Patents

Literature

36results about How to "Strong physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

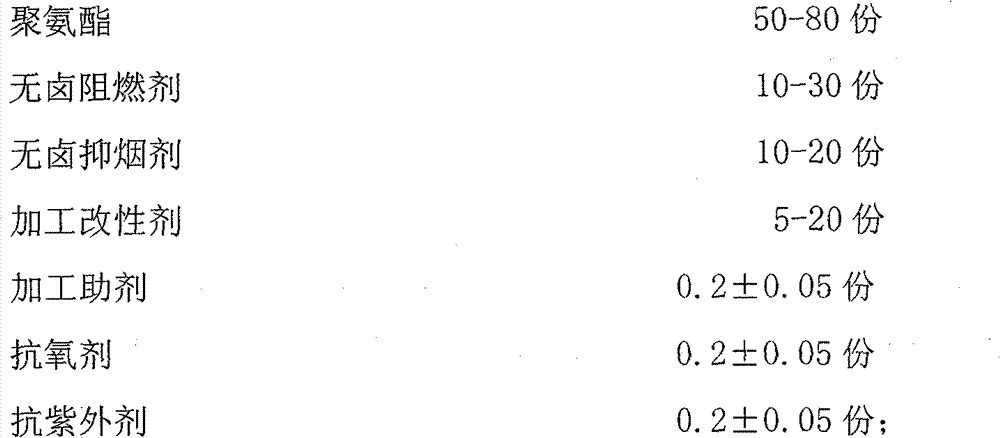

A kind of halogen-free flame-retardant thermoplastic polyurethane elastomer sheath material and its preparation and application

InactiveCN102295835ANo need to investWide extrusion processing temperatureInsulated cablesInsulated conductorsHalogenThermoplastic polyurethane

The invention discloses a zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material and a preparation method thereof. The zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material is prepared from the following raw material components in parts by weight: 50-80 parts of polyurethane, 10-30 parts of zero-halogen flame retardant, 10-20 parts of zero-halogen smoke suppressant, 5-20 parts of processing modifier, 0.2+ / -0.05 part of processing auxiliary agent, 0.2+ / -0.05 part of antioxidant and 0.2+ / -0.05 part of ultraviolet resistant. Compared with the prior art, the zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material prepared by the invention has the advantages of wider processing temperature range, ultrahigh physical and mechanical properties and flame retardant property of UL-94 and V-0 level.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Degradable plant starch-sodium caseinate composite packaging film for fruits and vegetables

InactiveCN104610581AEasy to degradeStrong physical and mechanical propertiesFlexible coversWrappersCitrate sodiumZinc sulfide

The invention discloses a degradable plant starch-sodium caseinate composite packaging film for fruits and vegetables and relates to the technical field of packaging films for the fruits and the vegetables. The packaging film is prepared from raw materials in parts by mass as follows: 80-90 parts of plant starch,40-50 parts of sodium caseinate, 15-20 parts of cloves, 15-20 parts of propolis, 15-18 parts of nano calcium carbonate, 12-15 parts of fumed silica, 10-12 parts of polyvinyl alcohol, 8-10 parts of sodium alginate, 8-10 parts of epoxidized soybean oil, 6-9 parts of zinc sulfide, 5-8 parts of konjac glucomannan, 5-8 parts of low-methoxyl pectin, 3-5 parts of sodium citrate, 3-6 parts of agar, 3-5 parts of genipin, 2-3 parts of polyglycerol fatty acid ester and 800-1000 parts of water. The plant starch and the sodium caseinate are used as main raw materials, and various aids are used as auxiliary materials, so that the produced packaging film has higher physical and mechanical properties, selective permeability and antibacterial and anti-oxidation effects; besides, the selected raw materials can be degraded easily, so that the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

Degradable cereal prolamin-chitosan composite packaging film for fruits and vegetables

InactiveCN104610757AEasy to degradeStrong physical and mechanical propertiesPolyvinyl alcoholEpoxidized soybean oil

The invention discloses a degradable cereal prolamin-chitosan composite packaging film for fruits and vegetables and relates to the technical field of packaging films for the fruits and the vegetables. The packaging film is prepared from raw materials in parts by mass as follows: 90-100 parts of cereal prolamin, 60-70 parts of carboxymethyl chitosan, 20-25 parts of cloves, 20-25 parts of propolis, 18-20 parts of sodium alginate, 15-20 parts of polyvinyl alcohol, 16-18 parts of nano calcium carbonate, 15-18 parts of epoxidized soybean oil, 12-15 parts of fumed silica, 10-12 parts of zinc sulfide, 10-12 parts of konjac glucomannan, 8-10 parts of low-methoxyl pectin, 8-10 parts of curdlan, 6-9 parts of soy isoflavone, 5-8 parts of genipin, 3-6 parts of polyglycerol fatty acid ester and 800-1000 parts of water. The cereal prolamin and the chitosan are used as main raw materials, and various aids are used as auxiliary materials, so that the produced packaging film has higher physical and mechanical properties, selective permeability and antibacterial and anti-oxidation effects; besides, the selected raw materials can be degraded easily, so that the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

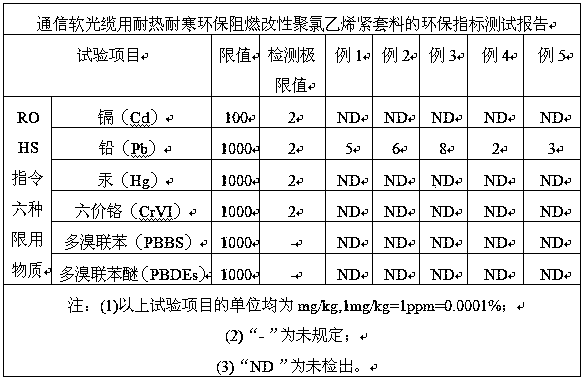

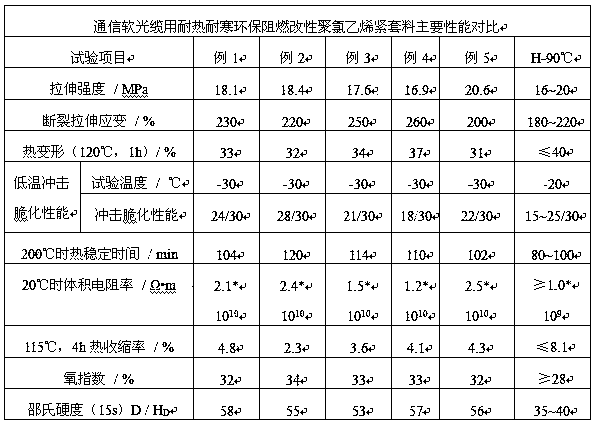

Environment-friendly modified polyvinyl chloride tight buffering material for soft communication optical cable and preparation method of material

InactiveCN104312057AOutstanding high temperature resistanceHighlight environmental protectionShrinkage ratePlasticizer

The invention discloses an environment-friendly modified polyvinyl chloride tight buffering material for a soft communication optical cable and a preparation method of the material. The material comprises the following raw materials in parts by weight: 95-100 parts of polyvinyl chloride resin, 30-35 parts of an environment-friendly plasticizer, 5-8 parts of a cold-resistant plasticizer, 5-8 parts of an environment-friendly stabilizer, 20-35 parts of a filling agent, 3-8 parts of a flame retardant, 0.5-2 parts of a lubricant, 4-9 parts of an anti-impact modifier and 3-5 parts of an anti-heat shrinkage modifier. Due to the addition of the cold-resistant plasticizer, the material is outstanding in high temperature resistance, low temperature resistance and environmental protection property; due to the anti-heat shrinkage modifier, the material is relatively low in heat shrinkage rate; due to the flame retardant, the material is relatively good in flame retardant property. According to the preparation method, the process is simple, the temperature is reasonable, and the produced material is guaranteed to be relatively good in flame retardant property, high and low temperature resistance and small in heat shrinkage rate.

