Patents

Literature

74results about How to "High print resolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

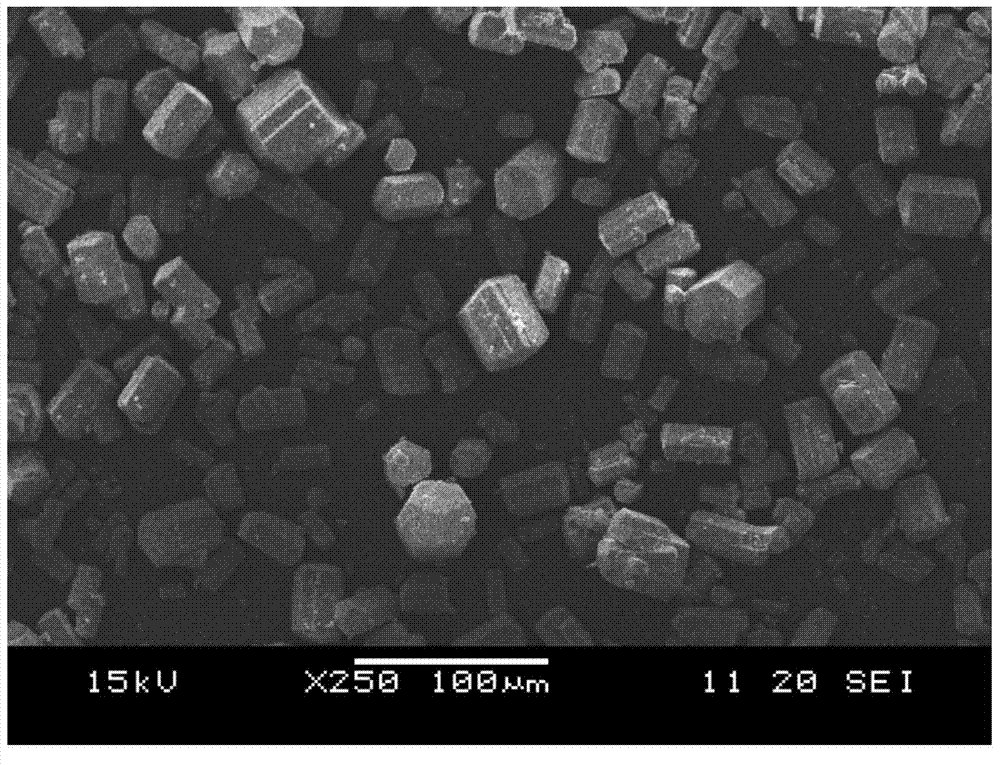

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

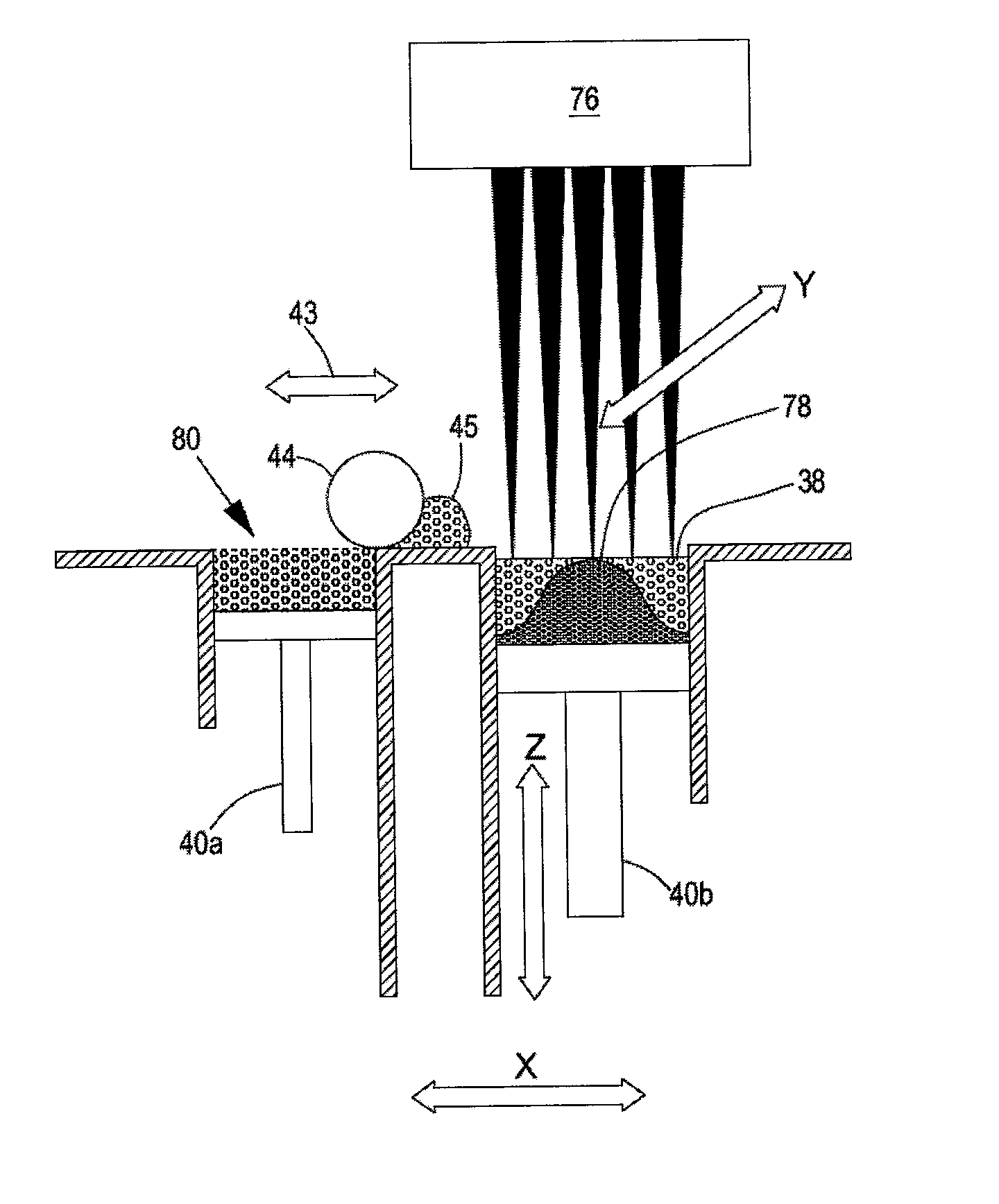

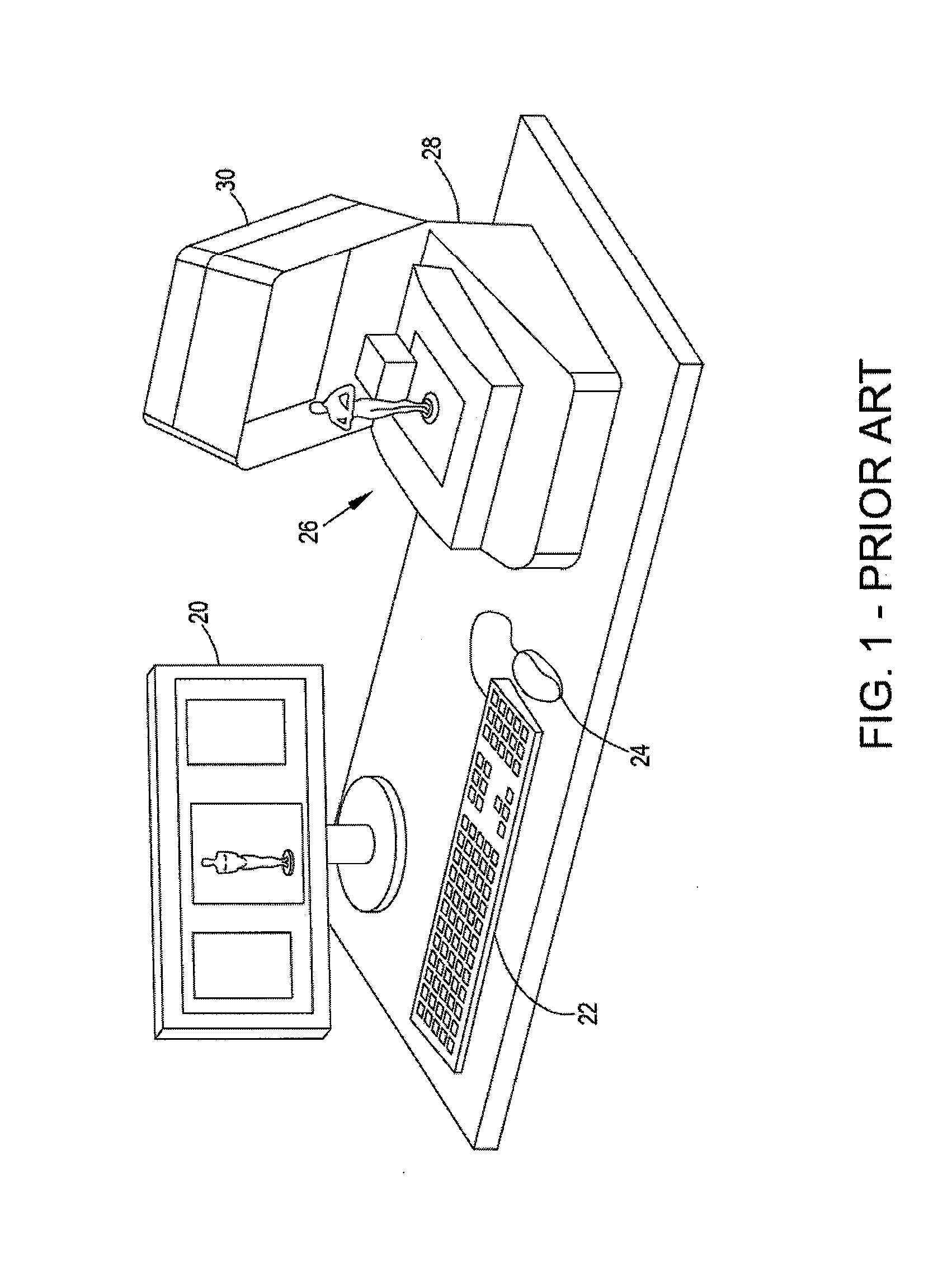

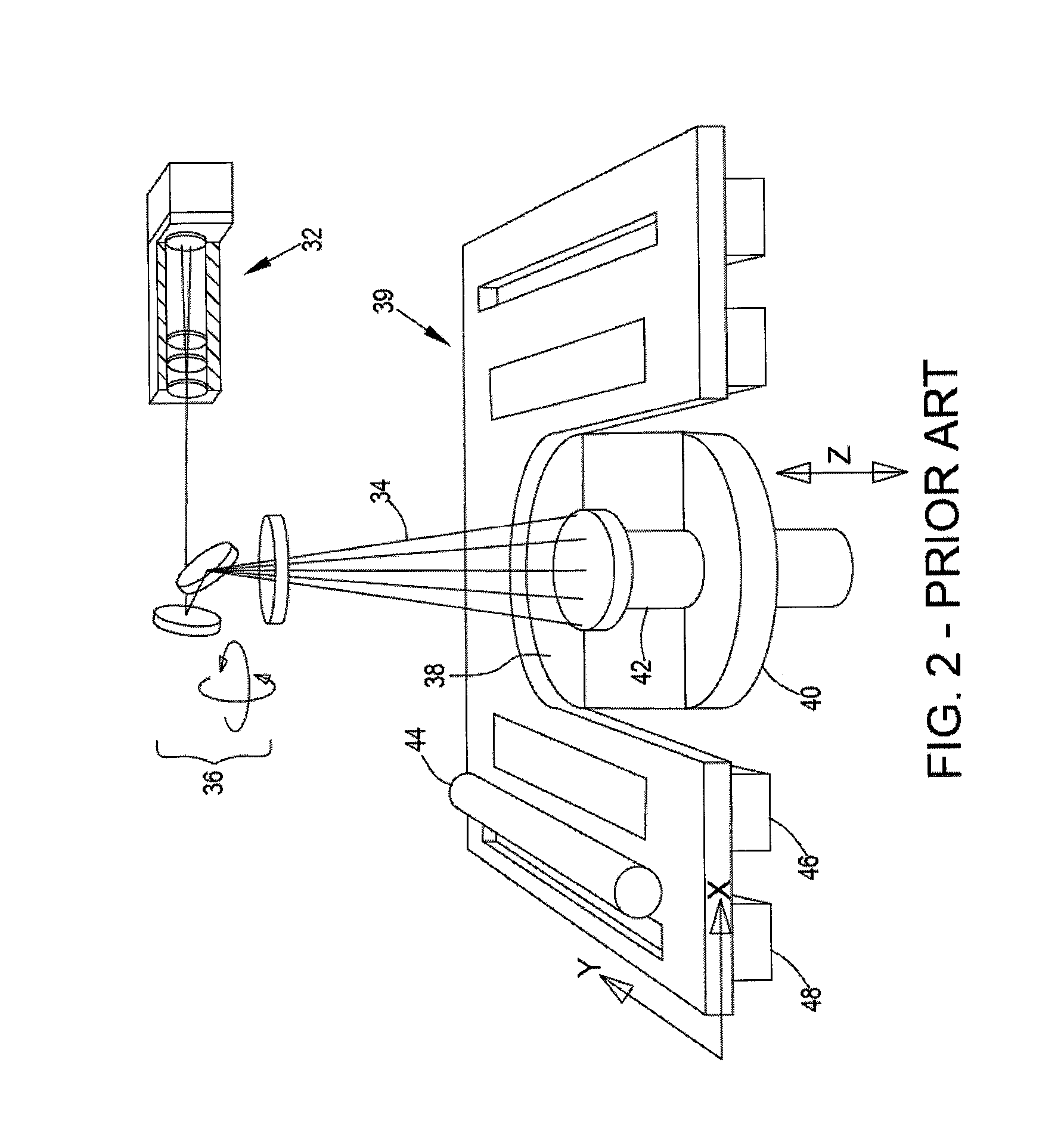

Device and a method for 3D printing and manufacturing of materials using quantum cascade lasers

ActiveUS20160082662A1More compact in sizeAbsorption of radiant energyAdditive manufacturing apparatusSemiconductor laser arrangementsChannel powerEngineering

A 3D printer device utilizing at least one Quantum Cascade Laser (QCL) image head having at least one beam focused in a focal plane of the device for building on a surface of the device a 3D model of a target object from a digital image. The inventive 3D printer is more compact in size due to the use of QCL image heads, which provides focused wavelengths of QCLs matching the absorption properties in plastics for more efficient absorption of the radiant energy. Each QCL channel power in the inventive 3D printer can be doubled by combining two lasers with a polarization beam splitter. The QCL image head is provided with Pulse Width Modulation (PWM) for compensating for imaging speed. The invention includes a method for scaling up the building speed of 3D printing regardless of detail level. The invention discloses an affordable 3D printer using QCL technology while maintaining high standards of resolution, use of quality materials, and rapid building speeds.

