Method for reducing nitrogen oxide exhaust of cement kiln

A nitrogen oxide, cement kiln technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve problems such as environmental pollution, and achieve the effects of reducing environmental pollution, large amplitude and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

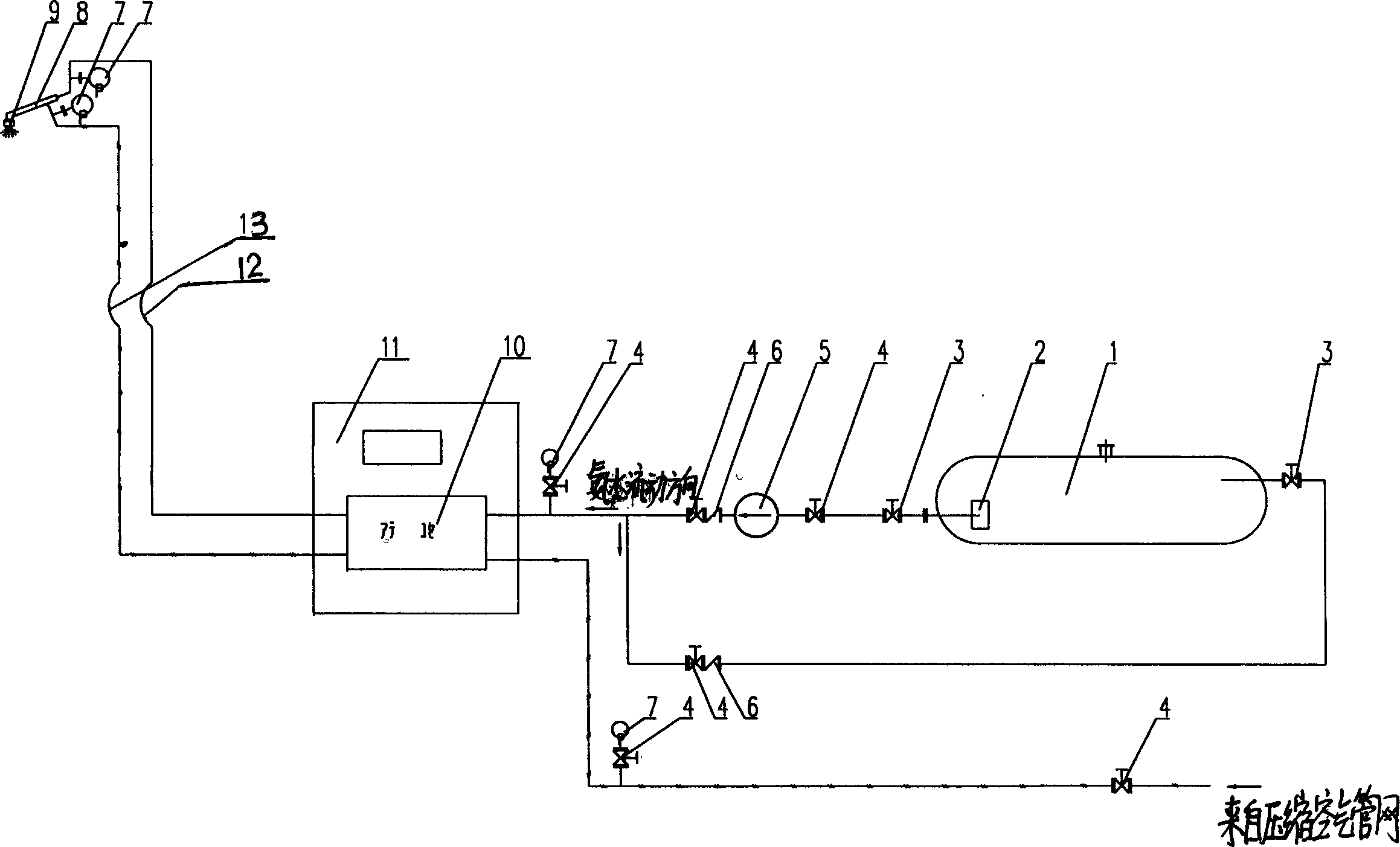

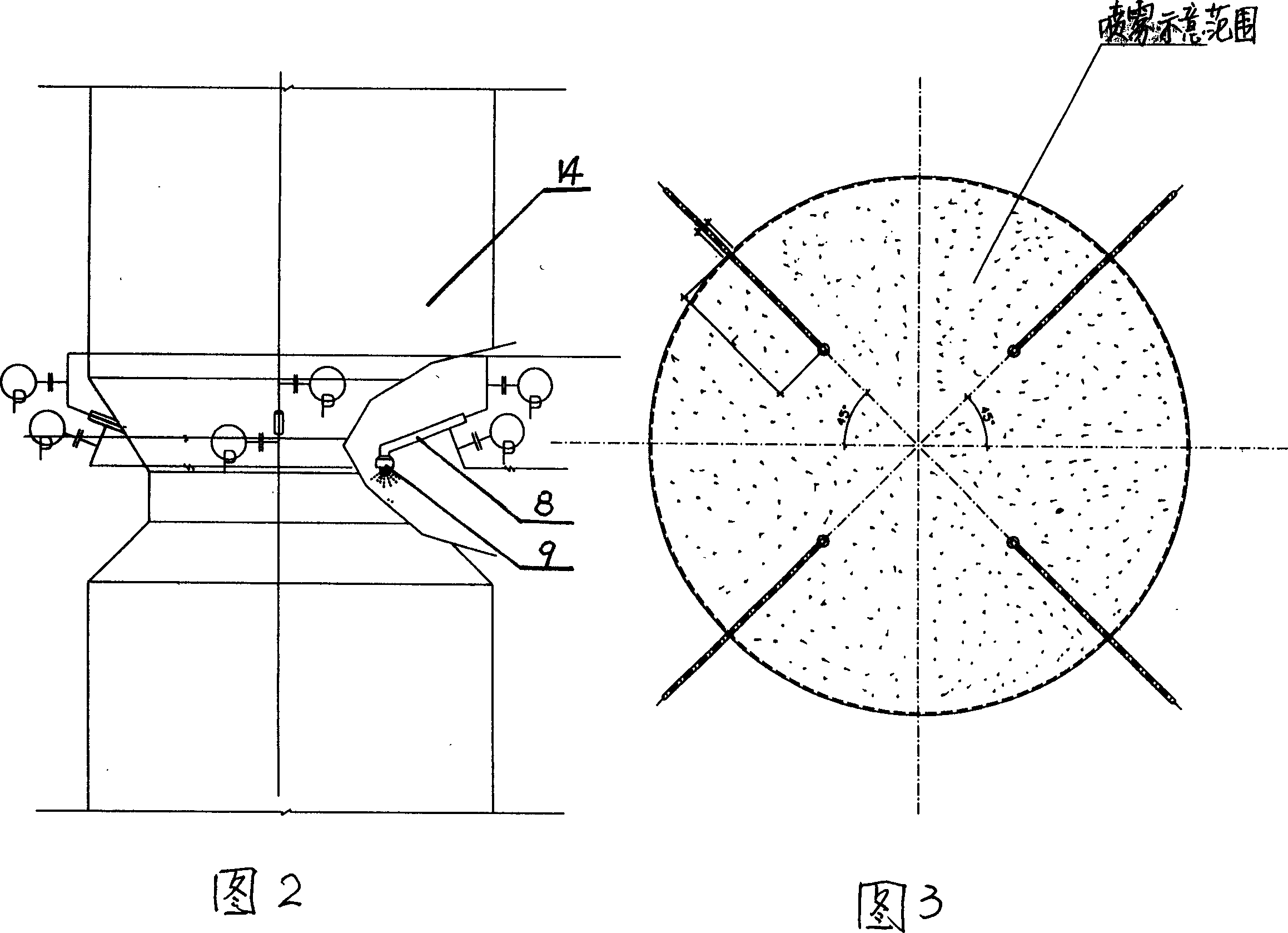

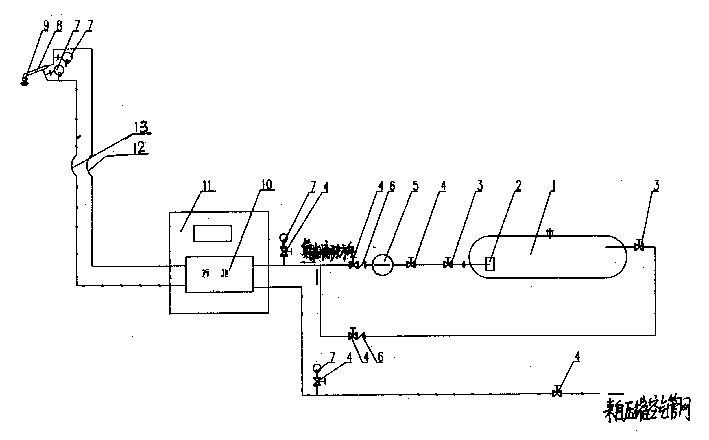

[0016] see figure 1 , a method for reducing nitrogen oxide emissions from cement kilns. When the temperature in the upper area of the calciner 14 of the cement pre-decomposition system is heated to 850-1050 ° C, the nozzle on the spray gun 8 is placed in this area, and the ammonia water pipeline is respectively opened And the valve body on the compressed air pipeline, so that the ammonia water in the ammonia water storage tank 1 placed on the ±0.00 plane is filtered by the filter 2, and then enters through the manual stop valve 3 and the flanged spherical plug valve 4. Arranged on the ±0.00 plane The first-stage booster pump 5, the ammonia water after the booster pump is transported to the liquid and gas supply pump station 10 on the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com