Owner:JIANGSU JIANGYANG TECH

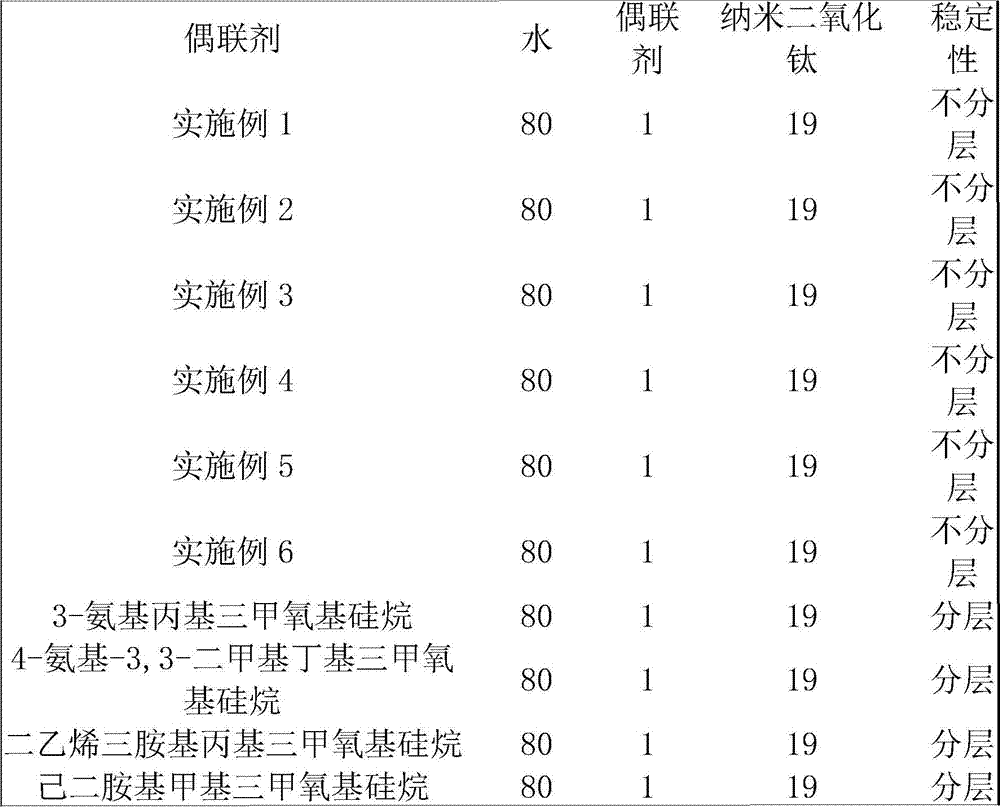

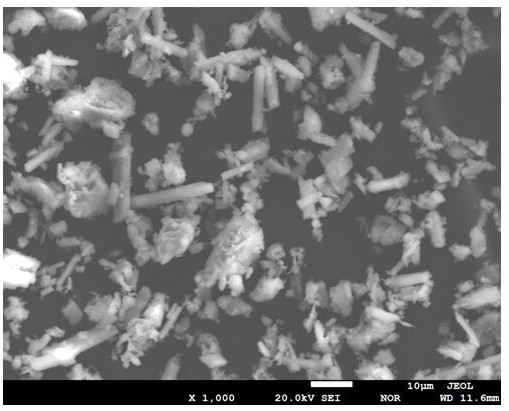

Dendritic macromolecular coupling agent and preparation method thereof

InactiveCN106893112AGood dispersionStrong physical and mechanical propertiesInorganic particleCoupling

The invention relates to a dendritic macromolecular coupling agent and a preparation method thereof. The dendritic macromolecular coupling agent comprises, by weight, 60-100 parts of terminal carboxyl group dendritic macromoleculars and 20-50 parts of amino silane. After the dendritic macromolecular coupling agent is applied to surface treatment of inorganic particles, dispersion effect of the modified particles in a polymer system has greater improvement than that of a micromolecular coupling agent, and meanwhile, the equivalent amount of the inorganic particles with the same quality is much smaller than that of the micromolecular coupling agent.

Owner:苏州炽蓝生物科技有限公司

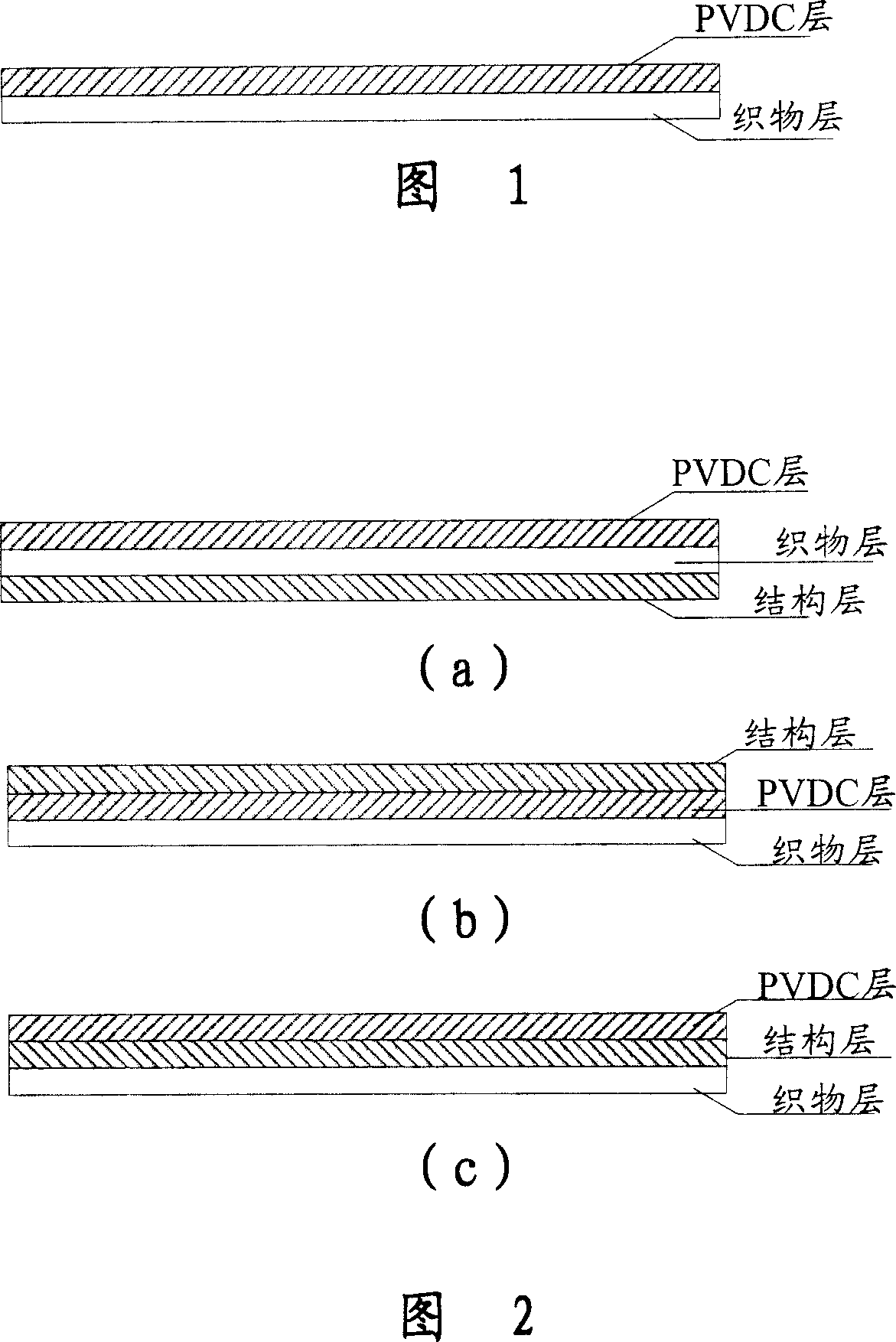

Composite material for weaving

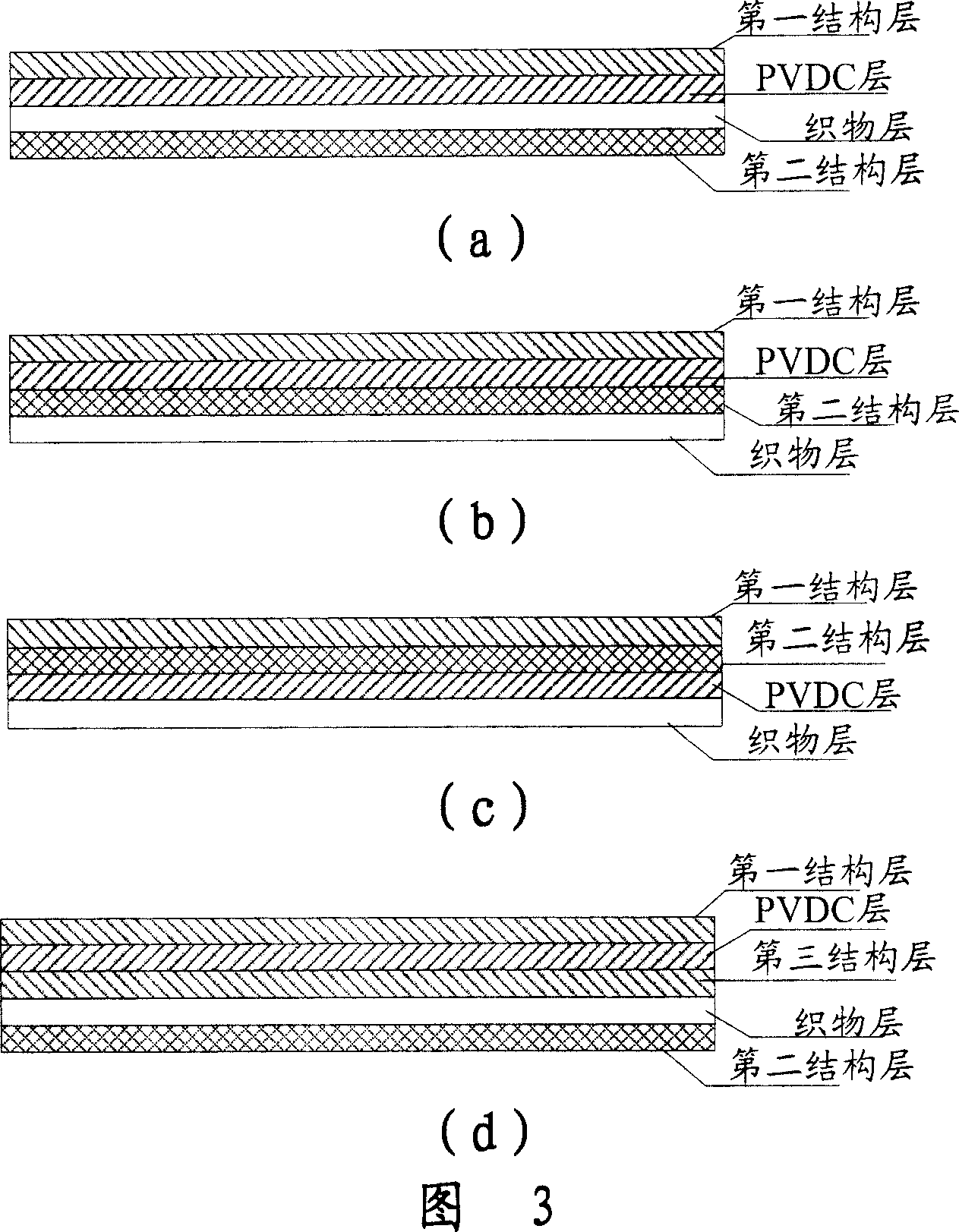

InactiveCN101112805ALight in massImprove the protective effectSynthetic resin layered productsProtective garmentEngineeringProtection layer