Owner:3DM DIGITAL MFG LTD

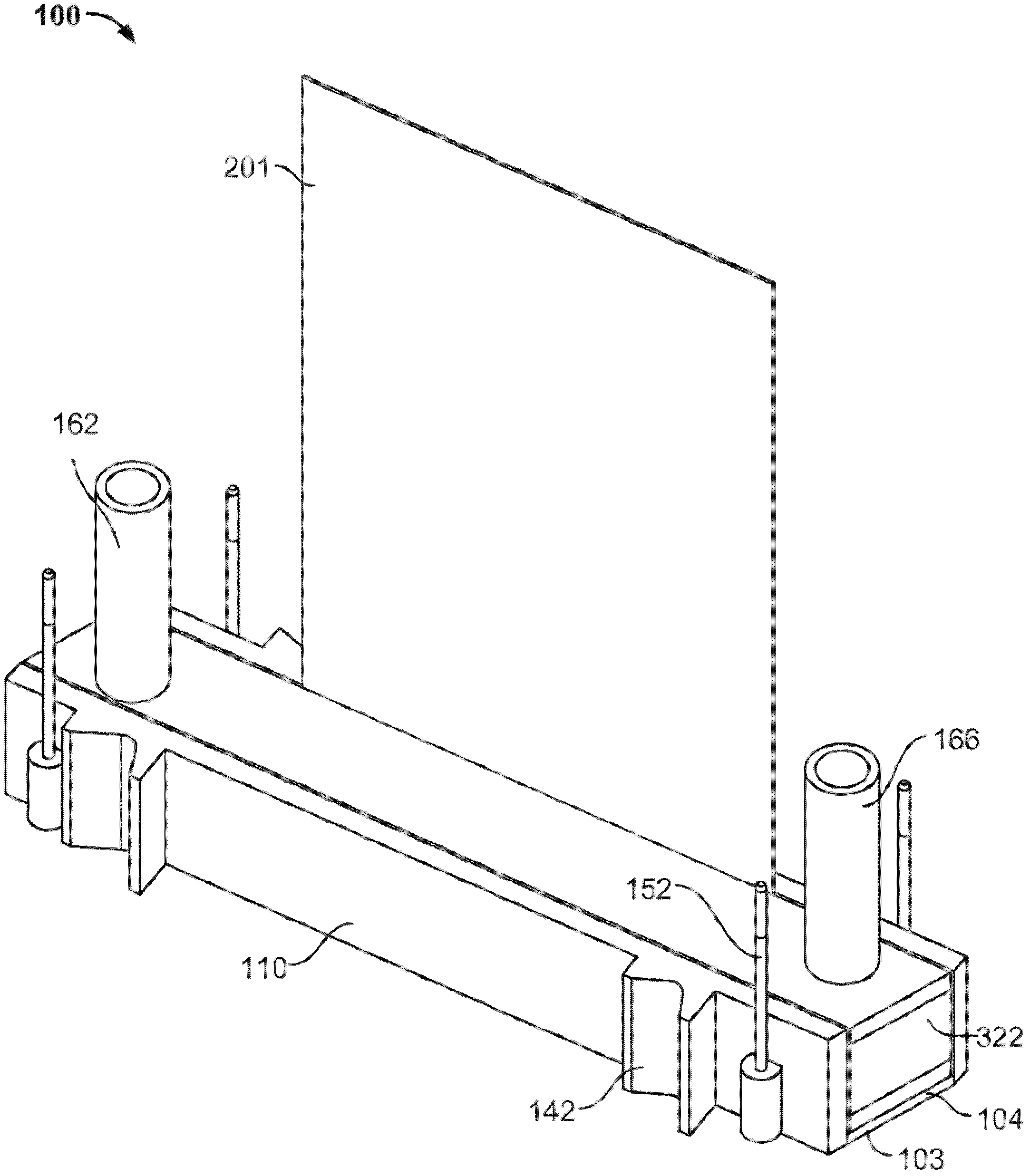

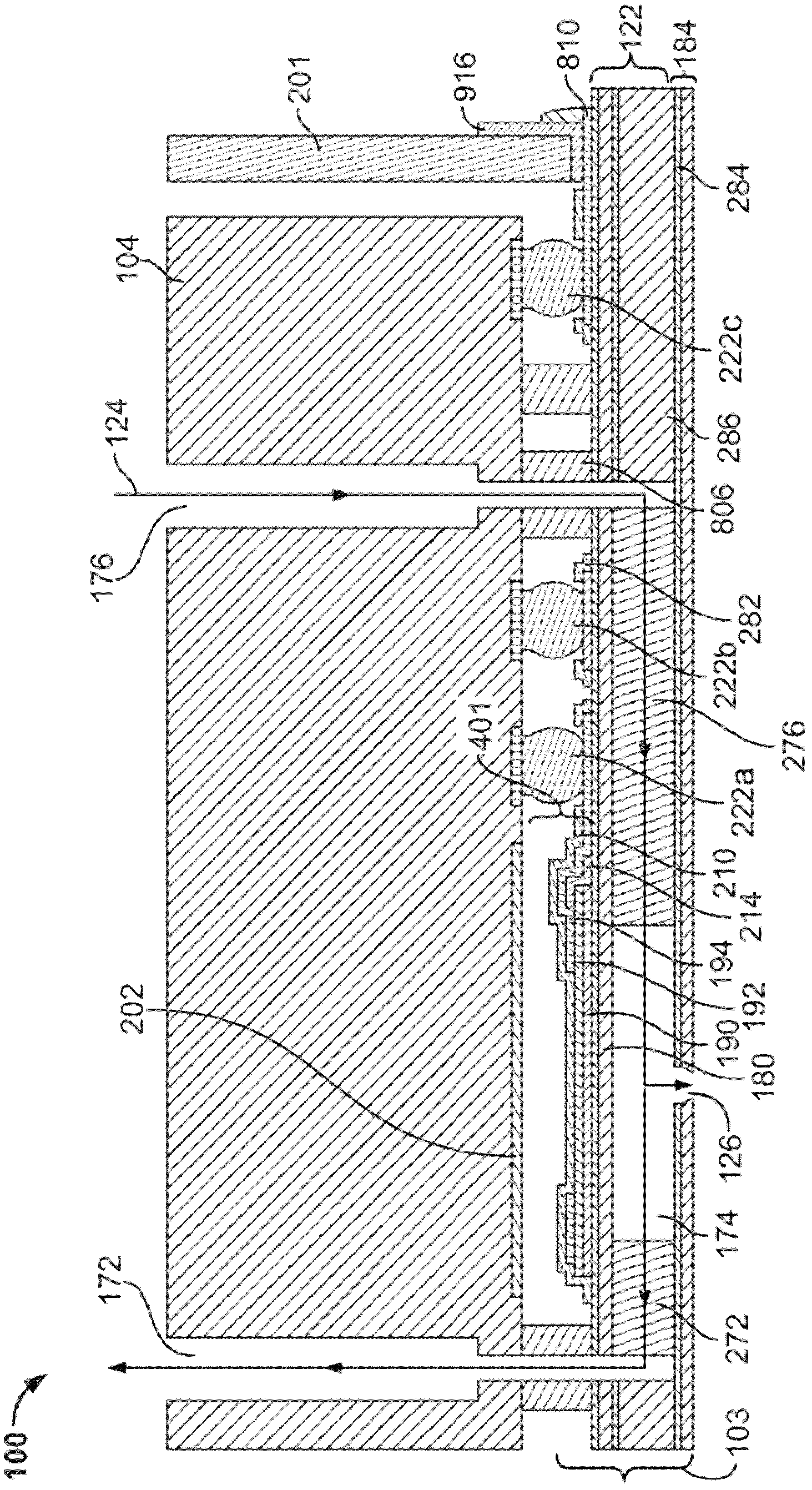

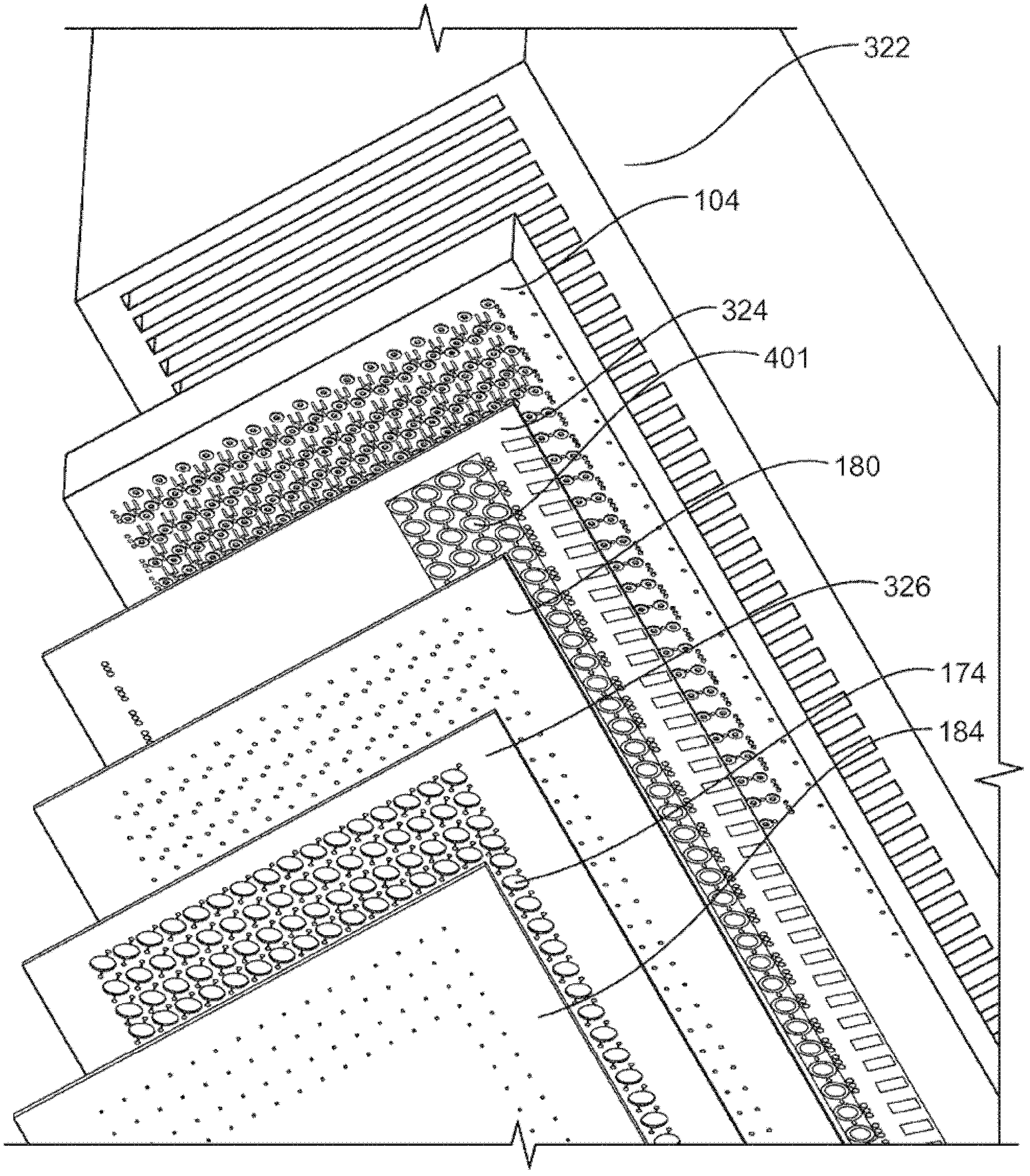

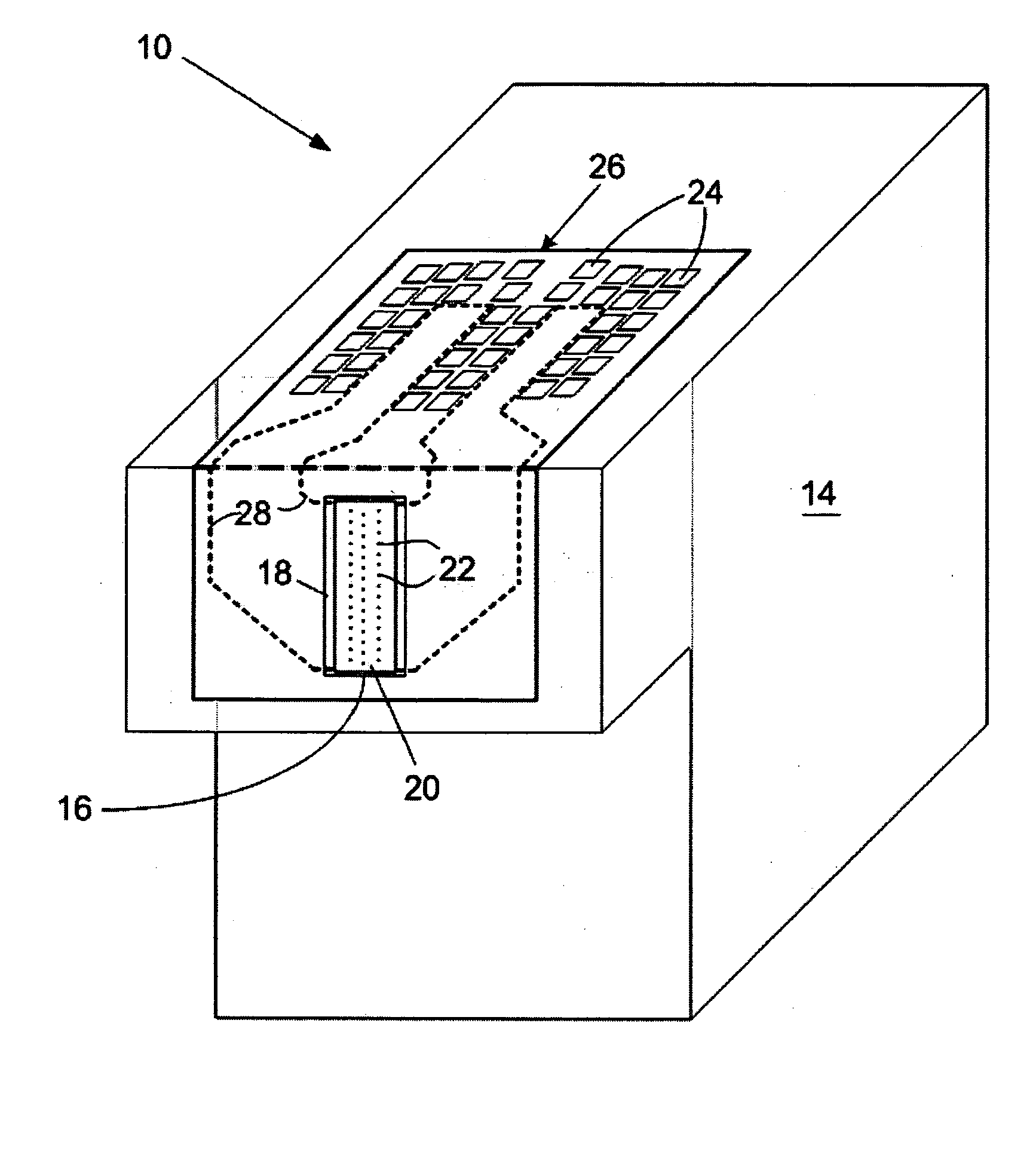

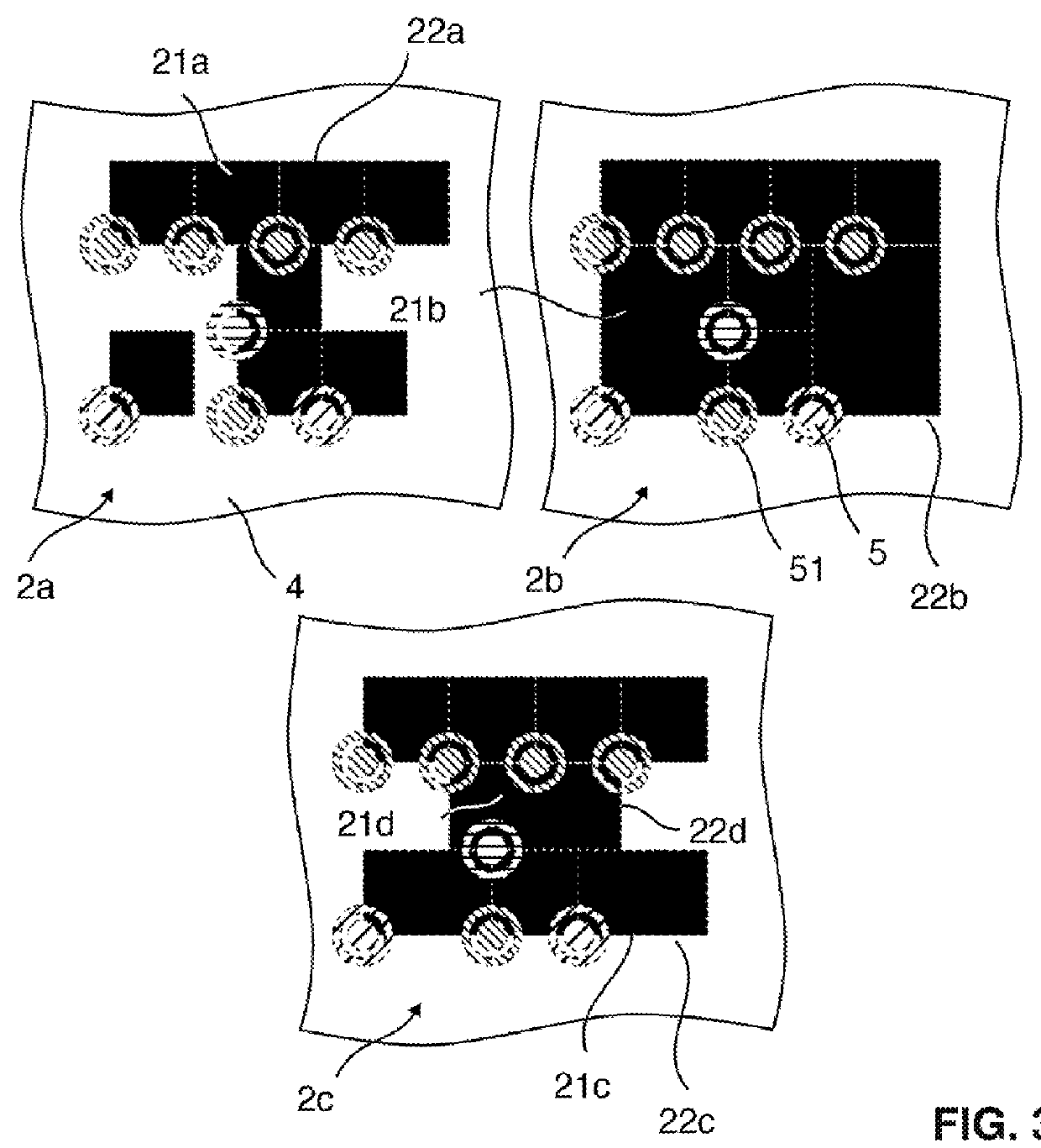

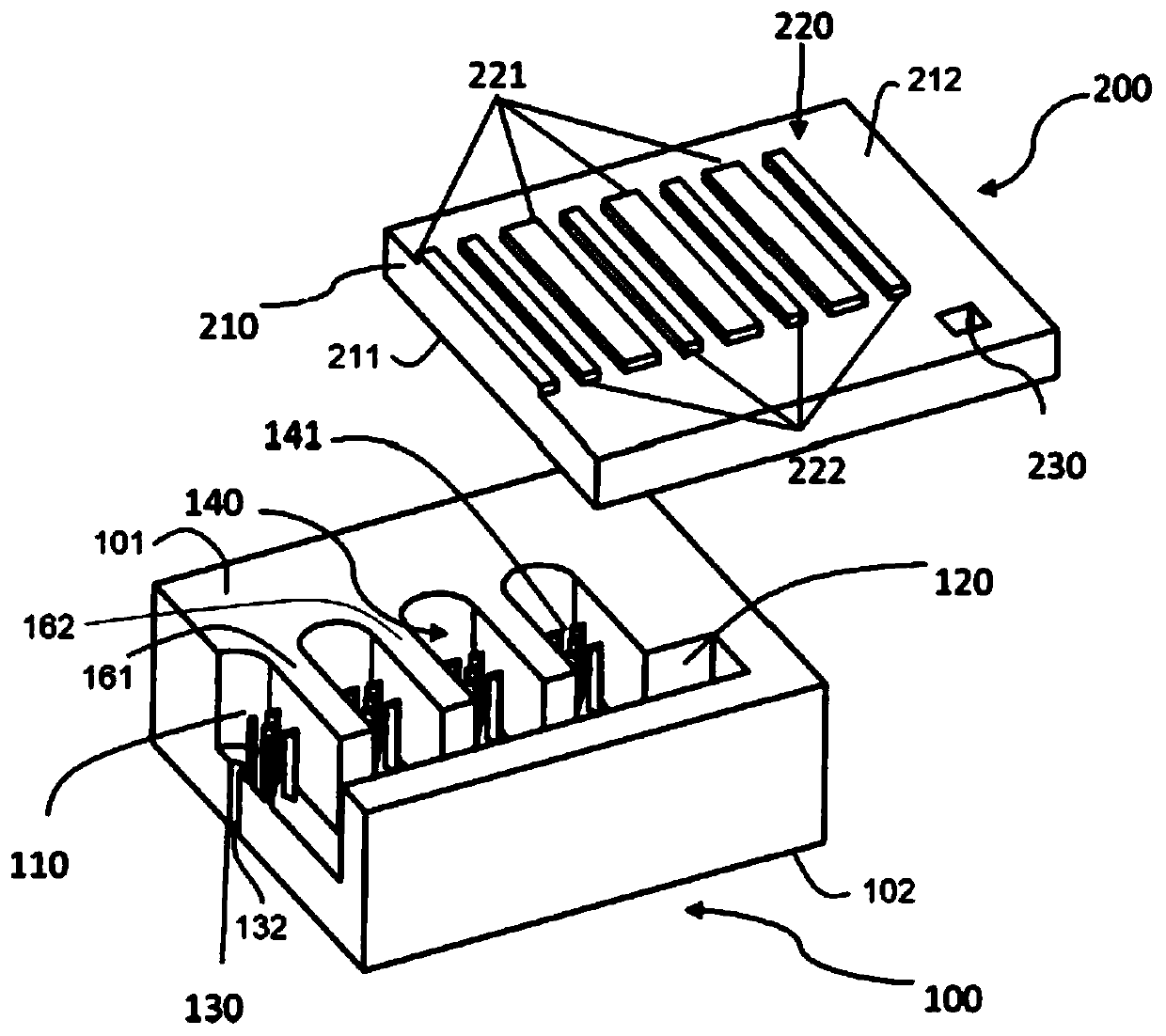

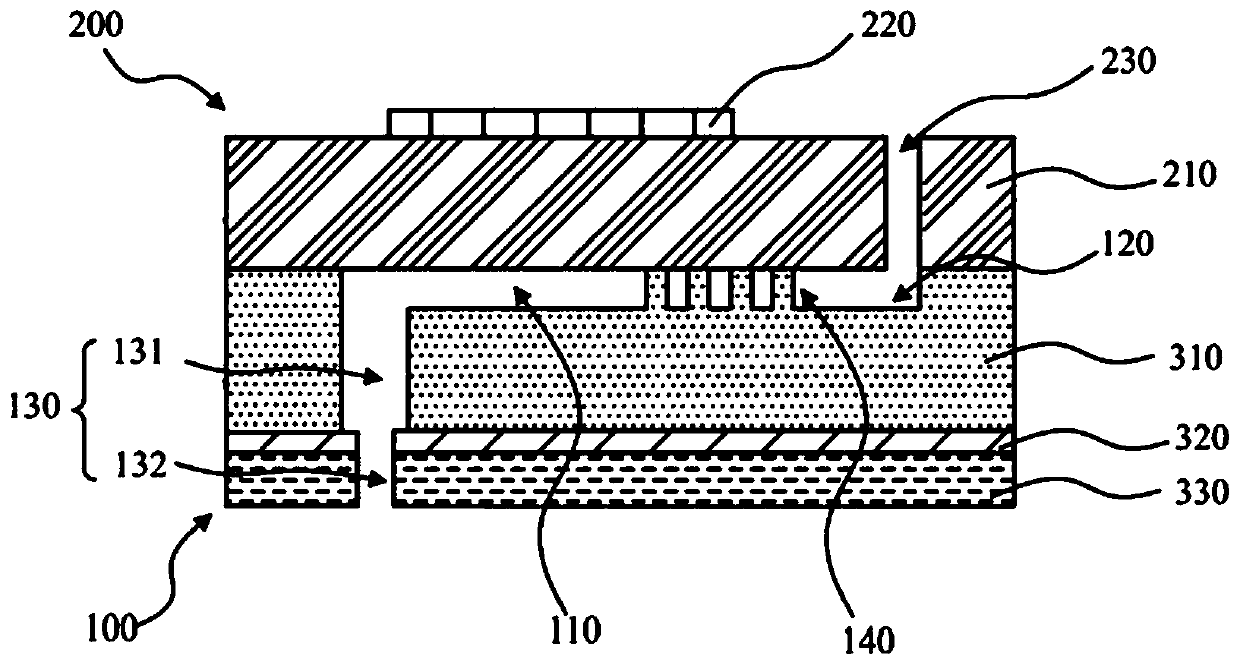

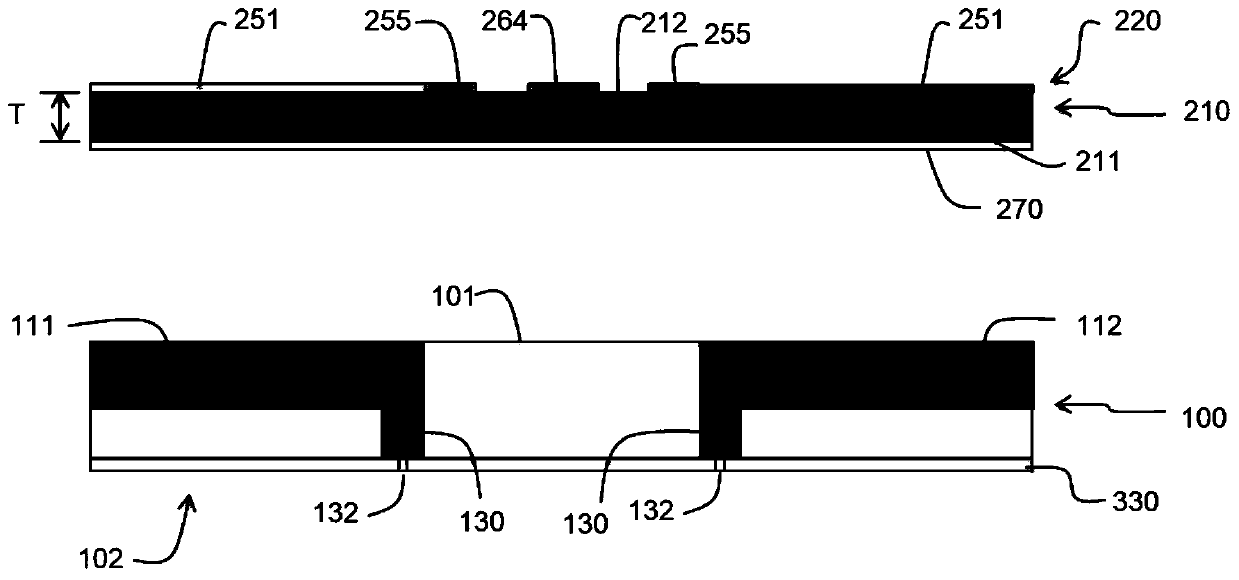

Mems Jetting Structure For Dense Packing

ActiveCN102481789AReduce maintenance downtimeHigh densityInking apparatusSpraying apparatusElectrical connectionEngineering

A fluid ejector includes a fluid ejection module having a substrate and a layer separate from the substrate. The substrate includes a plurality of fluid ejection elements arranged in a matrix, each fluid ejection element configured to cause a fluid to be ejected from a nozzle. The layer separate from the substrate includes a plurality of electrical connections, each electrical connection adjacent to a corresponding fluid ejection element.

Owner:FUJIFILM DIMATIX

Spray-painting advertising lamp box cloth

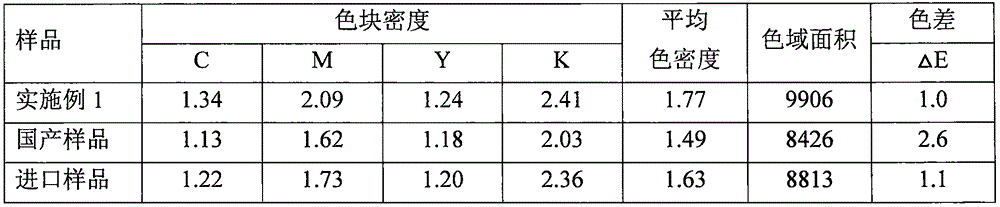

ActiveCN101905553AHigh print resolutionPrints dry fastSynthetic resin layered productsCoatingsEmulsionChemistry

The invention discloses spray-painting advertising lamp box cloth comprising an ink-absorbing coating, a primer coating, polyethylene woven cloth and a polyethylene laminated layer, wherein the ink-absorbing coating is formed by compounding 40 parts by weight of polyvinyl acetate emulsions with the solid content of 40%, 40 parts by weight of pure acrylic emulsion with the solid content of 40%, 6 parts by weight of calcium carbonate, 1.5 parts by weight of silicon dioxide powder, 1.5 parts by weight of titanium white, 0.2 part by weight of anti-foaming agent, 0.15 part by weight of wetting agents, 0.26 part by weight of brighteners, 0.32 part by weight of thickeners and ammonia water. By adopting the technical scheme, the spray-painting advertising lamp box cloth can be compatible to solvent type ink printing, mild solvent type ink printing and UV (Ultraviolet) solidification type ink printing and has the advantages of high print resolution which reaches 1440 dpi, high printing and drying speed and color density, good color rendition, environmental protection, no pollution and reproducibility.

Owner:江苏耐斯数码科技股份有限公司

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

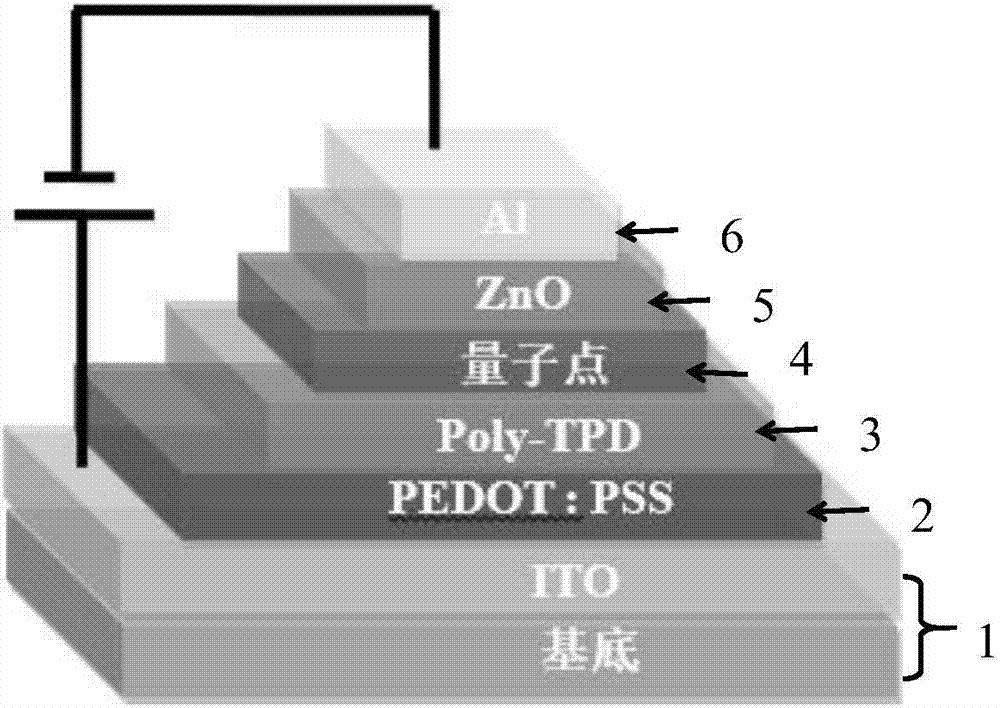

Quantum dot light-emitting diode and preparation method thereof

InactiveCN107275499AConducive to conductive lightConductive Luminescence GuaranteeSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotZinc

The invention provides a quantum dot light-emitting diode and preparation method thereof. The preparation method includes printing a mixed organic solution including poly(3,4-ethylenedioxythiophene) and polystyrolsulfon acid salt, an organic solution including a triphenyl diamine polymer, an organic solution including quantum dots and an organic solution including zinc oxide on a conductive substrate surface in sequence through an ink-jet printing method to obtain a primary quantum dot light-emitting diode; and depositing an electrode on the non-conductive substrate side of the obtained primary quantum dot light-emitting diode to obtain the quantum dot light-emitting diode. The preparation method realizes large-area simple preparation of quantum dot light-emitting diode by adoption of an ink-jet printing technology combined with a defined proportion of ink, and the operation is simple; and the ink used by the preparation method contributes to improvement of printing resolution, ensures uniformity of printing, and facilitates electric conduction light emission of the diode.

