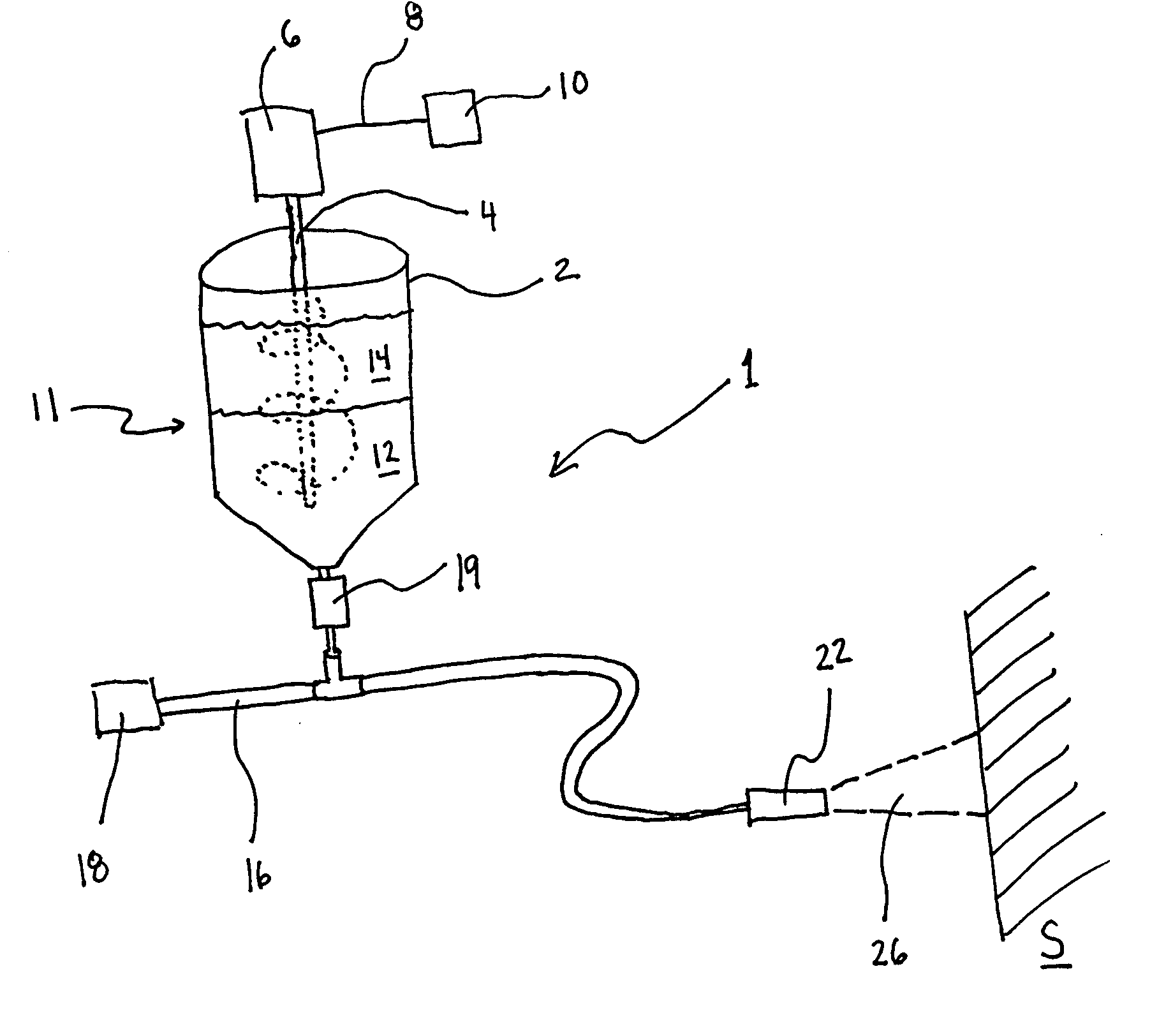

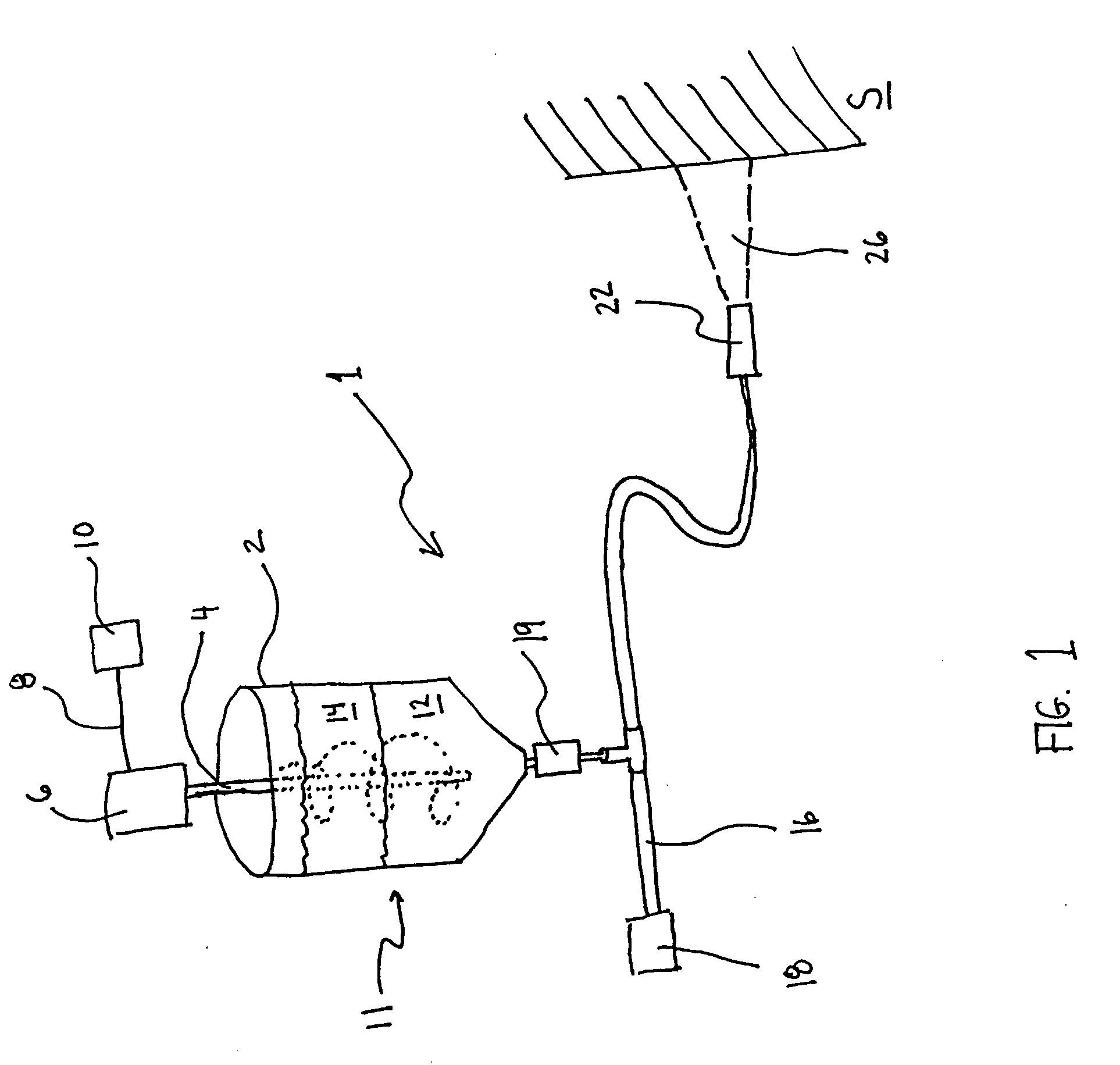

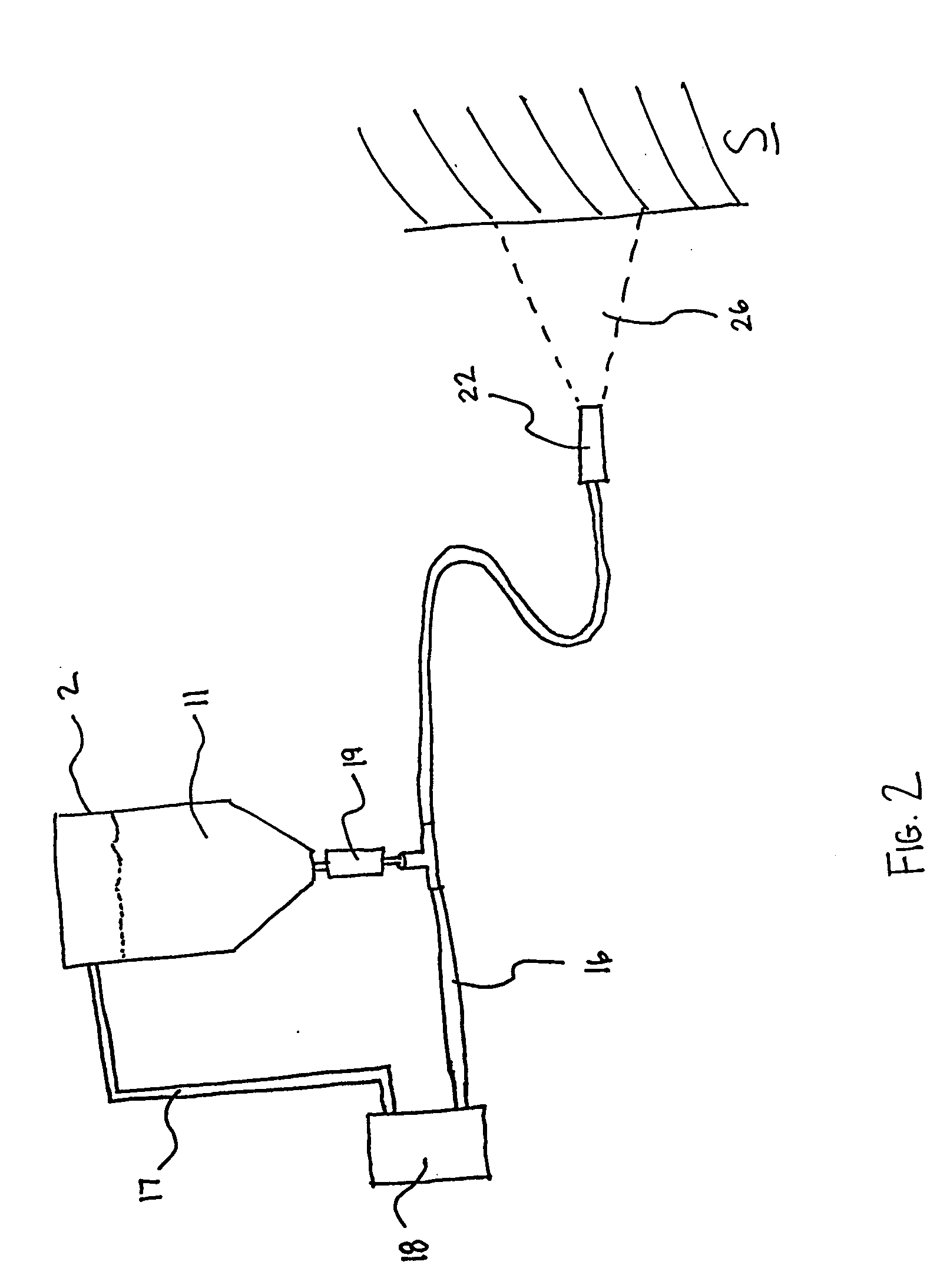

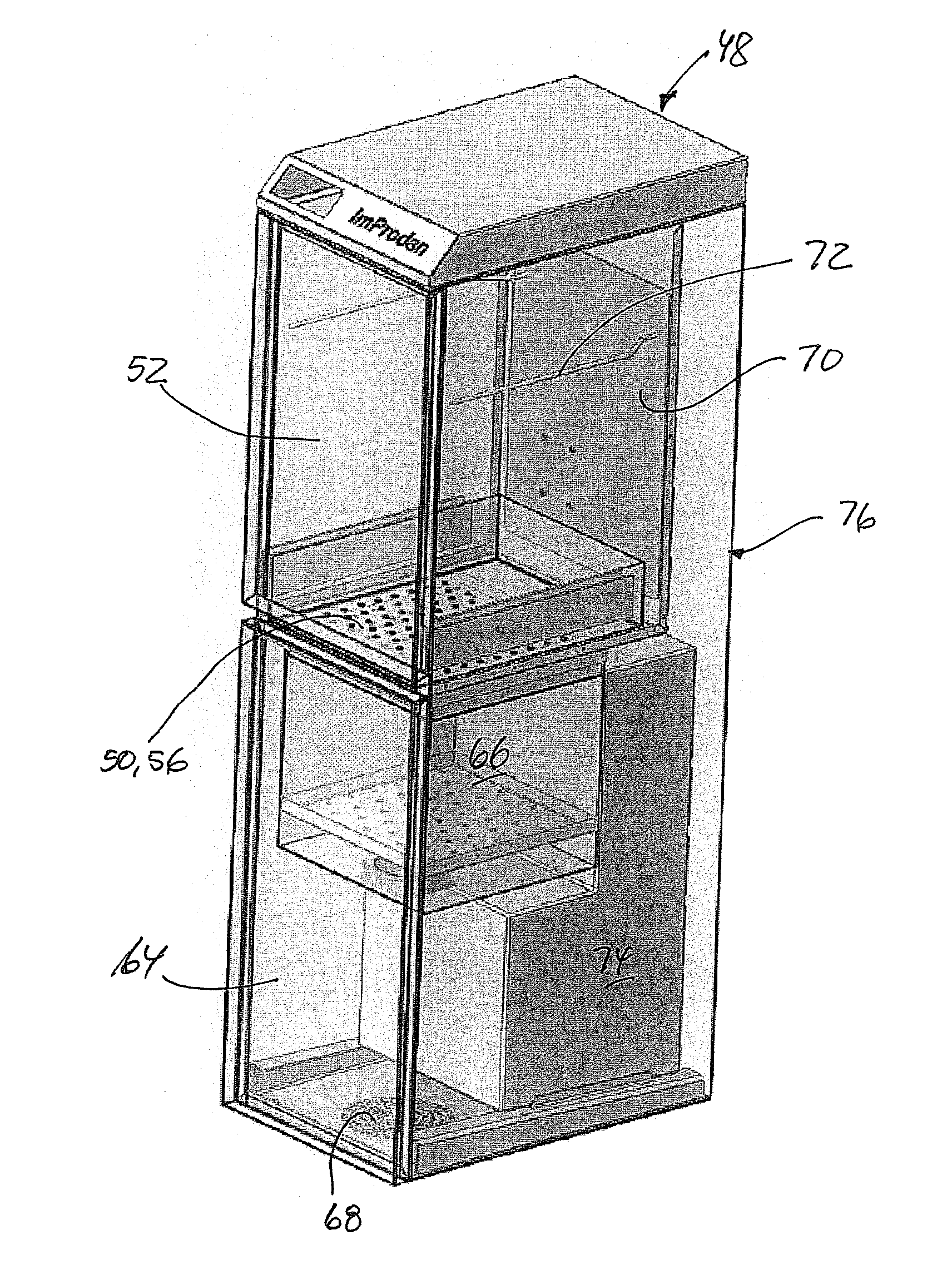

Method and apparatus for impregnation of items

ActiveUS20110091655A1Use minimizedGood surface treatmentInsolesVacuum evaporation coatingActivated carbonBiomedical engineering

A method and apparatus for surface treatment of footwear, bags, gloves, other leather items or leather-like items. The method includes optional covering a surface or a part of the items which are not to be treated; optional selecting time of operation of a spraying unit; placing items to be treated in a chamber; shutting the chamber and thereby manually or automatically initiating; activating the spraying unit for forming a mist of impregnating agent inside the chamber for applying impregnating agent onto the surfaces of the items; activating an air pump, ventilator or corresponding means for removal of excess impregnating agent from the chamber; and retaining excess impregnating agent in a filter which preferably is a filter containing activated carbon.