The invention provides a spinning composite material which comprises a protection layer and a fabric layer; wherein, the protection layer comprises a PVDC layer. The protection layer further comprises one layer or more than one structure layer; the structure layer can be arranged between the fabric layer and the PVDC layer or between the fabric layer and any external side of the PVDC layer. The structure layer comprises a PVDC layer, a fabric layer, a thermal synthesis layer, a framework layer, a camouflage layer, an agglutination layer and a protection layer. By the invention, the fabric composite material has high gas defense performance, physical and mechanical performance and anti-aging and weatherability, and light weight. The invention is especially suitable for making the safety protection of tents, blindages and protection clothes, etc.

Owner:中国人民解放军62026部队 +2

Powder coating

InactiveCN101104751AStrong physical and mechanical propertiesAdapt to the requirements of special environmentsPowdery paintsEpoxy resin coatingsGlass fiberMechanical property

The invention relates to a novel powder coating and a preparation method of the novel powder coating, belonging to the architectural coating field. Fiber glass is added into the formula of common powder coating to improve physical and mechanical property o the coating. The preparation method is that the glass fiber is crushed in high speed, and then is mixed, extruded, crushed and milled with the other raw materials for making the powder coating, then the powder coating is prepared.

Owner:XUZHOU ZENITH COATING

Edible plant starch-cellulose composite packaging film for meat products

InactiveCN104610580AStrong physical and mechanical propertiesAvoid white pollutionFlexible coversWrappersWaxSodium carboxymethylcellulose

The invention discloses an edible plant starch-cellulose composite packaging film for meat products and relates to the technical field of edible packaging films. The packaging film is prepared from raw materials in parts by mass as follows: 80-100 parts of plant starch, 50-60 parts of hydroxypropyl methylcellulose, 30-35 parts of sodium carboxymethyl cellulose, 15-18 parts of sodium alginate, 12-15 parts of curdlan, 10-12 parts of low-methoxyl pectin, 8-10 parts of calcium citrate, 10-15 parts of cloves, 10-15 parts of cassia bark, 10-15 parts of spices, 5-8 parts of tea polyphenols, 10-12 parts of rapeseed oil, 8-10 parts of agar, 6-9 parts of genipin, 5-8 parts of polyglycerol fatty acid ester, 3-6 parts of edible wax and 800-1000 parts of water. The plant starch and the cellulose are used as main raw materials, and proper aids are used as auxiliary materials, so that the prepared packaging film for the meat products has higher physical and mechanical properties, the barrier property and antibacterial and anti-oxidation effects; besides, the packaging film can be eaten together with the products, so that the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

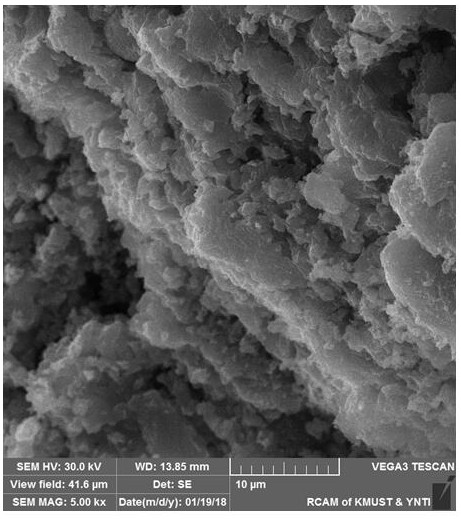

Solidification and stabilization treatment method for electrolytic manganese slag

ActiveCN108421805AInexpensive curing processReduce dosageTransportation and packagingSolid waste disposalChemical LinkageElectrolysis

The invention relates to a solidification and stabilization treatment method for electrolytic manganese slag, and belongs to the technical field of environmental protection. According to the method, amixture of nickel-iron slag and phosphate serves as a solidification and stabilization treating agent for the electrolytic manganese slag, and the solidified and stabilized electrolytic manganese slag is sent to a slag warehouse for stockpiling; by using the method, the usage amount of the chemical reagent can be decreased, the solidification treatment cost of the electrolytic manganese slag canbe lowered, and meanwhile, the effect of treating waste with waste can be achieved; and the electrolytic manganese slag is solidified by the mixture of the nickel-iron slag and the phosphate, solublemanganese and ammonium ions in the manganese slag can participate in the chemical reaction and can form a phosphate gel mineral in a chemical bonding mode, and a formed phosphate chemically-bonded material has the physical inclusion and adsorption effects; and through the chemical bonding, physical adsorption and physical inclusion effects, the high-efficiency and high-capacity solidification of the electrolytic manganese slag can be realized.

Owner:KUNMING UNIV OF SCI & TECH

Multilayer composite adhesive tape preventing chemicals from penetrating and preparation method thereof

ActiveCN104404782AImprove flame retardant performanceStrong physical and mechanical propertiesTextiles and paperRubber layered productsAdhesiveStrong acids

The invention discloses a multilayer composite adhesive tape preventing chemicals from penetrating and a preparation method thereof. The multilayer composite adhesive tape is prepared by coating aramid fiber base cloth with multiple rubber, concretely, one surface of the base cloth is coated with a fluorubber layer, and the other surface of the base cloth and the surface of the fluorubber layer are both coated with a chloroprene rubber layer. The preparation technology of the multilayer composite adhesive tape comprises preparing base cloth, coating one surface of the base cloth with the fluorubber layer, performing semi-sulfuration, coating the two surfaces of the coated base cloth with the chloroprene rubber layer, performing complete sulfuration, and obtaining the finished product adhesive tape. The multilayer composite adhesive tape employs aramid fiber fabric resistant to both acids and alkalis, possesses strong physical mechanical performances and is better than a nylon material. The multilayer composite adhesive tape has relatively strong acid and alkali resistance and chemical toxic agent resistance, and has the protection time up to 4 h. The multilayer composite adhesive tape has relatively good flame retardation performance, and can work at a high temperature. The multilayer composite adhesive tape employs chloroprene rubber and fluorubber as coating materials, is low in cost and superior in antitoxin performance.

Owner:SHANXI XINHUA CHEM

Peanut protein isolate and chitosan compounded fruit and vegetable packaging film

InactiveCN104610760AEasy to degradeStrong physical and mechanical propertiesFlexible coversWrappersPropolisEcological environment

The invention discloses a peanut protein isolate and chitosan compounded fruit and vegetable packaging film, and relates to the technical field of fruit and vegetable packaging films. The peanut protein isolate and chitosan compounded fruit and vegetable packaging film is prepared from raw materials in parts by mass as follows: 60-80 parts of peanut protein isolate, 40-50 parts of chitosan, 20-25 parts of sodium carboxymethyl cellulose, 15-20 parts of polyvinyl alcohol, 10-15 parts of propolis, 10-12 parts of sodium alginate, 10-12 parts of nano calcium carbonate, 8-10 parts of calcium citrate, 8-10 parts of fumed silica, 6-9 parts of agar, 5-8 parts of tea polyphenol, 5-8 parts of epoxidized soybean oil, 3-5 parts of genipin, 3-5 parts of polyglycerol fatty acid ester, 2-3 parts of plant essential oil and 800-1,000 parts of water. Peanut protein isolate and chitosan are taken as main raw materials and supplemented by a suitable auxiliary, so that the prepared packaging film has higher physical and mechanical property, selecting permeability and antioxidation; the selected raw materials are easy to degrade, so that the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

High-temperature-resisting breathable graphene/ultra-high molecular weight polyethylene fiber and preparation method

InactiveCN109234830AImprove breathabilityComfortable to wearMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberWater baths

The invention belongs to the technical field of preparation of polyethylene fibers and particularly relates to a high-temperature-resisting breathable graphene / ultra-high molecular weight polyethylenefiber and a preparation method. The preparation method comprises the following steps: preparing a graphene oxide solution, adding titanium dioxide rutile and adjusting a pH value; adding a reducing agent, carrying out hydrothermal reaction, cooling, filtering, washing, freezing and drying to obtain three-dimensional porous graphene / titanium dioxide; adding the three-dimensional porous graphene / titanium dioxide into polyethylene resin, adding white oil and a proper amount of functional additives, and swelling in a twin-screw extruder to form a spinning solution; extruding and carrying out water bath solidification to form gel silks; carrying out drying, multistage heat drawing, winding and the like through a guide roller to obtain the porous graphene / ultra-high molecular weight polyethylene fiber. Three-dimensional porous graphene / titanium dioxide powder is added when the spinning solution is prepared by adopting ultra-high molecular weight polyethylene, so that high temperature resistance and breathability of the fiber are improved. The graphene / ultra-high molecular weight polyethylene fiber prepared by adopting the method has excellent high temperature resistance, corrosion resistance and breathability.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