Owner:广州琉芯光电科技有限公司

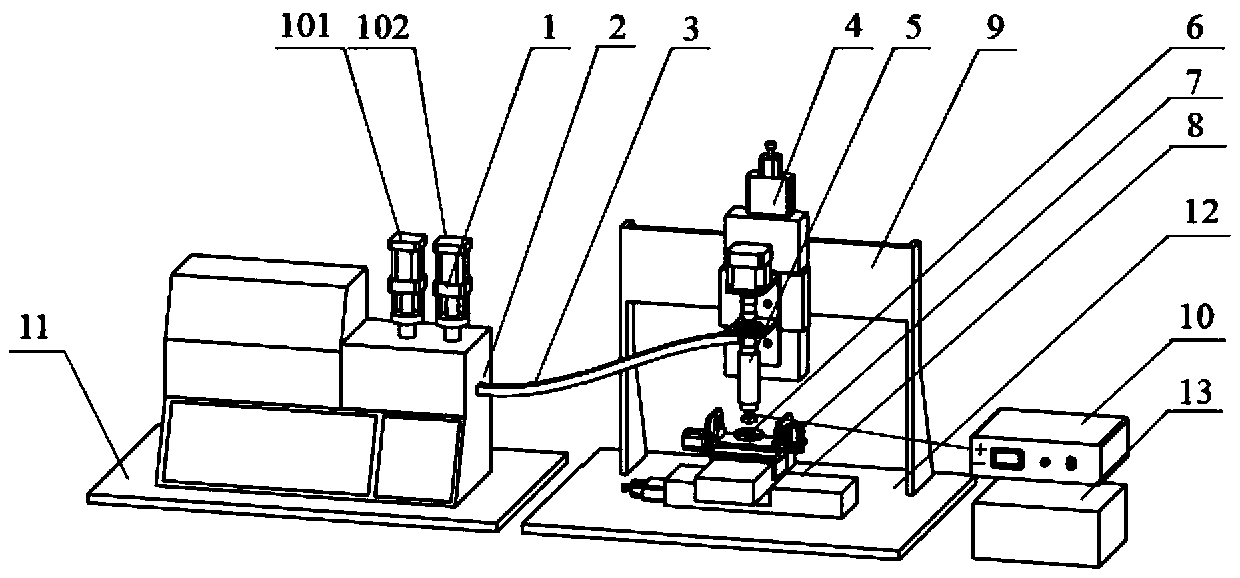

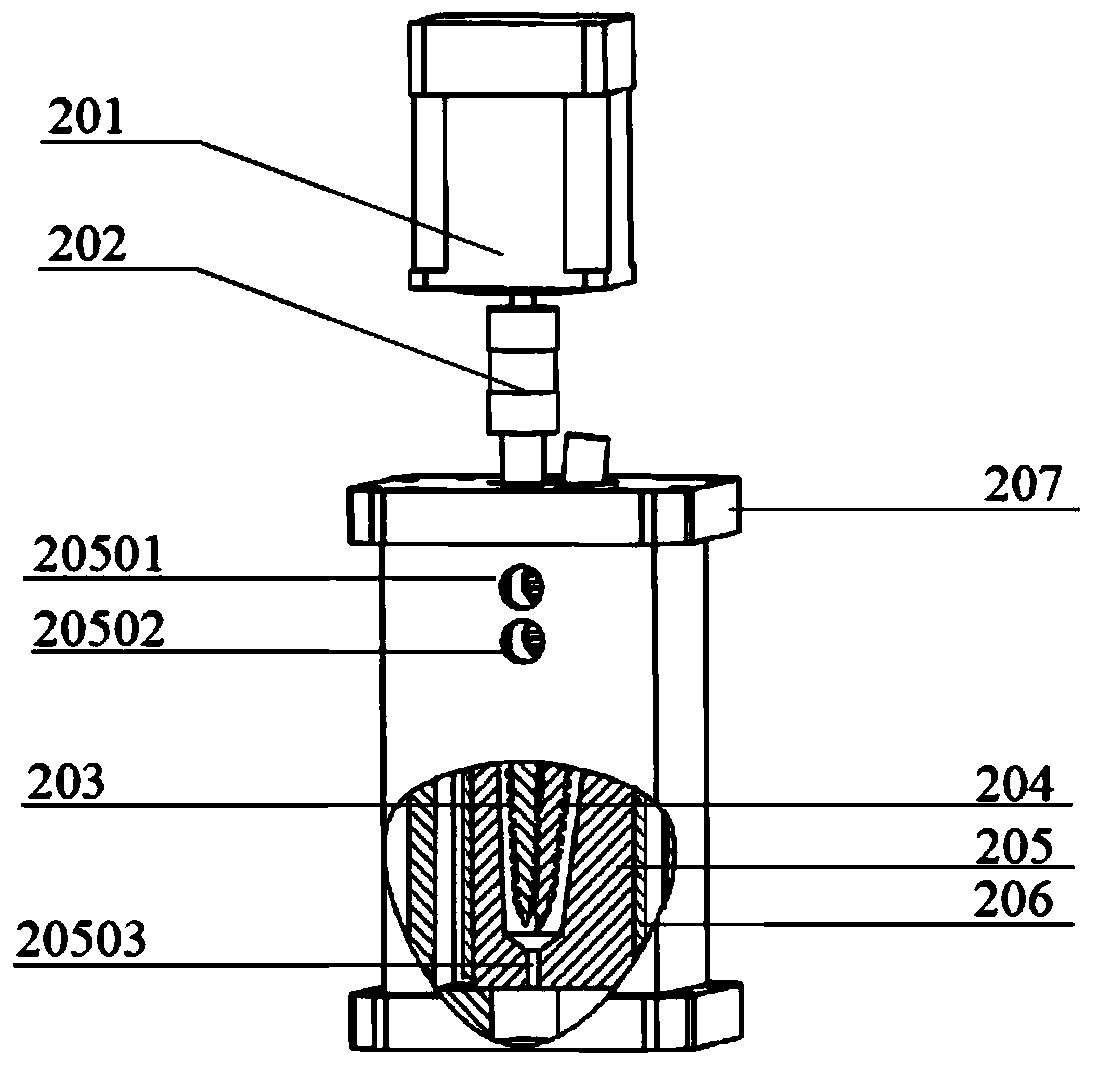

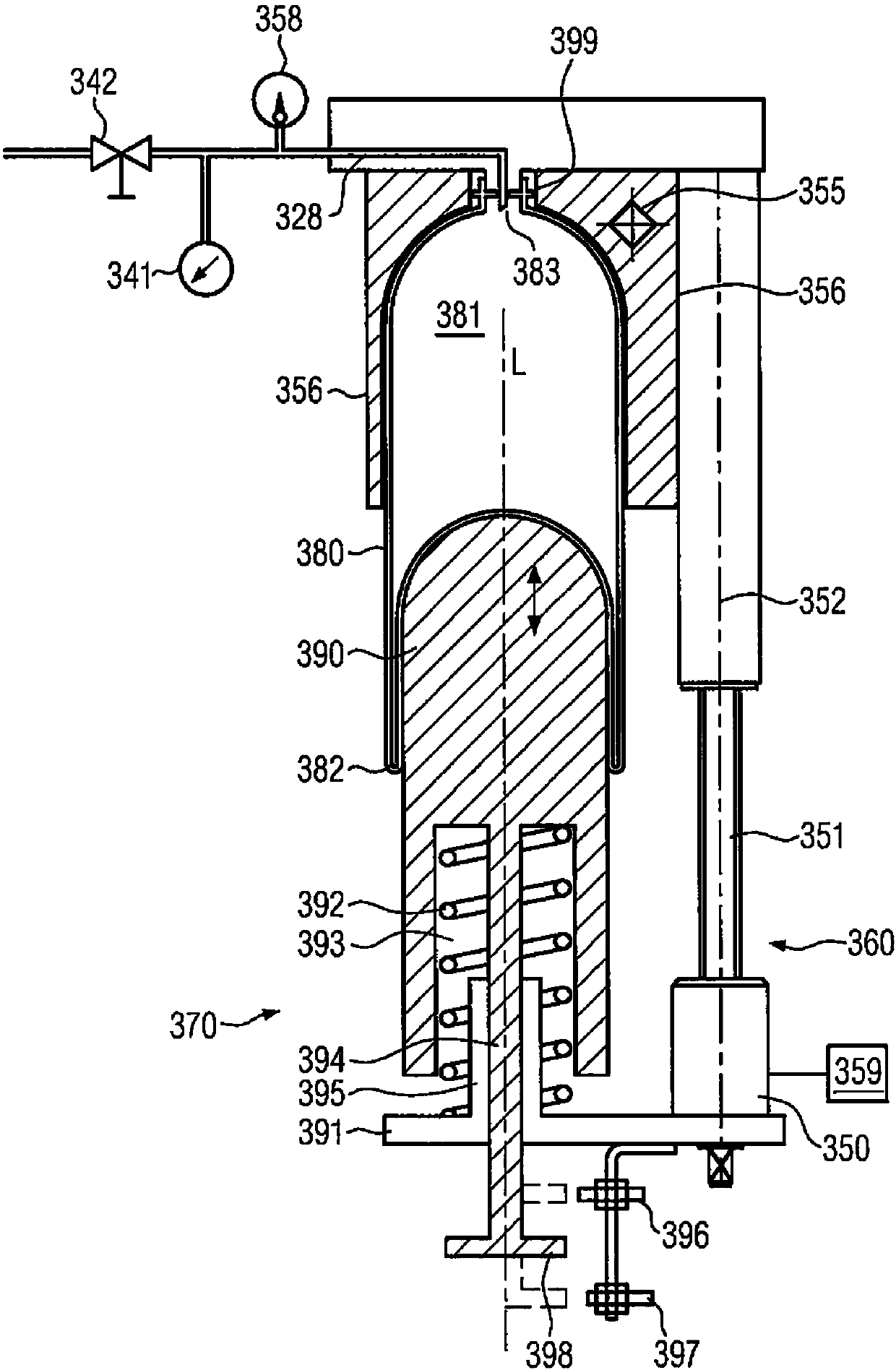

3D printer for integral manufacturing of functionally graded material and forming structure, and working method thereof

PendingCN109732905APrecise Controlled ExtrusionContinuous and stable printingAdditive manufacturing apparatus3D object support structuresImage resolutionEngineering

The invention provides a 3D printer for integral manufacturing of a functionally graded material and a forming structure, and a working method thereof. A feeding module, a mixing module and a printingsprayer are split; and through ingenious arrangement of the components, integral manufacturing of the continuous functionally graded material and the complex three-dimension structure can be achieved. The 3D printer has the characteristics and outstanding advantages of active, efficient and uniform mixing of various materials, high print resolution (due to micro-nano microscale characteristic structure printing), diverse applicable materials, high production efficiency, low cost and simple structure; and particularly, the 3D printer can achieve integral manufacturing of the continuous functionally graded material and the complex three-dimension structure based on material composition and microstructures.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