Owner:IMBOX SHOECARE

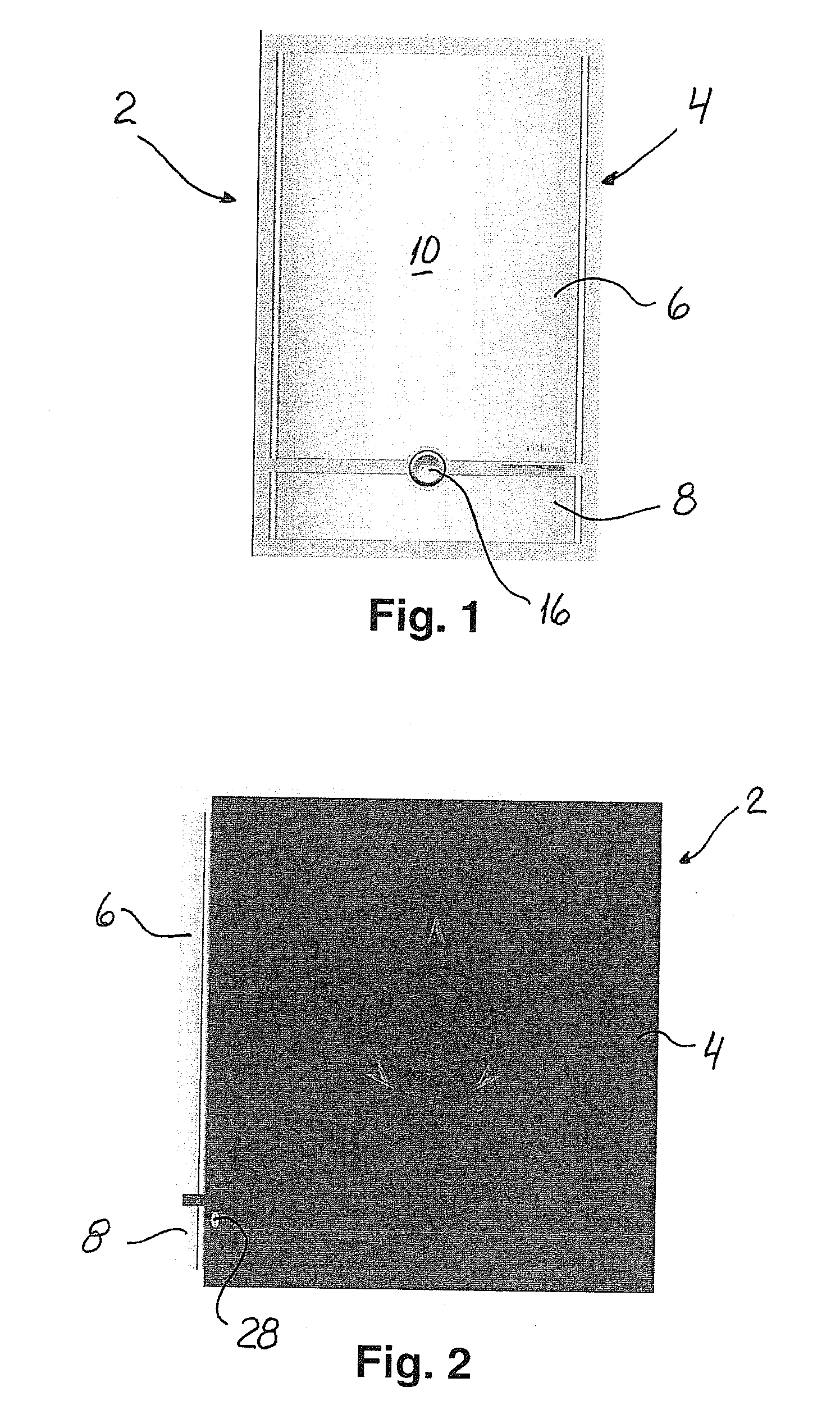

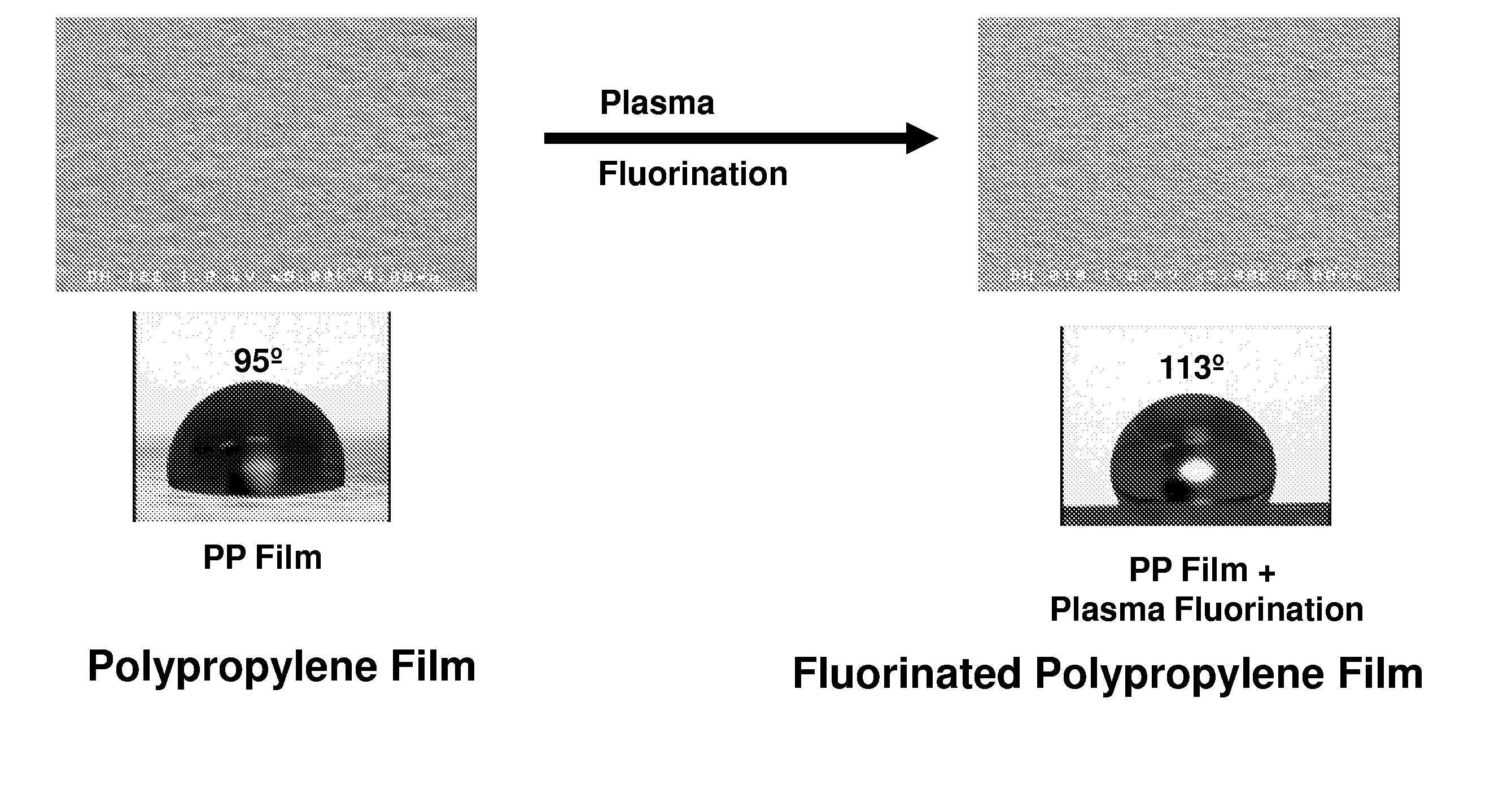

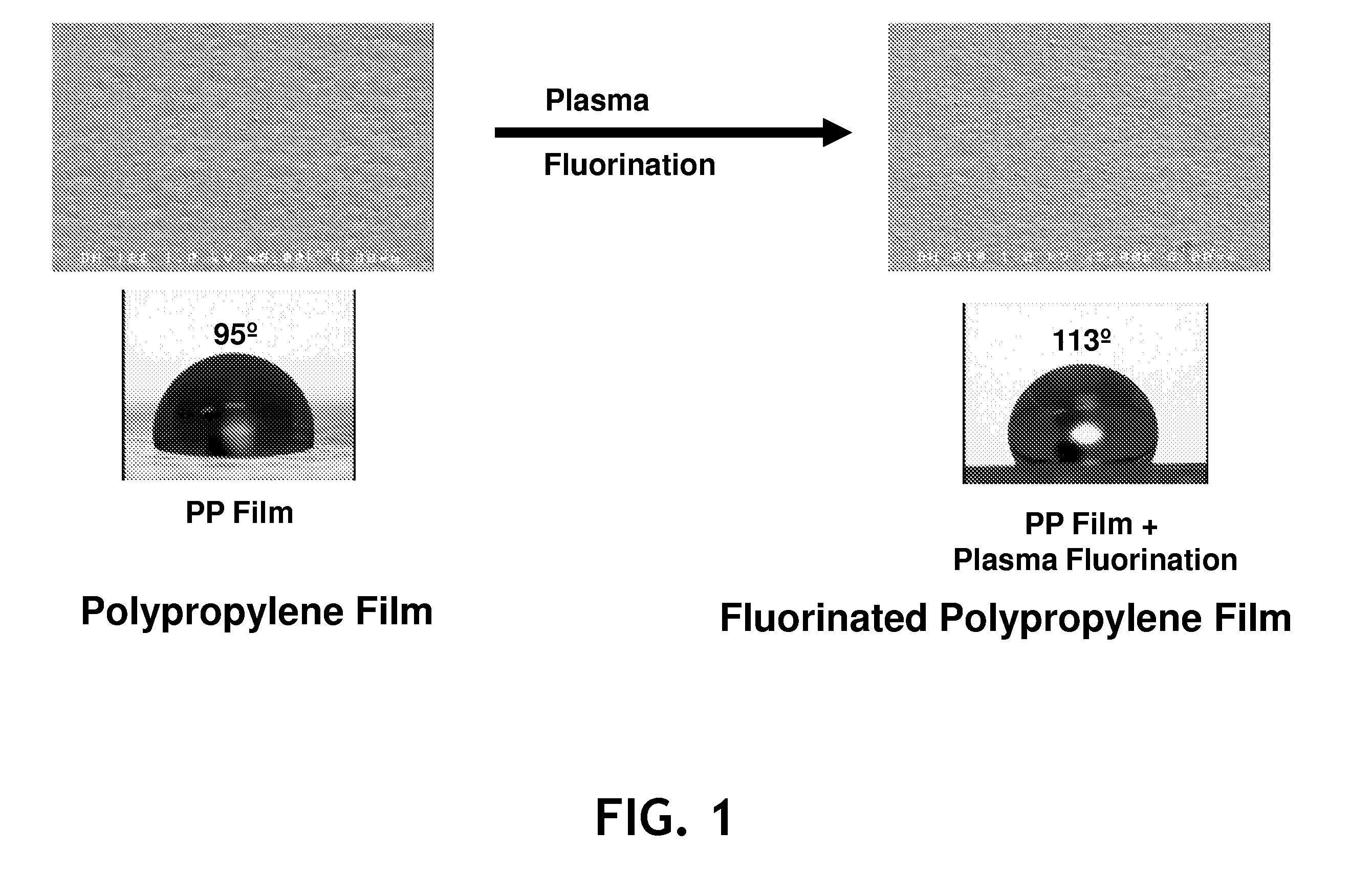

High repellency materials via nanotopography and post treatment

InactiveUS20100159195A1Good surface treatmentLotus effect fibresPhysical treatmentHigh energyNanotopography

A method is provided for making a high repellency material. In one embodiment the method includes the steps of providing a polymeric material having an external surface including particle-like nanotopography, etching the external surface with a high energy treatment; and depositing a fluorochemical onto the etched external surface by a plasma fluorination process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