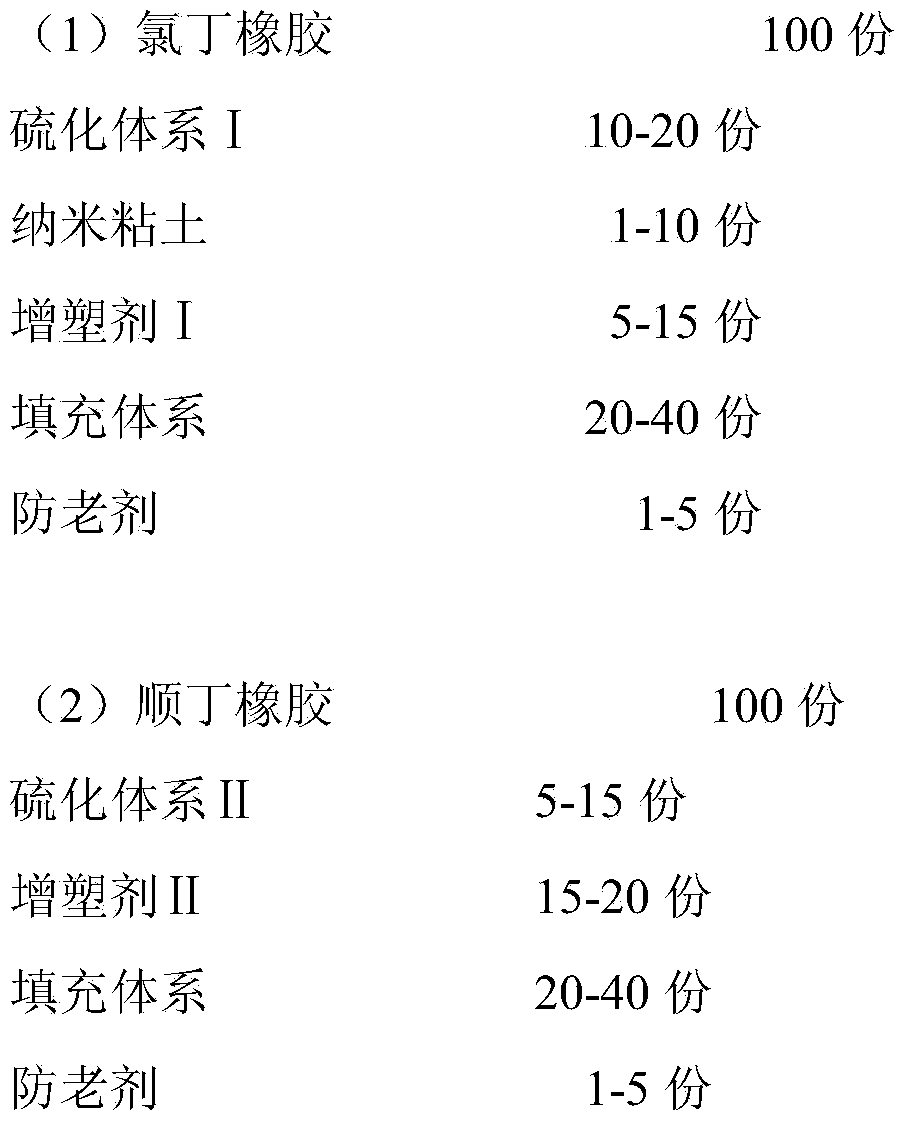

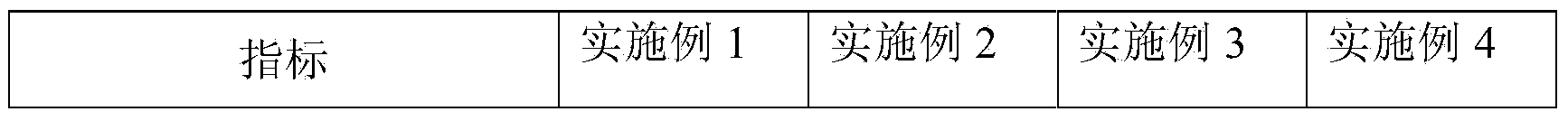

High-temperature underwater sound transmission rubber material and preparation method thereof

ActiveCN103589025AImprove sound transmission performanceImprove stabilityRubber materialVulcanization

The invention relates to a high-temperature underwater sound transmission rubber material and a preparation method thereof. The crystallization of chloroprene rubbers is restrained through selecting the chloroprene rubbers with slow crystallization speed and using butadiene rubbers (BR) with a certain ratio, so that the sound transmission performance and the temperature stability of the rubber material are improved; a certain parts of nanometer clay are added in a formula system to improve the water tightness of the sound transmission material; quick low-temperature and low-pressure vulcanization (100-120 DEG C, 30-40 minutes) of the rubber material is realized through optimizing the rubber material formula and the processing technique design. The underwater sound transmission rubber material with high sound transmission performance, high temperature stability, high water tightness and excellent physical and mechanical properties can be prepared through the method. The material can satisfy the requirements of a coating material of ship underwater sound equipment, and is an excellent underwater sound transmission material.

Owner:BEIJING UNIV OF CHEM TECH

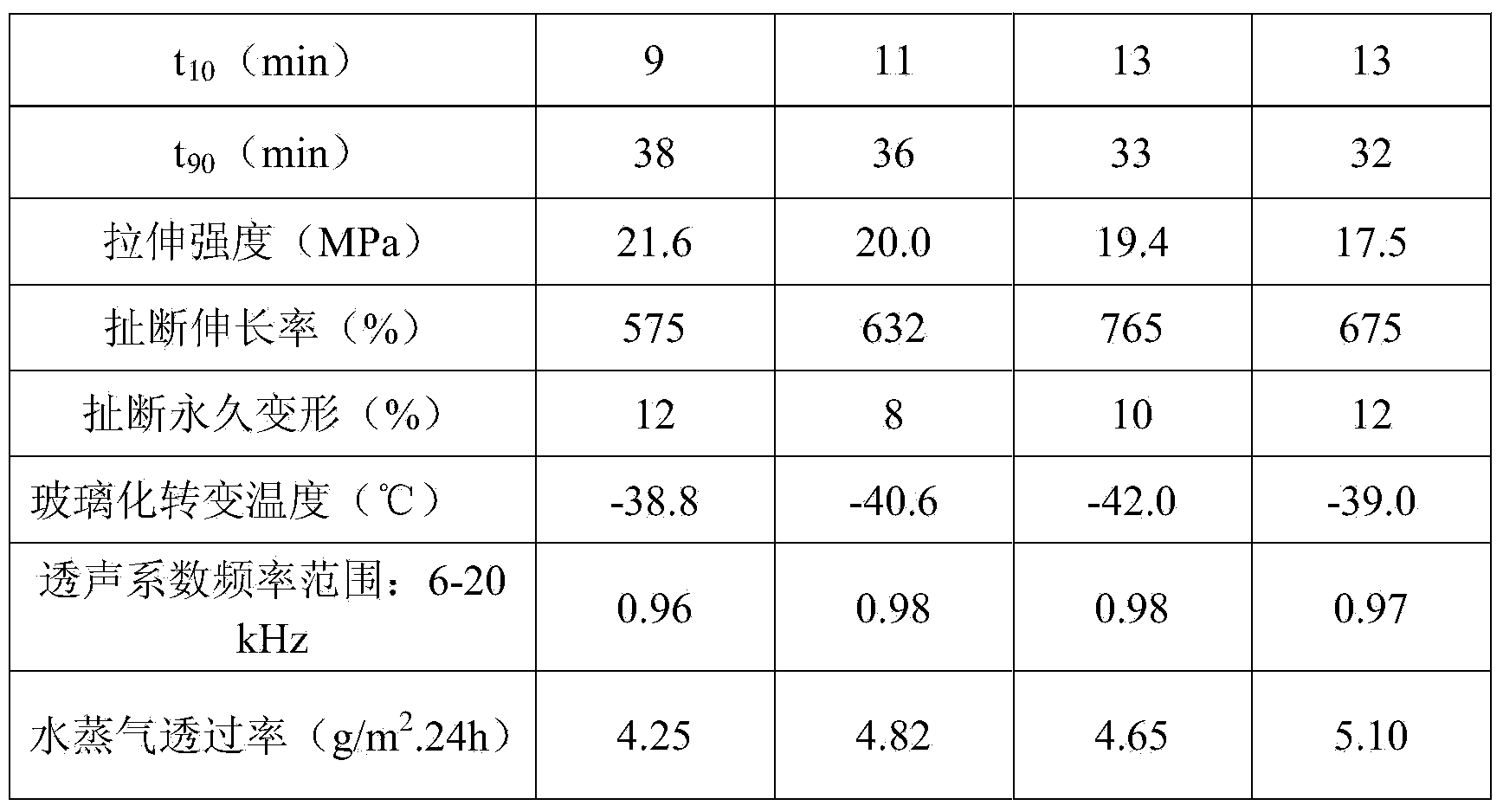

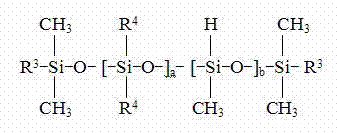

Thermal interface material and electronic device using same

InactiveCN1995265AStrong physical and mechanical propertiesGood flexibilityHeat-exchange elementsCooling/ventilation/heating modificationsSilicon rubberZinc