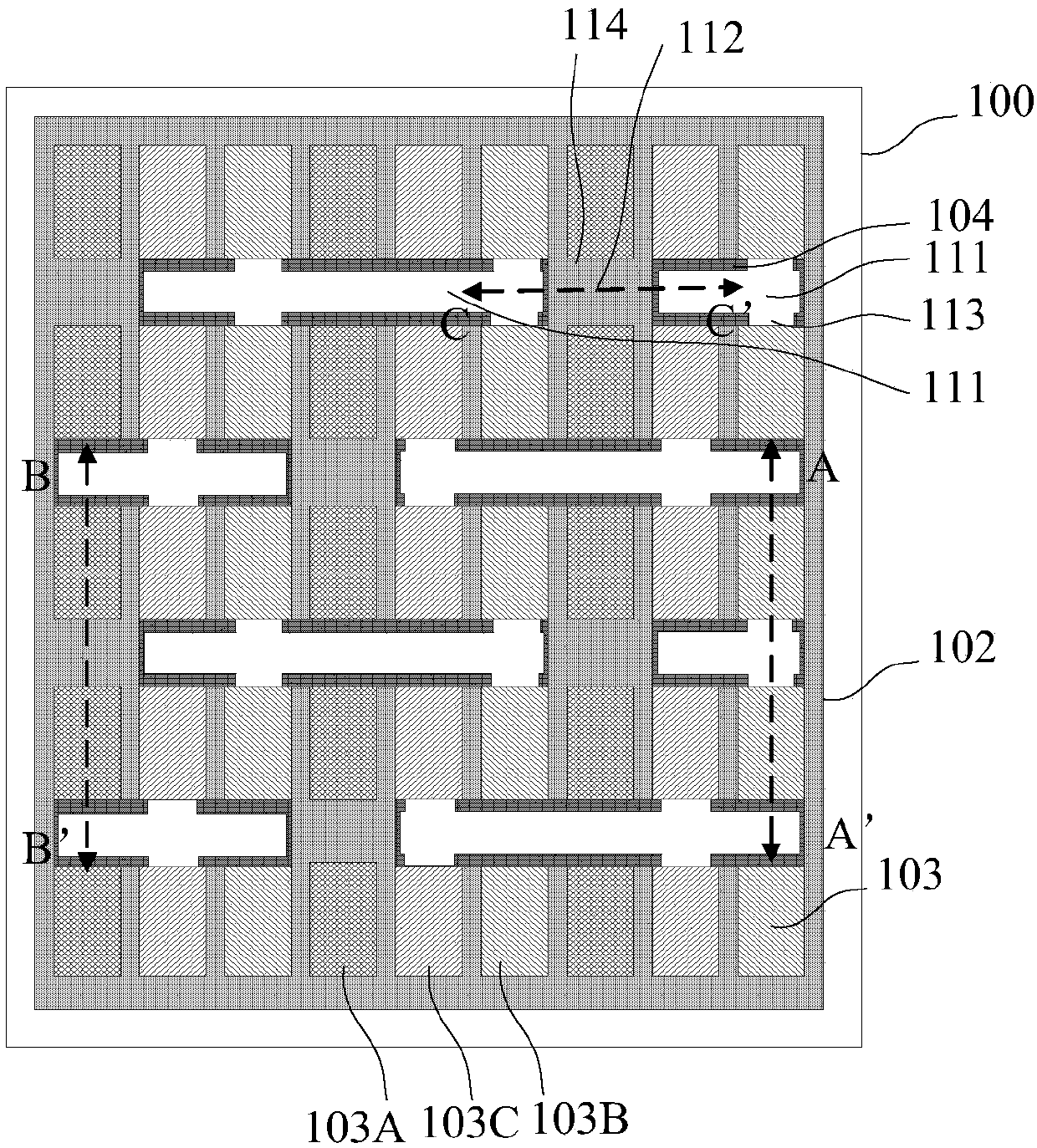

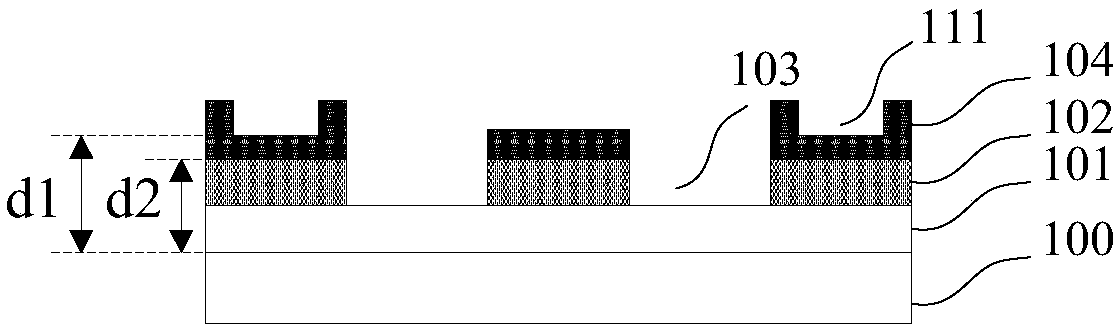

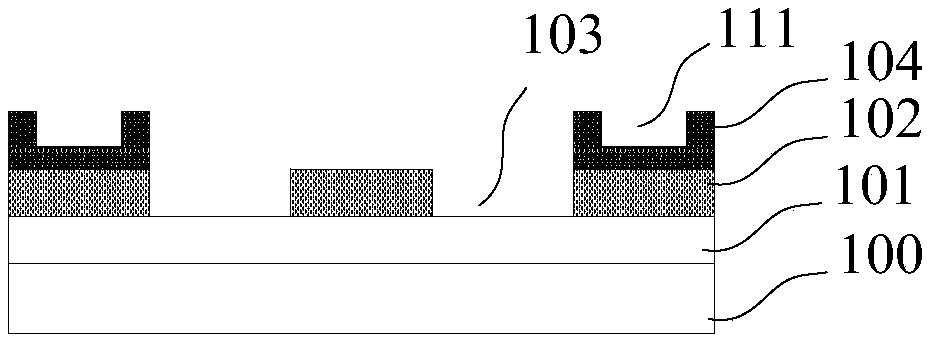

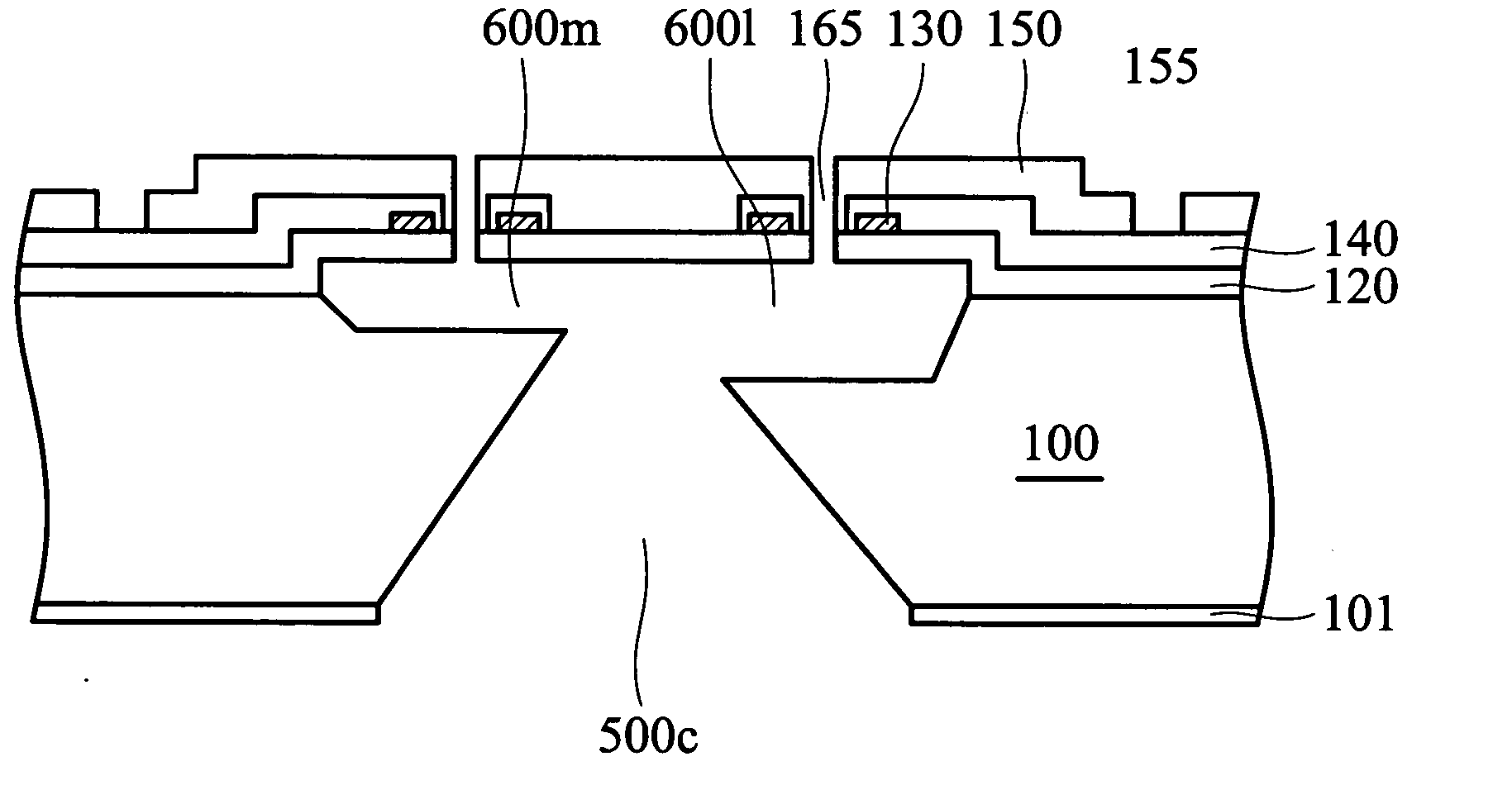

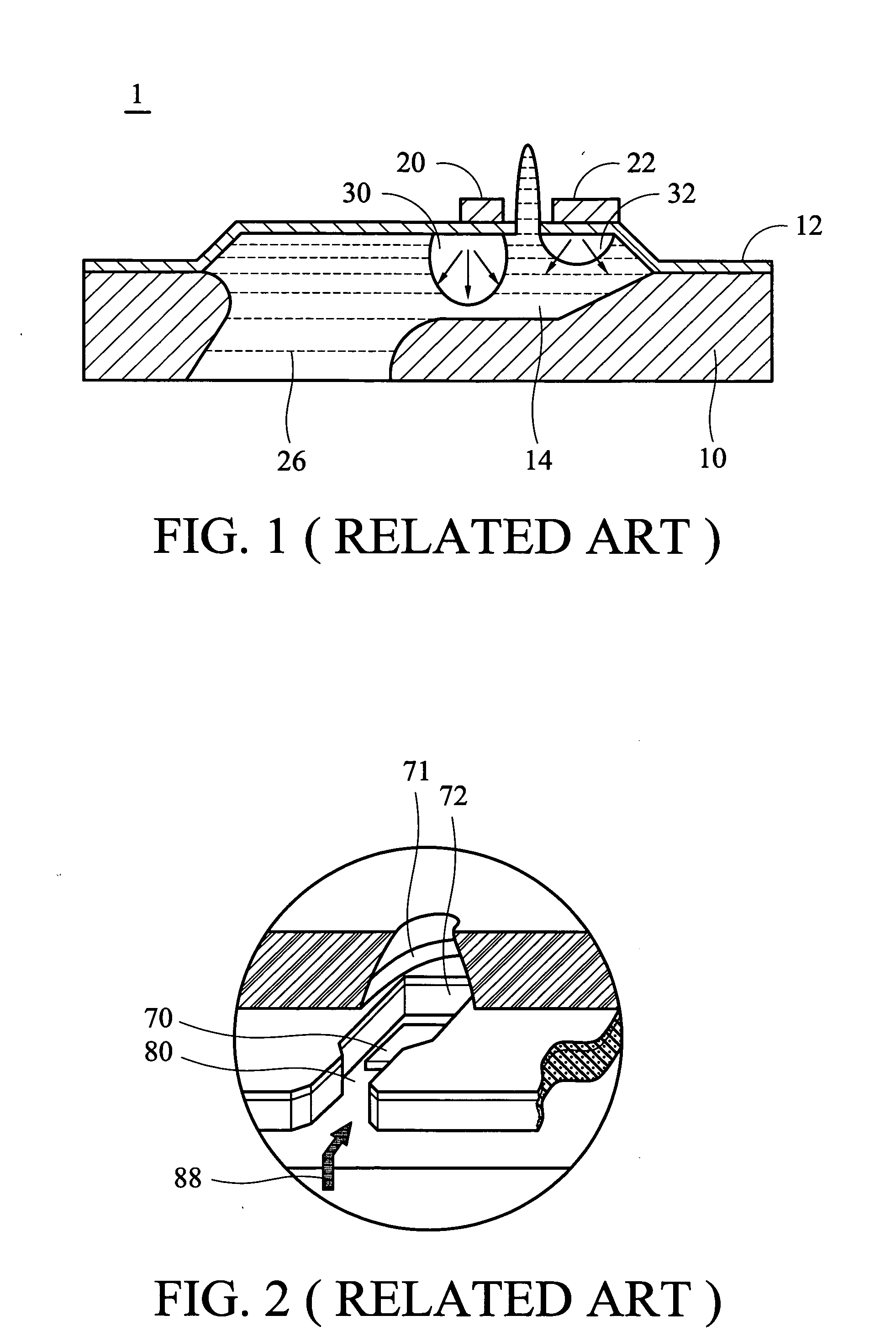

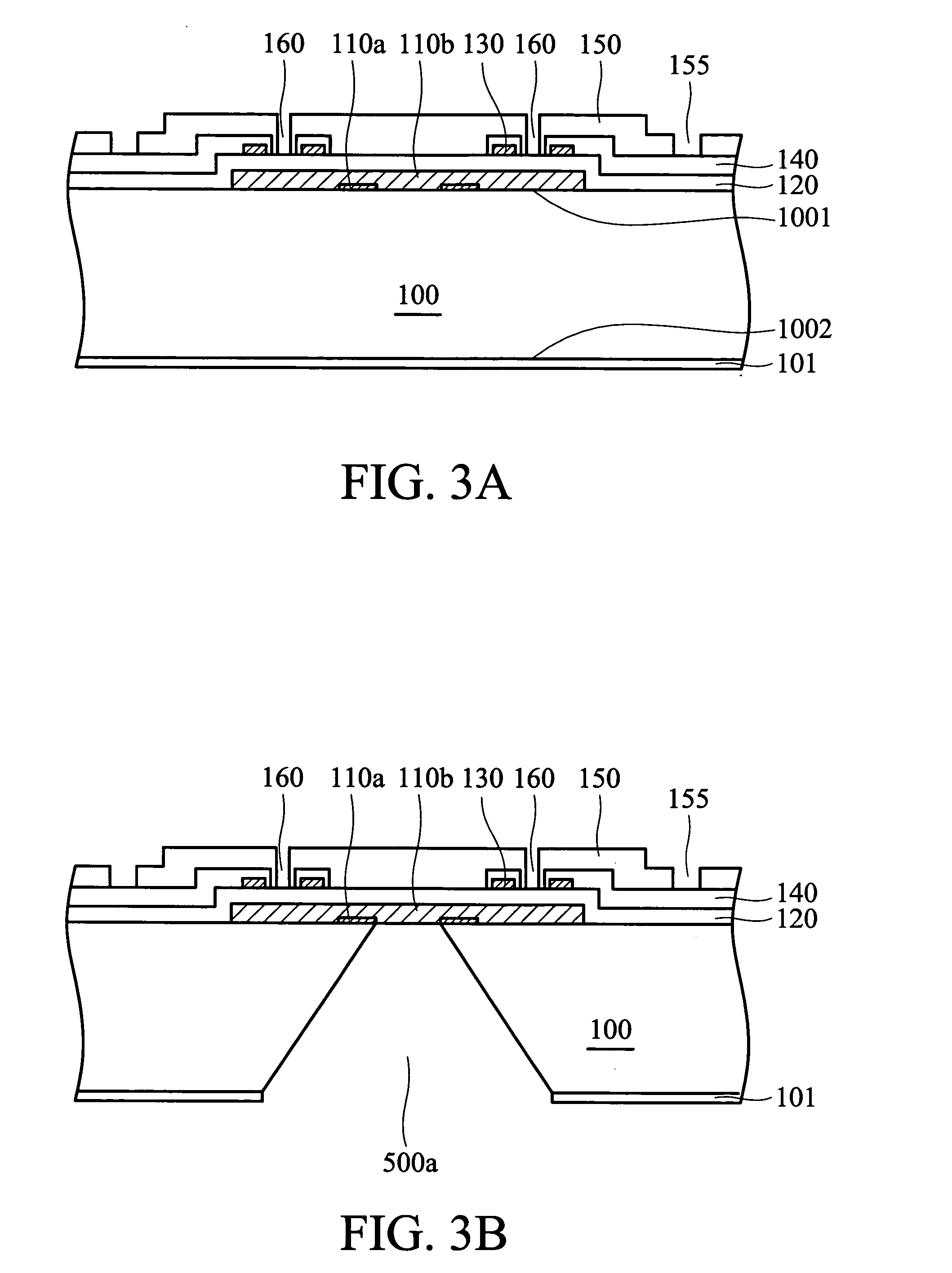

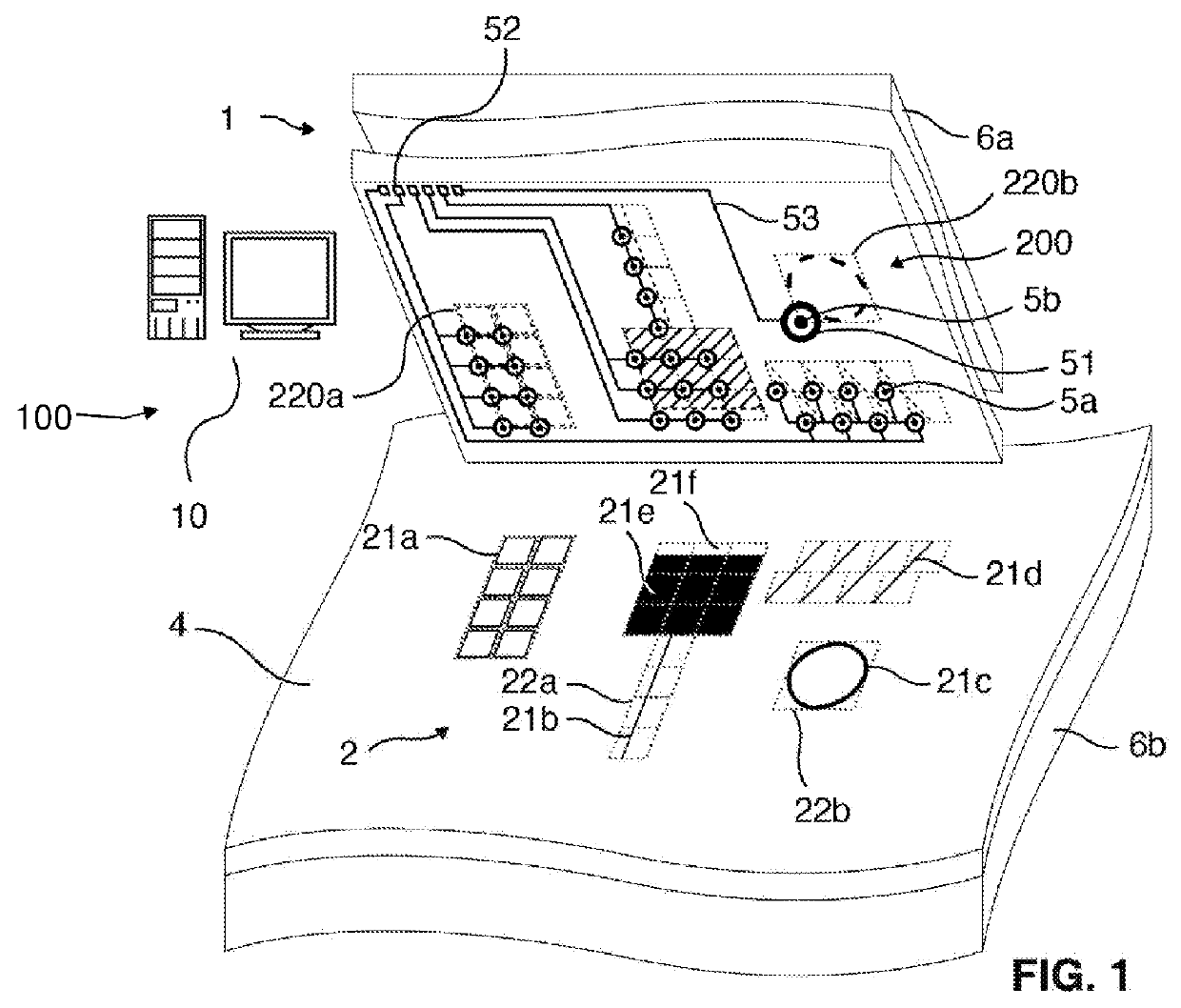

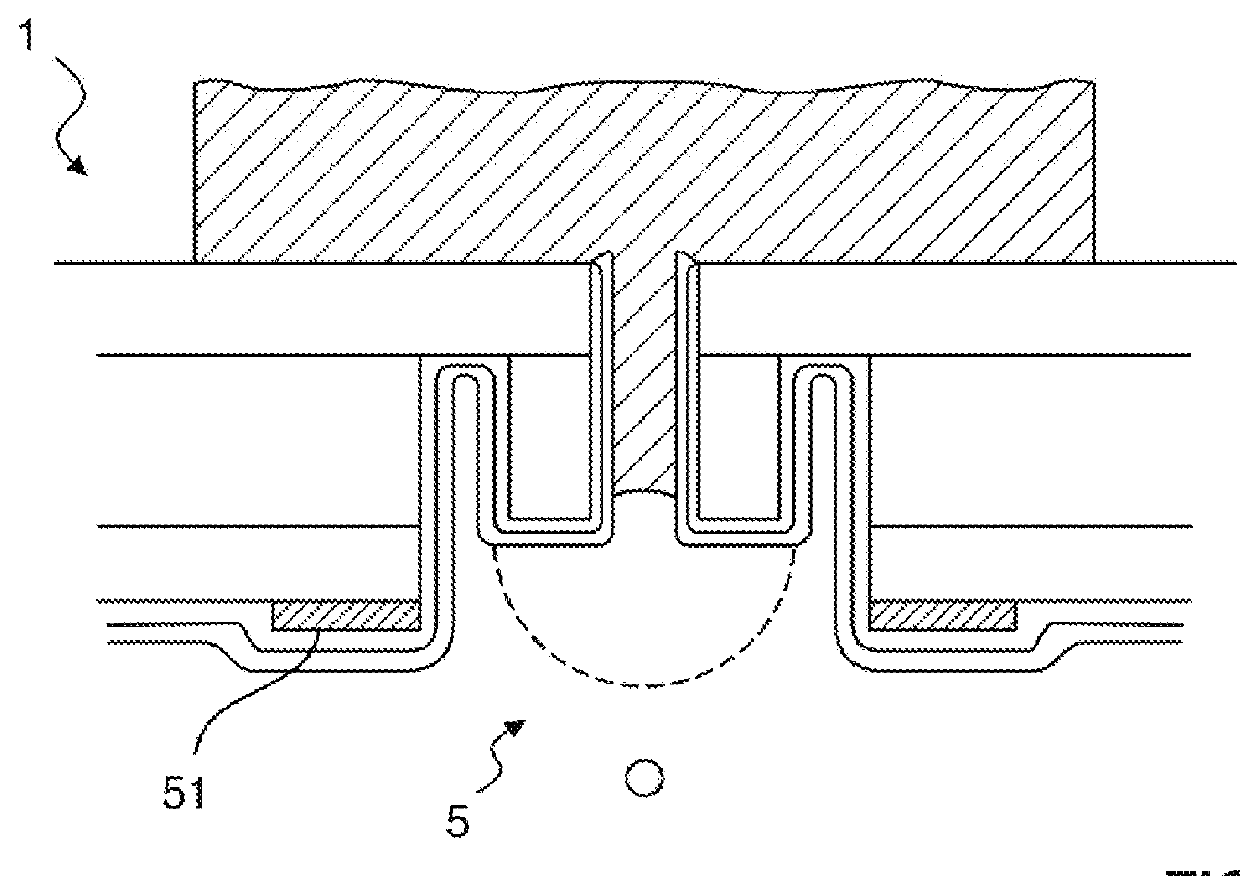

Array substrate, manufacturing method of array substrate, display panel and manufacturing method of display panel

ActiveCN107895736AReduce difficultyHigh print resolutionSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionEngineering

The invention provides an array substrate, a manufacturing method of the array substrate, a display panel and a manufacturing method of the display panel, and relates to the technical field of display. A second pixel defining layer is formed on a first pixel defining layer between two adjacent rows of sub-pixel areas, a plurality of first grooves are formed in the second pixel defining layer, andsecond grooves are formed between every two adjacent first grooves, a first opening is formed in one side, adjacent to the sub-pixel areas, of the first grooves, and a second opening is formed in oneside, adjacent to the sub-pixel areas, of the second grooves. When a light-emitting layer is subsequently printed, the light-emitting material is directly dripped into the first grooves, the first opening can enable the light-emitting material to flow into the sub-pixel areas communicated with the first grooves, and a luminescent material can also be dripped into the second grooves, and flows intothe sub-pixel areas communicated with the second grooves through the second opening. The structure of the pixel defining layers is changed, the printing resolution is improved on the premise that theexisting equipment is not changed, and the difficulty of the printing process is reduced.

Owner:BOE TECH GRP CO LTD

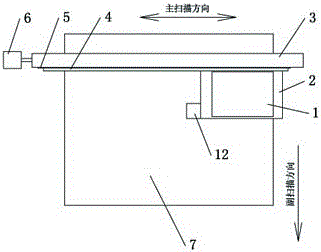

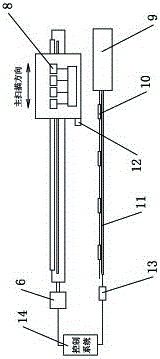

Scanning ink-jet printing method and ink-jet printing apparatus

InactiveCN105856886AImprove stabilityHigh precisionDuplicating/marking methodsOther printing apparatusComputer engineeringInkjet printing

The present invention proposes a scanning inkjet printing method, which is characterized in that it includes the following steps of obtaining the step error value of the printing medium in the scanning direction; correcting the feed value of the printing medium in the sub-scanning direction according to the step error value; using The interpolation printing method prints the image onto a print medium. The inkjet printing method of the present invention can realize accurate and high-precision printing by measuring the conveying error of each part of the paper-feeding roller and compensating the conveying error of each part of the paper-feeding roller before performing interpolation printing.

Owner:BEIJING BOYUAN HENGXIN TECH CO LTD

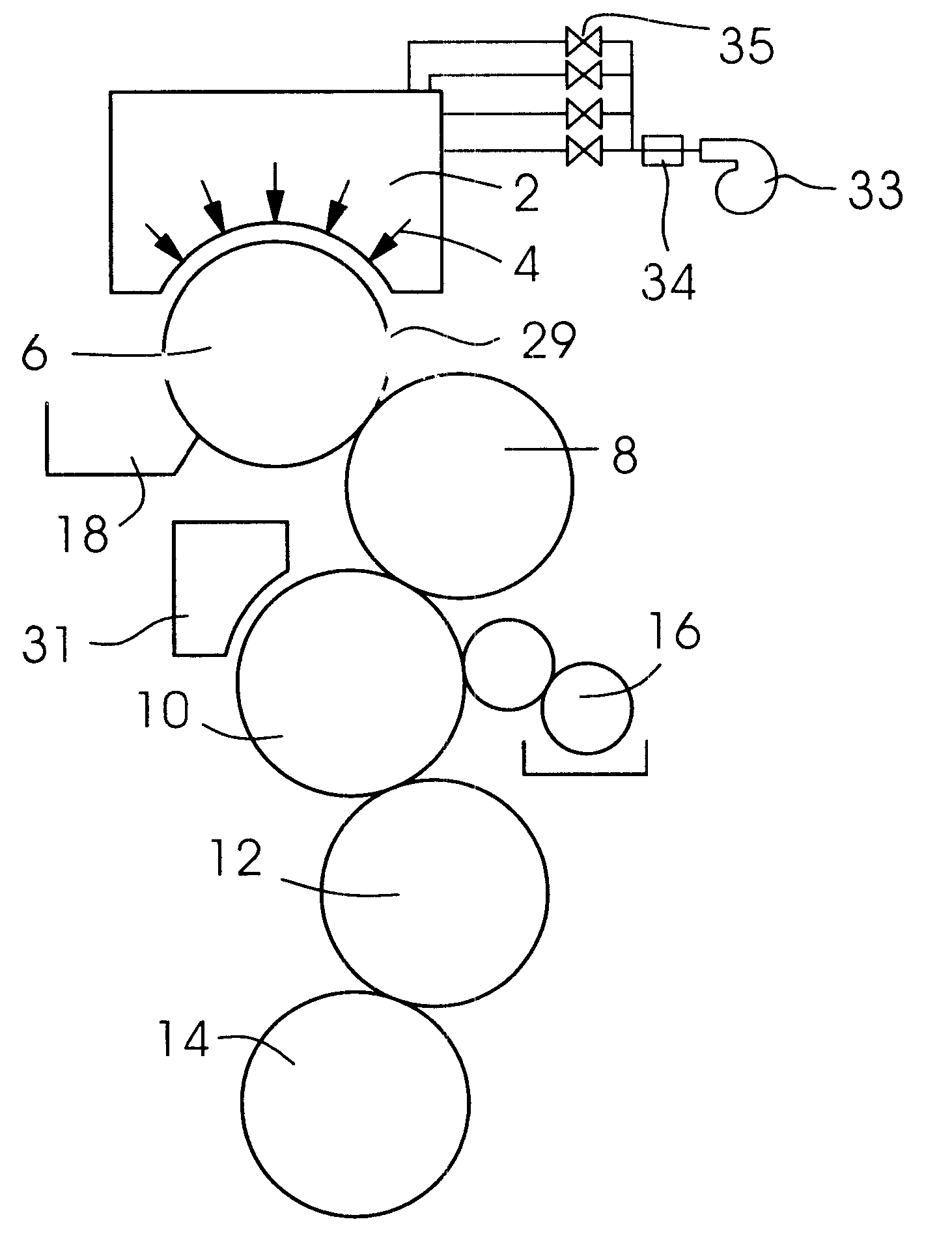

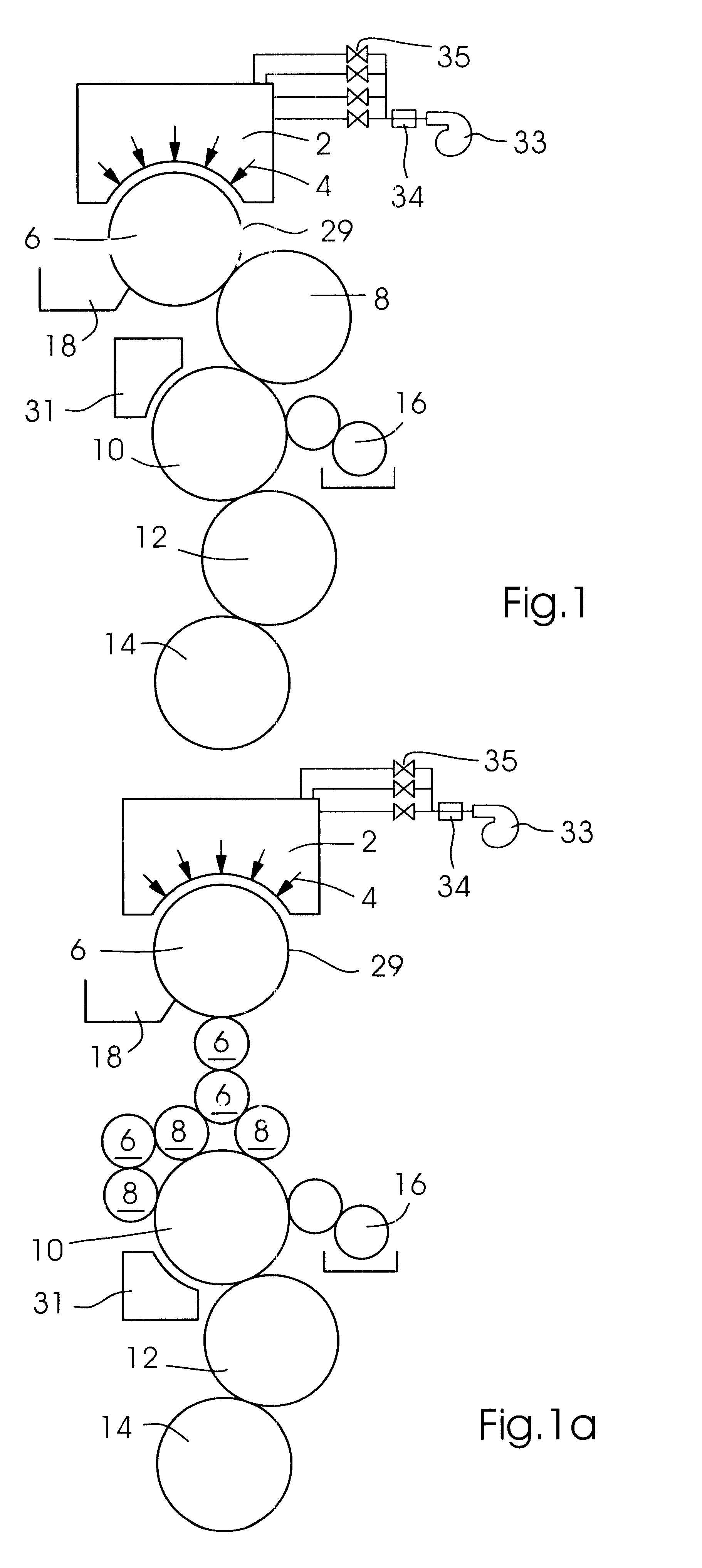

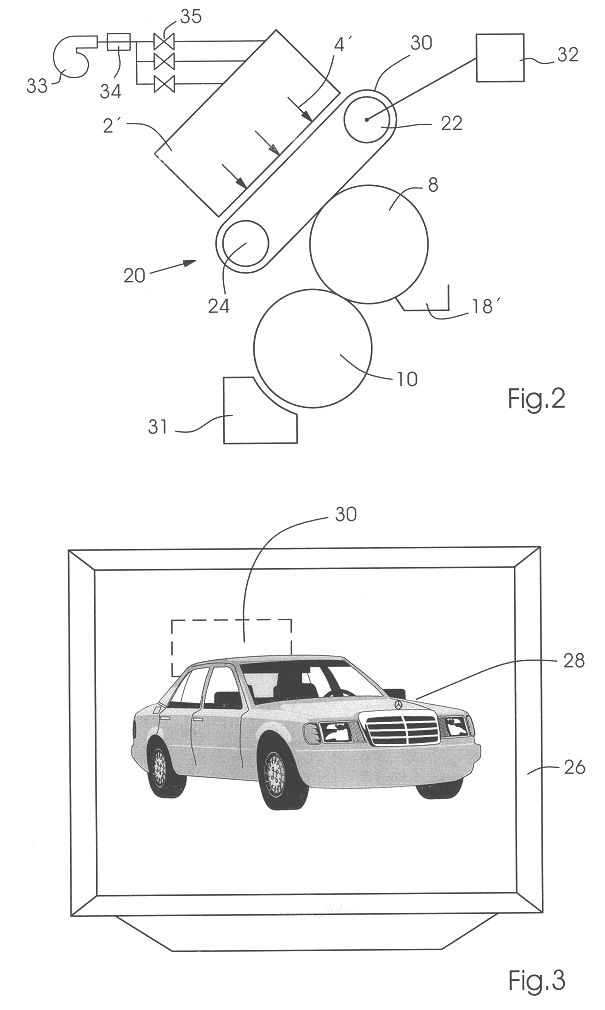

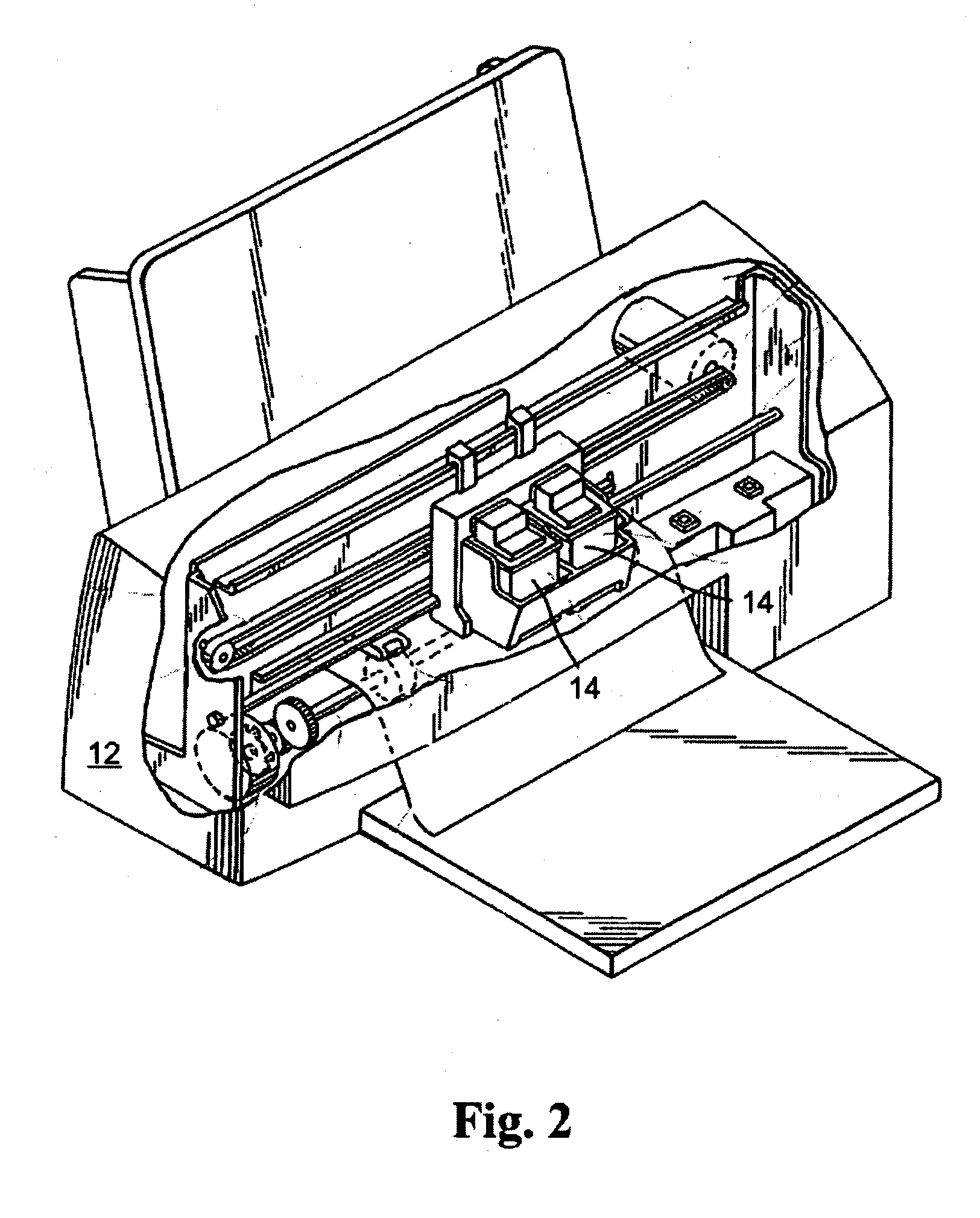

Inking unit

InactiveUS6427591B1High degreeHigh resolutionTypewritersPrinting press partsPrinting inkPrinting press

An inking unit for a printing machine, which includes at least one ink roller rolling on a plate cylinder of the printing machine, an ink jet printing apparatus with a plurality of ink jets that can be controlled selectively, and an ink transfer device with a rotating mantle surface for transferring printing ink from the ink jet printing apparatus to the at least one ink roller. A compact and stencil-free inking unit for high-quality printing is achieved and the at least one ink roller and the ink transfer device, and have the same outside circumference as the plate cylinder.