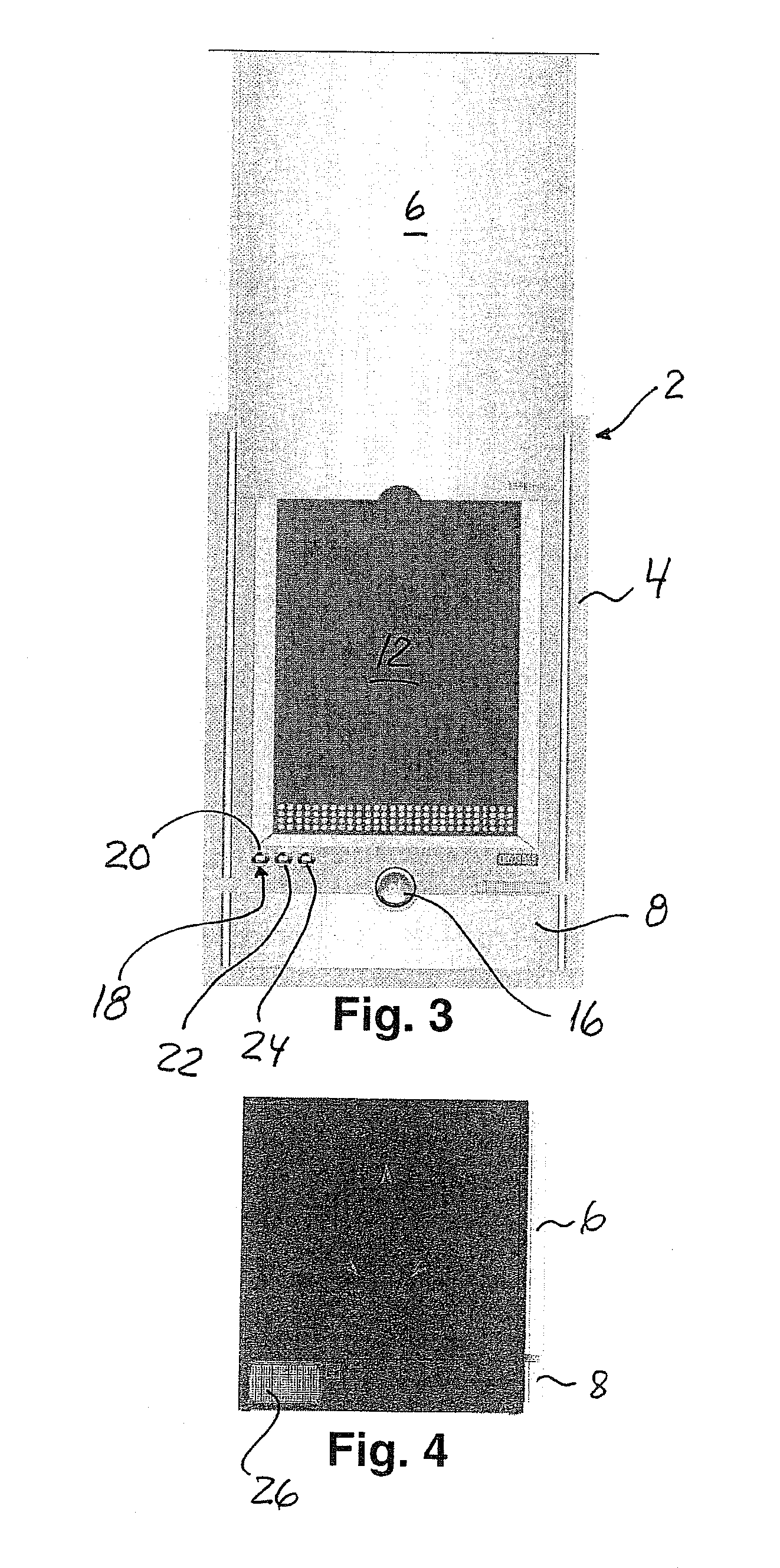

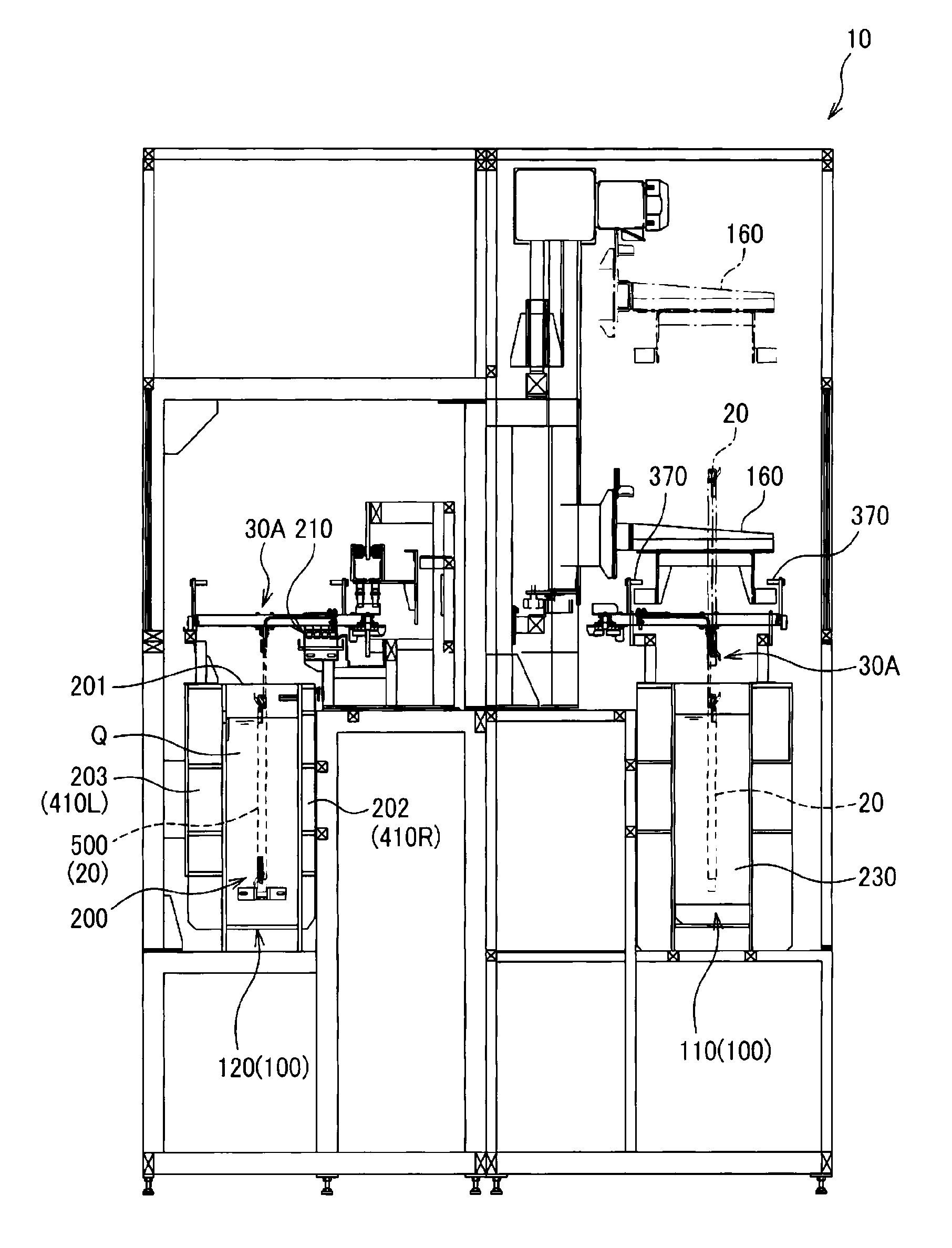

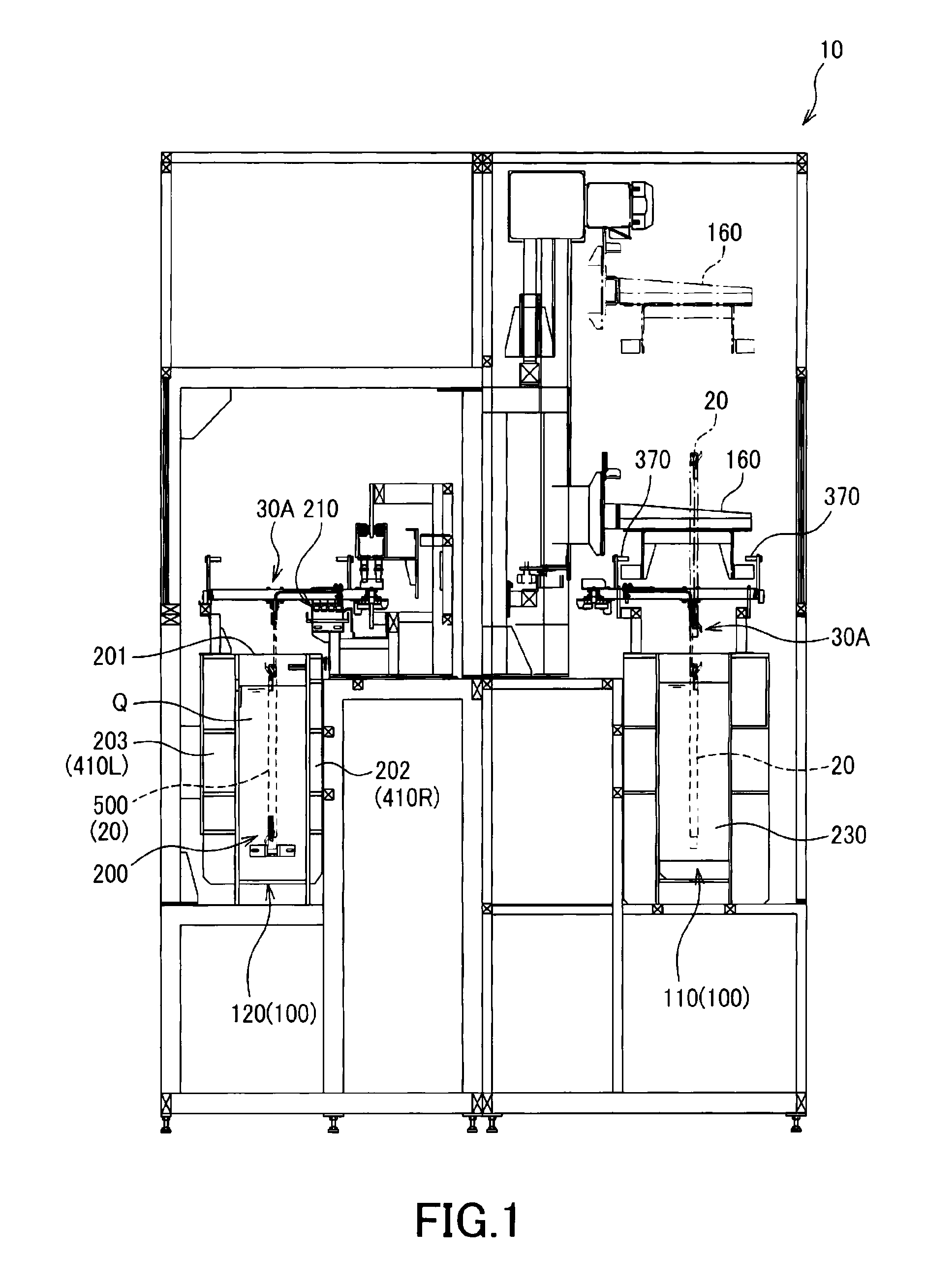

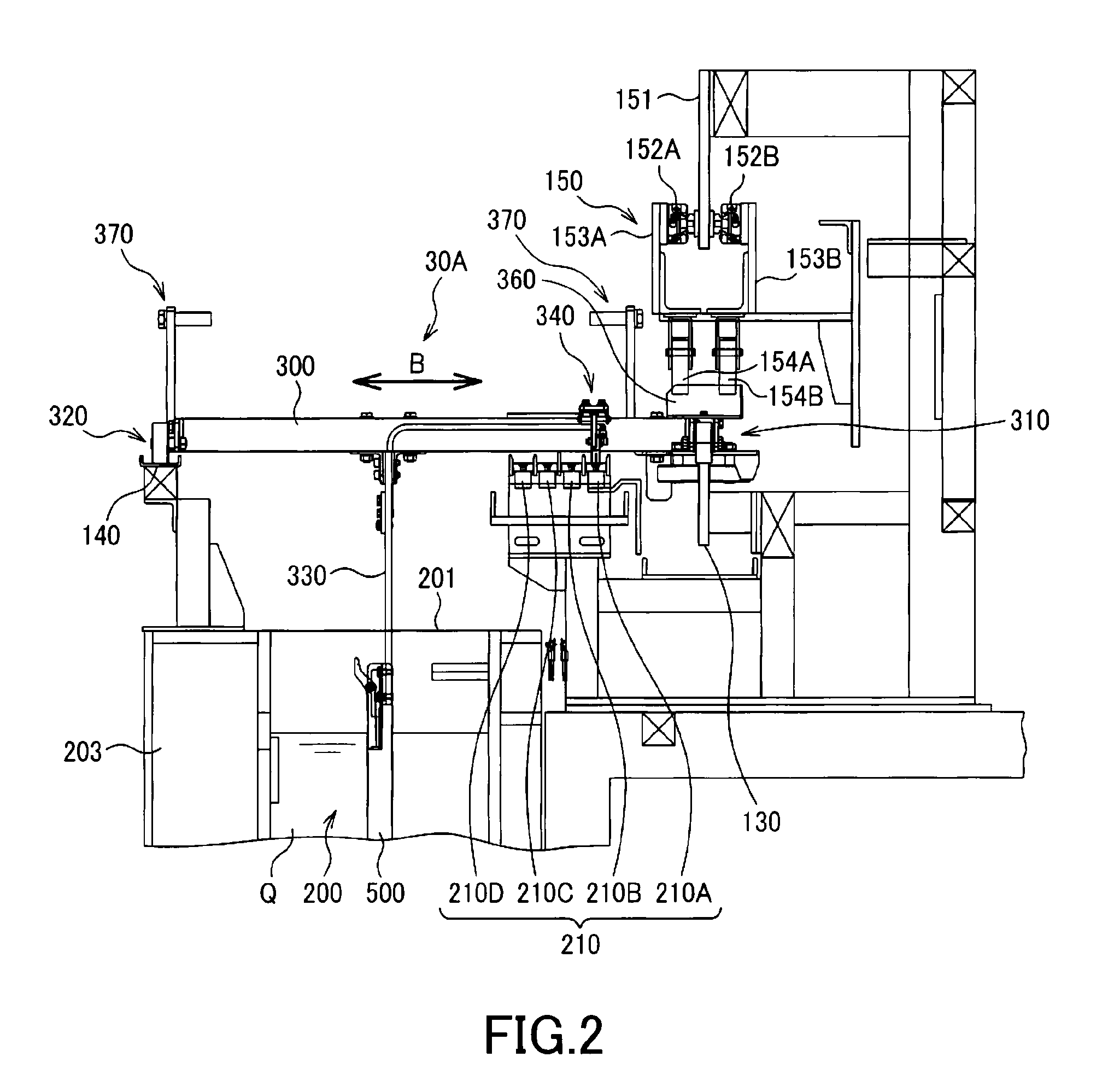

Surface treatment system and workpiece-holding jig

ActiveUS20130001073A1Improve in-plane uniformityGood surface treatmentCellsLiquid surface applicatorsEngineeringTreatment system

A surface treatment system includes a surface treatment tank, a first guide rail and a second guide rail that extend at a position offset from a position over the upper opening of the surface treatment tank, and a plurality of transfer jigs that respectively hold a workpiece and are supported by the first guide rail and the second guide rail. The transfer jig includes a horizontal arm section, a first guide target section that is guided by the first guide rail, a second guide target section that is guided by the second guide rail, and a vertical arm section that is suspended from the horizontal arm section at a position between the first guide target section and the second guide target section, and holds the workpiece.