The invention discloses an electronic device, which comprises the following parts: heating component, radiating component and heat interface material between heating and radiating components, wherein the heat interface material displays piece shape, which contains sulfurizing chip and reinforcing film buried in the sulfurizing chip; the sulfurizing chip consists of indoor-temperature sulfurizing silicon rubber and zinc oxide powder in the silicon rubber; the even grain size of zinc oxide is 0.1-5um; the reinforcing film improves physical strength of heat interface material, which can form different cutting shapes without breaking or damaging due to squeezing.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

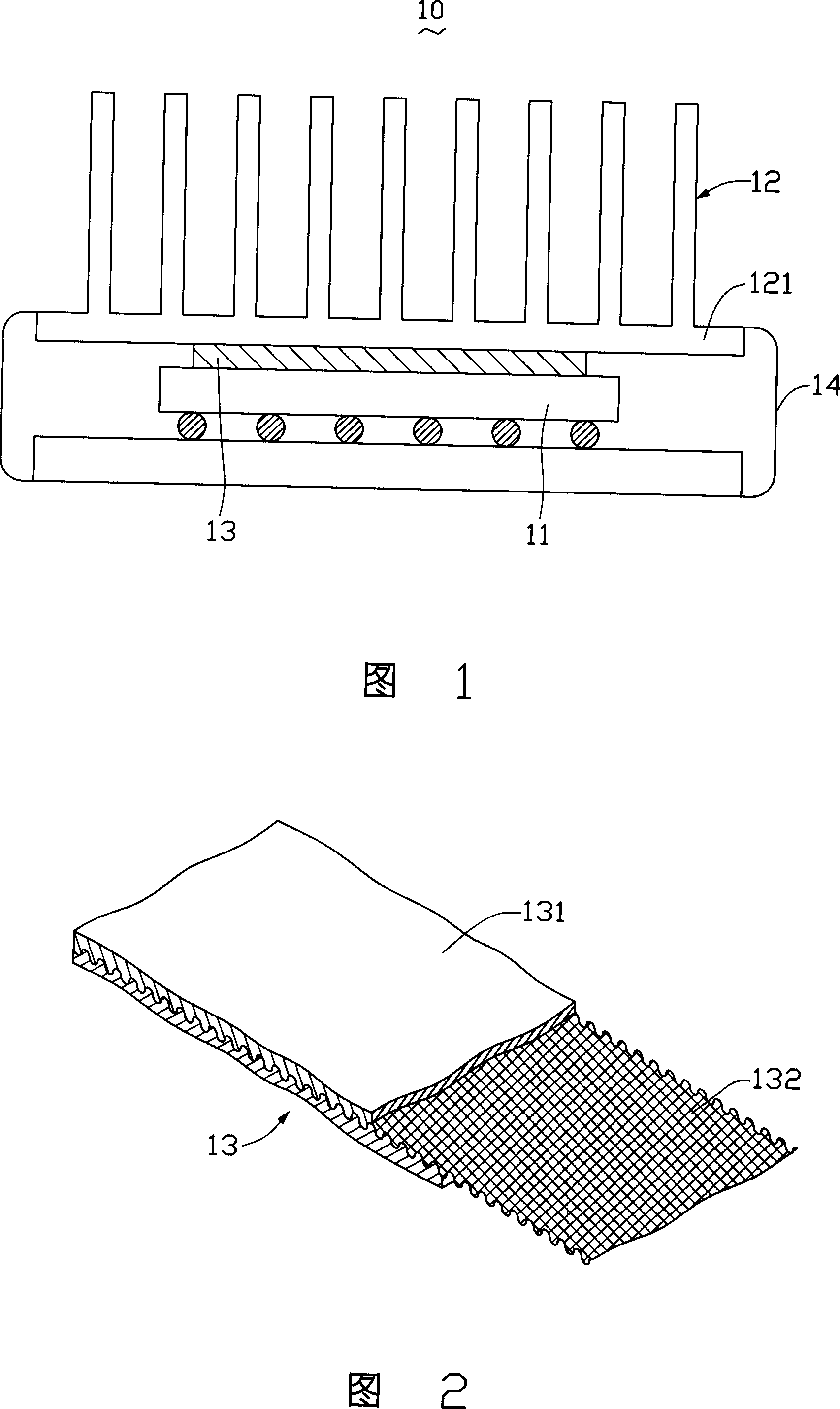

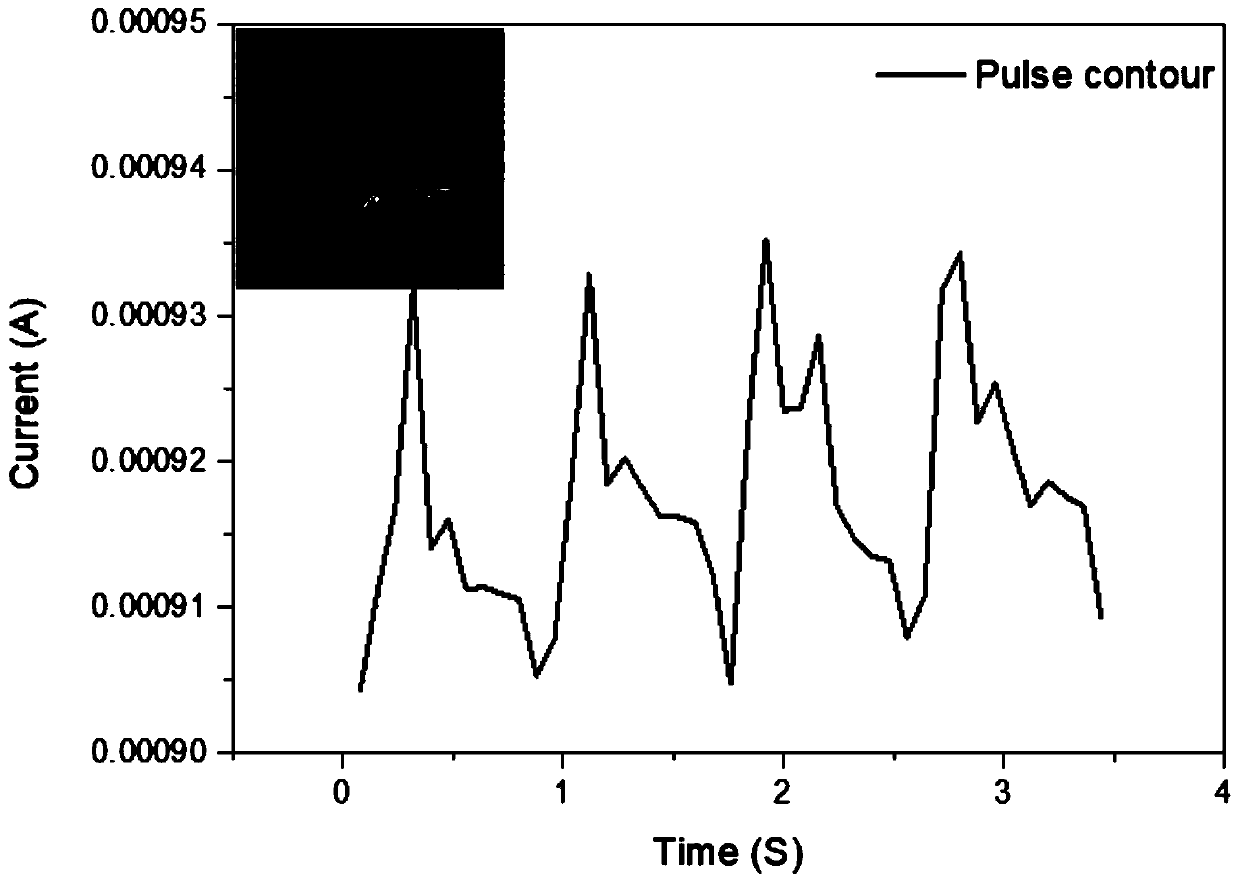

Preparation technology allowing large-scale production of flexible biomass-based pressure sensors

ActiveCN110849513AStrong physical and mechanical propertiesLow priceFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesCarbonizationProcess engineering

The invention disclose a preparation technology allowing large-scale production of flexible biomass-based pressure sensors and belongs to the field of wearable sensors. The preparation technology aimsto overcome the defects that in the existing flexible device production process, production cost is high, large-scale production cannot be realized, and electronic waste is generated. The method comprises the steps that firstly, biomass is subjected to high-temperature carbonization in an inert atmosphere after being treated to be in a certain shape; secondly, the biomass is sheared to be in a designed shape; and thirdly, the biomass is placed in a PDMS / n-hexane solution to be soaked and is solidified after being taken out, and the flexible biomass-based pressure sensors are obtained. Throughthe method, cost is low, large-scale production can be realized, generation of the electronic waste and pollution of the environment are avoided, and the obtained products have high sensitivity and stability; and the pressure sensors obtained through the method can monitor human pulse beating, joint movement, throat pronunciation and the like.