Owner:HEIDELBERGER DRUCKMASHINEN AG

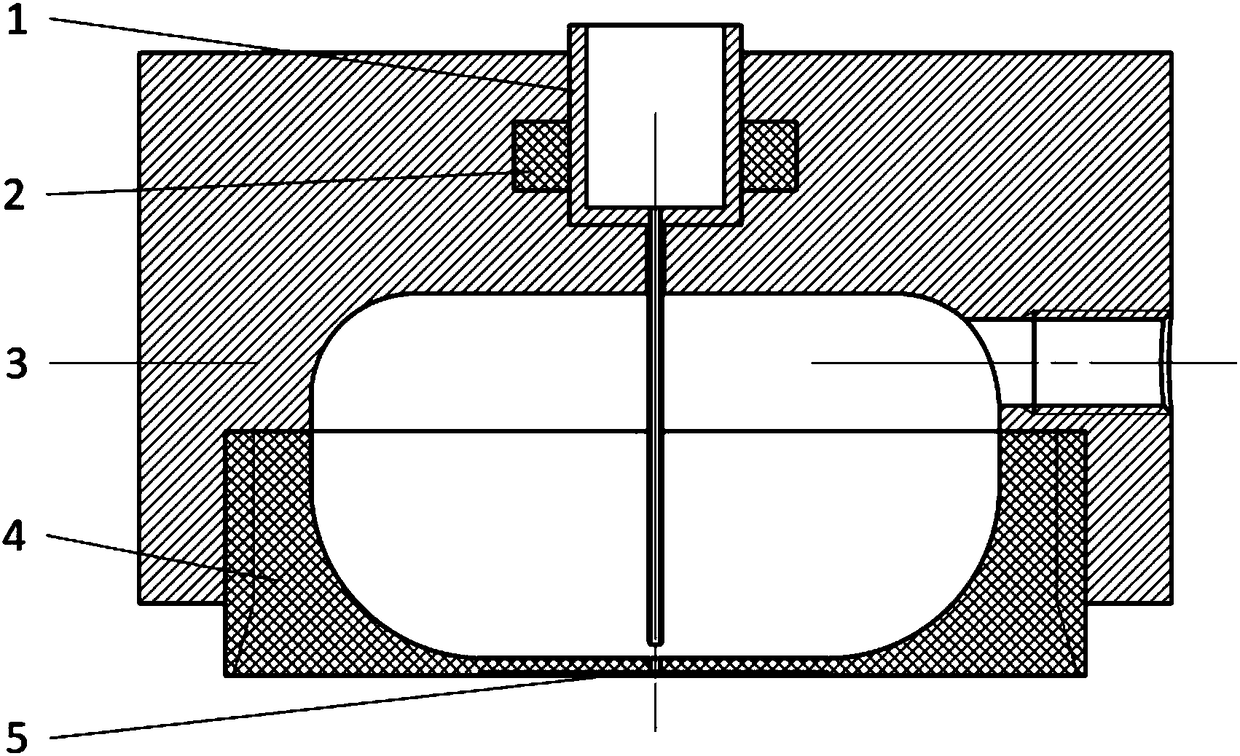

Method for fabricating an enlarged fluid chamber

A method for fabricating an enlarged fluid chamber using multiple sacrificial layers. The method comprises providing a plurality of patterned sacrificial layers between a substrate and a structural layer. A chamber neck is formed between a fluid chamber and a fluid channel using different sacrificial layers with different etching rates. The chamber neck can stabilize ejection of the fluid droplet. Additionally, a single print-head chip with different chamber sizes can also be formed, thereby ejecting droplets with different sizes.

Owner:BENQ CORP

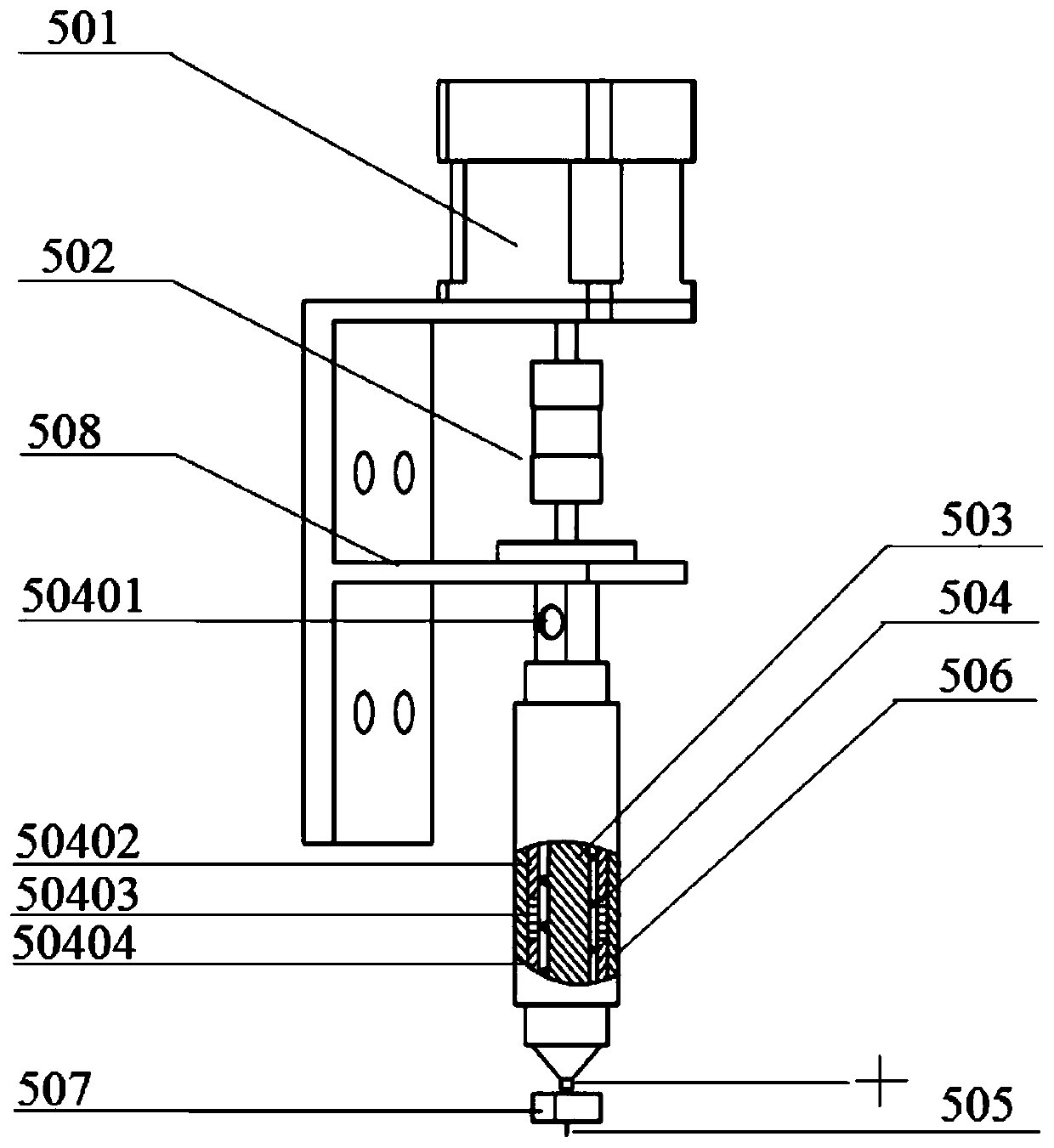

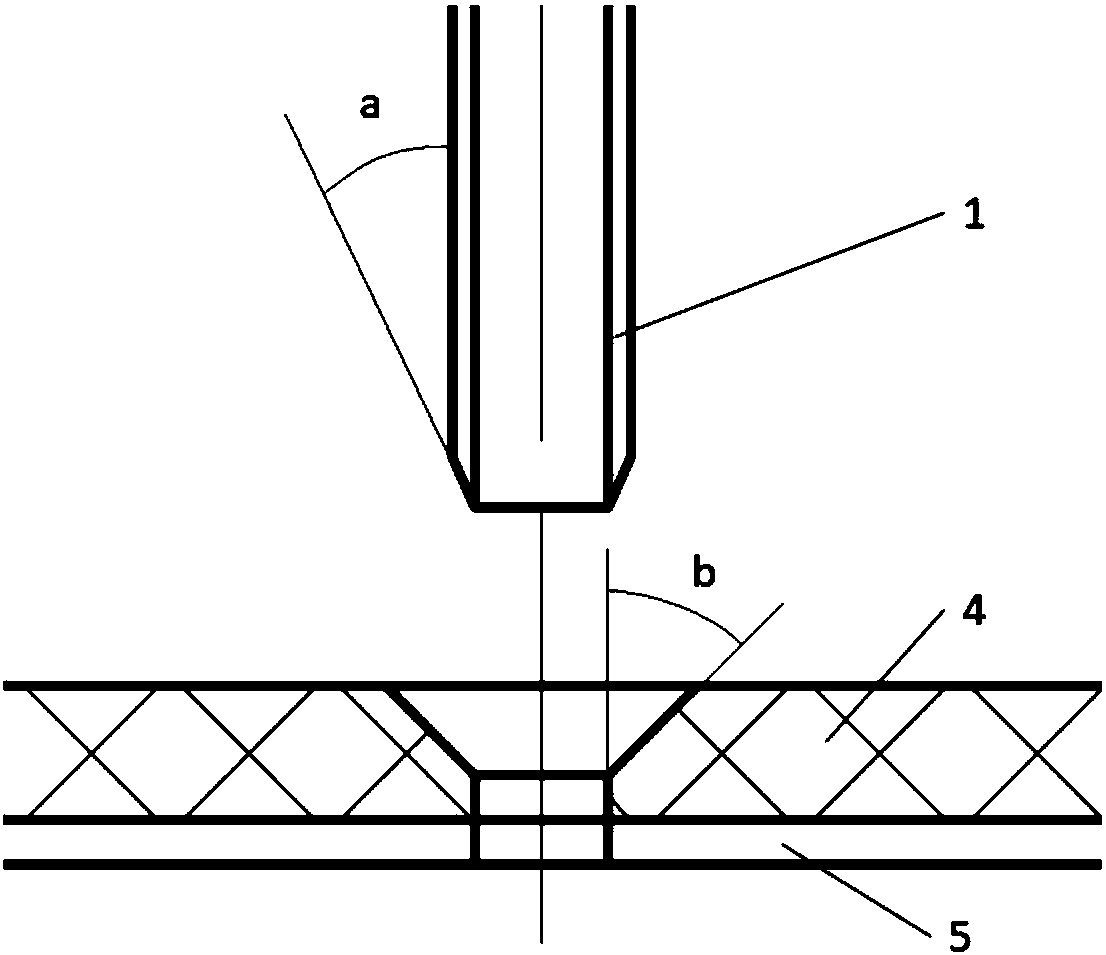

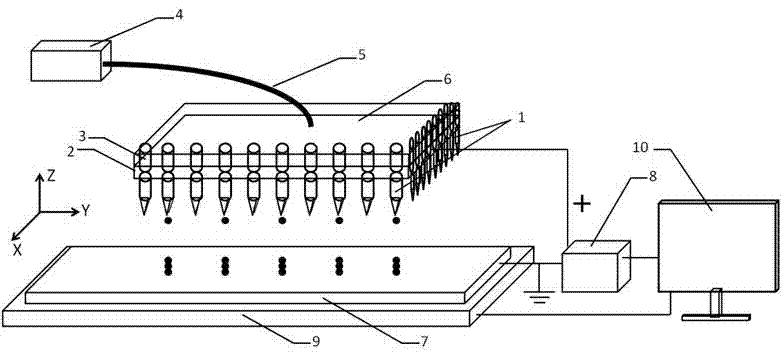

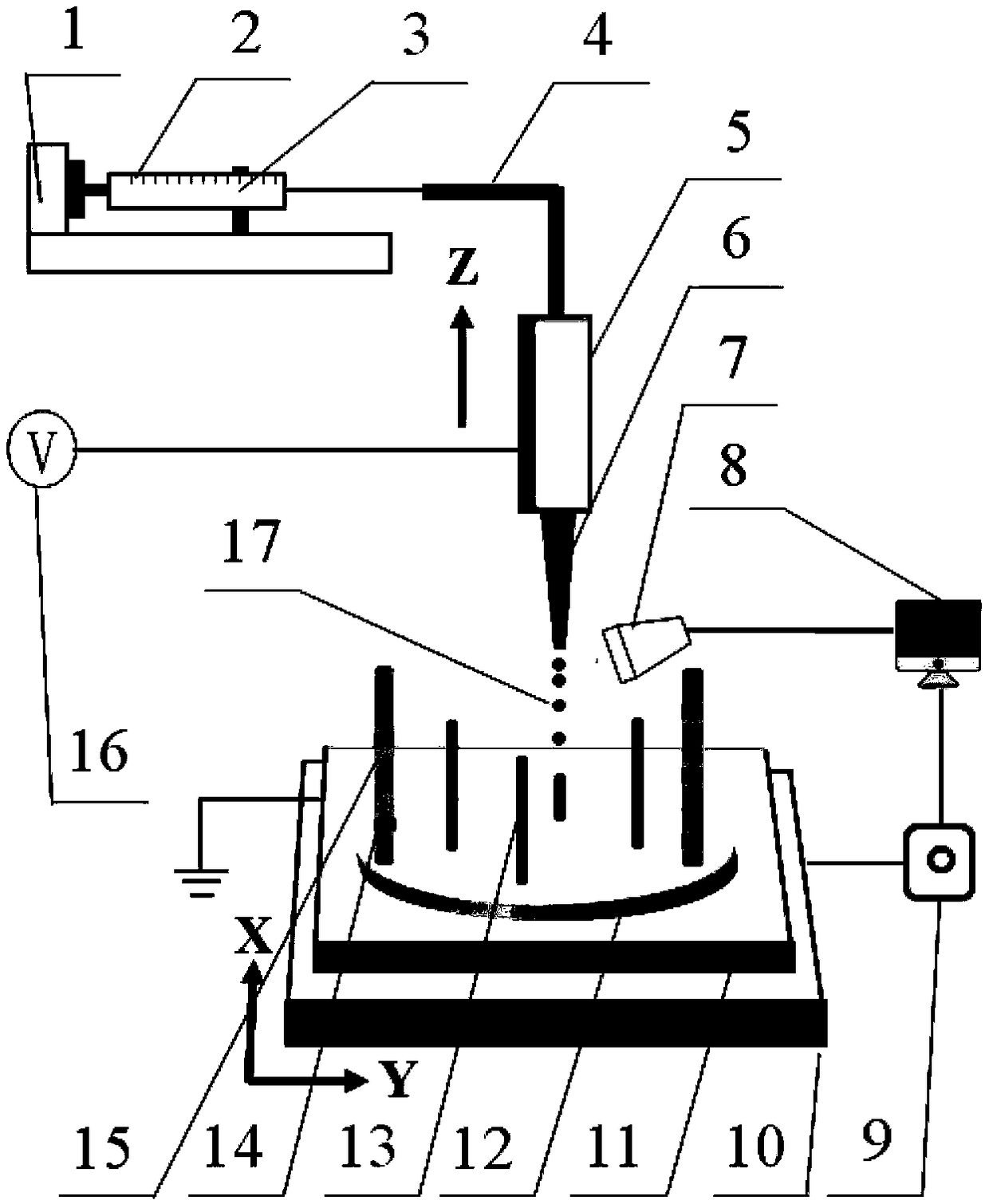

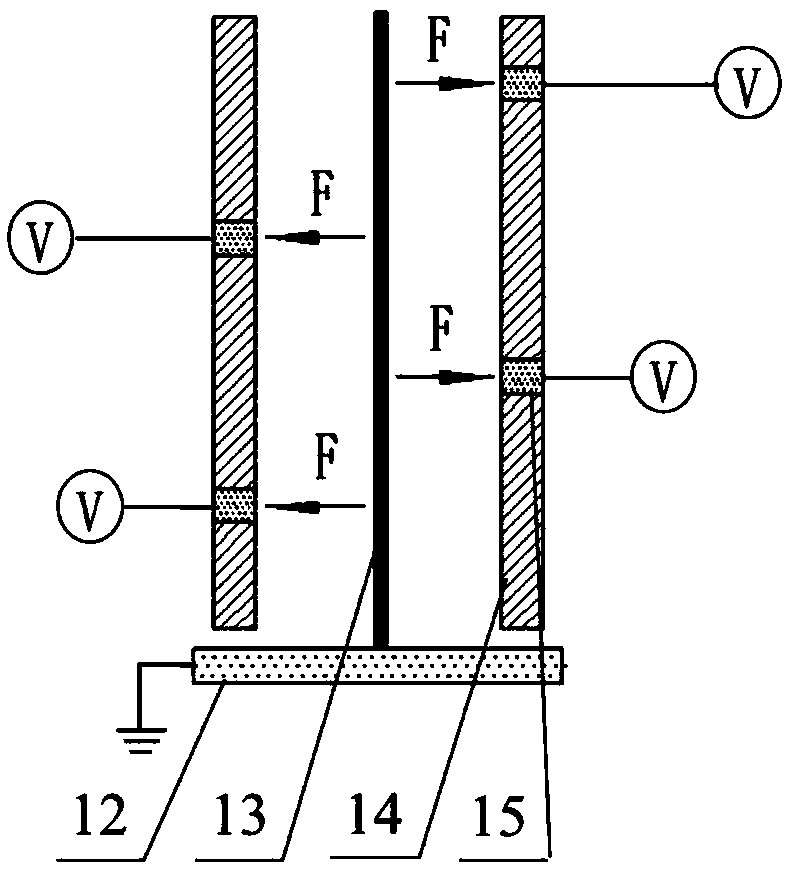

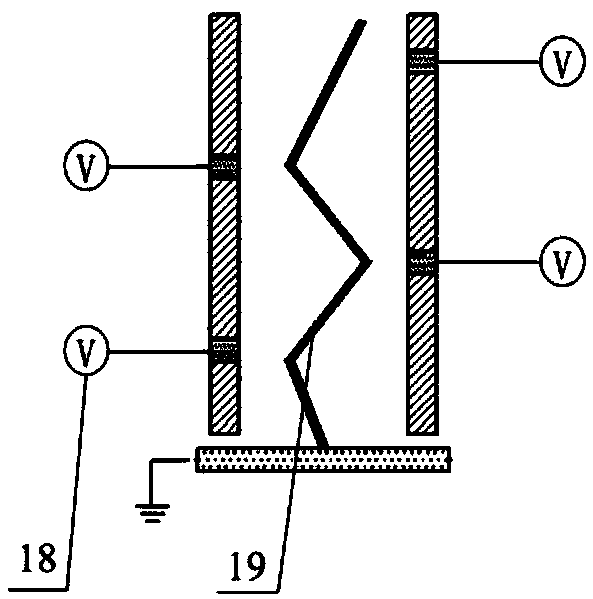

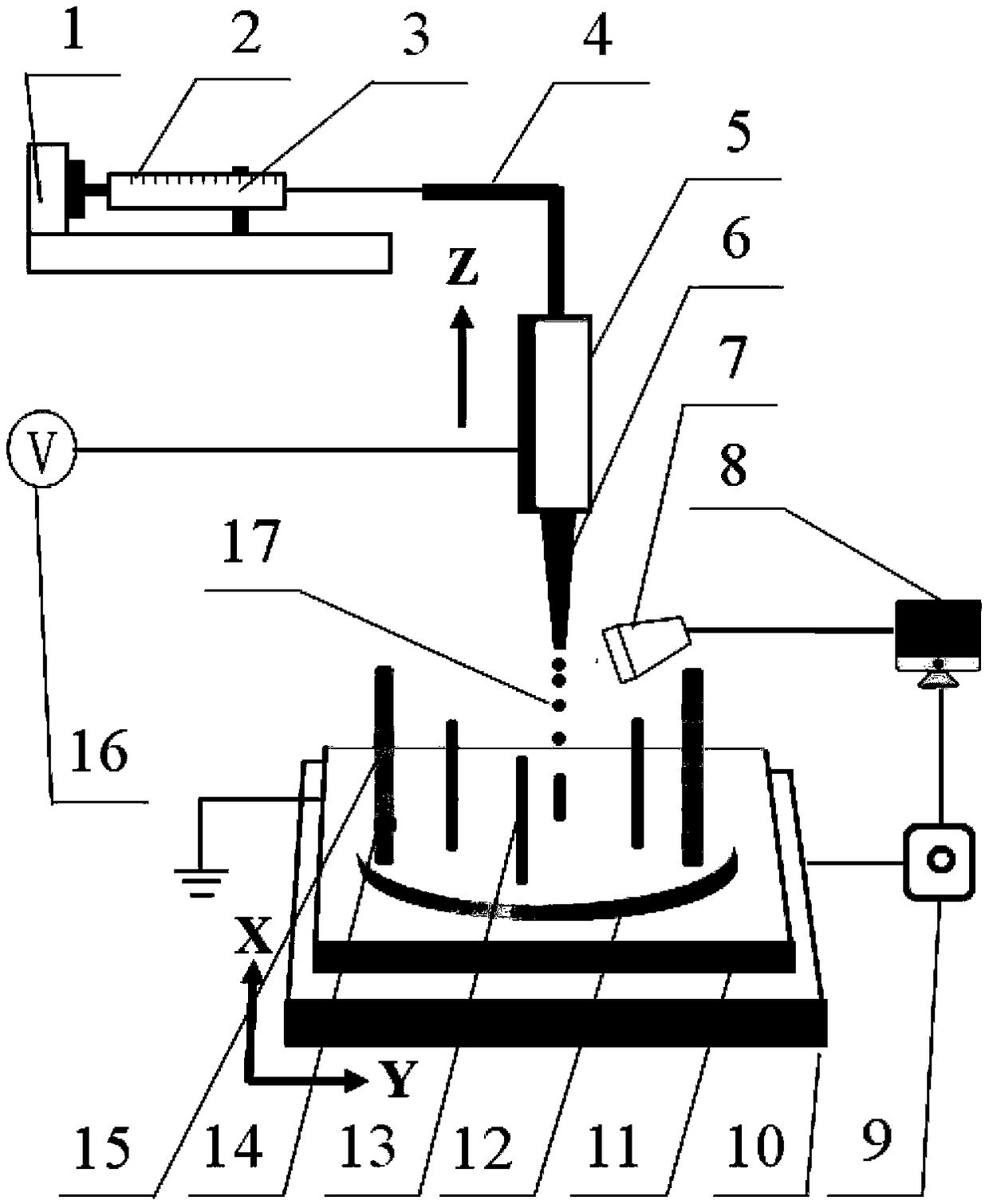

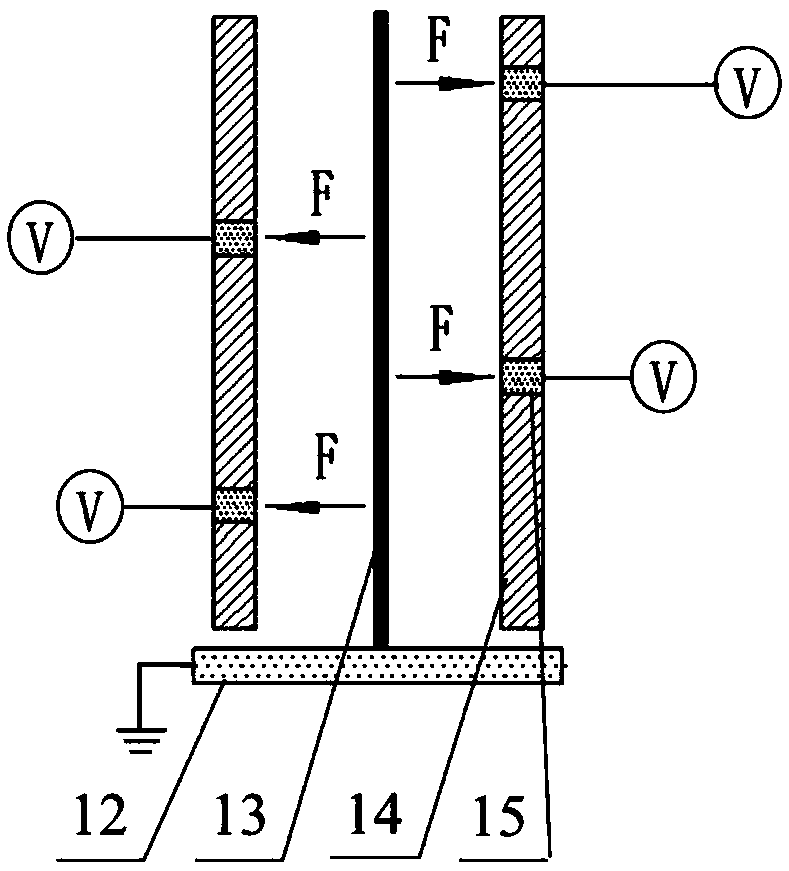

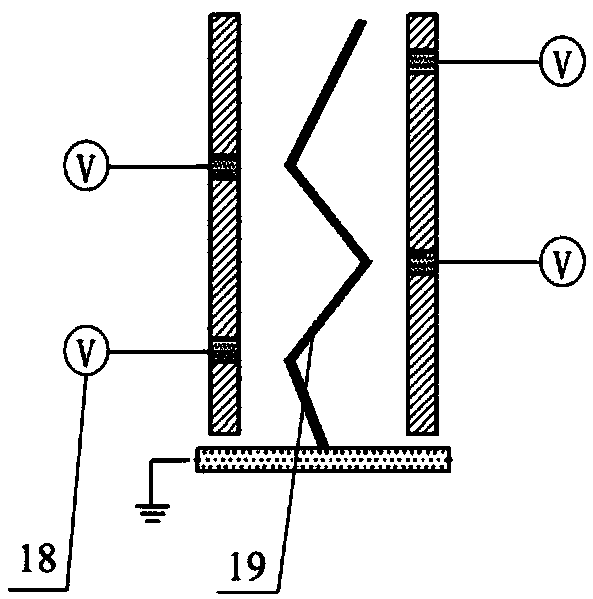

Electric field-flow field mixed controlled electrofluid jet printing method and device

The invention discloses an electric field-flow field mixed controlled electrofluid jet printing method and device and belongs to the technical field of micro / nano fabrication. According to the electric field-flow field mixed controlled electrofluid jet printing method and device, a sprayer outlet pipe is a capillary pipe; a fluid outlet with a chamfering angle is formed in the lower part of the capillary pipe; fluid around the capillary pipe forms a focused stable fluid flow field below a sprayer under the chamfering action of the fluid outlet; a grounding electrode is arranged below the fluidoutlet; a through hole coaxial with the fluid outlet is formed in the grounding electrode; a high voltage static electric field is applied between the sprayer and the grounding electrode; electrofluid flowing out of the capillary pipe forms Taylor Cone and pulls out a jet flow under the combined action of the high voltage static electric field and the fluid flow field; and the jet flow penetratesthrough the fluid outlet and the through hole for printing. According to the electric field-flow field mixed controlled electrofluid jet printing method and device, the electric current jet printingtechnology and the flowing focusing technology are combined to improve the printing precision and resolution ratio and solve the problem that general electrofluid jet printing cannot print on an insulating base plate or the base plate with a free hook face.