Owner:ALMEX PE INC

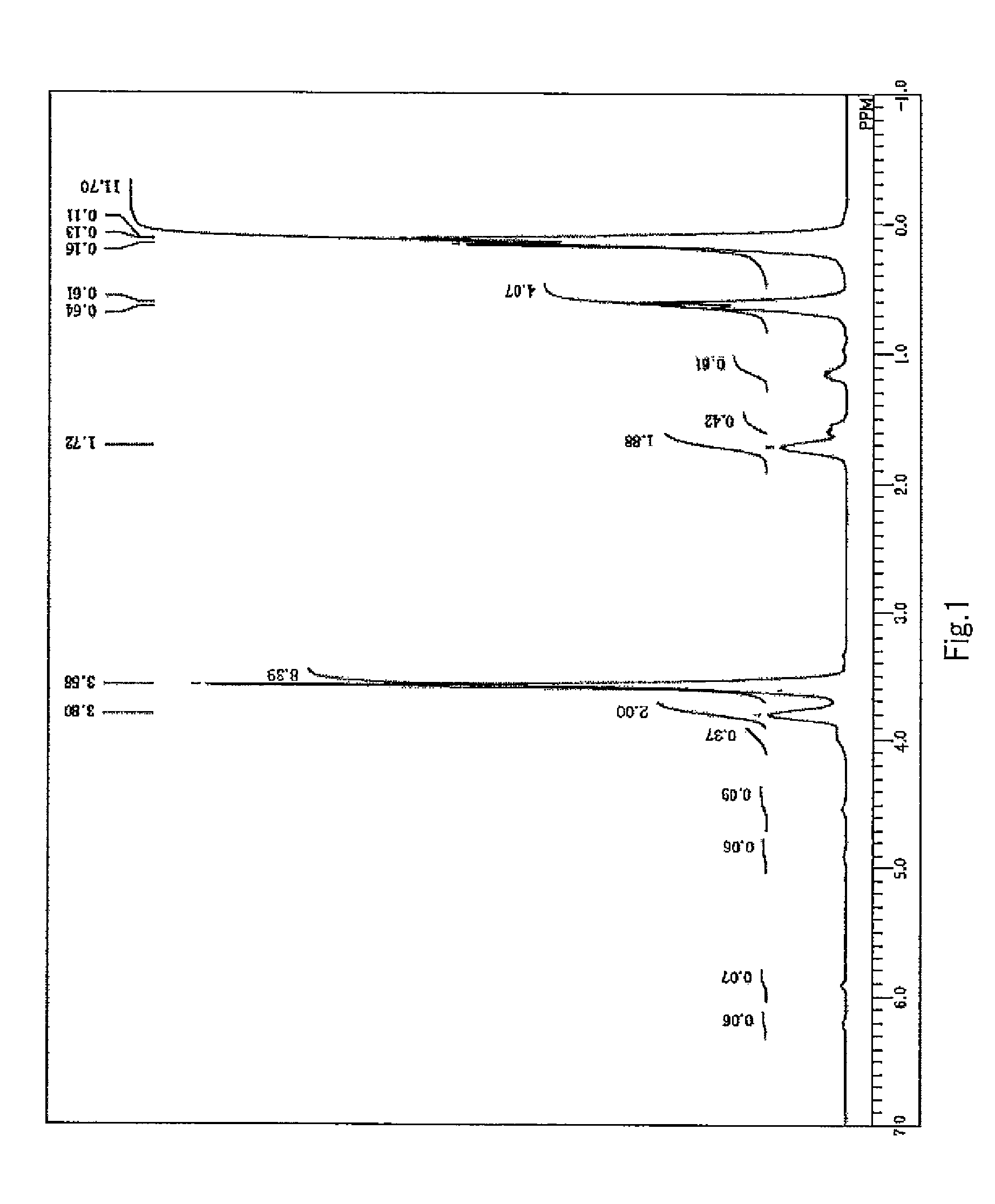

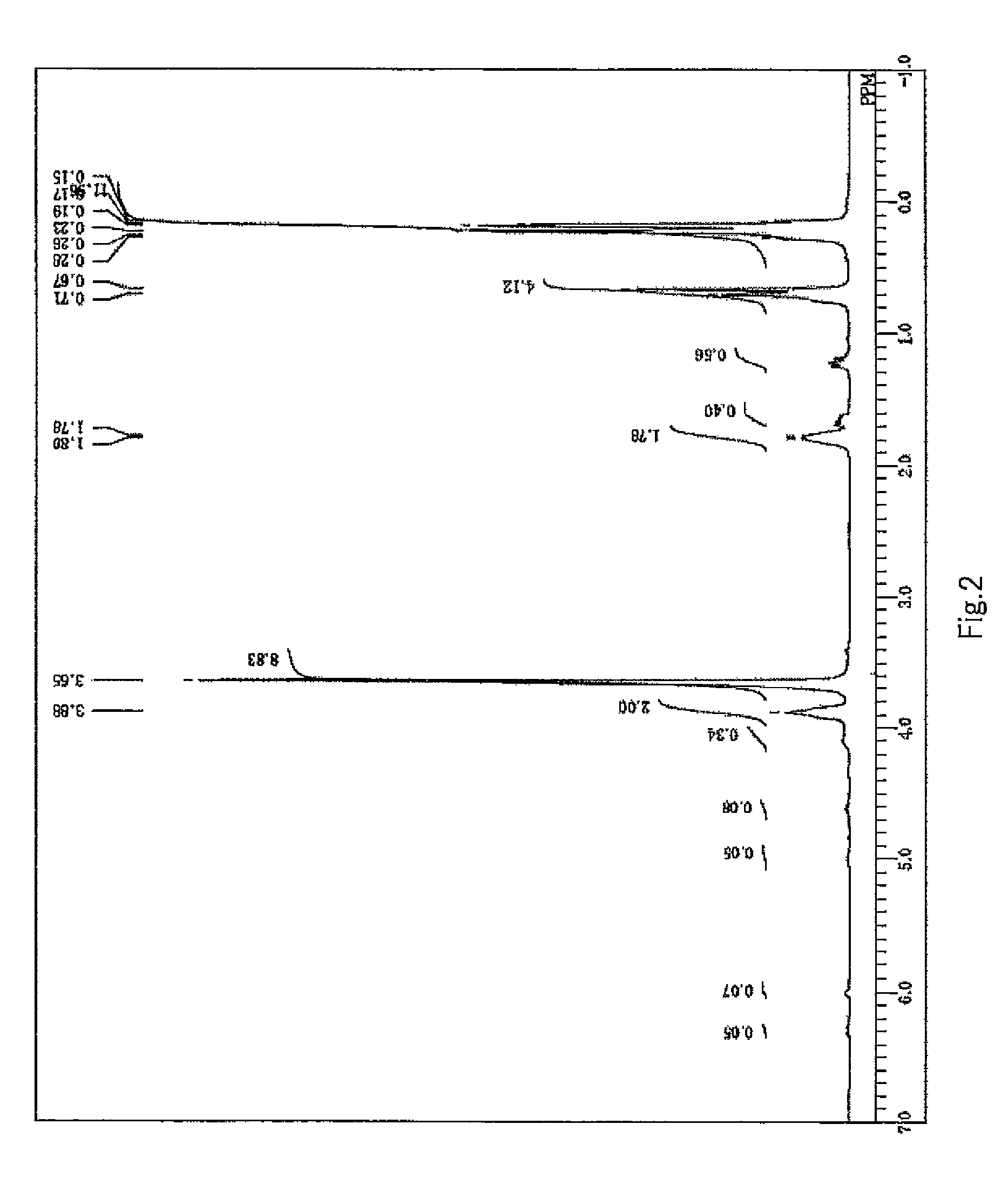

Perfluoropolyether-polyorganosiloxane block copolymer and a surface treatment agent comprising the same

InactiveUS7829649B2Good surface treatmentExcellent in surface slickness and transparencyPolymer sciencePerfluoropolyether

A perfluoropolyether-polyorganosiloxane block copolymer represented by the following formula (1), the block copolymer having a number average molecular weight, reduced to polystyrene, of from 2,000 to 20,000,W2-Q-Rf-Q-(W1-Q-Rf-Q)g-W2 (1)wherein Rf is a perfluoropolyether block, W1 is a polyorganosiloxane block having at least one group represented by the following formula (2)wherein X is a hydrolyzable group, R1 is a C1-4 alkyl group or a phenyl group, y is an integer of from 1 to 5, and a is 2 or 3,Q is a C2-12 divalent connecting group which may contain an oxygen atom and / or nitrogen atom,W2 is an organosiloxane residue having a group represented by the aforesaid formula (1), and g is an integer of from 1 to 11.

Owner:SHIN ETSU CHEM IND CO LTD

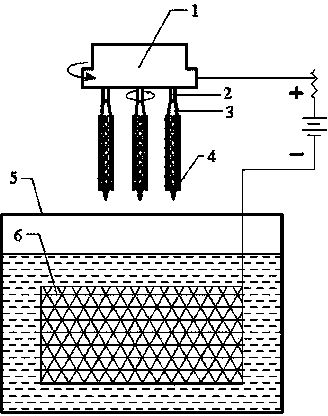

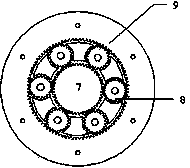

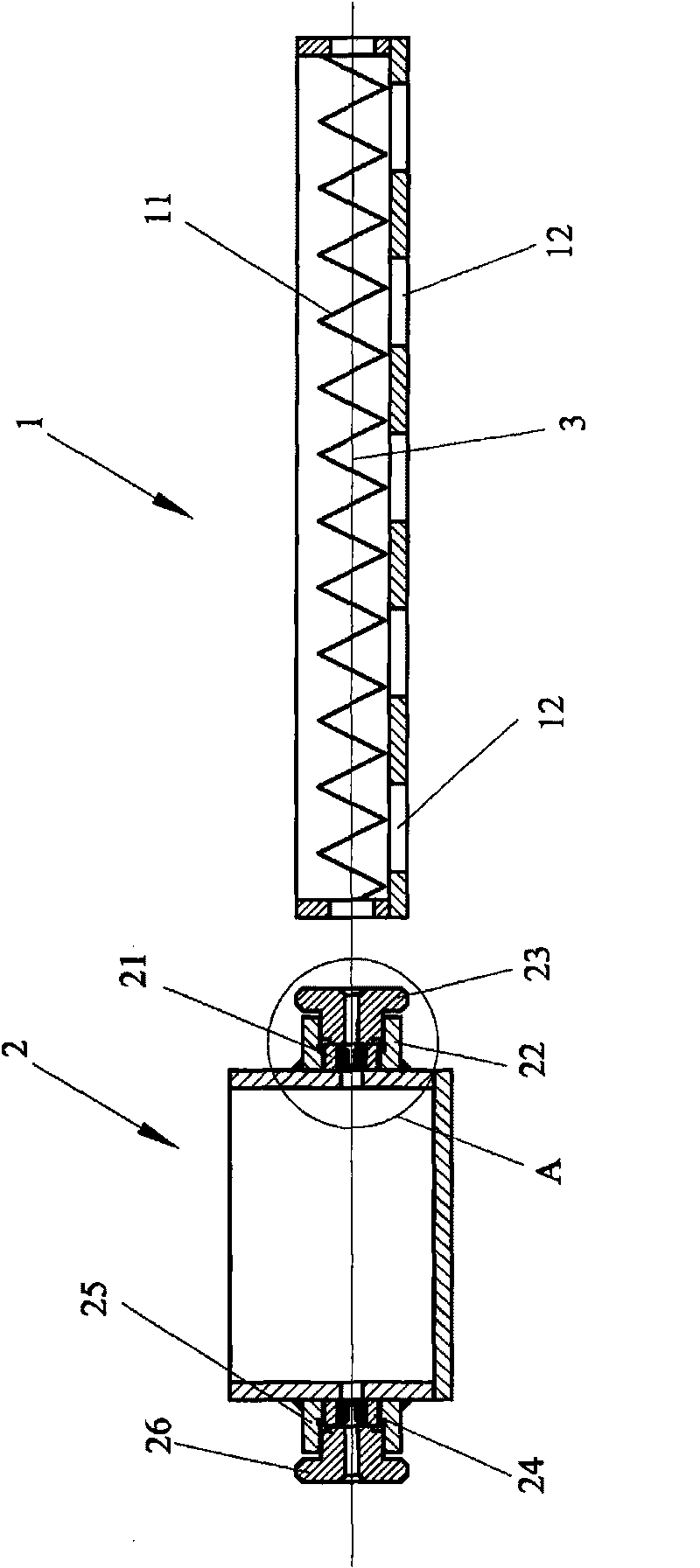

Electrochemical treatment method suitable for magnesium alloy interventional device and auxiliary equipment

ActiveCN104073868AGood biocompatibilityUnique and convenient clamping methodElectrolysis componentsElectrolysisSodium phosphates

The invention relates to an electrochemical treatment method suitable for a magnesium alloy interventional device. The electrochemical treatment method comprises surface pretreatment and electrochemical polishing, wherein the pretreatment comprises the sub-steps: ultrasonically cleaning the magnesium alloy interventional device in a pretreatment aqueous solution at the temperature of 40-70 DEG C for 5-30 minutes, and ultrasonically cleaning in absolute ethyl alcohol for 5-20 minutes, wherein 1L of pretreatment aqueous solution comprises the following components: 5-50g of sodium phosphate, 5-40g of sodium hydroxide, 10-100g of sodium silicate and the balance of distilled water. According to the pretreatment aqueous solution, the electrochemical polishing solution has high biocompatibility, the surface treatment effect is good, and the pretreatment aqueous solution is suitable for most of magnesium alloy interventional devices. Moreover, the related auxiliary equipment clamping mode is unique and convenient, the product can be uniformly polished, multiple samples of different types can be simultaneously clamped, and the method is suitable for electrochemical polishing of the meshed, rod-shaped, tubular, plate-shaped and other-shaped magnesium alloy interventional devices.

Owner:ZHENGZHOU UNIV

Surface treatment method of amorphous alloy

InactiveCN103993314AConsistent colorConsistent textureAnodisationSuperimposed coating processAluminum metalAluminium oxides

The invention relates to the technical field of amorphous alloy and in particular relates to a surface treatment method of amorphous alloy. The method comprises the following steps: 1, performing cold spraying, namely spraying an aluminum layer or an aluminum alloy layer to the surface of the amorphous alloy by adopting a cold spraying process to obtain a semi-finished product; 2, performing anodizing treatment, namely performing anodizing treatment on the aluminum layer or the aluminum alloy layer in the semi-finished product obtained in the step 1 to enable an aluminum oxide film to be formed on the surface the aluminum layer or the aluminum alloy layer to obtain a finished product. According to the method, the treated amorphous alloy product can be perfectly matched with an aluminum alloy product in appearance, and the appearance requirements of industrial design are met; moreover, compared with a PVD (physical vapor deposition) technology, the method has the characteristics that the appearance requirements can be well met on the basis of the advantage of low cost, and the application range of the amorphous alloy is greatly expanded.

Owner:WINTOP DONGGUAN INDAL TECH

Method and device for processing surface of flux-cored welding wire during drawing flux-cored welding wire

InactiveCN101708570AGood surface treatmentImproved arc stabilityWelding/cutting media/materialsSoldering mediaArc stabilitySurface cleaning

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Welding aluminum alloy sheet for railway motor train set with two hundred kilometers per hour and manufacturing method

ActiveCN101457319AMeet the use requirementsImprove applicabilityThick plateUltimate tensile strength

The invention discloses a weldable aluminum alloy plate for a railway motor train unit with the speed of 200km per hour and a manufacturing method and relates to an aluminum alloy plate and the manufacturing method thereof. The invention aims at solving the problems of heavy car body and high cost caused by the use of stainless steel plates in the railway motor train unit with the speed of 200km per hour currently. The plate comprises the following compositions by weight percent: 0.30% of Si, 0.35% of Fe, 0.20% of Cu, 0.20-0.70% of Mn, 1.00-2.00% of Mg, 0.30% of Cr, 4.00-5.00% of Zn, 0.20% of Ti, 0.25% of Zr, 0.10% of V and the balance of Al. The method comprises the following steps: setting the solid-melting treatment temperature between 468 and 472 DEG C; pre-stretching a thick plate for 60 to 90 minutes, and cold quenching in the water with the temperature below 34 DEG C. The plate has a tensile strength not smaller than 315N / mm<2>, a disproportionate extension strength not smaller than 195N / mm<2>, a simple process and a high qualified rate of products.