Owner:山东仁康医疗科技有限公司

Degradable high-toughness packaging film

The invention discloses a degradable high-toughness packaging film and relates to the technical field packaging films. According to the degradable high-toughness packaging film disclosed by the invention, starch and wool are utilized as main raw materials, then lignocelluloses is added, and varieties of additives are utilized as auxiliary materials; thus, by means of the formula, contents of protein and amino acid are improved; the prepared packaging film has the advantages of high protein, high amino acid, high toughness and stronger physical mechanical property, permselectivity, bacterial resistance and oxidation resistance; furthermore, the chosen raw materials are green, safe and easy to degrade; thus, white pollution is avoided, and ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

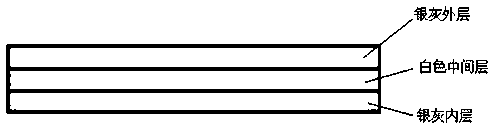

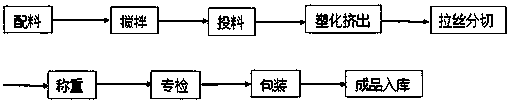

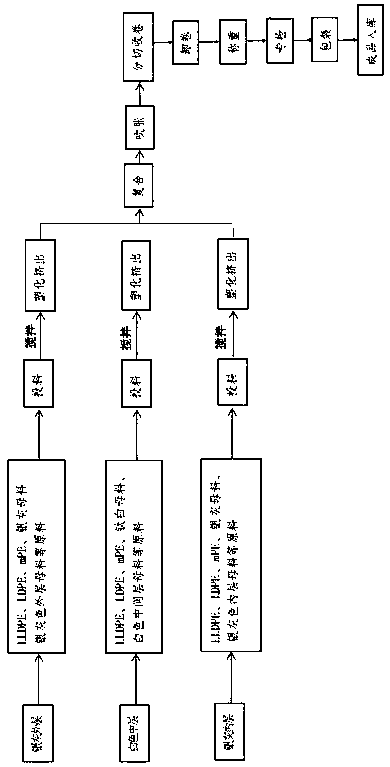

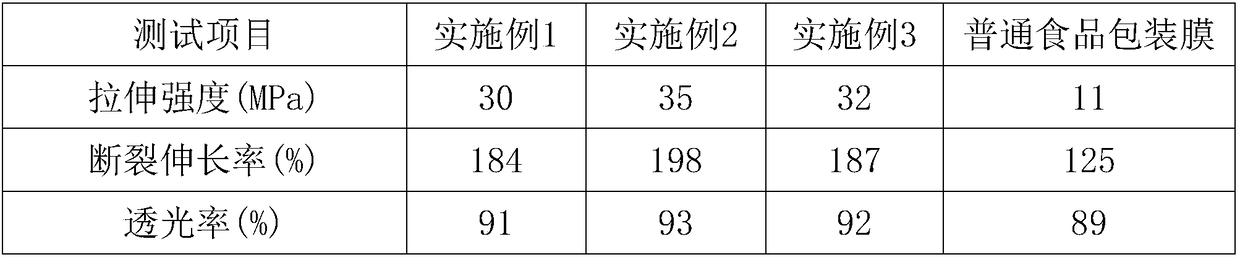

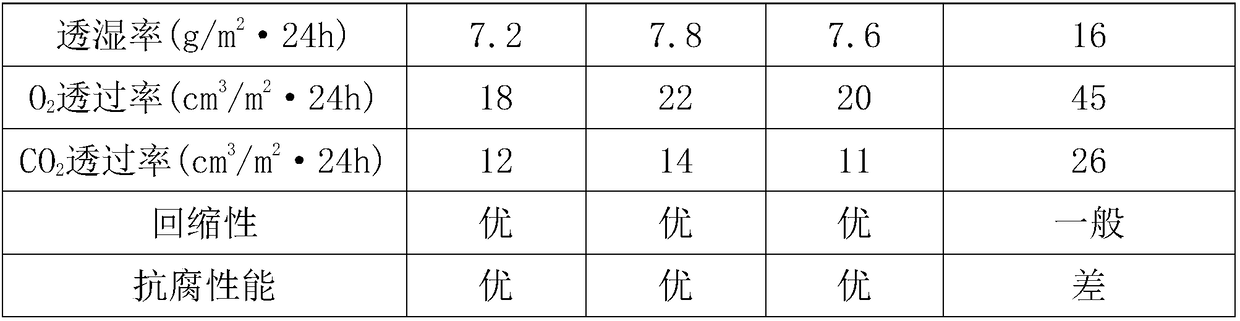

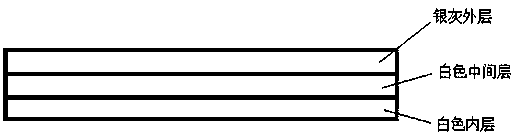

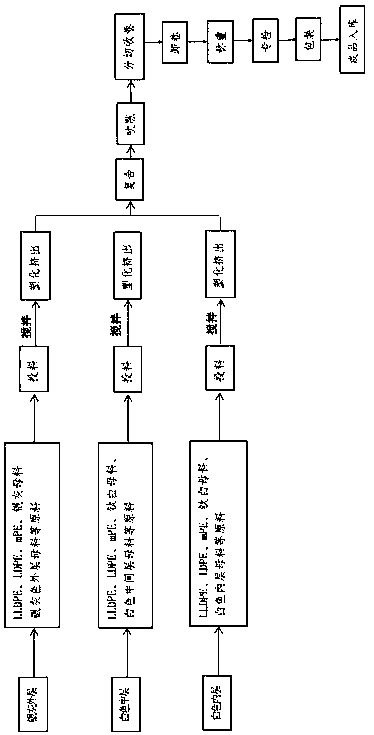

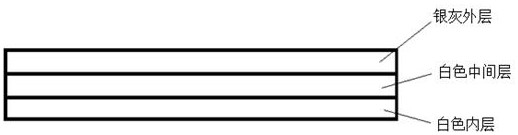

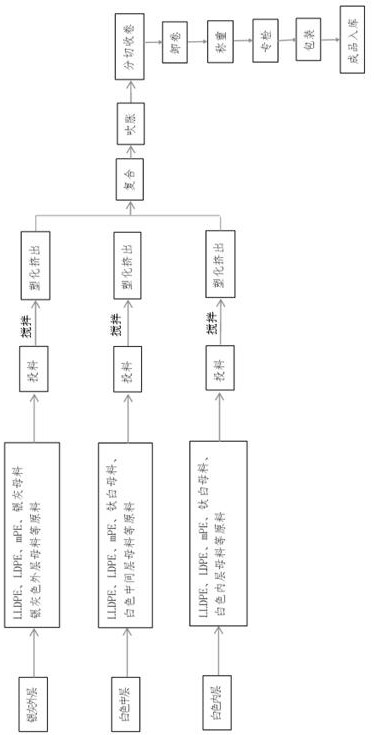

High-photosynthetic-efficiency environment-friendly weather-proof silver-white-silver three-layer composite mulching film and preparation method thereof

ActiveCN109937772APrevent agingExtended service lifeSynthetic resin layered productsFlat articlesLinear low-density polyethyleneAntioxidant

The invention relates to the technical field of production of mulching films, in particular to a high-photosynthetic-efficiency environment-friendly weather-proof silver-white-silver three-layer composite mulching film and a preparation method thereof. The high-photosynthetic-efficiency environment-friendly weather-proof silver-white-silver three-layer composite mulching film is formed by compounding a silver-gray outer film, a white middle film and a silver-gray inner film. The prepared composite mulching film comprises three kinds of linear low-density polyethylene with different properties,metallocene linear polyethylene, light stabilizing auxiliaries, B225-type composite antioxidants and ultraviolet light absorbers, and accordingly, the product has the advantages of high photosynthetic efficiency, high temperature, high soil moisture conservation performance, long service life and the like; after crop harvesting, old films still have high physical and mechanical properties, the tensile strength is slightly reduced, and the mulching films can be reused instead of replacement for each batch; the composite mulching film is quite easy to recycle and sort, and has high reutilization value; on the basis of ensuring heat insulation, soil moisture conservation, weeding and fertilizer efficiency conservation, effective reutilization of recycled resources is facilitated, and environmental pollution is reduced.

Owner:甘肃福雨塑业有限责任公司

Food-packaging film with preservation effect

InactiveCN108410198AStrong physical and mechanical propertiesImprove antioxidant capacityEcological environmentFood packaging

The invention discloses a food-packaging film with a preservation effect, which relates to the technical field of packaging films. According to the invention, with alga and bamboo as main materials, starch is then added, supplemented by various additives, so that the produced packaging film has high preserving property as well as high physical and mechanical properties and antibacterial and antioxidation effects. Moreover, the chosen materials are green, safe and easy to degrade, consequently, white pollution is prevented, and the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

Synthesis process for preparing polyvinyl chloride by aid of suspension methods

InactiveCN107151280AUniform molecular weight distributionExcellent physical and chemical propertiesPolyvinyl chlorideHeat stability

The invention provides a synthesis process for preparing polyvinyl chloride by the aid of suspension methods. The synthesis process includes particular steps of adding vinyl chloride liquid into composition systems with alkaline aqueous solution, initiators, macromolecular surfactants, relative molecular mass regulators and heat stabilizers; keeping the vinyl chloride liquid and the composition systems under the conditions of certain vacuum degrees; initiating polymerization reaction under illumination and pressurization conditions; carrying out vacuumizing again after the reaction is completely carried out; adding water into reaction products during post-treatment, stirring the water and the reaction products, carrying out centrifugal filtration and washing on the reaction products and drying the reaction products in a drum type drying oven to obtain polyvinyl chloride resin. Compared with the prior art, the synthesis process has the advantages that the synthesis process is reasonable in design, post-treatment is easy to implement, products are high in conversion rate, purity and physical and mechanical properties, quality defects such as fisheye can be prevented, and finished products are uniform in molecular weight distribution and good in heat stability; the products are good in appearance and optimal in physical and chemical properties, various physical and mechanical property indexes of the products are similar, and accordingly the synthesis process has a broad application prospect.