Owner:HUAZHONG UNIV OF SCI & TECH

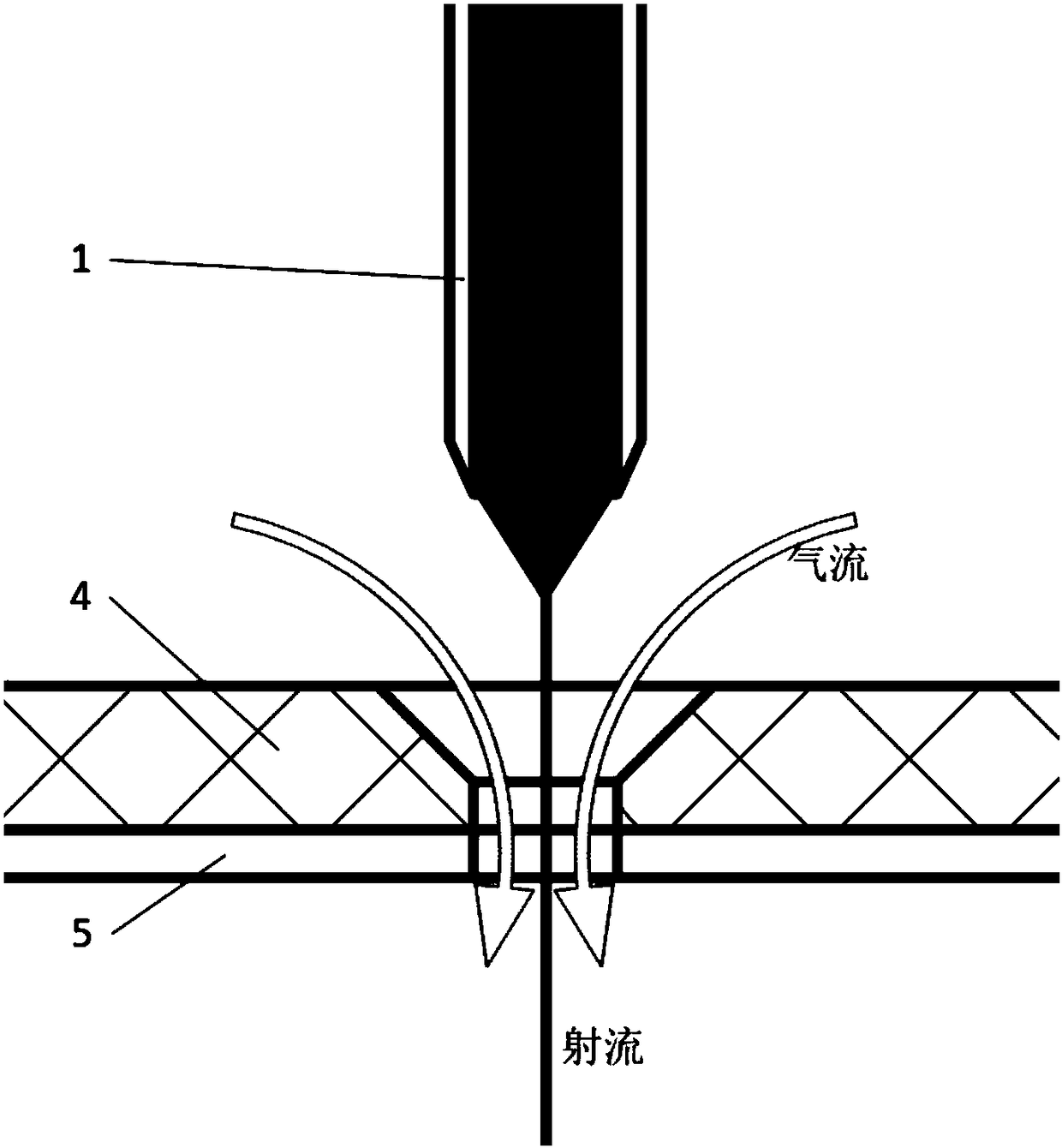

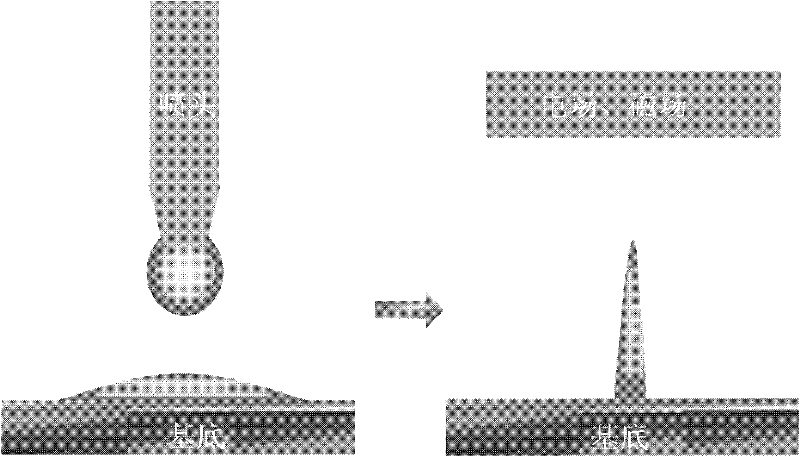

Large-scale ink-jet printing method for three-dimensional metamaterial array

The invention discloses a large-scale ink-jet printing method for a three-dimensional metamaterial array. Through design of a universal sprayer of an M x N nozzle array and a special sprayer of a specific topological structure, pattern information is directly and rapidly printed to a substrate through the nozzle array, and then a large-scale nano structure array can be rapidly and conveniently obtained. Through accurate control over the movement of a displacement table, the size and appearance features of the nano structure can be controlled, and three dimension, inclination, bending, spiral, a heterostructure and the like are included. By utilization of the ink-jet printing method, various complex topological structure arrays can be prepared. The large-scale ink-jet printing method is applicable to various materials and substrates and is widely applied to the demand field of different devices.

Owner:SOUTHEAST UNIV

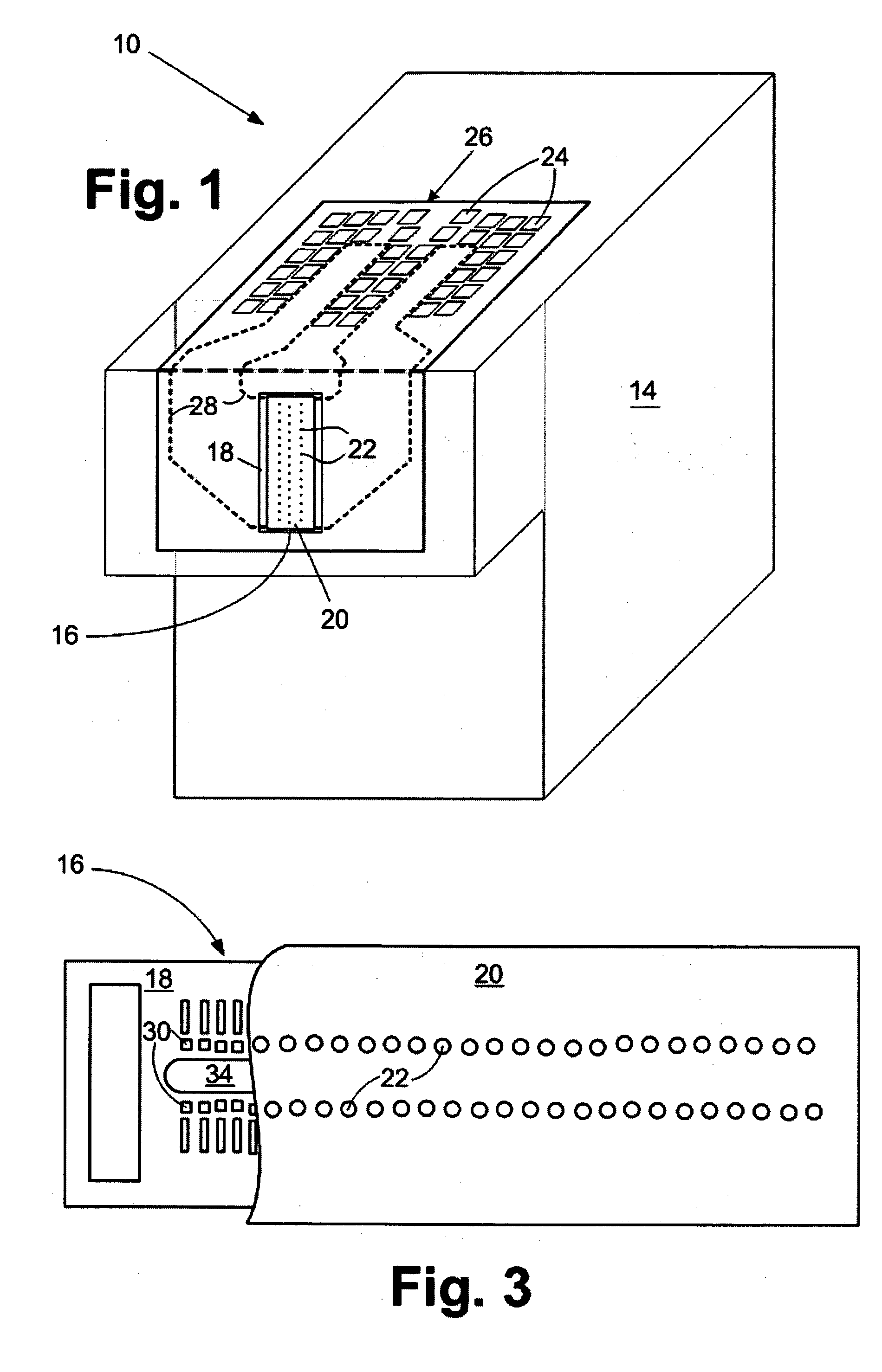

High resolution ink jet printhead

A high resolution printhead for an ink jet printer. The printhead includes a semiconductor substrate containing at least one ink feed edge and a plurality of ink ejection actuators spaced a distance from the ink feed edge. Each of the ink ejection actuators has an aspect ratio ranging from about 1.5:1 to about 6:1. A nozzle plate is attached to the semiconductor substrate. The nozzle plate contains a plurality of nozzle holes, ink chambers and ink channels laser ablated in the nozzle plate corresponding to the plurality of ink ejection actuators. Adjacent nozzle holes are spaced apart with a pitch ranging from about 600 to about 1200 dpi. The distance from the ink feed edge is substantially the same for each of the ink ejection actuators.

Owner:SLINGSHOT PRINTING LLC

Three-dimensional printing device capable of realizing electric field induction assisted electrospray

ActiveCN109228304AHigh print resolutionFast molding speedAdditive manufacturing apparatusAdditive manufacturing with liquidsLine widthElectric field

The invention belongs to the technical field of advanced manufacture and relates to a device for manufacturing a three-dimensional structure by electric field induction assisted electrospray printing.The device comprises an electrospray printing module and an electric field induced forming module. The electrospray printing module is used for delivering a functional material solution into a sprayneedle, shearing the functional material solution by utilizing an electric field force applied to the spray needle to form a micro / nano-scale stable jet flow smaller than the size of the spray needleand printing a micro / nano structure; and the electric field induced forming module is used for regulating and controlling the structure by utilizing a spatial electric field force generated by an induction electrode, and a complex micro / nano three-dimensional structure is obtained by electric field induction, stress deformation, cooling for curing and three-dimensional molding. The complex micro / nano three-dimensional structure manufactured by using the three-dimensional printing device disclosed by the invention has the advantages such as free molding of the spatial three-dimensional structure, high printing resolution and high molding speed, the complex micro / nano three-dimensional structure manufactured by using the device has the line width of dozens of nanometers, and the complex micro / nano three-dimensional structure manufactured by printing is widely applied to the fields such as electronics, information and energy.

Owner:DALIAN UNIV OF TECH

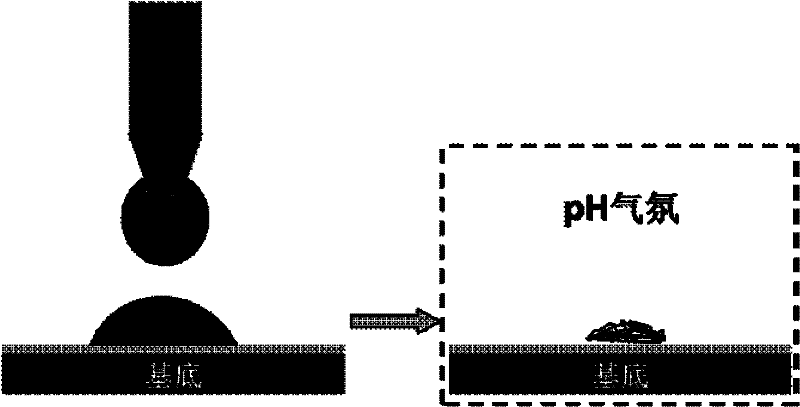

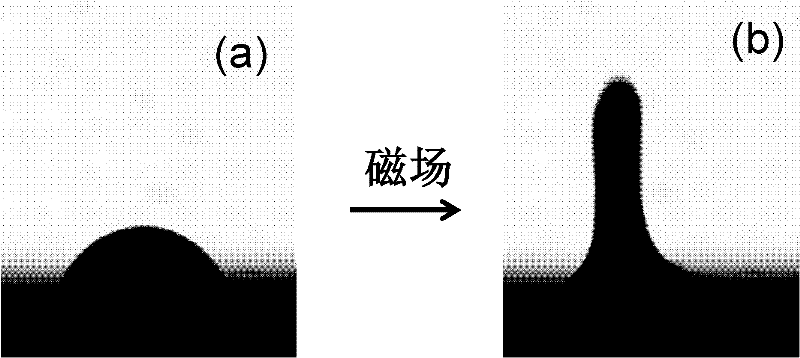

Method for improving resolution of inkjet printing by inducing de-infiltration of ink droplets based on external stimulus

The invention belongs to the technical field of inkjet printing and relates to a method for improving the printing resolution by inducing de-infiltration of ink droplets based on external stimulus. The method comprises the following steps: firstly dispersing inorganic particles or a polymer with external stimulus response in an appropriate substrate to get ink with the external stimulus responsiveness, then spraying the ink with the external stimulus responsiveness through an inkjet printing device, enabling the ink droplets to generate shape change and volume contraction or only generate thevolume contraction due to induction of the external stimulus before curing so as to generate de-infiltration on the substrate, further reducing the deposition area of the ink droplets on the substrate, appropriately curing the ink droplets, and finally improving the printing resolution of inkjet printed contents. The method for improving the printing resolution of the inkjet printed contents is simple to operate, has the characteristics of low cost, no special requirements on equipment, greatly improved resolution and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Print pattern generation on a substrate

A method of printing a print pattern onto a substrate with a print head comprises a plurality of nozzles, where the print head has a rectangular active print head area which includes all of the nozzles. The active print head area is delimited by four sides defining a primary and a secondary direction. The method comprises i) decomposing the print pattern into a plurality of print pattern segments that have dimensions along the primary and secondary direction which are smaller than the dimensions of the active print head area along the primary and secondary direction; ii) assigning each print pattern segment to exactly one nozzle; iii) causing each nozzle to print the print pattern segment assigned to said nozzle. The print head is moved during printing of each print pattern segment within an area that is smaller than said active print head area.

Owner:ETH ZZURICH

Environmental-friendly inkjet ink composition

InactiveUS20070123607A1High print resolutionImprove adhesionFilm/foil adhesivesInksAcetoacetatesOrganic solvent

There is provided an environmental-friendly inkjet ink composition, comprising an organic solvent, a pigment or a dye, a surfactant, a dispersant, and a wetting agent. The low-toxic, non-pungent, and high-boiling polyethylene glycol ether solvent, the fruit smelling acetoacetate solvent, the food grade resin, and the non-harmful additives containing silicon are used in the inkjet ink composition. Such an inkjet ink composition has excellent humectancy, high printing resolution, and has very good adhesion to a wide variety of substrates when applied in printing. Also, the inkjet ink composition is non-pungent, environmental-friendly and found no harmful to human bodies.

Owner:JETQ CORP

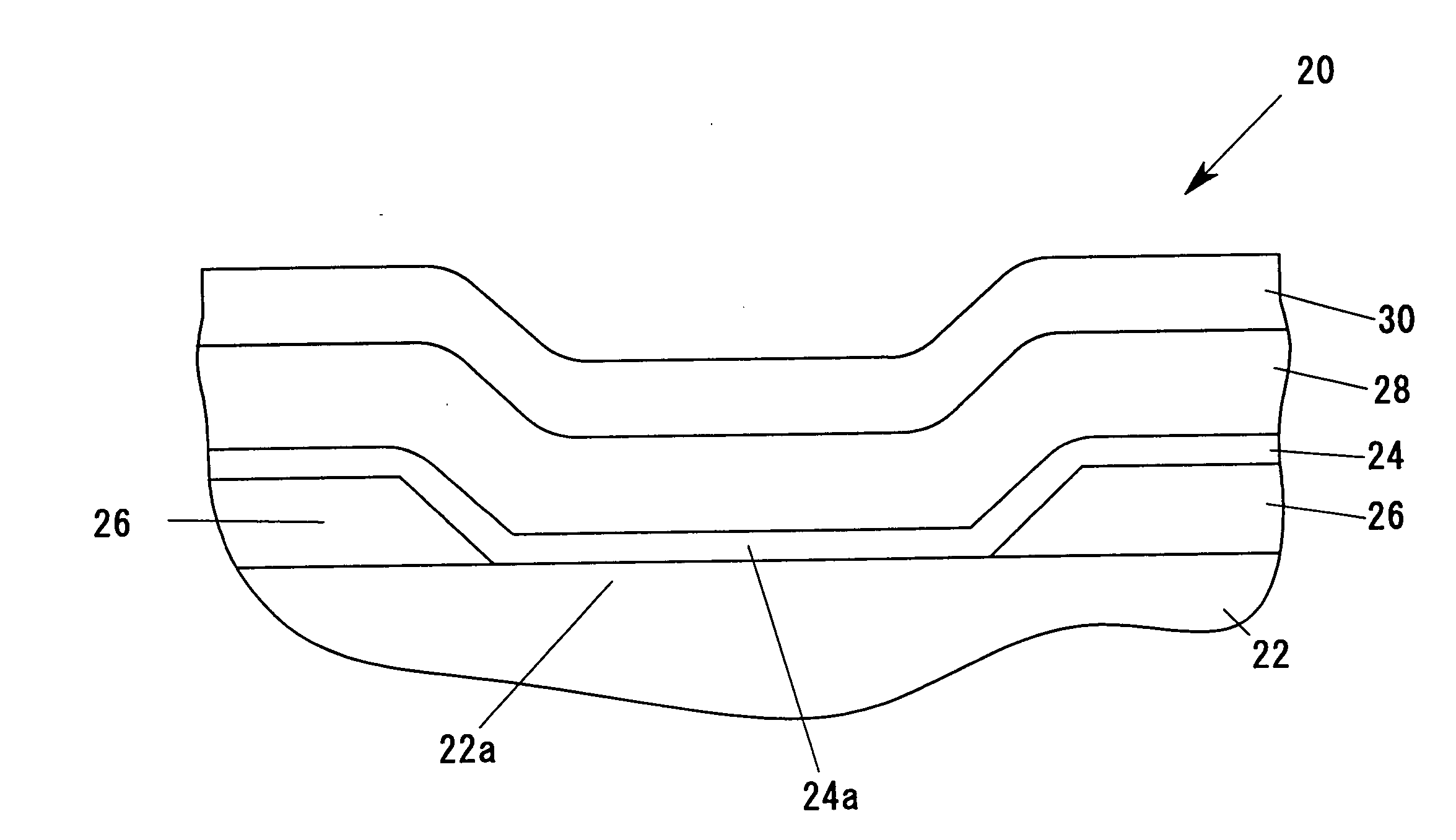

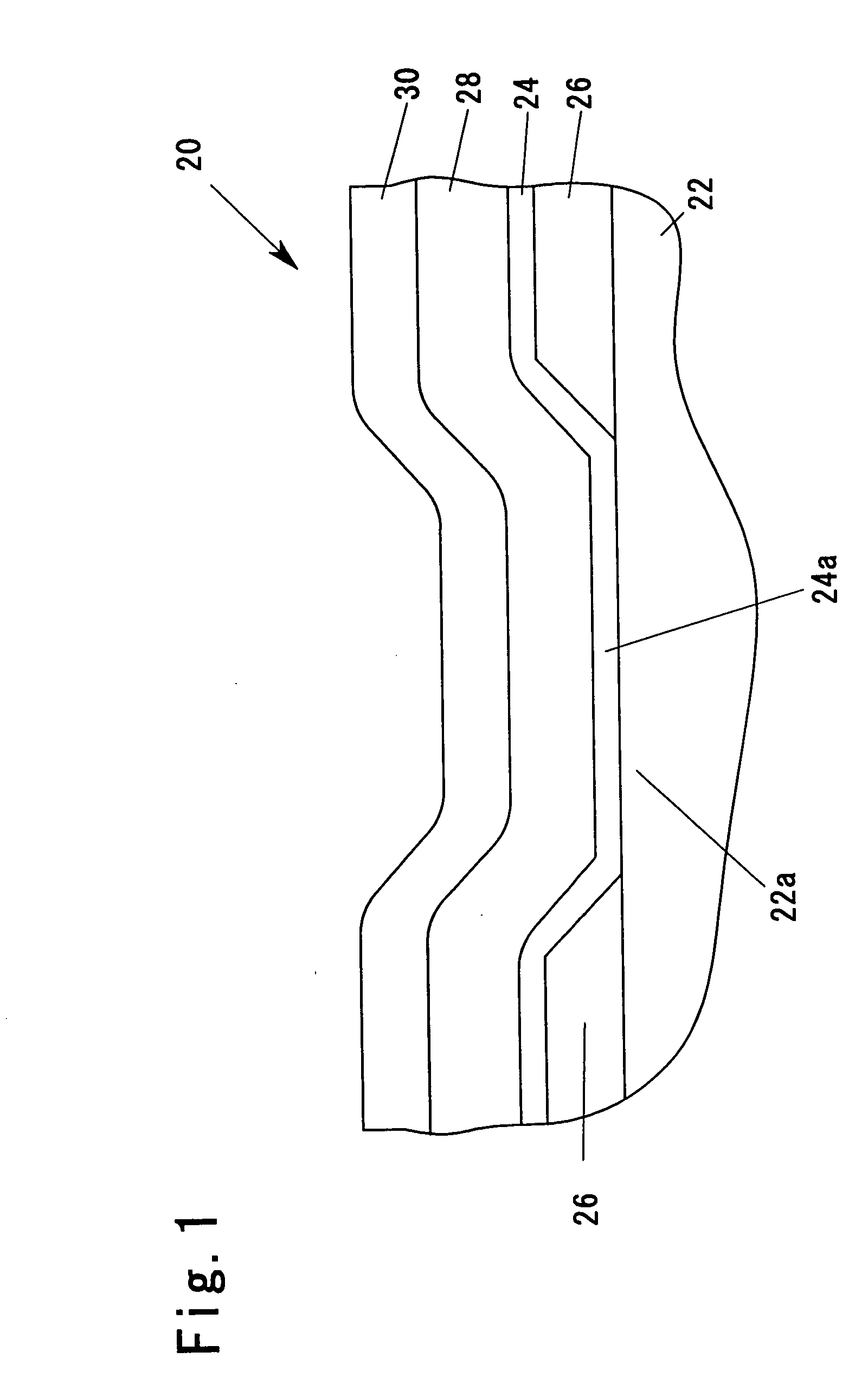

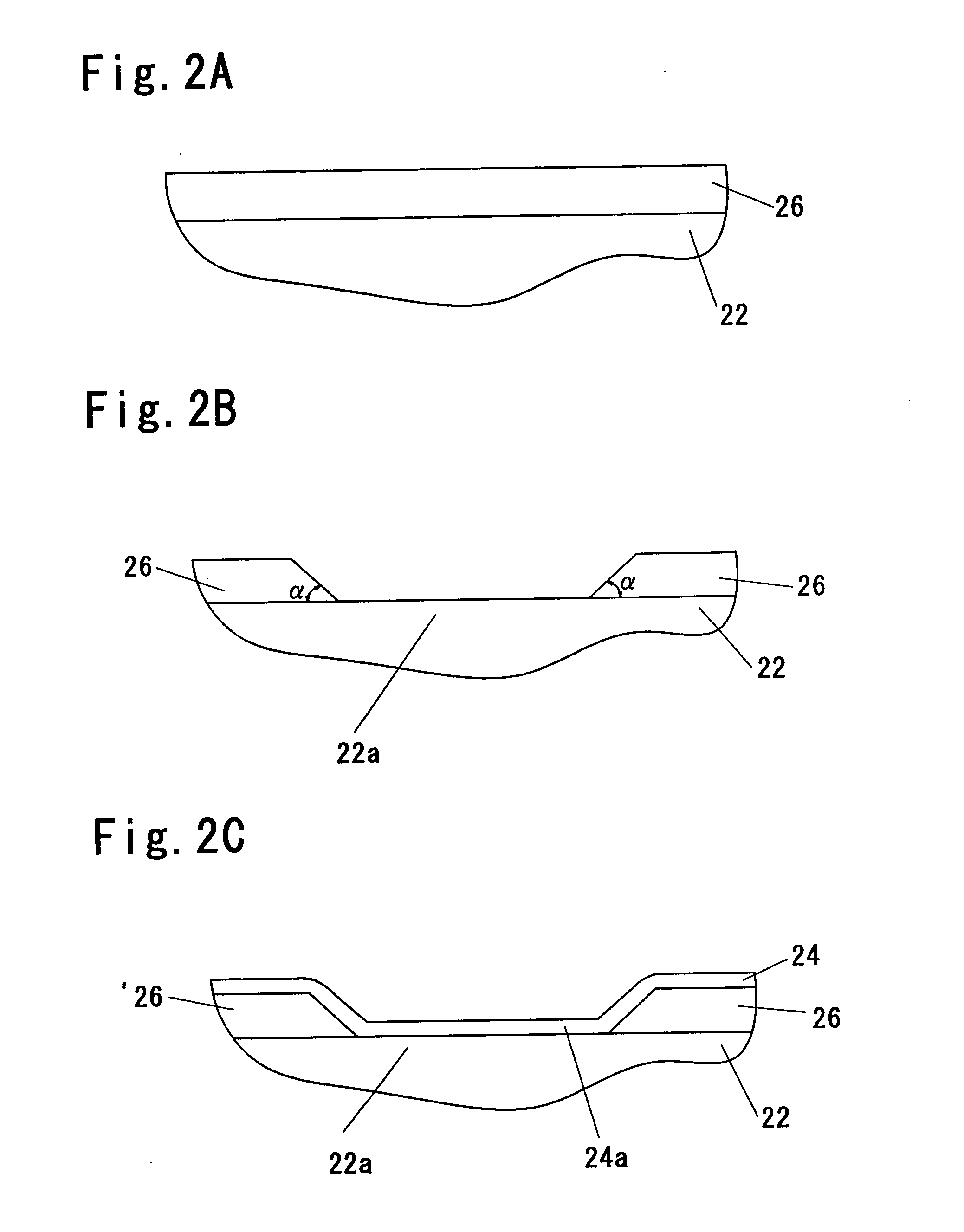

Heater for inkjet printer head and method for production thereof

To provide a heater for an inkjet printer head which consumes low power or has a long service life and a high printing resolution, and a method for production thereof. A heater layer 24 covers a heater locating section 22a of a base layer 22 and a wiring layer 26. The heater layer 24 is formed of a tantalum silicon oxide (TaSiO2) and thus has a large sheet resistance. Thus, predetermined heat can be produced on a small current. Also, since the heater layer 24 does not have to be thin, the service life of the device can be extended. In addition, the area of a heater section 24a can be reduced.