Owner:NORTHEAST LIGHT ALLOY CO LTD

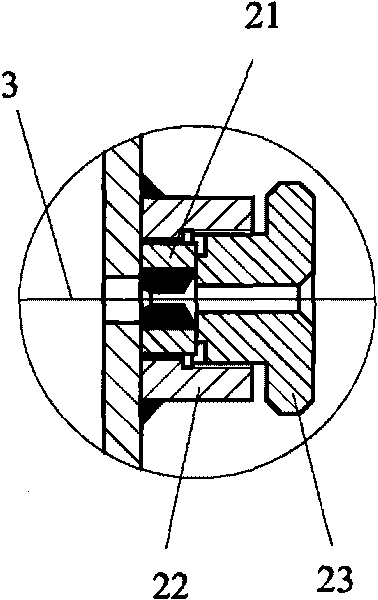

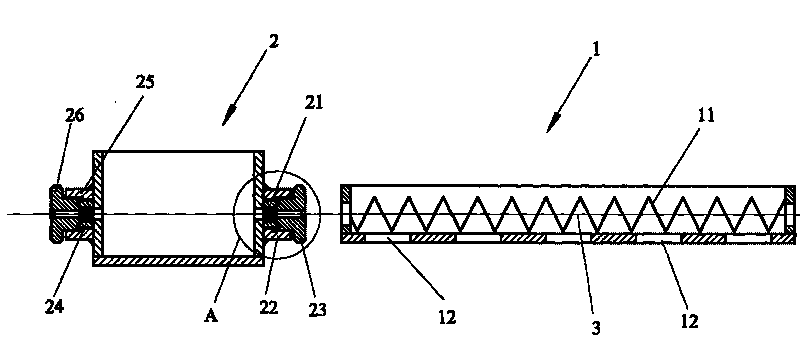

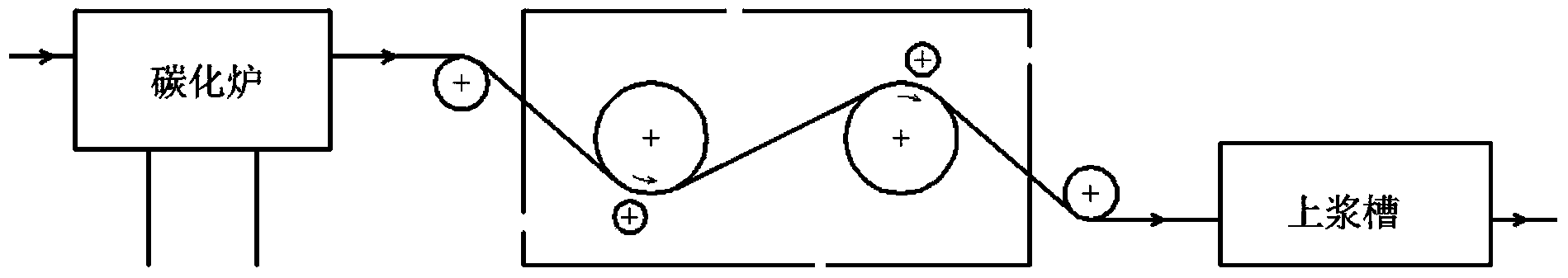

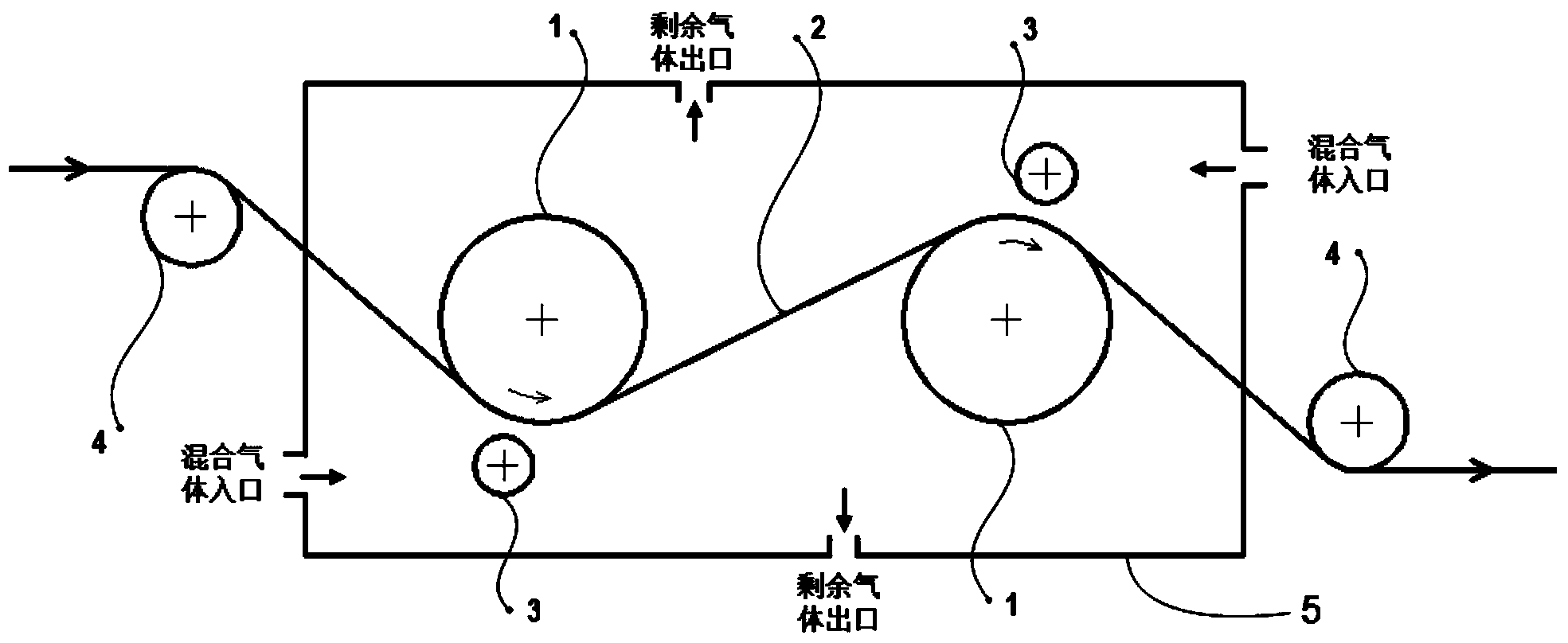

Corona discharge based carbon fiber surface treatment device and method

ActiveCN103938429ALittle loss of strengthGood surface treatmentUltrasonic/sonic fibre treatmentFiberCarbonization

The invention discloses a corona discharge based carbon fiber surface treatment device and method. The device comprises a large roller, a small roller, an auxiliary roller and a surface treatment cavity, wherein the surface treatment cavity is internally and at least provided with a set of corona discharge device composed of the large roller and the small roller, the distance between the outer surfaces of the large roller and the small roller is 3-15mm, and the large roller and the smaller roller are matched with each other to be used as two electrodes for corona discharge; a carbon fiber has waste heat after being output from a carbonization furnace, the temperature of the carbon fiber is controlled at 45-120 DEG C in the surface treatment cavity, and the carbon fiber is subjected to corona discharge surface treatment through the at least one set of corona discharge device in the surface treatment cavity. When the corona discharge based carbon fiber surface treatment device is used for carrying out surface treatment on the carbon fiber, the strength loss of the carbon fiber is low; the surface treatment effect for high-modulus carbon fiber with high surface crystallinity is remarkable; no waste liquid is discharged, and low environment pollution is caused; the surface free energy of the carbon fiber is increased, and the interlaminar shear strength of a carbon fiber composite is remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

Dendritic macromolecular coupling agent and preparation method thereof

InactiveCN106893112AGood dispersionStrong physical and mechanical propertiesInorganic particleCoupling

The invention relates to a dendritic macromolecular coupling agent and a preparation method thereof. The dendritic macromolecular coupling agent comprises, by weight, 60-100 parts of terminal carboxyl group dendritic macromoleculars and 20-50 parts of amino silane. After the dendritic macromolecular coupling agent is applied to surface treatment of inorganic particles, dispersion effect of the modified particles in a polymer system has greater improvement than that of a micromolecular coupling agent, and meanwhile, the equivalent amount of the inorganic particles with the same quality is much smaller than that of the micromolecular coupling agent.