Owner:HWASU

High-photosynthetic-efficiency environment-friendly weather-proof silver-white-white three-layer composite mulching film and preparation method thereof

ActiveCN109937773AStrong physical and mechanical propertiesLow tensile strengthSynthetic resin layered productsFlat articlesLinear low-density polyethyleneAntioxidant

The invention relates to the technical field of production of mulching films, in particular to a high-photosynthetic-efficiency environment-friendly weather-proof silver-white-white three-layer composite mulching film and a preparation method thereof. The high-photosynthetic-efficiency environment-friendly weather-proof silver-white-white three-layer composite mulching film is formed by compounding a silver-gray outer film, a white middle film and a white inner film. The prepared composite mulching film comprises three kinds of linear low-density polyethylene with different properties, metallocene linear polyethylene, light stabilizing auxiliaries, B225-type composite antioxidants and ultraviolet light absorbers, and accordingly, the product has the advantages of high photosynthetic efficiency, high temperature, high soil moisture conservation performance, long service life and the like; after crop harvesting, old films still have high physical and mechanical properties, the tensile strength is slightly reduced, and the mulching films can be reused instead of replacement for each batch; the composite mulching film is quite easy to recycle and sort, and has high reutilization value;on the basis of ensuring heat insulation, soil moisture conservation, weeding and fertilizer efficiency conservation, effective reutilization of recycled resources is facilitated, and environmental pollution is reduced.

Owner:甘肃福雨塑业有限责任公司

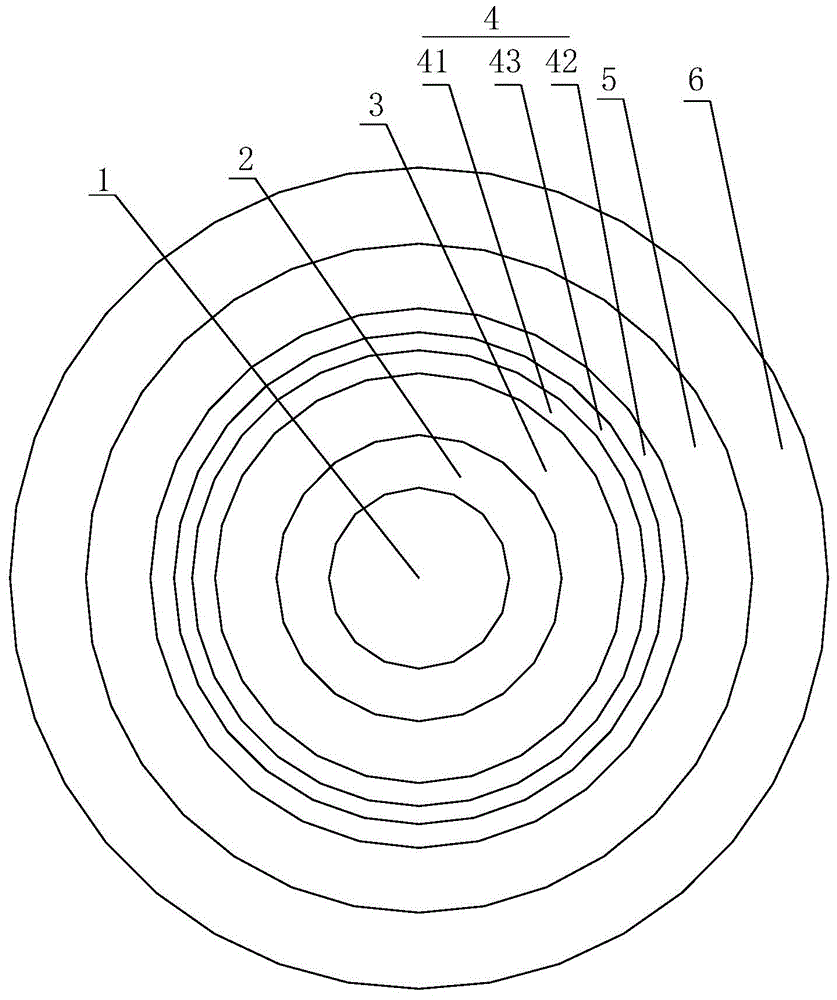

Waterproof shielding type control cable

InactiveCN104599755AAct as a force bufferImprove anti-electromagnetic interference performanceClimate change adaptationInsulated cablesYarnElectromagnetic interference

The invention discloses a waterproof shielding type control cable. The waterproof shielding type control cable comprises a conductor (1), an insulating layer (2) which covers the conductor (1), a waterproof layer (3) which covers the insulating layer (2), a shielding layer (4) which covers the waterproof layer (3), an isolating layer (5) which covers the shielding layer (4), and a protecting sleeve (6) which wraps the isolating layer (5); the waterproof layer (3) is manufactured from high water absorption and expansion type waterproof yarns; the shielding layer (4) comprises an inner shielding layer (41), and an outer shielding layer (42) which wraps the inner shielding layer (41); a filling layer (43) is arranged between the inner shielding layer (41) and the outer shielding layer (42). The waterproof shielding type control cable is environmentally friendly, high in electromagnetic interference resistance, outstanding in waterproof performance, and long in service life.

Owner:ANHUI LAND GRP

A kind of anti-chemical penetration multi-layer composite adhesive tape and preparation method thereof

ActiveCN104404782BImprove flame retardant performanceStrong physical and mechanical propertiesTextiles and paperRubber layered productsAdhesiveStrong acids

The invention discloses a multilayer composite adhesive tape preventing chemicals from penetrating and a preparation method thereof. The multilayer composite adhesive tape is prepared by coating aramid fiber base cloth with multiple rubber, concretely, one surface of the base cloth is coated with a fluorubber layer, and the other surface of the base cloth and the surface of the fluorubber layer are both coated with a chloroprene rubber layer. The preparation technology of the multilayer composite adhesive tape comprises preparing base cloth, coating one surface of the base cloth with the fluorubber layer, performing semi-sulfuration, coating the two surfaces of the coated base cloth with the chloroprene rubber layer, performing complete sulfuration, and obtaining the finished product adhesive tape. The multilayer composite adhesive tape employs aramid fiber fabric resistant to both acids and alkalis, possesses strong physical mechanical performances and is better than a nylon material. The multilayer composite adhesive tape has relatively strong acid and alkali resistance and chemical toxic agent resistance, and has the protection time up to 4 h. The multilayer composite adhesive tape has relatively good flame retardation performance, and can work at a high temperature. The multilayer composite adhesive tape employs chloroprene rubber and fluorubber as coating materials, is low in cost and superior in antitoxin performance.

Owner:SHANXI XINHUA CHEM

High-protein food packaging film

The invention discloses a high-protein food packaging film, and relates to the technical field of packaging films. According to the food packaging film, hair and wool are taken as main raw materials,starch is added, and various auxiliary agents are supplemented, so that the prepared packaging film has high protein content and high amino acid content, and has strong physical mechanical properties,selective permeability and antibacterial and antioxidant effects. In addition, the selected raw materials are green and safe and are easy to degrade, so that white pollution is avoided, and the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

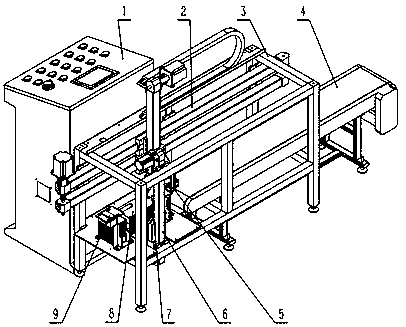

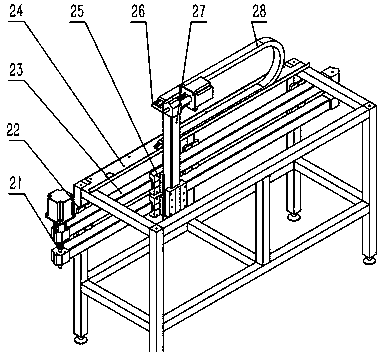

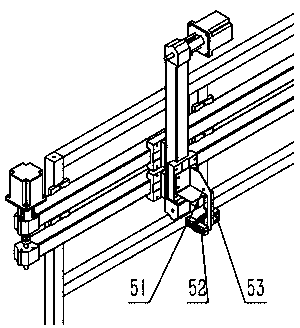

Large Bamboo Curtain Continuous Hot Pressing Recombination Bamboo Raw Material Unit Group Blank Paving Machine

ActiveCN106827110BBig-amplitudeArbitrary interception of lengthWood compressionWood veneer joiningEngineeringMechanical engineering

The invention discloses a large bamboo bundle curtain continuous hot-pressed recombined bamboo raw material unit assembly paver. The paver comprises a PLC control cabinet (1), a shifting device (2), a frame (3), a conveying belt paving assembly platform (4), a clamping device (5), a lifting device (6), a height detecting device (7), a storage bin (8) and a push rod device (9). The paver special for transfer and assembly raw material units of produced large bamboo bundle curtain continuous hot-pressed recombined bamboos has the advantages of capability of realizing automatic paving assembly of raw material units, speediness, uniformity, tidiness, time saving, labor saving, high working efficiency, various paving assembly modes, fast mode conversion and adjustment, difficult generation of mistakes, wide recombined bamboo boards formed by paving, random length, high physical and mechanical performances and wide application range.