Owner:ROHM CO LTD

Three-dimensional printing method capable of realizing electric field induction assisted electrospray

ActiveCN109228305AHigh print resolutionFast molding speedAdditive manufacturing apparatusAdditive manufacturing with liquidsElectricityNano structuring

The invention belongs to the technical field of advanced manufacture and relates to a three-dimensional printing method capable of realizing electric field induction assisted electrospray. A functional material solution is delivered into a spray needle at a constant flow rate, the functional material solution is sheared by utilizing an electric field force applied to the spray needle to form a micro / nano-scale stable jet flow smaller than the size of the spray needle, and a micro / nano structure is printed; and meanwhile, the structure is regulated and controlled by utilizing a spatial electricfield force generated by an induction electrode, and finally, a complex micro / nano three-dimensional structure is obtained by electric field induction, stress deformation, cooling for curing and three-dimensional molding. The complex micro / nano three-dimensional structure manufactured by using the three-dimensional printing method capable of realizing electric field induction assisted electrospray, disclosed by the invention, has the advantages such as free molding of the spatial three-dimensional structure, high printing resolution and high molding speed, the complex micro / nano three-dimensional structure manufactured by using the method has the line width of dozens of nanometers, and the complex micro / nano three-dimensional structure manufactured by printing can be widely applied to thefields such as electronics, information and energy.

Owner:DALIAN UNIV OF TECH

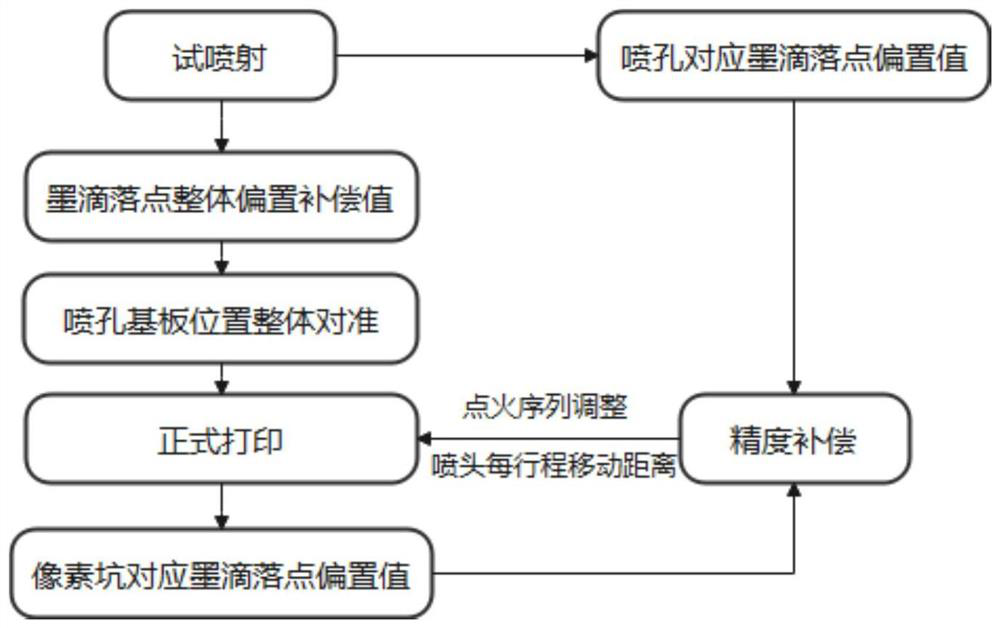

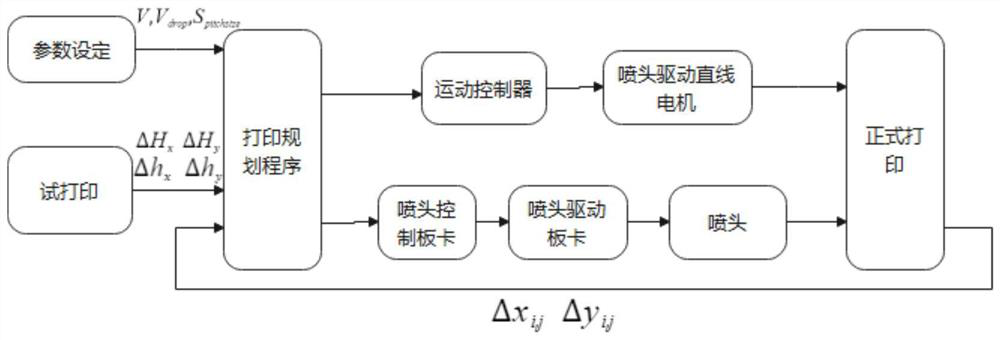

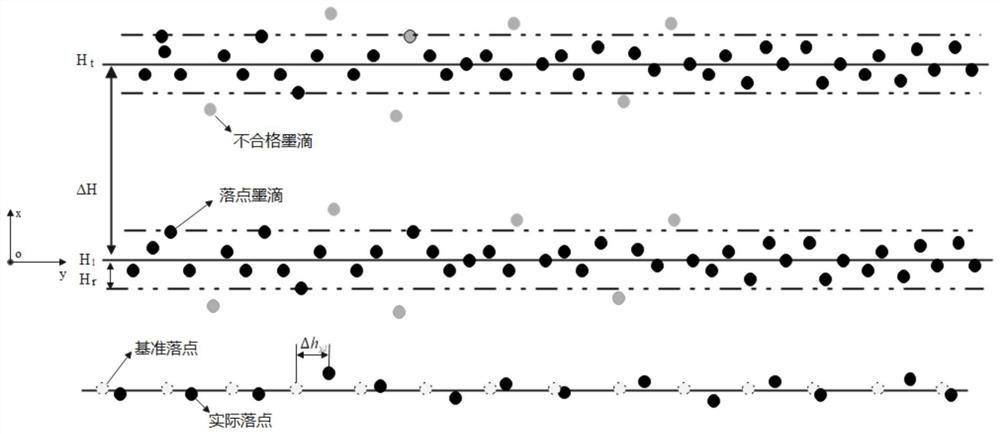

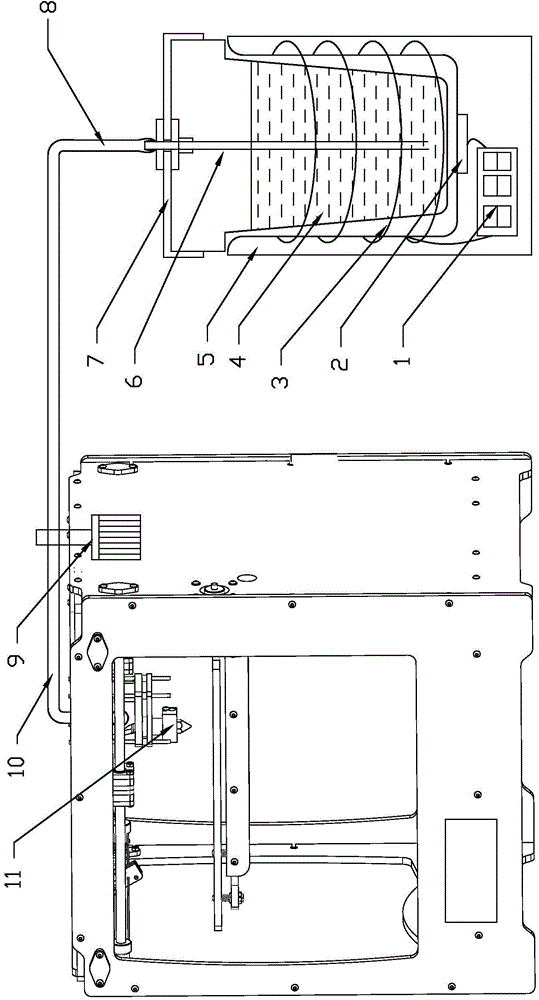

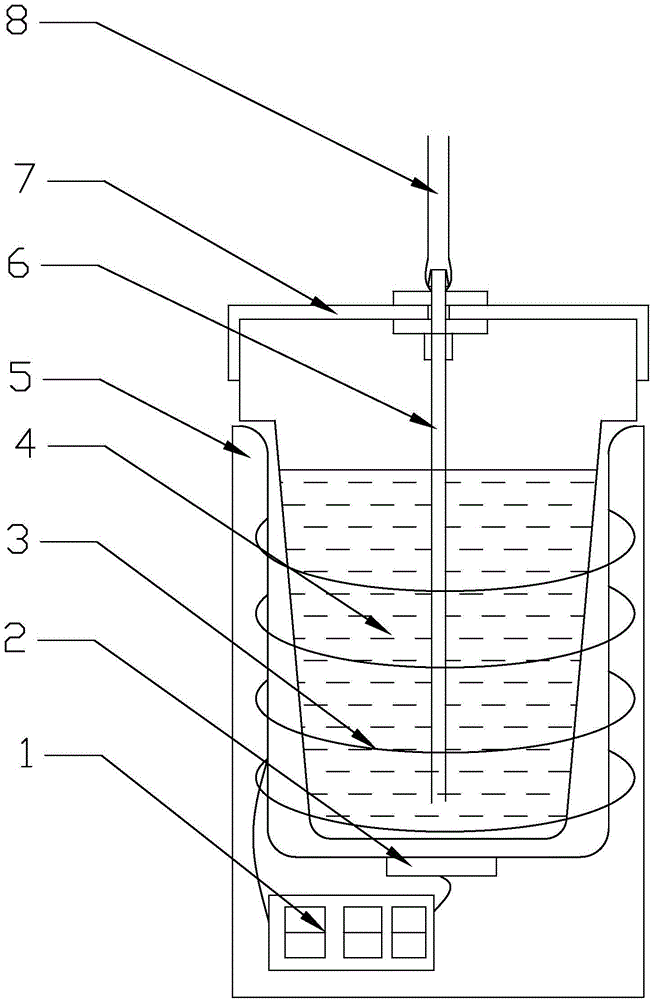

Ink drop point precision control method and system for ink-jet printing

ActiveCN113752698AAchieve precision controlCompensate for multiple errorsPrintingDisplay deviceElectronic component

The invention belongs to the technical field of ink-jet printing, and particularly discloses an ink drop point precision control method and system for ink-jet printing. The method comprises the steps that (1) spray holes are moved to a trial printing area for trial spraying, the offset value of an ink drop point corresponding to each spray hole is detected, and then the overall offset compensation value of the ink drop points is obtained; (2) the position precision of the spray holes relative to pixel pits of a substrate is integrally compensated by using the overall offset compensation value of the ink drop points; (3) the spray holes are started to implement formal printing, and the offset value of each ink drop point corresponding to each pixel pit is detected in the printing process; and 4) according to the offset value, on one hand, the compensation position precision of the ignition sequence is adjusted in the moving direction of the substrate, and on the other hand, the moving distance of each nozzle in each stroke is adjusted so as to compensate the position precision in the moving direction of the corresponding nozzle. Multiple errors in the ink-jet printing process can be compensated, and the ink-jet printing method is particularly suitable for being used in the application occasions of manufacturing high-resolution displayers, electronic components and the like in an ink-jet printing mode.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for printing 3D (three-dimensional) food and equipment thereof

InactiveCN103720021BPrecise control of molding temperatureRealize intelligenceFood coatingFood shapingImage resolutionComputer module

The invention discloses a method for printing 3D (three-dimensional) food and equipment thereof. The method mainly comprises the steps that (1) a computer controls a 3D printer to realize the 2.5-axis linkage printing of an X axis, a Y axis and a Z axis according to set printing speed V; (2) the computer controls an intelligent control and display module to realize intelligent temperature gradient control; (3) the computer controls the intelligent control and display module to realize intelligent food raw material print flow control. The method disclosed by the invention has the characteristics that flow and temperature can be accurately and intelligently controlled and the print resolution is high.

Owner:王晓军 +1

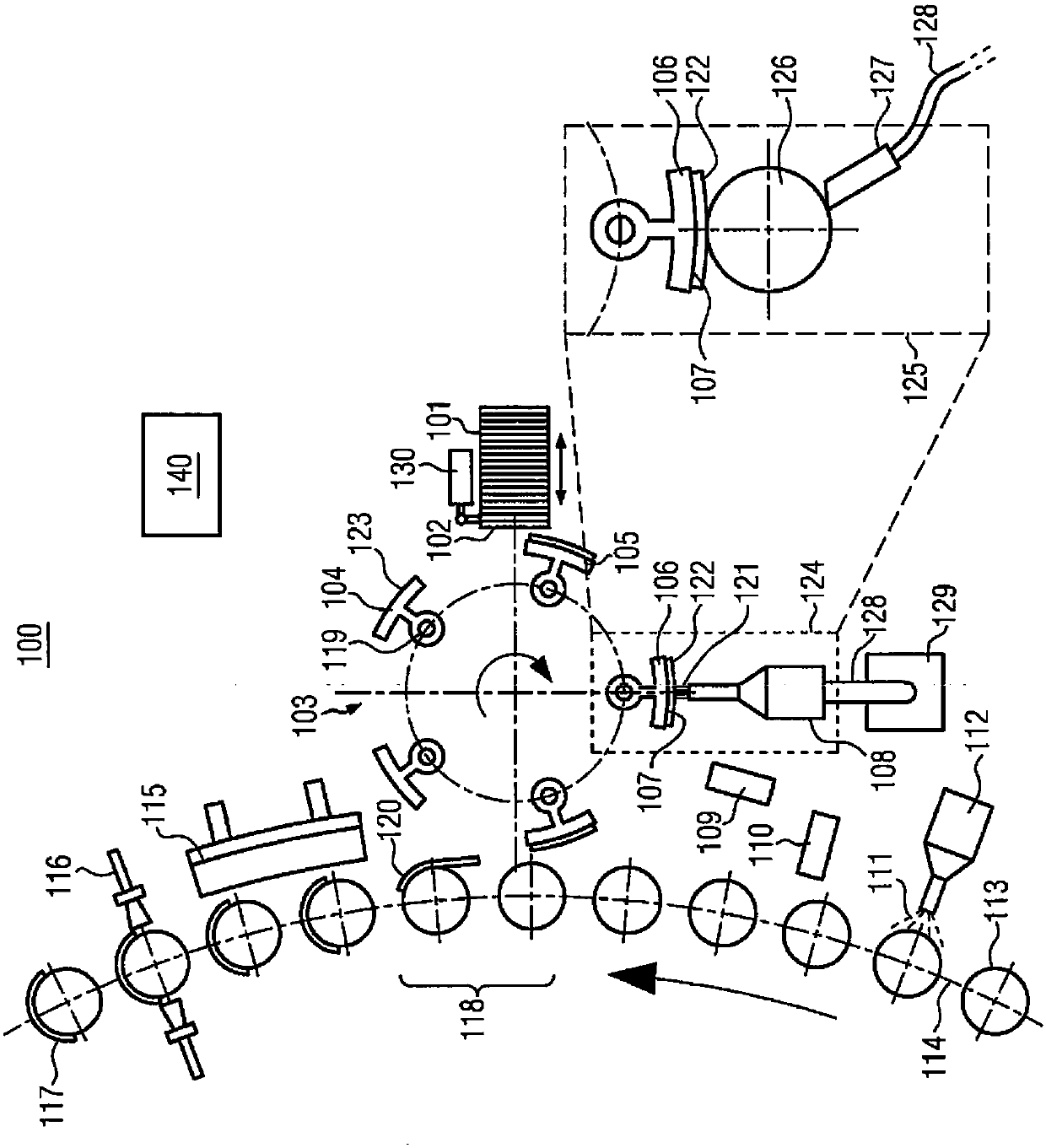

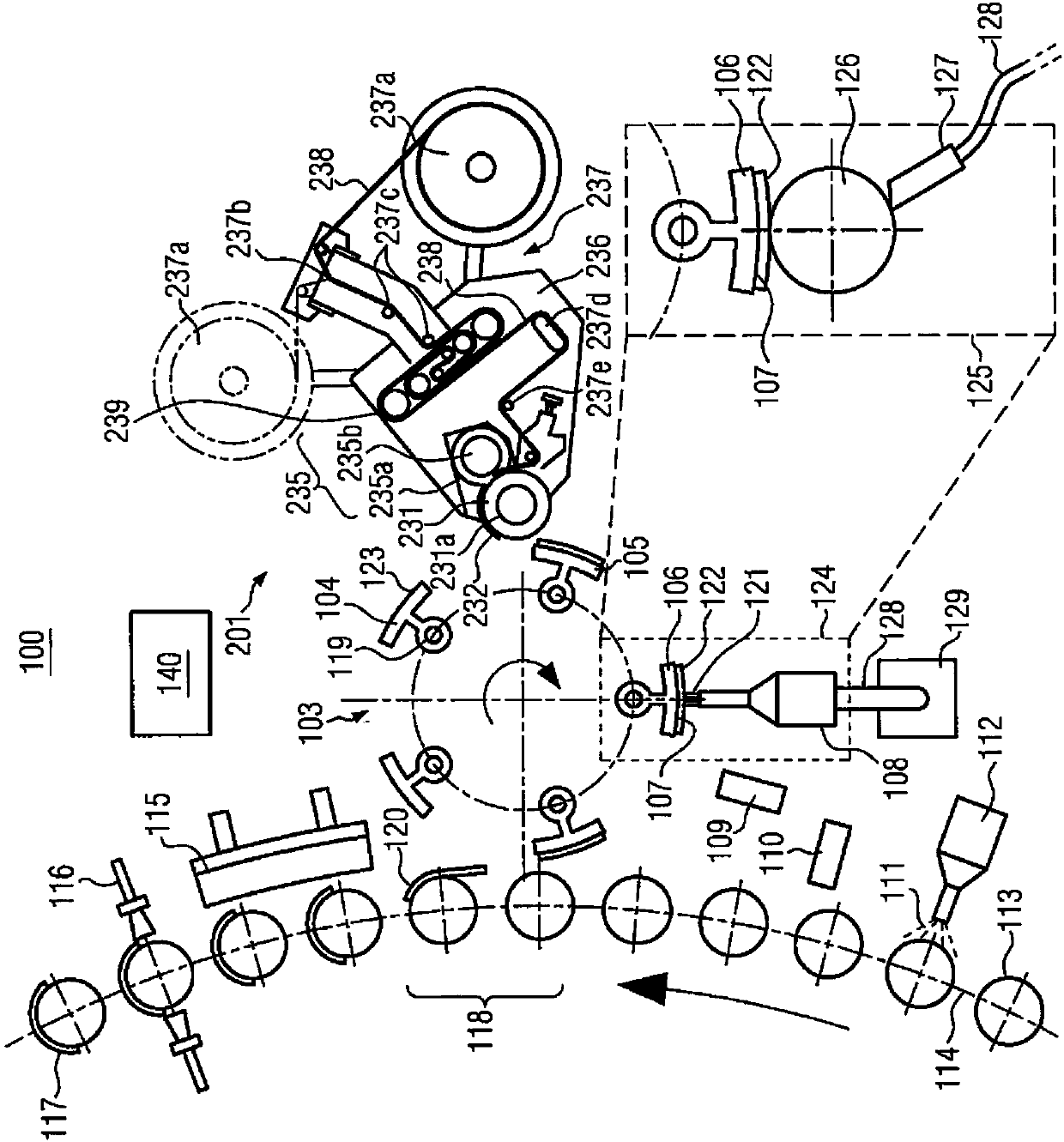

Apparatus and method for labelling containers

ActiveCN107735328AHigh print resolutionBest impact anglePrintingLabelling machinesControl mannerEngineering

The present invention provides an apparatus and a method for applying labels (102, 232, 607, 707) to containers (113) or multipacks (113), having the following steps: a pallet (105, 106), which can bepivoted in a controlled manner in particular about a pivot axis (419, 519) which is offset in relation to the axis of rotation, receives a label from a label-supply unit (101, 201) such that a glue-application surface (122) of the label is oriented away from the pallet; the label is transported, by way of the pallet, past a gluing unit (124, 125), where at least part of the glue-application surface of the label (107) is provided with cold glue; and the glued label (120) is then transferred directly to a container transported by a transporting apparatus (114) or to a multipack transported by the transporting apparatus.