Owner:苏州炽蓝生物科技有限公司

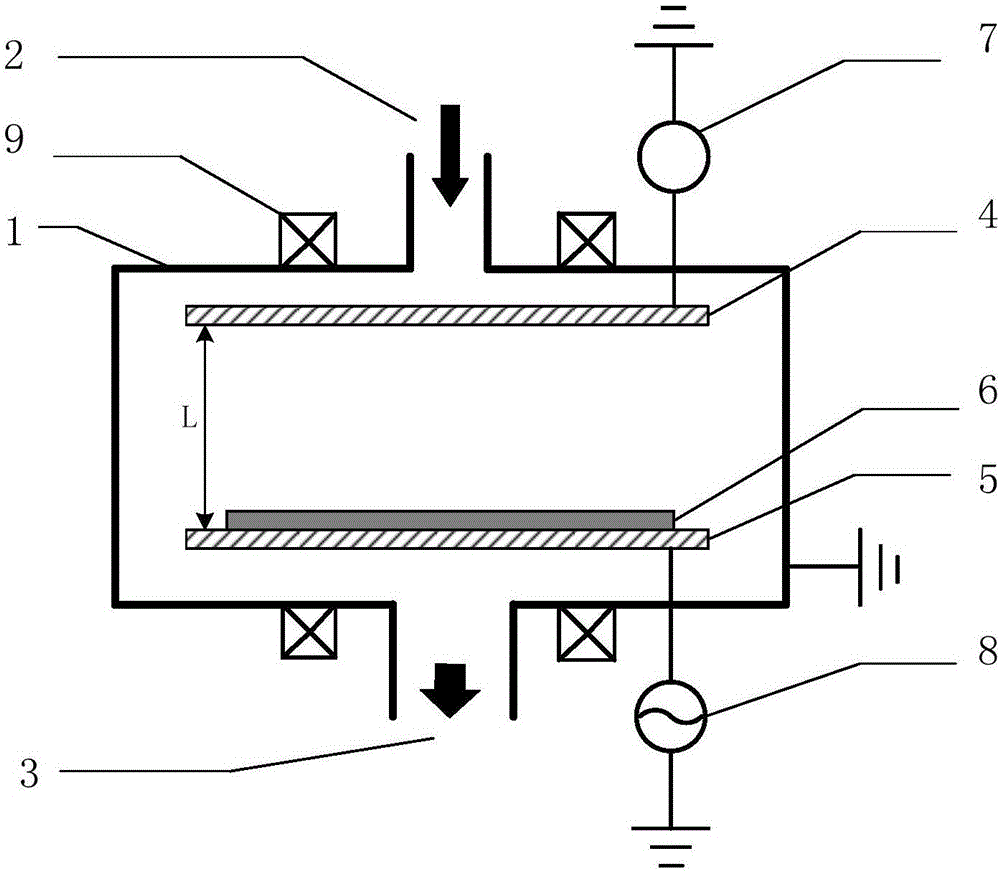

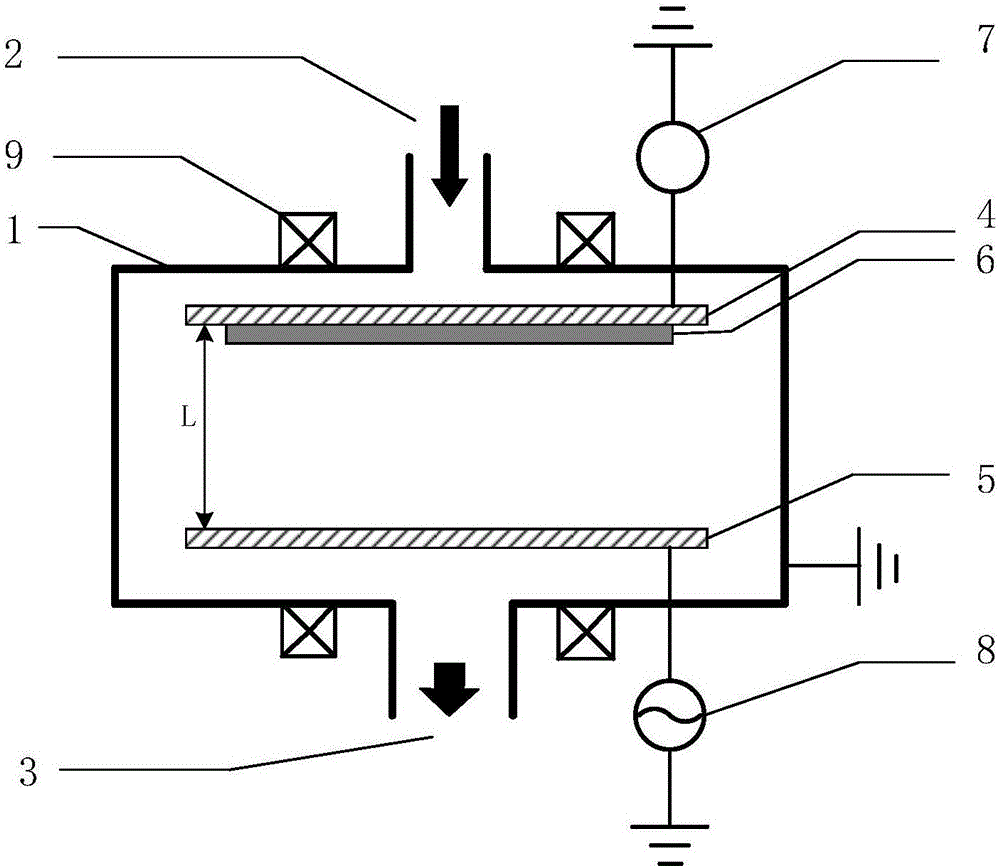

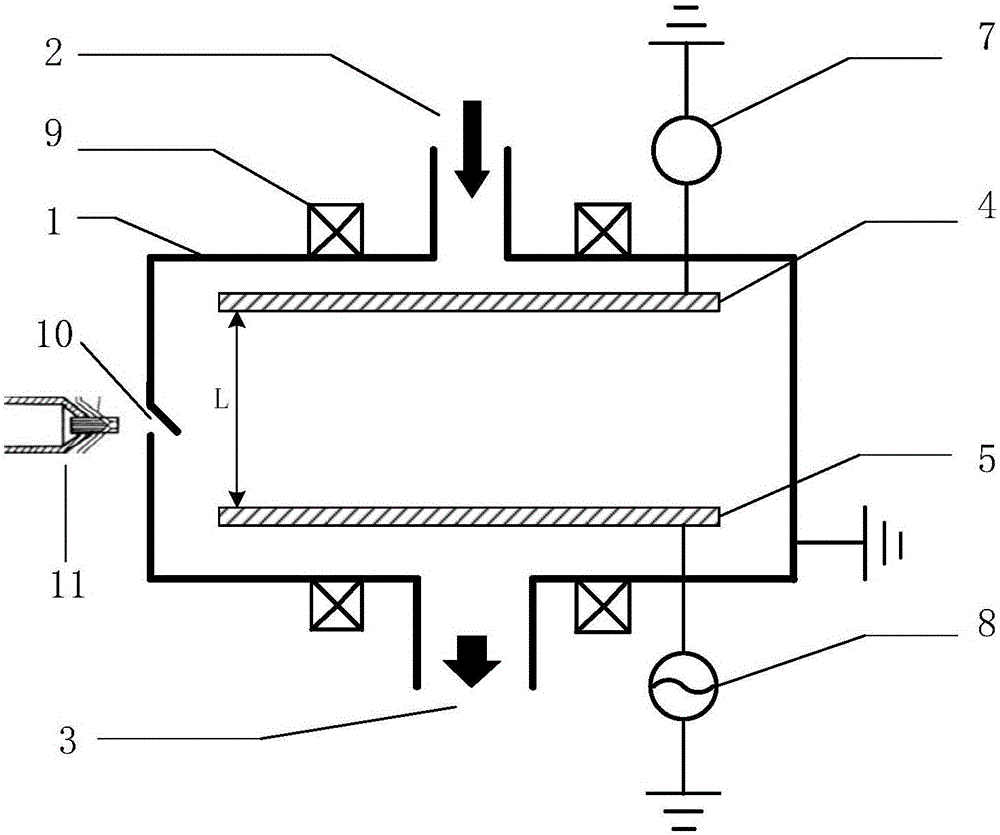

Magnetized CCP (Capacitively Coupled Plasma) source driven by RF and DC mixedly

InactiveCN106548918AHigh densityHigh degree of ionizationElectric discharge tubesPlasma techniquePlasma densityHigh energy

The invention discloses a magnetized CCP source driven by RF and DC mixedly. The magnetized CCP source comprises a plasma discharge cavity, a gas inlet, a gas outlet, a first pole plate, a second pole plate, a substrate, a DC source, an RF power supply and a magnetic field generator, the first and second pole plates are arranged in the plasma discharge cavity in parallel, one end of the DC power supply is connected to the first pole plate, the other end of the DC power supply is grounded, one end of the RF power supply is connected to the second pole plate, the other end of the RF power supply is grounded, the substrate is arranged on the second pole plate and positioned in the surface opposite to the first pole plate, the gas inlet is arranged in one side of the plasma discharge cavity, the gas outlet is arranged in the other side of the plasma discharge cavity, the magnetic field generator is arranged outside the plasma discharge cavity, and a magnetic field generated by the magnetic field generator is parallel with the first pole plate and the second pole plate. Due to influence of the magnetic field, high-energy secondary electrons and thermions are limited in a main plasma area, the ionization degree is improved, and the plasma density is increased greatly.

Owner:HUAZHONG UNIV OF SCI & TECH

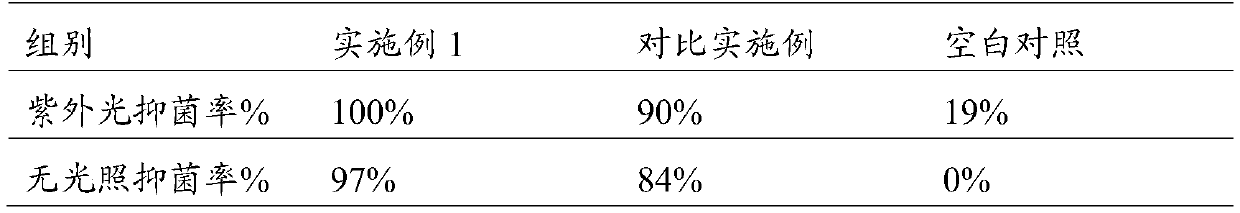

Bacteriostatic isolation coating composition for medical inspection platform and preparation method thereof

PendingCN110144150AImprove mechanical propertiesImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesCompound organicComponent Load

