Vertical BJT, manufacturing method thereof

A region and collector technology, applied in the field of vertical BJT and its manufacturing, can solve problems such as the best current gain of vertical BJT devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

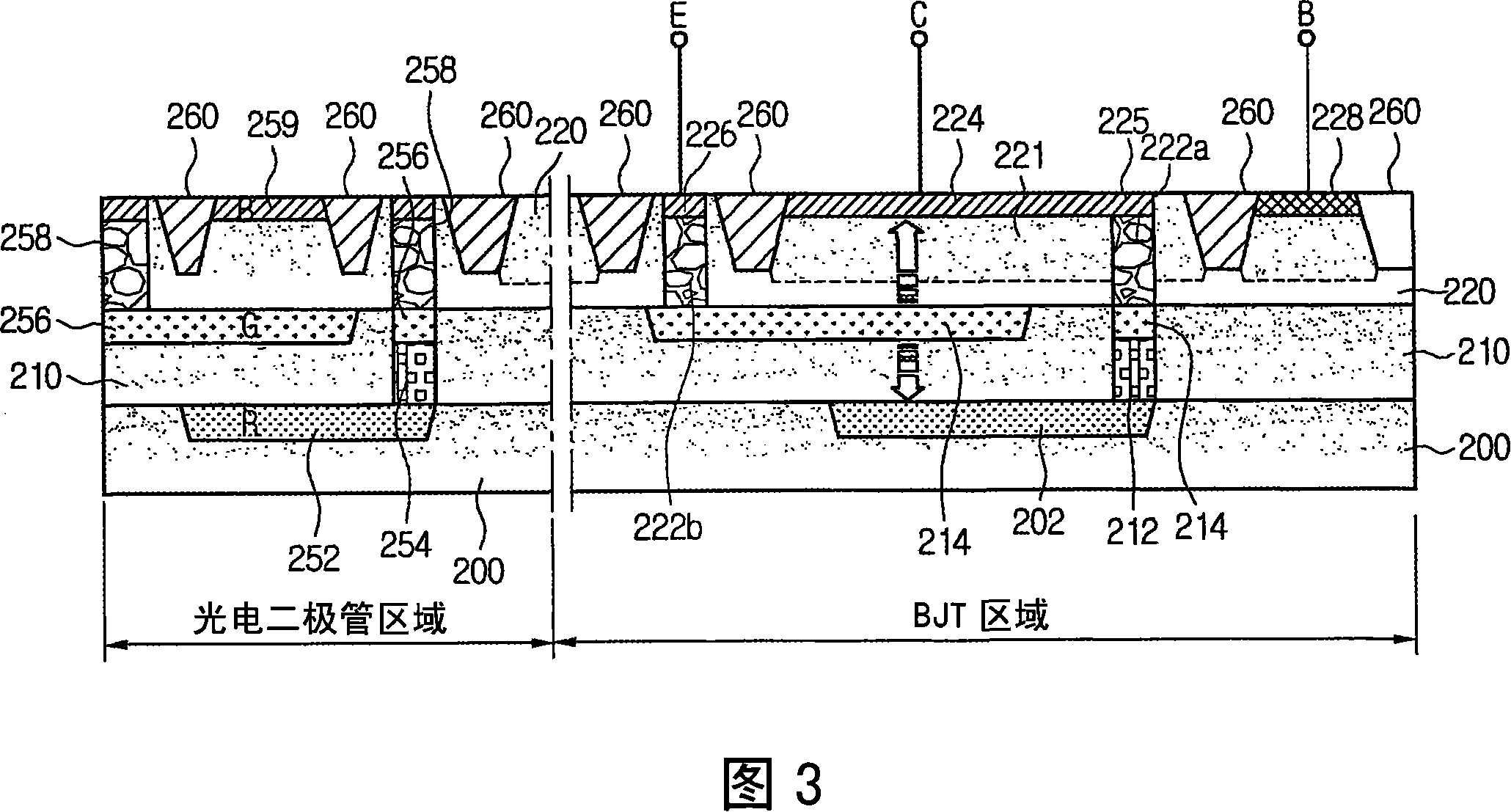

[0013] As shown in FIG. 3 , in the photodiode region, a red photodiode region 252 is formed in the first epitaxial layer 200 formed over the semiconductor substrate. The second epitaxial layer 210 is grown, and the second P-type epitaxial layer 210 is formed by implanting P-type ions into the second epitaxial layer 210 . The first plug 254 is formed by implanting high-concentration ions into the second P-type epitaxial layer 210 to connect the second P-type epitaxial layer 210 to the red photodiode region 252 for sending signals.

[0014] After forming a photoresist layer pattern on the second P-type epitaxial layer 210, a green photodiode region 256 is formed in the second P-type epitaxial layer 210 by partially implanting ions into the second P-type epitaxial layer 210. , grow a third epitaxial layer 220 on the second P-type epitaxial layer 210 including the green photodiode region 256 , and form an STI region 260 in the third epitaxial layer 220 to define an active region. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com