Chinese art paper for micro-spraying

A technology of rice paper and art, applied in the field of inkjet printing paper, can solve the problems of color inconsistency, product quality fluctuation, high production cost, etc., and achieve the effect of uniform pore distribution, uniform color and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

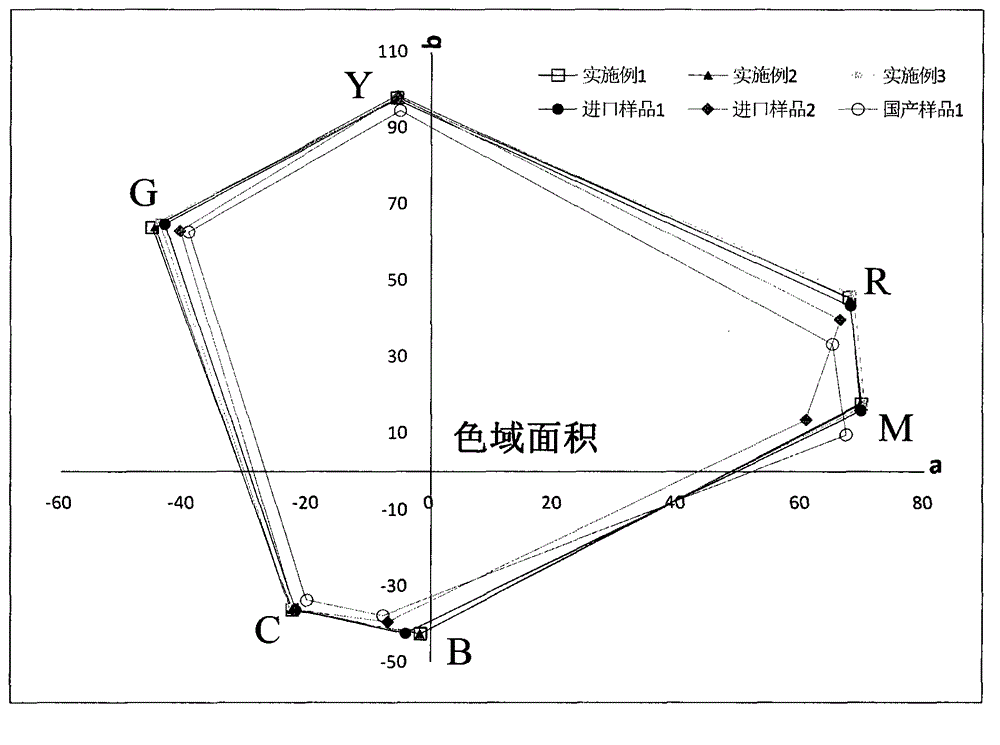

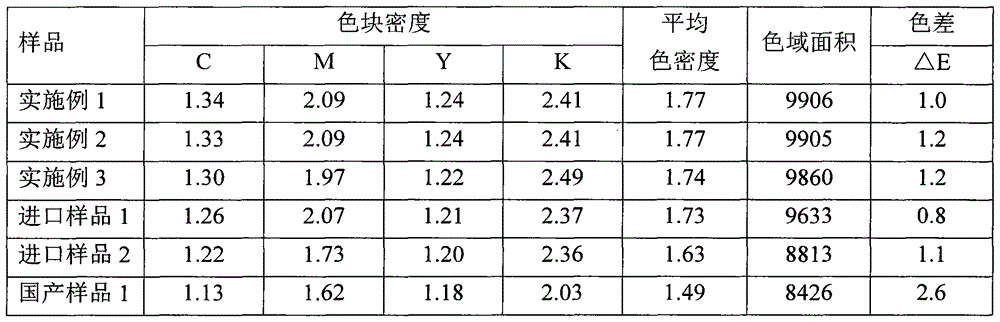

Examples

Embodiment approach 1

[0021] Artistic rice paper adopts 50g / m 2 The machine-made Xuan paper is base paper, the front primer and top coat are all applied by curtain coating, the back is coated by gravure roller, the bottom, surface and back are all coated once, and the coating production is completed at one time , the coating speed is 150m / min, and the curtain coating die head is the curtain type; in the primer, the amount of silica with a particle size of 5-8μm is 50%, the amount of calcium silicate is 30%, and the amount of light calcium carbonate The dosage of PVA is 15%, the dosage of VAE is 15%, the dosage of cationic color fixing agent is 10%, the dosage of CMC water-retaining agent is 2%, and the dosage of thickener is 0.6%. , the amount of wetting agent is 0.3%, the amount of defoamer is 0.2%, the solid content of the coating is 30%, the coating temperature is controlled at 20-23°C during coating, and the coating amount is 6-7g / m 2 ; In the top coating, the amount of silicon dioxide with a ...

Embodiment approach 2

[0025] As described in Embodiment 1, the machine-made rice paper used for the base paper has a basis weight of 75g / m 2 , the front primer adopts the film transfer coating method, and the coating speed is 300m / min; the amount of silicon dioxide in the primer is 40%, the amount of calcium silicate is 30%, the amount of light calcium carbonate is 30%, and the degree of polymerization is 1700. The amount of PVA with alcoholysis degree of 88% is 12%, the amount of CMC water retaining agent is 2.5%, the amount of thickener is 0.2%, the amount of wetting agent is 0.1%, the amount of defoamer is 0.1%, and the solid content of paint is 33%. , the coating weight is 8g / m 2 ; In the top coating, the amount of silicon dioxide is 80%, the amount of calcium silicate is 20%, the amount of light calcium carbonate is 0%, the degree of polymerization is 1700, the amount of PVA with an alcoholysis degree of 88% is 25%, and the amount of VAE is 15%. %, the amount of cationic color fixing agent is...

Embodiment approach 3

[0028] As described in Embodiment 1, the machine-made rice paper used for the base paper has a basis weight of 60g / m 2 , the front primer is coated by gravure roller, and the coating speed is 200m / min; the amount of silicon dioxide in the primer is 60%, the amount of calcium silicate is 10%, and the amount of light calcium carbonate is 30%. The dosage of molecular synthetic water-retaining agent is 3%, the dosage of thickener is 0.1%, the dosage of wetting agent is 0%, the dosage of defoamer is 0.1%, the solid content of coating is 25%, and the coating amount is 5g / m 2 ; In the top coating, the amount of silicon dioxide is 65%, the amount of calcium silicate is 35%, the amount of light calcium carbonate is 0%, the degree of polymerization is 1700, the amount of PVA with alcoholysis degree of 99% is 23%, and the amount of VAE is 15%. %, the amount of cationic color fixing agent is 18%, the amount of thickener is 1.0%, the amount of PAPU water repellent agent is 1.0%, the solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com