The invention relates to a bacteriostatic isolation coating film-forming liquid for a medical inspection platform and a preparation method thereof. The film-forming liquid containing solid micro-particles comprises a silica sol component loaded with nano silver-titanium dioxide, a nano silver-doped organic-modified mesoporous silica antibacterial composite microsphere component, a composite organic resin component, polyhexamethylene biguanide hydrochloride or phosphate, and an other auxiliary agent component. The bacteriostatic isolation coating film-forming liquid can be used for the surfacefilm-forming isolation use of the hospital inspection platform such as various working or operating tables, appliance storage-taking brackets or working cabinets, and has excellent disinfection bacteriostatic function and hydrophobic and easy-cleaning function.

Owner:杨茂本

Glass composition and glass substrate

InactiveUS7396788B2Improve fracture toughnessLow alkali elutionBase layers for recording layersRecord information storageOptical communicationRecording media

A glass substrate for use as the substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD or of an optical communication device, and a glass composition for making such a glass substrate, contains the following glass ingredients: 45 to 75% by weight of SiO2; 1 to 20% by weight of Al2O3; 0 to 15% by weight, zero inclusive, of B2O3; SiO2+Al2O3+B2O3 accounting for 65 to 90% by weight; a total of 7 to 20% by weight of R2O compounds, where R=Li, Na, and K; and a total of 0 to 12% by weight, zero inclusive, of R′O compounds, where R′=Mg, Ca, Sr, Ba, and Zn. Moreover, the following conditions are fulfilled: B2O3=0% by weight, or Al2O3 / B2O3≧1.0; and (SiO2+Al2O3+B2O3) / (the total of R2O compounds+the total of R2O compounds)≧3.

Owner:HOYA CORP

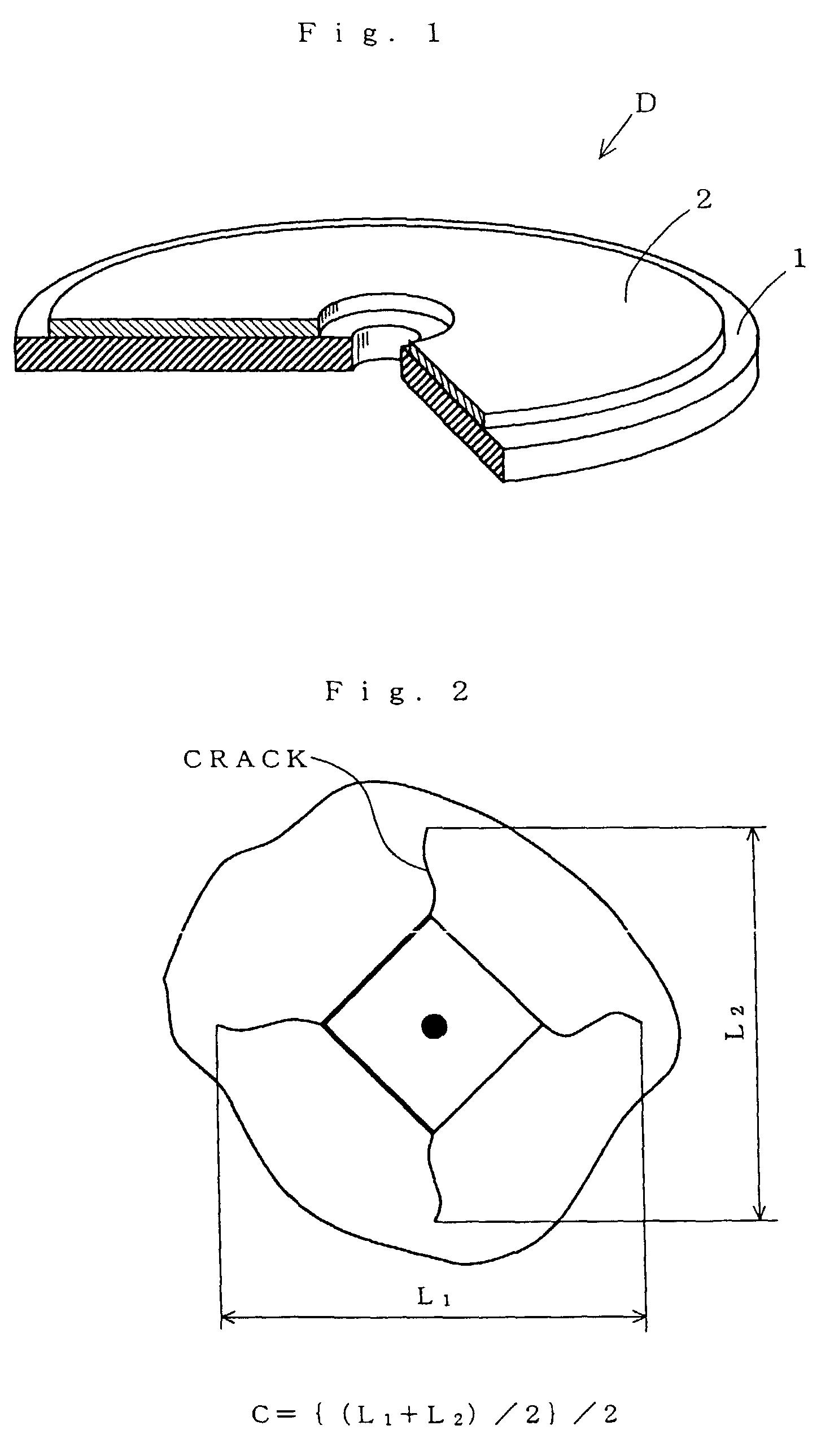

Resin composition, thermoplastic resin laminate, and production methods thereof

InactiveUS6916545B2Improve impact resistanceImprove rigidityLiquid surface applicatorsUnderstructuresHydroxy groupPolymer chemistry

A resin composition to be used as a material for a various part of an automotive vehicle. The resin composition comprises a copolymer (A) formed by copolymerization of a first unsaturated monomer (a) and a second mononer (b). The first unsaturated monomer has a functional group which is bondable by hydrogen bond to a hydroxyl group. The second monomer is copolymerizable with the first unsaturated monomer. A metal oxide (B) is dispersed in the copolymer and having hydroxyl groups and hydrophobic groups at surface of the metal oxide.