Owner:KRONES AG

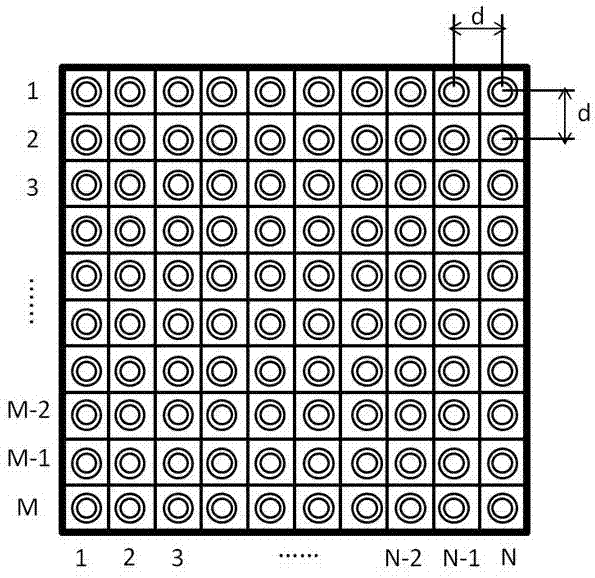

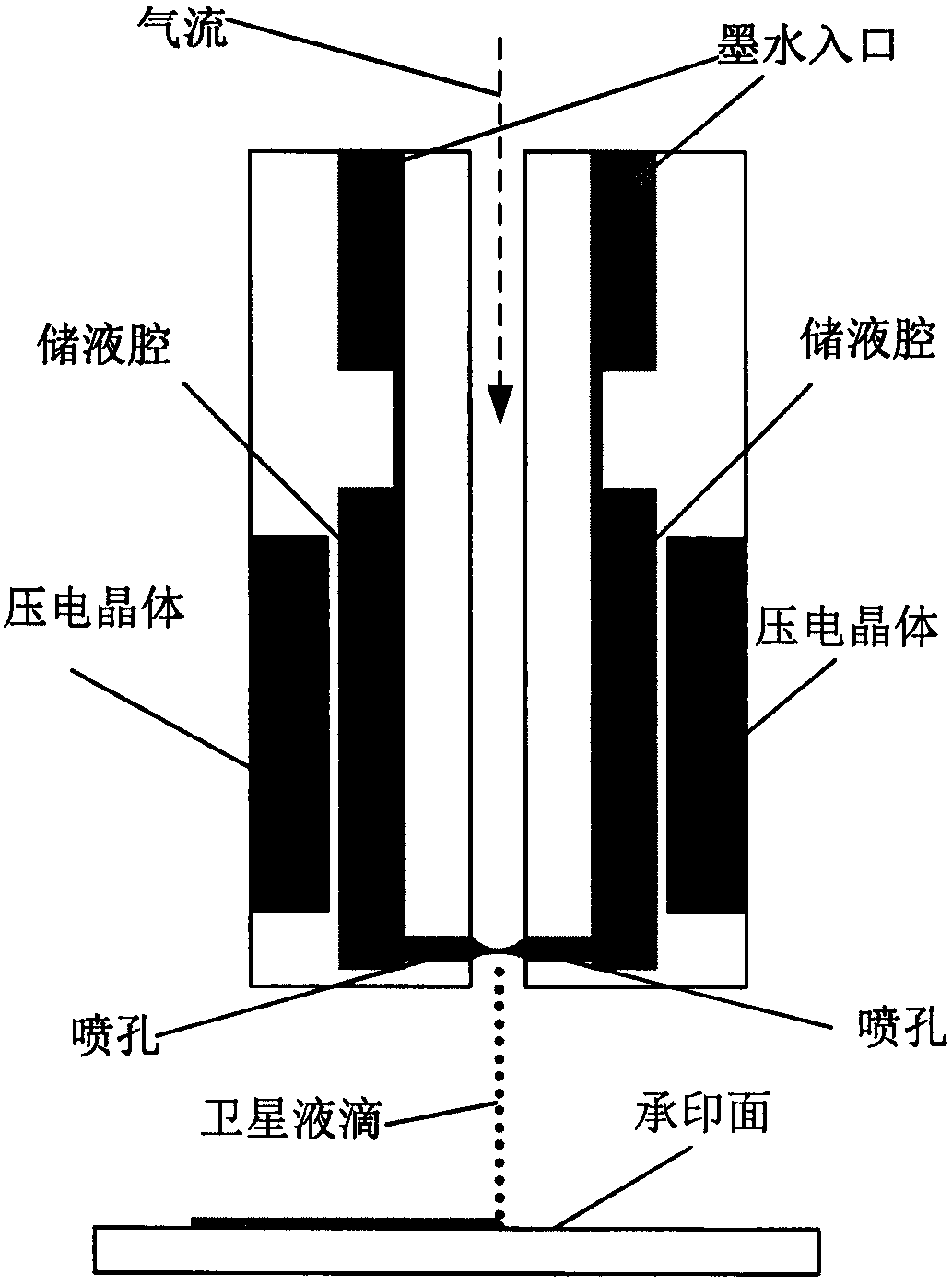

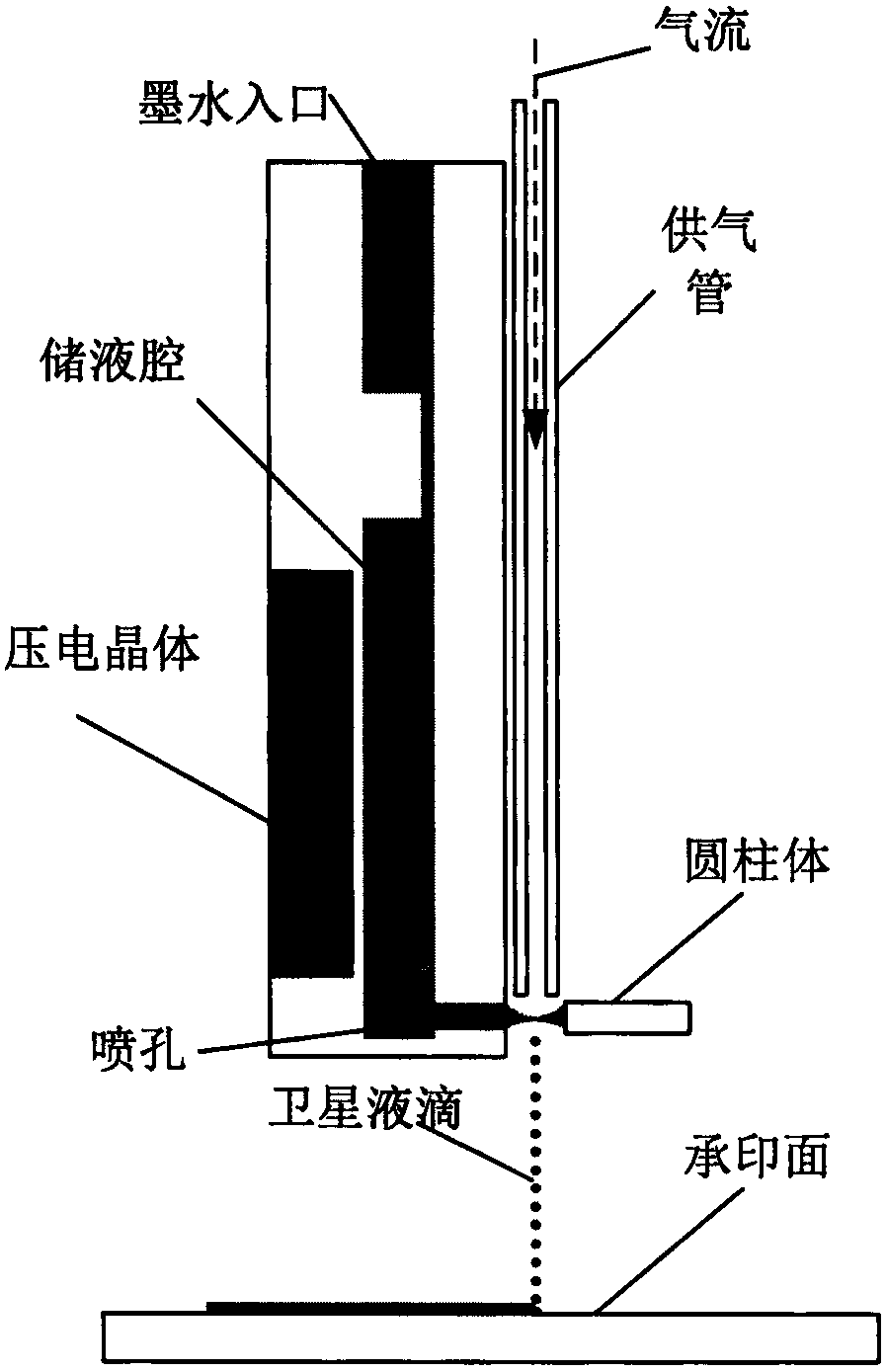

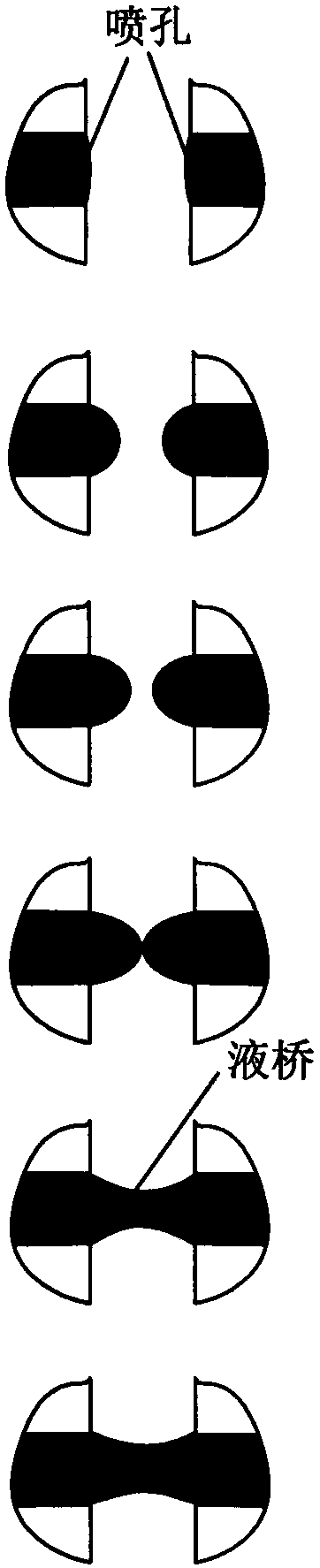

Novel high-resolution printing method based on satellite droplet

The invention relates to a novel high-resolution printing method in the field of ink-jet printing. According to the method, the phenomenon that satellite droplets are formed by fracture of a liquid bridge is utilized, so that the novel method for carrying out high-resolution printing by utilizing the satellite droplets is developed. The method is characterized in that the center lines of two sprayholes are aligned, the two spray holes are oppositely placed at a certain distance; two micro-piezoelectric crystals simultaneously extrude the ink in two liquid storage cavities from the spray holes, so that two droplets which are not separated from the spray holes meet at the middle position and are fused to form a liquid bridge; then, ink in the liquid bridge is sucked into the liquid storagecavities through opposite-direction deformation of the piezoelectric crystals, so that the liquid bridge is broken, the satellite droplets needed by printing are formed; and then, the satellite droplets are dropped onto a printing surface of which the liquid drops are blown off through a proper amount of air flow so as to complete printing. The size of the satellite droplets can be adjusted through the geometric size of the liquid bridge, the speed of the ink in the liquid bridge sucked into the spray holes and the physical properties of the ink. In addition to a double-spraying-hole working mode described above, the method can also adopt a single-spraying-hole working mode.

Owner:张彦振 +1

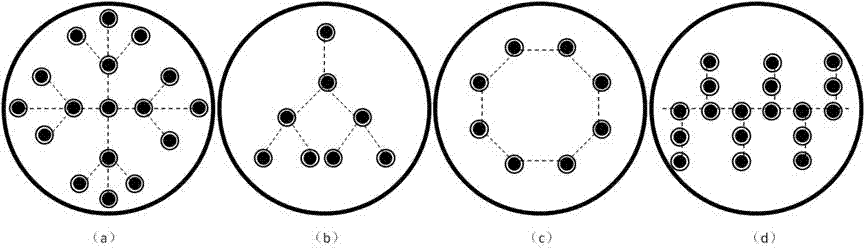

Piezoelectric ink-jet printing device with outer surface electrode layer

PendingCN111439033ACompact and reliable electrical interconnectionSave spacePrintingEngineeringGrounding electrodes

A piezoelectric ink-jet printing device comprises a base plate and a piezoelectric plate. A pair of liquid drop injector rows arranged in a staggered mode are arranged on the base plate in the arranging direction. Each liquid drop injector comprises a spray hole connected with pressure chamber liquid, and a pressure chamber is defined by a side wall. A first surface of the piezoelectric plate closely abuts against the pressure chambers. An electrode layer is arranged on the second outer surface, opposite to the first surface, of the piezoelectric plate. The electrode layer comprises signal lines corresponding to the liquid drop injectors in the staggered rows, and at least one public main ground electrode, and the public main ground electrodes are connected to ground electrodes which are located on the upper portions of the pressure chambers and are aligned along the side wall. Each signal line is connected to a corresponding signal input welding disc arranged between the staggered rows. The public main ground electrodes extend in the arranging direction and are connected to a return welding disc.

Owner:SUZHOU RUIFA PRINTING TECH CO LTD

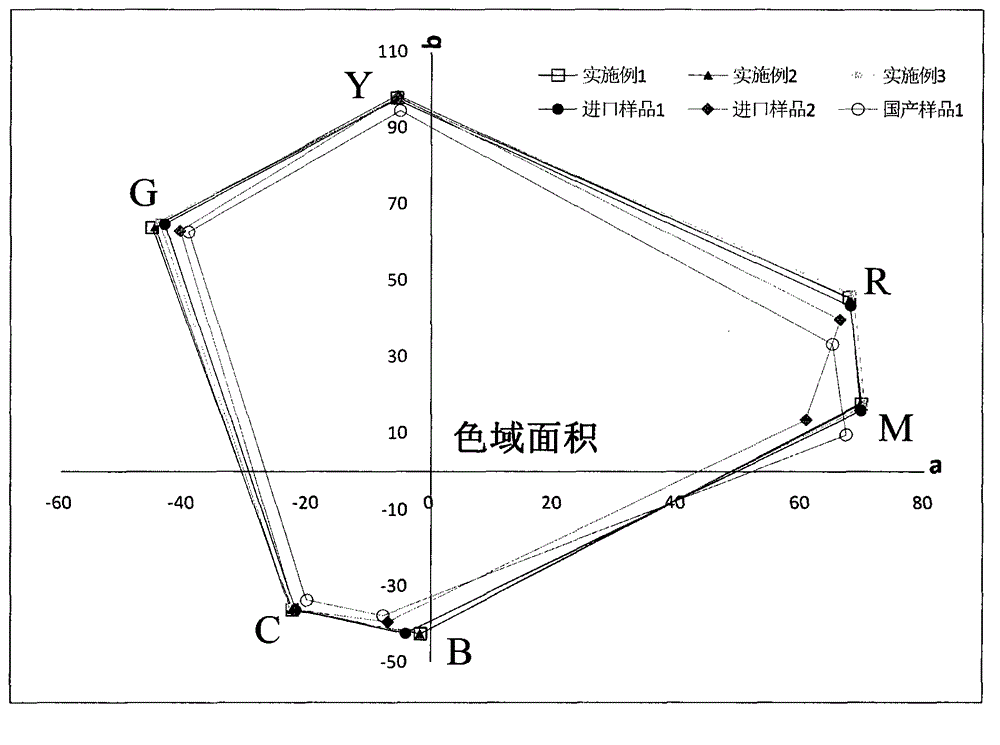

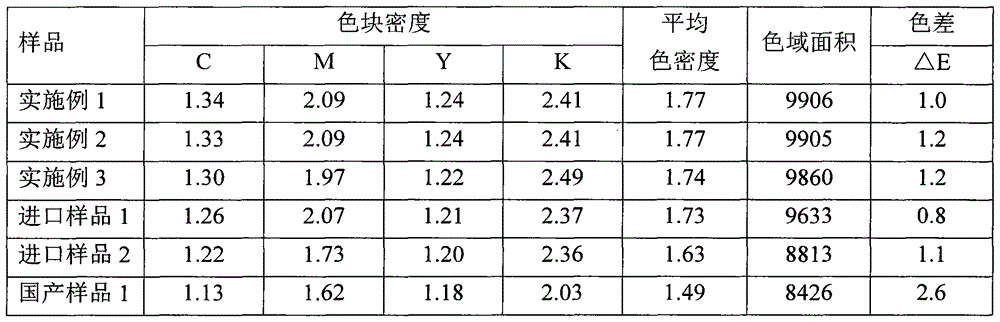

Chinese art paper for micro-spraying

ActiveCN106149469AUniform distribution of poresFast ink absorptionSpecial paperPaper/cardboardImage resolutionMoisture

The invention discloses Chinese art paper for micro-spraying and particularly provides Chinese art paper for artwork copying by adopting a multicolor micro-spraying printer and provided with a coating. The Chinese art paper is characterized in that continuously rolled machine-made Chinese art paper produced in large-scale mode is used as raw paper, bottom coating, face coating and back coating is conducted on the surface of the paper in an optimized combined coating mode, a coating formula and a coating process are optimized, and moisture drying is controlled. The produced Chinese art paper is uniform and consistent in coating distribution and coating Chinese art paper. During printing, the ink absorbing speed is high, color uniformity is consistent, and no printing stain problem is produced. Printed patterns are high in overall color density, wide in color gamut and high in resolution ratio, and ideal contrast reappearing can be obtained. The Chinese art paper adopts a high-end coating device and combines with an advanced coating process for production, stable production control can be achieved, and accordingly stable product quality can be obtained. The bottleneck problem that at present, high-grade products cannot be produced at home is solved.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD +1

Method for producing ink-jet printing substrate in curtain type coating manner

ActiveCN105730038AGuaranteed uptimeEvenly distributedDuplicating/marking methodsPore distributionEngineering

The invention discloses a method for producing an ink-jet printing substrate in a curtain type coating manner, and particularly relates to a manufacturing method for the coating-layer-provided substrate used when a multicolor ink-jet printing machine is adopted for conducting color pattern printing. The method is characterized in that a continuously-rolled machined sheet is adopted as a coating substrate, coating of an ink-jet printing coating layer is carried out on the front face of the coating substrate in the curtain type coating manner, and an optimized coating formula can meet the requirement that curtain type coating normally runs under the lower car speed condition; the produced coating layer of the ink-jet printing substrate and the pore distribution of the coating layer are even and consistent; during printing, the ink absorption speed is high, the color is even and consistent, and the problems of printing dots, printing patterns and the like are solved; and the quality of products in different batches is stable, and obvious chromatic aberration can be avoided. According to the manufacturing method, high-end coating equipment is adopted, an advanced coating process is used in a combined manner to conduct production, stable production control can be achieved, and therefore the stable product quality is obtained. The problem that at present, high-end products cannot be produced in China is solved.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

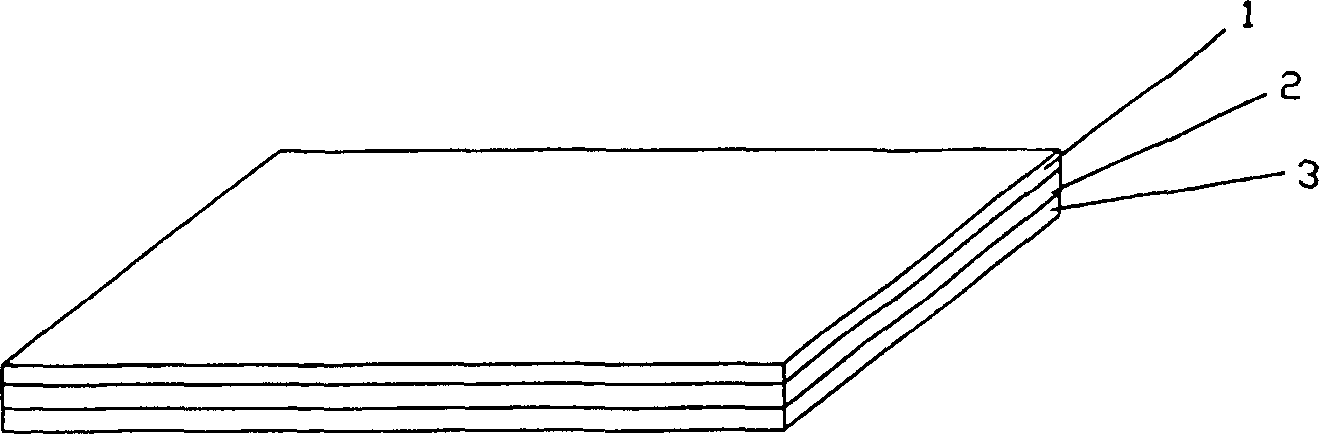

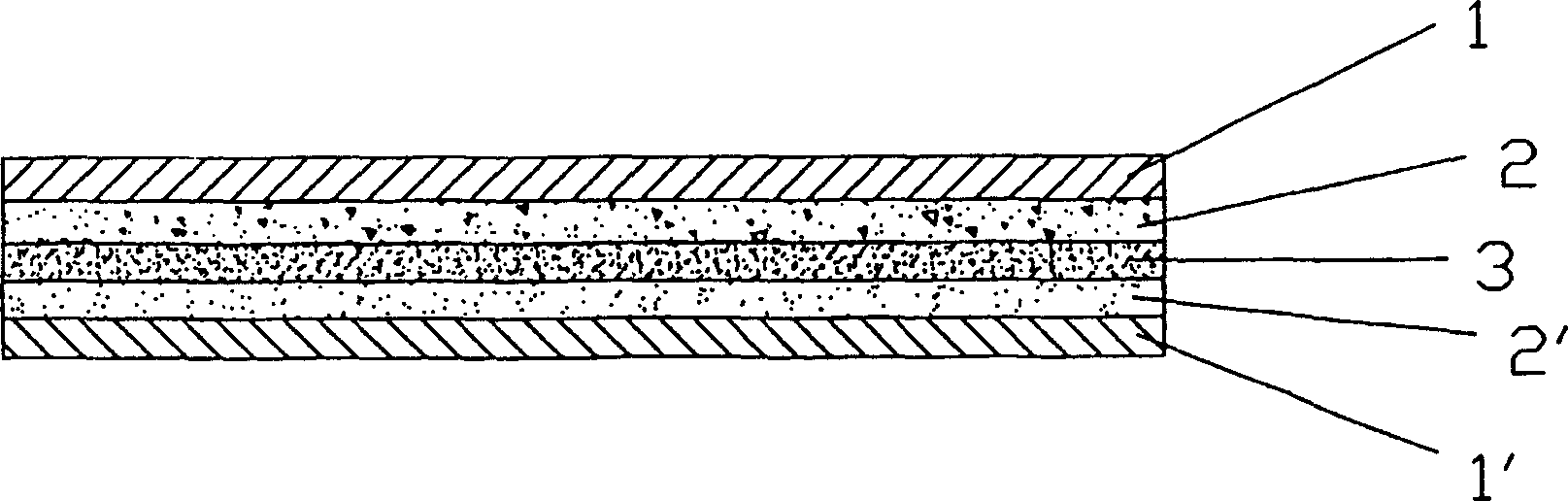

Substrate specially for digital card-making and its preparing method

InactiveCN1289288CAccurate color reproductionImprove clarityDuplicating/marking methodsSynthetic resin layered productsCLARITYImage resolution

The present invention relates to a new base sheet for digital card-making and its preparing method. Substrate of said base sheet is coated with bond layer and ink absorbent layer. Said base sheet can be directly printed, particularly can be directly printed letters and pattern with color reduced accurately, high clarity and good durability by color ink-jet printer. The present base sheet can be used to make various of standard or non-standard card. When printing, letters and pattern are printed on or reversed on transparent sheet, which printing resolution ratio is more than 1440 dpi. Through heat-laminated, digital card can be obtained with color reduction accurately, high clarity, good durability and low cost. The present base sheet is particularly suitable for short-edited card-making with high personality required. Cost of card-making is not restricted with yield.

Owner:TIANJIN BOYUAN NEW MATERIALS

Electronic ink for inkjet printing and with no silver nano-wire sedimentation, and preparation method thereof

The invention discloses an electronic ink for inkjet printing and with no silver nano-wire sedimentation, and a preparation method thereof, and belongs to the field of electric-conduction inks, wherein the electronic ink comprises, by mass, 5-10% of silver nano-wires, 5-10% of a macromolecule electric-conduction polymer, 0.2-0.5% of a surfactant, 0.5-1.5% of a buffer agent, and the balance of deionized water. According to the present invention, during the preparation of the inkjet printing ink, the macromolecule electric-conduction polymer is added to increase the viscosity of the printing inkso as to improve the resolution of the printing line, further prevent the silver nano-wire sedimentation, and improve the electric conductivity and the reliability of the printing ink; and by addingthe surfactant and the buffer agent, the obtained ink has good time stability and good temperature stability.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

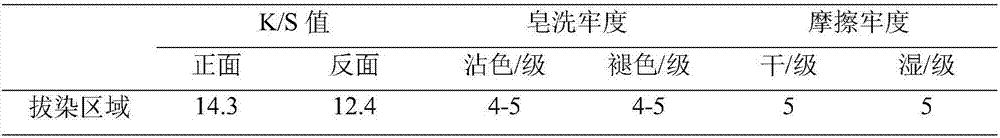

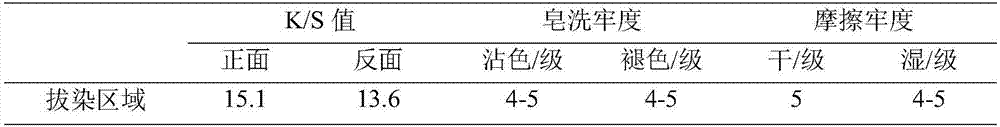

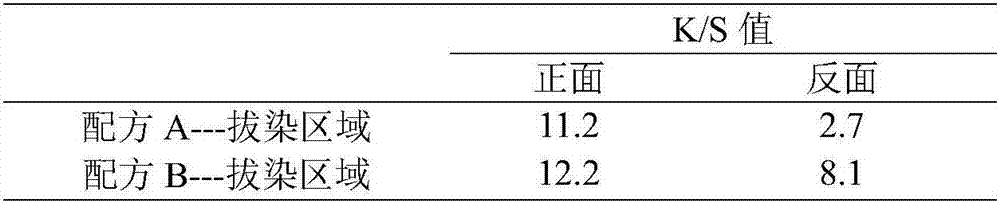

Discharge printing process of reactive dyes based on jet ink printing technology

The invention discloses a discharge printing process of reactive dyes based on a jet ink printing technology, and belongs to the technical field of jet ink printing. The process comprises the following steps: starching; drying; carrying out ground dyeing; carrying out computer printing color-separation draft-drawing (CAD) edition treatment; preparing discharge printing ink and carrying out spray printing; carrying out steam fixation; washing and drying. The discharge printing process of the reactive dyes based on the jet ink printing technology disclosed by the invention is simple and convenient to operate; the computer printing color-separation draft-drawing (CAD) edition treatment on patterns subjected to discharge printing is carried out so as to obtain desired patterns; an ink jet nozzle is controlled by a computer to print the patterns, and the outlines of the printed patterns are clear and the colors of the patterns are vivid and gorgeous; the preferable printing effect on the double sides of the patterns can be achieved, and meanwhile, the use quantity and the cost can be reduced.

Owner:绍兴柯桥越强助剂有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com