Owner:ZHEJIANG FORESTRY UNIVERSITY

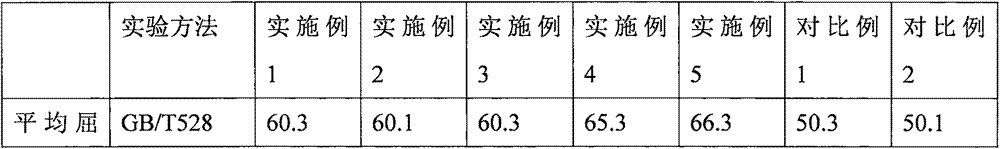

Nanocellulose enhanced and toughened MC nylon composite and preparation method thereof

InactiveCN107353402AImprove physical and mechanical propertiesHigh-performance nanocellulose as enhanced physical and mechanical propertiesNanofiberResin matrix

The invention discloses a nano-cellulose reinforced and toughened MC nylon composite material and a preparation method thereof. It is made of the following raw materials in parts by weight: 10-90 parts of caprolactam monomer, 10-75 parts of nanocellulose, 0.2-0.4 parts of catalyst, and 2-5 parts of cocatalyst. The invention adopts nanocellulose as reinforcement, and caprolactam monomer is the resin matrix, and utilizes the low viscosity and good fluidity of the caprolactam solution to ensure the infiltration of nanocellulose by caprolactam, greatly increasing the nanocellulose content of the product, and having a high Physical and mechanical properties.

Owner:扬州金尔泽科技有限公司

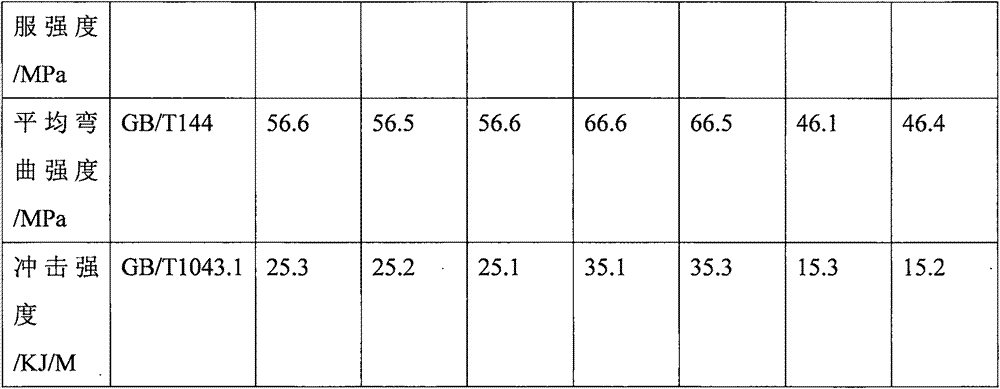

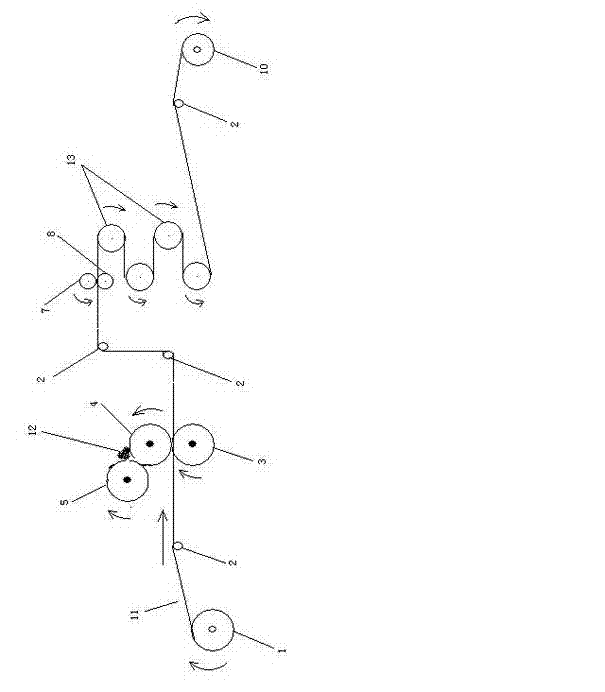

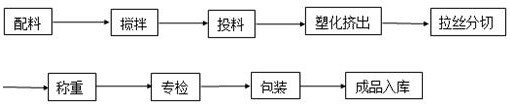

Environmental-friendly synthetic organosilicon leather and method for producing same

ActiveCN102174262BImprove plasticityEasy to shapeTextile/flexible product manufactureTextiles and paperMasterbatchVulcanization

The invention relates to environmental-friendly synthetic organosilicon leather and a method for producing the same. The synthetic organosilicon leather comprises vinyl polysiloxane gum, white carbon black, a structured treatment agent, a plastifying agent, an inhibitor, hydrogen containing silicone oil, a platinum catalyst and silicone rubber masterbatch. The method for producing the synthetic organosilicon leather comprises the following steps: mixing the raw materials to obtain solid mixed silicone rubber through vulcanization via addition, rolling the solid mixed silicone rubber by a multi-roll rolling machine to fit textile-based fabric, heating and vulcanizing to form the synthetic organosilicon leather. The environmental-friendly synthetic organosilicon leather is efficiently produced with a simple process and can be produced on a large scale. The produced synthetic organosilicon leather has good mechanical properties and excellent characteristics of being resistant to high andlow temperature, weathering aging and physical inertia, is easy to cut and sew and is waterproof and breathable. The combustion and decomposition product of the synthetic organosilicon leather contains no harmful substance, can be recycled and accords with environmental protection requirements.

Owner:东莞市贝特利新材料有限公司

High light-efficiency, environment-friendly, weather-resistant silver-white-white three-layer composite mulch film and preparation method thereof

ActiveCN109937773BStrong physical and mechanical propertiesLow tensile strengthSynthetic resin layered productsFlat articlesLinear low-density polyethyleneComposite film

The present invention relates to the technical field of mulching film production, and specifically relates to a high-efficiency environmental protection weather-resistant silver-white three-layer composite mulching film and a preparation method thereof. Efficient, environmentally friendly, weather-resistant, silver-white three-layer composite mulch film; the composite mulch film prepared by the present invention uses three kinds of linear low-density polyethylene, metallocene linear polyethylene, light stabilizing agent, B225 composite anti-corrosion film with different properties in the raw materials. Oxygen agent and ultraviolet absorber, so that the product has the characteristics of high light efficiency, high heat preservation, strong moisture retention performance, and long service life; after the crops are harvested, the old film also has strong physical and mechanical properties, and the tensile strength decreases less, so that each crop They all need to be mulched into one-time mulching for repeated use; it is very easy to recycle and sort, and has a high reuse value; on the basis of maintaining the effects of mulch film temperature increase, moisture conservation, weeding and fertilizer conservation, it is convenient to recycle resources effectively and reuse them. Use and reduce environmental pollution.

Owner:甘肃福雨塑业有限责任公司

Degradable food packaging film

InactiveCN108373551AEasy to degradeStrong physical and mechanical propertiesEcological environmentEngineering

The invention discloses a degradable food packaging film and relates to the technical field of packaging films. According to the degradable food packaging film disclosed by the invention, high glutenflour and starch are utilized as main raw materials, and varieties of additives are utilized as auxiliary materials; thus, the prepared packaging film has the advantages of stronger physical mechanical property, permselectivity, bacterial resistance and oxidation resistance; furthermore, the chosen raw materials are easy to degrade; thus, white pollution is avoided, and ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

A treatment method for solidification and stabilization of electrolytic manganese slag

ActiveCN108421805BInexpensive curing processReduce dosageSolid waste disposalTransportation and packagingChemical reactionPhosphate

The invention relates to a solidification and stabilization treatment method for electrolytic manganese slag, belonging to the technical field of environmental protection; a mixture of ferronickel slag and phosphate is used as a solidification and stabilization treatment agent for electrolytic manganese slag, and the solidified and stabilized electrolytic manganese slag is sent to a slag storehouse Stockpiling; using this method can reduce the amount of chemical reagents, reduce the cost of solidification of electrolytic manganese slag, and at the same time can play a role in waste treatment; electrolytic manganese slag is solidified by a mixture of nickel-iron slag and phosphate, and the manganese slag Soluble manganese and ammonium ions can participate in chemical reactions and form phosphate gel minerals by chemical bonding. The phosphate chemical bonding material formed has physical wrapping and adsorption; through chemical bonding, physical adsorption, and physical wrapping triple action, Thereby realizing high efficiency and large capacity solidification of electrolytic manganese slag.

Owner:KUNMING UNIV OF SCI & TECH

Zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material and preparation as well as application thereof

InactiveCN102295835BNo need to investWide extrusion processing temperatureInsulated cablesInsulated conductorsPolymer scienceThermoplastic polyurethane

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com