Owner:NISSAN MOTOR CO LTD +2

Capacitance coupling structure of medium filter

InactiveCN109755700AGood surface treatmentGood for weight lossWaveguide type devicesCapacitanceCoupling

The invention discloses a capacitance coupling structure of a medium filter. The capacitance coupling structure comprises a medium filter body and two blind holes, wherein the two blind holes are formed in a surface of the medium filter body, each blind hole and a medium filled around each blind hole form a medium resonator, each blind hole is used for debugging a resonant frequency of the mediumresonator, a negative coupling hole is formed in the medium filter body and is arranged between the two medium filters, the negative coupling hole is used for achieving capacitance coupling between the two medium resonators, the negative coupling hole comprises a first through hole and a second through hole which are sequentially arranged from top to bottom, an upper end of the first through holepenetrates through an upper surface of the medium filter body, a lower end of the first through hole communicates with an upper end of the second through hole, a lower end of the second through hole penetrates through a lower surface of the medium filter body, and a conductive layer is plated on an inner wall of the second through hole. The capacitance coupling structure of the medium filter is reasonable in structure, is easy to process, form and surface-processed and is beneficial for weight reduction of the filter.

Owner:SUZHOU PERFECT ELECTRONICS TECH

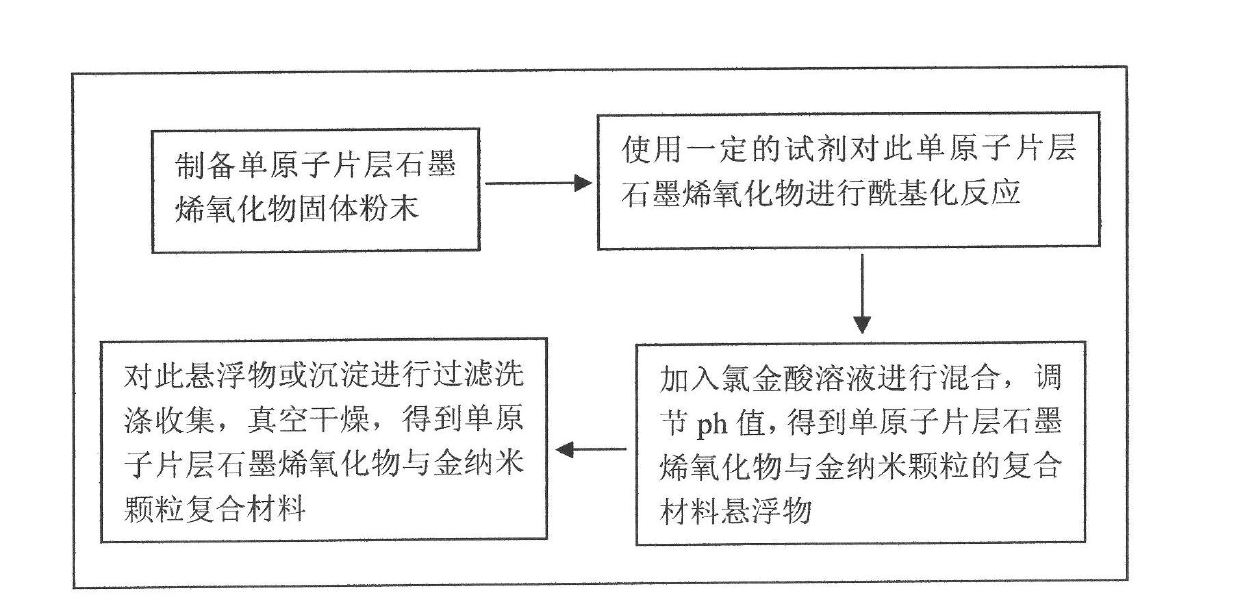

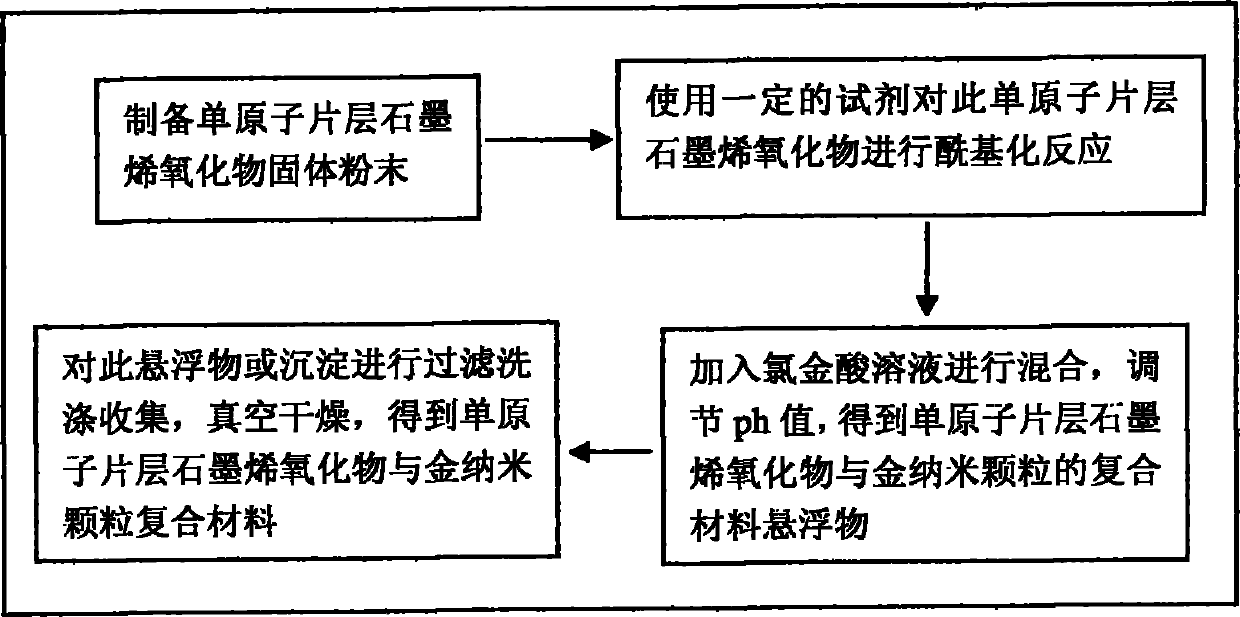

Preparation method of graphene oxide/nano-gold particulate composite material with mono-atomic thickness

InactiveCN102199415AHigh mechanical strengthLarge specific surface areaOther chemical processesNanotechnologyNanoparticleCvd graphene

The invention relates to the field of graphene preparation, and discloses a preparation method of graphene oxide / nano-gold particulate composite material with mono-atomic thickness. In prior arts, the preparation of mono-atomic thickness graphene oxide / nano-gold particulate composite material is complicated, requires special equipment, and cannot be prepared with industrialized production. The present invention assists in solving the problems, and provides a simple method for preparing the composite material with high efficiency. The preparation method comprises the steps that: (1) obtained graphene oxide is subject to an acylation reaction; (2) graphene oxide processed through the acylation reaction is subject to a reaction with a chlorauric acid solution; (3) the pH value of the material is regulated, the depositions are filtered, such that the graphene oxide / nano-gold particulate composite material is obtained. The method of the present invention has advantages of simple technology, high yield, large output, good product quality, and is suitable for industrialized production.

Owner:PLA AIR FORCE OIL MATERIAL RES INST +1

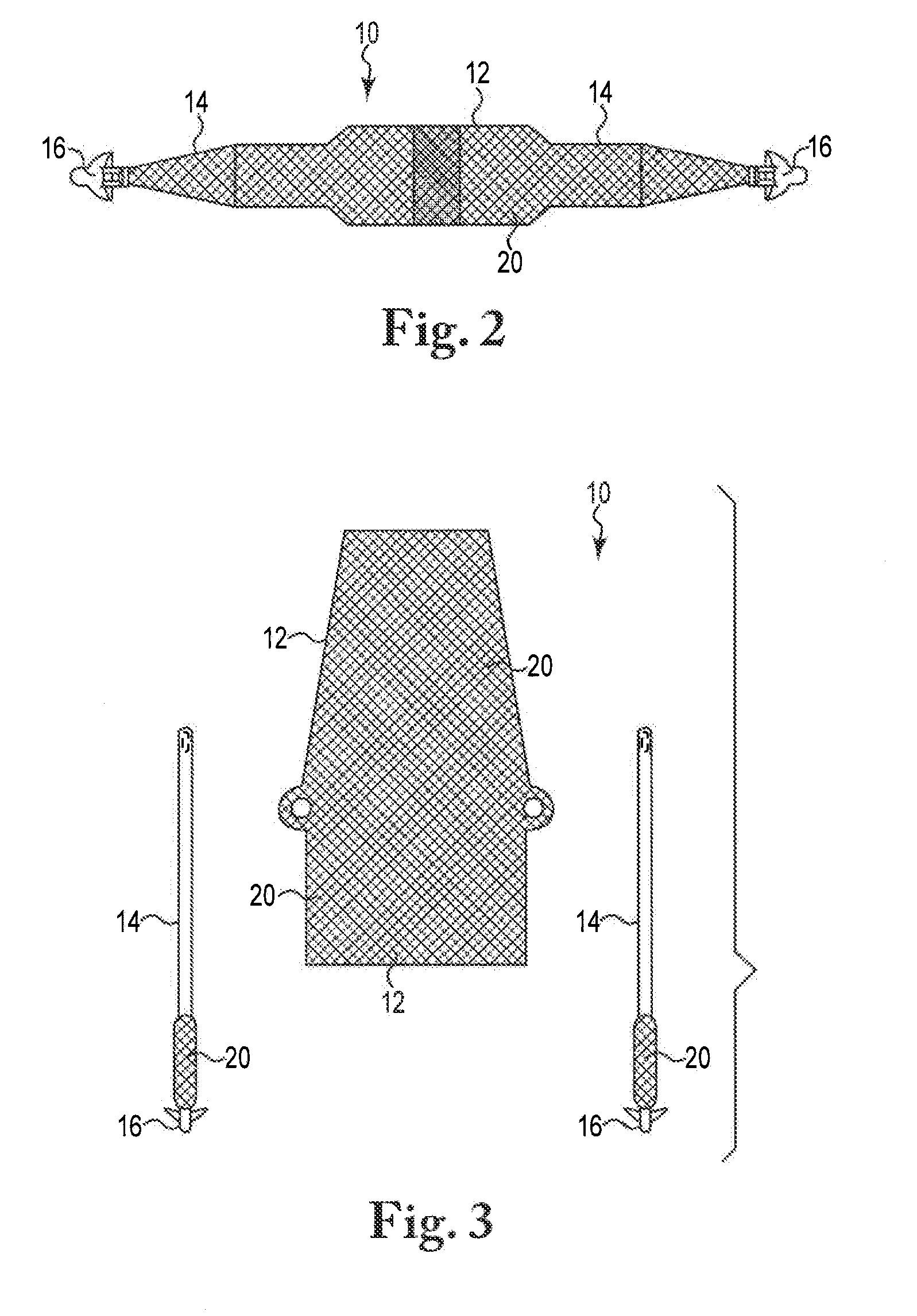

Coated Pelvic Implant Device and Method

InactiveUS20120022321A1Promote healingAdvantageous antimicrobialAnti-incontinence devicesBandagesPolypropylene meshImplanted device

Implant systems and methods are provided to include a treatment material with a pelvic implant device. The pelvic implant device, such as an incontinence sling, can include the treatment coating combination of polycarbonate (PC) and an infection prevention material, such as InhibiZone® (IZ) technology. The treatment material can be coated onto, or impregnation or integrated with, polypropylene mesh in order to prevent infection and promote healing.

Owner:AMS RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com