Large Bamboo Curtain Continuous Hot Pressing Recombination Bamboo Raw Material Unit Group Blank Paving Machine

The technology of bamboo bundle curtain and reconstituted bamboo is applied in the direction of wood compression, joining of wooden veneers, manufacturing tools, etc., and can solve the problems of poor physical and mechanical properties of reconstituted bamboo, uneven density of reconstituted bamboo, single way of forming blanks, etc. To achieve the effect of strong physical and mechanical properties, diverse methods, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

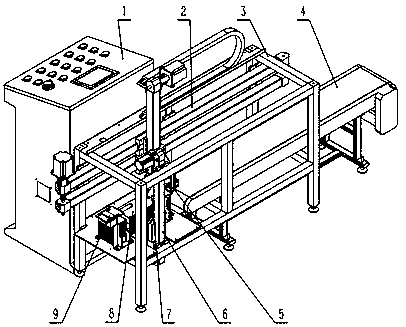

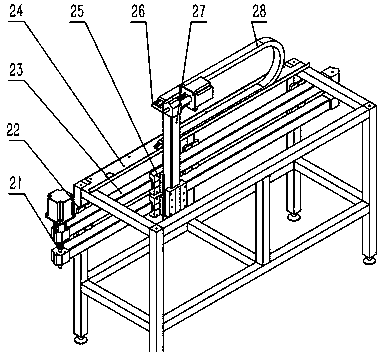

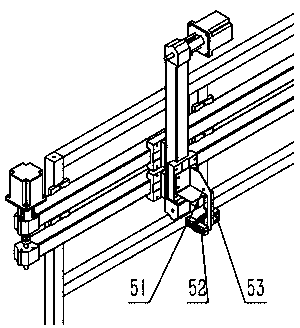

[0018] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing: see Figure 1-6 .

[0019] The recombined bamboo raw material unit paving machine for continuous hot-pressing of large bamboo bundle curtains includes a PLC control cabinet 1, a transfer device 2, a frame 3, a conveyor belt pavement assembly platform 4, a clamping device 5, a feeding device 6, a material High detection device 7, storage bin 8, push rod device 9, the PLC control cabinet 1 is installed on the side of the main machine; the transfer device 2 has two linear modules A 23 that move horizontally and one that moves vertically Linear module B 27, two horizontally moving linear modules A 23 are fixed on the frame 3 through the guide rail fixing plate A 22, and the rotating shafts of the two horizontally moving linear modules A 23 are connected to each other through a coupling 21 Together, the linear module B27 is fixed on the sliders of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com